Page 1

Base62inand72inMower

FormNo.3372-806RevA

Groundsmaster

ModelNo.30645—SerialNo.312000001andUp

ModelNo.30646—SerialNo.312000001andUp

®

3400TractionUnit

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Contents

Introduction

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Thisrotary-bladelawncuttingdeckismounted

toaride-onmachineandisintendedtobeused

byprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrass

onwell-maintainedlawnsinparks,sportselds,and

oncommercialgrounds.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongside

highways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.T oro.comfor

productandaccessoryinformation,helpndingadealer,

ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Themodel

andserialnumbersarestampedintoaplatethatis

mountedonthemowerhousing.Writethenumbersin

thespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Introduction.................................................................2

Safety...........................................................................3

SafeOperatingPractices.......................................3

ToroMowerSafety...............................................4

SafetyandInstructionalDecals.............................6

Setup...........................................................................7

1InstallingaCompletionKit................................7

2InstallingtheCastorWheelAssemblies...............8

3InstallingtheLiftArms......................................8

4InstallingtheCuttingUnitontheLift

Arms................................................................9

5ConnectingtheHydraulicDrive.........................9

6GreasingtheMachine......................................10

ProductOverview......................................................11

Specications.....................................................11

Attachments/Accessories...................................11

Operation...................................................................11

AdjustingtheHeight-of-Cut...............................11

AdjustingtheCuttingUnitPitch.........................12

AdjustingtheSkids.............................................13

AdjustingtheRollers..........................................13

CorrectingCuttingUnitMismatch......................13

OperatingTips...................................................14

Maintenance...............................................................15

RecommendedMaintenanceSchedule(s)................15

Lubrication.........................................................15

TiltingtheCuttingUnitforMaintenance.............16

SeparatingtheCuttingUnitfromtheTraction

Unit................................................................17

MountingtheCuttingUnittotheTraction

Unit................................................................17

ServicingtheBushingsintheCastor

Arms..............................................................18

ServicingtheCastorWheelsandBearings............18

CheckingforaBentBlade...................................19

RemovingandInstallingtheBlade(s)...................19

InspectingandSharpeningtheBlade(s)...............20

CheckingandCorrectingMismatchof

Blades............................................................21

ReplacingtheDriveBelt.....................................21

Figure1

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2012—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Safety

ThismachinemeetsorexceedsCENstandardEN

836:1997.

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalertsymbol,

whichmeansCAUTION,WARNING,orDANGER"personalsafetyinstruction."Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandard

EN836:1997.

Training

•Readtheoperator'smanualandothertraining

materialcarefully .Befamiliarwiththecontrols,

safetysigns,andtheproperuseoftheequipment.If

theoperatorormechaniccannotreadthelanguage

ofthismanual,itistheowner'sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeople,orproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glassesandearprotection.Longhair,looseclothing

orjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toysandwire

whichcanbethrownbythemachine.

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovefuelcaporaddfuelwithengine

running.Allowenginetocoolbeforerefueling.

Donotsmoke.

–Neverrefuelordrainthemachineindoors.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltankandcontainercapssecurely

•Replacefaultysilencers/mufers.

•Checkthatoperator'spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

•Beforeusing,alwaysvisuallyinspecttoseethatthe

blades,bladebolts,andcuttingassemblyarenot

wornordamaged.

•Onmulti-bladedmachines,takecareasrotatingone

bladecancauseotherbladestorotate

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Onlystartengine

fromtheoperator'sposition.

•Slowdownanduseextracareonhillsides.Besure

totravelintherecommendeddirectiononhillsides.

Turfconditionscanaffectthemachine'sstability.

Usecautionwhileoperatingneardrop-offs.

•Slowdownandusecautionwhenmakingturnsand

whenchangingdirectionsonslopes.

•Whenusinganyattachments,neverdirectdischarge

ofmaterialtowardbystandersnorallowanyonenear

themachinewhileinoperation.

•Neverraisedeckwiththebladesrunning.

•Neveroperatewithguardsnotsecurelyinplace.Be

sureallinterlocksareattached,adjustedproperly,

andfunctioningproperty.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,lowerthecuttingunits,

disengagedrives,engageparkingbrake(ifprovided),

shutoffengineandremovethekeyfromtheignition

beforeleavingtheoperator'spositionforanyreason.

•Stoptheequipment,engageparkingbrake(if

provided),shutoffengine,removethekeyfromthe

ignitionandinspectthebladesafterstrikingobjects

3

Page 4

orifanabnormalvibrationoccurs.Makenecessary

repairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Whenmachineistobeparked,stored,orleft

unattended,lowerthecuttingunitsunlessapositive

mechanicallockisprovided.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesifnot

mowing.

•Usecarewhencheckingblades.Wrapthebladesor

weargloves,andusecautionwhenservicingthem.

Onlyreplaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.W ear

protectiveclothinganduseinsulatedtools.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Theoperatorshallturnonashingwarninglights,

ifprovided,whenevertravelingonapublicroad,

exceptwheresuchuseisprohibitedbylaw.

MaintenanceandStorage

•Disengagedrives,lowerthecuttingunits,move

tractionpedaltoNeutral,setparkingbrake,stop

engineandremovekey.Waitforallmovementto

stopbeforeadjusting,cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,

muferandenginetohelppreventres.Letengine

coolbeforestoringanddonotstorenearames.

Cleanupoilorfuelspillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Donotstorefuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallowuntrained

personneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

ToroMowerSafety

Thefollowinglistcontainssafetyinformationspecicto

Toroproductsorothersafetyinformationthatyoumust

knowthatisnotincludedintheCENstandard.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustouserandbystanders.

•Knowhowtostoptheenginequickly .

•Donotoperatethemachinewhilewearingtennis

shoesorsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully .Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Usingthemachinedemandsattention.Toprevent

lossofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,

embankments,orotherhazards.

–Avoidsuddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Lowerthecuttingunitwhengoingdownslopes.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthe

positivelast.Reconnectpositiverstandnegative

last.

•Thegrassdeectormustalwaysbeinstalledandin

thelowestpositiononthesidedischargecutting

unit.Neveroperatethemowerwithoutthedeector

orentiregrasscollector.

•Ifthecuttingunitdischargeareaeverplugs,shutthe

engineoff,engagetheparkingbrakeandremove

4

Page 5

thekeyfromtheignitionbeforeremovingthe

obstruction.

•Cutgrassslopescarefully.Donotstart,stop,orturn

suddenly.

•Donottouchtheengineormuferwhiletheengine

isrunningorsoonafterithasstoppedbecausethese

areascouldbehotenoughtocauseburns.

MaintenanceandStorage

•Checktheblademountingboltsfrequentlytobesure

thattheyaretightenedtospecication.

•Makesurethatallhydrauliclineconnectorsare

tightandallhydraulichosesandlinesareingood

conditionbeforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunderhigh

pressure.Usepaperorcardboard,notyourhands,

tosearchforleaks.Hydraulicuidescapingunder

pressurecanhavesufcientforcetopenetratethe

skinandcauseseriousinjury.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinthesystemmust

berelievedbystoppingtheengineandloweringthe

cuttingunitstotheground.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthecutting

units,attachments,andanymovingparts.Keep

everyoneaway.

