Toro 30651, Groundsmaster 3400-D Operator's Manual

FormNo.3372-793RevA

G018031

Groundsmaster

®

3400-D4-Wheel

DriveTractionUnit

ModelNo.30651—SerialNo.312000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww .T oro.com.OriginalInstructions(EN)

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Introduction

Thismachineisaride-on,rotary-bladelawnmower

intendedtobeusedbyprofessional,hiredoperators

incommercialapplications.Itisprimarilydesigned

forcuttinggrassonparks,sportselds,caravanparks,

cemeteriesandcommercialgrounds.Itisnotdesigned

forcuttingbrushorforagriculturaluse.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyforproductandaccessory

information,helpndingadealer,ortoregisteryour

product.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Themodel

andserialnumbersareonaplatemountedontheleft

sideoftheframe.Writethenumbersinthespace

provided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure1

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2012—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroRidingMowerSafety....................................6

SoundPowerLevel...............................................7

SoundPressureLevel...........................................7

VibrationLevel.....................................................7

SafetyandInstructionalDecals.............................8

Setup.........................................................................10

1CheckingtheTirePressure...............................10

2ReadingtheManual.........................................10

ProductOverview......................................................11

Controls.............................................................11

Specications.....................................................20

Attachments/Accessories...................................20

Operation...................................................................21

CheckingtheEngineOilLevel............................21

CheckingtheCoolingSystem..............................22

AddingFuel.......................................................22

CheckingtheHydraulicFluid..............................23

ChecktheTorqueoftheWheelNuts...................24

OperatorPlatformLatchingMechanism.............24

OperatorPresenceControl.................................24

StartingandStoppingtheEngine........................25

CuttingUnitPositionControl.............................26

EngagingtheCuttingUnitDrive.........................26

UsingWeightTransfer/Traction

Assistance......................................................26

FoldingtheR.O.P .S.............................................27

JackingPoints.....................................................27

RaisingTheMowerOffTheGround..................27

OperatingTips...................................................28

Maintenance...............................................................30

RecommendedMaintenanceSchedule(s)................30

DailyMaintenanceChecklist...............................31

Pre-Maintenance...............................................32

Lubrication.............................................................33

GreasingtheBearings,Bushingsand

Pivots.............................................................33

EngineMaintenance...............................................34

ChecktheEngineOverheatWarning

System............................................................34

ServicingtheAirCleaner....................................34

ServicingtheEngineOilandFilter......................35

FuelSystemMaintenance.......................................36

ReplacingtheFuelFilter.....................................36

BleedingtheFuelSystem....................................36

DrainingtheFuelTank.......................................37

CheckingtheFuelLinesandConnections...........37

ElectricalSystemMaintenance................................37

CheckElectricalSystem......................................37

CheckBatteryCondition....................................37

ServicingtheBattery...........................................38

DriveSystemMaintenance.....................................38

ChangingtheTransmissionOilFilter..................38

ChangingtheHydraulicReturnFilter..................38

CheckRearWheelAlignment.............................39

CoolingSystemMaintenance..................................40

RemovingDebrisfromtheCooling

System............................................................40

BrakeMaintenance.................................................41

TowingtheMower.............................................41

BeltMaintenance....................................................42

TensioningtheAlternatorBelt............................42

ControlsSystemMaintenance.................................43

CheckForward/ReverseTravelPedal

Action............................................................43

OperatorPresenceSeatSwitch...........................43

CuttingUnitInterlockSwitch.............................43

ParkingBrakeInterlockSwitch...........................43

InspectTransmissionControlCableand

OperatingMechanism....................................43

TransmissionNeutralInterlockSwitch................44

HydraulicSystemMaintenance...............................44

ServicetheHydraulicSystem..............................44

ChecktheHydraulicOilOverheatW arning

System............................................................45

CheckingtheHydraulicLinesandHoses.............45

MiscellaneousMaintenance....................................46

WasteDisposal...................................................46

Storage.......................................................................46

PreparingtheTractionUnit................................46

PreparingtheEngine..........................................46

Troubleshooting.........................................................47

Schematics.................................................................49

3

Safety

ThismachinemeetsorexceedsstandardEN

836:1997specicationsineffectattimeof

production.

Improperuseormaintenancebytheoperator

orownercanresultininjury .T oreducethe

potentialforinjury,complywiththesesafety

instructionsandalwayspayattentiontothesafety

alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromthestandardEN

836:1997.

Training

•Readtheoperator'smanualandothertraining

materialcarefully .Befamiliarwiththecontrols,

safetysigns,andtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpets

arenearby .

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstruction

shouldemphasize:

–theneedforcareandconcentrationwhen

workingwithride-onmachines;

–controlofaride-onmachineslidingonaslope

willnotberegainedbytheapplicationofthe

brake.Themainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeople,orproperty.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,

longtrousers,hardhat,safetyglasses,andear

protection.Longhair,looseclothing,orjewelrymay

gettangledinmovingparts.Donotoperatethe

equipmentwhenbarefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning—Fuelishighlyammable.Takethe

followingprecautions:

–Storefuelincontainersspecicallydesignedfor

thispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely.

•Replacefaultysilencers/mufers.

•Onlyuseaccessoriesandattachmentsapprovedby

themanufacturer.

•Beforeusing,alwaysvisuallyinspecttoseethatthe

blades,bladeboltsandcutterassemblyarenotworn

ordamaged.Replacewornordamagedbladesand

boltsinsetstopreservebalance.

•AlwaysmakesurethatthefoldingR.O.P .Sissecured

initsverticaloperatingpositionbeforeuse.

•Onmulti-bladedmachines,takecareasrotatingone

bladecancauseotherbladestorotate.

•Checkthattheoperator'spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,engagethe

parkingbrake,disengagethecuttingunitdrive

systemandensurethattheforward/reversespeed

controlsareintheneutralposition.

•Donotuseonaslopeofmorethan16degrees.Care

shouldbetakenwhenusingthemoweronanyslope

4

wheregroundconditionsaresuchthattheremaybe

ariskofthemowerrollingover.Therequirements

of89/355/EEC,asamendedby95/63/EEC

‘ProvisionandUseofWorkEquipmentDirective’

shouldbeconsidered.

•Rememberthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.T o

guardagainstoverturning:

–donotstoporstartsuddenlywhengoingupor

downhill;

–machinespeedsshouldbekeptlowonslopes

andduringtightturns;

–stayalertforhumpsandhollowsandother

hiddenhazards;

–Donotturnsharply.Usecarewhenreversing.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischarge

ofmaterialtowardbystandersnorallowanyonenear

themachinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesinplace.

