Page 1

Mid–Size Mower

ProLine Gear 13hp with 32in or 36in

Side Discharge Mower

Model No. 30150—Serial No. 250000001 and Up

Model No. 30161—Serial No. 250000001 and Up

Form No. 3352-509

Operator’s Manual

Register your product at www.Toro.com

Original Instructions (EN)

Page 2

Warning

CALIFORNIA

Proposition 65 Warning

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

Important This engine is not equipped with a spark

arrester muffler. It is a violation of California Public

Resource Code Section 4442 to use or operate this engine

on any forest-covered, brush-covered, or grass-covered

land. Other states or federal areas may have similar laws.

This spark ignition system complies with Canadian

ICES-002.

Ce système d’allumage par étincelle de véhicule est

conforme à la norme NMB-002 du Canada.

The enclosed Engine Owner’s Manual is supplied for

information regarding The U.S. Environmental

Protection Agency (EPA) and the California Emission

Control Regulation of emission systems, maintenance,

and warranty.

Keep this engine Owner’s Manual with your mower.

Should this engine Owner’s Manual become damaged

or illegible, replace immediately. Replacements may be

ordered through the engine manufacturer.

Contents

Page

Introduction 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operating Practices 3. . . . . . . . . . . . . . . . . . . .

Toro Mower Safety 4. . . . . . . . . . . . . . . . . . . . . . . .

Slope Chart 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 9. . . . . . . . . . . . . . . . .

Gasoline and Oil 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Gasoline 12. . . . . . . . . . . . . . . . . . . . .

Using Fuel Stabilizer/Conditioner 12. . . . . . . . . . . . .

Filling the Fuel Tank 12. . . . . . . . . . . . . . . . . . . . . . .

Checking the Engine Oil Level 12. . . . . . . . . . . . . . .

Setup 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Front Casters 14. . . . . . . . . . . . . . . . . .

Installing the Upper Handle and Wire Harness 14. . .

Installing the Traction Control Rods 15. . . . . . . . . . .

Installing the Blade Control (PTO) Rod 15. . . . . . . .

Connecting the Throttle Cable 16. . . . . . . . . . . . . . . .

Connecting the Choke Cable 16. . . . . . . . . . . . . . . . .

Page

Installing the Shift Lever 16. . . . . . . . . . . . . . . . . . . .

Mounting the Fuel Tank 17. . . . . . . . . . . . . . . . . . . . .

Installing the Muffler 17. . . . . . . . . . . . . . . . . . . . . . .

Operation 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Think Safety First 18. . . . . . . . . . . . . . . . . . . . . . . . . .

Controls 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating the Parking Brake 19. . . . . . . . . . . . . . . . .

Starting the Engine 19. . . . . . . . . . . . . . . . . . . . . . . . .

Stopping the Engine 20. . . . . . . . . . . . . . . . . . . . . . . .

Operating the Blade Control (PTO) 20. . . . . . . . . . . .

Understanding the Safety Interlock System 20. . . . . .

Driving Forward or Backward 21. . . . . . . . . . . . . . . .

Operating the Lower Control Bar 21. . . . . . . . . . . . .

Stopping the Machine 22. . . . . . . . . . . . . . . . . . . . . .

Transporting the Mower 22. . . . . . . . . . . . . . . . . . . . .

Using the Side Discharge 22. . . . . . . . . . . . . . . . . . . .

Adjusting the Height-of-Cut 22. . . . . . . . . . . . . . . . .

Height-of-Cut Chart 24. . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Maintenance Schedule 25. . . . . . . . .

Servicing the Cutting Blades 26. . . . . . . . . . . . . . . . .

Servicing the Air Cleaner 27. . . . . . . . . . . . . . . . . . . .

Servicing the Engine Oil 28. . . . . . . . . . . . . . . . . . . .

Servicing the Spark Plugs 30. . . . . . . . . . . . . . . . . . .

Cleaning the Cooling System 30. . . . . . . . . . . . . . . . .

Checking the Tire Pressure 31. . . . . . . . . . . . . . . . . .

Greasing and Lubrication 31. . . . . . . . . . . . . . . . . . . .

Servicing the Brakes 32. . . . . . . . . . . . . . . . . . . . . . .

Servicing the Fuel Tank 33. . . . . . . . . . . . . . . . . . . . .

Servicing the Fuel Filter 33. . . . . . . . . . . . . . . . . . . . .

Checking the Belts 34. . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Wheel Belt 34. . . . . . . . . . . . . . . . . . . .

Replacing the Traction Belt 34. . . . . . . . . . . . . . . . . .

Replacing the Mower Belt 35. . . . . . . . . . . . . . . . . . .

Adjusting the Mower Belt Tension 36. . . . . . . . . . . .

Adjusting the Blade Brake 36. . . . . . . . . . . . . . . . . . .

Adjusting the Grass/Mud Scraper 37. . . . . . . . . . . . .

Replacing the Grass Deflector 37. . . . . . . . . . . . . . . .

Wiring Diagram 38. . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning and Storage 38. . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Toro Total Coverage Guarantee 44. . . . . . . . . . . . . .

2004 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Contact us at www.Toro.com

All Rights Reserved

2

Printed in the USA

Page 3

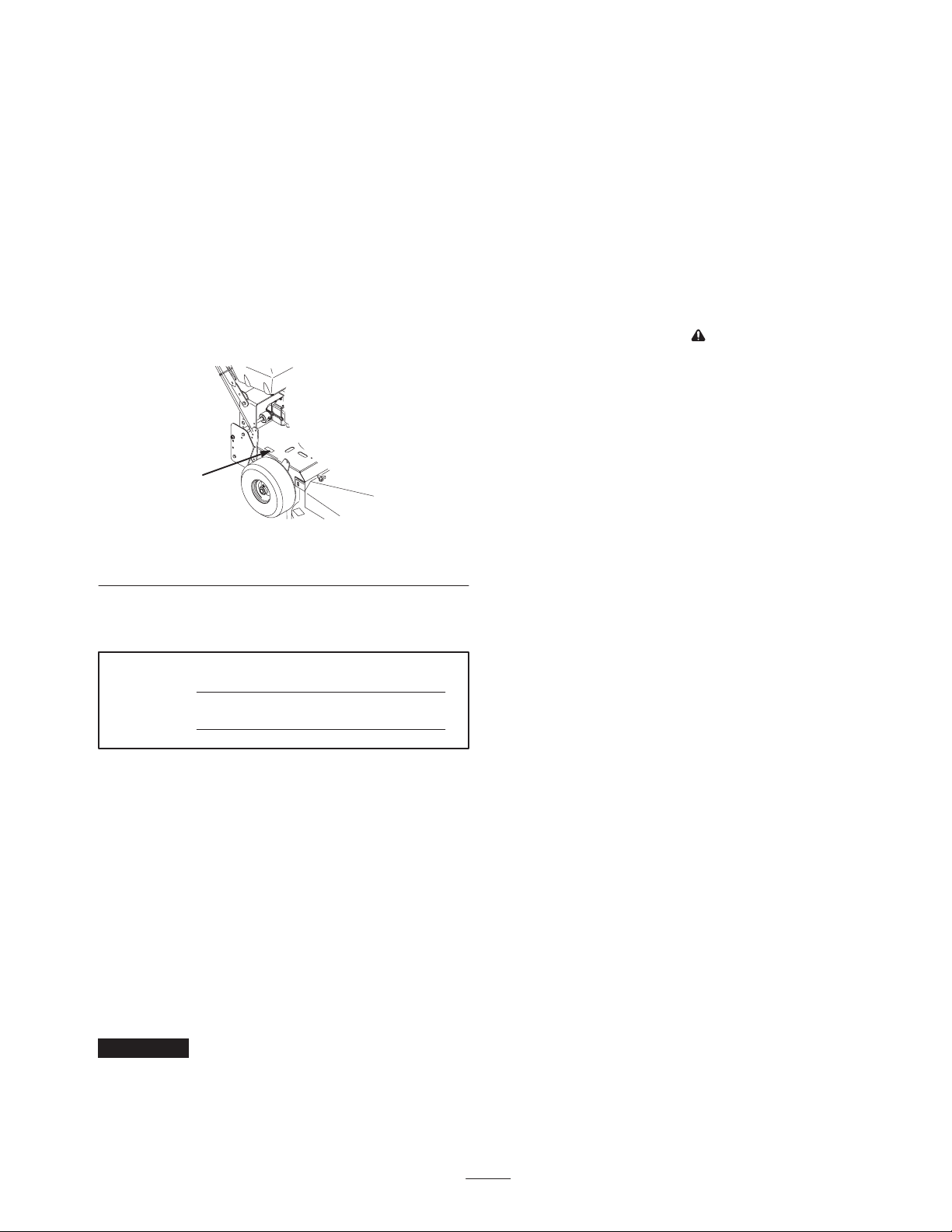

Introduction

Safety

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

serial numbers of your product ready. Figure 1 illustrates

the location of the model and serial numbers on the

product.

1

m-3775

Figure 1

1. Location of the model and serial numbers

Write the product model and serial numbers in the space

below:

Model No.

Serial No.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

This machine meets or exceeds the B71.4–1999

specifications of the American National Standards

Institute in effect at the time of production.

Note: The addition of attachments made by other

manufacturers that do not meet American National

Standards Institute certification will cause noncompliance

of this machine.

Improper use or maintenance by the operator or owner

can result in injury. To reduce the potential for injury,

comply with these safety instructions and always pay

attention to the safety alert

CAUTION, WARNING, or DANGER—“personal

safety instruction.” Failure to comply with the

instruction may result in personal injury or death.

symbol, which means

Safe Operating Practices

The following instructions are from ANSI standard

B71.4–1999.

Training

• Read the Operator’s Manual and other training material.

If the operator(s) or mechanic(s) can not read English it

is the owner’s responsibility to explain this material to

them.

• Become familiar with the safe operation of the

equipment, operator controls, and safety signs.

• All operators and mechanics should be trained. The

owner is responsible for training the users.

• Never let children or untrained people operate or

service the equipment. Local regulations may restrict

the age of the operator.

• The owner/user can prevent and is responsible for

accidents or injuries occurring to himself or herself,

other people or property.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

Caution signals a hazard that may cause minor or moderate

injury if you do not follow the recommended precautions.

This manual uses two other words to highlight information.

Important calls attention to special mechanical

information and Note: emphasizes general information

worthy of special attention.

Preparation

• Evaluate the terrain to determine what accessories and

attachments are needed to properly and safely perform

the job. Only use accessories and attachments approved

by the manufacturer.

• Wear appropriate clothing including hard hat, safety

glasses and ear protection. Long hair, loose clothing or

jewelry may get tangled in moving parts.

• Inspect the area where the equipment is to be used and

remove all objects such as rocks, toys and wire which

can be thrown by the machine.

3

Page 4

• Use extra care when handling gasoline and other fuels.

They are flammable and vapors are explosive.

• Use only an approved container.

• Never remove gas cap or add fuel with engine

running. Allow engine to cool before refueling.

Do not smoke.

• Never refuel or drain the machine indoors.

• Check that operator’s presence controls, safety switches

and shields are attached and functioning properly. Do

not operate unless they are functioning properly.

Operation

• Never run an engine in an enclosed area.

• Only operate in good light, keeping away from holes

and hidden hazards.

• Be sure all drives are in neutral and parking brake is

engaged before starting engine.

