Page 1

Form No. 3325-387 Rev A

Operator’s Manual

®

Groundsmaster®228-D

Traction Unit

Model No. 30241—210000001 and Up

English

Page 2

Contents 2

Introduction 3

Safety 3

Safe Operating Practices 3

Toro Mower Safety 5

Safety and Instruction Decals 8

Specifications 12

Installing Rear Weights 14

Before Operating 15

Check the Engine Oil 15

Check the Cooling System 15

Check Hydraulic System Fluid 15

Fill the Fuel Tank 16

Controls 17

Operation 20

Starting/Stopping the Engine 20

Bleeding the Fuel System 20

Checking the Interlock System 21

Operating Characteristics 22

Pushing or Towing the Traction Unit 22

Maintenance 23

Recommended Maintenance Schedule 23

Fluid Specifications/Change Intervals 24

Service Interval Charts 24

Daily Maintenance Checklist 25

General Air Cleaner Maintenance 27

Servicing the Air Cleaner 27

Cleaning the Radiator and Screen 28

Changing the Engine Oil and Filter 28

Servicing the Fuel System 28

Replacing the Fuel Pre Filter 29

Bleeding Air from Injectors 30

Alternator Belt 30

Adjusting the Throttle 30

Power Take-Off Belt 30

Power Take-Off Clutch Adjustment 31

Adjusting the Transmission for Neutral 31

Adjusting the Parking Brake

Interlock Switch 32

Changing the Hydraulic Oil and Filter 33

Adjusting the Service Brakes 34

Servicing the Battery 34

Wiring Harness Service 34

Fuses 34

Storage 35

2

Contents

2001 by The Toro Company 8111

Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

Printed in the USA

Page 3

Read this manual carefully to learn how to operate

and maintain your product properly. The information

in this manual can help you and others avoid injury

and product damage. Although Toro designs and

produces safe products, you are responsible for

operating the product properly and safely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model

and serial numbers of your product ready. Figure 1

illustrates the location of the model and serial

numbers on the product.

Figure 1

1. Location of the model and serial numbers

Write the product model and serial numbers in the

space below:

This manual identifies potential hazards and has

special safety messages that help you and others avoid

personal injury and even death. Danger, Warning, and

Caution are signal words used to identify the level of

hazard. However, regardless of the hazard, be

extremely careful.

Danger signals an extreme hazard that will cause

serious injury or death if you do not follow the

recommended precautions.

Warning signals a hazard that may cause serious

injury or death if you do not follow the recommended

precautions.

Caution signals a hazard that may cause minor or

moderate injury if you do not follow the

recommended precautions.

Safety

This machine meets or exceeds the B71.4 1999

specifications of the American National Standards

Institute when weights are installed according to

chart on page 14.

Note: The addition of attachments made by other

manufacturers that do not meet American National

Standards Institute certification will cause

noncompliance of this machine.

Improper use or maintenance by the operator or

owner can result in injury. To reduce the potential

for injury, comply with these safety instructions

and always pay attention to the safety alert symbol

, which means CAUTION, WARNING, or

DANGER—personal safety instruction.” Failure

to comply with the instruction may result in

personal injury or death.

Safe Operating Practices

Training

• Read the Operator’s Manual and other training

material. If the operator(s) or mechanic(s) cannot

read the language of the manual, it is the owner’s

responsibility to explain this material to them.

• Become familiar with the safe operation of the

equipment, operator controls, and safety signs.

• All operators and mechanics should be trained.

The owner is responsible for training the users.

• Never let children or untrained people operate or

service the equipment. Local regulations may

restrict the age of the operator.

• The owner/user can prevent and is responsible

3

Introduction

Model No. __________________________

Serial No. ___________________________

Page 4

for accidents or injuries occurring to himself or

herself, other people or property.

Preparation

• Evaluate the terrain to determine what

accessories and attachments are needed to

properly and safely perform the job. Only use

accessories and attachments approved by the

manufacturer.

•Wear appropriate clothing including hard hat,

safety glasses and ear protection. Long hair, loose

clothing or jewelry may get tangled in moving

parts.

• Inspect the area where the equipment will be

used and remove all objects such as rocks, toys

and wire that can be thrown by the machine.

• Use extra care when handling diesel and other

fuels. They are flammable and vapors are

explosive.

• Use only an approved container

• Never remove the fuel cap or add fuel with

the engine running. Allow the engine to cool

before refueling. Do not smoke.

• Never refuel or drain the machine indoors.

• Check that operator’s presence controls, safety

switches and shields are attached and functioning

properly. Do not operate unless they are

functioning properly.

Operation

• Never run an engine in an enclosed area.

• Only operate in good light, keeping away from

holes and hidden hazards.

• Be sure all drives are in neutral and the parking

brake is engaged before starting the engine. Only

start the engine from the operator’s position. Use

seat belts, if provided.

• Slow down and use extra care on hillsides. Be

sure to travel in the recommended direction on

hillsides. Turf conditions can affect the machine’s

stability. Use caution while operating near

drop–offs.

•Slow down and use caution when making turns

and when changing directions on slopes.

• Never raise the deck with the blades running.

• Never operate with the power take-off shield, or

other guards not securely in place. Be sure all

interlocks are attached, adjusted properly, and

functioning property.

• Do not change the engine governor setting or

overspeed the engine.

• Stop on level ground, lower the implements,

disengage the drives, engage the parking brake

(if provided), and shut off the engine before

leaving the operator’s position for any reason.

• Stop the equipment and inspect the blades after

striking objects or if an abnormal vibration

occurs. Make necessary repairs before resuming

operations.

• Keep your hands and feet away from the cutting

units.

• Look behind and down before backing up to be

sure of a clear path.

• Never carry passengers and keep pets and

bystanders away.

•Slow down and use caution when making turns

and crossing roads and sidewalks. Stop the

blades if not mowing.

• Do not operate the mower under the influence of

alcohol or drugs

• Use care when loading or unloading the machine

into a trailer or truck

• Use care when approaching blind corners,

shrubs, trees, or other objects that may obscure

4

Page 5

vision.

Maintenance and storage

• Disengage the drives, lower the implement, set

the parking brake, stop the engine and remove

the key. Wait for all movement to stop before

adjusting, cleaning or repairing.

• Clean grass and debris from the cutting units,

drives, mufflers, and engine to help prevent fires.

Clean up oil or fuel spillage.

• Let the engine cool before storing and do not

store near flame.

• Do not store fuel near flames or drain indoors.

• Park the machine on level ground. Never allow

untrained personnel to service the machine.

• Use jack stands to support components when

required.

• Carefully release pressure from components with

stored energy.

• Disconnect the battery before making any

repairs. Disconnect the negative terminal first

and the positive last. Reconnect positive first and

negative last.

• Use care when checking the blades. Wrap the

blade(s) or wear gloves, and use caution when

servicing them. Only replace the blades. Never

straighten or weld them.

• Keep your hands and feet away from moving

parts. If possible, do not make adjustments with

the engine running.

• Charge batteries in an open well ventilated area,

away from spark and flames. Unplug charger

before connecting or disconnecting from the

battery. Wear protective clothing and use

insulated tools.

• Keep all parts in good working condition and all

hardware tightened. Replace all worn or damaged

decals.

Toro Mower Safety

This product is capable of amputating hands and feet

and throwing objects. Always follow all safety

instructions to avoid serious injury or death.

This product is designed for cutting and recycling

grass. Any use for purposes other than these could

prove dangerous to user and bystanders.

General Operation

• Allow only responsible adults who are familiar

with the instructions to operate the machine.

• Be sure the area is clear of other people before

mowing.Stop the machine if anyone enters the

area.

• Do not mow in reverse unless absolutely

necessary. Always look down and behind before

and while backing.

• Slow down before turning. Sharp turns on any

terrain may cause loss of control.

•Turn off the blades when not mowing.

• Keep hands, feet, hair and loose clothing away

from attachment discharge area, underside of

mower and any moving parts while the engine is

running.

• Mow only in daylight or good artificial light.

•Watch for traffic when operating near or crossing

roadways.

• Do not touch equipment or attachment parts

which may be hot from operation. Allow to cool

before attempting to maintain, adjust or service.

• Before operating a machine with roll over

protection be certain the seat belts are attached

and seat is latched to prevent the seat from

pivoting forward.

5

Page 6

• Use only Toro-approved attachments. Warranty

may be voided if used with unapproved

attachments.

Slope Operation

Slopes and ramps are a major factor related to loss-ofcontrol and tip-over accidents, which can result in

severe injury or death. All slopes and ramps require

extra caution. If you cannot back up the slope or if

you feel uneasy on it, do not mow it.

DO

• If you must ascend a steep slope, back up the hill,

and drive forward down the hill, keeping the

machine in gear.

• Remove obstacles such as rocks, tree limbs, etc.

from the mowing area. Watch for holes, ruts or

bumps, as uneven terrain could overturn the

machine. Tall grass can hide obstacles.

• Use slow speed so that you will not have to stop

while on the slope.

• Follow the manufacturer’s recommendations for

wheel weights or counterweights to improve

stability.

• Use extra care with other attachments. These can

change the stability of the machine.

• Keep all movement on slopes slow and gradual.

Do not make sudden changes in speed or

direction.

•Avoid starting or stopping on a slope. If the tires

lose traction, disengage the blades and proceed

slowly straight down the slope. Avoid raising the

side decks on a slope.

• When operating the machine on slopes, banks or

near drop offs, always have roll-over protection

installed.

• When operating a machine with roll-over

protection always use seat belt.

• Be certain that the seat belt can be released

quickly if the machine is driven or rolls into

ponds or water.

• Check carefully for overhead clearances (i.e.,

branches, doorways, electrical wires) before

driving under any objects and do not contact

them.

