Page 1

FormNo.3385-788RevA

Groundsmaster

®

3500-Dand

3505-DRotaryMowers

ModelNo.30807—SerialNo.314000001andUp

ModelNo.30839—SerialNo.314000001andUp

ModelNo.30843—SerialNo.314000001andUp

ModelNo.30849—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3385-788*A

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

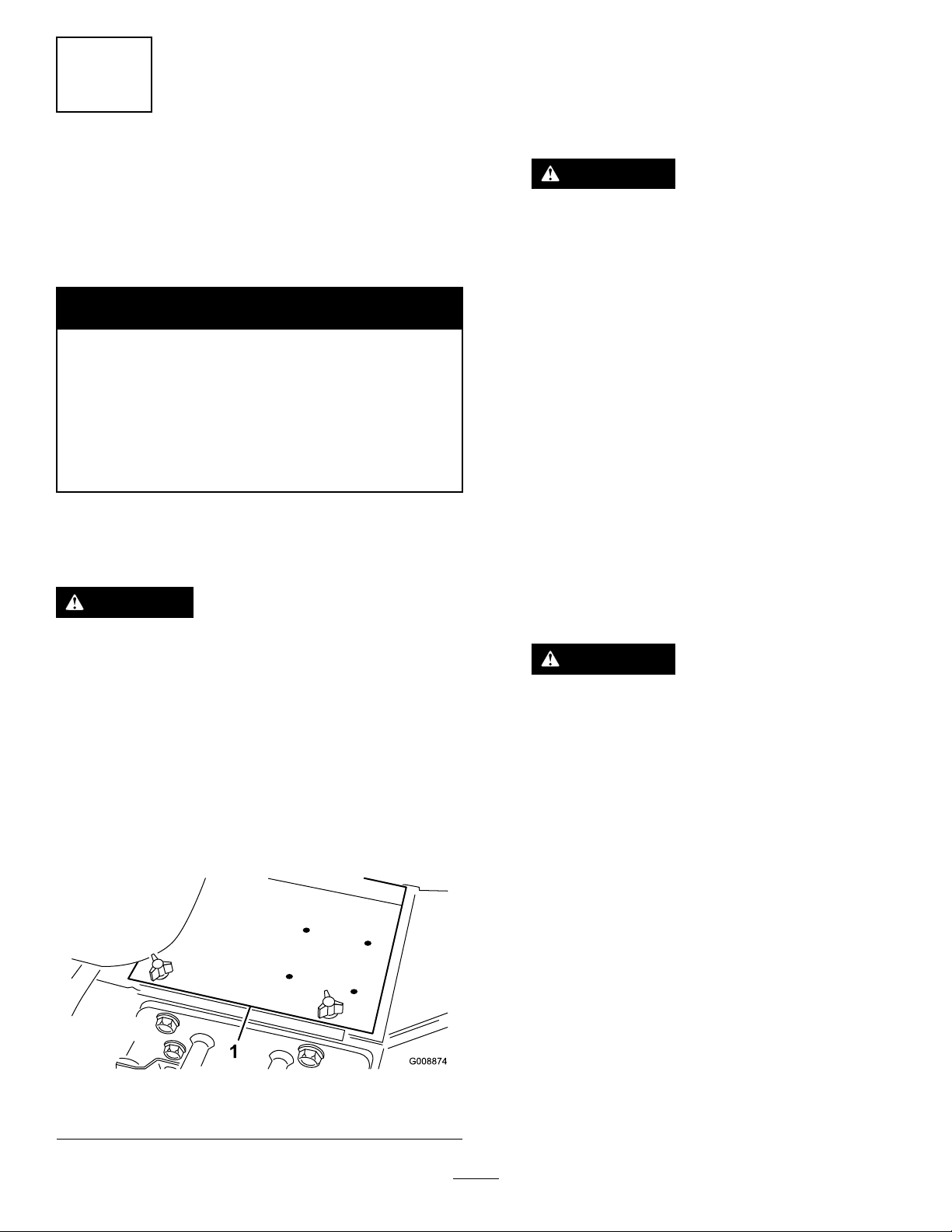

Figure1

1.Modelandserialnumberlocation

ModelNo.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Introduction

Thismachineisaride-on,rotary-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrasson

well-maintainedlawnsinparks,golfcourses,sportselds,

andoncommercialgrounds.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongsidehighways,

orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbers

ofyourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................6

SoundPowerLevel..................................................7

SoundPressureLevel...............................................7

VibrationLevel......................................................7

SafetyandInstructionalDecals.................................8

Setup...........................................................................15

1Activating,Charging,andConnectingthe

Battery..............................................................15

2CheckingtheAngleIndicator(Models30839,

30843and30807only).........................................17

3InstallingtheCEDecals........................................17

4InstallingtheHoodLatch(CEOnly).......................17

5InstallingtheExhaustGuard(CEOnly)..................18

6AdjustingtheLiftArms........................................19

7RearBallast.........................................................20

8AdjustingtheCarrierFrame..................................20

9AdjustingtheHeight-of-Cut..................................21

10AdjustingtheRollerScraper(Optional).................21

11InstallingtheMulchingBafe(Optional)...............22

ProductOverview.........................................................23

Controls...............................................................23

Specications........................................................25

Attachments/Accessories........................................25

Operation....................................................................25

CheckingtheEngineOilLevel.................................25

FillingtheFuelTank...............................................26

CheckingtheCoolingSystem...................................26

CheckingtheHydraulicSystem................................27

CheckingtheTirePressure......................................28

TorquingtheWheelNuts........................................28

StartingandStoppingtheEngine..............................28

BleedingtheFuelSystem.........................................29

CheckingtheInterlockSystem.................................29

TowingtheTractionUnit.........................................30

StandardControlModule(SCM)..............................30

SelectingaBlade.....................................................32

ChoosingAccessories.............................................33

OperatingTips......................................................34

Maintenance.................................................................37

RecommendedMaintenanceSchedule(s)......................37

DailyMaintenanceChecklist....................................38

ServiceIntervalChart.............................................40

PremaintenanceProcedures........................................40

RemovingtheHood...............................................40

UsingtheCuttingDeckServiceLatch.......................40

Lubrication...............................................................42

GreasingtheBearingsAndBushings.........................42

EngineMaintenance..................................................44

ServicingtheAirCleaner.........................................44

ChangingtheEngineOilandFilter...........................45

FuelSystemMaintenance...........................................46

ServicingtheFuelTank...........................................46

InspectingtheFuelLinesandConnections.................46

DrainingtheWaterSeparator...................................46

ChangingtheFuelFilterCanister..............................46

BleedingAirfromtheInjectors................................46

ElectricalSystemMaintenance....................................47

CaringfortheBattery..............................................47

Fuses....................................................................47

DriveSystemMaintenance.........................................48

AdjustingtheTractionDriveforNeutral....................48

CoolingSystemMaintenance......................................48

CleaningtheEngineCoolingSystem.........................48

BrakeMaintenance....................................................49

AdjustingtheParkingBrake.....................................49

BeltMaintenance......................................................49

ServicingtheEngineBelts.......................................49

ControlsSystemMaintenance.....................................50

AdjustingtheThrottle.............................................50

HydraulicSystemMaintenance....................................51

ChangingtheHydraulicFilter...................................51

ChangingtheHydraulicFluid...................................51

CheckingtheHydraulicLinesandHoses....................52

CuttingDeckMaintenance..........................................52

SeparatingtheCuttingDecksfromtheTraction

Unit..................................................................52

MountingtheCuttingDeckstotheTraction

Unit..................................................................53

ServicingtheBladePlane.........................................53

ServicingtheCutterBlade.......................................54

ServicingtheFrontRoller........................................55

Storage........................................................................56

StoringtheBattery..................................................56

PreparationforSeasonalStorage..............................56

3

Page 4

Safety

ThismachinemeetsorexceedsISOstandard5395:2013

(whenappropriatedecalsapplied),andANSIB71.4-2012

specicationsineffectatthetimeofproductionwhen

equippedwithrequiredweightaslistedinRearBallast

section.

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromtheISOstandard

5395:2013,andANSIB71.4-2012.

Training

•ReadtheOperator’sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Iftheoperatorormechaniccannotreadthelanguage

ofthismanual,itistheowner’sresponsibilitytoexplain

thismaterialtothem.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstructionshould

emphasizethefollowing:

–Theneedforcareandconcentrationwhenworking

withride-onmachines

–Controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolareasfollows:

◊Insufcientwheelgrip

◊Beingdriventoofast

◊Inadequatebraking

◊Thetypeofmachineisunsuitableforthetask

◊Lackofawarenessoftheeffectofground

conditions,especiallyslopes

◊Incorrecthitchingandloaddistribution

Preparation

•Whilemowing,alwayswearsubstantialfootwear,long

trousers,hardhat,safetyglasses,andhearingprotection.

Longhair,looseclothing,orjewelrymaygettangled

inmovingparts.Donotoperatetheequipmentwhen

barefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Replacefaultysilencers/mufers.

•Beforeusing,alwaysvisuallyinspecttoseethatthe

blades,bladebolts,andcuttingassemblyarenotworn

ordamaged.Replacewornordamagedbladesandbolts

insetstopreservebalance.

•Onmulti-bladedmachines,takecareasrotatingoneblade

cancauseotherbladestorotate.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Checkthatoperator’spresencecontrols,safetyswitches

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

4

Page 5

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutches,shiftintoneutral,andengagethe

parkingbrake.Onlystarttheenginefromtheoperator’s

position.NeverremovetheROPSandalwayswearthe

seatbeltsduringoperation.

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.Dothefollowing

toguardagainstoverturning:

–Donotstoporstartsuddenlywhengoingupor

downhill.

–Keepmachinespeedslowonslopesandduringtight

turns.

–Stayalertforhumpsandhollowsandotherhidden

hazards.

–Nevermowacrossthefaceoftheslope,unlessthe

mowerisdesignedforthispurpose.

•Stayalertforholesintheterrainandotherhiddenhazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesfromrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.Besureall

interlocksareattached,adjustedproperly ,andfunctioning

properly.

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Dothefollowingbeforeleavingtheoperator’ sposition:

–Stoponlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Changeintoneutralandsettheparkingbrake.

–Stoptheengineandremovethekey.

•Disengagethedrivetoattachments,stoptheengine,and

removetheignitionkeyinthefollowingconditions:

–Beforemakingheightadjustments,unlessthe

adjustmentcanbemadefromtheoperator’sposition.

–Beforeclearingblockages

–Beforechecking,cleaning,orworkingonthemower

–Afterstrikingaforeignobjectorifanabnormal

vibrationoccurs(checkimmediately).Inspectthe

mowerfordamageandmakerepairsbeforerestarting

andoperatingtheequipment.Torqueallthespindle

pulleynutsto176to203N-m(130to150ft-lb).

•Disengagethedrivetoattachmentswhentransportingor

whennotmachineisnotinuse.

•Stoptheengineanddisengagethedrivetoattachments

beforethefollowing:

–Refueling

–Makingheightadjustment,unlesstheadjustmentcan

bemadefromtheoperator'sposition

•Reducethethrottlesettingbeforestoppingtheengine

and,iftheengineisprovidedwithafuelshut-offvalve,

turnthefueloffattheconclusionofmowing.

•Neverraisethecuttingunitwiththebladesrunning.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Theoperatorshallturnonashingwarninglights,if

provided,whenevertravelingonapublicroad,except

wheresuchuseisprohibitedbylaw .

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentfuelstoragearea,

cuttingunitsanddrivesfreeofgrass,leaves,orexcessive

grease.Cleanupoilorfuelspillage.

•Replacewornordamagedpartsforsafety.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Onmulti-bladedmachines,takecareasrotatingoneblade

cancauseotherbladestorotate.

•Whenmachineistobeparked,stored,orleftunattended,

lowerthecuttingunitsunlessapositivemechanicallock

isprovided.

•Disengagedrives,lowerthecuttingunits,setparking

brake,stopengineandremovekey .Waitforallmovement

tostopbeforeadjusting,cleaningorrepairing.

•Shutofffuelwhilestoringortransporting.Donotstore

fuelnearames.

5

Page 6

•Parkthemachineonlevelground.Neverallowuntrained

personneltoservicemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectbatterybeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.Reconnect

positiverstandnegativelast.

•Usecarewhencheckingtheblades.Wrapthebladesor

weargloves,andusecautionwhenservicingthem.Only

replaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

ordisconnectingfrombattery.W earprotectiveclothing

anduseinsulatedtools.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCEN,ISO,orANSIstandards.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.Do

notrunengineindoorsorinanenclosedarea.

Preparation

Besuretoestablishyourownspecialproceduresandwork

rulesforunusualoperatingconditions(e.g.,slopestoosteep

foroperation).Surveythecompletemowingsiteto

determinewhichhillscanbesafelyoperatedon.When

performingthissitesurvey,alwaysusecommonsenseand

takeintoconsiderationtheturfconditionandtherolloverrisk.

Todeterminewhichhillsorslopesmaybesafelyoperated

on,usetheinclinometerprovidedwitheachmachine.To

performasitesurvey,followtheprocedureoutlinedinthe

Operationsectionofthethismanual.Themaximumside

hillangleisdetailedontheslopedecalafxednearthe

angleindicator.

Training

Theoperatormustbeskilledandtrainedinhowtodriveon

hillsides.Failuretousecautiononslopesorhillsmaycause

thevehicletotiporroll,possiblyresultinginpersonalinjury

ordeath.

Operation

•Knowhowtostopthemachineandenginequickly.

•Donotoperatethemachinewhilewearingtennisshoes

orsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Keephands,feet,andclothingawayfrommovingparts

andthemowerdischargearea.

•Fillthefueltankuntillevelis12mm(1/2inch)belowthe

bottomofthellerneck.Donotoverll.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Whenstartingtheengine,engagetheparkingbrake,put

thetractionpedalinneutral,anddisengagetheblade

drive.Aftertheenginestarts,releasetheparkingbrake

andkeepyourfootoffofthetractionpedal.Themachine

mustnotmove.Ifmovementisevident,refertothe

Maintenancesectionofthismanualtoadjustthetraction

drive.

•Useextremecautionwhenoperatingclosetosandtraps,

ditches,creeks,steephillsides,orotherhazards.

•Reducespeedwhenmakingsharpturns.

•Donotturnonhills.

•Donotoperateonasidehillthatistoosteep.Arollover

mayoccurbeforelosingtraction.

•Onmodels30839,30843and30807,theslopeangle

atwhichthemachineswilltipisdependentonmany

factors.Amongthesearemowingconditionssuchas

wetorundulatingterrain,speed(especiallyinturns),

positionofthecuttingunits(withtheSidewinder),tire

pressure,andoperatorexperience.Atsidehillangles

of20degreesorless,theriskofarolloverislow .As

theslopeangleincreasestoarecommendedmaximum

limitof25degrees,theriskofarolloverincreasestoa

moderatelevel.Donotexceeda25degreesidehill

slopeanglebecausetheriskofarolloverandserious

injuryordeathisveryhigh.

•Onmodel30849,theslopeangleatwhichthemachine

willtipisdependentonmanyfactors.Amongtheseare

mowingconditionssuchaswetorundulatingterrain,

speed(especiallyinturns),positionofthecutting

units(withtheSidewinder),tirepressure,andoperator

experience.Atsidehillanglesof15degreesorless,the

6

Page 7

riskofarolloverislow.Astheslopeangleincreasestoa

recommendedmaximumlimitof20degrees,theriskofa

rolloverincreasestoamoderatelevel.Donotexceeda

20degreesidehillslopeanglebecausetheriskofa

rolloverandseriousinjuryordeathisveryhigh.

•Forsteeringcontrol,lowerthecuttingunitswhengoing

downslopes.

