Page 1

60in,62in,and72inRotary

Mowers

FormNo.3389-362RevA

Groundsmaster

®

360Seriesand7200Series

TractionUnit

ModelNo.30353—SerialNo.315000001andUp

ModelNo.30354—SerialNo.315000001andUp

ModelNo.30456—SerialNo.315000001andUp

ModelNo.30457—SerialNo.315000001andUp

ModelNo.30481—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3389-362*A

Page 2

Mowerswithmodelnumbers30353,30457and30354

complywithallrelevantEuropeandirectives,fordetails

pleaseseetheseparateproductspecicDeclarationof

Conformity(DOC)sheet.

Figure1

Mowermodelnumber30456complieswithallrelevant

Europeandirectives,whentheCEKit,PartNo.117-9248

isinstalledonthemower.Mowermodelnumber30353

requiresCEkit30685,30457requiresCEkit30683,30354

requiresCEkit30679,30456requiresCEkit30658.

Fordetailspleaseseetheseparateproductspecic

DeclarationofConformity(DOC)sheet.

Mowermodelnumber30481doesnotcomplywithall

relevantEuropeandirectives.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Introduction

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Safety...........................................................................3

SafeOperatingPractices...........................................3

ToroRidingMowerSafety........................................4

SafetyandInstructionalDecals.................................5

Setup............................................................................7

RemovingtheExistingMower(ifapplicable)...............7

InstallingtheNewMower.........................................8

LevelingtheMower.................................................8

Operation.....................................................................9

Adjustments...........................................................9

OperatingTips......................................................12

Maintenance.................................................................13

RecommendedMaintenanceSchedule(s)......................14

DailyMaintenanceChecklist....................................14

Lubrication............................................................15

ReplacingtheBladeDriveBelts................................17

ServicingtheCuttingBlades.....................................17

CleaningUndertheMower......................................21

Storage........................................................................21

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Writethenumbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Safety

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromtheCEN

standardENISO5395:2013andANSIB71.4-2012.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Training

•ReadtheOperator'sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethisequipment.Localregulationscan

restricttheageoftheoperator.

•Neveroperatewhilepeople,especiallychildren,orpets

arenearby .

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversshouldseekandobtainprofessionaland

practicalinstruction.Suchinstructionshouldemphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊insufcientwheelgrip,especiallyonwetgrass;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrectloaddistribution.

Preparation

•Whileoperatingthemachine,alwayswearsubstantial

footwearandlongtrousers.Donotoperatethe

equipmentwhenbarefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Replacefaultysilencers/mufers.

•Ifamowerisinstalledonthemachine,beforeusingit,

alwaysvisuallyinspecttoseethattheblades,bladebolts

andcutterassemblyarenotwornordamaged.Replace

wornordamagedbladesandboltsinsetstopreserve

balance.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

Operation

•Bealert,slowdownandusecautionwhenmakingturns.

Lookbehindandtothesidebeforechangingdirections.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Operateonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutchesandshiftintoneutral.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.Toguardagainst

overturning:

–donotstoporstartsuddenlywhenonaslope;

–useslowspeedsonslopesandduringtightturns;

–stayalertforhumpsandhollowsandotherhidden

hazards;

•Watchoutfortrafcwhencrossingornearroadways.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.

3

Page 4

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition:

–disengagethepowertake-offandlowerthe

attachments;

–settheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachments,stoptheengine,and

removetheignitionkey:

–beforechecking,cleaningorworkingonthemachine;

–afterstrikingaforeignobject.Inspectthemachine

fordamageandmakerepairsbeforerestartingand

operatingtheequipment;

–ifthemachinestartstovibrateabnormally(check

immediately).

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Disengagedrivetoattachmentswhentransportingornot

inuse.

•Stoptheengineanddisengagedrivetoattachmentbefore

refueling.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuelstorage

areafreeofgrass,leaves,orexcessivegrease.

•Replacewornordamagedpartsforsafety.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Ifamowerisinstalledonthemachine,takecareas

manuallyrotatingonebladecancauseotherbladesto

rotate.

•Whenmachineistobeparked,storedorleftunattended,

lowertheattachment.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCENstandard.

•Engineexhaustcontainscarbonmonoxide,whichisan

odorless,deadlypoisonthatcankillyou.Donotrun

engineindoorsorinanenclosedarea.

•Keephands,feet,hairandlooseclothingawayfrom

attachmentdischargearea,undersideofmowerandany

movingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowtocoolbeforeattempting

tomaintain,adjust,orservice.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyesandclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Thismachineisnotdesignedorequippedforon-road

useandisa“slow-movingvehicle.”Ifyoumustcross

ortravelonapublicroad,youshouldbeawareofand

complywithlocalregulations,suchasrequiredlights,

slowmovingvehiclesigns,andreectors.

•Batterygasescanexplode.Keepcigarettes,sparksand

amesawayfrombattery.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

•UseonlyToroapprovedattachments.Warrantymaybe

voidedifusedwithunapprovedattachments.

SlopeOperation

•Donotoperateneardrop-offs,ditches,steepbanksor

water.Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,ordrowning.

•Donotoperateonslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcauseslidingand

lossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,etc.

fromtheoperatingarea.Tallgrasscanhideobstacles.

•Watchforditches,holes,rocks,dips,andrisesthatchange

theoperatingangle,asroughterraincouldoverturnthe

machine.

•Avoidsuddenstartswhenoperatinguphillbecausethe

machinemaytipbackwards.

•Alwaysavoidsuddenstartingorstoppingonaslope.If

tireslosetraction,disengagetheattachmentandproceed

slowlyofftheslope.

•Followthemanufacturer'srecommendationsforwheel

weightsorcounterweightstoimprovestability.

•Useextremecarewithallattachments.Thesecanchange

thestabilityofthemachineandcauselossofcontrol.