•Donotoverspeedtheenginebychanginggovernor

settings.T oensuresafetyandaccuracy,havean

AuthorizedToroDistributorcheckthemaximum

enginespeedwithatachometer.

•Theenginemustbeshutoffbeforecheckingtheoil

oraddingoiltothecrankcase.

•Performonlythosemaintenanceinstructions

describedinthismanual.Ifmajorrepairsare

everneededorifassistanceisdesired,contactan

AuthorizedToroDistributor.

•Tomakesureofoptimumperformanceand

continuedsafetycerticationofthemachine,use

onlygenuineTororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadebyother

manufacturerscouldbedangerous,andsuchuse

couldvoidtheproductwarranty.

5

Page 6

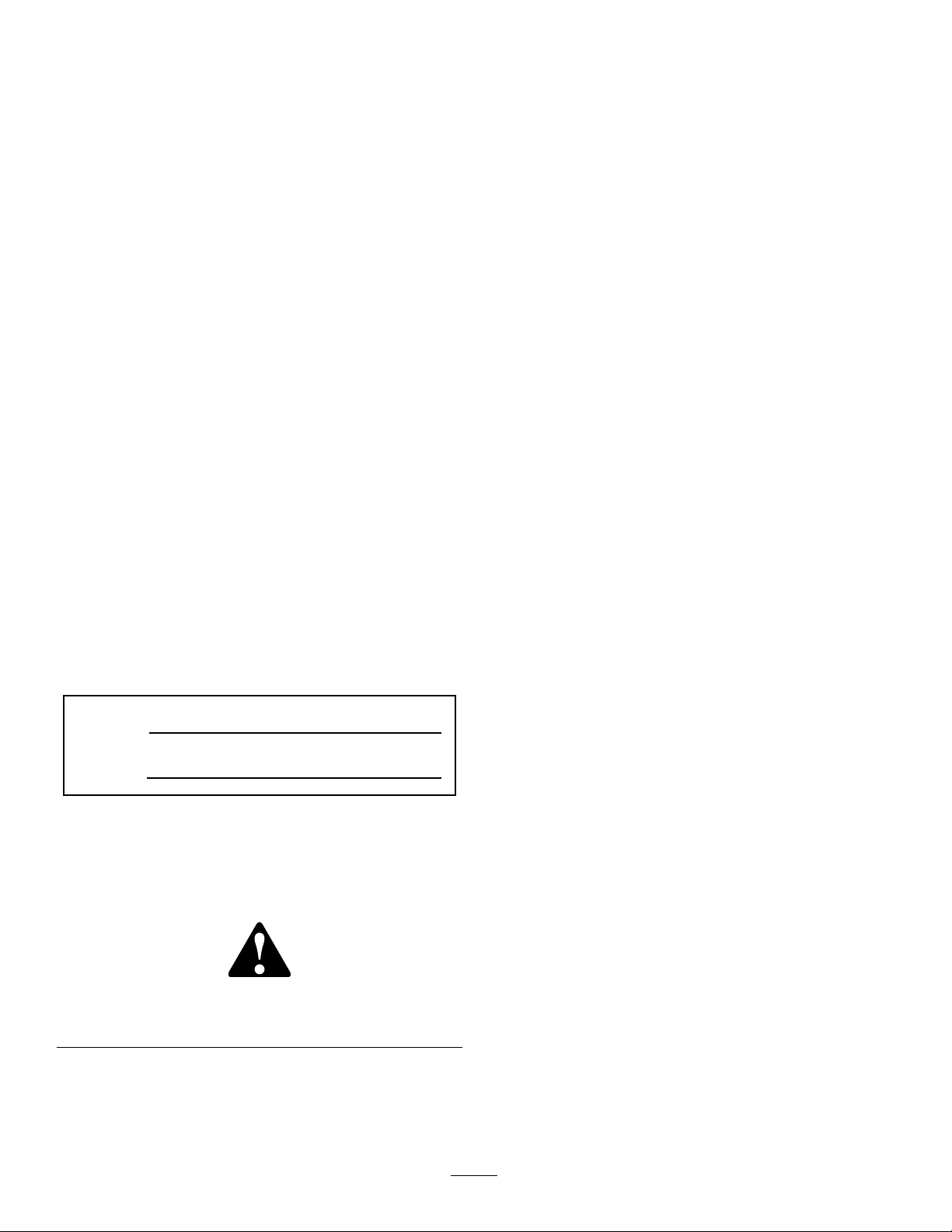

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

108-1988

1.Beltrouting

120-6604

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Cutting/dismembermenthazardofhand,mower

blade—stayawayfrommovingparts,keepallguardsand

shieldsinplace.

3.Cutting/dismembermenthazardoffoot,mowerblade—stay

awayfrommovingparts,keepallguardsandshieldsin

place.

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N-m(85-1 10ft-lb).

