Toro Groundsmaster 360 Series, 30456, 330457, Groundsmaster 7200 Series, 30481 Operator's Manual

Page 1

FormNo.3424-939RevA

60in,62in,or72inRotaryMower

Groundsmaster

®

360Seriesand7200Series

TractionUnit

ModelNo.30353—SerialNo.403373001andUp

ModelNo.30456—SerialNo.403373001andUp

ModelNo.30457—SerialNo.403373001andUp

ModelNo.30481—SerialNo.403373001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3424-939*A

Page 2

Model30456complieswithallrelevantEuropean

directiveswhentheCEKit(ModelNo.30658)is

installedonthecuttingunit.Modelnumber30353

requiresCEKitmodelnumber30685;30457requires

CEKit30683;30481requiresCEKit30679.For

additionaldetails,seetheseparateproductspecic

DeclarationofConformity(DOC)sheet.

g000502

Figure1

1.Safety-alertsymbol

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thisrotary-bladelawncuttingdeckismounted

toaride-onmachineandisintendedtobeused

byprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrass

onwell-maintainedlawnsinparks,sportselds,and

oncommercialgrounds.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely

Visitwww.T oro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................3

GeneralSafety...................................................3

SafeOperatingPractices....................................3

SafetyandInstructionalDecals..........................4

Setup........................................................................6

RemovingtheExistingCuttingUnit(If

Equipped).......................................................6

InstallingtheNewCuttingUnit............................7

LevelingtheCuttingUnit.....................................7

Operation..................................................................8

Adjustments........................................................8

OperatingTips.................................................12

Maintenance...........................................................13

RecommendedMaintenanceSchedule(s)...........14

DailyMaintenanceChecklist.............................14

Lubrication........................................................15

ReplacingtheBladeDriveBelts........................17

ServicingtheCuttingBlades.............................17

CleaningUndertheCuttingUnit........................20

Storage...................................................................21

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Themodel

andserialnumbersarestampedintoaplatethat

ismountedonthecuttingunithousing.Writethe

numbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure1),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Safety

Thismachinehasbeendesignedinaccordancewith

ANSIB71.4-2017andENISO5395:2013.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersandpetsasafedistanceawayfrom

themachine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Parkthemachineonalevelsurface,lowerthe

cuttingunits,disengagethedrives,engagethe

parkingbrake(ifprovided),shutofftheengine,

andremovethekeybeforeleavingtheoperator's

positionforanyreason.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

,which

•Wearappropriateclothing,includingeye

protection;substantial,slip-resistantfootwear;

longpants,andhearingprotection.Tiebacklong

hairanddonotwearloosejewelry .

•Inspecttheareawheretheequipmentistobe

usedandremoveallobjects,suchasrocks,toys,

andwire,thatthemachinecanthrow.

•Checkthatoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Stopthemachine,removethekey ,andwaitfor

allmovingpartstostopbeforeinspectingthe

attachmentafterstrikinganobjectorifthereis

anabnormalvibrationinthemachine.Makeall

necessaryrepairsbeforeresumingoperation.

•Keepyourhandsandfeetawayfromthecutting

units.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrowntowardyouor

bystanders,resultinginseriouspersonalinjuryor

death.

•Inspectthebladeperiodicallyforwearordamage.

•Usecarewhencheckingtheblades.Wrapthe

bladesorweargloves,andusecautionwhen

servicingtheblades.Onlyreplaceorsharpenthe

blades;neverstraightenorweldthem.

•Onmulti-bladedmachines,takecareasrotating1

bladecancauseotherbladestorotate.

•Checktheblademountingboltsfrequentlytobe

surethattheyaretightenedtospecication.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthisOperator’sManual.

SafeOperatingPractices

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

3

Page 4

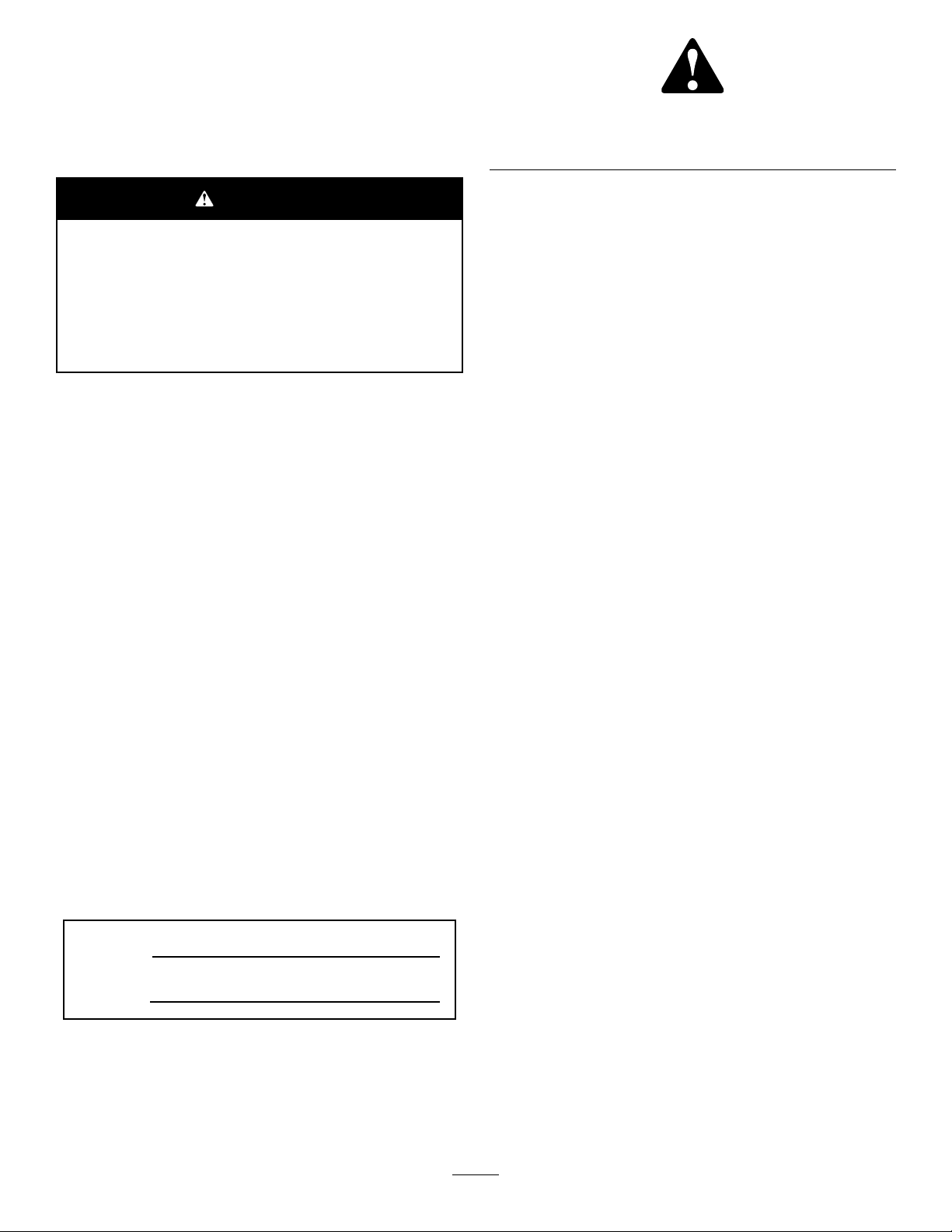

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

93-6687

decal93-6687

1.Donotstephere.

93–6696

1.Storedenergyhazard—readtheOperator'sManual.

93-6697

1.ReadtheOperator's

Manual.

2.AddSAE80w-90(API

GL-5)oilevery50hours.

decal93-7818

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N-m(85-110ft-lb).

decal93-6696

decal107-2908

107-2908

1.Thrownobjecthazard—keepbystandersasafedistance

decal93-6697

fromthemachine.

2.Thrownobjecthazard—donotoperatethemowerwiththe

deectoruporremoved,keepthedeectorinplace.

3.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

1.Removethekeyandreadthe

Operator'sManualbeforeservicingor

performingmaintenance.

107-2916

2.Thrownobjecthazard—donotoperate

themowerwiththedeectorupor

removed;keepthedeectorinplace;

keepbystandersasafedistanceaway

fromthemachine.

4

decal107-2916

3.Cutting/dismembermenthazardof

handorfoot,mowerblade—stayaway

frommovingparts.

Page 5

112-1461

1.Beltrouting

117–4979

1.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

decal133-8061

133-8061

decal112-1461

decal117-4979

120-6604

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Cutting/dismembermenthazardofhand,mower

blade—stayawayfrommovingparts,keepallguardsand

shieldsinplace.

3.Cutting/dismembermenthazardoffoot,mowerblade—stay

awayfrommovingparts,keepallguardsandshieldsin

place.

decal120-6604

5

Page 6

Setup

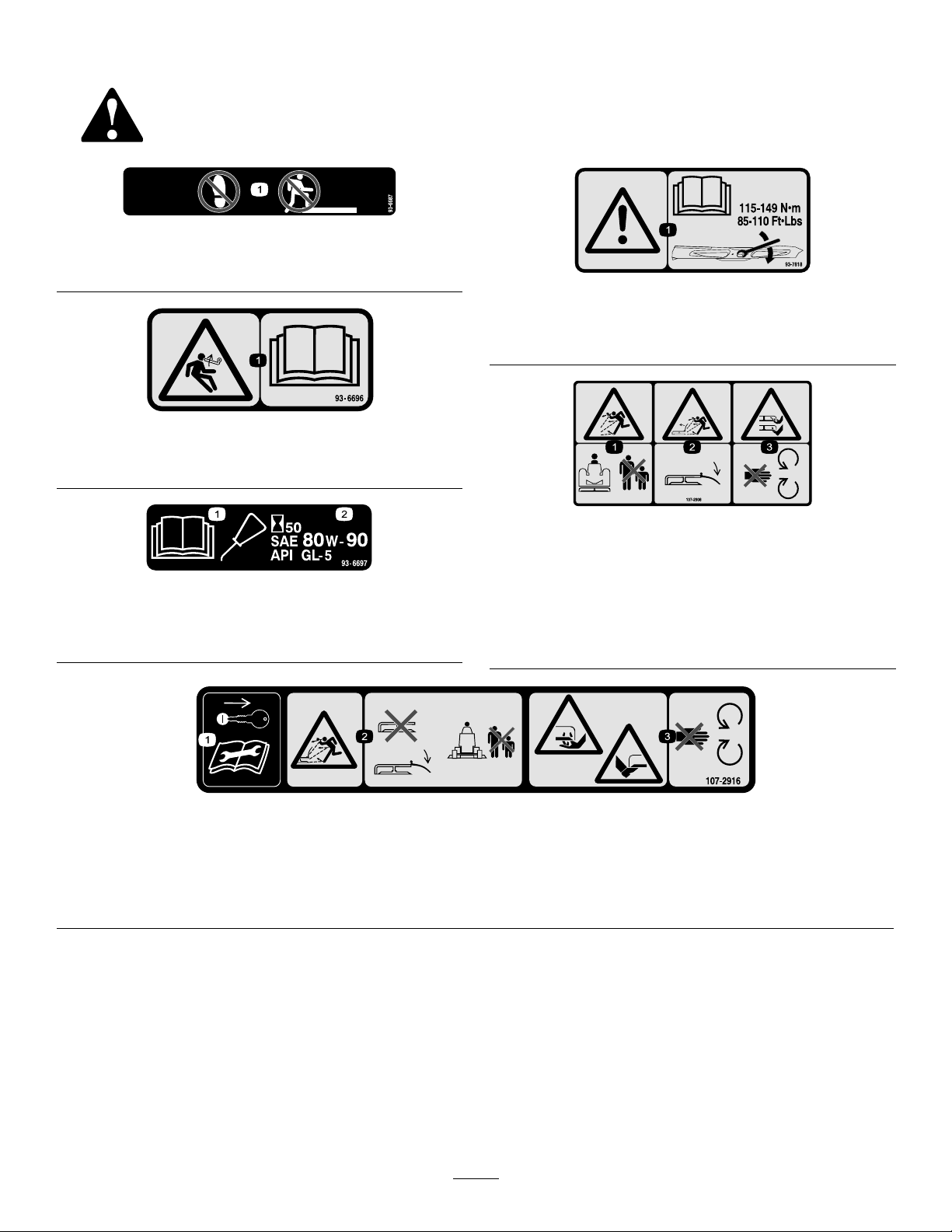

B.Carefullyslidetheretainerpinfromthe

carrierframeandthepulllink(Figure2).

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

RemovingtheExisting

CuttingUnit(IfEquipped)

1.Parkthemachineonalevelsurfacewiththe

cuttingunitinthefullyraisedposition.Shut

offtheengine,engagetheparkingbrake,and

removethekey.

Note:Whenthecuttingunitisintheraised

position,thepull-linktorsionspringtension

(Figure2)isreduced,makingitmucheasierto

disconnectthepulllinksfromthemachine.

3.NotethelocationoftheHOCpinintheHOC

bracketforassemblypurposes(Figure3).

RemovetheHOCpinfromtheHOCbracket.

g017278

Figure3

1.HOCpin2.HOCbracket

Figure2

1.Pulllink(cuttingunit

raised)

2.Shoulderscrew6.Clevispin

3.Retainerpin7.Adjustmentclevis

4.Torsionspring

2.Disconnectthepulllinkfromeachsideofthe

machine(Figure2).

5.Cuttingunitliftchain

CAUTION

Thepulllinktorsionspringsmaycause

somerotationofthepulllinksduringthe

removalprocess.

Usecautionwhendisconnectingthepull

links.

4.Starttheengine,lowerthecuttingunittothe

ground,shutofftheengine,andremovethekey .

Note:Loweringthecuttingunitontofurniture

dolliesaidsinremovingthecuttingunit.

g017279

WARNING

IftheengineisstartedandthePTO

driveshaftisallowedtorotate,serious

personalinjuryandmachinedamage

couldresult.

•Whenthedriveshaftisdisconnected

fromthecuttingunit,donotstartthe

engineandengagethePTOswitch.

•Ifthedriveshaftisdisconnectedfrom

themower,removefuseF1(15A)from

thefuseblocktopreventunintentional

engagementofthePTOclutch.

5.DisconnecttheendyokeofthePTOdriveshaft

fromthecuttingunitgearboxshaft:

A.Removetherollpinfromtheendyokeand

thegearboxshaft(Figure4).

A.Removetheshoulderscrewthatsecures

theretainerpintothecarrierframe(Figure

2).

6

Page 7

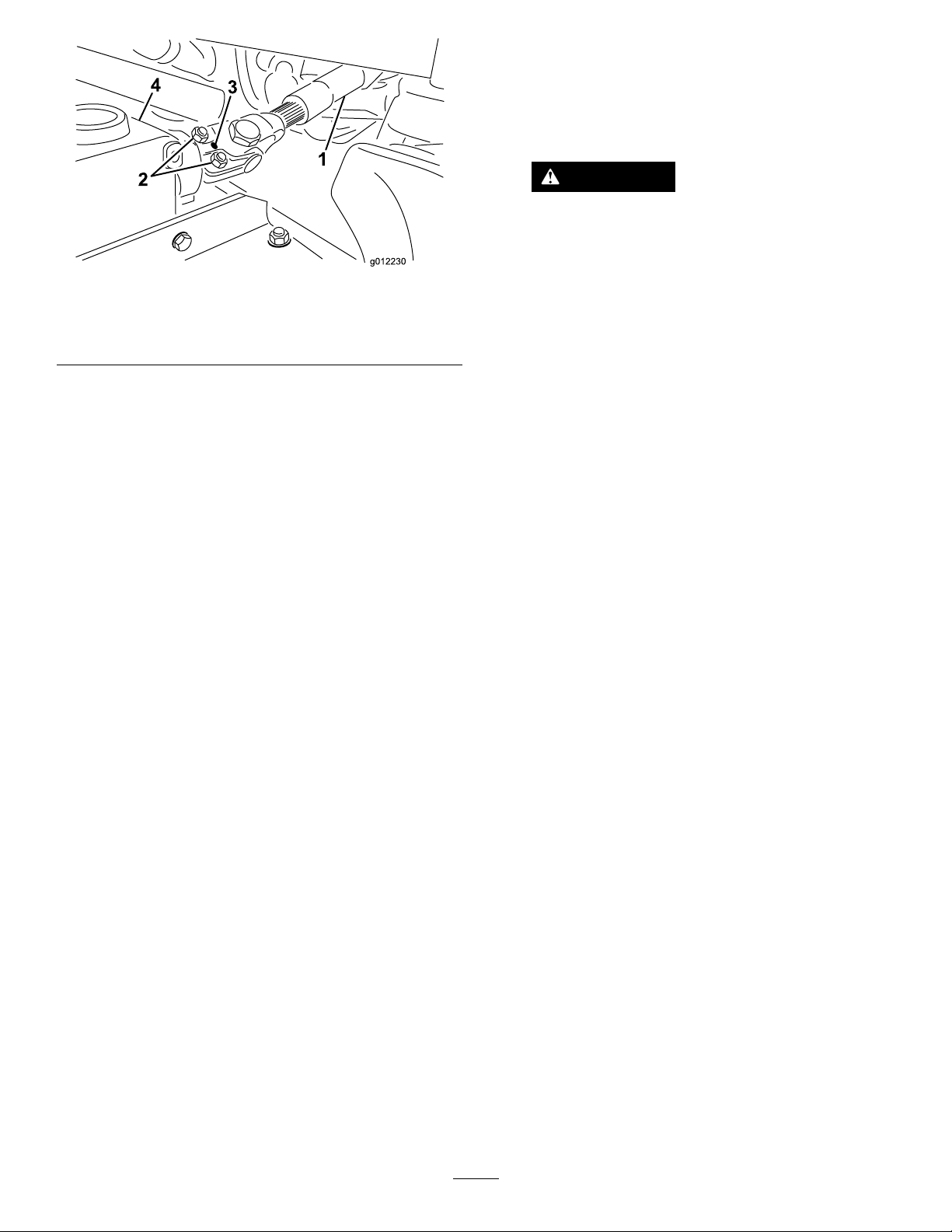

Figure4

1.Driveshaft

2.Capscrewsandlocknuts4.Gearbox

B.Loosenthe2capscrewsandlocknuts

(Figure4).

C.Slidethedriveshaftendyokefromthe

gearboxshaft.

3.Rollpin

Note:Raiseandtiethedriveshafttothe

frame.

6.Removethe4ringpinsandclevispinsthat

securetheliftchainstotheadjustmentclevises

onthemower(Figure2).

7.Slidethecuttingunitawayfromthemachine.

Note:Y oumayhavetoelevatethefrontofthe

tractionunittomovethecuttingunitawayfrom

themachine.

4.Starttheengineandfullyraisethecuttingunit.

Shutofftheengineandremovethekeyfromthe

ignitionswitch.

Note:Placeawoodblockorsimilarshimunder

eachlinktoholditintheraisedposition.

CAUTION

Thepulllinktorsionspringsmaycause

somerotationofthepulllinksduring

installation.

g012230

Usecautionwhenconnectingthepull

linkstothemachine.

5.Alignthepulllinktothecarrierframeandattach

thelinkwiththeretainerpin(Figure2).Secure

theretainerpintotheframewiththeshoulder

screw(Figure2).

6.InstalltheHOCpinintotheHOCbracketatthe

desiredheightofcut(Figure3).

7.LubricatethePTOdriveshaftgreasettings.

8.InstalltheF1fuse(15A)intothefuseblock.

LevelingtheCuttingUnit

LevelingSide-to-Side

1.Positionthemachineonalevelsurfaceonthe

shopoorandlowerthecuttingunit.

InstallingtheNewCutting

Unit

1.Slidethenewcuttingunitunderthecarrierframe

ofthemachine.

2.Installthe4clevispinsandringpinstosecure

thecuttingunitliftchainstotheadjustment

clevisesonthemower(Figure2).

3.ConnecttheendyokeofthePTOdriveshaftto

thecuttingunitgearbox;refertothefollowing

steps:

A.Alignthesplineandrollpinholesofthe

driveshaftyokewiththegearboxshaft.

B.SlidethePTOdriveshaftendyokeontothe

gearboxshaft.

C.SecuretheendyokeofthePTOdriveshaft

tothegearboxshaftwiththerollpin(Figure

4).

D.Tightenthelocknutstosecuretheendyoke

tothegearboxshaft(Figure4).T orquethe

locknutsto20to25N∙m(175to225in-lb).

2.MovethethrottlelevertotheSLOWposition,

shutofftheengine,engagetheparkingbrake,

andremovethekey.

3.Setthecuttingunittoa127mm(5inch)height

ofcut.

4.Checkandadjustthefrontandreartraction-unit

tirepressure;refertoOperator’sManualfor

pressurespecications.

5.Checkforbentblades;refertoCheckingfor

BentBlades(page18).

6.Rotatethebladeoneachspindleuntiltheends

faceforwardandbackward.

7.Measurefromtheoortothefronttipofthe

cuttingedge.

8.Adjustthejamnutssecuringthemower

yokes/chainstothemoweruntilthecuttingunit

islevel(Figure5).

7

Page 8

Figure5

1.Chain

2.Yoke4.Mower

3.Jamnut

LevelingFront-to-Back

Cuttingunitpitchisthedifferenceinheightofcutfrom

thefront-to-backofthebladeplane.Abladepitch

ofapproximately8to11mm(5/16to7/16inch)is

recommended(i.e.,thebackofthebladeplaneis8to

11mm(5/16to7/16inch)higherthanthefront).

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Adjustments

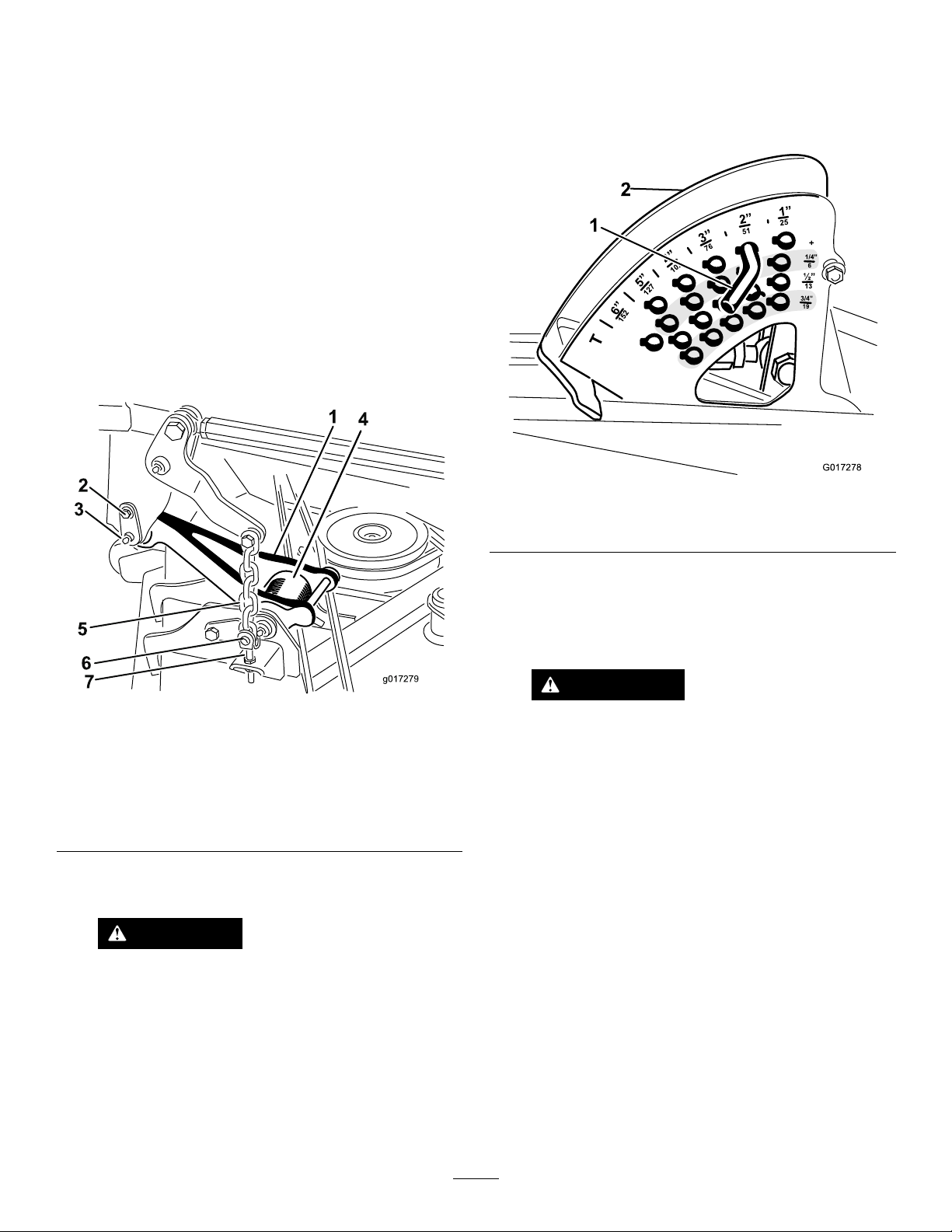

AdjustingtheHeight-of-Cut

Theheight-of-cutisadjustedfrom2.5to15.8cm(1to

6inches)in6mm(1/4inch)incrementsbyrelocating

thestoppinintodifferentholelocations.

1.Withtheenginerunning,pushbackonthe

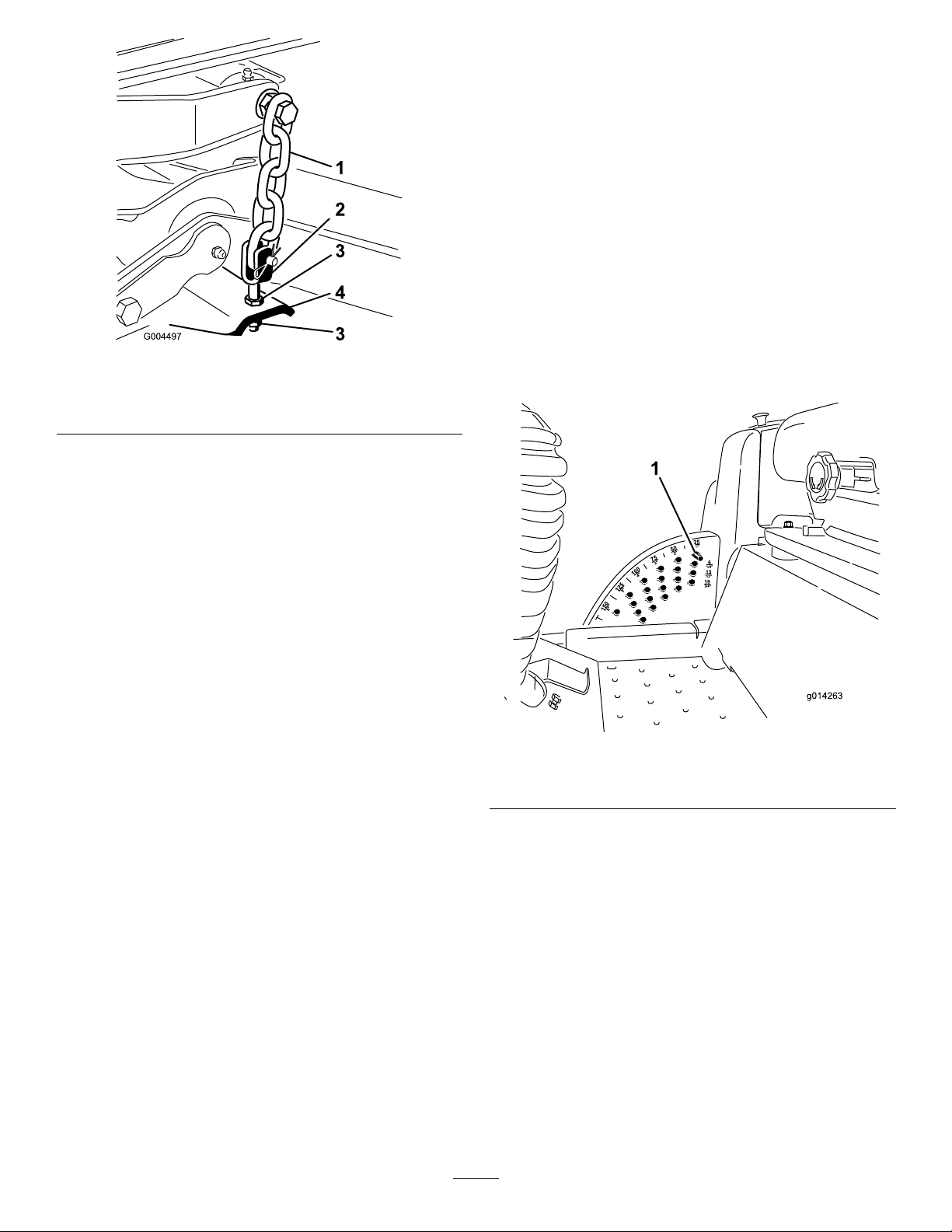

g004497

cuttingunitliftswitchuntilthecuttingunitisfully

raisedandreleasetheswitchimmediately

(Figure6).

1.Setthecuttingunittothedesiredheight-of-cut,

movethethrottlelevertotheSLOWposition,

shutofftheengine,engagetheparkingbrake,

andremovethekey.

2.Rotatethecenterbladesothatitpointsstraight

forward.

3.Usingashortruler,measurefromtheoorto

thefronttipoftheblade.

4.Rotatethesamebladetiptotherearand

measurefromtheoortothetipofthebladeat

therearofthecuttingunit.

5.Subtractthefrontdimensionfromtherear

dimensiontocalculatethebladepitch.

6.Adjustthejamnutssecuringtherearmower

yokes/chains(Figure5)toraisetherearofthe

cuttingunitsothatthebladepitchissetto8to

11mm(5/16to7/16inch).

g014263

Figure6

1.Stoppin

2.Toadjusttheheightofcut,rotatethestoppin

untilthenubonitlinesupwiththeslotsinthe

holesintheheight-of-cutbracketandremoveit

(Figure6).

3.Selectaholeintheheight-of-cutbracket

correspondingtotheheight-of-cutdesired,insert

thepin,androtateitdowntolockitinplace

(Figure6).

Note:Thereare4rowsofholepositions

(Figure6).Thetoprowgivesyoutheheightof

cutlistedabovethepin.Thesecondrowdown

givesyoutheheightlistedplus6mm(1/4inch).

Thethirdrowdowngivesyoutheheightlisted

plus12mm(1/2inch).Thebottomrowgives

youtheheightlistedplus18mm(3/4inch).For

the15.8cm(6inch)positionthereisonly1hole,

8

Page 9

locatedinthesecondrow.Thisdoesnotadd6

mm(1/4inch)tothe15.8cm(6inch)position.

4.Adjusttheanti-scalprollersandskidsas

required.

AdjustingtheRearAnti-Scalp Rollers

Wheneveryouchangetheheight-of-cut,adjustthe

heightoftherearanti-scalprollers.

AdjustingtheSkid(s)

Mounttheskidsinthelowerpositionwhenoperating

inheightofcutshigherthan64mm(2-1/2inches)and

inthehigherpositionwhenoperatinginheightofcuts

lowerthan64mm(2-1/2inches).

Note:OnGuardian

worn,youcanswitchtheskidtotheoppositesidesof

thecuttingunit,ippingthemover.Thiswillallowyou

tousetheskidslongerbeforereplacingthem.

1.DisengagethePTOandengagetheparking

brake.

2.MovethethrottlelevertotheSLOWposition,

shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Loosenthescrewatthefrontofeachskid.

Thereare2skidsonGuardianmowersand1

skidonside-dischargecuttingunits(Figure7).

®

mowers,whentheskidsbecome

1.DisengagethePTO,releasethetractionpedal,

andengagetheparkingbrake.

2.MovethethrottlelevertotheSLOWposition,

shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Afteradjustingtheheight-of-cut,adjustthe

rollersbyremovingtheangenut,bushing,

spacer,andbolt(Figure8).

Figure7

1.Screw3.Skid

2.Flange-headbolt4.Nut

4.Removetheange-headboltsandnutsfrom

eachskid.

5.Moveeachskidtothedesiredpositionand

securethemwiththeange-headboltsandnuts.

Note:Onlyusethetoporcentersetsofholes

toadjusttheskids.Thebottomholesareused

whenswitchingsidesonaGuardianmower,at

whichtimetheybecomethetopholesonthe

othersideofthecuttingunit.

6.Torquethescrewatthefrontofeachskidto9to

11N-m(80to100in-lb).

g004483

Figure8

1.Flangenut

2.Bushing5.Bolt

3.Anti-scalproller

g004479

4.Selectaholesotheanti-scalprollerispositioned

4.Spacer

tothenearestcorrespondingheight-of-cut

desired(Figure9).

9

Page 10

Figure9

1.38mm(1-1/2inches)3.63mm(2-1/2inches)

2.51mm(2inches)4.76mm(3inches)and

higher

5.Installtheangenutbushing,spacer,andbolt.

Torqueto54to61N∙m(40to45ft-lb)(Figure8).

AdjustingtheRollers

Mounttherollersinthelowerpositionwhenoperating

inheightofcutshigherthan64mm(2-1/2inches)and

inthehigherpositionwhenoperatinginheightofcuts

lowerthan64mm(2-1/2inches).

1.DisengagethePTO,releasethetractionpedal,

andengagetheparkingbrake.

2.MovethethrottlelevertotheSLOWposition,

shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Raisethefrontofthemachineandsupportiton

jackstands.

g004658

g004487

Figure10

AllCuttingUnits

1.Frontroller

2.Rollershaft

g004926

Figure11

Guardianmowersonly

1.Bolt4.Nut

2.Rearunder-cuttingunit

roller

3.Spacer

5.Bracket

4.Removethefastenerssecuringeachrolleron

yourcuttingunitandmovetherollersupordown

asdesired;refertoFigure10throughFigure14

asapplicableforyourcuttingunit.

Note:Youmayneedtoremovethefrontroller

forcertainGroundsmaster7200and7210

models.

Guardianmoweronly

1.Bolt3.Nut

2.Frontunder-cuttingunit

roller

10

g004923

Figure12

4.Bracket

Page 11

Figure13

Side-dischargecuttingunitsonly

1.Bolt4.Nut

2.Chute-sideroller

3.Spacer

Figure14

Side-dischargecuttingunitsonly

g004925

5.Bracket

g004924

1.Bolt

2.Rollershaft

5.Installthefastenersasillustrated.

3.Under-cuttingunitroller(2)

4.Bracket

11

Page 12

OperatingTips

insidethecuttingunit,cuttingqualitywilleventually

becomeunsatisfactory.

FastThrottleSetting/Ground

Speed

Tomaintainenoughpowerforthemachineanddeck

whilemowing,operatetheengineatthefastthrottle

positionandadjustyourgroundspeedforconditions.

Decreasethegroundspeedastheloadonthecutting

bladesincreases.Increasethegroundspeedasthe

loadonthebladesdecreases.

MowingDirection

Alternatemowingdirectiontoavoidmakingrutsin

theturfovertime.Thisalsohelpsdisperseclippings

whichenhancesdecompositionandfertilization.

CuttingSpeed

Toimprovecutquality ,useaslowergroundspeed.

AvoidCuttingTooLow

Ifthecuttingwidthofthecuttingunitiswiderthanthe

moweryoupreviouslyused,raisethecuttingheightto

ensurethatuneventurfisnotcuttooshort.

Toreducetheriskofrehazard,keeptheengine,

mufer,batterycompartment,parkingbrake,cutting

units,andfuelstoragecompartmentfreeofgrass,

leaves,orexcessivegrease.Cleanupanyspilledoil

orfuel.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.Checkthe

bladesdailyforsharpness,andforanywearor

damage.Sharpenthebladesasnecessary.Ifablade

isdamagedorworn,replaceitimmediatelywitha

genuineT ororeplacementblade.RefertoServicing

theCuttingBlades(page17).

SelecttheProperHeight-of-Cut

SettingtoSuitConditions

Removeapproximately1inch(25mm)orno

morethan1/3ofthegrassbladewhencutting.In

exceptionallylushanddensegrass,youmayhave

toslowdowntheforwardspeedand/orraisethe

height-of-cuttothenexthighersetting.

Important:Ifcuttingmorethan1/3ofthe

grassbladeoff,orinsparselonggrassor

dryconditions,theuseofatsailbladesis

recommendedtoreduceair-bornechaff,debris,

anddeckdrivecomponentstrain.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,

raisethecuttingheighthigherthanusualandcutthe

grassatthissetting.Thencutthegrassagainusing

thelower,normalsetting.

KeeptheCuttingUnitClean

Cleanclippingsanddirtfromtheundersideofthe

cuttingunitaftereachuse.Ifgrassanddirtbuildup

12

Page 13

Maintenance

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

WARNING

Ifyouraisethemachineusingonlyajackto

supportitwhileyouworkunderthecutting

unit,thejackcouldtip,causingthemower

decktofall,crushingyouorbystanders.

Alwayssecurethemachinewithatleast2jack

standswhenyouhavethemowerdeckraised.

CAUTION

Onthetopofthecuttingunitare2linksthat

connectthemtotheframe.Connectedto

theselinksaretorsionspringthatareunder

tension(Figure15).Ifyoudisconnectthelink,

thestoredenergyinthetorsionspringwillbe

releasedandcouldcausethelinkstomove,

damagingyourhandsorngers.

Becarefulwhenremovingthecuttingunit

fromtheframeandsecurethelinksbefore

disconnectingthemfromtheframe.

Figure15

1.Link2.Torsionspring

g004920

13

Page 14

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst50hours

Beforeeachuseordaily

Every50hours

MaintenanceProcedure

•Checktheconditionofthebladedrivebeltsonthecuttingunit.

•Checkthecuttingunitblades.

•Cleanthecuttingunit.

•Greasethebearingandbushinggreasettings.