4

Page 5

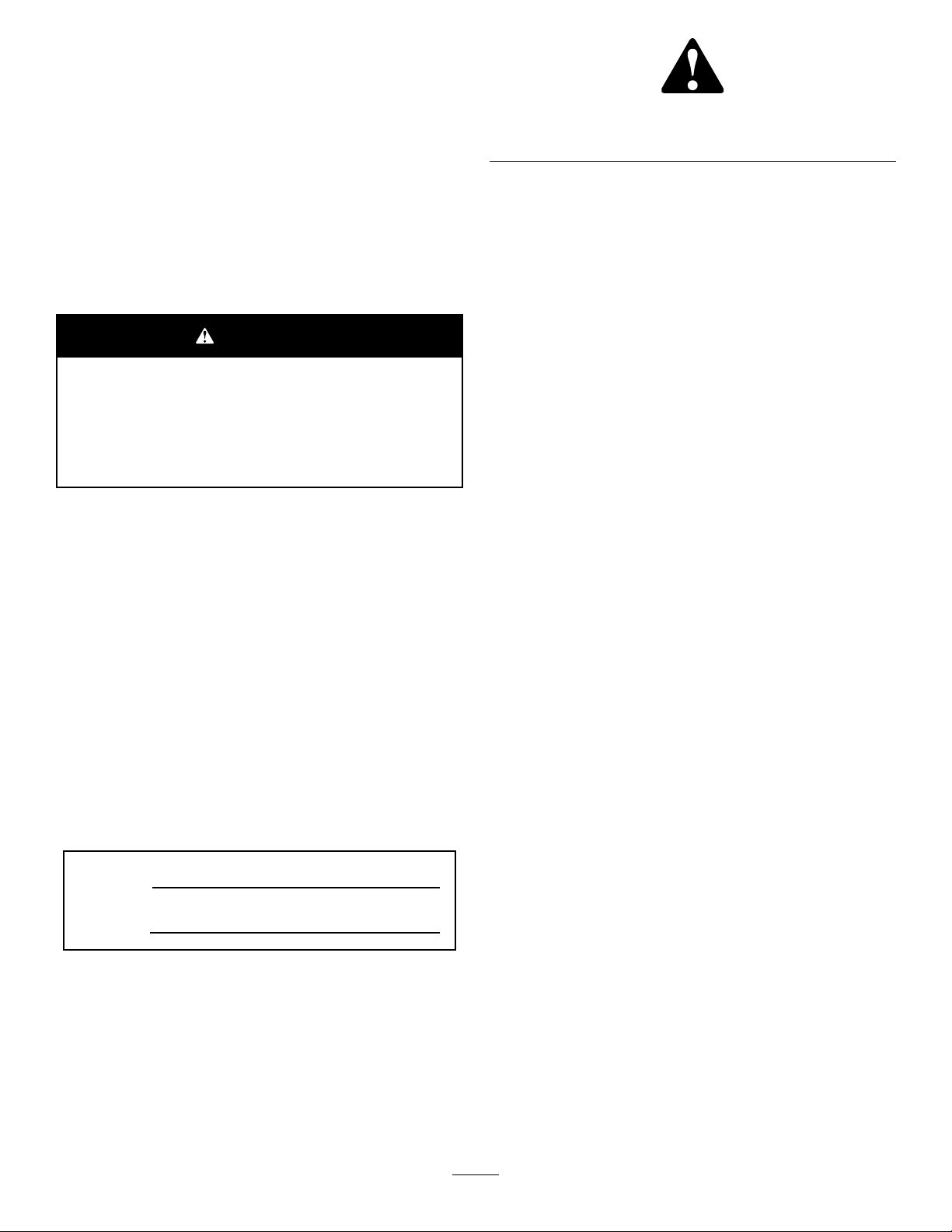

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-6697

112-1461

1.Beltrouting

107-2908

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard—donotoperatethemowerwiththe

deectoruporremoved,keepthedeectorinplace.

3.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

1.ReadtheOperator's

Manual.

1.Storedenergyhazard—readtheOperator'sManual.

1.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

2.AddSAE80w-90(API

GL-5)oilevery50hours.

93–6696

117–4979

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N-m(85-110ft-lb).

93-6687

1.Donotstephere.

5

Page 6

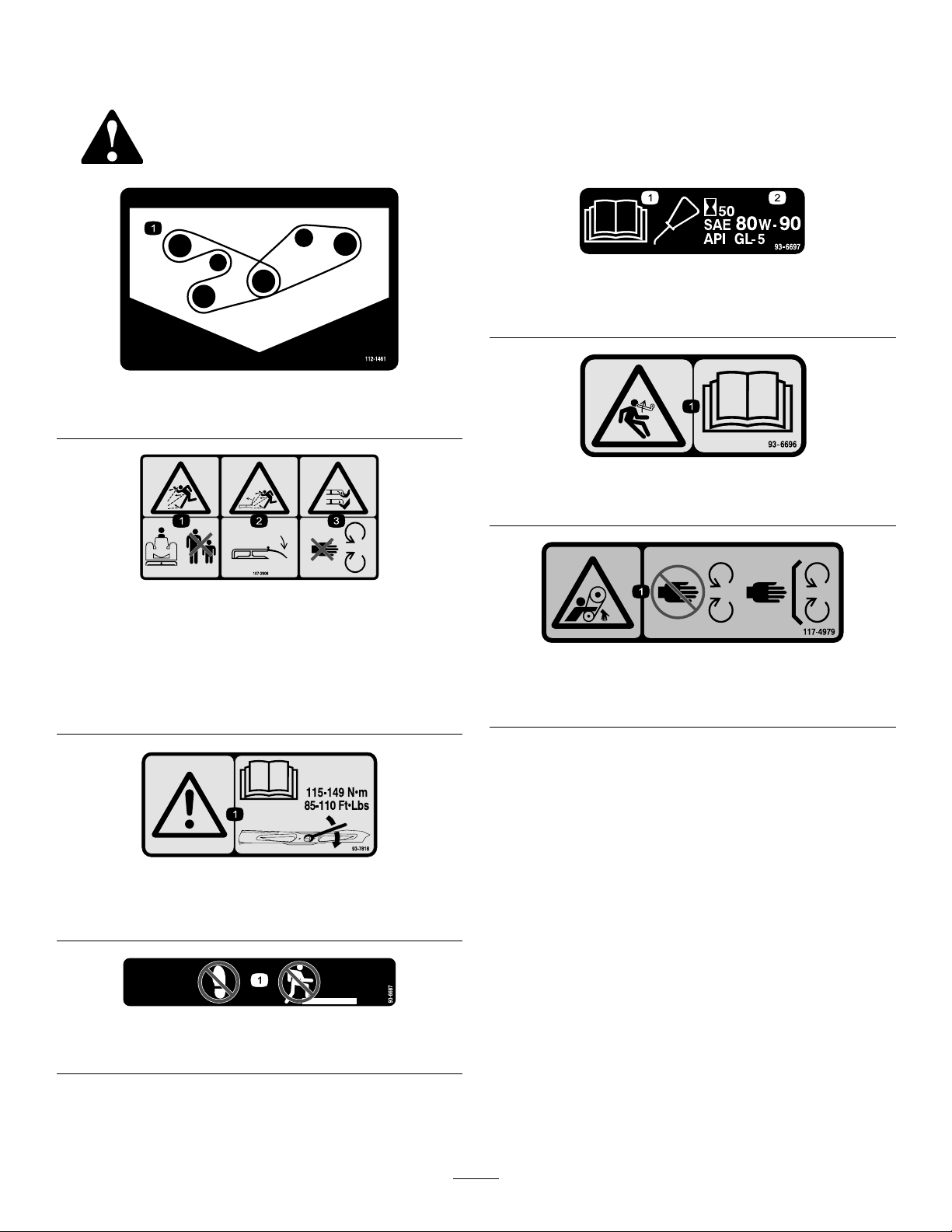

120-6604

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Cutting/dismembermenthazardofhand,mower

blade—stayawayfrommovingparts,keepallguardsand

shieldsinplace.