100-5622

1.Heightofcutadjustment

117–4979

1.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

108-1986

1.Heightofcut

6

Page 7

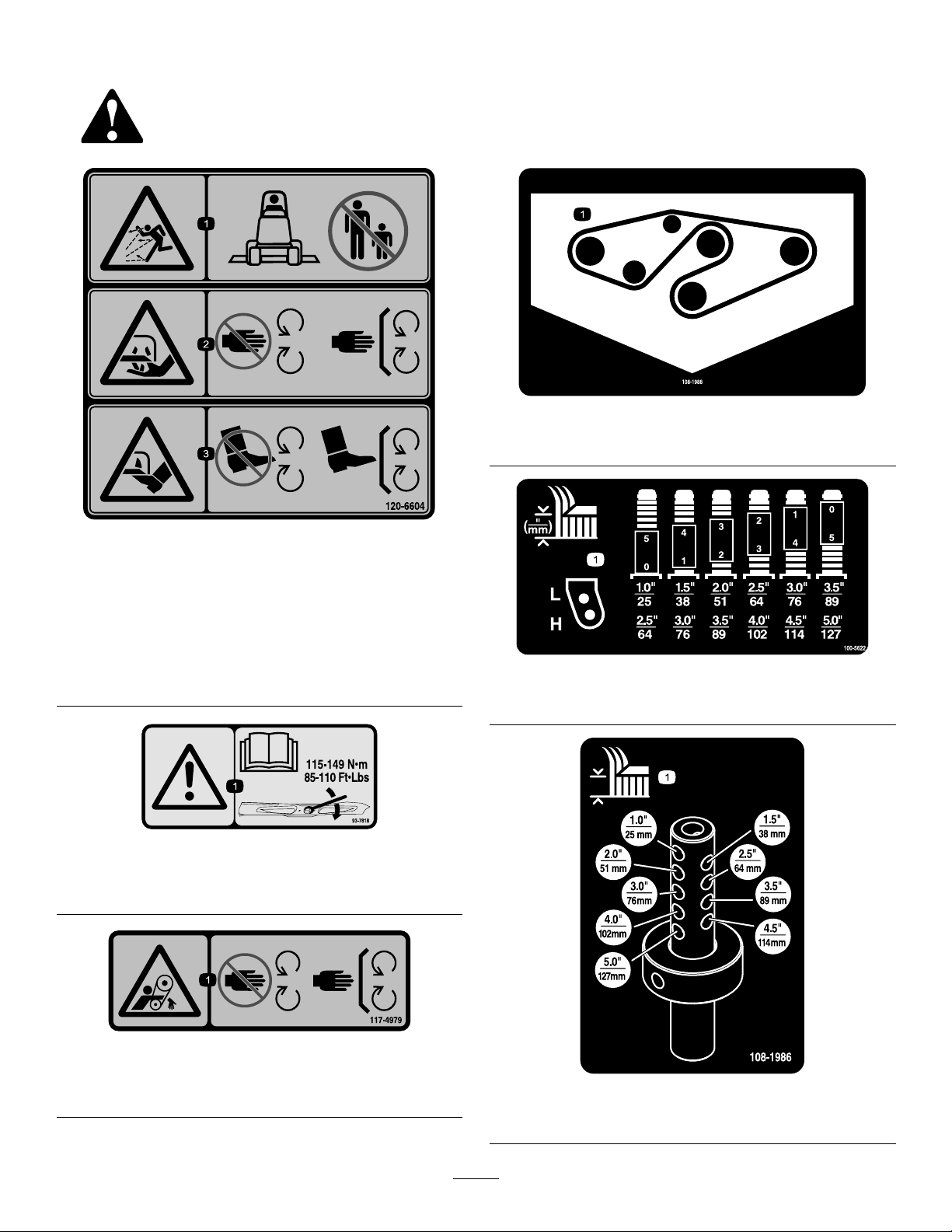

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

Completionkit(soldseparately)

Castorwheelassembly

Liftarm,right

Liftarm,left

Liftcylinderpin

Cylindercarriagebolt

Cylinderangenut

Thrustwasher4

Clevispin

Hairpincotter2

Height-of-cutcollar

Clevispin

Hairpincotter2

Nopartsrequired

Nopartsrequired

Qty.

1Installacompletionkit.

2Installthecastorwheelassemblies.

1

1

2

2

2

4

2

2

–

–

Installtheliftarms.

Installthecuttingunits

Connectthehydraulicdrive.

Greasethemachine.

Use

MediaandAdditionalParts

Description

PartsCatalog

Operator'sManual

Certicateofcompliance

Qty.

1

1

1

DANGER

Iftheengineisstartedandthehydraulichosesare

notcorrectlyconnectedseriousinjurycouldresult.

Makesurethehydraulichosesarecorrectly

connectedorblankingplugshavebeenttedbefore

startingtheengineandengagingthecuttingunit.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Use

1

InstallingaCompletionKit

Partsneededforthisprocedure:

1

Completionkit(soldseparately)

Procedure

Installoneofthefollowing62inchor72inch

completionkitstothebasedeckusingtheinstruction

providedinthekit:

•Model30648,62inchRearDischarge

•Model30306,62inchGuardian

7

Page 8

•Model30649,72inchRearDischarge

g017949

1

2

3

4

5

6

7

8

1

2

3

6

7

8

•Model30304,72inchGuardian

2

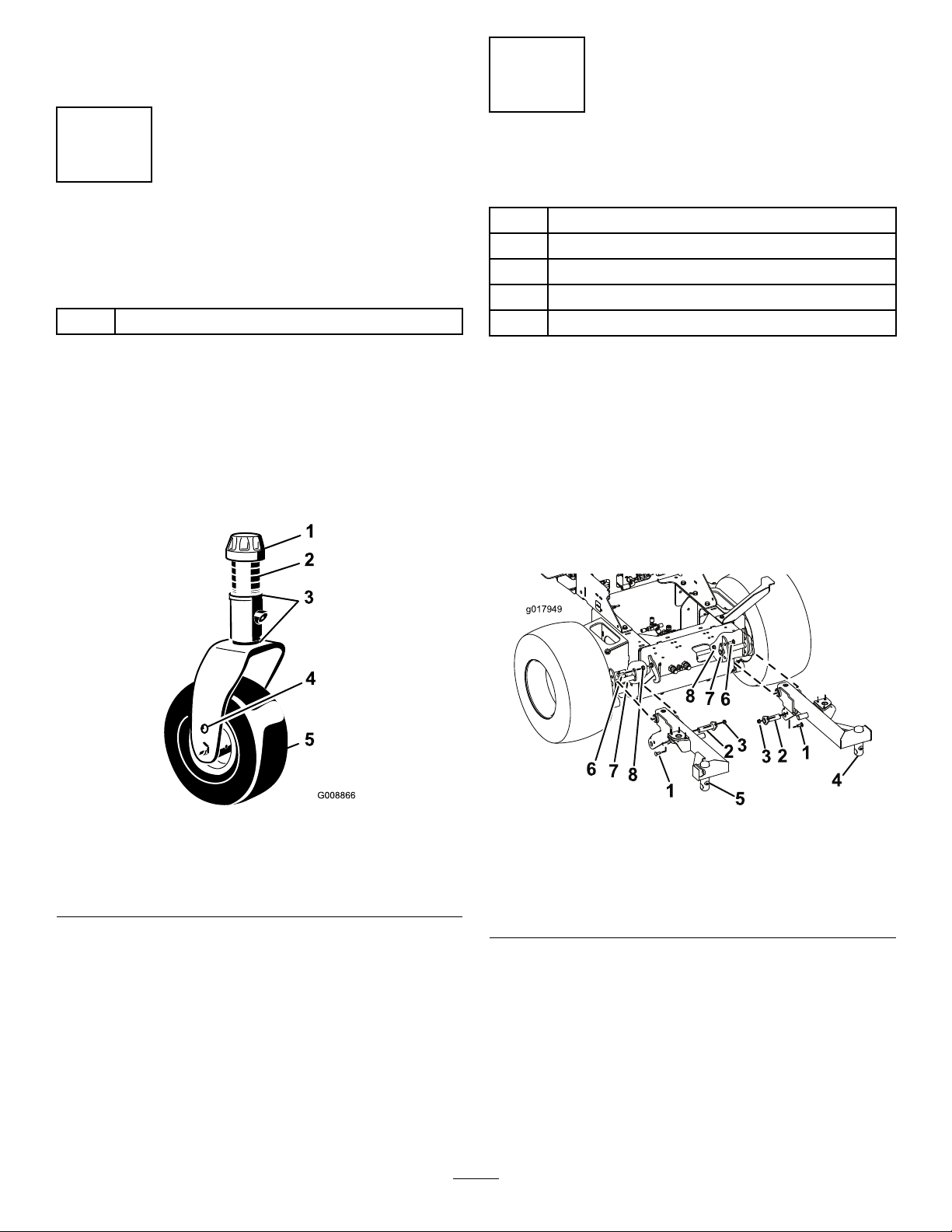

InstallingtheCastorWheel

Assemblies

Partsneededforthisprocedure:

2

Castorwheelassembly

3

InstallingtheLiftArms

Partsneededforthisprocedure:

1

Liftarm,right

1

Liftarm,left

2

Liftcylinderpin

2

Cylindercarriagebolt

2

Cylinderangenut

Procedure

Thethrustwashers,spacers,andtensioningcapshave

beeninstalledonthecastorwheelspindlesforshipping.

1.Removethetensioningcapsfromthespindle

shaftsandslideoffthespacersandthrustwashers

Figure2).

(

Figure2

Procedure

1.Releasethecabletiesthatareholdingupthetraction

unitliftcylindersandlowerittotheoor.

2.Openandraisethetractionunit’soperatorplatform.

