Page 1

FormNo.3383-154RevA

Groundsmaster

®

7210Traction

Unitwith72in,62in,and60in

Mowers

ModelNo.30363N—SerialNo.314000001andUp

ModelNo.30464N—SerialNo.314000001andUp

ModelNo.30465N—SerialNo.314000001andUp

ModelNo.30468N—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3383-154*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

1.Modelandserialnumberlocation

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Introduction

Thismachineisaride-on,rotary-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrass

onwell-maintainedlawnsinparks,sportselds,andon

commercialgrounds.Itisnotdesignedforcuttingbrush,

mowinggrassandothergrowthalongsidehighways,orfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualalsouses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

YoumaycontactT orodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1identiesthelocationofthe

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................5

SlopeIndicator.......................................................7

SafetyandInstructionalDecals.................................8

Setup...........................................................................14

1AdjustingtheROPS.............................................14

2CheckingtheTirePressure....................................14

3CheckingFluidLevels...........................................15

4ReadingtheManualsandViewingtheTraining

Materials............................................................15

ProductOverview.........................................................15

Controls...............................................................16

Specications........................................................17

Attachments/Accessories........................................17

Operation....................................................................18

AddingFuel...........................................................18

FillingtheFuelTank...............................................19

CheckingtheEngineOilLevel.................................19

CheckingtheCoolingSystem...................................19

CheckingtheHydraulicSystem................................19

UsingtheRolloverProtectionSystem(ROPS)............19

ThinkSafetyFirst...................................................20

OperatingtheParkingBrake....................................21

StartingandStoppingtheEngine..............................21

DrivingtheMachine...............................................22

StoppingtheMachine.............................................23

OperatingtheMower..............................................23

AdjustingtheHeight-of-Cut....................................24

AdjustingtheSkid(s)...............................................25

AdjustingtheRearAnti-ScalpRollers........................25

AdjustingtheRollers...............................................26

TheSafetyInterlockSystem.....................................27

PositioningtheSeat................................................28

UnlatchingtheSeat.................................................29

PushingtheMachinebyHand..................................29

LoadingMachines..................................................30

TransportingMachines............................................31

OperatingTips......................................................31

Maintenance.................................................................33

RecommendedMaintenanceSchedule(s)......................33

DailyMaintenanceChecklist....................................34

PremaintenanceProcedures........................................35

Lubrication...............................................................35

GreasingtheBearingsandBushings..........................35

ServicingtheMowerDeckGearBox

Lubricant...........................................................37

EngineMaintenance..................................................38

AirCleanerMaintenance........................................38

ServicingtheEngineOil..........................................39

FuelSystemMaintenance...........................................40

ServicingtheWaterSeparator..................................40

CleaningtheFuelTank............................................41

FuelLinesandConnections.....................................41

BleedingtheFuelSystem.........................................41

BleedingAirFromtheInjectors................................41

ElectricalSystemMaintenance....................................42

ServicingtheBattery...............................................42

StoringtheBattery..................................................43

CheckingtheFuses.................................................43

DriveSystemMaintenance.........................................44

CheckingtheTirePressure......................................44

ReplacingtheCastorWheelsandBearings..................44

CoolingSystemMaintenance......................................45

CheckingtheCoolingSystem..................................45

CleaningtheRadiator..............................................45

BrakeMaintenance....................................................46

AdjustingtheParkingBrakeInterlockSwitch..............46

BeltMaintenance......................................................47

CheckingtheAlternatorBelt...................................47

ReplacingtheBladeDriveBelts................................47

ControlsSystemMaintenance.....................................48

AdjustingtheControlLeverNeutralInterlock

Switch...............................................................48

AdjustingtheControlLeverNeutralReturn...............48

AdjustingtheTractionDriveforNeutral....................49

AdjustingtheMaximumGroundSpeed.....................50

AdjustingtheTracking............................................51

HydraulicSystemMaintenance....................................52

CheckingtheHydraulicSystem................................52

ChangingtheHydraulicOilandFilter........................52

MowerDeckMaintenance...........................................53

ServicingtheCuttingBlades.....................................53

CorrectingMowerDeckMismatch...........................56

AdjustingtheMowerDeckPitch..............................56

ReplacingtheGrassDeector..................................57

Cleaning...................................................................58

CleaningUndertheMower......................................58

WasteDisposal.......................................................58

Storage........................................................................58

Machine................................................................58

Engine..................................................................59

3

Page 4

Safety

ThisMachinemeetsorexceedsANSIB71.4–2012

specicationsineffectatthetimeofproduction

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theinstructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromtheCEN

standardEN836:1997andANSIB71.4-2012.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Training

•ReadtheOperator'sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethelawnmower.Localregulationscan

restricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversshouldseekandobtainprofessionaland

practicalinstruction.Suchinstructionshouldemphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthecontrol

levers.Themainreasonsforlossofcontrolare:

◊insufcientwheelgrip,especiallyonwetgrass;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrectloaddistribution.

Preparation

•Whilemowing,alwayswearsubstantialfootwearandlong

trousers.Donotoperatetheequipmentwhenbarefoot

orwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Replacefaultysilencers/mufers.

•Beforeusing,alwaysvisuallyinspecttoseethattheblades,

bladeboltsandcutterassemblyarenotwornordamaged.

Replacewornordamagedbladesandboltsinsetsto

preservebalance.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

Operation

•Bealert,slowdownandusecautionwhenmakingturns.

Lookbehindandtothesidebeforechangingdirections.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutchesandshiftintoneutral.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.Toguardagainst

overturning:

–donotstoporstartsuddenlywhenonaslope;

–useslowspeedsonslopesandduringtightturns;

4

Page 5

–stayalertforhumpsandhollowsandotherhidden

hazards;

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesfromrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition:

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachments,stoptheengine,and

removetheignitionkey:

–beforeclearingblockagesoruncloggingchute;

–beforechecking,cleaningorworkingonthelawn

mower;

–afterstrikingaforeignobject.Inspectthelawn

mowerfordamageandmakerepairsbeforerestarting

andoperatingtheequipment;

–ifthemachinestartstovibrateabnormally(check

immediately).

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Disengagedrivetoattachmentswhentransportingornot

inuse.

•Stoptheengineanddisengagedrivetoattachmentbefore

refuelling.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•KeeptheROPSinsafeoperatingconditionby

periodicallythoroughlyinspectingfordamageand

keepingallmountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorrevise.

•DonotremovetheROPS.

•AnyalterationstoaROPSmustbeapprovedbythe

manufacturer.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuelstorage

areafreeofgrass,leaves,orexcessivegrease.

•Replacewornordamagedpartsforsafety.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Onmulti-bladedmowers,takecareasmanuallyrotating

onebladecancauseotherbladestorotate.

•Whenmachineistobeparked,storedorleftunattended,

lowerthemowerdeck.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

ToroRidingMowerSafety

RolloverProtectionSystem(ROPS)UseandMaintenance

•TheROPSisanintegralandeffectivesafetydevice.Keep

afoldingROPSintheraisedandlockedpositionanduse

theseatbeltwhenoperatingthemachine.

•LowerafoldingROPStemporarilyonlywhenabsolutely

necessary.Donotweartheseatbeltwhenfoldeddown.

•Beawarethereisnorolloverprotectionwhenafolded

ROPSisinthedownposition.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Checktheareatobemowedandneverfolddowna

foldingROPSinareaswherethereareslopes,dropoffs

orwater.

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCENstandard.

•Engineexhaustcontainscarbonmonoxide,whichisan

odorless,deadlypoisonthatcankillyou.Donotrun

engineindoorsorinanenclosedarea.

•Keephands,feet,hairandlooseclothingawayfrom

attachmentdischargearea,undersideofmowerandany

movingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowtocoolbeforeattempting

tomaintain,adjust,orservice.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyesandclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

5

Page 6

•Thismachineisnotdesignedorequippedforon-road

useandisa“slow-movingvehicle.”Ifyoumustcross

ortravelonapublicroad,youshouldbeawareofand

complywithlocalregulations,suchasrequiredlights,

slowmovingvehiclesigns,andreectors.

•Batterygasescanexplode.Keepcigarettes,sparksand

amesawayfrombattery.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

•UseonlyToroapprovedattachments.Warrantymaybe

voidedifusedwithunapprovedattachments.

SlopeOperation

•Donotmowneardrop-offs,ditches,steepbanksor

water.Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,ordrowning.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcauseslidingand

lossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Useawalkbehindmowerand/orahandtrimmernear

drop-offs,ditches,steepbanksorwater.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,etc.

fromthemowingarea.Tallgrasscanhideobstacles.

•Watchforditches,holes,rocks,dips,andrisesthatchange

theoperatingangle,asroughterraincouldoverturnthe

machine.

•Avoidsuddenstartswhenmowinguphillbecausethe

mowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoingdownhill.

Weighttransfertothefrontwheelsmaycausedrive

wheelstoslipandcauselossofbrakingandsteering.

•Alwaysavoidsuddenstartingorstoppingonaslope.

Iftireslosetraction,disengagethebladesandproceed

slowlyofftheslope.

•Followthemanufacturer'srecommendationsforwheel

weightsorcounterweightstoimprovestability.

•Useextremecarewithattachments.Thesecanchangethe

stabilityofthemachineandcauselossofcontrol.

•Lowertherollbaronlywhenabsolutelynecessary.Do

notweartheseatbeltwiththerollbarfoldeddown.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

UsingtheRolloverProtectionSystem

(ROPS)

•Keeptherollbarintheraisedandlockedpositionand

usetheseatbeltwhenoperatingthemachine.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Beawarethereisnorolloverprotectionwhentheroll

barisdown.

•ChecktheareatobemowedandneverfoldtheROPSin

areaswherethereareslopes,dropoffsorwater.

