Page 1

72inRotaryMower

62inRotaryMower

60inRotaryMower

FormNo.3373-522RevA

Groundsmaster

®

360Seriesand7200Series

TractionUnit

ModelNo.30353—SerialNo.312000001andUp

ModelNo.30354—SerialNo.312000001andUp

ModelNo.30456—SerialNo.312000001andUp

ModelNo.30457—SerialNo.312000001andUp

ModelNo.30481—SerialNo.312000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Mowerswithmodelnumbers30353,30457and

30354complywithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecic

Introduction

DeclarationofConformity(DOC)sheet.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactT orodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndingadealer,

ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorT oroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Writethe

numbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure1

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Mowermodelnumber30456complieswithall

relevantEuropeandirectives,whentheCEKit,Part

No.117-9248isinstalledonthemower.Fordetails

pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

Mowermodelnumber30481doesnotcomplywith

allrelevantEuropeandirectives.

Contents

Introduction.................................................................2

Safety...........................................................................3

SafeOperatingPractices.......................................3

ToroRidingMowerSafety....................................4

SafetyandInstructionalDecals.............................5

Setup...........................................................................7

RemovingtheExistingMower(if

applicable)........................................................7

InstallingtheNewMower....................................8

LevelingtheMower..............................................8

Operation.....................................................................9

Adjustments.........................................................9

OperatingTips...................................................13

Maintenance...............................................................14

RecommendedMaintenanceSchedule(s)................15

DailyMaintenanceChecklist...............................15

Lubrication.........................................................16

CheckingtheTirePressure.................................18

ReplacingtheBladeDriveBelts..........................18

ServicingtheCuttingBlades...............................18

CleaningUndertheMower.................................22

Storage.......................................................................22

©2012—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Safety

–Storefuelincontainersspecicallydesignedfor

thispurpose.

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandard

EN836:1997andANSIB71.4-2004.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Training

•ReadtheOperator'sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,

andtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethisequipment.Localregulations

canrestricttheageoftheoperator.

•Neveroperatewhilepeople,especiallychildren,or

petsarenearby.

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Donotcarrypassengers.

•Alldriversshouldseekandobtainprofessional

andpracticalinstruction.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhen

workingwithride-onmachines;

–controlofaride-onmachineslidingonaslope

willnotberegainedbytheapplicationofthe

brake.Themainreasonsforlossofcontrolare:

◊insufcientwheelgrip,especiallyonwet

grass;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrectloaddistribution.

Preparation

•Whileoperatingthemachine,alwayswearsubstantial

footwearandlongtrousers.Donotoperatethe

equipmentwhenbarefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning—fuelishighlyammable.

–Refueloutdoorsonlyanddonotsmokewhile

refueling.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltankandcontainercapssecurely.

•Replacefaultysilencers/mufers.

•Ifamowerisinstalledonthemachine,beforeusing

it,alwaysvisuallyinspecttoseethattheblades,blade

boltsandcutterassemblyarenotwornordamaged.

Replacewornordamagedbladesandboltsinsets

topreservebalance.

Operation

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Operateonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageall

bladeattachmentclutchesandshiftintoneutral.

•Rememberthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.To

guardagainstoverturning:

–donotstoporstartsuddenlywhenonaslope;

–useslowspeedsonslopesandduringtightturns;

–stayalertforhumpsandhollowsandother

hiddenhazards;

•Watchoutfortrafcwhencrossingornearroadways.

•Whenusinganyattachments,neverdirectdischarge

ofmaterialtowardbystandersnorallowanyonenear

themachinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesinplace.

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatingtheengineat

excessivespeedmayincreasethehazardofpersonal

injury.

•Beforeleavingtheoperator'sposition:

–disengagethepowertake-offandlowerthe

attachments;

3

Page 4

–settheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachments,stoptheengine,and

removetheignitionkey:

–beforechecking,cleaningorworkingonthe

machine;

–afterstrikingaforeignobject.Inspectthe

machinefordamageandmakerepairsbefore

restartingandoperatingtheequipment;

–ifthemachinestartstovibrateabnormally(check

immediately).

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Stoptheengineanddisengagedrivetoattachment

beforerefueling.

•Keephands,feet,hairandlooseclothingawayfrom

attachmentdischargearea,undersideofmowerand

anymovingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowtocoolbefore

attemptingtomaintain,adjust,orservice.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyesandclothing.Protectyour

face,eyes,andclothingwhenworkingwithabattery.

•Thismachineisnotdesignedorequippedfor

on-roaduseandisa“slow-movingvehicle.”Ifyou

mustcrossortravelonapublicroad,youshould

beawareofandcomplywithlocalregulations,such

asrequiredlights,slowmovingvehiclesigns,and

reectors.

•Batterygasescanexplode.Keepcigarettes,sparks

andamesawayfrombattery.

•UseonlygenuineTororeplacementpartstoensure

thatoriginalstandardsaremaintained.

•UseonlyToroapprovedattachments.Warrantymay

bevoidedifusedwithunapprovedattachments.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumesmayreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuel

storageareafreeofgrass,leaves,orexcessivegrease.

•Replacewornordamagedpartsforsafety.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Ifamowerisinstalledonthemachine,takecareas

manuallyrotatingonebladecancauseotherblades

torotate.

•Whenmachineistobeparked,storedorleft

unattended,lowertheattachment.

ToroRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecicto

Toroproductsorothersafetyinformationthatyoumust

knowthatisnotincludedintheCENstandard.

SlopeOperation

•Donotoperateneardrop-offs,ditches,steepbanks

orwater.Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,death,

ordrowning.

•Donotoperateonslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,

etc.fromtheoperatingarea.Tallgrasscanhide

obstacles.

•Watchforditches,holes,rocks,dips,andrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenoperatinguphillbecause

themachinemaytipbackwards.

•Alwaysavoidsuddenstartingorstoppingonaslope.

Iftireslosetraction,disengagetheattachmentand

proceedslowlyofftheslope.

•Followthemanufacturer'srecommendationsfor

wheelweightsorcounterweightstoimprovestability.

•Engineexhaustcontainscarbonmonoxide,whichis

anodorless,deadlypoisonthatcankillyou.Donot

runengineindoorsorinanenclosedarea.

•Useextremecarewithallattachments.Thesecan

changethestabilityofthemachineandcauseloss

ofcontrol.

