Page 1

FormNo.3356-331RevE

Groundsmaster

®

4500-Dor

4700-DTractionUnit

ModelNo.30856—SerialNo.260000801andUp

ModelNo.30868—SerialNo.260000801andUp

Registeratwww.T oro.com.OriginalInstructions(EN)

Page 2

Warning

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisincorporated

withthemuferassembly.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Figure1

Important:Thisengineisequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,

orgrass-coveredlandwithoutasparkarrester

mufermaintainedinworkingorder,ortheengine

constricted,equipped,andmaintainedforthe

preventionofre.Otherstatesorfederalareasmay

havesimilarlaws.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Theenclosed

Engine Owner’ s Man ual

issupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

©2007—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroRidingMowerSafety....................................6

SoundPressureLevelfora4500-D.......................7

SoundPressureLevelfora4700-D.......................7

SoundPowerLevel...............................................7

VibrationLevel.....................................................7

SafetyandInstructionalDecals.............................8

Setup..........................................................................13

1InstallingtheSeat,SeatBelt,andManual

Tube...............................................................13

2ReplacingtheWarningDecal............................14

3GreasingtheMachine......................................14

4CheckingFluidLevels......................................14

5ReadingtheManualsandViewingthe

TrainingMaterial............................................14

ProductOverview......................................................15

Controls.............................................................15

Specications.....................................................19

TractionUnitSpecications................................19

Attachments/Accessories...................................19

Operation...................................................................20

CheckingtheEngineOilLevel............................20

CheckingtheCoolingSystem..............................20

FillingtheFuelTank...........................................21

CheckingtheHydraulicFluidLevel.....................21

CheckingtheTirePressure.................................22

StartingandStoppingtheEngine........................22

CheckingtheInterlockSwitches.........................23

PushingorTowingtheMachine..........................24

JackingPoints.....................................................24

TieDowns.........................................................24

OperatingCharacteristics...................................24

StandardControlModule(SCM)........................25

OperatingTips...................................................26

Maintenance...............................................................28

RecommendedMaintenanceSchedule(s)................28

DailyMaintenanceChecklist...............................29

ServiceIntervalChart.........................................30

PremaintenanceProcedures....................................31

RemovingtheHood...........................................31

Lubrication.............................................................31

GreasingtheBearingsandBushings....................31

EngineMaintenance...............................................33

ServicingtheAirCleaner....................................33

ServicingtheEngineOilandFilter......................34

AdjustingtheThrottle........................................34

FuelSystemMaintenance.......................................35

FuelTank...........................................................35

FuelLinesandConnections................................35

WaterSeparator.................................................35

ReplacingtheFuelPre-Filter...............................35

FuelPick-upTubeScreen...................................36

BleedingtheFuelSystem....................................36

BleedingAirfromtheInjectors...........................36

ElectricalSystemMaintenance................................37

ChargingandConnectingtheBattery..................37

BatteryCare.......................................................38

Fuses..................................................................38

DriveSystemMaintenance.....................................39

CheckingtheTorqueoftheWheel

Nuts...............................................................39

CheckingthePlanetaryGearDrive

Oil..................................................................39

ChangingthePlanetaryGearDrive

Oil..................................................................39

CheckingtheRearAxleLubricant.......................40

ChangingtheRearAxleLubricant.......................40

AdjustingtheTractionDriveforNeutral.............41

CheckingtheRearWheelToe-In.........................41

CoolingSystemMaintenance..................................42

ServicingtheEngineCoolingSystem..................42

BrakeMaintenance.................................................43

AdjustingtheServiceBrakes...............................43

BeltMaintenance....................................................44

ServicingtheAlternatorBelt...............................44

HydraulicSystemMaintenance...............................44

ChangingtheHydraulicFluid.............................44

ReplacingtheHydraulicFilters...........................44

CheckingtheHydraulicLinesandHoses.............45

HydraulicSystemTestPorts...............................45

AdjustingtheCounterbalance.............................46

Cleaning.................................................................47

ServicingtheSparkArrestorMufer...................47

Storage.......................................................................48

TractionUnit......................................................48

Engine...............................................................48

Schematics.................................................................49

3

Page 4

Safety

ThismachinemeetsorexceedsCENstandardEN

836:1997(whenappropriatedecalsapplied),andANSI

B71.4-2004specicationsineffectatthetimeof

productionwhenequippedwithrequiredweightsas

listedintheweightchart.

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.T oreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalertsymbol,

whichmeansCAUTION,WARNING,orDANGER"personalsafetyinstruction."Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004.

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeople,orproperty.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,

longtrousers,hardhat,safetyglasses,andhearing

protection.Longhair,looseclothing,orjewelrymay

gettangledinmovingparts.Donotoperatethe

equipmentwhenbarefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning-Fuelishighlyammable.Takethe

followingprecautions:

–Storefuelincontainersspecicallydesignedfor

thispurpose.

Training

•Readtheoperator’smanualandothertraining

materialcarefully .Befamiliarwiththecontrols,

safetysigns,andtheproperuseoftheequipment.

•Iftheoperatorormechaniccannotreadthelanguage

ofthismanual,itistheowner’ sresponsibilityto

explainthismaterialtothem.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpets

arenearby .

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstruction

shouldemphasize:

–theneedforcareandconcentrationwhen

workingwithride-onmachines;

–controlofaride-onmachineslidingonaslope

willnotberegainedbytheapplicationofthe

brake.Themainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforthetask;

–Refueloutdoorsonlyanddonotsmokewhile

refueling.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltankandcontainercapssecurely.

•Replacefaultysilencers/mufers.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Checkthatoperator’spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageall

bladeattachmentclutches,shiftintoneutral,and

engagetheparkingbrake.

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

4

Page 5

•Rememberthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.To

guardagainstoverturning:

–donotstoporstartsuddenlywhengoingupor

downhill;

–machinespeedsshouldbekeptlowonslopes

andduringtightturns;

–stayalertforhumpsandhollowsandother

hiddenhazards;

–nevermowacrossthefaceoftheslope,unless

themowerisdesignedforthispurpose.

–Usecounterweight(s)orwheelweightswhen

suggestedintheoperator’smanual.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesfromrotatingbeforecrossing

surfacesotherthangrass.

•Whenusinganyattachments,neverdirectdischarge

ofmaterialtowardbystandersnorallowanyonenear

themachinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesinplace.

Besureallinterlocksareattached,adjustedproperly,

andfunctioningproperly .

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatingtheengineat

excessivespeedmayincreasethehazardofpersonal

injury.

•Beforeleavingtheoperator’sposition:

–stoponlevelground;

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey.

Important:Allowenginetoidlefor5

minutesbeforeshuttingitoffafterafull

loadoperation.Failuretodosomayleadto

turbo-chargertrouble.

•Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Stoptheengineanddisengagedrivetoattachment

–beforerefuelling;

–beforeremovingthegrasscatcher/catchers;

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator’s

position.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthe

mower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperating

theequipment.

•Reducethethrottlesettingduringenginerun-out

and,iftheengineisprovidedwithashut-offvalve,

turnthefueloffattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesfrom

rotating.

•Beawareofthemowerdischargedirectionanddo

notpointitatanyone.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Thismachineisnotdesignedorequippedfor

on-roaduseandisaslowmovingvehicle.Ifyou

mustcrossortravelonapublicroad,youshould

beawareofandcomplywithlocalregulations,such

asrequiredlights,slowmovingvehiclesignsand

reectors.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumesmayreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuel

storageareafreeofgrass,leaves,orexcessivegrease.

•Keepallpartsingoodworkingconditionandall

hardwareandhydraulicttingstightened.Replaceall

wornordamagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachineto

prevententrapmentofthengersbetweenmoving

bladesandxedpartsofthemachine.

5

Page 6

•Onmulti-spindlemowers,takecareasrotatingone

bladecancauseotherbladestorotate.

•Disengagedrives,lowerthecuttingunits,setparking

brake,stopengineandremovekeyanddisconnect

sparkplugwire(gasengineonly).Waitforall

movementtostopbeforeadjusting,cleaningor

repairing.

•Cleangrassanddebrisfromcuttingunits,drives,

silencers/mufers,andenginetohelppreventres.

Cleanupoilorfuelspillage.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatteryandremovesparkplugwire(gas

engineonly)beforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.

Reconnectpositiverstandnegativelast.

•Usecarewhencheckingtheblades.W earglovesand

usecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.W ear

protectiveclothinganduseinsulatedtools.

•Storethemachinewiththecuttingunitsinthe

loweredpositionorsecurethewingdeckswiththe

storagelatchestopreventthemfromunintentionally

lowering.

ToroRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknowthatisnotincludedintheCEN,ISO,or

ANSIstandard.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustouserandbystanders.

Engineexhaustcontainscarbonmonoxide,

whichisanodorless,deadlypoisonthatcan

killyou.

Donotrunengineindoorsorinanenclosed

area.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennis

shoesorsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Beforestartingtheengine,sitontheseat.

•Usingthemachinedemandsattention.Toprevent

lossofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,

embankments,orotherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrol

ofthemachine.

•Whenoperatingamachineonslopes,bybanks,or

dropoffs,alwayshaveROPS(roll-overprotection

system)installed.

•WhenoperatingamachinewithROPS(roll-over

protectionsystem)alwaysusetheseatbelt.

•Raisethecuttingunitswhendrivingfromonework

areatoanother.

•Donottouchtheengine,silencer/mufer,or

exhaustpipewhiletheengineisrunningorsoon

afterithasstoppedbecausetheseareascouldbehot

enoughtocauseburns.

•Onanyhill,thereisthepossibilityoftippingor

rollingover,buttheriskincreasesastheslopeangle

increases.Steephillsshouldbeavoided.

Cuttingunitsmustbeloweredwhengoingdown

slopestomaintainsteeringcontrol

•Engagetractiondriveslowly,alwayskeepfooton

tractionpedal,especiallywhentravelingdownhill.

Usereverseontractionpedalforbraking.

6

Page 7

•Ifthemachinestallswhenclimbingaslope,do

notturnthemachinearound.Alwaysbackslowly,

straightdowntheslope.

SoundPressureLevelfora

4700-D

•Whenapersonorpetappearsunexpectedlyin

ornearthemowingarea,stopmowing.Careless

operation,combinedwithterrainangles,ricochets,

orimproperlypositionedguardscanleadtothrown

objectinjuries.Donotresumemowinguntilthe

areaiscleared.