DO NOT

• Do not mow slopes exceeding 15 degrees.

•Avoid turning on slopes. If you must turn, turn

slowly and gradually downhill, if possible.

• Do not mow near drop-offs, ditches, or

embankments. The machine could suddenly turn

over if a wheel goes over the edge of a cliff or

ditch, or if an edge caves in.

• Do not mow on wet grass. Reduced traction

could cause sliding.

• Do not try to stabilize the machine by putting

your foot on the ground.

Service

• Never store the machine or fuel container inside

where there is an open flame, such as near a

water heater or furnace.

• Keep nuts and bolts tight, especially the blade

attachment bolts. Keep equipment in good

condition.

• Never tamper with safety devices. Check safety

systems for proper operation before each use.

• Use only genuine replacement parts to ensure

that original standards are maintained.

• Check brake operation frequently. Adjust and

service as required.

• Battery acid is poisonous and can cause burns.

Avoid contact with skin, eyes and clothing.

Protect your face, eyes and clothing when

6

Page 7

working with a battery.

• Battery gases can explode. Keep cigarettes,

sparks and flames away from the battery.

• Hydraulic fluid escaping under pressure can

penetrate the skin and cause injury. Use

cardboard or paper to find hydraulic leaks. Never

use your hands.

Sound Pressure Level

This unit has an equivalent continuous A-weighted

sound pressure at the operator ear of: 90 dB(A), based

on measurements of identical machines per Directive

84/538/EEC and amendments.

Sound Power Level

This unit has a sound power level of: 105 dB(A) 1

pW, based on measurements of identical machines per

Directive 84/538/EEC and amendments.

Vibration Level

Hand-Arm

This unit does not exceed a vibration level of 2.5 m/s

2

at the hands based on measurements of identical

machines per ISO 5349 procedures.

Whole Body

This unit does not exceed a vibration level of 0.5

m/s2at the posterior based on measurements of

identical machines per ISO 2631 procedures.

7

Page 8

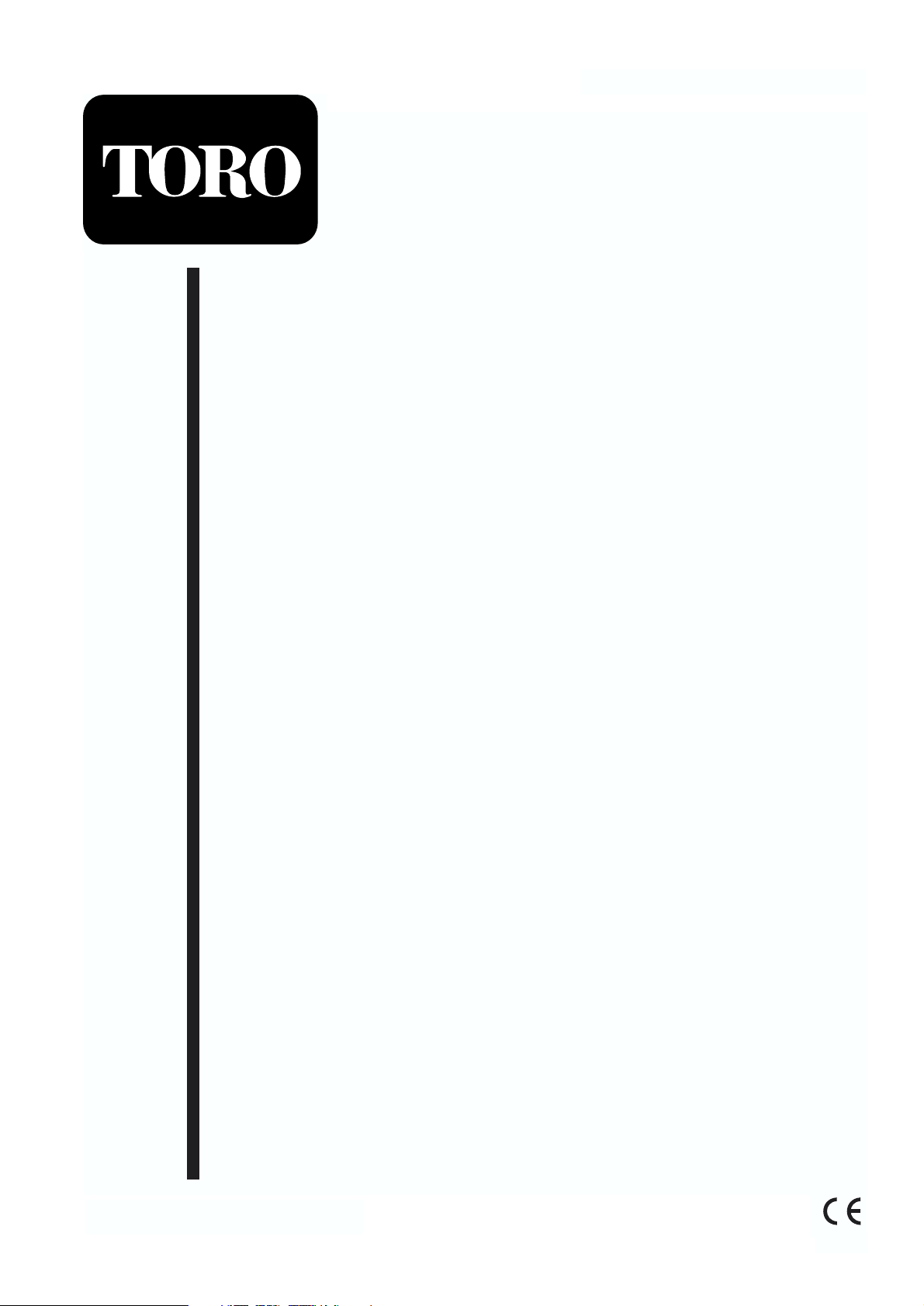

93-7830

1. Danger—See operator’s manual

2. Wheel torque specifications

93-7841

1. Danger—See operator’s manual

100-6577

1. Lock—Unlock the deck service lock

93-6680

1. Diesel fuel

93-7272

1. Fan blades can cause injury

2. Stay away from moving parts

93-7822

1. Danger

2. See Operator’s manual

3. Fill the fuel tank to 1” from bottom of the filler neck

105-2512

1. Read operator’s manual for starting instructions

2. Danger—Read operator’s manual

3. Tipping hazard—Go slow and avoid sharp turns on

slopes to avoid rollover. The deck must be lowered when

going down slopes for steering control. Always wear seat

belts with roll-over protection.

4. Thrown object hazard—keep bystanders away

5 Cutting hazard to hands or feet—stay away from rotating

blades or moving parts.

6. Danger—set the parking brake, stop the engine and

remove the key before leaving the operator’s position.

100-6574

1. Hot surface stay away

2. Stay away from moving parts

8

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any area of potential

danger. Replace any decal that is damaged or lost.

