Page 1

FormNo.3397-644RevA

Groundsmaster

®

4300-DTraction

Unit

ModelNo.30853—SerialNo.315000170andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3397-644*A

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Note:ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure1

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Introduction

Thismachineisaride-on,rotary-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrass

onwell-maintainedlawnsinparks,sportselds,andon

commercialgrounds.Itisnotdesignedforcuttingbrush,

mowinggrassandothergrowthalongsidehighways,orfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumanycontactTorodirectlyatwww.Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbers

ofyourproductready .Themodelandserialnumbersare

onaplatemountedontheleftsideoftheframeunderthe

footrest.Writethenumbersinthespaceprovided.

ModelNo.

SerialNo.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

GeneralSafety.........................................................4

SoundPowerLevel..................................................4

SoundPressureLevel...............................................4

VibrationLevel.......................................................4

SafetyandInstructionalDecals.................................5

Setup............................................................................9

1AdjustingtheControlArmPosition........................10

2RemovingtheShippingBlocksandPins..................10

3InstallingRearWeights.........................................11

4InstallingtheHoodLatchforCE

Compliance........................................................12

5InstallingtheThrottleStopforCE

Compliance........................................................12

6AdjustingtheCarrierFrame..................................12

7AdjustingtheRollerScraper(Optional)...................13

8InstallingtheMulchingBafe(Optional).................14

9PreparingtheMachine..........................................14

ProductOverview.........................................................15

Controls...............................................................15

Specications........................................................19

Attachments/Accessories........................................19

BeforeOperation......................................................20

BeforeOperationSafety..........................................20

CheckingtheEngine-OilLevel.................................21

CheckingtheCoolingSystem...................................21

CheckingtheHydraulicSystem................................21

FillingtheFuelTank...............................................21

CheckingtheTirePressure......................................22

CheckingtheTorqueoftheWheel-Lug

Nuts.................................................................22

AdjustingtheHeightofCut.....................................22

Breaking-intheMachine..........................................23

BleedingtheFuelSystem.........................................23

CheckingtheInterlockSwitches...............................24

CheckingtheBladeStoppingTime............................24

SelectingaBlade.....................................................24

TheDiagnosticLight..............................................25

ChangingtheCounterbalanceSettings.......................25

ChoosingAccessories.............................................26

DuringOperation.....................................................27

DuringOperationSafety.........................................27

StartingandStoppingtheEngine..............................28

OperatingTips......................................................28

AfterOperation........................................................29

AfterOperationSafety............................................29

IdentifyingtheTie-DownPoints..............................29

PushingorTowingtheMachine................................30

TransportingtheMachine........................................30

LoadingtheMachine..............................................30

Maintenance.................................................................32

RecommendedMaintenanceSchedule(s)......................32

DailyMaintenanceChecklist....................................33

ServiceIntervalChart.............................................34

PremaintenanceProcedures........................................34

Pre-MaintenanceSafety...........................................34

RaisingtheMachine................................................35

Lubrication...............................................................35

GreasingtheBearingsandBushings..........................35

EngineMaintenance..................................................37

EngineSafety.........................................................37

ServicingtheAirCleaner.........................................37

ServicingtheEngineOil..........................................38

FuelSystemMaintenance...........................................40

ServicingtheFuelSystem........................................40

ServicingtheWaterSeparator...................................41

ServicingtheFuel-PickupTube................................41

BleedingAirfromtheFuelInjectors..........................41

ElectricalSystemMaintenance....................................42

ElectricalSystemSafety...........................................42

ServicingtheBattery...............................................42

ReplacingtheFuses................................................42

DriveSystemMaintenance.........................................43

AdjustingtheTractionDriveforNeutral....................43

AdjustingtheRearWheelToe-in..............................43

CoolingSystemMaintenance......................................44

CheckingtheCoolingSystem...................................44

RemovingDebrisfromtheCoolingSystem................44

BrakeMaintenance....................................................45

AdjustingtheParkingBrakes....................................45

AdjustingtheParking-BrakeLatch............................46

BeltMaintenance......................................................46

TensioningtheAlternatorBelt.................................46

HydraulicSystemMaintenance....................................47

CheckingtheHydraulicFluidLevel...........................47

ChangingtheHydraulicFluid...................................48

ReplacingtheHydraulicFilters.................................48

CheckingtheHydraulicLinesandHoses....................49

TestingthePressureintheHydraulicSystem...............49

HydraulicValveSolenoidFunctions..........................49

CuttingDeckMaintenance..........................................49

SeparatingtheCuttingDecksfromtheTraction

Unit..................................................................49

MountingtheCuttingDeckstotheTraction

Unit..................................................................50

BladeMaintenance.....................................................50

BladeSafety...........................................................50

ServicingtheBladePlane.........................................50

RemovingandInstallingaBlade...............................51

InspectingandSharpeningtheBlade.........................52

MiscellaneousMaintenance.........................................53

ServicingtheFrontRoller........................................53

Storage........................................................................54

PreparingtheMachineforStorage............................54

CuttingDeck.........................................................54

3

Page 4

Safety

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013andANSIB71.4-2012.

GeneralSafety

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof105dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinEN11094.

Thisproductiscapableofamputatinghandsandfeetand

ofthrowingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustoyouandbystanders.

•ReadandunderstandthecontentsofthisOperator’ sManual

beforeyoustarttheengine.Ensurethateveryoneusing

thisproductknowshowtouseitandunderstandsthe

warnings.

•Donotputyourhandsorfeetnearmovingcomponents

ofthemachine.

•Donotoperatethemachinewithoutallguardsandother

safetyprotectivedevicesinplaceandworkingonthe

machine.

•Keepclearofanydischargeopening.Keepbystandersa

safedistancefromthemachine.

•Keepchildrenoutoftheoperatingarea.Neverallow

childrentooperatethemachine.

•Stopthemachineandshutofftheenginebeforeservicing,

fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecanresult

ininjury.T oreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safety-alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theseinstructionsmayresultinpersonalinjuryordeath.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof

93dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

CAUTION

Long-termexposuretonoisewhileoperatingthe

machinemaycausesomehearingloss.

Wearadequatehearingprotectionwheneveryou

operatethemachineforanextendedperiodoftime.

VibrationLevel

Hand-Arm

CAUTION

Long-termexposuretovibrationwhileoperating

thismachinemaycausesomenumbnessinthe

handsandwrists.

Wearglovesthatdampenthevibrationwhenever

youoperatethemachineforanextendedperiodof

time.

Youcanndadditionalitemsofsafetyinformationintheir

respectivesectionsthroughoutthismanual.

Measuredvibrationlevelforrighthand=0.72m/s

Measuredvibrationlevelforlefthand=0.86m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

2

WholeBody

Measuredvibrationlevel=0.65m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

4

2

2

2

2

Page 5

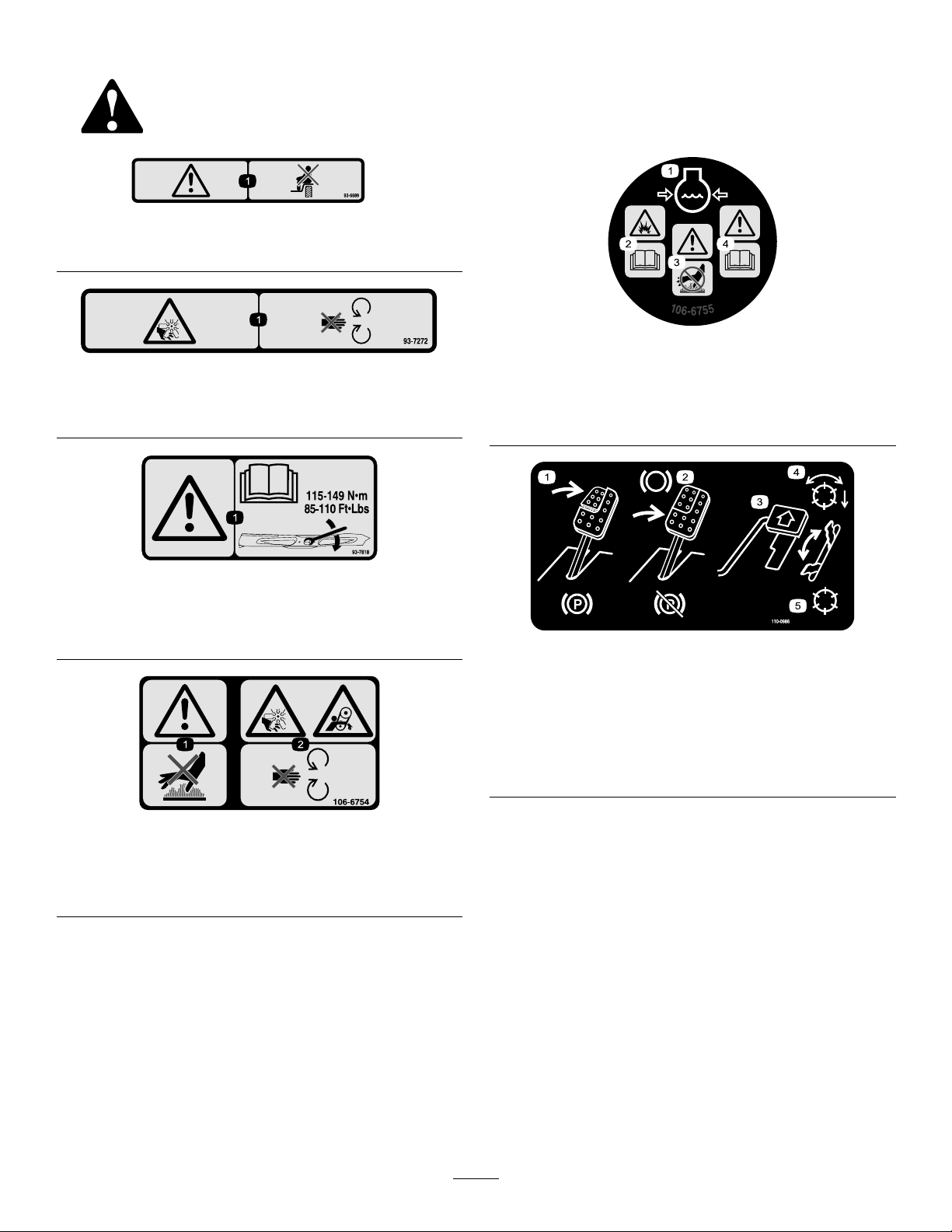

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibleandarelocatednearanyareaofpotentialdanger.Replace

anydecalthatisdamagedorlost.

93–6689

1.Danger—donotsitontheplasticshroud.

106-6755

93-7272

1.Cutting/dismembermenthazard;fan—stayawayfrom

movingparts.

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto1 15to149N∙m(85to110

ft-lb).

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

110-0986

1.Pressthebrakepedalandparkingbrakepedaltosetthe

parkingbrake.

2.Pressthebrakepedaltoapplythebrake.

3.Pressthetractionpedaltomovethemachineforward.

4.Reelenabledmode

5.Transportmode

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

5

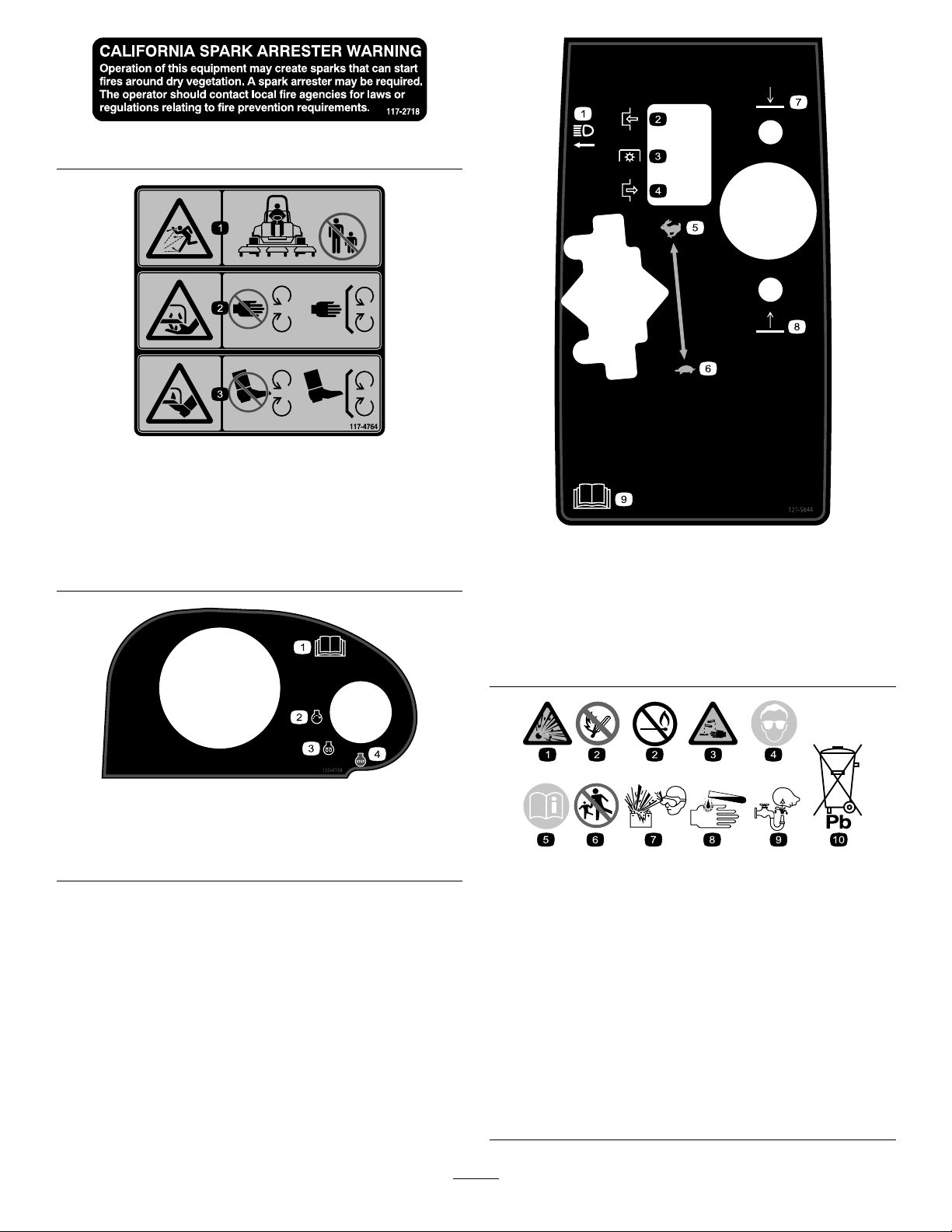

Page 6

110-8869

1.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

2.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

3.Tippinghazard—slowmachinebeforeturning,donotturn

athighspeeds;lowerthecuttingunitwhendrivingdown

slopes;usearolloverprotectionsystemandweartheseat

belt.AlwayswearaseatbeltwhenaROPSisinplace.