MaintenanceandStorage

•Makesureallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunder

highpressure.Usepaperorcardboard,notyour

hands,tosearchforleaks.Hydraulicuidescaping

underpressurecanhavesufcientforcetopenetrate

theskinandcauseseriousinjury.Seekimmediate

medicalattentionifuidisinjectedintoskin.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinthesystemmust

berelievedbystoppingtheengineandloweringthe

cuttingunitsandattachmentstotheground.

•Checkallfuellinesfortightnessandwearona

regularbasis.Tightenorrepairthemasneeded.

ThisunithasanequivalentcontinuousA-weighted

soundpressurelevelattheoperatorearof90dBA,

basedonmeasurementsofidenticalmachinesperISO

11201andEN836.

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof

105dBA/1pW ,basedonmeasurementsofidentical

machinesperISO11094.

VibrationLevel

Hand-Arm

Thisunitdoesnotexceedavibrationlevelof2.5m/s2at

thehandsbasedonmeasurementsofidenticalmachines

perEN1033andEN836.

WholeBody

Thisunitdoesnotexceedavibrationlevelof0.5m/s2

attheposteriorbasedonmeasurementsofidentical

machinesperEN1032andEN836.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthecutting

units,attachments,andanymovingparts.

•Toensuresafetyandaccuracy ,haveanAuthorized

ToroDistributorcheckthemaximumenginespeed

withatachometer.

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedToroDistributor.

•UseonlyToro-approvedattachmentsand

replacementparts.Thewarrantymaybevoidedif

usedwithunapprovedattachments.

SoundPressureLevelfora

4500-D

ThisunithasanequivalentcontinuousA-weighted

soundpressurelevelattheoperatorearof89dBA,

basedonmeasurementsofidenticalmachinesperISO

11201andEN836

7

Page 8

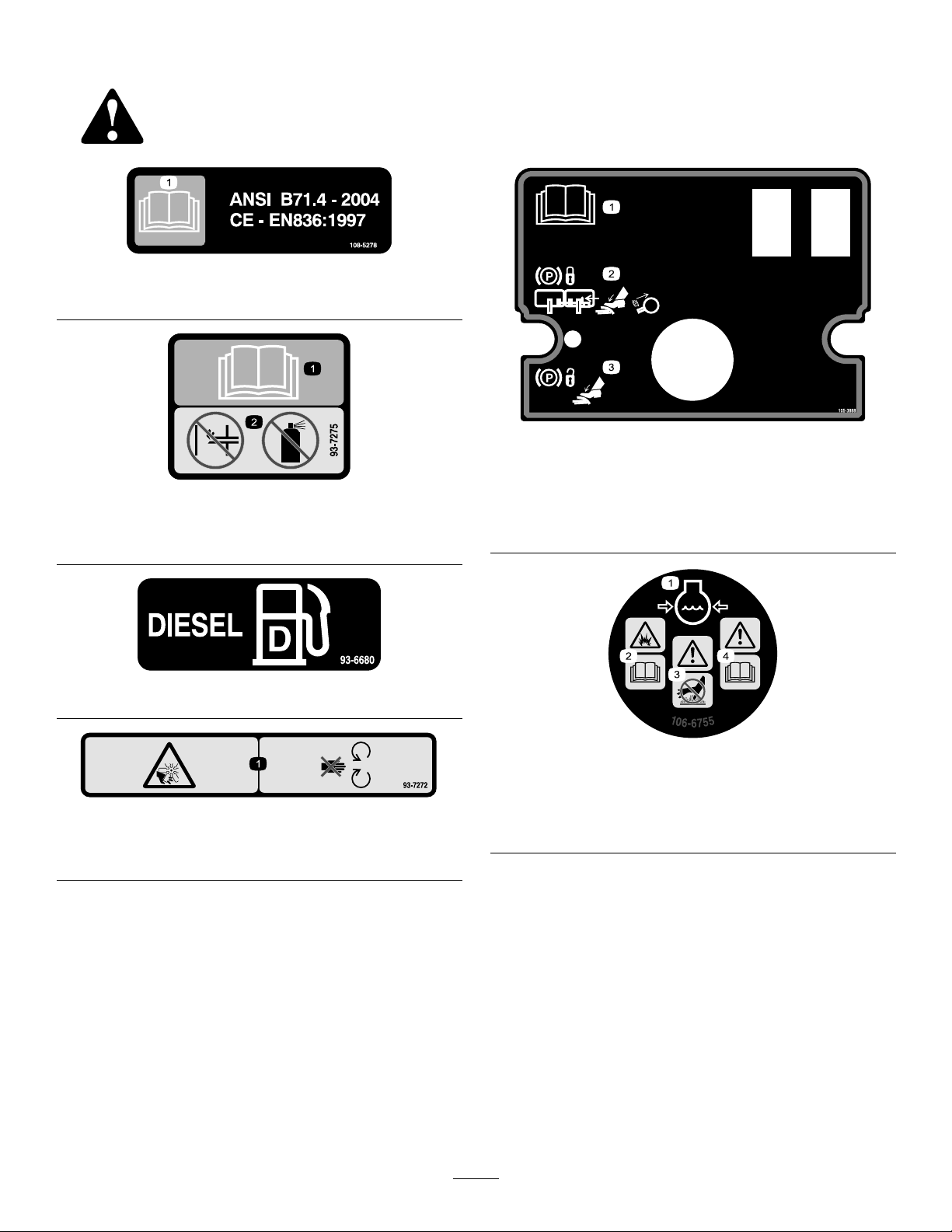

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

108–5278

1.ReadtheOperator’sManual.

93-7275

1.ReadtheOperator’sManual.

2.Donotusestartingaids.

105-3888

1.ReadtheOperator’sManual.

2.T olocktheparkingbrake,securethebrakepedalswiththe

lockingpin,pressthebrakepedals,andpullouttheparking

brakeknob.

3.T ounlocktheparkingbrake,pressthebrakepedal.

93-6680

93-7272

1.Cutting/dismembermenthazard;fan—stayawayfromoving

parts.

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator’sManual.

106-6755

3.Warning—donottouch

thehotsurface.

4.Warning—readthe

Operator’sManual.

8

Page 9

1.ReadtheOperator’s

Manual.

2.Engine—stop5.Engine—start

3.On

1.Machinespeed

2.Slow

105-7506

4.Engine—preheat

105-9223

1.Warning-readtheOperator’sManual.

2.T ostarttheengine(readtheOperator’sManual),sitinthe

operators’position,turntheignitionkeytotheEngine-run

positionuntiltheEngine-preheatlightturnsoff,turnthe

ignitionkeytotheEngine-startposition,andpressthe

brakepedal.

3.T ostoptheengine(readtheOperator’sManual),disengage

thePTO,turntheignitionkeytotheEngine-stopposition,

removethekey ,andlocktheparkingbrake.

93-6699

3.Continuousvariable

setting

4.Fast

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

106-6754

105-9830

(AfxforCE)

1.Lock2.Unlock

1.Hydraulicoil

9

93-6686

2.ReadtheOperator’s

Manual.

Page 10

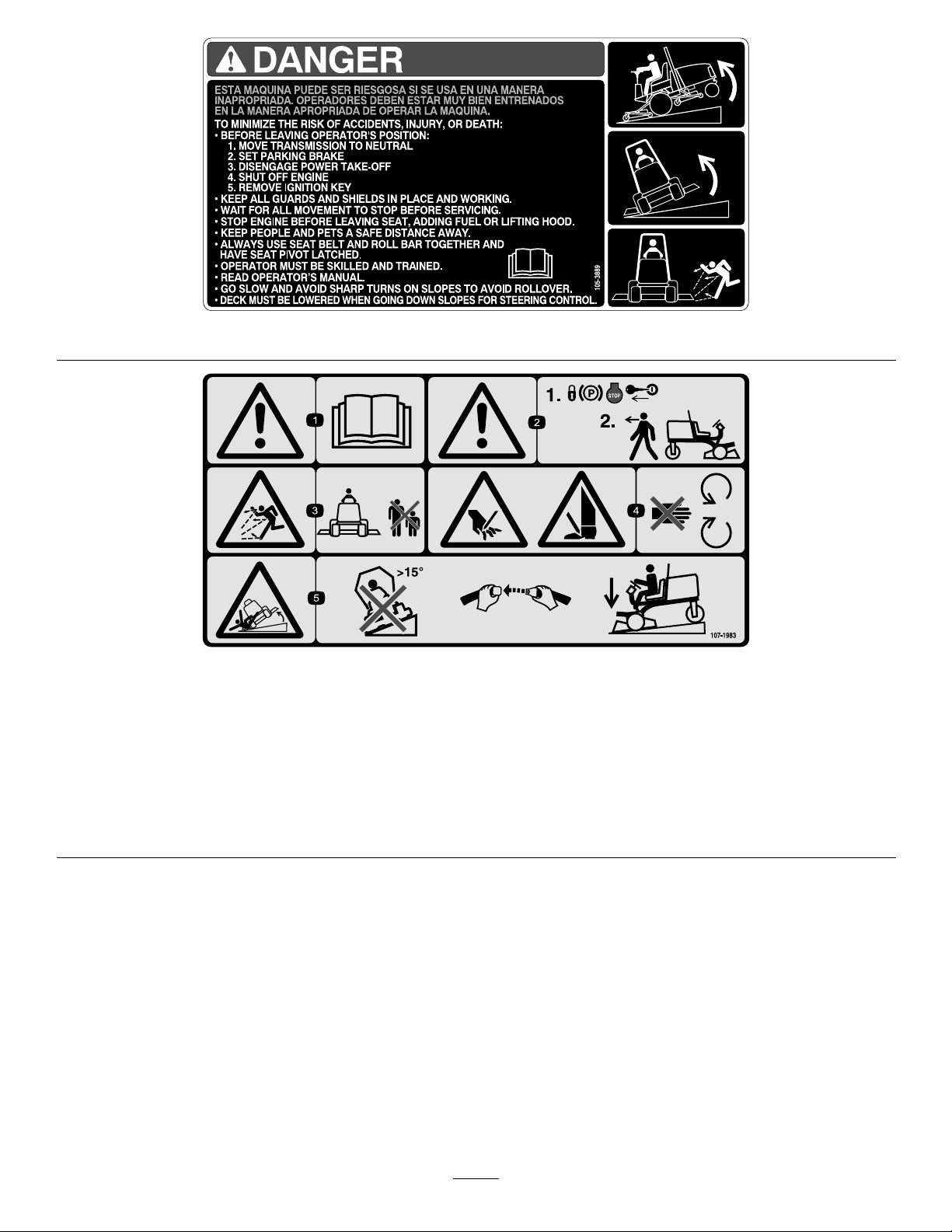

105-3889

107-1983

(Afxoverpartno.105–3889forCE)

*ThissafetydecalincludesaslopewarningrequiredonthemachineforcompliancetotheEuropeanLawnMowerSafetyStandardEN836:1997.Theconservativemaximum

slopeanglesindicatedforoperationofthismachineareprescribedbyandrequiredbythisstandard.

