Page 1

EATON MODEL 11 HYDROSTATIC TRANSMISSION REPAIR INFORMATION

Table of Contents – Page 1 of 1

PRODUCT IDENTIFICATION AND ORDERING INFORMATION

SPECIAL TOOLS TO AID IN DISASSEMBLY/REASSEMBLY

GENERAL PARTS LIST

DISASSEMBLY/REASSEMBLY

BODY/COVER--DISASSEMBLY

BODY ASSEMBLY-DISASSEMBLY

MOTOR ROTOR-DISASSEMBLY

PINTLE ASSEMBLY--REMOVAL

PINTLE ASSEMBLY--DISASSEMBLY/INSPECTION

RELIEF VALVE--REMOVAL/INSPECTION

RELIEF VALVE--INSTALLATION

DAMPENING PISTON--REMOVAL

DAMPENING PISTON--INSTALLATION

CHECK VALVE--REMOVAL

CHECK VALVE--INSTALLATION

ACCELERATION VALVES--REMOVAL

ACCELERATION VALVES--INSTALLATION

PUMP ROTOR ASSEMBLY-REMOVAL/INSPECTION

CAM RING--DISASSEMBLY/INSPECTION

CHARGE PUMP WITH BUSHING-- DIS ASS EM BL Y/INSPE CTION

CHARGE PUMP WITH BALL BEARI NG -- DISA S SEMBLY/INSPECT IO N

COVER ASSEMBLY--DISASSEMBLY/INSPECTION

COVER ASSEMBLY--REASSEMBLY

PUMP PLATE/PORT PLATE--INSTALLATION

CHARGE PUMP WITH BUSHING---INSTALLATION

CHARGE PUMP WITH BALL BEARI NG -- INST ALL ATION

CAM RING--INSTALLATION

PUMP ROTOR ASSEMBLY--INSTALLATION

PINTLE ASSEMBLY--INSTALLATION

MOTOR ROTOR ASSEMBLY--INSTALLATION

BODY ASSEMBL Y--REASSEMBLY

BODY/COVER--REASSEMBLY

START-UP PROCEDURE

TROUBLE SHOOTING INSTRUCTIONS

FLUID RECOMMENDATIONS

Page 2

Eaton

Hydraulics

Division

11

Model

Eaton Hydrostatic Transmissions

Page 3

Contents

Product Identification and Ordering Information

Exploded View

Part Description

Disassembly- Reassembly Procedures

Acceleration Valves-Removal

Installation

Body

Assembly-Disassembly

Reassembly

Body/Cover-Disassembly

Reassembly

Cam

Ring-Disassembly/lnspection

Installation

Charge Pump with

Charge Pump with Ball

Check Valves-Removal

Cover Assembly

(Input Shaft, Bushing,

Cover, Control Shaft) Disassembly/lnspection

