Page 1

FormNo.3398-359RevA

Groundsmaster

®

7200Series

TractionUnit

ModelNo.30473—SerialNo.315000501andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3398-359*A

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives;

fordetails,pleaseseetheseparateproduct-specic

DeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

ThissparkignitionsystemcomplieswithCanadianICES-002.

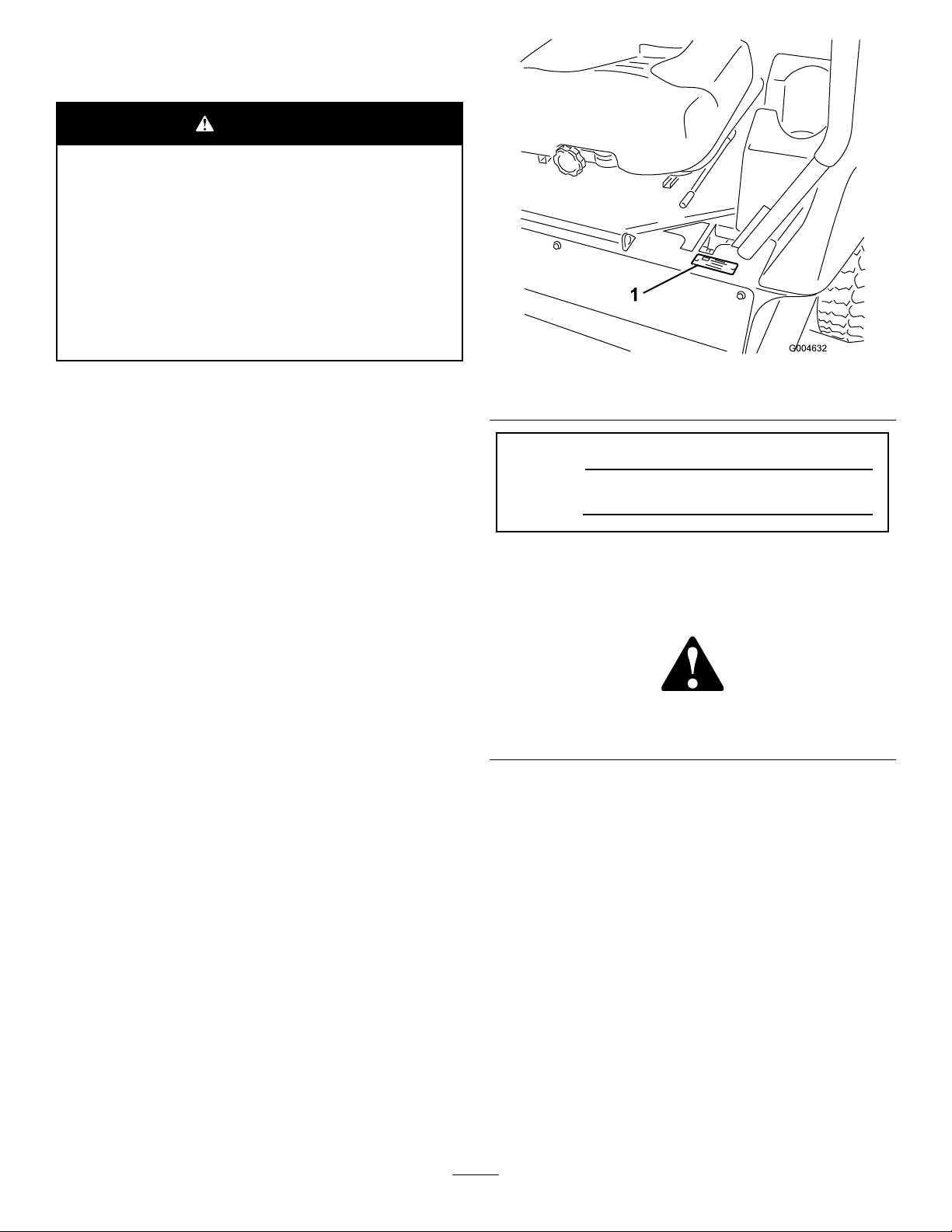

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Introduction

Thismachineisaride-on,rotary-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrass

onwell-maintainedlawnsinparks,sportselds,andon

commercialgrounds.Itisnotdesignedforcuttingbrush,

mowinggrassandothergrowthalongsidehighways,orfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

GeneralSafety.........................................................4

SafetyandInstructionalDecals.................................4

Setup............................................................................7

1CheckingFluidLevels............................................8

2ActivatingandChargingtheBattery.........................8

ProductOverview..........................................................9

Controls................................................................9

BeforeOperation......................................................11

BeforeOperationSafety..........................................11

AddingFuel...........................................................12

CheckingtheEngine-OilLevel.................................12

CheckingtheCoolingSystem...................................12

CheckingtheHydraulicSystem................................12

ThinkSafetyFirst...................................................13

UsingtheSafety-InterlockSystem.............................13

PositioningtheSeat................................................14

DuringOperation.....................................................15

DuringOperationSafety.........................................15

OperatingtheParkingBrake....................................16

StartingandShuttingofftheEngine..........................16

DrivingtheMachine...............................................17

EngagingthePowerTakeoff(PTO)..........................18

DisengagingthePTO.............................................18

AfterOperation........................................................18

AfterOperationSafety............................................18

PushingtheMachinebyHand..................................18

HaulingtheMachine...............................................19

Maintenance.................................................................20

RecommendedMaintenanceSchedule(s)......................20

DailyMaintenanceChecklist....................................21

PremaintenanceProcedures........................................22

Pre-MaintenanceSafety...........................................22

UnlatchingtheSeat.................................................22

Lubrication...............................................................23

GreasingtheBearingsandBushings..........................23

EngineMaintenance..................................................23

EngineSafety.........................................................23

CheckingtheAirCleaner.........................................23

ServicingtheEngineOil..........................................24

FuelSystemMaintenance...........................................25

ServicingtheWaterSeparator..................................25

CleaningtheFuelTank............................................26

CheckingtheFueltheLinesandConnections.............26

BleedingtheFuelSystem.........................................26

BleedingAirfromtheInjectors................................26

ElectricalSystemMaintenance....................................27

ElectricalSystemSafety...........................................27

ServicingtheBattery...............................................27

StoringtheBattery..................................................28

CheckingtheFuses.................................................28

CoolingSystemMaintenance......................................29

CheckingtheCoolingSystem..................................29

CleaningtheRadiator..............................................29

BrakeMaintenance....................................................30

AdjustingtheParking-BrakeInterlockSwitch.............30

BeltMaintenance......................................................30

CheckingtheAlternator-BeltTension........................30

ControlsSystemMaintenance.....................................31

AdjustingtheControl-Lever-NeutralInterlock

Switch...............................................................31

AdjustingtheControl-Lever-NeutralReturn..............31

AdjustingtheTractionDriveforNeutral....................32

AdjustingtheMaximumGroundSpeed.....................33

AdjustingtheTracking............................................33

HydraulicSystemMaintenance....................................34

HydraulicSystemSafety..........................................34

CheckingtheHydraulicSystem................................34

ChangingtheHydraulicFluidAndFilter....................35

Storage........................................................................36

Machine................................................................36

Engine..................................................................36

3

Page 4

Safety

ThismachinehasbeendesignedinaccordancewithCEN

standardISOEN5395:2013andANSIB71.4-2012whenthe

properCEKitshavebeeninstalledpertheDeclarationof

Conformity.

•Donotoperatethemachinewithoutallguardsandother

safetyprotectivedevicesinplaceandworkingonthe

machine.

•Keepclearofanydischargeopening.Keepbystandersa

safedistancefromthemachine.

•Keepchildrenoutoftheoperatingarea.Neverallow

childrentooperatethemachine.

GeneralSafety

Thisproductiscapableofamputatinghandsandfeetand

ofthrowingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustoyouandbystanders.

•ReadandunderstandthecontentsofthisOperator’ sManual

beforeyoustarttheengine.Ensurethateveryoneusing

thisproductknowshowtouseitandunderstandsthe

warnings.

•Donotputyourhandsorfeetnearmovingcomponents

ofthemachine.

