Page 1

FormNo.3379-923RevA

G017538

CommercialWalk-BehindMower

FixedDeck,T-Bar,GearDrivewith32in,36in,

or48inCuttingUnit

ModelNo.30672—SerialNo.314000001andUp

ModelNo.30674—SerialNo.314000001andUp

ModelNo.30678—SerialNo.314000001andUp

ModelNo.39674—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3379-923*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

•ForModels30672,30674.and30678:

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareasmay

havesimilarlaws.

•ForModel39674:

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisincorporated

withthemuferassembly .

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Thisrotary-blade,lawnmowerisintendedtobeused

byresidentialhomeownersorprofessional,hired

operators.Itisdesignedprimarilyforcuttinggrasson

well-maintainedlawnsonresidentialorcommercial

properties.Itisnotdesignedforcuttingbrushorfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely .

YoumaycontactTorodirectlyatwww .T oro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorT oro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Important:Thisengineisequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,

orgrass-coveredlandwithoutasparkarrester

mufermaintainedinworkingorder,ortheengine

constricted,equipped,andmaintainedforthe

preventionofre.Otherstatesorfederalareasmay

havesimilarlaws.

WARNING

Removingstandardoriginalequipmentpartsand

accessoriesmayalterthewarranty,traction,and

safetyofthemachine.FailuretouseoriginalToro

partscouldcauseseriousinjuryordeath.Making

unauthorizedchangestotheengine,fuelorventing

system,mayviolateEP AandCARBregulations.

Replaceallpartsincluding,butnotlimitedto,tires,

belts,blades,andfuelsystemcomponentswith

originalToroparts.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Engine Owner's Man ual

issuppliedfor

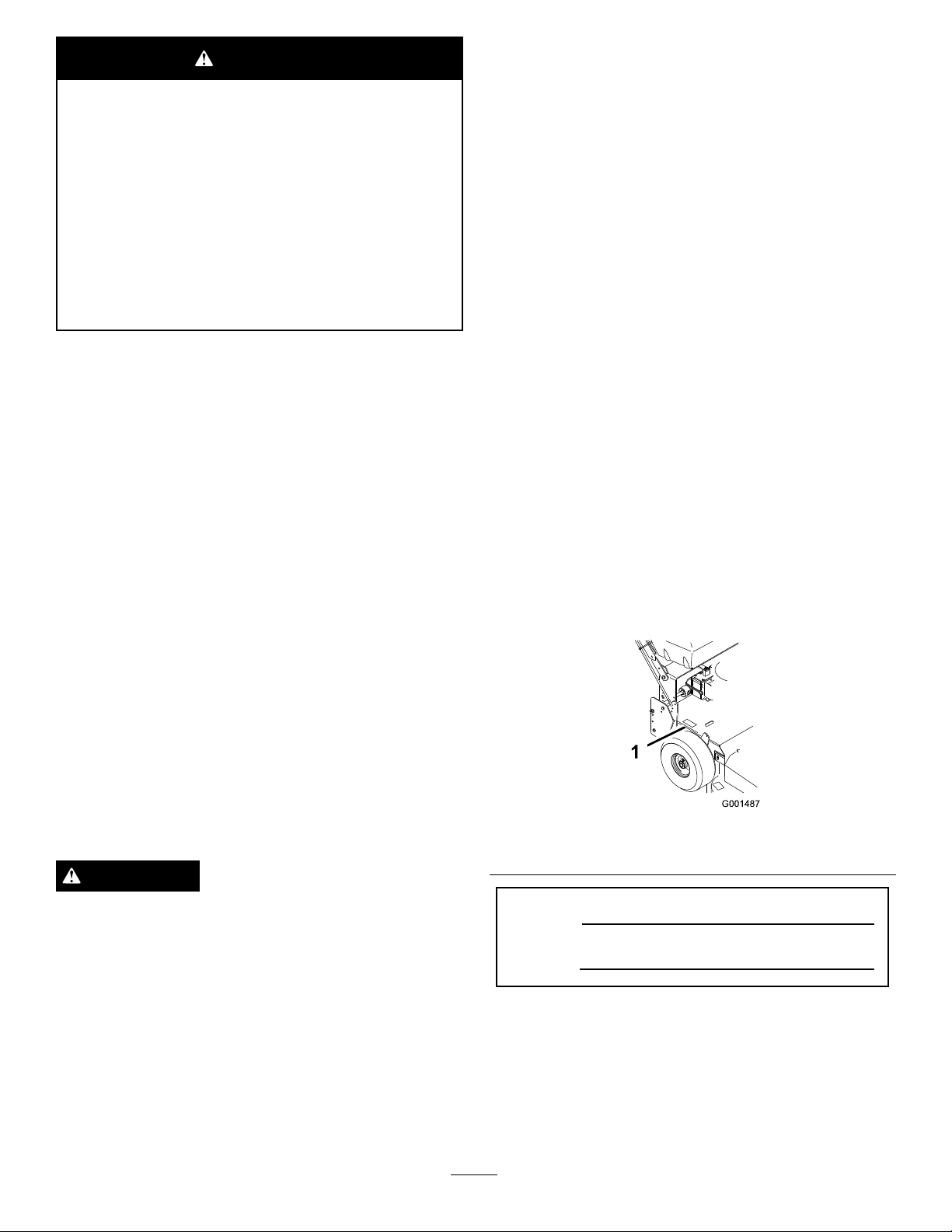

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................6

SlopeIndicator.......................................................7

SafetyandInstructionalDecals.................................8

ProductOverview.........................................................11

Controls...............................................................11

Specications........................................................12

Attachments/Accessories........................................12

Operation....................................................................13

AddingFuel...........................................................13

UsingFuelStabilizer/Conditioner............................13

FillingtheFuelTank...............................................14

CheckingtheEngine-oilLevel..................................14

ThinkSafetyFirst...................................................14

OperatingtheParkingBrake....................................14

StartingandStoppingtheEngine..............................14

OperatingtheBlade-controlLever(PTO)..................15

TheSafety-interlockSystem.....................................16

DrivingForwardorBackward..................................16

UsingtheLowerControlBar...................................16

StoppingtheMachine.............................................17

TransportingtheMachine........................................17

AdjustingtheFlowBafe........................................18

PositioningtheFlowBafe......................................18

SideDischargingorMulchingtheGrass.....................19

AdjustingtheHeightofCut.....................................19

AdjustingtheHandleHeight....................................20

AdjustingtheControlRods......................................21

Height-of-cutChart................................................22

Maintenance.................................................................23

RecommendedMaintenanceSchedule(s)......................23

Lubrication...............................................................24

LubricatingtheMachine..........................................24

LubricatingtheCasterandWheelBearings.................24

GreasingtheTransmissionCouplers.........................24

GreasingtheMowerBeltIdler..................................24

EngineMaintenance..................................................25

ServicingtheAirCleaner.........................................25

ServicingtheEngineOil..........................................25

ServicingtheSparkPlugs.........................................27

FuelSystemMaintenance...........................................28

ServicingtheFuelSystem........................................28

DriveSystemMaintenance.........................................30

CheckingtheTirePressure......................................30

CoolingSystemMaintenance......................................30

CleaningtheAir-intakeScreen..................................30

CleaningtheCoolingSystem....................................30

BrakeMaintenance....................................................31

ServicingtheBrakes................................................31

BeltMaintenance......................................................32

CheckingtheBelts..................................................32

ReplacingtheTractionDriveBelt.............................32

ReplacingtheDriveBelt..........................................32

ReplacingtheMowerBelt........................................32

3

Page 4

AdjustingtheMowerBeltTension............................34

MowerDeckMaintenance...........................................37

ServicingtheCuttingBlades.....................................37

AdjustingtheBladeBrake........................................40

ReplacingtheGrassDeector..................................41

Storage........................................................................41

Troubleshooting...........................................................43

Schematics...................................................................45

Safety

Note:Theadditionofattachmentsmadebyother

manufacturersthatdonotmeetAmericanNationalStandards

Institutecerticationwillcausenoncomplianceofthis

machine.

Improperlyusingormaintainingthemachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeans

Danger

withtheinstructionmayresultinpersonalinjuryor

death.

—personalsafetyinstruction.Failuretocomply

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromANSI

B71.4-2012.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadorunderstand

theinformationitistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleordamageto

property.

Caution, W ar ning ,

or

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glasses,andhearingprotection.Longhair,looseclothing,

orjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwirewhichcan

bethrownbythemachine.

•Checkthatoperator'spresencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly .Donot

operateunlesstheyarefunctioningproperly.

Operation

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

4

Page 5

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingtheengine.Onlystarttheengine

fromtheoperator'sposition.

•Besureofyourfootingwhileusingthismachine,

especiallywhenbackingup.Walk;donotrun.Never

operateonwetgrass.Reducedfootingcouldcause

slipping.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

thestabilityofthemachine.Usecautionwhileoperating

neardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neverraisedeckwiththebladesrunning.

•NeveroperatewiththePTOshieldorotherguardsnot

securelyinplace.Besureallinterlocksareattached,

adjustedproperly,andfunctioningproperly.

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,disengagedrives,engagethe

parkingbrake(ifprovided),andshutofftheenginebefore

leavingtheoperator'spositionforanyreason,including

emptyingthecatchersoruncloggingthechute.

•Stopequipmentandinspectbladesafterstrikingobjects

orifanabnormalvibrationoccurs.Makenecessary

repairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Nevercarrypassengersonthemachine.

•Keeppetsandbystandersaway.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesifnotmowing.

•Beawareofthemowerdischargedirectionanddonot

pointitatanyone.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

•Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

MaintenanceandStorage

•Disengagedrives,settheparkingbrake,stoptheengine

andremovethekeyordisconnectthespark-plugwire.

Waitforallmovementtostopbeforeadjusting,cleaning

orrepairingthemachine.

•Cleangrassanddebrisfromthecuttingunit,thedrives,

themufers,andtheenginetohelppreventres.Clean

upoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Shutoffthefuelwhilestoringortransporting.Donot

storefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Settheparkingbrake.

Neverallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorthespark-plugwirebefore

makinganyrepairs.Disconnectthenegativeterminal

rstandthepositivelast.Connectthepositiverstand

negativelast.

•Usecarewhencheckingtheblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.Only

replaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonToro

genuineparts.Whenitcomestoreliability,Torodelivers

5

Page 6

replacementpartsdesignedtotheexactengineering

specicationsofourequipment.Forpeaceofmind,insist

onT orogenuineparts.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsandothersafetyinformationyoumustknow.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrassor,

whenequippedwithagrassbagger,forcatchingcutgrass.

Anyuseforpurposesotherthanthesecouldprovedangerous

touserandbystanders.

Service

•Neverstorethemachineorfuelcontainerinsidewhere

thereisanopename,suchasnearawaterheateror

furnace.

•Keepnutsandboltstight,especiallythebladeattachment

bolts.Keepequipmentingoodcondition.

•Nevertamperwithsafetydevices.Checksafetysystems

forproperoperationbeforeeachuse.

•Useonlygenuinereplacementpartstoensurethatoriginal

standardsaremaintained.

•Checkbrakeoperationfrequently.Adjustandserviceas

required.

GeneralOperation

•Besuretheareaisclearofotherpeoplebeforemowing.

Stopthemachineifanyoneentersthearea.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowtocoolbeforeattempting

tomaintain,adjustorservice.

•UseonlyToroapprovedattachments.Warrantymaybe

voidedifusedwithunapprovedattachments.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforeoperatingunderany

objectsanddonotcontactthem.

