Page 1

FormNo.3391-556RevB

G017536

CommercialWalk-BehindMower

FixedDeck,PistolGrip,GearDrivewith32in,

36inor48inCuttingUnit

ModelNo.30632—SerialNo.315000001andUp

ModelNo.30634—SerialNo.315000001andUp

ModelNo.30638—SerialNo.315000001andUp

ModelNo.39634—SerialNo.315000001andUp

ModelNo.39638—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3391-556*B

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwith

asparkarrestermufer.Itisaviolationof

CaliforniaPublicResourceCodeSection4442to

useoroperatetheengineonanyforest-covered,

brush-covered,orgrass-coveredland.Other

statesorfederalareasmayhavesimilarlaws.

WARNING

Removingstandardoriginalequipmentparts

andaccessoriesmayalterthewarranty,

traction,andsafetyofthemachine.Failureto

useoriginalT oropartscouldcauseserious

injuryordeath.Makingunauthorizedchanges

totheengine,fuelorventingsystem,may

violateEPAandCARBregulations.

Replaceallpartsincluding,butnotlimited

to,tires,belts,blades,andfuelsystem

componentswithoriginalToroparts.

Theenclosedengineowner’smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

YoumaycontactT orodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

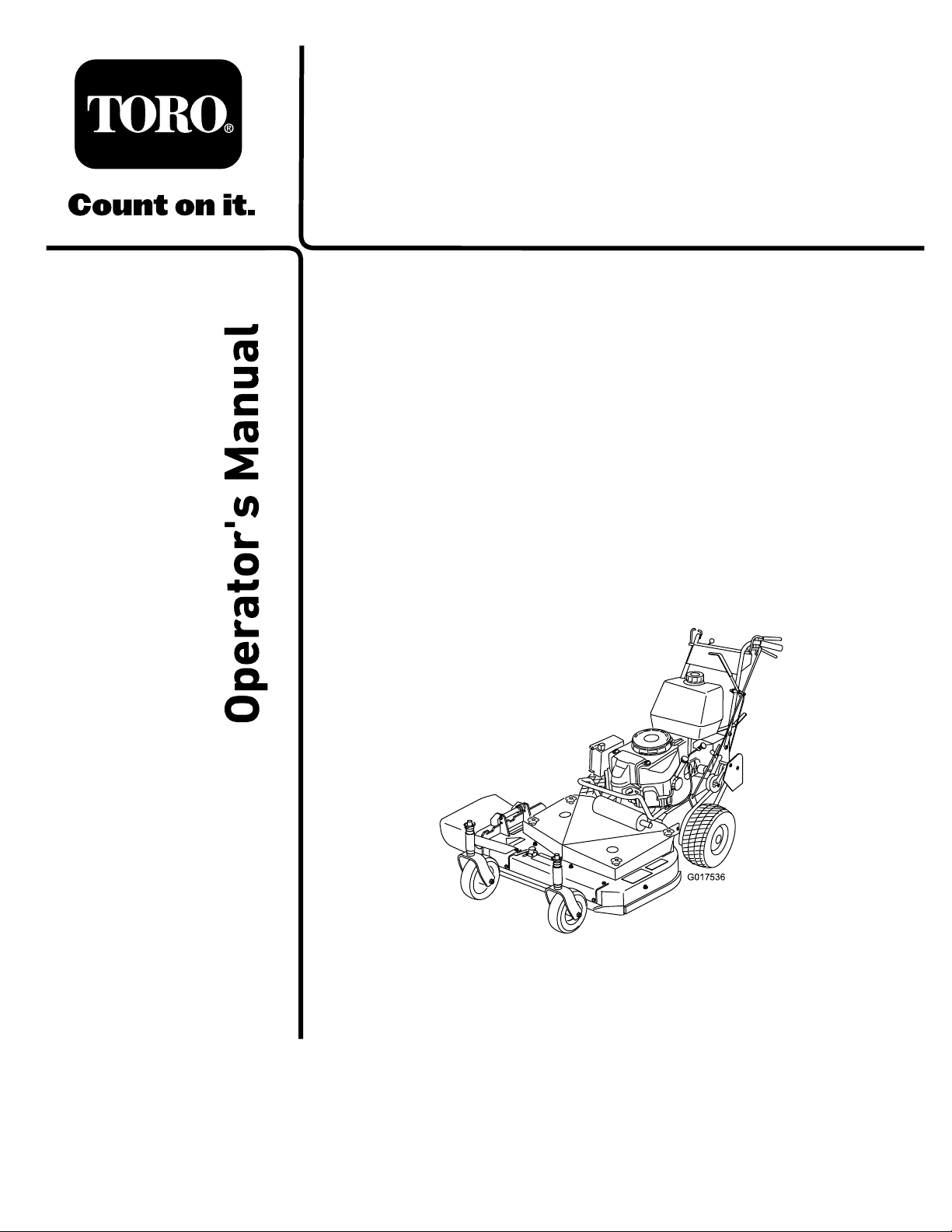

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g001487

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safetyalertsymbol

Introduction

Thisrotary-blade,lawnmowerisintendedtobe

usedbyresidentialhomeownersorprofessional,

hiredoperators.Itisdesignedprimarilyforcutting

grassonwell-maintainedlawnsonresidential

orcommercialproperties.Itisnotdesignedfor

cuttingbrushorforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Y ouareresponsiblefor

operatingtheproductproperlyandsafely .

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

2

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

ToroMowerSafety..............................................5

SlopeIndicator...................................................7

SafetyandInstructionalDecals..........................8

ProductOverview....................................................11

Controls............................................................11

Specications..................................................12

Attachments/Accessories.................................12

Operation................................................................12

AddingFuel......................................................12

UsingFuelStabilizer/Conditioner.....................13

CheckingtheEngine-OilLevel..........................13

FillingtheFuelTank..........................................13

PuttingSafetyFirst...........................................13

OperatingtheParkingBrakeandNeutral

Locks............................................................14

StartingandStoppingtheEngine......................14

OperatingtheBlade-Control(PTO)

Lever.............................................................15

TheSafety-InterlockSystem.............................15

DrivingForwardorBackward............................16

StoppingtheMower..........................................16

TransportingtheMachine.................................17

SideDischargingorMulchingthe

Grass............................................................17

AdjustingtheWheel-Drive-BeltT ension............17

AdjustingtheHeightofCut...............................18

AdjustingtheFlowBafe..................................19

PositioningtheFlowBafe................................19

AdjustingtheHandleHeight.............................20

Height-of-CutChart..........................................22

Maintenance...........................................................23

RecommendedMaintenanceSchedule(s)...........23

Lubrication..........................................................24

LubricatingtheMachine....................................24

LubricatingtheCasterandWheel

Bearings........................................................24

GreasingtheTransmissionCouplers................24

GreasingtheMower-BeltIdler..........................24

EngineMaintenance...........................................25

ServicingtheAirCleaner..................................25

ServicingtheEngineOil....................................25

ServicingtheSparkPlugs.................................27

FuelSystemMaintenance...................................28

ServicingtheFuelSystem................................28

DriveSystemMaintenance..................................30

CheckingtheTirePressure...............................30

CoolingSystemMaintenance..............................31

CleaningtheAir-intakeScreen.........................31

CleaningtheCoolingSystem............................31

BrakeMaintenance.............................................32

ServicingtheBrakes.........................................32

BeltMaintenance................................................33

CheckingtheBelts............................................33

ReplacingtheTractionDriveBelt......................33

ReplacingtheDriveBelt...................................33

ReplacingtheMowerBelt.................................33

AdjustingtheMowerBeltT ension.....................35

ControlsSystemMaintenance.............................38

AdjustingtheControlRods...............................38

MowerDeckMaintenance....................................39

ServicingtheCuttingBlades.............................39

AdjustingtheBladeBrake.................................41

ReplacingtheGrassDeector..........................42

Storage...................................................................43

CleaningandStorage.......................................43

Troubleshooting......................................................44

Schematics.............................................................46

3

Page 4

Safety

Note:Theadditionofattachmentsmadeby

othermanufacturersthatdonotmeetAmerican

NationalStandardsInstitutecerticationwillcause

noncomplianceofthismachine.

Improperlyusingormaintainingthemachinecan

resultininjury.Toreducethepotentialforinjury ,

complywiththesesafetyinstructionsandalways

payattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—personal

safetyinstruction.Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromANSI

B71.4-2012.

Training

•ReadtheOperator'sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readorunderstandtheinformationitistheowner's

responsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtopeopleor

damagetoproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Useonlyaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,

substantial,slip-resistantfootwear,safetyglasses,

andhearingprotection.Longhair,looseclothing,

orjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobe

usedandremoveallobjectssuchasrocks,toys,

andwire,whichcanbethrownbythemachine.

•Checkthatoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyare

functioningproperly.

Operation

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Neverrunanengineinanenclosedarea.

•Operatethemachineonlyingoodlight,keeping

awayfromholesandhiddenhazards.

•Besurethatalldrivesareinneutralandthe

parkingbrakeisengagedbeforestartingthe

engine.Starttheengineonlyfromtheoperator's

position.

•Besureofyourfootingwhileusingthismachine,

especiallywhenbackingup.Walk;donotrun.

Neveroperateonwetgrass.Reducedfooting

couldcauseslipping.

•Slowdownanduseextracareonhillsides.Be

suretotravelsidetosideonhillsides.Turf

conditionscanaffectthestabilityofthemachine.

Usecautionwhileoperatingneardrop-offs.

•Slowdownandusecautionwhenmakingturns

andwhenchangingdirectiononslopes.

•Neverraisethedeckwiththebladesrunning.

•NeveroperatewiththePTOshieldorotherguards

notsecurelyinplace.Besureallinterlocksare

attached,adjustedproperly,andfunctioning

properly.

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessyouareusingagrass

catcher.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,disengagedrives,engage

theparkingbrake(ifprovided),andshutoffthe

enginebeforeleavingtheoperator'spositionfor

anyreason,includingemptyingthecatchersor

uncloggingthechute.

•Stoptheequipmentandinspecttheblades

afterstrikingobjectsorifanabnormalvibration

occurs.Makenecessaryrepairsbeforeresuming

operation.

•Keephandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Nevercarrypassengersonthemachine.

•Keeppetsandbystandersaway .

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Stopthe

bladesifyouarenotmowing.

4

Page 5

•Beawareofthemowerdischargedirectionand

donotpointitatanyone.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoorfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Usefull-widthrampsforloadingmachineinto

trailerortruck.

•Tiethemachinedownsecurelyusingstraps,

chains,cable,orropes.Bothfrontandrearstraps

shouldbedirecteddownandoutwardfromthe

machine.

ToroMowerSafety

MaintenanceandStorage

•Disengagedrives,settheparkingbrake,stop

theengineandremovethekeyordisconnect

thespark-plugwire.Waitforallmovementto

stopbeforeadjusting,cleaning,orrepairingthe

machine.

•Cleangrassanddebrisfromthecuttingunit,the

drives,themufers,andtheenginetohelpprevent

res.Cleanupoilorfuelspills.

•Lettheenginecoolbeforestoring,anddonot

storeitnearaame.

•Shutoffthefuelwhilestoringortransportingthe

machine.Donotstorefuelnearamesordrainit

indoors.

•Parkthemachineonlevelground.Settheparking

brake.Neverallowuntrainedpersonneltoservice

themachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatteryorthespark-plugwire

beforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositivelast.

Connectthepositiverstandnegativelast.

•Usecarewhencheckingtheblades.Wrapthe

blade(s)orweargloves,andusecautionwhen

servicingthem.Onlyreplaceblades.Never

straightenorweldthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Tobestprotectyourinvestmentandmaintain

optimalperformanceofyourToroequipment,count

onT orogenuineparts.Whenitcomestoreliability ,

Torodeliversreplacementpartsdesignedtothe

exactengineeringspecicationsofourequipment.

Forpeaceofmind,insistonT orogenuineparts.

Hauling

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

Thefollowinglistcontainssafetyinformationspecic

toToroproductsandothersafetyinformationyou

mustknow.

Thisproductisdesignedforcuttingandrecycling

grassor,whenequippedwithagrassbagger,for

catchingcutgrass.Anyuseforpurposesotherthan

thesecouldprovedangeroustoyouandbystanders.

GeneralOperation

•Besurethattheareaisclearofotherpeople

beforemowing.Stopthemachineifanyoneenters

thearea.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowthemtocool

beforeattemptingtomaintain,adjust,orservice

them.