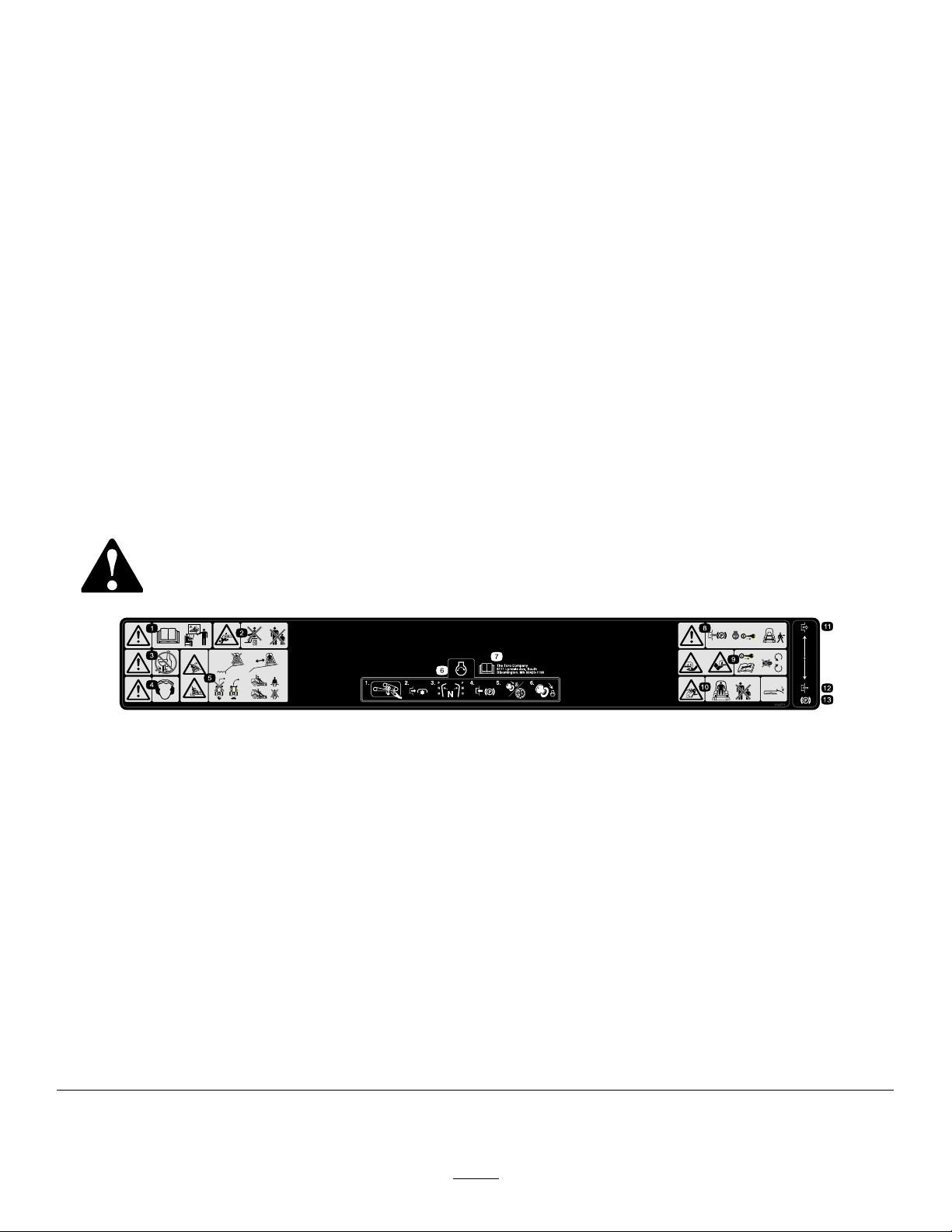

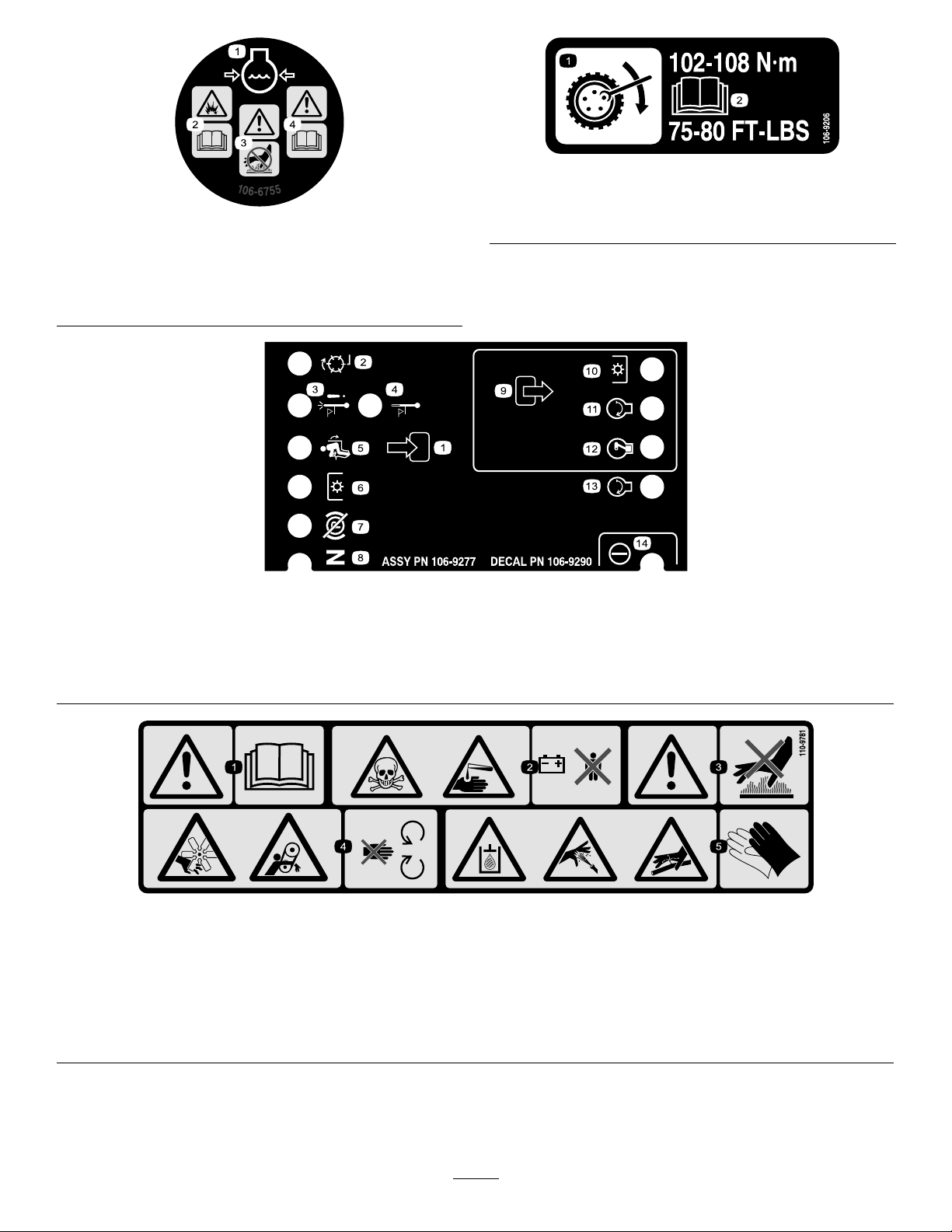

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

•Stopthemachineandshutofftheenginebeforeservicing,

fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecanresult

ininjury.T oreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safety-alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theseinstructionsmayresultinpersonalinjuryordeath.

Youcanndadditionalitemsofsafetyinformationintheir

respectivesectionsthroughoutthismanual.

1.Warning—readtheOperator'sManualbeforeoperatingand

donotoperatethismachineunlessyouaretrained.

2.Crushing/dismembermenthazardofbystanders—donot

carrypassengers,keepbystandersasafedistancefromthe

machine.

3.Warning—donotusedrugsoralcohol.

4.Warning—wearhearingprotection.11.Disengage

5.Tipping,dropoffhazard—donotoperatenearwaterdrop-offs,

stayasafedistancefromdrop-offs,slowmachinebefore

turning,donotturnathighspeeds,wearaseatbeltwhen

aROPSisinplace,donotwearaseatbeltwhenROPSis

lowered.

6.Tostarttheengine:clearanydebrisfromtheattachment,

disengagethePTO,movethemotion-controlleverstothe

neutralposition,engagetheparkingbrake,turntheignitionto

Runandwaitfortheglowpluglighttoturnoff,turntheignition

keytoStart.

7.ReadtheOperator'sManual.

110-9772

8.Warning—engagetheparkingbrake,stoptheengineand

removetheignitionkeybeforeleavingthemachine.

9.Cuttinghazardofhandorfoot—removetheignitionkey

andreadtheinstructionsbeforeservicingorperforming

maintenance,keepawayfrommovingparts.

10.Thrownobjecthazard—keepbystandersasafedistancefrom

themachine;keepalldeectorsandshieldsinplace.

12.Engage

13.Parkingbrake

4

Page 5

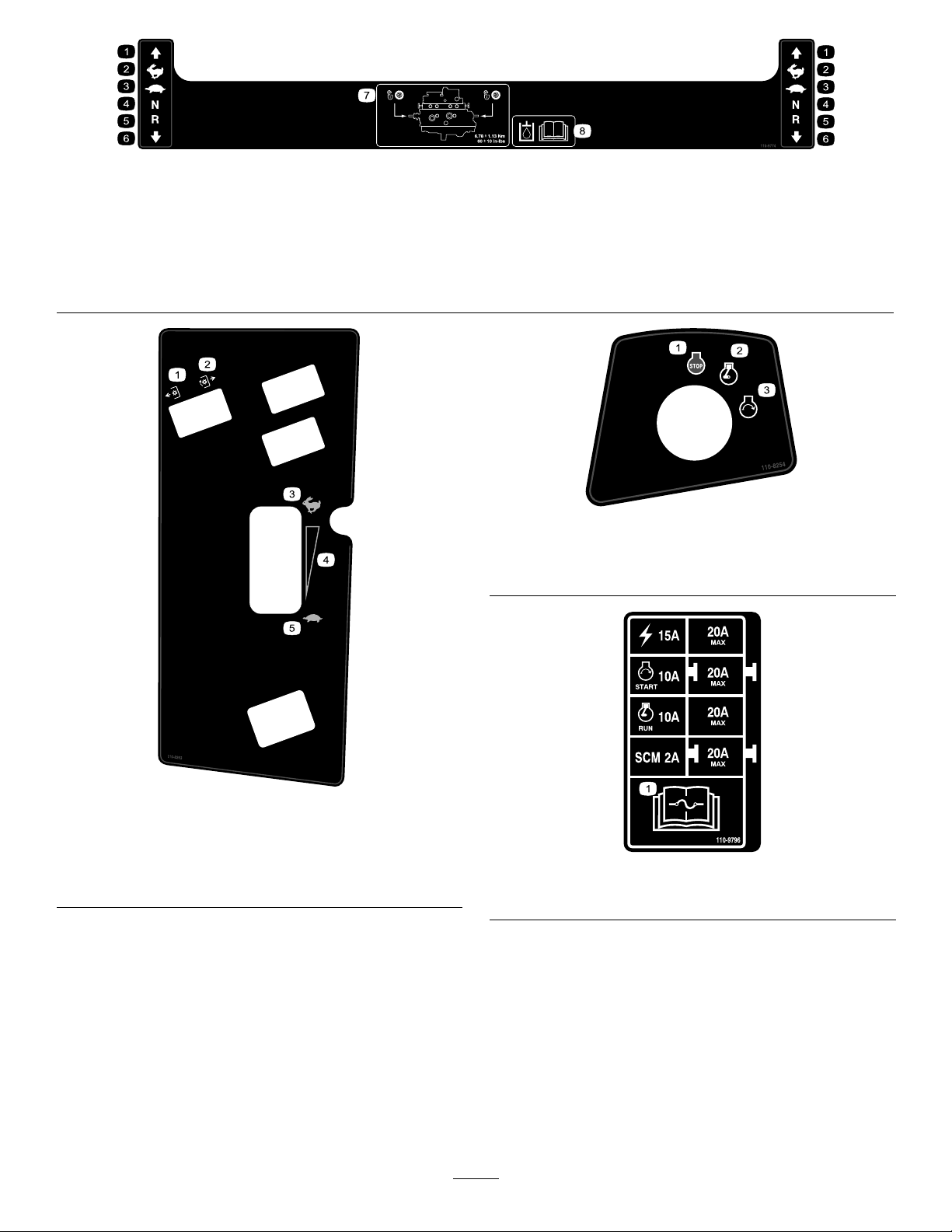

110-9774

1.Forward

2.Fast4.Neutral6.Backward

3.Slow

5.Reverse7.Towvalvelocation;torque

thetowvalvesto6.78±

1.13N⋅m(60±10in-lb).

8.ReadtheOperator's

Manualformore

informationonthehydraulic

oil.

110-8254

1.Engine–Stop3.Engine—Start

2.Engine—Run

110-8253

1.PTO–Off4.Continuousvariable

setting

2.PTO—On5.Slow

3.Fast

110-9796

1.ReadtheOperator'sManualforinformationonfuses.

5

Page 6

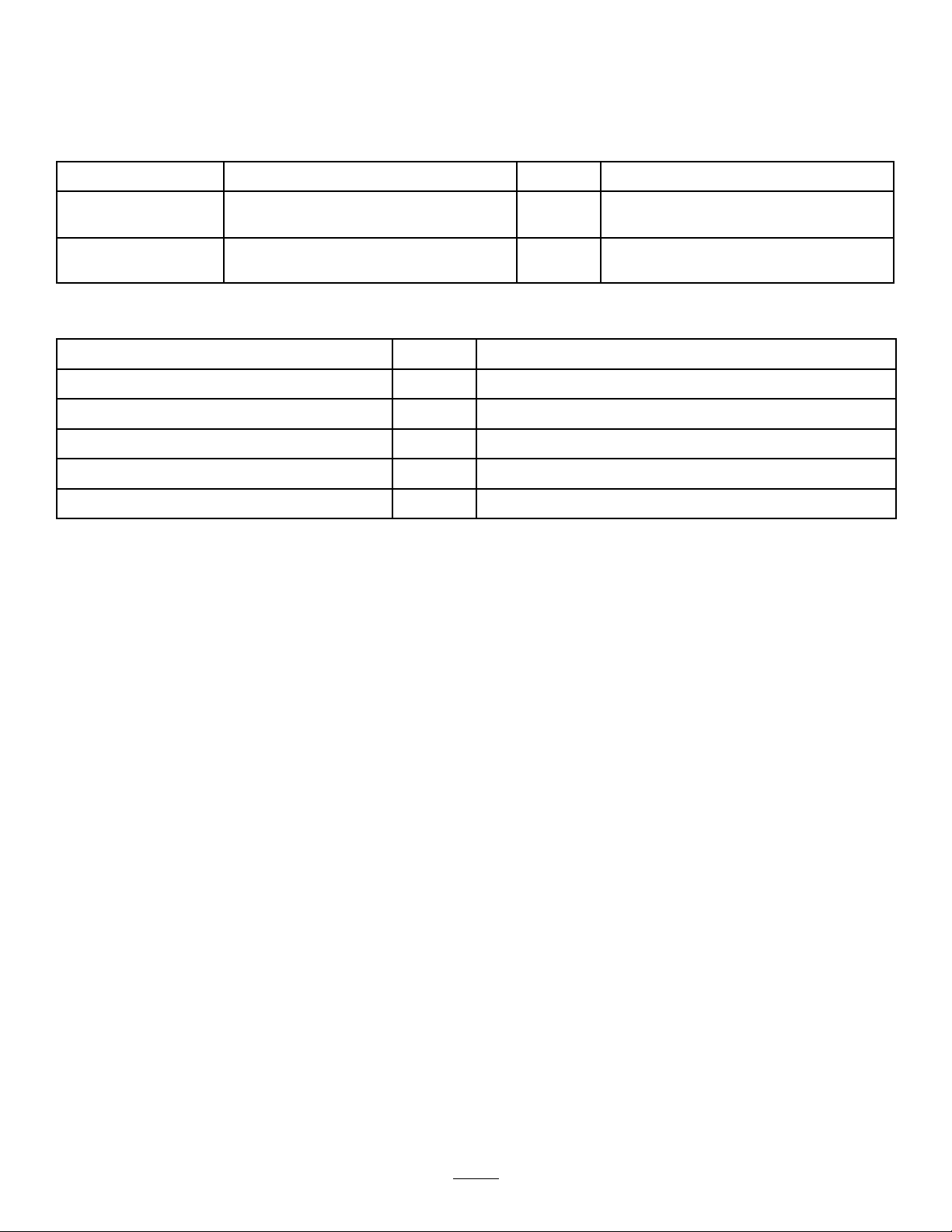

106-9206

1.Wheeltorquespecications

106-6755

2.ReadtheOperator'sManual.