4

Page 5

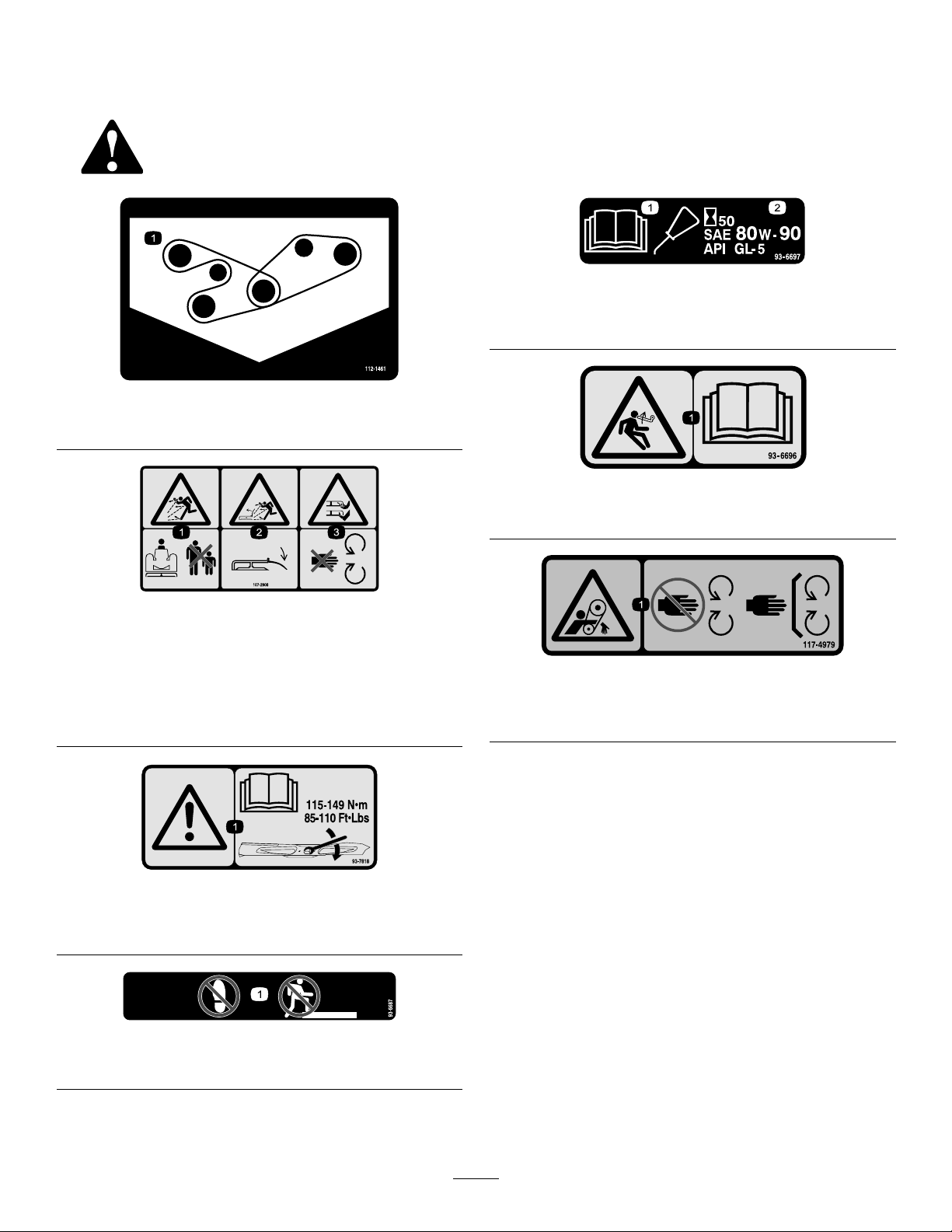

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

93-6697

112-1461

1.Beltrouting

107-2908

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard—donotoperatethemowerwiththe

deectoruporremoved,keepthedeectorinplace.

3.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

1.ReadtheOperator's

Manual.

1.Storedenergyhazard—readtheOperator'sManual.

1.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

2.AddSAE80w-90(API

GL-5)oilevery50hours.

93–6696

117–4979

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N-m(85-110ft-lb).

93-6687

1.Donotstephere.

