Page 1

FormNo.3360-525RevA

Groundsmaster

®

328-D

2&4WheelDriveTractionUnits

ModelNo.30626—SerialNo.280000201andUp

ModelNo.30627—SerialNo.280000201andUp

ModelNo.30630—SerialNo.280000201andUp

ModelNo.30631—SerialNo.280000201andUp

Registeratwww.T oro.com.OriginalInstructions(EN)

Page 2

Warning

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Theengineinthisproductisnot

equippedwithasparkarrestermufer.Itisa

violationofCaliforniaPublicResourceCode

Section4442touseoroperatethisengineonany

forest-covered,brush-covered,orgrass-covered

landasdenedinCPRC4126.Otherstatesor

federalareasmayhavesimilarlaws.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroRidingMowerSafety....................................6

SoundPower........................................................7

SoundPressure.....................................................7

Vibration..............................................................7

SafetyandInstructionalDecals.............................8

Setup..........................................................................14

1InstallingtheSteeringCylinder(Models

30627&30631only).......................................14

2InstallingtheTieRod(Models30627&

30631only)....................................................15

3InstallingtheRearBumper(Models30627

&30631only).................................................15

4InstallingtheFrontandRearWheels.................16

5RemovingtheBatteryfromtheChassis.............16

6InstallingtheSeat.............................................16

7InstallingtheSeatBelt......................................18

8InstallingtheRollBar.......................................19

9PushingtheTractionUnitOffofthe

Pallet..............................................................19

10ActivatingandChargingtheBattery................19

11InstallingtheBatteryintheChassis.................20

12InstallingtheBallJointandConnectingthe

LiftCylinder...................................................21

13InstallingtheRearWeight...............................22

14FinishingtheSetup........................................23

ProductOverview......................................................24

Controls.............................................................24

Specications.....................................................26

Attachments/Accessories...................................26

Operation...................................................................27

©2008—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

BeforeOperating................................................27

Starting/StoppingEngine...................................30

BleedingFuelSystem..........................................31

CheckingtheInterlockSwitches.........................31

PushingorTowingtheTractionUnit...................32

OperatingCharacteristics...................................32

Maintenance...............................................................34

RecommendedMaintenanceSchedule(s)................34

DailyMaintenanceChecklist...............................35

Lubrication.............................................................36

EngineMaintenance...............................................37

GeneralAirCleanerMaintenance.......................37

ServicingAirCleaner..........................................37

CleaningtheRadiatorandScreen........................38

ChangingEngineOilAndFilter..........................38

BleedingAirFromInjectors...............................39

FuelSystemMaintenance.......................................39

FuelTank...........................................................39

FuelLinesandConnections................................39

ServicingtheWaterSeparator.............................39

ElectricalSystemMaintenance................................40

Fuses..................................................................40

ServicingtheBattery...........................................40

DriveSystemMaintenance.....................................41

AdjustingRearWheelToe–in(Models30626

&30630only).................................................41

AdjustingSteeringStops(Models30627&

30631only)....................................................41

AdjustingtheRearWheelBearings(Models

30626&30630only).......................................41

ChangingRearAxleLubricant(Models30627

&30631only).................................................42

CheckingSteeringCylinderBoltTorque

(Models30627&30631only).........................42

ChangingBidirectionalClutchLubricant

(Models30627&30631only).........................42

CoolingSystemMaintenance..................................43

CleaningRadiatorAndScreen............................43

ChangingCoolantInCoolingSystem..................43

BrakeMaintenance.................................................44

AdjustingtheBrakes...........................................44

BeltMaintenance....................................................45

ServicingtheEngineBelts..................................45

AdjustingPTODriveBeltTension.....................46

ControlsSystemMaintenance.................................46

AdjustingThrottle..............................................46

AdjustingTractionControlRod..........................46

AdjustingTractionPedalFrictionWheel.............47

AdjustingtheTractionDriveforNeutral.............47

AdjustingtheTractionInterlockSwitch..............48

ReplacingthePTOSwitch..................................48

AdjustingtheParkingBrakeInterlock

Switch............................................................48

AdjustingtheTiltSteeringControl......................49

HydraulicSystemMaintenance...............................49

ReplacingtheHydraulicFluidFilter....................49

ChangingtheHydraulicSystemFluid..................50

Storage.......................................................................51

TractionUnit......................................................51

Engine...............................................................51

Schematics.................................................................53

3

Page 4

Safety

responsiblefortrainingtheusers.Suchinstruction

shouldemphasize:

Models30630and30631meetorexceedCEN

standardEN836:1997,ISOstandard5395:1990,and

ANSIB71.4-2004specicationsineffectatthetime

ofproduction,whenweightsareinstalledaccording

tochartintheSetupsection.

Models30626and30627meetorexceedtheB71.4

2004specicationsoftheAmericanNational

StandardsInstitute,ineffectattimeofproduction,

whenweightsareinstalledaccordingtochartin

theSetupsection.

Note:Theadditionofattachmentsmadeby

othermanufacturersthatdonotmeetAmerican

NationalStandardsInstitutecerticationwillcause

noncomplianceofthismachine.

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalert

symbol,whichmeansCAUTION,WARNING,

orDANGER—“personalsafetyinstruction.”

Failuretocomplywiththeinstructionmayresultin

personalinjuryordeath.

–theneedforcareandconcentrationwhen

workingwithride-onmachines;

–controlofaride-onmachineslidingonaslope

willnotberegainedbytheapplicationofthe

brake.Themainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrecthitchingandloaddistribution.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeople,orproperty.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,

longtrousers,hardhat,safetyglasses,andhearing

protection.Longhair,looseclothing,orjewelrymay

gettangledinmovingparts.Donotoperatethe

equipmentwhenbarefootorwearingopensandals.

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004.

Training

•ReadtheOperator’ sManualandothertrainingmaterial

carefully.Iftheoperatorormechaniccannot

readthelanguageofthismanualitistheowner’s

responsibilitytoexplainthismaterialtothem.

•Befamiliarwiththecontrols,safetysigns,andthe

properuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpets

arenearby .

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Donotcarrypassengers.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning-Fuelishighlyammable.Takethe

followingprecautions:

–Storefuelincontainersspecicallydesignedfor

thispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refueling.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely.

•Replacefaultysilencers/mufers.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Alloperatorsandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

•Checktheoperatorpresencecontrols,safety

switchesandshieldstomakesuretheyareattached

4

Page 5

andfunctioningproperly .Donotoperateunless

theyarefunctioningproperly.

Adequaterearweightisnecessarytoprevent

therearwheelsfromleavingtheground.Do

notstopsuddenlywhiledeckorimplementis

raised.Donottraveldownhillwiththedeckor

implementraised.Iftherearwheelleavesthe

ground,steeringislost.

•Neveroperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesinplace.

Besureallinterlocksareattached,adjustedproperly ,

andfunctioningproperly .

•Donotchangetheenginegovernorsettingsorover

speedtheengine.Operatingtheengineatexcessive

speedmayincreasethehazardofpersonalinjury.

•Beforeleavingtheoperator’sposition:

–stoponlevelground;

–disengagethepowertake-offandlowerthe

attachments;

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

Engineexhaustcontainscarbonmonoxide,

whichisanodorless,deadlypoisonthatcan

killyou.

Donotrunengineindoorsorinanenclosed

area.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageall

bladeattachmentclutches,shiftintoneutral,and

engagetheparkingbrake.

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Rememberthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.To

guardagainstoverturning:

–donotstoporstartsuddenlywhengoingupor

downhill;

–machinespeedsshouldbekeptlowonslopes

andduringtightturns;

–stayalertforhumpsandhollowsandother

hiddenhazards;

–nevermowacrossthefaceoftheslope.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfaces

otherthangrass.

•Neverdirectthedischargeofmaterialtoward

bystandersnorallowanyonenearthemachinewhile

inoperation.

–Settheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Stoptheengineanddisengagedrivetoattachment

–beforerefuelling;

–beforeremovingthegrasscatcher/catchers;

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator’s

position.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthe

mower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperating

theequipment.

•Keephandsandfeetawayfromthemowerdeck.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Disengagebladesif

notmowing.

•Beawareofthemowerdischargedirectionanddo

notpointitatanyone.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

5

Page 6

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumesmayreachanopen

ameorspark.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuel

storageareafreeofgrass,leaves,orexcessivegrease.

•Keepallpartsingoodworkingconditionandall

hardwareandhydraulicttingstightened.Replaceall

wornordamagedpartsanddecals

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachineto

prevententrapmentofthengersbetweenmoving

bladesandxedpartsofthemachine.

•Onmulti-spindlemowers,takecareasrotatingone

bladecancauseotherbladestorotate.

•Disengagedrives,lowerthedeck,setparkingbrake,

stopengineandremovethekeyfromtheignition.

Waitforallmovementtostopbeforeadjusting,

cleaningorrepairing.

•Cleangrassanddebrisfromdecks,drives,

silencers/mufers,engineandundersideofmachine

tohelppreventres.Cleanupoilorfuelspillage.

Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustouserandbystanders.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennis

shoesorsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Beforestartingtheengine,sitontheseat.

•Usingthemachinedemandsattention.Toprevent

lossofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,

orotherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthe

positivelast.Reconnectpositiverstandnegative

last.

•Usecarewhencheckingtheblades.Weargloves

andusecautionwhenservicingthem.Onlyreplace

blades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.W ear

protectiveclothinganduseinsulatedtools.

ToroRidingMowerSafety

–Thismachineisnotdesignedorequippedfor

on-roaduseandisa“slow-movingvehicle.”

Ifyoumustcrossortravelonapublicroad,

youshouldbeawareofandcomplywithlocal

regulations,suchasrequiredlights,slowmoving

vehiclesigns,andreectors.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrol

ofthemachine.

•Raisethedeckwhendrivingfromoneworkareato

another.

•Donottouchtheengine,silencer/mufer,or

exhaustpipewhiletheengineisrunningorsoon

afterithasstoppedbecausetheseareascouldbehot

enoughtocauseburns.

•Iftheenginestallsormachinecannotmakeitto

thetopofaslope,donotturnthemachinearound.

Alwaysbackslowly,straightdowntheslope.

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknowthatisnotincludedintheCEN,ISO,or

ANSIstandard.

•Whenapersonorpetappearsunexpectedlyin

ornearthemowingarea,stopmowing.Careless

operation,combinedwithterrainangles,ricochets,

orimproperlypositionedguardscanleadtothrown

6

Page 7

objectinjuries.Donotresumemowinguntilthe

areaiscleared.

MaintenanceandStorage

•Makesureallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunder

highpressure.Usepaperorcardboard,notyour

hands,tosearchforleaks.Hydraulicuidescaping

underpressurecanhavesufcientforcetopenetrate

theskinandcauseseriousinjury.Seekimmediate

medicalattentionifuidisinjectedintoskin.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinthesystemmust

berelievedbystoppingtheengineandloweringthe

deckandattachmentstotheground.

•Checkallfuellinesfortightnessandwearona

regularbasis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthedeck,

attachments,andanymovingparts,especiallythe

screenatthesideoftheengine.Keepeveryoneaway .