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

1.Inputs5.Inseat

2.Notactive

3.Hightemperatureshutdown

4.Hightemperaturewarning8.Neutral

3.Warning—donottouchthe

4.Warning—readthe

6.PowerT akeoff(PTO)10.PowerT akeoff(PTO)

7.Parkingbrakeoff11.Start

hotsurface.

Operator'sManual.

106-9290

9.Outputs13.Start

14.Power

12.EnergizetoRun(ETR)

110-9781

1.Warning—readtheOperator'sManual.

2.Poisonandcausticliquid/chemicalburnhazard—keepchildrenasafedistancefromthebattery.

3.Warning—donottouchthehotsurface.

4.Cutting/dismembermenthazard,fanandentanglementhazard,belt—stayawayfrommovingparts.

5.Hydraulicoilinsystemunderpressure,escapinghydraulicoilpenetratingskinhazard,brokenhydrauliclineshazard—wear

protectivehandprotectionwhenhandlinghydraulicsystemcomponents.

6

Page 7

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

Nopartsrequired

Nopartsrequired

MediaandAdditionalParts

Description

Operator'sManual

Engineowner’smanual1

PartsCatalog

Operatortrainingmaterials

Enginewarranty1

Qty.

–

–

Qty.

1

1Usetolookupandorderparts.

1

Readbeforeoperatingthemachine.

Readbeforeoperatingthemachine.

Viewbeforeoperatingthemachine.

Saveforfutureuse.

Use

Checkthehydraulicuid,engineoil,

andcoolantlevels.

Activateandchargethebattery.

Use

7

Page 8

1

CheckingFluidLevels

NoPartsRequired

Procedure

1.Checkthehydraulicuidlevelbeforestartingthe

engine;refertoCheckingtheHydraulicSystem(page

34).

2.Checktheengine-oillevelbeforeandafterstartingthe

engine;refertoCheckingtheEngine-OilLevel(page

24).

3.Checkthecoolingsystembeforestartingtheengine;

refertoCheckingtheCoolingSystem(page29).

3.Carefullylleachcellwithelectrolyteuntiltheplates

arecoveredwithabout6mm(1/4inch)ofuid(Figure

4).

Figure4

4.Waitapproximately20to30minutesfortheelectrolyte

tosoakintotheplates.

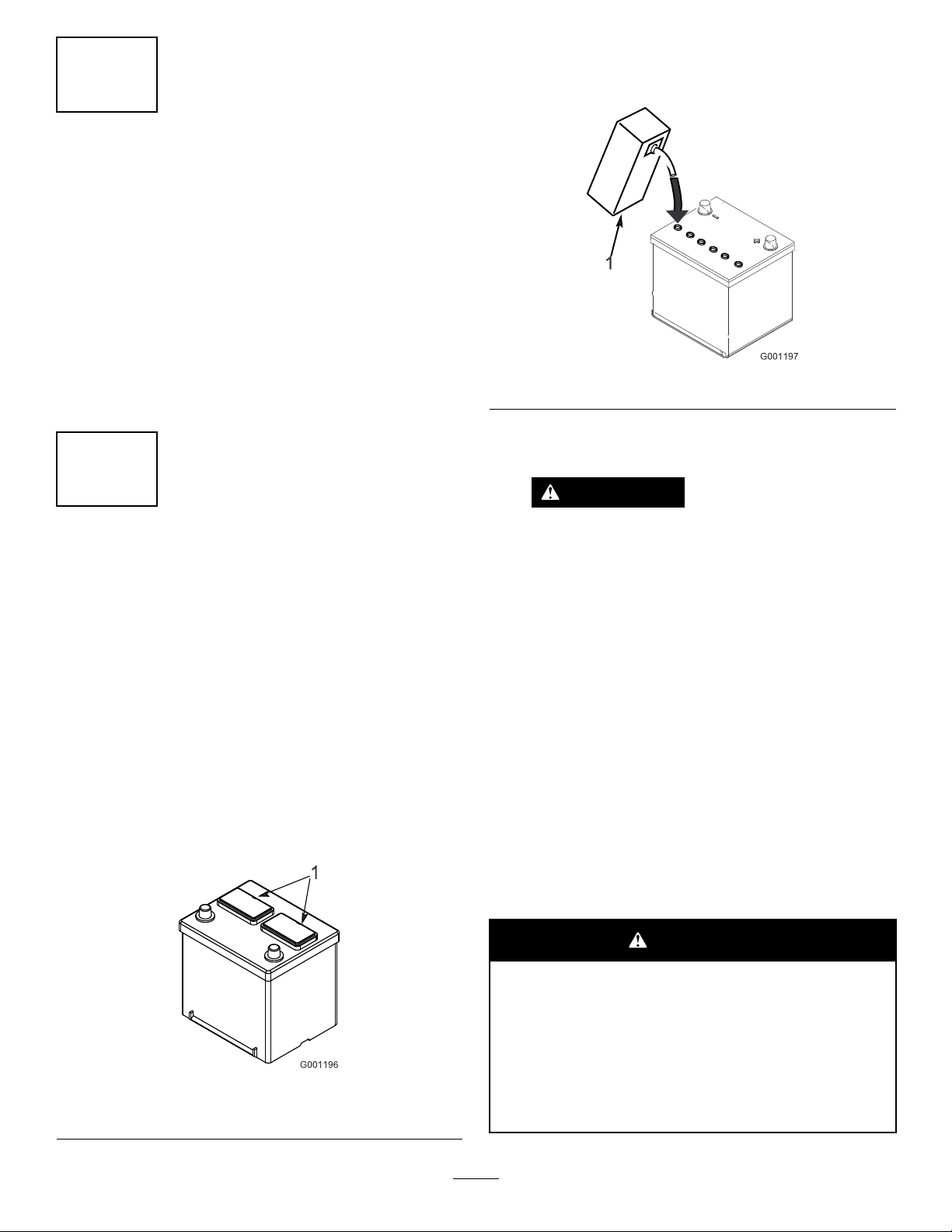

2

ActivatingandChargingthe Battery

NoPartsRequired

Procedure

Useonlyelectrolyte(1.265SpecicGravity)tollthebattery

initially.

1.Removethebatteryfromthemachine.

Important:Donotaddelectrolytewhilethe

batteryisinthemachine.Y oucouldspillit,

causingcorrosion.

2.Cleanthetopofthebatteryandremovetheventcaps

(Figure3).

WARNING

Chargingthebatteryproducesgassesthatcan

explodeandcauseseriousinjuryordeath.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

5.Fillthecellsasnecessarytobringtheelectrolyteto

withinabout6mm(1/4inch)ofthebottomofthell

well(Figure4).

6.Connecta3to4Abatterychargertothebatteryposts.

7.Chargethebatteryatarateof3to4Auntilthespecic

gravityis1.25orhigherandthetemperatureisatleast

16°C(60°F),withallcellsgassingfreely.

8.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

Note:Afteryouactivatethebattery,addonly

distilledwatertoreplacenormalloss,although

maintenance-freebatteriesshouldnotrequirewater

undernormaloperatingconditions.

WARNING

1.Ventcaps

Figure3

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

8

Page 9

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalcomponents,causingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsof

themachine.

9.Installthebatteryintothemachineandsecureit.

Note:Thebatteryshouldnotmoveorwigglewhen

pushed.

10.Installthepositivecable(red)tothepositive(+)

terminalandtheninstallthenegativecable(black)to

thenegative(-)terminalofthebattery.

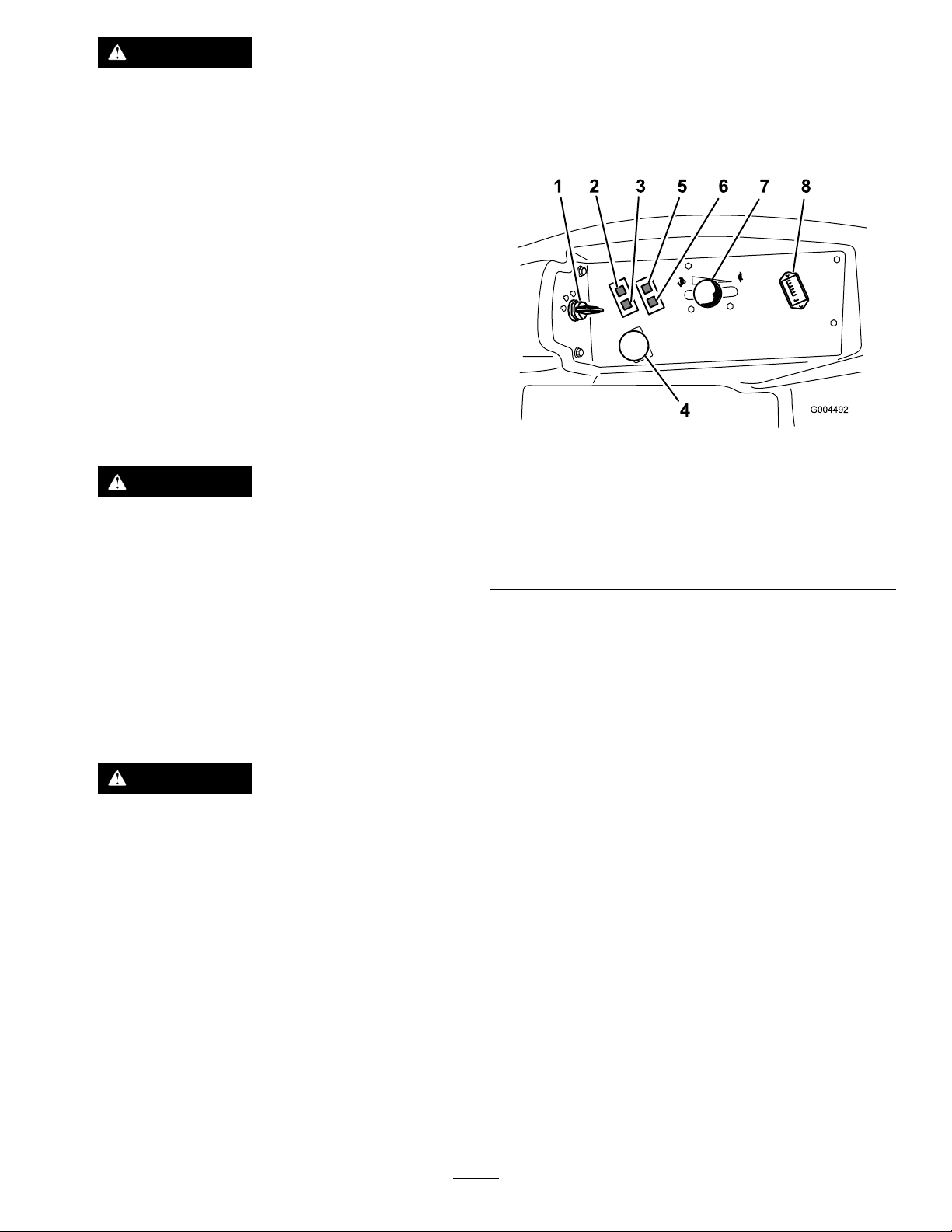

ProductOverview

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine(Figure5).

Figure5

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcables,causingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

WARNING

Connectingcablestothewrongpostcould

damagetheelectricalsystemandresultin

personalinjury.

Important:Routethebatterycablesawayfrom

anysharpedgesormovingparts.

11.Slidetherubberbootoverthepositiveterminalto

preventapossibleshortfromoccurring.

1.Ignitionswitch

2.Engine-coolant-temperature

warninglight

3.Glow-pluglight

4.Power-takeoff(PTO)

switch

5.Oil-pressurewarninglight

6.Charge-indicatorlight

7.Throttlelever

8.Hourmeter

Motion-ControlLevers

Themotion-controlleverscontroltheforwardandrearward

motionsaswellastheturningofthemachine.Referto

DrivingtheMachine(page17).

IgnitionSwitch

Theignitionswitchhas3positions:OFF,ON/PREHEAT,and

START.