5

Page 6

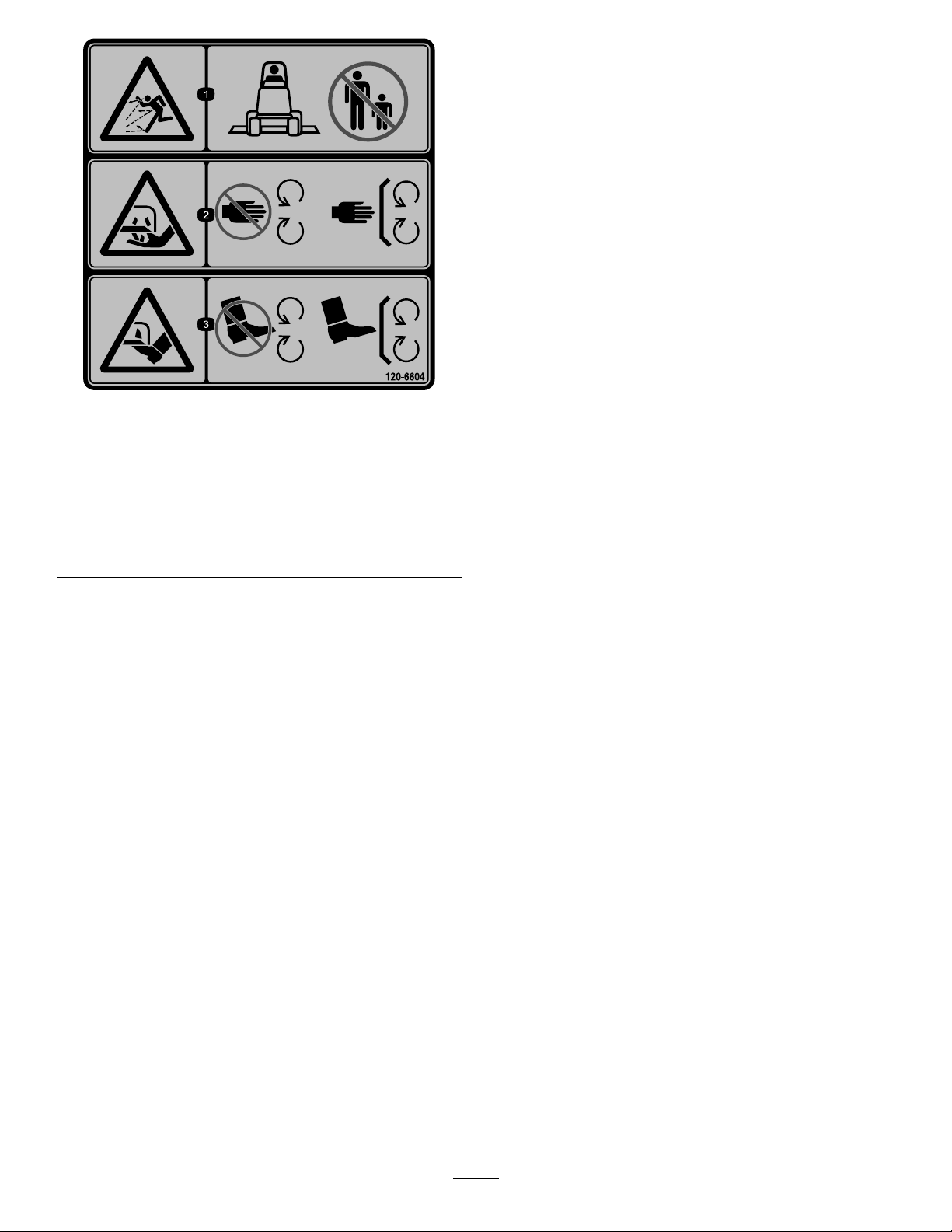

120-6604

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Cutting/dismembermenthazardofhand,mower

blade—stayawayfrommovingparts,keepallguardsand

shieldsinplace.

3.Cutting/dismembermenthazardoffoot,mowerblade—stay

awayfrommovingparts,keepallguardsandshieldsin

place.

6

Page 7

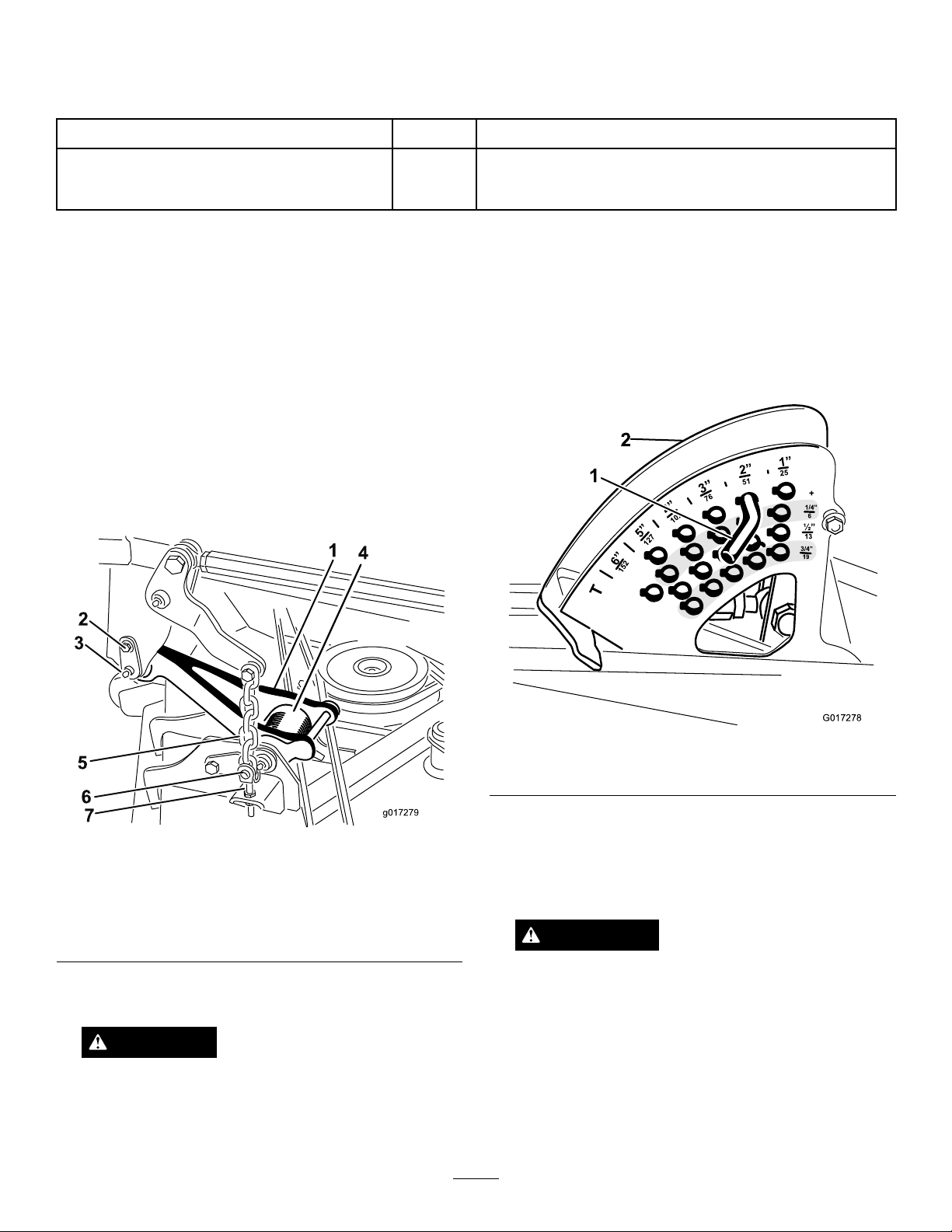

Setup

g017279

1

2

3

4

5

6

7

1

2

G017278

MediaandAdditionalParts

Description

Partscatalog1

Operator'sManual

CerticateofCompliance

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

RemovingtheExistingMower

(ifapplicable)

1.Parkthemachineonalevelsurfacewiththemower

inthefullyraisedposition.Stoptheengine,engage

theparkingbrakeandremovethekeyfromthe

ignitionswitch.

Note:Whenthemowerisintheraisedposition,the

pulllinktorsionspringtension(

makingitmucheasiertodisconnectthepulllinks

fromthemachine.

Figure2)isreduced

Qty.

