Page 1

FormNo.3356-682RevB

CommercialWalk-BehindMower

FixedDeck,T-Bar,Gearwitha32inCutting

Unitor36inTURBOFORCE®CuttingUnit

ModelNo.30692—SerialNo.270000001andUp

ModelNo.30694—SerialNo.270000001andUp

Registeratwww.T oro.com.OriginalInstructions(EN)

Page 2

Warning

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

Theenclosed

Engine Owner’ s Man ual

issupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorToroCustomerServiceandhave

themodelandserialnumbersofyourproductready .

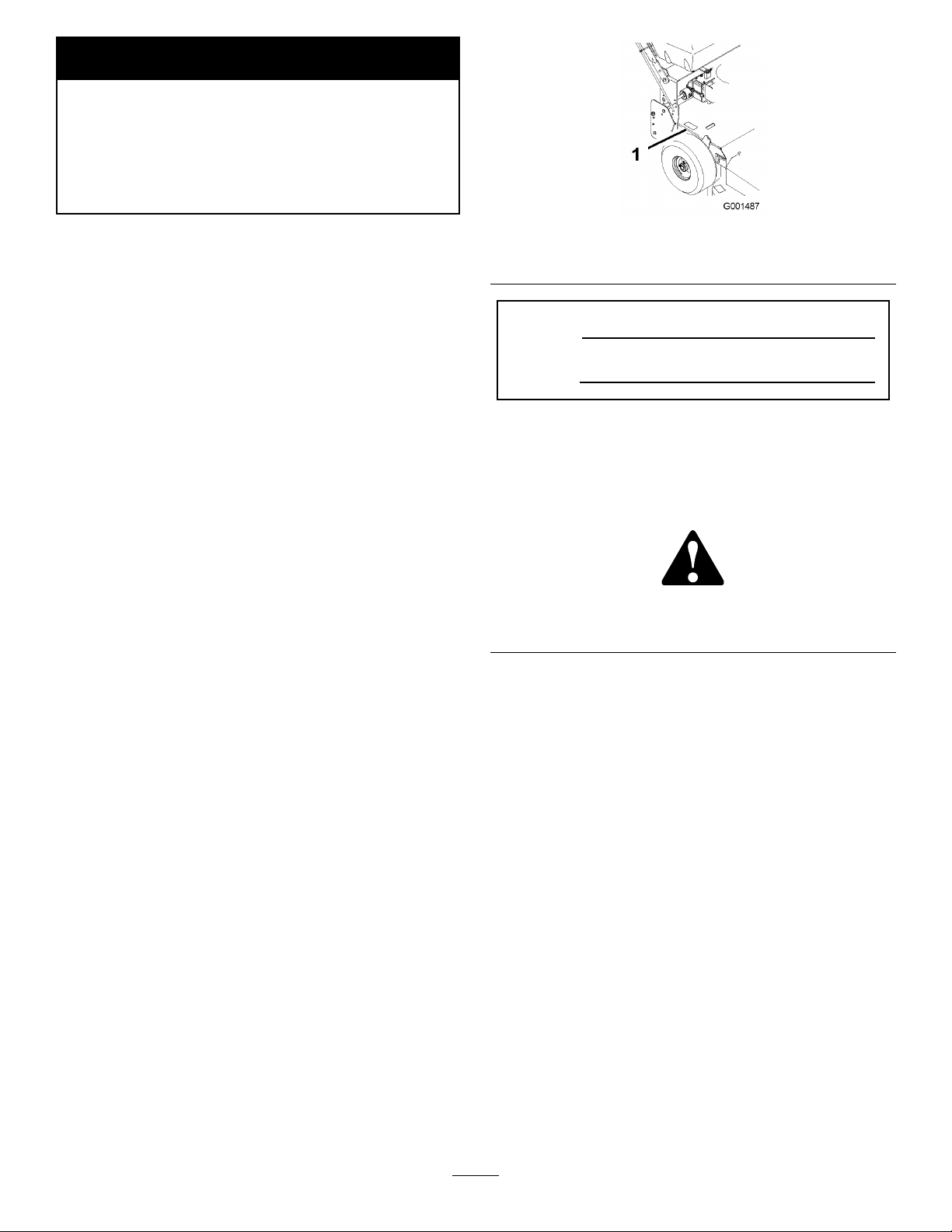

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Introduction.................................................................2

Safety...........................................................................3

SafeOperatingPractices.......................................3

ToroMowerSafety...............................................4

SlopeChart..........................................................6

SafetyandInstructionalDecals.............................7

Setup..........................................................................10

1CheckingtheFluidsandTirePressure..............10

2ReadingtheManualandViewingtheSafety

Information...................................................10

ProductOverview......................................................11

Controls.............................................................11

Specications.....................................................12

Attachments/Accessories...................................12

Operation...................................................................13

©2007—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

AddingFuel.......................................................13

ThinkSafetyFirst...............................................14

OperatingtheParkingBrake...............................14

StartingandStoppingtheEngine........................14

OperatingtheBladeControlLever

(PTO)............................................................15

TheSafetyInterlockSystem................................16

DrivingForwardorBackward.............................16

UsingtheLowerControlBar..............................16

StoppingtheMachine.........................................17

TransportingMachines.......................................18

SideDischargingorMulchingtheGrass..............18

AdjustingtheHeight-of-Cut...............................18

AdjustingtheHandleHeight..............................19

HeightofCutChart............................................21

Maintenance...............................................................22

RecommendedMaintenanceSchedule(s)................22

Lubrication.............................................................22

HowtoGrease...................................................22

LubricatingtheCasterandWheel

Bearings.........................................................23

GreasingtheTransmissionCouplers...................23

GreasingtheMowerBeltIdler............................23

EngineMaintenance...............................................24

ServicingtheAirCleaner....................................24

ServicingtheEngineOil.....................................25

ServicingtheSparkPlugs....................................26

FuelSystemMaintenance.......................................28

ServicingtheFuelTank......................................28

ServicingtheFuelFilter......................................28

DriveSystemMaintenance.....................................29

CheckingtheTirePressure.................................29

CoolingSystemMaintenance..................................30

CleaningtheAirIntakeScreen............................30

CleaningtheCoolingSystem...............................30

BrakeMaintenance.................................................30

ServicingtheBrakes...........................................30

BeltMaintenance....................................................31

CheckingtheBelts..............................................31

ReplacingtheTractionDriveBelt........................31

ReplacingtheTransmissionDriveBelt................31

ReplacingtheMowerBelt...................................32

AdjustingtheMowerBeltTension......................33

MowerDeckMaintenance......................................34

ServicingtheCuttingBlades...............................34

AdjustingtheBladeBrake...................................36

ReplacingtheGrassDeector.............................36

Storage.......................................................................37

Troubleshooting.........................................................39

Schematics.................................................................41

Safety

Note:Theadditionofattachmentsmadeby

othermanufacturersthatdonotmeetAmerican

NationalStandardsInstitutecerticationwillcause

noncomplianceofthismachine.

Improperuseormaintenancebytheoperatororowner

canresultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol,whichmeans

CAUTION,WARNING,orDANGER-“personalsafety

instruction."Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.4-2004.

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readEnglishitistheowner’ sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glassesandhearingprotection.Longhair,loose

clothingorjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toysandwire

whichcanbethrownbythemachine.

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer

3

Page 4

–Neverremovegascaporaddfuelwithengine

running.Allowenginetocoolbeforerefueling.

Donotsmoke.

–Neverrefuelordrainthemachineindoors.

•Checkthatoperator’spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

•Beawareofthemowerdischargedirectionanddo

notpointitatanyone.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoorfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Onlystartengine

fromtheoperator’sposition.

•Besureofyourfootingwhileusingthismachine,

especiallywhenbackingup.Walk,don’trun.Never

operateonwetgrass.Reducedfootingcouldcause

slipping.

•Slowdownanduseextracareonhillsides.Besure

totravelsidetosideonhillsides.Turfconditions

canaffectthemachine’ sstability.Usecautionwhile

operatingneardrop-offs.

•Slowdownandusecautionwhenmakingturnsand

whenchangingdirectionsonslopes.

•Neverraisedeckwiththebladesrunning.

•NeveroperatewiththePTOshield,orotherguards

notsecurelyinplace.Besureallinterlocksare

attached,adjustedproperly,andfunctioningproperly.

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,disengagedrives,engage

parkingbrake(ifprovided),shutoffenginebefore

leavingtheoperator’spositionforanyreason

includingemptyingthecatchersoruncloggingthe

chute.

•Stopequipmentandinspectbladesafterstriking

objectsorifanabnormalvibrationoccurs.Make

necessaryrepairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Keeppetsandbystandersaway.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesifnot

mowing.

Maintenanceandstorage

•Disengagedrives,setparkingbrake,stopengineand

removekeyordisconnectsparkplugwire.Waitfor

allmovementtostopbeforeadjusting,cleaningor

repairing.

•Cleangrassanddebrisfromcuttingunit,drives,

mufers,andenginetohelppreventres.Cleanup

oilorfuelspillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransporting.Donot

storefuelnearamesordrainindoors.

•Parkmachineonlevelground.Setparkingbrake.

Neverallowuntrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatteryorremovesparkplugwire

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositivelast.Reconnectthe

positiverstandnegativelast.

•Usecarewhencheckingblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.

Onlyreplaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

ToroMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsandothersafetyinformationyoumust

know .

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

4

Page 5

Thisproductisdesignedforcuttingandrecyclinggrass

or,whenequippedwithagrassbagger,forcatching

cutgrass.Anyuseforpurposesotherthanthesecould

provedangeroustouserandbystanders.

GeneralOperation

•Besuretheareaisclearofotherpeoplebefore

mowing.Stopthemachineifanyoneentersthearea.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowtocoolbefore

attemptingtomaintain,adjustorservice.

•UseonlyToro-approvedattachments.Warrantymay

bevoidedifusedwithunapprovedattachments.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

operatingunderanyobjectsanddonotcontact

them.

