Page 1

72 Side Discharge Mower

Groundsmaster 200 Series

Model No. 30553—Serial No. 240000001 and Up

Form No. 3350–815

Operator’s Manual

English (EN, GB)

Page 2

Contents

Introduction

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operating Practices 3. . . . . . . . . . . . . . . . . . . .

Toro Mower Safety 4. . . . . . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 5. . . . . . . . . . . . . . . . .

Specifications 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 7. . . . . . . . . . . . . . . . . . . . .

Optional Equipment 7. . . . . . . . . . . . . . . . . . . . . . . .

Setup 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Castor Wheel Assemblies 9. . . . . . . .

Installing the Lift Arms to the Traction Unit 9. . . . .

Connecting the Lift Arms to the Cutting Unit 10. . . .

Connecting PTO Shaft to Cutting Unit Gear Box 11.

Installing the Weight Transfer Kit 11. . . . . . . . . . . . .

Installing Rear Weight 12. . . . . . . . . . . . . . . . . . . . . .

Before Operating 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Height-of-Cut 13. . . . . . . . . . . . . . . . .

Adjusting the Rollers and Gage Wheel 14. . . . . . . . .

Checking the Lubricant in the Gear Box 15. . . . . . . .

Greasing the Cutting Unit 15. . . . . . . . . . . . . . . . . . .

Operation 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Grass Deflector 15. . . . . . . . . . . . . . . . . . .

Adjusting the Tension Spring 16. . . . . . . . . . . . . . . . .

Maintenance 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Maintenance Schedule 17. . . . . . . . .

Greasing the Bearings, Bushings, and Gear Box 17. .

Separating the Cutting Unit from the Traction Unit 18

Mounting the Cutting Unit to the Traction Unit 19. .

Servicing the Castor Arm Bushings 20. . . . . . . . . . . .

Servicing the Castor Wheels and Bearings 20. . . . . .

Checking for a Bent Blade 21. . . . . . . . . . . . . . . . . . .

Removing the Cutting Blade 21. . . . . . . . . . . . . . . . .

Inspecting and Sharpening the Blade 21. . . . . . . . . . .

Correcting Cutting Unit Mismatch 22. . . . . . . . . . . .

Replacing the Grass Deflector 23. . . . . . . . . . . . . . . .

Adjusting the Idler Pulley 23. . . . . . . . . . . . . . . . . . .

Adjusting the Cover Latches 24. . . . . . . . . . . . . . . . .

Replacing the Drive Belt 24. . . . . . . . . . . . . . . . . . . .

Troubleshooting 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Toro General Commercial Products Warranty 28. . .

Page

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

serial numbers of your product ready. The numbers are

stamped into a plate which is located on the carrier frame

behind the right front castor wheel.

Write the product model and serial numbers in the space

below:

Model No.

Serial No.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

Caution signals a hazard that may cause minor or moderate

injury if you do not follow the recommended precautions.

This manual uses two other words to highlight information.

Important calls attention to special mechanical

information and Note: emphasizes general information

worthy of special attention.

Safety

This machine meets or exceeds CEN standard EN

836:1997, ISO standard 5395:1990, and ANSI

B71.4-1999 specifications in effect at the time of

production.

Improper use or maintenance by the operator or owner

can result in injury. To reduce the potential for injury,

comply with these safety instructions and always pay

attention to the safety alert

CAUTION, WARNING, or DANGER—“personal

safety instruction.” Failure to comply with the

instruction may result in personal injury or death.

symbol, which means

2004 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

Printed in the USA

2

Page 3

Safe Operating Practices

The following instructions are from the CEN standard EN

836:1997, ISO standard 5395:1990, and ANSI B71.4-1999.

Training

• Read the Operator’s Manual and other training material.

If the operator(s) or mechanic(s) can not read English it

is the owner’s responsibility to explain this material to

them.

• Become familiar with the safe operation of the

equipment, operator controls, and safety signs.

• All operators and mechanics should be trained. The

owner is responsible for training the users.

• Never let children or untrained people operate or

service the equipment. Local regulations may restrict

the age of the operator.

• The owner/user can prevent and is responsible for

accidents or injuries occurring to himself or herself,

other people or property.

Preparation

• Evaluate the terrain to determine what accessories and

attachments are needed to properly and safely perform

the job. Only use accessories and attachments approved

by the manufacturer.

• Wear appropriate clothing including hard hat, safety

glasses and ear protection. Long hair, loose clothing or

jewelry may get tangled in moving parts.

• Inspect the area where the equipment is to be used and

remove all objects such as rocks, toys and wire which

can be thrown by the machine.

• Use extra care when handling gasoline and other fuels.

They are flammable and vapors are explosive.

– Use only an approved container.

– Never remove fuel cap or add fuel with engine

running. Allow engine to cool before refueling. Do

not smoke.

– Never refuel or drain the machine indoors.

• Check that operator’s presence controls, safety switches

and shields are attached and functioning properly. Do

not operate unless they are functioning properly.

Operation

• Never run an engine in an enclosed area.

• Only operate in good light, keeping away from holes

and hidden hazards.

• Be sure all drives are in neutral and parking brake is

engaged before starting engine. Only start engine from

the operator’s position. Use seat belts if provided.

• Slow down and use extra care on hillsides. Be sure to

travel in the recommended direction on hillsides. Turf

conditions can affect the machine’s stability. Use

caution while operating near drop-offs.

• Slow down and use caution when making turns and

when changing directions on slopes.

• Never raise deck with the blades running.

• Never operate with guards not securely in place. Be

sure all interlocks are attached, adjusted properly, and

functioning property.

• Do not change the engine governor setting or overspeed

the engine.

• Stop on level ground, lower the cutting units, disengage

drives, engage parking brake (if provided), shut off

engine before leaving the operator’s position for any

reason.

• Stop equipment and inspect the blades after striking

objects or if an abnormal vibration occurs. Make

necessary repairs before resuming operations.

• Keep hands and feet away from the cutting units.

• Look behind and down before backing up to be sure of

a clear path.

• Never carry passengers and keep pets and bystanders

away.

• Slow down and use caution when making turns and

crossing roads and sidewalks. Stop blades if not

mowing.

• Do not operate the mower under the influence of

alcohol or drugs.

• Use care when loading or unloading the machine into a

trailer or truck.

• Use care when approaching blind corners, shrubs, trees,

or other objects that may obscure vision.

• The operator shall turn on flashing warning lights, if

provided, whenever traveling on a public road, except

where such use is prohibited by law.

Maintenance and Storage

• Disengage drives, lower the cutting units, move traction

pedal to Neutral, set parking brake, stop engine and

remove key and disconnect spark plug wire. Wait for all

movement to stop before adjusting, cleaning or

repairing.

• Clean grass and debris from cutting units, drives,

mufflers, and engine to help prevent fires. Clean up oil

or fuel spillage.

3

Page 4

• Let engine cool before storing and do not store near

flame.

• Shut off fuel while storing or transporting. Do not store

fuel near flames or drain indoors.

• Park machine on level ground. Never allow untrained

personnel to service machine.

• Use jack stands to support components when required.

• Carefully release pressure from components with stored

energy.

• Disconnect battery or remove spark plug wire before

making any repairs. Disconnect the negative terminal

first and the positive last. Reconnect positive first and

negative last.

• Check the safety interlock switches daily for proper

operation. If a switch should fail, replace the switch

before operating the machine. After every two years,

replace all three interlock switches in the safety system,

regardless if they are working properly or not.

• Pay attention when using the machine. To prevent loss

of control:

– Do not drive close to sand traps, ditches, creeks, or

other hazards.

– Avoid sudden stops and starts.

– Watch for traffic when near or crossing roads.

Always yield the right-of-way.

– Lower the cutting unit when going down slopes.

• Use care when checking blades. Wrap the blades or

wear gloves, and use caution when servicing them.

Only replace blades. Never straighten or weld them.

• Keep hands and feet away from moving parts. If

possible, do not make adjustments with the engine

running.

• Charge batteries in an open well ventilated area, away

from spark and flames. Unplug charger before

connecting or disconnecting from battery. Wear

protective clothing and use insulated tools.

• Keep all parts in good working condition and all

hardware tightened. Replace all worn or damaged

decals.

Toro Mower Safety

The following list contains safety information specific to

Toro products or other safety information that you must

know that is not included in the ANSI standards.

This product is capable of amputating hands and feet and

throwing objects. Always follow all safety instructions to

avoid serious injury or death.

Use of this product for purposes other than its intended use

could prove dangerous to user and bystanders.

• The grass deflector must always be installed and in the

lowest position on the side discharge cutting unit. Never

operate the mower without the deflector or entire grass

collector.

• If the cutting unit discharge area ever plugs, shut the

engine off before removing the obstruction.

• Cut grass slopes carefully. Do not start, stop, or turn

suddenly.

• Do not touch the engine or muffler while the engine is

running or soon after it has stopped because these areas

could be hot enough to cause burns.

Maintenance and Storage

• Check the blade mounting bolts frequently to be sure

that they are tightened to specification.

• Make sure that all hydraulic line connectors are tight

and all hydraulic hoses and lines are in good condition

before applying pressure to the system.

• Keep your body and hands away from pin hole leaks or

nozzles that eject hydraulic fluid under high pressure.

Use paper or cardboard, not your hands, to search for

leaks. Hydraulic fluid escaping under pressure can have

sufficient force to penetrate the skin and cause serious

injury.

Operation

• Know how to stop the machine and engine quickly.

• Always wear substantial shoes. Do not operate the

machine while wearing sandals, tennis shoes, or

sneakers.

• Wearing safety shoes and long pants is advisable and

required by some local ordinances and insurance

regulations.

