Page 1

62inBlowerKit

Groundsmaster

ModelNo.30506—SerialNo.315000001andUp

®

200/3280-D/3320SeriesSideDischargeMowers

FormNo.3391-800RevA

Operator'sManual

Safety

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

ThisproductcomplieswithallrelevantEuropeandirectives.

Fordetails,pleaseseetheDeclarationofIncorporation(DOI)

atthebackofthispublication.

Improperlyusingormaintainingthemachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbols,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomply

withtheinstructionmayresultinpersonalinjuryor

death.

BeforeOperating

•Readandunderstandthecontentsofthismanualbefore

startingandoperatingthemachine.Becomefamiliarwith

allcontrolsandknowhowtostopquickly.

•Neverallowchildrentooperatethemachine.Donot

allowadultstooperatethemachinewithoutproper

instruction.Onlytrainedoperators,skilledinslope

operationandwhohavereadthismanualshouldoperate

thismachine.

•Neveroperatemachinewhenundertheinuenceof

drugsoralcohol.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Removealldebrisorotherobjectsthatmightbepicked

upandthrownbycutterblades.Keepallbystandersaway

fromtheoperatingarea.

•Keepallshieldsandsafetydevicesinplace.Ifashield,

safetydevice,ordecalisdefectiveordamaged,repairor

replaceitbeforeoperatingmachine.Also,tightenany

loosenuts,bolts,andscrewstoinsuremachineisinsafe

operatingcondition.

•Donotwearloosettingclothingbecauseitcouldget

caughtinmovingparts.Alwayswearlongpantsand

substantial,slip-resistantfootwear.W earingsafetyglasses,

safetyshoes,andahelmetisadvisableandrequiredby

somelocalordinancesandinsuranceregulations.

•Besureinterlockswitchesareadjustedcorrectlysothe

enginecannotbestartedunlessthetractionpedalis

inreleased-neutralposition-andPTOswitchisinthe

disengageposition.

•Fillfueltankbeforestartingtheengine.Avoidspillingany

fuel.Sincefuelisammable,handleitcarefully .

–Useanapprovedfuelcontainer.

–Donotllfueltankwhenengineishotorrunning.

–Donotsmokewhilehandlingfuel.

–Fillfueltankoutdoorsanduptoabout25mm(1

inch)fromthetopofthetank,notthellerneck.

–Wipeupanyspilledfuel.

WhileOperating

•Sitontheseatwhenstartingtheengineandoperating

themachine.

•Alwaysmakesureseatpivotretainingpinisinstalled.

•Beforestartingtheengine:

–Engageparkingbrake.

–MakesuretractionpedalisinneutralandPTOisin

disengageposition.

–Afterengineisstarted,releaseparkingbrakeandkeep

footofftractionpedal.Machinemustnotmove.If

movementisevident,theneutralreturnmechanism

isadjustedincorrectly.Shutengineoffandadjust

untilmachinedoesnotmovewhentractionpedalis

released.

•Donotruntheengineinaconnedareawithout

adequateventilation.Exhaustfumesarehazardousand

couldpossiblybedeadly .

•Maximumseatingcapacityisoneperson.Therefore,

nevercarrypassengers.

•Checkcarefullyforoverheadclearancesbeforedriving

underanyobjects.

•Thegrassdeectororcompleteblowerassemblymust

alwaysbeinstalledoncuttingunit.

•Operatormustbeskilledandtrainedinhowtodriveon

hillsides.Failuretousecautiononslopesorhillsmay

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

*3391-800*A

Page 2

causelossofcontrolandvehicletotiporroll,possibly

resultinginpersonalinjuryordeath.

•Traverseslopescarefully.Donotstartorstopsuddenly

whentraversingslopesorwhentravelinguphillor

downhill.

•Ifenginestallsormachinelosesheadwayandcannot

makeittothetopofaslope,donotturnmachinearound.

Alwaysbackslowlystraightdowntheslope.

•Usingthemachinedemandstheoperator'scomplete

attention.Topreventlossofcontrol:

–Operateonlyindaylightorwhenthereisgood

articiallight.

–Driveslowly .

–Avoidsuddenstartsandstops.

–Lookbehindmachinebeforebackingup.

–Watchforholesorotherhiddenhazards.

–Donotdriveclosetoasandtrap,ditch,creek,or

hazard.

–Reducespeedwhenmakingsharpturnsandwhen

turningonahillside.

–Thecuttingdeckmustbeloweredwhengoingdown

slopesforsteeringcontrol.

•Thegrassdeectormustalwaysbeinstalledandinlowest

positiononthecuttingunitwhenblowerassemblyis

removed.Thisproductisdesignedtodriveobjectsinto

thegroundwheretheyloseenergyquicklyingrassyareas.

However,don'ttakeaninjuryrisk!Whenapersonor

petappearsunexpectedlyinornearthemowingarea,

stopmowing.Carelessoperation,combinedwithterrain

angles,ricochets,orimproperlypositionedguards,can

leadtothrownobjectinjuries.Donotresumemowing

untilareaiscleared.

•Neverraisethecuttingunitwhilethebladesorother

partsarerotating.

•Ifcuttingbladesstrikeasolidobjectorthemachine

vibratesabnormally,disengagePTO,movethrottleto

SLOW,setparkingbrake,andshutengineoff.Remove

keyfromswitchtopreventpossibilityofaccidental

starting.Checkcuttingunit,blowerassemblyandtraction

unitfordamageanddefectiveparts.Repairanydamage

beforerestartingtheengineandoperatingthecutting

unit.Assurecuttingunitbladesareingoodconditionand

bladeboltsaretightenedtopropertorquespecications

(SeeCuttingDeckOperator'sManual).

•Ifthecuttingunitdischargeareaorblowerassembly

everplugs,disengagePTOandshutengineoffbefore

removingtheobstruction.

•Tostopmachine,removefootfromthetractionpedal.

Graduallyreversingthetractionpedalcanprovide

additionalbraking.

•Donottouchengine,mufer,oritadjacentshroudwhile

engineisrunningorsoonafterithasstopped.These

areascouldbehotenoughtocauseaburn.

•Lowerthecuttingunittothegroundandremovekey

fromswitchwhenevermachineisleftunattended.

•Beforegettingoftheseat:

–Movetractionpedaltoneutralpositionandremove

footfrompedal.

–SettheparkingbrakeanddisengagethePTO .

–Shuttheengineoffandremovekeyfromignition

switch.Waitforallmovementtostopbeforegetting

offtheseat.

Maintenance

•Removekeyfromignitionswitchtopreventaccidental

startingoftheenginewhenservicing,adjusting,orstoring

themachine.

