Page 1

Form No. 3353-610 Rev C

Groundsmaster® 3280-D 2 &

4-Wheel Drive Traction Units

Model No. 30308 —Serial No. 250000001 and Up

Model No. 30309 —Serial No. 250000001 and Up

Register your product at www.Toro.com Original Instructions (EN)

Page 2

Warning

CALIFORNIA

Pr oposition 65 W ar ning

Diesel engine exhaust and some of its

constituents ar e kno wn to the State of

Calif or nia to cause cancer , bir th defects, and

other r epr oducti v e har m.

T his spark ignition system complies with Canadian

ICES-002

Important: T his engine is not equipped

with a spar k ar r ester muf fler . It is a

violation of Calif or nia Public R esource Code

Section 4442 to use or operate the engine

on an y f or est-co v er ed, br ush-co v er ed, or

g rass-co v er ed land. Other states or federal

ar eas may ha v e similar la ws.

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safe Operating Practices . . . . . . . . . . . . . . . . . . . . . . 5

T oro Riding Mo w er Safety . . . . . . . . . . . . . . . . . . . 7

Safety and Instr uctional Decals . . . . . . . . . . . . 9

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1 Installing the Steering W heel . . . . . . . . . . . 16

2 Installing the Hood Handle . . . . . . . . . . . . . 16

3 Installing the Seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 Installing the Seat Belt . . . . . . . . . . . . . . . . . . . . . 17

5 Installing the Man ual T ube . . . . . . . . . . . . . . 18

6 Acti v ating and Charging the

Batter y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7 Adjusting the R OPS . . . . . . . . . . . . . . . . . . . . . . . . 20

8 Chec king the Tire Pressure . . . . . . . . . . . . . . 20

9 Installing R ear W eights . . . . . . . . . . . . . . . . . . . . 22

10 Chec king Fluid Lev els . . . . . . . . . . . . . . . . . . . 23

11 R eading the Man uals and

Viewing the D VD . . . . . . . . . . . . . . 23

Product Ov er view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Chec king the Engine Oil Lev el . . . . . . . . . . . 29

Chec king the Cooling System . . . . . . . . . . . . 29

Chec king the Hy draulic

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Adding Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Chec king the R ear Axle Lubricant

(Model 30309 only) . . . . . . . . . . . . 31

Chec king the Bidirectional Clutc h

Lubricant (Model 30309

only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Using the R ollo v er Protection

System (R OPS) . . . . . . . . . . . . . . . . . . 32

Star ting/Stopping the Engine . . . . . . . . . . . . 33

Bleeding the Fuel System . . . . . . . . . . . . . . . . . . . 33

Chec king the Interloc k System . . . . . . . . . . . 34

Pushing or T o wing the

Mac hine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Standard Control Module

(SCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Operating Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

R ecommended Maintenance

Sc hedule(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Daily Maintenance Chec klist . . . . . . . . . . . . . . 39

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Greasing the Bearings and

Bushings . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

General Air Cleaner Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Changing the Engine Oil And

Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Fuel System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Draining the W ater Se parator . . . . . . . . . . . . 45

Cleaning the Fuel T ank . . . . . . . . . . . . . . . . . . . . . . 45

R e placing Fuel Pre Filter . . . . . . . . . . . . . . . . . . . . 45

Fuel Lines and Connections . . . . . . . . . . . . . . . 46

Bleeding Air F rom the

Injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Electrical System Maintenance . . . . . . . . . . . . . . . . . . . 46

Ser vicing the Batter y . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Storing the Batter y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Ser vicing the Wiring Har ness . . . . . . . . . . . . . 47

Accessing the Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Dri v e System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 47

Changing the R ear Axle Lubricant

(Model 30309 only) . . . . . . . . . . . . 47

Changing the Bidirectional Clutc h

Lubricant (Model 30309

only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Adjusting the T raction Dri v e for

Neutral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Adjusting R ear W heel T oe-in

(Model 30309 only) . . . . . . . . . . . . 49

Cooling System Maintenance . . . . . . . . . . . . . . . . . . . . . 49

© 2005—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Contact us at www.Toro.com.

2

Printed in the USA.

All Rights Reserved

Page 3

Cleaning the Radiator and the

Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Brak e Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Adjusting the P arking Brak e

Interloc k Switc h . . . . . . . . . . . . . . . . 50

Adjusting the Ser vice Brak es . . . . . . . . . . . . . . 50

Belt Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Chec king the Alter nator Belt . . . . . . . . . . . . . 51

Ser vicing the PTO Belt . . . . . . . . . . . . . . . . . . . . . . 51

Controls System Maintenance . . . . . . . . . . . . . . . . . . . . 52

Adjusting the PTO Clutc h . . . . . . . . . . . . . . . . . 52

Adjusting the T raction P edal . . . . . . . . . . . . . . 52

Adjusting the Tilt Steering

Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Hy draulic System Maintenance . . . . . . . . . . . . . . . . . . 54

Changing the Hy draulic Oil And

Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Adjusting the Counterbalance

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Storag e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Mac hine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Sc hematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Introduction

R ead this infor mation carefully to lear n ho w to

operate and maintain y our product properly and

to a v oid injur y and product damag e . Y ou are

responsible for operating the product properly

and safely .

Y ou ma y contact T oro directly at www .T oro .com

for product and accessor y infor mation, help

finding a dealer , or to register y our product.

W henev er y ou need ser vice , g en uine T oro par ts ,

or additional infor mation, contact an A uthorized

Ser vice Dealer or T oro Customer Ser vice and ha v e

the model and serial n umbers of y our product

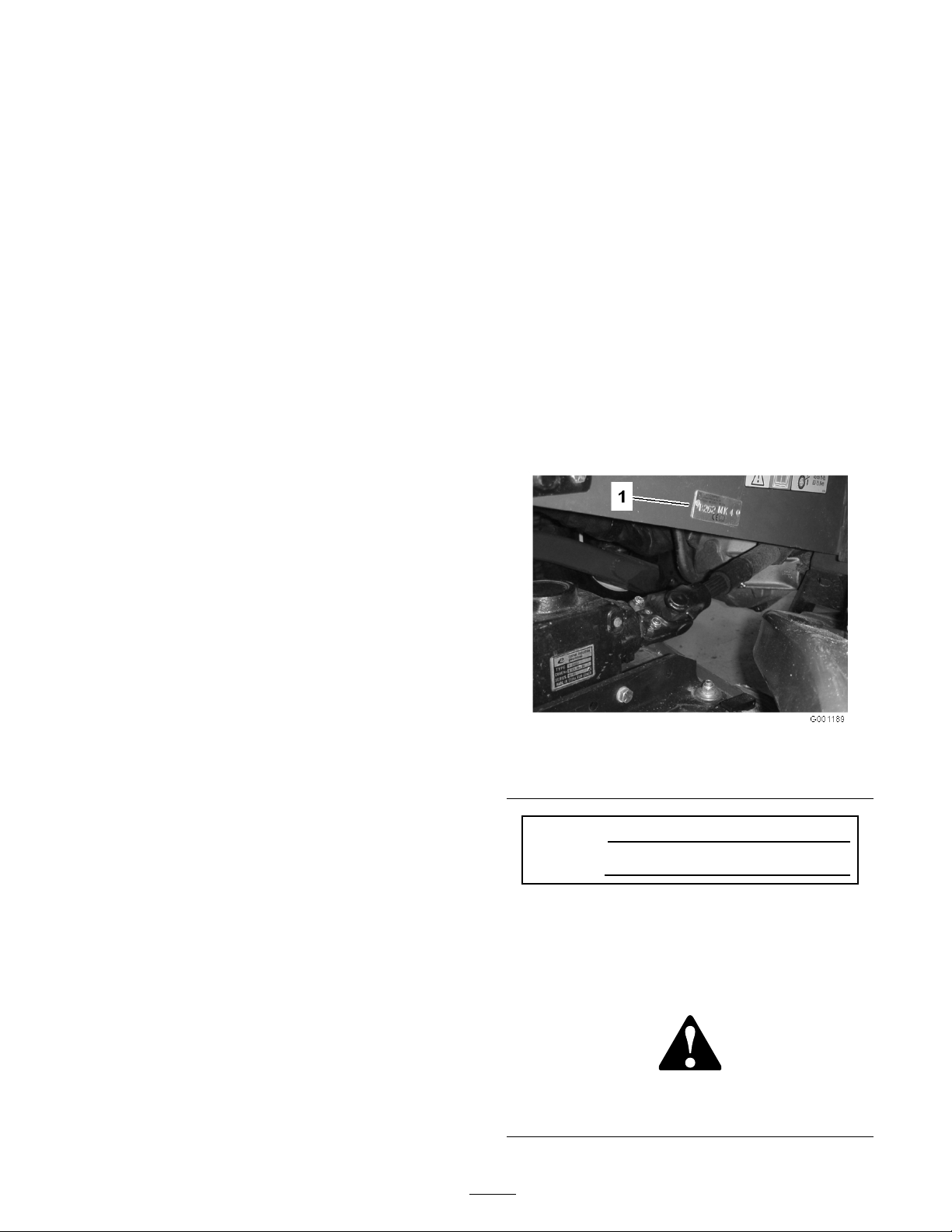

ready . Figure 1 identifies the location of the model

and serial n umbers on the product. W rite the

n umbers in the space pro vided.

Figure 1

1. Model and serial number location

Model No.

Serial No.

T his man ual identifies potential hazards and has

safety messag es identified b y the safety aler t

symbol ( Figure 2 ), whic h signals a hazard that ma y

cause serious injur y or death if y ou do not follo w

the recommended precautions .

Figure 2

1. Safety alert symbol.

3

Page 4

T his man ual uses tw o other w ords to highlight

infor mation. Impor tant calls attention to special

mec hanical infor mation and Note emphasizes

g eneral infor mation w or th y of special attention.

4

Page 5

Safety

of the brak e . T he main reasons for loss of

control are:

T his mac hine meets or ex ceeds CEN standard

EN 836:1997, ISO standard 5395:1990 (when

appropriate decals applied), and ANSI B71.4-2004

specifications in effect at the time of production

when equipped with rear w eight as listed in the

implement Operator’ s Man ual.

Improper use or maintenance b y the operator or

o wner can result in injur y . T o reduce the potential

for injur y , comply with these safety instr uctions

and alw a ys pa y attention to the safety aler t

symbol, whic h means CA UTION , W ARNING ,

or D ANGER—“personal safety instr uction. ”

F ailure to comply with the instr uction ma y result

in personal injur y or death.

Safe Operating Practices

T he follo wing instr uctions are from the CEN

standard EN 836:1997, ISO standard 5395:1990,

and ANSI B71.4-2004.

Training

• R ead the Operator’ s Manual and other training

material carefully . If the operator or mec hanic

can not read the languag e of this man ual it

is the o wner’ s responsibility to explain this

material to them.

• Be familiar with the controls , safety signs , and

the proper use of the equipment.

• Nev er allo w c hildren or people unfamiliar with

these instr uctions to use or ser vice the mo w er .

Local regulations ma y restrict the ag e of the

operator .

• Nev er mo w while people , especially c hildren,

or pets are nearb y .

• K ee p in mind that the operator or user is

responsible for accidents or hazards occur ring

to other people or their proper ty .

• Do not car r y passeng ers .

• All operators and mec hanics should seek and

obtain professional and practical instr uction.

T he o wner is responsible for training the users .

Suc h instr uction should emphasize:

– the need for care and concentration when

w orking with ride-on mac hines;

– control of a ride-on mac hine sliding on a

slope will not be reg ained b y the application

◊ insufficient wheel g rip;

◊ being dri v en too fast;

◊ inadequate braking;

◊ the type of mac hine is unsuitable for its

task;

◊ lac k of a w areness of the effect of

g round conditions , especially slopes;

◊ incor rect hitc hing and load distribution.

• T he o wner/user can prev ent and is responsible

for accidents or injuries occur ring to himself

or herself , other people , or proper ty .