ThrottleLever

Thethrottlelevercontrolsthespeedoftheengine,thespeed

oftheblades,and,inconjunctionwithmotion-controllevers,

thegroundspeedofthemachine..Movingthethrottlelever

forwardtowardtheFASTpositionincreasestheenginespeed.

MovingitrearwardtowardtheSLOWpositiondecreasesthe

enginespeed.Alwaysrunthemachinewiththethrottleinthe

FASTpositionwhencuttinggrass.

Power-Takeoff(PTO)Switch

Thepower-takeoff(PTO)switchstartsandstopsthemower

blades.

9

Page 10

HourMeter

Thehourmeterrecordsthenumberofhoursthatyouoperate

themachinewiththekeyswitchintheRUNposition.Use

thesetimesforschedulingregularmaintenance.

Glow-PlugLight(OrangeLight)

Theglow-plugindicatorlightilluminateswhenyouturn

theignitionswitchtotheONposition.Itremainslitfor6

seconds.Whenthelightturnsoff,theengineisreadytostart.

Engine-Coolant-TemperatureWarning

Light

Thislightilluminatesandthecuttingbladesstopifthe

engine-coolanttemperatureishigh.Ifyoudonotstopthe

machineandthecoolanttemperaturerisesanother11°C

(20°F),theenginestops.

Important:Ifthemowerdeckshutsdownandthe

temperaturewarninglightison,pushthePTOknob

down,drivetoasafe,atarea,movethethrottleleverto

theSLOWposition,movethemotion-controlleversinto

theNEUTRAL-LOCKposition,andengagetheparking

brake.Idletheengineforseveralminuteswhileitcools

toasafelevel.Stoptheengineandcheckthecooling

system;refertoCheckingtheHydraulicSystem(page

34).

Charge-IndicatorLight

Thecharge-indicatorlightilluminateswhenthesystem

chargingcircuitmalfunctions.

Oil-Pressure-WarningLight

Figure6

1.Parking-brakelever

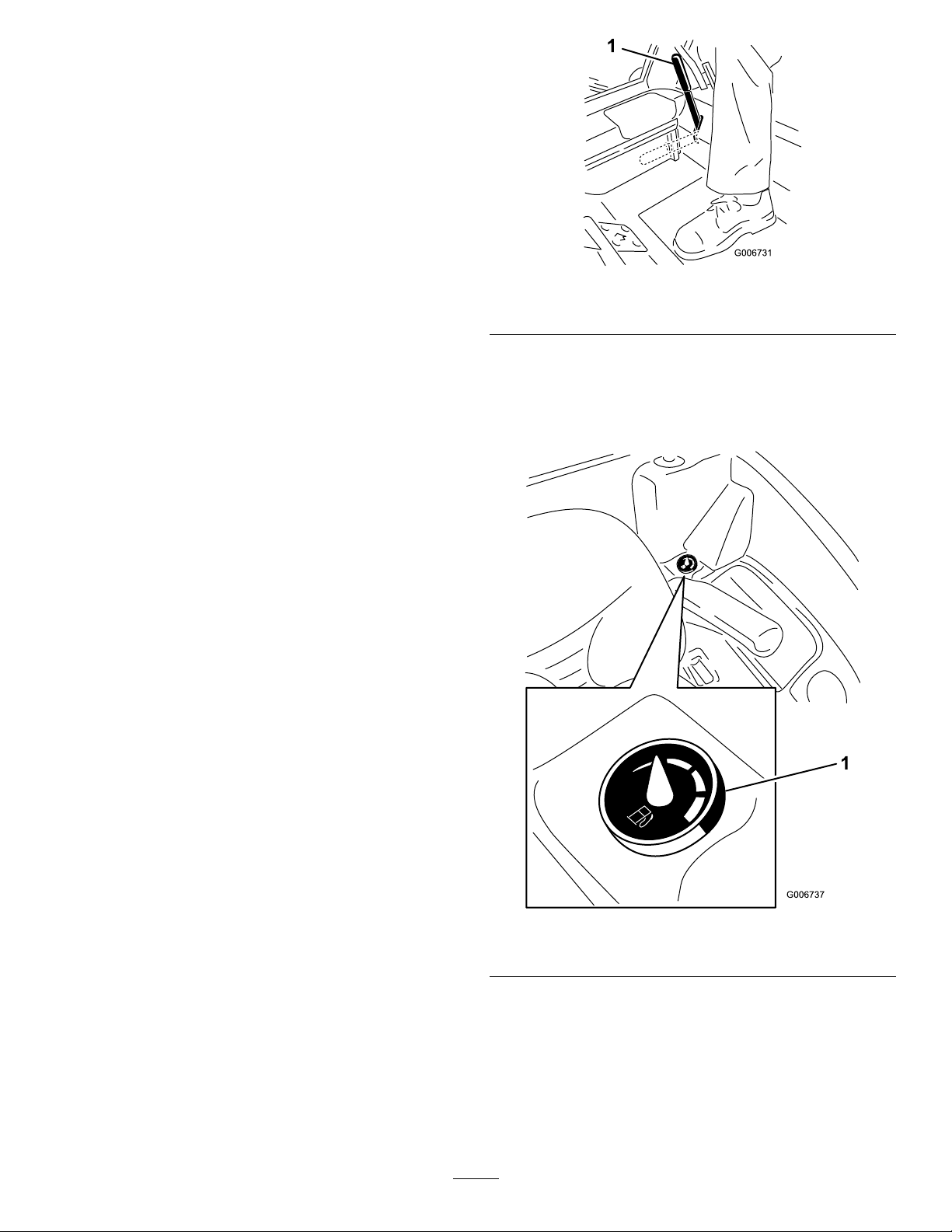

FuelGauge

Thefuelgaugeindicatesthequantityoffuelremainingin

thefueltanks(Figure7).

Theoil-pressure-warninglightilluminateswhentheoil

pressureinenginedropsbelowasafelevel.Iftheoilpressure

islow,stoptheengineanddeterminethecause.Repairthe

damagebeforestartingtheengineagain.

Parking-BrakeLever

Wheneveryoushutofftheengine,engagetheparkingbrake

topreventaccidentalmovementofthemachine.Toengage

theparkingbrake,pulltheparking-brakeleverrearward

andup(Figure6).Toreleasetheparkingbrake,pushthe

parking-brakeleverforwardanddown.

Figure7

1.Fuelgauge

10

Page 11

Operation

FuelSafety

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Read,understand,andfollowallinstructionsonthe

machineandinthemanual(s)beforestartingthemachine.

•Neverallowchildrenoruntrainedpeopletooperateor

servicethemachine.Localregulationsmayrestrictthe

ageoftheoperator.Theownerisresponsiblefortraining

alloperatorsandmechanics.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.Knowhowtostop

themachineandenginequickly.

•Checkthatallsafetydevicesareattachedand

functioningproperly.Thisincludes,butisnotlimitedto,

operator-presencecontrols;safetyswitchesandshields;

therolloverprotectionsystem(ROPS);attachments;and

brakes.Donotoperatethemachineunlessallsafety

devicesareinpositionandfunctioningasintendedby

themanufacturer.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana180-daysupplyoffuel.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Alwaysinspectthemachinetoensurethattheblades,

bladebolts,andcuttingassemblyarenotwornor

damaged.Replacewornordamagedbladesandboltsin

setstopreservebalance.

•Inspecttheareawhereyouwillusethemachineand

removeallobjectsthatthemachinecouldpotentially

throw .

•EnsurethatallthedrivesareintheNEUTRALposition,

theparkingbrakeisengaged,andthatyouareinthe

operatingpositionbeforeyoustarttheengine.

•Keepyourhandsandfaceawayfromthenozzle

andthefuel-tankopening.

•Keepfuelawayfromyoureyesandskin.

•Useonlyanapprovedfuelcontainer.

•Neverremovethefuelcaporaddfueltothefueltank

whiletheengineisrunning.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundandawayfromyourvehiclebeforelling.

•Removetheequipmentfromthetruckortrailerandadd

fueltoitwhileitisontheground.Ifthisisnotpossible,

thenaddfuelusingaportablecontainerratherthanfrom

afuel-dispensernozzle.

•Keepthefuel-dispensernozzleincontactwiththerimof

thefueltankorcontaineropeningatalltimesuntilfueling

iscomplete.Donotuseanozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyourclothing

immediately.

•Fillthefueltankuntilthefuellevelis25mm(1inch)

belowthebottomofthellerneck.Donotoverllthe

fueltank.Replacethefuel-tankcapandtightenitsecurely .

11

Page 12

AddingFuel

RecommendedFuel

Useonlyclean,freshdieselfuelwithultralow(<15

ppm)sulfurcontentmeetingASTMD975orEN590

specications.Theminimumcetaneratingshouldbe40.

Purchasefuelinquantitiesthatcanbeusedwithin180days

toensurefuelfreshness.

Important:Useofnon-ultralowsulfurfuelcauses

damagetotheengineemissionsystem.

Fueltankcapacity:43.5L(11.5USgallons)

Usesummer-gradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Usingwinter-grade

fuelatlowertemperaturesprovideslowerashpointand

cold-owcharacteristics,whicheasesstartingandreduces

fuellterplugging.

Usingsummer-gradefuelabove-7°C(20°F)contributes

towardlongerfuel-pumplifeandincreasedpowercompared

towinter-gradefuel.

FillingtheFuelTank

Important:Thefueltanksareconnected,butthefuel

doesnottransferquicklyfromonetanktotheother.Itis

importantwhenllingthatyouparkonalevelsurface.

Ifyouparkonahill,youmayinadvertentlyoverllthe

tanks.

Important:Donotoverllthefueltanks.

Important:Donotopenthefueltankswhenparkedon

ahill.Thefuelcouldspillout.

Important:Donotusekeroseneorgasolineinstead

ofdieselfuel.Failuretoobservethiscautiondamages

theengine.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionmustbeultralowsulfur.Observethefollowing

precautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

•Monitorseals,hoses,gasketsincontactwithfuelasthey

maybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblendedfuel.

•Contactyourdistributorifyouwishmoreinformation

onbiodiesel.

Figure8

Note:Ifpossible,llthefueltanksaftereachuse.This

minimizesbuildupofcondensationinsidethefueltank.

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page24).

CheckingtheCoolingSystem

Beforeyoustarttheengineandusethemachine,checkthe

coolingsystem;refertoCheckingtheCoolingSystem(page

29).

CheckingtheHydraulic System

Beforeyoustarttheengineandusethemachine,checkthe

hydraulicsystem;refertoCheckingtheHydraulicSystem

(page34).

12

Page 13

ThinkSafetyFirst

G009027

1

2

Pleasereadallsafetyinstructionsandsymbolsinthesafety

section.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

DANGER

Operatingonicyorsteepslopescancausesliding

andlossofcontrol.

Atrackdroppingoveranedgecancausearollover,

whichmayresultinseriousinjury,death,or

drowning.

Alwaysusetheseatbeltwhentherollbarisup.

Readandfollowtherollover-protectioninstructions

andwarnings.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotoperateneardrop-offsornearwater.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

Figure10

1.Weareyeprotection.2.Wearhearingprotection.

UsingtheSafety-Interlock System

CAUTION

Ifthesafety-interlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly,

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafety-Interlock

System

Thesafety-interlocksystempreventstheenginefromstarting

unless:

•Youaresittingontheseatortheparkingbrakeisengaged.

•Thepowertakeoff(PTO)isdisengaged.

•Themotion-controlleversareintheNEUTRAL-LOCK

position.

•Theenginetemperatureisbelowthemaximumoperating

temperature.

Figure9

1.SafeZone3.Water/unsafeice

2.Usewalk-behind

equipmentneardrop-offs

andwater.

Thesafety-interlocksystemalsostopstheenginewhenyou

movethetractioncontrolsfromtheNEUTRAL-LOCKposition

withtheparkingbrakeengaged.Ifyourisefromtheseat

whenthePTOisengaged,thereisa1-seconddelayandthen

theenginestops.

TestingtheSafety-InterlockSystem

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator’searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,hands,feet,

andheadisrecommended.

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Sitontheseat,engagetheparkingbrake,andmovethe

PTOtotheONposition.Trystartingtheengine;the

engineshouldnotcrank.

13

Page 14

2.Sitontheseat,engagetheparkingbrake,andmovethe

PTOtotheOFFposition.Moveeithermotion-control

leveroutoftheNEUTRAL-LOCKposition.Trystarting

theengine;theengineshouldnotcrank.Repeatfor

othermotion-controllever.

