Page 1

FormNo.3401-570RevC

LT-F3000Heavy-DutyTripleTurf

FlailMower

ModelNo.30659—SerialNo.316000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3401-570*C

Page 2

ThisproductcomplieswithallrelevantEuropean

directives.Fordetails,pleaseseetheseparate

productspecicDeclarationofConformity(DOC)

sheet.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Introduction

Thismachineisaride-onlawnmowerintendedtobe

usedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrass

onparks,sportselds,caravanparks,cemeteries,

andcommercialgrounds.Itisdesignedforcutting

longandshortgrass.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

Visitwww.Toro.comformoreinformation,including

safetytips,trainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

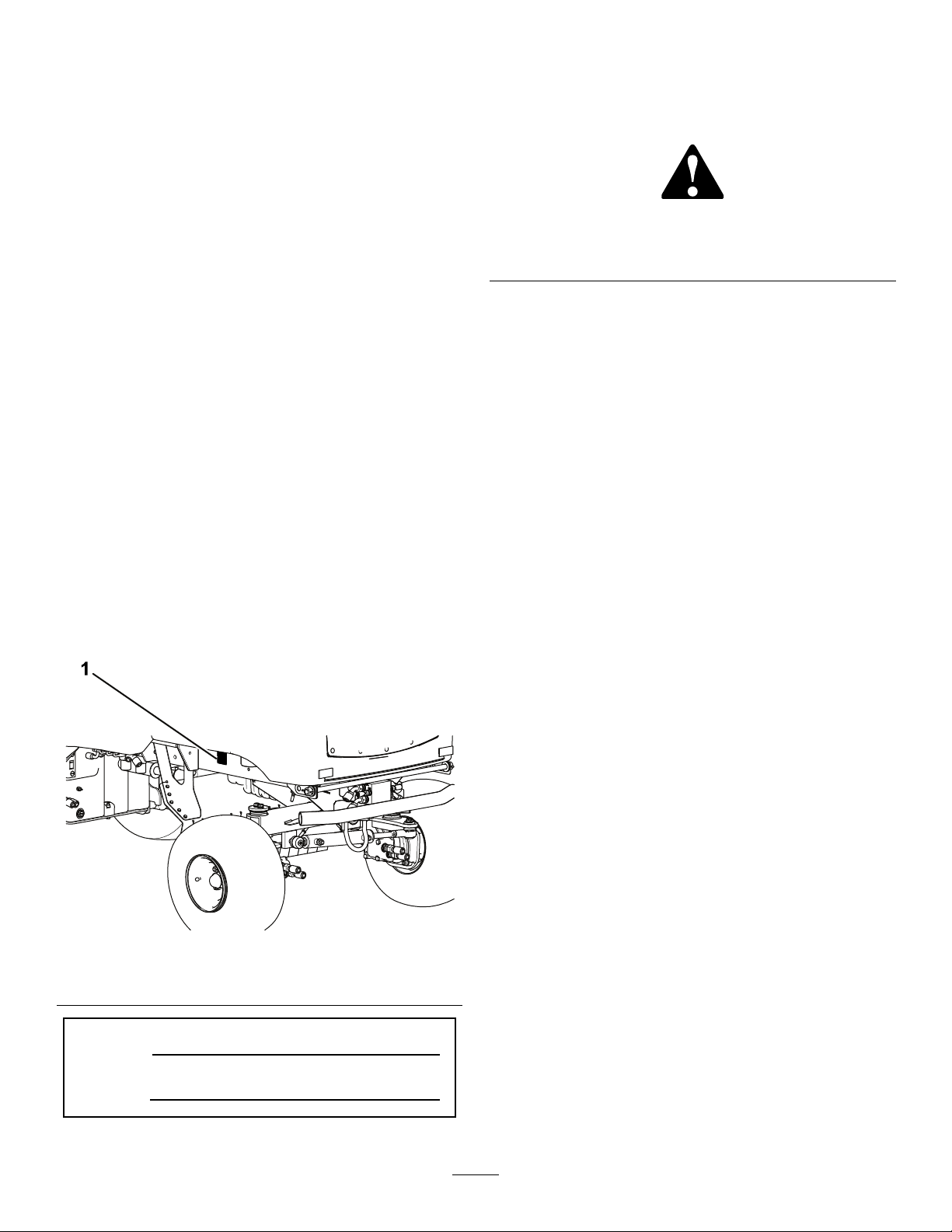

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

©2019—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

g281378

Contactusatwww.Toro.com.

2

PrintedintheUK

AllRightsReserved

Page 3

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

Setup......................................................................10

ProductOverview...................................................10

Controls............................................................11

Specications..................................................19

Attachments/Accessories.................................19

BeforeOperation.................................................20

BeforeOperationSafety...................................20

PerformingDailyMaintenance..........................20

FillingtheFuelTank..........................................20

DuringOperation.................................................21

DuringOperationSafety...................................21

UsingtheOperatorPlatformLatching

Mechanism...................................................22

UnderstandingtheOperatorPresence

Controls........................................................22

FoldingtheRollBar..........................................23

CheckingtheInterlockSwitches.......................24

StartingtheEngine...........................................24

ShuttingOfftheEngine.....................................25

FlailCuttingUnitGeneralInformation...............25

AdjustingtheHeightofCut...............................25

ControllingthePositionoftheIndividual

CuttingUnits.................................................26

UsingtheCuttingUnitAuto-LimitedLiftin

Reverse........................................................26

EngagingtheCuttingUnitDrive........................27

UsingWeight-Transfer/Traction

Assistance....................................................27

OperatingTips.................................................28

AfterOperation....................................................28

AfterOperationSafety......................................28

IdentifyingtheTie-DownPoints........................29

HaulingtheMachine.........................................29

LocatingtheJackingPoints..............................29

TowingtheMachine..........................................29

Maintenance...........................................................32

MaintenanceSafety..........................................32

RecommendedMaintenanceSchedule(s)...........33

DailyMaintenanceChecklist.............................35

Lubrication..........................................................36

GreasingtheBearings,Bushings,and

Pivots............................................................36

EngineMaintenance...........................................36

EngineSafety...................................................36

CheckingtheEngineOverheatWarning

System..........................................................36

ServicingtheAirCleaner..................................37

CheckingtheEngine-OilLevel..........................38

ServicingtheEngineOilandFilter....................38

FuelSystemMaintenance...................................39

DrainingtheFuelT ank......................................39

CheckingtheFuelLinesand

Connections..................................................39

BleedingtheFuelSystem.................................39

ReplacingtheFuelFilter...................................40

ElectricalSystemMaintenance...........................41

ElectricalSystemSafety...................................41

CheckingtheElectricalSystem.........................41

CheckingtheBatteryCondition.........................41

ServicingtheBattery.........................................41

DriveSystemMaintenance..................................42

CheckingtheTirePressure...............................42

CheckingtheT orqueoftheWheel-Lug

Nuts..............................................................42

ChangingtheTransmissionOilFilter................42

ChangingtheHydraulic-ReturnFilter................42

CheckingtheRear-WheelAlignment................43

InspectingtheTransmissionControlCable

andOperatingMechanism............................43

CoolingSystemMaintenance..............................44

CoolingSystemSafety.....................................44

RemovingDebrisfromtheCooling

System..........................................................44

BeltMaintenance................................................45

TensioningtheAlternatorBelt...........................45

ControlsSystemMaintenance.............................46

CheckingtheForward/ReverseTravelPedal

Action............................................................46

CheckingtheOperator-Presence-Seat

Switch...........................................................46

CheckingtheCutter-Drive-Interlock

Switch...........................................................46

CheckingtheParking-Brake-Interlock

Switch...........................................................46

CheckingtheTransmission-Neutral-Interlock

Switch...........................................................46

HydraulicSystemMaintenance...........................47

HydraulicSystemSafety...................................47

CheckingtheHydraulicLinesand

Hoses............................................................47

CheckingtheHydraulicFluid............................47

ServicingtheHydraulicSystem........................48

CheckingtheHydraulic-Fluid-Overheat

WarningSystem............................................48

CuttingUnitMaintenance.....................................49

BladeSafety.....................................................49

ReplacingtheBlades........................................49

CheckingtheBladeBolts..................................49

InspectingtheBlades.......................................49

CheckingtheRearGuard.................................50

ClearingaBlockedRotor..................................50

CheckingtheRubberGuard.............................51

CheckingtheCuttingUnitPivot.........................51

CheckingtheRotor...........................................51

CheckingtheRear-RollerBearing

Adjustment....................................................51

CheckingtheRear-RollerScraperWire

Tension.........................................................52

Cleaning..............................................................52

WashingtheMachine.......................................52

Storage...................................................................53

3

Page 4

StorageSafety..................................................53

PreparingtheTractionUnit...............................53

PreparingtheEngine........................................53

Troubleshooting......................................................54

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395.

GeneralSafety

Thisproductiscapableofamputatinghandsandfeet

andofthrowingobjects.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Keepbystandersandchildrenoutoftheoperating

area.Neverallowchildrentooperatethemachine.

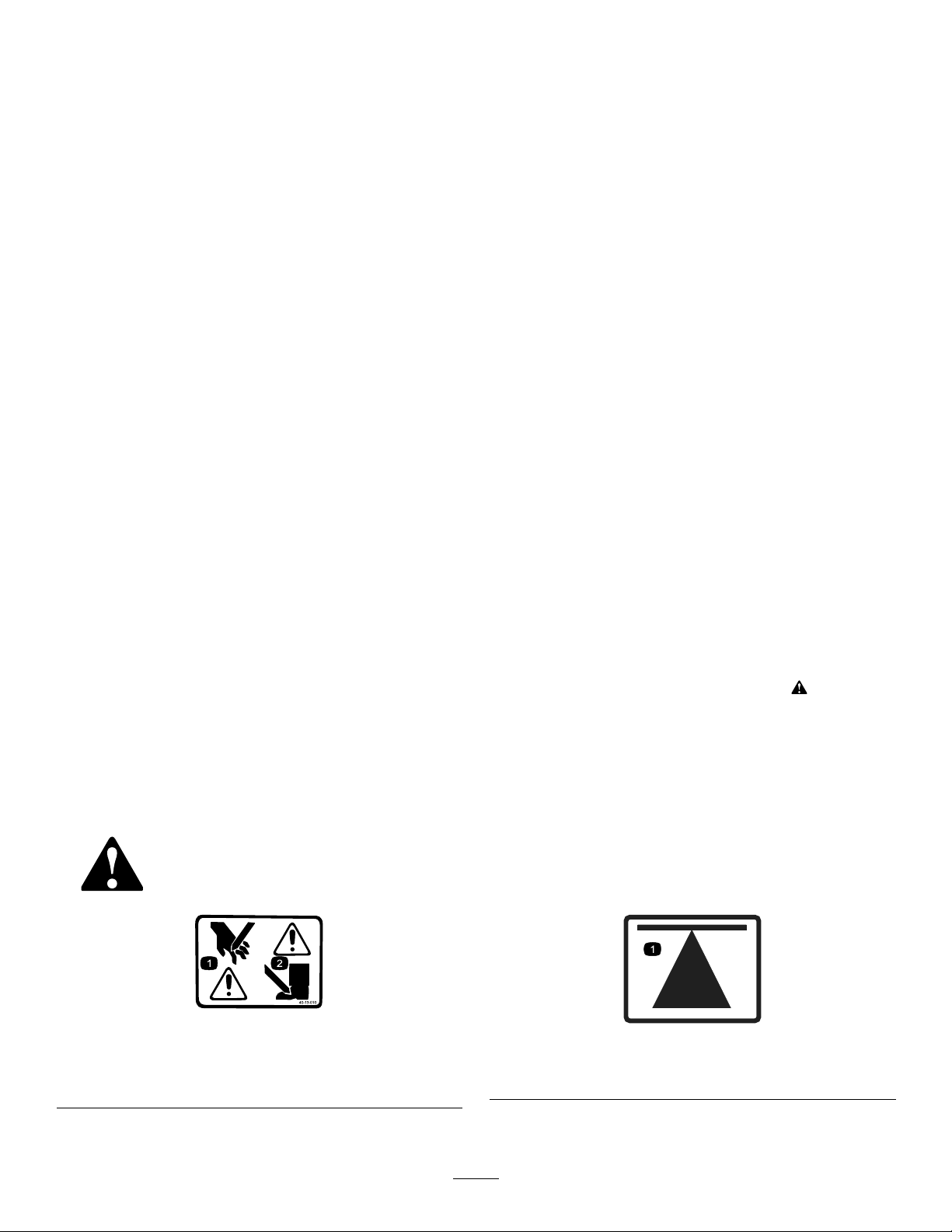

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

•Shutofftheengine,removethekey,andwait

forallmovementtostopbeforeyouleavethe

operator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

Improperlyusingormaintainingthismachinecan

resultininjury .Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

,which

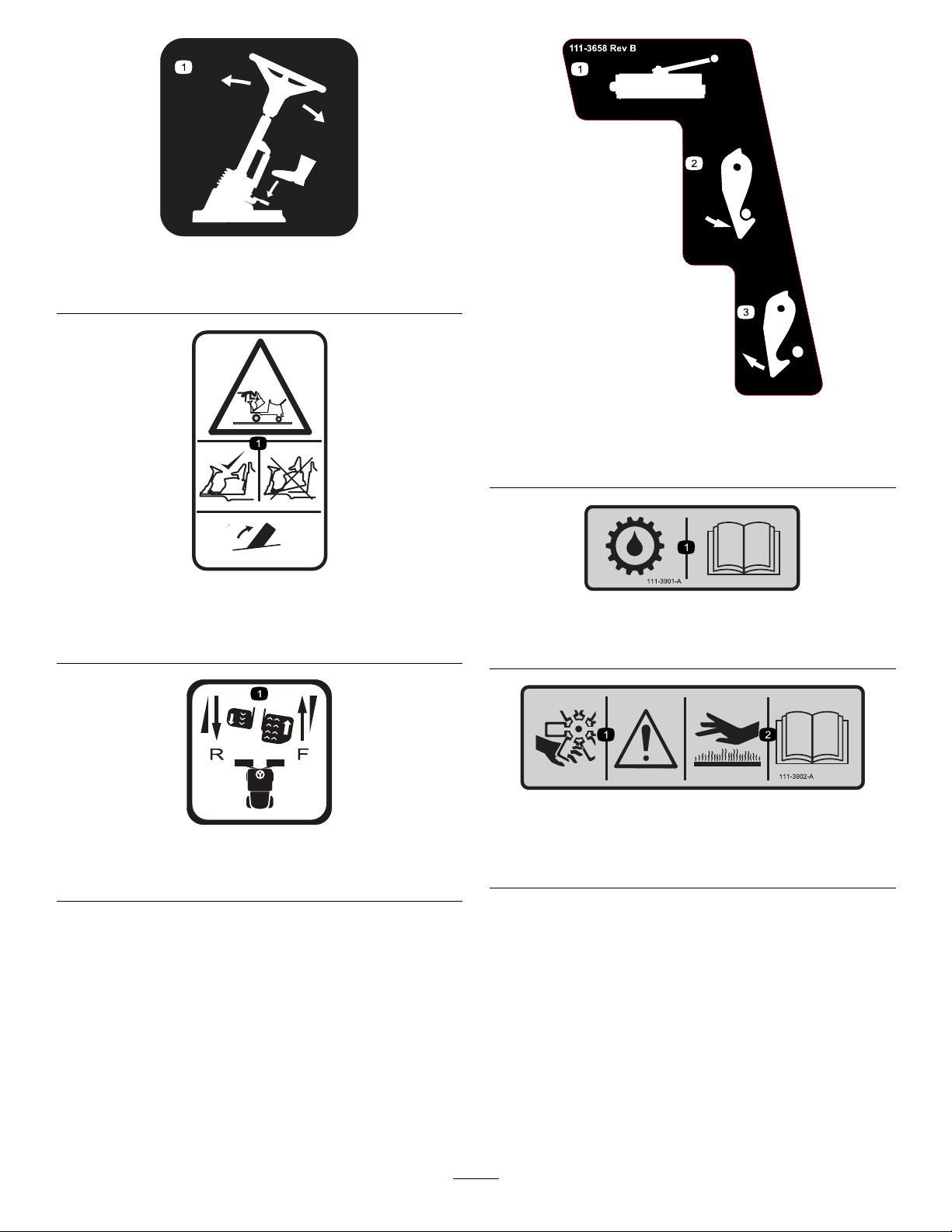

1.Cuttinghazardofhand

2.Cuttinghazardoffoot

decal40-13-010

40-13–010

70-13-072

1.Jackingpoint

4

decal70-13-072

Page 5

70-13-077

1.Warning—shutofftheengineandremovetheignitionkey

beforereleasingoroperatingsafetylatches.

950889

1.Warning—hotsurfaces.