Preparation

• W hile mo wing, alw a ys w ear substantial

footw ear , long trousers , hard hat, safety glasses ,

and hearing protection. Long hair , loose

clothing, or jew elr y ma y g et tangled in mo ving

par ts . Do not operate the equipment when

barefoot or w earing open sandals .

• T horoughly inspect the area where the

equipment is to be used and remo v e all objects

whic h ma y be thro wn b y the mac hine .

• W ar ning-Fuel is highly flammable . T ak e the

follo wing precautions:

– Store fuel in containers specifically designed

for this pur pose .

– R efuel outdoors only and do not smok e

while refueling .

– Add fuel before star ting the engine . Nev er

remo v e the cap of the fuel tank or add fuel

while the engine is r unning or when the

engine is hot.

– If fuel is spilled, do not attempt to star t the

engine but mo v e the mac hine a w a y from

the area of spillag e and a v oid creating any

source of ignition until fuel v apors ha v e

dissipated.

– R e place all fuel tanks and container caps

securely .

• R e place faulty silencers/m ufflers .

• Ev aluate the ter rain to deter mine what

accessories and attac hments are needed to

properly and safely perfor m the job . Only use

5

Page 6

accessories and attac hments appro v ed b y the

man ufacturer .

• W atc h out for traffic when crossing or near

roadw a ys .

• Chec k the operator’ s presence controls , safety

switc hes and shields to mak e sure they are

attac hed and functioning properly . Do not

operate unless they are functioning properly .

Adequate r ear w eight is necessar y to

pr ev ent the r ear wheels fr om lea ving the

g r ound. Do not stop suddenl y while deck

or implement is raised. Do not tra v el

do wn hill with the deck or implement

raised. If the r ear wheel lea v es the

g r ound, steering is lost.

Operation

• Do not operate the engine in a confined space

where dang erous carbon mono xide fumes can

collect.

Engine exhaust contains carbon

mono xide, which is an odor less, deadl y

poison that can kill y ou.

• Stop the blades rotating before crossing

surfaces other than g rass .

• Nev er direct the disc harg e of material to w ard

b ystanders nor allo w any one near the mac hine

while in operation.

• Nev er operate the mac hine with damag ed

guards , shields , or without safety protecti v e

devices in place . Be sure all interloc ks are

attac hed, adjusted properly , and functioning

properly .

• Do not c hang e the engine g o v er nor settings or

o v er speed the engine . Operating the engine

at ex cessi v e speed ma y increase the hazard of

personal injur y .

• Before lea ving the operator’ s position:

– stop on lev el g round;

– diseng ag e the po w er tak e-off and lo w er the

attac hments;

– Set the parking brak e;

– stop the engine and remo v e the k ey .

• Diseng ag e dri v e to attac hments when

transpor ting or not in use .

Do not r un engine indoor s or in an

enclosed ar ea.

• Mo w only in da ylight or in g ood ar tificial light.

• Before attempting to star t the engine ,

diseng ag e all blade attac hment clutc hes , shift

into neutral, and eng ag e the parking brak e .

• Do not put hands or feet near or under rotating

par ts . K ee p clear of the disc harg e opening at

all times .

• R emember there is no suc h thing as a safe

slope . T ra v el on g rass slopes requires par ticular

care . T o guard ag ainst o v er tur ning:

– do not stop or star t suddenly when g oing

up or do wnhill;

– mac hine speeds should be k e pt lo w on

slopes and during tight tur ns;

– sta y aler t for humps and hollo ws and other

hidden hazards;

– nev er mo w across the face of the slope .

• Sta y aler t for holes in the ter rain and other

hidden hazards .

• Stop the engine and diseng ag e dri v e to

attac hment

– before refuelling;

– before remo ving the g rass catc her/catc hers;

– before making height adjustment unless

adjustment can be made from the operator’ s

position.

– before clearing bloc kag es;

– before c hec king, cleaning or w orking on

the mo w er;

– after striking a foreign object or if an

abnor mal vibration occurs . Inspect the

mo w er for damag e and mak e re pairs before

restar ting and operating the equipment.

• K ee p hands and feet a w a y from the mo w er

dec k.

• Look behind and do wn before bac king up to

be sure of a clear path.

• Slo w do wn and use caution when making tur ns

and crossing roads and sidew alks . Diseng ag e

blades if not mo wing .

6

Page 7

• Be a w are of the mo w er disc harg e direction and

do not point it at any one .

• Do not operate the mo w er under the influence

of alcohol or dr ugs

• Use care when loading or unloading the

mac hine into a trailer or tr uc k

• Use care when approac hing blind cor ners ,

shr ubs , trees , or other objects that ma y obscure

vision.

Maintenance and Storage

• K ee p all n uts , bolts and screws tight to be sure

the equipment is in safe w orking condition.

• Nev er store the equipment with fuel in the

tank inside a building where fumes ma y reac h

an open flame or spark.

• Allo w the engine to cool before storing in any

enclosure .

• T o reduce the fire hazard, k ee p the engine ,

silencer/m uffler , batter y compar tment and fuel

storag e area free of g rass , lea v es , or ex cessi v e

g rease .

• K ee p all par ts in g ood w orking condition and

all hardw are and h y draulic fittings tightened.

R e place all w or n or damag ed par ts and decals

• If the fuel tank has to be drained, do this

outdoors .

• Be careful during adjustment of the mac hine

to prev ent entrapment of the fing ers betw een

mo ving blades and fix ed par ts of the mac hine .

• On m ulti-spindle mo w ers , tak e care as rotating

one blade can cause other blades to rotate .

• Diseng ag e dri v es , lo w er the dec k, set parking

brak e , stop engine and remo v e the k ey from

the ignition. W ait for all mo v ement to stop

before adjusting, cleaning or re pairing .

• Clean g rass and debris from dec ks , dri v es ,

silencers/m ufflers , engine and underside of

mac hine to help prev ent fires . Clean up oil or

fuel spillag e .

• Use jac k stands to suppor t components when

required.

• Carefully release pressure from components

with stored energ y .

• Disconnect batter y before making any re pairs .

Disconnect the neg ati v e ter minal first and

the positi v e last. R econnect positi v e first and

neg ati v e last.

• Use care when c hec king the blades . W ear

glo v es and use caution when ser vicing them.

Only re place blades . Nev er straighten or w eld

them.

• K ee p hands and feet a w a y from mo ving par ts .

If possible , do not mak e adjustments with the

engine r unning .

• Charg e batteries in an open w ell v entilated

area, a w a y from spark and flames . Unplug

c harg er before connecting or disconnecting

from batter y . W ear protecti v e clothing and use

insulated tools .

Toro Riding Mower Safety

T he follo wing list contains safety infor mation

specific to T oro products or other safety

infor mation that y ou m ust kno w that is not

included in the CEN , ISO , or ANSI standard.

T his product is capable of amputating hands and

feet and thro wing objects . Alw a ys follo w all safety

instr uctions to a v oid serious injur y or death.

Use of this product for pur poses other than its

intended use could pro v e dang erous to user and

b ystanders .

• Kno w ho w to stop the engine quic kly .

• Do not operate the mac hine while w earing

tennis shoes or sneak ers .

• W earing safety shoes and long pants is advisable

and required b y some local ordinances and

insurance regulations .

• Handle fuel carefully . Wipe up any spills .

• Chec k the safety interloc k switc hes daily

for proper operation. If a switc h should

fail, re place the switc h before operating the

mac hine . After ev er y tw o years , re place all

interloc k switc hes in the safety system, whether

they are w orking properly or not.

• Before star ting the engine , sit on the seat.

• Using the mac hine demands attention. T o

prev ent loss of control:

– Do not dri v e close to sand traps , ditc hes ,

creeks , or other hazards .

– R educe speed when making shar p tur ns .

A v oid sudden stops and star ts .

– W hen near or crossing roads , alw a ys yield

the right-of-w a y .

7

Page 8

– Apply the ser vice brak es when g oing

do wnhill to k ee p forw ard speed slo w and

to maintain control of the mac hine .

• Raise the dec k when dri ving from one w ork

area to another .

• Do not touc h the engine , silencer/m uffler , or

exhaust pipe while the engine is r unning or

soon after it has stopped because these areas

could be hot enough to cause bur ns .

• If the engine stalls or mac hine cannot mak e it

to the top of a slope , do not tur n the mac hine

around. Alw a ys bac k slo wly , straight do wn the

slope .

• W hen a person or pet appears unexpectedly

in or near the mo wing area, stop mo wing .

Careless operation, combined with ter rain

angles , ricoc hets , or improperly positioned

guards can lead to thro wn object injuries . Do

not resume mo wing until the area is cleared.

Using the Rollover Protection System

(ROPS)

high pressure . Use paper or cardboard, not

y our hands , to searc h for leaks . Hy draulic fluid

escaping under pressure can ha v e sufficient

force to penetrate the skin and cause serious

injur y . Seek immediate medical attention if

fluid is injected into skin.

• Before disconnecting or perfor ming any w ork

on the h y draulic system, all pressure in the

system m ust be reliev ed b y stopping the engine

and lo w ering the dec k and attac hments to the

g round.

• Chec k all fuel lines for tightness and w ear on a

regular basis . Tighten or re pair them as needed.

• If the engine m ust be r unning to perfor m a

maintenance adjustment, k ee p hands , feet,

clothing, and any par ts of the body a w a y from

the dec k, attac hments , and any mo ving par ts ,

especially the screen at the side of the engine .

K ee p ev er y one a w a y .

• If major re pairs are ev er needed or if assistance

is desired, contact an A uthorized T oro

Distributor .

• K ee p the roll bar in the raised and loc k ed

position and use the seat belt when operating

the mac hine .

• Be cer tain that the seat belt can be released

quic kly in the ev ent of an emerg ency .

• Be a w are there is no rollo v er protection when

the roll bar is do wn.

• Chec k the area to be mo w ed and nev er fold

do wn the R OPS in areas where there are

slopes , drop offs or w ater .

• Lo w er the rollbar only when absolutely

necessar y . Do not w ear the seat belt with the

roll bar folded do wn.

• Chec k carefully for o v erhead clearances (i.e

branc hes , doorw a ys , electrical wires) before

dri ving under any objects and do not contact

them.

Maintenance and Storage

• Mak e sure all h y draulic line connectors are

tight and all h y draulic hoses and lines are in

g ood condition before applying pressure to the

system.

• K ee p y our body and hands a w a y from pin hole

leaks or nozzles that eject h y draulic fluid under

• Use only T oro appro v ed attac hments and

re placement par ts . T he w ar ranty ma y be

v oided if used with unappro v ed attac hments .

Sound Pressure Level

T his unit has an equi v alent contin uous A-w eighted

sound pressure at the operator ear of: 90 dB(A),

based on measurements of identical mac hines per

EN 11094 and EN 836.

Sound Power Level

T his unit has a sound po w er lev el of: 105 dB(A) 1

pW , based on measurements of identical mac hines

per EN 11094.

Vibration Level

Hand-Ar m

T his unit does not ex ceed a vibration lev el of

2.5 m/s² at the hands based on measurements of

identical mac hines per EN 1033.