•Avoidsuddenstopsandstarts.

•Usethereversepedalforbraking.

•Watchfortrafcwhennearorcrossingroads.Always

yieldtheright-of-way.

•Raisethecuttingunitswhendrivingfromoneworkarea

toanother.

•Donottouchtheengine,mufer,exhaustpipe,or

hydraulictankwhiletheengineisrunningorsoonafter

ithasstoppedbecausetheseareascouldbehotenough

tocauseburns.

•Theenginemustbeshutoffbeforecheckingtheoilor

addingoiltothecrankcase.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof104dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

•Thismachineisnotdesignedorequippedforon-roaduse

andisaslow-movingvehicle.Ifyoumustcrossortravel

onapublicroad,youshouldbeawareofandcomplywith

localregulations,suchasrequiredlights,slowmoving

vehiclesigns,andreectors.

MaintenanceandStorage

•Beforeservicingormakingadjustments,stoptheengine

andremovetheignitionkey.

•Ensurethattheentiremachineisproperlymaintained

andingoodoperatingcondition.Frequentlycheckall

nuts,bolts,screws,andhydraulicttings.

•Makesureallhydrauliclineconnectorsaretightandall

hydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.Ifuidisinjectedintotheskinitmustbesurgically

removedwithinafewhoursbyadoctorfamiliarwiththis

formofinjuryorgangrenemayresult.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringthecutting

unitstotheground.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof90

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=0.5m/s

Measuredvibrationlevelforlefthand=0.7m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

WholeBody

Measuredvibrationlevel=0.44m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

2

2

2

2

2

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunits,attachments,and

anymovingparts.Keepeveryoneaway.

•Donotoverspeedtheenginebychanginggovernor

settings.Toensuresafetyandaccuracy,havean

AuthorizedToroDistributorcheckthemaximumengine

speedwithatachometer.

7

Page 8

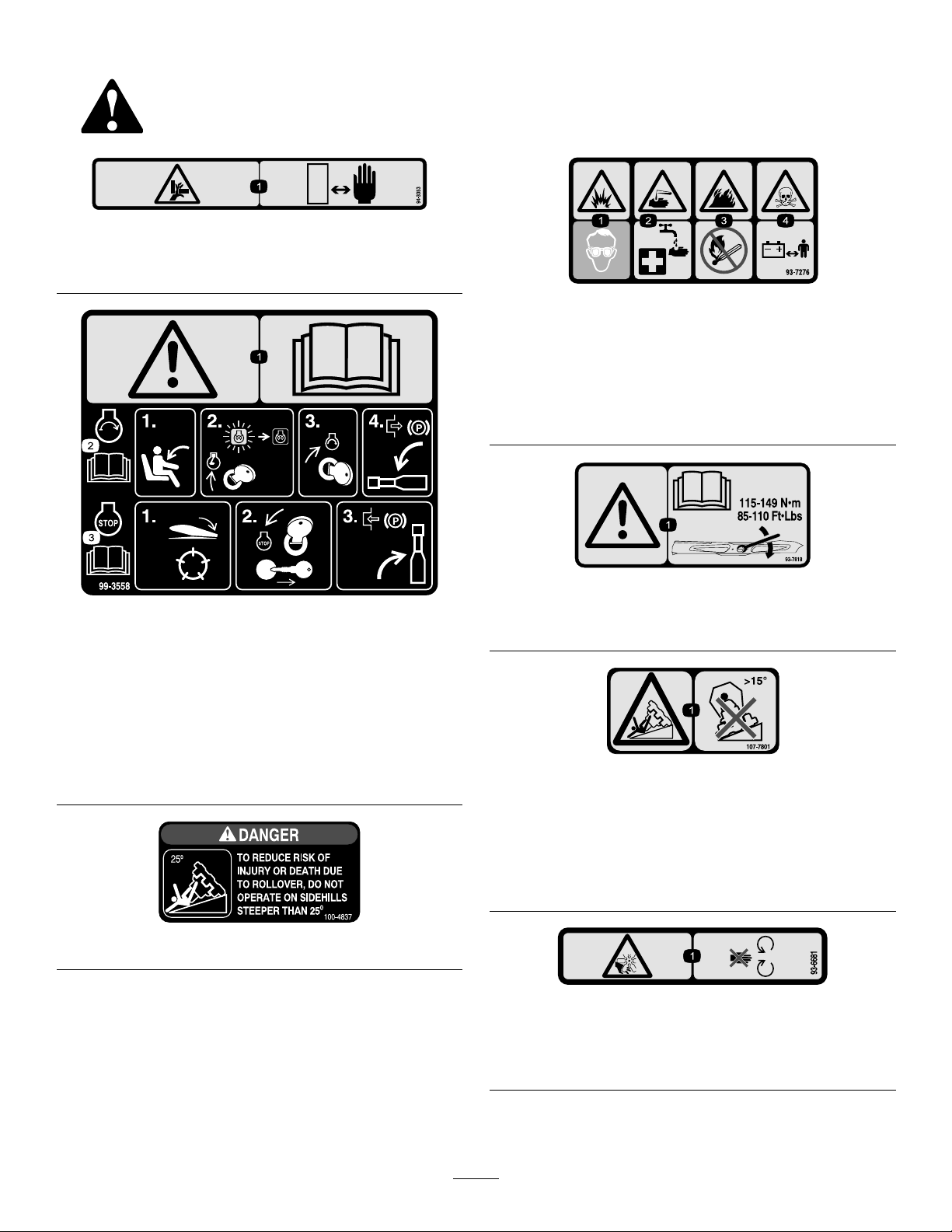

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

94-3353

1.Crushinghazardofhand—keepyourhandsasafedistance

away.

93-7276

1.Explosionhazard—weareyeprotection.

2.Causticliquid/chemicalburnhazard—toperformrstaid,

ushwithwater.

3.Firehazard—nore,openames,orsmoking.

4.Poisonhazard—keepchildrenasafedistancefromthe

battery.

99-3558

(CEonly)

1.Warning—readtheOperator’sManual.

2.Tostarttheengine,sitontheseatandrotatetheignition

keytoOn/Preheatuntiltheglowplugindicatorlightgoes

out.Rotatethekeytostartanddisengagetheparking

brake.ReadtheOperator’sManualforfurtherinstructions.

3.Tostoptheengine,disengagethecuttingunits,rotatethe

ignitionkeytoOff,andremovethekey.Engagetheparking

brake.ReadtheOperator’sManualforfurtherinstructions.

100-4837

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N-m(85-110ft-lb).

107-7801

*Thissafetydecalincludesaslopewarningrequiredonthemachineforcomplianceto

theEuropeanLawnMowerSafetyStandardEN836:1997.Theconservativemaximum

slopeanglesindicatedforoperationofthismachineareprescribedbyandrequiredby

thisstandard.

1.Tippinghazard—donotdriveonslopesgreaterthan15

degrees.

93-6681

(CEOnly)

1.Cutting/dismemberment—hazard,fan-stayawayfrom

movingparts.

8

Page 9

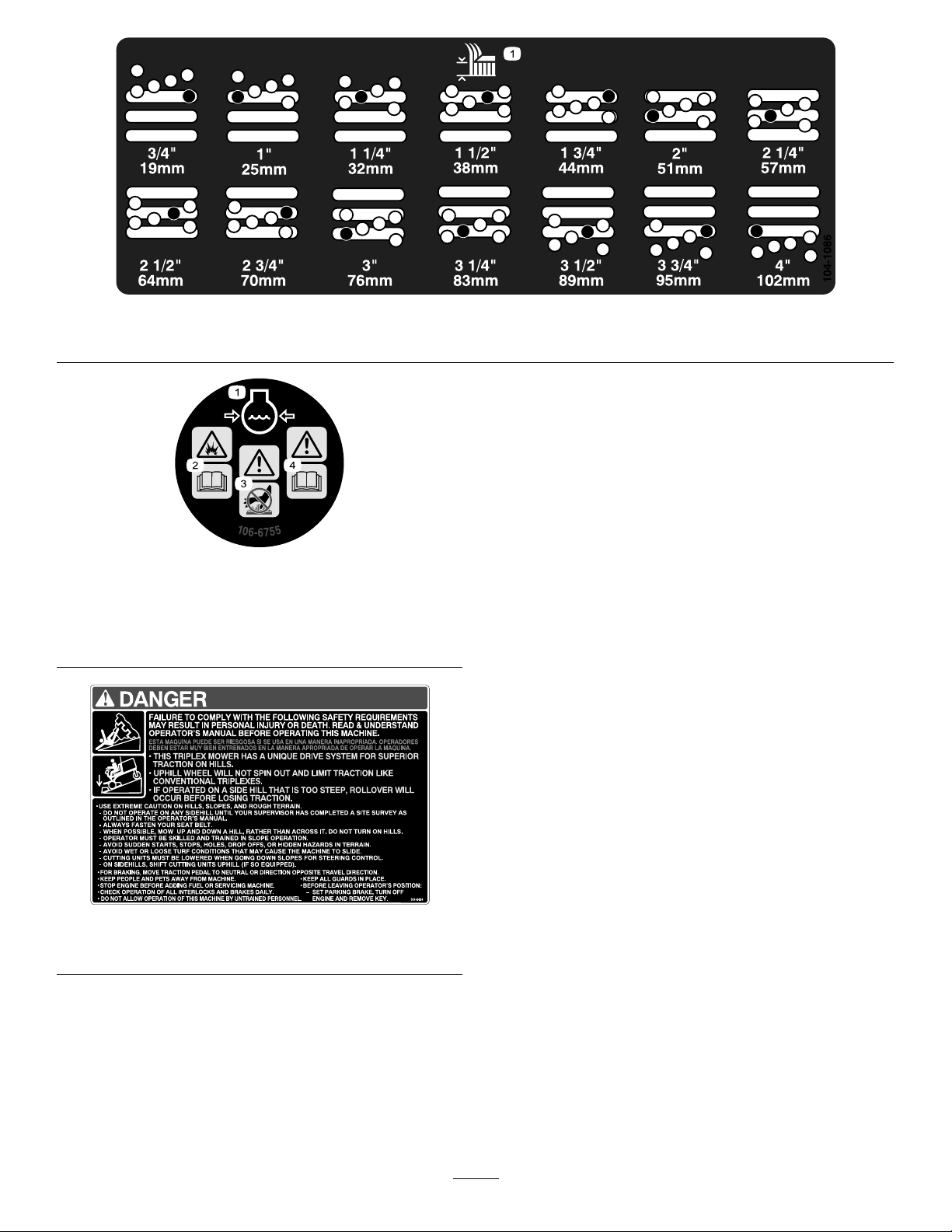

1.Heightofcut

104-1086

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

104-0484

(Model30807,30839and30843)

9

Page 10

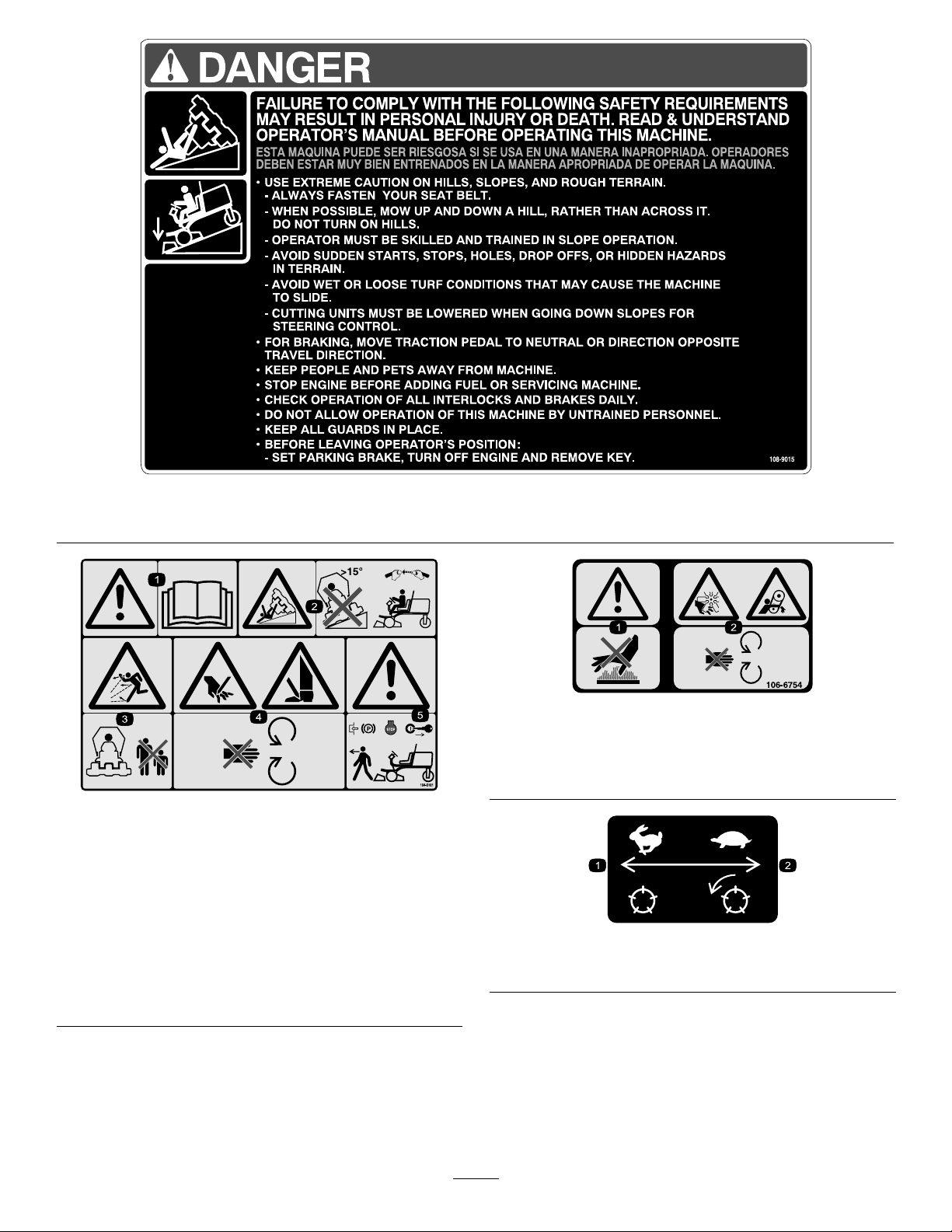

104-5181

99-3444

(CEonly)

1.Warning—readtheOperator’sManual.

2.Tippinghazard—donotdriveonslopesgreaterthan15

degreesand,iftherollbarisinstalled,weartheseatbelt.

3.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

4.Cuttinghazardofhandorfoot—stayawayfrommoving

parts.

5.Warning—locktheparkingbrake,stoptheengine,and

removetheignitionkeybeforeleavingthemachine.

