Page 1

Base62inand72inMower

FormNo.3425-822RevA

Groundsmaster

ModelNo.30403—SerialNo.403330001andUp

ModelNo.30404—SerialNo.403330001andUp

®

3320/3280-DTractionUnit

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3425-822*A

Page 2

ThisproductcomplieswithallrelevantEuropean

directives.Fordetails,pleaseseetheDeclarationof

Incorporation(DOI)atthebackofthispublication.

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

g243406

Figure1

Introduction

Thisrotary-bladelawncuttingunitismountedto

aride-onmachineandisintendedtobeused

byprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrass

onwell-maintainedlawnsinparks,sportselds,

andoncommercialgrounds.Usingthisproductfor

purposesotherthanitsintendedusecouldprove

dangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

Visitwww.T oro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Safety.......................................................................3

GeneralSafety...................................................3

CuttingUnitSafety..............................................3

SafetyandInstructionalDecals..........................5

Setup........................................................................7

1PreparingtheMachine.....................................7

2InstallingaCompletionKit................................7

3InstallingtheCastorWheelAssemblies............8

4InstallingtheLiftArms......................................8

5InstallingtheCuttingUnitsontheLift

Arms...............................................................9

6ConnectingthePTOShafttotheCutting

UnitGearbox.................................................10

7GreasingtheMachine....................................10

ProductOverview....................................................11

Specications...................................................11

Attachments/Accessories..................................11

Operation.................................................................11

AdjustingtheHeight-of-Cut................................11

AdjustingtheCuttingUnitPitch.........................13

AdjustingtheSkids...........................................13

AdjustingtheRollers.........................................14

CorrectingCuttingUnitMismatch.....................14

OperatingTips.................................................15

Maintenance...........................................................16

RecommendedMaintenanceSchedule(s)...........16

DailyMaintenanceChecklist.............................16

Lubrication........................................................17

CheckingtheLubricantintheGearbox..............17

SeparatingtheCuttingUnitfromtheTraction

Unit...............................................................18

MountingtheCuttingUnittotheTraction

Unit...............................................................19

ServicingtheBushingsintheCastor

Arms.............................................................19

ServicingtheCastorWheelsand

Bearings........................................................20

ServicingtheCuttingBlades.............................20

CheckingandCorrectingMismatchof

Blades...........................................................22

ReplacingtheDriveBelt...................................22

CleaningUndertheCuttingUnit........................23

Storage...................................................................23

Thismachinehasbeendesignedinaccordancewith

ENISO5395:2013andANSIB71.4-2017.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersandpetsawayfromthemachine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Parkthemachineonalevelsurface,lowerthe

cuttingunits,disengagethedrives,engagethe

parkingbrake(ifprovided),shutofftheengine,

andremovethekeybeforeleavingtheoperator's

positionforanyreason.

Improperlyusingormaintainingthismachinecan

resultininjury .Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthisOperator’sManual.

,which

CuttingUnitSafety

•Thecuttingunitisonlyapartofacomplete

machinewheninstalledonatractionunit.Read

thetractionunitOperator’sManualcarefully

forcompleteinstructionsonthesafeuseofthe

machine.

•Stopthemachine,removethekey ,andwaitfor

allmovingpartstostopbeforeinspectingthe

attachmentafterstrikinganobjectorifthereis

anabnormalvibrationinthemachine.Makeall

necessaryrepairsbeforeresumingoperation.

3

Page 4

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Useonlyaccessories,attachments,and

replacementpartsapprovedbyT oro.

4

Page 5

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal117-4979

117–4979

1.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

120-6604

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Cutting/dismembermenthazardofhand,mower

blade—stayawayfrommovingparts,keepallguardsand

shieldsinplace.

3.Cutting/dismembermenthazardoffoot,mowerblade—stay

awayfrommovingparts,keepallguardsandshieldsin

place.

93-6697

1.ReadtheOperator's

Manual.

2.AddSAE80w-90(API

GL-5)oilevery50hours.

decal120-6604

decal108-1988

108-1988

1.Beltrouting

decal93-6697

decal100-5622

100-5622

1.Height-of-cutadjustment

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto1 15to149N∙m(85to110

ft-lb).

