Page 1

HYDRO-GEAR BDP-10L SERVICE AND REPAIR MANUAL

Table of Contents – Page 1 of 1

INTRODUCTION/GENERAL DESCRIPTION: BDP-10L VARIABLE PUMP

INTRODUCTION

GENERAL DESCRIPTION

BDP-10L VARIABLE PUMP: SU PPO RT SYSTEM

TRANSMISSION HYDRAULIC SUPPORT SYSTEM

SAFETY PRECAUTIO NS

CONTROLS AND FEATURES: BDP- 10L V ARI AB LE PUM P

DIRECT DISPLACEMENT CONTROL

CHARGE PUMPS

BYPASS VALVE

BDP-10L VARIABLE PUMP: START-UP & MAINTENANCE

FLUIDS

START-UP PROCEDURE

MAINTENANCE

TROUBLESHOOTNG CHART: BDP-10L VARIABLE PUMP

BDP-10L VARIABLE PUMP: MINOR REP AIR

GENERAL

PLUG/FITTING TORQUES

SHAFT SEALS

CHARGE CHECK VALVES

BYPASS VALVE

CHARGE PUMP

BDP-10L VARIABLE PUMP: MAJO R REPAIR

GENERAL

DISASSEMBLY PRO CED URES FOR VARIABLE PUMP

RECONDITIONING AND REPLACEMENT OF PARTS

ASSEMBLY PROCEDURES FOR VARIABLE PUMP

PARTS DRAWING & PARTS LIST: BDP-10L VARIABLE PUMP

VARIATION CHART: BDP-10L

PRODUCT LINE: HYDRO-GEAR

A WORLD LEADER IN TURF CARE TRANSMISSION PRODUCTS

Page 2

Hydro-Gear

Page 3

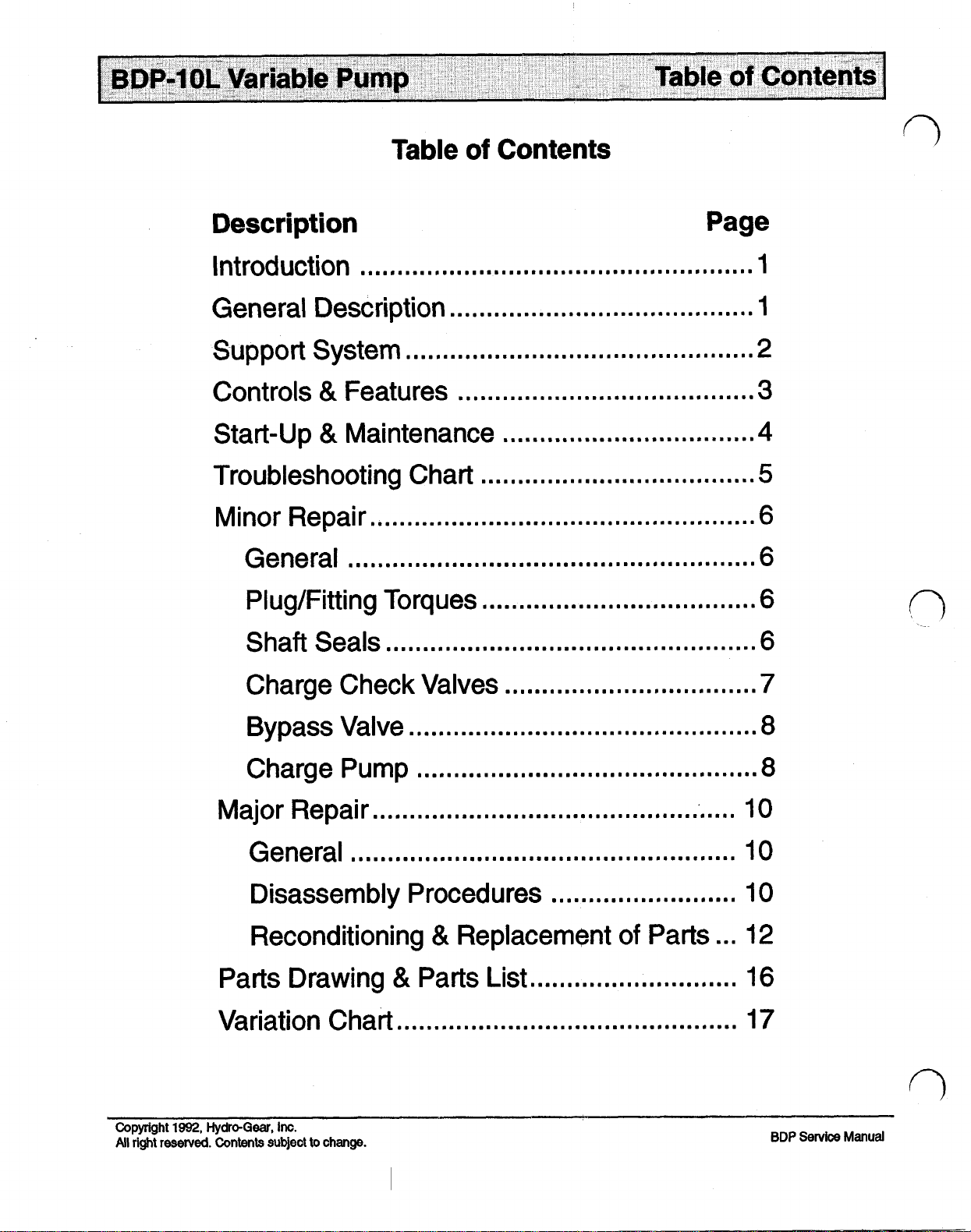

Table

of

Contents

Description

Introduction

General Description

Support System

Controls & Features

.....................................................