1

2

1

1

1

1

2

1

2

1

2

3

3

4

4

5

5

6

6

1

1

2

2

2

Page 9

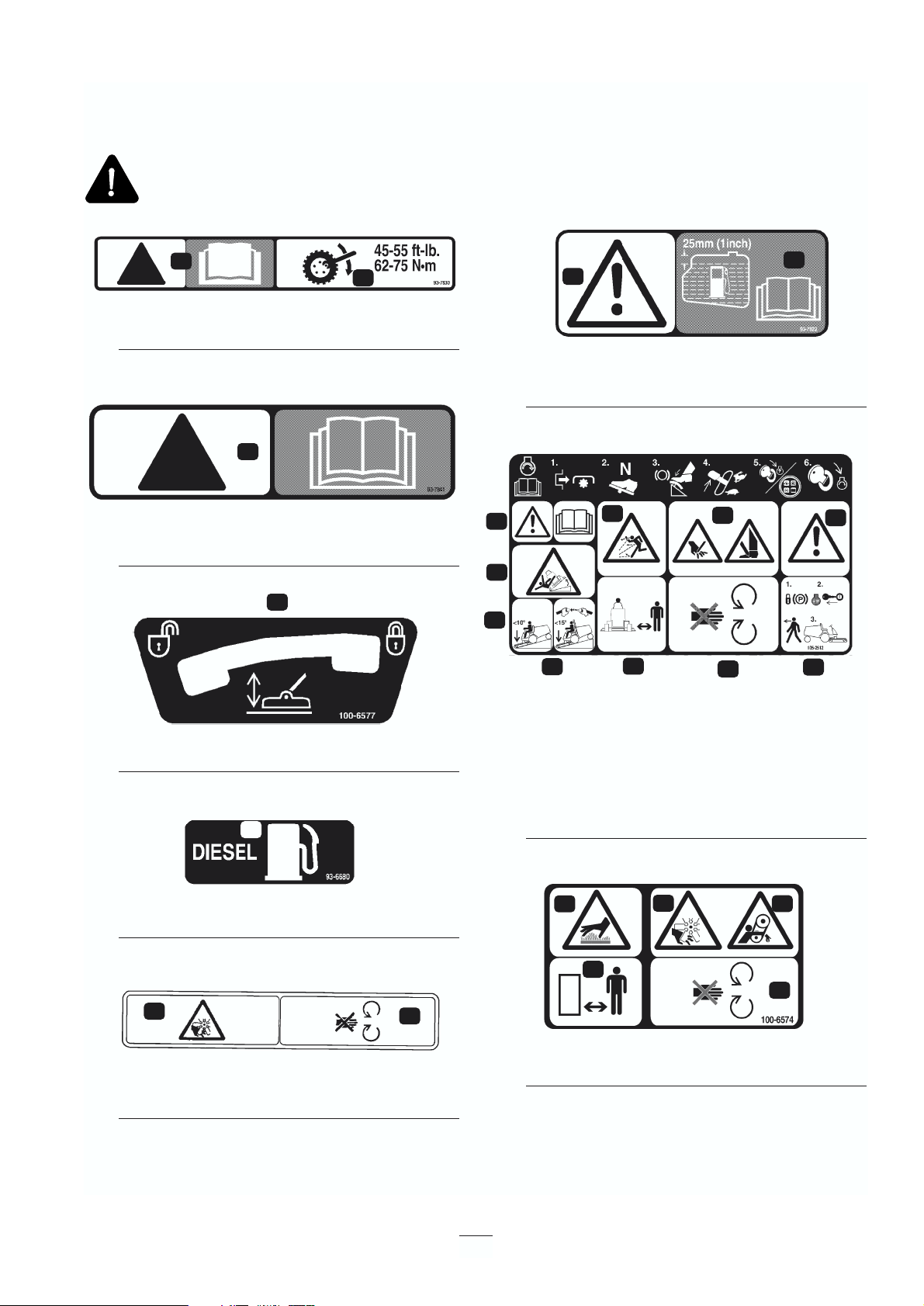

93-7276

1. Explosion hazard—wear eye protection.

2. Caustic liquid hazard—flush with water and seek first aid.

3. Fire hazard — no sparks, flame, or smoking

4. Poison—keep children a safe distance from the battery.

93-7840

1. Coolant level

2. Hot surface—keep a safe distance

3. Danger—rear the operator’s manual

4. Explosion hazard—stay away

93-6668

1. The battery contains lead. Do not throw it in the garbage.

100-6581

1. To lock parking brake—Latch pedals together, apply

brake pedals and pull up on knob

2. To unlock parking brake—step on brake pedals

100-6552

1. Refer to Operator’s Manual for engine oil specifications

9

1

3

4

2

1

1

1

2

2

3

3

4

4

1

2

1

Page 10

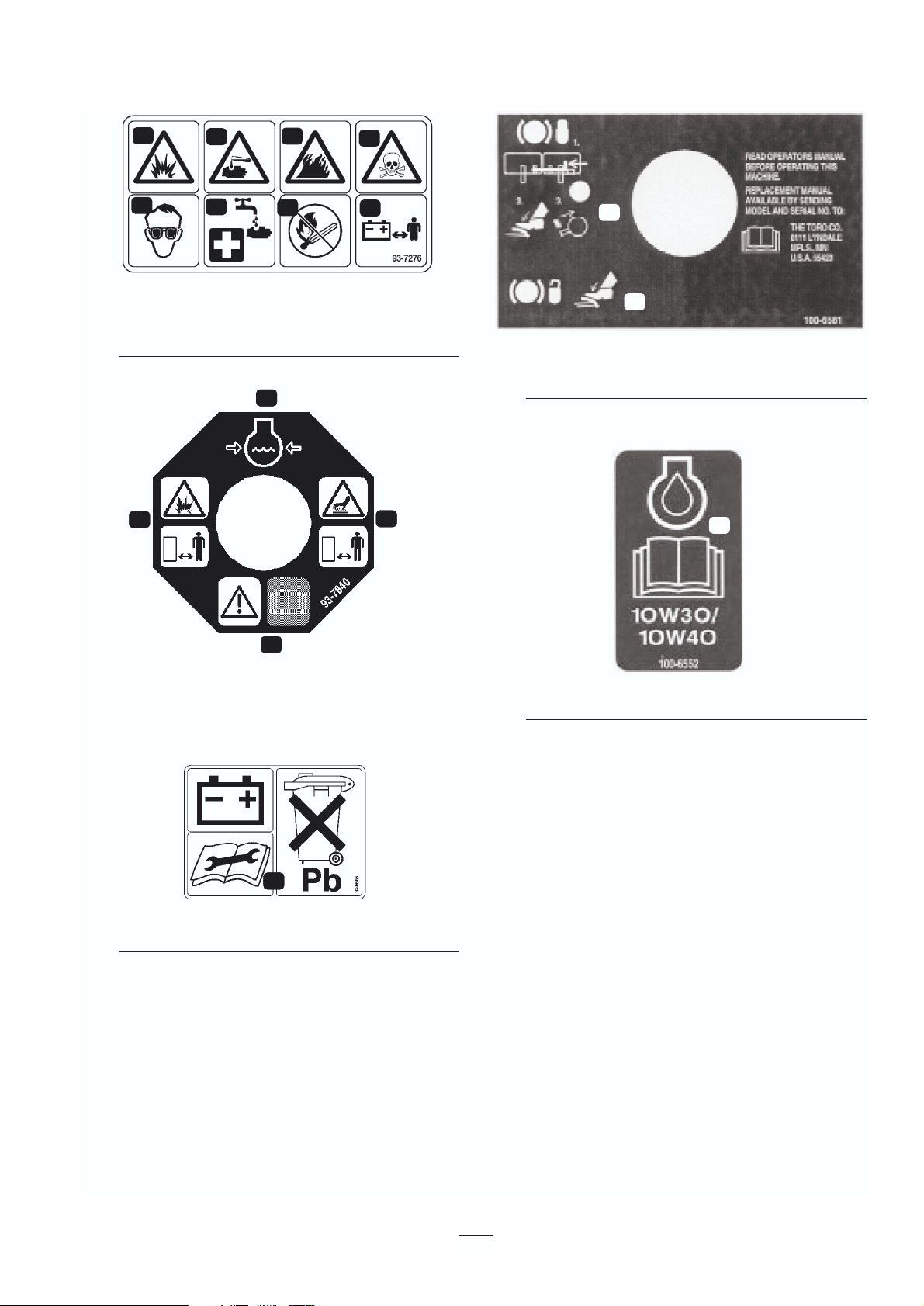

93-7834

1. No step

2. Traction pedal

3. Traction—forward

4. Traction—reverse

5. Danger—Shut off power take-off prior to raising decks

6. Danger—Do not operate decks when they are in raised

position

93-7833

1. Throttle control

2. Throttle—fast

3. Throttle—slow

4. Tipping hazard—Lower the deck when going down slopes

greater than 10 degrees

5. Tipping hazard—Lower the deck when going down slopes

greater than 10 degrees

6. Danger—tipping hazard

7. Lift lever—raise position

8. Lift lever—lower position

9. Lift lever—float position

10

1

1

3

3

2

4

5

6

1

2

3

4

5

6

7

8

9

Page 11

11

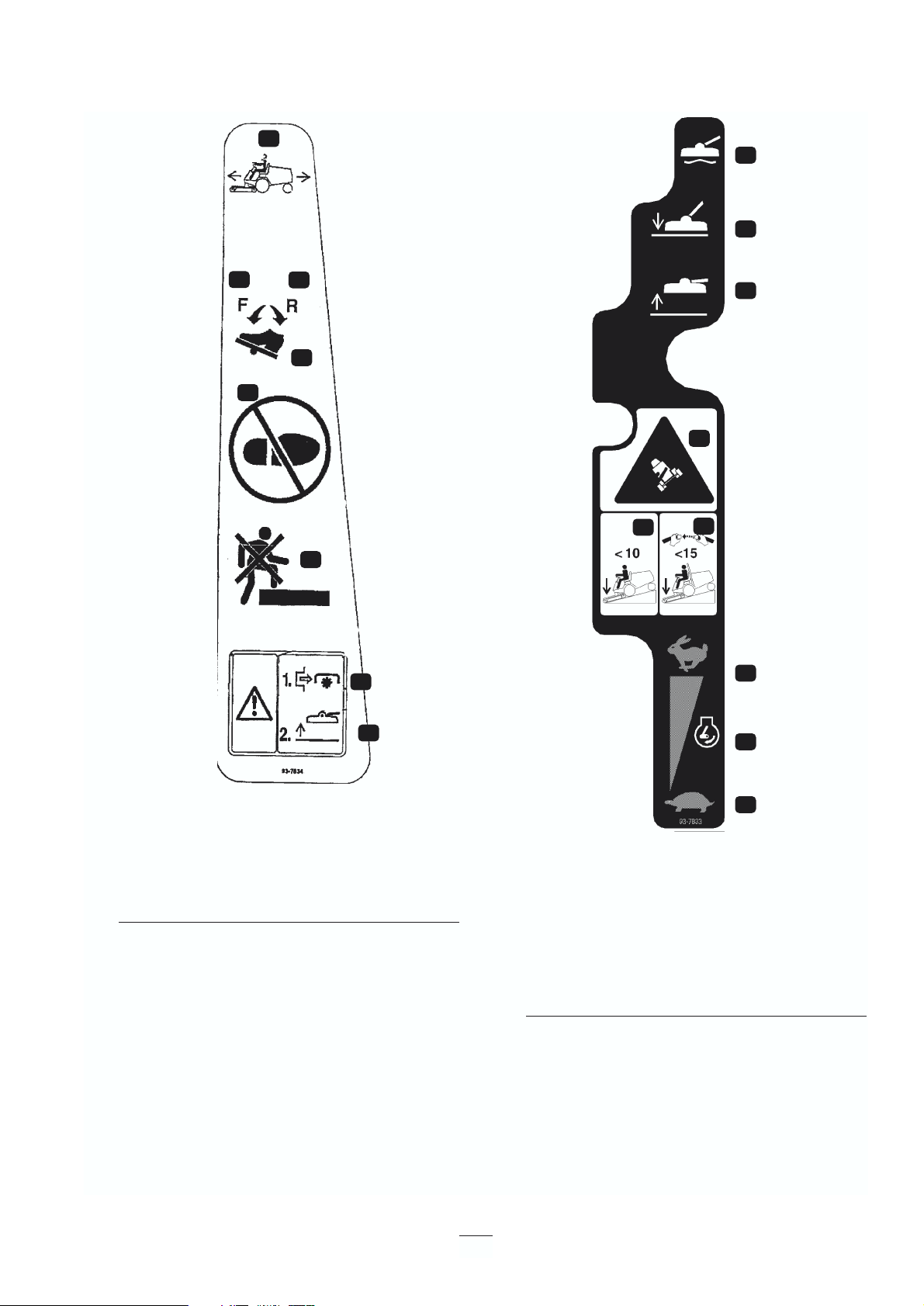

Part No. 104-3484

1. See the operator’s manual

Part No. 105-0054

1. Headlights—off

2. Headlights—on

3. Power take-off—off

4. Power take-off—on

5. Engine coolant temperature

6. Engine—start

7. Engine—stop

1

1

2

3

4

5

6

7

Page 12

12

Specifications

Note: Specifications and design subject to change without notice.General Specifications

Engine Kubota three-cylinder, 4-cycle, liquid-cooled diesel engine. 26 hp @ 3000. Engine

governed to 3200–3250 rpm high idle, no load.