108–9015

(Model30849)

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

99-3444

1.Reelspeed—fast

2.Reelspeed—slow

10

Page 11

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

117-4764

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cuttinghazardofhand,mowerblade—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

3.Cuttinghazardoffoot,mowerblade—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

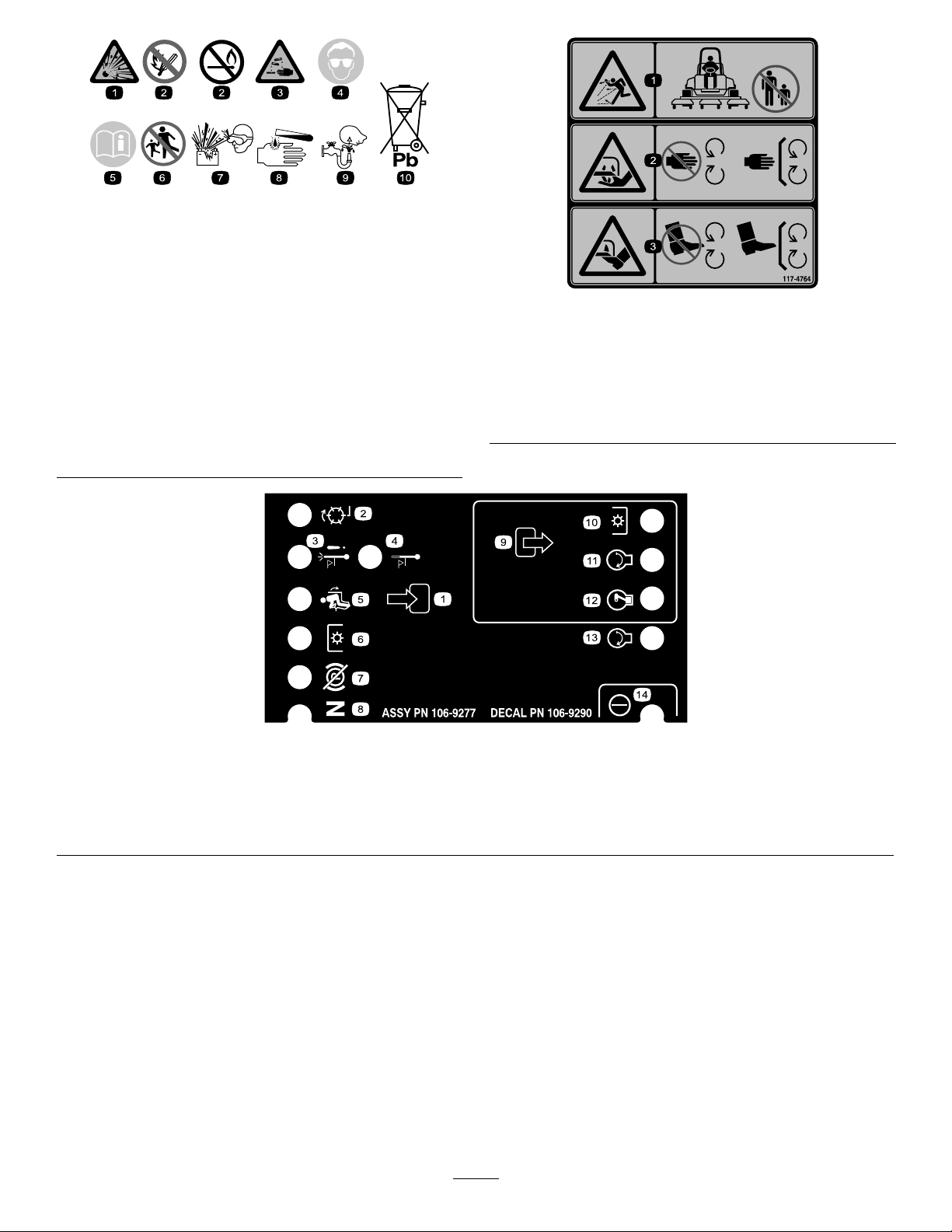

1.Inputs5.Inseat

2.Notactive

3.Hightemperatureshutdown

4.Hightemperaturewarning8.Neutral

6.PowerT ake-off(PTO)10.PowerT akeOff(PTO)

7.ParkingbrakeOff11.Start

106-9290

9.Outputs13.Start

14.Power

12.EnergizetoRun(ETR)

11

Page 12

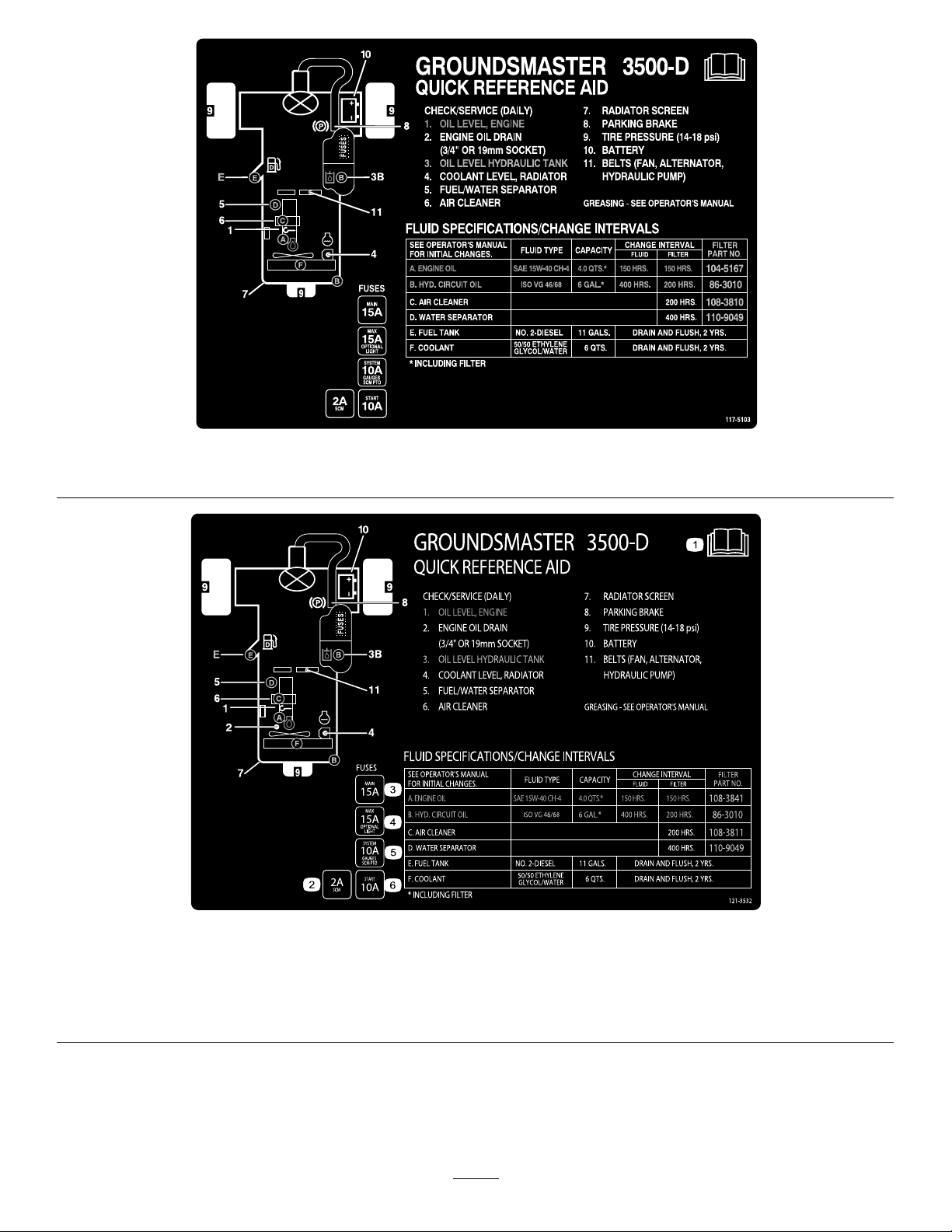

117-5103

(Models30849,30839and30843)

121–3532

(Model30807)

1.ReadtheOperator’sManual.4.Optionalligh—15A

2.SCM-2A5.Systemgauges—10A

3.Main—15A6.Enginestart—10A

12

Page 13

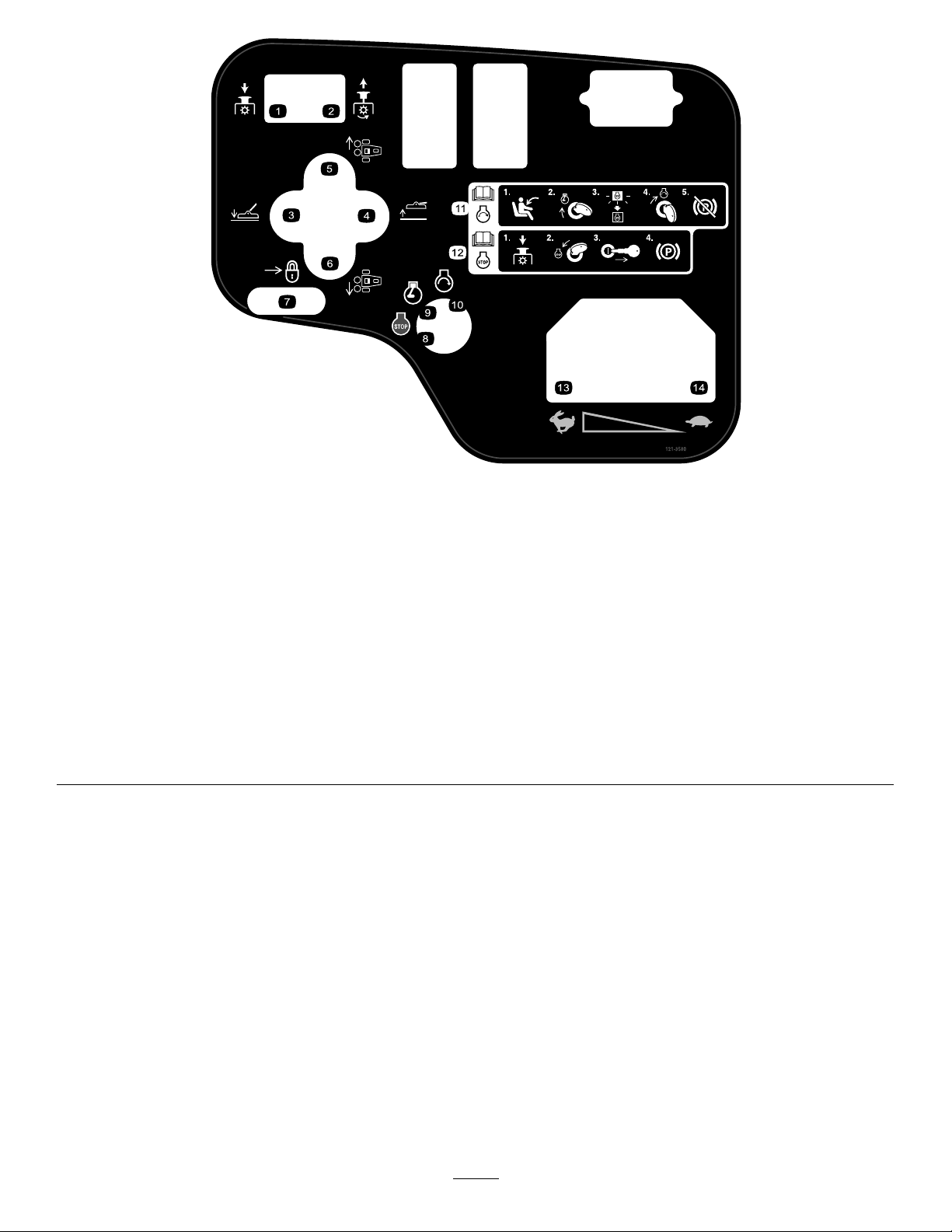

121–3580

(Models30807,30839and30843)

1.PushdowntodisengagePTO.

2.PulluptoengagePTO.

3.Lowerthedeck.10.Engine—run

4.Raisethedeck.

5.Middleandright-handdecks

6.Middleandlef-handdecks

7.Slidetolock14.Slow

8.Engine—stop

9.Engine—run

11.Formoreinformationonstartingtheengine,readthe

Operator’sManual—1)Sitintheoperator’sposition;2)Turn

theignitionkeytotheenginerunposition;3)Waitforthe

enginepreheatlighttoturnoff;4)Turntheignitionkeytothe

enginestartposition;5)Disengagetheparkingbrake.

12.Formoreinformationonstoppingtheengine,readthe

Operator’sManual—1)DisengagethePTO;2)Turnthe

ignitionkeytotheenginestopposition;3)Removethekey

fromtheignition;4)Engagetheparkingbrake.

13.Fast

13

Page 14

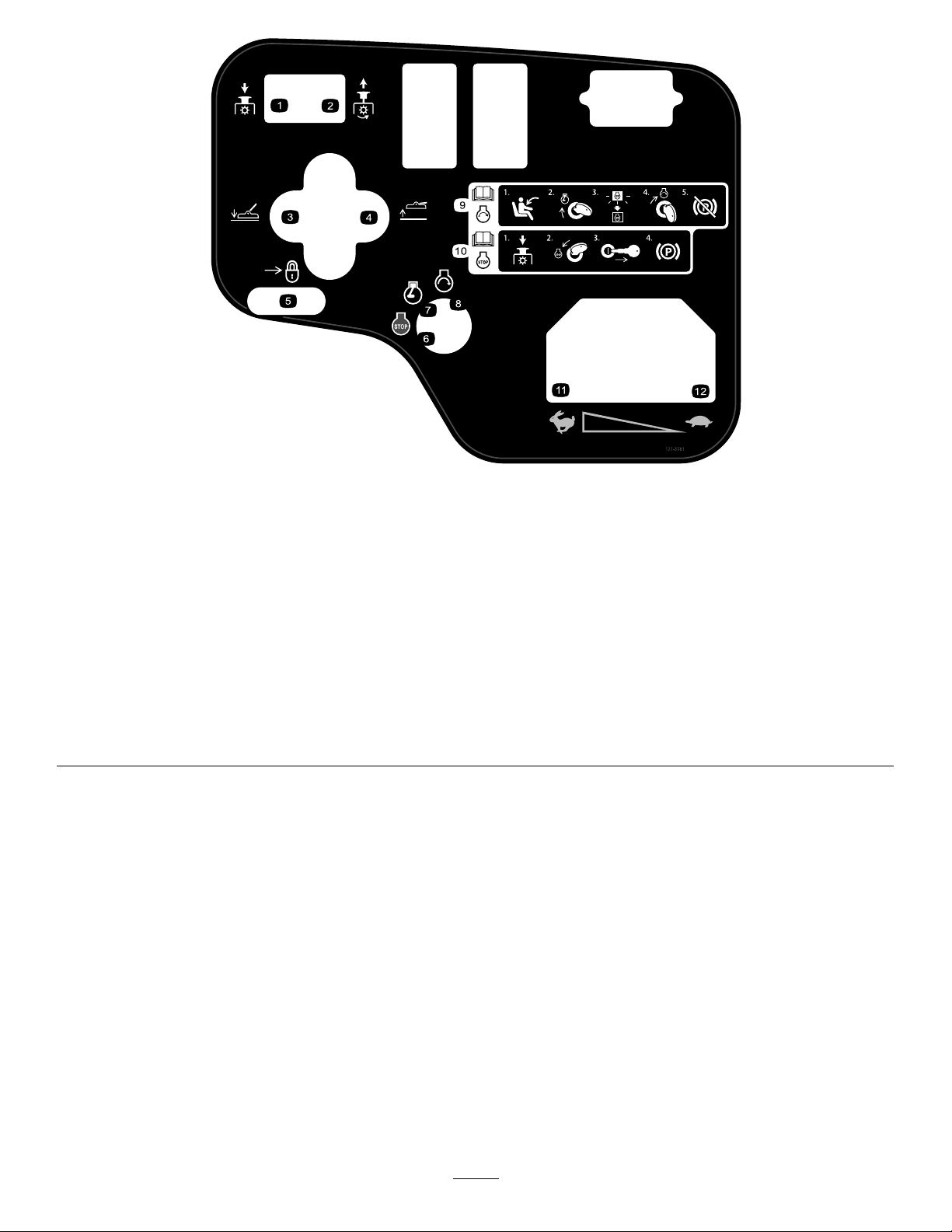

121–3581

(Model30849)

1.PushdowntodisengagePTO.

2.PulluptoengagePTO.

3.Lowerthedeck.

4.Raisethedeck.

