Page 1

60inand72inSideDischarge

Mower

FormNo.3363-107RevC

Groundsmaster

ModelNo.30366—SerialNo.310000001andUp

ModelNo.30368—SerialNo.310000001andUp

®

3320/3280-DTractionUnits

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Introduction

Thisrotary-bladelawncuttingdeckismounted

toaride-onmachineandisintendedtobeused

byprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrass

onwell-maintainedlawnsinparks,sportselds,and

oncommercialgrounds.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongside

highways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Themodel

andserialnumbersarestampedintoaplatethatis

mountedonthemowerhousing.Writethenumbersin

thespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure1),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure1

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Introduction.................................................................2

Safety...........................................................................3

SafeOperatingPractices.......................................3

ToroMowerSafety...............................................4

SafetyandInstructionalDecals.............................6

Setup............................................................................8

1MountingtheGrassDeector(Model30368

only).................................................................9

2InstallingtheLiftArmstotheTraction

Unit..................................................................9

3ConnectingtheLiftArmstotheCutting

Unit................................................................10

4ReplacingtheTractionUnitPTOShaft

(CuttingUnitModel30366only).....................10

5ConnectingthePTOShafttotheCutting

UnitGearBox................................................11

6GreasingtheMachine......................................11

ProductOverview......................................................12

Specications.....................................................12

Attachments/Accessories...................................12

Operation...................................................................12

CheckingtheLubricantintheGear

Box................................................................12

AdjustingtheHeight-of-Cut...............................13

AdjustingtheRollers..........................................14

AdjustingtheSkids.............................................14

AdjustingtheAnti-ScalpRollers.........................15

AdjustingtheFlowBafe...................................15

PositioningtheFlowBafe.................................15

AdjustingtheCuttingUnitPitch.........................16

CorrectingCuttingUnitMismatch......................16

UsingtheSideDischarge....................................17

OperatingTips...................................................17

Maintenance...............................................................18

RecommendedMaintenanceSchedule(s)................18

Lubrication.........................................................19

PreMaintenance.................................................20

SeparatingtheCuttingUnitfromtheTraction

Unit................................................................20

MountingtheCuttingUnittotheTraction

Unit................................................................21

ServicingtheBushingsintheCastor

Arms..............................................................21

ServicingtheCastorWheelsandBearings............22

CheckingforaBentBlade...................................22

RemovingandInstallingtheBlade(s)...................22

InspectingandSharpeningtheBlade(s)...............23

CheckingandCorrectingMismatchof

Blades............................................................24

ReplacingtheDriveBelt.....................................24

ReplacingtheGrassDeector.............................25

©2011—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Safety

ThismachinemeetsorexceedsCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004specicationsineffectatthetimeof

production.

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalertsymbol,

whichmeansCAUTION,W ARNING,orDANGER"personalsafetyinstruction."Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

–Useonlyanapprovedcontainer.

–Neverremovefuelcaporaddfuelwithengine

running.Allowenginetocoolbeforerefueling.

Donotsmokewhilerefueling.

–Neverrefuelordrainthemachineindoors.

•Checkthatoperator’spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

ThefollowinginstructionsarefromtheCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004.

Training

•Readtheoperator’smanualandothertraining

materialcarefully .Befamiliarwiththecontrols,

safetysigns,andtheproperuseoftheequipment.If

theoperatorormechaniccannotreadthelanguage

ofthismanual,itistheowner’sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeople,orproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glassesandearprotection.Longhair,looseclothing

orjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toysandwire

whichcanbethrownbythemachine.

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Onlystartengine

fromtheoperator’ sposition.Alwaysusetheseat

beltswhentheROPSisintheraisedposition.Do

notusetheseatbeltswhentheROPSisinthe

loweredposition.

•Slowdownanduseextracareonhillsides.Besure

totravelintherecommendeddirectiononhillsides.

Turfconditionscanaffectthemachine’sstability.

Usecautionwhileoperatingneardrop-offs.

•Slowdownandusecautionwhenmakingturnsand

whenchangingdirectionsonslopes.

•Neverraisedeckwiththebladesrunning.

•Neveroperatewithguardsnotsecurelyinplace.Be

sureallinterlocksareattached,adjustedproperly,

andfunctioningproperty.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,lowerthecuttingunits,

disengagedrives,engageparkingbrake(ifprovided),

shutoffenginebeforeleavingtheoperator’sposition

foranyreason.

•Stopequipmentandinspectthebladesafterstriking

objectsorifanabnormalvibrationoccurs.Make

necessaryrepairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesifnot

mowing.

3

Page 4

•Donotoperatethemowerundertheinuenceof

alcoholordrugs.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Theoperatorshallturnonashingwarninglights,

ifprovided,whenevertravelingonapublicroad,

exceptwheresuchuseisprohibitedbylaw .

MaintenanceandStorage

•Disengagedrives,lowerthecuttingunits,move

tractionpedaltoNeutral,setparkingbrake,stop

engineandremovekey.Waitforallmovementto

stopbeforeadjusting,cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,

mufer.Letenginecoolbeforestoringanddonot

storenearames,andenginetohelppreventres.

Cleanupoilorfuelspillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransporting.Donot

storefuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallowuntrained

personneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthe

positivelast.Reconnectpositiverstandnegative

last.

•Usecarewhencheckingblades.Wrapthebladesor

weargloves,andusecautionwhenservicingthem.

Onlyreplaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

ToroMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknowthatisnotincludedintheCEN,ISO ,or

ANSIstandard.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustouserandbystanders.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennis

shoesorsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Usingthemachinedemandsattention.Toprevent

lossofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,

embankments,orotherhazards.

–Avoidsuddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Lowerthecuttingunitwhengoingdownslopes.

•Thegrassdeectormustalwaysbeinstalledandin

thelowestpositiononthesidedischargecutting

unit.Neveroperatethemowerwithoutthedeector

orentiregrasscollector.

•Ifthecuttingunitdischargeareaeverplugs,shutthe

engineoffbeforeremovingtheobstruction.

•Cutgrassslopescarefully .Donotstart,stop,orturn

suddenly.

•Donottouchtheengineormuferwhiletheengine

isrunningorsoonafterithasstoppedbecausethese

areascouldbehotenoughtocauseburns.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.Wear

protectiveclothinganduseinsulatedtools.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

MaintenanceandStorage

•Checktheblademountingboltsfrequentlytobe

surethattheyaretightenedtospecication.

•Makesurethatallhydrauliclineconnectorsare

tightandallhydraulichosesandlinesareingood

conditionbeforeapplyingpressuretothesystem.

4

Page 5

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunderhigh

pressure.Usepaperorcardboard,notyourhands,

tosearchforleaks.Hydraulicuidescapingunder

pressurecanhavesufcientforcetopenetratethe

skinandcauseseriousinjury.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinthesystemmust

berelievedbystoppingtheengineandloweringthe

cuttingunitstotheground.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthecutting

units,attachments,andanymovingparts.Keep

everyoneaway.

•Donotoverspeedtheenginebychanginggovernor

settings.T oensuresafetyandaccuracy,havean

AuthorizedToroDistributorcheckthemaximum

enginespeedwithatachometer.

•Theenginemustbeshutoffbeforecheckingtheoil

oraddingoiltothecrankcase.

•Makesurethatthemowerfueltankisemptyifthe

machineistobestoredinexcessof30days.Do

notstorethemowernearanyopenameorwhere

gasolinefumesmaybeignitedbyaspark.