6

Page 7

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

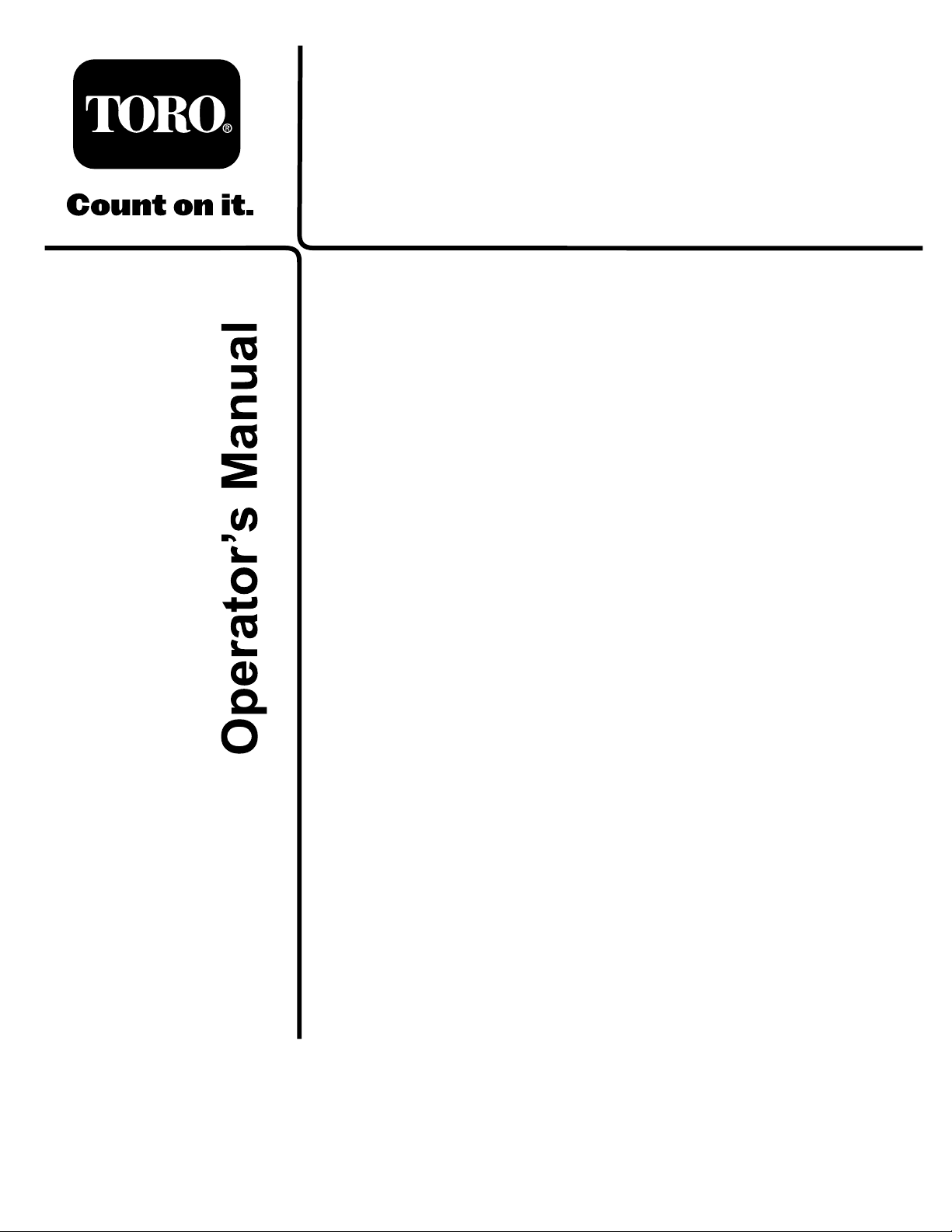

107-2908

1.Thrownobjecthazard—keepbystandersasafedistance

112-1461

1.Beltrouting

fromthemachine.

2.Thrownobjecthazard—donotoperatethemowerwiththe

deectoruporremoved,keepthedeectorinplace.

3.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

1.Warning—readtheOperator'sManualbeforeoperatingand

donotoperatethismachineunlessyouaretrained.

2.Crushing/dismembermenthazardofbystanders—donot

carrypassengers,keepbystandersasafedistancefromthe

machine.

3.Warning—donotusedrugsoralcohol.

4.Warning—wearhearingprotection.11.Disengage

5.Tipping,dropoffhazard—donotoperatenearwaterdrop-offs,

stayasafedistancefromdrop-offs,slowmachinebefore

turning,donotturnathighspeeds,wearaseatbeltwhen

aROPSisinplace,donotwearaseatbeltwhenROPSis

lowered.

6.Tostarttheengine:clearanydebrisfromtheattachment,

disengagethePTO,movethemotioncontrolleverstothe

neutralposition,engagetheparkingbrake,turntheignitionto

Runandwaitfortheglowpluglighttoturnoff,turntheignition

keytoStart.

7.ReadtheOperator'sManual.

110-9772

8.Warning—engagetheparkingbrake,stoptheengineand

removetheignitionkeybeforeleavingthemachine.

9.Cuttinghazardofhandorfoot—removetheignitionkey

andreadtheinstructionsbeforeservicingorperforming

maintenance,keepawayfrommovingparts.

10.Thrownobjecthazard—keepbystandersasafedistancefrom

themachine;keepalldeectorsandshieldsinplace.

12.Engage

13.Parkingbrake

8

Page 9

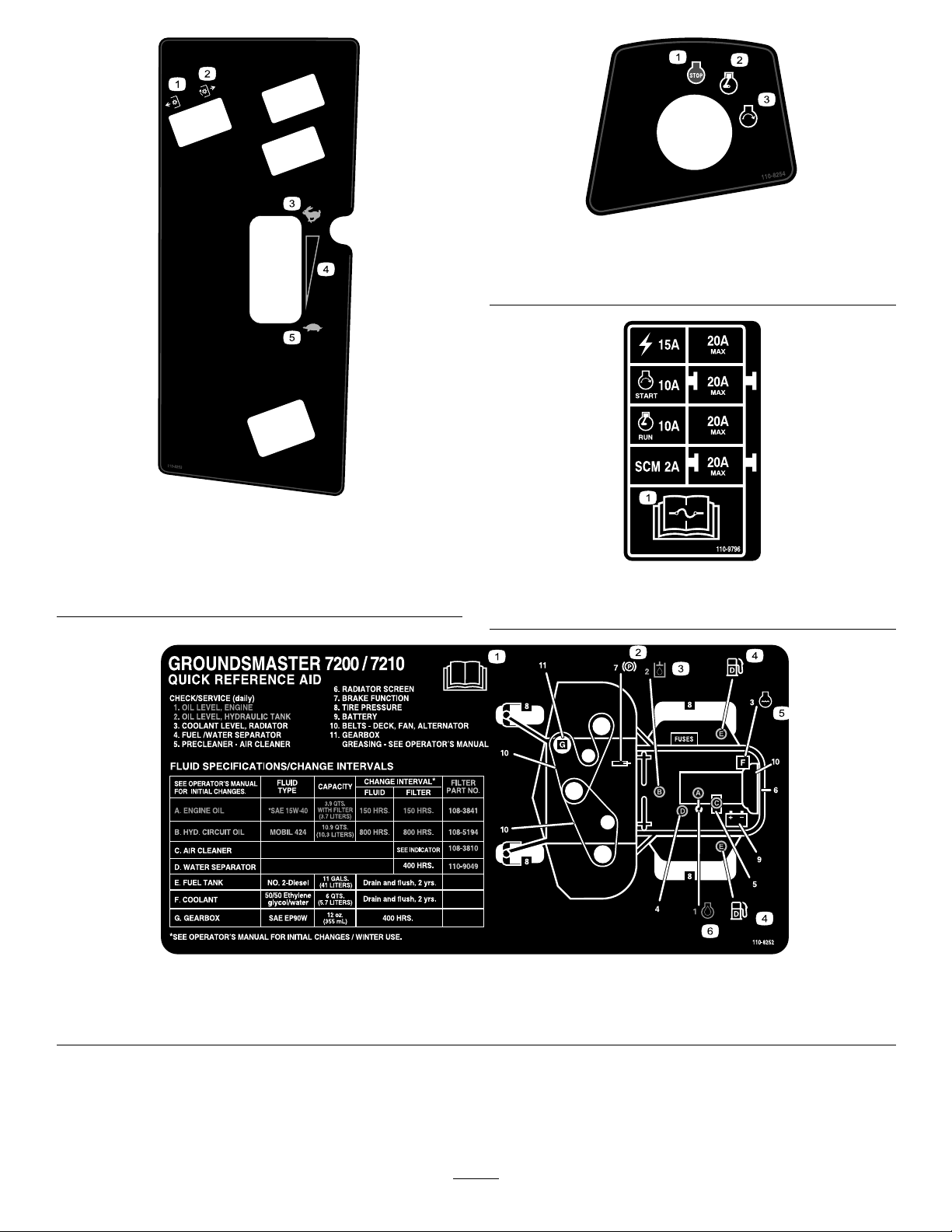

110-8254

1.Engine–Stop3.Engine—Start

2.Engine—Run

110-8253

1.PTO–Off4.Continuousvariable

setting

2.PTO—On5.Slow

3.Fast

110-9796

1.ReadtheOperator'sManualforinformationonfuses.

110-8252

1.ReadtheOperator'sManual.

2.Parkingbrake4.Fuel6.Engineoil

3.Hydraulicoil5.Enginecoolant

9

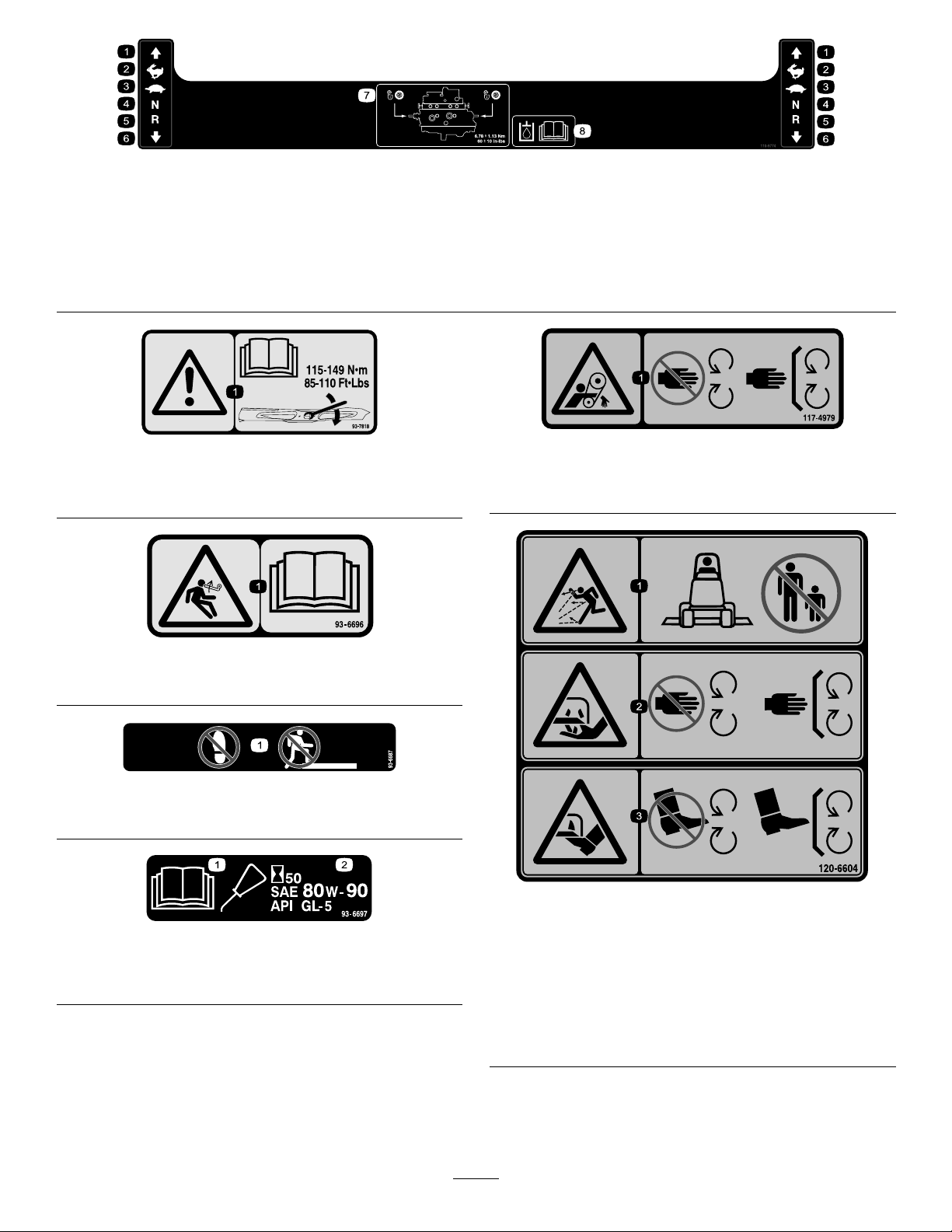

Page 10

110-9774

1.Forward

2.Fast4.Neutral6.Backward

3.Slow

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N-m(85-110ft-lb).

