Page 1

Base62inand72inMower

FormNo.3383-247RevA

Groundsmaster

ModelNo.30403—SerialNo.314000001andUp

ModelNo.30404—SerialNo.314000001andUp

®

3320/3280-DTractionUnit

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3383-247*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Introduction

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

Thisrotary-bladelawncuttingdeckismountedtoaride-on

machineandisintendedtobeusedbyprofessional,hired

operatorsincommercialapplications.Itisprimarilydesigned

forcuttinggrassonwell-maintainedlawnsinparks,sports

elds,andoncommercialgrounds.Itisnotdesignedfor

cuttingbrush,mowinggrassandothergrowthalongside

highways,orforagriculturaluses.

Figure1

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbers

ofyourproductready .Themodelandserialnumbersare

stampedintoaplatethatismountedonthemowerhousing.

Writethenumbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Safety

Introduction..................................................................2

Safety...........................................................................3

SafeOperatingPractices...........................................3

ToroMowerSafety..................................................5

SafetyandInstructionalDecals.................................6

Setup............................................................................8

1InstallingaCompletionKit....................................8

2InstallingtheCastorWheelAssemblies....................8

3InstallingtheLiftArms..........................................9

4InstallingtheCuttingUnitsontheLift

Arms.................................................................9

5ConnectingthePTOShafttotheCuttingUnit

GearBox...........................................................10

6GreasingtheMachine...........................................11

ProductOverview.........................................................11

Specications........................................................11

Attachments/Accessories........................................11

Operation....................................................................12

CheckingtheLubricantintheGearBox.....................12

AdjustingtheHeight-of-Cut....................................12

AdjustingtheCuttingUnitPitch...............................13

AdjustingtheSkids.................................................13

AdjustingtheRollers...............................................14

CorrectingCuttingUnitMismatch............................14

OperatingTips......................................................14

Maintenance.................................................................16

RecommendedMaintenanceSchedule(s)......................16

Lubrication............................................................16

SeparatingtheCuttingUnitfromtheTraction

Unit..................................................................17

MountingtheCuttingUnittotheTraction

Unit..................................................................18

ServicingtheBushingsintheCastorArms.................19

ServicingtheCastorWheelsandBearings..................19

CheckingforaBentBlade........................................19

RemovingandInstallingtheBlade(s).........................20

InspectingandSharpeningtheBlade(s)......................20

CheckingandCorrectingMismatchof

Blades...............................................................21

ReplacingtheDriveBelt..........................................21

ThismachinemeetsorexceedsCENstandardEN836:1997,

ISOstandard5395:1990,andANSIB71.4-2004specications

ineffectatthetimeofproduction,whenequippedwith

properballast.Refertothetractionunitoperatorsmanual

fortheballastrequirements.

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCAUTION,WARNING,or

DANGER-"personalsafetyinstruction."Failuretocomply

withtheinstructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromtheCEN

standardEN836:1997,ISOstandard5395:1990,andANSI

B71.4-2012.

Training

•Readtheoperator'smanualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.Iftheoperatoror

mechaniccannotreadthelanguageofthismanual,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,orproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glassesandearprotection.Longhair,looseclothingor

jewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toysandwirewhichcan

bethrownbythemachine.

•Checkthatoperator'spresencecontrols,safetyswitches

andshieldsareattachedandfunctioningproperly .Donot

operateunlesstheyarefunctioningproperly.

3

Page 4

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Onlystartenginefrom

theoperator'sposition.Useseatbeltsifprovided.

•Slowdownanduseextracareonhillsides.Besureto

travelintherecommendeddirectiononhillsides.Turf

conditionscanaffectthemachine'sstability .Usecaution

whileoperatingneardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neverraisedeckwiththebladesrunning.

•Neveroperatewithguardsnotsecurelyinplace.Be

sureallinterlocksareattached,adjustedproperly ,and

functioningproperty.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,lowerthecuttingunits,disengage

drives,engageparkingbrake(ifprovided),shutoffengine

beforeleavingtheoperator'spositionforanyreason.

•Stopequipmentandinspectthebladesafterstriking

objectsorifanabnormalvibrationoccurs.Make

necessaryrepairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesifnotmowing.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Theoperatorshallturnonashingwarninglights,if

provided,whenevertravelingonapublicroad,except

wheresuchuseisprohibitedbylaw.

MaintenanceandStorage

•Disengagedrives,lowerthecuttingunits,movetraction

pedaltoNeutral,setparkingbrake,stopengineand

removekey .Waitforallmovementtostopbefore

adjusting,cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,and

mufer.Cleanupoilorfuelspillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransporting.Donotstore

fuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallowuntrained

personneltoservicemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectbatterybeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.Reconnect

positiverstandnegativelast.

•Usecarewhencheckingblades.Wrapthebladesor

weargloves,andusecautionwhenservicingthem.Only

replaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

ordisconnectingfrombattery.W earprotectiveclothing

anduseinsulatedtools.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

4

Page 5

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine

•Makesurethatallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCEN,ISO,orANSIstandards.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennisshoes

orsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,

embankments,orotherhazards.

–Avoidsuddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Lowerthecuttingunitwhengoingdownslopes.

•Thegrassdeectormustalwaysbeinstalledandinthe

lowestpositiononthesidedischargecuttingunit.Never

operatethemowerwithoutthedeectororentiregrass

collector.

•Ifthecuttingunitdischargeareaeverplugs,shutthe

engineoffbeforeremovingtheobstruction.

•Cutgrassslopescarefully.Donotstart,stop,orturn

suddenly.

•Donottouchtheengineormuferwhiletheengineis

runningorsoonafterithasstoppedbecausetheseareas

couldbehotenoughtocauseburns.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringthecutting

unitstotheground.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunits,attachments,and

anymovingparts.Keepeveryoneaway.

•Donotoverspeedtheenginebychanginggovernor

settings.Toensuresafetyandaccuracy,havean

AuthorizedToroDistributorcheckthemaximumengine

speedwithatachometer.

