Page 1

JLO L/RM252 ENGINE MECHANICS HANDBOOK

Table of Contents – Page 1 of 1

PREFACE

TECHNICAL DATA

OPERATING - AND MAINTENANCE INSTRUCTIONS

A. BEFORE STARTING

B. SERVICE AND MAINTENANCE

C. ADDITIONAL INSTRUCTIONS

D. GENERAL TROUBLE SHOOTING

ASSEMBLY GROUP 1

RECOIL STARTER

ASSEMBLY GROUP 2

FLYWHEEL, IGNITION SYSTEMS

ASSEMBLY GROUP 3

TIMING PROCEDURE

ASSEMBLY GROUP 4

SPEED CONTROL - RM 252 FLYBALL GOVERNOR

ADJUSTMENT INSTRUCTIONS - MECHANICAL

SPEED CONTROL--L 252 TOP SPEED LIMITER

ASSEMBLY GROUP 5

CARBURETTOR, CARBURETTOR DATA

ASSEMBLY GROUP 6

PISTON, CYLINDER

ASSEMBLY GROUP 7

CRANKCASE,CRANKSHAFT-RM 252

CRANKCASE , CRANKSHAFT - L252

TABLE OF SPECIFICATION

Page 2

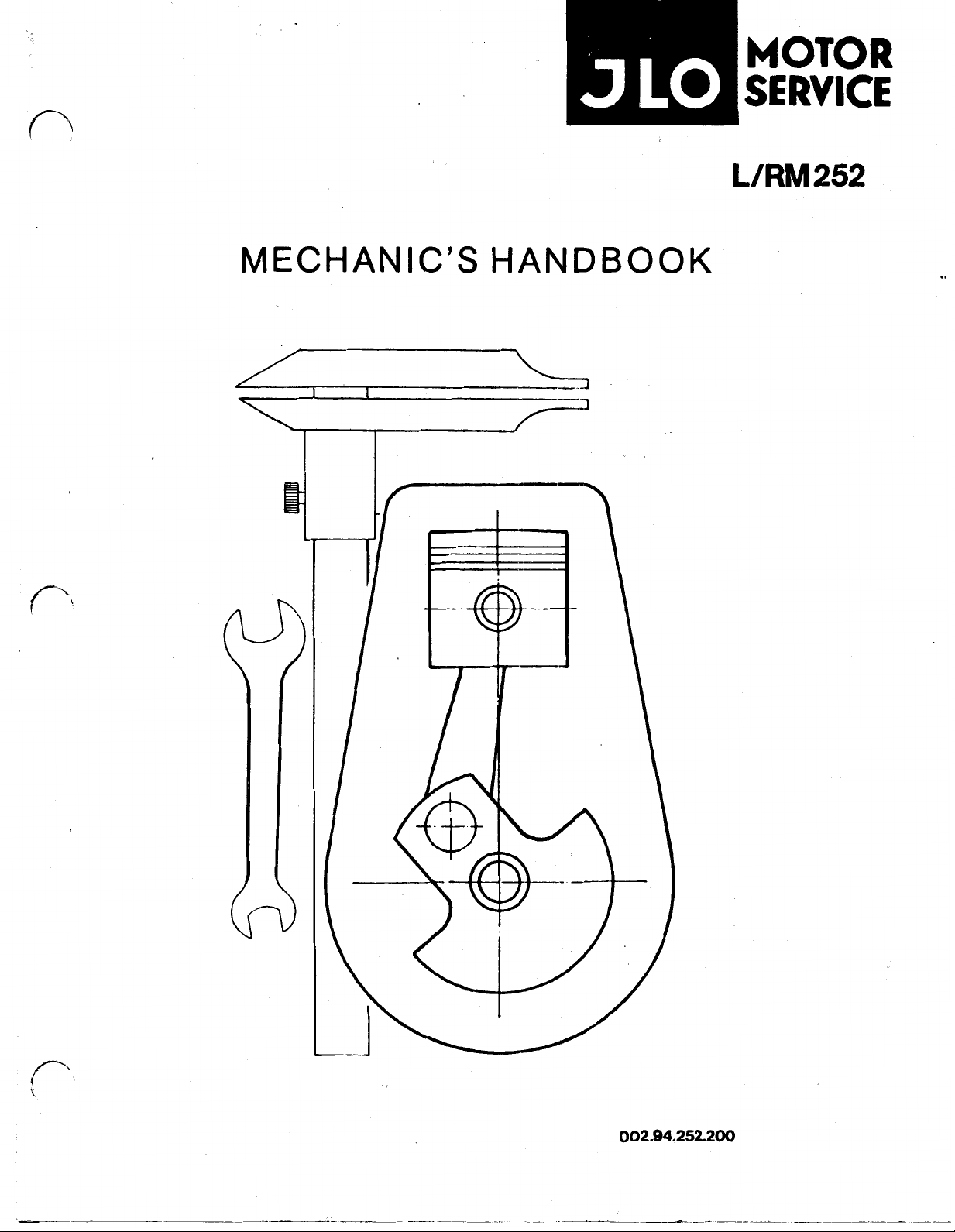