• Be sure of your footing while using pedestrian

controlled equipment, especially when backing up.

Walk, don’t run. Never operate on wet grass. Reduced

footing could cause slipping.

• Slow down and use extra care on hillsides. Be sure to

travel side-to-side on hillsides. Turf conditions can

affect the machine’s stability. Use caution while

operating near drop-offs.

• Slow down and use caution when making turns and

crossing roads and sidewalks. Stop blades if not

mowing.

• Be aware of the mower discharge direction and do not

point it at anyone.

• Do not operate the mower under the influence of

alcohol or drugs.

• Use care when loading or unloading the machine into or

from a trailer or truck.

• Use care when approaching blind corners, shrubs, trees,

or other objects that may obscure vision.

Maintenance and storage

• Disengage drives, set parking brake, stop engine and

disconnect spark plug wire. Wait for all movement to

stop before adjusting, cleaning or repairing.

• Clean grass and debris from cutting unit, drives,

mufflers, and engine to help prevent fires. Clean up oil

or fuel spillage.

• Let engine cool before storing and do not store near

flame.

• Shut off fuel while storing or transporting. Do not store

fuel near flames or drain indoors.

• Park machine on level ground. Set parking brake. Never

allow untrained personnel to service machine.

• Slow down and use caution when making turns and

when changing directions on slopes.

• Never raise deck with the blades running.

• Never operate with the PTO shield, or other guards not

securely in place. Be sure all interlocks are attached,

adjusted properly, and functioning properly.

• Never operate with the discharge deflector raised,

removed or altered, unless using a grass catcher.

• Do not change the engine governor setting or overspeed

the engine.

• Stop on level ground, disengage drives, engage parking

brake (if provided), shut off engine before leaving the

operator’s position for any reason including emptying

the catchers or unclogging the chute.

• Stop equipment and inspect blades after striking objects

or if an abnormal vibration occurs. Make necessary

repairs before resuming operations.

• Keep hands and feet away from the cutting unit.

• Look behind and down before backing up to be sure of

a clear path.

• Keep pets and bystanders away.

• Use jack stands to support components when required.

• Carefully release pressure from components with stored

energy.

• Remove spark plug wire before making any repairs.

• Use care when checking blades. Wrap the blades or

wear gloves, and use caution when servicing them.

Only replace blades. Never straighten or weld them.

• Keep hands and feet away from moving parts. If

possible, do not make adjustments with the engine

running.

• Keep all parts in good working condition and all

hardware tightened. Replace all worn or damaged

decals.

Toro Mower Safety

The following list contains safety information specific to

Toro products and other safety information you must know.

This product is capable of amputating hands and feet and

throwing objects. Always follow all safety instructions to

avoid serious injury or death.

4

Page 5

This product is designed for cutting and recycling grass or,

when equipped with a grass bagger, for catching cut grass.

Any use for purposes other than these could prove

dangerous to user and bystanders.

General Operation

• Be sure the area is clear of other people before mowing.

Stop the machine if anyone enters the area.

• Do not touch equipment or attachment parts which may

be hot from operation. Allow to cool before attempting

to maintain, adjust or service.

• Use only Toro-approved attachments. Warranty may be

voided if used with unapproved attachments.

• Check carefully for overhead clearances (i.e. branches,

doorways, electrical wires) before operating under any

objects and do not contact them.

Slope Operation

All slopes and ramps require extra caution. If you feel

uneasy on a slope, do not mow it.

• Remove obstacles such as rocks, tree limbs, etc. from

the mowing area.

• Watch for holes, ruts or bumps. Tall grass can hide

obstacles.

• Use caution near drop-offs, ditches, or embankments.

The machine could suddenly turn over if a wheel goes

over the edge of a cliff or ditch, or if an edge caves in.

• Use extra care with grass catchers or other attachments.

These can change the stability of the machine.

• Keep all movement on slopes slow and gradual. Do not

make sudden changes in speed or direction.

• Mow slopes side to side.

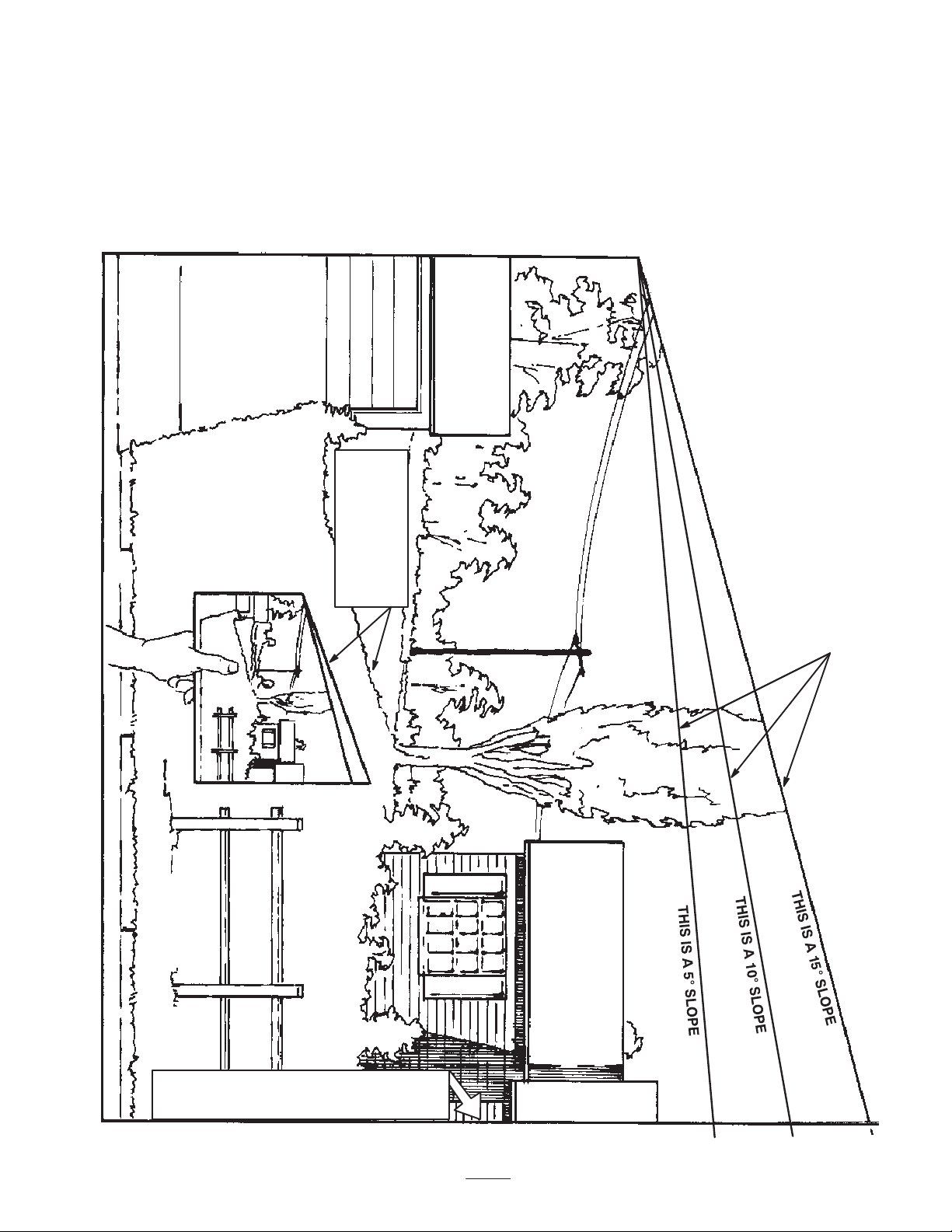

• Do not mow slopes greater than 15 degrees.

Service

• Never store the machine or fuel container inside where

there is an open flame, such as near a water heater or

furnace.

• Keep nuts and bolts tight, especially the blade

attachment bolts. Keep equipment in good condition.

• Never tamper with safety devices. Check safety systems

for proper operation before each use.

• Use only genuine replacement parts to ensure that

original standards are maintained.

• Check brake operation frequently. Adjust and service as

required.

5

Page 6

6

Page 7

Slope Chart

Example: Compare

slope with folded

edge.

Fold along appropriate line

Align this edge with a vertical surface

(Tree, Building, Fence post, pole, etc.)

7

Page 8

8

Page 9

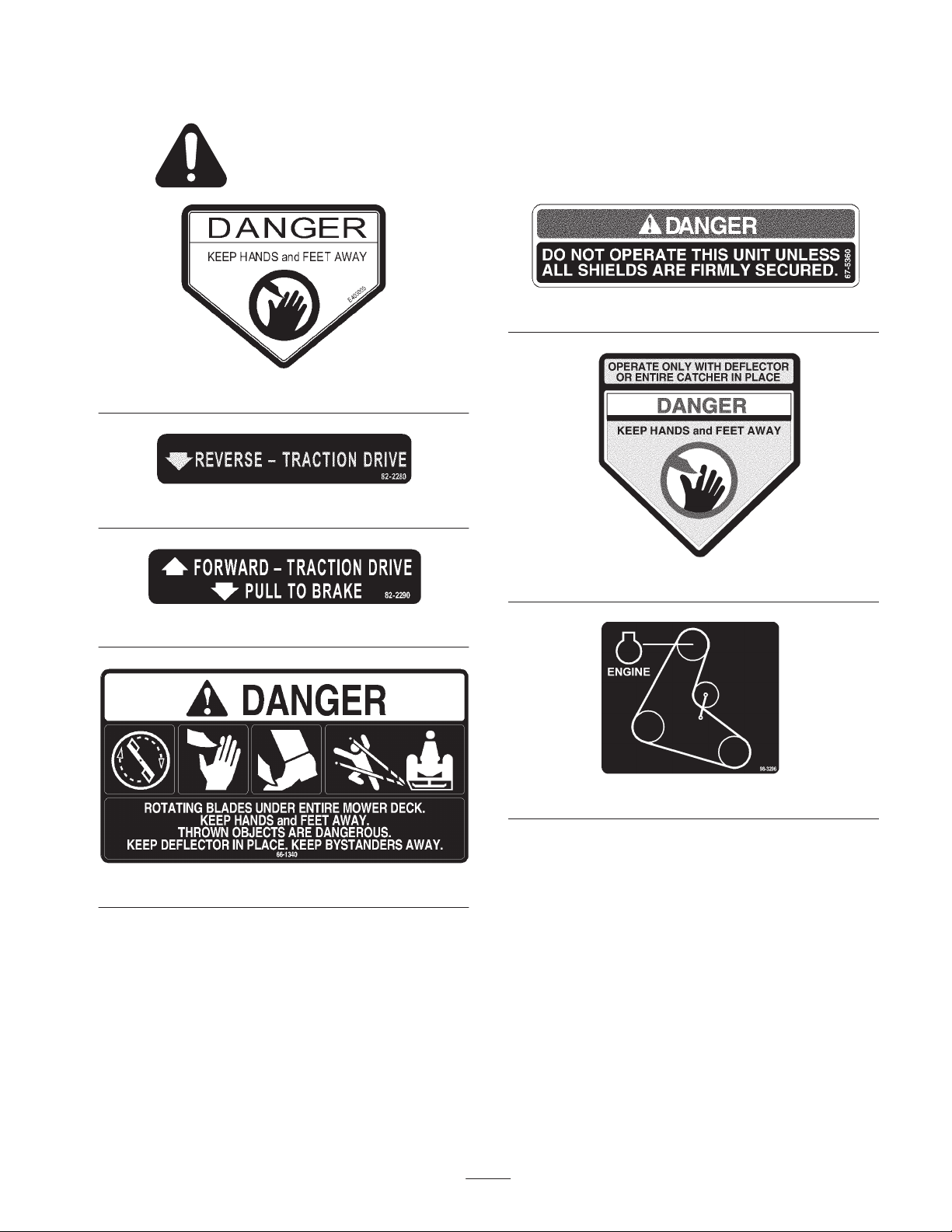

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any area

of potential danger. Replace any decal that is damaged or lost.

