Page 1

FormNo.3360-344RevB

Groundsmaster

®

4000-DTraction

Unit

ModelNo.30412—SerialNo.2900000001andUp

Registeratwww.T oro.com.OriginalInstructions(EN)

Page 2

Warning

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisincorporated

withthemuferassembly.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:Thisengineisequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,

orgrass-coveredlandwithoutasparkarrester

mufermaintainedinworkingorder,ortheengine

constricted,equipped,andmaintainedforthe

preventionofre.Otherstatesorfederalareasmay

havesimilarlaws.

Figure1

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Writethe

numbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure1),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

©2008—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroMowerSafety...............................................6

SoundPressureLevel...........................................7

SoundPowerLevel...............................................7

VibrationLevel.....................................................7

SafetyandInstructionalDecals.............................7

Setup..........................................................................14

1GreasingtheMachine......................................14

2ReplacingtheWarningDecal............................14

3ReadingtheManualsandViewingthe

TrainingMaterials...........................................14

ProductOverview......................................................15

Controls.............................................................15

Specications.....................................................17

Attachments/Accessories...................................17

Operation...................................................................18

BeforeOperating................................................18

StartingandStoppingtheEngine........................27

EngineCoolingFanOperation...........................28

CheckingtheInterlockSwitches.........................28

PushingorTowingtheMachine..........................28

JackingPoints.....................................................29

TieDowns.........................................................29

OperatingCharacteristics...................................29

OperatingTips...................................................30

Maintenance...............................................................32

RecommendedMaintenanceSchedule(s)................32

ServiceIntervalChart.........................................33

Lubrication.............................................................33

GreasingtheBearingsandBushings....................33

EngineMaintenance...............................................37

AirCleanerMaintenance....................................37

ServicingtheEngineOilandFilter......................38

FuelSystemMaintenance.......................................39

ServicingtheFuelSystem...................................39

ServicingtheWaterSeparator.............................39

BleedingAirfromtheInjectors...........................39

ElectricalSystemMaintenance................................40

BatteryCare.......................................................40

Fuses..................................................................41

DriveSystemMaintenance.....................................42

ChangingthePlanetaryGearDrive

Oil..................................................................42

ChangingtheRearAxleLubricant.......................43

CheckingtheRearWheelToe-In.........................44

CoolingSystemMaintenance..................................44

ServicingtheEngineCoolingSystem..................44

BrakeMaintenance.................................................45

AdjustingtheServiceBrakes...............................45

BeltMaintenance....................................................46

ServicingtheAlternatorBelt...............................46

Re-tensioningtheBladeDriveBelts....................46

ReplacingtheBladeDriveBelt............................46

ControlsSystemMaintenance.................................47

AdjustingtheThrottleCable...............................47

AdjustingtheTractionPedalLinkage..................47

HydraulicSystemMaintenance...............................48

ChangingtheHydraulicFluid.............................48

ReplacingtheHydraulicFilters...........................49

CheckingtheHydraulicLinesandHoses.............49

AdjustingtheCounterbalancePressure...............49

AdjustingtheCuttingUnitFlowControl.............50

MowerMaintenance...............................................50

AdjustingtheTransportLatch............................50

Pivoting(Tilting)theFrontCuttingUnit

Upright..........................................................51

PivotingtheFrontCuttingUnitDown................51

AdjustingtheCuttingUnitPitch.........................52

ServicingtheCastorArmBushings.....................52

ServicingtheCastorWheelsandBearings............53

BladeMaintenance.................................................54

CheckingforaBentBlade...................................54

RemovingandInstallingtheCutter

Blade(s)..........................................................54

InspectingandSharpeningtheCutter

Blade(s)..........................................................54

CorrectingCuttingUnitMismatch......................55

SparkArrestorMaintenance...................................56

ServicingtheSparkArrestorMufer...................56

Storage.......................................................................57

PreparingforSeasonalStorage............................57

Schematics.................................................................58

3

Page 4

Safety

ThismachinemeetsorexceedsCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004specicationsineffectatthetimeof

production.

Improperuseormaintenancebytheoperator

orownercanresultininjury.Toreducethe

potentialforinjury,complywiththesesafety

instructionsandalwayspayattentiontothesafety

alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

standardB71.4-2004.

Training

•ReadtheOperator’ sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,

andtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethemower.Localregulationsmay

restricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpets

arenearby .

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtohimselfor

herself,otherpeople,orproperty.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstruction

shouldemphasize:

–theneedforcareandconcentrationwhen

workingwithride-onmachines;

–controlofaride-onmachineslidingonaslope

willnotberegainedbytheapplicationofthe

brake.Themainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrecthitchingandloaddistribution.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,

longtrousers,hardhat,safetyglasses,andhearing

protection.Longhair,looseclothingorjewelrymay

gettangledinmovingparts.Donotoperatethe

equipmentwhenbarefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning–fuelishighlyammable.Takethe

followingprecautions:

–Storefuelincontainersspecicallydesignedfor

thispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltankandcontainercapssecurely.

•Replacefaultysilencers/mufers.

•Beforeusing,alwaysvisuallyinspecttoseethatthe

blades,bladebolts,andcuttingassemblyarenot

wornordamaged.Replacewornordamagedblades

andboltsinsetstopreservebalance.

•Onmulti-bladedmachines,takecareasrotatingone

bladecancauseotherbladestorotate.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Checkthatoperatorspresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageall

bladeattachmentclutches,shiftintoneutral,and

engagetheparkingbrake.Onlystarttheenginefrom

theoperator’sposition.Usetheseatbelts.

•Rememberthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.To

guardagainstoverturning:

4

Page 5

–Donotstoporstartsuddenlywhengoingupor

downhill.

–Themachinespeedshouldbekeptlowonslopes

andduringtightturns.

–Stayalertforhumpsandhollowsandother

hiddenhazards.

–Nevermowacrossthefaceoftheslope,unless

themachineisdesignedforthatpurpose.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Usecarewhenusingheavyequipment.

–Donotturnsharply.Usecarewhenreversing.

–Usecounterweight(s)orwheelweightswhen

suggestedintheOperator’ sManual.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesfromrotatingbeforecrossing

surfacesotherthangrass.

•Whenusinganyattachments,neverdirectdischarge

ofmaterialtowardbystandersnorallowanyonenear

themachinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesinplace.

Besureallinterlocksareattached,adjustedproperly,

andfunctioningproperly .

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatingtheengineat

excessivespeedmayincreasethehazardofpersonal

injury.

•Beforeleavingtheoperatorsposition:

–Stoponlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Changeintoneutralandsettheparkingbrake.

–Stoptheengineandremovethekey.

•Disengagedrivetoattachments,stoptheengine,and

removetheignitionkey:

–beforeclearingblockages;

–beforechecking,cleaning,orworkingonthe

machine;

–afterstrikingaforeignobject.Inspectthe

machinefordamageandmakerepairsbefore

restartingandoperatingtheequipment.Torque

allthespindlepulleynutsto130to150ft-lb(176

to203N⋅m);

–ifthemachinestartstovibrateabnormally(check

immediately).

•Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Stoptheengineanddisengagedrivetoattachment:

–beforerefuelling;

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator’s

position.

•Reducethethrottlesettingbeforestoppingengine

andclosethefuelshut-offvalveattheconclusion

ofmowing.

•Neverraisedeckwiththebladesrunning.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Theoperatorshallturnonashingwarninglights,

ifprovided,whenevertravelingonapublicroad,

exceptwheresuchuseisprohibitedbylaw .

MaintenanceandStorage

•Keepallnuts,bolts,andscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumesmayreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosureanddonotstorenearame.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartment,cuttingunits,

drives,andfuelstorageareafreeofgrass,leaves,or

excessivegrease.Cleanupoilorfuelspillage.

•Replacewornordamagedpartsforsafety.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Onmulti-bladedmachines,takecareasrotatingone

bladecancauseotherbladestorotate.

•Whenmachineistobeparked,stored,orleft

unattended,lowerthecuttingunitsunlessapositive

mechanicallockisprovided.

•Disengagedrives,lowerthecuttingunits,move

tractionpedaltoNeutral,setparkingbrake,stop

engineandremovekey.Waitforallmovementto

stopbeforeadjusting,cleaningorrepairing.

•Shutofffuelwhilestoringortransporting.Donot

storefuelnearames.

5

Page 6

•Parkmachineonlevelground.Neverallowuntrained

personneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthe

positivelast.Reconnectpositiverstandnegative

last.

•Usecarewhencheckingblades.Wrapthebladesor

weargloves,andusecautionwhenservicingthem.

Onlyreplaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.W ear

protectiveclothinganduseinsulatedtools.

•Makesureallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunderhigh

pressure.Usepaperorcardboard,notyourhands,

tosearchforleaks.Hydraulicuidescapingunder

pressurecanhavesufcientforcetopenetratethe

skinandcauseseriousinjury.Ifuidisinjectedinto

theskinitmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury

organgrenemayresult.

ToroMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknowthatisnotincludedintheCEN,ISO,or

ANSIstandards.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustouserandbystanders.

Engineexhaustcontainscarbonmonoxide,

whichisanodorless,deadlypoisonthatcan

killyou.

Donotrunengineindoorsorinanenclosed

area.

Operation

•BeforeoperatingamachinewithROPS(rollover

protectionsystem),becertainthattheseatbeltsare

attachedandtheseatislatchedtopreventtheseat

frompivotingforward.

•Knowhowtostopthemachineandenginequickly .

•Donotoperatethemachinewhilewearingtennis

shoesorsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Keephands,feet,andclothingawayfrommoving

partsandthemowerdischargeareaandundersideof

themowerwhiletheengineisrunning.

•Fillfueltankuntillevelis1inch(25mm)belowthe

bottomofthellerneck.Donotoverll.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)beforedriving

underanyobjectsanddonotcontactthem.

•Donotmowinreverseunlessabsolutelynecessary.

•Reducespeedwhenmakingsharpturns.

•Avoidstartingorstoppingonaslope.Iftireslose

traction,disengagethebladesandproceedslowly

straightdowntheslope.Avoidraisingtheside

cuttingunitsonaslope.

•Avoidturningonslopes.Ifyoumustturn,turn

slowlyandgraduallydownhill,ifpossible.

•WhenoperatingamachinewithaROPS,alwaysuse

aseatbelt.

•Becertainthattheseatbeltcanbereleasedquicklyif

themachineisdrivenorrollsintoapondorwater.

•Watchfortrafcwhennearorcrossingroads.

Alwaysyieldtheright-of-way .

•Thismachineisnotdesignedorequippedfor

on-roaduseandisa“slow-movingvehicle”.Ifyou

mustcrossortravelonapublicroad,youshould

beawareofandcomplywithlocalregulations,such

6

Page 7

asrequiredlights,slowmovingvehiclesigns,and

reectors.

•Donotmowneardrop-offs,ditches,or

embankments.Themachinecouldsuddenlyturn

overifawheelgoesovertheedgeofaclifforditch,

orifanedgecavesin.

•Donotmowonwetgrass.Reducedtractioncould

causesliding.

•Useextracarewithotherattachments.Thesecan

changethestabilityofthemachine.

•Theenginemustbeshutoffbeforecheckingtheoil

oraddingoiltothecrankcase.

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedToroDistributor.

•Tomakesureofoptimumperformanceand

continuedsafetycerticationofthemachine,use

onlygenuineTororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadebyother

manufacturerscouldbedangerous,andsuchuse

couldvoidtheproductwarranty.

•Turnoffthebladeswhennotmowing.

MaintenanceandStorage

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowtocoolbefore

attemptingtomaintain,adjust,orservice.

•Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

•Keepnutsandboltstight,especiallytheblade

attachmentbolts.Keepequipmentingood

condition.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthecutting

units,attachments,andanymovingparts.Keep

everyoneaway.

•Checkbrakeoperationfrequently.Adjustandservice

asrequired.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyour

face,eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks,

andamesawayfromthebattery.

SoundPressureLevel

ThisunithasanequivalentcontinuousA-weighted

soundpressurelevelattheoperatorearof89dBA,

basedonmeasurementsofidenticalmachinesperISO

11201andEN836.

SoundPowerLevel

ThisunithasanequivalentcontinuousA-weighted

soundpowerlevelattheoperatorearof105dBA,based

onmeasurementsofidenticalmachinesperEN11094.

VibrationLevel

Hand-Arm

ThisunithasanequivalentcontinuousA-weighted

hand/armvibrationlevelof2.5m/s

measurementsofidenticalmachinesperEN1033and

EN836.

WholeBody

ThisunithasanequivalentcontinuousA-weighted

hand/armvibrationlevelof0.5m/s

measurementsofidenticalmachinesperEN1032and

EN836.

