Page 1

FormNo.3358-640RevB

Groundsmaster

®

7200and7210

Mower

ModelNo.30360—SerialNo.280000001andUp

ModelNo.30360TE—SerialNo.280000001andUp

ModelNo.30363—SerialNo.280000001andUp

ModelNo.30363TC—SerialNo.280000001andUp

ModelNo.30363TE—SerialNo.280000001andUp

ModelNo.30461—SerialNo.280000001andUp

ModelNo.30462—SerialNo.280000001andUp

ModelNo.30464—SerialNo.280000001andUp

ModelNo.30465—SerialNo.280000001andUp

ModelNo.30464TC—SerialNo.280000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Warning

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrestor,contactyour

AuthorizedServiceDealer.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,

orgrass-coveredlandwithoutasparkarrester

mufermaintainedinworkingorder,ortheengine

constricted,equipped,andmaintainedforthe

preventionofre.Otherstatesorfederalareasmay

havesimilarlaws.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

©2008—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Thismanualalsouses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroRidingMowerSafety....................................5

SoundPressureLevel...........................................6

SoundPowerLevel...............................................6

VibrationLevel.....................................................6

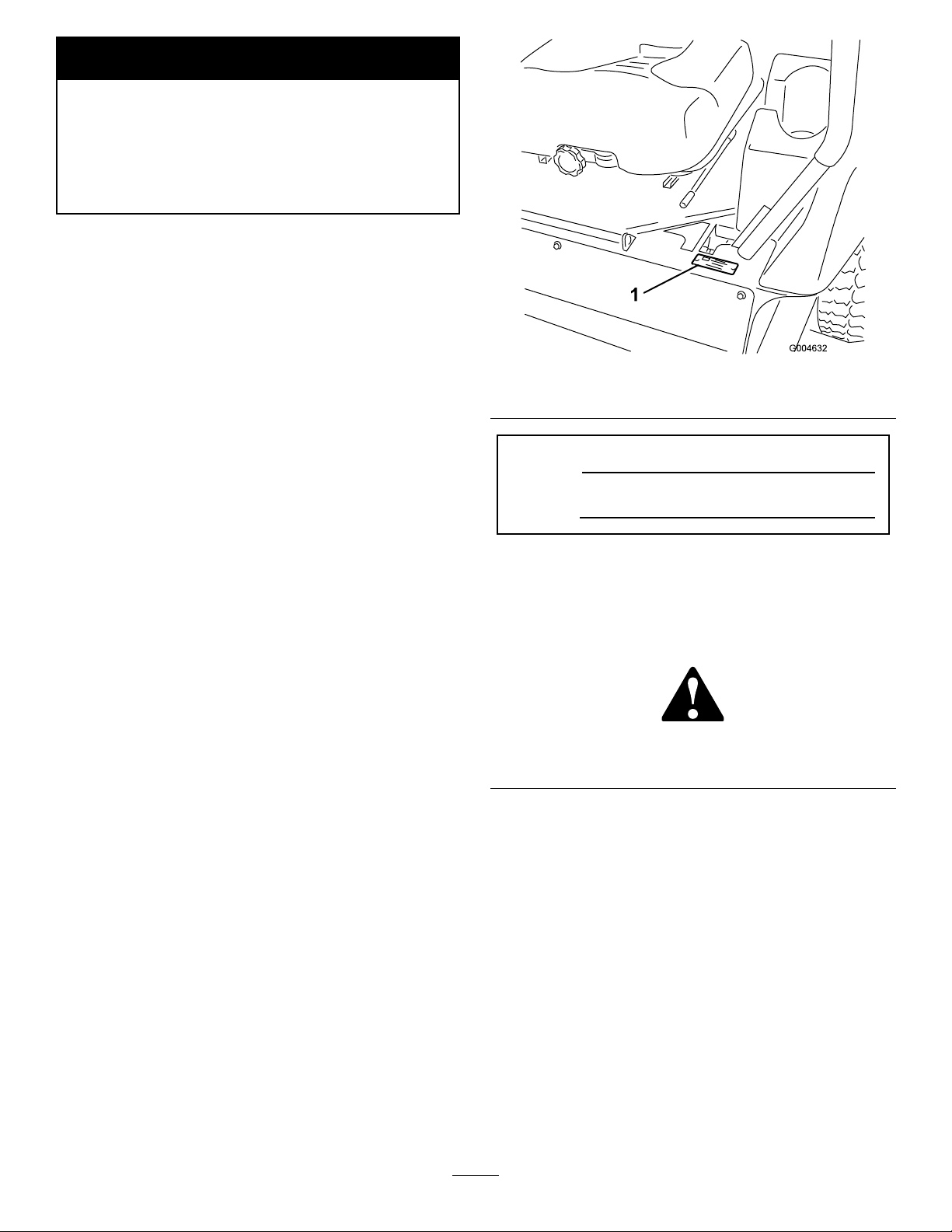

SlopeChart..........................................................7

SafetyandInstructionalDecals.............................8

Setup..........................................................................14

1InstallingtheLeftRearTire(Model30464TC

and30363TCOnly)........................................14

2ActivatingandChargingtheBattery(Model

30464TCand30363TCOnly).........................14

3AdjustingtheROPS.........................................16

4CheckingtheTirePressure...............................16

5InstallingW eights(ForCECompliance)...........17

6CheckingFluidLevels......................................17

7ReadingtheManualsandViewingthe

TrainingMaterials...........................................17

ProductOverview......................................................18

Controls.............................................................18

Specications.....................................................20

Attachments/Accessories...................................20

Operation...................................................................21

AddingFuel.......................................................21

FillingtheFuelTank...........................................22

CheckingtheEngineOilLevel............................22

CheckingtheCoolingSystem..............................22

CheckingtheHydraulicSystem...........................22

UsingtheRolloverProtectionSystem

(ROPS)..........................................................22

ThinkSafetyFirst...............................................23

OperatingtheParkingBrake...............................24

StartingandStoppingtheEngine........................25

DrivingtheMachine...........................................26

StoppingtheMachine.........................................26

OperatingtheMower.........................................27

AdjustingtheHeight-of-Cut...............................28

AdjustingtheSkids.............................................28

AdjustingtheRearAnti-ScalpRollers..................29

AdjustingtheRollers..........................................29

TheSafetyInterlockSystem................................31

PositioningtheSeat............................................32

UnlatchingtheSeat.............................................33

PushingtheMachinebyHand.............................33

LoadingMachines..............................................34

TransportingMachines.......................................35

OperatingTips...................................................35

Maintenance...............................................................37

RecommendedMaintenanceSchedule(s)................37

DailyMaintenanceChecklist...............................38

Lubrication.............................................................39

GreasingtheBearingsandBushings....................39

ServicingtheMowerDeckGearBox

Lubricant.......................................................41

EngineMaintenance...............................................43

AirCleanerMaintenance....................................43

ServicingtheEngineOil.....................................43

FuelSystemMaintenance.......................................45

ServicingtheW aterSeparator.............................45

CleaningtheFuelTank.......................................45

FuelLinesandConnections................................45

BleedingtheFuelSystem....................................45

BleedingAirFromtheInjectors..........................46

ElectricalSystemMaintenance................................47

ServicingtheBattery...........................................47

StoringtheBattery..............................................47

CheckingtheFuses.............................................47

DriveSystemMaintenance.....................................48

CheckingtheTirePressure.................................48

ReplacingtheCastorWheelsand

Bearings.........................................................48

CoolingSystemMaintenance..................................49

CheckingtheCoolingSystem.............................49

CleaningtheRadiator.........................................50

BrakeMaintenance.................................................51

AdjustingtheParkingBrakeInterlock

Switch............................................................51

BeltMaintenance....................................................52

CheckingtheAlternatorBelt..............................52

ReplacingtheBladeDriveBelts..........................52

ControlsSystemMaintenance.................................53

AdjustingtheControlLeverNeutralInterlock

Switch............................................................53

AdjustingtheControlLeverNeutral

Return............................................................53

AdjustingtheTractionDriveforNeutral.............54

AdjustingtheMaximumGroundSpeed..............55

AdjustingtheTracking........................................56

HydraulicSystemMaintenance...............................57

CheckingtheHydraulicSystem...........................57

ChangingtheHydraulicOilAndFilter................58

MowerDeckMaintenance......................................59

ServicingtheCuttingBlades...............................59

CorrectingMowerDeckMismatch.....................61

AdjustingtheMowerDeckPitch.........................62

ReplacingtheGrassDeector.............................62

Cleaning.................................................................63

CleaningUndertheMower.................................63

WasteDisposal...................................................63

Storage.......................................................................64

Machine.............................................................64

Engine...............................................................64

Schematics.................................................................65

3

Page 4

Safety

Machineswithmodelnumbers30360TE,30461,30462,

30363TC,30363TE,30464,30465,or30464TCmeet

orexceedCENstandardEN836:1997andANSI

B71.4-2004specicationsineffectatthetimeof

production.Machineswithmodelnumbers30360and

30363meetorexceedANSIB71.4–2004specications

ineffectatthetimeofproduction

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandard

EN836:1997andANSIB71.4-2004.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Training

•ReadtheOperator’sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,

andtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwith

theseinstructionstousethelawnmower.Local

regulationscanrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpets

arenearby .

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Donotcarrypassengers.

•Alldriversshouldseekandobtainprofessional

andpracticalinstruction.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhen

workingwithride-onmachines;

–controlofaride-onmachineslidingonaslope

willnotberegainedbytheapplicationofthe

controllevers.Themainreasonsforlossof

controlare:

◊insufcientwheelgrip,especiallyonwet

grass;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrectloaddistribution.

Preparation

•Whilemowing,alwayswearsubstantialfootwearand

longtrousers.Donotoperatetheequipmentwhen

barefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning—fuelishighlyammable.

–Storefuelincontainersspecicallydesignedfor

thispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refueling.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltankandcontainercapssecurely.

•Replacefaultysilencers/mufers.

•Beforeusing,alwaysvisuallyinspecttoseethatthe

blades,bladeboltsandcutterassemblyarenotworn

ordamaged.Replacewornordamagedbladesand

boltsinsetstopreservebalance.

•Onmulti-bladedmachines,takecareasrotatingone

bladecancauseotherbladestorotate.

Operation

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageall

bladeattachmentclutchesandshiftintoneutral.

•Rememberthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.To

guardagainstoverturning:

4

Page 5

–donotstoporstartsuddenlywhenonaslope;

•Replacewornordamagedpartsforsafety .

–useslowspeedsonslopesandduringtightturns;

–stayalertforhumpsandhollowsandother

hiddenhazards;

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesfromrotatingbeforecrossing

surfacesotherthangrass.

•Whenusinganyattachments,neverdirectdischarge

ofmaterialtowardbystandersnorallowanyonenear

themachinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesinplace.

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatingtheengineat

excessivespeedmayincreasethehazardofpersonal

injury.

•Beforeleavingtheoperator’sposition:

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachments,stoptheengine,and

removetheignitionkey:

–beforeclearingblockagesoruncloggingchute;

–beforechecking,cleaningorworkingonthelawn

mower;

–afterstrikingaforeignobject.Inspectthelawn

mowerfordamageandmakerepairsbefore

restartingandoperatingtheequipment;

–ifthemachinestartstovibrateabnormally(check

immediately).

•Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Stoptheengineanddisengagedrivetoattachment

beforerefuelling.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumesmayreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuel

storageareafreeofgrass,leaves,orexcessivegrease.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Onmulti-bladedmowers,takecareasmanually

rotatingonebladecancauseotherbladestorotate.

•Whenmachineistobeparked,storedorleft

unattended,lowerthemowerdeck.

ToroRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecicto

Toroproductsorothersafetyinformationthatyoumust

knowthatisnotincludedintheCENstandard.

•Engineexhaustcontainscarbonmonoxide,whichis

anodorless,deadlypoisonthatcankillyou.Donot

runengineindoorsorinanenclosedarea.

•Keephands,feet,hairandlooseclothingawayfrom

attachmentdischargearea,undersideofmowerand

anymovingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowtocoolbefore

attemptingtomaintain,adjust,orservice.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyesandclothing.Protectyour

face,eyes,andclothingwhenworkingwithabattery.

•Thismachineisnotdesignedorequippedfor

on-roaduseandisa“slow-movingvehicle.”Ifyou

mustcrossortravelonapublicroad,youshould

beawareofandcomplywithlocalregulations,such

asrequiredlights,slowmovingvehiclesigns,and

reectors.

•Batterygasescanexplode.Keepcigarettes,sparks

andamesawayfrombattery.

•UseonlygenuineTororeplacementpartstoensure

thatoriginalstandardsaremaintained.

•UseonlyToroapprovedattachments.Warrantymay

bevoidedifusedwithunapprovedattachments.

SlopeOperation

•Donotmowneardrop-offs,ditches,steepbanks

orwater.Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,death,

ordrowning.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

•Reducespeedanduseextremecautiononslopes.

5

Page 6

•Removeormarkobstaclessuchasrocks,treelimbs,

etc.fromthemowingarea.Tallgrasscanhide

obstacles.

•Watchforditches,holes,rocks,dips,andrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoing

downhill.Weighttransfertothefrontwheelsmay

causedrivewheelstoslipandcauselossofbraking

andsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagethebladesand

proceedslowlyofftheslope.

•Followthemanufacturer’srecommendationsfor

wheelweightsorcounterweightstoimprovestability.

SoundPressureLevel

Note:Thedatacontainedinthissectiononlypertains

tounitsmarkedwiththeCElogo().

ThisunithasanequivalentcontinuousA-weighted

soundpressurelevelattheoperatorearof90dBA,based

onmeasurementsofidenticalmachinesperEN11201.

SoundPowerLevel

Note:Thedatacontainedinthissectiononlypertains

tounitsmarkedwiththeCElogo().

Thisunithasaguaranteedsoundpowerlevelof105

dBA,basedonmeasurementsofidenticalmachinesper

EN11094.

