Toro 30551, Groundsmaster 200 Series, Groundsmaster 3320 Series, Groundsmaster 3280-D Series Operator's Manual

Page 1

62inSideDischargeMower

FormNo.3383-259RevA

Groundsmaster

®

200,3320and3280-D

SeriesTractionUnit

ModelNo.30551—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3383-259*A

Page 2

Figure1

Introduction

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Thisrotary-bladelawncuttingdeckismountedtoaride-on

machineandisintendedtobeusedbyprofessional,hired

operatorsincommercialapplications.Itisprimarilydesigned

forcuttinggrassonwell-maintainedlawnsinparks,sports

elds,andoncommercialgrounds.Itisnotdesignedfor

cuttingbrush,mowinggrassandothergrowthalongside

highways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

YoumaycontactTorodirectlyatwww.Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbers

ofyourproductready .Themodelandserialnumbersare

stampedintoaplatelocatedonthecarrierframebehindthe

rightfrontcastorwheel.Writethenumbersinthespace

provided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................5

SafetyandInstructionalDecals.................................7

Setup............................................................................9

1InstallingtheCastorWheelAssemblies....................9

2InstallingtheLiftArms.........................................10

3ConnectingtheLiftArmstotheCutting

Unit..................................................................11

4MountingthePTOShaftGuardandConnecting

thePTOShafttotheCuttingUnitGear

Box...................................................................11

5InstallingtheRearW eight......................................12

ProductOverview.........................................................13

Specications........................................................13

Attachments/Accessories........................................13

Operation....................................................................13

AdjustingtheHeight-of-Cut....................................13

AdjustingtheRollersandGageWheel.......................14

............................................................................15

CheckingtheGearBoxLubricant.............................15

GreasingtheCuttingUnit........................................15

AdjustingtheWeightTransfer..................................15

UsingtheGrassDeector.......................................15

Maintenance.................................................................16

Lubrication............................................................16

SeparatingtheCuttingUnitfromtheTraction

Unit..................................................................16

MountingtheCuttingUnittotheTraction

Unit..................................................................17

ServicingtheBushingsintheCastorArms.................17

ServicingtheCastorWheelsandBearings..................18

CheckingforaBentBlade........................................18

RemovingtheCuttingBlade.....................................18

InspectingandSharpeningtheBlade.........................19

CheckingandCorrectingMismatchof

Blades...............................................................20

ReplacingtheGrassDeector..................................20

AdjustingtheIdlerPulley........................................21

ReplacingtheDriveBelt..........................................21

Troubleshooting...........................................................23

3

Page 4

Safety

ThismachinemeetsorexceedsCENstandardEN836:1997,

ISOstandard5395:1990,andANSIB71.4-2012specications

ineffectatthetimeofproduction.

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCAUTION,WARNING,or

DANGER-"personalsafetyinstruction."Failuretocomply

withtheinstructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromtheCEN

standardEN836:1997,ISOstandard5395:1990,andANSI

B71.4-2012.

Training

•Readtheoperator'smanualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.Iftheoperatoror

mechaniccannotreadthelanguageofthismanual,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,orproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glassesandearprotection.Longhair,looseclothingor

jewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toysandwirewhichcan

bethrownbythemachine.

•Checkthatoperator'spresencecontrols,safetyswitches

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Onlystartenginefrom

theoperator'sposition.Useseatbeltsifprovided.

•Slowdownanduseextracareonhillsides.Besureto

travelintherecommendeddirectiononhillsides.Turf

conditionscanaffectthemachine'sstability .Usecaution

whileoperatingneardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neverraisedeckwiththebladesrunning.

•Neveroperatewithguardsnotsecurelyinplace.Be

sureallinterlocksareattached,adjustedproperly ,and

functioningproperty.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,lowerthecuttingunits,disengage

drives,engageparkingbrake(ifprovided),shutoffengine

beforeleavingtheoperator'spositionforanyreason.

•Stopequipmentandinspectthebladesafterstriking

objectsorifanabnormalvibrationoccurs.Make

necessaryrepairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunits.

4

Page 5

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesifnotmowing.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Theoperatorshallturnonashingwarninglights,if

provided,whenevertravelingonapublicroad,except

wheresuchuseisprohibitedbylaw .

MaintenanceandStorage

•Disengagedrives,lowerthecuttingunits,movetraction

pedaltoNeutral,setparkingbrake,stopengineand

removekey .Waitforallmovementtostopbefore

adjusting,cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,mufers,

andenginetohelppreventres.Letenginecoolbefore

storinganddonotstorenearame.Cleanupoilorfuel

spillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransporting.Donotstore

fuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallowuntrained

personneltoservicemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectbatterybeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.Reconnect

positiverstandnegativelast.

•Usecarewhencheckingblades.Wrapthebladesor

weargloves,andusecautionwhenservicingthem.Only

replaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

ordisconnectingfrombattery.W earprotectiveclothing

anduseinsulatedtools.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCEN,ISO ,orANSIstandard.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennisshoes

orsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,

embankments,orotherhazards.

–Avoidsuddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Lowerthecuttingunitwhengoingdownslopes.

•Thegrassdeectormustalwaysbeinstalledandinthe

lowestpositiononthesidedischargecuttingunit.Never

operatethemowerwithoutthedeectororentiregrass

collector.

•Ifthecuttingunitdischargeareaeverplugs,shutthe

engineoffbeforeremovingtheobstruction.

•Cutgrassslopescarefully.Donotstart,stop,orturn

suddenly.

•Donottouchtheengineormuferwhiletheengineis

runningorsoonafterithasstoppedbecausetheseareas

couldbehotenoughtocauseburns.

MaintenanceandStorage

•Checktheblademountingboltsfrequentlytobesurethat

theyaretightenedtospecication.

5

Page 6

•Makesurethatallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringthecutting

unitstotheground.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunits,attachments,and

anymovingparts.Keepeveryoneaway.

•Donotoverspeedtheenginebychanginggovernor

settings.Toensuresafetyandaccuracy ,havean

AuthorizedToroDistributorcheckthemaximumengine

speedwithatachometer.

•Theenginemustbeshutoffbeforecheckingtheoilor

addingoiltothecrankcase.

•Makesurethatthemowerfueltankisemptyifthe

machineistobestoredinexcessof30days.Donotstore

themowernearanyopenameorwheregasolinefumes

maybeignitedbyaspark.

•Performonlythosemaintenanceinstructionsdescribed

inthismanual.Ifmajorrepairsareeverneededor

ifassistanceisdesired,contactanAuthorizedT oro

Distributor.