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedToroDistributor.

•UseonlyToroapprovedattachmentsand

replacementparts.Thewarrantymaybevoidedif

usedwithunapprovedattachments.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof105

dBA,basedonmeasurementsofidenticalmachinesper

ISO11094.

SoundPressure

Thisunithasamaximumsoundpressurelevelatthe

operator’searof89dBA,basedonmeasurementsof

identicalmachinesperEN836andISO11201.

Vibration

Thisunitdoesnotexceedahand/armvibrationlevelof

2.5m/s2,basedonmeasurementsofidenticalmachines

perEN836andEN1033.

Thisunitdoesnotexceedawholebodyvibration

levelof0.5m/s2,basedonmeasurementsofidentical

machinesperEN836andEN1032.

7

Page 8

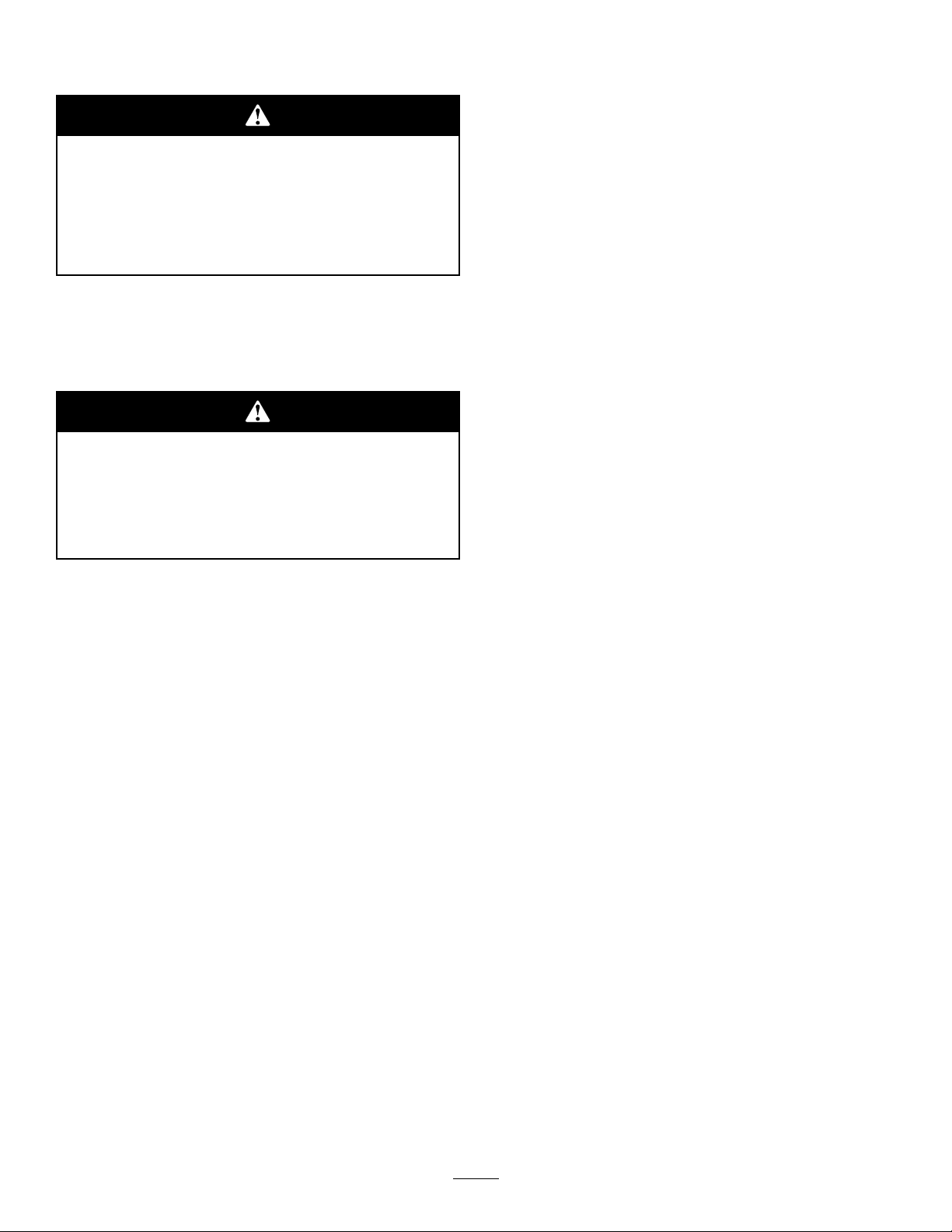

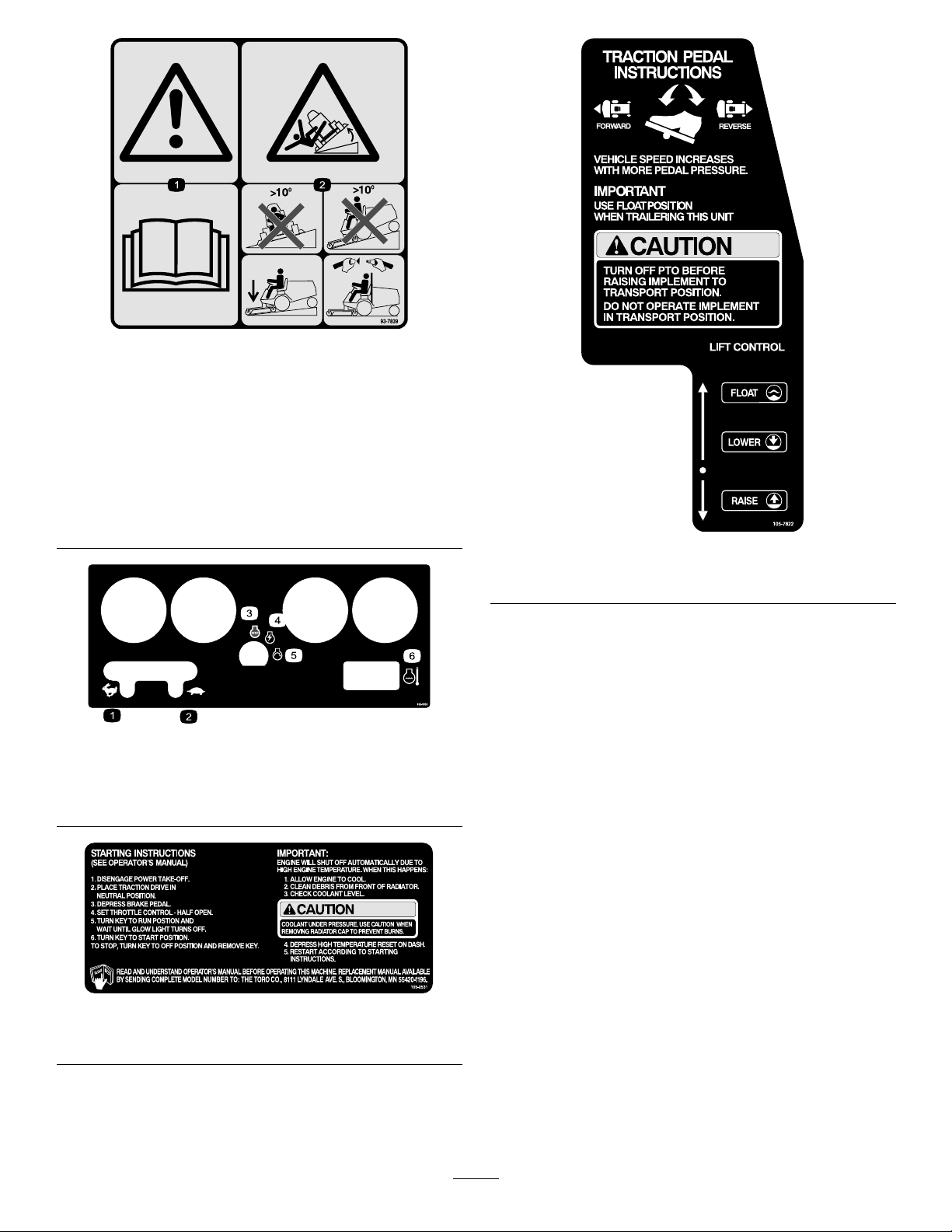

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

107-2918

(Models30630&30631)

*ThissafetydecalincludesaslopewarningrequiredonthemachineforcompliancetotheEuropeanLawnMowerSafetyStandardEN836:1997.Theconservativemaximum

slopeanglesindicatedforoperationofthismachineareprescribedbyandrequiredbythisstandard.

1.On3.Off5.Cuttinghazardofhand

2.Powertake-off(PTO)

4.Warning—readthe

Operator’sManual.

orfoot—stayawayfrom

movingparts.

6.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

7.Warning—locktheparking

brake,stoptheengine,and

removetheignitionkey

beforeleavingthemachine.

8.Tippinghazard—donot

drivethemachineona

slopegreaterthan10

degrees,lowerthecutting

unitwhendrivingdown

slopes,andiftherollbaris

installed,weartheseatbelt.

27-7310

(Models30626&30627)

27-7290

(Models30630&30631)

8

Page 9

55-4300

(Models30626&30627)

67-1710

(Models30626&30627)

70-2560

(Model30627)

82-8930

(Models30626&30627)

1.Parkingbrake—readtheOperator’sManualforfurther

instructions.

82-8940

1.Locked3.Unlocked

2.Tiltsteering

72-3700

(Models30626&30627)

77-3100

(Models30626&30627)

1.Fanbladescancauseinjury—stayawayfrommovingparts.