Use

1

1

Reviewthematerialandsaveinanappropriateplace:

A.Removetheshoulderscrewthatsecuresthe

retainerpintothecarrierframe(

Figure2).

B.Carefullyslidetheretainerpinfromthecarrier

frameandthepulllink(Figure2).

3.NotethelocationoftheHOCpinintheHOC

bracketforassemblypurposes(

Figure3).Remove

theHOCpinfromtheHOCbracket.

Figure3

1.HOCpin2.HOCbracket

4.Starttheengineandfullylowerthemower.Stopthe

Figure2

1.Pulllink(mowerraised)5.Mowerliftchain

2.Shoulderscrew6.Clevispin

3.Retainerpin7.Adjustmentclevis

4.Torsionspring

2.Disconnectthepulllinkfromeachsideofthe

machine(Figure2).

CAUTION

Becarefulwhendisconnectingthepulllinks.

Thepulllinktorsionspringsmaycausesome

rotationofthepulllinksduringtheremoval

process.

engineandremovethekeyfromtheignitionswitch.

Note:Loweringthemowerontofurnituredollies

willeasetheremovalofthemower.

WARNING

DonotstarttheengineandengagethePTO

switchwhenthePTOdriveshaftisdisconnected

fromthemower.Iftheengineisstartedandthe

PTOshaftisallowedtorotate,seriouspersonal

injuryandmachinedamagecouldresult.If

thePTOdriveshaftisdisconnectedfromthe

mower,removethefuseF1(15amp)fromthe

fuseblocktopreventunintentionalengagement

ofthePTOclutch.

7

Page 8

5.DisconnecttheendyokeofthePTOdriveshaft

fromthemowergearboxshaft:

4.Starttheengineandfullyraisethemower.Stopthe

engineandremovethekeyfromtheignitionswitch.

A.Removetherollpinfromtheendyokeandthe

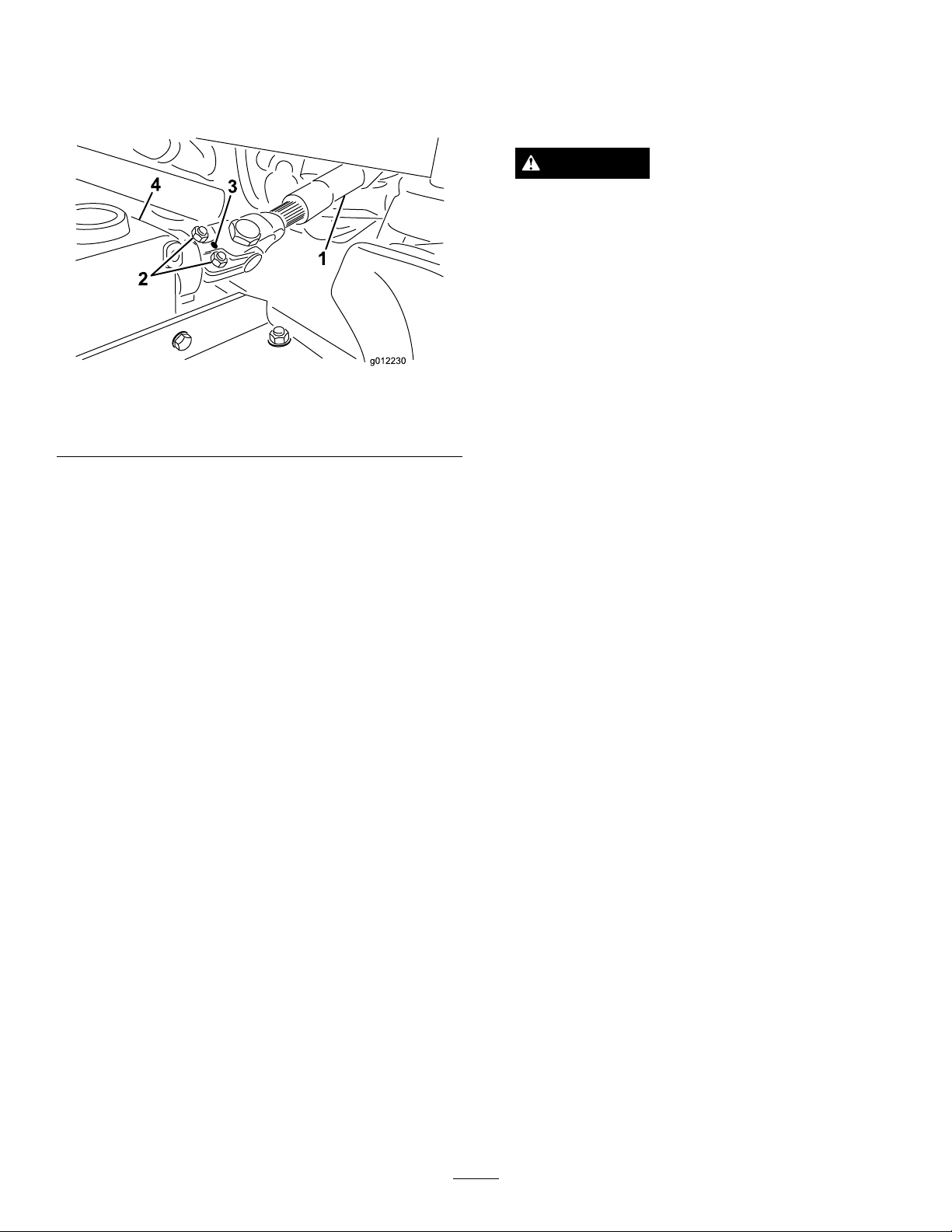

gearboxshaft(Figure4).

Figure4

1.Driveshaft

2.Capscrewsandlocknuts4.Gearbox

B.Loosenthe(2)capscrewsandlocknuts(Figure4).

C.Slidethedriveshaftendyokefromthegearbox

shaft.

3.Rollpin

Note:Placeawoodblockorsimilarshimunder

eachlinktoholditintheraisedposition.

CAUTION

Becarefulwhenconnectingthepulllinksto

themachine.Thepulllinktorsionspringsmay

causesomerotationofthepulllinksduring

installation.

5.Alignthepulllinktothecarrierframeandattach

thelinkwiththeretainerpin(Figure2).Securethe

retainerpintotheframewiththeshoulderscrew

Figure2).

(

6.InstalltheHOCpinintotheHOCbracketatthe

desiredheightofcut(Figure3).