Besureallinterlocksareattached,adjustedproperly,

andfunctioningproperly.

•Donotchangetheenginegovernorsettingsor

over-speedtheengine.Operatingtheengineat

excessivespeedmayincreasethehazardofpersonal

injury.

•Beforeleavingtheoperator'sposition:

–stoponlevelground;

–disengagethedrivetotheattachment,

–lowertheattachmenttotheground;

–Ensurethetransmissionisinneutralandengage

theparkingbrake;

–stoptheengineandremovethekey.

•Whentransportingthemower:

–disengagethedrivetothecuttingunit,

–raisethecuttingunittothetransportposition.

•Stoptheengineanddisengagedrivetothecutting

unit:

–beforerefuelling;

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator's

position.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthe

mower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperating

theequipment.

•Reducethethrottlesettingduringenginerun-out

and,iftheengineisprovidedwithashut-offvalve,

turnthefueloffattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•AlwaysweartheseatbeltwhenthefoldingR.O.P .S

isinitsverticaloperatingposition.

•NeverweartheseatbeltwhenthefoldingR.O.P .Sis

NOTinitsverticaloperatingposition.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopcuttingunitif

notmowing.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumesmayreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuel

storageareafreeofgrass,leaves,orexcessivegrease.

•Keepallpartsingoodworkingconditionandall

hardwareandhydraulicttingstightened.Replaceall

wornordamagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachineto

prevententrapmentofthengersbetweenmoving

bladesandxedpartsofthemachine.

•Disengagedrives,lowerthecuttingunits,setparking

brake,stopengineandremovekeyfromignition.

5

Waitforallmovementtostopbeforeadjusting,

cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,

silencers/mufers,andenginetohelppreventres.

Cleanupoilorfuelspillage.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthe

positivelast.Reconnectpositiverstandnegative

last.

•Usecarewhencheckingtheblades.Weargloves

andusecautionwhenservicingthem.Onlyreplace

blades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.Wear

protectiveclothinganduseinsulatedtools.

ToroRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecicto

Toroproductsorothersafetyinformationthatyoumust

knowthatisnotincludedinthesafetystandards.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustouserandbystanders.

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennis

shoesorsneakers.

•Wearingsafetyshoesisadvisableandrequiredby

somelocalordinancesandinsuranceregulations.

•Handlefuelcarefully .Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Beforestartingtheengine,sitontheseat.

•Usingthemachinedemandsattention.Toprevent

lossofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,

orotherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrol

ofthemachine.

•Raisethecuttingunitswhendrivingfromonework

areatoanother.

•Donottouchtheengine,silencer/mufer,or

exhaustpipewhiletheengineisrunningorsoon

afterithasstoppedbecausetheseareascouldbehot

enoughtocauseburns.

•Iftheenginestallsorlosesheadwayandcannotmake

ittothetopofaslope,donotturnthemachine

around.Alwaysbackslowly,straightdowntheslope.

•Whenapersonorpetappearsunexpectedlyin

ornearthemowingarea,stopmowing.Careless

operation,combinedwithterrainangles,ricochets,

orimproperlypositionedguardscanleadtothrown

objectinjuries.Donotresumemowinguntilthe

areaiscleared.

MaintenanceandStorage

•Makesureallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunder

highpressure.Usepaperorcardboard,notyour

hands,tosearchforleaks.Hydraulicuidescaping

underpressurecanhavesufcientforcetopenetrate

theskinandcauseseriousinjury.Seekimmediate

medicalattentionifuidisinjectedintoskin.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinthesystemmust

berelievedbystoppingtheengineandloweringthe

cuttingunitsandattachmentstotheground.

•Checkallfuellinesfortightnessandwearona

regularbasis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthecutting

units,attachments,andanymovingparts.Keep

everyoneaway.

6

•Toensuresafetyandaccuracy,haveanAuthorized

ToroDistributorcheckthemaximumenginespeed

withatachometer.Maximumgovernedenginespeed

shouldbe3000RPM.

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedToroDistributor.

•UseonlyToro-approvedattachmentsand

replacementparts.Thewarrantymaybevoidedif

usedwithunapprovedattachments.

WholeBody

Measuredvibrationlevel=0.5m/s

UncertaintyValue(K)=0.3m/s

2

2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

Model30651+30646

Hand-Arm

SoundPowerLevel

Model30651+30645

Thisunithasaguaranteedsoundpowerlevelof104

dBA,whichincludesanUncertaintyValue(K)of2dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

Model30651+30646

Thisunithasaguaranteedsoundpowerlevelof105

dBA,whichincludesanUncertaintyValue(K)of2dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Model30651+30645

Thisunithasasoundpressurelevelattheoperator’sear

of93dBA,whichincludesanUncertaintyValue(K)of2

dBA.Soundpressurelevelwasdeterminedaccordingto

theproceduresoutlinedinEN836

Measuredvibrationlevelforrighthand=1.5m/s

UncertaintyValue(K)=0.8m/s

2

Measuredvibrationlevelforlefthand=1.0m/s

UncertaintyValue(K)=0.5m/s

2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

WholeBody

Measuredvibrationlevel=0.5m/s

UncertaintyValue(K)=0.3m/s

2

2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

2

2

Model30651+30646

Thisunithasasoundpressurelevelattheoperator’sear

of94dBA,whichincludesanUncertaintyValue(K)of2

dBA.Soundpressurelevelwasdeterminedaccordingto

theproceduresoutlinedinEN836.

