Page 1

FormNo.3364-522RevB

CommercialWalk-BehindMower

FloatingDeck,SplitLever,HydroDrivewith

36in,40in,48inor52inTURBOFORCE

CuttingUnit

ModelNo.30484—SerialNo.310000001andUp

®

ModelNo.30486—SerialNo.310000001andUp

ModelNo.30488—SerialNo.310000001andUp

ModelNo.30489—SerialNo.310000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

Figure1

1.Modelandserialnumberlocation

Theenclosed

Engine Owner’ s Man ual

issupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

Introduction

Thisrotary-blade,lawnmowerisintendedtobe

usedbyresidentialhomeownersorprofessional,

hiredoperators.Itisdesignedprimarilyforcutting

grassonwell-maintainedlawnsonresidential

orcommercialproperties.Itisnotdesignedfor

cuttingbrushorforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .

Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

©2010—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroMowerSafety...............................................5

SlopeIndicator.....................................................7

SafetyandInstructionalDecals.............................8

ProductOverview......................................................11

Controls.............................................................11

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Specications.....................................................12

Operation...................................................................13

AddingFuel.......................................................13

CheckingtheEngineOilLevel............................14

ThinkSafetyFirst...............................................14

OperatingtheParkingBrake...............................14

StartingandStoppingtheEngine........................14

OperatingtheMowerBladeControl

(PTO)............................................................15

TheSafetyInterlockSystem................................16

DrivingForwardorBackward.............................16

StoppingtheMachine.........................................17

PushingtheMachinebyHand.............................17

TransportingMachines.......................................18

SideDischargingorMulchingtheGrass..............18

AdjustingtheHeight-of-Cut...............................18

AdjustingtheAnti-ScalpRollers.........................19

AdjustingtheFlowBafe...................................20

PositioningtheFlowBafe.................................20

UsingtheMid-SizeWeight..................................22

Maintenance...............................................................23

RecommendedMaintenanceSchedule(s)................23

Lubrication.............................................................24

HowtoGrease...................................................24

LubricatingtheBearings.....................................24

GreasingthePTODriveBeltIdlerandMower

DeckBeltIdler...............................................24

EngineMaintenance...............................................25

ServicingtheAirCleaner....................................25

ServicingtheEngineOil.....................................26

ServicingtheSparkPlugs....................................27

FuelSystemMaintenance.......................................28

DrainingtheFuelTank.......................................28

ServicingtheFuelFilter......................................29

ElectricalSystemMaintenance................................30

ServicingtheBattery...........................................30

ServicingtheFuses.............................................32

DriveSystemMaintenance.....................................33

AdjustingtheTracking.......................................33

CheckingtheTirePressure.................................33

ReplacingtheCasterWheelFork

Bushings........................................................33

ServicingtheCasterWheelandBearings.............34

AdjustingtheElectricClutch..............................34

CoolingSystemMaintenance..................................35

CleaningtheAirIntakeScreen............................35

BrakeMaintenance.................................................36

ServicingtheBrake.............................................36

BeltMaintenance....................................................37

ReplacingtheMowerBelt...................................37

ReplacingthePTODriveBelt.............................37

AdjustingthePTODriveBeltIdlerSpring

Anchor...........................................................38

ReplacingthePumpDriveBelt...........................39

ControlsSystemMaintenance.................................40

AdjustingtheMotionControlHandle

Positions........................................................40

HydraulicSystemMaintenance...............................42

ServicingtheHydraulicSystem...........................42

MowerDeckMaintenance......................................44

ServicingtheCuttingBlades...............................44

CorrectingtheMowerQualityofCut..................47

FrameSetUp.....................................................47

CheckingtheMowerDeckFront-to-Rear

Pitch...............................................................49

ChangingtheMowerDeckFront-to-Rear

Pitch...............................................................49

CheckingtheMowerDeckSide-to-Side

Height............................................................50

ChangingtheMowerDeckSide-to-Side

Height............................................................50

MatchingHeightofCut......................................50

ReplacingtheGrassDeector.............................51

Cleaning.................................................................52

CleaningUndertheMower.................................52

WasteDisposal...................................................52

Storage.......................................................................52

CleaningandStorage..........................................52

Troubleshooting.........................................................54

Schematics.................................................................56

3

Page 4

Safety

Note:Theadditionofattachmentsmadeby

othermanufacturersthatdonotmeetAmerican

NationalStandardsInstitutecerticationwillcause

noncomplianceofthismachine.

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol,whichmeans

CAUTION,WARNING,orDANGER-“personalsafety

instruction."Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

–Neverremovegascaporaddfuelwithengine

running.Allowenginetocoolbeforerefueling.

Donotsmoke.

–Neverrefuelordrainthemachineindoors.

•Checkthatoperator’spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.4-2004.

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readEnglishitistheowner’sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeopleorproperty.

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Onlystartengine

fromtheoperator’sposition.

•Besureofyourfootingwhileusingthismachine,

especiallywhenbackingup.Walk,don’trun.Never

operateonwetgrass.Reducedfootingcouldcause

slipping.

•Slowdownanduseextracareonhillsides.Besure

totravelsidetosideonhillsides.Turfconditions

canaffectthemachine’ sstability.Usecautionwhile

operatingneardrop-offs.

•Slowdownandusecautionwhenmakingturnsand

whenchangingdirectionsonslopes.

•Neverraisedeckwiththebladesrunning.

•NeveroperatewiththePTOshield,orotherguards

notsecurelyinplace.Besureallinterlocksare

attached,adjustedproperly,andfunctioningproperly .

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glassesandhearingprotection.Longhair,loose

clothingorjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toysandwire

whichcanbethrownbythemachine.

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,disengagedrives,engage

parkingbrake,shutoffenginebeforeleavingthe

operator’spositionforanyreasonincludingemptying

thecatchersoruncloggingthechute.

•Stopequipmentandinspectbladesafterstriking

objectsorifanabnormalvibrationoccurs.Make

necessaryrepairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

4

Page 5

•Keeppetsandbystandersaway.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesifnot

mowing.

•Beawareofthemowerdischargedirectionanddo

notpointitatanyone.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoorfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

Maintenanceandstorage

•Disengagedrives,setparkingbrake,stopengineand

removekeyordisconnectsparkplugwire.Waitfor

allmovementtostopbeforeadjusting,cleaningor

repairing.

•Cleangrassanddebrisfromcuttingunit,drives,

mufers,andenginetohelppreventres.Cleanup

oilorfuelspillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransporting.Donot

storefuelnearamesordrainindoors.

•Parkmachineonlevelground.Setparkingbrake.

Neverallowuntrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatteryorremovesparkplugwire

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositivelast.Reconnectthe

positiverstandnegativelast.

•Usecarewhencheckingblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.

Onlyreplaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

ToroMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsandothersafetyinformationyoumust

know .

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrass

or,whenequippedwithagrassbagger,forcatching

cutgrass.Anyuseforpurposesotherthanthesecould

provedangeroustouserandbystanders.

GeneralOperation

•Besuretheareaisclearofotherpeoplebefore

mowing.Stopthemachineifanyoneentersthearea.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowtocoolbefore

attemptingtomaintain,adjustorservice.

•UseonlyToroapprovedattachments.W arrantymay

bevoidedifusedwithunapprovedattachments.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

operatingunderanyobjectsanddonotcontact

them.

SlopeOperation

Allslopesandrampsrequireextracaution.Ifyoufeel

uneasyonaslope,donotmowit.

•Removeobstaclessuchasrocks,treelimbs,etc.from

themowingarea.

•Watchforholes,rutsorbumps.Tallgrasscanhide

obstacles.

•Usecautionneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyturnoverifawheel

goesovertheedgeofaclifforditch,orifanedge

cavesin.

•Useextracarewithgrasscatchersorother

attachments.Thesecanchangethestabilityofthe

machine.

•Keepallmovementonslopesslowandgradual.Do

notmakesuddenchangesinspeedordirection.

•Mowslopessidetoside.

•Donotmowslopesgreaterthan20degrees.

Service

•Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

•Keepnutsandboltstight,especiallytheblade

attachmentbolts.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.Checksafety

systemsforproperoperationbeforeeachuse.

5

Page 6

•Useonlygenuinereplacementpartstoensurethat

originalstandardsaremaintained.

•Checkbrakeoperationfrequently.Adjustandservice

asrequired.

6

Page 7

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis20degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan20degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