3.Fromundertheraisedoperatorplatform,remove

thenutsandcarriageboltsthatsecuretheliftarm

pivotpinstothetractionunitandremovetheLH

andRHliftarmpivotpins(

Figure3

Figure3).

1.Tensioningcap4.Axlemountingholes

2.Spacers5.Castorwheel

3.Thrustwashers

2.Slidethespacersontothecastorspindletogetthe

desiredheight-of-cut;refertoFigure7&Figure8to

determinethecombinationsofspacersforthe

setting.Slideathrustwasherontothespindle,push

thecastorthroughthecastorarm.Installanother

thrustwasherandtheremainingspacersontothe

spindleandinstallthetensioningcaptosecurethe

assembly(Figure2).

1.Cylindercarriagebolt5.RHliftarm

2.Liftcylinderpin6.Liftarmcarriagebolt

3.Cylinderangenut7.Liftarmpivotpin

4.LHliftarm8.Liftarmnut

4.Mounttheliftarmstothetractionunitwiththe

bendspositionedoutwards,andsecureitusingthe

previouslyremovedliftarmpivotpins,carriagebolts,

andnuts(Figure3).

5.Raiseandsecuretheliftarms.

6.Turnonthetractionunit’signitionandmovethe

cuttingunittotheoatposition.

8

Page 9

7.Securetheliftcylinderstotheliftarmsusingthe

g017950

1

2

3

4

5

6

7

8

9

10

suppliedliftcylinderpins,carriagebolts,andnuts

(Figure3).

8.Turnoffthetractionunit,andlowerandsecurethe

operatorplatform.

4

InstallingtheCuttingUniton

theLiftArms

Partsneededforthisprocedure:

4Thrustwasher

4

Clevispin

2Hairpincotter

2

Height-of-cutcollar

2

Clevispin

2Hairpincotter

Procedure

Figure4

1.Liftarm6.Clevispin

2.Castorarmbracket

3.Height-of-cutrod8.Height-of-cutcollar

4.Liftarmpads9.Clevispin

5.Thrustwashers10.Hairpincotter

7.Hairpincotter

1.Movethecuttingunitintopositioninfrontofthe

tractionunit.

2.Turnonthetractionunit’signitionandmovethe

cuttingunittotheoatposition.Pushaliftarm

downuntiltheholesintheliftarmlineupwiththe

holesinthecastorarmbracketandtheheightofcut

rodcanbeinsertedintotheliftarmpads(

3.Securetheliftarmtothecastorarmwith2thrust

washers,aclevispinandahairpincotter.Position

thethrustwashersbetweentheliftarmandthecastor

armbracket(

theslotinthecastorarmtabtoretaincotterpin.

4.Repeattheprocedureontheoppositeliftarm.

5.Startthetractionunitandraisethecuttingunit.

6.Pushdownontherearofthecuttingunitandinsert

7.Installtheheightofcutcollarsontotheheightof

8.Lowerthedeckandswitchthetractionunitignition

theheightofcutrodsthroughtheliftarmpads.

cutrodsandsecurewiththeclevispinsandhairpin

cotters(Figure4).

switchtotheoffposition.

Figure4).Insertendofcotterpininto

Figure4).

5

ConnectingtheHydraulic

Drive

NoPartsRequired

Procedure

Important:Foryoursafetythecuttervalveelectrical

connectorhasbeendisconnectedtodisablethe

operationofthecutterdrive.Reconnectthe

electricalconnectoronceallhoselineconnections

havebeenmadecorrectly.

9

Page 10

WARNING

g017951

1

2

3

4

5

6

g017952

1

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Makesureallhydraulicuidhosesandlinesare

ingoodconditionandallhydraulicconnections

andttingaretightbeforeapplyingpressureto

thehydraulicsystem.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

•Seekimmediatemedicalattentionifuidis

injectedintotheskin.

Note:Somehydraulicuidlossmayoccur.

1.Turnoffthecutters,lowerthecuttingunits,stopthe

engine,engagetheparkingbreak,andremovethe

ignitionkey .

A.Removethehoselineendplug.

B.Removetheportcap.

C.Connectthehosetotheport.

D.Tighteneachhoseconnection.

4.Ensurethatallhosesarecorrectlyrouted,

connectionscleaned,andhoselinestightened.

Retainthehoseplugsandportcapsforfutureuse.

5.Usethecabletiesprovidedtosecurethehoselines.

6.Raisethetractionunit’soperatorplatform,and

connectthecuttervalveelectricalconnector

Figure6).

(

2.Cleantheareasaroundthehydraulicportsandthe

hydraulichoselineends(

Figure5).

Figure6

7.Checktheuidlevels,securethetractionunit’s

operatorplatform,andverifythatthecutterdeck

isworkingcorrectly.

6

Figure5

1.Cap5/8,blanking4.Drainport(tocuttervalve

2.Cap3/8,blanking5.Returnport(tocuttervalve

3.Cableties6.Pressureport(fromcutter

3.Identifythe3hydraulichoselinesandports.Referto

Figure5foreachhose’sappropriateport.Perform

thefollowingprocessforeachconnection:

teeonCDport)

M2port)

valveM1port)

GreasingtheMachine

NoPartsRequired

Procedure

Beforeoperatingthemachine,itmustbegreased

toensureproperlubricatingcharacteristics;referto

GreasingtheBearingsandBushings.Failuretoproperly

greasethemachinewillresultinprematurefailureof

criticalparts.

10

Page 11

ProductOverview

Operation

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Widthof

Cut

Height

ofCut

Net

Weight

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

62inches(1.575m)or72inches(1.829m)

Adjustablefrom1to5inches(25to127mm)in1/2

inch(13mm)increments

Model30645–463lbs.(210kg)

Model30646–496lbs.(225kg)

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

CAUTION

Ifyouleavethekeyintheignitionswitch,someone

couldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudo

anymaintenance.

AdjustingtheHeight-of-Cut

Theheight-of-cutisadjustablefrom1to5inches(25

to127mm)in1/2inch(13mm)increments.Toadjust

theheight-of-cut,positionthecastorwheelaxlesinthe

upperorlowerholesofthecastorforks,addorremove

anequalnumberofspacersfromthecastorforksand

securetheheightofcutcollartothedesiredholesin

theheightofcutrod.

1.Starttheengineandraisethecuttingunitoffthe

oorsothattheheight-of-cutcanbechanged.Stop

theengineandremovethekeyafterthecuttingunit

israised.

2.Positionthecastorwheelaxlesinthesameholesin

bothcastorforks.Referto

determinethecorrectholesforthesetting.

Note:Whenoperatingin2–1/2inch(64mm)

heightofcutorhigher,theaxleboltmustbe

installedinthelowercastorforkholetoprevent

grassbuildupbetweenthewheelandthefork.

Whenoperatinginheightofcutslowerthan2–1/2

inches(64mm)andgrassbuildupisdetected,

reversethemachinesdirectiontopullanyclippings

awayfromthewheel/forkarea.

3.Removethetensioningcapfromthespindleshaft

Figure7)andslidethespindleoutofthecastor

(

arm.Putthe2shims(1/8inch)ontothespindle

shaftastheywereoriginallyinstalled.Theseshims

arerequiredtoachievealevelacrosstheentirewidth

ofthecuttingunits.Slidetheappropriatenumber

of1/2inchspacersontothespindleshafttogetthe

desiredheight-of-cut;thenslidethewasheronto

theshaft.