•Performonlythosemaintenanceinstructions

describedinthismanual.Ifmajorrepairsare

everneededorifassistanceisdesired,contactan

AuthorizedToroDistributor.

•Tomakesureofoptimumperformanceand

continuedsafetycerticationofthemachine,use

onlygenuineTororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadebyother

manufacturerscouldbedangerous,andsuchuse

couldvoidtheproductwarranty.

5

Page 6

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

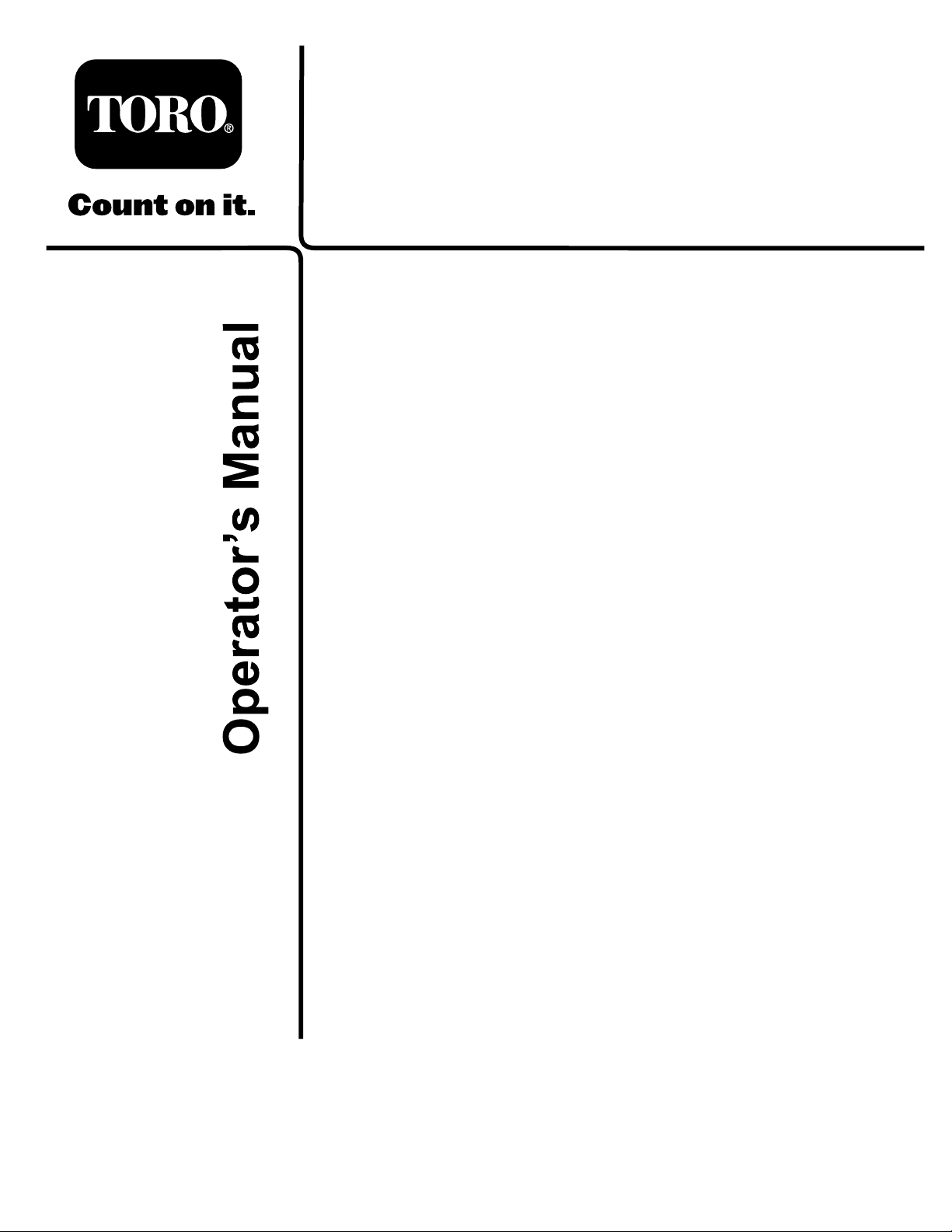

106-6753

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

93-6697

1.ReadtheOperator’s

Manual.

2.AddSAE80w-90(API

GL-5)oilevery50hours.

93-7818

1.Warning—readtheOperator’sManualforinstructionson

torquingthebladebolt/nutto1 15-149N-m(85-110ft-lb).

1.Removetheignitionkeyandreadthe

Operator’sManualbeforeservicingor

performingmaintenance.

100-6578

1.Entanglementhazard,belt—donotoperatethemachine

withtheshieldsorguardsremoved;alwayskeepthe

shieldsandguardsinplace;stayawayfrommovingparts.

107-2916

2.Thrownobjecthazard—donotoperate

themowerwiththedeectorupor

removed,keepthedeectorinplace;

keepbystandersasafedistancefrom

themachine.

1.Thrownobjecthazard—keepbystandersasafedistance

2.Thrownobjecthazard—donotoperatethemowerwiththe

3.Cutting/dismembermenthazardofhandorfoot,mower

3.Cutting/dismembermenthazardof

handorfoot,mowerblade—stayaway

frommovingparts.

107-2908

fromthemachine.

deectoruporremoved,keepthedeectorinplace.

blade—stayawayfrommovingparts.

