Page 1

FormNo.3396-206RevA

Groundsmaster

®

3500-GRotary

Mower

ModelNo.30809—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3396-206*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

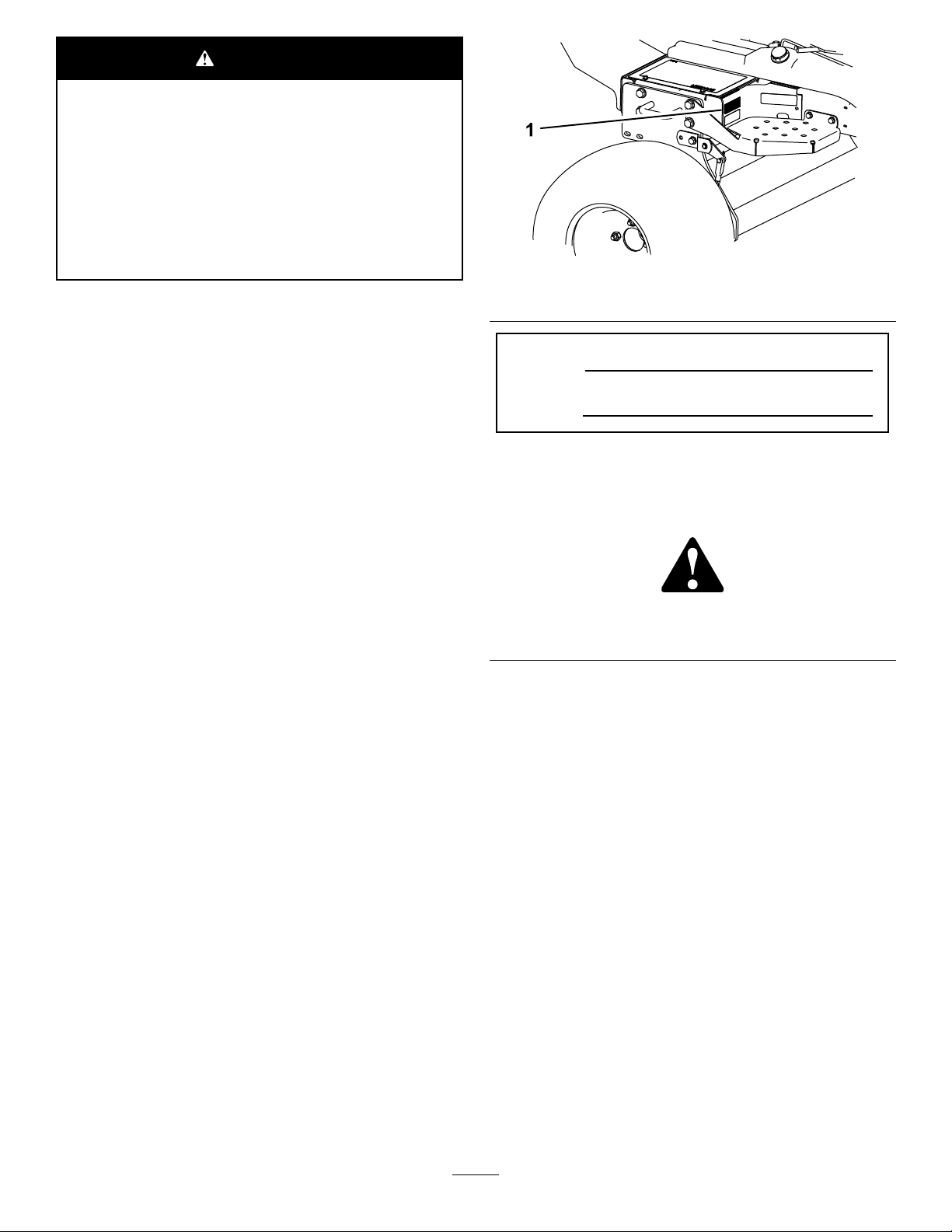

Figure1

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Introduction

Thismachineisaride-on,rotary-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrasson

well-maintainedlawnsinparks,golfcourses,sportselds,

andoncommercialgrounds.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongsidehighways,

orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

SoundPowerLevel..................................................6

SoundPressureLevel...............................................6

VibrationLevel......................................................6

SafetyandInstructionalDecals.................................7

Setup...........................................................................11

1Activating,Charging,andConnectingthe

Battery..............................................................12

2CheckingtheAngleIndicator.................................13

3AdjustingtheLiftArms........................................13

4AdjustingtheCarrierFrame..................................14

5AdjustingtheHeightofCut...................................15

6CheckingtheMachinebeforeOperation..................16

7AdjustingtheOptionalRollerScraper

........................................................................16

8InstallingtheOptionalMulchingBafe

........................................................................16

ProductOverview.........................................................17

Controls...............................................................17

Specications........................................................19

Attachments/Accessories........................................19

Operation....................................................................19

ThinkSafetyFirst...................................................19

CheckingtheEngine-OilLevel.................................19

FillingtheFuelTank...............................................20

CheckingtheCoolingSystem...................................22

CheckingtheHydraulicSystem................................22

CheckingtheTirePressure......................................23

RearWheelBallast..................................................23

StartingandStoppingtheEngine..............................24

CheckingtheInterlockSystem.................................24

TowingtheTractionUnit.........................................24

StandardControlModule(SCM)..............................25

ChoosingAccessories.............................................27

SelectingaBlade.....................................................27

OperatingTips......................................................28

Maintenance.................................................................30

RecommendedMaintenanceSchedule(s)......................30

DailyMaintenanceChecklist....................................31

ServiceIntervalChart.............................................32

PremaintenanceProcedures........................................32

RemovingtheHood...............................................32

UsingtheCutting-UnitServiceLatch........................33

Lubrication...............................................................33

GreasingtheBearingsAndBushings.........................33

EngineMaintenance..................................................36

ServicingtheAirCleaner.........................................36

ChangingtheEngineOilandFilter...........................37

ReplacingtheSparkPlugs........................................37

FuelSystemMaintenance...........................................38

ReplacingtheFuel-PumpFilter................................38

ServicingtheFuelTank...........................................39

InspectingtheFuelLinesandConnections.................39

ElectricalSystemMaintenance....................................39

CaringfortheBattery..............................................39

Fuses....................................................................40

DriveSystemMaintenance.........................................40

TorquingtheWheelNuts........................................40

AdjustingtheTractionDriveforNeutral....................40

CoolingSystemMaintenance......................................41

CleaningtheEngineCoolingSystem.........................41

BrakeMaintenance....................................................42

AdjustingtheParkingBrake.....................................42

BeltMaintenance......................................................42

ServicingtheEngineBelts.......................................42

HydraulicSystemMaintenance....................................43

ChangingtheHydraulicFilter...................................43

ChangingtheHydraulicFluid...................................44

CheckingtheHydraulicLinesandHoses....................44

MaintainingtheCuttingUnit.......................................45

SeparatingtheCuttingUnitfromtheTraction

Unit..................................................................45

MountingtheCuttingUnitstotheTraction

Unit..................................................................45

ServicingtheBladePlane.........................................45

ServicingtheCutterBlade.......................................46

ServicingtheFrontRoller........................................47

Storage........................................................................49

StoringtheBattery..................................................49

PreparationforSeasonalStorage..............................49

3

Page 4

Safety

ThismachinemeetsorexceedsANSIB71.4-2012

specicationswhenequippedwithrequiredweightas

listedinRearBallastsection.

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromANSIstandard

B71.4-2012.

Training

•ReadtheOperator'sManualandothertrainingmaterial.

Iftheoperator(s)ormechanic(s)cannotreadEnglishitis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleordamageto

property.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toysandwirewhichcan

bethrownbythemachine.

•Checkthatoperator'spresencecontrols,safetyswitches

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

Operation

•Thisproductiscapableofamputatinghandsandfeet,and

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

•Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustotheuserandbystanders.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxideandotherexhaustgasses

cancollect.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Onlystartenginefrom

theoperator'sposition.

•Alwayswearsubstantial,slip-resistantfootwear,long

trousers,hardhat,safetyglasses,andhearingprotection

whilemowing.Longhair,looseclothing,orjewelrymay

gettangledinmovingparts.Donotoperatethemachine

whenbarefootorwearingopensandals.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

themachine'sstability.Usecautionwhileoperatingnear

drop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neverraisedeckwiththebladesrunning.

•NeveroperatewiththePTOshield,orotherguardsnot

securelyinplace.Besureallinterlocksareattached,

adjustedproperly ,andfunctioningproperly.

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Beforeleavingtheoperator'spositionforanyreason

includingemptyingthecatchersoruncloggingthechute,

stoponlevelground,disengagedrives,engageparking

brake(ifprovided),shutoffengineandremovethekey

fromtheignition.

•Stopequipmentandinspectbladesafterstrikingobjects

orifanabnormalvibrationoccurs.Makenecessary

repairsbeforeresumingoperations.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Keeppetsandbystandersaway .

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesifnotmowing.

•Beawareofthemowerdischargedirectionanddonot

pointitatanyone.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Knowhowtostopthemachineandenginequickly.

•Keephands,feet,andclothingawayfrommovingparts

andthecuttingunit.

4

Page 5

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Whenstartingtheengine,engagetheparkingbrake,put

thetractionpedalinneutral,anddisengagetheblade

drive.Aftertheenginestarts,releasetheparkingbrake

andkeepyourfootoffofthetractionpedal.Themachine

mustnotmove.Ifmovementisevident,refertothe

Maintenancesectionofthismanualtoadjustthetraction

drive.

•Useextremecautionwhenoperatingclosetosandtraps,

ditches,creeks,steephillsides,orotherhazards.

•Reducespeedwhenmakingsharpturns.

•Donotturnonhills.

•Donotoperateonasidehillthatistoosteep.Arollover

mayoccurbeforelosingtraction.

•Theslopeangleatwhichthemachinewilltipisdependent

onmanyfactors.Amongthesearemowingconditions

suchaswetorundulatingterrain,speed(especiallyin

turns),positionofthecutting-units(withtheSidewinder),

tirepressure,andoperatorexperience.Atsidehillangles

of20degreesorless,theriskofarolloverislow .As

theslopeangleincreasestoarecommendedmaximum

limitof25degrees,theriskofarolloverincreasestoa

moderatelevel.Donotexceeda25degreesidehill

slopeanglebecausetheriskofarolloverandserious

injuryordeathisveryhigh.

•Forsteeringcontrol,lowerthecutting-unitswhengoing

downslopes.

•Avoidsuddenstopsandstarts.

•Usethereversepedalforbraking.

•Watchfortrafcwhennearorcrossingroads.Always

yieldtheright-of-way.

•Raisethecutting-unitswhendrivingfromoneworkarea

toanother.

•Donottouchtheengine,mufer,exhaustpipe,or

hydraulictankwhiletheengineisrunningorsoonafterit

hasstopped.Theseareascouldbehotenoughtocause

burns.

•Thismachineisnotdesignedorequippedforon-roaduse

andisaslow-movingvehicle.Ifyoumustcrossortravel

onapublicroad,youshouldbeawareofandcomplywith

localregulations,suchasrequiredlights,slowmoving

vehiclesigns,andreectors.

RolloverProtectionSystem(ROPS)UseandMaintenance

•TheROPSisanintegralandeffectivesafetydevice.

•DonotremovetheROPS.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•AnyalterationstoaROPSmustbeapprovedbythe

manufacturer.

•KeeptheROPSinsafeoperatingcondition.Thoroughly

inspectfordamageperiodicallyandalwayskeepall

mountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorrevise.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelock-opendevice.

•Fillthefueltankuntillevelis6to13mm(1/4to1/2

inch)belowthebottomofthellerneck.Donotoverll.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

MaintenanceandStorage

•Disengagedrives,setparkingbrake,stopengineand

removekeyordisconnectsparkplugwire.W aitforall

movementtostopbeforeadjusting,cleaning,orrepairing.

•Cleangrassanddebrisfromcuttingunit,drives,mufers,

andenginetohelppreventres.Cleanupoilorfuel

spillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransporting.Donotstore

fuelnearamesordrainindoors.

•Parkmachineonlevelground.Setparkingbrake.

•Neverallowuntrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhenrequired.