83-9150

(Models30626&30627)

9

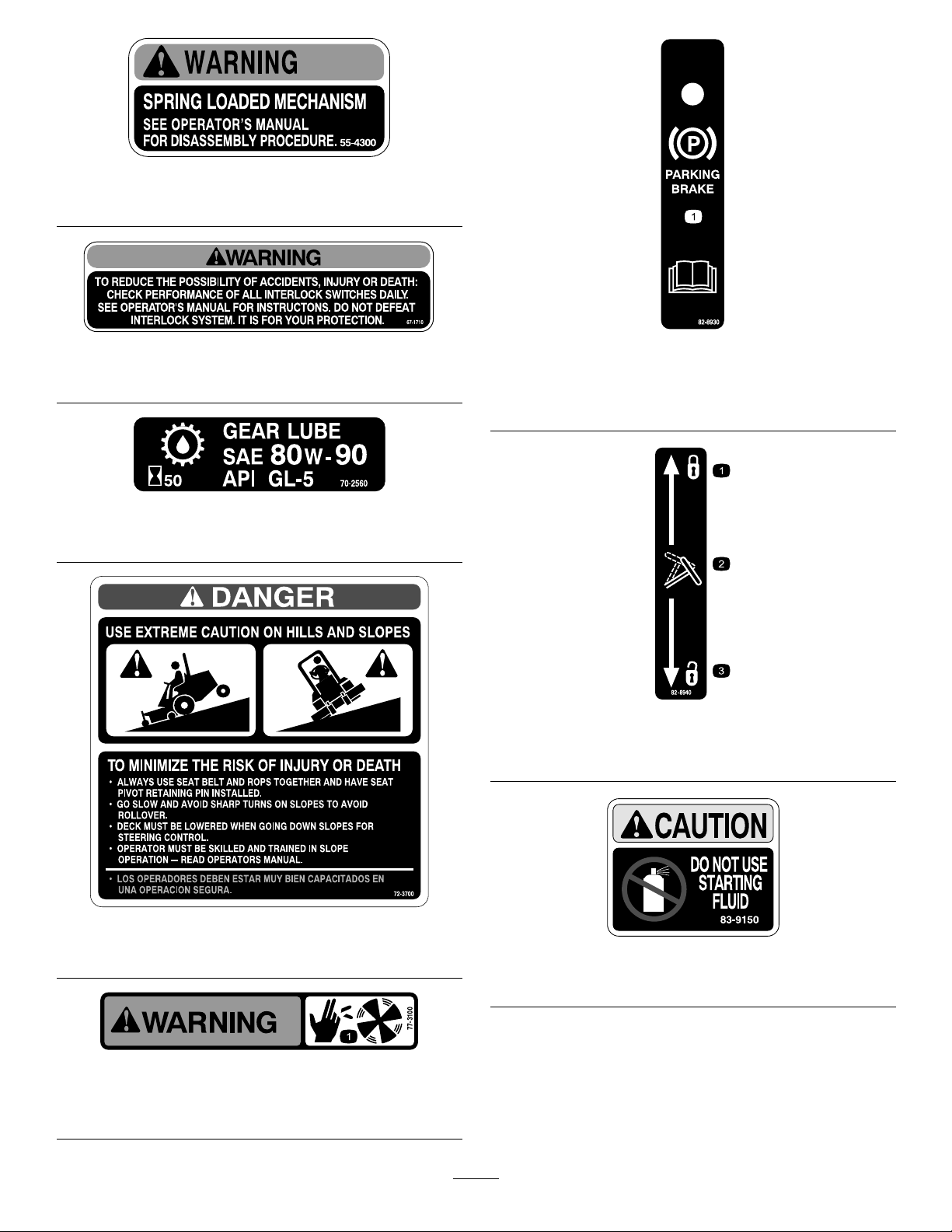

Page 10

1.ReadtheOperator’sManual.

1.Hydraulicoil

2.ReadtheOperator’sManual.

1.ReadtheOperator’s

Manual.

114-9600

93-7822

(Models30630&30631

1.Caution—llfueltankto1in(25mm)belowllerneck.

ReadtheOperator’sManualforfurtherinstructions.

93-6686

93-7830

1.Caution—readtheOperator’sManualforfurther

instructions.

2.Torquewheelfastenersto45-55ft-lb(62-75N-m)

93-6697

(Model30631)

2.AddSAE80w-90(API

GL-5)oilevery50hours.

93-7272

(Models30630&30631)

1.Cutting/dismembermenthazard;fan—stayawayfromoving

parts.

93-7275

(Model30630&30631)

1.ReadtheOperator’sManual.

2.Donotusestartingaids.

93-7831

1.Parkingbrake—readtheOperator’sManualforfurther

instructions.

93-7836

1.Tomovethetractionunitforwardorbackward,depressthe

tractionpedal.

10

Page 11

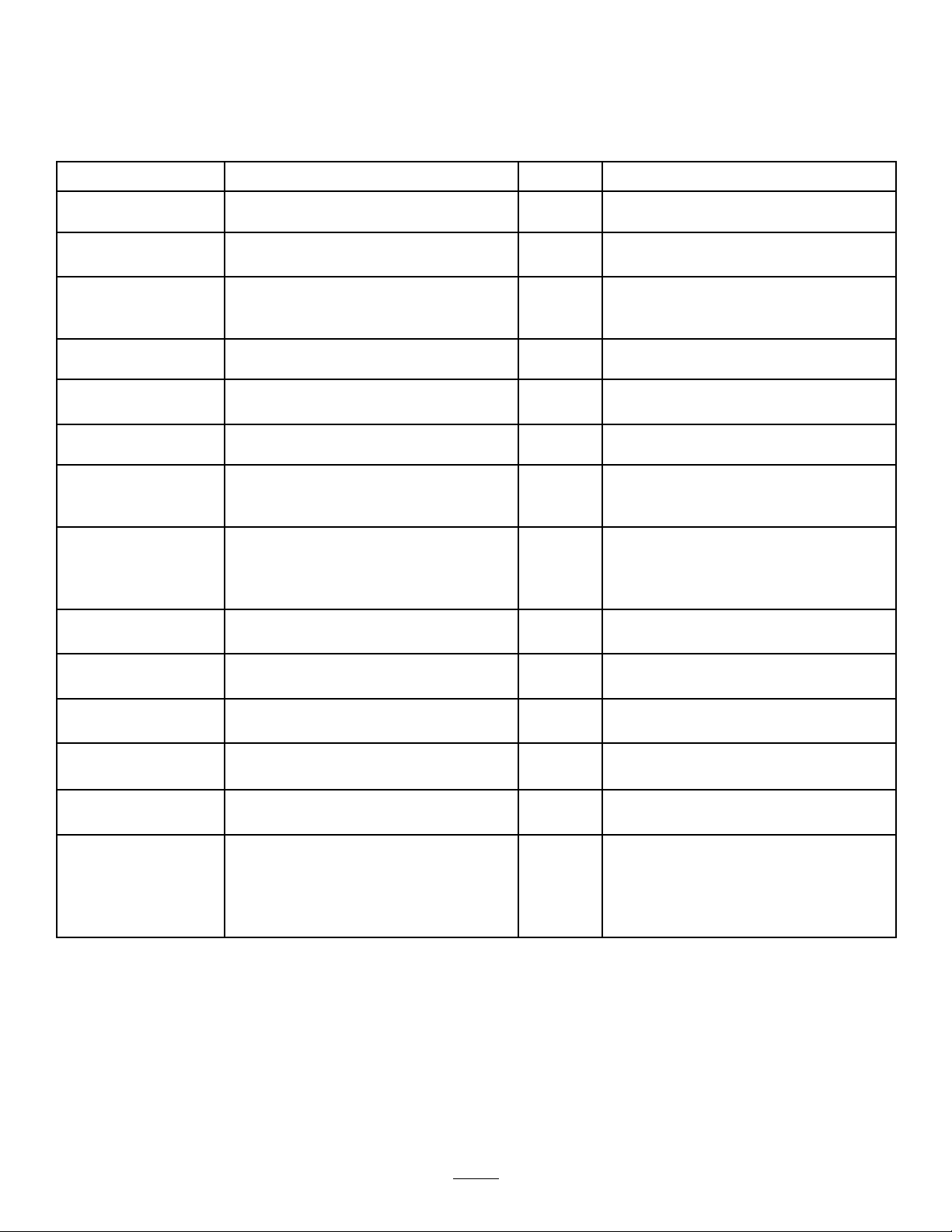

93-7839

(Model30630&30631)

*Thissafetydecalincludesaslopewarningrequiredonthemachineforcompliance

totheEuropeanLawnMowerSafetyStandardEN836:1997.Theconservative

maximumslopeanglesindicatedforoperationofthismachineareprescribed

byandrequiredbythisstandard.

1.Warning—readtheOperator’sManual.

2.Tippinghazard—donotdrivethemachineonaslope

greaterthan10degrees;whendrivingdownslopes,lower

thecuttingunit,andiftherollbarisinstalled,weartheseat

belt.

105-0056

1.Fast4.Engine—run

2.Slow

3.Engine—stop6.Enginetemperature

5.Engine—start

105-7822

(Models30626&30627)

105-2531

(Model30626&30627)

11

Page 12

105-7823

(Models30630&30631)

1.Tractiondrive—todriveforward,pressthetopofthetraction

controlpedalforwardanddown;todriveinreverse,press

thebottomofthetractioncontrolpedalrearwardanddown.

2.Warning—disengagethepowertake-off(PTO)before

raisingthecuttingunit(s).

3.Floatthecuttingunit(s)overtheground.

4.Lowerthecuttingunit(s).

5.Raisethecuttingunit(s).

106-6754

(Models30630&30631)

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

106-8120

(Models30626&30627)

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cuttinghazardofhandandfoot—stayawayfrommoving

parts.

107-2927

(Models30630&30631)

1.Tostarttheengine,readtheOperator’sManual,disengage

thepowertake–off(PTO),placethetractiondrivein

neutral,pressthebrake,movethethrottlelevertotheFast

position,turnthekeytotheEngine—powerpositionuntil

theglowpluglightilluminates,andthenturnthekeytothe

Engine—startposition.

2.Toover-ridetheenginetemperaturewarning,pressthe

button.

1.Enginecoolantunder

pressure

2.Explosionhazard—read

theOperator’sManual.

106-5976

3.Warning—donottouch

4.Warning—readthe

thehotsurface.

Operator’sManual.

Manufacturer’sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

12

Page 13

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

13

Page 14

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

Qty.

Screw,M10x30mm

Washer4

Tierod1Installthetierod.

Bumper1

Capscrew,1/4x1/2inch

Flangenut1/4inch

Rearwheel2

Frontwheel2

Nopartsrequired

Manualtube(shippedintoolbox)

R-clamp2

Seatbelt

Bolt,7/16x1inch

Lockwasher,7/16inch

RollBar(ROPS)

Bolt,3/4x5-1/2inch

Lockwasher,3/4inch

Nut,3/4inch

4

1

1

–

1

1

2

2

1

4

4

4

Installthesteeringcylinder.

Installtherearbumper.

Installthefrontandrearwheels.

Removethebatteryfromthechassis.

Installtheseat.

Installtheseatbelt.

Installtherollbar.

Use

9

10

11

12

13

14

Nopartsrequired

Nopartsrequired

Nopartsrequired

Right-handballjoint(shippedintool

box)

Nopartsrequired

Hydraulicoillter

Partscatalog1

Operator’sManual(tractionunit)

OperatorTrainingMaterial

CerticateofQuality

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Note:Somemodelsmayhavealreadybeenset-upat

factory.

–

–

–

1

–

1

2

1

1

Pushthetractionunitoffofthepallet.

Activateandchargingthebattery.

Installingthebatteryinthechassis.

Installtheballjointandconnectingthe

liftcylinder.

Installtherearweight.

Finishthesetup.

14

Page 15

1

G005678

2

1

G005679

1

2

InstallingtheSteeringCylinder

(Models30627&30631only)

Partsneededforthisprocedure:

4

Screw,M10x30mm

4Washer

Procedure

1.RemovescrewandR-clampsecuringsteering

cylindertopackaging.RetainR-clampforfuture

installation.

2.Mountcylindersupportbrackettorearofaxlewith

4screws(M10x30)screwsandwashers(Figure3).

ApplyLoctite242,orequivalent,andtorquescrews

to48-60ft-lb.(65-81N-m).

InstallingtheTieRod(Models

30627&30631only)

Partsneededforthisprocedure:

1Tierod

Procedure

1.Removecotterpinsandcastlenutsfromballjoint

endsoftierod.Insertballjointendsintorearhole

ofeachaxlesteeringarm.Insertballjointsfrom

bottomofeachsteeringarm(Figure4).