1.Warning—readtheOperator’sManual.

2.Warning—locktheparkingbrake,stoptheengine,andremovetheignitionkeybeforeleavingthemachine.

3.Thrownobjecthazard—keepbystandersasafedistancefromthemachine.

4.Cuttinghazardofhandorfoot—stayawayfrommovingparts.

5.Tippingandcrushinghazard—donotdrivemachineonaslopegreaterthan15degrees,weartheseatbelt,andlowerthe

cuttingunitwhendrivingdownslopes.

10

Page 11

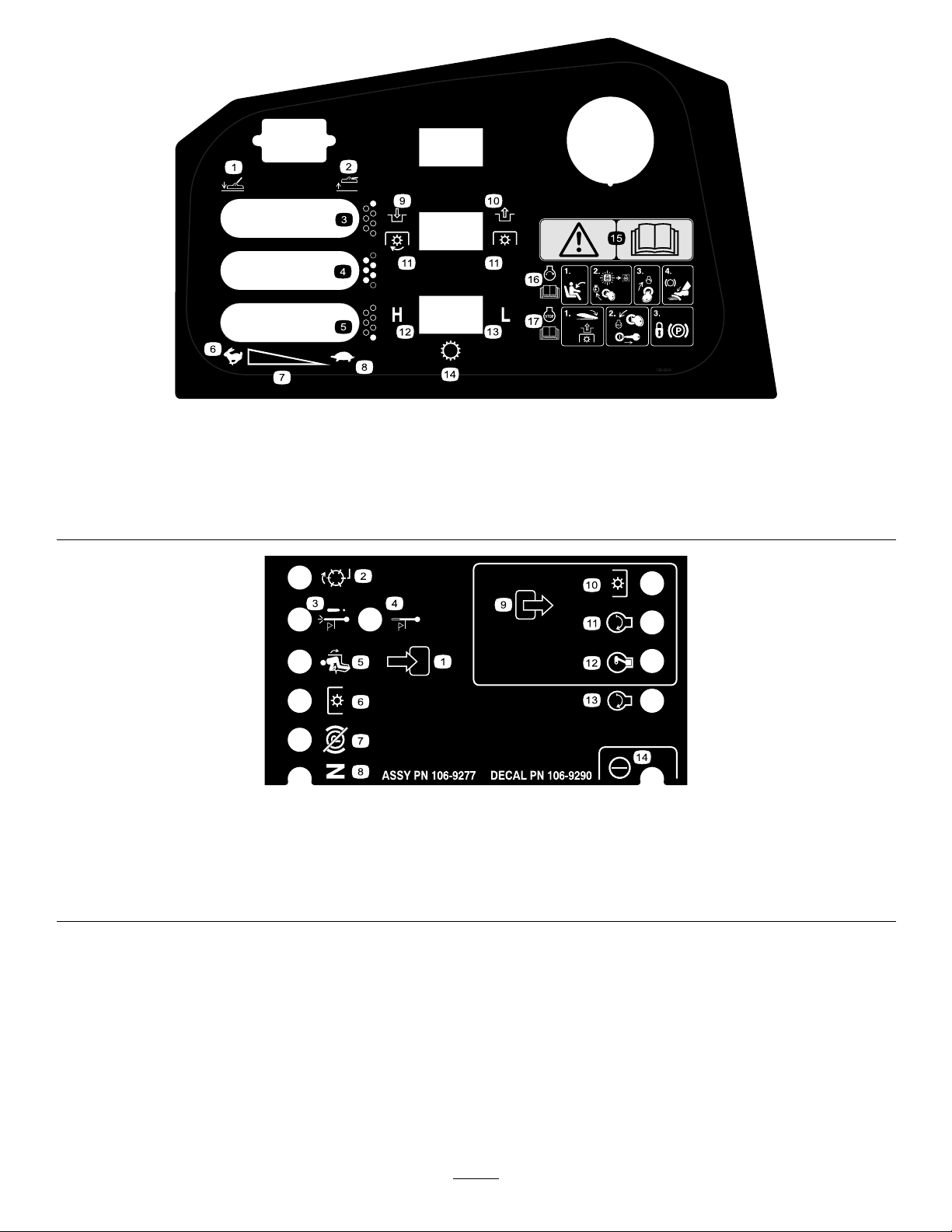

108-4044

1.Lowerthecuttingunit(s).

2.Raisethecuttingunit(s).7.Continuousvariablesetting

3.Rightcuttingunit(GM4700-Donly)8.Slow

4.Centercuttingunits

5.Leftcuttingunit(GM4700-Donly)

6.Fast

9.Engage14.Transmission

10.Disengage

106–9290

1.Input5.Inseat

2.Backlap

3.Hightempshutdown

4.Hightempwarning(not

used)

6.PTOswitch10.PTO

7.Parkbrakeoff11.Start

8.Neutral12.ETR

11.PowerT ake-off(PTO)

12.High

13.Low

9.Output13.Start

14.Power

11

Page 12

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

105-9895

12

Page 13

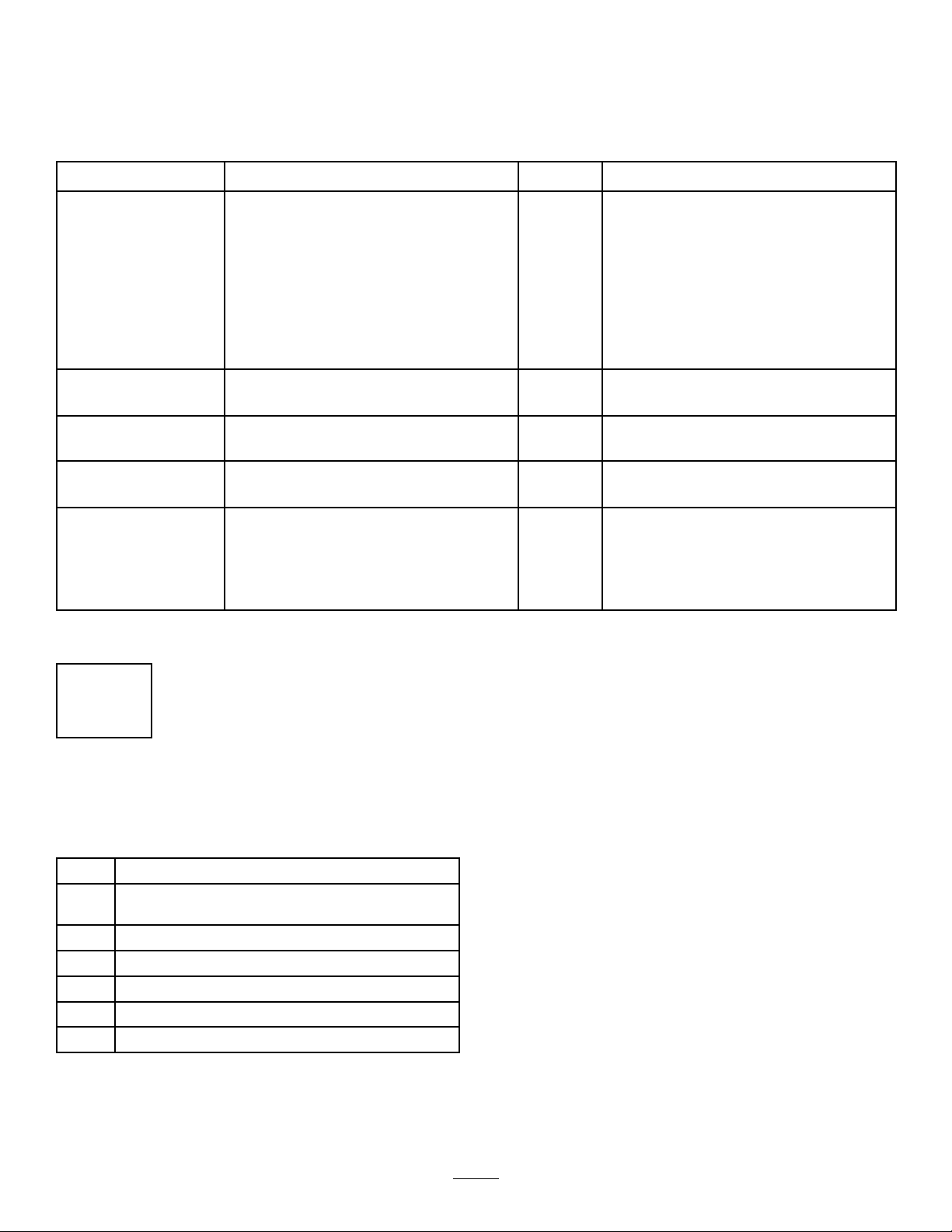

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

SeatKit,Model30398(soldseparately)

SeatSuspensionKit,Model30312

(Mechanical)or30313(Air)(sold

separately)

Seatbelt

Capscrew,7/16-20x1inch

Lockwasher,7/16inch

ManualTube1

R-clamp2

WarningDecal1

Nopartsrequired

Nopartsrequired

Operator’sManual

EngineOperator’sManual

PartsCatalog

OperatorTrainingMaterial

Pre-deliveryInspectionSheet

Qty.

Use

1

1

1

2

2

–

–

1

1

1

1

1

Installtheseat,seatbelt,andmanual

tube.

Usedonlyonmachinesoutsidethe

U.S.A.

Greasethemachine.

Checktherearaxlelubricant,hydraulic

uid,andengineoillevels

Readthemanualsandwatchthe

trainingmaterialbeforeoperatingthe

machine.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Kit,ModelNo.30312or30313,mustbepurchasedand

installed.