111-0773

1.Warning—crushingofngers,forceappliedfromside.

decal70-13-077

decal950889

decal11 1-3277

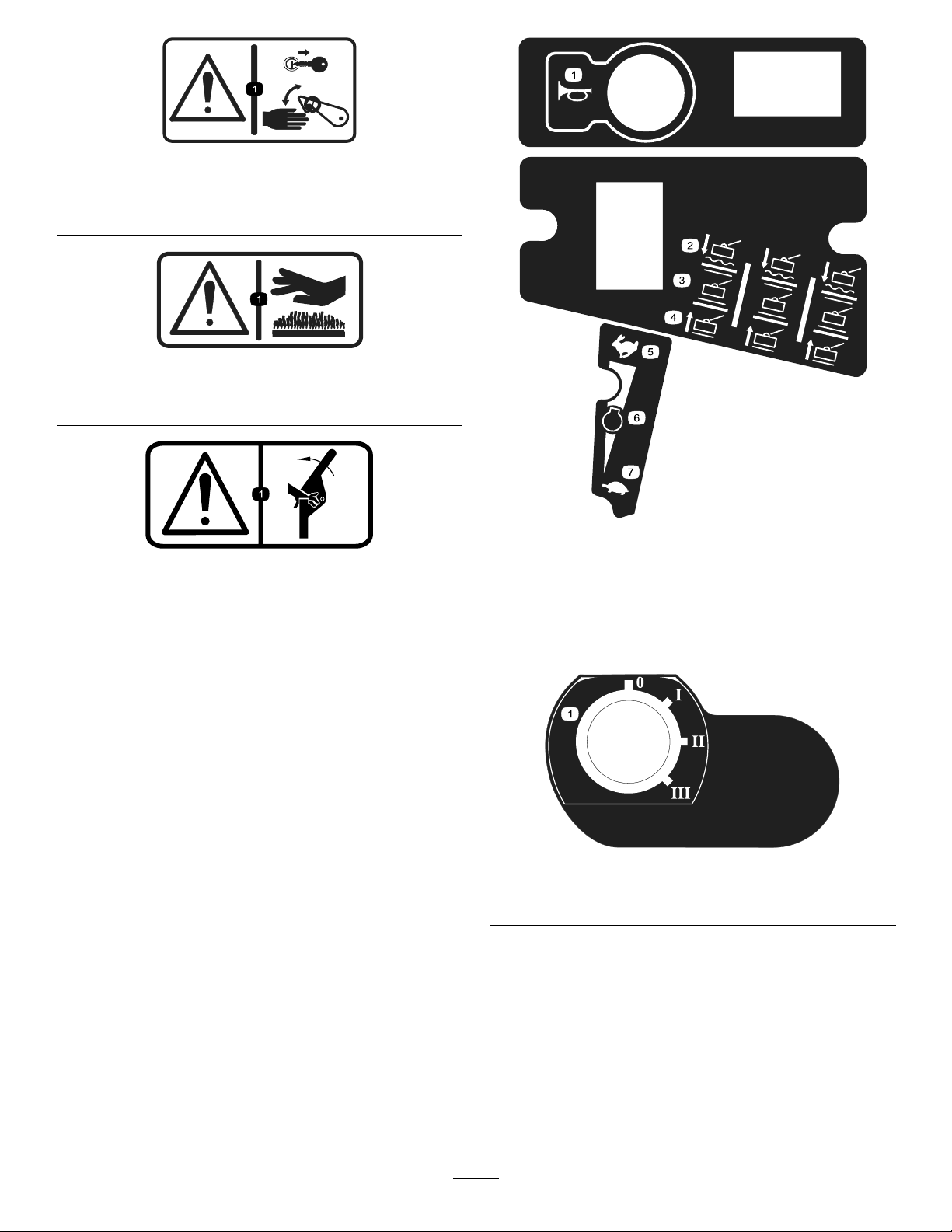

111-3277

decal11 1-0773

1.Horn5.Fast

2.Cuttingunits—lower/oat

3.Cuttingunits—hold

4.Cuttingunits—raise

6.Enginespeed

7.Slow

decal11 1-3344

111-3344

1.Ignitionswitch

5

Page 6

111-3562

1.Pressthepedaltoadjustthesteeringwheelangle.

decal11 1-3562

decal11 1-3658

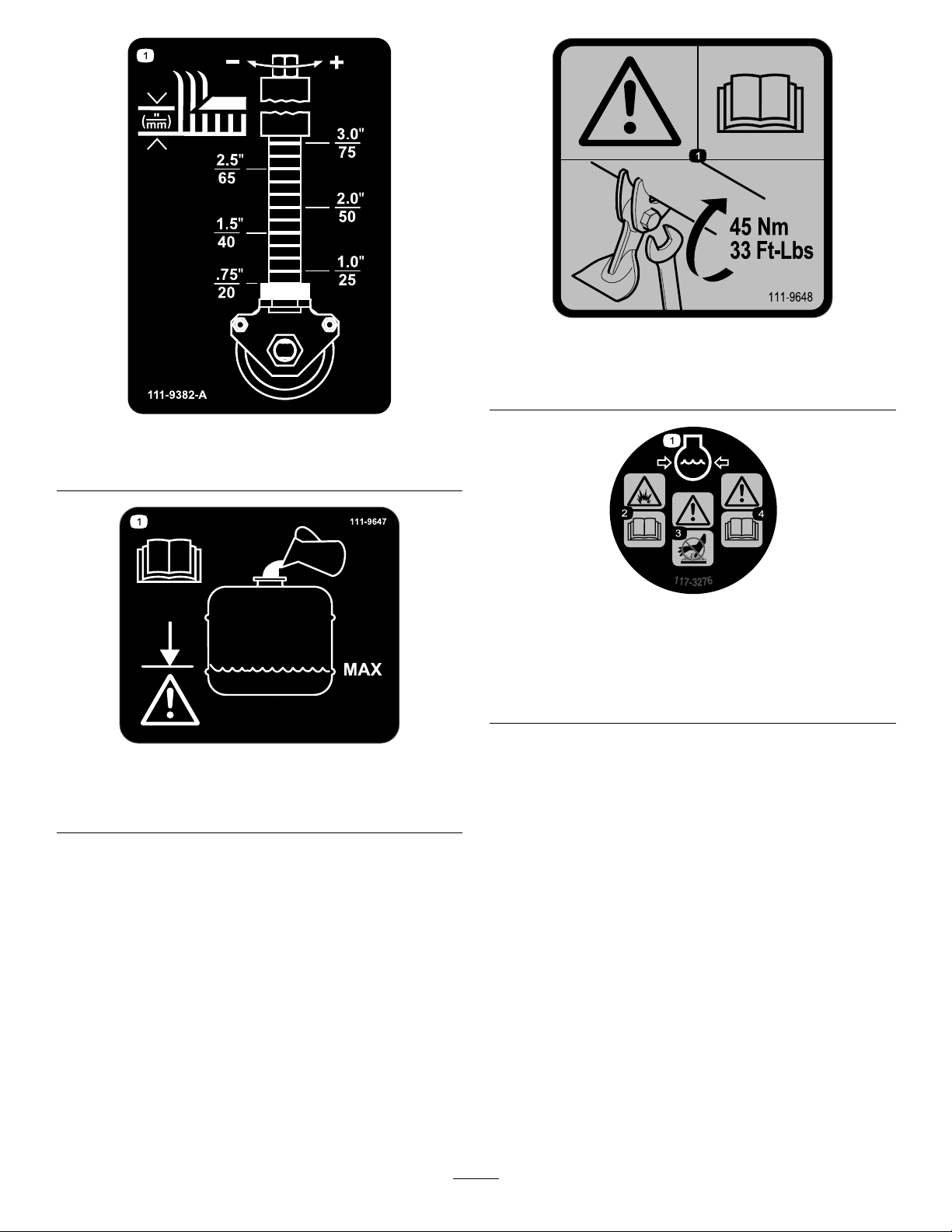

111-3658

111-3566

1.Falling,crushinghazard—ensurethattheoperator-platform

latchisengagedbeforeoperating.

111-3567

1.Pedaloperation

1.Cutterhead

3.Unlatch

2.Latch

decal11 1-3566

decal11 1-3901

111-3901

1.Transmissionuid—readtheOperator'sManual.

decal11 1-3902

111-3902

decal11 1-3567

1.Yourhandcanbecutbythefan;warning

2.Hotsurfaces;readtheOperator'sManual.

6

Page 7

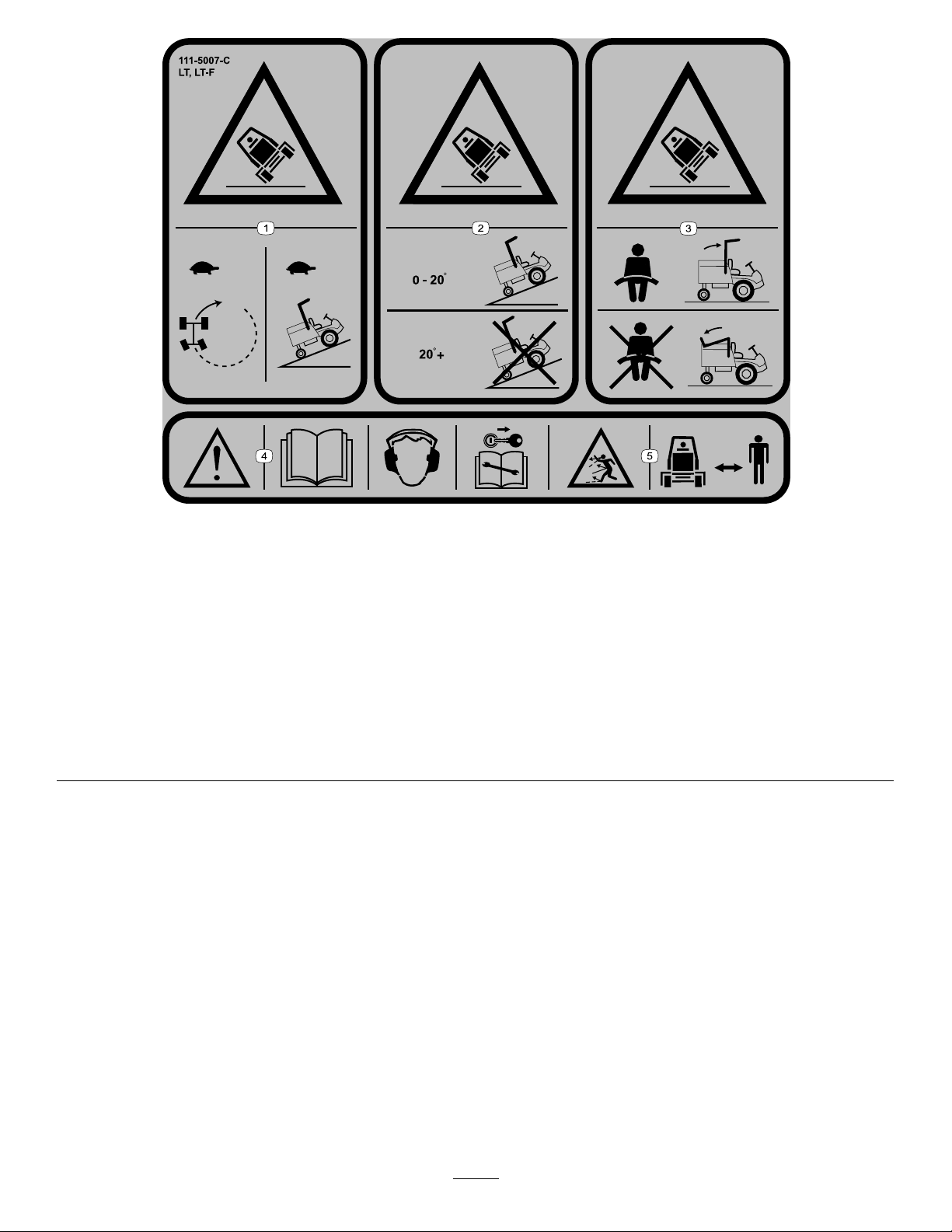

1.Height-of-cutchart

decal11 1-9648

111-9648

1.Warning—readtheOperator'sManual;torquethenutsto

45N∙m(33ft-lb).

decal11 1-9382

111-9382

decal117-3276

117-3276

111-9647

1.ReadtheOperator'sManual—lltothemaximumlevel;

donotoverll.

1.Enginecoolantunder

pressure

2.Explosionhazard—read

theOperator'sManual.

decal11 1-9647

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

7

Page 8

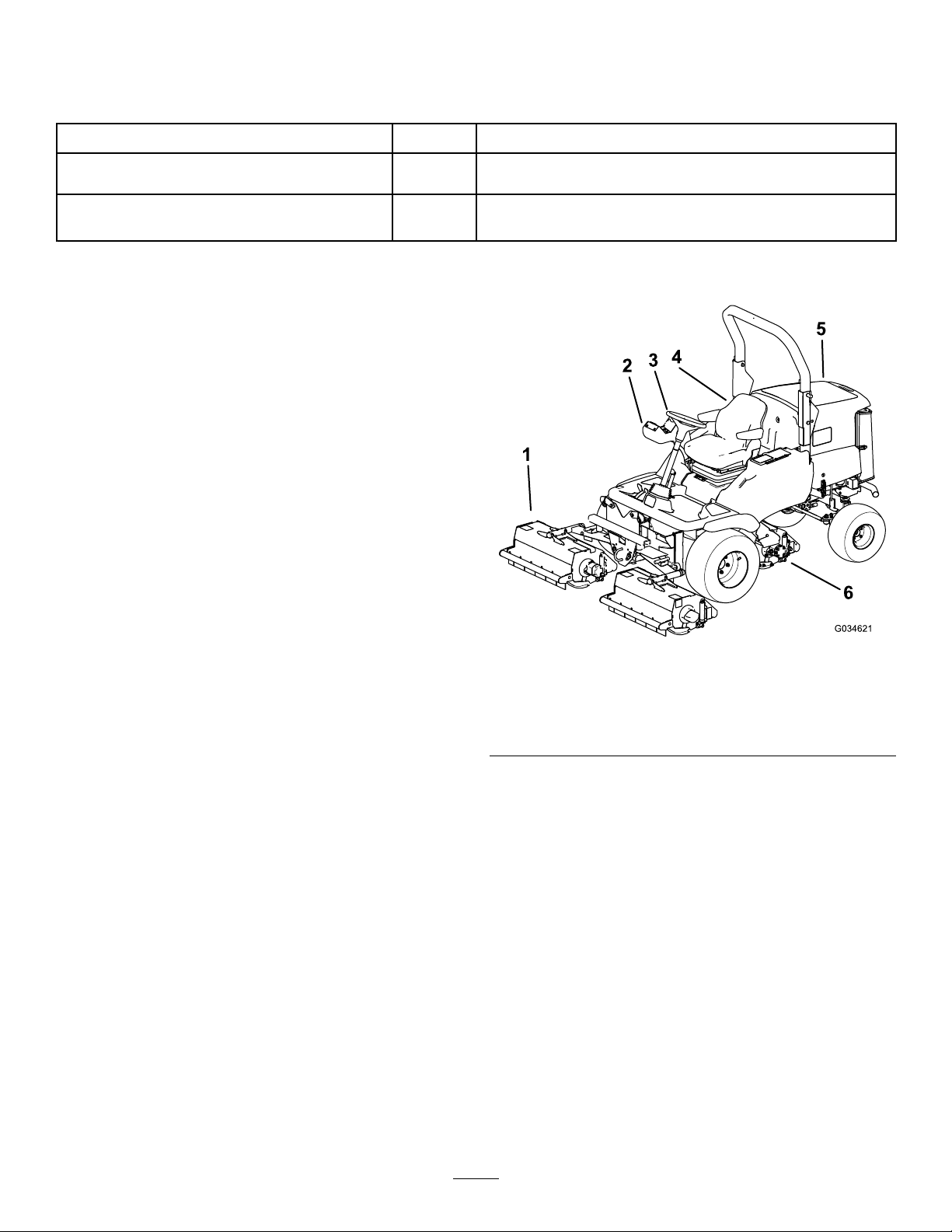

111-5007

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineintheconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

decal11 1-5007

1.Tippinghazard—driveslowlywhenturningorgoingupslopes.

2.Tippinghazard—onlydriveupslopesthatarebetween0and

20°;donotdriveupslopesthataregreaterthan20°.

3.Tippinghazard—wearaseatbeltwhentherollbarisup;donot

wearaseatbeltwhentherollbarisdown.

4.Warning—readtheOperator'sManual;wearhearing

protection;removethekeybeforeperformingany

maintenance.

5.Thrownobjecthazard—keepbystandersaway .

8

Page 9

decal11 1-9649

111-9649

1.ReadtheOperator'sManualformoreinformationonservice

8.Ensurethebladesstopwhenyouleavetheoperatingposition.

andmaintenance.

2.Tirepressure—1bar(14.5psi)9.Checktheairlter.

3.Checkallfasteners.10.Inspectthebladesforwear.

4.Checkforhydraulicleaks.11.Ensurethebottleislledtothelowline.

5.Checkthetransmission-oillevel.12.Cleanthecoolingsystem.

6.Checkthefuellevel.13.Cleanthemachineandtorquethefrontwheelto200N∙m

andtherearwheelto54N∙m.

7.Checktheoillevel.

9

Page 10

Setup

MediaandAdditionalParts

Description

Operator'sManual

Engineowner’smanual1

DeclarationofConformity

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Qty.

Use

1

1

Readthemanualsbeforeoperatingthemachine.

TheDeclarationofConformityservesasconrmationof

CEcompliance.