•UseonlyT oroapprovedattachments.The

warrantymaybevoidedifyouusethemachine

withunapprovedattachments.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

operatingthemachineunderanyobjects,anddo

notcontactthem.

SlopeOperation

Allslopesandrampsrequireextracaution.Ifyoufeel

uneasyonaslope,donotmowit.

•Removeobstaclessuchasrocks,treelimbs,etc.

fromthemowingarea.

•Watchforholes,ruts,orbumps.Tallgrasscan

hideobstacles.

•Usecautionneardrop-offs,ditches,or

embankments.Themachinecouldsuddenlyturn

overifawheelgoesovertheedgeofacliffor

ditch,orifanedgecavesin.

•Useextracarewithgrasscatchersorother

attachments.Thesecanchangethestabilityof

themachine.

•Keepallmovementonslopesslowandgradual.

Donotmakesuddenchangesinspeedor

direction.

•Mowslopessidetoside.

•Donotmowslopesgreaterthan20degrees.

5

Page 6

Service

•Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasneara

waterheaterorfurnace.

•Keepnutsandboltstight,especiallytheblade

attachmentbolts.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.Checksafety

systemsforproperoperationbeforeeachuse.

•Useonlygenuinereplacementpartstoensurethat

originalstandardsaremaintained.

•Checkbrakeoperationfrequently.Adjustand

serviceasrequired.

6

Page 7

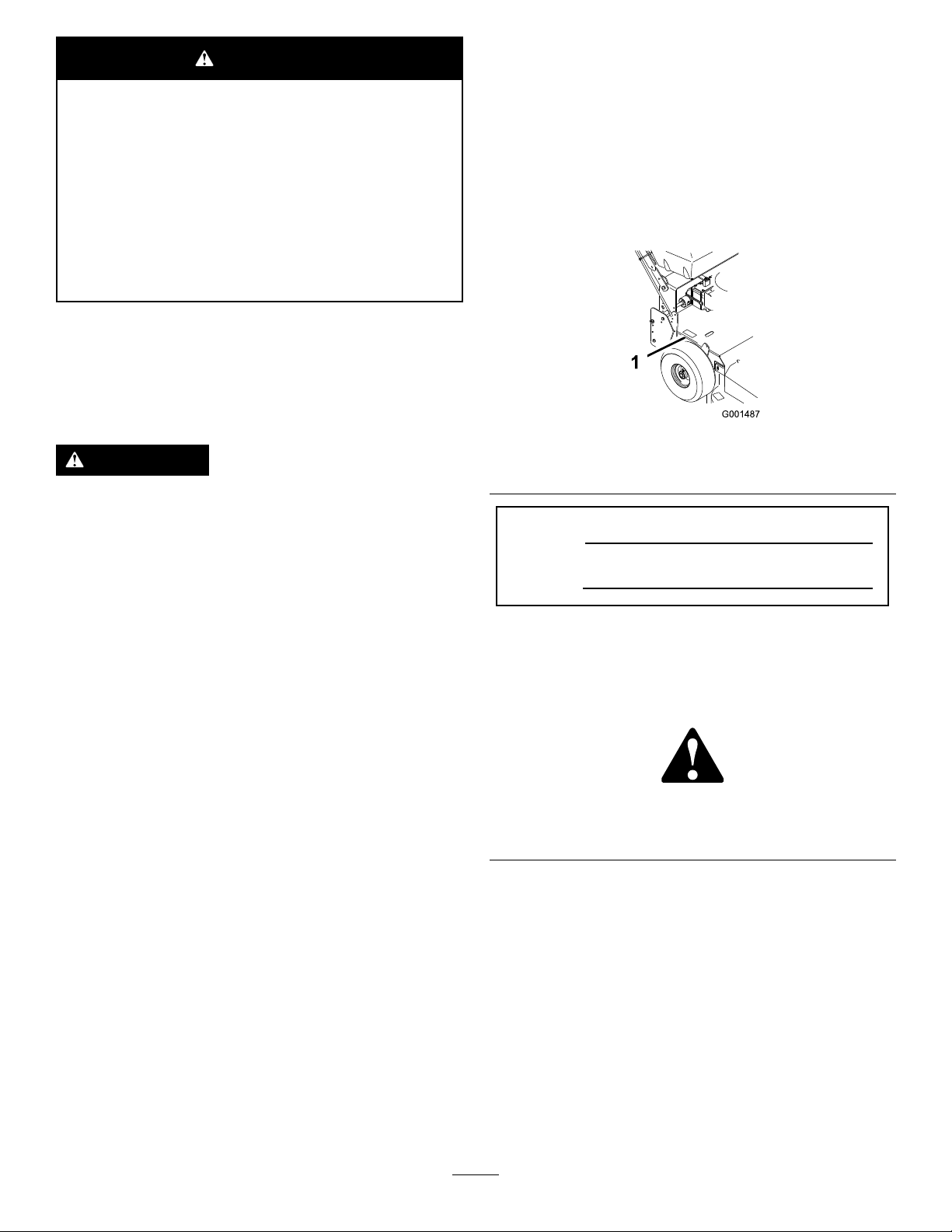

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis20degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan20degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

g011841

Page 8

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedorlost.

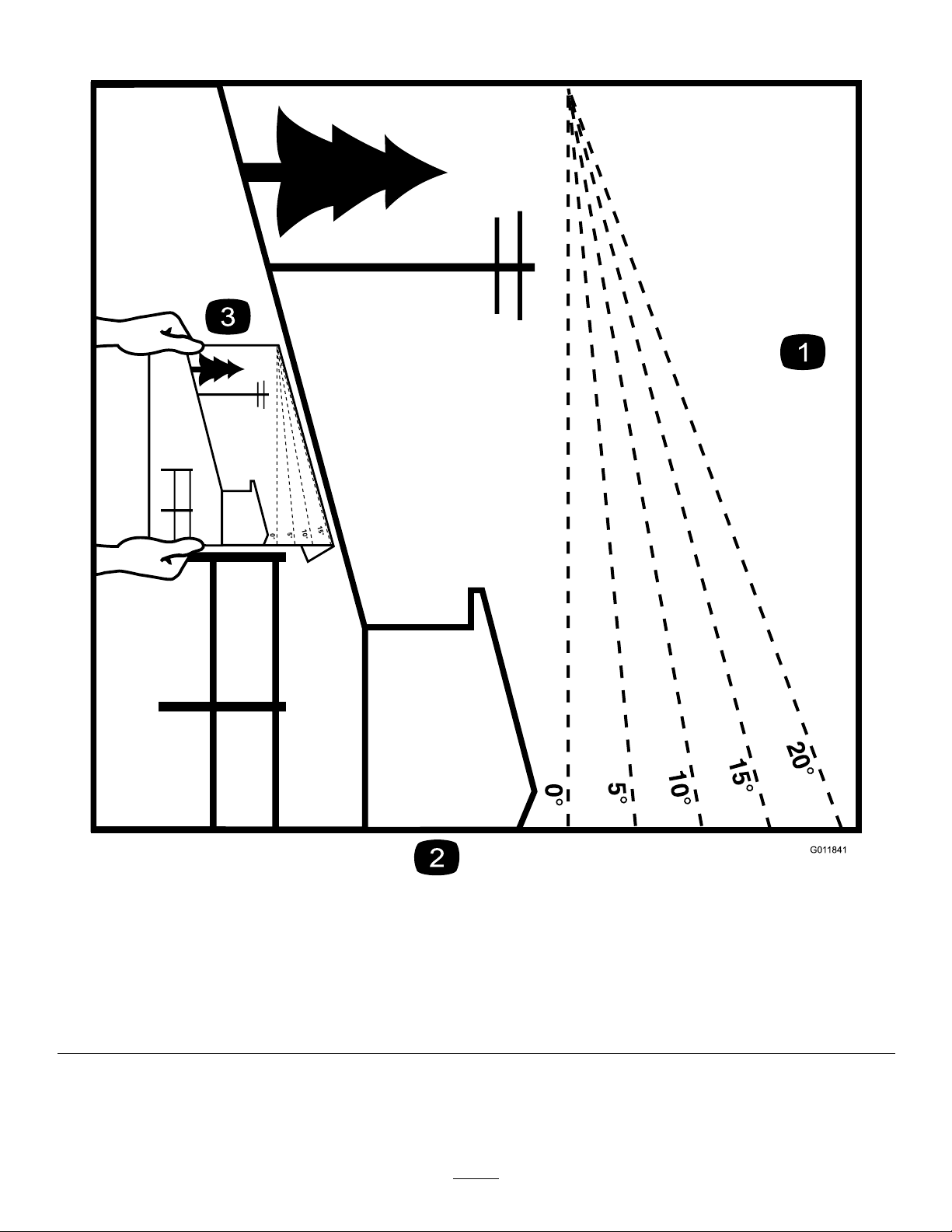

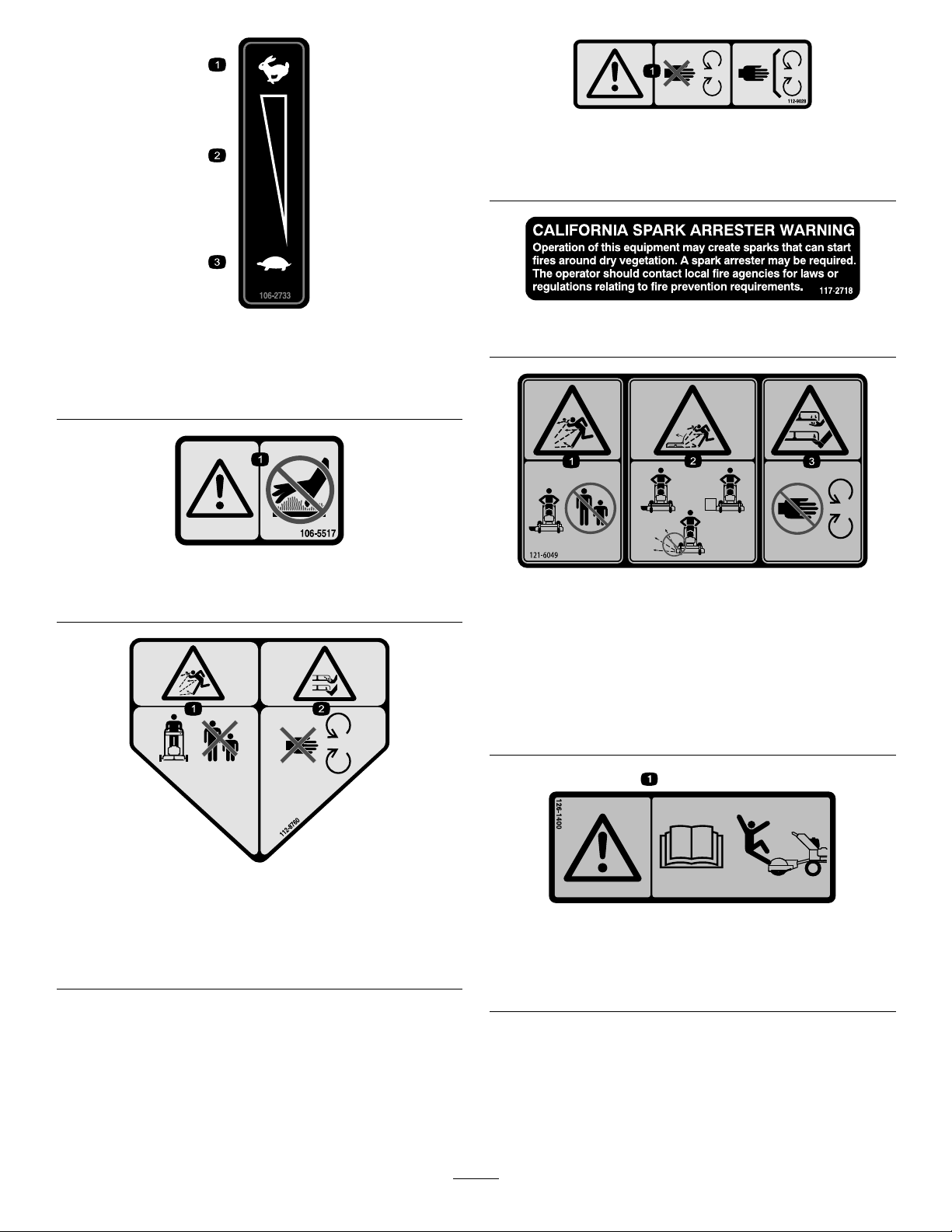

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

93-7010

decaloemmarkt

decal98-5130

98-5130

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto75-80ft-lb(102-106N⋅m).

decal93-7010

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—keepthedeectorinplace.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

95-5537

1.ReadtheOperator's

Manualforinstructionson

operatingthecuttingblade

2.Pushforwardtoengage

3.Pullbacktodisengage

decal99-3943

99-3943

1.Engine

decal105-4104

105-4104

1.Reverse3.Transmissionspeeds

2.Neutral

decal95-5537(gear)

8

Page 9

decal112-9028

112-9028

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

1.Fast

2.Continuousvariable

setting

1.Warning—donottouchthehotsurface.

decal106-2733

106-2733

117–2718

decal117-2718

3.Slow

decal106-5517

106-5517

decal121-6049

121-6049

1.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Thrownobjecthazard,

mower—donotoperate

themowerwithguardsor

shieldsremoved.