•Tomakesureofoptimumperformanceandcontinued

safetycerticationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

6

Page 7

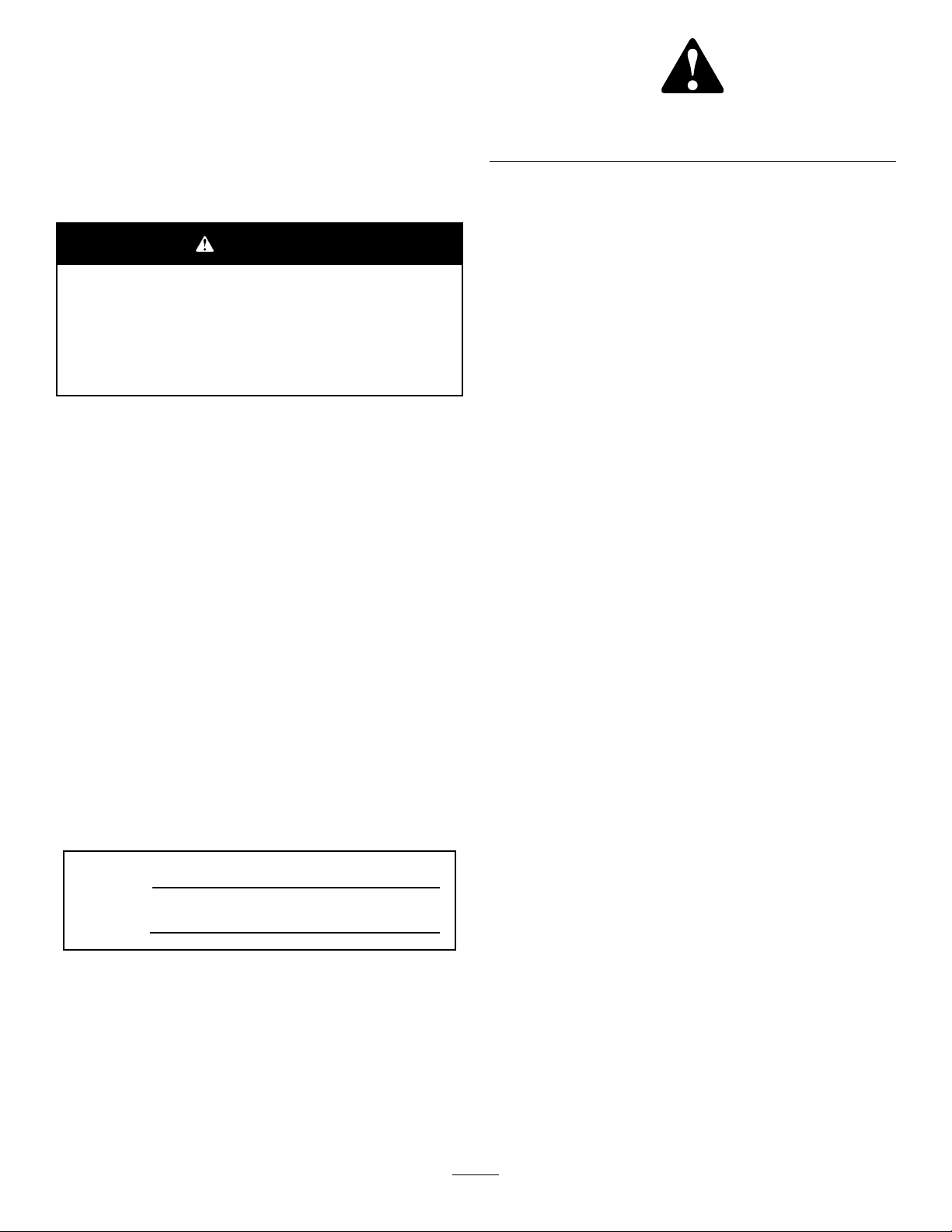

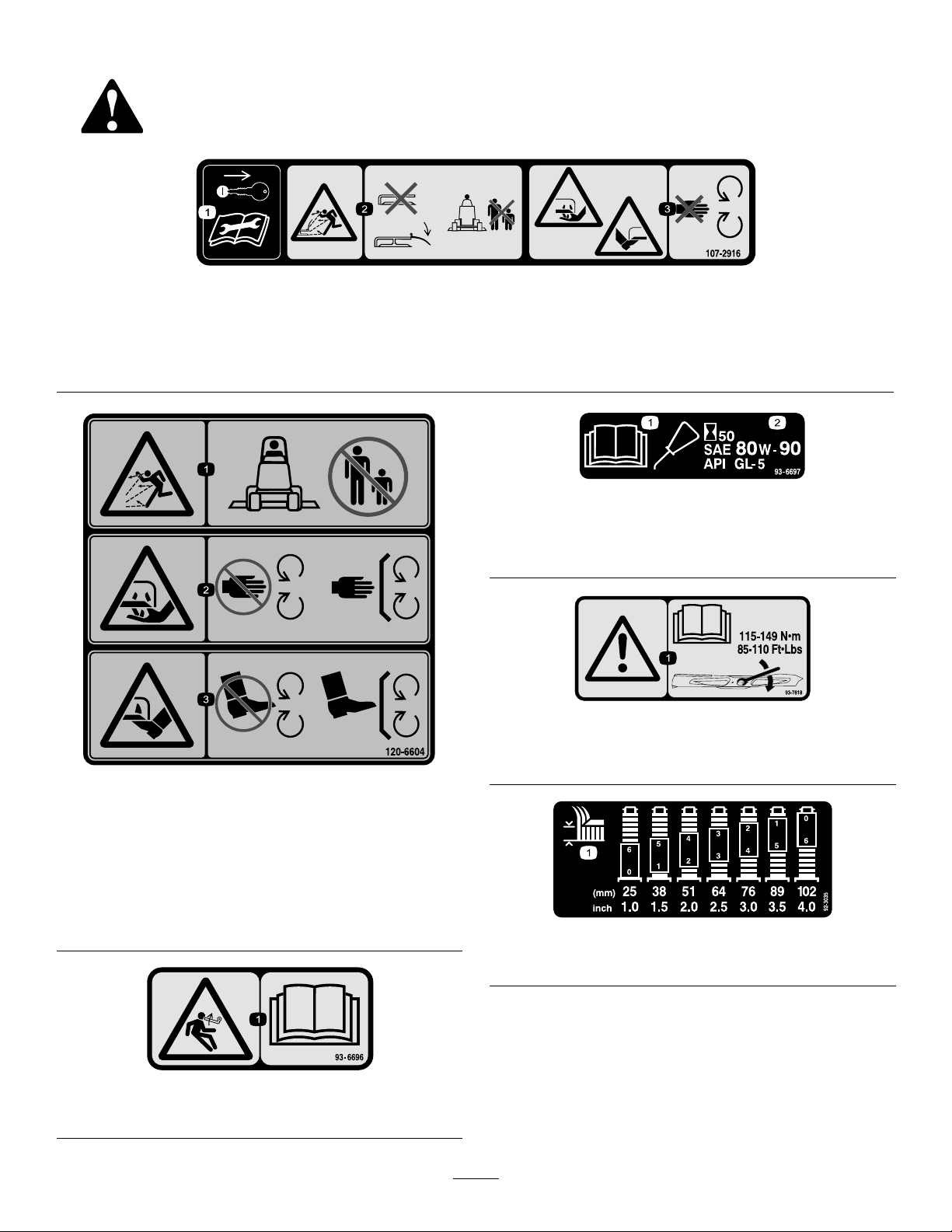

SafetyandInstructionalDecals.