5.Reverse7.Towvalvelocation;torque

thetowvalvesto6.78±

1.13N⋅m(60±10in-lbs).

8.ReadtheOperator's

Manualformore

informationonthehydraulic

oil.

117–4979

1.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

93–6696

1.Storedenergyhazard—readtheOperator'sManual.

93-6687

1.Donotstephere.

93-6697

1.ReadtheOperator's

Manual.

2.AddSAE80w-90(API

GL-5)oilevery50hours.

120-6604

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Cutting/dismembermenthazardofhand,mower

blade—stayawayfrommovingparts,keepallguardsand

shieldsinplace.

3.Cutting/dismembermenthazardoffoot,mowerblade—stay

awayfrommovingparts,keepallguardsandshieldsin

place.

10

Page 11

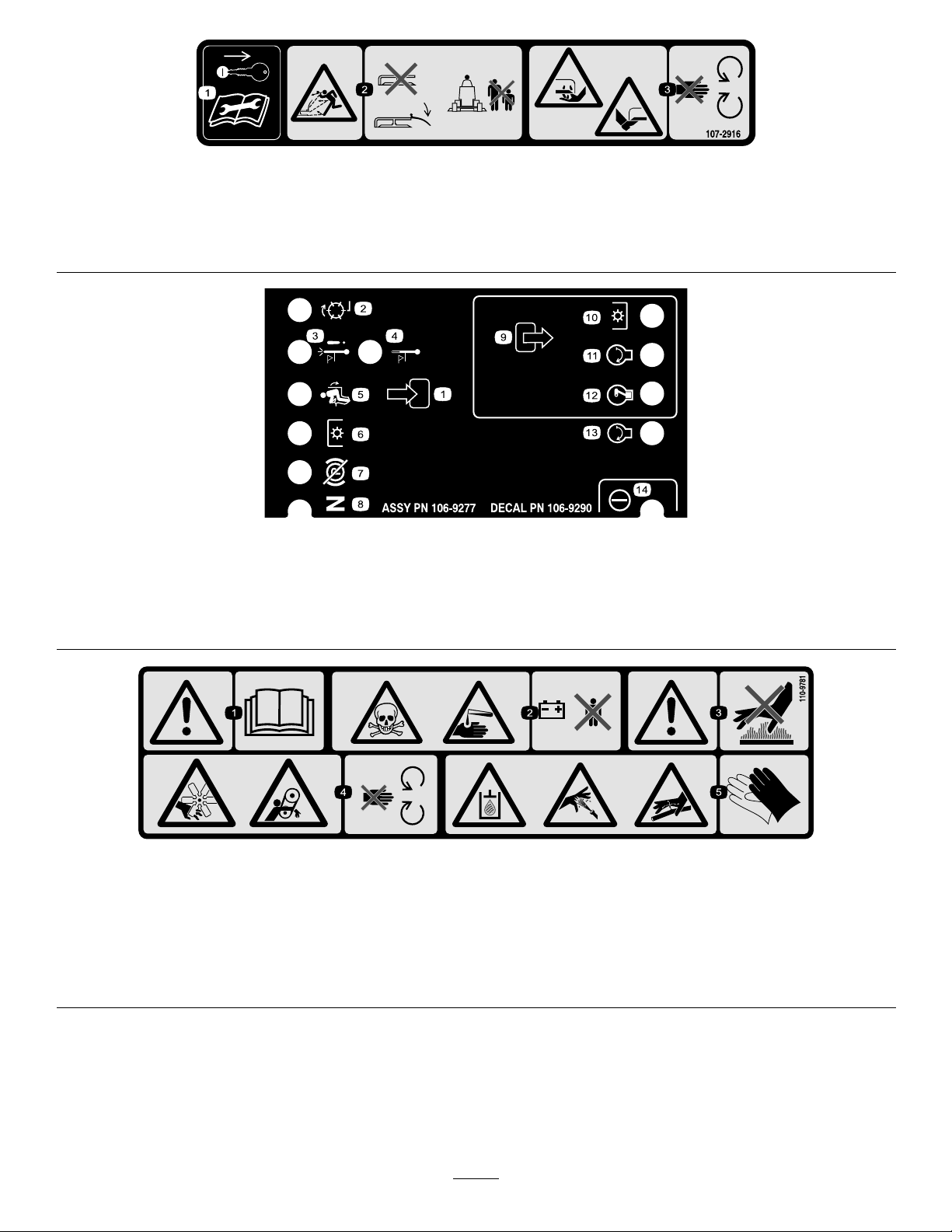

107-2916

1.Removetheignitionkeyandreadthe

Operator'sManualbeforeservicingor

performingmaintenance.

1.Inputs5.Inseat

2.Notactive

3.Hightemperatureshutdown

4.Hightemperaturewarning8.Neutral

6.PowerTake-off(PTO)10.PowerTakeOff(PTO)

7.ParkingbrakeOff11.Start

2.Thrownobjecthazard—donotoperate

themowerwiththedeectorupor

removed,keepthedeectorinplace;

keepbystandersasafedistancefrom

themachine.

106-9290

9.Outputs13.Start

12.EnergizetoRun(ETR)

3.Cutting/dismembermenthazardof

handorfoot,mowerblade—stayaway

frommovingparts.

14.Power

110-9781

1.Warning—readtheOperator'sManual.

2.Poisonandcausticliquid/chemicalburnhazard—keepchildrenasafedistancefromthebattery.

3.Warning—donottouchthehotsurface.

4.Cutting/dismembermenthazard,fanandentanglementhazard,belt—stayawayfrommovingparts.

5.Hydraulicoilinsystemunderpressure,escapinghydraulicoilpenetratingskinhazard,brokenhydrauliclineshazard—wear

protectivehandprotectionwhenhandlinghydraulicsystemcomponents.