Referto

combinationsofspacersforthesetting.

Figure7&Figure8todeterminethe

Figure7&Figure8to

11

Page 12

Figure9

Figure7

1.Tensioningcap4.Axlemountingholes

2.Spacers5.CastorWheel

3.Shims

Figure8

4.Pushthecastorspindlethroughthecastorarm.

Installtheshims(astheywereoriginallyinstalled)

andtheremainingspacersontothespindleshaft.

Installthetensioningcaptosecuretheassembly.

1.Height-of-cutrod3.Clevispinandhairpin

cotter

2.Height-of-cutcollar

6.Aligntheheight-of-cutcollartothedesired

height-of-cutholesontheheightofcutrod

(Figure10).

5.Removethehairpinandclevispinsecuringthe

heightofcutcollartotheheightofcutrodonthe

rearofthecuttingunit(

Figure9).

Figure10

7.Securetheadjustmentwiththeclevispinandhair

pin.

Note:Positiontheheadoftheclevispintoward

thefrontofthedeck,ifpossible.

Note:Whenusing1inch(25mm),1-1/2inch(38

mm),oroccasionally2inch(51mm)height–of–cut,

movetheskidsandrollertothehighestholes.

AdjustingtheCuttingUnit

Pitch

Cuttingunitpitchisthedifferenceinheight-of-cut

fromthefrontofthebladeplanetothebackofthe

bladeplane.Tororecommendsabladepitchof1/2

12

Page 13

inch(13mm).Thatisthebackofthebladeplaneis1/2

inch(13mm)higherthanthefront.

1.Positionthemachineonalevelsurfaceontheshop

oor.

2.Setthecuttingunittothedesiredheight-of-cut.

3.Rotate1bladesothatitpointsstraightforward.

4.Usingashortruler,measurefromtheoortothe

fronttipoftheblade.Rotatethebladetiptotherear

andmeasurefromtheoortothetipoftheblade.

Figure12

5.Subtractthefrontdimensionfromtherear

dimensiontocalculatethebladepitch.

6.Loosenthejamnutsonthebottomofthe

height-of-cutrods(

1.Height-of-cut

7.Rotatetheheight-of-cutrodstoraiseorlowerthe

rearofthecuttingunitandattainthecorrectcutting

unitpitch.

Figure11).

Figure11

2.Jamnut

1.Skid

AdjustingtheRollers

Note:Ifthecuttingunitistobeusedinthe1or1-1/2

inch(25or38mm)height-of-cutsetting,thecutting

unitrollersmustberepositionedinthetopbracket

holes.

1.Removethescrewandnutsecuringtherollershaft

tothedeckbracket(

Figure13).

8.Tightenthejamnuts.

AdjustingtheSkids

Theskidsshouldbemountedinthelowerposition

whenoperatinginheightofcutsgreaterthan2-1/2

inches(64mm)andinthehigherpositionwhen

operatinginheightofcutslowerthan2-1/2inches(64

mm).

Adjusttheskidsbyremovingtheangeboltandnuts,

positioningthemasdesired,andinstallingthefasteners

(Figure12).

Figure13

1.Roller

2.Slidetheshaftoutofthelowerbracketholes,align

therollerwiththetopholes,andinstalltheshaft.

3.Installthescrewandnuttosecuretheassemblies.

2.Rollershaft

CorrectingCuttingUnit

Mismatch

Duetodifferencesingrassconditionsandthe

counterbalancesettingofthetractionunit,itisadvised

thatgrassbecutandappearancecheckedbeforeformal

cuttingisstarted.

1.Setthecuttingunittothedesiredheightofcut;

refertoAdjustingtheHeightofCut.

13

Page 14

2.Checkandadjustfrontandreartractortirepressure

to10psi(0.7BAR).

3.Checkandadjustallcastortirepressuresto50psi

(3.4BAR).

4.Checkforbentblades;refertoCheckingforaBent

Blade.

5.Cutgrassinatestareatodetermineifallcutting

unitsarecuttingatthesameheight.

6.Ifcuttingunitadjustmentsarestillneeded,ndaat

surfaceusinga6foot(2m)orlongerstraightedge.

7.Toeasemeasuringbladeplane,raisetheheightof

cuttothehighestposition;refertoAdjustingthe

HeightofCut.

8.Lowercuttingunitontotheatsurface.Remove

thecoversfromthetopofthecuttingunits.

9.Rotatethebladeoneachspindleuntiltheendsface

forwardandbackward.

10.Measurefromtheoortothefronttipofthe

cuttingedge.

11.Adjust1/8inch(3mm)shimsoncastorfork(s)to

matchheightofcuttodecal(

AdjustingtheCuttingUnitPitch.

Figure14);referto

damagethatcanbecausedbydirectsunlightonthe

sensitive,freshlymowedgrass.

SelecttheProperHeight-of-CutSetting

toSuitConditions

Removeapproximately1inch(25mm)ornomorethan

1/3ofthegrassbladewhencutting.Inexceptionally

lushanddensegrass,youmayhavetoraisethe

height-of-cuttothenextsetting.

MowatProperIntervals

Undermostnormalconditionsyouwillneedtomow

approximatelyevery4–5days.Butremember,grass

growsatdifferentratesatdifferenttimes.Thismeans

thatinordertomaintainthesameheight-of-cut,which

isagoodpractice,youwillneedtocutmorefrequently

inearlyspring;asthegrassgrowthrateslowsinmid

summer,cutonlyevery8–10days.Ifyouareunableto

mowforanextendedperiodduetoweatherconditions

orotherreasons,mowrstwiththeheight-of-cutata

highlevel;thenmowagain2–3dayslaterwithalower

heightsetting.

AlwaysMowwithSharpBlades

Figure14

1.Tensioningcap4.Axlemountingholes

2.Spacers5.Castorwheel

3.Shims

OperatingTips

Asharpbladecutscleanlyandwithouttearingor

shreddingthegrassbladeslikeadullblade.Tearingand

shreddingcausesthegrasstoturnbrownattheedges

whichimpairsgrowthandincreasessusceptibilityto

diseases.

AfterOperating

Toensureoptimumperformance,cleantheunderside

ofthemowerhousingaftereachuse.Ifresidueis

allowedtobuildupinthemowerhousing,cutting

performancewilldecrease.

CuttingUnitPitch

Werecommendabladepitchof1/2inch(13mm).A

pitchlargerthan1/2inch(13mm)willresultinless

powerrequired,largerclippings,andapoorerquality

ofcut.Apitchlessthan1/2inch(13mm)willresult

inmorepowerrequired,smallerclippingsandabetter

qualityofcut.