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

107-2916

1.Removetheignitionkeyandreadthe

Operator'sManualbeforeservicingor

performingmaintenance.

120-6604

2.Thrownobjecthazard—donotoperate

themowerwiththedeectorupor

removed,keepthedeectorinplace;

keepbystandersasafedistancefrom

themachine.

1.ReadtheOperator's

1.Warning—readtheOperator'sManualforinstructionson

3.Cutting/dismembermenthazardof

handorfoot,mowerblade—stayaway

frommovingparts.

93-6697

Manual.

2.Checktheoilevery50

hours.AddSAE80w-90

(APIGL-5)oilifneeded.

93-7818

torquingthebladebolt/nutto115-149N-m(85-110ft-lb).

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Cutting/dismembermenthazardofhand,mower

blade—stayawayfrommovingparts,keepallguardsand

shieldsinplace.

3.Cutting/dismembermenthazardoffoot,mowerblade—stay

awayfrommovingparts,keepallguardsandshieldsin

place.

93-6696

1.Storedenergyhazard—readtheOperator'sManual.

92–3035

1.Height-of-cut

7

Page 8

99–5172

117–4979

1.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

107-2915

1.Entanglementhazard,shaft-keepbystandersasafe

distancefromthemachine.

107-2926

1.Cutting/dismembermenthazard,impeller—stayawayfrom

movingparts.

2.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

105–9553

1.Warning—readtheOperator'sManual.

2.Tippinghazard—lowerthecuttingunitwhendrivingdown

slopes.For2wheeldriveunits,adda25kg(55lb.)rear

weighttoGM228Dunitsanda48kg(105lb.)rearweight

toGM225units.For4wheeldriveunits,donotaddweight.

107-2908

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard—donotoperatethemowerwiththe

deectoruporremoved,keepthedeectorinplace.

3.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

93–7301

1.Warning-readtheOperator'sManual.

2.Thrownobjecthazard-stayawayfrommovingparts;keep

allguardsandshieldsinplace.

8

Page 9

Setup

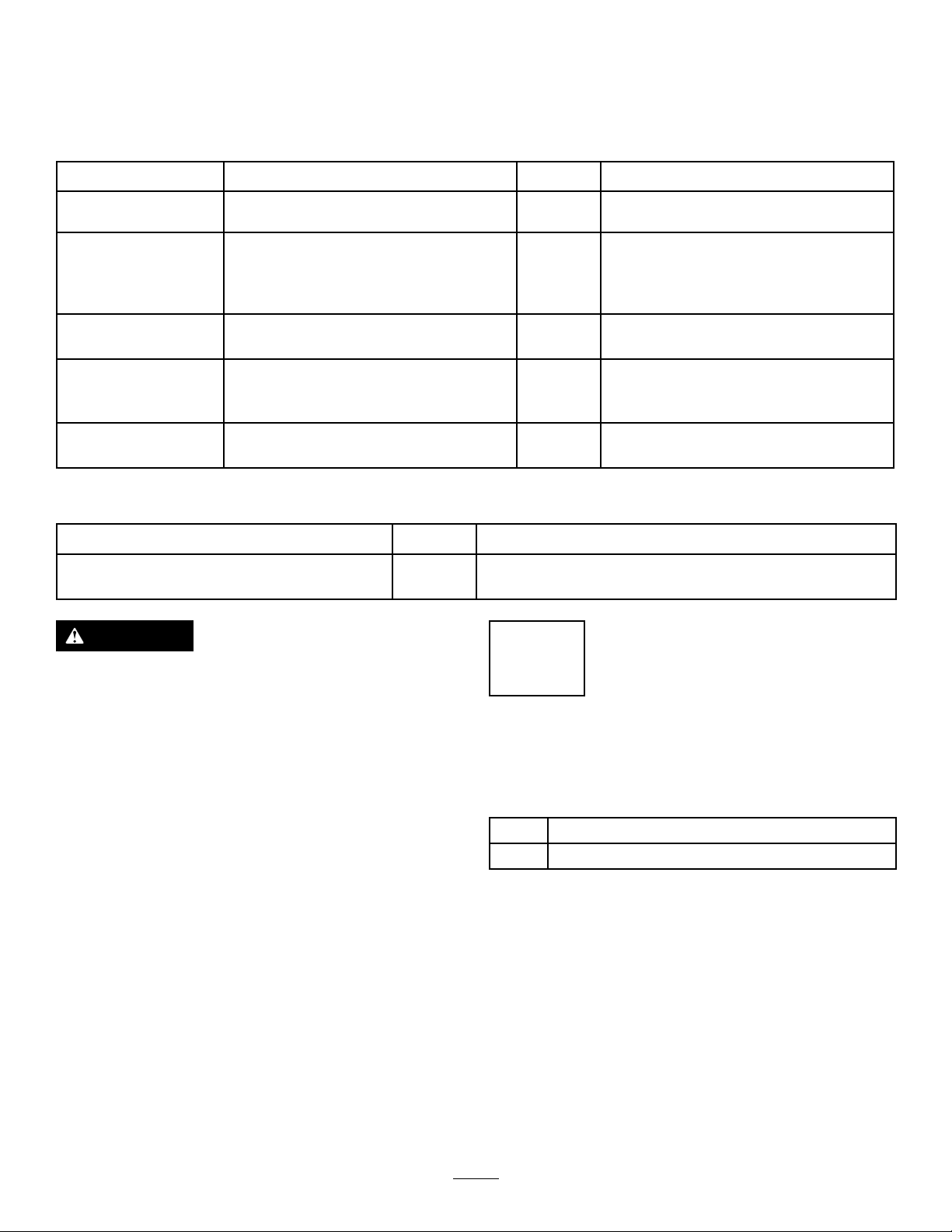

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

MediaandAdditionalParts

Description

PartsCatalog

Operator'sManual

Frontcastorwheelassembly2

Rearcastorwheelassembly2

Right-handliftarm

Left-handliftarm

Pivotpin2

Cotterpin(5/32x1-3/4inches)

Nopartsrequired

Nopartsrequired

Nopartsrequired

Qty.

