Page 1

FormNo.3358-498RevB

Groundsmaster

®

3320

TractionUnit

ModelNo.30343—SerialNo.280000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Introduction

Important:Theengineinthisproductisnot

equippedwithasparkarrestermufer.Itisa

violationofCaliforniaPublicResourceCode

Section4442touseoroperatethisengineonany

forest-covered,brush-covered,orgrass-covered

landasdenedinCPRC4126.Otherstatesor

federalareasmayhavesimilarlaws.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Warning

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Contents

Introduction.................................................................2

Safety...........................................................................3

SafeOperatingPractices.......................................3

ToroRidingMowerSafety....................................6

SafetyandInstructionalDecals.............................7

Setup..........................................................................12

1InstallingtheSteeringWheel............................12

2InstallingtheHandletotheHood.....................13

3InstallingtheSeat.............................................14

4InstallingtheSeatBelt......................................14

5InstallingtheManualTube...............................14

6AdjustingtheROPS.........................................15

7ActivatingandChargingtheBattery..................15

8CheckingtheTirePressure...............................17

9InstallingtheRearW eight.................................18

10AdjustingtheCounterbalance

Pressure.........................................................19

ProductOverview......................................................20

Controls.............................................................20

Specications.....................................................23

Attachments/Accessories...................................23

Operation...................................................................23

ThinkSafetyFirst...............................................23

CheckingtheEngineOil.....................................23

CheckingtheCoolingSystem..............................24

CheckingtheHydraulicSystem...........................24

FillingtheFuelTank...........................................25

UsingtheRolloverProtectionSystem

(ROPS)..........................................................26

©2009—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Starting/StoppingtheEngine.............................26

CheckingInterlockSystem.................................27

PushingOrTowingtheMachine.........................27

OperatingCharacteristics...................................28

StandardControlModule(SCM)........................28

Maintenance...............................................................31

RecommendedMaintenanceSchedule(s)................31

DailyMaintenanceChecklist...............................32

Lubrication.............................................................34

GreasingtheBearingsAndBushings...................34

EngineMaintenance...............................................36

GeneralAirCleanerMaintenance.......................36

ServicingtheAirCleaner....................................36

ChangingtheEngineOilAndFilter....................37

FuelSystemMaintenance.......................................38

ServicingtheFuelSystem...................................38

ElectricalSystemMaintenance................................39

AdjustingthePTOClutch..................................39

ServicingtheBattery...........................................39

StoringtheBattery..............................................40

ServicingtheWiringHarness..............................40

ServicingtheFuses.............................................40

DriveSystemMaintenance.....................................41

AdjustingtheTractionDriveforNeutral.............41

AdjustingtheTractionPedal...............................41

AdjustingRearWheelToe-in..............................42

CoolingSystemMaintenance..................................43

CleaningtheRadiatorandtheScreen...................43

BrakeMaintenance.................................................43

AdjustingtheParkingBrakeInterlock

Switch............................................................43

AdjustingtheServiceBrakes...............................44

BeltMaintenance....................................................45

ServicingtheAlternatorBelt...............................45

ServicingthePTOBelt.......................................45

ControlsSystemMaintenance.................................46

AdjustingtheTiltSteeringControl......................46

HydraulicSystemMaintenance...............................46

ChangingtheHydraulicOilAndFilter................46

Storage.......................................................................47

TractionUnit......................................................47

Engine...............................................................47

Schematics.................................................................49

Safety

ThismachinemeetsorexceedsANSIB71.4-2004

specicationsineffectatthetimeofproduction

whenequippedwithrearweight.Refertothe

sectioninthismanualonRearWeight.Improper

useormaintenancebytheoperatororowner

canresultininjury.T oreducethepotentialfor

injury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalert

symbol,whichmeansCAUTION,WARNING,

orDANGER—“personalsafetyinstruction.”

Failuretocomplywiththeinstructionmayresultin

personalinjuryordeath.

Note:Theadditionofattachmentsmadeby

othermanufacturersthatdonotmeetAmerican

NationalStandardsInstitutecerticationwillcause

noncomplianceofthismachine.

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalert

symbol,whichmeansCAUTION,WARNING,

orDANGER—“personalsafetyinstruction.”

Failuretocomplywiththeinstructionmayresultin

personalinjuryordeath.

SafeOperatingPractices

Training

•ReadtheOperator’sManualandothertrainingmaterial

carefully.Iftheoperatorormechaniccannot

readthelanguageofthismanualitistheowner’s

responsibilitytoexplainthismaterialtothem.

•Befamiliarwiththecontrols,safetysigns,andthe

properuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpets

arenearby .

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Donotcarrypassengers.

•Alloperatorsandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstruction

shouldemphasize:

3

Page 4

–theneedforcareandconcentrationwhen

workingwithride-onmachines;

–controlofaride-onmachineslidingonaslope

willnotberegainedbytheapplicationofthe

brake.Themainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrecthitchingandloaddistribution.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeople,orproperty.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,

longtrousers,hardhat,safetyglasses,andhearing

protection.Longhair,looseclothing,orjewelrymay

gettangledinmovingparts.Donotoperatethe

equipmentwhenbarefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning–Fuelishighlyammable.Takethe

followingprecautions:

–Storefuelincontainersspecicallydesignedfor

thispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refueling.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely .

•Replacefaultysilencers/mufers.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Checktheoperatorpresencecontrols,safety

switchesandshieldstomakesuretheyareattached

andfunctioningproperly.Donotoperateunless

theyarefunctioningproperly .

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

Engineexhaustcontainscarbonmonoxide,

whichisanodorless,deadlypoisonthatcan

killyou.

Donotrunengineindoorsorinanenclosed

area.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageall

bladeattachmentclutches,shiftintoneutral,and

engagetheparkingbrake.

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Rememberthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.To

guardagainstoverturning:

–donotstoporstartsuddenlywhengoingupor

downhill;

–engageclutchslowly ,alwayskeepmachinein

gear,especiallywhentravellingdownhill’

–machinespeedsshouldbekeptlowonslopes

andduringtightturns;

–stayalertforhumpsandhollowsandother

hiddenhazards;

–nevermowacrossthefaceoftheslope.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Usecarewhenpullingloadsorheavyequipment.

–Useonlyapproveddrawbarhitchpoints.

–Limitloadstothoseyoucansafelycontrol.

–Donotturnsharply.Usecarewhenreversing.

–Usecounterweight(s)orwheelweightswhen

suggestedintheoperator’smanual.

•Thismachineisnotdesignedorequippedfor

on–roaduseandisa“slow–movingvehicle.”Ifyou

mustcrossortravelonapublicroad,youshould

beawareofandcomplywithlocalregulations,such

asrequiredlights,slowmovingvehiclesigns,and

reector.

•Stopthebladesrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischarge

ofmaterialtowardbystandersnorallowanyonenear

themachinewhileinoperation.

4

Page 5

•Neveroperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesinplace.

Besureallinterlocksareattached,adjustedproperly,

andfunctioningproperly .

•Donotchangetheenginegovernorsettingsorover

speedtheengine.Operatingtheengineatexcessive

speedmayincreasethehazardofpersonalinjury.

•Beforeleavingtheoperator’sposition:

–stoponlevelground;

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Stoptheengineanddisengagedrivetoattachment

UsingtheRolloverProtectionSystem

(ROPS)

•Keeptherollbarintheraisedandlockedposition

andusetheseatbeltwhenoperatingthemachine

•Becertaintheseatbeltcanbereleasedquicklyinthe

eventofanemergency.

•Beawarethereisnorolloverprotectionwhenthe

rollbarisdown.

•Checktheareatobemowedandneverfoldthe

ROPSintheareaswherethereareslopes,dropoffs

orwater

•Lowertherollbaronlywhenabsolutelynecessary.

Donotweartheseatbeltwiththerollbarfolded

down.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)beforedriving

underanyobjectsanddonotcontactthem.

–beforerefuelling;

–beforeremovingthegrasscatcher/catchers;

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator’ s

position.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthe

mower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperating

theequipment.

•Reducethethrottlesettingbeforeengineshutdown

and,iftheengineisprovidedwithashut-offvalve,

turnthefueloffattheconclusionofmowing.

•Keephandsandfeetawayfromthemowerdeck.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Disengagebladesif

notmowing.

•Beawareofthemowerdischargedirectionanddo

notpointitatanyone.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumesmayreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuel

storageareafreeofgrass,leaves,orexcessivegrease.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Keepallpartsingoodworkingconditionandall

hardwareandhydraulicttingstightened.Replaceall

wornordamagedpartsanddecals

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachineto

prevententrapmentofthengersbetweenmoving

bladesandxedpartsofthemachine.

•Onmulti-spindlemowers,takecareasrotatingone

bladecancauseotherbladestorotate.

•Disengagedrives,lowerthedeck,setparkingbrake,

stopengineandremovethekeyfromtheignition.

Waitforallmovementtostopbeforeadjusting,

cleaningorrepairing.

•Cleangrassanddebrisfromdecks,drives,

silencers/mufers,engineandundersideofmachine

tohelppreventres.Cleanupoilorfuelspillage.

•Usejackstandstosupportcomponentswhen

required.

5

Page 6

•Carefullyreleasepressurefromcomponentswith

storedenergy.

regulations,suchasrequiredlights,slowmoving

vehiclesigns,andreectors.

•Disconnectbatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthe

positivelast.Reconnectpositiverstandnegative

last.

•Usecarewhencheckingtheblades.Weargloves

andusecautionwhenservicingthem.Onlyreplace

blades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.Wear

protectiveclothinganduseinsulatedtools.

ToroRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknowthatisnotincludedintheCEN,ISO ,or

ANSIstandard.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrol

ofthemachine.

•Raisethedeckwhendrivingfromoneworkareato

another.

•Donottouchtheengine,silencer/mufer,or

exhaustpipewhiletheengineisrunningorsoon

afterithasstoppedbecausetheseareascouldbehot

enoughtocauseburns.

•Iftheenginestallsormachinecannotmakeitto

thetopofaslope,donotturnthemachinearound.

Alwaysbackslowly,straightdowntheslope.

•Whenapersonorpetappearsunexpectedlyin

ornearthemowingarea,stopmowing.Careless

operation,combinedwithterrainangles,ricochets,

orimproperlypositionedguardscanleadtothrown

objectinjuries.Donotresumemowinguntilthe

areaiscleared.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustouserandbystanders.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennis

shoesorsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Beforestartingtheengine,sitontheseat.

•Usingthemachinedemandsattention.T oprevent

lossofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,

orotherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Thismachineisnotdesignedorequippedfor

on-roaduseandisa“slow-movingvehicle.”

Ifyoumustcrossortravelonapublicroad,

youshouldbeawareofandcomplywithlocal

MaintenanceandStorage

•Makesureallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunder

highpressure.Usepaperorcardboard,notyour

hands,tosearchforleaks.Hydraulicuidescaping

underpressurecanhavesufcientforcetopenetrate

theskinandcauseseriousinjury.Seekimmediate

medicalattentionifuidisinjectedintoskin.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinthesystemmust

berelievedbystoppingtheengineandloweringthe

deckandattachmentstotheground.

•Checkallfuellinesfortightnessandwearona

regularbasis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthedeck,

attachments,andanymovingparts,especiallythe

screenatthesideoftheengine.Keepeveryoneaway.

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedToroDistributor.

•UseonlyToroapprovedattachmentsand

replacementparts.Thewarrantymaybevoidedif

usedwithunapprovedattachments.