Air Cleaner Heavy-duty remote mounted.

Fuel Tank Capacity 8.5 gal. (32 l) Equipped with a fuel filter/water separator to capture water in the fuel.

Fuel Pump 12-volt electric (transistor type) w/replaceable fuel filter.

Cooling System 7 qt (6.6 l) capacity. Remote-mounted expansion tank 1 qt (0.946 l) capacity. System

contains a 50/50 mix of ethylene glycol anti-freeze and water. Front mounted air/oil

cooler used to cool hydraulic oil for the hydrostatic transmission.

Electrical 12 volt with 530 cold cranking amps at 0° F and 75-minute reserve capacity at 80° F.

Drive Coupling Transmission driven by steel shaft with flexible rubber couplings at each end.

Transmission Hydrostatic, U-type. Implement Relief Setting—700–800 psi (4,826–5,516 kPa).

Hydraulic Filter Replaceable 25-micron filter mounted directly to the transmission.

Drive Axle The front axle serves as a hydraulic fluid reservoir and mates directly with the

transmission. Approximately 6 qt (5.7 l) capacity.

Brakes Mechanical drum-type. Individually controlled by two pedals connected by cable and

conduit for steering assist. Pedals may be latched together for two wheel braking. Lever

provided for parking brake.

Tires Front Tires—23 x 8.50-12, Rear Tires—16 x 6.50-8. All tires: 4-ply rating, tubeless

type. Pressure—20 psi (138 kPa).

Ground Speed 0–16 kmh forward and reverse.

Main Frame Frame is welded, formed steel.

Instrumentation Fuel gauge, water temperature gauge, hour meter and warning lights for high

temperature shutdown, oil pressure, amperage and glow plug are mounted on the

console.

Controls Throttle, power take-off switch, parking brake, implement lift, implement lift lock,

ignition switch and high temperature override switch are all hand-operated.

Forward/reverse traction pedal and turning brakes are foot-operated.

Power take-off drive The power take-off shaft is clutched by a belt directly from the engine output shaft. The

power take-off shaft engaged by an electric clutch/brake assembly. Power take-off

speed—2200 RPM@3250 RPM engine speed.

Page 13

Measurements

Length 208 cm (82 in.)

Width (Rear Wheels) 119.4 cm (47 in.)

Height 127 cm (50 in.)

Weight 442 kg (1185 lb.)

Optional Equipment

52” Side Discharge Cutting Unit Model No. 30555

52” Rear Discharge Cutting Unit Model No. 30568

62” Side Discharge Cutting Unit Model No. 30551

62” Guardian Recycler Cutting Unit Model No. 30569

72” Side Discharge Cutting Unit Model No. 30553

48” V-Plow Kit Model No. 30750

V-Plow Mounting Kit Model No. 30749*

Arm Rest Kit Model No. 30707

Rear Discharge Shield Kit Model No. 30578

Rear Weight Box Kit Part No. 24-5780

Grass Collection System Model No. 30502**

Wide Tires w/rim

23 x 10.5-12, 4 ply Part No. 62-7020

23 x 10.5-12, 6 ply Part No. 69-9870

Wheel Weights-50 lbs. (23kg.) Part No. 11-0440

Rear Weight Kit—70 lbs. (32 kg.) Part No. 24-5780

Weight Kit—20 lbs. Part No. 92-8763

Tire Chains (Front) Part No. 11-0390

Standard Seat Kit Model No. 30624

Deluxe Seat Kit Model No. 30625

*Required with 30750 V-plow. Tire chains, part no.

11-0390 recommended.

** 52” Blower Kit (for Model 30555 deck) or Model

30506 62” Blower Kit (for Model 30551 deck) can be

used with either Model No. 30504, 9 cu. ft. Hopper

Kit or Model No. 30505, 15 cu. ft. Hopper Kit.

13

Implement Connection Universal joint and telescoping shaft assembly.

Lift Cylinders Two with 2 in. (51 mm) bore, 3.5 in. (89 mm) stroke.

Interlock Switches Prevent engine starting if the traction pedal or power take-off switch are engaged. Stops

the engine if the operator leaves the seat with either the traction pedal or power take-off

switch engaged. Stops the engine if the traction pedal is engaged with parking brake

engaged.

Page 14

14

Two-Wheel Drive Groundsmaster 228-D Series traction units comply with ANSI B71.4-1999 Standard when

equipped with rear weight. Use chart below to determine combinations of weight required. Order parts from your

local Authorized Toro Distributor.

* 75 lb. wheel weight (included with 15 cu. ft. hopper) required on the left wheel

1

Rear

Weight

Required

Left Side

Weight

Required

Weight Description

Quantity

Weight Part

Number

52” Rear Discharge

Deck (Model 30568) or

52” Side Discharge

Deck

52” Side Discharge

Deck with 9 cu. ft.

Hopper

52” Side Discharge

Deck with 15 cu. ft.

Hopper

Rear Weight Kit

& Weight Kit-20 lb.

1

1

10 lbs.

0 lbs.

24-5780

& 92-8763

24-5790

325-8

3253-7

3-8847

3217-9

92-8763

92-8763 Weight Kit – 20 lb.

215 lbs.

0 lbs.

75 lb.*

77-6700 &

92-9670 &

24-5780

0 lbs.

0 lbs.

20 lbs.

0 lbs.

0 lbs.

0 lbs.

55 lbs.

* 77-6700 75 lb. Wheel Weight

62” Side Discharge

Deck (Model 30564) or

62” Side Discharge

Deck with 9 cu. ft.

Hopper

62” Side Discharge

Deck with 15 cu. ft.

Hopper

62” Guardian Recycler

Deck (Model 30569)

72” Side Discharge

Deck (Model 30575)

Rear Weight—35 lb.

Capscrew-

1

⁄2-13 x 2”

Lockwasher-

1

⁄2

Spacer

Nut-

1

⁄2

& Weight Kit-20 lb

75 lb. Wheel Weight

& Bracket Kit

& Rear Weight Kit

1

1

1

70 lbs

90 lbs

-- --

1

2

2

2

2

1

24-5780

Installing Rear Weights

Page 15

Check the Engine Oil

The engine is shipped with 4 qt (3.8 l) of oil in the

crankcase; however, check the oil level before and

after you first start the engine.

1. Park the machine on a level surface, stop the

engine and remove the key from the ignition

switch. Open the hood.

2. Remove the dipstick (Fig. 2), wipe it clean and

reinstall it. Remove it again and check the oil

level. The level should be up to the FULL mark

on the dipstick

Figure 2

1. Dipstick

2. Oil fill

3. If the oil is below the FULL mark, remove the fill

cap and add SAE 10W-30 CD, CE, CF, CF-4 or

CG-4 classification oil until the level reaches the

FULL mark on the dipstick. DO NOT

OVERFILL.

4. Install the oil fill cap and close the hood.

Check the Cooling System

Clean debris from the screen and radiator/oil cooler

daily, more often if conditions are extremely dusty

and dirty; refer to Engine Cooling System.

The cooling system is filled with a 50/50 solution of

water and permanent ethylene glycol anti-freeze.

Check the level of coolant in the expansion tank at the

beginning of each day before you start the engine.

Cooling system capacity is 7 quarts (6.6 l).

1. Check the level of coolant in the expansion tank.

Coolant level should be between the marks on

the side of the tank.

Figure 3

1. Expansion tank

2. If the coolant level is low, remove the expansion

tank cap and replenish the system. DO NOT

OVERFILL.

3. Install the expansion tank cap.

Check Hydraulic System Fluid

The hydraulic system will operate with any highquality detergent oil having the American Petroleum

Institute—API—“service classification” SF, CC or

CD. Oil viscosity—weigh —must be selected

according to anticipated ambient temperature.

Temperature/viscosity recommendations are:

15

Before Operating

if the engine has been running, pressurized hot

coolant can escape and cause burns when you

remove the radiator cap.

CAUTION

1

1

2

Page 16

Expected Ambient

Temperature

(Extreme) over 32° C SAE 30, Type SF, CC or CD

engine oil

(Normal) 4–37° C SAE 10W-30 or 10W-40,

Type SF,CC or CD engine oil

(Cool) –1 to 10° C SAE 5W-30, Type SF, CC or

CD engine oil

(Winter) Below –1° C Type “F” or “FA” ATF

Automatic Transmission Fluid

Note: Do not mix engine oil and automatic

transmission fluid or hydraulic component damage

may result. When changing fluids, also change the

transmission filter. DO NOT USE DEXRON II ATF.

The transmission and axle housing are shipped from

the factory with approximately 5 quarts (4.7 l) of SAE

10W-30 engine oil. However, check the level of

transmission oil before first starting the engine and

daily thereafter.