3.Cutting/dismemberment

hazardofhandorfoot,

mowerblade—keephands

awayfrommovingparts.

112-8760

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

decal112-8760

decal126-1400

126-1400

1.Warning-ReadtheOperator’smanual.UseonlyTororiding

attachments.Useofotherridingattachmentsmaycreatea

hazardousconditionresultingininjury.

9

Page 10

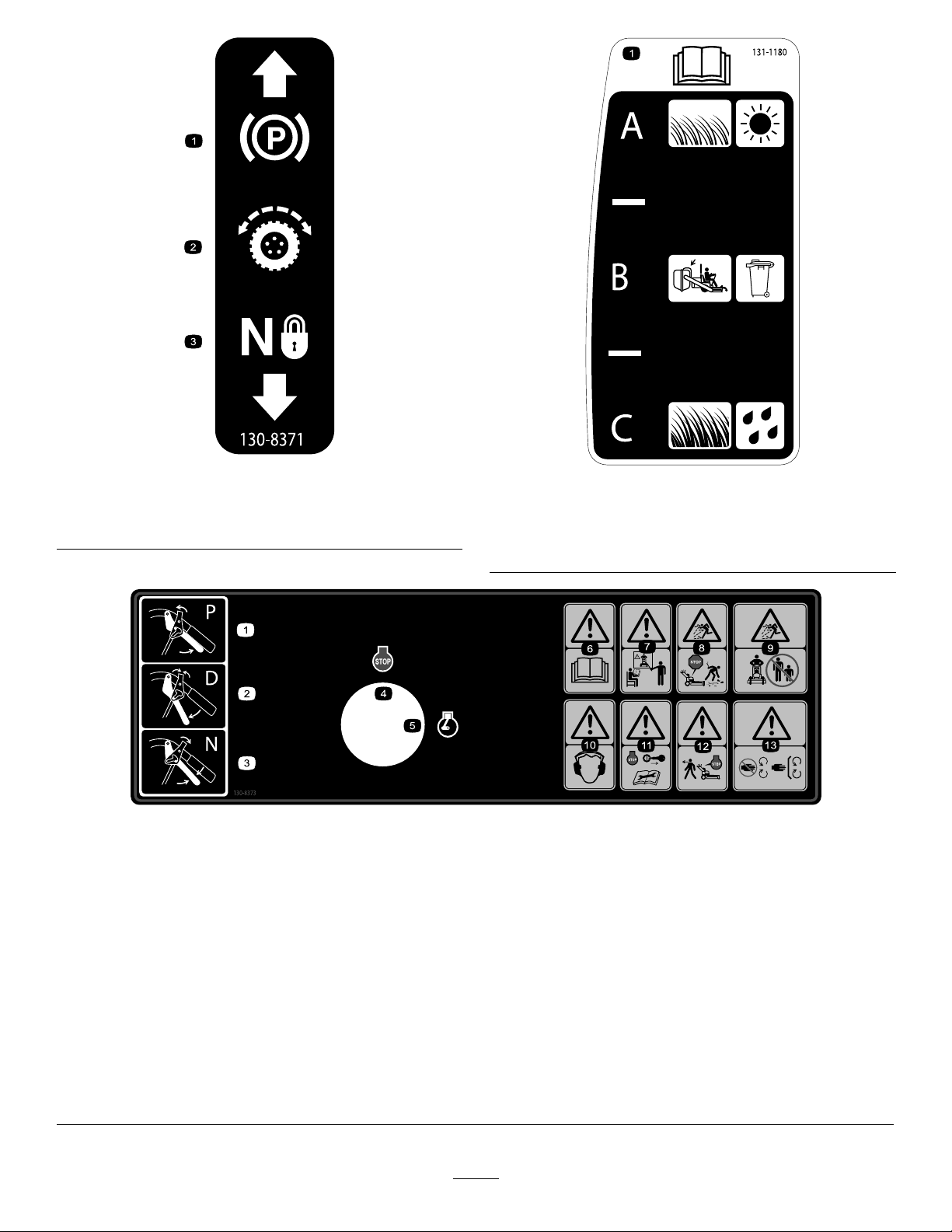

130-8371

1.Parkingbrake3.Neutrallock

2.Tractiondrive

decal130-8371

decal131-1180

131-1180

1.ReadtheOperator'sManual.(A)Short,lightgrass;dry

conditions;maximumdispersion;(B)Baggingsetting;(C)

Tall,densegrass;wetconditions;maximumgroundspeed

decal130-8373

130-8373

1.Parkingposition5.Engine—run9.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Driveposition6.Warning—readthe

Operator'sManual.

3.Neutralposition7.Warning—donotoperate

themachinewithout

receivingpropertraining.

10.Warning—wearhearing

protection.

11.Warning—stoptheengine,

removethekeyfromthe

ignition,andreadthe

Operator'sManualbefore

servicingorperforming

maintenance.

4.Engine—stop8.Thrownobject

hazard—stoptheengine

andpickupanydebrisin

theareabeforeoperating

12.Warning,releasethebar

andensuretheenginehas

stoppedbeforewalking

awayfromthemachine.

themachine.

10

13.Warning—stayawayfrom

movingparts;keepall

guardsandshieldsinplace.

Page 11

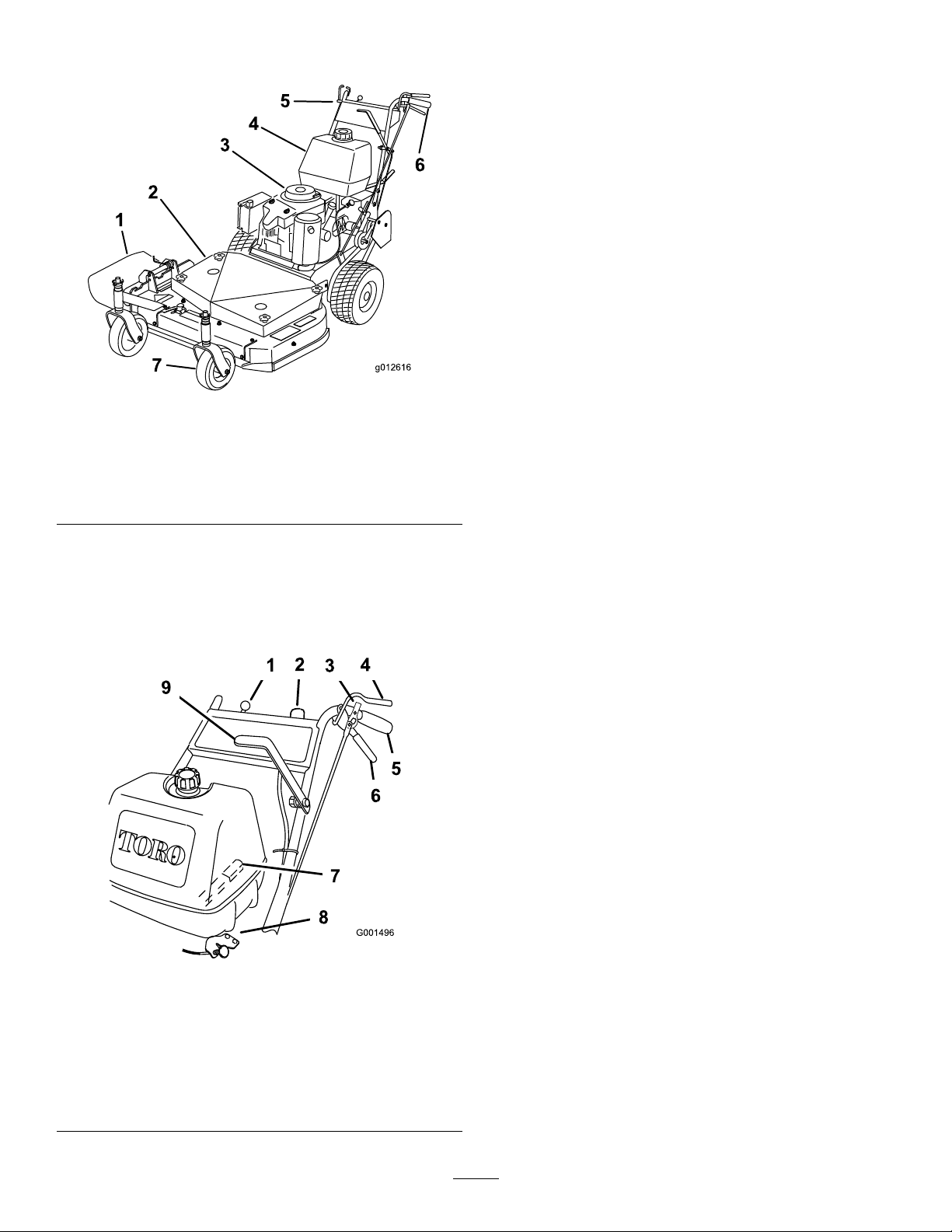

ProductOverview

g012616

1

2

3

4

5

6

7

1.Sidedischarge5.Controls

2.Mowerdeck6.Handle

3.Recoil-starthandle

4.Fueltank

Figure4

7.Casterwheel

ThrottleControl

Thethrottlecontrolhas2positions:FastandSlow.

Operator-Presence-Control(OPC)

Levers

WhenyousqueezetheOPCleversagainstthe

handles,theOPCsystemsensesthattheoperatoris

inthenormaloperatingposition.Whenyourelease

theOPClevers,theOPCsystemsensesthatthe

operatorhasleftthenormaloperatingposition,and

thesystemwillstoptheengineifeitherthegear-shift

leverisnotintheNeutralpositionortheblade-control

(PTO)leverisengaged.

Gear-ShiftLever

g012616

Thetransmissionhas5forwardspeeds,neutral,and

reverse,andhasanin-lineshiftpattern.

Important:Donotshiftwhilethemachineis

moving,astransmissiondamagemayoccur.

DriveLevers

Controls

Becomefamiliarwithallthecontrols(Figure5)before

youstarttheengineandoperatethemachine.

1.Throttlecontrol6.Drivelever

2.Ignitionswitch

3.Neutral/parkingbrakelock8.Choke

4.Operator-presence-control

(OPC)lever

5.Handle

Figure5

7.Gear-shiftlever

9.Power-take-offlever(PTO)

Releasethedriveleverstoengagetheforward

tractionoperation.Squeezetheright-handdrivelever

toturnrightandtheleft-handdrivelevertoturnleft.

Neutral/Parking-BrakeLock

Squeezethedriveleversandmovethelocksrearward

forneutrallock.Squeezethedriveleversandmove

thelocksforwardtosettheparkingbrake.

Blade-ControlLever(PTO)

ThisleverisusedinconjunctionwiththeOPClevers

toengageordisengagethemowerdeckbeltand

drivethemowerblades.

Recoil-StartHandle

Pulltherecoil-starthandletostarttheengine(not

showninFigure5).

g001496

Fuel-ShutoffValve

Closethefuel-shutoffvalvewhentransportingor

storingthemachine.

IgnitionSwitch

Thisswitchisusedinconjunctionwiththerecoil

starterandhas2positions:RunandOff.

11

Page 12

Choke

Usethechoketostartacoldengine.

Operation

AddingFuel

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

32-inchmowers:

Widthwithdeectordown116cm(46inches)

Length

Height

Weight

36-inchmowers:

Widthwithdeectordown118cm(47inches)

Length

Height

Weight

48-inchmowers:

Widthwithdeectordown161cm(63-1/2inches)

Length

Height

Weight

198cm(78inches)

104cm(41inches)

182kg(402lb)

203cm(80inches)

104cm(41inches)

210kg(462lb)

199cm(78inches)

104cm(41inches)

227kg(500lb)

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.EthanolandMTBE

arenotthesame.Gasolinewith15%ethanol

(E15)byvolumeisnotapprovedforuse.Never

usegasolinethatcontainsmorethan10%ethanol

byvolume,suchasE15(contains15%ethanol),

E20(contains20%ethanol),orE85(contains85%

ethanol).Usingunapprovedgasolinemaycause

performanceproblemsand/orenginedamage

whichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizer

isused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty .

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.

Addfueltothefueltankuntilthelevelis25

mm(1inch)belowthebottomoftheller

neck.Thisemptyspaceinthetankallows

thefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerand

keepitoutofthereachofchildren.Donot

buymorethana30-daysupplyoffuel.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworking

condition.

12

Page 13

DANGER

CheckingtheEngine-Oil

Incertainconditionsduringfueling,static

electricitycancauseaspark,whichcanignite

thefuelvapors.Areorexplosionfromfuel

canburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruck-bedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removefuel-powered

equipmentfromthetruckortrailerand

fueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

fuel-dispensernozzle.

•Ifafueldispensermustbeused,keepthe

nozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntil

fuelingiscomplete.

Level

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheEngine-oilLevel.

FillingtheFuelTank

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundthefuel-tankcapandremovethe

cap.Addunleadedregulargasolinetothefuel

tank,untilthelevelis6to13mm(1/4to1/2

inch)belowthebottomofthellerneck.This

spaceinthetankallowsgasolinetoexpand.Do

notllthefueltankcompletelyfull.

3.Installthefuel-tankcapsecurely.Wipeupany

gasolinethatmayhavespilled.

PuttingSafetyFirst

Carefullyreadallthesafetyinstructionsanddecals

inthesafetysection.Knowingthisinformationcould

helpyouoranybystandersavoidinjury.

Theuseofprotectiveequipmentforeyes,hearing,

feetandheadisrecommended.

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleand

fueltankorconditioneropening.

•Keepfuelawayfromeyesandskin.

UsingFuel Stabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

keepthefuelfreshduringstorageof90daysorless.

Ifyouarestoringthemachineforlonger,drainthefuel

tank;refertoDrainingtheFuelT ank(page28).

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditionerto

thefuel,andfollowthedirectionsofthemanufacturer.

Note:Fuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.T ominimizethe

chanceofvarnishdepositsinthefuelsystem,usefuel

stabilizeratalltimes.

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator'searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

decal98-4387

Figure6

1.Warning—wearhearingprotection.

13

Page 14

OperatingtheParking BrakeandNeutralLocks

Alwayssettheparkingbrakeswhenyoustopthe

machineorleaveitunattended.

ReleasingtheNeutralLocks

1.Squeezethedriveleversback.

2.Placeyourthumbsontheupperpartofthelocks

andmovethemforwarduntiltheyareinthe

Driveposition(Figure7).

WARNING

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwayssettheparkingbrakewhenleaving

themachineunattended,evenifjustforafew

minutes.

SettingtheParkingBrakes

1.Squeezethedrivelevers(Figure7).

Figure7

1.Handle

2.Neutral/parkingbrakelock

3.Parkposition6.Neutralposition

2.Placeyourthumbsontheupperpartofthelocks

andmovethemforwardinintotheparkposition

(Figure7).

3.Releasethedrivelevers.

4.Fullspeedforward

5.Drivelever

ReleasingtheParkingBrakes

1.Squeezethedriveleversback(Figure7).

2.Placeyourthumbsontheupperpartofthelocks

andmovethemrearwarduntiltheyareinthe

Driveposition(Figure7).

SettingtheNeutralLocks

1.Squeezethedriveleversback(Figure7).

2.Placeyourthumbsontheupperpartofthelocks

andmovethemrearwardintotheNeutralLock

position(Figure7).

StartingandStoppingthe Engine

StartingtheEngine

1.Connectthewirestothesparkplugs.

2.Openthefuelvalve.

3.Disengagetheblade-control(PTO)leverand

movetheshiftlevertotheNeutralposition.

4.Settheparkingbrakes.

5.TurntheignitionkeytotheRunposition(Figure

8).

6.T ostartacoldengine,movethethrottlecontrol

midwaybetweentheFastandSlowpositions.

7.T ostartawarmengine,movethethrottlecontrol

totheFastposition.

8.Pullthechokeknobiftheengineiscold(Figure

8).

Note:Awarmorhotengineusuallydoesnot

requireanychoking.

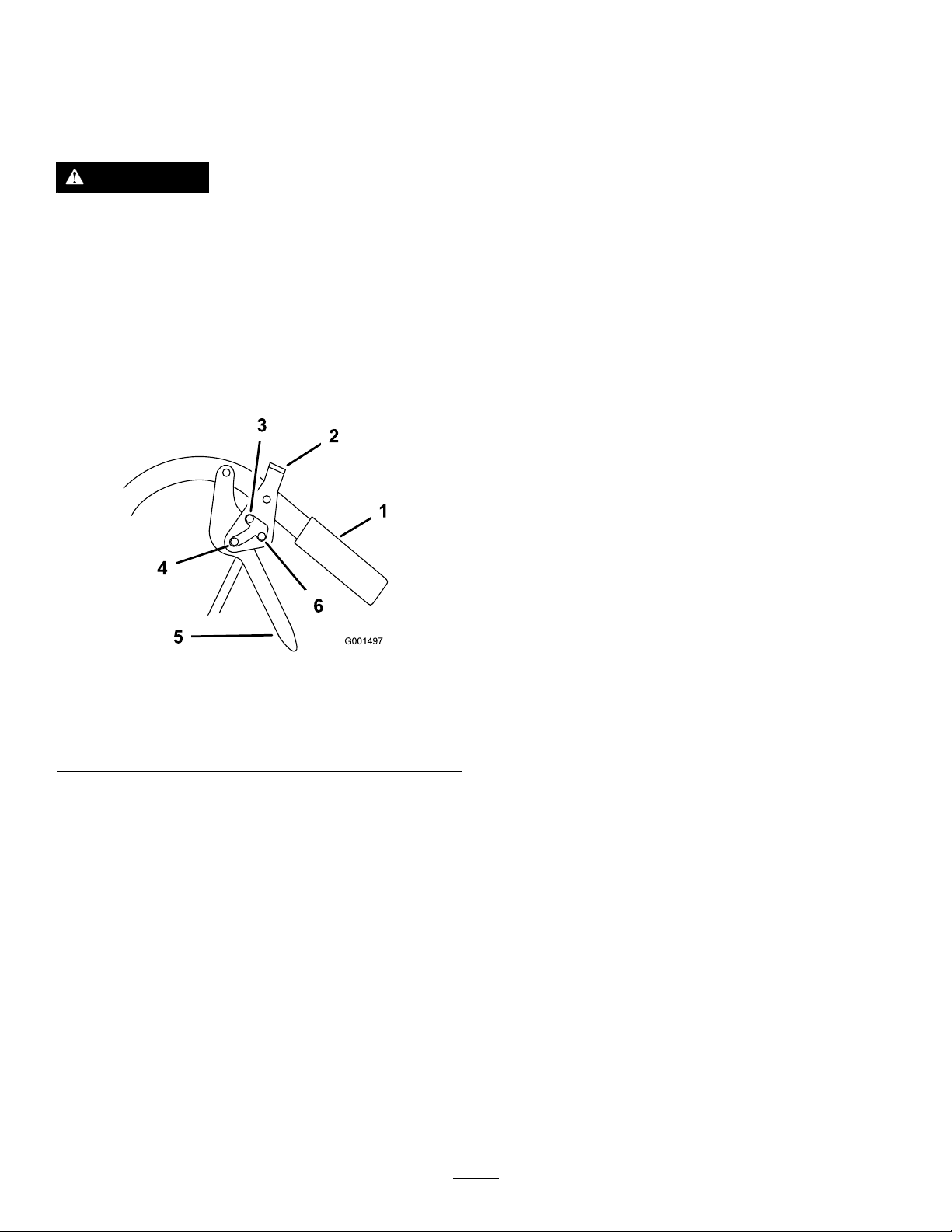

g001497

9.Grasptherecoil-starthandlermlyandpullitout

untilpositiveengagementresults;thenpullthe

handlevigorouslytostarttheengine.

Note:Allowtheropetorecoilslowly.

Important:Donotpulltherecoilropetoits

limitorreleasethestarterhandlewhenyou

pullouttheropebecausetheropemaybreak

ortherecoilassemblymaybedamaged.

10.PushthechoketotheOffpositionastheengine

warmsup.

11.Iftheengineiscold,allowittowarmupandthen

movethethrottlecontroltotheFastposition.

StoppingtheEngine

Important:Inanemergency,youcanstopthe

engineimmediatelybyturningtheignitionkeyto

theOffposition.

1.Movethethrottlelevertotheslowposition

(Figure8).

Note:Iftheenginehasbeenworkinghardor

ishot,letitidleforaminutebeforestoppingit

tohelpcoolit.

2.TurntheignitionkeytotheOffposition.

14

Page 15

3.Settheparkingbrakesandremovethekey.

4.Disconnectthewirefromthesparkplugto

preventsomeonefromaccidentallystartingthe

machinewhiletransportingorstoringit.

5.Closethefuel-shutoffvalvebeforetransporting

orstoringthemachine.

Important:Closethefuel-shutoffvalve

beforetransportingorthestoringthe

machine,topreventfuelleakage.

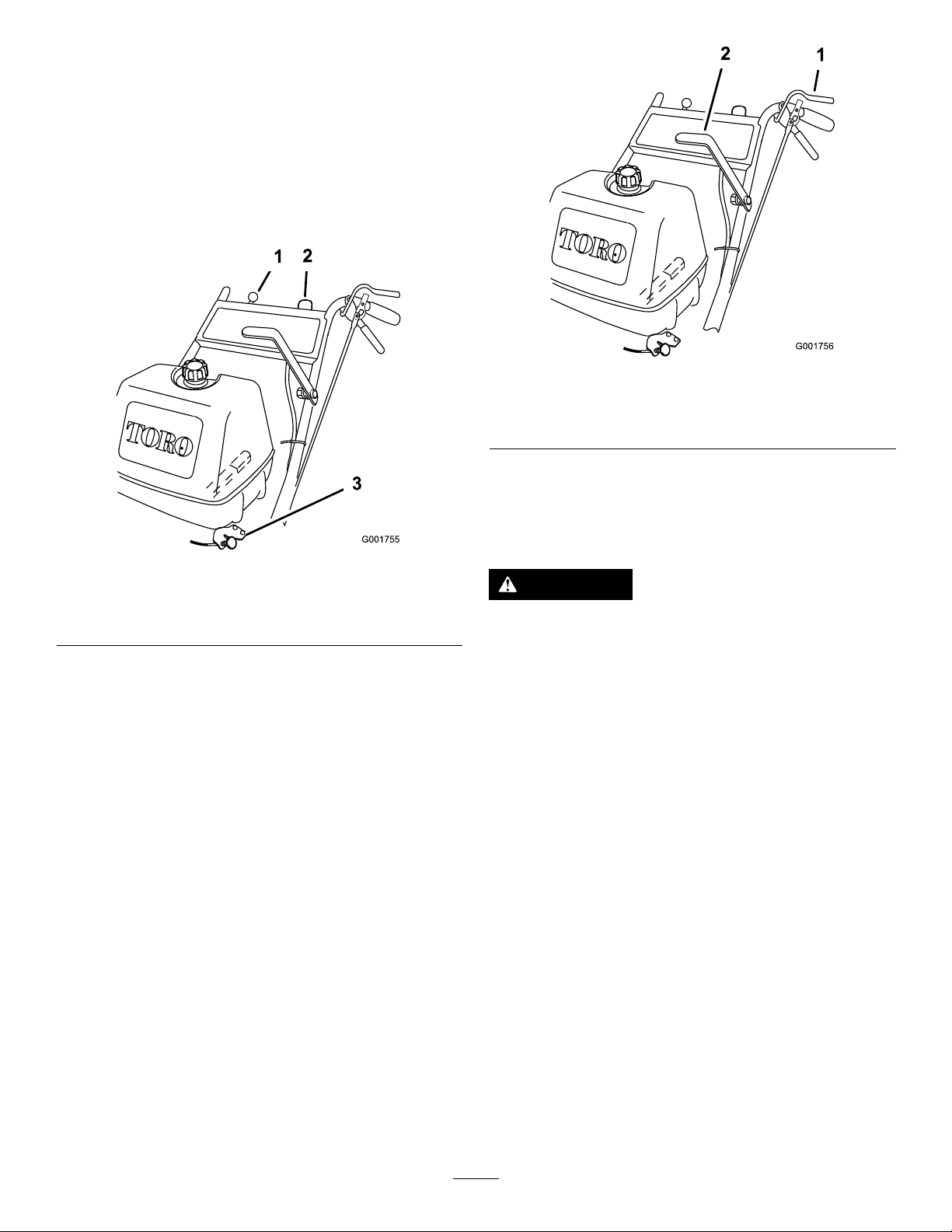

g001756

Figure9

Figure8

1.Throttlecontrol

2.Ignitionswitch

3.Choke

Operatingthe Blade-Control(PTO)Lever

Theblade-control(PTO)leverengagesand

disengagesthepowertothemowerblades.