SlopeOperation

Allslopesandrampsrequireextracaution.Ifyoufeeluneasy

onaslope,donotmowit.

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

mowingarea.

•Watchforholes,rutsorbumps.Tallgrasscanhide

obstacles.

•Usecautionneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyturnoverifawheelgoes

overtheedgeofaclifforditch,orifanedgecavesin.

•Useextracarewithgrasscatchersorotherattachments.

Thesecanchangethestabilityofthemachine.

•Keepallmovementonslopesslowandgradual.Donot

makesuddenchangesinspeedordirection.

•Mowslopessidetoside.

•Donotmowslopesgreaterthan20degrees.

6

Page 7

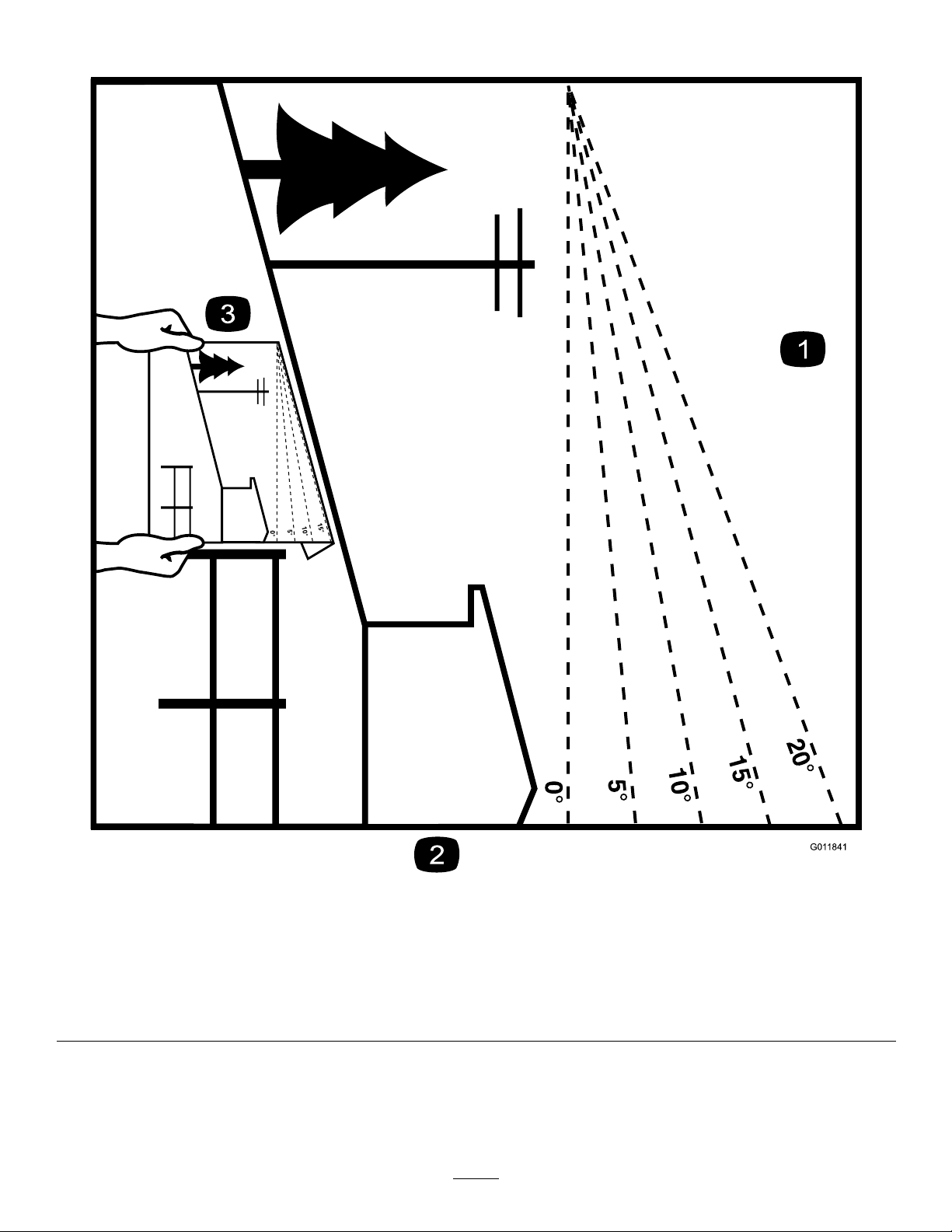

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis20degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan20degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

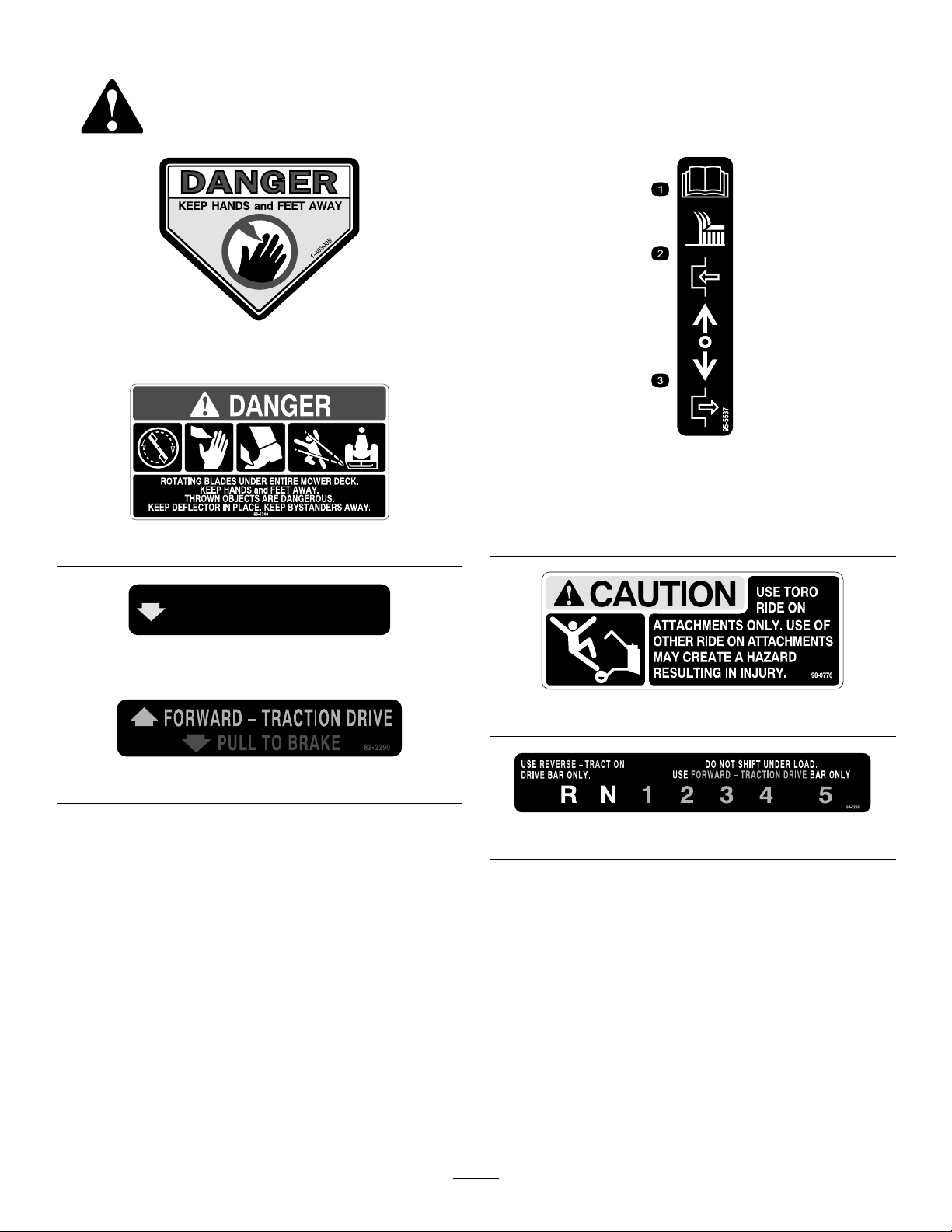

SafetyandInstructionalDecals

82- 2280

REV E R S E TRACT ION DR I V E

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

1-403005

95-5537

1.ReadtheOperator's

Manualforinstructionson

operatingthecuttingblade

66-1340

82-2280

82-2290

2.Pushforwardtoengage

3.Pullbacktodisengage

98-0776

98-3256

8

Page 9

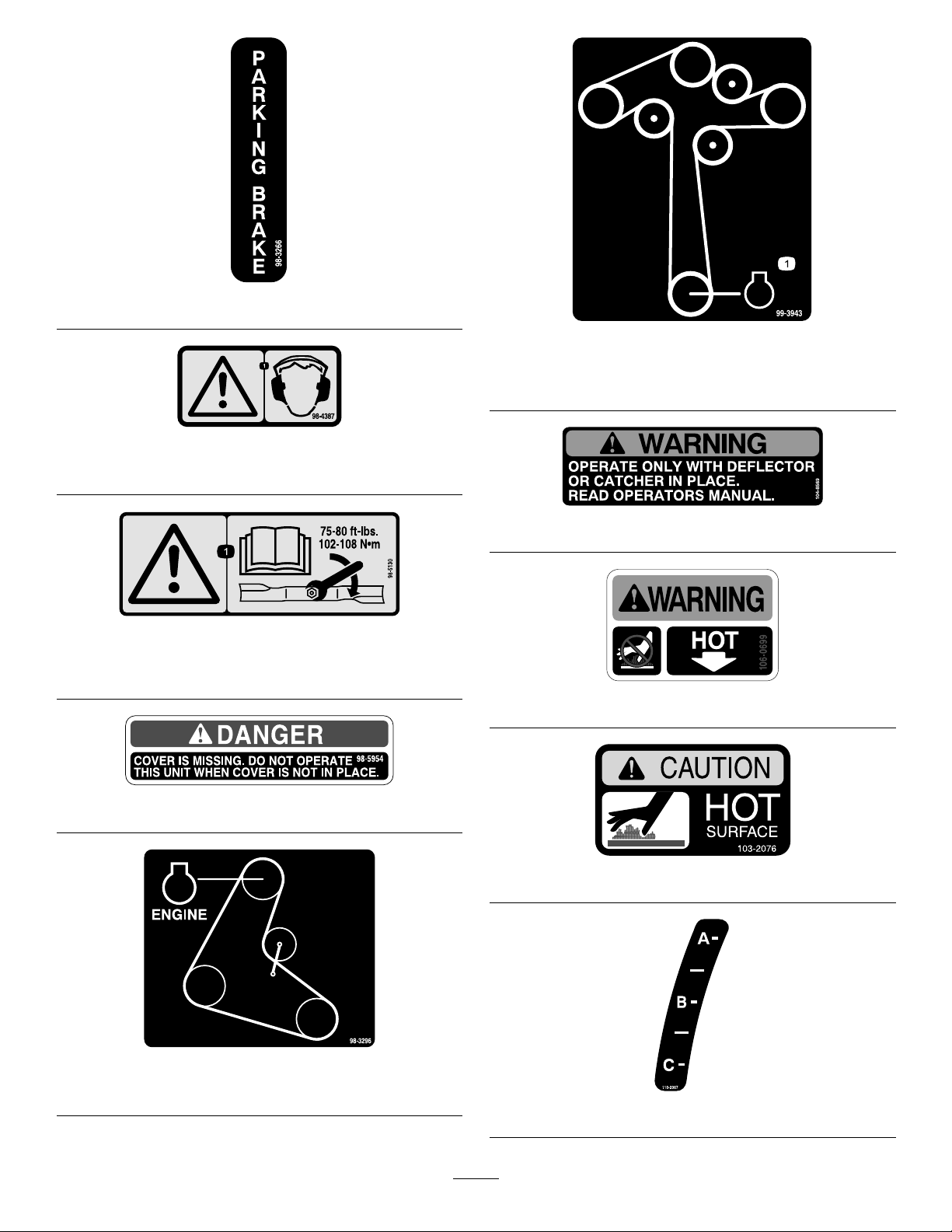

98-3266

98-4387

1.Warning—wearhearingprotection.