3.Cutting/dismembermenthazardoffoot,mowerblade—stay

awayfrommovingparts,keepallguardsandshieldsin

place.

6

Page 7

Setup

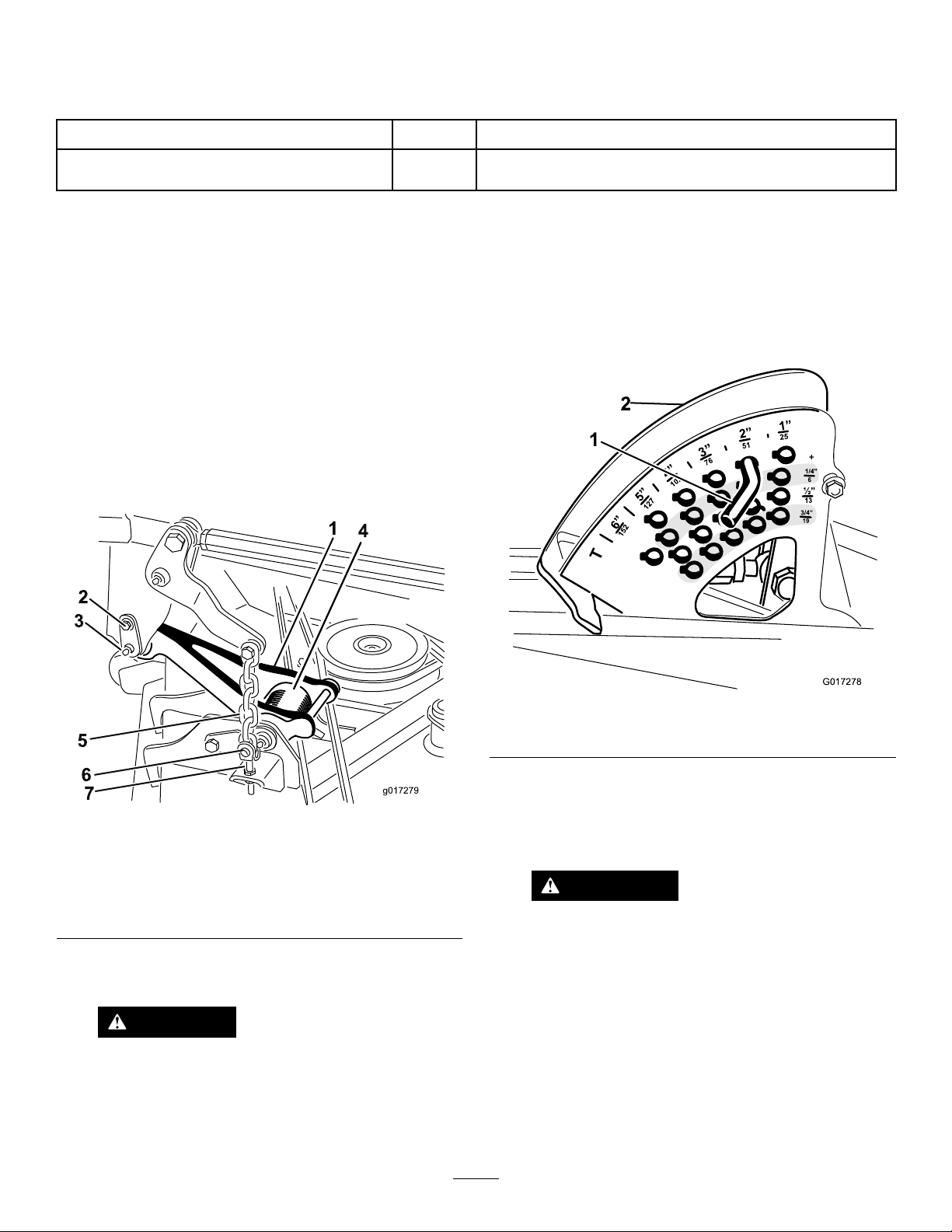

g017279

1

2

3

4

5

6

7

1

2

G017278

MediaandAdditionalParts

Description

Partscatalog1

Operator'sManual

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

RemovingtheExistingMower

(ifapplicable)

1.Parkthemachineonalevelsurfacewiththemowerin

thefullyraisedposition.Stoptheengine,engagethe

parkingbrakeandremovethekeyfromtheignition

switch.

Note:Whenthemowerisintheraisedposition,the

pulllinktorsionspringtension(Figure2)isreduced

makingitmucheasiertodisconnectthepulllinksfrom

themachine.

Qty.

Use

1

Reviewthematerialandsaveinanappropriateplace:

A.Removetheshoulderscrewthatsecuresthe

retainerpintothecarrierframe(Figure2).

B.Carefullyslidetheretainerpinfromthecarrier

frameandthepulllink(Figure2).

3.NotethelocationoftheHOCpinintheHOCbracket

forassemblypurposes(Figure3).RemovetheHOC

pinfromtheHOCbracket.

Figure3

1.HOCpin2.HOCbracket

4.Starttheengineandfullylowerthemower.Stopthe

engineandremovethekeyfromtheignitionswitch.

Figure2

1.Pulllink(mowerraised)5.Mowerliftchain

2.Shoulderscrew6.Clevispin

3.Retainerpin7.Adjustmentclevis

4.T orsionspring

2.Disconnectthepulllinkfromeachsideofthemachine

(Figure2).

Note:Loweringthemowerontofurnituredollieswill

easetheremovalofthemower.

WARNING

Donotstarttheengineandengagethe

PTOswitchwhenthePTOdriveshaftis

disconnectedfromthemower.Iftheengine

isstartedandthePTOshaftisallowedto

rotate,seriouspersonalinjuryandmachine

CAUTION

Becarefulwhendisconnectingthepulllinks.

