Page 1

FormNo.3401-570RevA

LT-F3000Heavy-DutyTripleTurf

FlailMower

ModelNo.30659—SerialNo.316000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3401-570*A

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives.

Fordetails,pleaseseetheseparateproductspecic

DeclarationofConformity(DOC)sheet.

Introduction

Thismachineisaride-onlawnmowerintendedtobeusedby

professional,hiredoperatorsincommercialapplications.It

isprimarilydesignedforcuttinggrassonparks,sportselds,

caravanparks,cemeteries,andcommercialgrounds.Itis

designedforcuttinglongandshortgrass.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactToroforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpndinga

dealer,ortoregisteryourproductdirectlyatwww .Toro.comor

ToroCommercialProductsServiceDepartment,Spellbrook,

BishopsStortford,CM234BU,England,+44(0)1279603019,

Email:uk.service@toro.com.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Themodelandserialnumbersareona

platemountedontheleftsideoftheframeunderthefoot

rest.Writethenumbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure1

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUK

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................6

SoundPowerLevel..................................................7

SoundPressureLevel...............................................7

VibrationLevel......................................................7

SafetyandInstructionalDecals.................................8

Setup...........................................................................12

ProductOverview.........................................................12

Controls...............................................................13

Specications........................................................20

Attachments/Accessories........................................20

Operation....................................................................21

ThinkSafetyFirst...................................................21

CheckingtheEngine-OilLevel.................................21

CheckingtheCoolingSystem...................................22

AddingFuel...........................................................23

CheckingtheHydraulicFluid...................................23

CheckingtheTirePressure......................................24

CheckingtheTorqueoftheWheel-Lug

Nuts.................................................................24

UsingtheOperatorPlatformLatching

Mechanism........................................................25

UnderstandingtheOperator-Presence

Controls............................................................25

StartingandShuttingOfftheEngine.........................25

FlailCuttingUnitGeneralInformation......................27

AdjustingtheHeightofCut.....................................27

ControllingthePositionoftheIndividualCutting

Units.................................................................28

UsingtheCuttingUnitAuto-LimitedLiftin

Reverse.............................................................28

EngagingtheCuttingUnitDrive..............................29

UsingW eight-Transfer/TractionAssistance...............29

FoldingtheROPS..................................................29

LocatingtheJackingPoints......................................30

HaulingtheMachine...............................................30

TowingtheMachine...............................................31

OperatingTips......................................................33

Maintenance.................................................................34

RecommendedMaintenanceSchedule(s)......................34

DailyMaintenanceChecklist....................................35

PreparingtheMachineforMaintenance.....................37

ServiceIntervalChart.............................................37

Lubrication...............................................................38

GreasingtheBearings,Bushings,andPivots...............38

EngineMaintenance..................................................39

CheckingtheEngineOverheatWarning

System..............................................................39

ServicingtheAirCleaner.........................................39

ServicingtheEngineOilandFilter............................40

FuelSystemMaintenance...........................................41

DrainingtheFuelTank...........................................41

CheckingtheFuelLinesandConnections..................41

BleedingtheFuelSystem.........................................41

ReplacingtheFuelFilter..........................................42

ElectricalSystemMaintenance....................................42

CheckingtheElectricalSystem.................................42

CheckingtheBatteryCondition................................42

ServicingtheBattery...............................................43

DriveSystemMaintenance.........................................43

ChangingtheTransmissionOilFilter........................43

ChangingtheHydraulic-ReturnFilter........................44

CheckingtheRear-WheelAlignment.........................44

InspectingtheTransmissionControlCableand

OperatingMechanism.........................................45

CoolingSystemMaintenance......................................45

RemovingDebrisfromtheCoolingSystem................45

BeltMaintenance......................................................46

TensioningtheAlternatorBelt.................................46

ControlsSystemMaintenance.....................................47

CheckingtheForward/ReverseTravelPedal

Action...............................................................47

CheckingtheOperator-Presence-SeatSwitch.............47

CheckingtheCutter-Drive-InterlockSwitch...............47

CheckingtheParking-Brake-InterlockSwitch.............47

CheckingtheTransmission-Neutral-Interlock

Switch...............................................................47

HydraulicSystemMaintenance....................................48

ServicingtheHydraulicSystem.................................48

CheckingtheHydraulic-Fluid-OverheatWarning

System..............................................................48

CheckingtheHydraulicLinesandHoses....................49

CuttingUnitSystemMaintenance.................................49

InspectingtheBlades..............................................49

ReplacingtheBlades...............................................50

CheckingtheBladeBolts.........................................50

CheckingtheBackGuard........................................51

ClearingtheFlailRotors..........................................51

CheckingtheRubberGuard.....................................51

CheckingtheCuttingUnitPivot...............................51

CheckingtheRotor.................................................52

CheckingtheRear-RollerBearingAdjustment............52

CheckingRear-RollerScraperWireTension................53

RaisingtheMachineOfftheGround.........................53

DisposingofWaste.................................................53

Storage........................................................................54

PreparingtheTractionUnit.....................................54

PreparingtheEngine..............................................54

Troubleshooting...........................................................55

3

Page 4

Safety

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013.

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Replacedamagedorwornsilencers/mufers.

•Onlyuseaccessoriesandattachmentsapprovedbythe

manufacturer.

•Beforeusing,alwaysvisuallyinspecttoseethattheblades,

bladebolts,andcuttingunitsarenotwornordamaged.

Replacewornordamagedbladesandboltsinsetsto

preservebalance.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Training

•Readtheoperator'smanualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstructionshould

emphasize:

–Theneedforcareandconcentrationwhenworking

withride-onmachines.

–Controlofaride-onmachineslidingonaslopeisnot

regainedbytheapplicationofthebrake.Themain

reasonsforlossofcontrolare:

◊Insufcientwheelgrip

◊Beingdriventoofast

◊Inadequatebraking

◊Thetypeofmachineisunsuitableforitstask

◊Lackofawarenessoftheeffectofground

conditions,especiallyslopes

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtootherpeopleordamage

toproperty.

Preparation

•Whilemowing,alwayswearsubstantial,slip-resistant

footwear,longtrousers,safetyglasses,andearprotection.

Tiebacklonghairanddonotwearjewelry.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxideandotherexhaustgasses

cancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,engagetheparking

brake,disengagethecuttingunitdrivesystem,andensure

thattheforward/reversespeedcontrolsareintheneutral

position.

•Donotuseonaslopeofmorethan20°.Careshouldbe

takenwhenusingthemoweronanyslopewhereground

conditionsaresuchthattheremaybeariskofthemower

rollingover.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.T oguardagainst

overturning:

–Donotstoporstartsuddenlywhengoingupor

downhill.

–Machinespeedsshouldbekeptlowonslopesand

duringtightturns.

–Stayalertforhumpsandhollowsandotherhidden

hazards.

–Donotturnsharply.Usecarewhenreversing.

•Stayalertforholesintheterrainandotherhiddenhazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfacesother

thangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.Besureall

interlocksareattached,adjustedproperly ,andfunctioning

properly.

•Donotchangetheenginegovernorsettingsorover-speed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition:

4

Page 5

–Stoponlevelground.

–Disengagethedrivetothecuttingunits.

–Liftcuttingunitstothetransportpositionand

securelylockthesafetylatchesoralternativelylower

cuttingunitstotheground.

–Ensurethatthetransmissionisinneutralandengage

theparkingbrake.

–Shutofftheengineandremovethekey .

•Whentransportingthemower:

–Disengagethedrivetothecuttingunits.

–Liftcuttingunitstothetransportpositionand

securelylockthesafetylatches.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey .

•Whendrivingthemowerbetweenworksitesitis

importanttoensurethatthecuttingunitscannotbe

inadvertentlyloweredandstarted:

–Disengagethedrivetothecuttingunits.

–Raisethecuttingunitstothetransportposition.

–Engagethetransportlatchesandsafetylockingrings.

•Shutofftheengineanddisengagedrivetothecutting

units:

–beforerefuelling;

–beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator'sposition.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthemower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforestartingandoperatingthe

equipment.

•Reducethethrottlesettingduringenginerun-outand,if

theengineisprovidedwithashut-offvalve,turnthefuel

offattheconclusionofmowing.

•Keepyourhandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopthecuttingunitsif

youarenotmowing.

•Donotoperatethemowerwhentired,ill,orunderthe

inuenceofalcoholordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,useextreme

careinhandlingfuel.Fuelisextremelyammableandthe

vaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fuel-dispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

RolloverProtectionSystem(ROPS)

•TheROPSisanintegralandeffectivesafetydevice.Keep

afoldingROPSintheraisedandlockedpositionanduse

theseatbeltwheneveryouoperatethemachine.

•LowerafoldingROPStemporarilyonlywhenitis

absolutelynecessary.Donotweartheseatbeltwhenthe

ROPSisfoldeddown.

•Beawarethereisnorolloverprotectionwhenafolded

ROPSisinthedownposition.

•Becertainthatyoucanreleasetheseatbeltquicklyinthe

eventofanemergency.

•Checktheareatobemowedandneverfolddown

afoldableROPSinareaswherethereareslopes,

embankments,dropoffsorwater.

•Checkcarefullyforoverheadclearances(i.e.,branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•KeeptheROPSinsafeoperatingconditionbythoroughly

inspectingitperiodicallyfordamageandkeepingall

mountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorreviseit.

•DonotremovetheROPS.

•AnyalterationstoaROPSmustbeapprovedbyThe

Toro®Company.

5

Page 6

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuelstorage

areafreeofgrass,leaves,orexcessivegrease.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damagedpartsanddecals.

•Ifyoumustdrainthefueltank,dothisoutdoors.

•Becarefulduringadjustmentofthemachinetoprevent

entrapmentofthengersbetweenmovingbladesand

xedpartsofthemachine.

•Onmulti-cuttingunitmachines,takecareasrotatinga

cuttingunitcancauseothercuttingunitstorotate.

•Disengagedrives,lowerthecuttingunits,setparking

brake,shutofftheengine,andremovethekeyfromthe

ignition.W aitforallmovementtostopbeforeadjusting,

cleaning,orrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,

silencers/mufers,andenginetohelppreventres.Clean

upoilorfuelspills.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectbatterybeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.Connect

positiverstandnegativelast.

•Usecarewhencheckingthecuttingunits.Weargloves

andusecautionwhenservicingthem.

•Keepyourhandsandfeetawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

ordisconnectingfrombattery.W earprotectiveclothing

anduseinsulatedtools.

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

•Knowhowtoshutofftheenginequickly .

•Wearingsafetyshoesisadvisableandrequiredbysome

localordinancesandinsuranceregulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafety-interlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Beforestartingtheengine,sitontheseat.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,or

otherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrolof

themachine.

•Raisethecuttingunitswhendrivingfromaworkarea

toanother.

•Donottouchtheengine,silencer/mufer,orexhaust

pipewhiletheengineisrunningorsoonafterithas

stoppedbecausetheseareascouldbehotenoughtocause

burns.

•Iftheenginestallsorlosesheadwayandcannotmakeit

tothetopofaslope,donotturnthemachinearound.

Alwaysbackslowly,straightdowntheslope.

•Whenapersonorpetappearsunexpectedlyinornearthe

mowingarea,stopmowing.Carelessoperation,combined

withterrainangles,ricochets,orimproperlypositioned

guardscanleadtothrownobjectinjuries.Donotresume

mowinguntiltheareaiscleared.

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedinthesafetystandards.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

MaintenanceandStorage

•Makesurethatallhydraulic-lineconnectorsaretightand

allhydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompin-holeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.Seekimmediatemedicalattentionifuidis

injectedintotheskin.

6

Page 7

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringthecutting

unitsandattachmentstotheground.

SoundPowerLevel

Thisunithasameasuredsoundpowerlevelof105dB(A),

whichincludesanUncertaintyValueof1dBA.

•Checkallfuellinesfortightnessandwearonaregular

basis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keepyourhands,feet,clothing,andanyparts

ofthebodyawayfromthecuttingunits,attachments,and

anymovingparts.Keepeveryoneaway.

•Toensuresafetyandaccuracy ,haveanAuthorizedToro

Distributorcheckthemaximumenginespeedwitha

tachometer.Themaximumgovernedenginespeed

shouldbe3,000rpm.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlyTororeplacement

partsandaccessories.Replacementpartsandaccessories

madebyothermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof91

dB(A),whichincludesanUncertaintyValue(K)of3dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