1-403005

82-2280

67-5360

82-2290

66-1340

54-9220

98-3296

9

Page 10

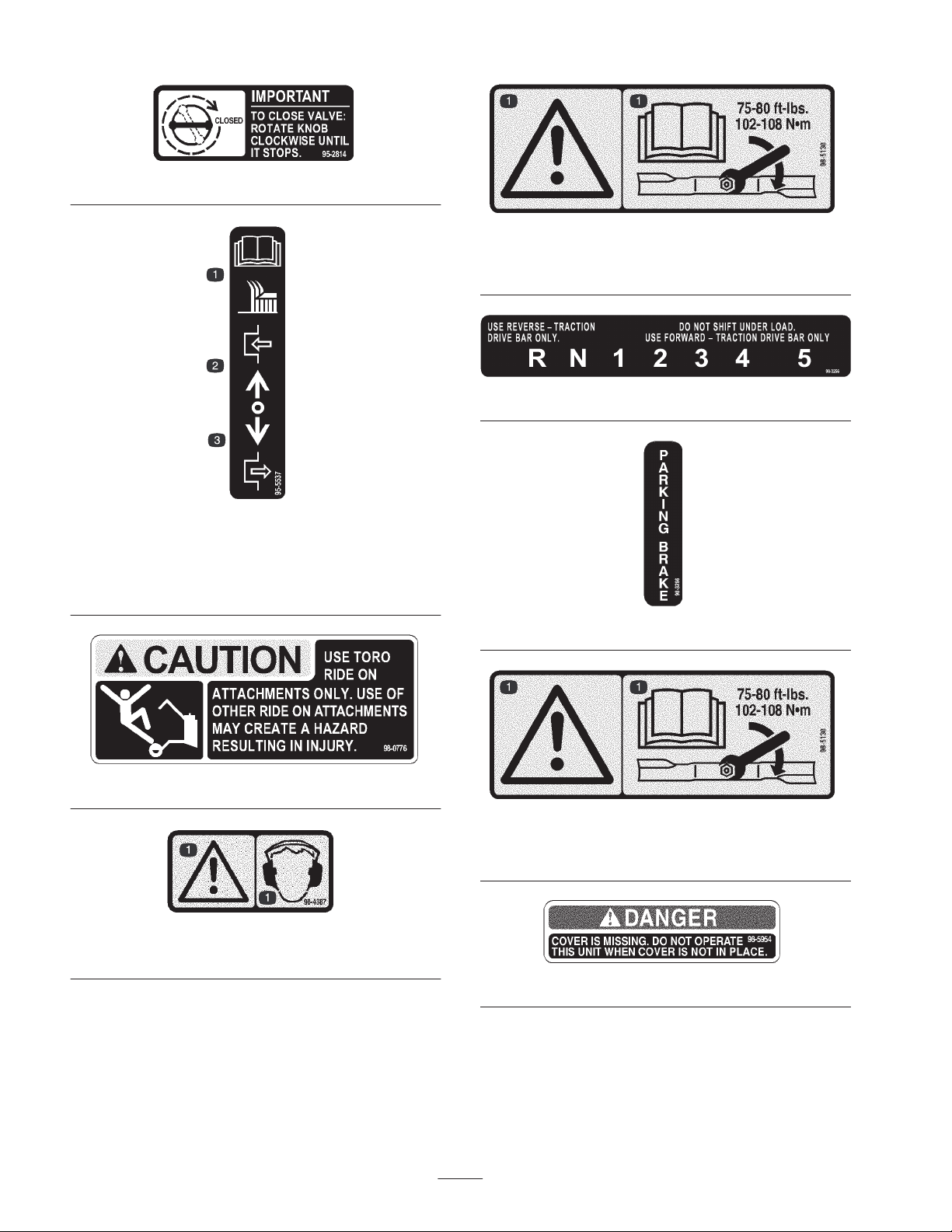

1. Read the

cutting blade

2. Push forward to engage

3. Pull back to disengage

Operator’s Manual

95-2814

95-5537

for instructions on operating the

98-5130

1. Warning—read the

torquing the blade bolt/nut to 75–80 ft.-lb.(102–106 N⋅m).

Operator’s Manual

for instructions on

98-3256

98-3266

98-0776

98-4387

1. Warning—wear hearing protection.

1. Warning—read the

torquing the blade bolt/nut to 75–80 ft.-lb.(102–106 N⋅m).

10

98-5130

Operator’s Manual

98-5954

for instructions on

Page 11

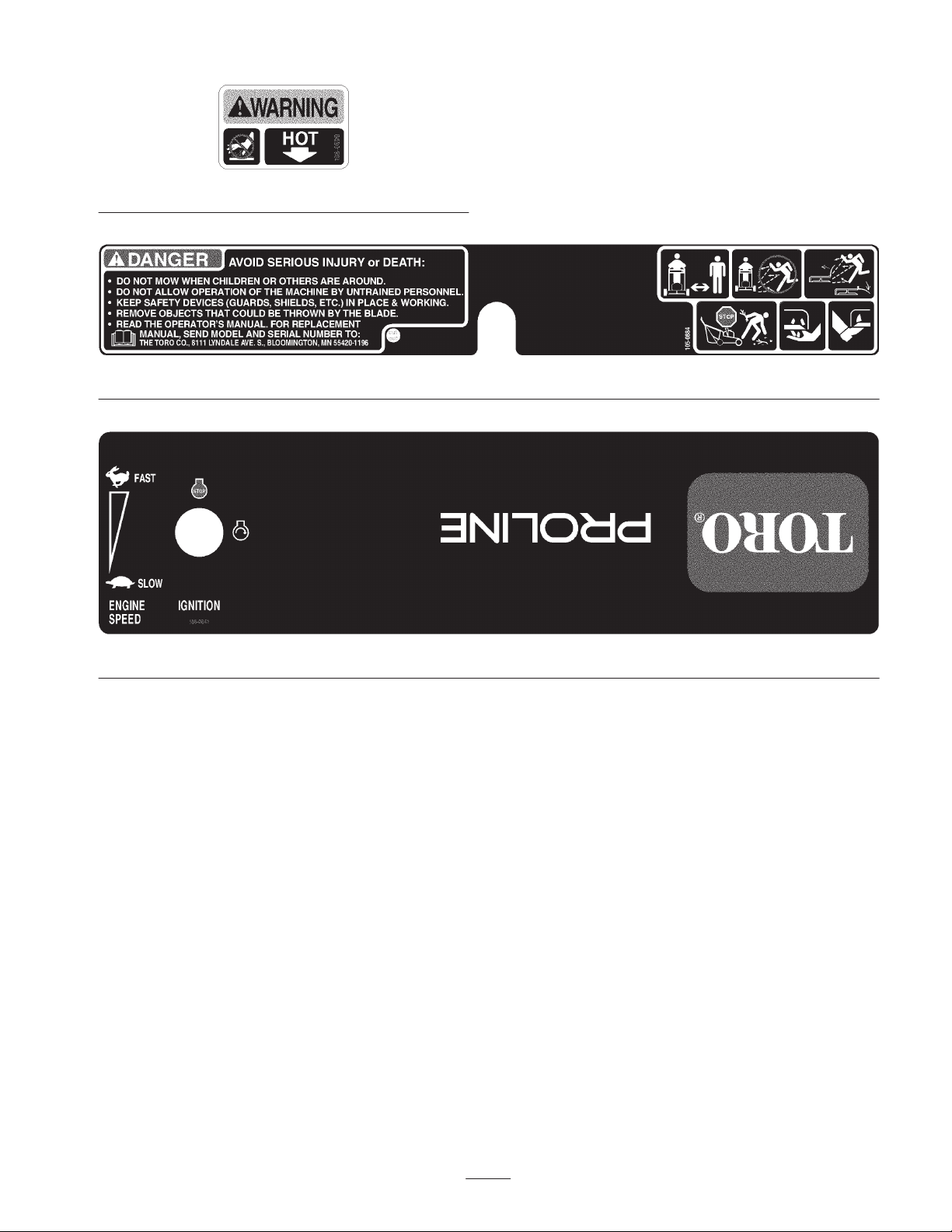

106-0699

105-0884

106-0841

11

Page 12

Gasoline and Oil

Warning

Recommended Gasoline

Use unleaded regular gasoline suitable for automotive use

(85 pump octane minimum). Use leaded regular gasoline if

unleaded regular is not available.

Important Never use methanol, gasoline containing

methanol, or gasohol containing more than 10% ethanol

because the fuel system could be damaged. Do not mix oil

with gasoline.

Danger

In certain conditions, gasoline is extremely

flammable and highly explosive. A fire or

explosion from gasoline can burn you and others

and can damage property.

• Fill the fuel tank outdoors, in an open area,

when the engine is cold. Wipe up any gasoline

that spills.

• Never fill the fuel tank inside an enclosed trailer.

• Do not fill the fuel tank completely full. Add

gasoline to the fuel tank until the level is 1/4 to

1/2 inch (6 to 13 mm) below the bottom of the

filler neck. This empty space in the tank allows

the gasoline to expand.

• Never smoke when handling gasoline, and stay

away from an open flame or where gasoline

fumes may be ignited by a spark.

• Store gasoline in an approved container and

keep it out of the reach of children. Never buy

more than a 30-day supply of gasoline.

• Always place gasoline containers on the ground

and away from your vehicle before filling.

• Do not fill gasoline containers inside a vehicle or

on a truck or trailer bed because interior

carpets or plastic truck bed liners may insulate

the container and slow the loss of any static

charge.

• When practical, remove gas-powered equipment

from the truck or trailer and refuel the

equipment with its wheels on the ground.

• If this is not possible, then refuel such

equipment on a truck or trailer from a portable

container, rather than from a gasoline dispenser

nozzle.

• If a gasoline dispenser nozzle must be used, keep

the nozzle in contact with the rim of the fuel

tank or container opening at all times until

fueling is complete.

Gasoline is harmful or fatal if swallowed.

Long-term exposure to vapors can cause serious

injury and illness.

• Avoid prolonged breathing of vapors.

• Keep face away from nozzle and fuel tank or

conditioner opening.

• Keep gasoline away from eyes and skin.

Using Fuel

Stabilizer/Conditioner

Use a fuel stabilizer/conditioner in the machine to provide

the following benefits:

• Keeps gasoline fresh during storage of 90 days or less

(For longer storage, drain the fuel tank.)

• Cleans the engine while it runs

• Eliminates gum-like varnish buildup in the fuel system,

which causes hard starting

Important Do not use fuel additives containing

methanol or ethanol.

Add the correct amount of fuel stabilizer/conditioner to the

gasoline.