Thepulllinktorsionspringsmaycausesome

damagecouldresult.IfthePTOdriveshaftis

disconnectedfromthemower,removethefuse

F1(15amp)fromthefuseblocktoprevent

unintentionalengagementofthePTOclutch.

rotationofthepulllinksduringtheremoval

process.

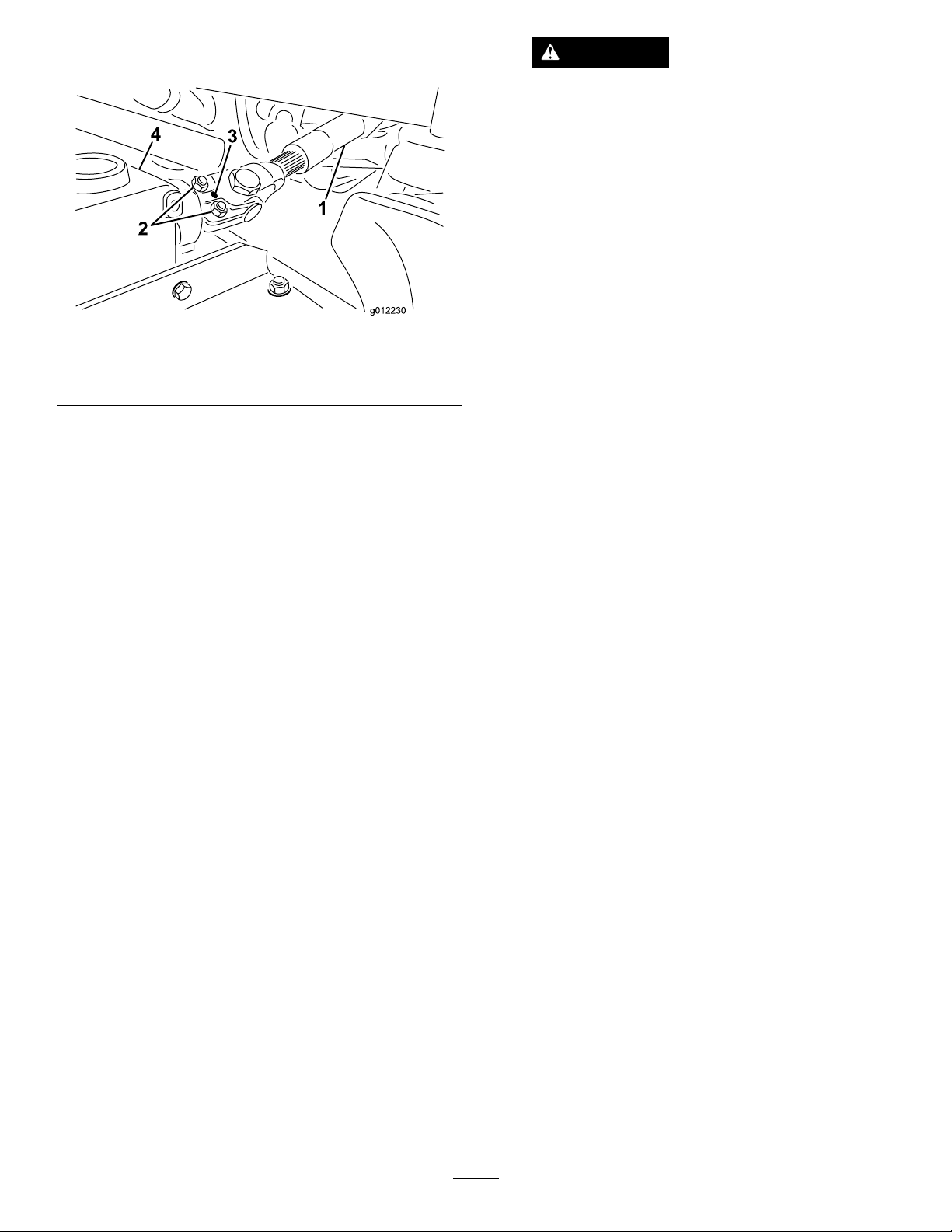

5.DisconnecttheendyokeofthePTOdriveshaftfrom

themowergearboxshaft:

7

Page 8

A.Removetherollpinfromtheendyokeandthe

gearboxshaft(Figure4).

CAUTION

Becarefulwhenconnectingthepulllinksto

themachine.Thepulllinktorsionsprings

maycausesomerotationofthepulllinks

duringinstallation.

5.Alignthepulllinktothecarrierframeandattachthe

linkwiththeretainerpin(Figure2).Securetheretainer

pintotheframewiththeshoulderscrew(Figure2).

6.InstalltheHOCpinintotheHOCbracketatthe

desiredheightofcut(Figure3).

7.LubricatethePTOdriveshaftgreasettings.

Figure4

1.Driveshaft

2.Capscrewsandlocknuts4.Gearbox

B.Loosenthe(2)capscrewsandlocknuts(Figure4).

C.Slidethedriveshaftendyokefromthegearbox

shaft.

Note:Raiseandtiethedriveshafttotheframe.

6.Removethe(4)ringpinsandclevispinsthatsecure

theliftchainstotheadjustmentclevisesonthemower

(Figure2).

7.Slidethemowerawayfromthemachine.

Note:Thefrontofthetractionunitmayhaveto

elevatedtomovethemowerawayfromthemachine.

3.Rollpin

InstallingtheNewMower

1.Slidethenewmowerunderthecarrierframeofthe

machine.

2.Installthe(4)clevispinsandringpinstosecurethe

mowerliftchainstotheadjustmentclevisesonthe

mower(Figure2).

3.ConnecttheendyokeofthePTOdriveshafttothe

mowergearbox:

A.Alignthesplineandrollpinholesofthedrive

shaftyokewiththegearboxshaft.

B.SlidethePTOdriveshaftendyokeontothe

gearboxshaft.

C.SecuretheendyokeofthePTOdriveshafttothe

gearboxshaftwiththerollpin(Figure4).

D.Tightenthelocknutstosecuretheendyoketothe

gearboxshaft(Figure4).Torquethelocknutsto

20to25N-m(175to225in-lb).

4.Starttheengineandfullyraisethemower.Stopthe

engineandremovethekeyfromtheignitionswitch.

8.InstallthefuseF1(15amp)intothefuseblock.

LevelingtheMower

LevelingSidetoSide

1.Positionthemachineonalevelsurfaceontheshop

oor.

2.MovethethrottlelevertotheSlowposition,stopthe

engine,settheparkingbrake,andremovetheignition

key.

3.Setthemowertothe127mm(5inch)heightofcut

setting.