Figure3

1.Cylindersupportbracket2.Steeringarm

3.Removecastlenutandcotterpinfromballjointend

ofsteeringcylinder.Insertballjointendintocenter

holeofaxlesteeringarm.Inserttheballjointfrom

thetopofthesteeringarm.

4.Secureballjointendtosteeringarmwithcastlenut

(Figure3)andtorqueitto70-90ft-lb.(94-122N-m).

Installcotterpin.

Figure4

1.Tierod

2.Secureballjointendstosteeringarmswithacastle

nutandtorqueitto40-60ft-lb.(54-81N-m).Install

acotterpin.

3

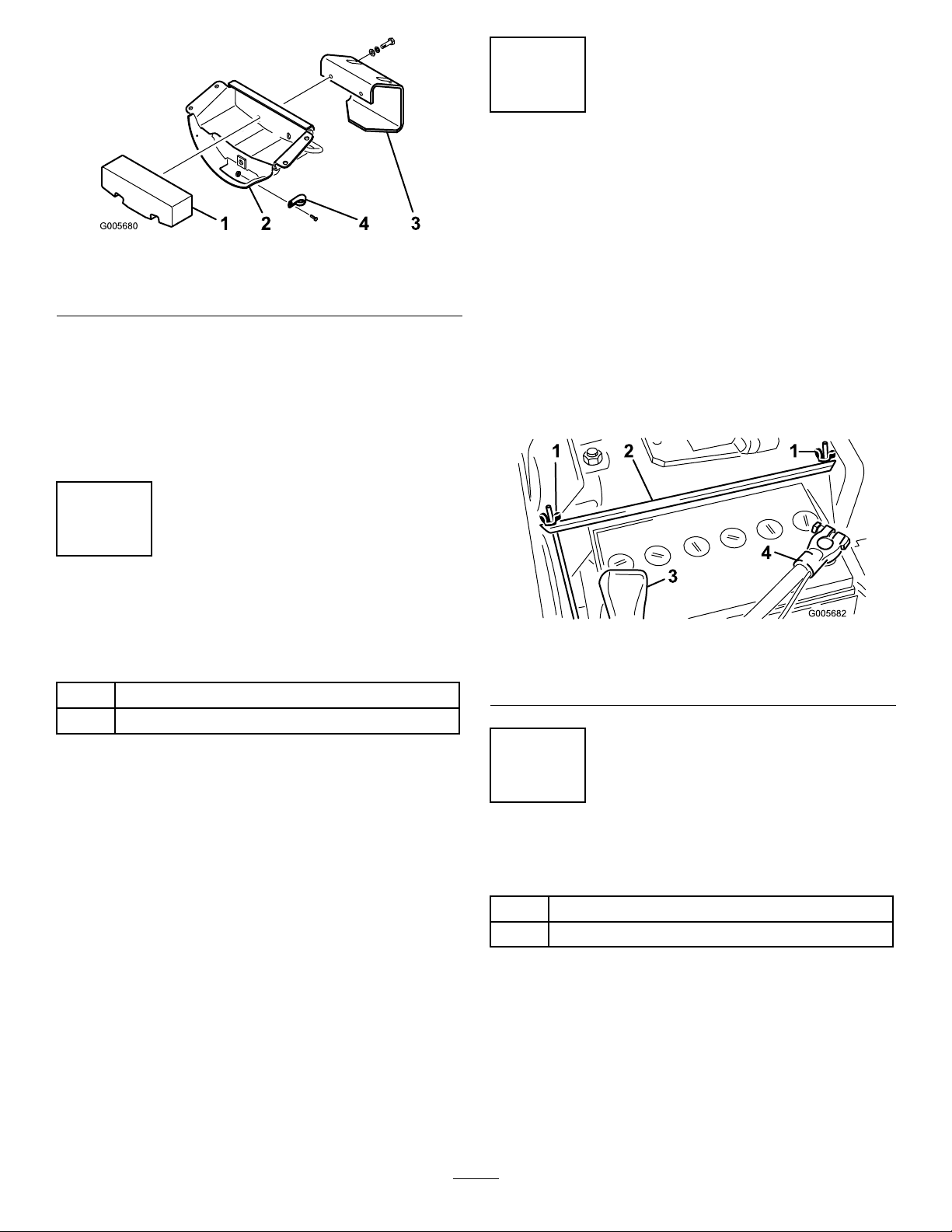

InstallingtheRearBumper

(Models30627&30631only)

Partsneededforthisprocedure:

1Bumper

1

Capscrew,1/4x1/2inch

1

Flangenut1/4inch

Procedure

1.Remove2capscrews(1/2x3/4inch),lockwashers,

andatwasherssecuringrearweighttoaxlesupport

15

(Figure5).

Page 16

G005680

1243

Figure5

1.Rearweight3.Bumper

2.Axlesupport4.R-clamp

2.Usingcapscrews,lockwashersandatwashers

previouslyremoved,mountbumperandrearweight

toaxlesupport.

3.UsingR-clamppreviouslyremoved,securesteering

hosestoaxlesupportwithacapscrew(1/4x1/2

inch)andangenutsupplied,inlooseparts.

4

5

RemovingtheBatteryfromthe

Chassis

NoPartsRequired

Procedure

1.Releasethetwolatchesholdinginstrumentcoverin

place.Carefullyremoveinstrumentcovertoexpose

thebattery.

2.Removetwowingnutsandholddownstrapthat

securesbattery(Figure6).Liftbatteryoutofchassis.

Keepwingnutsandholddownstrapinsafeplace

forlateruse.

InstallingtheFrontandRear

Wheels

Partsneededforthisprocedure:

2Rearwheel

2Frontwheel

Procedure

1.Removeanddiscardfastenerssecuringwheelsto

packaging.

2.Removewheelnutsfromstudsonaxles.

Note:FrontwheelnutsareEnglishandrearwheel

nutsaremetric.

3.Mountwheelsandtorquemountingnutsto45-55

ft-lb.(61-75N-m).

Figure6

1.Wingnuts3.Positiveterminal

2.Holddownstrap4.Negativeterminal

6

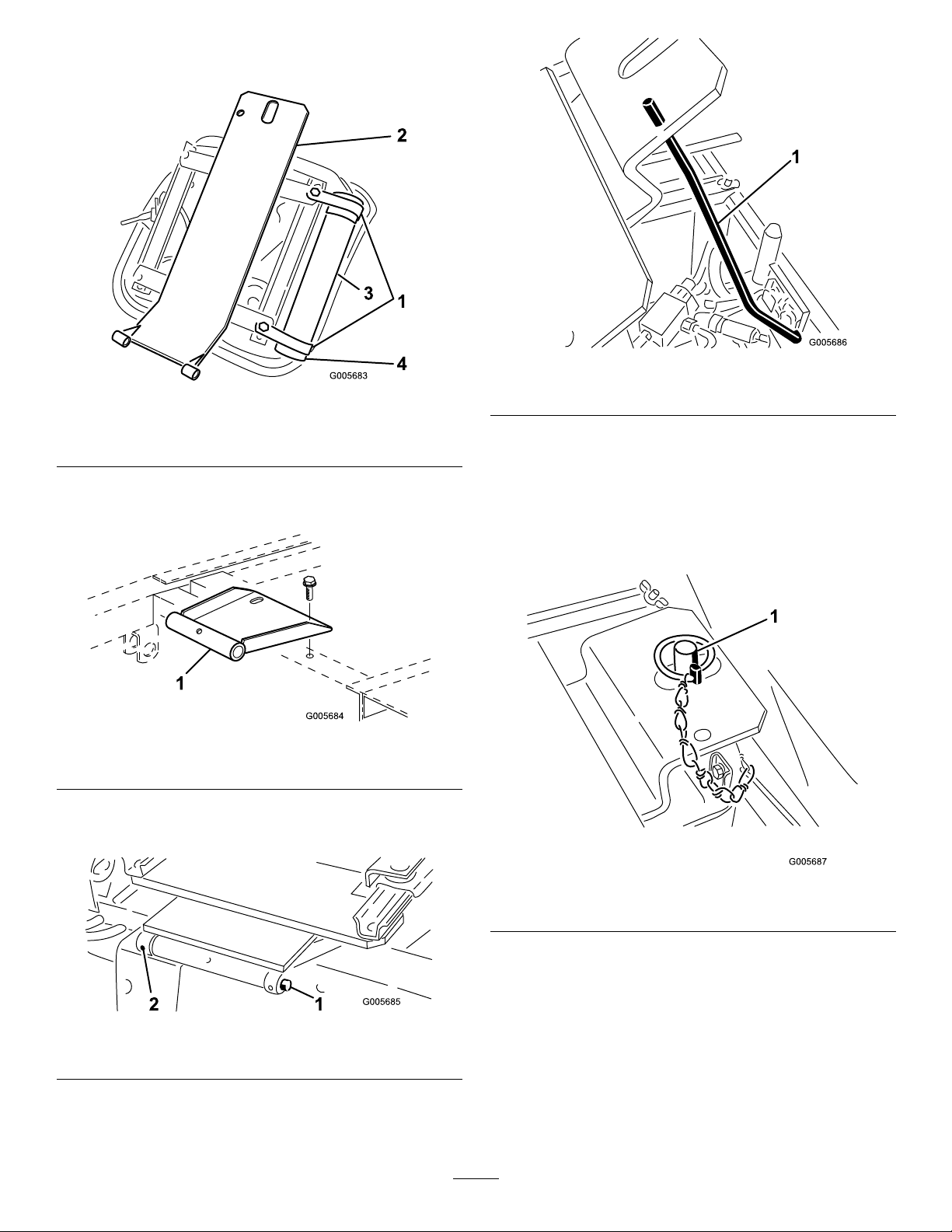

InstallingtheSeat

Partsneededforthisprocedure:

1

Manualtube(shippedintoolbox)

2R-clamp

SeatKit,ModelNo.30623,Standard

Seat

Themachineisshippedwithouttheseatassembly.

EitheroptionalSeatKit,ModelNo.30623or30625

mustbeinstalled.

1.Looselysecure(2)R-clampstorightsideofseat

bottomwith2capscrewsandatwasherssupplied

16

Page 17

inkit(Fig.6).InstallmanualtubeintoR-clampsand

G005684

1

tightencapscrews(Figure7).

Figure7

1.R-clamps3.Manualtube

2.Seatsupport4.Cap

Figure10

1.Seatsupportrod

5.Plugwireharnessconnectorintoseatswitch

connectoronbottomofseat.

2.Mountseatpivotbrackettoframewith2ange

screwssuppliedinkit(Figure8).

Figure8

1.Seatpivotbracket

3.Mountseatandseatsupporttoseatpivotbracket

withpivotshaftandrollpin(Figure9).

6.Disengageseatsupportrodandpivotdownward.

Pivotseatdownandpushlynchpinthroughseat

latchstud.Flipwireendofpinoverlatchstud

(Figure11).

Figure11

1.Lynchpin

Figure9

1.Pivotshaft

2.Rollpin

4.Holdseatupwithseatsupportrod(Figure10).

