Toro 30834, groundsmaster 4500-D, groundsmaster 3500-G, groundsmaster 3500-D, groundsmaster 4700-D Operator's Manual

Page 1

27inRotaryCuttingUnit

FormNo.3363-477RevB

Groundsmaster

®

3500-D/3500-G/3505-D/4500-D/4700-D

ModelNo.30834—SerialNo.310000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Introduction

Thisrotary-bladelawncuttingdeckismounted

toaride-onmachineandisintendedtobeused

byprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrass

onwell-maintainedlawnsinparks,sportselds,and

oncommercialgrounds.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongside

highways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndingadealer,

ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Themodel

andserialnumbersarestampedonaplateontherearof

thecuttingunit,underthecover.Writethenumbersin

thespaceprovided.

ModelNo.

Contents

Introduction.................................................................2

Safety...........................................................................3

SafetyandInstructionalDecals.............................3

Setup...........................................................................4

AdjustingtheCarrierFrame(Groundsmaster

3500-Dand3500-Gonly).................................4

AdjustingtheHeight-of-Cut.................................4

AdjustingtheRollerScraper(Optional).................5

InstallingtheMulchingBafe(Optional)...............5

ProductOverview........................................................6

Specications.......................................................6

DimensionsandWeights(approx.)........................6

Attachments/Accessories.....................................6

Operation.....................................................................6

SelectingaBlade...................................................6

OperatingTips.....................................................7

Maintenance.................................................................9

RecommendedMaintenanceSchedule(s)..................9

UsingtheCuttingDeckServiceLatch

(Groundsmaster3500-Dand3500-G

only).................................................................9

GreasingtheBearings...........................................9

SeparatingtheCuttingDecksfromthe

TractionUnit..................................................10

MountingtheCuttingDeckstotheTraction

Unit................................................................10

ServicingtheBladePlane....................................10

RemovingtheCutterBlade.................................11

InspectingandSharpeningtheBlade...................12

CheckingtheBladeStoppingTime......................13

ServicingtheFrontRoller...................................13

Storage.......................................................................14

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure1

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2013—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Safety

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

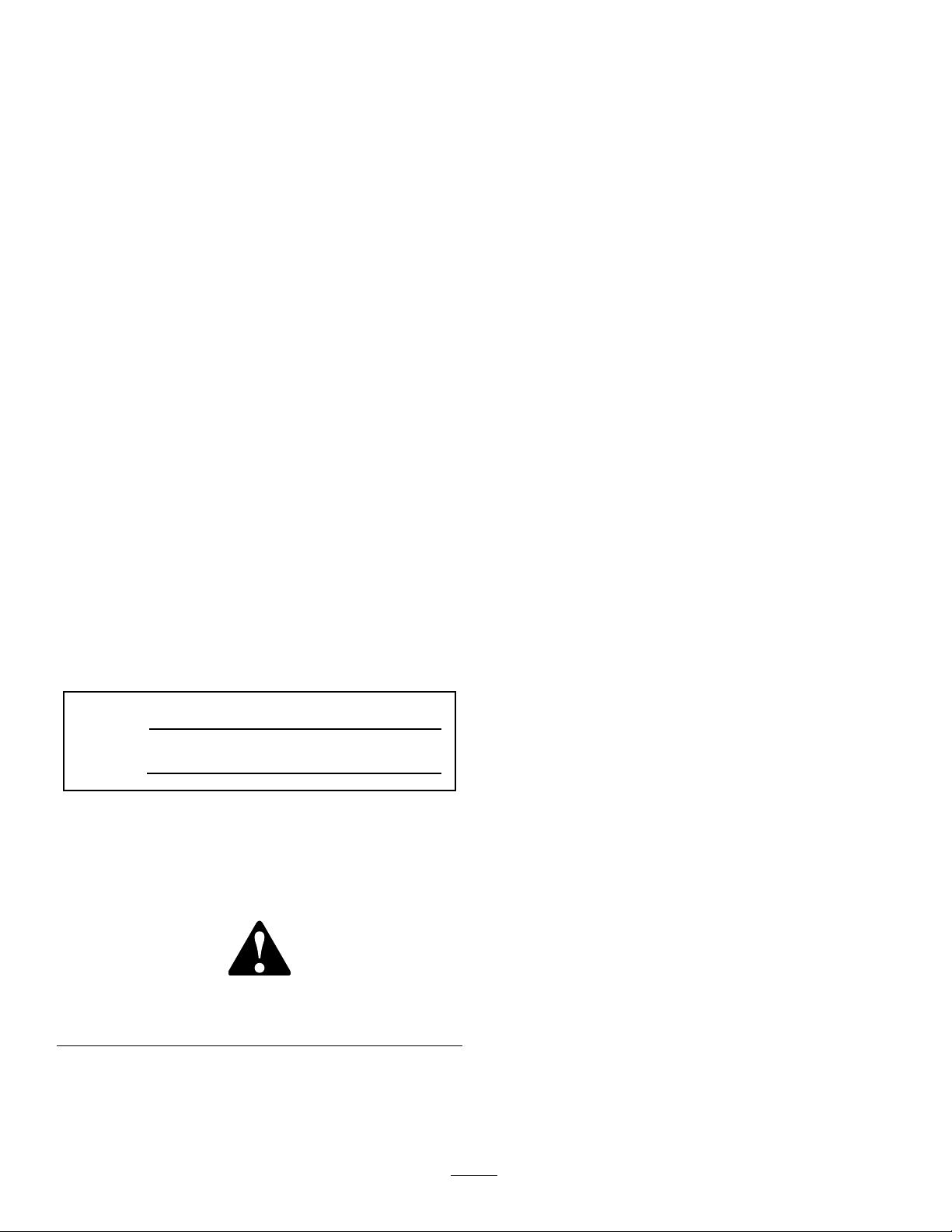

104-1086

1.Heightofcut

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N-m(85-110ft-lb).