1. Position the machine on a level surface. Place all

controls in neutral position and start the engine.

Run the engine at lowest possible RPM to purge

the system of air. DO NOT ENGAGE the power

take-off. Turn the steering wheel several times

fully to the left and right. Raise the cutting unit to

extend the lift cylinders, aiming the wheels

straight forward, and stop the engine.

2. Remove the dipstick cap (Fig. 4) from the filler

neck and wipe it with a clean cloth. Screw the

dipstick cap finger-tight onto the filler neck; then

remove it and check the level of fluid. If the level

is not within

1

⁄

2 inch (13 mm) from the groove in

the dipstick (Fig. 4), add SAE 10W-30 engine oil,

or, if used, automatic transmission fluid to raise

the level to groove mark. Do not overfill.

When adding transmission fluid to

the hydraulic system, use a funnel with a fine

wire screen—200 mesh or finer—and make sure

the funnel and transmission fluid are

immaculately clean. This prevents accidentally

contaminatimg the hydraulic system.

3. Thread the dipstick fill cap finger-tight onto the

filler neck. It isn’t necessary to tighten the cap

with a wrench.

4. Check all hoses and fittings for leaks.

Figure 4

1. Hydraulic system reservoir fluid/add dipstick cap

Fill the Fuel Tank

1. Using a clean cloth, clean area around the fuel

tank cap.

2. Remove the cap from the fuel tank (Fig. 5).

3. Fill the 8.5 gallon (32 l) tank to within 1 inch (25

Important

Recommended

Viscosity and Type

16

Under certain conditions, diesel fuel and fuel vapors

are highly flammable and explosive. A fire or

explosion from fuel can burn you and others and can

cause property damage.

• Use a funnel and fill the fuel tank outdoors, in

an open area, when the engine is off and is cold.

Wipe up any fuel that spills.

• Do not fill the fuel tank completely full. Add

fuel to the fuel tank until the level is 1 in. (25

mm) below the bottom of the filler neck. This

empty space in the tank allows the fuel to

expand.

• Never smoke when handling fuel, and stay

away from an open flame or where fuel fumes

may be ignited by a spark.

• Store fuel in a clean, safety-approved container

and keep the cap in place.

CAUTION

1

Page 17

Service Brakes

The left and right brake pedals (Fig. 6) are connected

to the left and right front wheels. Since both brakes

work independently, the brakes can be used to turn

sharply or to increase traction if one wheel tends to

slip while operating on certain slope conditions.

However, wet grass or soft turf can be damaged when

brakes are used to turn sharply. To make a “quickstop”, depress both brake pedals together. Always lock

the brakes together when transporting the traction

unit.

Figure 6

1. Parking brake knob

2. Right brake pedal

3. Left brake pedal

Figure 7

1. Left brake pedal

2. Right brake pedal

3. Lock arm

Parking Brake

Whenever the engine is shut off, the parking brake

must be engaged to prevent accidental movement of

the machine. To engage the parking brake, push the

lock arm (Fig. 7) on so that it locks together with the

right pedal. Next, push down fully on both pedals and

pull parking brake knob out (Fig. 6) then release the

pedals. To release the parking brake, depress both

pedals until the parking brake knob retracts. Before

starting the engine, however, the lock arm may be

disengaged from the left brake pedal so both pedals

work independently with each front wheel

17

mm) from the bottom of the filler neck with

diesel fuel.

4. Install the fuel tank cap tightly after filling tank.

Figure 5

1. Fuel tank cap

Controls

1

1

1

2

3

2

3

Page 18

Traction Pedal

The traction pedal (Fig. 8) has two functions: to make

the machine move forward, and to make it move

backward. Depress the top of the pedal to move

forward and bottom of the pedal to move rearward.

Ground speed is proportionate to how far you depress

the pedal. For maximum ground speed, the traction

pedal must be fully depressed while the throttle is in

the FAST position. Maximum speed forward is 10

mph (16 Km/hr) (approx.). To get maximum power

with a heavy load or when climbing a hill, have the

throttle in the FAST position while depressing the

traction pedal slightly to keep engine rpm high. When

engine rpm begins to decrease, release the traction

pedal slightly to allow rpm to increase.

Figure 8

1. Traction pedal

Hydraulic Lift Lever

The hydraulic lift lever (Fig. 9) has three positions:

FLOAT, TRANSPORT and RAISE. To lower the

cutting unit to the ground, move the lift lever forward

into the notch in the seat platform—FLOAT. Use the

FLOAT position for mowing and when the machine is

not in operation. To raise the cutting unit, pull the lift

lever rearward to the RAISE position.

After the cutting unit is raised, let the lift lever move

to the TRANSPORT position. The cutting unit must

be raised when driving from one work area to another.

Figure 9

1. Hydraulic lift lever

2. Power take-off switch

3. Temperature gauge

4. Fuel gauge

5. Ignition key switch

6. Temperature override switch

7. Throttle

8. Hour meter

9. Engine coolant temperature

10. Glow plug indicator

11. Charge indicator

12. Oil pressure indicator

13. Lift lever lock

Power Take-Off Switch

Pull up on the sleeve on the toggle switch handle and

move handle to ON to engage the power take-off

clutch (Fig. 9). Pull up on the sleeve and move the

handle to OFF to disengage the power take-off clutch.

The only time the power take-off switch should be in

the ENGAGE position is when the implement is

down, in operating position and ready to begin

operation.

Temperature Gauge

The temperature gauge (Fig. 9) registers the

temperature of the coolant in the cooling system. If

coolant temperature becomes too high, the engine will

shut off automatically.

Fuel Gauge

The fuel gauge (Fig. 9) indicates the quantity of fuel

remaining in the fuel tank.

Ignition Key Switch

Three positions: OFF, ON/Preheat and START

(Fig. 9).

18

Never raise the cutting unit while the blades are

rotating because it is hazardous.

CAUTION

1

1

2

3

4

5

6

7

13

12

11

10

9

8

Page 19

Temperature Override Switch

Press and hold the over-ride switch (Fig. 9) to start the

engine after a high-temperature shut down. Use only

for emergency operation.

Throttle

The throttle (Fig. 9) is used to operate the engine at

various speeds. Moving the throttle forward increases

engine speed—FAST; rearward decreases engine

speed—SLOW. The throttle controls the speed of the

cutter blades and, with the traction pedal, controls the

traction unit’s ground speed.

Hour Meter

The hour meter (Fig. 9) registers accumulated hours

of engine operation.

Engine Coolant Temperature Warning

Light

The light illuminates and the engine shuts down when

coolant reaches an excessively high temperature

(Fig. 9).

Glow Plug Indicator

When lit, indicates that the glow plugs are on (Fig. 9).

Charge Indicator

Illuminates when the system’s charging circuit

malfunctions (Fig. 9).

Oil Pressure Warning Light

The oil pressure warning light (Fig. 9) glows when

engine oil pressure drops below a safe level. If low oil

pressure occurs, stop the engine and determine the

cause. Repair the damage before starting the engine

again.

Lift Lever Lock

Lock the lift lever (Fig. 9) in the raised position when

performing maintenance on the cutting unit.

Seat Adjusting Handle

To adjust the seat, loosen the adjusting knobs and

slide the seat to the desired position. Tighten the

knobs to lock the seat in place.

Seat Adjusting Handle—Deluxe Seat

To adjust the seat, move the lever on the left side

outward, slide the seat to the desired position and

release the lever so it will lock in that position.

19

Page 20

Note: Determine the left and right sides of the

machine from the normal operating position.

Starting/Stopping the Engine

the fuel system must be bled if any of

the following situation have occurred.

A. Initial start up of a new machine.

B. The engine has ceased running due to lack of

fuel.

C. Maintenance has been performed on fuel system

components; i.e., filter replaced, separator

serviced, etc.

Refer to Bleeding the Fuel System.

1. Ensure the parking brake is set, the power take-

off switch is in the OFF position and the lift lever

is in the TRANSPORT or FLOAT position.

Remove your foot from the traction pedal and

make sure it is in neutral.

2. Move the throttle control to the 1/2-speed

position.

3. Turn the ignition switch to the ON/Preheat

position. An automatic timer will control preheat

for 6 seconds. After preheat, turn the key to the

START position. CRANK THE ENGINE FOR

NO LONGER THAN 15 SECONDS. Release the

key when the engine starts. If additional preheat

is required, turn the key to the OFF position then

to the ON/preheat position. Repeat the process as

required.

4. Run the engine at idle speed or partial throttle

until the engine warms up.

Note: Move the throttle to the

1

⁄

2-speed position

when restarting a warm engine.

5. When the engine is started for the first time, or

after an engine oil change, or overhaul of the

engine, transmission or axle, operate the machine

in forward and reverse for one to two minutes.

Also operate the lift lever and power take-off

lever to assure proper operation of all parts. Turn

the steering wheel to the left and right to check

steering response. Then shut the engine off and

check fluid levels. Also check for oil leaks, loose

parts and any other noticeable malfunctions.

6. To stop the engine, move the throttle control

backward to the SLOW position, move the power

take-off switch to the OFF position and turn the

ignition key to OFF. Remove the key from the

switch to prevent accidental starting.

Bleeding the Fuel System

1. Park the machine on a level surface. Make sure

the fuel tank is at least half full.

Important

20

Operation

Shut the engine off and wait for all moving

parts to stop before checking for oil leaks, loose

parts or other malfunctions.

CAUTION

Under certain conditions, diesel fuel and fuel

vapors are highly flammable and explosive. A

fire or explosion from fuel can burn you and

others and can cause property damage.