3.Sitontheseat,engagetheparkingbrake,movethe

PTOswitchtotheOFFposition,andmovethe

motion-controlleverstotheNEUTRAL-LOCKposition.

Starttheengine.Whiletheengineisrunning,release

theparkingbrake,engagethePTO,andriseslightly

fromtheseat;theengineshouldstopwithin2seconds.

4.Withoutanoperatorontheseat,engagetheparking

brake,movethePTOswitchtotheOFFposition,and

movethemotion-controlleverstotheNEUTRAL-LOCK

position.Starttheengine.Whiletheengineisrunning,

centereithermotioncontrol;theengineshouldstop

within2seconds.Repeatfortheothermotion-control

lever.

5.Withoutanoperatorontheseat,disengagetheparking

brake,movethePTOswitchtotheOFFposition,and

movethemotion-controlleverstotheNEUTRAL-LOCK

position.Trystartingtheengine;theengineshould

notcrank.

UsingtheSCMtoDiagnoseSystem

Problems

Themachineisequippedwithastandardcontrolmodule

(SCM)monitoringsystemthattracksthefunctionofvarious

keysystems.TheSCMislocatedundertherightcontrol

panel.Accessitthroughthesidepanelcover(Figure11).

Toopenthesidepanelcover,releasethe2latchesandpull

outonit.

theselightsforsystemdiagnosis.RefertoFigure12fora

descriptionofwhateachlightmeans.Fordetailsonusingthe

restoftheSCMfunctions,refertotheServiceManual,available

throughyourAuthorizedToroDistributor.

Figure12

1.Hightemperatureshutdown—theenginetemperaturehas

exceededsafelevelsandtheenginehasbeenshutdown.

Checkthecoolingsystem.

2.Hightemperaturewarning—theenginetemperatureis

approachingunsafelevelsandthemowerdeckhasbeen

shutdown.Checkthecoolingsystem.

3.Operatorisintheseat.

4.ThePTOison.

5.Theparkingbrakeisnotengaged.

6.Controlsareinneutral.

7.TheSCMisreceivingpowerandisoperational.

PositioningtheSeat

Figure11

1.Sidepanelcover

2.Latches

OnthefaceoftheSCMare11LEDsthatilluminate

toindicatevarioussystemconditions.Youcanuse7of

Figure13

1.Back-restknob3.Lumbar-support-adjustment

knob

2.Seat-suspensionknob4.Seat-position-adjustment

lever

14

Page 15

ChangingtheSeatPosition

Youcanmovetheseatforwardandbackward.Positionthe

seatwhereyouhavethebestcontrolofthemachineandare

mostcomfortable.

Figure14

ChangingtheSeatSuspension

Youcanadjusttheseatforasmoothandcomfortableride.

Positiontheseatwhereyouaremostcomfortable.

Withoutsittingontheseat,turntheknobinfronteither

direction(Figure13).

Figure15

1.Seat-suspensionknob2.Operator-weightsetting

ChangingtheBackPosition

Youcanadjustthebackoftheseatforacomfortableride.

Positionthebackoftheseatwhereyouaremostcomfortable.

Toadjustit,turntheknob,undertherightarmrest,ineither

direction(Figure13).

ChangingtheLumbarSupport

Youcanadjustthelumbarsupportforyourlowerback.

Toadjustit,turntheknob,undertheleftarmrest,ineither

direction(Figure13).

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/usercanpreventandisresponsiblefor

accidentsthatmaycauseinjuriestohimself/herselfand

othersandfordamagetoproperty.

•Wearappropriateclothing,includingeyeprotection;

slip-resistant,substantialfootwear;andhearing

protection.Wearingsafetyshoesandlongpantsis

advisableandrequiredbysomelocalordinancesand

insuranceregulations.Tiebacklonghair,secureloose

clothing,anddonotwearjewelry.

•EnsurethatalldrivesareintheNEUTRALposition,the

parkingbrakeisengaged,andyouareintheoperating

positionbeforeyoustarttheengine.

•Keepallbodyparts,includinghandsandfeet,awayfrom

allmovingparts.

•Donotoperatethemachinewhileill,tired,orunderthe

inuenceofalcoholordrugs.

•Keepthedirectionofthemowerdischargeawayfrom

peopleandpets.

•Donotmowinreverseunlessitisabsolutelynecessary.If

youmustmowinreverse,lookbehindanddownforsmall

childrenbeforeandwhilemovingthemachineinreverse.

Stayalertandstopthemachineifachildentersthearea.

•Useextremecarewhenapproachingblindcorners,

shrubs,trees,orotherobjectsthatmayblockyourview.

•Donotmowneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyrolloverifawheelgoes

overtheedgeoriftheedgecavesin.

•Nevercarrypassengersonthemachine.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperatethe

machinewhenthereistheriskoflighting.

•Donotmowonwetgrass.Reducedtractioncouldcause

themachinetoslide.

•Neverraisethemowerdeckwiththebladesrunning.

•Stopthemachineandinspectthebladesafterstrikingan

objectorifthereisanabnormalvibrationinthemachine.

Makeallnecessaryrepairsbeforeresumingoperation.

•Stopthebladeswheneveryouarenotmowing,especially

whilecrossinglooseterrainsuchasgravel.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalkswiththemachine.Always

yieldtheright-of-way.

•Turnontheashingwarninglightsonthemachine

wheneveryoutravelonapublicroad,exceptwheresuch

useisprohibitedbylaw.

•Disengagethedrivetotheattachmentandshutoffthe

enginebeforeaddingfuelandadjustingtheheightofcut.

15

Page 16

•Reducethethrottlesettingbeforestoppingtheengine

and,iftheenginehasafuel-shutoffvalve,shutoffthe

fuelwhenyouhavenishedoperatingthemachine.

•Neverrunanengineinanareawhereexhaustgasesare

enclosed.

•Neverleavearunningengineunattended.

•Beforeleavingtheoperatingposition,dothefollowing:

–Stopthemachineonlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Settheparkingbrake.

–Shutofftheengineandremovethekey .

–Waitforallmovingpartstostop.

•Donotchangethegovernorsettingsonoroverspeed

theengine.Operatingtheengineatexcessivespeedmay

increasethepotentialforpersonalinjury.

•Donotusethemachineasatowingvehicle.

•UseaccessoriesandattachmentsapprovedbyTheToro®

Companyonly.

RolloverProtectionSystem(ROPS)

Safety

•DonotremovetheROPSfromthemachine.

•Ensurethattheseatbeltisattachedandthatyoucan

releaseitquicklyintheeventofanemergency.

•AlwayswearyourseatbeltwhentheROPSisup.

•Checkcarefullyforoverheadclearances,suchasbranches,

doorways,andelectricalwires,beforedrivingthemachine

underthem.Donotcontactthem.

•KeeptheROPSinsafeoperatingconditionbythoroughly

inspectingitperiodicallyfordamageandkeepingallthe

mountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorreviseit.

•AnyalterationstoaROPSmustbeapprovedbyThe

Toro®Company.

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.

SettingtheParkingBrake

WARNING

Theparkingbrakemaynotholdthemachine

parkedonaslopeandcouldcausepersonalinjury

orpropertydamage.

Donotparkthemachineonslopesunlessthe

wheelsarechockedorblocked.

Figure16

ReleasingtheParkingBrake

Figure17

SlopeSafety

•Slowdownthemachineanduseextracareonhillsides.

Travelintherecommendeddirectiononhillsides.Turf

conditionscanaffectthestabilityofthemachine.

•Avoidstarting,stopping,orturningthemachineona

slope.Ifthetireslosetraction,disengagetheblade(s)and

proceedslowlystraightdowntheslope.

•Donotturnthemachinesharply .Usecarewhenreversing

themachine.

•Whenoperatingthemachineonaslope,alwayskeepall

cuttingunitslowered.

•Avoidturningthemachineonslopes.Ifyoumustturn,

turnslowlyandgraduallydownhill,ifpossible.

•Useextracarewhileoperatingthemachinewith

attachments;theycanaffectthestabilityofthemachine.

StartingandShuttingoffthe Engine

StartingtheEngine

Note:Theglowpluglightilluminatesfor6secondswhen

youturntheignitionkeytotheRUNposition.Turnthe

ignitiontotheSTARTpositionafterthelightgoesout.

Important:Usestartingcyclesofnomorethan

15secondsperminutetoavoidoverheatingthestarter

motor.

Important:Whenyoustarttheenginefortherst

time,changetheengineoiloroverhaultheengine,

transmission,orwheelmotorandoperatethemachine

16

Page 17

withthethrottleleverintheSLOWpositioninboth

theforwardandreversedirectionsfor1to2minutes.

OperatetheliftleverandPTOlevertoensurethat

theyoperateproperly.Shuttheengineoff,checkuid

levels,andcheckforoilleaks,looseparts,andanyother

noticeablemalfunctions.

Figure19

DrivingtheMachine

Thethrottlecontrolregulatestheenginespeedasmeasuredin

rpm(revolutionsperminute).Placethethrottlecontrolinthe

FASTpositionforbestperformance.Alwaysoperateinthe

FASTthrottlepositionwhenrunningpoweredattachments.

Figure18

Note:LeavethethrottlemidwaybetweentheSLOWand

FASTpositionsuntiltheengineandhydraulicsystemwarmup.

ShuttingofftheEngine

CAUTION

Childrenorbystandersmaybeinjuredifthey

attempttomoveoroperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

CAUTION

Themachinecanturnveryrapidly.Youmaylose

controlofitandcausepersonalinjuryordamage

themachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

1.Releasetheparkingbrake.

Note:Theengineshutsoffifyoumovethe

motion-controlleversoutoftheNEUTRAL-LOCK

positionwiththeparkingbrakeengaged.

2.Movetheleverstothecenter,unlockedposition.

3.Drivethemachineasfollows:

•Tomovestraightforward,slowlypushthe

motion-controlleversforward(Figure20).

•Tomovestraightrearward,slowlypullthe

motion-controlleversrearward(Figure20).

•Toturn,slowthemachinebypullingbackonboth

leversandthenpushforwardontheleveronthe

oppositesidefromwhichyouwanttoturn(Figure

20).

•Tostop,pullthemotion-controlleverstothe

NEUTRALposition.

Note:Thefartheryoumovethemotion-controllevers

ineitherdirection,thefasterthemachinemovesinthat

direction.

17

Page 18

Figure20

G008945

G009174

1.Motion-control

lever—NEUTRAL-LOCK

position

2.Center,unlockedposition

3.Forward

4.Backward

EngagingthePowerTakeoff (PTO)

Thepower-takeoff(PTO)switchstartsandstopspowered

attachments.

Note:Iftheengineiscold,allowtheenginetowarmup5

to10minutesbeforeengagingthePTO.

DisengagingthePTO

Figure22

AfterOperation

AfterOperationSafety

GeneralSafety

•Cleangrassanddebrisfromthecuttingunits,drives,

mufers,andenginetohelppreventres.Cleanupoil

orfuelspills.

•Shutoffthefuelwhilestoringortransportingthe

machine,ifapplicable.

•Disengagethedrivetotheattachmentwheneveryouare

transportingornotusingthemachine.

•Usefull-widthrampsforloadingthemachineintoa

trailerortruck.Donotexceeda15°anglebetweenthe

rampandthetrailerortruck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

•Allowtheenginetocoolbeforestoringthemachinein

anyenclosure.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlight,suchasonawater

heateroronotherappliances.

Figure21

PushingtheMachinebyHand

Ifthemachinebreaksdown,runsoutoffuel,etc.,youmay

needtopullitwithawinchtoloaditontoatrailer.Todoso,

yourstneedtoopenthehydraulicbypassvalves.

Important:Nevertowthemachine,becausehydraulic

damagemayoccur.

ChangingtoMachineOperation

Rotateeachbypassvalveclockwise1turnandhand-tighten

them(Figure23).

Note:Thetorqueshouldbeapproximately8N∙m(71in-lb).

Donotovertightenthebypassvalves.

Youcannotdrivethemachineunlessthebypassvalvesare

turnedinward.

18

Page 19

Figure23

1.By-passvalves

HaulingtheMachine

•Usecarewhenloadingorunloadingthemachineintoa

traileroratruck.