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingdecks,stoptheengine,and

removetheignitionkeybeforeleavingthemachine.

5.Warning—readtheOperator'sManual,donottowthe

machine.

110-8921

110-8973

(AfxoverPartNumber1 10–8869forCE*)

*Thissafetydecalincludesaslopewarningrequiredonthemachinefrocomplianceto

theEuropeanLawnMowerStandardENISO5395:2013.Theconservativemaximum

slopeanglesindicatedforoperationofthismachineareprescribedbyandrequiredby

thisstandard.

1.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

2.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

3.Tippinghazard—donotoperateonslopesgreaterthan15°;

lowerthecuttingdeckswhenoperatingonslopes;wear

thesafetybelt.

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingdecks,stoptheengine,and

removetheignitionkeybeforeleavingthemachine.

5.Warning—readtheOperator'sManualbeforetowingthe

machine.

1.Tractionunitspeed

2.Slow

3.Fast

117–0169

1.ReadtheOperator'sManual.

2.Powerpoint—10A

3.Headlights—10A

4.Power—10A

5.Enginestart—15A

6.Optionalairrideseatsuspension—20A

7.EnginecomputermanagementC—7.5A

8.EnginecomputermanagementB—7.5A

9.EnginecomputermanagementA—7.5A

6

Page 7

117–2718

117-4764

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cuttinghazardofhand,mowerblade—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

3.Cuttinghazardoffoot,mowerblade—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

121–5644

1.Lightswitch

2.Engage7.Lower

3.Powertake-off

4.Disengage

5.Fast

6.Slow

8.Raise

9.ReadtheOperator’s

Manual.

1.ReadtheOperator’s

Manual.

2.Engine—start4.Engine—stop

120–4158

3.Engine—preheat

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

7

Page 8

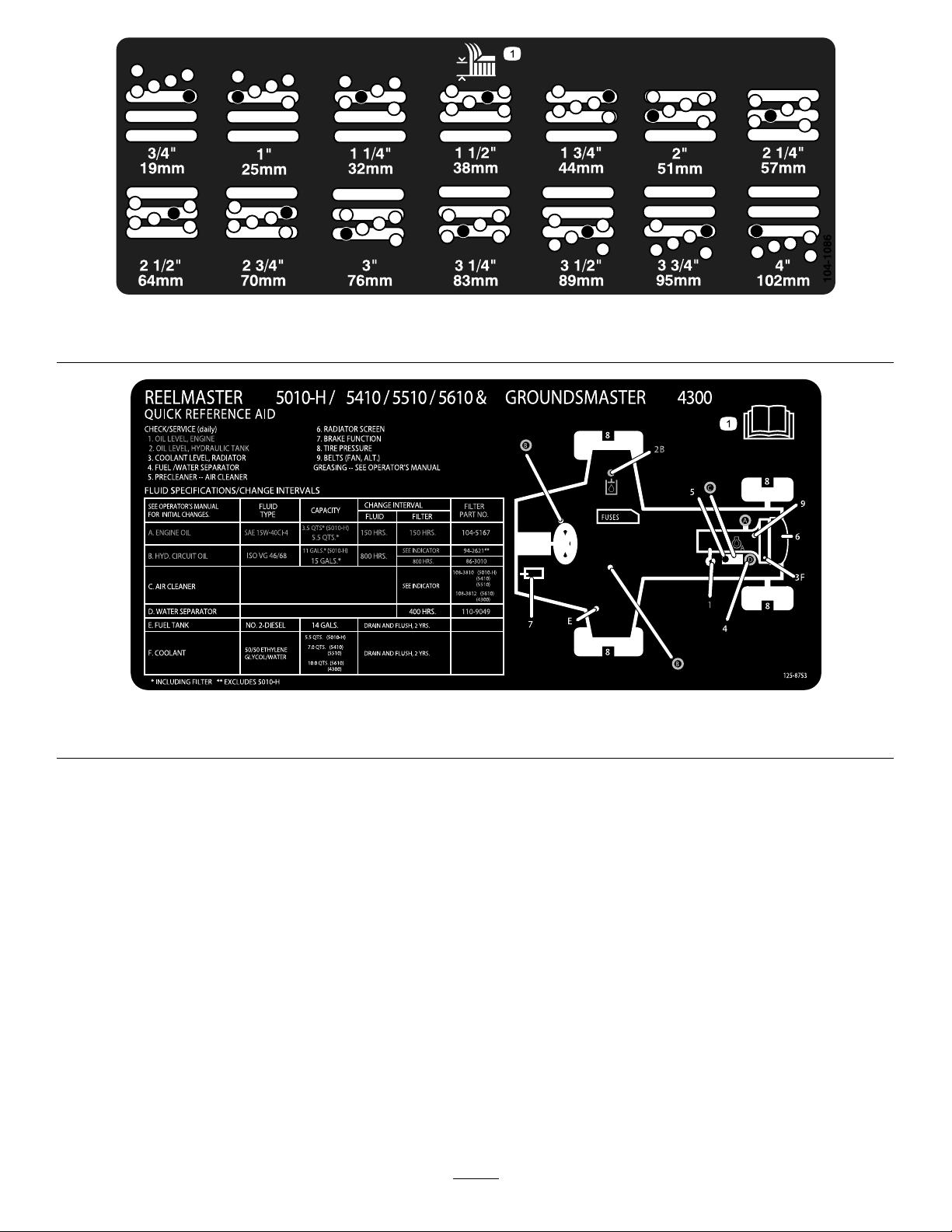

1.Heightofcut

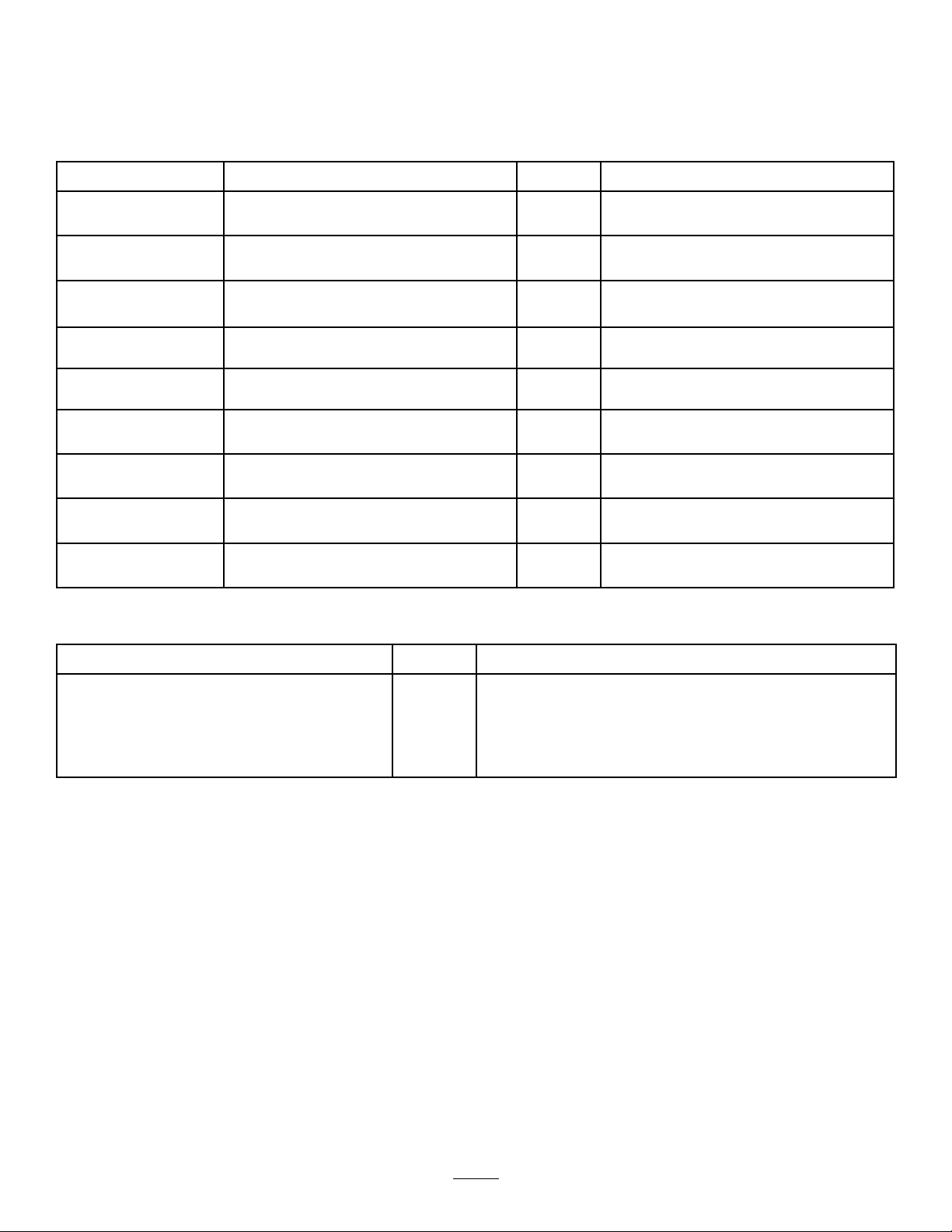

1.ReadtheOperator'sManualformoremaintenanceinformation.

104-1086

125-8753

8

Page 9

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

MediaandAdditionalParts

Nopartsrequired

Nopartsrequired

Rearweights(quantityvarieswith

conguration).

Hoodlatchassembly1

Washer1

Throttlestop1

Setscrew

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Varies

Qty.

Use

–

–

1

–

–

–

–

Adjustthecontrolarmposition.

Removetheshippingblocksandpins.

Installrearweights(orderfromyour

ToroDistributor).

InstallthehoodlatchforCEcompliance.

InstallthethrottlestopforCE

compliance.

Adjustthecarrierframe.

Adjusttherollerscraper(Optional).

Installthemulchingbafe(Optional).

Preparethemachine.

Description

Operator'sManual

EngineOperator'sManual

PartsCatalog

DeclarationofConformity

OperatorTrainingMaterial

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Qty.

Use

1

1

1

1

1

Reviewbeforeoperatingmachine

9

Page 10

1

2

AdjustingtheControlArm Position

NoPartsRequired

Procedure

Thecontrolarmpositioncanbeadjustedfortheoperator’s

comfort.

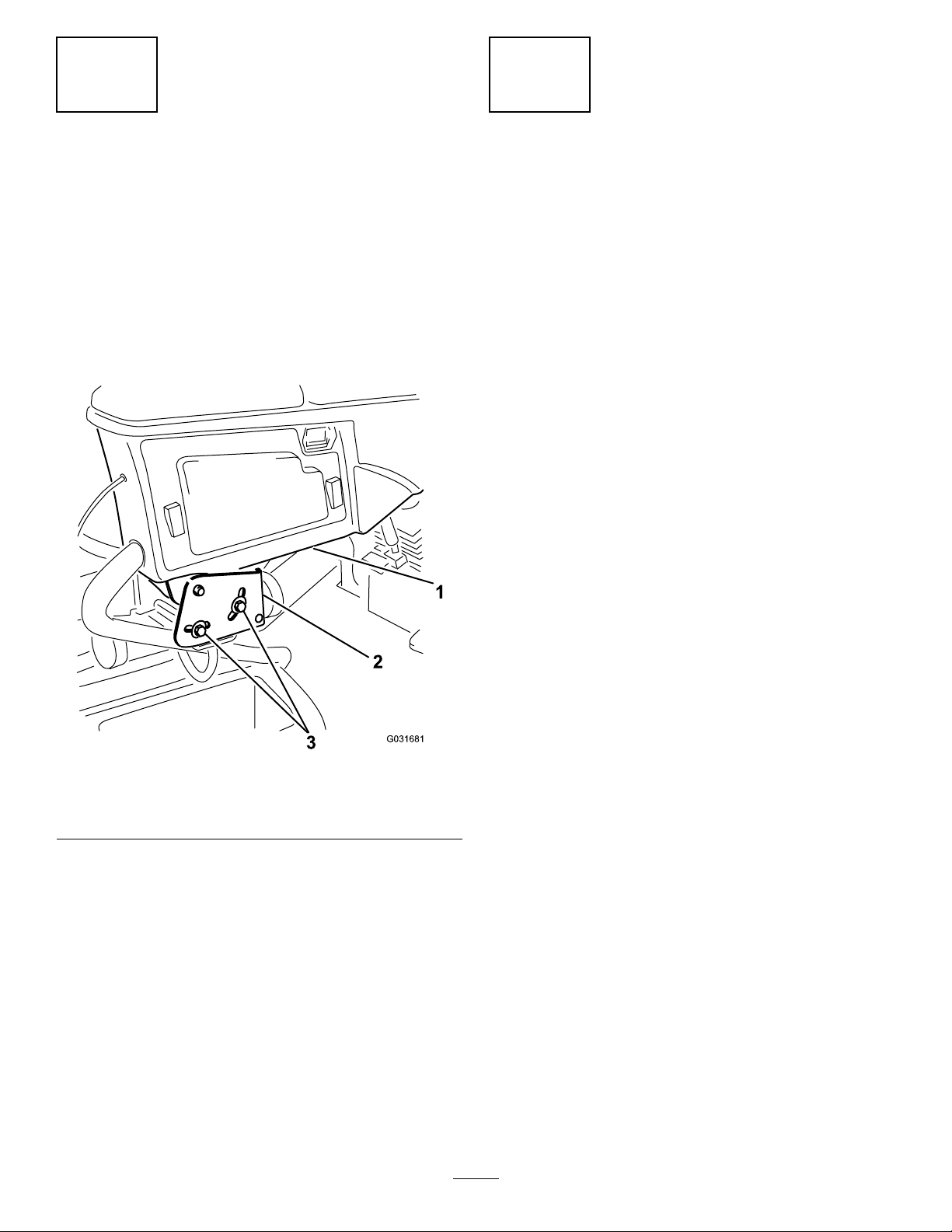

1.Loosenthe2boltssecuringthecontrolarmtothe

retainingbracket(Figure2).