VibrationLevel

•Useextremecarewithattachments.Thesecan

changethestabilityofthemachineandcauseloss

ofcontrol.

UsingtheRolloverProtectionSystem

(ROPS)

•Keeptherollbarintheraisedandlockedposition

andusetheseatbeltwhenoperatingthemachine.

•Becertainthattheseatbeltcanbereleasedquickly

intheeventofanemergency.

•Beawarethereisnorolloverprotectionwhenthe

rollbarisdown.

•Checktheareatobemowedandneverfoldthe

ROPSinareaswherethereareslopes,dropoffsor

water.

•Lowertherollbaronlywhenabsolutelynecessary.

Donotweartheseatbeltwiththerollbarfolded

down.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)beforedriving

underanyobjectsanddonotcontactthem.

Hand-Arm

Thisunitdoesnotexceedahand/armvibrationlevelof

2.5m/s

perEN1033.

2

,basedonmeasurementsofidenticalmachines

WholeBody

Thisunitdoesnotexceedawholebodyvibration

levelof0.5m/s

machinesperEN1032.

2

,basedonmeasurementsofidentical

6

Page 7

SlopeChart7SafetyandInstructional

Decals

Page 8

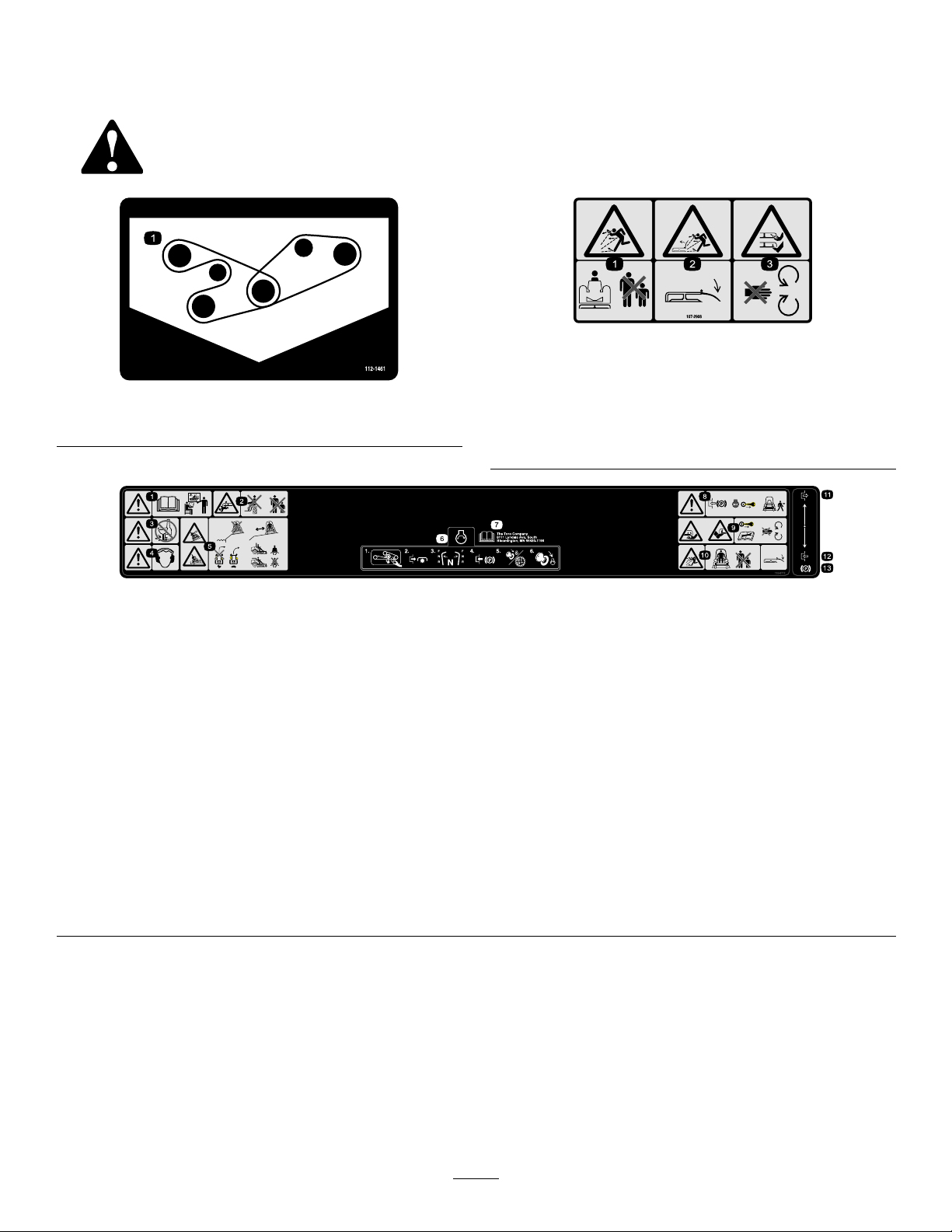

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

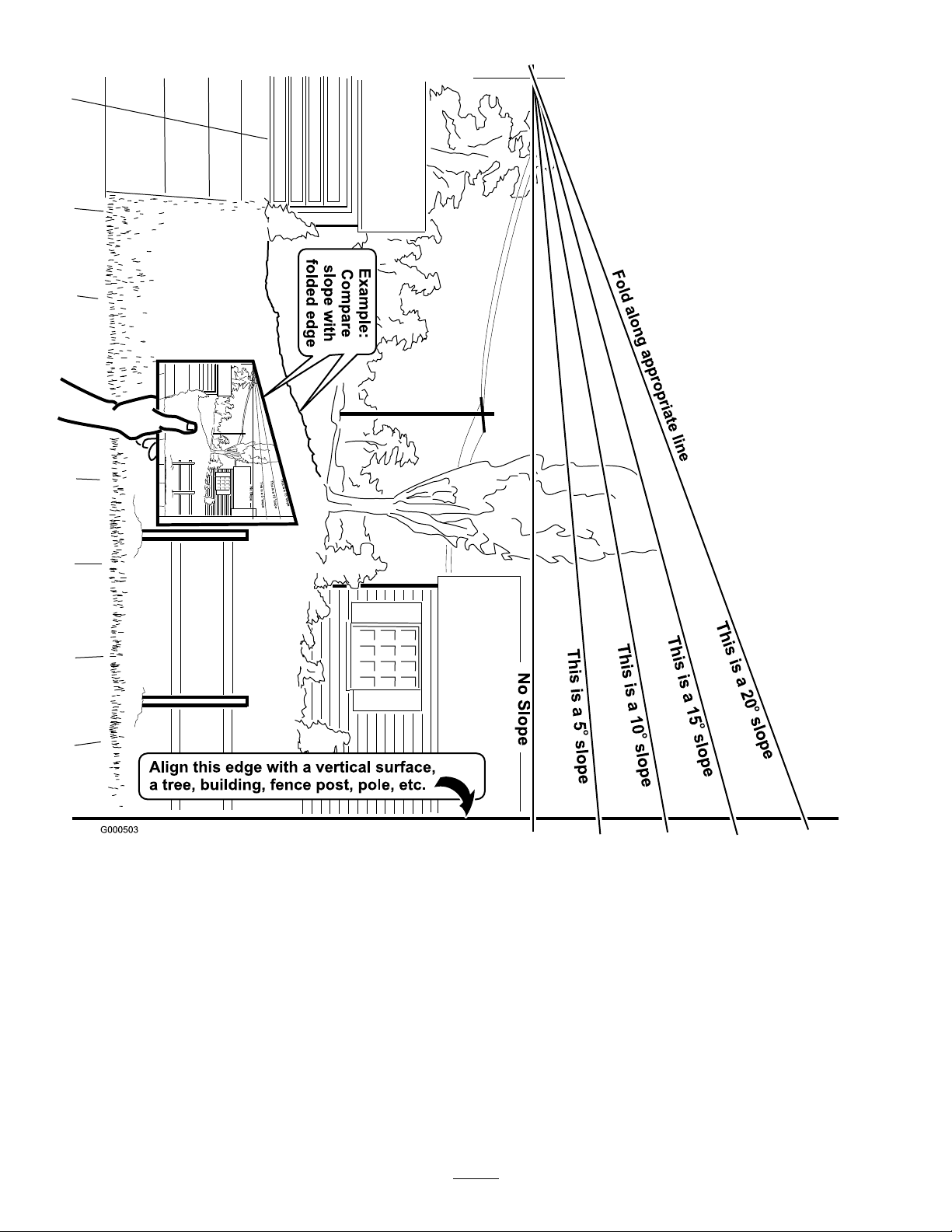

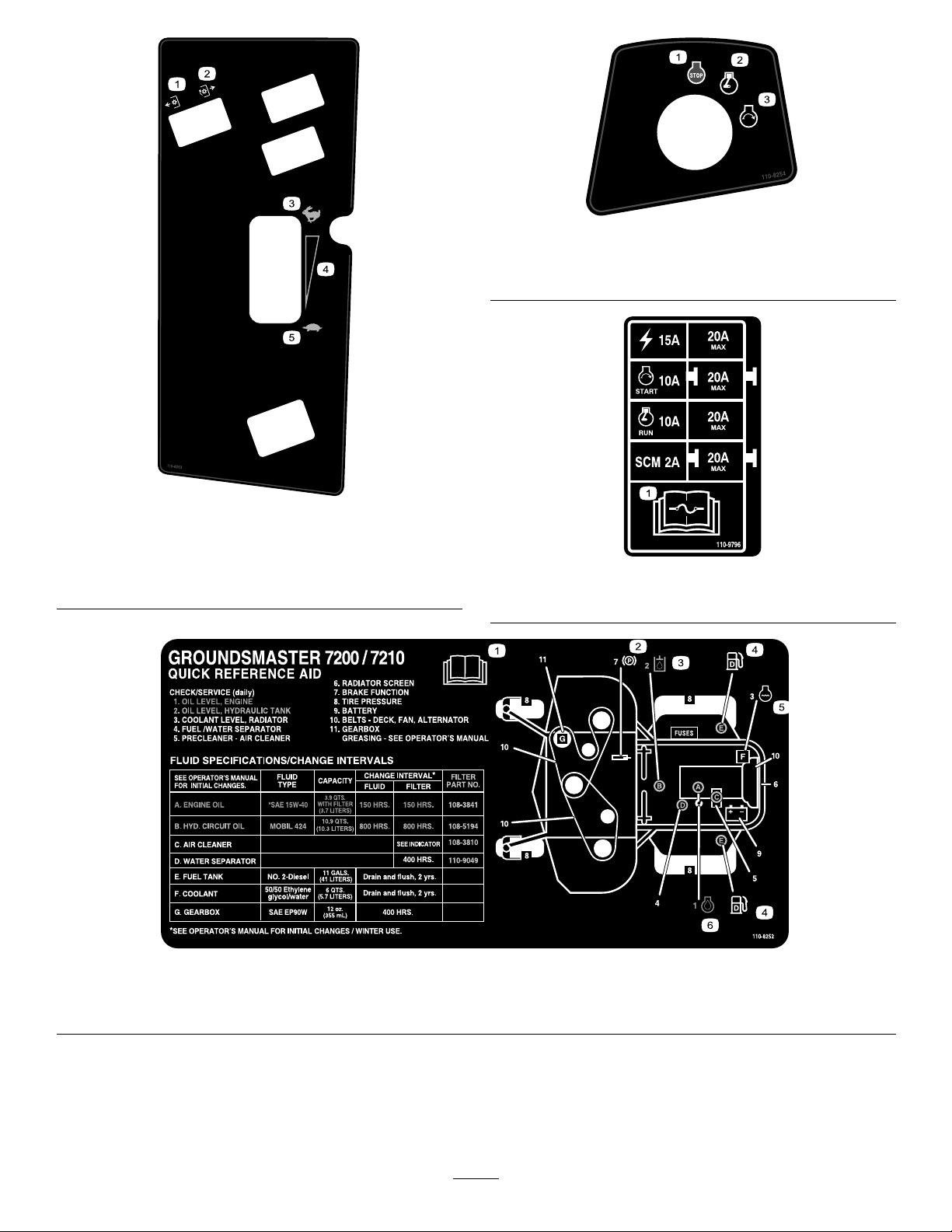

107-2908

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

112-1461

1.Beltrouting

2.Thrownobjecthazard—donotoperatethemowerwiththe

deectoruporremoved,keepthedeectorinplace.

3.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

1.Warning—readtheOperator’sManualandreceivetraining.

2.Crushing/dismembermenthazardofbystanders—donot

carrypassengers,keepbystandersasafedistancefromthe

machine.

3.Warning—donotusedrugsoralcohol.

4.Warning—wearhearingprotection.11.Disengage

5.Tipping,dropoffhazard—donotoperatenearwaterdrop-offs,

stayasafedistancefromdrop-offs,slowmachinebefore

turning,donotturnathighspeeds,wearaseatbeltwhen

aROPSisinplace,donotwearaseatbeltwhenROPSis

lowered.

6.Tostarttheengine:clearanydebrisfrommowerbelt,

disengagethePTO,movethemotioncontrolleverstothe

neutralposition,engagetheparkingbrake,turntheignitionto

Runandwaitfortheglowpluglighttoturnoff,turntheignition

keytoStart.

7.ReadtheOperator’sManual.

110-9772

8.Warning—engagetheparkingbrake,stoptheengineand

removetheignitionkeybeforeleavingthemachine.

9.Cuttinghazardofhandorfoot—removetheignitionkey

andreadtheinstructionsbeforeservicingorperforming

maintenance,keepawayfrommovingparts.

10.Thrownobjecthazard—keepbystandersasafedistancefrom

themachine;keepalldeectorsandshieldsinplace.

12.Engage

13.Parkingbrake

8

Page 9

110-8253

1.PTO–Off4.Continuousvariable

setting

2.PTO—On5.Slow

3.Fast

110-8254

1.Engine–Stop3.Engine—Start

2.Engine—Run

110-9796

1.ReadtheOperator’sManualforinformationonfuses.