Note: A fuel stabilizer/conditioner is most effective when

mixed with fresh gasoline. To minimize the chance of

varnish deposits in the fuel system, use fuel stabilizer at all

times.

Filling the Fuel Tank

1. Stop the engine, wait for all moving parts to stop, and

set the parking brakes.

2. Clean around the fuel tank cap and remove the cap. Add

unleaded regular gasoline to the fuel tank until the level

is 1/4 to 1/2 inch (6 mm to 13 mm) below the bottom of

the filler neck. This space in the tank allows the

gasoline to expand. Do not fill the fuel tank completely

full.

3. Install the fuel tank cap securely. Wipe up any spilled

gasoline.

Checking the Engine Oil Level

Before you start the engine and use the machine, check the

oil level in the engine crankcase; refer to Checking the

Engine Oil Level, page 28.

12

Page 13

Setup

Note: Determine the left and right sides of the machine from the normal operating position.

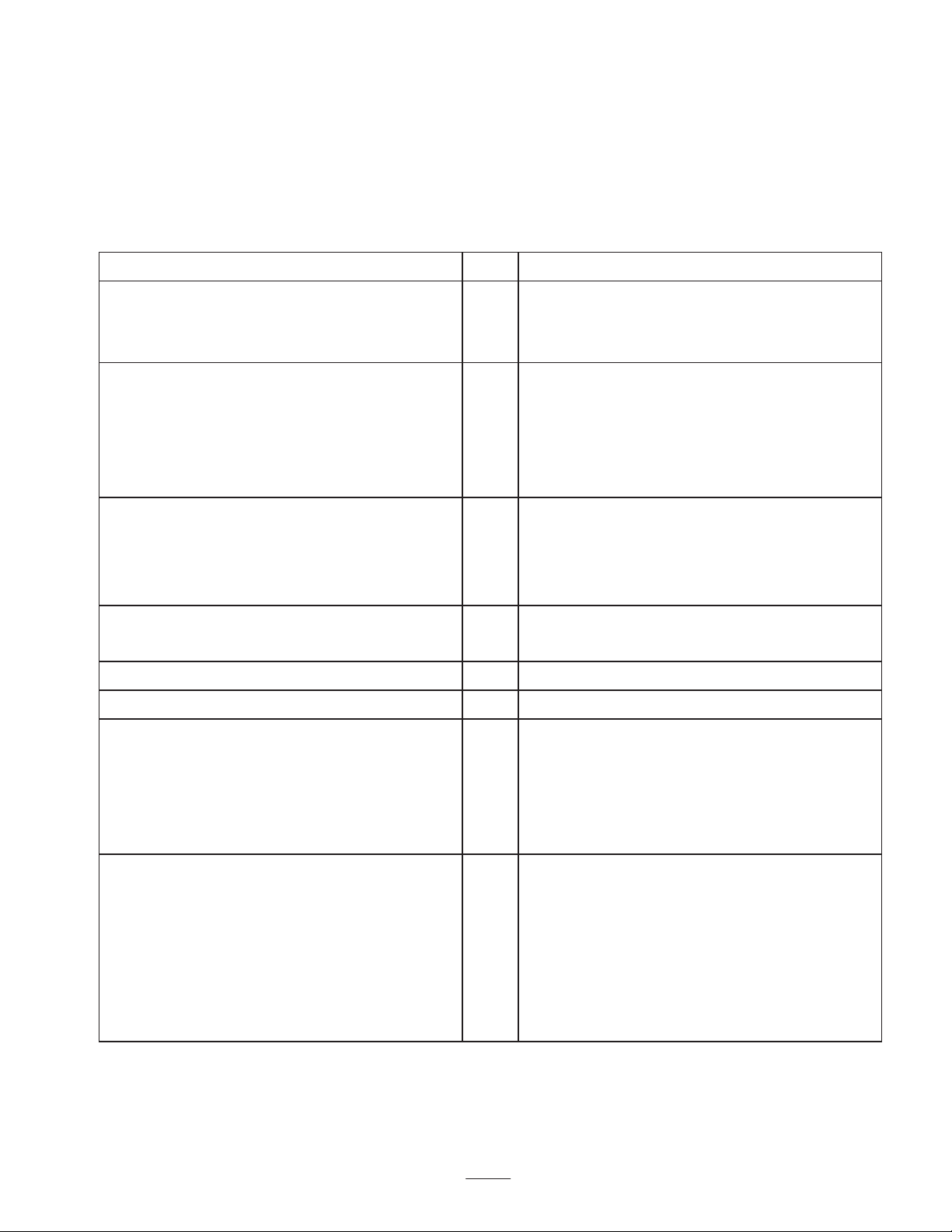

Loose Parts

Note: Use the chart below to verify all parts have been shipped.

DESCRIPTION QTY. USE

Caster assemblies

Bolt, 3/8 x 3/4 inch

Flange nut, 3/8 inch

Upper handle

Bolt, 3/8 x 1 inch

Locknut, 3/8 inch

Plastic terminal

Wire tie

Rod fitting

Clevis pin

Washer, 1/4 inch

Hairpin cotter

PTO rod

Hairpin cotter

No parts needed – Connecting the throttle cable

No parts needed – Connecting the choke cable

Shift lever

2

8

8

1

4

4

1

1

2

2

2

4

1

2

1

Installing the front casters

Installing the upper handle and wire harness

Installing the traction control rods

Installing the blade control (PTO) rod

Rubber seal

Square hole washer

Spring washer

Locknut

Fuel tank

Bolt, 5/16 x 7/8 inch

Lock washer, 5/16 inch

Washer, 5/16 inch

Stud

Spring

Hose clamp

1

1

1

1

1

2

2

4

2

2

1

13

Installing the shift lever

Mounting the fuel tank

Page 14

DESCRIPTION USEQTY.

No parts needed – Installing the muffler

Operator’s Manual

Engine Operator’s Manual

Parts Catalog

Registration card

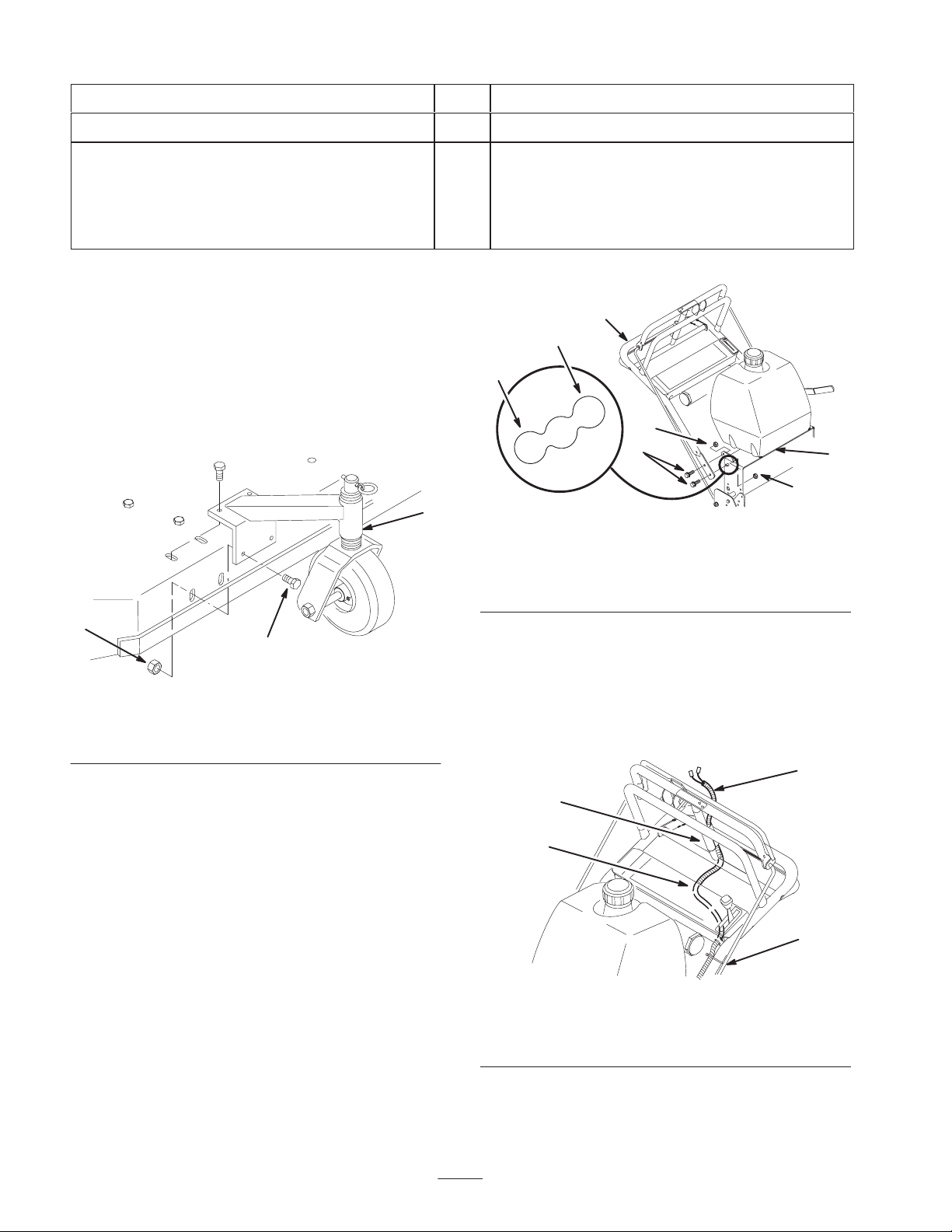

Installing the Front Casters

1. Align casters with holes on top and front of mower and

insert 8 bolts (3/8 x 3/4 inch) through mower. Secure

with 8 flange nuts (3/8 inch) below mower (Fig. 2).

Note: Tighten lower bolts first to pull caster against front,

then top bolts last.

2. Torque bolts to 30–35 ft–lb (40–47 Nm).

1

Read before operating machine

1

1

1

Fill out and return to Toro

1

5

6

4

3

1

4

2

m–4213

Figure 3

1. Upper handle

2. Rear frame

3. Bolt, 3/8 x 1 inch

4. Locknut, 3/8 inch

5. Low

6. High

3

2

m–3777

Figure 2

1. Front caster

2. Bolt, 3/8 x 3/4 inch

3. Flange nut, 3/8 inch

Installing the Upper Handle and

Wire Harness

1. Position handle outside frame and align upper handle

mounting holes with desired mounting holes in rear

frame. Select high, medium or low according to

operators height (Fig. 3).

2. Secure each side with 2 bolts (3/8 x 1 inch) and

2 locknuts (3/8 inch) (Fig. 3).

3. Torque bolts to 25 ft–lb (34 Nm).

4. Route wire harness inside of frame, along left handle

and over throttle cable. Compress wire harness covering

and press into lower and upper holes in rear of control

panel (Fig. 4).

5. Thread harness up through rear tube of traction handle

(Fig. 4).

1

3

2

4

m–3774

Figure 4

1. Wire harness

2. Control panel

3. Rear tube

4. Wire tie

14

Page 15

6. Insert terminals into plastic plug until the clips snap into

position (Fig. 5). If they do not snap, turn the plastic

plug around and try again.

7. Push plug onto switch until it latches (Fig. 5).

8. Secure wire harness and throttle cable to left handle,

away from PTO lever, with wire tie (Fig. 4).

4

1

3

Note: The upper control bar and fixed bar must be parallel

in the engaged, relaxed and brake positions.