decal93-7818

5

Page 6

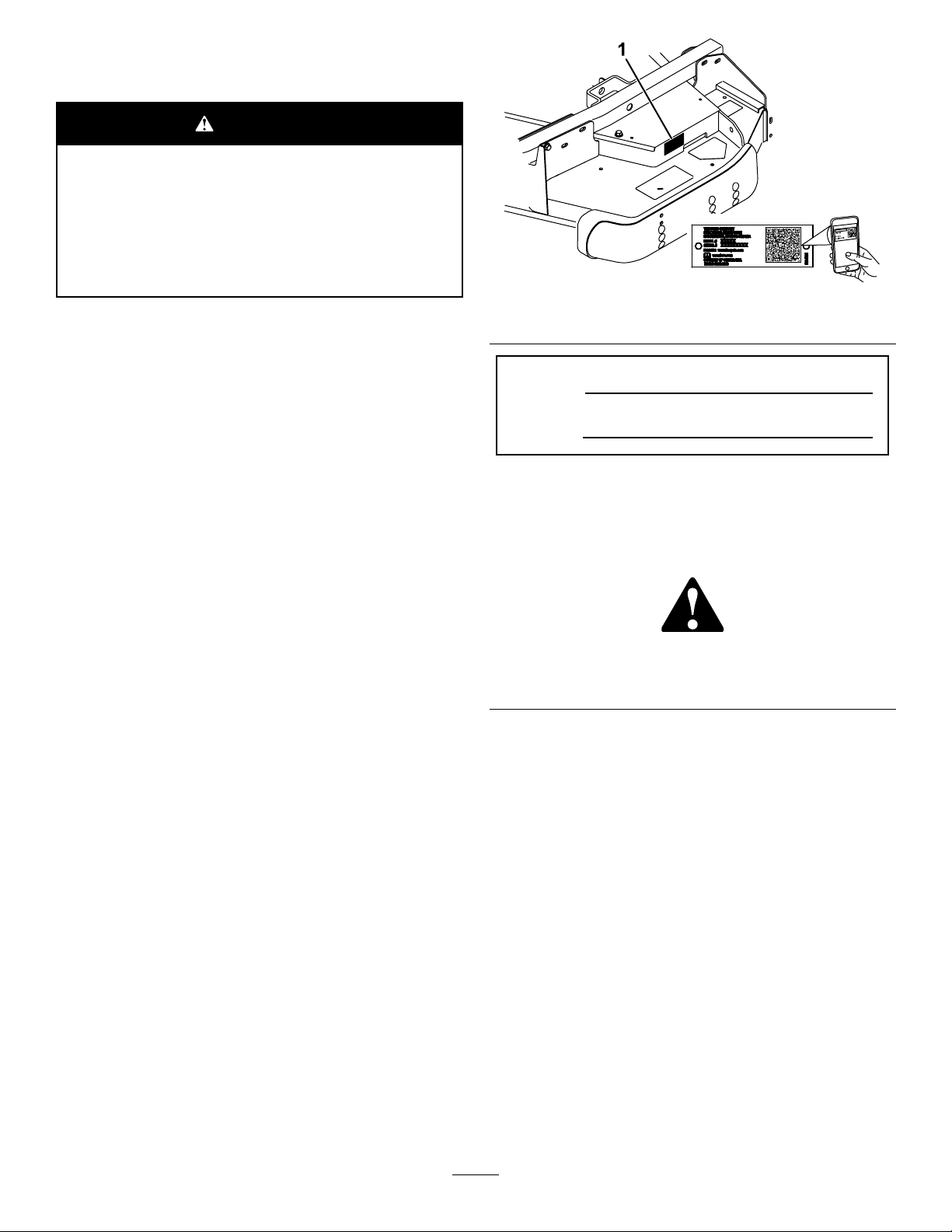

108-1986

1.Heightofcut

115-4505

1.Warning—readtheOperator'sManual.

2.Tippinghazard—lowerthecuttingunitwhendrivingdown

slopes.For2wheeldriveunits,adda16kg(35lb)rear

weighttoGM3280Dunitsanda32kg(70lb)rearweightto

GM3320units.For4wheeldrive3280Dunits,adda16

kg(35lb)rearweight.

decal108-1986

decal115-4505

decal133-8061

133-8061

6

Page 7

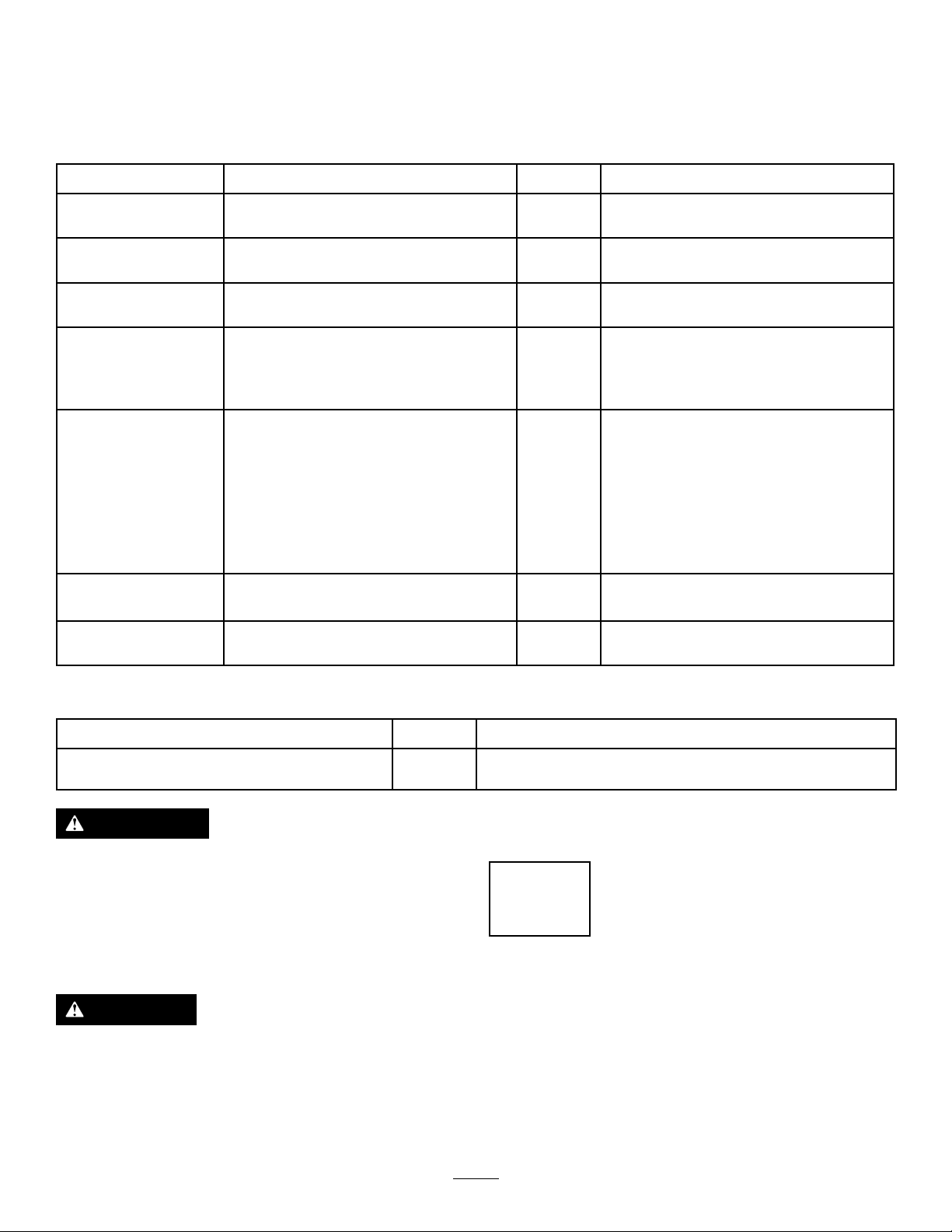

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

Nopartsrequired

Completionkit(soldseparately)

Castorwheelassembly

Rightliftarm

Leftliftarm

Pivotpin2

Cotterpin

Thrustwasher4

Clevispin

Hairpincotter2

Height-of-cutcollar

Clevispin

Hairpincotter2

Bolt(1/2x3/4inch)

Washer2

Nopartsrequired

Qty.

–

1Installacompletionkit.

2Installthecastorwheelassemblies.

1

1

2

4

2

2

2

–

Preparethemachine.

Installtheliftarms.

Installthecuttingunits

ConnectthePTOshafttothecutting

unitgearbox.

Use

7

Nopartsrequired

MediaandAdditionalParts

Description

PartsCatalog

Operator'sManual

WARNING

Ifyouleavethekeyintheignitionswitch,

someonecouldaccidentallystarttheengine

andseriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionswitch

beforeyoudoanymaintenance.

DANGER

IftheengineisstartedandthePTOshaftis

allowedtorotate,seriousinjurycouldresult.

DonotstarttheengineandengagethePTO

leverwhenthePTOshaftisnotconnectedto

thegearboxonthecuttingunit.

Qty.

–

1

1

Readmaterialbeforeoperation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Greasethemachine.

Use

1

PreparingtheMachine

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey.