•Theenginemustbeshutoffbeforecheckingtheoilor

addingoiltothecrankcase.

•Makesurethatthemowerfueltankisemptyifthe

machineistobestoredinexcessof30days.Donotstore

themowernearanyopenameorwheregasolinefumes

maybeignitedbyaspark.

•Performonlythosemaintenanceinstructionsdescribed

inthismanual.Ifmajorrepairsareeverneededor

ifassistanceisdesired,contactanAuthorizedToro

Distributor.

•Tomakesureofoptimumperformanceandcontinued

safetycerticationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

MaintenanceandStorage

•Checktheblademountingboltsfrequentlytobesurethat

theyaretightenedtospecication.

5

Page 6

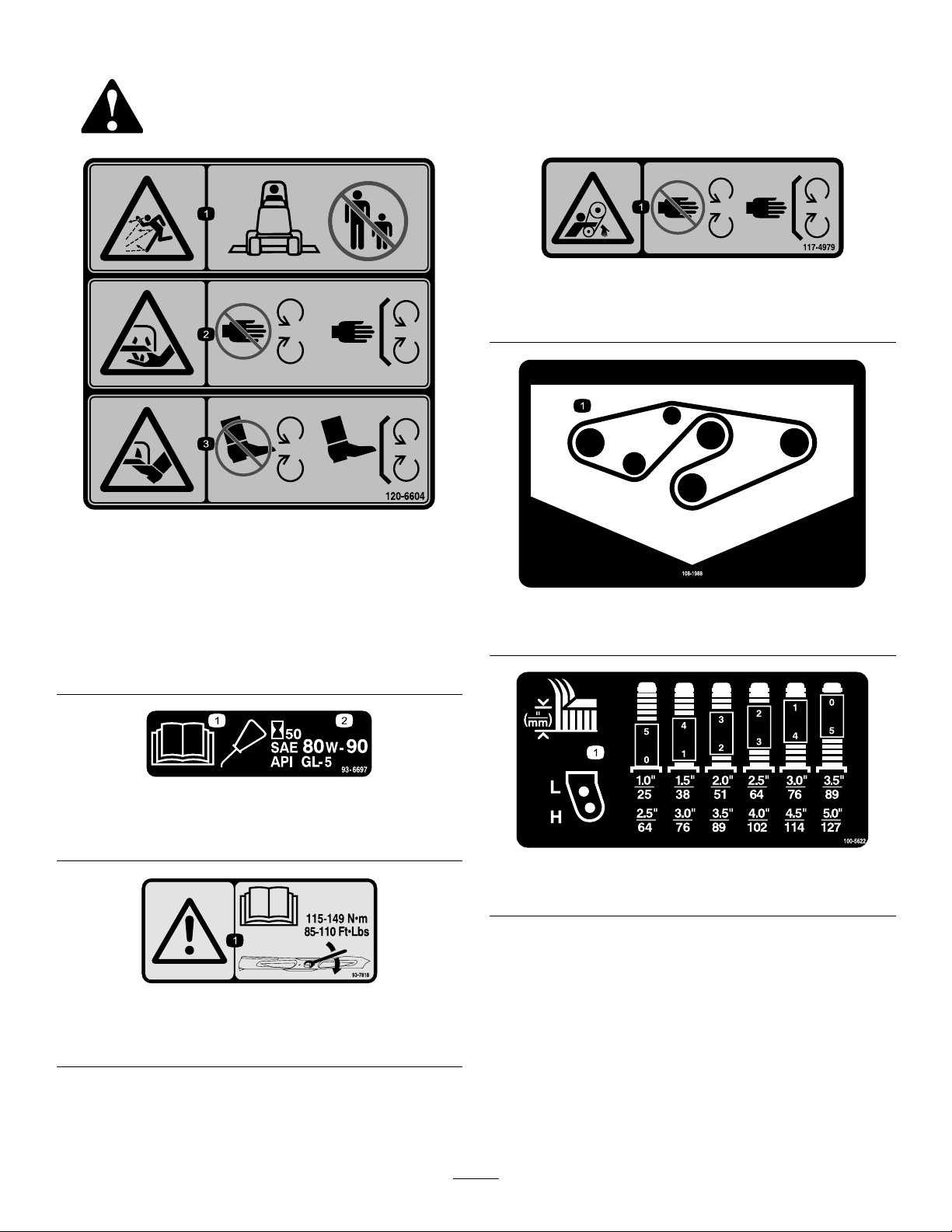

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

117–4979

1.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

120-6604

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Cutting/dismembermenthazardofhand,mower

blade—stayawayfrommovingparts,keepallguardsand

shieldsinplace.

3.Cutting/dismembermenthazardoffoot,mowerblade—stay

awayfrommovingparts,keepallguardsandshieldsin

place.

93-6697

1.ReadtheOperator's

Manual.

2.AddSAE80w-90(API

GL-5)oilevery50hours.

108-1988

1.Beltrouting

100-5622

1.Heightofcutadjustment

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N-m(85-110ft-lb).