VibrationLevel

Hand-Arm

Measuredvibrationlevel=1.3m/s

UncertaintyValue(K)=0.7m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

WholeBody

Measuredvibrationlevel=0.4m/s

2

2

2

UncertaintyValue(K)=0.2m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

2

7

Page 8

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

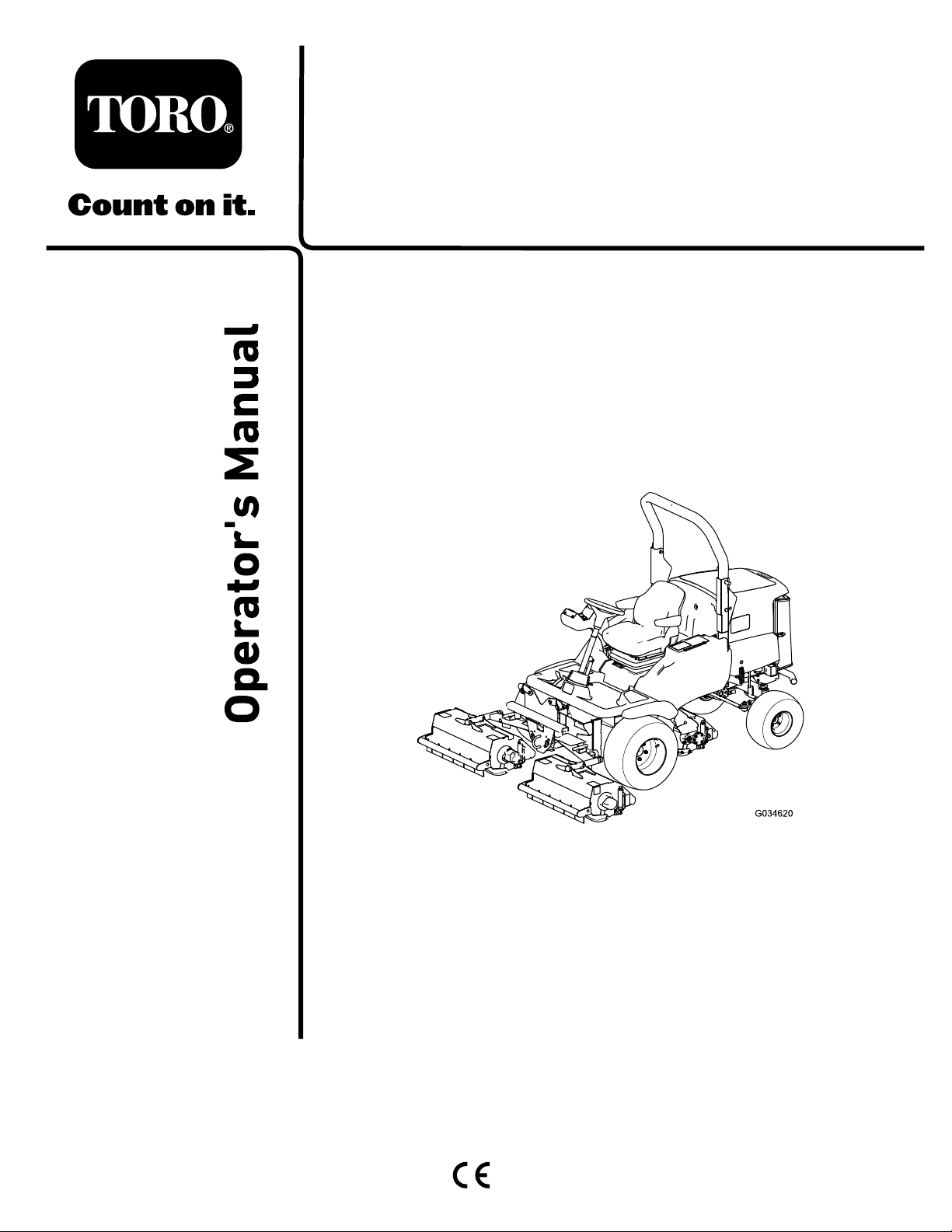

40-13–010

1.Cuttinghazardofhand

2.Cuttinghazardoffoot

70-13-072

1.Jackingpoint

70-13-077

1.Warning—shutofftheengineandremovetheignitionkey

beforereleasingoroperatingsafetylatches.

950889

1.Warning—hotsurfaces.

111-3277

1.Horn5.Fast

2.Cutters—lower/oat

3.Cutters—hold7.Slow

4.Cutters—raise

6.Enginespeed

111-0773

1.Warning—crushingofngers,forceappliedfromside.

111-3344

1.Ignitionswitch

8

Page 9

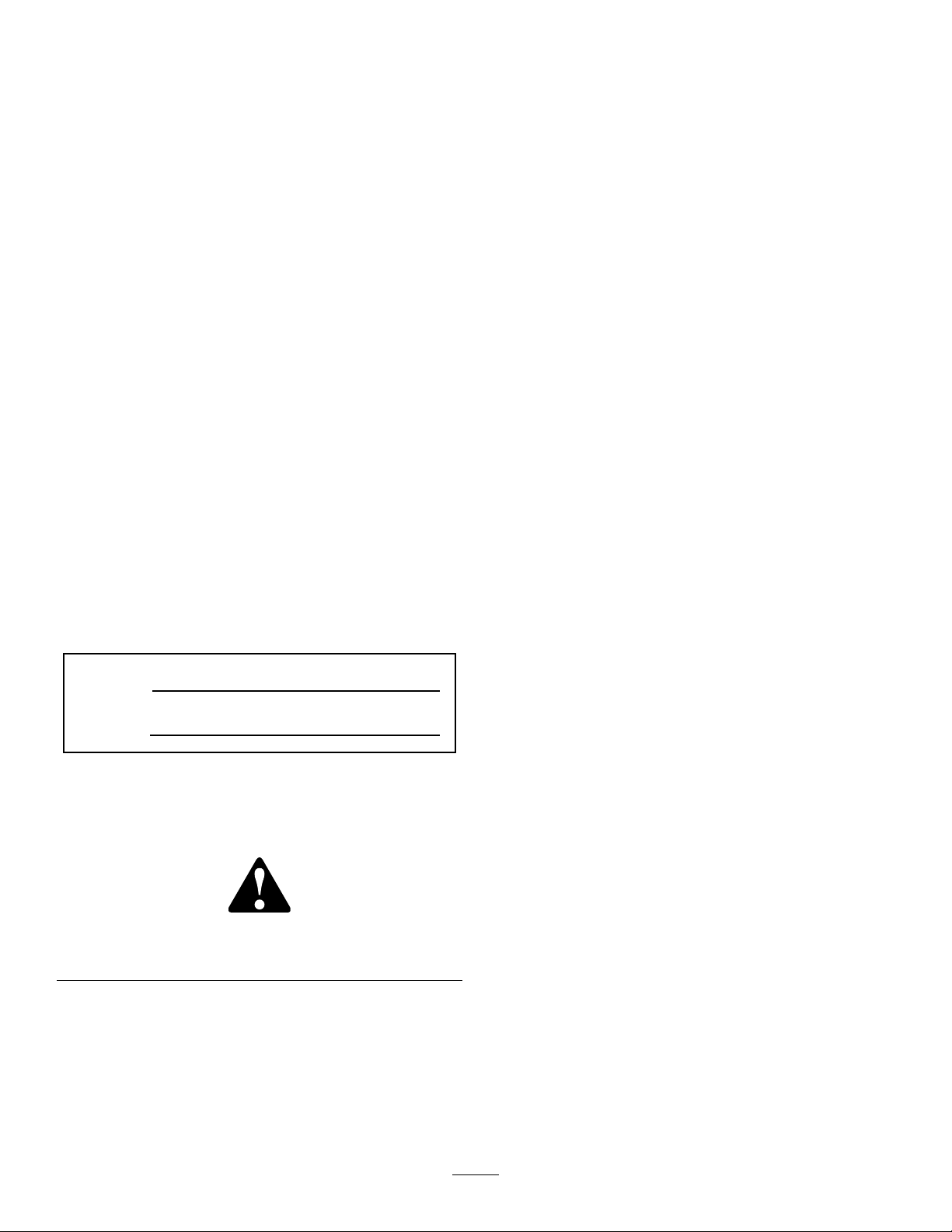

111-3562

111-3 658 Rev B

1.Presspedaltoadjuststeeringwheeltilt.

111-3658

111-3566

1.Falling,crushinghazard—ensurethattheoperator-platform

latchisengagedbeforeoperating.

111-3567

1.Pedaloperation

1.Cutterhead

2.Latch

3.Unlatch

111-3901

1.Transmissionoil—readtheOperator'sManualformore

information.

111-3902

1.Warning—cuttinghazardofhand,fan.

2.Hotsurfaces—readtheOperator'sManualformore

information.

9

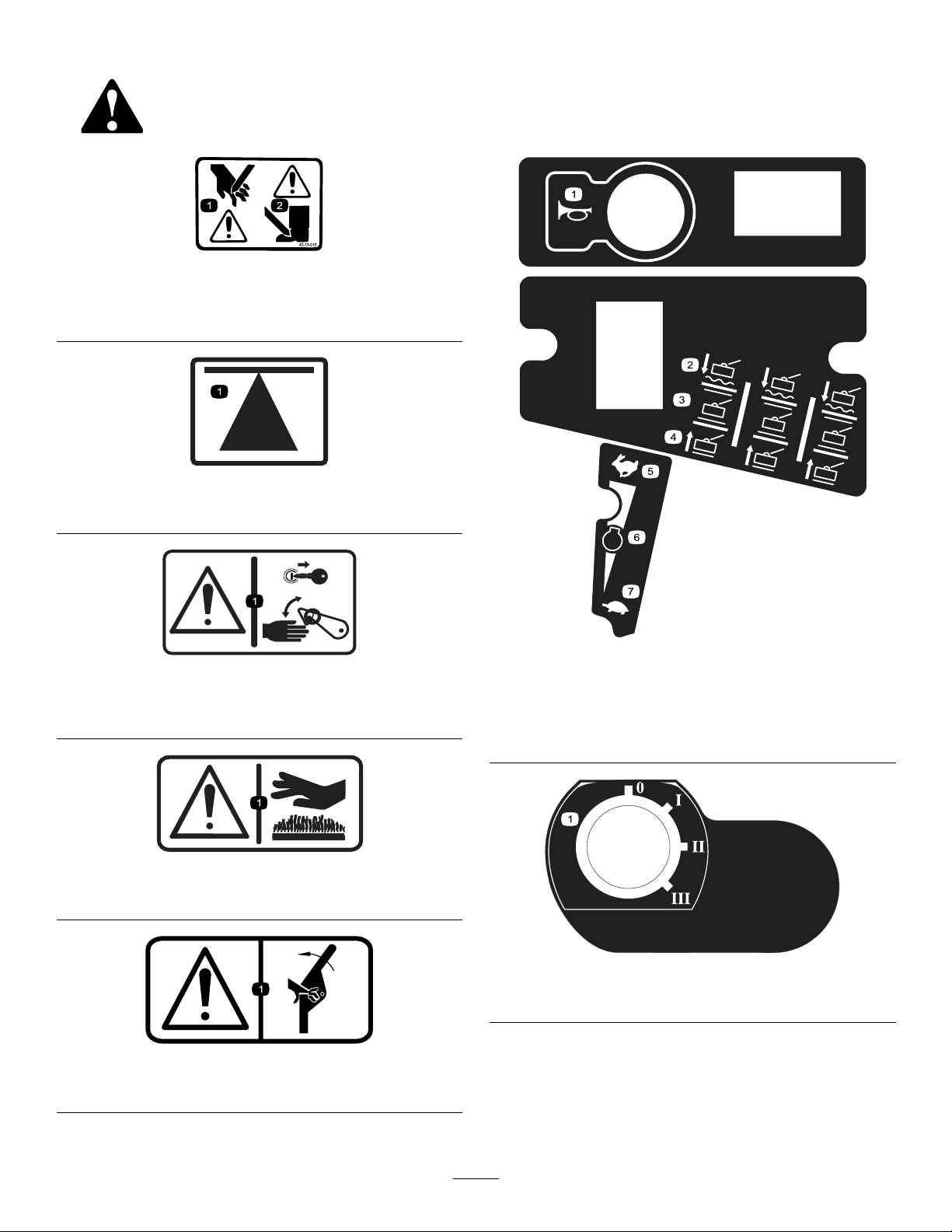

Page 10

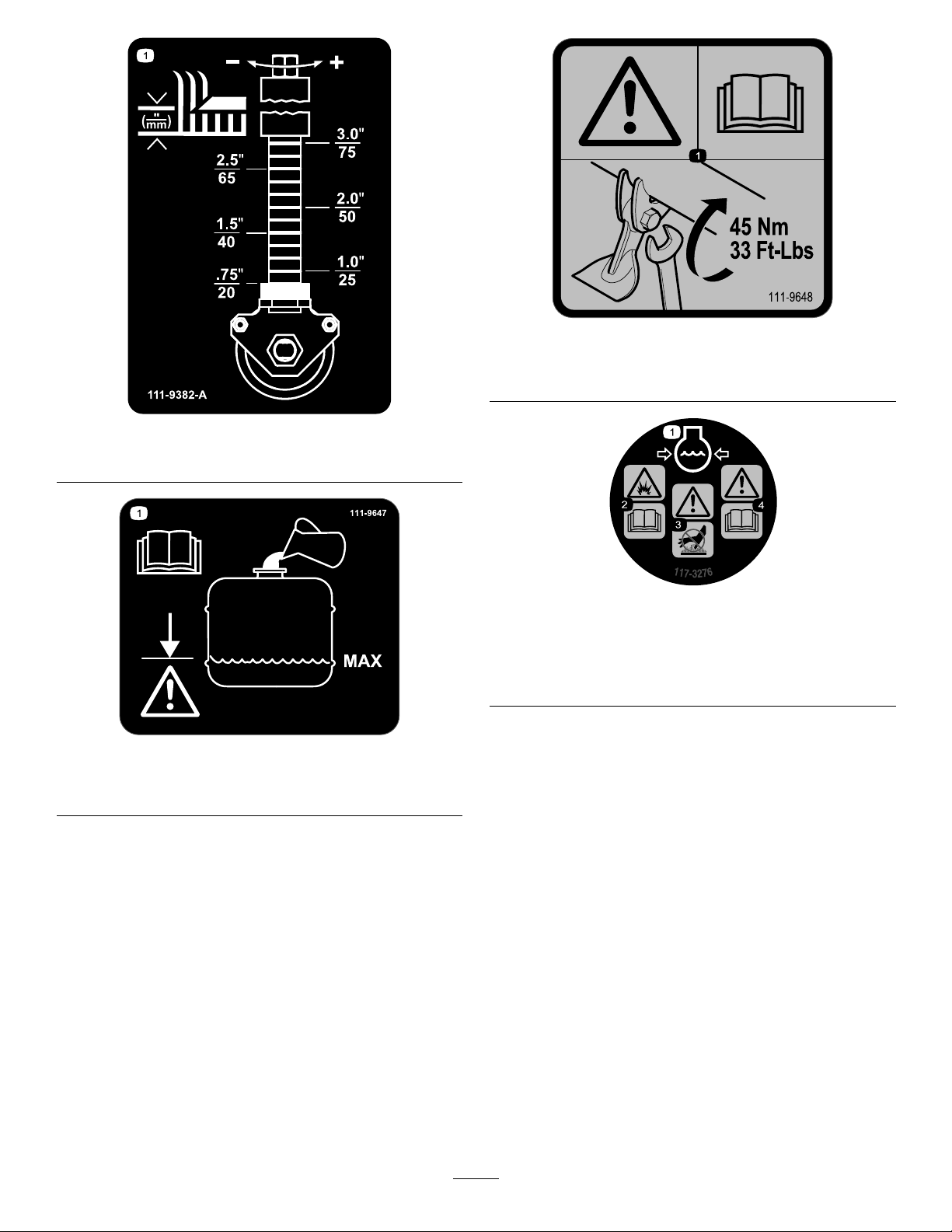

1.Height-of-cutchart

111-9648

1.Warning—readtheOperator'sManual;torquethenutsto

45N∙m(33ft-lb).