• Use a funnel and fill the fuel tank

outdoors, in an open area, when the engine

is off and is cold. Wipe up any fuel that

spills.

• Do not fill the fuel tank completely full.

Add fuel to the fuel tank until the level is 1

in. (25 mm) below the bottom of the filler

neck. This empty space in the tank allows

the fuel to expand.

• Never smoke when handling fuel, and stay

away from an open flame or where fuel

fumes may be ignited by a spark.

• Store fuel in a clean, safety-approved

container and keep the cap in place.

DANGER

Page 21

2. Unlatch and raise the hood.

3. Open the air bleed screw on the fuel injection

pump (Fig. 10).

Figure 10

1. Fuel injection pump bleed screw

4. Turn the key in the ignition switch to the ON

position. The electric fuel pump will begin

operation, forcing air out around air bleed screw.

Leave the key in the ON position until a solid

stream of fuel flows out around the screw.

Tighten the screw and turn the key to OFF.

Note: Normally, the engine should start after

these bleeding procedures. However, if it doesn’t,

air may be trapped between the injection pump

and the injectors; refer to Bleeding Air from the

Injectors.

Checking the Interlock System

The purpose of the safety interlock system is to

prevent the engine from cranking or starting unless the

traction pedal is in neutral and the power take-off

switch is in the OFF position. Also, the engine will

stop when the power take-off control is engaged or the

traction pedal is depressed with operator off the seat

or when the parking brake is engaged.

1. Move the power take-off switch to the OFF

position and remove your foot from the traction

pedal.

2. Turn the ignition key to START. The engine

should crank. If the engine cranks, go to step 3.

If the engine does not crank, there may be a

malfunction in the interlock system.

3. Rise off the seat and engage the power take-off

switch while the engine is running. The engine

should stop within 2 seconds. If the engine stops,

the switch is operating correctly; go to step 4. If

the engine does not stop, there is a malfunction in

the interlock system.

4. Rise off the seat and depress the traction pedal

while the engine is running the power take-off

lever is disengaged. The engine should stop

within 2 seconds. If the engine stops, the switch

is operating correctly; go to step 5. If the engine

does not stop, there is a malfunction in the

interlock system.

5. Engage the parking brake. Depress the traction

pedal while the engine is running and the power

take-off lever is disengaged. The engine should

stop within 2 seconds. If the engine stops, the

switch is operating correctly; continue operation.

If the engine does not stop, there is a malfunction

in the interlock system.

Operating Characteristics

Practice driving the GROUNDSMASTER 228-D

before initial operation because it has a hydrostatic

transmission and its characteristics are different than

some turf maintenance machines with which you may

be familiar. Pay attention to the transmission, engine

speed, load on the cutting blades, and the importance

of the brakes.

To maintain enough power for the traction unit and

21

If the safety interlock switches are disconnected or

damaged, the machine could operate unexpectedly

and cause personal injury.

• Do not tamper with the interlock switches.

• Check the operation of the interlock switches

daily and replace any damaged switches before

operating the machine.

• Replace switches every two years, regardless of

whether they are operating properly.

CAUTION

1

Page 22

cutting unit while mowing, regulate the traction pedal

to keep engine rpm high and somewhat constant. A

good rule to follow is: decrease ground speed as the

load on the cutting blades increases; and increase

ground speed as load on the blades decreases. This

lets the engine—working with the transmission—

sense the proper ground speed while maintaining the

high blade speed necessary for good quality of cut.

Therefore, allow the traction pedal to move upward as

engine speed decreases, and depress the pedal slowly

as speed increases. By comparison, when driving from

one work area to another—with no load and the

cutting unit raised—have the throttle in the FAST

position and depress the traction pedal slowly, but

fully, to attain maximum ground speed.

You can use the brakes to assist in turning the

machine; however, use them carefully, especially on

soft or wet grass because the turf may be torn

accidentally. The brakes can be used to great

advantage to control the direction of the cutting unit

when trimming along fences or similar objects. The

other benefit of the brakes is to maintain traction. For

example; in some slope conditions, the uphill wheel

may slip and lose traction. If this occurs, depress the

uphill brake pedal gradually and intermittently until

the uphill wheel stops slipping. If you don’t want

independent braking, engage the lever on the left

brake pedal with the right pedal. This provides

simultaneous braking at both wheels.

Before stopping the engine, disengage all controls and

move the throttle to SLOW. Moving the throttle to

SLOW reduces engine speed, noise and vibration.

Turn the ignition key to OFF to stop the engine.

Pushing or Towing the Traction

Unit

In an emergency, the you can push or tow the traction

unit for a very short distance. However, Toro does not

recommend this as standard procedure.

Do not push or tow the traction unit

faster than 3.2 to 4.8 kmh because transmission may

be damaged. If you want to move the traction unit a

considerable distance, transport it on a truck or trailer.

Whenever the traction unit is pushed or towed, bypass valve must be open.

1. Remove the hair pin, pivot the seat platform

forward and locate the seat support rod in the

detent notch.

2. Depress and hold the pins located in the center of

the two (2) check valve assemblies in the top of

the transmission (Fig. 11) while pushing or

towing the machine.

Figure 11

1. Transmission check valve by-pass pins (2)

3. Start the engine momentarily after completing

repairs and make sure the pins are in the full,

disengaged (fully up) position.

Running the machine with the by-

pass valve open will overheat the transmission.

Important

Important

22

This machine produces sound levels in excess of

85dBA at the operator’s ear and can cause hearing

loss through extended periods of exposure. Wear

hearing protection when operating this machine.

CAUTION

1

Page 23

23

Maintenance

Service Interval Maintenance Procedure

After the first 10 hours • Check the power take-off belt tension.

• Check the fan and alternator belt tension.

• Change the transmission filter.

• Torque the wheel lug nuts.

After first 50 hours • Change the engine oil filter.

• Torque the engine head and check engine RPM.

Every 50 hours • Check the battery electrolyte level.

• Check the battery cable connections.

• Lubricate all grease fittings.

• Lubricate the brake cables.

• Check the cutting unit gear box oil level.

• Clean under the cutting unit belt covers.

• Check the cutting unit drive belt adjustment.

• Change the engine oil.

• Inspect the air filter and baffle

Every 100 hours • Change the engine oil filter.

• Check the electric clutch gap adjustment

• Check the power take off belt tension.

• Check the fan and alternator belt tension.

• Inspect the cooling system hoses.

Every 200 hours • Check rear wheel toe-in and steering linkage.

• Change the transmission filter.

• Torque the wheel lug nuts.

Every 400 hours • Service the air filter

• Drain and clean the fuel tank.

• Change the cutting unit’s gear box oil

• Change the fuel/water separator filter.

• Pack the rear wheel bearings.

• Coat the transmission bypass pins with grease

• Torque the head, adjust the valves and heck engine RPM.

Every 1000 hours or 2 • Replace moving hoses.

years, whichever • Replace safety switches.

occurs first • Flush and replace the coolant system fluid.

• Replace the hydraulic oil.

Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

Recommended Maintenance Schedule

Page 24

24

CHECK/SERVICE (DAILY)

1. Oil levels (Engine/Trans)

2. Coolant level

3. Tire pressure

4. Belts (Fan and power take off)

5. Fuel—Diesel only

6. Battery

7. Grease, lube points

8. Radiator screen

9. Air filter

10. Electrical clutch gap .017-.030

11.PTO Belt tension

12. Water separator

13. Fuel filter

Service Interval Charts

Fluid Specifications/Change Intervals

2 years

Type>0° C Type<0° C Capacity Change Intervals

Engine oil

Transmission

oil

Fuel

Coolant

SAE 30 CD SAE 10W-30 CD 50 hours filter 100 hours

filter 200 hours

filter 400 hours

*

Type F or FA

transmission

fluid

No. 1-D

50/50 mix Ethylene glycol anti-

freeze/water

No. 2-D

SAE 10W-30 SF, CC,

CD

7.6 l

32.2 l

5.7 l

3.7 l with filter

Filters Part No.

A. Air 98-9763

B. Fuel 98-7612

C. Fuel 98-9764

D. Transmission oil 23-2300

E. Engine oil 99-8384

Page 25

Daily Maintenance Checklist

✓ Check safety interlock operation.

✓ Check that the grass deflector is in the down

position.

✓ Check brake operation.

✓ Check fuel level

✓ Check the engine oil level.

✓ Check the cooling system fluid level.

✓ Drain and drain the water/fuel separator.

✓ Check the air cleaner restriction indicator

3

.

✓ Check the radiator and screen for debris.

✓ Check unusual engine noises.

1

✓ Check unusual operating noises

✓ Check the transmission oil level.

✓ Check the hydraulic hoses for damage.

✓ Check for fluid leaks.

✓ Check the tire pressure.

✓ Check instrument operation.

✓ Check blade condition.

✓ Lubricate all grease fittings.

2

✓ Touch up damaged paint.

1

Check the glow plug and injector nozzles if hard starting,

excess smoke, or rough running is noted.

2

Immediately after every washing, regardless of the interval

listed.

3

If indicator shows red

Lubrication

Greasing Bearings And Bushings

The traction unit has grease fittings that must be

lubricated regularly with No. 2 General Purpose

Lithium Base Grease. If the machine is operated under

normal conditions, lubricate all bearings and bushings

after every 50 hours of operation. Bearings and

bushings must be lubricated daily when operating

conditions are extremely dusty and dirty. Dusty and

dirty operating conditions could cause dirt to get into

the bearings and bushings, resulting in accelerated

wear. Lubricate grease fitting immediately after every

washing, regardless of interval specified.