11

Page 12

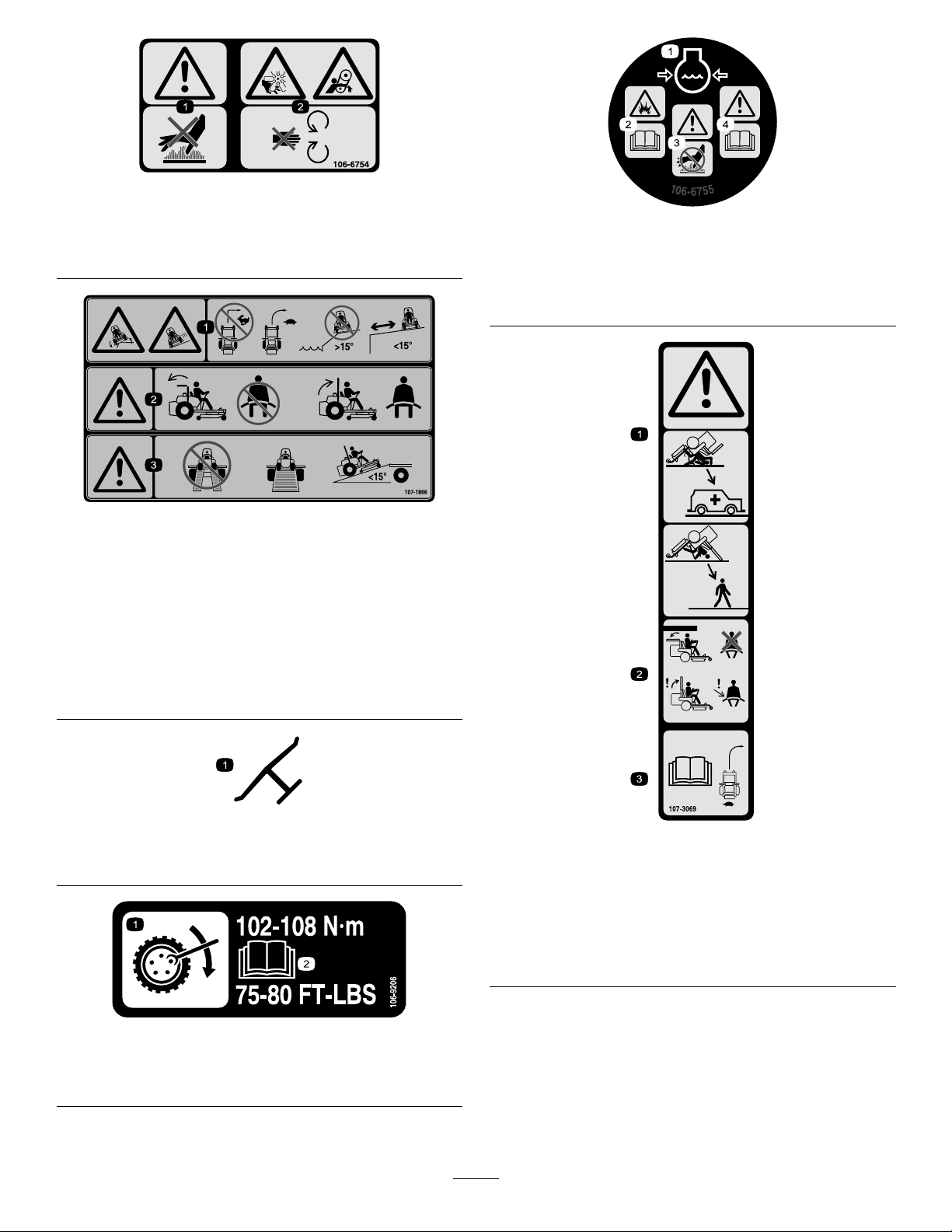

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

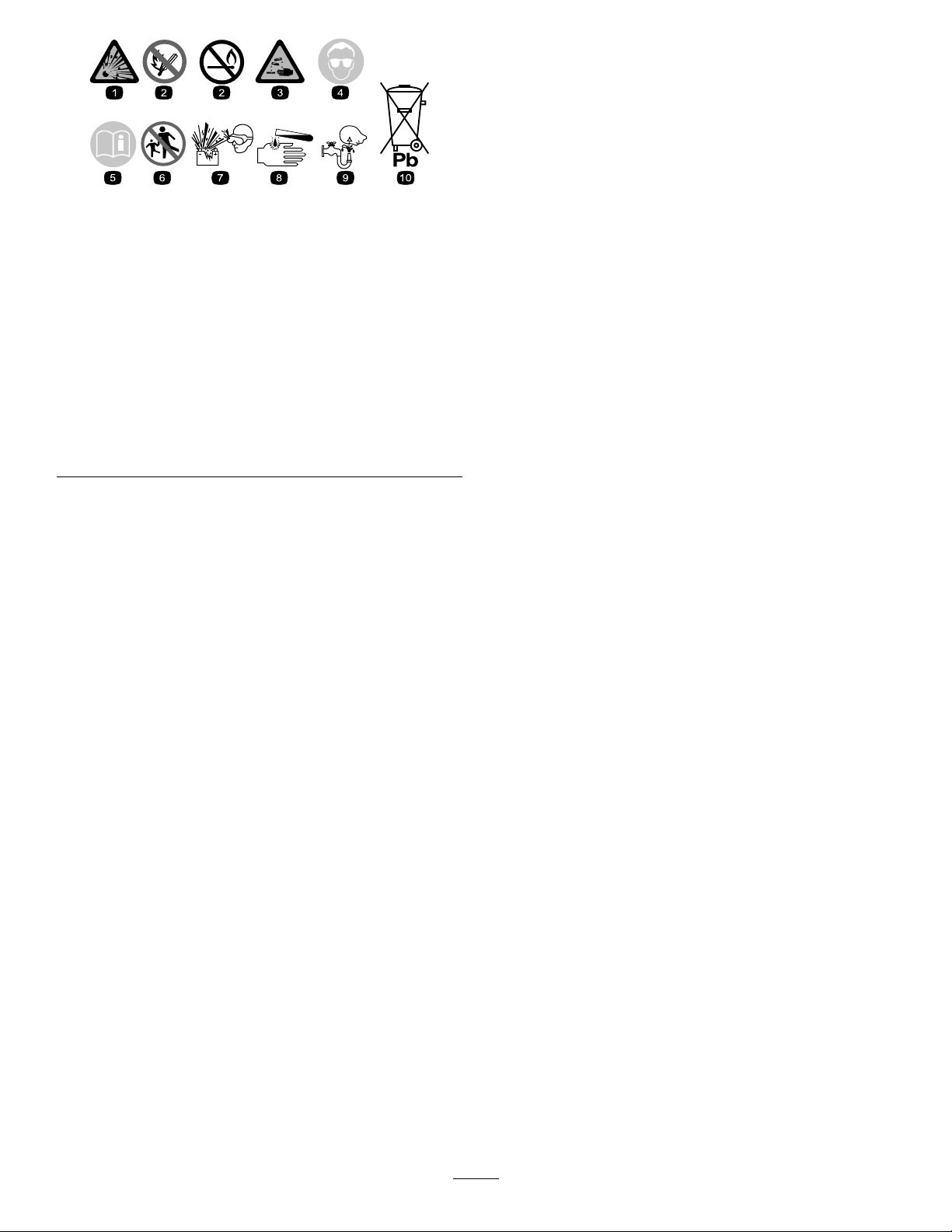

107-1866

1.Tippinghazardandslidingorlossofcontrolhazard,

drop-offs—donotturnsharplywhiletravelingfast,instead,

slowdownandturngradually ,donotoperatethemachine

neardrop-offs,slopesgreaterthan15degrees,orwater;

keepasafedistancefromdrop-offs.

2.Warning—iftherollbarislowered,donotweartheseat

belt,iftherollbarisraised,weartheseatbelt.

3.Warning—donotusesplitramps,useafullrampswhen

transportingmachine,onlyuserampswithinclinesless

than15degrees.

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

106-6755

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

106-9206

1.Wheeltorquespecications

2.ReadtheOperator'sManual.

107-3069

1.Warning–thereisnorolloverprotectionwhentherollbaris

down.

2.Toavoidinjuryordeathfromarolloveraccident,keepthe

rollbarintheraisedandlockedpositionandweartheseat

belt.Lowertherollbaronlywhenabsolutelynecessary;do

notweartheseatbeltwhentherollbarisdown.

3.ReadtheOperator'sManual;driveslowlyandcarefully.

12

Page 13

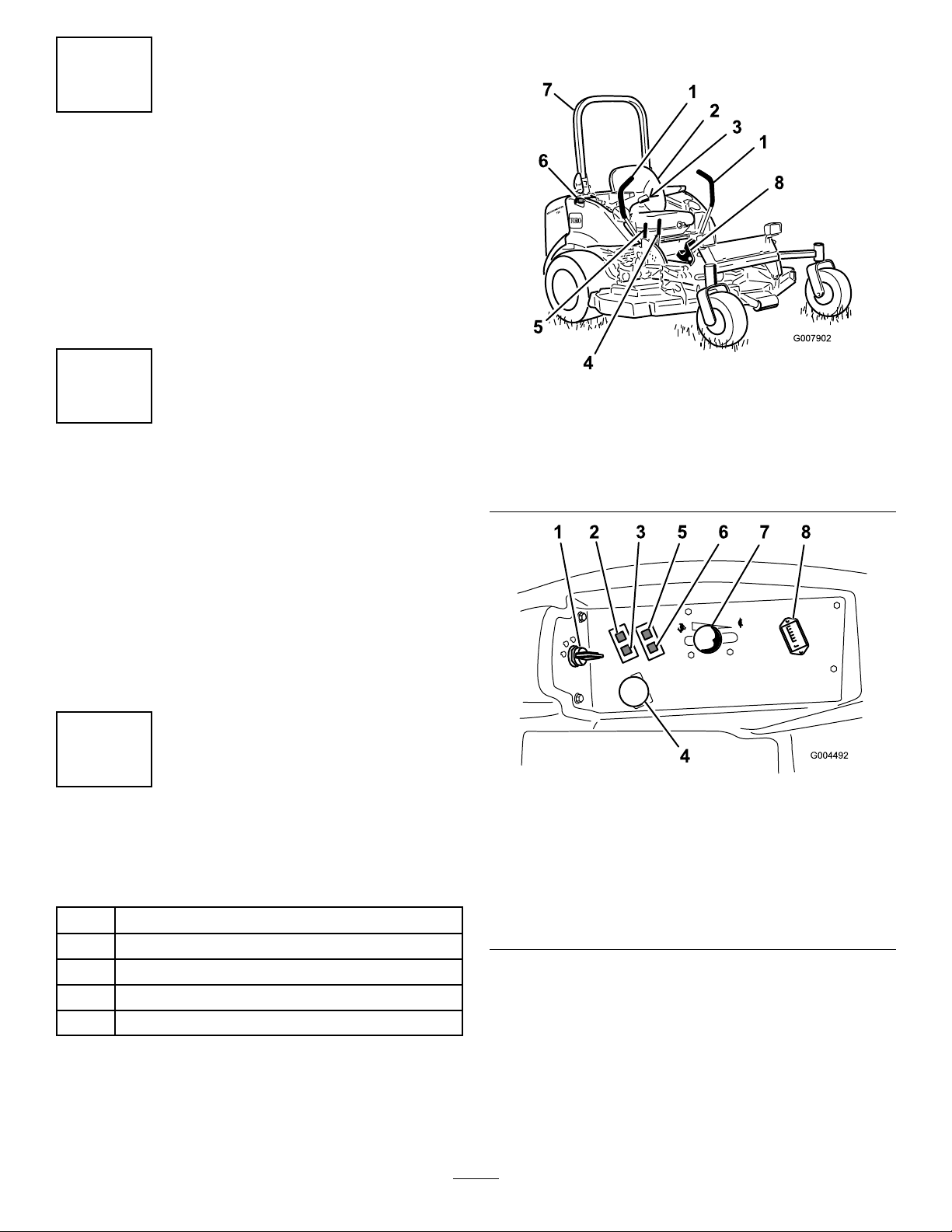

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

13

Page 14

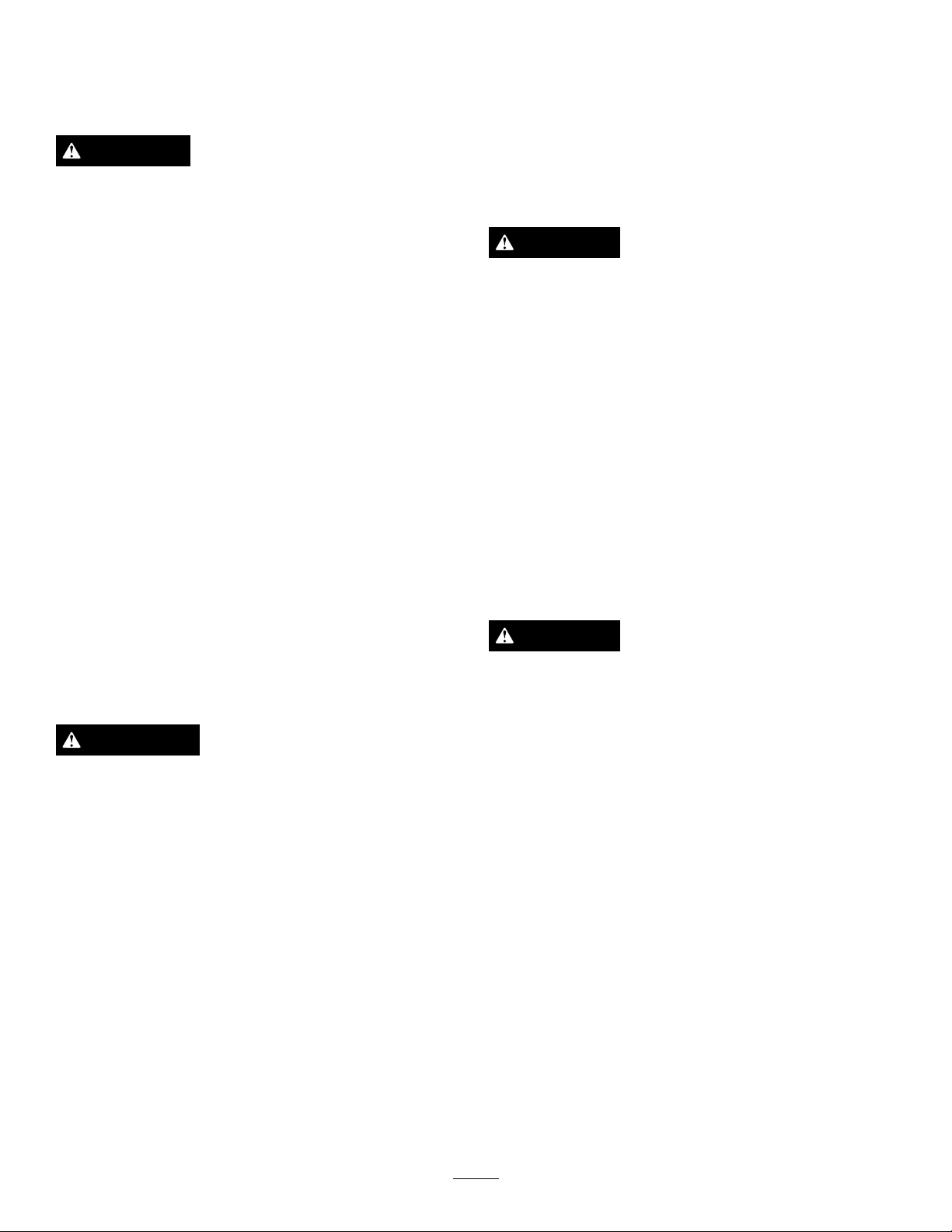

Setup

G004634

1

2

3

4

5

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Nopartsrequired

Nopartsrequired

Nopartsrequired

Operator'sManual

EngineOperator'sManual

PartsCatalog

OperatorTrainingMaterial

Enginewarranty1

1

AdjustingtheROPS

NoPartsRequired

Procedure

1.Removethehairpincotterpinsandremovethetwo

pinsfromtherollbar(Figure4).

