Page 1

Debris Blower

Groundsmaster) 4000–D

Model No. 30425—Serial No. 220000001 and Up

Form No. 3326–246 Rev B

Operator’s Manual

English (EN)

Page 2

Contents

Introduction

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before Operating 3. . . . . . . . . . . . . . . . . . . . . . . . . .

While Operating 3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sound Pressure Level 4. . . . . . . . . . . . . . . . . . . . . . .

Sound Power Level 4. . . . . . . . . . . . . . . . . . . . . . . .

Vibration Level 4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 5. . . . . . . . . . . . . . . . .

Specifications 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 6. . . . . . . . . . . . . . . . . . . . .

Optional Equipment 6. . . . . . . . . . . . . . . . . . . . . . . .

Setup 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Front Cutting Unit 8. . . . . . . . . . . . . . . . . .

Mount Arm Assemblies 9. . . . . . . . . . . . . . . . . . . . .

Mount Bumper Assembly 9. . . . . . . . . . . . . . . . . . .

Install Handle Assembly 9. . . . . . . . . . . . . . . . . . . .

Install Linkage Rod 10. . . . . . . . . . . . . . . . . . . . . . . .

Mount Blower To Traction Unit 10. . . . . . . . . . . . . . .

Install Hydraulic Motor To Blower 11. . . . . . . . . . . .

Grease Blower 11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Tips 12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting Castor Wheels 12. . . . . . . . . . . . . . . . . . . .

Adjust Discharge Opening 13. . . . . . . . . . . . . . . . . . .

Adjust Discharge Direction 13. . . . . . . . . . . . . . . . . .

Maintenance 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Greasing the Blower 14. . . . . . . . . . . . . . . . . . . . . . . .

Disconnect Blower From Traction Unit 14. . . . . . . . .

Servicing Bumper Bushings 14. . . . . . . . . . . . . . . . . .

Servicing Castor Wheel And Bearing 15. . . . . . . . . .

Alignment Tool 15. . . . . . . . . . . . . . . . . . . . . . . . . . .

The Toro General Commercial Products Warranty 16. . .

Page

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

serial numbers of your product ready. The two numbers are

stamped on a plate which is located on the blower housing.

Write the product model and serial numbers in the space

below:

Model No.

Serial No.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

Caution signals a hazard that may cause minor or moderate

injury if you do not follow the recommended precautions.

This manual uses two other words to highlight information.

Important calls attention to special mechanical

information and Note: emphasizes general information

worthy of special attention.

W 2002 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

Printed in the USA

2

Page 3

Safety

Hazard control and accident prevention are dependent

upon the awareness, concern, and proper training of the

personnel involved in the operation, transport,

maintenance, and storage of the machine. Improper use

or maintenance of the machine can result in injury or

death. To reduce the potential for injury or death,

comply with the following safety instructions.

Before Operating

• Read and understand the contents of this Operator’s

Manual before operating the machine. Become familiar

with all of the controls and know how to stop quickly. A

free replacement manual is available by sending the

complete Model and Serial Number to The Toro

Company, 8111 Lyndale Avenue South, Bloomington,

Minnesota 55420-1196.

• Never allow children to operate the machine. Do not

allow adults to operate machine without proper

instruction. Only trained operators who have read this

manual should operate this machine.

• Never operate the machine when under the influence of

drugs or alcohol.

• Keep all bystanders away from the operating area.

• Keep all shields and safety devices in place. If a shield,

safety device, or decal is illegible or damaged, repair or

replace it before operation is commenced. Also tighten

any loose nuts, bolts, and screws to ensure that the

machine is in safe operating condition.

• Do not operate the machine while wearing sandals,

tennis shoes, sneakers, or shorts. Also, do not wear

loose fitting clothing which could get caught in moving

parts. Always wear long pants and substantial shoes.

Wearing safety glasses, safety shoes, and a helmet is

advisable and required by some local ordinances and

insurance regulations.

While Operating

• This product may exceed noise levels of 85 dB(A) at

the operator position. Ear protectors are recommended

for prolonged exposure to reduce the potential of

permanent hearing damage.