•Ifmajorrepairsareeverneededorassistanceisdesired,

contactanAuthorizedToroDistributor.

•Toreducepotentialrehazard,keeptheenginefreeof

excessivegrease,grass,leaves,andaccumulationsofdirt.

•Makesuremachineisinsafeoperatingconditionby

keepingnuts,bolts,andscrewstight.Checkallcutting

unitblademountingboltsfrequentlytoassuretheyare

tightenedtopropertorquespecications(SeetheCutting

DeckOperator'sManual).

•Makesureallhydrauliclineconnectorsaretight,andall

hydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepbodyandhandsawayfrompinholeleaksornozzles

thatejecthydraulicuidunderhighpressure.Usepaper

orcardboard,nothands,tosearchforleaks.Hydraulic

uidescapingunderpressurecanhavesufcientforceto

penetrateskinandcauseseriousinjury.Ifuidisejected

intotheskin,itmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjuryor

gangrenemayresult.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinsystemmustberelieved

bystoppingengineandloweringimplementtothe

ground.

•Iftheenginemustberunningtoperformmaintenance

oranadjustment,keepclearofPTOshaft,cuttingunit

blades,andothermovingparts.

•Atthetimeofmanufacture,themachineconformedto

safetystandardsineffectforridingmowers.Toensure

optimumperformanceandcontinuedsafetycertication

ofthemachine,usegenuineTOROreplacementparts

andaccessories.Replacementpartsandaccessoriesmade

byothermanufacturersmayresultinnon-conformance

withthesafetystandards,andthewarrantymaybevoided.

2

Page 3

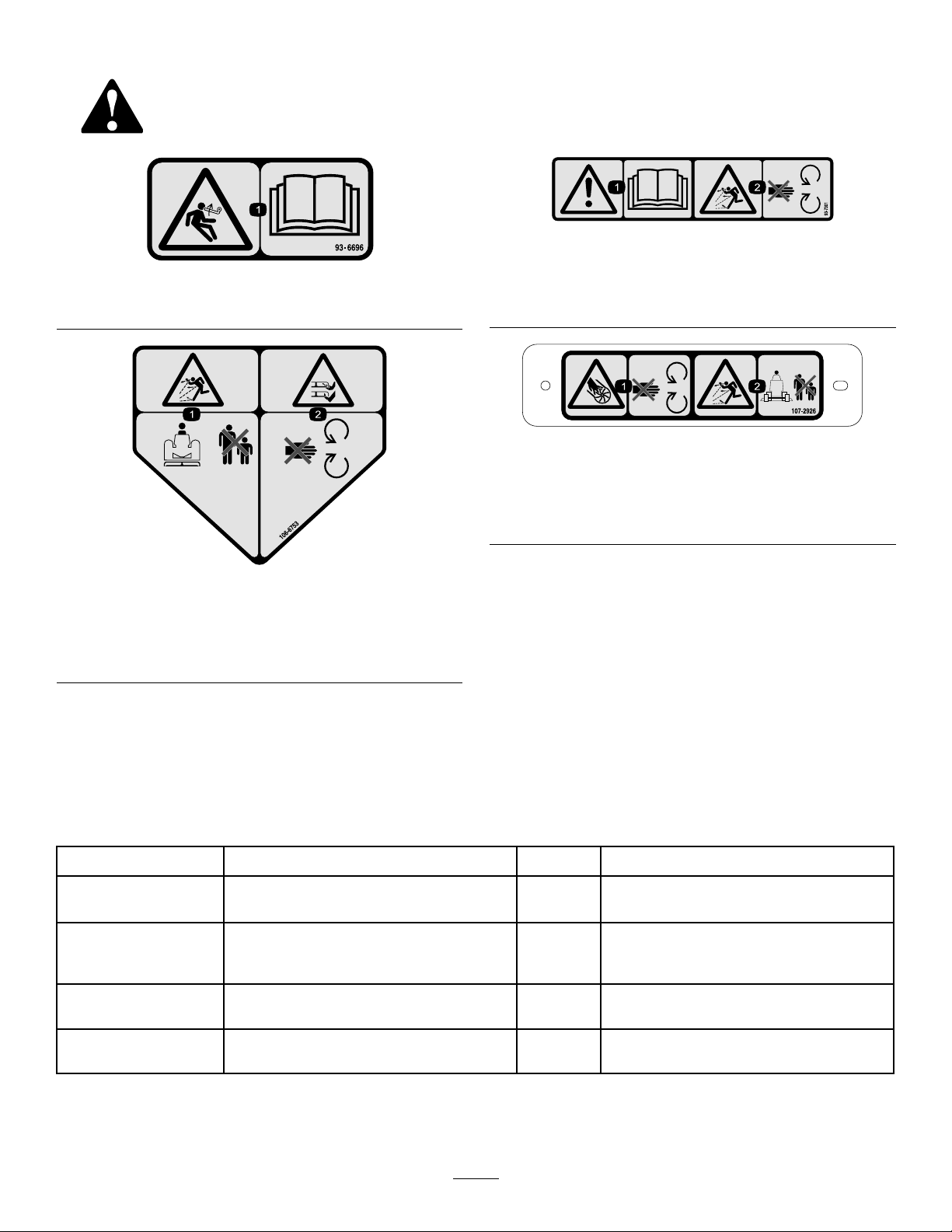

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93–7301

93–6696

1.Storedenergyhazard—readtheOperator'sManual.

106-6753

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

1.Warning-readtheOperator'sManual.

2.Thrownobjecthazard-stayawayfrommovingparts;keep

allguardsandshieldsinplace.

107-2926

1.Cutting/dismembermenthazard,impeller—stayawayfrom

movingparts.

2.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Nopartsrequired

Doublepulley1

Pulleynut1

Nutcover1

Blade3Installthenewblades.

Pivotbrackets2

Qty.

–

3

Removethecuttingunitfromtraction

unit.

Installthenewspindlepulley .

Removeandmodifythegrassdeector.

Use

Page 4

ProcedureDescription

5

6

7

8

Blowerassemblywithmounting

brackets

Capscrew,5/16x1inch

Locknut,5/16

Carriagebolt,3/8inchx3/4inch

Flangenut,3/8inch

Frontdeector

Reardeector

Rearshelf

Leftshelf

Rightshelf

Capscrew,5/16x5/8inch

Locknut,5/16inch

Capscrew,3/8x1inch

Lockwasher,3/8inch

Capscrew,1/4x1inch

Capscrew,1/4x3/4inch

Locknut,1/4inch

Deectorstop

Capscrew,1/4x3/4inch

Locknut,1/4inch

Idlerarmassembly1

Pivotscrew1

Bushing1

Washer2

Locknut,3/8inch

Spring

Threadedrod1

Flangenut,5/16inch

Springbracket

Capscrew,1/4x1inch

Locknut,1/4inch

Qty.