116-1716

117-4764

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cuttinghazardofhand,mowerblade—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

3.Cuttinghazardoffoot,mowerblade—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

1.Fuel6.Hourmeter

2.Empty

3.Half

4.Full9.Neutral

5.Battery

7.PTO

8.Parkingbrake

10.Operatorpresenceswitch

3

Page 4

Setup

MediaandAdditionalParts

Description

CEDecal

Operator'sManual

PartsCatalog

AdjustingtheCarrierFrame

(Groundsmaster3500-Dand

3500-Gonly)

AdjustingtheFrontCuttingDecks

Thefrontandrearcuttingdecksrequiredifferent

mountingpositions.Thefrontcuttingdeckhastwo

mountingpositionsdependingonwhatheight-of-cut

anddegreeofdeckrotationyoudesire.

1.Forheightsofcutinthe3/4to3inch(2to7.6cm)

range,mountthefrontcarrierframesinthelower

frontmountingholes(

Note:Thispermitsmoreuptravelofthecutting

decksrelativetotractorwhenapproachingquick

uphillchangesinterrain.Itdoeshoweverlimitthe

clearanceofthechambertothecarrierwhencresting

sharpknolls.

Figure2).

Qty.

1

1

1Usetolookupparts.

ApplytothecuttingdeckforCEcompliance.

Readbeforeoperating.

AdjustingtheRearCuttingDeck

Thefrontandrearcuttingdecksrequiredifferent

mountingpositions.Therearcuttingdeckhasone

mountingpositionforproperalignmentwiththe

sidewinderunderframe.

Forallheightsofcut,mounttherearcuttingdeckinthe

rearmountingholes(Figure2).