• Optional attachments may impact the operating

characteristics of the traction unit. For example, slopes

that have been mowed with cutting decks may be unsafe

to travel on with a narrow attachment, such as a blower,

due to the loss of support and stability provided by the

width of the decks. Further, the decks may have

prevented the traction unit from coming too close to

holes, dips, drop offs, obstacles and uneven terrain

which may cause a roll over. Use extra caution when

operating a traction unit with a blower attached in place

of mowing decks.

• Rollover protection and seat belts are recommended for

use on hillsides.

• Using the machine demands attention. To prevent loss

of control:

– Operate only in daylight or when there is good

artificial light.

– Drive slowly and watch for holes or other hidden

hazards.

– Do not drive close to a sand trap, ditch, creek, or

other hazard.

– Reduce your speed when making sharp turns and

when turning on hillsides.

– Avoid sudden starts and stops.

– Before backing up, look to the rear and ensure that

no one is behind the machine.

– Watch out for traffic when near or crossing roads.

Always yield the right-of-way.

• Stay away from the discharge opening when the

machine is operating. Keep all bystanders away from

the discharge opening and don’t direct discharge toward

bystanders.

• If the engine stalls or the machine loses headway and

cannot make it to the top of a slope, do not turn the

machine around. Always back slowly straight down the

slope.

• Do not take an injury risk! When a person or pet

appears unexpectedly in or near the operating area, stop

operation. Careless operation, combined with terrain

angles, ricochets, or improperly positioned guards can

lead to thrown object injuries. Do not resume operation

until the area is cleared.

• Lower the blower to the ground and remove the key

from the ignition switch whenever the machine is left

unattended.

Maintenance

• Remove the key from the ignition switch to prevent

accidental starting of the engine when servicing,

adjusting, or storing the machine.

• Perform only those maintenance instructions described

in this manual. If major repairs are ever needed or

assistance is desired, contact an Authorized Toro

Distributor.

3

Page 4

• Be sure that the machine is in safe operating condition

by keeping nuts, bolts, and screws tight. Check all bolts

and nuts frequently to be sure that they are tightened to

specification.

• To ensure optimum performance and safety, always

purchase genuine Toro replacement parts and

accessories to keep the machine all Toro. Never use

“will-fit” replacement parts and accessories made by

other manufacturers. Look for the Toro logo to ensure

genuineness. Using unapproved replacement parts and

accessories could void the warranty.

Sound Pressure Level

This unit has an equivalent continuous A–weighted sound

pressure level at the operator ear of 91 dBA, based on

measurements of identical machines per Directive

98/37/EC and amendments.

Sound Power Level

This unit has a guaranteed sound power level of

111 dBA/1 pW, based on measurements of identical

machines per Directive 2000/14/EC and amendments.

Vibration Level

Hand-Arm

This unit does not exceed a vibration level of 2.5 m/s2 at

the hands based on measurements of identical machines per

ISO 5349 procedures.

Whole Body

This unit does not exceed a vibration level of .5 m/s2 at the

posterior based on measurements of identical machines per

ISO 2631 procedures.

