Page 1

FORM NO. 3318-239 GB Rev. B

© The Toro Company—1996

®

MODEL NO. 30233TE—60001 & UP

MODEL NO. 30243TE—6

0001 & UP

GROUNDSMASTER

2-Wheel and 4-Wheel Drive Traction Units

OPERATOR’S

MANUAL

®

223D

Page 2

To assure maximum safety, optimum performance,

and to gain knowledge of the product, it is essential

that you or any other operator of the mower read and

understand the contents of this manual before the

engine is ever started. Pay particular attention to the

SAFETY INSTRUCTIONS highlighted by this symbol:

The safety alert symbol means CAUTION, WARNING or DANGER—personal safety instruction.

Failure to comply with the instruction may result in

personal injury.

FOREWORD

The GROUNDSMASTER 223-D was developed to

satisfy the demand for a maneuverable, intermediate

size, turf maintenance rotary mower. The machine

has advanced concepts in engineering, design and

safety; and if maintained properly, it will give excellent service.

Since the GROUNDSMASTER 223-D is a high

quality product, Toro is concerned about the future

use of the machine and the safety of the user. Read

this manual to familiarize yourself with the proper

set up, operation, and maintenance instructions.

Certain information in this manual is emphasized.

DANGER, WARNING and CAUTION identify personal safety related information. IMPORTANT identifies mechanical information demanding special

attention. Be sure to read the directive because it

deals with the possibility of damaging a part or parts

of the machine. NOTE identifies general information

worthy of special attention.

If help concerning set up, operation, maintenance or

safety is ever needed, contact a local Authorized

Toro Distributor. In addition to genuine Toro replacement parts, the distributor also has optional equipment form the complete line of Toro turf care equipment. Keep your Toro all Toro – buy genuine Toro

replacement parts and accessories.

Whenever you have questions or need service, contact your local authorized Toro Distributor. In addition to having a complete line of accessories and

professional turf care service technicians, the distributor has a complete line of genuine TORO replacement parts to keep your machine operating properly.

Keep your TORO all TORO. Buy genuine TORO

parts and accessories.

TABLE OF CONTENTS

SAFETY INSTRUCTIONS 3

SPECIFICATIONS 9

BEFORE OPERATING 11

CONTROLS 15

OPERATING INSTRUCTIONS 17

LUBRICATION 20

QUICK REFERENCE AID 22

PREPARATION FOR SEASONAL STORAGE 23

PRODUCT IDENTIFICATION 23

2

Page 3

3

Safety

Training

1. Read the instructions carefully. Be familiar

with the controls and the proper use of the

equipment.

2. Never allow children or people unfamiliar with

these instructions to use the lawnmower. Local

regulations may restrict the age of the operator.

3. Never mow while people, especially children, or

pets are nearby.

4. Keep in mind that the operator or user is

responsible for accidents or hazards occurring

to other people or their property.

5. Do not carry passengers.

6. All drivers should seek and obtain professional

and practical instruction. Such instruction

should emphasize:

• the need for care and concentration when

working with rideon machines;

• control of a ride on machine sliding on a

slope will not be regained by the application

of the brake. The main reasons for loss of

control are:

– insufficient wheel grip;

– being driven too fast;

– inadequate braking;

– the type of machine is unsuitable for its

task;

– lack of awareness of the effects of ground

conditions, especially slopes;

Preparation

1. While mowing, always wear substantial

footwear and long trousers. Do not operate the

equipment when barefoot or wearing open sandals.

2. Thoroughly inspect the area where the equip-

ment is to be used and remove all objects which

may be thrown by the machine.

3. WARNING—Petrol is highly flammable.

• Store fuel in containers specifically designed

for this purpose.

• Refuel outdoors only and do not smoke

while refueling.

• Add fuel before starting the engine. Never

remove the cap of the fuel tank or add petrol

while the engine is running or when the

engine is hot.

• If petrol is spilled, do not attempt to start the

engine but move the machine away from the

area of spillage and avoid creating any

source of ignition until petrol vapors have

dissipated.

• Replace all fuel tanks and container caps

securely.

4. Replace faulty silencers.

5. Before using, always visually inspect to see that

the blades, blade bolts and cutter assembly are

not worn or damaged. Replace worn or damaged blades and bolts in sets to preserve balance.

6. On multi-bladed machines, take care as rotating

one blade can cause other blades to rotate.

Operation

1. Do not operate the engine in a confined space

where dangerous carbon monoxide fumes can

collect.

2. Mow only in daylight or in good artificial light.

3. Before attempting to start the engine, disengage

all blade attachment clutches and shift into neutral.

4. Do not use on slopes of more than:

• Never mow side hills over 5°

• Never mow uphill over 10°

• Never mow downhill over 15°

5. Remember there is no such thing as a “safe”

slope. Travel on grass9 slopes requires particu-

Page 4

Safety

4

lar care. To guard against overturning:

• do not stop or start suddenly when going up

or downhill;

• engage clutch slowly, always keep machine

in gear, especially when travailing downhill;

• machine speeds should be kept low on

slopes and during tight turns;

• stay alert for bumps and hollows and other

hidden hazards;

• never mow across the face of the slope,

unless the lawnmower is designed for this

purpose.

6. Use care when pulling loads or using heavy

equipment.

• Use only approved drawbar hitch points.

• Limit loads to those you can safely control.

• Do not turn sharply. Use care when reversing.

• Use counterweight(s) or wheel weights when

suggested in the instruction handbook .

7. Watch out for traffic when crossing or near

roadways.

8. Stop the blades rotating before crossing surfaces

other than grass.

9. When using any attachments, never direct dis-

charge of material toward bystanders nor allow

anyone near the machine while in operation .

10. Never operate the lawnmower with defective

guards, shields or without safety protective

devices in place.

11. Do not change the engine governor settings or

overspeed the engine. Operating the engine at

excessive speeds may increase the hazard of

personal injury.