Use

1

3

4

4

3

1

1

1

1

1

6

6

4

4

3

3

6

1

2

2

1

1

2

1

2

2

Installtheblowermountingbrackets.

Installthedeckdeectors.

Mountthenewdeectorstop.

Mounttheidlerassembly.

9

10

11

12

13

14

15

16

Belt1Mounttheblower.

Bumper1

Capscrew,5/16x3inch

Locknut,5/16inch

Trimmolding1

Deckcover1

Beltguard1

Pulleyguard1

Counterbalancespring

Nopartsrequired

Decal,danger1Installthenewdecal.

Chuteassembly

4

4

4

1Installthenewcounterbalancespring.

–

1Mounttheblowerhousingchute.

Installbumper

Installthenewdeckcover.

Installthenewsafetyguards.

Installthecuttingunittothetractionunit.

Page 5

MediaandAdditionalParts

Description

Installationinstructions1

Partscatalog1

Certicateofcompliance

1

RemovingtheCuttingUnit fromtheTractionUnit

NoPartsRequired

Procedure

1.Positionthemachineonalevelsurface,raisethe

cuttingunit,engagetheparkingbrake,ensurethatthe

tractionpedalisintheneutralpositionandthePTO

leverintheOffposition,stoptheengine,andremove

thekeyfromtheswitch.

Qty.

Use

Readbeforeinstallation

Usetoreferencepartnumbers

1

CEcertication

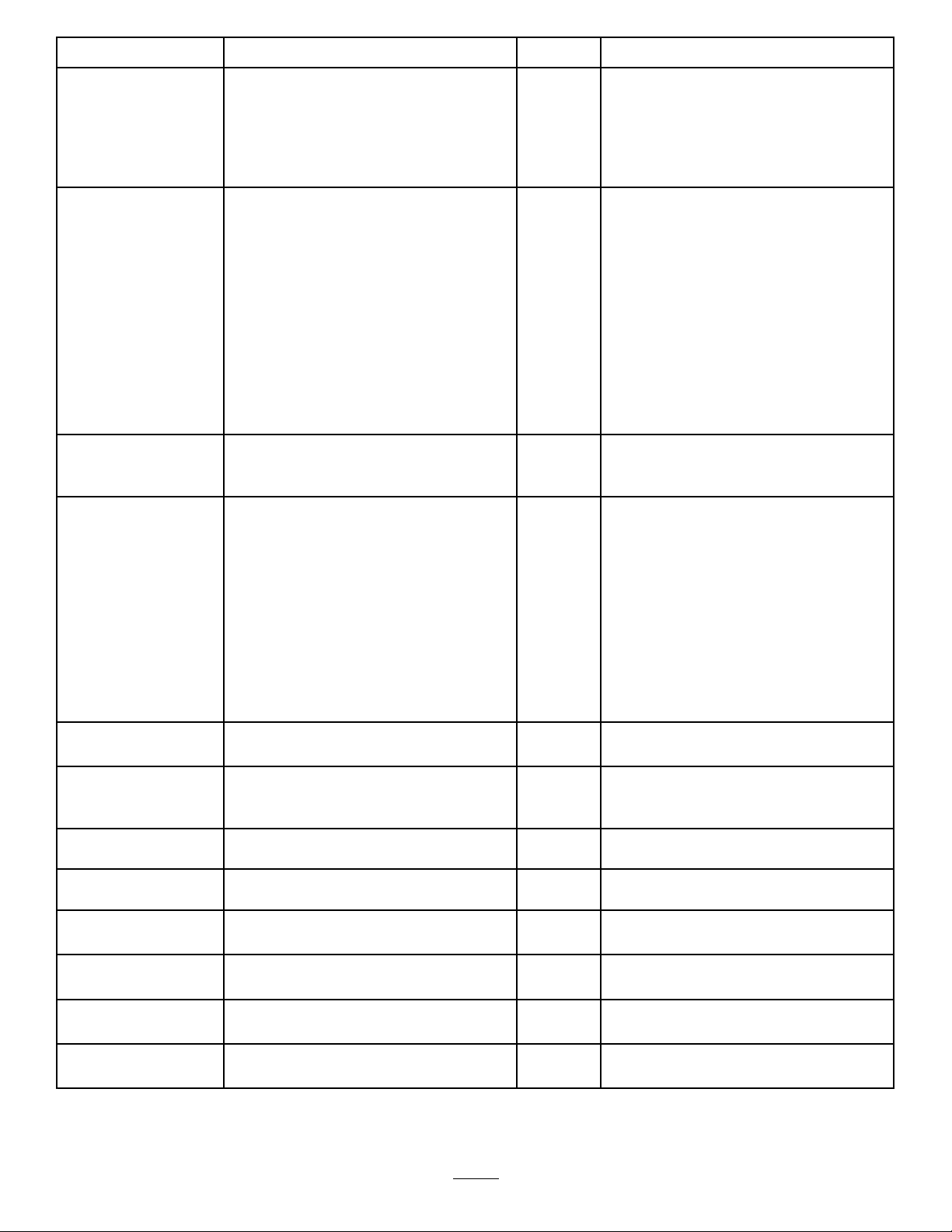

1.Lockpin

2.Bracket

Figure1

3.Springtensionassembly

CAUTION

Thecounterbalancespringisintensionwhen

thedeckisinthelowerposition(200series

tractionunitsonly).

Alwaysraisethedeckbeforeadjustingor

removingthespring.

2.On200seriestractionunitsonly,disconnectthe

counterbalancefromthetractionunit,removethelock

pinsfromthebrackets,separatethespringtension

assembliesfromthebrackets,andlaythemdownon

thedeck.Looselysecurethelockpinstothebrackets

topreventlosingthem(Figure1).