6

Page 7

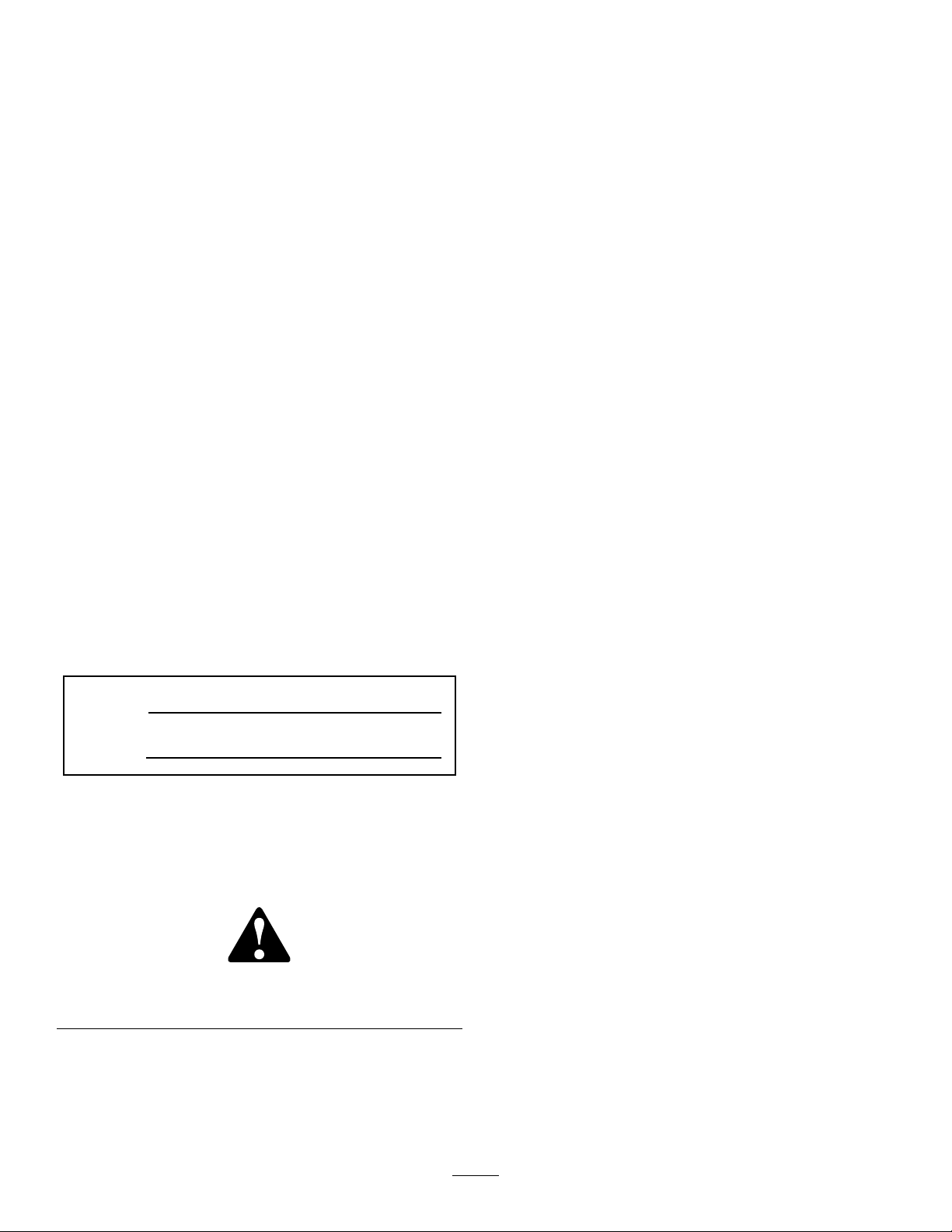

1.Beltrouting

1.Heightofcutadjustment

115-4505

(Model30368only)

1.Warning—readtheOperator’sManual.

2.Tippinghazard—lowerthecuttingunitwhendrivingdown

slopes.For2wheeldriveunits,adda16kg(35lb)rear

108-1988

weighttoGM3280Dunitsanda32kg(70lb)rearweightto

GM3320units.For4wheeldrive3280Dunits,adda16

kg(35lb)rearweight.

100-5622

107-1622

1.Heightofcut

108-1986

7

Page 8

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

Dischargedeectorassembly(rubber)

Screw,5/16x7-1/2inch

Spacertube

Torsionspring1

Flangenut,5/16

Pivotpinassembly2

Cotterpin

Liftarm,right

Liftarm,left

Thrustwasher-nylon4

Clevispin

Hairpin2

Heightofcutcollar

Clevispin

Hairpin2

Capscrew,1/2x3/4inch

Washer2

Nopartsrequired

Nopartsrequired

Qty.

Use

1

1

1

1

2

1

1

4

2

2

2

–

–

Mountthegrassdeector(Model30368

only)

Installtheliftarmstothetractionunit

Connecttheliftarmstothecuttingunit

ReplacetheTractionUnitPTOShaft

(CuttingUnitModel30366only)

ConnectthePTOshafttothecutting

unitgearbox.

6

Nopartsrequired

MediaandAdditionalParts

Description

Operator’sManual

PartsCatalog

DeclarationofConformity

WARNING

Ifyouleavethekeyintheignitionswitch,someone

couldaccidentallystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionswitchbeforeyou

doanymaintenance.

–

Qty.

1Reviewthematerialandsaveinanappropriateplace

1

1

Usetoreferencepartnumbers

Greasethemachine.

Use

DANGER

IftheengineisstartedandthePTOshaftisallowed

torotate,seriousinjurycouldresult.

DonotstarttheengineandengagethePTOswitch

whenthePTOshaftisnotconnectedtothegear

boxonthecuttingunit.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

8

Page 9

Important:Ifthe72inchSideDischargeCutting

Unit,model30368,isbeingmountedtoamodel

30307,30308,30309,30343,30344or30345traction

unitwithaserialnumberpriorto311000301,the

CuttingUnitAlignmentKit,partnumber120–6599

mustbeinstalledtothecuttingunitpriortobeing

mountedtotractionunit.

1

MountingtheGrassDeector

(Model30368only)

Partsneededforthisprocedure:

1

Dischargedeectorassembly(rubber)

1

Screw,5/16x7-1/2inch

1

Spacertube

1Torsionspring

1

Flangenut,5/16

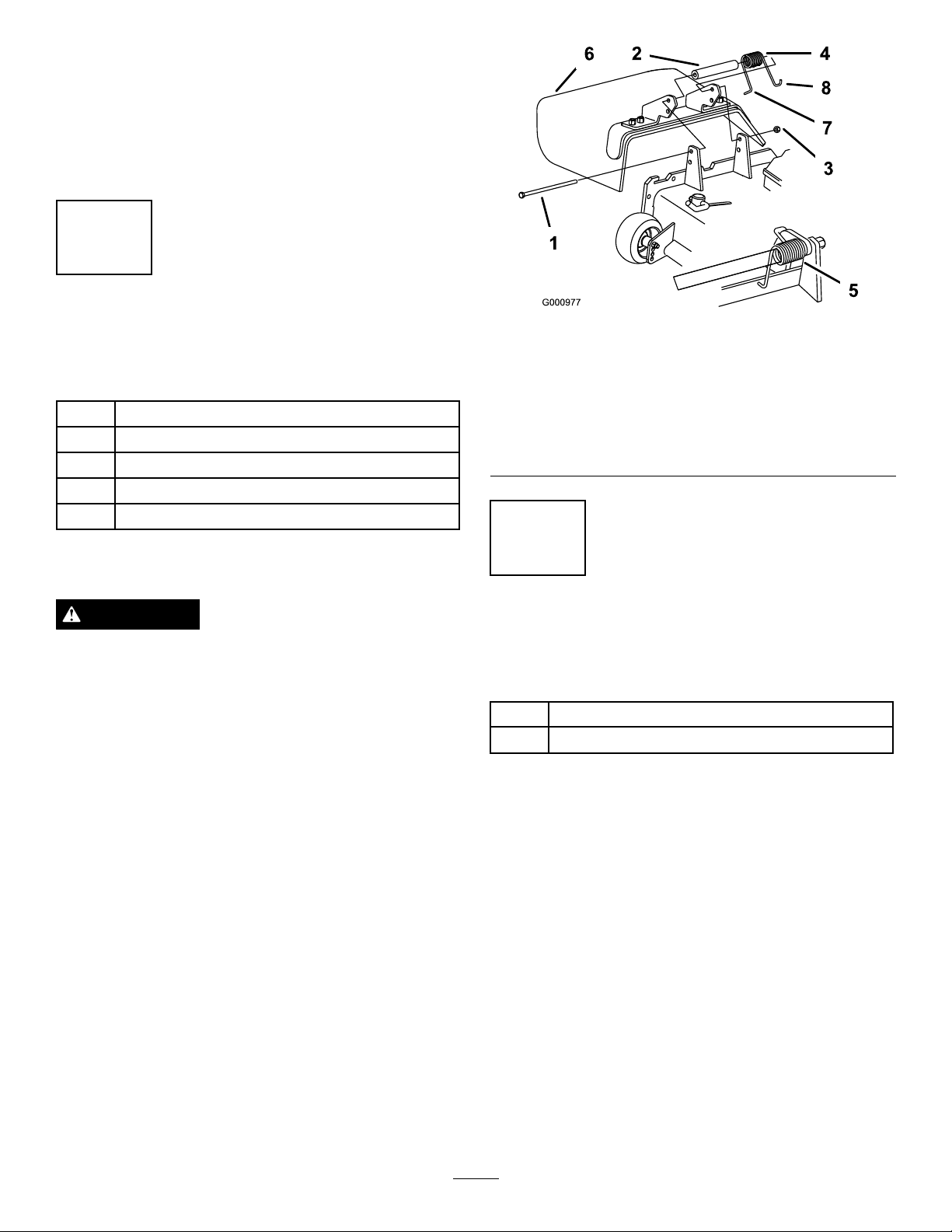

Figure2

1.Bolt

2.Spacer6.GrassDeector

3.Locknut

4.Spring8.Righthandhookendof

5.Springinstalled

7.Lefthandhookendof

spring,placebehinddeck

edgebeforeinstallingbolt

spring

Procedure

WARNING

Anuncovereddischargeopeningcouldallowthe

lawnmowertothrowobjectsintheoperator’sor

bystander’sdirectionandresultinseriousinjury.