5

Page 6

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Disconnectthebatteryorremovesparkplugwirebefore

makinganyrepairs.Disconnectthenegativeterminalrst

andthepositivelast.Reconnectthepositiverstand

negativelast.

•Usecarewhencheckingblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.Only

replaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replacewornordamageddecals.

•Keepyourbodyandhandsawayfrompin-holeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Ifuidisinjectedintotheskin,itmustbesurgically

removedwithinafewhours,byadoctorfamiliarwiththis

formofinjuryorgangrenemayresult.

•Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.Usepaperorcardboard,notyourhands,tosearch

forleaks.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinthesystemmust

berelievedbystoppingtheengineandloweringthe

cutting-unitstotheground.

•Makesurethatallhydraulic-lineconnectorsaretightand

allhydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecutting-units,attachments,and

anymovingparts.Keepeveryoneaway.

•Donotoverspeedtheenginebychanginggovernor

settings.Toensuresafetyandaccuracy,havean

AuthorizedToroDistributorcheckthemaximumengine

speedwithatachometer.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof106dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof93

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=0.5m/s

Measuredvibrationlevelforlefthand=0.7m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

WholeBody

Measuredvibrationlevel=0.44m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

2

2

2

2

2

•Theenginemustbeshutoffbeforecheckingtheoilor

addingoiltothecrankcase.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

6

Page 7

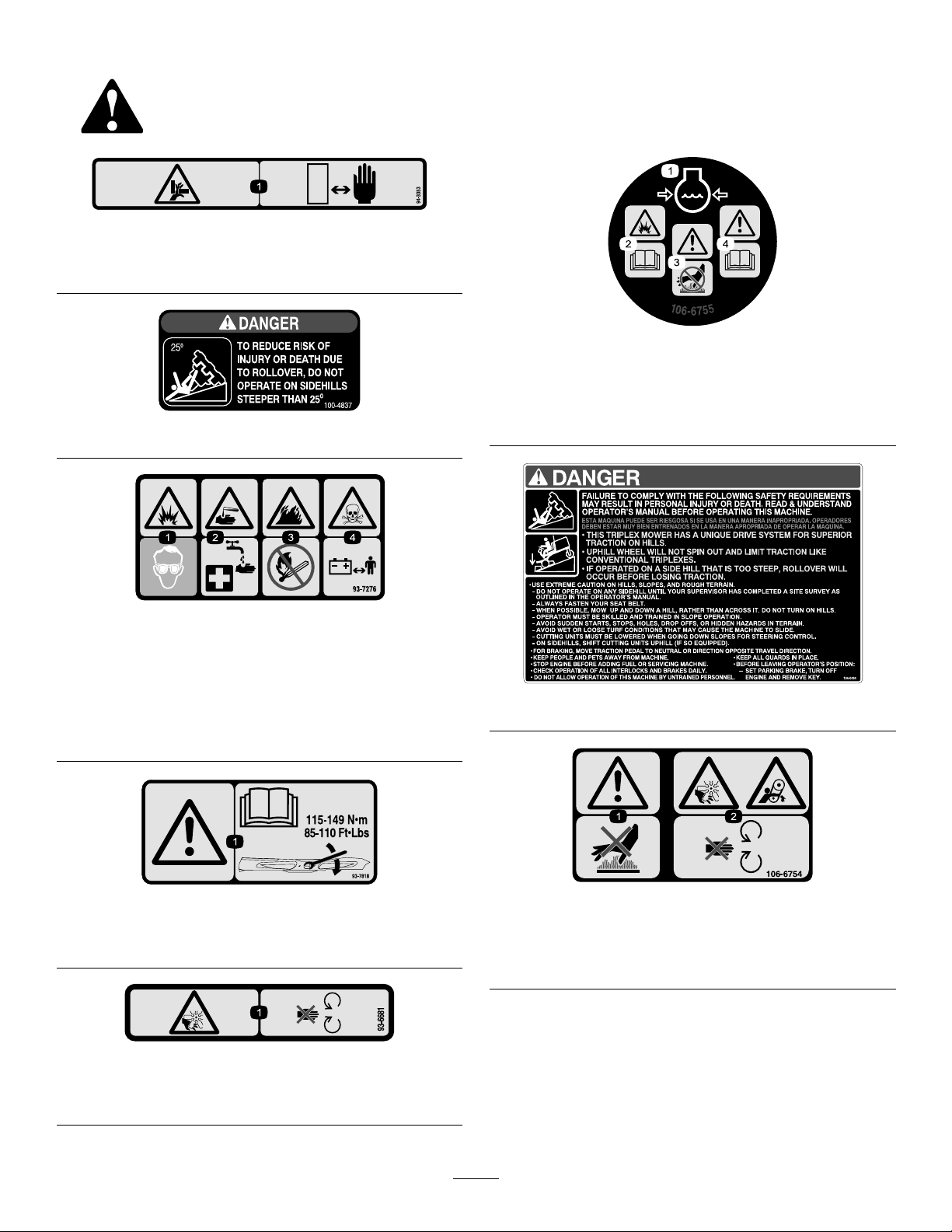

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

94-3353

1.Crushinghazardofhand—keepyourhandsasafedistance

away.

106-6755

100-4837

93-7276

1.Explosionhazard—weareyeprotection.

2.Causticliquid/chemicalburnhazard—toperformrstaid,

ushwithwater.

3.Firehazard—nore,openames,orsmoking.

4.Poisonhazard—keepchildrenasafedistancefromthe

battery.

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

104-0484

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto85-110ft-lb(115-149N-m).

93-6681

1.Cutting/dismemberment—hazard,fan-stayawayfrom

movingparts.

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

7

Page 8

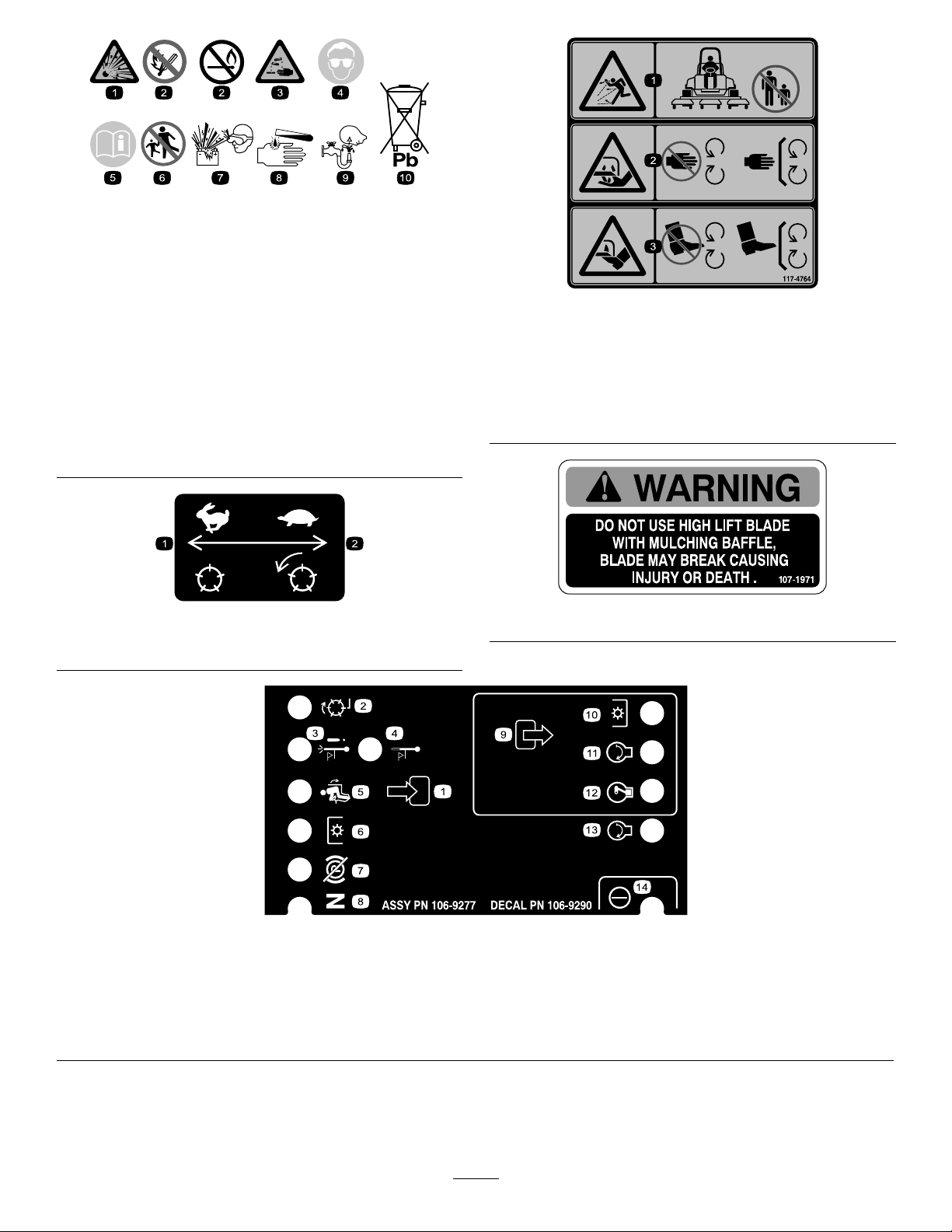

BatterySymbols

99-3444

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

99-3444

1.Transportspeed—fast

2.Mowingspeed—slow

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

117-4764

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cuttinghazardofhand,mowerblade—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

3.Cuttinghazardoffoot,mowerblade—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

107–1971

1.Inputs5.Inseat

2.Notactive

3.High-temperature

shutdown

4.High-temperaturewarning8.Neutral

6.PowerTake-off(PTO)10.PowerTake-off(PTO)

7.ParkingbrakeOff11.Start

106-9290

9.Outputs13.Start

14.Power

12.EnergizetoRun(ETR)

8

Page 9

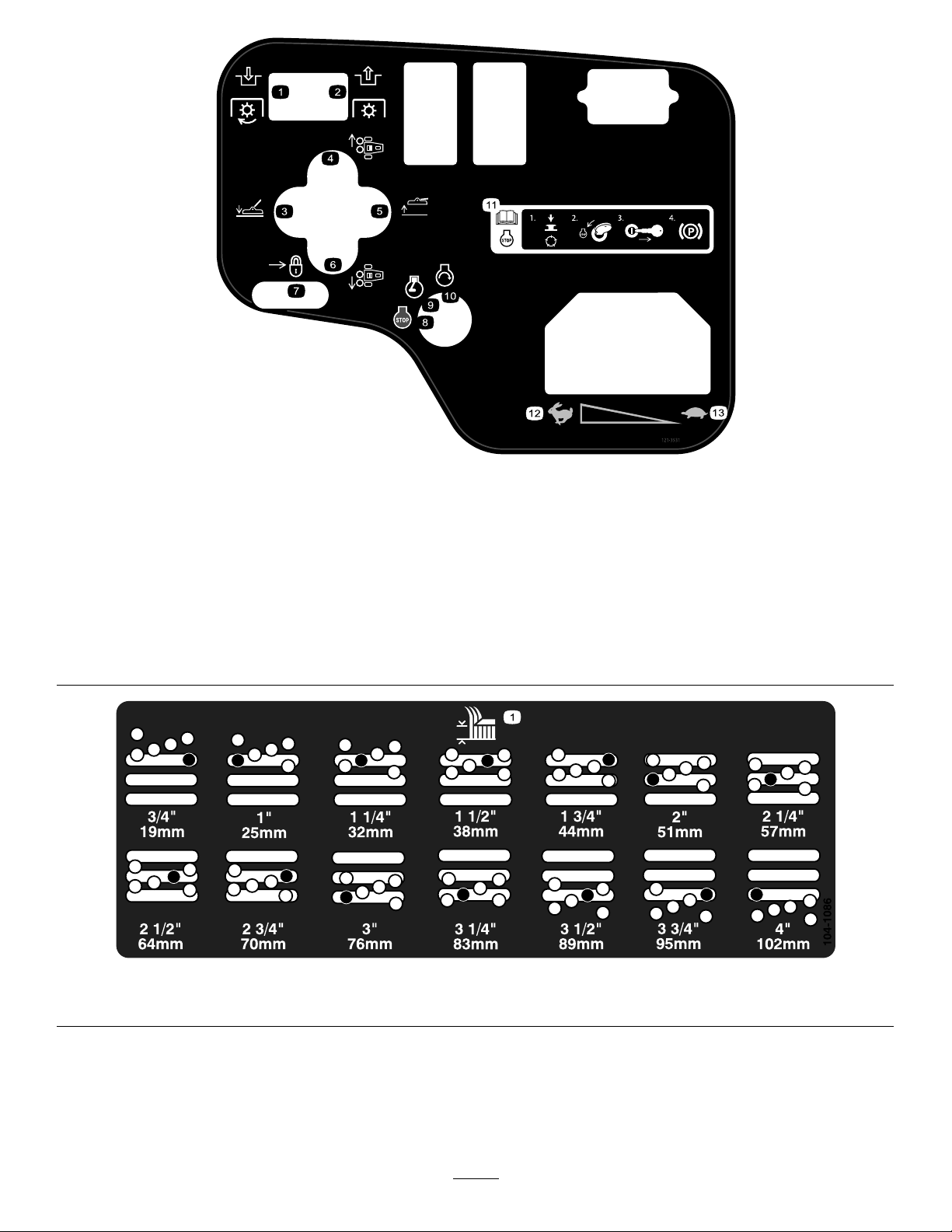

121–3531

1.EngagePTO6.Moveleft11.ReadtheOperator’sManualfor

2.DisengagePTO

3.Lowercuttingunit8.Engine—stop

4.Moveright9.Engine—run

5.Raisecuttingunit10.Engine—start

7.Lock12.Fast

informationonstoppingtheengine—

1)Disengagethereel;2)Movethekey

totheenginestopposition;3)Remove

thekeyfromtheignition;4)Engage

theparkingbrake.