7

Page 8

2

InstallingaCompletionKit

Partsneededforthisprocedure:

1

Completionkit(soldseparately)

Procedure

Install1ofthefollowing62-inchor72-inchcompletion

kitstothebasedeckusingtheinstructionprovided

inthekit:

•Model30303,72-inchRearDischarge

•Model30304,72-inchGuardian

•Model30305,62-inchRearDischarge

•Model30306,62-inchGuardian

3

InstallingtheCastorWheel Assemblies

Partsneededforthisprocedure:

2

Castorwheelassembly

Procedure

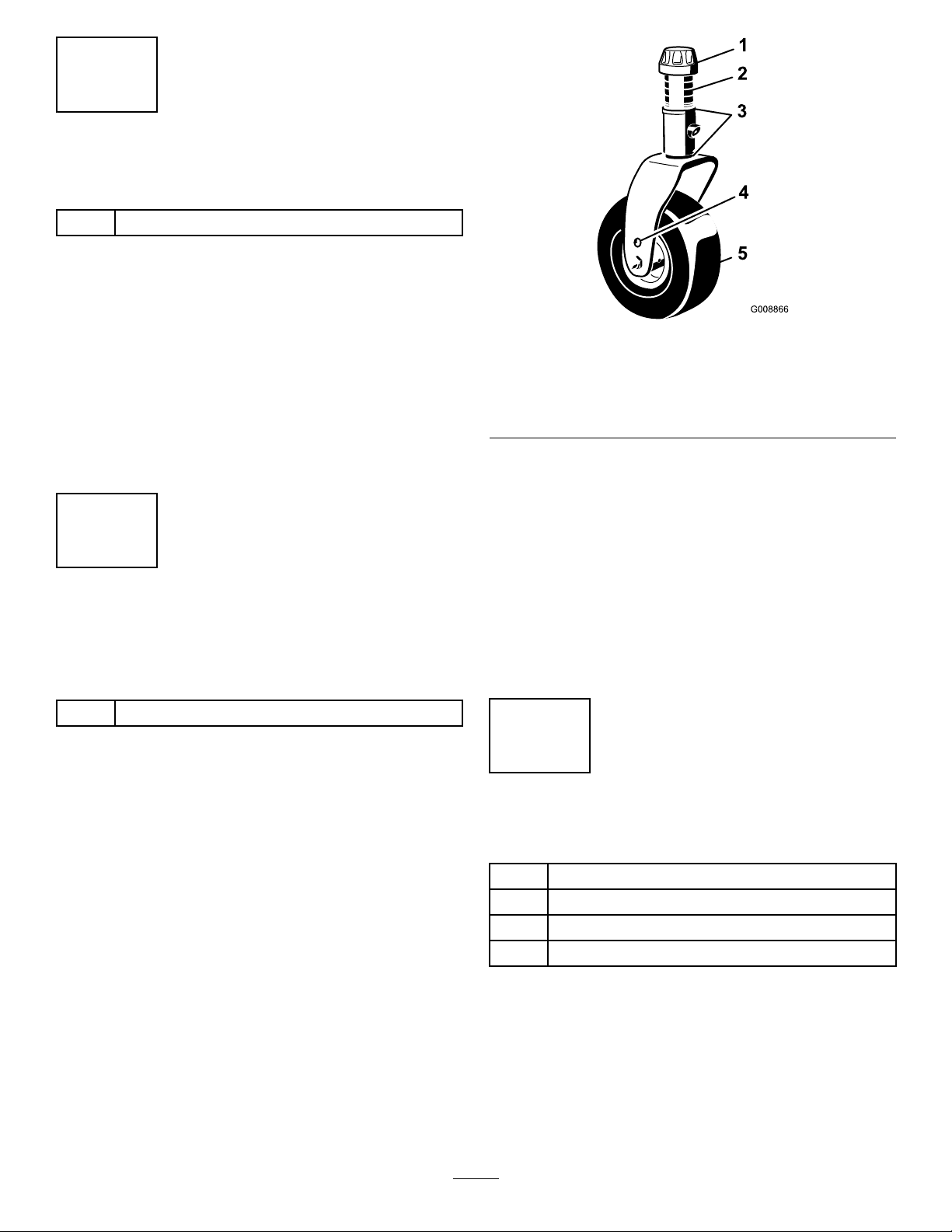

g008866

Figure3

1.Tensioningcap4.Axlemountingholes

2.Spacers5.Castorwheel

3.Thrustwashers

2.Slidethespacersontothecastorspindleto

getthedesiredheight-of-cut;refertoFigure7

andFigure8todeterminethecombinationsof

spacersforthesetting.Slideathrustwasher

ontothespindle,pushthecastorthroughthe

castorarm.Installanotherthrustwasherand

theremainingspacersontothespindleand

installthetensioningcaptosecuretheassembly

(Figure3).

Important:Thethrustwashers,notthe

spacers,mustcontactthetopandbottom

ofthecastorarm.

4

Thethrustwashers,spacers,andtensioningcaps

havebeeninstalledonthecastorwheelspindlesfor

shipping.

1.Removethetensioningcapsfromthespindle

shaftsandslideoffthespacersandthrust

washers(Figure3).

InstallingtheLiftArms

Partsneededforthisprocedure:

1

Rightliftarm

1

Leftliftarm

2Pivotpin

2

Cotterpin

Procedure

1.On1sideofthetractionunit,loosen(donot

remove)thewheelnutssecuringthewheeland

tireassemblytothefrontwheelstuds.

2.Jackupthemachineuntilthefrontwheelisoffof

theoor.Usejackstandsorblockthemachine

topreventitfromaccidentallyfalling.

8

Page 9

3.Removethewheelnutsandslidethewheeland

tireassemblyoffofthestuds.

4.Mountaliftarmtothepivotbracketwithapivot

pinandacotterpin(Figure4).Mounttheliftarm

withthebendpositionedoutward.

Figure4

1.Pivotpin3.Pivotbracket

2.Liftarm

4.Brakereturnspring

5.Hookthebrakereturnspringtothetabonthe

liftarm(Figure4).

2.MovetheliftlevertotheFLOATposition.Push

aliftarmdownuntiltheholesintheliftarmline

upwiththeholesinthecastorarmbracketand

theheightofcutrodcanbeinsertedintothelift

armpads(Figure5).

3.Securetheliftarmtothecastorarmwith2

thrustwashers,aclevispinandahairpincotter.

Positionthethrustwashersbetweentheliftarm

andthecastorarmbracket(Figure5).Insert

endofcotterpinintotheslotinthecastorarm

tabtoretaincotterpin.

g012393

6.Installthewheelandtireassembly.T orquethe

wheelnutsto102to108N·m(75to80ft-lb).

7.Repeattheprocedureontheoppositesideof

themachine.