110-8252

1.ReadtheOperator’sManual.

2.Parkingbrake4.Fuel6.Engineoil

3.Hydraulicoil5.Enginecoolant

9

Page 10

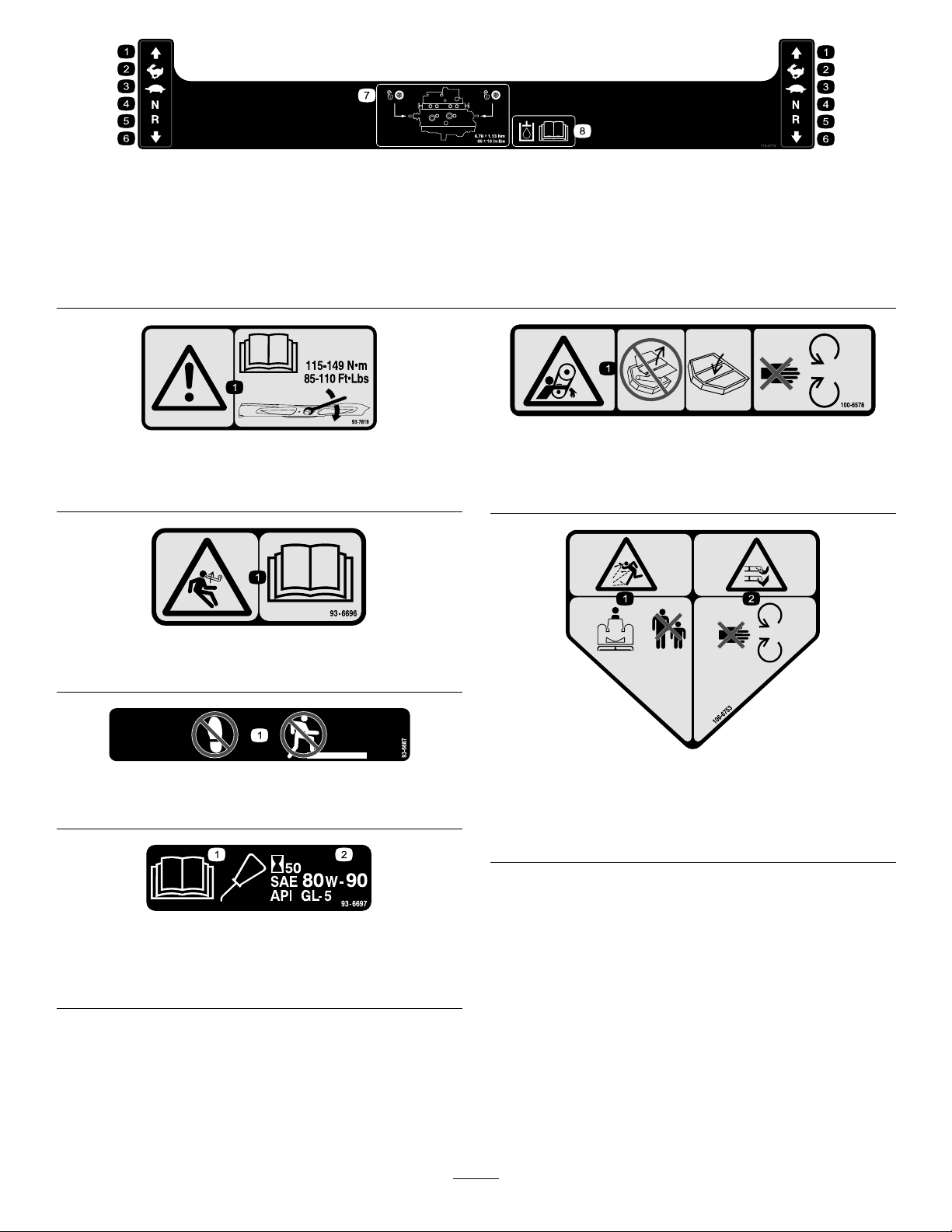

1.Forward

2.Fast4.Neutral6.Backward

3.Slow

110-9774

5.Reverse7.Towvalvelocation;torque

thetowvalvesto6.78±

1.13N⋅m(60±10in-lbs).

8.ReadtheOperator’s

Manualformore

informationonthehydraulic

oil.

93-7818

1.Warning—readtheOperator’sManualforinstructionson

torquingthebladebolt/nutto1 15-149N•m(85-110ft-lb).

93-6696

1.Storedenergyhazard—readtheOperator’sManual.

93-6687

1.Donotstephere.

100-6578

1.Entanglementhazard,belt—donotoperatethemachine

withtheshieldsorguardsremoved;alwayskeepthe

shieldsandguardsinplace;stayawayfrommovingparts.

106-6753

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

1.ReadtheOperator’s

Manual.

93-6697

2.Checktheoilevery50

hours.AddSAE80w-90

(APIGL-5)oilifneeded.

10

Page 11

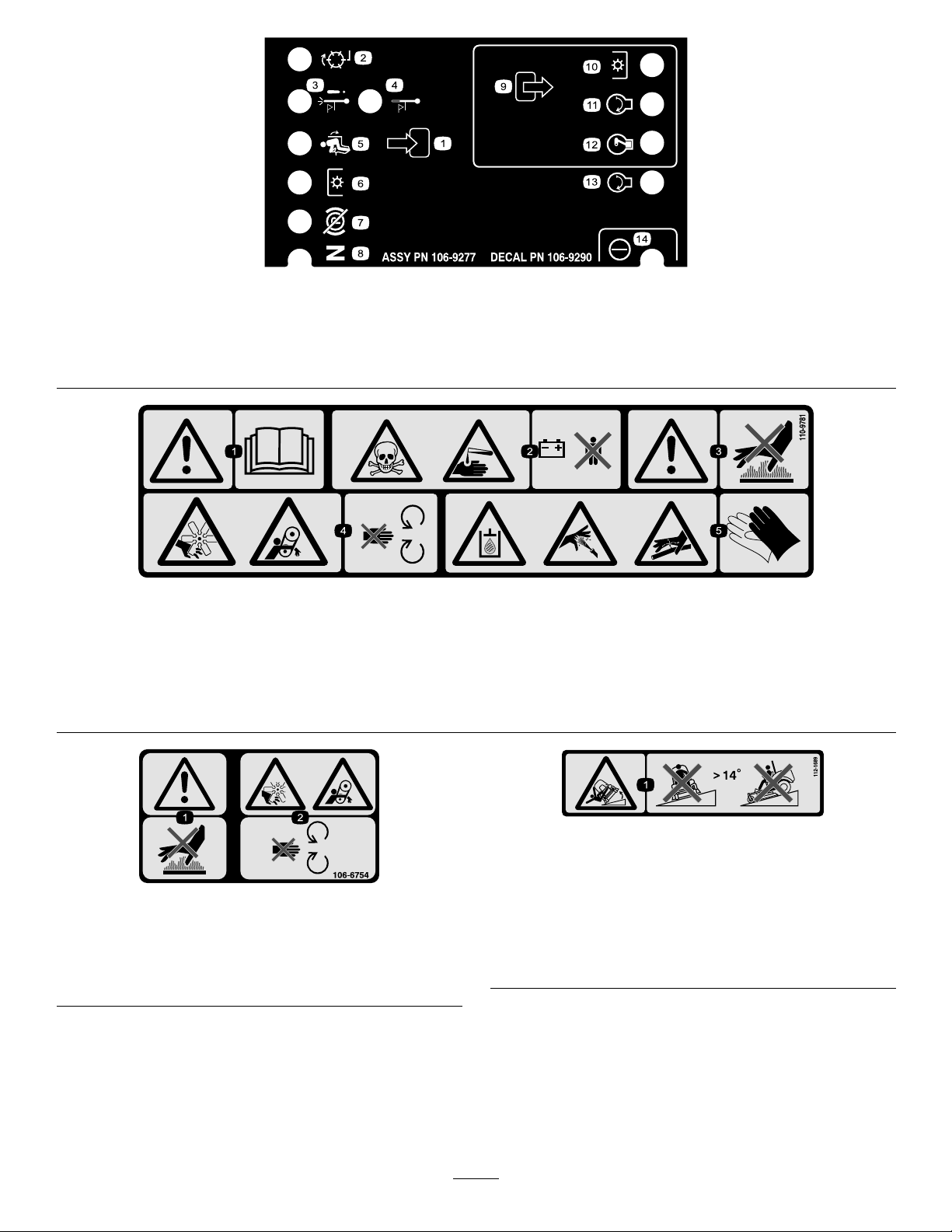

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator’sManual.

106-9206

1.Wheeltorquespecications

2.ReadtheOperator’sManual.

3.Warning—donottouch

thehotsurface.

4.Warning—readthe

Operator’sManual.

107-3069

1.Warning—thereisnorolloverprotectionwhentherollbaris

down.

2.Toavoidinjuryordeathfromarolloveraccident,keepthe

rollbarintheraisedandlockedpositionandweartheseat

belt.Lowertherollbaronlywhenabsolutelynecessary;do

notweartheseatbeltwhentherollbarisdown.

3.ReadtheOperator’sManual;driveslowlyandcarefully.

1.Removetheignitionkeyandreadthe

Operator’sManualbeforeservicingor

performingmaintenance.

107-2916

SideDischargeModelsOnly

2.Thrownobjecthazard—donotoperate

themowerwiththedeectorupor

removed,keepthedeectorinplace;

keepbystandersasafedistancefrom

themachine.

11

3.Cutting/dismembermenthazardof

handorfoot,mowerblade—stayaway

frommovingparts.

Page 12

106-9290

1.Inputs5.Inseat

2.(notactiveonthismachine)6.PowerTake-off(PTO)10.PowerT ake-off(PTO)

3.Hightemperatureshutdown

7.ParkingbrakeOff11.Start

4.Hightemperaturewarning8.Neutral

9.Outputs13.Start

12.EnergizetoRun(ETR)

110-9781

1.Warning—readtheOperator’sManual.

2.Poisonandcausticliquid/chemicalburnhazard—keepchildrenasafedistancefromthebattery.

3.Warning—donottouchthehotsurface.

4.Cutting/dismembermenthazard,fanandentanglementhazard,belt—stayawayfrommovingparts.

5.Hydraulicoilinsystemunderpressure,escapinghydraulicoilpenetratingskinhazard,brokenhydrauliclineshazard—wear

protectivehandprotectionwhenhandlinghydraulicsystemcomponents.

14.Power

106-6754

CEMarkedModelsOnly(WiththeCEKitInstalled)

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

112-1689

CEMarkedModelsOnly(WiththeCEKitInstalled)

*Thissafetydecalincludesaslopewarningrequiredonthemachineforcompliance

totheEuropeanLawnMowerSafetyStandardEN836:1997.Theconservative

maximumslopeanglesindicatedforoperationofthismachineareprescribedby

andrequiredbythisstandard.

1.Tippinghazard—donotoperateonslopesgreaterthan14

degrees.

12

Page 13

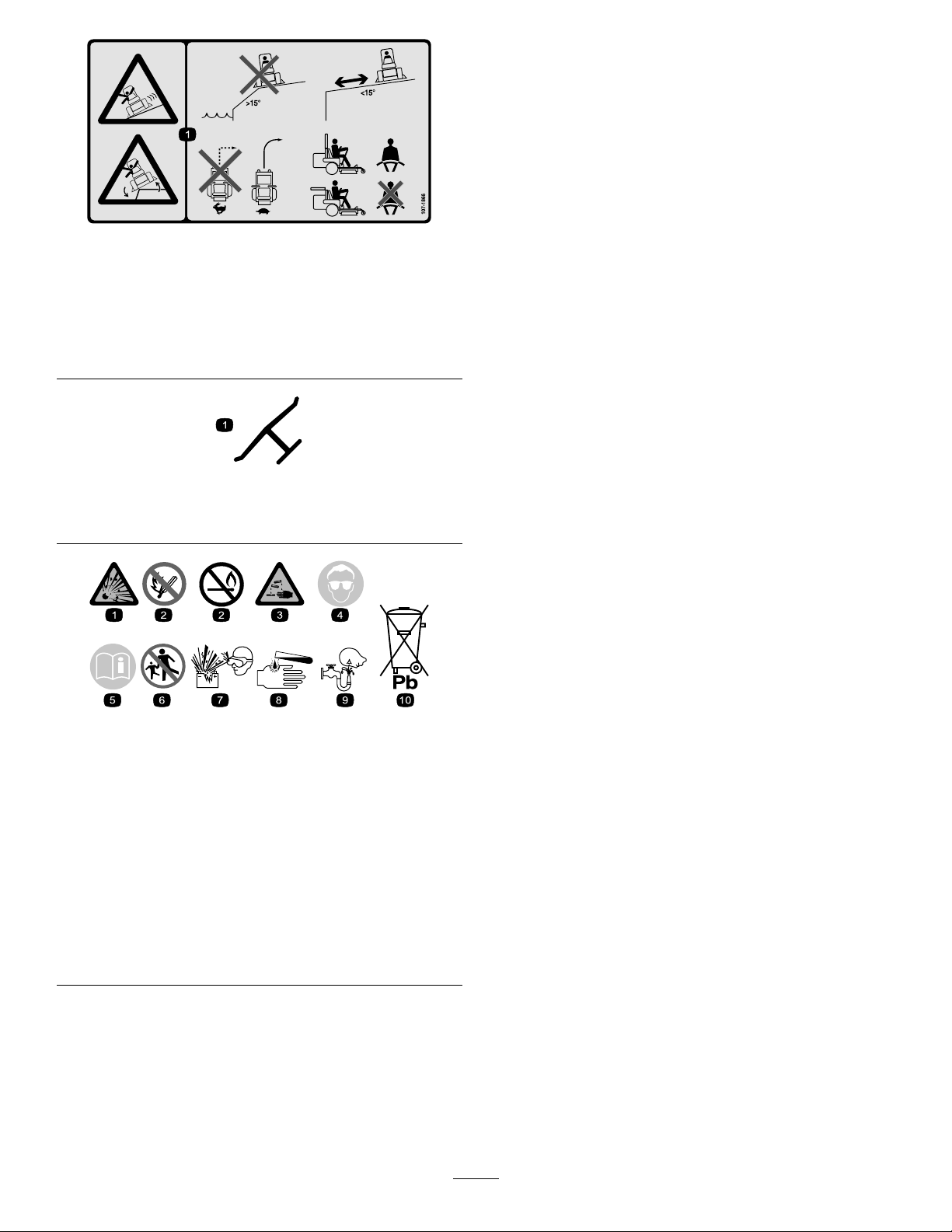

107-1866

1.Slidingandlossofcontrolhazardandtippinghazard,

drop-offs—donotoperatethemachineneardrop-offs,

slopesgreaterthan15degrees,orwater;keepasafe

distancefromdrop-offs;donotturnsharplywhiletraveling

fast,instead,slowdownandturngradually;iftherollbar

israised,weartheseatbelt;iftherollbarislowered,do

notweartheseatbelt.