W hole Body

T his unit does not ex ceed a vibration lev el of

.5 m/s² at the posterior based on measurements of

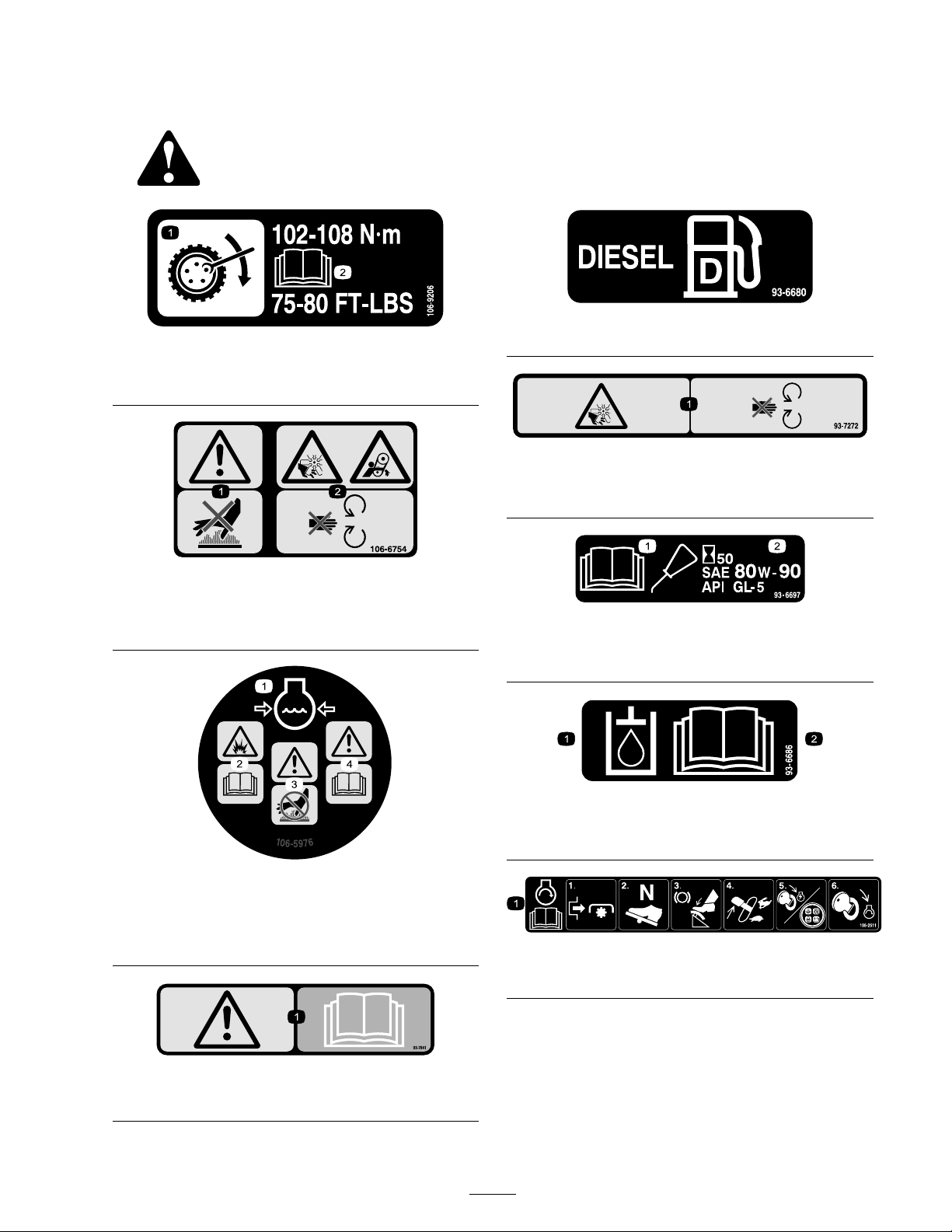

identical mac hines per EN 1032.

8

Page 9

Safety and Instructional Decals

Safety decals and instr uctions are easily visible to the operator and are located near any

area of potential dang er . R e place any decal that is damag ed or lost.

106-9206

1. Wheel torque specications

2. Read the Operator’s Manual .

93-6680

93-7272

1. Cutting/dismemberment hazard; fan—stay away from

moving parts.

106-6754

1. Warning—do not touch the hot surface.

2. Cutting/dismemberment hazard, fan and entanglement

hazard, belt—stay away from moving parts.

106-5976

1. Engine coolant under

pressure

2. Explosion hazard—read the

Operator’s Manual .

3. Warning—do not touch the

hot surface.

4. Warning—read the

Operator’s Manual .

93-6697

1. Read the Operator’s

Manual .

93-6686

1. Hydraulic oil

2. Read the Operator’s Manual.

105-2511

1. Read Operator’s Manual for starting instructions.

2. Add SAE 80w-90 (API GL-5)

oil every 50 hours.

93-7841

1. Warning—read the Operator’s Manual .

9

Page 10

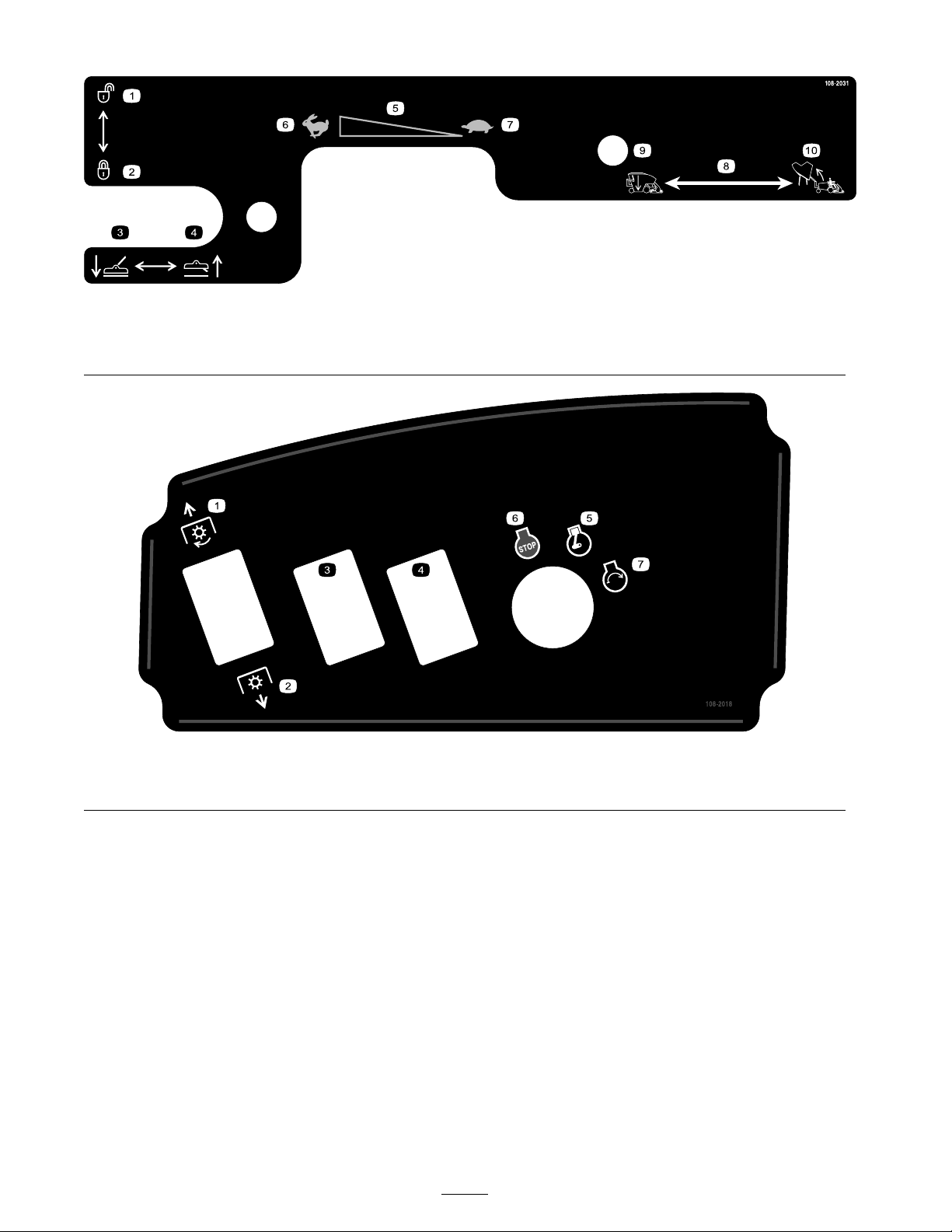

108-2031

1. Unlocked 4. Raise the cutting units 7. Slow 10. Raise the hopper

2. Locked 5. Engine speed 8. Hopper control

3. Lower the cutting units

6. Fast

9. Lower the hopper

108-2018

1. PTO–Off 3. Optional Equipment

2. PTO—On

4. Optional Equipment

5. Engine—Run 7. Engine—Start

6. Engine—Stop

10

Page 11

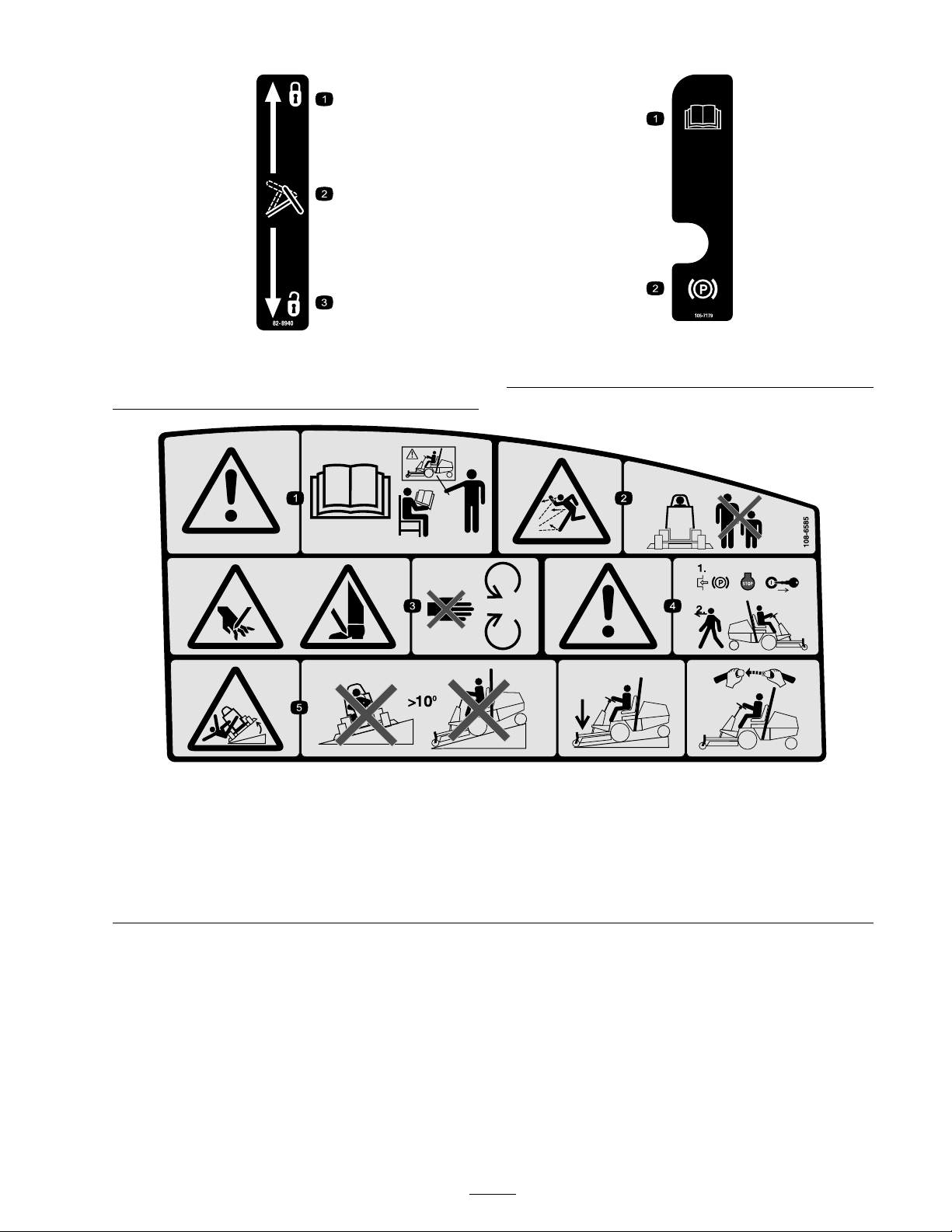

82-8940

1. Locked 3. Unlocked

2. Tilt steering

1. Warning—read the Operator’s Manual ,

all operators should be trained before

operating the machine.

2. Thrown object hazard—keep bystanders

a safe distance from the machine and

keep the deector in place.