111-9382

117-3276

111-9647

1.ReadtheOperator'sManual—lltothemaximumlevel;

donotoverll.

1.Enginecoolantunder

pressure

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

10

Page 11

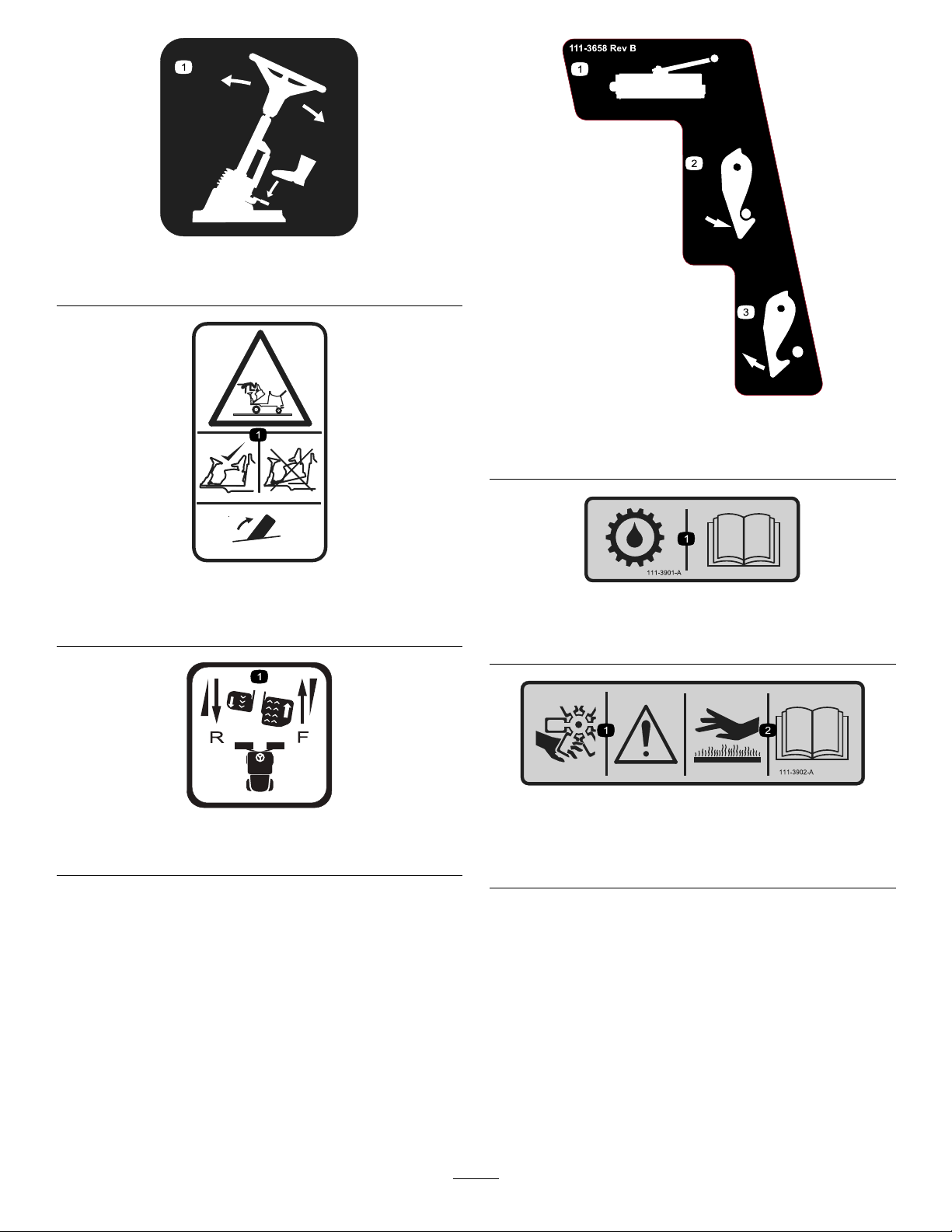

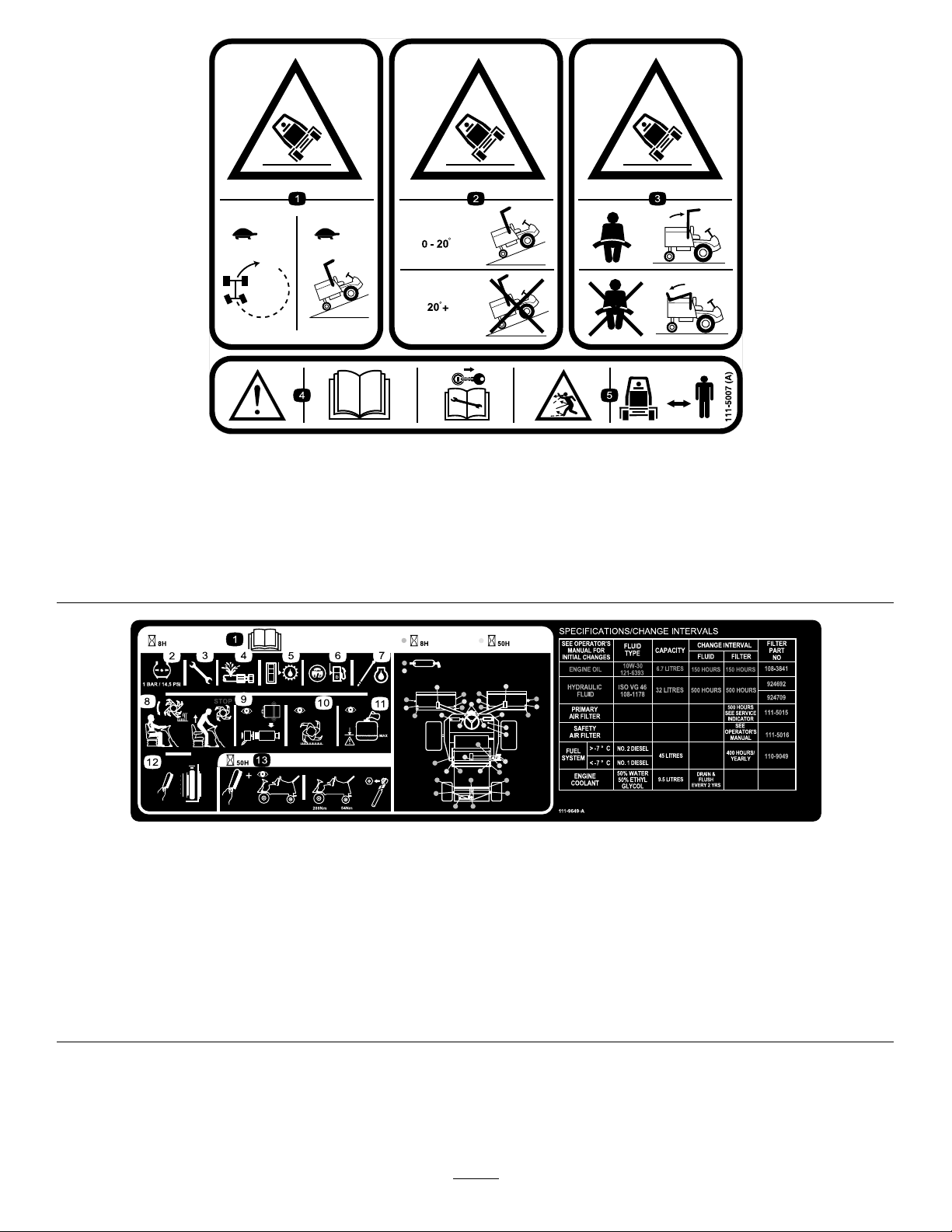

111-5007

1.Tippinghazard—slowmachinebeforeturning.

2.Tippinghazard—operateonslopeslessthan20degrees,donotoperateonslopesgreaterthan20degrees.

3.Tippinghazard—alwaysweartheseatbeltwhenarolloverprotectionsystem(ROPS)isinuse,donotwearaseatbeltwhen

theROPSbarislowered.

4.Warning—readtheOperator'sManual,removetheignitionkeybeforeperforminganymaintenance.

5.Thrownobjecthazard—keepbystandersasafedistancefromthemachine.

111-9649

1.ReadtheOperator'sManualformoreinformationonservice

andmaintenance.

2.Tirepressure—1bar(14.5psi)9.Checktheairlter.

3.Checkallfasteners.10.Inspectthebladesforwear.

4.Checkforhydraulicleaks.11.Ensurethebottleislledtothelowline.

5.Checkthetransmission-oillevel.12.Cleanthecoolingsystem.

6.Checkthefuellevel.13.Cleanthemachineandtorquethefrontwheelto200N∙m

7.Checktheoillevel.

8.Ensurethebladesstopwhenyouleavetheoperatingposition.

andtherearwheelto54N∙m.

11

Page 12

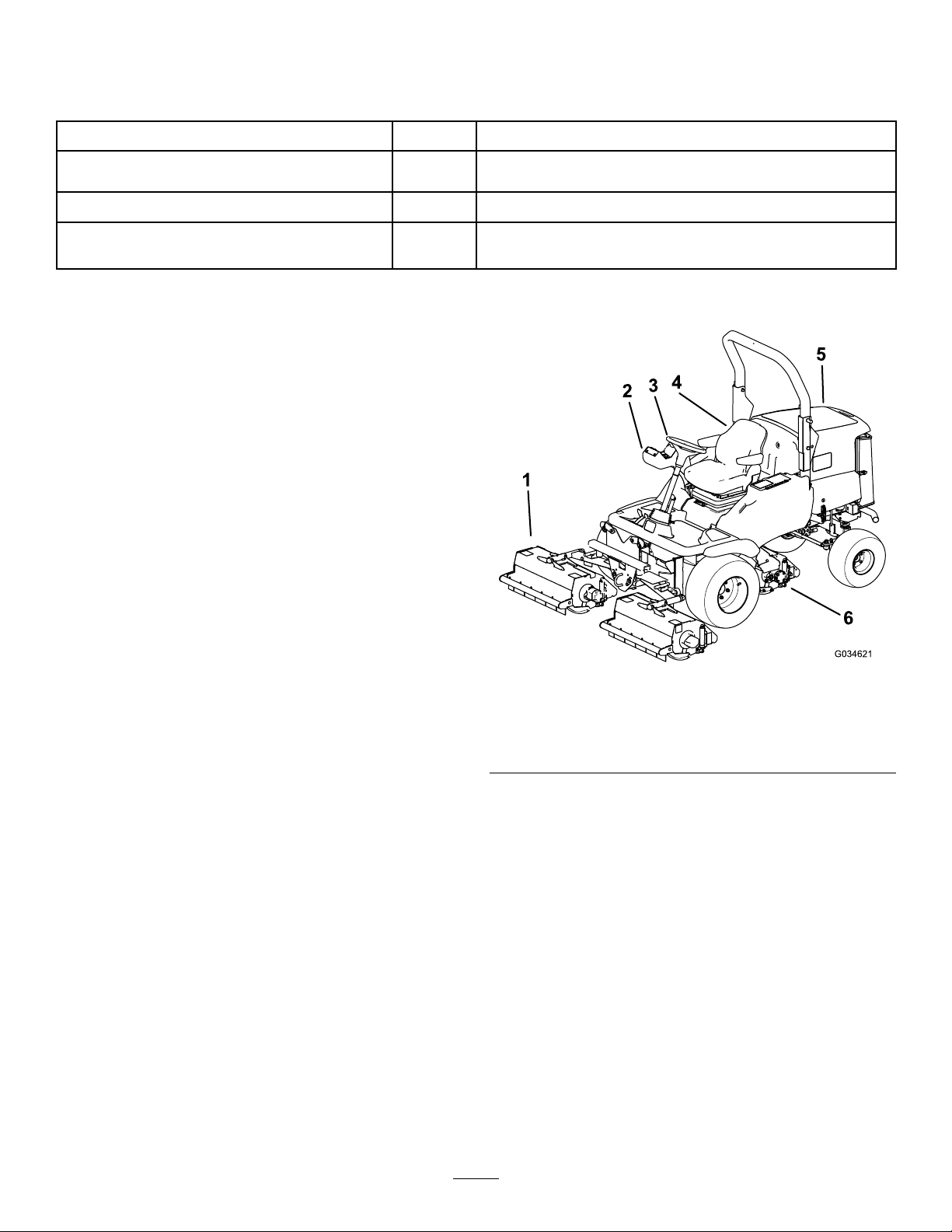

Setup

MediaandAdditionalParts

Description

Operator'sManual

Engineoperator’smanual1

PartsCatalog

DeclarationofConformity

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Qty.

1

1Usethepartscatalogtolookupandorderparts.

1

Readthemanualsbeforeoperatingthemachine.

TheDeclarationofConformityservesasconrmationof

CEcompliance.