Apply a liberal coating of grease to the check valve

pins once each year (Fig. 11). Also grease the bearings

in the rear axle every 500 hours, or yearly, whichever

comes first (not shown). The traction unit has bearings

and bushings that must be lubricated, and these

lubrication points are: power take-off universal shaft

(Fig. 12); lift arm pivot bushings (Fig. 13), brake pivot

bushings (Fig. 14); rear wheel spindle bushings (Fig.

15); steering plate bushings (Fig. 16); axle pin

bushing (Fig. 16); power take-off tension pivot (Fig.

17) and rear power take-off bearing (Fig. 17). Also

apply grease to both brake cables at the drive wheel

and brake pedal ends (Fig. 14).

1. Wipe grease fitting clean so foreign matter

cannot be forced into the bearing or bushing.

2. Pump grease into the bearing or bushing.

3. Wipe up excess grease.

Figure 12

25

If you leave the key in the ignition switch,

someone could accidentally start the engine and

seriously injure you or other bystanders.

Remove the key from the ignition and

disconnect the wire from the spark plug before

you do any maintenance. Set the wire aside so

that it does not accidentally contact the spark

plug.

CAUTION

Page 26

Figure 13

Figure 14

Figure 15

Figure 16

Figure 17

26

Page 27

General Air Cleaner

Maintenance

1. Check air cleaner body for damage that could

possibly cause an air leak. Replace a damaged air

cleaner body.

2. Service the air cleaner filter when the air cleaner

indicator (Fig. 18) shows red or every 400 hours

(more often in extreme dusty or dirty conditions).

Do not over-service the air filter.

Figure 18

1. Air cleaner indicator

3. Be sure the cover seals around the air cleaner

body.

Servicing the Air Cleaner

1. Pull the latch outward and turn the air cleaner

cover counter-clockwise. Remove the cover from

the body (Fig. 19). Clean the inside of the air

cleaner cover.

Figure 19

1. Air cleaner latch

2. Air cleaner cover

2. Gently slide the filter (Fig. 20) out of the air

cleaner body to reduce the amount of dust

dislodged. Avoid knocking the filter against the

air cleaner body.

Figure 20

1. Filter

3. Inspect the filter and discard it if it is damaged.

Do not wash or reuse a damaged filter.

Cleaning the Air Filter

A. Blow compressed air from inside to the

outside of dry filter element. Do not exceed

689 kPa (100 psi) to prevent damage to the

element.

B. Keep the air hose nozzle at least 2” from the

filter and move the nozzle up and down

while rotating the filter element. Inspect for

holes and tears by looking through the filter

toward a bright light.

4. Inspect the new filter for shipping damage.

Check the sealing end of the filter. Do not install

a damaged filter.

5. Insert the new filter into the air cleaner body.

Make sure the filter is sealed properly by

applying pressure to the outer rim of filter when

installing. Do not press on the flexible center of

the filter.

6. Reinstall the cover and secure the latch. Make

sure the cover is positioned with the TOP side up.

7. Reset the indicator (Fig. 18) if it is showing red.

27

1

1

1

2

Page 28

Cleaning the Radiator and

Screen

To prevent the engine from overheating, the screen

and radiator must be kept clean. Normally, check the

screen and radiator daily and clean any debris off

these parts. However, it will be necessary to check and

clean the screen and radiator more often in extremely

dusty and dirty conditions.

Note: If the engine shuts off due to overheating, first

check the radiator and screen for excessive build-up of

debris.

To thoroughly clean the radiator:

1. Remove the screen.

2. Working from the fan side of the radiator, either

spray the radiator with a water hose or blow with

compressed air.

3. After the radiator is thoroughly cleaned, clean

out debris that may have collected in the channel

at the radiator base.

4. Clean and install the screen.

Changing the Engine Oil and

Filter

Check the oil level after each day’s operation or each

time you use the machine. Change oil after every 50

hours of operation; change the oil filter after first 50

hours and every 100 hours operation thereafter. If

possible, run the engine just before changing the oil

because warm oil flows better and carries more

contaminants.

1. Position the machine on a level surface.

2. Open the hood. Set a drain pan under the oil pan,

in line with the drain plug (Fig. 21).

3. Clean the area around the drain plug.

Figure 21

1. Drain plug

4. Remove the oil drain plug and let oil to flow into

drain pan.

5. Remove and replace the oil filter (Fig. 22).

Figure 22

1. Oil filter

6. After the oil has drained, reinstall the drain plug

and wipe up any oil that spilled.

7. Fill the crankcase with oil; refer to Check the

Engine Oil.

Servicing the Fuel System

Note: Refer to Fill the Fuel Tank with Diesel Fuel for

proper fuel recommendations.

Fuel Tank

Drain and clean the fuel tank after every 800 hours

operation or yearly, whichever comes first. Also, drain

and clean the tank if the fuel system becomes

contaminated or if the machine will be stored for an

extended period. Use clean diesel fuel to flush out the

tank.

28

1

1

Page 29

Fuel Lines and Connections

Check the lines and connections every 400 hours or

yearly, whichever comes first. Inspect for

deterioration, damage or loose connections.

Water Separator

Drain water or other contaminants from the water

separator (Fig. 23) daily.

1. Place a clean container under the fuel filter.

2. Loosen the drain plug on the bottom of filter

canister. Tighten the plug after draining.

Figure 23

1. Water separator

2. Drain plug

Replace the filter canister after every 400 hours of

operation.

1. Clean the area where the filter canister mounts.

2. Remove the filter canister and clean the

mounting surface.

3. Lubricate the gasket on the filter canister with

clean oil.

4. Install the filter canister by hand until the gasket

contacts the mounting surface, then turn it an

additional

1

⁄2 turn.

Replacing the Fuel Pre Filter

Replace the fuel pre filter (Fig. 24), located between

the fuel tank and the fuel pump, after every 400

operating hours or yearly, whichever occurs first.

1. Clamp both fuel lines that connect to the fuel

filter so fuel cannot drain when you remove the

lines (Fig. 24).

2. Loosen the hose clamps at both ends of the filter

and pull the fuel lines off the filter.

Figure 24

1. Fuel pre filter

3. Slide the hose clamps onto the ends of the fuel

lines. Push the fuel lines onto the fuel filter and

secure them with hose clamps. Be sure the arrow

on the side of the filter points toward the

29

Under certain conditions, diesel fuel and fuel

vapors are highly flammable and explosive. A

fire or explosion from fuel can burn you and

others and can cause property damage.

• Use a funnel and fill the fuel tank

outdoors, in an open area, when the engine

is off and is cold. Wipe up any fuel that

spills.

• Do not fill the fuel tank completely full.

Add fuel to the fuel tank until the level is 1

in. (25 mm) below the bottom of the filler

neck. This empty space in the tank allows

the fuel to expand.

• Never smoke when handling fuel, and stay

away from an open flame or where fuel

fumes may be ignited by a spark.

• Store fuel in a clean, safety-approved

container and keep the cap in place.

DANGER

1

2

Page 30

injection pump.

Bleeding Air from Injectors

Note: This procedure should be used only if the fuel

system has been purged of air through normal priming

procedures and the engine will not start; refer to

Bleeding the Fuel System.

1. Loosen the pipe connection to the No. 1 injector

nozzle and holder assembly at injection pump.

Figure 25

1. No. 1 injector nozzle

2. Move the throttle to the FAST position.

3. Turn the key in the key switch to START and

watch the fuel flow around the connector. Turn

the key to OFF when you see a solid fuel flow.

4. Tighten the pipe connector securely.

5. Repeat these steps on the remaining nozzles.

Alternator Belt

1. Condition and Tension—Check the condition and

tension of the belts (Fig. 26) after every 100

operating hours.

A. Proper tension will allow

3

⁄8 in. (10 mm)

deflection when a force of 10 lbs. is applied

on the belt midway between the pulleys.

B. If deflection is not

3

⁄8 in. (10 mm), loosen the

alternator mounting bolts. Increase or

decrease alternator belt tension and tighten

the bolts. Check belt deflection again to

assure tension is correct.

Figure 26

1. Alternator

2. Mounting bolt

Adjusting the Throttle

1. Adjust the throttle cable (Fig. 27) so the governor

lever on the engine contacts the low- and highspeed set bolts before the throttle lever contacts

the slot in the control panel.

Figure 27

1. Throttle cable

Power Take-Off Belt

To Check Tension:

1. Turn the engine off and remove the ignition key.

Set the parking brake. Raise the engine hood and

allow the engine to cool.

2. Loosen the tensioning rod jam nut (Fig. 28).

30

1

2

1

1

Page 31

Figure 28

1. Tensioning spring

2. Tensioning rod jam nut

3. Tension adjusting bolt

3. Use a 1⁄2” wrench to tighten or loosen the belt-

tensioning spring (Fig. 28). Adjust the spring to a

length of 1-

1

⁄

2” (38 mm).

4. Tighten the jam nut.

To Replace the Belt:

1. Turn off the engine and remove the ignition key.

Set the parking brake. Raise the hood and let the

engine cool.

2. Loosen the tensioning rod jam nut (Fig. 28).

3. Using a

1

⁄2” wrench, loosen the belt tensioning

spring (Fig. 28) completely.

4. Turn power take-off pulley toward the engine and

remove the belt (Fig. 29).

5. Install the new power take-off belt and re-tension

the pulley spring to 1-

1

⁄2” (38 mm) (Fig. 28).

6. Tighten the jam nut (Fig. 28) and close the hood.

Power Take-Off Clutch

Adjustment

The power take-off electric clutch can be adjusted by

following the following procedure:

1. Turn the engine off and remove the ignition key.

Set the parking brake. Raise the engine hood and

let the engine cool.

2. Remove the left-hand bracket nut and bolt so that

you can remove the retainer bracket’s rubber

bumper (Fig. 29).