4.Checkandadjustfrontandreartractionunittire

pressure;refertoOperator’sManualforspecications.

5.Checkforbentblades;RefertoCheckingforBent

Blades.

6.Rotatethebladeoneachspindleuntiltheendsface

forwardandbackward.

7.Measurefromtheoortothefronttipofthecutting

edge.

8.Adjustthejamnutssecuringthemoweryokes/chains

tothemoweruntilthemowerislevel(Figure5).

Note:Placeawoodblockorsimilarshimundereach

linktoholditintheraisedposition.

8

Page 9

Figure5

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Adjustments

AdjustingtheHeight-of-Cut

Theheight-of-cutisadjustedfrom2.5to15.8cm(1to

6inches)in6mm(1/4inch)incrementsbyrelocatingthe

stoppinintodifferentholelocations.

1.Withtheenginerunning,pushbackonthemowerlift

switchuntilthemowerisfullyraisedandreleasethe

switchimmediately(Figure6).

1.Chain

2.Y oke4.Mower

3.Jamnut

LevelingFronttoBack

Cuttingunitpitchisthedifferenceinheight-of-cutfromthe

frontofthebladeplanetothebackofthebladeplane.Toro

recommendsabladepitchofapproximately8to11mm

(5/16to7/16inch).Thatisthebackofthebladeplaneis8

to11mm(5/16to7/16inch)higherthanthefront.

1.Positionthemachineonalevelsurfaceontheshop

oor.

2.Setthemowertothedesiredheight-of-cut,movethe

throttlelevertotheSlowposition,stoptheengine,set

theparkingbrake,andremovetheignitionkey.

3.Rotatethecenterbladesothatitpointsstraight

forward.

4.Usingashortruler,measurefromtheoortothefront

tipoftheblade.

5.Rotatethesamebladetiptotherearandmeasurefrom

theoortothetipofthebladeattherearofthemower.

6.Subtractthefrontdimensionfromthereardimension

tocalculatethebladepitch.

7.Adjustthejamnutssecuringtherearmower

yokes/chains(Figure5)toraisetherearofthemower

sothatthebladepitchissetto8to11mm(5/16to

7/16inch).

Figure6

1.Stoppin

2.Toadjust,rotatethestoppinuntilthenubonitlinesup

withtheslotsintheholesintheheight-of-cutbracket

andremoveit(Figure6).

3.Selectaholeintheheight-of-cutbracketcorresponding

totheheight-of-cutdesired,insertthepin,androtateit

downtolockitinplace(Figure6).

Note:Therearefourrowsofholepositions(Figure

6).Thetoprowgivesyoutheheightofcutlistedabove

thepin.Thesecondrowdowngivesyoutheheight

listedplus6mm(1/4inch).Thethirdrowdown

givesyoutheheightlistedplus12mm(1/2inch).The

bottomrowgivesyoutheheightlistedplus18mm

(3/4inch).Forthe15.8cm(6inch)positionthereis

onlyonehole,locatedinthesecondrow .Thisdoesnot

add6mm(1/4inch)tothe15.8cm(6inch)position.

4.Adjusttheanti-scalprollersandskidsasrequired.

9

Page 10

AdjustingtheSkid(s)

Mounttheskidsinthelowerpositionwhenoperatingin

heightofcutshigherthan64mm(2-1/2inches)andinthe

higherpositionwhenoperatinginheightofcutslowerthan

64mm(2-1/2inches).

Note:OnGuardian

youcanswitchtheskidtotheoppositesidesofthemower,

ippingthemover.Thiswillallowyoutousetheskidslonger

beforereplacingthem.

1.DisengagethePTOandsettheparkingbrake.

2.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Loosenthescrewatthefrontofeachskid.Thereare2

skidsonGuardianmowersand1skidonside-discharge

mowers(Figure7).

®

mowers,whentheskidsbecomeworn,

3.Afteradjustingtheheight-of-cut,adjusttherollersby

removingtheangenut,bushing,spacer,andbolt

(Figure8).

Figure8

Figure7

1.Screw3.Skid

2.Flange-headbolt4.Nut

4.Removetheange-headboltsandnutsfromeachskid.

5.Moveeachskidtothedesiredpositionandsecurethem

withtheange-headboltsandnuts.

Note:Onlyusethetoporcentersetsofholestoadjust

theskids.Thebottomholesareusedwhenswitching

sidesonaGuardianmower,atwhichtimetheybecome

thetopholesontheothersideofthemower.

6.Torquethescrewatthefrontofeachskidto9to11

N-m(80to100in-lb).

AdjustingtheRearAnti-ScalpRollers

Wheneveryouchangetheheight-of-cut,adjusttheheight

oftherearanti-scalprollers.

1.DisengagethePTO,releasethetractionpedal,andset

theparkingbrake.

2.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

1.Flangenut

2.Bushing5.Bolt

3.Anti-scalproller

4.Spacer

4.Selectaholesotheanti-scalprollerispositionedtothe

nearestcorrespondingheight-of-cutdesired(Figure9).

Figure9

1.38mm(1-1/2inches)3.63mm(2-1/2inches)

2.51mm(2inches)4.76mm(3inches)and

higher

5.Installtheangenutbushing,spacer,andbolt.Torque

to54-61N-m(40-45ft-lb)(Figure8).

AdjustingtheRollers

Mounttherollersinthelowerpositionwhenoperatingin

heightofcutshigherthan64mm(2-1/2inches)andinthe

higherpositionwhenoperatinginheightofcutslowerthan

64mm(2-1/2inches).

1.DisengagethePTO,releasethetractionpedalandset

theparkingbrake.

10

Page 11

2.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Raisethefrontofthemachineandsupportitonjack

stands.

4.Removethefastenerssecuringeachrolleronyour

mowerandmovetherollersupordownasdesired;

refertoFigure10throughFigure14asapplicablefor

yourmower.

Figure12

GuardianMowerOnly

1.Bolt3.Nut

2.Frontunder-mowerroller4.Bracket

Figure10

AllMowers

1.Frontroller

Figure11

GuardianMowersOnly

1.Bolt4.Nut

2.Rearunder-mowerroller5.Bracket

3.Spacer

2.Rollershaft

Figure13

Side-dischargeMowersOnly

1.Bolt4.Nut

2.Chute-sideroller

3.Spacer

5.Bracket

11

Page 12

densegrass,youmayhavetoslowdowntheforwardspeed

and/orraisetheheight-of-cuttothenexthighersetting.