.........................................

...............................................

........................................

Start-up & Maintenance

Troubleshooting Chart

Minor Repair

General

....................................................

.......................................................

Plug/Fitting Torques

Shaft Seals

..................................................

.....................................

.....................................

..................................

Page

1

1

2

3

4

5

6

6

6

6

Copyright

All

right

reserved

Charge Check Valves

Bypass Valve

Charge Pump

Major Repair

General

Disassembly Procedures

Reconditioning & Replacement

Parts Drawing & Parts List

Variation Chart

1992.

Hydro-Gear.

.

Contents

Inc.

.

subject

..................................

...............................................

..............................................

.................................................

....................................................

.........................

of

............................

..............................................

to

change

.

Parts

...

7

8

8

10

10

10

12

16

17

BDP

Service

Manual

Page 4

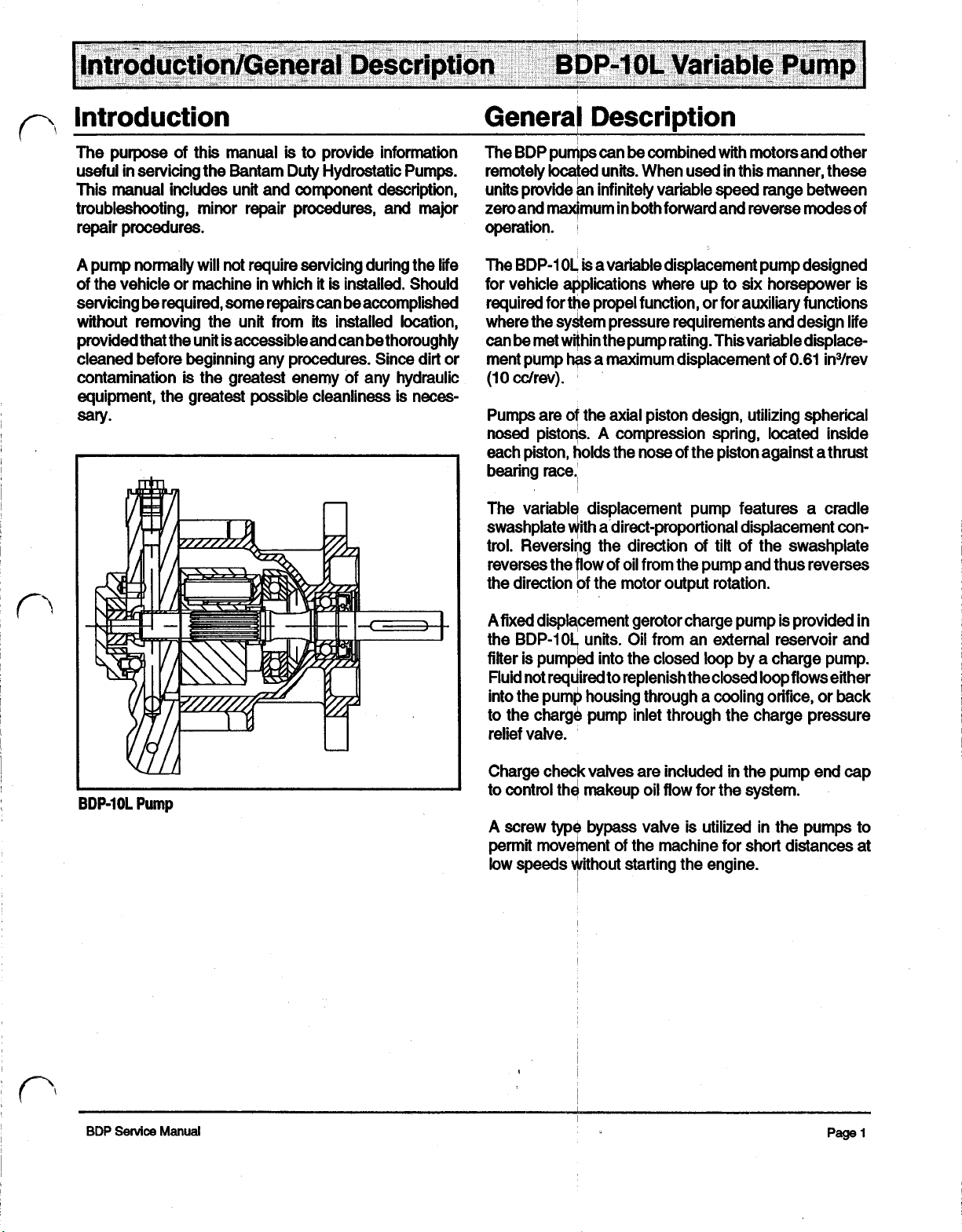

Introduction General Description

The purpose of this manual

useful

in

servicing the Bantam Duty Hydrostatic Pumps.

This manual includes unit and component description,

troubleshooting, minor repair procedures, and major

repair procedures.

A

pump normally will not require servicing during the lie

of the vehicle or machine in which

servicing be required, some repairscan beaccomplished

without removing the unit from

provided that the unit is accessible and can be thoroughly

cleaned before beginning any procedures. Since dirt or

contamination is the greatest enemy of any hydraulic

equipment, the greatest possible cleanliness is neces-

sary.

is

to provide information

it

is

installed. Should

its

installed location,

The BDP pumps can be combined with motors and other

remotely

units provide an infinitely variable speed range between

zero and maximum in both forward and reverse modes of

operation.