Qty.

–

–

–

1

1

1

1

Note:Ifyoumustlowertherollbar,pushthebar

forwardtorelievepressureonthepins,removethe

pins,lowerthebarslowly,andsecureitwiththepinsso

thatitdoesnotdamagethehood.

AdjusttheROPS.

Checkthetirepressure.

Checkthehydraulicuid,engineoil,

andcoolantlevels.

Readthemanualsandviewthe

trainingmaterialsbeforeoperatingthe

machine.Usetheremainingpartsfor

theinstallationofattachments.

Use

WARNING

Toavoidinjuryordeathfromrollover:keepthe

rollbarintheraisedlockedpositionandusethe

seatbelt.

Ensurethattherearpartoftheseatissecuredwith

theseatlatch.

WARNING

Thereisnorolloverprotectionwhentherollbaris

inthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbaris

inthedownposition.

•Driveslowlyandcarefully.

Figure4

RightSideShown

1.Rollbar3.Hairpincotterpin

2.Pin

2.Raisetherollbartotheuprightpositionandinstall

thetwopinsandsecurethemwiththehairpincotter

pins(Figure4).

•Raisetherollbarassoonasclearancepermits.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontact

them.

Important:Lowertherollbaronlywhenabsolutely

necessary.

14

Page 15

2

CheckingtheTirePressure

NoPartsRequired

Procedure

Thetiresareoverinatedforshipping.Therefore,release

someoftheairtoreducethepressure.Thecorrectair

pressureis103kPa(15psi)inthereartiresand172kPa(25

psi)inthecasterwheels.

ProductOverview

Figure5

3

CheckingFluidLevels

NoPartsRequired

Procedure

1.Checkthehydraulicuidlevelbeforestartingthe

engine,refertoCheckingtheHydraulicFluidLevel.

2.Checktheengineoillevelbeforeandafterstartingthe

engine,refertoCheckingtheEngineOilLevel.

3.Checkthecoolingsystembeforestartingtheengine;

refertoCheckingtheCoolingSystem.

4

ReadingtheManualsand ViewingtheTrainingMaterials

Partsneededforthisprocedure:

1

Operator'sManual

1

EngineOperator'sManual

1

PartsCatalog

1

OperatorTrainingMaterial

1Enginewarranty

1.Motioncontrollever

2.Seat6.Fuelcap(bothsides)

3.Seatbelt

4.Parkingbrakelever

1.Ignitionswitch

2.Enginecoolant

temperaturewarning

light

3.Glowpluglight

4.Powertakeoff(PTO)

Switch

5.Mowerdeckliftlever

7.Rollbar

8.Footoperatedmowerlift

pedal

Figure6

5.Oilpressurewarninglight

6.Chargeindicatorlight

7.Throttlelever

8.Hourmeter

Procedure

1.Readthemanuals.

2.Viewtheoperatortrainingmaterials.

15

Page 16

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine(Figure5andFigure6).

MotionControlLevers

Themotioncontrolleverscontroltheforwardandrearward

motionsaswellastheturningofthemachine.Referto

DrivingForwardorBackward.

ParkingBrakeLever

Whenevertheengineisshutoff,engagetheparkingbraketo

preventaccidentalmovementofthemachine.Toengagethe

parkingbrake,pulltheparkingbrakeleverrearwardandup

(

Figure7).Toreleasetheparkingbrake,pushtheparking

brakeleverforwardanddown.

Figure8

1.Footoperateddeckliftlever

IgnitionSwitch

Theignitionswitchhasthreepositions:Off,On/Preheat,

andStart.

Figure7

1.Parkingbrakelever

2.Mowerdeckliftlever

CAUTION

Donotparkthetractionunitonaslope.

HandOperatedDeckLiftLever

Thedeckliftlever(Figure7)activatesthehydrauliccircuit

thatraisesandlowersthemowerdeck.Pullbackonthelever

toraisethemowerdeckandpushforwardonittolowerit.

FootOperatedDeckLiftPedal

ThrottleLever

Thethrottlelevercontrolsthespeedoftheengine.Moving

thethrottleleverforwardtowardtheFastpositionincreases

theenginespeed.MovingitrearwardtowardtheSlow

positiondecreasestheenginespeed.Thethrottlecontrolsthe

speedofthebladesand,inconjunctionwithmotioncontrol

levers,controlsgroundspeedofthemachine.Alwaysrunthe

machinewiththethrottleintheFastpositionwhencutting

grass.

PowerTakeOff(PTO)Switch

Thepowertakeoff(PTO)switchstartsandstopsthemower

blades.

HourMeter

Thehourmeterrecordsthenumberofhourstheengine

hasoperated.ItoperateswhenthekeyswitchisintheRun

position.Usethesetimesforschedulingregularmaintenance.

GlowPlugLight(OrangeLight)

Thedeckliftpedal(Figure8)raisesandlowersthemower

deck.Theenginemustberunningforyoutousethispedal.

Pressdownonthetopoftheliftpedaltoraisethemower

deckandonthebottomoftheliftpedaltolowerthemower

deck.

Theglowplugindicatorlightturnsonwhentheignition

switchisturnedtotheOnposition.Itremainslitfor6

seconds.Whenthelightturnsoff,theengineisreadytobe

started.

16

Page 17

EngineCoolantTemperatureWarning

Light

Thislightglowsandthecuttingbladesstopiftheengine

coolanttemperatureishigh.Ifthemachineisnotstopped

andthecoolanttemperaturerisesanother20°F,theengine

willstop.

Important:Ifthemowerdeckshutsdownandthe

temperaturewarninglightison,pushPTOknobdown,

drivetoasafeatarea,movethethrottlelevertothe

Slowposition,movethemotioncontrolleversintothe

neutrallockedposition,andengagetheparkingbrake.

Allowtheenginetoidleforseveralminuteswhileitcools

toasafelevel.Stoptheengineandcheckthecooling

system;refertoCheckingtheCoolingSystem.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Length

Width(RearWheels)144.8cm(57inches)

Height(RollBarUp)182.9cm(72inches)

Height(RollBarDown)121.9cm(48inches)

Weight,Model30363N

Weight,Model30464N

Weight,Model30465N

Weight,Model30468N

246.4cm(97inches)

1011kg(2230lb)

1000kg(2206lb)

975kg(2151lb)

971kg(2140lb)

ChargeIndicator

Illuminateswhenthesystemchargingcircuitmalfunctions.

OilPressureWarningLight

Theoilpressurewarninglightglowswhentheoilpressure

inenginedropsbelowasafelevel.Iflowoilpressureever

occurs,stoptheengineanddeterminethecause.Repairthe

damagebeforestartingtheengineagain.

FuelGauge

Thefuelgauge(Figure9)indicatesthequantityoffuel

remaininginthefueltanks.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

1.Fuelgauge

Figure9

17

Page 18

Operation

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CAUTION

Thismachineproducessoundlevelsinexcessof85

dBAattheoperatorsearandcancausehearingloss

throughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

AddingFuel

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultralow(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchasefuelin

quantitiesthatcanbeusedwithin180daystoensurefuel

freshness.

Fueltankcapacity:43.5liters(11.5USgallons)

Usesummergradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Useofwintergrade

fuelatlowertemperaturesprovideslowerashpointand

coldowcharacteristicswhichwilleasestartingandreduce

fuellterplugging.

Useofsummergradefuelabove-7°C(20°F)willcontribute

towardlongerfuelpumplifeandincreasedpowercompared

towintergradefuel.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepfuelawayfromeyesandskin.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultralowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

•Monitorseals,hoses,gasketsincontactwithfuelasthey

maybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblended.

•Contactyourdistributorifyouwishformoreinformation

onbiodiesel.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipmentwithits

wheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromafueldispenser

nozzle.

•Ifafueldispensernozzlemustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

18

Page 19

FillingtheFuelTank

UsingtheRolloverProtection

1.Parkthemachineonalevelsurface.

Important:Thefueltanksareconnected,butthe

fueldoesnottransferquicklyfromonetanktothe

other.Itisimportantwhenllingthatyoupark

onalevelsurface.Ifyouparkonahill,youmay

inadvertentlyoverllthetanks.

2.Shuttheengineoffandsettheparkingbrake.

3.Cleanaroundeachfueltankcapandremovethecap.

Important:Donotopenthefueltankswhen

parkedonahill.Thefuelcouldspillout.

4.Addfueltobothfueltanks,untilthelevelisevenwith

thebottomofthellerneck(Figure10).Donotover

llthefueltanks.

Figure10

1.Bottomofthellerneck

5.Installthefueltankcapssecurely.Wipeupanyfuel

thatmayhavespilled.

Note:Ifpossible,llthefueltanksaftereachuse.This

willminimizepossiblebuildupofcondensationinsidethe

fueltank.

System(ROPS)

WARNING

Toavoidinjuryordeathfromrollover:keepthe

rollbarintheraisedlockedpositionandusethe

seatbelt.

Ensurethattherearpartoftheseatissecuredwith

theseatlatch.

WARNING

Thereisnorolloverprotectionwhentherollbaris

inthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbaris

inthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearancepermits.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontact

them.

Important:Lowertherollbaronlywhenabsolutely

necessary.

1.Tolowertherollbar,removethehairpincotters,push

therollbarforwardagainstthesprings,andremove

thetwopins(Figure11).

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,checktheoil

levelintheenginecrankcase;refertoCheckingOilLevel.

CheckingtheCoolingSystem

Beforeyoustarttheengineandusethemachine,checkthe

coolingsystem;refertoCheckingtheCoolingSystem.

CheckingtheHydraulic System

Beforeyoustarttheengineandusethemachine,checkthe

hydraulicsystem;refertoCheckingtheHydraulicSystem.

Figure11

1.Rollbar3.Hairpincotter

2.Pin

19

Page 20

2.Lowertherollbartothedownposition(Figure12).

Figure12

1.Pin3.Mountinghole

2.Rollbar

DANGER

Operatingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Thereisnorolloverprotectionwhentherollbaris

down.

Alwayskeeptherollbarintheraisedandlocked

positionandusetheseatbelt.

Readandfollowtherolloverprotectioninstructions

andwarnings.

Toavoidlossofcontrolandpossibilityofrollover:

3.Installthetwopinsandsecurethemwiththehairpin

cotterpins(Figure11).

Important:Ensurethattherearpartoftheseatis

securedwiththeseatlatch.

4.Toraisetherollbar,removethehairpincotterpinsand

removethetwopins(Figure11).

5.Raisetherollbartotheuprightpositionandinstallthe

twopinsandsecurethemwiththehairpincotterpins

(Figure11).

Important:Alwaysusetheseatbeltwhentherollbar

isintheraisedandlockedposition.Donotusetheseat

beltwhentherollbarisintheloweredposition.

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthesafety

section.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

•Donotoperateneardrop-offsornearwater.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

Figure13

1.SafeZone

2.Usewalkbehindmower

and/orhandtrimmernear

drop-offsandwater.

3.Water

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperatorsearandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,feetandhead

isrecommended.