Dampening Pistons-Removal

Rotor

Motor

Pintle Assembly-Removal

Pump Rotor

Pump Plate/Port Plate-Installation

Relief

Valves-Removal/Inspection

Assembly-Disassembly

Assembly-Removal/lnspection

Bushing-Disassembly/lnspection

Installation

Bearing-Disassembly/lnspection

Installation

Installation

Oil

Seal,

Resassembly

Installation

Installation

Disassembly/lnspection

Installation

Installation

Installation

5

6

7

8-2 1

11

11

8

21

8

21

12

19

12-13

17

13-14

18

10

11

14-15

15-16

10

10

8-9

20

9

9- 10

20

12

20

16

10

10

3

Start/up Procedures

Trouble Shooting

Fluid Recommendations

Copyright

1982

Eaton Corporatlon

21

22-23

24

Page 4

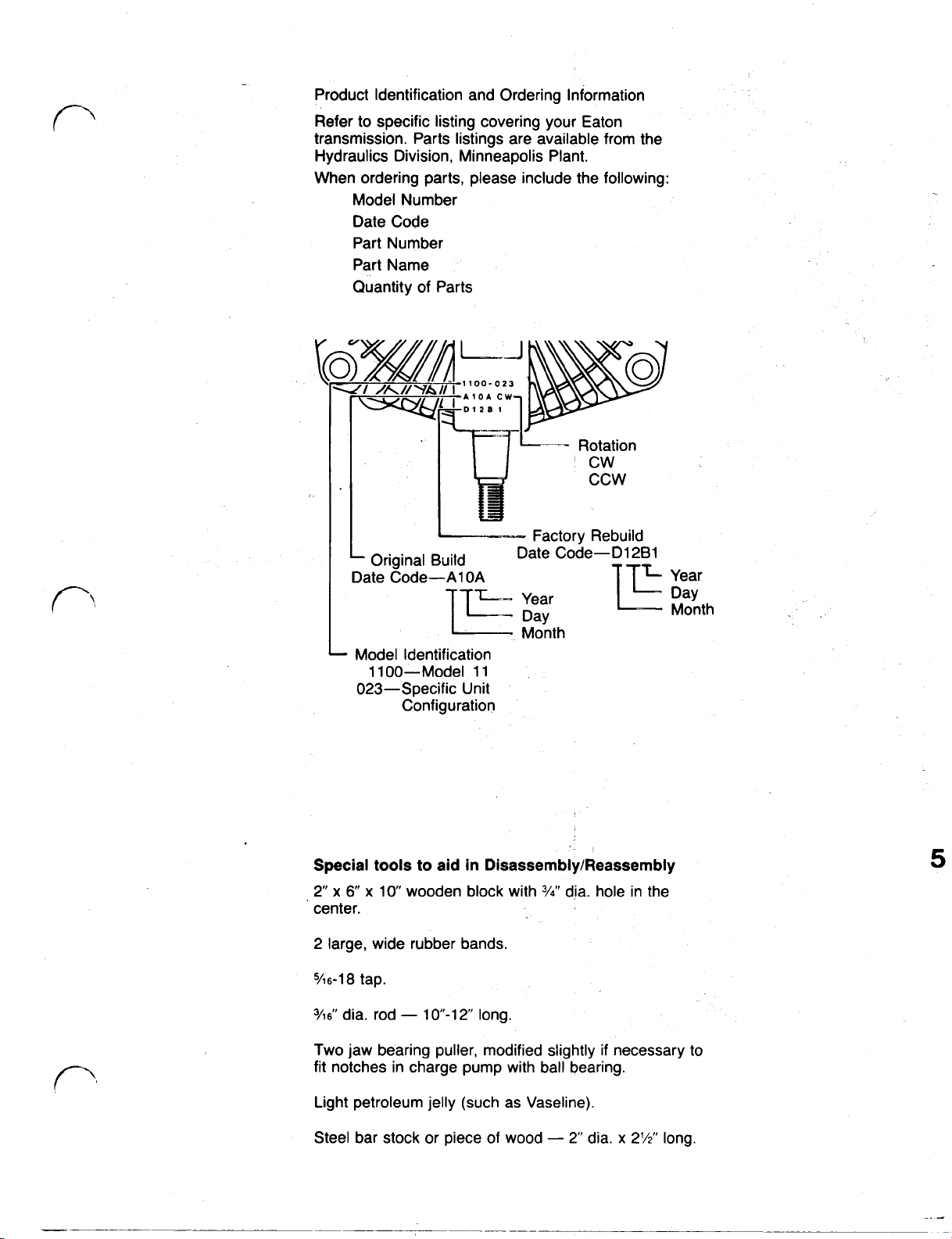

Product Identification and Ordering Information

Refer

to

specific listing covering your Eaton

transmission. Parts listings are available from the

Hydraulics Division, Minneapolis Plant.

When ordering parts, please include the following:

Model Number

Date Code

Part Number

Part Name

Quantity of Parts

Rotation

cw

ccw

Factory Rebuild

Original Build

Date Code-A1OA Year

Model Identification

1

1 00-Model 1 1

023-Specific Unit

Configuration

Date Code-Dl 2B1

Month

Day

Month

Special

2"

center.

2 large, wide rubber bands.

5/16-18 tap.

3/16"

Two jaw bearing puller, modified slightly if necessary

fit notches in charge pump with ball bearing.

Light petroleum jelly (such as Vaseline).

Steel bar stock or piece

tools

to

aid in Disassembly/Reassembly

x

6"

x

10"

wooden block with

dia. rod 10"-12" long.

3/4”

of

wood 2" dia.

dia. hole in the

x

2%"

long.

5

to

Page 5

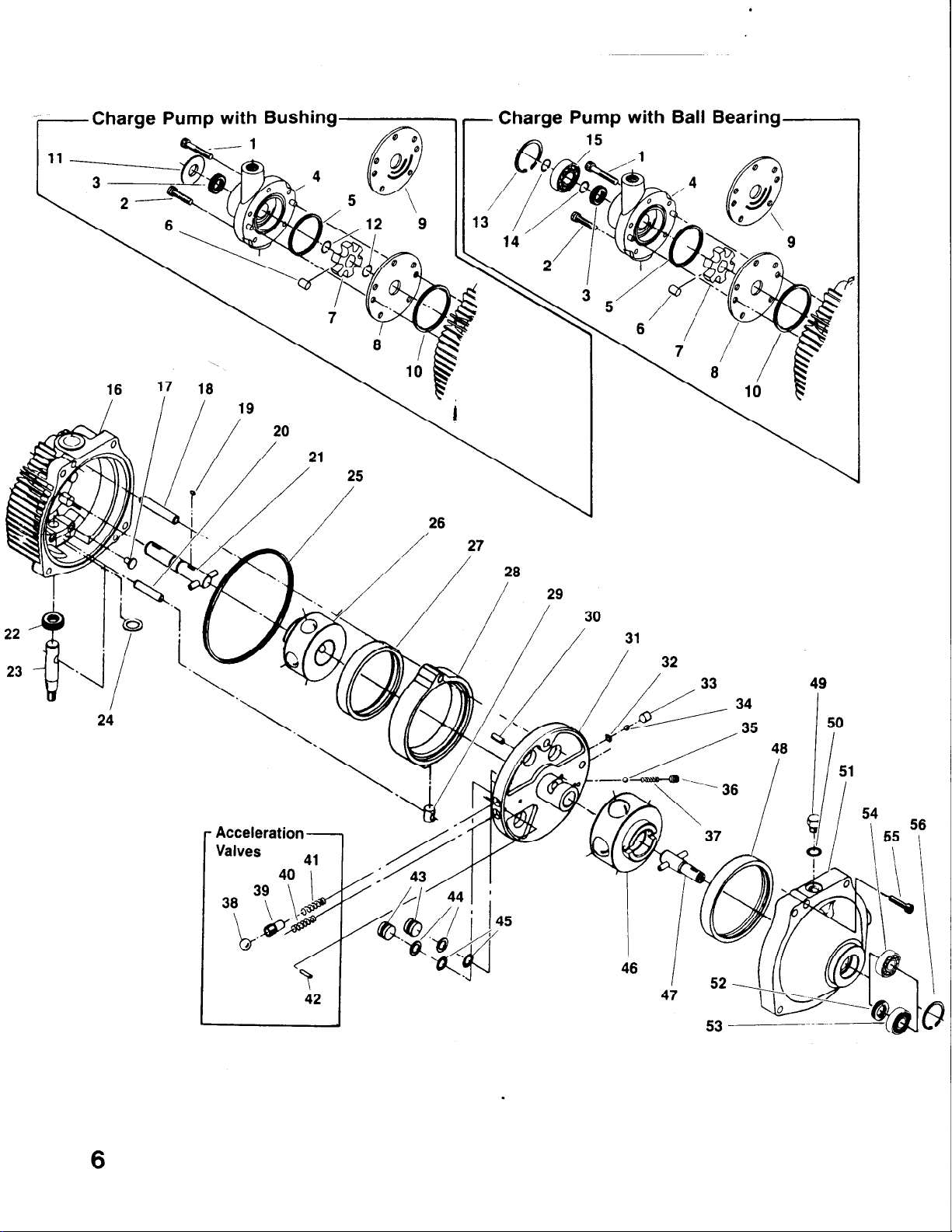

Charge Pump with Bushing

Charge Pump with Ball Bearing

24

I

Acceleration Valves

40 9’