98-5130

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto75-80ft-lb(102-106N⋅m).

99-3943

ForModelwith3–BladeMowerDecks

1.Engine

104-8569

106-0699

98-5954

98-3296

ForModelswith2–BladeMowerDecks

103–2076

110-2067

9

Page 10

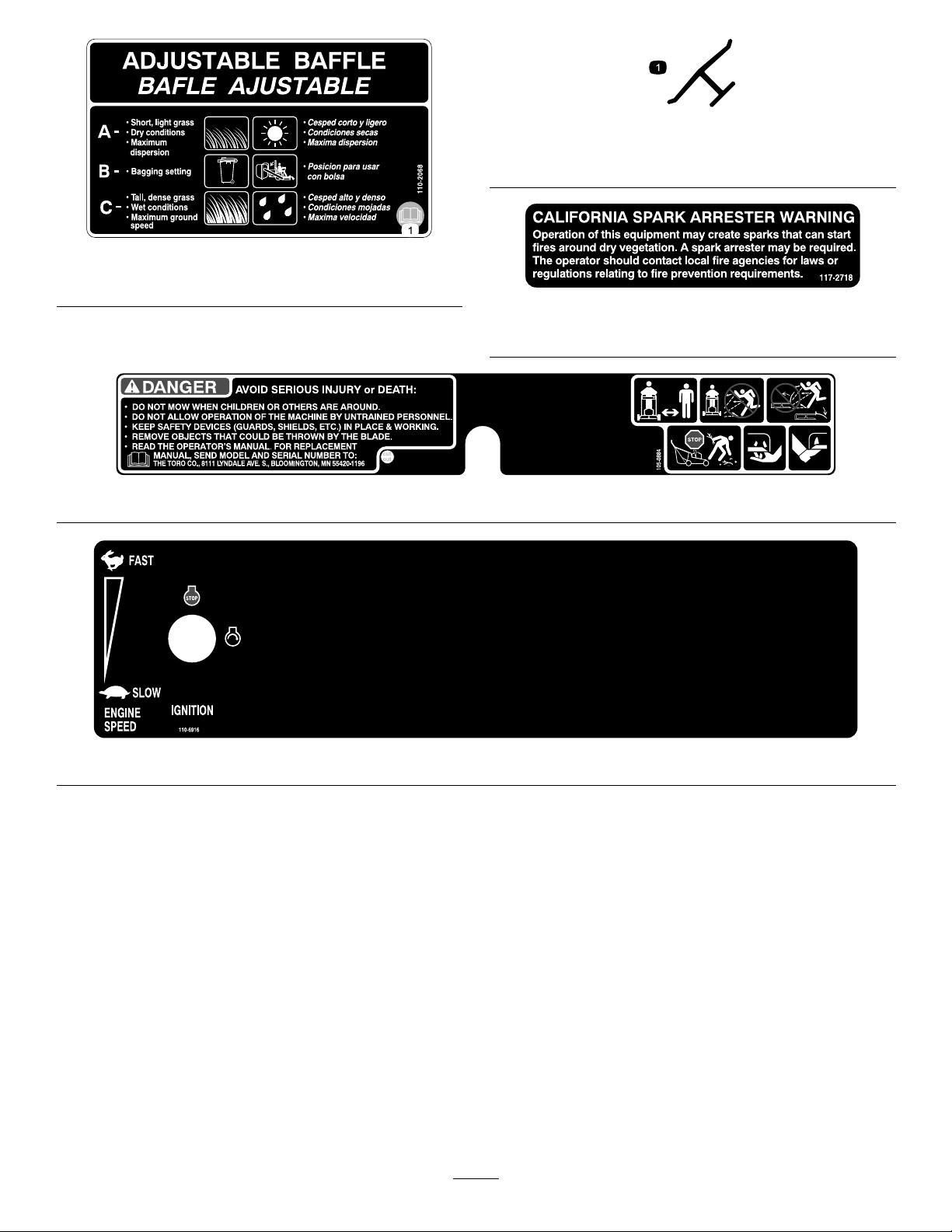

110-2068

1.ReadtheOperator'sManual.

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

117–2718

(Model39674only)

105-0884

110-6916

10

Page 11

ProductOverview

G017539

Controls

Becomefamiliarwithallthecontrols(Figure5)beforeyou

starttheengineandoperatethemachine.

Figure4

1.Sidedischarge

2.Mowerdeck6.Handle

3.Recoil-starthandle7.Frontcasterwheel

4.Gastank

5.T-barcontrol

Figure5

1.Throttlecontrol7.Parkingbrake

2.Blade-controlbail

3.Powertake-offlever(PTO)

4.Gear-shiftlever

5.Uppercontrolbar11.Lowerhandle

6.Lowercontrolbar

lever—releasedposition

8.Choke

9.Ignitionswitch

10.Upperhandle

ThrottleControl

Thethrottlecontrolhas2positions:FastandSlow.

Blade-controlBail

Thebailisusedinconjunctionwiththeblade-controllever

(PTO)toengagetheclutchanddrivethemowerblades.

Releasingthebladecontrolbailwillstoptheenginewiththe

PTOengaged.

Blade-controlLever(PTO)

Thisleverisusedinconjunctionwiththeblade-controlbail

toengageanddisengagethemowerdeckbeltanddrivethe

mowerblades.

Gear-shiftLever

Thetransmissionhas5forwardspeeds,neutral,andreverse,

andhasanin-lineshiftpattern.

11

Page 12

Important:Donotshiftwhilethemachineismoving,

astransmissiondamagemayoccur.

UpperControlBar

Shifttothedesiredgearandpushforwardontheupper

controlbarandbladecontrolbailtoengageforwardtraction

operationandpullbacktobrakeforwardmovement.Pull

backonrightsideofuppercontrolbartoturnrightandleft

sidetoturnleft.

LowerControlBar

Shifttransmissiontoreverseandsqueezethelowercontrol

barandhandletogethertoengagetherearwardtractionassist.

Parking-brakeLever

Pullbackonuppercontrolbarandswingbrakeleverup

againsttheupperhandletosettheparkingbrake(Figure5).

IgnitionSwitch

Thisswitchisusedinconjunctionwithrecoilstarterandhas

twopositions:RunandOff.

RecoilStarter

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

32-inchmowers:

Widthwithdeectordown116.3cm(45.8inches)

Length

Height

Weight

36-inchmowers:

Widthwithdeectordown118.4cm(46.6inches)

Length

Height

Weight

48-inchmowers:

Widthwithdeectordown161.3cm(63-1/2inches)

Length

Height

Weight

183cm(72inches)

104.1cm(41inches)

181kg(400lb)

188cm(74inches)

104.1cm(41inches)

209kg(460lb)

183.6cm(72-3/8inches)

104.1cm(41inches)

226kg(598lb)

Pulltherecoil-starthandletostarttheengine(notshown

inFigure4).

Fuel-shutoffValve

Closethefuel-shutoffvalvewhentransportingorstoringthe

machine.

Choke

Usethechoketostartacoldengine.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

12

Page 13

Operation

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontainsmore

than10%ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85(contains

85%ethanol).Usingunapprovedgasolinemaycause

performanceproblemsand/orenginedamagewhichmay

notbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Addfuel

tothefueltankuntilthelevelis25mm(1inch)

belowthebottomofthellerneck.Thisempty

spaceinthetankallowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Donotbuymore

thana30-daysupplyoffuel.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworkingcondition.

DANGER

Incertainconditionsduringfueling,static

electricitycancauseaspark,whichcanignitethe

fuelvapors.Areorexplosionfromfuelcanburn

youandothersandcandamageproperty.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruck-bedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removefuel-poweredequipment

fromthetruckortrailerandfueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromafuel-dispenser

nozzle.

•Ifafueldispensermustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepgasawayfromeyesandskin.

UsingFuel Stabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetokeepthe

fuelfreshduringstorageof90daysorless.Ifyouarestoring

themachineforlonger,drainthefueltank;referto

(page41).

Storage

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditionertothe

fuel,andfollowthedirectionsofthemanufacturer.

Note:Fuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

13

Page 14

FillingtheFuelTank

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundthefuel-tankcapandremovethecap.

Addunleadedregulargasolinetothefueltank,untilthe

levelis6to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisspaceinthetankallowsgasoline

toexpand.Donotllthefueltankcompletelyfull.

3.Installthefuel-tankcapsecurely .Wipeupanygasoline

thatmayhavespilled.

CheckingtheEngine-oilLevel

Beforeyoustarttheengineandusethemachine,checktheoil

levelintheenginecrankcase;refertoCheckingtheEngine-oil

Level.

ThinkSafetyFirst

Carefullyreadallthesafetyinstructionsanddecalsinthe

safetysection.Knowingthisinformationcouldhelpyouor

anybystandersavoidinjury.

Theuseofprotectiveequipmentforeyes,hearing,feetand

headisrecommended.

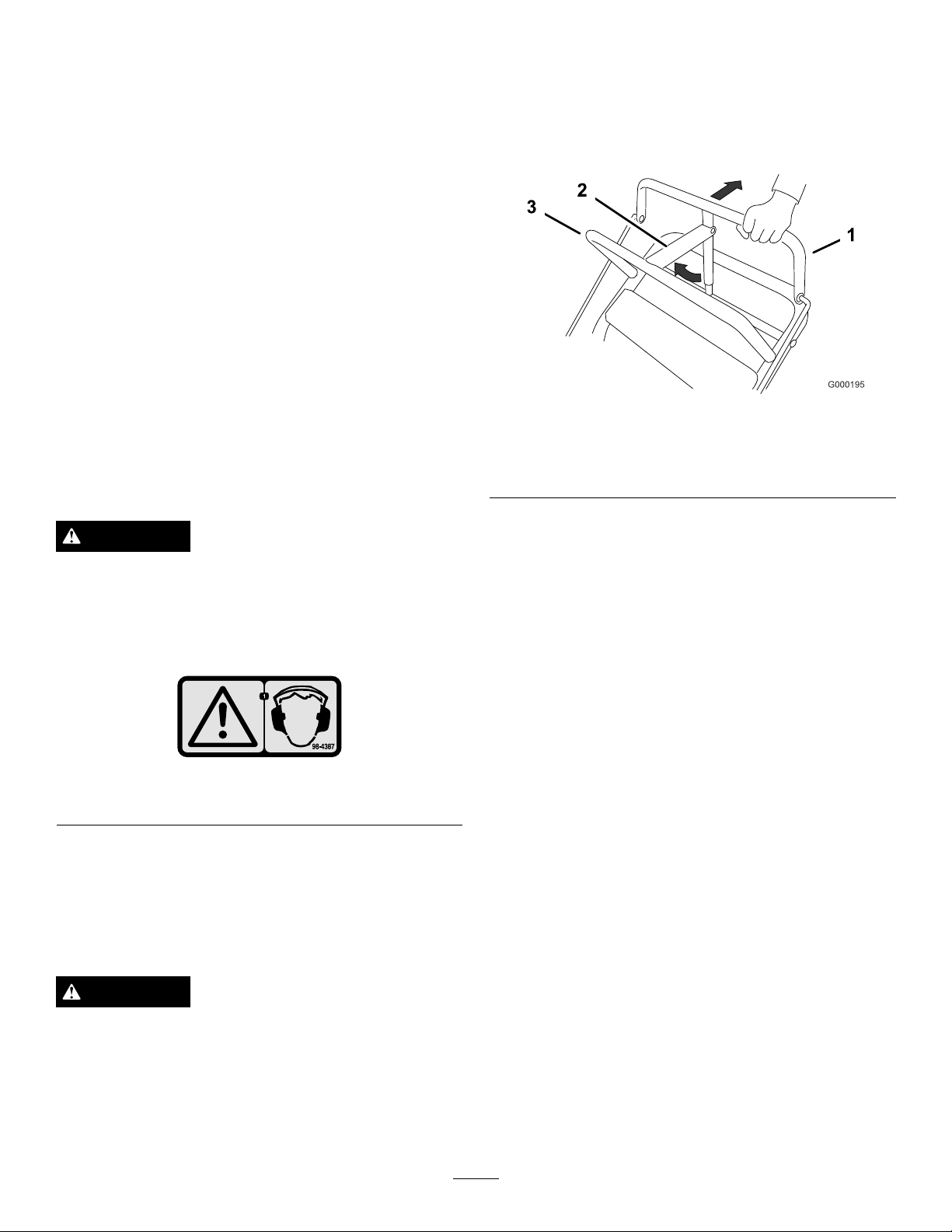

SettingtheParkingBrake

1.Pulltheuppercontrolbarrearwardandholditinthis

position(Figure7).