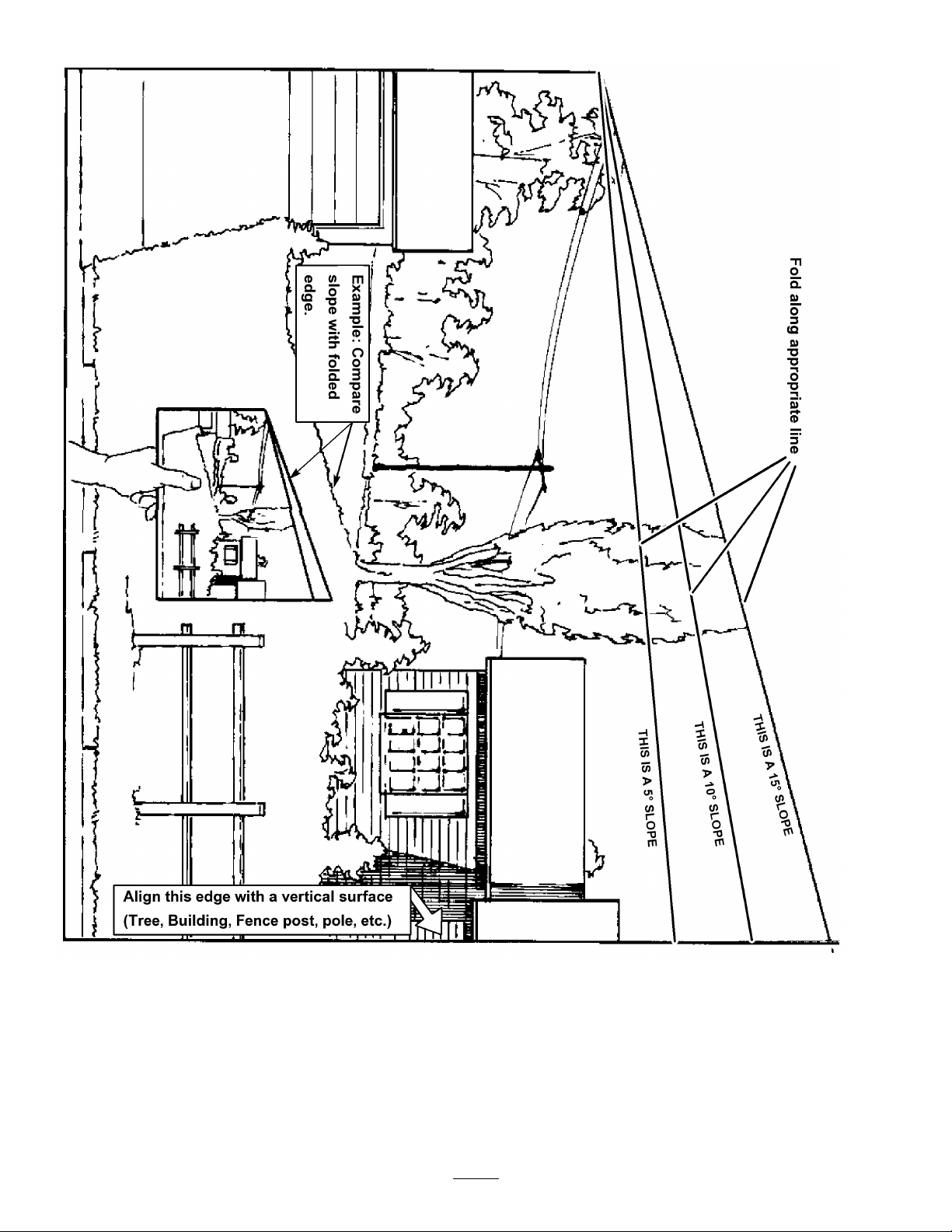

SlopeOperation

•Useonlygenuinereplacementpartstoensurethat

originalstandardsaremaintained.

•Checkbrakeoperationfrequently.Adjustandservice

asrequired.

Allslopesandrampsrequireextracaution.Ifyoufeel

uneasyonaslope,donotmowit.

•Removeobstaclessuchasrocks,treelimbs,etc.from

themowingarea.

•Watchforholes,rutsorbumps.Tallgrasscanhide

obstacles.

•Usecautionneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyturnoverifawheel

goesovertheedgeofaclifforditch,orifanedge

cavesin.

•Useextracarewithgrasscatchersorother

attachments.Thesecanchangethestabilityofthe

machine.

•Keepallmovementonslopesslowandgradual.Do

notmakesuddenchangesinspeedordirection.

•Mowslopessidetoside.

•Donotmowslopesgreaterthan15degrees.

Service

•Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

•Keepnutsandboltstight,especiallytheblade

attachmentboltsandnuts.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.Checksafety

systemsforproperoperationbeforeeachuse.

5

Page 6

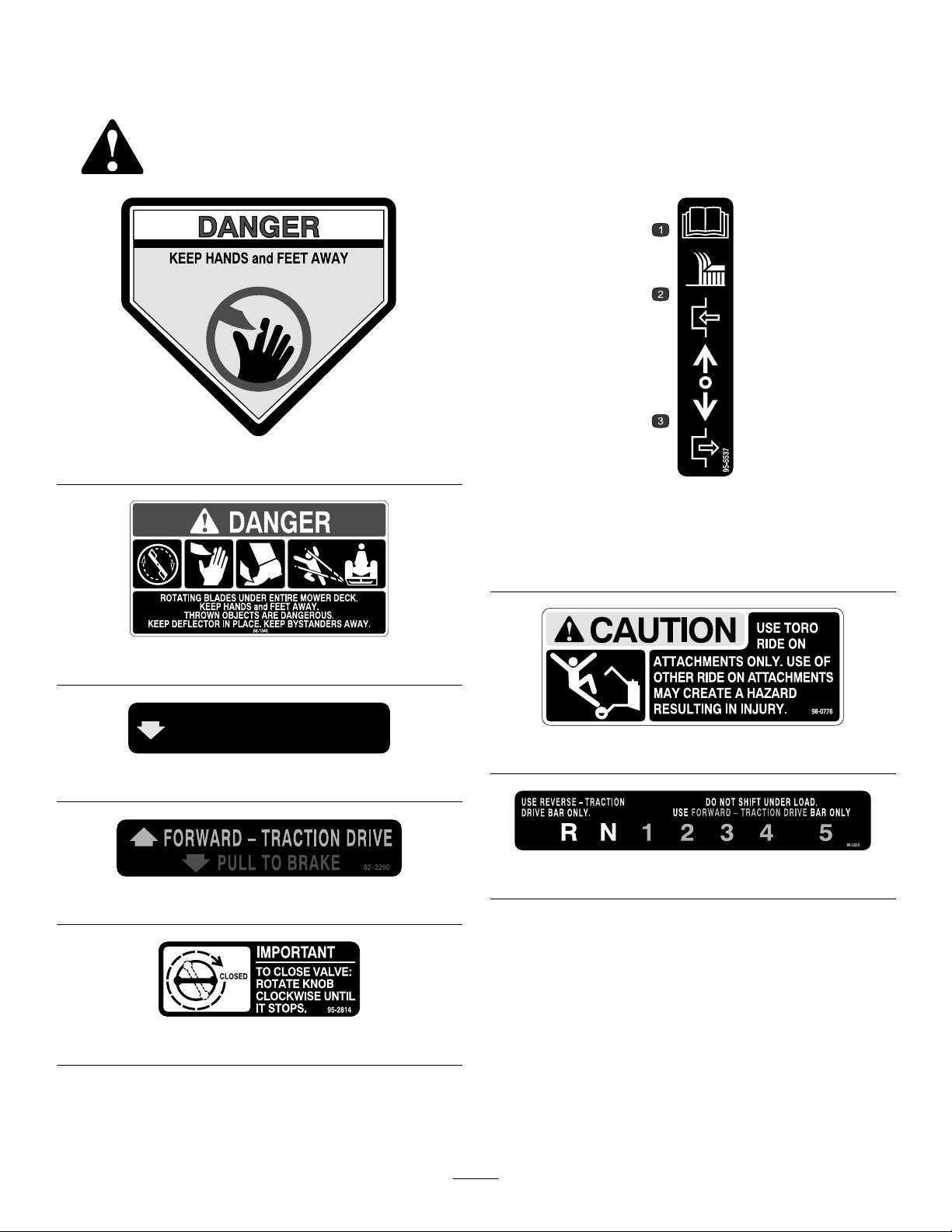

SlopeChart6SafetyandInstructional

Decals

Page 7

82- 2280

REV E R SE TRACT ION DR I V E

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

43-8480

95-5537

1.ReadtheOperator’s

Manualforinstructionson

operatingthecuttingblade

2.Pushforwardtoengage

3.Pullbacktodisengage

66-1340

98-0776

82-2280

98-3256

82-2290

95-2814

7

Page 8

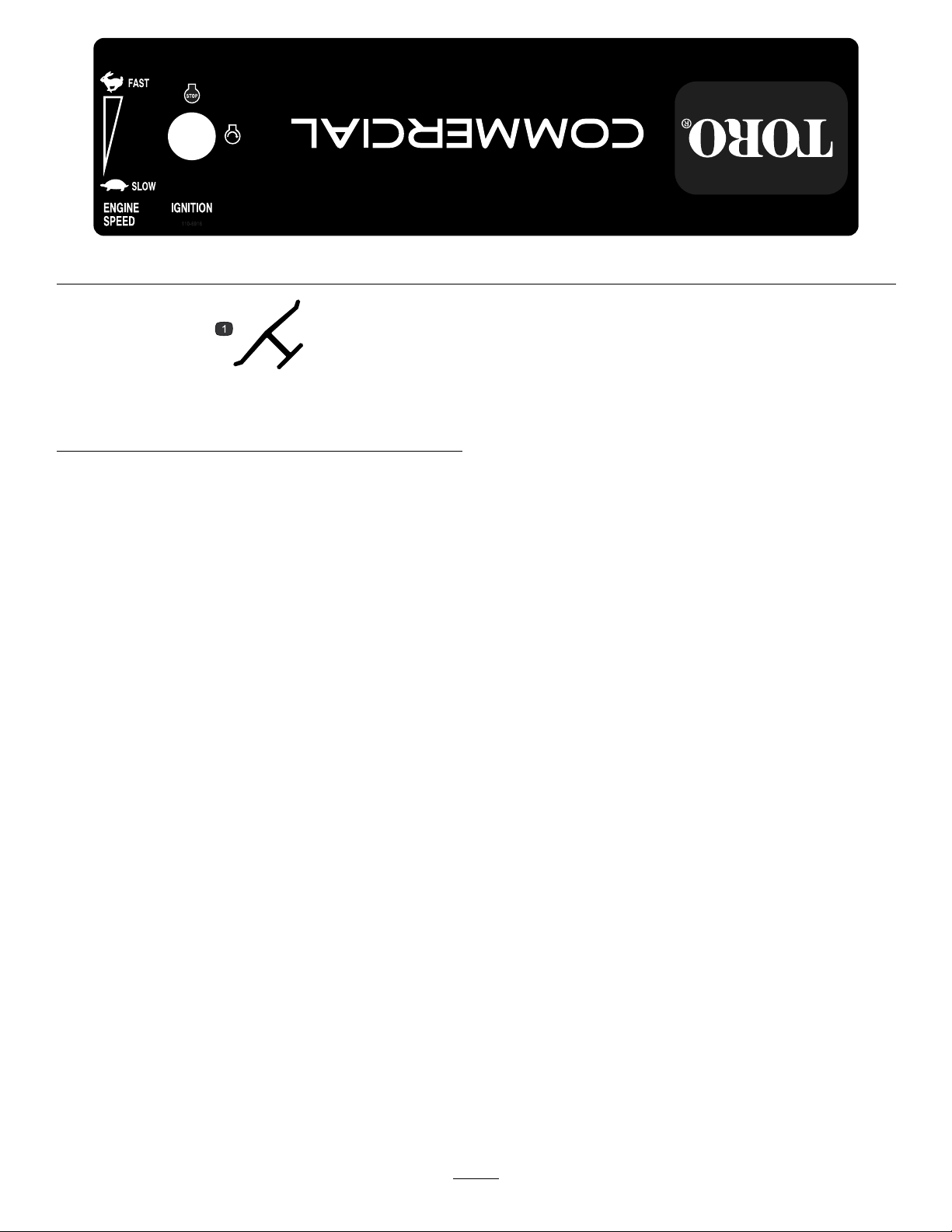

1.Warning—wearhearingprotection.

98-5954

98-3266

98-3296

98-4387

104-8569

98-5130

1.Warning—readtheOperator’sManualforinstructionson

torquingthebladebolt/nutto75-80ft-lb(102-106N⋅m).

