Page 1

FormNo.3388-972RevA

DebrisBlower

Groundsmaster

ModelNo.30393—SerialNo.315000001andUp

®

7200/7210TractionUnit

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3388-972*A

Page 2

Figure2

Introduction

Thedebrisblowerismountedtoaride-onmachinewhich

isintendedtobeusedbyprofessional,hiredoperatorsin

commercialapplications.Itisprimarilydesignedtousewind

powertoquicklyclearlargeareasofunwanteddebrison

well-maintainedlawnsinparks,golfcourses,sportselds,

andoncommercialgrounds.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

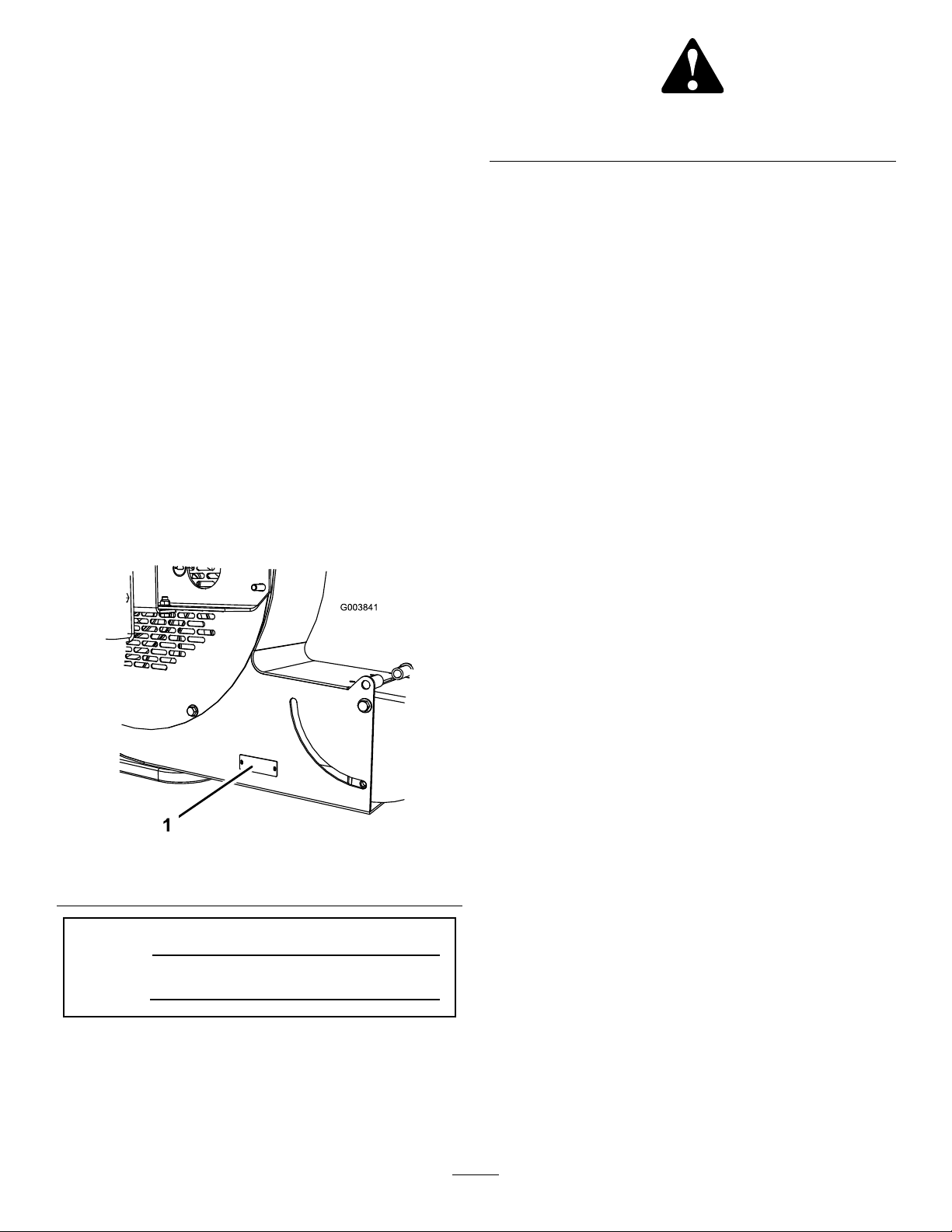

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Safety...........................................................................3

BeforeOperating....................................................3

WhileOperating......................................................3

Maintenance...........................................................3

SafetyandInstructionalDecals.................................4

Setup............................................................................6