Figure 29

1. Clutch

2. .015” air gap

3. Adjusting nut (3)

4. Left retainer bracket nut & bolt

5. Electrical connector

6. Power take-off belt

3. Unplug the clutch’s electric connector (Fig. 29).

4. Adjust the air gap so that a 0.015-inch feeler

gauge slides between the clutch lining and

friction plate with light pressure (Fig. 29). The

gap can be decreased by turning the adjusting nut

clockwise.

5. Rotate the clutch by hand and adjust all three air

gaps. After all three gaps have been set, check all

three again. Adjusting one gap can alter the other

gaps.

6. Reinstall the bracket and retaining nut and bolt.

Reconnect the clutch’s electrical connector.

Adjusting the Transmission for

Neutral

The machine must not creep when you release the

traction pedal. If it does, an adjustment is required.

1. Park the machine on a level surface and shut the

31

2

4

5

2

6

1

1

3

3

38 mm

Page 32

engine off. Depress only the right brake pedal

and engage the parking brake.

2. Jack up the left front side of the machine until the

tire is off the shop floor. Support the machine

with jack stands to prevent it from falling

accidentally.

3. Lift the seat. Visually inspect the traction linkage

for a possible binding condition. Correct it, if

necessary, and check machine operation. If the

condition still exists, repeat steps 1 and 2 and go

to step 4.

4. Loosen the two locknuts securing the pump plate

so the plate can move freely (Fig. 30).

5. Start the engine and rotate pump plate (Fig. 30)

in either direction until the wheel ceases rotation.

Figure 30

1. Pump plate

2. Locknut

6. Stop the engine and tighten the locknuts to secure

the pump plate (Fig. 30).

7. Start the engine and check adjustment. Repeat

the adjustment, if necessary.

8. Stop the engine and release the right brake.

Remove the jack stands and lower the machine to

the shop floor. Test drive the machine to be sure

it doesn’t creep.

Adjusting the Parking Brake

Interlock Switch

1. Turn the engine off and remove the ignition key.

Do not engage the parking brake.

2. Remove the (6) screws securing the front steering

tower cover to frame and remove the cover

(Fig. 31).

Figure 31

1. Front steering tower cover

2. Parking brake lever/rod

3. Disconnect the switch pigtail connector from the

wire harness (Fig. 32).

4. Connect a continuity tester or ohmmeter to the

switch harness connector.

Figure 32

1. Parking brake interlock switch

2. Parking brake rod collar

3. Wire harness connector

5. Loosen the set screw securing the collar to the

parking brake rod (Fig. 32).

6. Slowly move the collar on the rod until it is

aligned with cross hairs on the switch label

(Fig. 32). Tighten the collar set screw.

7. With the parking brake disengaged, the switch

circuit should have continuity. If there is no

continuity, move the collar slightly up the rod

until there is continuity and tighten the collar set

32

2

1

1

2

3

2

1

Page 33

screw.

8. Check adjustment as follows:

Engage the parking brake. Depress the traction

pedal while the engine is running and the power

take-off lever is disengaged. The engine should

stop within 2 seconds. If the engine stops, the

switch is operating correctly; you may continue

operation. If the engine does not stop, there is a

malfunction in the interlock system.

9. Connect the switch and install the steering tower

cover.

Changing the Hydraulic Oil and

Filter

Initially, replace the hydraulic system oil and filter

after the first full day’s operation—NOT TO

EXCEED 10 HOURS. Replace the oil and filter every

250 hours thereafter. The hydraulic system is designed

to operate on any high-quality detergent oil having the

American Petroleum Institute— API—“service

classification”

SF/CC or CD. Oil viscosity—weight—must be

selected according to anticipated ambient temperature

for the season in which product will be used.

Temperature/viscosity recommendations are:

Expected Ambient

Temperature

(Extreme) over 32° C SAE 30, Type SF/CC or CD

engine oil

(Normal) 4–37° C SAE 10W-30 or 10W-40,

Type SF/CC or CD engine oil

(Cool) –1 to 10° C SAE 5W-30, Type SF/CC or

CD engine oil

(Winter) Below –1° C Type “F” or “FA” ATF

Automatic Transmission Fluid

Note: Do not mix engine oil and automatic

transmission fluid or hydraulic component damage

may result. When changing fluids, also change

transmission filter. DO NOT USE DEXRON II ATF.

Note: Fluid to operate the power steering is supplied

by the hydraulic system transmission charge pump.

Cold weather start-up may result in “stiff” operation

of the steering until the hydraulic system has warmed

up. Using proper weight hydraulic oil in the system

will minimize this condition.

The transmission and axle housing are shipped from

the factory with approximately 5 quarts (4.7 l) of SAE

10W-30 engine oil. However, check the level of

transmission oil before first starting the engine, and

daily thereafter.

1. Lower the cutting unit to the shop floor, set the

parking brake, and turn the engine OFF. Block

the two rear wheels.

2. Jack up both sides of the front axle and support it

with jack stands.

3. Clean the area around the hydraulic oil filter and

remove the filter (Fig. 33).

Figure 33

1. Filter

2. Return line

3. Suction line

4. Remove the tube that connects the axle housing

to the transmission and let the oil to flow into a

drain pan.

5. Install the new hydraulic oil filter and connect

the tube between the axle housing and

transmission. Fill the axle (reservoir)(approx. 5

qt.); refer to Check Hydraulic System Fluid.

Remove the jack stands.

6. Start the engine, cycle the steering and lift

cylinders, and check for oil leaks. Let the engine

run for about five minutes. Then shut the engine

Recommended

Viscosity and Type

33

2

1

3

Page 34

off.

7. After two minutes, check the transmission fluid

level; refer to Check Hydraulic System Fluid.

Adjusting the Service Brakes

Adjust the service brakes when there is more than one

inch (25 mm) of “free travel” of the brake pedals, or

when the brakes don’t work effectively. Free travel is

the distance the brake pedal moves before you feel

braking resistance.

Check brake adjustment after the first 25 hours of

operation. After that, they should only need adjusting

after considerable use. These periodic adjustments can

be performed where the brake cable connects to the

bottom of the brake pedals. When the cable is no

longer adjustable, the star nut on inside of the brake

drum must be adjusted to move the brake shoes

outward. However, the brake cables must be adjusted

again to compensate for this adjustment.

1. Disengage the lock arm from the right brake

pedal so both pedals work independently.

2. To reduce free travel of the brake pedals, loosen

the front nut on the threaded end of the brake

cable (Fig. 34). Then tighten the rear nut to move

the cable backward, until the brake pedals have

13 mm to 25 mm of free travel. Tighten the front

nut after the brakes are correctly adjusted.

Figure 34

1. Brake cable jam nuts

Servicing the Battery

Before welding on the machine,

disconnect the ground cable from the battery to

prevent damage to the electrical system

.

Note: Check battery condition weekly or after every

50 hours of operation. Keep the terminals and the

entire battery case clean because a dirty battery will

slowly discharge. To clean the battery, wash the entire

case with a solution of baking soda and water. Rinse

with clear water. Coat the battery posts and cable

connector with Grafo 112X (Skin-over) grease, Toro

Part No. 505-47 or petroleum jelly to prevent

corrosion.

Wiring Harness Service

Prevent corrosion of wiring terminals by applying

Grafo 112X (Skin-over) grease, Toro Part No. 505-47,

to the inside of all harness connectors whenever the

harness is replaced.

Whenever working with the electrical system, always

disconnect battery cables, negative (–) cable first, to

prevent possible wiring damage from short-outs.

Fuses

Fuses are accessible under the seat plate (Fig. 35).

Figure 35

1. Fuse block

Important

34

1

1

1

Page 35

Storage

Traction Unit

1. Thoroughly clean the traction unit, cutting unit

and the engine, paying special attention to these

areas:

• Radiator and radiator screen

• Underneath the cutting unit

• Under the cutting unit belt covers

• Counterbalance springs

• Power take-off shaft assembly

• All grease fittings and pivot points

• Remove control panel and clean the inside

of the control box

• Beneath the seat plate and the top of

transmission

2. Check the tire pressure. Inflate all traction unit

tires to 138 kPa.

3. Remove, sharpen and balance the cutting unit’s

blades. Reinstall the blades and torque the blade

fasteners to 85-110 ft-lb (115-149 N m).

4. Check all fasteners for looseness; tighten as

necessary.

5. Grease or oil all grease fittings, pivot points, and

transmission by-pass valve pins. Wipe off any

excess lubricant.

6. Lightly sand and use touch up the paint on where

paint is scratched, chipped or rusted. Repair any

dents in the metal body.

7. Service the battery and cables as follows:

A. Remove the battery terminals from the

battery posts.

B. Clean the battery, terminals and posts with a

wire brush and baking soda solution.

C. Coat the cable terminals and battery posts

with Grafo 112X skin-over grease (Toro Part

No. 505-47), or petroleum jelly to prevent

corrosion.

D. Slowly recharge the battery for 24 hours

every 60 days to prevent lead sulfation of

the battery.

Engine

1. Drain the engine oil from the oil pan and replace

the drain plug.

2. Remove and discard the oil filter. Install a new

filter.

3. Refill the engine with 4 quarts (3.8 l) of

recommended motor oil. Refer to Changing the

Engine Oil.

4. Start the engine and run it at idle speed for two

minutes.

5. Drain diesel fuel from the fuel tank, fuel lines,

pump, filter and separator. Flush the fuel tank

with clean diesel fuel and connect all fuel lines.

6. Thoroughly clean and service the air cleaner

assembly.

7. Seal the air cleaner inlet and the exhaust outlet

with weather-proof masking tape.

8. Check the oil filler cap and fuel tank cap to

ensure they are securely in place.

35

Page 36

Loading...

Loading...