ProductOverview

1.Frontcuttingunits

2.Controlarm

3.Steeringwheel

g034621

Figure3

4.Operator'sseat

5.Enginehood

6.Rearcuttingunit

10

Page 11

Controls

ControlPanelComponents

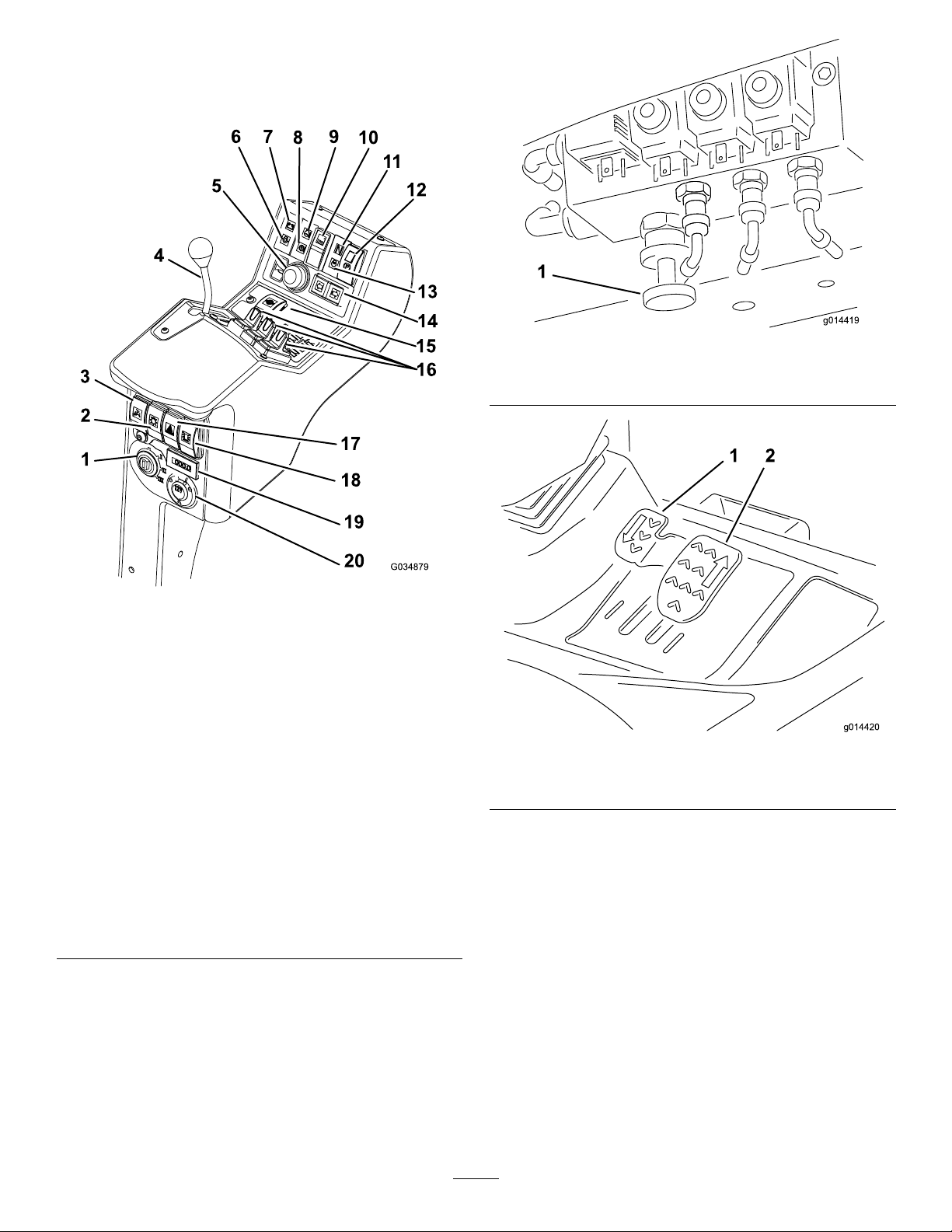

g014419

Figure5

1.Weighttransfercontrol

Figure4

1.Ignitionswitch11.Transmission-neutral

2.Lightingswitch(supplied

withlightingkit)

3.Limited-lift-in-reverse

switch

4.Throttle-controllever14.Direction-indicatorswitch

5.Hornbutton

6.Engine-oil-warninglight

7.Battery-charge-warning

light

8.Hydraulic-uid-warning

light

9.Engine-coolant-warning

light

10.Cutting-unit-driveswitch

indicator

12.Parking-brakeswitch

13.Engine-preheat-indicator

light

(suppliedwithlightingkit)

15.Differential-lockswitch

16.Lift-controlswitches

17.Hazard-warningswitch

(suppliedwithlightingkit)

18.Warning-beaconswitch

(suppliedwithbeaconkit)

19.Hourmeter

20.Auxiliary12Vsocket

g034879

g014420

Figure6

1.Reversetravelpedal2.Forwardtravelpedal

BrakingSystem

ParkingBrake

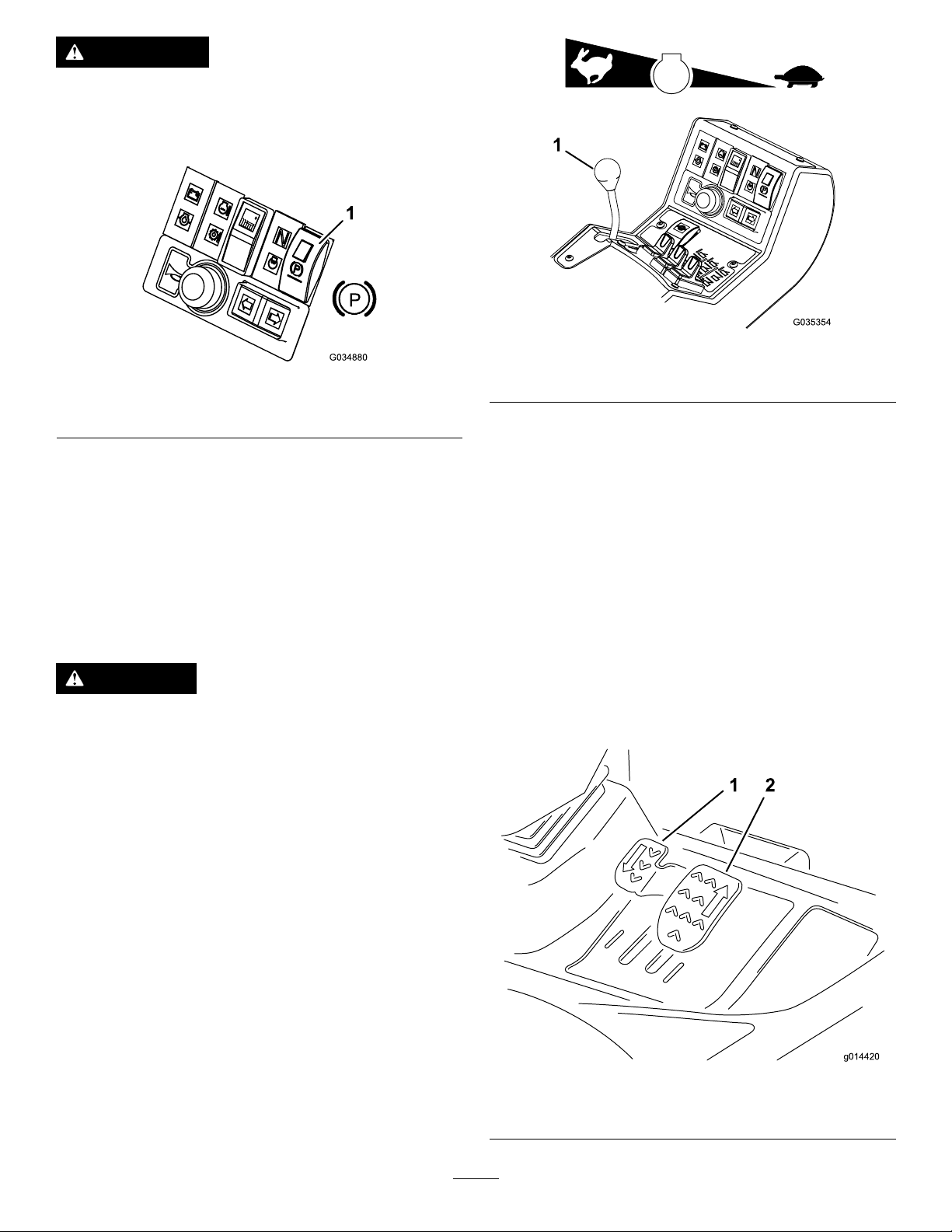

Movetheparking-brakeswitchtotheforwardposition

bypressingthesmallerlockingbuttonandmovingthe

switchforwardtoengagetheparkingbrake(Figure7).

Note:Donotoperatethemowerwiththeparking

brakeengagedanddonotengagetheparkingbrake

whilethemowerismoving.

Thislightilluminateswhentheparkingbrakeis

engagedandtheignitionkeyisturnedtopositionI.

11

Page 12

WARNING

Theparkingbrakeoperatesonthefront

wheelsonly.

Donotparkthemachineonaslope.

Figure7

1.Parking-brakeswitch

g035354

Figure8

g034880

1.Throttle-controllever

Travel

ServiceBrake

Servicebrakingisachievedbythehydraulic

transmissionsystem.Whentheforwardorreverse

travelpedalsarereleasedortheenginespeedis

reduced,servicebrakingbecomeseffectiveandtravel

speedisautomaticallyreduced.Toincreasethe

brakingeffect,pushthetransmissionpedalintothe

NEUTRALposition.Servicebrakingiseffectiveonthe

frontwheelsonly.

DANGER

Theservicebrakingsystemdoesnotholdthe

moweratastandstill.

Alwaysensurethattheparkingbrakeis

engagedtoparkthemoweratastandstill.

EmergencyBrake

Intheeventofservicebrakefailure,turntheignition

offtobringthemowertoastandstill.

ThrottleControl

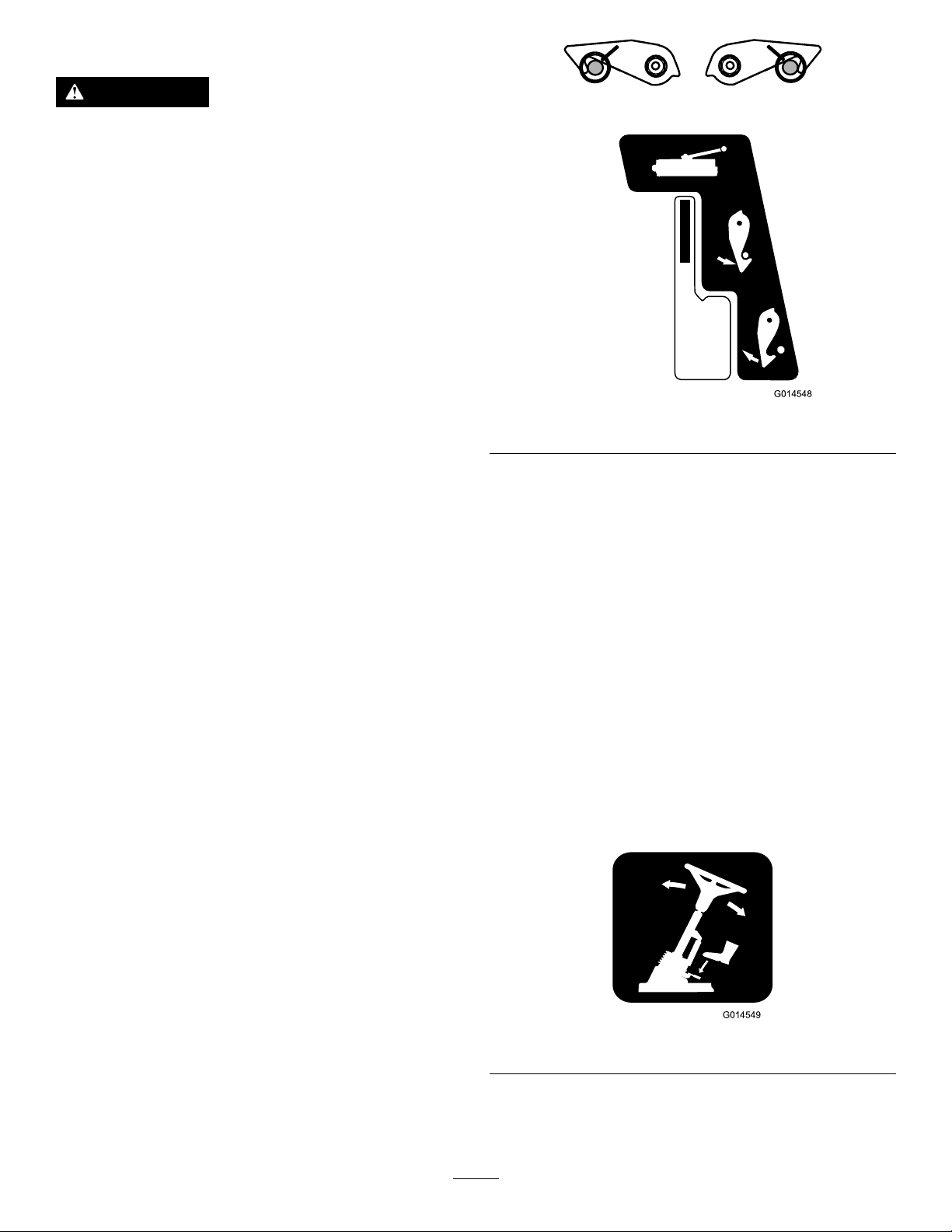

Forwardtravel:Presstheforwardtravelpedalto

increaseforwardtravelspeed.Releasethepedalto

reducespeed(Figure9).

Reversetravel:Pressthereversetravelpedalto

increasereversetravelspeed.Releasethepedalto

reducespeed(Figure9).

Stop(Neutral):T ostopthemachine,use1ofthe

followingprocedures:

•Reduceyourfootpressureonthetractionpedal

andallowittoreturntotheneutralposition.The

machinedynamicallybrakestoasmoothstop.

•Taporholdthereversepedalbriey .Thisstops

themachinefasterthandynamicbraking.

Operatethethrottlecontrolinaforwarddirection

toincreasetheenginespeed.Operatethethrottle

controlinarearwarddirectiontoreduceenginespeed

(Figure8).

Note:Theenginespeeddictatesthespeedofthe

otherfunctions,i.e.,travel,ail-rotorrotationspeed,

andcuttingunitliftspeed.

g014420

Figure9

1.Reversetravelpedal2.Forwardtravelpedal

12

Page 13

DifferentialLock

WARNING

Theturningradiusincreaseswhenthe

differentiallockisengaged.Usingthe

differentiallockathighspeedmayleadtoloss

ofcontrolandcauseseriousinjuryand/or

propertydamage.

Donotusethedifferentiallockathighspeed.

Usethedifferentiallocktopreventexcessivewheel

spinwhenthedrivewheelslosetraction.The

differentiallockoperatesinbothforwardandreverse.

Youcanlockthedifferentialwhilethemachineis

travelingslowly.Enginepowerdemandincreases

whenthedifferentialislocked.Preventexcessive

powerrequirementsbyusingthedifferentiallockonly

atlowspeed.

Tolockthedifferential,pressthedifferential-lock

switch.

g014548

Figure10

Tounlockthedifferential,releasethedifferential-lock

switch.

Cutting-UnitsPositionControls

Usethecutting-unitspositioncontrolstoindependently

raiseandlowerthecuttingunits;refertoControlling

thePositionoftheIndividualCuttingUnits(page26).

TransportLatches

AlwaysraisethecuttingunitstotheTRANSPORT

positionandsecurewiththetransportlatchesand

safetylockswhentravellingbetweenworkareas

(Figure10).

Cutting-Unit-DriveSwitch

Toengagethecuttingunitdrive,refertoEngagingthe

CuttingUnitDrive(page27).

Note:Alwaysputthecutting-unit-driveswitchinthe

OFFpositionwhentravellingbetweenworkareas.

AdjustableSteeringColumn

Adjustmentofthesteeringwheelandsteeringcolumn

shouldonlybecarriedoutwhenthemowerisata

standstillwiththeparkingbrakeengaged.

1.Totiltthesteeringwheel,pressthefootpedal

down.