20

Page 21

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.

SettingtheParkingBrake

1.Movethemotioncontrollevers(Figure18)outtothe

neutrallockedposition.

2.Pullupandbackontheparkingbrakelevertosetthe

parkingbrake(Figure14).Theparkingbrakelever

shouldstayrmlyintheengagedposition.

Figure15

StartingandStoppingthe Engine

StartingtheEngine

Figure14

1.Parkingbrakelever

WARNING

Theparkingbrakemaynotholdthemachine

parkedonaslopeandcouldcausepersonal

injuryorpropertydamage.

Donotparkonslopesunlessthewheelsare

chockedorblocked

ReleasingtheParkingBrake

Pushforwardanddownontheparkingbrakelevertorelease

theparkingbrake(Figure14).

1.Raisetherollbarupandlockitintoplace,sitonthe

seat,andfastentheseatbelt.

2.Ensurethatthemotioncontrolsareintheneutral

lockedposition.

3.Settheparkingbrake;refertoSettingtheParking

Brake.

4.MovethePTO(powertakeoff)switchtotheoff

position(Figure16).

Figure16

1.Ignitionswitch

2.Throttlecontrol

5.MovethethrottlelevermidwaybetweentheFastand

Slowpositions(

6.TurntheignitionkeyclockwisetotheRunposition

(Figure17).

21

Figure16).

3.Glowpluglight

4.Powertakeoffswitch

(PTO)

Page 22

Theglowpluglightwillturnonfor6seconds.

Important:Makesuretoremovethekeyasthe

fuelpumporaccessoriesmayrunandcausethe

batterytolosecharge.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhile

itisunattended.

Figure17

1.Ignitionswitch

2.Off4.Start

7.Aftertheglowplugindicatorlightgoesout,turnthe

keytotheStartposition.Whentheenginesstarts

releasethekey.

Important:Usestartingcyclesofnomorethan

15secondsperminutetoavoidoverheatingthe

startermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeencompletelydrained.

8.LeavethethrottlemidwaybetweentheSlowandFast

positionsuntiltheengineandhydraulicsystemwarm

up.

Important:Whenengineisstartedfortherst

time,orafteranengineoilchange,oranoverhaul

oftheengine,transmission,orwheelmotor,

operatethemachinewiththethrottleleverinthe

Slowpositioninboththeforwardandreverse

directionsforonetotwominutes.Alsooperatethe

liftleverandPTOlevertoensureproperoperation

ofallparts.Thenshuttheengineoffandcheck

uidlevels,checkforoilleaks,looseparts,and

anyothernoticeablemalfunctions.

3.Run/glowpug

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

DrivingtheMachine

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

theFastpositionforbestperformance.Alwaysoperateinthe

Fastthrottlepositionwhenmowing.

CAUTION

Themachinecanturnveryrapidly.Youmaylose

controlofitandcausepersonalinjuryordamage

tomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake.

Note:Theenginewillkillifthetractioncontrollevers

aremovedwiththeparkingbrakeengaged.

2.Movetheleverstothecenter,unlockedposition.

3.Drivethemachineasfollows:

CAUTION

Shuttheengineoffandwaitforallmoving

partstostopbeforecheckingforoilleaks,

looseparts,orothermalfunctions.

StoppingtheEngine

1.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedposition,settheparkingbrake,and

movethethrottlelevertotheSlowposition.

2.Lettheengineidlefor60seconds.

3.TurntheignitionkeytotheOffposition(

Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

4.Removethekeybeforetransportingorstoringmachine.

Figure17).

•Togostraightforward,slowlypushthemotion

controlleversforward(

Figure18).

•Togostraightbackward,slowlypullthemotion

controlleversrearward(Figure18).

•Toturn,slowthemachinebypullingbackonboth

leversandthenpushforwardontheleveronthe

oppositesidefromwhichyouwanttoturn(Figure

18

).

•Tostop,pullthemotioncontrolleverstothe

neutralposition.

Note:Thefartheryoumovethetractioncontrol

leversineitherdirection,thefasterthemachinewill

moveinthatdirection.

22

Page 23

1.Motioncontrol

lever-neutrallocked

position

2.Centerunlockposition

Figure18

OperatingtheMower

RaisingandLoweringtheMowerwith

theDeckLiftLever

Thedeckliftleverraisesandlowersthemowerdeck(Figure

19).Theenginemustberunningforyoutousethislever.

Figure19

1.Deckliftlever

3.Forward

•Tolowerthemowerdeck,pushtheleverforward.

4.Backward

•Toraisethemoverdeck,pulltheleverrearward.

StoppingtheMachine

Tostopthemachine,movethetractioncontrolleversto

neutralandtothelockedposition,disengagethepowertake

off(PTO),movethethrottletotheSlowposition,andstop

theengine.

Settheparkingbrakewhenyouleavethemachine;referto

SettingtheParkingBrake.Remembertoremovethekeyfrom

theignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

attempttomoveoroperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Important:Donotcontinuetoholdtheleverbackor

forwardafterthemowerhasfullyraisedorlowered.

Doingsowilldamagethehydraulicsystem.

Note:Tolockthemowerdeckinaraisedposition,raisethe

deckpastthe15cm(6inch)position,removetheheightofcut

stoppin(refertoAdjustingtheHeight-of-Cut),andplacethe

pininthe15cm(6inch)height-of-cutposition(Figure22).

RaisingandLoweringtheMowerwith

theDeckLiftPedal

Thefootoperatedliftpedalraisesandlowersthemowerdeck

(Figure20).Theenginemustberunningforyoutousethis

pedal.

23

Page 24

Figure20

1.Footoperateddeckliftpedal

•Pressdownonthetopofliftpedaltoraisethemower

deck.

•Pressdownonthebottomofliftpedaltolowerthe

mowerdeck.

Important:Donotcontinuetoholdthepedal

downafterthemowerdeckhasbeenfullyraisedor

lowered.Doingsowilldamagethehydraulicsystem.

DisengagingthePTO

Todisengage,pushthePTOswitchtotheoffposition.

AdjustingtheHeight-of-Cut

Theheight-of-cutisadjustedfrom2.5to15.8cm(1to

6inches)in6mm(1/4inch)incrementsbyrelocatingthe

stoppinintodifferentholelocations.

1.Withtheenginerunning,pullbackonthedecklift

leveruntilthemowerdeckisfullyraisedandrelease

theleverimmediately(Figure22).

2.Toadjust,rotatethestoppinuntiltherollpininit

linesupwiththeslotsintheholesintheheight-of-cut

bracketandremoveit(Figure22).

3.Selectaholeintheheight-of-cutbracketcorresponding

totheheight-of-cutdesired,insertthepin,androtateit

downtolockitinplace(

Note:Therearefourrowsofholepositions(

22).Thetoprowgivesyoutheheightofcutlisted

abovethepin.Thesecondrowdowngivesyouthe

heightlistedplus6mm(1/4inch).Thethirdrow

downgivesyoutheheightlistedplus12mm(1/2inch).

Thebottomrowgivesyoutheheightlistedplus18mm

(3/4inch).Forthe15.8cm(6inch)positionthereis

onlyonehole,locatedinthesecondrow .Thisdoesnot

add6mm(1/4inch)tothe15.8cm(6inch)position.

Figure22).

Figure

Note:Tolockthemowerdeckinaraisedposition,raisethe

deckpastthe15cm(6inch)position,removetheheightofcut

stoppin(refertoAdjustingtheHeight-of-Cut),andplacethe

pininthe15cm(6inch)height-of-cutposition(

Figure22).

EngagingthePowerTakeOff(PTO)

Thepowertakeoff(PTO)switchstartsandstopsthemower

bladesandsomepoweredattachments.

1.Iftheengineiscold,allowtheenginetowarmup5to

10minutesbeforeengagingthePTO.

2.Whileseatedintheseat,releasethepressureonthe

tractioncontrolleversandplacetheminneutral.

3.PulluponthePTOswitchtoengageit(Figure21).

1.PTOswitch

Figure21

Figure22

1.Deckliftlever3.Heightofcutstop

2.Stoppin

24

Page 25

4.Adjusttheanti-scalprollersandskidsasrequired.

1.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedposition,andsettheparkingbrake.

AdjustingtheSkid(s)

Mounttheskidsinthelowerpositionwhenoperatingin

heightofcutshigherthan64mm(2-1/2inches)andinthe

higherpositionwhenoperatinginheightofcutslowerthan

64mm(2-1/2inches).

Note:OnGuardian

youcanswitchtheskidtotheoppositesidesofthemower,

ippingthemover.Thiswillallowyoutousetheskidslonger

beforereplacingthem.

1.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedposition,andsettheparkingbrake.

2.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Loosenthescrewatthefrontofeachskid(2skidson

Guardiandecksand1skidonside-dischargedecks).

®

mowers,whentheskidsbecomeworn,

2.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Afteradjustingtheheight-of-cut,adjusttherollersby

removingtheangenut,bushing,spacer,andbolt

(Figure24).

Figure23

1.Screw3.Skid

2.Flange-headbolt4.Nut

4.Removetheange-headboltsandnutsfromeachskid.

5.Moveeachskidtothedesiredpositionandsecurethem

withtheange-headboltsandnuts.

Note:Onlyusethetoporcentersetsofholestoadjust

theskids.Thebottomholesareusedwhenswitching

sidesonaGuardianmowerdeck,atwhichtimethey

becomethetopholesontheothersideofthemower.

6.Torquethescrewatthefrontofeachskidto9to11

N-m(80to100in-lb).

AdjustingtheRearAnti-Scalp

Figure24

1.Flangenut

2.Bushing5.Bolt

3.Anti-scalproller

4.Spacer

4.Selectaholesotheanti-scalprollerispositionedtothe

nearestcorrespondingheight-of-cutdesired(Figure

25).

Figure25

1.38mm(1-1/2inches)3.63mm(2-1/2inches)

2.51mm(2inches)4.76mm(3inches)and

higher

Rollers

Wheneveryouchangetheheight-of-cut,adjusttheheight

oftherearanti-scalprollers.

5.Installtheangenutbushing,spacer,andbolt.Torque

to54-61N-m(40-45ft-lb)(

25

Figure24).

Page 26

AdjustingtheRollers

Mounttherollersinthelowerpositionwhenoperatingin

heightofcutshigherthan64mm(2-1/2inches)andinthe

higherpositionwhenoperatinginheightofcutslowerthan

64mm(2-1/2inches).

1.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

2.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Raisethefrontofthemachineandsupportitonjack

stands.

4.Removethefastenerssecuringeachrolleronyour

mowerdeckandmovetherollersupordownas

desired;refertoFigure26throughFigure30as

applicableforyourmower.

Figure26

AllMowerDecks

1.Frontroller

2.Rollershaft

Figure28

GuardianMowerDecksOnly

1.Bolt3.Nut

2.Frontunder-deckroller4.Bracket

Figure27

GuardianMowerDecksOnly

1.Bolt4.Nut

2.Rearunder-deckroller5.Bracket

3.Spacer

Side-dischargeMowerDecksOnly

1.Bolt4.Nut

2.Chute-sideroller

3.Spacer

26

Figure29

5.Bracket

Page 27

TestingtheSafetyInterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafetyinterlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Sittingontheseat,engagetheparkingbrakeandmove

thePTOtoon.Trystartingtheengine;theengine

shouldnotcrank.