4

Page 5

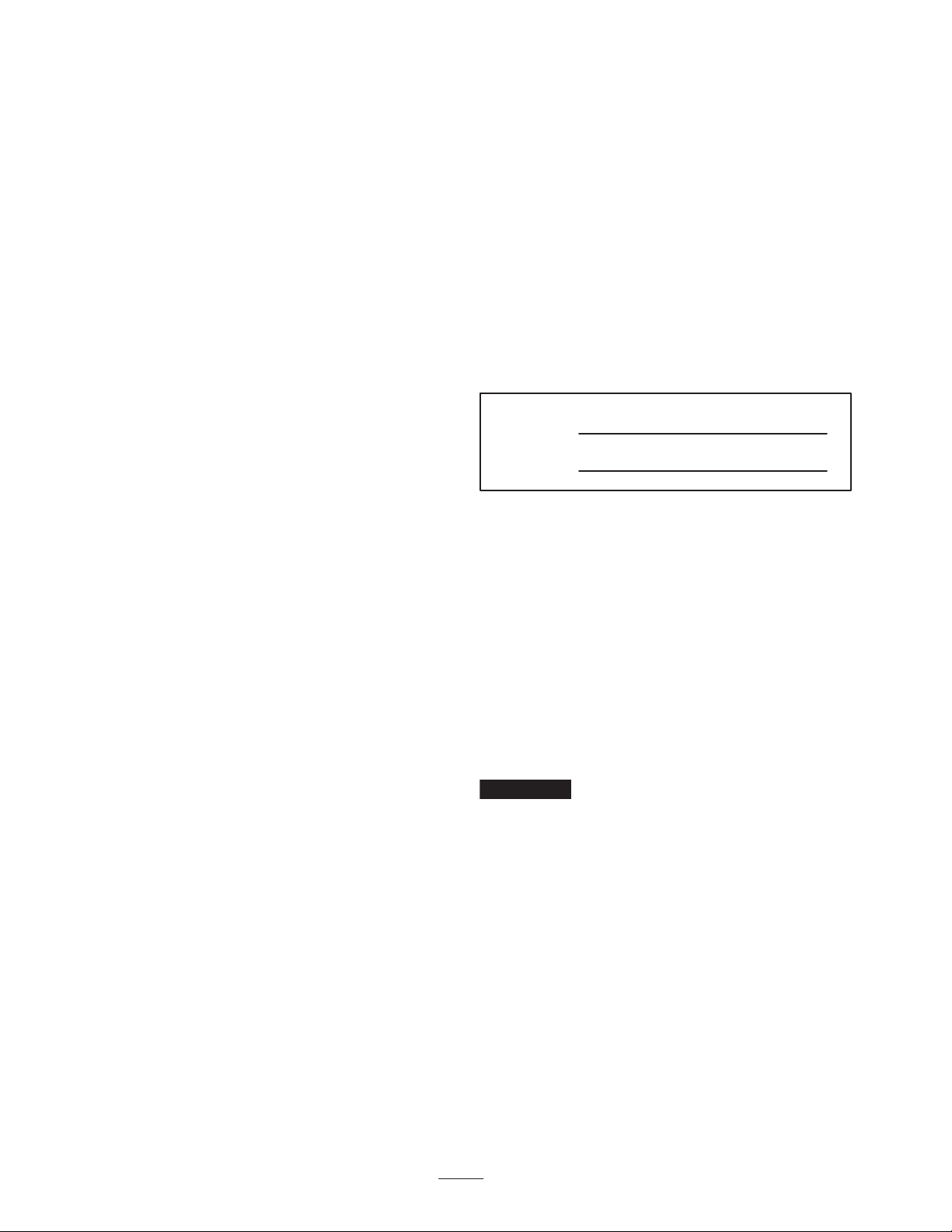

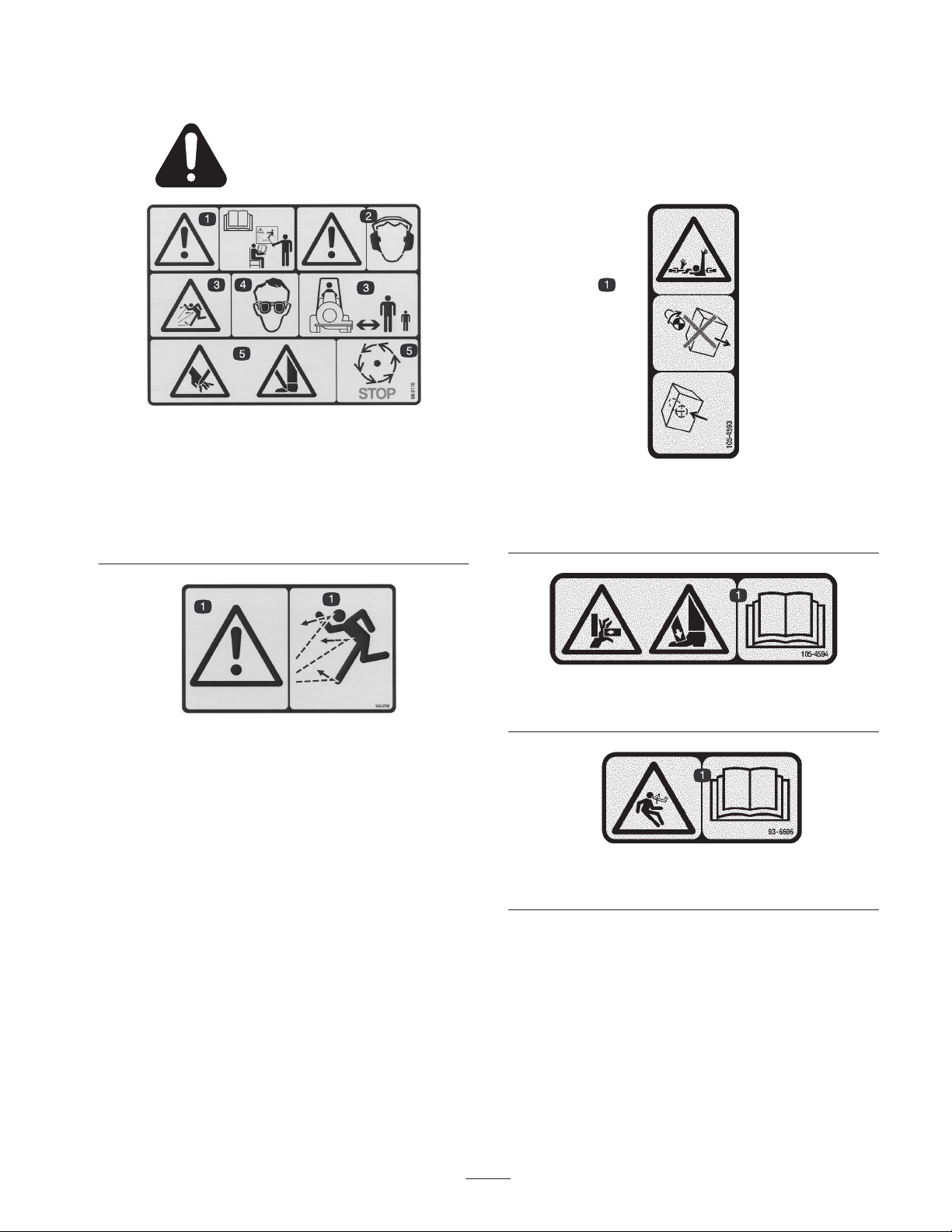

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any area

of potential danger. Replace any decal that is damaged or lost.

98-3110

1. Danger–See Operator’s

Manual

2. Danger–Wear ear

protection

3. Thrown object

hazard–Keep bystanders

away.

4. Always wear eye

protection

5. Cutting hazard to hands

or feet–wait until all

machine components

have stopped before

touching them.

105-4593

1. Entanglement hazard, PTO shaft—do not operate the machine

with the shields or guards removed; always keep the shields

and guards in place.

105–0708

1. Danger–Blown object hazard–Keep bystanders away from

chute outlet.

105-4594

1. Crushing hazard, hand and foot—read the Operator’s Manual.

93-6696

1. Stored energy hazard—read the Operator’s Manual.

5

Page 6

Specifications

General Specifications

Fan Output

Fan Speed 2575 RPM

Outlet Area Adjustable outlet opening, 39 to 70 square inches

Directional Control 90 degree outlet deflector operated from seat

Castor Wheels Two 8 x 3–1/2 inch solid rubber tires

Height Adjustment 4 to 6–1/2 inches Adjustment is with 1/2 inch spacers and holes in castor fork

Ground Clearance–Transport 11–1/4 inches

Fan

Fan Housing

Drive

Weight: 321 lbs.

Note: Specifications and design subject to change without notice.

5000 CFM

165 MPH

Backward curved, cast aluminium fan. 12 blades per side, 21 inch outside diameter,

6–3/8 inch width, weight 34 lbs.

10 gauge steel face plates welded to 14 gauge wrapper. Eight degree increase scroll form

cutoff.

Gear motor directly coupled to fan shaft via Rotex coupling. 1–1/4 inch diameter fan shaft

rotates on two greaseable ball bearings.

Optional Equipment

180 Degree Deflector Kit Part No. 95–5909

6

Page 7

Setup

Note: Use this chart as a checklist to ensure that all parts have been received. Without these parts, total setup cannot be

completed.

Description

Blower Housing Assembly 1

Arm Assembly – R.H.