MowWhenGrassisDry

Moweitherinthelatemorningtoavoidthedew,which

causesgrassclumping,orinlateafternoontoavoidthe

14

Page 15

Maintenance

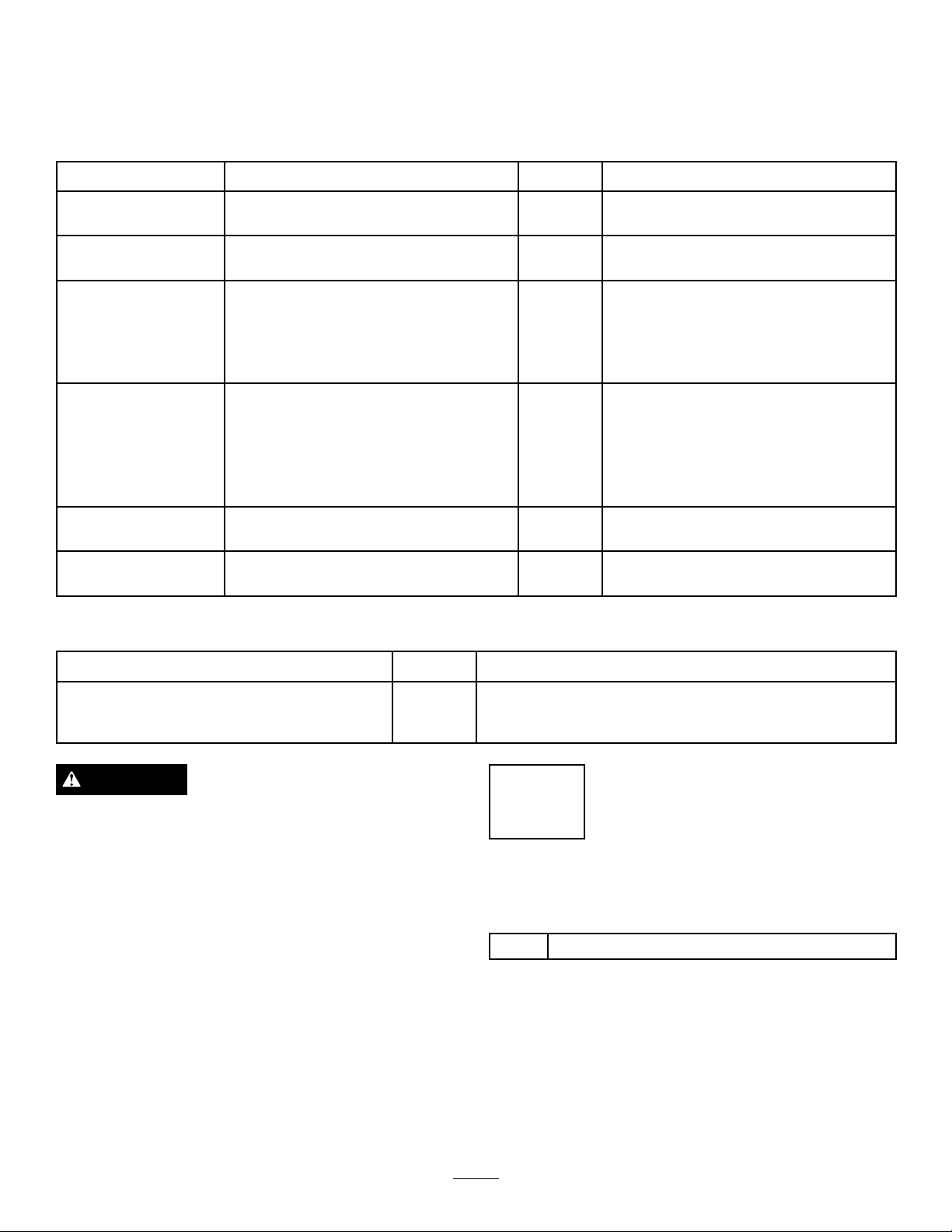

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Aftertherst10hours

Beforeeachuseordaily

Every50hours

Every400hours

1

Immediatelyaftereverywashing,regardlessoftheintervallisted

MaintenanceProcedure

•Tightenthecastorwheelnuts

•Tightenthecastorwheelnuts

•T orquethebladebolts

•Checktheblades

•Lubricatethegreasettings1

•Checkthegearboxoillevel

•Tightenthecastorwheelnuts

•T orquethebladebolts

•Checkthebladedrivebeltadjustment

•Cleanunderthecuttingunitbeltcovers

•Changethegearboxoil

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentallystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionswitchbeforeyoudoanymaintenance.

Important:Thefastenersonthecoversofthismachinearedesignedtoremainonthecoverafterremoval.

Lubrication

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBase

Grease.Ifthemachineisoperatedundernormal

conditions,lubricateallbearingsandbushingsafter

every50hoursofoperationorimmediatelyafterevery

washing.

Lubricatethefollowingareas:

•Castorforkshaftbushings(2)(

Figure15)

Figure15

•Spindleshaftbearings(3)(locatedunderthepulley)

(Figure16).

15

Page 16

g017953

Figure16

g017954

g017955

g017956

1

2

3

4

5

6

8

7

9

10

•Idlerarmshaftbearings(Figure16).

•Liftarmpivots,front(2)(

Figure17).

TiltingtheCuttingUnitfor

Maintenance

Topreparetheunitformaintenance:

1.Positionthemachineonalevelsurface,raisethe

cuttingunit,turnofftheengine,engagetheparking

break,andapplytheliftarmlatches.

Note:Ifthecuttingunitisa72inch(183cm)

modelwithareardischargekittted,therearLH

footguardshouldberemovedpriortocarryingout

thisoperation.

2.Removethehairpinandclevispinsecuringthe

height-of-cutcollartotheheight-of-cutrodonthe

rearofthecuttingunit(

height-of-cutcollars.

Figure19).Removethe

Figure17

•Liftarmpivots,rear(2)(Figure18).

Figure18

Figure19

1.Liftarmlatches6.Liftarmpads

2.Hairpincotter

3.Clevispin

4.Height-of-cutcollar9.RHliftarm

5.Height-of-cutrod

7.Clevispin

8.Hairpincotter

10.RHcasterarm

3.Pivotthedeckuntiltheclevispincanbeinserted

throughtheholeintheRHcastorarmandsecure

ittotheRHliftarm.Securetheclevispinwitha

haripincotter(Figure19).

Tolowerthedeckfromthetiltedposition:

1.Removethehairpincotter.Liftthedeckuntilthe

clevispincanbeeasilyremovedfromtheholeinthe

RHcastorarm(

Figure19).

2.Lowerandtiltthedeckbackensuringthe

height-of-cutrodsdonotgetcaughtonanypartof

thetractionunit.

3.Pushdownontherear,right-handsideofthecutting

unitandinserttheheight-of-cutrodsthroughthe

16

Page 17

liftarmpads.RepeatfortheLHside,makingsure

g017957

1

2

3

g017958

1

2

3

4

g017959

1

2

3

theRHsideheight-of-cutroddoesnotfallout

(Figure19).

4.Installtheheight-of-cutcollarsontotheheight-of-cut

rodsandsecurethemwiththeclevispinsandhair

pincotters(

Figure19).Makesuretheheadofthe

clevispinistowardthefrontofthedeck.

SeparatingtheCuttingUnit

fromtheTractionUnit

1.Positionthemachineonlevelsurface,raisethe

cuttingunit,movetheliftlevertotheFloatposition,

shuttheengineoff,andengagetheparkingbrake.

2.Removethehairpinandclevispinsecuringthe

height-of-cutrodtotherearofthecuttingunit

Figure20).Removetheheight-of-cutcollars.

(

Figure20

Figure21

1.Liftarm

2.Clevispin4.Castorarmbracket

3.Hairpincotter

5.Removethehydraulicmotorcovers,removethe

bolts,thenremovethehydraulicmotorfromthe

cuttingunit.(Figure22).