•Usefull-widthrampsforloadingthemachineintoa

traileroratruck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

Figure24

1.Fronttie-downs

2.Reartie-down(leftside

shown)

19

Page 20

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst10hours

Aftertherst50hours

Aftertherst200hours

Beforeeachuseordaily

Every50hours

Every100hours

Every150hours

Every200hours

Every400hours

MaintenanceProcedure

•Checkthealternator-belttension.

•Torquethewheellugnuts.

•Changetheengineoilandlter.

•Changethehydraulicuidandlter.

•Testthesafety-interlocksystem.

•Checktheengine-oillevel.

•Drainwaterorothercontaminantsfromthewaterseparator.

•Checktheengine-coolantlevel.

•Cleantheradiatorwithcompressedair(moreoftenindirtyanddustyconditions).

•Checkthehydraulicuidlevel.

•Greasethebearingandbushinggreasettings(moreoftenindirtyordusty

conditionsandaftereverywashing).

•Checkthebatterycableconnections.

•Checkthealternator-belttension.

•Changetheengineoilandlter.

•Inspectthecooling-systemhosesandseals.Replacethemifcrackedortorn.

•Torquethewheellugnuts.

•Servicetheaircleaner.

•Replacethefuel-ltercanisterforthewaterseparator.

•Checkthefuellinesandconnections.

Every800hours

Every1,500hours

Every2years

•Changethehydraulicuidandlter.

•Inspecttheengine-valveclearance.Refertoyourengineownersmanual.

•Replacemovinghoses.

•Drainandcleanthefueltank.

•Flushandreplacethecooling-systemuid.

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.AdetailedServiceManual

isalsoavailableforpurchasefromyourAuthorizedToroDistributor.

20

Page 21

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Checkthesafety-interlock

operation.

Checktheparking-brake

operation.

Checkthefuellevel.

Checkthehydraulicoillevel.

Checktheengine-oillevel.

Checkthecooling-system

uidlevel.

Checkthedrainwater/fuel

separator.

Checktheair-lterrestriction

indicator.

Checktheradiatorand

screenfordebris

Checkforunusualengine

noises.

Checkforunusualoperating

noises.

Checkthehydraulichoses

fordamage

Checkforuidleaks.

Checkthetirepressure.

Checktheinstrument

operation.

Lubricateallgreasettings.

Touchupdamagedpaint.

1.Iftheindicatorshowsred

1

2

3

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

2.Checktheglowplugandinjectornozzlesifyounoticehardstarting,excesssmoke,orroughrunning.

3.Immediatelyaftereverywashing,regardlessoftheintervallisted.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

21

Information

Page 22

CAUTION

G020871

1

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

Premaintenance

Procedures

Important:Thefastenersonthecoversofthismachine

aredesignedtoremainonthecoverafterremoval.

Loosenallofthefastenersoneachcoverafewturns

sothatthecoverisloosebutstillattached,thengo

backandloosenthemuntilthecovercomesfree.This

preventsyoufromaccidentallystrippingtheboltsfree

oftheretainers.

Pre-MaintenanceSafety

•Keepallpartsofthemachineingoodworkingcondition

andallhardwaretightened,especiallyblade-attachment

hardware.Replaceallwornordamageddecals.

•Neverallowuntrainedpersonneltoservicethemachine.

•Beforeadjusting,cleaning,orrepairingthemachine,do

thefollowing:

1.Movethemachinetolevelground.

2.Disengagethedrives.

•Ifyourmachinerequiresmajorrepairsorifyoudesire

assistance,contactanAuthorizedToroDistributor.

•UseonlygenuineTororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadebyother

manufacturerscouldbedangerous,andsuchusecould

voidtheproductwarranty.

UnlatchingtheSeat

Toaccessthehydraulicandothersystemsundertheseat,

unlatchtheseatandswingitforward.

1.Usetheseat-positionadjustmentlevertoslidetheseat

allthewayforward.

2.Pulltheseatlatchleverforwardandliftuptounlatch

theseat(Figure25).

3.Lowerthecuttingunits.

4.MovethetractionpedaltotheNEUTRALposition.

5.Engagetheparkingbrake.

6.MovethethrottleswitchtotheLOW-IDLEposition.

7.Shutofftheengineandremovethekey.

8.Waitforallmovingpartstostop.

•Wheneveryouparkorstorethemachine,orleaveit

unattended,lowerthecuttingunitsunlessyouusea

positivemechanicallock.

•Ifpossible,donotperformmaintenanceonthemachine

whiletheengineisrunning.Ifyoumustruntheengineto

performmaintenanceonthemachine,keepyourhands,

feet,otherbodyparts,andclothingawayfromallmoving

parts,themower-dischargearea,andtheundersideof

themowers.

•Donottouchpartsofthemachineoranattachment

thatmaybehotfromoperation.Allowthepartstocool

beforeattemptingtomaintain,adjust,orservicethem.

•Usejackstandstosupportthemachineand/orits

componentswhenrequired.

Figure25

1.Seatlatch

•Carefullyreleasepressurefromcomponentswithstored

energy.

22

Page 23

Lubrication

G004501

123456

7

EngineMaintenance

GreasingtheBearingsand Bushings

ServiceInterval:Every50hours(moreoftenindirty

ordustyconditionsandafterevery

washing).

GreaseType:No.2lithiumgrease.

Important:Lubricatethegreasettingsimmediately

aftereverywashing,regardlessofintervalspecied.

Bearinglifecanbenegativelyaffectedbyimproperwash

downprocedures.Donotwashdowntheunitwhenit

isstillhotandavoiddirectinghigh-pressureorhigh

volumesprayatthebearingsorseals.

1.Wipethegreasettingscleansothatforeignmatter

cannotbeforcedintothebearingorbushing.

2.Pumpgreaseintothettings.

3.Wipeoffexcessgrease.

EngineSafety

Shutofftheenginebeforecheckingtheoiloraddingoilto

thecrankcase.

CheckingtheAirCleaner

1.Checktheair-cleanerbodyfordamage,which

couldpossiblycauseanairleak.Replaceadamaged

air-cleanerbody .

2.Checktheair-intakesystemforleaks,damage,orloose

hoseclamps(Figure26).

Important:Donotover-servicetheairlter.

Figure26

1.Air-cleanercover5.Air-cleanerbody

2.Air-cleanerlatch6.Air-cleanerindicator

3.Gasket

4.Filter

3.Besurethatthecoverisseatedcorrectlyandsealswith

theair-cleanerbody.

7.Rubberoutletvalve

ServicingtheAirCleaner

ServiceInterval:Every400hours

Note:Ifthefoamgasketinthecoverisdamaged,replaceit.

Important:Avoidusinghigh-pressureair,whichcould

forcedirtthroughthelterintotheintaketract.

Important:Donotcleantheusedltertoavoid

damagingtheltermedia.

Important:Donotuseadamagedlter.

Important:Donotapplypressuretotheexiblecenter

ofthelter.

23

Page 24

Note:T oroPremiumEngineoilisavailablefromyour

distributorineither15W-40or10W-30viscosity.Seethe

partscatalogforpartnumbers.

1.Parkthemachineonalevelsurface,lowerthemower

deck,movethethrottlelevertotheSLOWposition,

stoptheengine,andremovethekeyfromtheignition

switch.

2.Openthehood.

3.Checktheengineoil

Figure27

ServicingtheEngineOil

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;however,

checktheoillevelbeforeandafteryourststarttheengine.

Checktheoillevelbeforeoperatingthemachineeachdayor

eachtimeyouusethemachine.

Thecrankcasecapacityisapproximately3.8L(4.0qt)with

thelter.Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4orhigher.

•Preferredoil:SAE15W-40(above-17°C(0°F)

•Alternateoil:SAE10W-30or5W-30(alltemperatures)

Figure28

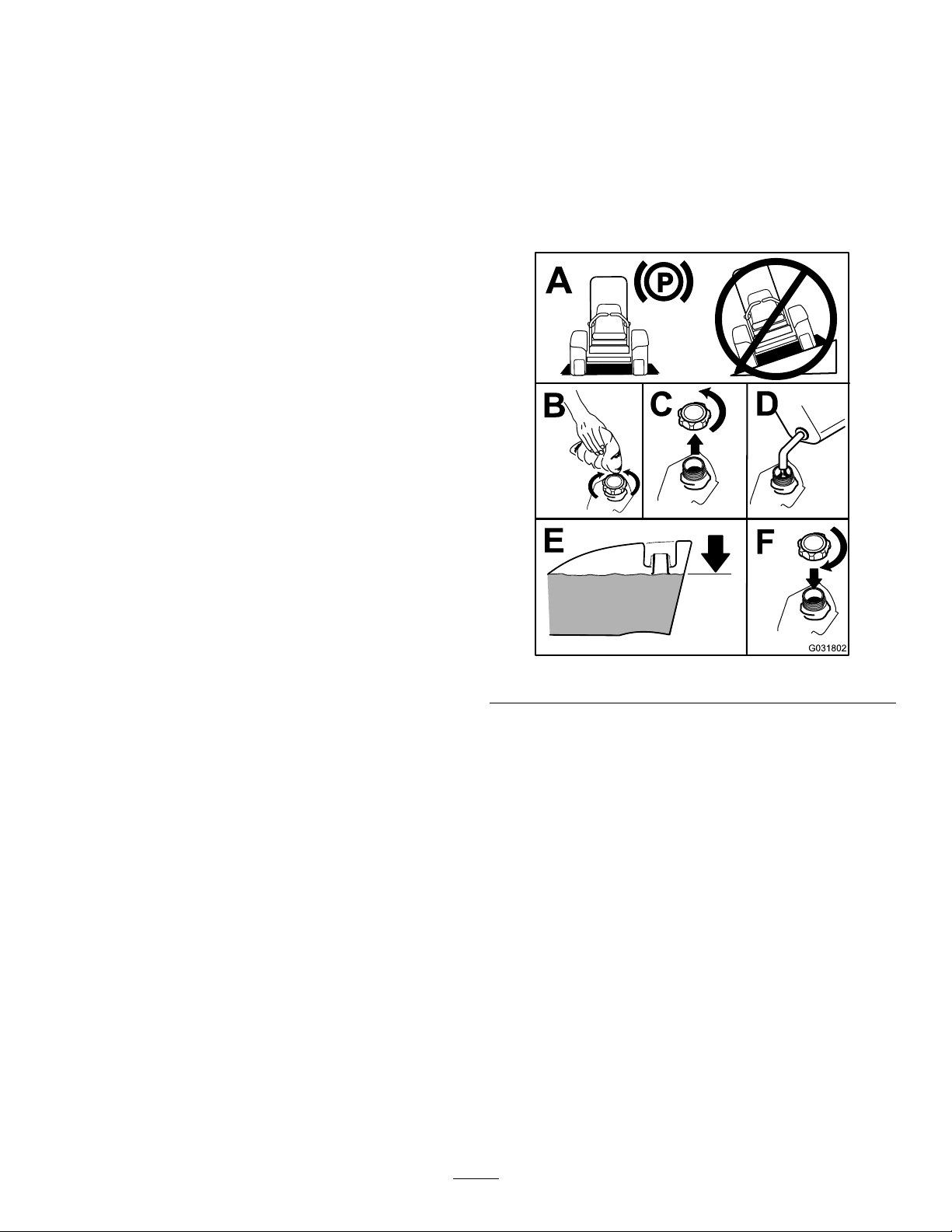

ChangingtheEngineOilandFilter

ServiceInterval:Aftertherst50hours

Every150hours

Ifpossible,runtheenginejustbeforechangingtheoil,

becausewarmoilowsbetterandcarriesmorecontaminants

thancoldoil.

1.Positionthemachineonalevelsurface.

2.Openthehood.

3.Changetheoil(Figure29).

24

Page 25

Figure29

B

A

C D

E

F

3/4

g027477

4.Replacetheoillter(Figure30).

FuelSystem

Maintenance

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Addfuel

tothefueltankuntilthelevelistothebottom

ofthellerneck.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinaclean,safety-approvedcontainer

andkeepthecapinplace.

5.Fillthecrankcasewithoil;refertoCheckingthe

Engine-OilLevel(page24).

ServicingtheWaterSeparator

ServiceInterval:Every400hours

Beforeeachuseordaily

Figure30

25

Page 26

BleedingtheFuelSystem

CAUTION

Theenginemaystartduringthisprocedure.

Movingfansandbeltsinarunningenginecan

severelyinjureyouorbystanders.

Keephands,ngers,looseclothing/jewelry,and

hairawayfromtheenginefanandbeltduringthis

procedure.