2.Lifttheparking-brakelockupandgraduallyreleasethe

uppercontrolbar.Thebrakelockshouldstayintheset

(locked)position(Figure7).

Figure7

1.Uppercontrolbar3.Fixedbar

2.Parking-brakelever—set

position

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator'searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Figure6

1.Warning—wearhearingprotection.

OperatingtheParkingBrake

Stoponlevelground,disengagedrives,engagetheparking

brake,stoptheengine,andremovethekey.Alwaysset

theparkingbrakewhenyoustopthemachineorleaveit

unattended.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

ReleasingtheParkingBrake

1.Pullrearwardontheuppercontrolbar.Lowerthe

parking-brakelocktothereleasedposition.

2.Graduallyreleasetheuppercontrolbar.

StartingandStoppingthe Engine

StartingtheEngine

1.Connectthewirestothesparkplugs.

2.Openthefuelvalve.

3.Disengagetheblade-control(PTO)leverandmovethe

shiftlevertotheneutralposition.

4.Settheparkingbrake.

5.Turntheignitionkeytotherunposition(

6.Tostartacoldengine,movethethrottlecontrol

midwaybetweenthefastandslowpositions.

7.Tostartawarmengine,movethethrottlecontrolto

thefastposition.

8.Pullthechokeknobtotheonpositioniftheengineis

cold(Figure8).

Note:Awarmorhotengineusuallydoesnotrequire

usingthechoke.

9.Grasptherecoilstarterhandlermlyandpullitout

untilpositiveengagementresults;thenpullthehandle

vigorouslytostarttheengine.Allowtheropetorecoil

slowly.

Figure8).

14

Page 15

Important:Donotpulltherecoilropetoitslimit

orreleasethestarterhandlewhenyoupullout

theropebecausetheropemaybreakortherecoil

assemblymaybedamaged.

10.Pushthechoketotheoffpositionastheenginewarms

up.

OperatingtheBlade-control Lever(PTO)

Theblade-controllever(PTO)engagesanddisengagespower

tothemowerblades.

11.Iftheengineiscold,allowittowarmupandthen

movethethrottlecontroltothefastposition.

StoppingtheEngine

Important:Inanemergency,youcanstoptheengine

immediatelybyturningtheignitionkeytothe

position.

1.Movethethrottlelevertotheslowposition(

2.Lettheengineidlefor30to60secondsbeforeturning

theignitionkeytotheoffposition.

3.Turntheignitionkeytotheoffposition(Figure8).

of f

Figure8).

EngagingtheMowerBlades

1.Toengagetheblades,squeezetheblade-controlbail

againsttheuppercontrolbar(Figure9).

2.Pushtheblade-controllever(PTO)rmlyforward,

untilitlatchesover-center.

3.Starttheengineandrepeattheproceduretoengagethe

mowerbladesiftheblade-controlbailisreleased.

Figure8

1.Blade-controllever(PTO)

2.Throttlelever

4.Settheparkingbrakeandremovethekey.

5.Disconnectthewiresfromthesparkplugstoprevent

thepossibilityofaccidentallystartingbeforestoringor

performingmaintenanceonthemachine.

6.Closethefuel-shutoffvalvebeforestoringor

transportingthemachine.

Important:Makesurethatthefuel-shutoff

valveisclosedbeforetransportingorstoringthe

machine,asfuelleakagemayoccur.

3.Ignitionkey

Figure9

1.Uppercontrolbar

2.Blade-controlbail

3.Blade-controllever(PTO)

DisengagingtheMowerBlades(PTO)

Todisengagetheblades,pulltheblade-controllever(PTO)

rearwardalltheway(Figure9).Theenginewillstopwhen

theblade-controlbailisreleasedwiththeblade-controllever

engaged.

Note:Itisnecessarytofullyandmanuallydisengagethe

blade-controllever.

15

Page 16

TheSafety-interlockSystem

3.Slowlypressontheuppercontrolbartomoveforward

(

Figure10).

CAUTION

Ifsafety-interlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly,

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

daily,andreplaceanydamagedswitchesbefore

operatingthemachine.

Thesafety-interlocksystemisdesignedtopreventtheengine

fromstartingwhen:

•Theblade-controllever(PTO)isengaged.

•Theignitionkeyisintheoffposition.

Thesafety-interlocksystemisalsodesignedtostopthe

enginewhen:

•The-bladecontrolbailisreleasedwiththeblade-control

lever(PTO)engaged.

•Theignitionswitchisturnedtotheoffposition.

TestingtheSafety-interlockSystem

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately .

1.Settheparkingbrake,disengagethePTO,andplace

thethrottleforward.

2.Starttheengine.

3.Withtheenginerunningsqueezetheblade-control

bailagainstuppercontrolbarandpushthe

mower-blade-controlleverforward.Themowerblades

shouldbeginrotating.

4.Withtheenginerunning,releasetheblade-controlbail.

Theengineshouldstop.

5.Starttheengineagain.

6.Withtheenginerunning,turntheignitionkeytothe

offposition.Theengineshouldstop.

Togostraight,applyequalpressuretobothendsofthe

uppercontrolbar(Figure10).

Toturn,releasepressureontheuppercontrolbarside

inthedirectionyouwanttoturn(Figure10).

Figure10

1.Uppercontrolbar

2.Lowercontrolbar4.Lowerhandle

3.Shiftlever

DrivingBackward

1.Togobackward,movetheshiftlevertothereverse

gear.

2.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake.

3.Slowlysqueezethelowercontrolbarandlowerhandle

togethertomoverearward(

Figure10).

UsingtheLowerControlBar

Thisprocedureisfordrivingupacurb.Thiscanbe

performedwhiledrivingforwardorbackward.

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

thefastpositionforbestmowingperformance.

DrivingForward

1.Togoforward,movetheshiftlevertoaforwardgear

(Figure10).

2.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake.

Note:Somecurbsdonotallowthereardrivetirestocontact

thecurb.Ifthishappens,drivethemachineupthecurbatan

angle.

WARNING

Abladecanbebentordamagedwhendrivingup

acurb.Piecesofbladethatmaybethrowncould

seriouslyinjureorkillyouorbystanders.

Donotrunbladeswhiledrivingupacurbforward

orbackward.

16

Page 17

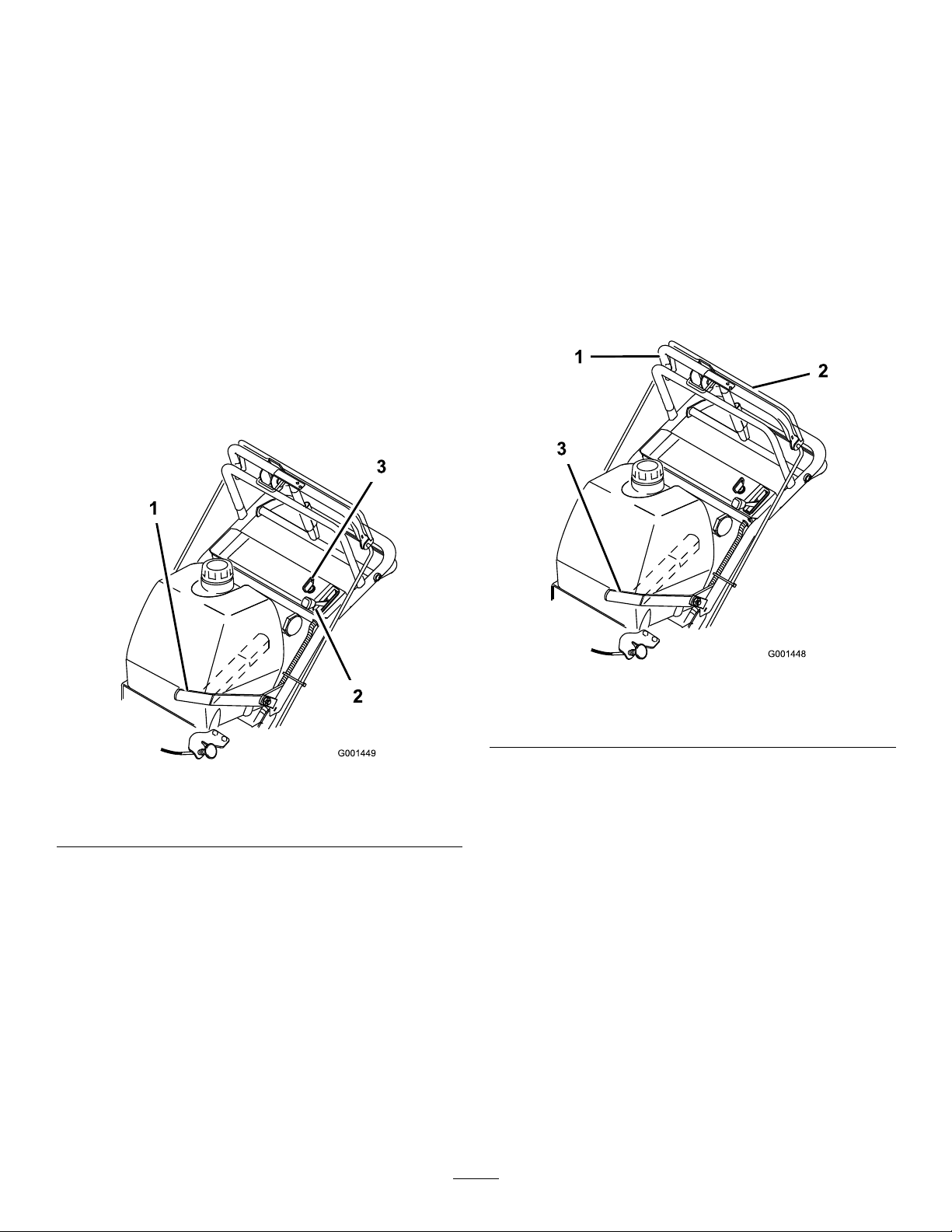

DrivingForwardupaCurb

1.Disengagethemowerblades.