RemovingtheShippingBlocks andPins

NoPartsRequired

Procedure

1.Removeanddiscardtheshippingblocksfromthe

cuttingdecks.

2.Removeanddiscardtheshippingpinsfromthe

cutting-decksuspensionarms.

Important:Theshippingpinsstabilizethecutting

decksduringshipping,removethembeforeoperation.

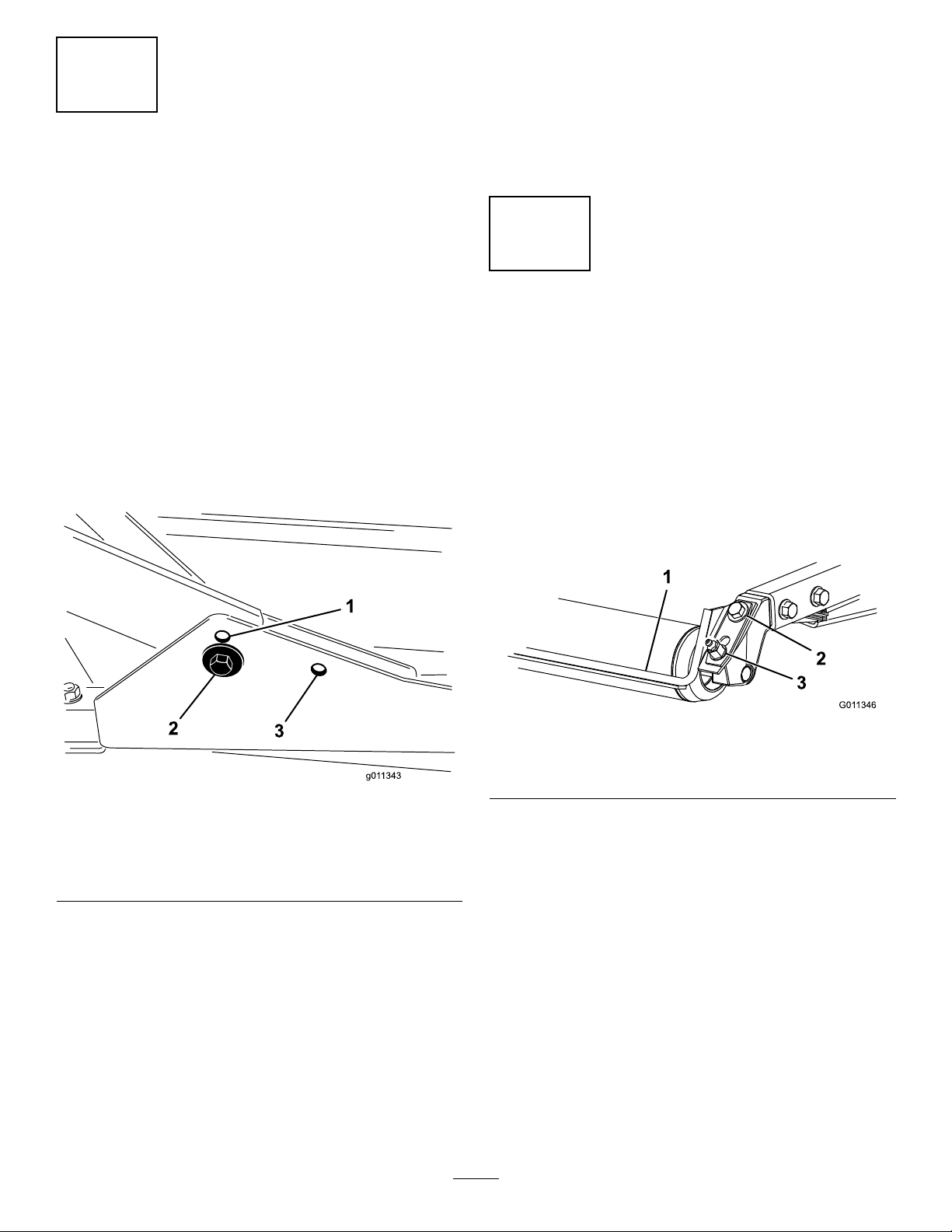

Figure2

1.Controlarm3.Bolts(2)

2.Retainingbrackets

2.Rotatethecontrolarmtothedesiredpositionand

tightenthe2bolts.

10

Page 11

3

InstallingRearWeights

Partsneededforthisprocedure:

Varies

Rearweights(quantityvarieswithconguration).

Procedure

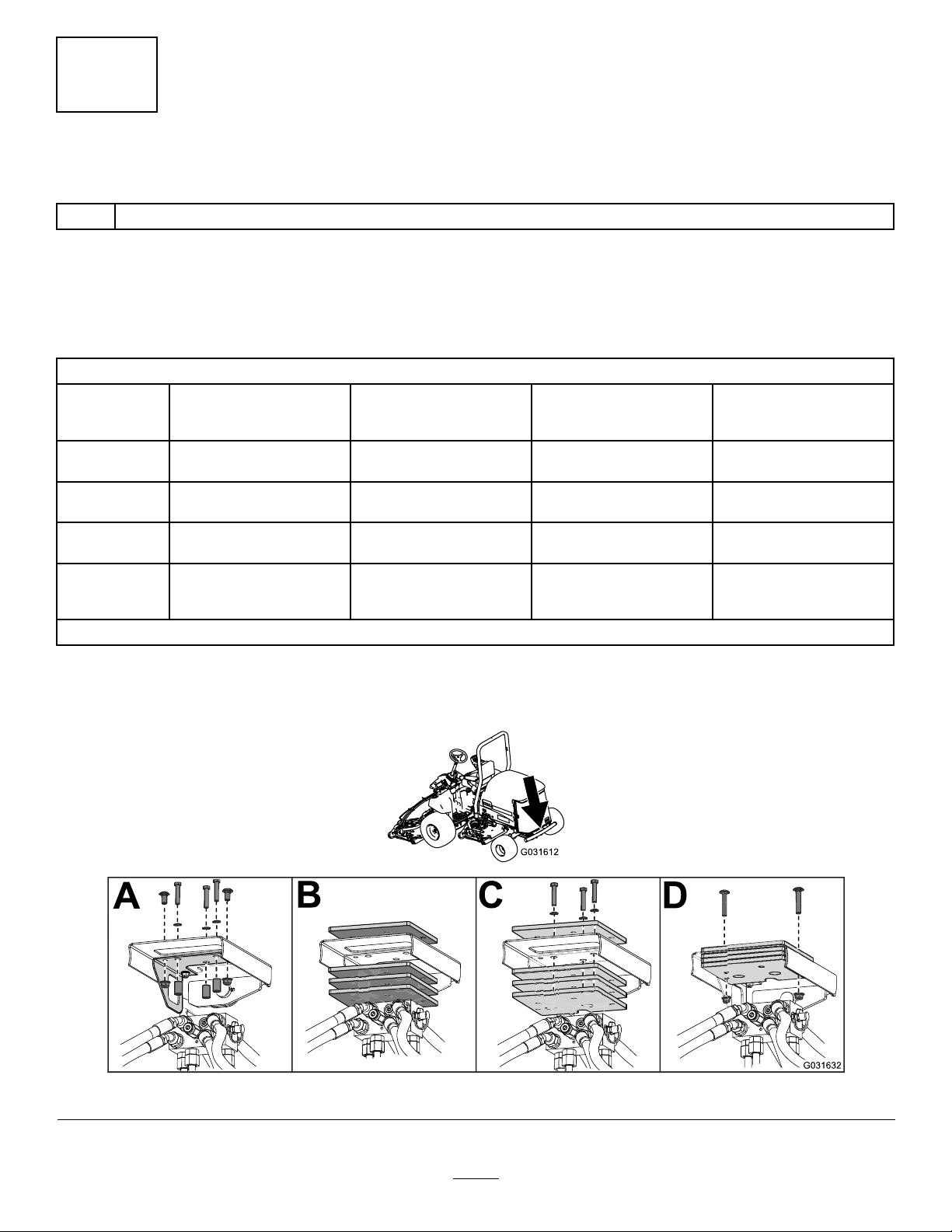

TheGroundsmaster4300–DTractionUnitcomplieswithENISO5395:2013andANSIB71.4-2012standardswhenequipped

withrearweightsand/or40.8kg(90lb)ofcalciumchlorideballastisaddedtorearwheels.Usethefollowingchartsto

determinethecombinationsofweightsrequiredforyourconguration.OrderpartsfromyourT oroDistributor.

WeightP/N110-8985-03

Conguration

BaseUnit60

WithRecycler

Kit

With

Sunshade

With4Post

ROPS&

Sunshade

Numberofweights

tomeetANSI(US)

standards

40.8kg(90lb)calcium

chloride*

40.8kg(90lb)calcium

chloride*

40.8kg(90lb)calcium

chloride*

*Installtubesinsidethereartiresbeforeaddingcalciumchloride.

Numberofweightsto

meetCE(European)

standards

0

4

4

Fasteners(2each

required)forweights

3231–34CarriageBolt

104–8301Nut

N/AN/A

3231–7CarriageBolt

104–8301Nut

3231–7CarriageBolt

104–8301Nut

WeightLocation

3ontopofbumperand

3underbumper

1ontopofbumperand

3underbumper

1ontopofbumperand

3underbumper

Important:Alwaysinstalltubesinsidethereartiresbeforecalciumchlorideisinstalled.Ifapunctureoccursina

tirewithcalciumchloride,removethemachinefromtheturfareaasquicklyaspossible.Topreventpossibledamage

totheturf,immediatelysoaktheaffectedareawithwater.

Figure3

11

Page 12

4.Outsidethehood,insertthehookendofthelatch

throughtheholeinthehoodandmakesurethatthe

4

rubber-sealingwasherremainstotheoutersideofthe

hood(Figure5).

InstallingtheHoodLatchfor CECompliance

Partsneededforthisprocedure:

1Hoodlatchassembly

1Washer

Procedure

1.Unlatchandraisethehood.

2.Removetherubbergrommetfromtheholeintheleft

sideofthehood(Figure4).

5.Insidethehood,insertthemetalwasherontothelatch

andsecurewiththenutandmakesurethatthelatch

engagestheframecatchwhenitislocked.Usethe

enclosedhood-latchkeytooperatethehoodlatch.

5

InstallingtheThrottleStopfor CECompliance

Partsneededforthisprocedure:

1Throttlestop

1

Setscrew

Procedure

1.Loosenthesetscrewonthethrottlestop(Figure6).

2.Slidethethrottlestopontothehigh-idlestopscrew

(Figure6).Thechamferedendofthethrottlestopis

tobepositionedoutward.

Figure4

1.Rubbergrommet

3.Removethenutfromthehoodlatchassembly(Figure

5).

Figure5

1.Hoodlatch3.Rubberwasher

2.Nut4.Metalwasher

Figure6

1.Throttlestop

3.TurnthekeyintheignitionswitchtotheONposition

andallowtheenginetorunfor5to10minutes.

4.Adjustthehighidleto2860rpmwiththecuttingdecks

disengaged.

5.Tightenthesetscrew.

6.Applyadhesiveintothesetscrewtopreventtampering.

12

2.Setscrew

Page 13

6

G011346

1

2

3

AdjustingtheCarrierFrame

NoPartsRequired

AdjustingtheFrontCuttingDecks

Thefrontandrearcuttingdecksrequiredifferentmounting

positions.Thefrontcuttingdeckhas2mountingpositions

dependingonwhatheightofcutanddegreeofdeckrotation

youdesire.

1.Forheightsofcutbetween2.0to7.6cm(0.75to3

inches),mountthefrontcarrierframesinthelower

frontmountingholes(Figure7).

AdjustingtheRearCuttingDeck

Thefrontandrearcuttingdecksrequiredifferentmounting

positions.Therearcuttingdeckhas1mountingpositionfor

properalignmentwiththesidewinderunderframe.