1MountingtheCastorWheel....................................6

2MountingtheDebrisBlowertotheTraction

Unit...................................................................7

3AdjustingtheLinkAssembly..................................7

4GreasingtheBlower..............................................8

5InstallingtheFrontW eight.....................................8

ProductOverview.........................................................11

Specications........................................................11

Attachments/Accessories........................................11

Operation....................................................................11

AdjustingtheDischargeOpening.............................11

SwitchOperation...................................................11

OperatingTips.......................................................12

Maintenance.................................................................13

Lubrication............................................................13

BearingAlignment..................................................13

TorquingFasteners.................................................14

ServicingtheCastorArmBushings...........................14

ServicingtheCastorWheelsandBearings..................15

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Safety

Hazardcontrolandaccidentpreventionaredependent

upontheawareness,concern,andpropertraining

ofthepersonnelinvolvedintheoperation,transport,

maintenance,andstorageofthemachine.Improper

useormaintenanceofthemachinecanresultininjury

ordeath.T oreducethepotentialforinjuryordeath,

complywiththefollowingsafetyinstructions.

BeforeOperating

•ReadandunderstandthecontentsofthisOperator’ s

Manualbeforeoperatingthemachine.Becomefamiliar

withallofthecontrolsandknowhowtostopquickly.

Afreereplacementmanualisavailablebysendingthe

completeModelandSerialNumbertoTheToro®

Company,8111LyndaleAvenueSouth,Bloomington,

Minnesota55420-1196.

•Neverallowchildrentooperatethemachine.Do

notallowadultstooperatemachinewithoutproper

instruction.Onlytrainedoperatorswhohavereadthis

manualshouldoperatethismachine.

•Neveroperatethemachinewhenundertheinuenceof

drugsoralcohol.

•Keepallbystandersawayfromtheoperatingarea.

•Keepallshieldsandsafetydevicesinplace.Ifashield,

safetydevice,ordecalisillegibleordamaged,repairor

replaceitbeforeoperationiscommenced.Alsotighten

anyloosenuts,bolts,andscrewstoensurethatthe

machineisinsafeoperatingcondition.

•Donotoperatethemachinewhilewearingsandals,

tennisshoes,sneakers,orshorts.Also,donotwearloose

ttingclothingwhichcouldgetcaughtinmovingparts.

Alwayswearlongpantsandsubstantialshoes.Wearing

safetyglasses,safetyshoes,andahelmetisadvisable

andrequiredbysomelocalordinancesandinsurance

regulations.

WhileOperating

•Donotruntheengineinaconnedareawithout

adequateventilation.Exhaustfumesarehazardousand

couldpossiblybedeadly.

•Themaximumseatingcapacityisoneperson.Never

carrypassengers.

•Sitontheseatwhenstartingtheengineandoperating

themachine.

•Thisproductmayexceednoiselevelsof90dB(A)atthe

operatorposition.Earprotectorsarerecommendedfor

prolongedexposuretoreducethepotentialofpermanent

hearingdamage.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Operateonlyindaylightorwhenthereisgood

articiallight.

–Driveslowlyandwatchforholesorotherhidden

hazards.

–Donotdriveclosetoasandtrap,ditch,creek,or

otherhazard.

–Reduceyourspeedwhenmakingsharpturnsand

whenturningonhillsides.

–Avoidsuddenstartsandstops.

–Beforebackingup,looktotherearandensurethat

nooneisbehindthemachine.

–Watchoutfortrafcwhennearorcrossingroads.

Alwaysyieldtheright-of-way.

•Stayawayfromthedischargeopeningwhenthemachine

isoperating.Keepallbystandersawayfromthedischarge

openinganddon’tdirectdischargetowardbystanders.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Iftheenginestallsorthemachinelosesheadwayand

cannotmakeittothetopofaslope,donotturnthe

machinearound.Alwaysbackslowlystraightdownthe

slope.

•Donottakeaninjuryrisk!Whenapersonorpet

appearsunexpectedlyinorneartheoperatingarea,stop

operation.Carelessoperation,combinedwithterrain

angles,ricochets,orimproperlypositionedguardscan

leadtothrownobjectinjuries.Donotresumeoperation

untiltheareaiscleared.

•Donottouchtheengineormuferwhiletheengineis

runningorsoonafteritisstopped.Theseareascouldbe

hotenoughtocauseaburn.