2.Selecttherstgeartodrivethemachine.

3.Drivemachineuntilthecasterwheelscontactthecurb

(Figure11).

4.Liftthefrontofthemachinebypushingdownonthe

lowerhandle(

5.Drivethemachineuntilthedrivewheelscontactthe

curb(Figure11).

6.Lowerthefrontofthemachine(Figure11).

Note:Bothdrivewheelsshouldcontactthecurband

casterwheelsstraight.

7.Atthesametimeengagethelowercontrolbarandlift

uponthelowerhandletodriveoverthecurb(Figure

10andFigure11).

Figure11).

Note:Liftinguponthelowerhandlewillassistdriving

themachineupacurbandnotspinthedrivewheels.

Figure12

Note:Liftinguponthelowerhandlewillassistdriving

themachineupacurbandnotspinthedrivewheels.

Figure11

1.Lowercontrolbarengaged

andmowerinreverse

2.Pulluptoassistmachine

3.Lowercontrolbarengaged

andmowergoingforward

DrivingBackwardupaCurb

1.Disengagethemowerblades.

2.Selectreversetodrivethemachine.

3.Drivethemachineuntildrivewheelscontactcurb

(Figure11).

Note:Bothdrivewheelsshouldcontactthecurband

casterwheelsstraight.

4.Atthesametimeengagelowercontrolbarandliftup

onthelowerhandle(Figure10andFigure12).

1.Lowercontrolbar

(engaged)

2.Handle

StoppingtheMachine

Tostopthemachine,pullbackontheuppercontrolbar,

releasetheblade-controlbail,turntheignitionkeytotheoff

position,andsettheparkingbrake;referto

ParkingBrake(page14)

theignitionswitch.

.Remembertoremovethekeyfrom

Operatingthe

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarylightingand

markingasrequiredbylaw .Pleasecarefullyreadallthesafety

instructions.Knowingthisinformationcouldhelpyou,your

family,petsorbystandersavoidinjury.

Totransportthemachine:

1.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

2.Securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropes.

3.Ifusingatrailer,securethetrailertothetowingvehicle

andinstallthesafetychains.

17

Page 18

AdjustingtheFlowBafe

g012676

1 2

G012677

G012678

Themowerdischargeowcanbeadjustedfordifferenttypes

ofmowingconditions.Positionthebafetogivethebest

qualityofcut.

1.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Toadjustthebafe,loosenthenut(

4.Adjustthebafeandnutintheslottothedesired

dischargeowandtightenthenut.

Figure13

1.Slot

2.Nut

PositioningtheFlowBafe

Figure13).

Figure14

PositionB

Usethispositionwhenbagging(Figure15).

Thefollowingguresareonlyrecommendationsforuse.

Adjustmentswillvarybygrasstype,moisturecontent,and

heightofgrass.

Note:Iftheenginepowerdrawsdownandthemower

groundspeedisthesame,openupthebafe.

PositionA

Thisisthefullrearposition(seeFigure14).Thesuggested

useforthispositionisafollows.

•Useforshort,lightgrassmowingconditions.

•Useindryconditions.

•Forsmallergrassclippings.

•Propelsgrassclippingsfartherawayfromthemower.

Figure15

PositionC

Thisisthefullopenposition.Thesuggesteduseforthis

positionisasfollows(Figure16).

•Useintall,densegrassmowingconditions.

•Useinwetconditions.

•Lowerstheenginepowerconsumption.

•Allowsincreasedgroundspeedinheavyconditions.

18

Page 19

G012679

Figure16

SideDischargingorMulching theGrass

Thismowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

adjustmentrange,in6mm(1/4inch)increments,ofcutting

heightinanyaxleposition.Usethesamenumberofblade

spacersonallbladestoachievealevelcut(2aboveand

2below,1aboveand3below ,etc.).

1.Disengagethebladecontrol(PTO)leverandsetthe

parkingbrakes.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Holdthebladeboltandremovethenut(Figure17).

DANGER

Withoutthegrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthemower

becausethegrassdeectorroutesmaterialdown

towardtheturf.Ifthegrassdeectorisever

damaged,replaceitimmediately.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytocleardischargeareaormower

bladesunlessyoureleasethebailandthepower

takeoff(PTO)isoff.Rotatetheignitionkeyto

Off.Alsoremovethekeyandpullthewiresoff

thesparkplug(s).

AdjustingtheHeightofCut

Thismachinehasa26to108mm(1to4-1/4inch)range

fortheheightofcut.Thiscanbeachievedbyadjusting

thebladespacers,rearaxleheight,andfrontcasterspacers.

UsetheHeight-of-CutCharttoselectthecombinationof

adjustmentsrequired.

Figure17

1.Blade

2.Bladebolt5.Thinwasher

3.Curvedwasher

4.Slidetheboltdownthroughthespindle,andchange

thespacersasneeded(Figure17).

5.Installtheboltandcurvedwasher,addextraspacer(s),

andsecurethemwithathinwasherandanut(Figure

17).

6.Torquethebladeboltto75-80ft-lb(101-108N-m).

4.Spacer

6.Nut

AdjustingtheBladeHeight

Adjustthebladesbyusingthe4spacers(6mm)(1/4inch),

onthebladespindlebolts.Thisallowsfora25mm(1-inch)

19

Page 20

AdjustingtheAxleHeight

Adjusttheaxlepositiontotheselectedheight-of-cutsetting.

RefertotheHeight-of-CutChart.

1.Disengagethebladecontrol(PTO)leverandsetthe

parkingbrakes.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Loosen,butdonotremove,the2axlepivotboltsand

the2axleadjustmentbolts(Figure18).

Figure19

Figure18

1.Axlepivotbolt2.Axleadjustmentbolt

4.Placeajackundertherearcenteroftheengineframe.

Raisethebackendoftheengineframeupenoughto

removethefront2axleadjustmentbolts(Figure18).

Note:Usejackstandstosupportthemachine.

5.Raiseorlowertheengineframewiththejacksothat

youcaninstallthefront2axleadjustmentboltsinthe

desiredholelocation(Figure18).

Note:Useataperedpunchtohelpaligntheholes.

6.Tightenall4boltsandlowerthemower.

7.Adjustthecontrolrodsandthebrakelinkagesas

required.RefertoServicingtheBrakesandAdjusting

theControlRods.

1.Latchpin

2.Spacer,5mm(3/16inch)

3.Spacer,13mm(1/2inch)

2.Removethelatchpin,slidethecasterfromthesupport,

andchangethespacers(Figure19).

3.Installthecasterinthesupportandinsertthevpin

(Figure19).

AdjustingtheHandleHeight

Thehandlepositioncanbeadjustedtomatchtheoperator's

heightpreference.

1.Removehairpincotter,washerandclevispinsecuring

controlrodttingtoidlerbracket(

Figure20).

Important:Y oumustadjustthecontrolrods

andthebrakelinkagewhenyouchangetheaxle

positionsforpropertractionandbrakefunction.

AdjustingtheCasterPosition

1.UsingtheHeight-of-CutChart,adjustthecaster

spacerstomatchwiththeaxleholeselected(Figure19).

Figure20

1.Controlrod4.Clevispin

2.Controlrodtting

3.Idlerbracket6.Hairpincotterpin

5.Washer

2.Loosentheupperangebolts(3/8x1inch)andange

nutsecuringhandletorearframe(Figure21).

20

Page 21

Figure21

g018809

1

2

3

4

5

1.Upperhandle

2.Rearframe

3.Flangebolt(3/8x1inch)

4.Locknut(3/8inch)

5.Uppermountinghole

6.Lowermountinghole

3.Removethelowerangebolts(3/8x1inch)andange

nutssecuringhandletorearframe(Figure21).

4.Pivothandletodesiredoperatingpositionandinstall

lowerangebolts(3/8x1inch)andangenutsinto

mountingholes.Tightenallangebolts.

5.Threadrodttingupordownonroduntilproper

positionisattainedandinstallintottingtoidler

bracketwithclevispin,washerandhairpincotter.

6.Checktheparkingbrakeadjustment.RefertoChecking

theBrakesinBrakeMaintenance(page31).

AdjustingtheControlRods

1.Checkthegapbetweentheuppercontrolbarandthe

xedbarwiththewheeldrivefullyengaged.Thegap

willneedtobeapproximately25to32mm(1to1-1/4

inches);refertoFigure22.

Figure22

1.25to32mm(1to1-1/4

inches)gap

2.Fixedcontrolbar

3.Parking-brakelever

4.Uppercontrolbar

5.Controlrod

Note:Theuppercontrolbarandthexedbarmust

beparallelintheengaged,relaxedandbrakepositions.

2.Checktheoperation.Ifadjustmentisrequired,remove

thehairpincotterpinsecuringtherodtotheupper

controlbar.Threadtherodinoroutofthecontrolrod

ttingforproperpositionandinstallthecontrolrod

intotheuppercontrolbarwiththehairpincotterpin.

3.Afteradjustingthecontrolrods,checktheparking

brakeadjustment;refertoServicingtheBrakeinBrake

Maintenance(page31).

21

Page 22

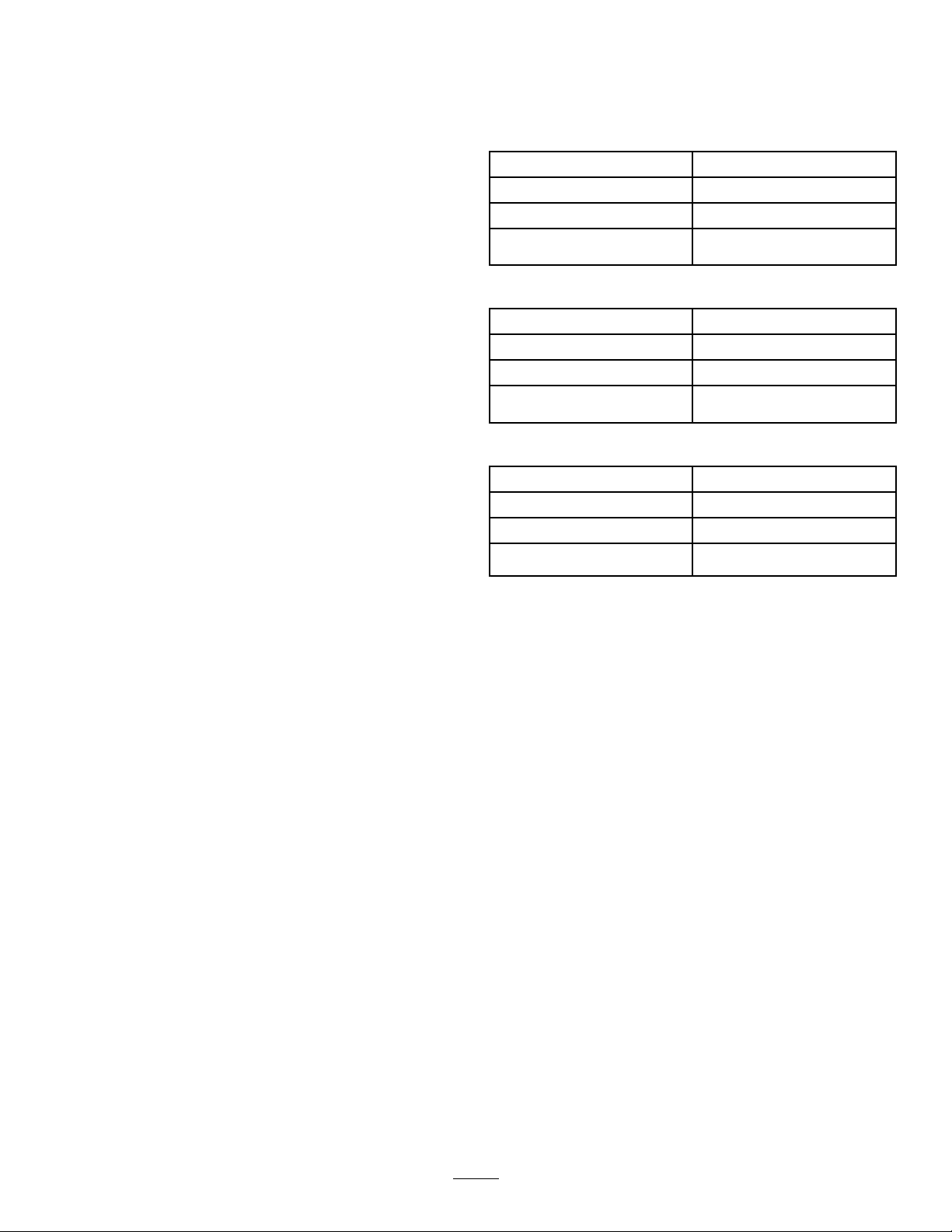

Height-of-cutChart

Numberofspacers

13mm

Axleposition

A00

A01

A10

B01

B10

B11

B20

C

C

C

C

D21

D30

D31

D40

E31

E40

E41

(1/2inch)