2.Positionthesteeringtowertothemost

comfortablepositionandreleasethepedal

(Figure1 1).

g014549

Figure11

13

Page 14

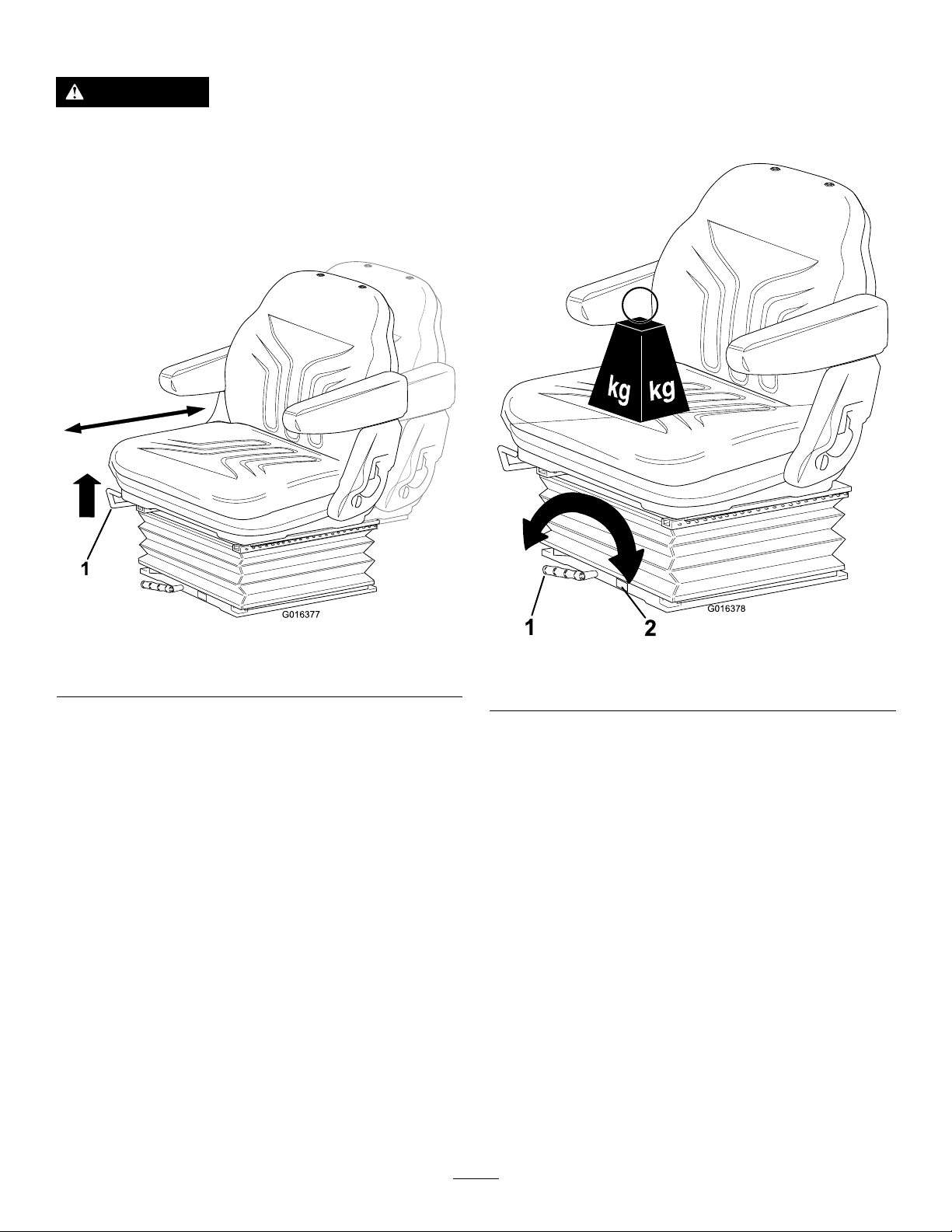

OperatorSeat

WARNING

Ensurethattheoperator-platformlatchis

engagedbeforeoperatingthemachine.

•Forward/BackwardAdjustment:Movethelever

upwardtoadjusttheforward/backwardposition

oftheseat.Releasethelevertolocktheseatin

position(Figure12).

•Operatorweightadjustment:Rotatethehandle

clockwisetoincreasesuspensionstiffnessand

counterclockwisetodecreasethestiffness.The

dialindicateswhentheoptimumsuspension

adjustmenthasbeensetaccordingtooperator

weight(kg);refertoFigure13.

g016377

Figure12

Figure13

1.Lever

1.Lever2.Dial

g016378

14

Page 15

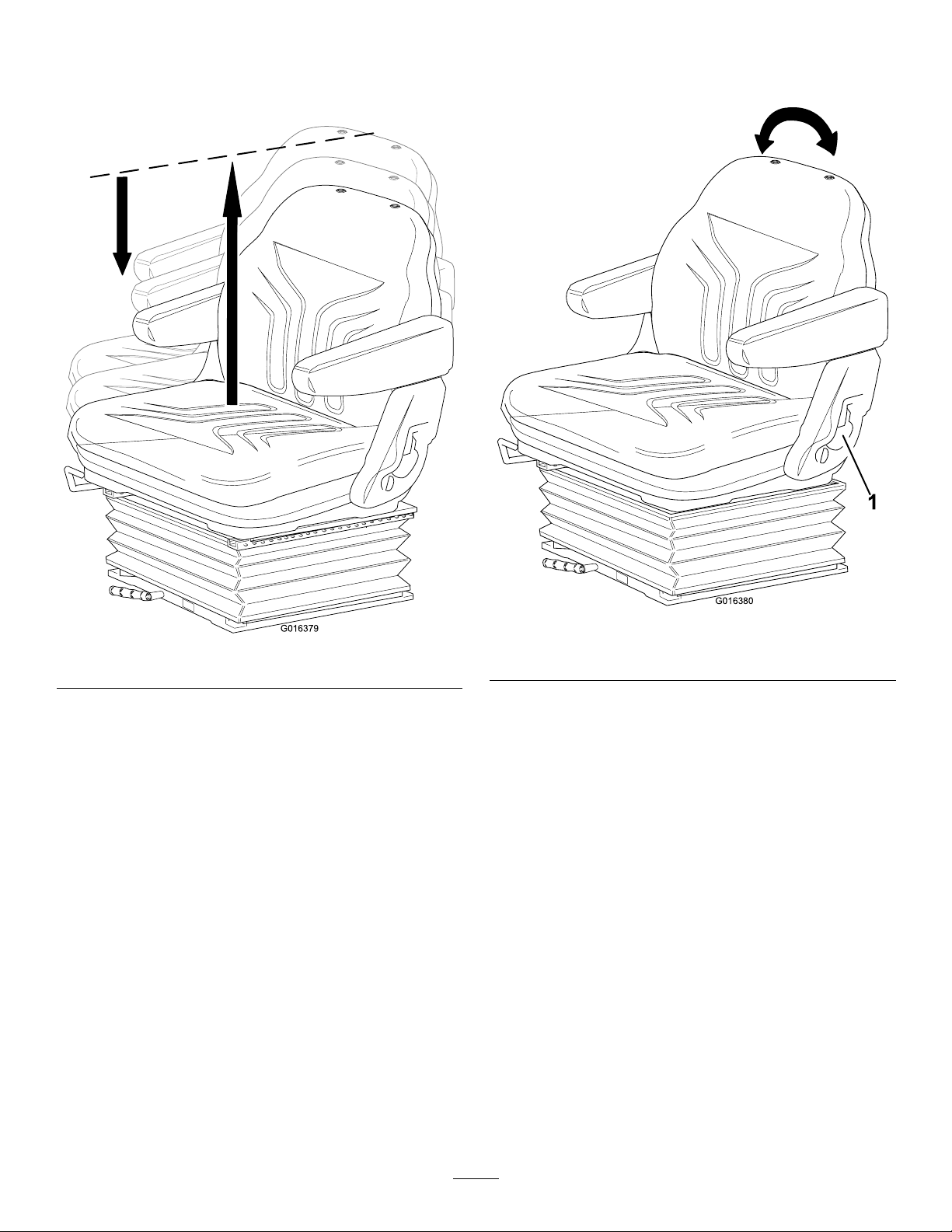

•Heightadjustment:Manuallylifttheseatfor

incrementalheightadjustment.T olowertheseat,

liftitbeyondthehighestsetting,thenallowitto

droptothelowestsetting(Figure14).

•Backrestadjustment:Pullthehandleoutwardto

adjusttheseatbackrestangle.Releasethehandle

tolocktheseatbackrestinposition(Figure15).

Figure14

g016380

g016379

1.Handle

Figure15

15

Page 16

WarningSystems

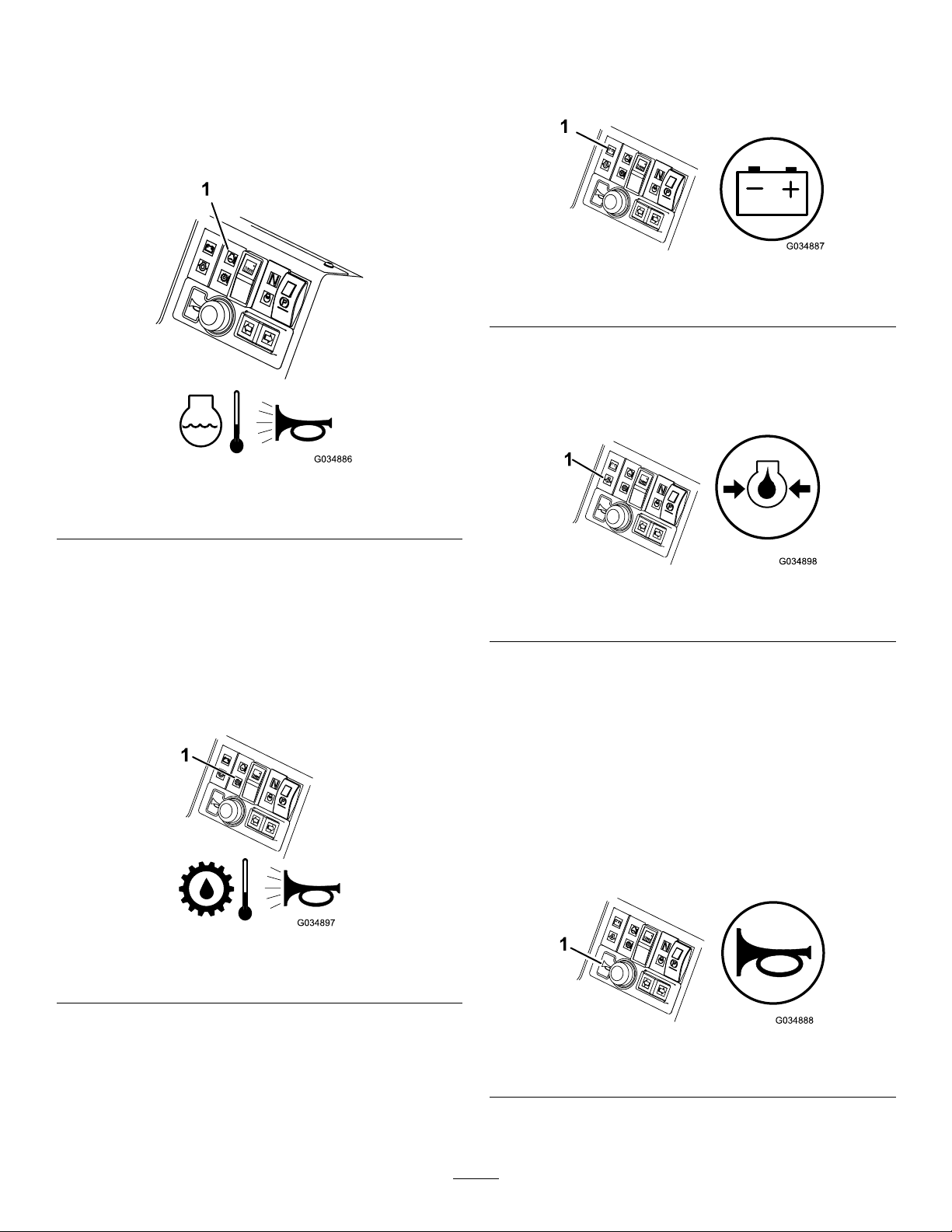

Battery-Charge-WarningLight

Engine-Coolant-Temperature-WarningLight

Theengine-coolant-temperature-warninglight

illuminates,thehornisactuated,andthecuttingunits

stopwhentheenginebecomestoohot(Figure16).

Figure16

1.Engine-coolant-temperature-warninglight

Thebattery-charge-warninglightilluminateswhenthe

batteryislowofcharge(Figure18).

g034887

Figure18

1.Battery-charge-warninglight

Engine-Oil-Pressure-WarningLight

Theengine-oil-pressure-warninglightilluminates

whentheoilpressureistoolow(Figure19).

g034886

Note:Theailrotorsdisengagewhentheoperating

temperaturereaches1 15°C(239°F).

Hydraulic-Fluid-Temperature-WarningLight

Thehydraulic-uid-temperature-warninglight

illuminateswhenoverheatingoccursandthehorn

isactuatedwhenthehydraulicuidinthereservoir

exceeds95°C(203°F);refertoFigure17.

Figure17

1.Hydraulic-uid-temperature-warninglight

g034898

Figure19

1.Engine-oil-pressure-warninglight

AudibleWarningHorn

ServiceInterval:Beforeeachuseordaily—Check

thehorn.

Pressthehornbuttontoprovideanaudiblewarning

(Figure20).

Important:Thehornisautomaticallyactuated

whenanenginecoolantorhydraulicuidoverheat

conditionoccurs.Shutofftheengineimmediately

andxthemachinebeforestartingitagain.

g034897

g034888

Figure20

1.Horn

16

Page 17

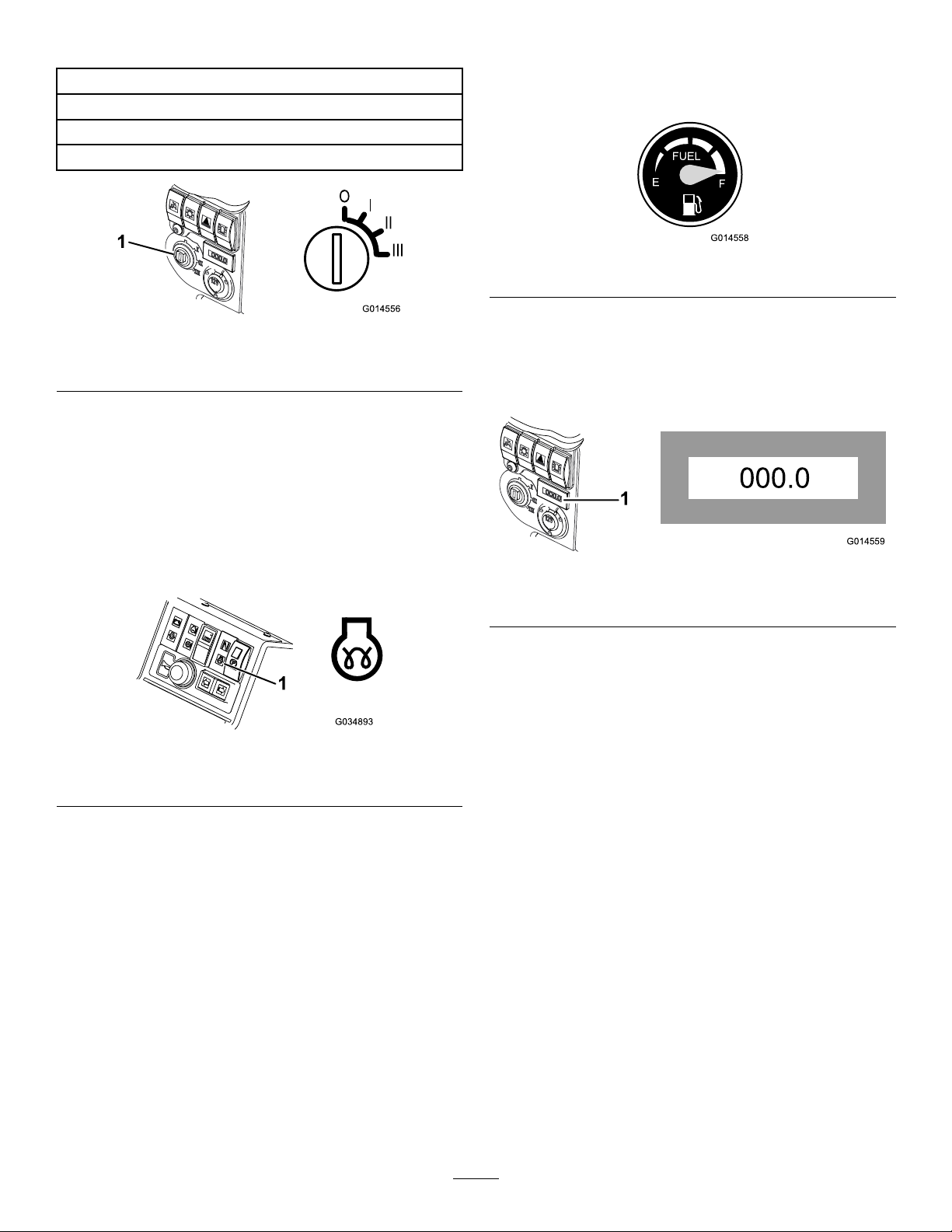

KeySwitch

FuelGauge

0=Engineoff

I=Enginerun/Auxiliaryon

II=Enginepre-heat

III=Enginestart

Figure21

1.Keyswitch

EnginePre-HeatIndicatorLight

TurnthekeytopositionII.Theenginepreheat

indicatorlightwillilluminateandheattheglowplugs

(Figure22).

Thefuelgaugeshowstheamountoffuelinthetank

(Figure23).

g014558

Figure23

g014556

HourMeter

Thehourmetershowsthetotalhoursthatthemachine

hasbeenoperated(Figure24).

Important:Attemptingtostartacoldengine

beforethepre-heatisusedcancauseunnecessary

weartothebattery.

Figure22

1.Enginepre-heatindicatorlight

g014559

Figure24

1.Hourmeter

Transmission-Neutral-Indicator

Light

g034893

Thislightilluminateswhenthetravel-controlpedalis

intheNEUTRALpositionandtheignitionkeyisturned

topositionI(Figure25).

Note:Theparkingbrakemustbeengagedforthe

transmissionneutralindicatorlighttoilluminate.