EngagingtheMowerBlades(PTO)

1.Squeezetheoperatorpresencecontrol(OPC)

leversagainstthehandles(Figure9).

2.Pushtheblade-control(PTO)leverrmly

forwarduntilitlatchesoverthecenter(Figure9).

3.Starttheengineandrepeattheprocedure

toengagethemowerbladesiftheoperator

presencecontrol(OPC)leversarereleased.

DisengagingtheMowerBlades

(PTO)

Todisengagetheblades,pulltheblade-controllever

rearwardalltheway(Figure9).Theenginewill

stopwhentheOPCleversarereleasedwiththe

blade-controlleverengaged.

1.OperatorPresence

Control(OPC)lever

2.Powertake-offlever(PTO)

TheSafety-Interlock System

g001755

CAUTION

Ifsafety-interlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedly,causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdaily,andreplaceanydamaged

switchesbeforeoperatingthemachine.

Understandingthe

Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Theblade-control(PTO)leverisdisengaged.

•ThemachineisshiftedintotheNeutralposition.

•TheignitionkeyisintheRunposition.

Thesafety-interlocksystemisdesignedtostop

theenginewhen:

•Theoperator-presence-control(OPC)leversare

releasedwhenthetransmissionorthebladesare

engaged.

•TheignitionkeyisturnedtotheOffposition.

15

Page 16

•Themachineisshiftedintogearwithoutholding

theOPClevers.

•Theblade-control(PTO)leverisengagedwithout

holdingtheOPClevers.

TestingtheSafety-Interlock

System

DrivingForwardor Backward

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Move

thethrottlecontrolintotheFastpositionforthebest

mowingperformance.

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribed,haveanAuthorizedService

Dealerrepairthesafetysystemimmediately.

1.Settheparkingbrakes,movetheshiftleverinto

theNeutralposition,disengagetheblade-control

(PTO)leverandplacethethrottleforward.

2.Starttheengine;refertoStartingtheEngine

(page14).

3.Withoutholdingtheoperator-presence-control

(OPC)levers,engagetheblade-control(PTO)

lever.

Note:Theengineshouldstop.

4.Disengagetheblade-control(PTO)lever.

5.Withtheenginerunning,holddowntheOPC

leversandengagetheblade-control(PTO)lever.

Note:Themowerbeltshouldengageandthe

mowerbladesshouldbeginrotating.

6.ReleasetheOPClevers.

Note:Theengineshouldstop.

7.Withtheenginerunning,movetheshiftlever

intogearandreleasetheOPClevers.

DrivingForward

1.Ensurethattheparkingbrakesareengaged.

2.SqueezetheOPCleversagainstthehandles.

3.Movetheshiftleverintoaforwardgear.

4.Releasetheparkingbrakes;refertoReleasing

theParkingBrakes(page14).

5.Slowlyreleasethedrivelevers.

Note:T ogostraight,releasethedrivelevers

equally.T oturn,squeezethedriveleveronthe

samesideasthedirectionyouwanttoturn.

DrivingBackward

1.Ensurethattheparkingbrakesareengaged.

2.SqueezetheOPCleversagainstthehandles.

3.Movetheshiftleverintothereversegear.

4.Releasetheparkingbrakes;refertoReleasing

theParkingBrakes(page14).

5.Slowlyreleasethedrivelevers.

Note:Youmustpullthemowerbackwardto

assistitsrearwardmovement.

Note:Theengineshouldstop.

8.Withtheenginerunning,turntheignitionkey

totheOffposition.

Note:Theengineshouldstop.

9.Ifalltheaboveconditionsarenotmet,have

anAuthorizedServiceDealerrepairthesafety

systemimmediately.

StoppingtheMower

1.Squeezethedriveleversallthewaybackto

engagethebrakes.

2.Settheparkingbrakes.RefertoSettingthe

ParkingBrakes(page14).

3.ShifttransmissionintotheNeutralposition.

4.MovethethrottletotheStopposition,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

CAUTION

Childrenorbystandersmaybeinjured

iftheymoveorattempttooperatethe

machinewhileitisunattended.

Alwaysremovetheignitionkeyand

settheparkingbrakewhenleavingthe

machineunattended,evenifjustfora

fewminutes.

16

Page 17

TransportingtheMachine

Adjustingthe

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarylightingandmarkingasrequiredbylaw.

Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

pets,orbystandersavoidinjury.

Totransportthemachine:

1.Stoptheengine,removethekey,setthebrake,

andclosethefuelvalve.

2.Securelyfastenthemachinetothetraileror

truckwithstraps,chains,cable,orropes.

3.Secureatrailertotowingvehiclewithsafety

chains.

4.Ifapplicable,connectthetrailerbrakes.

SideDischargingor MulchingtheGrass

Thismowerhasahingedgrassdeectorthat

dispersesclippingstothesideanddowntowardthe

turf.

Wheel-Drive-BeltTension

Youmayneedtoincreasethewheel-drive-belttension

undercertainoperatingconditions,suchasmowing

overhillyterrainorwhilepullingasulky.

1.Stoptheengine,removethekey ,andwaitforall

movingpartstostop.

2.Disconnectthewiresfromthesparkplugs.

3.Disengagetheneutral/parkingbrakelocks,and

releasethedriveleverstoreducethespring

force.

4.Removethedrivespringfromtheadjustment

bolt(Figure10).

DANGER

Withoutthegrassdeector,dischargecover,

orcompletegrasscatcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebris

willcauseinjuryordeath.

•Neverremovethegrassdeectorfrom

themower,becausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mower.

•Nevertrytocleardischargeareaormower

bladesunlessyoureleasetheOPClevers

andthepowertake-off(PTO)isoff.Rotate

theignitionkeytotheOffposition.Also

removethekeyandpullthewireoffthe

sparkplug(s).

Figure10

1.PositionA4.Drivespring

2.PositionB

3.PositionC

5.Removethelocknutthatsecurestheadjustment

bolttothedrive-pulleyshield(Figure10).

6.Locateboltassemblyinthedesiredtension

positionasfollows:

5.Adjustmentbolt(inposition

A)

6.Drive-pulleyshield

•PositionAfornormalconditions

•PositionBformoresevereconditions

•PositionCforthemostsevereconditions

Note:Thewheeldrivetensionislowest

whentheboltassemblyisinPositionA.

ThetensionincreasesinPositionsBandC

(Figure10).

g001498

7.Installtheadjustmentboltandthedrivespring.

8.Repeatstepsthroughfortheoppositeside.

17

Page 18

AdjustingtheHeightofCut

Thismachinehasa26to108mm(1to4-1/4inch)

rangefortheheightofcut.Thiscanbeachievedby

adjustingbladespacers,rearaxleheight,andfront

casterspacers.UsetheHeight-of-CutChart(page

22)toselectthecombinationofadjustmentsrequired.

AdjustingtheBladeHeight

4.Slidetheboltdownthroughthespindle,and

changethespacersasneeded(Figure11).

5.Installtheboltandcurvedwasher,addextra

spacer(s),andsecurethemwithathinwasher

andanut(Figure11).

6.T orquethebladeboltto101to108N-m(75to

80ft-lb).

Adjustthebladesbyusingthe4spacers(6mm)

(1/4inch)onthebladespindlebolts.Thisallowsfora

25mm(1inch)adjustmentrange,in6mm(1/4inch)

increments,ofcuttingheightinanyaxleposition.Use

thesamenumberofbladespacersonallbladesto

achievealevelcut(2aboveand2below,1above

and3below,etc.).

1.Disengagetheblade-control(PTO)leverand

settheparkingbrakes.

2.Stoptheengineandwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Holdthebladeboltandremovethenut(Figure

11).

AdjustingtheAxleHeight

Adjusttheaxlepositiontotheselectedheight-of-cut

setting.RefertotheHeight-of-CutChart(page22).

1.Disengagetheblade-control(PTO)leverand

settheparkingbrakes.

2.Stoptheengineandwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Loosen,butdonotremove,the2axlepivotbolts

andthe2axleadjustmentbolts(Figure12).

g001455

Figure12

Figure11

1.Blade

2.Bladebolt5.Thinwasher

3.Curvedwasher

1.Axlepivotbolt2.Axleadjustmentbolt

4.Placeajackundertherearcenteroftheengine

frame.Raisethebackendoftheengineframe

upenoughtoremovethefront2axleadjustment

bolts(Figure12).

Note:Usejackstandstosupportthemachine.

5.Raiseorlowertheengineframewiththejackso

thatyoucaninstallthefront2axleadjustment

boltsinthedesiredholelocation(Figure12).

Note:Useataperedpunchtohelpalignthe

holes.

6.Tightenall4boltsandlowerthemower.

7.Adjustthecontrolrodsandthebrakelinkages

asrequired.RefertoAdjustingtheControlRods

g001454

(page38)andAdjustingtheBrakes(page32).

Important:Youmustadjustthecontrolrods

4.Spacer

6.Nut

andthebrakelinkagewhenyouchangethe

axlepositionsforpropertractionandbrake

function.

18

Page 19

AdjustingtheCasterPosition

g012676

1 2

G012677

1.UsingtheHeight-of-CutChart(page22),adjust

thecasterspacerstomatchwiththeaxlehole

selected(Figure13).

g012676

Figure14

Figure13

1.Latchpin

2.Spacer,5mm(3/16inch)

3.Spacer,13mm(1/2inch)

2.Removethelatchpin,slidethecasterfromthe

support,andchangethespacers(Figure13).

3.Installthecasterinthesupportandinsertthe

latchpin(Figure13).

AdjustingtheFlowBafe

Youcanadjustthemowerdischargeowfordifferent

typesofmowingconditions.Positionthecamlock

andbafetogivethebestqualityofcut.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

1.Slot

g001456

2.Nut

PositioningtheFlowBafe

Thefollowingguresareonlyrecommendationsfor

use.Adjustmentswillvarybygrasstype,moisture

content,andheightofgrass.

Note:Iftheenginepowerdrawsdownandthe

mowergroundspeedisthesame,openupthebafe.

PositionA

Thisisthefull-rearposition(seeFigure15).The

suggesteduseforthispositionisafollows:

•Useforshort,lightgrassmowingconditions.

•Useindryconditions.

•Useforsmallergrassclippings.

•Usetopropelgrassclippingsfartherawayfrom

themower.

3.Loosenthenut(Figure14).

4.Adjustthebafeandnutintheslottothedesired

dischargeow,andtightenthenut.

g012677

Figure15

19

Page 20

PositionB

G012678

G012679

g012931

AdjustingtheHandle

Usethispositionwhenbagging(Figure16).

Figure16

PositionC

Thisisthefullopenposition.Thesuggestedusefor

thispositionisasfollows(Figure17):

•Useintall,densegrassmowingconditions.

•Useinwetconditions.

•Usetolowertheenginepowerconsumption.

•Useatanincreasedgroundspeedinheavy

conditions.

Height

Youcanadjustthehandlepositiontomatchyour

heightpreference.

1.Removethehairpincotterpinsandclevispins

fromthedriveleversandneutrallocks(Figure

18).

g012678

g012931

Figure18

1.Controlrod

2.Clevispin

3.OperatorPresence

Controllever(OPC)

4.Handle

5.Neutrallock

6.Hairpincotterpin

7.Drivelever

Figure17

2.Loosentheupperbolts(3/8x1-1/4inches)and

angenutsecuringhandletorearframe(Figure

19).

3.Removethelowerbolts(3/8x1inch)andange

nutssecuringthehandletotherearframe

(Figure19).

4.Pivotthehandletothedesiredoperatingposition

andinstallthelowerangebolts(3/8x1inch)

andangenutsintothemountingholes.

Note:Tightenallangebolts.

g012679

20

Page 21

Figure19

1.Upperhandle6.Lowermountingholes

2.Rearframe

3.Flangebolt(3/8x1inch)

4.Locknut(3/8inch)

5.Uppermountinghole

7.Lowposition

8.Middleposition

9.Highposition

5.Adjustthecontrolrodlengthbyrotatingthe

controlrodintherodtting(Figure18).