VibrationLevel

Model30651+30645

Hand-Arm

Measuredvibrationlevelforrighthand=1.5m/s

UncertaintyValue(K)=0.8m/s

2

Measuredvibrationlevelforlefthand=1.0m/s

UncertaintyValue(K)=0.5m/s

2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

2

2

7

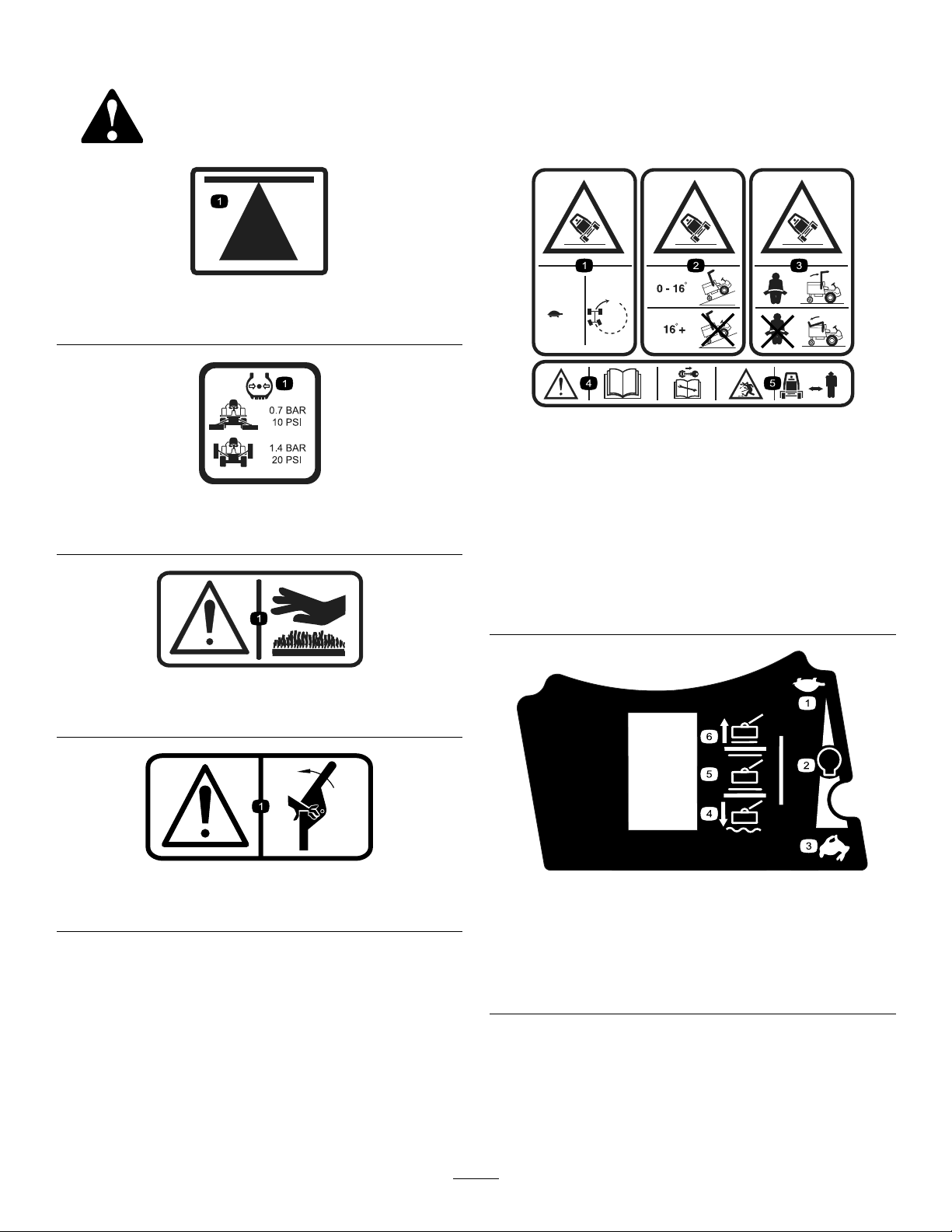

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

70-13-072

1.Jackingpoint

950832

1.Tirepressure

111-0936

1.Tippinghazard—slowmachinebeforeturning.

2.Tippinghazard—operateonslopeslessthan16degrees,

donotoperateonslopesgreaterthan16degrees.

3.Tippinghazard—alwaysweartheseatbeltwhenarollover

protectionsystem(ROPS)isinuse,donotwearaseatbelt

whentheROPSbarislowered.

4.Warning—readtheOperator'sManual,removetheignition

keybeforeperforminganymaintenance.

5.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

950889

1.Warning—hotsurfaces.

111-0773

1.Warning—crushingofngers,forceappliedfromside.