17

Page 18

Cutting-Unit-Drive-Switch-Indicator

Light

Thislightilluminateswhenthecuttingunitdriveswitch

isOnandtheignitionkeyisturnedtopositionI(Figure

26).

Figure25

1.Transmission-neutral-indicatorlight

g034894

Toengagethecuttingunitdrive,refertoEngagingthe

CuttingUnitDrive(page27).

g034895

Figure26

1.Cutting-unit-drive-switch-indicatorlight

18

Page 19

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Specication

TransportWidth

Widthofcut76cm(30inches)to212cm(83.5inches)

Heightofcut20mm(3/4inch)to75mm(3inches)

Length

Height

Weight

Engine

Fueltankcapacity

Transportspeed

Mowingspeed

Kubota32.8kw(44hp)at3000rpmDIN70020

302.5cm(1 19.1inches)

216cm(85.0inches)withROPS

209cm(82.3inches)withcab

1392kg(3069lb)withROPS

1592kg(3510lb)withcab

LT -F3000

157.5cm(62inches)

45L(1 1.9USgallons)

25km/h(15.5mph)

11km/h(6.85mph)

Hydraulicsystemcapacity

Enginespeed3000rpm

Rotorspeed3000rpm

32L(8.5USgallons)

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.Toro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

19

Page 20

Operation

PerformingDaily

Maintenance

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Shutofftheengine,removethekey,andwait

forallmovementtostopbeforeyouleavethe

operator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

ServiceInterval:Beforeeachuseordaily

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedinMaintenance

(page32).

FillingtheFuelTank

FuelTankCapacity

45L(11.9USgallons)

FuelSpecication

Failuretoobservethefollowingcautionsmaydamage

theengine.

•Neverusekeroseneorgasolineinsteadofdiesel

fuel.

•Nevermixkeroseneorusedengineoilwiththe

dieselfuel.

•Neverkeepfuelincontainerswithzincplatingon

theinside.

•Donotusefueladditives.

•Beforemowing,alwaysinspectthemachineto

ensurethatthecuttingunitsareingoodworking

condition.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

PetroleumDiesel

Useonlyclean,freshdieselfuelorbiodieselfuelswith

low(<500ppm)orultra-low(<15ppm)sulfurcontent.

Theminimumcetaneratingshouldbe40.Purchase

fuelinquantitiesthatcanbeusedwithin180days

toensurefuelfreshness.

Usesummer-gradedieselfuel(Number2-D)at

temperaturesabove-7°C(20°F)andwinter-grade

dieselfuel(Number1-DorNumber1-D/2-Dblend)

below-7°C(20°F).Usingwinter-gradefuelatlower

temperaturesprovidesalowerashpointand

cold-owcharacteristics,whichwilleasestartingand

reducefuel-lterplugging.

Usingsummer-gradefuelabove-7°C(20°F)will

contributetowardlongerfuel-pumplifeandincreased

powercomparedtowinter-gradefuel.

AddingFuel

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,engagetheparkingbrake,shutoff

theengine,andremovethekey.

2.Usingacleanrag,cleantheareaaroundthe

fuel-tankcap.

3.Removethecapfromthefueltank.

4.Fillthetankuntilthelevelistothebottomofthe

llerneckwithfuel.

20

Page 21

5.Installfuel-tankcaptightlyafterllingtank.

–Parkthemachineonalevelsurface.

Note:Ifpossible,llthefueltankaftereachuse.

Thisminimizespossiblebuildupofcondensation

insidethefueltank.

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;longtrousers;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Beforeyoustarttheengine,ensurethatalldrives

areinneutral,theparkingbrakeisengaged,and

youareintheoperatingposition.

•Donotcarrypassengersonthemachineandkeep

bystandersandchildrenoutoftheoperatingarea.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Avoidmowingonwetgrass.Reducedtraction

couldcausethemachinetoslide.

•Keepyourhandsandfeetawayfromthecutting

units.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Stopthecuttingunitswheneveryouarenot

mowing.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Operatetheengineonlyinwell-ventilatedareas.

Exhaustgasescontaincarbonmonoxide,which

islethalifinhaled.

•Donotleavearunningmachineunattended.

•Beforeyouleavetheoperator’sposition,dothe

following:

–Disengagethecuttingunit(s)andlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey .

–Waitforallmovementtostop.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflightning.

RolloverProtectionSystem

(ROPS)Safety

•DonotremoveanyoftheROPScomponentsfrom

themachine.

•Ensurethattheseatbeltisattachedandthatyou

canreleaseitquicklyinanemergency.

•Alwayswearyourseatbelt.

•Checkcarefullyforoverheadobstructionsanddo

notcontactthem.

•KeeptheROPSinsafeoperatingconditionby

thoroughlyinspectingitperiodicallyfordamage

andkeepingallthemountingfastenerstight.

•ReplacealldamagedROPScomponents.Donot

repairoralterthem.

MachineswithaFoldableRollBar

•Alwaysusetheseatbeltwiththerollbarinthe

raisedposition.

•TheROPSisanintegralsafetydevice.Keepa

foldingrollbarintheraisedandlockedposition,

andusetheseatbeltwhenoperatingthemachine

withtherollbarintheraisedposition.

•Lowerafoldingrollbartemporarilyonlywhen

necessary.Donotweartheseatbeltwhenthe

rollbarisfoldeddown.

•Beawarethatthereisnorolloverprotectionwhen

afoldedrollbarisinthedownposition.

•Checktheareathatyouwillbemowingandnever

folddownafoldingrollbarinareaswherethere

areslopes,drop-offs,orwater.

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Y ouareresponsibleforsafeslope

operation.Operatingthemachineonanyslope

requiresextracaution.

•Evaluatethesiteconditionstodetermineifthe

slopeissafeformachineoperation,including

21

Page 22

surveyingthesite.Alwaysusecommonsense

andgoodjudgmentwhenperformingthissurvey .

•Reviewtheslopeinstructions,listedbelow,for

operatingthemachineonslopes.Beforeyou

operatethemachine,reviewthesiteconditionsto

determinewhetheryoucanoperatethemachine

intheconditionsonthatdayandatthatsite.

Changesintheterraincanresultinachangein

slopeoperationforthemachine.

–Avoidstarting,stopping,orturningthemachine

onslopes.Avoidmakingsuddenchangesin

speedordirection.Maketurnsslowlyand

gradually.

–Donotoperateamachineunderanyconditions

wheretraction,steering,orstabilityisin

question.

–Removeormarkobstructionssuchasditches,

holes,ruts,bumps,rocks,orotherhidden

hazards.T allgrasscanhideobstructions.

Uneventerraincouldoverturnthemachine.

–Beawarethatoperatingthemachineonwet

grass,acrossslopes,ordownhillmaycause

themachinetolosetraction.

ReleasingthePlatform

1.Movethelockinglatchhandletowardsthefront

ofthemoweruntilthelatchhooksclearthe

lockingbar.

2.Raisetheplatform.Thegasspringwillprovide

assistance.

SecuringthePlatform

1.Lowertheplatformcarefully .

Note:Thegasspringwillprovideassistance.

2.Movethelockinglatchhandletowardsthefront

ofthemowerastheplatformnearsthefully

loweredposition.

Note:Thiswillensurethatthelatchhooksclear

thelockingbar.

3.Fullylowertheplatformandmovethelocking

handletowardstherearofthemoweruntilthe

latchhooksfullyengagethelockingbar.

–Useextremecautionwhenoperating

themachineneardrop-offs,ditches,

embankments,waterhazards,orother

hazards.Themachinecouldsuddenlyrollover

ifawheelgoesovertheedgeortheedge

cavesin.Establishasafetyareabetweenthe

machineandanyhazard.

–Identifyhazardsatthebaseoftheslope.

Iftherearehazards,mowtheslopewitha

pedestrian-controlledmachine.

–Ifpossible,keepthecuttingunitsloweredto

thegroundwhileoperatingonslopes.Raising

thecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

UsingtheOperatorPlatform

LatchingMechanism

Donotoperatethemowerwithoutrstcheckingthat

theoperatorplatformlatchingmechanismisfully

engagedandingoodworkingorder.

g014422

Figure27

Understandingthe

OperatorPresence

Controls

WARNING

Neveroperatethemowerwithoutrst

checkingthattheoperatorplatformlatching

mechanismisfullyengagedandingood

workingorder.

Note:Theenginestopsiftheoperatorleavesthe

seatwithoutengagingtheparkingbrake.

EngineStartLockout:Theenginecanonlybe

startedwhentheforward/reversetravelpedalisinthe

Neutralposition,thecuttingunitdriveswitchisin

theOffpositionandtheparkingbrakeisengaged.

Whenthesecircumstancesaresatised,switchesare

activatedpermittingtheenginetobestarted.

22

Page 23

EngineRunInterlock:Oncetheengineisstarted

theoperatormustbeseatedbeforetheparkingbrake

isdisengagedfortheenginetocontinuetorun.

CuttingUnitDriveLockout:Thedrivetothecutting

unitsisonlypossiblewhentheoperatorisseated.If

theoperatorraisesofftheseatforaperiodofmore

thanonesecond,aswitchisactivatedandthedrive

tothecuttingunitsisautomaticallydisengaged.To

engagethedrivetothecuttingunits,theoperator

mustreturntotheseat,thenoperatethecuttingunit

driveswitchtotheOffpositionbeforemovingitback

totheOnposition.Iftheoperatorrisesofftheseat

forabriefmomentduringnormalwork,drivetothe

cuttingunitsisnotaffected.

Theenginecanonlybestartedwiththecuttingunit

driveswitchintheOffposition.

WARNING

Donotoperatetheturfmoweriftheoperator

presencecontrolsaremalfunctioninginany

way.Alwaysreplacedamagedorwornparts

andcheckthattheyfunctioncorrectlybefore

operatingthemachine.

CAUTION

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

WARNING

Thereisnorolloverprotectionwhentheroll

barisinthedownposition.

•Donotoperatethemachineonuneven

groundoronahillsidewiththerollbarin

thedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbar

isinthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearance

permits.

•Checkcarefullyforoverheadclearances

(i.e.,branches,doorways,electricalwires)

beforedrivingunderanyobjectsanddo

notcontactthem.

Important:Alwaysusetheseatbeltwhenthe

rollbarisintheraisedandlockedposition.Do

notusetheseatbeltwhentherollbarisinthe

loweredposition.

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,engagetheparkingbrake,shutoff

theengine,andremovethekey.

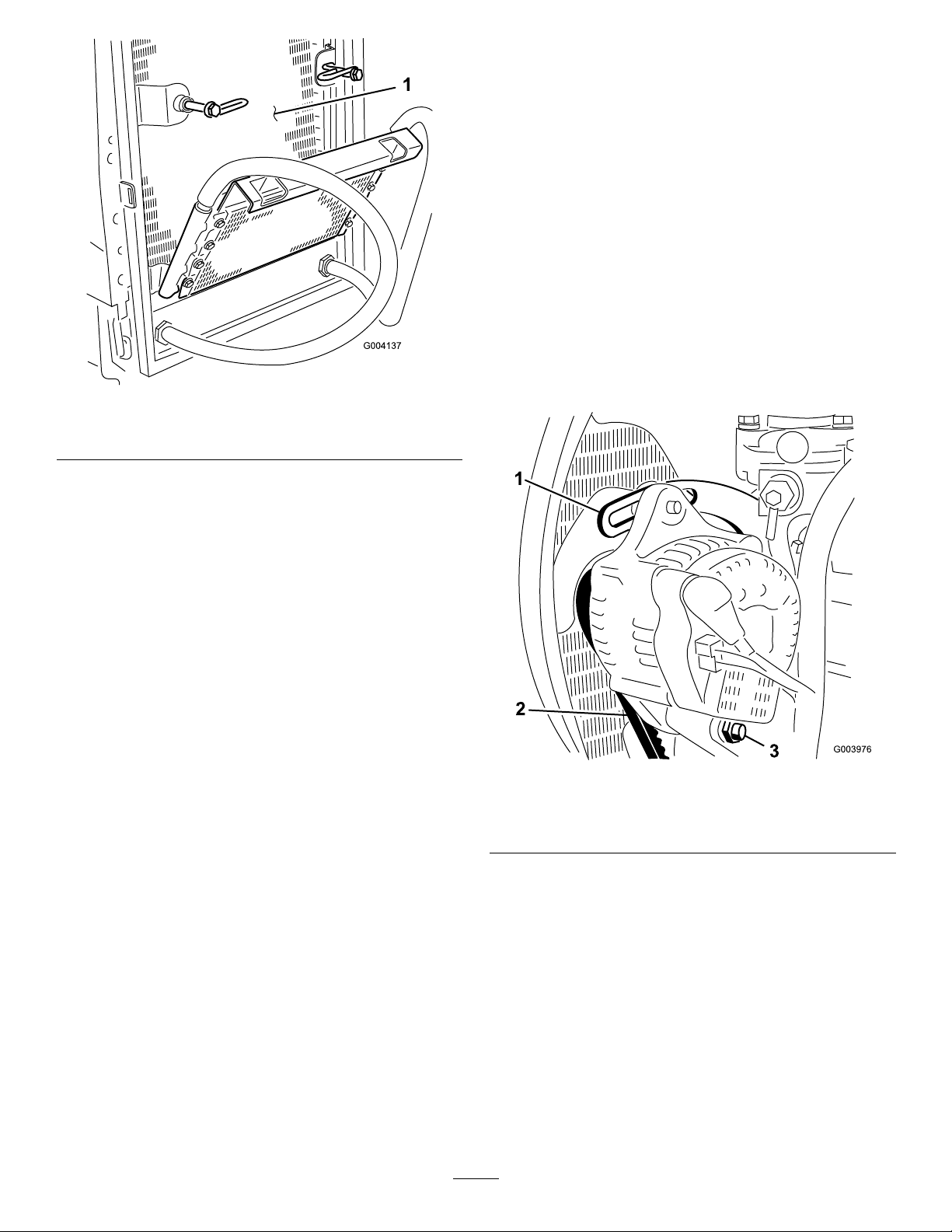

2.Supporttheweightoftheupperframeoftheroll

barwhileremovingthesnappinsandclevispins

fromthepivotbrackets(Figure28).

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

FoldingtheRollBar

WARNING

Toavoidinjuryordeathfromrollover:keep

therollbarintheraisedlockedpositionand

usetheseatbelt.

Ensurethattheseatissecuredwiththeseat

latch.

Figure28

1.Upperframeinraised

position

2.Clevispinsandsnappins4.Upperframeinlowered

3.Lowerholes

position

g280225

23

Page 24

3.Carefullylowertheframedownwarduntilitrests

onthestops.

4.Inserttheclevispinsinthelowerholesand

securethemwiththesnappinstosupportthe

upperframeinitsloweredposition.

5.Toraisetheframe,followtheseinstructionsin

reverseorder.

CheckingtheInterlock

4.Disengagetheparkingbrake.Theindicatorlight

shouldgooutandtheengineshouldnotstart

whentheignitionkeyisturned.

5.Engagetheparkingbrake,sitontheoperator

seat,andstarttheengine.

6.Disengagetheparkingbrake.

7.Risefromtheoperatorseatandcheckthatthe

engineshutsoff.

Switches

CheckingtheForward/Reverse

TravelPedalAction

Withtheengineshutoff,operatetheforwardand

reversetravelpedalsthroughthefullrangeof

articulationandensurethatthemechanismreturns

freelytotheneutralposition.

CheckingtheOperatorPresence

SeatSwitch

ServiceInterval:Beforeeachuseordaily

1.Sitontheoperatorseatandstarttheengine.

2.Lowerthecuttingunitstotheground.

3.Engagethatthecuttingunitdriveintheforward

direction.

4.Risefromtheoperatorseatandcheckthatthe

cuttingunitscometoastopafteraninitial0.5

to1seconddelay.

CheckingtheCuttingUnitDrive

InterlockSwitch

1.Shutofftheengine.

2.Operatethecuttingunitdriveswitchtotheoff

positionandturntheignitionkeytoposition

I.Thecuttingunitdriveswitchindicatorlight

shouldnotilluminate.

3.Operatetheswitchtotheforwardposition.The

indicatorlightshouldilluminateandtheengine

shouldnotstartwhentheignitionkeyisturned.

Repeatforthereverseposition.

CheckingtheParkingBrake

InterlockSwitch

1.Shutofftheengine.

2.Engagetheparkingbrake.

3.TurntheignitionkeytopositionI.Theparking

brakeindicatorlightshouldilluminate.

CheckingtheTransmission

NeutralInterlockSwitch

1.Shutofftheengine.

2.Removeyourfootfromtheforward/reverse

travelpedals.

3.TurntheignitionkeytopositionIandthe

transmissionneutralindicatorlightshould

illuminate.

4.Applylightpressuretothetravelpedalsina

forwardandreversedirectiontocheckthatthe

indicatorlightturnsoff.

Note:Takeextremecaretoensurethatthearea

aroundthemachineisclearbeforecheckingthatthe

enginewillnotstartunderthiscondition.

StartingtheEngine

Important:Youmustbleedthefuelsystembefore

startingtheengineifyouarestartingtheengine

forthersttime,theenginehasstoppeddueto

lackoffuel,oryouhaveperformedmaintenance

onthefuelsystem;refertoBleedingtheFuel

System(page39).