Arm Assembly – L.H.

Capscrew

Flatwasher

Locknut

Bumper Assembly

Capscrew

Flatwasher

Locknut

Handle Assembly

Capscrew

Flatwasher

Linkage Rod

Flatwasher

Cotter Pin

Capscrew

Flatwasher

Locknut

Clamping Plate

Reinforcing Plate

Capscrew

Flatwasher

Flange Nut

Qty. Use

1

1

4

4

4

1

8

8

8

1

2

2

1

2

2

4

8

4

2

2

4

4

4

Mount to blower assembly.

Mount to arm assemblies.

Mount to blower housing.

Mount to handle assembly and deflector

assembly.

Mount blower to traction unit.

Cable Tie 1 Secure hydraulic hoses to blower housing

Operator’s Manual 1 Read before operating the machine.

Parts Catalog 1

Registration card 1 Fill out and return to Toro.

Declaration of Conformity 1

7

Page 8

Note: Determine the left and right sides of the machine

from the normal operating position.

Remove Front Cutting Unit

1. Position machine on a level surface, lower mower decks

to the floor, engage parking brake, be sure traction

pedal is in neutral position, PTO lever in OFF position,

shut engine OFF and remove key from switch.

2. Remove bolts securing hydraulic motor to deck (Fig. 1).

Lift motor off deck and lay it on a clean, out of the way,

surface. Do not damage aluminium coupler.

2

4. Remove hair pin cotters and clevis pins securing

height-of-cut chains to rear of deck (Fig. 3). Retain hair

pin cotters and clevis pins for re–installation of front

deck

1

2

Figure 3

1. Height of cut chain 2. Clevis pin & hairpin cotter

2

1

Figure 1

1. Hydraulic motor 2. Mounting bolts

3. Remove spider from inside pulley coupler. Inspect for

wear and replace if worn. Retain for installation on

blower (Fig. 2).

Note: Inspect motor spider hub for wear and replace if

worn (Fig. 2).

2

3

1

Figure 2

1. Spider

2. Motor spider hub

3. Pulley coupler

5. Remove bolts, washers and locknuts securing each lift

arm ball joint mount to cutting unit castor arm tube

(Fig. 4).

1

1

Figure 4

1. Lift arm ball joint mount (2)

6. Move mower deck away from traction unit.

8

Page 9

Mount Arm Assemblies

1. Align the rear set of mounting holes in each lift arm

with holes in the blower housing mounting brackets.

Position lift arms as shown in figure 5.

2. Loosely secure each lift arm to mounting bracket with

(2) capscrews, flatwashers and locknuts. Do not tighten

locknuts.

2

3

1

Figure 6

1. Bumper assembly

Install Handle Assembly

1. Position handle mounting tube between tabs on top of

blower housing (Fig. 7).

Note: When mounting a debris blower on a traction unit

equipped with a cab, rotate handle 180_ when installing.

2. Secure each end of tube to a housing tab with a

capscrew and flatwasher.

1

Figure 5

1. Lift arm

2. Blower housing

3. Mounting brackets

Mount Bumper Assembly

1. While aligning mounting holes, position bumper

assembly onto lift arms (Fig. 6).

2. Loosely secure bumper assembly to each lift arm with

(4) capscrews, flatwashers and locknuts.

2

1

Figure 7

1. Handle assembly 2. Handle grip

3. Insert handle grip onto handle (Fig. 7).

9

Page 10

Install Linkage Rod

1. Insert front end of linkage rod through hole in handle

assembly while hooking rear end of linkage rod thru

hole in rear tab on deflector assembly (Fig. 8).

Note: When mounting a debris blower on a traction unit

equipped with a cab, rotate handle 180_ and use front tab

on deflector for rod installation.

2. Secure each end of rod with a flatwasher and cotter pin.

2

1

3

1

2

Figure 9

1. Manifold block 2. Orifice

Mount Blower To Traction Unit

Figure 8

1. Linkage rod

2. Handle assembly

3. Rear tab

Replace PTO Manifold Orifice

Note: On traction units that have a gold colored PTO

manifold (Fig. 9) orifice must be removed and replaced. If

PTO manifold is silver, orifice does not need to be

replaced.