1

1

Reviewthematerialandsaveinanappropriateplace:

Qty.

Use

Installthecastorwheelassemblies.

1

1

2

–

–

–

Installtheliftarms.

Connecttheliftarmstothecuttingunit.

MountthePTOshaftguardandconnect

thePTOshafttothecuttingunitgear

box.

Installtherearweight.

Use

DANGER

IftheengineisstartedandthePTOshaftisallowed

torotate,seriousinjurycouldresult.

DonotstarttheengineandengagethePTOlever

whenthePTOshaftisnotconnectedtothegear

boxonthecuttingunit.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Note:Wheninstallingthe62inchdeckontoa

Groundsmaster200Seriestractionunit,theWeightTransfer

Kit,T oroPartNumber70-8100mustbeinstalled.

1

InstallingtheCastorWheel Assemblies

Partsneededforthisprocedure:

2Frontcastorwheelassembly

2Rearcastorwheelassembly

Procedure

Thethrustwashers,spacers,andtensioningcapshavebeen

installedonthecastorwheelspindlesforshipping.

1.Removethetensioningcapsfromthespindleshafts

andslideoffthespacersandthrustwashers(Figure

2andFigure3).

9

Page 10

Figure2

FrontCastorWheelAssembly

1.Tensioningcap

2.Thrustwashers4.Frontcastorspindle

3.Spacers

3.Slideathrustwasherontothespindle,pushtheround

castorspindlethroughthefrontcastorarm,andthe

hexcastorspindlethroughtherearcastorarm.

4.Installanotherthrustwasherandtheremainingspacers

ontothespindleandinstallthetensioningcaptosecure

theassembly.

Important:Thethrustwashers,notthespacers,

mustcontactthetopandbottomofthecastorarm.

5.Ensurethatallfourcastorwheelsaresetatthesame

height-of-cutandrollthecuttingunitoffofthepallet.

2

InstallingtheLiftArms

Partsneededforthisprocedure:

1

Right-handliftarm

1

Left-handliftarm

2Pivotpin

2

Cotterpin(5/32x1-3/4inches)

Procedure

1.Ononesideofthetractionunit,loosen(donot

remove)thewheelnutsthatsecurethewheelandtire

assemblytothefrontwheelstuds.

2.Jackupthemachineuntilthefrontwheelisoffthe

oor.

Figure3

RearCastorWheelAssembly

1.Tensioningcap

2.Thrustwashers4.Rearcastorspindle

2.Slidethespacersontothecastorspindletogetthe

desiredheight-of-cut;refertothechartinAdjusting

theHeight-of-CutintheOperationsection.

3.Spacers

Note:Usejackstandsorblockthemachinetoprevent

itfromaccidentallyfalling.

3.Removethewheelnutsandslidethewheelandtire

assemblyoffthestuds.

4.Mountaliftarm(withtheballjointendpositioned

outward)tothepivotbracketwithapivotpinanda

cotterpin(5/32x1-3/4inches)(Figure4).

Figure4

1.Pivotpin

2.Liftarm

3.Liftarmpivotbracket

4.Brakereturnspring

10

Page 11

5.Mounttherearoftheliftarmtotheliftcylinderwitha

pivotpinand2cotterpins(suppliedwiththetraction

unit).

6.Hookthebrakereturnspringtotheholeinthelift

arm(Figure4).

7.Repeattheprocedureontheoppositesideofthe

machine.

3

ConnectingtheLiftArmsto theCuttingUnit

4.Securetheballjointmountstoeachcastorarmwith

2capscrews(7/16x3inches)andangenuts(7/16

inches)(Figure6).

NoPartsRequired

Procedure

1.Movethecuttingunitintopositioninfrontofthe

tractionunit.

2.Measurethedistancefromtheendofeachliftarmto

thecenteroftheballjoint(greasetting).Thedistance

shouldbe2-1/4inches(57mm)(Figure5).

Note:Ifthedistanceisnot2-1/4inches(57mm),

loosenthejamnutthatsecurestheballjointtothelift

armandrotatetheballjointinoroutuntilthedistance

isattained.Donottightenthejamnutsatthistime.

Figure6

1.Castorarm4.Capscrew

2.Balljointmount5.Flangenut

3.Balljoint

Note:Theballjointmountshouldbeabovethecastor

armwhenitisassembled.

5.Tightenthelargejamnutthatsecurestheballjointto

theliftarm(Figure6).

Note:Whentighteningthejamnut,holdtheballjoint

straighttopermitproperoscillationduringraisingand

loweringofthecuttingunit.

4

MountingthePTOShaftGuard andConnectingthePTOShaft totheCuttingUnitGearBox

Figure5

1.Liftarm

2.Balljoint

3.MovetheliftlevertotheFloatposition.Pushthelift

armsdownuntiltheholesintheballjointmounts

lineupwiththeholesinthecastorarms.

Note:OntheGroundsmaster3280–Dand3320the

enginemustberunningtolowertheliftarms.

3.Jamnut

4.2–1/4inch(57mm)

NoPartsRequired

Procedure

1.Removethe2capscrewsandlockwashersthatsecure

thePTOguardmountingbracketstothegearbox

(Figure7).

11

Page 12

Figure7

1.PTOguard2.Gearbox

Note:Retainthefastenersforfutureinstallation.

2.SlidethePTOshaftguardontothePTOshaft,

positioningtheguardasshowninFigure7.

3.SlidethemalePTOshaftintothefemalePTOshaft.

Note:Alignthemountingholesinthegearcaseinput

shaftwiththeholesinthePTOshaftandslidethem

together.

4.Securethemwitharollpin.

TwoWheelDriveGroundsmaster3280-Dand

Groundsmaster3320tractionunitswithserialnumbers

260000101andupdonotneedadditionalrearweightto

complywithCENstandardEN836:1997,ISOstandard

5395:1990andtheANSIB71.4-2012Standard.

FourWheelDriveGroundsmaster3280-Dtractionunits

donotneedadditionalrearweighttocomplywithCEN

standardEN836:1997,ISOstandard5395:1990andthe

ANSIB71.4-2012Standard.

5.Tightenthecapscrewsandnuts.

6.AttachthePTOshaftguardtothegearboxwiththe2

capscrewsandlockwasherspreviouslyremoved.

5

InstallingtheRearWeight

NoPartsRequired

Procedure

TwoWheelDriveGroundsmaster1000and200Series

tractionunitscomplywithCENstandardEN836:1997,ISO

standard5395:1990andtheANSIB71.4-2012Standardwhen

equippedwithrearweight.Refertothechartinthetraction

unitOperator’sManualtodeterminethecombinationsof

weightrequired.OrderthepartsfromyourlocalAuthorized

ToroDistributor.