11

20

21

30

belowcaster

5mm

(3/16inch)

26mm

29mm

(1-1/8inch)

35mm

(1-3/8inch)

35mm

(1-3/8inch)

41mm

(1-5/8inch)

45mm

(1-3/4inch)

51mm

48mm

(1-7/8inch)

55mm

(2-1/8inch)

57mm

(2-1/4inch)

64mm

(2-1/2inch)

61mm

(2-3/8inch)

64mm

(2-1/2inch)

70mm

(2-3/4inch)

76mm

73mm

(2-7/8inch)

79mm

(3-1/8inch)

82mm

(3-1/4inch)

Numberof1/4inchbladespacersbelowspindle

43210

(1inch)

(2inch)

(3inch)

32mm

(1-1/4inch)

35mm

(1-3/8inch)

41mm

(1-5/8inch)

41mm

(1-5/8inch)

48mm

(1-7/8inch)

51mm

(2inch)

57mm

(2-1/4inch)

54mm

(2-1/8inch)

60mm

(2-3/8inch)

64mm

(2-1/2inch)

70mm

(2-3/4inch)

67mm

(2-5/8inch)

70mm

(2-3/4inch)

76mm

(3inch)

82mm

(3-1/4inch)

79mm

(3-1/8inch)

86mm

(3-3/8inch)

89mm

(3-1/2inch)

38mm

(1-1/2inch)

41mm

(1-5/8inch)

48mm

(1-7/8inch)

48mm

(1-7/8inch)

54mm

(2-1/8inch)

57mm

(2-1/4inch)

64mm

(2-1/2inch)

60mm

(2-3/8inch)

67mm

(2-5/8inch)

70mm

(2-3/4inch)

76mm

(3inch)

73mm

(2-7/8inch)

76mm

(3inch)

82mm

(3-1/4inch)

89mm

(3-1/2inch)

86mm

(3-3/8inch)

92mm

(3-5/8inch)

95mm

(3-3/4inch)

45mm

(1-3/4inch)

48mm

(1-7/8inch)

54mm

(2-1/8inch)

54mm

(2-1/8inch)

60mm

(2-3/8inch)

64mm

(2-1/2inch)

70mm

(2-3/4inch)

67mm

(2-5/8inch)

73mm

(2-7/8inch)

76mm

(3inch)

83mm

(3-1/4inch)

79mm

(3-1/8inch)

82mm

(3-1/4inch)

89mm

(3-1/2inch)

95mm

(3-3/4inch)

92mm

(3-5/8inch)

98mm

(3-7/8inch)

102mm

(4inch)

51mm

(2inch)

54mm

(2-1/8inch)

60mm

(2-3/8inch)

60mm

(2-3/8inch)

67mm

(2-5/8inch)

70mm

(2-3/4inch)

76mm

(3inch)

73mm

(2-7/8inch)

79mm

(3-1/8inch)

83mm

(3-1/4inch)

89mm

(3-1/2inch)

86mm

(3-3/8inch)

89mm

(3-1/2inch)

95mm

(3-3/4inch)

102mm

(4inch)

98mm

(3-7/8inch)

105mm

(4-1/8inch)

108mm

(4-1/4inch)

22

Page 23

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst25hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every200hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthemowerbelttension.

•Checkthemowerbelttension.

•Checkthesafetysystem.

•Greasethecasterwheelsandcasterpivot.

•Checktheengine-oillevel.

•Cleantheair-intakescreen.

•Checkthebrakes.

•Inspecttheblades.

•Cleanthemowerdeck.

•Cleanthefoamair-cleanerelement.

•Greasethemowerbeltidler.

•Checkthepaperair-cleanerelement.

•Checkthetirepressure.

•Checkthebelts.

•Checkthemowerbelttension.

•Changetheengineoil.

•Checkthesparkplugs.

•Checkandcleantheengine-coolingnsandshrouds.

•Replacethepaperair-cleanerelement.

•Changetheoillter.

•Replacethefuellter.

•Replacethefuelventlter.

Every250hours

Every400hours

Beforestorage

•Greasethetransmissioncouplers(moreoftenindirtyordustyconditions).

•Greasethewheelbearings(moreoftenindirtyordustyconditions).

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthespark-plugwire(s)fromthesparkplug(s)beforeyou

doanymaintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

23

Page 24

Lubrication

GreaseType:#2general-purposelithium-basedor

molybdenum-basedgrease

LubricatingtheMachine

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanthegreasettingswitharag.Makesuretoscrape

anypaintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pumpgrease

intothettingsuntilgreasebeginstooozeoutofthe

bearings.

5.Wipeupanyexcessgrease.

Figure24

GreasingtheMowerBeltIdler

Greasethettingonthemowerbelt-idlerarmpivot(Figure

25).

LubricatingtheCasterand WheelBearings

1.Lubricatethefrontwheelbearingsandfrontspindles

(Figure23).

2.Lubricatethedrivewheelbearings(Figure23).

Figure23

Note:Removethemowerdeckcovertoaccessthegrease

ttingforthemowerbelt-idlerarm.

Figure25

32-inchand36-inchmowerdeck

GreasingtheTransmission Couplers

Lubricatethetransmissioncouplersandidlerarmpivots

locatedinthebackofthemachine(Figure24).

Figure26

48-inchmowerdeck

24

Page 25

EngineMaintenance

ServicingtheAirCleaner

CleaningtheFoamAir-cleanerElement

1.Washthefoamelementinliquidsoapandwarmwater.

Whentheelementisclean,rinseitthoroughly.

2.Drytheelementbysqueezingitinacleancloth.

ServiceInterval/Specication

ServiceInterval:Every25hours—Cleanthefoam

air-cleanerelement.

Every50hours—Checkthepaperair-cleanerelement.

Every200hours—Replacethepaperair-cleaner

element.

Note:Servicetheaircleanermorefrequently(everyfew

operatinghours)iftheoperatingconditionsareextremely

dustyorsandy.

Important:Donotoilthefoamorpaperelement.

RemovingtheFoamandPaper

Elements

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage(Figure27).

4.Unscrewthecoverknobsandremovetheair-cleaner

cover(Figure27).

5.Unscrewthehoseclampandremovetheaircleaner

assembly(Figure27).

6.Carefullypullthefoamelementoffthepaperelement

(Figure27).

Important:Replacethefoamelementifitistorn

orworn.

ServicingthePaperAir-cleanerElement

1.Donotcleanthepaperlter,replaceit(Figure27).

2.Inspecttheelementfortears,anoilylm,ordamageto

therubberseal.

3.Replacethepaperelementifitisdamaged.

InstallingtheFoamandPaperElements

Important:Topreventenginedamage,alwaysoperate

theenginewiththecompletefoamandpaperaircleaner

assemblyinstalled.

1.Carefullyslidethefoamelementontothepaper

air-cleanerelement(Figure27).

2.Placetheaircleanerassemblyontotheaircleanerbase

andsecureitwiththe2wingnuts(

3.Placetheair-cleanercoverintopositionandtighten

thecoverknob(Figure27).

Figure27).

ServicingtheEngineOil

ServiceInterval:Beforeeachuseordaily—Checkthe

engine-oillevel.

Aftertherst8hours—Changetheengineoil.

Every100hours—Changetheengineoil.

Figure27

1.Cover

2.Hoseclamp4.Foamelement

3.Paperelement

Every200hours—Changetheoillter.

Note:Changetheoilmorefrequentlywhentheoperating

conditionsareextremelydustyorsandy.

OilType:Detergentoil(APIserviceSF ,SG,SH,SJorSL)

CrankcaseCapacity:1.7L(1.8USqt)withthelter

removed;1.5L(1.6USqt)withoutthelterremoved

Viscosity:Refertothetable(Figure28).

25

Page 26

ChangingtheEngineOil

1.Parkthemachinesothatthedrainsideisslightlylower

thantheoppositesidetoensurethattheoildrains

completely.

2.DisengagethePTOandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.Slidethedrainhoseovertheoildrainvalve.

5.Placeapanbelowthedrainhose.Rotateoildrainvalve

toallowoiltodrain(Figure30).

Figure28

CheckingtheEngine-oilLevel

1.Parkthemachineonalevelsurface.

2.DisengagethePTOandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.Cleanaroundtheoildipstick(Figure29)sothatdirt

cannotfallintothellerholeanddamagetheengine.

6.Whenoilhasdrainedcompletely ,closethedrainvalve.

7.Removethedrainhose(

Figure30).

Note:Disposeoftheusedoilatarecyclingcenter.

Figure29

1.Oildipstick

2.Fillertube

5.Unscrewtheoildipstickandwipetheendclean(Figure

29).

6.Slidetheoildipstickfullyintothellertube,butdonot

threaditontothetube(Figure29).

7.Pullthedipstickoutandlookattheend.Iftheoillevel

islow,slowlypouronlyenoughoilintothellertube

toraisetheleveltotheFullmark.

Important:Donotoverllthecrankcasewithoil

andruntheengine;enginedamagecanresult.

Figure30

1.Oildrainvalve2.Oildrainhose

8.Slowlypourapproximately80%ofthespeciedoil

intothellertube(

Figure29).

9.Checktheoillevel;refertoCheckingtheEngineOil

Level.

10.SlowlyaddtheadditionaloiltobringittotheFull

mark.

ChangingtheOilFilter

Note:Changetheoilltermorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

2.Removetheoldlter(

26

Figure31).

Page 27

Figure31

1

1.Oillter

2.Adapter

3.Applyathincoatofnewoiltotherubbergasketon

thereplacementlter(Figure31).

4.Installthereplacementoilltertothelteradapter,

turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional3/4turn(

Figure31).

5.Fillthecrankcasewiththepropertypeofnewoil;refer

toServicingtheEngineOil.

6.Runtheengineforabout3minutes,stoptheengine,

andcheckforoilleaksaroundtheoillteranddrain

valve.

7.Checktheengineoillevelandaddoilifneeded.

8.Wipeupanyspilledoil.

ServicingtheSparkPlugs

ServiceInterval:Every100hours—Checkthesparkplugs.