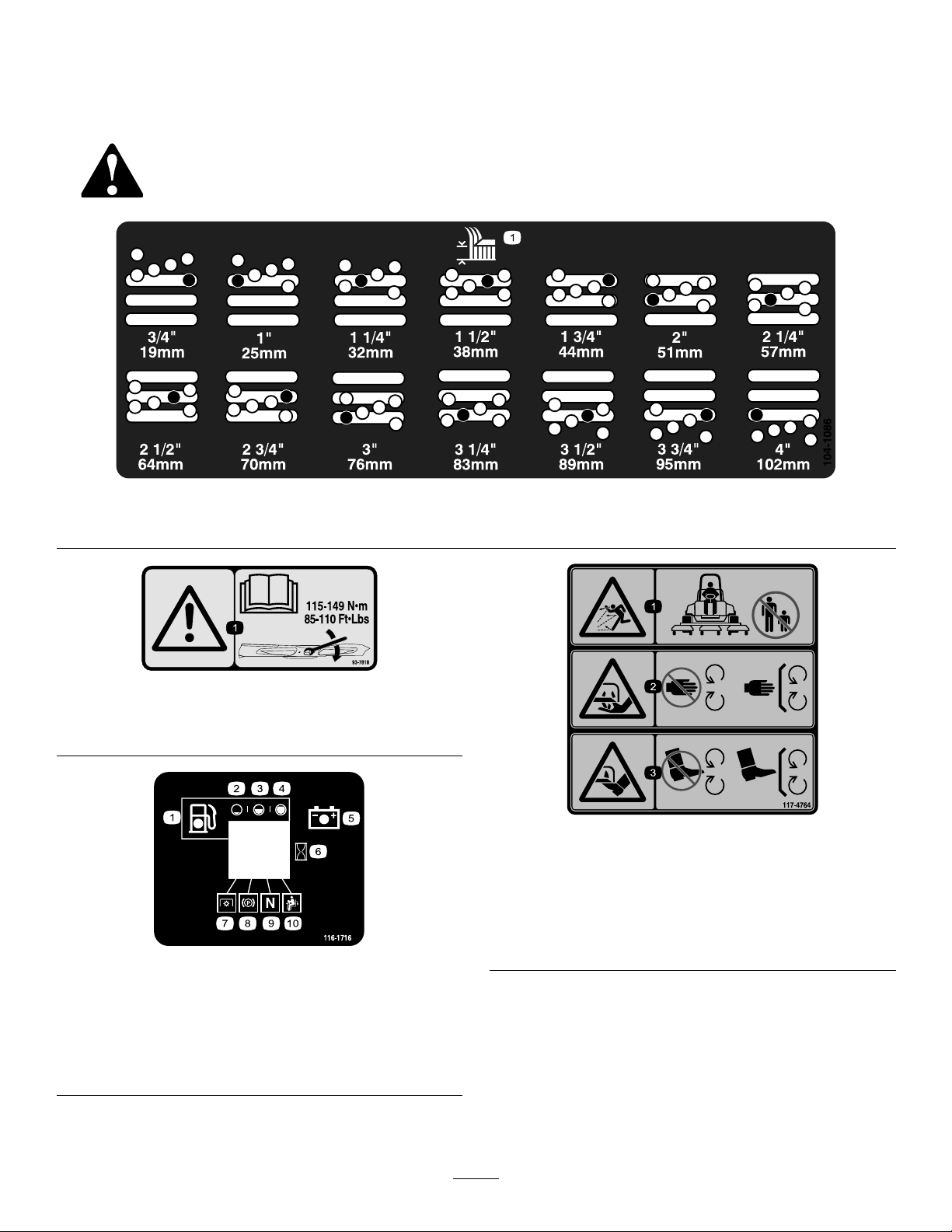

AdjustingtheHeight-of-Cut

Important:Thiscuttingdeckoftencuts

approximately1/4inch(6mm)lowerthanareel

cuttingunitwiththesamebenchsetting.Itmaybe

necessarytohavetheserotarycuttingdeck’sbench

set1/4inch(6mm)abovethatofreelscuttingin

thesamearea.

Use

Note:Thisincreasesthechambertocarrier

clearanceduetothehigherpositionofthecutting

chamber,butwillcausethecuttingdecktoreach

theirmaximumuptravelsooner.

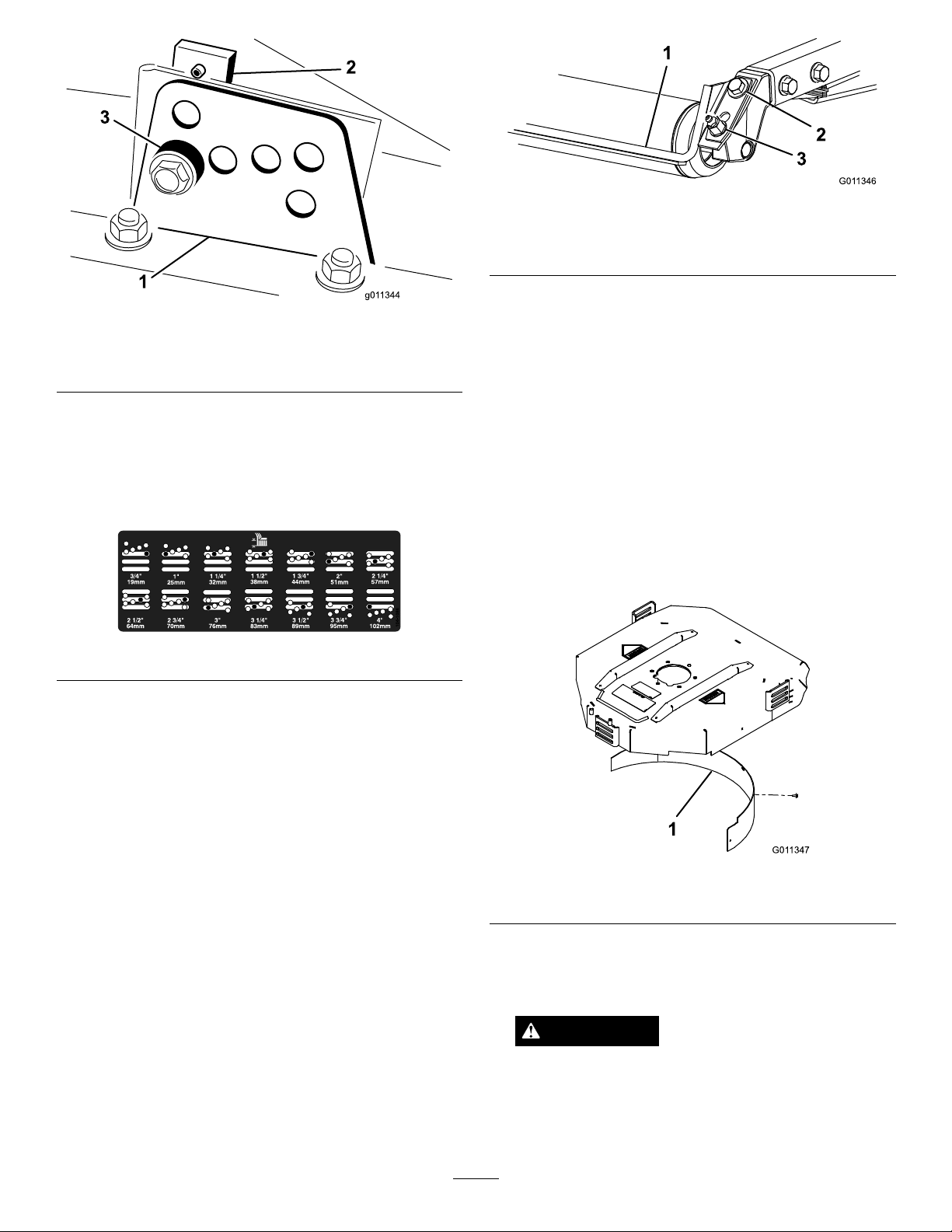

Figure2

1.Frontdeckmountinghole

(upper)

2.Frontdeckmountinghole

(lower)

2.Forheightsofcutinthe2-1/2to4inch(6.3to10

cm)range,mountthefrontcarrierframesinthe

upperfrontmountingholes(Figure2).