2

,basedon

2

,basedon

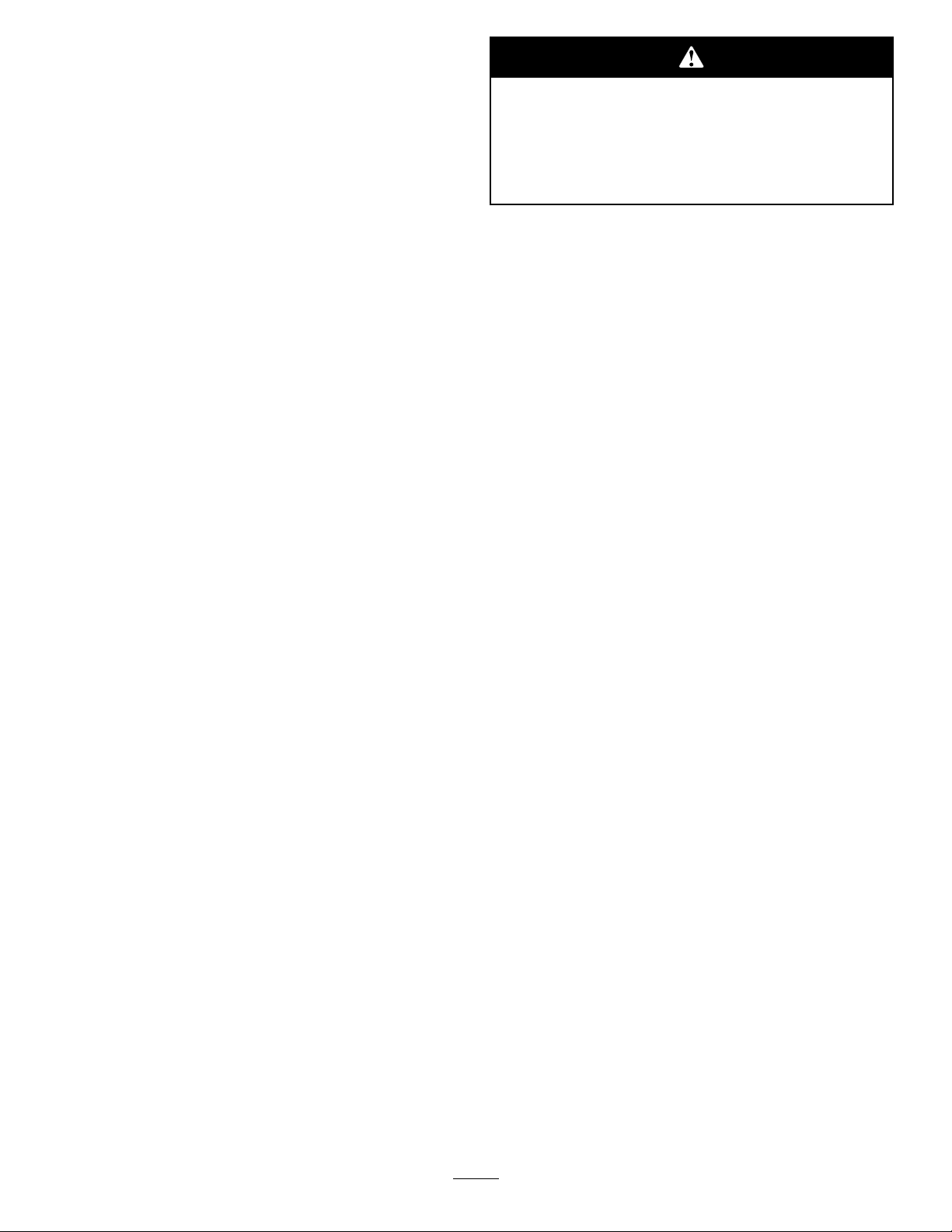

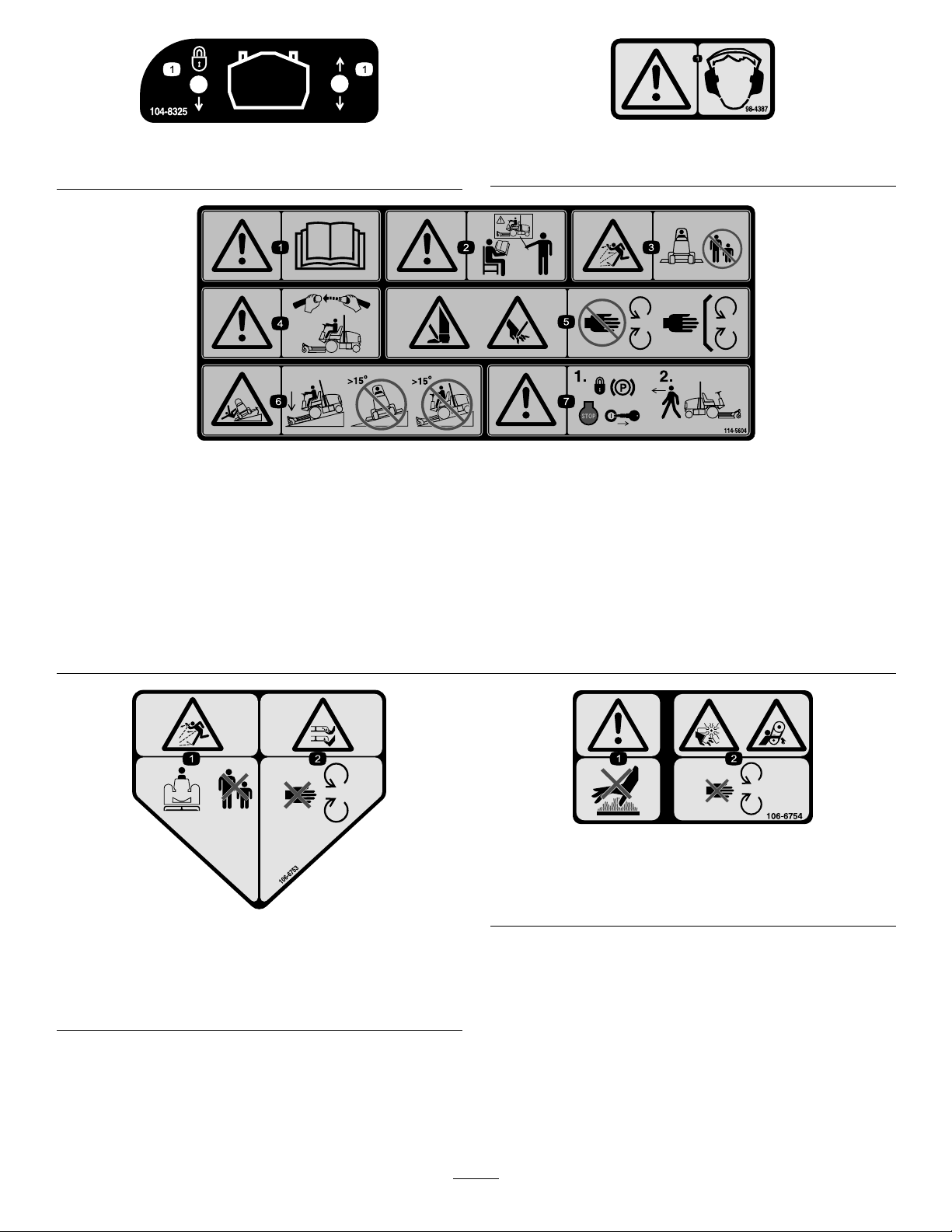

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

93-7272

1.Cutting/dismembermenthazard;fan—stayawayfrom

movingparts.

7

Page 8

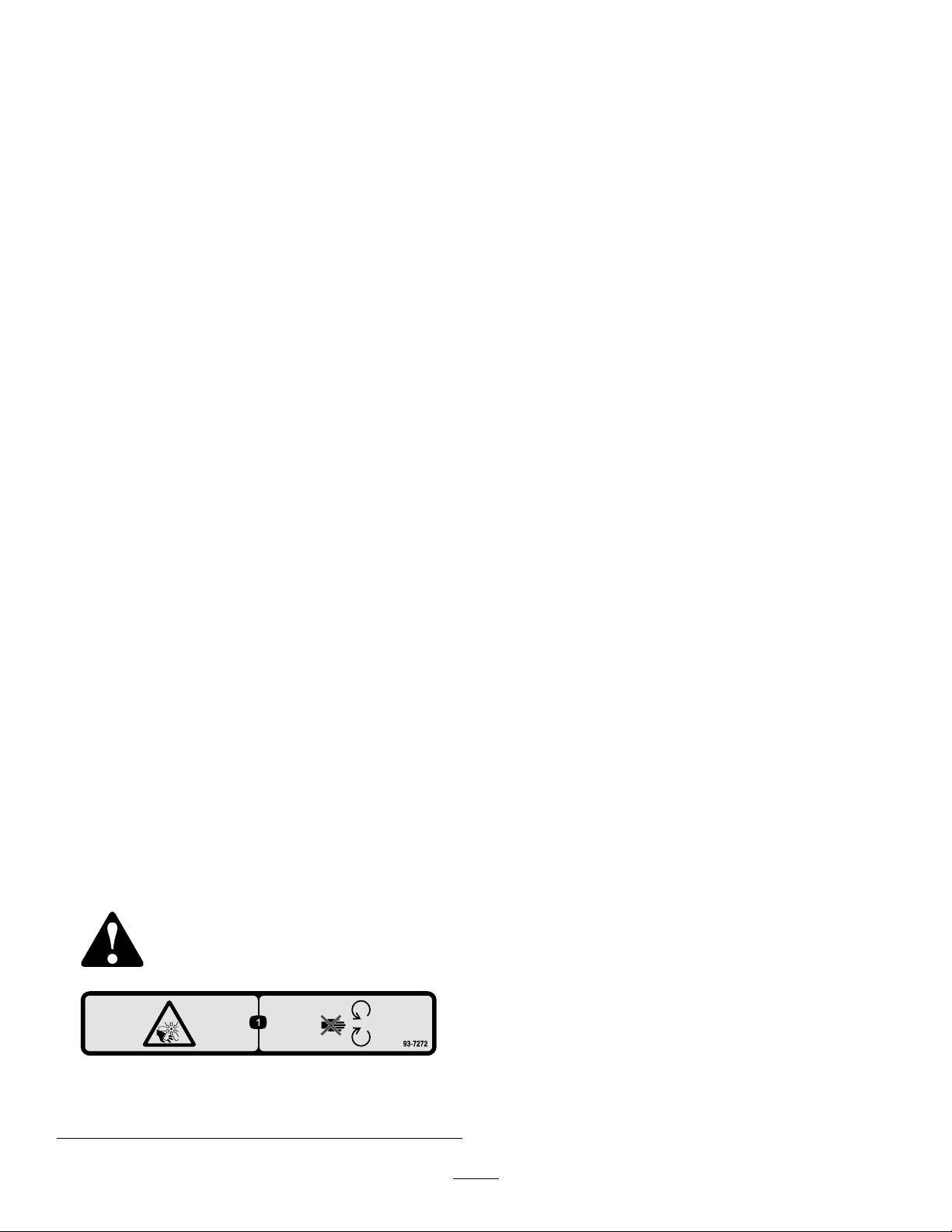

93-7275

1.ReadtheOperator’sManual.

2.Donotusestartingaids.

93-7818

1.Warning—readtheOperator’sManualforinstructionson

torquingthebladebolt/nutto115to149N•m(85to1 10

ft-lb).