111–5233

1.Slow

2.Continuousvariable

enginespeed

3.Fast6.Floatthecuttingunitover

4.Raisethecuttingunit

5.Neutralcuttingunit

theground

8

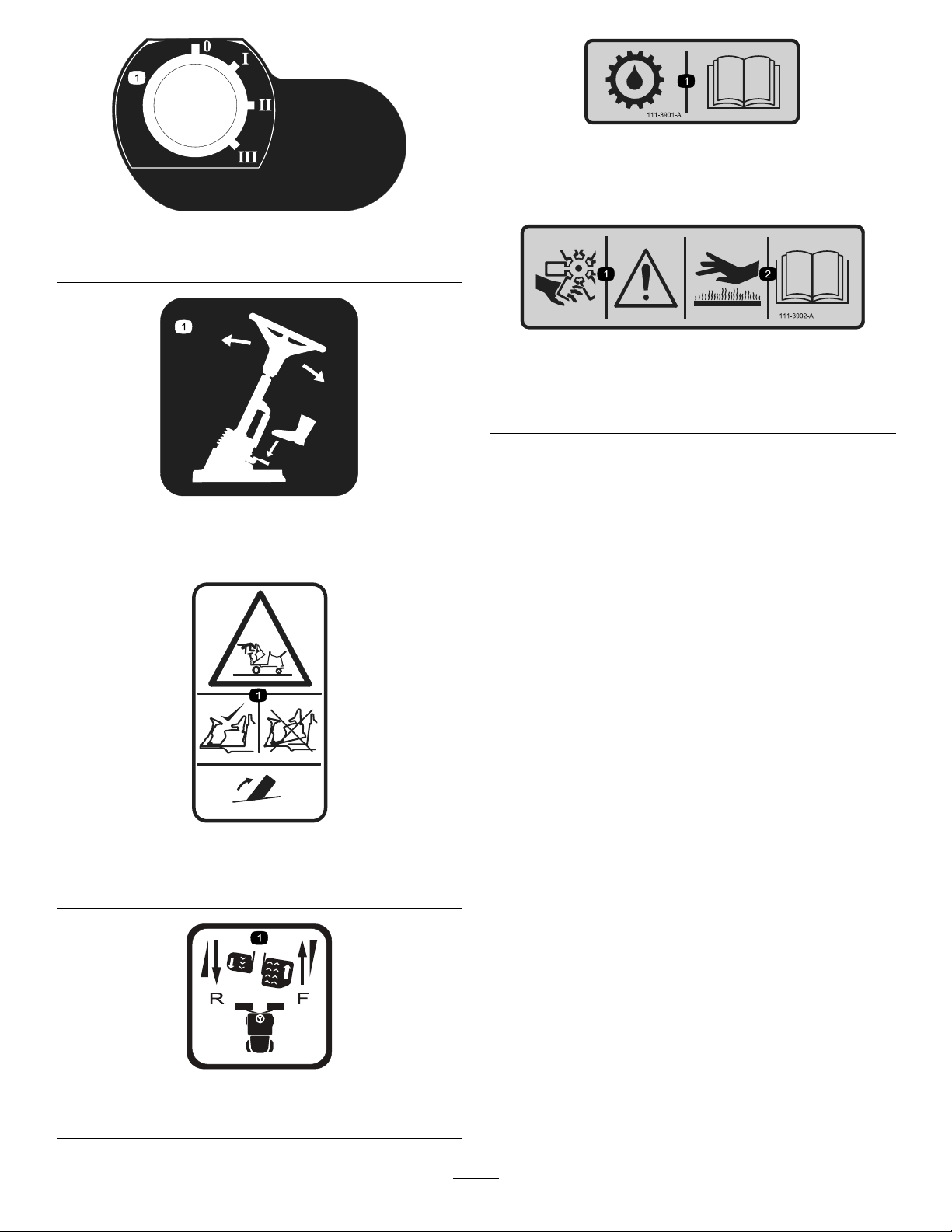

111-3344

1.Ignitionswitch

111-3562

1.Presspedaltoadjuststeeringwheeltilt.

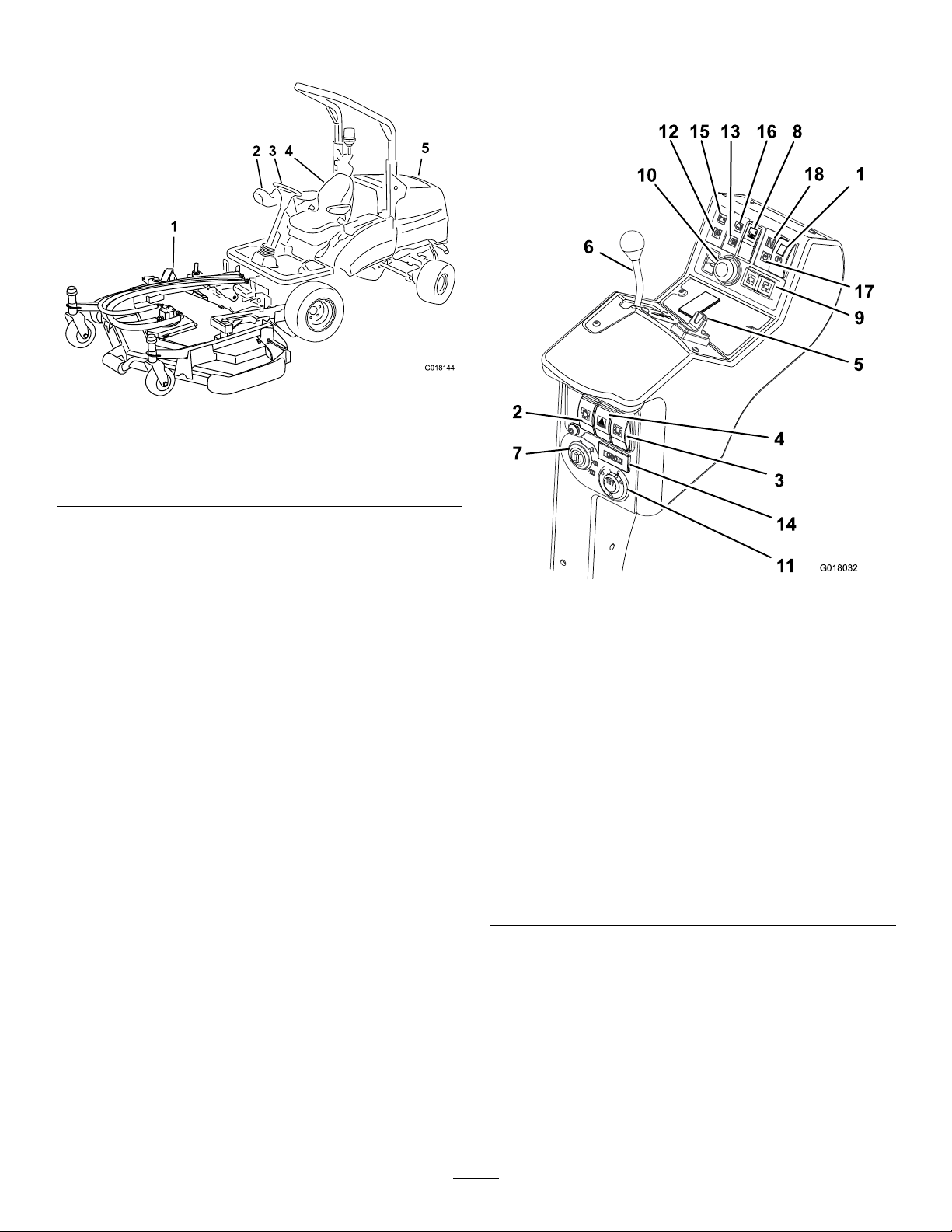

111-3901

1.Transmissionoil—readtheOperator'sManualformore

information.