4. Check operation. If adjustment is required, remove

hairpin cotter securing rod to upper control bar. Thread

rod in or out of trunion for proper position and install

into upper control bar with hairpin cotter.

5. After adjusting control rods, check parking brake

adjustment; refer to Servicing the Brake, page 32.

5

2

4

3

2

m–3782

Figure 5

1. Terminal

2. Clip

3. Plastic plug

4. Switch

Installing the Traction Control

Rods

1. Thread trunnions equal distance onto each control rod.

For a starting point, thread on approximately 2 inch

(51 mm) (Fig. 6).

2. With trunnion rod up, slide clevis pins through rod

fittings and mounting holes in idler brackets (from

outside) (Fig. 6). Secure with washers (1/4 inch) and

hairpin cotters (Fig. 6).

1

6

5

2

4

1

m–3770

Figure 7

1. Control rod

2. Fixed control bar

3. Parking brake lever

4. Upper control bar

5. 1 to 1–1/4 inch

(25–32 mm) gap

Installing the Blade Control

(PTO) Rod

1. Rotate the blade control (PTO) lever vertically away

from the left handle so that the blade control (PTO) rod

drops down (Fig. 8).

1

2

3

m–3785

Figure 6

1. Control rod

2. Trunnion

3. Idler bracket

4. Clevis pin

5. Washer, 1/4 inch

6. Hairpin cotter

3. Check the gap between upper control bar and fixed bar

with wheel drive fully engaged. Gap should be

approximately 1 to 1-1/4 inch (25–32 mm) (Fig. 7).

3

4

Figure 8

1. Blade control lever

2. Blade control (PTO) rod

3. Bell crank

4. Hairpin cotter

2. Remove the hairpin cotter from the bottom end of the

blade control (PTO) rod (Fig. 8).

3. Secure the blade control (PTO) rod through the hole in

the bell crank with the hairpin cotters (Fig. 8).

15

m–3783

Page 16

Connecting the Throttle Cable

Installing the Shift Lever

1. Hook the throttle cable inner wire into the hole of the

speed control lever (Fig. 9).

2. Move the throttle control lever to the Fast position

(Fig. 9).

3. Loosen the throttle cable clamp screw (Fig. 9).

4. Pull the throttle cable slightly to remove any slack in

the inner wire (Fig. 9).

5. Tighten the cable clamp screw to lock the adjustment in

place (Fig. 9).

6. Move the throttle lever to make sure the carburetor

valve moves.

6 7

2

3

4

54

m–7537

Figure 9

1. Throttle cable

2. Throttle cable inner wire

3. Speed control lever

4. Cable clamp screw

5. Choke cable

6. Choke control lever

7. Choke cable inner wire

1. Remove the locknut (3/8 inch) and spring washer from

the stud on top of the transmission (Fig. 10).

Note: Do not remove rubber seal washer and square hole

washer from transmission shaft.

2. Slide the shift lever through the control panel and align

the mounting hole in lever with square on transmission

shaft (Fig. 10).

3. Secure lever to transmission with previously removed

spring washer and locknut (Fig. 10).

4. Replace the spring washer, dish down, and locknut

(Fig. 10).

5. Torque the nut to 35 ft–lb (47 Nm).

6

5

1

4

3

1

2

m–3772

Figure 10

1. Shift lever

2. Control panel

3. Rubber seal washer

4. Square hole washer

5. Spring washer

6. Locknut 3/8

Connecting the Choke Cable

1. Move the choke control to the Open position (Fig. 9).

2. Hook the choke cable inner wire into the hole of the

choke control lever (Fig. 9).

3. Loosen the choke cable clamp screw (Fig. 9).

4. Pull the choke cable slightly to remove any slack in the

inner wire (Fig. 9).

5. Tighten the cable clamp screw to lock the adjustment in

place (Fig. 9).

6. Move the choke control to make sure the carburetor

choke valve moves.

Adjusting the Shift Lever Plate

1. Shift lever to second gear and check alignment of lever

in slot of shifter lever plate. The clearance between top

and bottom of the shift lever should be equal (Fig. 11).

2. If clearance is not correct, remove lever and bend it

slightly to adjust (Fig. 11).

Note: Do not bend lever while attached to transmission

shaft or damage may occur.

3. Shift lever to neutral and check alignment of lever in

slot of shifter lever plate. The clearance on the sides of

shift lever should be equal (Fig. 11).

16

Page 17

4. If clearance is not correct, loosen shift lever plate and

adjust it side–to–side. Tighten the shift lever plate.

1

2

4

4

Rear View

2

3

2

1

1. Bolt, 5/16 x 7/8 inch

2. Lock washer, 5/16 inch

3. Washer, 5/16 inch

m–3771

4

3

5

6

Figure 12

4. Stud

5. Spring

6. Locknut

3

m–7454

Figure 11

1. Shift lever, 2nd gear

2. Shift lever plate

3. Shift lever, neutral

4. Equal distance

Mounting the Fuel Tank

1. Align fuel tank with the top of the rear frame (Fig. 12).

2. Secure the right side of the fuel tank to the rear frame

with 2 bolts (5/16 x 7/8 inch), lock washers (5/16 inch)

and washers (5/16 inch) (Fig. 12).

3. Secure the left side of the fuel tank to the rear frame

with 2 studs, washers (5/16 inch), springs and locknuts

(5/16 inch) (Fig. 12).

Note: Tighten left side of the fuel tank until it is completely

tight and then unscrew locknut one full turn. This will

allow the spring to work.

4. Slide the hose clamp onto the fuel line (Fig. 13).

5. Push the fuel line onto the fuel tank connection and

secure it with a hose clamp (Fig. 13).

2

3

1

m–6442

Figure 13

1. Fuel line

2. Hose clamp

3. Fuel fitting

Installing the Muffler

1. Loosen the clamp (Fig. 14).

17

Page 18

Operation

1

3

2

m–5941

Figure 14

1. Muffler

2. Clamp

2. Rotate the muffler forward into the position shown in

Figure 14.

3. Secure the muffler bracket (Fig. 14) to the engine

bracket with the hardware provided.

4. Tighten the clamp.

3. Muffler bracket

Note: Determine the left and right sides of the machine

from the normal operating position.

Think Safety First

Carefully read all the safety instructions and decals in the

safety section. Knowing this information could help you,

your family, pets or bystanders avoid injury.

The use of protective equipment for eyes, hearing, feet and

head is recommended.

Caution

This machine produces sound levels in excess of

85dBA at the operator’s ear and can cause hearing

loss through extended periods of exposure.

Wear hearing protection when operating this

machine.

1

2

Figure 15

1. Caution 2. Wear hearing protection

Controls

Become familiar with all the controls (Fig. 16) before you

start the engine and operate the machine.

Throttle Control – The throttle control has Choke, Fast,

Slow and Stop positions.

Bail – The bail, in conjunction with the PTO switch, allows

the engine to be started with the PTO disengaged. With the

bail compressed the blade control (PTO) can be engaged.

Release the bail with the PTO engaged and the engine

stops.

Blade Control (PTO) – The blade control lever (PTO)

engages and disengages power to the mower blades. Move

the PTO lever forward to engage the blades. Pull rearward

to stop driving mower blades

Gear Shift Lever – Transmission has five forward speeds,

neutral and reverse, and has an in-line shift pattern. Do not

shift while unit is moving, as transmission damage may

occur.

18

Page 19

Upper Control Bar – Shift to desired gear and push

forward on control bar to engage forward traction operation

and pull back to brake. Pull right side of control bar to turn

right and left side to turn left.

2. Lift the parking brake lock up and gradually release the

upper control bar (Fig. 17). The brake lock should stay

in the set (locked) position.

Lower Control Bar – Shift transmission to reverse and

pull rearward on lower control bar to engage rearward

traction operation.

Parking Brake Lever – Pull back on upper control bar and

swing brake lever up against the upper handle to keep brake

engaged.

Recoil Starter – Pull recoil starter handle to start engine.

Fuel Shut–off Valve – (In fuel line) Close fuel shut–off

valve when transporting or storing mower.

Choke – Use the choke to start a cold engine.

2

7

5

6

Releasing the Parking Brake

1. Pull rearward on the upper control bar (Fig. 17). Lower

the parking brake lock to the released position.

2. Gradually release the upper control bar.

1

2

m–4212

Figure 17

1. Upper control bar 2. Parking brake lock

Starting the Engine

1. Connect the wires to the spark plugs.

1

4

3

8

m–7587

Figure 16

1. Throttle control

2. Bail

3. Blade control (PTO)

4. Gear shift lever

5. Upper control bar

6. Lower control bar

7. Parking brake lever

8. Choke

Operating the Parking Brake

Always set the parking brake when you stop the machine or

leave it unattended.

Setting the Parking Brake

1. Pull the upper control bar rearward and hold it in this

position (Fig. 17).

2. Open the fuel valve.

3. Disengage the blade control (PTO) lever and move the

shift lever to the Neutral position.

4. Set the parking brakes.

5. Turn the ignition key to the Run position.

6. Move the throttle control midway between the Fast and

Slow positions before starting a cold engine.

Note: A warm or hot engine usually does not require

any choking. To start a warm engine, move the throttle

control to the Fast position.

7. Pull the choke knob.

8. Grasp the recoil starter handle firmly and pull it out

until positive engagement results; then pull the handle

vigorously to start the engine. Allow the rope to recoil

slowly.

Important Do not pull the recoil rope to its limit or

release the starter handle when you pull out the rope

because the rope may break or the recoil assembly may be

damaged.

9. If the engine is cold, allow it to warm up and then move

the throttle control to the Fast position.

19

Page 20

Stopping the Engine

1. Move the throttle lever to slow (Fig. 18).

Note: If the engine has been working hard or is hot, let it

idle for a minute before stopping. This helps cool the

engine. In an emergency, the engine may be stopped by

pulling the throttle all the way back, to stop.

2. To stop the engine pull the throttle all the way back, to

stop (Fig. 18).

1

2

3

2

1

1. Blade control (PTO) 2. Throttle lever

3. Set the parking brake.

4. Pull wire off spark plug(s) to prevent possibility of

someone accidentally starting the machine while

transporting or storing the machine.

5. Close the fuel shut off valve before transporting or

storing machine.

Important Make sure the fuel shut off valve is closed

before transporting or storing machine, or fuel leakage may

occur.

Figure 18

m–7587

Operating the Blade Control

Figure 19

1. Upper control bar

2. Bail

3. Blade control (PTO)

Disengaging the Mower Blades (PTO)

1. To disengage the blade(s), pull blade control lever

rearward, all the way (Fig. 19).

Note: It is necessary to fully and manually disengage

mower.

Understanding the Safety

Interlock System

Caution

If safety interlock switches are disconnected or

damaged the machine could operate unexpectedly

causing personal injury.

• Do not tamper with the interlock switches.

• Check the operation of the interlock switches

daily and replace any damaged switches before

operating the machine.

m–7587

(PTO)

The blade control (PTO) lever engages and disengages

power to the mower blades.

Engaging the Mower Blades (PTO)

1. Pull on the upper control bar to stop the machine

(Fig. 19).

2. Hold the bail against the upper control bar (Fig. 19).

3. To engage blade(s), push the blade control lever firmly

forward, until it latches over-center (Fig. 19).