MECHANIC'S HANDBOOK

L/RM

252

Page 3

MOTOR

SERVICE

1

U

7

5

1

4

4

Page 4

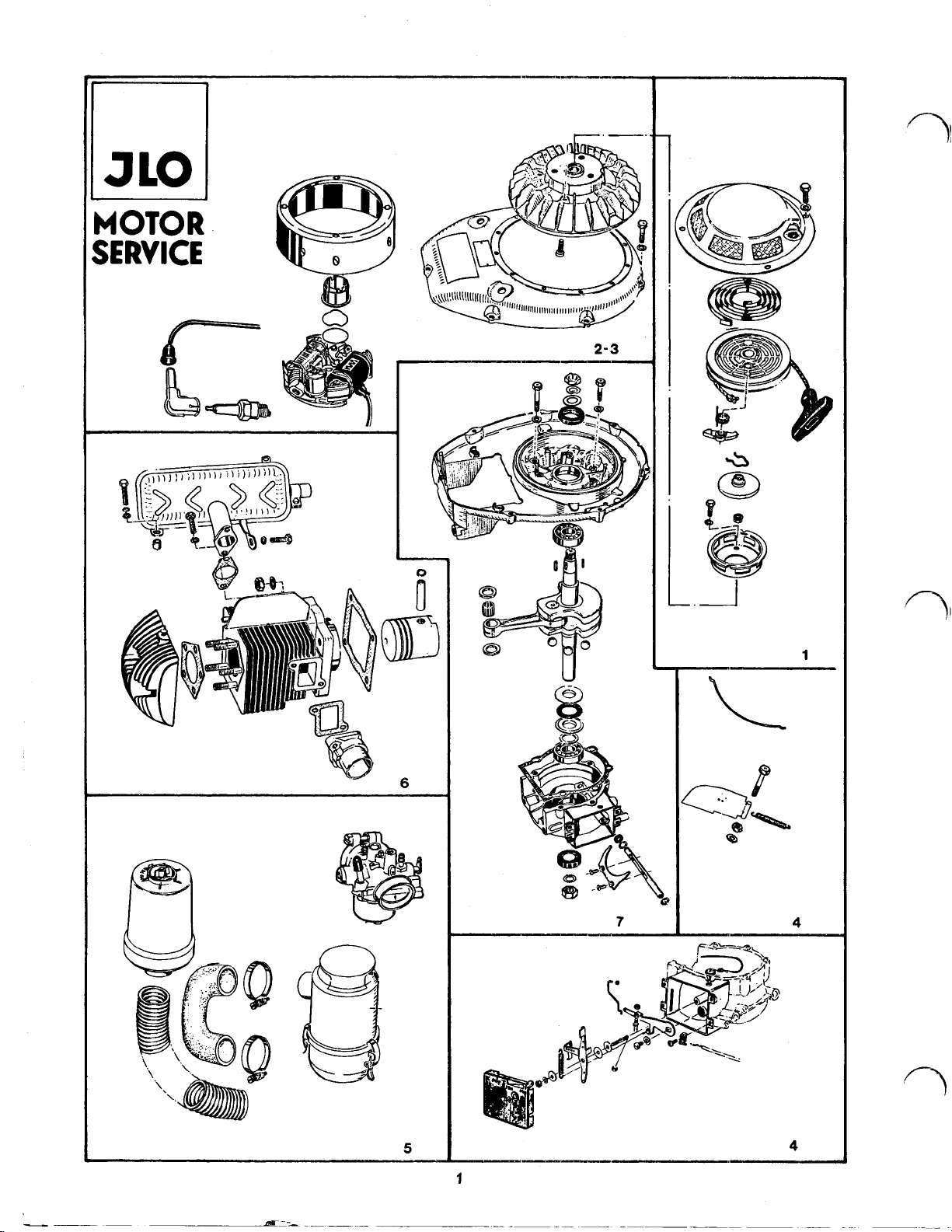

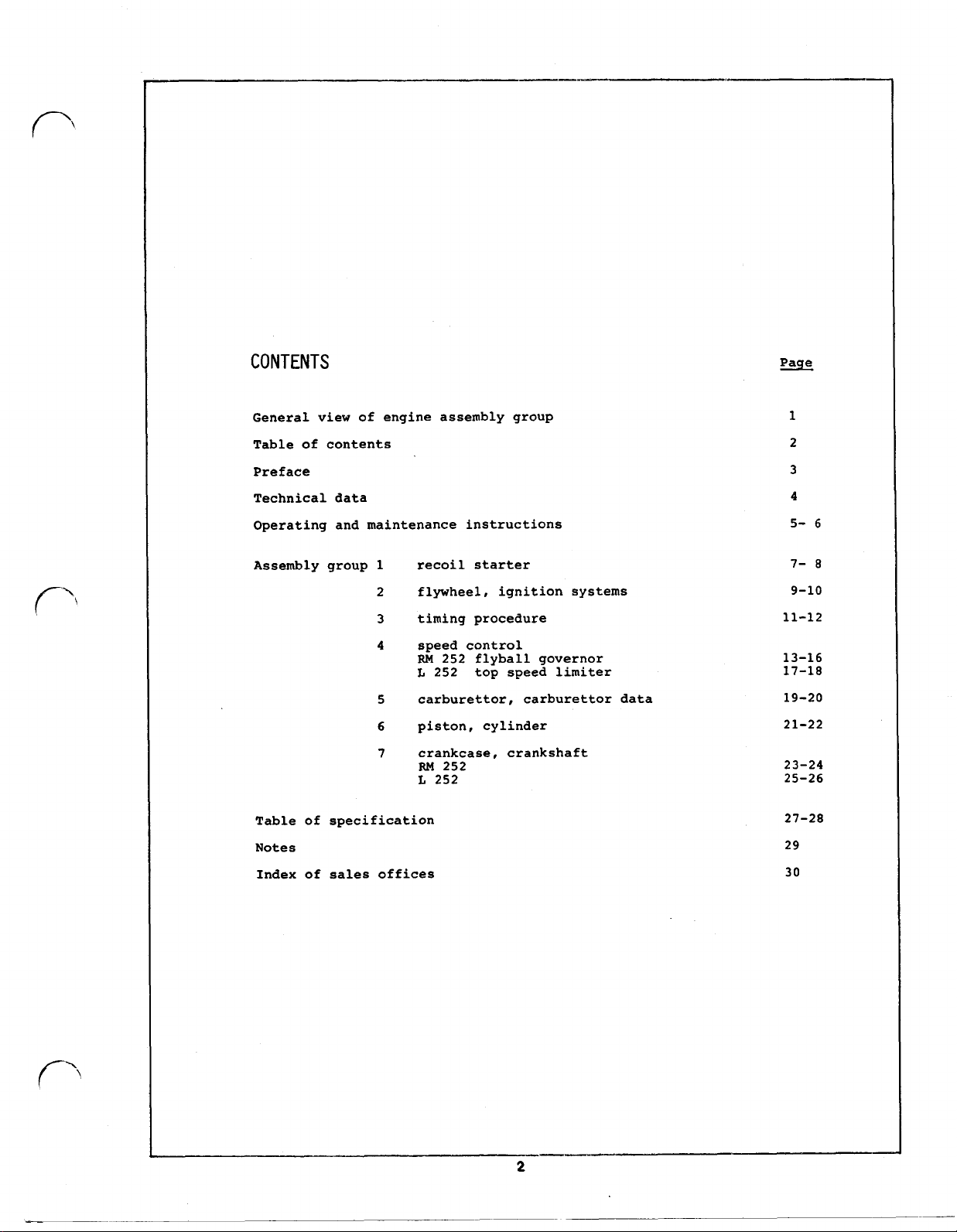

CONTENTS

Page

General vic

of

Table

Preface

Technical data

Operating and maintenance instructions

Assembly group 1 recoil starter

contents

2 flywheel, ignition systems

3

4 speed control

timing procedure

RM

L

5 carburettor, carburettor data

6 piston, cylinder

7 crankcase, crankshaft

L

of

Table

Notes

Index of sales offices

specification

embl of engine ass

252 flyball governor

252 top speed limiter

RM

252

252

1

2

3

4

5-

6

7-

8

9-10

11-12

13-16

17-18

19-20

21-22

23-24

25-26

27-28

29

30

Page 5

This Mechanic's Handbook contains comprehensive information to properly operate, service, and repair JLO en-

L

252

and

RM

gine models

252.

The repair procedures are described in detail and are

supplemented by useful illustrations.

1.

2.

3.

Each assembly group

is

subdivided into DISASSEMBLY

and ASSEMBLY.

The illustration numbers shown in the general view

on page

1

refer to the individual assembly groups

in the procedure section.

When ordering replacement parts, please refer to

the pertinent spare parts list to determine the

correct part number. If the required spare part

cannot be identified, please describe the part and

state engine model and serial number (shown on

name plate) on your order form.

In case of a complete engine overhaul, please do

not try to save money by re-using worn or defec-

tive parts. It is always more sensible to replace

one part too many than to re-use a part which

condition is doubtful. When repairing an engine

is

which

in poor condition, please use available

shortblocks rather than repairing the engine with

individual parts. This and the use of JLO subassembled repair kits will help to save time and

money.

of

The part numbers and exact descriptions

shortblocks and repair kits may be found at the end of

the spare parts list.

4.

5.

Always use genuine JLO spare parts!

To secure certain screws or nuts, a thread locking

compound

249",

"Casco

used.

184"

We

recommend to use "Loctite

or equivalent.