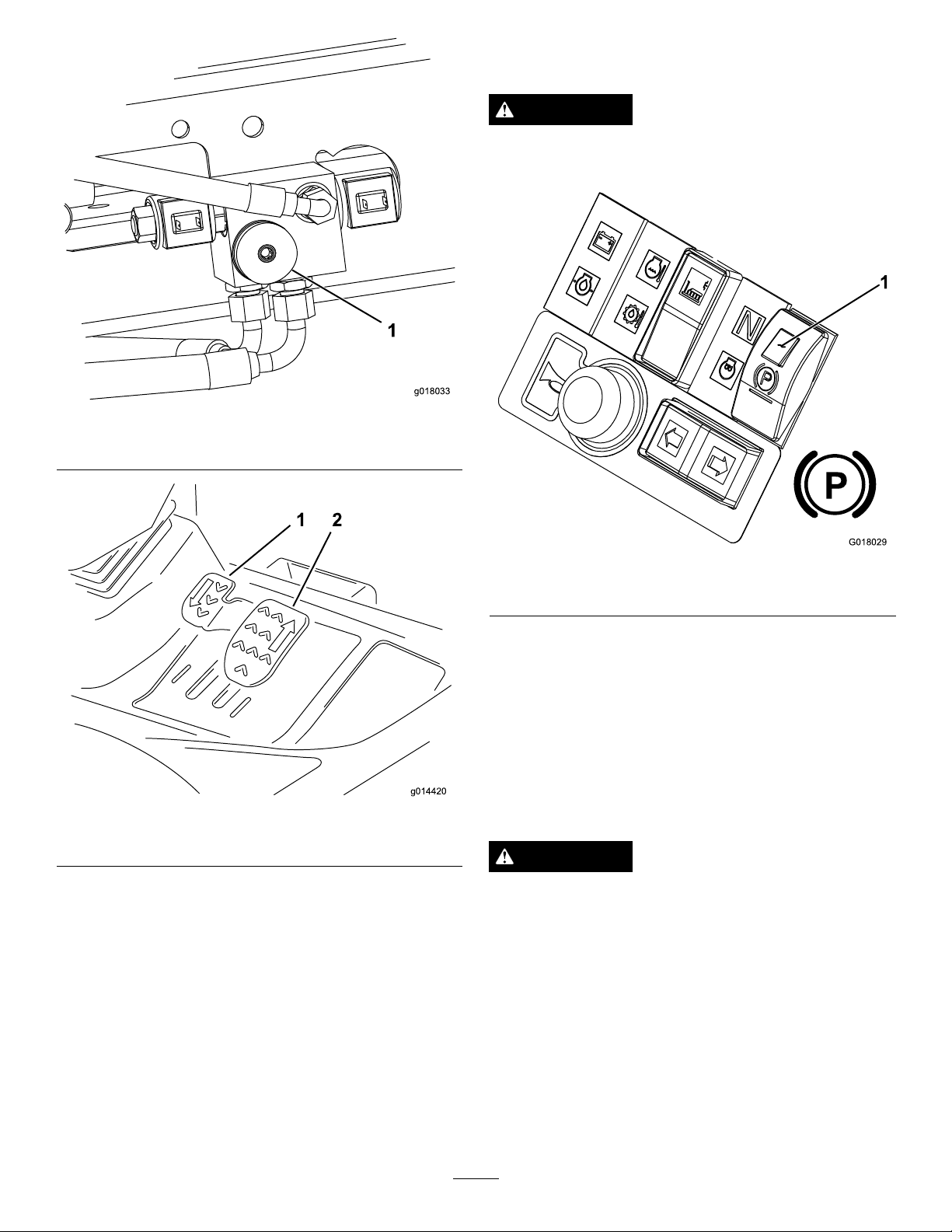

111-3902

1.Warning—cuttinghazardofhand,fan.

2.Hotsurfaces—readtheOperator'sManualformore

information.

111-3566

1.Falling,crushinghazard—ensureplatformlatchinengaged

beforeoperating.

111-3567

1.Pedaloperation

9

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

Tirepressuregauge(notsupplied)

Operator'sManual

EngineOperator'sManual

PartsCatalog

CEcerticate

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1

CheckingtheTirePressure

Partsneededforthisprocedure:

1

Tirepressuregauge(notsupplied)

Qty.

1

1

1

1

1

2

ReadingtheManual

Partsneededforthisprocedure:

1

Operator'sManual

1

EngineOperator'sManual

1

PartsCatalog

1

CEcerticate

Use

Checkthetirepressure.

ReadtheOperator'sManualbefore

operatingthemachine.

Procedure

Correctairpressureinthefrontandreartires.Seethe

chartbelowforthecorrectpressure.

Important:Maintaincorrecttirepressuresinall

tirestoensurecorrectcontactwiththeturf.

TiresTireT ypeRecommendedTirePressures

Conditions

20psi(1.4

20psi(1.4

Road

25psi(1.7

bar)

25psi(1.7

bar)

FrontAxle26x12.00

RearAxle20x10.00

Turf

Conditions

-12BKT

turfpattern

-86BKT

turfpattern

10psi(0.7

bar)

10psi(0.7

bar)

Procedure

•ReadtheOperator'sManual.

•Storealldocumentationinasafeplaceforfutureuse.

Max

Pressure

bar)

bar)