1. Read Operator’s Manual .

108-6585

3. Cutting/dismemberment hazard of

hands or feet, mower blade—stay away

from moving parts.

4. Warning—engage the parking brake,

and remove the ignition key before

leaving the machine.

105-7179

2. Parking brake

5. Tipping hazard—do not drive the

machine on a slope greater than 10

degrees; when driving down slopes,

lower the cutting unit, and if the roll bar

is raised, wear the seat belt.

11

Page 12

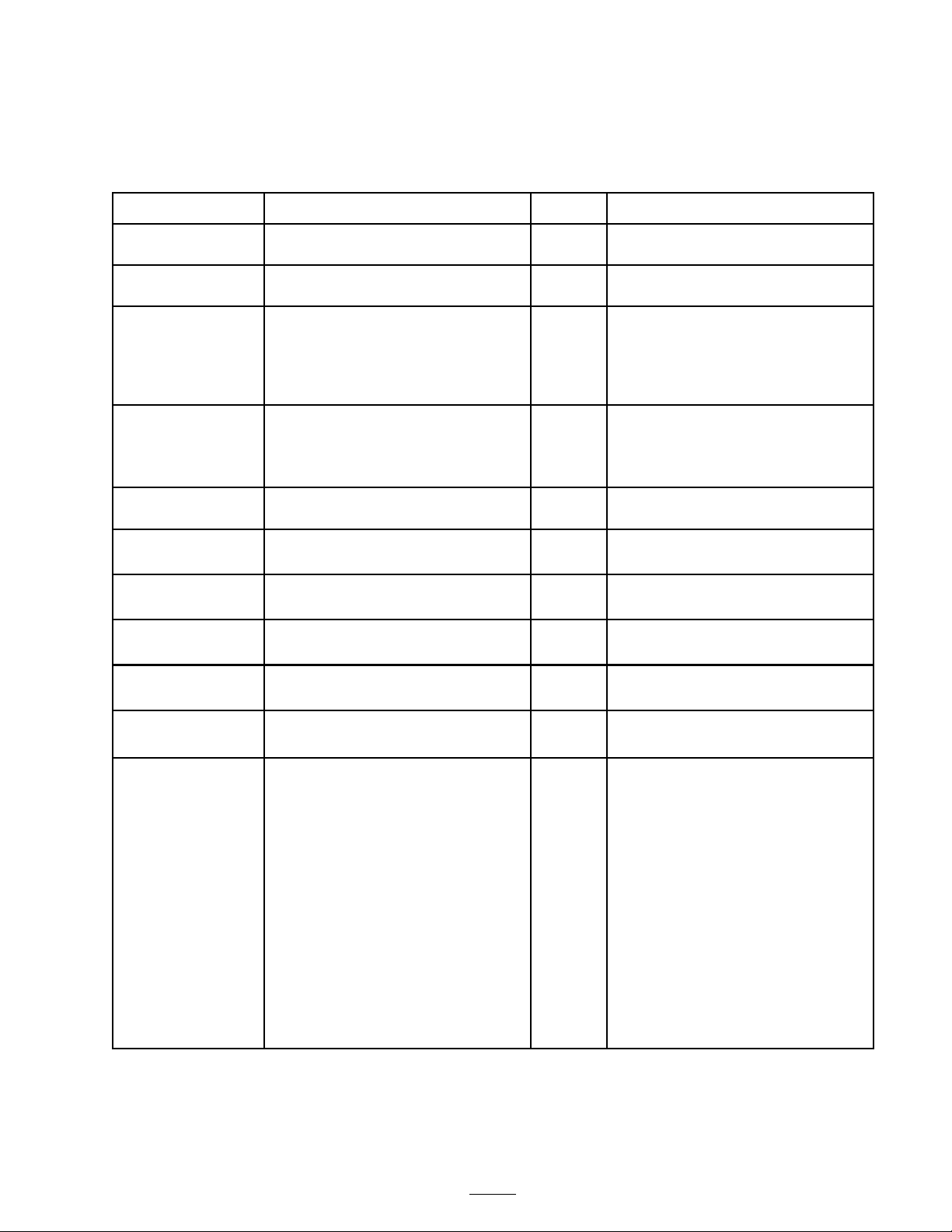

1. Read the Operator’s Manual .

1. Inputs 5. In seat

2. Backlap

3. High temperature shutdown 7. Parking brake Off

4. High temperature warning 8. Neutral

6. Power Take-off (PTO) 10. Power Take Off (PTO)

108-6583

106-9290

9. Outputs 13. Start

14. Power

11. Start

12. Energize to Run (ETR)

12

Page 13

108-2073

1. Warning—there is no rollover protection when the roll bar is

down.

2. To avoid injury or death from a rollover accident, keep the

roll bar in the raised and locked position and wear the seat

belt. Lower the roll bar only when absolutely necessary; do

not wear the seat belt when the roll bar is down.

3. Read the Operator’s Manual ; drive slowly and carefully.

93-7834

1. No step

2. Traction pedal 5. Warning—shut off PTO

3. Traction-forward

4. Traction-reverse

prior to raising decks; do

not operate decks when

they are in raised position

13

Page 14

Battery Symbols

Some or all of these symbols are on your battery

1. Explosion hazard 6. Keep bystanders a safe

2. No re, open ame, or

smoking.

3. Caustic liquid/chemical

burn hazard

4. Wear eye protection

5. Read the Operator’s

Manual.

distance from the battery.

7. Wear eye protection;

explosive gases can cause

blindness and other injuries

8. Battery acid can cause

blindness or severe burns.

9. Flush eyes immediately

with water and get medical

help fast.

10. Contains lead; do not

discard.

Manufacturer’s Mark

1. Indicates the blade is identied as a part from the original

machine manufacturer.

14

Page 15

Setup

Loose Parts

Use the chart below to verify that all parts have been shipped.

Step

Steering wheel

1

2

3

4

5

6

7

8

Cover

Handle

Screws 2

Seat, Model 30398 and the

Mechanical Seat Suspension Kit,

Model No. 30312 or the Pneumatic

Seat Suspension Kit, Model No.

30313 (obtained separately)

Seat belt

Bolts

Lock washer

Flat washer

Manual tube

R-clamp

No parts required

No parts required

No parts required

Description

Qty.

1

1

1

1

2

2

2

2

1

2

–

–

–

Install the steering wheel.

Install the hood handle.

Install the seat.

Install the seat belt.

Install the manual tube.

Activate and charge the battery.

Adjust the ROPS.

Check the tire pressure.

Use

9

10

11

Rear weight kit(s) as needed

No parts required

Operator’s Manual

Engine Operator’s Manual

Parts Catalog

Operator Training DVD

Pre-delivery Inspection Sheet

Engine warranty

CE certicate

Certicate of Quality

Roll pin

Bolt (5/16 x 1-3/4 inches)

Lock nut (5/16 inch)

Cylinder pin

Cotter pin (3/16 x 1-1/2 inches)

Brake return springs

Note: Deter mine the left and right sides of the

mac hine from the nor mal operating position.

-

–

1

1

1

1

1

1

1

1

1

2

2

2

4

2

Install rear weights if needed.

Check the rear axle lubricant,

hydraulic uid, and engine oil levels

Read the manuals and watch the

DVD before operating the machine.

Use the remaining parts for the

installation of attachments.

15

Page 16

T he PT O uni v er sal shaft is attached to the

machine frame. Do not enga ge the PT O

without fir st r emo ving the uni v er sal shaft or

coupling it to a suita ble implement.

Step

1

Installing the Steering

Wheel

Parts needed for this step:

1

Steering wheel

1

Cover

Procedure

1. R emo v e the steering wheel from the seat plate .

2. R emo v e the co v er from the steering wheel

( Figure 3 ).

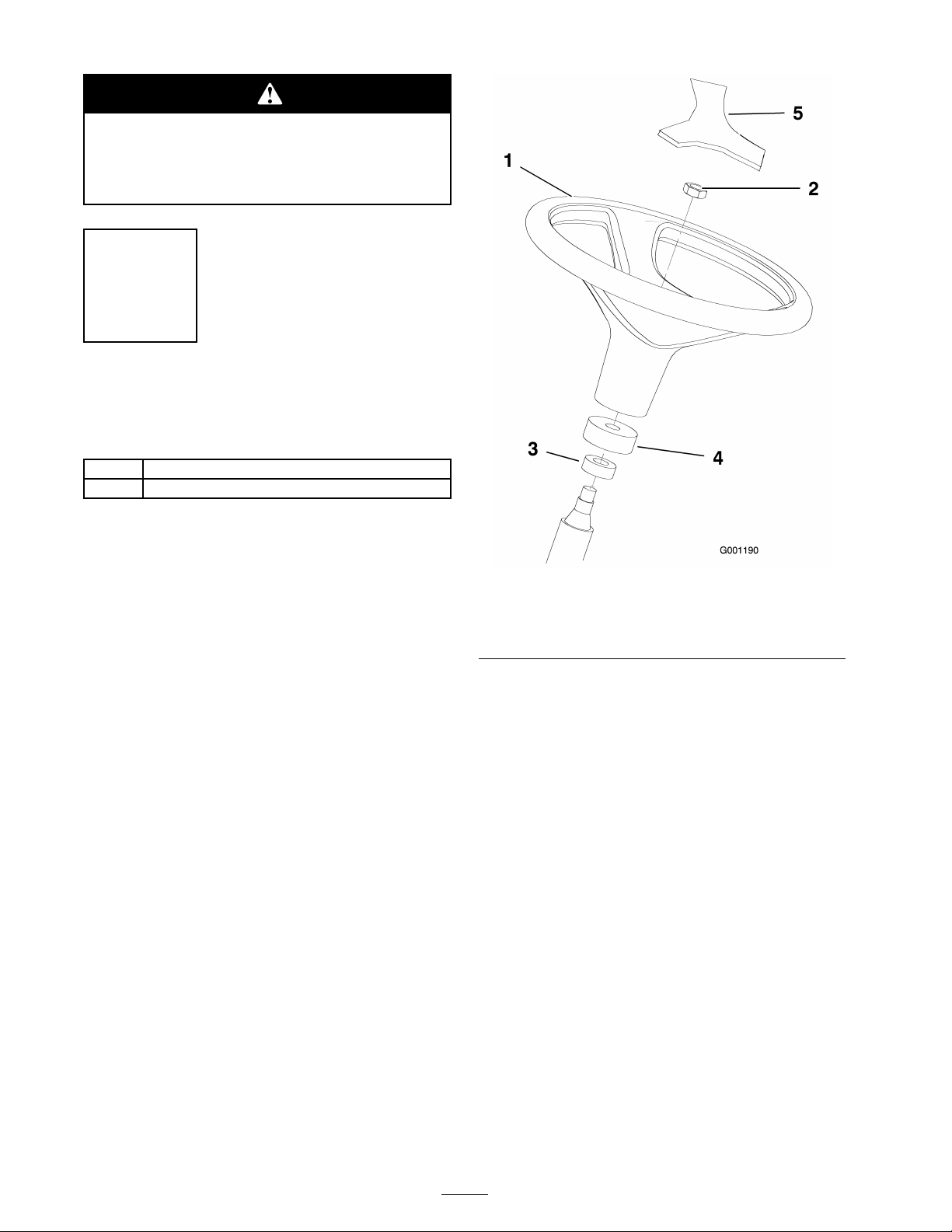

Figure 3

1. Steering wheel 4. Foam collar

2. Jam nut 5. Cover

3. Dust cover

3. R emo v e the jam n ut from the steering shaft.

Ensure that the foam collar and dust co v er are

on the steering shaft ( Figure 3 ).

4. Slide the steering wheel onto the steering shaft

( Figure 3 ).

5. Secure the steering wheel to the shaft with the

jam n ut and tighten it to 17-23 ft-lb .

6. Mount the co v er to the steering wheel

( Figure 3 ).