The safety interlock system is designed to prevent the

engine from starting if:

• The throttle lever is all the way back, to stop.

• The blade control lever (PTO) is engaged.

The safety interlock system is also designed to stop the

engine if you released the bail with the PTO engaged or

move the throttle all the way back, to stop.

20

Page 21

Testing the Safety Interlock System

Driving Backward

Test the safety interlock system before you use the machine

each time. If the safety system does not operate as

described below, have an Authorized Service Dealer repair

the safety system immediately.

1. Set the parking brake, disengage the PTO and place the

throttle forward. Start the engine. With the engine

running squeeze the bail against upper control bar and

push the mower blade control lever forward. The

mower blades begin rotating.

2. With the engine running, release the bail. The engine

should stop.

3. Start the engine again.

4. With the engine running, move the throttle lever all the

way back, to stop. The engine should stop.

Driving Forward or Backward

The throttle control regulates the engine speed as measured

in rpm (revolutions per minute). Place the throttle control in

the fast position for best performance.

Driving Forward

1. To go forward, move the shift lever to a forward gear.

2. Release the parking brake; refer to Releasing the

Parking Brake, page 19.

3. Slowly press on the upper control bar to move forward

(Fig. 20).

To go straight, apply equal pressure to both ends of the

upper control bar (Fig. 20).

To turn, release pressure on the upper control bar side

toward the direction you want to turn (Fig. 20).

1. To go backward, move the shift lever to a reverse gear.

2. Release the parking brake; refer to Releasing the

Parking Brake, page 19.

3. Slowly squeeze on the lower control bar and handle

together to move rearward (Fig. 20).

Operating the Lower Control

Bar

This procedure is for driving up a curb. This can be

performed while driving forward or backward.

1. Disengage the mower blades.

Warning

A blade can be bent or damaged when driving up a

curb. Pieces of blade that may be thrown could

seriously injure or kill you or bystanders.

• Do not run blades while driving up a curb

forward or backward.

2. Select first gear or reverse to drive machine.

3. Drive machine until drive wheels contact curb (Fig. 22).

Note: Both drive wheels should contact the curb and caster

wheels straight.

4. At the same time engage lower control bar and lift up

on handle (Fig. 21 and 22).

Note: Lifting up on handle will assist driving the machine

up a curb and not spin the drive wheels.

1

2

Figure 20

1. Upper control bar 2. Lower control bar

m–7587

1. Lower Control Bar

(Engaged)

21

m–5704

Figure 21

2. Handle

Page 22

1

2

m–4185

Figure 22

1. Lower Control Bar

engaged and mower in

reverse.

2. Pull up to assist machine

Stopping the Machine

To stop the machine apply the brakes, pull back on the

upper control bar, release the bail and set the parking brake;

refer to Setting the Parking Brake, page 19.

Caution

Using the Side Discharge

This mower has a hinged grass deflector that disperses

clippings to the side and down toward the turf.

Danger

Without the grass deflector, discharge cover, or

complete grass catcher assembly mounted in place,

you and others are exposed to blade contact and

thrown debris. Contact with rotating mower

blades and thrown debris will cause injury or

death.

• Never remove the grass deflector from the

mower because the grass deflector routes the

material down toward the turf. If the grass

deflector is ever damaged, replace it

immediately.

• Never put your hands or feet under the mower.

• Never try to clear the discharge area or the

mower blades unless you disengage the power

take-off (PTO), stop the engine and wait for all

moving parts to stop, and disconnect the wire

from the spark plug.

Children or bystanders may be injured if they

move or attempt to operate the machine while it is

unattended.

Always set the parking brake when leaving the

machine unattended, even if just for a few minutes.

Transporting the Mower

Use a heavy-duty trailer or truck to transport the mower.

Ensure that the trailer or truck has all the necessary lighting

and markings as required by law. Please carefully read all

the safety instructions. Knowing this information could

help you, your family, pets, or bystanders avoid injury.

To transport the mower:

• Lock the brakes and block the wheels.

• Securely fasten the mower to the trailer or truck with

straps, chains, cable, or ropes.

• Secure the trailer to the towing vehicle with safety

chains.

Adjusting the Height-of-Cut

This machine has a 1 to 4-1/4 inch (26 to 108 mm) range

for the height-of-cut. This can be achieved by adjusting

blade spacers, rear axle height, and front caster spacers.

Use the Height-of-Cut Chart on page 24 to select the

combination required.

Adjusting the Blade Height

Adjust the blades by using the 4 spacers (1/4 inch) on the

blade spindle bolts. This allows a range, in 1/4 inch (6 mm)

increments, of cutting height in any axle position. Use the

same number of blade spacers on all blades to achieve a

level cut (2 above and 2 below, 1 above and 3 below, etc.).

1. Disengage the blade control (PTO) lever and set the

parking brakes.

2. Stop the engine and wait for all moving parts to stop

before leaving the operating position.

3. Hold the blade bolt and remove the nut (Fig. 23).

22

Page 23

6

5

4

4

5. Raise or lower the engine frame with the jack so that

you can install the front 2 axle adjustment bolts in the

desired hole location (Fig. 24).

Note: Use a tapered punch to help align the holes.

1

3

2

m–3779

Figure 23

1. Blade

2. Blade bolt

3. Cone washer

4. Spacer

5. Thin washer

6. Nut

4. Slide the bolt down through the spindle, and change the

spacers as needed (Fig. 23).

5. Insert a bolt, add extra spacer(s), and secure them with a

thin washer and a nut (Fig. 23).

6. Torque the blade bolt to 75–80 ft-lb (101–108 N m).

Adjusting the Axle Height

You can obtain the desired height-of-cut range by adjusting

the rear axle and placing the caster spacers above or below

the caster arm. Refer to the Height-of-Cut Chart, page 24.

1. Disengage the blade control (PTO) lever and set the

parking brakes.

2. Stop the engine and wait for all moving parts to stop

before leaving the operating position.

6. Tighten all 4 bolts and lower the mower.

7. Adjust the control rods and the brake linkages as

required. Refer to Servicing the Brakes, page 32 and

Installing the Control Rods, page 15.

Important You must adjust the control rods and the

brake linkage when you change the axle positions for

proper traction and brake function.

Adjusting the Caster Position

1. Using the Height-of-Cut Chart (on page ), adjust the

caster spacers to match with the axle hole selected

(Fig. 25).

2

m–3791

Figure 25

1. Clevis pin

2. Spacer, 3/16 inch (5 mm)

3. Spacer, 1/2 inch (13 mm)

1

3

3. Loosen, but do not remove, the 2 axle pivot bolts and

the 2 axle adjustment bolts (Fig. 24).

1

2

A

B

C

D

E

m–3789

Figure 24

1. Axle pivot bolt 2. Axle adjustment bolt

4. Place a jack under the rear center of the engine frame.

Raise the back end of the engine frame up enough to

remove the front 2 axle adjustment bolts (Fig. 24).

2. Remove the clevis pin, slide the caster from the support,

and change the spacers (Fig. 25).

3. Install the caster in the support and insert the clevis pin

(Fig. 25).

23

Page 24

Height-of-Cut Chart

No. of Spacers Below

Caster

Number of 1/4 inch Blade Spacers Below Spindle

Axle

Position

A 0 0

A 0 1

A 1 0

B 0 1

B 1 0

B 1 1

B 2 0

C 1 1

C 2 0

1/2 inch

(13mm)

3/16 inch

(5 mm)

4 3210

1 inch

(26 mm)

1–1/8 inch

(29 mm)

1–3/8 inch

(35 mm)

1–3/8 inch

(35 mm)

1–5/8 inch

(41 mm)

1–3/4 inch

(45 mm)

2 inch

(45 mm)

1–7/8 inch

(48 mm)

2–1/8 inch

(55 mm)

1–1/4 inch

(32 mm)

1–3/8 inch

(35 mm)

1–5/8 inch

(41 mm)

1–5/8 inch

(41 mm)

1–7/8 inch

(48 mm)

2 inch

(52 mm)

2–1/4 inch

(58 mm)

2–1/8 inch

(55 mm)

2–3/8 inch

(61 mm)

1–1/2 inch

(38 mm)

1–5/8 inch

(41 mm)

1–7/8 inch

(48 mm)

1–7/8 inch

(48 mm)

2–1/8 inch

(55 mm)

2–1/4 inch

(58 mm)

2–1/2 inch

(64 mm)

2–3/8 inch

(61 mm)

2–5/8 inch

(67 mm)

1–3/4 inch

(45 mm)

1–7/8 inch

(48 mm)

2–1/8 inch

(55 mm)

2–1/8 inch

(55 mm)

2–3/8 inch

(61 mm)

2–1/2 inch

(64 mm)

2–3/4 inch

(70 mm)

2–5/8 inch

(67 mm)

2–7/8 inch

(73 mm)

2 inch

(45 mm)

2–1/8 inch

(55 mm)

2–3/8 inch

(55 mm)

2–3/8 inch

(61 mm)

2–5/8 inch

(67 mm)

2–3/4 inch

(70 mm)

3 inch

(76 mm)

2–7/8 inch

(73 mm)

3–1/8 inch

(79 mm)

C 2 1

C 3 0

D 2 1

D 3 0

D 3 1

D 4 0

E 3 1

E 4 0

E 4 1

2–1/4 inch

(58 mm)

2–1/2 inch

(64 mm)

2–3/8 inch

(61 mm)

2–1/2 inch

(64 mm)

2–3/4 inch

(70 mm)

3 inch

(76 mm)

2–7/8 inch

(73 mm)

3–1/8 inch

(79 mm)

3–1/4 inch

(82 mm)

2–1/2 inch

(64 mm)

2–3/4 inch

(70 mm)

2–5/8 inch

(67 mm)

2–3/4 inch

(70 mm)

3 inch

(76 mm)

3–1/4 inch

(82 mm)

3–1/8 inch

(79 mm)

3–3/8 inch

(86 mm)

3–1/2 inch

(89 mm)

2–3/4 inch

(70 mm)

3 inch

(76 mm)

2–7/8 inch

(73 mm)

3 inch

(76 mm)

3–1/4 inch

(82 mm)

3–1/2 inch

(89 mm)

3–3/8 inch

(86 mm)

3–5/8 inch

(92 mm)

3–3/4 inch

(96 mm)

3 inch

(76 mm)

3–1/4 inch

(82 mm)

3–1/8 inch

(79 mm)

3–1/4 inch

(82 mm)

3–1/2 inch

(89 mm)

3–3/4 inch

(96 mm)

3–5/8 inch

(92 mm)

3–7/8 inch

(99 mm)

4 inch

(102 mm)

3–1/4 inch

(82 mm)

3–1/2 inch

(89 mm)

3–3/8 inch

(86 mm)

3–1/2 inch

(89 mm)

3–3/4 inch

(96 mm)

4 inch

(102 mm)

3–7/8 inch

(99 mm)

4–1/8 inch

(105 mm)

4–1/4 inch

(108 mm)

24

Page 25

Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

Important Refer to your engine operator’s manual for additional maintenance procedures.