7.Slideseatcompletelyforwardandbackwardto

ensureproperoperationandthatseatswitchwires

andconnectorsarenotpinchedordonocontactany

movingparts.

17

Page 18

SeatKit,ModelNo.30625,DeluxeSeat

withModelNo.30628SeatAdapterKit

Themachineisshippedwithouttheseatassembly.

EitheroptionalSeatKit,ModelNo.30623or30625

mustbeinstalled.

1.Mountseatsuspensionassemblyto4capscrewson

seatbottomandsecurewith4lockwashers,at

washers,andnuts(Figure12).

Figure13

1.Seatswitchwireharness

8.Disengageseatsupportrodandpivotdownward.

Pivotseatdownandpushlynchpinthroughseat

latchstud.Flipwireendofpinoverlatchstud

(Figure11).

9.Slideseatcompletelyforwardandbackwardto

ensureproperoperationandthatseatswitchwires

andconnectorsarenotpinchedordonocontactany

movingparts.

Figure12

1.Seatsuspensionassembly

2.R-clamps

3.Lockwasher ,atwasher,

andnut

2.Looselysecure2R-clampstorightsideofseat

bottomwith2capscrewsandatwasherssupplied

inkit(Figure12).InstallmanualtubeintoR-clamps

andtightencapscrews(Figure12).

3.Mountseatsupportoverfourthreadedstudsatthe

bottomofseatsuspensionassemblyandsecurein

placewithangenuts(Figure12).

4.Mountseatpivotbrackettoframewith(2)ange

screwssuppliedinkit(Figure8)

5.Mountseatandseatsupporttoseatpivotbracket

withpivotshaftandrollpin(Figure9).

6.Holdseatupwithseatsupportrod(Figure10).

7.Routeseatswitchharnessthroughholesinseat

supportandseatsuspension(Figure13).Plugwire

harnessconnectorintoseatswitchconnectoron

bottomofseat.

4.Manualtube

5.Cap

6.Seatsupport

7

InstallingtheSeatBelt

Partsneededforthisprocedure:

1

Seatbelt

2

Bolt,7/16x1inch

2

Lockwasher,7/16inch

Procedure

Installseatbelttoholesinbackofseatwith2bolts(7/16

x1inch)andlockwashers(Figure14).Tightensecurely.

Important:Mountthelatchsideofthebelttothe

rightsideoftheseat.

18

Page 19

9

PushingtheTractionUnitOff

ofthePallet

NoPartsRequired

Figure14

1.Seatbelt

8

InstallingtheRollBar

Partsneededforthisprocedure:

1

RollBar(ROPS)

4

Bolt,3/4x5-1/2inch

4

Lockwasher,3/4inch

4

Nut,3/4inch

Procedure

1.Lowerrollbarontoframe,aligningmountingholes

asshowninFigure15.

2.Securerollbartoframewith4bolts(3/4x5-1/2

inch),lockwashers,andnuts(Figure15).Tighten

securely.

Procedure

1.Reachinandrotatebypassvalveontransmission

(Figure16)counterclockwise1/2to1turn.Opening

thevalveopensaninternalpassageinthepump,

therebybypassingtransmissionoil.Becauseuid

isbypassed,themachinecanbepushedwithout

damagingthetransmission.

Figure16

1.Bypassvalve

2.Liftmachineovershippingbracesandpushmachine

offpallet.

3.Closebypassvalvebyrotatingitclockwiseuntilitis

securelyseated.Donotexceed5to8ft-lb.(7to11

N-m).Donotstartenginewhenvalveisopen.

1.Rollbar

Figure15

10

ActivatingandChargingthe

Battery

NoPartsRequired

Procedure

Useonlyelectrolyte(1.265SpecicGravity)toll

batteryinitially.

1.Removethebatteryfromthemachine.

Important:Donotaddelectrolytewhilethe

batteryisinthemachine.Youcouldspillit,

causingcorrosion.

19

Page 20

2.Cleanthetopofthebatteryandremovethevent

caps(Figure17).

Figure17

3.Carefullylleachcellwithelectrolyteuntiltheplates

arecoveredwithabout1/4inch(6mm)ofuid.

Note:Afterthebatteryhasbeenactivated,add

onlydistilledwatertoreplacenormalloss,although

maintenance–freebatteriesshouldnotrequirewater

undernormaloperatingconditions.

Warning

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Batteryterminalsormetaltoolscouldshort

againstmetaltractorcomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

Figure18

4.Allowapproximately20to30minutesforthe

electrolytetosoakintotheplates.Rellasnecessary

tobringtheelectrolytetowithinabout1/4inch(6

mm)ofthebottomofthellwell(Figure18).

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthetractor.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

tractor.

5.Connecta3to4ampbatterychargertothebattery

posts.Chargethebatteryatarateof3to4amps

untilthespecicgravityis1.250orhigherandthe

temperatureisatleast60degreesF(16degreesC)

withallcellsgasingfreely.

6.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

20

Page 21

andsliderubberbootoverpositiveterminal

(Figure6).

11

InstallingtheBatteryinthe

Chassis

NoPartsRequired

Procedure

Batteryterminalsormetaltoolscouldshort

againstmetaltractorcomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthetractor.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

tractor.

5.Installtheinstrumentcoverandlockthetwolatches.

12

InstallingtheBallJointand

ConnectingtheLiftCylinder

Partsneededforthisprocedure:

1

Right-handballjoint(shippedintoolbox)

Procedure

Note:Balljointsarenotrequiredforallimplements;

refertoimplementoperator’smanualforrequirements.

1.Threadjamnutfullyontoright-handballjoint.

2.Screwballjointintorighthandpusharmuntilcenter

ofballjointis2-3/8inch(60mm)awayfromfront

ofpusharm(Figure19).Donottightenjamnut.

1.Installbatteryandsecurewithholddownstrapand

wingnuts(Figure6).Removetapeoverendsofeach

cable.

2.Slidethered,positivebatterycable(Figure6)onto

positivebatterypostandtightennutsecurely .

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Always

batterycablebeforedisconnectingthe

positive(red)cable.

•Always

cablebeforeconnectingthenegative(black)

cable.

3.Slidetheblack,negativebatterycable(Figure6)onto

negativebatterypostandtightennutsecurely.

disconnect

connect

thenegative(black)

thepositive(red)battery

Figure19

1.Jamnut

2.Balljointmount4.Right-handpusharm

Suddenreleaseofthespring-loadedpusharms

couldcauseinjury.

Acquirethehelpofanotherpersontohelppush

thearmsdownduringinstallationoftheball

jointsorotherimplements.

3.2-3/8inch(60mm)

4.CoatbothbatteryconnectionswitheitherGrafo

112X(skin-over)grease,ToroPartNo.505-47,

petroleumjellyorlightgreasetopreventcorrosion

3.Haveahelperpushdownontheleftpusharm.

Theninserta2x4inch(51x102mm)blockof

woodbetweentheframeandtopofthepusharm

(Figure20).Screwballjointintolefthandpusharm

21

Page 22

untilcenterofballjointis2-3/8inch(60mm)away

fromfrontofpusharm(Figure20).Donottighten

jamnut.

Figure20

1.Jamnut4.Balljointmount

2.2x4inch(51x102mm)

block

3.Left-handpusharm

5.2-3/8inch(60mm)

5.Removespringpinfromcylinderpinandslide

cylinderpinoutofcylinder.

6.Raisefrontofliftarmuntilholeinmovableend

ofcylinderlinesupwithholesinliftarmbrackets.

Usecautionasliftarmisspring-loaded.Holdparts

togetherwithcylinderpin,springpin,andcotterpin.

Cotterpinmustbetotheoutside.

7.Installimplement;refertoimplementOperator’s

Manualforproperinstallationprocedures.

4.Carefullyremove2x4inch(51x102mm)blockof

woodfrombetweenframeandpusharm.

13

InstallingtheRearWeight

NoPartsRequired

Procedure

TocomplywithCENstandardEN836:1997,ISOstandard5395:1990andANSI/OPEIB71.4–2004Standard,rear

weightmustbeaddedtorearoftwowheeldrivetractionunits.Usechartbelowtodetermineweightrequirements.

OrderpartsfromyourlocalAuthorizedToroDistributor.Noadditionalweightisrequiredonfourwheeldrive

models.

Note:Arearweightkit,partno.24–5780issuppliedwithModelNo.30630.

TwoWheelDrive

72″SideDischarge

(ModelNo.30722)

72″RearDischarge

(ModelNo.30710)

Guardian72″Recycler

(ModelNo.30716)

CuttingUnit

Description

RearWeight

Required

70lb.24–5780

70lb.24–5780

70lb.24–5780

WeightPart

Number

WeightDescription

RearWeightKit(two35lb.weightsand

mountinghardware)

RearWeightKit(two35lb.weightsand

mountinghardware)

RearWeightKit(two35lb.weightsand

mountinghardware)

Qty.

1

1

1

22

Page 23

•OperatorTrainingMaterial.Reviewbeforeoperating

themachine.

14

FinishingtheSetup

Partsneededforthisprocedure:

1

Hydraulicoillter

1Partscatalog

2

Operator’sManual(tractionunit)

1

OperatorTrainingMaterial

1

CerticateofQuality

Procedure

CheckingtheTirePressure

Thetiresareover-inatedforshipping.Therefore,

releasesomeoftheairtoreducethepressure.Correct

airpressureinthefrontandreartiresis21psi(145kPa).

CheckingtheT orqueoftheFrontWheelNuts

•CerticateofQuality:Saveforreference.

Failuretomaintainpropertorqueofthefront

wheelnutscouldresultinfailure,lossofwheel,

orpersonalinjury.

Torquethefrontwheelnutsto45–55ft-lb.

(61–75N-m)after1–4hoursofoperationand

againafter10hoursofoperation.Torqueevery

250hoursthereafter.

GreasingtheTractionUnit

Beforethemachineisoperated,itmustbegreased

toassureproperoperatingcharacteristics;referto

LubricationMaintenance.Failuretogreasethemachine

willresultinprematurefailureofcriticalparts.

Note:Aftersetuphasbeencompleted,remove

protectiveedging(usedforshipping)fromfenders.

Reviewthefollowinglooseparts

•Hydraulicoillter

Changeafter10hours

•Partscatalog:

Saveforreference.

•Operator’sManual(tractionunit)Readbefore

operatingthemachine.

23

Page 24

ProductOverview

Figure21

1.Tractionpedal4.Parkingbrakeknob

2.Turnpedals5.Tiltsteeringcontrol

3.Brakepedal

TurnPedals

Theleftandrightturnpedals(Figure21)areconnected

totheleftandrightfrontwheelbrakessincebothbrakes

workindependentlyofeachother.Thebrakescanbe

usedtoturnsharplyortoincreasetractionifonewheel

tendstoslipwhileoperatingonahillside.However,wet

grassorsoftturfcouldbedamagedwhenbrakesare

usedtoturn.

TiltSteeringControl

Thetiltsteeringcontrolisaleveronrightsideofsteering

column(Figure21).Pullleverrearwardtoadjuststeering

wheeltodesiredforeoraftoperatingpositionandpush

leverforwardtolockadjustment.