Also,contactwiththebladecouldoccur.

•Neveroperatethelawnmowerunlessyouinstall

acoverplate,amulchplate,oragrasschuteand

catcher.

•Makesurethegrassdeectorisinthedown

position.

1.Placethespacerandspringbetweenthegrass

deectorbrackets(Figure2).PlacethelefthandJ

hookendofspringbehinddeckedge.

Note:MakesurethelefthandJhookendofthe

springisinstalledbehindthedeckedgebefore

installingtheboltasshowninFigure2.

2.Installtheboltandnut.PlacetherighthandJ

hookendofthespringaroundthegrassdeector

(Figure2).

2

InstallingtheLiftArmstothe

TractionUnit

Partsneededforthisprocedure:

2Pivotpinassembly

2

Cotterpin

Procedure

1.Ononesideofthetractionunit,loosen(donot

remove)thewheelnutssecuringthewheelandtire

assemblytothefrontwheelstuds.

2.Jackupthemachineuntilthefrontwheelisoffof

theoor.Usejackstandsorblockthemachineto

preventitfromaccidentallyfalling.

3.Removethewheelnutsandslidethewheelandtire

assemblyoffofthestuds.

4.Mountaliftarmtothepivotbracketwithapivotpin

andacotterpin(

thebendpositionedoutward.

Figure3).Mounttheliftarmwith

Important:Thegrassdeectormustbeableto

lowerdownintoposition.Liftthedeectorup

totestthatitlowersintothefulldownposition.

5.Hookthebrakereturnspringtothetabonthelift

arm(Figure3).

9

Page 10

Figure3

1.Pivotpin4.Brakereturnspring

2.Liftarm

3.Pivotbracket

5.Tab

6.Installthewheelandtireassembly.Torquethewheel

nutsto75–80ft-lb(102–108N-m).

7.Repeattheprocedureontheoppositesideofthe

machine.

3

ConnectingtheLiftArmsto

theCuttingUnit

Partsneededforthisprocedure:

1

Liftarm,right

1

Liftarm,left

4Thrustwasher-nylon

4

Clevispin

2Hairpin

2

Heightofcutcollar

2

Clevispin

2Hairpin

2

Capscrew,1/2x3/4inch

2Washer

Procedure

1.Movethecuttingunitintopositioninfrontofthe

tractionunit.

2.MovetheliftlevertotheFloatposition.Pushalift

armdownuntiltheholesintheliftarmlineupwith

theholesinthecastorarmbracketandtheheight

ofcutrodcanbeinsertedintotheliftarmpads

(

Figure4).

Figure4

1.Liftarm

2.Castorarmbracket8.Height-of-cutcollar

3.Height-of-cutrod9.Clevispin

4.Liftarmpads

5.Thrustwashers11.Bolt

6.Clevispin

7.Hairpincotter

10.Hairpincotter

3.Securetheliftarmtothecastorarmwith(2)thrust

washers,aclevispinandahairpincotter.Position

thethrustwashersbetweentheliftarmandthe

castorarmbracket(Figure4).Insertendofcotter

pinintotheslotinthecastorarmtabtoretaincotter

pin.

4.Repeattheprocedureontheoppositeliftarm.

5.Startthetractionunitandraisethecuttingunit.

6.Pushdownontherearofthecuttingunitandinsert

theheightofcutrodsthroughtheliftarmpads.

7.Installtheheightofcutcollarsontotheheightof

cutrodsandsecurewiththeclevispinsandhair

pincotters(Figure4).Headofclevispintobe

positionedtowardthefrontofthedeck.

8.Installa1/2x3/4inchboltandawashertotopof

eachheightofcutrod(Figure4).

10

Page 11

4

ReplacingtheTractionUnit

PTOShaft(CuttingUnitModel

30366only)

NoPartsRequired

Procedure

CuttingunitModel30366isequippedwithashorter

PTOshaftwhichmustbeinstalledonthetractionunit

asfollows:

1.Removethecotterpin,boltsandlocknutssecuring

thefemaleendofthePTOshafttothetractionunit

shaft.

2.RemovethePTOshaftfromthetractionunitshaft

andretainitforfutureapplications.

3.InstallthefemaleendofthePTOshaft,supplied

withthecuttingunit,tothetractionunitshaftwith

thecotterpin.

4.Tightentheboltsandlocknuts.

Figure5

1.PTOshaft3.Gearcase

2.Boltsandlocknuts4.Rollpin

2.Securethemwitharollpin.

3.Tightentheboltsandnuts.

6

GreasingtheMachine

NoPartsRequired

5

ConnectingthePTOShaftto

theCuttingUnitGearBox

NoPartsRequired

Procedure

1.SlidethemalePTOshaftintothefemalePTOshaft.

Alignthemountingholesinthegearcaseinput

shaftwiththeholesinthePTOshaftandslidethem

together.

Procedure

Beforeoperatingthemachine,itmustbegreased

toensureproperlubricatingcharacteristics;referto

GreasingtheBearingsandBushings.Failuretoproperly

greasethemachinewillresultinprematurefailureof

criticalparts.

11

Page 12

ProductOverview

Operation

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Widthof

Cut

Height

ofCut

Net

Weight

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

60inches(1.52m)or72inches(1.829m)

Adjustablefrom1to5inches(25to127mm)in1/2

inch(13mm)increments

Model30368–600lb.(272kg)

Model30366–450lb.(204kg)

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

CAUTION

Ifyouleavethekeyintheignitionswitch,someone

couldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudo

anymaintenance.

CheckingtheLubricantinthe

GearBox

ServiceInterval:Every50hours

ThegearboxindesignedtooperateonSAE80–90

wt.gearlube.Althoughthegearboxisshippedwith

lubricantfromthefactory,checkthelevelbefore

operatingthecuttingunit.Thegearboxcapacityis12

oz.(283ml).

1.Positionthemachineandcuttingunitonalevel

surface.

2.Removethedipstick/llplugfromthetopof

thegearbox(

lubricantisbetweenthemarksonthedipstick.If

thelubricantlevelislow ,addenoughlubricantuntil

thelevelisbetweenthemarks.

1.Dipstick/llplug

Figure6)andmakesurethatthe

Figure6

12

Page 13

AdjustingtheHeight-of-Cut

Theheight-of-cutisadjustablefrom1to5inches(25

to127mm)in1/2inch(13mm)increments.Toadjust

theheight-of-cut,positionthecastorwheelaxlesinthe

upperorlowerholesofthecastorforks,addorremove

anequalnumberofspacersfromthecastorforksand

securetheheightofcutcollartothedesiredholesin

theheightofcutrod.