Recommended Maintenance Schedule

Maintenance Service

Interval

Each Use

After first 8 Hours

8 Hours

After first 25 Hours • Mower Belt—check tension

25 Hours • Foam Air Cleaner—clean

50 Hours

100 Hours

Maintenance Procedure

• Engine Oil—check the level

• Safety System—check

• Brakes—check

• Engine—clean engine screen

• Idler Pivots—grease

• Engine Oil—change

• Mower Belt—check the tension

• Cutting Blades—check

• Mower Housing—clean

• Caster Wheels—grease

• Wheel Bearings—grease

• Belts—check for wear/cracks

• Mower Belt—check the tension

• Mower Belt Idler Pivots—grease

• Tires—check pressure

• Engine Oil—change

• Engine—clean cooling system

• Transmission Couplings—grease

• Spark Plug—check

1

1

1

1

• Engine Oil Filter—change (200 hours or every other oil change)

200 Hours

At storage

1

More often in dusty, dirty conditions.

Important Refer to your engine operator’s manual for additional maintenance procedures.

• Fuel Filter—replace

• Paper Air Cleaner—replace

• Chipped Surfaces—paint

• Perform all maintenance procedures listed above before storing the mower

1

Caution

Someone could accidently start the engine and seriously injure you or other bystanders.

Disconnect the wire from the spark plug before you do any maintenance. Set the wire aside so

that it does not accidentally contact the spark plug.

25

Page 26

Servicing the Cutting Blades

To ensure a superior quality of cut, keep the blades sharp.

For convenient sharpening and replacement, keep extra

blades on hand.

Warning

Front

A worn or damaged blade can break, and a piece

of the blade could be thrown into the operator’s or

bystander’s area, resulting in serious personal

injury or death.

• Inspect the blades periodically for wear or

damage.

• Replace a worn or damaged blade.

Before Inspecting or Servicing the Blades

Park the machine on a level surface, disengage the blade

control (PTO) lever, and set the parking brakes.

Inspecting the Blades

1. Inspect the cutting edges (Fig 26). If the edges are not

sharp or have nicks, remove and sharpen the blades.

Refer to Sharpening the Blades, page 27.

2

1

1666

Figure 27

2. Measure from a level surface to the cutting edge of the

blades (Fig. 28). Note this dimension.

MEASURE FROM CUTTING

EDGE TO A LEVEL SURFACE

Figure 28

3. Rotate the opposite ends of the blades forward.

4. Measure from a level surface to the cutting edge of the

blades at the same position as in step 1 above. The

difference between the dimensions obtained in steps 1

and 2 must not exceed 1/8 inch (3 mm).

Note: If this dimension exceeds 1/8 inch (3 mm), the

blade is bent and must be replaced. Refer to Removing

the Blades, page 26 and Installing the Blades, page 27.

m–2558

3

m–151

Figure 26

1. Cutting edge

2. Curved area

2. Inspect the blades, especially the curved area (Fig. 26).

If you notice any damage, wear, or a slot forming in this

area (item 3 in Fig. 26), immediately install a new

blade.

3. Wear/slot forming

Checking for Bent Blades

1. Rotate the blades until the ends face forward and

backward (Fig. 27).

Warning

A blade that is bent or damaged could break apart

and could seriously injure or kill you or

bystanders.

• Always replace bent or damaged blade with a

new blade.

• Never file or create sharp notches in the edges

or surfaces of the blade.

Removing the Blades

Replace the blades if you hit a solid object or if the blades

are out of balance or bent. To ensure optimum performance

and continued safety conformance of the machine, use

genuine Toro replacement blades. Replacement blades

made by other manufacturers may result in

non-conformance with safety standards.

1. Hold the blade bolt with a wrench.

26

Page 27

2. Remove the nut, blade bolt, cone washer, blade,

spacers, and thin washer from the spindle (Fig. 29).

4

2

6

5

4

1

Figure 31

1. Blade 2. Balancer

m–1855

1

3

2

m–3779

Figure 29

1. Blade

2. Blade bolt

3. Cone washer

4. Spacer

5. Thin washer

6. Nut

Sharpening the Blades

1. Use a file to sharpen the cutting edge at both ends of the

blade (Fig. 30). Maintain the original angle. The blade

retains its balance if the same amount of material is

removed from both cutting edges.

2

1

Installing the Blades

1. Place the blade onto the bolt and over the cone washer.

Select the proper number of spacer(s) for the height-ofcut, and slide the bolt into the spindle (Fig. 29).

Important The curved part of the blade must point

upward toward the inside of the mower to ensure proper

cutting.

2. Install the remaining spacer(s) and secure them with a

thin washer and a nut (Fig. 29).

3. Torque the blade bolt to 75–80 ft-lb (101–108 N m).

Servicing the Air Cleaner

Service Interval/Specification

Foam element: Clean it after every 25 operating hours.

Paper element: Replace it after every 200 operating hours

or yearly, which ever comes first.

Inspect the foam and paper elements, and replace them if

they are damaged or excessively dirty.

m–1854

Figure 30

1. Sharpen at original angle 2. Sail

2. Check the balance of the blade by putting it on a blade

balancer (Fig. 31). If the blade stays in a horizontal

position, the blade is balanced and can be used. If the

blade is not balanced, file some metal off the end of the

sail area only (Fig. 30). Repeat this step until the blade

is balanced.

Note: Service the air cleaner more frequently (every few

operating hours) if the operating conditions are extremely

dusty or sandy.

Important Do not oil the foam or paper element.

Removing the Foam and Paper Elements

1. Disengage the PTO and set the parking brake.

2. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Clean around the air cleaner to prevent dirt from getting

into the engine and causing damage (Fig. 32).

4. Unscrew the cover knob and remove the air cleaner

cover (Fig. 32).

27

Page 28

5. Unscrew the 2 wing nuts and remove the air cleaner

assembly (Fig. 32).

3. Replace the paper element if it is damaged or dirty.

6. Carefully pull the foam element off the paper element

(Fig. 32).

6

2

3

4

5

1

m–7452

Figure 32

1. Engine

2. Cover

3. Wing nut

4. Foam element

5. Paper element

6. Cover knob

Installing the Foam and Paper Elements

Important To prevent engine damage, always operate

the engine with the complete foam and paper air cleaner

assembly installed.

1. Carefully slide the foam element onto the paper air

cleaner element (Fig. 32).

2. Place the air cleaner assembly onto the air cleaner base

and secure it with the 2 wing nuts (Fig. 32).

3. Place the air cleaner cover into position and tighten the

cover knob (Fig. 32).

Servicing the Engine Oil

Service Interval/Specification

Change the engine oil:

• After the first 8 operating hours

• After every 100 operating hours

Note: Change the oil more frequently when the operating

conditions are extremely dusty or sandy.

Oil Type: Detergent oil (API service SF, SG, SH, or SJ)

Crankcase Capacity: 58 ounces (1.7 liter) with the filter

removed; 51 ounces (1.5 liter) without the filter removed

Viscosity: Refer to the table below

Cleaning the Foam Element

1. Wash the foam element in liquid soap and warm water.

When the element is clean, rinse it thoroughly.

2. Dry the element by squeezing it in a clean cloth.

Important Replace the foam element if it is torn or

worn.

Cleaning the Paper Element

Note: Never try to brush dirt off the paper element;

brushing forces the dirt into the fibers.

Important Never clean the paper element with

pressurized air or liquids, such as solvent, gas, or kerosene.

Replace the paper element if it is damaged, defective, or

cannot be cleaned thoroughly.

1. Lightly tap the element on a flat surface to remove dust

and dirt (Fig. 32).

2. Inspect the element for tears, an oily film, or damage to

the rubber seal.

USE THESE SAE VISCOSITY OILS

Checking the Engine Oil Level

1. Park the machine on a level surface.

2. Disengage the PTO and set the parking brake.

3. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

4. Clean around the oil dipstick (Fig. 33) so that dirt

cannot fall into the filler hole and damage the engine.

28

Page 29

2

1

m–7449

Figure 33

1. Oil dipstick 2. Filler tube

5. Unscrew the oil dipstick and wipe the end clean

(Fig. 33).

6. Slide the oil dipstick fully into the filler tube, but do

not thread onto tube (Fig. 33).

7. Pull the dipstick out and look at the end. If the oil level

is low, slowly pour only enough oil into the filler tube

to raise the level to the Full mark.

Important Do not overfill the crankcase with oil and

run the engine; engine damage can result.

Changing the Oil

1. Start the engine and let it run five minutes. This warms

the oil so it drains better.

2. Park the machine so that the drain side is slightly lower

than the opposite side to assure the oil drains

completely.

m–7453

1

Figure 34

1. Oil drain valve

9. Slowly pour approximately 80% of the specified oil

(refer to Service Interval/Specification, page 28) into

the filler cap (Fig. 33).

10.Check the oil level; refer to Checking the Engine Oil

Level, page 28.

11. Slowly add the additional oil to bring it to the Full

mark.

Changing the Oil Filter

Replace the oil filter every 200 operating hours or every

other oil change.

Note: Change the oil filter more frequently when the

operating conditions are extremely dusty or sandy.

1. Drain the oil from the engine; refer to Changing the Oil,

page 29.

2. Remove the old filter (Fig. 35).

3. Disengage the PTO and set the parking brake.

4. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

5. Slide the drain hose over the oil drain valve.

6. Place a pan below the drain hose. Rotate oil drain valve

to allow oil to drain (Fig. 34).

7. When oil has drained completely, close the drain valve.

8. Remove the drain hose (Fig. 34).

Note: Dispose of the used oil at a recycling center.

2

1

m–7451

Figure 35

1. Oil filter 2. Adapter

3. Apply a thin coat of new oil to the rubber gasket on the

replacement filter (Fig. 35).

29

Page 30

4. Install the replacement oil filter to the filter adapter,

turn the oil filter clockwise until the rubber gasket

contacts the filter adapter, then tighten the filter an

additional 3/4 turn (Fig. 35).

5. Fill the crankcase with the proper type of new oil; refer

to Servicing the Engine Oil, page 28.

6. Run the engine for about 3 minutes, stop the engine,

and check for oil leaks around the oil filter.

7. Check the engine oil level and add oil if needed.

Servicing the Spark Plugs

Service Interval/Specification

Check the spark plugs after every 100 operating hours.

Ensure that the air gap between the center and side

electrodes is correct before installing the spark plug. Use a

spark plug wrench for removing and installing the spark

plugs and a gapping tool/feeler gauge to check and adjust

the air gap. Install a new spark plugs if necessary.

Type: Champion

Air Gap: 0.030 inch (0.75 mm)

RCJ-8Y or equivalent

Checking the Spark Plugs

1. Look at the center of the spark plugs (Fig. 37). If you

see light brown or gray on the insulator, the engine is

operating properly. A black coating on the insulator

usually means that the air cleaner is dirty.

2. If needed, clean the spark plug with a wire brush to

remove carbon deposits.

2

1

Figure 37

1. Center electrode insulator

2. Side electrode

3. Air gap (not to scale)

3

0.030 inch

(0.75 mm)

Removing the Spark Plugs

1. Disengage the PTO and set the parking brake.

2. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Disconnect the wires from the spark plugs (Fig. 36).

1

m–7453

Figure 36

1. Spark-plug wire/spark

plug

Important Always replace the spark plugs when it has

a black coating, worn electrodes, an oily film, or cracks.

3. Check the gap between the center and side electrodes

(Fig. 37). Bend the side electrode (Fig. 37) if the gap is

not correct.

Installing the Spark Plugs

1. Install the spark plugs and the metal washer. Ensure that

the air gap is set correctly.