7.LubricatethePTOdriveshaftgreasettings.

8.InstallthefuseF1(15amp)intothefuseblock.

LevelingtheMower

Note:Raiseandtiethedriveshafttotheframe.

6.Removethe(4)ringpinsandclevispinsthatsecure

theliftchainstotheadjustmentclevisesonthe

mower(Figure2).

7.Slidethemowerawayfromthemachine.

Note:Thefrontofthetractionunitmayhaveto

elevatedtomovethemowerawayfromthemachine.

InstallingtheNewMower

1.Slidethenewmowerunderthecarrierframeofthe

machine.

2.Installthe(4)clevispinsandringpinstosecurethe

mowerliftchainstotheadjustmentclevisesonthe

mower(Figure2).

3.ConnecttheendyokeofthePTOdriveshafttothe

mowergearbox:

A.Alignthesplineandrollpinholesofthedrive

shaftyokewiththegearboxshaft.

B.SlidethePTOdriveshaftendyokeontothe

gearboxshaft.

LevelingSidetoSide

1.Positionthemachineonalevelsurfaceontheshop

oor.

2.MovethethrottlelevertotheSlowposition,stop

theengine,settheparkingbrake,andremovethe

ignitionkey.

3.Setthemowertothe5inch(127mm)heightofcut

setting.

4.Checkandadjustfrontandreartractionunit

tirepressure;refertoOperator’sManualfor

specications.

5.Checkforbentblades;RefertoCheckingforBent

Blades.

6.Rotatethebladeoneachspindleuntiltheendsface

forwardandbackward.

7.Measurefromtheoortothefronttipofthecutting

edge.

8.Adjustthejamnutssecuringthemoweryokes/chains

tothemoweruntilthemowerislevel(

Figure5).

C.SecuretheendyokeofthePTOdriveshaftto

thegearboxshaftwiththerollpin(Figure4).

D.Tightenthelocknutstosecuretheendyoketo

thegearboxshaft(Figure4).Torquethelocknuts

to175to225in-lb(20to25N-m)

8

Page 9

Figure5

1.Chain

2.Yoke4.Mower

3.Jamnut

LevelingFronttoBack

Cuttingunitpitchisthedifferenceinheight-of-cutfrom

thefrontofthebladeplanetothebackoftheblade

plane.T ororecommendsabladepitchofapproximately

5/16to7/16inch(8to11mm).Thatisthebackofthe

bladeplaneis5/16to7/16inch(8to11mm)higher

thanthefront.

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Adjustments

AdjustingtheHeight-of-Cut

Theheight-of-cutisadjustedfrom1to6inches

(2.5to15.8cm)in1/4inch(6mm)incrementsby

relocatingthestoppinintodifferentholelocations.

1.Withtheenginerunning,pushbackonthemower

liftswitchuntilthemowerisfullyraisedandrelease

theswitchimmediately(

Figure6).

1.Positionthemachineonalevelsurfaceontheshop

oor.

2.Setthemowertothedesiredheight-of-cut,movethe

throttlelevertotheSlowposition,stoptheengine,

settheparkingbrake,andremovetheignitionkey .

3.Rotatethecenterbladesothatitpointsstraight

forward.

4.Usingashortruler,measurefromtheoortothe

fronttipoftheblade.

5.Rotatethesamebladetiptotherearandmeasure

fromtheoortothetipofthebladeattherearof

themower.

6.Subtractthefrontdimensionfromtherear

dimensiontocalculatethebladepitch.

7.Adjustthejamnutssecuringtherearmower

yokes/chains(

mowersothatthebladepitchissetto5/16to7/16

inch(8to11mm).

Figure5)toraisetherearofthe

Figure6

1.Stoppin

2.Toadjust,rotatethestoppinuntilthenubonitlines

upwiththeslotsintheholesintheheight-of-cut

bracketandremoveit(

3.Selectaholeintheheight-of-cutbracket

correspondingtotheheight-of-cutdesired,insert

thepin,androtateitdowntolockitinplace

(Figure6).

Note:Therearefourrowsofholepositions

Figure6).Thetoprowgivesyoutheheightofcut

(

listedabovethepin.Thesecondrowdowngives

youtheheightlistedplus1/4inch(6mm).The

thirdrowdowngivesyoutheheightlistedplus1/2

inch(12mm).Thebottomrowgivesyoutheheight

listedplus3/4inch(18mm).Forthe6inch(15.8

cm)positionthereisonlyonehole,locatedinthe

Figure6).

9

Page 10

secondrow .Thisdoesnotadd1/4inch(6mm)to

the6inch(15.8cm)position.

4.Adjusttheanti-scalprollersandskidsasrequired.

AdjustingtheRearAnti-ScalpRollers

Wheneveryouchangetheheight-of-cut,adjustthe

heightoftherearanti-scalprollers.

AdjustingtheSkid(s)

Mounttheskidsinthelowerpositionwhenoperating

inheightofcutshigherthan2-1/2inches(64mm)and

inthehigherpositionwhenoperatinginheightofcuts

lowerthan2-1/2inches(64mm).

Note:OnGuardian

worn,youcanswitchtheskidtotheoppositesidesof

themower,ippingthemover.Thiswillallowyouto

usetheskidslongerbeforereplacingthem.

1.DisengagethePTOandsettheparkingbrake.

2.MovethethrottlelevertotheSlowposition,stop

theengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Loosenthescrewatthefrontofeachskid.There

are2skidsonGuardianmowersand1skidon

side-dischargemowers(

®

mowers,whentheskidsbecome

Figure7).

1.DisengagethePTO,releasethetractionpedal,and

settheparkingbrake.

2.MovethethrottlelevertotheSlowposition,stop

theengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Afteradjustingtheheight-of-cut,adjusttherollers

byremovingtheangenut,bushing,spacer,and

Figure8).

bolt(

Figure7

1.Screw3.Skid

2.Flange-headbolt4.Nut

4.Removetheange-headboltsandnutsfromeach

skid.

5.Moveeachskidtothedesiredpositionandsecure

themwiththeange-headboltsandnuts.

Note:Onlyusethetoporcentersetsofholesto

adjusttheskids.Thebottomholesareusedwhen

switchingsidesonaGuardianmowermower,at

whichtimetheybecomethetopholesontheother

sideofthemower.