5

InstallingtheCuttingUnits ontheLiftArms

Partsneededforthisprocedure:

4Thrustwasher

4

Clevispin

2Hairpincotter

2

Height-of-cutcollar

2

Clevispin

2Hairpincotter

2

Bolt(1/2x3/4inch)

2Washer

Figure5

1.Liftarm

2.Castorarmbracket8.Height-of-cutcollar

3.Height-of-cutrod

4.Liftarmpads

5.Thrustwashers11.Bolt

6.Clevispin

7.Hairpincotter

9.Clevispin

10.Hairpincotter

4.Repeattheprocedureontheoppositeliftarm.

g012229

Procedure

1.Movethecuttingunitintopositioninfrontofthe

tractionunit.

5.Startthetractionunitandraisethecuttingunit.

6.Pushdownontherearofthecuttingunitand

inserttheheightofcutrodsthroughtheliftarm

pads.

9

Page 10

7.Installtheheightofcutcollarsontotheheight

ofcutrodsandsecurewiththeclevispinsand

hairpincotters(Figure5).Positiontheheadof

theclevispintowardthefrontofthedeck,if

possible.

8.Installabolt(1/2x3/4inch)andawashertotop

ofeachheightofcutrod(Figure5).

6

ConnectingthePTOShaft totheCuttingUnitGearbox

NoPartsRequired

Procedure

1.SlidethemalePTOshaftintothefemalePTO

shaft(Figure6).Alignthemountingholesinthe

gearcaseinputshaftwiththeholesinthePTO

shaftandslidethemtogether.

7

GreasingtheMachine

NoPartsRequired

Procedure

Beforeoperatingthemachine,itmustbegreasedto

ensureproperlubricatingcharacteristics;referto7

GreasingtheMachine(page10).Failuretoproperly

greasethemachinewillresultinprematurefailureof

criticalparts.

Figure6

1.PTOshaft3.Gearcase

2.Boltsandlocknuts4.Rollpin

2.Securethemwitharollpin(Figure6).

3.Tightentheboltsandnuts(Figure6).

g012230

10

Page 11

ProductOverview

Operation

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Width

ofCut

Height

ofCut

Net

Weight

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.Toro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

1.575m(62inches)or1.829m(72inches)

Adjustablefrom25to127mm(1to5inches)in13

mm(1/2inch)increments

Model30403–190kg(420lbs.)

Model30404–231kg(510lbs.)

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

CAUTION

Ifyouleavethekeyintheignitionswitch,

someonecouldaccidentlystarttheengine

andseriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyou

doanymaintenance.

AdjustingtheHeight-of-Cut

Theheight-of-cutisadjustablefrom25to127mm(1

to5inches)in13mm(1/2inch)increments.Toadjust

theheight-of-cut,positionthecastorwheelaxlesin

theupperorlowerholesofthecastorforks,addor

removeanequalnumberofspacersfromthecastor

forksandsecuretheheightofcutcollartothedesired

holesintheheightofcutrod.

1.Starttheengineandraisethecuttingunitoffthe

oorsothatyoucanchangetheheight-of-cut.

Shutofftheengineandremovethekeyafter

youraisethecuttingunit.

2.Positionthecastorwheelaxlesinthesame

holesinbothcastorforks.RefertoFigure7and

Figure8todeterminethecorrectholesforthe

setting.

Note:Whenoperatingin64mm(2–1/2inches)

heightofcutorhigher,installtheaxleboltinthe

lowercastorforkholetopreventgrassbuildup

betweenthewheelandthefork.Whenoperating

inheightofcutslowerthan64mm(2–1/2

inches)andthereisgrassbuildup,reversethe

machinesdirectiontopullanyclippingsaway

fromthewheel/forkarea.

3.Removethetensioningcapfromthespindle

shaft(Figure7)andslidethespindleoutofthe

castorarm.Putthe2shims(1/8inch)ontothe

spindleshaftastheywereoriginallyinstalled.

Theseshimsarerequiredtoachievealevel

acrosstheentirewidthofthecuttingunits.Slide

theappropriatenumberof1/2inchspacersonto

thespindleshafttogetthedesiredheight-of-cut;

thenslidethewasherontotheshaft.

RefertoFigure7andFigure8todeterminethe

combinationsofspacersforthesetting.

11

Page 12

Figure9

g012231

Figure7

1.Tensioningcap4.Axlemountingholes

2.Spacers5.Castorwheel

3.Shims

Figure8

4.Pushthecastorspindlethroughthecastor

arm.Installtheshims(astheywereoriginally

installed)andtheremainingspacersontothe

spindleshaft.Installthetensioningcapto

securetheassembly.

5.Removethehairpinandclevispinsecuringthe

heightofcutcollartotheheightofcutrodonthe

rearofthecuttingunit(Figure9).

1.Height-of-cutrod3.Clevispinandhairpin

g008866

2.Height-of-cutcollar

cotter

6.Aligntheheight-of-cutcollartothedesired

height-of-cutholesontheheight-of-cutrod

(Figure10).

decal100-5622

decal108-1986

Figure10

7.Securetheadjustmentwiththeclevispinand

hairpin.

Note:Positiontheheadoftheclevispintoward

thefrontofthedeck,ifpossible.

Note:Whenusing25mm(1inch),38mm

(1-1/2inch),oroccasionally51mm(2inch)

height-of-cut,movetheskidsandrollertothe

highestholes.

12

Page 13

AdjustingtheCuttingUnit

AdjustingtheSkids

Pitch

Cuttingunitpitchisthedifferenceinheight-of-cutfrom

thefrontofthebladeplanetothebackoftheblade

plane.Useabladepitchof6mm(1/4inch).Thatis

thebackofthebladeplaneis6mm(1/4inch)higher

thanthefront.

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey.

4.Setthecuttingunittothedesiredheight-of-cut.

5.Rotate1bladesothatitpointsstraightforward.

6.Usingashortruler,measurefromtheoorto

thefronttipoftheblade.Rotatethebladetipto

therearandmeasurefromtheoortothetip

oftheblade.

7.Subtractthefrontdimensionfromtherear

dimensiontocalculatethebladepitch.

8.Loosenthejamnutsonthebottomofthe

height-of-cutrods(Figure11).

Mounttheskidsinthelowerpositionwhenoperating

inheightofcutshigherthan64mm(2-1/2inches)and

inthehigherpositionwhenoperatinginheightofcuts

lowerthan64mm(2-1/2inches).

Note:Whentheskidsbecomeworn,youcanswitch

theskidtotheoppositesidesofthemower,ipping

themover.Thiswillallowyoutousetheskidslonger

beforereplacingthem.

1.DisengagethePTOandengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Loosenthescrewatthefrontofeachskid

(Figure12).

4.Removetheange-headboltsandnutsfrom

eachskid.