Maintenance

•Removethekeyfromtheignitionswitchtoprevent

accidentalstartingoftheenginewhenservicing,adjusting,

orstoringthemachine.

•Performonlythosemaintenanceinstructionsdescribedin

thismanual.Ifmajorrepairsareeverneededorassistance

isdesired,contactanAuthorizedT oroDistributor.

•Toreduceapotentialrehazard,keeptheenginefreeof

excessivegrease,grass,leaves,andaccumulationsofdirt.

Neverwashawarmengineoranyelectricalpartswith

water.

•Besurethatthemachineisinsafeoperatingconditionby

keepingnuts,bolts,andscrewstight.Checkthefanshaft

bearingmountingboltsandnutsfrequentlytobesure

thattheyaretightenedtospecication.

•Makesurethatallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksin

hydrauliclinesthatejecthighpressurehydraulicuid.

3

Page 4

Usecardboardorpapertondhydraulicleaks.Hydraulic

uidescapingunderpressurecanpenetrateskinand

causeinjury.Fluidaccidentallyinjectedintotheskinmust

besurgicallyremovedwithinafewhoursbyadoctor

familiarwiththisformofinjuryorgangrenemayresult.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringtheblower

totheground.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andotherpartsof

thebodyawayfromthefanandothermovingparts.

•Donotoverspeedtheenginebychangingthegovernor

settings.Tobesureofsafetyandaccuracy,havean

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

AuthorizedToroDistributorcheckthemaximumengine

speedwithatachometer.

•Theenginemustbeshutoffbeforecheckingtheoilor

addingoiltothecrankcase.

•Toensureoptimumperformanceandsafety,always

purchasegenuineT ororeplacementpartsandaccessories

tokeepthemachineallT oro.Neveruse“will-t”

replacementpartsandaccessoriesmadebyother

manufacturers.LookfortheTorologotoensure

genuineness.Usingunapprovedreplacementpartsand

accessoriescouldvoidthewarranty.

98-3110

1.Warning—readtheOperator’sManualandreceivetraining.

2.Warning—wearhearingprotection.

3.Thrownobjecthazard—weareyeprotectionandkeep

bystandersasafedistancefromthemachine.

4.Cuttinghazardofhandorfoot—waitformovingpartsto

stop.

98-3111

1.Pointofrotation

93-9083

1.Cutting/dismembermenthazard,fan—stayawayfrom

movingparts.

58-6520

1.Grease

106-5517

1.Warning—donottouchthehotsurface.