Ensurethattheairgapbetweenthecenterelectrodeandthe

sideelectrodeiscorrectbeforeinstallingeachsparkplug.Use

aspark-plugwrenchforremovingandinstallingthespark

plugsandagappingtoolorafeelergaugetocheckandadjust

theairgap.Installnewsparkplugsifnecessary.

Figure32

1.Spark-plugwire/sparkplug

4.Cleanaroundthesparkplugstopreventdirtfrom

fallingintotheengineandpotentiallycausingdamage.

5.Removethesparkplugsandthemetalwashers.

CheckingtheSparkPlugs

1.Lookatthecenterofthesparkplugs(Figure33).If

youseelightbrownorgrayontheinsulator,theengine

isoperatingproperly.Ablackcoatingontheinsulator

usuallymeansthattheaircleanerisdirty.

2.Ifneeded,cleanthesparkplugwithawirebrushto

removecarbondeposits.

Type:Champion®RCJ8Yorequivalent

AirGap:0.75mm(0.030inch)

RemovingtheSparkPlugs

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Disconnectthewiresfromthesparkplugs(

Figure32).

Figure33

1.Centerelectrode;insulator3.Airgap(nottoscale)

2.Sideelectrode

Important:Alwaysreplacethesparkplugswhen

theyhavewornelectrodes,anoilylm,ora

crackedinsulator.

3.Checkthegapbetweenthecenterelectrodeandthe

sideelectrode(

Figure33).Bendthesideelectrode

(Figure33)ifthegapisnotcorrect.

27

Page 28

InstallingtheSparkPlugs

1.Installthesparkplugsandthemetalwasher.Ensure

thattheairgapissetcorrectly.

2.Tightenthesparkplugsto22N-m(16ft-lb).

FuelSystem

Maintenance

3.Connectthewirestothesparkplugs(Figure33).

ServicingtheFuelSystem

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

DrainingtheFuelTank

1.Parkthemachineonalevelsurfacetoensurethatthe

fueltankdrainscompletely;thendisengagethepower

take-off(PTO),settheparkingbrake,andturnthe

ignitionkeytotheoffposition.Removethekey .

2.Closethefuel-shutoffvalveatthefueltank(Figure34).

3.Squeezetheendsofthehoseclamptogetherandslide

itupthefuellineawayfromfuellter(Figure34).

4.Pullthefuellineoffthefuellter(Figure34).Open

thefuel-shutoffvalveandallowthegasolinetodrain

intoagascanordrainpan.

Note:Nowisthebesttimetoinstallanewfuellter

becausethefueltankisempty.RefertoReplacingthe

FuelFilter.

5.Installthefuellineontothefuellter.Slidethehose

clampclosetothevalvetosecurethefuelline.

1.Fuel-shutoffvalve2.Clamp

28

Figure34

Page 29

ReplacingtheFuelFilter

g014686

1 2

ServiceInterval:Every200hours/Yearly(whichevercomes

rst)

Neverinstalladirtylterifitisremovedfromthefuelline.

Note:Notehowthefuellterisinstalledinordertoinstall

thenewltercorrectly.

Note:Wipeupanyspilledfuel.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Closethefuel-shutoffvalveatthefueltank(

4.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure35).

Figure35

1.Hoseclamp3.Filter

2.Fuelline

Figure34).

Figure36

1.Fuelventlter2.Rightsideofengine

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclampscloseto

thelter.

7.Openthefuel-shutoffvalveatthefueltank(Figure34).

8.Checkforfuelleaks,andrepairifneeded.

9.Wipeupanyfuelthatspilled.

ServicingtheFuelVentSystem

ServiceInterval:Every200hours/Yearly(whichevercomes

rst)

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removetheexistingfuelventlter(

4.Installanewlter.

Figure36).

29

Page 30

DriveSystem

CoolingSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthereartiresat83to97kPa(12

to14psi).Uneventirepressurecancauseanunevencut.

Note:Thefronttiresaresemi-pneumatictiresanddonot

requireairpressuremaintenance.

Maintenance

CleaningtheAir-intakeScreen

Beforeeachuse,removeanybuildupofgrass,dirt,or

otherdebrisfromthecylinderandcylinder-headcooling

ns,theair-intakescreenontheywheelend,andthe

carburetor-governorleversandlinkage.Thiswillhelpensure

adequatecoolingandcorrectenginespeedandwillreduce

thepossibilityofoverheatingandmechanicaldamagetothe

engine.

CleaningtheCoolingSystem

ServiceInterval:Every100hours/Yearly(whichevercomes

rst)

Cleantheairintakescreenfromgrassanddebrisbeforeeach

use.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

Figure37

3.Removetheair-intakescreen,therecoilstarter,and

thefanhousing(Figure38).

4.Cleanthedebrisandgrassfromtheengineparts.

5.Installtheair-intakescreen,therecoilstarter,andthe

fanhousing(Figure38).

1.Air-intakescreen4.Bolt

2.Fanhousing5.Nut

3.Recoilstarter

30

Figure38

Page 31

BrakeMaintenance

ServicingtheBrakes

3.Checkthebrakebeforeyouadjustit;refertoChecking

theBrakes.

4.Releasetheparkingbrake;refertoReleasingthe

ParkingBrakeinOperation.

Beforeeachuse,checkbrakesonbothalevelsurfaceand

slope.

Alwayssettheparkingbrakewhenyoustopthemachine

orleaveitunattended.Iftheparkingbrakedoesnothold

securely,anadjustmentisrequired.

CheckingtheBrakes

1.Parkthemachineonalevelsurface,disengagethe

bladecontrol(PTO).

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Applytheparkingbrake.Thewheelsmustlockwhen

youtrytopushthemachineforward.

4.Ifthewheelsdonotlock,adjustthebrakes.Referto

AdjustingtheBrakes.

5.Releasethebrakeandpressuppercontrolbarvery

lightly,approximately13mm(1/2inch).Thewheels

shouldrotatefreely;ifnot,refertoAdjustingthe

Brakes.

5.Toadjustthebrake,rotatethewingnutsonthebrake

Figure39).Turnthewingnutsclockwiseto

rods(

tightenthebrakeandcounterclockwisetoloosenthe

brake.

Figure39

1.Brakerod2.Wingnut

Note:Controlbarshouldbeparallelwiththe

referencebarwhenproperlyadjusted.

AdjustingtheBrakes

Thebrakeleverisontheuppercontrolbar.Iftheparking

brakedoesnotholdsecurely,anadjustmentisrequired.

1.Parkthemachineonalevelsurface,disengagethe

PTO,andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

6.Checkthebrakeoperationagain;refertoChecking

theBrakes.

Important:Withtheparkingbrakereleased,the

rearwheelsmustrotatefreelywhenyoupushthe

mower.Ifbrakeactionandfreewheelrotation

cannotbeachievedcontactyourservicedealer

immediately.

31

Page 32

BeltMaintenance

CheckingtheBelts

ServiceInterval:Every50hours/Monthly(whichever

comesrst)—Checkthebelts.

Checkthebeltsforcracks,frayededges,burnmarks,wear,

signsofoverheating,oranyotherdamage.Replaceany

damagedbelts.

ReplacingtheTractionDrive Belt

1.Removethehairpincottersecuringthebrakerodto

thebrakearmtorelaxthebeltidlertension(Figure40).

2.Removethebottomboltandloosenthetopboltofthe

shieldtorotateitforbeltclearance(Figure40).

3.Liftthebeltpasttheidlerandoffthedrivepulley

(Figure40).

4.Raisethewheeloffthegroundenoughtoallowfor

beltremoval.

5.Replacethetractiondrivebelt.

6.Securetheshieldwiththepreviouslyremovedboltand

tightenthebolts(Figure40).

7.Securethebrakerodtothebrakearmwiththehairpin

cotter(Figure40).

4.Removethemowerbelt(Figure41).

Figure41

1.Idlerpulleyinslot4.Beltguide

2.Tractionbelt

3.Mowerbelt6.Mowerbelt

5.Loosenthepivotboltenoughtoslidetheidlerpulleyin

theslotandremovethetractionbeltfromtheengine

andthedrivepulleys(Figure41).

6.Installthenewdrivebeltaroundtheengineandthe

drivepulleys(Figure41).

7.Slidetheidlerpulleyintheengineframetotensionthe

tractionbelt(Figure41).

8.Installthemowerbelt(Figure41).

9.Checkthebeltguideundertheengineframeforthe

properadjustment(Figure41).

5.19mm(3/4inch)

Figure40

1.Hairpincotter

2.Brakerod4.Drivebelt

3.Shield

ReplacingtheDriveBelt

1.Disengagetheblade-control(PTO)leverandsetthe

parkingbrakes.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Raisetherearofthemachineandholditupwithjack

stands.

Note:Thedistancebetweenthebeltguideandmower

beltshouldbe19mm(3/4inch)whenthemower

beltisengaged.Adjustthebeltifnecessary.The

disengagedbeltshouldnotdragorfalloffthepulley

whentheguidesareproperlyadjusted.

ReplacingtheMowerBelt

Important:Thebrakeneedstobeadjustedwhenthe

belttensionorthebrakelinkageisadjusted.

1.Disengagetheblade-control(PTO)leverandsetthe

parkingbrakes.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Removetheknobsandthebeltcoveronthemower.

4.Removetheidlerpulleyandthewornbelt.

5.Installthenewmowerbelt.

6.Installtheidlerpulley.

7.Engagetheblade-control(PTO)leverandcheck

thebelttension.RefertoAdjustingtheMowerBelt

Tension.

32

Page 33

Note:Thepropermowerbelttensionis44to67N-m

(10to15ft-lb)withthebeltdeected13mm(1/2inch)

halfwaybetweenthepulleys(Figure45orFigure46).

8.Engagetheblade-control(PTO)lever.

9.Checktheclearancebetweenthebellcrankandthe

transmissionoutputshaft(Figure42).

Figure42

1.2to3mm(1/16to1/8inch)

2.Bellcrank

3.Transmissionoutputshaft6.Clevis

4.Hairpincotter

5.Clevispin

Figure43

32-inchand36-inchmowerdeck

1.13mm(1/2inch)deection

here

2.Assistarm5.Turnbuckle

3.Frontstop

4.Locknut

Note:Theclearanceshouldbe2to3mm(1/16to

1/8inch).

10.Removethehairpincotterpinandtheclevispinfrom

thebellcrank.

11.Rotatetheclevisclockwiseontherodtoincreasethe

clearance;rotateitcounterclockwisetodecreaseit

Figure42).

(

12.Disengagetheblade-control(PTO)lever.

Note:Iftheassistarmdoesnotcontactthefrontstop

onthemowerdeck(Figure43orFigure44),adjustthe

clevistobringthebellcrankclosertothetransmission

outputshaft(Figure42).

Figure44

48-inchmowerdeck

1.13mm(1/2inch)deection

here

2.Assistarm5.Turnbuckle

3.Frontstop

4.Locknut

13.Checkthebeltguideundertheengineframeforthe

properadjustment(Figure41).

Note:Thedistancebetweenthebeltguideandthe

mowerbeltshouldbe32mm(1-1/4inch)whenyou

engagethemowerbelt.Adjustthemowerbeltas

33

Page 34

necessary.Thedisengagedbeltshouldnotdragorfall

offthepulleywhentheguidesareproperlyadjusted.

AdjustingtheMowerBelt Tension

AdjustingtheTensionfor32-inchand

36-inchMowerDecks

ServiceInterval:Aftertherst8hours—Checkthemower

belttension.

Aftertherst25hours—Checkthemowerbelt

tension.

Every50hours—Checkthemowerbelttension.