10

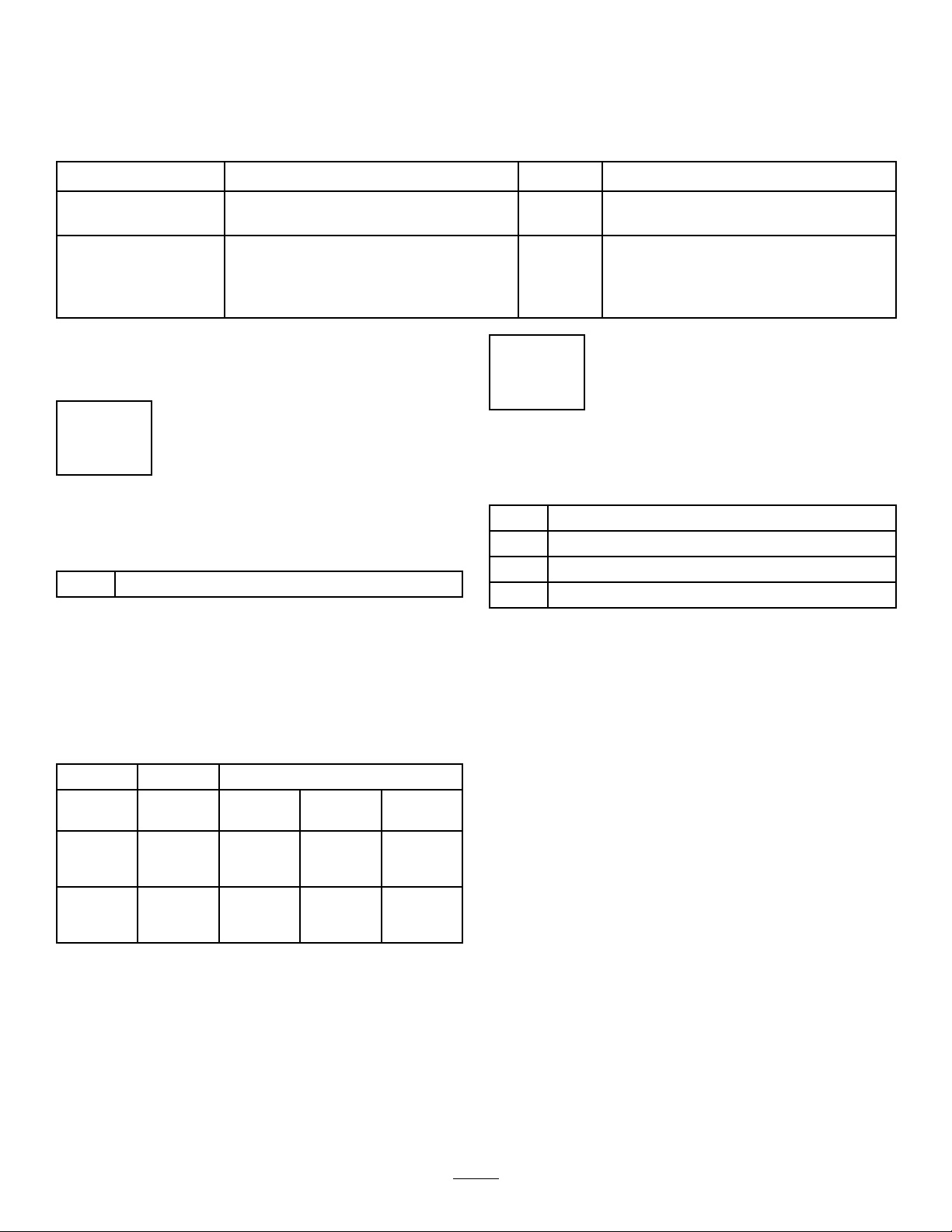

ProductOverview

G018144

1

2 3 4

5

17

9

5

18 1

2

7

14

11

10

6

12 15 13 16 8

4

3

G018032

Figure2

1.Cuttingunit4.Operator'sseat

2.Controlarm

3.Steeringwheel

5.Hood

Controls

ControlPanelComponents

Figure3

1.Parkingbrakeswitch

2.Lightswitch(suppliedwith

lightkit)

3.Warningbeaconswitch

(suppliedwithbeaconkit)

4.Hazardwarningswitch

(suppliedwithlightingkit)

5.Cuttingunitposition

control

6.Throttlecontrollever15.Batterywarningindicator

7.Ignitionswitch16.Enginetemperature

8.Cuttingunitdriveswitch17.Glowplugindicator

9.Directionindicatorswitch

(suppliedwithlightingkit)

10.Hornbutton(suppliedwith

lightkit)

11.Auxiliary12voltsocket

(suppliedwitha12Vkit)

12.Oilpressureindicator

13.Transmissiontemperature

indicator

14.Hourmeter

warningindicator

18.Transmissionneutral

indicator

11

1

g018033

1.Weighttransfercontrol

g014420

1 2

P

1

G018029

Thislightilluminateswhentheparkingbrakeisengaged

andtheignitionkeyisturnedtopositionI.

WARNING

Theparkingbrakeoperatesonthefrontwheels

only.Donotparkthemoweronaslope.

Figure4

Figure5

1.Reversetravelpedal2.Forwardtravelpedal

BrakingSystem

ParkingBrake

Movetheparkingbrakeswitchtoitsforwardpositionby

depressingthesmallerlockingbuttonandmovingthe

switchforwardtoengagetheparkingbrake(

Figure6).

Figure6

1.Parkingbrake

ServiceBrake

Servicebrakingisachievedbythehydraulictransmission

system.Whentheforwardorreversetravelpedalsare

releasedortheenginespeedreduced,servicebraking

becomeseffectiveandtravelspeedisautomatically

reduced.Toincreasethebrakingeffect,pushthe

transmissionpedalintotheneutralposition.Service

brakingiseffectiveonthefrontwheelsonly.

WARNING

Theservicebrakingsystemwillnotholdthemower

atastandstill.ALWAYSensuretheparkingbrakeis

engagedtoparkthemoweratastandstill.

EmergencyBrake

Intheeventofservicebrakefailure,turntheignitionoff

tobringthemowertoastandstill.

Note:Donotoperatethemowerwiththeparking

brakeengagedanddonotengagetheparkingbrake

whilethemowerismoving.

12

WARNING

1

G018034

g014420

1 2

G014549

Takecarewhenusingtheemergencybraking .

Remainseatedandholdontothesteeringwheel

topreventejectionfromthemowercausedbythe

frontwheelbrakesbeingappliedsuddenlywhen

travelling.

ThrottleControl

Operatethethrottlecontrolinaforwarddirectionto

increasetheenginespeed.Operatethethrottlecontrol

inarearwarddirectiontoreduceenginespeed(Figure7).

Note:Theenginespeeddictatesthespeedoftheother

functions,i.e.travel,cuttingbladerotationspeedand

cuttingunitliftspeed.

Figure8

1.Reversetravelpedal2.Forwardtravelpedal

CuttingUnitDriveSwitch

AlwaysputthecuttingunitdriveswitchintheOff

positionwhentravellingbetweenworkareas.

Figure7

1.Throttlecontrol

Travel

Forwardtravel:Depresstheforwardtravelpedalto

increaseforwardtravelspeed.Releasethepedalto

reducespeed(

Reversetravel:Depressthereversetravelpedalto

increasereversetravelspeed.Releasethepedaltoreduce

speed(Figure8).

Stop(Neutral):Releasetheforwardorreversetravel

pedal.

Figure8).

AdjustableSteeringColumn

WARNING

Neveroperatethemowerwithoutrstcheckingthat

thesteeringcolumnadjustermechanismisingood

workingorderandthat,onceadjustedandlocked,

thesteeringwheelremainssecurelyinposition.

Adjustmentofthesteeringwheelandsteeringcolumn

shouldonlybecarriedoutwhenthemowerisata

standstillwiththeparkingbrakeengaged.

1.Totiltthesteeringwheel,pressthefootpedaldown.

2.Positionthesteeringtowertothemostcomfortable

positionandreleasethepedal(

Figure9

Figure9).