39

38

\ l4

.&Tw

,

&

/

I

42

6

Page 6

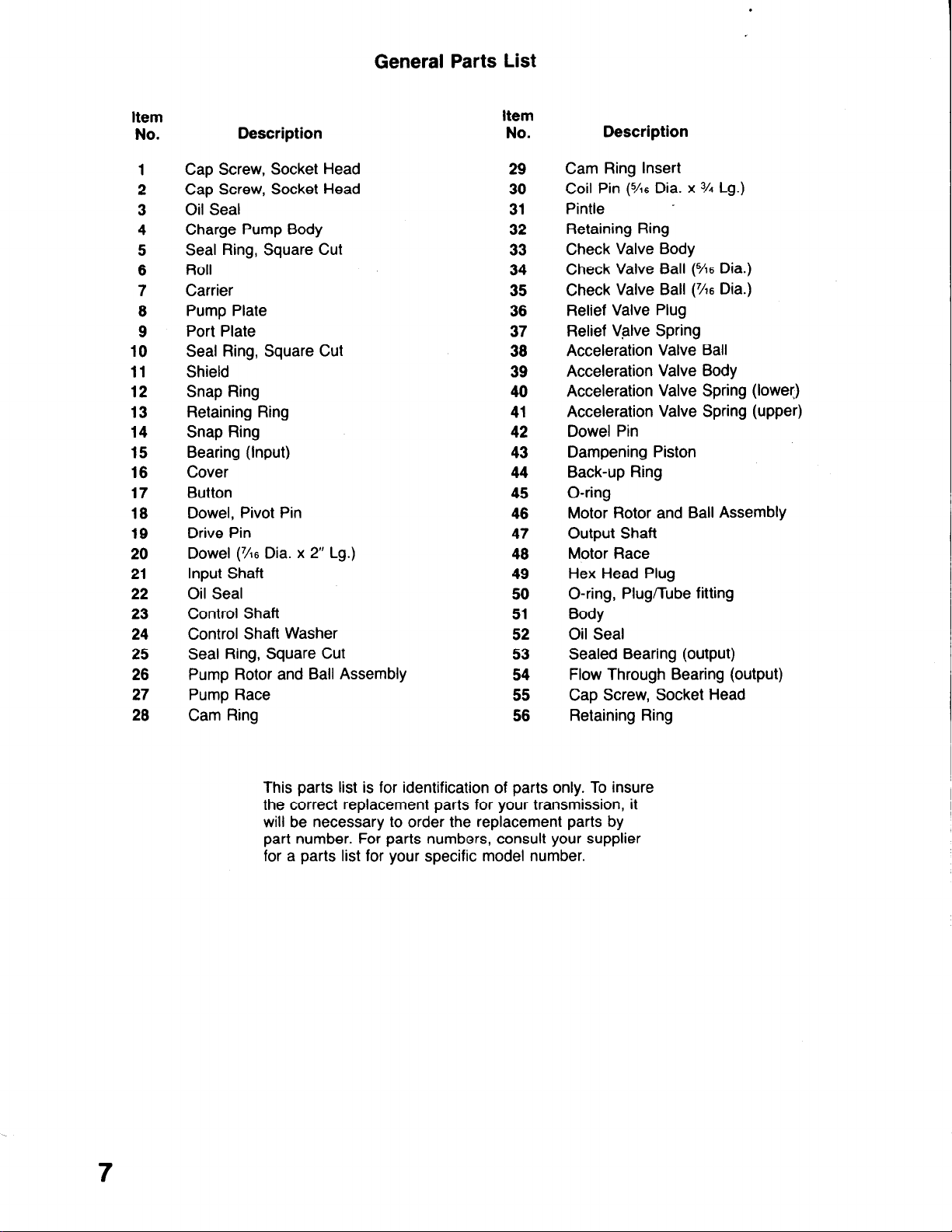

General Parts List

Item

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

item

Description

No.

Cap Screw, Socket Head 29

Cap Screw, Socket Head 30

Oil Seal 31

Charge Pump Body

Seal Ring, Square Cut

Roll

Carrier

Pump Plate

Port Plate

32

33

34

35

36

37

Seal Ring, Square Cut 38

Shield 39

Snap Ring

Retaining Ring

40

41

Snap Ring 42

Bearing (Input)

Cover

Button

Dowel, Pivot Pin

Drive Pin

Dowel (36 Dia. x 2” Lg.)

Input Shaft

Oil Seal

Control Shaft

Control Shaft Washer

Seal Ring, Square Cut

Pump Rotor and Ball Assembly

Pump Race

Cam Ring

43

44

45

46

47

48

49

50

51

52

53

54

55

56

Description

Cam Ring Insert

Coil Pin

(%6

Dia. x % Lg.)

Pintle -

Retaining Ring

Check Valve Body

Check Valve Ball

(%6

Dia.)

Check Valve Ball (X6 Dia.)

Relief Valve Plug

Relief Valve Spring

Acceleration Valve Ball

Acceleration Valve Body

Acceleration Valve Spring (lower)

Acceleration Valve Spring (upper)

Dowel Pin

Dampening Piston

Back-up Ring

O-ring

Motor Rotor and Ball Assembly

Output Shaft

Motor Race

Hex Head Plug

O-ring, Plug/Tube fitting

Body

Oil Seal

Sealed Bearing (output)

Flow Through Bearing (output)

Cap Screw, Socket Head

Retaining Ring

7

This parts list is for identification of parts only. To insure

the correct replacement parts for your transmission, it

will be necessary to order the replacement parts by

part number. For parts numbers, consult your supplier

for a parts list for your specific model number.