5.Moveeachskidtothedesiredpositionand

securethemwiththeange-headboltsandnuts

(Figure12).

Note:Onlyusethetoporcentersetsofholes

toadjusttheskids.Thebottomholesareused

whenswitchingsidesonaGuardianmower,at

whichtimetheybecomethetopholesonthe

othersideofthemower.

Figure11

1.Height-of-cut

9.Rotatetheheight-of-cutrodstoraiseorlower

therearofthecuttingunitandattainthecorrect

cuttingunitpitch.

10.Tightenthejamnuts.

2.Jamnut

g012232

g268888

Figure12

1.Screw3.Skid

2.Flange-headbolt4.Nut

6.Torquethescrewatthefrontofeachskidto9to

11N⋅m(80to100in-lb).

13

Page 14

AdjustingtheRollers

Note:Ifthecuttingunitistobeusedinthe25or38

mm(1or1-1/2inch)height-of-cutsetting,positionthe

cuttingunitrollersinthetopbracketholes.

1.Removethescrewandnutsecuringtheroller

shafttothedeckbracket(Figure13).

Figure13

8.Lowercuttingunitontotheatsurface.Remove

thecoversfromthetopofthecuttingunits.

9.Rotatethebladeoneachspindleuntiltheends

faceforwardandbackward.

10.Measurefromtheoortothefronttipofthe

cuttingedge.

11.Adjust1/8inchshimsoncastorfork(s)tomatch

heightofcuttodecal(Figure14);referto

AdjustingtheCuttingUnitPitch(page13).

g004487

1.Roller

2.Slidetheshaftoutofthelowerbracketholes,

aligntherollerwiththetopholes,andinstallthe

shaft.

3.Installthescrewandnuttosecurethe

assemblies.

2.Rollershaft

CorrectingCuttingUnit Mismatch

Duetodifferencesingrassconditionsandthe

counterbalancesettingofthetractionunit,itisadvised

thatgrassbecutandappearancecheckedbefore

formalcuttingisstarted.

1.Setthecuttingunittothedesiredheightofcut;

refertoAdjustingtheHeight-of-Cut(page1 1).

2.Checkandadjustfrontandreartractortire

pressureto172to207kPa(25to30psi).

3.Checkandadjustallcastortirepressuresto345

kPa(50psi).

4.Checkforbentblades;refertoCheckingfora

BentBlade(page20).

5.Cutgrassinatestareatodetermineifallcutting

unitsarecuttingatthesameheight.

6.Ifcuttingunitadjustmentsarestillneeded,nda

atsurfaceusinga2m(6ft)orlongerstraight

edge.

7.Toeasemeasuringbladeplane,raisetheheight

ofcuttothehighestposition;refertoAdjusting

theHeight-of-Cut(page1 1).

g008866

Figure14

1.Tensioningcap4.Axlemountingholes

2.Spacers5.Castorwheel

3.Shims

14

Page 15

OperatingTips

insidethecuttingunit,cuttingqualitywilleventually

becomeunsatisfactory.

FastThrottleSetting/Ground

Speed

Tomaintainenoughpowerforthemachineanddeck

whilemowing,operatetheengineatthefastthrottle

positionandadjustyourgroundspeedforconditions.

Decreasethegroundspeedastheloadonthecutting

bladesincreases.Increasethegroundspeedasthe

loadonthebladesdecreases.

MowingDirection

Alternatemowingdirectiontoavoidmakingrutsin

theturfovertime.Thisalsohelpsdisperseclippings

whichenhancesdecompositionandfertilization.

CuttingSpeed

Toimprovecutquality ,useaslowergroundspeed.

AvoidCuttingTooLow

Ifthecuttingwidthofthecuttingunitiswiderthanthe

moweryoupreviouslyused,raisethecuttingheightto

ensurethatuneventurfisnotcuttooshort.

Toreducetheriskofrehazard,keeptheengine,

mufer,batterycompartment,parkingbrake,cutting

units,andfuelstoragecompartmentfreeofgrass,

leaves,orexcessivegrease.Cleanupanyspilledoil

orfuel.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.Checkthe

bladesdailyforsharpness,andforanywearor

damage.Sharpenthebladesasnecessary.Ifablade

isdamagedorworn,replaceitimmediatelywitha

genuineT ororeplacementblade.RefertoServicing

theCuttingBlades(page20).

SettingtheCuttingUnitPitch

Werecommendabladepitchof8mm(5/16inch).A

pitchlargerthan8mm(5/16inch)willresultinless

powerrequired,largerclippings,andapoorerquality

ofcut.Apitchlessthan8mm(5/16inch)willresultin

morepowerrequired,smallerclippingsandabetter

qualityofcut.

SelecttheProperHeight-of-Cut

SettingtoSuitConditions

Removeapproximately1inch(25mm)orno

morethan1/3ofthegrassbladewhencutting.In

exceptionallylushanddensegrass,youmayhave

toslowdowntheforwardspeedand/orraisethe

height-of-cuttothenexthighersetting.

Important:Ifcuttingmorethan1/3ofthe

grassbladeoff,orinsparselonggrassor

dryconditions,theuseofatsailbladesis

recommendedtoreduceair-bornechaff,debris,

anddeckdrivecomponentstrain.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,

raisethecuttingheighthigherthanusualandcutthe

grassatthissetting.Thencutthegrassagainusing

thelower,normalsetting.

KeeptheCuttingUnitClean

Cleanclippingsanddirtfromtheundersideofthe

cuttingunitaftereachuse.Ifgrassanddirtbuildup

15

Page 16

Maintenance

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Aftertherst10hours

Beforeeachuseordaily

Every50hours

Every400hours

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

MaintenanceProcedure

•Tightenthecastorwheelnuts.

•Tightenthecastorwheelnuts.

•T orquethebladebolts.

•Lubricatethecastorarmbushings.

•Lubricatethecastorwheelbearings.

•Checktheblades.

•Cleanthecuttingunit.

•Lubricatethegreasettings.Lubricatethegreasettingsimmediatelyafterevery

washing.

•Checkthegearboxlubricant.

•Tightenthecastorwheelnuts.

•T orquethebladebolts.

•Checkthebladedrivebeltadjustment.

•Cleanunderthecuttingunitbeltcovers.

•Changethegearboxlubricant.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

CheckGrassDeectorin

DownPosition(ifapplicable)

CheckTirePressure

CheckConditionofBlades

LubricateAllGreaseFittings

Touch-upDamagedPaint

1.Immediatelyaftereverywashing,regardlessoftheintervallisted.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

1

Sat.Sun.

Information

16

Page 17

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

Important:Thefastenersonthecoversofthismachinearedesignedtoremainonthecoverafter

removal.Loosenallthefastenersoneachcoverafewturnssothatthecoverisloosebutstillattached,

thengobackandloosenthemuntilthecovercomesfree.Thispreventsyoufromaccidentallystripping

theboltsfreeoftheretainers.