1

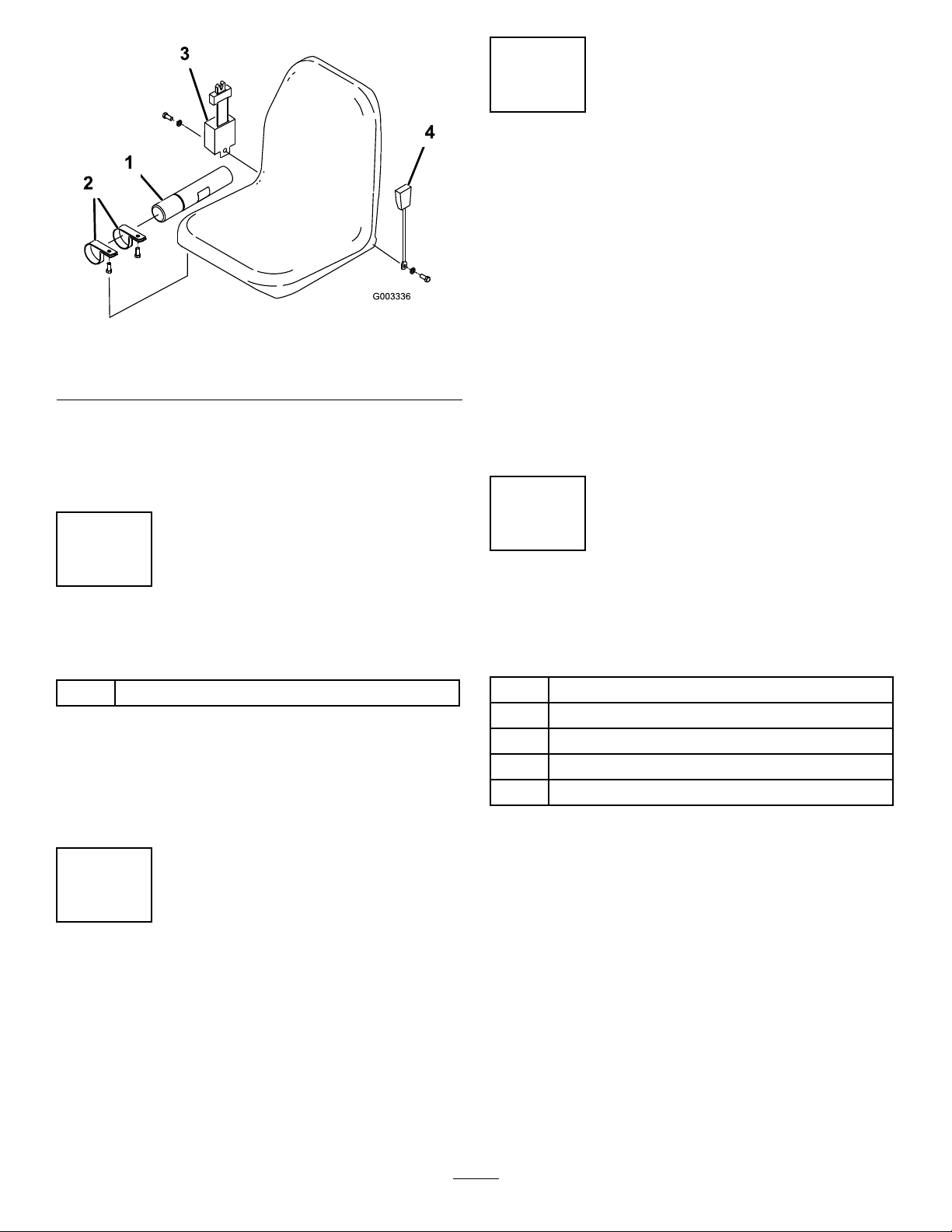

1.Mountthemanualtubetotheseatsuspensionwith

the2R-clampsincludedinlooseparts(Figure3).

InstallingtheSeat,SeatBelt,

andManualTube

2.Installtheseatbelttoeachsideoftheseatwithabolt

andlockwasher,suppliedinlooseparts(Figure3).

Theseatbeltretractoristobemountedtotheright

Partsneededforthisprocedure:

sideoftheseatandtheseatbeltbuckletotheleft

side.

1

SeatKit,Model30398(soldseparately)

SeatSuspensionKit,Model30312(Mechanical)or

1

30313(Air)(soldseparately)

1

Seatbelt

2

Capscrew,7/16-20x1inch

2

Lockwasher,7/16inch

1ManualTube

2R-clamp

Important:Makesurethattheseatswitchis

connectedtotheseatswitchconnectoronthe

harness.

Procedure

Themachineisshippedwithouttheseatassembly.

DeluxeSeatKit,ModelNo.30398,andSeatSuspension

13

Page 14

Figure3

1.Manualtube

2.R-clamp

3.Slidetheseatcompletelyforwardandbackwardto

ensureproperoperationandthatseatswitchwires

andconnectorsarenotpinchedordonocontactany

movingparts.

3.Seatbeltretractor

4.Seatbeltbuckle

4

CheckingFluidLevels

NoPartsRequired

Procedure

1.Checktherearaxlelubricantlevelbeforetheengine

isrststarted,refertoCheckingtheRearAxle

LubricantinDriveSystemMaintenance,page39.

2.Checkthehydraulicuidlevelbeforetheengineis

rststarted,refertoCheckingtheHydraulicFluid

LevelinOperation,page20.

3.Checktheengineoillevelbeforeandaftertheengine

isrststarted,refertoCheckingtheEngineOil

LevelinOperation,page20.

5

2

ReplacingtheWarningDecal

Partsneededforthisprocedure:

1WarningDecal

Procedure

OnmachinesrequiringCEcompliance,replacewarning

decal,partno.107–1983withwarningdecalpartno.

105–3889.

3

GreasingtheMachine

NoPartsRequired

ReadingtheManualsand

ViewingtheTrainingMaterial

Partsneededforthisprocedure:

1

Operator’sManual

1

EngineOperator’sManual

1

PartsCatalog

1

OperatorTrainingMaterial

1

Pre-deliveryInspectionSheet

Procedure

1.Readthemanuals.

2.Viewthetrainingmaterial.

3.Storethedocumentationinasafeplace.

Procedure

Beforethemachineisoperated,itmustbegreased

toensureproperlubrication.RefertoLubrication,

page31.Failuretoproperlygreasethemachinewill

resultinprematurefailureofcriticalparts.

14

Page 15

ProductOverview

1.Steeringwheel

2.Brakes5.Manualtube

3.Cuttingunit6.Hood/enginecompartment

4.Tractionpedal

Controls

TractionPedal

Thetractionpedal(Figure5)controlsforwardand

reverseoperation.Depressthetopofthepedaltomove

forwardandthebottomtomovebackward.Ground

speeddependsonhowfarthepedalisdepressed.For

noload,maximumgroundspeed,fullydepressthepedal

whilethethrottleisinFast.

Tostop,reduceyourfootpressureonthetractionpedal

andallowittoreturntothecenterposition.

ForwardSpeedControl

Presettheforwardspeedcontrol(Figure5)tolimit

theamountthetractionpedalcanbedepressedinthe

forwarddirectiontomaintainaconstantmowingspeed.

Figure4

7.ROPS(RolloverProtectionSystem)

EngineOilPressureWarningLight

Thelight(Figure5)illuminateswhentheengineoil

pressureisdangerouslylow .

KeySwitch

Thekeyswitch(Figure5)hasthreepositions:Off,

On/Preheat,andStart.

15

Page 16

Figure5

1.Tractionpedal

2.Forwardspeedcontrol6.Enginecoolant

3.Keyswitch

4.Engineoilpressure

warninglight

5.Chargeindicator

7.Glowplugindicatorlight

ChargeIndicator

temperaturewarning

light

Figure6

1.Forwardspeedlimiter

screw

2.Reversespeedlimiter

screw

BrakePedals

Twofootpedals(Figure7)operateindividualwheel

brakesforturningassistance,parking,andtoaidin

obtainingbettersidehilltraction.Alatchconnectsthe

pedalsforparkingbrakeoperationandtransport.

Thechargeindicator(Figure5)illuminateswhenthe

systemchargingcircuitmalfunctions.

EngineCoolantTemperatureWarning

Light

Thelight(Figure5)illuminatesandtheengineshuts

downwhencoolantreachesanexcessivelyhigh

temperature.

GlowPlugIndicatorLight

Whenlit,theglowplugindicatorlight(Figure5)

indicatesthattheglowplugsareon.

SpeedLimiterScrews

Adjustthescrew(s)(Figure6)tolimittheamountthe

tractionpedalcanbedepressedintheforwardorreverse

directiontolimitspeed.

Important:Thespeedlimiterscrewmuststopthe

tractionpedalbeforethepumpreachesfullstroke

ordamagetothepumpmayoccur.

Figure7

1.Brakepedals3.Parkingbrakelatch

2.Pedallockinglatch

PedalLockingLatch

Thepedallockinglatch(Figure7)connectsthepedals

togethertoengagetheparkingbrake.

ParkingBrakeLatch

Aknobontheleftsideoftheconsoleactuatesthe

parkingbrakelock(Figure7).T oengagetheparking

brake,connectthepedalswiththelockinglatch,push

downonbothpedals,andpulltheparkingbrakelatch

out.Toreleasetheparkingbrake,depressbothpedals

untiltheparkingbrakelatchretracts.

ThrottleControl

Movethecontrol(Figure8orFigure9)forwardto

increasetheenginespeedandrearwardtodecreasethe

speed.

16

Page 17

Model4500-D

PTOSwitch

ThePTOswitch(Figure8)hastwopositions:On

(engage)andOff(disengage).PushthePTOswitch

forwardtotheOnpositiontostarttheimplementor

cuttingunitblades.PushtheswitchbackwardtotheOff

positiontostopimplementoperation.

Hi-LoSpeedControl

Theswitch(Figure8)allowsthespeedrangetoincrease

fortransportofthemachine.Cuttingdeckswillnot

operateinhighrange.

Figure8

PowerPoint

1.Throttlecontrol

2.Liftlever

3.Hourmeter7.Powerpoint

4.Enginetemperaturegauge

Model4700-D

1.Throttlecontrol

2.Liftlever

3.Hourmeter7.Powerpoint

4.Enginetemperaturegauge

5.PTOswitch

6.Hi-Lospeedcontrol

Figure9

5.PTOswitch

6.Hi-Lospeedcontrol

Thepowerpoint(Figure8)isusedtopoweroptional12

voltelectricalaccessories.

FuelGauge

Thefuelgauge(Figure10)indicatestheleveloffuelin

thetank.