Page 7

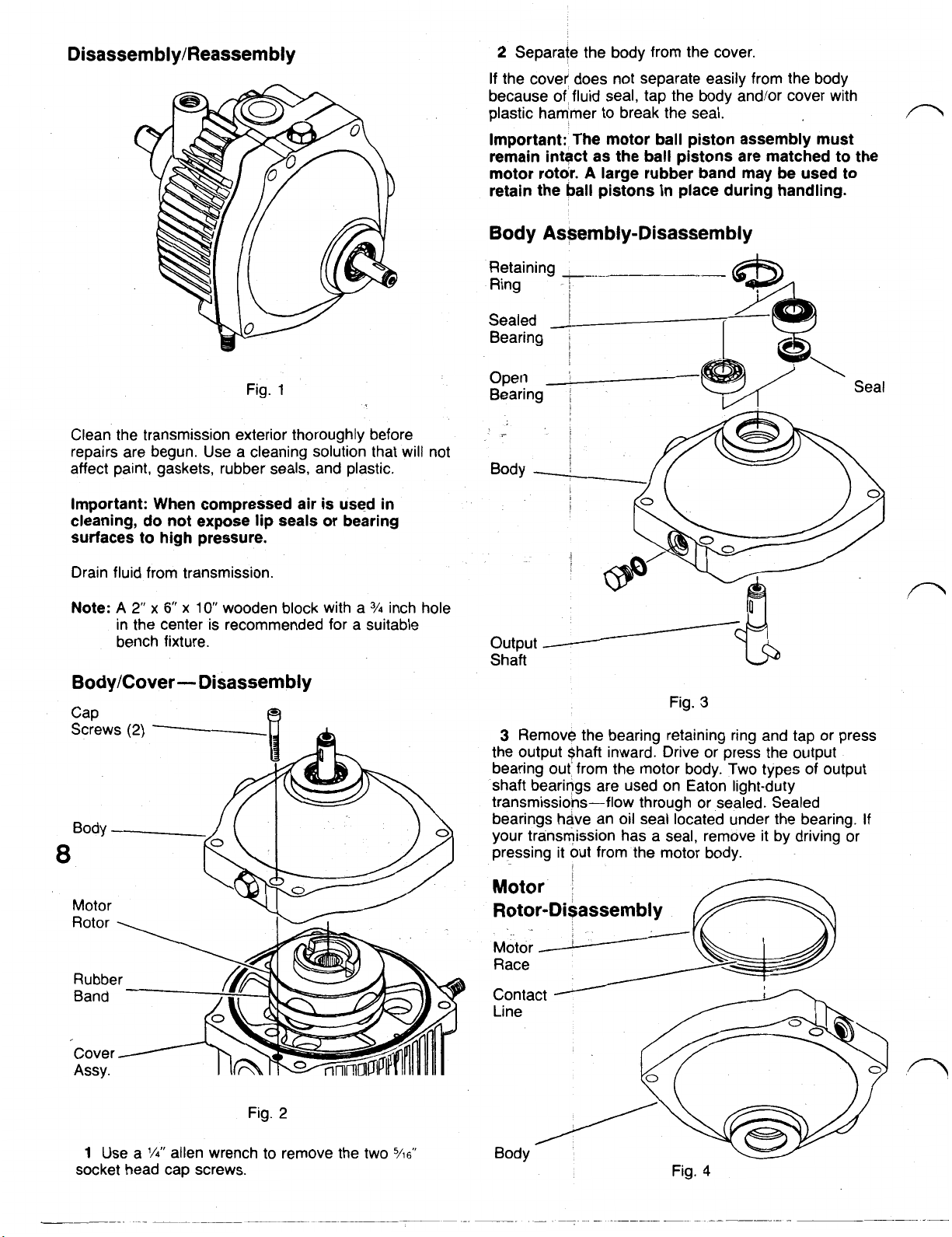

Disassembly/Reassembly

2

Separate the body from the cover.

If

the cover' does not separate easily from the body

because of' fluid seal, tap the body and/or cover with

plastic hammer to break the seal.

Important: The motor ball piston assembly must

remain intact as the ball pistons are matched to the

motor rotor.

retain the

A

large rubber band may be used to

ball

pistons in place during handling.

Body Assembly-Disassembly

Retaining

Ring

Sealed

Bearing

Fig.

1

Clean the transmission exterior thoroughly before

repairs are begun. Use a cleaning solution that will not

affect paint, gaskets, rubber seals, and plastic.

Important: When compressed air is used in

cleaning, do not expose lip seals or bearing

surfaces to high pressure.

Drain fluid from transmission.

Note:

A

2"

x

6"

x

10

wooden block with a

3/4

inch hole

in the center is recommended for a suitable

bench fixture.

Body/Cover- Disassembly

8

Open

Bearing Seal

Body

output

Shaft

Fig.

3

3

Remove the bearing retaining ring and tap or press

the output $haft inward. Drive or press the output

bearing out' from the motor body. Two types of output

shaft bearings are used on Eaton light-duty

transmissions-flow through or sealed. Sealed

bearings have an oil seal located under the bearing.

your transmission has a seal, remove it by driving or

pressing it out from the motor body.

If

1

Use a

l/4"

allen wrench to remove the two

socket head cap screws.

Fig.

2

5/16"

Fig.

4

Page 8

4

Inspect the contact line of the motor ball pistons-on Motor

in

be

damaged.

Fig.

body. This contact area must Rotor

If

it

is

7

Fig.

Pintle Assembly- Removal

5

the motor race located

be smooth and completely free of any irregularities.

any irregularities are noted, replace the motor race.

If

Note:

reasonable to assume that one or more ball pistons and

rotor bores will also

Motor

Rotor

Assy.

irregularities are noted in the motor race,

Assy.

Pintle

Assy.

Cover

Assy.

ubber

Band

5

Hold the pintle assembly in position against the

cover and remove the motor rotor assembly intact.

Rotor assembly out.

Bore

Piston ball

Fig.

6

6

Inspect the rotor assembly. Remove the piston balls

from the rotor, one at a time, by working clockwise from

the letter stamped in the face of the rotor and placing in

a prepared container.

Note: Each ball must be replaced in the same bore

from which it was removed. Use a suitable container for

piston ball storage such as an egg carton or ice cube

tray.

7

Inspect the piston balls. They must be smooth and

completely free of any irregularities.

Fig. 8

9

Hold the pump assembly in the bottom position and

tap lightly on the cover. Use a wood or plastic hammer

so

as not to damage aluminum cover. Lift the pintle

Important: The pump ball piston assembly must

as

remain intact

pump rotor. Use a wide rubber band

pistons

Pintle

Plugs

pintle

Assembly-Disassembly/lnspection

(2)

the ball pistons are matched to the

to

retain the

in

place

during

handling.

Bearing

8

Inspect rotor bores, rotor bushing and pintle journals Fig.

for irregularities or excessive clearance. The ball piston

fit

to rotor bore clearance is select

\.0002

to

.0006

of an inch. When irregularities or

excessive clearance are noted, replace the complete

rotor assembly.

Install motor ball pistons in their matching bores. Hold Note:

them in place with a rubber band.

electronically to

10

pintle assembly for cleaning. Normal flushing should

all that is required. However,

required, use the following procedures:

pintle journal.

we

do

not

Do

not remove the

9

complete

if

two

large plugs located on

disassembly

complete disassembly is

of

the

be

Page 9

Relief

Valve-Removal/lnspection

Dampening Piston-Installation

Relief Valve Plug

Ball position.