Forallheightsofcut,mounttherearcuttingdeckinthe

rear-mountingholes(Figure7).

7

AdjustingtheRollerScraper (Optional)

NoPartsRequired

Note:Thispermitsmoreuptravelofthecutting

decksrelativetotractorwhenapproachingquickuphill

changesinterrain.Itdoeshoweverlimittheclearance

ofthechambertothecarrierwhencrestingsharp

knolls.

Figure7

1.Frontdeckmountinghole

(upper)

2.Frontdeckmountinghole

(lower)

2.Forheightsofcutbetween6.3to10cm(2.5to4

inches),mountthefrontcarrierframesintheupper

frontmountingholes(Figure7).

3.Reardeckmountinghole

Procedure

Theoptionalrearrollerscraperisdesignedtoworkbestwhen

thereisanevengapof0.5to1mm(0.020to0.040inch)

betweenthescraperandroller.

1.Loosenthegreasettingandthemountingscrew

(Figure8).

Figure8

1.Rollerscraper

2.Mountingscrew

2.Slidethescraperupordownuntilagapof0.5to1

mm(0.020to0.040inch)isachievedbetweentherod

andtheroller.

3.Securethegreasettingandtorqueto41N∙m(30ft-lb)

inanalternatingsequence.

3.Greasetting

Note:Thisincreasesthechambertocarrierclearance

duetothehigherpositionofthecuttingchamber,but

willcausethecuttingdeckstoreachtheirmaximum

uptravelsooner.

13

Page 14

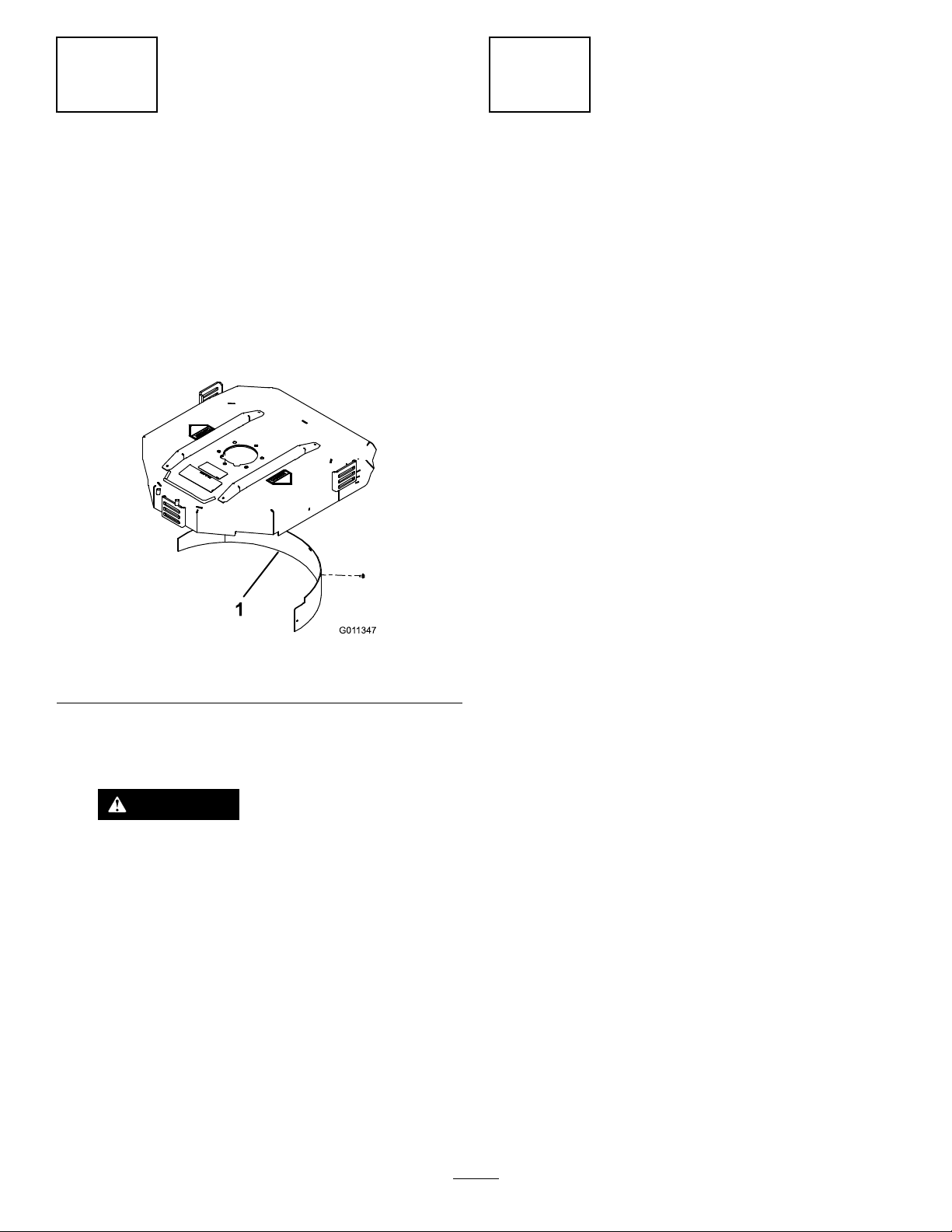

8

G011347

1

9

InstallingtheMulchingBafe

(Optional)

NoPartsRequired

Procedure

1.Thoroughlycleandebrisfromthemountingholeson

therearwallandleftsidewallofthechamber.

2.Installthemulchingbafeintherearopeningand

secureitwith5ange-headbolts(Figure9).

PreparingtheMachine

NoPartsRequired

CheckingtheTirePressure

Checkthetirepressurebeforeuse;refertoCheckingtheTire

Pressure(page22).

Important:Maintainpressureinalltirestoensurea

goodquality-of-cutandpropermachineperformance.

Do not underinate the tir es.

CheckingtheFluidLevels

1.Checktheengine-oillevelbeforestartingtheengine;

refertoCheckingtheEngine-OilLevel(page38).

2.Checkthehydraulic-uidlevelbeforestartingthe

engine;refertoCheckingtheHydraulicFluidLevel

(page47).

3.Checkthecoolingsystembeforestartingtheengine;

refertoCheckingtheCoolingSystem(page44).

Figure9

1.Mulchingbafe

3.Verifythatthemulchingbafedoesnotinterferewith

thetipofthebladeanddoesnotprotrudeinsidethe

surfaceoftherearchamberwall.

DANGER

Donotusethehigh-liftbladewiththe

mulchingbafe.Thebladecouldbreak,

resultinginpersonalinjuryordeath.

GreasingtheMachine

Greasethemachinebeforeuse;refertoGreasingtheBearings

andBushings(page35).Failuretoproperlygreasethe

machineresultsinprematurefailureofcriticalparts.

14

Page 15

ProductOverview

Controls

Seat-AdjustingKnobs

Theseat-adjustinglever(Figure10)allowsyoutoadjustthe

seatforeandaft.Theweight-adjustingknobadjuststhe

seatfortheoperator’sweight.Theweightgaugeindicates

whentheseatisadjustedtotheoperator’sweight.The

height-adjustingknobadjuststheseatfortheoperator’s

height.

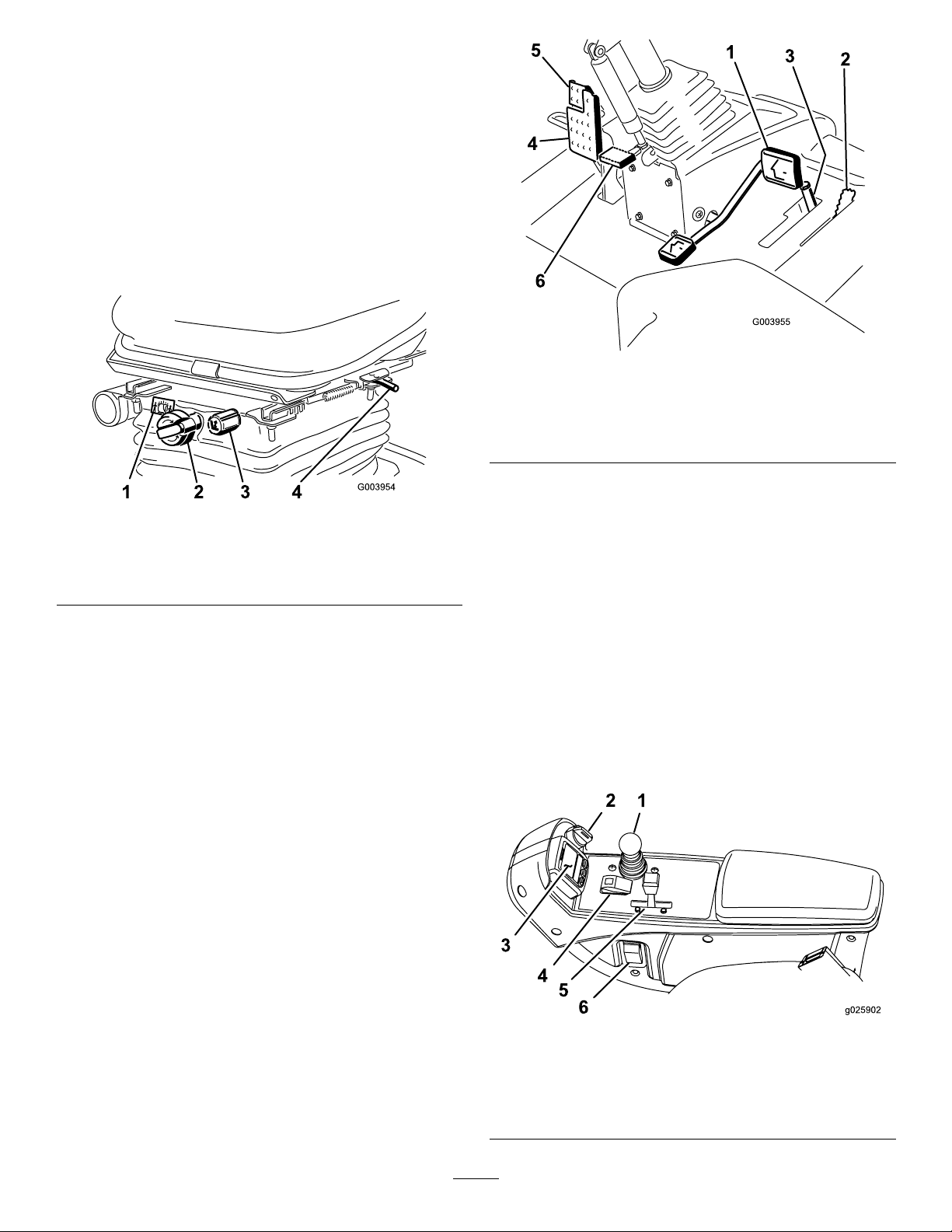

Figure11

1.Tractionpedal4.Brakepedal

2.Mow-speedlimiter5.Parkingbrake

3.Spacers

6.Tilt-steeringpedal

Figure10

1.Weightgauge3.Height-adjustingknob

2.Weight-adjustingknob

4.Adjustinglever(foreand

aft)

TractionPedal

Thetractionpedal(Figure11)controlstheforwardand

reverseoperation.Pressthetopofthepedaltomoveforward

andthebottomtomovebackward.

Tostop,reducefootpressureonthetractionpedalandallow

ittoreturntothecenterposition.

Mow-SpeedLimiter

Whenthemow-speedlimiter(Figure11)isippedupitwill

controlthemowspeedandallowthecuttingdeckstobe

engaged.Eachspaceradjuststhemowingspeedby0.8km/h

(0.5mph).Themorespacersyouhaveonthetopofthebolt,

thesloweryouwillgo.Fortransport,ipbackthemowspeed

limiterformaximum-transportspeed.

Tilt-SteeringPedal

Totiltthesteeringwheeltowardsyou,pressthefootpedal

(Figure11)down,andpullthesteeringtowertowardyouto

themostcomfortablepositionandthenreleasethepedal.

HeadlightSwitch

Pivottheswitchdownwardtoturnontheheadlights

(Figure12).

ThrottleControl

Movethethrottlecontrol(Figure12)forwardtoincreasethe

enginespeedandbackwardtodecreasespeed.

BrakePedal

Pressthebrakepedal(Figure11)tostopthemachine.

ParkingBrake

Toengagetheparkingbrake,(Figure11)pushdownonthe

brakepedalandpressthetopforwardtolatch.Toreleasethe

parkingbrake,pressthebrakepedaluntiltheparking-brake

latchretracts.

Figure12

1.Lowermow/raisecontrol

lever

2.Keyswitch5.Throttlecontrol

3.InfoCenter

15

4.Enable/disableswitch

6.Headlightswitch

Page 16

KeySwitch

1

g020650

2

3

4

TORO

Thekeyswitch(Figure12)has3positions:OFF,

ON/PREHEAT,andSTART.

LowerMow/RaiseControlLever

Thislever(Figure12)raisesandlowersthecuttingdecks

andalsostartsandstopsthemowerswhenthemowersare

enabledinthemowmode.Whenstartingthedecksinthe

downposition,thisleverwillturnthedecksonifthePTO

andthemowspeedlimiterareengaged.

Enable/DisableSwitch

Usetheenable/disableswitch(Figure12)inconjunctionwith

thelowermow/raisecontrollevertooperatethemowers.

Themowerscannotbeloweredwhenthemow/transport

leverisinthetransportposition.