Lubrication

ServiceInterval:Every50hoursLubricatethe

greasettingsimmediatelyafter

everywashing.

Themachinehasgreasettingsthatyoumust

lubricateregularlywithNo.2lithiumgrease.

Lubricatethefollowingareas:

•Castorforkshaftbushings(4)(Figure15).

Figure17

g012235

Figure15

•Spindleshaftbearings(3)(locatedunderthe

pulley)(Figure16)

1.Liftarm

2.Clevispin

3.Hairpincotter

4.Pivotsupport

•Liftarmpivots,rear(2)(Figure18)

g011557

g010550

Figure18

CheckingtheLubricantin

Figure16

•Idlerarmshaftbearings(Figure16)

•Liftarmpivots,front(2)(Figure17)

theGearbox

ServiceInterval:Every50hours

ThegearboxindesignedtooperateonSAE80–90

g012234

weightgearlube.Althoughthegearboxcomeswith

lubricantfromthefactory,checkthelevelbefore

operatingthecuttingunit.Thegearboxcapacityis

283ml(12oz).

1.Parkthemachineandcuttingunitonalevel

surface.

17

Page 18

2.Removethedipstick/llplugfromthetopof

thegearbox(Figure19)andensurethatthe

lubricantisbetweenthemarksonthedipstick.If

thelubricantlevelislow,addenoughlubricant

untilthelevelisbetweenthemarks.

therearofthecuttingunit(Figure20).Remove

theheightofcutcollar.

4.Removethehairpincottersandclevispins

securingtheliftarmstothecastorarmbrackets

(Figure21).

g012237

Figure21

Figure19

1.Dipstick/llplug

SeparatingtheCuttingUnit fromtheTractionUnit

1.Positionthemachineonlevelsurface,lowerthe

cuttingunittotheoor,movetheliftlevertothe

Floatposition,shuttheengineoff,andengage

theparkingbrake.

2.Removetheboltandwashermountedtothetop

ofeachheightofcutrod(Figure20).

1.Liftarm

g010548

2.Clevispin4.Castorarmbracket

3.Hairpincotter

5.Rollthecuttingunitawayfromthetractionunit,

separatingthemaleandfemalesectionsofthe

PTOshaft(Figure22).

g010552

Figure22

1.PTOshaft

Figure20

1.Height-of-cutrod3.Height-of-cutcollar

2.Boltandwasher4.Hairpincotterandclevis

pin

3.Removethehairpinandclevispinsecuringthe

heightofcutcollartotheheightofcutrodon

DANGER

IftheengineisstartedandthePTOshaft

isallowedtorotate,seriousinjurycould

result.

g012236

18

Donotstarttheengineandengagethe

PTOleverwhenthePTOshaftisnot

connectedtothegearboxonthecutting

unit.

Page 19

MountingtheCuttingUnit totheTractionUnit

1.Positionthemachineonalevelsurfaceandshut

theengineoff.

2.Movethecuttingunitintopositioninfrontofthe

tractionunit.

3.SlidethemalePTOshaftintothefemalePTO

shaft(Figure22).

4.MovetheliftlevertotheFLOA Tposition.Push

aliftarmdownuntiltheholesintheliftarmline

upwiththeholesinthecastorarmbracketand

youcaninserttheheight-of-cutrodintothelift

armpads(Figure23).

andthecastorarmbracket(Figure23).Insert

endofcotterpinintotheslotinthecastorarm

tabtoretaincotterpin.

6.Repeattheprocedureontheoppositeliftarm.

7.Startthetractionunitandraisethecuttingunit.

8.Pushdownontherearofthecuttingunitand

inserttheheightofcutrodsthroughtheliftarm

pads.

9.Installtheheight-of-cutcollarsontothe

height-of-cutrodsandsecurewiththeclevis

pinsandhairpincotters(Figure23).

Positiontheheadoftheclevispintowardthe

frontofthedeck.

10.Installabolt(1/2x3/4inch)andawashertothe

topofeachheight-of-cutrod(Figure23).

ServicingtheBushingsin theCastorArms

Thecastorarmshavebushingspressedintothe

topandbottomofthetube,andaftermanyhours

ofoperation,thebushingswillwear.Tocheckthe

bushings,movethecastorforkbackandforthand

fromsidetoside.Ifthecastorspindleislooseinside

thebushings,thebushingsarewornandmustbe

replaced.

Figure23

1.Liftarm

2.Castorarmbracket8.Height-of-cutcollar

3.Height-of-cutrod9.Clevispin

4.Liftarmpads

5.Thrustwashers11.Bolt

6.Clevispin

5.Securetheliftarmtothecastorarmwith2

thrustwashers,aclevispinandahairpincotter.

Positionthethrustwashersbetweentheliftarm

7.Hairpincotter

10.Hairpincotter

1.Raisethecuttingunitsothatthewheelsare

offoftheoor.Blockthecuttingunitsothatit

cannotaccidentallyfall.

2.Removethetensioningcap,spacer(s),and

thrustwasherfromthetopofthecastorspindle.

3.Pullthecastorspindleoutofthemountingtube.

Allowthethrustwasherandspacer(s)toremain

onthebottomofthespindle.

4.Insertapinpunchintothetoporbottomofthe

mountingtubeanddrivethebushingoutofthe

tube(Figure24).Also,drivetheotherbushing

outofthetube.Cleantheinsideofthetubes

toremovedirt.

g012229

g004737

Figure24

1.Castorarmtube

2.Bushings

19

Page 20

5.Applygreasetotheinsideandoutsideofthe

newbushings.Usingahammerandatplate,

drivethebushingsintothemountingtube.

6.Inspectthecastorspindleforwearandreplace

itifdamaged.

7.Pushthecastorspindlethroughthebushings

andmountingtube,slidethethrustwasher

andspacer(s)ontothespindle,andinstallthe

tensioningcaponthecastorspindle.

ServicingtheCutting Blades

BladeSafety

Awornordamagedbladecanbreak,andapieceof

thebladecouldbethrowntowardyouorbystanders,

resultinginseriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearordamage.

ServicingtheCastor WheelsandBearings

1.Removethelocknutfromtheboltholdingthe

castorwheelassemblybetweenthecastorfork

().Graspthecastorwheelandslidetheboltout

oftheforkorpivotarm.

Figure25

1.Castorwheel3.Bearing(2)

2.Castorfork

2.Removethebearingfromthewheelhuband

allowthebearingspacertofallout().Remove

thebearingfromtheoppositesideofthewheel

hub.

3.Checkthebearings,spacer,andinsideofthe

wheelhubforwear.Replaceanydamaged

parts.