Figure10

1.Fuelgauge

CuttingUnitLiftLatch(CE)

Thecuttingunitliftlatch(Figure11orFigure12)locks

thecentervecuttingunitliftleverswhenthecutting

unitsareintheraisedposition.

LiftLever

Thelever(Figure8)raisesandlowersthecuttingunits.

HourMeter

Thehourmeter(Figure8)showsthetotalhoursthatthe

machinehasbeenoperated.

EngineTemperatureGauge

Thisgauge(Figure8)indicatestheenginecoolant

temperature.

17

Page 18

1.Cuttingunitliftlatch

1.Cuttingunitliftlatch

Figure11

Model4500-D

Figure12

Model4700-D

18

Page 19

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

TractionUnitSpecications

4500-D4700-D

Widthofcut109inches(2.8m)150inches(3.8m)

Overallwidth,

cuttingunits

down

Overallwidth,

cuttingunitsup

(transport)

Overalllength145.8inches(370cm)145.8inches(370cm)

Heightwith

ROPS

Ground

clearance

TrackWidth,

front

TrackWidth,rear

Wheelbase

Weight(with

cuttingunitsand

nouids)

Engine

CoolingsystemCapacityis2-3/4gallons(10.4l)of50/50mixtureofethyleneglycolanti-freeze.

Kubota,four-cycle,fourcylinder,122inchdisplacement,water-cooledturbodieselengine.Rated58hp@

2600RPM,23:1compressionratio.Lowidle-1300RPM,highidle-2800RPM.Oilcapacityis8qt.(7.6l)withlter.

112.8inches(286cm)153.8inches(391cm)

88.25inches(224cm)88.25inches(224cm)

85inches(216cm)85inches(216cm)

6inches(15cm)6inches(15cm)

88.25inches(224cm)88.25inches(224cm)

55.5inches(141cm)55.5inches(141cm)

67-1/2inches(171cm)67-1/2inches(171cm)

4123lb(1400kg)4674lb(2120kg)

Fuelsystem

Hydraulic

system

GroundspeedMow:0-7MPH(0-1 1.3km/h)Transport:0-13MPH(0-21km/h)

TiresFront:29x14.00-15,6-ply,tubelessultra-tracktreadRear:20x12.00-10,6-ply,tubelessmultitracktread

Electricalsystem

Replaceableinlinelterandspin-onfuellter/waterseparator.Capacityis21gallons(79.5l)of#2dieselfuel.

Reservoircapacityis7.5gallons(30l).Tworeplaceablespin-onlterelements.

Frontandbacktirepressureis20psi(138kPa).

12volt,1 10minutereservecapacity(DIN)batteryand40amp.alternator .Negativeground.

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

19

Page 20

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

Ifyouleavethekeyintheignitionswitch,

someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudo

anymaintenance.

Figure13

1.Dipstick

4.IftheoilisbelowtheFULLmark,removethell

cap(Figure14)andaddoiluntilthelevelreaches

theFULLmark.Donotoverll.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;

however,theoillevelmustbecheckedbeforethe

engineisrststarted.

Thecrankcasecapacityisapproximately8qt.(7.6l)

withthelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4or

higher.

•Preferredoil:SAE15W -40(above0°F)

•Alternateoil:SAE10W -30or5W-30(all

temperatures)

Note:ToroPremiumEngineoilisavailable

fromyourdistributorineither15W -40or10W -30

viscosity.Seethepartscatalogforpartnumbers.

1.Parkthemachineonalevelsurface.

2.Unlocktheenginecoverlatchesandopenthe

enginecover.

3.Removethedipstick,wipeitclean,installthe

dipstickintothetube,andpullitoutagain.

Figure14

1.Oilllcap

Note:Whenusingdifferentoil,drainalloldoil

fromthecrankcasebeforeaddingnewoil.

5.Installtheoilllcapanddipstick.

6.Closetheenginecoverandsecureitwiththelatches.

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily

Checklevelofcoolantatthebeginningofeachday.

Capacityofsystemis2-3/4gal.(10.4l).

1.Carefullyremovetheradiatorcapandexpansion

tankcap(Figure15).

TheoillevelshouldbeuptotheFULLmark

(Figure13).

20

Page 21

Iftheenginehasbeenrunning,thepressurized,

hotcoolantcanescapeandcauseburns.

•Donotopentheradiatorcapwhenthe

engineisrunning.

•Usearagwhenopeningtheradiatorcap,

andopenthecapslowlytoallowsteamto

escape.

Figure16

1.Fueltankcap

2.Fillthetanktoabout1inch(25mm)belowthetop

ofthetank,notthellerneck,withNo.2diesel

fuel.Theninstallthecap.

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

Figure15

1.Expansiontank

2.Checkthecoolantlevelintheradiator.Theradiator

shouldbelledtothetopofthellerneckandthe

expansiontanklledtotheFULLmark.

3.Ifthecoolantislow ,adda50/50mixtureofwater

andethyleneglycolanti-freeze.Donotusewater

onlyoralcohol/methanolbasecoolants.

4.Installtheradiatorcapandexpansiontankcap.

FillingtheFuelTank

Thecapacityofthefueltankis21gallons(79l).

1.Removethefueltankcap(Figure16).

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1/4to

1/2in.(6to13mm)belowthebottomof

thellerneck.Thisemptyspaceinthetank

allowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

CheckingtheHydraulicFluid

Level

ServiceInterval:Beforeeachuseordaily

Themachinesreservoirislledatthefactorywith

approximately7.5U.S.gallons(13.2l)ofhighquality

hydraulicuid.Checkthelevelofthehydraulicuid

beforetheengineisrststartedanddailythereafter.

Therecommendedreplacementuidisasfollows:

21

Page 22

ToroPremiumAllSeasonHydraulicFluid(Availablein5

gallonpailsor55gallondrums.SeepartscatalogorT oro

distributorforpartnumbers.)

Alternateuids:IftheTorouidisnotavailable,other

uidsmaybeusedprovidedtheymeetallthefollowing

materialpropertiesandindustryspecications.W edo

notrecommendtheuseofsyntheticuid.Consult

withyourlubricantdistributortoidentifyasatisfactory

productNote:Torowillnotassumeresponsibilityfor

damagecausedbyimpropersubstitutions,souseonly

productsfromreputablemanufacturerswhowillstand

behindtheirrecommendation.

HighViscosityIndex/LowPourPointAnti-wearHydraulic

Fluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to48

ViscosityIndexASTM

D2270

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0

cSt@100°C7.9to8.5

140to160

Figure17

1.Hydraulictankcap

3.Removethedipstickfromthellerneckandwipe

itwithacleanrag.Insertthedipstickintotheller

neck;thenremoveitandchecktheuidlevel.The

uidlevelshouldbebetweenthetwomarksonthe

dipstick.

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditive

forthehydraulicsystemoilisavailablein2/3oz.(20

ml)bottles.Onebottleissufcientfor4-6gal(15-22

1)ofhydraulicoil.Orderpartno.44-2500fromyour

authorizedTorodistributor.

BiodegradableHydraulicFluid-Mobil224H

ToroBiodegradableHydraulicFluid(Availablein5

gallonpailsor55gallondrums.SeepartscatalogorT oro

distributorforpartnumbers.)

Alternateuid:MobilEAL224H

Note:Thisisvegetable-oilbasedbiodegradableoil

testedandapprovedbyToroforthismodel.Thisuid

isnotasresistanttohightemperaturesasstandard

uid,soinstallanoilcoolerifrequiredbytheoperator

manualandfollowrecommendeduidchangeintervals

withthisuid.Contaminationbymineral-based

hydraulicuidswillchangethebiodegradabilityand

toxicityofthisoil.Whenchangingfromstandarduid

tothebiodegradabletype,becertaintofollowthe

approvedushingprocedure.ContactyourlocalToro

Distributorfordetails.

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,andremovethekey.

2.Cleantheareaaroundthellerneckandcapofthe

hydraulictank(Figure17).Removethecapfrom

thellerneck.

4.Ifthelevelislow,addtheappropriateuidtoraise

theleveltotheuppermark.

5.Installthedipstickandcapontothellerneck.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Thetiresareover-inatedforshipping.Therefore,

releasesomeoftheairtoreducethepressure.The

correctairpressureinthetiresis20psi(138kPa).

Checkthetirepressuredaily.

Important:Maintaintherecommendedpressure

inalltirestoensureagoodquality-of-cut

andpropermachineperformance.Donot

under-inate.

StartingandStoppingthe

Engine

StartingtheEngine

Important:Thefuelsystemmustbebledifanyof

thefollowingsituationshaveoccurred:

•Theenginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponthefuel

systemcomponents.

RefertoBleedingtheFuelSysteminFuelSystem

Maintenance,page35.

22

Page 23

1.Removeyourfootfromthetractionpedaland

ensurethatitisinneutral.Ensurethattheparking

brakeisset.

2.Movethethrottlecontroltothelowidleposition.

3.TurntheignitionkeytotheRunposition.Theglow

indicatorwilllight.

4.Whentheglowindicatordims,turntheignitionkey

totheStartposition.Releasethekeyimmediately

whentheenginestartsandallowittoreturnto

theRunposition.Movethethrottlecontroltothe

desiredposition.

Important:Donotrunthestartermotor

morethan15secondsatatimeorpremature

starterfailuremayresult.Iftheenginefailsto

startafter15seconds,turnthekeytotheOff

position,recheckthecontrolsandprocedures,

wait15additionalseconds,andrepeatthe

startingprocedure.

2.MovethePTOlevertotheOffposition.

3.Settheparkingbrake.

4.RotatetheignitionkeytoOff.

5.Removethekeyfromtheswitchtoprevent

accidentalstarting.

CheckingtheInterlock

Switches

ServiceInterval:Beforeeachuseordaily

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

Whenthetemperatureislessthan20°F(-7°C),the

startermotorcanberunfor30secondsonthen60

secondsofffor2attempts.

5.Whentheengineisstartedforthersttime,or

afteranoverhauloftheengine,transmission,or

axle,operatethemachineinforwardandreversefor

oneortwominutes.Alsooperatetheliftleverand

PTOlevertoensureproperoperationofallparts.

Turnthesteeringwheeltotheleftandrightto

checksteeringresponse.Thenshuttheengineoff

andcheckforoilleaks,looseparts,andanyother

noticeabledifculties.

Shuttheengineoffandwaitforallmoving

partstostopbeforecheckingforoilleaks,loose

parts,andothermalfunctions.