12. Before leaving the operator's position:

• disengage the power take-off and lower the

attachments;

• change into neutral and set the parking

brake;

• stop the engine and remove the key.

13. Disengage drive to attachments, stop the engine,

and disconnect the spark plug wire(s)or remove

the ignition key

• before cleaning blockages or unclogging

chute;

• before checking, cleaning or working on the

lawnmower;

• after striking a foreign object. Inspect the

lawnmower for damage and make repairs

before restarting and operating the equipment;

• if the machine starts to vibrate abnormally

(check immediately).

14. Disengage drive to attachments when transport-

ing or not in use.

15. Stop the engine and disengage drive to attach-

ment

• before refueling;

• before removing the grass catcher;

• before making height adjustment unless

adjustment can be made from the operator's

position.

16. Reduce the throttle setting during engine runout

and, if the engine is provided with a shutoff

valve, turn the fuel off at the conclusion of

mowing.

Maintenance and Storage

1. Keep all nuts, bolts and screws tight to be sure

the equipment is in safe working condition.

2. Never store the equipment with petrol in the

tank inside a building where fumes may reach

an open flame or spark.

3. Allow the engine to cool before storing in any

enclosure.

4. To reduce the fire hazard, keep the engine,

silencer, battery compartment and petrol storage

area free of grass, leaves, or excessive grease.

5. Check the grass catcher frequently for wear or

Page 5

5

Safety

deterioration.

6. Replace worn or damaged parts for safety.

7. If the fuel tank has to be drained, this should be

done outdoors

8. On multi-bladed machines, take care as rotating

one blade can cause other blades to rotate.

9. When machine is to be parked, stored or left

unattended, lower the cutting means unless a

positive mechanical lock is used.

Sound & Vibration Levels

Sound Levels

This unit has an equivalent continuous A-weighted

sound pressure at the operator ear of: 80 dB(A),

based on measurements of identical machines per

84/538/EEC.

This unit has a sound power level of 104

dB(A)/1pW, based on measurements of identical

machines per procedures outlined in Directive

84/538/EEC and amendments

Vibration Levels

This unit has a vibration level of 5.0 m/s2at the

hands, based on measurements of identical machines

per ISO 5349 procedures.

This unit does not exceed a vibration level of 0.5

m/s

2

at the posterior based on measurements of iden-

tical machines per ISO 2631 procedures.