FourWheelDriveGroundsmaster200Seriestractionunits

donotneedadditionalrearweighttocomplywithCEN

standardEN836:1997,ISOstandard5395:1990andthe

ANSIB71.4-2012Standard.

TwoWheelDriveGroundsmaster3280-Dand

Groundsmaster3320tractionunitswithserialnumbers

250000101through259999999complywithCEN

standardEN836:1997,ISOstandard5395:1990andthe

ANSIB71.4-2012Standardwhenequippedwiththerear

weightkit,partnumber24-5780.

12

Page 13

ProductOverview

Operation

Specications.

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Width

ofCut

Height

ofCut

Blade

Tip

Speed

Cutting

Blades

Castor

Wheels

Drive

System

Net

Weight

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .T oro.comforalistofallapproved

attachmentsandaccessories.

1.56m(61-5/8inches)

Adjustablefrom25to102mm(1to4inches)in13

mm(1/2inch)increments

15,480ft/minute@3250engineRPM

3heat-treatedsteelblades,each4.8mm(3/16inch)

thickand55cm(24-3/4inches)long

203mm(8inch)diametergreaseablerollerbearings

(inatedto241-345kPa[35-50psi])

PTOdrivengearboxtransmitspowerthrougha"AA"

sectionbelttoallbladespindles.

244kg(539lb)

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

AdjustingtheHeight-of-Cut

Theheight-of-cutisadjustablefrom25to102mm(1to

4inches)in13mm(1/2inch)increments,byaddingor

removinganequalnumberofspacersonthefrontand

rearcastorforks.Theheight-of-cutchartbelowgivesthe

combinationsofspacerstouseforallheight-of-cutsettings.

Setting

25mm(1inch)

38mm(1-1/2

inches)

51mm(2inches)

64mm(2-1/2

inches)

76mm(3inches)

89mm(3-1/2

inches)

102mm(4inches)

1.Starttheengineandraisethecuttingunitsothatthe

height-of-cutcanbechanged.

2.Stoptheengineafterthecuttingunitisraised.

SpacersBelowCastorArm Height-of-Cut

FrontRear

00

11

22

33

44

55

66

AdjustingtheFrontCastorWheels

1.Removethetensioningcapfromthespindleshaftand

slidethespindleoutofthefrontcastorarm(Figure8).

Figure8

1.Frontcastorwheel

2.Tensioningcap4.Thrustwashers

3.Spacers

13

Page 14

2.Removethewasherfromthespindleshaft.

3.Slidethespacersontothespindleshafttogetthe

desiredheight-of-cut,thenslidethewasherontothe

shaft.

4.Pushthecastorspindlethroughthefrontcastorarm.

5.Installtheotherthrustwasherandremainingspacers

ontothespindle.

6.Installthetensioningcaptosecuretheassembly.

AdjustingtheRearCastorWheels

1.Removethetensioningcapsecuringthegagewheelto

thecuttingunitbrackets(Figure9).

AdjustingtheRollersand GageWheel

Note:Ifthecuttingunitistobeusedinthe25mm(1inch)

or38mm(1-1/2inches)height-of-cutsetting,thecutting

unitrollersmustberepositionedinthetopbracketholes.

AdjustingtheFrontRoller

1.Removethecapscrewandnutsecuringtherollershaft

tothecuttingunitbracket(Figure10).

Figure9

1.Rearcastorwheel

2.Tensioningcap4.Thrustwashers

2.Removeoradd”C”shapedspacersatthenarrow

portionofthespindleshaft,belowthecastorarm,to

getthedesiredheight-of-cut.

Note:Ensurethatthethrustwashers,notthespacers,

contactthetopandbottomofthecastorarm.

3.Installthetensioningcaptosecuretheassembly.

Note:Ensurethatallfourcastorwheelsaresetatthe

sameheight-of-cut.

3.Spacers

Figure10

1.Externalroller

2.Slidetheshaftoutofthelowerbracketholes,alignthe

rollerwiththetopholes,andinstalltheshaft.

3.Securetherollershafttothecuttingunitbracketwith

thecapscrewandnut.

2.Rollershaft

AdjustingtheFrontGageWheel

1.Removethecapscrewandnutsecuringthegagewheel

tothecuttingunitbrackets(Figure11).

Figure11

1.Gagewheel

2.Aligntherollerandspacerwiththetopholesinthe

bracketsandsecurethemwiththecapscrewandnut.

14

Page 15

AdjustingtheRear(Internal)Rollers

1.Removethecotterpinssecuringtherollershaftstothe

bracketsontheundersideofthedeck(Figure12).

GreasingtheCuttingUnit

Beforethecuttingunitisoperated,itmustbegreasedto

ensureproperlubricatingcharacteristics;refertoLubrication

SectionofManual.Failuretoproperlygreasethecuttingunit

willresultinprematurefailureofcriticalparts.

AdjustingtheWeightTransfer

OnGroundsmaster3280-Dand3320modelsonly,referto

thetractionunitOperator'sManualfortheproceduretoadjust

thecounterbalancepressureforbestperformance.

UsingtheGrassDeector

Figure12

1.Internalrollers

2.Slidetheshaftsoutofthelowerbracketholes,alignthe

rollerswiththetopholes,andinstalltheshafts.

3.Installthecotterpinstosecuretheassemblies.

CheckingtheGearBox Lubricant

ThegearboxisdesignedtooperateonSAE80-90wt.gear

lube.Althoughthegearboxisshippedwithlubricantfrom

thefactory,checkthelevelbeforeoperatingthecuttingunit.

1.Positionthemachineandcuttingunitonalevelsurface.

2.Removethedipstick/llplugfromthetopofthegear

box(Figure13)andensurethatthelubricantisbetween

themarksonthedipstick.Ifthelubricantlevelislow ,

addenoughlubricantuntilthelevelisbetweenthe

marks.

DANGER

Withoutthegrassdeectormountedinplace,you

andothersareexposedtobladecontactandthrown

debris.Contactwiththerotatingmowerblade(s)

andthrowndebriswillcauseinjuryordeath.

•Neverremovethegrassdeectorfromthemower

becausethegrassdeectorroutesmaterialdown

towardtheturf.Ifthegrassdeectorisever

damaged,replaceitimmediately .

•Neverputyourhandsorfeetunderthemower.

•Neveroperatethemowerwiththedeector

removedfromthecuttingunitortied/blocked

inaraisedposition.