3.Reardeckmountinghole

Important:Accesstotherearcuttingunitsis

greatlyimprovedbyremovingthecuttingunit

fromthetractor.Iftheunitisequippedwitha

Sidewinder®,sidewindthecuttingunitstothe

right,removetherearcuttingunit,andslideitout

totherightside.

1.Lowerthecuttingdecktotheground,stopthe

engine,andremovethekeyfromignitionswitch.

2.Loosentheboltsecuringeachheight-of-cutbracket

totheheight-of-cutplate(frontandeachside)

Figure3).

(

3.Beginningwithfrontadjustment,removethebolt.

4

Page 5

G011346

1

2

3

Figure5

G011347

1

Figure3

1.Heightofcutbracket3.Spacer

2.Heightofcutplate

4.Whilesupportingthechamber,removethespacer

Figure3).

(

5.Movethechambertothedesiredheight-of-cutand

installaspacerintothedesignatedheight-of-cuthole

andslot(Figure4).

Figure4

1.Rollerspacer

2.Mountingscrew

3.Greasetting

2.Slidethescraperupordownuntilagapof0.020to

0.040inch(0.5to1mm)isachievedbetweenthe

rodandtheroller.

3.Securethegreasettingandscrewto30ft-lb(41

N-m)inanalternatingsequence.

InstallingtheMulchingBafe

(Optional)

1.Thoroughlycleandebrisfromthemountingholes

ontherearwallandleftsidewallofthechamber.

2.Installthemulchingbafeintherearopeningand

secureitwith5angeheadbolts(Figure6).

6.Positionthetappedplateinlinewiththespacer.

7.Installtheboltngertight.

8.Repeatsteps4–7foreachsideadjustment.

9.Tightenallthreeboltsto30ft-lb(41N-m).Always

tightenthefrontboltrst.

Note:Adjustmentsofmorethan1-1/2inches

(3.8cm)mayrequiretemporaryassemblytoan

intermediateheighttopreventbinding(e.g.changing

from1.25to2.75inch(3.1to7cm)height-of-cut).

AdjustingtheRollerScraper

(Optional)

Theoptionalrearrollerscraperisdesignedtoworkbest

whenthereisanevengapof0.020–0.040inch(0.5to1

mm)betweenthescraperandroller.

1.Loosenthegreasettingandmountingscrew

(

Figure5).

Figure6

1.Mulchingbafe

3.Verifythatmulchingbafedoesnotinterferewith

thetipofthebladeanddoesnotprotrudeinsidethe

surfaceoftherearchamberwall.

WARNING

Donotusethehighliftbladewiththemulching

bafe.Thebladecouldbreak,resultingin

personalinjuryordeath.

5

Page 6

ProductOverview

Operation

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

DimensionsandWeights(approx.)

Length

Width

Height

Weight

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

34inches(86.4cm)

34inches(86.4cm)

9.6inches(24.4cm)tocarriermount

10–1/2inches(26.7cm)at3/4inchheightofcut

13–3/4inches(34.9cm)at4inchheightofcut

195pounds(88kg)

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

SelectingaBlade

StandardCombinationSail

Thisbladewasdesignedtoprovideexcellentliftand

dispersioninalmostanycondition.Ifmoreorlesslift

anddischargevelocityisrequired,consideradifferent

blade.

Attributes:Excellentliftanddispersioninmost

conditions.

AngledSail

Thebladegenerallyperformsbestinlowerheightsof

cut—3/4to2–1/2inch(1.9to6.4cm).

Attributes:

•Dischargeremainsmoreevenatlowerheightsof

cut.

•Dischargehaslesstendencytothrowleftandthusa

cleanerlookaroundbunkersandfairways.

•Lowerpowerrequirementatlowerheightsand

denseturf.

HighLiftParallelSail

Thebladegenerallyperformsbetterinthehigher

heightsofcut—2to4inch(7to10cm).

Attributes:

•Moreliftandhigherdischargevelocity.

•Sparseorlimpturfispickedupsignicantlyat

higherheightsofcut.

•Wetorstickyclippingsaredischargedmore

efcientlyreducingcongestioninthedeck.

•Requiresmorehorsepowertorun.

•Tendstodischargefurtherleftandcantendto

windrowatlowerheightsofcut.

WARNING

Donotusethehighliftbladewiththemulching

bafe.Thebladecouldbreak,resultinginpersonal

injuryordeath.

6

Page 7

AtomicBlade

Thisbladewasdesignedtoprovideexcellentleaf

mulching.

Attributes:Excellentleafmulching

OperatingTips

MowwhentheGrassisDry

Moweitherinthelatemorningtoavoidthedew,which

causesgrassclumping,orinlateafternoontoavoidthe

damagethatcanbecausedbydirectsunlightonthe

sensitive,freshlymowedgrass.

SelecttheProperHeight-of-CutSetting

toSuitConditions

Removeapproximatelyoneinchornomorethan1/3of

thegrassbladewhencutting.Inexceptionallylushand

densegrassyoumayhavetoraiseyourheight–of–cut

settinganothernotch.

AlwaysStartMowingwithSharp

Blades

Asharpbladecutscleanlyandwithouttearingor

shreddingthegrassbladeslikeadullblade.Tearing

andshreddingcausesthegrasstoturnbrownatthe

edgeswhichimpairsgrowthandincreasessusceptibility

todiseases.Makesurebladeisingoodconditionand

afullsailispresent.