Page 6

6

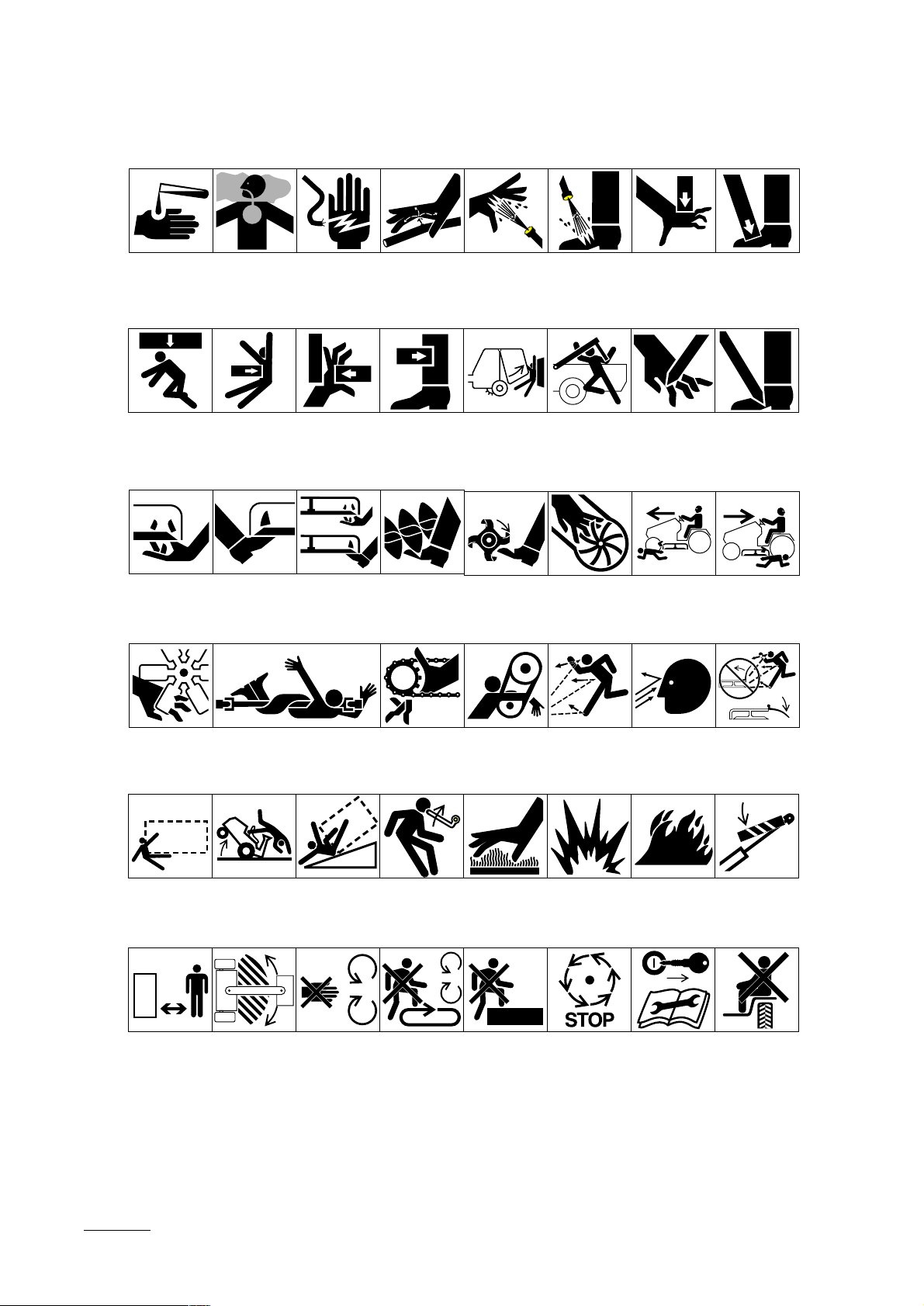

Symbol Glossary

Caustic liquids,

chemical burns to

fingers or hand

Poisonous

fumes or toxic

gases, asphyxiation

Electrical shock,

electrocution

High pressure

fluid, injection

into body

High pressure

spray, erosion of

flesh

High pressure

spray, erosion of

flesh

Crushing of

fingers

or hand,

force

applied from

above

Crushing of

toes or foot, force

applied from above

Crushing of

whole body,

applied from

above

Crushing of

torso, force

applied from side

Crushing of fingers

or hand/, force

applied from side

Crushing of

whole body

Crushing of

head, torso and

arms

Cutting of

fingers or hand

Cutting of footCrushing of leg,

force applied

from side

Severing of

fingers or hand,

mower blade

Severing of

toes or foot,

mower blade

Severing of

toes or fingers,

rotary mower

blade

Cutting or

entanglement of

foot, rotating auger

Severing of

foot, rotating

knives

Severing of

fingers or hand,

impeller blade

Dismemberment, front engine

mower in forward

motion

Dismemberment, front engine

mower in rearward

motion

Severing of

fingers or hand,

engine fan

Whole body entanglement,

implement input drive line

Fingers or

hand entanglement, chain

drive

Hand & arm

entanglement,

belt drive

Thrown or flying

objects, whole

body exposure

Thrown or

flying objects,

face exposure

Thrown or flying

objects, rotary

mover

Runover/backover, vehicle

Machine

tipping, riding

mower

Machine rollover,

ROPS (rear

engine mower)

Stored energy

hazard, kickback

or upward motion

Hot surfaces,

burns to fingers

or hands

Explosion Fire or open

flame

Secure lifting

cylinder with locking

device before getting

in hazardous area

Do not step on

loading platform

if PTO is connected to tractor &

engine is running

Do not step Wait until all

machine components have

completely

stopped before

touching them

Shut off engine

& remove key

before performing maintenance

or repair work

Stay a safe

distance from

the machine

Stay clear of

articulation area

while engine is

running

Do not open

or remove safety

shields while

engine is

running

Riding on this

machine is allowed

only on a passenger seat & only if the

driver’s view is not

hindered

Page 7

7

Safety

Consult technical

manual for proper

service

procedures

Head protection

must be worn

Brake system

Filter Temperature Failure/

Fasten seat

belts

Hearing

protection must

be worn

Oil Coolant (water) Intake air Exhaust gas Pressure Level indicator Liquid level

Caution, toxic

risk

Malfunction

Safety alert

triangle

Start switch/

mechanism

Outline safety

alert symbol

Flush with water Engine Transmission Hydraulic systemFirst aid

On/start Off/stop Engage

Read operator’s

manual

Fire, open light

and smoking

prohibited

Eye protection

must be worn

Disengage

Plus/increase/

positive polarity

Volume empty Volume full Machine travel

Oil lubrication

point

Engine lubricating

oil temperature

Minus/decrease/

negative polarity

Lift point Jack or

Engine coolant

Horn

direction,

forward/

rearward

support point

Engine coolant

pressure

Battery charging

condition

Control lever

operating

direction, dual

direction

Draining/

emptying

Engine coolant

filter

Hourmeter/

elapsed operating

hours

Control lever

operating

direction, multiple

direction

Engine lubricating oil

Engine coolant

temperature

Fast Slow Continuous

Clockwise

rotation

Engine

lubricating

oil pressure

Engine intake/

combustion air

Counter-clockwise rot ation

Engine lubricating

oil level

Engine intake/combustion air pressure

variable, linear

Grease

lubrication

point

Engine lubricating

oil filter

Engine intake/air

filter

Page 8

Safety

8

Engine start Engine stop Engine failure/

malfunction

Engine rotational

speed/frequency

Choke Primer (start aid) Electrical preheat

(low temperature

start aid)

n/min

Transmission

oil

Transmission

oil pressure

Transmission

oil temperature

Transmission

failure/malfunction

Clutch Neutral High Low Forward

NHLF

Reverse

Park First gear

Second gear

Third gear (other #'s

may be used until the

maximum # of forward

gears is reached.)

Hydraulic oil

Hydraulic oil

pressure

Hydraulic oil

level

RP 2 31

Hydraulic oil

filter

Hydraulic oil

temperature

Hydraulic oil

failure/malfunction

Fuel level

Parking brake Fuel

Fuel filter Fuel system

failure/malfunction

Lock Unlock Differential lock 4-Wheel drive Power Take-OffDiesel fuel Unleaded fuel Headlights

Cutting unit,

lower

Cutting unit,

hold

Cutting unit,

float

Cutting unit Cutting unit,

raise

Power Take-Off,

rotational speed

Blade cutting

element

Blade cutting

element, height

adjustment

Cutting unit,

transport

position

Cutting unit,

raise to transport

position

Cutting unit,

lower to transport

position

Attachment

lower

Attachment

raise

Spacing distance Snow thrower,

collector auger

Traction

Above working

temperature

range

Drilling Manual metal

arc welding

Manual Water pump Keep dry Weight Do not dispose

in the garbage

CE logo

Page 9

Engine:

Manufacturer—Mitsubishi.

Horsepower—22 (16 Kw) @ 3000 RPM.

Torque—40 ft-lb (54.2 Nm) @ 2400 RPM.

Displacement—58.1 cu in. (952 cc).

Crankcase Capacity—3.8 qt. (3.6 L).