6.Installahairpincotterbetweenthedrivelevers

andtheneutrallocksandintotheclevispins

(Figure18).

Note:Makesurethattheclevispinsare

insertedintotheneutrallocks.

7.Checktheparkingbrakeadjustment.Refer

toCheckingtheBrakesinBrakeMaintenance

(page32).

g001493

21

Page 22

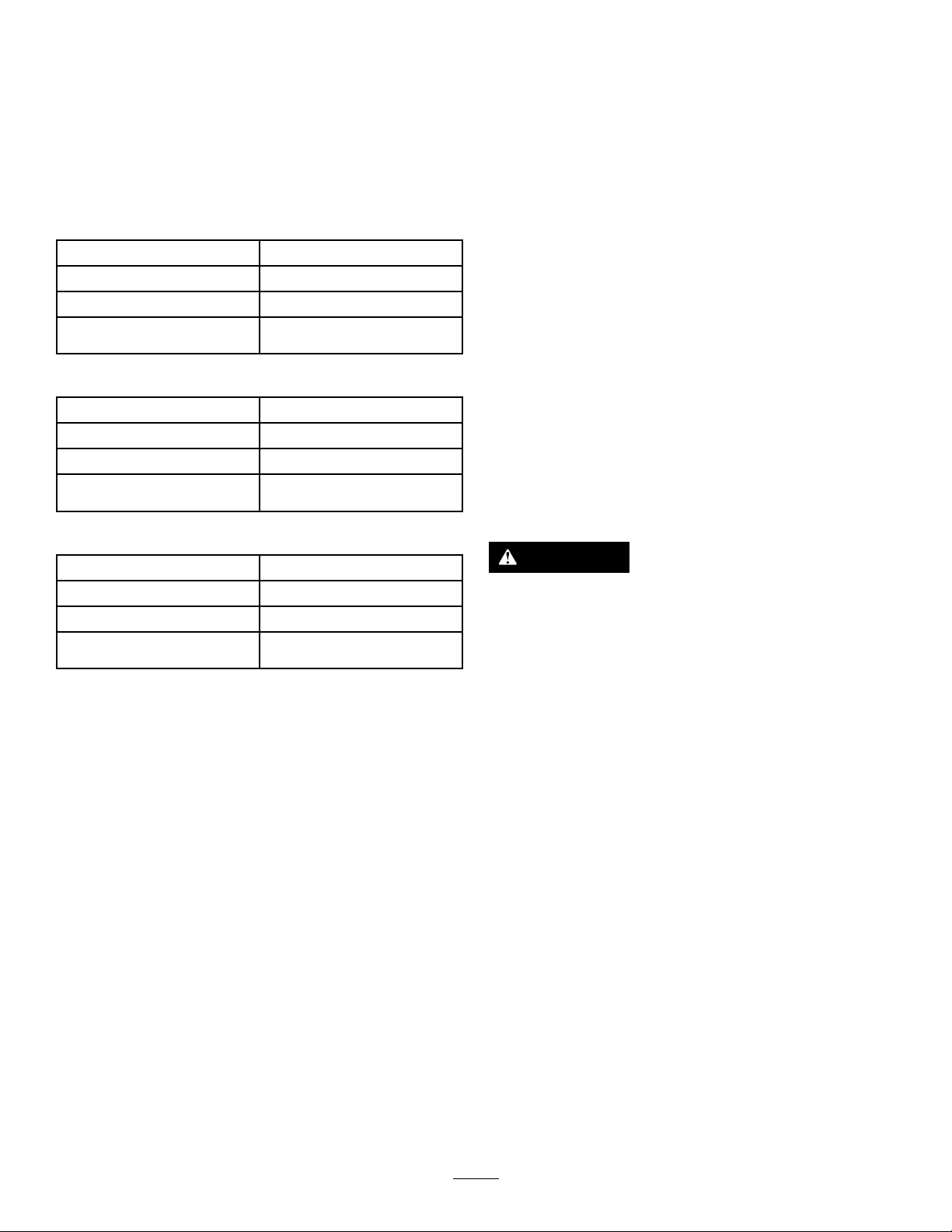

Height-of-CutChart

Numberofspacersbelow

Axle

position

A00

A01

A10

B01

B10

B11

B20

C

C

C

C

D21

D30

D31

D40

E31

E40

E41

thecaster

13mm

(1/2inch)

11

20

21

30

Numberof1/4inchbladespacersbelowthespindle

5mm

(3/16inch)

43210

26mm

(1inch)

29mm

(1-1/8inch)

35mm

(1-3/8inch)

35mm

(1-3/8inch)

41mm

(1-5/8inch)

45mm

(1-3/4inch)

51mm

(2inch)

48mm

(1-7/8inch)

55mm

(2-1/8inch)

57mm

(2-1/4inch)

64mm

(2-1/2inch)

61mm

(2-3/8inch)

64mm

(2-1/2inch)

70mm

(2-3/4inch)

76mm

(3inch)

73mm

(2-7/8inch)

79mm

(3-1/8inch)

82mm

(3-1/4inch)

32mm

(1-1/4inch)

35mm

(1-3/8inch)

41mm

(1-5/8inch)

41mm

(1-5/8inch)

48mm

(1-7/8inch)

51mm

(2inch)

57mm

(2-1/4inch)

54mm

(2-1/8inch)

60mm

(2-3/8inch)

64mm

(2-1/2inch)

70mm

(2-3/4inch)

67mm

(2-5/8inch)

70mm

(2-3/4inch)

76mm

(3inch)

82mm

(3-1/4inch)

79mm

(3-1/8inch)

86mm

(3-3/8inch)

89mm

(3-1/2inch)

38mm

(1-1/2inch)

41mm

(1-5/8inch)

48mm

(1-7/8inch)

48mm

(1-7/8inch)

54mm

(2-1/8inch)

57mm

(2-1/4inch)

64mm

(2-1/2inch)

60mm

(2-3/8inch)

67mm

(2-5/8inch)

70mm

(2-3/4inch)

76mm

(3inch)

73mm

(2-7/8inch)

76mm

(3inch)

82mm

(3-1/4inch)

89mm

(3-1/2inch)

86mm

(3-3/8inch)

92mm

(3-5/8inch)

95mm

(3-3/4inch)

45mm

(1-3/4inch)

48mm

(1-7/8inch)

54mm

(2-1/8inch)

54mm

(2-1/8inch)

60mm

(2-3/8inch)

64mm

(2-1/2inch)

70mm

(2-3/4inch)

67mm

(2-5/8inch)

73mm

(2-7/8inch)

76mm

(3inch)

83mm

(3-1/4inch)

79mm

(3-1/8inch)

82mm

(3-1/4inch)

89mm

(3-1/2inch)

95mm

(3-3/4inch)

92mm

(3-5/8inch)

98mm

(3-7/8inch)

102mm

(4inch)

51mm

(2inch)

54mm

(2-1/8inch)

60mm

(2-3/8inch)

60mm

(2-3/8inch)

67mm

(2-5/8inch)

70mm

(2-3/4inch)

76mm

(3inch)

73mm

(2-7/8inch)

79mm

(3-1/8inch)

83mm

(3-1/4inch)

89mm

(3-1/2inch)

86mm

(3-3/8inch)

89mm

(3-1/2inch)

95mm

(3-3/4inch)

102mm

(4inch)

98mm

(3-7/8inch)

105mm

(4-1/8inch)

108mm

(4-1/4inch)

22

Page 23

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst25hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthemowerbelttension.

•Checkthemowerbelttension.

•Checkthesafetysystem.

•Greasethecasterwheelsandcasterpivot.

•Checktheengine-oillevel.

•Cleantheair-intakescreen.

•Cleantheairintakescreenfromgrassanddebrisbeforeeachuse.

•Checkthebrakes.

•Inspecttheblades.

•Cleanthemowerdeck.

•Cleanthefoamair-cleanerelement.

•Greasethemower-beltidler.

•Checkthepaperair-cleanerelement.

•Checkthetirepressure.

•Checkthebelts.

•Checkthemowerbelttension.

•Changetheengineoil.

•Checkthesparkplugs.

•Checkandcleantheengine-coolingnsandshrouds.

•Replacethepaperair-cleanerelement.

Every200hours

Every250hours

Every400hours

Beforestorage

•Changetheoillter .

•Replacethefuellter.

•Replacethefuel-ventlter.

•Greasethetransmissioncouplers(moreoftenindirtyordustyconditions).

•Greasethewheelbearings(moreoftenindirtyordustyconditions).

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnectthespark-plugwire(s)fromthesparkplug(s)

beforeyoudoanymaintenance.Setthewireasidesothatitdoesnotaccidentallycontact

thesparkplug.

23

Page 24

Lubrication

GreaseType:#2general-purposelithium-basedor

molybdenum-basedgrease

LubricatingtheMachine

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettingswitharag.Makesure

toscrapeanypaintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pump

greaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

5.Wipeupanyexcessgrease.

LubricatingtheCasterand WheelBearings

g001458

Figure21

GreasingtheMower-Belt Idler

Greasethettingonthemower-belt-idler-armpivot

(Figure22).

Note:Removethemower-deckcovertoaccessthe

greasettingforthemower-belt-idlerarm.

1.Lubricatethefront-wheelbearingsandfront

spindles(Figure20).

2.Lubricatethedrive-wheelbearings.

Figure20

GreasingtheTransmission Couplers

g001459

Figure22

g001457

32-inchand36-inchmowerdeck

Lubricatethetransmissioncouplersandidlerarm

pivotslocatedinthebackofthemachine(Figure21).

g001781

Figure23

48-inchmowerdeck

24

Page 25

EngineMaintenance

CleaningtheFoamAir-Cleaner

Element

ServicingtheAirCleaner

ServiceInterval:Every25hours—Cleanthefoam

air-cleanerelement.

Every50hours—Checkthepaperair-cleaner

element.

Every200hours—Replacethepaperair-cleaner

element.

Note:Servicetheaircleanermorefrequently(every

fewoperatinghours)iftheoperatingconditionsare

extremelydustyorsandy.

Important:Donotoilthefoamorpaperelement.

RemovingtheFoamandPaper

Elements

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage

(Figure24).

4.Unscrewthecoverknobsandremovethe

air-cleanercover(Figure24).

5.Unscrewthehoseclampandremovetheair

cleanerassembly(Figure24).

6.Carefullypullthefoamelementoffthepaper

element(Figure24).

1.Washthefoamelementinliquidsoapand

warmwater.Whentheelementisclean,rinse

itthoroughly.

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifit

istornorworn.

ServicingthePaperAir-Cleaner

Element

1.Donotcleanthepaperlter,replaceit(Figure

24).

2.Inspecttheelementfortears,anoilylm,or

damagetotherubberseal.

3.Replacethepaperelementifitisdamaged.

InstallingtheFoamandPaper

Elements

Important:Topreventenginedamage,always

operatetheenginewiththecompletefoamand

paperaircleanerassemblyinstalled.

1.Carefullyslidethefoamelementontothepaper

air-cleanerelement(Figure24).

2.Placetheaircleanerassemblyontotheair

cleanerbaseandsecureitwiththe2wingnuts

(Figure24).

3.Placetheair-cleanercoverintopositionand

tightenthecoverknob(Figure24).

Figure24

1.Cover

2.Hoseclamp4.Foamelement

3.Paperelement

ServicingtheEngineOil

ServiceInterval:Beforeeachuseordaily—Check

theengine-oillevel.

Aftertherst8hours—Changetheengineoil.

Every100hours—Changetheengineoil.

Every200hours—Changetheoillter.

Note:Changetheoilmorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy .

OilType:Detergentoil(APIserviceSF,SG,SH,SJ

orSL)

g012619

CrankcaseCapacity:1.7L(1.8USqt)withthelter

removed;1.5L(1.6USqt)withoutthelterremoved

Viscosity:Refertothetable(Figure25).

25

Page 26

ChangingtheEngineOil

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoensurethatthe

oildrainscompletely.

2.DisengagethePTOandsettheparkingbrake.

3.Stoptheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

4.Slidethedrainhoseovertheoildrainvalve.

5.Placeapanbelowthedrainhose.

Figure25

CheckingtheEngine-OilLevel

1.Parkthemachineonalevelsurface.

2.DisengagethePTOandsettheparkingbrake.