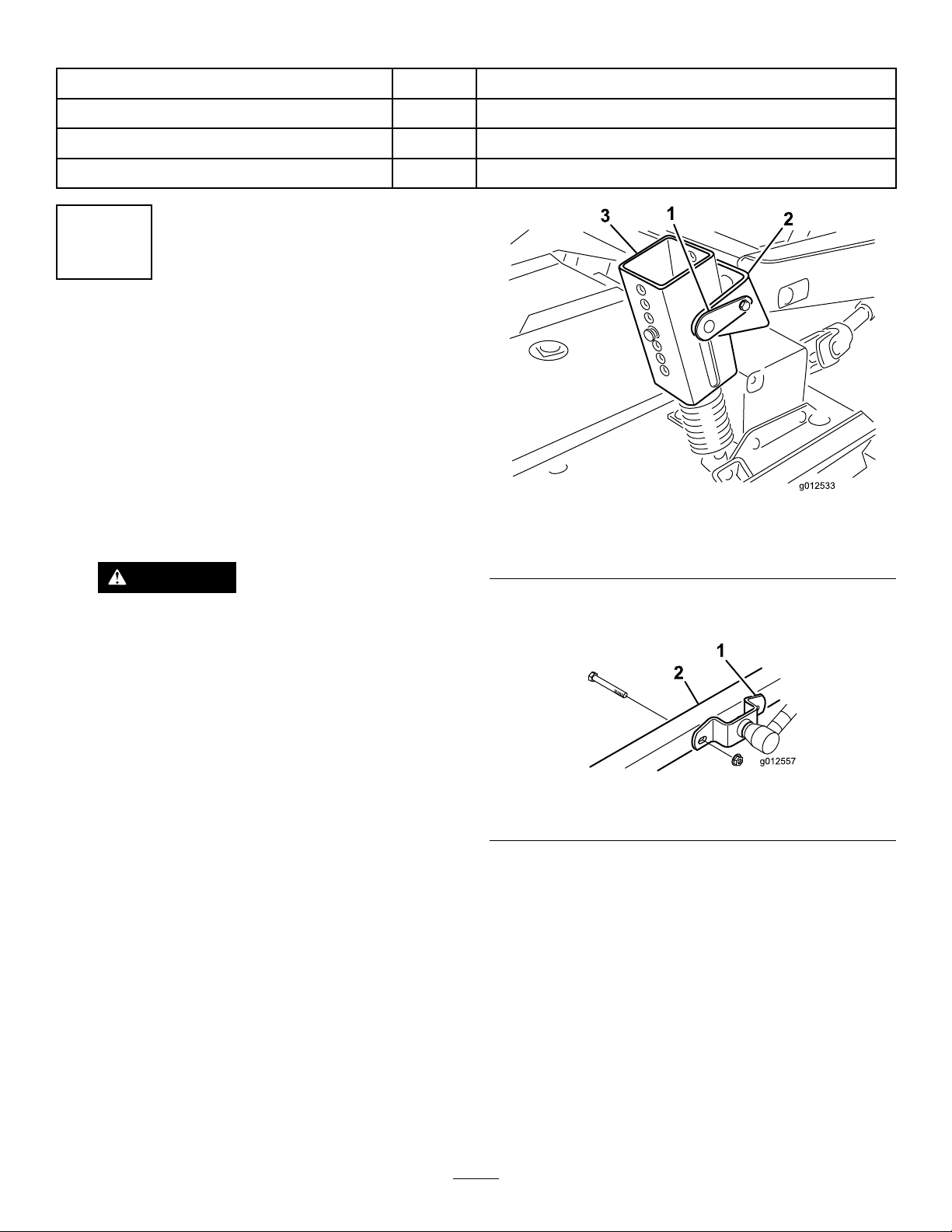

3.Lowerthecuttingunitandremovethe4boltsandnuts

securingliftarmbracketstocastorarms(Figure2).

Figure2

1.Liftarmbracket

4.Starttheengineandraisethetractionunitliftarms.

5.Stoptheengineandslidethecuttingunitawayfromthe

tractionunit,separatingthemaleandfemalesections

ofPTOshaft(Figure3).

2.Rightcastorarm

5

Page 6

Figure3

1.PTOshaft

CAUTION

IftheengineisstartedandthePTOshaftis

allowedtorotate,seriousinjurycouldresult.

DonotstarttheengineandengagethePTO

leverwhenthePTOshaftisnotconnectedto

thegearboxonthecuttingunit.