Governor—Mechanical.

Governor Limit—3100–3250 RPM.

Idle Speed—1700 RPM.

Air Cleaner: Donaldson heavy duty with precleaner. Remote mounted.

Fuel Tank Capacity: 8.5 gal. (32 l).

Fuel Filter/Water Separator: 3-micron spin–on

type element. Replaceable (Toro Part No. 63-8300).

Fuel Pump: 12-volt electric (transistor type)

w/replaceable fuel filter (Toro Part No. 43-2550).

Cooling System:

Radiator—6 qt (5.7 l) capacity.

Expansion Tank—Remote mounted; 1 qt (0.946 l)

capacity. System contains a 50/50 mix of ethylene

glycol anti-freeze and water.

Electrical: Battery—12 volt, BCI group size 26, 530

Amp at 0° F. 35-amp alternator with regulator/rectifier.

Drive Coupling: Transmission driven by steel shaft

with flexible rubber couplings at each end.

Transmission:

Manufacturer & Type—Sundstrand hydrostatic, Type

U15.Normal Charge Pressure – 70–150 psi

(483–1034 kPa).

Implement Relief Setting – 700–800 psi

(4 826 – 5 516 kPa).

Hydraulic Filter: 25-micron mounted directly to

transmission. Replaceable (Toro Part No. 23-2300).

Drive Axle: Manufacturer – Dana Corp., Model

GT–20. Axle serves as a hydraulic fluid reservoir

and mates directly with the transmission.

Approximately 5 qt (4.7 l) capacity. 4-Wheel Drive

has mechanical rear axle coupled to front axle by a

drive shaft and clutch.

Brakes: Mechanical drum type, 7 in. (17.8 cm) dia.

x 1-3/4 in. (45 mm) wide. Individually controlled by

two pedals connected by cable and conduit for steering assist. Pedals may be latched together for two

wheel braking. Lever provided for the parking

brake.

Tires, Wheels, Pressure:

Front Tires—23 x 8.50 - 12

Rear Tires—16 x 6.50 - 8

All tires 4 ply rating, tubeless type.

Pressure—20 psi (138 kPa).

Steering: 13 in. (33 cm) steering wheel. TRW power

steering valve.

Main Frame: Frame is welded, formed steel.

Instrumentation: Fuel gauge, water temperature

gauge, hour meter and warning lights for high temperature shutdown, oil pressure, amperage and glow

plug are mounted on the console.

Controls: Throttle, PTO switch, parking brake,

implement lift, ignition switch and glow plug switch

are all hand-operated. Forward/reverse traction pedal

and turning brakes are foot operated.

PTO Drive: PTO shaft is clutched by a torqueteamed HA Section, spring tensioned V-belt directly

from the engine output shaft. PTO shaft engaged by

electric clutch/brake assembly. PTO speed – 2200

RPM @ 3250 RPM engine speed.

Implement Connection—Universal joint and telescoping shaft assembly.

Lift Cylinders: Two, with 2 in. (51 mm) bore, 3.5

in. (89 mm) stroke.

Interlock Switches: Prevents engine starting if traction pedal or PTO switch are engaged. Stops the

engine if operator leaves seat with either traction

pedal or PTO switch engaged.

Dimensions and Weight:

Length: 208 cm (82 in.)

Width (2-Wheel drive): 111 cm (44 in.)

(4-Wheel drive): 119 cm (47 in)

Height: 127 cm (50 in.)

Weight: 418 kg (1120 lb)

9

Specifications

Page 10

CHECK THE ENGINE OIL

The engine is shipped with 3.8 qt (3.6 l) of oil in the

crankcase; however, check the oil level before and

after you first start the engine.

1. Position the machine on a level surface.

2. Open the hood.

3. Remove the dipstick and wipe it with a clean

rag. Insert the dipstick into the tube and make

sure it is seated fully. Remove the dipstick and

check the level of oil (Fig. 1). If the oil level is

low, add enough oil to raise the level to the

FULL mark on the dipstick. Do not overfill

(Fig. 2).

Figure 1

1. Engine oil dipstick

2. Engine oil filter

3. Oil drain plug

Note: If the level of oil is at the ADD mark on

the dipstick, add 1 pint (0.47 l) of oil and

recheck the level. Do not overfill.

4. The engine uses any high-quality 10W30 deter-

gent oil having the American Petroleum

Institute – API–”service classification” CD.

IMPORTANT: Check the level of oil every 5

operating hours or daily. Change oil after

every 50 hours of operation.

Figure 2

1. Engine oil fill

5. Insert the dipstick into the tube.

CHECK COOLING SYSTEM

Clean debris off screen and front of radiator daily

(Fig. 3), hourly if conditions are extremely dusty and

dirty.

Figure 3

1. Radiator

2. Radiator screen

3. Screen channel

The cooling system is filled with a 50/50 solution of

water and permanent ethylene glycol anti-freeze.

Check the level of coolant at the beginning of each

day (Fig. 4) before starting the engine. Capacity of

the cooling system is 6 quarts (5.7 l).

1. Carefully remove the radiator cap and the

10

Before Operating

Page 11

expansion tank cap.

Figure 4

1. Radiator cap

2. Expansion tank cap

3. Expansion tank fill marks

2. Check the level of coolant in the radiator. The

radiator should be filled to the top of the filler

neck and the expansion tank filled to between

the marks on its side.

3. If the coolant level is low, replenish the system.

DO NOT OVERFILL.

4. Install the radiator and expansion tank caps.

CHECK HYDRAULIC SYSTEM

FLUID

The hydraulic system was designed to operate on

any high quality detergent oil having the American

Petroleum Institute–API–“service classification” SF,

CC or CD. Oil viscosity—weight—must be selected

according to anticipated ambient temperature.

