Page 1

FormNo.3428-854RevA

Groundsmaster

®

7210Series

TractionUnit

ModelNo.30487TC—SerialNo.403440001andUp

ModelNo.30487TE—SerialNo.400000000andUp

ModelNo.30495—SerialNo.403440001andUp

ModelNo.30495TC—SerialNo.403440001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3428-854*A

Page 2

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparate

product-specicDeclarationofConformity(DOC)

sheet.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

WARNING

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

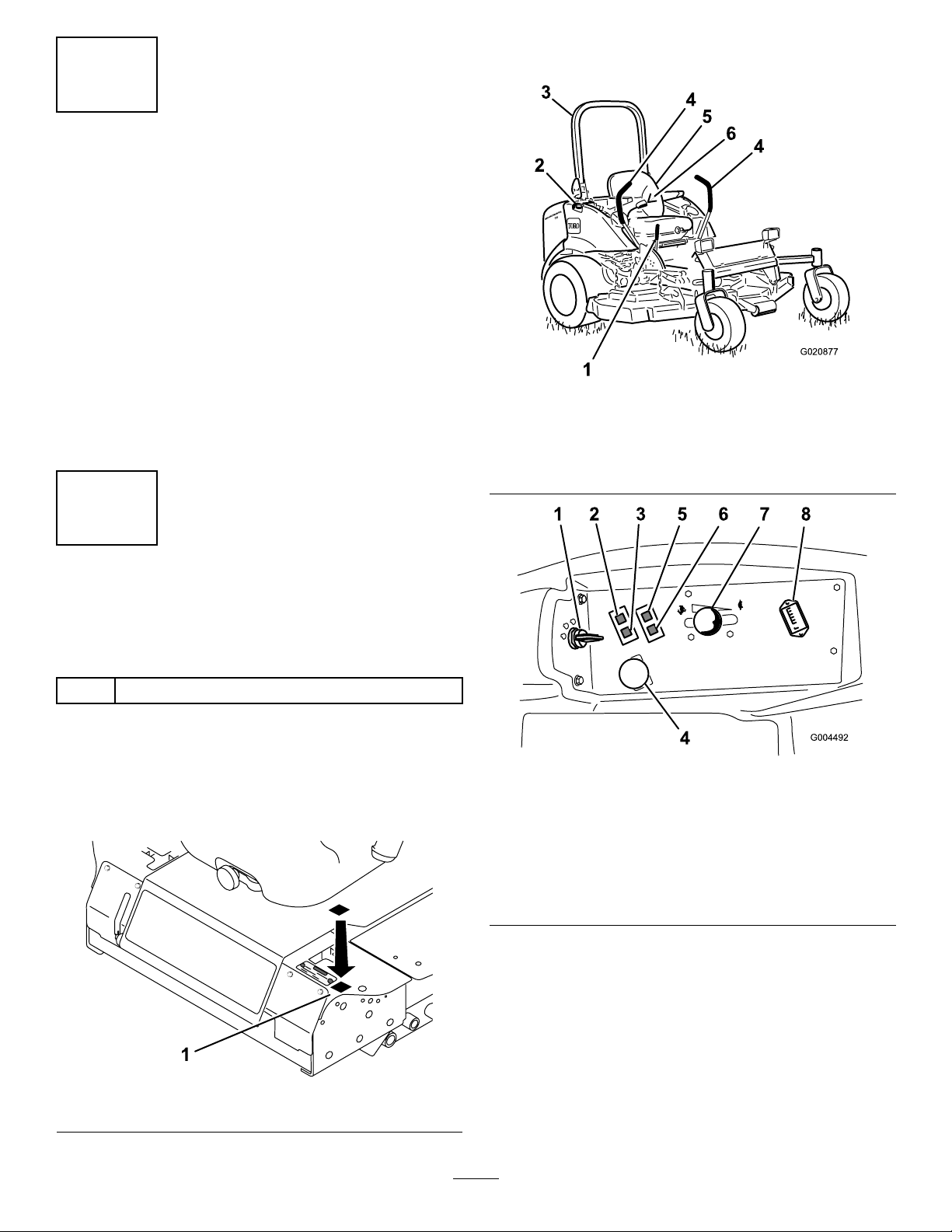

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g241316

Figure1

1.Modelandserialnumberlocation

Introduction

Thismachineisaride-on,rotary-bladelawnmower

intendedtobeusedbyprofessional,hiredoperators

incommercialapplications.Itisprimarilydesigned

forcuttinggrassonwell-maintainedlawnsinparks,

sportselds,andoncommercialgrounds.Itisnot

designedforcuttingbrush,mowinggrassandother

growthalongsidehighways,orforagriculturaluses.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

1.Safety-alertsymbol

Contactusatwww.Toro.com.

2

g000502

PrintedintheUSA

AllRightsReserved

Page 3

Thismanualalsouses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

3

Page 4

Contents

Safety.......................................................................5

GeneralSafety...................................................5

SafetyandInstructionalDecals..........................5

Setup......................................................................12

1RaisingtheRollBar.......................................12

2InstallingtheCuttingUnit...............................12

3AdjustingtheLeft,FrontCaster

Wheel............................................................12

4CheckingtheTirePressure............................13

5InstallingWeights(forCE

Compliance)..................................................14

6CheckingtheFluidLevels..............................15

7InstallingtheDecal(CEMachines

Only).............................................................15

ProductOverview...................................................15

Controls...........................................................15

Specications..................................................18

Attachments/Accessories.................................19

BeforeOperation.................................................19

BeforeOperationSafety...................................19

AddingFuel......................................................20

CheckingtheEngine-OilLevel..........................21

CheckingtheCoolingSystem...........................21

CheckingtheHydraulicSystem........................21

AdjustingtheRollBar.......................................21

UsingtheSafety-InterlockSystem....................22

PositioningtheSeat..........................................23

ChangingtheSeatSuspension.........................24

UnlatchingtheSeat..........................................24

DuringOperation.................................................24

DuringOperationSafety...................................24

OperatingtheParkingBrake.............................26

StartingtheEngine...........................................26

DrivingtheMachine..........................................27

ShuttingOfftheEngine.....................................28

OperatingtheMower........................................28

AdjustingtheHeightofCut...............................29

OperatingTips.................................................29

AfterOperation....................................................30

GeneralSafety.................................................30

PushingtheMachine........................................30

HaulingtheMachine.........................................31

LoadingtheMachine........................................32

Maintenance...........................................................33

MaintenanceSafety..........................................33

RecommendedMaintenanceSchedule(s)...........33

DailyMaintenanceChecklist.............................35

Lubrication..........................................................36

GreasingtheBearingsandBushings................36

ServicingtheCutting-UnitGearbox

Lubricant.......................................................36

EngineMaintenance...........................................37

EngineSafety...................................................37

CheckingtheAirCleaner..................................37

ServicingtheAirCleaner..................................38

ServicingtheEngine-Oil...................................38

FuelSystemMaintenance...................................40

ServicingtheWaterSeparator.........................40

DrainingtheFuelT ank......................................40

InspectingtheFuelLinesand

Connections..................................................41

BleedingtheFuelSystem.................................41

BleedingAirfromtheInjectors..........................41

ElectricalSystemMaintenance...........................42

ElectricalSystemSafety...................................42

ServicingtheBattery.........................................42

StoringtheBattery............................................42

CheckingtheFuses..........................................42

DriveSystemMaintenance..................................43

CheckingtheTirePressure...............................43

ReplacingtheCasterWheelsand

Bearings........................................................44

CoolingSystemMaintenance..............................44

CoolingSystemSafety.....................................44

CheckingtheCoolingSystem..........................44

CleaningtheRadiator.......................................45

BrakeMaintenance.............................................45

AdjustingtheParking-BrakeInterlock

Switch...........................................................45

BeltMaintenance................................................46

CheckingtheAlternator-BeltT ension................46

ControlsSystemMaintenance.............................47

AdjustingtheControl-LeverNeutral-Interlock

Switch...........................................................47

AdjustingtheControl-LeverNeutral

Return...........................................................47

AdjustingtheTractionDriveforNeutral.............48

AdjustingtheMaximumGroundSpeed.............50

AdjustingtheTracking......................................51

HydraulicSystemMaintenance...........................52

HydraulicSystemSafety...................................52

HydraulicFluidCapacity...................................52

HydraulicFluidSpecication.............................52

CheckingtheHydraulicSystem........................52

ChangingtheHydraulicFluidAnd

Filter..............................................................53

Cleaning..............................................................53

CleaningUndertheCuttingUnit........................53

WasteDisposal.................................................53

Storage...................................................................54

StorageSafety..................................................54

PreparingtheMachineforStorage...................54

PreparingtheEngine........................................54

4

Page 5

Safety

Thismachinehasbeendesignedinaccordancewith

CENstandardANSIB71.4-2017andISOEN5395

whenyouinstalltheproperCEKitsandcompletethe

setupprocedures.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Keepyourhandsandfeetawayfromrotating

parts.Keepclearofthedischargeopening.

•Keepbystandersandchildrenoutoftheoperating

area.Neverallowchildrentooperatethemachine.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury .

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

Manufacturer'sMark

•Shutofftheengine,removethekey(ifequipped),

andwaitforallmovementtostopbeforeyouleave

theoperator’sposition,Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

Improperlyusingormaintainingthismachinecan

resultininjury .T oreducethepotentialforinjury ,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

decaloemmarkt

,which

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

BatterySymbols

Someorallofthesesymbolsareonyourbattery.

1.Explosionhazard6.Keepbystandersaway

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

fromthebattery .

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard

decalbatterysymbols

5

Page 6

93-6696

1.Storedenergyhazard—readtheOperator'sManual.

decal93-6696

decal106-6755

106-6755

93-6697

1.ReadtheOperator's

Manual.

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

2.AddSAE80w-90(API

GL-5)oilevery50hours.

1.Enginecoolantunder

pressure.

decal93-6697

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

decal106-9206

106-9206

1.Wheeltorquespecications

decal106-6754

2.ReadtheOperator'sManual.