is

Edition

10/86

3

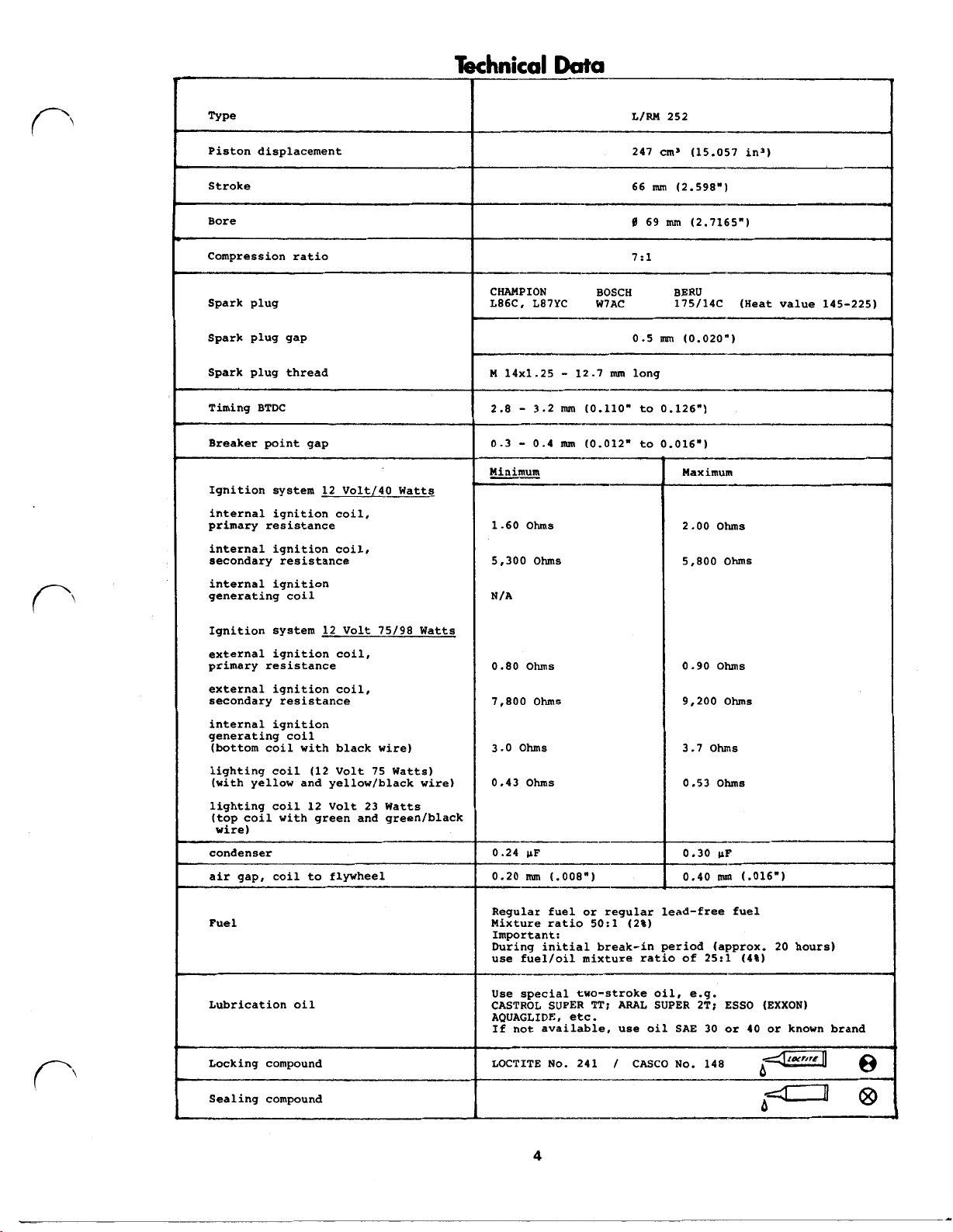

Page 6

Type

L/RM 252

Piston displacement

Stroke

Bore

Compression ratio

Spark plug

Spark plug gap

Spark plug thread

Timing BTDC

Breaker point gap

Ignition system 12 Volt/40 Watts

internal ignition coil,

primary

internal ignition coil,

secondary resistance

internal ignition

generating coil

resistance

247

cm³

(15.057 in³)

66

mm

(2.598")

69

nun

(2.7165")

7:1

CHAMPION

L86C, L87YC

M 14x1.25 - 12.7

2.8 - 3.2

0.3 - 0.4

Minimum Maximum

1.60

Ohms

5,300

Ohms

N/A

BOSCH BERU

W7AC 175/14C (Heat value 145-225)

0.5

mm

(0.020")

mm

long

mm

(0.110" to 0.126")

mm

(0.012" to 0.016")

2

.00

ohms

5,800

Ohms

Ignition system 12 Volt 75/98 Watts

external ignition coil,

primary resistance

external ignition coil,

secondary resistance

internal ignition

generating coil

(bottom coil with black wire) 3.0

lighting coil (12 Volt 75 Watts)

(with yellow and yellow/black wire)

lighting coil 12 Volt 23 Watts

(top coil with green and green/black

wire)

condenser

Fuel

Lubrication oil

Locking compound

0.80

7,800

0.43

0.24

0.20

Regular

Mixture ratio

Important:

During initial break-in period (approx. 20 hours)

use fuel/oil mixture ratio of 25:1

Use special two-stroke oil, e.g.

CASTROL SUPER

AQUAGLIDE, etc.

If not available, use oil SAE 30 or 40 or known brand

LOCTITE No. 241 / CASCO No. 148

Ohms

Ohms

Ohms

Ohms

mm

(.008")

fuel or regular lead-free fuel

(2%)

TT;

ARAL SUPER 2T; ESSO (EXXON)

0

.90

9,200

3.7

ohms

0.53

0.30

0.40

ohms

Ohms

Ohms

mm

(.016") air gap, coil to flywheel

(4%)