3.Stoptheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

4.Cleanaroundtheoildipstick(Figure26)sothat

dirtcannotfallintothellerholeanddamage

theengine.

g004216

Note:Rotateoildrainvalvetoallowoiltodrain

(Figure27).

6.Whenoilhasdrainedcompletely,closethedrain

valve.

7.Removethedrainhose(Figure27).

Note:Disposeoftheusedoilatarecycling

center.

Figure26

1.Oildipstick

2.Fillertube

5.Unscrewtheoildipstickandwipetheendclean

(Figure26).

6.Slidetheoildipstickfullyintothellertube,but

donotthreaditontothetube(Figure26).

7.Pullthedipstickoutandlookattheend.Ifthe

oillevelislow,slowlypouronlyenoughoilinto

thellertubetoraisetheleveltotheFullmark.

Important:Donotoverllthecrankcase

withoilandruntheengine;enginedamage

canresult.

g001464

g001466

Figure27

1.Oildrainvalve2.Oildrainhose

8.Slowlypourapproximately80%ofthespecied

oilintothellertube(Figure26).

9.Checktheoillevel;refertoCheckingthe

Engine-OilLevel(page13)

10.Slowlyaddtheadditionaloiltobringittothe

Fullmark.

26

Page 27

ChangingtheOilFilter

1

ServicingtheSparkPlugs

Note:Changetheoilltermorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy .

1.Draintheoilfromtheengine;refertoChanging

theEngineOil(page26).

2.Removetheoldlter(Figure28).

Figure28

1.Oillter

3.Applyathincoatofnewoiltotherubbergasket

onthereplacementlter(Figure28).

2.Adapter

ServiceInterval:Every100hours—Checkthespark

plugs.

Ensurethattheairgapbetweenthecenterelectrode

andthesideelectrodeiscorrectbeforeinstallingeach

sparkplug.Useaspark-plugwrenchforremoving

andinstallingthesparkplugsandagappingtoolora

feelergaugetocheckandadjusttheairgap.Install

newsparkplugsifnecessary.

Type:Champion®RCJ8Yorequivalent

AirGap:0.75mm(0.030inch)

RemovingtheSparkPlugs

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwait

g001465

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Disconnectthewiresfromthesparkplugs

(Figure29).

4.Installthereplacementoilltertothelter

adapter,turntheoillterclockwiseuntilthe

rubbergasketcontactsthelteradapter,then

tightenthelteranadditional3/4turn(Figure

28).

5.Fillthecrankcasewiththepropertypeofnew

oil;refertoServicingtheEngineOil(page25).

6.Runtheengineforabout3minutes,stopthe

engine,andcheckforoilleaksaroundtheoil

lteranddrainvalve.

7.Checktheengineoillevelandaddoilifneeded.

8.Wipeupanyspilledoil.

g001469

Figure29

1.Spark-plugwire/sparkplug

4.Cleanaroundthesparkplugstopreventdirt

fromfallingintotheengineandpotentially

causingdamage.

5.Removethesparkplugsandthemetalwashers.

CheckingtheSparkPlugs

1.Lookatthecenterofthesparkplugs(Figure30).

Note:Ifyouseelightbrownorgrayonthe

insulator,theengineisoperatingproperly .A

blackcoatingontheinsulatorusuallymeans

thattheaircleanerisdirty.

2.Ifneeded,cleanthesparkplugwithawirebrush

toremovecarbondeposits.

27

Page 28

Figure30

1.Centerelectrode;insulator3.Airgap(nottoscale)

2.Sideelectrode

Important:Alwaysreplacethesparkplugs

whentheyhavewornelectrodes,anoilylm,

oracrackedinsulator.

3.Checkthegapbetweenthecenterelectrode

andthesideelectrode(Figure30).

Note:Bendthesideelectrode(Figure30)ifthe

gapisnotcorrect.

InstallingtheSparkPlugs

1.Installthesparkplugsandthemetalwasher.

Ensurethattheairgapissetcorrectly.

2.Tightenthesparkplugsto22N-m(16ft-lb).

3.Connectthewirestothesparkplugs(Figure30).

FuelSystem

Maintenance

ServicingtheFuelSystem

DANGER

Incertainconditions,gasolineisextremely

g001470

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopen

area.Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,and

stayawayfromanopenameorwherea

sparkmayignitethegasolinefumes.

DrainingtheFuelTank

1.Parkthemachineonalevelsurfacetoensure

thatthefueltankdrainscompletely;then

disengagethepowertake-off(PTO),setthe

parkingbrake,andturntheignitionkeytothe

Offposition.Removethekey.

2.Closethefuel-shutoffvalveatthefueltank

(Figure31).

3.Squeezetheendsofthehoseclamptogether

andslideitupthefuellineawayfromfuellter

(Figure31).

4.Pullthefuellineoffthefuellter(Figure31).

Note:Openthefuel-shutoffvalveandallowthe

gasolinetodrainintoafuelcontaineroradrain

pan.

Note:Nowisthebesttimetoinstallanewfuel

lterbecausethefueltankisempty .Referto

ReplacingtheFuelFilter(page29).

5.Installthefuellineontothefuellter.Slidethe

hoseclampclosetothevalvetosecurethefuel

line.

28

Page 29

Figure31

g001467

1.Fuel-shutoffvalve2.Clamp

ReplacingtheFuelFilter

ServiceInterval:Every200hours/Yearly(whichever

comesrst)

Neverinstalladirtylterifitisremovedfromthefuel

line.

Note:Notehowthefuellterisinstalledinorderto

installthenewltercorrectly.

Note:Wipeupanyspilledfuel.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Closethefuel-shutoffvalveatthefueltank

(Figure31).

4.Squeezetheendsofthehoseclampstogether

andslidethemawayfromthelter(Figure32).

g001468

Figure32

1.Hoseclamp3.Filter

2.Fuelline

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclamps

closetothelter.

7.Openthefuel-shutoffvalveatthefueltank

(Figure31).

8.Checkforfuelleaks,andrepairifneeded.

9.Wipeupanyfuelthatspilled.

29

Page 30

ServicingtheFuel-VentSystem

g014686

1 2

ServiceInterval:Every200hours/Yearly(whichever

comesrst)

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removetheexistingfuel-ventlter(Figure33).

4.Installanewlter.

DriveSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthereartiresat83to97

kPa(12to14psi).Uneventirepressurecancause

anunevencut.

Note:Thefronttiresaresemi-pneumatictiresanddo

notrequireairpressuremaintenance.

Figure33

1.Fuel-ventlter2.Rightsideoftheengine

g001055

g014686

Figure34

30

Page 31

CoolingSystem

Maintenance

CleaningtheAir-intake Screen

Beforeeachuse,removeanybuildupofgrass,dirt,

orotherdebrisfromthecylinderandcylinder-head

coolingns,theair-intakescreenontheywheelend,

andthecarburetor-governorleversandlinkage.This

willhelpensureadequatecoolingandcorrectengine

speedandwillreducethepossibilityofoverheating

andmechanicaldamagetotheengine.

CleaningtheCooling System

ServiceInterval:Beforeeachuseordaily

Every100hours/Yearly(whichevercomesrst)

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removetheair-intakescreen,therecoilstarter,

andthefanhousing(Figure35).

4.Cleanthedebrisandgrassfromtheengine

parts.

5.Installtheair-intakescreen,therecoilstarter,

andthefanhousing(Figure35).

g001472

Figure35

1.Air-intakescreen4.Bolt

2.Fanhousing5.Nut

3.Recoilstarter

31

Page 32

BrakeMaintenance

ServicingtheBrakes

Beforeeachuse,checkthebrakesonbothalevel

surfaceandaslope.

Alwayssettheparkingbrakewhenyoustopthe

machineorleaveitunattended.Iftheparkingbrake

doesnotholdthemachinesecurely,adjustit.

CheckingtheBrakes

1.Parkthemachineonalevelsurface,disengage

theblade-control(PTO)lever.

2.Stoptheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Applytheparkingbrakes.

Note:Thewheelsmustlockwhenyoutryto

pushthemachineforward.

4.Ifthewheelsdonotlock,adjustthebrakes;refer

toAdjustingtheBrakes(page32).

5.Releasethebrakesandmovetheneutral/brake

lockstotheNeutralposition.

Note:Thewheelsshouldrotatefreely;ifthey

donot,refertoAdjustingtheBrakes(page32).

AdjustingtheBrakes

Iftheparkingbrakesdonotholdsecurely,adjustthem.

1.Checkthebrakesbeforeyouadjustthem;refer

toCheckingtheBrakes(page32).

g001561

Figure36

1.Brakerod2.Wingnut

4.Positionthewingnutssothatthebrakesengage

whenyousqueezethedriveleversenoughto

placetheneutral/parkingbrakelocksforward,

andthensetthebrakes.

5.Checktheoperationofthebrakesagain;referto

CheckingtheBrakes(page32).

Important:Whenyoureleasetheparking

brakes,therearwheelsshouldrotatefreely

whenyoupushthemower.Iftheydo

not,contactanAuthorizedServiceDealer

immediately.

6.Checkthecontrolrodlength,refertoAdjusting

theBrakes(page32).

2.Releasetheparkingbrakes;refertoReleasing

theParkingBrakes(page14).

3.T oadjustthebrakes,rotatethewingnutsonthe

brakerods(Figure36).

Note:Rotatethewingnutsclockwisetotighten

thebrakes;rotatethemcounterclockwiseto

loosenthem.

32

Page 33

BeltMaintenance

CheckingtheBelts

ServiceInterval:Every50hours/Monthly(whichever

comesrst)—Checkthebelts.

Checkthebeltsforcracks,frayededges,burnmarks,

wear,signsofoverheating,oranyotherdamage.

Replaceanydamagedbelts.

ReplacingtheTraction DriveBelt

1.Removethehairpincottersecuringthebrake

rodtothebrakearmtorelaxthetensiononthe

beltidler(Figure37).

2.Removethebottomboltandloosenthetopbolt

oftheshieldtorotateitforbeltclearance(Figure

37).

3.Liftthebeltpasttheidlerandoffthedrivepulley

(Figure37).

4.Raisethewheeloffthegroundenoughto

removethebelt.

5.Replacethetraction-drivebelt.

6.Securetheshieldwiththepreviouslyremoved

bolt,andtightenthebolts(Figure37).

7.Securethebrakerodtothebrakearmwiththe

hairpincotter(Figure37).

3.Raisetherearofthemachineandholditupwith

jackstands.

4.Removethemowerbelt(Figure38).

Figure38

1.Idlerpulleyinslot4.Beltguide

2.Tractionbelt

3.Mowerbelt6.Mowerbelt

5.Loosenthepivotboltenoughtoslidetheidler

pulleyintheslot,andremovethetractionbelt

fromtheengineandthedrivepulleys(Figure

38).

6.Installthenewdrivebeltaroundtheengineand

thedrivepulleys(Figure38).

7.Slidetheidlerpulleyintheengineframeto

tensionthetractionbelt(Figure38).

8.Installthemowerbelt(Figure38).

5.19mm(3/4inch)

g001475

Figure37

1.Drivebelt3.Tire

2.Drivespring4.Adjustmentbolt

ReplacingtheDriveBelt

1.Disengagetheblade-control(PTO)leverand

settheparkingbrakes.

2.Stoptheengineandwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

9.Checkthebeltguideundertheengineframefor

theproperadjustment(Figure38).

Note:Thedistancebetweenthebeltguideand

mowerbeltshouldbe19mm(3/4inch)when

youengagethemowerbelt.Adjustthebeltif

necessary.Thedisengagedbeltshouldnotdrag

orfalloffthepulleywhentheguidesareproperly

adjusted.

g001562

ReplacingtheMowerBelt

Important:Thebrakeneedstobeadjustedwhen

thebelttensionorthebrakelinkageisadjusted.

1.Disengagetheblade-control(PTO)leverand

settheparkingbrakes.

2.Stoptheengineandwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Removetheknobsandthebeltcoveronthe

mower.

4.Removetheidlerpulleyandthewornbelt.

5.Installthenewmowerbelt.

33

Page 34

6.Installtheidlerpulley.

7.Engagetheblade-control(PTO)leverandcheck

thebelttension.RefertoCheckingtheBelts

(page33).

Note:Thepropermowerbelttensionis44to

67N-m(10to15ft-lb)withthebeltdeected

13mm(1/2inch)halfwaybetweenthepulleys

(Figure42orFigure43).

8.Engagetheblade-control(PTO)lever.