1.Inputs5.Inseat

2.Notactive

3.Hightemperatureshutdown

6.Powertakeoff(PTO)10.Powertakeoff(PTO)

7.Parkingbrakeoff11.Start

4.Hightemperaturewarning8.Neutral

decal106-9290

106-9290

9.Outputs13.Start

14.Power

12.Energizetorun(ETR)

6

Page 7

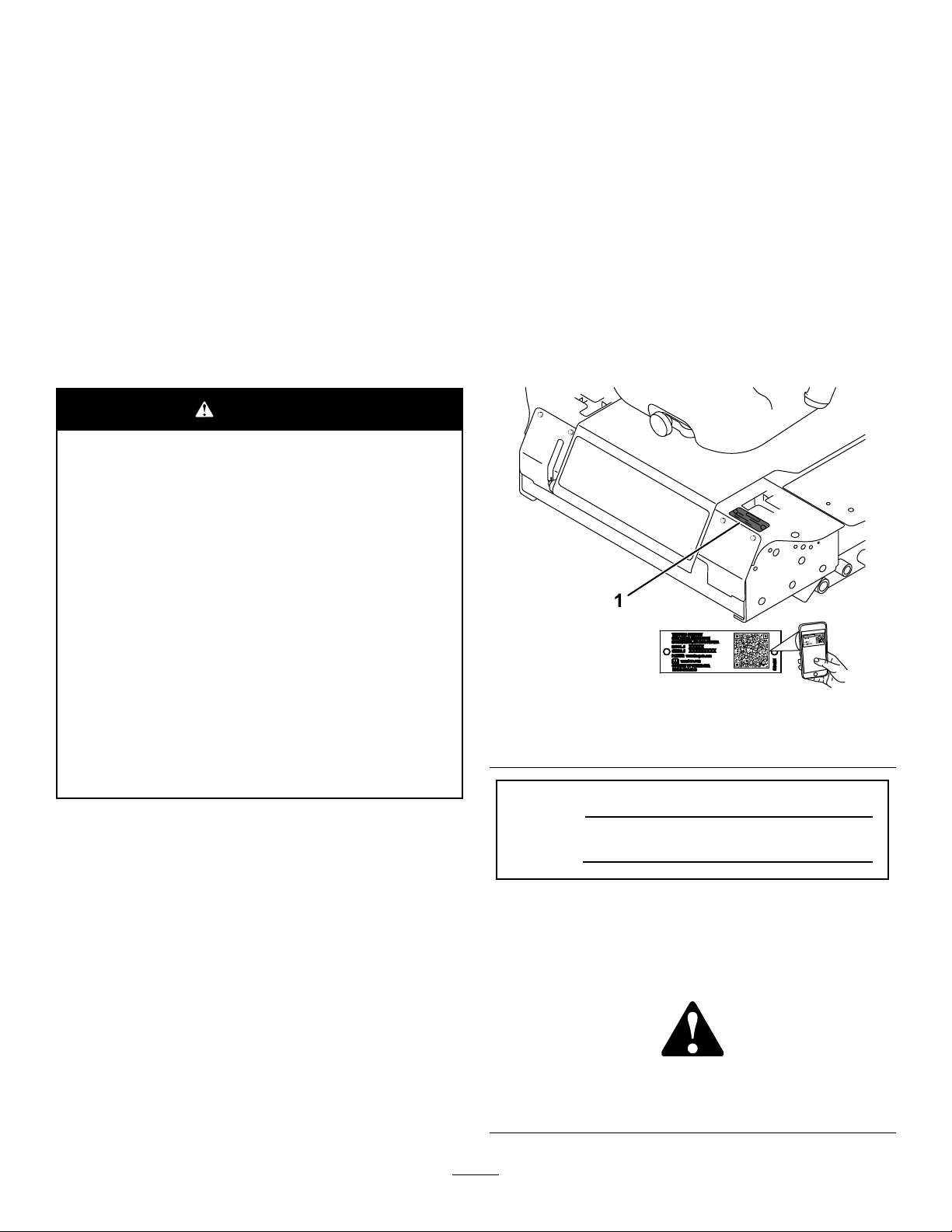

decal107-1866

107-1866

Note:Thismachinecomplieswiththeindustrystandard

stabilitytestinthestaticlateralandlongitudinaltestswiththe

maximumrecommendedslopeindicatedonthedecal.Reviewthe

instructionsforoperatingthemachineonslopesintheOperator’s

Manualaswellastheconditionsinwhichyouwouldoperatethe

machinetodeterminewhetheryoucanoperatethemachineinthe

conditionsonthatdayandatthatsite.Changesintheterraincan

resultinachangeinslopeoperationforthemachine.Ifpossible,

keepthecuttingunitsloweredtothegroundwhileoperatingthe

machineonslopes.Raisingthecuttingunitswhileoperatingon

slopescancausethemachinetobecomeunstable.

1.Sliding/lossofcontrolhazard;tippinghazard,drop-offs—do

notturnathighspeeds;turnatlowspeeds;donotuseon

slopesnearopenwater;donotuseonslopesgreaterthan

15°;stayawayfromdrop-offs.

2.Warning—iftherollbarislowered,donotweartheseatbelt;

iftherollbarisraised,weartheseatbelt.

3.Warning—donotusedualrampswhenloadingontoa

trailer;use1rampwideenoughforthemachine;usea

rampwithaslopelessthan15°.

decal107-3069

107-3069

1.Warning–thereisnorolloverprotectionwhentherollbaris

down.

2.T oavoidinjuryordeathfromarolloveraccident,keepthe

rollbarintheraisedandlockedpositionandweartheseat

belt.Lowertherollbaronlywhenabsolutelynecessary;do

notweartheseatbeltwhentherollbarisdown.

3.ReadtheOperator'sManual;driveslowlyandcarefully.

7

Page 8

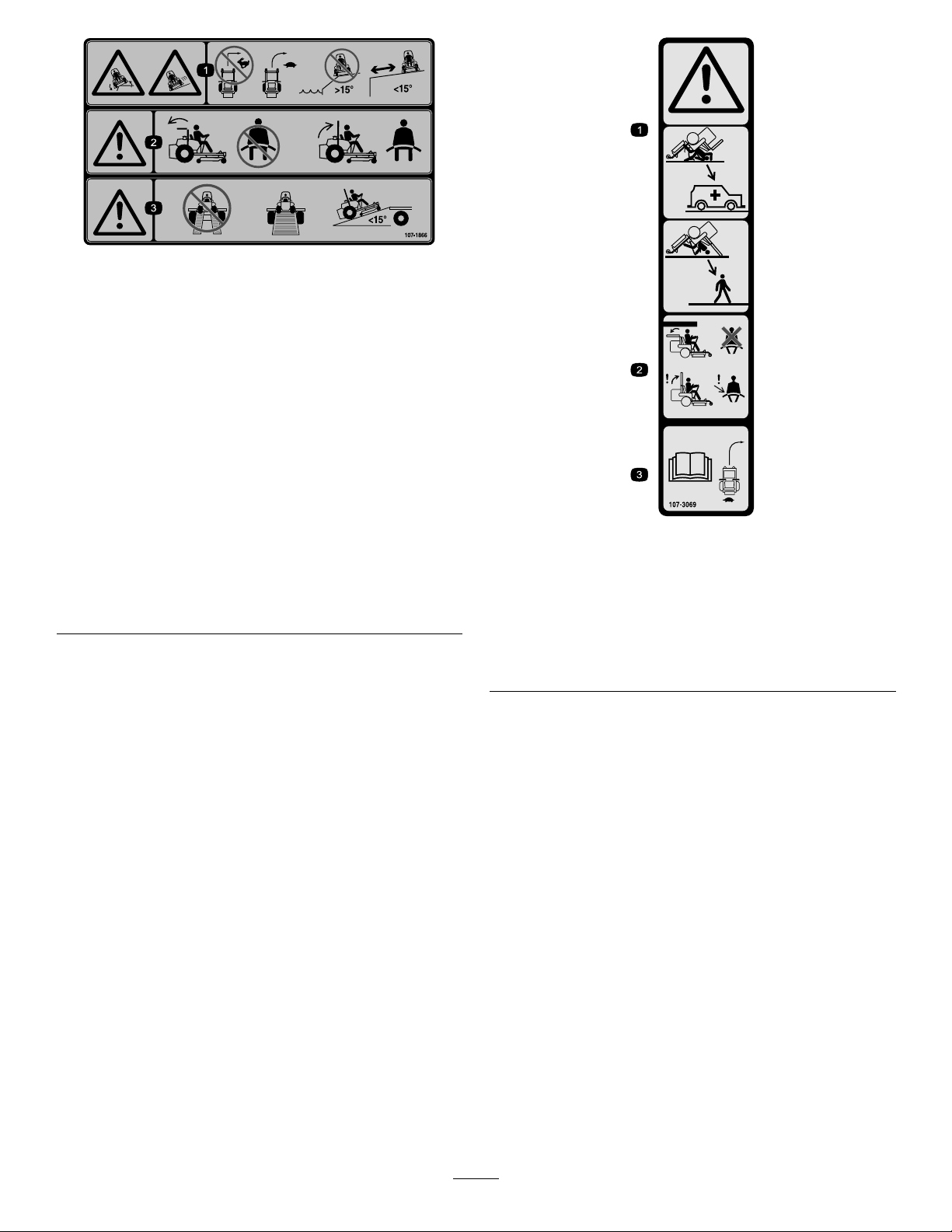

110-9796

1.ReadtheOperator'sManualforinformationonfuses.

decal110-9796

110-8253

1.PTO–Off4.Continuous-variable

2.PTO—On5.Slow

3.Fast

110-8254

1.Engine–Stop3.Engine—Start

2.Engine—Run

decal110-8253

decal133-5618

133-5618

setting

decal110-8254

8

Page 9

decal110-8252

110-8252

1.ReadtheOperator'sManual.

3.Hydraulicoil5.Enginecoolant

2.Parkingbrake4.Fuel6.Engineoil

110-9781

1.Warning—readtheOperator'sManual.

2.Poisonhazard;causticliquid/chemicalburnhazard—keepchildrenawayfromthebattery.

3.Warning—donottouchthehotsurface.

4.Cutting/dismembermenthazard,fan;entanglementhazard,belt—stayawayfrommovingparts.

5.Hydraulicuidunderpressurehazard;highpressuresprayhazard;highpressureuidhazard,injectionintothebody—wear

handandskinprotection.

decal110-9781

9

Page 10

120-9195

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineintheconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

decal120-9195

1.Warning—readtheOperator’sManual;donotoperatethe

machineunlessyouaretrained.

2.Cutting/dismembermenthazard,mowerblade—keep

bystandersaway;donotcarrypassengersonthemachine.

3.Sliding/lossofcontrolhazard;tippinghazard,drop-offs—do

notmowneardrop-offs;keepawayfromdrop-offs;donotturn

athighspeeds;turnatlowspeeds.

4.Tippinghazard—weartheseatbeltwhenarollbarisinplace;

donotweartheseatbeltwhentherollbarislowered.

5.Thrownobjecthazard—keepbystandersaway;lowerthe

deectorbeforeusingthemachine.

6.Warning—engagetheparkingbrake,shutofftheengine,and

removethekeybeforeleavingthemachine.

7.Cutting/dismembermenthazardofhandsorfeet,mower

blade—removethekeyandreadtheOperator’sManual

beforeperformingmaintenance;stayawayfrommovingparts;

keepallguardsandshieldsinplace.

8.Warning—wearhearingprotection.

9.Disengage

10.Engage

11.Parkingbrake

12.Starttheengine—Cleangrassanddebrisfromthemower

beltandpulleys,disengagethePTO,setthedriveinneutral,

engagetheparkingbrake,turnthekeytopoweronthe

mower,andturnthekeyfullytostarttheengine.

13.ReadtheOperator’sManual.

120-9196

1.Forward

3.Slow

2.Fast4.Neutral6.T owvalvelocation;torque

5.Reverse

thetowvalvesto5.65to

7.91N∙m(50to70in-lb).

10

decal120-9196

7.ReadtheOperator's

Manualformore

informationonthehydraulic

uid.