Donotleaveleverinunlockedposition.

BrakePedal

Controls

TractionPedal

Thetractionpedal(Figure21)hastwofunctions;one

istomakethemachinemoveforward,theotheristo

makeitmovebackward.Usingtheheelandtoeofthe

rightfoot,depresstopofpedaltomoveforwardand

bottomofpedaltomovebackward.Groundspeed

isproportionatetohowfarpedalisdepressed.For

maximumgroundspeedwithnoload,tractionpedal

mustbefullydepressedwhilethrottleisinFAST

position.Maximumspeedforwardisapproximately9.5

mph(15km/h).Togetmaximumpowerunderheavy

loadorwhenascendingahill,havethrottleinFAST

positionwhiledepressingtractionpedalslightlytokeep

enginerpmhigh.Whenenginerpmbeginstodecrease,

releasetractionpedalslightlytoallowenginerpmto

increase.

Whenfootisremovedfromthetractionpedal,

machineshouldstop;itmustnotcreepineither

direction.Ifmachinedoescreep,donotoperate

untilneutralassemblyhasbeenrepairedand

adjusted;refertoAdjustingTractionDrivefor

Neutral.

Whenevertheengineisshutoff,theparkingbrake

(Figure21)mustbeengagedtopreventaccidental

movementofthemachine.

Thehydrostatictransmissionwillnot,atanytime,act

asaparkingbrakeforthemachine.T oengageparking

brake,pushdownfullyonbrakepedalandpullparking

brakeknobout;thenreleasethepedal.Torelease

parkingbrake,depressbrakepedaluntilparkingbrake

knobretracts.Tostopquickly ,removerightfootfrom

tractionpedalanddepressthebrakepedal.Topermit

straightstops,brakecablesmustbeevenlyadjusted.

LiftLever

Thehydraulicliftlever(Figure22)hasthreepositions:

FLOAT,TRANSPORT,andRAISE.Tolower

implementtotheground,moveliftleverforwardinto

detent,whichistheFLOATposition.TheFLOAT

positionisusedforoperationandalsowhenmachine

isnotinoperation.Toraiseimplement,pullliftlever

backwardtotheRAISEposition.Afterimplementis

raised,allowliftlevertomovetotheTRANSPORT

position.Normally,implementshouldberaisedwhen

drivingfromoneworkareatoanother,exceptwhen

descendingsteepslopes.

24

Page 25

Theexposed,rotatingbladesofthecuttingunit

orotherimplementsarehazardous.

FuelGauge

Thefuelgauge(Figure23)indicatesquantityoffuel

remaininginfueltank.

Neverraiseacuttingunitorimplementwhile

thebladesorothercomponentsarerotating.

Figure22

1.Liftlever

PTOLever

ThePTOlever(Figure23)hastwopositions:ON

(engage)andOFF(disengage).SlowlypushPTOlever

fullyforwardtoONpositiontostarttheimplement

orcuttingunitblades.Slowly,pullleverbackwardto

OFFpositiontostopimplementoperation.Theonly

timePTOlevershouldbeintheONpositioniswhen

implementorcuttingunitisdowninoperatingposition.

HourMeter

Thehourmeter(Figure23)registersaccumulatedhours

ofengineoperation.

OilPressureWarningLight

Theoilpressurewarninglight(Figure23)glowswhen

oilpressureinenginedropsbelowasafelevel.Iflow

oilpressureeveroccurs,stopengineanddeterminethe

cause.Repairthedamagebeforestartingtheengine

again.

ChargeIndicator

Illuminateswhensystemchargingcircuitmalfunctions

(Figure23).

EngineCoolantTemperatureWarning

Light

Thelightilluminatesandengineshutsdownwhen

coolantreachesaexcessivelyhightemperature

(Figure23).

TemperatureGauge

Thetemperaturegauge(Figure23)registersthe

temperatureofthecoolantinthecoolingsystem.If

temperatureofcoolantgetstoohightheenginewillshut

offautomatically .

Figure23

1.PTOlever7.Chargeindicator

2.Fuelgauge8.Temperaturegauge

3.Hourmeter9.Temperatureoverride

4.Oilpressureindicator

5.Enginetemperature11.Throttlecontrol

6.Glowplugindicator

switch

10.Keyswitch

12.Batterycover

TemperatureOverrideSwitch

Pressandholdoverrideswitchtostartengineafter

hightemperatureshutdown.Useonlyforemergency

operation.

GlowPlugIndicator

Whenlit,indicatesglowplugsareon(Figure23).

KeySwitch

Threepositions:OFF ,ON/PreheatandSTART

(Figure23).

ThrottleControl

Thethrottle(Figure23)isusedtooperateengineat

variousspeeds.Movingthrottleforwardincreases

enginespeed—FAST;backwarddecreasesengine

speed—SLOW .Thethrottleregulatesthespeedofthe

25

Page 26

cutterbladesorotherimplementcomponentsand,in

conjunctionwithtractionpedal,controlsgroundspeed

ofthetractionunit.

SeatAdjustingLever

Toadjuststandardseat,pushlever(Figure24)backward

andslideseattothedesiredposition.Releaseleverto

lockseatinplace.Thesuspensionseatmaybeadjusted

forwardorrearwardbypullingouttheleverattheleft

sideoftheseat,slidingtheseattothedesiredposition,

andreleasingthelever.Theweightadjustmentknob

maybeadjustedforanyoperator’scomfort.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

DimensionsandWeights(approx.)

Figure24

1.Seatadjustinglever

Widthof4wheeldrivemodels(measuredfromoutsideofreartires)

Widthof2wheeldrivemodels(measuredfromoutsideoffronttires)

Lengthof4wheeldrivemodels

Lengthof2wheeldrivemodels

HeightwithROPSofallmodels78.5inches(199cm)

DryWeightof4WheelDrivemodels(withoutcuttingdeck)

DryWeightof2WheelDrivemodels(withoutcuttingdeck)

WheelBaseof4WheelDrivemodels

WheelBaseof2WheelDrivemodels

47.6inches(121cm)

46inches(1 17cm)

94inches(239cm)

91inches(231cm)

1665lb.(755kg)

1385lb.(628kg)

51inches(130cm)

49inches(124cm)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

26

Page 27

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperating

HoodProp(Models30626&30627

only)

1.Positionthemachineonalevelsurface.

2.Disengagehoodlatchandopenthehood.

3.Slidebottomofhoodprop(Figure25)outof

retainingbracket.Lowerhoodprop,pivotupward,

thendownwardtopropuphood.

2.Removedipstick(Figure26),wipecleanandreinstall

dipstick.Removedipstickandcheckoillevel.Oil

levelshouldbeuptoFULLmarkondipstick.

Figure26

1.Dipstick

3.IfoilisbelowFULLmark,removellcapandadd

oiluntillevelreachesFULLmarkondipstick.DO

NOTOVERFILL.

Figure25

1.Hoodprop

CheckingtheCrankcaseOil

Theengineisshippedwithoilinthecrankcase;

however,theoillevelmustbecheckedbeforeandafter

theengineisrststarted.

Crankcasecapacityisapproximately3.25qt.(3.1l)with

thelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH–4,CI–4or

higher.

•Preferredoil:SAE15W–40(above0F)

•Alternateoil:SAE10W–30or5W–30(all

temperatures)

ToroPremiumEngineoilisavailablefromyour

distributorineither15W–40or10W–30viscosity.See

thepartscatalogforpartnumbers.

1.Parkmachineonalevelsurface,stopengineand

removekeyfromignitionswitch.Openhoodand

installhoodprop.

Figure27

1.Oilll

4.Installoilllcapandclosehood.

Important:Besuretokeeptheengineoillevel

betweentheupperandlowerlimitsontheoil

gauge.Enginefailuremayoccurasaresultof

overllingorunderllingtheengineoil.

FillingtheFuelTank

Useonlyclean,freshdieselfuelorbiodieselfuelswith

low(<500ppm)orultralow(<15ppm)sulfurcontent.

Theminimumcetaneratingshouldbe40.Purchase

fuelinquantitiesthatcanbeusedwithin180daysto

ensurefuelfreshness.

Fueltankcapacity:6.5U.S.gallons(25l)

Usesummergradedieselfuel(No.2–D)at

temperaturesabove20degreesF(–7degreesC)and

27

Page 28

wintergrade(No.1–DorNo.1–D/2–Dblend)below

thattemperature.Useofwintergradefuelatlower

temperaturesprovideslowerashpointandcoldow

characteristicswhichwilleasestartingandreducefuel

lterplugging.

Useofsummergradefuelabove20degreesF(–7

degreesC)willcontributetowardlongerfuelpumplife

andincreasedpowercomparedtowintergradefuel.

Tipseatforwardandpropitwiththesupportrodsoit

cannotfallaccidentally.Usingacleanrag,cleanarea

aroundfueltankcap(Figure28).

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomof

thellerneck.Thisemptyspaceinthetank

allowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,sealed,safety-approved

container.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

Figure28

1.Fueltankcap

CheckCoolingSystem

Cleandebrisoffscreenandradiator/oilcoolerdaily ,

moreoftenifconditionsareextremelydustyanddirty.

Thecoolingsystemislledwitha50/50solution

ofwaterandpermanentethyleneglycolanti–freeze.

Checklevelofcoolantinexpansiontankatbeginning

ofeachdaybeforestartingtheengine.Capacityof

coolingsystemis6quarts(5.6l).

Ifenginehasbeenrunning,pressurized

hotcoolantcanescapewhenradiatorcapis

removedandcauseburns.

1.Checklevelofcoolantinexpansiontank.Coolant

levelshouldbebetweenthemarksonsideoftank.

•Thebiodieselportionofthefuelmustmeet

specicationASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuelas

theymaybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblends.

•Contactyourdistributorifyouwishformore

informationonbiodiesel.

Figure29

1.Expansiontank

2.Ifcoolantlevelislow ,removeexpansiontankcap

andreplenishthesystem.DONOTOVERFILL.

3.Installexpansiontankcap.

28

Page 29

CheckingtheHydraulicSystemFluid

IndustrySpecications:(cont'd.)

Thefrontaxlehousingactsasthereservoirforthe

system.Thetransmissionandaxlehousingareshipped

fromthefactorywithapproximately5quarts(4.7l)of

highqualityhydraulicuid.However,checkuidlevel

beforeengineisrststartedanddailythereafter.

Note:Fluidtooperatethepowersteeringissupplied

bythehydraulicsystemtransmissionchargepump.

Coldweatherstart-upmayresultin“stiff”operationof

thesteeringuntilthehydraulicsystemhaswarmedup.

Thefollowinglistisnotassumedtobeall–inclusive.

Hydraulicuidsproducedbyothermanufacturers

maybeusediftheycancrossreferencetond

anequivalenttotheproductslisted.Torowill

notassumeresponsibilityfordamagecausedby

impropersubstitutions,souseonlyproductsfrom

reputablemanufacturerswhowillstandbehindtheir

recommendation.