• Fill fuel tank until level is 1 in. (25 mm) below the

bottom of the filler neck. Do not overfill.

• Before disconnecting or performing any work on the

hydraulic system, all pressure in the system must be

relieved by stopping the engine and lowering the cutting

units to the ground.

• If the engine must be running to perform a maintenance

adjustment, keep hands, feet, clothing, and any parts of

the body away from the cutting units, attachments, and

any moving parts. Keep everyone away.

• Do not overspeed the engine by changing governor

settings. To ensure safety and accuracy, have an

Authorized Toro Distributor check the maximum engine

speed with a tachometer.

4

Page 5

• The engine must be shut off before checking the oil or

adding oil to the crankcase.

• Make sure that the mower fuel tank is empty if the

machine is to be stored in excess of 30 days. Do not

store the mower near any open flame or where gasoline

fumes may be ignited by a spark.

• Perform only those maintenance instructions described

in this manual. If major repairs are ever needed or if

assistance is desired, contact an Authorized Toro

Distributor.

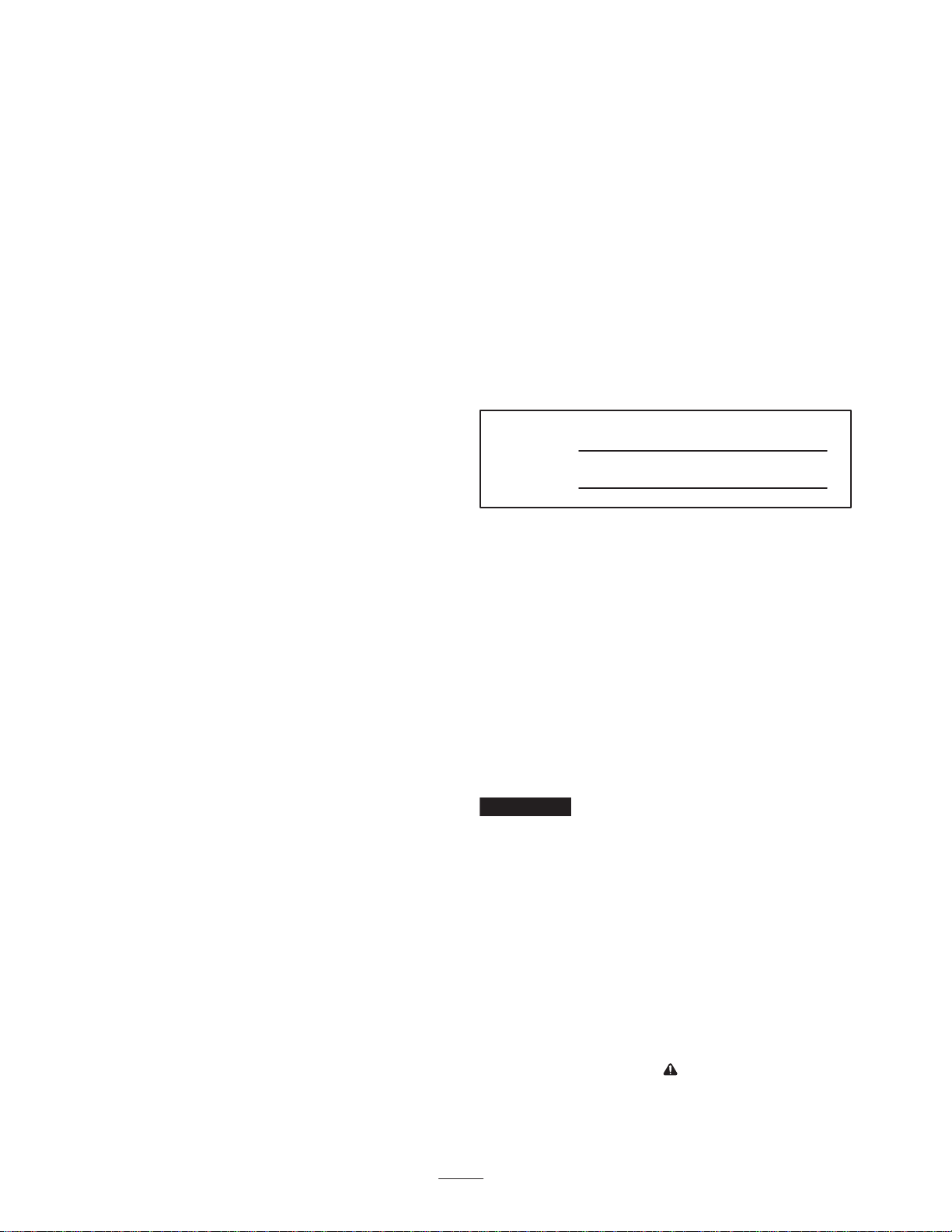

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any area

of potential danger. Replace any decal that is damaged or lost.

• To make sure of optimum performance and continued

safety certification of the machine, use only genuine

Toro replacement parts and accessories. Replacement

parts and accessories made by other manufacturers

could be dangerous, and such use could void the

product warranty.

107-2908

1. Thrown object

hazard—keep bystanders

a safe distance from the

machine.

2. Thrown object hazard,

mower—keep the

deflector in place.

1. Remove the ignition key and

read the instructions before

servicing or performing

maintenance.

3. Cutting/dismemberment

hazard of hand or foot,

mower blade—stay away

from moving parts.

2. Do not operate the mower

with the deflector up or

removed; keep the deflector

in place.

1. Warning—read the

torquing the blade bolt/nut to 115–149 N⋅m (85–110 ft.-lb.).

1. Height of cut 2. Height settings

107-2916

3. Thrown object hazard—keep

bystanders a safe distance

from the machine.

93-7818

Operator’s Manual

92-3035

4. Cutting/dismemberment

hazard of hand or foot,

mower blade—stay away

from moving parts

for instructions on

5

Page 6

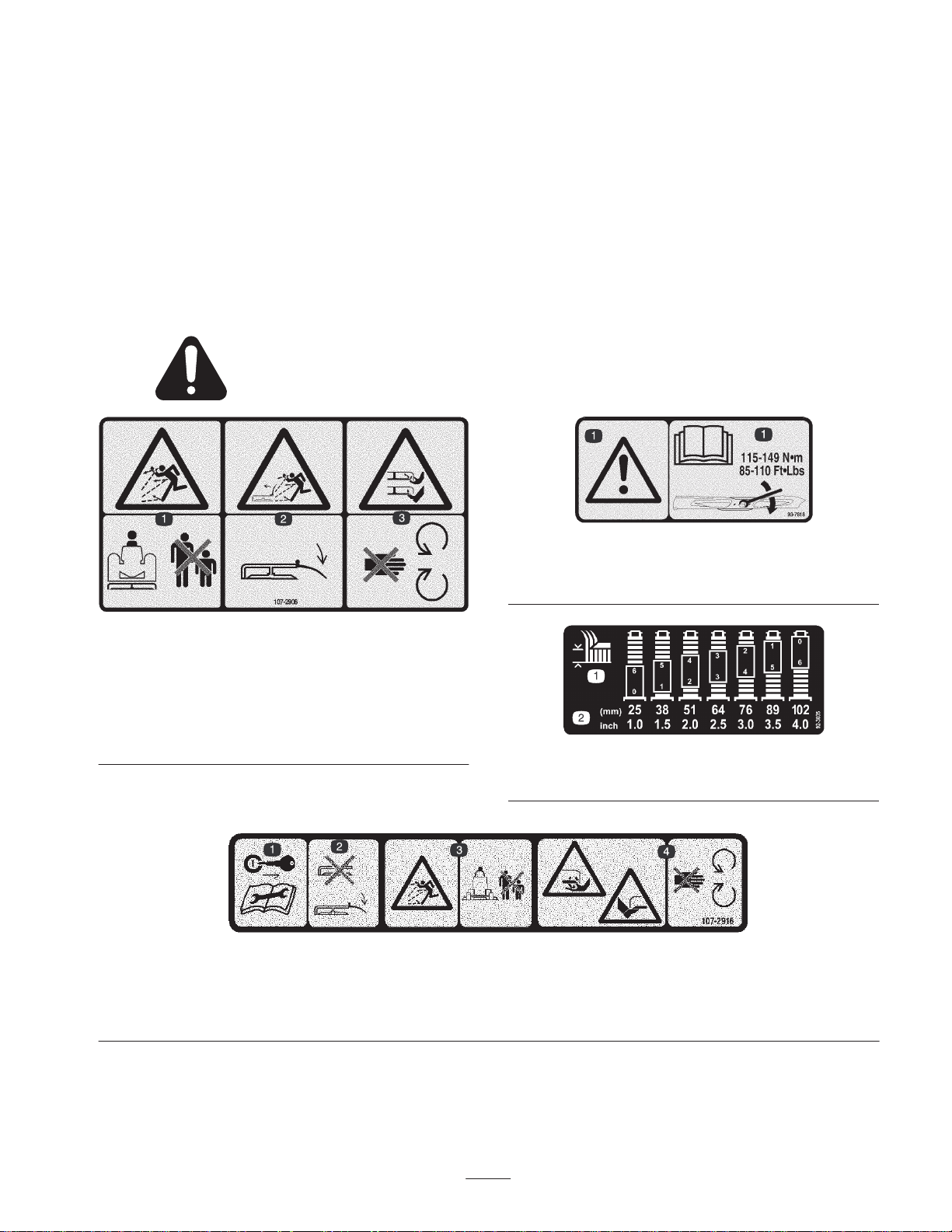

93-6697

1. Read the

Manual.

Operator’s

2. Add SAE 80w–90 (API

GL-5) oil every 50 hours.