6

Page 7

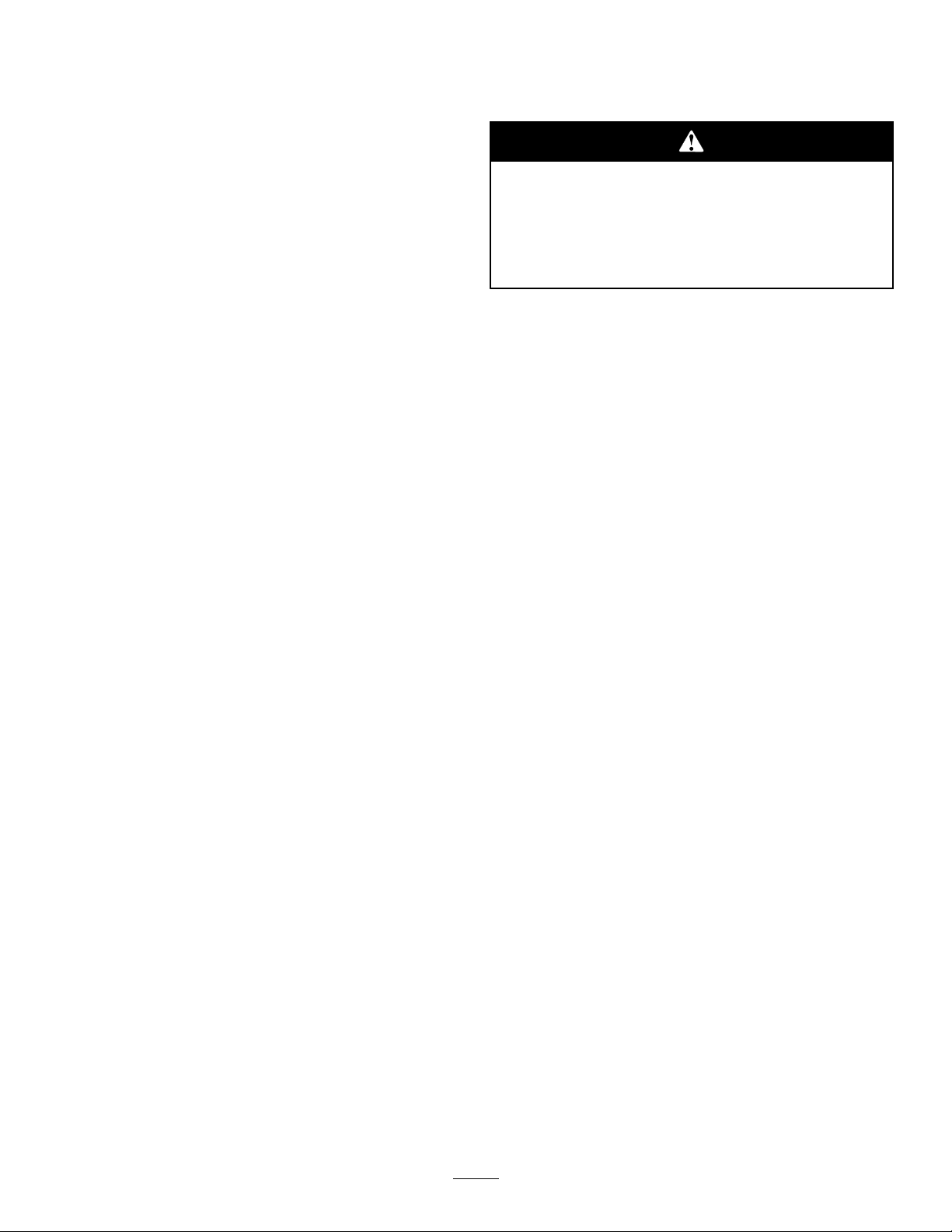

SafetyandInstructionalDecals

71-37 30

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

106-9206

1.Wheeltorquespecications

2.ReadtheOperator’sManual.

93-7841

1.Warning—readtheOperator’sManual.

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

105-9584

71-3730

1.Hydraulicoil

2.ReadtheOperator’sManual.

93-6686

76-8750

108-9691

1.Unlocked

2.Locked

3.Fast

4.Continuousvariablesetting

5.Slow

6.Choke

7.Lowerthehopper10.Raisethecuttingunits

8.Raisethehopper

9.Lowerthecuttingunits

7

Page 8

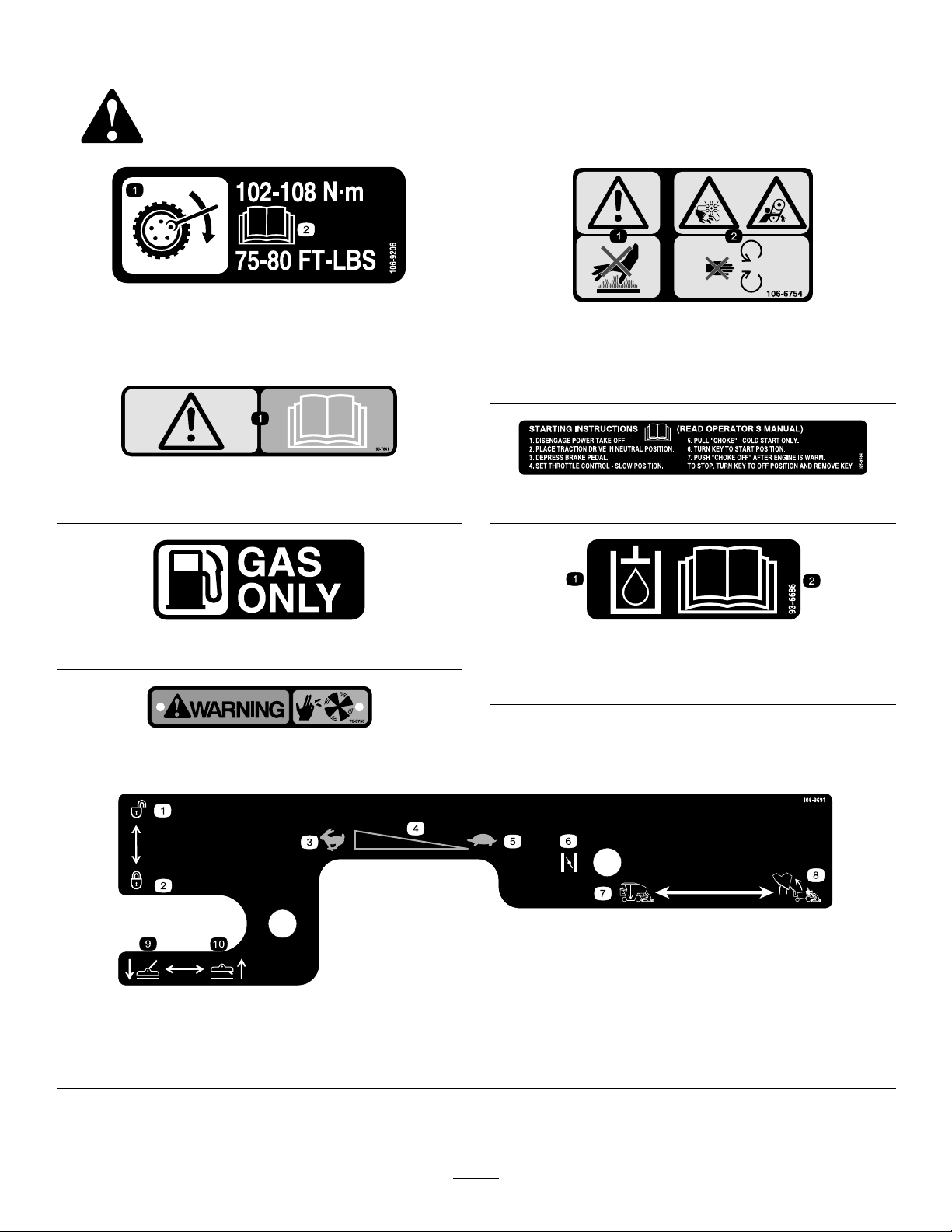

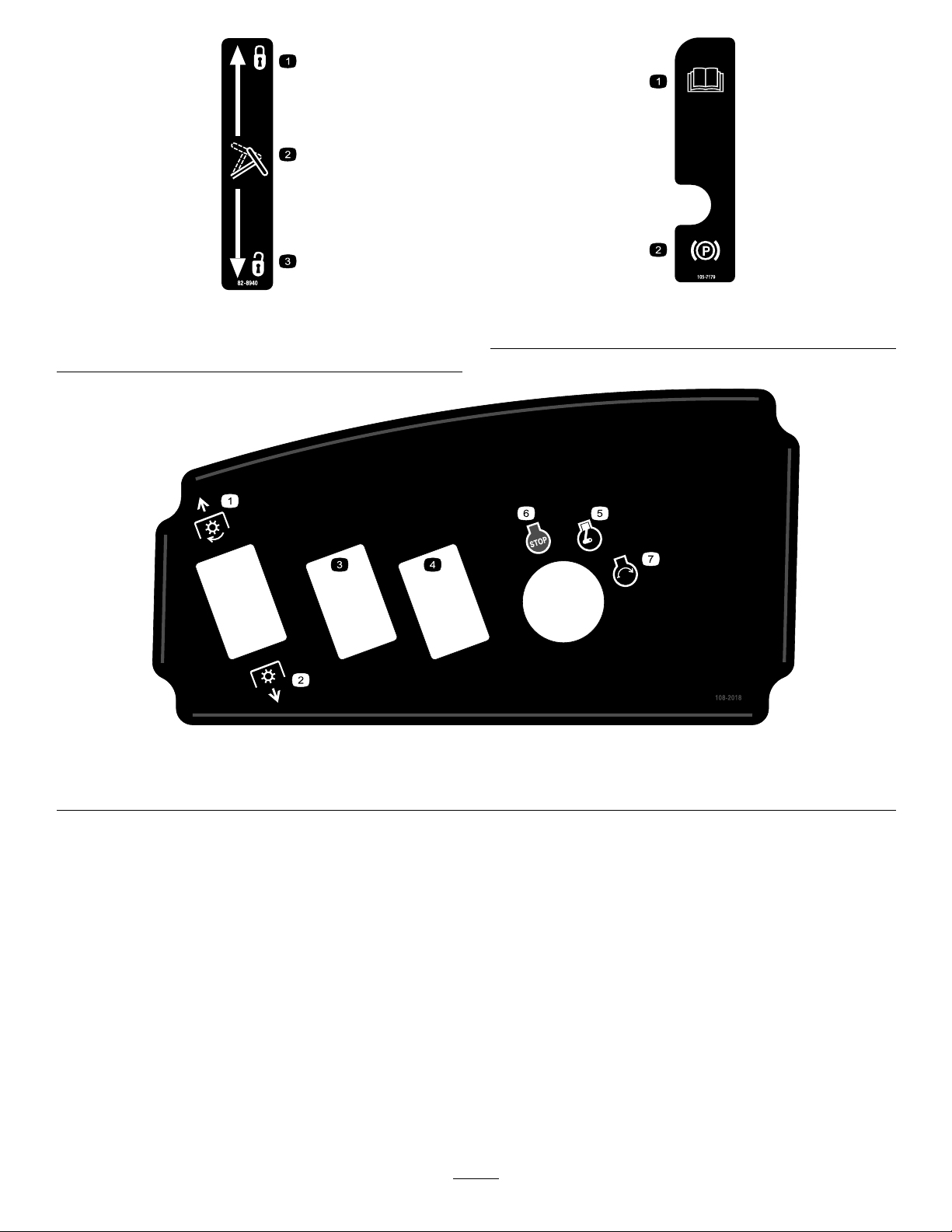

82-8940

1.Locked3.Unlocked

2.Tiltsteering

1.PTO–Off3.OptionalEquipment

2.PTO—On4.OptionalEquipment6.Engine—Stop

105-7179

1.ReadOperator’sManual.

2.Parkingbrake

108-2018

5.Engine—Run

7.Engine—Start

8

Page 9

1.Warning—readtheOperator’sManual,

alloperatorsshouldbetrainedbefore

operatingthemachine.

2.Thrownobjecthazard—keep

bystandersasafedistancefromthe

machineandkeepthedeectorin

place.

114-2855

3.Cutting/dismembermenthazardof

handsorfeet,mowerblade—stay

awayfrommovingparts.

4.Warning—engagetheparkingbrake,

andremovetheignitionkeybefore

leavingthemachine.

5.Tippinghazard—whendrivingdown

slopes,lowerthecuttingunit,slow

machinebeforeturning,donotturnat

highspeeds;iftherollbarisinstalled,

weartheseatbelt.

1.ReadtheOperator’sManual.