Temperature/viscosity recommendations are:

Expected Ambient Recommended Viscosity

Temperature and type

Over 32°C SAE 30, Type SF, CC or

CD

4–38° C SAE 10W-30 or 10W40

Type SF, CC or CD

–1–10° C SAE 5W30, Type SF, CC

or CD

Below –1° C Type “F” or “FA”

Automatic Transmission Fluid

Note: Do not mix engine oil and automatic transmis-

sion fluid or hydraulic component damage may

result. When changing fluids, also change transmission filter. DO NOT USE DEXRON II ATF.

The axle housing acts as the reservoir for the system.

The transmission and axle housing are shipped from

the factory with approximately 5 quarts (4.7 l) of

SAE 10W–30 engine oil. However, check the level

of transmission oil before the engine is first started

and daily thereafter.

1. Position the machine on a level surface. Place

all controls in their neutral position and start the

engine. Run the engine at lowest possible RPM

to purge the system of air. DO NOT ENGAGE

THE PTO. Turn the steering wheel several

times fully to the left and right. Raise the cutting unit to extend the lift cylinders, aiming

steering wheels straight forward and stop the

engine.

2. Remove the dipstick cap (Fig. 5) from filler

neck and wipe it with a clean cloth. Screw the

dipstick cap finger-tight onto filler neck; then

remove it and check the level of fluid. If the

level is not within 1/2 inch (13 mm) from the

groove in the dipstick (Fig. 5), add SAE

10W–30 engine oil, or, if used, automatic transmission fluid to raise the level to groove mark.

Do not overfill.

IMPORTANT: When adding transmission

fluid to the hydraulic system, use a funnel

with a fine wire screen—200 mesh or finer—

and make sure funnel and transmission fluid

are immaculately clean. This procedure prevents accidental contamination of the

hydraulic system.

11

Before Operating

If the engine has been running, pressurized hot

coolant can escape and cause burns when the

radiator cap is removed.

CAUTION

Page 12

Figure 5

1. Hydraulic system reservoir fluid/add dipstick cap

3. Thread the dipstick fill cap finger-tight onto

filler neck. It is not necessary to tighten cap

with a wrench.

4. Check all hoses and fittings for leaks.

FILL THE FUEL TANK

The engine runs on No. 2-D or 1-D automotive type

diesel fuel with a minimum cetane rating of 40.

Note; Higher cetane rated fuel may be required if

the machine is to be used at high altitude and lowatmospheric temperatures.

Use No. 2-D diesel fuel at temperatures above 20° F

(–7° C). and No. 1-D diesel fuel below 20° F (–7°

C). Use of No. 1-D diesel fuel at lower temperatures

provides lower flash point and pour point characteristics, therefore easing startability and lessening

chances of chemical separation of the fuel due to low

temperatures (wax appearance, which may plug filters).

Use of No. 2-D diesel fuel above 20° F (–7° C) will

contribute toward longer life of the pump components. Do not use furnace oil.

Store fuel outside of buildings in a convenient location. Tipping the front of the tank up slightly will

allow contaminants to collect at the lower end away

from the outlet. Never empty the tank below 4 in.

(10 cm) from the bottom of the tank to avoid picking

up water and other contaminants that may have collected at the bottom. Either filter the remainder at

the bottom through a chamois or dispose of it periodically to prevent excessive build-up of contaminants.

Keep all fuel containers free of dirt, water, scale and

other contaminants. Many engine difficulties can be

traced to contaminants in the fuel.

Use only metal containers for fuel storage. DO NOT

store the fuel in a galvanized metal container. A

chemical reaction will result, which will plug the filters and cause possible fuel system damage.

If possible, fill the fuel tank at the end of each day.

This will prevent possible buildup of condensation

inside the fuel tank, preventing possible engine damage. Allow the engine to thoroughly cool down

before refueling.

1. Using a clean cloth, clean the area around the

fuel tank cap.

2. Remove cap from the fuel tank (Fig. 6) and fill

the 8 gallon (34 l) tank to within 1 inch (25

mm) from the top with diesel fuel. Install fuel

tank cap tightly after filling tank.

Before Operating

12

Because diesel fuel is flammable, use caution

when storing or handling it. Do not fill the fuel

tank while the engine is running, hot or when

the machine is in an enclosed area. Vapors may

build up and be ignited by a spark or flame

source many feet away. DO NOT SMOKE

while filling the fuel tank to prevent the possibility of an explosion. Always fill the fuel tank

outdoors and wipe up any spilled diesel fuel

before starting the engine. Use a funnel or

spout to prevent spilling diesel fuel and fill the

tank to about 25 mm below the filler neck.

Store diesel fuel in a clean, safety-approved

container and keep the cap in place on the container. Keep diesel in a cool, well-ventilated

place; never in an enclosed area such as a hot

storage shed. To assure volatility and to prevent

contamination, do not buy more than a 6-month

supply.

DANGER

Page 13

Figure 6

1. Fuel tank cap

Four-Wheel Drive Models Only:

Check Rear Axle Lubricant

The rear axle has three separate reservoirs which use

SAE 80W-90 gear lub. Although the axle is shipped

with lubricant from the factory, check the level

before operating the machine.

1. Position the machine on a level surface.

2. Remove a check plug from each end of the axle

and make sure lubricant is up to the bottom of

the hole. If the level is low, remove one of the

mounting bolts above each end plug and add

enough lubricant to bring the level up to the

bottom of the hole (Fig. 7).

3. Remove the plug in the center of the axle and

check the level. If the level is low, add enough

lubricant to bring the level up to the bottom of

the hole.

4. To make sure that the cavities at each end of the

axle tube are filled, jack up each side of the axle

6 inches. Then with the axle level, check the

level at the center plug hole.