Manufacturer’sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

13

Page 14

Setup

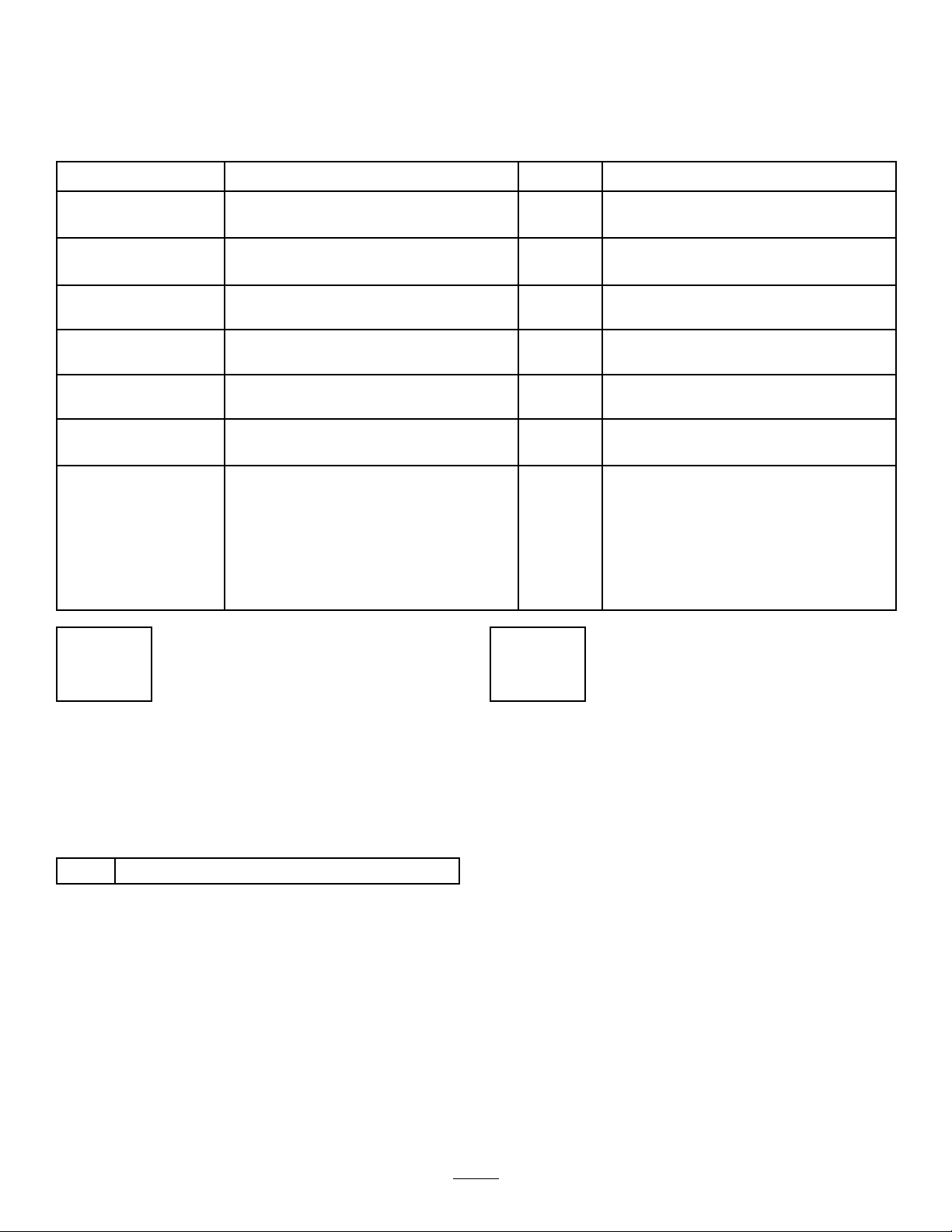

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

Tire1

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Operator’sManual

EngineOperator’sManual

PartsCatalog

OperatorTrainingMaterial

Pre-deliveryInspectionSheet

Enginewarranty1

CEcerticate

Qty.

Use

Installtheleftreartire(model30464TC

and30363TConly).

–

–

–

–

–

1

1

1

1

1

1

Activateandchargethebattery(model

30464TCand30363TConly).

AdjusttheROPS.

Checkthetirepressure.

Installweights.

Checkthehydraulicuid,engineoil,

andcoolantlevels.

Readthemanualsandviewthe

trainingmaterialsbeforeoperatingthe

machine.Usetheremainingpartsfor

theinstallationofattachments.

1

InstallingtheLeftRearTire

(Model30464TCand30363TC

Only)

Partsneededforthisprocedure:

1Tire

Procedure

1.Supporttheleftrearofthemachinewithjackstands.

2.Removethelugnutsfromthetiremountingstuds.

3.Pullthecrateandbracketoffofthewheelhub.

4.Installthereartireontothehubandsecureitusing

thelugnutspreviouslyremoved.

5.Torquethelugnutsto75to80ft-lb(102to108

N⋅m).

2

ActivatingandChargingthe

Battery(Model30464TCand

30363TCOnly)

NoPartsRequired

Procedure

Useonlyelectrolyte(1.265SpecicGravity)toll

batteryinitially.

1.Removethebatteryfromthemachine.

Important:Donotaddelectrolytewhilethe

batteryisinthemachine.Youcouldspillit,

causingcorrosion.

2.Cleanthetopofthebatteryandremovethevent

caps(Figure3).

14

Page 15

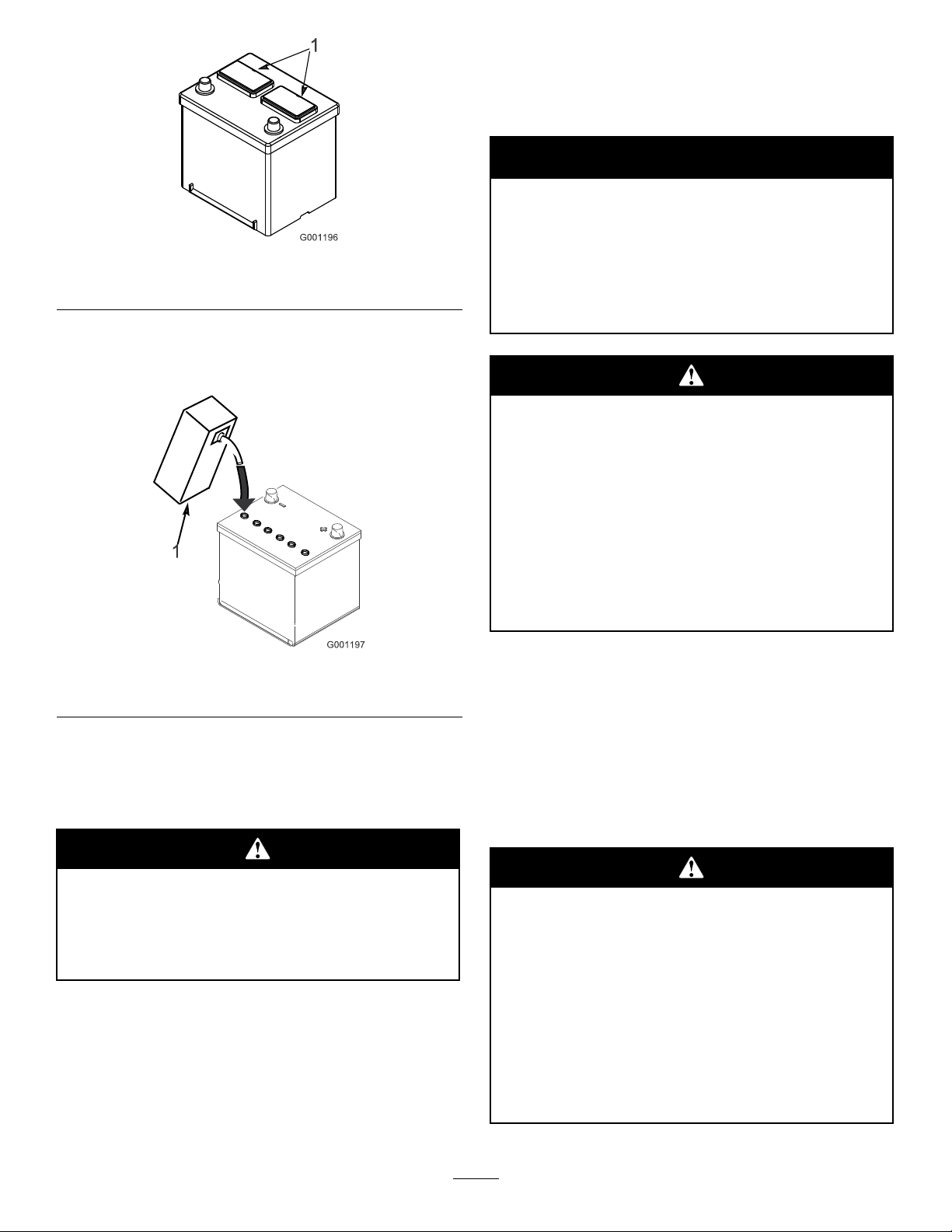

Figure3

1.Ventcaps

3.Carefullylleachcellwithelectrolyteuntiltheplates

arecoveredwithabout1/4inch(6mm)ofuid

(Figure4).

Note:Afterthebatteryhasbeenactivated,add

onlydistilledwatertoreplacenormalloss,although

maintenance-freebatteriesshouldnotrequirewater

undernormaloperatingconditions.

Warning

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Batteryterminalsormetaltoolscouldshort

againstmetaltractorcomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

Figure4

1.Electrolyte

4.Allowapproximately20to30minutesforthe

electrolytetosoakintotheplates.Rellasnecessary

tobringtheelectrolytetowithinabout1/4inch(6

mm)ofthebottomofthellwell(Figure4).

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthetractor.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

tractor.

7.Installthebatteryintothemachineandsecureit.

Important:Thebatterymustnotbeableto

moveorwigglewhenpushed.

8.First,installthepositivecable(red)tothepositive

(+)terminalandthenthenegativecable(black)to

thenegative(-)terminalofthebattery.Slidethe

rubberbootoverthepositiveterminaltopreventa

possibleshortfromoccurring.

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

5.Connecta3to4ampbatterychargertothebattery

posts.Chargethebatteryatarateof3to4amps

untilthespecicgravityis1.250orhigherandthe

temperatureisatleast60°F.(16°C)withallcells

gasingfreely.

6.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative(black)

cable.

15

Page 16

Connectingcablestothewrongpostcould

damagetheelectricalsystemandresultin

personalinjury.

4

CheckingtheTirePressure

Note:Ensurethatthebatterycablesarerouted

awayfromanysharpedgesormovingparts.

3

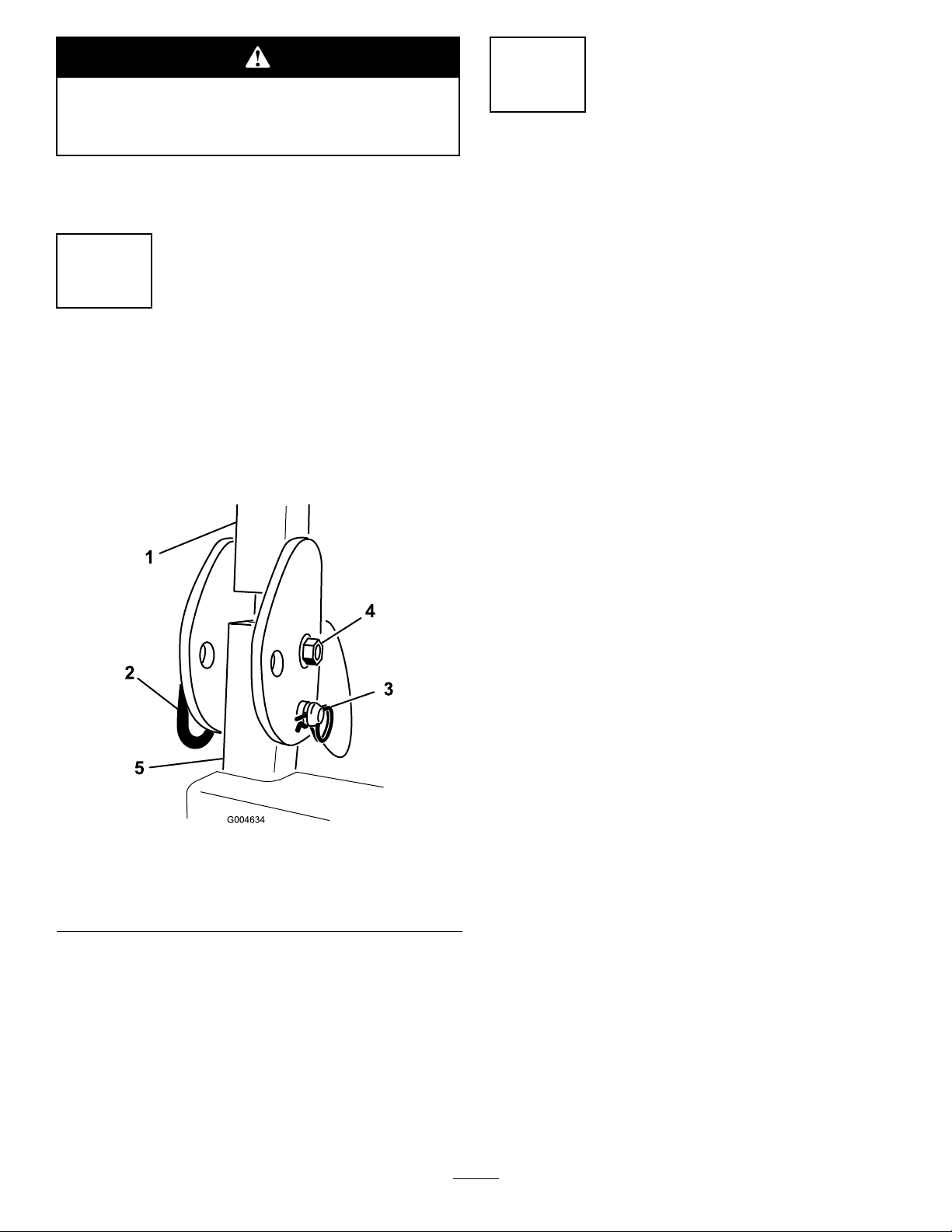

AdjustingtheROPS

NoPartsRequired

Procedure

1.Removethehairpincotterpinsandremovethetwo

pinsfromtherollbar(Figure5).