2.Sittingontheseat,engagetheparkingbrakeandmove

thePTOtooff.Moveeithermotioncontrollever(out

ofneutrallockedposition).Trystartingtheengine;the

engineshouldnotcrank.Repeatforothercontrollever.

Figure30

Side-dischargeMowerDecksOnly

1.Bolt

2.Rollershaft

5.Installthefastenersasillustrated.

3.Under-deckroller(2)

4.Bracket

TheSafetyInterlockSystem

CAUTION

Ifthesafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventtheengine

fromstartingunless:

3.Sittingontheseat,engagetheparkingbrake,movethe

PTOswitchtooffandmovethemotioncontrollevers

totheneutrallockedposition.Nowstarttheengine.

Whiletheengineisrunning,releasetheparkingbrake,

engagethePTOandriseslightlyfromtheseat;the

engineshouldstopwithin2seconds.

4.Withoutanoperatorontheseat,engagetheparking

brake,movethePTOswitchtooffandmovethe

motioncontrolleverstotheneutrallockedposition.

Nowstarttheengine.Whiletheengineisrunning,

centereithermotioncontrol;theengineshouldstop

within2seconds.Repeatfortheothermotioncontrol.

5.Withoutanoperatorontheseat,disengagetheparking

brake,movethePTOswitchtooff,andmovethe

motioncontrolleverstotheneutrallockedposition.

Trystartingtheengine;theengineshouldnotcrank.

UsingtheSCMtoDiagnoseSystem

Problems

Themachineisequippedwithastandardcontrolmodule

(SCM)monitoringsystemthattracksthefunctionofvarious

keysystems.TheSCMislocatedundertherightcontrol

panel.Accessitthroughthesidepanelcover(Figure31).

Toopenthesidepanelcover,releasethe2latchesandpull

outonit.

•Youaresittingontheseatortheparkingbrakeisengaged.

•Thepowertakeoff(PTO)isdisengaged.

•Themotioncontrolleversareintheneutrallocked

position

•Theenginetemperatureisbelowthemaximumoperating

temperature.

Thesafetyinterlocksystemalsoisdesignedtostoptheengine

whenthetractioncontrolsaremovedfromtheneutrallocked

positionwiththeparkingbrakeengaged.Ifyourisefromthe

seatwhenthePTOisengagedthereisa1seconddelayand

thentheenginestops.

27

Page 28

Figure31

PositioningtheSeat

ChangingtheSeatPosition

Theseatcanmoveforwardandbackward.Positiontheseat

whereyouhavethebestcontrolofthemachineandaremost

comfortable.

1.Toadjust,movetheleversidewaystounlocktheseat

(Figure33).

1.Sidepanelcover

2.Latches

OnthefaceoftheSCMare11LEDsthatilluminateto

indicatevarioussystemconditions.Sevenoftheselightscan

beusedbytheoperatorforsystemdiagnosis.RefertoFigure

32

foradescriptionofwhateachlightmeans.Fordetails

onusingtherestoftheSCMfunctions,refertotheService

Manual,availablethroughyourAuthorizedToroDistributor.

Figure32

1.Hightemperatureshutdown—theenginetemperaturehas

exceededsafelevelsandtheenginehasbeenshutdown.

Checkthecoolingsystem.

2.Hightemperaturewarning—theenginetemperatureis

approachingunsafelevelsandthemowerdeckhasbeen

shutdown.Checkthecoolingsystem.

3.Operatorisintheseat

4.ThePTOisOn

5.Theparkingbrakeisnotengaged

6.ControlsareinNeutral

7.TheSCMisreceivingpowerandisoperational

Figure33

1.Backrestknob3.Lumbarsupport

2.Seatsuspensionknob4.Seatpositionadjustment

adjustmentknob

lever

2.Slidetheseattothedesiredpositionandreleaselever

tolockinposition.

3.Verifythattheseathaslockedintoplacebyattempting

tomoveitbackandforth.

ChangingtheSeatSuspension

Theseatcanbeadjustedtoprovideasmoothandcomfortable

ride.Positiontheseatwhereyouaremostcomfortable.

Withoutsittingontheseat,turntheknobinfronteither

directiontoprovidethebestcomfort(

Figure33).

28

Page 29

Figure34

1.Seatsuspensionknob2.Operatorweightsetting

ChangingtheBackPosition

Thebackoftheseatcanbeadjustedtoprovideacomfortable

ride.Positionthebackoftheseatwhereitismost

comfortable.

Figure35

Toadjustit,turntheknob,undertheright-sidearmrest,in

eitherdirectiontoprovidethebestcomfort(Figure33).

ChangingtheLumbarSupport

Thebackoftheseatcanbeadjustedtoprovideacustomized

lumbarsupportforyourlowerback.

Toadjustit,turntheknob,undertheleft-sidearmrest,in

eitherdirectiontoprovidethebestcomfort(Figure33).

UnlatchingtheSeat

Toaccessthehydraulicandothersystemsundertheseat,you

needtounlatchtheseatandswingitforward.

1.Usetheseatpositionadjustmentlevertoslidetheseat

allthewayforward.

2.Pushoneoftheseatlatches,locatedbehindandtothe

sidesoftheseat,rearwardtounlatchtheseatandpull

forwardonthetopoftheseat(Figure35).

1.Seatlatch

PushingtheMachinebyHand

Ifthemachinebreaks,runsoutoffuel,etc.youmayneedto

pushit.T odoso,yourstneedtoopenthehydraulicby-pass

valves.

Important:Alwayspushthemachinebyhand.Never

towthemachinebecausehydraulicdamagemayoccur.

PushingtheMachine

1.Disengagethepowertakeoff(PTO)andturnthe

ignitionkeytooff.Movetheleverstotheneutral

lockedpositionandapplytheparkingbrake.Remove

thekey.

2.Lifttheseat.

3.Rotateeachby-passvalvecounterclockwise1turn

Figure36).

(

Thisallowshydraulicuidtoby-passthepump

enablingthewheelstoturn.

Important:Donotrotatetheby-passvalvesmore

than1turn.Thispreventsvalvesfromcomingout

ofthebodyandcausinguidtorunout.

29

Page 30

Figure36

1.Rightby-passvalve

4.Disengagetheparkingbrakebeforepushing.

2.Leftby-passvalve

WARNING

Loadingaunitontoatrailerortruckincreasesthe

possibilityofbackwardtip-overandcouldcause

seriousinjuryordeath.

•Useextremecautionwhenoperatingauniton

aramp.

•Useonlyasingle,fullwidthramp;Donotuse

individualrampsforeachsideoftheunit.

•Ifindividualrampsmustbeused,useenough

rampstocreateanunbrokenrampsurfacewider

thantheunit.

•Donotexceeda15degreeanglebetweenramp

andgroundorbetweenrampandtrailerortruck.

•Avoidsuddenaccelerationwhiledrivingunitup

aramptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebackingunit

downaramptoavoidtippingbackward.

ChangingtoMachineOperation

Rotateeachby-passvalveclockwise1turnandhandtighten

them(torqueofapproximately8N-m(71in-lb)(Figure36).

Note:Donotovertightentheby-passvalves.

Themachinewillnotdriveunlessby-passvalvesareturnedin.

LoadingMachines

Useextremecautionwhenloadingunitsontrailersortrucks.

Onefullwidthrampthatiswideenoughtoextendbeyond

thereartiresisrecommendedinsteadofindividualrampsfor

eachsideoftheunit(

thetractorframeextendsbackbetweentherearwheelsand

servesasastopfortippingbackward.Havingafullwidth

rampprovidesasurfacefortheframememberstocontactif

theunitstartstotipbackward.Ifitisnotpossibletouseone

fullwidthramp,useenoughindividualrampstosimulatea

fullwidthcontinuousramp.

Therampshouldbelongenoughsothattheanglesdonot

exceed15degrees(Figure37).Asteeperanglemaycause

mowercomponentstogetcaughtastheunitmovesfrom

ramptotrailerortruck.Steeperanglesmayalsocausethe

unittotipbackward.Ifloadingonornearaslope,position

thetrailerortrucksoitisonthedownsideoftheslopeand

therampextendsuptheslope.Thiswillminimizetheramp

angle.Thetrailerortruckshouldbeaslevelaspossible.

Figure37).Thelowerrearsectionof

Figure37

1.Trailer3.Notgreaterthan

15degrees

2.Fullwidthramp4.Fullwidthramp—sideview

Important:Donotattempttoturntheunitwhileonthe

ramp;youmaylosecontrolanddriveofftheside.

Avoidsuddenaccelerationwhendrivinguparampand

suddendecelerationwhenbackingdownaramp.Both

maneuverscancausetheunittotipbackward.

30

Page 31

TransportingMachines

OperatingTips

WARNING

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow

movingvehicleemblemisdangerousandcanlead

toaccidentscausingpersonalinjury.

Donotdrivemachineonapublicstreetorroadway

withoutsigns,lights,and/ormarkingsrequiredby

localregulations.

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarylightingand

markingasrequiredbylaw.Pleasecarefullyreadallthesafety

instructions.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

Totransportthemachine:

•Ensurethatyourvehicle,hitch,safetychains,andtrailer

areadequatefortheloadyouarepullingandthatthey

meetalllocaltrafcregulationsforyourarea.

•Lockthebrakeandblockthewheels.

•Securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropesasrequiredbylocaltrafc

regulationsinyourarea(Figure38).

FastThrottleSetting/GroundSpeed

Tomaintainenoughpowerforthemachineanddeckwhile

mowing,operatetheengineatthefastthrottlepositionand

adjustyourgroundspeedforconditions.Agoodruleto

followis:decreasegroundspeedastheloadonthecutting

bladesincreases;andincreasegroundspeedasloadonthe

bladesdecreases.

MowingDirection

Alternatemowingdirectiontoavoidmakingrutsintheturf

overtime.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

CuttingSpeed

Toimprovecutquality,useaslowergroundspeedincertain

conditions.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthemower

youpreviouslyused,raisethecuttingheighttoensurethat

uneventurfisnotcuttooshort.

SelecttheProperHeight-of-CutSetting

toSuitConditions

1.Fronttie-down(leftside

shown)

Figure38

Removeapproximately25mm(1inch)ornomorethan1/3

ofthegrassbladewhencutting.Inexceptionallylushand

densegrass,youmayhavetoslowdowntheforwardspeed

and/orraisetheheight-of-cuttothenexthighersetting.

Important:Ifcuttingmorethat1/3ofthegrassblade

off,orinsparselonggrassordryconditions,theuse

ofatsailbladesisrecommendedtoreduceair-borne

chaff,debris,anddeckdrivecomponentstrain.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

cuttingheighthigherthanusualandcutthegrassatthis

setting.Thencutthegrassagainusingthelower,normal

setting.

KeeptheMowerClean

Cleanclippingsanddirtfromtheundersideofthemower

2.Reartie-downs

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

Toreducetheriskofrehazard,keeptheengine,mufer,

batterycompartment,parkingbrake,cuttingunits,andfuel

storagecompartmentfreeofgrass,leaves,orexcessivegrease.