Page 11

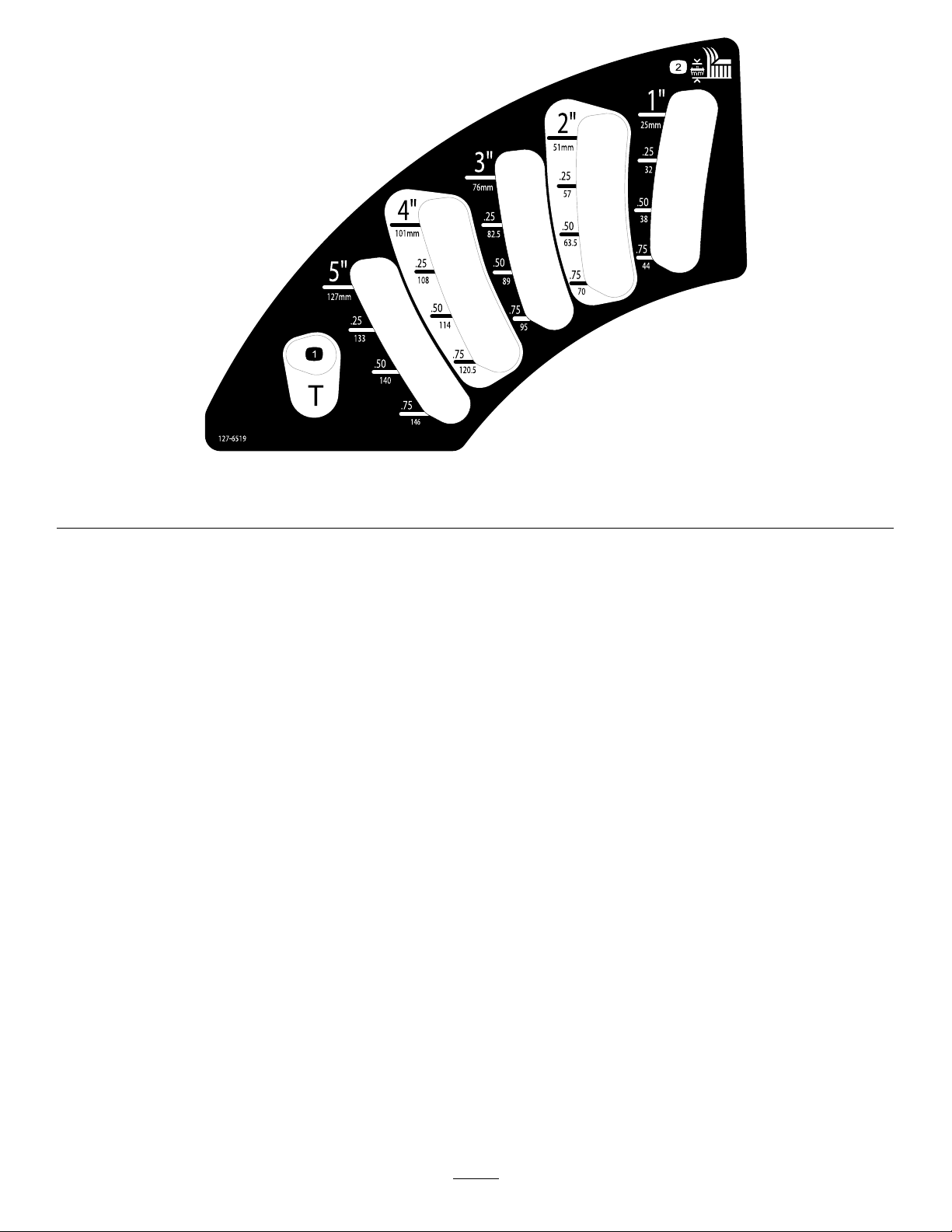

decal127-6519

127-6519

1.Transportposition

2.Heightofcut

11

Page 12

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

MediaandAdditionalParts

Description

Operator'sManual

Nopartsrequired

CuttingunitInstallationInstructions

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Production-yeardecal1

Qty.

1

Reviewitbeforeoperatingthemachine.

Qty.

–

1Installthecuttingunit.

–

–

–

–

RaisetheROPS.

Adjusttheleft,frontcasterwheel.

Checkthetirepressure.

Installweights.

Checkthehydraulicuid,engineoil,

andcoolantlevels.

Installthedecal(CEMachinesOnly).

Use

Use

Engineowner'smanual1

Ignitionkeys2

1

RaisingtheRollBar

NoPartsRequired

Procedure

Raisetherollbar;refertoAdjustingtheRollBar(page

21).

Useittoreferenceengineinformation.

Starttheengine.

2

InstallingtheCuttingUnit

Partsneededforthisprocedure:

1

CuttingunitInstallationInstructions

Procedure

InstallthecuttingunitusingtheInstallationInstructions

forthatcuttingunit.

12

Page 13

3

AdjustingtheLeft,Front

CasterWheel

NoPartsRequired

Procedure

Adjusttheleft,frontcasterwheeltotheoutside

positionfor72-inchcuttingunitsandtotheinside

positionfor60-inchand62-inchcuttingunits.

4

CheckingtheTirePressure

NoPartsRequired

Procedure

Checkthetirepressure;refertoCheckingtheTire

Pressure(page43).

Important:Maintainpressureinalltiresto

ensureagoodquality-of-cutandpropermachine

performance.Donotunderinatethetires.

13

Page 14

5

InstallingWeights(forCECompliance)

NoPartsRequired

Procedure

Machineswith183cm(72inch)decksinstalledandnootherattachmentsdonotneedaddedweighttomeet

CEstandards.However,youmayneedtopurchaseandinstalladditionalweightdependingonthemowerdeck

size/typeandtheattachmentsthatyouinstallonthemachine.Thefollowingtableliststhevariousattachment

congurationsandtheadditionalfrontweightneededforeachmodel:

AttachmentConguration

Groundsmaster7200/7210

TractionUnitwithnoAdded

Attachments

Groundsmaster7200/7210

TractionUnitandHardCanopy

Groundsmaster7200/7210

TractionUnit,HardCanopy,

andRoadLightKit

Groundsmaster7200/7210

TractionUnit,HardCanopy,

RoadLightKit,andJackStand

Groundsmaster7200/7210

TractionUnit,HardCanopy,

andJackStand

Groundsmaster7200/7210

TractionUnit,RoadLightKit,

andJackStand

Groundsmaster7200/7210

TractionUnitandRoadLight

Kit

Groundsmaster7200/7210

TractionUnitandJackStand

WeightRequiredwitha

157.5cm(62inch)Base

Deck(30457)

10kg(22lb)0kg(0lb)0kg(0lb)

34kg(75lb)9.5kg(21lb)15kg(33lb)

32.2kg(71lb)28.5kg(63lb)10kg(22lb)

18kg(40lb)17kg(37lb)10kg(22lb)

14kg(31lb)10kg(22lb)10kg(22lb)

0kg(0lb)0kg(0lb)0kg(0lb)

11.3kg(25lb)0kg(0lb)0kg(0lb)

0kg(0lb)0kg(0lb)0kg(0lb)

WeightRequiredwitha

183cm(72inch)Base

Deck(30353)

WeightRequiredwitha183

cm(72inch)Side-discharge

(30481)

ContactyourauthorizedT orodistributortoobtaintheappropriatekitsandweightsforyourmachine.

14

Page 15

6

CheckingtheFluidLevels

NoPartsRequired

Procedure

1.Checkthehydraulic-uidlevelbeforestarting

theengine,refertoCheckingtheHydraulic

System(page52).

2.Checktheengine-oillevelbeforestartingthe

engine,refertoCheckingtheEngine-OilLevel

(page38).

3.Checkthecoolingsystembeforestartingthe

engine;refertoCheckingtheCoolingSystem

(page44).

ProductOverview

Figure4

1.Parking-brakelever4.Motion-controllever

2.Fuelcap(bothsides)5.Seat

3.Rollbar

6.Seatbelt

g020877

7

InstallingtheDecal(CE

MachinesOnly)

Partsneededforthisprocedure:

1Production-yeardecal

Procedure

OnmachinesrequiringCEcompliance,installthe

production-yeardecalincludedinthelooseparts

(Figure3).

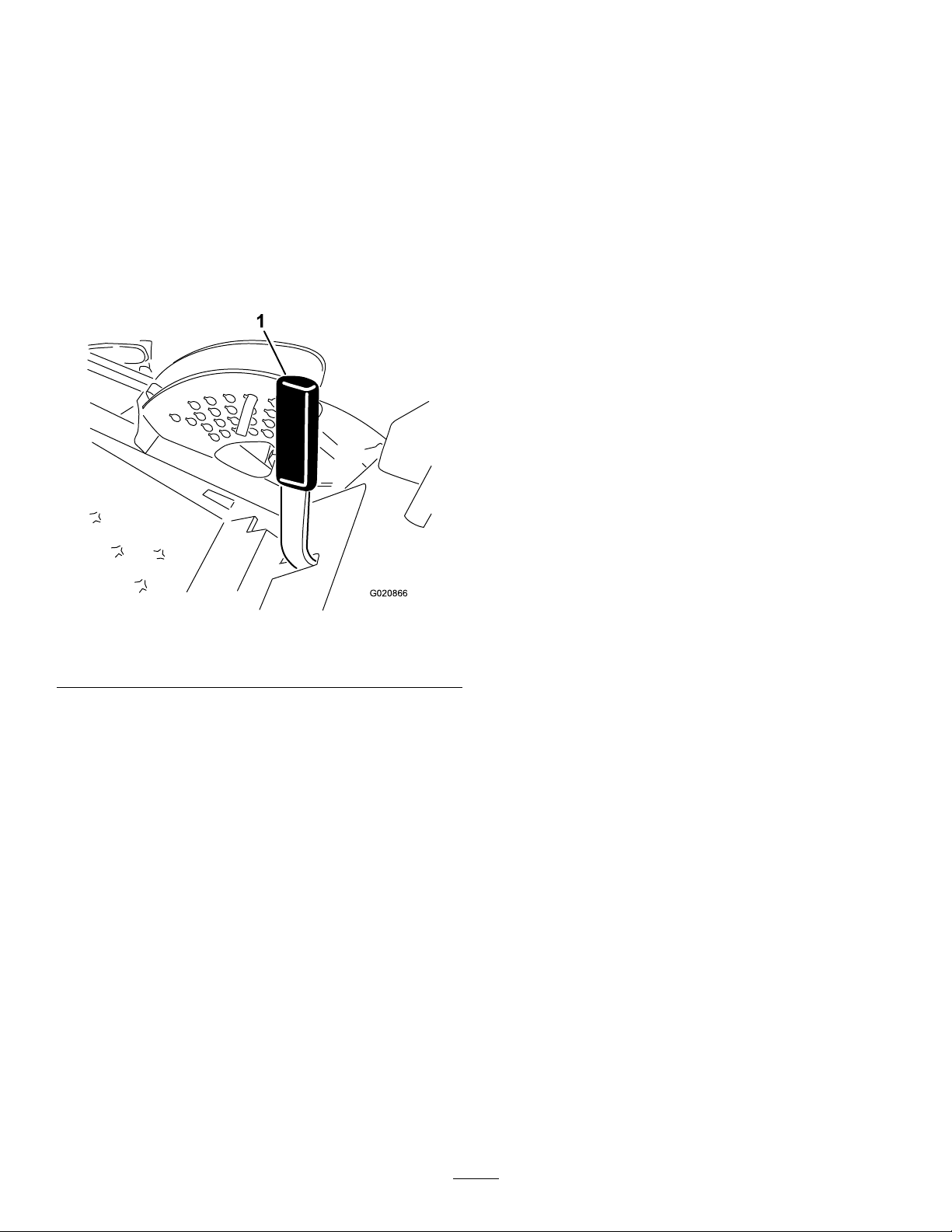

1.Ignitionswitch

2.Engine-coolant-temperature

warninglight

3.Glow-pluglight

4.Power-takeoff(PTO)

switch

Controls

g004492

Figure5

5.Oil-pressurewarninglight

6.Charge-indicatorlight

7.Throttlelever

8.Hourmeter

Figure3

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine(Figure4and

Figure5).

g278244

15

Page 16

Motion-ControlLevers

Glow-Plug-IndicatorLight(Orange

Themotion-controlleverscontroltheforwardand

rearwardmotionsaswellastheturningofthe

machine.RefertoDrivingtheMachine(page27).