15

Install new back-up rings nearest to the smooth

piston face and O-rings in grove on a new piston.

16

Lubricate outer surface of the pistons. Press pistons

(smooth face up) in bores in pintle to the bottom

Check Valve-Removal

Note:

Removal of check valves is not necessary

check valve balls move freely and seat properly.

Fig. 10

11

Use a

1/4”

allen wrench to remove relief valve plug.

Then remove spring and ball.

12

Inspect all parts for irregularities. Replace any

defective part.

Relief Valve-Installation

13

Install ball, spring and plug in pintle. Screw plug in

Do

to just below surface of pintle.

not tighten

Check Valve

Body

Dampening Piston- Removal

if

Note:

Remove only

Dampening

Piston

Bolt Glued

To Piston

if

surface is scored.

lo

O-ring Seals (2)

Fig. 11

14

To remove pistons, firmly tap the outside edge of

pintle on a work surface. Remove back-up ring and

O-ring from pistons.

Important: When dislodging dampening pistons, do

not hit pintle journals or the pintle housing

ruined.

If

Note:

use adhesive to cement a bolt or similar object to the

pistons and pull them from the bore.

tapping of pintle does not dislodge the pistons,

will

be

Retaining'

(2)-

Rings

17

Press or drive out the coil pin that retains the

check valve bodies. Use a four blade 5/16-18 tap to tap

holes in check valve bodies. Insert a long bolt or a

puller, pull the check valve bodies from the pintle

housing and discard them.

18

Remove check balls and retaining ring.

Note:

On

23-25

for check valve removal.

19

Inspect check valve balls and retaining rings.

Replace any defective parts.

Coil Pin

Fig. 12

two

units with acceleration valves-see steps

Page 10

Check

20

of pintle. Press new check valve bodies in bores. Press

far enough in for coil pin clearance.

Valve-Installation

Install retaining rings and check valve balls

in

bores

Important:

do

not

21

Press coil pin into pintle until flush with or slightly

below surface.

To

prevent dislodging

drive check valve bodies into bores.

of

retaining rings

Acceleration Valves- Removal

Note:

Not all models have acceleration valves.

model has them-they are located directly opposite the

check valves.

See Figure 13,

If

your

3/16"

Dia.

Rod

Fig. 15

Check Replace Ball

Valve

Fig. 16

24

Insert the rod through the check valve body against

the acceleration valve body and drive both the valve

body and ball out of the bore. Repeat method for

second valve body and ball. Remove springs.

Note:

Some models use different springs for forward

and reverse. Be sure to identify the springs with the

so

acceleration valves

same bore from which they were removed.

they can be replaced in the

Acceleration

in

Check Valve

Valves

Body.

Fig. 13

22

Press solid pin from pintle housing. See Figure 13.

3/16"

Dia. Check Valve Body Check Valve

Rod Ball

\

Fig. 14

23

Insert

3/16

diameter rod through the check valve

(see

body. Tap the rod against the

ball to dislodge the retaining rings. Repeat for the

second check valve ball and ring. Shake dislodged

rings and balls out the large port area of pintle journal.

Fig. 14) check valve

25

Press or drive coil pin from pintle housing. Replace

the ball through the port into the check valve body.

3/16

Place the

valve bore against the check valve ball and drive the

check valve body and ball from the pintle housing.

Repeat this method for the second check valve body.

diameter rod through the acceleration

Acceleration Valves-Installation

26

Clean all parts thoroughly. Inspect parts for defects.

Replace all defective parts, including retaining rings,

which were damaged when driven out of their seats.

27

Install acceleration valve springs and acceleration

valves. Be sure that both acceleration valve bodies

slide freely in the bores and that the orifices are clean.

28

Press the two balls against the acceleration valve

bodies until the solid pin will clear. Press or drive the

dowel pin in

pintle surface.

29

Install new check valve retaining rings and balls in

pintle bores.

30

Press new check valve bodies into bores until coil

will

pin

clear.

so

it is flush with or slightly below the

11

Page 11

Important: Use a press to install check valve

bodies. Driving them into position

retaining rings.

31

Press or drive the coil pin in

below pintle surface.

may

dislodge the

to

flush or slightly

Pump Rotor AssemblyRemoval/lnspection

Rotor Assy.

Pump

Rubber

Band

33

Slide the cam ring from the pivot pin and control

shaft in the cover. Then lift ring from the cover.

34

Remove the control shaft insert.

35

Inspect area where the ball pistons contact the

race. This: area must be-smooth and completely free of

irregularities.

Note:

The pump race is press fit in the cam ring and

will require a press

pump race are available as an assembly.

If

it is not, replace the pump race.

19

Fig.

to

remove it. The cam ring and

Fig.

17

32

Remove seal from cover, lift pump rotor assembly

intact from the cover assembly.

Important:

pistons in place during handling. The pump ball

piston assembly must remain intact

pistons are matched to the pump rotor.

If

complete disassembly, inspection and reassembly of

pump rotor is necessary follow same procedures as for

motor rotor-see steps

Use

a wide rubber band to retain the ball

as

the ball

5

through

8.

Cam Ring-Disassembly/lnspection

12

Control Insert Shaft

36

Remove the two buttons from cover.

Charge' Pump with Bushing-Disassembly/

Inspection

Note:

Before removing the charge pump polish the

to

input shaft

Socket

Head

Cap

'Screws

Shield

Charge

Pump

remove paint, burrs, nicks, etc.

(5)

Fig.

18

Buttons

Control

Shaft

Fig.

37

Remove shield.

38

Use

a

1/4”

allen wrench

cap screws.

39

Carefully remove the charge pump.

to

20

remove the 5 socket head

Page 12

40

Remove the square cut seal from the charge pump

housing.

Fig.

21

41

Press or drive the oil seal from the charge pump

Important: Be careful not to damage the input

shaft bushing.

Top Snap

51

Use

1/4”

allen wrench to remove five cap screws.

Fig.

23

Use a modified two jaw bearing puller, pulling

52

two

against the

remove the charge pump assembly.

notches machined in the housing to

Ring

Carrier

Rolls

(6)

Fig.

22

42

Remove six carrier rolls.

43

Remove top snap ring from input shaft.

44

Mark top of carrier indicating which side is up.