98-5954

43-8480

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

66-1340

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

68-8340

104-8185

36inmowerdecks

98-0776

8

Page 9

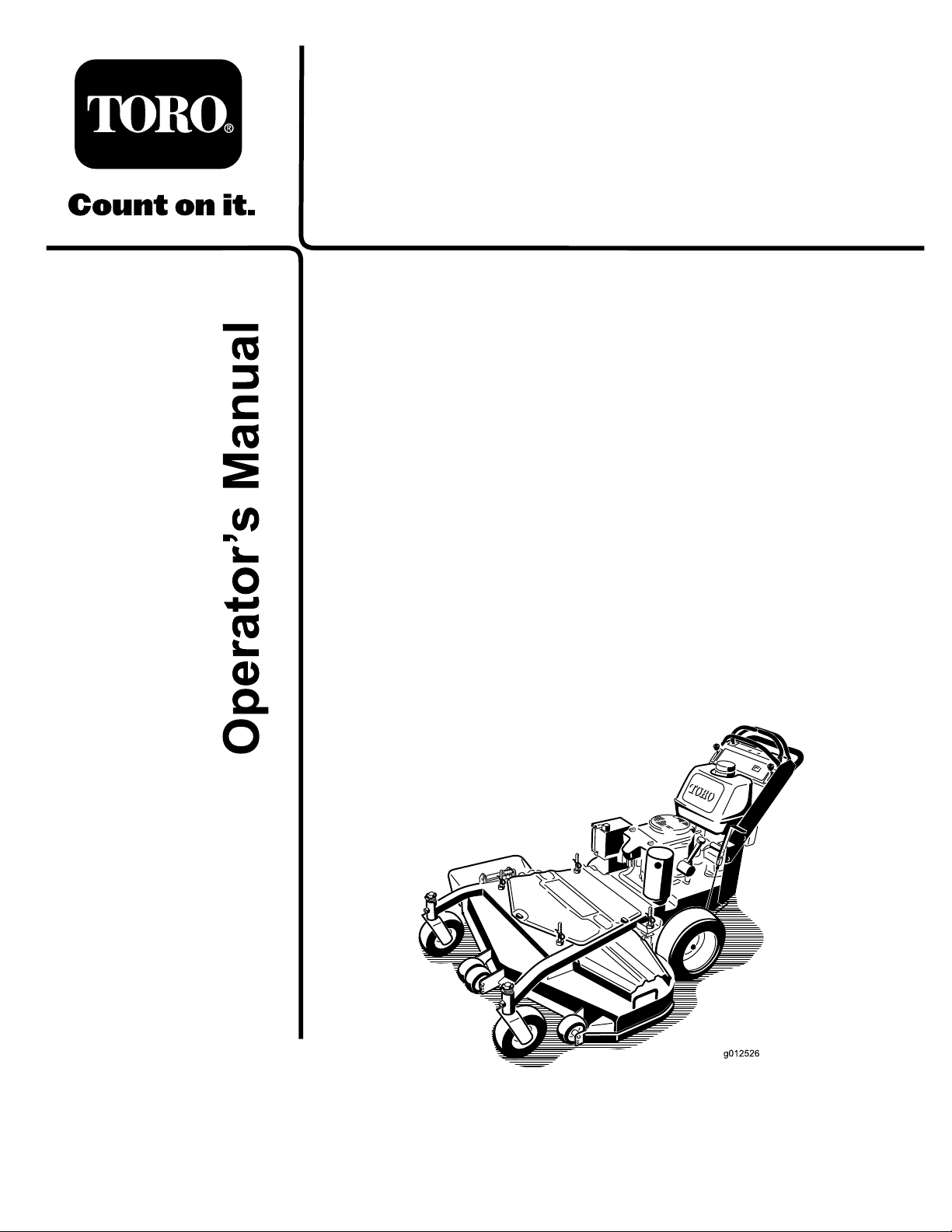

104-8186

40inandlargermowerdecks

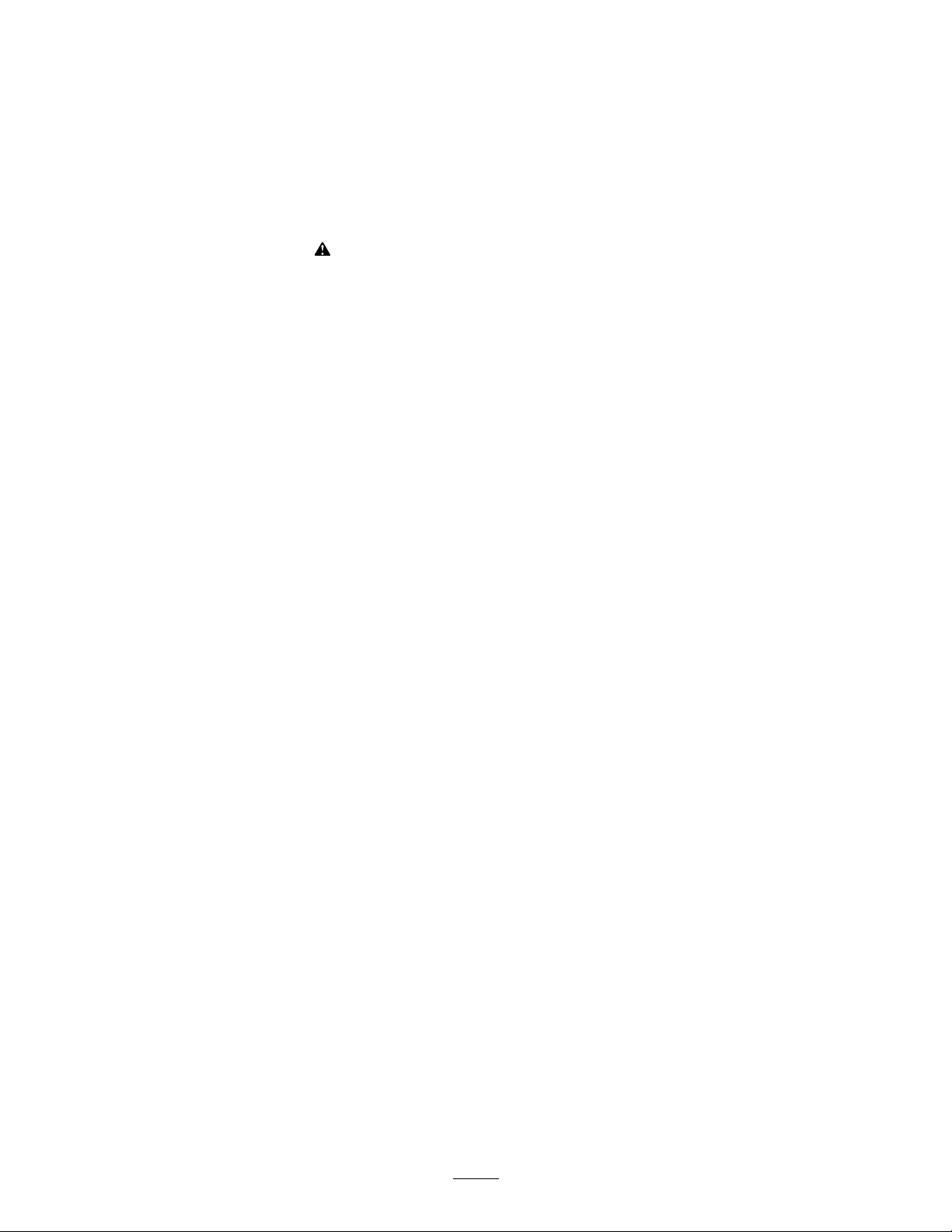

104-8569

Manufacturer’sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

110-2067

110-2068

105-7798

1.ReadtheOperator’sManual.

106-0635

112-8720

106-0699

9

Page 10

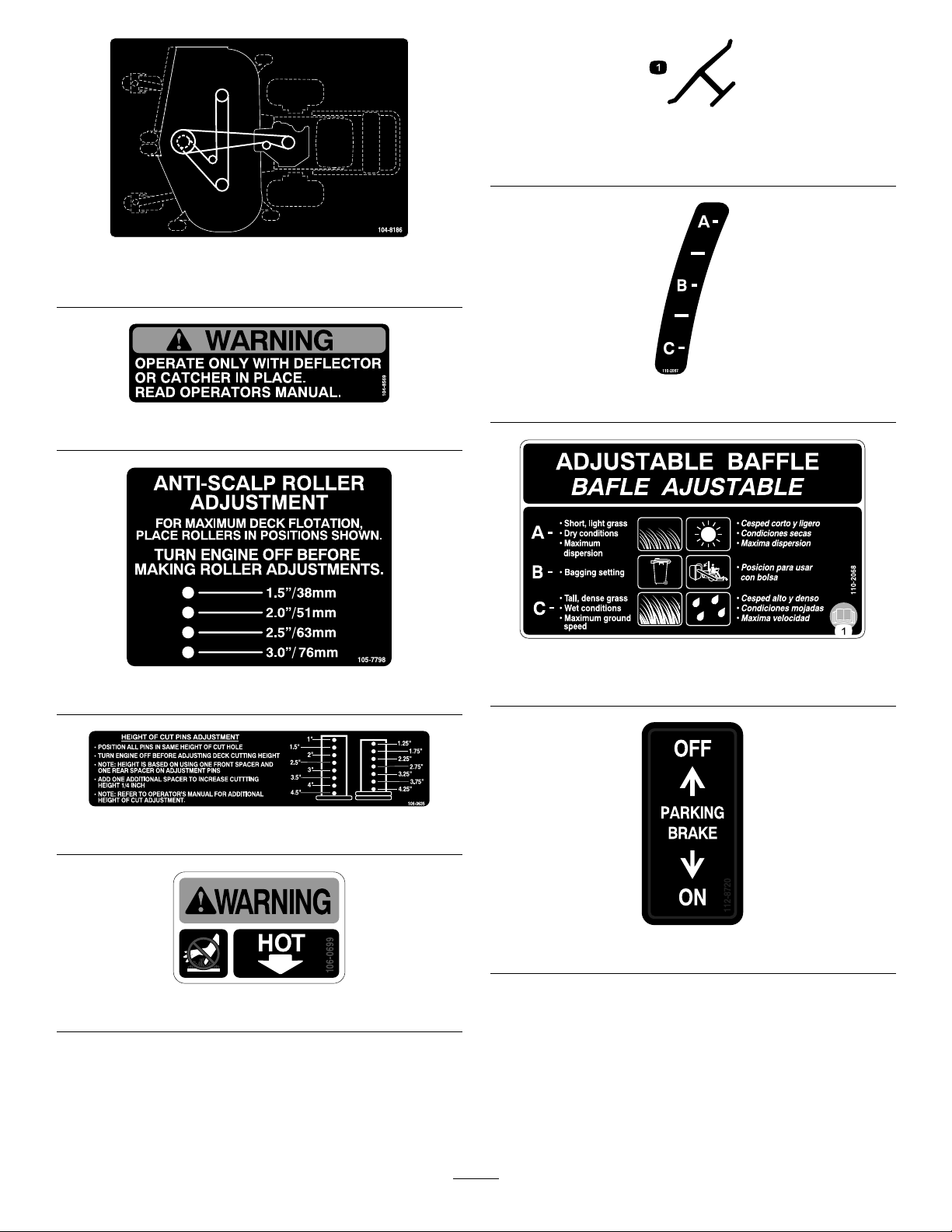

115-4212

1.Hydraulicoillevel3.Warning—donottouch

thehotsurface.

2.ReadtheOperator’s

Manual.

1.Interval

2.PowerT ake-off(PTO)

3.Parkingbrake

4.Neutral

5.Operatorpresenceswitch

6.Battery

115-4186

115–4179

1.Movethemotioncontrollevertotheneutralposition,thenpull

outonPTO(PowerTakeOff)switchtoengagetheblades.

2.PushinonthePTO(PowerT akeOff)todisengagetheblades.7.Thrownobjecthazard—keepbystandersasafedistancefrom

3.Warning—readtheOperator’sManual.8.Thrownobjecthazard—keepdeectorinplace.

4.Warning—donotoperatethismachineunlessyouaretrained.

5.Warning—stoptheengineandremovethesparkplugwire

beforeperforminganymaintenanceonthemachine.

6.Warning—stoptheenginebeforeleavingthemachine.

themachine.

9.Cutting,dismembermenthazardofhandorfoot—stayaway

frommovingparts;keepallguardsandshieldsinplace.