NoPartsRequired

Procedure

Thetiresareoverinatedforshipping.Therefore,

releasesomeoftheairtoreducethepressure.The

correctairpressureis15psi(103kPa)inthereartires

and25psi(172kPa)inthecasterwheels.

Figure5

RightSideShown

1.Rollbar3.Hairpincotterpin

2.Pin

2.Raisetherollbartotheuprightpositionandinstall

thetwopinsandsecurethemwiththehairpincotter

pins(Figure5).

Note:Ifyoumustlowertherollbar,pushthebar

forwardtorelievepressureonthepins,removethe

pins,lowerthebarslowly,andsecureitwiththepins

sothatitdoesnotdamagethehood.

16

Page 17

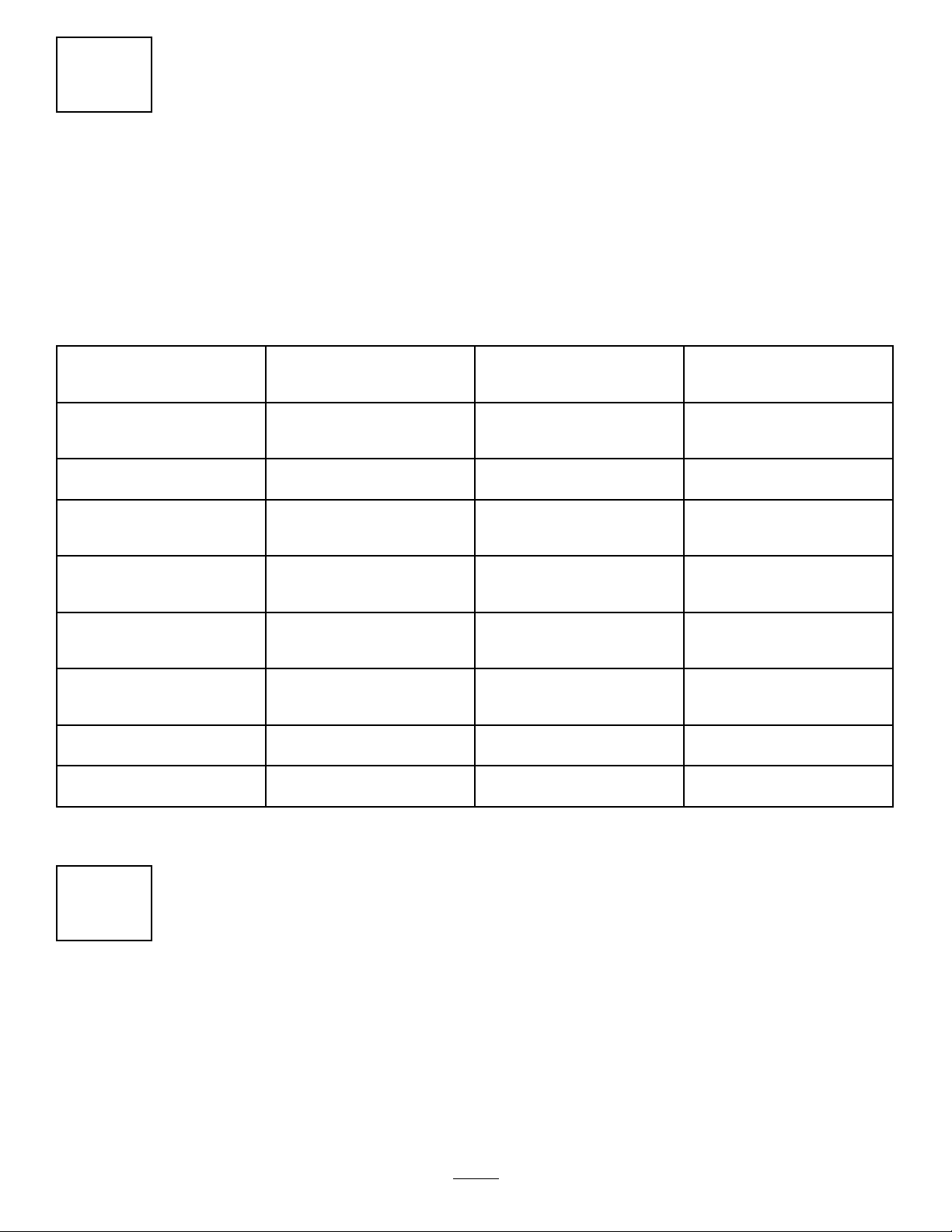

5

InstallingWeights(ForCECompliance)

NoPartsRequired

Procedure

Machineswith72inchdecksinstalledandnootherattachments,donotneedaddedweighttomeetCEstandards.

However,youmayneedtopurchaseandinstalladditionalweightdependingonmowerdecksize/typeandthe

attachmentsyouinstallonthemachine.Thefollowingtableliststhevariousattachmentcongurationsandthe

additionalfrontweightneededforeachmodel:

AttachmentConguration

Groundsmaster7200/7210

TractionUnitwithnoAdded

Attachments

Groundsmaster7200/7210

TractionUnitandHardCanopy

Groundsmaster7200/7210

TractionUnit,HardCanopy,and

RoadLightKit

Groundsmaster7200/7210

TractionUnit,HardCanopy,

RoadLightKit,andJackStand

Groundsmaster7200/7210

TractionUnit,HardCanopy,and

JackStand

Groundsmaster7200/7210

TractionUnit,RoadLightKit,

andJackStand

Groundsmaster7200/7210

TractionUnitandRoadLightKit

Groundsmaster7200/7210

TractionUnitandJackStand

WeightRequiredwitha62

inch(157.5cm)Guardian

Mower

22lb(10kg)0lb(0kg)0lb(0kg)

75lb(34kg)21lb(9.5kg)33lb(15kg)

71lb(32.2kg)63lb(28.5kg)22lb(10kg)

40lb(18kg)37lb(17kg)22lb(10kg)

31lb(14kg)22lb(10kg)22lb(10kg)

0lb(0kg)0lb(0kg)0lb(0kg)

25lb(11.3kg)0lb(0kg)0lb(0kg)

0lb(0kg)0lb(0kg)0lb(0kg)

WeightRequiredwitha72

inch(183cm)Guardian

Mower

inch(183cm)Side-discharge

WeightRequiredwitha72

Mower

ContactyourAuthorizedToroDistributortoobtaintheappropriatekitsandweightsforyourmachine.

2.Checktheengineoillevelbeforeandafterstarting

theengine,refertoCheckingtheEngineOilLevel

6

in,page.

3.Checkthecoolingsystembeforestartingtheengine;

CheckingFluidLevels

refertoCheckingtheCoolingSystemin,page

NoPartsRequired

Procedure

1.Checkthehydraulicuidlevelbeforestartingthe

engine,refertoCheckingtheHydraulicFluidLevel

in,page.

17

Page 18

7

ReadingtheManualsand

ViewingtheTrainingMaterials

Partsneededforthisprocedure:

1

Operator’sManual

1

EngineOperator’sManual

1

PartsCatalog

1

OperatorTrainingMaterial

1

Pre-deliveryInspectionSheet

1Enginewarranty

1

CEcerticate

Procedure

1.Readthemanuals.

ProductOverview

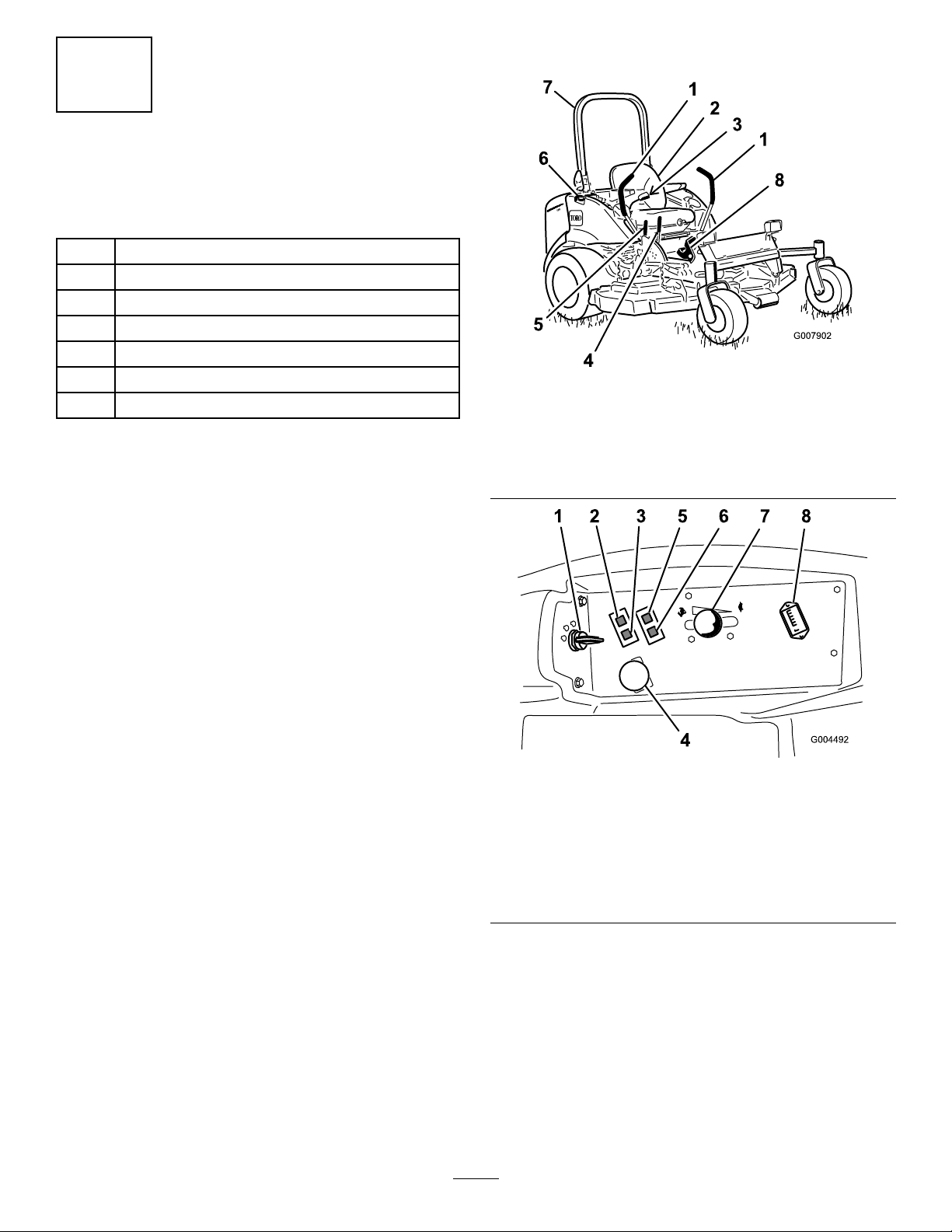

Figure6

1.Motioncontrollever

2.Seat6.Fuelcap(bothsides)

3.Seatbelt

4.Parkingbrakelever

5.Mowerdeckliftlever

7.Rollbar

8.Footoperatedmowerlift

pedal

2.Viewtheoperatortrainingmaterials.

1.Ignitionswitch

2.Enginecoolant

temperaturewarning

light

3.Glowpluglight

4.Powertakeoff(PTO)

Switch

Controls

Figure7

5.Oilpressurewarninglight

6.Chargeindicatorlight

7.Throttlelever

8.Hourmeter

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine(Figure6andFigure7).