16

Page 17

Step

Step

2

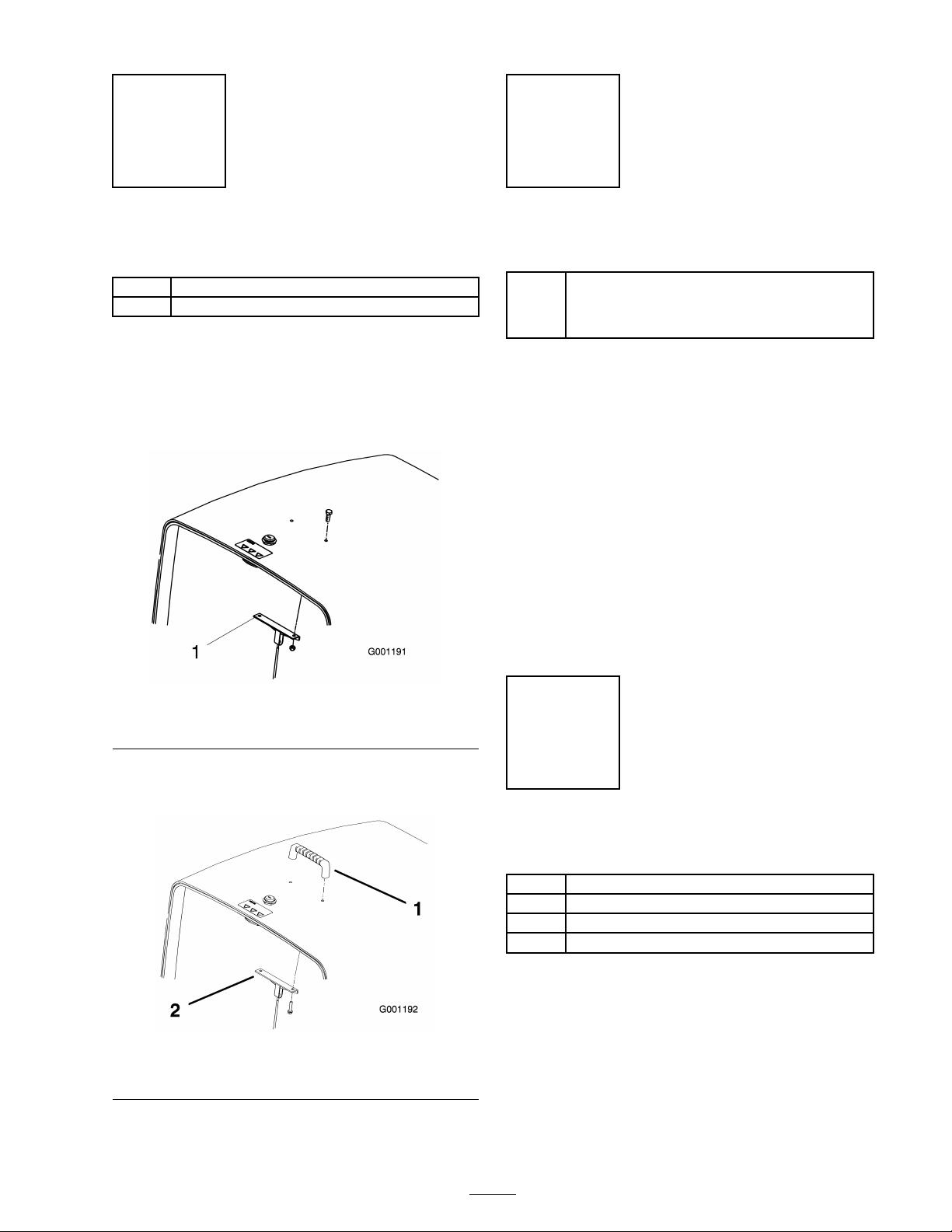

Installing the Hood Handle

Parts needed for this step:

1

Handle

2 Screws

Procedure

1. R emo v e and discard the 2 screws and n uts

securing the hood cable brac k et and to the

underside of the hood ( Figure 4 ).

3

Installing the Seat

Parts needed for this step:

Seat, Model 30398 and the Mechanical Seat

Suspension Kit, Model No. 30312 or the

1

Pneumatic Seat Suspension Kit, Model No.

30313 (obtained separately)

Procedure

T he Groundsmaster 3280-D is shipped without

the seat assembly . T he optional Seat, Model 30398

and the Mec hanical Seat Suspension Kit, Model

No . 30312 or the Pneumatic Seat Suspension Kit,

Model No . 30313 m ust be obtained and installed.

R efer to the seat kit for the installation instr uctions .

Note: An A uxiliar y P o w er Unit Kit, Model No .

30382, m ust be obtained and installed before

installing a Pneumatic Suspension Seat Kit to the

mac hine .

Figure 4

1. Hood cable bracket

2. Mount the handle and the cable brac k et to the

hood with 2 screws ( Figure 5 ).

Figure 5

1. Handle 2. Hood cable bracket

Note: R efer to Installing the Man ual T ube before

the seat is mounted to the seat suspension.

Step

4

Installing the Seat Belt

Parts needed for this step:

2

Seat belt

2

Bolts

2

Lock washer

2

Flat washer

Procedure

Install eac h end of the seat belt in the holes in the

bac k of the seat with 2 bolts (7/16 x 1 inc h), flat

w ashers (7/16 inc h), and loc k w ashers (7/16 inc h)

( Figure 6 ).

Important: Mount the latch side of the belt

to the right side of the seat.

17

Page 18

1. Seat belt latch

Step

Figure 6

Figure 7

1. R-clamps 4. Manual tube

2. Upper seat bracket 5. Vinyl cap

3. Seat suspension

5

Installing the Manual Tube

Parts needed for this step:

1

Manual tube

2

R-clamp

Procedure

1. R emo v e the man ual tube and R-clamps secured

to the seat plate , Discard the 2 mounting bolts

and flat w ashers .

2. R emo v e the 2 n uts and vinyl caps (if previously

installed) securing the upper seat brac k et to the

left side of the seat suspension ( Figure 7 ).

3. Loosely mount the R-clamps to the seat

brac k et studs with the 2 n uts previously

remo v ed. ( Figure 7 ). T he R-clamps are to be

positioned under the seat suspension tabs .

4. Install the man ual tube into the R-clamps and

tighten the n uts ( Figure 7 ).

5. Inser t the vinyl caps onto the seat brac k et

studs .

Step

6

Activating and Charging the

Battery

No Parts Required

Procedure

Use only electrolyte (1.265 Specific Gra vity) to fill

batter y initially .

1. R emo v e the batter y from the mac hine .

Important: Do not add electr ol yte while

the batter y is in the machine. Y ou could

spill it, causing cor r osion.

2. Clean the top of the batter y and remo v e the

v ent caps ( Figure 8 ).

18

Page 19

Figure 8

1. Vent caps

3. Carefully fill eac h cell with electrolyte until the

plates are co v ered with about 1/4 inc h (6 mm)

of fluid ( Figure 9 ).

higher and the temperature is at least F . (16°C)

with all cells g asing freely .

6. W hen the batter y is c harg ed, disconnect the

c harg er from the electrical outlet and batter y

posts .

Note: After the batter y has been acti v ated,

add only distilled w ater to re place nor mal loss ,

although maintenance-free batteries should

not require w ater under nor mal operating

conditions .

Warning

CALIFORNIA

Pr oposition 65 W ar ning

Batter y posts, ter minals, and r elated

accessories contain lead and lead

compounds, chemicals kno wn to the

State of Calif or nia to cause cancer and

r epr oducti v e har m. W ash hands after

handling .

Figure 9

1. Electrolyte

4. Allo w appro ximately 20 to 30 min utes for the

electrolyte to soak into the plates . R efill as

necessar y to bring the electrolyte to within

about 1/4 inc h (6 mm) of the bottom of the

fill w ell ( Figure 9 ).

Charging the batter y pr oduces gasses

that can explode.

Nev er smok e near the batter y and k eep

spar ks and flames a w ay fr om batter y .

Batter y ter minals or metal tools could

shor t a gainst metal tractor components

causing spar ks. Spar ks can cause the

batter y gasses to explode, r esulting in

per sonal injur y .

• W hen r emo ving or installing the

batter y , do not allo w the batter y

ter minals to touch an y metal par ts of

the tractor .

• Do not allo w metal tools to shor t

betw een the batter y ter minals and

metal par ts of the tractor .

7. Install the batter y into the mac hine .

8. First, install the positi v e cable (red) to the

positi v e (+) ter minal and then the neg ati v e

cable (blac k) to the neg ati v e (-) ter minal of

the batter y ( Figure 10 ). Slide the r ubber boot

o v er the positi v e ter minal to prev ent a possible

shor t from occur ring .

5. Connect a 3 to 4 amp batter y c harg er to the

batter y posts . Charg e the batter y at a rate of 3

to 4 amps until the specific g ra vity is 1.250 or

19

Page 20

Incor r ect batter y ca ble r outing could

dama ge the machine and ca bles causing

spar ks. Spar ks can cause the batter y

gasses to explode, r esulting in per sonal

injur y .

Step

7

Adjusting the ROPS

• Al w ays disconnect the negati v e

(black) batter y ca ble bef or e

disconnecting the positi v e (r ed)

ca ble.

• Al w ays connect the positi v e (r ed)

batter y ca ble bef or e connecting the

negati v e (black) ca ble.

Figure 10

1. Positive (+) 2. Negative (-)

No Parts Required

Procedure

1. R emo v e the hair pin cotter pins and remo v e the

tw o pins from the roll bar ( Figure 11 ).

Figure 11

1. Roll bar

2. Pin

3. Hairpin cotter pin

Connecting ca bles to the wr ong post

could dama ge the electrical system and

r esult in per sonal injur y .

Note: Ensure that the batter y cables are

routed a w a y from any shar p edg es or mo ving

par ts .

2. Raise the roll bar to the upright position and

install the tw o pins and secure them with the

hair pin cotter pins ( Figure 11 ).

Note: If the roll bar m ust be lo w ered, lo w er

it slo wly so damag e to hood does not occur .

20

Page 21

Step

8

Checking the Tire Pressure

No Parts Required

Procedure

T he tires are o v er inflated for shipping . T herefore ,

release some of the air to reduce the pressure .

Cor rect air pressure in front and rear tires is 20 psi.

21

Page 22

Step

9

Installing Rear Weights

Parts needed for this step:

-

Rear weight kit(s) as needed

Procedure

T he Groundsmaster 3280-D Series mac hines comply with ANSI B71.4-2004 Standard when equipped

with rear w eight. Use c har ts belo w to deter mine combinations of w eight required. Order par ts from

y our local A uthorized T oro Distributor .

Two Wheel Drive Chart Rear Weight

52 inch Side Discharge

Deck (Model 30555)

52 inch Side Discharge Deck

with 15 cu. ft. Hopper

60 inch Side Discharge

Deck (Model 30366)

or

62 inch Rear Discharge

Deck (Model 30367)

or

62 inch Guardian Recycler

Deck (Model 30376)

60 inch Side Discharge Deck

with 15 cu. ft. Hopper

72 inch Side Discharge

Deck (Model 30368)

72 inch Rear Discharge

Deck (Model 30369)

or

72 inch Guardian Recycler

Deck (Model 30379)

Required

0 lb. 0 lb.

0 lb. 145 lb.*

170 lb. 0 lb.

0 lb. 110 lb.

240 lb. 0 lb.

205 lb. 0 lb.

Left Side

Weight

Required

Weight Part

Number

- - -

*77-6700

92-9670

24-5780

24-5790

325-8

3253-7

3-8847 Spacer 2

3217-9

24-5780

108-9682

*77-6700

92-9670

24-5790

325-8

3253-7

3-8847 Spacer 2

3217-9

24-5780

108-9682

24-5790

325-8

3253-7

3-8847 Spacer 2

3217-9

24-5780

108-9682

Weight Description

75 lb. Wheel Weight

Bracket Kit

Rear Weight Kit

Rear Weight, 35 lb

Bolt (1/2 x 2 inches)

Lock washer (1/2 inch)

Nut (1/2 inch)

Rear Weight Kit

Rear Weight Kit

75 lb. Wheel Weight

Bracket Kit

Rear Weight, 35 lb

Bolt (1/2 x 2 inches)

Lock washer (1/2 inch)

Nut (1/2 inch)

Rear Weight Kit

Rear Weight Kit

Rear Weight, 35 lb

Bolt (1/2 x 2 inches)

Lock washer (1/2 inch)

Nut (1/2 inch)

Rear Weight Kit

Rear Weight Kit

Qty.