1. Using a 1/8” Allen wrench, remove orifice plug from

MR port of front PTO manifold (Fig. 9).

2. Order plug Part No. 3246–17 from your Toro distributor

and install into MR port of manifold with a 5/32” Allen

wrench.

1. Move traction unit up to blower until lift arms are

aligned with blower arm assemblies (Fig. 10).

3

1

2

4

Figure 10

1. Lift arm ball joint mount

2. Arm assembly

3. Clamping plate

4. Reinforcing plate

10

Page 11

2. Mount each lift arm ball joint mount to each side of

blower arm assembly with (2) capscrews (4) flatwashers

and (2) locknuts. Position fasteners as shown in

figure 10.

3. Mount each lift arm to top of each blower arm assembly

with (2) capscrews (2) flatwashers, clamping plate,

reinforcing plate and (2) locknuts. Position components

as shown in figure 10.

2

3

4. Tighten all blower and lift arm mounting fasteners.

Install Hydraulic Motor To

Blower

1. Remove (2) socket head screws and flange nuts

securing alignment tool to motor mount (Fig. 11).

4

3

1

2

Figure 11

1. Alignment tool

2. Motor mount

3. Mount bracket

4. Bearing mount bracket

1

2

Figure 12

1. Hydraulic motor

2. Large hoses

3. Small hose

4. Install hydraulic motor and spider to blower mount with

(2) socket head screws and flange nuts as shown in

figure 13.

Note: Motor to be installed with hoses exiting to the left

side of blower.

2

1

Note: Retain alignment tool for re–aligning components if

ever disassembled.

2. Remove the two larger diameter hydraulic hoses from

hydraulic motor and loosely install in opposite ports

(Fig. 12).

Note: If hoses are not reversed, blower will rotate

backwards.

3. Loosen the small diameter hydraulic hose to motor.

3

Figure 13

1. Hydraulic motor

2. Spider

3. Blower mount

5. Tighten and torque hydraulic hoses as follows:

• Torque (2) larger hoses to 43–48 ft./lb.

• Torque smaller hose to 23 ft./lb.

11

Page 12

6. Secure hydraulic hoses to blower housing with wire tie

(Fig. 14).

2

Operation

Note: Determine the left and right sides of the machine

from the normal operating position.

Operating Tips

Warning

1

Figure 14

1. Hydraulic hoses 2. Wire tie

Note: Hoses must not contact sharp edges or moving parts

and must be free of twists.

Grease Blower

Before the Debris Blower is operated, it must be greased to

assure proper lubricating characteristics: refer to

Lubrication section of manual. Failure to properly grease

the unit will result in premature failure of critical parts.

Discharged air has considerable force and could

cause injury or loss of footing.

• Stay away from the discharge opening when the

machine is operating.

• Keep bystanders away from the discharge

opening when the machine is running.

1. Practice blowing material. It is advisable to blow the

same direction the wind is blowing to prevent material

from blowing back into the cleared area.

Adjusting Castor Wheels

The castor wheel height is adjustable from 4 to 6–1/2

inches in 1/2 inch increments by adding or removing an

equal amount of spacers from each castor wheel. Adjust

castor height for different turf conditions.

1. Start engine and raise blower. Stop engine after blower

unit is raised.

2. Remove locking cap securing castor spindle to bumper

(Fig. 15).

3. Move desired amount of spacers (Fig. 15) to top or

bottom of bumper. Make sure spacers are equal on both

castor wheels.

4. Install locking cap and lower blower.

12

Page 13

1

1. Locking cap

2. Spacers

3

3

Figure 15

3. Thrust washers

2

3

2

1

Figure 16

1. Discharge opening

deflector screw

2. Discharge direction

deflector

3. Handle assembly

Adjust Discharge Opening

The discharge opening (Fig. 16) is adjustable to increase or

decrease air output velocity and volume. Decreasing

discharge opening size will increase velocity.

1. Loosen discharge opening deflector mounting screws.

2. Pivot deflector to desired opening.

3. Tighten mounting screws.

Adjust Discharge Direction

Lower deflector assembly in front of discharge opening to

change from side discharge to front discharge (Fig. 16).

1. Pivot handle assembly to the left to lower deflector

assembly over opening, directing discharge forward.