100-5624

1.Heightofcutadjustment

100-5693

1.Heightofcutadjustment

1.Heightofcutadjustment

1.Lowheightofcut

adjustment

100-5622

100-5623

2.Highheightofcut

100-5694

1.Heightofcutadjustment

100-6578

1.Entanglementhazard,belt—donotoperatethemachine

withtheshieldsorguardsremoved;alwayskeepthe

shieldsandguardsinplace;stayawayfrommovingparts.

adjustment

8

Page 9

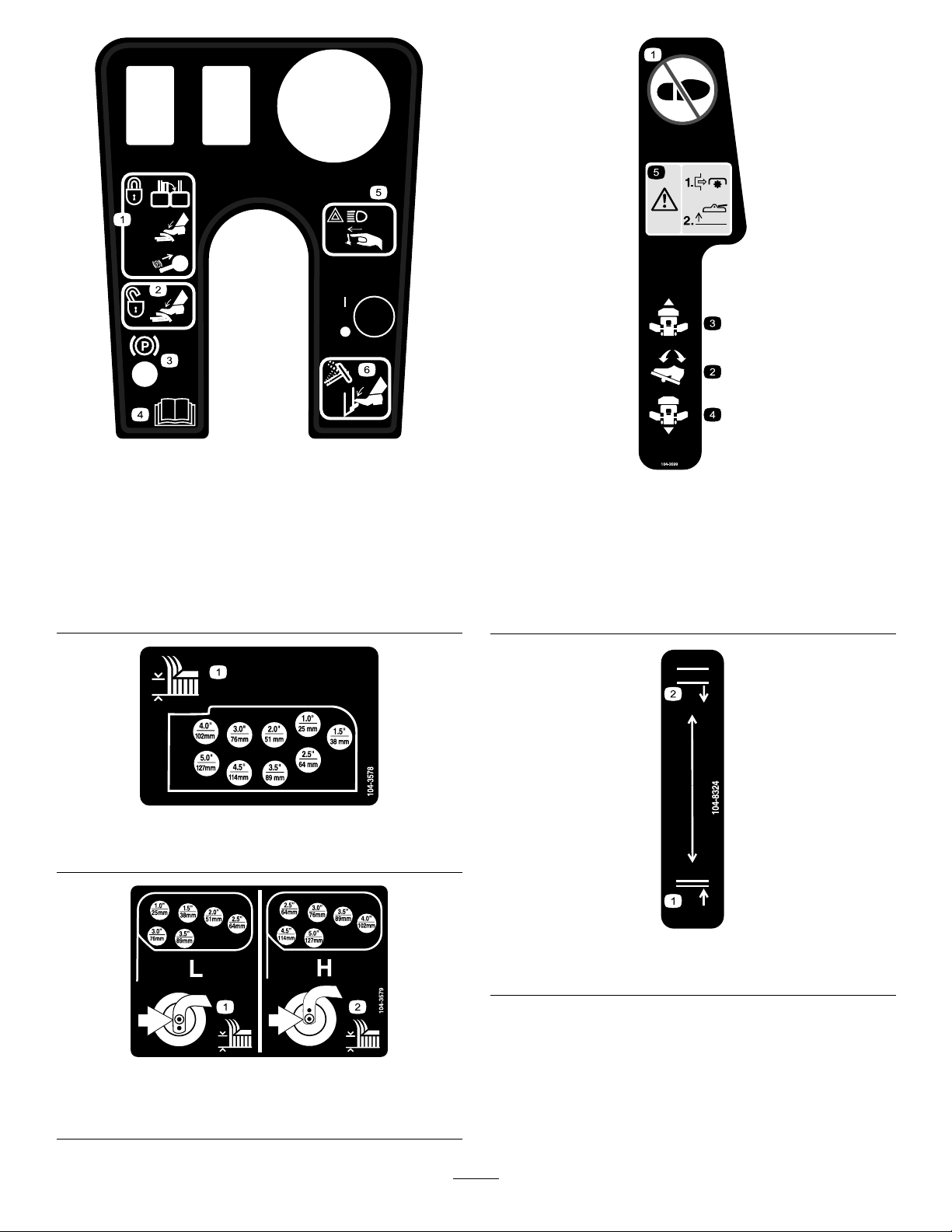

104-2277

2.

3.

1.

1.Tolocktheparkingbrake,

latchthepedalstogether,

applythebrakepedals,

andpullupontheknob.

2.Tounlocktheparking

brake,steponthebrake

pedals.

3.Parkingbrakelock

indicator

1.Heightofcutadjustment

104-2277

4.ReadtheOperator’s

Manual.

5.Pressforoptional

headlights.

6.Pressdownontheleverto

tiltthesteeringwheel.

104-3578

104-3599

1.Donotstephere.

2.Tractionpedal

3.Traction—forward

4.Traction—reverse

5.Danger—shutoffPTOpriortoraisingthecuttingunits;do

notoperatethecuttingunitswhentheyareintheraised

position.

1.Lowheightofcut

adjustment

104-8324

1.Raisecuttingunits2.Lowercuttingunits

104-3579

2.Highheightofcut

adjustment

9

Page 10

104-8325

1.Lock/unlockthecuttingunitservicelock.

1.Warning—wearhearingprotection.

98-4387

114-5604

(Afxoverpartno.114–5605forCE*)

*ThissafetydecalincludesaslopewarningrequiredonthemachineforcompliancetotheEuropeanLawnMowerSafetyStandardEN836:1997.Theconservativemaximum

slopeanglesindicatedforoperationofthismachineareprescribedbyandrequiredbythisstandard.

1.Warning—readtheOperator’sManual.

2.Warning—donotoperatethismachineunlessyouaretrained.

3.Thrownobjecthazard—keepbystandersasafedistancefromthemachine.

4.Warning—weartheseatbeltwhenseatedintheoperator’sposition.

5.Cuttinghazardofhandorfoot—stayawayfrommovingparts;keepallguardsinplace.

6.Tippinghazard—lowerthecuttingunitwhendrivingdownslopes;donotoperateonslopesgreaterthan15degrees.

7.Warning—locktheparkingbrake,stoptheengineandremovetheignitionkeybeforeleavingthemachine.

106-6753

1.Enginecoolantunderpressure

2.Explosionhazard—readtheOperator’sManual.

3.Warning—donottouchthehotsurface.

4.Warning—readtheOperator’sManual.

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

10

Page 11

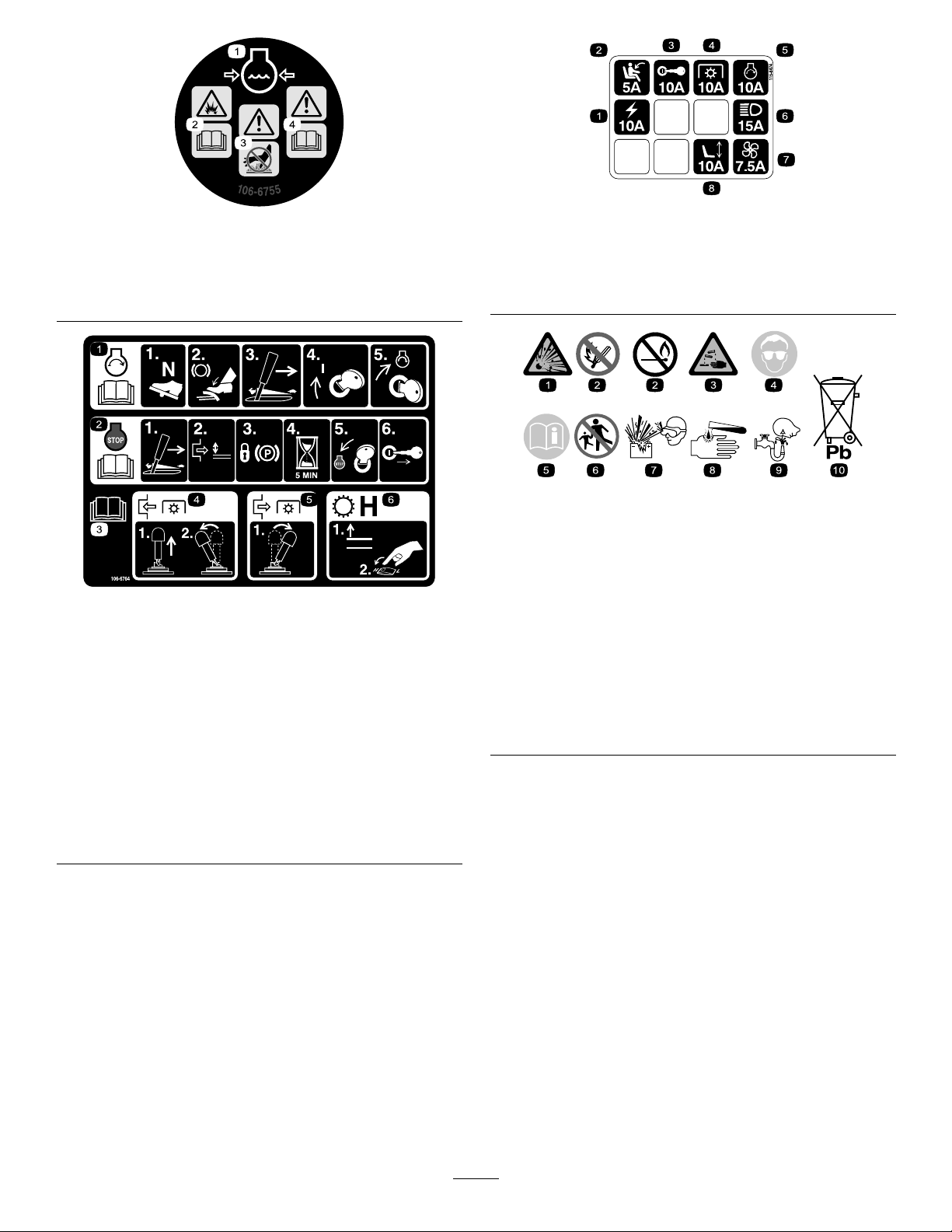

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator’sManual.

3.Warning—donottouch

thehotsurface.

4.Warning—readthe

Operator’sManual.

106-6764

1.Tostarttheengine,movethetractionpedaltoNeutral,

pressthebrakepedal,movethethrottlelevertomididle,

turntheignitionkeytoOn,andthenturntheignitionkeyto

Start;readtheOperatorsManual.

2.Tostoptheengine,movethethrottlelevertoslow,

disengagethePTO,settheparkingbrake,wait5minutes,

turntheignitionkeytoStop,andremovethekey;readthe

OperatorsManual.

3.ReadtheOperatorsManual.

4.ToengagethePTO,pulluponthePTOswitchandmove

itforward.

5.TodisengagethePTO,movethePTOswitchback.

6.Toswitchthetransmissiontohighspeed,raisethe

attachmentliftandswitchthespeedcontroltoHigh.

115-8474

1.Poweroutlet

2.Seatswitch

3.Ignitionswitch7.Fan

4.PowerTakeOff(PTO)

5.Startersolenoid

6.LightKit

8.Powerseat

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

11

Page 12

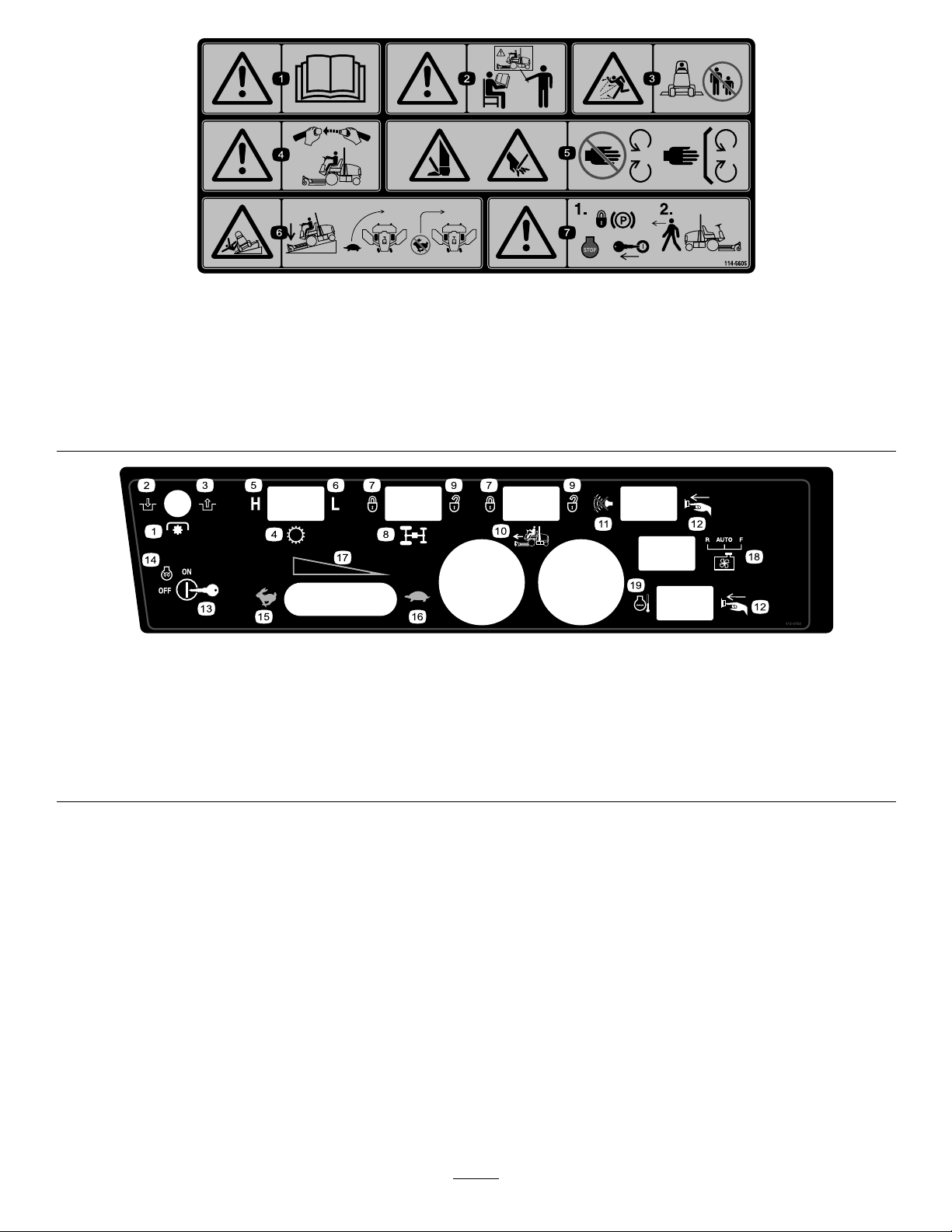

114-5605

1.Warning—readtheOperator’sManual.