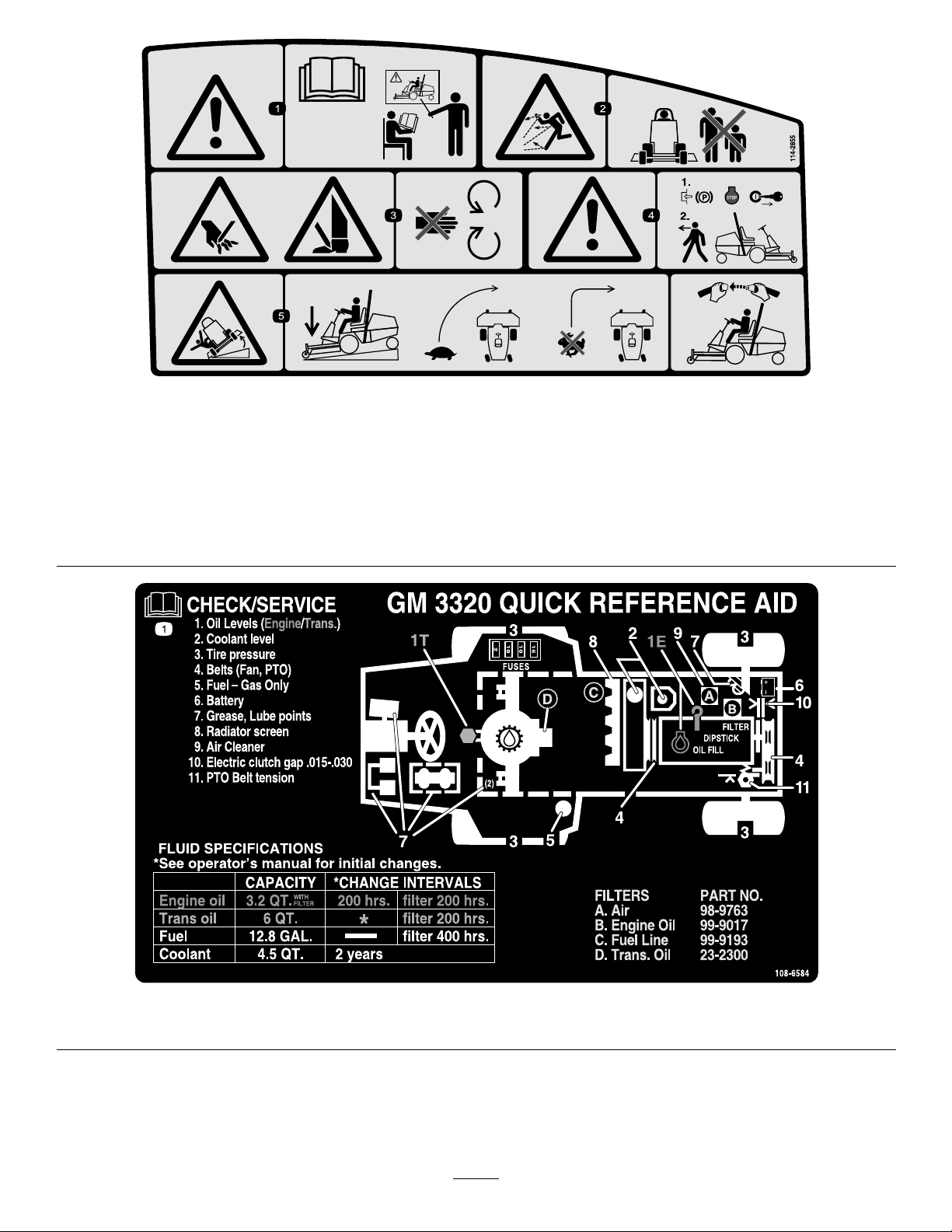

108-6584

9

Page 10

1.Inputs5.Inseat

2.Backlap

3.Hightemperatureshutdown

4.Hightemperaturewarning8.Neutral

6.PowerT ake-off(PTO)10.PowerT ake-off(PTO)

7.ParkingbrakeOff11.Start

106-9290

9.Outputs13.Start

14.Power

12.EnergizetoRun(ETR)

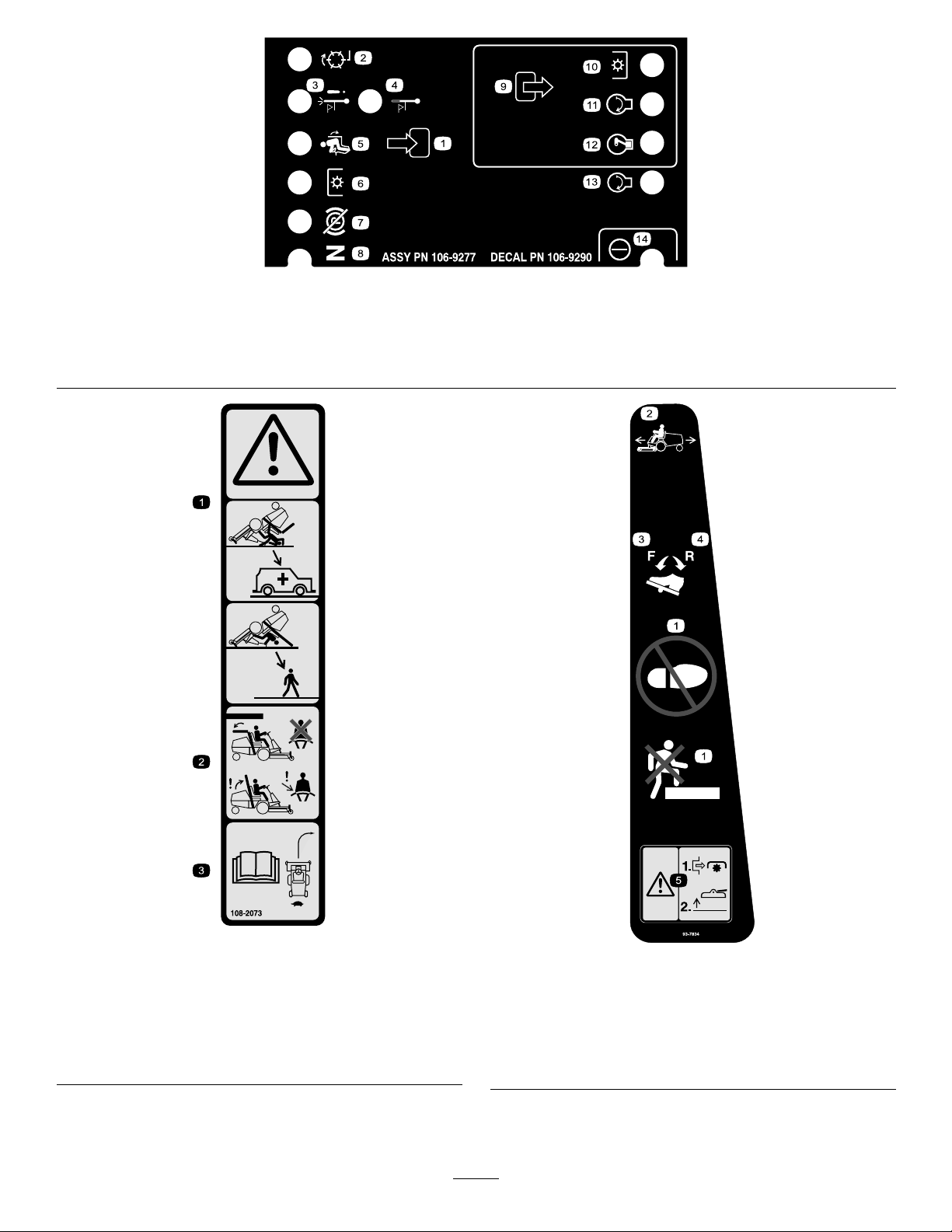

108-2073

1.Warning—thereisnorolloverprotectionwhentherollbaris

down.

2.Toavoidinjuryordeathfromarolloveraccident,keepthe

rollbarintheraisedandlockedpositionandweartheseat

belt.Lowertherollbaronlywhenabsolutelynecessary;do

notweartheseatbeltwhentherollbarisdown.

3.ReadtheOperator’sManual;driveslowlyandcarefully.

1.Nostep4.Traction-reverse

2.Tractionpedal

3.Traction-forward

10

93-7834

5.Warning—shutoffPTO

priortoraisingdecks;do

notoperatedeckswhen

theyareinraisedposition

Page 11

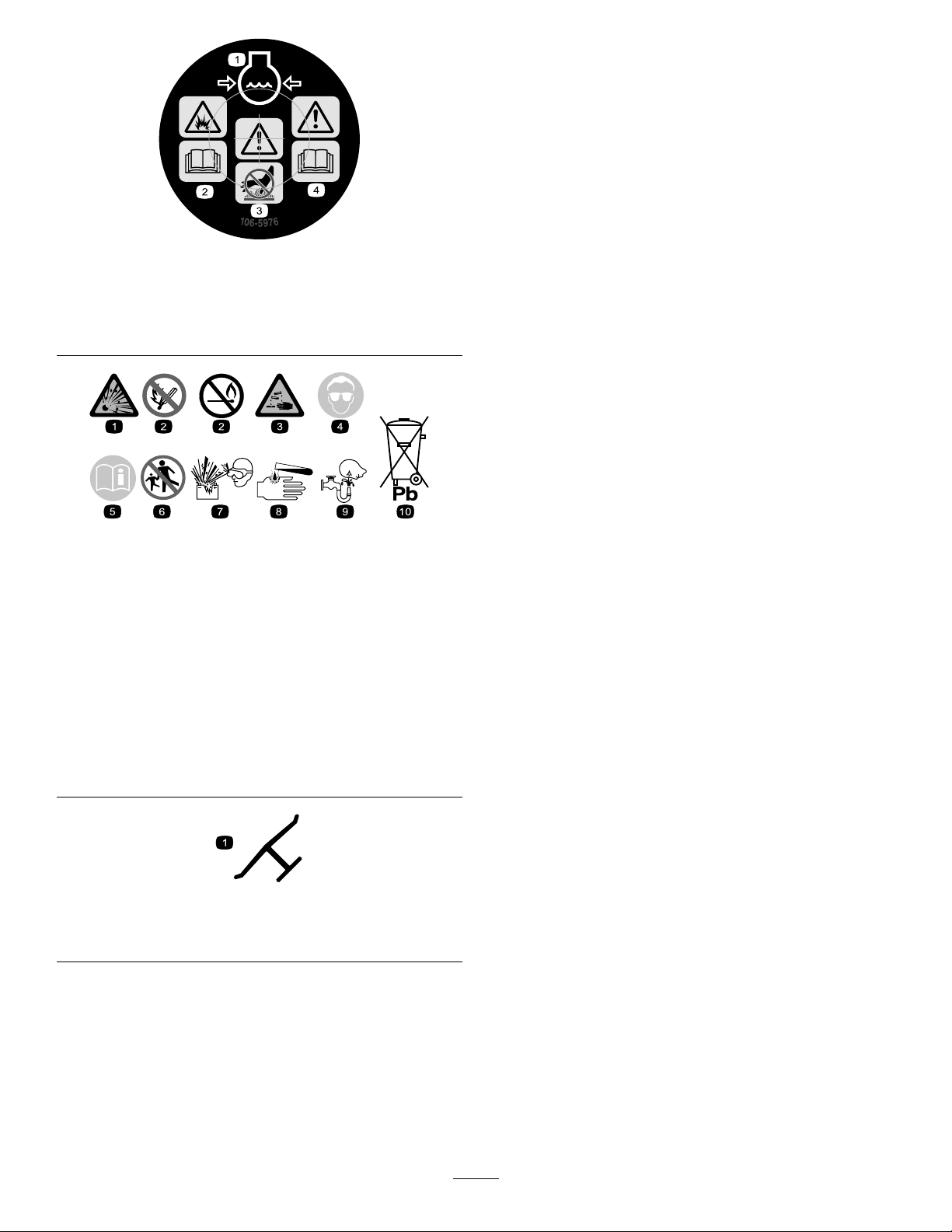

106-5976

1.Enginecoolantunder

pressure

2.Explosionhazard—read

theOperator’sManual.

3.Warning—donottouch

4.Warning—readthe

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

thehotsurface.

Operator’sManual.

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

Manufacturer’sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

11

Page 12

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

Steeringwheel

Cover

Handle1

Screws

Nopartsrequired

SeatBelt

Bolt2

Lockwasher2

Flatwasher2

ManualTube&Cap

R-clamp2

Nopartsrequired

Electrolyte(notincluded)A/R

Nopartsrequired

Rearweight(s)(notincluded)A/R

Qty.

Use

1

1

2

–

2

1

–

–

Installthesteeringwheel.

Installthehandletothehood.

Installtheseat.

Mounttheseatbelt.

Installthemanualtubeontheleft

undersideoftheseat.

AdjusttheROPS.

Activateandchargethebattery.

Checkthetirepressure.

Installtherearweight.

10

Nopartsrequired

MediaandAdditionalParts

Description

Operator’sManual

EngineOperator’sManual

PartsCatalog

OperatorTrainingMaterial

CerticateofQuality

IgnitionKey1

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Note:Usethischartasachecklisttoensurethat

allpartsnecessaryforassemblyhavebeenreceived.