Important:

manner that would damage the carrier surface.

Do

not mark the

roll

carrier in such a

Important:

removing the charge pump body. Apply a steady

pull only.

Important:

shaft during removal

Remove the square cut seal from the pump

53

assembly.

Pump

Do

not pound on the bearing puller while

Do

not damage the bore

of

charge pump.

for

the input

13

45

Remove carrier and drive pin. Fig.

46

Remove lower snap ring and pump or port plate. charge pump. Discard the

47

Inspect the input shaft bushing, carrier, rolls and

If

inner race contact areas in the charge pump.

irregularities are found, replace the complete pump

assembly.

48

Remove square cut seal from cover.

any

Charge Pump with Ball Bearing-

Disassembly/lnspection

49

Remove pump retaining ring. See Figure

50

Remove shaft retaining ring.

24.

24

54

Remove the bearing and the oil seal from the

Pump

Fig.

oil

seal.

25

Page 13

Snap

62

Reposition cover assembly as shown

Then remove input shaft.

in

Figure 27.

Carrier

Rolls

(6)

Fig. 26

55

Remove six carrier

56

Remove snap ring.

57

Mark top of carrier indicating which side is up.

Important:

would damage the carrier surface.

58

Remove carrier and carrier drive pin from input

shaft.

Do

not mark the roll carrier in a way that

rolls.

Important: Be careful not to damage the input shaft

bushing in the cover.

63

Inspect, input shaft for stripped keyways or other

irregularities.

64

Inspect, bushing located in face of cover for broken

bushing

cover.

65

Use a sharp narrow edged tool to pierce the top

metal part :of the oil seal and remove seal from the

cover.

Important:

distort the seal counter bore when removing seal.

If

found, replace the input shaft.

or

other irregularities.

Do

not scratch the control shaft or

Fig. 28

If

found, replace the

Oil Seal

Ass’y

n

59

Remove pump (or port) plate.

Remove square cut seal from cover and discard.

60

Inspect the ball bearing.

present, replace the bearing.

61

Inspect the carrier, rolls, inner race contact areas in

the charge pump housing and pump plate.

irregularities are found, replace the complete charge

pump assembly.

Cover

Assembly-Disassembly/lnspection

If

any irregularities are

If

any

Inspect cover assembly, especially around the

66

if

control shaft area. Replace the cover assembly

if

broken, cracked or

shaft and Cover exceeds .006".

67

In most cases, it

the control shaft from the cover.

broken in the control shaft, remove the shaft using the

following procedures.

Measure this Distance Control

side clearance between control

will

not be necessary to remove

If

the dowel is loose or

it is

Shaft

Fig. 27

Fig. 29

68

Measure the distance between center of dowel pin

and the end of the shaft as shown in Figure 29.

Page 14

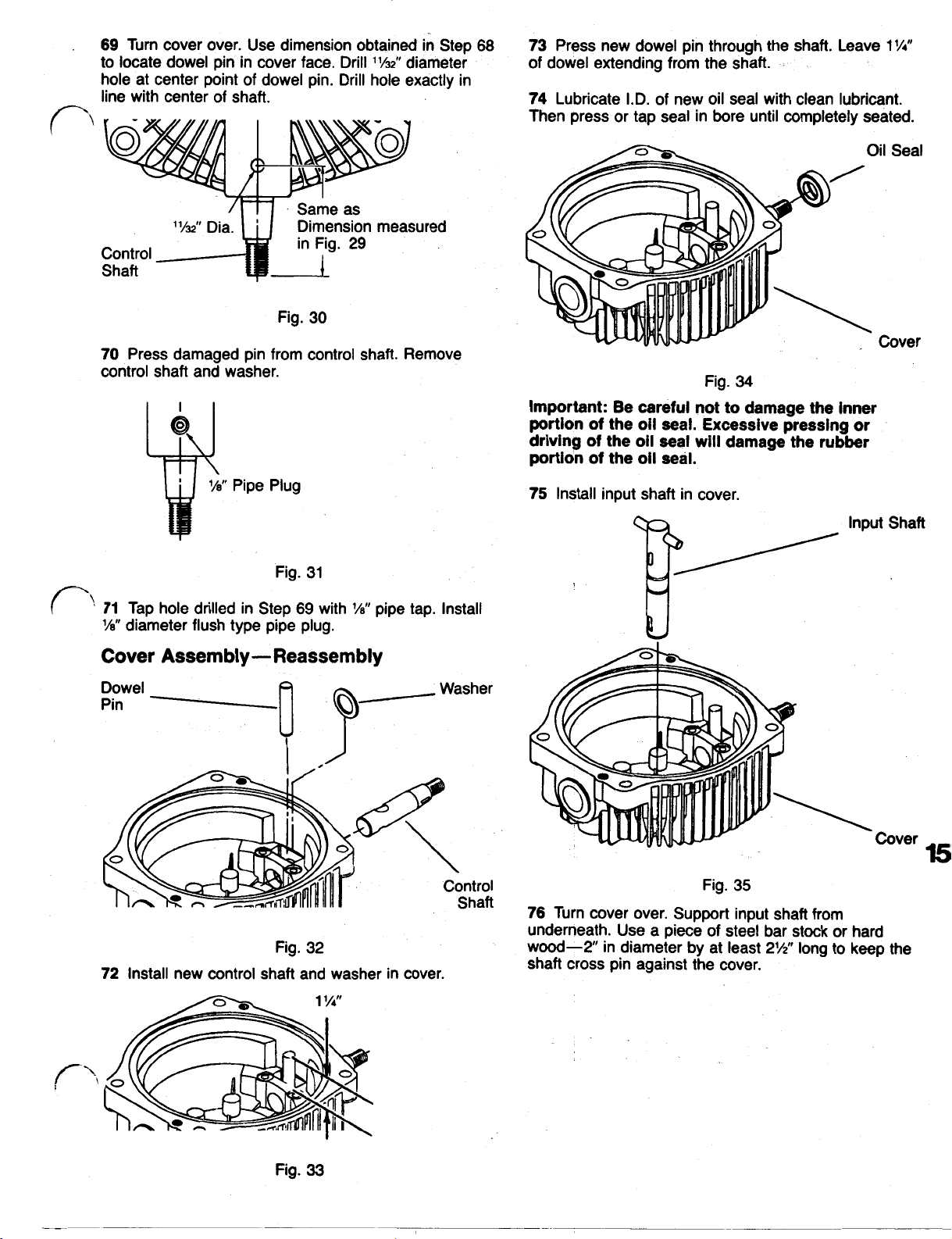

69

Turn cover over. Use dimension obtained in Step

to locate dowel pin in cover face. Drill

11/32”

diameter

hole at center point of dowel pin. Drill hole exactly in

of

line with center

shaft.