1

1

1

1

2

2

2

1

1

1

1

1

2

2

2

2

1

1

2

2

2

2

1

* 75 lb . wheel w eight (included with 15 cu. ft. hopper) required on left wheel

22

Page 23

Four Wheel Drive Chart Rear Weight

52 inch Side Discharge

Deck (Model 30555)

52 inch Side Discharge Deck

with 15 cu. ft. Hopper

Required

0 lb. 0 lb.

0 lb. 145 lb.*

Left Side

Weight

Required

Weight Part

Number

- - -

*77-6700

92-9670

24-5780

Weight Description

75 lb. Wheel Weight

Bracket Kit

Rear Weight Kit

Qty.

1

1

1

60 inch Side Discharge

Deck (Model 30366)

62 inch Rear Discharge

Deck (Model 30367)

or

62 inch Guardian Recycler

Deck (Model 30376)

60 inch Side Discharge Deck

with 15 cu. ft. Hopper

72 inch Side Discharge

Deck (Model 30368)

or

72 inch Rear Discharge

Deck (Model 30369)

or

72 inch Guardian Recycler

Deck (Model 30379)

35 lb. 0 lb.

0 lb. 0 lb.

0 lb. 110 lb.*

70 lb. 0 lb.

24-5790

325-8

3253-7

3-8847 Spacer 2

3217-9

- - -

*77-6700

92-9670

24-5790

325-8

3253-7

3-8847 Spacer 2

3217-9

24-5780

Rear Weight, 35 lb

Bolt (1/2 x 2 inches)

Lock washer (1/2 inch)

Nut (1/2 inch)

75 lb. Wheel Weight

Bracket Kit

Rear Weight, 35 lb

Bolt (1/2 x 2 inches)

Lock washer (1/2 inch)

Nut (1/2 inch)

Rear Weight Kit

1

2

2

2

1

1

1

2

2

2

1

* 75 lb . wheel w eight (included with 15 cu. ft. hopper) required on left wheel

Step

2. Chec k the h y draulic fluid lev el before the

engine is first star ted, refer to Chec king the

Hy draulic Fluid Lev el in Operation , pag e 29 .

10

3. Chec k the engine oil lev el before and after the

engine is first star ted, refer to Chec king the

Checking Fluid Levels

Engine Oil Lev el in Operation , pag e 29 .

No Parts Required

Procedure

1. Chec k the rear axle lubricant lev el before the

engine is first star ted, refer to Chec king the R ear

Axle Lubricant in Dri v e System Maintenance ,

pag e 47 .

23

Page 24

Step

11

Reading the Manuals and

Viewing the DVD

Parts needed for this step:

1

Operator’s Manual

1

Engine Operator’s Manual

1

Parts Catalog

1

Operator Training DVD

1

Pre-delivery Inspection Sheet

1

Engine warranty

1

CE certicate

1

Certicate of Quality

1

Roll pin

2

Bolt (5/16 x 1-3/4 inches)

2

Lock nut (5/16 inch)

2

Cylinder pin

4

Cotter pin (3/16 x 1-1/2 inches)

2

Brake return springs

Procedure

1. R ead the man uals .

2. View the Operator D VD .

3. Sa v e the roll pin, bolts (5/16 x 1-3/4 inc hes),

and loc kn uts (5/16 inc h) to secure the uni v ersal

shaft to an implement.

4. Sa v e the cylinder pin and otter pin (3/16 x

1-1/2 inc hes) to secure the dec k lift ar ms to

the lift cylinder .

5. Sa v e the brak e retur n springs to mount the

dec k lift ar ms .

24

Page 25

Product Overview

Figure 12

1. Steering wheel 3. Brakes 5. Hood/engine compartment

2. Traction pedal

4. Cutting unit

Controls

Service Brakes

T he left and right brak e pedals ( Figure 13 ) are

connected to the left and right front wheels . Since

both brak es w ork inde pendently of eac h other , the

brak es can be used to tur n shar ply or to increase

traction if one wheel tends to slip while operating

on cer tain slope conditions . Ho w ev er , w et g rass or

soft turf could be damag ed when brak es are used

to tur n shar ply . T o stop quic kly , press both brak e

pedals tog ether . Alw a ys loc k the brak es tog ether

when transpor ting the mac hine .

6. ROPS (Rollover Protection System)

25

Page 26

Figure 13

1. Parking brake knob 3. Left brake pedal

2. Right brake pedal

Parking Brake

W henev er the engine is shut off , the parking brak e

m ust be eng ag ed to prev ent accidental mo v ement

of the mac hine . T o eng ag e the parking brak e ,

push the loc k ar m ( Figure 14 ) on the left brak e

pedal so that it loc ks tog ether with the right pedal.

Next, push do wn fully on both pedals and pull the

parking brak e knob out ( Figure 13 ) then release

the pedals . T o release the parking brak e , press

both pedals until the parking brak e knob retracts .

Before star ting the engine , ho w ev er , the loc k ar m

ma y be diseng ag ed from the left brak e pedal so

both pedals w ork inde pendently with eac h front

wheel.

Traction Pedal

T he traction pedal ( Figure 15 ) has tw o functions:

one is to mak e the mac hine mo v e forw ard, the

other is to mak e it mo v e rearw ard. Using the heel

and toe of the right foot, press the top of the pedal

to mo v e forw ard and the bottom of the pedal to

mo v e rearw ard. Ground speed is propor tionate

to ho w far the pedal is pressed. F or maxim um

g round speed, the traction pedal m ust be fully

de pressed while throttle is in the F ast position.

Maxim um speed forw ard is 10 mph (appro x.).

T o g et maxim um po w er under hea vy load or

when ascending a hill, ha v e the throttle in the

F ast position while pressing traction pedal slightly

to k ee p the engine r pm high. W hen the engine

r pm begins to decrease , release the traction pedal

slightly to allo w the r pm to increase .

Figure 15

1. Traction pedal

Figure 14

1. Left brake pedal 3. Lock arm

2. Right brake pedal

Tilt Steering Control

T he tilt steering control is a lev er on the right side

of the steering column ( Figure 16 ). Pull the lev er

rearw ard to adjust the steering wheel to the desired

fore or aft operating position and push the lev er

forw ard to loc k the adjustment.

26

Page 27

Figure 16

1. Tilt steering control

Nev er raise the deck while the blades ar e

r otating . Contact with r otating blades can

cause serious injur y .

Hydraulic Lift Lever

T he h y draulic lift lev er ( Figure 17 ) has three lev er

positions that actuate four operating modes; LIFT ,

LO WER, FLO A T & HOLD . T o lo w er the dec k,

in pre paration for mo wing, lightly tap the lev er

forw ard and then allo w the lev er to freely retur n.

T his will allo w the dec k to drop at a controlled

rate and enables the dec k g round follo wing float

function. If the lev er is held in the forw ard

(LO WER) position, the dec k will drop quic kly .

T o raise the dec k and hold it in the transpor t

position, pull and hold the lift lev er rearw ard until

the dec k has fully raised, then release the lev er to

allo w it to retur n. T he dec k will no w hold in the

transpor t position. T he dec k m ust be raised when

transpor ting betw een mo wing locations . T he dec k

should be lo w ered when not in use .

Figure 17

1. Hydraulic Lift lever 7. Oil pressure indicator

2. PTO Switch 8. Glow plug indicator

3. Ignition switch 9. Charge indicator

4. Throttle 10. Lift lever lock

5. Hour meter

6. Engine coolant

temperature indicator

11. Power point

PTO Switch

Pull up on the switc h knob to eng ag e the electric

PTO clutc h ( Figure 17 ). Push do wn on the knob

to diseng ag e the electric PTO clutc h. T he only

time the PTO switc h should be in the eng ag e

position is when the implement is do wn in the

operating position and ready to begin operation.

If the operator lea v es the seat when the PTO

switc h is eng ag ed, the mac hine will shut do wn. T o

re-eng ag e the PTO , push do wn and pull up on the

knob .

Fuel Gauge

T he fuel g aug e ( Figure 18 ) indicates quantity of

fuel remaining in fuel tank.

27

Page 28

Figure 18

1. Fuel gauge

Ignition Switch

T he ignition switc h has three positions: Off ,

On/Preheat, and Star t. ( Figure 17 ).

Throttle

Charge Indicator

Illuminates when the system c harging circuit

malfunctions ( Figure 17 ).

Oil Pressure Warning Light

T he oil pressure w ar ning light ( Figure 17 ) glo ws

when the oil pressure in engine drops belo w a

safe lev el. If lo w oil pressure ev er occurs , stop

the engine and deter mine the cause . R e pair the

damag e before star ting the engine ag ain.

Lift Lever Lock

Loc k the lift lev er ( Figure 17 ), in the raised

position, when perfor ming maintenance on the

dec k.

Specications

Note: Specifications and design are subject to

c hang e without notice .

Length 82 inches

Width (Rear Wheels)

47 inches

T he throttle ( Figure 17 ) is used to operate the

engine at v arious speeds . Mo ving the throttle

forw ard to w ard the F ast position increases the

engine speed. Mo ving it rearw ard to w ard the

Slo w position decreases the engine speed. T he

throttle controls the speed of the blades and, in

conjunction with traction pedal, controls g round

speed of the mac hine . T he detent is the high idle

position.

Hour Meter

T he hour meter ( Figure 17 ) registers accum ulated

hours of engine operation.

Engine Coolant Temperature Warning

Light

T he temperature w ar ning light ( Figure 17 ) glo ws

and the implement stops if the engine coolant

temperature is high. If the mac hine is not stopped

and the coolant temperature rises another 20° F ,

the engine will kill.

Height without ROPS 50 inches

Height with ROPS 77 inches

Weight, Model 30308 1300 lb

Weight, Model 30309 1520 lb

Attachments/Accessories

A selection of T oro appro v ed attac hments and

accessories are a v ailable for use with the mac hine

to enhance and expand its capabilities . Contact

y our A uthorized Ser vice Dealer or Distributor or

g o to www .T oro .com for a list of all appro v ed

attac hments and accessories .

Glow Plug Indicator

W hen lit, indicates that the glo w plugs are on

( Figure 17 ).

28

Page 29

Operation

T his machine pr oduces sound lev els in

ex cess of 85 dB A at the operator s ear and

can cause hearing loss thr ough extended

periods of exposur e.

W ear hearing pr otection when operating

this machine.

Adequate r ear w eight is necessar y to pr ev ent

the r ear wheels fr om lea ving the g r ound. Do

not stop suddenl y while deck or implement

is raised. Do not tra v el do wn hill with the

deck or implement raised. If the r ear wheel

lea v es the g r ound, steering is lost.

Checking the Engine Oil

Level

T he engine is shipped with oil in the crankcase;

ho w ev er , the oil lev el m ust be c hec k ed before and

after the engine is first star ted.

T he crankcase capacity is appro ximately 4 qt.

(3.8 l) with the filter . Use high-quality engine oil

that meets the follo wing specifications:

• API Classification Lev el R equired: CH-4, CI-4

or higher .

• Prefer red oil: SAE 15W -40 (abo v e 0°F)

• Alter nate oil: SAE 10W -30 or 5W -30 (all

temperatures)

Figure 19

1. Dipstick

3. If the oil lev el is belo w the Full mark, remo v e

the fill cap ( Figure 20 ) and add oil until the

lev el reac hes the Full mark on the dipstic k. Do

not o v erfill. .

Figure 20

1. Oil ll

4. Install the oil fill cap and close the hood.

Note: T oro Premium Engine oil is a v ailable

from y our distributor in either 15W -40 or 10W -30

viscosity . See the par ts catalog for par t n umbers .