Withouttheseparts,totalset-upcannotbecompleted.

Somepartsmayhavealreadybeenassembledatthe

factory.

Qty.

–

1

1

1

1

1

AdjustCounterbalancePressure

Use

PTOuniversalshaftisattachedtomachine

frame.DONOTENGAGEPTOwithoutrst

removinguniversalshaftorcouplingittoa

suitableimplement.

12

Page 13

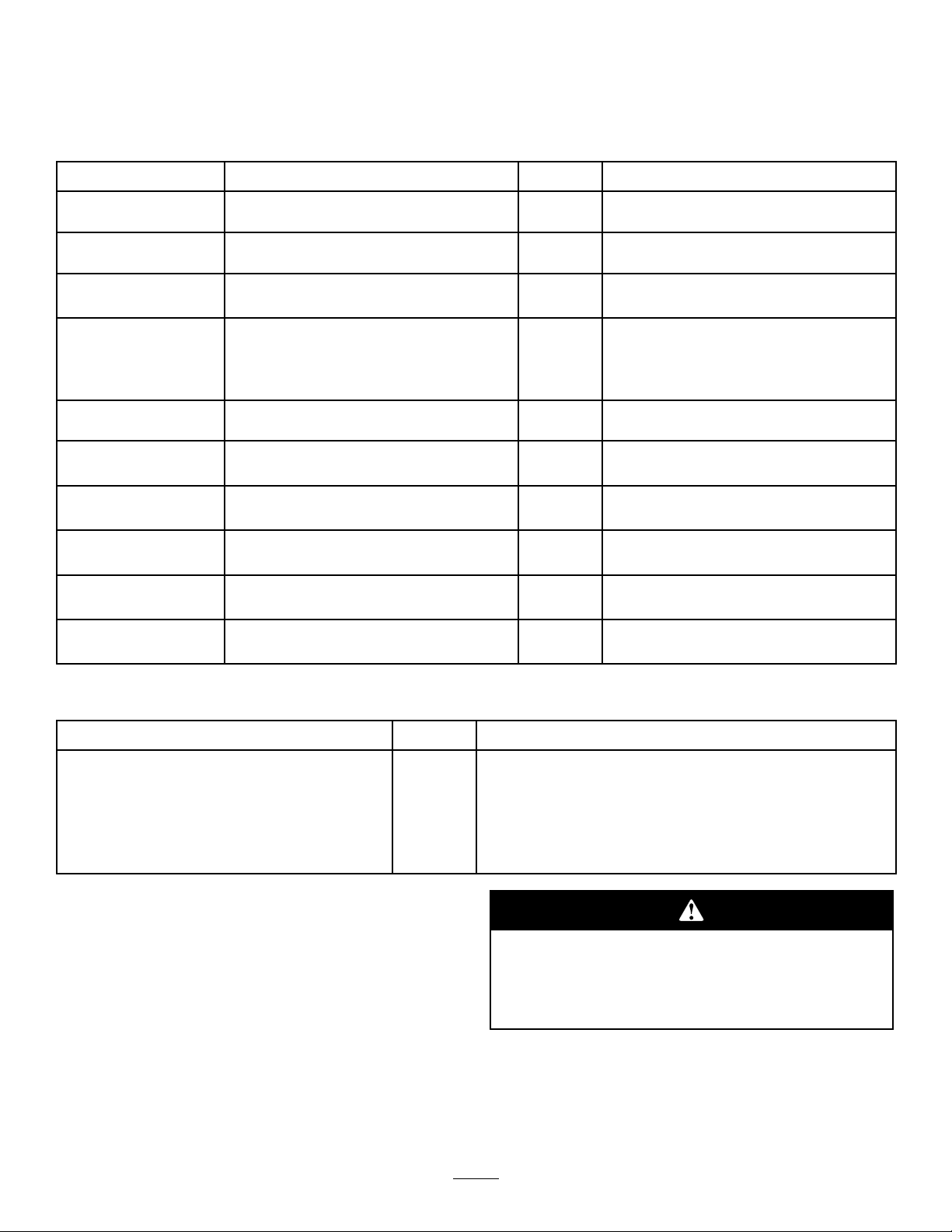

1

2

InstallingtheSteeringWheel

Partsneededforthisprocedure:

1

Steeringwheel

1

Cover

Procedure

1.Removethesteeringwheelfromtheshippingskid.

InstallingtheHandletothe

Hood

Partsneededforthisprocedure:

1Handle

2

Screws

Procedure

1.Removeanddiscardthe(2)screwsandnutssecuring

thehoodcablebracketandtotheundersideofthe

hood(Figure4).

Figure3

1.Steeringwheel

2.Jamnut

3.Dustcover6.Washer

2.Removethejamnutandwasherfromthesteering

shaft.Ensurethatthefoamcollaranddustcover

remainonthesteeringshaft(Figure3).

3.Slidethesteeringwheelandwasherontothesteering

shaft(Figure3).

4.Securethesteeringwheeltotheshaftwiththejam

nut.Tightenthejamnutto20-26ft-lb.

5.Mountthecovertothesteeringwheel(Figure3).

4.Foamcollar

5.Cover

Figure4

1.Hoodcablebracket

2.Mountthehandleandthecablebrackettothehood

with(2)screws(Figure5).

13

Page 14

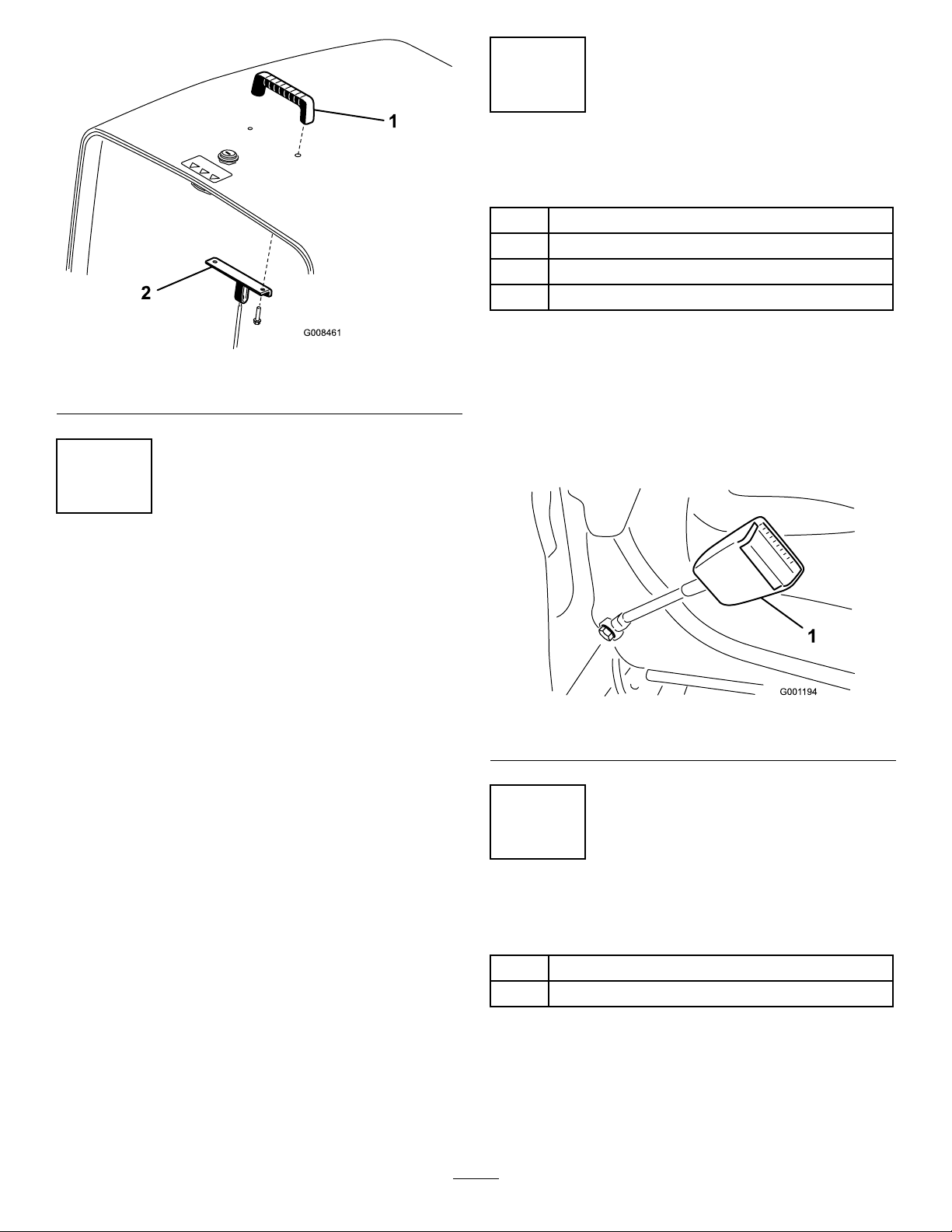

4

InstallingtheSeatBelt

Partsneededforthisprocedure:

2

SeatBelt

2Bolt

2Lockwasher

2Flatwasher

Figure5

1.Handle2.Hoodcablebracket

3

InstallingtheSeat

NoPartsRequired

Procedure

TheGroundsmaster3320isshippedwithouttheseat

assembly.TheSeat,Model30398andtheMechanical

SeatSuspensionKit,ModelNo.30312orthePneumatic

SeatSuspensionKit,ModelNo.30313mustbeobtained

andinstalled.Refertotheseatkitforinstallation

instructions.

Note:AnAuxiliaryPowerUnitKit,ModelNo.30382,

mustbeobtainedandinstalledbeforeinstallinga

PneumaticSuspensionSeatKittothemachine.

Procedure

Installeachendoftheseatbeltintheholesintheback

oftheseatwith(2)7/16x1inchbolts,7/16inch

atwashersand7/16lockwashers(Figure6).Tighten

securely.Thelatchsideofthebeltistobemountedto

theleftsideoftheseat.

Figure6

1.Seatbelt

5

InstallingtheManualTube

Partsneededforthisprocedure:

1

ManualTube&Cap

2R-clamp

Procedure

1.RemovemanualtubeandR–clampssecuredto

theseatplate.Discardthe(2)mountingboltsand

atwashers.

14

Page 15

2.Removethe2nutsandvinylcaps(ifpreviously

installed)securingtheupperseatbrackettotheleft

sideoftheseatsuspension(Figure7).

Figure7

1.R-clamps4.Manualtube

2.Upperseatbracket5.Vinylcap

3.Seatsuspension

Figure8

1.Rollbar3.Hairpincotterpin

2.Pin

2.Raisetherollbartotheuprightpositionandinstall

thetwopinsandsecurethemwiththehairpincotter

pins(Figure8).

Note:Lowerrollbarslowlysodamagetohooddoes

notoccur.

3.LooselymounttheR–clampstotheseatbracket

studswiththe2nutspreviouslyremoved(Figure7).

TheR–clampsaretobepositionedundertheseat

suspensiontabs.

4.InstallthemanualtubeintotheR–clampsand

tightenthenuts(Figure7).

5.Insertthevinylcapsontotheseatbracketstuds.

6

AdjustingtheROPS

NoPartsRequired

Procedure

1.Removethehairpincotterpinsandremovethetwo

pins(Figure8).