106-0699

105-0884

8

Page 9

Manufacturer’sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

110-6916

9

Page 10

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Nopartsrequired

Operator’sManual

EngineOperator’sManual

PartsCatalog

SafetyVideo/DVD

RegistrationCard

Oildrainhose

1

CheckingtheFluidsandTire

Pressure

NoPartsRequired

ReadingtheManualand

ViewingtheSafetyInformation

Partsneededforthisprocedure:

Qty.

–

1

1

1

1

1

1

2

Use

Checktheuidsandtirepressure.

ReadtheOperator’sManualandwatch

thevideobeforeoperatingthemachine.

Procedure

•Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheEngineOilLevel.

•Checkthegreaseforthemowerandmowerdeck.

•Checkthetirepressure;refertoCheckingtheTire

Pressure.

Note:Thecuttingbladesaresettoa3inch(76mm)

height-of-cutatinitialpurchase.TheaxlepositionisD,

with4spacersbelowboththespindleandthecaster.

1

Operator’sManual

1

EngineOperator’sManual

1

PartsCatalog

1

SafetyVideo/DVD

1

RegistrationCard

1

Oildrainhose

Procedure

•ReadtheOperator’sManual.

•Viewthesafetyvideo.

•Fillouttheregistrationcardandmailitinorregister

onlineatwww .Toro.com.

•Usetheoildrainhosewhenchangingtheengineoil.

10

Page 11

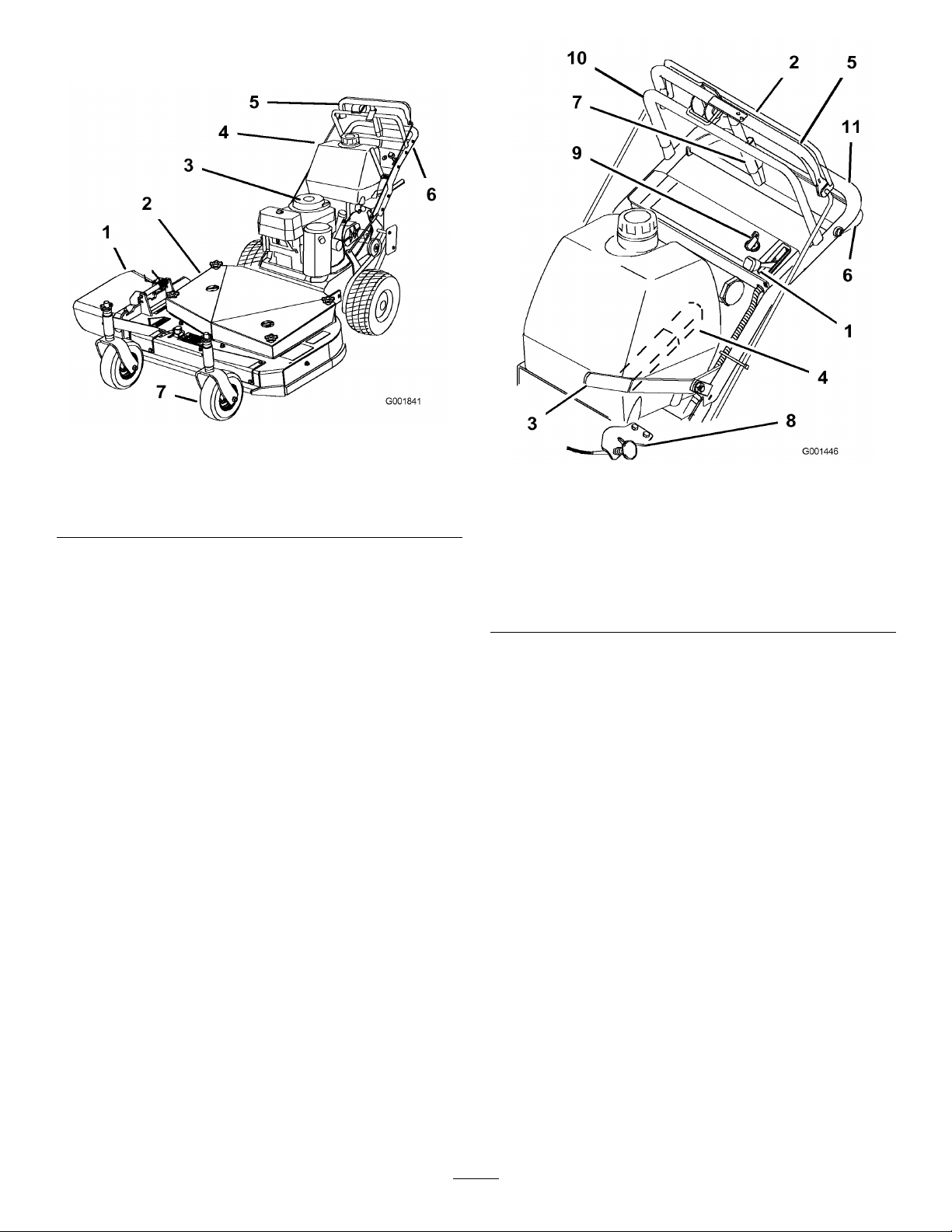

ProductOverview

Figure3

1.Sidedischarge

2.Mowerdeck6.Handle

3.Recoilstarter7.Frontcasterwheel

4.Gastank

Controls

Becomefamiliarwithallthecontrols(Figure4)before

youstarttheengineandoperatethemachine.

5.T-barcontrol

Figure4

1.Throttlecontrol7.Parkingbrake

2.Bladecontrolbail

3.Powertakeofflever(PTO)

4.Gearshiftlever

5.Uppercontrolbar11.Lowerhandle

6.Lowercontrolbar

lever-releasedposition

8.Choke

9.Ignitionswitch

10.Upperhandle

ThrottleControl

Thethrottlecontrolhastwopositions:FastandSlow.

BladeControlBail

Thebailisusedinconjunctionwiththebladecontrol

lever(PTO)toengagetheclutchanddrivethemower

blades.Releasingthebladecontrolbailwillstopthe

enginewiththePTOengaged.

BladeControlLever(PTO)

Thisleverisusedinconjunctionwiththebladecontrol

bailtoengageanddisengagethemowerdeckbeltand

drivethemowerblades.

GearShiftLever

Thetransmissionhasveforwardspeeds,neutraland

reverse,andhasanin-lineshiftpattern.

Important:Donotshiftwhileunitismoving,as

transmissiondamagemayoccur.

11

Page 12

UpperControlBar

Shifttothedesiredgearandpushforwardontheupper

controlbarandbladecontrolbailtoengageforward

tractionoperationandpullbacktobrakeforward

movement.Pullbackonrightsideofuppercontrolbar

toturnrightandleftsidetoturnleft.

LowerControlBar

Shifttransmissiontoreverseandsqueezethelower

controlbarandhandletogethertoengagetherearward

tractionassist.

ParkingBrakeLever

Pullbackonuppercontrolbarandswingbrakelever

upagainsttheupperhandletosettheparkingbrake

(Figure4).

IgnitionSwitch

Thisswitchisusedinconjunctionwithrecoilstarterand

hastwopositions:RunandOff.

Height

Weight

41inches(104.1cm)

460lb(209kg)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

RecoilStarter

Pullrecoilstarterhandletostartengine(notshownin

Figure4).

FuelShut-offValve

Closethefuelshut-offvalvewhentransportingor

storingmower.

Choke

Usethechoketostartacoldengine.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

32inchmowers:

Widthwithdeectordown45.8inches(1 16.3cm)

Length

Height

Weight

72inches(183cm)

41inches(104.1cm)

400lb(181kg)

36inchmowers:

Widthwithdeectordown46.6inches(1 18.4cm)

Length

74inches(188cm)

12

Page 13

Operation

AddingFuel

UseUnleadedRegularGasolinesuitablefor

automotiveuse(85pumpoctaneminimum).Leaded

regulargasolinemaybeusedifunleadedregularisnot

available.

Important:Neverusemethanol,gasoline

containingmethanol,orgasoholcontainingmore

than10%ethanolbecausethefuelsystemcouldbe

damaged.Donotmixoilwithgasoline.

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupany

gasolinethatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4

to1/2inch(6to13mm)belowthebottomof

thellerneck.Thisemptyspaceinthetank

allowsgasolinetoexpand.

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethegasolinevapors.Are

orexplosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowtheloss

ofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancauseserious

injuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Keepgasawayfromeyesandskin.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysor

less.Forlongerstorageitisrecommendedthatthe

fueltankbedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

13

Page 14

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountofgas

stabilizer/conditionertothegas.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshgasoline.To

minimizethechanceofvarnishdepositsinthefuel

system,usefuelstabilizeratalltimes.

FillingtheFuelTank

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundfueltankcapandremovethecap.

Addunleadedregulargasolinetofueltank,untilthe

levelis1/4to1/2inch(6to13mm)belowthe

bottomofthellerneck.Thisspaceinthetank

allowsgasolinetoexpand.Donotllthefueltank

completelyfull.

3.Installfueltankcapsecurely.Wipeupanygasoline

thatmayhavespilled.

ThinkSafetyFirst

Carefullyreadallthesafetyinstructionsanddecalsin

thesafetysection.Knowingthisinformationcould

helpyouoranybystandersavoidinjury.