1.Fast2.Enginespeed

115–4189

3.Slow4.Choke

10

Page 11

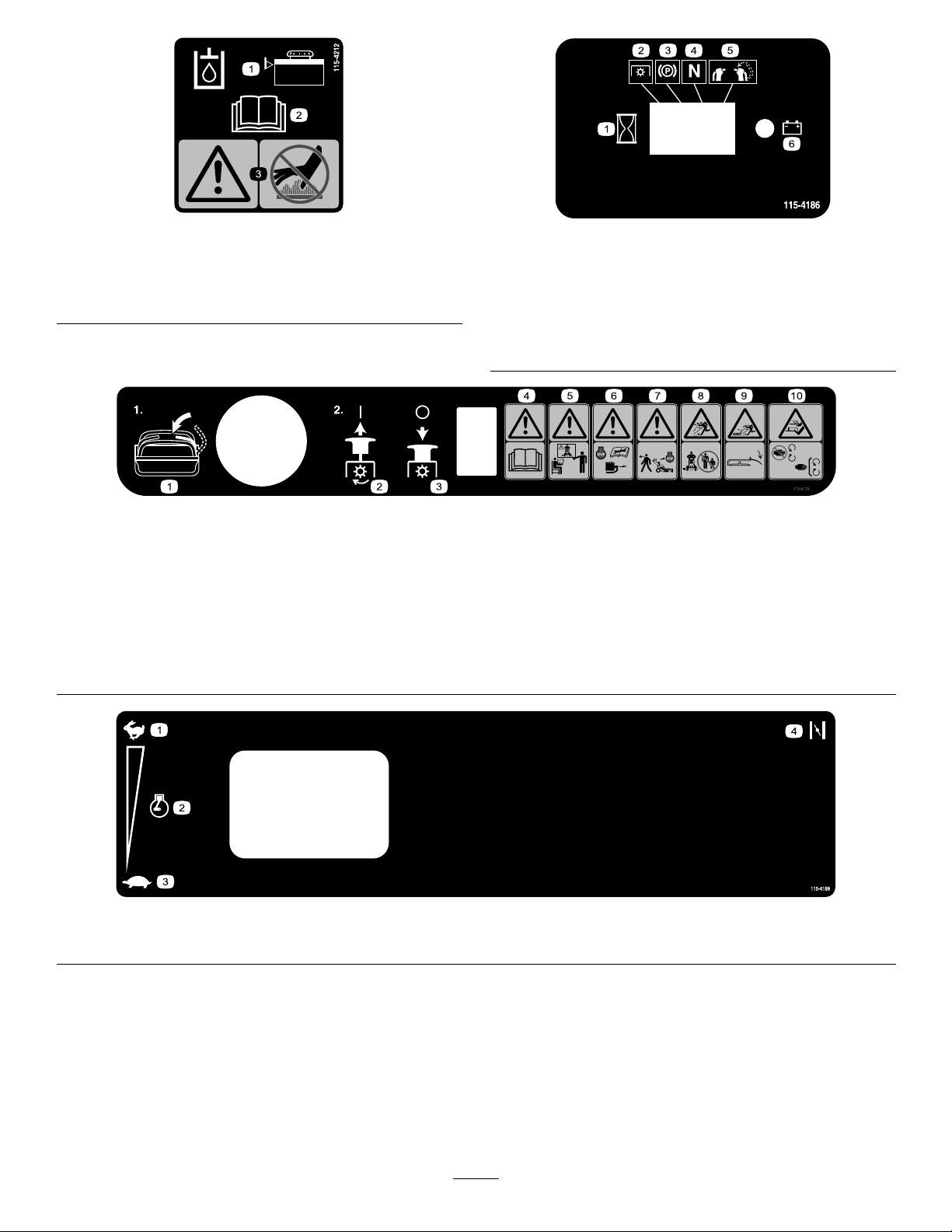

1.Tractioncontrol

2.Fast4.Neutral

ProductOverview

Figure4

1.Sidedischargechute

2.Engine6.Mowerdeck

3.Gastank

4.Controls

5.Parkingbrake

7.Frontcasterwheel

114-3424

3.Slow

1.Ignitionswitch

2.Leftmotioncontrollever7.Neutrallockpositionfor

3.Throttlecontrol8.Rightmotioncontrollever

4.Hourmeter

5.Fueltank

5.Reverse

6.DisengagethePTO(PowerTakeOff)

Figure5

6.Choke

rightmotioncontrollever

9.bladecontrolswitch(PTO)

10.Operatormanualtube

HourMeter

Controls

Becomefamiliarwithallthecontrols(Figure5)before

youstarttheengineandoperatethemachine.

Thehourmeterrecordsthenumberofhourstheengine

hasoperated.Itoperateswhentheengineisrunning.

Usethesetimesforschedulingregularmaintenance

Figure6).

(

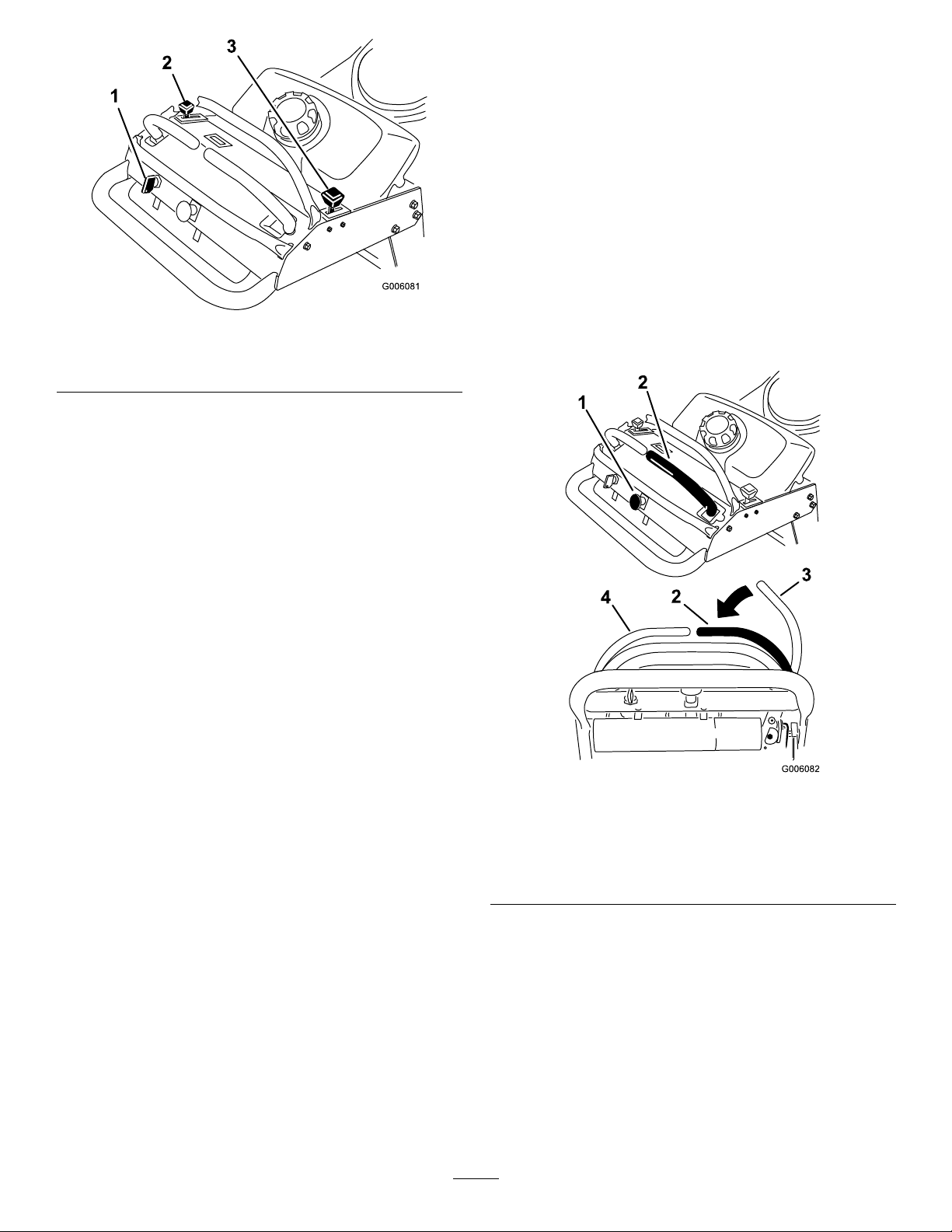

SafetyInterlockIndicators

Therearesymbolsonthehourmeterandindicatewith

ablacktrianglethattheinterlockcomponentisinthe

correctposition(Figure6).

BatteryIndicatorLight

WhentheignitionkeyisinitiallyturnedtotheOn

position,thebatteryvoltagewillbedisplayedinthearea

wherethehoursarenormallydisplayed.

Thebatterylightturnsonwhentheignitionisturned

onandwhenthechargeisbelowthecorrectoperating

level(

Figure6).

11

Page 12

Figure6

1.Safetyinterlocksymbols

2.Batterylight

3.Hourmeter

ThrottleControl

Thethrottlecontrolhastwopositions:FastandSlow.

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

36inchmowers:

Widthwithdeectordown51–1/8inches(130cm)

Length

Height

Weight

78–1/2inches(199cm)

46inches(117cm)

667lb(303kg)

Choke

Usethechoketostartacoldengine.

BladeControlSwitch(PTO)

Thebladecontrolswitch(PTO)isusedtoengage

theelectricclutchtodrivethemowerbladeswiththe

rightsidemotioncontrolleverinthecenter,un-locked

position.Pulltheswitchuptoengagethebladesand

release.Todisengagetheblades,pushthebladecontrol

switch(PTO)downormoveorreleasetherightside

motioncontrolleverintotheneutrallockposition.

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhas

threepositions:Start,RunandOff.

MotionControlLevers

Themotioncontrolleversareusedtodrivethemachine

forward,reverse,andturneitherdirection.

40inchmowers:

Widthwithdeectordown55–1/2inches(141cm)

Length

Height

Weight

75–3/8inches(192cm)

46inches(117cm)

667lb(303kg)

48inchmowers:

Widthwithdeectordown63–1/2inches(161cm)

Length

Height

Weight

77–3/4inches(198cm)

46inches(117cm)

682lb(309kg)

52inchmowers:

Widthwithdeectordown67–5/8inches(171.7cm)

Length

Height

Weight

77–3/4inches(198cm)

46inches(117cm)

721lb(327kg)

NeutralLockPosition

Theneutrallockpositionisusedwiththesafetyinterlock

systemtoengageanddisengagethemowerbladesand

todetermineneutralposition.

FuelShut-offValve

Closethefuelshut-offvalve(underthefueltank)when

transportingorstoringthemower.

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

12

Page 13

Operation

AddingFuel

UseUnleadedRegularGasolinesuitablefor

automotiveuse(85pumpoctaneminimum).Leaded

regulargasolinemaybeusedifunleadedregularisnot

available.

Important:Neverusemethanol,gasoline

containingmethanol,orgasoholcontainingmore

than10%ethanolbecausethefuelsystemcouldbe

damaged.Donotmixoilwithgasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystem

inplaceandinproperworkingcondition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmayinsulate

thecontainerandslowthelossofanystatic

charge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancauseserious

injuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepgasawayfromeyesandskin.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysor

less.Forlongerstorageitisrecommendedthatthe

fueltankbedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountofgas

stabilizer/conditionertothegas.

13

Page 14

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshgasoline.To

minimizethechanceofvarnishdepositsinthefuel

system,usefuelstabilizeratalltimes.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileit

isunattended.

FillingtheFuelT ank

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundfueltankcapandremovethecap.

Addunleadedregulargasolinetofueltank,untilthe

levelis1/4to1/2inch(6to13mm)belowthe

bottomofthellerneck.Thisspaceinthetank

allowsgasolinetoexpand.Donotllthefueltank

completelyfull.

3.Installfueltankcapsecurely.Wipeupanygasoline

thatmayhavespilled.