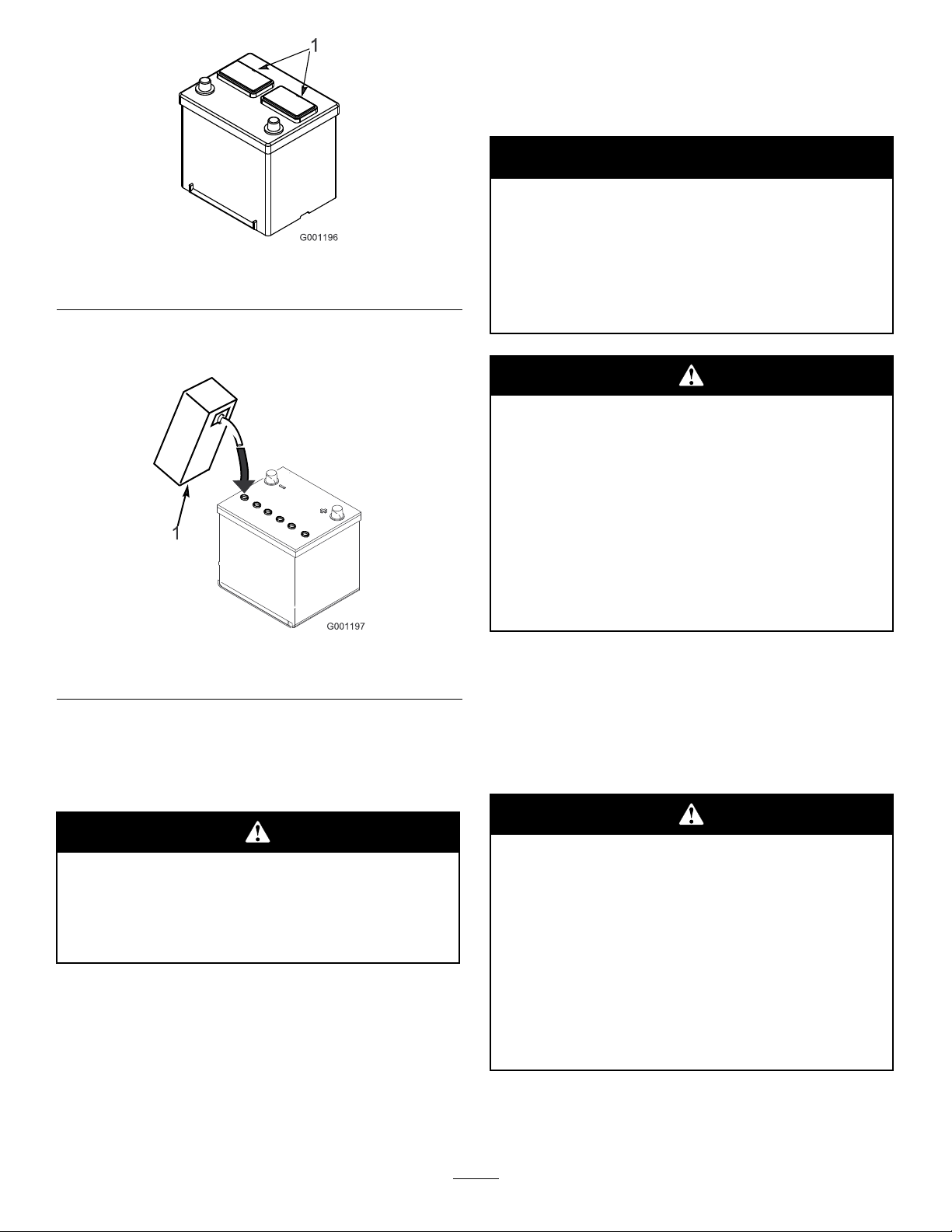

7

ActivatingandChargingthe

Battery

Partsneededforthisprocedure:

A/RElectrolyte(notincluded)

Procedure

Useonlyelectrolyte(1.265SpecicGravity)toll

batteryinitially.

1.Removethebatteryfromthemachine.

Important:Donotaddelectrolytewhilethe

batteryisinthemachine.Youcouldspillit,

causingcorrosion.

2.Cleanthetopofthebatteryandremovethevent

caps(Figure9).

15

Page 16

Figure9

1.Ventcaps

3.Carefullylleachcellwithelectrolyteuntiltheplates

arecoveredwithabout1/4inch(6mm)ofuid.

Note:Afterthebatteryhasbeenactivated,add

onlydistilledwatertoreplacenormalloss,although

maintenance–freebatteriesshouldnotrequirewater

undernormaloperatingconditions.

Warning

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Batteryterminalsormetaltoolscouldshort

againstmetaltractorcomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

Figure10

1.Electrolyte

4.Allowapproximately20to30minutesforthe

electrolytetosoakintotheplates.Rellasnecessary

tobringtheelectrolytetowithinabout1/4inch(6

mm)ofthebottomofthellwell(Figure10).

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

5.Connecta3to4ampbatterychargertothebattery

posts.Chargethebatteryatarateof3to4amps

untilthespecicgravityis1.250orhigherandthe

temperatureisatleast60degreesF(16degreesC)

withallcellsgassingfreely.

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthetractor.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

tractor.

7.Reinstallthebatterytothemachine.

8.First,installthepositivecable(red)tothepositive

(+)terminalandthenthenegativecable(black)to

thenegative(–)terminalofthebattery(Figure11).

Slidetherubberbootoverthepositiveterminalto

preventapossibleshortfromoccurring.

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative(black)

cable.

6.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

16

Page 17

Figure11

1.Positive(+)2.Negative(-)

Connectingcablestothewrongpostcould

damagetheelectricalsystemandresultin

personalinjury.

Note:Makesurebatterycablesareroutedawayfrom

anysharpedgesormovingparts.

8

CheckingtheTirePressure

NoPartsRequired

Procedure

Thetiresareover–inatedforshipping.Therefore,

releasesomeoftheairtoreducethepressure.Correct

airpressureinfrontandreartiresis20psi.

17

Page 18

9

InstallingtheRearWeight

Partsneededforthisprocedure:

A/RRearweight(s)(notincluded)

Procedure

TheGroundsmaster3320SeriesTractionUnitscomplywithCENstandardEN836:1997,ISOstandard5395:1990

andtheANSIB71.4–2004Standardwhenequippedwithrearweight.215lb.ofrearweightisinstalledatthe

factory.Usethechartbelowtodeterminethecombinationsofadditionalweightrequired.Orderpartsfrom

yourlocalAuthorizedToroDistributor.

CuttingUnit

Description

52”SideDischarge

Deck(Model30555)

52”SideDischarge

Deckwith15cu.

ft.Hopper

62”RearDischarge

Deck(Model30403

w/30305)

62”Guardian

RecyclerDeck

(Model30403w/

30306)

60”SideDischarge

Deck(Model30366)

60”SideDischarge

Deckwith15cu.

ft.Hopper

RearWeight

Required

0lb0lb

0lb

0lb0lb

or

or

0lb

LeftSide

Weight

Required

180lb*

75lb**77–6700

WeightPart

Number

———

*77–6700

&&

92–9670BracketKit1

&&

24–5780RearWeightKit1

&&

24–5790RearWeight-35lb1

325–8

3253–7

3217–9

———

WeightDescription

75lbWheelWeight1

Bolt–1/2–13x2”

Lockwasher–1/2

Nut–1/2

75lbWheelWeight1

Quantity

2

2

2

18

Page 19

72”SideDischarge

Deck(Model30368)

or

72”RearDischarge

Deck(Model30404

w/30303)

or

72”Guardian

RecyclerDeck

(Model30404w/

30304)

70lb0lb24–5780RearWeightKit1

*75lbwheelweight(includedwith15cufthopper)requiredonleftwheel

10

AdjustingtheCounterbalance

Pressure

NoPartsRequired

Procedure

Forbestperformance,thecuttingunitbounceon

uneventurfisminimalanditdoesnotrideheavilyover

atterrain.Ifscalpingoccursorthecutisunevenfrom

sidetoside,theremaybetoomuchweightonthedeck

andtheweightmayhavetobetransferredtothetraction

unit:i.e.increasedcounterbalancepressure.

Bycontrast,iftoomuchweightistransferredtothe

tractionunit,thedeckwillbounceexcessivelyandthe

cutwillbeuneven.Ifthecuttingunitdoesnotperform

properly,adjustthecounterbalancepressureasfollows:

1.Ensuretheparkingbrakeisset,thePTOswitchis

inOFFpositionandtheliftleverisintheFLOAT

position.

2.Connectapressuregaugetothetestportbehindthe

rightliftcylinder(Figure12).

Figure12

1.TestPort

2.Rightliftcylinder

3.Loosenthejamnutatthebottomofthe

counterbalancevalve(Figure13).Thevalveis

locatedontherightsideofthemachine.

1.Liftvalve

2.Counterbalancevalve4.Spool

19

Figure13

3.Jamnut

Page 20

4.Starttheengineandsetthethrottletohighidle.

5.UsinganAllenwrench,adjusttheliftvalvespool

untilthedesiredpressureisattainedonthegauge.

Seethechartbelowfortherecommendedpressure

settingforthecuttingdeck.

CuttingDeckCounterbalancePressure

52”SideDischargeDeck

(Model30555)

60”SideDischargeDeck

(Model30366)

or

62”RearDischargeDeck

(Model30403w/30305)

or

62”GuardianRecyclerDeck

(Model30403w/30306)

72”SideDischargeDeck

(Model30368)

or

72”RearDischargeDeck

(Model30404w/30303)

or

72”GuardianRecyclerDeck

(Model30404w/30304)

100psi

175psi

220psi

ProductOverview

Controls

ServiceBrakes

Theleftandrightbrakepedals(Figure14)areconnected

totheleftandrightfrontwheels.Sincebothbrakes

workindependentlyofeachother,thebrakescanbe

usedtoturnsharplyortoincreasetractionifonewheel

tendstoslipwhileoperatingoncertainslopeconditions.

However,wetgrassorsoftturfcouldbedamagedwhen

brakesareusedtoturnsharply.Tomakea“quick-stop”,

depressbothbrakepedalstogether.Alwayslockbrakes

togetherwhentransportingthetractionunit.

6.Stoptheengine.

7.Tightenthejamnutontheliftvalve.Torquethenut

to10–12ft–lb.

8.Removethepressuregaugefromthetestport.

1.Parkingbrakeknob

2.Rightbrakepedal

1.Leftbrakepedal

2.Rightbrakepedal

Figure14

3.Leftbrakepedal

Figure15

3.Lockarm

TractionPedal

Tractionpedal(Figure16)hastwofunctions:oneisto

makethemachinemoveforward,theotheristomakeit

20

Page 21

moverearward.Usingtheheelandtoeoftherightfoot,

depresstopofpedaltomoveforwardandbottomof

pedaltomoverearward.Groundspeedisproportionate

tohowfarpedalisdepressed.Formaximumground

speed,tractionpedalmustbefullydepressedwhile

throttleisinFASTposition.Maximumspeedforwardis

10mph(16Km/hr)(approxamately).Togetmaximum

powerunderheavyloadorwhenascendingahill,have

throttleinFASTpositionwhiledepressingtraction

pedalslightlytokeepenginerpmhigh.Whenengine

rpmbeginstodecrease,releasetractionpedalslightly

toallowrpmtoincrease.

Figure17

1.Tiltsteeringcontrol

Neverraisedeckwhilebladesarerotating

becauseitishazardous.

Figure16

1.Tractionpedal

ParkingBrake

Whenevertheengineisshutoff,theparkingbrakemust

beengagedtopreventaccidentalmovementofthe

machine.Toengagetheparkingbrake,pushlockarm

(Figure15)onleftbrakepedalsothatitlockstogether

withtherightpedal.Next,pushdownfullyonboth

pedalsandpullparkingbrakeknobout(Figure14)then

releasethepedals.Toreleaseparkingbrake,depressboth

pedalsuntilparkingbrakeknobretracts.Beforestarting

theengine,however,lockarmmaybedisengagedfrom

leftbrakepedalsobothpedalsworkindependentlywith

eachfrontwheel.

TiltSteeringControl

Thetiltsteeringcontrolisaleveronrightsideofsteering

column(Figure17).Pullleverrearwardtoadjuststeering

wheeltodesiredforeoraftoperatingpositionandpush

leverforwardtolockadjustment.

HydraulicLiftLever

Thehydraulicliftlever(Figure18)hasthreelever

positionsthatactuatefouroperatingmodes;LIFT,

LOWER,FLOAT&HOLD .Tolowerthedeck,in

preparationformowing,movetheleverforwardand

thenallowthelevertofreelyreturn.Thiswillallow

thedecktodropatacontrolledrateandenablesthe

deckgroundfollowingoatfunction.Toraisethedeck

andholditinthetransportposition,pullandholdthe

liftleverrearwarduntilthedeckhasfullyraised,then

releasethelevertoallowittoreturn.Thedeckwillnow

holdinthetransportposition.Thedeckmustberaised

whentransportingbetweenmowinglocations.Thedeck

shouldbeloweredwhennotinuse.

PTOSwitch

PullupontheswitchknobtoENGAGEtheelectric

PTOclutch(Figure18).Pushdownontheknobto

DISENGAGEelectricPTOclutch.Theonlytimethe

PTOswitchshouldbeintheENGAGEpositionis

whentheimplementisdowninoperatingpositionand

readytobeginoperation.Iftheoperatorleavestheseat

whenthePTOswitchisengaged,thetractionunitwill

shutdown.Tore–engagethePTO,pushdownandpull

upontheknob.