Use

ProductOverview

1.Frontcuttingunits

2.Controlarm

3.Steeringwheel

Figure2

4.Operator'sseat

5.Enginehood

6.Rearcuttingunit

12

Page 13

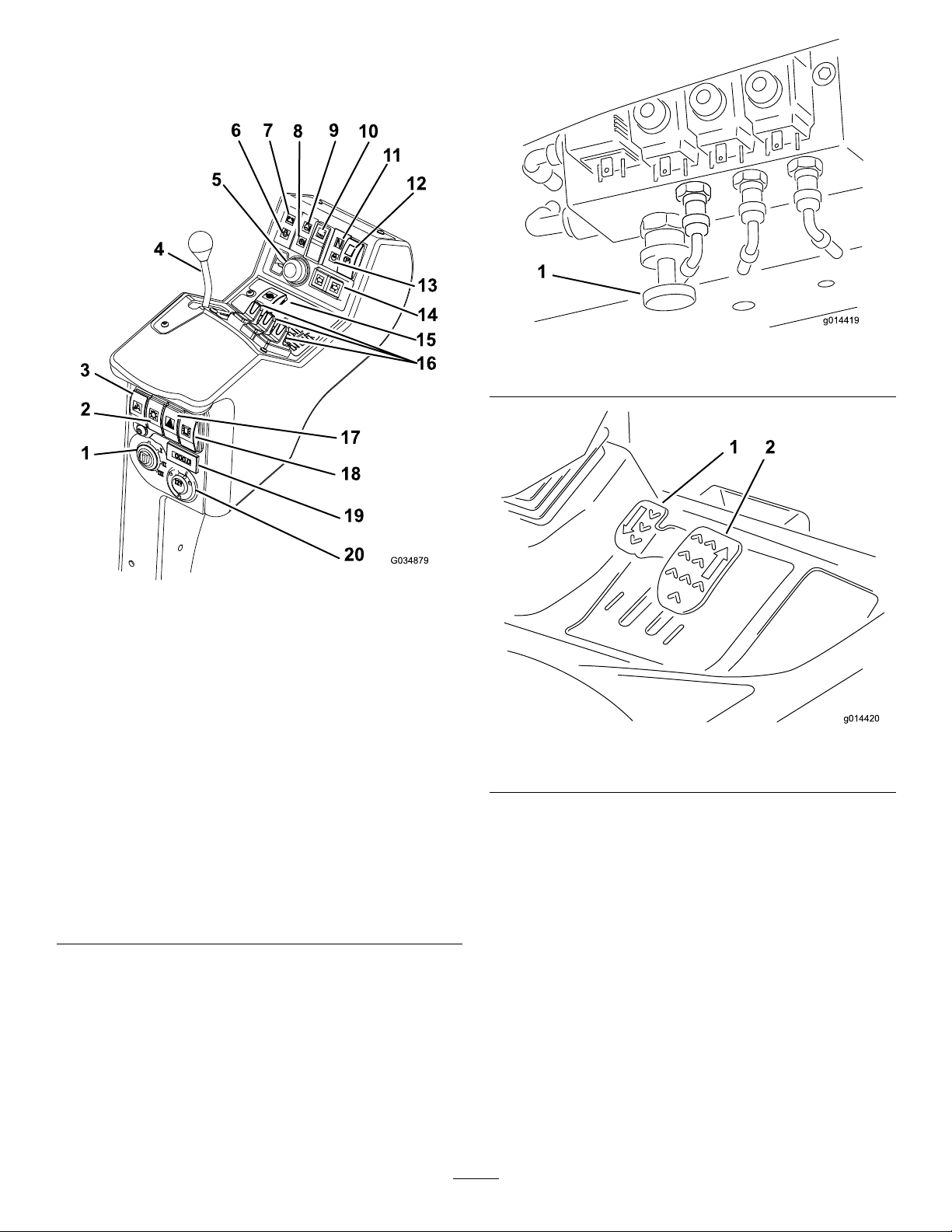

Controls

g014419

1

g014420

1 2

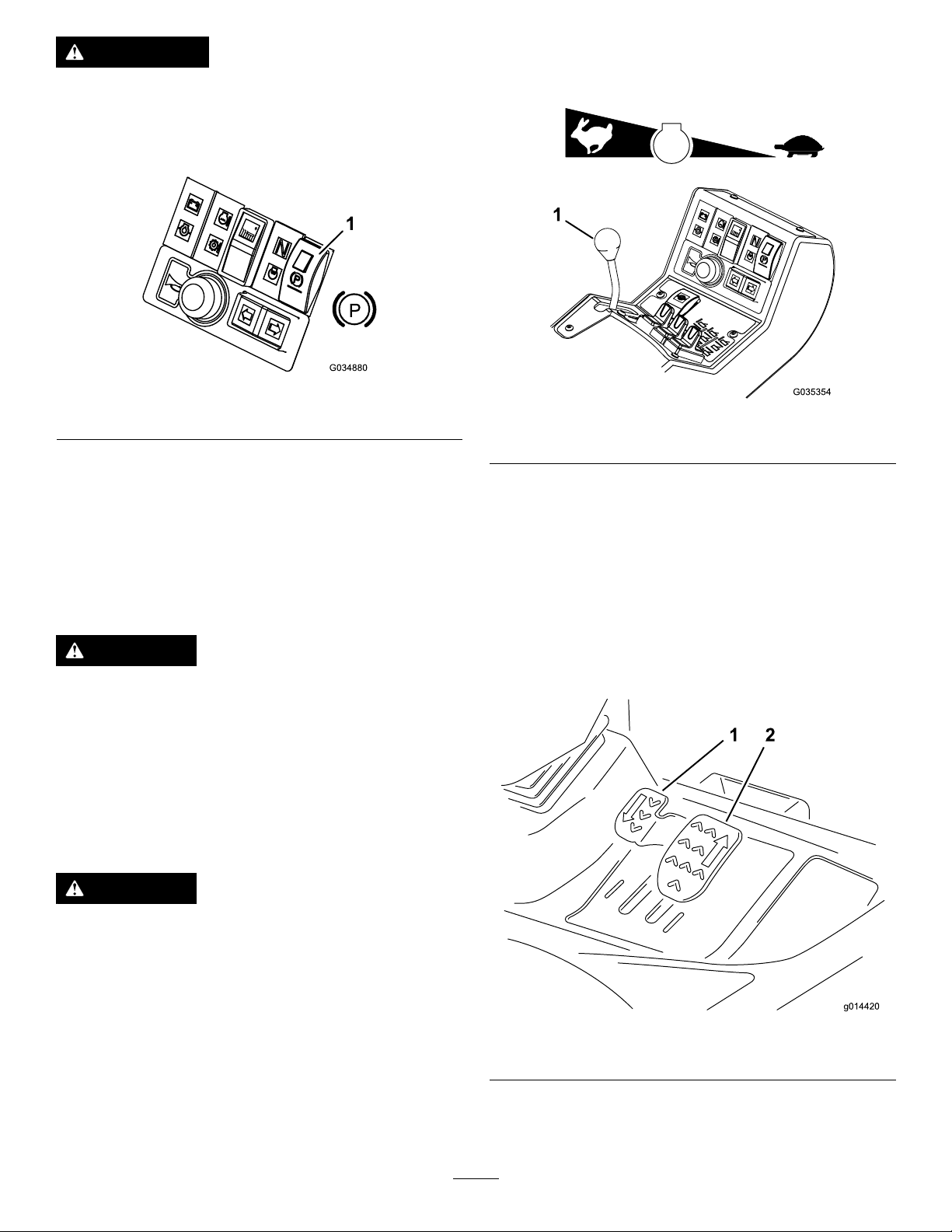

ControlPanelComponents

Figure4

1.Weighttransfercontrol

Figure3

1.Ignitionswitch11.Transmission-neutral

2.Lightingswitch(supplied

withlightingkit)

3.Limited-lift-in-reverse

switch

4.Throttle-controllever14.Direction-indicatorswitch

5.Hornbutton

6.Engine-oil-warninglight

7.Battery-charge-warning

light

8.Hydraulic-uid-warning

light

9.Engine-coolant-warning

light

10.Cutting-unit-driveswitch

indicator

12.Parking-brakeswitch

13.Engine-preheat-indicator

light

(suppliedwithlightingkit)

15.Differential-lockswitch

16.Lift-controlswitches

17.Hazard-warningswitch

(suppliedwithlightingkit)

18.Warning-beaconswitch

(suppliedwithbeaconkit)

19.Hourmeter

20.Auxiliary12Vsocket

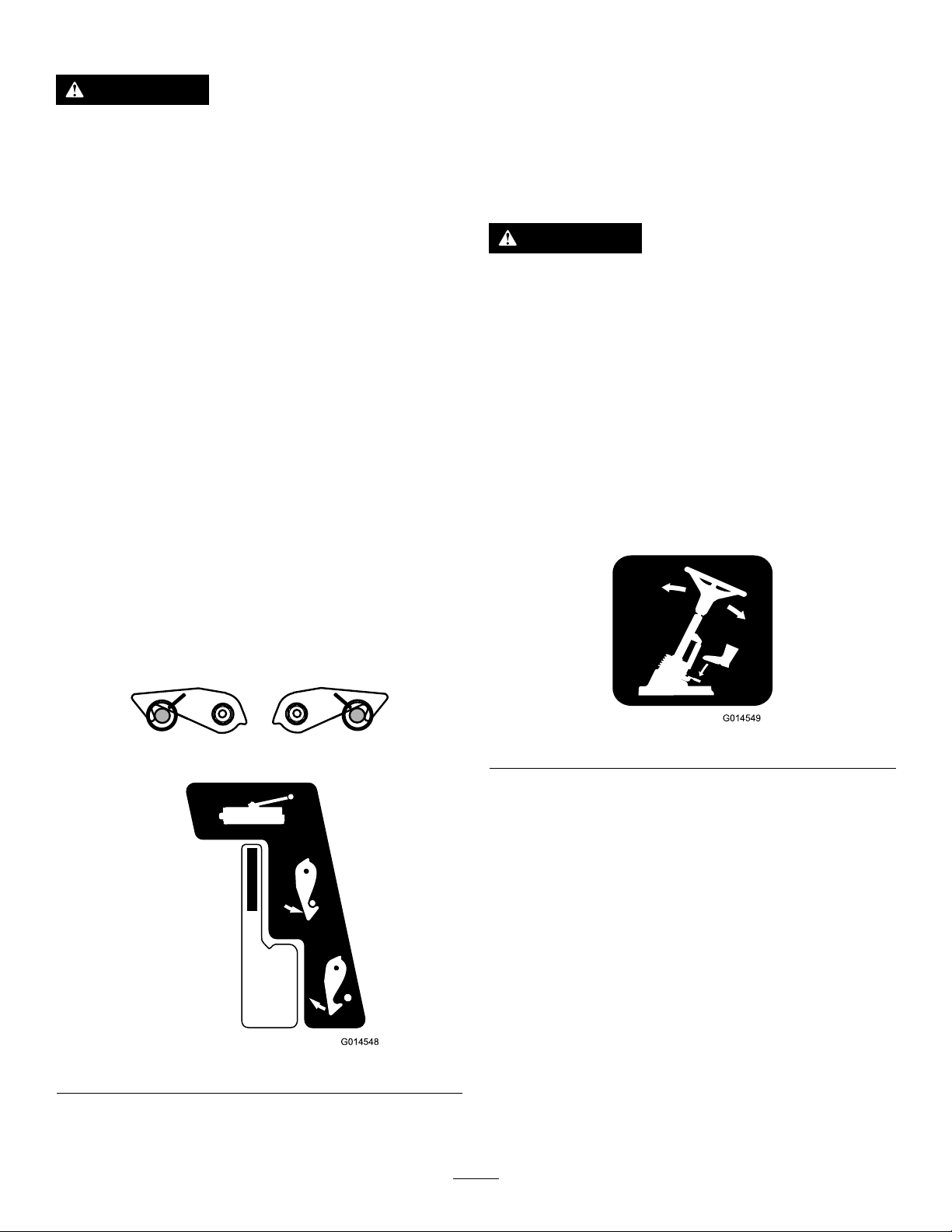

Figure5

1.Reversetravelpedal2.Forwardtravelpedal

BrakingSystem

ParkingBrake

Movetheparking-brakeswitchtotheforwardpositionby

pressingthesmallerlockingbuttonandmovingtheswitch

forwardtoengagetheparkingbrake(Figure6).

Note:Donotoperatethemowerwiththeparkingbrake

engagedanddonotengagetheparkingbrakewhilethe

mowerismoving.

Thislightilluminateswhentheparkingbrakeisengagedand

theignitionkeyisturnedtopositionI.

13

Page 14

WARNING

g014420

1 2

Theparkingbrakeoperatesonthefrontwheels

onlyandthemachinecouldrolloverandmaycause

ejectionfromthemachine,paralysis,orevendeath.

Donotparkthemachineonaslope.

Figure6

Note:Theenginespeeddictatesthespeedoftheother

functions,i.e.,travel,ail-rotorrotationspeed,andcutting

unitliftspeed.

1.Parking-brakeswitch

ServiceBrake

Servicebrakingisachievedbythehydraulictransmission

system.Whentheforwardorreversetravelpedalsare

releasedortheenginespeedisreduced,servicebraking

becomeseffectiveandtravelspeedisautomaticallyreduced.

Toincreasethebrakingeffect,pushthetransmissionpedal

intotheNEUTRALposition.Servicebrakingiseffectiveon

thefrontwheelsonly.

DANGER

Theservicebrakingsystemdoesnotholdthe

moweratastandstillandcouldcausesevereinjury

ordeath.

Alwaysensurethattheparkingbrakeisengagedto

parkthemoweratastandstill.

EmergencyBrake

Intheeventofservicebrakefailure,turntheignitionoffto

bringthemowertoastandstill.

Figure7

1.Throttle-controllever

Travel

Forwardtravel:Presstheforwardtravelpedaltoincrease

forwardtravelspeed.Releasethepedaltoreducespeed

(Figure8).

Reversetravel:Pressthereversetravelpedaltoincrease

reversetravelspeed.Releasethepedaltoreducespeed

(Figure8).

Stop(Neutral):Releasetheforwardorreversetravelpedal.

DANGER

Thismachineisequippedwithanemergency

brakingsystemwhichcancauseejection,serious

injury,paralysis,orevendeath.

Usecautionwhenusingtheemergencybraking

system,remainseated,andholdontothesteering

wheel.

ThrottleControl

Operatethethrottlecontrolinaforwarddirectiontoincrease

theenginespeed.Operatethethrottlecontrolinarearward

directiontoreduceenginespeed(Figure7).

Figure8

1.Reversetravelpedal2.Forwardtravelpedal

14

Page 15

DifferentialLock

G014548

G014549

Cutting-Unit-DriveSwitch

WARNING

Theturningradiusincreaseswhenthedifferential

lockisengaged.Usingthedifferentiallockathigh

speedmayleadtolossofcontrolandcauseserious

injuryand/orpropertydamage.

Donotusethedifferentiallockathighspeed.

Usethedifferentiallocktopreventexcessivewheelspinwhen

thedrivewheelslosetraction.Thedifferentiallockoperates

inbothforwardandreverse.Youcanlockthedifferential

whilethemachineistravelingslowly.Enginepowerdemand

increaseswhenthedifferentialislocked.Preventexcessive

powerrequirementsbyusingthedifferentiallockonlyatlow

speed.

Tolockthedifferential,pressthedifferential-lockswitch.

Tounlockthedifferential,releasethedifferential-lockswitch.

Cutting-UnitsPositionControls

Usethecutting-unitspositioncontrolstoindependentlyraise

andlowerthecuttingunits;refertoControllingthePosition

oftheIndividualCuttingUnits(page28).

Toengagethecuttingunitdrive,refertoEngagingthe

CuttingUnitDrive(page29).