4

Page 5

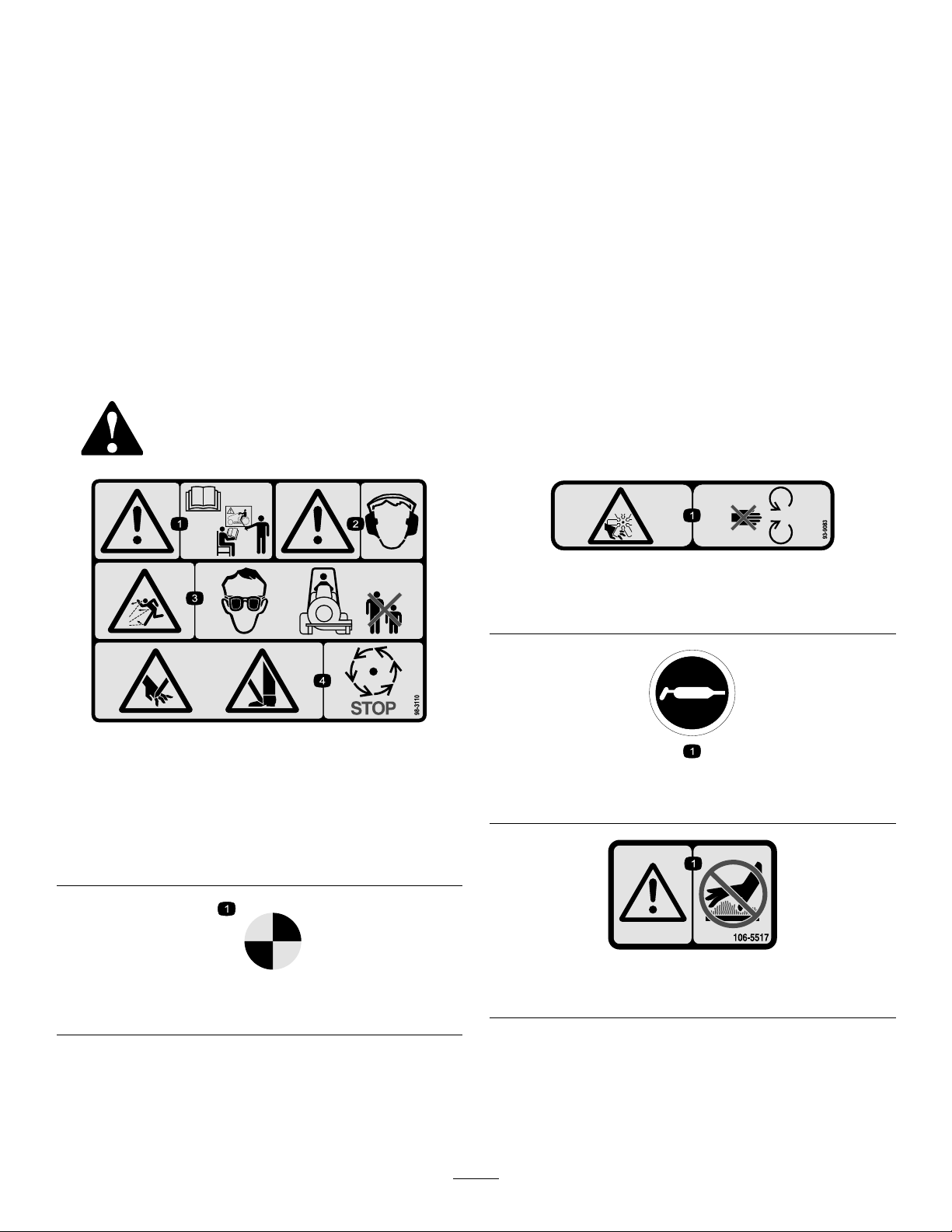

105-4593

1.Entanglementhazard,shaft—donotremovecoverwhile

partsaremoving,keepallguardsinplace.

114–4054

1.Warning—readtheOperator’sManual,donotoperatethe

machinewithoutthecrosspininplace.

5

Page 6

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

Nopartsrequired

Debrisblowerassembly1

Lockingpin1

Hairpincotter1

Nopartsrequired

Nopartsrequired

Nopartsrequired

MediaandAdditionalParts

Description

Operator'sManual

PartsCatalog

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Qty.

Qty.

–

–

–

–

1

1

Reviewthemanualbeforeoperatingthemachine.

Usethecatalogtoreferenceproductpartnumbers.

Mountthecastorwheel.

Mountthedebrisblowertothetraction

unit.

Adjustthelinkassembly .

Greasetheblower.

Installthefrontweight.

Use

Use

Note:Toinstallandoperatethedebrisblower,thetraction

unitmustbeequippedwiththeRearQuickAttachSystem,

Model30377andtheAuxiliaryHydraulicPowerKit,Model

30380.