13.Slow

1.Heightofcut

104-1086

9

Page 10

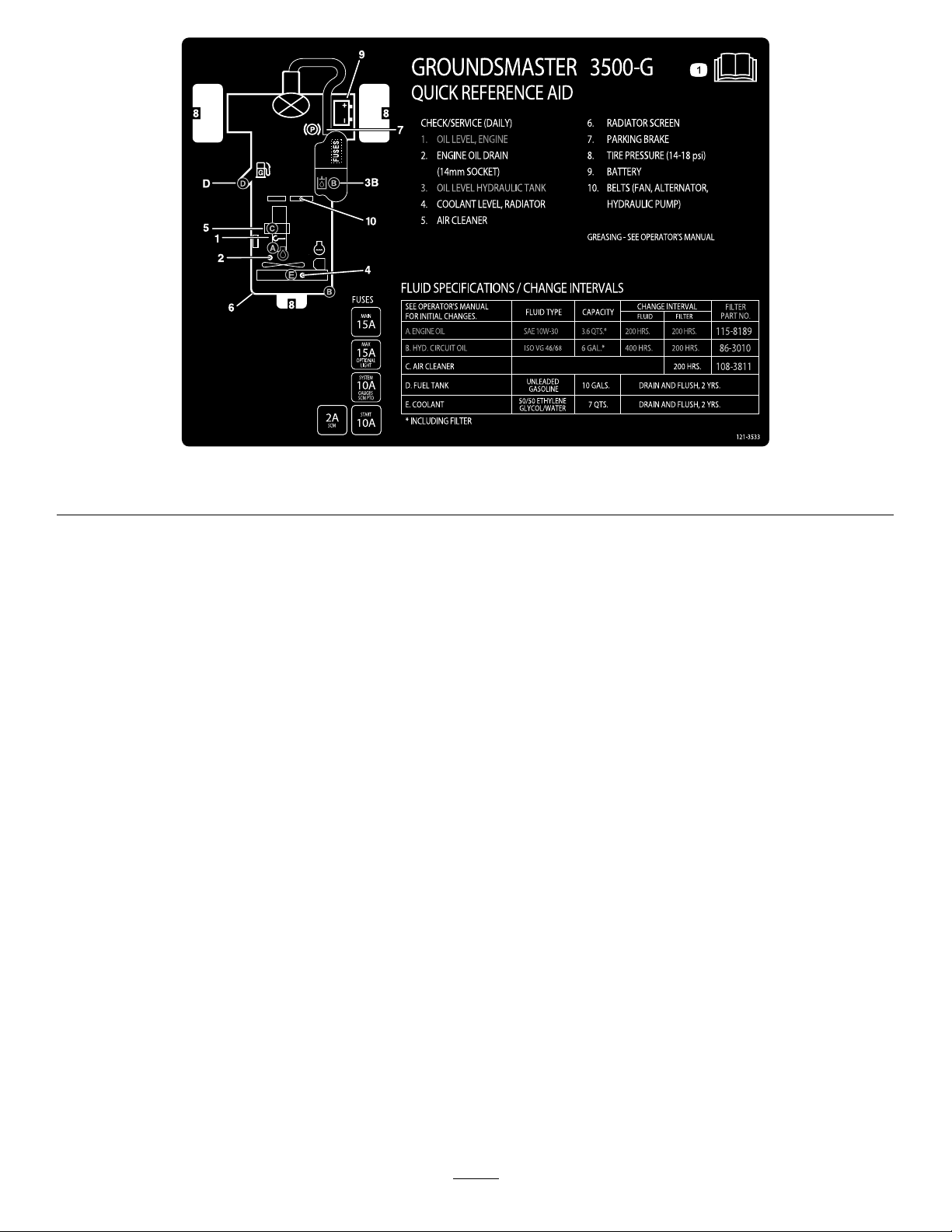

1.ReadtheOperator’sManualforinformationonmaintenance.

121–3533

10

Page 11

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

MediaandAdditionalParts

Description

Qty.

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Qty.

–

–

–

–

–

–

–

–

Activate,charge,andconnectthe

battery.

Checktheangleindicator.

Adjusttheliftarms.

Adjustthecarrierframe.

Adjusttheheightofcut.

Checktheuidlevels.

Adjusttheoptionalrollerscraper.

Installtheoptionalmulchingbafe.

Use

Use

Ignitionkeys2

Operator'sManual

EngineOperator'sManual

PartsCatalog

Operatorvideo

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

1

1

1Usetolookupandorderparts.

1

Starttheengine.

Readbeforeoperatingthemachine.

Viewbeforeoperatingthemachine.

11

Page 12

3.Removethellercapsfromthebatteryandslowlyll

eachcelluntilelectrolyteisjustabovetheplates.

1

Activating,Charging,and ConnectingtheBattery

NoPartsRequired

Procedure

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

W ash hands after handling .

Note:Ifthebatteryisnotlledwithelectrolyteoractivated,

bulkelectrolytewith1.260specicgravitymustbepurchased

fromalocalbatterysupplyoutletandaddedtothebattery.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyes,orclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

1.Openthehood.

2.Removethebatterycover(Figure3).

4.Installthellercapsandconnecta3to4ampbattery

chargertothebatteryposts.Chargethebatteryata

rateof3to4amperesfor4to8hours.

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

•Keepsparksandamesawayfrombattery.

•Neversmokenearthebattery.

5.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

6.Removethellercaps.Slowlyaddelectrolytetoeach

celluntilthelevelisuptothellring.Installtheller

caps.

Important:Donotoverllthebattery.Electrolyte

willoverowontootherpartsofthemachineand

severecorrosionanddeteriorationwillresult.

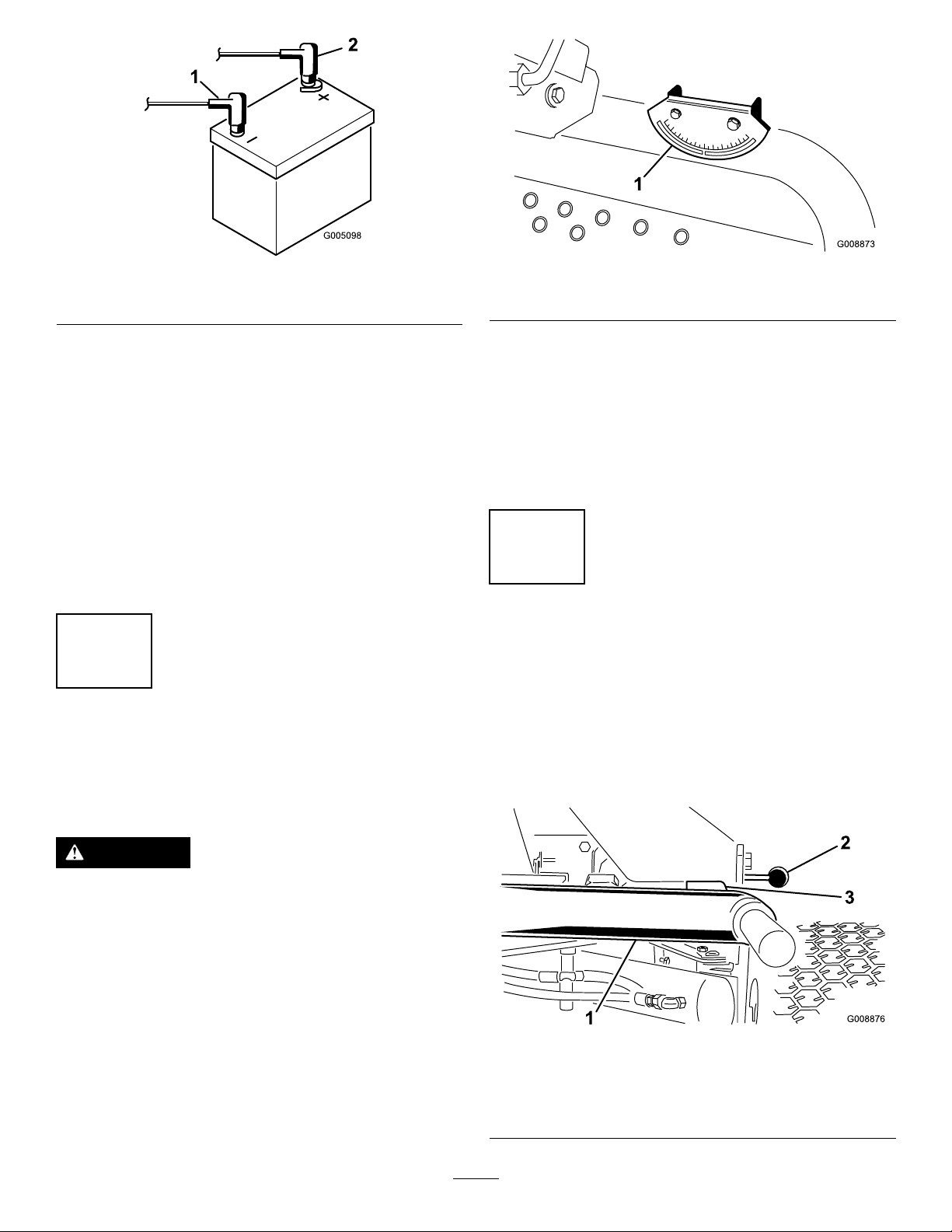

7.Installthepositivecable(red)tothepositive(+)

terminalandthenegativecable(black)tothenegative

(–)terminalofthebatteryandsecurethemwithbolts

andnuts(Figure4).Makesurethatthepositive(+)

terminalisallofthewayontothepostandthecable

ispositionedsnugtothebattery.Thecablemustnot

contactthebatterycover.

WARNING

Incorrectbatterycableroutingcoulddamage

thetractionunitandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

1.Batterycover

Figure3

12

Page 13

Figure4

1.Positive(+)batterycable2.Negative(–)batterycable

Figure5

1.Angleindicator

Important:Ifthebatteryiseverremoved,make

surethatthebatteryclampboltsareinstalledwith

theboltheadspositionedonthebottomsideand

thenutsonthetopside.Iftheclampboltsare

reversed,theymayinterferewiththehydraulic

tubeswhenshiftingthecutting-units.

8.CoatbothbatteryconnectionswithGrafo112X(skin

over)grease,T oroPartNo.505-47,petroleumjelly ,or

lightgreasetopreventcorrosion.

9.Slidetherubberbootoverthepositiveterminalto

preventapossibleshortfromoccurring.

10.Installthebatterycover.