2.Warning—donotoperatethismachineunlessyouaretrained.

3.Thrownobjecthazard—keepbystandersasafedistancefromthemachine.

4.Warning—weartheseatbeltwhenseatedintheoperator’sposition.

5.Cuttinghazardofhandorfoot—stayawayfrommovingparts;keepallguardsinplace.

6.Tippinghazard—lowerthecuttingunitwhendrivingdownslopes;slowmachinebeforeturning,donotturnathighspeeds

7.Warning—locktheparkingbrake,stoptheengineandremovetheignitionkeybeforeleavingthemachine.

115-3753

1.PowerTake-off(PTO)

2.Engage7.Lock12.Pressthebutton

3.Disengage8.Flowdivider13.Keyswitch

4.Transmission9.Unlock14.Engine—preheat19.Enginecoolanttemperature

5.High

6.Low

10.Cruisecontrol(optional)

11.Silencerswitch16.Slow

17.Throttle-Continuous

variablesetting

18.Enginecoolingfanswitch

resetswitch

15.Fast

12

Page 13

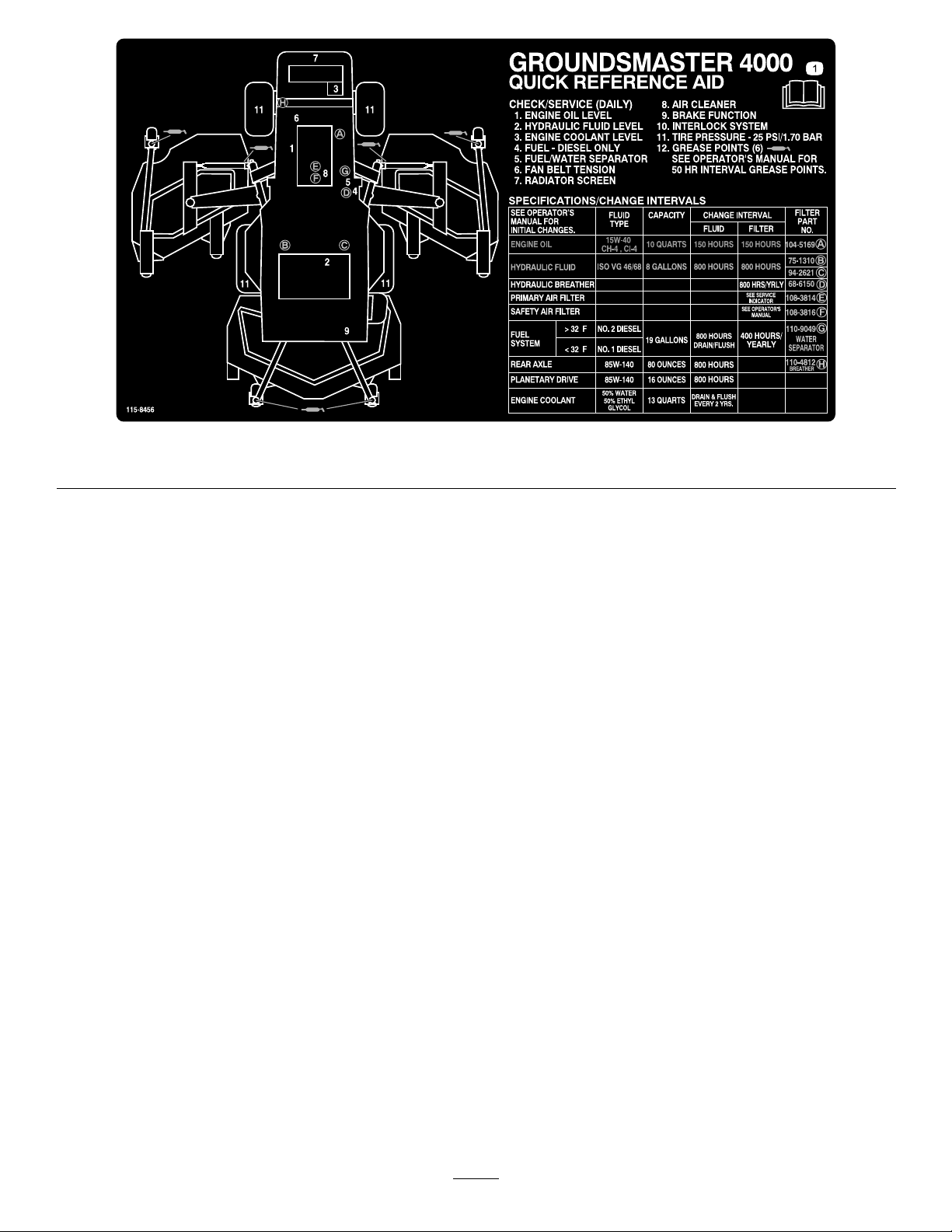

1.ReadtheOperator’sManual.

115-8456

13

Page 14

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Nopartsrequired

WarningDecal1

Operator’sManual

EngineOperator’sManual

PartsCatalog

OperatorTrainingMaterials

Pre-deliveryInspectionSheet

Declarationofconformity

1

GreasingtheMachine

Qty.

–

1

1

1

1

1

1

Greasethemachine.

Usedonlyonmachinesrequiring

EuropeanCEcompliance.

Readthemanualsandviewthe

trainingmaterialsbeforeoperatingthe

machine.Usetheremainingpartsfor

theinstallationofattachments.

3

ReadingtheManualsand

ViewingtheTrainingMaterials

Partsneededforthisprocedure:

Use

NoPartsRequired

Procedure

Beforethemachineisoperated,itmustbegreased

toensureproperlubricatingcharacteristics;referto

GreasingtheBearingsandBushingsprocedureof

Lubrication,page33.Failuretoproperlygreasethe

machinewillresultinprematurefailureofcriticalparts.

2

ReplacingtheWarningDecal

Partsneededforthisprocedure:

1WarningDecal

Procedure

1

Operator’sManual

1

EngineOperator’sManual

1

PartsCatalog

1

OperatorTrainingMaterials

1

Pre-deliveryInspectionSheet

1

Declarationofconformity

Procedure

1.Readthemanuals.

2.ViewtheOperatorTrainingmaterials.

OnmachinesrequiringEuropeanCEcompliance,

replacethewarningdecal,partno.114–5605withthe

warningdecalpartno.114–5604.

14

Page 15

ProductOverview

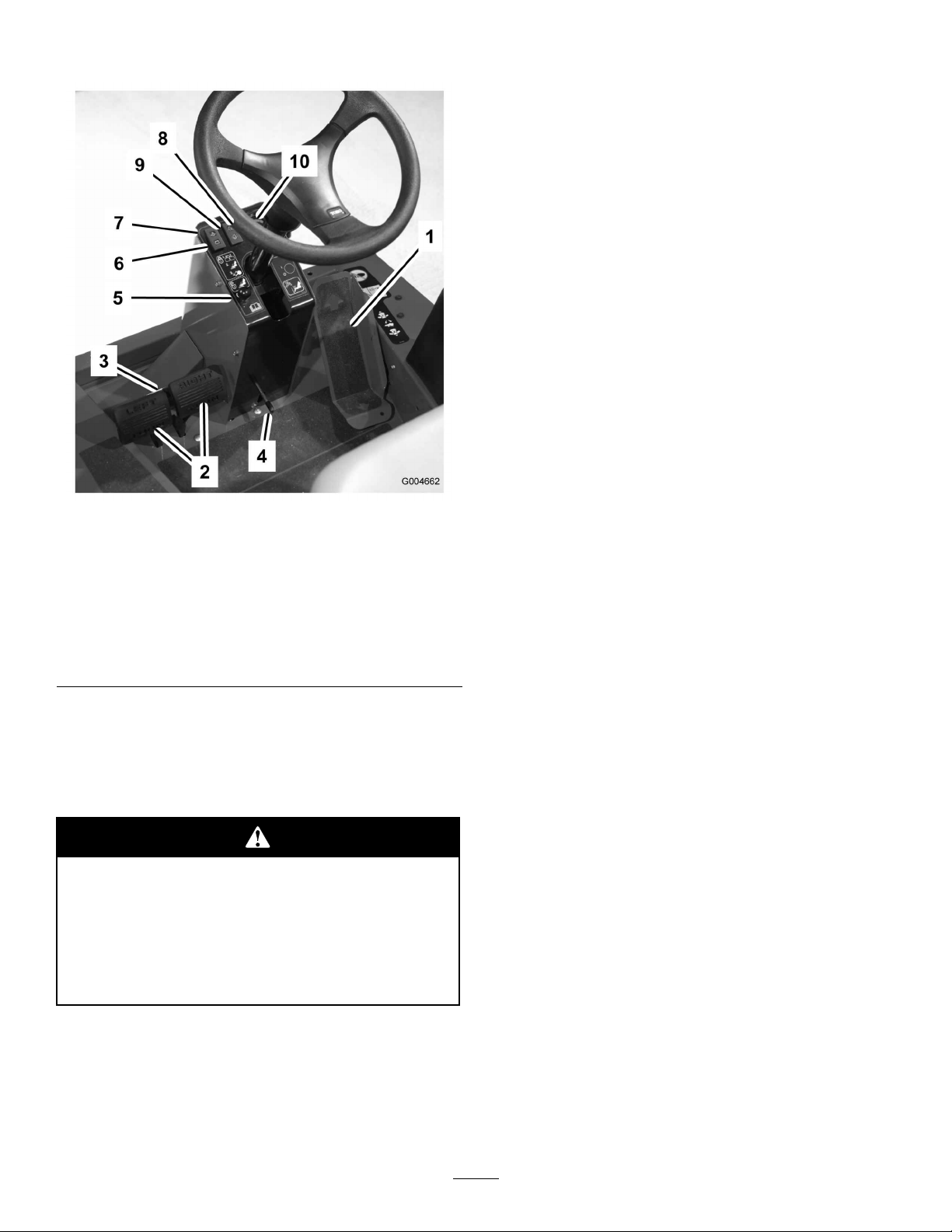

Figure2

1.Tractionpedal

2.Brakepedals7.Engineoilpressure

3.Pedallockinglatch8.Enginecoolant

4.Tiltsteeringlever

5.Parkingbrakelatch10.Temperaturegauge

6.Chargeindicator

warninglight

temperaturewarning

light

9.Glowplugindicatorlight

BrakePedals

Twofootpedals(Figure2)operateindividualwheel

brakesforturningassistance,parking,andtoaidin

obtainingbettersidehilltraction.Alatchconnectsthe

pedalsforparkingbrakeoperationandtransport.

PedalLockingLatch

Thepedallockinglatch(Figure2)connectsthepedals

togethertoengagetheparkingbrake.

TiltSteeringLever

Pressthelever(Figure2)downtotiltthesteeringwheel

tothedesiredposition.Thenreleasethelevertolock

theadjustment.

ParkingBrakeLatch

Aknobontheleftsideoftheconsoleactuatesthe

parkingbrakelock(Figure2).Toengagetheparking

brake,connectthepedalswiththelockinglatch,push

downonbothpedals,andpulltheparkingbrakelatch

out.Toreleasetheparkingbrake,pressbothpedalsuntil

theparkingbrakelatchretracts.

ChargeIndicator

Thechargeindicator(Figure2)illuminateswhenthe

systemchargingcircuitmalfunctions.

Controls

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Thismachineproducessoundlevelsinexcess

of85dBAattheoperatorsearandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

TractionPedal

Tostop,reduceyourfootpressureonthetractionpedal

andallowittoreturntothecenterposition.

EngineOilPressureWarningLight

Thelight(Figure2)illuminateswhentheengineoil

pressureisdangerouslylow .

EngineCoolantTemperatureWarning

Light

Thelight(Figure2)illuminatesandtheengineshuts

downwhencoolantreachesanexcessivelyhigh

temperature.

GlowPlugIndicatorLight

Whenlit,theglowplugindicatorlight(Figure2)

indicatesthattheglowplugsareon.

EngineTemperatureGauge

Thisgauge(Figure2)indicatestheenginecoolant

temperature.

15

Page 16

SpeedLimiter

Ifdesired,thescrewcanbeadjusted(Figure3)tolimit

theamountthetractionpedalcanbedepressedinthe

forwarddirectiontolimitthemowingspeed.

pulltheswitchbackwardtotheOffpositiontostop

implementoperation.

Hi-LoSpeedControl

Important:Thetractionpedalmustcontactthe

speedlimiterbeforereachingtheendofthepump

stroketopreventpumpdamage.

Figure3

1.Speedlimiter

Important:Wheninthemowposition,thespeed

limiterscrewmuststopthetractionpedalbeforethe

pumpreachesfullstrokeordamagetothepump

mayoccur.

Thecontrol(Figure4)allowsthespeedrangetoincrease

fortransportofthemachine.

FlowDividerSwitch(optional)

Whenoperatinginmow(low)speed,pressandhold

owdividerswitch(Figure4)toenhancetractiondrive

performanceincompromisedoperatingconditions.