Figure 7

1. Check plugs (2)

2. Mounting bolts

13

Before Operating

Page 14

Service Brakes (Fig. 8 )—The left and right brake

pedals are connected to the left and right front

wheels. Since both brakes work independently of

each other, the brakes can be used to turn sharply or

to increase traction if one wheel tends to slip while

operating on certain slope conditions. However, wet

grass or soft turf could be damaged when the brakes

are used to turn sharply. To make a “quick-stop”,

depress both brake pedals together. Always lock the

brakes together when transporting the traction unit.

Figure 8

1. Parking brake knob

2. Right brake pedal

3. Left brake pedal

Parking Brake—Whenever the engine is shut off,

the parking brake must be engaged to prevent accidental movement. To engage the parking brake, push

lock arm (Fig. 9) on left brake pedal so that it locks

together with the right pedal. Next, push down fully

on both pedals and pull the parking brake knob out

(Fig. 8) then release the pedals. To release the parking brake, depress both pedals until the parking

brake knob retracts. Before starting the engine, however, the lock arm may be disengaged from the left

brake pedal so both pedals work independently with

each front wheel.

Amp Light (Fig. 10)—The amp light should be off

when the engine is running. If it is on, the charging

system should be checked and repaired if necessary.

Hour Meter (Fig. 10)—Accumulated engine operating time registers on the hour meter.

Figure 9

1. Left brake pedal

2. Right brake pedal

3. Lock arm

Temperature Gauge and High Temperature Light

(Fig. 10)—The coolant temperature gauge registers

the coolant temperature in the system. If the temperature gets too high, the engine will automatically

shut off and the High Temperature shutoff light will

light. When this happens, turn the ignition key off,

check the radiator for debris, check the fan belt and

check the expansion tank for proper coolant level.

The high temperature shutoff will automatically reset

when the coolant temperature has reached a safe

level.

Figure 10

1. Left brake pedal

2. Right brake pedal

3. Lock arm

4. High temperature shutoff light

5. Ignition key switch

6. Oil pressure light

7 PTO switch

8. Glow plug indicator

9. Glow plug switch

10. Throttle

11. Hydraulic lift lever

12. Fuel gauge

Low Oil Pressure Light (Fig. 10)—If engine oil

14

Controls

Page 15

pressure falls below a safe level, the light glows.

Stop the engine and repair before resuming operation.

PTO Switch (Fig. 10)—Pull up on the sleeve on the

toggle switch handle and move the handle to ON to

ENGAGE electric PTO clutch. Pull up on the sleeve

and move the handle to OFF to DISENGAGE electric PTO clutch. The only time the PTO switch

should be in the ENGAGE position is when the

implement is down in operating position and ready

to begin operation.

Ignition Key Switch (Fig. 10)—The ignition

switch, which is used to start and stop the engine,

has three positions: OFF, RUN and START. Turn the

key clockwise—START position—to engage the

starter motor. Release the key when the engine starts.

The key will move automatically to the ON position.

To shut the engine off, turn the key counterclockwise

to the OFF position.

Glow Plug Switch and Indicator (Fig. 10)—Use to

preheat the engine cylinders prior to cold engine

starting procedures—cylinders are preheated automatically during warm engine start operation. For

cold starting, push the switch lever upward and hold

while viewing the indicator. The indicator will glow

orange when the glow plugs are activated. Length of

time necessary to preheat cylinders should be determined by atmospheric temperature.

Throttle (Fig. 10)—The throttle is used to operate

the engine at various speeds. Moving the throttle

forward increases engine speed—FAST; rearward

decreases engine speed—SLOW. The throttle controls the speed of the cutter blades and, together with

traction pedal, controls the ground speed of the traction unit.

Hydraulic Lift Lever (Fig. 10)—The hydraulic lift

lever has three positions: FLOAT, TRANSPORT and

RAISE. To lower the cutting unit to the ground,

move the lift lever forward into the notch FLOAT.

The FLOAT position is used for mowing and when

the machine is not in operation. To raise the cutting

unit, pull the lift lever rearward to the RAISE position. After the cutting unit is raised, allow the lift

lever to move to the TRANSPORT position. The

cutting unit must be raised when driving from one

work area to another.

Traction Pedal (Fig. 11 )—The traction pedal has

two functions: one is to make the machine move forward, the other is to make it move rearward. Using

the heel and toe of the right foot, depress the top of

the pedal to move forward and the bottom of the

pedal to move rearward. Ground speed is proportionate to how far pedal is depressed. For maximum

ground speed, the traction pedal must be fully

depressed while the throttle is in the FAST position.

Maximum speed forward is 10 mph (16 Km/hour).

To get maximum power under heavy load or when

ascending a hill, have the throttle in the FAST position while depressing the traction pedal slightly to

keep engine rpm high. When engine rpm begins to

decrease, release the traction pedal slightly to allow

rpm to increase.

Figure 11

1. Traction pedal

Seat Adjusting Handle—To adjust the seat, loosen

the adjusting knobs and slide the seat to the desired

position. Tighten the knobs to lock the seat in place.

Seat Adjusting Handle—Deluxe Seat—To adjust

the seat, move the lever on left side outward, slide

the seat to the desired position and release the lever

so it will lock in track.

15

Controls

Never raise the cutting unit while blades are

rotating because it is hazardous.

CAUTION

Page 16

STARTING/STOPPING THE

ENGINE

IMPORTANT: The fuel system must be bled if

any of the following situations have occurred.

A. Initial start up of a new machine.

B. The engine has ceased running due to lack of

fuel.

C. Maintenance has been performed upon fuel sys-

tem components; i.e., filter replaced, separator

serviced, etc.

Refer to Bleeding The Fuel System.

1. Ensure the parking brake is set, the PTO switch

is in OFF and the lift lever is in the TRANSPORT or FLOAT position (Fig. 9). Remove

your foot from the traction pedal and make sure

it is in neutral.

2. Move the throttle control (Fig. 9) to the full

FAST position.

3. When temperature is below 15°C (60° F), push

glow plug switch to ON (Fig. 9) and hold for

the suggested interval.