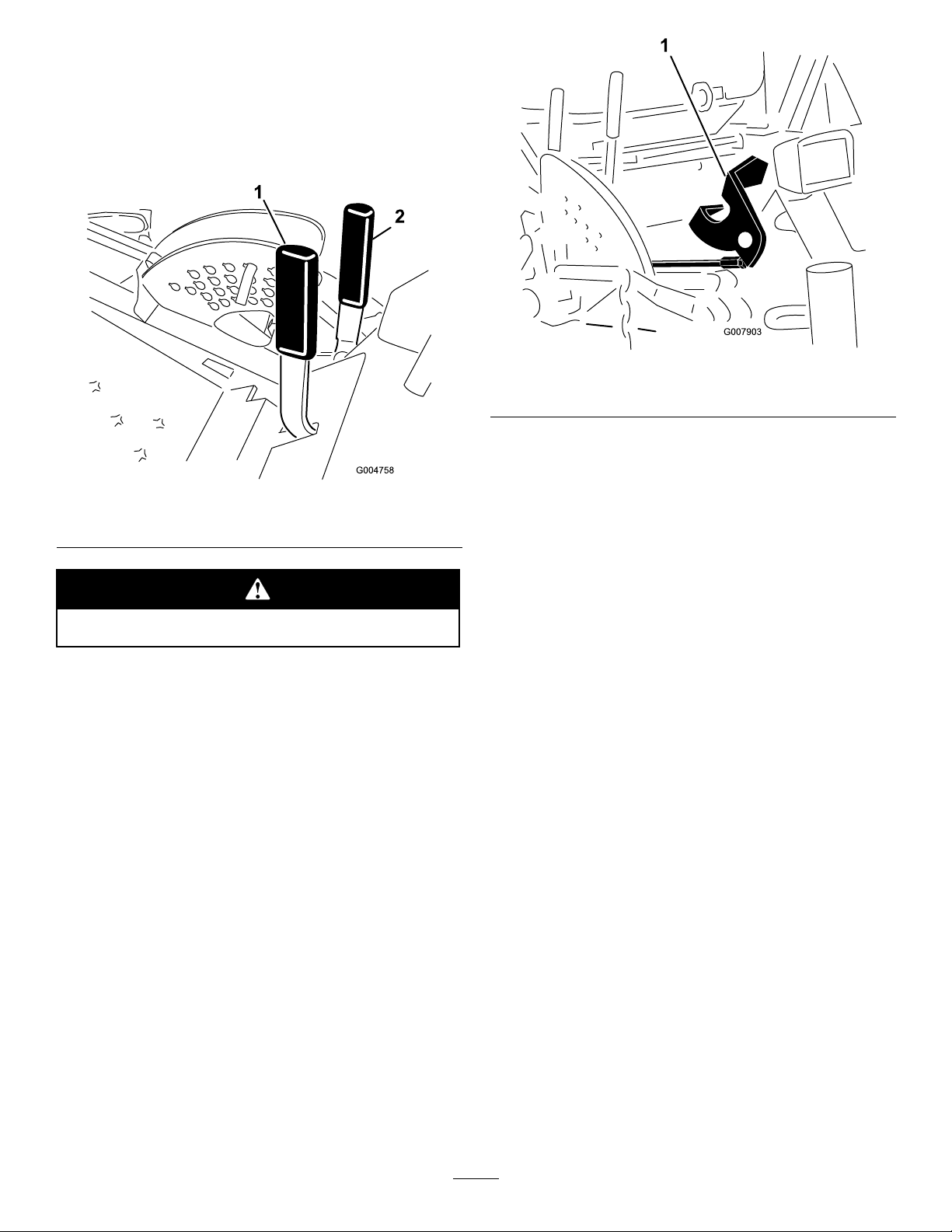

MotionControlLevers

Themotioncontrolleverscontroltheforwardand

rearwardmotionsaswellastheturningofthemachine.

RefertoDrivingForwardorBackwardin,page.

18

Page 19

ParkingBrakeLever

Whenevertheengineisshutoff,engagetheparking

braketopreventaccidentalmovementofthemachine.

Toengagetheparkingbrake,pulltheparkingbrakelever

rearwardandup(Figure8).Toreleasetheparkingbrake,

pushtheparkingbrakeleverforwardanddown.

Figure9

1.Footoperateddeckliftlever

IgnitionSwitch

Figure8

1.Parkingbrakelever

Donotparkthetractionunitonaslope.

2.Mowerdeckliftlever

HandOperatedDeckLiftLever

Thedeckliftlever(Figure8)activatesthehydraulic

circuitthatraisesandlowersthemowerdeck.Pullback

onthelevertoraisethemowerdeckandpushforward

onittolowerit.

FootOperatedDeckLiftPedal

Thedeckliftpedal(Figure9)raisesandlowersthe

mowerdeck.Theenginemustberunningforyoutouse

thispedal.Pressdownonthetopoftheliftpedalto

raisethemowerdeckandonthebottomoftheliftpedal

tolowerthemowerdeck.

Theignitionswitchhasthreepositions:Off,

On/Preheat,andStart.

ThrottleLever

Thethrottlelevercontrolsthespeedoftheengine.

MovingthethrottleleverforwardtowardtheFast

positionincreasestheenginespeed.Movingitrearward

towardtheSlowpositiondecreasestheenginespeed.

Thethrottlecontrolsthespeedofthebladesand,in

conjunctionwithmotioncontrollevers,controlsground

speedofthemachine.Alwaysrunthemachinewiththe

throttleintheFastpositionwhencuttinggrass.

PowerTakeOff(PTO)Switch

Thepowertakeoff(PTO)switchstartsandstopsthe

mowerblades.

HourMeter

Thehourmeterrecordsthenumberofhourstheengine

hasoperated.Itoperateswhenthekeyswitchisinthe

Runposition.Usethesetimesforschedulingregular

maintenance.

GlowPlugLight(OrangeLight)

Theglowplugindicatorlightturnsonwhentheignition

switchisturnedtotheOnposition.Itremainslitfor6

seconds.Whenthelightturnsoff,theengineisready

tobestarted.

19

Page 20

EngineCoolantTemperatureWarning

Light

Thislightglowsandthecuttingbladesstopiftheengine

coolanttemperatureishigh.Ifthemachineisnot

stoppedandthecoolanttemperaturerisesanother20°

F,theenginewillstop.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Length

Width(RearWheels)57inches(144.8cm)

97inches(246.4cm)

Important:Ifthemowerdeckshutsdownandthe

temperaturewarninglightison,pushPTOknob

down,drivetoasafeatarea,movethethrottle

levertotheSlowposition,movethemotioncontrol

leversintotheneutrallockedposition,andengage

theparkingbrake.Allowtheenginetoidlefor

severalminuteswhileitcoolstoasafelevel.Stop

theengineandcheckthecoolingsystem;referto

CheckingtheCoolingSystemin,page.

ChargeIndicator

Illuminateswhenthesystemchargingcircuit

malfunctions.

OilPressureWarningLight

Theoilpressurewarninglightglowswhentheoil

pressureinenginedropsbelowasafelevel.Iflowoil

pressureeveroccurs,stoptheengineanddeterminethe

cause.Repairthedamagebeforestartingtheengine

again.

Height(RollBarUp)72inches(182.9cm)

Height(RollBarDown)48inches(121.9cm)

Weight,Model30360,

30360TE,30363,30363TE,

30363TC

Weight,Model30461and

30464

Weight,Model30462and

30465

2230lb(101 1kg)

2206lb(1000kg)

2151lb(975kg)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

FuelGauge

Thefuelgauge(Figure10)indicatesthequantityoffuel

remaininginthefueltanks.

Figure10

1.Fuelgauge

20

Page 21

Operation

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Thismachineproducessoundlevelsinexcess

of85dBAattheoperatorsearandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

AddingFuel

Useonlyclean,freshdieselfuelorbiodieselfuelswith

low(<500ppm)orultralow(<15ppm)sulfurcontent.

Theminimumcetaneratingshouldbe40.Purchase

fuelinquantitiesthatcanbeusedwithin180daysto

ensurefuelfreshness.

Fueltankcapacity:11.5USgallons(43.5l)

Usesummergradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwintergrade(No.1-Dor

No.1-D/2-Dblend)belowthattemperature.Useof

wintergradefuelatlowertemperaturesprovideslower

ashpointandcoldowcharacteristicswhichwillease

startingandreducefuellterplugging.

Useofsummergradefuelabove20°F(-7°C)will

contributetowardlongerfuelpumplifeandincreased

powercomparedtowintergradefuel.

Important:Donotusekeroseneorgasoline

insteadofdieselfuel.Failuretoobservethis

cautionwilldamagetheengine.

•Thebiodieselportionofthefuelmustmeet

specicationASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuelas

theymaybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblended.

•Contactyourdistributorifyouwishformore

informationonbiodiesel.

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerandkeep

itoutofthereachofchildren.Neverbuy

morethana30-daysupplyoffuel.

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepfuelawayfromeyesandskin.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

21

Page 22

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfromafuel

dispensernozzle.

•Ifafueldispensernozzlemustbeused,keep

thenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntil

fuelingiscomplete.

FillingtheFuelTank

Figure11

1.Bottomofthellerneck

5.Installthefueltankcapssecurely.Wipeupanyfuel

thatmayhavespilled.

Note:Ifpossible,llthefueltanksaftereachuse.

Thiswillminimizepossiblebuildupofcondensation

insidethefueltank.

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoChecking

OilLevelin,page

CheckingtheCoolingSystem

Beforeyoustarttheengineandusethemachine,check

thecoolingsystem;refertoCheckingtheCooling

Systemin,page

1.Parkthemachineonalevelsurface.

Important:Thefueltanksareconnected,but

thefueldoesnottransferquicklyfromonetank

totheother.Itisimportantwhenllingthat

youparkonalevelsurface.Ifyouparkonahill,

youmayinadvertentlyoverllthetanks.

2.Shuttheengineoffandsettheparkingbrake.

3.Cleanaroundeachfueltankcapandremovethecap.

Important:Donotopenthefueltankswhen

parkedonahill.Thefuelcouldspillout.

4.Addfueltobothfueltanks,untiltheleveliseven

withthebottomofthellerneck(Figure11).Do

notoverllthefueltanks.

CheckingtheHydraulic

System

Beforeyoustarttheengineandusethemachine,check

thehydraulicsystem;refertoCheckingtheHydraulic

Systemin,page

UsingtheRolloverProtection

System(ROPS)

Toavoidinjuryordeathfromrollover:keepthe

rollbarintheraisedlockedpositionanduse

theseatbelt.

Ensurethattherearpartoftheseatissecured

withtheseatlatch.

22

Page 23

Thereisnorolloverprotectionwhentherollbar

isinthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbaris

inthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearance

permits.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontact

them.

Important:Lowertherollbaronlywhen

absolutelynecessary.

1.Tolowertherollbar,removethehairpincotters,

pushtherollbarforwardagainstthesprings,and

removethetwopins(Figure12).

Figure13

3.Installthetwopinsandsecurethemwiththehairpin

cotterpins(Figure12).

Important:Ensurethattherearpartofthe

seatissecuredwiththeseatlatch.

4.Toraisetherollbar,removethehairpincotterpins

andremovethetwopins(Figure12).

5.Raisetherollbartotheuprightpositionandinstall

thetwopinsandsecurethemwiththehairpincotter

pins(Figure12).

Important:Alwaysusetheseatbeltwhentheroll

barisintheraisedandlockedposition.Donot

usetheseatbeltwhentherollbarisinthelowered

position.

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury.

Figure12

1.Rollbar3.Pin

2.Raisedposition4.Hairpincotter

2.Lowertherollbartothedownposition(Figure13).

23

Page 24

Operatingonwetgrassorsteepslopescan

causeslidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Thereisnorolloverprotectionwhentheroll

barisdown.

Alwayskeeptherollbarintheraisedandlocked

positionandusetheseatbelt.

Thismachineproducessoundlevelsinexcess

of85dBAattheoperatorsearandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,feetand

headisrecommended.

Readandfollowtherolloverprotection

instructionsandwarnings.

Toavoidlossofcontrolandpossibilityof

rollover:

•Donotoperateneardrop-offsornearwater.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthe

machineorleaveitunattended.

SettingtheParkingBrake

1.Movethemotioncontrollevers(Figure19)outto

theneutrallockedposition.

2.Pullupandbackontheparkingbrakelevertoset

theparkingbrake(Figure15).Theparkingbrake

levershouldstayrmlyintheengagedposition.

1.SafeZone

2.Usewalkbehindmower

and/orhandtrimmernear

drop-offsandwater.

Figure14

3.Water

Figure15

Theparkingbrakemaynotholdthemachine

parkedonaslopeandcouldcausepersonal

injuryorpropertydamage.

Donotparkonslopesunlessthewheelsare

chockedorblocked

24

Page 25

ReleasingtheParkingBrake

Pushforwardanddownontheparkingbrakeleverto

releasetheparkingbrake(Figure15).

5.MovethethrottlelevermidwaybetweentheFast

andSlowpositions(Figure17).

6.TurntheignitionkeyclockwisetotheRunposition

(Figure18).

Theglowpluglightwillturnonfor6seconds.

Figure18

1.Ignitionswitch

2.Off4.Start

3.Run/glowpug

Figure16

StartingandStoppingthe

Engine

StartingtheEngine

1.Raisetherollbarupandlockitintoplace,sitonthe

seat,andfastentheseatbelt.

2.Ensurethatthemotioncontrolsareintheneutral

lockedposition.

3.Settheparkingbrake;refertoSettingtheParking

Brake.

4.MovethePTO(powertakeoff)switchtotheoff

position(Figure17).

7.Aftertheglowplugindicatorlightgoesout,turn

thekeytotheStartposition.Whentheengines

startsreleasethekey.

Important:Usestartingcyclesofnomorethan

15secondsperminutetoavoidoverheatingthe

startermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthe

fuelsystemhasbeencompletelydrained.

8.LeavethethrottlemidwaybetweentheSlowand

Fastpositionsuntiltheengineandhydraulicsystem

warmup.

Important:Whenengineisstartedforthe

rsttime,orafteranengineoilchange,oran

overhauloftheengine,transmission,orwheel

motor,operatethemachinewiththethrottle

leverintheSlowpositioninboththeforward

andreversedirectionsforonetotwominutes.

AlsooperatetheliftleverandPTOleverto

ensureproperoperationofallparts.Thenshut

theengineoffandcheckuidlevels,checkfor

oilleaks,looseparts,andanyothernoticeable

malfunctions.