The BDP-1

for vehicle applications where up to

required for the propel function, or for auxiliary functions

where the system pressure requirements and design life

can be met within the pump rating. This variable

ment pump

(10

Pumps are of the

nosed

each piston, holds the

bearing

The variable displacement pump features a cradle

swashplate with a direct-proportional displacement con-

trol. Reversing the direction of tilt of the swashplate

reverses the flow of oil from the pump and thus reverses

the direction of the motor output rotation.

located

cc/rev).

pistons. A compression spring, located inside

units. When used in this manner, these

0L

is

a variable displacement pump designed

six

horsepower

has

a maximum displacement of

axial

piston design, utilizing spherical

nose

of the piston against a thrust

0.61

race.

is

displace-

in³/rev

BDP-10L

Pump

A

fixed displacement gerotor charge pump is provided in

the BDP-10L units. Oil from an external reservoir and

fitter is pumped into the closed loop by a charge pump.

Fluid not required to replenish theclosed loop flows either

into the pump housing through a cooling orifice, or back

to the charge pump inlet through the charge pressure

relief valve.

Charge check valves are included in the pump end cap

to control the makeup oil

flow

for the system.

valve is utilized in the pumps to

for short distances at

the engine.

BDP

Service

Manual

Page 5

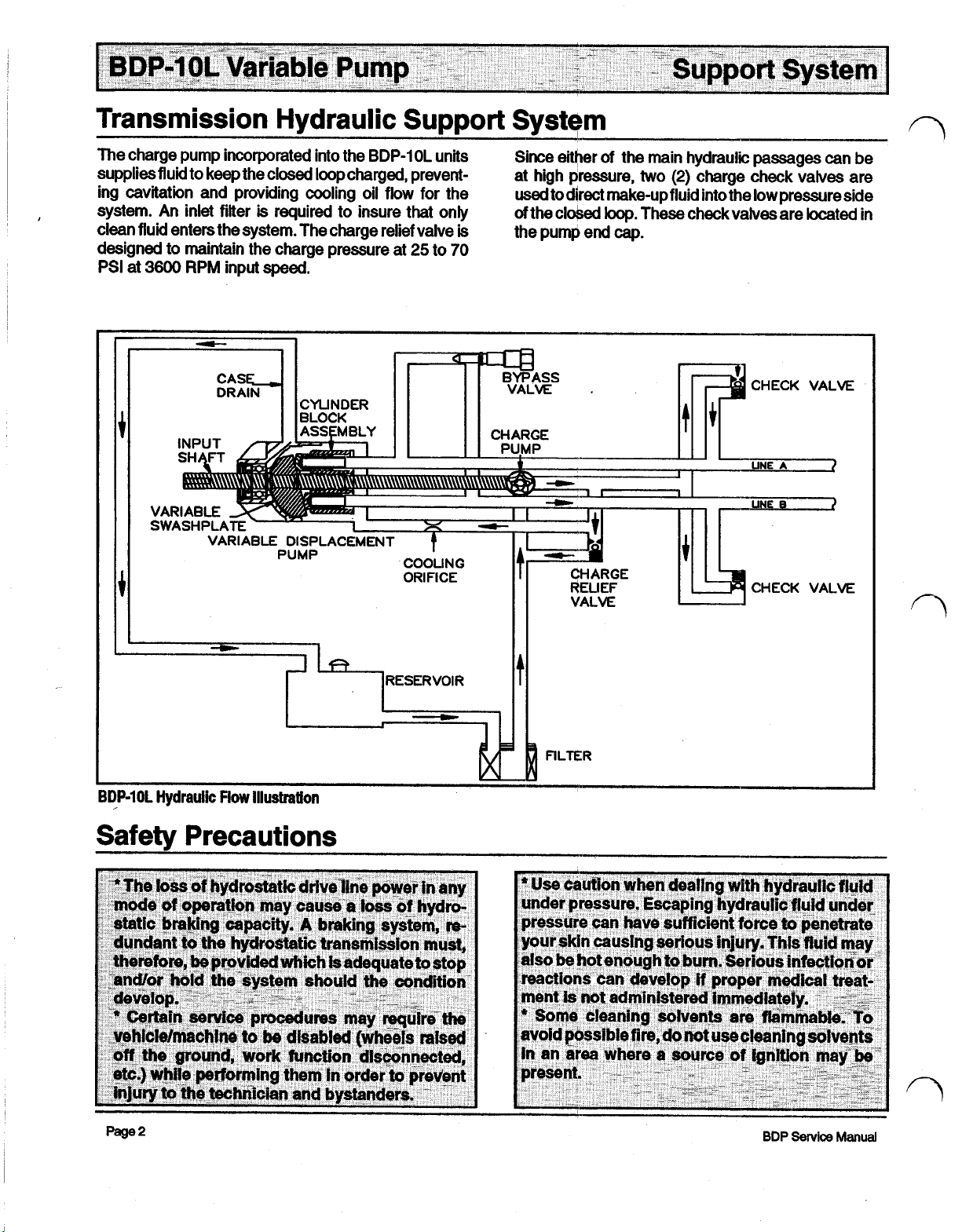

Transmission Hydraulic Support System

The charge pump incorporated into the

supplies fluid to keep the closed loop charged, prevent- at high pressure,

ing cavitation and providing cooling oil flow for the

system. An inlet filter

clean fluid enters the system. The charge relief valve

designed

PSI

at

to

maintain the charge pressure at

3600

RPM

is

required to insure that

input speed.

BDP-1

0L

units Since either

only

is

25

to

70

used

to

direct make-up fluid into the low pressure side

of

the closed

the pump end

of

the main hydraulic passages can be

two

(2)

charge check valves are

loop.