6

Page 7

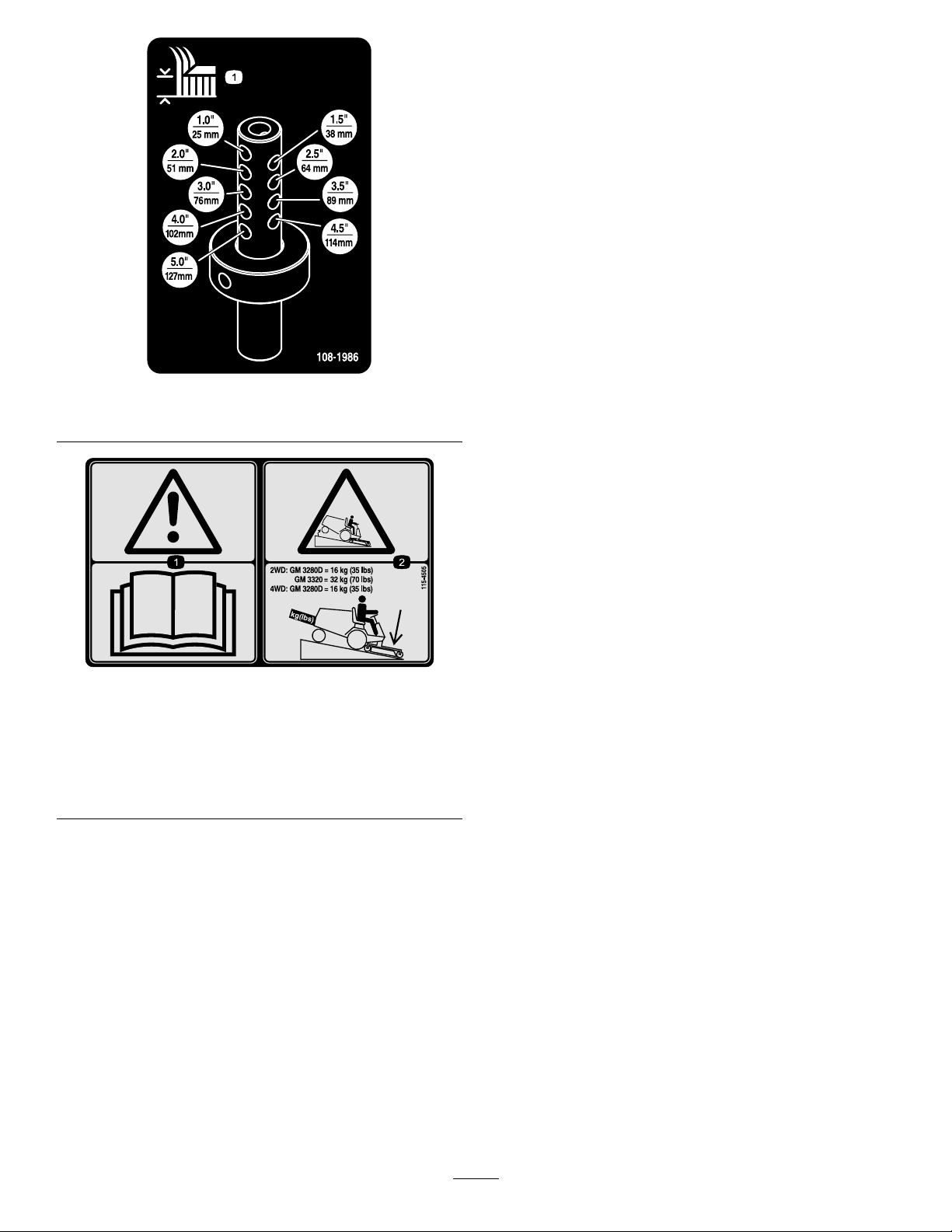

108-1986

1.Heightofcut

115-4505

1.Warning—readtheOperator'sManual.

2.Tippinghazard—lowerthecuttingunitwhendrivingdown

slopes.For2wheeldriveunits,adda16kg(35lb)rear

weighttoGM3280Dunitsanda32kg(70lb)rearweightto

GM3320units.For4wheeldrive3280Dunits,adda16

kg(35lb)rearweight.

7

Page 8

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

Completionkit(soldseparately)

Castorwheelassembly

Liftarm,right

Liftarm,left

Pivotpinassembly2

Cotterpin

Thrustwasher4

Clevispin

Hairpincotter2

Height-of-cutcollar

Clevispin

Hairpincotter2

Bolt(1/2x3/4inch)

Washer2

Nopartsrequired

Nopartsrequired

Qty.

1Installacompletionkit.

2Installthecastorwheelassemblies.

1

1

2

4

2

2

2

–

–

Installtheliftarms.

Installthecuttingunits

ConnectthePTOshafttothecutting

unitgearbox.

Greasethemachine.

Use

MediaandAdditionalParts

Description

PartsCatalog

Operator'sManual

DANGER

IftheengineisstartedandthePTOshaftisallowed

torotate,seriousinjurycouldresult.

DonotstarttheengineandengagethePTOlever

whenthePTOshaftisnotconnectedtothegear

boxonthecuttingunit.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Qty.

Use

1

1

1

InstallingaCompletionKit

Partsneededforthisprocedure:

1

Completionkit(soldseparately)

Procedure

Installoneofthefollowing62inchor72inchcompletionkits

tothebasedeckusingtheinstructionprovidedinthekit:

•Model30303,72inchRearDischarge

•Model30304,72inchGuardian

•Model30305,62inchRearDischarge

•Model30306,62inchGuardian

8

Page 9

2

3

InstallingtheCastorWheel

Assemblies

Partsneededforthisprocedure:

2

Castorwheelassembly

Procedure

Thethrustwashers,spacers,andtensioningcapshavebeen

installedonthecastorwheelspindlesforshipping.

1.Removethetensioningcapsfromthespindleshafts

andslideoffthespacersandthrustwashers(Figure2).

InstallingtheLiftArms

Partsneededforthisprocedure:

1

Liftarm,right

1

Liftarm,left

2Pivotpinassembly

2

Cotterpin

Procedure

1.Ononesideofthetractionunit,loosen(donot

remove)thewheelnutssecuringthewheelandtire

assemblytothefrontwheelstuds.

2.Jackupthemachineuntilthefrontwheelisoffofthe

oor.Usejackstandsorblockthemachinetoprevent

itfromaccidentallyfalling.

3.Removethewheelnutsandslidethewheelandtire

assemblyoffofthestuds.

4.Mountaliftarmtothepivotbracketwithapivotpin

andacotterpin(

bendpositionedoutward.

Figure3).Mounttheliftarmwiththe

Figure2

1.Tensioningcap4.Axlemountingholes

2.Spacers5.Castorwheel

3.Thrustwashers

2.Slidethespacersontothecastorspindletogetthe

desiredheight-of-cut;refertoFigure7&Figure8to

determinethecombinationsofspacersforthesetting.