CheckingtheHydraulicSystem

Thefrontaxlehousingactsasthereservoirforthe

system.Thetransmissionandaxlehousingareshipped

fromthefactorywithapproximately5quarts(4.7l)of

highqualityhydraulicuid.Checkthelevelofthe

hydraulicuidbeforetheengineisrststarted

anddailythereafter.Therecommendedreplacement

uidis:

APIGL–4,AGCOPoweruid821XL,FordNewHolland

FNHA–2–C–201.00,KubotaUDT ,JohnDeereJ20C,Vickers

35VQ25andVolvoWB–101/BM.

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemoilisavailablein2/3oz.(20ml)

bottles.Onebottleissufcientfor4–6gal(15–221)

ofhydraulicoil.Orderpartno.44–2500fromyour

authorizedTorodistributor.

1.Positionmachineonalevelsurface,raisethe

implement,andstoptheengine.

2.Unscrewdipstickcap(Figure30)fromtheller

neckandwipeitwithacleanrag.Screwdipstickcap

ngertightontollerneck.Unscrewthedipstick

andchecklevelofuid.Iflevelisnotwithin1/2

inch(13mm)fromthegrooveinthedipstick

(Figure30),addenoughuidtoraiseleveltogroove

mark.Donotoverllbymorethan1/2inch(13

mm)abovegroove.

ToroPremiumTransmission/HydraulicTractor

Fluid

(Availablein5gallonpailsor55gallondrums.Seeparts

catalogorTorodistributorforpartnumbers.)

Alternateuids:IftheTorouidisnotavailable,other

petroleum–basedUniversalTractorHydraulicFluids

(UTHF)maybeusedprovideditsspecicationsfall

withinthelistedrangeforallthefollowingmaterial

propertiesanditmeetsindustrystandards.Wedonot

recommendtheuseofsyntheticuid.Consultwith

yourlubricantdistributortoidentifyasatisfactory

productNote:Torowillnotassumeresponsibilityfor

damagecausedbyimpropersubstitutions,souseonly

productsfromreputablemanufacturerswhowillstand

behindtheirrecommendation.

MaterialProperties:

Viscosity,ASTMD445cSt@40C55to62

ViscosityIndexASTMD2270

PourPoint,ASTMD97

IndustrySpecications:

cSt@100C9.1to9.8

140–152

–35Fto–46F

Figure30

1.Dipstickcap

2.Groove

Important:Whenaddingoiltothehydraulic

system,useafunnelwithanewire

screen—200mesh—andensurefunneland

oilareimmaculatelyclean.Thisprocedure

preventsaccidentalcontaminationofthe

hydraulicsystem.

3.Screwdipstickllercapnger–tightontollerneck.

Itisnotnecessarytotightencapwithawrench.

4.Lowertheimplement.

CheckingtheRearAxle

(Models30627&30631only

Therearaxlehasthreeseparatereservoirswhichuse

SAE80W -90wt.gearlube.Althoughtheaxleis

29

Page 30

shippedwithlubricantfromthefactory,checkthelevel

beforeoperatingthemachine.

1.Positionthemachineonalevelsurface.

2.Removecheckplugsfromaxleandmakesure

lubricantisuptobottomofeachhole.Iflevelis

low,removellplugsandaddenoughlubricantto

bringtheleveluptothebottomofthecheckplug

holes(Figure31).

Starting/StoppingEngine

Important:Thefuelsystemmustbebledifanyof

thefollowingsituationhaveoccurred.

•Initialstartupofanewmachine.

•Enginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponfuel

systemcomponents;i.e.,lterreplaced,

separatorserviced,etc.

RefertoBleedingTheFuelSystem.

1.Ensureparkingbrakeisset,PTOswitchisin

OFFpositionandliftleverisinTRANSPORTor

FLOATposition.Removefootfromtractionpedal

andinsureitisinneutral.

Figure31

1.Checkplug

2.Fill/checkplug(oneon

eachendofaxle)

3.Fillplug

CheckBidirectionalClutchLubricant

(Models30627&30631only)

1.Positionthemachineonalevelsurface.

2.Rotateclutch(Figure32)socheckplug(shownin

12o’clockposition)ispositionedat4o’clock.

Figure32

1.Bidirectionalclutch

2.Checkplug

2.Movethrottlecontrolto1/2throttleposition.

3.TurnignitionswitchtoON/Preheatposition.

Anautomatictimerwillcontrolpreheatfor10

seconds.Afterpreheat,turnkeytoSTARTposition.

CRANKENGINEFORNOLONGERTHAN

15SECONDS.Releasekeywhenenginestarts.

Ifadditionalpreheatisrequired,turnkeytoOFF

positionthentoON/preheatposition.Repeat

processasrequired.

4.Runengineatidlespeedorpartialthrottleuntil

enginewarmsup.

Note:Movethrottleto1/2throttlepositionwhen

restartingawarmengine.

5.Whenengineisstartedforthersttime,or

afterengineoilchange,oroverhaulofengine,

transmissionoraxle,operatethemachineinforward

andreverseforonetotwominutes.Alsooperatethe

liftleverandPTOlevertoassureproperoperation

ofallparts.Turnpowersteeringwheeltotheleft

andrighttochecksteeringresponse.Thenshut

engineoffandcheckuidlevels,checkforoilleaks,

loosepartsandanyothernoticeablemalfunctions.

3.Removecheckplug.Fluidlevelshouldbeupto

holeinclutch.Ifuidlevelislow ,addMobilFluid

424.Clutchshouldbeapproximately1/3full.

4.Installcheckplug.

Note:Donotuseengineoil(i.e.10W30)in

bidirectionalclutch.Anti-wearandextremepressure

additiveswillcauseundesirableclutchperformance.

Shutengineoffandwaitforallmovingpartsto

stopbeforecheckingforoilleaks,looseparts

orothermalfunctions.

6.Tostopengine,movethrottlecontrolbackwardto

SLOWposition,movePTOswitchtoOFFposition

androtateignitionkeytoOFF .Removekeyfrom

switchtopreventaccidentalstarting.

30

Page 31

BleedingFuelSystem

1.Parkthemachineonalevelsurface.Makesurefuel

tankisatleasthalffull.

enginedoesnotstart,airmaybetrappedbetween

injectionpumpandinjectors;refertoBleedingAir

FromInjectors.

2.Unlatchandraisehood.

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1inch

(25mm)belowthebottomofthellerneck.

Thisemptyspaceinthetankallowsthefuel

toexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

3.Opentheairbleedscrewonthefuelinjectionpump

(Figure33).

CheckingtheInterlock

Switches

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Themachinehasinterlockswitchesintheelectrical

system.Theseswitchesaredesignedtostopthe

enginewhenoperatorgetsofftheseatwhileeitherthe

PTOleverisengagedortractionpedalisdepressed.

However,operatormaygetofftheseatwhileengineis

running.AlthoughenginewillcontinuetorunifPTO

leverisdisengagedandtractionpedalisreleased,it

isstronglyrecommendedthattheenginebestopped

beforedismountingfromtheseat.

Tocheckoperationofinterlockswitches:

Figure33

1.Fuelinjectionpumpbleedscrew

4.TurnkeyinignitionswitchtotheONposition.

Electricfuelpumpwillbeginoperation,thereby

forcingairoutaroundairbleedscrew .Leavekey

inONpositionuntilsolidstreamoffuelowsout

aroundscrew .TightenscrewandturnkeytoOFF .

Note:Normally,engineshouldstartafterabove

bleedingproceduresarefollowed.However,if

1.Drivethemachineslowlytoalarge,relativelyopen

area.Lowercuttingunit,stoptheengineandapply

parkingbrake.

2.Sitonseat.MovePTOlevertoONposition.With

thetractionpedalinneutralposition,trytostart

theengine.Theengineshouldnotcrank.Ifthe

enginecranks,thereisamalfunctionintheinterlock

systemthatshouldbecorrectedbeforebeginning

operation.

3.Sitonseat.MovePTOlevertoOFFanddepress

thetractionpedal.Trytostarttheengine.The

engineshouldnotcrank.Iftheenginecranks,there

isamalfunctionintheinterlocksystemthatshould

becorrectedbeforebeginningoperation.

Donotoperatethemachinewithoutan

implementunlessthePTOdriveshaftisalso

removed.

4.Sitonseatandstarttheengine.Disengagethe

parkingbrake.Raiseofftheseatandmovethe

31

Page 32

PTOlevertoON.Theengineshouldstopwithin

2–3seconds.Iftheenginedoesnotstop,thereisa

malfunctionintheinterlocksystemthatshouldbe

correctedbeforebeginningoperation.

5.Engagetheparkingbrake.Depressthetraction

pedalwhileengineisrunningandthePTOlever

isdisengaged.Theengineshouldstopwithin2

seconds.Ifenginestops,theswitchisoperating

correctly;thus,continueoperation.Ifenginedoes

notstop,thereisamalfunctionintheinterlock

systemthatshouldbecorrectedbeforebeginning

operation.

PushingorTowingthe

TractionUnit

Inanemergency,thetractionunitcanbepushedor

towedforaveryshortdistance.However,T orodoes

notrecommendthisasstandardprocedure.

Important:Donopushortowthetractionunit

fasterthan2to3MPH(3to4.8km/h)because

transmissionmaybedamaged.Iftractionunit

mustbemovedaconsiderabledistance,transport

itonatruckortrailer.Whenevertractionunitis

pushedortowed,bypassvalvemustbeopen.

1.Reachundertractionunitandrotatebypass

valve(Figure34)1/2to1turncounterclockwise.

Openingthevalveopensaninternalpassagein

thetransmission,therebybypassingtransmission

oil.Becauseuidisbypassed,tractionunitcanbe

movedwithoutdamagingthetransmission.

OperatingCharacteristics

Practicedrivingthemachinebecauseithasahydrostatic

transmissionanditscharacteristicsaredifferentthan

manyturfmaintenancemachines.Somepointsto

considerwhenoperatingthetractionunit,cutting

unit,orotherimplementarethetransmission,engine

speed,loadonthecuttingbladesorotherimplement

components,andtheimportanceofthebrakes.

Tomaintainenoughpowerforthetractionunitand

implementwhileoperating,regulatetractionpedalto

keepenginerpmhighandsomewhatconstant.Agood

ruletofollowis:decreasegroundspeedastheloadon

theimplementincreases,andincreasegroundspeed

astheloaddecreases.

Therefore,allowtractionpedaltomovebackward

asenginerpmdecrease,anddepresspedalslowlyas

rpmincrease.Bycomparison,whendrivingfromone

workareatoanother—withnoloadandcuttingunit

raised—havethrottleinFASTpositionanddepress

tractionpedalslowlybutfullytoattainmaximum

groundspeed.

Anothercharacteristictoconsideristheoperationof

theturningpedalsthatareconnectedtothebrakes.

Thebrakescanbeusedtoassistinturningthemachine.

However,usethemcarefully,especiallyonsoftorwet

grassbecausetheturfmaybetornaccidentally.Another

benetoftheturningbrakesistomaintaintraction.