2

CheckingtheAngleIndicator

NoPartsRequired

Procedure

3.Iftheinclinometerdoesnotreadzerodegrees,move

themachinetoalocationwhereazerodegreereading

isobtained.Theangleindicator,mountedonthe

machine,shouldnowreadzerodegreesaswell.

4.Iftheangleindicatordoesnotreadzerodegrees,loosen

the2screwsandnutssecuringtheangleindicatorto

themountingbracket,adjusttheindicatortoobtaina

zerodegreereading,andtightenthebolts.

3

AdjustingtheLiftArms

NoPartsRequired

Procedure

1.Starttheengine,raisethecutting-units,andcheckto

ensurethattheclearancebetweeneachliftarmandthe

oor-platebracketis5to8mm(0.18to0.32inch)as

showninFigure6.

DANGER

Donotoperatethemachineonsidehillssteeper

than25ºtoreduceriskofinjuryordeathdueto

rollover.

1.Parkthemachineonaat,levelsurface.

2.Verifythatthemachineislevelbyplacingahandheld

inclinometer(suppliedwiththemachine)ontheframe

crossrail,bythefueltank(Figure5).Theinclinometer

shouldreadzerodegreeswhenviewedfromthe

operator’sposition.

Figure6

cutting-unitsremovedforclarity

1.Liftarm3.Clearance

2.Floor-platebracket

13

Page 14

Iftheclearanceisnotinthisrange,adjustitasfollows:

A.Backoffthestopbolts(Figure7).

Figure7

1.Stopbolt3.Clearance

2.Liftarm

B.Backoffthejamnutonthecylinder(Figure8).

Figure9

1.Wearbar2.Bumperstrap

Iftheclearanceisnotinthisrange,adjusttherear

cylinderasfollows:

Note:Iftherearliftarmclunksduringtransport,

clearancecanbereduced.

A.Lowerthecutting-unitsandbackoffthejamnut

onthecylinder(Figure10).

Figure8

1.Frontcylinder2.Jamnut

C.Removethepinfromtherodendandrotatethe

clevis.

D.Installthepinandchecktheclearance.Repeat

theprocedureifrequired.

E.Tightentheclevis-jamnut.

2.Checktomakesurethattheclearancebetweeneachlift

armandstopboltis0.13to1.02mm(0.005to0.040

inch)asshowninFigure7.Iftheclearanceisnotin

thisrange,adjustthestopboltstoattainclearance.

3.Starttheengine,raisethecuttingunits,andcheckto

makesurethattheclearancebetweenthewearstrap

onthetopoftherearcuttingunitwearbarandthe

bumperstrapis0.51to2.54mm(0.02to0.10inch)as

showninFigure9.

Figure10

1.Rearcylinder2.Adjustingnut

B.Graspthecylinderrodclosetothenutwitha

pliersandrag,androtatetherod.

C.Raisethecutting-unitsandchecktheclearance.

Repeattheprocedureifrequired.

D.Tightentheclevis-jamnut.

Important:Lackofclearanceatthefrontstopsorrear

wearbarcoulddamagetheliftarms.

4

AdjustingtheCarrierFrame

NoPartsRequired

AdjustingtheFrontCuttingUnit

Thefrontandrearcuttingunitsrequiredifferentmounting

positions.Thefrontcuttingunithas2mountingpositions

dependingonwhatheightofcutanddegreeofrotationyou

desire.

14

Page 15

1.Foraheightofcutinthe2to7.6cm(3/4to3inch)

range,mountthefrontcarrierframesinthelower,

frontmountingholes(Figure11).

samebenchsetting.Itmaybenecessarytohavethe

rotary-cuttingunitbenchset6mm(1/4inch)abovethat

ofareel-cuttingunitinthesamearea.

Note:Thispermitsmoreuptravelofthecuttingunit

relativetothetractionunitwhenapproachingquick

uphillchangesinterrain.Itdoeshoweverlimitthe

clearanceofthechambertothecarrierwhencresting

sharpknolls.

Figure11

1.Upper,frontmountinghole

2.Lower,frontmountinghole

3.Rearmountinghole

Important:Accesstotherear,cuttingunitsisgreatly

improvedbyremovingthecuttingunitfromthetraction

unit.IftheunitisequippedwithaSidewinder®,

sidewindthecuttingunitstotheright,removetherear

cuttingunit,andslideitouttotherightside.

1.Lowerthecuttingunittotheground,stoptheengine,

andremovethekeyfromtheignition.

2.Loosentheboltsecuringeachheightofcutbracketto

theheightofcutplate(frontandeachside)asshown

inFigure12.

3.Beginningwithfrontadjustment,removethebolt.

2.Foraheightofcutinthe6.3to10cm(2-1/2to4inch)

range,mountthefront,carrierframesintheupper,

frontmountingholes(Figure11).

Note:Thisincreasesthechamber-to-carrierclearance

duetothehigherpositionofthecuttingchamber,but

willcausethecuttingunittoreachtheirmaximumup

travelsooner.

AdjustingtheRear,CuttingUnit

Thefrontandrear,cuttingunitsrequiredifferentmounting

positions.Therearcuttingunithasonemountingposition

forproperalignmentwiththesidewinder-underframe.

Forallheightsofcut,mounttherearcuttingunitintherear

mountingholes(Figure11).

5

AdjustingtheHeightofCut

NoPartsRequired

Procedure

Figure12

1.Heightofcutbracket3.Spacer

2.Heightofcutplate

4.Whilesupportingthechamber,removethespacer

(Figure13).

5.Movethechambertothedesiredheightofcutand

installaspacerintothedesignatedheightofcuthole

andslot(Figure13).

Figure13

6.Positionthetappedplateinlinewiththespacer.

7.Hand-tightenthebolts.

8.Repeatsteps4-7foreachsideadjustment.

Important:Thiscuttingunitoftencutsapproximately

6mm(1/4inch)lowerthanareel-cuttingunitwiththe

9.Tightenall3boltsto41N-m(30ft-lb).Alwaystighten

thefrontboltrst.

15

Page 16

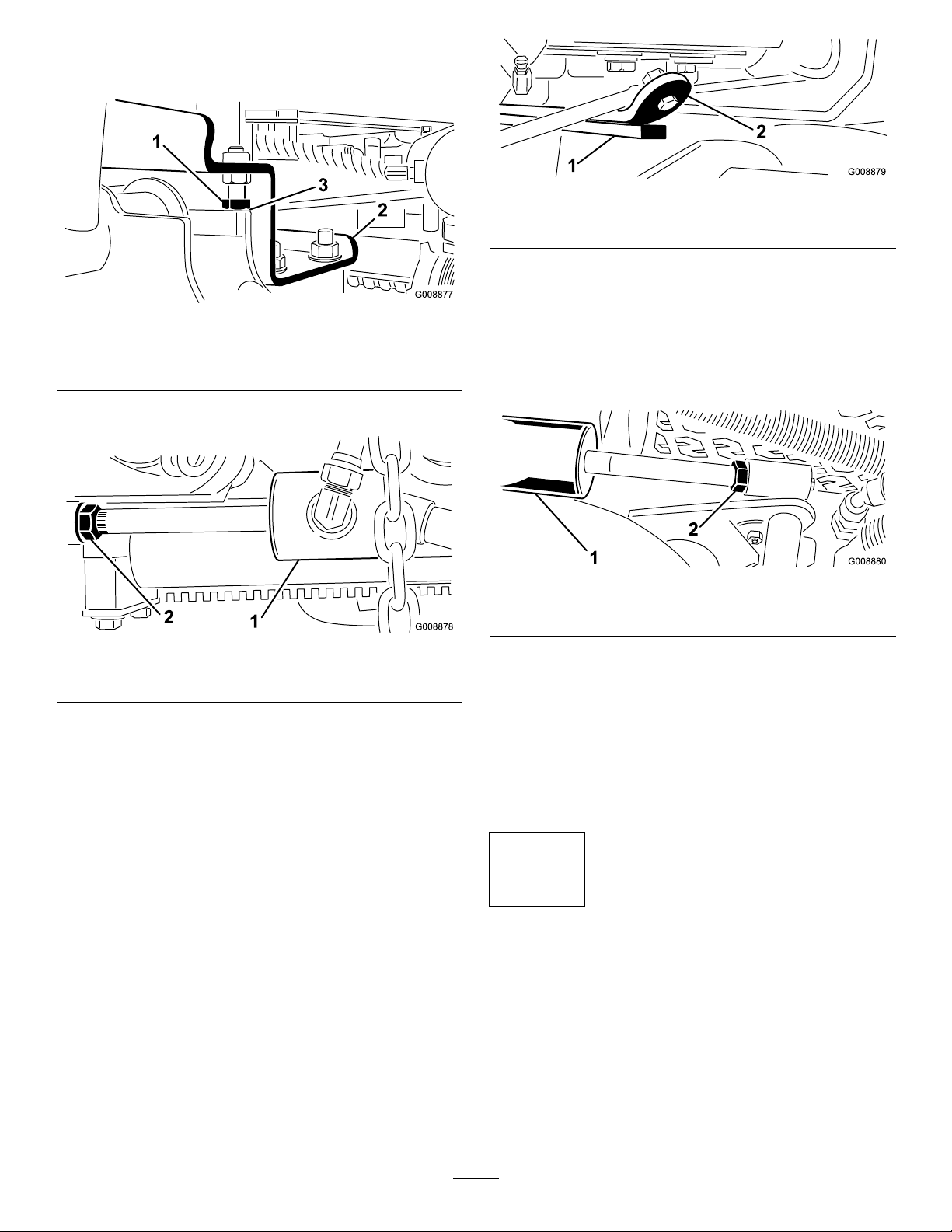

Note:Adjustmentsofmorethan3.8cm(1-1/2inch)

G011346

1

2

3

G011347

1

mayrequiretemporaryassemblytoanintermediate

heighttopreventbinding.

6

2.Slidethescraperupordownuntilagapof0.5to1

mm(0.020to0.040inch)isachievedbetweentherod

andtheroller.

3.Securethegreasettingandscrewto41N-m(30ft-lb)

inanalternatingsequence.

CheckingtheMachinebefore Operation

NoPartsRequired

Procedure

Performthefollowingcheckbeforeoperation:

•CheckingtheEngine-OilLevel(page19)

•CheckingtheCoolingSystem(page22)

•CheckingtheHydraulicSystem(page22)

•CheckingtheTirePressure(page23)

•TorquingtheWheelNuts(page40)

7

AdjustingtheOptionalRoller

8

InstallingtheOptional

MulchingBafe

NoPartsRequired

Procedure

1.Thoroughlycleandebrisfromthemountingholeson

therearandleft,sidewallsofthechamber.

2.Installthemulchingbafeintherearopeningand

secureitwith5ange-headbolts(Figure15).

Scraper

NoPartsRequired

Procedure

Theoptionalrear-rollerscraperisdesignedtoworkbest

whenthereisanevengapof0.5to1mm(0.020–0.040inch)

betweenthescraperandroller.

1.Loosenthegreasettingandthemountingscrew

(Figure14).

Figure14

1.Rollerscraper

2.Mountingscrew

3.Greasetting

Figure15

1.Mulchingbafe

3.Verifythatmulchingbafedoesnotinterferewith

thetipofthebladeanddoesnotprotrudeinsidethe

surfaceoftherear,chamberwall.

WARNING

Donotusethehigh-liftbladewiththe

mulchingbafe.Thebladecouldbreak,

resultinginpersonalinjuryordeath.

16

Page 17

ProductOverview

g021539

Controls

Figure16

1.Forward-tractionpedal4.Tilt-steeringlever

2.Reverse-tractionpedal5.Indicatorslot

3.Mow/transportslide

6.Angleindicator

Tilt-SteeringLever

Pullthetilt-steeringlever(Figure16)backtotiltthesteering

wheeltothedesiredposition.Pushtheleverforwardtolock

thesteeringwheelintoposition.

IndicatorSlot

Theslotintheoperatorplatform(Figure16)indicateswhen

thecutting-unitsareinthecenterposition.

AngleIndicator

Theangleindicator(Figure16)indicatestheside-hillangleof

themachineindegrees.

IgnitionSwitch

Usetheignitionswitch(Figure18)isusedtostartandstop

theengine.The3positionsoftheswitchare;Off,On,and

Start.RotatethekeytotheStartpositiontostarttheengine.