100-6578

1. Entanglement hazard, belt—do not operate the machine with

the shields or guards removed; always keep the shields and

guards in place. Stay away from moving parts.

99-5172

105-9554

1. Warning—read the

2. Tipping hazard—lower the cutting unit when driving down

slopes. For 2 wheel drive units, add a 41 kg (90 lb) rear weight

to GM 228D units and a 63.5 kg (140 lb) rear weight to GM

225 units. For 4 wheel drive units, do not add weight.

Operator’s Manual.

Cover 43–8480 for CE

1. Thrown object

hazard—keep bystanders

a safe distance from the

machine.

106-6753

2. Cutting/dismemberment

43-8480

hazard of hand or foot,

mower blade—stay away

from moving parts.

107-2915

1. Entanglement hazard, shaft—keep bystanders a safe distance

from the machine.

93-6696

1. Stored energy hazard—read the

Operator’s Manual.

6

Page 7

Specifications

General Specifications

Width of Cut 71-5/8 in. (1.82 m)

Height of Cut Adjustable from 1 to 4 in. (25 to 102 mm) in 1/2 inch increments

Blade Tip Speed 16,270 ft./min. @ 3250 engine RPM

Cutting Blades 3 heat-treated steel blades, each 3/16 in. (4.8 mm) thick and 24-3/4 in. (55 cm) long

Unit Drive System

Castor Wheels

Note: Specifications and design subject to change without notice.

PTO driven gear box transmits power through a “AA” section belts to all blade

spindles.

Front: 8 in. (203 mm) diameter pneumatic wheels with greaseable roller bearings

(inflated to 35–50 psi [241–345 kPa])

Rear: 6 in. (152 mm) diameter hard rubber wheels with greaseable roller bearings

Optional Equipment

Leaf Mulcher Model No. 30779

Leaf Mulcher Discharge Plate Part No. 57-0700

Baffle Kit Part No. 99–5155

Atomic Blade Part No. 104–1304

Front Castor Wheel (Foam Filled) Part No. 93–5974

7

Page 8

Setup

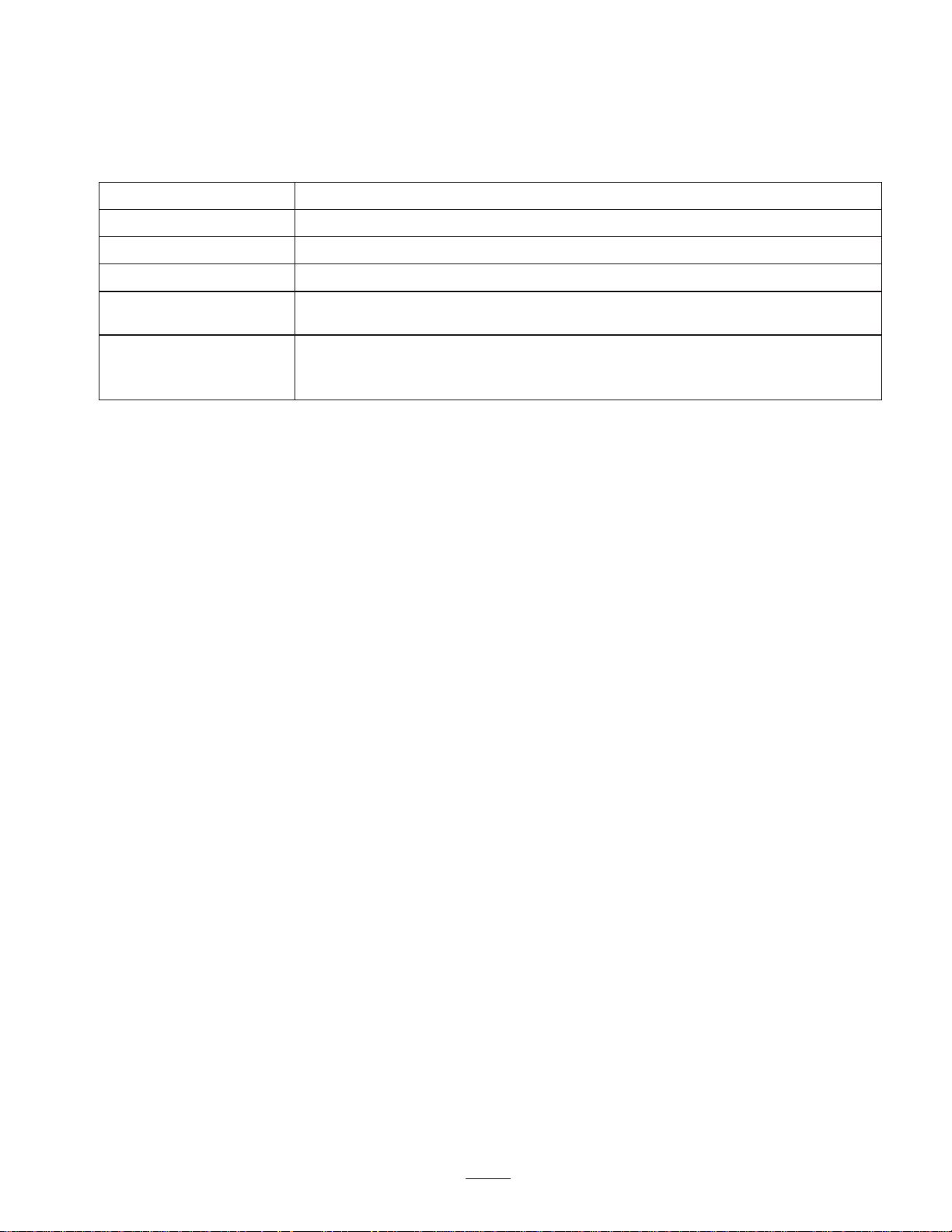

Loose Parts

Note: Use this chart as a checklist to ensure that all parts have been received. Without these parts, total setup cannot be

completed.

Description Qty. Use

Front castor wheel assembly

Rear castor wheel assembly

Right-hand lift arm

Left-hand lift arm

Pivot pin assembly

Cotter pin, 5/32 in. x 1-3/4 in.

Capscrew, 7/16 x 3 in.

Flange nut, 7/16 in.

Mounting bracket

Lock pin assembly

Self-tapping screw

Spring cover assembly

Clevis pin

Hairpin cotter

Spring end—top

Heavy extension spring

Lower spring end

Knee link

Capscrew, 3/8 x 2-1/4 in.

Capscrew, 3/8 x 1 in.

Shoulder bolt

Flat washer

Locknut, 3/8 in.

2

2

1

1

2

2

4

4

2

4

4

2

2

2

2

2

2

2

4

4

4

4

12

Installing the castor wheel assemblies

Mount to traction unit pivot brackets

Connecting the lift arms to the cutting unit

Mounting the weight transfer kit

Decal 1 Apply for CE

Parts Catalog 1

Operator’s Manual 1 Read before operating the machine.

Note: Determine the left and right sides of the machine from the normal operating position.

8

Page 9

Danger

If the engine is started and the PTO shaft is

allowed to rotate, serious injury could result.

Do not start the engine and engage the PTO lever

when the PTO shaft is not connected to the gear

box on the cutting unit.

Install another thrust washer and the remaining spacers

onto the spindle and install the tensioning cap to secure

the assembly.

Important The thrust washers, not the spacers, must

contact the top and bottom of the castor arm.

3. Ensure that all four castor wheels are set at the same

height-of-cut and roll the cutting unit off of the pallet.