1.Height-of-cutrod

2.Height-of-cutcollar

3.Turnontheignitionswitchandlowerthecutting

unittotheoor.Leavetheliftswitchintheoat

position.

Note:Makesuretheengineisnotrunning.

4.Removethehairpincottersandclevispinssecuring

theliftarmstothecastorarmbrackets(Figure21).

3.Hairpincotterandclevis

pin

Figure22

6.Raisetheliftarms,latchthemintheraisedposition,

androllthecuttingunitawayfromthetractionunit.

Turnofftheignitionswitch.

DANGER

Donotengagethecuttingunitdrivewhilethe

hydraulicmotorisnotconnectedtothecutting

unit.

MountingtheCuttingUnitto

theTractionUnit

1.Positionthemachineonalevelsurfaceandshutthe

17

engineoff.Leavetheignitionswitchon.

Page 18

2.Movethecuttingunitintopositioninfrontofthe

g017960

1

2

3

4

5

6

7

8

9

10

tractionunit.

3.Installthehydraulicmotorontothecuttingunit,

secureitusingthetwobolts,theninstallthetwo

hydraulicmotorcovers(

Figure22).

4.MovetheliftswitchtotheFloatposition.Pusha

liftarmdownuntiltheholesintheliftarmlineup

withtheholesinthecastorarmbracketandthe

heightofcutrodcanbeinsertedintotheliftarm

pads(Figure23).

pincotters(

Figure23).Headofclevispintobe

positionedtowardthefrontofthedeck.

ServicingtheBushingsinthe

CastorArms

Thecastorarmshavebushingspressedintothetopand

bottomofthetubeandaftermanyhoursofoperation,

thebushingswillwear.Tocheckthebushings,movethe

castorforkbackandforthandfromsidetoside.Ifthe

castorspindleislooseinsidethebushings,thebushings

arewornandmustbereplaced.

1.Raisethecuttingunitsothatthewheelsareoffof

theoor.Latchthecuttingunitsothatitcannot

accidentallyfall.

2.Removethetensioningcap,spacer(s),andthrust

washerfromthetopofthecastorspindle.

3.Pullthecastorspindleoutofthemountingtube.

Allowthethrustwasherandspacer(s)toremainon

thebottomofthespindle.

4.Insertapinpunchintothetoporbottomofthe

mountingtubeanddrivethebushingoutofthetube

Figure24).Alsodrivetheotherbushingoutofthe

(

tube.Cleantheinsideofthetubestoremovedirt.

Figure23

1.Liftarm6.Clevispin

2.Castorarmbracket

3.Height-of-cutrod8.Height-of-cutcollar

4.Liftarmpads9.Clevispin

5.Thrustwashers10.Hairpincotter

5.Securetheliftarmtothecastorarmwith(2)thrust

washers,aclevispinandahairpincotter.Position

thethrustwashersbetweentheliftarmandthecastor

armbracket(Figure23).Insertendofcotterpininto

theslotinthecastorarmtabtoretaincotterpin.

7.Hairpincotter

6.Repeattheprocedureontheoppositeliftarm.

7.Startthetractionunitandraisethecuttingunit.

8.WorkingontheRHside,pushdownontherear

ofthecuttingunitandinserttheheightofcutrods

throughtheliftarmpads.RepeatontheLHside

takingcarenottoallowtheRHsideheight-of-cut

rodtofallout.

9.Installtheheightofcutcollarsontotheheightof

cutrodsandsecurewiththeclevispinsandhair

Figure24

1.Castorarmtube

2.Bushings

5.Applygreasetotheinsideandoutsideofthenew

bushings.Usingahammerandatplate,drivethe

bushingsintothemountingtube.

6.Inspectthecastorspindleforwearandreplaceitif

damaged.

7.Pushthecastorspindlethroughthebushingsand

mountingtube.Slidethethrustwasherandspacer(s)

ontothespindle.Installthetensioningcaponthe

castorspindletoretainallpartsinplace.

ServicingtheCastorWheels

andBearings

1.Removethelocknutfromtheboltholdingthecastor

wheelassemblybetweenthecastorfork(Figure25).

18

Page 19

Graspthecastorwheelandslidetheboltoutofthe

G010549

G010555

1

2

forkorpivotarm.

Figure25

1.Castorwheel3.Bearing(2)

2.Castorfork

4.Bearingspacer

2.Removethebearingfromthewheelhubandallow

thebearingspacertofallout(Figure25).Remove

thebearingfromtheoppositesideofthewheelhub.

3.Checkthebearings,spacer,andinsideofthewheel

hubforwear.Replaceanydamagedparts.

4.Toassemblethecastorwheel,pushthebearinginto

thewheelhub.Wheninstallingthebearings,press

ontheouterraceofthebearing.

5.Slidethebearingspacerintothewheelhub.Pushthe

otherbearingintotheopenendofthewheelhubto

captivatethebearingspacerinsidethewheelhub.

Figure26

3.Rotatetheoppositeendofthebladeforward.

Measurebetweenthecuttingunitandcuttingedge

ofthebladeatthesamepositionasinstep2The

differencebetweenthedimensionsobtainedin

steps2and3mustnotexceed1/8inch(3mm).If

thedimensionexceeds1/8inch(3mm),replace

thebladebecauseitisbent;refertoRemovingthe

CuttingBlade.

RemovingandInstallingthe

Blade(s)

Theblademustbereplacedifasolidobjectishit,the

bladeisout-of-balance,worn,orbent.Alwaysuse

genuineTororeplacementbladestoensuresafetyand

optimumperformance.Neverusebladesmadebyother

manufacturersbecausetheycouldbedangerous.

1.Raisethecuttingunittothehighestposition,engage

theparkingbrake,stoptheengine,andremovethe

ignitionkey.Latchthecuttingunittopreventitfrom

accidentallyfalling.

2.Grasptheendofthebladeusingaragorthickly

paddedglove.Removethebladebolt,anti-scalpcup,

andbladefromthespindleshaft(

Figure27).

6.Installthecastorwheelassemblybetweenthecastor

forkandsecureitinplacewiththeboltandlocknut.

CheckingforaBentBlade

1.Positionthemachineonalevelsurface.Raisethe

cuttingunit,engagetheparkingbrake,putthe

tractionpedalinneutral,putthecuttingunitdrive

switchintheOffposition,stoptheengine,and

removetheignitionkey.Latchthecuttingunitto

preventitfromaccidentallyfalling.

2.Rotatethebladeuntiltheendsfaceforwardand

backward.Measurefromtheinsideofthecutting

unittothecuttingedgeatthefrontoftheblade

(Figure26),andrememberthisdimension.

Figure27

1.Bladebolt2.Anti-scalpcup

3.Installtheblade-sailfacingtowardthecutting

unit-withtheanti-scalpcupandbladebolt.Tighten

thebladeboltto85-110ft-lb(115-149N-m).

Important:Thecurvedpartoftheblademust

bepointingtowardtheinsideofthecuttingunit

toensurepropercutting .

19

Page 20

InspectingandSharpeningthe

Blade(s)

DANGER

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Donottrytostraightenabladethatisbent.

Figure28

1.Cuttingedge3.Wear/slotforming

2.Curvedarea/sail4.Crack

•Neverweldabrokenorcrackedblade.

•Replaceawornordamagedbladewitha

newT orobladetoensurecontinuedsafety

certicationoftheproduct.