1.Parkthemachineonalevelsurface.Ensurethatthe

fueltankisatleasthalffull.

2.Unlatchandraisethehood.

3.Placearagundertheair-bleedscrewonthe

fuel-injectionpumpandopenit(Figure32).

Figure31

CleaningtheFuelTank

ServiceInterval:Every2years

Removeandcleanthein-linestrainersafterdrainingthetank.

Usecleandieselfueltoushoutthetank.

Important:Drainandcleanthetankifthefuelsystem

becomescontaminatedorifyouarestoringthemachine

foranextendedperiod.

CheckingtheFueltheLines andConnections

ServiceInterval:Every400hours/Yearly(whichevercomes

rst)

Inspectthefuellinesfordeterioration,damage,chafng,or

looseconnections.

Figure32

1.Fuel-injection-pumpbleedscrew

4.TurntheignitionkeytotheONposition.

Note:Theelectricfuelpumpbeginsoperation,

therebyforcingairoutattheair-bleedscrew.

5.LeavethekeyintheONpositionuntilasolidstream

offuelowsoutaroundthescrew .

6.TightenthescrewandturnkeytotheOFFposition.

Note:Normally,theengineshouldstartafteryou

bleedthefuelsystem.However,ifenginedoesnot

start,airmaybetrappedbetweeninjectionpumpand

injectors;refertoBleedingAirfromtheInjectors(page

26).

BleedingAirfromtheInjectors

Note:Usethisprocedureonlyifyoupurgedthefuelsystem

throughnormalprimingproceduresandtheenginedoesnot

start;refertoBleedingtheFuelSystem(page26).

1.Placearagunderthepipeconnectioncomingfrom

theinjectionpumptotheNo.1injectornozzleas

illustratedinFigure33.

26

Page 27

Figure33

1.PipeconnectionfromtheinjectionpumptotheNo.1

injectornozzle

2.MovethethrottletotheFASTposition.

3.TurntheignitionkeytheSTARTpositionandwatchthe

fuelowaroundtheconnector.

CAUTION

Theenginemaystartduringthisprocedure.

Movingfansandbeltsinarunningenginecan

severelyinjureyouorbystanders.

Keephands,ngers,looseclothing/jewelry,

andhairawayfromtheenginefanandbelt

duringthisprocedure.

ElectricalSystem

Maintenance

Important:Wheneverworkingwiththeelectrical

system,alwaysdisconnectthebatterycables,negative

(-)cablerst,topreventpossiblewiringdamagefrom

short-outs.

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthemachine.

Disconnectthenegativeterminalrstandthepositive

last.Connectthepositiveterminalrstandthenegative

last.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithyourskin,eyes,andclothing.Protectyour

face,eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks,and

amesawayfromthebattery.

•Chargethebatteriesinanopen,well-ventilatedarea,

awayfromsparksandames.Unplugthechargerbefore

connectingordisconnectingthebattery.Wearprotective

clothinganduseinsulatedtools.

•Donotuseapressurewashernearanyelectronic

components.

WARNING

4.Tightenthepipeconnectorsecurelywhenitattainsa

solidow .

5.TurnthekeytotheOFFposition.

6.Repeatthisprocedurefortheremainingnozzles.

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

ServicingtheBattery

ServiceInterval:Every50hours

Ifyoustorethemachineinalocationwheretemperaturesare

extremelyhigh,thebatteryrunsdownmorerapidlythanifthe

machineisstoredinalocationwherethetemperatureiscool.

Keepthetopofthebatterycleanbywashingitperiodically

withabrushdippedinammoniaorbicarbonatesodasolution.

Flushthetopsurfacewithwateraftercleaningit.

Important:Donotremovethellcapswhilecleaning

thebattery.

Thebatterycablesmustbetightontheterminalstoprovide

goodelectricalcontact.

Ifcorrosionoccursattheterminals,disconnectthecables,

negative(-)cablerst,andscrapetheclampsandterminals

27

Page 28

separately.Connectthecables,positive(+)cablerst,and

coattheterminalswithpetroleumjelly.

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponents,causingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

Figure34

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcables,causingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)batterycable

beforeconnectingthenegative(black)cable.

StoringtheBattery

Ifyouarestoringthemachinemorethan30days,removethe

batteryandchargeitfully .Eitherstoreitonashelforonthe

machine.Donotconnectthecablesifyoustoreitonthe

machine.Storethebatteryinacoolenvironmenttoprevent

thebatteryfromdischargingrapidly.Topreventthebattery

fromfreezing,makesurethatitisfullycharged.Thespecic

gravityofafullychargedbatteryis1.265to1.299.

1.Sidepanelcover

2.Latches

Figure35

CheckingtheFuses

Themachinefusesarelocatedunderthecontrolpanel.

Accessthemthroughthesidepanelcover(Figure34).To

openthesidepanelcover,releasethe2latchesandpullout

onit.

Ifthemachinestopsorhasotherelectricalsystemissues,

checkthefuses.Graspeachfuseinturnandremovethem1

atatime,checkingifanyareblown.

Important:Ifyouneedtoreplaceafuse,alwaysusethe

sametypeandamperage-ratedfuseastheoneyouare

replacing,otherwiseyoucoulddamagetheelectrical

system.Refertothedecalnexttothefusesforadiagram

ofeachfuseanditsamperage(Figure35).

Note:Ifafuseblowsfrequently,youprobablyhaveashort

intheelectricalsystemandshouldhaveitservicedbya

qualiedservicetechnician.

28

Page 29

CoolingSystem

Maintenance

DANGER

Dischargeofhotpressurizedcoolantortouching

hotradiatorandsurroundingpartscancausesevere

burns.

•Donotremovetheradiatorcapwhentheengine

ishot.Alwaysallowtheenginetocoolatleast

15minutesoruntiltheradiatorcapiscool

enoughtotouchwithoutburningyourhand

beforeremovingtheradiatorcap.

•Donottouchradiatorandsurroundingparts

thatarehot.

Note:Thecoolantlevelshouldbebetweenthemarks

onthesideofthetank.

DANGER

Therotatingfananddrivebeltcancausepersonal

injury.

•Donotoperatethemachinewithoutthecovers

inplace.

•Keepngers,handsandclothingclearof

rotatingfananddrivebelt.

•Shutofftheengineandremovetheignitionkey

beforeperformingmaintenance.

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily—Checkthe

engine-coolantlevel.

Thecoolingsystemislledwitha50/50solutionofwater

andpermanentethylene-glycolantifreeze.Thecapacityofthe

coolingsystemis7.5L(6quarts).

1.Checkthelevelofthecoolantintheexpansiontank

(Figure36).

Figure36

1.Expansiontank

2.Ifcoolantlevelislow ,removetheexpansion-tankcap

andreplenishthesystem.

Important:Donotoverll

3.Installtheexpansion-tankcap.

CleaningtheRadiator

ServiceInterval:Beforeeachuseordaily

Cleantheradiatortopreventtheenginefromoverheating.

Note:Ifthemowerdeckorengineshutsoffdueto

overheating,checktheradiatorforexcessivebuildupofdebris.

Cleantheradiatorasfollows:

1.Openthehood.

2.Workingfromthefansideoftheradiator,blow

outdebriswithlowpressure(345kPaor50psi),

compressedair.Repeatfromthefrontoftheradiator

andtheotherfanside.

Important:Donotusewater.

3.Afteryouthoroughlycleantheradiator,cleanout

debristhatmayhavecollectedinthechannelatthe

radiatorbase.

4.Closethehood.

29

Page 30

BrakeMaintenance

BeltMaintenance

AdjustingtheParking-Brake InterlockSwitch

1.Stopthemachine,movethemotion-controlleversto

theNEUTRAL-LOCKposition,settheparkingbrake,

andremovetheignitionkey.

2.Unlatchtheseatandpivotitforward.

Note:Ifyouneedadditionalaccessundertheseat,

youcanremovethesidepanels.

3.Loosenthe2jamnutssecuringtheparking-brake

interlockswitchtothemountingbracket.

CheckingtheAlternator-Belt Tension

ServiceInterval:Aftertherst10hours

Every100hours

1.Apply44N(10lb)offorcetothealternatorbelt,

midwaybetweenthepulleys.

2.Ifthedeectionisnot10mm(3/8inch),loosenthe

alternatormountingbolts(Figure38).

Figure37

1.Brake-shaftsensor

2.4mm(5/32inch)

4.Movetheswitchupordownonthebracketuntilthe

distancebetweenthebrake-shaftsensorandtheswitch

plungeris4mm(5/32inch)asshowninFigure37.

Note:Makesurethatthebrake-shaftsensordoesnot

contacttheswitchplunger.

5.Securetheswitchjamnuts.

6.Testtheadjustmentasfollows:

A.Ensurethattheparkingbrakeisengagedandyou

arenotsittingontheseat,thenstarttheengine.

B.MovethecontrolleversoutoftheNEUTRAL-LOCK

position.

Note:Theengineshouldstop.Ifnot,checkthe

adjustmentthatyoumadetotheswitch.

7.Lowertheseat.

3.Jamnut

4.Parking-brakeinterlock

switch

Figure38

1.Mountingbolt2.Alternator

3.Increaseordecreasethealternator-belttension.

4.Tightenthemountingbolts.

5.Checkthedeectionofthebeltagaintoensurethat

thetensioniscorrect.

30

Page 31

ControlsSystem

Maintenance

Adjustingthe Control-Lever-Neutral InterlockSwitch

1.Stopthemachine,movethemotion-controlleversto

theNEUTRAL-LOCKposition,settheparkingbrake,

andremovetheignitionkey.

2.Unlatchtheseatandpivotitforward.

Note:Ifadditionalaccessisrequiredundertheseat,

thesidepanelsmayberemoved.

3.Loosenthe2screwssecuringtheinterlockswitch

(Figure39).

1.DisengagethePTO ,movethecontrollevertothe

NEUTRAL-LOCKposition,andsettheparkingbrake.

2.MovethethrottlelevertotheSLOWposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Unlatchtheseatandpivotitforward.

Note:Ifyouneedadditionalaccessundertheseat,

youcanremovethesidepanels.

4.MovethecontrollevertotheNEUTRALpositionbut

notlocked(Figure41).

5.Pulltheleverbackuntiltheclevispin(onanarm

abovethepivotshaft)contactstheendoftheslot(just

beginningtoputpressureonthespring)asshownin

Figure40.

Figure39

1.Controllever3.Screw

2.Neutral-interlockswitch

4.Holdingthecontrolleveragainsttheframe,movethe

switchtowardtheleveruntilthedistancebetweenthe

leverandswitchbodyis0.4to1mm(0.015to0.045

inch)asshowninFigure39.

5.Securetheswitch.

6.Repeatsteps3to5fortheotherlever.

7.Lowertheseat.

4.0.4to1mm(0.015to

0.045inch)

Figure40

1.Clevispin

2.Slot

3.Jamnut

6.Checkwherethecontrolleverisrelativetonotchinthe

console(Figure41).

Note:Thecontrollevershouldbecentered,allowing

levertopivotoutwardtotheNEUTRAL-LOCKposition.

4.Adjustmentbolt

5.Yoke

Adjustingthe Control-Lever-NeutralReturn

Ifthemotion-controlleversdonotalignwiththeneutral

slotswhenreleasedfromtheREVERSEposition,adjustment

isrequired.Adjusteachlever,spring,androdseparately.

Figure41

1.NEUTRALposition2.NEUTRAL-LOCKposition

31

Page 32

7.Ifadjustmentisneeded,loosenthenutandjamnut

againsttheyoke(Figure40).

8.Applyingslightrearwardpressureonthe

motion-controllever,turntheheadoftheadjustment

boltintheappropriatedirectionuntilthecontrollever

iscenteredintheNEUTRAL-LOCKposition(Figure40).

Note:Rearwardpressureontheleverkeepsthepin

attheendoftheslotandallowtheadjustmentboltto

movethelevertotheappropriateposition.

9.Tightenthenutandjamnut(Figure40).

10.Repeatsteps4through9fortheothercontrollever.

11.Installthefrontpanel.

AdjustingtheTractionDrive forNeutral

Makethisadjustmentwiththedrivewheelsturning.

DANGER

Mechanicalorhydraulicjacksmayfailtosupport

themachineandcauseaseriousinjury.

correspondingwheelisstillorslightlycreepingin

reverse(Figure42).

•Usejackstandswhensupportingthemachine.