5.Slidetolock

6.Engine—stop

7.Engine—run

8.Engine—run

9.Formoreinformationonstartingtheengine,readthe

Operator’sManual—1)Sitintheoperator’sposition;2)Turn

theignitionkeytotheenginerunposition;3)Waitforthe

enginepreheatlighttoturnoff;4)Turntheignitionkeytothe

enginestartposition;5)Disengagetheparkingbrake.

10.Formoreinformationonstoppingtheengine,readthe

Operator’sManual—1)DisengagethePTO;2)Turnthe

ignitionkeytotheenginestopposition;3)Removethekey

fromtheignition;4)Engagetheparkingbrake.

11.Fast

12.Slow

14

Page 15

Setup

LooseParts

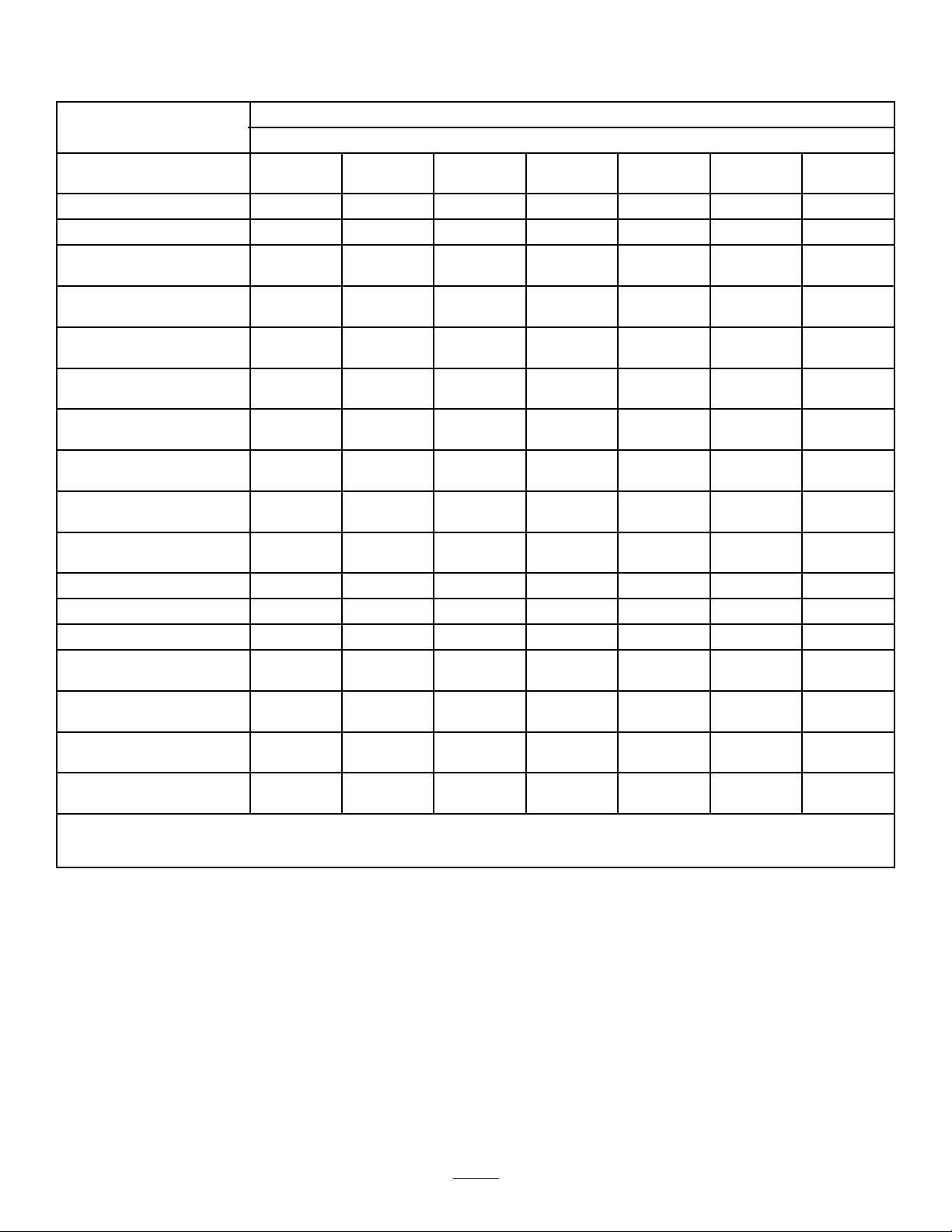

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

Nopartsrequired

Inclinometer1

Warningdecal(104–5181)

Warningdecal(99–3558)

Warningdecal(107–1972)

Lockbracket1

Rivet2

Washer1

Screw,1/4x2inches

Locknut,1/4inch

Exhaustguard1

Self-tappingscrew

Nopartsrequired

Nopartsrequired

Nopartsrequired

Qty.

Use

–

1

1

3

1

1

4

–

–

–

Activate,charge,andconnectthe

battery.

Checktheangleindicator(Models

30839,30843and30807only)

InstalltheCEdecals,ifrequired.

InstalltheHoodLatch(CE).

InstalltheExhaustGuard(CE).

Adjusttheliftarms.

Rearballast.

Adjustthecarrierframe

9

10

11

Nopartsrequired

Nopartsrequired

Nopartsrequired

MediaandAdditionalParts

Description

Ignitionkeys2

Operator'sManual

EngineOperator'sManual

PartsCatalog

Operatorvideo

DeclarationofConformity

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

–

–

–

Qty.

Starttheengine.

1

1

1Usetolookupandorderparts.

1

1

Readbeforeoperatingthemachine.

Viewbeforeoperatingthemachine.

EnsureCEcompliance.

Adjusttheheight-of-cut

Adjusttherollerscraper(Optional)

Installthemulchingbafe(Optional)

Use

15

Page 16

3.Removethellercapsfromthebatteryandslowlyll

eachcelluntilelectrolyteisjustabovetheplates.

1

Activating,Charging,and

ConnectingtheBattery

NoPartsRequired

Procedure

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

W ash hands after handling .

Note:Ifthebatteryisnotlledwithelectrolyteoractivated,

bulkelectrolytewith1.260specicgravitymustbepurchased

fromalocalbatterysupplyoutletandaddedtothebattery.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyes,orclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

1.Openthehood.

2.Removethebatterycover(Figure3).

4.Installthellercapsandconnecta3to4ampbattery

chargertothebatteryposts.Chargethebatteryata

rateof3to4amperesfor4to8hours.

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

•Keepsparksandamesawayfrombattery.

•Neversmokenearthebattery.

5.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

6.Removethellercaps.Slowlyaddelectrolytetoeach

celluntilthelevelisuptothellring.Installtheller

caps.

Important:Donotoverllthebattery.Electrolyte

willoverowontootherpartsofthemachineand

severecorrosionanddeteriorationwillresult.

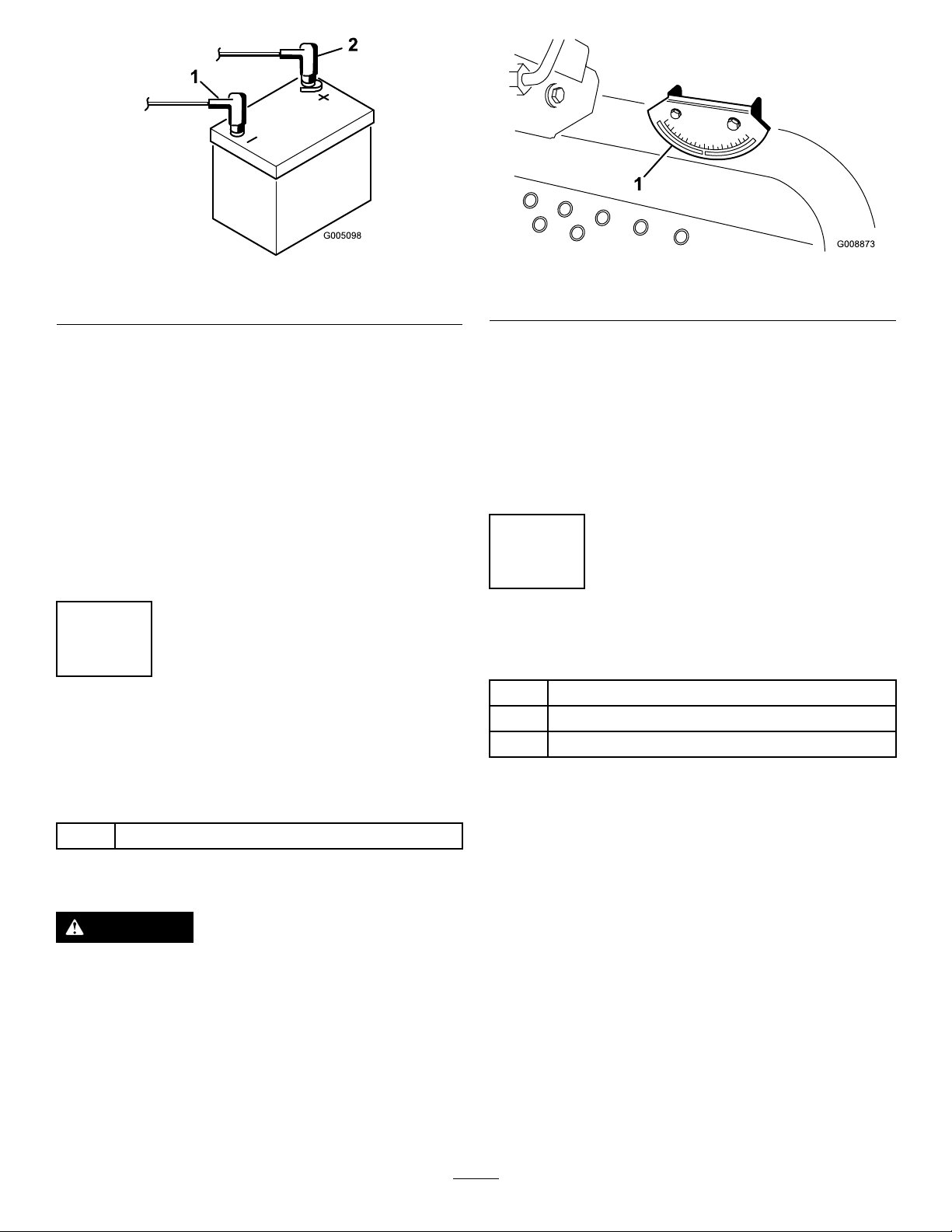

7.Installthepositivecable(red)tothepositive(+)

terminalandthenegativecable(black)tothenegative

(–)terminalofthebatteryandsecurethemwithbolts

andnuts(Figure4).Makesurethatthepositive(+)

terminalisallofthewayontothepostandthecable

ispositionedsnugtothebattery.Thecablemustnot

contactthebatterycover.

WARNING

Incorrectbatterycableroutingcoulddamage

thetractorandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

1.Batterycover

Figure3

16

Page 17

Figure4

1.Positive(+)batterycable2.Negative(–)batterycable

Figure5

1.Angleindicator

Important:Ifthebatteryiseverremoved,make

surethatthebatteryclampboltsareinstalledwith

theboltheadspositionedonthebottomsideand

thenutsonthetopside.Iftheclampboltsare

reversed,theymayinterferewiththehydraulic

tubeswhenshiftingthecuttingunits.

8.CoatbothbatteryconnectionswithGrafo112X(skin

over)grease,T oroPartNo.505-47,petroleumjelly ,or

lightgreasetopreventcorrosion.

9.Slidetherubberbootoverthepositiveterminalto

preventapossibleshortfromoccurring.

10.Installthebatterycover.

2

CheckingtheAngleIndicator (Models30839,30843and 30807only)

3.Iftheinclinometerdoesnotreadzerodegrees,move

themachinetoalocationwhereazerodegreereading

isobtained.Theangleindicator,mountedonthe

machine,shouldnowreadzerodegreesaswell.

4.Iftheangleindicatordoesnotreadzerodegrees,

loosenthetwoscrewsandnutssecuringtheangle

indicatortothemountingbracket,adjusttheindicator

toobtainazerodegreereading,andtightenthebolts.

3

InstallingtheCEDecals

Partsneededforthisprocedure:

1

Warningdecal(104–5181)

1

Warningdecal(99–3558)

3

Warningdecal(107–1972)

Partsneededforthisprocedure:

1Inclinometer

Procedure

DANGER

Toreduceriskofinjuryordeathduetorollover,do

notoperatethemachineonsidehillssteeperthan

25º.

1.Parkthemachineonaat,levelsurface.

2.Verifythatthemachineislevelbyplacingahandheld

inclinometer(suppliedwiththemachine)ontheframe

crossrail,bythefueltank(Figure5).Theinclinometer

shouldreadzerodegreeswhenviewedfromthe

operator’sposition.

Procedure

IfthismachinewillbeusedforCE,afxtheCEwarning

decalsoverthecorrespondingEnglishwarningdecals.

17

Page 18

4

G012628

1

2

G012629

1

2

G012630

1

G012631

1

2

3

InstallingtheHoodLatch(CE

Only)

Partsneededforthisprocedure:

1Lockbracket

2Rivet

1Washer

1

Screw,1/4x2inches

1

Locknut,1/4inch

Procedure

1.Unhookthehoodlatchfromthehoodlatchbracket.

2.Removethe(2)rivetssecuringthehoodlatchbracket

tothehood(Figure6).Removethehoodlatchbracket

fromthehood.

Figure7

1.CElockbracket

4.Alignthewasherswiththeholesontheinsideofthe

hood.

5.Rivetthebracketsandthewasherstothehood(Figure

7).

6.Hookthelatchontothehoodlatchbracket(Figure8).

2.Boltandnutassembly

Figure8

1.Hoodlatch

Figure6

1.Hoodlatchbracket2.Rivets

3.Whilealigningthemountingholes,positiontheCE

lockbracketandthehoodlatchbracketontothehood.

Thelockbracketmustbeagainstthehood(Figure7).

Donotremoveboltandnutassemblyfromthelock

bracketarm.

7.Screwtheboltintotheotherarmofhoodlockbracket

tolockthelatchinposition(Figure9).Tightenbolt

securelybutdonottightennut.

Figure9

1.Bolt

2.Nut

3.Armofhoodlockbracket

18

Page 19

5

InstallingtheExhaustGuard

(CEOnly)

Partsneededforthisprocedure:

1Exhaustguard

4

Self-tappingscrew

oorplatebracketis5to8mm(0.18to0.32inches)

(Figure11).

Procedure

1.Positiontheexhaustguardaroundthemuferwhile

aligningthemountingholeswiththeholesintheframe

(Figure10).

Figure11

cuttingunitsremovedforclarity

1.Liftarm3.Clearance

2.Floorplatebracket

Iftheclearanceisnotinthisrange,adjustitasfollows:

A.Backoffthestopbolts(Figure12).

Figure12

1.Stopbolt3.Clearance

2.Liftarm

Figure10

1.Exhaustguard

2.Securetheexhaustguardtotheframewith4

self-tappingscrews(Figure10).

6

AdjustingtheLiftArms

NoPartsRequired

Procedure

1.Starttheengine,raisethecuttingunits,andcheckto

ensurethattheclearancebetweeneachliftarmandthe

B.Backoffthejamnutonthecylinder(Figure13).

Figure13

1.Frontcylinder2.Jamnut

C.Removethepinfromtherodendandrotatethe

clevis.

19

Page 20

D.Installthepinandchecktheclearance.Repeat

theprocedureifrequired.

E.Tightentheclevisjamnut.

2.Checktomakesurethattheclearancebetweeneachlift

armandstopboltis0.13to1.02mm(0.005to0.040

inches)(Figure12).Iftheclearanceisnotinthisrange,

adjustthestopboltstoattainclearance.