These check valves are located in

cap.

FILTER

Page 6

Controls and Features

Direct Displacement Control

The direct-proportional displacement control

vides a simple method of

swashplate control shaft produces a proportional swashplate movement and change in pump flow and/or direction.

If

difficulties are encountered with the control, inspect the

connection of the control linkage to the swashplate

control

tached.

the neutral

shaft

to insure that the linkage

The vehicle/machine control system determines

position

of the linkage.

control.

Movement of the

(DDC)

is

properly at-

pro-

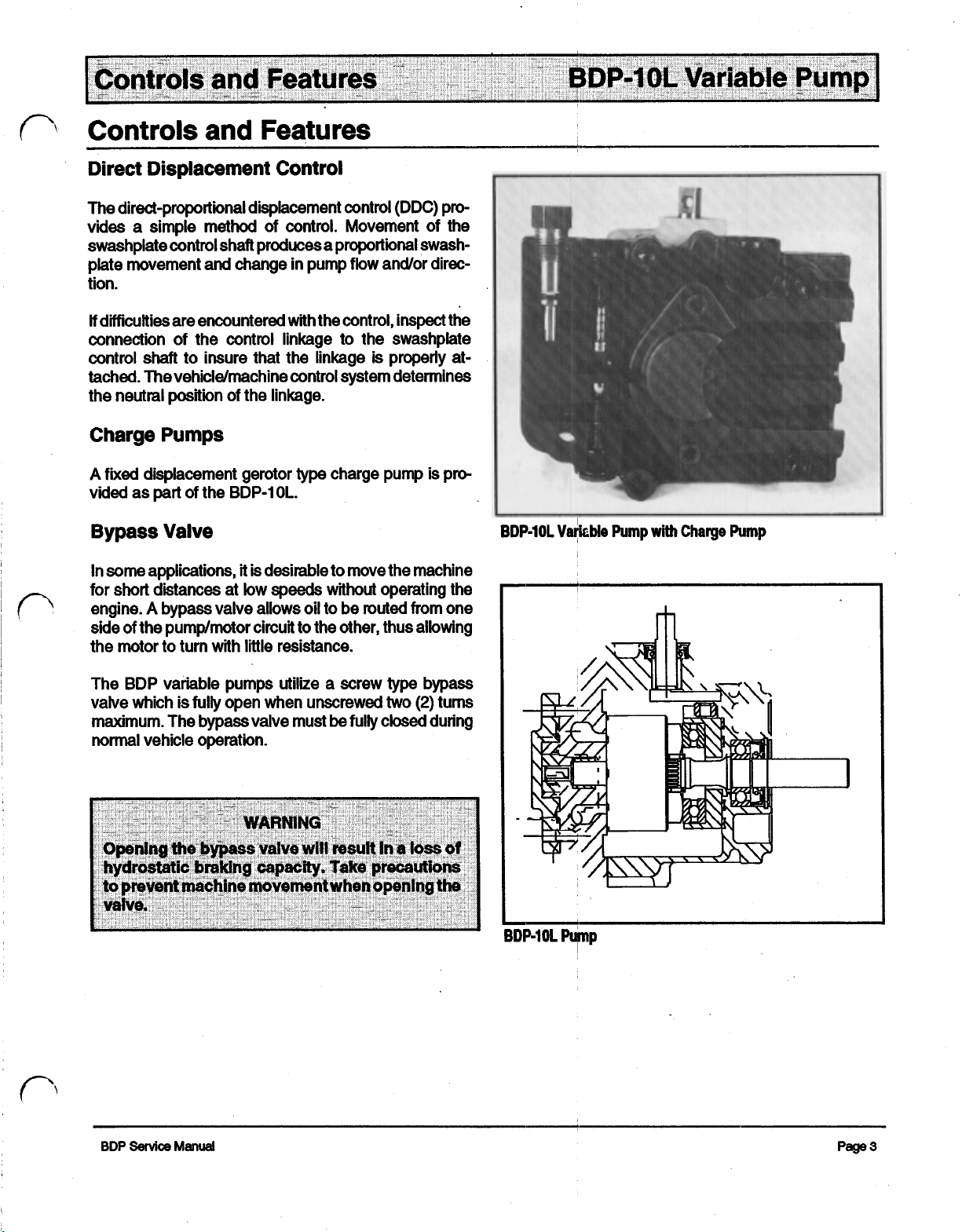

Charge Pumps

A

fixed displacement gerotor type charge pump is pro-

vided as

Bypass

In

for

engine.

side of the pump/motor circuit to the other, thus allowing

the motor to turn with little resistance.

part

some

applications, it

short

distances at low

A

of

the

BDP-1

0L.