Important:Ifcuttingmorethan1/3ofthegrassblade

off,orinsparselonggrassordryconditions,theuse

ofatsailbladesisrecommendedtoreduceair-borne

chaff,debris,anddeckdrivecomponentstrain.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

cuttingheighthigherthanusualandcutthegrassatthis

setting.Thencutthegrassagainusingthelower,normal

setting.

Figure14

Side-dischargeMowersOnly

1.Bolt

2.Rollershaft

5.Installthefastenersasillustrated.

3.Under-mowerroller(2)

4.Bracket

OperatingTips

FastThrottleSetting/GroundSpeed

Tomaintainenoughpowerforthemachineanddeckwhile

mowing,operatetheengineatthefastthrottlepositionand

adjustyourgroundspeedforconditions.Agoodruleto

followis:decreasegroundspeedastheloadonthecutting

bladesincreases;andincreasegroundspeedasloadonthe

bladesdecreases.

MowingDirection

Alternatemowingdirectiontoavoidmakingrutsintheturf

overtime.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

KeeptheMowerClean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

Toreducetheriskofrehazard,keeptheengine,mufer,

batterycompartment,parkingbrake,cuttingunits,andfuel

storagecompartmentfreeofgrass,leaves,orexcessivegrease.

Cleanupanyspilledoilorfuel.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthebladesdailyforsharpness,andforany

wearordamage.Sharpenthebladesasnecessary.Ifabladeis

damagedorworn,replaceitimmediatelywithagenuineToro

replacementblade.RefertoServicingtheCuttingBlades.

CuttingSpeed

Toimprovecutquality,useaslowergroundspeed.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthemower

youpreviouslyused,raisethecuttingheighttoensurethat

uneventurfisnotcuttooshort.

SelecttheProperHeight-of-CutSetting

toSuitConditions

Removeapproximately1inch(25mm)ornomorethan1/3

ofthegrassbladewhencutting.Inexceptionallylushand

12

Page 13

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

WARNING

Ifyouraisethemachineusingonlyajacktosupport

itwhileyouworkunderthemowerdeck,thejack

couldtip,causingthemowerdecktofall,crushing

youorbystanders.

Alwayssecurethemachinewithatleast2jack

standswhenyouhavethemowerdeckraised.

CAUTION

Onthetopofthemowerdeckaretwolinksthat

connectthemtotheframe.Connectedtotheselinks

aretorsionspringthatareundertension(Figure

15).Ifyoudisconnectthelinkthestoredenergyin

thetorsionspringwillbereleasedandcouldcause

thelinkstomove,damagingyourhandsorngers.

Becarefulwhenremovingthemowerdeckfrom

theframeandsecurethelinksbeforedisconnecting

themfromtheframe.

Figure15

1.Link2.T orsionspring

13

Page 14

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst50hours

Beforeeachuseordaily

Every50hours

MaintenanceProcedure

•Checktheconditionofthebladedrivebeltsonthemower.

•Checkthemowerblades.

•Cleanthemower.

•Greasethebearingandbushinggreasettings.

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

CheckSafetyInterlock

Operation

CheckGrassDeectorin

DownPosition(ifapplicable)

CheckParkingBrake

Operation

CheckFuelLevel

CheckTirePressure

CheckInstrumentOperation

CheckConditionofBlades

LubricateAllGreaseFittings

Touch-upDamagedPaint

1.Immediatelyaftereverywashing,regardlessoftheintervallisted.

1

Sat.Sun.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Information

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

14

Page 15

Lubrication

GreasingtheBearingsandBushings

ServiceInterval:Every50hours

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBaseGrease.

Ifthemachineisoperatedundernormalconditions,lubricate

allbearingsandbushingsafterevery50hoursofoperation.

Bearingsandbushingsmustbelubricateddailywhen

operatingconditionsareextremelydustyanddirty.Dusty

anddirtyoperatingconditionscouldcausedirttogetinto

thebearingsandbushings,resultinginacceleratedwear.

Lubricatethegreasettingsimmediatelyaftereverywashing,

regardlessofintervalspecied.

1.Wipethegreasettingscleansoforeignmattercannot

beforcedintothebearingorbushing.

2.Pumpgreaseintothettings.

3.Wipeoffexcessgrease.

Figure16

15

Page 16

Note:Bearinglifecanbenegativelyaffectedbyimproper

washdownprocedures.Donotwashdowntheunitwhenit

isstillhotandavoiddirectinghigh-pressureorhighvolume

sprayatthebearingsorseals.