2

Figure4

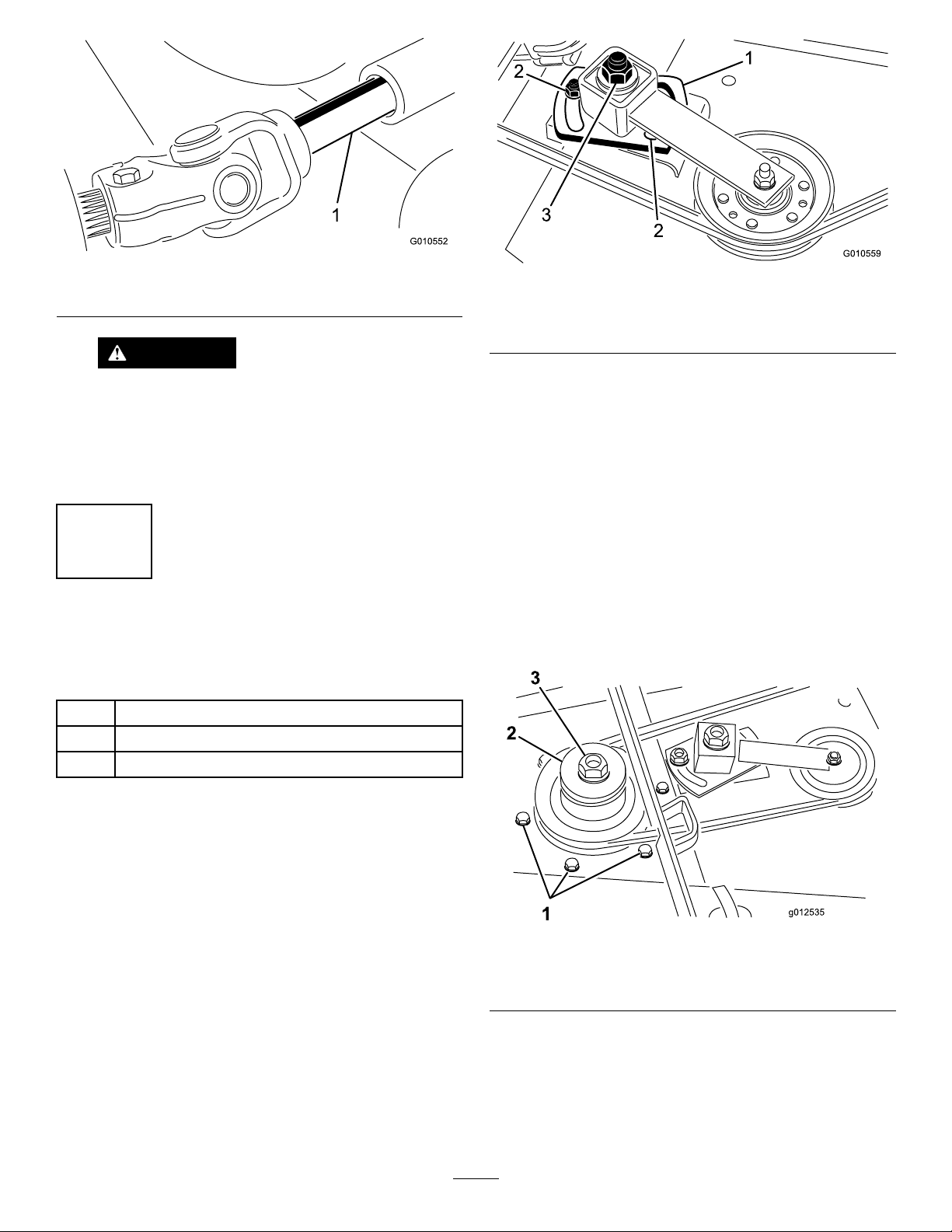

1.Idlerplate3.Idleradjustingnut

2.Nut(2)

3.Removethebeltfromtherightspindlepulley(Figure

4).

4.Removethesixcarriageboltsandangenutssecuring

thespindlehousingassemblytothecuttingunit(Figure

5).Slidethespindlehousingassemblyoutofthe

bottomofthecuttingunit.

5.Removethenutandwasherretainingthepulleyonthe

spindleshaft.Removethepulleyfromtheshaft.

6.Slidethenewdoublespindlepulleyontothespindle

shaft.Donotinstallthepulleynutatthistime.

InstallingtheNewSpindle Pulley

Partsneededforthisprocedure:

1Doublepulley

1Pulleynut

1Nutcover

Procedure

1.Unhookthelatchessecuringtherightcovertothetop

ofthecuttingunit.Removethecoverfromthecutting

unit.

2.Loosenthe2nutssecuringtheidlerplatesothetension

oftheidlerpulleyagainstthebeltisreleased(Figure4).

7.Slidethepulleyendofspindlehousingassembly

throughtheholeinthecuttingunit,andloopthe

beltaroundthepulleyandidler.Mountthespindle

assemblyinplacewith6carriageboltsandangenuts.

Figure5

1.Carriagebolts

2.Doublespindlepulley

8.Installtheoriginalwasherandnewpulleynutontothe

spindleshaftandtightenitto100ft-lb(135.5N-m).

Installthenutcover.

3.Pulleynut

9.Adjust(tighten)theidleradjustingnutto35to40ft-lb

(48to54N-m)toachievetheproperbelttension.

Tightentheidlerplatenuts.

6

Page 7

3

G010555

1

2

InstallingtheNewBlades

Partsneededforthisprocedure:

3Blade

Procedure

1.Grasptheendofbladeusingathicklypaddedglove.

Removethebladebolt,anti-scalpcup,andbladefrom

thespindleshaft(Figure6).

2.Removethecarriageboltsandangenutssecuringthe

pivotbracketstothehousing(Figure7).Removethe

pivotbrackets.Retainthefastenersforfutureuse.

3.Removethe2carriagebolts,atwashers,andlocknuts

securingthereinforcementplatetotheundersideof

thehousingandthestiffenerplatetothetopofthe

housing(Figure7).

Figure7

Figure6

1.Bladebolt2.Anti-scalpcup

2.Insequence,installanewblade(sailfacingtowardthe

cuttingunit)andanti-scalpcup.Securethepartsin

placewiththebladebolt.Tightenthebladeboltto85

to110ft-lb(115to149N-m).

3.Repeatthisprocedureonallblades.

4

RemovingandModifyingthe

GrassDeector

Partsneededforthisprocedure:

2Pivotbrackets

1.Grassdeector3.Reinforcementplate

2.Pivotbrackets

4.Usingthebolts,locknuts,andspringspreviously

removed,installthenewpivotbracketstothedeector

mounts(Figure8).Donotovertightenthenuts

becausethebracketsmustbeallowedtopivot.Save

thisassemblyforsidedischargeoperation.

1.Grassdeector

4.Stiffenerplate

Figure8

2.Pivotbrackets

Procedure

1.Removethebolts,locknuts,andspringssecuringthe

deectormountstothepivotbrackets(Figure7).

Removethedeector.

7

Page 8

5

InstallingtheBlowerMounting

Brackets

Partsneededforthisprocedure:

3.Positionthenewreinforcementplateunderthedeck

aligningthemountingholeswiththeholespreviously

usedformountingthegrassdeector(Figure9).

4.Mountthefrontandrearbracketsandreinforcement

platetothedeckwith2previouslyremovedcarriage

bolts(3/8-16x7/8inch)andangenutseach(Figure

9).Theboltheadsmustbeontopofthedeck.

5.Removethe2knobssecuringtheblowertothe

mountingbrackets.Removetheblower.

1Blowerassemblywithmountingbrackets

3

Capscrew,5/16x1inch

4

Locknut,5/16

4

Carriagebolt,3/8inchx3/4inch

3

Flangenut,3/8inch

Procedure

1.Removethefastenerssecuringtherighthanddeck

coverspringlatchtotherightsideofthecuttingdeck

(Figure9).Removeandretainthelatchforfutureuse

withtherighthandcover.

2.Positiontheblowerandmountingbracketsonthe

deck,aligningthemountingholeswiththeholes

previouslyusedformountingthegrassdeector.

Figure9isshownwiththeblowerremovedfromthe

brackets.Makesurethereisnogapbetweentheblower

andcuttingdeck.

6.Usingeachbracketasatemplate,markthelocationand

drill2additional11/32inchdiameterholes.(2holes

fortherearbracketand1forthefrontbracket.Usethe

reinforcementplateforatemplatetodrilloneofthe

11/32inchdiameterholesfortherearbracket.

Note:Usecautionwhendrillingtheholessothatthe

castorarmisnotdamaged.

7.Securethebracketsandreinforcementplatetothedeck

withbolts(5/16-18x3/4inch)andlocknuts(Figure

9).Theboltheadsmustbeontopofthedeck.

8.Mounttheblowerbracetotherearmountingbracket

with2bolts(3/8-16x1inch)andlocknuts(Figure9)

andtothecastorarmwithabolt(3/8-16x1inch).

9.Whenmountingtheliftarmbracketstothecastor

arms,mountothersideoftheblowerbracetothelift

armbracketandtherightcastorarmwiththeboltand

nutpreviouslyremoved.