Valve

is

desirable to move the machine

speeds

bypass valve allows oil to be routed from one

without operating the

BDP-10L

Variable

Pump

with

Charge

Pump

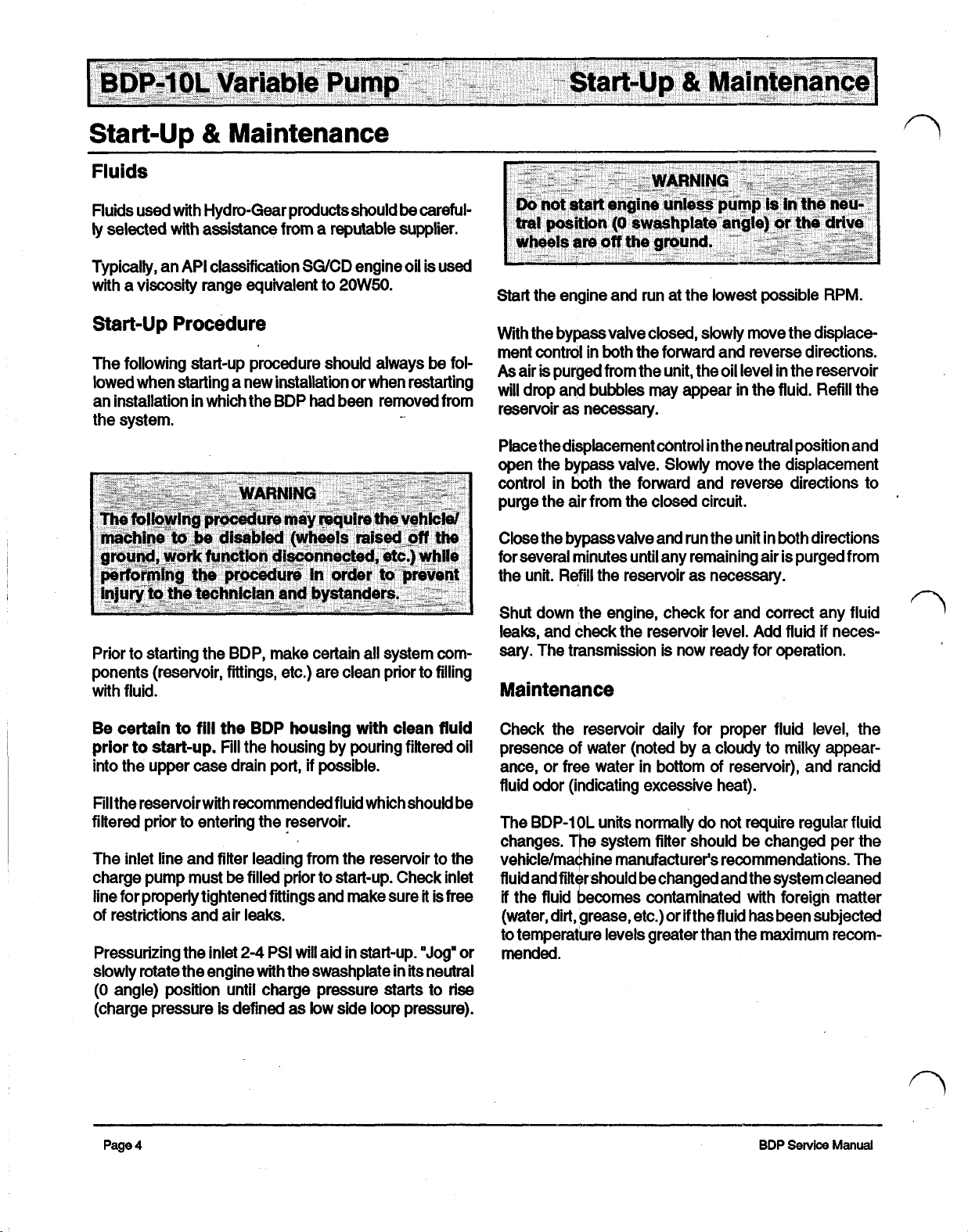

The

BDP

variable pumps utilize a screw type bypass

valve which is

maximum. The bypass valve must

normal

vehicle operation.

fully

open when unscrewed

be

two

(2)

turns

fully closed during

Page 7

Start-up & Maintenance

Fluids

Fluids used with Hydro-Gear products should

ly selected with assistance from a reputable supplier.

Typically, an API classification SG/CD engine oil is used

with a viscosity range equivalent to

Start-up

The following start-up procedure should always be fol-

lowed when starting a new installatiin or when restarting

an installation in which the BDP had been removed from

the system.

Procedure

20W50.

be

careful-

-

Start the engine and run at the lowest possible RPM.

With the bypass valve closed, slowly move the displace-

ment control in both the forward and reverse directions.

As

will

reservoir

Place thedisplacement control in the neutral position and

open

control in both the forward and reverse directions to

purge the air from the closed circuit.

Close the bypass valve and run the unit in both directions

for several minutes until any remaining air is purged from

the unit.

Shut down the engine, check for and correct any fluid

leaks, and check the reservoir level. Add fluid

Prior to starting the BDP, make certain all system components (reservoir, fittings, etc.) are clean prior to filling

with fluid.

sary. The transmission is now ready for operation.

Maintenance

air

is

purged from the unit, the oil level in the reservoir

drop and bubbles may appear

as

necessary.

the bypass valve. Slowly move the displacement

Refill

the reservoir as necessary.

in

the fluid. Refill the

if

neces-

Be

certain to

prior

to

into the upper case drain

Fill the reservoirwith

filtered prior to entering the reservoir.

The inlet line and filter leading from the reservoir to the

charge pump must

line for properly tightened fittings and make sure it is free

of restrictions and air

Pressurizing the inlet

slowly rotate the engine with the swashplate in its neutral

(0

angle) position until charge pressure starts to rise

(charge pressure is defined as

Page

4

fill

start-up.

the

BDP

housing with clean fluid

Fill the housing by pouring filtered oil

port,

if

possible.

recommended fluid which

be

filled prior to start-up. Check inlet

leaks.

2-4

PSI

will

aid in start-up.

low

side loop pressure).

should

be

"Jog"

or

Check the reservoir daily for proper fluid level, the

presence of water (noted by a cloudy to milky appearance,

or

free water in bottom of reservoir), and rancid

fluid odor (indicating excessive heat).