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoChecking

OilLevelinEngineMaintenance.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

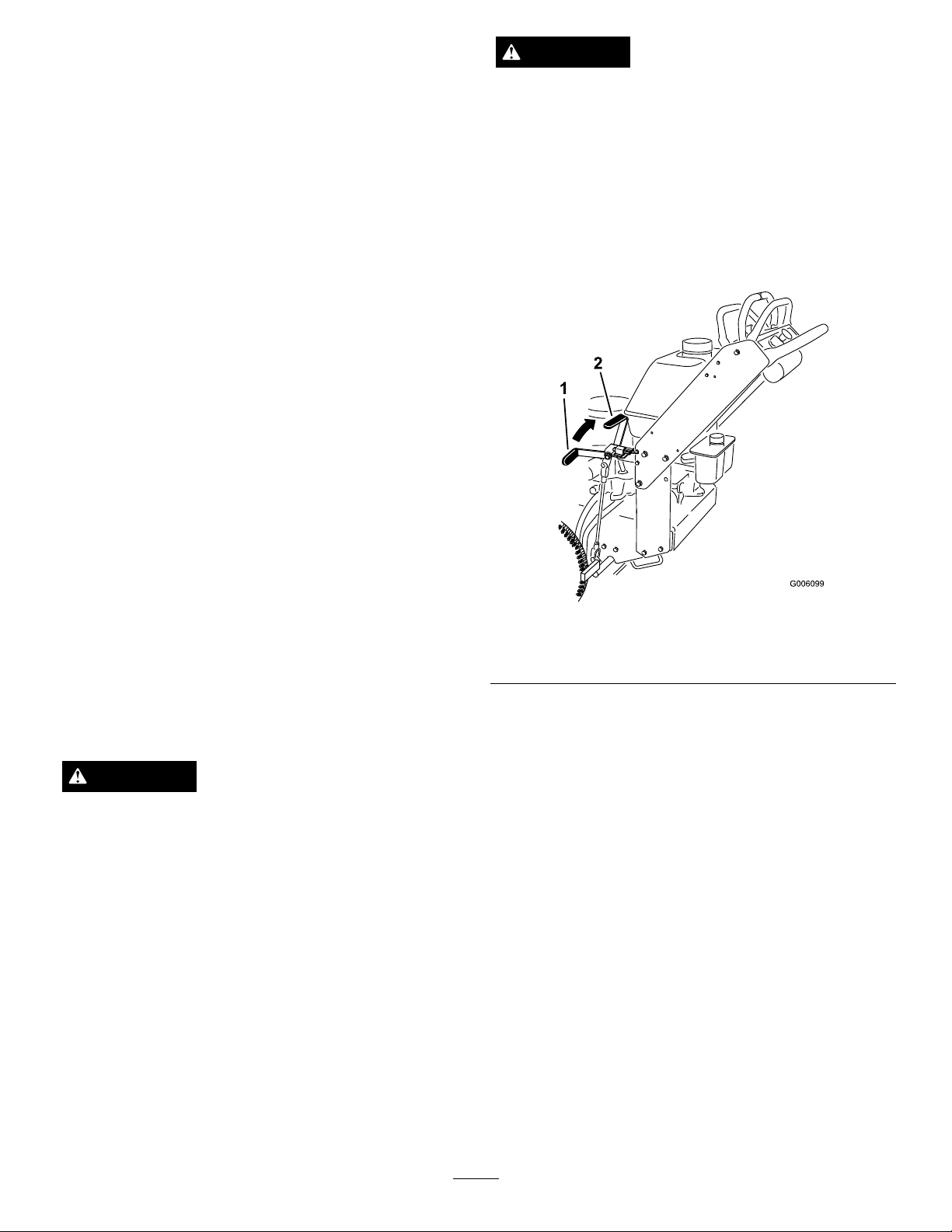

SettingtheParkingBrake

Pulltheparkingbrakeleverrearward(Figure7).

ThinkSafetyFirst

Carefullyreadallthesafetyinstructionsanddecalsin

thesafetysection.Knowingthisinformationcould

helpyouoranybystandersavoidinjury.

Theuseofprotectiveequipmentforeyes,hearing,feet

andheadisrecommended.

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator’searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthe

machineorleaveitunattended.Beforeeachuse,check

theparkingbrakeforproperoperation.

Iftheparkingbrakedoesnotholdsecurely,adjustit.

RefertoServicingtheParkingBrake.

Figure7

1.Parkingbrakelever(inthe

releasedposition)

2.Parkingbrakelever(inthe

engagedposition)

ReleasingtheParkingBrake

Pushtheparkingbrakeleverforward.

StartingandStoppingthe

Engine

StartingtheEngine

1.Connectthewirestothesparkplugs.

2.Openthefuelvalve.

3.Settheparkingbrake.

4.Movethethrottlecontroltofastandmovethe

chokelevertotheonpositionbeforestartingacold

engine(Figure8).

Note:Awarmorhotenginemaynotrequire

choking.Tostartawarmengine,movethrottle

controlmidwaybetweenthefastandslow

positions.

14

Page 15

Figure8

1.Ignitionswitch

2.Throttlelever

3.Choke

5.Turntheignitionkeytothestartpositionto

energizethestarter.Whentheenginestarts,release

thekey .

Note:Donotengagethestarterformorethan

5secondsatatime.Iftheenginefailstostart,

allowfora15secondcool-downperiodbetween

attempts.Failuretofollowtheseinstructionscan

burnoutthestartermotor.

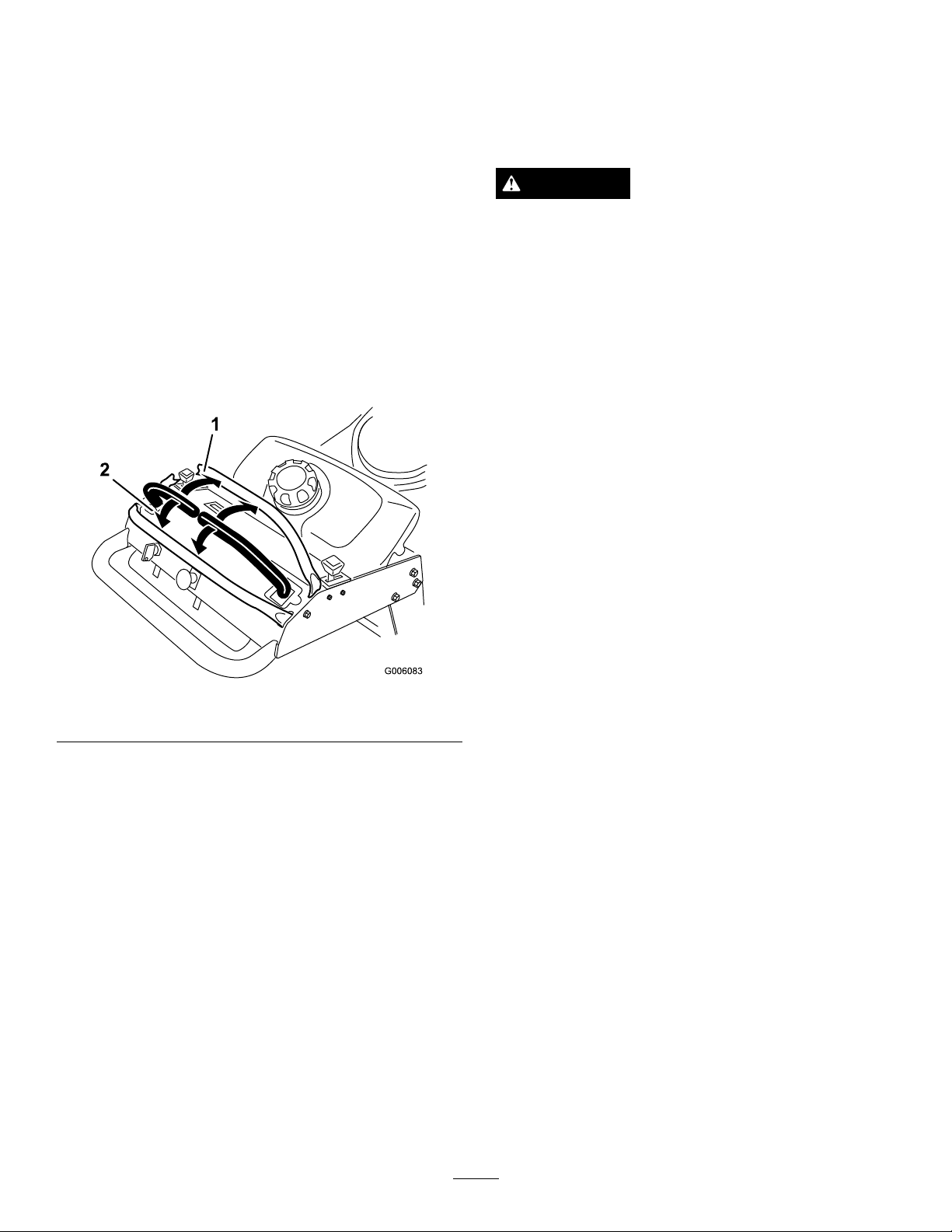

OperatingtheMowerBlade

Control(PTO)

Thebladecontrolswitch(PTO)isusedinconjunction

withtherightsidemotioncontrollevertoengageand

disengagethemowerblades.

EngagingtheMowerBlades(PTO)

1.Toengagethemowerblades,movetherightside

motioncontrollevertothecenter,un-locked

position(Figure9).

2.Pullthebladecontrolswitch(PTO)upandrelease

itwhileholdingdowntherightsidemotioncontrol

leverinthecenter,un-lockedposition.

6.Whenenginestarts,movethethrottlecontrol

betweenthefastandslowpositionandmovethe

chokelevertotheoffposition.Allowtheengine

towarmupandthenmovethethrottlecontrolto

thefastposition.

StoppingtheEngine

1.Movethemotioncontrolleverstoneutralandmove

therightsidemotioncontrolleverintotheneutral

lockposition.

2.Movethethrottlelevertoslow(Figure8).

3.Iftheenginehasbeenworkinghardorishot,let

theengineidlefor30to60secondsbeforeturning

theengineoff.

4.Tostoptheengine,turntheignitionkeytooff.

Important:Makesurefuelshutoffvalve

isclosedbeforetransportingorstoringthe

machine,asfuelleakagemayoccur.Before

storingthemachine,pullwireoffsparkplug(s)

topreventpossibilityofaccidentalstarting.

Figure9

1.Bladecontrolswitch(PTO)

2.Rightsidemotioncontrol

leverpusheddownintothe

center,un-lockedposition

3.Rightmotioncontrollever

inneutrallockposition

4.Leftmotioncontrollever

DisengagingtheMowerBlades(PTO)

Thefollowingaretwooptionsfordisengagingthe

mowerblades.

•Pushthebladecontrolswitch(PTO)downtothe

offposition.

•Movethemotioncontrolleverstoneutralandmove

therightsidemotioncontrolleverintotheneutral

lockposition.

15

Page 16

TheSafetyInterlockSystem

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventthe

mowerbladesfromrotatingunless:

•Therightsidemotioncontrolleverismovedtothe

center,un-lockedposition.

•Thebladecontrolswitch(PTO)ispulledon.

Thesafetyinterlocksystemisdesignedtostopthe

mowerbladesifyoumoveorreleasetherightside

motioncontrolleverintotheneutrallockposition.