1

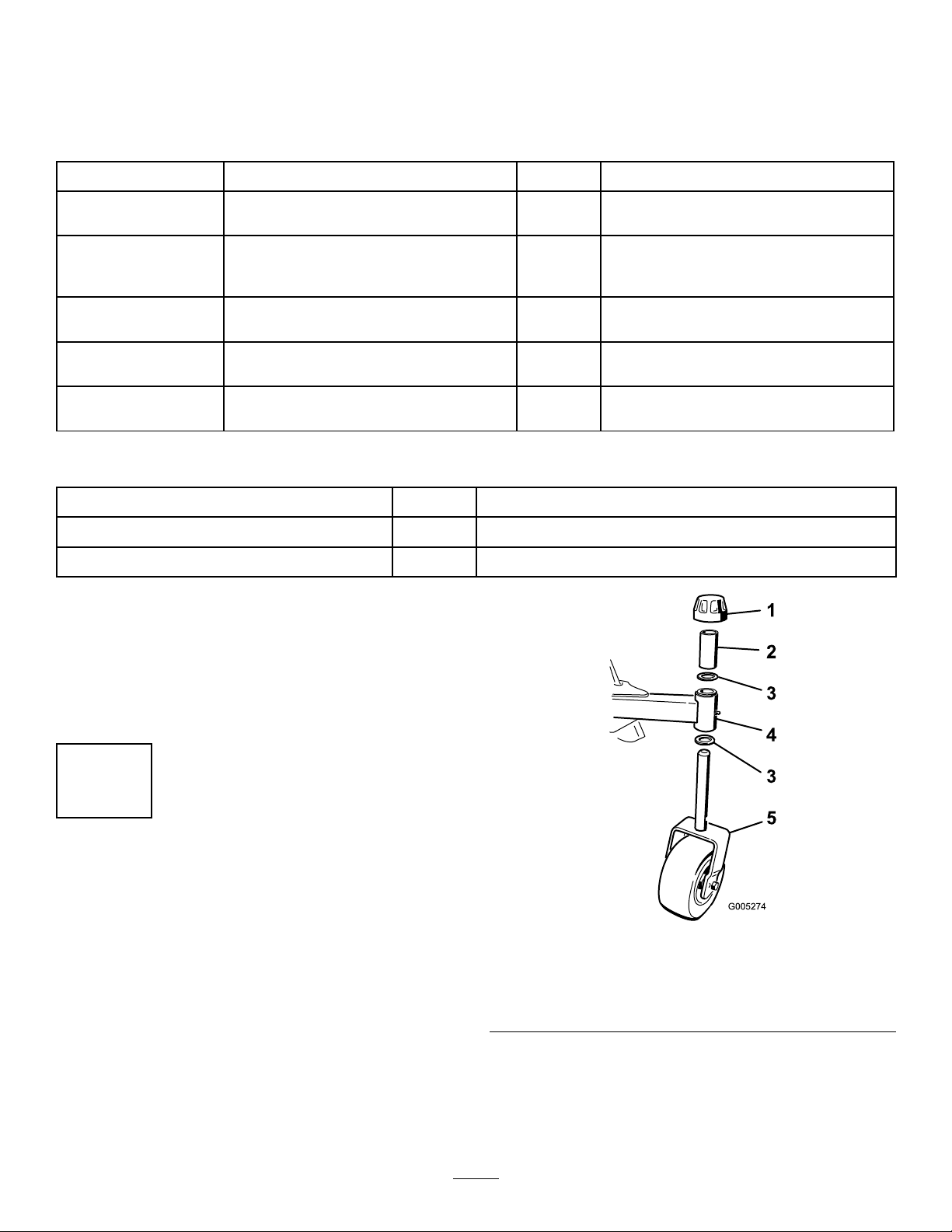

MountingtheCastorWheel

NoPartsRequired

Procedure

1.Removethetensioningcapfromthecastorwheel

spindleshaft(Figure3).Slidethespacerandonethrust

washeroffthespindleshaft.Leaveonethrustwasher

ontheshaft.

Figure3

1.Tensioningcap

2.Spacer5.Castorwheel

3.Thrustwasher(2)

2.Pushthecastorspindleupthroughthebushingsinthe

blowerframe,insertanotherthrustwasherontothe

shaft,slidethespacerontothespindleshaftandinstall

thetensioningcaptosecuretheassembly(Figure3).

4.Blowerframecastortube

6

Page 7

3.Makesurethecastorwheelassemblytireisinatedto

G003810

1

2

1

G006618

35to50psi.

2

MountingtheDebrisBlowerto theTractionUnit

Partsneededforthisprocedure:

1Debrisblowerassembly

1Lockingpin

1Hairpincotter

Procedure

5.Insertthelockingpinthroughtheadaptersandsecure

withahairpincotter(Figure5).

1.Removeanyattachmentfromtherearofthemachine.

2.Backthetractionunitintopositionbehindthe

attachmentadapter.

Note:Makesurethelockinglever(Figure4)ispivoted

totheleft(unlockedposition)asviewedfromtherear

ofthemachine.

1.Lockingpin

6.Routethehosesthroughthehosesupportloop.

7.Removethedustplugsfromthehydrauliccouplers

andmakesurethatthecouplersarefreeofanydirtor

contamination.

8.Connecttheattachmenthydraulichosecouplerstothe

hydrauliccouplersonthetractionunitrearauxiliary

hydraulicpowerkit.

Important:Wheneverthehydraulichosecouplers

aredisconnected,makesurethatthedustplugs

areinstalledtopreventcontaminationfrom

enteringeitherhydraulicsystem.

Figure5

3

AdjustingtheLinkAssembly

NoPartsRequired

Figure4

1.Attachmentadapter2.Lockinglever

3.Raisethetractionunitadapterintotheattachment

adapter.

4.Pivotthelockinglevertotherighttolocktheadapters

together.

Procedure

1.Withthedebrisblowermountedandsecuredonthe

tractionunit,raisetheattachment.

2.Measurethegapbetweenthetopwasherandthe

spacerinthelinkassemblyontheattachmentadapter

asshowninFigure6.