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

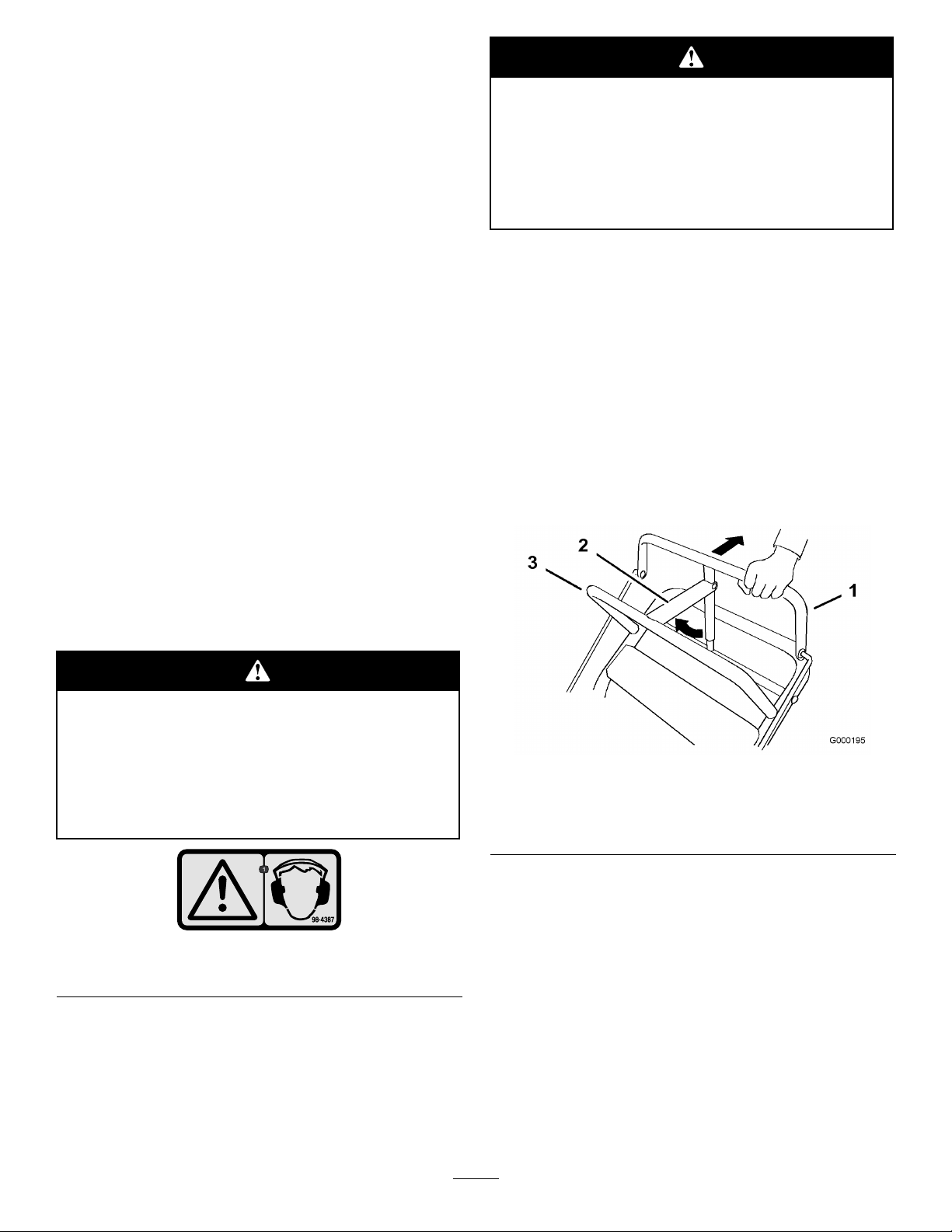

SettingtheParkingBrake

1.Pulltheuppercontrolbarrearwardandholditin

thisposition(Figure6).

2.Lifttheparkingbrakelockupandgraduallyrelease

theuppercontrolbar.Thebrakelockshouldstayin

theset(locked)position(Figure6).

ReleasingtheParkingBrake

1.Pullrearwardontheuppercontrolbar.Lowerthe

parkingbrakelocktothereleasedposition.

2.Graduallyreleasetheuppercontrolbar.

Theuseofprotectiveequipmentforeyes,hearing,feet

andheadisrecommended.

Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

Figure5

1.Warning—wearhearingprotection.

OperatingtheParkingBrake

Stoponlevelground,disengagedrives,engageparking

brake,shutoffengineandremovekey.Alwayssetthe

parkingbrakewhenyoustopthemachineorleaveit

unattended.

Figure6

1.Uppercontrolbar3.Fixedbar

2.Parkingbrakelever-set

position

StartingandStoppingthe

Engine

StartingtheEngine

1.Connectthewirestothesparkplugs.

2.Openthefuelvalve.

3.Disengagethebladecontrol(PTO)leverandmove

theshiftlevertotheneutralposition.

4.Settheparkingbrakes.

5.Turntheignitionkeytotherunposition(Figure7).

14

Page 15

6.Tostartacoldengine,movethethrottlecontrol

midwaybetweenthefastandslowpositions.

7.Tostartawarmengine,movethethrottlecontrol

tothefastposition.

8.Pullthechokeknobiftheengineiscold(Figure7).

5.Pullwireoffsparkplug(s)topreventpossibilityof

accidentalstartingbeforestoringorperforming

maintenanceonthemachine.

6.Closethefuelshutoffvalvebeforestoringor

transportingthemachine.

Note:Awarmorhotengineusuallydoesnot

requireanychoking.

9.Grasptherecoilstarterhandlermlyandpullit

outuntilpositiveengagementresults;thenpullthe

handlevigorouslytostarttheengine.Allowthe

ropetorecoilslowly .

Important:Donotpulltherecoilropetoits

limitorreleasethestarterhandlewhenyoupull

outtheropebecausetheropemaybreakorthe

recoilassemblymaybedamaged.

10.Pushthechoketooffastheenginewarmsup.

11.Iftheengineiscold,allowittowarmupandthen

movethethrottlecontroltothefastposition.

StoppingtheEngine

Important:Inanemergency ,youcanstopthe

engineimmediatelybyturningtheignitionkeyto

the

of f

position.

1.Movethethrottlelevertotheslowposition

(Figure7).

Important:Makesurefuelshutoffvalveis

closedbeforetransportingorstoringmachine,

asfuelleakagemayoccur.

OperatingtheBladeControl

Lever(PTO)

Thebladecontrollever(PTO)engagesanddisengages

powertothemowerblades.

EngagingtheMowerBlades

1.Toengagetheblades,squeezebladecontrolbail

againsttheuppercontrolbar(Figure8).

2.Pushthebladecontrolleverrmlyforward,untilit

latchesover-center.

3.Restarttheengineandrepeattheprocedureto

engagethemowerbladesifthebladecontrolbail

isreleased.

2.Letengineidlefor30to60secondsbeforeturning

theignitionkeytooff.

3.Turntheignitionkeytooff(Figure7).

Figure7

1.Bladecontrollever(PTO)

2.Throttlelever

3.Ignitionkey

4.Settheparkingbrakeandremovekey.

Figure8

1.Uppercontrolbar

2.Bladecontrolbail

3.Bladecontrollever(PTO)

DisengagingtheMowerBlades(PTO)

Todisengagetheblades,pullthebladecontrollever

rearwardalltheway(Figure8).Theenginewillkill

whenthebladecontrolbailisreleasedwiththeblade

controlleverengaged.

15

Page 16

Note:Itisnecessarytofullyandmanuallydisengage

thebladecontrollever.

throttlecontrolinthefastpositionforbestmowing

performance.

TheSafetyInterlockSystem

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Thesafetyinterlocksystemisdesignedtopreventthe

enginefromstartingwhen:

•Thebladecontrollever(PTO)isengaged.

•Theignitionkeyisoff.

Thesafetyinterlocksystemisalsodesignedtostopthe

enginewhen:

•Thebladecontrolbailisreleasedwiththeblade

controllever(PTO)engaged.

DrivingForward

1.Togoforward,movetheshiftlevertoaforward

gear(Figure9).

2.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake.

3.Slowlypressontheuppercontrolbartomove

forward(Figure9).

Togostraight,applyequalpressuretobothendsof

theuppercontrolbar(Figure9).

Toturn,releasepressureontheuppercontrolbar

sideinthedirectionyouwanttoturn(Figure9).

•Theignitionswitchisturnedtotheoffposition.

TestingtheSafetyInterlockSystem

Testthesafetyinterlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow ,haveanAuthorizedService

Dealerrepairthesafetysystemimmediately .

1.Settheparkingbrake,disengagethePTOandplace

thethrottleforward.

2.Starttheengine.

3.Withtheenginerunningsqueezethebladecontrol

bailagainstuppercontrolbarandpushthemower

bladecontrolleverforward.Themowerblades

beginrotating.

4.Withtheenginerunning,releasethebladecontrol

bail.Theengineshouldstop.

5.Starttheengineagain.

6.Withtheenginerunning,turnthekeyswitchtothe

offposition.Theengineshouldstop.

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedas

measuredinRPM(revolutionsperminute).Placethe

Figure9

1.Uppercontrolbar

2.Lowercontrolbar4.Lowerhandle

3.Shiftlever

DrivingBackward

1.Togobackward,movetheshiftlevertoreversegear.

2.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake.

3.Slowlysqueezethelowercontrolbarandlower

handletogethertomoverearward(Figure9).

UsingtheLowerControlBar

Thisprocedureisfordrivingupacurb.Thiscanbe

performedwhiledrivingforwardorbackward.

Note:Somecurbsdonotallowthereardrivetiresto

contactthecurb.Ifthishappens,drivethemachineup

thecurbatanangle.

16

Page 17

Abladecanbebentordamagedwhendriving

upacurb.Piecesofbladethatmaybethrown

couldseriouslyinjureorkillyouorbystanders.

Donotrunbladeswhiledrivingupacurb

forwardorbackward.

DrivingBackwardUpaCurb

1.Disengagethemowerblades.

2.Selectreversetodrivethemachine.

3.Drivethemachineuntildrivewheelscontactcurb

(Figure10).

Note:Bothdrivewheelsshouldcontactthecurb

andcasterwheelsstraight.

DrivingForwardUpaCurb

1.Disengagethemowerblades.

2.Selectrstgeartodrivethemachine.

3.Drivemachineuntilthecastorwheelscontactcurb

(Figure10).

4.Liftthefrontofthemachinebypushingdownon

thelowerhandle(Figure10).

5.Drivethemachineuntildrivewheelscontactthe

curb(Figure10).

6.Lowerthefrontofthemachine(Figure10).

Note:Bothdrivewheelsshouldcontactthecurb

andcasterwheelsstraight.

7.Atthesametimeengagethelowercontrolbarand

liftuponthelowerhandletodriveoverthecurb

(Figure9andFigure10).

Note:Liftinguponthelowerhandlewillassist

drivingthemachineupacurbandnotspinthe

drivewheels.

4.Atthesametimeengagelowercontrolbarandlift

uponthelowerhandle(Figure9andFigure11).

Note:Liftinguponthelowerhandlewillassist

drivingthemachineupacurbandnotspinthe

drivewheels.

Figure11

1.Lowercontrolbar

(engaged)

2.Handle

1.LowerControlBar

engagedandmower

inreverse.

2.Pulluptoassistmachine

Figure10

3.LowerControlBar

engagedandmower

goingforward.

StoppingtheMachine

Tostopthemachine,pullbackontheuppercontrol

bar,releasethebladecontrolbail,turntheignitionkey

tooffandsettheparkingbrake;refertoSettingthe

ParkingBrakeinOperation,page13.Rememberto

removethekeyfromtheignitionswitch.

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

17

Page 18

TransportingMachines

AdjustingtheBladeHeight

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarylightingandmarkingasrequiredbylaw .

Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily ,

petsorbystandersavoidinjury.

Totransportthemachine:

1.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

2.Securelyfastenthemachinetothetrailerortruck

withstraps,chains,cable,orropes.

3.Ifusingatrailer,securethetrailertothetowing

vehicleandinstallthesafetychains.

SideDischargingorMulching

theGrass

Thismowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

Adjustthebladesbyusingthe4spacers(1/4inch)

(6mm)onthebladespindlebolts.Thisallowsfora

1-inch(25mm)adjustmentrange,in1/4inch(6mm)

increments,ofcuttingheightinanyaxleposition.Use

thesamenumberofbladespacersonallbladesto

achievealevelcut(2aboveand2below,1aboveand3

below,etc.).

1.Disengagethebladecontrol(PTO)leverandset

theparkingbrakes.

2.Stoptheengineandwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Holdthebladeboltandremovethenut(Figure12).

Withoutthegrassdeector,dischargecover,

orcompletegrasscatcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebriswill

causeinjuryordeath.

•Neverremovethegrassdeectorfrom

themowerbecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mower.

•Nevertrytocleardischargeareaormower

bladesunlessyoureleasethebailandthe

powertakeoff(PTO)isoff.Rotatethe

ignitionkeytoOff.Alsoremovethekeyand

pullthewiresoffthesparkplug(s).