StoppingtheEngine

Important:Allowenginetoidlefor5minutes

beforeshuttingitoffafterafullloadoperation.

Thisallowstheturbochargertocooldownbefore

shuttingtheengineoff.Failuretodosomaylead

toturbo-chargertrouble.

Note:Lowercuttingunitstothegroundwhenever

machineisparked.Thisrelievesthehydraulicloadfrom

thesystem,preventswearonsystempartsandalso

preventsaccidentalloweringofthecuttingunits.

1.MovethethrottlecontrolbackwardtotheSlow

position.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Themachinehasinterlockswitchesintheelectrical

system.Theseswitchesaredesignedtostoptheengine

whenoperatorgetsoffoftheseatwhenthetraction

pedalisdepressed.However,theoperatormaygetoff

oftheseatwhiletheengineisrunningandthetraction

pedalisinneutral.Althoughtheenginewillcontinue

torunifthePTOleverisdisengagedandthetraction

pedalisreleased,itisstronglyrecommendedthatthe

enginebestoppedbeforerisingfromtheseat.

Tochecktheoperationoftheinterlockswitches,

performthefollowingprocedure:

1.Drivethemachineslowlytoalarge,relativelyopen

area.Lowerthecuttingunit,stoptheengine,and

applytheparkingbrake.

2.Sitontheseatanddepressthetractionpedal.Try

tostarttheengine.Theengineshouldnotcrank.

Iftheenginecranks,thereisamalfunctioninthe

interlocksystemthatshouldbecorrectedbefore

beginningoperation.

3.Sitontheseatandstarttheengine.Risefromthe

seatandmovethePTOlevertoOn.ThePTO

shouldnotengage.IfthePTOengages,thereisa

malfunctionintheinterlocksystemthatshouldbe

correctedbeforebeginningoperation.

4.Sitontheseat,engagetheparkingbrakeandstart

theengine.Movethetractionpedaloutofthe

neutralposition.Theengineshouldkill.Ifthe

23

Page 24

enginedoesnotkill,thereisamalfunctioninthe

interlocksystemthatshouldbecorrectedbefore

beginningoperation.

JackingPoints

•Onthefrontofthemachineontheframeonthe

insideofeachdrivetire

PushingorTowingthe

Machine

Inanemergency,themachinecanbemovedforwardby

actuatingthebypassvalveinthevariabledisplacement

hydraulicpumpandpushingortowingthemachine.

Donotpushortowthemachineformorethan1/4

mile(0.4km).

Important:Donotpushortowthemachine

fasterthan2-3MPH(3-4.8km/h)becauseinternal

transmissiondamagemayoccur.Thebypassvalve

mustbeopenwheneverthemachineispushedor

towed.

Important:Ifthemachinemusttobepushedor

towedinreverse,thecheckvalveinthefour-wheel

drivemanifoldmustalsobebypassed.Tobypass

thecheckvalve,connectahoseassembly(Hose

PartNo.95-8843,CouplerFittingNo.95-0985

[Qty.2],andHydraulicFittingNo.340-77[Qty.2])

tothereversetractionpressuretestportandthe

reversefour-wheeldrivepressureport.

1.Openhoodandremovethecentershroud

2.Rotatethebypassvalve90°(1/4turn)ineither

directiontoopenandallowoiltobypassinternally

(Figure18).Becauseuidisbypassed,themachine

canbeslowlymovedwithoutdamagingthe

transmission.Notethepositionofthevalvewhen

openingorclosing.

•Ontherearofthemachineatthecenteroftheaxle

TieDowns

•Oneachsideoftheframeunderthefrontsteps

•Therearbumper

OperatingCharacteristics

Practicedrivingthemachinebecauseithasahydrostatic

transmissionanditscharacteristicsaredifferentthan

manyturfmaintenancemachines.Somepointsto

considerwhenoperatingthetractionunit,cutting

units,orotherimplementsarethetransmission,engine

speed,loadonthecuttingbladesorotherimplement

components,andtheimportanceofthebrakes.

Tomaintainenoughpowerforthetractionunitand

implementwhileoperating,regulatethetractionpedal

tokeeptheengineRPMhighandsomewhatconstant.

Agoodruletofollowistodecreasethegroundspeed

astheloadontheimplementincreases,andincreasethe

groundspeedastheloaddecreases.

Therefore,allowthetractionpedaltomovebackward

astheengineRPMdecreases,anddepressthepedal

slowlyastheRPMincreases.Bycomparison,when

drivingfromoneworkareatoanother,withnoload

andcuttingunitraised,havethethrottleintheFast

positionanddepressthetractionpedalslowlybutfully

toattainmaximumgroundspeed.

Figure18

1.Bypassvalve

3.Closethebypassvalve90°(1/4turn)backbefore

startingtheengine.However,donotexceed

5-8ft.-lb.(7-11N·m)torquetoclosethevalve.

Anothercharacteristictoconsideristheoperation

ofthepedalsthatareconnectedtothebrakes.The

brakescanbeusedtoassistinturningthemachine.

However,usethemcarefully,especiallyonsoftor

wetgrassbecausetheturfmaybetornaccidentally.

Anotherbenetofthebrakesistomaintaintraction.

Forexample,insomeslopeconditions,theuphillwheel

slipsandlosestraction.Ifthissituationoccurs,depress

theuphillturnpedalgraduallyandintermittentlyuntil

theuphillwheelstopsslipping,thus,increasingtraction

onthedownhillwheel.

Useextracarewhenoperatingthemachineonslopes.

Makesurethattheseatlatchisproperlysecuredandthe

seatbeltisbuckled.Driveslowlyandavoidsharpturns

onslopestopreventrollovers.Forsteeringcontrol,the

cuttingunitmustbeloweredwhengoingdownhill.

24

Page 25

Thisproductisdesignedtodriveobjectsinto

thegroundwheretheyloseenergyquickly

ingrassareas.However,carelessoperation,

combinedwithterrainangle,ricochets,or

improperlypositionedsafetyguardcanleadto

thrownobjectinjuries.

•Whenapersonorpetappearssuddenlyinor

nearthemowingarea,stopmowing.

•Donotresumemowinguntiltheareais

cleared.

Important:Allowenginetoidlefor5minutes

beforeshuttingitoffafterafullloadoperation.

Thisallowstheturbochargertocooldownbefore

shuttingtheengineoff.Failuretodosomaylead

toturbo-chargertrouble.

Beforestoppingtheengine,disengageallcontrolsand

movethethrottletoSlow .MovingthethrottletoSlow

reduceshighengineRPM,noise,andvibration.Turn

thekeytoOfftostoptheengine.

StandardControlModule

(SCM)

TheStandardControlModuleisa"potted"electronic

deviceproducedina"onesizetsall"conguration.

Themoduleusessolidstateandmechanical

componentstomonitorandcontrolstandardelectrical

featuresrequiredforsafeproductoperation.

Themodulemonitorsinputsincludingneutral,parking

brake,PTO ,start,backlap,andhightemperature.The

moduleenergizesoutputsincludingPTO ,Starter,and

ETR(energizetorun)solenoid.

Themoduleisdividedintoinputsandoutputs.Inputs

andoutputsareidentiedbygreenLEDindicators

mountedontheprintedcircuitboard.

Thestartcircuitinputisenergizedby12VDC.All

otherinputsareenergizedwhenthecircuitisclosedto

ground.EachinputhasaLEDthatisilluminatedwhen

thespeciccircuitisenergized.UsetheinputLED’s

forswitchandinputcircuittroubleshooting.

Outputcircuitsareenergizedbyanappropriatesetof

inputconditions.ThethreeoutputsincludePTO ,ETR,

andSTART.OutputLED’smonitorrelaycondition

indicatingthepresenceofvoltageatoneofthree

specicoutputterminals.

Outputcircuitsdonotdetermineoutputdevice

integritysoelectricaltroubleshootingincludesoutput

LEDinspectionandconventionaldeviceandwire

harnessintegritytesting.Measuredisconnected

componentimpedance,impedancethroughwire

harness(disconnectatSCM),orbytemporarily"test

energizing"thespeciccomponent.

TheSCMdoesnotconnecttoanexternalcomputeror

handhelddevice,cannotbere-programmed,anddoes

notrecordintermittentfaulttroubleshootingdata.

ThedecalontheSCMonlyincludessymbols.Three

LEDoutputsymbolsareshownintheoutputbox.

AllotherLED’sareinputs.Figure19identiesthe

symbols.

Figure19

1.Input5.Inseat

2.Backlap

3.Hightempshutdown

4.Hightempwarning8.Neutral12.ETR

6.PTOswitch10.PTO

7.Parkbrakeoff11.Start

HerearethelogicaltroubleshootingstepsfortheSCM

device.

25

9.Output13.Start

14.Power

1.Determinetheoutputfaultyouaretryingtoresolve

(PTO,START,orETR).

Page 26

2.Movekeyswitchto"ON"andensurethered

"power"LEDisilluminated.

3.MoveallinputswitchestoensureallLED’schange

state.

4.Positioninputdevicesatappropriatepositionto

achievetheappropriateoutput.Usethefollowing

logiccharttodeterminetheappropriateinput

condition.

5.IfspecicoutputLEDisilluminatedwithout

appropriateoutputfunction,checkoutputharness,

connections,andcomponent.Repairasrequired.

6.IfspecicoutputLEDisnotilluminated,check

bothfuses.

7.IfspecicoutputLEDisnotilluminatedandinputs

areinappropriatecondition,installnewSCMand

determineiffaultdisappears.

Eachrow(across)inthelogicchartbelowidenties

inputandoutputrequirementsforeachspecic

productfunction.Productfunctionsarelistedin

theleftcolumn.Symbolsidentifyspeciccircuit

conditionincluding:energizedtovoltage,closedto

ground,andopentoground.

Note:-Indicatesacircuitclosedtoground.-LEDON

OIndicatesacircuitopentogroundorde-energized-LEDOFF

+Indicatesanenergizedcircuit(clutchcoil,solenoid,orstartinput)LEDON.

""ABlankindicatesacircuitthatisnotinvolvedwiththelogic.

Totroubleshoot,turnonthekeywithoutstarting

theengine.Identifythespecicfunctionthatdoes

notworkandworkacrossthelogicchart.Inspect

theconditionofeachinputLED’stoensureit

matchesthelogicchart.