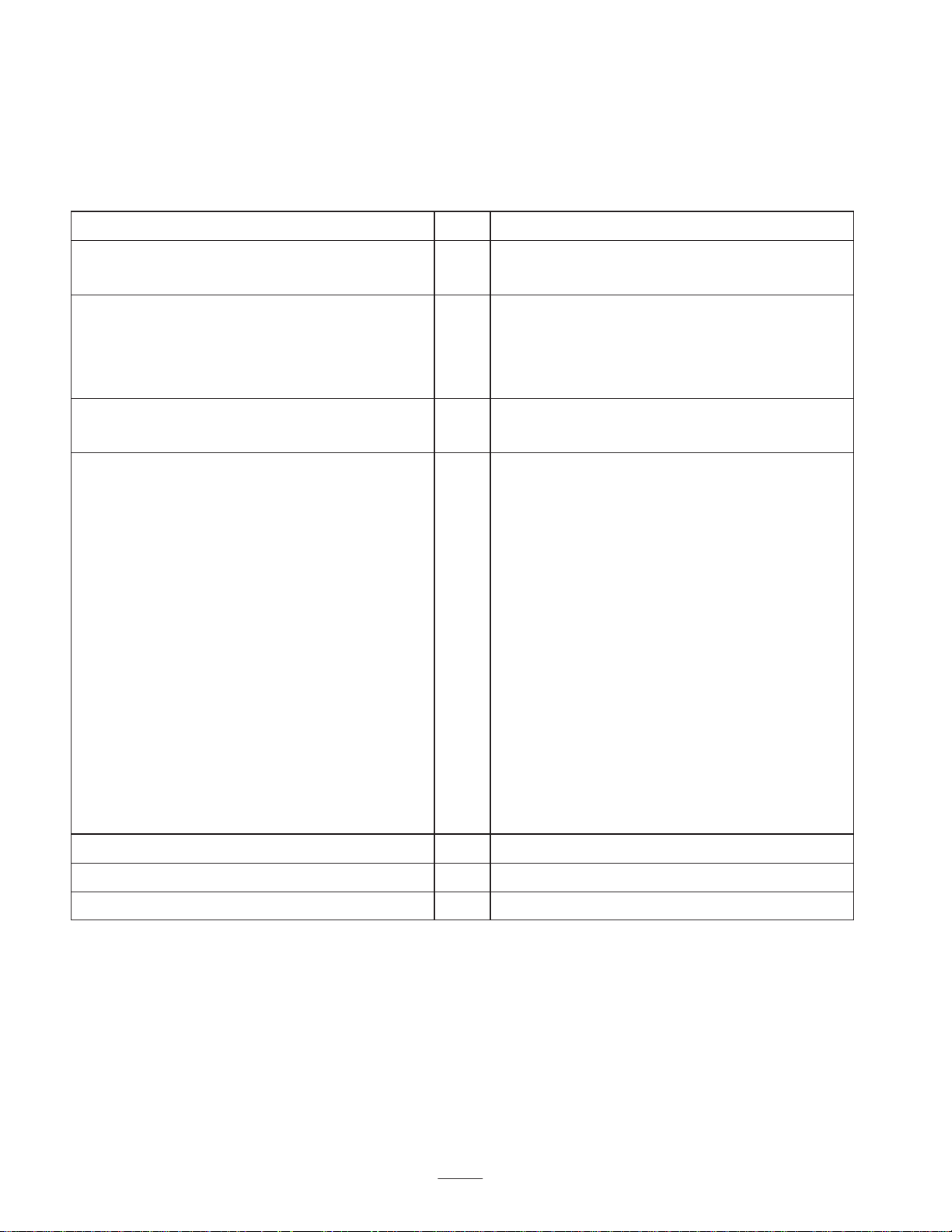

Installing the Castor Wheel

Assemblies

The thrust washers, spacers, and tensioning caps have been

installed on the castor wheel spindles for shipping.

1. Remove the tensioning caps from the spindle shafts and

slide off the spacers and thrust washers (Fig. 1 and 2).

3

1

2

2

4

1

2

2

1. Tensioning cap

2. Thrust washers

3

4

Figure 2

3. Spacers

4. Rear castor spindle

Figure 1

1. Tensioning cap

2. Thrust washers

2. Slide the spacers onto the castor spindle to get the

desired height-of-cut; refer to the Height-of-Cut Chart

on page 13. Slide a thrust washer onto the spindle, push

the round castor spindle through the front castor arm,

and the hex castor spindle through the rear castor arm.

3. Spacers

4. Front castor spindle

Installing the Lift Arms to the

Traction Unit

1. On one side of the traction unit, loosen (do not remove)

the wheel nuts securing the wheel and tire assembly to

the front wheel studs.

2. Jack up the machine until the front wheel is off of the

floor. Use jack stands or block the machine to prevent it

from accidentally falling.

3. Remove the wheel nuts and slide the wheel and tire

assembly off of the studs.

4. Mount a lift arm to the pivot bracket with a pivot pin

and cotter pin (5/32 x 1-3/4 in.) (Fig. 3). Mount the lift

arm with the ball joint end positioned outward.

5. Mount the rear of the lift arm to the lift cylinder with a

pivot pin and 2 cotter pins (supplied with the traction

unit).

9

Page 10

2

1

3

2-1/4 in.

(57 mm)

1

3

4

Figure 3

1. Pivot pin

2. Lift arm

3. Lift arm pivot bracket

4. Brake return spring

6. Hook the brake return spring to the hole in the lift arm

(Fig. 3).

7. Install the wheel and tire assembly. Torque the wheel

nuts to 45–55 ft.-lb. (62–72 N⋅m).

8. Repeat the procedure on the opposite side of the

machine.

Connecting the Lift Arms to the

Cutting Unit

1. Move the cutting unit into position in front of the

traction unit.

2. Measure the distance from the end of each lift arm to

the center of the ball joint (grease fitting). The distance

should be 2-1/4 in. (57 mm) (Fig. 4). If distance is not

2-1/4 in. (57 mm), loosen the jam nut securing the ball

joint to the lift arm and rotate the ball joint in or out

until the distance is attained. Do not tighten the jam nuts

at this time.

2

Figure 4

1. Lift arm

2. Ball joint

3. Jam nut

3. Move the lift lever to the Float position. Push the lift

arms down until the holes in the ball joint mounts line

up with the holes in the castor arms.

4. Secure the ball joint mounts to each castor arm with 2

capscrews (7/16 x 3 in.) and flange nuts (7/16 in.)

(Fig. 5).

Note: The ball joint mount should be above the castor arm

when it is assembled.

3

5

2

4

1

Figure 5

1. Castor arm

2. Ball joint mount

3. Ball joint

4. Capscrew

5. Flange nut

5. Tighten the large jam nut securing the ball joint to the

lift arm (Fig. 5). When tightening the jam nut, hold the

ball joint straight to permit proper oscillation during

raising and lowering of the cutting unit.

10

Page 11

Connecting the PTO Shaft to

the Cutting Unit Gear Box

1. Remove (2) capscrews and lockwashers securing PTO

guard mounting brackets to gearbox (Fig. 6). Retain

fasteners for re–installation.

2

1

3

Figure 6

1. Gearbox

2. PTO guard

2. Slide PTO shaft guard onto PTO shaft, positioning

guard as shown in figure 6.

3. Slide male PTO shaft into female PTO shaft. Align

mounting holes in gear case input shaft with holes in

PTO shaft and slide together.

4. Secure with roll pin.

5. Tighten capscrews and nuts.

3. PTO shaft

123 34

Figure 7

1. 52″ side discharge deck

2. 52″ deck w/bagger

3. To install the mounting brackets, insert 2 flange head

capscrews (3/8 x 1 in.) through the slotted bracket

holes. Thread the screws into the captivated frame nuts

and torque them to 45–50 ft.-lb. (61–68 N⋅m) (Fig. 8).

2

1

3. 62″ and 72″ decks

4. 52″ rear discharge deck

3

6. Re–install PTO shaft guard to gearbox with (2)

capscrews and lockwashers previously removed.

Installing the Weight Transfer

Kit

1. Fully raise the cutting deck, set the parking brake, stop

the engine, and remove the ignition key.

2. Place blocks under the cutting deck to prevent it from

falling during assembly.

Note: The mounting brackets for the weight transfer kit

must be installed in different locations depending on the

cutting deck. Refer to Figure 7 for mounting location.

Figure 8

1. Flange head capscrew

2. Slotted hole

4. Thread the top extension spring coil into the top spring

end holes and the bottom extension spring coil into the

bottom spring end holes (Fig. 9).

5. Mount the knee link to the lower spring end with the

wide part of the knee link pointing forward and the

spring end stop pointing forward. Secure the knee link

to the outer side of the spring end (Fig. 11) with a

shoulder bolt, washer, and locknut (Fig. 9 and 10).

Important The knee link must be assembled pointing

in the proper direction or the spring will not pivot correctly

when the deck is raised.

6. Mount the bottom of the knee link to the deck bracket

with a shoulder bolt and locknut.

3. Frame

11

Page 12

7. Align the slotted holes in the spring cover (slot toward

the bottom) with the mounting bracket holes. Insert the

lock pin assemblies into the bracket holes and secure

each to the bracket with the self-tapping screws (Fig. 9).

Torque the screws to 20 ft.-lb. (27 N⋅m).

4

3

2

1

2

8

11

12

10

1. Mounting bracket

2. Spring cover

3. Lock pin assembly

4. Self-tapping screw

5. Extension spring

6. Top spring end

7. Bottom spring end

Figure 9

9

6

5

7

13

8. Clevis pin

9. Hairpin cotter

10. Knee link

11. Shoulder bolt

12. Spring end stop

13. Locknut (2)

1

3

4

5

6

Figure 11

1. Weight transfer spring

2. Spring end plate

3. Knee link bracket

4. Deck bracket

5. Deck frame

6. Flotation frame

8. From the bottom, insert the spring and top spring end

into the spring cover. Select a hole that matches the

cutter deck height-of-cut setting; i.e., the top cover hole

matches the highest height setting, the bottom cover

hole the lowest, etc. Align the top spring end hole with

the selected spring cover holes and insert the clevis pin

to secure the spring inside the cover (Fig. 9). Secure the

clevis pin with a hairpin cotter.

1. Wide part of knee link

Figure 10

9. Remove the blocks from under the cutting unit. Make

the final counterbalance adjustments under actual

cutting conditions; refer to Adjusting the Tension

Spring, page 16.

1

Installing Rear Weight

Two Wheel Drive Groundsmaster 1000 and 200 Series

traction units comply with the ANSI B71.4-1999 Standard

when equipped with rear weight. Refer to the chart in the

traction unit Operator’s Manual to determine the

combinations of weight required. Order the parts from your

local Authorized Toro Distributor.

Four Wheel Drive Groundsmaster 200 Series traction units

do not need additional rear weight to comply with the

ANSI B71.4-1999 Standard.

12

Page 13

Before Operating

2

Adjusting the Height-of-Cut

The height-of-cut is adjustable from 1 to 4 inches (25 to

102 mm) in 1/2 inch (13 mm) increments, by adding or

removing an equal number of spacers on the front and rear

castor forks. The height-of-cut chart below gives the

combinations of spacers to use for all height-of-cut settings.

Height-of-Cut

Setting

(inches)

1 (25 mm) 0 0

1-1/2 (38 mm) 1 1

2 (51 mm) 2 2

2-1/2 (64 mm) 3 3

3 (76 mm) 4 4

3-1/2 (89 mm) 5 5

4 (102 mm) 6 6

Start the engine and raise the cutting unit so that the

height-of-cut can be changed. Stop the engine after the

cutting unit is raised.

Spacers Below Castor Arm

Front Rear

3

4

1

Figure 12

1. Front castor wheel

2. Tensioning cap

2. Push the castor spindle through the front castor arm,

install the other thrust washer and remaining spacers

onto the spindle, and install the tensioning cap to secure

the assembly.