Cleanupanyspilledoilorfuel.

31

Page 32

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthebladesdailyforsharpness,andforany

wearordamage.Sharpenthebladesasnecessary.Ifabladeis

damagedorworn,replaceitimmediatelywithagenuineToro

replacementblade.RefertoServicingtheCuttingBlades.

32

Page 33

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:Refertoyour

Engine Operator's Man ual

foradditionalmaintenanceprocedures.

Note:LookingforanElectricalSchematicorHydraulicSchematicforyourmachine?Downloadafreecopyoftheschematicby

visitingwww .T oro.comandsearchingforyourmachinefromtheManualslinkonthehomepage.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst10hours

Aftertherst50hours

Aftertherst200hours

Beforeeachuseordaily

MaintenanceProcedure

•Checkthealternatorbelttension.

•Torquetheframemountingbolts.

•Torquewheellugnuts.

•Changethemowerdeckgearboxlubricant

•Changetheengineoilandlter.

•Changethehydraulicoilandlter.

•Testthesafetysystem.

•Checktheengineoillevel.

•Checktheenginecoolantlevel.

•Cleantheradiatorwithcompressedair(donotusewater)

•Checkthehydraulicuidlevel.

•Checkthemowerblades.

•Cleanthemowerdeck.

Every50hours

Every150hours

Every200hours

Every400hours

Every800hours

Every1,500hours

Every2years

•Greasethebearingandbushinggreasettings.

•Checkbatterycableconnections.

•Checkthetirepressure.

•Checktheconditionofthebladedrivebeltsonthemowerdeck.

•Checkthelubricantinthemowerdeckgearbox.

•Changetheengineoilandlter.

•Inspectcoolingsystemhosesandseals.Replacethemifcrackedortorn.

•Checkthealternatorbelttension.

•Torquewheellugnuts.

•Changethemowerdeckgearboxlubricant

•Servicetheaircleaner.

•Replacethefuelltercanister.

•Checkthefuellinesandconnections.

•Changethehydraulicoilandlter.

•Inspectenginevalveclearance.RefertoyourEngineOperator'sManual.

•Replacemovinghoses

•Drainandcleanthefueltank.

•Flushandreplacecoolingsystemuid.

33

Page 34

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

CheckSafetyInterlock

Operation

CheckGrassDeectorin

DownPosition(ifapplicable)

CheckParkingBrake

Operation

CheckFuelLevel

CheckHydraulicOilLevel

CheckEngineOilLevel

CheckCoolingSystemFluid

Level

CheckDrainWater/Fuel

Separator

CheckAirFilterRestriction

Indicator

CheckRadiator&Screenfor

Debris

CheckUnusualEngine

Noises

CheckUnusualOperating

Noises

CheckHydraulicHosesfor

Damage

CheckFluidLeaks

CheckTirePressure

CheckInstrumentOperation

CheckConditionofBlades

LubricateAllGreaseFittings

Touch-upDamagedPaint

1.Checkglowplugandinjectornozzles,ifhardstarting,excesssmokeorroughrunningisnoted.

3

1

2

Sat.Sun.

2.Immediatelyaftereverywashing,regardlessoftheintervallisted.

3.Ifindicatorshowsred

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Information

34

Page 35

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

Figure39

ServiceIntervalChart

Premaintenance

Procedures

Important:Thefastenersonthecoversofthismachine

aredesignedtoremainonthecoverafterremoval.

Loosenallofthefastenersoneachcoverafewturnsso

thatthecoverisloosebutstillattached,thengoback

andloosenthemuntilthecovercomesfree.Thiswill

preventyoufromaccidentallystrippingtheboltsfree

oftheretainers.

Lubrication

GreasingtheBearingsand Bushings

ServiceInterval:Every50hours

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBaseGrease.

Ifthemachineisoperatedundernormalconditions,lubricate

allbearingsandbushingsafterevery50hoursofoperation.

Bearingsandbushingsmustbelubricateddailywhen

operatingconditionsareextremelydustyanddirty.Dusty

anddirtyoperatingconditionscouldcausedirttogetinto

thebearingsandbushings,resultinginacceleratedwear.

Lubricatethegreasettingsimmediatelyaftereverywashing,

regardlessofintervalspecied.

1.Wipethegreasettingscleansoforeignmattercannot

beforcedintothebearingorbushing.

2.Pumpgreaseintothettings.

3.Wipeoffexcessgrease.

Figure40andFigure41illustratethelocationsofthegrease

ttings.

Important:Thettingsontheaxlesofthecasterwheels

arenotillustrated.Ensurethatyougreasethesettings

aswell.

35

Page 36

Figure40

36

Page 37

Figure41

Note:Bearinglifecanbenegativelyaffectedbyimproper

washdownprocedures.Donotwashdowntheunitwhenit

isstillhotandavoiddirectinghigh-pressureorhighvolume

sprayatthebearingsorseals.

ServicingtheMowerDeck GearBoxLubricant

ThegearboxisdesignedtooperatewithSAE80-90gear

lube.Althoughthegearboxisshippedwithlubricantfrom

thefactory,checkthelevelbeforeoperatingthecuttingunit

forthersttimeandevery150operatinghoursthereafter.

Changethelubricantinthegearboxevery400operating

hours.

CheckingtheMowerDeckGearBox

Lubricant

ServiceInterval:Every150hours

1.Positionthemachineandcuttingunitonalevelsurface.

2.Lowerthemowerdecktothe2.5cm(1inch)

height-of-cut.

3.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

4.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

5.Liftthefootrest,exposingthetopofthemowerdeck.

37

Page 38

6.Removethedipstick/llplugfromthetopofthegear

G004501

123456

7

box(Figure42)andmakesurethatthelubricantis

betweenthemarksonthedipstick.

Figure42

1.Fillpluganddipstick

EngineMaintenance

AirCleanerMaintenance

•Checktheaircleanerbodyfordamagewhichcould

possiblycauseanairleak.Replaceadamagedaircleaner

body.Checkthewholecleanairintakesystemforleaks,

damage,orloosehoseclamps.

•Servicetheaircleanerlterwhentheaircleanerindicator

(Figure43)showsredorevery400hours(morefrequently

inextremelydustyordirtyconditions).Donotover

servicetheairlter.

7.Ifthelubricantlevelislow,addenoughlubricantuntil

thelevelisbetweenthemarksonthedipstick.

Note:Donotoverllorthegearboxmaybedamaged.

ChangingtheMowerDeckGearBox

Lubricant

ServiceInterval:Aftertherst50hours

Every400hours

1.Positionthemachineandcuttingunitonalevelsurface.

2.Lowerthemowerdecktothe2.5cm(1inch)

height-of-cut.

3.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

4.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

5.Liftthefootrest,exposingthetopofthemowerdeck.

6.Removethedipstick/llplugfromthetopofthegear

box(Figure42).

7.Placeafunnelanddrainpanunderthedrainplug

locatedunderthefrontofthegearboxandremovethe

plug,drainingthelubricantintothepan.

8.Replacethedrainplug.

9.Addenoughlubricant,approximately283ml(12oz.),

untilthelevelisbetweenthemarksonthedipstick.

Note:Donotoverllorthegearboxmaybedamaged.

Figure43

1.Aircleanercover5.Aircleanerindicator

2.Gasket

3.Filter7.Rubberoutletvalve

4.Aircleanerbody

6.Aircleanerlatch

•Besurethecoverisseatedcorrectlyandsealswiththe

aircleanerbody.

ServicingtheAirCleaner

ServiceInterval:Every400hours

1.Pullthelatchoutwardandrotatetheaircleanercover

counter-clockwise(Figure43).

2.Removethecoverfromtheaircleanerbody(Figure

43).

3.Beforeremovingthelter,uselowpressureair(40psi,

cleananddry)tohelpremovelargeaccumulationsof

debrispackedbetweenoutsideofprimarylterand

thecanister.

Thiscleaningprocesspreventsdebrisfrommigrating

intotheintakewhentheprimarylterisremoved.

Important:Avoidusinghighpressureairwhich

couldforcedirtthroughthelterintotheintake

tract.

4.Removeandreplacetheprimarylter(

Figure43).

38

Page 39

Important:Donotcleantheusedelementto

avoiddamagetotheltermedia.

5.Inspectthenewlterforshippingdamage,checking

thesealingendofthelterandthebody.

Important:Donotuseadamagedelement.

6.Ensurethatthefoamgasketisinplaceinthecover

andthatitisnottornordamaged(

damaged,replaceit.

7.Insertthenewlterbyapplyingpressuretotheouter

rimoftheelementtoseatitinthecanister.

Important:Donotapplypressuretotheexible

centerofthelter.

8.Cleanthedirtejectionportlocatedintheremovable

cover,asfollows:

A.Removetherubberoutletvalvefromthecover

(Figure43).

B.Cleanthecavity.

C.Replacetheoutletvalve.

9.Installthecoverorientingtherubberoutletvalveina

downwardposition—betweenapproximately5:00to

7:00whenviewedfromtheend.

10.Resettheindicator(

Figure43)ifshowingred.

Figure43).Ifitis

TheoillevelshouldbeuptotheFullmarkonthe

dipstick.

Figure44

1.Dipstick

3.IftheoillevelisbelowtheFullmark,removethell

cap(Figure44)andaddoiluntilthelevelreachesthe

Fullmarkonthedipstick.

Important:Donotoverll.

2.Oilll

ServicingtheEngineOil

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;however,the

oillevelmustbecheckedbeforeandaftertheengineisrst

started.Checkoillevelbeforeeachday'soperationoreach

timemachineisused.

Thecrankcasecapacityisapproximately3.8liters(4quarts)

withthelter.Usehigh-qualityengineoilthatmeetsthe

followingspecications:

•APIClassicationLevelRequired:CH-4,CI-4orhigher.

•Preferredoil:SAE15W-40(above-17°C(0°F)

•Alternateoil:SAE10W-30or5W-30(alltemperatures)

Note:T oroPremiumEngineoilisavailablefromyour

distributorineither15W-40or10W-30viscosity.Seethe

partscatalogforpartnumbers.

1.Parkthemachineonalevelsurface,lowerthemower

deck,movethethrottlelevertotheSlowposition,

stoptheengine,andremovethekeyfromtheignition

switch.Openthehood.

Note:Useacleanfunneltopreventspills.

4.Installtheoilllcapandclosethehood.

ChangingtheEngineOilAndFilter

ServiceInterval:Aftertherst50hours

Every150hours

Changetheoilandlterinitiallyafterrst50hoursof

operationandthenevery150hoursofoperationthereafter.If

possible,runtheenginejustbeforechangingtheoilbecause

warmoilowsbetterandcarriesmorecontaminantsthan

coldoil.

1.Positionthemachineonalevelsurface.

2.Openthehood.

3.Setadrainpanundertheoilpanandinlinewiththe

drainplug(

Figure45).

2.Removethedipstick(Figure44),wipeitclean,and

installthedipstick.Removethedipstickandcheckthe

oillevel.

39

Page 40

Figure45

1.Oillter

4.Cleantheareaaroundthedrainplug.

2.Drainplug

FuelSystem

Maintenance

Note:RefertoAddingFuelforproperfuel

recommendations.

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.