21

Page 22

Figure18

1.Hydraulicliftlever7.Oilpressureindicator

2.PTOwitch8.Chargeindicator

3.Ignitionswitch

4.Throttle10.Powerpoint

5.Hourmeter

6.Enginecoolant

temperature

9.Liftleverlock

11.Choke

HourMeter

Thehourmeter(Figure18)registersaccumulatedhours

ofengineoperation.

EngineCoolantTemperatureWarning

Light

Thetemperaturewarninglight(Figure18)glowsand

theimplementstopsiftheenginecoolanttemperature

ishigh.Ifthemachineisnotstoppedandthecoolant

temperaturerisesanother20°F ,theenginewillkill.

Choke

Tostartengine,closecarburetorchoke(Figure18)

bypullingchokecontrolupward.Afterenginestarts,

regulatechoketokeepenginerunningsmoothly.As

soonaspossible,openthechokebypushingitinward.

Awarmenginerequireslittleornochoking.

FuelGauge

Thefuelgauge(Figure19)indicatesquantityoffuel

remaininginfueltank.

Figure19

1.Fuelgauge

IgnitionSwitch

ChargeIndicator

Illuminateswhensystemchargingcircuitmalfunctions

(Figure18).

OilPressureWarningLight

Theoilpressurewarninglight(Figure18)glowswhen

oilpressureinenginedropsbelowasafelevel.Iflow

oilpressureeveroccurs,stopengineanddeterminethe

cause.Repairthedamagebeforestartingtheengine

again.

LiftLeverLock

Lockliftlever(Figure18),inraisedposition,when

performingmaintenanceondeck.

Threepositions:OFF,RUNandSTART.(Figure18).

Throttle

Throttle(Figure18)isusedtooperateengineatvarious

speeds.Movingthrottleforwardincreasesenginespeed

—FAST;rearwarddecreasesenginespeed—SLOW .

Thethrottlecontrolsthespeedofthecutterbladesand,

inconjunctionwithtractionpedal,controlsground

speedofthemachine.Thedetentisthehighidle

position.

22

Page 23

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

DimensionsandWeights(approx.)

Width(measuredfromoutside

offronttires)

Length(withoutcutterdeck)83.5inches(212cm)

Height(withROPSraised)77inches(196cm)

DryWeight(withoutcutter

deck)

47inches(120cm)

1555lb(705kg)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructions

andsymbolsinthesafetysection.Knowingthis

informationcouldhelpyouorbystandersavoidinjury.

Theuseofprotectiveequipment,suchasbutnot

limitedto,foreyes,ears,feet,andheadisrecommended.

Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

CheckingtheEngineOil

ServiceInterval:Beforeeachuseordaily—Checkthe

engineoil.

Theengineisshippedwithoilinthecrankcase;

however,theoillevelmustbecheckedbeforeandafter

theengineisrststarted.

Crankcasecapacityisapproximately3.2quarts(3l)

withthelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

APIClassicationLevelRequired:SJ,SK,SLorhigher.

Preferredoil:SAE10W–30(alltemperatures)

Alternateoil:SAE5W–30(alltemperatures)SAE30

(above32F)

ToroPremiumEngineoilisavailablefromyour

distributorin10W–30viscosity.Seethepartscatalog

forpartnumbers.

1.Parkthemachineonalevelsurface,lowerthe

cuttingdeck,stoptheengineandremovethekey

fromtheignitionswitch.Openthehood.

2.Removethedipstick(Figure20),wipeitcleanand

reinstallthedipstick.Removethedipstickand

checktheoillevel.Theoillevelshouldbeuptothe

FULLmarkonthedipstick

23

Page 24

Figure20

1.Dipstick

3.IftheoillevelisbelowtheFULLmark,remove

thellcap(Figure20)andaddoiluntilitlevel

reachestheFULLmarkonthedipstick.DONOT

OVERFILL.

4.Installtheoilllcapandclosethehood.

Iftheenginehasbeenrunning,pressurizedhot

coolantcanescapewhentheradiatorcapis

removedandcauseburns.

1.Checkthelevelofthecoolantintheexpansiontank

(Figure22).Thecoolantlevelshouldbebetween

themarksonthesideofthetank.

Figure22

1.Expansiontank

Figure21

1.Oilll

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily

Cleandebrisoffthescreenandtheradiator/oilcooler

daily,moreoftenifconditionsareextremelydustyand

dirty;refertosectiononEngineCoolingSystem.

Thecoolingsystemislledwitha50/50solutionof

waterandpermanentethyleneglycolantifreeze.Check

thelevelofthecoolantintheexpansiontankatthe

beginningofeachdaybeforestartingtheengine.The

capacityofthecoolingsystemis4qt(3.7l).

2.Ifcoolantlevelislow ,removeexpansiontankcap

andreplenishthesystem.DONOTOVERFILL.

3.Installexpansiontankcap.

CheckingtheHydraulic

System

ServiceInterval:Beforeeachuseordaily

Themachinesreservoirislledatthefactorywith

approximately5quarts(4.7l)ofhighqualityhydraulic

uid.Checkthelevelofthehydraulicuidbefore

theengineisrststartedanddailythereafter.The

recommendedreplacementuidis:

ToroPremiumTransmission/HydraulicTractor

Fluid

(Availablein5gallonpailsor55gallondrums.Seeparts

catalogorTorodistributorforpartnumbers.)

Alternateuids:IftheTorouidisnotavailable,other

petroleum–basedUniversalTractorHydraulicFluids

(UTHF)maybeusedprovideditsspecicationsfall

withinthelistedrangeforallthefollowingmaterial

propertiesanditmeetsindustrystandards.Wedonot

recommendtheuseofsyntheticuid.Consultwith

yourlubricantdistributortoidentifyasatisfactory

24

Page 25

productNote:Torowillnotassumeresponsibilityfor

damagecausedbyimpropersubstitutions,souseonly

productsfromreputablemanufacturerswhowillstand

behindtheirrecommendation.

3.Threaddipstickllcapnger-tightontollerneck.

Itisnotrecommendedtotightencapwithawrench.

4.Checkallhosesandttingsforleaks.

MaterialProperties:

Viscosity,ASTMD445cSt@40C.55to62cSt@

100C9.1to9.8

ViscosityIndexASTMD2270140–152

PourPoint,ASTMD97–35Fto–46F

IndustrySpecications:

APIGL–4,AGCOPoweruid821XL,FordNew

HollandFNHA–2–C–201.00,KubotaUDT,John

DeereJ20C,Vickers35VQ25andVolvoWB–101/BM.

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemoilisavailablein2/3oz.(20ml)

bottles.Onebottleissufcientfor4–6gal(15–221)

ofhydraulicoil.Orderpartno.44–2500fromyour

authorizedTorodistributor.

1.Positionmachineonalevelsurface.Placeallcontrol

inneutralpositionandstarttheengine.Runengine

atlowestpossibleRPMtopurgethesystemofair.

DONOTENGAGEPTO.Cyclesteeringwheel

severaltimesfullytotheleftandright.Raisethe

decktoextendliftcylinders,aimingsteeringwheels

straightforwardandstoptheengine.

2.Removedipstickcap(Figure23)fromllerneck

andwipeitwithacleanrag.Screwdipstickcap

nger-tightontollerneck;thenremoveitand

checklevelofuid.Iflevelisnotwithin1/2inch

(13mm)fromthegrooveinthedipstick(Figure23),

addenoughhighqualityhydraulicuidtoraiselevel

togroovemark.Donotoverll.

FillingtheFuelTank

Fueltankcapacityisapproximately12.8gallon(48.5l).

1.Usingacleanrag,cleanareaaroundfueltankcap.

2.Removecapfromthefueltank(Figure24).

Figure24

1.Fueltankcap

3.Fillthetankuntilthelevelistothebottomofthe

llerneckwithunleadedfuel.

4.Installfueltankcaptightlyafterllingtank.

Undercertainconditions,fuelandfuelvapors

arehighlyammableandexplosive.Areor

explosionfromfuelcanburnyouandothers

andcancausepropertydamage.

Figure23

1.Hydraulicsystemreservoiruid/adddipstickcap

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelistothe

bottomofthellerneck.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

25

Page 26

UsingtheRolloverProtection

System(ROPS)

Toavoidinjuryordeathfromrollover:keepthe

rollbarintheraisedlockedpositionanduse

theseatbelt.

Ensurethattherearpartoftheseatissecured

withtheseatlatch.

Thereisnorolloverprotectionwhentherollbar

isinthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

Figure25

1.Rollbar3.Hairpincotterpin

2.Pin

2.Lowertherollbartothedownposition.

3.Installthetwopinsandsecurethemwiththehairpin

cotterpins(Figure25).

•Donotweartheseatbeltwhentherollbaris

inthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearance

permits.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontact

them.

•Lowerrollbarslowlysodamagetohood

doesnotoccur.

Important:Lowertherollbaronlywhen

absolutelynecessary.

1.Tolowertherollbar,removethehairpincotterpins

andremovethetwopins(Figure25).

Important:Alwaysusetheseatbeltwiththe

rollbarintheraisedposition.

4.Toraisetherollbar,removethehairpincotterpins

andremovethetwopins(Figure25).

5.Raisetherollbartotheuprightpositionandinstall

thetwopinsandsecurethemwiththehairpincotter

pins(Figure25).

Starting/StoppingtheEngine

1.Ensureparkingbrakeisset,PTOswitchisin

OFFpositionandliftleverisinTRANSPORTor

FLOATposition.Removefootfromtractionpedal

andinsureitisinneutral.

2.Pullchoketofullchokepositionandmovethrottle

controltoSLOWposition.

3.TurnkeyinignitionswitchtoSTARTposition.

Releasekeyimmediatelywhenenginestartsand

allowittoreturntoRUNposition.Regulatechoke

tokeepenginerunningsmoothly.

Note:Donotrunstartermotormorethan20

secondsatatimeorprematurestarterfailuremay

result.Ifenginefailstostartafter20seconds,

turnkeytoOFFposition,recheckcontrolsand

procedures,wait10additionalsecondsandrepeat

starteroperation.

4.Whenengineisstartedforthersttime,or

afterengineoilchange,oroverhaulofengine,

transmissionoraxle,operatethemachineinforward

andreverseforonetotwominutes.Alsooperatethe

liftleverandPTOlevertoensureproperoperation

ofallparts.Turnpowersteeringwheeltotheleft

26

Page 27

andrighttochecksteeringresponse.Thenshut

engineoffandcheckuidlevels,checkforoilleaks,

loosepartsandanyothernoticeablemalfunctions.

Shutengineoffandwaitforallmovingpartsto

stopbeforecheckingforoilleaks,looseparts

orothermalfunctions.

5.Tostopengine,movethrottlecontrolbackwardto

SLOWposition,movePTOswitchtoOFFposition

androtateignitionkeytoOFF.Removekeyfrom

switchtopreventaccidentalstarting.

CheckingInterlockSystem

Thepurposeofthesafetyinterlocksystemistoprevent

theenginefromcrankingorstartingunlessthetraction

pedalisinneutralandthePTOswitchisintheOFF

position.Inaddition,theenginewillstopwhenthe

PTOcontrolisengagedortractionpedalisdepressed

withoperatorofftheseatorwhenparkingbrakeis

engaged.

correctly;thus,proceedtostep5Ifenginedoesnot

stop,thereisamalfunctionintheinterlocksystem.

5.Engagetheparkingbrake.Depressthetraction

pedalwhileengineisrunningandthePTOlever

isdisengaged.Theengineshouldstopwithin2

seconds.Ifenginestops,theswitchisoperating

correctly;thus,continueoperation.Ifenginedoes

notstop,thereisamalfunctionintheinterlock

system.

PushingOrTowingthe

Machine

Inanemergency,themachinecanbepushedortowed

foraveryshortdistance.However,T orodoesnot

recommendthisasstandardprocedure.

Important:Donotpushortowthemachine

fasterthan2to3mph(3.2to4.8Km/hr)because

transmissionmaybedamaged.Ifthemachine

mustbemovedaconsiderabledistance,transport

itonatruckortrailer.Whenevermachineis

pushedortowed,by-passvalvemustbeopen.

1.Loosentheknobandremovetheaccesscoverat

therearoftheseatmountingplate(Figure26).

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

1.MovePTOswitchtoOFFpositionandremove

footfromtractionpedalsoitisfullyreleased.

2.RotatetheignitionkeytoSTART.Engineshould

crank.Ifenginecranks,proceedtostep3.Ifengine

doesnotcrank,theremaybeamalfunctioninthe

interlocksystem.