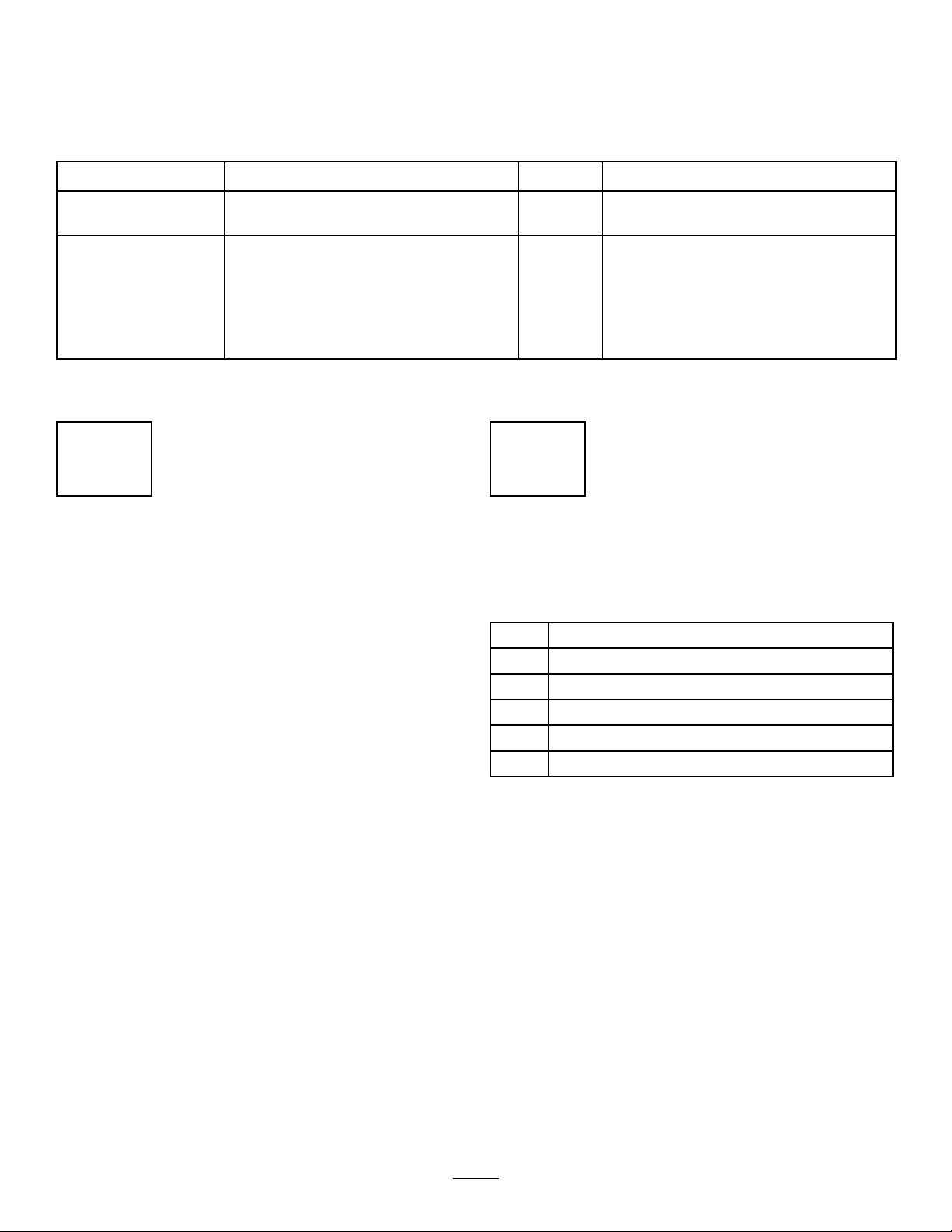

AdjustingtheHeight-of-Cut

Thismachinehasa1to4-1/4inch(26to108mm)

rangefortheheight-of-cut.Thiscanbeachievedby

adjustingbladespacers,rearaxleheight,andfront

casterspacers.UsetheHeight-of-CutCharttoselect

thecombinationofadjustmentsrequired.

Figure12

1.Blade

2.Bladebolt5.Thinwasher

3.Curvedwasher

4.Slidetheboltdownthroughthespindle,andchange

thespacersasneeded(Figure12).

5.Installtheboltandcurvedwasher,addextra

spacer(s),andsecurethemwithathinwasheranda

nut(Figure12).

6.Torquethebladeboltto75-80ft-lb(101-108N•m).

4.Spacer

6.Nut

18

Page 19

AdjustingtheAxleHeight

Adjusttheaxlepositiontotheselectedheight-of-cut

setting.RefertotheHeight-of-CutChart.

1.Disengagethebladecontrol(PTO)leverandset

theparkingbrakes.

2.Stoptheengineandwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Loosen,butdonotremove,the2axlepivotbolts

andthe2axleadjustmentbolts(Figure13).

Figure13

1.Axlepivotbolt2.Axleadjustmentbolt

Figure14

1.Latchpin

2.Spacer,3/16inch(5mm)

3.Spacer,1/2inch(13mm)

2.Removethelatchpin,slidethecasterfromthe

support,andchangethespacers(Figure14).

3.Installthecasterinthesupportandinsertthevpin

(Figure14).

AdjustingtheHandleHeight

4.Placeajackundertherearcenteroftheengine

frame.Raisethebackendoftheengineframeup

enoughtoremovethefront2axleadjustmentbolts

(Figure13).

Note:Usejackstandstosupportthemachine.

5.Raiseorlowertheengineframewiththejackso

thatyoucaninstallthefront2axleadjustmentbolts

inthedesiredholelocation(Figure13).

Note:Useataperedpunchtohelpaligntheholes.

6.Tightenall4boltsandlowerthemower.

7.Adjustthecontrolrodsandthebrakelinkages

asrequired.RefertoServicingtheBrakesand

AdjustingtheControlRods.

Important:Youmustadjustthecontrolrods

andthebrakelinkagewhenyouchangethe

axlepositionsforpropertractionandbrake

function.

AdjustingtheCasterPosition

Thehandlepositioncanbeadjustedtomatchthe

operator’sheightpreference.

1.Removehairpincotter,washerandclevispin

securingcontrolrodttingtoidlerbracket

(Figure15).

Figure15

1.Controlrod4.Clevispin

2.Controlrodtting

3.Idlerbracket6.Hairpincotterpin

5.Washer

1.UsingtheHeight-of-CutChart,adjustthecaster

spacerstomatchwiththeaxleholeselected

(Figure14).

2.Loosentheupperangebolts(3/8x1inch)and

angenutsecuringhandletorearframe(Figure16).

19

Page 20

Figure16

1.Upperhandle

2.Rearframe

3.Flangebolt(3/8x1inch)

4.Locknut(3/8inch)

5.Uppermountinghole

6.Lowermountinghole

3.Removethelowerangebolts(3/8x1inch)

andangenutssecuringhandletorearframe

(Figure16).

4.Pivothandletodesiredoperatingpositionand

installlowerangebolts(3/8x1inch)andange

nutsintomountingholes.Tightenallangebolts.

5.Threadrodttingupordownonroduntilproper

positionisattainedandinstallintottingtoidler

bracketwithclevispin,washerandhairpincotter.

6.Checktheparkingbrakeadjustment.Referto

CheckingtheBrakesinBrakeMaintenance,

page30.

20

Page 21

HeightofCutChart

Numberofspacers

1/2inch

AxlePosition

A00

A01

A10

B01

B10

B11

B20

C

C

C

C

D21

D30

D31

D40

E31

E40

E41

(13mm)

11

20

21

30

belowcaster

3/16inch(5

mm)

1inch(26

1–1/8inch

(29mm)

1–3/8inch

(35mm)

1–3/8inch

(35mm)

1–5/8inch

(41mm)

1–3/4inch

(45mm)

2inch(51

1–7/8inch

(48mm)

2–1/8inch

(55mm)

2–1/4inch

(57mm)

2–1/2inch

(64mm)

2–3/8inch

(61mm)

2–1/2inch

(64mm)

2–3/4inch

(70mm)

3inch(76

2–7/8inch

(73mm)

3–1/8inch

(79mm)

3–1/4inch

(82mm)

Numberof1/4inchbladespacersbelowspindle

43210

mm)

mm)

mm)

1–1/4inch

(32mm)

1–3/8inch

(35mm)

1–5/8inch

(41mm)

1–5/8inch

(41mm)

1–7/8inch

(48mm)

2inch(51

mm)

2–1/4inch

(57mm)

2–1/8inch

(54mm)

2–3/8inch

(60mm)

2–1/2inch

(64mm)

2–3/4inch

(70mm)

2–5/8inch

(67mm)

2–3/4inch

(70mm)

3inch(76

mm)

3–1/4inch

(82mm)

3–1/8inch

(79mm)

3–3/8inch

(86mm)

3–1/2inch

(89mm)

1–1/2inch

(38mm)

1–5/8inch

(41mm)

1–7/8inch

(48mm)

1–7/8inch

(48mm)

2–1/8inch

(54mm)

2–1/4inch

(57mm)

2–1/2inch

(64mm)

2–3/8inch

(60mm)

2–5/8inch

(67mm)

2–3/4inch

(70mm)

3inch(76

2–7/8inch

(73mm)

3inch(76

3–1/4inch

(82mm)

3–1/2inch

(89mm)

3–3/8inch

(86mm)

3–5/8inch

(92mm)

3–3/4inch

(95mm)

1–3/4inch

(45mm)

1–7/8inch

(48mm)

2–1/8inch

(54mm)

2–1/8inch

(54mm)

2–3/8inch

(60mm)

2–1/2inch

(64mm)

2–3/4inch

(70mm)

2–5/8inch

(67mm)

2–7/8inch

(73mm)

3inch(76

mm)

mm)

mm)

3–1/4inch

(83mm)

3–1/8inch

(79mm)

3–1/4inch

(82mm)

3–1/2inch

(89mm)

3–3/4inch

(95mm)

3–5/8inch

(92mm)

3–7/8inch

(98mm)

4inch(102

mm)

2inch(51

mm)

2–1/8inch

(54mm)

2–3/8inch

(60mm)

2–3/8inch

(60mm)

2–5/8inch

(67mm)

2–3/4inch

(70mm)

3inch(76

mm)

2–7/8inch

(73mm)

3–1/8inch

(79mm)

3–1/4inch

(83mm)

3–1/2inch

(89mm)

3–3/8inch

(86mm)

3–1/2inch

(89mm)

3–3/4inch

(95mm)

4inch(102

mm)

3–7/8inch

(98mm)

4–1/8inch

(105mm)

4–1/4inch

(108mm)

21

Page 22

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst25hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every200hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthemowerbelttension.

•Checkthemowerbelttension.

•Checkthesafetysystem.

•Greasethecasterwheelsandcasterpivot.

•Checktheengineoillevel.

•Cleantheairintakescreen.

•Checkthebrakes.

•Inspecttheblades.

•Cleanthemowerdeck.

•Cleanfoamaircleanerelement.

•Greasethemowerbeltidler .

•Checkthepaperaircleanerelement.

•Checkthetirepressure.

•Checkthebelts.

•Checkthemowerbelttension.

•Changetheengineoil.

•Checkthesparkplugs.

•Checkandcleanenginecoolingnsandshrouds.

•Replacethepaperaircleanerelement.

•Replacetheoillter.

•Replacethefuellter.

Every250hours

Every400hours

Beforestorage

•Greasethetransmissioncouplers(moreoftenindirtyordustyconditions).