Note:Thegapbetweenthewasherandtheshoulder

shouldbe1.5to2.0mm(0.060to0.080inch).

7

Page 8

G00381 1

1

2

3

Figure6

5

InstallingtheFrontWeight

NoPartsRequired

Procedure

CAUTION

Whenanattachmentisnotinstalledonthe

machine,looseweightsmustberemoved.Never

operatethemachinewithnoattachmentinstalled

andfrontweightsonthemachine.

Usethefollowingweightchartstodeterminethecorrect

amountoffrontweightrequiredforyourmachine.

1.1.5to2.0mm(0.060to

0.080inch)

2.Jamnut

3.Adjustmentnut

4

GreasingtheBlower

NoPartsRequired

Procedure

BeforetheDebrisBlowerisoperated,itmustbegreasedto

assureproperlubrication.RefertotheLubricationsectionof

themanual.Failuretoproperlygreasetheunitwillresultin

prematurefailureofcriticalparts.

8

Page 9

72-inchwidthofcut

Groundsmaster7200/7210withNOhardcanopy

Attachment

RearQASandno

attachment(Model

30377)

QASnishgrader/box

rake(Model08754)

Steeldragmat(Model

08757)

Toothrake(Model

08751)

Toothrakewithspring

rake(Model08752)

Cocodragmat(Model

08758)

QASnaildrag(Model

08761)

QASdebrisblower

(Model08759)

Rahngroomer(allied

product)

Additionalfrontweight

0kg(0lb)n/a

0kg(0lb)n/a

0kg(0lb)n/a

0kg(0lb)n/a

0kg(0lb)n/a

30.4kg(67lb)

30.4kg(67lb)

49.4kg(109lb)

49.4kg(109lb)

required

Weightpartnumber(s)

114-4090and

114-4096

114-4090and

114-4096

114-4090and

114-4096

114-4090and

114-4096

Weightdescription

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

Qty

1

1

1

1

1

2

1

2

72-inchwidthofcut

Groundsmaster7200/7210withhardcanopy

Attachment

RearQASandno

attachment(Model

30377)

QASnishgrader/box

rake(Model08754)

Steeldragmat(Model

08757)

Toothrake(Model

08751)

Toothrakewithspring

rake(Model08752)

Cocodragmat(Model

08758)

QASnaildrag(Model

08761)

QASdebrisblower

(Model08759)

Rahngroomer(allied

product)

Additionalfrontweight

required

0kg(0lb)n/a

11.3kg(25lb)

11.3kg(25lb)

11.3kg(25lb)

11.3kg(25lb)

49.4kg(109lb)

49.4kg(109lb)

68.5kg(151lb)

68.5kg(151lb)

WeightpartnumberWeightdescription

114-4090or

Model30375

114-4090or

Model30375

114-4090or

Model30375

114-4090or

Model30375

114-4090and

114-4096

114-4090and

114-4096

114-4090and

114-4096

114-4090and

114-4096

frontweightbracketor

Jack-StandKit

frontweightbracketor

Jack-StandKit

frontweightbracketor

Jack-StandKit

frontweightbracketor

Jack-StandKit

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

Qty

1

1

1

1

1

1

1

1

1

2

1

2

1

3

1

3

9

Page 10

62-inchwidthofcut

Groundsmaster7200/7210withNOhardcanopy

Attachment

RearQASandno

attachment(Model

30377)

QASnishgrader/box

rake(Model08754)

Steeldragmat(Model

08757)

Toothrake(Model

08751)

Toothrakewithspring

rake(Model08752)

Cocodragmat(Model

08758)

QASnaildrag(Model

08761)

QASdebrisblower

(Model08759)

Rahngroomer(allied

product)

Additionalfrontweight

30.4kg(67lb)

68.5kg(151lb)

68.5kg(151lb)

49.4kg(109lb)

68.5kg(151lb)

68.5kg(151lb)

68.5kg(151lb)

68.5kg(151lb)

68.5kg(151lb)

requiredWeightpartnumber(s)WeightdescriptionQty

114-4090and

114-4096

114-4090and

114-4096

114-4090and

114-4096

114-4090and

114-4096

114-4090and

114-4096

114-4090and

114-4096

114-4090and

114-4096

114-4090and

114-4096

114-4090and

114-4096

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

1

1

1

3

1

3

1

2

1

3

1

3

1

3

1

3

1

3

62-inchwidthofcut

Groundsmaster7200/7210withhardcanopy

Attachment

RearQASandno

attachment(Model

30377)