Important:Thismachineisttedwithanengine

startlockout;refertoUnderstandingtheOperator

PresenceControls(page22).

1.Sitontheseat,keepyourfootoffthetraction

pedalssothatitisinNEUTRAL,ensurethat

thecuttingunitdriveswitchisoff,engagethe

parkingbrake,andsetthethrottletothe70

percentfull-throttleposition.

2.TurnthekeytotheonpositionIandcheck

thattheengineoilpressureandbatterycharge

warninglightsilluminate.

3.Iftheengineiscold,turnthekeytothepreheat

positionIIsothatthepre-heatindicatorlightis

on(Figure22).Holditfor5secondstoheatthe

glowplugs.

4.Afterpreheatingtheglowplugsoriftheengine

isalreadywarm,turnthekeytothestartposition

IIIandholdittheretocranktheengine.

24

Page 25

Cranktheenginefornolongerthan15seconds.

ReleasethekeybacktopositionIwhenthe

enginestarts.

5.Runtheengineatlowidlespeeduntilitwarms

up.

Important:Whentheengineisoperatingall

warninglightsshouldbeoff.Ifawarninglight

illuminates,shutofftheengineimmediatelyand

xtheissuebeforestartingtheengine.

ShuttingOfftheEngine

WARNING

Keephandsclearofmovingobjectsandhot

enginepartswhiletheengineisrunning.

1.MoveallcontrolstoNEUTRAL,engagethe

parkingbrake,movethethrottletothelowidle

positionandallowtheenginetoreachlowidle

speed.

minimumpowerconsumption,andagoodqualityof

cut.

Theailheadisanecutailandshouldonlybe

usedformaintaininggrass.Itsrecommendedthata

maximumof1/3ofthetotalgrasslengthisremoved

whencut.

Thescraperwiresarettedtoremovedebrisfrom

theroller,indryconditionsthesemaynotberequired

anditsrecommendedtheyareremoved.Indamp

wetconditionsensurethatscraperwiresdonotget

pluggedwithdebris.

Thecuttingunitoatsandcanpivotlaterallytofollow

groundcontours.

Thecuttingunitsaredesignedtobeoperatedat

fullenginerpm.Forwardspeedshouldbeadjusted

dependingongrassconditionsandtonotoverload

thepowerunitsortheheads.Thelowertheforward

speedthehigherthequalityofcutandaftercut

appearance.

Important:Allowtheenginetoidlefor5

minutesbeforeshuttingitoffafterafull

loadoperation.Failuretodosomayleadto

troubleonaturbo-chargedengine.

2.Lettheengineidlefor5minutes.

3.Turnthekeytoposition0.

Iftheenginefailstoshutoffwhenthekeyis

turnedto0,operatetheengineshutoffleverin

theforwarddirection(Figure29).

Figure29

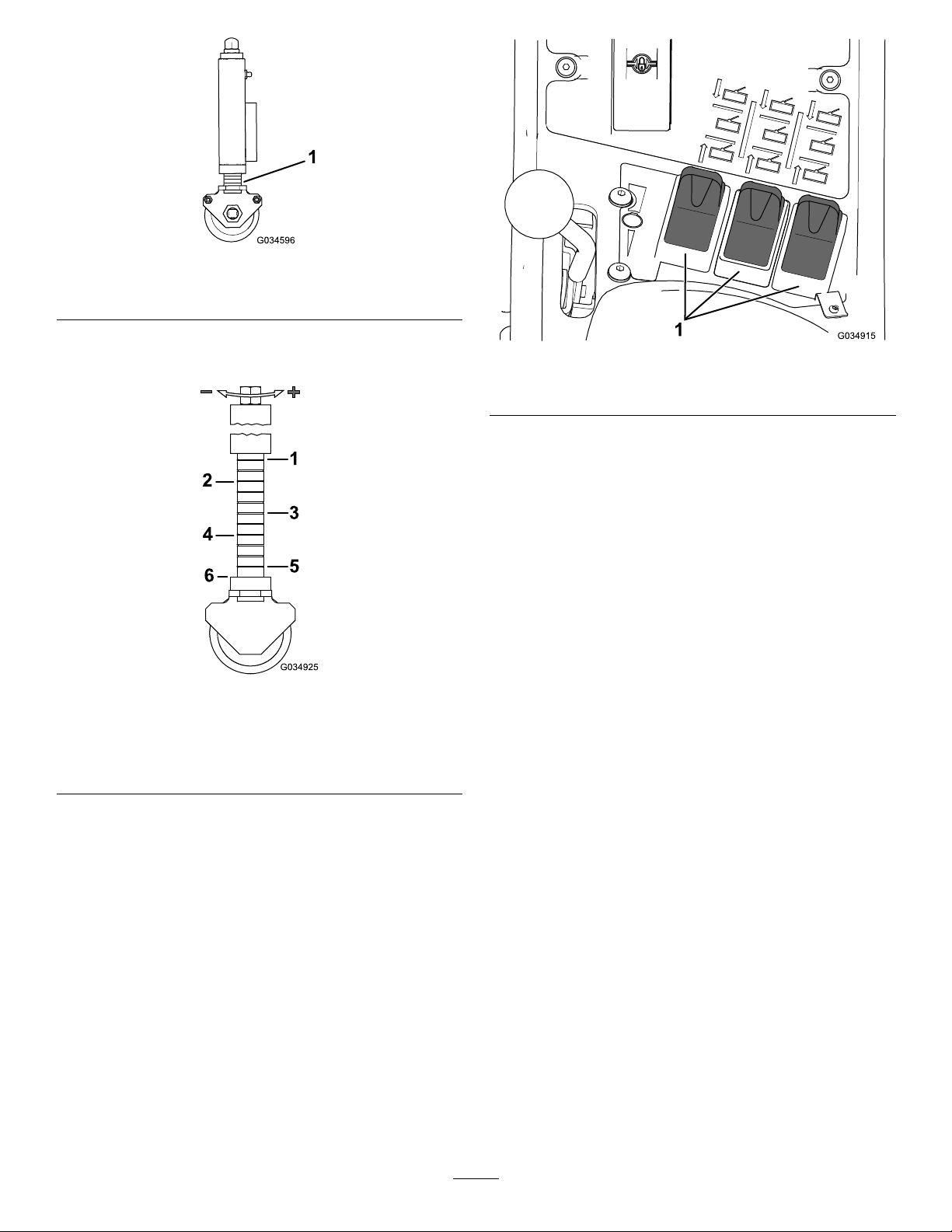

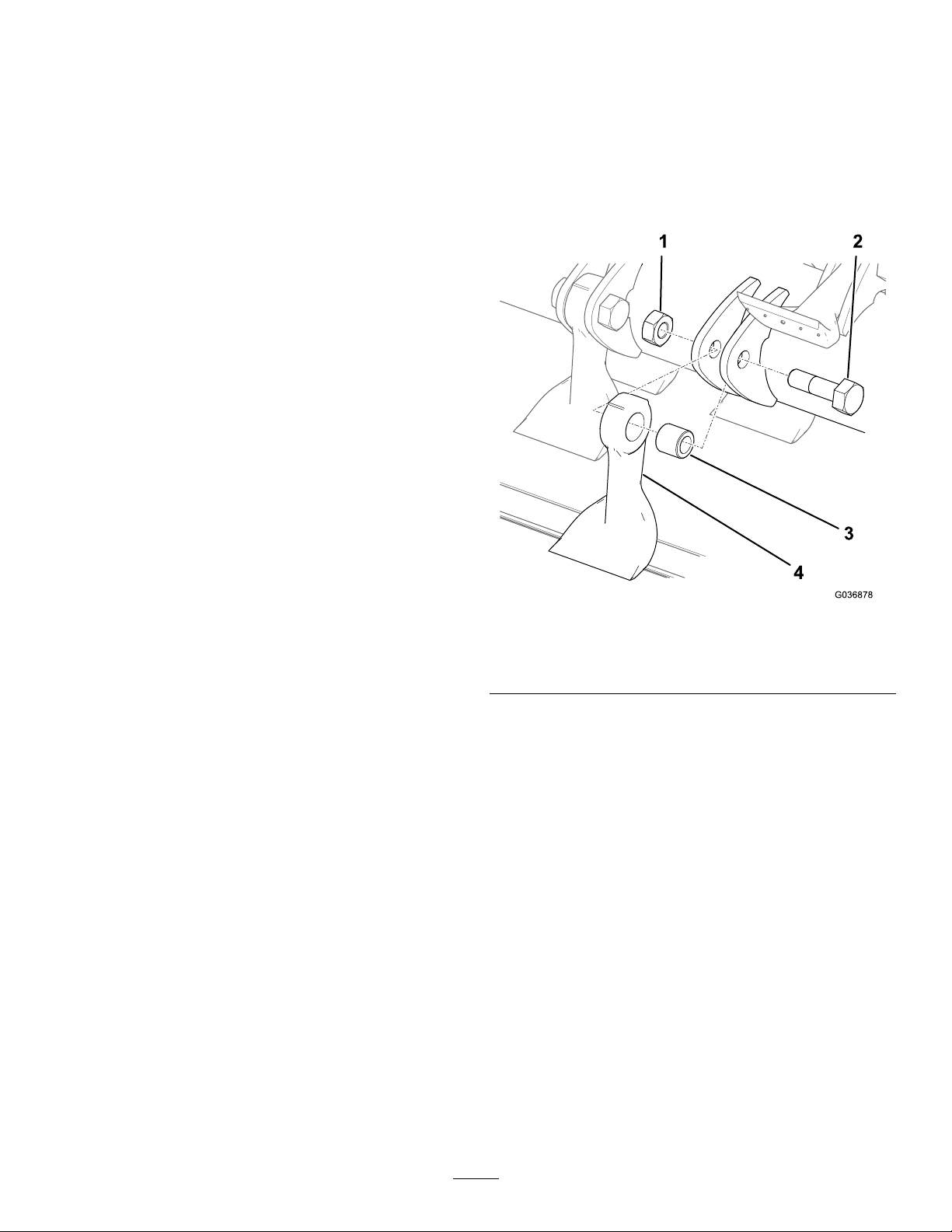

AdjustingtheHeightofCut

Note:Theheightofcutisgaugedbytherearroller.

Bladewear,worncuttingunitpivots,bent/damaged

cuttingunitpins,andbent/damagedarmscanaffect

theheight-of-cutsetting.

1.Turntheadjusting-nutassemblyonbothends

clockwisetodecreasetheheightofcutor

counter-clockwisetoincreasetheheightofcut

(Figure30).

g034595

g014563

1.Heightofcut

Figure30

2.Adjusting-nutassembly

FlailCuttingUnitGeneral

Information

Itisimportanttokeeptheailbladessharpandin

goodconditiontoensuregoodcuttingperformance,

Important:Donotattempttounlockthenut

assemblies.

2.Ensurethatallcuttingunitsaresetatthesame

heightofcutbyreferringtotheindicatorrings

(Figure31).

25

Page 26

1.Indicatorrings

g034596

Figure31

Note:RefertoFigure32fortheheight-of-cut

settings.

Figure32

1.75mm(3.0inches)4.40mm(1.5inches)

2.65mm(2.5inches)5.25mm(1.0inches)

3.50mm(2.0inches)6.20mm(0.75inches)

g034915

Figure33

1.Lift-controlswitches

2.Toraisethecuttingunits,operatethelift-control

switchesinanupwarddirectionandholdin

position3.Ifthecutting-unit-driveswitchisin

theONpositiontheailrotordrivedisengages.

3.Releasethelift-controlswitcheswhenthecutting

unitsareattherequiredheight.

Note:Thecontrolswitchesautomatically

returntoposition2(NEUTRAL)andthearmsare

hydraulicallylockedintoposition.

Toraisethecuttingunitstothelimitedlift

position:momentarilyoperatetheswitchesinan

g034925

upwarddirection.

Theailrotordrivedisengagesimmediatelyandthe

cuttingunitsstopraising,approximately150mm(6

inches)abovegroundlevel.

Thisoperateswiththecuttingunitsloweredand

rotating.

ControllingthePositionof

theIndividualCuttingUnits

Thecuttingunitsmayberaisedorlowered

independentlyusingthebankof3lift-controlswitches.

1.Tolowerthecuttingunits,operatethelift-control

switchesinadownwarddirectionandrelease.

Note:Thecutting-unit-driveswitchmustbeon

todothis,theailrotordriveengageswhen

thecuttingunitsareapproximately150mm(6

inches)abovegroundlevel.Thecuttingunits

arenowin‘oat’modeandfollowtheground

contours.

Autolimitedliftinreversecausesthecuttingunits

toriseautomaticallytothelimitedliftpositionwhen

reversing.Theyreturntotheoatingpositionwhen

returningtoforwardtravel.Theailrotorscontinueto

rotateduringthisoperation.

UsingtheCuttingUnit

Auto-LimitedLiftinReverse

Toactivate,presstheauto-limited-liftswitchtotheON

position(Figure34).

Todeactivate,presstheauto-limited-liftswitchtothe

OFFposition(Figure34).

Manuallimitedliftusingthe3lift-controlswitchesis

alwaysavailableregardlessofthepositionoftheauto

switch.

26

Page 27

thelift-controlswitch(s)inadownwarddirection.

Themachinedriveswhenthecuttingunitsare

approximately150mm(6inches)abovegroundlevel.

Using

Weight-Transfer/Traction

Assistance

Avariablehydraulicweighttransfersystemisprovided

forimprovingtiregripwiththegrasssurface—traction

assistance.

Hydraulicpressureinthecuttingunitsliftsystem

providesaliftingforcewhichreducestheweightofthe

cuttingunitsonthegroundandtransferstheweight

asadownwardforceontothetiresofthemachine.

Thisactionisknownasweighttransfer.

Toengageweighttransfer:Theamountofweight

transfercanbevariedtosuitoperatingconditionsby

rotatingtheweight-transferhandwheel(Figure36)

asfollows:

Figure34

EngagingtheCuttingUnit

Drive

Figure35

1.On2.Off

1.Releasethevalvelocknut1/2turn

counterclockwiseandhold(Figure36).

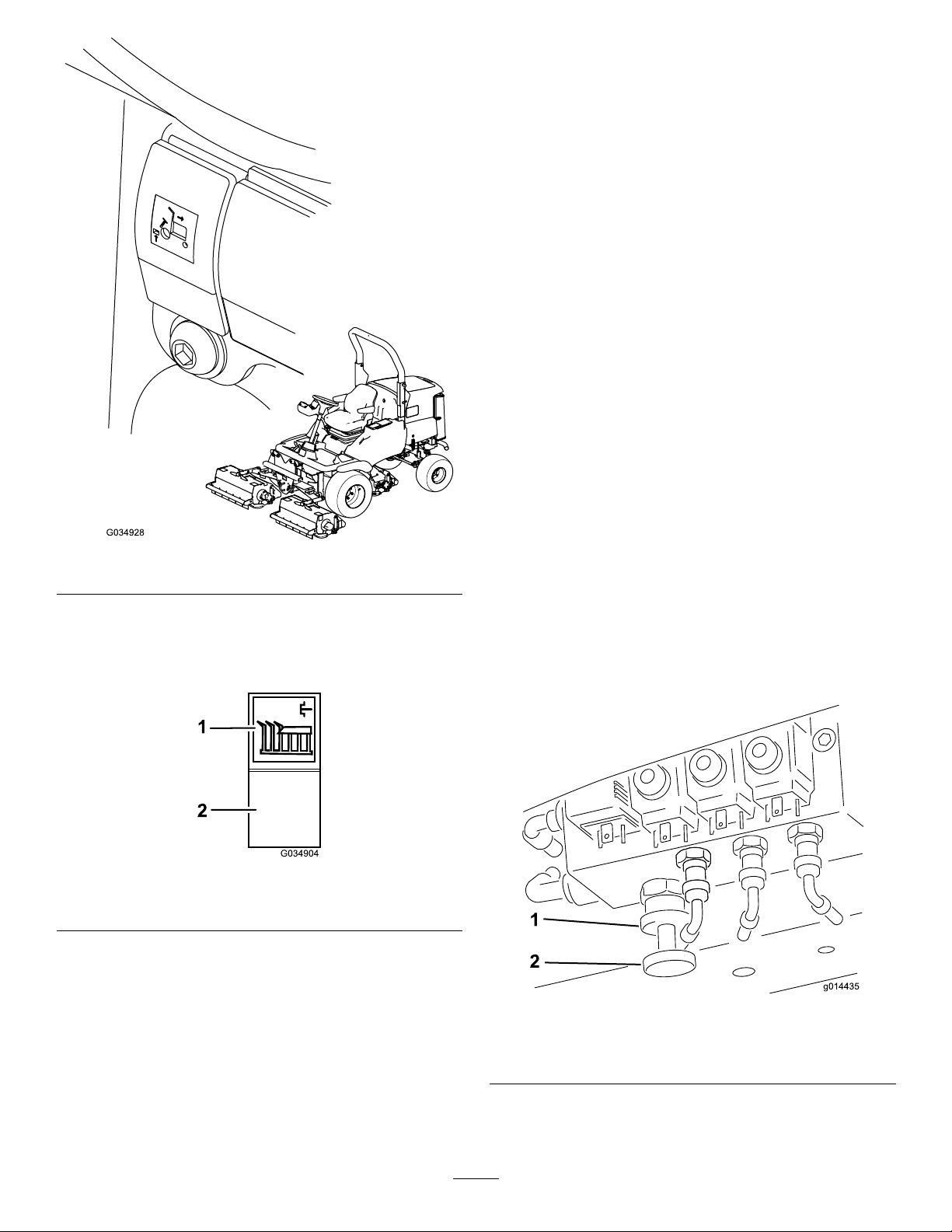

g034928

2.Rotatethevalvehandwheel(Figure36)

counterclockwisetoreduceweighttransferor

clockwisetoincreaseweighttransfer.