The BDP-1

changes. The system filter should be changed per the

vehicle/machine manufacturer's recommendations. The

fluid and fitter should

if

the fluid becomes contaminated with foreign matter

(water, dirt, grease, etc.) or if the fluid has been subjected

to temperature levels greater than the maximum recom-

mended.

0L

units normally do not require regular fluid

be

changed and the system cleaned

BDP

Service

Manual

Page 8

Troubleshooting

Chart

Symptom

Vehicle will not attain

maximum speed.

Vehicle

control

Vehicle jerky or operating erratic.

will

not move when vehicle

is

moved.

normal

Probable

Engine not operating at correct

Speed.

Control linkage damaged or

binding.

Bypass valve stuck partially open.

Charge check valve held open.

(Problem in one direction only)

Control linkage damaged or not

connected.

Drive between engine and transmission damaged.

Transmission

Plugged filter.

Inlet air leak.

low

Cause

on fluid.

Suggested

Repair engine governor.

Repair control linkage.

Repair bypass valve.

Remove foreign material from

valve.

Repair or reconnect control

linkage.

Repair drive (replace broken belt,

repair sheared key, repair splined

coupling, etc.)

Refill reservoir. Purge air from

transmission.

Inspect inlet condition and

filter.

Remedy

Vehicle is "sluggish" under load

(operates

OK

on level surface).

Loose

drive belt between engine

and transmission.

Transmission

Large amount of water in

transmission fluid (evaporates

when hot, resulting in low fluid

level).

low

on fluid.

Tension drive belt (replace

necessary).

Refill reservoir. Purge air from

transmission

Drain fluid from reservoir and

unit, replace filter element and

refill with new fluid.

if

necessary.

if

BDP

Service

Manual

Page 9

Minor

Repair

General

Minor repairs may

dures in this section, without voiding the unit warranty.

Cleanliness is a primary means of assuring satisfactory

lie on either new or repaired units. Cleaning

using a clean solvent wash and air drying

adequate.

must

Protect all

from damage and foreign material.

It

is

lubricate all O-rings with clean petroleum jelly prior

assembly.

As

be

kept free of foreign materials and chemicals.

exposed

recommended that all O-rings be replaced. Lightly

be

performed, following the proce-

parts

is

usually

with any precision equipment, all

sealing surfaces and open cavities

by

parts

Fitting/Plug

If

during

the accompanying tables:

r

Case Drain Fitting

(9/16-18 0-Ring)

System

(3/4-16 O-Ring)

Inlet Fitting/Plug

(7/16-20 0-Ring)

Check

to

(9/16- 18 0-Ring)

Bypass Valve

Torques

any plugs are removed from the housing

servicing,

Ports

Valve Plugs

they should be torqued as indicated in

Item

I

I

1

I

I

I

Torque

15-20

15-20

8-10

15-20

7-10

ft.

ft.

ft.

ft.

ft.

or

Ibs.

Ibs.

Ibs.

Ibs

lbs

end

cap

I

I

input

-

-

Input

Page 6

Shaft

Shaft

Seal

Retaining

Seal

Removal

Ring

Removal

Input

Shaft

Seal,

Spacer

Washer,

Shaft

Lip type

ment control shaft of the BDP-1 0L variable pumps. These

seals

unit. However, replacement of these seals generally

requires removal of the pump from the machine.

To

retaining ring from the housing.

Carefully pull the

type tool may be used to grasp the seal and pull

a

seal. Care

bore, shaft sealing surface, or bearing. Once removed,

the seal

Seals

seals

are

used

can

be

replaced without major disassembly of the

replace the pump input shaft

seal

out of the housing bore. A “hook”

slide hammer type puller may be used to re-move the

must

be taken so as not to damage the housing

is

not

reusable.

and

Retaining Ring Removed

on the input shaft and displace-

seal,

first remove the

it

out, or

BDP

Service

Manual

Page 10

Install Input

Shaft

Seal

Note:

Once the pump input shaft

pump block spring may push the shaft partially

the housing.

housing. Internal parts could move

fall into the transmission, requiring major disassembly

of

the unit.

Inspect the dealing area on the shaft for rust, wear or

contamination. Polish the sealing area on the shaft

necessary.

Lubricate the new seal with petroleum jelly.

Wrap the spline or key end of the shaft with thin plastic to

prevent damage to the seal lip during installation.

Slide the seal over the shaft and press it into the housing

bore. Be careful not to damage the seal.

bo

not attempt to pull the shaft

seal

is removed, the

out

of

alignment or

out

out

of

of the

if

Install Input Shaft

Remove Charge Check

Seal

Retaining Ring

Valve

Plugs

Install the

Charge Check

Remove the check valve plug with a

wrench.

Remove the' valve spring and check ball (or poppets)

from the pump end cap.

Inspect the check

the end cap for damage or foreign material.

seal

retaining ring in the housing.

Valves

balls

(or poppets) and mating seats in

1/4"

internal hex

Charge Check

BDP

Service

Manual

Valve

Components

(Poppets

Opt,

Balls

Std.)

Lay the pump on

,

poppets)

Becertain the check ball does not fall into the closed loop

passage. Torque the plug to

over and repeat for the other check valve.

spring, and plug (with O-ring) into the end cap.

P

its

side and reinstall the check ball (or

15-20

ft. lbs.

Turn the unit

Page

7

Page 11

I

Bypass

Unscrew the, bypass valve from the end cap.

Valve

Bypass

Valve

At

Variations

NOTE:

Inspect the valve and mating seat in the end cap for

damage or foreign material.

O-ring and backup ring be replaced.