Releasethekeywhentheenginestarts.Thekeyautomatically

movestotheOnpositionwhenyoureleaseit.Toshutthe

engineoff,rotatethekeytotheOffposition.Removethe

keyfromtheignitiontopreventsomeonefromstartingthe

machineunintentionally .

TractionPedals

Presstheforward-tractionpedal(Figure16)tomoveforward.

Pressthereverse-tractionpedal(Figure16)tomovebackward

ortoassistinstoppingwhenmovingforward.Tostopthe

tractionunit,movethepedalto,orallowittomoveto,the

neutralposition.

Mow/TransportSlide

UsingyourheeltomovetheMow/Transportslide(Figure

16)tothelefttotransport,andtotherighttomow .The

cutting-unitswillonlyoperateintheMowposition.

Note:Themowingspeedofthemachineissetatthefactory

to9.7km/h(6mph).Themowingspeedcanbeincreasedor

decreasedbyadjustingthespeed-stopscrew(Figure17).

Figure18

1.Throttle

2.Hourmeter

3.Temperaturelight9.Ignitionswitch

4.Oilpressurelight

5.Checkenginelight11.Liftleverlock

6.Alternatorlight

7.PTOswitch

8.Cutting-unitshiftlever

10.Parkingbrake

Throttle

1.Speed-stopscrew

Figure17

Movethethrottle(Figure18)forwardtoincreasetheengine

speedandrearwardtodecreasetheenginespeed.

PTOSwitch

ThePTOswitch(Figure18)has2positions:Out(start)and

In(stop).PullthePTOswitchouttoengagethecutting-unit

blades.Pushtheswitchintodisengagethecutting-unitblades.

17

Page 18

HourMeter

g021400

2

1

Lift-LeverLock

Thehourmeter(Figure18)indicatesthetotalhoursof

machineoperation.Thehourmeterstartstofunction

wheneverthekeyswitchisintheOnposition.

Cutting-UnitLever

Tolowerthecuttingunitstotheground,movethe

cutting-unitlever(Figure18)forward.Thecuttingunitswill

notdropunlesstheengineisrunning.Toraisethecutting

units,pulltheleverrearwardtotheRaiseposition.

Note:Theleverdoesnothavetobeheldintheforward

positionwhilethecuttingunitsarelowered.

Movethelevertotherightorleft,tomovethecuttingunits

totherightorleft.Thisshouldonlybedonewhenthe

cuttingunitsareraisedoriftheyareonthegroundandthe

machineismoving.

DANGER

Shiftthecuttingunitstotheuphillsideofthe

machinewhenonthesideofahill.

Usingthecuttingunitsonthedownhillsideofthe

machinecandecreasestability.Thiscouldcause

arollover,whichmayresultinpersonalinjuryor

death.

Coolant-TemperatureLight

Movethelift-leverlock(Figure18)rearwardtopreventthe

cuttingunitsfromdropping.

FuelGauge

Thefuelgauge(Figure19)indicatestheamountoffuelin

thefueltank.

Figure19

1.Seat-locklever

2.Fuelgauge

Thecoolant-temperaturelight(Figure18)willturnonifthe

coolanttemperatureraisesaboveasetlevel.Theenginewill

stopifthecoolanttemperatureraisesanother10°F .

Oil-PressureLight

Theoil-pressurelight(Figure18)willturnoniftheoil

pressuredropsbelowasetlevel.

AlternatorLight

Checkorrepairthechargingsystemifthealternatorlight

turnsonwhentheengineisrunning(Figure18).

Check-EngineLight

Checkorrepairtheengineifthecheck-enginelightturnson

whentheengineisrunning(Figure18).RefertotheService

Manualforpossiblecauses.

ParkingBrake

Engagetheparkingbrakewhenevertheengineisshutoff

(Figure18).Pulluponthelevertoengagetheparkingbrake.

AdjustingtheSeatForwardor

Backward

Movethelever(Figure19)onthesideoftheseatoutward

andslidetheseattothedesiredposition.Releasethelever

tolocktheseatintoposition.

Note:Theenginewillstopifyoupressthetractionpedal

withtheparkingbrakeengaged.

18

Page 19

Specications

G009027

1

2

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

OverallWidth182cm(71.8inch)

WidthofCut173cm(68inch)

Length

HeighttotopofROPS180cm(70.8inch)

Wheelbase

295cm(1 16inch)

149cm(58.5inch)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

ThinkSafetyFirst

Carefullyreadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

Trackwidth

Groundclearance15.3cm(6inch)

Weightwithcuttingunits

CuttingDeck

Length

Width

Height

34.9cm(13–3/4inch)at4

Weight

145cm(57inch)

963kg(2,124lb)

86.4cm(34inch)

86.4cm(34inch)

24.4cm(9.6inch)

tocarriermount

26.7cm(10–1/2inch)

at3/4inchheightofcut

inchesheightofcut

88kg(195lb)

Attachments/Accessories

Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonTorogenuine

parts.Whenitcomestoreliability ,Torodeliversreplacement

partsdesignedtotheexactengineeringspecicationofour

equipment.Forpeaceofmind,insistonT orogenuineparts.

DANGER

Operatingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,or

drowning.

Usetheseatbelt.

Readandfollowtherolloverprotectioninstructions

andwarnings.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotoperateneardrop-offsornearwater.

•Donotoperateonslopesgreaterthan25º.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

CAUTION

Thismachineproducessoundlevelsthatcancause

hearinglossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,hands,feet,

andheadisrecommended.

Figure20

1.Wearsafetyglasses.

2.Wearhearingprotection.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

19

Page 20

Theengineisshippedwithoilinthecrankcase;however,the

G016095

g021401

2

oillevelmustbecheckedbeforeandaftertheengineisrst

started.

3.Iftheoillevelislow,removethellercap(Figure22)

andaddenoughoiltoraisethelevel-of-the-oiltothe

Fullmarkonthedipstick.

Crankcasecapacityisapproximately3.3L(3.5USqt)with

thelter.

Note:T oroPremiumEngineoilisavailablefromyour

distributorineither15W-40or10W-30viscosity.Seethe

partscatalogforpartnumbers.

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscoolbeforeithasbeenstartedfortheday.Ifithas

alreadybeenrun,allowtheoiltodrainbackdowntothe

sumpforatleast10minutesbeforechecking.Iftheoillevelis

atorbelowtheAddmarkonthedipstick,addoiltobringthe

oilleveltotheFullmark.Donotoverll.Iftheoillevelis

betweentheFullandAddmarks,additionaloilisnotrequired.

Theengineusesanyhigh-quality10W -30detergentoilhaving

theAmericanPetroleumInstitute(API)serviceclassication

SJ,SK,SL,SM,orhigher.Chooseaviscosityaccordingto

thetableinFigure21.

Note:Whenaddingoil,removedipsticktoallow

properventing.Pouroilslowlyandcheckthe

level-of-the-oiloftenduringthisprocess.Donot

overll.

Important:Whenaddingengineoilorllingoil,

theremustbeclearancebetweentheoillldevice

andtheoilllholeinthevalvecoverasshownin

Figure23.Thisclearanceisnecessarytopermit

ventingwhenlling,whichpreventsoilfrom

overrunningintothebreather.

Figure21

1.Positionthemachineonalevelsurfaceandopenthe

hood.

2.Removethedipstick(Figure22)andwipeitwitha

cleanrag.Insertthedipstickintothetubeandmake

surethatitisseatedfully.Removedipstickandcheck

thelevel-of-the-oil.

Figure22

1.Dipstick2.Fillercap

Figure23

1.Noteclearance

4.Installthedipstickrmlyinplace.

5.Installtheoil-llcapandclosethehood.

FillingtheFuelTank

•Fueltankcapacity:38L(10USgallons)

•RecommendedFuel:

–Forbestresults,useonlyclean,fresh(lessthan30

daysold),unleadedgasolinewithanoctaneratingof

87orhigher((R+M)/2ratingmethod).

–Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)by

volumeisacceptable.EthanolandMTBEarenot

thesame.Gasolinewith15%ethanol(E15)by

volumeisnotapprovedforuse.Neverusegasoline

thatcontainsmorethan10%ethanolbyvolume,

suchasE15(contains15%ethanol),E20(contains

20%ethanol),orE85(containsupto85%ethanol).

Usingunapprovedgasolinemaycauseperformance

problemsand/orenginedamagewhichmaynotbe

coveredunderwarranty.

20

Page 21

–Donotusegasolinecontainingmethanol.

–Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizeris

used.

–Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

Important:Donotusefueladditivesotherthanafuel

stabilizer/conditioner.Donotusefuelstabilizerswithan

alcoholbasesuchasethanol,methanol,orisopropanol.

1.Cleantheareaaroundthefuel-tankcap(Figure24).

2.Removethefuel-tankcap.

3.Fillthetanktothebottomofthellerneck.Donot

overll.Installthecap.

4.Topreventarehazard,wipeupanyfuelthatmay

havespilled.

Figure24

1.Fuel-tankcap

•Beforeremovingthefuel-tankcap,make

surethatthevehicleispositionedonalevel

surface.Openthefuel-tankcapslowly.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupany

gasolinethatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.

Addgasolinetothefueltankuntilthelevel

is6to13mm(1/4to1/2inch)belowthe

bottomofthellerneck.Thisemptyspace

inthetankallowsgasolinetoexpand.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

Neverbuymorethana30-daysupplyof

gasoline.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

21

Page 22

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethegasolinevapors.Are

orexplosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Alwaysplacethegasolinecontainerson

thegroundawayfromyourvehiclebefore

lling.

•Donotllthegasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwiththewheelson

theground.

•Ifthisisnotpossible,refuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.

Cleantheradiator/oilhourlyifconditionsareextremely

dustyordirty;refertoCleaningtheEngineCoolingSystem

(page41).

Thecoolingsystemislledwitha50/50solutionofwater

andpermanentethyleneglycolantifreeze.Checkthecoolant

levelatthebeginningofeachday,beforestartingtheengine.

CAUTION

Iftheenginehasbeenrunning,thepressurized-hot

coolantcanescapeandcauseburns.

•Donotopentheradiator-capwhentheengine

isrunning.

•Usearagtoopeningtheradiator-cap,andopen

thecapslowlytoallowthesteamtoescape.

1.Checkthecoolantlevelintheexpansiontank(Figure

26).Withacoldengine,thecoolantlevelshouldbe

approximatelymidwaybetweenthemarksontheside

ofthetank.

2.Ifthecoolantlevelislow,removetheexpansion-tank

capandreplenishthesystem.Donotoverll.

3.Installtheexpansion-tankcap.

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily

Thecapacityofthecoolingsystemisapproximately5.7L

(6USqt).

Cleandebrisoffoftheradiator/oilcoolerdaily(Figure25).

Figure25

1.Radiator/Oilcooler

Figure26

1.Expansiontank

CheckingtheHydraulic System

ServiceInterval:Beforeeachuseordaily—Checkthe

hydraulicuidlevel.

Thetractionunitreservoirislledatthefactorywith

approximately22.7L(6USgallons)ofhigh-qualityhydraulic

uid.Checkthelevelofthehydraulicuidbefore

theengineisrststartedanddailythereafter.The

recommendedreplacementuidisToroPremiumAll

SeasonHydraulicFluidavailablein5-gallonpailsor

55-gallondrums.SeeyourAuthorizedToroDistributor.

22

Page 23

Alternateuids:IftheT orouidisnotavailable,youmay

useotheruidsprovidedthattheymeetallthefollowing

materialpropertiesandindustryspecications.Torodoes

notrecommendtheuseofsyntheticuid.Consultwithyour

lubricantdistributortoidentifyasatisfactoryproduct.Note:

Torowillnotassumeresponsibilityfordamagecausedby

impropersubstitutions,souseonlyproductsfromreputable

manufacturerswhowillstandbehindtheirrecommendation.

HighViscosityIndex/LowPourPointAnti-wearHydraulic

Fluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to48

ViscosityIndexASTM

D2270

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0

cSt@100°C7.9to8.5

140to160

PremiumBiodegradableHydraulicFluid-MobilEAL

EnviroSyn46H

Important:MobilEALEnviroSyn46Histheonly

syntheticbiodegradableuidapprovedbyT oro.This

uidiscompatiblewiththeelastomersusedinToro

hydraulicsystemsandissuitableforawide-range

oftemperatureconditions.Thisuidiscompatible

withconventionalmineraloils,butformaximum

biodegradabilityandperformancethehydraulicsystem

shouldbethoroughlyushedofconventionaluid.The

oilisavailablein5gallonpailsor55gallondrumsfrom

yourMobilDistributor.