Figure9

1.Springlatch4.Reinforcementplate

2.Rearmountingbracket5.Blowerbrace

3.Frontmountingbracket

Figure10

1.Liftarmbracket

8

2.Rightcastorarm

Page 9

6

InstallingtheDeckDeectors

Partsneededforthisprocedure:

1

Frontdeector

1

Reardeector

1

Rearshelf

1

Leftshelf

1

Rightshelf

6

Capscrew,5/16x5/8inch

6

Locknut,5/16inch

4

Capscrew,3/8x1inch

4

Lockwasher,3/8inch

3

Capscrew,1/4x1inch

3

Capscrew,1/4x3/4inch

6

Locknut,1/4inch

Figure12

1.Frontdeector4.Leftshelf

2.Reardeector5.Rightshelf

3.Rearshelf

Procedure

1.Insertthefrontdeectorintothedeck,aligningthe

endofthedeectorwiththeedgeofthedischarge

opening(Figure11andFigure12).

Figure11

1.Frontdeector

2.Usingthedeectorasatemplate,markanddrillthree

11/32inchdiameterholesthroughfrontandtopof

deck.

Figure13

1.Reardeector

5.Usingthedeectorasatemplate,markanddrillthree

11/32inchdiameterholesthroughthedeck.

6.Securethedeectortothedeckwith3bolts(5/16-18x

5/8inch)andlocknuts(5/16-18inch).

7.Beforemountingtheleftandrightshelvestothedeck,

youmustgrindtheweldsoffofthebottomedgeofthe

deck.Paintthedeckaftergrinding.

8.Usingtheexistingholes,mounttherearshelftothe

deckwith4bolts(3/8-16x1inch)andlockwashers

(3/8inch)(Figure14).

3.Securethe2frontmountingtabsofdeectortothe

deckwithbolts(5/16-18x5/8inch)andlocknuts

(5/16-18inch).

4.Securethefrontrightcornerofthefrontmounting

bracketandthetoptabofthedeectortothedeck

withabolt(5/16-18x1inch)andlocknut.

9

Page 10

Figure14

1.Rearshelf

9.Aligntheleftshelfwiththeleftendoftherearshelf

andtheedgeofthedeck(Figure12andFigure14).

10.Securetheleftshelftothedeckwith2bolts(1/4-20x1

inch),1bolt(1/4-20x3/4inch),and3locknuts(Figure

15).Positiontheboltheadstotheinsideofthedeck.

Figure15

Figure16

1.Rightshelf

12.Securetherightshelftothedeckwith1bolt(1/4-20

x1inch),2bolts(1/4-20x3/4inch),and3locknuts.

Positiontheboltheadstotheinsideofthedeck.

7

MountingtheNewDeector

Stop

Partsneededforthisprocedure:

1

Deectorstop

2

Capscrew,1/4x3/4inch

2

Locknut,1/4inch

1.Leftshelf

11.Aligntherightshelfwiththerightendoftherearshelf

andtheedgeofthedeck(Figure12andFigure16).

Usingtheleftshelfasatemplate,locate,mark,anddrill

three9/32inchdiameterholesinthedeck.

Procedure

1.Usingthenewdeectorstopasatemplate,setitonthe

originalatdeectorstop(Figure17).Ensurethatthe

newdeectorstopisushatthebottom,contacting

thesideofthedeck,andparallelwiththeoutsideedge

ofthedeectorsupport.

10

Page 11

Figure17

1.Newdeectorstop

2.Markanddrillholes

3.Boltsandlocknuts

2.Locate,markanddrilltwo9/32inchdiameterholes

throughtheolddeectorsupport.

3.Mountthenewdeectorsupporttotheolddeector

stopwith2bolts(1/4-20x3/4inch)andlocknuts

(1/4-20inch),asshowninFigure17.

8

MountingtheIdlerAssembly

Partsneededforthisprocedure:

1Idlerarmassembly

1Pivotscrew

1Bushing

2Washer

1

Locknut,3/8inch

1

Spring

1Threadedrod

2

Flangenut,5/16inch

1

Springbracket

2

Capscrew,1/4x1inch

2

Locknut,1/4inch

Figure18

1.6-13/16inches2.9-1/8inches

2.UsingthedimensionsshowninFigure19,locate,mark,

anddrilla13/16inchdiameterholeandtwo13/32

inchdiameterholesintherightbridgebar.

Figure19

1.5inches

2.1-1/16inches(2)5.13/16inchdiameter

3.1inch

4.13/32inchdiameter(2)

3.Threadaangenut(5/16-18inch)approximately2

inches(5cm)ontothethreadedrod(Figure20).

Procedure

1.UsingthedimensionsshowninFigure18,locate,mark,

anddrilla13/32inchdiameterholeinthedeck.The

dimensionsshownarefromtherightfrontcornerof

thedeckandfromtheedgeofthedischargeopening.

Theblowerbracketsareremovedforclarity.

Figure20

1.Idlerpulleyarm3.Threadedrod

2.Springbracket4.Spring

11

Page 12

4.Inserttheendofthethreadedrodthroughthelarge

holeinthespringbracketandlooselysecureitwith

anotherangenut(5/16-18inch)(Figure20).Donot

tightentheangenuts.

5.Inserttheotherendofthethreadedrodthroughthe

holeinthebridgebarandsecurethespringbracketto

thebridgewith2boltsandlocknuts(Figure20).

6.Hooktheshortloopofthespringintotheholeinthe

threadedrodandthelongloopintheholeintheidler

arm(Figure20).

7.Mounttheidlerpulleyarmtothedeckwiththe

followingparts,inthisorder:apivotscrew(3/8-16

inch),athrustwasher(1/2inch),theidlerarm,athrust

washer(3/8inch),thedeck,andalocknut(3/8-16

inch)(Figure20).(Donottightentheangenutson

thethreadedrodatthistime.Adjustthespringtension

aftertheblowerassemblyandbelthavebeeninstalled.)

Figure21

9

MountingtheBlower

Partsneededforthisprocedure:

1Belt

Procedure

1.Routethebeltaroundthesmalldeckspindlepulley.

2.Slidetheblowerontothemountingbracketalignment

studs(Figure21)whileroutingthebeltaroundthe

blowerpulley.

Note:Iftheblowerdoesnoteasilyslideontothe

mountingbrackets,loosenthealignmentboltsslightly .

3.Securetheblowertothebracketswith2knobs.

4.Adjustthespringlengthto4-7/8inches(12.4cm)for

properbelttensionbyadjustingtheangenutsonthe

threadedrod.

10

InstalltheBumper

Partsneededforthisprocedure:

1Bumper

4

Capscrew,5/16x3inch

4

Locknut,5/16inch

Procedure

1.UsingdimensionsshowninFigure22,locate,markand

drilla11/32inchdiameterholethroughbothwallsof

therightfrontcastorarmbracket.