4.T oassemblethecastorwheel,pushthebearing

intothewheelhub.Wheninstallingthebearings,

pressontheouterraceofthebearing.

5.Slidethebearingspacerintothewheelhub.

Pushtheotherbearingintotheopenendofthe

wheelhubtocaptivatethebearingspacerinside

thewheelhub.

6.Installthecastorwheelassemblybetweenthe

castorforkandsecureitinplacewiththebolt

andlocknut.

4.Bearingspacer

•Usecarewhencheckingtheblades.Wrapthe

bladesorweargloves,andusecautionwhen

servicingtheblades.Onlyreplaceorsharpenthe

blades;neverstraightenorweldthem.

•Onmulti-bladedmachines,takecareasrotating1

bladecancauseotherbladestorotate.

CheckingforaBentBlade

1.Positionthemachineonalevelsurface.Raise

thecuttingunit,engagetheparkingbrake,put

thetractionpedalinneutral,putthePTOlever

intheOFFposition,shutofftheengine,and

removetheignitionkey.Blockthecuttingunitto

preventitfromaccidentallyfalling.

2.Rotatethebladeuntiltheendsfaceforward

andbackward.Measurefromtheinsideofthe

cuttingunittothecuttingedgeatthefrontofthe

blade(Figure26),andrememberthisdimension.

g004738

g010549

Figure26

3.Rotatetheoppositeendofthebladeforward.

Measurebetweenthecuttingunitandcutting

edgeofthebladeatthesamepositionasin

step2Thedifferencebetweenthedimensions

obtainedinsteps2and3mustnotexceed3

mm(1/8inch).Ifthedimensionexceeds3mm

(1/8inch),replacethebladebecauseitisbent;

refertoRemovingandInstallingtheBlade(s)

(page20).

RemovingandInstallingthe Blade(s)

Theblademustbereplacedifasolidobjectishit,

thebladeisout-of-balance,worn,orbent.Always

usegenuineT ororeplacementbladestoensure

safetyandoptimumperformance.Neveruseblades

madebyothermanufacturersbecausetheycouldbe

dangerous.

20

Page 21

1.Raisethecuttingunittothehighestposition,

engagetheparkingbrake,stoptheengine,and

removetheignitionkey.Blockthecuttingunitto

preventitfromaccidentallyfalling.

2.Grasptheendofthebladeusingaragorthickly

paddedglove.Removethebladebolt,anti-scalp

cup,andbladefromthespindleshaft(Figure

27).

Figure27

1.Bladebolt2.Anti-scalpcup

goodquality-of-cut.Thesailisimportantbecauseit

pullsgrassupstraight,therebyproducinganeven

cut.However,thesailwillgraduallyweardown

duringoperation,andthisconditionisnormal.As

thesailwearsdown,thequality-of-cutwilldegrade

somewhat,althoughthecuttingedgesaresharp.

Thecuttingedgeoftheblademustbesharpsothat

thegrassiscutratherthantorn.Adullcuttingedge

isevidentwhenthetipsofthegrassappearbrown

andshredded.Sharpenthecuttingedgestocorrect

thiscondition.

1.Parkthemachineonalevelsurface.Raisethe

cuttingunit,engagetheparkingbrake,putthe

tractionpedalinneutral,putthePTOleverinthe

OFFposition,shutofftheengine,andremove

thekey .

2.Examinethecuttingendsofthebladecarefully,

especiallywheretheatandcurvedpartsof

theblademeet(Figure28).Sincesandand

abrasivematerialcanwearawaythemetalthat

g010555

connectstheatandcurvedpartsoftheblade,

checkthebladebeforeusingthemachine.Ifyou

seewear(Figure28),replacetheblade;referto

RemovingandInstallingtheBlade(s)(page20).

3.Installtheblade-sailfacingtowardthecutting

unit-withtheanti-scalpcupandbladebolt.

Tightenthebladeboltto115to149N∙m(85to

110ft-lb).

Important:Thecurvedpartoftheblade

mustpointtowardtheinsideofthecutting

unittoensurepropercutting.

InspectingandSharpeningthe Blade(s)

ServiceInterval:Beforeeachuseordaily

Every50hours

DANGER

Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrowntowardyou

orbystanders,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Donottrytostraightenabladethatisbent.

•Donotweldabrokenorcrackedblade.

•Replaceawornordamagedbladewitha

newTorobladetoensurecontinuedsafety

certicationoftheproduct.

g006530

Figure28

1.Cuttingedge3.Wear/slotforming

2.Curvedarea/sail4.Crack

WARNING

Ifthebladeisallowedtowear,aslot

willformbetweenthesailandatpart

oftheblade(Figure28).Eventually,a

pieceoftheblademaybreakoffandbe

thrownfromunderthehousing,possibly

resultinginseriousinjurytoyourselfor

bystanders.

•Inspectthebladeperiodicallyforwear

ordamage.

•Replaceawornordamagedbladewith

anewTorobladetoensurecontinued

safetycerticationoftheproduct.

Bothcuttingedgesandthesail,whichistheturned

upportionoppositethecuttingedge,contributetoa

3.Examinethecuttingedgesofallblades.

Sharpenthecuttingedgesiftheyaredullor

21

Page 22

nicked.Sharpenonlythetopsideofthecutting

edgeandmaintaintheoriginalcuttingangleto

ensuresharpness(Figure29).Thebladewill

remainbalancedifthesameamountofmetalis

removedfrombothcuttingedges.

Figure29

1.Sharpenatoriginalangle

Note:Removethebladesandsharpenthemon

agrinder;refertoRemovingtheCuttingBlades.

Aftersharpeningthecuttingedges,installthe

bladewiththeanti-scalpcupandbladebolt.The

bladesailsmustbeontopoftheblade.Tighten

thebladeboltto115to149N·m(85to110ft-lb).

CheckingandCorrecting MismatchofBlades

Ifthereismismatchbetweentheblades,thegrasswill

appearstreakedwhenitiscut.Thisproblemcanbe

correctedbymakingsurethatthebladesarestraight

andallofthebladesarecuttingonthesameplane.

1.Usinga1m(3ft)longcarpenterslevel,nda

levelsurfaceontheshopoor.

2.Raisetheheight-of-cuttothehighestposition;

refertoAdjustingtheHeight-of-Cut(page1 1).

3.Lowerthecuttingunitontotheatsurface.

Removethecoversfromthetopofthecutting

unit.

4.Rotatethebladesuntiltheendsfaceforward

andbackward.Measurefromtheoortothe

fronttipofthecuttingedge.Rememberthis

dimension.Thenrotatethesamebladesothat

theoppositeendisforward,andmeasureagain.

Thedifferencebetweenthedimensionsmust

notexceed1m(3ft).Ifthedimensionexceeds

1m(3ft),replacethebladebecauseitisbent.