Note:Alwaysputthecutting-unit-driveswitchintheOFF

positionwhentravellingbetweenworkareas.

AdjustableSteeringColumn

WARNING

Thesteeringcolumnmaycauseinjuryifitisnotin

workingorder.

Checkthatthesteeringcolumnadjustermechanism

isingoodworkingorderandthat,onceadjusted

andlocked,thesteeringwheelremainssecurelyin

position.

Adjustmentofthesteeringwheelandsteeringcolumnshould

onlybecarriedoutwhenthemowerisatastandstillwith

theparkingbrakeengaged.

1.Totiltthesteeringwheel,pressthefootpedaldown.

2.Positionthesteeringtowertothemostcomfortable

positionandreleasethepedal(Figure10).

TransportLatches

AlwaysraisethecuttingunitstotheTRANSPORTposition

andsecurewiththetransportlatchesandsafetylockswhen

travellingbetweenworkareas(Figure9).

Figure10

Figure9

15

Page 16

OperatorSeat

1

G016377

1

2

G016378

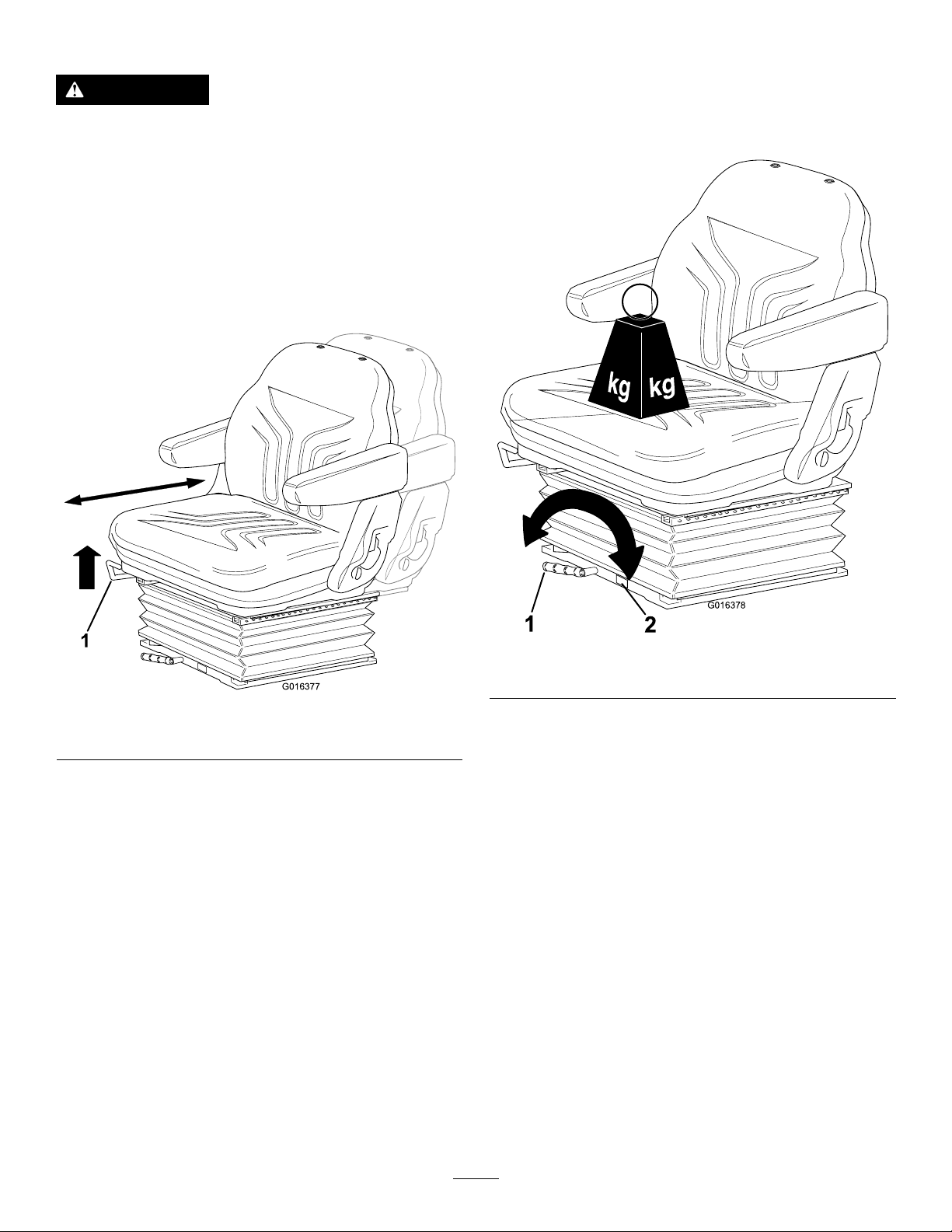

WARNING

Iftheoperator-platformlatchisnotfullyengaged

beforeoperationtheseatmayfallandcrushthe

operator.

Ensurethattheoperator-platformlatchisengaged

beforeoperatingthemachine.

•Forward/BackwardAdjustment:Movethelever

upwardtoadjusttheforward/backwardpositionofthe

seat.Releasethelevertolocktheseatinposition(Figure

11).

•Operatorweightadjustment:Rotatethehandle

clockwisetoincreasesuspensionstiffnessand

counterclockwisetodecreasethestiffness.Thedial

indicateswhentheoptimumsuspensionadjustmenthas

beensetaccordingtooperatorweight(kg);refertoFigure

12.

Figure12

1.Lever2.Dial

Figure11

1.Lever

16

Page 17

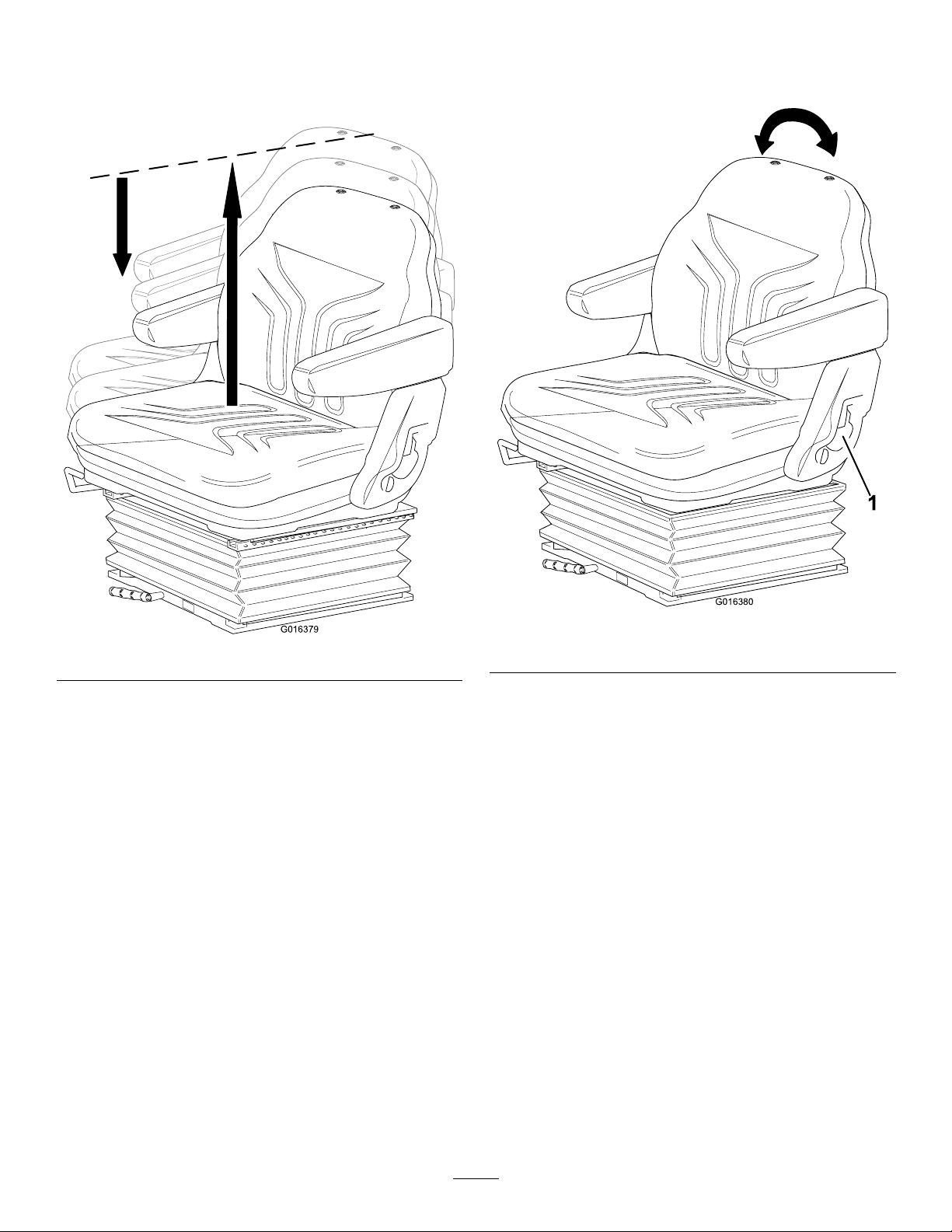

•Heightadjustment:Manuallylifttheseatfor

G016379

1

G016380

incrementalheightadjustment.Tolowertheseat,liftit

beyondthehighestsetting,thenallowittodroptothe

lowestsetting(Figure13).

•Backrestadjustment:Pullthehandleoutwardtoadjust

theseatbackrestangle.Releasethehandletolockthe

seatbackrestinposition(Figure14).

Figure13

Figure14

1.Handle

17

Page 18

WarningSystems

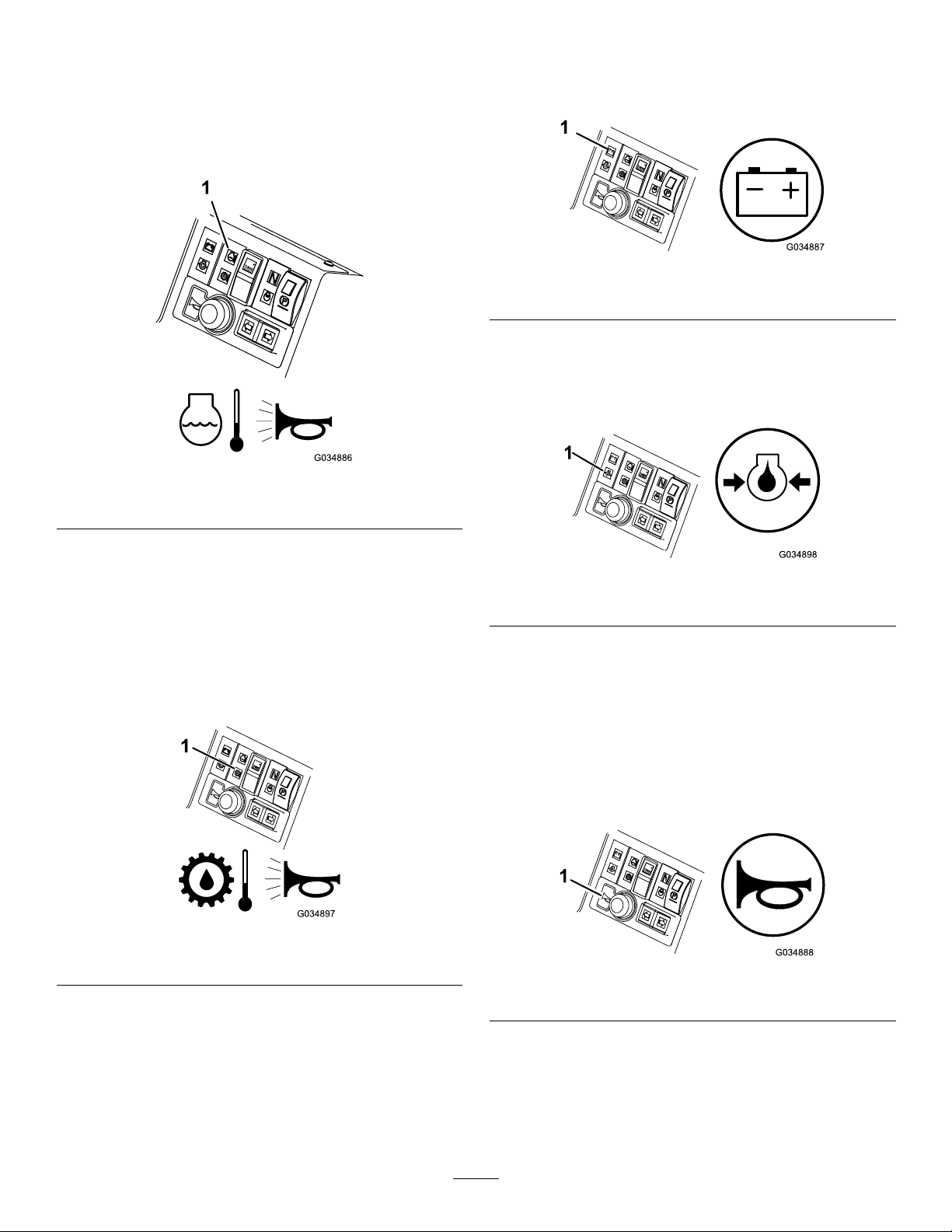

Battery-Charge-WarningLight

Engine-Coolant-Temperature-WarningLight

Theengine-coolant-temperature-warninglightilluminates,

thehornisactuated,andthecuttingunitsstopwhenthe

enginebecomestoohot(Figure15).

Figure15

1.Engine-coolant-temperature-warninglight

Thebattery-charge-warninglightilluminateswhenthebattery

islowofcharge(Figure17).

Figure17

1.Battery-charge-warninglight

Engine-Oil-Pressure-WarningLight

Theengine-oil-pressure-warninglightilluminateswhenthe

oilpressureistoolow(Figure18).

Note:Theailrotorsdisengagewhentheoperating

temperaturereaches115°C(239°F).

Hydraulic-Fluid-Temperature-WarningLight

Thehydraulic-uid-temperature-warninglightilluminates

whenoverheatingoccursandthehornisactuatedwhenthe

hydraulicuidinthereservoirexceeds95°C(203°F);refer

toFigure16.

Figure16

1.Hydraulic-uid-temperature-warninglight

Figure18

1.Engine-oil-pressure-warninglight

AudibleWarningHorn

Pressthehornbuttontoprovideanaudiblewarning(Figure

19).