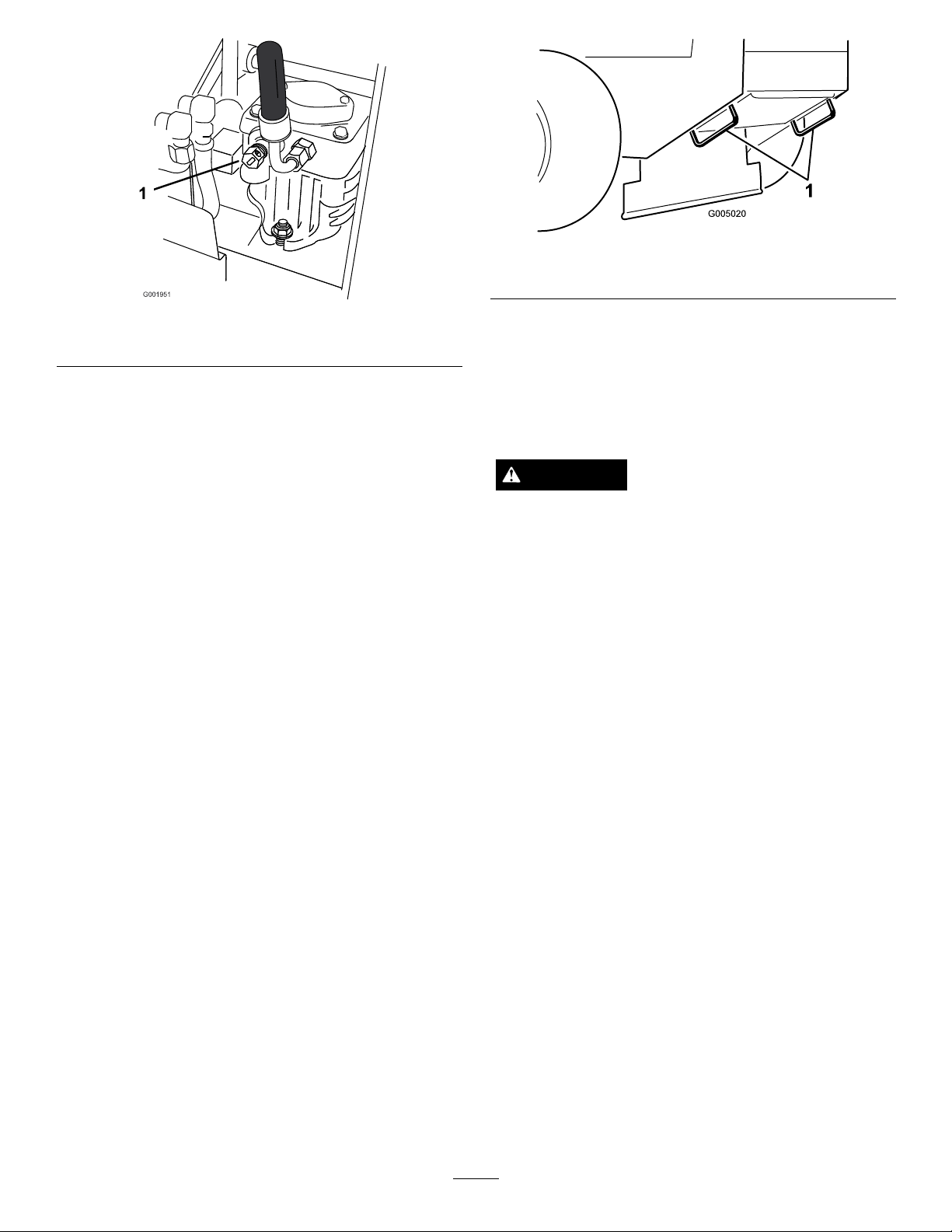

Thehourmeterhassymbolstonotifytheuserwhen

theinterlockcomponentisinthecorrectposition.

Whenthecomponentisinthecorrectposition,a

trianglewilllightupinthecorrespondingsquare.

2.Settheparkingbrake.

3.Movetherightsidemotioncontrollevertothe

center,un-lockedposition.Thebladesshould

notrotate.

4.Movethemotioncontrolleversforward.The

engineshouldkill.

5.Starttheengineandreleasetheparkingbrake.

6.Movetherightsidemotioncontrollevertothe

center,un-lockedposition.

7.Continueholdingtherightsidemotioncontrollever

inthecenter,un-lockedpositionandpulluponthe

bladecontrolswitch(PTO)andrelease.Theclutch

shouldengageandthemowerbladesbeginrotating.

8.Moveorreleasetherightsidemotioncontrollever

intotheneutrallockposition.Thebladesshould

stoprotating.

9.Movetherightsidemotioncontrollevertothe

center,un-lockedposition.

10.Continueholdingtherightsidemotioncontrollever

inthecenter,un-lockedpositionandpulluponthe

bladecontrolswitch(PTO)andrelease.Theclutch

shouldengageandthemowerbladesbeginrotating.

11.Pushthebladecontrolswitch(PTO)downtothe

offposition.Thebladesshouldstoprotating.

12.Withtheenginerunning,pullupthebladecontrol

switch(PTO)andreleasewithoutholdingright

sidemotioncontrollevertothecenter,un-locked

position.Thebladesshouldnotrotate.

Figure10

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition

TestingtheSafetyInterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafetyinterlocksystembeforeyouusethe

machineeachtime.

Note:Ifthesafetysystemdoesnotoperateas

describedbelow,haveanAuthorizedServiceDealer

repairthesafetysystemimmediately .

1.Starttheengine;refertoStartingandStoppingthe

Enginein

Operation(page13).

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolinthefastpositionforbest

performance.Alwaysoperateinthefullthrottle

positionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormaylose

controlofmachineandcausepersonalinjuryor

damagetomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

DrivingForward

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrakeinOperation(page13).

16

Page 17

2.Movetherightsidemotioncontrollevertothe

center,un-lockedposition.

theneutrallockposition,disengagethepowertakeoff

(PTO),andturntheignitionkeytooff.

3.Togoforward,slowlypushthemotioncontrol

leversforward(Figure11).

Note:Theenginewillkillifthetractioncontrol

leversaremovedwiththeparkingbrakeengaged.

Togostraight,applyequalpressuretobothmotion

controllevers(

Toturn,movethemotioncontrollevertoward

neutralinthedirectionyouwanttoturn(Figure11).

Thefartheryoumovethetractioncontrolleversin

eitherdirection,thefasterthemachinewillmovein

thatdirection.

Tostop,pullthemotioncontrolleversbacktothe

neutralposition.

Figure11).

Settheparkingbrakewhenyouleavethemachine;refer

toSettingtheParkingBrakein

Remembertoremovethekeyfromtheignitionswitch.

Operation(page13).

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

PushingtheMachinebyHand

Theby-passvalvesallowthemachinetobepushedby

handwithouttheenginerunning.

Important:Alwayspushthemachinebyhand.

Nevertowthemachinebecausehydraulicdamage

mayoccur.

Figure11

1.Forward2.Backward

DrivingBackward

1.Movetherightsidemotioncontrollevertothe

center,un-lockedposition.

2.Togobackward,slowlypullthemotioncontrol

leversrearward(Figure11).

Togostraight,applyequalpressuretobothmotion

controllevers(Figure11).

Toturn,releasepressureonthemotioncontrollever

towardthedirectionyouwanttoturn(Figure11).

ToPushtheMachine

1.DisengagethePTO,movethemotioncontrol

leverstotheneutrallockedpositionandsetthe

parkingbrake.

2.Opentheby-passvalveonbothpumpsbyturning

themcounterclockwise1to2turns.Thisallows

hydraulicuidtoby-passthepumpsandthewheels

toturn(

Note:Rotatetheby-passvalvesamaximumof2

turnssothevalvedoesnotcomeoutofthebody

causinguidtorunout.

Figure12).

Tostop,pushthemotioncontrolleverstothe

neutralposition.

StoppingtheMachine

Tostopthemachine,movethemotioncontrolleversto

neutral,movetherightsidemotioncontrolleverinto

17

Page 18

1.Pumpby-passvalve

Figure13

1.Tractionunittiedownloop

Figure12

SideDischargingorMulching

3.Releasetheparkingbrake.

4.Pushthemachinetothedesiredlocation.

5.Settheparkingbrake.

6.Closetheby-passvalves,butdonotovertighten

them.

Important:Donotstartoroperatethe

machinewiththeby-passvalvesopen.Damage

tosystemmayoccur.

TransportingMachines

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarybrakes,lighting,andmarkingasrequiredby

law .Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

petsorbystandersavoidinjury.

Totransportthemachine:

1.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

theGrass

Thismowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutthegrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthe

mowerbecausethegrassdeectorroutes

materialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytocleardischargeareaormower

bladesunlessyoureleasethebailandthepower

takeoff(PTO)isoff.Rotatetheignitionkeyto

Off.Alsoremovethekeyandpullthewire(s)

offthesparkplug(s).

3.Loadthemachineontothetrailerortruck.

4.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Usethemetaltiedownloopsonthemachineto

securelyfastenthemachinetothetrailerortruck

withstraps,chains,cable,orropes(

6.Fastenthefrontofthemachinetothetraileror

truckwithstraps,chains,cable,orropes.

Figure13).

AdjustingtheHeight-of-Cut

Theheight-of-cutcanbeadjustedfrom1to4-1/2

inch(25to114mm)in1/4inch(6mm)increments.

Adjustmentisdonebyrelocatingfourhairpincotter

pinsindifferentholelocationandbyaddingor

removingspacers.

Note:Allheight-of-cutpinsneedatleastonespacer

ordamagecanoccurtobushingifnoneareused.

Note:Allheight-of-cutpinscanusetwospacers

maximum.

18

Page 19

1.Selectholeinheight-of-cutpostandnumberof

spacerscorrespondingtotheheight-of-cutdesired

(Figure14).

2.Usingthelifthandle,raisesideofdeckandremove

hairpincotter(

Figure14).

3.Addorremovespacersifneededandthenalign

holesandinserthairpincotter(Figure14).

(10mm)clearanceabovetheground(Figure15,

Figure16,Figure17).

2.Ifadjustmentisneeded,removethebolt,washers

andnut(

Figure15,Figure16,Figure17).

3.Selectaholepositionsotheanti-scalprollersare

aminimumof3/8inch(10mm)offtheground

(Figure15,Figure16,Figure17).

Note:Spareheight-of-cutspacersmaybestored

onpostsandretainedbyahairpincotter.

Important:Allfourhairpincotterpinsmustbe

inthesameholelocationandwiththecorrect

numberofspacersforalevelcut.

4.Installtheboltandnut(Figure15,Figure16,

Figure17).

Figure15

40inch,48inch,and52inchMowerDecks

1.Mowerdeck

2.Bolt5.Nut

3.Spacer

4.Anti-ScalpRollers

Figure14

1.CarrierFrame4.Spacers

2.HairpinCotter5.Frontheight-of-cutpost

3.Backheight-of-cutpost

AdjustingtheAnti-Scalp

Rollers

Theanti-scalprollersneedtobeadjustedintheproper

holelocationforeachheight-of-cutposition.There

needstobe3/8inch(10mm)minimumclearance

abovetheground.

Note:Iftheanti-scalprollersareadjustedtoolowit

cancauseexcesswearoftherollers.

1.Afteradjustingheight-of-cut,checktheanti-scalp

rollerssothatthereisaminimumof3/8inch

19

Page 20

Figure16

40inch,48inch,and52inchMowerDecks

1.Mowerdeck4.Bushing

2.Bolt

3.Spacer

5.Anti-ScalpRollers

6.Nut

1.DisengagethePTO,movethemotioncontrol

leverstotheneutrallockedpositionandsetthe

parkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Toadjustthecamlock,swingtheleveruptoloosen

thecamlock(

Figure18).

4.Adjustthebafeandcamlockintheslottothe

desireddischargeow .

5.Swingtheleverbackovertotightenthebafeand

camlock(

Figure18).

6.Ifthecamdoesnotlockthebafeintoplaceoritis

tootight,loosentheleverandthenrotatethecam

lock.Adjustthecamlockuntilthedesiredlocking

pressureisachieved.