1.Starttheengineandraisethecuttingunitoffthe

oorsothattheheight-of-cutcanbechanged.Stop

theengineandremovethekeyafterthecuttingunit

israised.

2.Positionthecastorwheelaxlesinthesameholesin

bothcastorforks.Referto

determinethecorrectholesforthesetting.

Figure7andFigure8to

reversethemachinesdirectiontopullanyclippings

awayfromthewheel/forkarea.

3.Removethetensioningcapfromthespindleshaft

Figure7)andslidethespindleoutofthecastor

(

arm.Putthe2shims(1/8inch)ontothespindle

shaftastheywereoriginallyinstalled.Theseshims

arerequiredtoachievealevelacrosstheentire

widthofthecuttingunits.Slidetheappropriate

numberof1/2inchspacersontothespindleshaft

togetthedesiredheight-of-cut;thenslidethe

washerontotheshaft.

Referto

Figure8todeterminethecombinations

ofspacersforthesetting.

4.Pushthecastorspindlethroughthecastorarm.

Installtheshims(astheywereoriginallyinstalled)

andtheremainingspacersontothespindleshaft.

Installthetensioningcaptosecuretheassembly .

5.Removethehairpinandclevispinsecuringthe

heightofcutcollartotheheightofcutrodonthe

rearofthecuttingunit(

Figure9).

Figure7

1.Tensioningcap4.Axlemountingholes

2.Spacers5.CastorWheel

3.Shims

Figure8

Note:Whenoperatingin2–1/2inch(64mm)

heightofcutorhigher,theaxleboltmustbe

installedinthelowercastorforkholetoprevent

grassbuildupbetweenthewheelandthefork.

Whenoperatinginheightofcutslowerthan2–1/2

inches(64mm)andgrassbuildupisdetected,

Figure9

1.Height-of-cutrod3.Clevispinandhairpin

cotter

2.Height-of-cutcollar

6.Aligntheheight-of-cutcollartothedesired

height-of-cutholesontheheightofcutrod

(Figure10).

13

Page 14

Figure10

7.Securetheadjustmentwiththeclevispinandhair

pin.

2.Slidetheshaftoutofthelowerbracketholes,align

therollerwiththetopholes,andinstalltheshaft.

3.Installthescrewandnuttosecuretheassemblies.

Toadjusttherear(internal)rollers(Figure12)

Figure12

1.Internalrollers

Note:Positiontheheadoftheclevispintoward

thefrontofthedeck,ifpossible.

Note:Whenusing1inch(25mm),1-1/2inch(38

mm),oroccasionally2inch(51mm)height–of–cut,

movetheskidsandrollertothehighestholes.

AdjustingtheRollers

Note:Ifthecuttingunitistobeusedinthe1or1-1/2

in.(25or38mm)height-of-cutsetting,thecuttingunit

rollersmustberepositionedinthetopbracketholes.

Toadjustthefrontrollers(

1.Removethescrewandnutsecuringtherollershaft

tothedeckbracket.

Figure11).

AdjustingtheSkids

Theskidsshouldbemountedinthelowerposition

whenoperatinginheightofcutsgreaterthan2-1/2

inches(64mm)andinthehigherpositionwhen

operatinginheightofcutslowerthan2-1/2inches(64

mm).

Adjusttheskidsbyremovingtheangeboltandnuts,

positioningthemasdesired,andinstallingthefasteners

Figure13).

(

Figure13

1.Skid

Figure11

1.Roller

2.Rollershaft

14

Page 15

AdjustingtheAnti-Scalp

G008961

1

2

3

4

Rollers

Wheneveryouchangetheheight-of-cut,itis

recommendedtoadjusttheheightoftheanti-scalp

rollers.

1.Afteradjustingtheheight-of-cut,adjusttherollers

byremovingtheangenut,bushing,spacer,and

Figure14).

bolt(

Figure14

1.Anti-scalproller4.FlangeNut

2.Spacer

3.Bushing

5.Bolt

Figure15

1.Unlocklever

2.Rotatethecamlockto

increaseordecrease

lockingpressure

3.Positionthebafe

4.Locklever

PositioningtheFlowBafe

Thefollowingguresareonlyrecommendationsfor

use.Adjustmentswillvarybygrasstype,moisture

content,andheightofgrass.

Note:Iftheenginepowerdrawsdownandthemower

groundspeedisthesame,openupthebafe.

PositionA

2.Selectaholesotheanti-scalprollerispositionedto

thenearestcorrespondingheight-of-cutdesired.

3.Installtheangenut,bushing,spacer,andbolt.

Torqueto40-45ft-lb(54-61N-m)(Figure14).

AdjustingtheFlowBafe

Themowerdischargeowcanbeadjustedfordifferent

typesofmowingconditions.Positionthecamlocks

andbafetogivethebestqualityofcut.

1.Toadjustthecamlocks,swingtheleverupto

loosenthecamlock(Figure15).

2.Adjustthebafeandcamlocksintheslotstothe

desireddischargeow .

3.Swingtheleverbackovertotightenthebafeand

camlocks(Figure15).

4.Ifthecamlocksdonotlockthebafeintoplace

oritistootight,loosentheleverandthenrotate

thecamlock.Adjustthecamlockuntilthedesired

lockingpressureisachieved.

Thisisthefullrearposition.Thesuggesteduseforthis

positionisafollows.

•Useforshort,lightgrassmowingconditions.

•Useindryconditions.

•Forsmallergrassclippings.

•Propelsgrassclippingsfartherawayfromthe

mower.

Figure16

PositionB

Usethispositionwhenbagging.Alwaysalignitwith

thebloweropening.

15

Page 16

Figure17

PositionC

Thisisthefullopenposition.Thesuggestedusefor

thispositionisasfollows.

•Useintall,densegrassmowingconditions.

•Useinwetconditions.

•Lowerstheenginepowerconsumption.

•Allowsincreasedgroundspeedinheavyconditions.

6.Loosenthejamnutsonthebottomofthe

height-of-cutrods(

1.Height-of-cut

7.Rotatetheheight-of-cutrodstoraiseorlowerthe

rearofthecuttingunitandattainthecorrectcutting

unitpitch.

8.Tightenthejamnuts.

Figure19).

Figure19

2.Jamnut

Figure18

AdjustingtheCuttingUnit

Pitch

Cuttingunitpitchisthedifferenceinheight-of-cut

fromthefrontofthebladeplanetothebackofthe

bladeplane.Tororecommendsabladepitchof1/4in.

(6mm).Thatisthebackofthebladeplaneis1/4in.(6

mm)higherthanthefront.

1.Positionthemachineonalevelsurfaceontheshop

oor.

2.Setthecuttingunittothedesiredheight-of-cut.

3.Rotate1bladesothatitpointsstraightforward.

4.Usingashortruler,measurefromtheoortothe

fronttipoftheblade.Rotatethebladetiptotherear

andmeasurefromtheoortothetipoftheblade.

5.Subtractthefrontdimensionfromtherear

dimensiontocalculatethebladepitch.

CorrectingCuttingUnit

Mismatch

Duetodifferencesingrassconditionsandthe

counterbalancesettingofthetractionunit,itisadvised

thatgrassbecutandappearancecheckedbeforeformal

cuttingisstarted.

1.Setthecuttingunittothedesiredheightofcut;

refertoAdjustingtheHeightofCut.

2.Checkandadjustfrontandreartractortirepressure

to20psi(138kPa).

3.Checkandadjustallcastortirepressuresto50psi

(345kPa).