2. Tighten the spark plugs to 16 ft-lb (22 Nm).

3. Connect the wires to the spark plugs (Fig. 36).

Cleaning the Cooling System

Clean the air intake screen from grass and debris before

each use.

Check and clean cooling fins and engine shrouds every

100 hours or yearly, which ever comes first.

1. Disengage the PTO and set the parking brake.

4. Clean around the spark plugs to prevent dirt from

falling into the engine and potentially causing damage.

5. Remove the spark plugs and the metal washers.

2. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Remove the air intake screen, recoil starter and fan

housing.

4. Clean the debris and grass from the engine parts.

30

Page 31

5. Install air intake screen, recoil starter and fan housing.

Greasing and Lubrication

3

1

Figure 38

1. Air intake screen

2. Fan housing

3. Recoil starter

4. Bolt

5. Nut

Checking the Tire Pressure

5

2

4

Service Interval/Specification

Grease the areas shown at the intervals given in the

Locating Where to Add Grease section below. Grease them

more frequently when operating conditions are extremely

dusty or sandy.

Grease with No. 2 general-purpose lithium-base or

molybdenum-base grease.

Applying the Grease

1. Disengage the blade control (PTO) lever and set the

parking brakes.

2. Clean the grease fittings with a rag and scrape any paint

from the front of the fitting(s).

m–7450

3. Connect a grease gun to the fitting and pump grease

into the fittings until grease begins to ooze out of the

bearings.

4. Wipe up any excess grease.

Locating Where to Apply Grease

1. Lubricate the drive and caster wheel bearings and front

spindles (Fig. 40) after every 8 operating hours.

Service Interval/Specification

Maintain the air pressure in the front and rear tires as

specified. Check the pressure at the valve stem after every

50 operating hours or monthly, whichever occurs first

(Fig. 39). Check the tires when they are cold to get the most

accurate pressure reading.

Pressure: 15 psi (103 kPa) rear tires

25–30 psi (172–207 kPa) caster tires

1

Figure 39

1. Valve stem

m–3780

Figure 40

2. Lubricate the transmission couplers after every

100 operating hours and the idler bracket pivots after

every 8 operating hours (Fig 41).

31

Page 32

Figure 41

m–5389

2. Rear wheels must lock when you try to push the

machine forward or backward. Adjustment is required if

the wheels turn and do not lock; refer to Adjusting the

Brake, page 32.

3. Release the brake and press upper control bar very

lightly, approximately 1/2 inch (13 mm), wheels should

rotate freely.

4. If both conditions are met, no adjustment is required.

Adjusting the Brakes

The brake lever is on the upper control bar (Fig. 16). If the

parking brake does not hold securely, an adjustment is

required.

3. Lubricate the blade belt idler arm pivot (Fig. 42) after

every 50 operating hours.

m-4749

Figure 42

Servicing the Brakes

Service Interval/Specification

Before each use, check brakes for proper operation.

Always set the parking brake when you stop the machine or

leave it unattended. If the parking brake does not hold

securely, an adjustment is required.

1. Check the brake before you adjust it; refer to Checking

the Brake, page 32.

2. Release the parking brake; refer to Releasing the

Parking Brake, page 19.

3. To adjust brake set the parking brake latch, and rotate

the wing nuts on the brake rods (Fig. 43). Clockwise to

tighten the brake and counterclockwise to loosen the

brake.

Note: Control bar should be parallel with reference bar

when properly adjusted.

4. Check the brake operation again; refer to Checking the

Brake, page 32.

Important With the parking brake released, the rear

wheels must rotate freely when you push the mower. If

brake action and free wheel rotation cannot be achieved

contact your service dealer immediately.

Checking the Brakes

1. Park the machine on a level surface, disengage the

blade control (PTO) and set the parking brake.

32

Page 33

Note: Now is the best time to install a new fuel filter

1

because the fuel tank is empty. Refer to Replacing the Fuel

Filter; page 33.

5. Install the fuel line onto the fuel filter. Slide the hose

clamp close to the valve to secure the fuel line.

2

m-3773

Figure 43

1. Brake rod 2. Wing nut

Servicing the Fuel Tank

Danger

In certain conditions, gasoline is extremely

flammable and highly explosive. A fire or

explosion from gasoline can burn you and others

and can damage property.

• Drain gasoline from the fuel tank when the

engine is cold. Do this outdoors in an open area.

Wipe up any gasoline that spills.

• Never smoke when draining gasoline, and stay

away from an open flame or where a spark may

ignite the gasoline fumes.

Draining the Fuel Tank

1. Park the machine on a level surface, to assure fuel tank

drains completely. Then disengage the power take off

(PTO), set the parking brake, and turn the ignition key

to off. Remove the key.

2. Close fuel shut–off valve at fuel tank (Fig. 44).

3. Squeeze the ends of the hose clamp together and slide it

up the fuel line away from fuel filter (Fig. 44).

4. Pull the fuel line off the fuel filter (Fig. 44). Open fuel

shut-off valve and allow gasoline to drain into a gas can

or drain pan.

2

1

Figure 44

1. Fuel shut-off valve 2. Clamp

m–5235

Servicing the Fuel Filter

Service Interval/Specification

Replace the fuel filter after every 200 operating hours or

yearly, whichever occurs first.

Replacing the Fuel Filter

Never install a dirty filter if it is removed from the fuel line.

Note: Note how the fuel filter is installed.

Note: Wipe up any spilt fuel.

1. Disengage the PTO and set the parking brake.

2. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Close fuel shut–off valve at fuel tank (Fig. 44).

4. Squeeze the ends of the hose clamps together and slide

them away from the filter (Fig. 45).

5. Remove the filter from the fuel lines.

6. Install a new filter and move the hose clamps close to

the filter.

33

Page 34

7. Open fuel shut-off valve at fuel tank (Fig. 44).

8. Check for fuel leaks and repair if needed.

1

1

2

3

3

1

2

m–7545

Figure 45

1. Hose clamp

2. Fuel line

3. Filter

Checking the Belts

Service Interval/Specification

Check all belts after every 50 operating hours or monthly,

whichever occurs first. Look for dirt, wear, cracks and signs

of overheating.

Replacing the Wheel Belt

1. Remove hairpin cotter securing brake rod to brake arm

to relax belt idler tension (Fig. 46).

2. Remove bottom and loosen top bolts of shield to rotate

for belt clearance (Fig. 46).

4

m–3793

Figure 46

1. Hairpin cotter

2. Brake rod

3. Shield

4. Drive belt

Replacing the Traction Belt

1. Disengage the blade control (PTO) lever and set the

parking brakes.

2. Stop the engine and wait for all moving parts to stop

before leaving the operating position.

3. Raise the rear of the machine and hold it up with jack

stands.

4. Remove the mower belt (Fig. 47).

1

2

3

3. Lift belt past idler and off drive pulley (Fig. 46).

4. Raise wheel off ground enough to allow belt removal.

Note: Make sure that the mud and grass scraper is adjusted

properly and centered in the pulley grooves (see page 37).

The pointed part of the scraper should be centered and as

deep in the pulley groove as possible, without rubbing at

any point.

5. Replace the drive belt.

6. Secure shield with previously removed bolt and tighten

bolts (Fig. 46).

7. Secure brake rod to brake arm with hairpin cotter

(Fig. 46).

6

5

4

4

Figure 47

1. Idler pulley in slot

2. Traction belt

3. Mower belt

4. Belt guide

5. 1-1/4 inch (32 mm)

6. Mower belt

5. Loosen the pivot bolt enough to slide the idler pulley in

the slot and remove the traction belt from the engine

and the drive pulleys (Fig. 47).

6. Install the new traction belt around the engine and the

drive pulleys (Fig. 47).

7. Slide the idler pulley in the engine frame to tension the

traction belt (Fig. 47).

34

m–4726

Page 35

8. Install the mower belt (Fig. 47).

9. Check the belt guide under the engine frame for the

proper adjustment (Fig. 47).

Note: The distance between the belt guide and mower

belt should be 1-1/4 inch (32 mm) when the mower belt

is engaged. Adjust the belt if necessary. The disengaged

belt should not drag or fall off the pulley when the

guides are properly adjusted.

3

2

1

4

Replacing the Mower Belt

1. Disengage the blade control (PTO) lever and set the

parking brakes.

2. Stop the engine and wait for all moving parts to stop

before leaving the operating position.

3. Remove the knobs and the belt cover on the mower.

4. Remove the idler pulley and the worn belt (Fig. 47).

5. Install the new mower belt.

6. Install the idler pulley.

7. Engage the blade control (PTO) lever and check the belt

tension. Refer to Adjusting the Mower Belt Tension,

page 36.

Note: The proper mower belt tension is 10–15 lbf.

(44–67 N) with the belt deflected 1/2 inch (13 mm) halfway

between the pulleys (Fig. 48).

1/2 in.

2

(13 mm)

5

6

m–3860

Figure 49

1. 1/16–1/8 inch (2–3 mm)

2. Bell crank

3. Transmission output shaft

4. Hairpin cotter

5. Clevis pin

6. Clevis

Note: The clearance should be 1/16–1/8 inch (2–3 mm).

10.Remove the hairpin cotter and the clevis pin from the

bell crank.

11. Rotate the clevis clockwise on the rod to increase the

clearance; rotate it counterclockwise to decrease it

(Fig. 49).

12.Disengage the blade control (PTO) lever.

Note: If the assist arm does not contact the front stop on

the mower deck (Fig. 50), adjust the clevis to bring the

bell crank closer to the transmission output shaft

(Fig. 49).

4

5

3

1

Figure 48

1. Mower belt with 1/2 inch

(13mm) deflection

2. Idler pulley

8. Engage the blade control (PTO) lever.

9. Check the clearance between the bell crank and the

transmission output shaft (Fig. 49).

m-4750

Figure 50

1. 1/2 inch (13 mm)

deflection here

2. Assist arm

3. Front stop

4. Locknut

5. Turnbuckle

13.Check the belt guide under the engine frame for the

proper adjustment (Fig. 47).

35

2

1

m–4739

Page 36

Note: The distance between the belt guide and the mower

belt should be 1-1/4 inch (32 mm) when you engage the

mower belt. Adjust the mower belt as necessary. The

disengaged belt should not drag or fall off the pulley when

the guides are properly adjusted.

Adjusting the Mower Belt

Tension

3

Service Interval/Specification

Check the belt tension after the first 8 operating hours and

25 operating hours thereafter. Check the belt tension after

every 50 operating hours.

Important The belt must be tight enough to not slip

during heavy loads while cutting grass. Over tensioning the

belt will reduce the bearing life of the belt and the spindle.

1. Disengage the blade control (PTO) lever and set the

parking brakes.

2. Stop the engine and wait for all moving parts to stop

before leaving the operating position.

3. Loosen the locknut on the turnbuckle (Fig. 50).

4. Rotate the turnbuckle toward the rear of the mower to

increase the tension on the belt. Rotate the turnbuckle

toward the front of the mower to decrease the tension

on the belt (Fig. 50).

Note: The eyebolt threads on both ends of the

turnbuckle should be engaged a minimum of 5/16 inch

(8 mm).

2

m–47271

Figure 51

1. Spring mounting bolts

2. Blade brake pad

4. Adjust the nut at the end of the blade brake rod until

there is 1/8–3/16 inch (3–5 mm) between the nut and

the spacer (Fig. 51).

5. Engage the blades, and ensure that the blade brake pad