Parking-BrakeLever

Wheneveryoushutofftheengine,engagetheparking

braketopreventaccidentalmovementofthemachine.

Toengagetheparkingbrake,pulltheparking-brake

leverrearwardandup(Figure6).Toreleasethe

parkingbrake,pushtheparking-brakeleverforward

anddown.

Figure6

1.Parking-brakelever

Light)

Theglow-plug-indicatorlight(Figure5)turnsonwhen

youturntheignitionswitchtotheONposition.It

remainsonfor6seconds.Whenthelightturnsoff,

youcanstarttheengine.

HourMeter

Thehourmeterrecordsthenumberofhoursthat

youoperatethemachinewiththekeyswitchinthe

RUNposition.Usethesetimesforschedulingregular

maintenance.

Engine-Coolant-Temperature

WarningLight

Thislightilluminatesandthecuttingbladesstopif

theengine-coolanttemperatureishigh.Ifyoudonot

stopthemachineandthecoolanttemperaturerises

another11°C(20°F),theengineshutsoff.

Important:Ifthemowerdeckshutsdownand

thetemperaturewarninglightison,pushthe

PTOknobdown,drivetoasafe,atarea,move

thethrottlelevertotheSLOWposition,move

themotion-controlleversintotheNEUTRAL-LOCK

position,andengagetheparkingbrake.Idlethe

g020866

engineforseveralminuteswhileitcoolstoasafe

level.Shutofftheengineandcheckthecooling

system;refertoCheckingtheCoolingSystem

(page44).

IgnitionSwitch

Theignitionswitchhas3positions:OFF,ON/PREHEAT,

andST ART.

ThrottleLever

Thethrottlelevercontrolsthespeedoftheengine,

thespeedoftheblades,and,inconjunctionwith

motion-controllevers,thegroundspeedofthe

machine.Movingthethrottleleverforwardtowardthe

FASTpositionincreasestheenginespeed.Moving

itrearwardtowardtheSLOWpositiondecreasesthe

enginespeed.Alwaysrunthemachinewiththe

throttleintheFASTpositionwhencuttinggrass.

Power-Takeoff(PTO)Switch

Thepower-takeoff(PTO)switchstartsandstopsthe

mowerblades.

ChargeIndicator

Thechargeindicatorilluminatesifelectricalcharging

systemisoperatingaboveorbelowthenormal

operatingrange(Figure5).Checkand/orrepairthe

electricalchargingsystem.

Oil-PressureWarningLight

Theoil-pressurewarninglightglowsiftheengine-oil

pressuredropsbelowasafelevel(Figure5).Ifthe

oilpressureislow,shutofftheengineanddetermine

thecause.Repairtheengine-oilsystembeforeyou

starttheengineagain.

16

Page 17

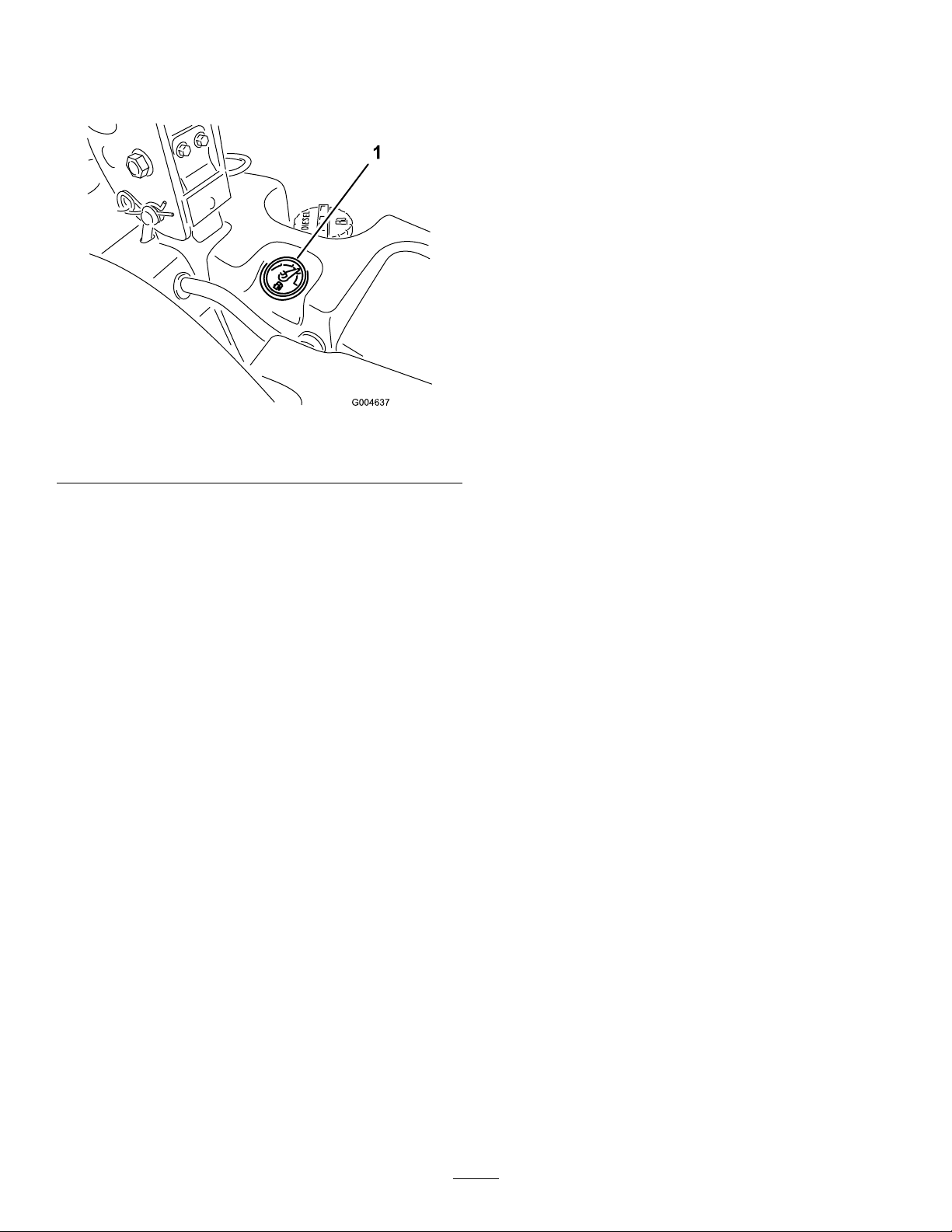

FuelGauge

Thefuelgauge(Figure7)indicatesthequantityoffuel

remaininginthefueltanks.

Figure7

1.Fuelgauge

g004637

17

Page 18

Specications

Figure8

DescriptionFigure8

Heightwithrollbarup

Heightwithrollbardown

Overalllength

Overallwidth

Wheelbase

Wheeltread(tirecentertocenter)rear

reference

C183cm(72inches)

D

F

B

E

A

18

g242892

DimensionorWeight

125cm(49inches)

246cm(97inches)

145cm(57inches)

145cm(57-1/4inches)

114cm(45inches)

Page 19

Groundclearance15cm(6inches)

Weight,with72-inchSide-DischargeCuttingunit(30354or30481)934kg(2,060lb)

Weight,with60-inchSide-DischargeCuttingunit(30456)900kg(1,985lb)

Weight,with72-inchBaseCuttingunit(30353)876kg(1,932lb)

Weight,with62-inchBaseCuttingunit(30457)855kg(1,884lb)

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhance

andexpanditscapabilities.ContactyourAuthorizedServiceDealerorauthorizedTorodistributororgoto

www.T oro.comforalistofallapprovedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafetycerticationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacementpartsandaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty .

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Shutofftheengine,removethekey(ifequipped),

andwaitforallmovementtostopbeforeyouleave

theoperator’sposition,Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

Replacewornordamagedbladesandboltsinsets

topreservebalance.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

•Checkthatoperator-presencecontrols,safety

switches,andguardsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Beforemowing,alwaysinspectthemachineto

ensurethattheblades,bladebolts,andcutting

assembliesareingoodworkingcondition.

19

Page 20

AddingFuel

Important:Thepetroleumdieselportionmust

beultra-lowsulfur.

FuelSpecication

•Neverusekeroseneorgasolineinsteadofdiesel

fuel.

•Nevermixkeroseneorusedengineoilwiththe

dieselfuel.

•Neverkeepfuelincontainerswithzincplatingon

theinside.

•Donotusefueladditives.

PetroleumDiesel

Cetanerating:40orhigher

Sulfurcontent:Lowsulfur(<500ppm)orultra-low

sulfur(<15ppm)

FuelTable

Dieselfuelspecication

ASTMD975

No.1-DS15

No.2-DS15

EN590EuropeanUnion

ISO8217DMX

JISK2204GradeNo.2

KSM-2610

Location

USA

International

Japan

Korea

Observethefollowingprecautions:

•Biodieselblendsmaydamagepaintedsurfaces.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuel

astheymaydegradeovertime.

•Fuellterpluggingmayoccurforatimeafteryou

converttobiodieselblends.

•Formoreinformationonbiodiesel,contactyour

authorizedT orodistributor.

FuelTankCapacity

43.5L(11.5USgallons)

FillingtheFuelTank

Important:Thefueltanksareconnected,butthe

fueldoesnottransferquicklyfromonetanktothe

other.Itisimportantwhenllingthatyoupark

onalevelsurface.Ifyouparkonahill,youmay

inadvertentlyoverllthetanks.

Important:Donotoverllthefueltanks.

Important:Donotopenthefueltankswhen

parkedonahill.Thefuelcouldspillout.

•Useonlyclean,freshdieselfuelorbiodieselfuels.

•Purchasefuelinquantitiesthatcanbeusedwithin

180daystoensurefuelfreshness.

Usesummer-gradedieselfuel(No.2-D)at

temperaturesabove-7°C(20°F)andwinter-grade

fuel(No.1-DorNo.1-D/2-Dblend)belowthat

temperature.

Note:Useofwinter-gradefuelatlowertemperatures

provideslowerashpointandcoldowcharacteristics

whicheasesstartingandreducesfuellterplugging.

Usingsummer-gradefuelabove-7°C(20°F)

contributestowardlongerfuelpumplifeandincreased

powercomparedtowinter-gradefuel.

UsingBiodiesel

Thismachinecanalsouseabiodiesel-blendedfuelof

uptoB20(20%biodiesel,80%petrodiesel).

Sulfurcontent:Ultra-lowsulfur(<15ppm)

Biodieselfuelspecication:ASTMD6751or

EN14214

Blendedfuelspecication:ASTMD975,EN590,

orJISK2204

g031802

Figure9

Note:Ifpossible,llthefueltanksaftereachuse.

Thisminimizesbuildupofcondensationinsidethe

fueltank.

20

Page 21

CheckingtheEngine-Oil

Level

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheEngine-OilLevel(page38).

CheckingtheCooling

System

Beforeyoustarttheengineandusethemachine,

checkthecoolingsystem;refertoCheckingthe

CoolingSystem(page21).