3.RaiseofftheseatandengagethePTOswitch

whiletheengineisrunning.Theengineshould

stopwithin2seconds.Ifenginestops,theswitch

isoperatingcorrectly;thus,proceedtostep4.If

enginedoesnotstop,thereisamalfunctioninthe

interlocksystem.

Figure26

1.Accesscoverknob

2.Depressandholdthepinslocatedinthecenterof

thetwo(2)checkvalveassembliesinthetopofthe

transmission(Figure27)whilepushingortowing

themachine.Figure27isshownwithseatandseat

mountingplateremoved.

4.Raiseofftheseatanddepressthetractionpedal

whileengineisrunningandthePTOleveris

disengaged.Theengineshouldstopwithin2

seconds.Ifenginestops,theswitchisoperating

27

Page 28

Figure27

1.Transmissioncheckvalveby–passpins(2)

Thismachineproducessoundlevelsinexcess

of85dBAattheoperatorsearandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

3.Starttheenginemomentarilyaftertherepairsare

completedandmakesurethepinsareinthefull

disengaged(fullyup)position.

Important:Runningthemachinewithby-pass

valveopenwillcausethetransmissionto

overheat.

4.Reinstalltheaccesscover.

OperatingCharacteristics

PracticedrivingtheGROUNDSMASTER3320

beforeinitialoperationbecauseithasahydrostatic

transmissionanditscharacteristicsaredifferentthan

someturfmaintenancemachines.Somepointsto

considerwhenoperatingthetractionunitanddeck

arethetransmission,enginespeed,loadonthecutting

blades,andtheimportanceofthebrakes.

Tomaintainenoughpowerforthetractionunitand

deckwhilemowing,regulatetractionpedaltokeep

enginerpmhighandsomewhatconstant.Agood

ruletofollowis:decreasegroundspeedastheload

onthecuttingbladesincreases;andincreaseground

speedasloadonthebladesdecreases.Thisallowsthe

engine,workingwiththetransmission,tosensethe

propergroundspeedwhilemaintaininghighbladetip

speednecessaryforgoodquality-of-cut.Therefore,

allowtractionpedaltomoveupwardasenginespeed

decreases,anddepresspedalslowlyasspeedincreases.

Bycomparison,whendrivingfromoneworkareato

another—withnoloadanddeckraised—havethrottle

inFASTpositionanddepresstractionpedalslowlybut

fullytoattainmaximumgroundspeed.

Adequaterearweightisnecessarytoprevent

therearwheelsfromleavingtheground.Do

notstopsuddenlywhiledeckorimplementis

raised.Donottraveldownhillwiththedeckor

implementraised.Iftherearwheelleavesthe

ground,steeringislost.

Anothercharacteristictoconsideristheoperationof

thebrakes.Thebrakescanbeusedtoassistinturning

themachine;however,usethemcarefully,especially

onsoftorwetgrassbecausetheturfmaybetorn

accidentally.Thebrakescanbeusedtogreatadvantage

tocontrolthedirectionofthedeckwhentrimming

alongfencesorsimilarobjects.Theotherbenetof

thebrakesistomaintaintraction.Forexample;in

someslopeconditions,theuphillwheelslipsandloses

traction.Ifthissituationoccurs,depressuphillbrake

pedalgraduallyandintermittentlyuntiltheuphillwheel

stopsslipping;thus,increasingtractiononthedownhill

wheel.Ifindependentbrakingisnotdesired,engage

theleveronleftbrakepedalwithrightpedal.This

providessimultaneousbrakingatbothwheels.

Beforestoppingtheengine,disengageallcontroland

movethrottletoSLOW .MovingthrottletoSLOW

reduceshighenginespeed,noiseandvibration.Turn

ignitionkeytoOFFtostoptheengine.

StandardControlModule

(SCM)

TheStandardControlModuleisa”potted”electronic

deviceproducedina”onesizetsall”conguration.

Themoduleusessolidstateandmechanical

componentstomonitorandcontrolstandardelectrical

featuresrequiredforsafeproductoperation.

Themodulemonitorsinputsincludingneutral,parking

brake,PTO,start,backlap,andhightemperature.The

moduleenergizesoutputsincludingPTO,Starter,and

ETR(energizetorun)solenoid.

28

Page 29

Themoduleisdividedintoinputsandoutputs.Inputs

andoutputsareidentiedbyyellowLEDindicators

mountedontheprintedcircuitboard.

Thestartcircuitinputisenergizedby12VDC.All

otherinputsareenergizedwhenthecircuitisclosedto

ground.EachinputhasaLEDthatisilluminatedwhen

thespeciccircuitisenergized.UsetheinputLED’s

forswitchandinputcircuittroubleshooting.

Outputcircuitsareenergizedbyanappropriatesetof

inputconditions.ThethreeoutputsincludePTO,ETR,

andSTART.OutputLED’smonitorrelaycondition

indicatingthepresenceofvoltageatoneofthree

specicoutputterminals.

Outputcircuitsdonotdetermineoutputdeviceintegrity

soelectricaltroubleshootingincludesoutputLED

inspectionandconventionaldeviceandwireharness

integritytesting.Measuredisconnectedcomponent

impedance,throughwireharness(disconnectat

SCM),orbytemporarily“testenergizing”thespecic

component.

TheSCMdoesnotconnecttoanexternalcomputeror

handhelddevice,cannotbere–programmed,anddoes

notrecordintermittentfaulttroubleshootingdata.

ThedecalontheSCMonlyincludessymbols.Three

LEDoutputsymbolsareshownintheoutputbox.All

otherLED’sareinputs.Thechartbelowidentiesthe

symbols.

Figure28

1.Inputs5.Inseat

2.Backlap

3.Hightemperatureshutdown

4.Hightemperaturewarning8.Neutral

6.PowerT ake-off(PTO)10.PowerT ake-off(PTO)

7.ParkingbrakeOff11.Start

HerearethelogicaltroubleshootingstepsfortheSCM

device.

1.Determinetheoutputfaultyouaretryingtoresolve

(PTO,START,orETR).

2.Movekeyswitchto”ON”andensurethered

”power”LEDisilluminated.

3.MoveallinputswitchestoensureallLED’schange

state(Seat,Brake,TractionPedal,PTOandStart.

4.Positioninputdevicesatappropriatepositionto

achievetheappropriateoutput.Usethefollowing

9.Outputs13.Start

14.Power

12.EnergizetoRun(ETR)

logiccharttodeterminetheappropriateinput

condition.

5.IfspecicoutputLEDisilluminatedwithout

appropriateoutputfunction,checkoutputharness,

connections,andcomponent.Repairasrequired.

6.IfspecicoutputLEDisnotilluminated,check

bothfuses.

7.IfspecicoutputLEDisnotilluminatedandinputs

areinappropriatecondition,installnewSCMand

determineiffaultdisappears.

Note:Eachrow(across)inthelogicchartbelowidentiesinputandoutputrequirementsforeachspecicproduct

function.Productfunctionsarelistedintheleftcolumn.Symbolsidentifyspeciccircuitconditionincluding:

energizedtovoltage,closedtoground,andopentoground.

29

Page 30

INPUTSOUTPUTS

FunctionPower

ON

Start

Run(Off

Unit)

Run(On

Unit)

Mow

HiT emp

Warning

HiT emp

Shutdown

——

——

—

—

—

—

In

Neutral

OO

OO

Start

ON

Brake

ON

+

OOOOOON/AO

OO—(AN/A

O

OO

—

———

(—)Indicatesacircuitclosedtoground.–LEDON

(O)Indicatesacircuitopentogroundorde–energized

–LEDOFF

(+)Indicatesanenergizedcircuit(clutchcoil,solenoid,

orstartinput)LEDON.

“”ABlankindicatesacircuitthatisnotinvolvedwith

thelogic.

PTO

ON

InSeat

O

HiT emp

Shutdown

—

—

HiT emp

Warning

OON/A

OON/AO

OON/AO

—

Back

Lap

N/AOOO

++

++

+

+

++

O

O

O

O

(A)PTOinputmustbere–initiatedafterenginecool

down(cyclekeyon–off)

N/ANotapplicable

Totroubleshoot,turnonthekeywithoutstartingthe

engine.Identifythespecicfunctionthatdoesnot

workandworkacrossthelogicchart.Inspectthe

conditionofeachinputLED’stoensureitmatchesthe

logicchart.

IftheinputLED’sarecorrect,checktheoutput

LED.IftheoutputLEDisilluminatedbutthedevice

isnotenergized,measureavailablevoltageatthe

outputdevice,continuityofthedisconnecteddevice,

andpotentialvoltageonthegroundcircuit(oating

ground).Repairswillvarydependingonyourndings.

30

Page 31

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst10hours

Aftertherst50hours

Beforeeachuseordaily

Every50hours

Every200hours

MaintenanceProcedure

•Replacethehydraulicoillter.

•Checkthebrakeoperation

•Checkthealternatorbelttension.

•CheckthePTObelttension.

•T orquewheellugnuts

•Changetheoilandoillter.

•Checkthebrakeoperation

•CheckthePTObelttension.

•Checktheengineoil.

•Cleandebrisoffthescreenandtheradiator/oilcooler.

•Checkthelevelofthehydraulicuid.

•Checkthescreenandradiator

•Lubricateallbearingsandbushings.(Lubricateallbearingsandbushingsdailywhen

conditionsaredustyanddirty.)

•Checktheelectrolytelevel.(Ifthemachineisinstorage,checktheelectrolytelevel

every30days.)

•Changetheoilandoillter.

•AdjustthePTOClutch

•Checktherearwheeltoe-in.

•Checkthealternatorbelttension.

•CheckthePTObelttension.

•Replacethehydraulicoillter.

•T orquewheellugnuts

•Inspectcoolingsystemhoses

•Checkrearwheeltoe-inandsteeringlinkage

•Servicetheaircleaner.(Servicemorefrequentlyinextremelydustyordirty

conditions.)

Every400hours

Every1,500hours

•Replacethefuelprelter

•Checkfuellinesandconnections.

•Coattransmissionbypasspinswithgrease

•AdjustvalvesandcheckengineRPM

•Replacethehydraulicoil.

•Replacemovinghoses

•Coolantsystem-ush/replaceuid

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

31

Page 32

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof:

MaintenanceCheckItem

Checkthesafetyinterlock

operation.

Checkthatthegrassdeector

isinthedownposition

Checkthebrakeoperation.

Checkthefuellevel.

Checktheengineoillevel.

Checkthecoolingsystem

uidlevel

Inspecttheairlterrestriction

indicator

Checktheradiatorand

screenfordebris

Checkforunusualengine

noises

Checkforunusualoperating

noises

Checkthetransmissionoil

level

Checkhydraulichosesfor

damage

Checkforuidleaks

Checkthetirepressure

Checktheinstrument

operation

Checktheconditionofthe

blades

Lubricateallthegrease

ttings

Touch-upanydamagedpaint

1

=Immediatelyaftereverywashing,regardlessoftheintervallisted

2

=Iftheindicatorshowsred

2

1

Mon.T ues.Wed.Thurs.Fri.

Sat.Sun.

Important:Refertoyourengine

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Operator’ s Man ual

foradditionalmaintenanceprocedures.

Information

32

Page 33

ServiceIntervalChart

Figure29

33

Page 34

Lubrication

GreasingtheBearingsAnd

Bushings

ServiceInterval:Every50hours(Lubricateallbearings

andbushingsdailywhenconditions

aredustyanddirty.)

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBase

Grease.Bearingsandbushingsmustbelubricateddaily

whenoperatingconditionsareextremelydustyand

dirty.Dustyanddirtyoperatingconditionscouldcause

dirttogetintothebearingsandbushings,resultingin

acceleratedwear.Lubricategreasettingimmediately

aftereverywashing,regardlessofintervalspecied.

Applyaliberalcoatingofgreasetothecheckvalvepins

onceeachyear(Figure27).Alsogreasethebearingsin

therearaxleevery500hours,oryearly,whichevercomes

rst(notshown).Thebearingandbushinglubrication

pointsare:

•PTOuniversalshaft(Figure30)

•Brakepivotbushings(Figure32)

Figure32

•Brakecables(drivewheelandbrakepedalends)

(Figure33)

•PTOtensionpivot(Figure33)

Figure30

•Liftarmpivotbushings(Figure31)

Figure33

•RearPTObearing(Figure33)

•Transmissionneutralshaft(Figure34)

Figure34

Figure31

34

Page 35

•Rearwheelspindlebushings(Figure35)

providegoodperformanceandlifeundernormaluse,

butperiodicinspectionsofbearingconditionandseal

integrityshouldbeconductedtoavoiddowntime.These

bearingsshouldbeinspectedseasonallyandreplacedif

damagedorworn.Bearingsshouldoperatesmoothly

withnodetrimentalcharacteristicssuchashighheat,

noise,loosenessorindicationsofcorrosion(rust).

