Page 1

V–Plow Mounting Kit

Groundsmaster) 200 Series

(To be used with V–Plow Model No. 30750)

Model No. 30749

Form No. 3313–786

Installation Instructions

Note: Installation of this kit requires that the traction unit

be equipped with bolt on type lift arm assemblies, Part

numbers 67–1910 or 76–3080 and 67–1920 or 76–3090.

Remove Cutting Unit and

Carrier Frame from Traction

Unit

1. Remove the cutting unit and carrier frame from the

traction unit. Refer to the cutting unit Operator’s

Manual for the removal procedure.

Danger

Do not start the engine and engage the PTO lever

when PTO shaft is not connected to gear box on

cutting unit or or completely removed from the

traction unit because the PTO shaft will rotate

with enough force to cause serious injury.

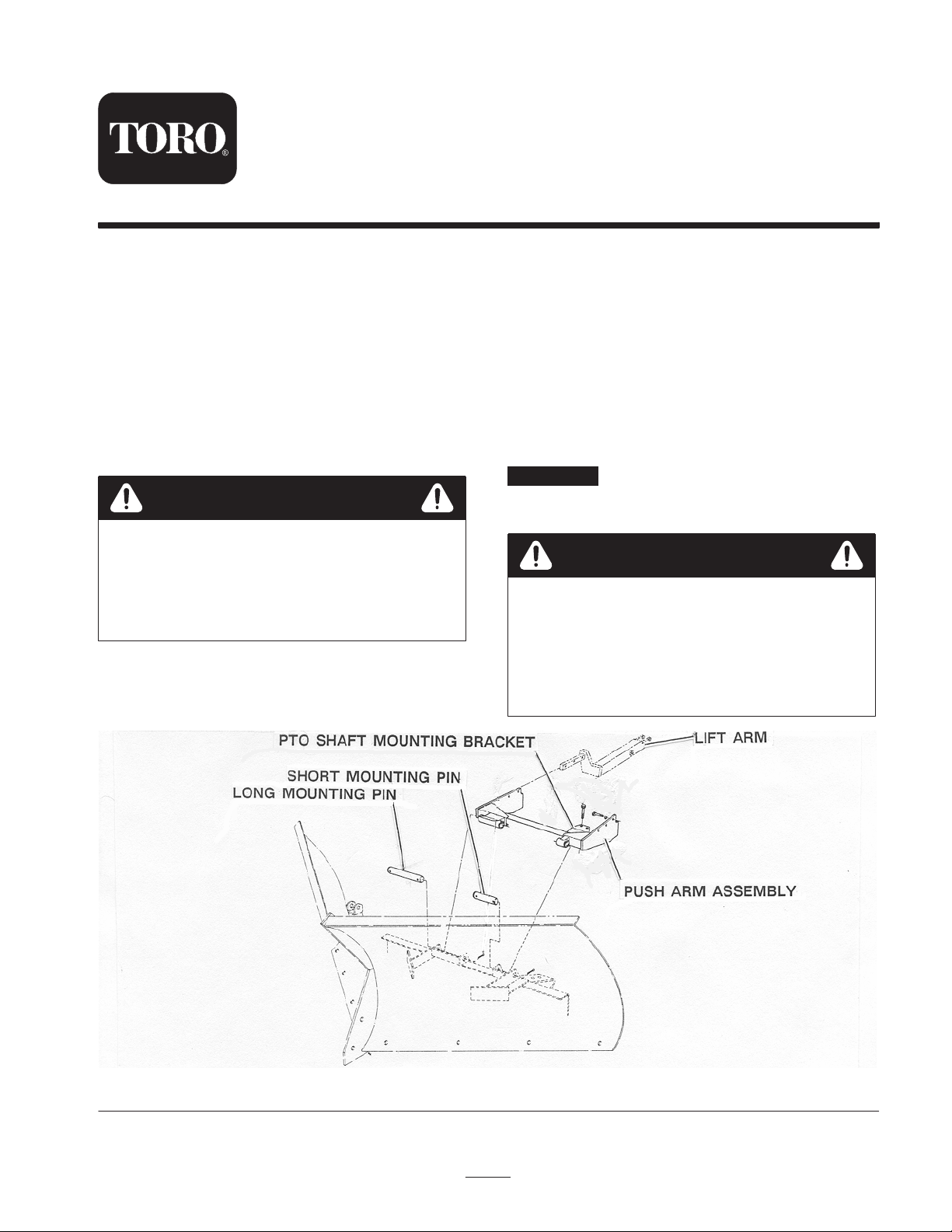

Mount the Push Arm Assembly

to the Lift Arms

1. Slide the push arm assembly onto the lift arms aligning

the mounting holes. Secure each side of the push arm

assembly to the lift arms with (3) new capscrews and

lockwashers as shown in figure 1. Torque capscrews to

70–80 ft–lb.

2. Secure the PTO shaft to the mounting bracket on the

push arm assembly with the (2) capscrews and

locknuts supplied in the kit (Fig. 1).

Important If the PTO shaft does not have the bolt on,

clevis end type, disconnect and remove the complete PTO

shaft assembly from the traction unit output shaft.