IftheinputLED’sarecorrect,checktheoutput

LED.IftheoutputLEDisilluminatedbutthe

deviceisnotenergized,measureavailablevoltageat

theoutputdevice,continuityofthedisconnected

device,andpotentialvoltageonthegroundcircuit

(oatingground).Repairswillvarydependingon

yourndings.

OperatingTips

MowWhenGrassisDry

Moweitherinthelatemorningtoavoidthedew,which

causesgrassclumping,orinlateafternoontoavoidthe

damagethatcanbecausedbydirectsunlightonthe

sensitive,freshlymowedgrass.

SelecttheProperHeight-of-CutSetting

toSuitConditions

Removeapproximately1in.(25mm)ornomorethan

1/3ofthegrassbladewhencutting.Inexceptionally

lushanddensegrass,youmayhavetoraisethe

height-of-cuttothenextsetting.

MowatProperIntervals

Undermostnormalconditionsyouwillneedtomow

approximatelyevery4-5days.Butremember,grass

growsatdifferentratesatdifferenttimes.Thismeans

thatinordertomaintainthesameheight-of-cut,which

isagoodpractice,youwillneedtocutmorefrequently

inearlyspring;asthegrassgrowthrateslowsinmid

summer,cutonlyevery8-10days.Ifyouareunableto

mowforanextendedperiodduetoweatherconditions

orotherreasons,mowrstwiththeheight-of-cutata

highlevel;thenmowagain2-3dayslaterwithalower

heightsetting.

AlwaysMowwithSharpBlades

Asharpbladecutscleanlyandwithouttearingor

shreddingthegrassbladeslikeadullblade.Tearingand

shreddingcausesthegrasstoturnbrownattheedges

26

Page 27

whichimpairsgrowthandincreasessusceptibilityto

diseases.

Transporting(Groundsmaster4700–D

Only)

Usethetworeartransportlatcheswhentransporting

overlongdistances,roughterrain,orwhentrailering.

AfterOperating

Toensureoptimumperformance,cleantheunderside

ofthemowerhousingaftereachuse.Ifresidueis

allowedtobuildupinthemowerhousing,cutting

performancewilldecrease.

Note:Lowercuttingunitstothegroundwhenever

machineisparked.Thisrelievesthehydraulicloadfrom

thesystem,preventswearonsystempartsandalso

preventsaccidentalloweringofthecuttingunits.

27

Page 28

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Aftertherst200hours

Beforeeachuseordaily

Every50hours

Every100hours

Every150hours

Every200hours

MaintenanceProcedure

•Torquethewheelnuts.

•Changetheengineoilandlter.

•Changetheplanetarygeardriveoil.

•Changetherearaxlelubricant.

•Changethehydrauliclters.

•Checktheengineoillevel.

•Checkthecoolingsystem.

•Checkthehydraulicuidlevel.

•Checkthetirepressure.

•Checktheinterlockswitches.

•Drainwaterorothercontaminantsfromthewaterseparator.

•Removedebrisfromtheenginearea,oilcooler,andradiator.

•Inspectthehydrauliclinesandhosesforleaks,kinkedlines,loosemounting

supports,wear,loosettings,weatherdeterioration,andchemicaldeterioration.

•Greasethebearingsandbushings.

•Checkthebatterycondition.

•Checktheconditionandtensionofthealternatorbelt.

•Changetheengineoilandlter.

•Torquethewheelnuts.

•Cleanthesparkarrestormufer .

Every400hours

Every800hours

Beforestorage

Yearly

Important:Refertoyourengine

maintenanceprocedures.

•Servicetheaircleaner.(Servicetheaircleanerearlieriftheaircleanerindicator

showsred.Serviceitmorefrequentlyinextremelydirtyordustyconditions.)

•Checkthefuellinesandconnections.

•Replacethefuelpre-lter.

•Checktheplanetarygeardriveoillevel(soonerifexternalleakageisnoticed).

•Checktherearaxlelubricantlevel.

•Drainandcleanthefueltank.

•Changetheplanetarygeardriveoil.

•Changetherearaxlelubricant.

•Checktherearwheeltoe-in.

•Changethehydraulicuid.

•Changethehydrauliclters.

•Drainandcleanthefueltank.

•Checkthetirepressure.

•Checkallfasteners.

•Greaseoroilallgreasettingsandpivotpoints.

•Paintchippedsurfaces.

•Checkthefuellinesandconnections.

•Replacethefuelpre-lter.

•Changetheplanetarygeardriveoil.

•Checktherearwheeltoe-in.

Operator’ s Man ual

andcuttingunit

Operator’ s Man ual

foradditional

28

Page 29

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Maintenance

CheckItem

Checkthe

safetyinterlock

operation.

Checkthebrake

operation.

Checktheengine

oilandfuellevel.

Checkthecooling

systemuidlevel.

Drainthe

water/fuel

separator.

Checktheair

lterrestriction

indicator.

Checkthe

radiator,oilcooler,

andscreenfor

debris.

Checkunusual

enginenoises.

Checkunusual

operatingnoises.

Checkthe

hydraulicsystem

oillevel.

Checkhydraulic

hosesfor

damage.

Checkforuid

leaks.

Checkthetire

pressure.

Checkthe

instrument

operation.

Lubricateall

greasettings.

Touch-up

damagedpaint.

1

2

Fortheweekof:

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

1.Checktheglowplugandinjectornozzlesifhardstarting,excesssmoke,orroughrunningisnoted.

2.Immediatelyaftereverywashing,regardlessoftheintervallisted.

29

Page 30

ServiceIntervalChart

Figure21

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

30

Page 31

Premaintenance

Lubrication

Procedures

GreasingtheBearingsand

RemovingtheHood

Togainadditionalaccesstoenginecompartment,the

hoodmayberemovedfromtractionunit.

1.Releasehoodlatches(Figure22)andraisehood.

Figure22

1.Hoodlatch

2.Unhooklanyardfromhoodpin,removepinand

slidehoodtubesrearwardoffguides(Figure23).

Bushings

ServiceInterval:Every50hours

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBase

Grease.Ifthemachineisoperatedundernormal

conditions,lubricateallbearingsandbushingsafter

every50hoursofoperationorimmediatelyafterevery

washing.

Thegreasettinglocationsandquantitiesareasfollows:

•Brakeshaftpivotbearings(5)(Figure24)

Figure24

•Rearaxlepivotbushings(2)(Figure25)

1.Hoodpin

Figure23

Figure25

•Steeringcylinderballjoints(2)(Figure26)

31

Page 32

Figure26

1.T opttingonkingpin

•Tierodballjoints(2)(Figure26)

•Kingpinbushings(2)(Figure26).Thetoptting

onthekingpinshouldonlybelubricated

annually(2pumps).

•Liftarmbushings(1perdeck)(Figure27)

Figure28

•Cuttingunitcarrierarmbushings(1percuttingunit)

(Figure28)

•Rearrollerbearings(2percuttingunit)(Figure29

orFigure30)

Figure29

Important:Makesurethegreasegroovein

eachrollermountalignswiththegreaseholein

eachendoftherollershaft.Tohelpalignthe

grooveandhole,thereisalsoanalignmentmark

ononeendoftherollershaft.

Figure27

•Liftcylinderbushings(2perdeck)(Figure27)

•Cuttingunitspindleshaftbearings(1percutting

unit)(Figure28)

Note:Onrollersequippedwithushgrease

ttings(Figure30)agreasegunnozzleadapteris

required.OrderT oroPartNo.107-1998fromyour

AuthorizedToroDistributor.

Figure30

32

Page 33

EngineMaintenance

ServicingtheAirCleaner

whichcouldforcedirtthroughthelterintothe

intaketract.

Thiscleaningprocesspreventsdebrisfrommigrating

intotheintakewhentheprimarylterisremoved.

ServiceInterval:Every400hours

Checktheaircleanerbodyfordamagewhichcould

causeanairleak.Replaceifdamaged.Checkthewhole

intakesystemforleaks,damageorloosehoseclamps.

Servicetheaircleanerlteronlywhentheservice

indicator(Figure31)requiresit.Changingtheairlter

beforeitisnecessaryonlyincreasesthechanceofdirt

enteringtheenginewhenthelterisremoved.

Figure31

1.Aircleanerindicator

3.Removeandreplacetheprimarylter(Figure33).

Cleaningoftheusedelementisnotrecommended

duetothepossibilityofdamagetotheltermedia.

Inspectthenewlterforshippingdamage,checking

thesealingendofthelterandthebody.Donot

useadamagedelement.Insertthenewlterby

applyingpressuretotheouterrimoftheelementto

seatitinthecanister.Donotapplypressuretothe

exiblecenterofthelter.

Important:Besurethecoverisseatedcorrectly

andsealswiththeaircleanerbody .

1.Pullthelatchoutwardandrotatetheaircleaner

covercounterclockwise(Figure32).

Figure32

1.Aircleanerlatch2.Aircleanercover

2.Removethecoverfromtheaircleanerbody.Before

removingthelter,uselowpressureair(40psi,

cleananddry)tohelpremovelargeaccumulations

ofdebrispackedbetweenoutsideofprimarylter

andthecanister.Avoidusinghighpressureair

Figure33

1.Aircleanerprimarylter

Important:Neverattempttocleanthesafety

lter(Figure34).Replacethesafetylterwitha

newoneaftereverythreeprimarylterservices.

Figure34

1.Aircleanersafetylter

4.Cleanthedirtejectionportlocatedintheremovable

cover.Removetherubberoutletvalvefromthe

cover,cleanthecavityandreplacetheoutletvalve.

33

Page 34

5.Installthecoverorientingtherubberoutletvalvein

adownwardposition—betweenapproximately5:00

to7:00whenviewedfromtheend.

6.Resettheindicator(Figure31)ifitshowsred.

ServicingtheEngineOiland

Filter

ServiceInterval:Aftertherst50hours

Every150hours

Changetheoilandlterinitiallyaftertherst50hours

ofoperation;thereafterchangetheoilandlterevery

150hours.

1.Removethereardrainplug(Figure35)andletthe

oilowintoadrainpan.Whentheoilstops,install

thedrainplug.

AdjustingtheThrottle

Adjustthethrottlecable(Figure37)sothatthegovernor

leverontheenginecontactsthelowandhighspeedset

boltsbeforethethrottlelevercontactstheslotinthe

seatbase.

Figure37

1.Throttlecable

Figure35

1.Engineoildrainplug

2.Removetheoillter(Figure36).Applyalightcoat

ofcleanoiltothenewltersealbeforescrewingit

on.Donotovertighten.