Figure4

1.Liftlever

2.Keyswitch10.T emperatureresetswitch

3.PTOswitch

4.Hi-lospeedcontrol12.Fuelgauge

5.Flowdividerswitch

(optional)

6.Cruisecontrol(optional)

7.Alarmsilenceswitch15.Frontcuttingunitservice

8.Fanswitch

9.Audiblealarm

11.Hourmeter

13.Throttle

14.Powerpoint

lock

LiftLevers

Thelevers(Figure4)raiseandlowerthecuttingunits.

CuttingUnitServiceLock

Thecuttingunitservicelock(Figure4)locksthefront

cuttingunitliftleverwhenthecuttingunitisinthe

raisedposition.

KeySwitch

Thekeyswitch(Figure4)hasthreepositions:Off,

On/Preheat,andStart.

PTOSwitch

ThePTOswitch(Figure4)hasthreepositions:On

(engage),Neutral,andOff(disengage).Carefullylift

andpushthePTOswitchforwardtotheOnposition

tostarttheimplementorcuttingunitblades.Slowly

CruiseControl(Optional)

Thecruisecontrol(Figure4)setsthespeedofthe

machine.

FuelGauge

Thefuelgauge(Figure4)indicatestheleveloffuelin

thetank.

HourMeter

Thehourmeter(Figure4)showsthetotalhoursthatthe

machinehasbeenoperated.

TemperatureOverrideSwitch

Pressandholdtheresetswitch(Figure4)tostartthe

engineafterhightemperatureshutdown.Useonlyfor

emergencyoperation.

16

Page 17

AudibleAlarm

Thealarm(Figure4)isactivatedwhenthelowengine

oilpressurelightilluminatesorthehighcoolant

temperaturelightilluminates.

Wheeltread(tocenteroftire)

front45inch(1 14cm)

rear

Wheelbase

47inch(119cm)

55-1/2in(141cm)

AlarmSilenceSwitch

Thisswitch(Figure4)shutsofftheaudiblealarm.

ThrottleControl

Movethecontrol(Figure4)forwardtoincreasethe

enginespeedandrearwardtodecreasethespeed.

PowerPoint

Thepowerpoint(Figure4)isusedtopoweroptional

electricalaccessories.

EngineCoolingFanSwitch

Themachineisequippedwithahydraulicallydrivenauto

reversingenginecoolingfan.Thefanswitch(Figure4)

hasthreepositionsR(manualreverse),Auto(normal)

andF(forwardonly).RefertoEngineCoolingFan

OperationintheOperationSectionofmanual

FanSwitch

Weight(withcuttingunitsanduids)4166lb(1890kg)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

ThefanswitchhasthreepositionsR(manualreverse),

Auto(normal)andF(forwardonly).

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Widthofcut

overall

frontcuttingunit62inch(157cm)

sidecuttingunit

frontandonesidecuttingunit97inch(246cm)

Overallwidth

cuttingunitsdown

cuttingunitsup(transports)72inch(183cm)

Overalllength135inch(342cm)

Height

HeightwithROPS81inch(206cm)

132inch(335cm)

42inch(107cm)

136inch(345cm)

55inch(140cm)

Groundclearance6-1/2inch(17cm)

17

Page 18

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperating

Ifyouleavethekeyintheignitionswitch,

someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudo

anymaintenance.

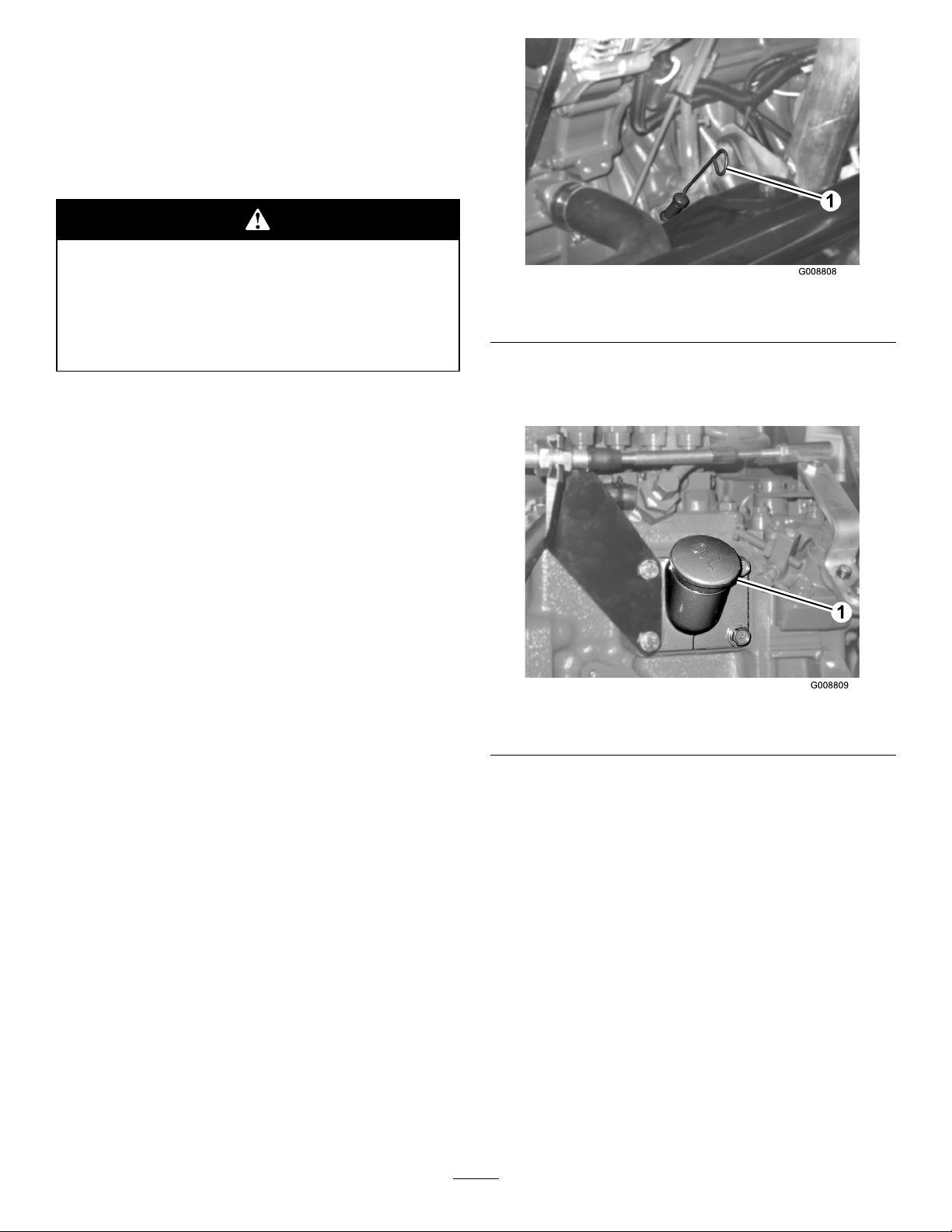

CheckingtheEngineOil

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;

however,theoillevelmustbecheckedbeforeandafter

theengineisrststarted.

Figure5

1.Dipstick

4.IftheoilisbelowtheFullmark,removethellcap

(Figure6)andaddoiluntilthelevelreachestheFull

mark.Donotoverll.

Thecrankcasecapacityis10qt(9.5l)withthelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4or

higher.

•Preferredoil:SAE15W -40(above0°F)

•Alternateoil:SAE10W-30or5W -30(all

temperatures)

ToroPremiumEngineOilisavailablefromyour

distributorineither15W-40or10W-30viscosity .See

thepartscatalogforpartnumbers.

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscoolbeforeithasbeenstartedfortheday .Ifit

hasalreadybeenrun,allowtheoiltodrainbackdown

tothesumpforatleast10minutesbeforechecking.

Iftheoillevelisatorbelowthe“add”markonthe

dipstick,addoiltobringtheoilleveltothe“full”mark.

DONOTOVERFILL.Iftheoillevelisbetweenthe

“full”and“add”marks,nooiladditionisrequired.

1.Parkthemachineonalevelsurface.Unlockthe

enginecoverlatches.

Figure6

1.Oilllcap

5.Installtheoilllcapanddipstick.

6.Closetheenginecoverandsecureitwiththelatches.

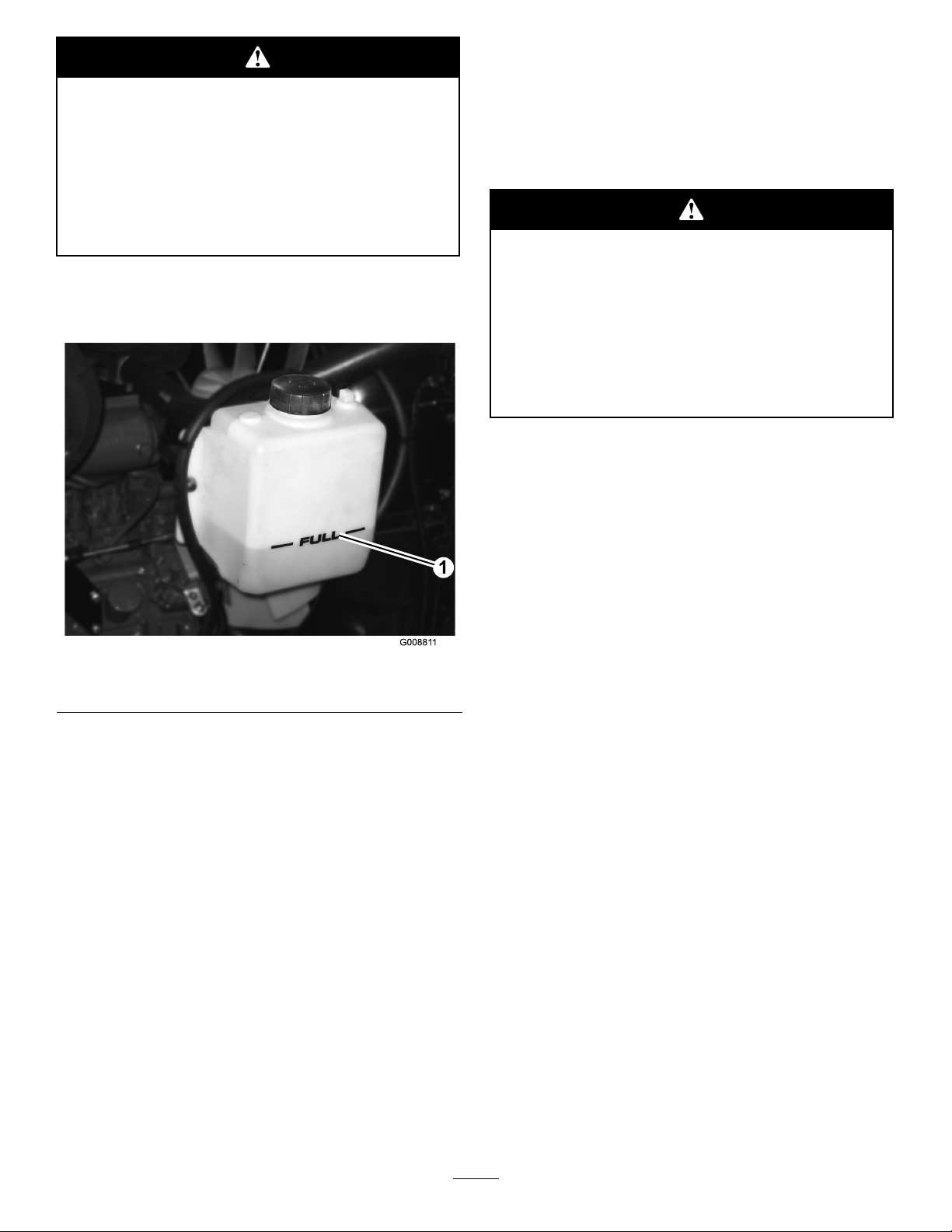

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily

Checklevelofcoolantatthebeginningofeachday.

Capacityofsystemis13qts.(12.3l).

1.Carefullyremovetheradiatorcapandexpansion

tankcap(Figure7).

2.Opentheenginecover.

3.Removethedipstick,wipeitclean,installthe

dipstickintothetube,andpullitoutagain.Theoil

levelshouldbeuptotheFullmark(Figure5).

18

Page 19

Iftheenginehasbeenrunning,thepressurized,

hotcoolantcanescapeandcauseburns.

•Donotopentheradiatorcapwhenthe

engineisrunning.

•Usearagwhenopeningtheradiatorcap,

andopenthecapslowlytoallowsteamto

escape.

2.Checkthecoolantlevelintheradiator.Theradiator

shouldbelledtothetopofthellerneckandthe

expansiontanklledtotheFullmark.

Useofsummergradefuelabove20°F(-7°C)will

contributetowardlongerfuelpumplifeandincreased

powercomparedtowintergradefuel.

Important:Donotusekeroseneorgasoline

insteadofdieselfuel.Failuretoobservethis

cautionwilldamagetheengine.