9.Checktheclearancebetweenthebellcrankand

thetransmissionoutputshaft(Figure39).

g001478

Figure40

32-inchand36-inchmowerdeck

Figure39

1.2to3mm(1/16to1/8inch)

2.Bellcrank

3.Transmissionoutputshaft6.Clevis

4.Hairpincotter

5.Clevispin

Note:Theclearanceshouldbe2to3mm(1/16

to1/8inch).

10.Removethehairpincotterpinandtheclevispin

fromthebellcrank.

11.Rotatetheclevisclockwiseontherodtoincrease

theclearance;rotateitcounterclockwiseto

decreaseit(Figure39).

12.Disengagetheblade-control(PTO)lever.

Note:Iftheassistarmdoesnotcontactthe

frontstoponthemowerdeck(Figure40or

Figure41),adjusttheclevistobringthebell

crankclosertothetransmissionoutputshaft

(Figure39).

1.13mm(1/2inch)deection

here

2.Assistarm5.Turnbuckle

3.Frontstop

g001477

48-inchmowerdeck

1.13mm(1/2inch)deection

here

2.Assistarm5.Turnbuckle

3.Frontstop

4.Locknut

g001566

Figure41

4.Locknut

13.Checkthebeltguideundertheengineframefor

theproperadjustment(Figure38).

Note:Thedistancebetweenthebeltguideand

themowerbeltshouldbe32mm(1-1/4inch)

whenyouengagethemowerbelt.Adjustthe

34

Page 35

mowerbeltasnecessary.Thedisengagedbelt

shouldnotdragorfalloffthepulleywhenthe

guidesareproperlyadjusted.

AdjustingtheMowerBelt Tension

AdjustingtheTensionfor32-inch

and36-inchMowerDecks

ServiceInterval:Aftertherst8hours—Checkthe

mowerbelttension.

Aftertherst25hours—Checkthemowerbelt

tension.

Every50hours—Checkthemowerbelttension.

Important:Adjustthebrakewheneveryouadjust

thebelttensionorthebrakelinkage.

Important:Thebeltmustbetightenoughto

notslipduringheavyloadswhilecuttinggrass.

Over-tensioningthebeltwillreducethelifeofthe

spindlebearing,thebelt,andtheidlerpulley.

Thebeltmustbetightenoughsothatitdoesnot

slipduringheavyloadswhilecuttinggrass,and

over-tensioningwillreducebeltandspindlebearing

life.

1.Disengagetheblade-control(PTO)leverand

settheparkingbrakes.

2.Stoptheengineandwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Loosenthelocknutontheturnbuckle(Figure

42).

4.Rotatetheturnbuckletowardtherearofthe

mowertoincreasethetensiononthebelt.

Rotatetheturnbuckletowardthefrontofthe

mowertodecreasethetensiononthebelt

(Figure42).

Figure42

32-inchand36-inchmowerdeck

1.Mowerbeltwith13mm

(1/2inch)deection

6.Tightenthelocknutontheturnbuckle.

7.Checktheadjustmentofthebladebrake;refer

toAdjustingtheBladeBrake(page41).

2.Idlerpulley

AdjustingtheTensionfor48-inch

MowerDecks

Important:Thebeltmustbetightenoughto

notslipduringheavyloadswhilecuttinggrass.

Over-tensioningthebeltwillreducethespindle

bearinglife,thebeltlifeandtheidlerpulleylife.

Important:Thebrakeneedstobeadjustedwhen

thebelttensionorthebrakelinkageisadjusted.

1.Disengagetheblade-control(PTO)leverand

settheparkingbrakes.

2.Stoptheengineandwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

g001476

Note:Theeyeboltthreadsonbothendsofthe

turnbuckleshouldbeengagedaminimumof8

mm(5/16inch).

5.Engagetheblade-controllever(PTO)andcheck

thebelttension.Adjustthetensionuntilitis

correct.

Note:Thepropermowerbelttensionis44to

67N-m(10to15ft-lb)withthebeltdeected

13mm(1/2inch)halfwaybetweenthepulleys

(Figure42).

3.Loosenthelocknutontheturnbuckle(Figure

44).

4.Adjustthetensionofthebelt.

•Rotatetheturnbuckletowardtherearofthe

mowertoincreasethetensiononthebelt.

•Rotatetheturnbuckletowardthefrontofthe

mowertodecreasethetensiononthebelt

(Figure44).

Note:Thepropermowerbelttensionis44to

67N-m(10to15ft-lb)withthebeltdeected

13mm(1/2inch)halfwaybetweenthepulleys

(Figure43).

35

Page 36

Figure43

48-inchmowerdeck

1.Idlerpulley2.Mowerbeltwith13mm

(1/2inch)deection

Note:Theeyeboltthreadsonbothendsofthe

turnbuckleshouldbeengagedaminimumof8

mm(5/16inch).

6.Ifthereisnoadjustmentleftintheturnbuckle

andthebeltisstillloose,therearidlerpulley

needstobepositionedtothemiddleorfront

hole(Figure45).Usetheholethatwillgivethe

correctadjustment.

7.Whenyoumovetheidlerpulley,youmustmove

thebeltguide.Movethebeltguidetothefront

position(Figure45).

g001565

r:\g001848

Figure45

1.Rearidlerpulley4.Beltguideinbackposition

2.Middlehole5.Frontidlerpulley

3.Fronthole

8.Checkthebeltguideundertheengineframefor

properadjustment(Figure46).

Figure44

1.13mm(1/2inch)deection

here

2.Assistarm5.Turnbuckle

3.Frontstop

4.Locknut

5.Engagetheblade-controllever(PTO)andcheck

thebelttension.

Note:Thedistancebetweenthebeltguideand

themowerbeltshouldbe19mm(3/4inch)when

youengagethemowerbelt(Figure46).Adjust

themowerbeltasnecessary.Thedisengaged

beltshouldnotdragorfalloffthepulleywhenthe

guidesandbelttensionareproperlyadjusted.

9.Checktheadjustmentofthebladebrake;refer

toAdjustingtheBladeBrake(page41).

r:\g001566

36

Page 37

Figure46

1.Idlerpulleyinslot4.Beltguide

2.Tractionbelt

3.Mowerbelt6.Mowerbelt

5.19mm(3/4inch)

AdjustingthePTO-Engagement

Linkage

TheadjustmentforthePTO-engagementlinkage

islocatedbeneaththefrontleft-handcornerofthe

enginedeck.

1.Disengagetheblade-control(PTO)leverand

settheparkingbrakes.

2.Stoptheengineandwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Engagetheblade-controllever(PTO).

4.Adjustthelinkagelengthtowherethelower

endofthebellcrankjustclearstheaxlesupport

gusset(Figure47).

g001475

g001847

Figure47

1.Bellcrank4.Yoke

2.Safetyswitchlocated

underenginedeck

3.Bellcrankjustclearsthe

gussetwiththePTO

engaged

5.Nut

6.Assistarmlink

5.Makesurethattheassistarmisagainstthe

rear-assist-armstoponthedeck(Figure48).

6.Pushtheblade-controllever(PTO)downtothe

disengagedposition.

7.Theassistarmshouldcontactthe

front-assist-armstoponthedeck.Ifit

doesnotcontact,adjustthebellcranksothatit

isclosertothegusset(Figure48).

Figure48

1.Yoke5.Assistarmlink

2.Nut6.Assistarm

3.Rearassistarmstop7.Turnbuckle

4.Frontassistarmstop

37

g001849

Page 38

8.T oadjusttheassistarmlink,removethehairpin

g012931

cotterpinfromtheassistarm(Figure48).

ControlsSystem

9.Loosenthenutagainsttheyoke(Figure47).

10.Removetheassistarmlinkfromtheassistarm

androtatethelinktoadjustthelength.

11.Installtheassistarmlinkintotheassistarmand

secureitwiththehairpincotterpin(Figure48).

12.Checkiftheassistarmhitsagainstthestops

correctly.

AdjustingthePTOSafetySwitch

1.Disengagetheblade-control(PTO)leverand

settheparkingbrakes.

2.Stoptheengineandwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Disengagetheblade-controllever(PTO).

Makesurethattheassistarmisagainstthe

front-assist-armstop.

4.Ifneeded,adjusttheblade-safetyswitchby

looseningtheboltsholdingtheswitchbracket

(Figure49).

5.Movethemountingbracketuntilthebellcrank

pressestheplungerby6mm(1/4inch).

Note:Makesurethatthebellcrankdoesnot

touchtheswitchbody;otherwise,damagetothe

switchcouldoccur(Figure49).

Maintenance

AdjustingtheControlRods

1.Removethehairpincotterpinsandclevispins

fromthedriveleversandneutrallocks(Figure

50).

Figure50

1.Controlrod

2.Clevispin

3.Operator-presence-control

lever(OPC)

4.Handle8.Drivelever

5.Neutrallock

6.Hairpincotter

7.Lefthandleshown

g012931

Figure49

1.Bellcrank

2.Boltsandnuts

6.Tightentheswitchmountingbracket.

2.Adjustthecontrolrodlengthbythreadingthe

rodinoroutoftherodttinguntilthereisa5to6

mm(3/16to1/4inches)clearancebetweenthe

controlrodandthebottomoftheneutral/parking

brakelock(Figure51).

g001855

3.Switchmountingbracket

4.Switchbody

38

Page 39

Figure51

1.Handle4.Drivelever

2.Neutral/parkingbrakelock

3.5to6mm(3/16to1/4

inch)clearance

5.Forwardspeed

6.Controlrod

MowerDeck Maintenance

ServicingtheCutting Blades

Toensureasuperiorqualityofcut,keeptheblades

sharp.Forconvenientsharpeningandreplacement,

youmaywanttokeepextrabladesonhand.

g001495

WARNING

Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrownintothe

operator'sorbystander'sarea,resultingin

seriouspersonalinjuryordeath.

3.Installthecontrolrodtothedriveleverandthe

neutral/parkingbrakelock.Securethecontrol

rodwithaclevispinandahairpincotter(Figure

51).

4.Checktheoperationofthecontrolrod.

Note:Ifyouneedtoadjustit,removethe

hairpincotterandtheclevispinthatsecurethe

controlrodtothedrivelevers.

5.Adjustthecontrolrodlengthbyrepeatingthe

previoussteps.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

PreparingtoInspectorService

theBlades

1.Parkthemachineonalevelsurface,disengage

theblade-controllever,andsettheparking

brake.

2.TurntheignitionkeytotheOffposition.

3.Removethekeyanddisconnectthespark-plug

wire(s)fromthesparkplug(s).

39

Page 40

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure52).Ifthe

edgesarenotsharporhavenicks,removeand

sharpentheblades.RefertoSharpeningthe

Blades(page41).

g001564

Figure54

2.Measurefromalevelsurfacetothecutting

edge,positionA,oftheblades(Figure55).

Figure52

1.CuttingEdge3.Wear/slotformingin

curvedarea

2.Sail4.Crackinthecurvedarea

2.Inspecttheblades,especiallythecurvedarea

(Figure52).Ifyounoticeanydamage,wear,or

aslotforminginthisarea(item3.inFigure52),

immediatelyinstallanewblade.

CheckingforBentBlades

1.Rotatethebladesuntiltheendsfaceforward

andbackward(Figure53).

g006530

Note:Notethisdimension.

g001563

Figure55

1.Measurefromthecuttingedgetoalevelsurface

3.Rotatetheoppositeendsofthebladesforward.

4.Measurefromalevelsurfacetothecuttingedge

ofthebladesatthesamepositionasinstep1.

Note:Thedifferencebetweenthedimensions

obtainedinsteps1and2mustnotexceed3mm

(1/8inch).Ifthisdimensionexceeds3mm(1/8

inch),thebladeisbentandmustbereplaced.

RefertoRemovingtheBlades(page41)and

InstallingtheBlades(page41).

WARNING

Figure53

Abladethatisbentordamagedcould

breakapartandcouldseriouslyinjureor

killyouorbystanders.

g001481

•Alwaysreplacebentordamaged

bladewithanewblade.

•Neverleorcreatesharpnotchesin

theedgesorsurfacesofblade.

40

Page 41

RemovingtheBlades

Replacethebladesifyouhitasolidobjectorifthe

bladesareoutofbalanceorbent.T oensureoptimum

performanceandcontinuedsafetyconformanceof

themachine,usegenuineTororeplacementblades.

Replacementbladesmadebyothermanufacturers

mayresultinnon-conformancewithsafetystandards.

1.Holdthebladeboltwithawrench.

2.Removethenut,bladebolt,curvedwasher,

blade,spacers,andthinwasherfromthespindle

(Figure56).

g000276

Figure57

1.Sharpenatoriginalangle