Slideathrustwasherontothespindle,pushthecastor

throughthecastorarm.Installanotherthrustwasher

andtheremainingspacersontothespindleandinstall

thetensioningcaptosecuretheassembly(

Important:Thethrustwashers,notthespacers,

mustcontactthetopandbottomofthecastorarm.

Figure2).

Figure3

1.Pivotpin3.Pivotbracket

2.Liftarm

5.Hookthebrakereturnspringtothetabonthelift

arm(Figure3).

6.Installthewheelandtireassembly.Torquethewheel

nutsto102–108N-m(75–80ft-lb).

7.Repeattheprocedureontheoppositesideofthe

machine.

4.Brakereturnspring

9

Page 10

4

InstallingtheCuttingUnitson

theLiftArms

Partsneededforthisprocedure:

4Thrustwasher

4

Clevispin

2Hairpincotter

2

Height-of-cutcollar

2

Clevispin

2Hairpincotter

2

Bolt(1/2x3/4inch)

2Washer

Procedure

1.Movethecuttingunitintopositioninfrontofthe

tractionunit.

2.MovetheliftlevertotheFloatposition.Pushaliftarm

downuntiltheholesintheliftarmlineupwiththe

holesinthecastorarmbracketandtheheightofcut

rodcanbeinsertedintotheliftarmpads(Figure4).

Figure4

1.Liftarm

2.Castorarmbracket8.Height-of-cutcollar

3.Height-of-cutrod9.Clevispin

4.Liftarmpads

5.Thrustwashers11.Bolt

6.Clevispin

3.Securetheliftarmtothecastorarmwith2thrust

washers,aclevispinandahairpincotter.Positionthe

thrustwashersbetweentheliftarmandthecastorarm

bracket(Figure4).Insertendofcotterpinintotheslot

inthecastorarmtabtoretaincotterpin.

4.Repeattheprocedureontheoppositeliftarm.

5.Startthetractionunitandraisethecuttingunit.

6.Pushdownontherearofthecuttingunitandinsert

theheightofcutrodsthroughtheliftarmpads.

7.Installtheheightofcutcollarsontotheheightofcut

rodsandsecurewiththeclevispinsandhairpincotters

(Figure4).Positiontheheadoftheclevispintoward

thefrontofthedeck,ifpossible.

7.Hairpincotter

10.Hairpincotter

8.Installabolt(1/2x3/4inch)andawashertotopof

eachheightofcutrod(

10

Figure4).

Page 11

ProductOverview

5

ConnectingthePTOShaftto

theCuttingUnitGearBox

NoPartsRequired

Procedure

1.SlidethemalePTOshaftintothefemalePTOshaft

(Figure5).Alignthemountingholesinthegearcase

inputshaftwiththeholesinthePTOshaftandslide

themtogether.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Widthof

Cut

Height

ofCut

Net

Weight

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

1.575m(62inches)or1.829m(72inches)

Adjustablefrom25to127mm(1to5inches)in13

mm(1/2inch)increments

Model30403–190kg(420lbs.)

Model30404–231kg(510lbs.)

Figure5

1.PTOshaft3.Gearcase

2.Boltsandlocknuts4.Rollpin

2.Securethemwitharollpin(Figure5).

3.Tightentheboltsandnuts(Figure5).

6

GreasingtheMachine

NoPartsRequired

Procedure

Beforeoperatingthemachine,itmustbegreasedtoensure

properlubricatingcharacteristics;refertoGreasingthe

BearingsandBushings.Failuretoproperlygreasethemachine

willresultinprematurefailureofcriticalparts.

11

Page 12

Operation

engineandremovethekeyafterthecuttingunitis

raised.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CAUTION

Ifyouleavethekeyintheignitionswitch,someone

couldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoany

maintenance.

CheckingtheLubricantinthe GearBox

ThegearboxindesignedtooperateonSAE80–90wt.gear

lube.Althoughthegearboxisshippedwithlubricantfrom

thefactory,checkthelevelbeforeoperatingthecuttingunit.

1.Positionthemachineandcuttingunitonalevelsurface.

2.Removethedipstick/llplugfromthetopofthegear

box(Figure6)andmakesurethatthelubricantis

betweenthemarksonthedipstick.Ifthelubricant

levelislow,addenoughlubricantuntilthelevelis

betweenthemarks.

2.Positionthecastorwheelaxlesinthesameholesin

bothcastorforks.Referto

determinethecorrectholesforthesetting.

Note:Whenoperatingin64mm(2–1/2inch)height

ofcutorhigher,theaxleboltmustbeinstalledinthe

lowercastorforkholetopreventgrassbuildupbetween

thewheelandthefork.Whenoperatinginheightof

cutslowerthan64mm(2–1/2inch)andgrassbuildup

isdetected,reversethemachinesdirectiontopullany

clippingsawayfromthewheel/forkarea.

3.Removethetensioningcapfromthespindleshaft

(Figure7)andslidethespindleoutofthecastorarm.

Putthe2shims(1/8inch)ontothespindleshaftas

theywereoriginallyinstalled.Theseshimsarerequired

toachievealevelacrosstheentirewidthofthecutting

units.Slidetheappropriatenumberof1/2inchspacers

ontothespindleshafttogetthedesiredheight-of-cut;

thenslidethewasherontotheshaft.

RefertoFigure7&Figure8todeterminethe

combinationsofspacersforthesetting.

Figure7&Figure8to

Figure6

1.Dipstick/llplug

AdjustingtheHeight-of-Cut

Theheight-of-cutisadjustablefrom25to127mm(1to

5inches)in13mm(1/2inch)increments.Toadjustthe

height-of-cut,positionthecastorwheelaxlesintheupper

orlowerholesofthecastorforks,addorremoveanequal

numberofspacersfromthecastorforksandsecuretheheight

ofcutcollartothedesiredholesintheheightofcutrod.