Figure17

36inchMowerDeck

1.Mowerdeck

2.Bolt5.Nut

3.Spacer

4.Anti-ScalpRollers

5.Incertainmowingconditionsandterrain,a

mismatchofcuttingheightmaybeseen.Adjusting

theoutsideanti-scalprollerstotheminimumsetting

of3/8inch(10mm)willhelppreventthemower

deckcuttingtoolowontheoutsideandminimize

themismatch.

AdjustingtheFlowBafe

Themowerdischargeowcanbeadjustedfordifferent

typesofmowingconditions.Positionthecamlockand

bafetogivethebestqualityofcut.

Figure18

1.Camlock

2.Lever

3.Rotatecamtoincreaseor

decreaselockingpressure

4.Slot

PositioningtheFlowBafe

Thefollowingguresareonlyrecommendationsfor

use.Adjustmentswillvarybygrasstype,moisture

content,andheightofgrass.

Note:Iftheenginepowerdrawsdownandthemower

groundspeedisthesame,openupthebafe.

PositionA

Thisisthefullrearposition(seeFigure19).The

suggesteduseforthispositionisafollows.

•Useforshort,lightgrassmowingconditions.

•Useindryconditions.

•Forsmallergrassclippings.

•Propelsgrassclippingsfartherawayfromthe

mower.

20

Page 21

Figure19

PositionB

Usethispositionwhenbagging(Figure20).

Figure21

Figure20

PositionC

Thisisthefullopenposition.Thesuggestedusefor

thispositionisasfollows(Figure21).

•Useintall,densegrassmowingconditions.

•Useinwetconditions.

•Lowerstheenginepowerconsumption.

•Allowsincreasedgroundspeedinheavyconditions.

•ThispositionissimilartothebenetsoftheT oro

SFSmower.

21

Page 22

UsingtheMid-SizeWeight

Weightsareinstalledoncertainmowerstoimprove

balanceandimproveperformance.Theweightscanbe

movedorremovedtocreateoptimizedperformance

underdifferentmowingconditionsandforoperator

preference(Figure22orFigure23).

Thefollowingtableindicatesthepositionoftheweight

asinstalledatthefactory.

MowerDeckSizeNumberofweights

36inches1Front

40inches1Front

48inches

52inches1Rear

install

nonenone

•Anyrearweightmustberemovedwhena

Tru–Track

•WhenaTru–Track

®

Sulkyisinstalled.

®

Sulkyisinstalledfrontweights

areneeded.ContactanAuthorizedServiceDealer

forthecorrectquantityofweightsandplacement.

Positionofthe

weight

Figure23

Installingtherearweight.

1.Nut3.Washer

2.Weight4.Bolt

WARNING

Thefrontendofthemachinecanrapidlyriseup

whenthemowerisremoved.Thiscouldcause

seriousinjurytoyouorbystanders.

Supporttherearofthemachinewhenremoving

themowerfromthecarrierframe.

Figure22

Installingthefrontweight.

1.Bolt3.Weight

2.Washer4.Nut

22

Page 23

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthehydraulicuidlevel.

•Changethehydrauliclter.

•Checkthesafetyinterlocksystem.

•Greasethefrontcasterpivotbearing.

•Checktheengineoillevel.

•Cleantheairintakescreen.

•Checkthebrakes.

•Inspecttheblades.

•Cleanthemowerdeck.

•Cleanfoamaircleanerelement.

•Checkthebatteryelectrolytelevel.

•Checkthehydraulicuidlevel.

•Greasethesidebearings.

•GreasethePTObeltidler.

•Greasethemowerdeckbeltidler.

•Checkthepaperaircleanerelement.

•Checkthetirepressure.

•Checkthemowerbelt.

•CheckthePTOdrivebelt.

•Checkthepumpdrivebelt.

•Changetheengineoil.

•Checkthesparkplugs.

•Adjusttheelectricclutch.

•Checkthehydrauliclines.

•Replacethepaperaircleanerelement.

Every200hours

Every250hours

Every400hours

Every500hours

Beforestorage

Important:Refertoyour

•Changetheoillter.

•Replacethefuellter.

•ChangethehydrauliclterandhydraulicoilwhenusingMobil®1oil.

•Greasethefrontwheelbearings(moreoftenindirtyordustyconditions).

•ChangethehydrauliclterandhydraulicoilwhenusingT oro®HYPR-OIL™500

hydraulicoil.

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

Engine Operator’ s Man ual

foradditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthesparkplugwiresfromthesparkplugsbeforeyoudo

anymaintenance.Setthewiresasidesothattheydonotaccidentallycontactthesparkplugs.

23

Page 24

Lubrication

GreasingthePTODriveBelt

GreasewithNo.2generalpurposelithiumbaseor

molybdenumbasegrease.

HowtoGrease

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Cleanthegreasettingswitharag.Makesureto

scrapeanypaintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pumpgrease

intothettingsuntilgreasebeginstooozeoutof

thebearings.

5.Wipeupanyexcessgrease.

LubricatingtheBearings

ServiceInterval:Beforeeachuseordaily

IdlerandMowerDeckBelt

Idler

ServiceInterval:Every50hours

Every50hours

Greasetheidlerpulleypivots(Figure25orFigure26).

Note:Youwillhavetoremovethecarriercoversto

accessthegreasettingforthemowerdeck.

Every400hours

Every50hours

Lubricatethefrontcasterwheelbearingsandfront

pivots(Figure24).

Note:Makesuretherearwheelgreasecapsare

removedbeforelubricatingrearwheels.

Figure25

40inch,48inch,and52inchMowerDeckshown

Figure24

Figure26

36inchMowerDeckshown

24

Page 25

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval/Specication

ServiceInterval:Every25hours—Cleanfoamair

cleanerelement.

Every50hours—Checkthepaperair

cleanerelement.

Every200hours—Replacethepaper

aircleanerelement.

Note:Servicetheaircleanermorefrequently(every

fewoperatinghours)iftheoperatingconditionsare

extremelydustyorsandy .

Important:Donotoilthefoamorpaperelement.

RemovingtheFoamandPaper

Elements

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Cleanaroundtheaircleanertopreventdirt

fromgettingintotheengineandcausingdamage

Figure27).

(

4.Unscrewthecoverknobsandremovetheaircleaner

cover(

5.Unscrewthehoseclampandremovetheaircleaner

assembly(Figure27).

6.Carefullypullthefoamelementoffthepaper

element(Figure27).

Figure27).

Figure27

1.Cover

2.Hoseclamp4.Foamelement

3.Paperelement

CleaningtheFoamAirCleanerElement

1.Washthefoamelementinliquidsoapandwarm

water.Whentheelementisclean,rinseitthoroughly.

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifitis

tornorworn.

ServicingthePaperAirCleaner

Element

1.Donotcleanthepaperlter,replaceit(Figure27).

2.Inspecttheelementfortears,anoilylm,ordamage

totherubberseal.

3.Replacethepaperelementifitisdamaged.

InstallingtheFoamandPaperElements

Important:Topreventenginedamage,always

operatetheenginewiththecompletefoamand

paperaircleanerassemblyinstalled.

1.Carefullyslidethefoamelementontothepaperair

cleanerelement(Figure27).

2.Placetheaircleanerassemblyontotheaircleaner

baseandsecureitwiththe2wingnuts(Figure27).

3.Placetheaircleanercoverintopositionandtighten

thecoverknob(Figure27).

25

Page 26

ServicingtheEngineOil

ServiceInterval/Specication

ServiceInterval:Beforeeachuseordaily—Checkthe

engineoillevel.

Aftertherst8hours—Changethe

engineoil.

Every100hours—Changetheengine

oil.

Every200hours—Changetheoil

lter.

Note:Changetheoilmorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

OilType:Detergentoil(APIserviceSF ,SG,SH,SJ

orSL)

CrankcaseCapacity:58ounces(1.7liter)withthelter

removed;51ounces(1.5liter)withoutthelterremoved

Figure29

1.Oildipstick

2.Fillertube

5.Unscrewtheoildipstickandwipetheendclean

(Figure29).

6.Slidetheoildipstickfullyintothellertube,butdo

notthreadontotube(Figure29).

7.Pullthedipstickoutandlookattheend.Iftheoil

levelislow ,slowlypouronlyenoughoilintotheller

tubetoraisetheleveltotheFullmark.

Viscosity:Refertothetable(

Figure28

Figure28).

CheckingtheEngineOilLevel

1.Parkthemachineonalevelsurface.

2.DisengagethePTOandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Cleanaroundtheoildipstick(

cannotfallintothellerholeanddamagetheengine.

Figure29)sothatdirt

Important:Donotoverllthecrankcasewith

oilandruntheengine;enginedamagecan

result.

ChangingtheEngineOil

1.Starttheengineandletitrunveminutes.This

warmstheoilsoitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

3.DisengagethePTOandsettheparkingbrake.

4.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

5.Slidethedrainhoseovertheoildrainvalve.

6.Placeapanbelowthedrainhose.Rotateoildrain

valvetoallowoiltodrain(

7.Whenoilhasdrainedcompletely,closethedrain

valve.

8.Removethedrainhose(Figure30).

Note:Disposeoftheusedoilatarecyclingcenter.

Figure30).

26

Page 27

Figure30

1

1.Oildrainvalve2.Oildrainhose

9.Slowlypourapproximately80%ofthespeciedoil

intothellertube(Figure29).

10.Checktheoillevel;refertoCheckingtheEngineOil

Level.

11.SlowlyaddtheadditionaloiltobringittotheFull

mark.

ChangingtheOilFilter

Note:Changetheoilltermorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

4.Installthereplacementoilltertothelteradapter,

turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional3/4turn(

Figure31).

5.Fillthecrankcasewiththepropertypeofnewoil;

refertoServicingtheEngineOil.

6.Runtheengineforabout3minutes,stoptheengine,

andcheckforoilleaksaroundtheoillteranddrain

valve.

7.Checktheengineoillevelandaddoilifneeded.

8.Wipeupanyspilledoil.

ServicingtheSparkPlugs

ServiceInterval:Every100hours

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstallingthe

sparkplugsandagappingtool/feelergaugetocheckand

adjusttheairgap.Installanewsparkplugsifnecessary.

Type:Champion®RCJ8YorequivalentAirGap:

0.030inch(0.75mm)

RemovingtheSparkPlugs

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Disconnectthewiresfromthesparkplugs

(Figure32).

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

2.Removetheoldlter(

1.Oillter

Figure31).

Figure31

2.Adapter

3.Applyathincoatofnewoiltotherubbergasketon

thereplacementlter(Figure31).

Figure32

1.Spark-plugwire/sparkplug

4.Cleanaroundthesparkplugstopreventdirtfrom

fallingintotheengineandpotentiallycausing

damage.

5.Removethesparkplugsandthemetalwashers.

27

Page 28

CheckingtheSparkPlugs

1.Lookatthecenterofthesparkplugs(Figure33).

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly .Ablackcoatingonthe

insulatorusuallymeansthattheaircleanerisdirty.

2.Ifneeded,cleanthesparkplugwithawirebrushto

removecarbondeposits.

Figure33

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

Important:Alwaysreplacethesparkplugs

whenithaswornelectrodes,anoilylmonit,

orhascracksintheporcelain.

3.Checkthegapbetweenthecenterandsideelectrodes

Figure33).Bendthesideelectrode(Figure33)if

(

thegapisnotcorrect.