Forexample:insomeslopeconditions,theuphillwheel

slipsandlosestraction.Ifthissituationoccurs,depress

uphillturnpedalgraduallyandintermittentlyuntilthe

uphillwheelstopsslipping,thus,increasingtractionon

thedownhillwheel.

Figure34

1.Bypassvalve

2.Beforestartingengine,closebypassvalveby

rotatingitclockwiseuntilitissecurelyseated.Do

notexceed5to8ft-lb.(7to11N-m).Donotstart

enginewhenvalveisopen.

Important:Runningthemachinewithbypass

valveopenwillcausethetransmissionto

overheat.

Useextracarewhenoperatingmachineonslopes.

Alwayshaveseatpivotretainingpininstalled.Drive

slowlyandavoidsharpturnsonslopestopreventroll

overs.Thecuttingdeckmustbeloweredwhengoing

downhillforsteeringcontrol.

Thegrassdeectormustalwaysbeinstalledandin

lowestpositiononthesidedischargecuttingunit.

Carelessoperation,combinedwithterrain

angle,ricochets,orimproperlypositioned

safetyguardscanleadtothrownobjectinjuries.

Apersonorpetmaysuddenlyappearinornear

themowingarea.

Stopmowinganddonotresumemowinguntil

theareaiscleared.

32

Page 33

Beforestoppingtheengine,disengageallcontrolsand

movethrottletoSLOW .MovingthrottletoSLOW

reduceshighenginerpm,noise,andvibration.Turn

keytoOFFtostopengine.

33

Page 34

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Aftertherst10hours

Aftertherst50hours

Beforeeachuseordaily

Every50hours

Every100hours

Every200hours

Every250hours

MaintenanceProcedure

•T orquethefrontwheelnuts

•Checkbelttension

•CheckPTObelttension

•Changehydraulicuidlter

•T orquethefrontwheelnuts

•Changetheengineoilandlter

•CheckPTObelttension

•CheckengineRPM

•CheckthescreenandradiatorMorefrequentlyinextremelydustyanddirtyconditions

•Inspectaircleaner

•Checkbatteryconditionandelectrolytelevel

•Changetheengineoilandlter

•Inspectthehoses

•Checkbelttension

•CheckPTObelttension

•Inspectthecoolingsystemhoses

•Checkrearwheeltoe–in

•Changehydraulicuidlter

•T orquethefrontwheelnuts

•Serviceaircleanerlter

•Checkfuellinesandconnections

•Replacethefuelltercanister.

Every400hours

Every1,000hours

•Packtherearwheelbearings

•Changetherearaxleoil

•Changethebidirectionalclutchoil

•T orque,head,adjustvalvesandcheckengineRPM

•Drainandcleanfueltank

•Flushandreplacethecoolantsystemuid

•Changethehydraulicsystemuid

•Replacemovinghoses

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

34

Page 35

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

CheckSafetyInterlock

Operation

CheckGrassDeectorin

DownPosition

CheckBrakeOperation

CheckFuelLevel

CheckEngineOilLevel

CheckCoolingSystemFluid

Level

CheckDrainWater/Fuel

Separator

CheckAirFilterRestriction

Indicator3

CheckRadiator&Screenfor

Debris

CheckUnusualEngine

Noises1

CheckUnusualOperating

Noises

CheckTransmissionOilLevel

CheckHydraulicHosesfor

Damage

CheckFluidLeaks

CheckTirePressure

CheckInstrumentOperation

CheckConditionofBlades

LubricateAllGreaseFittings2

Touch-upDamagedPaint

1.Checkglowplugandinjectornozzles,ifhardstarting,excesssmokeorroughrunningisnoted.

Sat.Sun.

2.Immediatelyaftereverywashing,regardlessoftheintervallisted.

3.Ifindicatorshowsred

Important:Refertoyour

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Engine Operator’ s Man ual

foradditionalmaintenanceprocedures.

Information

35

Page 36

Lubrication

Thetractionunitmustbelubricatedregularly .Ifmachine

isoperatedundernormalconditions,lubricateall

bearingsandbushingsafterevery50hoursofoperation.

Thetractionunitbearingsandbushingsthatmustbe

lubricatedare:

AllModels

•PTOshaftandyokes(3)(Figure35)

•Liftarmpivots(Figure35)

•Rightandleftpusharmballjoints(Figure35)

•Pusharmpivotbushings(Figure36)

•PTOpivothousingblocks(Figure37)

•Brakepivotbushings(Figure38)

•Engineoutputshaftbearing(Figure39)

FourWheelDriveModels

•Axletierod(2)(Figure40)

•Axlepivotpin(Figure40)

•Axlesteeringpivots(2)(Figure40)

•Cylinderrodends(4)(Figure40)

•Driveshaft(3)(Figure41)

•Clutchhousing(Figure41)

TwoWheelDriveModels

Figure36

Figure37

•Rearwheelspindlebushings(Figure42)

•Steeringplatebushings(Figure42)

•Axlepinbushing(Figure42)

Note:Applygreasetobothbrakecablesatthedrive

wheelandbrakepedalends.

Figure35

Figure38

Figure39

36

Page 37

Figure40

EngineMaintenance

GeneralAirCleaner

Maintenance

ServiceInterval:Every50hours—Inspectaircleaner

Every400hours—Serviceaircleaner

lter

•Checkaircleanerbodyfordamagewhichcould

possiblycauseanairleak.Replaceadamagedair

cleanerbody .

•Servicetheaircleanerlterswhenaircleaner

indicator(Figure43)showsredorevery400

hours(morefrequentlyinextremedustyordirty

conditions).Donotoverserviceairlter.

Figure41

Figure42

Figure43

1.Aircleanerindicator

ServicingAirCleaner

1.Pulllatchoutwardandrotateaircleanercover

counter–clockwise(Figure44).

Figure44

1.Aircleanerlatch3.Dirtejectionport

2.Aircleanercover

37

Page 38

2.Removethecoverfromtheaircleanerbody.Before

removingthelter,uselowpressureair(40psi,

cleananddry)tohelpremovelargeaccumulations

ofdebrispackedbetweenoutsideofprimarylter

andthecanister.Avoidusinghighpressureairwhich

couldforcedirtthroughthelterintotheintake

tract.Thiscleaningprocesspreventsdebrisfrom

migratingintotheintakewhentheprimarylteris

removed.

3.Removeandreplacetheprimarylter(Figure45).

Cleaningoftheusedelementisnotrecommended

duetothepossibilityofdamagetotheltermedia.

Inspectthenewlterforshippingdamage,checking

thesealingendofthelterandthebody.Donotuse

adamagedelement.Insertthenewlterbyapplying

pressuretotheouterrimoftheelementtoseatitin

thecanister.Donotapplypressuretotheexible

centerofthelter.

4.Cleanthedirtejectionportlocatedintheremovable

cover(Figure44).Removetherubberoutletvalve

fromthecover,cleanthecavityandreplacethe

outletvalve.

5.Installthecoverorientingtherubberoutletvalvein

adownwardposition–betweenapproximately5:00

to7:00whenviewedfromtheend.

hourandradiatorcheckedeveryhourinextremelydusty

anddirtyconditions.

Note:Thissituationmaybeparticularlyprevalentifthe

reardischargecuttingunitisbeingused.Thefrontof

theradiatorcanbecleanedthoroughlybyblowingwith

compressedairfromthefansideoftheradiator.Make

suretocleanoutanydebristhatsettlestothebottom

ofthescreen.Thescreeninfrontofradiatorcanbe

removed—bylooseningwingnutsattopofscreen—to

makecleaningeasier.

ChangingEngineOilAndFilter

ServiceInterval:Aftertherst50hours

Every100hours

Checkoillevelaftereachday’soperationoreachtime

machineisused.Changeoilandlterinitiallyafter

rst50hoursofoperation;changeoilandlterafter

every100hoursofoperationthereafter.Ifpossible,run

enginejustbeforechangingoilbecausewarmoilows

betterandcarriesmorecontaminantsthancoldoil.

1.Positionmachineonalevelsurface.

2.Openthehood.Setdrainpanundertheoilpanand

inlinewithdrainplug(Figure46).

Figure45

1.Primarylter

6.Resetindicator(Figure43)ifshowingred.

CleaningtheRadiatorand

Screen

Thescreenandfrontoftheradiatormustbekeptclean

topreventtheenginefromoverheating.Normally,check

thescreenandfrontofradiatordailyand,ifnecessary,

cleananydebrisofftheseparts.However,itwillbe

necessarytocheckandtocleanthescreeneachquarter

Figure46

1.Drainplug

3.Cleanareaarounddrainplug.

4.Removeoildrainplugandallowoiltoowinto

drainpan.

5.Removeandreplaceoillter(Figure47).

38

Page 39

Figure47

1.Oillter

6.Afteroilisdrained,reinstalldrainplugandwipeup

anyoilthatisspilled.

7.Fillcrankcasewithoil;refertoCheckCrankcaseOil.

BleedingAirFromInjectors

Note:Thisprocedureshouldbeusedonlyiffuel

systemhasbeenpurgedofairthroughnormalpriming

proceduresandenginewillnotstart;refertoBleeding

FuelSystem.

1.LoosenthepipeconnectiontotheNo.1injector

nozzleandholderassemblyatinjectionpump

(Figure48).

FuelSystem

Maintenance

Note:RefertoFillFuelTankWithDieselFuelfor

properfuelrecommendations.

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1inch

(25mm)belowthebottomofthellerneck.

Thisemptyspaceinthetankallowsthefuel

toexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

Figure48

1.No.1injectornozzle

2.MovethrottletoFASTposition.

3.TurnkeyinkeyswitchtoSTARTpositionand

watchfuelowaroundconnector.TurnkeytoOFF

positionwhensolidowisobserved.

4.Tightenpipeconnectorsecurely

5.Repeatstepsonremainingnozzles.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

FuelTank

ServiceInterval:Every1,000hours

Drainandcleanfueltankevery1000hoursoperationor

every2years,whichevercomesrst.Also,drainand

cleantankiffuelsystembecomescontaminatedorif

machineistobestoredforanextendedperiod.Use

cleandieselfueltoushoutthetank.

FuelLinesandConnections

ServiceInterval:Every400hours

Checklinesandconnectionsevery400hoursoryearly,

whichevercomesrst.Inspectfordeterioration,damage

orlooseconnections.

ServicingtheWaterSeparator

ServiceInterval:Every400hours

Drainwaterorothercontaminantsfromwaterseparator

(Figure49)daily.Replaceltercanisterafterevery400

hoursofoperation.

1.Placeacleancontainerunderthefuellter.

39

Page 40

2.Loosenthedrainplugonthebottomofthelter

canister.

Figure49

1.Waterseparatorltercanister

ElectricalSystem

Maintenance

Fuses

Thefuseblockislocatedbelowcontrolpanel.

3.Cleantheareawheretheltercanistermounts.

4.Removetheltercanisterandcleanthemounting

surface.

5.Lubricatethegasketontheltercanisterwithclean

oil.

6.Installtheltercanisterbyhanduntilthegasket

contactsmountingsurface,thenrotateitan

additional1/2turn.

7.Tightenthedrainplugonthebottomofthelter