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepfuelawayfromeyesandskin.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

Figure7

1.Expansiontank

3.Ifthecoolantislow ,adda50/50mixtureofwater

andethyleneglycolanti-freeze.Donotusewater

onlyoralcohol/methanolbasecoolants.

4.Installtheradiatorcapandexpansiontankcap.

AddingFuel

Useonlyclean,freshdieselfuelorbiodieselfuelswith

low(<500ppm)orultralow(<15ppm)sulfurcontent.

Theminimumcetaneratingshouldbe40.Purchase

fuelinquantitiesthatcanbeusedwithin180daysto

ensurefuelfreshness.

Fueltankcapacity:19USgallons(72l)

•Thebiodieselportionofthefuelmustmeet

specicationASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuelas

theymaybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblends.

•Contactyourdistributorifyouwishformore

informationonbiodiesel.

Usesummergradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwintergrade(No.1-Dor

No.1-D/2-Dblend)belowthattemperature.Useof

wintergradefuelatlowertemperaturesprovideslower

ashpointandcoldowcharacteristicswhichwillease

startingandreducefuellterplugging.

19

Page 20

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Neverllthefueltankinsideanenclosed

trailer.

2.Usingacleanrag,cleanareaaroundfueltankcap.

3.Removecapfromthefueltank(Figure8).

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerandkeep

itoutofthereachofchildren.Neverbuy

morethana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfromafuel

dispensernozzle.

•Ifafueldispensernozzlemustbeused,keep

thenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntil

fuelingiscomplete.

1.Parkthemachineonalevelsurface.

Figure8

1.Fueltankcap

4.Fillthetankuntilthelevelistothebottomofthe

llerneckwithdieselfuel.

5.Installfueltankcaptightlyafterllingtank.

Note:Ifpossible,llthefueltankaftereachuse.

Thiswillminimizepossiblebuildupofcondensation

insidethefueltank.

CheckingtheHydraulicFluid

ServiceInterval:Beforeeachuseordaily

Themachinesreservoirislledatthefactorywith

approximately8U.S.gallons(30.2l)ofhighquality

hydraulicuid.Checkthelevelofthehydraulic

uidbeforetheengineisrststartedanddaily

thereafter.Therecommendedreplacementuidis:

ToroPremiumAllSeasonHydraulicFluid

(Availablein5gallonpailsor55gallondrums.Seeparts

catalogorTorodistributorforpartnumbers.)

Alternateuids:IftheTorouidisnotavailable,other

uidsmaybeusedprovidedtheymeetallthefollowing

materialpropertiesandindustryspecications.W edo

notrecommendtheuseofsyntheticuid.Consult

withyourlubricantdistributortoidentifyasatisfactory

product.

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehind

theirrecommendation.

HighViscosityIndex/LowPourPointAnti-wear

HydraulicFluid,ISOVG46

MaterialProperties:

St@40°C44to48 Viscosity,ASTMD445

St@100°C7.9to8.5

20

Page 21

HighViscosityIndex/LowPourPointAnti-wear

HydraulicFluid,ISOVG46(cont'd.)

ViscosityIndexASTMD2270

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:VickersI-286-S(Quality

Level),VickersM-2950-S

(QualityLevel),Denison

140to160

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemoilisavailablein2/3oz(20ml)

bottles.Onebottleissufcientfor4-6gallons(15-22

1)ofhydraulicoil.Orderpartno.44-2500fromyour

authorizedTorodistributor.

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,andremovethekey.

2.Unlatchtheseat,raiseit,andengagetheproprod.

3.Cleantheareaaroundthellerneckandcapofthe

hydraulictank(Figure9).Removethecapfromthe

llerneck.

CheckingthePlanetaryGearDriveOil

ServiceInterval:Every400hours

Checktheoillevelafterevery400hoursofoperation

orifexternalleakageisnoted.UsehighqualitySAE

85W-140gearlubeasareplacement.

Thecapacityofthesystemisapproximately16oz(0.5

HF-0

l).

1.Withthemachineonalevelsurface,positionthe

wheelsothatthecheck/drainplug(Figure10)isat

eitherthe2or10o’clockposition.

Figure9

1.Hydraulictankcap

4.Removethedipstickfromthellerneckandwipe

itwithacleanrag.Insertthedipstickintotheller

neck;thenremoveitandchecktheuidlevel.The

uidlevelshouldbebetweenthetwomarksonthe

dipstick.

5.Ifthelevelislow,addtheappropriateuidtoraise

theleveltotheuppermark.

6.Installthedipstickandcapontothellerneck.

Figure10

1.Check/drainplug

2.Removetheplugontheplanetary(Figure10)

andchecktheplugonthebacksideofthebrake

(Figure11).Oilshouldbeatthebottomofthe

checkplugholeonthebacksideofthebrake.

Figure11

1.Brakehousing

2.Checkplug

21

Page 22

3.Addgearoiltotheholeintheplanetary,ifnecessary,

tobringtheoiluptotheproperlevel.Installthe

plug.

4.Repeatsteps1-3ontheoppositegearassembly.

CheckingtheRearAxleLubricant

ServiceInterval:Every400hours

TherearaxleislledwithSAE85W -140gearlube.

Checktheoillevelbeforetheengineisrststartedand

every400hoursthereafter.Thecapacityis80oz(2.4l).

Visuallyinspectforleaksdaily.

1.Positionthemachineonalevelsurface.

2.Removeacheckplugfromoneendoftheaxle

(Figure12)andmakesurethatthelubricantisupto

thebottomofthehole.Ifthelevelislow,remove

thellplug(Figure12)andaddenoughlubricantto

bringtheleveluptothebottomofthecheckplug

holes.

Figure13

1.Gearbox2.Check/llplug

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Thetiresareover-inatedforshipping.Therefore,

releasesomeoftheairtoreducethepressure.The

correctairpressureinthefrontandreartiresis25-30

psi(172-207kPa).

Figure12

1.Checkplug

2.Fillplug

CheckingtheRearAxleGearBox

Lubricant

ServiceInterval:Every400hours

ThegearboxislledwithSAE85W-140gearlube.

Checktheoillevelbeforetheengineisrststartedand

every400hoursthereafter.Thecapacityis16oz(0.5l).

Visuallyinspectforleaksdaily.

1.Positionthemachineonalevelsurface.

2.Removethecheck/llplugfromtheleftsideofthe

gearbox(Figure13)andmakesurethatlubricant

isuptothebottomofthehole.Ifthelevelislow,

addenoughlubricanttobringtheleveluptothe

bottomofthehole.

Important:Maintainevenpressureinalltiresto

ensureagoodquality-of-cutandpropermachine

performance.

Do not under -inate.

CheckingtheTorqueoftheWheelNuts

orBolts

ServiceInterval:Aftertherst10hours

Every200hours

Failuretomaintainpropertorqueofthewheel

nutscouldresultinfailureorlossofwheeland

mayresultinpersonalinjury.

Torquethefrontwheelnutsandrearboltsto85

to100ft-lb(115to136N⋅ ⋅⋅m)after1-4hoursof

operationandagainafter10hoursofoperation.

Torqueevery200hoursthereafter.

AdjustingtheHeight-of-Cut

FrontCuttingUnit

Theheight-of-cutisadjustablefrom1to5inches(25

to127mm)in1/2inch(13mm)increments.Toadjust

theheight-of-cutonthefrontcuttingunit,positionthe

castorwheelaxlesintheupperorlowerholesofthe

22

Page 23

castorforks,addorremoveanequalnumberofspacers

fromthecastorforks,andsecuretherearchaintothe

desiredhole.

1.Starttheengineandraisethecuttingunitssothat

theheight-of-cutcanbechanged.Stoptheengine

andremovethekeyafterthecuttingunitisraised.

2.Positionthecastorwheelaxlesinthesameholes

inallcastorforks.Refertothefollowingchartto

determinethecorrectholesforthesetting.

below)ontothespindleshafttogetthedesired

height-of-cut;thenslidethewasherontotheshaft.

Refertothefollowingcharttodeterminethe

combinationsofspacersforthesetting:

Figure15

4.Pushthecastorspindlethroughthefrontcastor

arm.Installtheshims(astheywereoriginally

installed)andtheremainingspacersontothe

spindleshaft.Installthetensioningcaptosecure

theassembly .

5.Removethehairpincotterandclevispinsecuring

theheight-of-cutchainstotherearofthecutting

unit(Figure16).

Figure14

1.Castorwheel4.Shims

2.Tensioningcap5.Axlemountingholes

3.Spacers

Note:Whenoperatingin2-1/2inch(64mm)

heightofcutorhigher,theaxleboltmustbe

installedinthelowercastorforkholetoprevent

grassbuildupbetweenthewheelandthefork.

Whenoperatinginheightofcutslowerthan2-1/2

inches(64mm)andgrassbuildupisdetected,

reversethemachinesdirectiontopullanyclippings

awayfromthewheel/forkarea.

3.Removethetensioningcapfromthespindleshaft

(Figure14)andslidethespindleoutofthecastor

arm.Putthe2shims(1/8inch[3mm])ontothe

spindleshaftastheywereoriginallyinstalled.These

shimsarerequiredtoachievealevelacrosstheentire

widthofthecuttingunits.Slidetheappropriate

numberof1/2inchspacers(refertothechart

Figure16

1.Height-of-cutchain

2.U-bolt

6.Mounttheheight-of-cutchainstothedesired

height-of-cuthole(Figure17)withtheclevispin

andhairpincotter.

Figure17

23

Page 24

Note:Whenusing1inch(25mm),1-1/2inch(38

mm),oroccasionally2inch(51mm)height-of-cut,

movetheskidsandgagewheelstothehighest

position.

SideCuttingUnits

Toadjusttheheight-of-cutonthesidecuttingunits,add

orremoveanequalnumberofspacersfromthecastor

forks,positionthecastorwheelaxlesinthehighorlow

height-of-cutholesinthecastorforks,andsecurethe

pivotarmstotheselectedheight-of-cutbracketholes.

1.Positionthecastorwheelaxlesinthesameholes

inallofthecastorforks(Figure18andFigure20).

Refertothefollowingcharttodeterminethe

correctholeforthesetting.

2.Removethetensioningcapfromthespindleshaft

(Figure18)andslidethespindleoutofcastorarm.

Putthetwoshims(1/8inch[3mm])ontospindle

shaftastheywereoriginallyinstalled.Theseshims

arerequiredtoachievealevelacrosstheentire

widthofthecuttingunits.Slidetheappropriate

numberof1/2inchspacersontothespindleshaft

togetthedesiredheight-of-cut;thenslidethe

washerontotheshaft.

Refertothefollowingcharttodeterminethe

combinationsofspacersforthesetting.

Figure19

3.Pushthecastorspindlethroughthecastorarm.

Installtheshims(asoriginallyinstalled)andthe

remainingspacersontothespindleshaft.Installthe

tensioningcaptosecuretheassembly .

4.Removethehairpincotterandclevispinsfromthe

castorpivotarms(Figure20).

5.Rotatetensionrodtoraiseorlowerpivotarm

untilholesarealignedwithselectedheight-of-cut

bracketholesinthecuttingunitframe(Figure20

andFigure21).

6.Inserttheclevispinsandinstallthehairpincotters.

7.Rotatetensionrodcounterclockwise(ngertight)

toputtensiononadjustment.

Figure20

1.Castorpivotarm3.Clevispinandhairpin

2.Axlemountingholes4.Tensionrod

cotter

Figure18

1.Castorwheel4.Shims

2.Tensioningcap5.Axlemountingholes

3.Spacers

24

Page 25

Figure21

Figure23

8.Removethehairpincottersandclevispinssecuring

thedamperlinkstothecuttingunitbrackets

(Figure22).Alignthedamperlinkholeswiththe

selectedheight-of-cutbracketholesinthecutting

unitframe(Figure23),inserttheclevispins,and

installthehairpincotters.

Important:Thedamperlinklengthshould

neverbeadjusted.Thelengthbetweenthehole

centersshouldbe5-3/8inch(13.7cm).

AdjustingtheSkids

Theskidsshouldbemountedinthelowerposition

whenoperatinginheightofcutsgreaterthan2-1/2

inches(64mm)andinthehigherpositionwhen

operatinginheightofcutslowerthan2-1/2inches(64

mm).

Adjusttheskidsbyremovingtheangeboltandnuts,

positioningthemasdesired,andinstallingthefasteners

(Figure24).

Figure24

1.Skid

1.Damperlink

Figure22

AdjustingtheCuttingUnitRollers

Thecuttingunitrollersshouldbemountedinthelower

positionwhenoperatinginheightofcutsgreaterthan

2-1/2inches(64mm)andinthehigherpositionwhen

operatinginheightofcutslowerthan2-1/2inches(64

mm).

1.Removetheboltandnutsecuringthegagewheelto

thecuttingunitbrackets(Figure25).