Important:Thebrakeneedstobeadjustedwhenthe

belttensionorthebrakelinkageisadjusted.

Important:Thebeltmustbetightenoughtonotslip

duringheavyloadswhilecuttinggrass.Over-tensioning

thebeltwillreducethespindlebearinglife,thebeltlife,

andtheidlerpulleylife.

Figure45

32-inchand36-inchmowerdeck

1.Mowerbeltwith13mm

(1/2inch)deection

6.Tightenthelocknutontheturnbuckle.

2.Idlerpulley

Thebeltmustbetightenoughsothatitdoesnotslipduring

heavyloadswhilecuttinggrass,andover-tensioningwill

reducebeltandspindlebearinglife.

1.Disengagetheblade-control(PTO)leverandsetthe

parkingbrakes.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Loosenthelocknutontheturnbuckle(Figure45).

4.Rotatetheturnbuckletowardtherearofthemowerto

increasethetensiononthebelt.Rotatetheturnbuckle

towardthefrontofthemowertodecreasethetension

onthebelt(Figure45).

Note:Theeyeboltthreadsonbothendsofthe

turnbuckleshouldbeengagedaminimumof8mm

(5/16inch).

5.Engagetheblade-controllever(PTO)andcheckthe

belttension.Adjustthetensionuntilitiscorrect.

Note:Thepropermowerbelttensionis44to67N-m

(10to15ft-lb)withthebeltdeected13mm(1/2inch)

halfwaybetweenthepulleys(Figure45).

7.Checkthebladebrakeadjustment;refertoAdjusting

theBladeBrake.

AdjustingtheTensionfor48-inch

MowerDecks

Important:Thebeltmustbetightenoughtonotslip

duringheavyloadswhilecuttinggrass.Over-tensioning

thebeltwillreducethespindlebearinglife,thebeltlife

andtheidlerpulleylife.

Important:Thebrakeneedstobeadjustedwhenthe

belttensionorthebrakelinkageisadjusted.

1.Disengagetheblade-control(PTO)leverandsetthe

parkingbrakes.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Loosenthelocknutontheturnbuckle(Figure47).

4.Rotatetheturnbuckletowardtherearofthemowerto

increasethetensiononthebelt.Rotatetheturnbuckle

towardthefrontofthemowertodecreasethetension

onthebelt(Figure47).

Note:Thepropermowerbelttensionis44to67N-m

(10to15ft-lb)withthebeltdeected13mm(1/2inch)

halfwaybetweenthepulleys(Figure46).

34

Page 35

positionedtothemiddleorfronthole(Figure48).Use

g017651

theholethatwillgivethecorrectadjustment.

7.Whentheidlerpulleyismovedthebeltguidemust

bemoved.Movethebeltguidetothefrontposition

(Figure48).

Figure46

48-inchmowerdeck

1.Idlerpulley2.Mowerbeltwith13mm

(1/2inch)deection

Note:Theeyeboltthreadsonbothendsofthe

turnbuckleshouldbeengagedaminimumof8mm

(5/16inch).

Figure48

1.Rearidlerpulley4.Beltguideinbackposition

2.Middlehole5.Frontidlerpulley

3.Fronthole

8.Checkthebeltguideundertheengineframeforproper

adjustment(Figure49).

Note:Thedistancebetweenthebeltguideandthe

mowerbeltshouldbe19mm(3/4inch)whenyou

engagethemowerbelt(Figure49).Adjustthemower

beltasnecessary.Thedisengagedbeltshouldnotdrag

orfalloffthepulleywhentheguidesandbelttension

areproperlyadjusted.

9.Checkthebladebrakeadjustment;refertoAdjusting

theBladeBrake.

Figure47

1.13mm(1/2inch)deection

here

2.Assistarm5.Turnbuckle

3.Frontstop

4.Locknut

5.Engagetheblade-controllever(PTO)andcheckthe

belttension.

6.Ifthereisnoadjustmentleftintheturnbuckleand

thebeltisstillloose,therearidlerpulleyneedstobe

Figure49

1.Idlerpulleyinslot4.Beltguide

2.Tractionbelt

3.Mowerbelt6.Mowerbelt

35

5.19mm(3/4inch)

Page 36

AdjustingthePTOEngagement

g017648

1

2

3

4

g017649

Linkage

ThePTOengagementlinkageadjustmentislocatedbeneath

thefrontleft-handcorneroftheenginedeck.

1.Disengagetheblade-control(PTO)leverandsetthe

parkingbrakes.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Engagetheblade-controllever(PTO).

4.Adjustthelinkagelengthtowherethelowerendofthe

bellcrankjustclearstheaxlesupportgusset(Figure50).

Figure51

1.Yoke5.Assistarmlink

2.Nut6.Assistarm

3.Rearassistarmstop7.Turnbuckle

4.Frontassistarmstop

8.Toadjusttheassistarmlink,removethehairpincotter

pinfromtheassistarm(Figure51).

9.Loosenthenutagainsttheyoke(Figure50).

10.Removetheassistarmlinkfromtheassistarmand

Figure50

1.Bellcrank4.Yoke

2.Safetyswitchlocated

underenginedeck

3.Bellcrankjustclearsthe

gussetwiththePTO

engaged

5.Nut

6.Assistarmlink

rotatethelinktoadjustthelength.

11.Installtheassistarmlinkintotheassistarmandsecure

itwiththehairpincotterpin(Figure51).

12.Checkiftheassistarmhitsagainstthestopscorrectly.

AdjustingthePTOSafetySwitch

1.Disengagetheblade-control(PTO)leverandsetthe

5.Makesuretheassistarmisagainsttherearassistarm

stoponthedeck(Figure51).

6.Pushtheblade-controllever(PTO)downtothe

disengagedposition.

7.Theassistarmshouldcontactthefrontassistarmstop

onthedeck.Ifitdoesnotcontact,adjustthebellcrank

sothatitisclosertothegusset(

Figure51).

parkingbrakes.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Disengagetheblade-controllever(PTO).Makesure

thattheassistarmisagainstthefrontassistarmstop.

4.Ifneeded,adjusttheblade-safetyswitchbyloosening

theboltsholdingtheswitchbracket(Figure52).

5.Movethemountingbracketuntilthebellcrankpresses

theplungerby6mm(1/4inch);referto(Figure52).

Note:Makesurethatthebellcrankdoesnottouch

theswitchbody,ordamagetotheswitchcouldoccur.

6.Tightentheswitchmountingbracket.

36

Page 37

2

3

g017650

1

1.Bellcrank

2.Boltsandnuts

Figure52

3.Switchmountingbracket

4.Switchbody

MowerDeck Maintenance

ServicingtheCuttingBlades

Toensureasuperiorqualityofcut,keepthebladessharp.

Forconvenientsharpeningandreplacement,youmaywant

tokeepextrabladesonhand.

WARNING

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

PreparingtoInspectorServicethe

Blades

Parkthemachineonalevelsurface,disengagethe

blade-controlbail,andsettheparkingbrake.Turntheignition

keytotheoffposition.Removethekeyanddisconnectthe

spark-plugwiresfromthesparkplugs.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure53).Iftheedges

arenotsharporhavenicks,removeandsharpenthe

blades.RefertoSharpeningtheBlades.

Figure53

1.CuttingEdge3.Wear/slotformingin

2.Sail4.Crackinthecurvedarea

curvedarea

2.Inspecttheblades,especiallythecurvedarea(Figure

53).Ifyounoticeanydamage,wear,oraslotforming

inthisarea(item3.inFigure53),immediatelyinstall

37

anewblade.

Page 38

CheckingforBentBlades

1

G024247

1.Disengagetheblade-controlswitch(PTO)andsetthe

parkingbrake.

inch).Ifthisdimensionexceeds3mm(1/8inch),the

bladeisbentandmustbereplaced.RefertoRemoving

theBladesandInstallingtheBlades.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Rotatethebladesuntiltheendsfaceforwardand

backward(Figure54).

Figure54

WARNING

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplacebentordamagedblade

withanewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofblade.

RemovingtheBlades

Replacethebladesifyouhitasolidobjectorifthebladesare

outofbalanceorbent.T oensureoptimumperformanceand

continuedsafetyconformanceofthemachine,usegenuine

Tororeplacementblades.Replacementbladesmadebyother

manufacturersmayresultinnon-conformancewithsafety

standards.

1.Holdthebladeboltwithawrench.

2.Removethenut,bladebolt,curvedwasher,blade,

spacers,andthinwasherfromthespindle(Figure57).

Figure55

4.Measurefromalevelsurfacetothecuttingedge,

positionA,oftheblades(

Note:Notethisdimension.

Figure56

1.Measurefromthecuttingedgetoalevelsurface

5.Rotatetheoppositeendsofthebladesforward.

6.Measurefromalevelsurfacetothecuttingedgeofthe

bladesatthesamepositionasinstep3.

Note:Thedifferencebetweenthedimensions

obtainedinsteps3and4mustnotexceed3mm(1/8

Figure56).

38

Page 39

balanced,lesomemetalofftheendofthesailarea

only(

Figure59).Repeatthisprocedureuntiltheblade

isbalanced.

Figure59

1.Blade2.Balancer

InstallingtheBlades

1.Installthecurvedwasherandthenthebladeontothe

bolt.Selectthepropernumberofspacer(s)forthe

heightofcut,andslidetheboltintothespindle(Figure

57).

Important:Thecurvedpartoftheblademust

pointupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installtheremainingspacer(s)andsecurethemwitha

thinwasherandanut(Fig.Figure57).

Figure57

1.Blade

2.Bladebolt5.Thinwasher

3.Curvedwasher

4.Spacer

6.Nut

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure58).

Note:Maintaintheoriginalangle.Thebladeremains

balancedifthesameamountofmaterialisremoved

frombothcuttingedges.

3.Torquethebladeboltto101to108N-m(75to

80ft-lb).

Figure58

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure59).

Note:Ifthebladestaysinahorizontalposition,the

bladeisbalancedandcanbeused.Ifthebladeisnot

39

Page 40

AdjustingtheBladeBrake

1.DisengagethePTO,turntheignitionkeytotheoff

position,andremovethekey .

2.Waitforallmovingpartstostopbeforeleavingthe

operatingpositionandthensettheparkingbrake.

3.Ifnecessary,adjustthespringmountingboltssothat

thebladebrakepadrubsagainstbothsidesofthe

pulleygroove(Figure60).

4.Adjustthenutattheendofthebladebrakeroduntil

thereis3mmto5mm(1/8to3/16inch)betweenthe

nutandthespacer(Figure60).

5.Engagetheblades.Ensurethatthebladebrakepadno

longercontactsthepulleygroove.

Figure60

1.Springmountingbolts3.3mmto5mm(1/8to

2.Bladebrakepad

3/16inch)

40

Page 41

ReplacingtheGrassDeector

g015594

1

6 2

4

7

3

5

Storage

WARNING

Anuncovereddischargeopeningcouldallowthe

lawnmowertothrowobjectsintheoperator'sor

bystander'sdirectionandresultinseriousinjury.

Also,contactwiththebladecouldoccur.

Neveroperatethelawnmowerunlessyouinstalla

coverplate,amulchplate,grassdeectororbagger.

1.Removethelocknut,bolt,springandspacerholding

thedeectortothepivotbrackets(Figure61).Remove

thedamagedorworngrassdeector.

Figure61

1.Bolt

2.Spacer6.GrassDeector

3.Locknut

4.Spring

2.Placethespacerandspringontothegrassdeector.

PlaceoneJendofthespringbehindthedeckedge.

Note:MakesureoneJendofthespringisinstalled