Same as

Dimension measured

Control

in Fig.

29

Shaft

Fig.

30

Press damaged pin from control shaft. Remove

70

control shaft and washer.

68

73

Press new dowel pin through the shaft. Leave

1

1/4”

of dowel extending from the shaft.

74

Lubricate I.D.

of

new oil seal with clean lubricant.

Then press or tap seal in bore until completely seated.

Cover

Fig.

34

important: Be careful not to damage the inner

portion of the oil seal. Excessive pressing or

of

driving

the oil

portion of the oil

seal

seal.

will

damage the rubber

Pipe Plug

31

Fig.

71

Tap hole drilled in Step

1/8”

diameter flush type pipe plug.

69

with

1/8”

pipe tap. Install

Cover Assembly-Reassembly

Dowel

Pin

32

Fig.

72

Install new control shaft and washer in cover.

Washer

75

Install input shaft in cover.

input Shaft

Fig.

35

Turn cover over. Support input shaft from

76

underneath. Use a piece of steel bar stock or hard

wood-2 in diameter by at least

2 1/2”

long to keep the

shaft cross pin against the cover.

15

Fig.

33

Page 15

Fig.

36

77

Lightly lubricate new square cut seal and install in

seal groove in cover.

Pump

Plate

(or Port

Plate)

Seal

Outlet

r

Outlet Outlet

Port (Inlet)

Plate

Identification

16

’

Cover

Fig.

37

Pump Plate/Port Plate-Installation

78 Install pump plate or port plate on cover. Either side

of

the pump plate may face.

input rotation. However, the port plate must be installed

per specific input rotation. See Figure

Important: Stamping on cover indicates

pump rotation is clockwise or counter clockwise.

the

cover regardless

38.

if

charge

of

Pump Plate

38

Fig.

Page 16

79

For counter clockwise (CCW) rotation, the letter

must be up, facing the charge pump. For clockwise shaft (against carrier).

(CW) rotation the letter

A

must face down toward the

A

82

Install snap ring in upper snap ring groove in input

Snap Ring

cover

Charge Pump with Bushing-Installation

For charge pumps with ball bearing, see Steps

through

Install snap ring in lower snap ring groove (against

plate) of input shaft.

Snap Carrier

Ring Drive

Lower

Snap

Ring Groove

80

a small amount

pin

Carrier rubber lip toward the bore. Make sure seal is

Rolls

94

for installation.

Fig.

39

Install carrier drive pin in keyway

of

petroleum jelly or equivalent to hold

in

place.

(6)

of

input shaft. Use in the carrier.

89

Fig.

42

Lightly lubricate the six carrier rolls and install them

83

84

Lubricate inner surface of new oil seal and install in

charge pump housing as shown in Figure

completely seated.

I

43

with the

Fig.

40

Install carrier over input shaft with side marked “up”

81

57).

(see step

drive pin in output shaft.

Important: For correct carrier rotation the leading

edge of carrier must rotate in the same direction as

the input shaft. Install as shown in Figure 41.

Be sure keyway in carrier fits over carrier

Toward Bore

New Oil Seal

Fig.

43

Important: Excessive pressing or force on oil seal

may cause damage to rubber sealing portion or

may distort counterbore of housing.

Square

cut

Seal

Charge

Pump

44

Fig.

Lightly lubricate new square cut seal with petroleum

85

of

jelly and, install in seal groove

pump housing.

17

Fig.

41

Important:

it

inlet,

pump.

Charge

must be installed before mounting charge

pump

If

an elbow fitting

wlth

Bearlng

see

page

is

used in the pump

18

Page 17

86

Align charge pump dowel pins with holes in cover.

Then guide pump over shaft, carrier and rolls until pins

engage holes.

Important: Protect oil seal lip from keyways, snap

ring grooves and shaft splines.

Screw (4)

5/16"

1' 1/4”

90

Install carrier over input shaft with side marked "up"

(see step

drive pin in input shaft.

Important: For correct carrier rotation the leading

edge of carrier must rotate in the same direction as

the input shaft. Install as shown

57).

Be sure keyway in carrier fits over carrier

in

Figure

48.

Screw

5/16"

Shield

Fig. 45

87

Install 4 screws

1 3/4”

in pump housing. Torque

Important: Install 1 3/4”

charge pump body. If installed and tightened in any

of the other four holes, internal damage could

occur.

88

Install protective shield on housing.

Important: Install protective shield

is

pointing away from oil

seal

oil

if installed improperly.

(5/16"

x

1 1/4”

screw

seal.

and one screw

to

15

foot pounds.

in

thicker section of

so

that flange

Shield may damage

(1)

13/4"

Charge

Pump

Housing

5/16”

x

\

Leading Edge

ccw

Fig. 48

91

Lightly lubricate and install the six carrier rolls in the

a

carrier. Use'

equivalent

Toward

to

small amount

hold the rolls in place.

of

petroleum jelly

or

Char

Installation

18

89

Lubricate carrier drive pin and install in keyway

input shaft.

e

Pump

with Ball Bearing-

Fig. 46

Fig.

47

Carrier

Drive

Carrier

Rolls

Carrier

of

49

Fig.

92

Lubricate inner surface

charge pump housing as shown in Figure 49 with the

rubber lip toward the bore. Make sure seal is

completely seated

Important: 'Excessive pressing or force on

may cause damage to rubber sealing portion or

may distort counterbore

Square

cut

Seal

(6)

Charge

Pump

I

93

Lightly lubricate new square. cut seal and install in

seal groove

Important: If an elbow fitting

inlet,

pump.

of

pump housing.

it

must be installed before mounting charge

of

new oil seal and install in

of

housing.

Fig.

50

is

used in the pump

oil

seal

Page 18

94

Align charge pump dowel pins with holes in cover.

Protect

shaft splines. Then guide pump over shaft, carrier and

rolls until pins engage holes.

Screw (4)

Charge

Pump

Housing

oil

seal lip from keyways, snap ring grooves and

Retaining

Ring

53

Fig.