•Greasethewheelbearings(moreoftenindirtyordustyconditions).

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator’smanualforadditionalmaintenanceprocedures.

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnectthesparkplugwirefromthesparkplug(s)beforeyou

doanymaintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

Lubrication

GreasewithNo.2generalpurposelithiumbaseor

molybdenumbasegrease.

HowtoGrease

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

22

Page 23

3.Cleanthegreasettingswitharag.Makesureto

scrapeanypaintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pumpgrease

intothettingsuntilgreasebeginstooozeoutof

thebearings.

5.Wipeupanyexcessgrease.

LubricatingtheCasterand

WheelBearings

1.Lubricatethefrontwheelbearingsandfrontspindles

(Figure17).

Note:Removethemowerdeckcovertoaccessthe

greasettingforthemowerbeltidlerarm.

2.Lubricatethedrivewheelbearings(

Figure17

Figure17).

GreasingtheTransmission

Couplers

Lubricatethetransmissioncouplersandidlerarmpivots

locatedinthebackofthemachine(Figure18).

Figure19

Figure18

GreasingtheMowerBeltIdler

Greasethettingonthemowerbeltidlerarmpivot

(Figure19).

23

Page 24

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval/Specication

Foamelement:Cleanitafterevery25operatinghours.

Paperelement:Checkitafterevery50operatinghours.

Replaceitafterevery200operatinghoursoryearly,

whichevercomesrst.

Inspectthefoamandpaperelementsandreplacethem

iftheyaredamagedorexcessivelydirty.

Note:Servicetheaircleanermorefrequently(every

fewoperatinghours)iftheoperatingconditionsare

extremelydustyorsandy .

Important:Donotoilthefoamorpaperelement.

RemovingtheFoamandPaper

Elements

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Cleanaroundtheaircleanertopreventdirt

fromgettingintotheengineandcausingdamage

(Figure20).

4.Unscrewthecoverknobandremovetheaircleaner

cover(Figure20).

5.Removethe2wingnutsandremovetheaircleaner

assembly(Figure20).

6.Carefullypullthefoamelementoffthepaper

element(Figure20).

Figure20

1.Engine4.Foamelement

2.Cover

3.Wingnut

5.Paperelement

6.Coverknob

CleaningtheFoamAirCleanerElement

1.Washthefoamelementinliquidsoapandwarm

water.Whentheelementisclean,rinseitthoroughly.

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifitis

tornorworn.

ServicingthePaperAirCleaner

Element

1.Donotcleanthepaperlter.Replaceitafter200

operatinghours(Figure20).

2.Inspecttheelementfortears,anoilylm,ordamage

totherubberseal.

3.Replacethepaperelementifitisdamaged.

InstallingtheFoamandPaperElements

Important:Topreventenginedamage,always

operatetheenginewiththecompletefoamand

paperaircleanerassemblyinstalled.

1.Carefullyslidethefoamelementontothepaperair

cleanerelement(Figure20).

24

Page 25

2.Placetheaircleanerassemblyontotheaircleaner

baseandsecureitwiththe2wingnuts(Figure20).

3.Placetheaircleanercoverintopositionandtighten

thecoverknob(Figure20).

ServicingtheEngineOil

ServiceInterval/Specication

Changetheengineoilasfollows:

•Aftertherst8operatinghours

•Afterevery100operatinghours

Note:Changetheoilmorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

OilType:Detergentoil(APIserviceSF ,SG,SH,

orSJ)

CrankcaseCapacity:58ounces(1.7liter)withthe

lterremoved;51ounces(1.5liter)withoutthelter

removed

Viscosity:Refertothetablein(

Figure21).

Figure22

1.Oildipstick

2.Fillertube

5.Unscrewtheoildipstickandwipetheendclean

(Figure22).

6.Slidetheoildipstickfullyintothellertube,butdo

notthreadontotube(Figure22).

7.Pullthedipstickoutandlookattheend.Iftheoil

levelislow,slowlypouronlyenoughoilintotheller

tubetoraisetheleveltotheFullmark.

Important:Donotoverllthecrankcasewith

oilandruntheengine;enginedamagecan

result.

ChangingtheOil

1.Starttheengineandletitrunveminutes.This

warmstheoilsoitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

Figure21

CheckingtheEngineOilLevel

1.Parkthemachineonalevelsurface.

2.DisengagethePTOandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Cleanaroundtheoildipstick(Figure22)sothatdirt

cannotfallintothellerholeanddamagetheengine.

3.DisengagethePTOandsettheparkingbrake.

4.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

5.Slidethedrainhoseovertheoildrainvalve.

6.Placeapanbelowthedrainhose.Rotateoildrain

valvetoallowoiltodrain(Figure23).

7.Whenoilhasdrainedcompletely,closethedrain

valve.

8.Removethedrainhose(Figure23).

Note:Disposeoftheusedoilatarecyclingcenter.

25

Page 26

3.Applyathincoatofnewoiltotherubbergasketon

thereplacementlter(Figure24).

4.Installthereplacementoilltertothelteradapter,

turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional3/4turn(Figure24).

5.Fillthecrankcasewiththepropertypeofnewoil;

refertoServicingtheEngineOil.

6.Runtheengineforabout3minutes,stoptheengine,

andcheckforoilleaksaroundtheoillteranddrain

valve.

7.Checktheengineoillevelandaddoilifneeded.

ServicingtheSparkPlugs

Figure23

1.Oildrainvalve2.Oildrainhose

9.Slowlypourapproximately80%ofthespeciedoil

intothellertube(Figure22).

10.Checktheoillevel;refertoCheckingtheEngineOil

Level.

11.SlowlyaddtheadditionaloiltobringittotheFull

mark.

ChangingtheOilFilter

Replacetheoillterevery200operatinghoursorevery

otheroilchange.

Note:Changetheoilltermorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy .

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

2.Removetheoldlter(Figure24).

ServiceInterval/Specication

Checkthesparkplugsafterevery100operatinghours.

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstallingthe

sparkplugsandagappingtool/feelergaugetocheckand

adjusttheairgap.Installanewsparkplugsifnecessary.

Type:Champion®RCJ8YorequivalentAirGap:

0.030inch(0.75mm)

RemovingtheSparkPlugs

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Disconnectthewiresfromthesparkplugs

(Figure25).

1.Oillter

Figure24

2.Adapter

26

Page 27

Figure25

1.Spark-plugwire/sparkplug

4.Cleanaroundthesparkplugstopreventdirtfrom

fallingintotheengineandpotentiallycausing

damage.

Important:Alwaysreplacethesparkplugs

whenithasablackcoating,wornelectrodes,

anoilylm,orcracks.

3.Checkthegapbetweenthecenterandsideelectrodes

(Figure26).Bendthesideelectrode(Figure26)if

thegapisnotcorrect.

InstallingtheSparkPlugs

1.Installthesparkplugsandthemetalwasher.Ensure

thattheairgapissetcorrectly.

2.Tightenthesparkplugsto16ft-lb(22N•m).

3.Connectthewirestothesparkplugs(Figure26).

5.Removethesparkplugsandthemetalwashers.

CheckingtheSparkPlugs

1.Lookatthecenterofthesparkplugs(Figure26).

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly .Ablackcoatingonthe

insulatorusuallymeansthattheaircleanerisdirty.

2.Ifneeded,cleanthesparkplugwithawirebrushto

removecarbondeposits.

Figure26

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

27

Page 28

FuelSystem

Maintenance

ServicingtheFuelTank

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopen

area.Wipeupanygasolinethatspills.

Figure27

1.Fuelshut-offvalve2.Clamp

•Neversmokewhendraininggasoline,and

stayawayfromanopenameorwherea

sparkmayignitethegasolinefumes.

DrainingtheFuelTank

1.Parkthemachineonalevelsurface,toassurefuel

tankdrainscompletely.Thendisengagethepower

takeoff(PTO),settheparkingbrake,andturnthe

ignitionkeytooff.Removethekey.

2.Closethefuelshut-offvalveatthefueltank

(Figure27).

3.Squeezetheendsofthehoseclamptogether

andslideitupthefuellineawayfromfuellter

(Figure27).

4.Pullthefuellineoffthefuellter(Figure27).Open

thefuelshut-offvalveandallowthegasolinetodrain

intoagascanordrainpan.

Note:Nowisthebesttimetoinstallanewfuellter

becausethefueltankisempty.RefertoReplacing

theFuelFilter.

ServicingtheFuelFilter

Replacethefuellterafterevery200operatinghoursor

yearly,whicheveroccursrst.

ReplacingtheFuelFilter

Neverinstalladirtylterifitisremovedfromthefuel

line.

Note:Notehowthefuellterisinstalledinorderto

installthenewltercorrectly.

Note:Wipeupanyspilledfuel.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Closefuelshut-offvalveatthefueltank(Figure27).

4.Squeezetheendsofthehoseclampstogetherand

slidethemawayfromthelter(Figure28).

5.Installthefuellineontothefuellter.Slidethehose

clampclosetothevalvetosecurethefuelline.

28

Page 29

Figure28

1.Hoseclamp3.Filter

2.Fuelline

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclampsclose

tothelter.

DriveSystem

Maintenance

CheckingtheTirePressure

Checkthepressureatthevalvestemafterevery

50operatinghoursormonthly,whicheveroccursrst

(Figure29).

Maintaintheairpressureinthereartiresat12-14psi

(83-97kPa).Uneventirepressurecancauseanuneven

cut.

Note:Thefronttiresaresemi-pneumatictiresanddo

notrequireairpressuremaintenance.

7.Openfuelshut-offvalveatfueltank(Figure27).

8.Checkforfuelleaksandrepairifneeded.

9.Wipeupanyfuelthatspilled.

Figure29

29

Page 30

CoolingSystem

Maintenance

BrakeMaintenance

ServicingtheBrakes

CleaningtheAirIntakeScreen

Beforeeachuseremoveanybuild-upofgrass,dirt

orotherdebrisfromthecylinderandcylinderhead

coolingns,airintakescreenonywheelend,and

carburetor-governorleversandlinkage.Thiswillhelp

insureadequatecoolingandcorrectenginespeedand

willreducethepossibilityofoverheatingandmechanical

damagetotheengine.

CleaningtheCoolingSystem

Cleantheairintakescreenfromgrassanddebrisbefore

eachuse.

Checkandcleancoolingnsandengineshroudsevery

100hoursoryearly,whichevercomesrst.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removetheairintakescreen,recoilstarterandfan

housing(Figure30).

4.Cleanthedebrisandgrassfromtheengineparts.

5.Installairintakescreen,recoilstarterandfanhousing

(Figure30).

Beforeeachuse,checkbrakesonbothalevelsurface

andslope.

Alwayssettheparkingbrakewhenyoustopthemachine

orleaveitunattended.Iftheparkingbrakedoesnot

holdsecurely,anadjustmentisrequired.

CheckingtheBrakes

1.Parkthemachineonalevelsurface,disengagethe

bladecontrol(PTO).

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Applytheparkingbrake.Thewheelsmustlock

whenyoutrytopushthemachineforward.

4.Ifthewheelsdonotlock,adjustthebrakes.Refer

toAdjustingtheBrakes.

5.Releasethebrakeandpressuppercontrolbarvery

lightly,approximately1/2inch(13mm).Thewheels

shouldrotatefreely ,ifnot;refertoAdjustingthe

Brakes.