12

Page 13

Figure22

g029097

1.2-1/2inches2.3/8inch

2.Securethetopmountingholeofthefrontmounting

plateofthebumpertothecastorarmbracketwitha

bolt(5/16-18x3inch)andlocknut(Figure23).

11

InstallingtheNewDeckCover

Partsneededforthisprocedure:

1Trimmolding

1Deckcover

Procedure

1.Insertatrimmoldingontotherightbridgebar,sothe

sideofthespringbracketis10cm(4inches)tothefar

edgeofthetrimmolding(Figure24).

Figure23

1.Bumper

3.Usingbothmountingplatesofthebumperas

templates,locate,mark,anddrill3additional11/32

inchdiameterholesthroughbothwallsofthefrontand

rearcastorarmbrackets.

Figure24

1.Trimmolding3.Bolt

2.Cover

2.Hooktherearofthedeckcover(Figure24)ontothe

rearchannelpinwhilealigningthecovermounting

boltwiththeholeintherightcastorarm.Thecover

istorestonthetrimmolding.Adjustthemoldingas

required.

3.Securethecovertotherightcastorarmwiththebolt.

12

InstallingtheNewSafety Guards

Partsneededforthisprocedure:

1Beltguard

1Pulleyguard

Procedure

1.Installthebeltguardontothemachine(Figure25).

Note:Useexistinghardwareonthemachineby

removingitandusingittoinstalltheguard.

13

Page 14

1

3

2

g029097

Figure25

1

3

22

g029099

1.Beltguard3.Bolt

2.Nut

13

InstallingtheNew CounterbalanceSpring (200seriestractionunitsonly)

Partsneededforthisprocedure:

1

Counterbalancespring

Procedure

Tocompensatefortheadditionalweightoftheblower

assembly,theoriginallightcounterbalancespringattheright

sideofthemachine,mustbereplacedwiththeheavierspring

included(Figure27).

2.Installthepulleyguardontothemachine(Figure26).

Figure26

1.Pulleyguard3.Bolt

2.Nut

Note:Useexistinghardwareonthemachineby

removingitandusingittoinstalltheguard.

1.Removethehairpincotterandclevispinandslidethe

springassemblyoutoftheretainingbracket.

2.Screwthespringoffofthetopandbottommounting

brackets.

3.Screwthenewheavyspringontobothmounting

brackets.Ensurethatthespringiscompletelythreaded

throughallholesanditcontactstheatsideofthe

bracket.

Figure27

1.Hairpincotter

2.Clevispin

3.Topbracket

4.Spring

5.Bottombracket

4.Installthespringassemblyintotheretainingbracket

withaclevispinandhairpincotter.

14

Page 15

14

16

InstallingtheCuttingUnitto

theTractionUnit

NoPartsRequired

Procedure

1.Engagetheparkingbrake,ensurethatthetractionpedal

isinneutralandthePTOleverisintheOffposition.

Starttheengineandraisetheliftarms.Stoptheengine.

2.Positionthecuttingunitinfrontofthetractionunit

aligningthegearcaseinputshaftwiththePTOshaft

andinstalltheshaft.

3.Carefullylowertheliftarmswhilealigningtheliftarm

bracketswiththecastorarms.AlignPTOshafthole

withgearcaseinputshaftholeandinstallrollpin.

4.Securetheliftarmbracketsandthesideoftheblower

bracetothecastorarmswith4boltsandnuts.

5.Starttheengineandraisethecuttingunit.Secure

thecounterbalancespringstothecuttingunitwith

shoulderboltsandlocknuts.

MountingtheBlowerHousing Chute

Partsneededforthisprocedure:

1

Chuteassembly

Procedure

Important:WhenthechuteintheBlowerKitisused

witha15cubicfootHopperKit,youmustcutoffa

sectionofthechutetoensurepropertbetweenthe

blowerandthehopper.Ifusedwithanotherkit,proceed

tostep3.

1.UsingthedimensionsshowninFigure28,useatape

measureandmarkthechute.

Note:Forconvenience,somechutesmayhavealight

scribemarkwherethechutemustbecutoff.

15

InstallingtheNewDecal

Partsneededforthisprocedure:

1Decal,danger

Procedure

InstalltheDangerDecal(PartNumber66-1340or93-7824

forCE)onthefrontedgeofthedeck,insidetherightcastor

arm.

Figure28

1.61.2cm(24.12inches)2.70.5cm(27.75inches)

2.Drawlinesaroundallsidesofthechuteandcutoff

withasaw .

3.Setthedecktothedesiredheight-of-cutsetting.

4.Slidethechuteoverthebloweropeningandontothe

mountingstuds(Figure29).

15

Page 16

Figure29

1.Chute2.Chutebrackets

5.Lowerthehopperhoodandalignthechutewith

thehoodsnout.Securethechuteinpositionwith4

locknuts(5/16inch)andchutebrackets.Positionthe

wideendofbracketstotherear.

Operation

OperatingCharacteristics

(Whenusedwitha9cu.ft.or15cu.ft.HopperKit)

baggerstrikingastationaryobject.Stayfarenough

awayfromobstructionstoavoidcollisions.Trimwith

theleftsideofthecuttingunitonly.

CAUTION

Usecaretoavoidcollisionbetweenthehopper

andanystationaryobjects.Alwaystrimwith

theleftsideofthecuttingunit.

4.Whileoperating,checkfrequentlyforexcessive

clippingsleftontheturforuncutgrass.Ifthose

conditionsoccur,theblowerorcuttingunitmaybe

plugged.Stoptheunit,disengagethePTO,setthe

brake,andstoptheengine.Checkforobstructionsin

thechute,blowerorcuttingunit.Clearanyobstruction

usingastickorsimilartool.Checktheblowerbelt

tension.Ifitisslipping,readjustthetension.

5.Cutgrassoften,especiallywhenitgrowsrapidly .If

shorterturfisdesired,cutthegrassagain.Overlapthe

swathstoproduceanevencuttingpattern.

Important:Whentransportingtheunit,tiedown

thegrasscollectorhoodorbackitontothetruck

ortrailertoavoidwindthrowingthehoodopen

anddamagingit.

CAUTION

Whenthegrasscollectorisremoved,neveroperate

withoutthedeectorinplace.

Forbestperformance,regulatethetractionpedaltokeep

theenginerpmhighandsomewhatconstant.Agoodrule

tofollowis:decreasegroundspeedastheloadonthe

cuttingbladeincreases;andincreasegroundspeedasthe

loadonthebladedecreases.Thisallowstheengine,working

withthetransmission,tosensethepropergroundspeed

whilemaintaininghighbladetipspeednecessaryforgood

quality-of-cut,vacuumingaction,andtothrowgrassinto

hopper.Ifblowerspeeddropstoolow ,pluggingmayresult.