CheckConditionofDeck

Makesurethatthecuttingchambersareingood

condition.Straightenanybendsinthechamber

componentstoensurethecorrectbladetip/chamber

clearance.

AfterOperating

Toensureoptimumperformance,cleantheunderside

ofmowerhousing.Ifyouallowresiduetobuildupin

mowerhousing,cuttingperformancewilldecrease.

7

Page 8

ChoosingAccessories

AngleSailBladeHighLiftParallel

GrassCutting:0.75to

1.75inch(1.9to4.4cm)

Height-of-Cut

GrassCutting:2.00to

2.50inch(5to6.4cm)

Height-of-Cut

GrassCutting:2.75to

4.00inch(7to10cm)

Height-of-Cut

LeafMulchingRecommendedforuse

ProsEvendischargeat

ConsDoesnotliftthegrass

Recommendedinmost

applications

Recommendedforthick

orlushturf

Mayworkwellinlushturf

withthemulchingbafe

lowerheightofcut

Cleanerlookaround

bunkersandfairways

Lowerpower

requirements

wellinhighheight

ofcutapplications

Wetorstickygrass

hasatendencytobuild

upinthechamber,

leadingtopoorquality

ofcutandhigherpower

requirement

OptionalEquipmentConguration

SailBlade

Donotusewiththe

mulchingbafe

Mayworkwellinlightor

sparseturf

Recommendedforlight

orsparseturf

Recommendedinmost

applications

NotAllowedUsewithcombinationsail

Moreliftandhigher

dischargevelocity

Sparseorlimpturf

ispickedupat

highheightofcut

Wetorstickyclippings

aredischargedefciently

Requiresmorepowerto

runinsomeapplications

Tendstowindrowatlower

heightofcutinlushgrass

Donotusewiththe

mulchingbafe

MulchingBafeRollerScraper

Hasbeenshownto

improvedispersionand

aftercutperformance

onnortherngrassesthat

arecutatleastthree

timesperweekandless

than1/3ofthegrass

bladeisremoved.

Donotusewiththe

highliftparallelsail

blade

oranglesailbladeonly

Mayimprovedispersion

andappearancein

certaingrasscutting

applicationsVerygood

forleafmulching

Grasswillbuildupinthe

chamberifattemptingto

removetoomuchgrass

withbafeinplace

Canbeusedanytime

thatrollersbuildup

withgrassorlargeat

grassclumpsofgrass

areseen.Thescrapers

mayactuallyincrease

clumpingincertain

applications.

Reducesrollerbuildupin

certainapplications

8

Page 9

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Beforeeachuseordaily

Every50hours

MaintenanceProcedure

•Checkthebladestoppingtime.

•Greasethebearings

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

UsingtheCuttingDeckService

Latch(Groundsmaster3500-D

8.Turnoffthemachineandremovethekey.

9.Reversethisproceduretounlatchthecuttingdecks.

and3500-Gonly)