AdjustingtheBrakes

Thebrakeleverisontheuppercontrolbar.Ifthe

parkingbrakedoesnotholdsecurely ,anadjustmentis

required.

Figure30

1.Airintakescreen4.Bolt

2.Fanhousing5.Nut

3.Recoilstarter

1.Parkthemachineonalevelsurface,disengagethe

PTO,andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Checkthebrakebeforeyouadjustit;referto

CheckingtheBrakes.

4.Releasetheparkingbrake;refertoReleasingthe

ParkingBrakeinOperation,page13.

5.Toadjustthebrake,rotatethewingnutsonthe

brakerods(Figure31).Turnthewingnutsclockwise

totightenthebrakeandcounterclockwisetoloosen

thebrake.

30

Page 31

Figure31

1.Brakerod2.Wingnut

Note:Controlbarshouldbeparallelwiththe

referencebarwhenproperlyadjusted.

6.Checkthebrakeoperationagain;refertoChecking

theBrakes.

Important:Withtheparkingbrakereleased,

therearwheelsmustrotatefreelywhenyou

pushthemower.Ifbrakeactionandfreewheel

rotationcannotbeachievedcontactyourservice

dealerimmediately .

BeltMaintenance

CheckingtheBelts

Checkallbeltsafterevery50operatinghoursor

monthly,whicheveroccursrst.

Lookfordirt,wear,cracksandsignsofoverheating.

ReplacingtheTractionDrive

Belt

1.Removehairpincottersecuringbrakerodtobrake

armtorelaxbeltidlertension(Figure32).

2.Removebottomandloosentopboltsofshieldto

rotateforbeltclearance(Figure32).

3.Liftthebeltpastidlerandoffthedrivepulley

(Figure32).

4.Raisethewheeloffgroundenoughtoallowbelt

removal.

5.Replacethetractiondrivebelt.

6.Secureshieldwithpreviouslyremovedboltand

tightenbolts(Figure32).

7.Securebrakerodtobrakearmwithhairpincotter

(Figure32).

Figure32

1.Hairpincotter

2.Brakerod4.Drivebelt

3.Shield

ReplacingtheTransmission

DriveBelt

1.Disengagethebladecontrol(PTO)leverandsetthe

parkingbrakes.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Raisetherearofthemachineandholditupwith

jackstands.

31

Page 32

4.Removethemowerbelt;refertoReplacingthe

MowerBelt(Figure33).

Figure33

1.Idlerpulleyinslot4.Beltguide

2.Tractionbelt

3.Mowerbelt6.Mowerbelt

5.3/4inch(19mm)

Note:Thepropermowerbelttensionis10-15lbf.

(44-67N)withthebeltdeected1/2inch(13mm)

halfwaybetweenthepulleys(Figure34).

5.Loosenthepivotboltenoughtoslidetheidlerpulley

intheslotandremovethetractionbeltfromthe

engineandthedrivepulleys(Figure33).

6.Installthenewdrivebeltaroundtheengineandthe

drivepulleys(Figure33).

7.Slidetheidlerpulleyintheengineframetotension

thetractionbelt(Figure33).

8.Installthemowerbelt(Figure33).

9.Checkthebeltguideundertheengineframeforthe

properadjustment(Figure33).

Note:Thedistancebetweenthebeltguideand

mowerbeltshouldbe3/4inch(19mm)whenthe

mowerbeltisengaged.Adjustthebeltifnecessary.

Thedisengagedbeltshouldnotdragorfalloffthe

pulleywhentheguidesareproperlyadjusted.

ReplacingtheMowerBelt

1.Disengagethebladecontrol(PTO)leverandsetthe

parkingbrakes.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

Figure34

1.Mowerbeltwith1/2inch

(13mm)deection

2.Idlerpulley

8.Engagethebladecontrol(PTO)lever.

9.Checktheclearancebetweenthebellcrankandthe

transmissionoutputshaft(Figure35).

Figure35

1.1/16-1/8inch(2-3mm)

2.Bellcrank

3.Transmissionoutputshaft6.Clevis

4.Hairpincotter

5.Clevispin

3.Removetheknobsandthebeltcoveronthemower.

4.Removetheidlerpulleyandthewornbelt(Figure34).

5.Installthenewmowerbelt.

6.Installtheidlerpulley.

7.Engagethebladecontrol(PTO)leverandcheck

thebelttension.RefertoAdjustingtheMowerBelt

Tension.

Note:Theclearanceshouldbe1/16—1/8inch

(2-3mm).

10.Removethehairpincotterandtheclevispinfrom

thebellcrank.

11.Rotatetheclevisclockwiseontherodtoincrease

theclearance;rotateitcounterclockwisetodecrease

it(Figure35).

32

Page 33

12.Disengagethebladecontrol(PTO)lever.

Note:Iftheassistarmdoesnotcontactthefront

stoponthemowerdeck(Figure36),adjusttheclevis

tobringthebellcrankclosertothetransmission

outputshaft(Figure35).

Figure37

1.Idlerpulleyinslot4.Beltguide

2.Tractionbelt

3.Mowerbelt6.Mowerbelt

5.1-1/4inch(32mm)

AdjustingtheMowerBelt

Tension

Figure36

1.1/2inch(13mm)deection

here

2.Assistarm5.Turnbuckle

3.Frontstop

4.Locknut

13.Checkthebeltguideundertheengineframeforthe

properadjustment(Figure33).

Note:Thedistancebetweenthebeltguideandthe

mowerbeltshouldbe1-1/4inch(32mm)when

youengagethemowerbelt(Figure37).Adjustthe

mowerbeltasnecessary.Thedisengagedbeltshould

notdragorfalloffthepulleywhentheguidesare

properlyadjusted.

Adjustthemowerbelttensionasfollows:

•Aftertherst8operatinghours.

•Aftertherst25operatinghours.

•Afterevery50operatinghours.

Checkthebelttensionaftertherst8operatinghours

and25operatinghoursthereafter.Checkthebelt

tensionafterevery50operatinghours.

Important:Thebladebrakeneedstobeadjusted

whenthebelttensionorthebrakelinkageis

adjusted.

Important:Thebeltmustbetightenoughtonot

slipduringheavyloadswhilecuttinggrass.Over

tensioningthebeltwillreducethebearinglifeof

thebeltandthespindle.

1.Disengagethebladecontrol(PTO)leverandsetthe

parkingbrakes.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Loosenthelocknutontheturnbuckle(Figure36).

4.Rotatetheturnbuckletowardtherearofthe

mowertoincreasethetensiononthebelt.Rotate

theturnbuckletowardthefrontofthemowerto

decreasethetensiononthebelt(Figure36).

Note:Theeyeboltthreadsonbothendsofthe

turnbuckleshouldbeengagedaminimumof

5/16inch(8mm).

33

Page 34

MowerDeck

Maintenance

ServicingtheCuttingBlades

Toensureasuperiorqualityofcut,keeptheblades

sharp.Forconvenientsharpeningandreplacement,you

maywanttokeepextrabladesonhand.

Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrownintothe

operator’sorbystander’sarea,resultingin

seriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagetheblade

controlbailandsettheparkingbrake.Turntheignition

keytooff.Removethekeyanddisconnectthespark

plugwire(s)fromthesparkplug(s).

InspectingtheBlades

Inspectthebladesevery8hours.

1.Inspectthecuttingedges(Figure38).Iftheedges

arenotsharporhavenicks,removeandsharpenthe

blades.RefertoSharpeningtheBlades.

Figure38

1.CuttingEdge3.Wear/slotForming

2.CurvedArea

2.Inspecttheblades,especiallythecurvedarea

(Figure38).Ifyounoticeanydamage,wear,or

aslotforminginthisarea(item3inFigure38),

immediatelyinstallanewblade.

CheckingforBentBlades

1.Rotatethebladesuntiltheendsfaceforwardand

backward(Figure39).

1.Measurefromcuttingedgetoalevelsurface

34

Figure39

Figure40

Page 35

2.Measurefromalevelsurfacetothecuttingedge,

positionA,oftheblades(Figure40).Notethis

dimension.

3.Rotatetheoppositeendsofthebladesforward.

4.Measurefromalevelsurfacetothecuttingedgeof

thebladesatthesamepositionasinstep1.The

differencebetweenthedimensionsobtainedinsteps

1and2mustnotexceed1/8inch(3mm).Ifthis

dimensionexceeds1/8inch(3mm),thebladeis

bentandmustbereplaced.RefertoRemovingthe

BladesandInstallingtheBlades.

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplacebentordamagedbladewith

anewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofblade.

RemovingtheBlades

Replacethebladesifyouhitasolidobjectorifthe

bladesareoutofbalanceorbent.T oensureoptimum

performanceandcontinuedsafetyconformanceof

themachine,usegenuineT ororeplacementblades.

Replacementbladesmadebyothermanufacturersmay

resultinnon-conformancewithsafetystandards.

1.Holdthebladeboltwithawrench.

2.Removethenut,bladebolt,curvedwasher,blade,

spacers,andthinwasherfromthespindle(Figure41).

Figure41

1.Blade

2.Bladebolt5.Thinwasher

3.Curvedwasher

4.Spacer

6.Nut

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothends

oftheblade(Figure42).Maintaintheoriginalangle.

Thebladeretainsitsbalanceifthesameamountof

materialisremovedfrombothcuttingedges.

Figure42

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitona

bladebalancer(Figure43).Ifthebladestaysina

horizontalposition,thebladeisbalancedandcanbe

used.Ifthebladeisnotbalanced,lesomemetaloff

35

Page 36

theendofthesailareaonly(Figure43).Repeatthis

procedureuntilthebladeisbalanced.

Figure43

1.Blade2.Balancer

InstallingtheBlades

1.Installthecurvedwasherandthenthebladeonto

thebolt.Selectthepropernumberofspacer(s)for

theheight-of-cut,andslidetheboltintothespindle

(Figure41).

Important:Thecurvedpartoftheblademust

pointupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installtheremainingspacer(s)andsecurethemwith

athinwasherandanut(Figure41).

Figure44

1.Springmountingbolts3.1/8-3/16inch(3mm-5mm)

2.Bladebrakepad

ReplacingtheGrassDeector

3.Torquethebladeboltto75-80ft-lb(101-108N•m).

AdjustingtheBladeBrake

1.DisengagethePTO,turntheignitionkeytooff,and

removethekey.

2.Waitforallmovingpartstostopbeforeleavingthe

operatingpositionandthensettheparkingbrakes.

3.Ifnecessary,adjustthespringmountingboltssothat

thebladebrakepadrubsagainstbothsidesofthe

pulleygroove(Figure44).

4.Adjustthenutattheendofthebladebrakeroduntil

thereis1/8-3/16inch(3mm-5mm)betweenthe

nutandspacer(Figure44).

5.Engagetheblades.Ensurethebladebrakepadno

longercontactsthepulleygroove.

Anuncovereddischargeopeningcouldallow

thelawnmowertothrowobjectsinthe

operator’sorbystander’sdirectionandresultin

seriousinjuryordeath.Also,contactwiththe

bladecouldoccur.

Neveroperatethelawnmowerwiththegrass

deectorremovedunlessyouinstallacover

plate,amulchplate,oragrasschuteand

catcher.

1.Removethelocknut,bolt,springandspacerholding

thedeectortothepivotbrackets(Figure45).