Figure17

16

Page 17

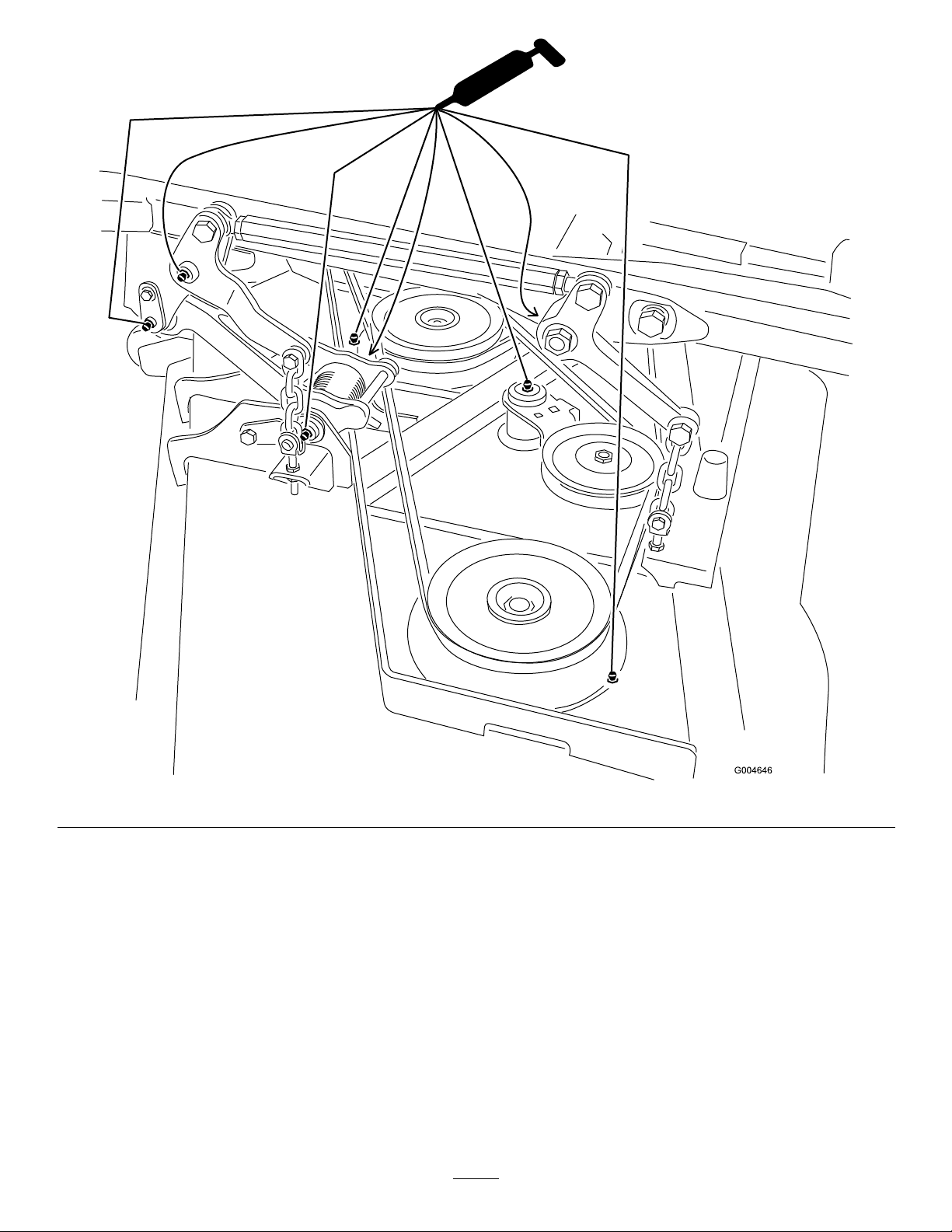

ReplacingtheBladeDrive

DANGER

Belts

ServiceInterval:Aftertherst50hours

Thebladedrivebelts,tensionedbythespringloadedidler

pulleys,areverydurable.However,aftermanyhoursofuse,

thebeltswillshowsignsofwear.Signsofawornbeltare:

squealingwhenbeltisrotating,bladesslippingwhencutting

grass,poorqualityofcut,frayededges,burnmarksand

cracks.Replacethebeltsifanyoftheseconditionsareevident.

1.Lowerthecuttingunittothe1inchheightofcut

setting,movethethrottlelevertotheSlowposition,

stoptheengine,settheparkingbrake,andremovethe

ignitionkey .

2.Removethebeltcoversfromthetopofthecuttingunit

andsetthecoversaside.

3.Usingabreakerbarorsimilartool,movetheidler

pulleyforthetopbelt(Figure18)awayfromthetop

drivebelttoreleasethebelttensionandallowthebelt

tobeslippedoffthepulleys.

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

Inspectandcheckthebladesevery8hours.

BeforeInspectingorServicingthe

Blades

1.DisengagethePTO,releasethetractionpedalandset

theparkingbrake.

2.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

Figure18

1.T opbelt3.Bottombelt

2.T opidlerpulley4.Bottomidlerpulley

4.Routeanewbeltaroundthegearboxpulley,bottom

spindlepulleys,andidlerpulleyassemblyasshownin

Figure18.

5.Routeanewbeltaroundthetopspindlepulleysand

idlerpulleyassemblyasshowninFigure18.

6.Greaseallmowerandmowerdrivegreasepoints.

7.Installthebeltcovers.

ServicingtheCuttingBlades

Maintainsharpbladesthroughoutthecuttingseasonbecause

sharpbladescutcleanlywithouttearingorshreddingthegrass

blades.Tearingandshreddingturnsgrassbrownattheedges,

whichslowsgrowthandincreasesthechanceofdisease.

1.Inspectthecuttingedges(Figure19).Iftheedges

arenotsharporhavenicks,removeandsharpenthe

blades.RefertoSharpeningtheBlades.

2.Inspecttheblades,especiallythesailarea(Figure19).

Ifyounoticeanydamage,wear,oraslotformingin

thisarea(Figure19),immediatelyinstallanewblade.

DANGER

Ifyouallowthebladetowear,aslotwillform

betweenthesailandatpartoftheblade.

Eventuallyapieceoftheblademaybreak

offandbethrownfromunderthehousing,

possiblyresultinginseriousinjurytoyouor

bystanders.

•Inspectthebladeperiodicallyforwearor

damage.

•Nevertrytostraightenabladethatisbent

orweldabrokenorcrackedblade.

•Replaceawornordamagedblade.

Checkthebladesdailyforsharpness,andforanywear

ordamage.Sharpenthebladesasnecessary.Ifabladeis

damagedorworn,replaceitimmediatelywithagenuineToro

replacementblade.

17

Page 18

Figure20

Figure19

1.CuttingEdge3.Wear/slotForming

2.SailArea4.Crack

CheckingforBentBlades

1.DisengagethePTO,releasethetractionpedalandset

theparkingbrake.

2.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Rotatethebladesuntiltheendsfaceforwardand

backward(Figure20).Measurefromalevelsurfaceto

thecuttingedge,positionA,oftheblades(Figure20).

Notethisdimension.

1.Measureherefromblade

tohardsurface

4.Rotatetheoppositeendsofthebladesforward.

5.Measurefromalevelsurfacetothecuttingedgeof

thebladesatthesamepositionasinstep3above.

Thedifferencebetweenthedimensionsobtainedin

steps3and4mustnotexceed3mm(1/8inch).Ifthis

dimensionexceeds3mm(1/8inch),thebladeisbent

andmustbereplaced;refertoRemovingtheBlades

andInstallingtheBlades.

2.PositionA

WARNING

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplacebentordamagedblade

withanewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofblade.

RemovingtheBlades

Bladesmustbereplacedifasolidobjectishit,ifthebladeis

outofbalanceorisbent.Toensureoptimumperformance

andcontinuedsafetyconformanceofthemachine,use

genuineT ororeplacementblades.Replacementbladesmade

byothermanufacturersmayresultinnon-conformancewith

safetystandards.

WARNING

Contactwithasharpbladecancauseseriousinjury.

Wearglovesorwrapsharpedgesofthebladewith

arag.

1.Holdthebladeendusingaragorthickly-paddedglove.

18

Page 19

2.Removethebladebolt,anti-scalpplate,andbladefrom

thespindleshaft(Figure23).

SharpeningtheBlades

WARNING

Whensharpeningblade,piecesofbladecouldbe

thrownandcauseseriousinjury.

Wearpropereyeprotectionwhensharpening

blades.

1.Sharpenthecuttingedgeatbothendsoftheblade

(Figure21).Maintaintheoriginalangle.Theblade

retainsitsbalanceifthesameamountofmaterialis

removedfrombothcuttingedges.