3.Starttheengine,raisethecuttingunits,andcheckto

makesurethattheclearancebetweenthewearstrap

onthetopoftherearcuttingunitwearbarandthe

bumperstrapis0.51to2.54mm(0.02to0.10inches)

(Figure14).

Figure14

1.Wearbar2.Bumperstrap

Iftheclearanceisnotinthisrange,adjusttherear

cylinderasfollows:

7

RearBallast

NoPartsRequired

Procedure

Models30843,30839and30807conformtoCENstandard

EN836:1997andANSIstandardB71.4-2004standardwhen

22.6kg(50lbs)ofcalciumchlorideballastisaddedtothe

rearwheels.Model30849conformstoCENstandardEN

836:1997andANSIstandardB71.4-2004standardwhen30

kg.(67lbs)ofcalciumchlorideballastisaddedtotherear

wheelandweight,partno.104-3965isaddedtotherearfork.

Important:Ifapunctureoccursinatirewithcalcium

chloride,removethemachinefromtheturfasquickly

aspossible.Topreventpossibledamagetotheturf,

immediatelysoaktheaffectedareawithwater.

8

Note:Iftherearliftarmclunksduringtransport,

clearancecanbereduced.

A.Lowerthecuttingunitsandbackoffthejamnut

onthecylinder(Figure15).

Figure15

1.Rearcylinder2.Adjustingnut

B.Graspthecylinderrodclosetothenutwitha

pliersandragandrotatetherod.

C.Raisethecuttingunitsandchecktheclearance.

Repeattheprocedureifrequired.

D.Tightentheclevisjamnut.

AdjustingtheCarrierFrame

NoPartsRequired

AdjustingtheFrontCuttingDecks

Thefrontandrearcuttingdecksrequiredifferentmounting

positions.Thefrontcuttingdeckhastwomountingpositions

dependingonwhatheight-of-cutanddegreeofdeckrotation

youdesire.

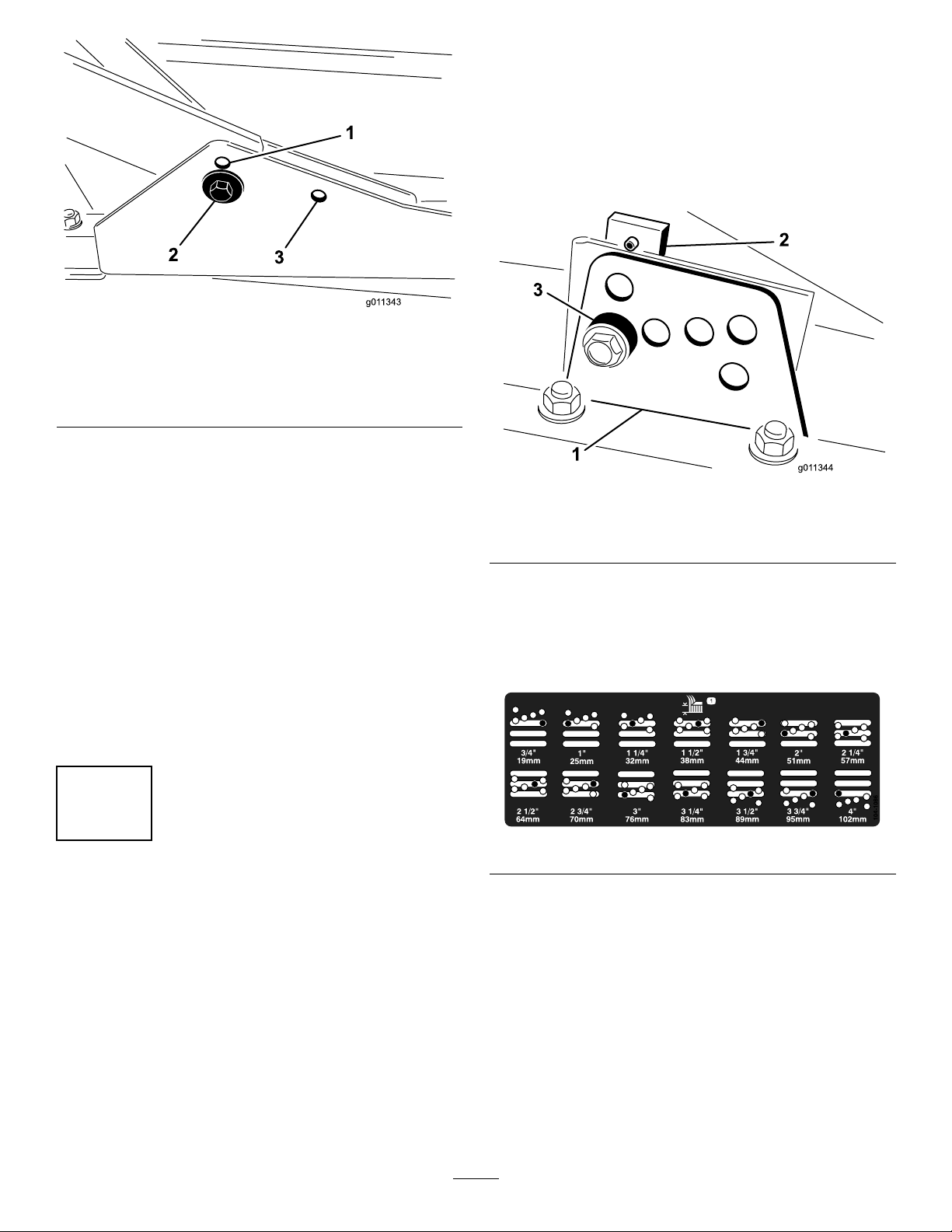

1.Forheightsofcutinthe2to7.6cm(3/4to3inch)

range,mountthefrontcarrierframesinthelowerfront

mountingholes(Figure16).

Note:Thispermitsmoreuptravelofthecutting

decksrelativetotractorwhenapproachingquickuphill

changesinterrain.Itdoeshoweverlimittheclearance

ofthechambertothecarrierwhencrestingsharp

knolls.

Important:Lackofclearanceatthefrontstopsorrear

wearbarcoulddamagetheliftarms.

20

Page 21

Figure16

cuttingunitstotheright,removetherearcuttingunit,

andslideitouttotherightside.

1.Lowerthecuttingdecktotheground,stoptheengine,

andremovethekeyfromignitionswitch.

2.Loosentheboltsecuringeachheight-of-cutbracketto

theheight-of-cutplate(frontandeachside)(Figure17).

3.Beginningwithfrontadjustment,removethebolt.

1.Frontdeckmountinghole

(upper)

2.Frontdeckmountinghole

(lower)

2.Forheightsofcutinthe6.3to10cm(2-1/2to4inch)

range,mountthefrontcarrierframesintheupper

frontmountingholes(Figure16).

Note:Thisincreasesthechambertocarrierclearance

duetothehigherpositionofthecuttingchamber,but

willcausethecuttingdecktoreachtheirmaximumup

travelsooner.

3.Reardeckmountinghole

AdjustingtheRearCuttingDeck

Thefrontandrearcuttingdecksrequiredifferentmounting

positions.Therearcuttingdeckhasonemountingposition

forproperalignmentwiththesidewinderunderframe.

Forallheightsofcut,mounttherearcuttingdeckintherear

mountingholes(Figure16).

Figure17

1.Heightofcutbracket3.Spacer

2.Heightofcutplate

4.Whilesupportingthechamber,removethespacer

(Figure17).

5.Movethechambertothedesiredheight-of-cutand

installaspacerintothedesignatedheight-of-cuthole

andslot(Figure18).

9

AdjustingtheHeight-of-Cut

NoPartsRequired

Procedure

Important:Thiscuttingdeckoftencutsapproximately

6mm(1/4inch)lowerthanareelcuttingunitwiththe

samebenchsetting.Itmaybenecessarytohavethese

rotarycuttingdeck’sbenchset6mm(1/4inch)above

thatofreelscuttinginthesamearea.

Important:Accesstotherearcuttingunitsisgreatly

improvedbyremovingthecuttingunitfromthetractor.

IftheunitisequippedwithaSidewinder®,sidewindthe

Figure18

6.Positionthetappedplateinlinewiththespacer.

7.Installtheboltngertight.

8.Repeatsteps4-7foreachsideadjustment.

9.Tightenallthreeboltsto41N-m(30ft-lb).Always

tightenthefrontboltrst.

Note:Adjustmentsofmorethan3.8cm(1-1/2

inches)mayrequiretemporaryassemblytoan

intermediateheighttopreventbinding(e.g.changing

from3.1to7cm(1.25to2.75inch)height-of-cut).

21

Page 22

10

G011346

1

2

3

G011347

1

AdjustingtheRollerScraper

(Optional)

NoPartsRequired

Procedure

Theoptionalrearrollerscraperisdesignedtoworkbest

whenthereisanevengapof0.5to1mm(0.020–0.040inch)

betweenthescraperandroller.

1.Loosenthegreasettingandthemountingscrew

(Figure19).

Figure19

1.Rollerscraper

2.Mountingscrew

2.Slidethescraperupordownuntilagapof0.5to1

mm(0.020to0.040inch)isachievedbetweentherod

andtheroller.

3.Securethegreasettingandscrewto41N-m(30ft-lb)

inanalternatingsequence.

3.Greasetting

Figure20

1.Mulchingbafe

3.Verifythatmulchingbafedoesnotinterferewith

thetipofthebladeanddoesnotprotrudeinsidethe

surfaceoftherearchamberwall.

WARNING

Donotusethehighliftbladewiththe

mulchingbafe.Thebladecouldbreak,

resultinginpersonalinjuryordeath.

11

InstallingtheMulchingBafe

(Optional)

NoPartsRequired

Procedure

1.Thoroughlycleandebrisfromthemountingholeson

therearwallandleftsidewallofthechamber.

2.Installthemulchingbafeintherearopeningand

secureitwith5angeheadbolts(Figure20).

22

Page 23

ProductOverview

Controls

TiltSteeringLever

Pullthetiltsteeringlever(Figure21)backtotiltthesteering

wheeltothedesiredposition.Thenpushtheleverforward

totighten.

IndicatorSlot

Models30839,30849&30807only

Theslotintheoperatorplatform(Figure21)indicateswhen

thecuttingunitsareinthecenterposition.

AngleIndicator

Models30839,30843&30807only

Theangleindicator(Figure21)indicatesthesidehillangleof

themachineindegrees.

Figure21

1.Forwardtractionpedal4.Tiltsteeringlever

2.Reversetractionpedal5.Indicatorslot

3.Mow/transportslide

6.Angleindicator

TractionPedals

Pressthetractionforwardpedal(Figure21)tomoveforward.

Presstractionreversepedal(Figure21)tomovebackwardor

toassistinstoppingwhenmovingforward.Also,allowthe

pedaltomoveormoveittotheneutralpositiontostopthe

machine.

Mow/TransportSlide

Usingyourheel,movethemow/transportslide(Figure21)

tothelefttotransportandtotherighttomow.Thecutting

unitswillonlyoperateinthemowposition.

Important:Themowspeedissetatthefactoryto9.7

km/h(6MPH).Itcanbeincreasedordecreasedby

adjustingthespeedstopscrew(Figure22).

IgnitionSwitch

Theignitionswitch(Figure23),usedtostart,stop,and

preheattheengine,hasthreepositions:Off,On/Preheat,and

Start.RotatethekeytotheOn/Preheatpositionuntilthe

glowplugindicatorlightgoesout(approximately7seconds);

thenrotatethekeytotheStartpositiontoengagethestarter

motor.Releasethekeywhentheenginestarts.Thekeywill

moveautomaticallytotheOn/Runposition.T oshutthe

engineoff,rotatethekeytotheOffposition.Removethekey

fromtheswitchtopreventaccidentalstarting.

1.Speedstopscrew

Figure22

Figure23

1.Throttle

2.Hourmeter

3.Temperaturelight9.Ignitionswitch

4.Oilpressurelight

5.Glowplugindicatorlight1 1.Liftleverlock

6.Alternatorlight

7.Cuttingunitdriveswitch

8.Cuttingunitshiftlever

10.Parkingbrake

Throttle

Movethethrottle(Figure23)forwardtoincreasetheengine

speedandrearwardtodecreasetheenginespeed.

23

Page 24

CuttingUnitDriveSwitch

ParkingBrake

Thecuttingunitdriveswitch(Figure23)hastwopositions:

EngageandDisengage.Therockerswitchoperatesasolenoid

valveonthevalvebanktodrivethecuttingunits.

HourMeter

Thehourmeter(Figure23)indicatesthetotalhoursof

machineoperation.Thehourmeterstartstofunction

wheneverthekeyswitchisOn.

CuttingUnitShiftLever

Tolowerthecuttingunitstotheground,movethecutting

unitshiftlever(Figure23)forward.Thecuttingunitswillnot

dropunlesstheengineisrunning.Toraisethecuttingunits,

pulltheshiftleverrearwardtotheRaiseposition.

OnModels30839,30849&30807,movethelevertothe

rightorlefttomovethecuttingunitsinthesamedirection.

Thisshouldonlybedonewhenthecuttingunitsareraisedor

iftheyareonthegroundandthemachineismoving.

Note:Theleverdoesnothavetobeheldintheforward

positionwhilethecuttingunitsarelowered.

Whenevertheengineisshutoff,engagetheparkingbrake

(Figure23)topreventaccidentalmovementofthemachine.

Toengagetheparkingbrake,pulluponthelever.Theengine

willstopifyoupressthetractionpedalwiththeparkingbrake

engaged.

LiftLeverLock

Movetheliftleverlock(Figure23)rearwardtopreventthe

cuttingunitsfromdropping.

FuelGauge

Thefuelgauge(Figure24)registerstheamountoffuelin

thetank.

DANGER

OnModels30839,30849&30807,shiftingthe

cuttingunitsdownhilldecreasesmachinestability.

Thiscouldcausearollover,whichmayresultin

personalinjuryordeath.

Shiftthecuttingunitsuphillwhileonasidehill.

EngineCoolantTemperatureWarning

Light

Thetemperaturewarninglight(Figure23)glowsiftheengine

coolanttemperatureishigh.Ifthetractionunitisnotstopped

andthecoolanttemperaturerisesanother10°F,theengine

willkill.

OilPressureWarningLight

Theoilpressurewarninglight(Figure23)glowsiftheengine

oilpressuredropsbelowasafelevel.

AlternatorLight

Figure24

1.Foreandaftlever

2.Fuelgauge

ForeandAftSeatAdjustments

Movethelever(Figure24)onthesideoftheseatoutward,

slidetheseattothedesiredposition,andreleasethelever

tolocktheseatintoposition.

Thealternatorlight(Figure23)shouldbeoffwhentheengine

isrunning.Ifitison,thechargingsystemshouldbechecked

andrepairedasnecessary.

GlowPlugIndicator

Theglowplugindicatorlight(Figure23)willglowwhenthe

glowplugsareoperating.

24

Page 25

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

TractionUnit

OverallWidth-68inchwidth

ofcut

OverallWidth-72inchwidth

ofcut

Length

HeighttotopofROPS180cm(70.8inches)

WheelBase

TrackWidth

GroundClearance15.3cm(6inches)

Weightwithcuttingunits

Models30839,

30843and30807

Model30849

CuttingDeck

Length

Width

Height

Weight

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

182cm(71.8inches)

193cm(75.8inches)

295cm(116inches)

149cm)(58.5inches)

145cm(57inches)

963kg(2,124lb)

952kg(2,099lb)

86.4cm(34inches)

86.4cm(34inches)

24.4cm(9.6inches)

tocarriermount

26.7cm(10–1/2inches)

at3/4inchheightofcut

34.9cm(13–3/4inches)at

4inchheightofcut

88kg(195pounds)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;however,the

oillevelmustbecheckedbeforeandaftertheengineisrst

started.