3. Spacers

4. Thrust washers

Rear Castor Wheels

Front Castor Wheels

1. Remove the tensioning cap from the spindle shaft and

slide the spindle out of the front castor arm (Fig. 12).

Remove the washer from the spindle shaft. Slide the

spacers onto the spindle shaft to get the desired

height-of-cut, then slide the washer onto the shaft.

1. Remove the tensioning cap from the spindle shaft

(Fig. 13).

2

3

4

1

Figure 13

1. Rear castor wheel

2. Tensioning cap

3. Spacers

4. Thrust washers

Note: The rear castor fork assembly does not need to be

removed from the castor arm to change the height-of-cut.

13

Page 14

2. Remove or add ”C” shaped spacers at the narrow

portion of the spindle shaft, below the castor arm, to get

the desired height-of-cut. Make sure that the thrust

washers, not the spacers, contact the top and bottom of

the castor arm.

3. Install the tensioning cap to secure the assembly.

4. Ensure that all four castor wheels are set at the same

height-of-cut.

Adjusting the Rollers and Gage

Wheel

Note: If the cutting unit is to be used in the 1 in. (25 mm)

or 1-1/2 in. (38 mm) height-of-cut setting, the cutting unit

rollers must be repositioned in the top bracket holes.

Adjusting the Front Gage Wheel

1. Remove the capscrew and nut securing the gage wheel

to the cutting unit brackets (Fig. 15).

2. Align the roller and spacer with the top holes in the

brackets and secure them with the capscrew and nut.

Adjusting the Front Roller

1. Remove the capscrew and nut securing the roller shaft

to the cutting unit bracket (Fig. 14).

2. Slide the shaft out of the lower bracket holes, align the

roller with the top holes, and install the shaft.

3. Secure the roller shaft to the cutting unit bracket with

the capscrew and nut.

1

Figure 14

1. External roller 2. Roller shaft

2

1

Figure 15

1. Gage wheel

Adjusting the Rear (Internal) Rollers

1. Remove the cotter pins securing the roller shafts to the

brackets on the underside of the deck (Fig. 16).

2. Slide the shafts out of the lower bracket holes, align the

rollers with the top holes, and install the shafts.

3. Install the cotter pins to secure the assemblies.

1. Internal rollers

14

1

Figure 16

Page 15

Checking the Lubricant in the

Gear Box

The gear box in designed to operate on SAE 80–90 wt. gear

lube. Although the gear box is shipped with lubricant from

the factory, check the level before operating the cutting

unit.

1. Position the machine and cutting unit on a level surface.

2. Position the machine and cutting unit on a level surface

and lower the cutting unit. Remove the dipstick/fill plug

from the top of the gear box (Fig. 23) and make sure

that the lubricant is between the marks on the dipstick.

If the lubricant level is low, add SAE 80–90 wt. gear

lube until the level is between the marks.

Operation

Note: Determine the left and right sides of the machine

from the normal operating position.

Using the Grass Deflector

Danger

Without the grass deflector mounted in place, you

and others are exposed to blade contact and

thrown debris. Contact with the rotating mower

blade(s) and thrown debris will cause injury or

death.

1

Figure 17

1. Fill/check plug

Greasing the Cutting Unit

Before the cutting unit is operated, it must be greased to

ensure proper lubricating characteristics; refer to Greasing

the Bearings, Bushings, and Gear Box, page 17. Failure to

properly grease the cutting unit will result in premature

failure of critical parts.

• Never remove the grass deflector from the

mower because the grass deflector routes

material down toward the turf. If the grass

deflector is ever damaged, replace it

immediately.

• Never put your hands or feet under the mower.

• Never operate the mower with the deflector

removed from the cutting unit or tied/blocked in

a raised position.

Note: The deflector is spring loaded into its downward

normal operating position (Fig. 18), but the operator can

temporarily swing it out of the way to facilitate loading in a

trailer or when otherwise necessary.

2

Figure 18

1. Grass deflector 2. Springs

15

1

Page 16

Adjusting the Tension Spring

For best performance, the cutting unit bounce on uneven

turf is minimal and it does not ride heavily over flat terrain.

If scalping occurs or the cut is uneven from side to side,

there may too much weight on the deck and weight may

have to be transferred to the traction unit: i.e. increased

spring tension.

By contrast, if too much weight is transferred to the traction

unit, the deck will bounce excessively and the cut will be

uneven. If the cutting unit does not perform properly, adjust

the tension spring as follows:

1. Stop the machine on a level surface, set the parking

brake, fully raise the cutting unit, turn the ignition key

to Off, and remove the key.

2. Remove the hairpin cotter from the clevis pin securing

the spring end to the spring cover and remove the clevis

pin. Align the top spring end hole with the new hole

selected in the spring cover, insert the clevis pin, and

secure it with the hairpin cotter.

3. Resume operations. If further adjustments are required,

repeat the procedure.

Caution

The counterbalance spring is in tension when the

deck is in the lowered position.

Always raise the deck before adjusting or

removing the spring.

16

Page 17

Maintenance

Note: Determine the left and right sides of the machine

from the normal operating position.

Recommended Maintenance Schedule

Maintenance Service

Interval

After first 2 hours • Tighten the castor wheel nuts.

After first 10 hours

Daily

Every 50 hours

Every 400 hours • Change the gear box oil.

Maintenance Procedure

• Tighten the castor wheel nuts.

• Torque the blade bolts.

• Check the blades.

• Lubricate the castor arm bushings.

• Lubricate the castor wheel bearings.

• Tighten the castor wheel nuts.

• Torque the blade bolts.

• Lubricate the grease fittings.

• Clean under the cutting unit belt covers.

• Check the blade drive belt adjustment.

• Check the gear box oil level.

Greasing the Bearings,

Bushings, and Gear Box

The cutting unit must be lubricated regularly. If the

machine is operated under normal conditions, lubricate the

castor bearings and bushings with No. 2 general purpose

lithium base grease or molybdenum base grease after every

8 hours of operation or daily, whichever comes first.

1. Lubricate the following areas:

• front castor spindle bushings (Fig. 19)

• rear castor spindle shaft (remove the shaft from the

castor arm and coat the hexagonal shaft with

designated grease every 50 hours) (Fig. 20)

• castor wheel bearings (Fig. 19 and 20)

• right and left lift arm pivot pins (Fig. 21)

• blade spindle bearings (Fig. 22)

• right and left push arm ball joints (Fig. 22)

Figure 19

17

Page 18

Figure 20

2. Position the machine and cutting unit on a level surface

and lower the cutting unit. Remove the dipstick/fill plug

from the top of the gear box (Fig. 23) and make sure

that the lubricant is between the marks on the dipstick.

If the lubricant level is low, add SAE 80–90 wt. gear

lube until the level is between the marks.

1

Figure 23

1. Fill/check plug

Figure 21

Figure 22

Separating the Cutting Unit

from the Traction Unit

1. Position the machine on a level surface, raise the cutting

unit, engage the parking brake, put the traction pedal in

neutral, the PTO lever in the Off position, shut the

engine off, and remove the ignition key.

Caution

The counterbalance spring is in tension when the

deck is in the lowered position.

Always raise the deck before adjusting or

removing the spring.

2. Disconnect the counterbalance from the traction unit,

remove the lock pins from the brackets, separate the

spring tension assemblies from the brackets, and lay

them down on the deck. Loosely secure the lock pins to

the brackets to prevent losing them (Fig. 24).

18

Page 19

1. Lock pin

2. Bracket

23

1

Figure 26

1. PTO shaft

Figure 24

3. Spring tension assembly

Danger

1

3. Position the machine on a level surface, lower the

cutting unit to the floor, move the lift lever to the float

position, shut the engine off, and engage the parking

brake.

4. Remove the capscrews and locknuts securing the ball

joint mounts to the castor arms on the cutting unit

(Fig. 25).

2

1

Figure 25

1. Castor arm 2. Ball joint mount

If the engine is started and the PTO shaft is

allowed to rotate, serious injury could result.

Do not start the engine and engage the PTO lever

when the PTO shaft is not connected to the gear

box on the cutting unit.

Mounting the Cutting Unit to

the Traction Unit

1. Position the machine on a level surface and shut the

engine off.

2. Move the cutting unit into position in front of the

traction unit.

3. Slide the male PTO shaft into the female PTO shaft.

(Fig. 26)

4. Move the lift lever to the Float position. Push the lift

arms down until the holes in the ball joint mounts line

up with the holes in the castor arms (Fig. 25).

5. Secure the ball joint mounts to the castor arms with the

capscrews and flange nuts.

5. Roll the cutting unit away from the traction unit,

separating the male and female sections of the PTO

shaft (Fig. 26).

6. Raise the cutting unit and place blocks under it to

prevent it from falling during assembly.

7. Connect the counterbalance to the traction unit brackets

with lock pins (Fig. 24).

8. Remove the blocks from under the cutting unit. Make

the final counterbalance adjustments under actual

cutting conditions; refer to Adjusting the Tension

Spring, page 16.