Figure21

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure22).Ifthebladestaysinahorizontal

position,thebladeisbalancedandcanbeused.Ifthe

bladeisnotbalanced,lesomemetalofftheendof

thesailareaonly(Figure23).Repeatthisprocedure

untilthebladeisbalanced.

Figure22

1.Blade2.Balancer

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure23).

Important:Thecurvedpartoftheblademustbe

pointingupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installtheanti-scalpplateandbladebolt(Figure23).

Figure23

1.Spindle

2.SailAreaofBlade

3.Torquethebladeboltto115-150N⋅m(85-110ft-lb).

3.Anti-scalpplate

4.BladeBolt

CorrectingMowerMismatch

Ifthecutisunevenacrossthemowerswath,correctitas

follows:

1.Positionthemachineonalevelsurfaceontheshop

oor.

2.Setthecuttingunittothedesiredheightofcut,move

thethrottlelevertotheSlowposition,stoptheengine,

settheparkingbrake,andremovetheignitionkey.

3.Checkandadjustfrontandreartractortirepressure;

refertoCheckingTirePressure.

4.Checkforbentblades.

5.Removethecoversfromthetopofthecuttingunits.

6.Rotatethebladeoneachspindleuntiltheendsface

forwardandbackward.

7.Measurefromtheoortothefronttipofthecutting

edge.

8.Adjustthejamnutssecuringthemoweryokes/chains

tothemoweruntilthemowerislevel(Figure24).

19

Page 20

Figure24

1.Frontmoweryokechain4.Y oke

2.Rearmoweryokechain5.Jamnut

3.Chain

6.Mower

AdjustingtheMowerPitch

ReplacingtheGrassDeector

WARNING

Anuncovereddischargeopeningcouldallowthe

machinetothrowobjectsintheoperator'sor

bystander'sdirectionandresultinseriousinjury.

Also,contactwiththebladecouldoccur.

•Neveroperatethemachinewithoutamulchkit

orgrassdeectorinstalled.

•Makesurethegrassdeectorisinthedown

position.

1.Lowerthecuttingunittotheshopoor,movethe

throttlelevertotheSlowposition,stoptheengine,set

theparkingbrake,andremovetheignitionkey.

2.Removethelocknut,bolt,springandspacerholding

thedeectortothepivotbrackets(Figure25).Remove

damagedorworngrassdeector.

Cuttingunitpitchisthedifferenceinheight-of-cutfromthe

frontofthebladeplanetothebackofthebladeplane.Toro

recommendsabladepitchofapproximately8mm(5/16

inch).Thatisthebackofthebladeplaneis8mm(5/16inch)

higherthanthefront.

1.Positionthemachineonalevelsurfaceontheshop

oor.

2.Setthecuttingunittothedesiredheight-of-cut,move

thethrottlelevertotheSlowposition,stoptheengine,

settheparkingbrake,andremovetheignitionkey.

3.Rotatethecenterbladesothatitpointsstraight

forward.

4.Usingashortruler,measurefromtheoortothefront

tipoftheblade.

5.Rotatethesamebladetiptotherearandmeasurefrom

theoortothetipofthebladeattherearofthemower.

6.Subtractthefrontdimensionfromthereardimension

tocalculatethebladepitch.

7.Adjustthejamnutssecuringtherearmower

yokes/chainstoraisetherearofthemowersothatthe

bladepitchissetto8mm(5/16inch)(Figure24).

Figure25

1.Bolt

2.Spacer6.GrassDeector

3.Locknut

4.Spring8.Righthandhookendof

5.Springinstalled

7.Lefthandhookendof

spring,placebehind

moweredgebefore

installingbolt

spring

3.Placethespacerandspringbetweenthereplacement

grassdeectorbrackets(Figure25).Placethelefthand

Jhookendofthespringbehindthemoweredge.

Note:MakesurethelefthandJhookendofthe

springisinstalledbehindthemoweredgebefore

installingtheboltasshowninFigure25.

4.Installtheboltandnut.PlacetherighthandJhookend

ofthespringaroundthegrassdeector(Figure25).

Important:Thegrassdeectormustbeableto

lowerdownintoposition.Liftthedeectorupto

testthatitlowersintothefulldownposition.

20

Page 21

CleaningUndertheMower

ServiceInterval:Beforeeachuseordaily

Removethegrassbuildupunderthemowerdaily.

Storage

1.Thoroughlycleanthemower,payingspecialattention

totheseareas:

1.DisengagethePTO,releasethetractionpedaltothe

neutralpositionandsettheparkingbrake.

2.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Raisethemowertothetransportposition.

4.Raisethefrontofthemachinebyusingjackstands.

5.Thoroughlycleantheundersideofthemowerwith

water.

•Underneaththemower

•Underthemowerbeltcovers

•PTOshaftassembly

•Allgreasettingsandpivotpoints

2.Checkandadjustfrontandreartirepressure;referto

CheckingTirePressure.

3.Remove,sharpen,andbalancethemowerblades.

Installthebladesandtorquethebladefastenersto

85-110ft-lb(115-149N-m).

4.Checkallfastenersforloosenessandtightenthemas

necessary.

5.Greaseoroilallgreasettingsandpivotpoints.Wipe

offanyexcesslubricant.

6.Lightlysandandusetouchuppaintonpaintedareas

thatarescratched,chippedorrusted.Repairanydents.

21

Page 22

Notes:

22

Page 23

DeclarationofIncorporation

TheT oroCompany,8111LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

30353315000001andUp72inRotaryMower

30354315000001andUp

30456315000001andUp

30457315000001andUp62inRotaryMower

30481315000001andUp

SerialNo.

ProductDescriptionInvoiceDescription

GM7200/GM36072in

BASEDECK

72inSideDischargeMowerGM720072inSDDECKCE

60inSideDischargeMowerGM720060inSDDECK

GM720062inBASEDECK

72inSideDischargeMower72inS.D.DECK(NON)C.E.

GeneralDescription

72inRotaryMower

72inRotaryMower

60inRotaryMower

62inRotaryMower

72inRotaryMower

Directive

2006/42/EC,

2000/14/EC

2006/42/EC,

2000/14/EC

2006/42/EC,

2000/14/EC

2006/42/EC,

2000/14/EC

2006/42/EC,

2000/14/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:EUTechnicalContact:

PeterT etteroo

ToroEuropeNV

B-2260Oevel-Westerloo

Belgium

DavidKlisTel.003214562960

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

September26,2013

Fax003214581911

23

Page 24

ToroGeneralCommercialProductWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.Torowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EPA)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevC

Loading...

Loading...