Important:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemoilisavailablein20ml(2/3oz)

bottles.Onebottleissufcientfor15to22L(4to6

gallons)ofhydraulicoil.Orderpartno.44-2500from

yourauthorizedT orodistributor.

Figure27

1.Hydraulictankcap

3.Removethedipstickfromthellerneckandwipeit

withacleanrag.

4.Insertthedipstickintothellerneck,thenremoveit

andchecktheuidlevel.

Note:Theuidlevelshouldbewithinthemarkson

thedipstick.

5.Ifthelevelislow ,addtheappropriateamountofuid

toraisetheleveltothefullmark.

6.Installthedipstickandcapontothellerneck.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Thetiresareover-inatedforshipping.Therefore,release

someoftheairtoreducethepressure.Thecorrectair

pressureinthetiresis97to124kPa(14to18psi).

Note:Maintaintherecommendedpressureinalltiresto

ensureagoodqualityofcutandpropermachineperformance.

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,andstoptheengine.

2.Cleantheareaaroundthellerneckandcapofthe

hydraulictank(Figure27).Removethecap.

DANGER

Lowtirepressuredecreasesmachinesidehill

stability.Thiscancausearollover,whichcanresult

inpersonalinjuryordeath.

Donotunder-inatethetires.

RearWheelBallast

ThemachineconformstoANSIstandardB71.4-2012

standardwhen22.6kg(50lb)ofcalcium-chlorideballastis

addedtotherearwheels.

Important:Ifapunctureoccursinatirecontaining

calciumchloride,removethemachinefromtheturfas

quicklyaspossible.Immediatelysoaktheaffectedarea

withwatertopreventpossibledamagetotheturf.

23

Page 24

StartingandStoppingthe

CheckingtheInterlockSystem

Engine

StartingtheEngine

1.Besurethattheparkingbrakeissetandthecutting

unitdriveswitchisintheDisengageposition.

2.Removeyourfootfromthetractionpedalandmake

surethatthepedalisintheNeutralposition.

3.Movethethrottlelevertothe1/2throttleposition.

4.InsertthekeyintotheswitchandrotateittotheStart

positiontoengagethestartermotor.

Note:Releasethekeywhentheenginestarts.Thekey

movesautomaticallytotheOn/Runposition.

Important:T opreventoverheatingofthestartermotor,

donotengagethestarterlongerthan15seconds.After

15secondsofcontinuouscranking,wait60seconds

beforeengagingthestartermotoragain.

StoppingtheEngine

1.MovethethrottlecontroltotheIdleposition.

ServiceInterval:Beforeeachuseordaily

1.Makesurethatallbystandersareawayfromthearea

ofoperation.

Note:Keephandsandfeetawayfromthecutting

units.

Note:Whilesittingontheseat,theenginemustnot

startwitheitherthecutting-unitswitchengagedorthe

tractionpedalengaged.Correcttheproblemifitisnot

operatingproperly.

2.Whilesittingontheseat,putthetractionpedalinthe

Neutralposition,theparkingbrakeintheOffposition,

andthecutting-unitswitchintheOffposition.

Note:Theengineshouldstart.

3.Risefromtheseatandslowlypressthetractionpedal.

Note:Theengineshouldstopin1to3seconds.

Correcttheproblemifitisnotoperatingproperly.

Note:Theenginestopswhenyoupressthetractionpedal

andengagetheparkingbrake.

2.Movethecutting-unitdriveswitchtoDisengage.

3.RotatethestarterkeytoOff.

4.Removethekeyfromtheignitionswitch.

TowingtheTractionUnit

Incaseofanemergency ,themachinecanbetowedfora

shortdistance.

Important:Donottowthemachinefasterthan3to

4km/h(2to3mph)becausethedrivesystemmay

becomedamaged.Ifthemachinemustbemoveda

considerabledistance,transportitonatruckortrailer.

1.Locatethebypassvalveonthepump(Figure28)and

rotateit90°.

Figure28

1.Bypassvalve

2.Beforestartingtheengine,closethebypassvalveby

rotatingit90°(1/4turn).

Note:Donotstarttheenginewhenthevalveisopen.

24

Page 25

StandardControlModule (SCM)

TheStandardControlModuleisapottedelectronicdevice

producedinaonesizetsallconguration.Themodule

usessolidstateandmechanicalcomponentstomonitorand

controlstandardelectricalfeaturesrequiredforsafeproduct

operation.

Themodulemonitorsinputsincludingneutral,parkingbrake,

PTO,start,backlap,andhightemperature.Themodule

energizesoutputsincludingPTO,Starter,andETR(energize

torun)solenoid.

Themoduleisdividedintoinputsandoutputs.Inputsand

outputsareidentiedbygreenLEDindicators.

circuitisenergized.UsetheinputLEDstotroubleshoot

switchesandinputcircuits.

Outputcircuitsareenergizedbyanappropriatesetofinput

conditions.The3outputsarePTO,ETR,andSTART.The

outputLEDindicatesthepresenceofvoltageattherelay .

Outputcircuitsdonotdeterminetheintegrityoftheoutput

device.Troubleshootingtheelectricalintegrityofanoutput

circuitshouldincludetheoutputLED ,thedevice,andthe

wiringharness.Measuredisconnectedcomponentimpedance,

impedancethroughthewiringharness(disconnectatSCM),

orbytemporarily”testenergizing”thespeciccomponent.

TheSCMdoesnotconnecttoanexternalcomputeror

hand-helddevice,itcannotbere–programmed,anditdoes

notrecordintermittentfaulttroubleshootingdata.

Thestartcircuitinputisenergizedby12VDC.Allother

inputsareenergizedwhenthecircuitisclosedtoground.

EachinputhasanLEDthatisilluminatedwhenthespecic

Figure29

HerearethelogicaltroubleshootingstepsfortheSCMdevice.

1.Determinetheoutputfaultyouaretryingtoresolve

(PTO,START,orETR).

2.MovekeyswitchtotheOnpositionandensurethat

theredpowerLEDisilluminated.

3.MoveallinputswitchestoensureallLEDschange

state.

4.Positioninputdevicesatappropriatepositionto

achievetheappropriateoutput.Usethefollowinglogic

charttodeterminetheappropriateinputcondition.

5.IfspecicoutputLEDisilluminatedwithout

appropriateoutputfunction,checktheoutputharness,

theconnections,andthecomponent.Repairas

required.

6.IfspecicoutputLEDisnotilluminated,checkboth

ofthefuses.

ThedecalontheSCMonlyincludessymbols.Thereare3

LEDoutputsymbolsareshownintheoutputbox.Allother

LEDsareinputs.Thechart(Figure29)identiesthesymbols.

7.IfspecicoutputLEDisnotilluminatedandthe

inputsareinanappropriatecondition,installanew

SCManddetermineifthefaultdisappears.

Eachrowinthelogicchartbelowidentiestheinputand

outputrequirementsforeachspecicfunction.Thefunctions

arelistedintheleftcolumn.Thesymbolsidentifyspecic

circuitconditionincluding:energizedtovoltage,closedto

ground,andopentoground.

•(–)Indicatesacircuitclosedtoground.–LEDON

•(O)Indicatesacircuitopentogroundorde–energized

–LEDOFF

•(+)Indicatesanenergizedcircuit(clutchcoil,solenoid,or

startinput)LEDON.

•ABlankindicatesacircuitthatisnotinvolvedwiththe

logic.

25

Page 26

INPUTSOUTPUTS

FunctionPower

Start

Run(Off

Unit)

Run(On

Unit)

Mow

Backlap

HiTemp

ON

——

——

—

—

——

—

In

Neutral

OO

OO

StartON

+

OOOOOOO

OO

O

Brake

ON

OO

—

———

Totroubleshoot,turnthekeytotheOnposition.Identify

thespecicfunctionthatisnotoperatingproperlyandwork

acrossthelogicchart.Inspecttheconditionofeachofthe

inputLEDstoensureitmatchesthelogicchart.

IftheinputLEDsarecorrect,checktheoutputLEDs.Ifthe

outputLEDsareilluminatedbutthedeviceisnotenergized,

measuretheavailablevoltageattheoutputdevice,continuity

ofthedisconnecteddevice,andpotentialvoltageonthe

groundcircuit(oatingground).Repairswillvarydepending

onyourndings.

PTOONInSeat

O

—

—

—

OO

HiTempBacklap

OO

OOO

OOO

—

—

Start

++

O

OOO

ETR

+

+

++

++

PTO

O

O

O

26

Page 27

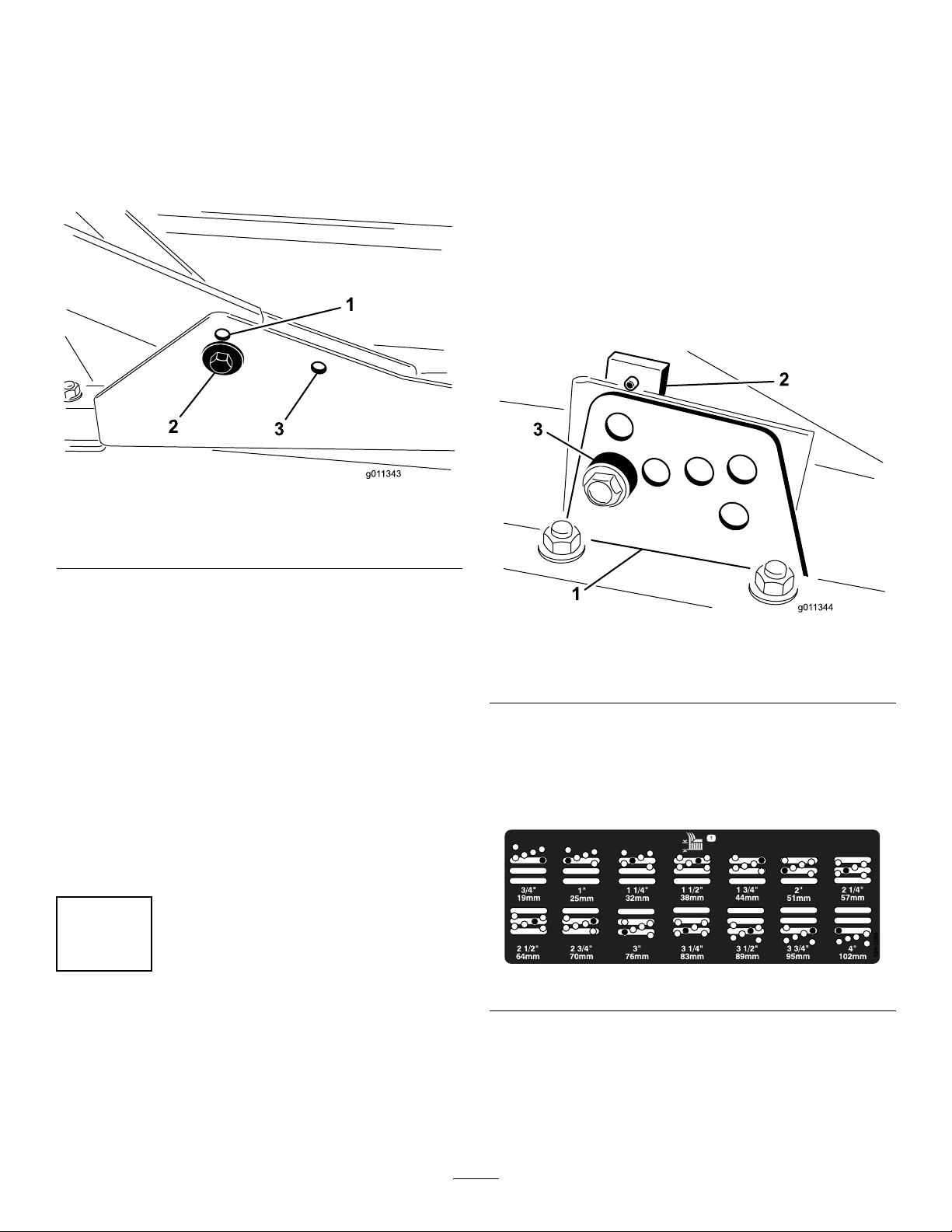

ChoosingAccessories

OptionalEquipmentCongurations

AngleSailBladeHighLiftParallel

HeightofCut

1.9to4.4cm(0.75

to1.75inches)