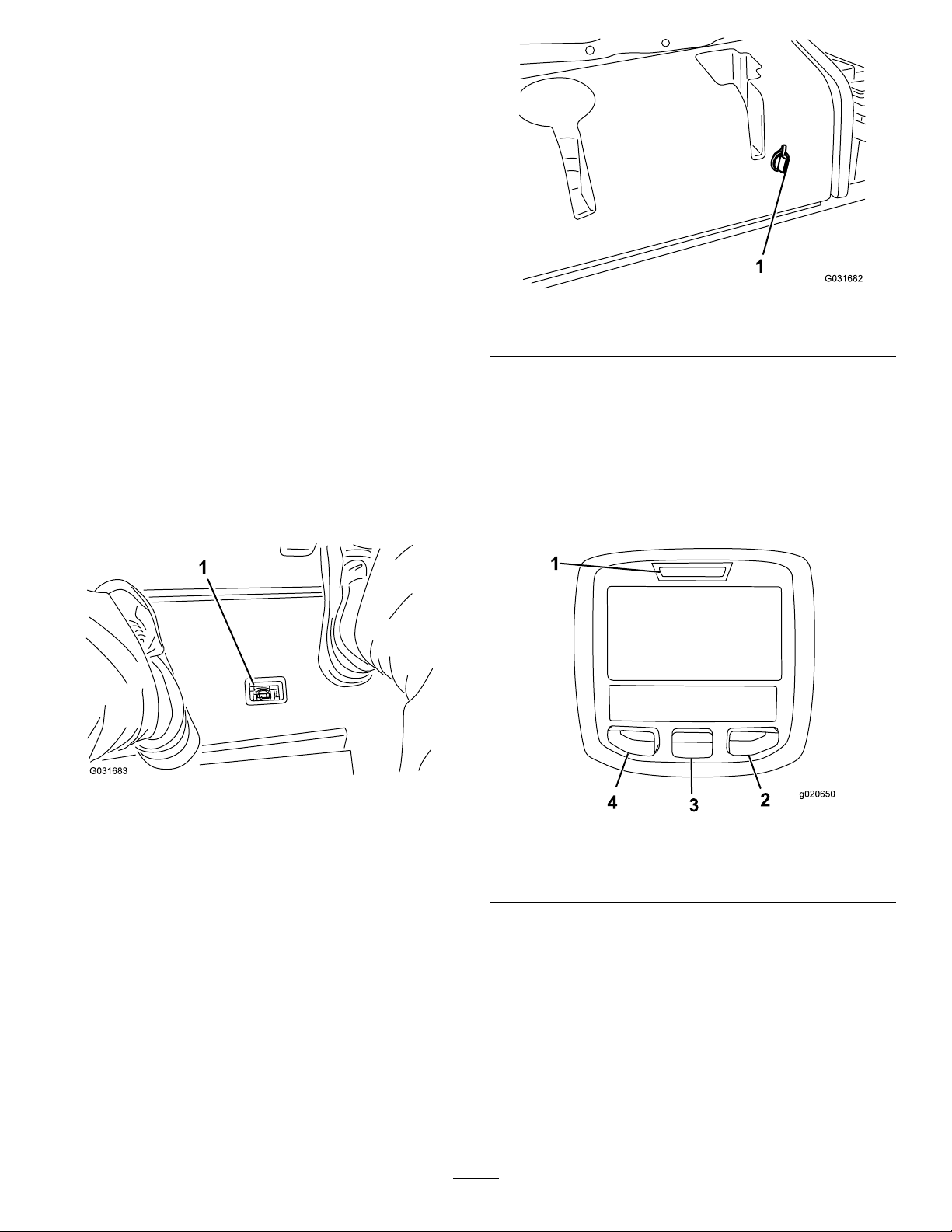

Hydraulic-Filter-RestrictionIndicator

Withtheenginerunningatnormaloperatingtemperature,

viewtheindicator(Figure13),itshouldbeinthegreenzone.

Whentheindicatorisintheredzone,changethehydraulic

lters.

Figure14

1.Powerpoint

UsingtheInfoCenterLCDDisplay

TheInfoCenterLCDdisplayshowstheoperatingstatus,

variousdiagnostics,andotherinformationaboutthemachine

(Figure15).Thereisasplashscreenandmaininformation

screenintheInfoCenter.PressanyoftheInfoCenterbuttons

andthenselecttheappropriatedirectionalarrowtoswitch

betweenthesplashscreenandthemaininformationscreen.

Figure13

1.Hydraulic-lter-restrictionindicator

1.Indicatorlight3.Middlebutton

PowerPoint

Thepowerpointisa12Vpowersupplyforelectronicdevices

(Figure14).

2.Rightbutton

•LeftButton,MenuAccess/BackButton—presstoaccess

theInfoCentermenus.Youcanuseittobackoutofany

menuyouarecurrentlyusing.

•MiddleButton—presstoscrolldownmenus.

•RightButton—presstoopenamenuwherearightarrow

indicatesadditionalcontent.

Note:Thepurposeofeachbuttonmaychangedepending

onwhatisrequiredatthetime.Eachbuttonislabeledwith

anicondisplayingitscurrentfunction.

16

Figure15

4.Leftbutton

Page 17

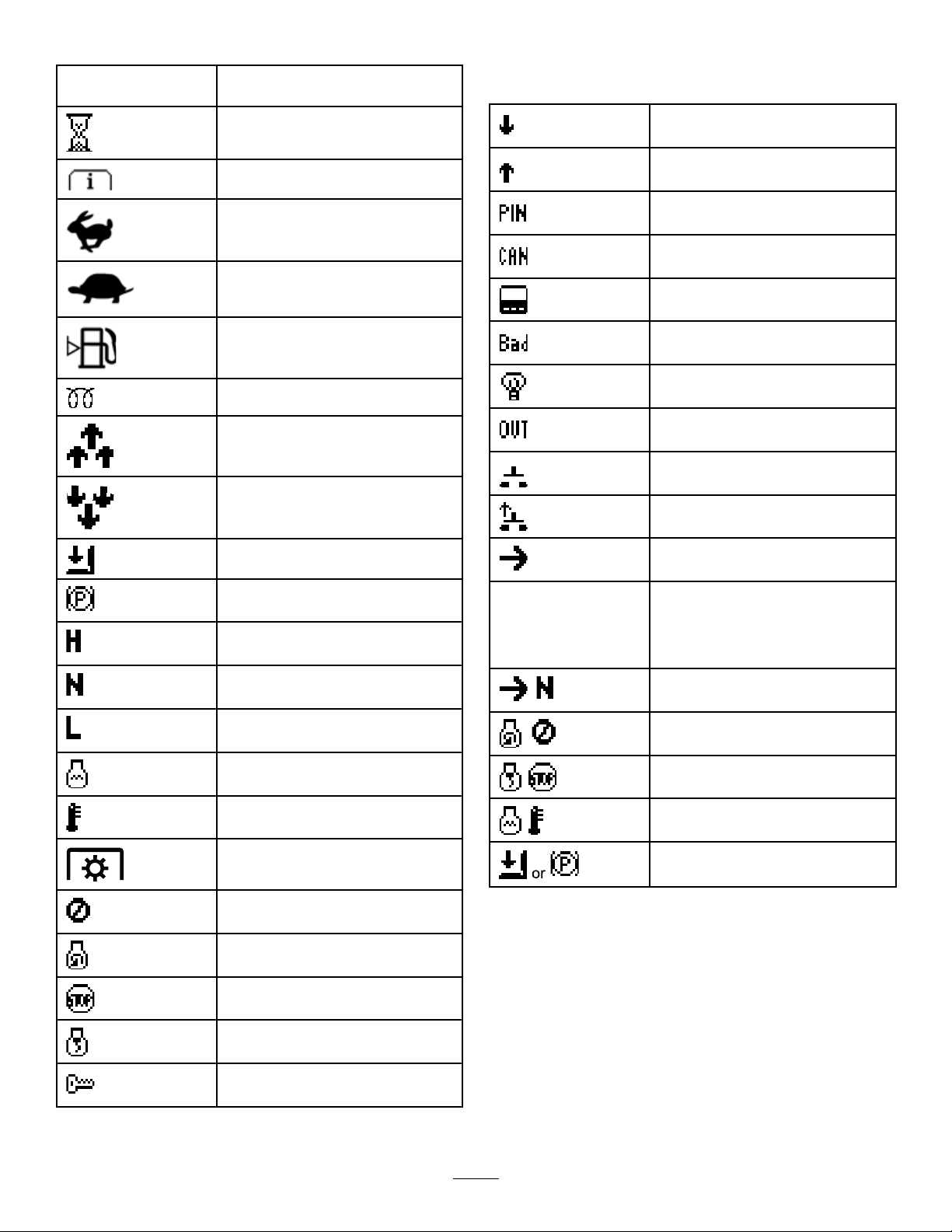

InfoCenterIconDescription

SERVICEDUE

Indicateswhenscheduledservice

shouldbeperformed

Hourmeter

InfoCenterIconDescription(cont'd.)

Cuttingunitsarelowering.

Infoicon

Fast

Slow

Fuellevel

Theglowplugsareactive.

Raisethecuttingunits.

Lowerthecuttingunits.

Sitintheseat.

TheparkingbrakeisOn.

Therangeishigh(Transport).

Neutral

Cuttingunitsareraising.

PINpasscode

CANbus

InfoCenter

Badorfailed

Bulb

OutputofTECcontrollerorcontrol

wireinharness

Switch

Releasetheswitch.

Changetoindicatedstate.

Symbolsareoften

combinedtoform

sentences.Some

examplesareshown

below

Putmachineintoneutral.

Therangeislow(Mow).

CoolantTemperature(°Cor°F)

Temperature(hot)

ThePTOisengaged

Notallowed

Starttheengine.

Stoptheengine.

Engine

Keyswitch

Enginestartisdenied.

Engineshutdown

Enginecoolantistoohot.

Sitdownorsetparkingbrake

17

Page 18

UsingtheMenus

ToaccesstheInfoCentermenusystem,pressthemenuaccess

buttonwhileatthemainscreen.Thiswillbringyoutothe

mainmenu.Refertothefollowingtablesforasynopsisof

theoptionsavailablefromthemenus:

MainMenu

MenuItemDescription

Faults

ServiceContainsinformationonthe

Diagnostics

Settings

AboutListsthemodelnumber,serial

Service

MenuItemDescription

Hours

Counts

Containsalistoftherecent

machinefaults.Referto

theServiceManualoryour

ToroDistributorformore

informationontheFaults

menuandtheinformation

containedthere.

machinesuchashoursofuse,

counters,andothersimilar

numbers.

Displaysthestateofeach

machineswitch,sensor,and

controloutput.Y oucanuse

thistotroubleshootcertain

issuesasitquicklytellsyou

whichmachinecontrolsare

ONandwhichareOFF.

Allowsyoutocustomizeand

modifycongurationvariables

ontheInfoCenterdisplay.

number,andsoftwareversion

ofyourmachine.

Liststhetotalnumberofhours

thatthemachine,engine,and

PTOhavebeenon,aswell

asthenumberofhoursthe

machinehasbeentransported

andservicedue.

Listsnumerouscountsthe

machinehasexperienced.

Settings

MenuItemDescription

Units

Language

LCDBacklightControlsthebrightnessofthe

LCDContrastControlsthecontrastofthe

ProtectedMenusAllowsthe

CounterbalanceControlstheamountof

Controlstheunitsusedonthe

InfoCenter(EnglishorMetric).

Controlsthelanguageused

ontheInfoCenter*.

LCDdisplay.

LCDdisplay.

superintendant/mechanic

toaccessprotectedmenusby

inputtingapasscode.

counterbalanceappliedtothe

cuttingdecks.

*Only"operator-faced"textistranslated.Faults,Service,and

Diagnosticsscreensare"service-faced".Titlesappearinthe

selectedlanguage,butmenuitemsareinEnglish.

About

MenuItemDescription

Model

SNListstheserialnumberofthe

MachineControllerRevisionListsthesoftwarerevisionof

InfoCenterRevisionListsthesoftwarerevisionof

CANBus

Liststhemodelnumberofthe

machine.

machine.

themastercontroller .

theInfoCenter.

Liststhemachine

communicationbusstatus.

Diagnostics

MenuItemDescription

CuttingUnitsIndicatestheinputs,qualiers,

Hi/LowRangeIndicatestheinputs,qualiers,

PTOIndicatestheinputs,qualiers,

EngineRun

andoutputsforraisingand

loweringthecuttingunits.

andoutputsfordrivingin

transportmode.

andoutputsforenablingthe

PTOcircuit.

Indicatestheinputs,qualiers,

andoutputsforstartingthe

engine.

18

Page 19

ProtectedMenus

Thereis1operatingcongurationsettingthatisadjustable

withintheSettingsMenuoftheInfoCenter:counterbalance.

ThissettingcanbelockedbyusingtheProtectedMenu.

Note:Atthetimeofdelivery,theinitialpasswordcodeis

programmedbyyourdistributor.

AccessingtheProtectedMenuSettings

1.FromtheMainMenu,scrolldowntotheSettings

Menuandpresstherightbutton.

2.IntheSettingsMenu,scrolldowntotheProtected

Menuandpresstherightbutton.

3.Toenterthepasscode,usethecenterbuttontosetthe

rstdigitandthenpresstherightbuttontomoveon

tothenextdigit.

4.Usethecenterbuttontosettheseconddigitandthen

presstherightbuttontomoveonthenextdigit.

5.Usethecenterbuttontosetthethirddigitandthen

presstherightbuttontomoveontothenextdigit.

6.Usethecenterbuttontosetthefourthdigitandthen

presstherightbutton.

7.Pressthemiddlebuttontoenterthecode.