1.Ignitionswitch

2.Throttlecontrol

Figure17

Shuttheengineoffandwaitforallmoving

partstostopbeforecheckingforoilleaks,loose

parts,orothermalfunctions.

3.Glowpluglight

4.Powertakeoffswitch

(PTO)

25

Page 26

StoppingtheEngine

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedposition,settheparkingbrake,

andmovethethrottlelevertotheSlowposition.

2.Lettheengineidlefor60seconds.

3.TurntheignitionkeytotheOffposition(Figure18).

Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

•TogoStraightbackward,slowlypullthemotion

controlleversrearward(Figure19).

•Toturn,slowthemachinebypullingbackon

bothleversandthenpushforwardonthelever

ontheoppositesidefromwhichyouwantto

turn(Figure19).

•Tostop,pullthemotioncontrolleverstothe

neutralposition.

4.Removethekeybeforetransportingorstoring

machine.

Important:Makesuretoremovethekeyasthe

fuelpumporaccessoriesmayrunandcause

thebatterytolosecharge.

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileit

isunattended.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

DrivingtheMachine

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFastpositionforbest

performance.AlwaysoperateintheFastthrottle

positionwhenmowing.

Note:Thefartheryoumovethetractioncontrol

leversineitherdirection,thefasterthemachinewill

moveinthatdirection.

Themachinecanturnveryrapidly.Youmay

losecontrolofitandcausepersonalinjuryor

damagetomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrakein,page.

Note:Theenginewillkillifthetractioncontrol

leversaremovedwiththeparkingbrakeengaged.

2.Movetheleverstothecenter,unlockedposition.

3.Drivethemachineasfollows:

•Togostraightforward,slowlypushthemotion

controlleversforward(Figure19).

Figure19

1.Motioncontrol

lever-neutrallocked

position

2.Centerunlockposition

3.Forward

4.Backward

StoppingtheMachine

Tostopthemachine,movethetractioncontrollevers

toneutralandtothelockedposition,disengagethe

powertakeoff(PTO),movethethrottletotheSlow

position,andstoptheengine.

Settheparkingbrakewhenyouleavethemachine;refer

toSettingtheParkingBrakein,page.Rememberto

removethekeyfromtheignitionswitch.

26

Page 27

Childrenorbystandersmaybeinjuredifthey

attempttomoveoroperatethetractorwhileit

isunattended.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

OperatingtheMower

RaisingandLoweringtheMowerwith

theDeckLiftLever

Thedeckliftleverraisesandlowersthemowerdeck

(Figure20).Theenginemustberunningforyouto

usethislever.

RaisingandLoweringtheMowerwith

theDeckLiftPedal

Thefootoperatedliftpedalraisesandlowersthe

mowerdeck(Figure21).Theenginemustberunning

foryoutousethispedal.

Figure21

1.Footoperateddeckliftpedal

Figure20

1.Deckliftlever

•Tolowerthemowerdeck,pushtheleverforward.

•Toraisethemoverdeck,pulltheleverrearward.

Important:Donotcontinuetoholdthelever

backorforwardafterthemowerhasfullyraised

orlowered.Doingsowilldamagethehydraulic

system.

Note:Tolockthemowerdeckinaraisedposition,

raisethedeckpastthe6inch(15cm)position,remove

theheightofcutstoppin(refertoAdjustingthe

Height-of-Cut),andplacethepininthe6inch(15cm)

height-of-cutposition(Figure23).

•Pressdownonthetopofliftpedaltoraisethe

mowerdeck.

•Pressdownonthebottomofliftpedaltolowerthe

mowerdeck.

Important:Donotcontinuetoholdthepedal

downafterthemowerdeckhasbeenfullyraised

orlowered.Doingsowilldamagethehydraulic

system.

Note:Tolockthemowerdeckinaraisedposition,

raisethedeckpastthe6inch(15cm)position,remove

theheightofcutstoppin(refertoAdjustingthe

Height-of-Cut),andplacethepininthe6inch(15cm)

height-of-cutposition(Figure23).

EngagingthePowerTakeOff(PTO)

Thepowertakeoff(PTO)switchstartsandstopsthe

mowerbladesandsomepoweredattachments.

1.Iftheengineiscold,allowtheenginetowarmup5

to10minutesbeforeengagingthePTO.

2.Whileseatedintheseat,releasethepressureonthe

tractioncontrolleversandplacetheminneutral.

3.PulluponthePTOswitchtoengageit(Figure22).

27

Page 28

Figure22

1.PTOswitch

DisengagingthePTO

Todisengage,pushthePTOswitchtotheoffposition.

AdjustingtheHeight-of-Cut

Theheight-of-cutisadjustedfrom1to6inches

(2.5to15.8cm)in1/4inch(6mm)incrementsby

relocatingthestoppinintodifferentholelocations.

1.Withtheenginerunning,pullbackonthedeck

liftleveruntilthemowerdeckisfullyraisedand

releasetheleverimmediately(Figure23).

2.Toadjust,rotatethestoppinuntiltherollpin

initlinesupwiththeslotsintheholesinthe

height-of-cutbracketandremoveit(Figure23).

Figure23

1.Deckliftlever3.Heightofcutstop

2.Stoppin

4.Adjusttheanti-scalprollersandskidsasrequired.

3.Selectaholeintheheight-of-cutbracket

correspondingtotheheight-of-cutdesired,insert

thepin,androtateitdowntolockitinplace

(Figure23).

Note:Therearefourrowsofholepositions

(Figure23).Thetoprowgivesyoutheheightofcut

listedabovethepin.Thesecondrowdowngives

youtheheightlistedplus1/4inch(6mm).The

thirdrowdowngivesyoutheheightlistedplus1/2

inch(12mm).Thebottomrowgivesyoutheheight

listedplus3/4inch(18mm).Forthe6inch(15.8

cm)positionthereisonlyonehole,locatedinthe

secondrow .Thisdoesnotadd1/4inch(6mm)to

the6inch(15.8cm)position.

AdjustingtheSkids

Mounttheskidsinthelowerpositionwhenoperating

inheightofcutshigherthan2-1/2inches(64mm)and

inthehigherpositionwhenoperatinginheightofcuts

lowerthan2-1/2inches(64mm).

Note:OnGuardian

worn,youcanswitchtheskidtotheoppositesidesof

themower,ippingthemover.Thiswillallowyouto

usetheskidslongerbeforereplacingthem.

1.DisengagethePTO,movethemotioncontrol

leverstotheneutrallockedposition,andsetthe

parkingbrake.

2.MovethethrottlelevertotheSlowposition,stop

theengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Loosenthescrewatthefrontofeachskid(2skids

onGuardiandecksand1skidonside-discharge

decks).

®

mowers,whentheskidsbecome

28

Page 29

Figure24

1.Screw3.Skid

2.Flange-headbolt4.Nut

4.Removetheange-headboltsandnutsfromeach

skid.

5.Moveeachskidtothedesiredpositionandsecure

themwiththeange-headboltsandnuts.

Note:Onlyusethetoporcentersetsofholesto

adjusttheskids.Thebottomholesareusedwhen

switchingsidesonaGuardianmowerdeck,atwhich

timetheybecomethetopholesontheotherside

ofthemower.

6.Torquethescrewatthefrontofeachskidto80to

100in-lb(9to11N⋅m).

AdjustingtheRearAnti-Scalp

Rollers

Wheneveryouchangetheheight-of-cut,adjustthe

heightoftherearanti-scalprollers.

1.DisengagethePTO,movethemotioncontrol

leverstotheneutrallockedposition,andsetthe

parkingbrake.

Figure25

1.Flangenut

2.Bushing5.Bolt

3.Anti-scalproller

4.Spacer

4.Selectaholesotheanti-scalprollerispositioned

tothenearestcorrespondingheight-of-cutdesired

(Figure26).

Figure26

1.1-1/2inches(38mm)3.2-1/2inches(63mm)

2.2inches(51mm)4.3inches(76mm)and

higher

2.MovethethrottlelevertotheSlowposition,stop

theengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Afteradjustingtheheight-of-cut,adjusttherollers

byremovingtheangenut,bushing,spacer,and

bolt(Figure25).

5.Installtheangenutbushing,spacer,andbolt.

Torqueto40-45ft-lb(54-61N⋅m)(Figure25).

AdjustingtheRollers

Mounttherollersinthelowerpositionwhenoperating

inheightofcutshigherthan2-1/2inches(64mm)and

inthehigherpositionwhenoperatinginheightofcuts

lowerthan2-1/2inches(64mm).

1.DisengagethePTO,movethemotioncontrol

leverstotheneutrallockedpositionandsetthe

parkingbrake.

29

Page 30

2.MovethethrottlelevertotheSlowposition,stop

theengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Raisethefrontofthemachineandsupportiton

jackstands.

4.Removethefastenerssecuringeachrolleronyour

mowerdeckandmovetherollersupordownas

desired;refertoFigure27throughFigure31as

applicableforyourmower.

Figure29

GuardianMowerDecksOnly

1.Bolt3.Nut

2.Frontunder-deckroller4.Bracket

Figure27

AllMowerDecks

1.Frontroller

Figure28

GuardianMowerDecksOnly

1.Bolt4.Nut

2.Rearunder-deckroller5.Bracket

3.Spacer

2.Rollershaft

Figure30

Side-dischargeMowerDecksOnly

1.Bolt4.Nut

2.Chute-sideroller

3.Spacer

5.Bracket

30

Page 31

IfyourisefromtheseatwhenthePTOisengaged

thereisa1seconddelayandthentheenginestops.

TestingtheSafetyInterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafetyinterlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow,haveanAuthorizedService

Dealerrepairthesafetysystemimmediately .

1.Sittingontheseat,engagetheparkingbrakeand

movethePTOtoon.Trystartingtheengine;the

engineshouldnotcrank.

Figure31

Side-dischargeMowerDecksOnly

1.Bolt

2.Rollershaft

3.Under-deckroller(2)

4.Bracket

5.Installthefastenersasillustrated.

TheSafetyInterlockSystem

Ifthesafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Youaresittingontheseatortheparkingbrakeis

engaged.

•Thepowertakeoff(PTO)isdisengaged.

•Themotioncontrolleversareintheneutrallocked

position

•Theenginetemperatureisbelowthemaximum

operatingtemperature.

2.Sittingontheseat,engagetheparkingbrakeand

movethePTOtooff.Moveeithermotioncontrol

lever(outofneutrallockedposition).Trystarting

theengine;theengineshouldnotcrank.Repeatfor

othercontrollever.

3.Sittingontheseat,engagetheparkingbrake,move

thePTOswitchtooffandmovethemotioncontrol

leverstotheneutrallockedposition.Nowstartthe

engine.Whiletheengineisrunning,releasethe

parkingbrake,engagethePTOandriseslightly

fromtheseat;theengineshouldstopwithin2

seconds.

4.Withoutanoperatorontheseat,engagetheparking

brake,movethePTOswitchtooffandmovethe

motioncontrolleverstotheneutrallockedposition.

Nowstarttheengine.Whiletheengineisrunning,

centereithermotioncontrol;theengineshould

stopwithin2seconds.Repeatfortheothermotion

control.

5.Withoutanoperatorontheseat,disengagethe

parkingbrake,movethePTOswitchtooff,and

movethemotioncontrolleverstotheneutral

lockedposition.Trystartingtheengine;theengine

shouldnotcrank.

UsingtheSCMtoDiagnoseSystem

Problems

Themachineisequippedwithastandardcontrol

module(SCM)monitoringsystemthattracksthe

functionofvariouskeysystems.TheSCMislocated

undertherightcontrolpanel.Accessitthroughthe

sidepanelcover(Figure32).T oopenthesidepanel

cover,releasethe2latchesandpulloutonit.

Thesafetyinterlocksystemalsoisdesignedtostopthe

enginewhenthetractioncontrolsaremovedfromthe

neutrallockedpositionwiththeparkingbrakeengaged.

31

Page 32

Figure32

1.Sidepanelcover

2.Latches

OnthefaceoftheSCMare11LEDsthatilluminate

toindicatevarioussystemconditions.Sevenofthese

lightscanbeusedbytheoperatorforsystemdiagnosis.

RefertoFigure33foradescriptionofwhateach

lightmeans.FordetailsonusingtherestoftheSCM

functions,refertotheServiceManual,availablethrough

yourAuthorizedToroDistributor.

PositioningtheSeat

ChangingtheSeatPosition

Theseatcanmoveforwardandbackward.Positionthe

seatwhereyouhavethebestcontrolofthemachine

andaremostcomfortable.

1.Toadjust,movetheleversidewaystounlockthe

seat(Figure34).

Figure34

1.Backrestknob3.Lumbarsupport

adjustmentknob

2.Seatsuspensionknob4.Seatpositionadjustment

lever

Figure33

1.Hightemperatureshutdown—theenginetemperaturehas

exceededsafelevelsandtheenginehasbeenshutdown.

Checkthecoolingsystem.

2.Hightemperaturewarning—theenginetemperatureis

approachingunsafelevelsandthemowerdeckhasbeen

shutdown.Checkthecoolingsystem.

3.Operatorisintheseat

4.ThePTOisOn

5.Theparkingbrakeisnotengaged

6.ControlsareinNeutral

7.TheSCMisreceivingpowerandisoperational

2.Slidetheseattothedesiredpositionandrelease

levertolockinposition.

3.Verifythattheseathaslockedintoplaceby

attemptingtomoveitbackandforth.

ChangingtheSeatSuspension

Theseatcanbeadjustedtoprovideasmoothand

comfortableride.Positiontheseatwhereyouaremost

comfortable.

Withoutsittingontheseat,turntheknobinfronteither

directiontoprovidethebestcomfort(Figure34).

32

Page 33

Figure35

1.Seatsuspensionknob2.Operatorweightsetting

ChangingtheBackPosition

Thebackoftheseatcanbeadjustedtoprovidea

comfortableride.Positionthebackoftheseatwhereit

ismostcomfortable.