19

Page 20

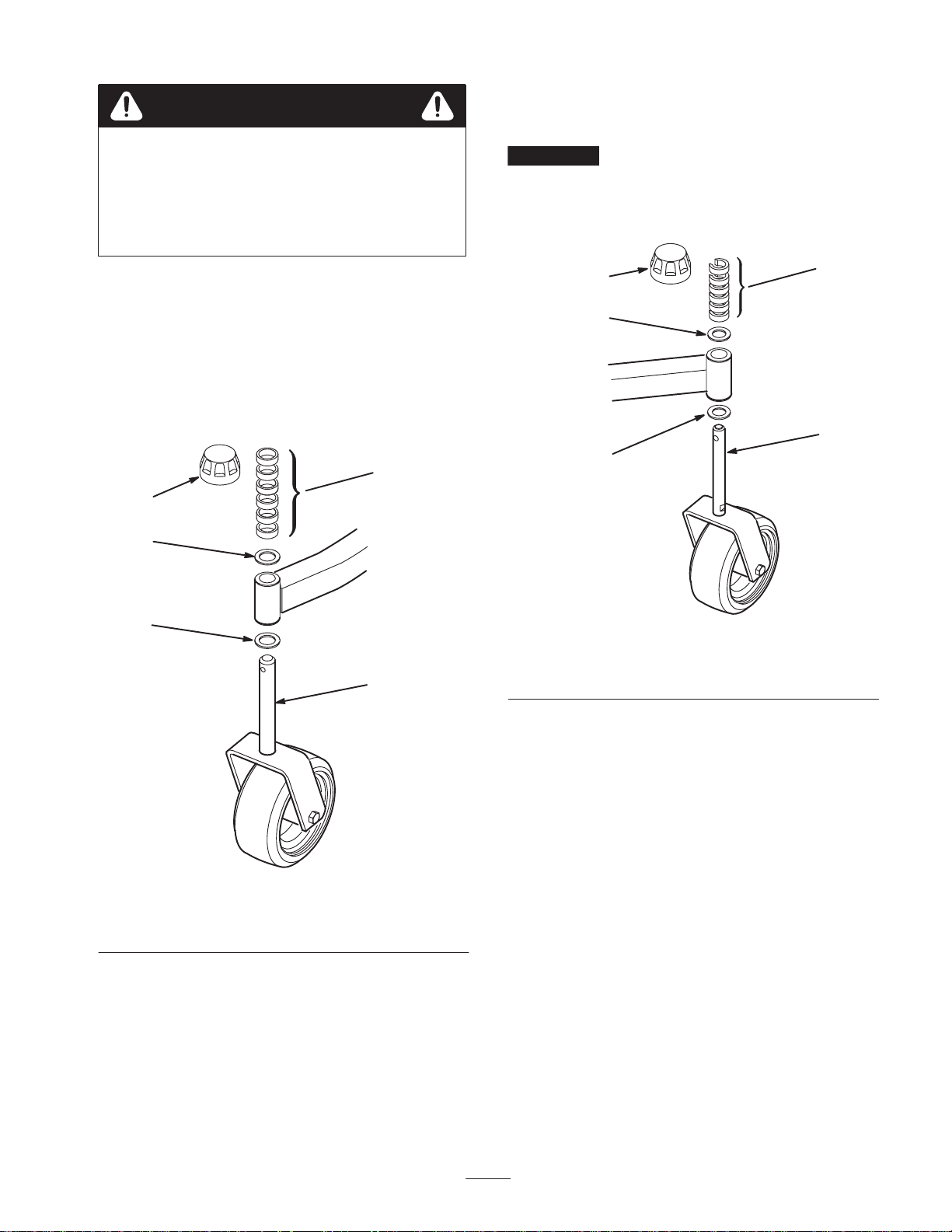

Servicing the Castor Arm

Bushings

lubricated, bearing wear will be minimal. However, failure

to keep the bearing lubricated will cause rapid wear. A

wobbly castor wheel usually indicates a worn bearing.

The castor arms have bushings pressed into the top and

bottom of the tube and after many hours of operation, the

bushings will wear. To check the bushings, move the castor

fork back and forth and from side to side. If the castor

spindle is loose inside the bushings, the bushings are worn

and must be replaced.

1. Raise the cutting unit so that the wheels are off of the

floor and block it so that it cannot accidentally fall.

2. Remove the tensioning cap, spacer(s), and thrust washer

from the top of the castor spindle.

3. Pull the castor spindle out of the mounting tube. Allow

the thrust washer and spacer(s) to remain on the bottom

of the spindle.

4. Insert a pin punch into the top or bottom of the

mounting tube and drive the bushing out of the tube.

Also drive the other bushing out of the tube (Fig. 27).

Clean the inside of the tubes to remove dirt.

2

1. Remove the locknut from the capscrew holding the

castor wheel assembly between the castor fork

(Fig. 28). Grasp the castor wheel and slide the capscrew

out of the fork.

2. Pull the spanner bushing out of the wheel hub (Fig. 28).

3. Remove the bushing from the wheel hub and allow the

bearing to fall out. Remove the bushing from the

opposite side of the wheel hub.

4. Check the bearing, spanner, and inside of the wheel hub

for wear. Replace damaged parts.

5. To assemble the castor wheel, push the bushing into the

wheel hub. Slide the bearing into the wheel hub. Push

the other bushing into the open end of the wheel hub to

captivate the bearing inside the wheel hub (Fig. 28).

6. Carefully slide the spanner through the bushings and the

wheel hub.

7. Install the castor wheel assembly between the castor

fork and secure it in place with the capscrew, washers,

and locknut.

8. Lubricate the castor wheel bearing through the grease

fitting, using No. 2 general purpose lithium base grease.

1

Figure 27

1. Front castor arm tube 2. Bushings

5. Apply grease to the inside and outside of the new

bushings. Using a hammer and flat plate, drive the

bushings into the mounting tube.

6. Inspect the castor spindle for wear and replace it if it is

damaged.

7. Push the castor spindle through the bushings and

mounting tube. Slide the thrust washer and spacer(s)

onto the spindle. Install the tensioning cap on the castor

spindle to retain all of the parts in place.

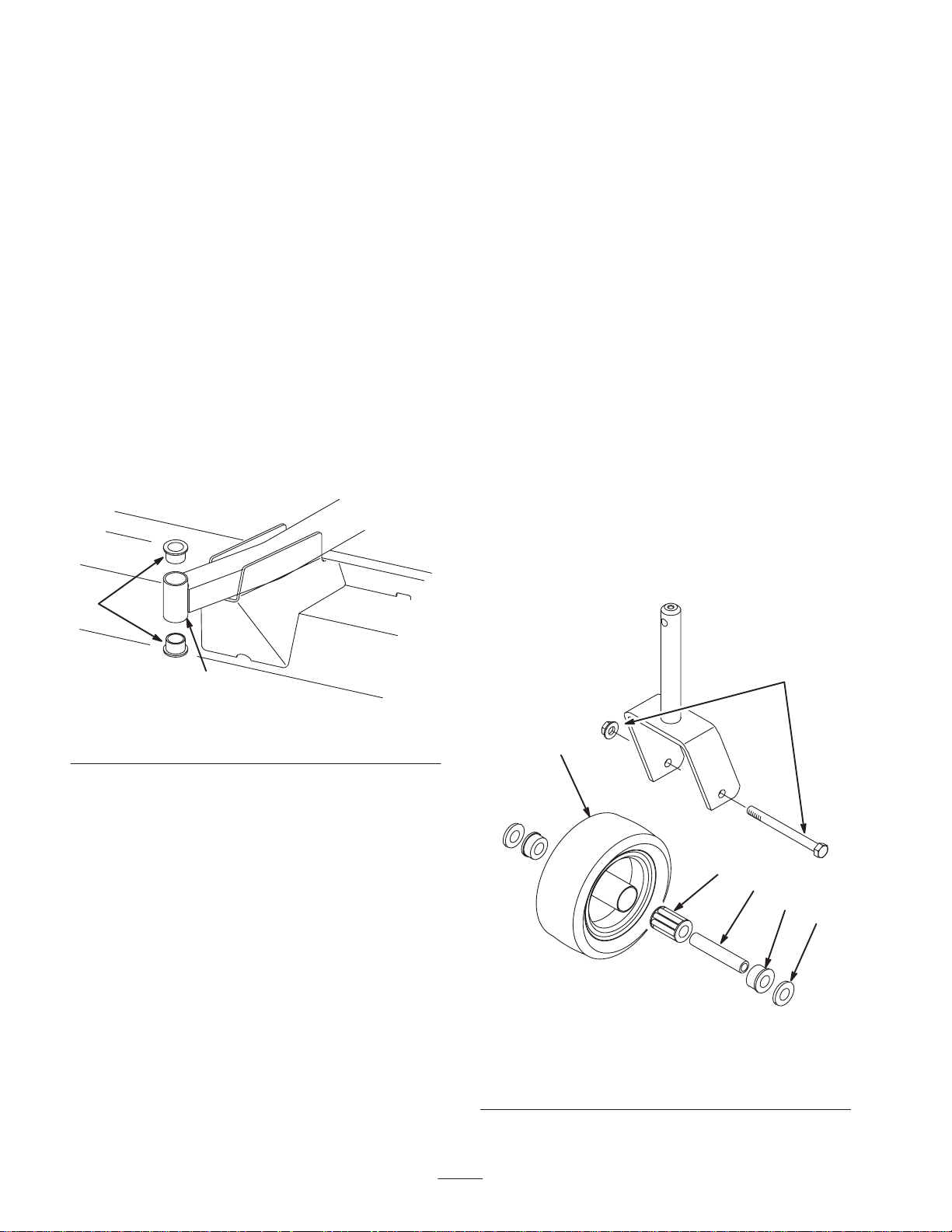

Servicing the Castor Wheels

and Bearings

The castor wheel rotates on a high-quality roller bearing

and is supported by a spanner bushing. Even after many

hours of use, provided that the bearing was kept well

1

1. Castor wheel

2. Capscrew and locknut

3. Bushing (2)

2

5

4

3

6

Figure 28

4. Spanner bushing

5. Roller bearing

6. Washer (2)

20

Page 21

Checking for a Bent Blade

1. Position the machine on a level surface, raise the cutting

unit, engage the parking brake, put the traction pedal in

neutral, the PTO lever in the Off position, shut the

engine Off, remove the ignition key, and disconnect the

wires from the spark plugs. Block the cutting unit to

prevent it from accidentally falling.