Figure8

1.Flangenut

2.Bushing5.Bolt

3.Anti-scalproller

4.Spacer

4.Selectaholesotheanti-scalprollerispositioned

tothenearestcorrespondingheight-of-cutdesired

Figure9).

(

6.Torquethescrewatthefrontofeachskidto80to

100in-lb(9to11N-m).

10

Page 11

Figure9

1.1-1/2inches(38mm)3.2-1/2inches(63mm)

2.2inches(51mm)4.3inches(76mm)and

higher

5.Installtheangenutbushing,spacer,andbolt.

Torqueto40-45ft-lb(54-61N⋅m)(

Figure8).

AdjustingtheRollers

Mounttherollersinthelowerpositionwhenoperating

inheightofcutshigherthan2-1/2inches(64mm)and

inthehigherpositionwhenoperatinginheightofcuts

lowerthan2-1/2inches(64mm).

1.DisengagethePTO ,releasethetractionpedaland

settheparkingbrake.

2.MovethethrottlelevertotheSlowposition,stop

theengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Raisethefrontofthemachineandsupportiton

jackstands.

Figure10

AllMowers

1.Frontroller

Figure11

GuardianMowersOnly

1.Bolt4.Nut

2.Rearunder-mowerroller5.Bracket

3.Spacer

2.Rollershaft

4.Removethefastenerssecuringeachrolleronyour

mowerandmovetherollersupordownasdesired;

referto

Figure10throughFigure14asapplicable

foryourmower.

Figure12

GuardianMowerOnly

1.Bolt3.Nut

2.Frontunder-mowerroller4.Bracket

11

Page 12

Figure13

Side-dischargeMowersOnly

1.Bolt4.Nut

2.Chute-sideroller

3.Spacer

Figure14

Side-dischargeMowersOnly

5.Bracket

1.Bolt

2.Rollershaft

5.Installthefastenersasillustrated.

3.Under-mowerroller(2)

4.Bracket

12

Page 13

OperatingTips

FastThrottleSetting/GroundSpeed

Tomaintainenoughpowerforthemachineanddeck

whilemowing,operatetheengineatthefastthrottle

positionandadjustyourgroundspeedforconditions.

Agoodruletofollowis:decreasegroundspeedas

theloadonthecuttingbladesincreases;andincrease

groundspeedasloadonthebladesdecreases.

MowingDirection

Alternatemowingdirectiontoavoidmakingrutsinthe

turfovertime.Thisalsohelpsdisperseclippingswhich

enhancesdecompositionandfertilization.

CuttingSpeed

Toimprovecutquality,useaslowergroundspeed.

AvoidCuttingTooLow

Toreducetheriskofrehazard,keeptheengine,

mufer,batterycompartment,parkingbrake,cutting

units,andfuelstoragecompartmentfreeofgrass,

leaves,orexcessivegrease.Cleanupanyspilledoilor

fuel.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshreddingturns

grassbrownattheedges,whichslowsgrowthand

increasesthechanceofdisease.Checkthebladesdaily

forsharpness,andforanywearordamage.Sharpen

thebladesasnecessary.Ifabladeisdamagedorworn,

replaceitimmediatelywithagenuineTororeplacement

blade.RefertoServicingtheCuttingBlades.

Ifthecuttingwidthofthemoweriswiderthanthe

moweryoupreviouslyused,raisethecuttingheightto

ensurethatuneventurfisnotcuttooshort.

SelecttheProperHeight-of-CutSetting

toSuitConditions

Removeapproximately1inch(25mm)ornomorethan

1/3ofthegrassbladewhencutting.Inexceptionally

lushanddensegrass,youmayhavetoslowdownthe

forwardspeedand/orraisetheheight-of-cuttothe

nexthighersetting.

Important:Ifcuttingmorethan1/3ofthegrass

bladeoff,orinsparselonggrassordryconditions,

theuseofatsailbladesisrecommendedto

reduceair-bornechaff,debris,anddeckdrive

componentstrain.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raise

thecuttingheighthigherthanusualandcutthegrassat

thissetting.Thencutthegrassagainusingthelower,

normalsetting.

KeeptheMowerClean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildupinside

themower,cuttingqualitywilleventuallybecome

unsatisfactory.

13

Page 14

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

WARNING

Ifyouraisethemachineusingonlyajacktosupport

itwhileyouworkunderthemowerdeck,thejack

couldtip,causingthemowerdecktofall,crushing

youorbystanders.

Alwayssecurethemachinewithatleast2jack

standswhenyouhavethemowerdeckraised.

CAUTION

Onthetopofthemowerdeckaretwolinksthat

connectthemtotheframe.Connectedtotheselinks

aretorsionspringthatareundertension(Figure15).

Ifyoudisconnectthelinkthestoredenergyinthe

torsionspringwillbereleasedandcouldcausethe

linkstomove,damagingyourhandsorngers.

Becarefulwhenremovingthemowerdeckfrom

theframeandsecurethelinksbeforedisconnecting

themfromtheframe.

Figure15

1.Link2.Torsionspring

14

Page 15

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst50hours

Beforeeachuseordaily

Every50hours

MaintenanceProcedure

•Checkthetirepressure.

•Checktheconditionofthebladedrivebeltsonthemower.

•Checkthemowerblades.

•Cleanthemower .

•Greasethebearingandbushinggreasettings.

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

CheckSafetyInterlock

Operation

CheckGrassDeectorin

DownPosition(ifapplicable)

CheckParkingBrake

Operation

CheckFuelLevel

CheckTirePressure

CheckInstrumentOperation

CheckConditionofBlades

LubricateAllGreaseFittings

Touch-upDamagedPaint

1.Immediatelyaftereverywashing,regardlessoftheintervallisted.

1

Sat.Sun.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Information

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

15

Page 16

Lubrication

GreasingtheBearingsandBushings

ServiceInterval:Every50hours

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBase

Grease.Ifthemachineisoperatedundernormal

conditions,lubricateallbearingsandbushingsafter

every50hoursofoperation.Bearingsandbushings

mustbelubricateddailywhenoperatingconditionsare

extremelydustyanddirty.Dustyanddirtyoperating

conditionscouldcausedirttogetintothebearings

andbushings,resultinginacceleratedwear.Lubricate

thegreasettingsimmediatelyaftereverywashing,

regardlessofintervalspecied.