Important: Input shaft should rotate freely by hand.

If

it does not, recheck installation.

Fig. 51

95

Install 4 screws

1 3/4”) in pump housing. Torque

Important: Install 1

charge pump body.

of the other four holes, internal damage could

Occur-

Upper Snap Ring

Snap Ring

(5/16”)

x

1 1/4”) and one screw

to

15 foot pounds.

3/4”

screw in thicker section of

If

installed and tightened in any

5/16"

x

Cam

100

Figure 54.

Ring-Installation

Install 2 buttons

in

the cover as shown in

Fig. 54

Cam

Control

Block

52

Fig.

96

Install snap ring in lower groove of input shaft.

97

With cover assembly separated from the body and

the input shaft properly supported (see Figure

input shaft bearing may be pressed into position.

to

Press

lousing against the retaining ring.

98

against inner bearing race.

99

housing.

the bottom position in the charge pump

Install snap ring in upper groove of input shaft

Install large snap ring used

to

retain bearing in

52)

the

101

Install the cam ring insert with the hole away from

the cam ring as shown in Figure 54.

102

Align the cam ring with the control shaft pin and

the cam ring pivot pin.

Install the cam ring with the flush side

race facing the cover. Press in firmly until the cam ring

has bottomed in the cover assembly.

Important: Cam ring must move freely from stop to

If

stop.

ring insert 180". Check the cam ring movement

again.

binding occurs at either stop rotate the cam

of

the bearing

19

Page 19

Pump Rotor Assembly-Installation

103

Align the

cross

pin. Install

Important: Keep rotor assembly intact with wide

rubber band. Remove rubber band after installing

rotor assembly

slot

in the pump

rotor

assembly on shaft.

in

cover assembly.

Fig.

55

rotor

with the input shaft

Do

Important:

It is a slip fit and the pintle must turn freely by

hand.

If

it

not force pintle over rotor assembly.

,does not, recheck the pintle installation.

Motor Rotor Assembly-Installation

106

Install the motor

Figure

Important:

pintle.

by hand.

Keep the

Remove rubber band after installing

Motor

Rotor

Assy

Rubber

Band

57.

Do

It

is a slip fit and

rotor

assembly intact with wide rubber band.

!

rotor

assembly on the pintle. See

not force the rotor assembly over the

the

rotor must rotate freely

rotor

assembly.

Pintle Assembly-Installation

Note:

To

determine pintle rotation, place a small

or

ruler

Figure

straight edge in the porting slot as shown in

56.

Pintle

Cam Ring

Pivot Pin

Fig.

Fig.

56

104

Align dowel pin hole in pintle assembly with cam

rotor

ring pivot pin and install over pump

105

Lightly grease a new square cut seal and install it

in the groove in the housing.

assembly.

Page 20

Body Assembly-Reassembly

Note:

Transmissions with sealed bearings incorporate

an oil seal under the output bearing.

“Retaining Sealed

Ring

Flow

Through

Bearing

Body/Cover-Reassembly

111

Install body. Align the output shaft with the bearing

1ocated: in pintle and shaft cross pin with the

5/16”

motor rotor assembly. Install two

15

cap screws Torque to

Important: Be sure the output shaft rotates freely

by hand. If it does not, recheck body installation.

5/16”

x

1

1/4”

(2)

foot pounds.

x

slot

1

1/4”

socket head

in the

Output Shaft

58

Fig.

107

When applicable, install oil seal in body with the

rubber lip toward the counter bore in the body. Press or

tap the seal into the bottom position in the counter

bore.

Important:

This may damage the rubber sealing portion

oil seal.

108

Install output bearing. Position bearing on the body

and press on the outer bearing race to the bottom

position in the body.

109

Install the bearing retaining ring.

110

Install output shaft. This is a press fit. Be sure to

support the inner race of the ball bearing while pressing

the shaft into the bearing.

Do

not over press or drive the oil seal.

of

the

Fig.

59

Start-up Procedure

112

Fill transmission with fluid. See page

recommendations. On transmission

flow through output bearing, fill through the axle

manufacturer’s specified fluid level.

On transmissions that incorporate sealed output shaft

bearing$, fill through the reservoir to the manufacturer’s

specified fluid level. Start the engine and run the

transmission in both directions at low engine speed for

a short time

Stop,

The transmission is now ready for use.

to

purge trapped air from the system.

shut off engine and recheck fluid level.

that

incorporates

24

for fluid

to

the

21

Page 21

Trouble Shooting Instructions

This fault-logic troubleshooting section is designed as a

diagnostic aid in locating transmission problems.

Match the transmission problem with the problem,

statements and follow the action steps shown in the

diagrams. This will give the user expedient aids in

correcting the problem and eliminating unnecessary

machine down time.

System Jerky/Noisy when Starting

22

Defective

Defective

I

Serviceable

Externally

System Operates in One Direction Only

Defective Defective Defective

Repair

I

or

Replace

I

Serviceable

Serviceable

Page 22

External

LOSS

Will

Not Operate in Either Direction

of

Power or System

Clogged

Replace

Defective

System Operating Hot

Defective Clogged

Replace

Defective

or

Replace

Transmission

Cooling Fins

Defective

I

Serviceable

Externally

23

Page 23

EATON

HYDROSTATIC TRANSMISSION

MODEL

"REPAIR

NO.

I.

11

MANUAL

7-402

Fluid

A

reputable supplier can help you make

Eaton light duty hydrostatic transmissions.

For satisfactory operation, the following fluid conditions apply:

1. Accurate level readings can be checked only when the fluid

2.

If

the natural color of the fluid has become black or milky,

contaminant problem exists.

3.

Proper viscosity is essential. At normal operating temperatures, the optimum range is between

80-180

4. The fluid should

Specific types of fluid meeting these requirements may be:

(1)

Premium hydraulic oil

(2)

Engine crankcase

(3)

Automatic transmission oil

(4)

Hydraulic transmission oil

Recommendations'-

the

best selection of hydraulic fluid for use in

SUS

(16-40

cSt

),

and it should never fall below 60

be

chemically stable, incorporating rust and oxidation inhibitors.

oil

I

is

cold.

it

is possible that an overheating or water

SUS

(10

cSt

).

Heprinted

with

permission

Part

#492-4310

Loading...

Loading...