CheckingtheHydraulic

Important:Alwaysusetheseatbeltwhenthe

rollbarisintheraisedandlockedposition.Do

notusetheseatbeltwhentherollbarisinthe

loweredposition.

LoweringtheRollBar

LowertherollbarasshowninFigure11.

Note:Pushthebarforwardtorelievepressureon

thepins.

System

Beforeyoustarttheengineandusethemachine,

checkthehydraulicsystem;refertoCheckingthe

HydraulicSystem(page52).

AdjustingtheRollBar

WARNING

Toavoidinjuryordeathfromrollover,keep

therollbarintheraisedlockedpositionand

usetheseatbelt.

Ensurethattheseatissecuredwiththeseat

latch.

WARNING

Thereisnorolloverprotectionwhentheroll

barisinthedownposition.

•Donotoperatethemachineonuneven

groundoronahillsidewiththerollbarin

thedownposition.

g031636

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbar

isinthedownposition.

•Driveslowlyandcarefully .

•Raisetherollbarassoonasclearance

permits.

•Checkcarefullyforoverheadclearances

(i.e.,branches,doorways,electricalwires)

beforedrivingunderanyobjectsanddo

notcontactthem.

g031635

Figure10

Note:Securetherollbarsothatitdoesnotdamage

thehood.

21

Page 22

RaisingtheRollBar

RaisetherollbarasshowninFigure10.

UsingtheSafety-Interlock

System

CAUTION

Ifthesafety-interlockswitchesare

disconnectedordamaged,themachinecould

operateunexpectedly,causingpersonal

g031624

injury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Understandingthe

Safety-InterlockSystem

Thesafety-interlocksystempreventstheenginefrom

startingunless:

•Youaresittingontheseatortheparkingbrake

isengaged.

•Thepowertakeoff(PTO)isdisengaged.

•Themotion-controlleversareintheNEUTRAL-LOCK

position.

•Theenginetemperatureisbelowthemaximum

operatingtemperature.

Figure11

Important:Alwaysusetheseatbeltwhenthe

rollbarisintheraisedandlockedposition.Do

notusetheseatbeltwhentherollbarisinthe

loweredposition.

Thesafety-interlocksystemalsoshutsoffthe

enginewhenyoumovethetractioncontrolsfrom

theNEUTRAL-LOCKpositionwiththeparkingbrake

engaged.IfyourisefromtheseatwhenthePTO

isengaged,thereisa1-seconddelayandthenthe

engineshutsoff.

g031631

TestingtheSafety-Interlock

System

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow,haveanAuthorized

ServiceDealerrepairthesafetysystemimmediately .

1.Sitontheseat,engagetheparkingbrake,and

movethePTOtotheONposition.Trystarting

theengine;theengineshouldnotcrank.

2.Sitontheseat,engagetheparkingbrake,

andmovethePTOtotheOFFposition.

Moveeithermotion-controlleveroutofthe

NEUTRAL-LOCKposition.Trystartingtheengine;

theengineshouldnotcrank.Repeatforother

motion-controllever.

3.Sitontheseat,engagetheparkingbrake,move

thePTOswitchtotheOFFposition,andmove

themotion-controlleverstotheNEUTRAL-LOCK

22

Page 23

position.Starttheengine.Whiletheengineis

running,releasetheparkingbrake,engagethe

PTO,andriseslightlyfromtheseat;theengine

shouldshutoffwithin2seconds.

4.Withoutanoperatorontheseat,engagethe

parkingbrake,movethePTOswitchtotheOFF

position,andmovethemotion-controlleversto

theNEUTRAL-LOCKposition.Starttheengine.

Whiletheengineisrunning,centereithermotion

control;theengineshouldshutoffwithin2

seconds.Repeatfortheothermotion-control

lever.

5.Withoutanoperatorontheseat,disengagethe

parkingbrake,movethePTOswitchtotheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Trystartingthe

engine;theengineshouldnotcrank.

UsingtheSCMtoDiagnose

SystemProblems

Themachineisequippedwithastandardcontrol

module(SCM)monitoringsystemthattracksthe

functionofvariouskeysystems.TheSCMislocated

undertherightcontrolpanel.Accessitthroughthe

sidepanelcover(Figure12).Toopenthesidepanel

cover,releasethe2latchesandpulloutonit.

g004927

Figure13

1.Hightemperatureshutdown—theenginetemperaturehas

exceededsafelevelsandtheenginehasbeenshutdown.

Checkthecoolingsystem.

2.Hightemperaturewarning—theenginetemperatureis

approachingunsafelevelsandthecuttingunithasbeen

shutdown.Checkthecoolingsystem.

3.Operatorisintheseat.

4.ThePTOison.

5.Theparkingbrakeisnotengaged.

6.Controlsareinneutral.

7.TheSCMisreceivingpowerandisoperational.

PositioningtheSeat

Figure12

1.Sidepanelcover

2.Latches

OnthefaceoftheSCMare11LEDsthatilluminate

toindicatevarioussystemconditions.Youcanuse7

oftheselightsforsystemdiagnosis.RefertoFigure

13foradescriptionofwhateachlightmeans.For

detailsonusingtherestoftheSCMfunctions,referto

theServiceManual,availablethroughyourauthorized

Torodistributor.

Theseatmovesforwardandbackward.Positionthe

seatwhereyouhavethebestcontrolofthemachine

andaremostcomfortable.

Toadjust,movetheleversidewaystounlocktheseat

(Figure14).

g004495

Figure14

g008962

23

Page 24

ChangingtheSeat

Suspension

DuringOperation

Theseatisadjustabletoprovideasmoothand

comfortableride.Positiontheseatwhereyouare

mostcomfortable.

Toadjustit,turntheknobinfronteitherdirectionto

providethebestcomfort(Figure15).

Figure15

1.Seat-suspensionknob

UnlatchingtheSeat

Toaccessthehydraulicandothersystemsunderthe

seat,unlatchtheseatandswingitforward.

1.Usetheseatpositionadjustmentlevertoslide

theseatallthewayforward.

2.Pulltheseatlatchforwardandliftuptounlatch

theseat(Figure16).

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

g019768

damagemayoccur.

•Beforeyoustarttheengine,ensurethatalldrives

areinneutral,theparkingbrakeisengaged,and

youareintheoperatingposition.

•Donotcarrypassengersonthemachineandkeep

bystandersandchildrenoutoftheoperatingarea.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Avoidmowingonwetgrass.Reducedtraction

couldcausethemachinetoslide.

•Keepyourhandsandfeetawayfromrotating

parts.Keepclearofthedischargeopening.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

1.Seatlatch

Figure16

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Stopthebladeswheneveryouarenotmowing.

•Stopthemachine,removethekey,andwaitfor

allmovingpartstostopbeforeinspectingthe

attachmentafterstrikinganobjectorifthereis

anabnormalvibrationinthemachine.Makeall

necessaryrepairsbeforeresumingoperation.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

g020871

•Disengagethedrivetothecuttingunit,shut

offtheengine,removethekey,andwaitforall

movingpartstostopbeforeadjustingtheheightof

cut(unlessyoucanadjustitfromtheoperating

position).

24

Page 25

•Operatetheengineonlyinwell-ventilatedareas.

Exhaustgasescontaincarbonmonoxide,which

islethalifinhaled.

•Neverleavearunningmachineunattended.

•Beforeyouleavetheoperator’sposition,dothe

following:

–Parkthemachineonalevelsurface.

–Disengagethepowertakeoffandlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey(if

equipped).

–Waitforallmovementtostop.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflightning.

•Donotusethemachineasatowingvehicle.

•Useaccessories,attachments,andreplacement

partsapprovedbyT oroonly .

RolloverProtectionSystem

(ROPS)Safety

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Y ouareresponsibleforsafeslope

operation.Operatingthemachineonanyslope

requiresextracaution.

•Evaluatethesiteconditionstodetermineifthe

slopeissafeformachineoperation,including

surveyingthesite.Alwaysusecommonsense

andgoodjudgmentwhenperformingthissurvey .

•Reviewtheslopeinstructionslistedbelowfor

operatingthemachineonslopesandtodetermine

whetheryoucanoperatethemachineinthe

conditionsonthatdayandatthatsite.Changes

intheterraincanresultinachangeinslope

operationforthemachine.

•Avoidstarting,stopping,orturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction.Maketurnsslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steering,orstabilityisinquestion.

•Removeormarkobstructionssuchasditches,

holes,ruts,bumps,rocks,orotherhiddenhazards.

Tallgrasscanhideobstructions.Uneventerrain

couldoverturnthemachine.

•DonotremoveanyoftheROPScomponentsfrom

themachine.

•Ensurethattheseatbeltisattachedandthatyou

canreleaseitquicklyinanemergency.

•Checkcarefullyforoverheadobstructionsanddo

notcontactthem.

•KeeptheROPSinsafeoperatingconditionby

thoroughlyinspectingitperiodicallyfordamage

andkeepingallthemountingfastenerstight.

•ReplacedamagedROPScomponents.Donot

repairoralterthem.

•Alwaysusetheseatbeltwiththerollbarinthe

raisedposition.

•TheROPSisanintegralsafetydevice.Keepa

foldingrollbarintheraisedandlockedposition,

andusetheseatbeltwhenoperatingthemachine

withtherollbarintheraisedposition.

•Lowerafoldingrollbartemporarilyonlywhen

necessary.Donotweartheseatbeltwhenthe

rollbarisfoldeddown.

•Beawarethatthereisnorolloverprotectionwhen

afoldedrollbarisinthedownposition.

•Beawarethatoperatingthemachineonwet

grass,acrossslopes,ordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.

•Useextremecautionwhenoperatingthemachine

neardrop-offs,ditches,embankments,water

hazards,orotherhazards.Themachinecould

suddenlyrolloverifawheelgoesovertheedge

ortheedgecavesin.Establishasafetyarea

betweenthemachineandanyhazard.

•Identifyhazardsatthebaseoftheslope.

Iftherearehazards,mowtheslopewitha

pedestrian-controlledmachine.

•Ifpossible,keepthecuttingunit(s)loweredtothe

groundwhileoperatingonslopes.Raisingthe

cuttingunit(s)whileoperatingonslopescancause

themachinetobecomeunstable.

•Useextremecautionwithgrass-collectionsystems

orotherattachments.Thesecanchangethe

stabilityofthemachineandcausealossofcontrol.

•Checktheareathatyouwillbemowingandnever

folddownafoldingrollbarinareaswherethere

areslopes,drop-offs,orwater.

25

Page 26

OperatingtheParking

StartingtheEngine

Brake

Alwaysengagetheparkingbrakewhenyoustopthe

machineorleaveitunattended.

EngagingtheParkingBrake

WARNING

Theparkingbrakemaynotholdthemachine

parkedonaslopeandcouldcausepersonal

injuryorpropertydamage.

Donotparkthemachineonslopesunlessthe

wheelsarechockedorblocked.

Note:Theglowpluglightilluminatesfor6seconds

whenyouturntheignitionkeytotheRUNposition.

TurntheignitiontotheST ARTpositionafterthelight

goesout.

Important:Usestartingcyclesofnomorethan

15secondsperminutetoavoidoverheatingthe

startermotor.

Important:Operatethemachinewiththethrottle

leverintheSLOWpositioninboththeforward

andreversedirectionsfor1to2minutesafter

changingtheengineoil,overhaulingeitherthe

engine,transmission,orwheelmotor,andwhen

youstarttheengineforthersttime.Operatethe

liftleverandPTOlevertoensurethattheyoperate

properly.Shuttheengineoff,checkuidlevels,

andcheckforoilleaks,looseparts,andanyother

noticeablemalfunctions.