QASnishgrader/box

rake(Model08754)

Steeldragmat(Model

08757)

Toothrake(Model

08751)

Toothrakewithspring

rake(Model08752)

Cocodragmat(Model

08758)

QASnaildrag(Model

08761)

QASdebrisblower

(Model08759)

Rahngroomer(allied

product)

Additionalfrontweight

required

49.4kg(109lb)

87.5kg(193lb)

87.5kg(193lb)

68.5kg(151lb)

87.5kg(193lb)

87.5kg(193lb)

87.5kg(193lb)

87.5kg(193lb)

87.5kg(193lb)

WeightpartnumberWeightdescription

114-4090and

114-4096

114-4090and

114-4096

114-4090and

114-4096

114-4090and

114-4096

114-4090and

114-4096

114-4090and

114-4096

114-4090and

114-4096

114-4090and

114-4096

114-4090and

114-4096

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

frontweightbracketand

19kg(42lb)frontweight

Qty

1

2

1

3

1

4

1

3

1

4

1

4

1

4

1

4

1

4

10

Page 11

ProductOverview

G003812

1

2

Operation

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Netweight

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

107kg(235lb)

AdjustingtheDischarge Opening

Thedischargeopening(Figure7)isadjustabletoincrease

ordecreaseairoutputvelocityandvolume.Decreasingthe

dischargeopeningsizeincreasesthevelocity.

1.Loosendischargeopeningdeectormountingscrews

(Figure7).

Figure7

1.Dischargeopening

deector

2.Pivotthedeectortothedesiredopening.

3.Tightenthemountingscrews.

2.Mountingscrew

SwitchOperation

Lift/Lowerswitch(Figure8)—MoveswitchtotheLift

positiontoraisetheattachmentandtotheLowerpositionto

lowertheattachment.

Float/Power-downSwitch(Figure8)—Movingtheswitch

totheFloatpositionallowstheattachmenttofollowthe

contouroftheground.MovingtheswitchtothePower-down

positionaddsweightfromthemachinetoincreaseground

engagementforce.Highergroundengagementforce

decreasesthetractioncapacityofthemachine.

Important:Onlyrunthedebrisblowerinthe

mode.Neverrunitinthe

totheblowerwilloccur.

P o w er -do wn

mode,ordamage

F loat

11

Page 12

Figure8

G003783

1

1.Float

2.Power-down

3.Lift/Lower

OperatingTips

WARNING

Dischargedairhasconsiderableforceandcould

causeinjuryorlossoffooting.

•Stayawayfromdischargeopeningwhen

machineisoperating.

•Keepbystandersawayfromdischargeopening

whenmachineisrunning.

Practiceblowingmaterial.Itisadvisabletoblowthesame

directionthewindisblowingtopreventmaterialfrom

blowingbackintotheclearedarea.

Donotclimbcurbswiththedebrisblowermountedtothe

machine.Alwaysndaramp.

Note:Iftheattachmentadapterbecomesstucktothe

tractionunitadapter,insertaprybar/screwdriverintothepry

slottodisengagetheparts(Figure9).

Figure9

1.Pryslot

12

Page 13

Maintenance

G003730

G003731

G003814

1223

Lubrication

Thedebrisblowerhasbearingsandbushingsthatmustbe

lubricatedregularly.Ifthemachineisoperatedundernormal

conditions,lubricatethebearingswith#2general-purpose,

lithium-basedgreaseafterevery8hoursofoperationordaily,

whichevercomesrst.Lubricatethettingsimmediately

aftereverywashing,regardlessoftheintervallisted.

Thelubricationpointsandquantitiesareasfollows:

Fanshaft—2(Figure10)

GreasingtheAttachmentAdapter

Ifthelockingleverontheattachmentadapterdoesnotpivot

freelyandeasily,applyalightcoatofgreasetotheareashown

inFigure12.

Figure12

BearingAlignment

Castorarmtube(Figure11)

Castorwheel(Figure11)

Ifthemotormountingbracketsareeverremoved,theymust

berealignedbeforethedebrisblowerisoperated.Refertothe

PartCatalogfortheAlignmentToolpartnumber.

1.Makesurethatthemountingbracketsareinstalledto

theblowerhousingbuttheboltsandnutsareloose

(Figure13).

Figure10

Figure13

1.Alignmenttool3.Fancoupler

2.Mountingbracket

Figure11

2.Insertthebearingalignmenttoolthroughthemounting

bracketsandintothefancoupler(Figure13).Make

surethatthespidercoupler(Figure14)isnotinthe

coupler.