1.Starttheengineandraisethecuttingunitofftheoor

sothattheheight-of-cutcanbechanged.Stopthe

Figure7

1.Tensioningcap4.Axlemountingholes

2.Spacers5.CastorWheel

3.Shims

Figure8

12

Page 13

4.Pushthecastorspindlethroughthecastorarm.Install

theshims(astheywereoriginallyinstalled)andthe

remainingspacersontothespindleshaft.Installthe

tensioningcaptosecuretheassembly.

5.Removethehairpinandclevispinsecuringtheheight

ofcutcollartotheheightofcutrodontherearofthe

cuttingunit(Figure9).

Figure9

1.Height-of-cutrod3.Clevispinandhairpin

cotter

2.Height-of-cutcollar

AdjustingtheCuttingUnit Pitch

Cuttingunitpitchisthedifferenceinheight-of-cutfromthe

frontofthebladeplanetothebackofthebladeplane.T oro

recommendsabladepitchof6mm(1/4inch).Thatisthe

backofthebladeplaneis6mm(1/4inch)higherthanthe

front.

1.Positionthemachineonalevelsurfaceontheshop

oor.

2.Setthecuttingunittothedesiredheight-of-cut.

3.Rotate1bladesothatitpointsstraightforward.

4.Usingashortruler,measurefromtheoortothefront

tipoftheblade.Rotatethebladetiptotherearand

measurefromtheoortothetipoftheblade.

5.Subtractthefrontdimensionfromthereardimension

tocalculatethebladepitch.

6.Loosenthejamnutsonthebottomoftheheight-of-cut

Figure11).

rods(

6.Aligntheheight-of-cutcollartothedesired

height-of-cutholesontheheightofcutrod(

Figure10

7.Securetheadjustmentwiththeclevispinandhairpin.

Figure10).

Figure11

1.Height-of-cut

7.Rotatetheheight-of-cutrodstoraiseorlowertherear

ofthecuttingunitandattainthecorrectcuttingunit

pitch.

8.Tightenthejamnuts.

2.Jamnut

AdjustingtheSkids

Theskidsshouldbemountedinthelowerpositionwhen

operatinginheightofcutsgreaterthan64mm(2-1/2inches)

andinthehigherpositionwhenoperatinginheightofcuts

lowerthan64mm(2-1/2inches).

Note:Positiontheheadoftheclevispintowardthe

frontofthedeck,ifpossible.

Note:Whenusing25mm(1inch),38mm(1-1/2

inch),oroccasionally51mm(2inch)height–of–cut,

movetheskidsandrollertothehighestholes.

Adjusttheskidsbyremovingtheangeboltandnuts,

positioningthemasdesired,andinstallingthefasteners

(

Figure12).

13

Page 14

4.Checkforbentblades;refertoCheckingforaBent

Blade.

5.Cutgrassinatestareatodetermineifallcuttingunits

arecuttingatthesameheight.

6.Ifcuttingunitadjustmentsarestillneeded,ndaat

surfaceusinga2m(6foot)orlongerstraightedge.

7.Toeasemeasuringbladeplane,raisetheheightofcut

tothehighestposition;refertoAdjustingtheHeight

ofCut.

Figure12

1.Skid

AdjustingtheRollers

Note:Ifthecuttingunitistobeusedinthe25or38mm(1

or1-1/2inch)height-of-cutsetting,thecuttingunitrollers

mustberepositionedinthetopbracketholes.

1.Removethescrewandnutsecuringtherollershaftto

thedeckbracket(Figure13).

8.Lowercuttingunitontotheatsurface.Removethe

coversfromthetopofthecuttingunits.

9.Rotatethebladeoneachspindleuntiltheendsface

forwardandbackward.

10.Measurefromtheoortothefronttipofthecutting

edge.

11.Adjust1/8inchshimsoncastorfork(s)tomatch

heightofcuttodecal(

CuttingUnitPitch.

Figure14);refertoAdjustingthe

Figure13

1.Roller

2.Slidetheshaftoutofthelowerbracketholes,alignthe

rollerwiththetopholes,andinstalltheshaft.

3.Installthescrewandnuttosecuretheassemblies.

2.Rollershaft

CorrectingCuttingUnit Mismatch

Duetodifferencesingrassconditionsandthecounterbalance

settingofthetractionunit,itisadvisedthatgrassbecutand

appearancecheckedbeforeformalcuttingisstarted.

1.Setthecuttingunittothedesiredheightofcut;referto

AdjustingtheHeightofCut.

2.Checkandadjustfrontandreartractortirepressureto

172–207kPa(25–30psi).

3.Checkandadjustallcastortirepressuresto345kPa

(50psi).

Figure14

1.Tensioningcap4.Axlemountingholes

2.Spacers5.Castorwheel

3.Shims

OperatingTips

MowWhenGrassisDry

Moweitherinthelatemorningtoavoidthedew ,whichcauses

grassclumping,orinlateafternoontoavoidthedamage

thatcanbecausedbydirectsunlightonthesensitive,freshly

mowedgrass.

SelecttheProperHeight-of-CutSetting

toSuitConditions

Removeapproximately25mm(1inch)ornomorethan1/3

ofthegrassbladewhencutting.Inexceptionallylushand

14

Page 15

densegrass,youmayhavetoraisetheheight-of-cuttothe

nextsetting.

MowatProperIntervals

Undermostnormalconditionsyouwillneedtomow

approximatelyevery4–5days.Butremember,grassgrowsat

differentratesatdifferenttimes.Thismeansthatinorderto

maintainthesameheight-of-cut,whichisagoodpractice,

youwillneedtocutmorefrequentlyinearlyspring;asthe

grassgrowthrateslowsinmidsummer,cutonlyevery8–10

days.Ifyouareunabletomowforanextendedperioddue

toweatherconditionsorotherreasons,mowrstwiththe

height-of-cutatahighlevel;thenmowagain2–3dayslater

withalowerheightsetting.

AlwaysMowwithSharpBlades

Asharpbladecutscleanlyandwithouttearingorshredding

thegrassbladeslikeadullblade.Tearingandshredding

causesthegrasstoturnbrownattheedgeswhichimpairs

growthandincreasessusceptibilitytodiseases.