Measurealloftheblades.

5.Comparethemeasurementsoftheouterblades

withthecenterblade.Thecenterblademust

notbemorethan1m(3ft)lowerthantheouter

blades.Ifthecenterbladeismorethan1m(3

ft)lowerthantheouterblades,proceedtostep

6andaddshimsbetweenthespindlehousing

andthebottomofthecuttingunit.

6.Removethebolts,atwashers,lockwashers,

andnutsfromtheouterspindleinthearea

wheretheshimsmustbeadded.Toraiseor

lowertheblade,addashim,PartNo.3256-24,

betweenthespindlehousingandthebottomof

thecuttingunit.Continuetocheckthealignment

ofthebladesandaddshimsuntilthetipsofthe

bladesarewithintherequireddimension.

Important:Donotusemorethan3shimsat

any1holelocation.Usedecreasingnumbers

ofshimsinadjacentholesifmorethan1

shimisaddedtoany1holelocation.

7.Installthebeltcovers.

g000276

ReplacingtheDriveBelt

Thebladedrivebelt,tensionedbythespringloaded

idlerpulley,isverydurable.However,aftermany

hoursofuse,thebeltwillshowsignsofwear.Signs

ofawornbeltaresquealingwhenbeltisrotating,

bladesslippingwhencuttinggrass,frayededges,

burnmarks,andcracks.Replacethebeltifanyof

theseconditionsoccur.

1.Lowerthecuttingunittotheshopoor.Remove

thebeltcoversfromthetopofthecuttingunit

andsetthecoversaside.

2.Usingatorquewrenchorsimilartool,movethe

idlerpulley(Figure30)awayfromthedrivebelt

toreleasethebelttensionandallowthebeltto

beslippedoffthegearboxpulley(Figure31).

g012238

Figure30

1.Idlerpulley

g012239

Figure31

1.Gearbox

22

Page 23

3.Removetheoldbeltfromaroundthespindle

pulleysandidlerpulley.

Storage

4.Routethenewbeltaroundthespindlepulleys

andidlerpulleyassemblyasshowninFigure32.

Figure32

1.Beltrouting

5.Installthebeltcovers.

CleaningUndertheCutting Unit

ServiceInterval:Beforeeachuseordaily

1.DisengagethePTO,releasethetractionpedal

totheneutralposition,andengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operator’sposition.

3.Allowtheenginetocoolbeforeadjusting,

cleaning,storing,orrepairingthemachine.

4.Thoroughlycleanthecuttingunit,payingspecial

attentiontotheseareas:

•Underneaththecuttingunit

•Underthecuttingunitbeltcovers

decal108-1988

•PTOshaftassembly

•Allgreasettingsandpivotpoints

5.Checkandadjustthetraction-unitfrontandrear

tirepressure;refertothetraction-unitOperator’s

Manual.

6.Remove,sharpen,andbalancethecuttingunit

blades.Installthebladesandtorquetheblade

fastenersto85to1 10ft-lb(115to149N∙m).

7.Checkallfastenersforloosenessandtighten

themasnecessary.

Removethegrassbuildupunderthecuttingunitdaily .

1.DisengagethePTO,releasethetractionpedal

totheneutralposition,andengagetheparking

brake.

2.MovethethrottlelevertotheSLOWposition,

shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operator’sposition.

3.RaisethecuttingunittotheTRANSPORTposition.

4.Useajacktoraisethefrontofthemachineand

supportitwithjackstands.

5.Thoroughlycleantheundersideofthecutting

unitwithwater.

8.Greaseoroilallgreasettingsandpivotpoints.

Wipeoffanyexcesslubricant.

9.Lightlysandandusetouchuppaintonpainted

areasthatarescratched,chippedorrusted.

Repairanydents.

23

Page 24

Notes:

Page 25

DeclarationofIncorporation

TheT oroCompany,8111LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

30403315000001andUpBase62inMower

30404315000001andUpBase72inMower

SerialNo.

ProductDescriptionInvoiceDescription

GeneralDescription

62”BASEDECK-GM3280

72”BASEDECK-GM3280

Base62inMower

Base72inMower

Directive

2006/42/EC,

2000/14/EC

2006/42/EC,

2000/14/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedT oromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:

JohnHeckel

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

September20,2018

AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

Belgium

Tel.+3216386659

Page 26

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproducts.Additionally,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerswithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalsprovideexposurelimitrequirements.WhiletheexposurefromToroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,TorohaselectedtoprovidetheProp65warnings.Moreover ,ifT orodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

Page 27

EEA/UKPrivacyNotice

Toro’sUseofY ourPersonalInformation

TheT oroCompany(“T oro”)respectsyourprivacy.Whenyoupurchaseourproducts,wemaycollectcertainpersonalinformationaboutyou,eitherdirectly

fromyouorthroughyourlocalT orocompanyordealer.T orousesthisinformationtofullcontractualobligations-suchastoregisteryourwarranty,

processyourwarrantyclaimortocontactyouintheeventofaproductrecall-andforlegitimatebusinesspurposes-suchastogaugecustomer

satisfaction,improveourproductsorprovideyouwithproductinformationwhichmaybeofinterest.Toromayshareyourinformationwithoursubsidiaries,

afliates,dealersorotherbusinesspartnersinconnectiontheseactivities.Wemayalsodisclosepersonalinformationwhenrequiredbylaworin

connectionwiththesale,purchaseormergerofabusiness.Wewillneversellyourpersonalinformationtoanyothercompanyformarketingpurposes.

RetentionofyourPersonalInformation

Torowillkeepyourpersonalinformationaslongasitisrelevantfortheabovepurposesandinaccordancewithlegalrequirements.Formoreinformation

aboutapplicableretentionperiodspleasecontactlegal@toro.com.

Toro’sCommitmenttoSecurity

YourpersonalinformationmaybeprocessedintheUSoranothercountrywhichmayhavelessstrictdataprotectionlawsthanyourcountryofresidence.

Wheneverwetransferyourinformationoutsideofyourcountryofresidence,wewilltakelegallyrequiredstepstoensurethatappropriatesafeguardsare

inplacetoprotectyourinformationandtomakesureitistreatedsecurely.

AccessandCorrection

Youmayhavetherighttocorrectorreviewyourpersonaldata,orobjecttoorrestricttheprocessingofyourdata.T odoso,pleasecontactusbyemail

atlegal@toro.com.IfyouhaveconcernsaboutthewayinwhichT orohashandledyourinformation,weencourageyoutoraisethisdirectlywithus.

PleasenotethatEuropeanresidentshavetherighttocomplaintoyourDataProtectionAuthority.

374-0282RevC

Page 28

TheToroWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.Torowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevD

Loading...

Loading...