Crankcasecapacityisapproximately2.8liters(4quarts)with

thelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4orhigher.

•Preferredoil:SAE15W-40(above0ºF(-17ºC))

•Alternateoil:SAE10W-30or5W-30(alltemperatures)

Note:T oroPremiumEngineoilisavailablefromyour

distributorineither15W-40or10W-30viscosity.Seethe

partscatalogforpartnumbers.

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscoolbeforeithasbeenstartedfortheday.Ifithas

alreadybeenrun,allowtheoiltodrainbackdowntothe

sumpforatleast10minutesbeforechecking.Iftheoillevel

isatorbelowthe“add”markonthedipstick,addoiltobring

theoilleveltothe“full”mark.DONOTOVERFILL.If

theoillevelisbetweenthe“full”and“add”marks,nooil

additionisrequired.

1.Positionthemachineonalevelsurface.

2.Removethedipstick(Figure25)andwipeitwitha

cleanrag.

Figure25

1.Dipstick

3.Pushthedipstickdownintothedipsticktubeandmake

surethatitisseatedfully.Pullthedipstickoutand

checktheoillevel.

4.Iftheoillevelislow,removetheoilllcap(Figure26)

andgraduallyaddsmallquantitiesofoil,checkingthe

25

Page 26

levelfrequently,untilthelevelreachestheFullmark

onthedipstick.

Figure26

1.Oilllcap

5.Installtheoilllcapandclosethehood.

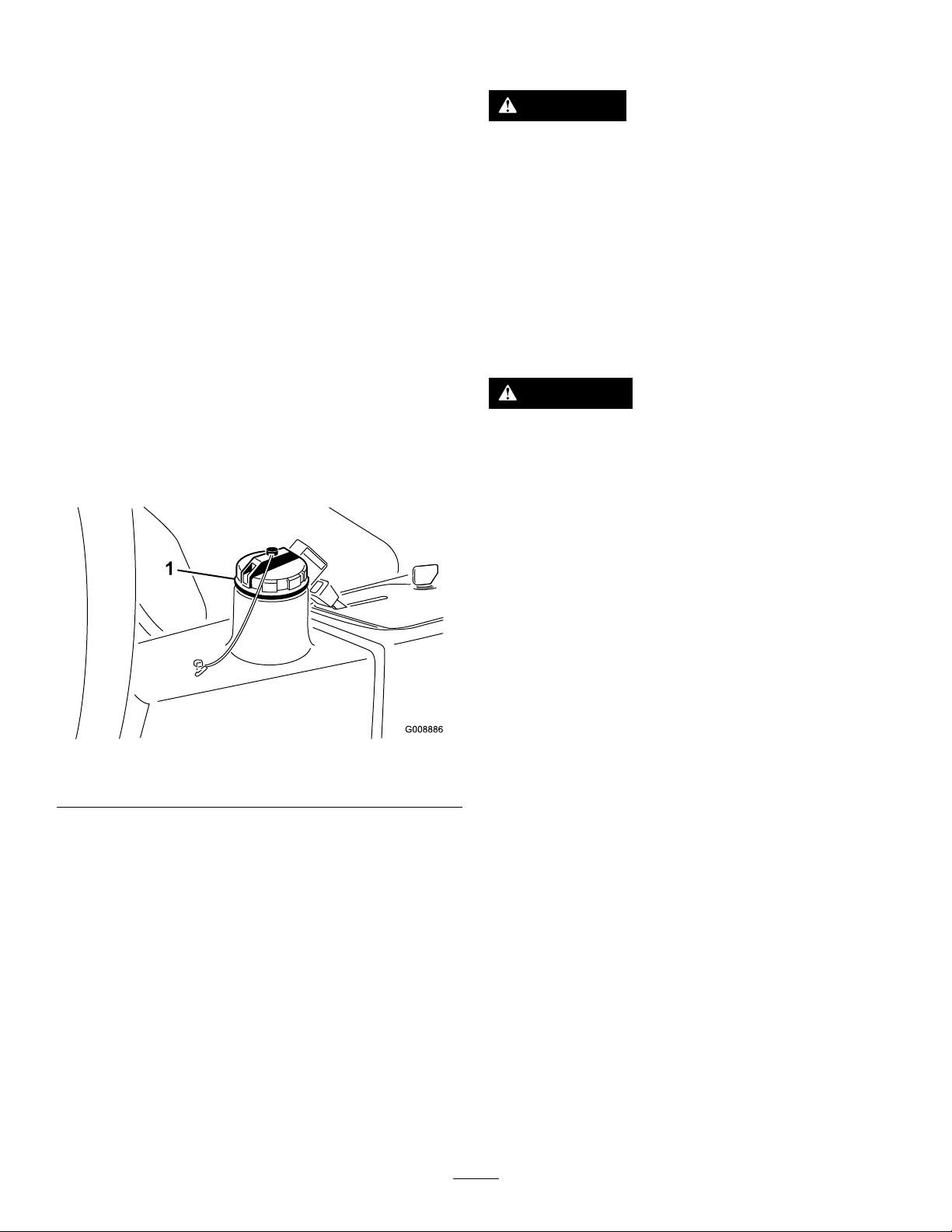

1.Cleantheareaaroundthefueltankcap(Figure27).

2.Removethefueltankcap.

3.Fillthetanktothebottomofthellerneck.Donot

overll.Installthecap.

4.Topreventarehazard,wipeupanyfuelthatmay

havespilled.

Figure27

FillingtheFuelTank

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultralow(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchasefuelin

quantitiesthatcanbeusedwithin180daystoensurefuel

freshness.

Thefueltankcapacityisapproximately42liters(11gallons).

Usesummergradedieselfuel(No.2–D)attemperatures

above20degreesF(–7degreesC)andwintergrade(No.

1-DorNo.1-D/2-Dblend)belowthattemperature.Useof

wintergradefuelatlowertemperaturesprovideslowerash

pointandcoldowcharacteristicswhichwilleasestarting

andreducefuellterplugging.

Useofsummergradefuelabove20degreesF(-7degreesC)

willcontributetowardlongerfuelpumplifeandincreased

powercomparedtowintergradefuel.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultralowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather

•Monitorseals,hoses,gasketsincontactwithfuelasthey

maybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblends.

•Contactyourdistributorifyouwishformoreinformation

onbiodiesel

1.Fueltankcap

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.

Addfueltothefueltankuntilthelevelis

6to13mm(1/4to1/2inch)belowthe

bottomofthellerneck.Thisemptyspace

inthetankallowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

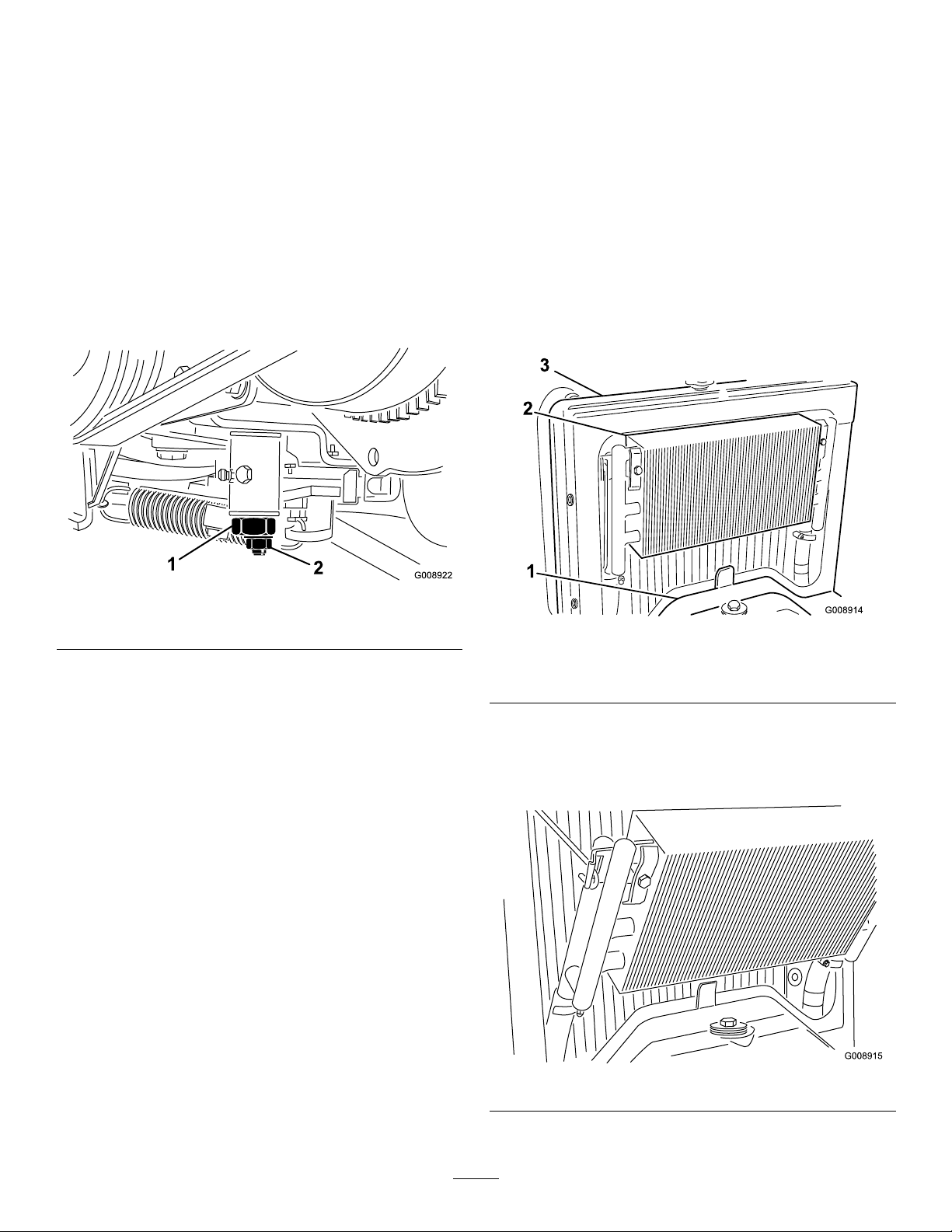

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily

Cleandebrisoffoftheradiatorandoilcoolerdaily(Figure

28).Cleantheradiatorhourlyifconditionsareextremely

dustyanddirty;refertoCleaningtheEngineCoolingSystem.

26

Page 27

1.Accesspanel

2.Radiator

Figure28

Figure29

3.Oilcooler

1.Expansiontank

Thecoolingsystemislledwitha50/50solutionofwater

andpermanentethyleneglycolanti-freeze.Checkthecoolant

levelatthebeginningofeachdaybeforestartingtheengine.

Thecapacityofthecoolingsystemisapproximately5.7liters

(6quarts).

CAUTION

Iftheenginehasbeenrunning,thepressurized,hot

coolantcanescapeandcauseburns.

•Donotopentheradiatorcapwhentheengine

isrunning.

•Usearagwhenopeningtheradiatorcap,and

openthecapslowlytoallowsteamtoescape.

1.Checkthecoolantlevelintheexpansiontank(Figure

29).Withacoldengine,thecoolantlevelshouldbe

approximatelymidwaybetweenthemarksontheside

ofthetank.

2.Ifthecoolantlevelislow,removetheexpansiontank

capandreplenishthesystem.Donotoverll.

3.Installtheexpansiontankcap.

CheckingtheHydraulic System

ServiceInterval:Beforeeachuseordaily—Checkthe

hydraulicuidlevel.

Themachinesreservoirislledatthefactorywith

approximately13.2liters(3.5U.S.gallons)ofhighquality

hydraulicuid.Checkthelevelofthehydraulicuid

beforetheengineisrststartedanddailythereafter.

TherecommendedreplacementuidisToroPremiumAll

SeasonHydraulicFluid(Availablein19liter(5gallon)pails

or55gallondrums.SeepartscatalogorTorodistributorfor

partnumbers.)

Alternateuids:IftheT orouidisnotavailable,other

uidsmaybeusedprovidedtheymeetallthefollowing

materialpropertiesandindustryspecications.Torodoes

notrecommendtheuseofsyntheticuid.Consultwithyour

lubricantdistributortoidentifyasatisfactoryproductNote:

Torowillnotassumeresponsibilityfordamagecausedby

impropersubstitutions,souseonlyproductsfromreputable

manufacturerswhowillstandbehindtheirrecommendation.

HighViscosityIndex/LowPourPointAnti-wearHydraulic

Fluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to48

ViscosityIndexASTM

D2270

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0

cSt@100°C7.9to8.5

140to160

Important:TheISOVG46Multigradeuidhasbeen

foundtoofferoptimalperformanceinawiderangeof

temperatureconditions.Foroperationinconsistently

highambienttemperatures,65°F(18°C)to120°F

(49°C),ISOVG68hydraulicuidmayofferimproved

performance.

27

Page 28

PremiumBiodegradableHydraulicFluid-MobilEAL

EnviroSyn46H

Note:Maintaintherecommendedpressureinalltiresto

ensureagoodqualityofcutandpropermachineperformance.

Important:MobilEALEnviroSyn46Histheonly

syntheticbiodegradableuidapprovedbyT oro.This

uidiscompatiblewiththeelastomersusedinToro

hydraulicsystemsandissuitableforawide-range

oftemperatureconditions.Thisuidiscompatible

withconventionalmineraloils,butformaximum

biodegradabilityandperformancethehydraulicsystem

shouldbethoroughlyushedofconventionaluid.The

oilisavailablein19liters(5gallon)containersor55

gallondrumsfromyourMobilDistributor.

Important:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemoilisavailablein20ml(2/3oz.)

bottles.Onebottleissufcientfor15-221iters(4-6U.S.

gallons)ofhydraulicoil.Orderpartno.44-2500from

yourauthorizedT orodistributor.

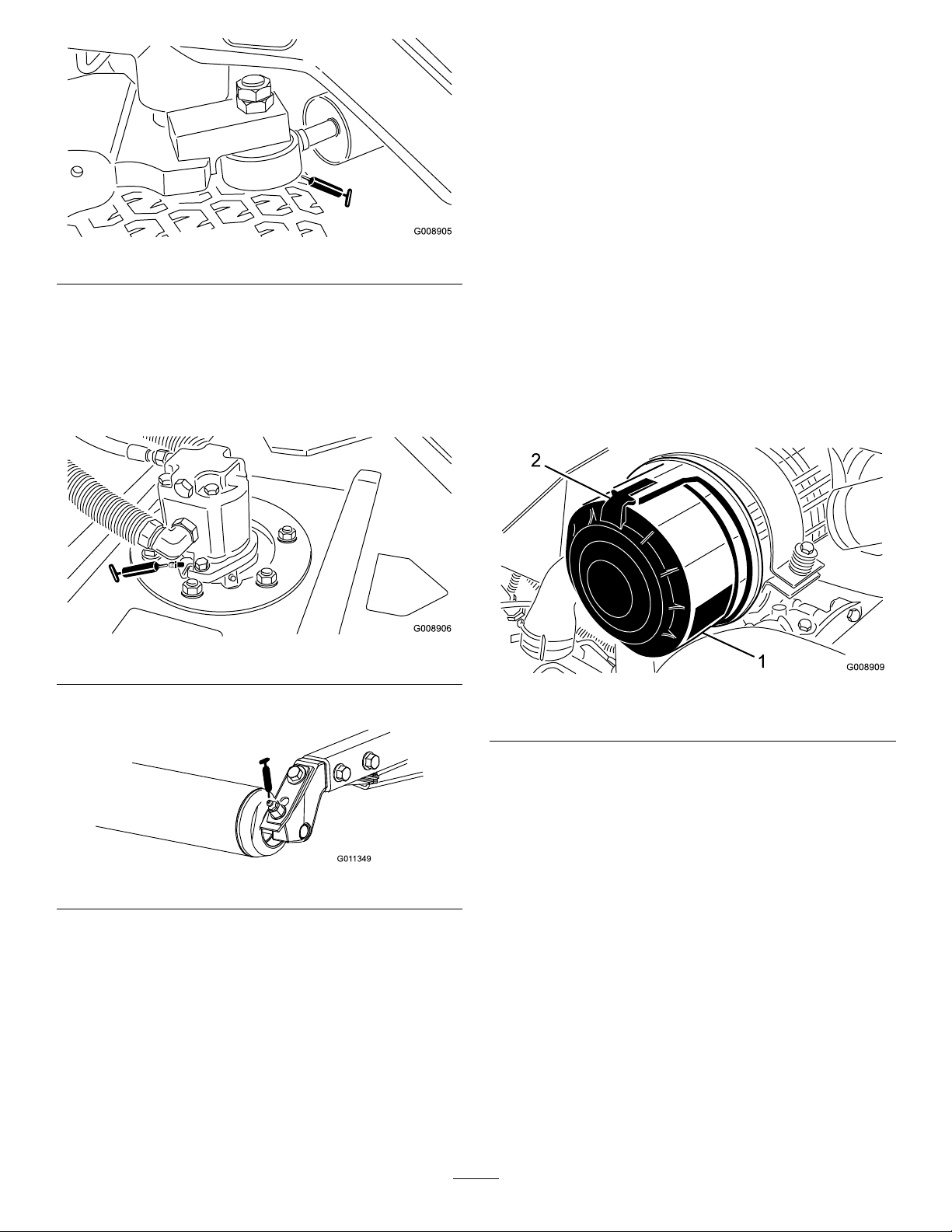

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,andstoptheengine.