Toadjustit,turntheknob,undertheright-sidearm

rest,ineitherdirectiontoprovidethebestcomfort

(Figure34).

ChangingtheLumbarSupport

Thebackoftheseatcanbeadjustedtoprovidea

customizedlumbarsupportforyourlowerback.

Figure36

1.Seatlatch

PushingtheMachinebyHand

Ifthemachinebreaks,runsoutoffuel,etc.youmay

needtopushit.T odoso,yourstneedtoopenthe

hydraulicby-passvalves.

Toadjustit,turntheknob,undertheleft-sidearm

rest,ineitherdirectiontoprovidethebestcomfort

(Figure34).

UnlatchingtheSeat

Toaccessthehydraulicandothersystemsunderthe

seat,youneedtounlatchtheseatandswingitforward.

1.Usetheseatpositionadjustmentlevertoslidethe

seatallthewayforward.

2.Pushoneoftheseatlatches,locatedbehindandto

thesidesoftheseat,rearwardtounlatchtheseat

andpullforwardonthetopoftheseat(Figure36).

Important:Alwayspushthemachinebyhand.

Nevertowthemachinebecausehydraulicdamage

mayoccur.

PushingtheMachine

1.Disengagethepowertakeoff(PTO)andturn

theignitionkeytooff.Movetheleverstothe

neutrallockedpositionandapplytheparkingbrake.

Removethekey.

2.Lifttheseat.

3.Rotateeachby-passvalvecounterclockwise1turn

(Figure37).

Thisallowshydraulicuidtoby-passthepump

enablingthewheelstoturn.

Important:Donotrotatetheby-passvalves

morethan1turn.Thispreventsvalvesfrom

comingoutofthebodyandcausinguidto

runout.

33

Page 34

Figure37

1.Rightby-passvalve

2.Leftby-passvalve

4.Disengagetheparkingbrakebeforepushing.

ChangingtoMachineOperation

Rotateeachby-passvalveclockwise1turnandhand

tightenthem(torqueofapproximately71in-lb(8

N⋅m))(Figure37).

Note:Donotovertightentheby-passvalves.

Themachinewillnotdriveunlessby-passvalvesare

turnedin.

slope.Thiswillminimizetherampangle.Thetraileror

truckshouldbeaslevelaspossible.

Important:Donotattempttoturntheunitwhile

ontheramp;youmaylosecontrolanddriveoff

theside.

Avoidsuddenaccelerationwhendrivinguparampand

suddendecelerationwhenbackingdownaramp.Both

maneuverscancausetheunittotipbackward.

Loadingaunitontoatrailerortruckincreases

thepossibilityofbackwardtip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatingaunit

onaramp.

•Useonlyasingle,fullwidthramp;Donot

useindividualrampsforeachsideofthe

unit.

•Ifindividualrampsmustbeused,use

enoughrampstocreateanunbrokenramp

surfacewiderthantheunit.

•Donotexceeda15degreeanglebetween

rampandgroundorbetweenrampand

trailerortruck.

•Avoidsuddenaccelerationwhiledrivingunit

uparamptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebacking

unitdownaramptoavoidtippingbackward.

LoadingMachines

Useextremecautionwhenloadingunitsontrailersor

trucks.Onefullwidthrampthatiswideenoughto

extendbeyondthereartiresisrecommendedinsteadof

individualrampsforeachsideoftheunit(Figure38).

Thelowerrearsectionofthetractorframeextends

backbetweentherearwheelsandservesasastopfor

tippingbackward.Havingafullwidthrampprovides

asurfacefortheframememberstocontactifthe

unitstartstotipbackward.Ifitisnotpossibletouse

onefullwidthramp,useenoughindividualrampsto

simulateafullwidthcontinuousramp.

Therampshouldbelongenoughsothattheangles

donotexceed15degrees(Figure38).Asteeperangle

maycausemowercomponentstogetcaughtastheunit

movesfromramptotrailerortruck.Steeperangles

mayalsocausetheunittotipbackward.Ifloadingon

ornearaslope,positionthetrailerortrucksoitison

thedownsideoftheslopeandtherampextendsupthe

34

Page 35

Figure38

1.Trailer3.Notgreaterthan

15degrees

2.Fullwidthramp4.Fullwidthramp—sideview

TransportingMachines

1.Fronttie-down(leftside

shown)

OperatingTips

Figure39

2.Reartie-downs

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow

movingvehicleemblemisdangerousandcan

leadtoaccidentscausingpersonalinjury.

Donotdrivemachineonapublicstreetor

roadwaywithoutsigns,lights,and/ormarkings

requiredbylocalregulations.

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarylightingandmarkingasrequiredbylaw .

Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyouorbystanders

avoidinjury.

Totransportthemachine:

•Ensurethatyourvehicle,hitch,safetychains,and

trailerareadequatefortheloadyouarepullingand

thattheymeetalllocaltrafcregulationsforyour

area.

•Lockthebrakeandblockthewheels.

•Securelyfastenthemachinetothetrailerortruck

withstraps,chains,cable,orropesasrequiredby

localtrafcregulationsinyourarea(Figure39).

FastThrottleSetting/GroundSpeed

Tomaintainenoughpowerforthemachineanddeck

whilemowing,operatetheengineatthefastthrottle

positionandadjustyourgroundspeedforconditions.

Agoodruletofollowis:decreasegroundspeedas

theloadonthecuttingbladesincreases;andincrease

groundspeedasloadonthebladesdecreases.

MowingDirection

Alternatemowingdirectiontoavoidmakingrutsinthe

turfovertime.Thisalsohelpsdisperseclippingswhich

enhancesdecompositionandfertilization.

CuttingSpeed

Toimprovecutquality,useaslowergroundspeedin

certainconditions.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthe

moweryoupreviouslyused,raisethecuttingheightto

ensurethatuneventurfisnotcuttooshort.

35

Page 36

SelecttheProperHeight-of-CutSetting

toSuitConditions

Removeapproximately1inch(25mm)ornomorethan

1/3ofthegrassbladewhencutting.Inexceptionally

lushanddensegrass,youmayhavetoslowdownthe

forwardspeedand/orraisetheheight-of-cuttothe

nexthighersetting.

Important:Ifcuttingmorethat1/3ofthegrass

bladeoff,orinsparselonggrassordryconditions,

theuseofatsailbladesisrecommendedto

reduceair-bornechaff,debris,anddeckdrive

componentstrain.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raise

thecuttingheighthigherthanusualandcutthegrassat

thissetting.Thencutthegrassagainusingthelower,

normalsetting.

KeeptheMowerClean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildupinside

themower,cuttingqualitywilleventuallybecome

unsatisfactory.

Toreducetheriskofrehazard,keeptheengine,

mufer,batterycompartment,parkingbrake,cutting

units,andfuelstoragecompartmentfreeofgrass,

leaves,orexcessivegrease.Cleanupanyspilledoilor

fuel.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.Checktheblades

dailyforsharpness,andforanywearordamage.

Sharpenthebladesasnecessary.Ifabladeisdamaged

orworn,replaceitimmediatelywithagenuineToro

replacementblade.RefertoServicingtheCutting

Bladesin,pageformoreinformationoridentifying

bladeproblemsandsharpeningtheblades.

36

Page 37

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst10hours

Aftertherst50hours

Aftertherst200hours

Beforeeachuseordaily

Every50hours

Every150hours

Every200hours

MaintenanceProcedure

•Checkthealternatorbelttension.

•T orquetheframemountingbolts.

•T orquewheellugnuts.

•Changethemowerdeckgearboxlubricant

•Changetheengineoilandlter.

•Changethehydraulicoilandlter.

•T estthesafetysystem.

•Checktheengineoillevel.

•Checktheenginecoolantlevel.

•Cleantheradiatorwithcompressedair(donotusewater)

•Checkthehydraulicuidlevel.

•Checkthemowerblades.

•Cleanthemowerdeck.

•Greasethebearingandbushinggreasettings.

•Checkbatterycableconnections.

•Checkthetirepressure.

•Checktheconditionofthebladedrivebeltsonthemowerdeck.

•Checkthelubricantinthemowerdeckgearbox.

•Changetheengineoilandlter.

•Inspectcoolingsystemhosesandseals.Replacethemifcrackedortorn.

•Checkthealternatorbelttension.

•T orquewheellugnuts.

•Changethemowerdeckgearboxlubricant

Every400hours

Every800hours

Every1,500hours

Every2years

Important:Refertoyour

•Servicetheaircleaner.

•Replacethefuelltercanister.

•Checkthefuellinesandconnections.

•Changethehydraulicoilandlter.

•Inspectenginevalveclearance.RefertoyourEngineOperator’sManual.

•Replacemovinghoses

•Drainandcleanthefueltank.

•Flushandreplacecoolingsystemuid.

Engine Operator’ s Man ual

foradditionalmaintenanceprocedures.Adetailed

ServiceManualisalsoavailableforpurchasefromyourAuthorizedT oroDistributor.

37

Page 38

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

CheckSafetyInterlock

Operation

CheckGrassDeectorin

DownPosition(ifapplicable)

CheckParkingBrake

Operation

CheckFuelLevel

CheckHydraulicOilLevel

CheckEngineOilLevel

CheckCoolingSystemFluid

Level

CheckDrainWater/Fuel

Separator

CheckAirFilterRestriction

Indicator

CheckRadiator&Screenfor

Debris

CheckUnusualEngine

Noises

CheckUnusualOperating

Noises

CheckHydraulicHosesfor

Damage

CheckFluidLeaks

CheckTirePressure

CheckInstrumentOperation

CheckConditionofBlades

LubricateAllGreaseFittings

Touch-upDamagedPaint

1.Checkglowplugandinjectornozzles,ifhardstarting,excesssmokeorroughrunningisnoted.

3

1

2

Sat.Sun.

2.Immediatelyaftereverywashing,regardlessoftheintervallisted.

3.Ifindicatorshowsred

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Information

38

Page 39

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

Figure40

ServiceIntervalChart

Lubrication

GreasingtheBearingsand

Bushings

ServiceInterval:Every50hours

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBase

Grease.Ifthemachineisoperatedundernormal

conditions,lubricateallbearingsandbushingsafter

every50hoursofoperation.Bearingsandbushings

mustbelubricateddailywhenoperatingconditionsare

extremelydustyanddirty.Dustyanddirtyoperating

conditionscouldcausedirttogetintothebearings

andbushings,resultinginacceleratedwear.Lubricate

thegreasettingsimmediatelyaftereverywashing,

regardlessofintervalspecied.

1.Wipethegreasettingscleansoforeignmatter

cannotbeforcedintothebearingorbushing.

2.Pumpgreaseintothettings.

Important:Thettingsontheaxlesofthecaster

wheelsarenotillustrated.Ensurethatyougrease

thesettingsaswell.

3.Wipeoffexcessgrease.

Figure41andFigure42illustratethelocationsofthe

greasettings.

39

Page 40

Figure41

40

Page 41

Figure42

Note:Bearinglifecanbenegativelyaffectedby

improperwashdownprocedures.Donotwashdownthe

unitwhenitisstillhotandavoiddirectinghigh-pressure

orhighvolumesprayatthebearingsorseals.

ServicingtheMowerDeck

GearBoxLubricant

ThegearboxisdesignedtooperatewithSAE80-90gear

lube.Althoughthegearboxisshippedwithlubricant

fromthefactory,checkthelevelbeforeoperatingthe

cuttingunitforthersttimeandevery150operating

hoursthereafter.Changethelubricantinthegearbox

every400operatinghours.

CheckingtheMowerDeckGearBox

Lubricant

ServiceInterval:Every150hours

1.Positionthemachineandcuttingunitonalevel

surface.

2.Lowerthemowerdecktothe1inch(2.5cm)

height-of-cut.

3.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

4.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey ,andwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

41

Page 42

5.Liftthefootrest,exposingthetopofthemower

deck.

6.Removethedipstick/llplugfromthetopofthe

gearbox(Figure43)andmakesurethatthelubricant

isbetweenthemarksonthedipstick.

Figure43

1.Fillpluganddipstick

8.Replacethedrainplug.

9.Addenoughlubricant,approximately12oz.(283

ml),untilthelevelisbetweenthemarksonthe

dipstick.

Note:Donotoverllorthegearboxmaybe

damaged.

7.Ifthelubricantlevelislow,addenoughlubricant

untilthelevelisbetweenthemarksonthedipstick.

Note:Donotoverllorthegearboxmaybe

damaged.

ChangingtheMowerDeckGearBox

Lubricant

ServiceInterval:Aftertherst50hours

Every400hours

1.Positionthemachineandcuttingunitonalevel

surface.

2.Lowerthemowerdecktothe1inch(2.5cm)

height-of-cut.

3.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

4.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey ,andwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

5.Liftthefootrest,exposingthetopofthemower

deck.

6.Removethedipstick/llplugfromthetopofthe

gearbox(Figure43).

7.Placeafunnelanddrainpanunderthedrainplug

locatedunderthefrontofthegearboxandremove

theplug,drainingthelubricantintothepan.

42

Page 43

EngineMaintenance

G004501

123456

7

AirCleanerMaintenance

Important:Avoidusinghighpressureairwhich

couldforcedirtthroughthelterintotheintake

tract.

4.Removeandreplacetheprimarylter(Figure44).

•Checktheaircleanerbodyfordamagewhichcould

possiblycauseanairleak.Replaceadamagedair

cleanerbody.Checkthewholecleanairintake

systemforleaks,damage,orloosehoseclamps.

•Servicetheaircleanerlterwhentheaircleaner

indicator(Figure44)showsredorevery400

hours(morefrequentlyinextremelydustyordirty

conditions).Donotoverservicetheairlter.

Figure44

1.Aircleanercover5.Aircleanerindicator

2.Gasket

3.Filter7.Rubberoutletvalve

4.Aircleanerbody

6.Aircleanerlatch

Important:Donotcleantheusedelementto