AfterOperating

Toensureoptimumperformance,cleantheundersideofthe

mowerhousingaftereachuse.Ifresidueisallowedtobuild

upinthemowerhousing,cuttingperformancewilldecrease.

CuttingUnitPitch

Werecommendabladepitchof6mm(1/4inch).Apitch

largerthan6mm(1/4inch)willresultinlesspowerrequired,

largerclippings,andapoorerqualityofcut.Apitchlessthan

6mm(1/4inch)willresultinmorepowerrequired,smaller

clippingsandabetterqualityofcut.

15

Page 16

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Aftertherst10hours

Beforeeachuseordaily

Every50hours

Every400hours

1

Immediatelyaftereverywashing,regardlessoftheintervallisted

MaintenanceProcedure

•Tightenthecastorwheelnuts

•Tightenthecastorwheelnuts

•T orquethebladebolts

•Checktheblades

•Lubricatethegreasettings1

•Checkthegearboxoillevel

•Tightenthecastorwheelnuts

•T orquethebladebolts

•Checkthebladedrivebeltadjustment

•Cleanunderthecuttingunitbeltcovers

•Changethegearboxoil

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentallystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionswitchbeforeyoudoanymaintenance.

Important:Thefastenersonthecoversofthismachinearedesignedtoremainonthecoverafterremoval.Loosen

allofthefastenersoneachcoverafewturnssothatthecoverisloosebutstillattached,thengobackandloosen

themuntilthecovercomesfree.Thiswillpreventyoufromaccidentallystrippingtheboltsfreeoftheretainers.

Lubrication

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBaseGrease.

Ifthemachineisoperatedundernormalconditions,lubricate

allbearingsandbushingsafterevery50hoursofoperationor

immediatelyaftereverywashing.

1.Lubricatethefollowingareas:

•Castorforkshaftbushings(2)(

Figure15)

Figure15

•Spindleshaftbearings(3)(locatedunderthepulley)

(Figure16)

16

Page 17

Figure16

•Idlerarmshaftbearings(Figure16)

•Liftarmpivots,front(2)(Figure17)

Figure17

•Liftarmpivots,rear(2)(Figure18)

Figure19

1.Dipstick/llplug

SeparatingtheCuttingUnit fromtheTractionUnit

1.Positionthemachineonlevelsurface,lowerthecutting

unittotheoor,movetheliftlevertotheFloat

position,shuttheengineoff,andengagetheparking

brake.

2.Removetheboltandwashermountedtothetopof

eachheightofcutrod(Figure20).

Figure18

2.Positionthemachineandcuttingunitonalevelsurface

andlowerthecuttingunit.Removethedipstick/ll

plugfromthetopofthegearbox(Figure19)andmake

surethatthelubricantisbetweenthemarksonthe

dipstick.Ifthelubricantlevelislow,addSAE80-90

wt.gearlubeuntilthelevelisbetweenthemarks.

Figure20

1.Height-of-cutrod3.Height-of-cutcollar

2.Boltandwasher4.Hairpincotterandclevis

pin

3.Removethehairpinandclevispinsecuringtheheight

ofcutcollartotheheightofcutrodontherearof

thecuttingunit(Figure20).Removetheheightofcut

collar.

4.Removethehairpincottersandclevispinssecuring

theliftarmstothecastorarmbrackets(

17

Figure21).

Page 18

Figure21

holesinthecastorarmbracketandtheheightofcut

rodcanbeinsertedintotheliftarmpads(

Figure23).

1.Liftarm

2.Clevispin4.Castorarmbracket

3.Hairpincotter

5.Rollthecuttingunitawayfromthetractionunit,

separatingthemaleandfemalesectionsofthePTO

shaft(Figure22).

Figure22

1.PTOshaft

DANGER

IftheengineisstartedandthePTOshaftis

allowedtorotate,seriousinjurycouldresult.

Figure23

1.Liftarm

2.Castorarmbracket8.Height-of-cutcollar

3.Height-of-cutrod9.Clevispin

4.Liftarmpads

5.Thrustwashers11.Bolt

6.Clevispin

7.Hairpincotter

10.Hairpincotter

DonotstarttheengineandengagethePTO

leverwhenthePTOshaftisnotconnectedto

thegearboxonthecuttingunit.

MountingtheCuttingUnitto theTractionUnit

1.Positionthemachineonalevelsurfaceandshutthe

engineoff.

2.Movethecuttingunitintopositioninfrontofthe

tractionunit.

3.SlidethemalePTOshaftintothefemalePTOshaft

Figure22).

(

4.MovetheliftlevertotheFloatposition.Pushaliftarm

downuntiltheholesintheliftarmlineupwiththe

5.Securetheliftarmtothecastorarmwith(2)thrust

washers,aclevispinandahairpincotter.Positionthe

thrustwashersbetweentheliftarmandthecastorarm

bracket(Figure23).Insertendofcotterpinintothe

slotinthecastorarmtabtoretaincotterpin.

6.Repeattheprocedureontheoppositeliftarm.

7.Startthetractionunitandraisethecuttingunit.

8.Pushdownontherearofthecuttingunitandinsert

theheightofcutrodsthroughtheliftarmpads.

9.Installtheheightofcutcollarsontotheheightofcut

rodsandsecurewiththeclevispinsandhairpincotters

(Figure23).Headofclevispintobepositionedtoward

thefrontofthedeck.

10.Installa1/2x3/4inchboltandawashertotopof

eachheightofcutrod(Figure23).

18

Page 19

ServicingtheBushingsinthe

G010549

CastorArms

Thecastorarmshavebushingspressedintothetopand

bottomofthetubeandaftermanyhoursofoperation,the

bushingswillwear.Tocheckthebushings,movethecastor

forkbackandforthandfromsidetoside.Ifthecastor

spindleislooseinsidethebushings,thebushingsareworn

andmustbereplaced.

1.Raisethecuttingunitsothatthewheelsareoffof

theoor.Blockthecuttingunitsothatitcannot

accidentallyfall.