13

OperatorSeat

Kg

Kg

CW

CCW

G018093

1

2

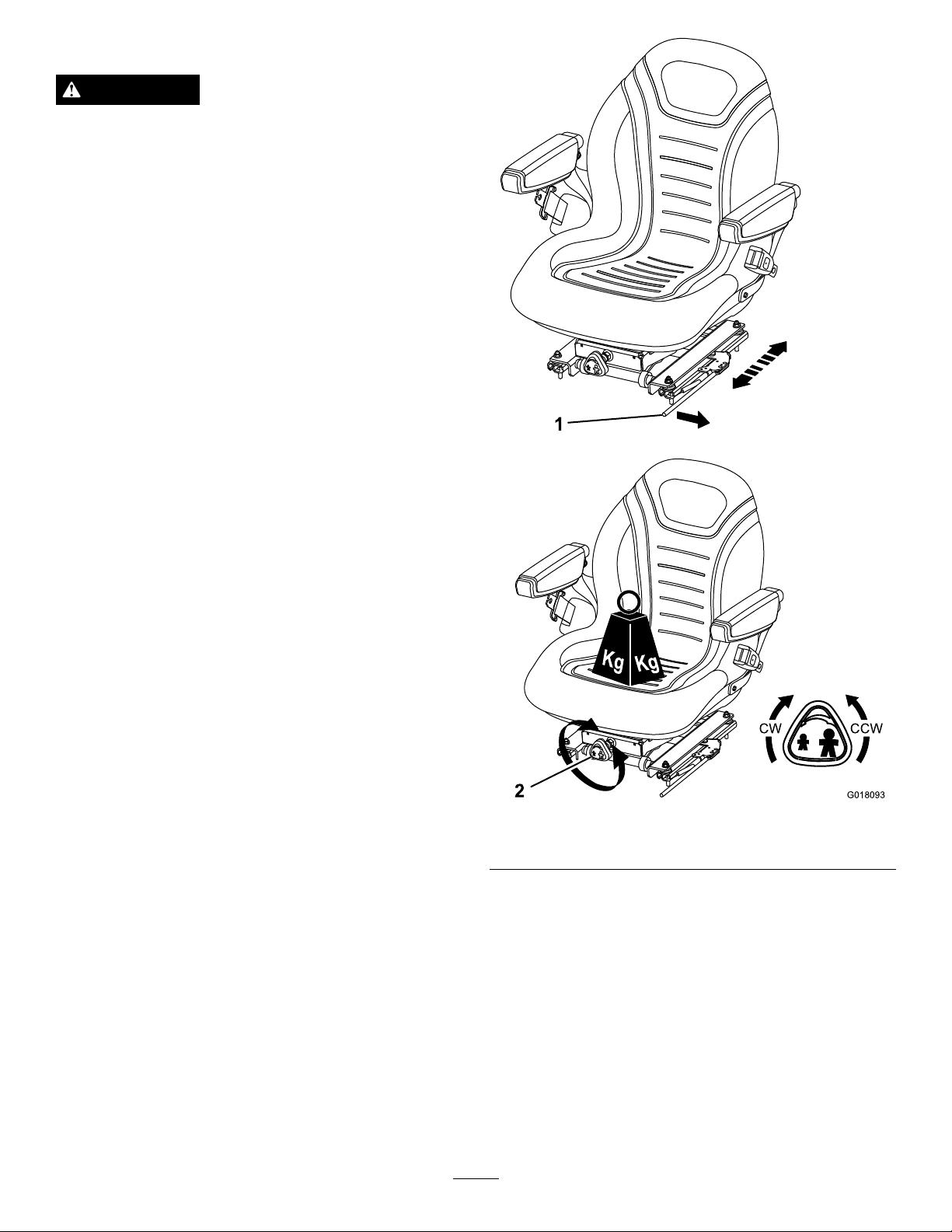

WARNING

Neveroperatethemowerwithoutrstchecking

thattheoperatorseatmechanismsareingood

workingorderandthat,onceadjustedandlocked,

theseatremainssecurelyinposition.

Adjustmentoftheseatmechanismsshouldonlybe

carriedoutwhenthemowerisatastandstillwith

theparkingbrakeengaged.

.Fore/AftAdjustment:Theseatadjustingleverallows

youtoadjusttheseatforeandaft(Figure10).

Operatorweightadjustment:Rotatethehandle

clockwise,asshown,toincreasesuspensionstiffnessand

counter-clockwisetodecrease(Figure10).