3.Tightenthenut.

Note:Therecommendedsettingistoincrease

weighttransferuntilheadsstarttolift,thenbackoff

1/2turn,andlock.

g034904

Thecuttingunitdrivecanbeengagedonlywhenthe

operatorisseatedcorrectly,refertoCheckingthe

Operator-Presence-SeatSwitch(page46).

Cuttingunitdriveengagement:Pressthetopofthe

cutting-unit-driveswitchtotheonposition(Figure35).

Allcuttingunitdrivesdisengagement:Setthe

switchtotheoffposition(Figure35).

Tolowerthecuttingunits:Thecuttingunitdrive

switchmustbesettotheonposition.Operate

g014435

Figure36

1.Lockwheel

27

2.Weight-transferhand

wheel

Page 28

OperatingTips

drivingbetweenobjectssothatyoudonotaccidentally

damagethemachineorthecuttingunits.

BecomingFamiliarwiththe

Machine

Beforemowinggrass,practiceoperatingthemachine

inanopenarea.Startandshutofftheengine.

Operateinforwardandreverse.Lowerandraise

thecuttingunitsandengageanddisengagethe

cuttingunits.Whenyoufeelfamiliarwiththemachine,

practiceoperatingupanddownslopesatdifferent

speeds.

UnderstandingtheWarning

System

Ifawarninglightcomesonduringoperation,stopthe

machineimmediatelyandcorrecttheproblembefore

continuingoperation.Seriousdamagecouldoccurif

youoperatethemachinewithamalfunction.

MowingGrass

Therotationalspeedoftheailrotorsshouldalways

bekeptashighaspossibleinordertomaintainthe

highestqualityofcut.Thisinturnrequiresthatthe

enginespeedbekeptashighaspossible.

Cuttingperformanceisbestwhencuttingagainstthe

lieofthegrass.Inordertotakeadvantageofthisfact,

theoperatorshouldattempttoalternatethedirection

ofmowingbetweencuts.

Takecarenottoleaveuncutstripsofgrassatthe

overlappointsbetweenadjacentcuttingunitsby

avoidingtightturns.

WARNING

Takecarewhentravellingoverobstacles

suchasroadsidecurbsassuchobstacles

mayallowthemachinetorolloverwhichmay

causesevereinjury.

Alwaystravelatslowspeedoverobstacles

topreventdamagetothetires,wheels,and

steeringsystem.Ensurethatthetiresare

inatedtotherecommendedpressures.

OperatingtheMachineonSlopes

Useextracarewhenoperatingthemachineonslopes.

Driveslowlyandavoidsharpturnsonslopesto

preventrollovers.Lowerthecuttingunitsforsteering

controlwhengoingdownhill.

UsingtheRearRollerScrapers

Itisgenerallywisetoremoverearrollerscrapers

whereconditionsallow,asoptimumgrassdischarge

isachievedwithoutthem.Installthescraperswhen

conditionsaresuchthatmudandgrassstartto

buildupontherollers.Wheninstallingthescraper

wires,ensurethattheyarecorrectlytensioned.

AfterOperation

AfterOperationSafety

MaximizingtheQualityofCut

Thequalityofcutdeterioratesiftheforwardspeed

isexcessive.Alwaysbalancethequalityofcutwith

theworkraterequiredandsettheforwardspeed

accordingly.

MaximizingEngineEfciency

Donotlettheenginelabor.Ifyounoticethatthe

enginestartstolabor,reducetheforwardspeedor

increasetheheightofcut.Checktomakesurethat

theailbladesaresharp.

DrivingtheMachineinTransport

Mode

Alwaysdisengagethecuttingunitdrivewhen

travellingacrossun-grassedareas.Becarefulwhen

GeneralSafety

•Shutofftheengine,removethekey,andwait

forallmovementtostopbeforeyouleavethe

operator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

•Cleangrassanddebrisfromthecuttingunits,

drives,mufers,coolingscreens,andengine

compartmenttohelppreventres.Cleanupoilor

fuelspills.

•Shutoffthefuelwhilestoringorhaulingthe

machine.

•Disengagethedrivetotheattachmentwhenever

youarehaulingornotusingthemachine.

•Maintainandcleantheseatbelt(s)asnecessary.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

28

Page 29

IdentifyingtheTie-Down

Points

Figure37

g014447

Figure38

1.Frontleftliftingpoint3.Rearliftingpoint

g282342

2.Frontrightliftingpoint

1.Fronttie-downpoint2.Reartie-downpoint

HaulingtheMachine

•Usefull-widthrampsforloadingthemachineonto

atrailerortruck.

•Tiethemachinedownsecurely.

LocatingtheJackingPoints

Note:Usejackstandstosupportthemachinewhen

required.

WARNING

Mechanicalorhydraulicjacksmayfailto

supportthemachineandcauseseriousinjury.

Usejackstandswhensupportingthe

machine.

TowingtheMachine

Ensurethatthetowingvehiclespecicationissuited

tobrakingthecombinedvehicleweightandableto

remainincompletecontrolatalltimes.Ensurethat

theparkingbrakeofthetowingvehicleisengaged.

Chockthefrontwheelsofthemachinetopreventthe

machinefromrollingaway.

Important:Donottowthemachinefasterthan

3to5km/h(2to3mph),otherwiseinternal

transmissiondamagemayoccur.

Decommissionthefrontwheelmotordiscbrakes

asfollows:

1.Connectarigidtowbarbetweenthetowingeye

onthefrontofthemowerandasuitabletowing

vehicle.

2.Identifytherightfrontwheelmotordiscbrake

assemblyandremovethehexplug(Figure39).

•Front—underthefrontarmmount

•Rear—axletubeontherearaxle

29

Page 30

Figure39

1.Hexplug

3.LocatetheM12x40mmsetscrewandwasher

storedunderneaththeoperatorplatform,onein

eachoftheplatformsupportrails.

4.InstallaM12x40mmlongsetscrewwithwasher

intotheholeinthecenterofthemotorendplate

(Figure40).

heavyasthereisnohydraulicassistancewhen

theengineisshutoff.

g014448

g014450

Figure41

Figure40

1.Hexplug

2.WasherM12

3.SetscrewM12x40

5.Tightenthesetscrewintothethreadedhole

inthebrakepistonuntilthebrakeisreleased

(Figure40).

6.Identifytheleftfrontwheelmotordiscbrake

assemblyandrepeatthepreviousprocedure

(Figure40).

7.Decommissionthehydraulicservicebraking

systembyturningthebypassvalve,located

underthetransmissionpump,counterclockwise,

amaximumof3turns(Figure41).

1.Transmissionbypassvalves

8.Themowerisnowinafreewheelconditionand

canbetowedforashortdistanceatslowspeed.

Note:Removethewheelchocksbeforetowing.

9.Aftertowingthemower:T oreturnthemower

toitsnormalworkingconditionthefollowing

proceduremustbedone:

A.Chockthefrontwheels.

g014449

B.Closethebypassvalveonthetransmission

pumpbyturningitclockwise.

10.Commissionthefrontwheelmotordisc

brakesasfollows:

Note:EnsurethattheM12x40mm

setscrewsandwashersareremovedandstored

underneaththeoperatorplatform.

A.Identifytherightfrontwheelmotordisc

brakeassembly.

B.Rotatethesetscrewcounterclockwiseand

removetogetherwiththewasher.

C.Assemblethehexplugintothemotorend

plate(Figure42).

Thesteeringmustbeoperatedmanuallywhen

themowerisbeingtowed.Thesteeringwillfeel

30

Page 31

Figure42

1.Frontwheelmoto3.WasherM12

2.Hexplug

4.SetscrewM12x40mm

D.Identifytheleftfrontwheelmotordisc

brakeassemblyandrepeattheprevious

procedure.

E.Removethewheelchocks.

F.Disconnectthetowbar.

Note:Themowerbrakingsystemwillnow

operateinthenormalway.

WARNING

Beforeusingthemower,ensurethatthe

brakingsystemoperatescorrectly.Carryout

initialcheckswiththemoweratslowspeed.

Donotoperatethemowerwithadamaged

brakingsystem.Donotoperatethemower

withthebrakesdecommissioned.

g014451

31

Page 32

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

MaintenanceSafety

•Beforeyouleavetheoperator’sposition,dothe

following:

–Parkthemachineonalevelsurface.

–Disengagethecuttingunit(s)andlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey .

–Waitforallmovementtostop.

•Allowmachinecomponentstocoolbefore

performingmaintenance.

•Ifpossible,donotperformmaintenancewhilethe

engineisrunning.Keepawayfrommovingparts.

•Supportthemachinewithjackstandswhenever

youworkunderthemachine.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Keepallpartsofthemachineingoodworking

conditionandallhardwaretightened.

•Replaceallwornordamageddecals.

•Toensuresafe,optimalperformanceofthe

machine,useonlygenuineT ororeplacement

parts.Replacementpartsmadebyother

manufacturerscouldbedangerous,andsuchuse

couldvoidtheproductwarranty .

32

Page 33

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

MaintenanceProcedure

•Checktheconditionandtensionofthealternatorbelt.

•Changetheengineoilandlter.

•Changethetransmission-oillter.

•Changethehydraulic-returnlter.

•Checktheenginespeed(idleandfullthrottle).

•Checkthehorn.

•Inspecttheseatbelt(s)forwear,cuts,andotherdamage.Replacetheseatbelt(s)if

anycomponentdoesnotoperateproperly.

•Checkthesafetyinterlocksystem.

•Checkthetirepressure.

•Greasethebearings,bushings,andpivots(greasethemimmediatelyafterevery

washingregardlessoftheintervallisted).

•Checktheair-cleaner-blockageindicator(servicetheaircleanerearlierifthe

air-cleanerindicatorshowsred;serviceitmorefrequentlyinextremelydirtyor

dustyconditions).

•Checktheengine-oillevel.

•Drainwaterorothercontaminantsfromthewaterseparator.

•Checkthetorquethewheel-lugnuts.

•Removedebrisfromthescreen,oilcoolers,andradiator(morefrequentlyindirty

operatingconditions).

•Checkthesafety-interlocksystem.

•Checkthehydrauliclinesandhoses.

•Checkthehydraulic-uidlevel.

•Checktheheight-of-cutsetting.

•Inspecttheailrotorsandbladesfordamage,cracks,andloosefasteners.Replace

anydamagedorcrackedparts.

•Checktherearguard.

•Checkthefrontrubberguard.

•Checkthecuttingunitpivot.

•Checkforanyunusualvibrationoftherotor.

•Checkthefastenersofthemachine.

•Checkthecuttingunits.

•Checktheforward/reversetravelpedalaction.

Every50hours

Every100hours

Every150hours

Every250hours

Every400hours

•Greasethebearings,bushings,andpivots(greasethemimmediatelyafterevery

washingregardlessoftheintervallisted).

•Checkthebladebolts.

•Inspectthebladesfordamageandexcessivewear.

•Makesurethateachbladeboltistorquedto45N∙m(33.2ft-lb).

•Checkthecuttingunitpivot.

•Checkforexcessiveplayintherotorbearings.

•Checktherear-rolleradjustment.

•Checktherear-rollerscraperwiretension.

•Inspectthecoolingsystemhoses.

•Checktheconditionandtensionofthealternatorbelt.

•Changetheengineoilandlter.

•Checktheconditionofthebattery.

•Checktheconditionofandcleanthebattery.

•Checkthebatterycableconnections.

•Checkthetransmission-controlcable.

•Checkthefuellinesandconnections.

•Checktheenginespeed(idleandfullthrottle).

33

Page 34

MaintenanceService

Every500hours

Interval

MaintenanceProcedure

•Checktheengineoverheatwarningsystem.

•Replacetheprimaryairlter(morefrequentlyinextremedustyordirtyconditions).

•Replacethefuel-ltercanister.

•Checktheelectricalsystem.

•Changethetransmission-oillter.

•Changethehydraulic-returnlter.

•Checktherear-wheelalignment.

•Servicethehydraulicsystem.

•Checkthehydraulic-uid-overheatwarningsystem.

Every800hours

Beforestorage

Every2years

•Drainandcleanthefueltank.

•Adjusttheenginevalves(refertotheengineoperator’smanual).

•Drainandcleanthefueltank.

Yearly

•Replacetheblades.

•Flushandreplacethecoolingsystemuid.

•Replaceallmovinghoses.

•Replacethetransmissioncable.

34

Page 35

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof:

MaintenanceCheckItem

Checkthesafetyinterlockoperation.

Checkthebrakeoperation.

Checktheengineoilandfuellevel.

Checktheairlterrestrictionindicator.

Checktheradiatorandscreenfordebris.

Checkunusualenginenoises.

Checkunusualoperatingnoises.

Checkthehydraulicsystemoillevel.

Checkhydraulichosesfordamage.

Checkforuidleaks.

Checkthetyrepressure.

Checktheinstrumentoperation.

Checktherotorandblades.

Checktheheight-of-cutadjustment.

Checkallgreasettingsforlubrication.

Touch-updamagedpaint.

Washthemachine.

1.Checktheglowplugandinjectornozzlesifhardstarting,excesssmoke,orroughrunningisnoted.

1

2

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

2.Immediatelyaftereverywashing,regardlessoftheintervallisted

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

1

2

3

4

5

6

7

8

Important:Refertoyourengineoperator’smanualforadditionalmaintenanceprocedures.

Note:Downloadafreecopyoftheelectricalorhydraulicschematicbyvisitingwww.Toro.comandsearching

foryourmachinefromtheManualslinkonthehomepage.

Information

35

Page 36

Lubrication

bearingsandbushingsimmediatelyafterevery

washing,regardlessoftheintervallisted.

GreasingtheBearings,

Bushings,andPivots

ServiceInterval:Beforeeachuseordaily

Every50hours

Lubricateallgreasettingsforthebearingsand

bushingswithNo.2lithiumgrease.Lubricatethe

Replaceanydamagedgreasettings.

Important:Use1pumpofgreaseonthe

height-of-cutadjustersand3pumpsofgreaseon

allothergreasettings.

Thegreasettinglocationsandquantitiesareas

follows:

Figure43

1.–Greaseevery50hours2.–Greasedaily

EngineMaintenance

CheckingtheEngine

OverheatWarningSystem

EngineSafety

•Shutofftheenginebeforecheckingtheoilor

addingoiltothecrankcase.

•Donotchangethegovernorspeedoroverspeed

theengine.

ServiceInterval:Every500hours

36

g034909

Page 37

Figure45

g014565

Figure44

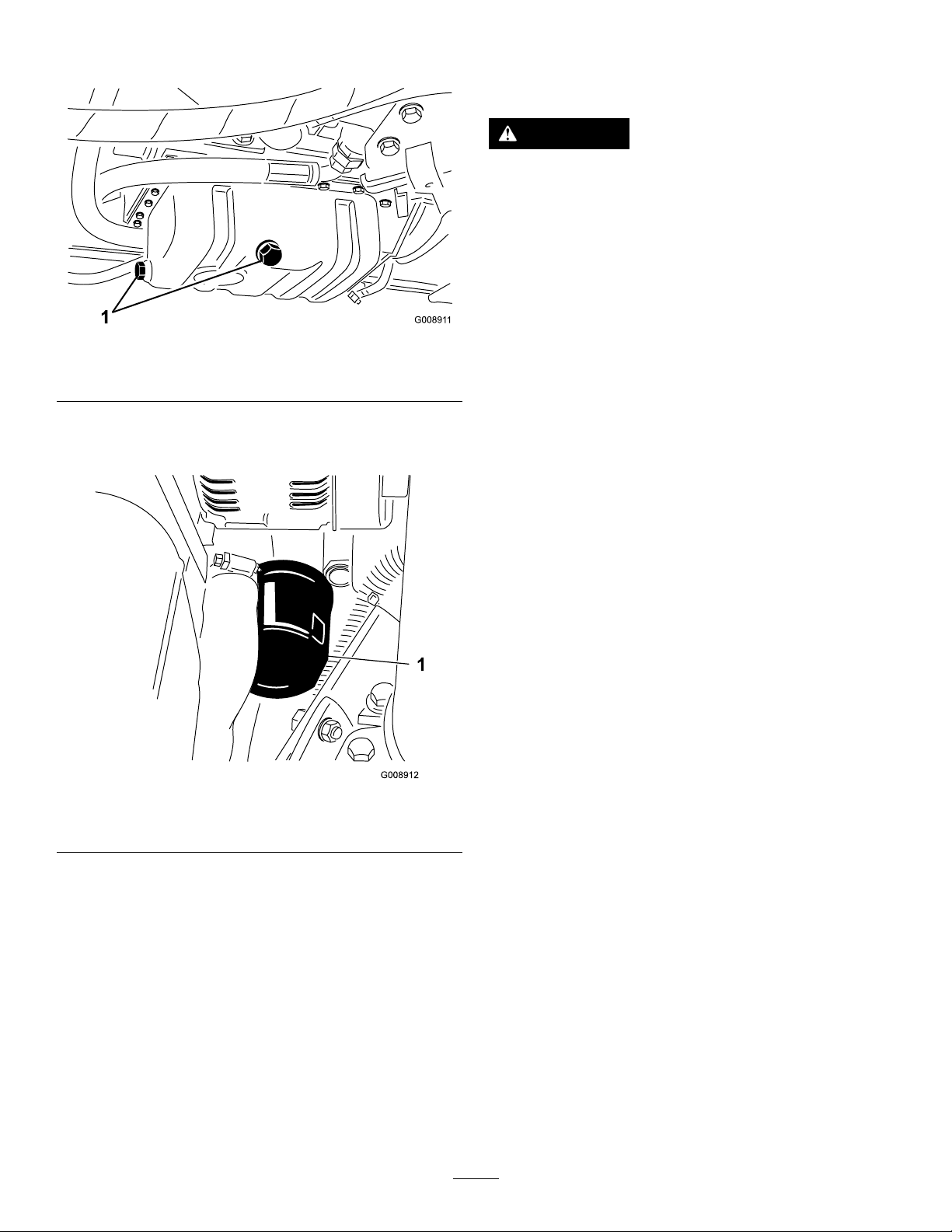

1.Temperatureswitch

1.TurntheignitionkeytotheignitiononpositionI.