4.Checkforbentblades;refertoCheckingforaBent

Blade.

5.Cutgrassinatestareatodetermineifallcutting

unitsarecuttingatthesameheight.

6.Ifcuttingunitadjustmentsarestillneeded,ndaat

surfaceusinga6foot(2m)orlongerstraightedge.

7.Toeasemeasuringbladeplane,raisetheheightof

cuttothehighestposition;refertoAdjustingthe

HeightofCut.

8.Lowerthecuttingunitontotheatsurface.Remove

thecoversfromthetopofthecuttingunits.

9.Rotatethebladeoneachspindleuntiltheendsface

forwardandbackward.

10.Measurefromtheoortothefronttipofthe

cuttingedge.

16

Page 17

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

orotherreasons,mowrstwiththeheight-of-cutata

highlevel;thenmowagain2–3dayslaterwithalower

heightsetting.

DANGER

Withoutagrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthe

mowerbecausethegrassdeectorroutes

materialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovethepowertakeoff

(bladecontrolswitch(PTO)totheoffposition,

rotatetheignitionkeytooffandremovethekey .

•Makesurethegrassdeectorisinthedown

position.

AlwaysMowwithSharpBlades

Asharpbladecutscleanlyandwithouttearingor

shreddingthegrassbladeslikeadullblade.Tearingand

shreddingcausesthegrasstoturnbrownattheedges

whichimpairsgrowthandincreasessusceptibilityto

diseases.

AfterOperating

Toensureoptimumperformance,cleantheunderside

ofthemowerhousingaftereachuse.Ifresidueis

allowedtobuildupinthemowerhousing,cutting

performancewilldecrease.

CuttingUnitPitch

Werecommendabladepitchof1/4in.(6mm).A

pitchlargerthan1/4in.(6mm)willresultinlesspower

required,largerclippings,andapoorerqualityofcut.A

pitchlessthan1/4in.(6mm)willresultinmorepower

required,smallerclippingsandabetterqualityofcut.

OperatingTips

MowWhenGrassisDry

Moweitherinthelatemorningtoavoidthedew ,which

causesgrassclumping,orinlateafternoontoavoidthe

damagethatcanbecausedbydirectsunlightonthe

sensitive,freshlymowedgrass.

SelecttheProperHeight-of-CutSetting

toSuitConditions

Removeapproximately1in.(25mm)ornomorethan

1/3ofthegrassbladewhencutting.Inexceptionally

lushanddensegrass,youmayhavetoraisethe

height-of-cuttothenextsetting.

MowatProperIntervals

Undermostnormalconditionsyouwillneedtomow

approximatelyevery4–5days.Butremember,grass

growsatdifferentratesatdifferenttimes.Thismeans

thatinordertomaintainthesameheight-of-cut,which

isagoodpractice,youwillneedtocutmorefrequently

inearlyspring;asthegrassgrowthrateslowsinmid

summer,cutonlyevery8–10days.Ifyouareunableto

mowforanextendedperiodduetoweatherconditions

17

Page 18

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Aftertherst10hours

Beforeeachuseordaily

Every50hours

Every400hours

MaintenanceProcedure

•Tightenthecastorwheelnuts

•Tightenthecastorwheelnuts

•Torquethebladebolts

•Lubricatethecastorarmbushings

•Lubricatethecastorwheelbearings

•Checktheblades

•Checkthegearboxlubricant

•Lubricatethegreasettings

•Tightenthecastorwheelnuts

•Torquethebladebolts

•Checkthebladedrivebeltadjustment

•Cleanunderthecuttingunitbeltcovers

•Changethegearboxlubricant

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentallystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionswitchbeforeyoudoanymaintenance.

18

Page 19

Lubrication

ServiceInterval:Every50hours

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBase

Grease.Ifthemachineisoperatedundernormal

conditions,lubricateallbearingsandbushingsafter

every50hoursofoperationorimmediatelyafterevery

washing.

1.Lubricatethefollowingareas:

•Castorforkshaftbushings(2)(

Figure20

•Spindleshaftbearings(3)(locatedunderthe

pulley)(Figure21)

Figure22

Figure20)

•Liftarmpivots,rear(2)(Figure23)

Figure23

2.Positionthemachineandcuttingunitonalevel

surfaceandlowerthecuttingunit.Removethe

dipstick/llplugfromthetopofthegearbox

(Figure24)andmakesurethatthelubricantis

betweenthemarksonthedipstick.Ifthelubricant

levelislow ,addSAE80-90wt.gearlubeuntilthe

levelisbetweenthemarks.Thegearboxcapacity

is12oz.(283ml).

Figure21

•Idlerarmshaftbearings(Figure21)

•Liftarmpivots,front(2)(Figure22)

19

Page 20

Figure24

1.Dipstick/llplug

PreMaintenance

Important:Thefastenersonthecoversofthis

machinearedesignedtoremainonthecoverafter

removal.Loosenallofthefastenersoneachcovera

fewturnssothatthecoverisloosebutstillattached,

thengobackandloosenthemuntilthecover

comesfree.Thiswillpreventyoufromaccidentally

strippingtheboltsfreeoftheretainers.

3.Removethehairpinandclevispinsecuringthe

heightofcutcollartotheheightofcutrodonthe

rearofthecuttingunit(Figure25).Removethe

heightofcutcollar.

4.Removethehairpincottersandclevispinssecuring

theliftarmstothecastorarmbrackets(

Figure26

1.Liftarm

2.Clevispin4.Castorarmbracket

3.Hairpincotter

5.Rollthecuttingunitawayfromthetractionunit,

separatingthemaleandfemalesectionsofthePTO

shaft(Figure27).

Figure26).

SeparatingtheCuttingUnit

fromtheTractionUnit

1.Positionthemachineonlevelsurface,lowerthe

cuttingunittotheoor,movetheliftlevertothe

Floatposition,shuttheengineoff,andengagethe

parkingbrake.

2.Removetheboltandwashermountedtothetopof

eachheightofcutrod(Figure25).

Figure25

1.Height-of-cutrod3.Height-of-cutcollar

2.Boltandwasher4.Hairpincotterandclevis

pin

Figure27

1.PTOshaft

DANGER

IftheengineisstartedandthePTOshaftis

allowedtorotate,seriousinjurycouldresult.

DonotstarttheengineandengagethePTO

leverwhenthePTOshaftisnotconnectedto

thegearboxonthecuttingunit.

20

Page 21

MountingtheCuttingUnitto

theTractionUnit

1.Positionthemachineonalevelsurfaceandshutthe

engineoff.

2.Movethecuttingunitintopositioninfrontofthe

tractionunit.

3.SlidethemalePTOshaftintothefemalePTOshaft

Figure27).

(

4.MovetheliftlevertotheFloatposition.Pushalift

armdownuntiltheholesintheliftarmlineupwith

theholesinthecastorarmbracketandtheheight

ofcutrodcanbeinsertedintotheliftarmpads

Figure28).

(

thethrustwashersbetweentheliftarmandthe

castorarmbracket(Figure28).Insertendofcotter

pinintotheslotinthecastorarmtabtoretaincotter

pin.

6.Repeattheprocedureontheoppositeliftarm.

7.Startthetractionunitandraisethecuttingunit.

8.Pushdownontherearofthecuttingunitandinsert

theheightofcutrodsthroughtheliftarmpads.

9.Installtheheightofcutcollarsontotheheightof

cutrodsandsecurewiththeclevispinsandhair

pincotters(

Figure28).Headofclevispintobe

positionedtowardthefrontofthedeck.