RefertotheCuttingUnitandTractionUnitOperator'sManual

foroperationofeach.

DANGER

Neverplacehandsorfeetinthechute,blower,or

cuttingunit.

1.Thisgrasscollectorisdesignedforuseinwetordry

conditions.Donotcollectextremelylonggrassasthe

hopperwilllltooquickly.

2.Whenbaggingwet,heavygrass,someclippingsmay

notbethrowncompletelythroughthechute.The

holeinthebottomofthechuteallowstheseclippings

todropoutwithoutpluggingthechute.Whenthis

happens,reducethegroundspeed.

3.Thebumperwhichprotectstheblowerhousingdoes

notextendfarenoughtoeliminatethechanceofthe

RemovingtheBlower

1.Stoptheengineanddisengagetheidler.Securetheidler

tothefrontcastorarmbracketwiththeretaininghook.

2.Removethebeltcoverandliftthebeltoffofthe

spindlepulley.Installthecover.

3.Removethe2knobssecuringtheblowertothe

mountingbracketsandremovetheblower,belt,and

chute.

4.Reversetheproceduretoinstalltheblowerassembly.

UsingtheGrassDeector

Atsometimeyoumaywishtooperatethecuttingdeck

withouttheblower.Sinceanewpivotshouldhavealready

beeninstalledonthegrassdeector,youcanquicklymount

thedeectortotheblowermountingbrackets.

1.Removethebumperfromthedeck.

2.Slidetheslotsatbottomofthedeectorpivotbracket

ontotheboltsatsideofthedeckbrackets(Figure30).

16

Page 17

Figure30

1.Grassdeector

2.Pivotbracket4.Knob

3.Securethedeectorinplacewiththe2knobs.

3.Deckbracket

Maintenance

•Checktheblowergearboximpellerfortightnessevery50

hours.T orquetheimpellershaftboltto25to25.8N-m

(220to230in-lb).

•Cleangrassclippingsfromthehood,chute,blower,and

cuttingunitaftereachuse.Washtheundersideofthe

cuttingunitdailywithhose.Anexcessivebuildupof

clippingswillimpairthecollectionsystemperformance.

•Checkthebelttensionandwearevery50hours.Toadjust

thebelttension,loosentheidlermountingscrews,engage

theidlerlever,andpushtheidlerpulleyrmlyintothe

blowerbelt.Tightenthemountingscrews.

•Theblowergearboxshouldneedlittlemaintenance.

Checkforleakageevery50hours.Ifleakageshould

occur,replacethesealsandrellitwith2oz.ofhigh

qualitymolydisuldegrease.Repackthebearingswith

thisgreasebeforeassembling.

•RefertoCuttingUnitandTractionUnitOperator'sManuals

fortheservicerequirementsofeach.

•Keeptheunitclean.Ensurethattheengineisfreeof

dirtandchaff.Makesureallfastenersaretight.Check

thedeectors,bafes,andshieldsforwearandreplace

asneeded.

17

Page 18

DeclarationofIncorporation

ModelNo.

30506315000001andUp

SerialNo.

ProductDescriptionInvoiceDescription

62inBlowerKit,

Groundsmaster

200/3280-D/3320Series

SideDischargeMowers

GM20062"BLOWERKIT

GeneralDescription

62inBlowerKit

Directive

2006/42/EC,

2000/14/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedT oromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:EUT echnicalContact:

PeterT etteroo

ToroEuropeNV

B-2260Oevel-Westerloo

Belgium

DavidKlisTel.003214562960

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

September29,2014

Fax003214581911

18

Page 19

InternationalDistributorList

Distributor:

AgrolancKft

BalamaPrimaEngineeringEquip.HongKong85221552163

B-RayCorporation

CascoSalesCompany

CeresS.A.CostaRica

CSSCTurfEquipment(pvt)Ltd.SriLanka

CyrilJohnston&Co.

CyrilJohnston&Co.RepublicofIreland

EquiverMexico525553995444ParklandProductsLtd.NewZealand6433493760

FemcoS.A.Guatemala

ForGarderOU

G.Y .K.CompanyLtd.

GeomechanikiofAthensGreece

GolfinternationalTurizm

GuandongGoldenStarChina

HakoGroundandGardenSweden

HakoGroundandGarden

HayterLimited(U.K.)

HydroturfInt.CoDubai

HydroturfEgyptLLC

IrrimacPortugal351212388260T oroEuropeNVBelgium3214562960

IrrigationProductsInt'lPvtLtd.India0091442449

JeanHeybroekb.v.Netherlands3130639461 1VictusEmakPoland48618238369

Country:

Hungary3627539640

Korea82325512076

PuertoRico7877888383

NorthernIreland442890813121

Estonia3723846060

Japan81726325861

Turkey902163365993Riversa

Norway4722907760

UnitedKingdom441279723444

UnitedArabEmirates97143479479T-MarktLogisticsLtd.Hungary3626525500

Egypt2025194308ToroAustraliaAustralia61395807355

PhoneNumber:Distributor:

5062391138

94112746100

442890813121

5024423277

30109350054

862087651338

4635100000

4387

Country:

MaquiverS.A.Colombia

MaruyamaMfg.Co.Inc.

Mountelda.s.CzechRepublic

Mountelda.s.Slovakia

MunditolS.A.

NormaGarden

OslingerTurfEquipmentSA

OyHakoGroundandGarden

Ab

Perfetto

PratoverdeSRL.

Prochaska&Cie

RTCohen2004Ltd.

LelyTurfcare

SolvertS.A.S.

SpyprosStavrinidesLimitedCyprus

SurgeSystemsIndiaLimited

ValtechMorocco21253766

Japan81332522285

Argentina54114821

Russia749541 16120

Ecuador59342396970

Finland35898700733

Poland48618208416

Italy390499128

Austria4312785100

Israel97298617979

Spain

Denmark4566109200

France331308177

India911292299901

Phone

Number:

5712364079

420255704

220

420255704

220

9999

128

34952837500

00

35722434131

3636

EuropeanPrivacyNotice

TheInformationT oroCollects

ToroWarrantyCompany(T oro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry .

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayToroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.T oromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany .Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw.

Toro'sCommitmenttoSecurityofY ourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oroDealer .

374-0269RevH

Page 20

ToroGeneralCommercialProductWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser .

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner .

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofToro.T orowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.Toromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty .

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirToroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevC

Loading...

Loading...