2. Pivot handle assembly to the right to raise deflector

from discharge opening, allowing side discharge.

13

Page 14

Maintenance

Note: Determine the left and right sides of the machine

from the normal operating position.

Greasing the Blower

The debris blower must be lubricated regularly. If machine

is operated under normal conditions, lubricate castor and

fan bearings and bushings with No. 2 general purpose

lithium base grease or molybdenum base grease, after every

8 hours of operation or daily, whichever comes first.

Lubricate fittings immediately after every washing,

regardless of the interval listed.

1. The debris blower has (4) bearings and bushings that

must be lubricated. The lubrication points are: castor

shaft bushings (2) and fan shaft bearings (2) (Fig. 17).

(2)

1

2

Figure 18

1. Stand 2. Snapper pin

3. Lower blower to the floor or any stable surface.

4. Remove cable tie securing hydraulic hoses to blower

housing.

5. Remove (2) socket head screws and flange nuts

securing hydraulic motor and spider to blower mount

(Fig. 13).

6. Remove (2) capscrews (4) flatwashers, clamping plate,

reinforcing plate and (2) locknuts securing each lift arm

to top of each blower arm assembly (Fig. 10).

7. Remove (2) capscrews (4) flatwashers and (2) locknuts

securing each lift arm ball joint mount to each side of

blower arm assembly (Fig. 10).

(2)

Figure 17

Disconnect Blower From

Traction Unit

Note: Implements are heavy and may require two people to

handle.

1. Remove snapper pin securing stand to tube on blower

(Fig. 18).

2. Lower stand. Re–install pin through upper set of holes

in stand and tube. Secure pin.

8. Stay clear of lift arms and move traction unit away from

blower.

Servicing Bumper Bushings

After many hours of operation, the bushings pressed into

the top and bottom of the bumper will wear. To check the

bushings, move castor fork fore and aft and from side to

side. If castor spindle is loose in the bushings, bushings are

worn and must be replaced.

1. Start traction unit and raise blower to highest possible

position and turn off engine. Block up blower frame so

it cannot accidentally fall.

2. Remove locking cap and thrust washers from top of

castor spindle.

3. Pull castor spindle out of bumper. Allow thrust washers

to remain on bottom of spindle.

14

Page 15

4. Insert pin punch into top or bottom of bumper and drive

bushing out of tube (Fig. 19). Also drive other bushing

out of bumper. Clean inside of bumper to remove any

dirt.

2

1

1

2

2

Figure 19

1. Bumper 2. Bushing

5. Apply grease to inside and outside of new bushings.

Using a hammer and flat plate, drive bushings into

bumper.

6. Inspect castor shaft for wear and replace if damaged.

7. Push castor shaft through bushings and bumper. Slide

spacers onto shaft and secure with locking cap.

Servicing Castor Wheel And

Bearing

The castor wheel rotates on a high–quality roller bearing

and is supported by a spanner bushing. Even after many

hours of use, provided that the bearing was kept well

lubricated, bearing wear will be minimal. However, failure

to keep bearing lubricated will cause rapid wear. A wobbly

castor wheel usually indicates a worn bearing.

1

Figure 20

1. Outer bearing 2. Inner bearing

Alignment Tool

If motor mount components are ever disassembled and

have to be realigned, proceed as follows:

• Loosen (4) screws and nuts securing motor mount to

mount bracket (Fig. 21).

• Loosen (4) screws, washers and nuts securing mount

bracket to bearing mount bracket (Fig. 21).

• Insert alignment tool into motor mount and secure

with (2) socket head screws and flange nuts

(Fig. 21).

• Tighten all fasteners securing motor mount, mount

bracket and bearing mount bracket.

4

1. Remove locknut from capscrew holding castor wheel

assembly in castor fork. Grasp castor wheel and slide

capscrew out of fork.

2. Remove outer bearing from wheel hub and allow inner

bearing to fall out (Fig. 20). Remove outer bearing from

opposite side of wheel hub.

3. Check the bearings and inside of wheel hub for wear.

Replace defective parts as required.

4. To assemble the castor wheel, push outer bearing into

wheel hub. Slide inner bearing into wheel hub. Push

other bearing into open end of wheel hub to captivate

the inner bearing inside the wheel hub.