8.Ifthecodehasbeenacceptedandtheprotectedmenu

hasbeenunlocked,“PIN”willbedisplayedinthe

upperrightcornerofthedisplayscreen.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

TransportWidth

Widthofcut229cm(90inches)

Length

Height

Netweight*1,412kg(3,114lb)

Fueltankcapacity

Transportspeed

Mowingspeed

*Withcuttingdecksanduids

CuttingDeck

Length

Width

Height

Weight

Attachments/Accessories

226cm(89inches)

320cm(126inches)

218cm(86inches)

53L(14USgallons)

0to16km/h(0to10mph)

0to13km/h(0to8mph)

86.4cm(34inches)

86.4cm(34inches)

24.4cm(9.6inches)

tocarriermount

26.7cm(10–1/2inches)

at3/4inchheightofcut

34.9cm(13–3/4inches)at

4inchheightofcut

88kg(195lb)

Note:Ifyouforgetormisplaceyourpasscode,contact

yourToroDistributorforassistance.

ViewingandChangingtheProtected

MenuSettings

1.IntheProtectedMenu,scrolldowntoProtectSettings.

2.Toviewandchangethesettingswithoutenteringa

passcode,usetherightbuttontochangetheProtect

SettingstoOFF.

3.Toviewandchangethesettingswithapasscode,use

theleftbuttontochangetheProtectSettingstoON,

setthepasscode,andturnthekeyintheignitionswitch

totheOFFpositionandthentotheONposition.

SettingtheCounterbalance

1.IntheSettingsMenu,scrolldowntoCounterbalance.

2.Presstherightbuttontoselectcounterbalanceand

changebetweenthelow ,medium,andhighsettings.

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonTorogenuine

parts.Whenitcomestoreliability ,Torodeliversreplacement

partsdesignedtotheexactengineeringspecicationofour

equipment.Forpeaceofmind,insistonT orogenuineparts.

19

Page 20

Operation

FuelSafety

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopletooperateor

servicethemachine.Localregulationsmayrestrictthe

ageoftheoperator.Theownerisresponsiblefortraining

alloperatorsandmechanics.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.Knowhowtostop

themachineandenginequickly.

•Checkthatallsafetydevicesareattachedand

functioningproperly.Thisincludes,butisnotlimitedto,

operator-presencecontrols;safetyswitchesandshields;

therolloverprotectionsystem(ROPS);attachments;and

brakes.Donotoperatethemachineunlessallsafety

devicesareinpositionandfunctioningasintendedby

themanufacturer.

•Alwaysinspectthemachinetoensurethattheblades,

bladebolts,andcuttingassemblyarenotwornor

damaged.Replacewornordamagedbladesandboltsin

setstopreservebalance.

•Inspecttheareawhereyouwillusethemachineand

removeallobjectsthatthemachinecouldpotentially

throw .

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessoriesrequiredto

operatethemachineproperlyandsafely.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana180-daysupplyoffuel.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepyourhandsandfaceawayfromthenozzle

andthefuel-tankopening.

•Keepfuelawayfromyoureyesandskin.

•Useonlyanapprovedfuelcontainer.

•Neverremovethefuelcaporaddfueltothefueltank

whiletheengineisrunning.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundandawayfromyourvehiclebeforelling.

•Removetheequipmentfromthetruckortrailerandadd

fueltoitwhileitisontheground.Ifthisisnotpossible,

thenaddfuelusingaportablecontainerratherthanfrom

afuel-dispensernozzle.

•Keepthefuel-dispensernozzleincontactwiththerimof

thefueltankorcontaineropeningatalltimesuntilfueling

iscomplete.Donotuseanozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyourclothing

immediately.

•Fillthefueltankuntilthefuellevelis25mm(1inch)

belowthebottomofthellerneck.Donotoverllthe

fueltank.Replacethefuel-tankcapandtightenitsecurely .

20

Page 21

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page38).

•Paintedsurfacesmaybedamagedbybiodieselblends.

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather.

•Monitorseals,hoses,gasketsincontactwithfuelasthey

maybedegradedovertime.

CheckingtheCoolingSystem

Beforeyoustarttheengineandusethemachine,checkthe

coolingsystem;refertoCheckingtheCoolingSystem(page

44).

CheckingtheHydraulic System

Beforeyoustarttheengineandusethemachine,checkthe

hydraulicsystem;refertoCheckingtheHydraulicLinesand

Hoses(page49).

FillingtheFuelTank

RecommendedFuel

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultralow(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchasefuelin

quantitiesthatcanbeusedwithin180daystoensurefuel

freshness.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblended.

•Contactyourdistributorifyouwishformoreinformation

onbiodiesel.

Fueltankcapacity:53L(14USgallons)

Usesummergradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Useofwintergrade

fuelatlowertemperaturesprovideslowerashpointand

coldowcharacteristicswhichwilleasestartingandreduce

fuellterplugging.

Useofsummergradefuelabove-7°C(20°F)willcontribute

towardlongerfuelpumplifeandincreasedpowercompared

towintergradefuel.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultralowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

Figure16

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

21

Page 22

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

1.Lowerthecuttingdecktotheground,turnthekeyin

theignitionswitchtotheOFFposition,andremove

thekey.

Thecorrectairpressureinthefrontandreartiresis83to

103kPa(12to15psi).

Important:Maintainevenpressureinalltirestoensure

thatcontactwiththeturfisuniform.

Figure17

CheckingtheTorqueofthe Wheel-LugNuts

ServiceInterval:Afterthersthour

Aftertherst10hours

Every250hours

Torquethewheel-lugnutsto94to122N∙m(70to90ft-lb)

after1-4hoursofoperationandagainafter10hoursof

operation.Torqueevery250hoursthereafter.

2.Loosentheboltsecuringeachheight-of-cutbracketto

theheight-of-cutplate(frontandeachside)(Figure18).

3.Beginningwiththefrontadjustment,removethebolt.

Figure18

1.Height-of-cutbracket3.Spacer

2.Height-of-cutplate

4.Whilesupportingthechamber,removethespacer

(Figure19).

5.Movethechambertothedesiredheightofcutand

installthespacerintothedesignatedheight-of-cuthole

andslot(Figure19).

WARNING

Failuretomaintainthepropertorqueofthewheel

nutscouldresultinfailureorlossofawheel,and

mayresultinpersonalinjury.

Torquethefrontandrear-wheelnutsto95to122

N·m(70to90ft-lb)after10hoursofoperation.

Torquethenutsevery250hoursthereafter.

AdjustingtheHeightofCut

Important:Therotarycuttingdeckcutsapproximately

6mm(1/4inch)lowerthanareelcuttingunitwiththe

samebenchsetting.Therefore,itmaybenecessaryto

havetherotarycuttingdeck'sbenchset6mm(1/4inch)

abovethatofreelscuttinginthesamearea.

Important:Accesstotherearcuttingunitsisgreatly

improvedbyremovingthecuttingunitfromthetractor.

IftheunitisequippedwithaSidewinder®,sidewindthe

cuttingunitstotheright,removetherearcuttingunit,

andslideitouttotherightside.

Figure19

6.Positionthetappedplatein-linewiththespacer.

7.Installtheboltnger-tight.

8.Repeatsteps4through7foreachsideadjustment.

9.Tightenall3boltsto41N∙m(30ft-lb).Alwaystighten

thefrontboltrst.

Note:Adjustmentsofmorethan3.8cm(1.5inches)

mayrequiretemporaryassemblytoanintermediate

heighttopreventbinding(e.g.changingfrom3.1to7.0

cm(1.25to2.75inches)heightofcut).

22

Page 23

Breaking-intheMachine

Toensureoptimumperformanceoftheparkingbrakesystem,

burnish(break-in)thebrakesbeforeuse.Settheforward

tractionspeedto6.4km/h(4mph)tomatchthereverse

tractionspeed.(All8spacersmovedtothetopofthemow

speedcontrol.)Withtheengineathighidle,proceedforward

withthemowspeedcontrolstopengagedandridethebrake

for15seconds.Proceedbackwardatfullreversespeedand

ridethebrakefor15seconds.Repeatthis5timeswaiting

1minutebetweeneachforwardandreversecycletoavoid

overheatingthebrakes.Anadjustmenttothebrakesmaybe

requiredafterbreak-in;refertoAdjustingtheParkingBrakes

(page45).

BleedingtheFuelSystem

Youmustbleedthefuelsystembeforestartingtheengineif

anyofthefollowingsituationshaveoccurred:

•Initialstart-upofanewmachine.

•Enginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponfuelsystem

components;i.e.,lterreplaced,separatorserviced,etc.

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

Figure20

1.Bleedscrew

4.TurnthekeyintheignitionswitchtotheONposition.

Theelectricfuelpumpwillbeginoperation,thereby

forcingairoutaroundtheairbleedscrew .Leavethe

keyintheONpositionuntilasolidstreamoffuelows

outaroundthescrew .

5.TightenthescrewandturnthekeytotheOFFposition.

Note:Normally,theengineshouldstartaftertheabove

bleedingproceduresarefollowed.However,ifenginedoes

notstart,airmaybetrappedbetweeninjectionpumpand

injectors;refertoBleedingAirfromtheFuelInjectors(page

41).

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis6to13mm

(0.25to0.50inch)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsthe

fueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinaclean,safety-approvedcontainer

andkeepthecapinplace.

1.Settheparkingbrake,turnthekeyintheignition

switchtotheOFFposition,parkthemachineonalevel

surface,andensurethatthefueltankisatleasthalffull.

2.Openthehood.

3.Opentheair-bleedscrewonthefuelinjectionpump

(Figure20)witha12mmwrench.

23

Page 24

CheckingtheInterlock Switches

Note:Makesurethatthedecksareloweredontoaclean

sectionofturforhardsurfacetoavoidthrowndustand

debris.

ServiceInterval:Beforeeachuseordaily

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Theinterlockswitchesstopthemachinewhentheoperator

getsofftheseatwhenthetractionpedalisdepressed.

However,theoperatormaygetofftheseatwhiletheengine

isrunningandthetractionpedalisintheNEUTRALposition.

AlthoughtheenginecontinuestorunifthePTOswitchis

disengagedandthetractionpedalisreleased,itisstrongly

recommendedthattheenginebestoppedbeforerisingfrom

theseat.

Tochecktheoperationoftheinterlockswitches,perform

thefollowingprocedure:

1.Parkthemachineonalevelsurface,lowerthecutting

unit,stoptheengine,andsettheparkingbrake.

2.Pressthetractionpedal.Turnthekeyintheignition

switchtotheONposition.

Note:Iftheenginecranks,thereisamalfunctionin

theinterlocksystem.Correctthismalfunctionbefore

operatingthemachine.

3.TurnthekeyintheignitionswitchtotheONposition,

risefromtheseat,andmovethePTOswitchtothe

ONposition.

Note:ThePTOshouldnotengage.IfthePTO

engages,thereisamalfunctionintheinterlocksystem.

Correctthismalfunctionbeforeoperatingthemachine.

4.Engagetheparkingbrake,turnthekeyintheignition

switchtotheONposition,starttheengine,andmove

thetractionpedaloutoftheNEUTRALposition.

Note:TheInfoCenterdisplays"tractiondenied"and

themachineshouldnotmove.Ifthemachinedoes

move,thereisamalfunctionintheinterlocksystem.

Correctthismalfunctionbeforeoperatingthemachine.

1.Haveasecondpersonstandbackfromthedeckat

least6m(20feet)andwatchthebladeson1ofthe

cuttingdecks.

2.Shutthecuttingdecksdownandrecordthetimeit

takesforthebladestocometoacompletestop.

Note:Ifthistimeisgreaterthan7seconds,the

brakingvalveneedsadjustment.CallyourToro

Distributorforassistanceinmakingthisadjustment.

SelectingaBlade

StandardCombinationSail

Thisbladewasdesignedtoprovideexcellentliftand

dispersioninalmostanycondition.Ifmoreorlessliftand

dischargevelocityisrequired,consideradifferentblade.

Attributes:Excellentliftanddispersioninmostconditions.

AngledSail

Thebladegenerallyperformsbestinlowerheightsofcut–

1.9to6.4cm(3/4to2–1/2inches).

Attributes:

•Dischargeremainsmoreevenatlowerheightsofcut.

•Dischargehaslesstendencytothrowleftandthusa

cleanerlookaroundbunkersandfairways.

•Lowerpowerrequirementatlowerheightsanddenseturf.

HighLiftParallelSail

Thebladegenerallyperformsbetterinthehigherheightsof

cut–7to10cm(2to4inches).

Attributes:

•Moreliftandhigherdischargevelocity.

•Sparseorlimpturfispickedupsignicantlyathigher

heightsofcut.

•Wetorstickyclippingsaredischargedmoreefciently

reducingcongestioninthedeck.

•Requiresmorehorsepowertorun.

CheckingtheBladeStopping Time

ServiceInterval:Beforeeachuseordaily

Thebladesofthecuttingdeckshouldcometoacomplete

stopinapproximately5secondsafteryoushutdownthe

cutting-deck-engagementswitch.

•Tendstodischargefurtherleftandcantendtowindrow

atlowerheightsofcut.

WARNING

Donotusethehigh-liftbladewiththemulching

bafe.Thebladecouldbreak,resultinginpersonal

injuryordeath.

24

Page 25

AtomicBlade

g021272

TORO

Thisbladewasdesignedtoprovideexcellentleafmulching.