Figure17

ReleasingtheParkingBrake

Figure18

g027914

g027915

g191137

Figure19

Note:LeavethethrottlemidwaybetweentheSLOW

andFASTpositionsuntiltheengineandhydraulic

systemwarmup.

26

Page 27

DrivingtheMachine

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFASTpositionforbest

performance.AlwaysoperateintheFASTthrottle

positionwhenrunningpoweredattachments.

CAUTION

Themachinecanturnveryrapidly.Youmay

losecontrolofitandcausepersonalinjuryor

damagethemachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

1.Releasetheparkingbrake.

Note:Theengineshutsoffifyoumovethe

motion-controlleversoutoftheNEUTRAL-LOCK

positionwiththeparkingbrakeengaged.

2.Movetheleverstothecenter,unlockedposition.

3.Drivethemachineasfollows:

•Tomovestraightforward,slowlypushthe

motion-controlleversforward(Figure20).

•Tomovestraightrearward,slowlypullthe

motion-controlleversrearward(Figure20).

•Toturn,slowthemachinebypullingbackon

bothleversandthenpushforwardonthe

leverontheoppositesidefromwhichyou

wanttoturn(Figure20).

•Tostop,pullthemotion-controlleverstothe

NEUTRALposition.

Note:Thefartheryoumovethemotion-control

leversineitherdirection,thefasterthemachine

movesinthatdirection.

Figure20

1.Motion-control

lever—NEUTRAL-LOCK

position

2.Center,unlockedposition5.Frontofthemachine

3.Forward

4.Backward

g004532

27

Page 28

ShuttingOfftheEngine

OperatingtheMower

CAUTION

Childrenorbystandersmaybeinjuredifthey

attempttomoveoroperatethetractorwhile

itisunattended.

Alwaysremovetheignitionkeyandengage

theparkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

UsingtheDeck-LiftSwitch

Thedeck-liftswitchraisesandlowersthecuttingunit

(Figure22).Theenginemustberunningforyouto

usethislever.

Figure21

g244208

g020873

Figure22

1.Deck-liftswitch

•Tolowerthecuttingunit,pushthedeck-liftswitch

down(Figure22).

Important:Whenyoulowerthecuttingunit,

itsetsinaoat/idleposition.

•Toraisethemoverdeck,pushthedeck-liftswitch

up(Figure22).

Important:Donotcontinuetoholdtheswitch

upordownafterthemowerhasfullyraisedor

lowered.Doingsodamagesthehydraulicsystem.

28

Page 29

EngagingthePowerTakeoff(PTO)

Thepower-takeoff(PTO)switchstartsandstopsthe

mowerbladesandsomepoweredattachments.

Note:Iftheengineiscold,allowtheenginetowarm

up5to10minutesbeforeengagingthePTO.

Figure23

DisengagingthePTO

locatedinthesecondrow.Thisdoesnotadd

6mm(1/4inch)tothe15.8cm(6inch)position.

g243799

Figure24

AdjustingtheHeightofCut

Youcanadjusttheheightofcutfrom2.5to15.8cm

(1to6inches)in6mm(1/4inch)incrementsby

relocatingthestoppinintodifferentholelocations.

1.Withtheenginerunning,pushthedeck-lift

switchupuntilthecuttingunitisfullyraisedand

releasetheswitchimmediately(Figure22).

2.Rotatethestoppinuntiltherollpininitlinesup

withtheslotsintheholesintheheight-of-cut

bracketandremoveit(Figure25).

3.Selectaholeintheheight-of-cutbracket

correspondingtotheheightofcutdesired,insert

thepin,androtateitdowntolockitinplace

(Figure25).

Note:Thereare4rowsofholepositions

(Figure25).Thetoprowgivesyoutheheightof

cutlistedabovethepin.Thesecondrowdown

givesyoutheheightlistedplus6mm(1/4inch).

Thethirdrowdowngivesyoutheheightlisted

plus12mm(1/2inch).Thebottomrowgivesyou

theheightlistedplus18mm(3/4inch).Forthe

15.8cm(6inch)position,thereisonly1hole,

g020870

Figure25

1.Stoppin2.Height-of-cutstop

g009174

4.Adjusttheanti-scalprollersandskidsas

required.

OperatingTips

FastThrottleSetting/Ground

Speed

Tomaintainenoughpowerforthemachineanddeck

whilemowing,operatetheengineattheFASTthrottle

positionandadjustyourgroundspeedforconditions.

Decreasethegroundspeedastheloadonthecutting

bladesincrease;increasethegroundspeedasthe

loadonthebladesdecrease.

AlternatingtheMowingDirection

Alternateyourmowingdirectiontoavoidmaking

rutsintheturf,whichcanappearovertime.This

alsohelpstodisperseclippings,whichenhances

decompositionandfertilization.

CuttingSpeed

Toimprovecutquality,useaslowergroundspeed

incertainconditions.

29

Page 30

AvoidingaLowCut

Ifthemachinecuttingwidthiswiderthanthemachine

thatyoupreviouslyused,raisethecuttingheightto

ensurethatuneventurfisnotcuttooshort.

SelecttheProperHeight-of-Cut

SettingtoSuitConditions

AfterOperation

GeneralSafety

•Shutofftheengine,removethekey(ifequipped),

andwaitforallmovementtostopbeforeyouleave

theoperator’sposition,Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

Removeapproximately25mm(1inch)orno

morethan1/3ofthegrassbladewhencutting.In

exceptionallylushanddensegrass,youmayneed

toslowdowntheforwardspeedand/orraisethe

height-of-cuttothenexthighersetting.

Important:Ifyouarecuttingmorethan1/3ofthe

grassblade,oraremowinginsparselonggrass

ordryconditions,usetheatsailofthebladesto

reduceair-bornechaff,debris,andstrainonthe

deck-drivecomponents.

CuttingLongGrass

Ifyouallowthegrasstogrowslightlylongerthan

normal,orifthegrasscontainsahighdegreeof

moisture,raisethecuttingheighttoahighersetting

andcutthegrassatthissetting.Thencutthegrass

againusingthelower,normalsetting.

KeepingtheMowerClean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildup

insidethemower,cuttingqualityeventuallybecomes

unsatisfactory.

Toreducetheriskofrehazard,keeptheengine,

mufer,batterycompartment,parkingbrake,cutting

units,andfuelstoragecompartmentfreeofgrass,

leaves,orexcessivegrease.Cleanupanyspilledoil

orfuel.

•Cleangrassanddebrisfromthecuttingunits,

mufers,andenginecompartmenttohelpprevent

res.Cleanupoilorfuelspills.

•Ifthecuttingunitsareinthetransportposition,use

thepositivemechanicallock(ifavailable)before

youleavethemachineunattended.

•Allowtheenginetocoolbeforestoringthemachine

inanyenclosure.

•Removethekeyandshutoffthefuel(ifequipped)

beforestoringorhaulingthemachine.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Maintainandcleantheseatbelt(s)asnecessary

PushingtheMachine

Inanemergency ,youcanmovethemachineavery

shortdistancebyactuatingthebypassvalvesinthe

hydraulicpumpandpushingthemachine.

Important:Alwayspushthemachinebyhand

andneveralongdistance.Nevertowthemachine,

becausedamagetothehydraulicsystemmay

occur.

Important:Thebypassvalvesmustbeopen

wheneveryoupushortowthemachine.Close

thevalvesonceyouhavepushedortowedthe

machinetothedesiredlocation.

MaintainingtheBlades

•Maintainsharpbladesthroughoutthecutting

season.Sharpbladescreateacleancutwithout

tearingorshreddingthegrassblades.Tearing

andshreddingcausesgrasstoturnbrownatthe

edges,whichslowsgrowthandincreasesthe

chanceofdisease.

•Checkthebladesdailyforsharpnessandfor

anywearordamage.Sharpenthebladesas

necessary.

•Ifabladeisdamagedorworn,replaceit

immediatelywithagenuineT ororeplacement

blade.RefertothecuttingunitOperator’sManual

forinstructionstoreplacetheblade.

1.Lifttheseat;refertoUnlatchingtheSeat(page

24)

2.Locatethebypassvalves(Figure26)androtate

eachbypassvalvecounterclockwise1turn.

Note:Thisallowshydraulicuidtobypassthe

pump,enablingthewheelstoturn.

Important:Donotrotatethebypassvalves

morethan1turn.Thispreventsvalvesfrom

comingoutofthebodyandcausinguidto

runout.

30

Page 31

Figure26

HaulingtheMachine

Useaheavy-dutytrailerortrucktohaulthemachine.

Ensurethatthetrailerortruckhasallthenecessary

brakes,lighting,andmarkingasrequiredbylaw.

Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

pets,orbystandersavoidinjury .

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerous

andcanleadtoaccidentscausingpersonal

injury.

Donotdrivethemachineonapublicstreet

g004644

orroadway.

1.Rightbypassvalve

3.Ensurethattheparkingbrakeisdisengagedand

pushthemachinetothedesiredlocation.

4.Closethevalvesbyrotatingeachvalve1

clockwiseturn(Figure26).

2.Leftbypassvalve

Note:Donotovertightenthevalves.

5.Torquethevalvestoapproximately8N∙m(71

in-lb).

Important:Ensurethatthebypassvalves

areclosedbeforeyoustarttheengine.

Runningtheenginewithopenbypassvalves

causesthetransmissiontooverheat.

1.Ifyouareusingatrailer,connectittothetowing

vehicle,andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck;refer

toLoadingtheMachine(page32).

4.Shutofftheengine,removethekey,engagethe

parkingbrake,andclosethefuelvalve.

5.Usethetie-downloopsonthemachineto

securelyfastenittothetrailerortruckwith

straps,chains,cable,orropes(Figure27).

1.Tractionunittie-downloops

31

g191318

Figure27

Page 32

LoadingtheMachine

Useextremecautionwhenloadingorunloading

machinesontoatraileroratruck.Useafull-width

rampthatiswiderthanthemachineforthisprocedure.

Drivethemachineuprampsinreverseanddriveit

downrampsinaforwarddirection(Figure28).

Figure28

g027995

1.Drivethemachineupthe

rampinreverse.

2.Drivethemachineforward

downtheramp.

Important:Donotusenarrowindividualramps

foreachsideofthemachine.

WARNING

Loadingthemachineontoatrailerortruck

increasesthepossibilityoftipoverandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•Whenloadingorunloadingthemachine,

usetheseatbeltandensurethattheroll

barisintheraisedposition.Ensurethat

therollbarcanclearthetopofanenclosed

trailer.

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan15°

g027996

Figure29

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.“H”indicatestheheightof

thetrailerortruckbedto

theground.

6.Trailer

•Donotexceeda15°anglebetweenthe

rampandtheground,orbetweentheramp

andthetrailerortruck.

•Ensurethattheramplengthisatleast4

timesaslongastheheightofthetraileror

truckbedtotheground.Thisensuresthat

therampangledoesnotexceed15°onat

ground.

•Drivethemachineuprampsinreverseand

driveitdownrampsinaforwarddirection.

•Whiledrivingthemachineonaramp,avoid

suddenaccelerationordeceleration,as

thiscouldcausealossofcontrolora

tipoversituation.

32

Page 33

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

MaintenanceSafety

•Beforeyouleavetheoperator’sposition,dothe

following:

–Parkthemachineonalevelsurface.

–Disengagethepowertakeoffandlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey(if

equipped).

–Waitforallmovementtostop.

•Allowmachinecomponentstocoolbefore

performingmaintenance.

•Ifthecuttingunitsareinthetransportposition,use

thepositivemechanicallock(ifequipped)before

youleavethemachineunattended.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

•Ifpossible,donotperformmaintenancewhilethe

engineisrunning.Keepawayfrommovingparts.

•Supportthemachinewithjackstandswhenever

youworkunderthemachine.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Keepallpartsofthemachineingoodworking

conditionandallhardwaretightened,especially

blade-attachmenthardware.

•Replaceallwornordamageddecals.

•Toensuresafe,optimalperformanceofthe

machine,useonlygenuineTororeplacement

parts.Replacementpartsmadebyother

manufacturerscouldbedangerous,andsuchuse

couldvoidtheproductwarranty.

Aftertherst10hours

Aftertherst50hours

Aftertherst200hours

Beforeeachuseordaily

Every50hours

Every100hours

Every150hours

Every200hours

•Torquetheframe-mountingbolts.

•Torquethewheellugnuts.

•Changethecutting-unitgearboxlubricant.

•Changetheengineoilandlter.

•Changethehydraulicuidandlter.

•Testthesafety-interlocksystem.

•Checktheengineoillevel.

•Checktheenginecoolantlevel.

•Cleantheradiatorwithcompressedair(moreoftenindirtyanddustyconditions).

•Checkthehydraulicuidlevel.

•Cleanthecuttingunitandmachine.

•Cleanthemachine.

•Cleanandmaintaintheseatbelt.

•Greasethebearingandbushinggreasettings(moreoftenindirtyordusty

conditionsandaftereverywashing).

•Checkbatterycableconnections.

•Checkthetirepressure.

•Checkthealternator-belttension.

•Checkthelubricantinthecutting-unitgearbox.

•Changetheengineoilandlter.

•Inspectthecooling-systemhosesandseals.Replacethemifcrackedortorn.

•Torquethewheellugnuts.

33

Page 34

MaintenanceService

Every400hours

Every800hours

Interval

MaintenanceProcedure

•Changethecutting-unitgearboxlubricant.

•Servicetheair-cleanerlter.—servicethelteralsowhentheair-cleanerindicator

showsred;servicetheair-cleanerltermorefrequentlyinextremelydustyordirty

conditions.

•Servicetheaircleaner.

•Replacethefuel-ltercanisterforthewaterseparator.

•Drainwaterorothercontaminantsfromthewaterseparator.

•Inspectthefuellinesandconnections.

•Drainandcleanthefueltank.

•Changethehydraulicuidandlter.

•Inspecttheengine-valveclearance.Refertoyourengineowner’smanual.

Every1,500hours

Beforestorage

Every2years

•Replacemovinghoses.

•Drainandcleanthefueltank.

•Flushandreplacethecooling-systemuid.

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

Note:Downloadafreecopyoftheelectricalorhydraulicschematicbyvisitingwww.T oro.comandsearching

foryourmachinefromtheManualslinkonthehomepage.

Important:Thefastenersonthecoversofthismachinearedesignedtoremainonthecoverafter

removal.Loosenallthefastenersoneachcoverafewturnssothatthecoverisloosebutstillattached,

thengobackandloosenthemuntilthecovercomesfree.Thispreventsyoufromaccidentallystripping

theboltsfreeoftheretainers.

34

Page 35

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Checkthesafety-interlock

operation.

Checkthegrassdeector

inthedownposition(if

applicable).

Checktheparking-brake

operation.

Checkthefuellevel.

Checkthehydraulicuid

level.

Checktheengine-oillevel.

Checkthecooling-system

uidlevel.

Checkthedrainwater/fuel

separator.

Checktheair-lterrestriction

indicator.

Checktheradiatorand

screenfordebris

Checkforunusualengine

noises.

Checkforunusualoperating

noises.

Checkthehydraulichoses

fordamage

Checkforuidleaks.

Checkthetirepressure.

Checktheinstrument

operation.

Checktheconditionofthe

blades.

Lubricateallgreasettings.

Cleanthemachine

Touchupdamagedpaint.

1.Iftheindicatorshowsred

1

2

3

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

2.Checkglowplugandinjectornozzlesifyounoticehardstarting,excesssmoke,orroughrunning.

3.Immediatelyaftereverywashing,regardlessoftheintervallisted.

Notationforareasofconcern

Inspectionperformedby:

ItemDate

35

Information

Page 36

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

Lubrication

GreasingtheBearingsand

Bushings

ServiceInterval:Every50hours(moreoftenindirty

ordustyconditionsandafterevery

washing).

Themachinehasgreasettingsthatyoumust

lubricateregularlywithNo.2lithiumgrease.Lubricate

moreoftenindirtyordustyconditionsbecausedirt

cangetintothebearingsandbushingsandcause

acceleratedwear.

1.Wipethegreasettingscleansothatforeign

mattercannotbeforcedintothebearingor

bushing.

2.Pumpgreaseintothettings.

3.Wipeoffexcessgrease.

Note:Improperwash-downprocedurescan

negativelyaffectbearinglife.Donotwashdown

themachinewhenitisstillhotandavoiddirecting

high-pressureorhigh-volumesprayatthebearings

orseals.

3.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

4.MovethethrottlelevertotheSLOWposition,

shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

5.Liftthefootrest,exposingthetopofthecutting

unit.

6.Removethedipstick/llplugfromthetopofthe

gearboxandmakesurethatthelubricantis

betweenthemarksonthedipstick(Figure30).

ServicingtheCutting-Unit

GearboxLubricant

ThegearboxisdesignedtooperatewithSAE

EP90Wgearlube.Althoughthegearboxcomes

fromthefactorywithlubricant,checkthelevelofthe

lubricantinthecuttingunitbeforeoperatingitandas

recommendedintheDailyMaintenanceChecklist

(page35).

CheckingtheCutting-Unit

GearboxLubricant

ServiceInterval:Every150hours

1.Positionthemachineandcuttingunitonalevel

surface.

2.Lowerthecuttingunittothe2.5cm(1inch)

heightofcut.

g004502

Figure30

1.Fillpluganddipstick

7.Ifthelubricantlevelislow,addenoughlubricant

untilthelevelisbetweenthemarksonthe

dipstick.

Important:Donotoverllthegearbox;

overllingthegearboxmaydamageit.

36

Page 37

ChangingtheCutting-Unit

GearboxLubricant

EngineMaintenance

ServiceInterval:Aftertherst50hours

Every400hours

1.Positionthemachineandcuttingunitonalevel

surface.

2.Lowerthecuttingunittothe2.5cm(1inch)

heightofcut.

3.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

4.MovethethrottlelevertotheSLOWposition,

shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

5.Liftthefootrest,exposingthetopofthecutting

unit.

6.Removethedipstick/llplugfromthetopofthe

gearbox(Figure30).

7.Placeafunnelanddrainpanunderthedrain

pluglocatedunderthefrontofthegearboxand

removetheplug,drainingthelubricantintothe

pan.

EngineSafety

•Shutofftheengineandremovethekeybefore

checkingtheoiloraddingoiltothecrankcase.

•Donotchangethegovernorspeedoroverspeed

theengine.

CheckingtheAirCleaner

ServiceInterval:Every400hours—servicethelter

alsowhentheair-cleanerindicator

showsred;servicetheair-cleaner

ltermorefrequentlyinextremely

dustyordirtyconditions.

1.Checktheair-cleanerbodyfordamage,which

couldpossiblycauseanairleak.Replacea

damagedair-cleanerbody.

2.Checktheair-intakesystemforleaks,damage,

orloosehoseclamps.

3.Servicetheair-cleanerlter(Figure31).

Important:Donotover-servicetheairlter.

8.Replacethedrainplug.

9.Addenoughlubricant,approximately283ml(12

oz),untilthelevelisbetweenthemarksonthe

dipstick.

Important:Donotoverllthegearbox;

overllingthegearboxmaydamageit.

Figure31

1.Air-cleanercover5.Air-cleanerindicator

2.Gasket

3.Filter7.Rubberoutletvalve

4.Air-cleanerbody

6.Air-cleanerlatch

g243914

4.Ensurethatthecoverisseatedcorrectlyand

sealswiththeair-cleanerbody.

37

Page 38

ServicingtheAirCleaner

ServiceInterval:Every400hours

Note:Ifthefoamgasketinthecoverisdamaged,

replaceit.

ServicingtheEngine-Oil

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Important:Avoidusinghigh-pressureair,which

couldforcedirtthroughthelterintotheintake

tract.

Important:Donotcleantheusedltertoavoid

damagetotheltermedia.

Important:Donotuseadamagedlter.

Important:Donotapplypressuretotheexible

centerofthelter.

Theengineisshippedwithoilinthecrankcase;

however,checktheoillevelbeforeandafteryourst

starttheengine.Checktheoillevelbeforeoperating

themachineeachdayoreachtimeyouusethe

machine.

Thecrankcasecapacityisapproximately3.8

L(4quarts)withthelter.Usehigh-qualityengineoil

thatmeetsthefollowingspecications:

•APIClassicationLevelRequired:CH-4,CI-4or

higher.

•Preferredoil:SAE15W-40(above0°F(-17°C)

•Alternateoil:SAE10W-30or5W-30(all

temperatures)

Note:T oroPremiumEngineoilisavailablefromyour

distributorineither15W-40or10W-30viscosity.See

thepartscatalogforpartnumbers.

1.Parkthemachineonalevelsurface,lowerthe

cuttingunit,movethethrottlelevertotheSLOW

position,shutofftheengine,andremovethekey

fromtheignitionswitch.

2.Openthehood.

Figure32

3.Removethedipstick,wipeitclean,installthe

dipstickintothetube,andpullitoutagain.

4.Checktheengine-oillevel.

Iftheoilisbetweenthemarksonthedipstick

(FofFigure33),theengineoilisatasufcient

level.Iftheoilisbelowthelowermarkonthe

dipstick(BofFigure33),addmoreoiluntilthe

oillevelisbetweenthemarksonthedipstick.

g243913

38

Page 39

Figure33

g029301

ChangingtheEngineOilAndFilter

ServiceInterval:Aftertherst50hours

Every150hours

Ifpossible,runtheenginejustbeforechangingthe

oilbecausewarmoilowsbetterandcarriesmore

contaminantsthancoldoil.

1.Positionthemachineonalevelsurface.

2.Openthehood.

3.Changetheoil(Figure34).

g027477

Figure35

5.Fillthecrankcasewithoil;refertoCheckingthe

Engine-OilLevel(page38).

Figure34

4.Replacetheoillter(Figure35).

g031623

39

Page 40

FuelSystem

ServicingtheWater

Maintenance

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelistothe

bottomofthellerneck.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

Separator

ServiceInterval:Every400hours

Every400hours

Figure36

DrainingtheFuelTank

ServiceInterval:Every800hours—Drainandclean

thefueltank.

Beforestorage—Drainandcleanthefueltank.

Inadditiontothelistedserviceinterval,drainandclean

thetankifthefuelsystembecomescontaminatedorif

youarestoringthemachineforanextendedperiod.

Usecleanfueltoushoutthetank.

40

g031412

Page 41

InspectingtheFuelLines

andConnections

ServiceInterval:Every400hours/Yearly(whichever

comesrst)

Inspectthefuellinesfordeterioration,damage,or

looseconnections.