10.Installa1/2x3/4inchboltandawashertotopof

eachheightofcutrod(

Figure28).

ServicingtheBushingsinthe

CastorArms

Thecastorarmshavebushingspressedintothetopand

bottomofthetubeandaftermanyhoursofoperation,

thebushingswillwear.Tocheckthebushings,movethe

castorforkbackandforthandfromsidetoside.Ifthe

castorspindleislooseinsidethebushings,thebushings

arewornandmustbereplaced.

Figure28

1.Liftarm

2.Castorarmbracket8.Height-of-cutcollar

3.Height-of-cutrod9.Clevispin

4.Liftarmpads

5.Thrustwashers11.Bolt

6.Clevispin

7.Hairpincotter

10.Hairpincotter

5.Securetheliftarmtothecastorarmwith(2)thrust

washers,aclevispinandahairpincotter.Position

1.Raisethecuttingunitsothatthewheelsareoffof

theoor.Blockthecuttingunitsothatitcannot

accidentallyfall.

2.Removethetensioningcap,spacer(s),andthrust

washerfromthetopofthecastorspindle.

3.Pullthecastorspindleoutofthemountingtube.

Allowthethrustwasherandspacer(s)toremainon

thebottomofthespindle.

4.Insertapinpunchintothetoporbottomofthe

mountingtubeanddrivethebushingoutofthetube

Figure29).Alsodrivetheotherbushingoutofthe

(

tube.Cleantheinsideofthetubestoremovedirt.

Figure29

1.Castorarmtube

2.Bushings

21

Page 22

5.Applygreasetotheinsideandoutsideofthenew

G010549

bushings.Usingahammerandatplate,drivethe

bushingsintothemountingtube.

6.Inspectthecastorspindleforwearandreplaceitif

damaged.

7.Pushthecastorspindlethroughthebushingsand

mountingtube.Slidethethrustwasherandspacer(s)

ontothespindle.Installthetensioningcaponthe

castorspindletoretainallpartsinplace.

ServicingtheCastorWheels

andBearings

CheckingforaBentBlade

1.Positionthemachineonalevelsurface.Raisethe

cuttingunit,engagetheparkingbrake,putthe

tractionpedalinneutral,putthePTOleverin

theOffposition,stoptheengine,andremovethe

ignitionkey .Blockthecuttingunittopreventitfrom

accidentallyfalling.

2.Rotatethebladeuntiltheendsfaceforwardand

backward.Measurefromtheinsideofthecutting

unittothecuttingedgeatthefrontoftheblade

(Figure31),andrememberthisdimension.

1.Removethelocknutfromtheboltholdingthecastor

wheelassemblybetweenthecastorfork(Figure30).

Graspthecastorwheelandslidetheboltoutofthe

forkorpivotarm.

Figure30

1.Castorwheel3.Bearing(2)

2.Castorfork

2.Removethebearingfromthewheelhubandallow

thebearingspacertofallout(Figure30).Remove

thebearingfromtheoppositesideofthewheelhub.

4.Bearingspacer

Figure31

3.Rotatetheoppositeendofthebladeforward.

Measurebetweenthecuttingunitandcuttingedge

ofthebladeatthesamepositionasinstep

differencebetweenthedimensionsobtainedinsteps

2and3mustnotexceed1/8inch(3mm).Ifthe

dimensionexceeds1/8inch(3mm),replacethe

bladebecauseitisbent;refertoRemovingthe

CuttingBlade.

2The

RemovingandInstallingthe

Blade(s)

Theblademustbereplacedifasolidobjectishit,the

bladeisout-of-balance,worn,orbent.Alwaysuse

genuineTororeplacementbladestoensuresafetyand

optimumperformance.Neverusebladesmadebyother

manufacturersbecausetheycouldbedangerous.

1.Raisethecuttingunittothehighestposition,engage

theparkingbrake,stoptheengine,andremovethe

ignitionkey .Blockthecuttingunittopreventitfrom

accidentallyfalling.

3.Checkthebearings,spacer,andinsideofthewheel

hubforwear.Replaceanydamagedparts.

4.Toassemblethecastorwheel,pushthebearinginto

thewheelhub.Wheninstallingthebearings,press

ontheouterraceofthebearing.

5.Slidethebearingspacerintothewheelhub.Pushthe

otherbearingintotheopenendofthewheelhubto

captivatethebearingspacerinsidethewheelhub.

6.Installthecastorwheelassemblybetweenthecastor

forkandsecureitinplacewiththeboltandlocknut.

2.Grasptheendofthebladeusingaragorthickly

paddedglove.Removethebladebolt,anti-scalpcup,

andbladefromthespindleshaft(

22

Figure32).

Page 23

G010555

1

2

Figure32

1.Bladebolt2.Anti-scalpcup

3.Installtheblade-sailfacingtowardthecutting

unit-withtheanti-scalpcupandbladebolt.Tighten

thebladeboltto85-110ft-lb(115-149N-m).

Important:Thecurvedpartoftheblademust

bepointingtowardtheinsideofthecuttingunit

toensurepropercutting.

cuttingedgesaresharp.Thecuttingedgeoftheblade

mustbesharpsothatthegrassiscutratherthantorn.

Adullcuttingedgeisevidentwhenthetipsofthegrass

appearbrownandshredded.Sharpenthecuttingedges

tocorrectthiscondition.

1.Positionthemachineonalevelsurface.Raisethe

cuttingunit,engagetheparkingbrake,putthe

tractionpedalinneutral,putthePTOleverin

theOffposition,stoptheengine,andremovethe

ignitionkey .

2.Examinethecuttingendsofthebladecarefully,

especiallywheretheatandcurvedpartsofthe

blademeet(

Figure33).Sincesandandabrasive

materialcanwearawaythemetalthatconnects

theatandcurvedpartsoftheblade,checkthe

bladebeforeusingthemachine.Ifwearisnoticed

Figure33),replacetheblade;refertoRemovingthe

(

CuttingBlade.

InspectingandSharpeningthe

Blade(s)

ServiceInterval:Beforeeachuseordaily

Every50hours

DANGER

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator’s

orbystander’sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Donottrytostraightenabladethatisbent.

•Neverweldabrokenorcrackedblade.

•Replaceawornordamagedbladewitha

newT orobladetoensurecontinuedsafety

certicationoftheproduct.

Twoareasmustbeconsideredwhencheckingand

servicingthecuttingblade:thesailandthecuttingedge.

Bothcuttingedgesandthesail,whichistheturnedup

portionoppositethecuttingedge,contributetoagood

quality-of-cut.Thesailisimportantbecauseitpullsgrass

upstraight,therebyproducinganevencut.However,

thesailwillgraduallyweardownduringoperation,and

thisconditionisnormal.Asthesailwearsdown,the

quality-of-cutwilldegradesomewhat,althoughthe

Figure33

1.Cuttingedge3.Wear/slotforming

2.Curvedarea/sail4.Crack

WARNING

Ifthebladeisallowedtowear,aslotwillform

betweenthesailandatpartoftheblade

(Figure33).Eventually,apieceoftheblademay

breakoffandbethrownfromunderthehousing,

possiblyresultinginseriousinjurytoyourself

orbystanders.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedbladewitha

newTorobladetoensurecontinuedsafety

certicationoftheproduct.