Note:Thedeectorisspringloadedintoitsdownward

normaloperatingposition(Figure14),buttheoperatorcan

temporarilyswingitoutofthewaytofacilitateloadingina

trailerorwhenotherwisenecessary.

1.Dipstick/llplug

Figure13

Figure14

1.Grassdeector2.Springhinges

15

Page 16

Maintenance

Lubrication

Thecuttingunitmustbelubricatedregularly.Ifthemachine

isoperatedundernormalconditions,lubricatethecastor

bearingsandbushingswithNo.2generalpurposelithium

basegreaseormolybdenumbasegreaseafterevery8hoursof

operationordaily,whichevercomesrst.Allotherbearings,

bushings,andthegearboxmustbelubricatedafterevery50

hoursofoperation.

1.Lubricatethefollowingareas:

•Bladespindlebearings(Figure17)

Figure17

•Frontcastorspindlebushings(Figure15)

•Frontandrearcastorwheelbearings(Figure15)

Figure15

•Rightandleftliftarmpivotpins(Figure16)

•Rightandleftpusharmballjoints(Figure17)

2.Positionthemachineandcuttingunitonalevelsurface

andlowerthecuttingunit.

3.Removethedipstick/llplugfromthetopofthegear

box(Figure18)andensurethatthelubricantisbetween

themarksonthedipstick.

Note:Ifthelubricantlevelislow,addSAE80-90wt.

gearlubeuntilthelevelisbetweenthemarks.

AlternativeSyntheticOil:MobilubeSHC75W -90

Figure16

Figure18

1.Fill/checkplug

SeparatingtheCuttingUnit fromtheTractionUnit

1.Positionthemachineonalevelsurface.

2.Raisethecuttingunit,engagetheparkingbrake,put

thetractionpedalinneutral,setthePTOleverinthe

Offposition,shuttheengineoff,andremovethe

ignitionkey .

3.Positionthemachineonalevelsurface,lowerthe

cuttingunittotheoor,movetheliftlevertotheoat

position,shuttheengineoff,andengagetheparking

brake.

16

Page 17

4.Removethecapscrewsandlocknutssecuringtheball

jointmountstothecastorarmsonthecuttingunit

(Figure19).

Figure19

1.Castorarm

5.Rollthecuttingunitawayfromthetractionunit,

separatingthemaleandfemalesectionsofthePTO

shaft(Figure20).

2.Balljointmount

DANGER

IftheengineisstartedandthePTOshaftis

allowedtorotate,seriousinjurycouldresult.

DonotstarttheengineandengagethePTO

leverwhenthePTOshaftisnotconnectedto

thegearboxonthecuttingunit.

4.MovetheliftlevertotheFloatposition.Pushthelift

armsdownuntiltheholesintheballjointmounts

lineupwiththeholesinthecastorarms(Figure19).

5.Securetheballjointmountstothecastorarmswiththe

capscrewsandangenuts.

ServicingtheBushingsinthe CastorArms

Thecastorarmshavebushingspressedintothetopand

bottomportionofthetubewhich,aftermanyhoursof

operation,willwear.Tocheckthebushings,movethecastor

forkbackandforthandfromsidetoside.Ifthecastorshaft

islooseinsidethebushings,thebushingsarewornandmust

bereplaced.

1.Raisethecuttingunitsothatthewheelsareoffthe

oorandblockitsothatitcannotaccidentallyfall.

2.Removethetensioningcap,spacer(s),andthrust

washerfromthetopofthecastorspindle.

3.Pullthecastorspindleoutofthemountingtube.

Allowthethrustwasherandspacer(s)toremainon

thebottomofthespindle.

4.Insertapinpunchintothetoporbottomofthe

mountingtube,anddrivethebushingoutofthetube

(Figure21).Also,drivetheotherbushingoutofthe

tube.

Figure20

1.PTOshaft

MountingtheCuttingUnitto theTractionUnit

1.Positionthemachineonalevelsurfaceandshutthe

engineoff.

2.Movethecuttingunitintopositioninfrontofthe

tractionunit.

3.SlidethemalePTOshaftintothefemalePTOshaft

(Figure20).

Figure21

1.Frontcastorarmtube2.Bushings

5.Cleantheinsideofthemountingtubestoremoveany

dirt.

6.Applygreasetotheinsideandoutsideofthenew

bushings.

7.Useahammerandatplatetodrivethebushingsinto

themountingtube.

8.Inspectthecastorspindleforwear,andreplaceitifit

isdamaged.

9.Pushthecastorshaftthroughthebushingsand

mountingtube.

10.Slidethethrustwasherandspacer(s)ontothespindle.

11.Installthetensioningcaponthecastorspindletoretain

allofthepartsinplace.

17

Page 18

ServicingtheCastorWheels

G010549

andBearings

9.Pushtheotherbushingintotheopenendofthewheel

hubtocaptivatethebearinginsidethewheelhub

(Figure22).

Thecastorwheelrotatesonahigh-qualityrollerbearingand

issupportedbyaspannerbushing.Evenaftermanyhours

ofuse,providedthatthebearingwaskeptwelllubricated,

bearingwearwillbeminimal.However,failingtokeepthe

bearinglubricatedwillcauserapidwear.Awobblycastor

wheelusuallyindicatesawornbearing.

1.Removethelocknutfromthecapscrewholdingthe

castorwheelassemblybetweenthecastorfork(Figure

22).

10.Carefullyslidethespannerthroughthebushingsand

thewheelhub.

11.Installthecastorwheelassemblybetweenthecastor

forkandsecureitinplacewiththecapscrew,washers,

andlocknut.

12.Lubricatethecastorwheelbearingthroughthegrease

tting,usingNo.2generalpurposelithiumbasegrease.

CheckingforaBentBlade

1.Positionthemachineonalevelsurface.

2.Raisethecuttingunit,engagetheparkingbrake,put

thetractionpedalinneutral,thePTOleverintheOff

position,shuttheengineoff,andremovetheignition

key.

3.Blockthecuttingunittopreventitfromaccidentally

falling.

4.Rotatethebladeuntiltheendsfaceforwardand

backward.Measurefromtheinsideofthecuttingunit

tothecuttingedgeatthefrontoftheblade(Figure23),

andrememberthisdimension.

Figure22

1.Castorwheel4.Spannerbushing

2.Capscrewandlocknut

3.Bushing(2)6.Washer(2)

2.Graspthecastorwheelandslidethecapscrewoutof

thefork.

3.Pullthespannerbushingoutofthewheelhub(Figure

22).

4.Removethebushingfromthewheelhubandallow

thebearingtofallout.

5.Removethebushingfromtheoppositesideofthe

wheelhub.

6.Checkthebearing,spanner,andinsideofthewheel

hubforwear,andreplaceanydamagedparts.