Danger

If the PTO shaft is not connected to the lift arm

mounting bracket or is not disconnected from the

engine output shaft, serious injury could result if

engine is started and the PTO shaft is allowed to

rotate. Refer to the cutting unit Operator’s

Manual for removal procedure.

W 1989 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Figure 1

1

All Rights Reserved

Printed in the USA

Page 2

3. Connect the right side with a long mounting pin and

(2) cotter pins (Fig. 1).

4. Connect the left side with a short mounting pin and (2)

cotter pins (Fig. 1).

Perform FInal Adjustments

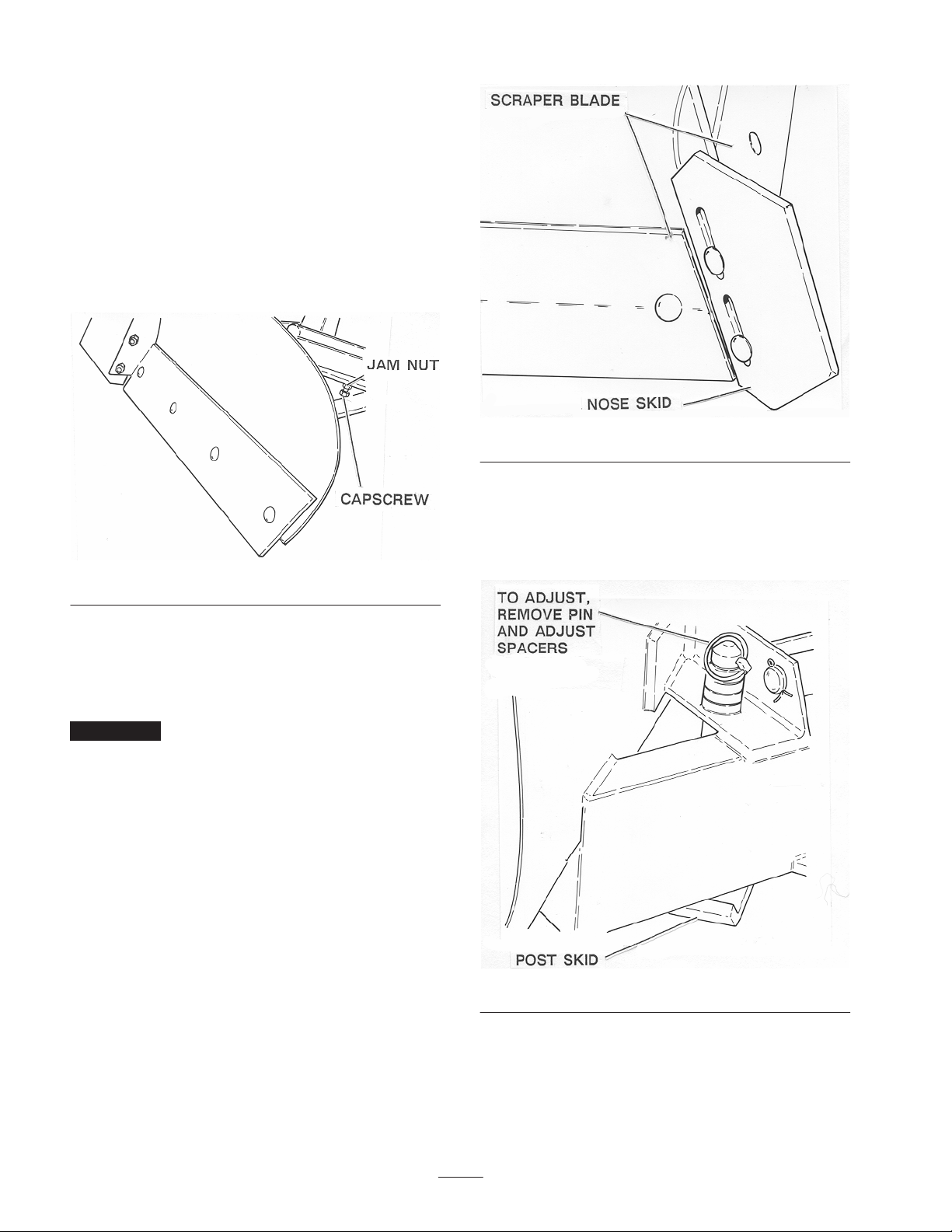

1. With plow contacting flat surface, adjust capscrew

(Fig. 2) upward against push arm–until front of plow

begins to move up: then bottom jam nut (Fig. 2)

against stop bracket.

Figure 2

Figure 3

3. If plow will be used on concrete or asphalt surfaces,

post skids (Fig. 4) must be adjusted upward so plow

contacts surface. By contrast, skids must be adjusted

downward–raise plow off surface–when plow will be

used on gravel or crushed rock surfaces.

2. Loosen carriage bolts and nuts retaining nose skid to

front of plow (Fig. 3). Next, adjust nose skid so it’s

bottom edge is even with bottom of plow (Fig. 3).

Lastly, tighten nuts and carriage bolts so nose skid

remains in place.

Important When scraper blades or nose skid (Fig. 3)

wear down, they can be reversed by removing carriage

bolts and nuts. Never allow scraper blades or nose skid to

wear even with bottom surface of plow. Reverse scraper

blades or nose skid before plow starts to wear.

Figure 4

2

Loading...

Loading...