1.Wipethegreasettingscleansoforeignmatter

cannotbeforcedintothebearingorbushing.

2.Pumpgreaseintothettings.

3.Wipeoffexcessgrease.

Figure16

16

Page 17

Note:Bearinglifecanbenegativelyaffectedby

improperwashdownprocedures.Donotwashdownthe

unitwhenitisstillhotandavoiddirectinghigh-pressure

orhighvolumesprayatthebearingsorseals.

Figure17

17

Page 18

CheckingtheTirePressure

ServiceInterval:Aftertherst50hours

Maintaintheairpressureinthefrontandreartires.

Thecorrectairpressureis25psi(172kPa)intherear

tiresand15psi(103kPa)inthefronttires.Ifacabis

installedonthemachine,thefrontandreartiresshould

beinatedto25psi(172kPa).Uneventirepressurecan

causeunevencut.Checkthetireswhentheyarecoldto

getthemostaccuratepressurereading.

ReplacingtheBladeDrive

5.Routeanewbeltaroundthetopspindlepulleysand

idlerpulleyassemblyasshowninFigure18.

6.Greaseallmowerandmowerdrivegreasepoints.

7.Installthebeltcovers.

ServicingtheCuttingBlades

Maintainsharpbladesthroughoutthecuttingseason

becausesharpbladescutcleanlywithouttearingor

shreddingthegrassblades.Tearingandshreddingturns

grassbrownattheedges,whichslowsgrowthand

increasesthechanceofdisease.

Belts

ServiceInterval:Aftertherst50hours

Thebladedrivebelts,tensionedbythespringloaded

idlerpulleys,areverydurable.However,aftermany

hoursofuse,thebeltswillshowsignsofwear.Signsof

awornbeltare:squealingwhenbeltisrotating,blades

slippingwhencuttinggrass,poorqualityofcut,frayed

edges,burnmarksandcracks.Replacethebeltsifanyof

theseconditionsareevident.

1.Lowerthecuttingunittothe1inchheightofcut

setting,movethethrottlelevertotheSlowposition,

stoptheengine,settheparkingbrake,andremove

theignitionkey.

2.Removethebeltcoversfromthetopofthecutting

unitandsetthecoversaside.

3.Usingabreakerbarorsimilartool,movetheidler

pulleyforthetopbelt(

drivebelttoreleasethebelttensionandallowthe

belttobeslippedoffthepulleys.

Figure18)awayfromthetop

Checkthebladesdailyforsharpness,andforanywear

ordamage.Sharpenthebladesasnecessary.Ifabladeis

damagedorworn,replaceitimmediatelywithagenuine

Tororeplacementblade.

DANGER

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

Inspectandcheckthebladesevery8hours.

BeforeInspectingorServicingthe

Blades

1.DisengagethePTO ,releasethetractionpedaland

settheparkingbrake.

Figure18

1.Topbelt3.Bottombelt

2.Topidlerpulley4.Bottomidlerpulley

4.Routeanewbeltaroundthegearboxpulley,bottom

spindlepulleys,andidlerpulleyassemblyasshown

in

Figure18.

2.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure19).Iftheedges

arenotsharporhavenicks,removeandsharpenthe

blades.RefertoSharpeningtheBlades.

2.Inspecttheblades,especiallythesailarea(Figure19).

Ifyounoticeanydamage,wear,oraslotformingin

thisarea(Figure19),immediatelyinstallanewblade.

18

Page 19

DANGER

Ifyouallowthebladetowear,aslotwillform

betweenthesailandatpartoftheblade.

Eventuallyapieceoftheblademaybreakoff

andbethrownfromunderthehousing,possibly

resultinginseriousinjurytoyouorbystanders.

•Inspectthebladeperiodicallyforwearor

damage.

•Nevertrytostraightenabladethatisbentor

weldabrokenorcrackedblade.

•Replaceawornordamagedblade.

2.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

3.Rotatethebladesuntiltheendsfaceforwardand

backward(Figure20).Measurefromalevelsurface

tothecuttingedge,positionA,oftheblades

(Figure20).Notethisdimension.

Figure19

1.CuttingEdge3.Wear/slotForming

2.SailArea4.Crack

Figure20

1.Measureherefromblade

tohardsurface

2.PositionA

4.Rotatetheoppositeendsofthebladesforward.

5.Measurefromalevelsurfacetothecuttingedgeof

thebladesatthesamepositionasinstep3above.

Thedifferencebetweenthedimensionsobtainedin

steps3and4mustnotexceed1/8inch(3mm).If

thisdimensionexceeds1/8inch(3mm),theblade

isbentandmustbereplaced;refertoRemovingthe

BladesandInstallingtheBlades.

WARNING

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplacebentordamagedbladewith

anewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofblade.

CheckingforBentBlades

1.DisengagethePTO ,releasethetractionpedaland

settheparkingbrake.

RemovingtheBlades

Bladesmustbereplacedifasolidobjectishit,ifthe

bladeisoutofbalanceorisbent.Toensureoptimum

performanceandcontinuedsafetyconformanceof

19

Page 20

themachine,usegenuineTororeplacementblades.

Replacementbladesmadebyothermanufacturersmay

resultinnon-conformancewithsafetystandards.

WARNING

Contactwithasharpbladecancauseseriousinjury .

Wearglovesorwrapsharpedgesofthebladewith

arag.

1.Holdthebladeendusingaragorthickly-padded

glove.

2.Removethebladebolt,anti-scalpplate,andblade

fromthespindleshaft(

Figure23).

SharpeningtheBlades

WARNING

Whensharpeningblade,piecesofbladecouldbe

thrownandcauseseriousinjury.

Wearpropereyeprotectionwhensharpening

blades.

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure23).

Important:Thecurvedpartoftheblademust

bepointingupwardtowardtheinsideofthe

mowertoensurepropercutting.

2.Installtheanti-scalpplateandbladebolt(

Figure23).

1.Sharpenthecuttingedgeatbothendsoftheblade

(Figure21).Maintaintheoriginalangle.Theblade

retainsitsbalanceifthesameamountofmaterialis

removedfrombothcuttingedges.

Figure21

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitona

bladebalancer(Figure22).Ifthebladestaysina

horizontalposition,thebladeisbalancedandcanbe

used.Ifthebladeisnotbalanced,lesomemetaloff

theendofthesailareaonly(

Figure23).Repeatthis

procedureuntilthebladeisbalanced.