2.Disconnectthered/bluewireterminalfromthe

engine-temperatureswitch.

3.Touchthemetalterminalofthiswireontoa

suitableearthpoint,ensuringthatthemetal

surfacesmakegoodcontact.

Thehornsoundsandthe

engine-coolant-temperature-warninglightilluminates

toconrmcorrectoperation.Ifthesystemis

malfunctioning,makerepairsbeforeoperatingthe

mower.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily

Every500hours

ServicingthePrimaryAirFilter

g014437

2.Beforeremovingthelter,uselowpressure

air(40psi,cleananddry)tohelpremove

largeaccumulationsofdebrispackedbetween

outsideofthelterandthecanister.Avoid

usinghigh-pressureairwhichcouldforce

dirtthroughthelterintotheintaketract.

Note:Thiscleaningprocesspreventsdebris

frommigratingintotheintakewhenthelteris

removed.

g022394

Figure46

1.Rubberoutletvalve

2.Removablecover

3.Airlter

Checktheair-cleanerbodyfordamagewhichcould

causeanairleak.Replaceifdamaged.Checkthe

wholeintakesystemforleaks,damageorloosehose

clamps.

Servicetheprimaryair-cleanerlteronlywhenthe

serviceindicator(Figure45)requiresit.Changing

theairlterbeforeitisnecessaryonlyincreasesthe

chanceofdirtenteringtheenginewhenthelteris

removed.

Important:Besurethatthecoverisseated

correctlyandsealswiththeair-cleanerbody.

1.Checkthelter-blockageindicator.Ifthe

indicatorisred,theairlterneedstobecleaned

orreplaced(Figure45).

3.Removethecoverfromtheair-cleanerbody .

4.Removeandreplacethelter(Figure46).

Cleaningoftheusedelementisnot

recommendedduetothepossibilityofdamage

totheltermedia.

5.Inspectthenewlterforshippingdamage,

checkingthesealingendofthelterandthe

body.Donotuseadamagedelement.

6.Insertthenewlterbyapplyingpressuretothe

outerrimoftheelementtoseatitinthecanister.

Donotapplypressuretotheexiblecenter

ofthelter.

7.Cleanthedirtejectionportlocatedinthe

removablecover.Removetherubberoutlet

valvefromthecover,cleanthecavityand

replacetheoutletvalve.

37

Page 38

8.Installthecoverorientingtherubberoutletvalve

inadownwardposition—betweenapproximately

5o’clockto7o’clockwhenviewedfromtheend.

9.Checktheconditionoftheair-cleanerhoses.

10.Securethecover.

ServicingtheSafetyFilter

Theairlterhasasecondary ,safetylterelement

insidetheprimaryairltertopreventdislodged

dustandotheritemsfromenteringtheenginewhile

changingthemainelement.

Replacethesafetylter,nevercleanit.

Important:Neverattempttocleanthesafety

lter.Ifthesafetylterisdirty,thentheprimary

lterisdamaged.Replacebothlters.

CheckingtheEngine-Oil

Level

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;

however,theoillevelmustbecheckedbeforeand

aftertheengineisrststarted.

g008881

Figure47

1.Dipstick

4.Removedipstickandcheckoillevelondipstick.

Note:TheoillevelshouldbeuptotheFULL

mark.

5.IftheoillevelisbelowtheFULLmark,remove

thellcap(Figure48)andaddoiluntillevel

reachestheFULLmarkondipstick.

Important:Donotoverll.

Crankcasecapacity:approximately6.7L(7.1US

qt)withthelter

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4or

higher

•Preferredoil:SAE15W-40(above0°F)

•Alternateoil:SAE10W-30or5W-30(all

temperatures)

ToroPremiumEngineoilisavailablefromyour

distributorineither15W-40or10W-30viscosity.

Note:Thebesttimetochecktheengineoiliswhen

theengineiscoolbeforeithasbeenstartedforthe

day.Ifithasalreadybeenrun,allowtheoiltodrain

backdowntothesumpforatleast10minutesbefore

checking.

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,engagetheparkingbrake,shutoff

theengine,andremovethekey.

2.Openthehood.

g004134

Figure48

1.Oil-llcap

6.Installtheoil-llcapandclosethehood.

ServicingtheEngineOil

3.Removethedipstick,wipeitclean,andinstallit

(Figure47).

andFilter

ServiceInterval:Aftertherst50hours

Every150hours

38

Page 39

1.Removethedrainplug(Figure49)andletthe

oilowintoadrainpan.

Figure49

1.Oil-drainplug

2.Whentheoilstops,installthedrainplug.

3.Removetheoillter(Figure50).

g008911

FuelSystem

Maintenance

DANGER

Undercertainconditions,fuelandfuelvapors

arehighlyammableandexplosive.Areor

explosionfromfuelcanburnyouandothers

andcancausepropertydamage.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineisoffandiscold.Wipeup

anyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis25mm

(1inch)belowthetopofthetank,notthe

llerneck.Thisemptyspaceinthetank

allowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

Figure50

1.Oillter

4.Applyalightcoatofcleanoiltothenewlter

seal.

5.Installthereplacementoilltertothelter

adapter.Turntheoillterclockwiseuntilthe

rubbergasketcontactsthelteradapter,then

tightenthelteranadditional1/2turn.

Important:Donotovertightenthelter.

6.Addoiltothecrankcase;refertoCheckingthe

Engine-OilLevel(page38).

DrainingtheFuelTank

ServiceInterval:Every800hours

Beforestorage

Drainandcleanthefueltankifthefuelsystem

becomescontaminatedorifthemachineistobe

storedforanextendedperiod.Usecleanfueltoush

outthetank.

CheckingtheFuelLines

g008912

andConnections

ServiceInterval:Every400hours/Y early(whichever

comesrst)

Checkthefuellinesandconnections.Inspectthem

fordeterioration,damage,orlooseconnections.

BleedingtheFuelSystem

Youmustbleedthefuelsystembeforestartingthe

engineifanyofthefollowingsituationshaveoccurred:

•Initialstart-upofanewmachine.

•Enginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponfuel

systemcomponents;i.e.,lterreplaced,separator

serviced,etc.

1.Parkthemachineonalevelsurfaceandensure

thatthefueltankisatleasthalffull.

39

Page 40

2.Openthehood.

3.TurnthekeyintheignitionswitchtotheON

positionandcranktheengine.

Note:Themechanicalpumpsucksfueloutof

thetank,llthefuellterandfuelhoseandforce

theairintotheengine.Thiscouldtakesome

timetofullypurgealltheairoutofthesystem

andtheenginemightreerraticallyuntilallair

ispurgedout.Whenallairispurgedandthe

engineisrunningsmoothly,itshouldberunfor

afewminutestoensurethatitisfullypurged.

ReplacingtheFuelFilter

ServiceInterval:Every500hours

Beforeeachuseordaily—Drainwaterorother

contaminantsfromthewaterseparator.

Important:Replacethefuel-ltercanister

periodicallytopreventwearofthe

fuel-injection-pumpplungerortheinjection

nozzle,duetodirtinthefuel.

1.Placeacleancontainerunderthefuel-lter

canister(Figure51).

Note:Thefuel-ltercanisterislocatednearthe

batteryundertheenginecover.

2.Loosenthedrainplugonthebottomofthelter

canister.

3.Cleantheareawheretheltercanistermounts.

Figure51

1.Fuel-ltercanister

4.Removetheltercanisterandcleanthe

mountingsurface.

5.Lubricatethegasketontheltercanisterwith

cleanoil.

6.Installthenewltercanisterbyhanduntilthe

gasketcontactsmountingsurfaceandthen

rotateitanadditional1/2turn.

7.Tightenthedrainplugonthebottomofthelter

canister.

8.Bleedthefuelsystem;refertoBleedingtheFuel

System(page39).

g007367

40

Page 41

ElectricalSystem

ServicingtheBattery

Maintenance

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

CheckingtheElectrical

System

ServiceInterval:Every500hours

Inspectallelectricalconnectionsandcablesand

replaceanywhicharedamagedorcorroded.Spraya

good-qualitywaterinhibitorontoexposedconnections

topreventmoistureingress.

CheckingtheBattery

Condition

ServiceInterval:Every250hours

DANGER

Batteryelectrolytecontainssulfuricacid

whichisadeadlypoisonandcausessevere

burns.

•Donotdrinkelectrolyteandavoidcontact

withskin,eyes,orclothing.Weareye

protectiontoshieldyoureyesandrubber

glovestoprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

WARNING

Chargingthebatteryproducesgassesthat

canexplode.

Neversmokenearthebatteryandkeepsparks

andamesawayfromit.

Checkthebatterycondition.Keeptheterminalsand

theentirebatterycasecleanbecauseadirtybattery

dischargesslowly.T ocleanthebattery,washthe

entirecasewithasolutionofbakingsodaandwater.

Rinseitwithclearwater.

ServiceInterval:Every250hours

Note:Whenremovingthebattery,alwaysdisconnect

thenegative(-)cablerst.

Note:Wheninstallingthebattery,alwaysconnect

thenegative(-)cablelast.

Raisetheenginecover.Removeanycorrosionfrom

thebatteryterminalsusingawirebrushandapply

petroleumjellytotheterminalstopreventfurther

corrosion.Cleanthebatterycompartment.

Undernormaloperatingconditionsthebatterydoes

notrequireanyfurtherattention.Ifthemachinehas

beensubjecttocontinuoususeunderhighambient

temperatureconditions,thebatteryelectrolytemay

requiretoppingup.

Removethecellcoversandtopupwithdistilledwater

toaheight15mmbelowthetopofthebattery.Install

thecellcovers.

Note:Checktheconditionofthebatterycables.

Installnewcableswhencurrentonesareshowing

signsofwearordamageandtightenanyloose

connectionsasnecessary.

41

Page 42

DriveSystem

ChangingtheTransmission

Maintenance

CheckingtheTirePressure

Checktheairpressureinthefrontandreartires.

Refertothechartbelowforthecorrectpressure.

Important:Maintaincorrecttirepressureinall

tirestoensurecorrectcontactwiththeturf.

Recommendedtirepressureis1bar(14.5psi)

forgeneralallarounduse.Tirepressurescanbe

adjustedaccordingtothefollowingtabledepending

onoperatingconditions.

RecommendedTirePressures TiresTireType

Turf

Conditions

FrontAxle26x

12.0-12

BKTturf

pattern

RearAxle20x10.0-

8BKTturf

pattern

0.7bar(10

psi)

0.7bar(10

psi)

CheckingtheTorqueofthe

Wheel-LugNuts

Conditions

1.4bar(20

1.4bar(20

Road

1.7bar(25

psi)

1.7bar(25

psi)

OilFilter

ServiceInterval:Aftertherst50hours

Every500hours

Maximum

Pressure

psi)

psi)

g018091

Figure52

RightSideofMachine

1.Transmission-oillter

ServiceInterval:Beforeeachuseordaily

Torquethewheel-lugnutsto200N∙m(148ft-lb)for

thefrontaxle,and54N∙m(40ft-lb)fortherearaxle.

WARNING

Failuretomaintainpropertorqueofthewheel

nutscouldresultinpersonalinjury.

Ensurethatthewheelnutsaretorqued

properly.

1.Unscrewandremovethebottomofthe

transmission-oil-lterhousing.

2.Withdrawthelterelementanddiscardit.

3.Installanewlterelement.

4.Installthehousing.

Changingthe

Hydraulic-ReturnFilter

ServiceInterval:Aftertherst50hours

Every500hours

1.Removethereturnlter.

2.Wipeoilontothenewreturnltergasket.

3.Installthenewreturnltertothemachine.

42

Page 43

LeftSideofMachine

Figure53

assembly.(Leftlocknuthasaleftthread).Rotatethe

trackrodtoachievethecorrectdistanceasdescribed

aboveandtightenthelocknutssecurely .

Inspectingthe

TransmissionControl

CableandOperating

Mechanism

ServiceInterval:Every250hours

Checktheconditionandsecurityofthecableand

operatingmechanismatthespeed-controlpedalsand

transmissionpumpends.

•Removebuildupofdirt,gritandotherdeposits.

g014491

•Ensurethattheballjointsaresecurelyanchored

andcheckthatthemountingbracketsandcable

anchorsaretightandfreefromcracks.

1.Hydraulic-uid-returnlter

CheckingtheRear-Wheel

Alignment

ServiceInterval:Every500hours

Topreventexcessivetirewearandensuresafe

machineoperation,therearwheelsmustbecorrectly

alignedto3to8mm(0.12to0.31inch).

Settherearwheelsinthestraightaheadposition.

Measureandcomparethedistancebetweenthefront

sidewallsandtherearsidewallsatthewheelcenter

height.Thedistancebetweenthefrontsidewallsmust

beset3to8mm(0.12to0.31inch)lessthanthe

distancebetweentherearsidewalls.

•Inspectendttingsforwear,corrosion,broken

springs,andreplaceifnecessary .

•Ensurethattherubbersealsarecorrectlylocated

andareingoodcondition.

•Ensurethatthearticulatingsleevessupporting

theinnercableareingoodconditionandrmly

attachedtotheoutercableassemblyatthe

crimpedconnections.Ifthereareanysigns

ofcrackingordetachmentinstallanewcable

immediately.

•Checkthatsleeves,rods,andinnercablearefree

frombends,kinks,orotherdamage.Iftheyare

not,installanewcableimmediately.

•Withtheengineshutoff,operatethepedal

controlsthroughtheentirerangeandensurethat

themechanismmovessmoothlyandfreelytothe

neutralpositionwithoutstickingorhangingup.

Figure54

1.Wheelcenterheight

2.Tire4.Track-rodassembly

Toadjustthealignmentoftherearwheels,rst

backofftheleftandrightlocknutsonthetrackrod

3.Directionofforwardtravel

g014571

Figure55

g014442

1.Outercover3.Sleeve

2.Rubberseal4.Rodend

43

Page 44

CoolingSystem

Maintenance

CoolingSystemSafety

•Swallowingenginecoolantcancausepoisoning;

keepoutofreachfromchildrenandpets.

•Dischargeofhot,pressurizedcoolantortouching

ahotradiatorandsurroundingpartscancause

severeburns.

–Alwaysallowtheenginetocoolatleast15

minutesbeforeremovingtheradiatorcap.

–Usearagwhenopeningtheradiatorcap,and

openthecapslowlytoallowsteamtoescape.

RemovingDebrisfromthe

CoolingSystem

g004138

Figure56

1.Rearscreenlatch2.Rearscreen

ServiceInterval:Beforeeachuseordaily

Every100hours

Every2years

Note:Topreventtheenginefromoverheating,the

radiatorandoilcoolermustbekeptclean.Normally ,

checkdailyand,ifnecessary,cleananydebrisoff

theseparts.However,itisnecessarytocheckand

cleanmorefrequentlyinextremelydustyanddirty

conditions.

1.Turntheengineoffandremovethekeyfromthe

ignitionswitch.

2.Thoroughlycleanalldebrisoutoftheengine

area.

3.Unlatchtheclampandpivotopentherear

screen(Figure56).

4.Cleanthescreenthoroughlywithcompressed

air.

5.Pivotthelatchesinwardtoreleasetheoilcooler

(Figure57).

g003974

Figure57

1.Oilcooler2.Oilcoolerlatches

6.Thoroughlycleanbothsidesoftheoilcoolerand

theradiator(Figure58)withcompressedair.

44

Page 45

Figure58

1.Radiator

7.Pivottheoilcoolerbackintopositionandsecure

thelatches.

BeltMaintenance

TensioningtheAlternator

Belt

ServiceInterval:Aftertherst8hours

Every100hours

1.Openthehood.

2.Checkthetensionofthealternatorbeltby

pressingit(Figure59)midwaybetweenthe

alternatorandthecrankshaftpulleyswith10kg

(22lb)offorce.

Note:Thebeltshoulddeect11mm(7/16

inch).Ifthedeectionisincorrect,proceedto

g004137

step3.Ifcorrect,continueoperation.