2.Cleantheareaaroundthellerneckandcapofthe

hydraulictank(Figure30).Removethecap.

DANGER

Lowtirepressuredecreasesmachinesidehill

stability.Thiscouldcausearollover,whichmay

resultinpersonalinjuryordeath.

Donotunder-inatethetires.

TorquingtheWheelNuts

ServiceInterval:Afterthersthour

Aftertherst10hours

Every200hours

Torquethewheelnutsto61to88N-m(45to65ft-lb).

WARNING

Failuretomaintainpropertorqueofthewheelnuts

couldresultinpersonalinjury.

StartingandStoppingthe Engine

Youmayneedtobleedthefuelsystemifanyofthefollowing

situationshaveoccurred(refertoBleedingtheFuelSystem):

•Initialstartupofanewengine

•Theenginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponthefuelsystem

components;i.e.lterreplaced,etc.

Figure30

1.Hydraulictankcap

3.Removethedipstickfromthellerneckandwipeit

withacleanrag.Insertthedipstickintothellerneck;

thenremoveitandchecktheuidlevel.Theuidlevel

shouldbewithin6mm(1/4inch)ofthemarkonthe

dipstick.

4.Ifthelevelislow ,addtheappropriateuidtoraisethe

leveltothefullmark.

5.Installthedipstickandcapontothellerneck.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Thetiresareover-inatedforshipping.Therefore,release

someoftheairtoreducethepressure.Thecorrectair

pressureinthetiresis97to124kPa(14to18psi).

StartingtheEngine

1.Besurethattheparkingbrakeissetandthecutting

unitdriveswitchisintheDisengageposition.

2.Removeyourfootfromthetractionpedalandmake

surethatthepedalisintheneutralposition.

3.Movethethrottlelevertothe1/2throttleposition.

4.Insertthekeyintotheswitchandrotateittothe

On/Preheatpositionuntiltheglowplugindicatorlight

goesout(approximately7seconds);thenrotatethe

keytotheStartpositiontoengagethestartermotor.

Releasethekeywhentheenginestarts.Thekeywill

moveautomaticallytotheOn/Runposition.

Important:Topreventoverheatingofthestarter

motor,donotengagethestarterlongerthan15

seconds.After10secondsofcontinuouscranking,

wait60secondsbeforeengagingthestartermotor

again.

5.Whentheengineisstartedforthersttimeorafteran

overhauloftheengine,operatethemachineinforward

andreverseforonetotwominutes.Alsooperatethe

liftleverandcuttingunitdriveswitchtobesureof

properoperationofallparts.

28

Page 29

Turnthesteeringwheeltotheleftandrighttocheck

steeringresponse;thenshuttheengineoffandcheck

foroilleaks,looseparts,andanyothernoticeable

malfunctions.

CAUTION

Stoptheengineandwaitforallmovingparts

tostopbeforecheckingforoilleaks,loose

parts,andothermalfunctions.

StoppingtheEngine

MovethethrottlecontroltotheIdleposition,movethe

cuttingunitdriveswitchtoDisengage,androtatethestarter

keytoOff.Removethekeyfromtheswitchtoprevent

accidentalstarting.

BleedingtheFuelSystem

1.Parkthemachineonalevelsurface.Makesurethatthe

fueltankisatleasthalffull.

2.Unlatchandraisethehood.

Figure31

1.Fuelinjectionpumpbleedscrew

4.TurnthekeyintheignitionswitchtotheOnposition.

Theelectricfuelpumpwillbeginoperation,thereby

forcingairoutaroundtheairbleedscrew .Leavethe

keyintheOnpositionuntilasolidstreamoffuelows

outaroundthescrew .

5.TightenthescrewandturnthekeytoOff.

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.

Addfueltothefueltankuntilthelevelis

6to13mm(1/4to1/2inch)belowthe

bottomofthellerneck.Thisemptyspace

inthetankallowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

3.Opentheairbleedscrewonthefuelinjectionpump

(Figure31).

Note:Normallytheengineshouldstartaftertheabove

bleedingproceduresarefollowed.However,iftheengine

doesnotstart,airmaybetrappedbetweentheinjectionpump

andinjectors;refertoBleedingAirfromtheInjectors.

CheckingtheInterlockSystem

ServiceInterval:Beforeeachuseordaily

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

1.Makesurethatallbystandersareawayfromtheareaof

operation.Keephandsandfeetawayfromthecutting

units.

2.Whilesittingontheseat,theenginemustnotstart

witheitherthecuttingunitswitchengagedorthe

tractionpedalengaged.Correcttheproblemifitisnot

operatingproperly.

3.Whilesittingontheseat,putthetractionpedalin

neutral,theparkingbrakeoff,andthecuttingunit

switchintheOffposition.Theengineshouldstart.

Risefromtheseatandslowlypressthetractionpedal,

theengineshouldstopinonetothreeseconds.Correct

problemifitisnotoperatingproperly.

29

Page 30

Note:Themachineisequippedwithaninterlockswitchon

theparkingbrake.Theenginewillstopifthetractionpedalis

pressedwiththeparkingbrakeengaged.

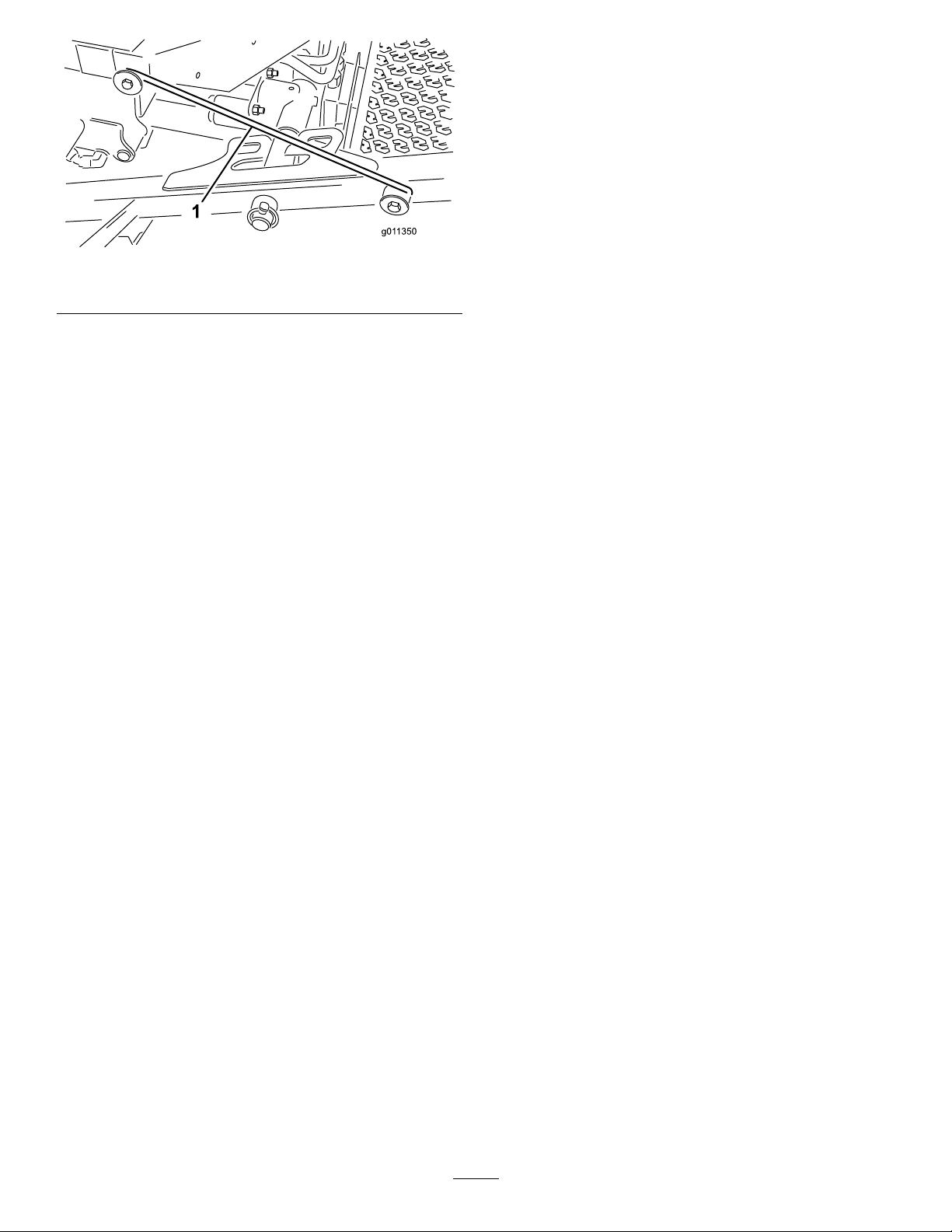

TowingtheTractionUnit

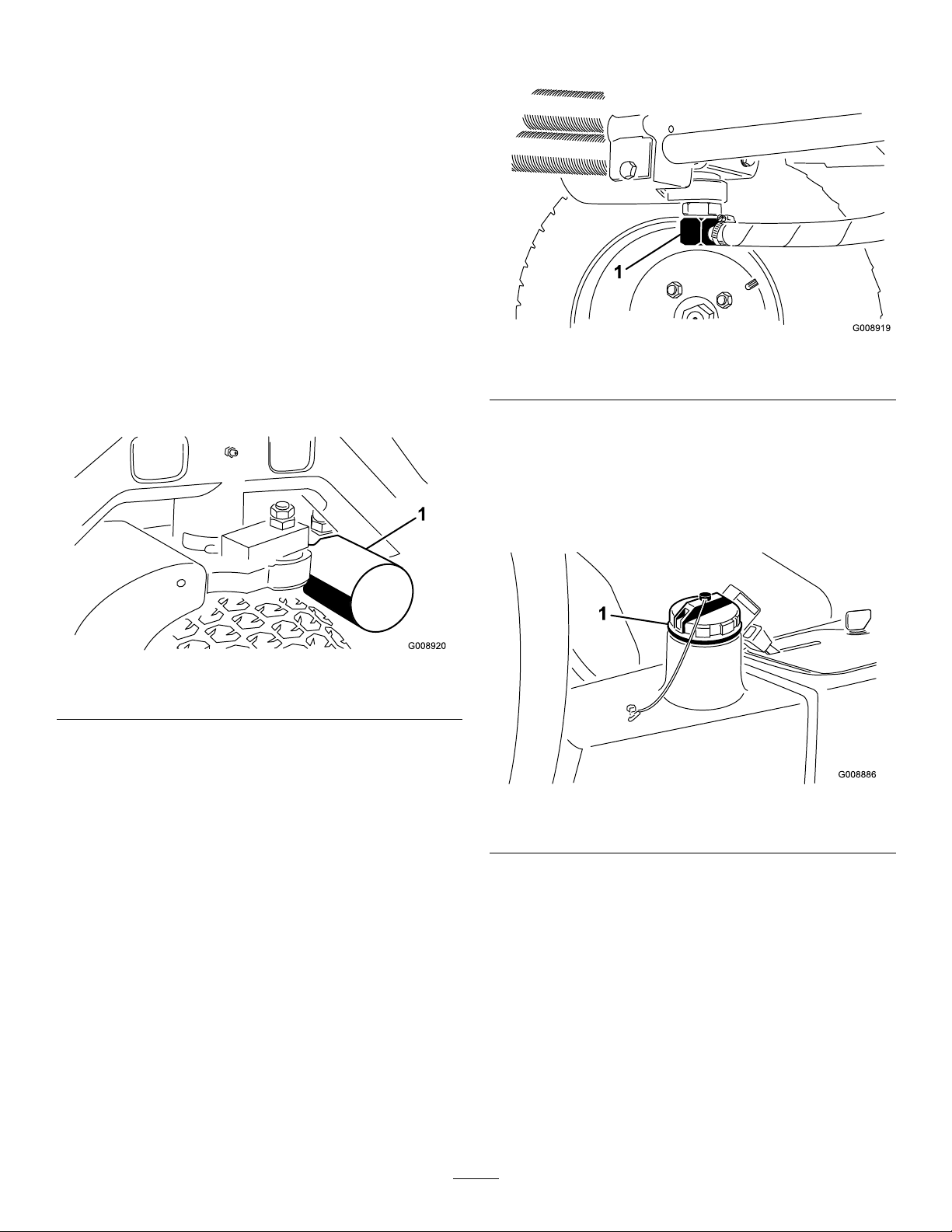

Incaseofanemergency ,themachinecanbetowedfora

shortdistance;however,Torodoesnotrecommendthisas

astandardprocedure.

Important:Donottowthemachinefasterthan3to

4km/h(2to3MPH)becausethedrivesystemmay

becomedamaged.Ifthemachinemustbemoveda

considerabledistance,transportitonatruckortrailer.

1.Locatethebypassvalveonthepump(Figure32)and

rotateit90°.

Figure32

1.Bypassvalve

usessolidstateandmechanicalcomponentstomonitorand

controlstandardelectricalfeaturesrequiredforsafeproduct

operation.

Themodulemonitorsinputsincludingneutral,parkingbrake,

PTO,start,backlap,andhightemperature.Themodule

energizesoutputsincludingPTO,Starter,andETR(energize

torun)solenoid.

Themoduleisdividedintoinputsandoutputs.Inputsand

outputsareidentiedbygreenLEDindicatorsmountedon

theprintedcircuitboard.

Thestartcircuitinputisenergizedby12VDC.Allother

inputsareenergizedwhenthecircuitisclosedtoground.

EachinputhasaLEDthatisilluminatedwhenthespecic

circuitisenergized.UsetheinputLED’ sforswitchandinput

circuittroubleshooting.

Outputcircuitsareenergizedbyanappropriatesetofinput

conditions.ThethreeoutputsincludePTO,ETR,and

START.OutputLED’ smonitorrelayconditionindicatingthe

presenceofvoltageatoneofthreespecicoutputterminals.

Outputcircuitsdonotdetermineoutputdeviceintegrityso

electricaltroubleshootingincludesoutputLEDinspection

andconventionaldeviceandwireharnessintegritytesting.