1. P ark the mac hine on a lev el surface , lo w er the

cutting dec k, stop the engine and remo v e the

k ey from the ignition switc h. Open the hood.

2. R emo v e the dipstic k ( Figure 19 ), wipe it clean

and reinstall the dipstic k. R emo v e the dipstic k

and c hec k the oil lev el. T he oil lev el should be

up to the Full mark on the dipstic k.

Checking the Cooling System

Clean debris off the screen and the radiator/oil

cooler daily , more often if conditions are extremely

dusty and dir ty; refer to Cleaning the Radiator

and the Screen in Cooling System Maintenance ,

pag e 49 .

T he cooling system is filled with a 50/50 solution

of w ater and per manent eth ylene glycol anti freeze .

Chec k the lev el of the coolant in the expansion

tank at the beginning of eac h da y before star ting

the engine . T he capacity of the cooling system is 8

quar ts (7.5 l).

29

Page 30

If the engine has been r unning , pr essuriz ed

hot coolant can escape when the radiator

cap is r emo v ed and cause bur ns.

1. Chec k the lev el of the coolant in the expansion

tank ( Figure 21 ). T he coolant lev el should be

betw een the marks on the side of the tank.

Figure 21

1. Expansion tank

2. If coolant lev el is lo w , remo v e expansion tank

cap and re plenish the system. Do not o v erfill .

3. Install expansion tank cap .

Checking the Hydraulic

System

T he mac hines reser v oir is filled at the factor y

with appro ximately 5 quar ts (4.7 l) of high quality

h y draulic fluid. Chec k the lev el of the h y draulic

fluid before the engine is first star ted and daily

thereafter . T he recommended re placement fluid is

as follo ws:

Material Properties:

Viscosity, ASTM D445

Viscosity Index ASTM

D2270

Pour Point, ASTM D97

Industry Specications:

API GL-4, AGCO Poweruid 821 XL, Ford

New Holland FNHA-2-C-201.00, Kubota UDT,

John Deere J20C, Vickers 35VQ25, and Volvo

WB-101/BM

cSt @ 40°C 44 to 48

cSt @ 100°C 9.1 to 9.8

140 to 152

-34°F to -46°F

Note: Many h y draulic fluids are almost colorless ,

making it difficult to spot leaks . A red dye additi v e

for the h y draulic system oil is a v ailable in 2/3 oz.

(20 ml) bottles . One bottle is sufficient for 4-6

g al (15-22 1) of h y draulic oil. Order par t n umber

44-2500 from y our authorized T oro distributor .

1. P osition mac hine on a lev el surface . Place

all control in neutral position and star t the

engine . R un engine at lo w est possible RPM to

purg e the system of air . Do not enga ge the

PT O . Cycle steering wheel sev eral times fully

to the left and right. Raise the dec k to extend

lift cylinders , aiming steering wheels straight

forw ard and stop the engine .

2. R emo v e dipstic k cap ( Figure 22 ) from filler

nec k and wipe it with a clean rag . Screw

dipstic k cap fing er -tight onto filler nec k; then

remo v e it and c hec k lev el of fluid. If lev el is not

within 1/2 inc h (13 mm) from the g roo v e in

the dipstic k, add enough high quality h y draulic

fluid to raise lev el to g roo v e mark. Do not

o v erfill.

Toro Premium All Season Hydraulic Fluid

(Available in 5 gallon pails or 55 gallon drums. See

parts catalog or Toro distributor for part numbers.)

Alter nate fluids: If the T oro fluid is not a v ailable ,

other fluids ma y be used pro vided they meet all

the follo wing material proper ties and industr y

specifications . W e do not recommend the use

of synthetic fluid. Consult with y our lubricant

distributor to identify a satisfactor y product

Note: T oro will not assume responsibility for

damag e caused b y improper substitutions , so use

only products from re putable man ufacturers who

will stand behind their recommendation.

Figure 22

1. Hydraulic system reservoir uid/add dipstick cap

3. T hread dipstic k fill cap fing er -tight onto filler

nec k. It is not recommended to tighten cap

with a wrenc h.

4. Chec k all hoses and fittings for leaks .

30

Page 31

Adding Fuel

Checking the Rear Axle

Fuel tank capacity is appro ximately 12.8 g allon

(48 l).

Under cer tain conditions, diesel fuel and fuel

v apor s ar e highl y flamma ble and explosi v e.

A fir e or explosion fr om fuel can bur n y ou

and other s and can cause pr oper ty dama ge.

• Use a funnel and fill the fuel tank

outdoor s, in an open ar ea, when the

engine is of f and is cold. W ipe up an y

fuel that spills.

• Do not fill the fuel tank completel y full.

Add fuel to the fuel tank until the lev el is

to the bottom of the filler neck.

• Nev er smok e when handling fuel, and

stay a w ay fr om an open flame or wher e

fuel fumes may be ignited by a spar k.

• Stor e fuel in a clean, safety-appr o v ed

container and k eep the cap in place.

Lubricant (Model 30309

only)

T he rear axle has three se parate reser v oirs whic h

use SAE 80W -90 wt. g ear lube . Although the axle

is shipped with lubricant from the factor y , c hec k

the lev el before operating the mac hine .

1. P osition the mac hine on a lev el surface .

2. R emo v e c hec k plugs from axle and mak e sure

lubricant is up to bottom of eac h hole . If

lev el is lo w , remo v e fill plugs and add enough

lubricant to bring the lev el up to the bottom of

the c hec k plug holes ( Figure 24 and Figure 25 ).

1. Using a clean rag, clean area around fuel tank

cap .

2. R emo v e cap from the fuel tank ( Figure 23 ).

Figure 23

1. Fuel tank cap

Figure 24

1. Check plug 2. Fill plug

Figure 25

1. Fill/check plug (one on each end of axle)

Checking the Bidirectional

3. Fill the tank until the lev el is to the bottom of

the filler nec k with diesel fuel.

4. Install fuel tank cap tightly after filling tank.

Clutch Lubricant (Model

30309 only)

1. P osition the mac hine on a lev el surface .

31

Page 32

2. R otate the clutc h ( Figure 26 ) so that the c hec k

plug (sho wn in the 12 o’cloc k position) is

positioned at 4 o’cloc k.

T her e is no r ollo v er pr otection when the r oll

bar is in the do wn position.

• Lo w er the r oll bar onl y when a bsolutel y

necessar y .

• Do not w ear the seat belt when the r oll

bar is in the do wn position.

• Dri v e slo wl y and car efull y .

• R aise the r oll bar as soon as clearance

per mits.

Figure 26

1. Bidirectional clutch 2. Check plug

3. R emo v e the c hec k plug .

T he fluid lev el should be up to the hole in the

clutc h. If the fluid lev el is lo w , add Mobil Fluid

424. T he clutc h should be appro ximately 1/3

full.

4. Install the c hec k plug .

Note: Do not use engine oil (i.e . 10W30) in

the bidirectional clutc h. Anti-w ear and extreme

pressure additi v es will cause undesirable clutc h

perfor mance .

Note: Deter mine the left and right sides

of the mac hine from the nor mal operating

position.

Using the Rollover

• Check car efull y f or o v erhead clearances

(i.e. branches, doorw ays, electrical wir es)

bef or e dri ving under an y objects and do

not contact them.

• Lo w er r oll bar slo wl y so dama ge to hood

does not occur .

Important: Lo w er the r oll bar onl y when

a bsolutel y necessar y .

1. T o lo w er the roll bar , remo v e the hair pin cotter

pins and remo v e the tw o pins ( Figure 27 ).

Protection System (ROPS)

T o a v oid injur y or death fr om r ollo v er : k eep

the r oll bar in the raised lock ed position and

use the seat belt.

Ensur e that the r ear par t of the seat is

secur ed with the seat latch.

Figure 27

1. Roll bar

2. Pin

3. Hairpin cotter pin

2. Lo w er the roll bar to the do wn position.

3. Install the tw o pins and secure them with the

hair pin cotter pins ( Figure 27 ).

32

Page 33

4. T o raise the roll bar , remo v e the hair pin cotter

pins and remo v e the tw o pins ( Figure 27 ).

5. Raise the roll bar to the upright position and

install the tw o pins and secure them with the

hair pin cotter pins ( Figure 27 ).

Important: Al w ays use the seat belt when

the r oll bar is in the raised and lock ed position.

Do not use the seat belt when the R OPS is in

the lo w er ed position.

Starting/Stopping the

Engine

Important: W hen engine is star ted f or

the fir st time, or after an engine oil change,

or o v erhaul of the engine, transmission,

or axle, operate the machine in f orw ard

and r ev er se f or one to tw o min utes. Also

operate the lift lev er and PT O lev er to

ensur e pr oper operation of all par ts. T ur n

the po w er steering wheel to the left and

right to check the steering r esponse. T hen

shut the engine of f and check fluid lev els,

check f or oil leaks, loose par ts, and an y

other noticea ble malfunctions.

Important: T he fuel system must be bled if

an y of the f ollo wing situations ha v e occur r ed:

the initial star t up of a new machine, the

engine has ceased r unning due to lack of fuel,

or maintenance has been perf or med upon

fuel system components (i.e., filter r eplaced,

separator ser viced, etc).

1. Raise the R OPS up and loc k into place , sit on

the seat and fasten the seat belt.

2. Ensure that the parking brak e is set and the

PTO switc h is in the Off position. R emo v e

y our foot from traction pedal and ensure that

it is in neutral

3. Mo v e the throttle control to the F ast position.

4. T ur n the ignition switc h to the On/Preheat

position.

An automatic timer will control preheat for 6

seconds .

5. After preheating, tur n the k ey to the Star t

position. Crank the engine f or no longer

than 15 seconds . R elease the k ey when

the engine star ts . If additional preheating is

required, tur n the k ey to the Off position,

then to the On/Preheat position. R e peat this

process as required.

6. R un the engine at idle speed or par tial throttle

until it w ar ms up .

Note: Mo v e the throttle to the F ast position

when restar ting a w ar m engine .

Shut engine of f and w ait f or all mo ving

par ts to stop bef or e checking f or oil

leaks, loose par ts or other malfunctions.

7. T o stop engine , mo v e the throttle control

bac kw ard to the Slo w position, mo v e the PTO

switc h to the Off position and rotate ignition

k ey to Off . R emo v e k ey from the switc h to

prev ent accidental star ting .

Bleeding the Fuel System

1. P ark the mac hine on a lev el surface . Ensure

that the fuel tank is at least half full.

2. Unlatc h and raise the hood.

Under cer tain conditions, diesel fuel and

fuel v apor s ar e highl y flamma ble and

explosi v e. A fir e or explosion fr om fuel

can bur n y ou and other s and can cause

pr oper ty dama ge.

• Use a funnel and fill the fuel tank

outdoor s, in an open ar ea, when the

engine is of f and is cold. W ipe up an y

fuel that spills.

• Do not fill the fuel tank completel y

full. Add fuel to the fuel tank until the

lev el is to the bottom of the filler neck.

• Nev er smok e when handling fuel,

and stay a w ay fr om an open flame or

wher e fuel fumes may be ignited by

a spar k.

• Stor e fuel in a clean, safety-appr o v ed

container and k eep the cap in place.

33

Page 34

3. Open the air bleed screw on the fuel injection

pump ( Figure 28 ).

If the safety inter lock s witches ar e

disconnected or dama ged the machine

could operate unexpectedl y causing

per sonal injur y .

• Do not tamper with the inter lock

s witches.

• Check the operation of the inter lock

s witches dail y and r eplace an y dama ged

s witches bef or e operating the machine.

Figure 28

1. Fuel injection pump bleed screw

4. T ur n the k ey in the ignition switc h to the On

position.

T he electric fuel pump will begin operation,

thereb y forcing air out around the air bleed

screw .

5. Lea v e the k ey in the On position until a solid

stream of fuel flo ws out around the screw .

6. Tighten the screw and tur n k ey to the Off

position.