Attributes:Excellentleafmulching

TheDiagnosticLight

Themachineisequippedwithadiagnosticlightwhich

indicatesifthemachinedetectsamalfunction.Thediagnostic

lightislocatedontheInfoCenter,abovethedisplayscreen

(Figure21).Whenthemachineisfunctioningproperlyand

thekeyintheignitionswitchisturnedtotheON/RUN

position,thediagnosticlightwillturnonbrieytoindicatethe

lightisworkingproperly.Whenamachineadvisorymessage

isdisplayed,thelightwillilluminatewhenthemessageis

present.Whenafaultmessageisdisplayed,thelightwillblink

untilthefaultisresolved.

Figure21

1.Diagnosticlight

ChangingtheCounterbalance Settings

Duringdifferenttimesofthemowingseasonorwhenturf

conditionsvary,theamountofcounterbalance(upwardlift)

requiredonthecuttingdeckscanbechangedtomeetthe

conditions.

1.Positionthemachineonalevelsurface,lowerthe

cuttingdecks,turnthekeyintheignitionswitchtothe

OFFposition,andengagetheparkingbrake.

2.TurnthekeyintheignitionswitchtotheRUNposition.

3.IntheInfoCenterSettingsMenu,scrolldownto

Counterbalance.

4.Presstherightbuttontoselectcounterbalanceand

changebetweenthelow ,medium,andhighsettings.

Note:Oncetheadjustmenthasbeencompleted,move

themachinetoatestareaandoperatethemachinewith

thenewsetting.Thenewcounterbalancedsettingmay

changetheeffectiveheightofcut.

25

Page 26

ChoosingAccessories

OptionalEquipmentCongurations

AngleSailBladeHighLiftParallelSail

GrassCutting:1.9to4.4

cm(0.75to1.75inches)

heightofcut

GrassCutting:5to6.4

cm(2.00to2.50inches)

heightofcut

GrassCutting:7to10

cm(2.75to4.00inches)

heightofcut

LeafMulchingRecommendedforuse

ProsEvendischargeatlower

ConsDoesnotliftthegrass

Recommendedinmost

applications

Recommendedforthick

orlushturf

Mayworkwellinlushturf

withthemulchingbafe

heightofcut.Cleaner

lookaroundbunkersand

fairwaysLowerpower

requirements

wellinhighheight-of-cut

applicationsWetor

stickygrasshasa

tendencytobuildupin

thechamber,leading

topoorqualityofcut

andhigherpower

requirements

Blade(Donotusewith

themulchingbafe)

Mayworkwellinlightor

sparseturf

Recommendedforlight

orsparseturf

Recommendedinmost

applications

NotAllowedUsewithcombination

Moreliftandhigher

dischargevelocity

Sparseorlimpturfis

pickedupathighheight

ofcutWetorsticky

clippingsaredischarged

efciently

Requiresmorepowerto

runinsomeapplications

Tendstowindrowat

lowerheightofcutin

lushgrassDonotuse

withthemulchingbafe

MulchingBafeRollerScraper

Hasbeenshownto

improvedispersionand

aftercutperformance

onnortherngrassesthat

arecutatleast3times

perweekandlessthan

1/3ofthegrassblade

isremoved.Donot

usewiththehighlift

parallelsailblade

sailoranglesailblade

only

Mayimprovedispersion

andappearancein

certaingrasscutting

applicationsVerygood

forleafmulching

Grasswillbuildupinthe

chamberifattemptingto

removetoomuchgrass

withbafeinplace

Canbeusedanytime

thatrollersbuildup

withgrassorlargeat

grassclumpsofgrass

areseen.Thescrapers

mayactuallyincrease

clumpingincertain

applications.

Reducesrollerbuildup

incertainapplications

26

Page 27

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/usercanpreventandisresponsiblefor

accidentsthatmaycauseinjuriestohimself/herselfand

othersandfordamagetoproperty.

•Wearappropriateclothing,includingeyeprotection;

slip-resistant,substantialfootwear;andhearing

protection.Wearingsafetyshoesandlongpantsis

advisableandrequiredbysomelocalordinancesand

insuranceregulations.Tiebacklonghair,secureloose

clothing,anddonotwearjewelry.

•EnsurethatalldrivesareintheNEUTRALposition,the

parkingbrakeisengaged,andyouareintheoperating

positionbeforeyoustarttheengine.

•Keepallbodyparts,includinghandsandfeet,awayfrom

allmovingparts.

•Donotoperatethemachinewhileill,tired,orunderthe

inuenceofalcoholordrugs.

•Keepthedirectionofthemowerdischargeawayfrom

peopleandpets.

•Donotmowinreverseunlessitisabsolutelynecessary.If

youmustmowinreverse,lookbehindanddownforsmall

childrenbeforeandwhilemovingthemachineinreverse.

Stayalertandstopthemachineifachildentersthearea.

•Useextremecarewhenapproachingblindcorners,

shrubs,trees,orotherobjectsthatmayblockyourview.

•Donotmowneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyrolloverifawheelgoes

overtheedgeoriftheedgecavesin.

•Nevercarrypassengersonthemachine.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperatethe

machinewhenthereistheriskoflighting.

•Donotmowonwetgrass.Reducedtractioncouldcause

themachinetoslide.

•Neverraisethemowerdeckwiththebladesrunning.

•Stopthemachineandinspectthebladesafterstrikingan

objectorifthereisanabnormalvibrationinthemachine.

Makeallnecessaryrepairsbeforeresumingoperation.

•Stopthebladeswheneveryouarenotmowing,especially

whilecrossinglooseterrainsuchasgravel.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalkswiththemachine.Always

yieldtheright-of-way.

•Turnontheashingwarninglightsonthemachine

wheneveryoutravelonapublicroad,exceptwheresuch

useisprohibitedbylaw.

•Disengagethedrivetotheattachmentandshutoffthe

enginebeforeaddingfuelandadjustingtheheightofcut.

•Reducethethrottlesettingbeforestoppingtheengine

and,iftheenginehasafuel-shutoffvalve,shutoffthe

fuelwhenyouhavenishedoperatingthemachine.

•Neverrunanengineinanareawhereexhaustgasesare

enclosed.

•Neverleavearunningengineunattended.

•Beforeleavingtheoperatingposition,dothefollowing:

–Stopthemachineonlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Settheparkingbrake.

–Shutofftheengineandremovethekey .

–Waitforallmovingpartstostop.

•Donotchangethegovernorsettingsonoroverspeed

theengine.Operatingtheengineatexcessivespeedmay

increasethepotentialforpersonalinjury.

•Donotusethemachineasatowingvehicle.

•UseaccessoriesandattachmentsapprovedbyTheToro®

Companyonly.

RolloverProtectionSystem(ROPS)

Safety

•DonotremovetheROPSfromthemachine.

•Ensurethattheseatbeltisattachedandthatyoucan

releaseitquicklyintheeventofanemergency.

•Alwayswearyourseatbelt.

•Checkcarefullyforoverheadclearances,suchasbranches,

doorways,andelectricalwires,beforedrivingthemachine

underthem.Donotcontactthem.

•KeeptheROPSinsafeoperatingconditionbythoroughly

inspectingitperiodicallyfordamageandkeepingallthe

mountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorreviseit.

•AnyalterationstoaROPSmustbeapprovedbyThe

Toro®Company.

SlopeSafety

•Slowdownthemachineanduseextracareonhillsides.

Travelintherecommendeddirectiononhillsides.Turf

conditionscanaffectthestabilityofthemachine.

•Avoidstarting,stopping,orturningthemachineona

slope.Ifthetireslosetraction,disengagetheblade(s)and

proceedslowlystraightdowntheslope.

•Donotturnthemachinesharply .Usecarewhenreversing

themachine.

•Whenoperatingthemachineonaslope,alwayskeepall

cuttingunitslowered.

•Avoidturningthemachineonslopes.Ifyoumustturn,

turnslowlyandgraduallydownhill,ifpossible.

•Useextracarewhileoperatingthemachinewith

attachments;theycanaffectthestabilityofthemachine.

27

Page 28

StartingandStoppingthe Engine

continuingoperation.Seriousdamagecouldoccurifyou

operatethemachinewithamalfunction.

Important:Y oumustbleedthefuelsystembefore

startingtheengineifyouarestartingtheengineforthe

rsttime,theenginehasstoppedduetolackoffuel,or

youhaveperformedmaintenanceonthefuelsystem;

refertoBleedingAirfromtheFuelInjectors(page41).

StartingtheEngine

1.Sitontheseat,keepyourfootoffthetractionpedalso

thatitisinNEUTRAL,engagetheparkingbrake,set

thethrottletotheFASTposition,andensurethatthe

Enable/DisableswitchisintheDISABLEposition.

2.TurnthekeyintheignitionswitchtotheON/PREHEAT

position.

Note:Anautomatictimerwillcontroltheglowplug

preheatfor6seconds.

3.Afterpreheatingtheglowplugs,turnthekeyinthe

ignitionswitchtotheSTARTposition.

4.Cranktheenginefornolongerthan15seconds.

Releasethekeywhentheenginestarts.

5.Ifadditionalpreheatingisrequired,turnthekeyin

theignitionswitchtotheOFFpositionandthento

theON/PREHEATposition.Repeatthisprocessas

required.

6.Runtheengineatlowidlespeeduntilitwarmsup.

StoppingtheEngine

1.MoveallcontrolstoNEUTRAL,settheparkingbrake,

movethethrottletotheLOWIDLEpositionandallow

theenginetoreachlowidlespeed.

Important:Allowtheenginetoidlefor5

minutesbeforeshuttingitoffafterafullload

operation.Failuretodosomayleadtotroubleon

aturbo-chargedengine.

2.TurnthekeyintheignitionswitchtotheOFFposition

andremovethekey.

Mowing

TurnthekeyintheignitionswitchtotheONposition,start

theengine,andmovethethrottletotheFASTposition.Move

theEnable/DisableswitchtotheENABLEpositionanduse

thelowermow/raiselevertocontrolthecuttingdecks.To

moveforwardandcutgrass,pressthetractionpedalforward.

Note:Allowtheenginetoidlefor5minutesbeforeshutting

itoffafterafullloadoperation.Failuretodosomayleadto

turbo-chargertrouble.

MowwhentheGrassIsDry

Moweitherinthelatemorningtoavoidthedew ,whichcauses

grassclumping,orinlateafternoontoavoidthedamage

thatcanbecausedbydirectsunlightonthesensitive,freshly

mowedgrass.

SelectingtheProperHeight-of-Cut

Setting

Removeapproximately25mm(1inch)ornomorethan1/3

ofthegrassbladewhencutting.Inexceptionallylushand

densegrassyoumayhavetoraisetheheight-of-cutsetting.

AlwaysStartMowingwithSharpBlades

Asharpbladecutscleanlyandwithouttearingorshredding

thegrassbladeslikeadullblade.Tearingandshredding

causesthegrasstoturnbrownattheedgeswhichimpairs

growthandincreasessusceptibilitytodiseases.Makesurethat

thebladeisingoodconditionandafullsailispresent.

CheckConditionofDeck

Makesurethatthecuttingchambersareingoodcondition.

Straightenanybendsinthechambercomponentstoensure

thatthecorrectbladetip/chamberclearanceismet.

OperatingTips

Familiarization

Beforemowinggrass,practiceoperatingthemachineinan

openarea.Startandstoptheengine.Operateinforward

andreverse.Lowerandraisethecuttingdecksandengage

anddisengagethemowers.Whenyoufeelfamiliarwiththe

machine,practiceoperatingupanddownslopesatdifferent

speeds.

WarningSystem

Ifawarninglightcomesonduringoperation,stopthe

machineimmediatelyandcorrecttheproblembefore

AfterOperating

Toensurethatoptimumperformanceismet,cleanthe

undersideofmowerhousing.Ifyouallowresiduetobuildup

inmowerhousing,cuttingperformancewilldecrease.

28

Page 29

Transport

G031851

MovetheEnable/DisableswitchtotheDISABLEpositionand

raisethecuttingdeckstotheTRANSPORTposition.Movethe

mow/transportlevertotheTRANSPORTposition.Becareful

whendrivingbetweenobjectssoyoudonotaccidentally

damagethemachineorcuttingdecks.Useextracarewhen

operatingthemachineonslopes.Driveslowlyandavoid

sharpturnsonslopestopreventrollingover.Lowerthe

cuttingdeckswhengoingdownhillforsteeringcontrol.

AfterOperation

AfterOperationSafety

GeneralSafety

•Cleangrassanddebrisfromthecuttingunits,drives,

mufers,andenginetohelppreventres.Cleanupoil

orfuelspills.

•Shutoffthefuelwhilestoringortransportingthe

machine.

•Disengagethedrivetotheattachmentwheneveryouare

transportingornotusingthemachine.

IdentifyingtheTie-Down Points

•Frontofthemachine—theholeintherectangularpad,

undertheaxletube,insideeachfronttire(Figure22).

Figure22

1.Fronttie-down

•Usefull-widthrampsforloadingthemachineintoa

trailerortruck.Donotexceeda15°anglebetweenthe

rampandthetrailerortruck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

•Allowtheenginetocoolbeforestoringthemachinein

anyenclosure.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlight,suchasonawater

heateroronotherappliances.

TowingSafety

•Towonlywithamachinethathasahitchdesignedfor

towing.Donotattachtowedequipmentexceptatthe

hitchpoint.

•Followthemanufacturer’ srecommendationforweight

limitsfortowedequipmentandtowingonslopes.On

slopes,theweightofthetowedequipmentmaycauseloss

oftractionandlossofcontrol.

•Neverallowchildrenorothersinorontowedequipment.

•Rearofthemachine—eachsideofthemachineonthe

rearframe(Figure23).