2.Removethetensioningcap,spacer(s),andthrust

washerfromthetopofthecastorspindle.

3.Pullthecastorspindleoutofthemountingtube.

Allowthethrustwasherandspacer(s)toremainon

thebottomofthespindle.

Figure25

1.Castorwheel3.Bearing(2)

2.Castorfork

4.Bearingspacer

4.Insertapinpunchintothetoporbottomofthe

mountingtubeanddrivethebushingoutofthetube

Figure24).Alsodrivetheotherbushingoutofthe

(

tube.Cleantheinsideofthetubestoremovedirt.

Figure24

1.Castorarmtube

5.Applygreasetotheinsideandoutsideofthenew

bushings.Usingahammerandatplate,drivethe

bushingsintothemountingtube.

6.Inspectthecastorspindleforwearandreplaceitif

damaged.

7.Pushthecastorspindlethroughthebushingsand

mountingtube.Slidethethrustwasherandspacer(s)

ontothespindle.Installthetensioningcaponthe

castorspindletoretainallpartsinplace.

2.Bushings

2.Removethebearingfromthewheelhubandallow

thebearingspacertofallout(Figure25).Removethe

bearingfromtheoppositesideofthewheelhub.

3.Checkthebearings,spacer,andinsideofthewheelhub

forwear.Replaceanydamagedparts.

4.Toassemblethecastorwheel,pushthebearingintothe

wheelhub.Wheninstallingthebearings,pressonthe

outerraceofthebearing.

5.Slidethebearingspacerintothewheelhub.Pushthe

otherbearingintotheopenendofthewheelhubto

captivatethebearingspacerinsidethewheelhub.

6.Installthecastorwheelassemblybetweenthecastor

forkandsecureitinplacewiththeboltandlocknut.

CheckingforaBentBlade

1.Positionthemachineonalevelsurface.Raisethe

cuttingunit,engagetheparkingbrake,putthetraction

pedalinneutral,putthePTOleverintheOffposition,

stoptheengine,andremovetheignitionkey.Blockthe

cuttingunittopreventitfromaccidentallyfalling.

2.Rotatethebladeuntiltheendsfaceforwardand

backward.Measurefromtheinsideofthecuttingunit

tothecuttingedgeatthefrontoftheblade(Figure26),

andrememberthisdimension.

ServicingtheCastorWheels andBearings

1.Removethelocknutfromtheboltholdingthecastor

wheelassemblybetweenthecastorfork(Figure25).

Graspthecastorwheelandslidetheboltoutofthe

forkorpivotarm.

Figure26

3.Rotatetheoppositeendofthebladeforward.Measure

betweenthecuttingunitandcuttingedgeofthe

bladeatthesamepositionasinstep2Thedifference

betweenthedimensionsobtainedinsteps2and3must

notexceed3mm(1/8inch).Ifthedimensionexceeds

19

Page 20

3mm(1/8inch),replacethebladebecauseitisbent;

G010555

1

2

refertoRemovingtheCuttingBlade.

InspectingandSharpeningthe Blade(s)

RemovingandInstallingthe Blade(s)

Theblademustbereplacedifasolidobjectishit,the

bladeisout-of-balance,worn,orbent.Alwaysusegenuine

Tororeplacementbladestoensuresafetyandoptimum

performance.Neverusebladesmadebyothermanufacturers

becausetheycouldbedangerous.

1.Raisethecuttingunittothehighestposition,engage

theparkingbrake,stoptheengine,andremovethe

ignitionkey.Blockthecuttingunittopreventitfrom

accidentallyfalling.

2.Grasptheendofthebladeusingaragorthickly

paddedglove.Removethebladebolt,anti-scalpcup,

andbladefromthespindleshaft(Figure27).

Figure27

1.Bladebolt2.Anti-scalpcup

3.Installtheblade-sailfacingtowardthecuttingunit-with

theanti-scalpcupandbladebolt.Tightentheblade

boltto115-149N-m(85-110ft-lb).

Important:Thecurvedpartoftheblademustbe

pointingtowardtheinsideofthecuttingunitto

ensurepropercutting.

DANGER

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Donottrytostraightenabladethatisbent.

•Neverweldabrokenorcrackedblade.

•Replaceawornordamagedbladewitha

newTorobladetoensurecontinuedsafety

certicationoftheproduct.

Twoareasmustbeconsideredwhencheckingandservicing

thecuttingblade:thesailandthecuttingedge.Bothcutting

edgesandthesail,whichistheturnedupportionopposite

thecuttingedge,contributetoagoodquality-of-cut.The

sailisimportantbecauseitpullsgrassupstraight,thereby

producinganevencut.However,thesailwillgraduallywear

downduringoperation,andthisconditionisnormal.Asthe

sailwearsdown,thequality-of-cutwilldegradesomewhat,

althoughthecuttingedgesaresharp.Thecuttingedgeof

theblademustbesharpsothatthegrassiscutratherthan

torn.Adullcuttingedgeisevidentwhenthetipsofthegrass

appearbrownandshredded.Sharpenthecuttingedgesto

correctthiscondition.

1.Positionthemachineonalevelsurface.Raisethe

cuttingunit,engagetheparkingbrake,putthetraction

pedalinneutral,putthePTOleverintheOffposition,

stoptheengine,andremovetheignitionkey.

2.Examinethecuttingendsofthebladecarefully,

especiallywheretheatandcurvedpartsoftheblade

meet(Figure28).Sincesandandabrasivematerialcan

wearawaythemetalthatconnectstheatandcurved

partsoftheblade,checkthebladebeforeusingthe

machine.Ifwearisnoticed(Figure28),replacethe

blade;refertoRemovingtheCuttingBlade.

Figure28

1.Cuttingedge3.Wear/slotforming

2.Curvedarea/sail4.Crack

20

Page 21

WARNING

Ifthebladeisallowedtowear,aslotwillform

betweenthesailandatpartoftheblade

Figure28).Eventually,apieceoftheblade

(

maybreakoffandbethrownfromunderthe

housing,possiblyresultinginseriousinjuryto

yourselforbystanders.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedbladewitha

newT orobladetoensurecontinuedsafety

certicationoftheproduct.