InstallingtheSparkPlugs

1.Installthesparkplugsandthemetalwasher.Ensure

thattheairgapissetcorrectly.

2.Tightenthesparkplugsto16ft-lb(22N-m).

3.Connectthewirestothesparkplugs(

Figure33).

FuelSystem

Maintenance

DrainingtheFuelTank

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

1.Parkthemachineonalevelsurface,toassurefuel

tankdrainscompletely.Thendisengagethepower

takeoff(PTO),settheparkingbrake,andturnthe

ignitionkeytooff.Removethekey.

2.Closethefuelshut-offvalveatthefueltank

Figure34).

(

3.Squeezetheendsofthehoseclamptogether

andslideitupthefuellineawayfromfuellter

Figure34).

(

4.Pullthefuellineoffthefuellter(Figure34).Open

thefuelshut-offvalveandallowthegasolinetodrain

intoagascanordrainpan.

Note:Nowisthebesttimetoinstallanewfuellter

becausethefueltankisempty.RefertoReplacing

theFuelFilter.

5.Installthefuellineontothefuellter.Slidethehose

clampclosetothevalvetosecurethefuelline.

6.Wipeupanyspilledfuel.

28

Page 29

Figure34

1.Fuellter3.Fuelshut-offvalve

2.Clamp

Figure35

1.Hoseclamp3.Filter

2.Fuelline

ServicingtheFuelFilter

ServiceInterval:Every200hours/Yearly(whichever

comesrst)

ReplacingtheFuelFilter

Neverinstalladirtylterifitisremovedfromthefuel

line.

Note:Notehowthefuellterisinstalledinorderto

installthenewltercorrectly.

Note:Wipeupanyspilledfuel.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Closefuelshut-offvalveatthefueltank(

4.Squeezetheendsofthehoseclampstogetherand

slidethemawayfromthelter(Figure35).

Figure34).

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclampsclose

tothelter.

7.Openfuelshut-offvalveatfueltank(

Figure34).

8.Checkforfuelleaksandrepairifneeded.

9.Wipeupanyspilledfuel.

29

Page 30

ElectricalSystem

Maintenance

ServicingtheBattery

Alwayskeepthebatterycleanandfullycharged.Use

apapertoweltocleanthebatterycase.Ifthebattery

terminalsarecorroded,cleanthemwithasolutionof

fourpartswaterandonepartbakingsoda.Applyalight

coatingofgreasetothebatteryterminalstoprevent

corrosion.

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•AlwaysDisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•AlwaysReconnectthepositive(red)battery

cablebeforereconnectingthenegative(black)

cable.

Voltage:12V

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Lifttheblackrubbercoveronthenegativecable.

Disconnectthenegativebatterycablefromthe

negative(-)batteryterminal(

4.Slidetheredterminalbootoffthepositive(red)

batteryterminal.Thenremovethepositive(red)

batterycable(Figure36).

5.Removethebatteryholddownplate(

removethebattery.

Figure36).

Figure36)and

InstallingtheBattery

1.Placethebatterontothemachine(Figure36).

2.Securethebatterywiththeholddownplate,j-bolts,

andlocknuts.

3.First,installthepositive(red)batterycableto

positive(+)batteryterminalwithanut,washerand

Figure36).Slidetherubbercoveroverthepost.

bolt(

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

4.Theninstallthenegativebatterycableandground

wiretothenegative(-)batteryterminalwithanut,

washerandbolt(

overthepost.

30

Figure36).Slidetherubbercover

Page 31

g012916

7

6

5

4

3

2

1

8

9

10

11

Figure36

1.J-bolt7.Wingnut

2.Positivecable8.Negativecable

3.Washer

4.Nut(5/16inch)

5.Rubbercover(red)

6.Batteryholddown

9.Rubbercover(black)

10.Bolt

11.Battery

Figure37

1.Ventcaps3.Lowerline

2.Upperline

2.Iftheelectrolyteislow,addtherequiredamountof

distilledwater;refertoAddingW atertotheBattery

inElectricalSystemMaintenance(page30).

AddingWatertotheBattery

Thebesttimetoadddistilledwatertothebatteryisjust

beforeyouoperatethemachine.Thisletsthewatermix

thoroughlywiththeelectrolytesolution.

1.Removethebatteryfromthemachine;

refertoRemovingtheBatteryin

ElectricalSystemMaintenance(page30).

Important:Neverllthebatterywithdistilled

waterwhilethebatteryisinstalledinthe

machine.Electrolytecouldbespilledonother

partsandcausecorrosion.

CheckingtheBatteryElectrolyteLevel

2.Cleanthetopofthebatterywithapapertowel.

3.Removetheventcapsfromthebattery(

Figure37).

ServiceInterval:Every25hours

4.Slowlypourdistilledwaterintoeachbatterycell

DANGER

untiltheelectrolytelevelisuptotheUpperline

Figure37)onthebatterycase.

(

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Important:Donotoverllthebatterybecause

electrolyte(sulfuricacid)cancausesevere

•Donotdrinkelectrolyteandavoidcontactwith

corrosionanddamagetothechassis.

skin,eyesorclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

5.Waitvetotenminutesafterllingthebatterycells.

Adddistilledwater,ifnecessary,untiltheelectrolyte

levelisuptotheUpperline(

Figure37)onthe

batterycase.

6.Reinstallthebatteryventcaps.

1.Lookatthesideofthebattery.Theelectrolytemust

beuptotheupperline(

electrolytetofallbelowtheLowerline(Figure37).

Figure37).Donotallowthe

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

31

Page 32

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespeciallyimportant

topreventbatterydamagewhenthetemperatureis

below32°F(0°C).

1.Removethebatteryfromthechassis;referto

RemovingtheBattery.

2.Checktheelectrolytelevel;refertoCheckingthe

ElectrolyteLevel.

3.Makesurethellercapsareinstalledinbattery.

Chargebatteryfor1hourat25to30ampsor6

hoursat4to6amps.

4.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthe

chargerleadsfromthebatteryposts(

Figure38).

5.Installthebatteryontothemachineandconnectthe

batterycables,refertoInstallingtheBattery.

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

Figure38

1.PositiveBatteryPost

2.NegativeBatteryPost

3.Red(+)ChargerLead

4.Black(-)ChargerLead

ServicingtheFuses

Figure39

1.Redwire3.Fuse,25amp,bladetype

2.Fuse,30amp,bladetype4.Violetwire

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance.Ifafuseblows,checkthecomponent

orcircuitforamalfunctionorshort.

1.Removethecoverunderthecontrolpanel.

2.Pulloutonthefusetoremoveorreplaceit

(Figure39).

3.Installthecoverunderthecontrolpanel.

Note:Ensurethecorrectsizefuseisinstallwiththe

correctwirecolorasshowninFigure39.

32

Page 33

DriveSystem

Maintenance

AdjustingtheTracking

1.Ifthemachinedoesnottrackstraight,adjustment

isrequired.

2.Checkthereartirepressure.RefertoCheckingthe

TirePressure.

3.Loosenthewingnutsontherightcontrolrodand

rotatetheturnbuckleinorouttoensuretheright

sidecontrolleveriscenteredintheneutrallock

position.Securetheturnbuckleinpositionwiththe

wingnuts(

Figure40).

Figure41

ReplacingtheCasterWheel

4.Loosenthewingnutsontheleftcontrolrodand

rotatetheturnbuckleinorouttochangethetracking.

Securetheturnbuckleinpositionwiththewingnuts

Figure40).

(

5.Checkforpropertracking.Adjusttheleftcontrol

rodifachangeisneeded.

Figure40

1.Turnbuckle

2.Bottomwingnut

3.Topwingnut(lefthand

threaded)

ForkBushings

Thecasterwheelforksaremountedinbushingspressed

intothetopandbottomofthecarrierframemounting

pivottubes.Tocheckthebushings,movethecaster

forksbackandforthandside-to-side.Ifacasterforkis

loose,thebushingsarewornandmustbereplaced.

1.Raisethecuttingunitsothecasterwheelsareoff

theoor,thensupportthefrontofthemowerwith

jackstands.

2.Removethelockingpinandspacer(s)fromthetop

ofthecasterwheelfork(

Figure42).

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Checkthepressureatthevalvestem(Figure41).

Maintaintheairpressureinthereartiresat12-14psi

(83-97kPa).Uneventirepressurecancauseanuneven

cut.

Note:Thefronttiresaresemi-pneumatictiresanddo

notrequireairpressuremaintenance.

Figure42

1.LockingPin

2.Spacers4.Casterwheelfork

3.Pullthecasterwheelforkoutofthemountingtube,

leavingthespacer(s)onthebottomofthefork.

33

3.Carrierframepivottube

Page 34

Rememberthelocationofthespacersoneachfork

toensurecorrectinstallation,andtomaintainalevel

deck.

4.Insertapinpunchintothemountingtubeand

carefullydriveoutthebushings(

Figure43).Clean

theinsideofthemountingtube.

Figure43

1.MountingTube2.Bushing

5.Greasetheinsideandoutsideofthenewbushings.

Useahammerandatplatetocarefullydrivethe

bushingsintothepivottubes.

6.Inspectthecasterwheelforkforwearandreplace

ifnecessary(

Figure42).

7.Slidethecasterwheelforkthroughthebushingsin

themountingtube.Replacethespacer(s)ontothe

forkandsecurewiththeretainingring(Figure42).

Important:Theinsidediameterofthebushings

maycollapseslightlywheninstalled.Ifthe

casterwheelforkdoesnotslideintothenew

bushings,reambothbushingstoaninside

diameterof1.126inch(29mm).

8.Greasethettingonthecarrierframepivottubes

usingNo.2generalpurposelithiumbaseor

molybdenumbasegrease.

1.Removethelocknutandwheelboltholdingthe

casterwheeltothecasterfork(Figure44).

Figure44

1.Locknut

2.WheelBolt5.RollerBearing

3.Bushing

4.SpannerBushing

2.Removeonebushing,thenpullthespannerbushing

androllerbearingoutofthewheelhub(

Figure44).

3.Removetheotherbushingfromthewheelhub

andcleananygreaseanddirtfromthewheelhub

(Figure44).

4.Inspecttherollerbearing,bushings,spannerbushing

andinsideofthewheelhubforwear.Replaceany

defectiveorwornparts(

Figure44).

5.Toassemble,placeonebushingintothewheelhub.

Greasetherollerbearingandspannerbushingand

slidethemintothewheelhub.Placethesecond

bushingintothewheelhub(Figure44).

6.Installthecasterwheelintothecasterforkand

securewiththewheelboltandlocknut.Tightenthe

locknutuntilthespannerbushingbottomsagainst

theinsideofthecasterforks(

Figure44).

7.Greasethettingonthecasterwheel.

ServicingtheCasterWheel

andBearings

Thecasterwheelsrotateonarollerbearingsupportedby

aspannerbushing.Ifthebearingiskeptwelllubricated,

wearwillbeminimal.Failuretokeepthebearingwell

lubricatedwillcauserapidwear.Awobblycasterwheel

usuallyindicatesawornbearing.

AdjustingtheElectricClutch

ServiceInterval:Every100hours

Theclutchisadjustabletoensureproperengagement

andproperbraking.