Note: Do not exceed 1 minute of continuous

use or glow plug may burn out prematurely.

Note: Refer to chart indicating approximate

preheat time suggested in various temperature

ranges.

Temperature Preheat time (sec)

Above 5° C 10

+5° C to –5° C 20

Below –5° C 30

4. Turn the key in ignition switch to START posi-

tion (Fig. ). Release the key immediately when

the engine starts and allow it to return to RUN

position. Move the throttle control to the SLOW

position.

Note: Do not run the starter motor more than

20 seconds at a time or premature starter failure

may result. If the engine fails to start after 20

seconds, turn the key to OFF, recheck the controls and procedures, wait 10 additional seconds

and repeat the starter operation.

5. When the engine is started for the first time, or

after the engine oil change or overhaul of the

engine, transmission or axle, operate the

machine in forward and reverse for one to two

minutes. Also operate the lift lever and PTO

lever to assure proper operation of all parts.

Turn the power steering wheel to the left and

right to check steering response. Then shut the

engine off and check fluid levels, check for oil

leaks, loose parts and any other noticeable malfunctions.

6. To stop the engine, move the throttle control

backward to SLOW, move the PTO switch to

OFF and turn the ignition key to OFF. Remove

the key from the switch to prevent accidental

starting.

BLEEDING THE FUEL SYSTEM

1. Raise the hood over the engine.

2. Loosen the air bleed screw on top of the fuel fil-

ter/water separator (Fig. 12).

3. Turn the ignition key switch to RUN. The elec-

tric fuel pump will begin operation, thereby

forcing air out around air bleed screw. Leave the

key in the RUN position until a solid stream of

fuel flows out around screw. Tighten the screw

and turn the key to OFF.

16

Operation

Shut the engine off and wait for all moving

parts to stop before checking for oil leaks,

loose parts or other malfunctions.

CAUTION

Page 17

Figure 12

1. Fuel filter

2. Air bleeder screw

4. Open the air bleed screw on the fuel injection

pump (Fig. 13) with a 10 mm wrench.

Figure 13

1. Fuel injection pump bleeder

5. Turn the key to the RUN position. The electric

fuel pump will begin operation, thereby forcing

air out around air bleed screw on fuel injection

pump. Leave the key in the RUN position until

solid stream of fuel flows out around the screw.

Tighten the screw and turn the key to OFF.

CHECKING THE INTERLOCK

SAFETY SYSTEM

The purpose of the safety interlock system is to prevent the engine from cranking or starting unless the

traction pedal is in neutral and the PTO switch is in

the OFF position. Also, the engine will stop when

the PTO control is engaged or the traction pedal is

depressed with the operator off the seat.

1. Move the PTO switch to OFF and remove your

foot from the traction pedal so it is fully

released.

2. Turn the key to START. The engine should

crank. If the engine cranks, go to step 3. If the

engine does not crank, there may be a malfunction in the interlock system.

3. Rise from the seat and engage the PTO switch

while the engine is running. The engine should

stop within 2 seconds. If the engine stops, the

switch is operating correctly; thus, go to step 4.

If the engine does not stop, there is a malfunction in the interlock system.

4. Rise from the seat and depress the traction

pedal while the engine is running and the PTO

lever is disengaged. The engine should stop

within 2 seconds. If the engine stops, the switch

is operating correctly; thus, continue operation.

If the engine does not stop, there is a malfunction in the interlock system.

OPERATING

CHARACTERISTICS

Practice driving the GROUNDSMASTER®223-D

before initial operation because it has a hydrostatic

transmission and its characteristics are different than

some turf maintenance machines. Some points to

consider when operating the traction unit and cutting

unit are the transmission, engine speed, load on the

cutting blades, and the importance of the brakes.

To maintain enough power for the traction unit and

cutting unit while mowing, regulate traction pedal to

keep engine rpm high and somewhat constant. A

good rule to follow is: decrease ground speed as the

load on the cutting blades increases; and increase

17

Operation

Do not disconnect the safety switches because

they are for the operator’s protection. Check

operation of the switches daily to be sure the

interlock system is operating correctly. If a

switch is malfunctioning, replace it before operating the machine. Replace the switches every

two years to be sure of maximum safety.

CAUTION

Page 18

ground speed as the load on the blades decreases.

This allows the engine, working with the transmission, to sense the proper ground speed while maintaining the high blade tip speed necessary for good

quality of cut. Therefore, let the traction pedal to

move upward as engine speed decreases, and depress

the pedal slowly as speed increases. By comparison,

when driving from one work area to another—with

no load and cutting unit raised—have the throttle in

the FAST position and depress the traction pedal

slowly but fully to attain maximum ground speed.

CAUTION: This product may exceed noise levels of

85 dB(A) at the operator position. Ear protectors are

recommended for prolonged exposure to reduce the

potential of permanent hearing damage.

Another characteristic to consider is the operation of

the brakes. The brakes can be used to assist in turning the machine; however, use them carefully, especially on soft or wet grass because the turf may be

torn accidentally. The brakes can be used to great

advantage to control the direction of the cutting unit

when trimming along fences or similar objects.

Another benefit of the brakes is to maintain traction.

For example; in some slope conditions, the uphill

wheel slips and loses traction. If this situation

occurs, depress the uphill brake pedal gradually and

intermittently until the uphill wheel stops slipping,

thereby increasing traction on the downhill wheel. If

independent braking is not desired, engage the lever

on the left brake pedal with right pedal. This provides simultaneous braking at both wheels.

Before stopping the engine, disengage all controls

and move the throttle to SLOW. Moving the throttle

to SLOW reduces high engine speed, noise and

vibration. Turn the ignition key to OFF to stop the

engine.

PUSHING OR TOWING THE

TRACTION UNIT

In an emergency, the traction unit can be pushed or

towed for a very short distance. However, Toro does

not recommend this as standard procedure.