7.Toassemblethecastorwheel,pushthebushinginto

thewheelhub.

5.Rollerbearing

Figure23

5.Rotatetheoppositeendofthebladeforward.

6.Measurebetweenthecuttingunitandcuttingedgeof

thebladeatthesamepositionasinstep4

Note:Thedifferencebetweenthedimensions

obtainedinsteps4and5mustnotexceed3mm(1/8

inch).Ifthedimensionexceeds3mm(1/8inch),

replacethebladebecauseitisbent;refertoRemoving

theCuttingBlade.

RemovingtheCuttingBlade

Theblademustbereplacedifasolidobjectishit,the

bladeisout-of-balance,worn,orbent.Alwaysusegenuine

Tororeplacementbladestoensuresafetyandoptimum

performance.Neverusebladesmadebyothermanufacturers

becausetheycouldbedangerous.

8.Slidethebearingintothewheelhub.

18

Page 19

DANGER

G010555

1

2

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Donottrytostraightenabladethatisbent.

•Neverweldabrokenorcrackedblade.

•Replaceawornordamagedbladewitha

newTorobladetoensurecontinuedsafety

certicationoftheproduct.

1.Positionthemachineonalevelsurface.

2.Raisethecuttingunit,engagetheparkingbrake,put

thetractionpedalinneutralandthePTOleverinthe

Offposition,shuttheengineoff,andremovethe

ignitionkey .

3.Blockthecuttingunittopreventitfromaccidentally

falling.

4.Grasptheendofthebladeusingaragorthickly

paddedglove.Removethebladebolt,anti-scalpcup,

andbladefromthespindleshaft(Figure24).

producinganevencut.However,thesailwillgraduallywear

downduringoperation,andthisconditionisnormal.Asthe

sailwearsdown,thequality-of-cutwilldegradesomewhat,

althoughthecuttingedgesaresharp.Thecuttingedgeof

theblademustbesharpsothatthegrassiscutratherthan

torn.Adullcuttingedgeisevidentwhenthetipsofthegrass

appearbrownandshredded.Sharpenthecuttingedgesto

correctthiscondition.

1.Positionthemachineonalevelsurface.

2.Raisethecuttingunit,engagetheparkingbrake,put

thetractionpedalinneutralandthePTOleverinthe

Offposition,shuttheengineoff,andremovethe

ignitionkey .

3.Blockthecuttingunittopreventitfromaccidentally

falling.

4.Examinethecuttingendsofthebladecarefully,

especiallywheretheatandcurvedpartsoftheblade

meet(Figure25).

Note:Sincesandandabrasivematerialcanwearaway

themetalthatconnectstheatandcurvedpartsofthe

blade,checkthebladebeforeusingthemachine.If

younoticewear(Figure25),replacetheblade;referto

RemovingtheCuttingBlade.

Figure24

1.Bladebolt2.Anti-scalpcup

5.Installtheblade(withthesailfacingtowardthecutting

unit),theanti-scalpcup,andthebladebolt.

Note:Tightenthebladeboltto115-149N-m(85-110

ft-lb).

InspectingandSharpeningthe Blade

Twoareasmustbeconsideredwhencheckingandservicing

thecuttingblade:thesailandthecuttingedge.Bothcutting

edgesandthesail,whichistheturnedupportionopposite

thecuttingedge,contributetoagoodquality-of-cut.The

sailisimportantbecauseitpullsgrassupstraight,thereby

Figure25

1.Cuttingedge3.Wear/slotforming

2.Curvedarea/sail4.Crack

WARNING

Ifthebladeisallowedtowear,aslotwillform

betweenthesailandatpartoftheblade

(Figure25).Eventually,apieceoftheblade

maybreakoffandbethrownfromunderthe

housing,possiblyresultinginseriousinjuryto

yourselforbystanders.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedbladewitha

newT orobladetoensurecontinuedsafety

certicationoftheproduct.

5.Examinethecuttingedgesofallblades,andsharpen

thecuttingedgesiftheyaredullornicked.

19

Page 20

Note:Sharpenonlythetopsideofthecuttingedge

G010556

A

B

C

A

B

C

A

B

C

G010557

1

andmaintaintheoriginalcuttingangletoensure

sharpness(Figure26).Thebladewillremainbalanced

ifthesameamountofmetalisremovedfromboth

cuttingedges.

Figure26

1.Sharpenatoriginalangle

Figure27

Note:Removethebladesandsharpenthemona

grinder;refertoRemovingtheCuttingBlades.

6.Installtheblade,theanti-scalpcup,andthebladebolt.

Note:Thebladesailsmustbeontopoftheblade.

Note:Tightenthebladeboltto115-149N-m(85-110

ft-lb).

CheckingandCorrecting MismatchofBlades

Ifonecuttingbladecutslowerthantheothers,correctthem

asfollows:

1.Lowerthecuttingunitontoalevelsurface,engagethe

parkingbrake,putthetractionpedalinneutralandthe

PTOleverintheOffposition,shuttheengineoff,and

removetheignitionkey.

2.Ensurethatthetirepressureisequalonalltires.

3.Raisetheheight-of-cuttothe102mm(4inches)

position;refertoAdjustingtheHeight-of-Cut.

4.Rotatethebladessothatthetipslineupwithone

another.

Note:Thetipsoftheadjacentbladesmustbewithin3

mm(1/8inch)ofeachother.Ifthetipsarenotwithin

3mm(1/8inch)ofeachother,proceedtostep10and

addshimsbetweenthespindlehousingandbottom

ofthecuttingunit.

5.Ensurethatthefrontheight-of-cutpinsareresting

properlyontheframecushions.Ifthepinsarenot

restingproperly,placeashimorshimsunderthe

cushiontoraiseitforproperalignment.

6.Positionall3bladesintheAposition(Figure27),

andmeasurefromthelevelsurfacetothebottomof

thetipendofeachblade(Figure28),andnotethe

measurement.

Figure28

1.Measurefromthebladetiptoalevelsurface.

7.RotatethebladestotheBposition(Figure27),measure

thedistanceofallofthebladestothelevelsurface,and

notethedimensions(Figure28).

8.RotatethebladestotheCposition,measure,andnote

thedistancemeasured(Figure27andFigure28).

9.Comparethemeasurementsatthevariouspositions.

Note:Alldimensionsmustbeequalwithin6mm

(1/4inch)fromany2adjacentblades.Thedifference

betweenthedimensionsofall3bladesmustnot

exceed10mm(3/8inch).Ifthedifferenceexceeds

specications,proceedtostep10.

10.Removethecapscrews,atwashers,andlocknutsfrom

theouterspindleintheareawheretheshimsmustbe

added.