Figure23

1.Reartie-down

•Travelslowlyandallowextradistancetostopwhen

towing.

29

Page 30

PushingorTowingthe Machine

Inanemergency,themachinecanbemovedbyactuatingthe

bypassvalveinthevariabledisplacementhydraulicpumpand

pushingortowingthemachine.

Important:Donotpushortowthemachinefasterthan

3to4.8km/h(2to3mph)becauseinternaltransmission

damagemayoccur.Thebypassvalvemustbeopen

wheneverthemachineispushedortowed.

1.Thebypassvalveislocatedontheleftsideofthe

hydrostat(Figure24).Rotatethebolt1–1/2turnsto

openandallowtheoiltobypassinternally.Because

uidisbypassed,themachinecanbemovedslowly

withoutdamagingthetransmission.

1.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Shutofftheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Usethemetaltie-downloopsonthemachine(Figure

25)tosecurelyfastenthemachinetothetrailerortruck

withstraps,chains,cable,orropes.

Figure25

Figure24

1.Bypassvalve

2.Closethebypassvalvebeforestartingtheengine.

However,donotexceed7to11N∙m(5to8ft-lb)

torquetoclosethevalve.

Important:Runningtheenginewiththebypass

valveopenwillcausethetransmissiontooverheat.

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,pets,orbystandersavoidinjury.

1.Tractionunittie-downloops

LoadingtheMachine

Useextremecautionwhenloadingthemachineontoatrailer

oratruck.1full-widthrampthatiswideenoughtoextend

beyondthereartiresisrecommendedinsteadofindividual

rampsforeachsideofthemachine(Figure26).Thelower

rearsectionofthemachineframeextendsbackbetweenthe

rearwheelsandservesasastopfortippingbackward.Having

afull-widthrampprovidesasurfacefortheframemembers

tocontactifthemachinestartstotipbackward.Ifitisnot

possibletouseonefull-widthramp,useenoughindividual

rampstosimulateafull-widthcontinuousramp.

Therampshouldbelongenoughsothattheanglesdonot

exceed15°(Figure26).Asteeperanglemaycausemower

componentstogetcaughtastheunitmovesfromtherampto

thetrailerortruck.Steeperanglesmayalsocausethemachine

totipbackward.Ifloadingonornearaslope,positionthe

trailerortrucksothatitisonthedownsideoftheslopeand

therampextendsuptheslope.Thiswillminimizetheramp

angle.Thetrailerortruckshouldbeaslevelaspossible.

WARNING

Drivingonstreetsorroadwayswithoutturnsignals,

lights,reectivemarkings,oraslow-movingvehicle

emblemisdangerousandcanleadtoaccidents

causingpersonalinjury.

Donotdrivethemachineonpublicstreetsor

roadways.

Important:Donotattempttoturnthemachinewhile

ontheramp;youmaylosecontrolanddriveofftheside.

Avoidsuddenaccelerationwhendrivinguparampand

suddendecelerationwhenbackingdownaramp.Both

maneuverscancausethemachinetotipbackward.

30

Page 31

DANGER

Loadingamachineontoatrailerortruckincreases

thepossibilityofbackwardtip-overandcouldcause

seriousinjuryordeath.

•Useextremecautionwhenoperatingamachine

onaramp.

•EnsurethattheROPSisintheuppositionwhile

usingtheseatbeltwhenloadingthemachine.

EnsurethattheROPSwillclearthetopofan

enclosedtrailer.

•Useonlyasingle,full-widthramp;donotuse

individualrampsforeachsideofthemachine.

•Ifindividualrampsmustbeused,useenough

rampstocreateanunbrokenrampsurfacewider

thanthemachine.

•Donotexceeda15°anglebetweentherampand

thegroundorbetweentherampandthetrailer

ortruck.

•Avoidsuddenaccelerationwhiledrivingthe

machineuparamp,toavoidtippingbackward.

•Avoidsuddendecelerationwhilebackingthe

machinedownaramp,toavoidtippingit

backward.

Figure26

1.Trailer

2.Full-widthramp4.Full-widthramp—side

3.Notgreaterthan15°

view

31

Page 32

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Afterthersthour

Aftertherst8hours

Aftertherst10hours

Aftertherst50hours

Beforeeachuseordaily

Every50hours

MaintenanceProcedure

•T orquethewheel-lugnutsto94to122N∙m(70to90ft-lb).

•Checktheconditionandtensionofthealternatorbelt.

•T orquethewheel-lugnutsto94to122N∙m(70to90ft-lb).

•Changetheengineoilandlter.

•Checktheenginerpm(idleandfullthrottle).

•Checkthetirepressure.

•Checktheoperationoftheinterlockswitches.

•Checkthebladestoppingtime

•Checktheengine-oillevel.

•Checkthelevelofcoolantintheexpansiontankandcleandebrisoffthescreen,oil

cooler,andfrontoftheradiator.

•Removedebrisfromthescreen,oilcoolers,andradiator(morefrequentlyindirty

operatingconditions).

•Checkthehydraulicuidlevel.

•Checkthehydrauliclinesandhosesforleaks,kinkedlines,loosemountingsupports,

wear,loosettings,weatherdeterioration,andchemicaldeterioration.

•Greasethebearingsandbushings.(Greasethemimmediatelyaftereverywashing

regardlessoftheintervallisted.)

•Checktheconditionofandcleanthebattery.

•Checkthebatterycableconnections.

Every100hours

Every150hours

Every200hours

Every250hours

Every400hours

Every800hours

Beforestorage

Every2years

•Inspectthecooling-systemhoses.

•Checktheconditionandtensionofthealternatorbelt.

•Changetheengineoilandlter.

•Drainmoisturefromthefuelandhydraulicuidtanks.

•T orquethewheel-lugnutsto94to122N∙m(70to90ft-lb).

•Servicetheaircleaner .(Orearlieriftheair-cleanerindicatorilluminatesred.Service

itmorefrequentlyinextremelydirtyordustyconditions.)

•Checkthefuellinesandconnectionsfordeterioration,damage,orloose

connections.(Oryearly ,whichevercomesrst).

•Replacethefuelltercanister.

•Checktheenginerpm(idleandfullthrottle).

•Drainandcleanthefueltank

•Checktherearwheeltoe-in.

•Changethehydraulicuid.

•Changethehydrauliclters(sooneriftheserviceintervalindicatorisintheredzone).

•Adjusttheenginevalves(refertotheengineoperator’smanual).

•Drainandcleanthefueltank

•Flushandreplacethecooling-systemuid.

•Drainandushthehydraulictank.

•Replaceallmovinghoses.

Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

32

Page 33

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof:

MaintenanceCheckItem

Checkthesafetyinterlockoperation.

Checkthebrakeoperation.

Checktheengineoilandfuellevel.

Drainthewater/fuelseparator.

Checktheairlterrestrictionindicator.

Checktheradiatorandscreenfordebris.

Checkunusualenginenoises.

Checkunusualoperatingnoises.

Checkthehydraulicsystemoillevel.

Checkthehydrauliclterindicator.

Checkhydraulichosesfordamage.

Checkforuidleaks.

Checkthetirepressure.

Checktheinstrumentoperation.

ChecktheHeight-of-Cutadjustment

CheckConditionofBlades

Checkallgreasettingsforlubrication.

Touch-updamagedpaint.

1.Checktheglowplugandinjectornozzlesifhardstarting,excesssmoke,orroughrunningisnoted.

1

2

3

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

2.Checkwiththeenginerunningandtheoilatoperatingtemperature

3.Immediatelyaftereverywashing,regardlessoftheintervallisted

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

1

2

3

4

5

6

7

8

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

Note:Downloadafreecopyoftheelectricalorhydraulicschematicbyvisitingwww .Toro.comandsearchingforyour

machinefromtheManualslinkonthehomepage.

Information

33

Page 34

ServiceIntervalChart

Figure27

Premaintenance

Procedures

Pre-MaintenanceSafety

•Keepallpartsofthemachineingoodworkingcondition

andallhardwaretightened,especiallyblade-attachment

hardware.Replaceallwornordamageddecals.

•Neverallowuntrainedpersonneltoservicethemachine.

•Beforeadjusting,cleaning,orrepairingthemachine,do

thefollowing:

1.Movethemachinetolevelground.

2.Disengagethedrives.

3.Lowerthecuttingunits.

4.MovethetractionpedaltotheNEUTRALposition.

5.Engagetheparkingbrake.

6.MovethethrottleswitchtotheLOW-IDLEposition.

7.Shutofftheengineandremovethekey.

8.Waitforallmovingpartstostop.

•Wheneveryouparkorstorethemachine,orleaveit

unattended,lowerthecuttingunitsunlessyouusea

positivemechanicallock.

•Ifpossible,donotperformmaintenanceonthemachine

whiletheengineisrunning.Ifyoumustruntheengineto

performmaintenanceonthemachine,keepyourhands,

feet,otherbodyparts,andclothingawayfromallmoving

parts,themower-dischargearea,andtheundersideof

themowers.

•Donottouchpartsofthemachineoranattachment

thatmaybehotfromoperation.Allowthepartstocool

beforeattemptingtomaintain,adjust,orservicethem.

•Usejackstandstosupportthemachineand/orits

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Ifyourmachinerequiresmajorrepairsorifyoudesire

assistance,contactyourToroDistributor.

•UseonlygenuineTororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadebyother

manufacturerscouldbedangerous,andsuchusecould

voidtheproductwarranty.

34

Page 35

RaisingtheMachine

Note:Usejackstandstosupportthemachinewhenrequired.

Lubrication

Usethefollowingaspointstojackupthemachine:

•Frontofthemachine—rectangularpad,undertheaxle

tube,insideeachfronttire(Figure28).

Figure28

1.Frontjackingpoint

GreasingtheBearingsand Bushings

Ifyouoperatethemachineundernormalconditions,lubricate

allgreasettingsforthebearingsandbushingsafterevery

50hoursofoperationwithNo.2lithiumgrease.Lubricate

bearingsandbushingsimmediatelyaftereverywashing,

regardlessoftheintervallisted.

Thegreasettinglocationsandquantitiesareasfollows:

•PumpdriveshaftU-joint(3)(Figure29)

Figure29

•Rearofthemachine—rectangularaxletubeontherear

axle.

•Cuttingunitlift-armcylinders(2each)(Figure30)

Figure30

•Lift-armpivots(1each)(Figure30)

35

Page 36

•Cuttingunitcarrier-framepivot(1each)(Figure31)

G011614

G011615

•Axle-steeringpivot(1)(Figure34)

Figure34

Figure31

•Lift-armpivotshaft(1each)(Figure32)

Figure32

•Rearaxletierod(2)(Figure33)

•Steering-cylinderballjoints(2)andrearaxle(1)(Figure

35)

Figure35

•Brakepedal(1)(Figure36)

Figure33

Figure36

36

Page 37

•Cuttingunitspindle-shaftbearings(2percuttingunit)

(Figure37)

EngineMaintenance

Note:Eitherttingcanbeused,whicheverismore

accessible.Pumpgreaseintothettinguntilasmall

amountappearsatbottomofthespindlehousing(under

thedeck).

Figure37

•Rear-rollerbearings(2percuttingunit)(Figure38)

EngineSafety

Shutofftheenginebeforecheckingtheoiloraddingoilto

thecrankcase.

ServicingtheAirCleaner

Checkthewholeintakesystemforleaks,damage,orloose

hoseclamps.Donotuseadamagedairlter.

Servicetheair-cleanerlteronlywhentheserviceindicator

requiresit.Changingtheairlterbeforeitisnecessaryonly

increasesthechanceofdirtenteringtheenginewhenthe

lterisremoved.

Important:Makesurethatthecoverisseatedcorrectly,

sealswiththeair-cleanerbody,andtherubberoutlet

valveisinadownwardposition—betweenthe5o’clock

and7o’clockpositionswhenviewedfromtheend.

Figure38

Note:Makesurethatthegreasegrooveineachroller

mountalignswiththegreaseholeineachendoftheroller

shaft.Tohelpalignthegrooveandhole,thereisalsoan

alignmentmarkon1endoftherollershaft.

37

Page 38

ServicingtheEngineOil

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;however,the

oillevelmustbecheckedbeforeandaftertheengineisrst

started.

Crankcasecapacityisapproximately5.2L(5.5USqt)with

thelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4orhigher

•Preferredoil:SAE15W-40(above-17.8°C(0°F))

•Alternateoil:SAE10W-30or5W-30(alltemperatures)

ToroPremiumEngineoilisavailablefromyourdistributorin

either15W -40or10W-30viscosity .

1.Parkthemachineonalevelsurface,stoptheengine,

settheparkingbrake,andremovethekeyfromthe

ignitionswitch.

Figure39

2.Checktheengine-oillevel(Figure40).

38

Page 39

ServicingtheEngineOilandFilter

Figure40

Important:Besuretokeeptheengine-oillevel

betweentheupperandlowerlimitsontheoil

gauge.Enginefailuremayoccurasaresultofover

llingorunderllingtheengineoil.

Figure41

Important:Donotover-tightenthelter.

Addoiltothecrankcase;refertoCheckingtheEngine-Oil

Level(page38).

39

Page 40

AdjustingtheThrottle

1.Positionthethrottleleverforwardsoitisapproximately

3mm(1/8inch)fromthefrontofthecontrol-armslot.

2.Loosenthethrottlecableconnector,onthethrottle

cable,nexttotheinjection-pumplever(Figure42).

FuelSystem

Maintenance

ServicingtheFuelSystem

DrainingtheFuelTank

ServiceInterval:Every800hours

Beforestorage

Drainandcleanthefueltankifthefuelsystembecomes