Removedamagedorworngrassdeector.

36

Page 37

Figure45

1.Bolt

2.Spacer6.GrassDeector

3.Locknut

4.Spring8.Jhookendofspring

5.Springinstalled

7.Lendofspring,place

behinddeckedgebefore

installingbolt

Storage

1.Disengagethepowertakeoff(PTO),settheparking

brake,andturntheignitionkeytooff.Removethe

key.

2.Removegrassclippings,dirt,andgrimefromthe

externalpartsoftheentiremachine,especiallythe

engine.Cleandirtandchafffromtheoutsideofthe

engine’scylinderheadnsandblowerhousing.

Important:Youcanwashthemachinewith

milddetergentandwater.Donotpressurewash

themachine.Avoidexcessiveuseofwater,

especiallyneartheshiftleverplate,andengine.

3.Checkthebrake;refertoServicingtheBrakein

BrakeMaintenance,page30.

4.Servicetheaircleaner;refertoServicingtheAir

Cleaner.

5.Greasethemachine;refertoGreasingand

LubricationinLubrication,page22.

6.Changethecrankcaseoil;refertoServicingthe

Enginein.

7.Checkthetirepressure;refertoCheckingtheTire

PressureinDriveSystemMaintenance,page29.

2.Placespacerandspringontograssdeector.Place

theLendofspringbehinddeckedge.

Note:MakesuretheLendofspringisinstalled

behinddeckedgebeforeinstallingtheboltasshown

inFigure45.

3.Installboltandnut.PlacetheJhookendofspring

aroundgrassdeector(Figure45).

Important:Thegrassdeectormustbefree

torotate.Liftthedeectoruptothefullopen

positionandensurethatitrotatesfreelywithout

bindingintothefulldownposition.

8.Forlong-termstorage:

A.Addstabilizer/conditioneradditivetofuelinthe

tank.

B.Runenginetodistributeconditionedfuelthrough

thefuelsystem(5minutes).

C.Stopengine,allowtocoolanddrainthefuel

tank;refertoServicingtheFuelTankinFuel

SystemMaintenance,page28,oroperateengine

untilitstops.

D.Restartengineandrununtilitstops.Repeat,on

Chokeuntilenginewillnotrestart.

E.Disposeoffuelproperly .Recycleasperlocal

codes.

Note:Donotstorestabilizer/conditioned

gasolineover90days.

9.Removethesparkplug(s)andcheckitscondition;

refertoServicingtheSparkPlug.Withthe

sparkplug(s)removedfromtheengine,pour

twotablespoonsofengineoilintothesparkplug

hole.Nowusethestartertocranktheengineand

distributetheoilinsidethecylinder.Installthespark

plug(s).Donotinstallthewireonthesparkplug(s).

10.Checkandtightenallbolts,nuts,andscrews.Repair

orreplaceanypartthatisdamagedordefective.

37

Page 38

11.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

12.Storethemachineinaclean,drygarageorstorage

area.Removethekeyfromtheignitionswitchand

keepitinamemorableplace.Coverthemachineto

protectitandkeepitclean.

38

Page 39

Troubleshooting

Problem

Enginewillnotstart,startshard,orfails

tokeeprunning.

Enginelosespower.

PossibleCauseCorrectiveAction

1.Fueltankisempty.

2.Fuelshutoffvalveisclosed.2.Openthefuelshutoffvalve.

3.Chokeisnoton.

4.Aircleanerisdirty.

5.Sparkplugwireislooseor

disconnected.

6.Sparkplugispitted,fouled,orthegap

isincorrect.

7.Dirtinthefuellter.7.Replacethefuellter.

8.Dirt,water,orstalefuelisinthefuel

system.

1.Engineloadisexcessive.1.Reducethegroundspeed.

2.Aircleanerisdirty.

3.Oillevelinthecrankcaseislow .

4.Coolingnsandairpassagesunder

theengineblowerhousingareplugged.

5.Sparkplugispitted,fouled,orthegap

isincorrect.

6.Ventholeinthefuelcapisplugged.6.Cleanorreplacethefuelcap.

7.Dirtinthefuellter.7.Replacethefuellter.

8.Dirt,water,orstalefuelisinthefuel

system.

1.Fillthefueltankwithgasoline.

3.Movethethrottlelevertochoke

position.

4.Cleanorreplacetheaircleaner

element.

5.Installthewireonsparkplug.

6.Installanew,correctlygappedspark

plug.

8.ContactanAuthorizedServiceDealer.

2.Cleantheaircleanerelement.

3.Addoiltothecrankcase.

4.Removetheobstructionfromthe

coolingnsandairpassages.

5.Installanew,correctlygappedspark

plug.

8.ContactanAuthorizedServiceDealer.

Engineoverheats.

Machinedoesnotdrive.

Abnormalvibration.

Unevencuttingheight.

1.Engineloadisexcessive.1.Reducethegroundspeed.

2.Oillevelinthecrankcaseislow .

3.Coolingnsandairpassagesunder

theengineblowerhousingareplugged.

1.Shiftleverisinneutral.1.Movetheshiftlevertoadrivegear

2.Tractionbeltisworn,looseorbroken.

3.Tractionbeltisoffapulley.3.Changethebelt.

1.Cuttingblade(s)is/arebentor

unbalanced.

2.Blademountingboltisloose.2.Tightentheblademountingbolt.

3.Enginemountingboltsareloose.3.Tightentheenginemountingbolts.

4.Looseenginepulley,idlerpulley ,or

bladepulley .

5.Enginepulleyisdamaged.

6.Bladespindleisbent.

1.Blade(s)notsharp.1.Sharpentheblade(s).

2.Cuttingblade(s)is/arebent.2.Installnewcuttingblade(s).

3.Mowerisnotlevel.

4.Undersideofmowerisdirty .4.Cleantheundersideofthemower.

5.Tirepressureisnotcorrect.5.Adjustthetirepressure.

6.Bladespindlebent.

2.Addoiltothecrankcase.

3.Removetheobstructionfromthe

coolingnsandairpassages.

position.

2.Changethebelt.

1.Installnewcuttingblade(s).

4.Tightentheappropriatepulley.

5.ContactanAuthorizedServiceDealer.

6.ContactanAuthorizedServiceDealer.

3.Levelthemowerfromside-to-sideand

front-to-rear.

6.ContactanAuthorizedServiceDealer.

39

Page 40

Problem

PossibleCauseCorrectiveAction

Bladesdonotrotate.

1.Mowerdeckbeltiswornorloose.

2.Mowerdeckbeltisbroken.2.Installanewdeckbelt.

3.Mowerdeckbeltisoffpulley .3.Inspectthebeltandreplaceifdamaged.

4.Brokenormissingidlerspring.4.Replacethespring.

1.Checkthebelttension.

Checkthepulleysandidlersandadjust

thebelttension.

40

Page 41

Schematics

ElectricalSchematic(Rev.-)

41

Page 42

Notes:

42

Page 43

Evaporative Emission Control Warranty Statement

California Evaporative Emission Control Warranty Statement

Your Warranty Rights and Obligations

Introduction

The California Air Resources Board and The Toro® Company are pleased to explain the evaporative emission control system’s warranty on your 2007 model

year equipment. In California, new equipment that use small off-road engines must be designed, built, and equipped to meet the State’s stringent anti-smog

standards. The Toro® Company must warrant the evaporative emission control system on your equipment for two years provided there has been no abuse,

neglect or improper maintenance of your equipment.

Your evaporative emission control system may include parts such as: fuel lines, fuel line ttings, and clamps.

Manufacturer’s Warranty Coverage:

This evaporative emission control system is warranted for two years. If any evaporative emission-related part on your equipment is defective, the part will be

repaired or replaced by The Toro® Company.

Owner’s Warranty Responsibilities:

• As the equipment owner, you are responsible for performance of the required maintenance listed in your Operator’s Manual. The Toro® Company recommends

that you retain all receipts covering maintenance on your equipment, but The Toro® Company cannot deny warranty solely for the lack of receipts.

• As the equipment owner, you should however be aware that The Toro® Company may deny you warranty coverage if your emission warranty parts have failed

due to abuse, neglect, or improper maintenance or unapproved modications.

• You are responsible for presenting your equipment to an Authorized Service Dealer as soon as the problem exists. The warranty repairs should be completed

in a reasonable amount of time, not to exceed 30 days. If you have a question regarding your warranty coverage, you should contact The Toro® Company at

1-952–948–4027 or call us toll free at the number listed in your Toro Warranty statement.

Defects Warranty Requirements:

1. The warranty period begins on the date the engine or equipment is delivered to an ultimate purchaser.

2. General Evaporative Emissions Warranty Coverage. The emission warranty parts must be warranted to the ultimate purchaser and any subsequent owner that

the evaporative emission control system when installed was:

A. Designed, built, and equipped so as to conform with all applicable regulations; and

B. Free from defects in materials and workmanship that causes the failure of a warranted part for a period of two years.

3. The warranty on evaporative emissions-related parts will be interpreted as follows:

A. Any warranted part that is not scheduled for replacement as required maintenance in the written instructions must be warranted for the warranty period

of two years. If any such part fails during the period of warranty coverage, it must be repaired or replaced by The Toro® Company. Any such part

repaired or replaced under the warranty must be warranted for a time not less than the remaining warranty period.

B. Any warranted part that is scheduled only for regular inspection in the written instructions must be warranted for the warranty period of two years. A

statement in such written instructions to the effect of “repair or replace as necessary” will not reduce the period of warranty coverage. Any such part

repaired or replaced under warranty must be warranted for a time not less than the remaining warranty period.

C. Any warranted part that is scheduled for replacement as required maintenance in the written instructions must be warranted for the period of time

prior to the rst scheduled replacement point for that part. If the part fails prior to the rst scheduled replacement, the part must be repaired or

replaced by The Toro® Company. Any such part repaired or replaced under warranty must be warranted for a time not less than the remainder of

the period prior to the rst scheduled replacement point for the part.

D. Repair or replacement of any warranted part under the warranty provisions of this article must be performed at no charge to the owner at an Authorized

Service Dealer.

E. Notwithstanding the provisions of subsection (D) above, warranty services or repairs must be provided at an Authorized Service Dealer.

F. The owner must not be charged for diagnostic labor that leads to the determination that a warranted part is in fact defective, provided that such

diagnostic work is performed at an Authorized Service Dealer.

G. Throughout the evaporative emission control system’s two year warranty period, The Toro® Company must maintain a supply of warranted parts

sufcient to meet the expected demand for such parts.

H. Manufacturer approved replacement parts must be used in the performance of any warranty maintenance or repairs and must be provided without

charge to the owner. Such use will not reduce the warranty obligations of The Toro® Company.

I. The use of any add-on or modied parts will be grounds for disallowing a warranty claim made in accordance with this article. The Toro® Company will

not be liable under this Article to warrant failures of warranted parts caused by the use of an add-on or modied part.

J. The Toro® Company shall provide any documents that describe the warranty procedures or policies within ve working days of request by the Air

Resources Board.

The following lists includes the parts covered under this warranty:

• Fuel Lines

• Fuel Line Fittings

• Clamps

Emission Warranty Parts List:

374-0092 Rev B

Page 44

Landscape

Contractor

Equipment (LCE)

The Toro Total Coverage Guarantee

A Limited Warranty

Conditions and Products Covered