Figure36

1.Engineoillter

3.Addoiltothecrankcase;refertoCheckingthe

EngineOilinOperation,page20.

34

Page 35

FuelSystem

Maintenance

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1/4to

1/2in.(6to13mm)belowthebottomof

thellerneck.Thisemptyspaceinthetank

allowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

2.Loosenthedrainplugonthebottomofthelter

canister(Figure38).Tightentheplugafterdraining.

Figure38

1.WaterSeparator

Replaceltercanisterafterevery400hoursof

operation.

3.Cleantheareawheretheltercanistermounts.

2.Drainplug

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

FuelTank

ServiceInterval:Every800hours

Beforestorage

Drainandcleanthefueltankevery800hours.Also,

drainandcleanthetankiffuelsystembecomes

contaminatedorifthemachinewillbestoredforan

extendedperiodoftime.Usecleanfueltoushout

thetank.

FuelLinesandConnections

ServiceInterval:Every400hours

Yearly

Checkthefuellinesandconnectionsevery400hours

oryearly,whichevercomesrst.Inspectthemfor

deterioration,damage,orlooseconnections.

4.Removetheltercanisterandcleanthemounting

surface.

5.Lubricatethegasketontheltercanisterwithclean

oil.

6.Installtheltercanisterbyhanduntilthegasket

contactsthemountingsurface;thenrotateitan

additional1/2turn.

ReplacingtheFuelPre-Filter

ServiceInterval:Every400hours

Yearly

Replacethefuelpre-lter(Figure39),locatedbetween

fuelthetankandfuelpump,afterevery400operating

hoursoryearly,whicheveroccursrst.

1.Clampbothfuellinesthatconnecttothefuellter

sothatfuelcannotdrainwhenthelinesareremoved.

2.Loosenthehoseclampsatbothendsofthelter

andpullthefuellinesoffofthelter.

WaterSeparator

ServiceInterval:Beforeeachuseordaily

Drainwaterorothercontaminantsfromthewater

separator(Figure38)daily.

1.Placeacleancontainerunderthefuellter.

35

Page 36

3.Opentheairbleedscrewonthefuelinjectionpump

(Figure40).

Figure39

1.Fuelpre-lter

3.Slidethehoseclampsontotheendsofthefuellines.

Pushthefuellinesontothefuellterandsecure

themwiththehoseclamps.Besurethatthearrow

onthesideofthelterpointstowardtheinjection

pump.

FuelPick-upTubeScreen

Thefuelpick-uptube,locatedinsidethefueltank,is

equippedwithascreentohelppreventdebrisfrom

enteringthefuelsystem.Removefuelpick-uptubeand

cleanscreenasrequired.

BleedingtheFuelSystem

1.Parkthemachineonalevelsurface.Makesurethat

thefueltankisatleasthalffull.

2.Unlatchandraisethehood.

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyfuelthatspills.

Figure40

1.Fuelinjectionpumpbleedscrew

4.TurnthekeyintheignitionswitchtotheOn

position.Theelectricfuelpumpwillbeginoperation,

therebyforcingairoutaroundtheairbleedscrew .

LeavethekeyintheOnpositionfor15seconds.Air

andfuelwillbeinternallydrainedbacktofueltank.

TightenthescrewandturnthekeytoOff.

Note:Normallytheengineshouldstartafterthe

abovebleedingproceduresarefollowed.However,

iftheenginedoesnotstart,airmaybetrapped

betweentheinjectionpumpandinjectors;referto

BleedingAirfromtheInjectors.

BleedingAirfromtheInjectors

Note:Thisprocedureshouldbeusedonlyifthe

fuelsystemhasbeenpurgedofairthroughnormal

primingproceduresandtheenginewillnotstart;refer

toBleedingtheFuelSystem.

1.LoosenthepipeconnectiontotheNo.1injector

nozzleandholderassemblyattheinjectionpump

(Figure41).

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1/4to

1/2in.(6to13mm)belowthebottomof

thellerneck.Thisemptyspaceinthetank

allowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

36

Page 37

Figure41

1.No.1injectornozzle

2.MovethethrottletotheFastposition.

3.TurnthekeyintheignitionswitchtotheStart

positionandwatchthefuelowaroundthe

connector.TurnthekeytotheOffpositionwhen

solidowisobserved.

4.Tightenthepipeconnectorsecurely.

5.Repeattheprocedureontheremainingnozzles.

ElectricalSystem

Maintenance

ChargingandConnectingthe

Battery

Warning

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

1.Unlatchandraisethehood.

2.Removethebatterystrapandcover(Figure42).

Figure42

1.Batterycover2.Batterystrap

Batteryelectrolytecontainssulfuricacidwhich

isadeadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontact

withskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

3.Connecta3to4amp.batterychargertothebattery

posts.Chargethebatteryatarateof3to4amperes

for4to8hours.

4.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

37

Page 38

BatteryCare

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

5.CoatbothbatteryconnectionswithGrafo112X

(skin-over)grease,T oroPartNo.505-47,petroleum

jelly,orlightgreasetopreventcorrosion.Slidethe

rubberbootoverthepositiveterminal.

Warning

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

6.Installthebatterycover.

ServiceInterval:Every50hours

Important:Beforeweldingonthemachine,

disconnectthecablefromthenegativebatterypost

topreventdamagetotheelectricalsystem.

Note:Checkthebatteryconditionweeklyorafter

every50hoursofoperation.Keeptheterminalsand

theentirebatterycasecleanbecauseadirtybatterywill

dischargeslowly.Tocleanthebattery,removeitfrom

themachine,washtheentirecasewithasolutionof

bakingsodaandwater.Rinsewithclearwater.Coatthe

batterypostsandcableconnectorswithGrafo112X

(skin-over)grease(ToroPartNo.505-47)orpetroleum

jellytopreventcorrosion.

Fuses

Thereare6fusesintheelectricalsystem.Theyare

locatedundertheoperatorscontrolpanel.Rotatelatches

andremovecontrolpanelcover.

Batteryterminalsormetaltoolscouldshort

againstmetalcomponentscausingsparks.

Sparkscancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

Figure43

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative(black)

cable.

38

Page 39

DriveSystem

Maintenance

CheckingtheTorqueofthe

WheelNuts

ServiceInterval:Aftertherst8hours

Every200hours

Failuretomaintainpropertorqueofthewheel

nutscouldresultinfailureorlossofwheeland

mayresultinpersonalinjury.

Torquethefrontandrearwheelnutsto

85-100ft.-lb.(115-136N·m)after1-4hoursof

operationandagainafter8hoursofoperation.

Torqueevery200hoursthereafter.

Note:Frontwheelnutsare1/2-20UNF .Rearwheel

nutsareM12x1.6-6H(Metric).

CheckingthePlanetaryGear

DriveOil

ServiceInterval:Every400hours

Checktheoillevelafterevery400hoursofoperation

orifexternalleakageisnoted.UsehighqualitySAE

85W-140wt.gearlubeasareplacement.

Thecapacityofthesystemisapproximately16oz.

(0.5l).

1.Withthemachineonalevelsurface,positionthe

wheelsothatthecheck/drainplug(Figure44)isat

eitherthe2or10o’clockposition.

Figure44

1.Check/drainplug

2.Removetheplugontheplanetary(Figure44).Oil

shouldbeatthebottomofthecheckplugholeon

thebacksideofthebrake.

3.Addgearoiltotheholeintheplanetary,ifnecessary,

tobringtheoiluptotheproperlevel.Installthe

plug.

4.Repeatsteps1–3ontheoppositegearassembly.

ChangingthePlanetaryGear

DriveOil

ServiceInterval:Aftertherst200hours

Every800hours

Yearly

Changetheoilinitiallyafterrst200hoursofoperation.

Thereafterchangetheoilevery800hours,oryearly ,

whicheveroccursrst.UseahighqualitySAE85W-140

wt.gearlube.

1.Withthemachineonalevelsurface,positionthe

wheelsothatthecheck/drainplug(Figure45)isat

thelowestposition(6o’clock).

39

Page 40

Figure45

1.Check/drainplug

2.Placeadrainpanunderthehub,removetheplug,

andallowtheoiltodrain.

3.Placeanotherdrainpanunderthebrakehousingon

theothersideofthewheel(Figure46).

CheckingtheRearAxle

Lubricant

ServiceInterval:Every400hours

Therearaxleisshippedfromthefactorylledwith

SAE85W-140wt.gearlube.Checktheoillevelbefore

theengineisrststartedandevery400hoursthereafter.

Thecapacityis80oz.(2.4l).Visuallyinspectforleaks

daily.

1.Positionthemachineonalevelsurface.

2.Removeacheckplugfromoneendoftheaxle

(Figure47)andmakesurethatthelubricantisupto

thebottomofthehole.Ifthelevelislow,remove

thellplug(Figure47)andaddenoughlubricantto

bringtheleveluptothebottomofthecheckplug

holes.

Figure46

1.Brakehousing

2.Drainplug

3.Checkplug

4.Removecheck/drainplugsfromthebrakehousing

andallowtheoiltodrain.

5.Whenalloftheoilhasdrained,installthebottom

pluginthebrakehousing.

6.Positionthewheelsothattheplugholeisattheten

ortwoo’clockpositionontheplanetary.

7.Slowlyaddapproximately16oz.(0.5l)ofhigh

qualitySAE85W -140wt.gearlubetotheplanetary

llhole(atthetenortwoo’clockposition)untilthe

levelisuptothebottomofthebrakehousingcheck

hole.Installtheplug.

Figure47

1.Checkplug

2.Fillplug

ChangingtheRearAxle

Lubricant

ServiceInterval:Aftertherst200hours

Every800hours

Changetheoilinitiallyaftertherst200hoursof

operationandevery800hoursofoperationthereafter.

1.Positionthemachineonalevelsurface.

2.Cleantheareaaroundthe3drainplugs,1oneach

endand1inthecenter(Figure48).

8.Repeattheprocedureontheopposite

planetary/brakeassembly .

40

Page 41

Figure48

1.Drainpluglocation

3.Removethe(3)oillevelcheckplugsandmainaxle

ventcaptoeaseindrainingoftheoil.

4.Removethedrainplugsandallowtheoiltodrain

intothepans.

5.Installtheplugs.

6.Removeacheckplugandllaxlewithapproximately

80oz.of85W-90gearlubeoruntillubricantisup

tobottomofhole.

7.Installcheckplug.

Figure49

1.Pumprod2.Pumpcontroltube