Twoareasmustbeconsideredwhencheckingand

servicingthecuttingblade:thesailandthecuttingedge.

Bothcuttingedgesandthesail,whichistheturnedup

portionoppositethecuttingedge,contributetoagood

quality-of-cut.Thesailisimportantbecauseitpullsgrass

upstraight,therebyproducinganevencut.However,

thesailwillgraduallyweardownduringoperation,and

thisconditionisnormal.Asthesailwearsdown,the

quality-of-cutwilldegradesomewhat,althoughthe

cuttingedgesaresharp.Thecuttingedgeoftheblade

mustbesharpsothatthegrassiscutratherthantorn.

Adullcuttingedgeisevidentwhenthetipsofthegrass

appearbrownandshredded.Sharpenthecuttingedges

tocorrectthiscondition.

1.Positionthemachineonalevelsurface.Raisethe

cuttingunit,engagetheparkingbrake,putthe

tractionpedalinneutral,putthecuttingunitdrive

switchintheOffposition,stoptheengine,remove

theignitionkey,andapplytheliftarmlatches.

WARNING

Ifthebladeisallowedtowear,aslotwillform

betweenthesailandatpartoftheblade

Figure28).Eventually,apieceoftheblademay

(

breakoffandbethrownfromunderthehousing,

possiblyresultinginseriousinjurytoyourself

orbystanders.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedbladewitha

newTorobladetoensurecontinuedsafety

certicationoftheproduct.

3.Examinethecuttingedgesofallblades.Sharpenthe

cuttingedgesiftheyaredullornicked.Sharpenonly

thetopsideofthecuttingedgeandmaintainthe

originalcuttingangletoensuresharpness(Figure29).

Thebladewillremainbalancedifthesameamount

ofmetalisremovedfrombothcuttingedges.

2.Examinethecuttingendsofthebladecarefully,

especiallywheretheatandcurvedpartsofthe

blademeet(

materialcanwearawaythemetalthatconnects

theatandcurvedpartsoftheblade,checkthe

bladebeforeusingthemachine.Ifwearisnoticed

(Figure28),replacetheblade;refertoRemovingthe

CuttingBlade.

Figure28).Sincesandandabrasive

Figure29

1.Sharpenatoriginalangle

Note:Removethebladesandsharpenthemona

grinder;refertoRemovingtheCuttingBlades.After

sharpeningthecuttingedges,installthebladewith

theanti-scalpcupandbladebolt.Thebladesails

mustbeontopoftheblade.Tightenthebladebolt

to85-110ft-lb(115-149N-m).

20

Page 21

CheckingandCorrecting

g017961

1

2

g017962

1

2

MismatchofBlades

Ifthereismismatchbetweentheblades,thegrasswill

appearstreakedwhenitiscut.Thisproblemcanbe

correctedbymakingsurethatthebladesarestraightand

allofthebladesarecuttingonthesameplane.

1.Usinga3foot(1meter)longcarpenterslevel,nd

alevelsurfaceontheshopoor.

2.Raisetheheight-of-cuttothehighestposition;refer

toAdjustingtheHeight-of-Cut.

3.Lowerthecuttingunitontotheatsurface.Remove

thecoversfromthetopofthecuttingunit.

4.Rotatethebladesuntiltheendsfaceforwardand

backward.Measurefromtheoortothefronttipof

thecuttingedge.Rememberthisdimension.Then

rotatethesamebladesothattheoppositeendis

forward,andmeasureagain.Thedifferencebetween

thedimensionsmustnotexceed1/8inch(3mm).

Ifthedimensionexceeds1/8inch(3mm),replace

thebladebecauseitisbent.Makesuretomeasure

alloftheblades.

5.Comparethemeasurementsoftheouterblades

withthecenterblade.Thecenterblademustnotbe

morethan3/8inch(10mm)lowerthantheouter

blades.Ifthecenterbladeismorethan3/8inch(10

mm)lowerthantheouterblades,proceedtostep

andaddshimsbetweenthespindlehousingandthe

bottomofthecuttingunit.

1.Lowerthecuttingunittotheshopoor.Remove

thebeltcoversfromthetopofthecuttingunitand

setthecoversaside.

2.Usingatorquewrenchorsimilartool,movetheidler

pulley(Figure30)awayfromthedrivebelttorelease

thebelttensionandallowthebelttobeslippedoff

thexedidlerpulley(Figure30).

Figure30

1.Idlerpulley2.Fixedidlerpulley

6

6.Removethebolts,atwashers,lockwashers,and

nutsfromtheouterspindleintheareawherethe

shimsmustbeadded.Toraiseorlowertheblade,

addashim,PartNo.3256-24,betweenthespindle

housingandthebottomofthecuttingunit.Continue

tocheckthealignmentofthebladesandaddshims

untilthetipsofthebladesarewithintherequired

dimension.

Important:Donotusemorethanthreeshimsat

anyoneholelocation.Usedecreasingnumbers

ofshimsinadjacentholesifmorethanoneshim

isaddedtoanyoneholelocation.

7.Installthebeltcovers.

ReplacingtheDriveBelt

Thebladedrivebelt,tensionedbythespringloaded

idlerpulley,isverydurable.However,aftermanyhours

ofuse,thebeltwillshowsignsofwear.Signsofaworn

beltare:squealingwhenbeltisrotating,bladesslipping

whencuttinggrass,frayededges,burnmarksandcracks.

Replacethebeltifanyoftheseconditionsareevident.

Figure31

1.Bolts2.Hydraulicmotor

3.Removetheboltsandhydraulicmotorasshownin

Figure31.

4.Removetheoldbeltfromaroundtheremaining

pulleys.

5.Routethenewbeltaroundthespindlepulleysand

idlerpulleyassemblyasshowninFigure32.

21

Page 22

Figure32

1.Beltrouting

6.Installthehydraulicmotorandsecureitwiththe

boltsremovedearlier(Figure31).

7.Installthebeltcovers.

22

Page 23

Notes:

23

Page 24

TheT oroT otalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany ,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenance

andadjustmentsstatedinyourOperator'sManual.Failuretoperform

requiredmaintenanceandadjustmentscanbegroundsfordisallowinga

warrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,

duringnormalProductoperationinclude,butarenotlimitedto,brake

padsandlinings,clutchlinings,blades,reels,rollersandbearings

(sealedorgreasable),bedknives,sparkplugs,castorwheelsand

bearings,tires,lters,belts,andcertainsprayercomponentssuchas

diaphragms,nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,

lubricants,additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damageto

seatsduetowearorabrasion,wornpaintedsurfaces,scratched

decalsorwindows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofToro.Torowill

makethenaldecisionwhethertorepairanyexistingpartorassemblyor

replaceit.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesToroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedT oroDistributororDealerisyoursoleremedy

underthiswarranty .

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty .ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.

Allimpliedwarrantiesofmerchantabilityandtnessforuseare

limitedtothedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.Thiswarranty

givesyouspeciclegalrights,andyoumayalsohaveotherrightswhich

varyfromstatetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EPA)and/ortheCaliforniaAir

ResourcesBoard(CARB).Thehourlimitationssetforthabovedonot

applytotheEmissionsControlSystemWarranty.RefertotheEngine

EmissionControlWarrantyStatementsuppliedwithyourproductor

containedintheenginemanufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.

374-0253RevB

Loading...

Loading...