Reinstall the bypass valve into the end cap. Torque to

10

Some

while others have a cross hole.

ft. lbs.

valves have a

5/8"

It

is recommended that the

hex end

7-

Charge Pump

The charge pump rotation

tion of the charge pump cover on the end cap. The cast

boss

on the Charge pump cover indicates the orientation.

is

determined by the orienta-

Orienting

Orienting Charge Pump

Charge

Pump Cover (CCW

Cover

Rotation)

(CW Rotation)

Make note

the

ing

Using a

screws

Remove the charge pump cover and O-ring.

Remove the charge pump gerotor assembly.

Remove the charge relief valve spring and

of

the correct orientation prior to remov-

charge pump cover.

5

mm

internal hex wrench, remove the

holding

the charge pump cover to the end cap.

ball.

two

(2)

Page

8

BDP

Service

Manual

Page 12

Inspect the gerotor assembly, charge pump cover, and

end

cap for abnormal wear, damage or foreign material.

Inspect the charge relief valve

ball

and spring. Inspect the

charge relief valve seat in the end cap for damage or

foreign material.

Prior to installilng the charge pump, apply a small quantity

of petroleum jelly to the

I.D.,

O.D.,

and side faces

of

the

gerotor assembly

Charge

install

Pump

Components

Gerotor

Assembly

and

Charge

Relief

Valve

Install the charge relief valve

ball

and spring.

Install the charge pump gerotor assembly.

Install the charge pump cover and O-ring. The charge

relief valve spring must enter the recess

in

the cover.

Install the charge pump cover screws. Toque each

screw to

7-1 0 ft.

Ibs.

BDP

Service

Manual

~

Page

9

Page 13

Major

Repair

General

The procedures on the following pages are for the

complete disassembly and reassembly (Major Repair) of

the BDP-1 0L variable pump.

Again, cleanliness is a primary means of assuring satis-

factory hydraulic unit life on either new or repaired units.

Cleaning parts by using a clean solvent wash and air

drying is usually adequate.

ment,

all

parts must be kept free of foreign materials and

chemicals. Protect all exposed sealing surfaces and

open cavities

During reassembly of the pump all surfaces which have

relative motion between

filmofclean

will

assure that these surfaces will

start-up.

It

is recommended that all O-rings and gaskets be re-

placed. Lightly lubricate all O-rings with clean petroleum

jelly prior to assembly.

be cleaned prior to installing new gaskets.

from

damage and foreign material.

oil or a lubricant such as petroleum jelly. This

As

with any precision equip-

two

parts must be coated with a

be

lubricated during

All

gasket sealing surfaces must

Remove

End

Cap

from

Housing

Disassembly Procedures

for

Variable

Pump

Prior to performing Major Repairs on the pump, remove

the external components

Repair" section of this manual. These include the following:

Bypass valve

Charge Check

Charge Pump

Lay the unit on its

remove the four

the pump housing.

The internal springs should separate the end cap from

the housing. Remove the end cap from the housing.

Valves

side.

(4)

as

described in the 'Minor

Using a 6 mm internal hexwrench,

screws which retain the end cap to

emove

Remove the gasket and

housing.

Remove the pump cylinder block

Remove the pump cylinder blockspring and washerfrom

the pump shaft.

Gasket

and

Aligning Pins

two

(2)

alignment pins from the

kit

from the pump shaft.

Page

10

BDP

Service

Manual

Page 14

Remove the thrust bearing from the swashplate.

Remove the pump swashplate from the housing.

Remove the swashplate cradle bearings from the

housing.

Remove the slot guide block from the displacement

control shaft.

Remove Pump Cylinder Block

Swashplate and

Remove

from Housing

Input

Cradle

Shaft

Retaining Ring,

Kit,

Block Spring and Washer,

Bearings from Housing

Seal

and

Input

Shaft

Remove the input shaft seal retaining ring.

Carefully pull the input shaft

A

hook may

type puller may

be taken

sealing surface

reusable.

Remove the bearing spacer washer.

Remove the pump shaft and bearing assembly from the

housing.

be

used to pry theseal

be

used to remove

so

as

not to damage the housing bore, shaft

or

bearing. Once removed, theseal is not

seal

out of the housing bore.

out,

or a slide hammer

the

seal. Care must

Remove Bearing

BDP

Service

from

Manual

Input

Shaft

Remove the outer bearing retaining ring (and washer,

used)

and press the shaft out of the bearing.

NOTE:

most

An

inner

bearing

shafts. Remove

retaining

it

from

the

ring

shaft if

is used

necessary.

Page

if

on

11

Page 15

If

the pump block spring retaining ring requires replace-

ment, remove

it

from the pump shaft.

Cylinder

Block

Kit

Components

Reconditioning and Replacement of Parts

After

disassembly,

in a suitable solvent. Replace all O-rings, gaskets and

shaft seals.

Inspect all parts for damage, nicks or unusual wear

patterns. Replace all parts having unusual or excessive

wear or discoloration.

Inspect the

splines. Polish the sealing areas on the shafts if

sary.

Replace any

all parts should be

seal

surfaces, bearing surfaces and

worn

or damaged parts.

thoroughly

cleaned

shaft

neces-

Remove the displacement control shaft

housing. Care must be taken

so

seal

out

of the

as not to damage the

housing bore.

is

The pump shaft bushing

should

not

be

removed.

The running surfaces of the cylinder blocks

and free from scratches.

on the running surface of the cylinder block or end

pressed into the end cap and

MUST

be flat

If

scratches or wear are found

cap,

polish or replace the parts. When polishing these sur-

faces, up to

0.0004

in. may be removed.

If

this is not

sufficient to obtain a flat surface, free of scratches, the

part

should be replaced.