25

Page 26

Figure25

1.Gagewheel

2.Aligntherollerandspacerwiththetopholesinthe

bracketsandsecurethemwiththeboltandnut.

CorrectingMismatchBetweenCutting

Units

Duetodifferencesingrassconditionsandthe

counterbalancesettingofthetractionunit,itisadvised

thatgrassbecutandappearancecheckedbeforeformal

cuttingisstarted.

FrontCuttingUnitSetup

Rotatebladeoneachspindleuntiltheendsfaceforward

andbackward.Measurefromtheoortothefront

tipofthecuttingedge.Adjust1/8inchshimson

frontcastorfork(s)tomatchheightofcuttodecal

(Figure26);refertoAdjustingtheCuttingUnitPitch

procedureinMowerMaintenance,page50.

1.Setallcuttingunitstothedesiredheightofcut;

refertoAdjustingtheHeightofCuttablein

Specications,page17.

2.Checkandadjustfrontandreartractortirepressure

to25-30psi(172-207kPa).

3.Checkandadjustallcastortirepressuresto50psi

(345kPa).

4.Checkchargeandcounterbalancepressures

withengineathighidleusingtestportsdened

inHydraulicSystemsTestPorts.Adjust

counterbalancesettingtobe220psi(1517kPa)

higherthanchargepressurereading.

5.Checkforbentblades;refertoCheckingforaBent

BladeprocedureinMowerMaintenance,page50.

6.Cutgrassinatestareatodetermineifallcutting

unitsarecuttingatthesameheight.

7.Ifcuttingunitadjustmentsarestillneeded,ndaat

surfaceusinga6foot(2m)orlongerstraightedge.

8.Toeasemeasuringbladeplane,raisetheheightof

cuttothehighestposition;refertoAdjustingthe

HeightofCut.

Figure26

1.Castorwheel4.Shims

2.Tensioningcap5.Axlemountingholes

3.Spacers

SideCuttingUnitSetup

Rotatebladeofeachspindleuntiltheendsfaceforward

andbackward.Measurefromtheoortothefront

tipofthecuttingedge.Adjust1/8inchshimson

frontcastorarm(s)tomatchheightofcuttodecal

(Figure27).Fortheoutsidebladespindleonly,referto

AdjustingtheCuttingUnitPitchprocedureinMower

Maintenance,page50.

9.Lowercuttingunitsontotheatsurface.Remove

thecoversfromthetopofthecuttingunits.

10.Loosentheangenut,securingtheidlerpulley,to

releasethebelttensiononeachcuttingunit.

26

Page 27

Figure27

1.Frontcastorarm

MatchingHeightOfCutBetweenCuttingUnits

1.Positionbladesidetosideonoutsidespindleof

bothsidecuttingunits.Measurefromtheoor

tothetipofthecuttingedgeonbothunitsand

compare.Thesenumbersshouldbewithin1/8inch

(3mm)ofeachother.Makenoadjustmentatthis

time.

2.Positionbladesidetosideoninsidespindleofside

cuttingunitandcorrespondingoutsidespindle

offrontcuttingunit.Measurefromtheoorto

thetipofthecuttingedgeoninsideedgeofside

cuttingunittocorrespondingoutsideedgeoffront

cuttingunitandcompare.Thesidecuttingunit

measurementshouldbeapproximately3/8inch

lessthanthefrontcuttingunitmeasurementtobe

correct.Whenpropermachinecounterbalanceis

appliedtothesidecuttingunitstheinsideedgewill

liftupapproximately3/8inch(10mm).

Note:Allthreesidecuttingunitscastorwheels

shouldremainonthegroundwithcounterbalance

applied.

edgeofsidecuttingunittooutsideedgeoffront

cuttingunit.

4.Ifinsideedgeisstilltoohigh,removeanadditional

1/8inchshimfrombottomoffrontinsidecastor

armofthesidecuttingunitandone1/8inchshim

fromthefrontoutsidecastorarmofthesidecutting

unit.

5.Iftheinsideedgeofthesidecuttingunitistoolow

relativetotheoutsideedgeofthefrontcuttingunit,

addone1/8inchshimtothebottomofthefront

insidecastorarmonthesidecuttingunit.Check

measurementbetweenoutsideedgesofbothside

cuttingunitsandinsideedgeofsidecuttingunitto

outsideedgeoffrontcuttingunit.

6.Ifinsideedgeisstilltoolow ,addanadditional1/8

inchshimtothebottomoffrontinsidecastorarm

ofthesidecuttingunitandaddone1/8inchshim

tothefrontoutsidecastorarmofthesidecutting

unit.

7.Oncecuttingheightmatchesattheedgesoffront

andsidecuttingunits,verifythatsidecuttingunit

pitchisstill1/4inch(6mm).Adjustasnecessary.

StartingandStoppingthe

Engine

Important:Thefuelsystemwillautomatically

bleeditselfwhenanyofthefollowingsituations

occur:

•Initialstartupofanewmachine.

•Theenginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponthefuel

systemcomponents.

1.Ensurethattheparkingbrakeisset.Removeyour

footfromthetractionpedalandensurethatitisin

neutral.

2.Movethethrottlecontroltothemid-idleposition.

3.TurntheignitionkeytotheRunposition.Theglow

indicatorwilllight.

Note:Ifadjustmentsneedtobemadetomatchthe

cutbetweenthefrontandsidecuttingunits,make

theadjustmentstothesidecuttingunitsonly.

3.Iftheinsideedgeofthesidecuttingunitistoo

highrelativetotheoutsideedgeofthefrontcutting

unit,removeone1/8inchshimfromthebottom

ofthefrontinsidecastorarmonthesidecutting

unit(Figure27).Recheckmeasurementbetween

outsideedgesofbothsidecuttingunitsandinside

4.Whentheglowindicatordims,turntheignitionkey

totheStartposition.Releasethekeyimmediately

whentheenginestartsandallowittoreturntothe

Runposition.Allowenginetowarmupatmid

speed(withoutload),thenmovethethrottlecontrol

tothedesiredposition.

Important:Donotrunthestartermotor

morethan15secondsatatimeorpremature

starterfailuremayresult.Iftheenginefailsto

27

Page 28

startafter15seconds,turnthekeytotheOff

position,recheckthecontrolsandprocedures,

wait15additionalseconds,andrepeatthe

startingprocedure.

Whenthetemperatureislessthan20°F(-75C),

preheatglowplugstwicepriortoinitialcranking

attempt.Thestartermotorcanberunfor30

secondsonthen60secondsofffor2attempts.

5.Tostoptheengine,movethethrottlecontrol

backwardtotheSlowposition,movethePTOlever

totheOffposition,settheparkingbrake,androtate

theignitionkeytoOff.Removethekeyfromthe

switchtopreventaccidentalstarting.

CheckingtheInterlock

Switches

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Important:Allowenginetoidlefor5minutes

beforeshuttingitoffafterafullloadoperation.

Failuretodosomayleadtoturbo-chargertrouble.

EngineCoolingFanOperation

Theenginecoolingfanswitchhasthreepositionsfor

controllingtheoperationofthefan.Thethreepositions

areR,AutoandF .Thefanhastheabilitytoreverse

toblowdebrisoffoftherearscreen.Undernormal

operatingconditions,theswitchshouldbeintheAuto

position.InAuto,thefanspeedwillbecontrolledby

thecoolanttemperatureandwillautomaticallyreverse

toblowdebrisoffoftherearscreen.Areversecycle

isautomaticallyinitiatedwheneitherthecoolantor

hydraulictemperaturereachesacertainpoint.By

pressingthefanswitchforwardintotheRposition,the

fanwillcompleteamanuallyinitiatedreversecycle.This

positionisspringloadedmeaningthattheswitchwill

returntotheAutopositionafterbeingpressedintothe

Rposition.Bypressingtheswitchbackwardsintothe

Fposition,thereversingfunctionofthefanisturned

off.Thefanwillonlyrunintheforwarddirectionwith

itsspeedbeingcontrolledbythecoolanttemperature.

Thispositionwouldbepreferredwhenitisundesirable

toblowdebrisoutofthebackofthemachine.

Themachinehasinterlockswitchesintheelectrical

system.Theseswitchesaredesignedtostoptheengine

whentheoperatorgetsoffoftheseatwhenthetraction

pedalisdepressed.However,theoperatormaygetoff

oftheseatwhiletheengineisrunningandthetraction

pedalisinneutral.Althoughtheenginewillcontinue

torunifthePTOleverisdisengagedandthetraction

pedalisreleased,itisstronglyrecommendedthatthe

enginebestoppedbeforerisingfromtheseat.

Tochecktheoperationoftheinterlockswitches,

performthefollowingprocedure:

1.Drivethemachineslowlytoalarge,relativelyopen

area.Lowerthecuttingunit,stoptheengine,and

applytheparkingbrake.

2.Sitontheseatanddepressthetractionpedal.Try

tostarttheengine.Theengineshouldnotcrank.

Iftheenginecranks,thereisamalfunctioninthe

interlocksystemthatshouldbecorrectedbefore

beginningoperation.

3.Sitontheseatandstarttheengine.Risefromthe

seatandmovethePTOlevertoOn.ThePTO

shouldnotengage.IfthePTOengages,thereisa

malfunctionintheinterlocksystemthatshouldbe

correctedbeforebeginningoperation.

4.Sitontheseat,engagetheparkingbrakeandstart

theengine.Movethetractionpedaloutofthe

neutralposition.Theengineshouldkill.Ifthe

enginedoesnotkill,thereisamalfunctioninthe

interlocksystemthatshouldbecorrectedbefore

beginningoperation.

PushingorTowingthe

Machine

Inanemergency,themachinecanbemovedforwardby

actuatingthebypassvalveinthevariabledisplacement

hydraulicpumpandpushingortowingthemachine.

28

Page 29

Donotpushortowthemachineformorethan1/4

mile(0.4km).

Important:Donotpushortowthemachine

fasterthan2-3MPH(3-4.8km/h)becauseinternal

transmissiondamagemayoccur.Thebypassvalve

mustbeopenwheneverthemachineispushedor

towed.

1.Raisetheseatandremovethebatterycover.The

bypassvalveislocatedinfrontofthebattery

(Figure28).

2.Rotatethevalve1/4turnineitherdirectiontoopen

andallowoiltobypassinternally.Becauseuidis

bypassed,themachinecanbeslowlymovedwithout

damagingthetransmission.Notethepositionof

thevalvewhenopeningorclosing.

3.Closethebypassvalvebeforestartingtheengine.

However,donotexceed5to8ft-lb(7to11N⋅m)

torquetoclosethevalve.

Figure29

1.Reversetractionpressuretestport

Figure28

1.Bypassvalveaccesshole

Important:Ifthemachinemusttobe

pushedortowedinreverse,thecheckvalve

inthefour-wheeldrivemanifoldmustalsobe

bypassed.Tobypassthecheckvalve,connect

ahoseassembly(HosePartNo.95-8843,

CouplerFittingNo.95-0985[Qty.2],and

HydraulicFittingNo.340-77[Qty.2])tothe

reversetractionpressuretestport(Figure29)

andthereversefour-wheeldrivepressureport

(Figure30).

Figure30

1.Reversefour-wheeldrivepressuretestport

JackingPoints

Therearejackingpointslocatedatthefrontandrear

ofthemachine.

•Ontheframeattheinsideofeachfrontdrivetire

•Atthecenteroftherearaxle

TieDowns

Therearetiedownslocatedatthefront,rearandsides

ofthemachine.

•Oneachsideoftheframebythesidecuttingunit

liftarms

•Frontcenteroftheoperator’splatform

•Therearbumper

OperatingCharacteristics

Practicedrivingthemachinebecauseithasahydrostatic

transmissionanditscharacteristicsaredifferentthan

manyturfmaintenancemachines.Somepointsto

considerwhenoperatingthetractionunit,cutting

unit,orotherimplementsarethetransmission,engine

29

Page 30

speed,loadonthecuttingbladesorotherimplement

components,andtheimportanceofthebrakes.

Tomaintainenoughpowerforthetractionunitand

implementwhileoperating,regulatethetractionpedal

tokeeptheenginespeedhighandsomewhatconstant.

Agoodruletofollowistodecreasethegroundspeed

astheloadontheimplementincreases,andincreasethe

groundspeedastheloaddecreases.

Therefore,allowthetractionpedaltomovebackward

astheenginespeeddecreases,anddepressthepedal

slowlyasthespeedincreases.Bycomparison,when

drivingfromoneworkareatoanother,withnoload

andcuttingunitraised,havethethrottleintheFast

positionanddepressthetractionpedalslowlybutfully

toattainmaximumgroundspeed.

Theowdividerenhancestractiondriveperformance

incompromisedoperatingconditions.Theowdivider

isforuseinlowspeedrangeonly.Whenapproaching

anareaknowntocausewheelspin,depressandhold

owdividerswitchuntilcompletelypastthearea.If

atirespinswhileclimbingormaneuveringonslopes,

depressswitchandslowlydriveoutofarea.Ifboth

afrontandrearwheelspins,thesteeringbrakecan

befeatheredtotransferthetorquefromthespinning

wheelstotheoppositefrontwheel.