•Donotusehydraulicjacks.

WARNING

Theenginemustberunningtoperformthis

adjustment.Contactwithmovingpartsorhot

surfacesmaycausepersonalinjury.

Keephands,feet,face,clothing,andotherbody

partsawayfromrotatingparts,mufer,andother

hotsurfaces.

1.Raisetheframeontostablejackstandssothatthedrive

wheelscanrotatefreely.

2.Slidetheseatforward,unlatchit,andswingitupand

forward.

3.Disconnecttheelectricalconnectorfromtheseat

safetyswitch.

4.Temporarilyinstallajumperwireacrosstheterminals

inthewireharnessconnector.

5.Starttheengine,ensurethatthethrottleleverismidway

betweentheFASTandSLOWpositions,andreleasethe

parkingbrake.

Note:Themotion-controlleversmustbein

theNEUTRAL-LOCKpositionwhileyoumakeany

adjustments.

Figure42

1.Rightpumprod5.Jamnut

2.Leftpumprod6.Hexshaft

3.Balljoint7.Balljoint

4.Bolt

7.Movethemotion-controlleverforwardandreverse,

thenbacktoneutral.

Note:Thewheelmuststopturningorslightlycreep

inreverse.

8.MovethethrottlelevertotheFASTposition.

Note:Makesurethatthewheelremainsstoppedor

slightlycreepsinreverse;adjustitifnecessary.

9.Repeatsteps6through8fortheothersideofthe

machine.

10.Tightenthejamnutsattheballjoints(Figure40).

11.MovethethrottlelevertotheSLOWpositionandshut

offtheengine.

12.Removethejumperwirefromthewireharness

connectorandplugtheconnectorintotheseatswitch.

6.Adjustthepumprodlengthononesidebyrotating

thehexshaft,intheappropriatedirection,untilthe

32

Page 33

WARNING

Theelectricalsystemdoesnotperformproper

safetyshutoffwiththejumperwireinstalled.

•Removethejumperwirefromthewire

harnessconnectorandplugtheconnector

intotheseatswitchwhenyoucomplete

adjustment.

•Neveroperatethemachinewiththejumper

installedandtheseatswitchbypassed.

7.Threadthestopboltout(towardthecontrollever)

untilthereisagapof1.5mm(0.060inch)betweenthe

headofthestopboltandthecontrollever.

Note:Ifyouwanttoreducethemaximummachine

speed,backeachstopboltoutanequalamounttoward

thecontrolleveruntilyoureachthedesiredmaximum

speed.Youmayneedtotestyouradjustmentseveral

times.

8.Tightenthejamnuttosecurethestopboltinplace.

9.Repeatsteps4through8fortheothercontrollever.

13.Lowertheseatintoposition.

14.Removethejackstands.

AdjustingtheMaximum GroundSpeed

1.DisengagethePTO ,movethemotion-controlleversto

theNEUTRAL-LOCKposition,andsettheparkingbrake.

2.MovethethrottlelevertotheSLOWposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Unlatchtheseatandpivotitforward.

Note:Ifyouneedadditionalaccessundertheseat,

youcanremovethesidepanels.

4.Loosenthejamnutonthestopboltforacontrollever

(Figure43).

10.Lowertheseat.

AdjustingtheTracking

1.DisengagethePTO ,movethemotion-controlleversto

theNEUTRAL-LOCKposition,andsettheparkingbrake.

2.MovethethrottlelevertotheSLOWposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Loosentheboltssecuringthecontrollevers(Figure44)

Figure43

1.Stopbolt

2.Controllever4.1.5mm(0.060inch)

5.Threadthestopboltallthewayin(awayfromthe

controllever).

6.Pushthecontrolleverallthewayforwarduntilitstops

andholditthere.

3.Jamnut

Figure44

1.Controllever

2.Control-leverpost

4.Havesomeonepushthecontrol-leverposts(not

thecontrollevers)allthewayforwardintothe

maximum-speedpositionandholdthemthere.

5.Adjustthecontrolleverssothattheylineupandtighten

thebolts,securingtheleverstotheposts(Figure45).

33

3.Bolts

Page 34

HydraulicSystem

Maintenance

Thereservoirislledatthefactorywithapproximately4.7L

(5.0USqt)ofhigh-qualitytractor-transmission/hydraulic

uid.Therecommendedreplacementuidisasfollows:

ToroPremiumTransmission/HydraulicTractorFluid

(Availablein5gallonpailsor55gallondrums.Seeparts

catalogorTorodistributorforpartnumbers.)

Alternateuids:IftheTorouidisnotavailable,Mobil®424

hydraulicuidmaybeused.

Note:Torowillnotassumeresponsibilityfordamagecaused

byimpropersubstitutions.

Note:Manyhydraulicuidsarealmostcolorless,makingit

difculttospotleaks.Areddyeadditiveforthehydraulic

systemoilisavailablein20ml(2/3oz)bottles.Onebottle

issufcientfor15to22L(4to6USgallons)ofhydraulic

oil.OrderPartNo.44-2500fromyourauthorizedToro

distributor.

HydraulicSystemSafety

Figure45

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Ensurethatallhydraulic-uidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretothehydraulicsystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

•Seekimmediatemedicalattentionifuidis

injectedintoskin.

CheckingtheHydraulic System

ServiceInterval:Beforeeachuseordaily

Checkthelevelofthehydraulicuidbeforeyourststartthe

engineanddailythereafter.

1.Positionthemachineonalevelsurface.

2.Movethemotion-controlleverstotheNEUTRAL-LOCK

positionandstarttheengine.

34

Page 35

Note:Runtheengineatthelowestpossiblerpmto

purgethesystemofair.

Important:DonotengagethePTO.

3.Raisethedecktoextendtheliftcylinders,shutoffthe

engine,andremovethekey.

4.Raisetheseattoaccessthehydraulicuidtank.

5.Removethehydraulicllcapfromthellerneck

(Figure46).

2.MovethethrottlelevertotheSLOWposition,shutoff

theengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Placealargepanunderthehydraulicreservoirand

transmissioncaseandremovetheplugs,drainingallof

thehydraulicuid(Figure47).

Figure47

Figure46

1.Dipstick2.Fillcap

6.Removethedipstickandwipeitwithacleanrag

(Figure46).

7.Placethedipstickintothellerneck;thenremoveit

andcheckthelevelofuid(Figure46).

Note:Ifthelevelisnotwithinthenotchedareaof

thedipstick,addenoughhigh-qualityhydraulicuidto

raisetheleveltowithinthenotchedarea.

Important:Donotoverll.

8.Replacethedipstickandthreadthellcapnger-tight

ontothellerneck.

9.Checkallhosesandttingsforleaks.

1.Hydraulic-reservoirdrain

plug

2.Filter

3.Transmission-casedrain

plug

4.Cleantheareaaroundthehydraulicuidlterand

removethelter(Figure47).

5.Immediatelyinstallanewhydraulicuidlter.

6.Installthehydraulic-reservoirandtransmission-case

drainplugs.

7.Fillthereservoirtotheproperlevel(approximately

5.7Lor6.0USqt);refertoCheckingtheHydraulic

System(page34).

8.Starttheengineandcheckforoilleaks.Allowthe

enginetorunforabout5minutes,thenshutitoff.

9.After2minutes,checkthelevelofthehydraulicuid;

refertoCheckingtheHydraulicSystem(page34).

ChangingtheHydraulicFluid AndFilter

ServiceInterval:Aftertherst200hours

Every800hours

1.DisengagethePTO ,movethemotion-controlleversto

theNEUTRAL-LOCKposition,andsettheparkingbrake.

35

Page 36

Storage

Machine

1.Thoroughlycleanthemachine,deck,andengine,

payingspecialattentiontotheseareas:

•Radiatorandradiatorscreen

•Underneaththedeck

•Underthedeckbeltcovers

•Counterbalancesprings

•PTO-shaftassembly

•Allgreasettingsandpivotpoints

•Insidethecontrolbox

•Beneaththeseatplateandtopofthetransmission

2.Checkallfastenersforloosenessandtightenthemas

necessary.

3.Greaseoroilallgreasettings,pivotpoints,and

transmission-bypass-valvepins.Wipeoffanyexcess

lubricant.

4.Lightlysandandusetouchuppaintonpaintedareas

thatarescratched,chippedorrusted.Repairanydents

inthemetalbody.

5.Servicethebatteryandcablesasfollows:

A.Removethebatteryterminalsfromthebattery

posts.

B.Cleanthebattery,terminals,andpostswithawire

brushandbakingsodasolution.

C.Coatthecableterminalsandbatterypostswith

Grafo112Xskin-overgrease(ToroPartNo.

505-47)orpetroleumjellytopreventcorrosion.

D.Slowlyrechargethebatteryfor24hoursevery60

daystopreventleadsulfationofthebattery.

Engine

1.Draintheengineoilfromtheoilpanandreplacethe

drainplug.

2.Removeanddiscardtheoillter.Installanewlter.

3.Filltheenginewith3.8L(4.0USqt)ofrecommended

motoroil.RefertoCheckingtheEngine-OilLevel

(page24).

4.Starttheengineandrunitatidlespeedfor2minutes.

5.Drainthefuelfromthefueltank,fuellines,pump,

lter,andseparator.Flushthefueltankwithclean

dieselfuelandconnectallfuellines.

6.Thoroughlycleanandservicetheair-cleanerassembly.

7.Sealtheaircleanerinletandtheexhaustoutletwith

weatherproofmaskingtape.

8.Checktheoil-llercapandfuel-tankcaptoensurethey

aresecurelyinplace.

36

Page 37

Notes:

37

Page 38

Notes:

38

Page 39

InternationalDistributorList

Distributor:

AgrolancKft

AsianAmericanIndustrial(AAI)

B-RayCorporation

BrisaGoodsLLC

CascoSalesCompany

CeresS.A.CostaRica

CSSCTurfEquipment(pvt)Ltd.SriLanka

CyrilJohnston&Co.

CyrilJohnston&Co.RepublicofIreland

FatDragon

FemcoS.A.Guatemala

FIVEMANSNew-T echCo.,LtdChina

ForGarderOU

G.Y .K.CompanyLtd.

GeomechanikiofAthensGreece

GolfinternationalTurizm

HakoGroundandGardenSweden

HakoGroundandGarden

HayterLimited(U.K.)

HydroturfInt.CoDubai

HydroturfEgyptLLC

IrrimacPortugal351212388260ToroEuropeNVBelgium3214562960

IrrigationProductsInt'lPvtLtd.India00914424494387ValtechMorocco212537663636

JeanHeybroekb.v.Netherlands31306394611VictusEmakPoland48618238369

Country:

Hungary3627539640

HongKong85224977804

Korea82325512076

Mexico12104952417

PuertoRico7877888383

NorthernIreland442890813121

China

Estonia3723846060

Japan81726325861Riversa

Turkey902163365993

Norway4722907760

UnitedKingdom441279723444

UnitedArabEmirates97143479479T-MarktLogisticsLtd.Hungary3626525500

Egypt2025194308T oroAustraliaAustralia61395807355

PhoneNumber:Distributor:

MaquiverS.A.Colombia

MaruyamaMfg.Co.Inc.

Mountelda.s.CzechRepublic

Mountelda.s.Slovakia

5062391138

94112746100

442890813121ParklandProductsLtd.NewZealand6433493760

8861080841322

5024423277

86-10-63816136

30109350054

4635100000

MunditolS.A.

NormaGarden

OslingerTurfEquipmentSA

OyHakoGroundandGardenAb

Perfetto

PratoverdeSRL.

Prochaska&Cie

RTCohen2004Ltd.

LelyTurfcare

Lely(U.K.)Limited

SolvertS.A.S.

SpyprosStavrinidesLimitedCyprus

SurgeSystemsIndiaLimited

Country:

Japan81332522285

Argentina541 148219999

Russia749541 16120

Ecuador59342396970

Finland35898700733

Poland48618208416

Italy390499128128

Austria4312785100

Israel97298617979

Spain

Denmark4566109200

UnitedKingdom441480226800

France33130817700

India911292299901

PhoneNumber:

5712364079

420255704220

420255704220

34952837500

35722434131

EuropeanPrivacyNotice

TheInformationToroCollects

ToroWarrantyCompany(Toro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.ToromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw .

Toro'sCommitmenttoSecurityofYourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToroDealer.

374-0269RevK

Page 40

TheT oroWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser .

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat: