Toro 30447N, 30449N, Groundsmaster 4100-D, Groundsmaster 4110-D, 30447 Operator's Manual

...Page 1

FormNo.3374-304RevA

Groundsmaster

®

4100-Dand

4110-DRotaryMower

ModelNo.30447N—SerialNo.313000001andUp

ModelNo.30449N—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3374-304*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisincorporatedwith

themuferassembly.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:Thisengineisequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure1

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Introduction

Thismachineisaride-on,rotary-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrass

onwell-maintainedlawnsinparks,sportselds,andon

commercialgrounds.Itisnotdesignedforcuttingbrush,

mowinggrassandothergrowthalongsidehighways,orfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Writethenumbersinthespaceprovided.

ModelNo.

SerialNo.

©2012—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................6

EngineEmissionCertication...................................7

SafetyandInstructionalDecals.................................7

Setup...........................................................................13

GreasingtheMachine.............................................13

ProductOverview.........................................................14

Controls...............................................................14

Specications........................................................17

Attachments/Accessories........................................17

Operation....................................................................18

BeforeOperating...................................................18

AdjustingtheMirrors..............................................26

AimingtheHeadlights............................................26

StartingandStoppingtheEngine..............................26

EngineCoolingFanOperation.................................27

CheckingtheInterlockSwitches...............................27

PushingorTowingtheMachine................................28

JackingPoints........................................................28

TieDowns............................................................28

OperatingCharacteristics........................................29

OperatingTips......................................................29

Maintenance.................................................................31

RecommendedMaintenanceSchedule(s)......................31

ServiceIntervalChart.............................................32

Lubrication...............................................................32

GreasingtheBearingsandBushings..........................32

EngineMaintenance..................................................36

AirCleanerMaintenance.........................................36

ServicingtheEngineOilandFilter............................37

FuelSystemMaintenance...........................................37

ServicingtheFuelSystem........................................37

BleedingAirfromtheInjectors................................38

ElectricalSystemMaintenance....................................38

BatteryCare...........................................................38

Fuses....................................................................39

DriveSystemMaintenance.........................................41

ChangingthePlanetaryGearDriveOil......................41

ChangingtheRearAxleLubricant.............................41

CheckingtheRearWheelToe-In..............................42

ChangingtheFrontTires.........................................42

CoolingSystemMaintenance......................................43

ServicingtheEngineCoolingSystem........................43

BrakeMaintenance....................................................44

AdjustingtheServiceBrakes....................................44

BeltMaintenance......................................................44

ServicingtheAlternatorBelt....................................44

Re-tensioningtheBladeDriveBelts..........................44

ReplacingtheBladeDriveBelt.................................45

ControlsSystemMaintenance.....................................46

AdjustingtheThrottleCable....................................46

AdjustingtheTractionPedalLinkage........................46

HydraulicSystemMaintenance....................................47

ChangingtheHydraulicFluid...................................47

ReplacingtheHydraulicFilters.................................47

CheckingtheHydraulicLinesandHoses....................48

AdjustingtheCounterbalancePressure......................48

MowerMaintenance...................................................49

Pivoting(Tilting)theFrontCuttingUnit

Upright.............................................................49

PivotingtheFrontCuttingUnitDown.......................49

AdjustingtheCuttingUnitPitch...............................49

ServicingtheCastorArmBushings...........................50

ServicingtheCastorWheelsandBearings..................50

ReplacingtheCuttingUnitHingeCovers...................51

BladeMaintenance.....................................................52

CheckingforaBentBlade........................................52

RemovingandInstallingtheCutterBlade(s)...............52

InspectingandSharpeningtheCutterBlade(s)............52

CorrectingCuttingUnitMismatch............................53

SparkArrestorMaintenance........................................54

ServicingtheSparkArrestorMufer.........................54

CabMaintenance.......................................................55

CleaningtheCabAirFilters.....................................55

Storage........................................................................56

PreparingforSeasonalStorage.................................56

Schematics...................................................................57

3

Page 4

Safety

ThismachinemeetsorexceedsISOstandard5395:1990

andANSIB71.4-2004specicationsineffectatthetime

ofproduction.

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheISOstandard

5395:1990andANSIstandardB71.4-2004.

Training

•ReadtheOperator'sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethemower.Localregulationsmay

restricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtohimselforherself,other

people,orproperty.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

Preparation

•Whilemowing,alwayswearsubstantialfootwear,long

trousers,hardhat,safetyglasses,andhearingprotection.

Longhair,looseclothingorjewelrymaygettangled

inmovingparts.Donotoperatetheequipmentwhen

barefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Warningfuelishighlyammable.Takethefollowing

precautions:

–Storefuelincontainersspecicallydesignedforthis

purpose.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

–Addfuelbeforestartingtheengine.Neverremove

thecapofthefueltankoraddfuelwhiletheengineis

runningorwhentheengineishot.

–Iffuelisspilled,donotattempttostarttheengine

butmovethemachineawayfromtheareaofspillage

andavoidcreatinganysourceofignitionuntilfuel

vaporshavedissipated.

–Replaceallfueltankandcontainercapssecurely .

•Replacefaultysilencers/mufers.

•Beforeusing,alwaysvisuallyinspecttoseethatthe

blades,bladebolts,andcuttingassemblyarenotworn

ordamaged.Replacewornordamagedbladesandbolts

insetstopreservebalance.

•Onmulti-bladedmachines,takecareasrotatingoneblade

cancauseotherbladestorotate.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Checkthatoperatorspresencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly .Donot

operateunlesstheyarefunctioningproperly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutches,shiftintoneutral,andengagethe

parkingbrake.Onlystarttheenginefromtheoperator's

position.Useseatbelts.

◊incorrecthitchingandloaddistribution.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,orproperty.

•Donotusethismachineonslopesgreaterthan15°.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.Toguardagainst

overturning:

4

Page 5

–Donotstoporstartsuddenlywhengoingupor

downhill.

–Engagetheclutchslowly,alwayskeepthemachinein

gear,especiallywhentravellingdownhill.

–Themachinespeedshouldbekeptlowonslopesand

duringtightturns.

–Stayalertforhumpsandhollowsandotherhidden

hazards.

–Nevermowacrossthefaceoftheslope,unlessthe

machineisdesignedforthatpurpose.

•Stayalertforholesintheterrainandotherhiddenhazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesfromrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.Besureall

interlocksareattached,adjustedproperly,andfunctioning

properly.

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperatorsposition:

–Stoponlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Changeintoneutralandsettheparkingbrake.

–Stoptheengineandremovethekey .

•Disengagedrivetoattachments,stoptheengine,and

disconnectthesparkplugwire(s)orremovetheignition

key:

–beforeclearingblockages;

–beforechecking,cleaning,orworkingonthemachine;

–afterstrikingaforeignobject.Inspectthemachine

fordamageandmakerepairsbeforerestartingand

operatingtheequipment.T orqueallthespindlepulley

nutsto130to150ft-lb(176to203N⋅m);

–ifthemachinestartstovibrateabnormally(check

immediately).

•Disengagedrivetoattachmentswhentransportingornot

inuse.

•Stoptheengineanddisengagedrivetoattachment:

–beforerefuelling;

–beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator'sposition.

•Reducethethrottlesettingbeforestoppingengineand

closethefuelshut-offvalveattheconclusionofmowing.

•Neverraisedeckwiththebladesrunning.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Theoperatorshallturnonashingwarninglights,if

provided,whenevertravelingonapublicroad,except

wheresuchuseisprohibitedbylaw .

MaintenanceandStorage

•Keepallnuts,bolts,andscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure

anddonotstorenearame.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartment,cuttingunits,

drives,andfuelstorageareafreeofgrass,leaves,or

excessivegrease.Cleanupoilorfuelspillage.

•Replacewornordamagedpartsforsafety .

•Ifthefueltankhastobedrained,dothisoutdoors.

•Onmulti-bladedmachines,takecareasrotatingoneblade

cancauseotherbladestorotate.

•Whenmachineistobeparked,stored,orleftunattended,

lowerthecuttingunitsunlessapositivemechanicallock

isprovided.

•Disengagedrives,lowerthecuttingunits,movetraction

pedaltoNeutral,setparkingbrake,stopengineand

removekey.Waitforallmovementtostopbefore

adjusting,cleaningorrepairing.

•Shutofffuelwhilestoringortransporting.Donotstore

fuelnearames.

•Parkmachineonlevelground.Neverallowuntrained

personneltoservicemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectbatterybeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.Reconnect

positiverstandnegativelast.

5

Page 6

•Usecarewhencheckingblades.Wrapthebladesor

weargloves,andusecautionwhenservicingthem.Only

replaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

ordisconnectingfrombattery.W earprotectiveclothing

anduseinsulatedtools.

•Makesureallhydrauliclineconnectorsaretightandall

hydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.Ifuidisinjectedintotheskinitmustbesurgically

removedwithinafewhoursbyadoctorfamiliarwiththis

formofinjuryorgangrenemayresult.

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheISOorANSIstandards.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

Operation

•BeforeoperatingamachinewithROPS(rollover

protectionsystem),becertainthattheseatbeltsare

attachedandtheseatislatchedtopreventtheseatfrom

pivotingforward.

•Knowhowtostopthemachineandenginequickly.

•Donotoperatethemachinewhilewearingtennisshoes

orsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Keephands,feet,andclothingawayfrommovingparts

andthemowerdischargeareaandundersideofthe

mowerwhiletheengineisrunning.

•Fillfueltankuntillevelis1inch(25mm)belowthe

bottomofthellerneck.Donotoverll.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•Donotmowinreverseunlessabsolutelynecessary.

•Reducespeedwhenmakingsharpturns.

•Ifasteepslopemustbeascended,driveforwardupthe

hillanddriverearwarddownthehill,keepingthetraction

driveengaged.

•Ifyoucannotbackupaslopeorifyoufeeluneasyonit,

donotmowit.

•Avoidstartingorstoppingonaslope.Iftireslosetraction,

disengagethebladesandproceedslowlystraightdown

theslope.Avoidraisingthesidecuttingunitsonaslope.

•Avoidturningonslopes.Ifyoumustturn,turnslowly

andgraduallydownhill,ifpossible.

•Becertainthattheseatbeltcanbereleasedquicklyifthe

machineisdrivenorrollsintoapondorwater.

•Watchfortrafcwhennearorcrossingroads.Always

yieldtheright-of-way.

Thismachineisnotdesignedorequippedforon-road

useandisa“slow-movingvehicle”.Ifyoumustcross

ortravelonapublicroad,youshouldbeawareofand

complywithlocalregulations,suchasrequiredlights,

slowmovingvehiclesigns,andreectors.

•Donotmowneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyturnoverifawheelgoes

overtheedgeofaclifforditch,orifanedgecavesin.

•Donotmowonwetgrass.Reducedtractioncouldcause

sliding.

•Useextracarewithotherattachments.Thesecanchange

thestabilityofthemachine.

•Whenapersonorpetappearsunexpectedlyinornear

themowingarea,stopmowing.Carelessoperation,

combinedwithterrainangles,ricochets,orimproperly

positionedguardscanleadtothrownobjectinjuries.Do

notresumemowinguntiltheareaiscleared.

•Turnoffthebladeswhennotmowing.

MaintenanceandStorage

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowtocoolbeforeattempting

tomaintain,adjust,orservice.

•Neverstorethemachineorfuelcontainerinsidewhere

thereisanopename,suchasnearawaterheateror

furnace.

•Keepnutsandboltstight,especiallythebladeattachment

bolts.Keepequipmentingoodcondition.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

6

Page 7

thebodyawayfromthecuttingunits,attachments,and

anymovingparts.Keepeveryoneaway.

•Checkbrakeoperationfrequently.Adjustandserviceas

required.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks,and

amesawayfromthebattery.

•Theenginemustbeshutoffbeforecheckingtheoilor

addingoiltothecrankcase.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•Tomakesureofoptimumperformanceandcontinued

safetycerticationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

EngineEmissionCertication

TheengineinthismachineisEP ATier4icompliant.

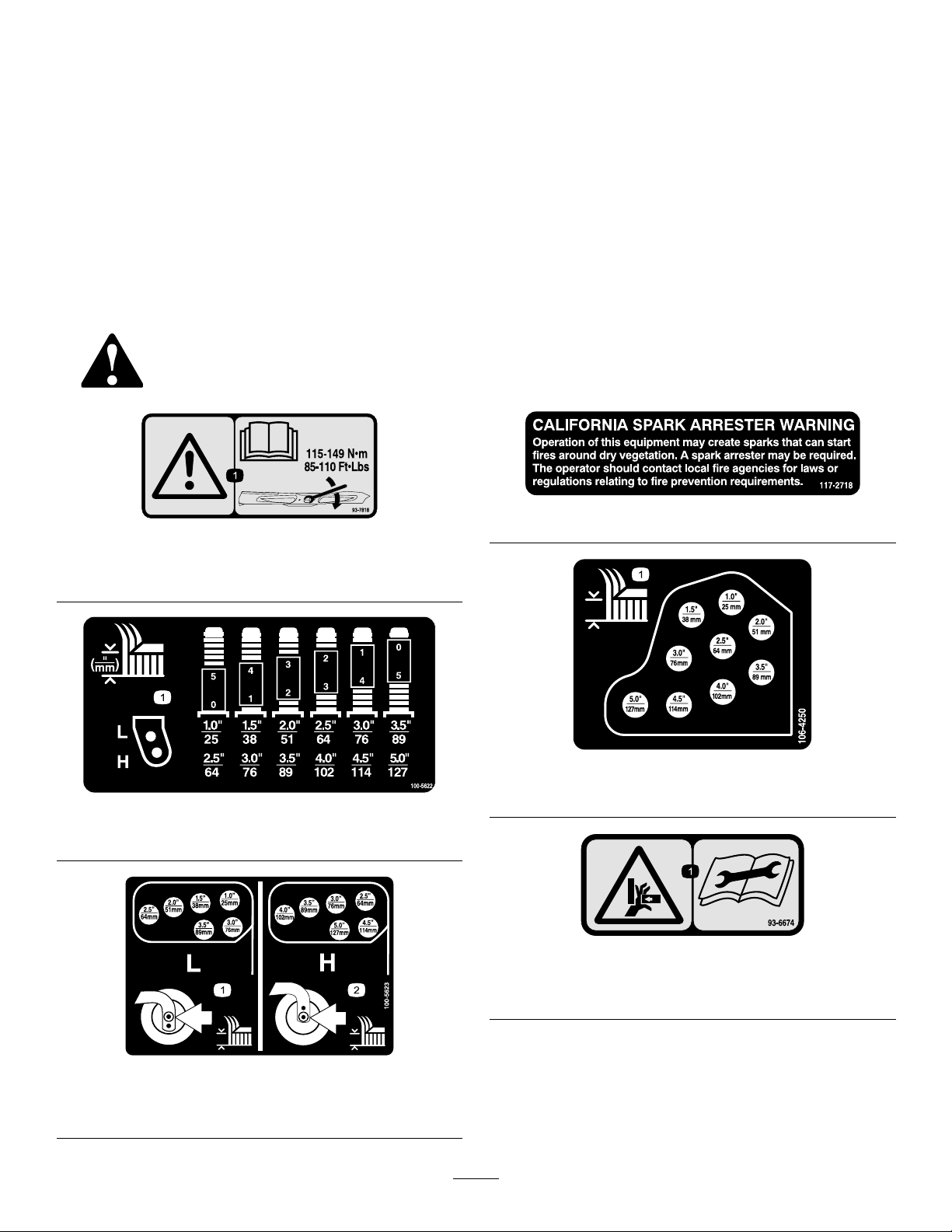

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N-m(85-110ft-lb).

100-5622

1.Heightofcutadjustment

117–2718

106-4250

1.Heightofcut

93-6674

1.Lowheightofcut

adjustment

1.Crushinghazard,hand—readtheinstructionsbefore

servicingorperformingmaintenance.

100-5623

2.Highheightofcut

adjustment

7

Page 8

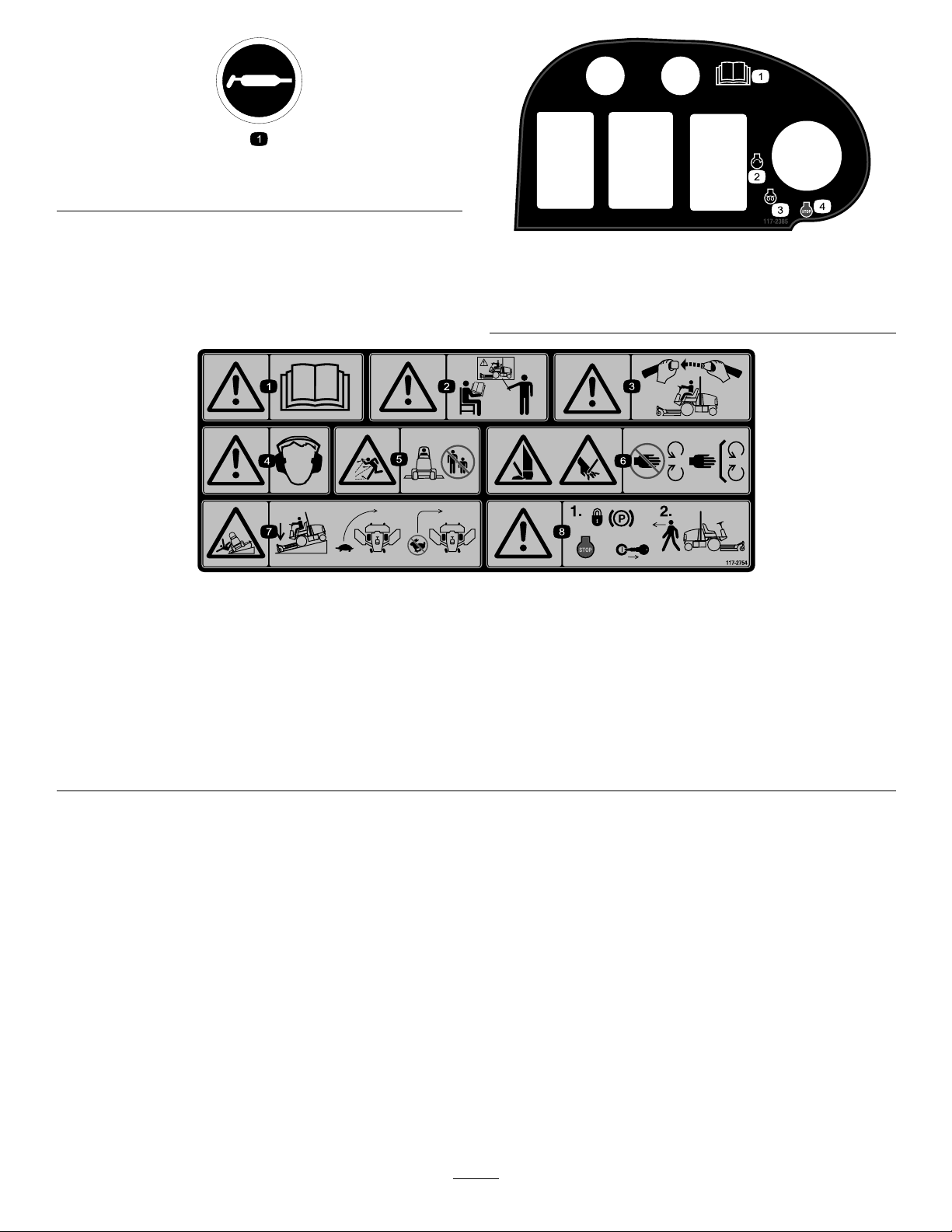

58-6520

1.Grease

117–2385

1.ReadtheOperators

Manual.

2.Engine—start4.Engine—stop

3.Engine—preheat

117–2754

1.Warning—readtheOperator'sManual.

2.Warning—donotoperatethismachineunlessyouaretrained.

3.Warning—weartheseatbeltwhenseatedintheoperator'sposition.

4.Warning—wearhearingprotection.

5.Thrownobjecthazard—keepbystandersasafedistancefromthemachine.

6.Cuttinghazardofhandorfoot—stayawayfrommovingparts;keepallguardsinplace.

7.Tippinghazard—lowerthecuttingunitwhendrivingdownslopes;slowmachinebeforeturning,donotturnathighspeeds

8.Warning—locktheparkingbrake,stoptheengineandremovetheignitionkeybeforeleavingthemachine.

8

Page 9

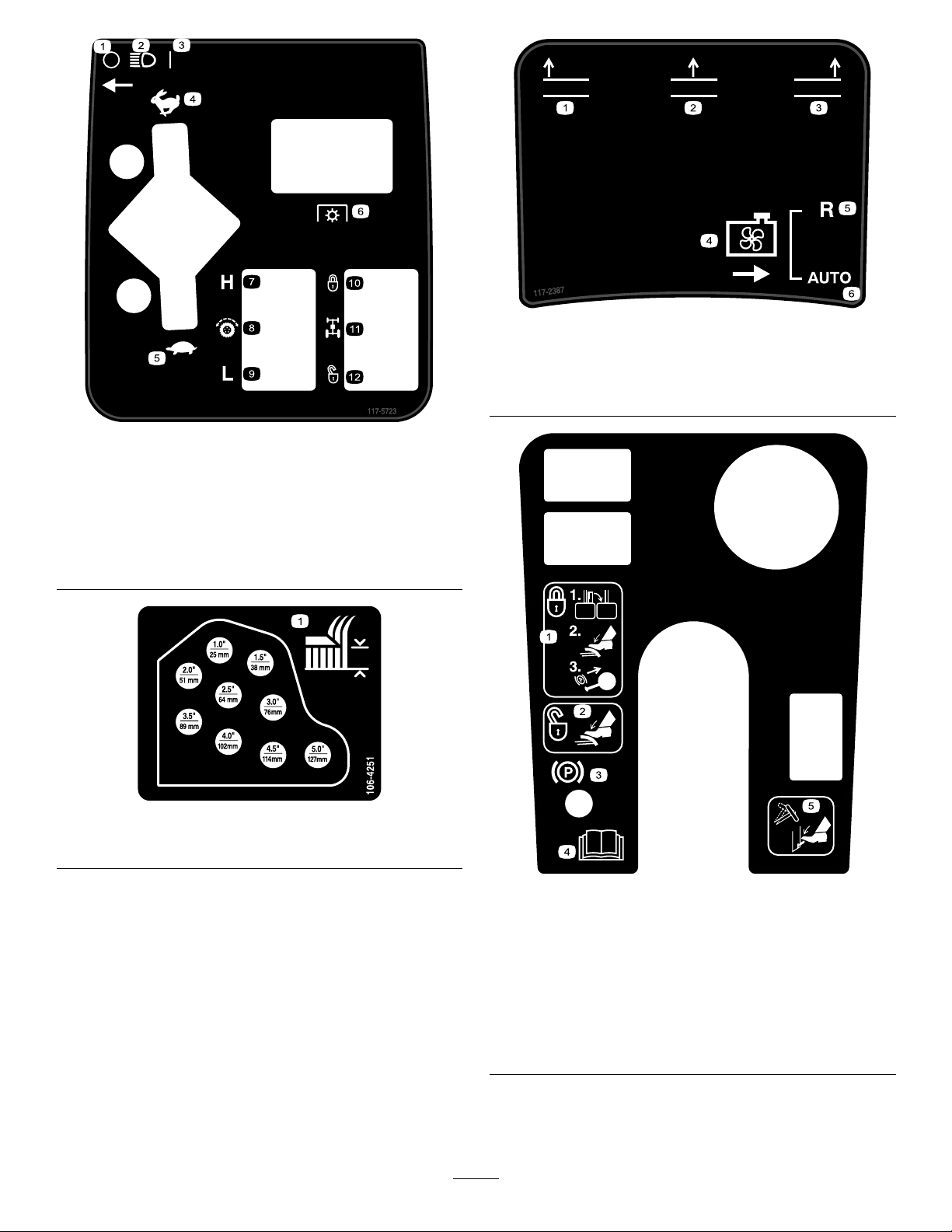

117–2387

1.Raiseleftdeck4.Coolingfan

2.Raisecenterdeck5.Reverse

3.Raiserightdeck6.Automatic

117-5723

1.Off

2.Headlights8.Tractioncontrol

3.On

4.Fast10.Locked

5.Slow

6.PowerT ake-off(PTO)

7.High

9.Low

11.Flowdivider

12.Unlocked

106-4251

1.Heightofcut

119-0067

1.Tolocktheparkingbrake,

latchthepedalstogether,

applythebrakepedals,

andpullupontheknob.

2.Tounlocktheparking

brake,steponthebrake

pedals.

3.Parkingbrakelock

indicator

9

4.ReadtheOperator's

Manual.

5.Pressdownontheleverto

tiltthesteeringwheel.

Page 10

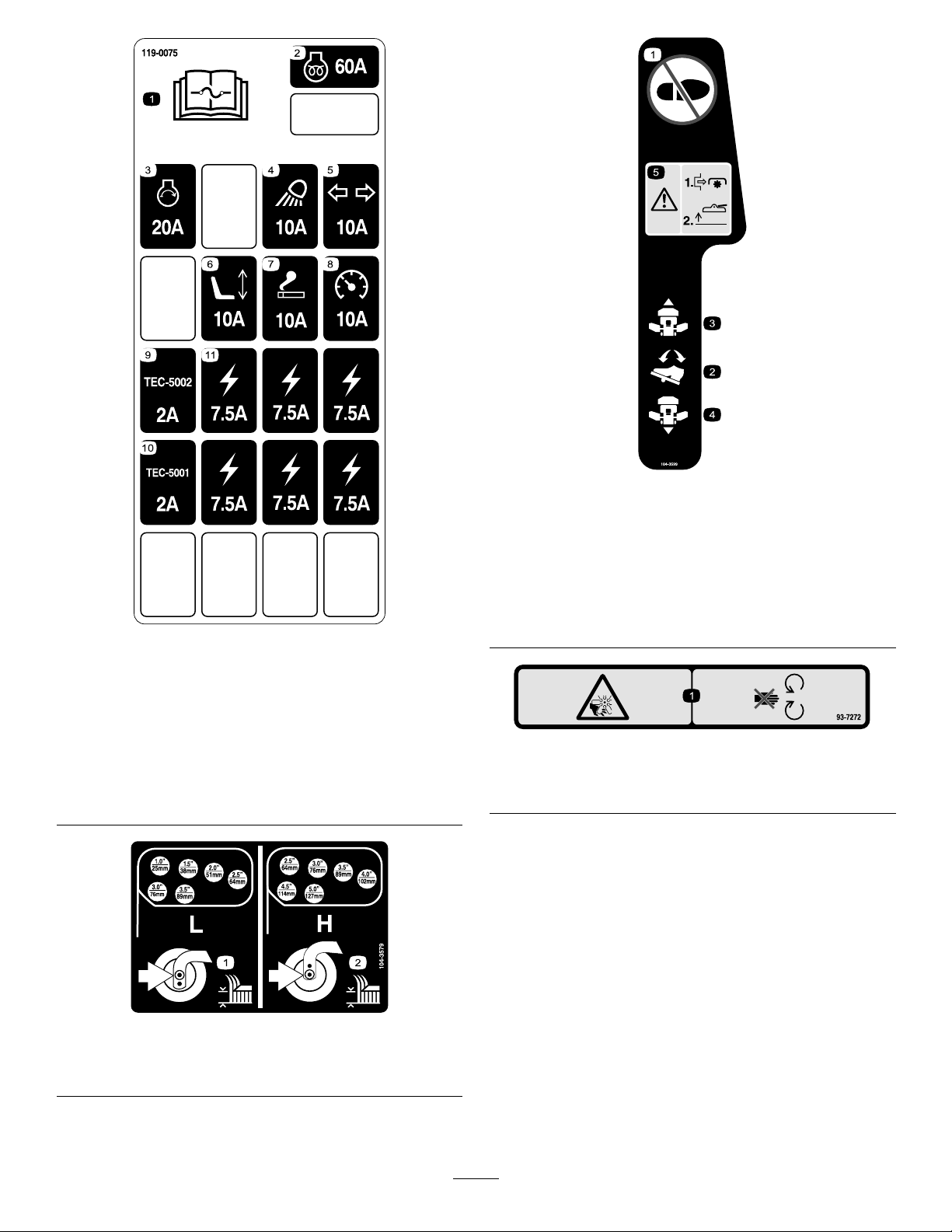

104-3599

1.Donotstephere.

2.Tractionpedal

3.Traction—forward

4.Traction—reverse

5.Danger—shutoffPTOpriortoraisingthecuttingunits;do

notoperatethecuttingunitswhentheyareintheraised

position.

119-0075

1.ReadtheOperator's

Manualforfuse

information.

2.Enginepreheat—60Afuse8.Instuments—10Afuse

3.Engine,start—20Afuse9.Controlmodule—2Afuse

4.Headlights—10Afuse10.Controlmodule—2Afuse

5.Turnsignal—10Afuse11.Powerpoint—7.5Afuse

6.Powerseat—10Afuse

7.Powerpoint—10Afuse

104-3579

1.Lowheightofcut

adjustment

2.Highheightofcut

adjustment

93-7272

1.Cutting/dismembermenthazard;fan—stayawayfromoving

parts.

10

Page 11

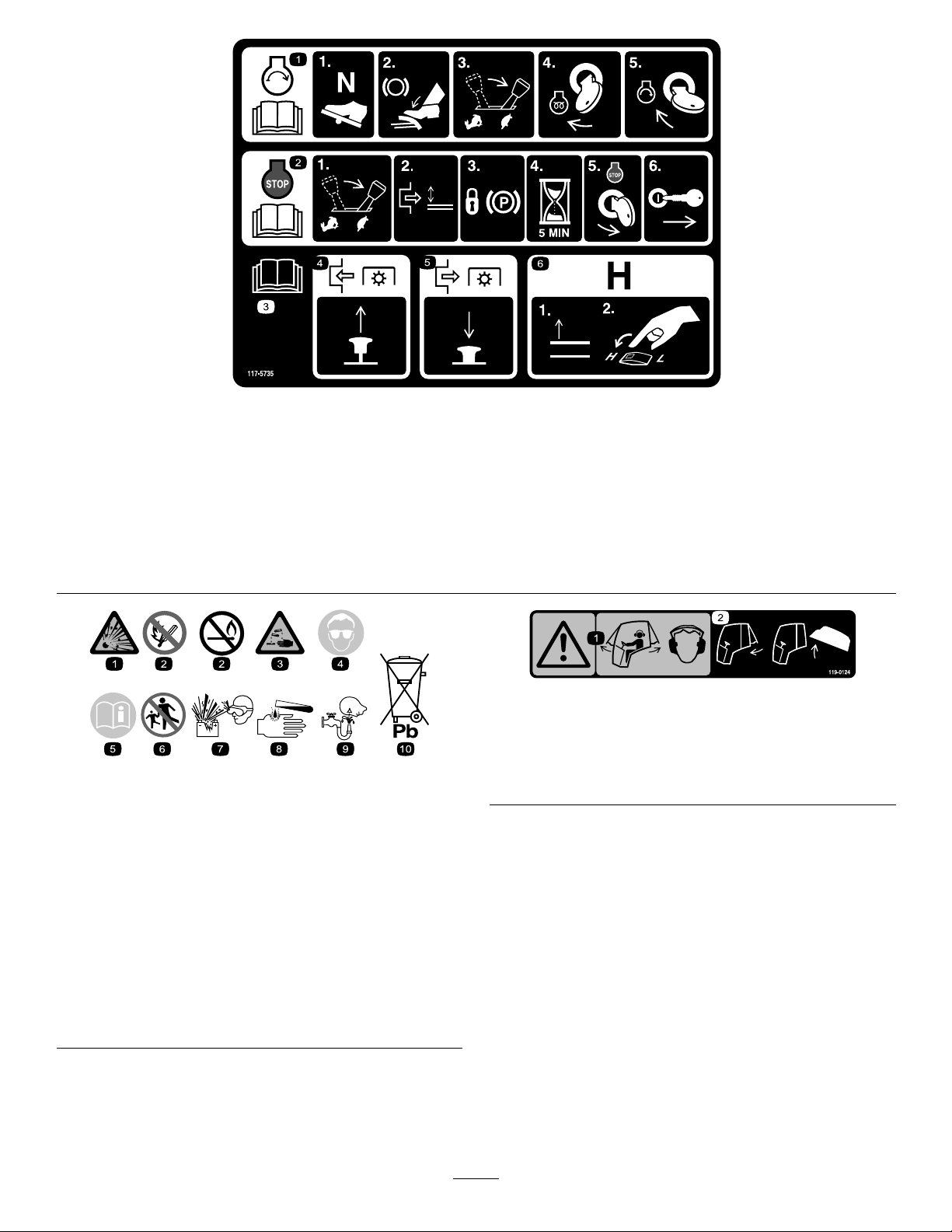

117-5735

1.ReadtheOperatorsManual;tostarttheengine,movethetractionpedaltoNeutral,applythebrake,movethethrottleswitchto

slow,turntheignitionkeytoPreheat.WhentheWaittoStartAdvisoryclearsontheInfoCenterthenturntheignitionkeytoStart.

2.ReadtheOperatorsManual;tostoptheengine,movethethrottlelevertoslow,disengagethePTO,settheparkingbrake,wait5

minutes,turntheignitionkeytoStop,andremovethekey;readtheOperatorsManual.

3.ReadtheOperatorsManual.

4.ToengagethePTO,pulluponthePTOswitch.

5.TodisengagethePTO,pushdownonthePTOswitch.

6.Toswitchthetransmissiontohighspeed,fullyraisetheattachmentsandswitchthespeedcontroltoHigh.

119–0124

(Model30447only)

1.Warning—whenthecabwindowsareopenwearhearing

BatterySymbols

Someorallofthesesymbolsareonyourbattery

protection.

2.Closetherearwindowbeforeattemptingtoopenthehood.

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery .

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

11

Page 12

1.ReadtheOperator'sManual.

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

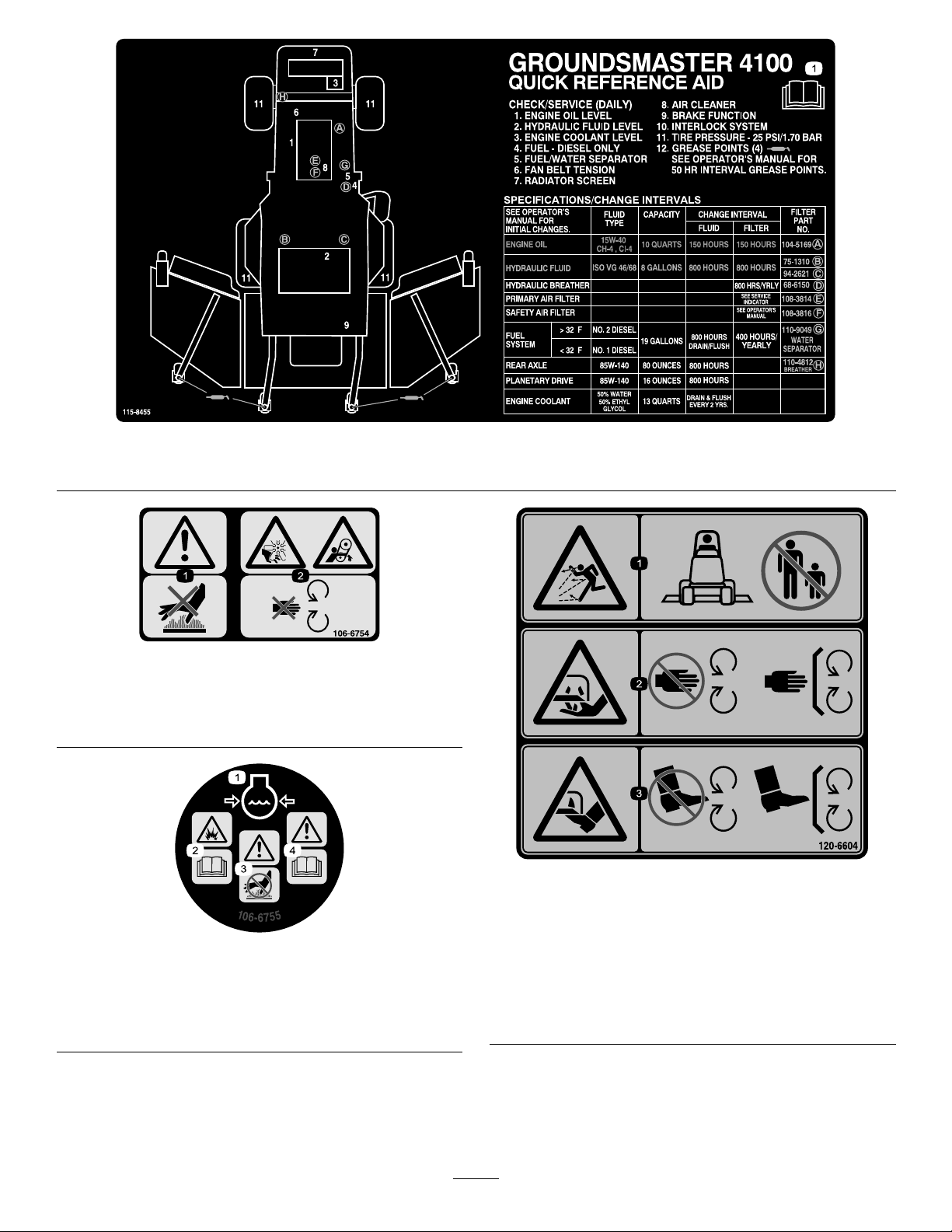

115-8455

120-6604

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

106-6755

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Cutting/dismembermenthazardofhand,mower

blade—stayawayfrommovingparts,keepallguardsand

shieldsinplace.

3.Cutting/dismembermenthazardoffoot,mowerblade—stay

awayfrommovingparts,keepallguardsandshieldsin

place.

12

Page 13

Setup

MediaandAdditionalParts

Description

Operator'sManual

EngineOperator'sManual

PartsCatalog

OperatorTrainingMaterials

Pre-deliveryInspectionSheet

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Qty.

GreasingtheMachine

Beforethemachineisoperated,itmustbegreasedtoensure

properlubricatingcharacteristics;refertoGreasingthe

BearingsandBushingsprocedureinLubrication.Failureto

properlygreasethemachinewillresultinprematurefailureof

criticalparts.

Use

1

1

1

1

1

Reviewbeforeoperatingmachine

Usetoreferenceengineinformation

Usetoreferencepartnumbers

Reviewbeforeoperatingmachine

13

Page 14

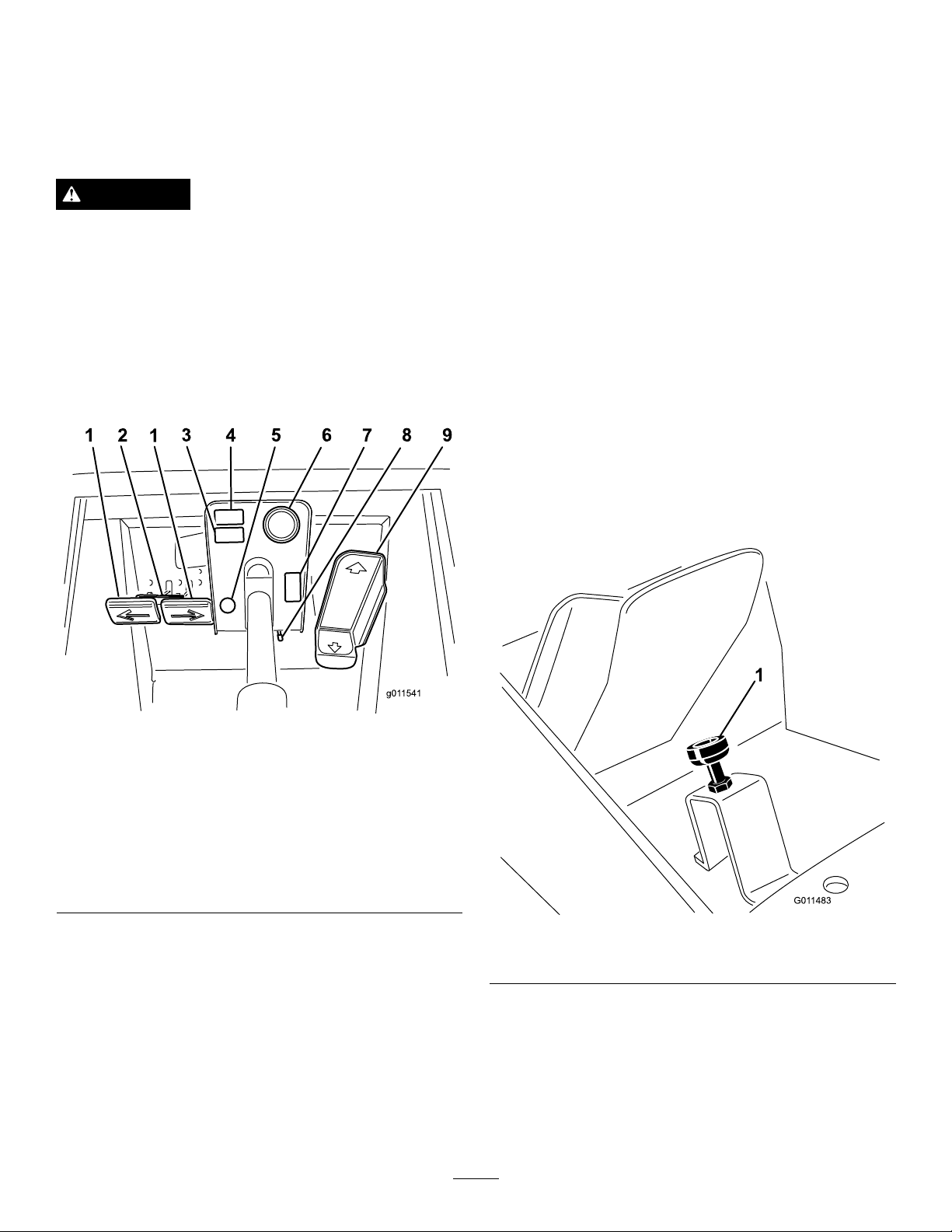

ProductOverview

Controls

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

TiltSteeringLever

PresstheleverFigure2downtotiltthesteeringwheelto

thedesiredposition.Thenreleasethelevertolockthe

adjustment.

ParkingBrakeLatch

CAUTION

Thismachineproducessoundlevelsinexcessof85

dBAattheoperatorsearandcancausehearingloss

throughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

TractionPedal

Tostop,reduceyourfootpressureonthetractionpedaland

allowittoreturntothecenterposition(Figure2).

Aknobontheleftsideoftheconsoleactuatestheparking

brakelock(Figure2).Toengagetheparkingbrake,connect

thepedalswiththelockinglatch,pushdownonbothpedals,

andpulltheparkingbrakelatchout.Toreleasetheparking

brake,pressbothpedalsuntiltheparkingbrakelatchretracts.

FuelGauge

Thefuelgauge(Figure2)indicatestheleveloffuelinthetank.

HazardLightSwitch(GM4100only)

Pressthehazardlightswitch(Figure2)toactivatethehazard

lights.

SpeedLimiter

Ifdesired,thescrewcanbeadjusted(Figure3)tolimitthe

amountthetractionpedalcanbedepressedintheforward

directiontolimitthemowingspeed.

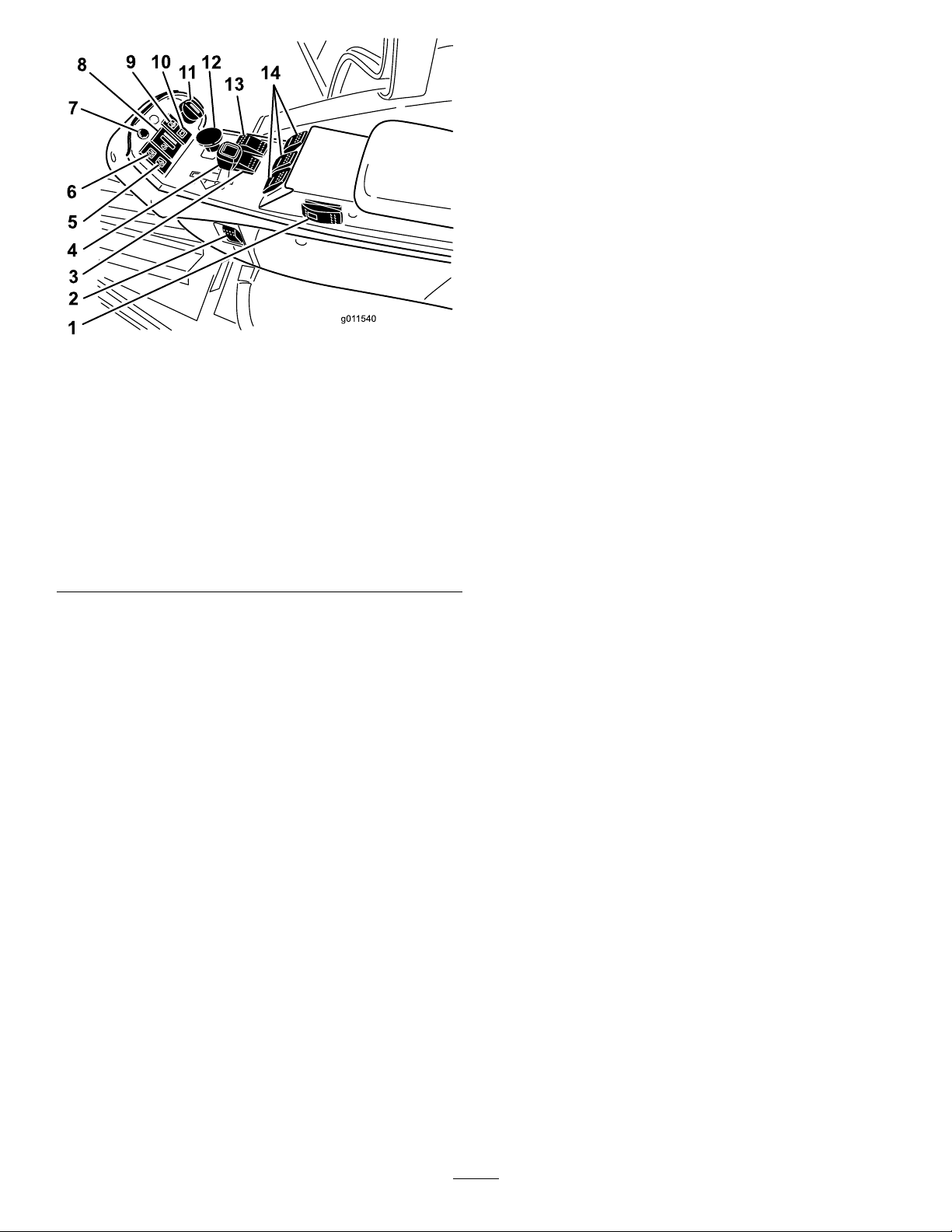

Figure2

1.Brakepedals6.Fuelgauge

2.Pedallockinglatch

3.Spaceforoptional

accessory

4.Spaceforoptional

accessory

5.Parkingbrakelatch

7.Hazardlightswitch(GM

4100only)

8.Tiltsteeringlever

9.Tractionpedal

BrakePedals

TwofootpedalsFigure2operateindividualwheelbrakesfor

turningassistance,parking,andtoaidinobtainingbetterside

hilltraction.Alatchconnectsthepedalsforparkingbrake

operationandtransport.

PedalLockingLatch

ThepedallockinglatchFigure2connectsthepedalstogether

toengagetheparkingbrake.

Figure3

1.Speedlimiter

Important:Wheninthemowposition,thespeedlimiter

screwmuststopthetractionpedalbeforethepump

reachesfullstrokeordamagetothepumpmayoccur.

DiagnosticLight

Thediagnosticlight(Figure4)willilluminateshouldasystem

faultberecognized.

14

Page 15

Figure4

FlowDividerSwitch(optional)

Whenoperatinginmow(low)speed,pressandhold

owdividerswitch(Figure4)toenhancetractiondrive

performanceincompromisedoperatingconditions.

Hi-LoSpeedControl

Theswitch(Figure4)allowsthespeedrangetoincreasefor

transportofthemachine.Cuttingdeckswillnotoperate

inhighrange.Also,thedeckscannotbeloweredfromthe

transportpositionwhentheswitchisinthehighrange.If

theswitchismovedfromLOtoHIwiththecuttingdecks

downand/orPTOonand/orcruisecontrolengaged,the

transmissionwillnotchangetoHI.Forthechangetobe

accomplished,theswitchmustbemovedtoLOandallthe

requirementssatised.

1.Cruisecontrol(optional)

2.Lightswitch9.Engineoilpressure

3.Hi-Lospeedcontrol

4.Throttlecontrol11.Keyswitch

5.Glowplugindicatorlight12.PTOswitch

6.Enginecoolant

temperaturewarning

light

7.Diagnosticlight

8.Enginecoolant

temperaturegauge

warninglight

10.Chargeindicator

13.Flowdividerswitch

(optional)

14.Liftswitches

EngineCoolantTemperatureGauge

Duringnormaloperatingconditionsthegauge(Figure4)

shouldbeinthegreenrange.Checkthecoolingsystemifthe

gaugegoestotheyelloworredrange.

EngineOilPressureWarningLight

Thelight(Figure4)illuminateswhentheengineoilpressure

isdangerouslylow.

LiftSwitches

Theliftswitches(Figure4)raiseandlowerthecutting

units.Presstheswitchesforwardtolowerthecuttingunits

andbackwardtoraisethecuttingunits.Whenstartingthe

machine,withthecuttingunitsinthedownposition,pressthe

liftswitchdowntoallowthecuttingunitstooatandmow.

Note:ThedeckswillnotlowerwhileintheHIspeedrange

andtheywillnotraiseorloweriftheoperatorisoutofthe

seatwhentheengineisrunning.

ThrottleControl

Movethecontrol(Figure4)forwardtoincreasetheengine

speedandrearwardtodecreasethespeed.

LightSwitch

Presstheloweredgeoftheswitch(Figure4)toturnonthe

lights.Presstheupperedgeoftheswitchtoturnoffthelights.

GlowPlugIndicatorLight

ChargeIndicator

Thechargeindicator(Figure4)illuminateswhenthesystem

chargingcircuitmalfunctions.

KeySwitch

Thekeyswitch(Figure4)hasthreepositions:Off,

On/Preheat,andStart.

PTOSwitch

ThePTOswitch(Figure4)hastwopositions:Out(start)

andIn(stop).PullthePTObuttonouttoengagethecutting

unitblades.Pushinthebuttontodisengagethecuttingunit

blades.

Whenlit,theglowplugindicatorlight(Figure4)indicates

thattheglowplugsareon.

EngineCoolantTemperatureWarning

Light

Thelight(Figure4)illuminatesandthecuttingunitsshut

down(PTOdisengages)iftheenginereachesanunsafe

operatingtemperature.Ifthetemperaturecontinuestorise

theenginewillshutdown.

EngineCoolingFanSwitch

Themachineisequippedwithahydraulicallydrivenauto

reversingenginecoolingfan.Thefanswitch(Figure5)has

15

Page 16

twopositionsR(manualreverse)andAuto(normal).Refer

G011547

1

2

3

toEngineCoolingFanOperationintheOperationSection

ofmanual.

Figure5

1.Powerpoint3.Hourmeter

2.Enginecoolingfanswitch

FanControl

Rotatethefancontrolknobtoregulatethespeedofthefan

(Figure6).

TemperatureControl

Rotatethetemperaturecontrolknobtoregulatetheair

temperatureinthecab(Figure6).

HourMeter

Thehourmeter(Figure5)showsthetotalhoursthatthe

machinehasbeenoperated.

PowerPoint

Thepowerpoint(Figure5)isusedtopoweroptional

electricalaccessories.

AudibleAlarm

Towarnbystanders,analarmwillsoundifthecuttingdecks

areloweredwiththeengineoff.Thealarmwillquitsounding

oncethedecklowerswitchisreleased.Also,thealarmwill

soundiftheenginecoolanttemperaturereachesaset-point

thatcutsoutthePTOoperation.Thealarmwillcontinue

tosounduntilthecoolanttemperaturedropsbelowthe

set-pointorthePTOswitchisdisengaged.

CabControls

Model30447only

Figure6

1.Windshieldwiperswitch5.Hazardlightswitch

2.Airconditioningswitch6.Turnsignalswitch

3.Temperaturecontrol7.Domelightswitch

4.Fancontrol

HazardLightSwitch

Presstheswitchtoactivatethehazardlights(Figure6).

TurnSignalSwitch

Presstheswitchtoactivatetheturnsignals(Figure6).

DomeLightSwitch

Presstheswitchtoactivatethedomelight(Figure6).

WindShieldLatch

WindShieldWiperSwitch

Pressfrontofswitchtoactivatethewindshieldwipers

(Figure6)andrearofswitchtoturnoffthewipers.

AirConditioningSwitch

Pressfrontofswitchtoactivatetheairconditioning(Figure6)

andrearofswitchtoturnofftheairconditioning.

Liftuponlatchestoopenthewindshield(Figure7).Press

inonlatchtolockwindshieldinopenposition.Pulloutand

downonlatchtocloseandsecurewindshield.

16

Page 17

1.Windshieldlatch

Figure7

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Widthofcut

overall

frontcuttingunit54inch(137cm)

sidecuttingunit

frontandonesidecuttingunit89inch(226cm)

Overallwidth

cuttingunitsdown

cuttingunitsup(transports)71inch(180cm)

Overalllength144inch(366cm)

Height

124inch(315cm)

37inch(94cm)

127inch(322cm)

58inch(147cm)

HeightwithROPS

Heightwithcab

Groundclearance6inch(15cm)

Wheeltread(tocenteroftire)

front45inch(1 14cm)

rear

Wheelbase

Weight(withcuttingunits)

(Weightwithcabwithcuttingunits)

81inch(206cm)

91inch(231cm)

47inch(1 19cm)

55-1/2inch(141cm)

4211lb(1910kg)

4715lb(2139kg)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesare

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

17

Page 18

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

BeforeOperating

CAUTION

Ifyouleavethekeyintheignitionswitch,someone

couldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoany

maintenance.

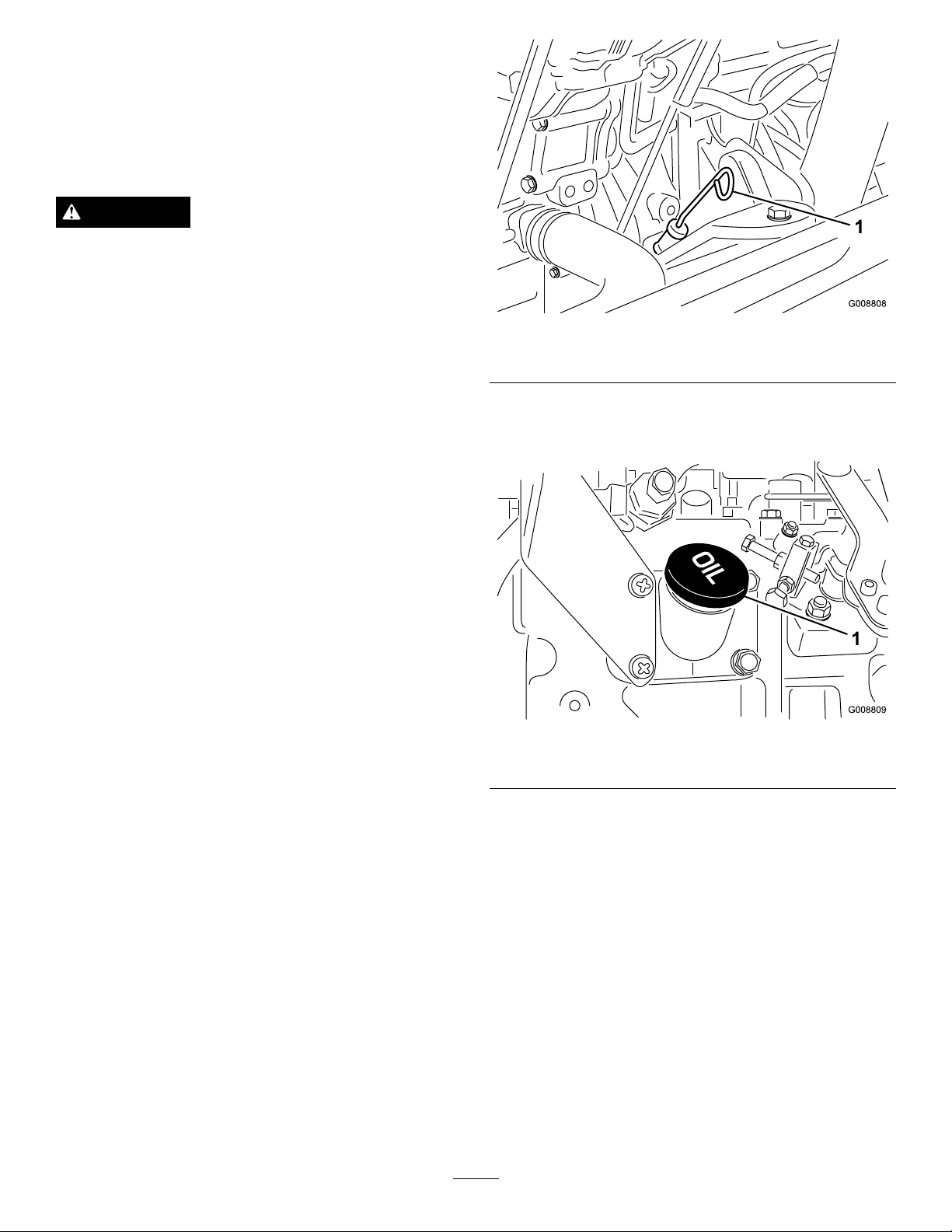

CheckingtheEngineOil

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;however,the

oillevelmustbecheckedbeforeandaftertheengineisrst

started.

Thecrankcasecapacityis10qt(9.5l)withthelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4orhigher.

•Preferredoil:SAE15W-40(above0°F)

•Alternateoil:SAE10W-30or5W-30(alltemperatures)

ToroPremiumEngineOilisavailablefromyourdistributor

ineither15W -40or10W -30viscosity .Seethepartscatalog

forpartnumbers.

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscoolbeforeithasbeenstartedfortheday.Ifithas

alreadybeenrun,allowtheoiltodrainbackdowntothe

sumpforatleast10minutesbeforechecking.Iftheoillevel

isatorbelowthe“add”markonthedipstick,addoiltobring

theoilleveltothe“full”mark.DONOTOVERFILL.If

theoillevelisbetweenthe“full”and“add”marks,nooil

additionisrequired.

1.Parkthemachineonalevelsurface.Unlocktheengine

coverlatches.

2.Opentheenginecover.

3.Removethedipstick,wipeitclean,installthedipstick

intothetube,andpullitoutagain.Theoillevelshould

beuptotheFULLmark(

Figure8).

Figure8

1.Dipstick

4.IftheoilisbelowtheFullmark,removethellcap

(Figure9)andaddoiluntilthelevelreachestheFull

mark.Donotoverll.

Figure9

1.Oilllcap

Note:Whenusingdifferentoil,drainalloldoilfrom

thecrankcasebeforeaddingnewoil.

5.Installtheoilllcapanddipstick.

6.Closetheenginecoverandsecureitwiththelatches.

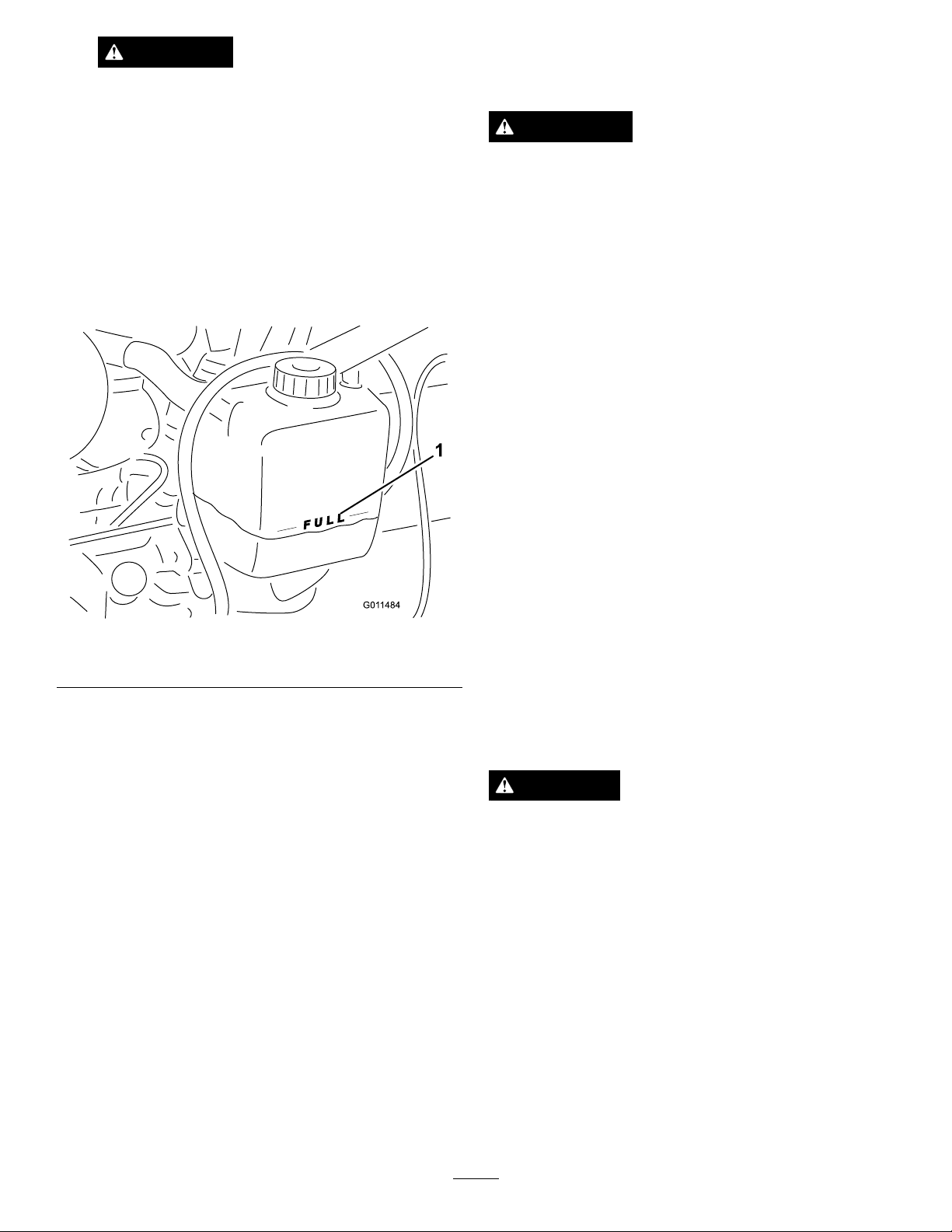

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily

Checklevelofcoolantatthebeginningofeachday .Capacity

ofsystemis13qts.(12.3l).

1.Carefullyremovetheradiatorcapandexpansiontank

cap(

Figure10).

18

Page 19

CAUTION

Iftheenginehasbeenrunning,the

pressurized,hotcoolantcanescapeandcause

burns.

•Donotopentheradiatorcapwhenthe

engineisrunning.

•Usearagwhenopeningtheradiatorcap,

andopenthecapslowlytoallowsteamto

escape.

2.Checkthecoolantlevelintheradiator.Theradiator

shouldbelledtothetopofthellerneckandthe

expansiontanklledtotheFullmark.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepfuelawayfromeyesandskin.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultralowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

Figure10

1.Expansiontank

3.Ifthecoolantislow ,adda50/50mixtureofwaterand

ethyleneglycolanti-freeze.Donotusewateronlyor

alcohol/methanolbasecoolants.

4.Installtheradiatorcapandexpansiontankcap.

AddingFuel

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultralow(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchasefuelin

quantitiesthatcanbeusedwithin180daystoensurefuel

freshness.

Fueltankcapacity:19USgallons(72l)

Usesummergradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Useofwintergrade

fuelatlowertemperaturesprovideslowerashpointand

coldowcharacteristicswhichwilleasestartingandreduce

fuellterplugging.

Useofsummergradefuelabove20°F(-7°C)willcontribute

towardlongerfuelpumplifeandincreasedpowercompared

towintergradefuel.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather.

•Monitorseals,hoses,gasketsincontactwithfuelasthey

maybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblendsd.

•Contactyourdistributorifyouwishformoreinformation

onbiodiesel.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

19

Page 20

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipmentwithits

wheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromafueldispenser

nozzle.

•Ifafueldispensernozzlemustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

1.Parkthemachineonalevelsurface.

2.Usingacleanrag,cleanareaaroundfueltankcap.

3.Removecapfromthefueltank(Figure11).

CheckingtheHydraulicFluid

ServiceInterval:Beforeeachuseordaily

Themachinesreservoirislledatthefactorywith

approximately8U.S.gallons(30.2l)ofhighqualityhydraulic

uid.Checkthelevelofthehydraulicuidbefore

theengineisrststartedanddailythereafter.The

recommendedreplacementuidis:

ToroPremiumAllSeasonHydraulicFluid(Availablein

5gallonpailsor55gallondrums.SeepartscatalogorToro

distributorforpartnumbers.)

Alternateuids:IftheTorouidisnotavailable,otheruids

maybeusedprovidedtheymeetallthefollowingmaterial

propertiesandindustryspecications.W edonotrecommend

theuseofsyntheticuid.Consultwithyourlubricant

distributortoidentifyasatisfactoryproduct.

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehindtheir

recommendation.

HighViscosityIndex/LowPourPointAnti-wear

HydraulicFluid,ISOVG46

MaterialProperties:

St@40°C44to48 Viscosity,ASTMD445

St@100°C7.9to8.5

ViscosityIndexASTMD2270

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:VickersI-286-S(Quality

Level),VickersM-2950-S

(QualityLevel),Denison

140to160

HF-0

Figure11

1.Fueltankcap

4.Fillthetankuntilthelevelistothebottomoftheller

neckwithdieselfuel.

5.Installfueltankcaptightlyafterllingtank.

Note:Ifpossible,llthefueltankaftereachuse.This

willminimizepossiblebuildupofcondensationinside

thefueltank.

Note:Manyhydraulicuidsarealmostcolorless,makingit

difculttospotleaks.Areddyeadditiveforthehydraulic

systemoilisavailablein2/3oz(20ml)bottles.Onebottle

issufcientfor4-6gallons(15-221)ofhydraulicoil.Order

partno.44-2500fromyourauthorizedTorodistributor.

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,andremovethekey.

2.Unlatchtheseat,raiseit,andengagetheproprod.

3.Cleantheareaaroundthellerneckandcapofthe

hydraulictank(

llerneck.

20

Figure12).Removethecapfromthe

Page 21

Figure12

1.Hydraulictankcap

4.Removethedipstickfromthellerneckandwipeit

withacleanrag.Insertthedipstickintothellerneck;

thenremoveitandchecktheuidlevel.Theuidlevel

shouldbebetweenthetwomarksonthedipstick.

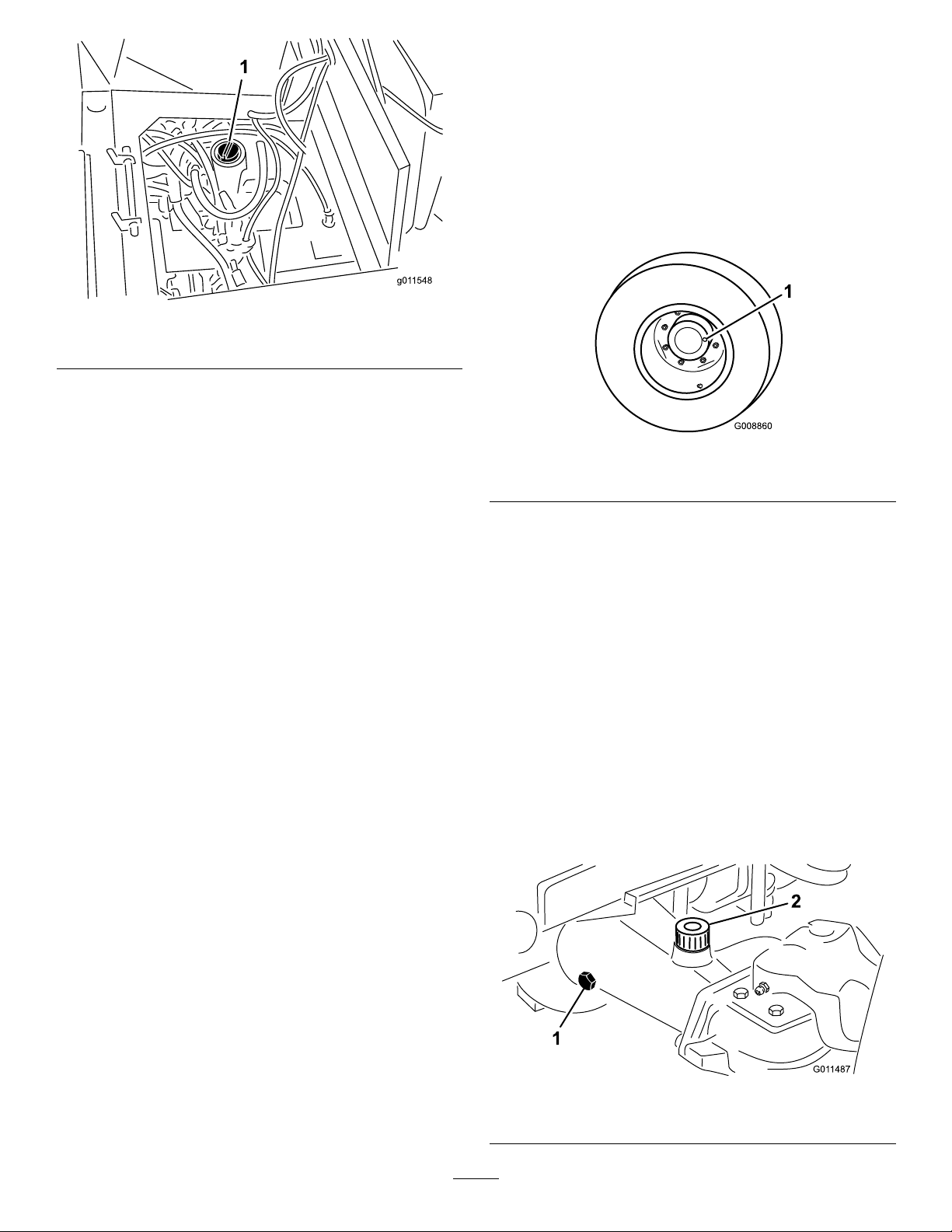

CheckingthePlanetaryGearDriveOil

ServiceInterval:Every400hours

Checktheoillevelafterevery400hoursofoperationorif

externalleakageisnoted.UsehighqualitySAE85W -140gear

lubeasareplacement.

Thecapacityofthesystemisapproximately16oz(0.5l).

1.Withthemachineonalevelsurface,positionthewheel

sothatthecheck/drainplug(Figure13)isateitherthe

3or9o'clockposition.

Figure13

5.Ifthelevelislow ,addtheappropriateuidtoraisethe

leveltotheuppermark.

6.Installthedipstickandcapontothellerneck.

1.Check/drainplug

2.Addgearoiltotheholeintheplanetary,ifnecessary,

tobringtheoiluptotheproperlevel.Installtheplug.

3.Repeattheprocedureontheoppositegearassembly.

CheckingtheRearAxleLubricant

ServiceInterval:Every400hours

TherearaxleislledwithSAE85W-140gearlube.Checkthe

oillevelbeforetheengineisrststartedandevery400hours

thereafter.Thecapacityis80oz(2.4l).Visuallyinspectfor

leaksdaily.

1.Positionthemachineonalevelsurface.

2.Removeacheckplugfromoneendoftheaxle

Figure14)andmakesurethatthelubricantisuptothe

(

bottomofthehole.Ifthelevelislow ,removethell

plug(Figure14)andaddenoughlubricanttobringthe

leveluptothebottomofthecheckplugholes.

Figure14

1.Checkplug

21

2.Fillplug

Page 22

CheckingtheRearAxleGearBox

Lubricant

ServiceInterval:Every400hours

ThegearboxislledwithSAE85W -140gearlube.Check

theoillevelbeforetheengineisrststartedandevery400

hoursthereafter.Thecapacityis16oz(0.5l).Visuallyinspect

forleaksdaily.

1.Positionthemachineonalevelsurface.

2.Removethecheck/llplugfromtheleftsideofthe

gearbox(Figure15)andmakesurethatlubricantis

uptothebottomofthehole.Ifthelevelislow,add

enoughlubricanttobringtheleveluptothebottom

ofthehole.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Thetiresareover-inatedforshipping.Therefore,release

someoftheairtoreducethepressure.Thecorrectair

pressureinthefrontandreartiresis25-30psi(172-207kPa).

Important:Maintainevenpressureinalltirestoensure

agoodquality-of-cutandpropermachineperformance.

Do not under -inate.

CheckingtheTorqueoftheWheelNuts

orBolts

ServiceInterval:Aftertherst10hours

Every200hours

WARNING

Failuretomaintainpropertorqueofthewheelnuts

couldresultinfailureorlossofwheelandmay

resultinpersonalinjury.

Torquethefrontwheelnutsandrearboltsto85-100

ft-lb(115-136N⋅ ⋅⋅m)after1-4hoursofoperationand

againafter10hoursofoperation.T orqueevery200

hoursthereafter.

Figure15

1.Gearbox2.Check/llplug

AdjustingtheHeight-of-Cut

CenterCuttingUnit

Theheight-of-cutisadjustablefrom1to5inches(25to

127mm)in1/2inch(13mm)increments.Toadjustthe

height-of-cutonthefrontcuttingunit,positionthecastor

wheelaxlesintheupperorlowerholesofthecastorforks,

addorremoveanequalnumberofspacersfromthecastor

forks,andsecuretherearchaintothedesiredhole.

1.Starttheengineandraisethecuttingunitssothatthe

height-of-cutcanbechanged.Stoptheengineand

removethekeyafterthecuttingunitisraised.

2.Positionthecastorwheelaxlesinthesameholesinall

castorforks.Refertothefollowingcharttodetermine

thecorrectholesforthesetting.

22

Page 23

Figure16

5.Removethehairpincotterandclevispinsecuringthe

height-of-cutchainstotherearofthecuttingunit

(

Figure18).

1.Tensioningcap4.Topaxlemountinghole

2.Spacers5.Castorwheel

3.Shims

Note:Whenoperatingin2-1/2inch(64mm)height

ofcutorhigher,theaxleboltmustbeinstalledinthe

lowercastorforkholetopreventgrassbuildupbetween

thewheelandthefork.Whenoperatinginheight

ofcutslowerthan2-1/2inches(64mm)andgrass

buildupisdetected,reversethemachinesdirectionto

pullanyclippingsawayfromthewheel/forkarea.

3.Removethetensioningcapfromthespindleshaft

(Figure16)andslidethespindleoutofthecastorarm.

Putthe2shims(1/8inch[3mm])ontothespindle

shaftastheywereoriginallyinstalled.Theseshimsare

requiredtoachievealevelacrosstheentirewidthof

thecuttingunits.Slidetheappropriatenumberof1/2

inchspacers(refertothechartbelow)ontothespindle

shafttogetthedesiredheight-of-cut;thenslidethe

washerontotheshaft.

Refertothefollowingcharttodeterminethe

combinationsofspacersforthesetting:

Figure18

1.Height-of-cutchain2.Clevispin&hairpincotter

6.Mounttheheight-of-cutchainstothedesired

height-of-cuthole(

Figure19)withtheclevispinand

hairpincotter.

Figure19

Note:Whenusing1inch(25mm),1-1/2inch(38

mm),oroccasionally2inch(51mm)height-of-cut,

movetheskidsandgagewheelstothehighestposition.

Figure17

4.Pushthecastorspindlethroughthefrontcastorarm.

Installtheshims(astheywereoriginallyinstalled)and

theremainingspacersontothespindleshaft.Installthe

tensioningcaptosecuretheassembly .

WingCuttingUnits

Toadjusttheheight-of-cutonthesidecuttingunits,add

orremoveanequalnumberofspacersfromthecastor

forks,positionthecastorwheelaxlesinthehighorlow

height-of-cutholesinthecastorforks,andsecurethepivot

armstotheselectedheight-of-cutbracketholes.

1.Positionthecastorwheelaxlesinthesameholesinall

ofthecastorforks(Figure20andFigure22).Referto

thefollowingcharttodeterminethecorrectholefor

thesetting.

2.Removethetensioningcapfromthespindleshaft

(

Figure20)andslidethespindleoutofcastorarm.Put

thetwoshims(1/8inch[3mm])ontospindleshaftas

theywereoriginallyinstalled.Theseshimsarerequired

toachievealevelacrosstheentirewidthofthecutting

units.Slidetheappropriatenumberof1/2inchspacers

23

Page 24

ontothespindleshafttogetthedesiredheight-of-cut;

thenslidethewasherontotheshaft.

Figure22

Figure20

1.Tensioningcap4.Topaxlemountinghole

2.Spacers5.Castorwheel

3.Shims

Refertothefollowingcharttodeterminethe

combinationsofspacersforthesetting.

Figure21

3.Pushthecastorspindlethroughthecastorarm.Install

theshims(asoriginallyinstalled)andtheremaining

spacersontothespindleshaft.Installthetensioning

captosecuretheassembly .

4.Removethehairpincotterandclevispinsfromthe

castorpivotarms(Figure22).

1.Castorpivotarm3.Clevispinandhairpin

cotter

2.Axlemountingholes4.T ensionrod

Figure23

AdjustingtheSkids

Theskidsshouldbemountedinthelowerpositionwhen

operatinginheightofcutsgreaterthan2-1/2inches(64mm)

andinthehigherpositionwhenoperatinginheightofcuts

lowerthan2-1/2inches(64mm).

Adjusttheskidsbyremovingtheangeboltandnuts,

positioningthemasdesired,andinstallingthefasteners

(Figure24).

5.Rotatetensionrodtoraiseorlowerpivotarm

untilholesarealignedwithselectedheight-of-cut

bracketholesinthecuttingunitframe(Figure22and

Figure23).

6.Inserttheclevispinsandinstallthehairpincotters.

7.Rotatetensionrodcounterclockwise(ngertight)to

puttensiononadjustment.

Figure24

1.Skid

24

Page 25

AdjustingtheCuttingUnitRollers

Thecuttingunitrollersshouldbemountedinthelower

positionwhenoperatinginheightofcutsgreaterthan2-1/2

inches(64mm)andinthehigherpositionwhenoperatingin

heightofcutslowerthan2-1/2inches(64mm).

1.Removetheboltandnutsecuringthegagewheelto

thecuttingunitbrackets(Figure25).

Figure25

1.Gagewheel

2.Aligntherollerandspacerwiththetopholesinthe

bracketsandsecurethemwiththeboltandnut.

Figure27

1.Adjusterbolt2.Jamnut

CorrectingMismatchBetweenCutting

Units

Duetodifferencesingrassconditionsandthecounterbalance

settingofthetractionunit,itisadvisedthatasampleareaof

grassbecutandappearancecheckedbeforeformalcutting

isstarted.

1.Setallcuttingunitstothedesiredheightofcut;referto

AdjustingtheHeightofCut.

2.Checkandadjustfrontandreartractortirepressureto

25-30psi(172-207kPa).

AdjustingtheBlade

Toensureproperoperationofthecuttingunit,theremustbe

0.38-0.62inch(10-16mm)clearancebetweenthetipsofthe

wingandcentercuttingunitblades(Figure26).

1.Raisecuttingunitsobladesarevisibleandblockcenter

decksectionsoitcannotfallaccidentally.Wingdecks

mustbehorizontaltocentercuttingunit.

2.Rotateacenterandadjoiningwingbladesothereblade

tipsarealigned.Measuredistancebetweenbladetips,

distanceshouldbeapproximately0.38-0.62inch(10-16

mm)(

Figure26).

Figure26

3.Toadjustdistance,locateadjusterboltonrearpivot

linkofcuttingunit(

adjusterbolt.Loosenortightenadjusterboltsuntil

0.38-0.62inch(10-16mm)clearanceisattained,then

tightenjamnut.

4.Repeatprocedureonoppositesideofcuttingdeck.

Figure27).Loosenjamnuton

3.Checkandadjustallcastortirepressuresto50psi(345

kPa).

4.Checkchargeandcounterbalancepressureswith

engineathighidleusingtestportsdenedinHydraulic

SystemsTestPorts.Adjustcounterbalancesettingtobe

230psi(1585kPa)higherthanchargepressurereading.

5.Checkforbentblades;refertoCheckingforaBent

Blade.

6.Cutgrassinatestareatodetermineifallcuttingunits

arecuttingatthesameheight.

7.Ifcuttingunitadjustmentsarestillneeded,ndaat

surfaceusinga6foot(2m)orlongerstraightedge.

8.Toeasemeasuringbladeplane,raisetheheightofcut

tothehighestposition;refertoAdjustingtheHeight

ofCut.

9.Lowercuttingunitsontotheatsurface.Removethe

coversfromthetopofthecuttingunits.

10.Loosentheangenut,securingtheidlerpulley,to

releasethebelttensiononeachcuttingunit.

CenterCuttingUnitSetup

Rotatebladeoneachspindleuntiltheendsfaceforwardand

backward.Measurefromtheoortothefronttipofthe

cuttingedge.Adjust1/8inchshimsonfrontcastorfork(s)to

matchheightofcuttodecal(Figure28);refertoAdjusting

theCuttingUnitPitch.

25

Page 26

Figure28

1.Tensioningcap4.Topaxlemountinghole

2.Spacers5.Castorwheel

3.Shims

WingCuttingUnitSetup

Rotatebladeofeachspindleuntiltheendsfaceforwardand

backward.Measurefromtheoortothefronttipofthe

cuttingedge.Adjust1/8inchshimsonfrontcastorarm(s)

tomatchheightofcuttodecal(

bladespindleonly,refertoAdjustingtheCuttingUnitPitch.

Figure29).Fortheoutside

AdjustingtheMirrors

Model30447only

RearViewMirror

Whilesittingintheseat,adjusttherearviewmirror

(Figure30)toattainthebestviewouttherearwindow .Pull

theleverrearwardtotiltthemirrortoreducethebrightness

andglareoflight.

SideViewMirrors

Whilesittingintheseat,haveahelperadjustthesideview

mirrors(Figure30)toattainthebestviewaroundthesideof

themachine.

Figure30

1.Sideviewmirrors

2.Rearviewmirror

3.Lever

Figure29

1.Castorarm3.Castorfork

2.Shims

MatchingHeightOfCutBetweenCuttingUnits

1.Positionbladesidetosideonoutsidespindleofboth

wingcuttingunits.Measurefromtheoortothetip

ofthecuttingedgeonbothunitsandcompare.These

numbersshouldbewithin1/8inch(3mm)ofeach

other.

2.Addorremove1/8inchshimsasneededonwing

castorwheels.Recheckmeasurementbetweenoutside

edgesofbothwingcuttingunitsandadjustasnecessary.

AimingtheHeadlights

1.Loosenthemountingnutsandpositioneachheadlight

sothatitpointsstraightahead.Tightenthemounting

nutjustenoughtoholdtheheadlightinposition.

2.Placeaatpieceofsheetmetaloverthefaceofthe

headlight.

3.Mountamagneticprotractorontotheplate.While

holdingtheassemblyinplace,carefullytilttheheadlight

downward3degrees,thentightenthenut.

4.Repeattheprocedureontheotherheadlight.

StartingandStoppingthe Engine

Important:Thefuelsystemwillautomaticallybleed

itselfwhenanyofthefollowingsituationsoccur:

•Initialstartupofanewmachine.

•Theenginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponthefuelsystem

components.

RefertotheBleedingAirfromtheInjectors.

26

Page 27

1.Ensurethattheparkingbrakeisset.Removeyourfoot

fromthetractionpedalandensurethatitisinneutral.

2.Movethethrottlecontroltothemid-idleposition.

CheckingtheInterlock Switches

3.TurntheignitionkeytotheRunposition.Theglow

indicatorwilllight.

4.Whentheglowindicatordims,turntheignitionkey

totheStartposition.Releasethekeyimmediately

whentheenginestartsandallowittoreturntothe

Runposition.Allowenginetowarmupatmidspeed

(withoutload),thenmovethethrottlecontroltothe

desiredposition.

Important:Donotrunthestartermotormore

than15secondsatatimeorprematurestarter

failuremayresult.Iftheenginefailstostartafter15

seconds,turnthekeytotheOffposition,recheck

thecontrolsandprocedures,wait15additional

seconds,andrepeatthestartingprocedure.

Whenthetemperatureislessthan20°F(-75C),preheat

glowplugstwicepriortoinitialcrankingattempt.The

startermotorcanberunfor30secondsonthen60

secondsofffor2attempts.

5.Tostoptheengine,movethethrottlecontrolbackward

totheSlowposition,movethePTOlevertotheOff

position,settheparkingbrake,androtatetheignition

keytoOff.Removethekeyfromtheswitchtoprevent

accidentalstarting.

Important:Allowenginetoidlefor5minutesbefore

shuttingitoffafterafullloadoperation.Failuretodo

somayleadtoturbo-chargertrouble.

EngineCoolingFanOperation

Theenginecoolingfanswitchhastwopositionsfor

controllingtheoperationofthefan.ThetwopositionsareR

andAuto.Thefanhastheabilitytoreversetoblowdebris

offoftherearscreen.Undernormaloperatingconditions,

theswitchwillbeintheAutoposition.InAuto,thefanspeed

willbecontrolledbythecoolantorhydraulicoiltemperature

andwillautomaticallyreversetoblowdebrisoffoftherear

screen.Areversecycleisautomaticallyinitiatedwheneither

thecoolantorhydraulictemperaturereachesacertainpoint.

BypressingthefanswitchforwardintotheRposition,the

fanwillcompleteamanuallyinitiatedreversecycle.Itis

recommendedtoreversethefanwhentherearscreenis

cloggedorpriortoenteringtheshoporthestoragearea.

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Themachinehasinterlockswitchesintheelectricalsystem.

Theseswitchesaredesignedtostoptheenginewhenthe

operatorgetsoffoftheseatwhenthetractionpedalis

depressed.However,theoperatormaygetoffoftheseat

whiletheengineisrunningandthetractionpedalisinneutral.

AlthoughtheenginewillcontinuetorunifthePTOleveris

disengagedandthetractionpedalisreleased,itisstrongly

recommendedthattheenginebestoppedbeforerisingfrom

theseat.

Tochecktheoperationoftheinterlockswitches,perform

thefollowingprocedure:

1.Drivethemachineslowlytoalarge,relativelyopen

area.Lowerthecuttingunit,stoptheengine,andapply

theparkingbrake.

2.Sitontheseatanddepressthetractionpedal.Tryto

starttheengine.Theengineshouldnotcrank.Ifthe

enginecranks,thereisamalfunctionintheinterlock

systemthatshouldbecorrectedbeforebeginning

operation.

3.Sitontheseatandstarttheengine.Risefromtheseat

andmovethePTOlevertoOn.ThePTOshouldnot

engage.IfthePTOengages,thereisamalfunctionin

theinterlocksystemthatshouldbecorrectedbefore

beginningoperation.

4.Sitontheseat,engagetheparkingbrakeandstartthe

engine.Movethetractionpedaloutoftheneutral

position.Theengineshouldkill.Iftheenginedoesnot

kill,thereisamalfunctionintheinterlocksystemthat

shouldbecorrectedbeforebeginningoperation.

5.Sitontheseat,starttheengineandsetspeedrangeto

low .MovePTOswitchforwardtoengagecuttingunits.

Important:Thecenterliftlevermustmomentarily

bepushedtothelowerpositiontoenablePTO

circuitactuationbyPTOswitch.

•Raiseeitherwingcuttingunittothetransportposition.

Thecuttingunitshouldturnoff.Ifthecuttingunitdoes

notstop,thereisamalfunctionintheinterlocksystem

thatshouldbecorrectedbeforeresumingoperation.

•Ifthewingcuttingunitisloweredagainthemotorshould

re-start.Ifthecuttingunitdoesnotre-start,thereis

27

Page 28

amalfunctionintheinterlocksystemthatshouldbe

correctedbeforeresumingoperation.

•Iftheoperatorrisesfromtheseatwiththecuttingunits

engagedand/orthetractionpedaloutofneutral,the

cuttingunitsmuststopinapproximatelyonesecondand

enginemustshutdowninapproximatelytwoseconds.If

thecuttingunitsdonotstopandtheenginedoesnot

shutdown,thereisamalfunctionintheinterlocksystem

thatshouldbecorrectedbeforeresumingoperation.

PushingorTowingthe Machine

Inanemergency,themachinecanbemovedforwardby

actuatingthebypassvalveinthevariabledisplacement

hydraulicpumpandpushingortowingthemachine.Donot

pushortowthemachineformorethan1/4mile(0.4km).

Important:Donotpushortowthemachinefasterthan

2-3MPH(3-4.8km/h)becauseinternaltransmission

damagemayoccur.Thebypassvalvemustbeopen

wheneverthemachineispushedortowed.

1.Raisetheseatandremovethebatterycover.Thebypass

valveislocatedinfrontofthebattery(Figure31).

2.Rotatethevalve90degrees(1/4turn)ineither

directiontoopenandallowoiltobypassinternally.

Becauseuidisbypassed,themachinecanbeslowly

movedwithoutdamagingthetransmission.

PartNo.95-8843,CouplerFittingNo.95-0985

[Qty.2],andHydraulicFittingNo.340-77

[Qty.2])tothereversetractionpressuretest

port(

Figure32)andthereversefour-wheeldrive

pressureport(Figure33).

Figure32

1.Reversetractionpressuretestport

Note:Resistancewillbefeltonthevalvewhenitis

movedtotheopenposition.

3.Rotatethevalve90degrees(1/4turn)backtoclosethe

bypassvalvebeforestartingtheengine.However,do

notexceed5to8ft-lb(7to11N⋅m)torquetoclose

thevalve.

Figure31

1.Bypassvalveaccesshole

Important:Ifthemachinemusttobepushedor

towedinreverse,thecheckvalveinthefour-wheel

drivemanifoldmustalsobebypassed.Tobypass

thecheckvalve,connectahoseassembly(Hose

Figure33

1.Reversefour-wheeldrivepressuretestport

JackingPoints

Therearejackingpointslocatedatthefrontandrearofthe

machine.

•Ontheframeattheinsideofeachfrontdrivetire

•Atthecenteroftherearaxle

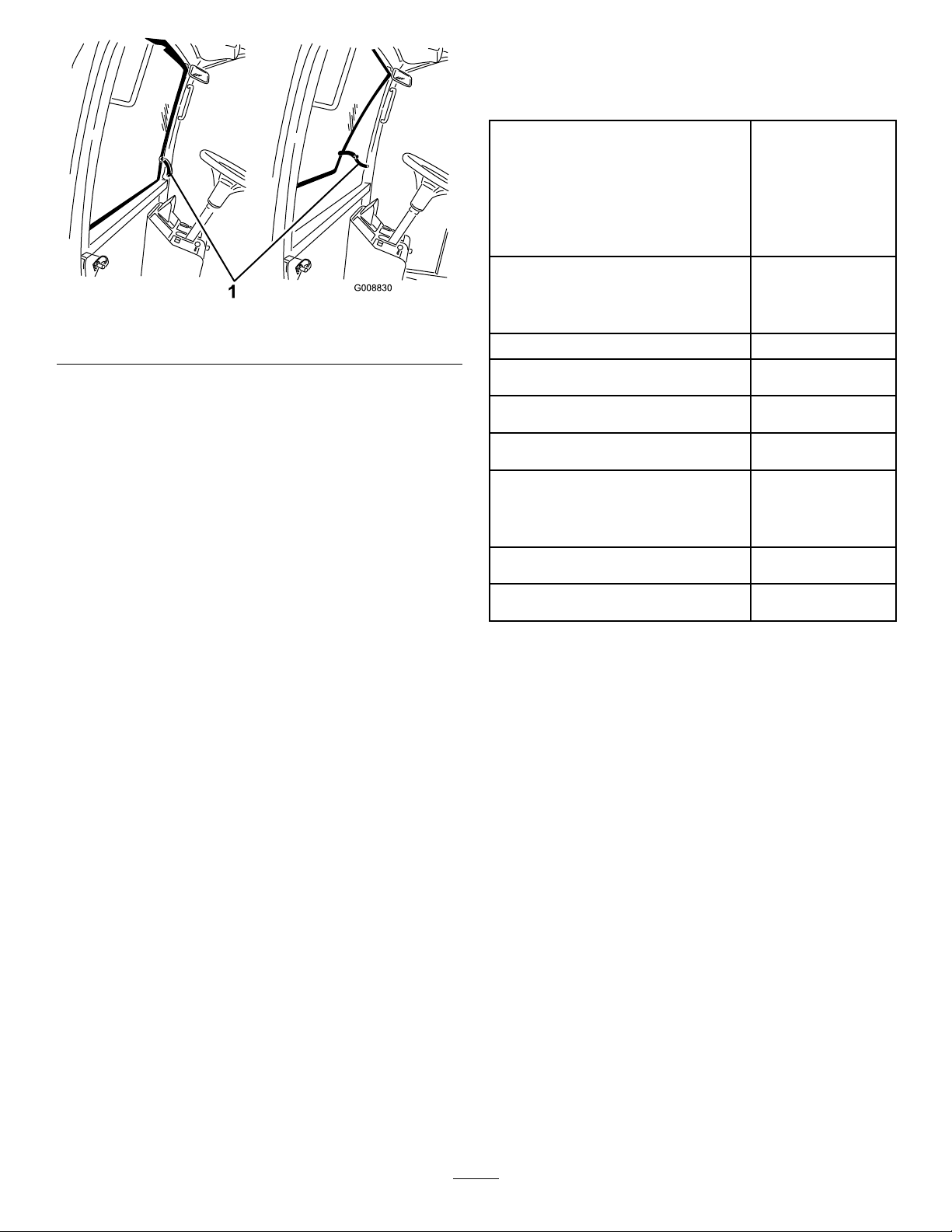

TieDowns

Therearetiedownslocatedatthefront,rearandsidesof

themachine.

•Oneachsideoftheframebythesidecuttingunitliftarms

•Frontcenteroftheoperator'splatform

•Therearbumper

28

Page 29

OperatingCharacteristics

Practicedrivingthemachinebecauseithasahydrostatic

transmissionanditscharacteristicsaredifferentthanmany

turfmaintenancemachines.Somepointstoconsiderwhen

operatingthetractionunit,cuttingunit,orotherimplements

arethetransmission,enginespeed,loadonthecuttingblades

orotherimplementcomponents,andtheimportanceofthe

brakes.

Tomaintainenoughpowerforthetractionunitand

implementwhileoperating,regulatethetractionpedalto

keeptheenginespeedhighandsomewhatconstant.Agood

ruletofollowistodecreasethegroundspeedastheload

ontheimplementincreases,andincreasethegroundspeed

astheloaddecreases.