I

Install

Page

12

Displacement

Control

Shaft

Assembly Procedures for Variable Pump

Clean and lightly oil parts prior to assembly

pump. Be sure to toque all threaded parts to recom-

mended torque levels.

Install the displacement control shaft into the housing.

J

of

the variable

BDP

Service Manual

Page 16

If

the block spring retaining ring was removed from the

pump shaft, install a new retaining ring onto the shaft.

(if

Install a new inner bearing retaining ring

used) onto the

pump shaft. Press the bearing onto the shaft. Install the

washer

(if

used) and a new outer bearing retaining ring.

Install Input

install

Bearing

In

Shaft

Spacer

Washer

NOTE:

Do

not stretch or

deform

the retaining ring.

Install, the pump shaft and bearing assembly into the

housing.

Install the bearing spacer washer.

Wrap the spline or key end of pump drive shaft with thin

plastic to prevent damage to the seal lip during installation. Lubricate the new pump shaft seal with petroleum

jelly.

Install Input

Shaft

Seal

Install Input

Shaft

Retaining Ring

Seal

Slide the seal over the shaft and press it into the housing

bore. Be careful not to damage seal.

Install the retaining ring.

Page

13

Page 17

Install the swashplate cradle bearings into the housing,

making sure they are located on the cast-in pins in the

housing.

Install the slot guide blockonto the displacement control

shaft.

Install Cradle Bearings and

Swashplate

Kit

Components

Guide

Block

Install the Swashplate into the housing. The slot on the

swashplate must engage the guide block on the displace-

ment control shaft. Use

magnet to

hold

the guide block in position while installing

a

tool such as a screwdriver or

the swashplate.

Hold

the swashplate in position and measure the side

play

of

the displacement control shaft using a dial indicator or depth gauge. Using a suitable sleeve, press the

control shaft bearing into the housing until the control

shaft end play is between

0.020

and

0.060

in.

Install Swashplate,

Page

14

Thrust

Washer

and

Block

Spring

Install the thrust washer and pump cylinder block spring

onto the pump shaft.

BDP

Service

Manual

Page 18

Install the springs, piston washers and pistons into the

cylinder block. The pistons must move freely in their

bores.

With the pump swashplate in the "neutral"

position and ;he pump housing laying on

the pump cylinder block

Check that the piston springs are centered in the cylinder

block bores.

screwdriver.

housing.

(0

angle)

its

side, install

kit

onto the pump shaft in the

If

necessary, position them with a small

Cylinder

Install

Pump

Block

Kit

Components

Cylinder Block

Kit

Install the two

(2)

aligning pins, and install a new end cap

gasket onto the housing.

Lubricate the running surfaces

of

the end

cap

and

cylinder blocks. Position the housing with the housing

opening UP,

When the end

springs

3/8

in.

Install the four

variable pump housing. Toque the screws evenly to

20 ft.

Rotate the shaft to assure

properly assembled, minimal torque should

to

turn the shaft.

will

Ibs.

and

install the end cap onto the housing.

cap

is properly installed, the internal

hold

it

away from the housing approximately

(4)

screws which retain the end cap to the

correct

assembly. When

be

15-

required

Install

BDP

Service

End

Cap

Manual

Wrap the end, of the displacement control shaft with thin

plastic to prevent damage to the

seal

lip during installation. Lubricate the new displacement control shaft seal

with petroleum jelly. Slide the

it

press

into the housing bore. Be careful not to damage

seal

over the shaft and

the seal.

Assemble the following components as described in the

"Minor Repair” section of this manual:

Charge Pump

Charge Check Valves

Bypass

Valve

Page

15

Page 19

No.

Description

Housing

1

seal-Up

2

End Cap Jut

End

Cap

Kit

Part

No.

2513017

2518016

1

Part

No.

Description

17

Ring,

Back

cump

-

Ball

Up

Shaft -

18

19 1

Bearing

1

No.

9006110-0120

2003020

2003073

2003043

Qty

1

1

Page

16

Charge Pump

Gerotor

I

11

Assembly

Valve

Kit

I

251008 Check

2510027

1

1

1

1

I

Spring

Washer

Washer

-

Piston

-

Piston

-

Block

Thrust

251 001 1

8

251 301

BDP

Service

Manual

Page 20

Variation

Chart

CHECK

Trunnion

Side Trunnion

I

I

2510008

MODEL NO.

BDP-1 0L-1 10 2003020 2513029 251 0008

BDP-10L-1

I I

I

I

Shaft

2003020

#

VALVE

I

I

BYPASS

KIT

2513029

VALVE KITS

Opp.

251 0008

251 0008

251 0008

251 0008

251 0008

251 0027

251 0008

251 0008

251 0027

251 0027

251

251 0027

251

251 0027

0008

0008

ROTATION

CW

CCW

CW

CCW

CCW

CCW

CCW

CCW

CCW

CCW

CW

CW

CW

CW

251 0008

2510008

CW

CCW

BDP

Service

Manual

Page

17

Page 21

A

World Leader in

Hydro-Gear is a leader in engineered products designed specifically for the turf care industry with a wide range of hydrostatic

transaxles, transmissions and pumps. Hydro-Gear and its associate companies provide complete worldwide service parts,

repair, and technical assistance.

Turf

Care Transmission

Products

210-2510L

ZT

Drive

Axles

210-101

OS

Transaxles

Bantam

Duty

Pumps

I

HYDRO-GEAR, 1411

Phone: (217)728-2581; FAX (21 7)72-7665

S.

Hamilton,

Sullivan,

IL

61951

Loading...

Loading...