GreasingtheBearings

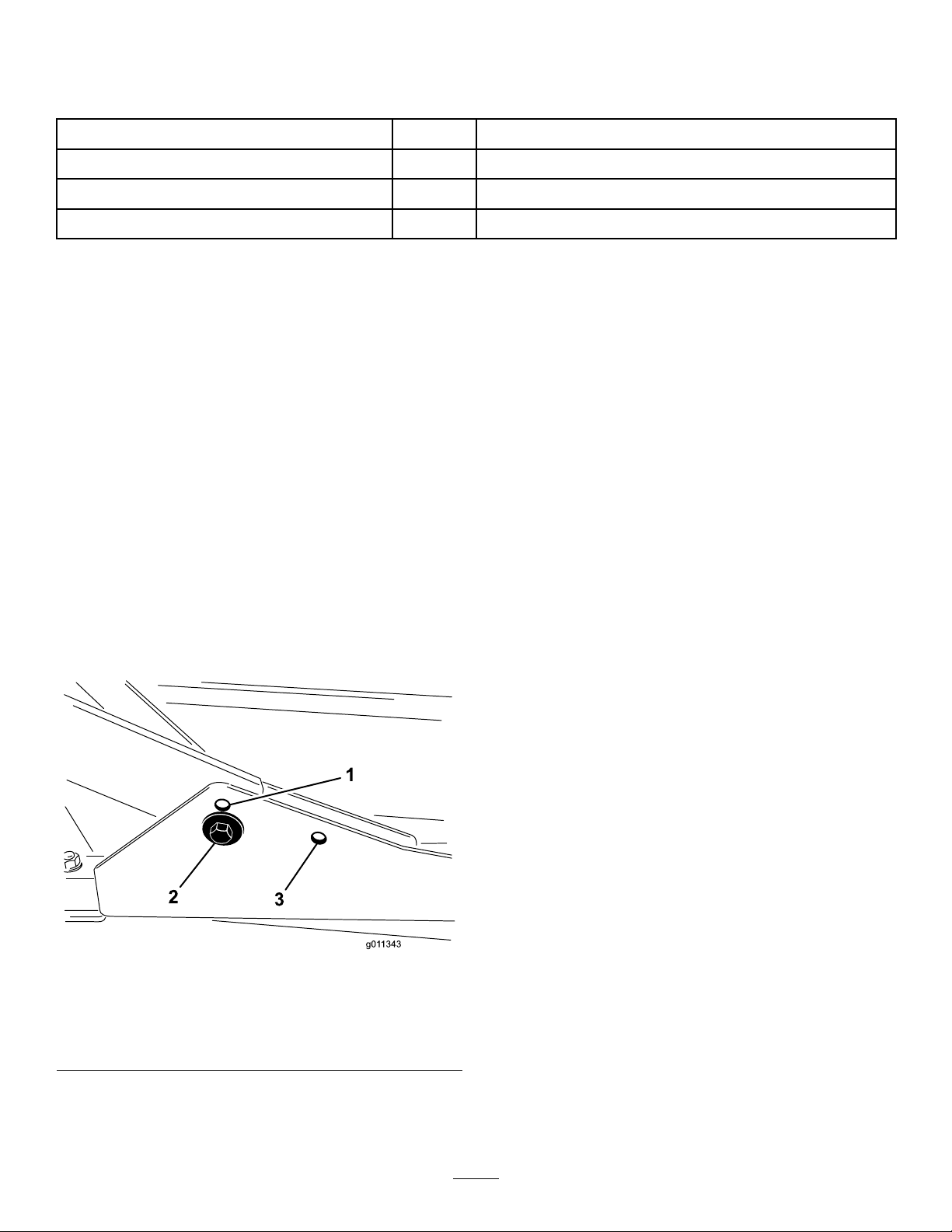

Whenservicingthecuttingdecks,usetheservicelatch

topreventinjury.

1.Centerthecuttingdecksidewinderwiththetraction

unit.

2.Raisethecuttingdeckstothetransportposition.

3.Settheparkingbrakeandturnoffthemachine.

4.Releasethelatchrod(Figure7)fromfrontcarrier

frameretainer.

ServiceInterval:Every50hours

Eachcuttingdeckhastwogreasettingsperspindle.

Eitherttingcanbeused,whicheverismoreaccessible.

Ifthemachineisoperatedundernormalconditions,

lubricatebladespindlebearings(

generalpurposelithiumbasegreaseormolybdenum

basegrease,afterevery50hoursofoperation.Pump

greaseintothettinguntilasmallamountappearsat

bottomofthespindlehousing(underthedeck).

Figure8)withNo.2

Figure7

1.Servicelatchhook

5.Lifttheoutsideofthefrontcuttingdecksandplace

thelatchovertheframepinmountedonthefrontof

theoperator'splatform(Figure7).

6.Sitontheoperatorseatandstartthetractionunit.

7.Lowerthecuttingdeckstothemowposition.

Figure8

Eachcuttingdeckhastwogreasettingsperrearroller.

Ifthemachineisoperatedundernormalconditions,

lubricaterearrollerbearings(

generalpurposelithiumbasegreaseormolybdenum

basegrease,afterevery50hoursofoperation.

9

Figure9)withNo.2

Page 10

G011349

Figure9

Important:Makesurethegreasegrooveineach

rollermountalignswiththegreaseholeineach

endoftherollershaft.T ohelpalignthegrooveand

hole,thereisalsoanalignmentmarkononeend

oftherollershaft.

1.Lynchpin

Figure11

2.Liftarmpivotpin

SeparatingtheCuttingDecks

fromtheTractionUnit

1.Positionthemachineonalevelsurface,lowerthe

cuttingdeckstotheoor,shuttheengineoff,and

engagetheparkingbrake.

2.Disconnectandremovethehydraulicmotorfrom

thedeck(

preventcontamination.

1.Motormountingscrews

3.Removethelynchpinorretainingnut(GM4700

only)securingthedeckcarrierframetotheliftarm

pivotpin(Figure11).

Figure10).Coverthetopofthespindleto

Figure10

4.Rollthecuttingdeckawayfromthetractionunit.

MountingtheCuttingDecksto

theTractionUnit

1.Positionmachineonalevelsurfaceandshutengine

off.

2.Movecuttingdeckintopositioninfrontoftraction

unit.

3.Slidedeckcarrierframeontoliftarmpivotpin.

Securewithlynchpinorretainingnut(GM4700

only)(

4.Installthehydraulicmotortothedeck(

MakesurethattheO-ringisinpositionandnot

damaged.

5.Greasethespindle.

Figure11).

Figure10).

ServicingtheBladePlane

Therotarydeckcomesfromthefactorypresetat2.00

inch(5cm)height-of-cutandbladerakeof0.310inch

(7.9mm).Theleft-handandright-handheightsarealso

presettowithin±0.030inch(0.7mm)oftheother.

Thecuttingdeckisdesignedtowithstandbladeimpacts

withoutdeformationofthechamber.Ifasolidobject

isstruck,inspectthebladefordamageandtheblade

planeforaccuracy.

InspectingtheBladePlane

1.Removethehydraulicmotorfromthecuttingdeck

andremovethecuttingdeckfromthetractor.

2.Useahoist(orminimumoftwopeople)andplace

thecuttingdeckonaattable.

3.Markoneendofthebladewithapaintpenor

marker.Usethisendofthebladetocheckallheights.

10

Page 11

4.Positionthecuttingedgeofthemarkedendofthe

G011353

6:00

12:00

9:00

3:00

bladeat12o’clock(straightaheadinthedirectionof

mowing)(Figure12)andmeasureheightfromtable

tocuttingedgeofblade.