Figure23

1.Spindle

2.SailAreaofBlade

3.Anti-scalpplate

4.BladeBolt

3.Torquethebladeboltto85-110ft-lb(115-150N⋅m).

CorrectingMowerMismatch

Ifthecutisunevenacrossthemowerswath,correct

itasfollows:

1.Positionthemachineonalevelsurfaceontheshop

oor.

2.Setthecuttingunittothedesiredheightofcut,

movethethrottlelevertotheSlowposition,stop

theengine,settheparkingbrake,andremovethe

ignitionkey.

Figure22

1.Blade2.Balancer

3.Checkandadjustfrontandreartractortirepressure;

refertoCheckingTirePressure.

4.Checkforbentblades.

20

Page 21

5.Removethecoversfromthetopofthecuttingunits.

6.Rotatethebladeoneachspindleuntiltheendsface

forwardandbackward.

7.Measurefromtheoortothefronttipofthecutting

edge.

6.Subtractthefrontdimensionfromtherear

dimensiontocalculatethebladepitch.

7.Adjustthejamnutssecuringtherearmower

yokes/chainstoraisetherearofthemowersothat

thebladepitchissetto5/16inch(8mm)(

Figure24).

8.Adjustthejamnutssecuringthemoweryokes/chains

tothemoweruntilthemowerislevel(

Figure24

1.Frontmoweryokechain4.Yoke

2.Rearmoweryokechain5.Jamnut

3.Chain

6.Mower

Figure24).

ReplacingtheGrassDeector

WARNING

Anuncovereddischargeopeningcouldallowthe

machinetothrowobjectsintheoperator'sor

bystander'sdirectionandresultinseriousinjury.

Also,contactwiththebladecouldoccur.

•Neveroperatethemachinewithoutamulchkit

orgrassdeectorinstalled.

•Makesurethegrassdeectorisinthedown

position.

1.Lowerthecuttingunittotheshopoor,movethe

throttlelevertotheSlowposition,stoptheengine,

settheparkingbrake,andremovetheignitionkey .

2.Removethelocknut,bolt,springandspacerholding

thedeectortothepivotbrackets(

Removedamagedorworngrassdeector.

Figure25).

AdjustingtheMowerPitch

Cuttingunitpitchisthedifferenceinheight-of-cutfrom

thefrontofthebladeplanetothebackoftheblade

plane.T ororecommendsabladepitchofapproximately

5/16inch(8mm).Thatisthebackofthebladeplaneis

5/16inch(8mm)higherthanthefront.

1.Positionthemachineonalevelsurfaceontheshop

oor.

2.Setthecuttingunittothedesiredheight-of-cut,

movethethrottlelevertotheSlowposition,stop

theengine,settheparkingbrake,andremovethe

ignitionkey.

3.Rotatethecenterbladesothatitpointsstraight

forward.

4.Usingashortruler,measurefromtheoortothe

fronttipoftheblade.

5.Rotatethesamebladetiptotherearandmeasure

fromtheoortothetipofthebladeattherearof

themower.

Figure25

1.Bolt

2.Spacer6.GrassDeector

3.Locknut

4.Spring8.Righthandhookendof

5.Springinstalled

7.Lefthandhookendof

spring,placebehind

moweredgebefore

installingbolt

spring

3.Placethespacerandspringbetweenthereplacement

grassdeectorbrackets(

Figure25).Placetheleft

21

Page 22

handJhookendofthespringbehindthemower

edge.

Storage

Note:MakesurethelefthandJhookendofthe

springisinstalledbehindthemoweredgebefore

installingtheboltasshownin

4.Installtheboltandnut.PlacetherighthandJ

hookendofthespringaroundthegrassdeector

(Figure25).

Important:Thegrassdeectormustbeableto

lowerdownintoposition.Liftthedeectorup

totestthatitlowersintothefulldownposition.

Figure25.

CleaningUndertheMower

ServiceInterval:Beforeeachuseordaily

Removethegrassbuildupunderthemowerdaily.

1.DisengagethePTO,releasethetractionpedaltothe

neutralpositionandsettheparkingbrake.

2.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

1.Thoroughlycleanthemower,payingspecialattention

totheseareas:

•Underneaththemower

•Underthemowerbeltcovers

•PTOshaftassembly

•Allgreasettingsandpivotpoints

2.Checkandadjustfrontandreartirepressure;refer

toCheckingTirePressure.

3.Remove,sharpen,andbalancethemowerblades.

Installthebladesandtorquethebladefastenersto

85-110ft-lb(115-149N-m).

4.Checkallfastenersforloosenessandtightenthem

asnecessary.

5.Greaseoroilallgreasettingsandpivotpoints.

Wipeoffanyexcesslubricant.

6.Lightlysandandusetouchuppaintonpaintedareas

thatarescratched,chippedorrusted.Repairany

dents.

3.Raisethemowertothetransportposition.

4.Raisethefrontofthemachinebyusingjackstands.

5.Thoroughlycleantheundersideofthemowerwith

water.

22

Page 23

Notes:

23

Page 24

TheToroTotalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter .

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1 196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenance

andadjustmentsstatedinyourOperator'sManual.Failuretoperform

requiredmaintenanceandadjustmentscanbegroundsfordisallowinga

warrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,

duringnormalProductoperationinclude,butarenotlimitedto,brake

padsandlinings,clutchlinings,blades,reels,rollersandbearings

(sealedorgreasable),bedknives,sparkplugs,castorwheelsand

bearings,tires,lters,belts,andcertainsprayercomponentssuchas

diaphragms,nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,

lubricants,additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damageto

seatsduetowearorabrasion,wornpaintedsurfaces,scratched

decalsorwindows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofToro.T orowill

makethenaldecisionwhethertorepairanyexistingpartorassemblyor

replaceit.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.

Allimpliedwarrantiesofmerchantabilityandtnessforuseare

limitedtothedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.Thiswarranty

givesyouspeciclegalrights,andyoumayalsohaveotherrightswhich

varyfromstatetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EPA)and/ortheCaliforniaAir

ResourcesBoard(CARB).Thehourlimitationssetforthabovedonot

applytotheEmissionsControlSystemWarranty.RefertotheEngine

EmissionControlWarrantyStatementsuppliedwithyourproductor

containedintheenginemanufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedToroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirToroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevB

Loading...

Loading...