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

CheckSafetyInterlock

Operation

CheckGrassDeectorin

DownPosition(ifapplicable)

CheckParkingBrake

Operation

CheckFuelLevel

CheckTirePressure

CheckInstrumentOperation

CheckConditionofBlades

LubricateAllGreaseFittings

Touch-upDamagedPaint

1.Immediatelyaftereverywashing,regardlessoftheintervallisted.

1

Sat.Sun.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Information

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

14

Page 15

Lubrication

GreasingtheBearingsand Bushings

ServiceInterval:Every50hours

Dustyanddirtyoperatingconditionscouldcause

dirttogetintothebearingsandbushings,resulting

inacceleratedwear.Lubricatethegreasettings

immediatelyaftereverywashing,regardlessof

intervalspecied.

1.Wipethegreasettingscleansoforeignmatter

cannotbeforcedintothebearingorbushing.

Themachinehasgreasettingsthatmustbe

lubricatedregularlywithNo.2lithiumgrease.

Bearingsandbushingsmustbelubricateddailywhen

operatingconditionsareextremelydustyanddirty.

2.Pumpgreaseintothettings.

3.Wipeoffexcessgrease.

Figure16

g004645

15

Page 16

g004646

Figure17

Note:Bearinglifecanbenegativelyaffectedbyimproperwashdownprocedures.Donotwashtheunitwhenit

isstillhotandavoiddirectinghigh-pressureorhighvolumesprayatthebearingsorseals.

16

Page 17

ReplacingtheBladeDrive Belts

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.

ServiceInterval:Aftertherst50hours

Thebladedrivebelts,tensionedbythespringloaded

idlerpulleys,areverydurable.However,aftermany

hoursofuse,thebeltswillshowsignsofwear.Signs

ofawornbeltincludesquealingwhenthebeltis

rotating,bladesslippingwhencuttinggrass,poor

qualityofcut,frayededges,andburnmarksand

cracks.Replacethebeltsifanyoftheseconditions

areevident.

1.Lowerthecuttingunittothe1inchheightof

cutsetting,movethethrottlelevertotheSLOW

position,shutofftheengine,engagetheparking

brake,andremovethekey.

2.Removethebeltcoversfromthetopofthe

cuttingunitandsetthecoversaside.

3.Usingabreakerbarorsimilartool,movethe

idlerpulleyforthetopbelt(Figure18)awayfrom

thetopdrivebelttoreleasethebelttensionand

allowthebelttobeslippedoffthepulleys.

Checkthebladesdailyforsharpness,andforany

wearordamage.Sharpenthebladesasnecessary.

Ifabladeisdamagedorworn,replaceitimmediately

withagenuineTororeplacementblade.

DANGER

Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrowntowardyou

orbystanders,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

Inspectandcheckthebladesevery8hours.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.DisengagethePTO,releasethetractionpedal,

andengagetheparkingbrake.

Figure18

1.Topbelt3.Bottombelt

2.Topidlerpulley4.Bottomidlerpulley

4.Routeanewbeltaroundthegearboxpulley ,

bottomspindlepulleys,andidlerpulleyassembly

asshowninFigure18.

5.Routeanewbeltaroundthetopspindlepulleys

andidlerpulleyassemblyasshowninFigure18.

6.Greaseallmowerandcuttingunitdrivegrease

points.

7.Installthebeltcovers.

ServicingtheCutting Blades

Maintainsharpbladesthroughoutthecuttingseason

becausesharpbladescutcleanlywithouttearingor

2.MovethethrottlelevertotheSLOWposition,

shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Inspectthecuttingedges(Figure19).Ifthe

edgesarenotsharporhavenicks,removeand

g004486

sharpentheblades.RefertoSharpeningthe

Blades(SharpeningtheBlades(page19)).

4.Inspecttheblades,especiallythesailarea

(Figure19).Ifyounoticeanydamage,wear,ora

slotforminginthisarea(Figure19),immediately

installanewblade.

DANGER

Ifyouallowthebladetowear,aslot

willformbetweenthesailandatpart

oftheblade.Eventuallyapieceofthe

blademaybreakoffandbethrownfrom

underthehousing,possiblyresultingin

seriousinjurytoyouorbystanders.

•Inspectthebladeperiodicallyforwear

ordamage.

•Nevertrytostraightenabladethat

isbentorweldabrokenorcracked

blade.

•Replaceawornordamagedblade.

17

Page 18

Figure20

g004633

Figure19

1.Cuttingedge3.Wear/slotforming

2.Sailarea4.Crack

CheckingforBentBlades

1.DisengagethePTO,releasethetractionpedal,

andengagetheparkingbrake.

1.Measureherefromblade

tohardsurface

4.Rotatetheoppositeendsofthebladesforward.

5.Measurefromalevelsurfacetothecuttingedge

ofthebladesatthesamepositionasinstep3

above.Thedifferencebetweenthedimensions

obtainedinsteps3and4mustnotexceed

3mm(1/8inch).Ifthisdimensionexceeds

3mm(1/8inch),thebladeisbentandmustbe

replaced;refertoRemovingtheBlades(page

18)andInstallingtheBlades(page19).

g004653

2.PositionA

WARNING

Abladethatisbentordamagedcould

breakapartandcouldseriouslyinjureor

killyouorbystanders.

•Alwaysreplacebentordamaged

bladewithanewblade.

•Neverleorcreatesharpnotchesin

theedgesorsurfacesofblade.

2.MovethethrottlelevertotheSLOWposition,

shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Rotatethebladesuntiltheendsfaceforward

andbackward(Figure20).Measurefromalevel

surfacetothecuttingedge,positionA,ofthe

blades(Figure20).Notethisdimension.

RemovingtheBlades

Bladesmustbereplacedifasolidobjectishit,ifthe

bladeisoutofbalanceorisbent.T oensureoptimum

performanceandcontinuedsafetyconformanceof

themachine,usegenuineTororeplacementblades.

Replacementbladesmadebyothermanufacturers

mayresultinnon-conformancewithsafetystandards.

WARNING

Contactwithasharpbladecancauseserious

injury.

Wearglovesorwrapsharpedgesoftheblade

witharag.

18

Page 19

1.DisengagethePTO,releasethetractionpedal,

andengagetheparkingbrake.

2.MovethethrottlelevertotheSLOWposition,

shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Holdthebladeendusingaragorthickly-padded

glove.

4.Removethebladebolt,anti-scalpplate,and

bladefromthespindleshaft;refertoFigure23

inInstallingtheBlades(page19).