Figure12

5.Rotatethemarkedendofthebladetothe3and

9o’clockpositions(Figure12)andmeasurethe

heights.

6.Comparethe12o’clockmeasuredheighttothe

height-of-cutsetting.Itshouldbewithin0.030inch

(0.7mm).The3and9o’clockheightsshouldbe

0.150±.090inch(3.8±2.2mm)higherthanthe12

o’clocksettingandwithin0.090inch(2.2mm)of

eachother.

Ifanyofthesemeasurementsarenotwithinspecication,

proceedtoAdjustingtheBladePlane.

AdjustingtheBladePlane

Startwiththefrontadjustment(changeonebracketata

time).

1.Removetheheight-of-cutbracket,(front,left,or

right)fromthedeckframe(Figure13).

Figure13

1.Heightofcutbracket2.Shims

3.Installtheheight-of-cutbrackettothedeckframe

withtheremainingshimsassembledbelowthe

height-of-cutbracket.

4.Securethesocketheadbolt/spacerandangenut.

Note:Socketheadbolt/spacerareheldtogether

withLoctitetopreventthespacerfromfallinginside

thedeckframe.

5.Verifythe12o’clockheightandadjustifneeded.

6.Determineifonlyoneorboth(right-handand

left-hand)height-of-cutbracketsneedtobeadjusted.

Ifthe3or9o’clocksideis0.150±0.090inch

(3.8±2.2mm)higherthanthenewfrontheightthen

noadjustmentisneededforthatside.Adjustthe

othersidetowithin±0.090inch(2.2mm)ofthe

correctside.

7.Adjusttherightand/orleftheight-of-cutbracketsby

repeatingsteps1through3.

8.Securethecarriageboltsandangenuts.

9.Again,verifythe12,3,and9o’clockheights.

2.Adjust0.060inch(1.5mm)shimsand/or0.030inch

(0.7mm)shimbetweenthedeckframeandbracket

toachievethedesiredheightsetting(Figure13).

RemovingtheCutterBlade

Theblademustbereplacedifasolidobjectishit,the

bladeisoutofbalance,orifthebladeisbent.Always

usegenuineTororeplacementbladestobesureofsafety

andoptimumperformance.Neverusereplacement

bladesmadebyothermanufacturersbecausetheycould

bedangerous.

1.Raisethecuttingdecktothehighestposition,

shuttheengineoff,andengagetheparkingbrake.

Blockthecuttingdecktopreventitfromfalling

accidentally.

2.Grasptheendofthebladeusingaragorthickly

paddedglove.Removethebladebolt,anti-scalpcup,

andbladefromthespindleshaft(Figure14).

11

Page 12

G011355

1

2

Figure14

1.Bladebolt2.Anti-scalpcup

3.Installtheblade,sailfacingtowardthecuttingdeck,

withtheanti-scalpcupandbladebolt(Figure14).

Tightenbladeboltto85–110ft-lb(115–149N-m).

DANGER

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator’s

orbystander’sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Neverweldabrokenorcrackedblade.

•Alwaysreplaceawornordamagedblade.

InspectingandSharpeningthe

Blade

DANGER

Ifthebladeisallowedtowear,aslotwillform

betweenthesailandatpartoftheblade

Figure15).Eventuallyapieceoftheblademay

(

breakoffandbethrownfromunderthehousing,

possiblyresultinginseriousinjurytoyourself

orbystanders.

•Inspectthebladeperiodicallyforwearor

damage.

•Alwaysreplaceawornordamagedblade.

Figure15

1.Cuttingedge3.Wear/slot/crack

2.Sail

3.Inspectthecuttingedgesofallblades.Sharpenthe

cuttingedgesiftheyaredullornicked.Sharpenonly

thetopofthecuttingedgeandmaintaintheoriginal

cuttingangletomakesureofsharpness(

Thebladewillremainbalancedifthesameamount

ofmetalisremovedfrombothcuttingedges.

Figure16).

1.Raisethecuttingdecktothehighestposition,

shuttheengineoff,andengagetheparkingbrake.

Blockthecuttingdecktopreventitfromfalling

accidentally.OntheGroundsmaster3500-Dand

3500-G,securethecuttingdeckservicelatch.

2.Examinethecuttingendsofthebladecarefully,

especiallywheretheatandcurvedpartsofthe

blademeet(

Figure15).Sincesandandabrasive

materialcanwearawaythemetalthatconnects

theatandcurvedpartsoftheblade,checkthe

bladebeforeusingthemachine.Ifwearisnoticed

(

Figure15),replacetheblade;refertoRemovingthe

CutterBlade.

Figure16

1.Sharpenatthisangleonly

4.Tocheckthebladeforbeingstraightandparallel,

laythebladeonalevelsurfaceandcheckitsends.

Theendsoftheblademustbeslightlylowerthan

thecenter,andthecuttingedgemustbelowerthan

theheeloftheblade.Thisbladewillproducegood

qualityofcutandrequireminimalpowerfromthe

engine.Bycontrastabladethatishigherattheends

thanthecenter,orifcuttingedgeishigherthan

12

Page 13

theheel,thebladeisbentorwarpedandmustbe

G011356

1

2

3

4

replaced.