Therefore,allowthetractionpedaltomovebackwardasthe

enginespeeddecreases,anddepressthepedalslowlyasthe

speedincreases.Bycomparison,whendrivingfromonework

areatoanother,withnoloadandcuttingunitraised,havethe

throttleintheFastpositionanddepressthetractionpedal

slowlybutfullytoattainmaximumgroundspeed.

Thebrakescanbeusedtoassistinturningthemachine.

However,usethemcarefully,especiallyonsoftorwetgrass

becausetheturfmaybetornaccidentally.Anotherbenet

ofthebrakesistomaintaintraction.Forexample,insome

slopeconditions,theuphillwheelslipsandlosestraction.If

thissituationoccurs,depresstheuphillturnpedalgradually

andintermittentlyuntiltheuphillwheelstopsslipping,thus,

increasingtractiononthedownhillwheel.

Useextracarewhenoperatingthemachineonslopes.Make

surethattheseatlatchisproperlysecuredandtheseatbelt

isbuckled.Driveslowlyandavoidsharpturnsonslopesto

preventrollovers.Forsteeringcontrol,thecuttingunitmust

beloweredwhengoingdownhill.

Figure34

1.Transportlatch(wingcuttingunits)

OperatingTips

MowWhenGrassisDry

Moweitherinthelatemorningtoavoidthedew ,whichcauses

grassclumping,orinlateafternoontoavoidthedamage

thatcanbecausedbydirectsunlightonthesensitive,freshly

mowedgrass.

SelecttheProperHeight-of-CutSetting

toSuitConditions

Removeapproximately1inch(25mm)ornomorethan1/3

ofthegrassbladewhencutting.Inexceptionallylushand

densegrass,youmayhavetoraisetheheight-of-cuttothe

nextsetting.

WARNING

Thiscuttingunitisdesignedtodriveobjectsinto

thegroundwheretheyloseenergyquicklyingrass

areas.However,carelessoperation,combinedwith

terrainangle,ricochets,orimproperlypositioned

safetyguardcanleadtothrownobjectinjuries.

•Whenapersonorpetappearssuddenlyinor

nearthemowingarea,

stop mo wing

•Donotresumemowinguntiltheareaiscleared.

Beforestoppingtheengine,disengageallcontrolsandmove

thethrottletoSlow.MovingthethrottletoSlowreduceshigh

enginespeed,noise,andvibration.TurnthekeytoOffto

stoptheengine.

Beforetransportingthemachine,raisethecuttingunitsand

securethetransportlatches(Figure34).

.

MowatProperIntervals

Undermostnormalconditionsyouwillneedtomow

approximatelyevery4-5days.Butremember,grassgrowsat

differentratesatdifferenttimes.Thismeansthatinorderto

maintainthesameheight-of-cut,whichisagoodpractice,

youwillneedtocutmorefrequentlyinearlyspring;asthe

grassgrowthrateslowsinmidsummer,cutonlyevery8-10

days.Ifyouareunabletomowforanextendedperioddue

toweatherconditionsorotherreasons,mowrstwiththe

height-of-cutatahighlevel;thenmowagain2-3dayslater

withalowerheightsetting.

AlwaysMowwithSharpBlades

Asharpbladecutscleanlyandwithouttearingorshredding

thegrassbladeslikeadullblade.Tearingandshredding

causesthegrasstoturnbrownattheedgeswhichimpairs

growthandincreasessusceptibilitytodiseases.

29

Page 30

Transporting

Usethetransportlatcheswhentransportingoverlong

distances,roughterrain,orwhentrailering.

AfterOperating

Toensureoptimumperformance,cleantheundersideofthe

mowerhousingaftereachuse.Ifresidueisallowedtobuild

upinthemowerhousing,cuttingperformancewilldecrease.

Also,removeanydebriswhichmayhavecollectedbetween

thedeckliftcylindersandthefoamdeckpads(Figure35).

Figure35

1.Deckliftcylinder

2.Foamdeckpad

CuttingUnitPitch

Abladepitchof1/4inch(6mm)isrecommended.Apitch

largerthan1/4inch(6mm)willresultinlesspowerrequired,

largerclippings,andapoorerqualityofcut.Apitchlessthan

1/4inch(6mm)willresultinmorepowerrequired,smaller

clippingsandabetterqualityofcut.

MaximizingAirConditioner

Performance

•Tolimitsolarheating,parkthemachineinashadedarea

orleavethedoorsopenindirectsun.

•Checktomakesuretheairconditioningcondenserns

areclean.

•Operatetheairconditionerbloweratthemidspeed

setting.

•Verifycontinuoussealbetweentheroofandtheheadliner.

Correctasrequired.

•Measuretheairtemperatureatthefrontcenterventin

theheadliner(Typicallystabilizeatlessthanorequalto

50degreesF .)

•RefertotheServiceManualforadditionalinformation.

30

Page 31

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst10hours

Aftertherst50hours

Aftertherst200hours

Beforeeachuseordaily

Every50hours

Every100hours

MaintenanceProcedure

•Torquethewheellugnuts.

•Checkthefanbelttension.

•Checkthebladedrivebelttension.

•Changetheengineoilandlter.

•Checktheenginespeed(atidleandfullthrottle).

•Changethefrontplanetarygearoil.

•Changetherearaxleoil.

•Changethehydraulicoil.

•Changethehydraulicoillters.

•Checktheengineoillevel.

•Checkthecoolantlevel.

•Checkthehydraulicuidlevel.

•Checkthetirepressure.

•Checktheaircleanerindicator.

•Checktheinterlockswitchoperation

•Lubricateallgreasettings.

•Checkthebladedrivebelttension.

•Checkthebatterylevelandcableconnections.

•Cleantheundersideofthemowerhousingandunderthebeltcovers.

•Inspectthecoolingsystemhosesandclamps.

•Checkthefanbelttension.

Every150hours

Every200hours

Every250hours

Every400hours

Every800hours

Every2years

•Changetheengineoilandlter.

•Torquethewheellugnuts.

•Servicethesparkarrestormufer

•Cleanthecabairlters.(Replacethemiftheyaretornorexcessivelydirty.)

•Checktheplanetarygeardriveoil.

•Checktherearaxlelubricant.

•Checktherearaxlegearboxlubricant.

•Servicetheairlter(iftheindicatorshowsred).

•Inspectthefuellinesandconnections.

•Replacethefuelltercanister.

•Checktheenginespeed(atidleandfullthrottle).

•Drainandcleanthefueltank.

•Changethefrontplanetarygearoil.

•Changetherearaxleoil.

•Checktherearwheeltoe-in.

•Inspectthebladedrivebelts.

•Changethehydraulicoil.

•Changethehydraulicoillters.

•Inspectthecuttingunitcastorwheelassemblies.

•Checkandadjustthevalveclearance.

•Flushthecoolingsystemandreplaceuid.

•Replacemovinghoses.

31

Page 32

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

ServiceIntervalChart

Lubrication

GreasingtheBearingsand Bushings

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBaseGrease.

Ifthemachineisoperatedundernormalconditions,lubricate

allbearingsandbushingsafterevery50hoursofoperationor

immediatelyaftereverywashing.

Bearingsrarelyfailfromdefectsinmaterialsorworkmanship.

Themostcommonreasonforfailureismoistureand

contaminationworkingitswaypasttheprotectiveseals.

Bearingsthataregreasedwillrelyuponregularmaintenance

topurgeharmfuldebrisfromthebearingarea.Sealed

bearings,suchasthecastorwheelbearings,relyonan

initialllofspecialgreaseandarobustintegralsealtokeep

contaminantsandmoistureoutoftherollingelements.

Thesealedbearingsrequirenolubricationorshortterm

maintenance.Thisminimizesroutineservicerequired

andreducesthepotentialofturfdamageduetogrease

contamination.Thesesealedbearingpackageswillprovide

goodperformanceandlifeundernormaluse,butperiodic

Figure36

inspectionsofbearingconditionandsealintegrityshould

beconductedtoavoiddowntime.Thesebearingsshould

beinspectedseasonallyandreplacedifdamagedorworn.

Bearingsshouldoperatesmoothlywithnodetrimental

characteristicssuchashighheat,noise,loosenessor

indicationsofcorrosion(rust).

Duetotheoperatingconditionsthesebearing/sealpackages

aresubjectto(i.e.sand,turfchemicals,water,impacts,etc.)

theyareconsiderednormalwearitems.Bearingsthatfaildue

tocausesotherthandefectsinmaterialsorworkmanshipare

typicallynotcoveredunderwarranty.

Note:Bearinglifecanbenegativelyaffectedbyimproper

washdownprocedures.Donotwashdowntheunitwhenit

isstillhotandavoiddirectinghigh-pressureorhighvolume

sprayatthebearings.

Thegreasettinglocationsandquantitiesare:

TractionUnit

ServiceInterval:Every50hours

•Brakeshaftpivotbearings(5)(Figure37)

•Tractionpedalpivotbushing(1)(Figure38)

32

Page 33

•Frontandrearaxlepivotbushings(2)(Figure39)

•Steeringcylinderballjoints(2)(Figure40)

•Tierodballjoints(2)(Figure40)

•Kingpinbushings(2)(

Figure40).

Thetopttingonthekingpinshouldonlybe

lubricatedannually(2pumps).

Figure37

Figure40

CenterCuttingUnit

Note:Deckmayhavetoberaisedtoexposethegrease

ttingsforthelatchpivotandthelowerlink.

Figure38

Figure39

•Latchpivot(2)(Figure42)

Note:Thelatch(Figure41)mayneedtobemanually

trippedtogainaccesstothegreasetting.Useaprybar

tocloseandre-openthelatch

Figure41

1.Latch

33

Page 34

Figure42

•Lowerlinkpivot(4)(Figure43)

•Upperlinkpivot(4)(Figure43)

•Castorforkshaftbushings(2)(Figure44)

•Spindleshaftbearings(3)(Figure45)

•Idlerarmpivotbushings(2)(Figure45)

Figure43

Figure44

Figure45

34

Page 35

CenterLiftAssemblies

WingLiftAssemblies

•Liftarmbushings(2)(Figure46)

•Liftcylinderbushings(4)(Figure46)

•Liftarmballjoints(2)(Figure47)

Figure46

Wingliftcylinder(4)(Figure48)

Figure48

WingCuttingUnits

•Castorforkshaftbushing(1each)(Figure49)

•Spindleshaftbearings(4)

•Idlerarmpivotbushings(1)(locatedontheidlerarm)

Figure47

Figure49

35

Page 36

EngineMaintenance

AirCleanerMaintenance

•Checktheaircleanerbodyfordamagewhichcouldcause

anairleak.Replaceifdamaged.Checkthewholeintake

systemforleaks,damageorloosehoseclamps.

•Servicetheaircleanerlteronlywhentheservice

indicatorrequiresitorevery400hours(morefrequently

inextremelydustyordirtyconditions).Changingtheair

lterbeforeitisnecessaryonlyincreasesthechanceof

dirtenteringtheenginewhenthelterisremoved.

•Besurethecoverisseatedcorrectlyandsealswiththe

aircleanerbody.

debrisfrommigratingintotheintakewhentheprimary

lterisremoved.

Figure51

1.Aircleanerprimarylter

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily

Every400hours

Checktheaircleanerbodyfordamagewhichcouldpossibly

causeanairleak.Replaceadamagedaircleanerbody.

Servicetheaircleanerlterswhentheaircleanerindicator

(Figure50)showsredorevery400hours(morefrequently

inextremelydustyordirtyconditions).Donotover-service

theairlter.

Besurethatthecoverissealingaroundtheaircleanerbody .

1.Pullthelatchoutwardandrotatetheaircleanercover

counterclockwise.Removethecoverfromthebody

(Figure50).Cleantheinsideoftheaircleanercover.

3.Removeandreplacetheprimarylter.Cleaningofthe

usedelementisnotrecommendedduetothepossibility

ofdamagetotheltermedia.Inspectthenewlterfor

shippingdamage,checkingthesealingendofthelter

andthebody .Donotuseadamagedelement.Insert

thenewlterbyapplyingpressuretotheouterrimof

theelementtoseatitinthecanister.Donotapply

pressuretotheexiblecenterofthelter.

Important:Neverattempttocleanthesafetylter

(Figure52).Replacethesafetylterwithanew

oneaftereverythreeprimarylterservices.

Figure52

Figure50

1.Aircleanerindicator3.Aircleanercover

2.Aircleanerlatch

2.Beforeremovingthelter(Figure51),uselow

pressureair(40psi,cleananddry)tohelpremove

largeaccumulationsofdebrispackedbetweenoutside

ofprimarylterandthecanister.Avoidusinghigh

pressureairwhichcouldforcedirtthroughthelter

intotheintakearea.Thiscleaningprocessprevents

1.Aircleanersafetylter

4.Cleanthedirtejectionportlocatedintheremovable

cover.Removetherubberoutletvalvefromthecover,

cleanthecavityandreplacetheoutletvalve.

5.Installthecoverorientingtherubberoutletvalveina

downwardposition-betweenapproximately5:00to

7:00whenviewedfromtheend.

6.Resettheindicator(

36

Figure50)ifitshowsred.

Page 37

ServicingtheEngineOiland Filter

ServiceInterval:Aftertherst50hours

FuelSystem

Maintenance

Every150hours

Changetheoilandlterinitiallyaftertherst50hoursof

operation;thereafterchangetheoilandlterevery150hours.

1.Removeeitherdrainplug(Figure53)andlettheoil

owintoadrainpan.Whentheoilstops,installthe

drainplug.

Figure53

1.Engineoildrainplug

2.Removetheoillter(Figure54).Applyalightcoatof

cleanoiltothenewltersealbeforescrewingiton.

Donotovertighten.

ServicingtheFuelSystem

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are