1.Inserta0.015–0.021inch(0.381–0.533mm)feeler

gaugethroughoneinspectionslotinthesideofthe

34

Page 35

assembly.Makesureitisbetweenthearmatureand

therotorfrictionsurfaces.

2.Tightenthelocknutsuntilthereisslightbindingon

thefeelergaugebutitcanbemovedeasilywithinthe

airgap(

3.Repeatthisfortheremainingslots.

4.Checkeachslotagainandmakeslightadjustments

untilthefeelergaugebetweentherotorandarmature

withveryslightcontactbetweenthem.

Figure45).

CoolingSystem

Maintenance

CleaningtheAirIntakeScreen

ServiceInterval:Beforeeachuseordaily

Beforeeachuseremoveanybuild-upofgrass,dirt

orotherdebrisfromthecylinderandcylinderhead

coolingns,airintakescreenonywheelend,and

carburetor-governorleversandlinkage.Thiswillhelp

insureadequatecoolingandcorrectenginespeedand

willreducethepossibilityofoverheatingandmechanical

damagetotheengine.

Figure45

1.Adjustingnut3.Feelergauge

2.Slot

35

Page 36

BrakeMaintenance

ServicingtheBrake

Beforeeachuse,checkbrakesonbothalevelsurface

andslope.

Alwayssettheparkingbrakewhenyoustopthemachine

orleaveitunattended.Iftheparkingbrakedoesnot

holdsecurely,anadjustmentisrequired.

CheckingtheParkingBrake

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface,disengagethe

PTO.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Applytheparkingbrake.Settingtheparkingbrake

shouldtakeareasonableamountofforce.Ifthe

parkingbrakedoesnotholdsecurely,anadjustment

isrequired.RefertoAdjustingtheParkingBrake.

Note:Whenthebrakeisengaged,thebrakehandle

shouldbeinthe1o’clockposition(

Figure46).

9.Tightenthetopandbottomjamnuts(Figure46).

10.Checkthebrakeoperationagain;refertoChecking

theBrake.

Figure46

1.Parkingbrakelever

(releasedposition)

2.1o’clockposition6.Yoke

3.Haripincotter7.JamNut

4.Lowerbrakelever8.Brakerod

5.Clevispin

AdjustingtheBrakes

Iftheparkingbrakedoesnotholdsecurely,an

adjustmentisrequired.

1.Parkthemachineonalevelsurface,disengagethe

PTO,andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Checkthebrakebeforeyouadjustit;referto

CheckingtheBrakes.

4.Releasetheparkingbrake;refertoReleasingthe

ParkingBrakeinOperation(page13).

5.Loosenthetopandbottomjamnuts(

6.Toadjustthebrake,removethehairpincotterand

clevispinfromthelowerbrakelever(

7.Rotatethebrakerodintheyokes.T otightenthe

brake,lengthentherodbetweentheyokes.To

loosenthebrake,shortentherodbetweentheyokes

(Figure46).

Figure46).

Figure46).

Note:Thebrakerodshouldbethreadedintoboth

yokesthesamedistance.

8.Securetheyoketolowerbrakeleverwiththehairpin

cotterandclevispin(Figure46).

36

Page 37

BeltMaintenance

ReplacingtheMowerBelt

ServiceInterval:Every50hours

Squealingwhenthebeltisrotating,bladesslippingwhen

cuttinggrass,frayedbeltedges,burnmarksandcracks

aresignsofaworndeckbelt.Replacethedeckbeltif

anyoftheseconditionsareevident.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Unlatchandremovethecarrierframecover.

4.Unlatchandremovethebeltcovers.

5.RemovethePTOdrivebelt.RefertoReplacingthe

PTODriveBelt.

6.Disconnecttheidlerarmspringtorelievetensionon

theidlerarmandidlerpulley,thenremovetheworn

mowerbelt(

Figure47orFigure48).

7.Installthenewmowerbeltaroundthetwooutside

spindlepulleys,theidlerpulley,andinthelower

grooveofthedoublespindlepulley(

Figure47or

Figure48).

8.Connecttheidlerarmspring(Figure47orFigure48).

9.InstallthePTOdrivebelt.RefertoReplacingthe

PTODriveBelt.

10.Adjustthebeltguidean1/8inch(3mm)fromthe

Figure47orFigure48).

belt(

11.Installthebeltcoversontothecuttingunitand

securethelatches.

Figure47

40inch,48inch,and52inchMowerDeckshown

1.Outsidepulley

2.PTODriveBelt

3.Idlerarmspring

4.Mowerdeckbelt

5.Beltguide

6.Centerspindlepulley

12.Installthecarrierframecoverontothecuttingunit

andsecurethelatches.

Figure48

36inchMowerDeckshown

1.Mowerdeckbelt4.Idlerarmspring

2.PTODriveBelt

3.Drivebeltpulley

5.Drivebeltpulley

ReplacingthePTODriveBelt

ServiceInterval:Every50hours

Squealingwhenthebeltisrotating,bladesslippingwhen

cuttinggrass,frayedbeltedges,burnmarksandcracks

37

Page 38

aresignsofaworndrivebelt.Replacethedrivebeltif

anyoftheseconditionsareevident.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Unlatchandremovethecarrierframecover.

4.Unlatchandremovethebeltcovers.

5.Removetheheatshieldfromtheenginedeckand

carrierframe.

6.Rollthebeltoffofthecenterpulleyonthemower

Figure49).RefertoFigure50torollthebelt

deck(

offleftpulleyfora36inchmowerdeck.Usecaution

whenremovingthebeltastensionwillincrease

becauseofthespringloadedidlerpulley .

7.Removethebeltfromtheenginepulleyandthe

springloadedidlerpulley(

Figure49).Referto

Figure50toremovethebeltfromthe36inchmower

deckpulleys.

Figure49

40inch,48inch,and52inchMowerDeckshown

1.PTOdrivebeltguide4.PTOengagementpulley

2.PTOdriveBelt5.PTOdrivebeltidlerpulley

3.Idlerspring

6.Centerspindlepulley

8.Installthenewbeltontotheenginepulleyandspring

loadedidlerpulley(

Figure49).

9.Rollthebeltontothecenterpulleyonthemower

deck(Figure49).Usecautionwheninstallthebelt

astensionwillincreasebecauseofthespringloaded

idlerpulley.RefertoFigure50torollthenewbelt

ontotheleftpulleyfora36inchmowerdeck.

10.Installtheheatshieldtotheenginedeckandcarrier

frame.

11.Adjustthebeltguidean1/8inch(3mm)fromthe

beltfor40,48and52inchmowerdecks(

Figure49).

12.Installthebeltcoversontothecuttingunitand

securethelatches.

13.Installthecarrierframecoverontothecarrierframe

andsecurethelatches.

1.Mowerdeckbelt

2.PTODriveBelt

3.Idlerarmandspring

Figure50

36inchMowerDeckshown

4.Clutchpulley

5.Idlerpulley

AdjustingthePTODriveBelt

IdlerSpringAnchor

ThepositionofthePTOidlercanbeadjustedto

increaseordecreasebelttension.

38

Page 39

UseFigure51fortheidlerpositionoptions.

Figure51

1.PTOdrivebeltidlerpulley4.Mosttensionforwornbelts

2.PTOdriveBelt5.Mediumtensionfornormal

3.Idlerspring

beltconditions

6.Leasttensionfornewbelts

Figure52

1.Hydraulicpumps

2.Idlerpulley6.Pivotbolt

3.Clutchretainer

4.Tensionspring8.Pumpdrivebelt

5.Clutchwireconnector

7.Drivepulley

7.Unhooktheidlerspringfromtheframe(Figure52).

ReplacingthePumpDriveBelt

ServiceInterval:Every50hours

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.RemovePTOdrivebelt.RefertoReplacingthe

PTODriveBeltinthe

4.Raisethemachineandsupportitwithjackstands.

5.Disconnecttheclutchwireconnectorfromthewire

harness.

6.Disconnecttheclutchretainerfromtheenginedeck

Figure52).

(

BeltMaintenance(page37).

8.Installthenewbeltaroundclutchandthetwodrive

pulleys.

9.Installtheidlerspringbetweenidlerarmandframe

bracket(

Figure52).

10.Installtheclutchretainertotheenginedeck

(Figure52).

11.Connecttheclutchwireconnectortothewire

harness.

12.InstallthePTOdrivebelt.

39

Page 40

ControlsSystem

Maintenance

AdjustingtheMotionControl

HandlePositions

AdjustingtheRightSideMotionControl

Lever

Ifthemotioncontrolleversdonotalignhorizontally,

adjusttherightsidemotioncontrollever.

Note:Adjustthehorizontalalignmentbeforethefront

tobackalignment.

1.DisengagethePTO,movetherightsidemotion

controllevertotheneutralpositionandsetthe

parkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Pushtherightmotioncontrolleverdownoutof

lockedneutralposition(

Figure53).

4.Checkifitalignshorizontallywiththeleftmotion

controllever(

1.Leftmotioncontrollever3.Checkthehorizontal

2.Rightmotioncontrollever

inneutrallockedposition

Figure53).

Figure53

alignmenthere

4.Rightmotioncontrollever

Figure54

1.Cam

2.Nutandbolt

3.Wingnut

4.Turnbuckle

5.Switchscrews

9.Afterthecamisadjusted,theleverswitchneedsto

bechecked.

10.Checkthegapbetweenthecontrolleverandswitch

asshownin

Figure55.Thegapneedstobean1/8

inch(3mm).

11.Ifneeded,loosenthescrewsholdingtheswitchand

adjusttheswitch.

12.Tightenthescrewsandinstallthecoverunderthe

controlpanel.

5.Toadjusttherightmotioncontrolleverhorizontally,

thecamneedstobeadjusted.

6.Removethecoverunderthecontrolpanel.

7.Loosenthenutandboltholdingthecam(

Figure54).

8.Adjustthecamuntilitalignswiththeleftmotion

controlleverandtightenthenutandboltforthe

cam.

40

Page 41

1.Rightsidemotioncontrol

leverpivotshownunder

controls

2.Rightsidemotioncontrol

lever

Figure55

3.1/8inch(3mm)gap

4.Switch

neededbetweenswitch

andcontrollever

Figure56

1.Leftmotioncontrollever

2.Rightmotioncontrollever4.Alignthecontrollevers

3.Neutrallockedposition

fronttobackhere

AdjustingtheNeutralPostionforthe

MotionControlLevers

Important:Ensurethetrackingofthemoweris

correctafteradjustingthemotioncontrollevers.

Afteradjustingthetracking,themotioncontrol

leversmaynotaligntheexactlyfronttoback

Figure56).

(

Ifthemotioncontrolleversdonotalignfronttoback,

ortherightsidecontrolleverdoesnotmoveeasilyinto

theneutrallockposition,adjustmentisrequired.Adjust

eachleverandcontrolrodseparately.

Note:Adjustthehorizontalalignmentbeforethefront

tobackalignment.

1.Afterthehorizontalalignmentisnished,checkthe

fronttobackalignment(

Figure56).

2.Loosenthewingnutsontherightcontrolrodand

rotatetheturnbuckleinorouttoensuretheright

sidecontrolleveriscenteredintheneutrallock

position.Securetheturnbuckleinpositionwiththe

wingnuts(Figure57).

3.Loosenthewingnutsontheleftcontrolrodand