2. Grasp the end of the blade using a rag or thickly padded

glove. Remove the blade bolt, anti-scalp cup, and blade

from the spindle shaft (Fig. 30).

2. Rotate the blade until the ends face forward and

backward. Measure from the inside of the cutting unit to

the cutting edge at the front of the blade (Fig. 29), and

remember this dimension.

Figure 29

3. Rotate the opposite end of the blade forward. Measure

between the cutting unit and cutting edge of the blade at

the same position as in step 2. The difference between

the dimensions obtained in steps 2 and 3 must not

exceed 1/8 in. (3 mm). If the dimension exceeds 1/8 in.

(3 mm), replace the blade because it is bent; refer to

Removing the Cutting Blade, page 21.

Removing the Cutting Blade

The blade must be replaced if a solid object is hit, or the

blade is out-of-balance, worn, or bent. Always use genuine

Toro replacement blades to ensure safety and optimum

performance. Never use blades made by other

manufacturers because they could be dangerous.

Danger

A worn or damaged blade can break, and a piece

of the blade could be thrown into the operator’s or

bystander’s area, resulting in serious personal

injury or death.

• Inspect the blade periodically for wear or

damage.

• Do not try to straighten a blade that is bent.

• Never weld a broken or cracked blade.

• Replace a worn or damaged blade with a new

Toro blade to ensure continued safety

certification of the product.

1. Position the machine on a level surface, raise the cutting

unit, engage the parking brake, put the traction pedal in

neutral, the PTO lever in the Off position, shut the

engine off, remove the ignition key, and disconnect the

wires from the spark plugs. Block the cutting unit to

prevent it from accidentally falling.

2

1

Figure 30

1. Blade bolt 2. Anti-scalp cup

3. Install the blade—sail facing toward the cutting

unit—with the anti-scalp cup and blade bolt. Tighten

the blade bolt to 85–110 ft.-lb. (115–149 N⋅m).

Inspecting and Sharpening the

Blade

Two areas must be considered when checking and servicing

the cutting blade: the sail and the cutting edge. Both cutting

edges and the sail, which is the turned up portion opposite

the cutting edge, contribute to a good quality-of-cut. The

sail is important because it pulls grass up straight, thereby

producing an even cut. However, the sail will gradually

wear down during operation, and this condition is normal.

As the sail wears down, the quality-of-cut will degrade

somewhat, although the cutting edges are sharp. The

cutting edge of the blade must be sharp so that the grass is

cut rather than torn. A dull cutting edge is evident when the

tips of the grass appear brown and shredded. Sharpen the

cutting edges to correct this condition.

1. Position the machine on a level surface, raise the cutting

unit, engage the parking brake, put the traction pedal in

neutral, the PTO lever in the Off position, shut the

engine off, remove the ignition key, and disconnect the

wires from the spark plugs. Block the cutting unit to

prevent it from accidentally falling.

2. Examine the cutting ends of the blade carefully,

especially where the flat and curved parts of the blade

meet (Fig. 31-A). Since sand and abrasive material can

wear away the metal that connects the flat and curved

parts of the blade, check the blade before using the

machine. If wear is noticed (Fig. 31-B), replace the

blade; refer to Removing the Cutting Blade, page 21.

21

Page 22

FLAT PART

OF BLADE

with the anti-scalp cup and blade bolt. The blade sails must

be on top of the blade. Tighten the blade bolt to

85–110 ft.-lb. (115–149 N⋅m).

A

SAIL

Correcting Cutting Unit

SAIL

B

WEAR

SAIL

C

SLOT

FORMED

Figure 31

3. Examine the cutting edges of all blades. Sharpen the

cutting edges if they are dull or nicked. Sharpen only

the top side of the cutting edge and maintain the

original cutting angle to ensure sharpness (Fig. 32). The

blade will remain balanced if the same amount of metal

is removed from both cutting edges.

Warning

If the blade is allowed to wear, a slot will form

between the sail and flat part of the blade

(Fig. 31-C). Eventually, a piece of the blade may

break off and be thrown from under the housing,

possibly resulting in serious injury to yourself or

bystanders.

Mismatch

If one cutting blade cuts lower than the others, correct them

as follows:

1. Lower the cutting unit onto a level surface, engage the

parking brake, put the traction pedal in neutral, the PTO

lever in the Off position, shut the engine off, remove the

ignition key, and disconnect the wires from the spark

plugs. Make sure that the tire pressure is equal on all

tires.

2. Raise the height-of-cut to the 4 in. (102 mm) position;

refer to Adjusting the Height-of-Cut, page 13.

3. Rotate the blades so that the tips line up with one

another. The tips of the adjacent blades must be within

1/8 in. (3 mm) of each other. If the tips are not within

1/8 in. (3 mm) of each other, proceed to step 9 and add

shims between the spindle housing and bottom of the

cutting unit.

4. Check to make sure that the front height-of-cut pins are

resting properly on the frame cushions. If the pins are

not resting properly, place a shim or shims under the

cushion to raise it for proper alignment.

5. Position all 3 blades in the “A” position (Fig. 33) and

measure from the level surface to the bottom of the tip

end of each blade (Fig. 34).

B

• Inspect the blade periodically for wear or

damage.

• Replace a worn or damaged blade with a new

Toro blade to ensure continued safety

certification of the product.

SHARPEN AT THIS

ANGLE ONLY

END VIEW

OF BLADE

Figure 32

Note: Remove the blades and sharpen them on a grinder;

refer to Removing the Cutting Blades, page 21, steps 1

and 2. After sharpening the cutting edges, install the blade

B

A

A

C

C

A

Figure 33

6. Note the measurement attained at “A”, rotate the blades

to the “B” position (Fig. 33), measure the distance of all

of the blades to the level surface, and note the

dimensions (Fig. 34).

22

B

C

Page 23

MEASURE FROM

BLADE TIP TO LEVEL

SURFACE

Figure 34

7. Rotate the blades to the “C” position, measure, and note

the distance measured (Fig. 33 and 34).

8. Compare the measurements at various positions. All

dimensions must be equal within 1/4 in. (6 mm) from

any 2 adjacent blades. The difference between the

dimensions of all 3 blades must not exceed 3/8 in.

(10 mm). If the difference exceeds specifications,

proceed to step 9.

9. Remove the capscrews, flat washers, and locknuts from

the outer spindle in the area where the shims must be

added. To raise or lower the blade, add a shim, Part No.

3256-24, between the spindle housing and bottom of the

cutting unit. Continue checking the alignment of the

blades and adding shims until the tips of the blades are

within the required dimension.

Replacing the Grass Deflector

1. Position the machine on a level surface, raise the cutting

unit, engage the parking brake, put the traction pedal in

neutral, the PTO lever in the Off position, shut the

engine off, and remove the ignition key. Block the

cutting unit to prevent it from accidentally falling.

2. Remove the 2 capscrews, locknuts, and springs securing

the deflector mounts to the pivot brackets (Fig. 35).

4. Install the pivot brackets on top of the discharge

opening with the carriage bolts and nuts. The head of

the carriage bolts must be on the inside of the cutting

unit.

5. Position the deflector mounts on the pivot brackets and

secure the parts together with the capscrews, locknuts,

and springs. Both locknuts must face each other.

Tighten the locknuts until they are flush against the

deflector pivots.

6. Lift the deflector and allow it to drop to check the

spring tension. The deflector must be held firmly in the

full downward position by the spring tension. Correct it

if necessary.

Adjusting the Idler Pulley

The idler pulley applies force against the belt so that power

can be transmitted to the blade pulleys. If the idler is not

tensioned against the belt with sufficient force, maximum

power will not be transmitted to the pulleys. Tension on the

belt requires 40 to 50 ft.-lb. (54 to 68 N⋅m) of torque on the

large nut, which applies force against the belt. If the idler is

not adjusted to these specifications, an adjustment is

necessary.

1. Position the machine on a level surface, lower the

cutting unit, engage the parking brake, put the traction

pedal in neutral, the PTO lever in the Off position, shut

the engine off, and remove the ignition key.

2. Release and unhook the latches securing the center

cover to the top of the cutting unit. Remove the cover

from the cutting unit.

3. Loosen the 2 nuts securing the idler plate in place.

Using a socket and torque wrench, tighten the idler

adjusting nut to 40–50 ft.-lb. (54 to 68 N⋅m) (Fig. 36).

1

2

3

Figure 35

1. Deflector mounts

2. Pivot brackets

3. Pivot springs

3. To remove the pivot brackets, remove the carriage bolts

and nuts (Fig. 35).

2

1

3

2

Figure 36

1. Idler plate

2. Nuts (2)

3. Idler adjusting nut

4. Hold the torque against the belt and tighten the 2 nuts so

that the idler plate is held securely in place. Release the

idler adjusting nut. Install the cover and secure the

latches.

23

Page 24

Adjusting the Cover Latches

If the cutting unit covers fit loose, the latch tension may be

adjusted by loosening the latch mounting screws and

sliding the latches (slotted mounting holes in the cutting

unit) to the proper position.

Replacing the Drive Belt

The blade drive belt, tensioned by the adjustable idler, is

very durable. However, after many hours of use, the belt

will show signs of wear. Signs of a worn belt are: squealing

when the belt is rotating, blades slipping when cutting

grass, frayed edges, burn marks, and cracks. Replace the

belt if any of these conditions are evident.