HeightofCut

5to6.4cm(2.00to

2.50inches)

HeightofCut

7to10cm(2.75to

4.00inches)

LeafMulchingRecommendedforuse

ProsEvendischargeat

ConsDoesnotliftthe

Recommendedinmost

applications

Recommendedforthick

orlushturf

Mayworkwellinlushturf

withthemulchingbafe

alowheightofcut

Cleanerlookaround

bunkersandfairways

Lowerpower

requirements

grasswellata

highheightofcut

Wetorstickygrass

hasatendencytobuild

upinthechamber,

leadingtopoorquality

ofcutandhigherpower

requirements

SailBlade

Donotusewiththe

mulchingbafe

Mayworkwellinlightor

sparseturf

Recommendedforlight

orsparseturf

Recommendedinmost

applications

NotAllowedUsewithcombination

Moreliftandhigher

dischargevelocity

Sparseorlimpturf

ispickedupata

highheightofcut

Wetorstickyclippings

aredischargedefciently

Requiresmorepowerto

runinsomeapplications

Tendstowindrow

atalowheightof

cutinlushgrass

Donotusewiththe

mulchingbafe

MulchingBafeRollerScraper

Hasbeenshownto

improvedispersionand

aftercutperformance

onnortherngrassesthat

arecutatleastthree

timesperweekand

whenlessthan1/3ofthe

grassbladeisremoved

Donotusewiththe

highliftparallelsail

blade

sailoranglesailblade

only

Mayimprovedispersion

andappearance

incertaingrass

cuttingapplications

Verygoodforleaf

mulching

Grasswillbuildupinthe

chamberifattemptingto

removetoomuchgrass

withbafeinplace

Canbeusedanytime

thatrollersbuildup

withgrassorlargeat

grassclumpsareseen

Thescrapersmay

actuallyincrease

clumpingincertain

applications

Reducesrollerbuildup

incertainapplications

SelectingaBlade

StandardCombinationSail

Thisbladewasdesignedtoprovideexcellentliftand

dispersioninalmostanycondition.Ifmoreorlessliftand

dischargevelocityisrequired,consideradifferentblade.

Attributes:Excellentliftanddispersioninmostconditions.

AngledSail

Thebladegenerallyperformsbestatalowerheightofcut,

1.9to6.4cm(3/4to2–1/2inches).

Attributes:

•Dischargeremainsmoreevenlyatalowerheightofcut.

•Dischargehaslesstendencytothrowleftandthusa

cleanerlookaroundbunkersandfairways.

•Lowerpowerrequirementatalowerheightofcutin

denseturf.

HighLiftParallelSail

Thebladegenerallyperformsbetteratahigherheightofcut,

7to10cm(2to4inches).

Attributes:

•Moreliftandhigherdischargevelocity.

•Sparseorlimpturfispickedupsignicantlyatahigher

heightofcut.

•Wetorstickyclippingsaredischargedmoreefciently,

reducingcongestioninthedeck.

27

Page 28

•Requiresmorehorsepowertorun.

•Tendstodischargefurtherleftandcantendtowindrow

atalowerheightofcut.

WARNING

Donotusethehigh-liftbladewiththemulching

bafe.Thebladecouldbreak,resultinginpersonal

injuryordeath.

AtomicBlade

Thisbladewasdesignedtoprovideexcellentleafmulching.

Attributes:Excellentleafmulching

OperatingTips

GeneralTips

•Practiceoperatingthemachineandbecomethoroughly

familiarwithit.

•Starttheengineandrunitathalfidleuntilitwarmsup.

Pushthethrottleleverallthewayforward,liftthecutting

units,disengagetheparkingbrake,presstheforward

tractionpedal,andcarefullydrivetoanopenarea.

•Practicemovingforwardandreverse,andstartingand

stoppingthemachine.Tostop,takeyourfootoffthe

tractionpedalandletitreturntoneutralorpressdown

onthereversepedaltostop.Goingdownahill,youmay

needtousethereversepedaltostop.

•Whendrivingonslopes,driveslowlytomaintainsteering

controlandavoidturnstopreventrollovers.Inside

hillsituations,shiftthesidewindercuttingunitstothe

uphillsidetogiveyoumorestability .Conversely,shifting

thecuttingunitstothedownhillsidewillgiveyouless

stability.Thisshouldalwaysbedonebeforegoingona

sidehill.

•Whenpossible,mowupanddownhillsratherthanacross

them.Havethecuttingunitsloweredwhengoingdowna

hilltomaintainsteeringcontrol.Donotattempttoturn

onahill.

•Practicedrivingaroundobstacleswiththecuttingunits

upanddown.Becarefulwhendrivingbetweennarrow

objectssoyoudonotdamagethemachineorthecutting

units.

•OntheSidewinderunit,getafeelforthereachofthe

cuttingunitssothatyoudonothangthemupordamage

theminanyway.

•Donotshiftthecuttingunitsfromsidetoside,unlessthe

cuttingunitsaredownandthemachineismoving,orthe

cuttingunitsareupinthetransportposition.Shiftingthe

cuttingunitswhentheyaredownandthemachineisnot

movingmaycauseturfdamage.

•Alwaysdriveslowlyinroughareas.

•Ifapersonappearsinorneartheoperatingarea,stopthe

machine,anddonotstartitagainuntiltheareaiscleared.

Themachineisdesignedfor1person.Neverletanyone

elserideonthemachinewithyou.Thisisextremely

dangerousandcouldresultinseriousinjury.

•Accidentscanhappentoanyone.Themostcommon

causesareexcessivespeed,suddenturns,terrain(not

knowingwhichslopesandhillscanbemowedsafely),not

stoppingtheenginebeforeleavingtheoperator’sseat,

anddrugs,whichimpairyouralertness.Coldcapsulesor

prescriptiondrugsmaycausedrowsiness,ascanalcohol

andotherdrugs.Stayalertandstaysafe.Failuretodoso

couldresultinseriousinjury.

•TheSidewinderoffersuptoamaximumof33cm(13

inch)ofoverhang,allowingyoutotrimclosertotheedge

ofsandtrapsandotherobstacles,whileatthesametime

keepingthetiresasfarawayfromtheedgeoftrapsor

waterhazardsaspossible.

•Ifanobstacleisintheway ,shiftthecuttingunitstoeasily

mowaroundit.

•Whendrivingthemachinefromoneworkareatoanother,

raisethecuttingunitstothefully-upposition,movethe

Mow/TransportslidetothelefttoTransport,andplace

thethrottletotheFastposition.

MowingPatterns

Changemowingpatternsoftentominimizeaftercut

appearanceissuesthatareinducedbyrepetitivemowingin

onlyonedirection.

Counterbalance

Thecounterbalancesystemmaintainshydraulicbackpressure

onthecuttingunitliftcylinders.Thiscounterbalancepressure

transferscutting-unitweighttothetraction-unitdrivewheels

toimprovetraction.Thecounterbalancepressurehasbeen

factorysettoanoptimalbalanceofaftercutappearanceand

tractioncapabilityinmostturfconditions.Decreasingthe

counterbalancesettingcanproduceamorestablecutting

unit,butcandecreasethetractioncapability .Increasingthe

counterbalancesettingcanincreasethetractioncapability,

butmayresultinaftercutappearanceissues.Referencethe

servicemanualforyourtractionunitforinstructionstoadjust

counterbalancepressure.

ResolvingAftercutAppearance

ReferencetheAftercutAppearanceTroubleshootingGuide

availableatwww .Toro.com

MowingTechniques

•Tobegincutting,engagethecuttingunits,thenapproach

themowingareaslowly.Oncethefrontcuttingunitsare

overthemowingarea,lowerthecuttingunits.

•Toachievetheprofessionalstraight-linecutandstriping

thatisdesirableforsomeapplications,ndatreeorother

objectinthedistanceanddrivestraighttowardit.

28

Page 29

•Assoonasthefrontcuttingunitsreachtheedgeof

themowingarea,liftthecuttingunitsandperforma

teardrop-shapedturntoquicklylineyouupforyournext

pass.

•Tomowaroundbunkers,ponds,orothercontours

easily,usetheSidewinderandmovethecontrolleverleft

orright,dependingonyourmowingapplication.The

cuttingunitscanalsobeshiftedtovarytiretracking.

•Thecuttingunitstendtothrowgrasstotheleftside

ofthemachine.Iftrimmingaroundbunkers,itisbest

tomowinaclockwisedirectiontopreventthrowing

clippingsintothebunker.

•Thecuttingunitscanbeequippedwithbolt-inmulching

bafes.Themulchingbafesperformwellwhenturfis

maintainedonaregularscheduletoavoidremovingmore

than25mm(1inch)ofgrowthpercutting.Whentoo

muchgrowthiscutwiththemulchingbafesinstalled,

aftercutappearancemaydeteriorateandtheobserved

powertocuttheturfincreases.Themulchingbafesalso

performwellforshreddingleavesinthefall.

MowWhenGrassIsDry

keptfreeofdirtorgrassclippings.Aftercleaning,inspectthe

machineforpossiblehydraulic-uidleaks,damage,orwear

tothehydraulicandmechanicalcomponents,andcheckthe

cutting-unitbladesforsharpness.

Important:Afterwashingthemachine,movethe

Sidewindermechanismfromlefttorightseveraltimesto

removewaterbetweenthebearingblocksandcrosstube.

Moweitherinthelatemorningtoavoidthedew,which

causesgrassclumping,orinlateafternoontoavoidthe

damagethatcanbecausedbydirectsunlightonthesensitive,

freshlycutgrass.

SelecttheProperHeightofCutSetting

toSuitConditions

Removeapproximately25mm(1inch)ornomorethan1/3

ofthegrassbladewhencutting.Inexceptionallylushand

densegrass,youmayhavetoraiseyourheightofcutsetting

toahighersetting.

AlwaysStartMowingwithSharpBlades

Asharpbladecutscleanlyandwithouttearingorshredding

thegrassbladeslikeadullblade.Tearingandshredding

causesthegrasstoturnbrownattheedgeswhichimpairs

growthandincreasessusceptibilitytodiseases.Makesurethat

thebladeisingoodconditionandafullsailispresent.

CheckConditionofCuttingUnit

Makesurethatcuttingchambersareingoodcondition.

Straightenanybendsinchambercomponentstoensure

correctbladetip/chamberclearance.

AfterMowing

Atthecompletionofmowingoperation,thoroughlywashthe

machinewithagardenhosewithoutanozzlesothatexcessive

waterpressurewillnotcontaminateanddamagetheseals

andbearings.Makesurethattheradiatorandoilcoolerare

29

Page 30

Maintenance

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Afterthersthour

Aftertherst8hours

Aftertherst10hours

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every50hours

Every200hours

MaintenanceProcedure

•Torquethewheelnuts.

•Checktheconditionandtensionofallbelts.

•Torquethewheelnuts.

•Changethehydrauliclter.

•Changetheoilandoillter.

•Checktheengineoillevel.

•Checktheenginecoolantlevel.

•Checkthehydraulicuidlevel.

•Checkthetirepressure.

•Checktheinterlocksystem.

•Cleandebrisoffoftheradiatorandoilcooler.

•Checkthehydrauliclinesandhoses.

•Checktheblade-stoppingtime.

•Checktheelectrolytelevel.(Ifmachineisinstorage,checkevery30days.)

•Lubricateallbearingsandbushings.(Lubricateallbearingsandbushingsdaily

whenconditionsaredustyanddirty.)

•ServicetheAirCleaner(Morefrequentlyinextremedustyordirtyconditions)

•Changetheoilandoillter.

•Torquethewheelnuts.

•Checktheparkingbrakeadjustment.

•Checktheconditionandtensionofallbelts.

•Changethehydrauliclter.

•Replacethesparkplugs.

Every400hours

Every500hours

Every2years

•Replacethefuel-pumplter.

•Checkthefuellinesandconnections.

•Changethehydraulicuid.

•Greasethebearingsintherearaxle.