Important:Thehornisautomaticallyactuatedwhen

anenginecoolantorhydraulic-uid-overheatcondition

occurs.Shutofftheengineimmediatelyandxthe

machinebeforestartingitagain.

Figure19

1.Horn

18

Page 19

IgnitionSwitch

G014556

1

I

II

III

G014558

FUEL

E

F

1

G014559

000.0

FuelGauge

0=Engineoff

I=Enginerun/auxiliaryon

II=Enginepreheat

III=Enginestart

WARNING

Ifyouleavethekeyintheignitionswitch,someone

couldaccidentallystarttheengineandseriously

injureyouorotherbystanders.

Lowerthecuttingunitstotheground,setthe

parkingbrake,andremovethekeyfromtheignition

switchwhenthemachineisnotinuse.

Figure20

Thefuelgaugeshowstheamountoffuelinthetank

(Figure22).

Figure22

HourMeter

Thehourmetershowsthetotalhoursthatthemachinehas

beenoperated(Figure23).

1.Ignitionswitch

Engine-Preheat-IndicatorLight

TurntheignitionkeytopositionII.Theenginepreheat

indicatorlightilluminatesandheatstheglowplugs

(Figure21).

Important:Attemptingtostartacoldenginebefore

thepreheatisusedcancauseunnecessaryweartothe

battery.

Tostartacoldengine,refertoStartingaColdEngine(page

26).

Figure21

Figure23

1.Hourmeter

Transmission-Neutral-IndicatorLight

Thislightilluminateswhenthetravel-controlpedalisinthe

NEUTRALpositionandtheignitionkeyisturnedtoposition

I(Figure24).

Note:Theparkingbrakemustbeengagedforthe

transmissionneutralindicatorlighttoilluminate.

Figure24

1.Transmission-neutral-indicatorlight

1.Engine-preheat-indicatorlight

19

Page 20

Cutting-Unit-Drive-Switch-Indicator

Light

ThislightilluminateswhenthecuttingunitdriveswitchisOn

andtheignitionkeyisturnedtopositionI(Figure25).

Toengagethecuttingunitdrive,refertoEngagingthe

CuttingUnitDrive(page29).

1.Cutting-unit-drive-switch-indicatorlight

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Figure25

Specication

TransportWidth

Widthofcut76cm(30inches)to212cm(83.5inches)

Heightofcut20mm(3/4inch)to75mm(3inches)

Length

Height

Weight

Engine

Fueltankcapacity

Transportspeed

Mowingspeed

Kubota32.8kw(44hp)at3,000rpmDIN70020

302.5cm(119.1inches)

216cm(85.0inches)withROPS

209cm(82.3inches)withcab

1,380kg(3,042lb)withROPS

1,580kg(3,483lb)withcab

LT -F3000

157.5cm(62inches)

45.7L(12USgallons)

25km/h(15.5mph)

11km/h(6.85mph)

Hydraulicsystemcapacity

Enginespeed3,000rpm

Rotorspeed3,000rpm

32L(8.5USgallons)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhanceandexpandits

capabilities.ContactyourAuthorizedServiceDealerorDistributor.

TobestprotectyourinvestmentandmaintainoptimalperformanceofyourToroequipment,countonTorogenuineparts.

Whenitcomestoreliability,Torodeliversreplacementpartsdesignedtotheexactengineeringspecicationofourequipment.

Forpeaceofmind,insistonT orogenuineparts.

20

Page 21

Operation

G009027

1

2

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CAUTION

Ifyouleavethekeyintheignitionswitch,someone

couldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Parkthemachineonlevelground,lowerthecutting

unitstotheground,settheparkingbrakeand

removethekeyfromtheignitionswitchbefore

servicingormakingadjustmentstothemachine.

ThinkSafetyFirst

Carefullyreadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

DANGER

Operatingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

•Donotoperateonslopesgreaterthan20

degrees.

•Reducespeedanduseextremecautionon

slopes.

•Donotoperatethemachinenearwater.

DANGER

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,or

drowning.

Figure26

1.Weareyeprotection.2.Wearhearingprotection.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;however,the

oillevelmustbecheckedbeforeandaftertheengineisrst

started.

Crankcasecapacity:approximately6.7L(7.1USqt)with

thelter

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4orhigher

•Preferredoil:SAE15W -40(above0°F)

•Alternateoil:SAE10W-30or5W-30(alltemperatures)

ToroPremiumEngineoilisavailablefromyourdistributorin

either15W -40or10W-30viscosity .

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscoolbeforeithasbeenstartedfortheday.Ifithas

alreadybeenrun,allowtheoiltodrainbackdowntothe

sumpforatleast10minutesbeforechecking.

1.Parkthemachineonalevelsurface,shutofftheengine,

settheparkingbrakeandremovethekeyfromthe

ignitionswitch.

2.Openthehood.

3.Removethedipstick,wipeitclean,andinstallit

(Figure27).

Donotoperatethemachineneardrop-offs.

CAUTION

Thismachineproducessoundlevelsthatcancause

hearinglossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,hands,feet,

andheadisrecommended.

1.Dipstick

4.Removedipstickandcheckoillevelondipstick.

21

Figure27

Page 22

Note:TheoillevelshouldbeuptotheFULLmark.

1

g025068

5.IftheoillevelisbelowtheFULLmark,removethell

cap(Figure28)andaddoiluntillevelreachestheFULL

markondipstick.

Important:Donotoverll.

Figure28

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily

CAUTION

Iftheenginehasbeenrunning,thepressurized,hot

coolantcanescapeandcauseburns.

•Donotopentheradiatorcapwhentheengine

isrunning.

•Usearagwhenopeningtheradiatorcap,and

openthecapslowlytoallowsteamtoescape.

Thecoolingsystemislledwitha50/50solutionofwater

andpermanentethyleneglycolantifreeze.

1.Cleandebrisoffthescreen,oilcooler,andfrontof

theradiatordailyandmoreoftenifconditionsare

extremelydustyanddirty.RefertoRemovingDebris

fromtheCoolingSystem(page45).

2.Checkthelevelofthecoolantintheexpansiontank

(Figure29).

Note:Whencold,thecoolantlevelshouldbeatthe

lowermarkonthesideofthetank.

1.Oil-llcap

6.Installtheoil-llcapandclosethehood.

Figure29

1.Expansiontank

3.Ifthecoolantlevelislow,removetheexpansion-tank

capandreplenishthesystem.

Note:Donotoverll.

4.Installtheexpansion-tankcap.

22

Page 23

AddingFuel

DANGER

ServiceInterval:Beforeeachuseordaily

Useonlyclean,freshdieselfuelwithlow(<50ppm)or

ultra-low(<15ppm)sulfurcontent.Theminimumcetane

ratingshouldbe40.Purchasefuelinquantitiesthatcanbe

usedwithin180daystoensurefuelfreshness.

Fueltankcapacity:45.7L(12USgallons)

Usesummergradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Useofwintergrade

fuelatlowertemperaturesprovideslowerashpointand

coldowcharacteristicswhicheasesstartingandreducesfuel

lterplugging.

Useofsummergradefuelabove-7°C(20°F)contributes

towardlongerfuelpumplifeandincreasedpowercompared

towintergradefuel.

Important:Donotusekeroseneorgasolineinstead

ofdieselfuel.Failuretoobservethiscautiondamages

theengine.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandfueltankor

conditioneropening.

•Keepfuelawayfromeyesandskin.

Incertainconditionsduringfueling,static

electricitycanbereleased,causingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruck-bedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandfueltheequipmentwiththe

wheelsontheground.

Ifthisisnotpossible,thenfuelsuchequipment

onatruckortrailerfromaportablecontainer,

ratherthanfromafuel-dispensernozzle.

•Ifafuel-dispensernozzlemustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

1.Parkthemachineonalevelsurface.

2.Usingacleanrag,cleantheareaaroundthefuel-tank

cap.

3.Removethecapfromthefueltank.

4.Fillthetankuntilthelevelistothebottomoftheller

neckwithdieselfuel.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana180-daysupplyoffuel.

•Donotoperatemachinewithoutentireexhaust

systeminplaceandinproperworkingcondition.

5.Installthefuel-tankcaptightlyafterllingthetank.

Note:Ifpossible,llthefueltankaftereachuse.This

minimizespossiblebuildupofcondensationinsidethe

fueltank.

CheckingtheHydraulicFluid

ServiceInterval:Beforeeachuseordaily

Thereservoirislledatthefactorywithapproximately32L

(8.5USgallons)ofhigh-qualityhydraulicuid.Thebesttime

tocheckthehydraulicuidiswhenitiscold.

Therecommendedreplacementuidis:

ToroPremiumAllSeasonHydraulicFluid:Available

in19L(5USgallon)containersor208L(55USgallon)

drums—seethePartsCatalogoryourT orodistributorforpart

numbers.

Alternativeuids:IftheTorouidisnotavailable,other

uidsmaybeusedprovidedthattheymeetallofthefollowing

materialpropertiesandindustryspecications.Checkwith

youroilsuppliertoidentifyasatisfactoryproduct.

23

Page 24

Note:T orodoesnotassumeresponsibilityfordamage

2

1

G014570

3

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhostandbehindtheir

recommendation.

HighViscosityIndex/LowPourPointAntiwearHydraulic

Fluid,ISOVG46Multigrade

MaterialProperties:

Viscosity,ASTMD445cSt@40°C(104°F)

Viscosityindex,ASTM

D2270

Pourpoint,ASTMD97-36.7°Cto-45°C(-34°Fto

FZG,failstage

Watercontent(newuid)500ppm(maximum)

IndustrySpecications:

VickersI-286-S,VickersM-2950-S,DenisonHF-0,

Vickers35VQ25(EatonATS373-C)

44to48

cSt@100°C(212°F)

7.9to9.1

140orhigher(high

viscosityindexindicatesa

multiweightuid)

-49°F)

11orbetter

Figure30

1.Hydraulic-tankcap

2.Fluidtank

3.Sight-levelgauge

Theproperhydraulicuidsmustbespeciedfor

mobilemachinery(asopposedtoindustrialplantusage),

multiweight-type,withZnDTPorZDDPantiwearadditive

package(notanashless-typeuid).

Important:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemoilisavailablein20ml(2/3oz)

bottles.Onebottleissufcientfor15to22L(4to6US

gallons)ofhydraulicuid.Orderpart44-2500fromyour

AuthorizedToroDistributor.

Synthetic,BiodegradableHydraulicFluid:Availablein

19L(5USgallon)containersor208L(55USgallon)

drums—seethe

P ar ts Catalo g

oryourTorodistributor

forpartnumbers.

Thishigh-quality,synthetic,biodegradableuidhasbeen

testedandfoundcompatibleforthisToromodel.Other

brandsofsyntheticuidmayhavesealcompatibilityproblems

andTorocannotassumeresponsibilityforunauthorized

substitutions.

Note:Thissyntheticuidisnotcompatiblewiththe

ToroBiodegradableFluidpreviouslysold.SeeyourToro

Distributorformoreinformation.

Alternativeuids:

•MobilEALEnvirosynH46(US)

•MobilEALHydraulicOil46(international)

4.Removethecapandllthetanktotheuppermark

onthesight-levelgauge.

Important:Donotoverllthetank.

5.Installthecapontothetank.

CheckingtheTirePressure

Checktheairpressureinthefrontandreartires.Refertothe

chartbelowforthecorrectpressure.

Important:Maintaincorrecttirepressureinalltiresto

ensurecorrectcontactwiththeturf.

Recommendedtirepressureis1bar(14.5psi)forgeneralall

arounduse.Tirepressurescanbeadjustedaccordingtothe

followingtabledependingonoperatingconditions.

RecommendedTirePressures TiresTireType

FrontAxle26x

12.0-12

BKTturf

pattern

RearAxle20x10.0-

8BKTturf

pattern

Conditions

0.7bar(10

0.7bar(10

Turf

psi)

psi)

Road

Conditions

1.4bar(20

psi)

1.4bar(20

psi)

Maximum

Pressure

1.7bar(25

psi)

1.7bar(25

psi)

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,andshutofftheengine.

2.Checkthesight-levelgaugeonthesideofthetank.

Note:Thelevelneedstobeattheuppermark.

3.Ifadditionalhydraulicuidisneeded,cleanthearea

aroundthellerneckandthecapofthehydraulictank

CheckingtheTorqueofthe Wheel-LugNuts

ServiceInterval:Beforeeachuseordaily

Torquethewheel-lugnutsto200N∙m(148ft-lb)forthefront

axle,and54N∙m(40ft-lb)fortherearaxle.

(Figure30)andremovethecap.

24

Page 25

WARNING

G014422

Understandingthe

Failuretomaintainpropertorqueofthewheelnuts

couldresultinpersonalinjury.

Ensurethatthewheelnutsaretorquedproperly.

UsingtheOperatorPlatform LatchingMechanism

Donotoperatethemowerwithoutrstcheckingthatthe

operatorplatformlatchingmechanismisfullyengagedand

ingoodworkingorder.

ReleasingthePlatform

1.Movethelocking-latchhandletowardthefrontofthe

moweruntilthelatchhooksclearthelockingbar.

2.Raisetheplatform.

Note:Thegasspringprovidesassistance.

SecuringthePlatform

1.Lowertheplatformcarefully .

Note:Thegasspringprovidesassistance.

Operator-PresenceControls

Note:Theenginestopsiftheoperatorleavestheseat

withoutengagingtheparkingbrake.

EngineStartLockout:Theenginecanonlybestarted

whentheforward/reversetravelpedalisintheNEUTRAL

position,thecuttingunitdriveswitchisintheOFFposition

andtheparkingbrakeisengaged.Whenthesecircumstances

aresatised,switchesareactivatedpermittingtheengineto

bestarted.

EngineRunInterlock:Oncetheengineisstartedthe

operatormustbeseatedbeforetheparkingbrakeisreleased

fortheenginetocontinuetorun.

FlailRotorDriveLockout:Thedrivetotheailrotorsis

onlypossiblewhentheoperatorisseated.Iftheoperator

raisesofftheseatforaperiodofmorethan1second,aswitch

isactivatedandthedrivetotheailrotorsisautomatically

disengaged.Toengagedrivetotheailrotors,theoperator

mustreturntotheseat,thenoperatethecuttingunitdrive

switchtotheOFFpositionbeforemovingitbacktotheON

position.Iftheoperatorrisesofftheseatforabriefmoment

duringnormalwork,drivetotheailrotorsisnotaffected.