3.Examinethecuttingedgesofallblades.Sharpenthe

cuttingedgesiftheyaredullornicked.Sharpenonly

thetopsideofthecuttingedgeandmaintainthe

originalcuttingangletoensuresharpness(

Thebladewillremainbalancedifthesameamount

ofmetalisremovedfrombothcuttingedges.

Figure34).

23

Page 24

1.Sharpenatoriginalangle

Figure34

Continuetocheckthealignmentofthebladesand

addshimsuntilthetipsofthebladesarewithinthe

requireddimension.

Important:Donotusemorethanthreeshimsat

anyoneholelocation.Usedecreasingnumbers

ofshimsinadjacentholesifmorethanoneshim

isaddedtoanyoneholelocation.

7.Installthebeltcovers.

Note:Removethebladesandsharpenthemona

grinder;refertoRemovingtheCuttingBlades.After

sharpeningthecuttingedges,installthebladewith

theanti-scalpcupandbladebolt.Thebladesails

mustbeontopoftheblade.Tightenthebladebolt

to85-110ft-lb(115-149N-m).

CheckingandCorrecting

MismatchofBlades

Ifthereismismatchbetweentheblades,thegrasswill

appearstreakedwhenitiscut.Thisproblemcanbe

correctedbymakingsurethatthebladesarestraightand

allofthebladesarecuttingonthesameplane.

1.Usinga3foot(1meter)longcarpenterslevel,nd

alevelsurfaceontheshopoor.

2.Raisetheheight-of-cuttothehighestposition;refer

toAdjustingtheHeight-of-Cut.

3.Lowerthecuttingunitontotheatsurface.Remove

thecoversfromthetopofthecuttingunit.

ReplacingtheDriveBelt

Thebladedrivebelt,tensionedbythespringloaded

idlerpulley,isverydurable.However,aftermanyhours

ofuse,thebeltwillshowsignsofwear.Signsofaworn

beltare:squealingwhenbeltisrotating,bladesslipping

whencuttinggrass,frayededges,burnmarksandcracks.

Replacethebeltifanyoftheseconditionsareevident.

1.Lowerthecuttingunittotheshopoor.Remove

thebeltcoversfromthetopofthecuttingunitand

setthecoversaside.

2.Usingatorquewrenchorsimilartool,movetheidler

pulley(

thebelttensionandallowthebelttobeslippedoff

thegearboxpulley(Figure36).

Figure35)awayfromthedrivebelttorelease

4.Rotatethebladesuntiltheendsfaceforwardand

backward.Measurefromtheoortothefronttipof

thecuttingedge.Rememberthisdimension.Then

rotatethesamebladesothattheoppositeendis

forward,andmeasureagain.Thedifferencebetween

thedimensionsmustnotexceed1/8inch(3mm).

Ifthedimensionexceeds1/8inch(3mm),replace

thebladebecauseitisbent.Makesuretomeasure

alloftheblades.

5.Comparethemeasurementsoftheouterbladeswith

thecenterblade.Thecenterblademustnotbemore

than3/8in.(10mm)lowerthantheouterblades.If

thecenterbladeismorethan3/8in.(10mm)lower

thantheouterblades,proceedtostep

shimsbetweenthespindlehousingandthebottom

ofthecuttingunit.

6.Removethebolts,atwashers,lockwashers,and

nutsfromtheouterspindleintheareawhere

theshimsmustbeadded.Toraiseorlowerthe

blade,addashim,PartNo.3256-24,betweenthe

spindlehousingandthebottomofthecuttingunit.

6andadd

Figure35

1.Idlerpulley

Figure36

1.Gearbox

3.Removetheoldbeltfromaroundthespindlepulleys

andidlerpulley.

24

Page 25

4.Routethenewbeltaroundthespindlepulleysand

idlerpulleyassemblyasshowninFigure37.

Figure37

1.Beltrouting

Figure38

1.Bolt

2.Spacer6.GrassDeector

3.Locknut

4.Spring8.Jhookendofspring

5.Springinstalled

7.Lendofspring,place

behinddeckedgebefore

installingbolt

5.Installthebeltcovers.

ReplacingtheGrassDeector

WARNING

Anuncovereddischargeopeningcouldallowthe

lawnmowertothrowobjectsintheoperator’sor

bystander’sdirectionandresultinseriousinjury.

Also,contactwiththebladecouldoccur.

•Neveroperatethelawnmowerunlessyouinstall

acoverplate,amulchplate,oragrasschuteand

catcher.

•Makesurethegrassdeectorisinthedown

position.

1.Removethelocknut,bolt,springandspacerholding

thedeectortothepivotbrackets(Figure38).

Removethedamagedorworngrassdeector.

2.Placethespacerandspringontograssdeector.

PlacetheLendofspringbehinddeckedge.

Note:MakesuretheLendofthespringisinstalled

behindthedeckedgebeforeinstallingtheboltas

shownin

Figure38.

3.Installtheboltandnut.PlacetheJhookendofthe

springaroundthegrassdeector(Figure38).

Important:Thegrassdeectormustbeableto

lowerdownintoposition.Liftthedeectorup

totestthatitlowersintothefulldownposition.

25

Page 26

Notes:

26

Page 27

Notes:

27

Page 28

TheT oroTotalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheToro

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

®

Companyanditsafliate,ToroWarrantyCompany,pursuant

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

CommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenance

andadjustmentsstatedinyourOperator’sManual.Failuretoperform

requiredmaintenanceandadjustmentscanbegroundsfordisallowinga

warrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligentorrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalProductoperationinclude,butarenotlimitedto,brakes

padsandlinings,clutchlinings,blades,reels,bedknives,tines,

sparkplugs,castorwheels,tires,lters,belts,andcertainsprayer

componentssuchasdiaphragms,nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,

fertilizers,water,orchemicals,etc.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damageto

seatsduetowearorabrasion,wornpaintedsurfaces,scratched

decalsorwindows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofToro.Torowill

makethenaldecisionwhethertorepairanyexistingpartorassemblyor

replaceit.T oromayuseremanufacturedpartsforwarrantyrepairs.

NoteRegardingDeepCycleBatteryWarranty:

Deepcyclebatterieshaveaspeciedtotalnumberofkilowatt-hoursthey

candeliverduringtheirlifetime.Operating,recharging,andmaintenance

techniquescanextendorreducetotalbatterylife.Asthebatteriesinthis

productareconsumed,theamountofusefulworkbetweencharging

intervalswillslowlydecreaseuntilthebatteryiscompletelywornout.

Replacementofwornoutbatteries,duetonormalconsumption,isthe

responsibilityoftheproductowner.Batteryreplacementmayberequired

duringthenormalproductwarrantyperiodatowner’sexpense.

MaintenanceisatOwner’sExpense

Enginetune-up,lubricationcleaningandpolishing,replacementof

ItemsandConditionsNotCoveredlters,coolant,andcompleting

RecommendedMaintenancearesomeofthenormalservicesT oro

productsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedT oroDistributororDealerisyoursoleremedy

underthiswarranty .

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheT oroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty .ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .

Allimpliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty .Somestatesdonotallowexclusions

ofincidentalorconsequentialdamages,orlimitationsonhowlongan

impliedwarrantylasts,sotheaboveexclusionsandlimitationsmaynot

applytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAir

ResourcesBoard(CARB).Thehourlimitationssetforthabovedonot

applytotheEmissionsControlSystemWarranty.RefertotheEngine

EmissionControlWarrantyStatementprintedinyourOperator’sManual

orcontainedintheenginemanufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor’sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany .

374-0253RevA

Loading...

Loading...