IMPORTANT: Do not push or tow the traction

unit faster than 2 to 3 mph (3.2 to 4.8 Km/hour)

because transmission may be damaged. If the

traction unit must be moved a considerable distance, transport it on a truck or trailer. Whenever

the traction unit is pushed or towed, the by-pass

valve must be open.

1. Remove the hair pin and pivot the seat platform

forward and locate seat support rod in the detent

notch.

2. Depress and hold the pins located in the center

of the two (2) check valve assemblies in the top

of the transmission (Fig. 14) while pushing or

towing the machine.

Figure 14

1. Transmission check valve bypass pins (2)

3. Start the engine momentarily after repairs are

completed and make sure the pins are in the

fully disengaged (fully up) position.

IMPORTANT: Running the machine with by-pass

valve open will cause the transmission to overheat.

Operation

18

Adequate rear weight is necessary to prevent the

rear wheels from leaving the ground. Do not

stop suddenly while cutting unit or implement is

raised. Do not travel down hill with the cutting

unit or implement raised. If the rear wheels

leave the ground, steering is lost.

CAUTION

Page 19

LUBRICATION

GREASING BEARINGS AND BUSHINGS

The traction unit has grease fittings that must be

lubricated regularly with No. 2 General Purpose

Lithium Base Grease. If the machine is operated

under normal conditions, lubricate all bearings and

bushings after every 50 hours of operation or immediately after every washing. Bearings and bushings

must be lubricated daily when operating conditions

are extremely dusty and dirty. Dusty and dirty operating conditions could cause dirt to get into the bearings and bushings, resulting in accelerated wear.

Apply a liberal coating of grease to the check valve

pins once each year (Fig. 14). The traction unit has

bearings and bushings that must be lubricated, and

these lubrication points are shown in the following

figures.

1. Wipe grease fitting clean so foreign matter can-

not be forced into the bearing or bushing.

2. Pump grease into the bearing or bushing.

3. Wipe up excess grease.

Figure 15

Figure 16

Figure 17

Figure 18 (Four-Wheel Drive)

19

Maintenance

Page 20

Figure 19

Figure 20 (2-Wheel Drive only)

Figure 21

Figure 22 (2-Wheel Drive only)

Maintenance

20

Page 21

21

Maintenance

Quick Reference

1. Oil levels

2. Coolant level

3. Tire Pressure

4. Belts

5. Fuel—Diesel Only

6. Battery

7. Grease, Lube points

8. Radiator screen

9. Air cleaner

10. Electric clutch gap

11. PTO belt tension

12. Water separator

FiltersPart No.

Air 277110

Fuel pump 43-2550

Fuel line 63-8300

Transmission oil 23-2300

Engine oil 67-4330

Change Intervals

Fluids >0° C <0° C Capacity Fluid Filter

Engine oil SAE 30 CD SAE 10W-30 CD 3.6 l 50 hours 100 hours

Fuel No. 2-D No. 1-D 34 l -------- 400 hours

Coolant 50/50 mix Ethylene glycol antifreeze 6 l 2 years

Page 22

Traction Unit

1. Thoroughly clean the traction unit, cutting unit

and the engine, paying special attention to these

areas:

- radiator and radiator screen

- underneath the cutting unit

- under the cutting unit belt covers

- counterbalance springs

- P.T.O. Shaft Assembly

- all grease fittings and pivot points

- remove control panel and clean out the inside

of the control box

- beneath seat plate and top of transmission

2. Check the tire pressure. Inflate all traction unit

tires to 20 psi.

3. Remove, sharpen and balance the cutting unit’s

blades. Reinstall the blades and torque the blade

fasteners to 85–110 ft-lb (115–149 Nm).

4. Check all fasteners for looseness; tighten as nec-

essary.

5. Grease or oil all grease fittings, pivot points, and

transmission by-pass valve pins. Wipe off any

excess lubricant.

6. Lightly sand and use touch up paint on painted

areas that are scratched, chipped or rusted.

Repair any dents in the metal body.

7. Service the battery and cables as follows:

a. Remove the battery terminals from the bat-

tery posts.

b. Clean the battery, terminals and posts with

a wire brush and baking soda solution.

c. Coat the cable terminals and battery posts

with Grafo 112X skin-over grease (Toro

Part Number 505-47), or petroleum jelly to

prevent corrosion.

d. Slowly recharge the battery for 24 hours

every 60 days to prevent lead sulfation of

the battery.

Engine

1. Drain the engine oil from the oil pan and replace

the drain plug.

2. Remove and discard the oil filter. Install a new

filter.

3. Refill the engine with 3.8 quarts (3.6 l) of rec-

ommended motor oil. Refer to Changing

Crankcase Oil.

4. Start the engine and run at idle speed for two

minutes.

5. Drain diesel fuel from the fuel tank, fuel lines,

pump, filter and separator. Flush fuel tank with

clean diesel fuel and connect all fuel lines.

6. Thoroughly clean and service the air cleaner

assembly.

7. Seal the air cleaner inlet and the exhaust outlet

with weather proof masking tape.

8. Check the oil filler cap and fuel tank cap to

ensure they are securely in place.

PRODUCT IDENTIFICATION

The traction unit has two identification numbers: a

model number and a serial number that are stamped

into a plate. The identification plate is located near

the left brake pedal on the frame (Fig. ). In any correspondence concerning the traction unit, supply the

model and serial numbers to ensure correct information and replacement parts are obtained.

To order replacement parts from an Authorized

TORO Distributor supply the following information:

1. Model and serial numbers of the traction unit.

2. Part number, description and quantity of parts

desired.

Note: Do not order by reference number if a parts

catalog is being used; use the part number.

22

Preparation for Seasonal Storage

Page 23

23

Maintenance

Figure 23

1. Model and serial ID plate

Page 24

Loading...

Loading...