Theenginecanonlybestartedwiththecuttingunitdrive

switchintheOFFposition.

2.Movethelocking-latchhandletowardthefrontofthe

mowerastheplatformnearsthefullyloweredposition.

Note:Thisensuresthatthelatchhooksclearthe

lockingbar.

3.Fullylowertheplatformandmovethelockinghandle

towardtherearofthemoweruntilthelatchhooksfully

engagethelockingbar.

WARNING

Operatingthemachinewhentheoperator-presence

controlsaremalfunctionsisdangerousandcanlead

toaccidentscausingpersonalinjury.

Alwaysreplacedamagedorwornpartsandcheck

thattheoperator-presencecontrolsarefunctioning

correctlybeforeoperatingthemachine.

CAUTION

Ifsafety-interlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

StartingandShuttingOffthe

Figure31

Engine

Important:Y oumustbleedthefuelsystembefore

startingtheengineifyouarestartingtheengineforthe

rsttime,theenginehasshutoffduetolackoffuel,or

youhaveperformedmaintenanceonthefuelsystem;

refertoBleedingtheFuelSystem(page41).

25

Page 26

WARNING

G014563

Operatingthemachineinanunsafemannercould

resultinpersonalinjury.

Beforestartingtheengine,ensurethatthefollowing

conditionsaremet:

•YouhavereadandunderstoodSafeOperating

Practices(page4).

•Theareaisclearofbystanders.

•Thecutting-unitdriveisdisengaged.

•Theparkingbrakeisset.

•Thetravel-controlpedalsareintheNEUTRAL

position.

StartingaWarmEngine

1.Sitontheseat,keepyourfootoffthetractionpedalso

thatitisintheNEUTRALposition,engagetheparking

brakeandsetthethrottletothe70percentfullthrottle.

2.TurntheignitionkeytotheignitiononpositionIand

checkthattheengineoilpressureandbatterycharge

warninglightsilluminate.

3.TurntheignitionkeytothestartpositionIIIandhold

tocranktheengine.

Note:Cranktheenginefornolongerthan15seconds.

ReleasetheignitionkeybacktopositionIwhenthe

enginestarts.

4.Runtheengineatlowidlespeeduntilitwarmsup.

Important:Thismachineisttedwithanenginestart

lockout;refertoUnderstandingtheOperator-Presence

Controls(page25).

StartingaColdEngine

1.Sitontheseat,keepyourfootoffthetractionpedals

sothatitisinNEUTRAL,engagetheparkingbrakeand

setthethrottletothe70percentfullthrottleposition.

2.TurntheignitionkeytotheignitiononpositionIand

checkthattheengineoilpressureandbatterycharge

warninglightsilluminate.

3.TurntheignitionkeytothepreheatpositionIIsothat

thepreheat-indicatorlightison.Holditfor5seconds

toheattheglowplugs.

4.Afterpreheatingtheglowplugs,turnkeytothestart

positionIIIandholdtocranktheengine.

Note:Cranktheenginefornolongerthan15seconds.

ReleasetheignitionkeybacktopositionIwhenthe

enginestarts.

5.Runtheengineatlowidlespeeduntilitwarmsup.

StoppingtheEngine

1.MoveallcontrolstoNeutral,settheparkingbrake,

movethethrottletothelowidlepositionandallowthe

enginetoreachlowidlespeed.

Important:Allowtheenginetoidlefor5

minutesbeforeshuttingitoffafterafullload

operation.Failuretodosomayleadtotroubleon

aturbo-chargedengine.

2.Lettheengineidlefor5minutes.

3.Turntheignitionkeytoposition0.

Note:Iftheenginefailstostopwhentheignition

keyisturnedto0,pushtheengine-stopleverforward

(Figure33).

WARNING

Touchingmovingobjectsmayresultin

pinchingandtouchinghotenginepartsmay

resultinburningoftheskin.

Keepyourhandsclearofmovingobjectsand

hotenginepartswhiletheengineisrunning.

Figure32

1.Engine-preheat-indicatorlight

WARNING

Operatingthemachinewithamalfunctioncould

causeseriousdamage.

Ifawarninglightcomesonduringoperation,stop

themachineimmediatelyandcorrecttheproblem

beforecontinuingoperation.

Figure33

26

Page 27

FlailCuttingUnitGeneral Information

Itisimportanttokeeptheailbladessharpandingood

conditiontoensuregoodcuttingperformance,minimum

powerconsumption,andagoodqualityofcut.

Theailheadisanecutailandshouldonlybeusedfor

maintaininggrass.Itsrecommendedthatamaximumof1/3

ofthetotalgrasslengthisremovedwhencut.

Thescraperwiresarettedtoremovedebrisfromthe

roller,indryconditionsthesemaynotberequiredandits

recommendedtheyareremoved.Indampwetconditions

ensurethatscraperwiresdonotgetpluggedwithdebris.

Thecuttingunitoatsandcanpivotlaterallytofollowground

contours.

Thecuttingunitsaredesignedtobeoperatedatfullengine

rpm.Forwardspeedshouldbeadjusteddependingongrass

conditionsandtonotoverloadthepowerunitsortheheads.

Thelowertheforwardspeedthehigherthequalityofcut

andaftercutappearance.

AdjustingtheHeightofCut

Note:Theheightofcutisgaugedbytherearroller.Blade

wear,worncuttingunitpivots,bent/damagedcuttingunit

pins,andbent/damagedarmscanaffecttheheight-of-cut

setting.

1.Turntheadjusting-nutassemblyonbothendsclockwise

todecreasetheheightofcutorcounter-clockwiseto

increasetheheightofcut(Figure34).

Figure35

1.Indicatorrings

Note:RefertoFigure36fortheheight-of-cutsettings.

Figure36

1.75mm(3.0inches)4.40mm(1.5inches)

2.65mm(2.5inches)5.25mm(1.0inches)

3.50mm(2.0inches)6.20mm(0.75inches)

Figure34

1.Heightofcut

Important:Donotattempttounlockthenut

assemblies.

2.Ensurethatallcuttingunitsaresetatthesameheight

ofcutbyreferringtotheindicatorrings(Figure35).

2.Adjusting-nutassembly

27

Page 28

ControllingthePositionofthe

UsingtheCuttingUnit

IndividualCuttingUnits

Thecuttingunitsmayberaisedorloweredindependently

usingthebankof3lift-controlswitches.

1.Tolowerthecuttingunits,operatethelift-control

switchesinadownwarddirectionandrelease.

Note:Thecutting-unit-driveswitchmustbeontodo

this,theailrotordriveengageswhenthecuttingunits

areapproximately150mm(6inches)aboveground

level.Thecuttingunitsarenowin‘oat’modeand

followthegroundcontours.

Auto-LimitedLiftinReverse

Toactivate,presstheauto-limited-liftswitchtotheON

position(Figure38).

Todeactivate,presstheauto-limited-liftswitchtotheOFF

position(Figure38).

Manuallimitedliftusingthe3lift-controlswitchesisalways

availableregardlessofthepositionoftheautoswitch.

Figure37

1.Lift-controlswitches

2.Toraisethecuttingunits,operatethelift-control

switchesinanupwarddirectionandholdinposition

3.Ifthecutting-unit-driveswitchisintheONposition

theailrotordrivedisengages.

3.Releasethelift-controlswitcheswhenthecuttingunits

areattherequiredheight.

Note:Thecontrolswitchesautomaticallyreturnto

position2(NEUTRAL)andthearmsarehydraulically

lockedintoposition.

Toraisethecuttingunitstothelimitedliftposition:

momentarilyoperatetheswitchesinanupwarddirection.

Theailrotordrivedisengagesimmediatelyandthecutting

unitsstopraising,approximately150mm(6inches)above

groundlevel.

Thisoperateswiththecuttingunitsloweredandrotating.

Autolimitedliftinreversecausesthecuttingunitstorise

automaticallytothelimitedliftpositionwhenreversing.They

returntotheoatingpositionwhenreturningtoforward

travel.Theailrotorscontinuetorotateduringthisoperation.

Figure38

28

Page 29

EngagingtheCuttingUnit

g014435

1

2

Drive

Figure39

1.On2.Off

Thecuttingunitdrivecanbeengagedonlywhenthe

operatorisseatedcorrectly,refertoCheckingthe

Operator-Presence-SeatSwitch(page47).

Cuttingunitdriveengagement:Pressthetopofthe

cutting-unit-driveswitchtotheonposition(Figure39).

Allcuttingunitdrivesdisengagement:Settheswitchto

theoffposition(Figure39).

Tolowerthecuttingunits:Thecuttingunitdriveswitch

mustbesettotheonposition.Operatethelift-control

switch(s)inadownwarddirection.Themachinedriveswhen

thecuttingunitsareapproximately150mm(6inches)above

groundlevel.

Using Weight-Transfer/Traction Assistance

Avariablehydraulicweighttransfersystemisprovidedfor

improvingtiregripwiththegrasssurface—tractionassistance.

Hydraulicpressureinthecuttingunitsliftsystemprovidesa

liftingforcewhichreducestheweightofthecuttingunits

onthegroundandtransferstheweightasadownwardforce

ontothetiresofthemachine.Thisactionisknownasweight

transfer.

Toengageweighttransfer:Theamountofweighttransfer

canbevariedtosuitoperatingconditionsbyrotatingthe

weight-transferhandwheel(Figure40)asfollows:

Figure40

1.Lockwheel

2.Weight-transferhand

wheel

FoldingtheROPS

YoucanfoldtheROPSframedowntoallowaccessintoareas

ofrestrictedheight.

WARNING

ThemachinedoesnothaveaRolloverProtection

SystemwhentheROPSisfoldeddownandshould

notbeconsideredasRolloverProtectionSystem.

DonotwearaseatbeltwhentheROPSislowered.

1.Parkthemachineonalevelsurface,engagetheparking

brake,andshutofftheengine.

2.Supporttheweightoftheupperframewhileremoving

theR-clipsandpinsfromthepivotbrackets(Figure41).

3.Carefullylowertheframedownwardsuntilitrestson

thestops.

4.Insertthepinsinthelowerholesandsecurewith

theR-clipstosupporttheupperframeinitslowered

position.

5.Toraisetheframe,followtheseinstructionsinreverse

order.

1.Releasethevalvelocknut1/2turncounterclockwise

andhold(Figure40).

2.Rotatethevalvehandwheel(Figure40)

counterclockwisetoreduceweighttransferor

clockwisetoincreaseweighttransfer.

3.Tightenthenut.

Note:Therecommendedsettingistoincreaseweight

transferuntilheadsstarttolift,thenbackoff1/2turn,and

lock.

29

Page 30

Figure41

3

1 2

G0144447

Important:Therollbarisanintegralandeffective

safetydevice.Keeptherollbarintheraisedposition

whenoperatingthemower.Lowertherollbar

temporarilyonlywhenabsolutelynecessary.

LocatingtheJackingPoints

Note:Usejackstandstosupportthemachinewhenrequired.

WARNING

Mechanicalorhydraulicjacksmayfailtosupport

themachineandcauseseriousinjury.

Usejackstandswhensupportingthemachine.

•Front—underthefrontarmmount

•Rear—axletubeontherearaxle

1.Upperframe

2.PinsandR-clips

3.Lowerholes

WARNING

TheROPSprotectionsystemmaynotbeeffectiveif

theROPSretainingboltassembliesareloosewhich

maycauseseriousinjuryorevendeathintheevent

ofarollover.

Whenintheraisedposition,bothretainingbolt

assembliesmustbeinstalledandfullytightenedto

ensurefullROPSprotection.

WARNING

WhenloweringandraisingtheROPSframe,ngers

maygetpinchedbetweenthemachineandthe

ROPS.

UsecautionwhenloweringandraisingtheROPS

toprevententrapmentofngersbetweenxedpart

andpivotpartofthestructure.

•Keepallnuts,bolts,andscrewscorrectlytorquedensure

thattheequipmentisinsafeworkingcondition.

•Replacewornordamagedpartsforsafety.

•Ensurethattheseatbeltandmountingsareinsafe

workingorder.

•Weartheseatbeltwhentherollbarisraisedandnoseat

beltwhentherollbarislowered.

Figure42

1.Frontleftliftingpoint3.Rearliftingpoint

2.Frontrightliftingpoint

HaulingtheMachine

•Usecarewhenloadingorunloadingthemachineintoa

traileroratruck.

•Usefull-widthrampsforloadingthemachineintoa

traileroratruck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

30

Page 31

TowingtheMachine

g014448

1

1 2 3

G014449

1

G014450

Ensurethatthetowingvehiclespecicationissuitedto

brakingthecombinedvehicleweightandabletoremainin

completecontrolatalltimes.Ensurethattheparkingbrake

ofthetowingvehicleisapplied.Chockthemowerfront

wheelstopreventthemowerfromrollingaway.

Important:Donottowthemachinefasterthan3to

5km/h(2to3mph),otherwiseinternaltransmission

damagemayoccur.

Disconnectthefront-wheel-motor-discbrakesasfollows:

1.Connectarigidtowbarbetweenthetowingeyeonthe

frontofthemowerandasuitabletowingvehicle.

2.Identifytherightfront-wheelmotor-disc-brake

assemblyandremovethehexplug(Figure43).

Figure43

1.Hexplug

Figure44

1.Hexplug

2.WasherM12

3.SetscrewM12x40

5.Tightenthesetscrewintothethreadedhole

inthebrakepistonuntilthebrakeisreleased

(Figure44).

6.Identifytheleftfront-wheelmotor-disc-brake

assemblyandrepeatthepreviousprocedure

(Figure44).

7.Decommissionthehydraulicservicebrakingsystemby

turningthebypassvalve,locatedunderthetransmission

pump,counterclockwise,amaximumof3turns(Figure

45).

Thesteeringmustbeoperatedmanuallywhenthe

mowerisbeingtowed.Thesteeringfeelsheavyasthere

isnohydraulicassistancewhentheengineisshutoff.

3.LocatetheM12x40mmsetscrewandwasherstored

underneaththeoperatorplatform,1ineachofthe

platformsupportrails.