Note: Nor mally , engine should star t after

abo v e bleeding procedures are follo w ed.

Ho w ev er , if engine does not star t, air ma y be

trapped betw een injection pump and injectors;

refer to Bleeding Air F rom the Injectors in

Fuel System Maintenance , pag e 45 .

Checking the Interlock

System

T he pur pose of the safety interloc k system is to

prev ent the engine from cranking or star ting unless

the traction pedal is in neutral and the PTO switc h

is in the Off position. In addition, the engine will

stop when:

• the PTO control is eng ag ed with the operator

off the seat;

• R eplace s witches ev er y tw o y ear s

r egardless of whether they ar e operating

pr oper l y or not.

1. Mo v e PTO switc h to Off position and remo v e

foot from traction pedal so it is fully released.

2. R otate the ignition k ey to Star t. Engine should

crank. If engine cranks , proceed to ste p 3 .

If engine does not crank, there ma y be a

malfunction in the interloc k system.

3. Raise off the seat and eng ag e the PTO switc h

while the engine is r unning . T he engine should

stop within 2 seconds . If engine stops , the

switc h is operating cor rectly; thus , proceed

to ste p 4 . If engine does not stop , there is a

malfunction in the interloc k system.

4. Raise off the seat and de press the traction

pedal while engine is r unning and the PTO

lev er is diseng ag ed. T he engine should stop

within 2 seconds . If engine stops , the switc h is

operating cor rectly; thus , proceed to ste p 5 If

engine does not stop , there is a malfunction in

the interloc k system.

5. Eng ag e the parking brak e . De press the traction

pedal while engine is r unning and the PTO

lev er is diseng ag ed. T he engine should stop

within 2 seconds . If engine stops , the switc h is

operating cor rectly; thus , contin ue operation.

If engine does not stop , there is a malfunction

in the interloc k system.

• the traction pedal is de pressed with the

operator off the seat;

• the traction pedal de pressed with the parking

brak e eng ag ed.

Pushing or Towing the

Machine

In an emerg ency , the mac hine can be pushed or

to w ed for a v er y shor t distance . Ho w ev er , T oro

does not recommend this as standard procedure .

34

Page 35

Important: Do not push or to w the

machine f aster than 2 to 3 mph because the

transmission may be dama ged. If the machine

must be mo v ed a considera ble distance,

transpor t it on a tr uck or trailer . W henev er the

machine is pushed or to w ed, the by-pass v alv e

must be open.

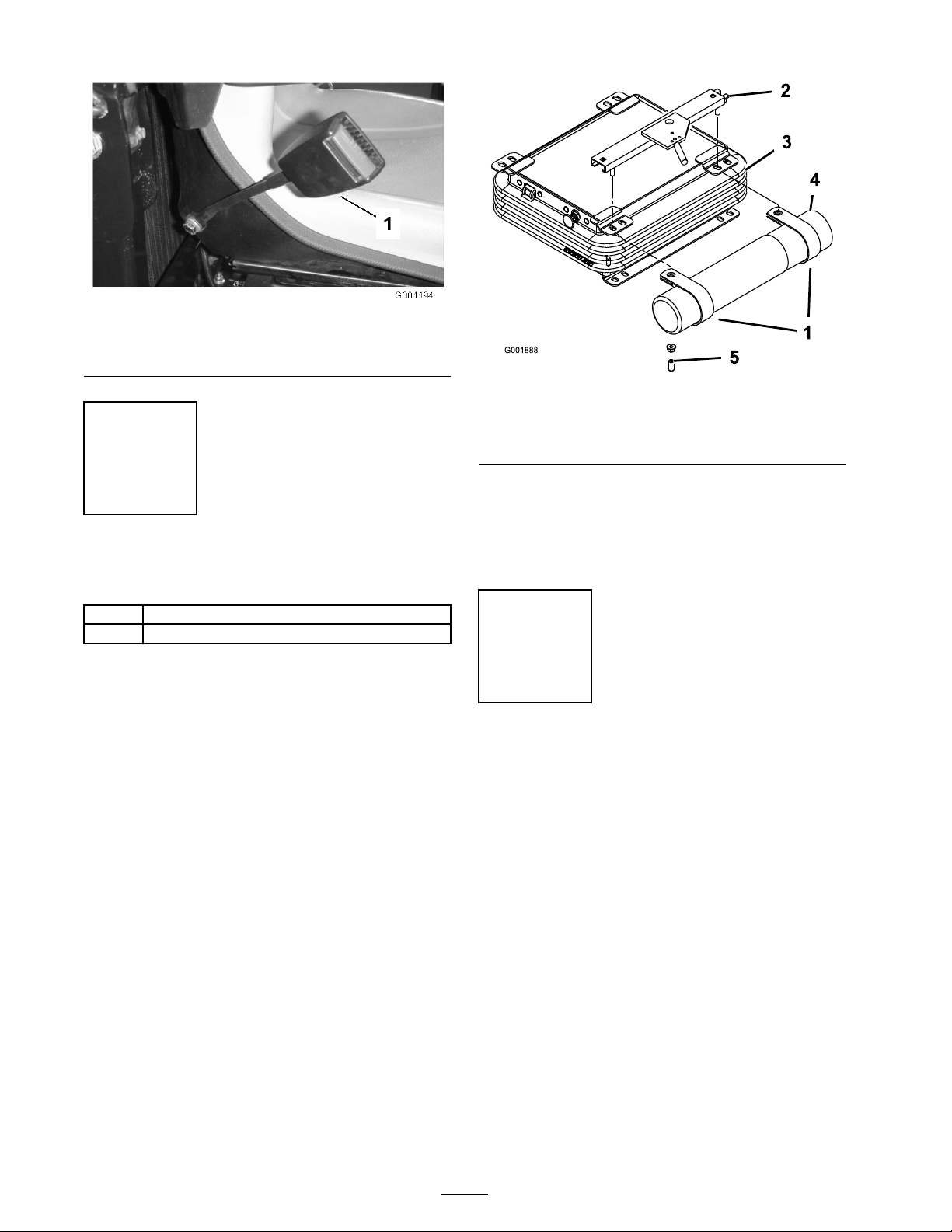

1. Loosen the knob and remo v e the access

co v er at the rear of the seat mounting plate

( Figure 29 ).

Important: R unning the machine with

the by-pass v alv e open will cause the

transmission to o v erheat.

4. Install the access co v er .

Standard Control Module

(SCM)

T he Standard Control Module is a potted

electronic device produced in a one size fits all

configuration. T he module uses solid state and

mec hanical components to monitor and control

standard electrical features required for safe

product operation.

T he module monitors inputs including neutral,

parking brak e , PTO , star t, bac klap , and high

temperature . T he module energizes outputs

including PTO , Star ter , and ETR (energize to r un)

solenoid.

T he module is di vided into inputs and outputs .

Inputs and outputs are identified b y yello w LED

indicators mounted on the printed circuit board.

Figure 29

1. Access cover knob

2. Press and hold the pins located in the center

of the 2 c hec k v alv e assemblies in the top of

the transmission ( Figure 30 ) while pushing or

to wing the mac hine . Figure 30 is sho wn with

seat and seat mounting plate remo v ed.

Figure 30

1. Transmission check valve by-pass pins (2)

T he star t circuit input is energized b y 12 VDC .

All other inputs are energized when the circuit is

closed to g round. Eac h input has a LED that is

illuminated when the specific circuit is energized.

Use the input LED’ s for switc h and input circuit

troubleshooting .

Output circuits are energized b y an appropriate

set of input conditions . T he three outputs include

PTO , ETR, and ST AR T . Output LED’ s monitor

rela y condition indicating the presence of v oltag e

at one of three specific output ter minals .

Output circuits do not deter mine output device

integ rity so electrical troubleshooting includes

output LED inspection and con v entional device

and wire har ness integ rity testing . Measure

disconnected component impedance , impedance

through wire har ness (disconnect at SCM), or b y

temporarily test energizing the specific component.

T he SCM does not connect to an exter nal

computer or hand held device , can not be

re-prog rammed, and does not record inter mittent

fault troubleshooting data.

3. Star t the engine momentarily after the re pairs

are completed and mak e sure the pins are in

the full diseng ag ed (fully up) position.

T he decal on the SCM only includes symbols .

T hree LED output symbols are sho wn in the

output bo x. All other LED’ s are inputs . T he c har t

belo w identifies the symbols .

35

Page 36

Figure 31

Here are the logical troubleshooting ste ps for the

SCM device .

1. Deter mine the output fault y ou are tr ying to

resolv e (PTO , Star t, or ETR).

2. Mo v e k ey switc h to the On position and ensure

the red po w er LED is illuminated.

3. Mo v e all input switc hes to ensure all LED’ s

c hang e state (Seat, Brak e , T raction P edal, PTO ,

and Star t).

4. P osition input devices at appropriate position

to ac hiev e the appropriate output. Use

the follo wing logic c har t to deter mine the

appropriate input condition.

5. If specific output LED is illuminated without

appropriate output function, c hec k output

Function

Start

Run

(Off

Unit)

Run

(On

Unit)

Mow

Temp

Warning

Power

On

— — +

— —

—

—

Hi

—

Neutral

In

⊗ ⊗

⊗ ⊗

Start

On

Brake

PTO On In Seat

On

⊗ ⊗

⊗ ⊗ ⊗ ⊗ ⊗ ⊗

—

— — —

⊗

⊗ ⊗

har ness , connections , and component. R e pair

as required.

6. If specific output LED is not illuminated,

c hec k both fuses .

7. If specific output LED is not illuminated and

inputs are in appropriate condition, install new

SCM and deter mine if fault disappears .

Eac h ro w (across) in the logic c har t belo w

identifies input and output requirements for eac h

specific product function. Product functions are

listed in the left column. Symbols identify specific

circuit condition including: energized to v oltag e ,

closed to g round, and open to g round.

Inputs

Hi

Temp

Shutdown

—

—

⊗ ⊗

⊗ ⊗

⊗ ⊗

Hi

Temp

Warning

— (A)

Back

Lap

N/A

N/A

N/A

N/A

N/A

Start

+ +

⊗

⊗

⊗

+ +

Outputs

ETR

+

+

+ +

PTO

⊗

⊗

⊗

⊗

36

Page 37

Hi

Temp

Shutdown

(-) Indicates a circuit closed to ground. - LED ON

( ⊗ ) Indicates a circuit open to ground or de-energized - LED OFF

(+) Indicates an energized circuit (clutch coil, solenoid, or start input) LED ON.

A Blank indicates a circuit that is not involved with the logic.

(A) PTO input must be re-initiated after engine cool down (cycle key on-off)

N/A Not applicable

—

⊗

—

N/A

⊗ ⊗ ⊗

T o troubleshoot, tur n on the k ey without star ting

the engine . Identify the specific function that does

not w ork and w ork across the logic c har t. Inspect

the condition of eac h input LED’ s to ensure it

matc hes the logic c har t.

If the input LED’ s are cor rect, c hec k the output

LED . If the output LED is illuminated but

the device is not energized, measure a v ailable

v oltag e at the output device , contin uity of the

disconnected device , and potential v oltag e on the

g round circuit (floating g round). R e pairs will v ar y

de pending on y our findings .

Operating Tips

• Practice dri ving the mac hine before initial

operation because it has a h y drostatic

transmission and its c haracteristics are different

than some turf maintenance mac hines . Some

points to consider when operating the mac hine

and dec k are the transmission, engine speed,

load on the cutting blades , and the impor tance

of the brak es .

• T o maintain enough po w er for the mac hine

and dec k while mo wing, regulate traction

pedal to k ee p engine r pm high and somewhat

constant. A g ood r ule to follo w is: decrease

g round speed as the load on the cutting blades

increases; and increase g round speed as load

on the blades decreases . T his allo ws the

engine , w orking with the transmission, to sense

the proper g round speed while maintaining

high blade tip speed necessar y for g ood

quality-of-cut. T herefore , allo w traction pedal

to mo v e upw ard as engine speed decreases ,