BleedingtheFuelSystem

1.Parkthemachineonalevelsurface.Ensure

thatthefueltankisatleasthalffull.

2.Unlatchandraisethehood.

3.Placearagundertheair-bleedscrewonthe

fuel-injectionpumpandopenit(Figure37).

enginedoesnotstart,airmaybetrapped

betweeninjectionpumpandinjectors;referto

BleedingAirfromtheInjectors(page41).

BleedingAirfromthe

Injectors

Note:Usethisprocedureonlyifyoupurgedthe

fuelsystemthroughnormalprimingproceduresand

theenginedoesnotstart;refertoBleedingtheFuel

System(page41).

1.Placearagunderthepipeconnectioncoming

fromtheinjectionpumptotheNo.1injector

nozzleasillustratedinFigure38.

Figure37

1.Fuel-injection-pumpbleedscrew

4.TurntheignitionkeytotheONposition.

Note:Theelectricfuelpumpbeginsoperation,

therebyforcingairoutattheair-bleedscrew.

CAUTION

Theenginemaystartduringthis

procedure.Movingfansandbeltsina

runningenginecanseverelyinjureyou

orbystanders.

Keephands,ngers,loose

clothing/jewelry,andhairaway

fromtheenginefanandbeltduringthis

procedure.

5.LeavethekeyintheONpositionuntilasolid

streamoffuelowsoutaroundthescrew.

6.TightenthescrewandturnthekeytotheOFF

position.

g007881

Figure38

g007882

1.PipeconnectionfromtheinjectionpumptotheNo.1

injectornozzle

2.MovethethrottletotheFASTposition.

3.TurntheignitionkeytotheSTARTpositionand

watchthefuelowaroundtheconnector.

CAUTION

Theenginemaystartduringthis

procedure.Movingfansandbeltsina

runningenginecanseverelyinjureyou

orbystanders.

Keephands,ngers,loose

clothing/jewelry,andhairaway

fromtheenginefanandbeltduringthis

procedure.

4.Tightenthepipeconnectorsecurelywhenit

attainsasolidow.

5.TurnthekeytotheOFFposition.

6.Repeatthisprocedurefortheremainingnozzles.

Note:Normally,theengineshouldstartafter

youbleedthefuelsystem.However,ifthe

41

Page 42

ElectricalSystem

Maintenance

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

ServicingtheBattery

ServiceInterval:Every50hours

Keepthetopofthebatteryclean.Ifyoustore

themachineinalocationwheretemperaturesare

extremelyhigh,thebatterywillrundownmorerapidly

thanifthemachineisstoredinalocationwherethe

temperatureiscool.

Keepthetopofthebatterycleanbywashingit

periodicallywithabrushdippedinammoniaor

bicarbonateofsodasolution.Flushthetopsurface

withwateraftercleaningit.Donotremovethellcaps

whilecleaningthebattery.

Thebatterycablesmustbetightontheterminalsto

providegoodelectricalcontact.

Ifcorrosionoccursattheterminals,disconnectthe

cables,negative(-)cablerst,andscrapetheclamps

andterminalsseparately.Connectthecables,positive

(+)cablerst,andcoattheterminalswithpetroleum

jelly.

WARNING

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

StoringtheBattery

Ifyouarestoringthemachinemorethan30days,

removethebatteryandchargeitfully .Eitherstore

itonashelforonthemachine.Donotconnect

thecablesifyoustoreitonthemachine.Storethe

batteryinacoolenvironmenttopreventthebattery

fromdischargingrapidly .T opreventthebatteryfrom

freezing,makesureitisfullycharged.Thespecic

gravityofafullychargedbatteryis1.265to1.299.

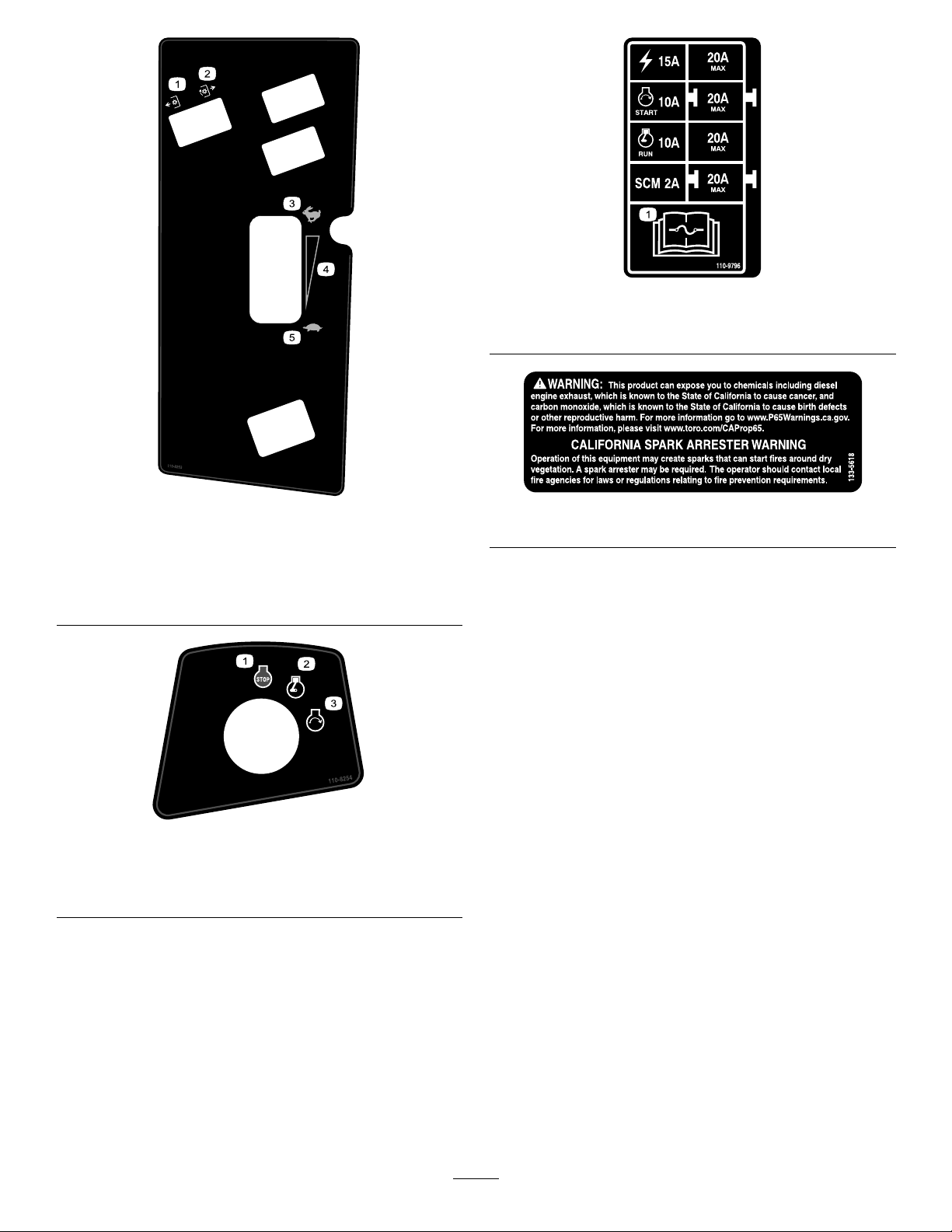

CheckingtheFuses

Thefusesarelocatedunderthecontrolpanel.Access

themthroughthesidepanelcover(Figure39).T o

openthesidepanelcover,releasethe2latchesand

pulloutonit.

Ifthemachinestopsorhasotherelectricalsystem

issues,checkthefuses.Graspeachfuseinturnand

removethem1atatime,checkingifanyareblown.

Important:Ifyouneedtoreplaceafuse,always

usethesametypeandamperage-ratedfuseas

theoneyouarereplacing,otherwiseyoucould

damagetheelectricalsystem.Refertothedecal

nexttothefusesforadiagramofeachfuseand

itsamperage(Figure40).

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponentscausing

sparks.Sparkscancausethebatterygasses

toexplode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery ,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

Note:Ifafuseblowsfrequently,youmayhavea

shortintheelectricalsystemandshouldhaveit

servicedbyaqualiedservicetechnician.

42

Page 43

Figure39

DriveSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every50hours

Checkthepressureafterevery50operatinghoursor

monthly,whicheveroccursrst(Figure41).

Maintaintheairpressureinthefrontandreartires.

Thecorrectairpressureis124kPa(15psi)inthe

reartiresand103kPa(25psi)inthecasterwheels.

Uneventirepressurecancauseanunevencut.

Checkthetireswhentheyarecoldtogetthemost

accuratepressurereading.

g004495

1.Sidepanelcover

2.Latch

g001055

Figure41

decal110-9796nc

Figure40

43

Page 44

ReplacingtheCaster

CoolingSystem

WheelsandBearings

1.Obtainanewcaster-wheelassembly,cone

bearings,andbearingsealsfromyour

AuthorizedT oroDistributor.

2.Removethelocknutfromthebolt(Figure42).

Figure42

1.Locknut

2.Bearingspacer

3.Outerbearingseal

4.Conebearing

5.Innerbearingseal

6.Spacer

7.Casterwheel

8.Axlebolt

9.Casterfork

Maintenance

CoolingSystemSafety

•Swallowingenginecoolantcancausepoisoning;

keepoutofreachfromchildrenandpets.

•Dischargeofhot,pressurizedcoolantortouching

ahotradiatorandsurroundingpartscancause

severeburns.

–Alwaysallowtheenginetocoolatleast15

minutesbeforeremovingtheradiatorcap.

–Usearagwhenopeningtheradiatorcap,and

openthecapslowlytoallowsteamtoescape.

•Donotoperatethemachinewithoutthecovers

inplace.

•Keepyourngers,handsandclothingclearof

rotatingfananddrivebelt.

CheckingtheCooling

g004760

System

ServiceInterval:Beforeeachuseordaily

Thecoolingsystemislledwitha50/50solutionof

waterandpermanentethyleneglycolantifreeze.The

capacityofthecoolingsystemis7.5L(6USqt).

1.Checkthelevelofthecoolantintheexpansion

tank(Figure43).

3.Graspthecasterwheelandslidetheboltout

oftheforkorpivotarm.

4.Discardtheoldcasterwheelandbearings.

5.Assemblethecasterwheelbypushingthecone

bearingsandseals,packedwithgrease,intothe

wheelhub,positionedasshowninFigure42.

6.Slidethespacerintothewheelhubthrough

thebearings,captivatingthespacerinsidethe

wheelhubwith2bearingspacers.

Important:Ensurethattheseallipsarenot

foldedinward.

7.Installthecaster-wheelassemblybetweenthe

castorforkandsecureitinplacewiththebolt

andlocknut.

8.Tightenthelocknutuntilthewheelnolonger

spinsfreely,thenbackitoffjustuntilthewheel

spinsfreely .

9.Attachagreaseguntothegreasettingonthe

casterwheelandllitwithNo.2lithiumgrease.

Note:Thecoolantlevelshouldbebetweenthe

marksonthesideofthetank.

g004649

Figure43

1.Expansiontank

44

Page 45

2.Ifcoolantlevelislow,removetheexpansion-tank

capandreplenishthesystem.

BrakeMaintenance

Important:Donotoverll.

3.Installtheexpansion-tankcap.

CleaningtheRadiator