4.InstallaM12x40mmlongsetscrewwithwasher

intotheholeinthecenterofthemotor-endplate

(Figure44).

Figure45

1.Transmission-bypassvalves

31

Page 32

8.Themowerisnowinafreewheelconditionandcanbe

1

2 3 4

g014451

towedforashortdistanceatslowspeed.

Note:Removethewheelchocksbeforetowing.

9.Aftertowingthemower:Toreturnthemowertoits

normalworkingconditionthefollowingprocedure

mustbedone:

A.Chockthefrontwheels.

B.Closethebypassvalveonthetransmissionpump

byturningitclockwise.

10.Commissionthefront-wheel-motordisc-brakes

asfollows:

Note:EnsurethattheM12x40mmsetscrews

andwashersareremovedandstoredunderneaththe

operatorplatform.

A.Identifytherightfront-wheel-motordisc-brake

assembly.

B.Rotatethesetscrewcounterclockwiseandremove

togetherwiththewasher.

C.Assemblethehexplugintothemotor-endplate

(Figure46).

Figure46

1.Front-wheelmotor3.WasherM12

2.Hexplug

4.SetscrewM12x40mm

D.Identifytheleftfront-wheel-motordisc-brake

assemblyandrepeatthepreviousprocedure.

E.Removethewheelchocks.

F.Disconnectthetowbar.

Note:Themowerbrakingsystemnowoperates

inthenormalway.

32

Page 33

OperatingTips

BecomingFamiliarwiththeMachine

Beforemowinggrass,practiceoperatingthemachineinan

openarea.Startandshutofftheengine.Operateinforward

andreverse.Lowerandraisethecuttingunitsandengageand

disengagethecuttingunits.Whenyoufeelfamiliarwiththe

machine,practiceoperatingupanddownslopesatdifferent

speeds.

WARNING

Takecarewhentravellingoverobstaclessuchas

roadsidecurbsassuchobstaclesmayallowthe

machinetorolloverwhichmaycausesevereinjury.

Alwaystravelatslowspeedoverobstaclesto

preventdamagetothetires,wheels,andsteering

system.Ensurethatthetiresareinatedtothe

recommendedpressures.

UnderstandingtheWarningSystem

Ifawarninglightcomesonduringoperation,stopthe

machineimmediatelyandcorrecttheproblembefore

continuingoperation.Seriousdamagecouldoccurifyou

operatethemachinewithamalfunction.

MowingGrass

Therotationalspeedoftheailrotorsshouldalwaysbekept

ashighaspossibleinordertomaintainthehighestqualityof

cut.Thisinturnrequiresthattheenginespeedbekeptas

highaspossible.

Cuttingperformanceisbestwhencuttingagainstthelieof

thegrass.Inordertotakeadvantageofthisfact,theoperator

shouldattempttoalternatethedirectionofmowingbetween

cuts.

Takecarenottoleaveuncutstripsofgrassattheoverlap

pointsbetweenadjacentcuttingunitsbyavoidingtightturns.

MaximizingtheQualityofCut

OperatingtheMachineonSlopes

Useextracarewhenoperatingthemachineonslopes.Drive

slowlyandavoidsharpturnsonslopestopreventrollovers.

Lowerthecuttingunitsforsteeringcontrolwhengoing

downhill.

UsingtheRearRollerScrapers

Itisgenerallywisetoremoverearrollerscraperswhere

conditionsallow ,asoptimumgrassdischargeisachieved

withoutthem.Installthescraperswhenconditionsaresuch

thatmudandgrassstarttobuildupontherollers.When

installingthescraperwires,ensurethattheyarecorrectly

tensioned.

Thequalityofcutdeterioratesiftheforwardspeedis

excessive.Alwaysbalancethequalityofcutwiththeworkrate

requiredandsettheforwardspeedaccordingly.

MaximizingEngineEfciency

Donotlettheenginelabor.Ifyounoticethattheengine

startstolabor,reducetheforwardspeedorincreasetheheight

ofcut.Checktomakesurethattheailbladesaresharp.

DrivingtheMachineinTransportMode

Alwaysdisengagethecuttingunitdrivewhentravellingacross

un-grassedareas.Becarefulwhendrivingbetweenobjects

sothatyoudonotaccidentallydamagethemachineorthe

cuttingunits.

33

Page 34

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Note:Toobtainanelectricalschematicorahydraulicschematicforyourmachine,visitwww .Toro.com.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

MaintenanceProcedure

•Checktheconditionandtensionofthealternatorbelt.

•Changetheengineoilandlter.

•Changethetransmission-oillter.

•Changethehydraulic-returnlter.

•Checktheenginespeed(idleandfullthrottle).

•Checktheengine-oillevel.

•Checkthecoolingsystem.

•Checkfuellevel.

•Checkthehydraulic-uidlevel.

•Checkthetorquethewheel-lugnuts.

•Checkthetirepressure.

•Greasethebearings,bushings,andpivots(greasethemimmediatelyafterevery

washingregardlessoftheintervallisted).

•Checktheair-cleaner-blockageindicator(servicetheaircleanerearlierifthe

air-cleanerindicatorshowsred;serviceitmorefrequentlyinextremelydirtyor

dustyconditions).

•Drainwaterorothercontaminantsfromthewaterseparator.

•Removedebrisfromthescreen,oilcoolers,andradiator(morefrequentlyindirty

operatingconditions).

•Checkthesafety-interlocksystem.

•Checkthehydrauliclinesandhosesforleaks,kinkedlines,loosemountingsupports,

wear,loosettings,weatherdeterioration,andchemicaldeterioration.

•Checktheheight-of-cutsetting.

•Inspecttheailrotorsandbladesfordamage,cracks,andloosefasteners.Replace

anydamagedorcrackedparts.

•Checkthebackguard.

•Verifythebladesandrotorsarefreeofdebrisandrotate/pivotfreely.

•Checkthefrontrubberguard.

•Checkthecuttingunitpivot.

•Checkforanyunusualvibrationoftherotor.

Every50hours

Every100hours

Every150hours

Every250hours

•Greasethebearings,bushings,andpivots(greasethemimmediatelyafterevery

washingregardlessoftheintervallisted).

•Inspectthebladesfordamageandexcessivewear.

•Makesurethateachbladeboltistorquedto45N∙m(33.2ft-lb).

•Checkthebladebolts.

•Checkthecuttingunitpivot.

•Checkforexcessiveplayintherotorbearings.

•Checktherear-rolleradjustment.

•Checktherear-rollerscraperwiretension.

•Inspectthecoolingsystemhoses.

•Checktheconditionandtensionofthealternatorbelt.

•Changetheengineoilandlter.

•Checktheconditionofthebattery.

•Checktheconditionofandcleanthebattery.

•Checkthebatterycableconnections.

•Checkthetransmission-controlcable.

34

Page 35

MaintenanceService

Interval

MaintenanceProcedure

Every400hours

Every500hours

Every800hours

Beforestorage

Yearly

Every2years

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

•Checkthefuellinesandconnections.

•Checktheenginespeed(idleandfullthrottle).

•Checktheengineoverheatwarningsystem.

•Replacetheprimaryairlter(morefrequentlyinextremedustyordirtyconditions).

•Replacethefuel-ltercanister.

•Checktheelectricalsystem.

•Changethetransmission-oillter.

•Changethehydraulic-returnlter.

•Checktherear-wheelalignment.

•Servicethehydraulicsystem.

•Checkthehydraulic-uid-overheatwarningsystem.

•Drainandcleanthefueltank.

•Adjusttheenginevalves(refertotheengineoperator’smanual).

•Drainandcleanthefueltank.

•Replacetheblades.

•Flushandreplacethecoolingsystemuid.

•Replaceallmovinghoses.

•Replacethetransmissioncable(contactyourAuthorizedT oroDistributor).

Fortheweekof:

MaintenanceCheckItem

Checkthesafetyinterlockoperation.

Checkthebrakeoperation.

Checktheengineoilandfuellevel.

Checktheairlterrestrictionindicator.

Checktheradiatorandscreenfordebris.

Checkunusualenginenoises.

Checkunusualoperatingnoises.

Checkthehydraulicsystemoillevel.

Checkhydraulichosesfordamage.

Checkforuidleaks.

Checkthetyrepressure.

Checktheinstrumentoperation.

Checktherotorandblades.

Checktheheight-of-cutadjustment.

Checkallgreasettingsforlubrication.

Touch-updamagedpaint.

1.Checktheglowplugandinjectornozzlesifhardstarting,excesssmoke,orroughrunningisnoted.

1

2

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

2.Immediatelyaftereverywashing,regardlessoftheintervallisted

35

Page 36

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

1

2

3

4

5

Important:Refertoyourengineoperator’smanualforadditionalmaintenanceprocedures.

Information

36

Page 37

PreparingtheMachineforMaintenance

Beforeperforminganymaintenanceparkthemachineonlevelground,shutofftheengine,removetheignitionkey,engage

theparkingbrake,ensurethereisnopressureinthehydraulicsystem,lowerthecuttingunitstotheground,andreadthe

safetyprecautionsinthismanual.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyouperformanymaintenance.

Important:Regularmaintenanceisessentialforthecontinuedsafeoperationofthemachine.Correctservicing

prolongstheworkinglifeofthemachineandsafeguardtheWarranty.AlwaysusegenuineT oroserviceparts

astheseareaccuratelymatchedtotherequiredduty.

Dirtandcontaminationaretheenemiesofanyhydraulicsystem.Whencarryingoutmaintenanceproceduresonthehydraulic

systemalwaysensurethattheworkareaandthecomponentsarethoroughlycleanbefore,duringandafterretting.Ensurethat

allopenhydrauliclinesandports,etc.arepluggedduringmaintenanceprocedures.

Therecommendedserviceintervalsarebasedonnormaloperatingconditions.Severeorunusualconditionsnecessitate

shorterserviceintervals.

Alwaysgreasethepivotpointsimmediatelyafterpressurewashingorsteamcleaning.

DANGER

Theengine,transmissionoil,andhydraulicsystemsarehotaftermachineuseandmaycausesevereburns.

Allowthesystemstocoolbeforeworkingonthemachine,particularlybeforeworkingontheengine

orwhenchangingtheoiloroillters.

ServiceIntervalChart

Figure47

37

Page 38

Lubrication

immediatelyaftereverywashing,regardlessoftheinterval

listed.

GreasingtheBearings, Bushings,andPivots

ServiceInterval:Beforeeachuseordaily

Every50hours

Lubricateallgreasettingsforthebearingsandbushingswith

No.2lithiumgrease.Lubricatethebearingsandbushings

Replaceanydamagedgreasettings.

Important:Use1pumpofgreaseontheheight-of-cut

adjustersand3pumpsofgreaseonallothergrease

ttings.

Thegreasettinglocationsandquantitiesareasfollows:

Figure48

1.–Greaseevery50hours2.–Greasedaily

38

Page 39

EngineMaintenance

1

G014437

G014565

1

2

3

g022394

CheckingtheEngineOverheat WarningSystem

ServiceInterval:Every500hours

1.Temperatureswitch

Figure50

2.Beforeremovingthelter,uselowpressureair(40psi,

cleananddry)tohelpremovelargeaccumulationsof

debrispackedbetweenoutsideofthelterandthe

canister.Avoidusinghigh-pressureairwhichcould

forcedirtthroughthelterintotheintaketract.

Note:Thiscleaningprocesspreventsdebrisfrom

migratingintotheintakewhenthelterisremoved.

Figure49

1.TurntheignitionkeytotheignitiononpositionI.

2.Disconnectthered/bluewireterminalfromthe

engine-temperatureswitch.

3.Touchthemetalterminalofthiswireontoasuitable

earthpoint,ensuringthatthemetalsurfacesmake

goodcontact.

Thehornsoundsandtheengine-coolant-temperature-warning

lightilluminatestoconrmcorrectoperation.Ifthesystemis

malfunctioning,makerepairsbeforeoperatingthemower.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily

Every500hours

ServicingthePrimaryAirFilter

Checktheair-cleanerbodyfordamagewhichcouldcausean

airleak.Replaceifdamaged.Checkthewholeintakesystem

forleaks,damageorloosehoseclamps.

Servicetheprimaryair-cleanerlteronlywhentheservice

indicator(Figure50)requiresit.Changingtheairlterbefore

itisnecessaryonlyincreasesthechanceofdirtenteringthe

enginewhenthelterisremoved.

Important:Besurethatthecoverisseatedcorrectly

andsealswiththeair-cleanerbody.

1.Checkthelter-blockageindicator.Iftheindicator

isred,theairlterneedstobecleanedorreplaced

(Figure50).

1.Rubberoutletvalve

2.Removablecover

3.Removethecoverfromtheair-cleanerbody.

4.Removeandreplacethelter(Figure51).

Cleaningoftheusedelementisnotrecommendeddue

tothepossibilityofdamagetotheltermedia.

5.Inspectthenewlterforshippingdamage,checking

thesealingendofthelterandthebody.Donotuse

adamagedelement.

6.Insertthenewlterbyapplyingpressuretotheouter

rimoftheelementtoseatitinthecanister.Donot

applypressuretotheexiblecenterofthelter.

7.Cleanthedirtejectionportlocatedintheremovable

cover.Removetherubberoutletvalvefromthecover,

cleanthecavityandreplacetheoutletvalve.

8.Installthecoverorientingtherubberoutletvalveina

downwardposition—betweenapproximately5o’clock

to7o’clockwhenviewedfromtheend.

9.Checktheconditionoftheair-cleanerhoses.

10.Securethecover.

Figure51

3.Airlter

39

Page 40

ServicingtheSafetyFilter

Theairlterhasasecondary,safetylterelementinsidethe

primaryairltertopreventdislodgeddustandotheritems

fromenteringtheenginewhilechangingthemainelement.

Replacethesafetylter,nevercleanit.

Important:Neverattempttocleanthesafetylter.

Ifthesafetylterisdirty,thentheprimarylteris

damaged.Replacebothlters.

ServicingtheEngineOiland Filter

ServiceInterval:Aftertherst50hours

Every150hours

1.Removethedrainplug(Figure52)andlettheoilow

intoadrainpan.

Figure53

1.Oillter

4.Applyalightcoatofcleanoiltothenewlterseal.

5.Installthereplacementoilltertothelteradapter.

Turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional1/2turn.

Figure52

1.Oil-drainplug