5. Install castor wheel assembly between castor forks and

secure in place with capscrew and locknut.

3

1

1. Alignment tool

2. Motor mount

15

2

Figure 21

3. Mount bracket

4. Bearing mount bracket

Page 16

The Toro General Commercial Products Warranty

A Two-Year Limited Warranty

Conditions and Products Covered

The Toro Company and its affiliate, Toro Warranty Company,

pursuant to an agreement between them, jointly warrant your Toro

Commercial Product (“Product”) to be free from defects in

materials or workmanship for two years or 1500 operational

hours*, whichever occurs first. Where a warrantable condition

exists, we will repair the Product at no cost to you including

diagnosis, labor, parts, and transportation. This warranty begins

on the date the Product is delivered to the original retail purchaser.

* Product equipped with hour meter

Instructions for Obtaining Warranty Service

You are responsible for notifying the Commercial Products

Distributor or Authorized Commercial Products Dealer from whom

you purchased the Product as soon as you believe a warrantable

condition exists.

If you need help locating a Commercial Products Distributor or

Authorized Dealer, or if you have questions regarding your

warranty rights or responsibilities, you may contact us at:

Toro Commercial Products Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

952-888-8801 or 800-982-2740

E-mail: commercial.service@toro.com

Owner Responsibilities

As the Product owner, you are responsible for required maintenance and adjustments stated in your operator’s manual. Failure

to perform required maintenance and adjustments can be grounds

for disallowing a warranty claim.

Items and Conditions Not Covered

Not all product failures or malfunctions that occur during the

warranty period are defects in materials or workmanship. This

express warranty does not cover the following:

• Product failures which result from the use of non-Toro

replacement parts, or from installation and use of add-on,

modified, or unapproved accessories

• Product failures which result from failure to perform required

maintenance and/or adjustments

• Product failures which result from operating the Product in an

abusive, negligent or reckless manner

• Parts subject to consumption through use unless found to be

defective. Examples of parts which are consumed, or used up,

during normal Product operation include, but are not limited to,

blades, reels, bedknives, tines, spark plugs, castor wheels,

tires, filters, belts, and certain sprayer components such as

diaphragms, nozzles, and check valves, etc.

• Failures caused by outside influence. Items considered to be

outside influence include, but are not limited to, weather,

storage practices, contamination, use of unapproved coolants,

lubricants, additives, or chemicals, etc.

• Normal “wear and tear” items. Normal “wear and tear” includes,

but is not limited to, damage to seats due to wear or abrasion,

worn painted surfaces, scratched decals or windows, etc.

Parts

Parts scheduled for replacement as required maintenance are

warranted for the period of time up to the scheduled replacement

time for that part.

Parts replaced under this warranty become the property of Toro.

Toro will make the final decision whether to repair any existing part

or assembly or replace it. Toro may use factory remanufactured

parts rather than new parts for some warranty repairs.

General Conditions

Repair by an Authorized Toro Distributor or Dealer is your sole

remedy under this warranty.

Neither The Toro Company nor Toro Warranty Company is

liable for indirect, incidental or consequential damages in

connection with the use of the Toro Products covered by this

warranty, including any cost or expense of providing substitute equipment or service during reasonable periods of

malfunction or non-use pending completion of repairs under

this warranty. Except for the Emissions warranty referenced

below, if applicable, there is no other express warranty. All

implied warranties of merchantability and fitness for use are

limited to the duration of this express warranty.

Some states do not allow exclusions of incidental or consequential

damages, or limitations on how long an implied warranty lasts, so

the above exclusions and limitations may not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Note regarding engine warranty: The Emissions Control System

on your Product may be covered by a separate warranty meeting

requirements established by the U.S. Environmental Protection

Agency (EPA) and/or the California Air Resources Board (CARB).

The hour limitations set forth above do not apply to the Emissions

Control System Warranty. Refer to the Engine Emission Control

Warranty Statement printed in your operator’s manual or contained in the engine manufacturer’s documentation for details.

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer)

to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with your Distributor’s service or

have difficulty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty

Company.

Part No. 374-0031 Rev. C

Loading...

Loading...