Thiscuttingunitsaredesignedtodriveobjects

intothegroundwheretheyloseenergyquickly

ingrassareas.However,carelessoperation,

combinedwithterrainangle,ricochets,or

improperlypositionedsafetyguardcanleadto

thrownobjectinjuries.

•Whenapersonorpetappearssuddenlyinor

nearthemowingarea,

•Donotresumemowinguntiltheareais

cleared.

Beforestoppingtheengine,disengageallcontrolsand

movethethrottletoSlow .MovingthethrottletoSlow

reduceshighenginespeed,noise,andvibration.Turn

thekeytoOfftostoptheengine.

Beforetransportingthemachine,raisethecuttingunits

andsecurethetransportlatches(Figure31).

stop mo wing

.

Thebrakescanbeusedtoassistinturningthemachine.

However,usethemcarefully,especiallyonsoftor

wetgrassbecausetheturfmaybetornaccidentally.

Anotherbenetofthebrakesistomaintaintraction.

Forexample,insomeslopeconditions,theuphillwheel

slipsandlosestraction.Ifthissituationoccurs,depress

theuphillturnpedalgraduallyandintermittentlyuntil

theuphillwheelstopsslipping,thus,increasingtraction

onthedownhillwheel.

Useextracarewhenoperatingthemachineonslopes.

Makesurethattheseatlatchisproperlysecuredandthe

seatbeltisbuckled.Driveslowlyandavoidsharpturns

onslopestopreventrollovers.Forsteeringcontrol,the

cuttingunitmustbeloweredwhengoingdownhill.

Figure31

1.Transportlatch(sidecuttingunits)

OperatingTips

MowWhenGrassisDry

Moweitherinthelatemorningtoavoidthedew,which

causesgrassclumping,orinlateafternoontoavoidthe

damagethatcanbecausedbydirectsunlightonthe

sensitive,freshlymowedgrass.

SelecttheProperHeight-of-CutSetting

toSuitConditions

Removeapproximately1inch(25mm)ornomorethan

1/3ofthegrassbladewhencutting.Inexceptionally

30

Page 31

lushanddensegrass,youmayhavetoraisethe

height-of-cuttothenextsetting.

MowatProperIntervals

Undermostnormalconditionsyouwillneedtomow

approximatelyevery4-5days.Butremember,grass

growsatdifferentratesatdifferenttimes.Thismeans

thatinordertomaintainthesameheight-of-cut,which

isagoodpractice,youwillneedtocutmorefrequently

inearlyspring;asthegrassgrowthrateslowsinmid

summer,cutonlyevery8-10days.Ifyouareunableto

mowforanextendedperiodduetoweatherconditions

orotherreasons,mowrstwiththeheight-of-cutata

highlevel;thenmowagain2-3dayslaterwithalower

heightsetting.

Transporting

Usethetransportlatcheswhentransportingoverlong

distances,roughterrain,orwhentrailering.

AfterOperating

Toensureoptimumperformance,cleantheunderside

ofthemowerhousingaftereachuse.Ifresidueis

allowedtobuildupinthemowerhousing,cutting

performancewilldecrease.

CuttingUnitPitch

Werecommendabladepitchof1/4inch(6mm).A

pitchlargerthan1/4inch(6mm)willresultinless

powerrequired,largerclippings,andapoorerquality

ofcut.Apitchlessthan1/4inch(6mm)willresult

inmorepowerrequired,smallerclippingsandabetter

qualityofcut.

31

Page 32

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst10hours

Aftertherst50hours

Aftertherst200hours

Beforeeachuseordaily

Every50hours

Every100hours

MaintenanceProcedure

•T orquethewheellugnuts.

•Checkthealternatorbelttension.

•Checkthebladedrivebelttension.

•Changetheengineoilandlter.

•Checktheenginespeed(atidleandfullthrottle).

•Changethefrontplanetarygearoil.

•Changetherearaxleoil.

•Changethehydraulicoil.

•Changethehydraulicoillters.

•Checktheengineoillevel.

•Checkthecoolantlevel.

•Checkthehydraulicuidlevel.

•Checkthetirepressure.

•Checktheaircleanerindicator

•Checktheinterlockswitchoperation

•Lubricateallgreasettings.

•Inspecttheaircleaner.

•Checkthebladedrivebelttension.

•Removealldebrisandchafffromtheradiatorandoilcooler.

•Inspectthecoolingsystemhosesandclamps.

•Checkthefanandalternatorbelttension.

Every150hours

Every200hours

Every400hours

Every800hours

Every2years

•Changetheengineoilandlter.

•T orquethewheellugnuts.

•Servicethesparkarrestormufer.

•Checktheplanetarygeardriveoil.

•Checktherearaxlelubricant.

•Checktherearaxlegearboxlubricant.

•Servicetheairlter(iftheindicatorshowsred).

•Inspectthefuellinesandconnections.

•Replacethefuelltercanister.

•Checktheenginespeed(atidleandfullthrottle).

•Drainandcleanthefueltank.

•Changethefrontplanetarygearoil.

•Changetherearaxleoil.

•Checktherearwheeltoe-in.

•Inspectthebladedrivebelts.

•Changethehydraulicoil.

•Changethehydraulicoillters.

•Inspectthesidecuttingunitdamper.

•Inspectthecuttingunitcastorwheelassemblies.

•Checkandadjustthevalveclearance.

•Flushthecoolingsystemandreplaceuid.

•Replacemovinghoses.

32

Page 33

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

ServiceIntervalChart

Lubrication

GreasingtheBearingsand

Bushings

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBase

Grease.Ifthemachineisoperatedundernormal

conditions,lubricateallbearingsandbushingsafter

every50hoursofoperationorimmediatelyafterevery

washing.

Thegreasettinglocationsandquantitiesare:

Figure32

TractionUnit

ServiceInterval:Every50hours

•Brakeshaftpivotbearings(5)(Figure33)

•Tractionpedalpivotbushing(1)(Figure34)

•Frontandrearaxlepivotbushings(2)(Figure35)

•Steeringcylinderballjoints(2)(Figure36)

•Tierodballjoints(2)(Figure36)

•Kingpinbushings(2)(Figure36).

Thetopttingonthekingpinshould

onlybelubricatedannually(2pumps).

33

Page 34

Figure33

Figure36

Figure34

Figure35

FrontCuttingUnit

•Castorforkshaftbushings(2)(Figure37)

•Spindleshaftbearings(3)(locatedunderthepulley)

(Figure38)

•Idlerarmpivotbushings(2)(Figure38)

Figure37

34

Page 35

Figure38

FrontLiftAssemblies

•Liftarmbushings(2)(Figure39)

•Liftcylinderbushings(4)(Figure39)

•Liftarmballjoints(2)(Figure40)

Figure40

SideCuttingUnits

•Castorforkshaftbushing(1)(Figure41)

•Spindleshaftbearings(2each)(locatedunderthe

pulley)

•Idlerarmpivotbushings(1)(locatedontheidler

arm)

Figure39

Figure41

SideLiftAssemblies

•Mainliftarmbushings(6)(Figure42andFigure43),

35

Page 36

•Bellcrankpivotbushings(2)(Figure44)

•Reararmbushings(4)(Figure44)

•Liftcylinderbushings(4)(Figure45)

Figure44

Figure42

Figure43

Figure45

36

Page 37

EngineMaintenance

AirCleanerMaintenance

•Checktheaircleanerbodyfordamagewhichcould

causeanairleak.Replaceifdamaged.Checkthe

wholeintakesystemforleaks,damageorloosehose

clamps.

•Servicetheaircleanerlteronlywhentheservice

indicatorrequiresitorevery400hours(more

frequentlyinextremelydustyordirtyconditions).

Changingtheairlterbeforeitisnecessaryonly

increasesthechanceofdirtenteringtheenginewhen

thelterisremoved.

•Besurethecoverisseatedcorrectlyandsealswith

theaircleanerbody.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily

Every50hours

Every400hours

1.Pullthelatchoutwardandrotatetheaircleaner

covercounterclockwise(Figure46).

2.Removethecoverfromtheaircleanerbody.Before

removingthelter,uselowpressureair(40psi,

cleananddry)tohelpremovelargeaccumulations

ofdebrispackedbetweenoutsideofprimarylter

andthecanister.Avoidusinghighpressureairwhich

couldforcedirtthroughthelterintotheintakearea.

Thiscleaningprocesspreventsdebrisfrommigrating

intotheintakewhentheprimarylterisremoved.

Figure46

1.Aircleanerindicator3.Aircleanercover

2.Aircleanerlatch

3.Removetheprimarylter(Figure47).Cleaningof

theusedelementisnotrecommendedduetothe

possibilityofdamagetotheltermedia.Inspectthe

newlterforshippingdamage,checkingthesealing

endofthelterandthebody .Donotuseadamaged

element.Donotremovethesafetylter(Figure48).

1.Aircleanerprimarylter

37

Figure47

Page 38

Figure48

1.Aircleanersafetylter

Important:Neverattempttocleanthesafety

lter(Figure48).Replacethesafetylterwitha

newoneaftereverythreeprimarylterservices.

4.Replacetheprimarylter(Figure47).

5.Insertthenewlterbyapplyingpressuretotheouter

rimoftheelementtoseatitinthecanister.Donot

applypressuretotheexiblecenterofthelter.

6.Cleanthedirtejectionportlocatedintheremovable

cover.Removetherubberoutletvalvefromthe

cover,cleanthecavityandreplacetheoutletvalve.

7.Installthecoverorientingtherubberoutletvalve

(Figure46)inadownwardposition-between

approximately5:00to7:00whenviewedfromthe

end.Securethelatch.

Figure49

1.Engineoildrainplug

2.Removetheoillter(Figure50).Applyalightcoat

ofcleanoiltothenewltersealbeforescrewingit

on.Donotovertighten.

Figure50

1.Engineoillter

3.Addoiltothecrankcase;refertoCheckingthe

EngineOil.

ServicingtheEngineOiland

Filter

ServiceInterval:Aftertherst50hours

Every150hours

Changetheoilandlterinitiallyaftertherst50hours

ofoperation;thereafterchangetheoilandlterevery

150hours.

1.Removeeitherdrainplug(Figure49)andlettheoil

owintoadrainpan.Whentheoilstops,installthe

drainplug.

38

Page 39

FuelSystem

Maintenance

ServicingtheFuelSystem

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomof

thellerneck.Thisemptyspaceinthetank

allowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

2.Loosenthedrainplugonthebottomofthelter

canister.

Figure51

1.Waterseparatorltercanister

3.Cleantheareawheretheltercanistermounts.

4.Removetheltercanisterandcleanthemounting

surface.

5.Lubricatethegasketontheltercanisterwithclean

oil.

6.Installtheltercanisterbyhanduntilthegasket

contactsmountingsurface,thenrotateitan

additional1/2turn.

7.Tightenthedrainplugonthebottomofthelter

canister.

FuelTank

ServiceInterval:Every800hours

Drainandcleanthefueltankevery800hours.Also,

drainandcleanthetankiffuelsystembecomes

contaminatedorifthemachinewillbestoredforan

extendedperiodoftime.Usecleanfueltoushout

thetank.

FuelLinesandConnections

ServiceInterval:Every400hours

Checkthefuellinesandconnectionsevery400hours

oryearly,whichevercomesrst.Inspectthemfor

deterioration,damage,orlooseconnections.

ServicingtheWaterSeparator

ServiceInterval:Every400hours

Drainwaterorothercontaminantsfromwaterseparator

(Figure51)daily.Replaceltercanisterafterevery400

hoursofoperation.

1.Placeacleancontainerunderthefuellter.

BleedingAirfromtheInjectors

1.LoosenthetubeconnectiontotheNumber1

injectornozzleandholderassemblyattheinjection

pump(Figure52).

Figure52

1.Number1injectornozzle

2.MovethethrottletotheFastposition.

3.TurnthekeyintheignitionswitchtotheStart

positionandwatchthefuelowaroundthe

connector.TurnthekeytotheOffpositionwhen

solidowisobserved.

39

Page 40

4.Tightenthetubeconnectorsecurely .

5.Repeattheprocedureontheremainingnozzles.

ElectricalSystem

Maintenance

BatteryCare

Batterytypeisgroup24.

Important:Beforeweldingonthemachine,

disconnectthenegativecablefromthebatteryto

preventdamagetotheelectricalsystem.

Note:Checkthebatteryconditionweeklyorafterevery

50hoursofoperation.Keeptheterminalsandtheentire

batterycasecleanbecauseadirtybatterywilldischarge

slowly.Tocleanthebattery,washtheentirecasewith

asolutionofbakingsodaandwater.Rinsewithclear

water.Coatthebatterypostsandcableconnectorswith

Grafo112X(skin-over)grease(ToroPartNo.505-47)

orpetroleumjellytopreventcorrosion.

Warning

CALIFORNIA