1. Position the machine on a level surface, lower the

cutting unit, engage the parking brake, put the traction

pedal in neutral, the PTO lever in the Off position, shut

the engine off, and remove the ignition key.

2. Release and unhook the latches securing the covers to

the top of the cutting unit. Remove the covers.

3. Loosen the 2 nuts securing the idler plate in place and

remove the old belt from the pulleys.

4. To install a new belt, the gear box base must be

removed. To do this, remove the 4 carriage bolts and

locknuts holding the gear box base.

5. Install the new belt around the gear box pulley, spindle

pulleys, stationary idler pulley, and adjustable idler

pulley (Fig. 37).

6. Install the gear box base with the carriage bolts and

locknuts.

7. Using a torque wrench, adjust the tension of the idler

pulley against the belt; refer to Adjusting the Idler

Pulley, page 23.

8. Install the covers and secure the latches.

2

3

1

Figure 37

1. Adjustable idler pulley

2. Stationary idler pulley

3. Gear box pulley

24

Page 25

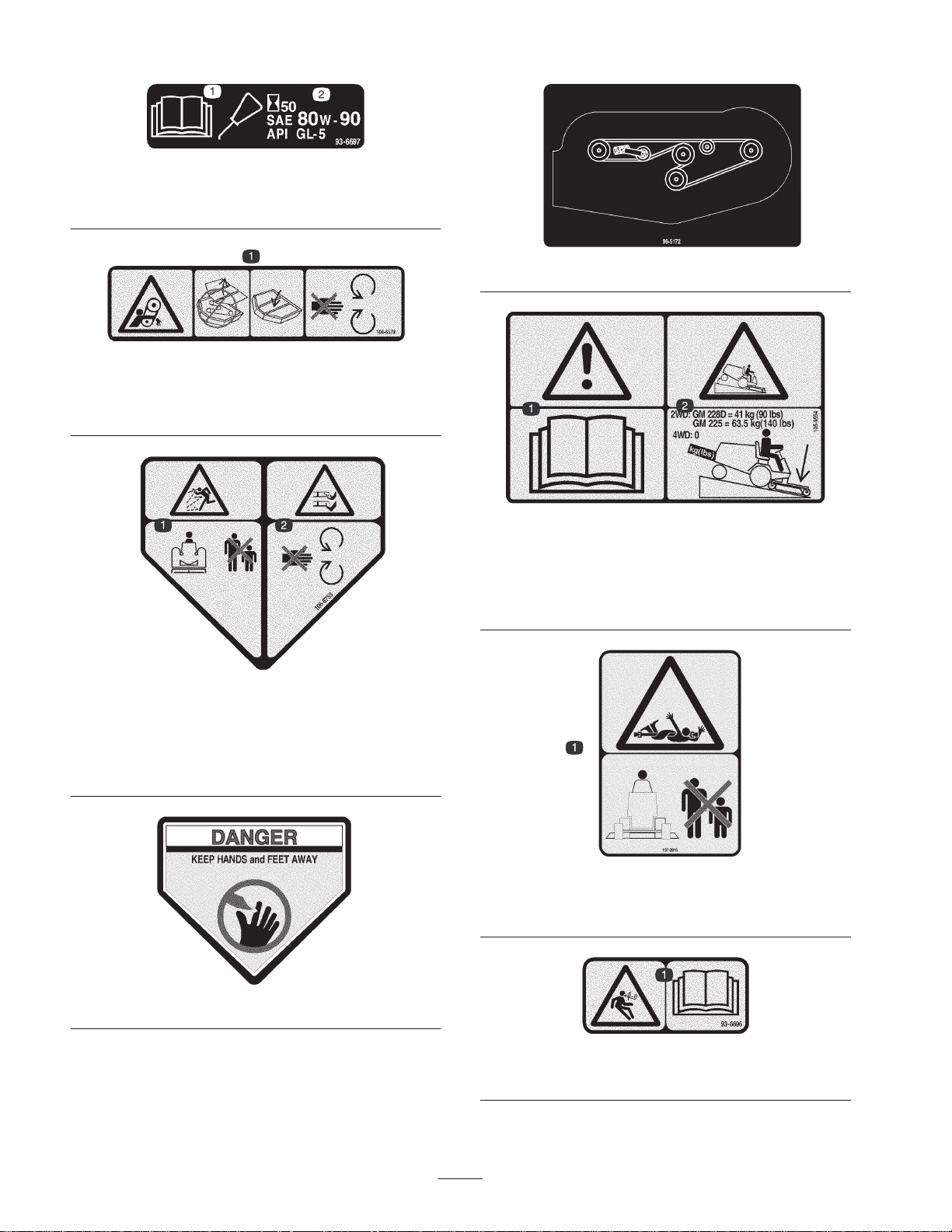

UNIT WILL NOT CUT OR CUTS POORLY

Troubleshooting

25

INSPECT

CUTTER

BLADES

DULL OR

BENT

SHARPEN

OR

REPLACE

INSPECT PULLEY

ON ENGINE

OUTPUT SHAFT

LOOSE OR

BROKEN

REPLACE

OK OK

INSPECT

SPINDLE

BOLTS

LOOSE

RETORQUE

85 TO 110

FOOT POUNDS

INSPECT

P.T.O.

SHAFT

BROKEN

REPLACE

INSPECT

CUTTER DECK

BELTS

LOOSE OR

BROKEN

TIGHTEN

OR

REPLACE

INSPECT

P.T.O.

PULLEY

LOOSE OR

BROKEN

TIGHTEN

OR

REPLACE

INSPECT

GEAR BOX

PULLEY

LOOSE

TIGHTEN

OR

REPLACE

OKOK OK

OKOK

INSPECT

GEAR BOX

SHAFTS

BROKEN

REPLACE

INSPECT

P.T.O.

BELT

BROKEN

REPLACE

Page 26

26

Page 27

27

Page 28

The Toro General Commercial Products Warranty

A Two-Year Limited Warranty

Conditions and Products Covered

The Toro Company and its affiliate, Toro Warranty Company,

pursuant to an agreement between them, jointly warrant your Toro

Commercial Product (“Product”) to be free from defects in

materials or workmanship for two years or 1500 operational

hours*, whichever occurs first. Where a warrantable condition

exists, we will repair the Product at no cost to you including

diagnosis, labor, parts, and transportation. This warranty begins

on the date the Product is delivered to the original retail purchaser.

* Product equipped with hour meter

Instructions for Obtaining Warranty Service

You are responsible for notifying the Commercial Products

Distributor or Authorized Commercial Products Dealer from whom

you purchased the Product as soon as you believe a warrantable

condition exists.

If you need help locating a Commercial Products Distributor or

Authorized Dealer, or if you have questions regarding your

warranty rights or responsibilities, you may contact us at:

Toro Commercial Products Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

952-888-8801 or 800-982-2740

E-mail: commercial.service@toro.com

Owner Responsibilities

As the Product owner, you are responsible for required maintenance and adjustments stated in your operator’s manual. Failure

to perform required maintenance and adjustments can be grounds

for disallowing a warranty claim.

Items and Conditions Not Covered

Not all product failures or malfunctions that occur during the

warranty period are defects in materials or workmanship. This

express warranty does not cover the following:

• Product failures which result from the use of non-Toro

replacement parts, or from installation and use of add-on,

modified, or unapproved accessories

• Product failures which result from failure to perform required

maintenance and/or adjustments

• Product failures which result from operating the Product in an

abusive, negligent or reckless manner

• Parts subject to consumption through use unless found to be

defective. Examples of parts which are consumed, or used up,

during normal Product operation include, but are not limited to,

blades, reels, bedknives, tines, spark plugs, castor wheels,

tires, filters, belts, etc.

• Failures caused by outside influence. Items considered to be

outside influence include, but are not limited to, weather,

storage practices, contamination, use of unapproved coolants,

lubricants, additives, or chemicals, etc.

• Normal “wear and tear” items. Normal “wear and tear”

includes, but is not limited to, damage to seats due to wear or

abrasion, worn painted surfaces, scratched decals or windows, etc.

Parts

Parts scheduled for replacement as required maintenance are

warranted for the period of time up to the scheduled replacement

time for that part.

Parts replaced under this warranty become the property of Toro.

Toro will make the final decision whether to repair any existing part

or assembly or replace it. Toro may use factory remanufactured

parts rather than new parts for some warranty repairs.

General Conditions

Repair by an Authorized Toro Distributor or Dealer is your sole

remedy under this warranty.

Neither The Toro Company nor Toro Warranty Company is

liable for indirect, incidental or consequential damages in

connection with the use of the Toro Products covered by this

warranty, including any cost or expense of providing substitute equipment or service during reasonable periods of

malfunction or non-use pending completion of repairs under

this warranty . Except for the Emissions warranty referenced

below, if applicable, there is no other express warranty. All

implied warranties of merchantability and fitness for use are

limited to the duration of this express warranty.

Some states d o n o t a l l o w exclusions of incidental or consequential

damages, or limitations on how long an implied warranty lasts, so

the above exclusions and limitations may not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Note regarding engine warranty: The Emissions Control

System on your Product may be covered by a separate warranty

meeting requirements established by the U.S. Environmental

Protection Agency (EPA) and/or the California Air Resources

Board (CARB). The hour limitations set forth above do not apply to

the Emissions Control System Warranty. Refer to the Engine

Emission Control Warranty Statement printed in your operator’s

manual or contained in the engine manufacturer’s documentation

for details.

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their T oro Distributor (Dealer)

to obtain guarantee policies for your country , province, or state. If for any reason you are dissatisfied with your Distributor’s service or

have difficulty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty

Company.

Part No. 374-0031 Rev. a

Loading...

Loading...