SharpeningtheBlades

WARNING

Whensharpeningblade,piecesofbladecould

bethrownandcauseseriousinjury.

Wearpropereyeprotectionwhensharpening

blades.

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure

23).

Important:Thecurvedpartoftheblade

mustpointupwardtowardtheinsideofthe

cuttingunittoensurepropercutting.

2.Installtheanti-scalpplateandbladebolt(Figure

23).

1.Sharpenthecuttingedgeatbothendsofthe

blade(Figure21).Maintaintheoriginalangle.

Thebladeretainsitsbalanceifthesameamount

ofmaterialisremovedfrombothcuttingedges.

Figure21

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingiton

abladebalancer(Figure22).Ifthebladestays

inahorizontalposition,thebladeisbalanced

andcanbeused.Ifthebladeisnotbalanced,

lesomemetalofftheendofthesailareaonly

(Figure23).Repeatthisprocedureuntilthe

bladeisbalanced.

Figure22

1.Blade2.Balancer

g000276

Figure23

1.Spindle

2.Sailareaofblade

3.Anti-scalpplate

4.Bladebolt

g004480

3.Torquethebladeboltto115-150N⋅m

(85-110ft-lb).

CorrectingCuttingUnitMismatch

Ifthecutisunevenacrossthecuttingunitswath,

correctitasfollows:

1.Positionthemachineonalevelsurface.

2.Setthecuttingunittothedesiredheightofcut,

g000277

movethethrottlelevertotheSLOWposition,

shutofftheengine,engagetheparkingbrake,

andremovethekey.

3.Checkandadjustfrontandreartraction-unittire

pressure;refertothetractionunitOperator’s

Manual.

4.Checkforbentblades.

19

Page 20

5.Removethecoversfromthetopofthecutting

units.

6.Rotatethebladeoneachspindleuntiltheends

faceforwardandbackward.

7.Measurefromtheoortothefronttipofthe

cuttingedge.

8.Adjustthejamnutssecuringthecuttingunit

yokes/chainstothemoweruntilthecuttingunit

islevel(Figure24).

g004485

Figure25

g004497

Figure24

1.Front-moweryokechain4.Yoke

2.Rear-moweryokechain5.Jamnut

3.Chain

6.Mower

ReplacingtheGrassDeector

WARNING

Anuncovereddischargeopeningallows

themachinetothrowobjectstowardyouor

bystanders,whichcanresultinseriousinjury.

Contactwiththebladecanalsooccur.

•Neveroperatethemachinewithoutamulch

kitorgrassdeectorinstalled.

•Ensurethatthegrassdeectorislowered.

1.Lowerthecuttingunittotheground,movethe

throttlelevertotheSLOWposition,shutoffthe

engine,engagetheparkingbrake,andremove

thekey.

2.Removethelocknut,bolt,springandspacer

holdingthedeectortothepivotbrackets(Figure

25).Removedamagedorworngrassdeector.

1.Bolt

2.Spacer6.Grassdeector

3.Locknut

4.Spring8.Right-handhookendof

5.Springinstalled

7.Left-handhookendof

spring,placebehindthe

cuttingunitedgebefore

installingbolt

spring

3.Placethespacerandspringbetweenthe

replacementgrassdeectorbrackets(Figure

25).PlacethelefthandJhookendofthespring

behindthecuttingunitedge.

Note:Ensurethattheleft-handhookendofthe

springisinstalledbehindthecuttingunitedge

beforeinstallingtheboltasshowninFigure25.

4.Installtheboltandnut.Placetheright-hand

hookendofthespringaroundthegrass

deector(Figure25).

Important:Thegrassdeectormustbeable

tolowerdownintoposition.Liftthedeector

uptotestthatitlowersintothefulldown

position.

CleaningUndertheCutting Unit

ServiceInterval:Beforeeachuseordaily

Removethegrassbuildupunderthecuttingunitdaily .

1.DisengagethePTO,releasethetractionpedal

totheneutralposition,andengagetheparking

brake.

2.MovethethrottlelevertotheSLOWposition,

shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operator’sposition.

3.RaisethecuttingunittotheTRANSPORTposition.

20

Page 21

4.Useajacktoraisethefrontofthemachineand

supportitwithjackstands.

Storage

5.Thoroughlycleantheundersideofthecutting

unitwithwater.

1.DisengagethePTO,releasethetractionpedal

totheneutralposition,andengagetheparking

brake.

2.MovethethrottlelevertotheSLOWposition,

shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operator’sposition.

3.Allowtheenginetocoolbeforeadjusting,

cleaning,storing,orrepairingthemachine.

4.Thoroughlycleanthecuttingunit,payingspecial

attentiontotheseareas:

•Underneaththecuttingunit

•Underthecuttingunitbeltcovers

•PTOshaftassembly

•Allgreasettingsandpivotpoints

5.Checkandadjustthetraction-unitfrontandrear

tirepressure;refertothetraction-unitOperator’s

Manual.

6.Remove,sharpen,andbalancethecuttingunit

blades.Installthebladesandtorquetheblade

fastenersto85to1 10ft-lb(115to149N∙m).

7.Checkallfastenersforloosenessandtighten

themasnecessary.

8.Greaseoroilallgreasettingsandpivotpoints.

Wipeoffanyexcesslubricant.

9.Lightlysandandusetouchuppaintonpainted

areasthatarescratched,chippedorrusted.

Repairanydents.

21

Page 22

DeclarationofIncorporation

TheT oroCompany,8111LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

30353403373001andUp72inRotaryMower

30456403373001andUp

30457403373001andUp62inRotaryMower

30481403373001andUp

SerialNo.

ProductDescriptionInvoiceDescription

GM7200/GM36072in

BASEDECK

60inSideDischargeMowerGM720060inSDDECK

GM720062inBASEDECK

72inSideDischargeMower72inS.D.DECK(NON)C.E.

GeneralDescription

72inRotaryMower

60inRotaryMower

62inRotaryMower

72inRotaryMower

Directive

2006/42/EC,

2000/14/EC

2006/42/EC,

2000/14/EC

2006/42/EC,

2000/14/EC

2006/42/EC,

2000/14/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:

AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

Belgium

JohnHeckel

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

August22,2018

Tel.+3216386659

Page 23

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproducts.Additionally ,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerswithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalsprovideexposurelimitrequirements.WhiletheexposurefromT oroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,T orohaselectedtoprovidetheProp65warnings.Moreover,ifT orodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

Page 24

TheToroWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser .

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.Torowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevD

Loading...

Loading...