Duetotheoperatingconditionsthesebearing/seal

packagesaresubjectto(i.e.sand,turfchemicals,water,

impacts,etc.)theyareconsiderednormalwearitems.

Bearingsthatfailduetocausesotherthandefectsin

materialsorworkmanshiparetypicallynotcovered

underwarranty.

Figure35

•Steeringplatebushings(Figure36)

•Axlepinbushing(Figure36)

Figure36

1.Wipegreasettingcleansoforeignmattercannotbe

forcedintothebearingorbushing.

Note:Bearinglifecanbenegativelyaffectedby

improperwashdownprocedures.Donotwash

downtheunitwhenitisstillhotandavoiddirecting

high–pressureorhighvolumesprayatthebearings.

2.Pumpgreaseintothebearingorbushing.

3.Wipeupexcessgrease.

Note:Bearingsrarelyfailfromdefectsinmaterialsor

workmanship.Themostcommonreasonforfailure

ismoistureandcontaminationworkingitswaypast

theprotectiveseals.Bearingsthataregreasedwillrely

uponregularmaintenancetopurgeharmfuldebrisfrom

thebearingarea.Sealedbearingsrelyonaninitial

llofspecialgreaseandarobustintegralsealtokeep

contaminantsandmoistureoutoftherollingelements.

Thesealedbearingsrequirenolubricationorshortterm

maintenance.Thisminimizesroutineservicerequired

andreducesthepotentialofturfdamageduetogrease

contamination.Thesesealedbearingpackageswill

35

Page 36

EngineMaintenance

GeneralAirCleaner

Maintenance

ServiceInterval:Every400hours(Servicemore

frequentlyinextremelydustyordirty

conditions.)

•Checkaircleanerbodyfordamagewhichcould

possiblycauseanairleak.Replaceadamagedair

cleanerbody .Checkthewholeintakesystemfor

leaks,damageorloosehoseclamps.

•Servicetheaircleanerlterwhenaircleanerindicator

(Figure37)showsredorevery400hours(more

frequentlyinextremedustyordirtyconditions).Do

notoverserviceairlter.

Figure38

1.Aircleanerlatch3.Rubberoutletvalve

2.Aircleanercover

2.Removethecoverfromtheaircleanerbody.Before

removingthelter,uselowpressureair(40psi,

cleananddry)tohelpremovelargeaccumulations

ofdebrispackedbetweenoutsideofprimarylter

andthecanister.Avoidusinghighpressureairwhich

couldforcedirtthroughthelterintotheintake

tract.Thiscleaningprocesspreventsdebrisfrom

migratingintotheintakewhentheprimarylteris

removed.

Figure37

1.Aircleanerindicator

•Besurethecoverisseatedcorrectlyandsealswith

theaircleanerbody.

ServicingtheAirCleaner

1.Pulllatchoutwardandrotateaircleanercover

counter–clockwise(Figure38).

3.Removeandreplacetheprimarylter(Figure39).

Cleaningoftheusedelementisnotrecommended

duetothepossibilityofdamagetotheltermedia.

Inspectthenewlterforshippingdamage,checking

thesealingendofthelterandthebody.Donotuse

adamagedelement.Insertthenewlterbyapplying

pressuretotheouterrimoftheelementtoseatitin

thecanister.Donotapplypressuretotheexible

centerofthelter.

Figure39

1.Filter

4.Cleanthedirtejectionportlocatedintheremovable

cover.Removetherubberoutletvalvefromthe

cover,cleanthecavityandreplacetheoutletvalve.

36

Page 37

5.Installthecoverorientingtherubberoutletvalvein

adownwardposition–betweenapproximately5:00

to7:00whenviewedfromtheend(Figure38).

6.Resetindicator(Figure37)ifshowingred.

ChangingtheEngineOilAnd

Filter

ServiceInterval:Aftertherst50hours—Changethe

oilandoillter.

Every200hours—Changetheoiland

oillter.

Ifpossible,runenginejustbeforechangingoilbecause

warmoilowsbetterandcarriesmorecontaminants

thancoldoil.

1.Positionmachineonalevelsurface.

2.Openthehood.Setdrainpanundertheoilpanand

inlinewithdrainplug(Figure40).

Figure41

1.Oillter

Figure40

1.Drainplug

3.Cleanareaarounddrainplug.

4.Removeoildrainplugandallowoiltoowinto

drainpan.

5.Removeandreplaceoillter(Figure41).

6.Afteroilisdrained,reinstalldrainplugandwipeup

anyoilthatisspilled.

7.Fillcrankcasewithoil;refertoCheckCrankcaseOil.

37

Page 38

FuelSystem

Maintenance

ServicingtheFuelSystem

FuelTank

Drainandcleanfueliftankbecomescontaminatedor

machineistobestoredforanextendedperiod.Use

cleansolventtoushoutthetank.

1.Lubricategasketonltercanisterwithcleanoil.

2.Installltercanisterbyhanduntilgasketcontacts

mountingsurface,thenrotateanadditional1/2turn.

ReplacingFuelPreFilter

ServiceInterval:Every400hours/Y early(whichever

comesrst)

1.Clampbothfuellinesthatconnecttothefuellterso

fuelcannotdrainwhenlinesareremoved(Figure42).

2.Loosenthehoseclampsatbothendsofthelter

andpullfuellinesofflter.

Undercertainconditions,fuelandfuelvapors

arehighlyammableandexplosive.Areor

explosionfromfuelcanburnyouandothers

andcancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelistothe

bottomofthellerneck.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

3.Slidehoseclampsontoendsoffuellines.Push

fuellinesontofuellterandsecurethemwithhose

clamps.Besurearrowonsideoflterpointstoward

theinjectionpump.

1.Fuelprelter

FuelLinesandConnections

ServiceInterval:Every400hours/Y early(whichever

comesrst)—Checkfuellinesand

connections.

Inspectfordeterioration,damageorlooseconnections.

Figure42

38

Page 39

ElectricalSystem

Maintenance

storedinalocationwheretemperaturesareextremely

high,thebatterywillrundownmorerapidlythanif

themachineisstoredinalocationwheretemperatures

arecool.

AdjustingthePTOClutch

ServiceInterval:Every200hours

Thepowertakeoffelectricclutchcanbeadjustedby

followingthefollowingprocedure:

1.Turnengineoffandremovetheignitionkey.Setthe

parkingbrake.Raisetheenginehoodandallowthe

enginetocool.

2.Unplugclutchelectricconnector(Figure43).

Maintainthecelllevelwithdistilledordemineralized

water.Donotllthecellsabovethebottomofthesplit

ringinsideeachcell.

Warning

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

W ash hands after handling .

Batteryelectrolytecontainssulfuricacidwhich

isadeadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontact

withskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

Figure43

1.Clutch

2..015”airgap(3)

3.Adjustingnut(3)

3.Adjusttheairgapsothata.015inchfeelergauge

slidesinbetweentheclutchliningandfrictionplate

withlightpressure(Figure43).Thegapcanbe

decreasedbyturningtheadjustingnutclockwise

(Figure43).Themaximumservicegapis0.030inch.

4.Rotatetheclutchbyhandandadjustallthreeairgaps.

Afterallthreegapshavebeenset,checkallthree

again.Adjustingonegapcanaltertheothergaps.

5.Reconnecttheclutchelectricalconnector.

4.Electricalconnector

5.Neutralreturnswitch

ServicingtheBattery

ServiceInterval:Every50hours—Checkthe

electrolytelevel.(Ifthemachineis

instorage,checktheelectrolytelevel

every30days.)

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

Keepthetopofthebatterycleanbywashingit

periodicallywithabrushdippedinammoniaor

bicarbonateofsodasolution.Flushthetopsurfacewith

wateraftercleaningit.Donotremovethellcapswhile

cleaningthebattery.

Thebatterycablesmustbetightontheterminalsto

providegoodelectricalcontact.

Ifcorrosionoccursattheterminals,disconnectthe

cables,negative(–)cablerst,andscrapetheclampsand

terminalsseparately.Reconnectthecables,positive(+)

cablerst,andcoattheterminalswithpetroleumjelly.

Thebatteryelectrolytelevelmustbeproperlymaintained

andthetopofthebatterykeptclean.lfthemachineis

39

Page 40

ServicingtheFuses

Batteryterminalsormetaltoolscouldshort

againstmetaltractorcomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthetractor.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

tractor.

Incorrectbatterycableroutingcoulddamage

thetractorandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

Fusesarelocatedunderthecontrolpanel(Figure44).

Figure44

1.Fuseblock

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative(black)

cable.

StoringtheBattery

Ifthemachinewillbestoredmorethan30days,remove

thebatteryandchargeitfully.Eitherstoreitonthe

shelfonthemachine.Leavethecablesdisconnectedif

itisstoredonthemachine.Storethebatteryinacool

atmospheretoavoidquickdeteriorationofthechargein

thebattery.Topreventthebatteryfromfreezing,make

sureitisfullycharged.Thespecicgravityofafully

chargedbatteryis1.265–1.299.

ServicingtheWiringHarness

PreventcorrosionofwiringterminalsbyapplyingGrafo

112X(Skin-over)grease,ToroPartNo.505-47,tothe

insideofallharnessconnectorswhenevertheharness

isreplaced.

Wheneverworkingwiththeelectricalsystem,always

disconnectbatterycables,negative(–)cablerst,to

preventpossiblewiringdamagefromshort-outs.

40

Page 41

DriveSystem

Maintenance

AdjustingtheTractionDrive

forNeutral

Ifthemachinemoveswhenthetractionpedalisinthe

neutralposition,thetractioncammustbeadjusted.

1.Parkthemachineonalevelsurfaceandturnthe

engineoff.

2.Raiseonefrontwheelandonerearwheeloffofthe

oorandplacesupportblocksundertheframe.

Ifthemachineisnotsupportedadequately,it

mayaccidentallyfall,injuringanyoneunder

themachine.

Onefrontwheelandonerearwheelmustbe

raisedoffofthegroundorthemachinewill

moveduringadjustment.

3.Loosentheretainingscrewontheoppositesideof

thetractionadjustmentcam(Figure45).

Theenginemustberunningsoanal

adjustmentofthetractionadjustmentcamcan

beperformed.Contactwithhotormovingparts

canresultinpersonalinjury.

Keephands,feet,face,andotherbodyparts

awayfromthemufer,otherhotpartsofthe

engine,andotherrotatingparts.

4.Starttheengineandrotatethecamhexforward

untilthefrontwheelstartstorotate,thenrotate

hexcambackwarduntilfrontwheelstartstorotate.

Determinethemidpositionoftheneutralspanand

tightentheretainingscrew .Doprocedureatlow

speedidleandathighenginespeed.

5.Tightenthescrewsecuringtheadjustment.Torque

to15–18ft–lb(20–24N-m)

6.Stoptheengine.

7.Adjustthescrewontheneutralreturnarm

(Figure45)untilthegapbetweentheendofthe

screwandtheswitchcontactis.090–.120inch.

8.Removethesupportblocksandlowerthemachine

totheshopoor.Testdrivethemachinetomake

sureitdoesnotmovewhenthetractionpedalisin

neutral.

Figure45

1.Tractionadjustmentcam4.Adjustingscrew

2.Retainingscrew5.Neutralreturnswitch

3.Neutralreturnarm

AdjustingtheTractionPedal

Thetractionpedalcanbeadjustedforoperatorcomfort

ortoreducethemaximumreversespeedofthemachine.

1.Checkthetractionpedalstopadjustment.Thepedal

stop(Figure46)shouldcontacttheframeslightly

beforethepumpreachesfullstroke.

Figure46

1.Tractionpedalstop

41

Page 42

2.Toadjustpedalstop,loosenjamnuts,pushdownon

tractionpedalandtightenjamnutswhenadjustment

isattained.

3.Ifmoreadjustmentisrequired,adjusttractionrod

(Figure47)asfollows:

Figure47

1.Rodend3.Tractionrod

2.Jamnut

Figure48

1.Steeringplate2.Samedimensionatfront

andrearofwheels