5.Installtheblade,sailfacingtowardcuttingdeck,with

theanti-scalpcupandbladebolt.Tightentheblade

boltto85–110ft-lb(115–149N-m).

CheckingtheBladeStopping

Time

ServiceInterval:Beforeeachuseordaily

Thebladesofthecuttingdeckshouldcometoa

completestopinapproximately5secondsafteryoushut

downthecuttingdeckengagementswitch.

Note:Makesurethedecksareloweredontoaclean

sectionofturforhardsurfacetoavoidthrowndustand

debris.

Toverifythisstoppingtime,haveasecondpersonstand

backfromthedeckatleast20feet(6m)andwatchthe

bladesononeofthecuttingdecks.Havetheoperator

shutthecuttingdecksdownandrecordthetimeit

takesforthebladestocometoacompletestop.Ifthis

timeisgreaterthan7seconds,thebrakingvalveneeds

adjustment.CallyourToroDistributorforassistance

inmakingthisadjustment.

ServicingtheFrontRoller

Inspectthefrontrollerforwear,excesswobble,or

binding.Serviceorreplacetherollerorcomponentsif

anyoftheseconditionsexist.

Figure17

1.Frontroller3.Bearing

2.mountingbolt4.Bearingspacer

3.Pushthesecondbearingoutinpress.

4.Inspecttherollerhousing,bearings,andbearing

spacerfordamage(Figure17).Replacedamaged

componentsandassemble.

AssemblingtheFrontRoller

1.Presstherstbearingintotherollerhousing

(Figure17).Pressontheouterraceonlyorequally

ontheinnerandouterrace.

2.Insertthespacer(

3.Pressthesecondbearingintotherollerhousing

(Figure17)pressingequallyontheinnerandouter

raceuntiltheinnerracecomesincontactwiththe

spacer.

4.Installtherollerassemblyintothedeckframe.

Figure17).

DisassemblingtheFrontRoller

1.Removetherollermountingbolt(Figure17).

2.Insertapunchthroughtheendoftherollerhousing

anddrivetheoppositebearingoutbyalternating

tapstotheoppositesideofinnerbearingrace.There

shouldbea0.060inch(1.5mm)lipofinnerrace

exposed.

13

Important:Securingtherollerassemblywith

agaplargerthan0.060inch(1.5mm)creates

asideloadonthebearingandcanleadto

prematurebearingfailure.

5.Verifythatthereisnomorethana0.060inch

gapbetweenrollerassemblyandtherollermount

bracketsofthedeckframe.Ifthereisagapover

0.060inch,installenough5/8inchdiameterwashers

totakeuptheslop.

6.Securethemountingboltto80ft-lb(108N-m).

Page 14

Storage

Ifthecuttingdeckisseparatedfromthetractionunitfor

anylengthoftime,installaspindlepluginthetopofthe

spindletoprotectthespindlefromdustandwater.

14

Page 15

Notes:

15

Page 16

TheT oroTotalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheToro

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

®

Companyanditsafliate,ToroWarrantyCompany,pursuant

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

CommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenance

andadjustmentsstatedinyourOperator’sManual.Failuretoperform

requiredmaintenanceandadjustmentscanbegroundsfordisallowinga

warrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligentorrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalProductoperationinclude,butarenotlimitedto,brakes

padsandlinings,clutchlinings,blades,reels,bedknives,tines,

sparkplugs,castorwheels,tires,lters,belts,andcertainsprayer

componentssuchasdiaphragms,nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,

fertilizers,water,orchemicals,etc.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damageto

seatsduetowearorabrasion,wornpaintedsurfaces,scratched

decalsorwindows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofToro.Torowill

makethenaldecisionwhethertorepairanyexistingpartorassemblyor

replaceit.T oromayuseremanufacturedpartsforwarrantyrepairs.

NoteRegardingDeepCycleBatteryWarranty:

Deepcyclebatterieshaveaspeciedtotalnumberofkilowatt-hoursthey

candeliverduringtheirlifetime.Operating,recharging,andmaintenance

techniquescanextendorreducetotalbatterylife.Asthebatteriesinthis

productareconsumed,theamountofusefulworkbetweencharging

intervalswillslowlydecreaseuntilthebatteryiscompletelywornout.

Replacementofwornoutbatteries,duetonormalconsumption,isthe

responsibilityoftheproductowner.Batteryreplacementmayberequired

duringthenormalproductwarrantyperiodatowner’sexpense.

MaintenanceisatOwner’sExpense

Enginetune-up,lubricationcleaningandpolishing,replacementof

ItemsandConditionsNotCoveredlters,coolant,andcompleting

RecommendedMaintenancearesomeofthenormalservicesT oro

productsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedT oroDistributororDealerisyoursoleremedy

underthiswarranty .

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheT oroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty .ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .

Allimpliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.Somestatesdonotallowexclusions

ofincidentalorconsequentialdamages,orlimitationsonhowlongan

impliedwarrantylasts,sotheaboveexclusionsandlimitationsmaynot

applytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAir

ResourcesBoard(CARB).Thehourlimitationssetforthabovedonot

applytotheEmissionsControlSystemWarranty.RefertotheEngine

EmissionControlWarrantyStatementprintedinyourOperator’sManual

orcontainedintheenginemanufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany .

374-0253RevA

Loading...

Loading...