Measuredisconnectedcomponentimpedance,impedance

throughwireharness(disconnectatSCM),orbytemporarily

”testenergizing”thespeciccomponent.

2.Beforestartingtheengine,closethebypassvalveby

rotatingit90°(1/4turn).Donotstarttheenginewhen

thevalveisopen.

StandardControlModule (SCM)

TheStandardControlModuleisapottedelectronicdevice

producedinaonesizetsallconguration.Themodule

TheSCMdoesnotconnecttoanexternalcomputerorhand

helddevice,cannotbere–programmed,anddoesnotrecord

intermittentfaulttroubleshootingdata.

ThedecalontheSCMonlyincludessymbols.ThreeLED

outputsymbolsareshownintheoutputbox.AllotherLED’s

areinputs.Thechartbelowidentiesthesymbols.

Figure33

30

Page 31

HerearethelogicaltroubleshootingstepsfortheSCMdevice.

1.Determinetheoutputfaultyouaretryingtoresolve

(PTO,START,orETR).

2.MovekeyswitchtotheOnpositionandensurethat

theredpowerLEDisilluminated.

3.MoveallinputswitchestoensureallLED’schange

state.

4.Positioninputdevicesatappropriatepositionto

achievetheappropriateoutput.Usethefollowinglogic

charttodeterminetheappropriateinputcondition.

5.IfspecicoutputLEDisilluminatedwithout

appropriateoutputfunction,checkoutputharness,

connections,andcomponent.Repairasrequired.

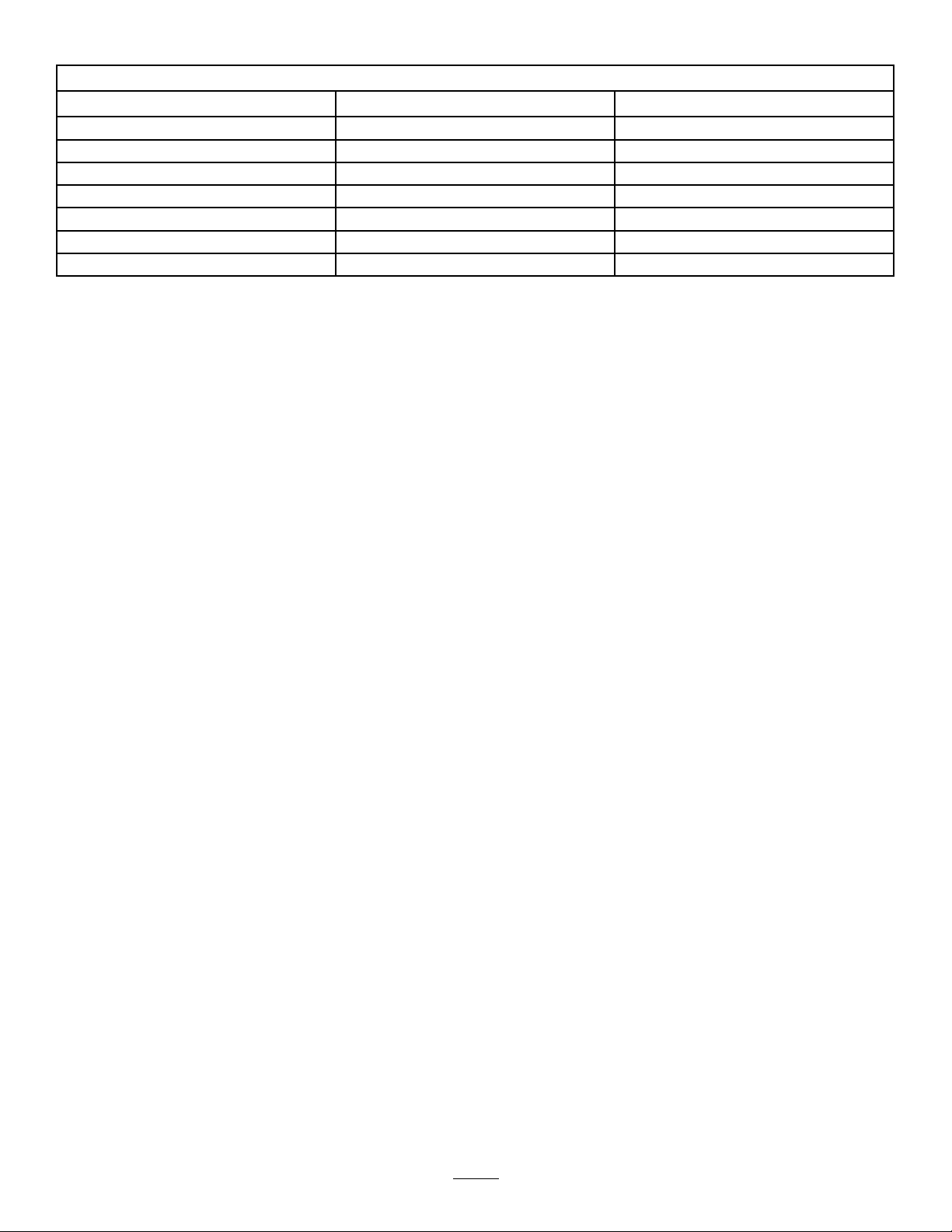

INPUTSOUTPUTS

FunctionPower

Start

Run(Off

Unit)

Run(On

Unit)

Mow

Backlap

HiTemp

ON

——

——

—

—

——

—

In

Neutral

OO

OO

StartON

+

OOOOOOO

OO

O

Brake

ON

OO

—

———

PTOONInSeat

O

—

6.IfspecicoutputLEDisnotilluminated,checkboth

fuses.

7.IfspecicoutputLEDisnotilluminatedandinputs

areinappropriatecondition,installnewSCMand

determineiffaultdisappears.

Eachrow(across)inthelogicchartbelowidentiesinput

andoutputrequirementsforeachspecicproductfunction.

Productfunctionsarelistedintheleftcolumn.Symbols

identifyspeciccircuitconditionincluding:energizedto

voltage,closedtoground,andopentoground.

—

—

OO

HiTempBacklap

OO

OOO

OOO

—

—

Start

++

O

OOO

ETR

+

+

++

++

PTO

O

O

O

•(–)Indicatesacircuitclosedtoground.–LEDON

•(O)Indicatesacircuitopentogroundorde–energized

–LEDOFF

•(+)Indicatesanenergizedcircuit(clutchcoil,solenoid,or

startinput)LEDON.

•ABlankindicatesacircuitthatisnotinvolvedwiththe

logic.

Totroubleshoot,turnonthekeywithoutstartingtheengine.

Identifythespecicfunctionthatdoesnotworkandwork

acrossthelogicchart.Inspecttheconditionofeachinput

LED’stoensureitmatchesthelogicchart.

IftheinputLED’sarecorrect,checktheoutputLED .Ifthe

outputLEDisilluminatedbutthedeviceisnotenergized,

measureavailablevoltageattheoutputdevice,continuityof

thedisconnecteddevice,andpotentialvoltageontheground

circuit(oatingground).Repairswillvarydependingonyour

ndings.

31

Page 32

SelectingaBlade

StandardCombinationSail

Thisbladewasdesignedtoprovideexcellentliftand

dispersioninalmostanycondition.Ifmoreorlessliftand

dischargevelocityisrequired,consideradifferentblade.

Attributes:Excellentliftanddispersioninmostconditions.

AngledSail

Thebladegenerallyperformsbestinlowerheightsofcut-

1.9to6.4cm(3/4to2–1/2inch).

Attributes:

•Dischargeremainsmoreevenatlowerheightsofcut.

•Dischargehaslesstendencytothrowleftandthusa

cleanerlookaroundbunkersandfairways.

•Lowerpowerrequirementatlowerheightsanddenseturf.

HighLiftParallelSail

Thebladegenerallyperformsbetterinthehigherheightsof

cut-7to10cm(2to4inch).

Attributes:

•Moreliftandhigherdischargevelocity.

•Sparseorlimpturfispickedupsignicantlyathigher

heightsofcut.

•Wetorstickyclippingsaredischargedmoreefciently

reducingcongestioninthedeck.

•Requiresmorehorsepowertorun.

•Tendstodischargefurtherleftandcantendtowindrow

atlowerheightsofcut.

WARNING

Donotusethehighliftbladewiththemulching

bafe.Thebladecouldbreak,resultinginpersonal

injuryordeath.

AtomicBlade

Thisbladewasdesignedtoprovideexcellentleafmulching.

Attributes:Excellentleafmulching

32

Page 33

ChoosingAccessories

OptionalEquipmentCongurations

AngleSailBladeHighLiftParallelSail

GrassCutting:1.9to4.4

cm(0.75to1.75inch)

Height-of-Cut

GrassCutting:5to6.4

cm(2.00to2.50inch)

Height-of-Cut

GrassCutting:7to10

cm(2.75to4.00inch)

Height-of-Cut

LeafMulchingRecommendedforuse

ProsEvendischargeatlower

ConsDoesnotliftthegrass

Recommendedinmost

applications

Recommendedforthick

orlushturf

Mayworkwellinlushturf

withthemulchingbafe

heightofcutCleaner

lookaroundbunkersand

fairwaysLowerpower

requirements

wellinhighheightof

cutapplicationsWet

orstickygrasshas

atendencytobuild

upinthechamber,

leadingtopoorquality

ofcutandhigherpower

requirements

Blade(Donotusewith

themulchingbafe)

Mayworkwellinlightor

sparseturf

Recommendedforlight

orsparseturf

Recommendedinmost

applications

NotAllowedUsewithcombination

Moreliftandhigher

dischargevelocity

Sparseorlimpturfis

pickedupathighheight

ofcutWetorsticky

clippingsaredischarged

efciently

Requiresmorepowerto

runinsomeapplications

Tendstowindrowat

lowerheightofcutin

lushgrassDonotuse

withthemulchingbafe

MulchingBafeRollerScraper

Hasbeenshownto

improvedispersionand

aftercutperformance

onnortherngrassesthat

arecutatleastthree

timesperweekandless

than1/3ofthegrass

bladeisremoved.Do

notusewiththehigh

liftparallelsailblade

sailoranglesailblade

only

Mayimprovedispersion

andappearancein

certaingrasscutting

applicationsVerygood

forleafmulching

Grasswillbuildupinthe

chamberifattemptingto

removetoomuchgrass

withbafeinplace

Canbeusedanytime

thatrollersbuildup

withgrassorlargeat

grassclumpsofgrass

areseen.Thescrapers

mayactuallyincrease

clumpingincertain

applications.

Reducesrollerbuildup

incertainapplications

33

Page 34

OperatingTips

units,disengagetheparkingbrake,presstheforward

tractionpedal,andcarefullydrivetoanopenarea.

GeneralTipsforModels30839,30843

and30807

DANGER

Themowerhasauniquetractionsystemthatwill

allowthemachinetomoveforwardonsidehills,

eveniftheuphillwheelshouldcomeoffofthe

ground.Ifthisshouldhappen,theoperatororany

bystanderscanbeseriouslyinjuredorkilledina

rollover.

Theslopeangleatwhichthemachinewilltipis

dependentonmanyfactors.Amongtheseare:

mowingconditionssuchaswetofundulatingturf,

speed(especiallyinturns),positionofthecutting

units(withSidewinder),tirepressure,andoperator

experience.

Atsidehillanglesof20degreesorless,theriskof

arolloverislow.Astheslopeangleincreasestoa

recommendedmaximumlimitof25degrees,the

riskofarolloverincreasestoamoderatelevel.

not ex ceed a 25 deg r ee side hill slope ang le because

the risk of a r ollo v er and serious injur y or death is

v er y high.

Todeterminewhichhillsorslopesyoumaysafely

operateon,asitesurveyofthemowingareamust

bedone.Whenperformingthissitesurvey,always

usecommonsenseandtakeintoconsiderationthe

turfconditionandtherolloverrisk.T odetermine

whichhillsorslopesmaybesafelyoperatedon,

usetheinclinometerprovidedwitheachmachine.

Toperformasitesurvey,laya4ft2x4(1.25meter

plank)ontheslopesurfaceandmeasuretheangle

oftheslope.The2x4willaveragetheslopebutwill

nottakeintoconsiderationdipsorholeswhich

cancauseasuddenchangeinsidehillangle.

maximum side hill ang le should not be g r eater than

25 deg r ees.

Additionally,themachineisequippedwithan

angleindicatormountedonthesteeringtube.This

indicatesthesidehillanglethemachineisonand

identiestherecommendedmaximumlimitof25

degrees.

Al w ays w ear y our seat belt.

T he

•Practicemovingforwardandreverse,andstartingand

stoppingthemachine.Tostop,takeyourfootoffofthe

tractionpedalandletitreturntoneutralorpressdown

onthereversepedaltostop.Goingdownahill,youmay

needtousethereversepedaltostop.

•Whendrivingonslopes,driveslowlytomaintainsteering

controlandavoidturnstopreventrollovers.Insidehill

situationsyoushouldshiftthesidewindercuttingunits

totheuphillsidetogiveyoumorestability.Conversely,

shiftingthecuttingunitstothedownhillsidewillgive

youlessstability.Thisshouldalwaysbedonebefore

goingonasidehill.

•Whenpossible,mowupanddownhillsratherthanacross

them.Havethecuttingunitsloweredwhengoingdowna

hilltomaintainsteeringcontrol.Donotattempttoturn

onahill.

•Practicedrivingaroundobstacleswiththecuttingunits

upanddown.Becarefulwhendrivingbetweennarrow

objectssoyoudonotdamagethemachineorcutting

units.

•OntheSidewinderunit,getafeelforthereachofthe

Do

cuttingunitssoyoudonothangthemupordamage

theminanyway.

•Donotshifttheunitsfromsidetoside,unlessthecutting

unitsaredownandthemachineismoving,orthecutting

unitsareupinthetransportposition.Shiftingthecutting

unitswhentheyaredownandthemachineisnotmoving

maycauseturfdamage.

•Alwaysdriveslowlyinroughareas.

•Ifapersonappearsinorneartheoperatingarea,stop

themachine,anddonotstartitagainuntiltheareais

cleared.Themachineisdesignedforoneperson.Never

letanyoneelserideonthemachinewithyou.Thisis

extremelydangerousandcouldresultinseriousinjury.

•Accidentscanhappentoanyone.Themostcommon

causesareexcessivespeed,suddenturns,terrain(not

knowingwhichslopesandhillscanbemowedsafely),not

stoppingtheenginebeforeleavingtheoperator’sseat,

anddrugswhichimpairyouralertness.Coldcapsulesor

prescriptiondrugsmaycausedrowsiness,ascanalcohol

andotherdrugs.Stayalertandstaysafe.Failuretodoso

couldresultinseriousinjury.

•TheSidewinderoffersuptoamaximumof33cm(13

inches)ofoverhang,allowingyoutotrimclosertothe

edgeofsandtrapsandotherobstacles,whileatthesame

timekeepingthetractortiresasfarawayfromtheedge

oftrapsorwaterhazardsaspossible.

•Practiceoperatingthemachineandbecomethoroughly

familiarwithit.

•Starttheengineandrunitathalfidleuntilitwarmsup.

Pushthethrottleleverallthewayforward,liftthecutting

•Ifanobstacleisintheway ,shiftthecuttingunitstoeasily

mowaroundit.

•Whentransportingthemachinefromoneworkareato

another,raisethecuttingunitstothefullyupposition,

34

Page 35

movethemow/transportslidetothelefttotransport,

andplacethethrottleintheFastposition.

MowingPatterns

Changemowingpatternsoftentominimizeaftercut

appearanceissuesinducedbyrepetitiveoperationinonlyone

direction.

GeneralTipsforModel30849

DANGER