•Drainandcleanthefueltank.

•Flushthecoolingsystemandreplaceuid.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

30

Page 31

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof:

MaintenanceCheckItem

Checkthesafetyinterlock

operation.

Checkthebrakeoperation.

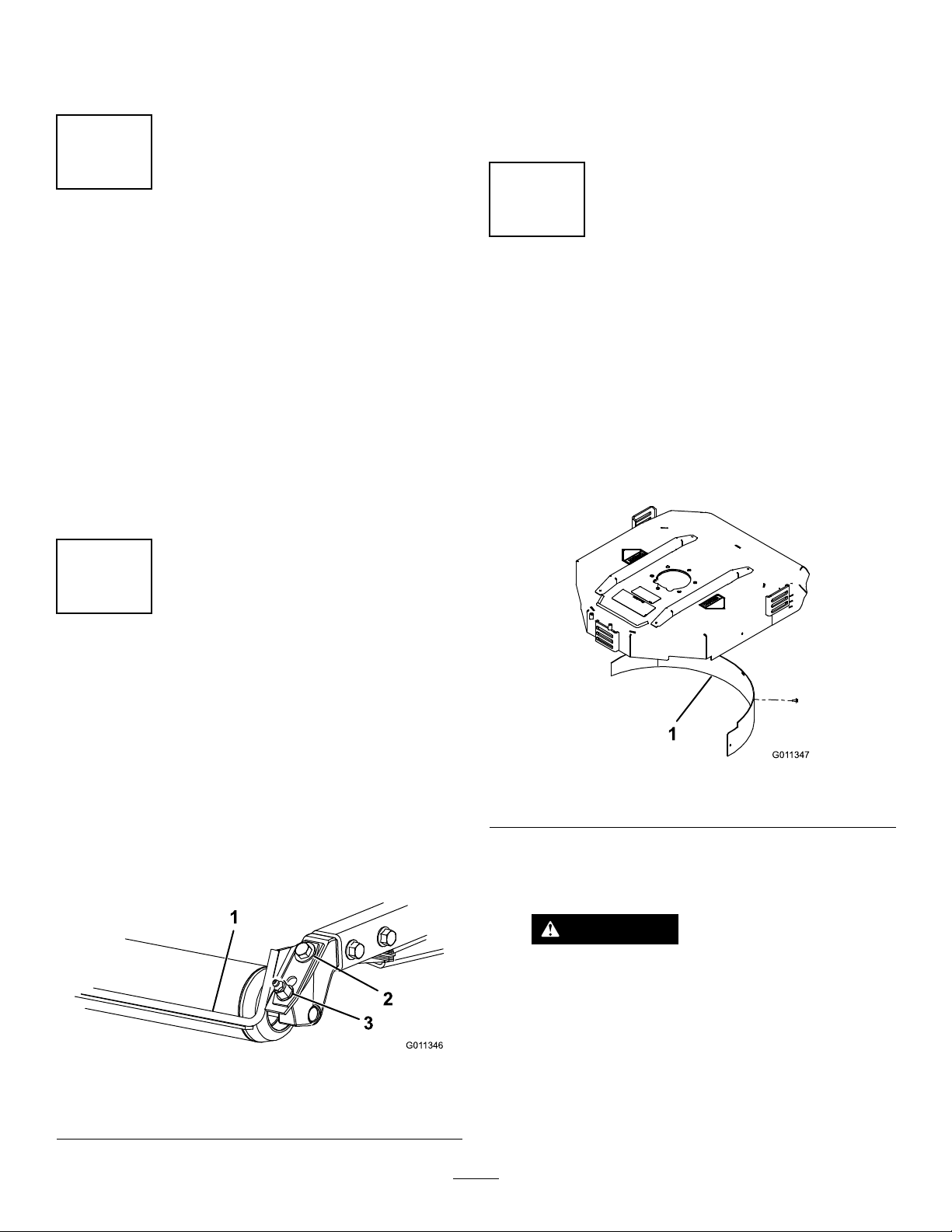

Checktheengineoillevel.

Checkthecoolingsystem

uidlevel.

Checktheairlter,dustcup,

andburpvalve.

Checkforunusualengine

2

noises.

Checktheradiatorand

screenfordebris.

Checkforunusualoperating

noises.

Checkthehydraulicsystem

oillevel.

Checkthehydraulichoses

fordamage.

Checkforuidleaks.

Checkthefuellevel.

Checkthetirepressure.

Checktheinstrument

operation.

Checktheheightofcut

adjustment.

Lubricateallthegrease

2

ttings.

Touch-upanydamaged

paint.

1

Checktheglowplugandinjectornozzlesifstartingishard,thereisexcesssmoke,orroughrunningisnoted.

2

Immediatelyaftereverywashing,regardlessoftheintervallisted.

Mon.T ues.Wed.Thurs.Fri.

Sat.Sun.

Important:Refertoyourengine

Operator's Man ual

foradditionalmaintenanceprocedures.

Note:LookingforanElectricalSchematicorHydraulicSchematicforyourmachine?Downloadafreecopyoftheschematicby

visitingwww .T oro.comandsearchingforyourmachinefromtheManualslinkonthehomepage.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

31

Information

Page 32

ServiceIntervalChart

Premaintenance

Procedures

RemovingtheHood

Thehoodmaybeeasilyremovedtoeasemaintenance

proceduresintheengineareaofthemachine.

1.Unlatchandraisethehood.

2.Removethehairpincottersecuringthehoodpivotto

themountingbrackets(Figure31).

Figure30

Figure31

1.Hairpincotter

3.Slidethehoodtotherightside,lifttheotherside,and

pullitoutofthebrackets.

Note:Reversetheproceduretoinstallthehood.

32

Page 33

UsingtheCutting-UnitService Latch

Lubrication

Whenservicingthecuttingunits,usetheservicelatchto

preventinjury.

1.Centerthecuttingunitsidewinderwiththetraction

unit.

2.Raisethecuttingunitstothetransportposition.

3.Settheparkingbrakeandturnoffthemachine.

4.Releasethelatchrod(Figure32)fromthefrontcarrier

frameretainer.

Figure32

1.Latchhook

GreasingtheBearingsAnd Bushings

ServiceInterval:Every50hours(Lubricateallbearingsand

bushingsdailywhenconditionsaredusty

anddirty.)

Every500hours/Yearly(whichevercomesrst)

LubricategreasettingsregularlywithNumber2

general-purpose,lithium-basedgrease.Lubricatethebearings

andbushingsdailywhenoperatingconditionsareextremely

dustyordirty.Dustyordirtyoperatingconditionscould

causedebristogetintothebearingsandbushings,resultingin

acceleratedwear.Lubricategreasettingsimmediatelyafter

everywashing,regardlessofintervalspecied.

Thegreasettinglocationsandquantitiesareasfollows:

•Rearcuttingunitpivot(Figure33)

5.Lifttheoutsideofthefrontcuttingunitsandplacethe

latchovertheframepinmountedonthefrontofthe

operator'splatform(Figure32).

6.Sitontheoperatorseatandstartthemachine.

7.Lowerthecuttingunitstothemowposition.

8.Turnoffthemachineandremovethekeyfromthe

ignition.

9.Reversethisproceduretounlatchthecuttingunits.

Figure33

•Frontcuttingunitpivot(Figure34)

Figure34

33

Page 34

•SideWindercylinderends2(Figure35)

Figure35

•Steeringpivot(Figure36)

•Rearlift-armpivotandliftcylinder2(Figure37)

Figure37

•Leftfrontlift-armpivotandliftcylinder2(Figure38)

Figure36

Figure38

•Rightfrontlift-armpivotandliftcylinder2(Figure39)

Figure39

•Neutral-adjustmechanism(Figure40)

34

Page 35

Figure40

•Steeringcylinder(Figure43).

•Mow/Transportslide(Figure41)

Figure41

•Belt-tensionpivot(Figure42)

Figure43

Note:Ifdesired,installanadditionalgreasettingin

theotherendofthesteeringcylinder.Removethetire,

installthetting,greasethetting,removethetting,and

installtheplug(Figure44).

Figure44

•Cuttingunitspindle-shaftbearings(2percuttingunit)

(Figure45)

Figure42

Note:Eitherttingcanbeused,whicheverismore

accessible.Pumpgreaseintothettinguntilasmall

amountappearsatbottomofthespindlehousing(under

thecuttingunit).

Figure45

35

Page 36

•Rearrollerbearings(2percuttingunit)(Figure46)

G011349

Figure46

Note:Makesurethatthegreasegrooveineachroller

mountalignswiththegreaseholeineachendoftheroller

shaft.Tohelpalignthegrooveandhole,thereisalsoan

alignmentmarkon1endoftherollershaft.

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Every200hours(Morefrequentlyin

extremedustyordirtyconditions)

Inspecttheaircleanerandhosesperiodicallytomaintain

maximumengineprotectionandtoensuremaximumservice

life.Checktheair-cleanerbodyfordamage,whichcould

causeanairleak.Replaceadamagedair-cleanerbody.

Inspectandchangetheair-cleanerlterasdescribedinthe

followingprocedure:

1.Pullthelatchoutwardandrotatetheair-cleanercover

counterclockwise.

Figure47

1.Air-cleanercover2.Filter

2.Beforeremovingthelter,uselow-pressureair(40psi,

cleananddry)tohelpremovelargeaccumulationsof

debrispackedbetweentheoutsideoftheprimarylter

andthecanister.

Important:Avoidusinghigh-pressureairwhich

couldforcedirtthroughthelterintotheintake

tract.Thiscleaningprocesspreventsdebrisfrom

migratingintotheintakewhenyouremovethe

primarylter.

3.Removeandreplacetheprimarylter.

Note:Cleaningoftheusedelementisnot

recommendedduetothepossibilityofdamagetothe

ltermedia.

4.Inspectthenewlterforshippingdamage,checking

thesealingendofthelterandthebody.

Important:Donotuseadamagedlter.

5.Insertthenewlterbyapplyingpressuretotheouter

rimoftheelementtoseatitinthecanister.

36

Page 37

6.Cleanthedirtejectionportlocatedintheremovable

g021403

1

g021414

1

cover.Removetherubberoutletvalvefromthecover,

cleanthecavity,andreplacetheoutletvalve.

7.Installthecoverorientingtherubber,outletvalveina

downwardposition,betweenapproximately5o'clock

to7o'clockwhenviewedfromtheend(Figure47).

8.Securethecoverlatches.

ChangingtheEngineOiland Filter

ServiceInterval:Aftertherst50hours

Every200hours

1.Removethedrainplug(Figure48)andletoilow

intoadrainpan.Whentheoilstopsowing,install

thedrainplug.

Figure49

1.Engineoillter

3.Addoiltothecrankcase;refertoCheckingthe

Engine-OilLevel(page19).

Figure48

1.Engineoildrainplug

2.Removetheoillter(Figure49).Applyalightcoat

ofcleanoiltothenewltersealbeforeinstallingthe

lter.Donotovertighten.

ReplacingtheSparkPlugs

ServiceInterval:Every400hours

Thesparkplugsusuallylastalongtime;however,removeand

checktheplugswhenevertheenginemalfunctionsorevery

400hours.Replacethesparkplugstoensureproperengine

performanceandreduceexhaustemissionlevel.

ThecorrectsparkplugtouseisaChampionRC14YCor

NGKBPR4ES.

1.Cleantheareaaroundthesparkplugssoforeignmatter

cannotfallintothecylinderwhenyouremovethe

sparkplug.

2.Pullthewiresoffthesparkplugsandremovetheplugs

fromthecylinderhead.

3.Checktheconditionofthesideelectrode,center

electrode,andcenter-electrodeinsulatortoensurethat

thereisnodamage.

Important:Acracked,fouled,dirty,orotherwise

malfunctioningsparkplugmustbereplaced.Do

notsandblast,scrape,orcleanelectrodesbyusing

awirebrushbecausegritmayeventuallyrelease

fromtheplugandfallintothecylinder.Theresult

isusuallyadamagedengine.

37

Page 38

Figure50

g021415

1

FuelSystem

Maintenance

ReplacingtheFuel-PumpFilter

ServiceInterval:Every400hours

1.Airgapat0.81mm(0.032inch)

4.Settheairgaponeachplugbetweenthecenterand