3.Examinethecuttingedgesofallblades.Sharpenthe

cuttingedgesiftheyaredullornicked.Sharpenonly

thetopsideofthecuttingedgeandmaintainthe

originalcuttingangletoensuresharpness(Figure29).

Thebladewillremainbalancedifthesameamountof

metalisremovedfrombothcuttingedges.

forward,andmeasureagain.Thedifferencebetween

thedimensionsmustnotexceed1meter(3foot).If

thedimensionexceeds1meter(3foot),replacethe

bladebecauseitisbent.Makesuretomeasureallof

theblades.

5.Comparethemeasurementsoftheouterbladeswith

thecenterblade.Thecenterblademustnotbemore

than1meter(3foot)lowerthantheouterblades.If

thecenterbladeismorethan1meter(3foot)lower

thantheouterblades,proceedtostep

betweenthespindlehousingandthebottomofthe

cuttingunit.

6.Removethebolts,atwashers,lockwashers,andnuts

fromtheouterspindleintheareawheretheshims

mustbeadded.Toraiseorlowertheblade,addashim,

PartNo.3256-24,betweenthespindlehousingand

thebottomofthecuttingunit.Continuetocheckthe

alignmentofthebladesandaddshimsuntilthetipsof

thebladesarewithintherequireddimension.

Important:Donotusemorethanthreeshimsat

anyoneholelocation.Usedecreasingnumbersof

shimsinadjacentholesifmorethanoneshimis

addedtoanyoneholelocation.

6andaddshims

Figure29

1.Sharpenatoriginalangle

Note:Removethebladesandsharpenthemona

grinder;refertoRemovingtheCuttingBlades.After

sharpeningthecuttingedges,installthebladewiththe

anti-scalpcupandbladebolt.Thebladesailsmustbe

ontopoftheblade.Tightenthebladeboltto115-149

N-m(85-110ft-lb).

CheckingandCorrecting MismatchofBlades

Ifthereismismatchbetweentheblades,thegrasswillappear

streakedwhenitiscut.Thisproblemcanbecorrectedby

makingsurethatthebladesarestraightandalloftheblades

arecuttingonthesameplane.

1.Usinga1meter(3foot)longcarpenterslevel,nda

levelsurfaceontheshopoor.

2.Raisetheheight-of-cuttothehighestposition;referto

AdjustingtheHeight-of-Cut.

3.Lowerthecuttingunitontotheatsurface.Remove

thecoversfromthetopofthecuttingunit.

4.Rotatethebladesuntiltheendsfaceforwardand

backward.Measurefromtheoortothefronttipof

thecuttingedge.Rememberthisdimension.Then

rotatethesamebladesothattheoppositeendis

7.Installthebeltcovers.

ReplacingtheDriveBelt

Thebladedrivebelt,tensionedbythespringloadedidler

pulley,isverydurable.However,aftermanyhoursofuse,

thebeltwillshowsignsofwear.Signsofawornbeltare:

squealingwhenbeltisrotating,bladesslippingwhencutting

grass,frayededges,burnmarksandcracks.Replacethebeltif

anyoftheseconditionsareevident.

1.Lowerthecuttingunittotheshopoor.Removethe

beltcoversfromthetopofthecuttingunitandsetthe

coversaside.

2.Usingatorquewrenchorsimilartool,movetheidler

pulley(Figure30)awayfromthedrivebelttorelease

thebelttensionandallowthebelttobeslippedoffthe

gearboxpulley(Figure31).

Figure30

1.Idlerpulley

21

Page 22

Figure31

1.Gearbox

3.Removetheoldbeltfromaroundthespindlepulleys

andidlerpulley.

4.Routethenewbeltaroundthespindlepulleysandidler

pulleyassemblyasshowninFigure32.

Figure32

1.Beltrouting

5.Installthebeltcovers.

22

Page 23

DeclarationofIncorporation

TheT oroCompany,811 1LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

30403314000001andUpBase62inMower

30404314000001andUpBase72inMower

SerialNo.

ProductDescriptionInvoiceDescription

GeneralDescription

62”BASEDECK-GM3280

72”BASEDECK-GM3280

Base62inMower

Base72inMower

Directive

2006/42/EC,

2000/14/EC

2006/42/EC,

2000/14/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:EUTechnicalContact:

PeterT etteroo

ToroEuropeNV

B-2260Oevel-Westerloo

Belgium

DavidKlisTel.003214562960

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

September26,2013

Fax003214581911

23

Page 24

TheToroT otalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourToroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenance

andadjustmentsstatedinyourOperator'sManual.Failuretoperform

requiredmaintenanceandadjustmentscanbegroundsfordisallowinga

warrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,

duringnormalProductoperationinclude,butarenotlimitedto,brake

padsandlinings,clutchlinings,blades,reels,rollersandbearings

(sealedorgreasable),bedknives,sparkplugs,castorwheelsand

bearings,tires,lters,belts,andcertainsprayercomponentssuchas

diaphragms,nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,

lubricants,additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damageto

seatsduetowearorabrasion,wornpaintedsurfaces,scratched

decalsorwindows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowill

makethenaldecisionwhethertorepairanyexistingpartorassemblyor

replaceit.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedT oroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorT oroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty ,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .

Allimpliedwarrantiesofmerchantabilityandtnessforuseare

limitedtothedurationofthisexpresswarranty .

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.Thiswarranty

givesyouspeciclegalrights,andyoumayalsohaveotherrightswhich

varyfromstatetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EPA)and/ortheCaliforniaAir

ResourcesBoard(CARB).Thehourlimitationssetforthabovedonot

applytotheEmissionsControlSystemWarranty.RefertotheEngine

EmissionControlWarrantyStatementsuppliedwithyourproductor

containedintheenginemanufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevB

Loading...

Loading...