Figure10

1.Seatadjustmentlever2.Operatorweighthandle

14

WarningSystems

G018035

1

G018036

1

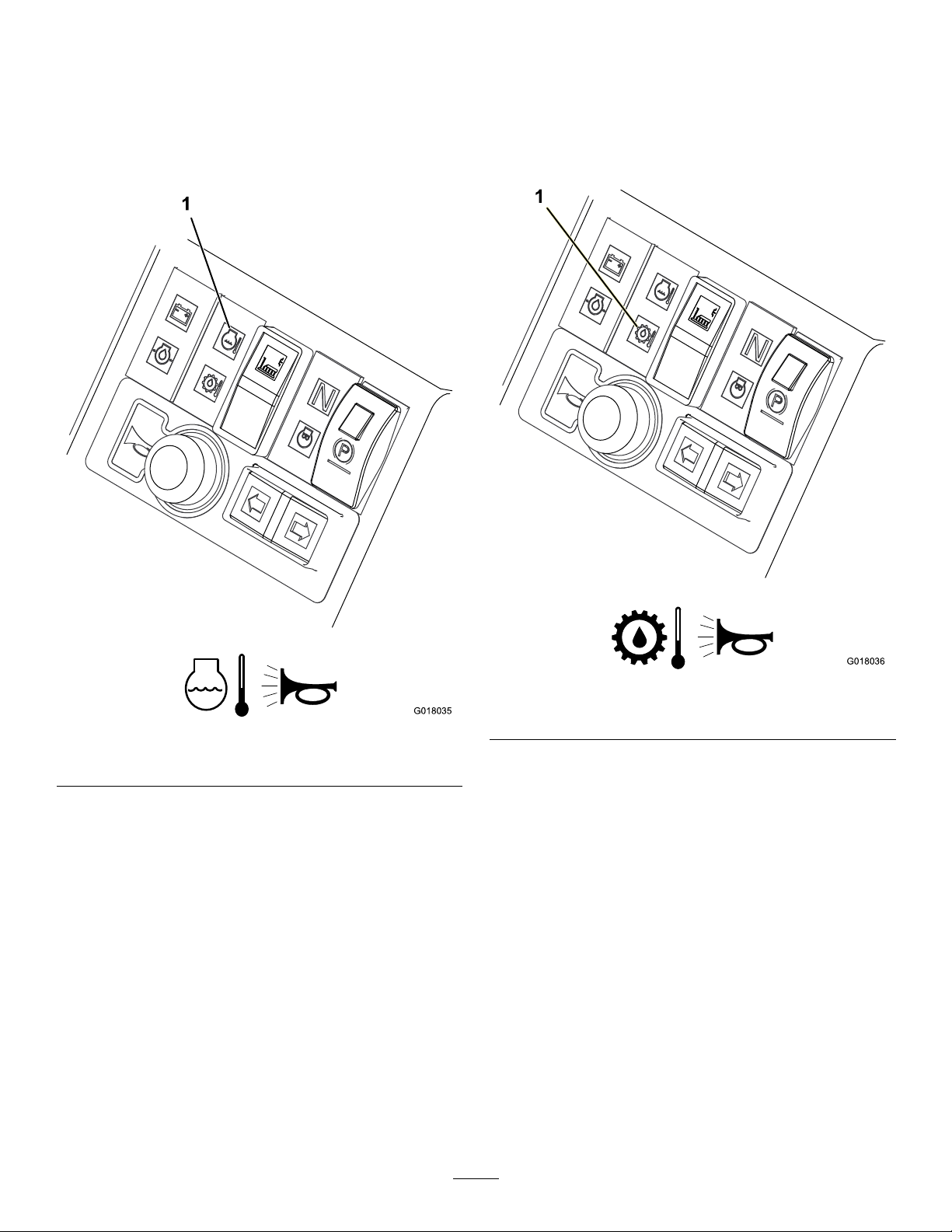

EngineCoolantOverheatingWarning

Light

Theenginecoolantwarninglightilluminatesandthe

hornisactuated(Figure11).

HydraulicOilOverheatingWarning

Light

Thehydraulicoilwarninglightilluminateswhen

overheatingoccursandthehornisactuatedwhenthe

hydraulicoilinthereservoirexceeds203degreesF(95

degreesC)(Figure12).

1.Enginecoolantoverheatingwarninglight

Figure12

1.Hydraulicoiloverheatingwarninglight

Figure11

15

LowBatteryChargeWarningLight

G018037

1

G018081

1

LowEngineOilPressureWarningLight

Thebatterychargewarninglightilluminateswhenlow

batterychargeoccurs(Figure13).

Theengineoilpressurewarninglightilluminateswhen

theoilpressureistoolow(Figure14).

Figure14

1.Lowbatterychargewarninglight

Figure13

1.Lowengineoilpressurewarninglight

16

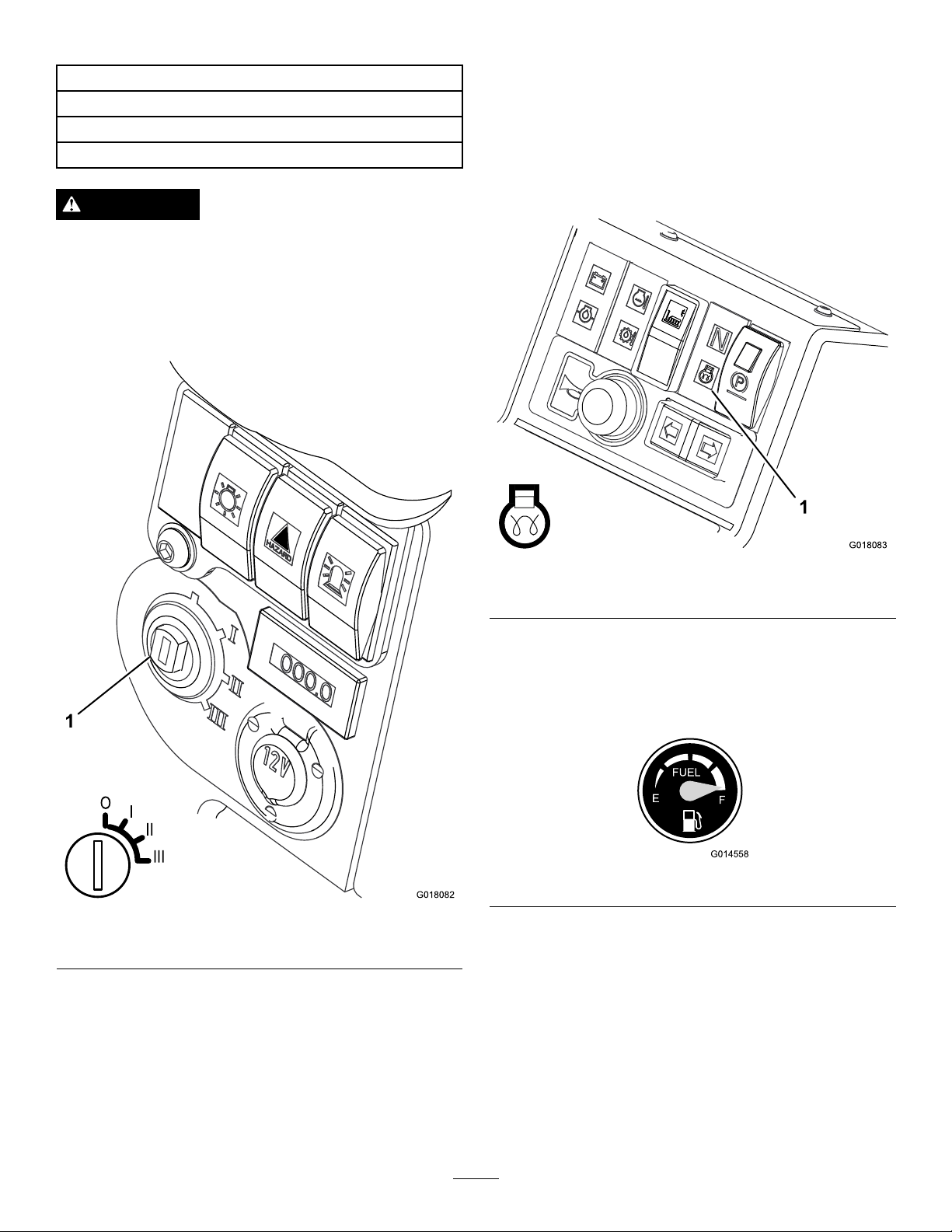

IgnitionKey

I

II

III

1

G018082

G018083

1

G014558

FUEL

E

F

EnginePre-HeatIndicatorLight

0=Engineoff.

I=Enginerun/Auxiliaryon.

II=Enginepre-heat.

III=Enginestart.

WARNING

Alwaysremovetheignitionkeywhenthemoweris

notinuse.

Important:Alwaysinstalltheprotectivecapwhen

theignitionkeyisremovedtopreventingressof

dirtandmoistureanddamagingthemechanism.

TurntheignitionkeytopositionII.Theenginepreheat

indicatorlightwillilluminateandheattheglowplugs

Figure16).

(

Important:Attemptingtostartacoldengine

beforethepre-heatisusedcancauseunnecessary

weartothebattery .

1.Ignitionswitch

Figure16

1.Enginepre-heatindicatorlight

FuelGauge

Thefuelgaugeshowstheamountoffuelinthetank

(Figure17).

Figure17

Figure15

17

Loading...

Loading...