13

Page 14

G003815

1

4

2

3

Figure14

G003816

1

G003817

1

1.Motorcoupler

2.Fancoupler

3.Setscrew(2each)

4.Couplerspider

3.Tightenthecapscrewsandthenutssecuringthe

mountingbracketstogetherandtotheblowerhousing.

4.Removethealignmenttoolandnishassembly.

TorquingFasteners

Ifthebloweriseverdisassembled,thefollowingfasteners

mustbetorquedasspecied.Also,applyLoctite242tothe

threadsbeforeinstalling.

•Thesetscrewssecuringthemotorandfanshaftcouplers

(Figure14)mustbetorquedto58to82in-lb.

•Thefanshaftbearingsetscrews(Figure15)mustbe

torquedto58to82in-lb.

Figure16

1.Fanmountingnut

ServicingtheCastorArm Bushings

Thecastorarmshavebushingspressedintothetopand

bottomofthetubeandaftermanyhoursofoperation,the

bushingswillwear.Tocheckthebushings,movethecastor

forkbackandforthandfromsidetoside.Ifthecastor

spindleislooseinsidethebushings,thebushingsareworn

andmustbereplaced.

1.Raisethedebrisblowersothatthewheelsareoffofthe

oor.Blocktheblowersothatitcannotaccidentally

fall.

2.Removethetensioningcap,spacer,andthrustwasher

fromthetopofthecastorspindle.

3.Pullthecastorspindleoutofthemountingtube.Allow

thethrustwasherandspacertoremainonthebottom

ofthespindle.

Figure15

1.Setscrew

•Thefanmountingnut(Figure16)mustbetorquedto

500ft-lb.

4.Insertapinpunchintothetoporbottomofthe

mountingtubeanddrivethebushingoutofthetube

(Figure17).Also,drivetheotherbushingoutofthe

tube.Cleantheinsideofthetubestoremovedirt.

14

Page 15

Figure17

1.Bushings

2.Castorarmtube

5.Applygreasetotheinsideandoutsideofthenew

bushings.Usingahammerandatplate,drivethe

bushingsintothemountingtube.

6.Inspectthecastorspindleforwearandreplaceitifit

isdamaged

7.Pushthecastorspindlethroughthebushingsand

mountingtube.Slidethethrustwasherandspaceronto

thespindle.Installthetensioningcaponthecastor

spindletoretainallpartsinplace.

ServicingtheCastorWheels andBearings

1.Removethelocknutfromtheboltholdingthecastor

wheelassemblyandwashersbetweenthecastorfork

(Figure18).Graspthecastorwheelandslidethebolt

outofthefork.Removethetirespannerfrominside

thewheelassembly.

Figure18

1.Locknut

2.Washer

3.Tirespanner6.Bolt

4.Castorfork

5.Castorwheel

2.Removeoneoftheouterbearingsfromthewheelhub

andallowtheinnerbearingtofallout(Figure19).

Removethebearingfromtheoppositesideofthe

wheelhub.

Figure19

1.Bearing(outer)3.Bearing(inner)

2.Wheelassembly

3.Checkthebearings(innerandouter),tirespanner,and

insideofthewheelhubforwear.Replaceanydamaged

parts.

4.Toassemblethecastorwheel,pushaouterbearinginto

thewheelhub.Wheninstallingthebearings,presson

theouterraceofthebearing.

5.Slidetheinnerbearingintothewheelhub.Pushthe

otherbearingintotheopenendofthewheelhubto

captivatethebearingspacerinsidethewheelhub.

6.Insertthetirespannerintothewheelassembly.

7.Installthecastorwheelassemblyandwashersbetween

thecastorforkandsecureitinplacewiththeboltand

locknut.

15

Page 16

Notes:

16

Page 17

Notes:

17

Page 18

Notes:

18

Page 19

DeclarationofIncorporation

TheT oroCompany ,8111LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

30393315000001andUpDebrisBlower

SerialNo.

ProductDescriptionInvoiceDescription

GeneralDescription

DEBRISBLOWER-GM

7200/7210

DebrisBlower

Directive

2006/42/EC,

2000/14/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:EUTechnicalContact:

PeterT etteroo

ToroEuropeNV

B-2260Oevel-Westerloo

Belgium

DavidKlisTel.003214562960

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

September26,2013

Fax003214581911

19

Page 20

ToroGeneralCommercialProductWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.Torowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevC

Loading...

Loading...