Note:Toraiseorlowertheblade,addashim,Part

No.3256-24,betweenthespindlehousingandbottom

ofthecuttingunit.

11.Continuecheckingthealignmentofthebladesand

addingshimsuntilthetipsofthebladesarewithinthe

requireddimension.

ReplacingtheGrassDeector

1.Positionthemachineonalevelsurface.

2.Raisethecuttingunit,engagetheparkingbrake,put

thetractionpedalinneutralandthePTOleverinthe

Offposition,shuttheengineoff,andremovethe

ignitionkey .

3.Blockthecuttingunittopreventitfromaccidentally

falling.

4.Removethe2capscrews,locknuts,andspringsthat

securethedeectormountstothepivotbrackets

(Figure29).

20

Page 21

Figure29

1.Bolt3.Pivotbrackets

2.Locknuts

5.Toremovethepivotbrackets,removethecarriage

boltsandnuts(Figure29).

6.Installthepivotbracketsontopofthedischarge

openingwiththecarriageboltsandnuts.

Note:Theheadofthecarriageboltsmustbeonthe

insideofthecuttingunit.

4.Spring

position,shuttheengineoff,andremovetheignition

key.

3.Removethecoverfromthecentercuttingunit.

4.Loosenthe2nutsthatsecuretheidlerplateinplace.

5.Useasocketandtorquewrenchtotightentheidler

adjustingnutto47to54N-m(35to40ft-lb)(Figure

30).

Figure30

1.Idlerplate3.Idleradjustingnut

2.Nuts(2)

7.Positionthedeectormountsonthepivotbrackets

andsecurethepartstogetherwiththecapscrews,

locknuts,andsprings.

Note:Bothlocknutsmustfaceeachother.Tightenthe

locknutsuntiltheyareushagainstthedeectorpivots.

8.Liftthedeectorandallowittodroptocheckthe

springtension.

Note:Thedeectormustbeheldrmlyinthefull

downwardpositionbythespringtension.Correctit

ifnecessary.

AdjustingtheIdlerPulley

Theidlerpulleyappliesforceagainstthebeltsothatpower

canbetransmittedtothebladepulleys.Iftheidlerisnot

tensionedagainstthebeltwithsufcientforce,maximum

powerwillnotbetransmittedtothepulleys.Tensiononthe

beltrequires47to54N-m(35to40ft-lb)oftorqueonthe

largenut,whichappliesforceagainstthebelt.Iftheidleris

notadjustedtothesespecications,adjustit.

Important:Thefastenersonthecoversofthismachine

aredesignedtoremainonthecoverafterremoval.

Loosenallofthefastenersoneachcoverafewturnsso

thatthecoverisloosebutstillattached,thengoback

andloosenthemuntilthecovercomesfree.Thiswill

preventyoufromaccidentallystrippingtheboltsfree

oftheretainers.

1.Positionthemachineonalevelsurface.

6.Holdthetorqueagainstthebeltandtightenthe2nuts

sothattheidlerplateisheldsecurelyinplace.

7.Releasetheidleradjustingnut.

8.Installthecover.

ReplacingtheDriveBelt

Thebladedrivebelt,tensionedbytheadjustableidler,isvery

durable.However,aftermanyhoursofuse,thebeltwillshow

signsofwear.Signsofawornbeltare:squealingwhenbelt

isrotating,bladesslippingwhencuttinggrass,frayededges,

burnmarks,andcracks.Replacethebeltifanyofthese

conditionsareevident.

Important:Thefastenersonthecoversofthismachine

aredesignedtoremainonthecoverafterremoval.

Loosenallofthefastenersoneachcoverafewturnsso

thatthecoverisloosebutstillattached,thengoback

andloosenthemuntilthecovercomesfree.Thiswill

preventyoufromaccidentallystrippingtheboltsfree

oftheretainers.

1.Positionthemachineonalevelsurface.

2.Lowerthecuttingunit,engagetheparkingbrake,put

thetractionpedalinneutralandthePTOleverinthe

Offposition,shuttheengineoff,andremovethe

ignitionkey .

3.Removethecoversfromthetopofthecuttingunit.

2.Lowerthecuttingunit,engagetheparkingbrake,put

thetractionpedalinneutral,thePTOleverintheOff

4.Loosenthe2nutsthatsecuretheidlerplateinplace,

andremovetheoldbeltfromthepulleys.

21

Page 22

5.Toinstallanewbelt,youmustremovethegearboxby

G010560

1

2

removingthe4carriageboltsandlocknutsholdingthe

gearboxbase.

6.Installthenewbeltaroundthegearboxpulley,spindle

pulleys,stationaryidlerpulley,andadjustableidler

pulley(Figure31).

Figure31

1.Adjustableidlerpulley

2.Gearboxpulley

7.Installthegearboxbasewiththecarriageboltsand

locknuts.

8.Useatorquewrenchtoadjustthetensionoftheidler

pulleyagainstthebelt;refertoAdjustingtheIdler

Pulley.

9.Installthecovers.

22

Page 23

Troubleshooting

Problem

Thecuttingunitwillnotcutorcutspoorly.

PossibleCauseCorrectiveAction

1.Thebladesaredull.

2.Oneormorebladesarebentor

damaged.

3.Thespindleboltsareloose.3.Torquethespindleboltsto115to149

4.Thecuttingunitbeltsarelooseor

broken.

5.Thegearboxpulleyisloose.5.Tightenorreplacethepulley.

6.Agearboxshaftisbroken.6.Replaceanybrokenshafts.

7.ThePTObeltisbroken.7.ReplacethePTObelt.

8.ThePTOpulleyislooseorbroken.

9.ThePTOshaftisbroken.9.ReplacethePTOshaft.

10.Thepulleyontheengineoutputshaft

islooseorbroken.

1.Sharpentheblades.

2.Replacetheblades.

N-m(85to110ft-lb).

4.Tightenorreplacethebeltsas

necessary.

8.Tightenorreplacethepulley.

10.Tightenorreplacethepulley.

23

Page 24

Notes:

24

Page 25

Notes:

25

Page 26

Notes:

26

Page 27

DeclarationofIncorporation

TheT oroCompany,8111LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

30551314000001andUp

SerialNo.

ProductDescriptionInvoiceDescription

62inSideDischargeMower

GeneralDescription

62”SIDEDISCHARGE

MOWER

62inSideDischargeMower

Directive

2006/42/EC,

2000/14/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:EUTechnicalContact:

PeterT etteroo

ToroEuropeNV

B-2260Oevel-Westerloo

Belgium

DavidKlisTel.003214562960

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

September26,2013

Fax003214581911

27

Page 28

TheToroTotalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EPA)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevB

Loading...

Loading...