Sealing compound

b

4

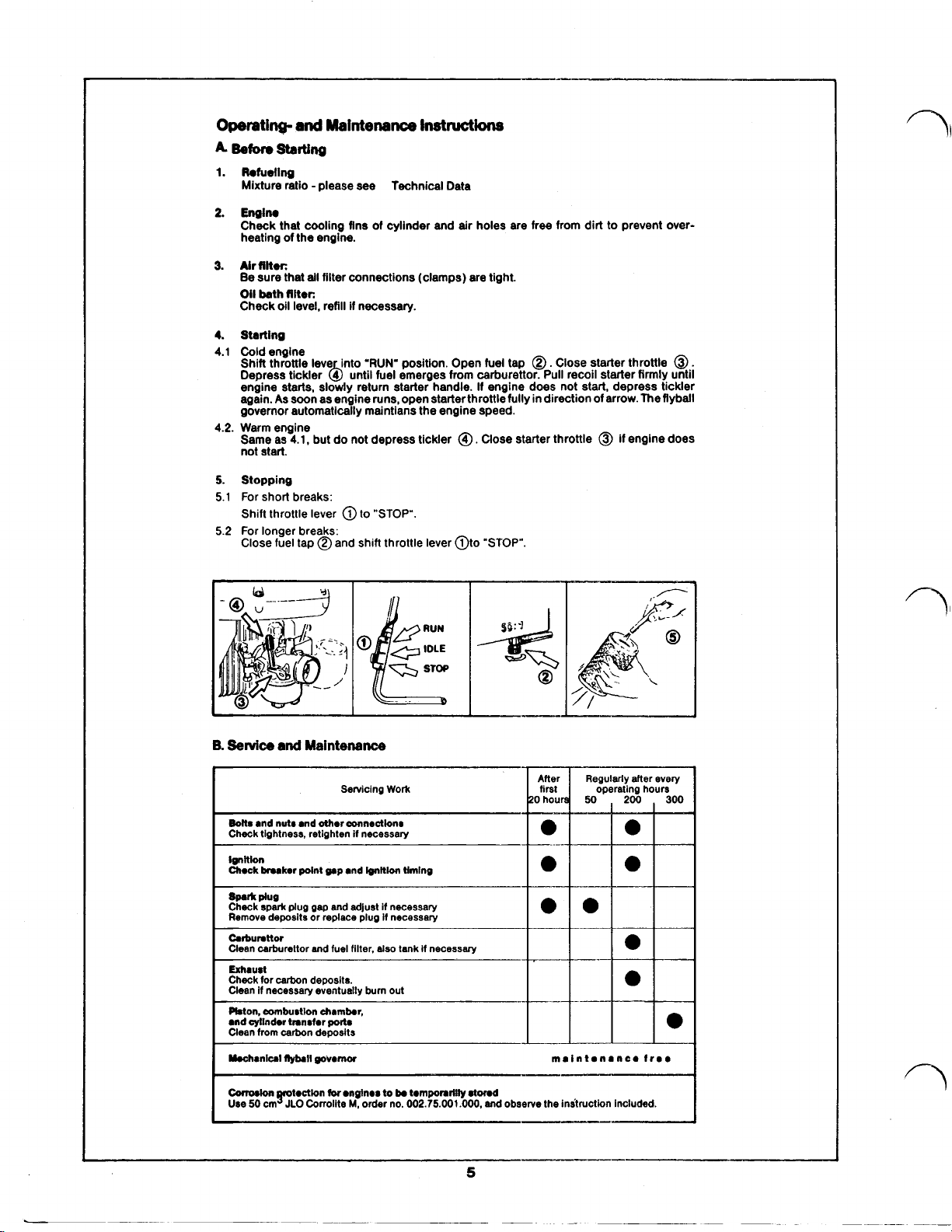

Page 7

Operating-

A.

Before starting

1.

Refueling

Mixture ratio -please

2.

Engine

Check that cooling fins

heating

3.

Air

Be sure that

Oil

Check oil level, refill

4.

Starting

4.1

Cold engine

Shift throttle lever into

Depress tickler until fuel emerges from carburettor. Pull recoil starter firmly until

engine starts. slowly return starter handle.

again.

governor automatically maintains the engine speed.

4.2.

Warm engine

Same as

not start.

5.

Stopping

5.1

For

Shift throttle lever

5.2

For longer breaks:

Close fuel tap shift throttle lever

and

Maintenance

see

of

the engine.

filter:

bath

all

filter connections (clamps) are tight.

filter:

As

soon as engine runs, open starter throttle fully in direction of arrow. The

4.1,

but do not depress tickler Close starter throttle

of

if

necessary.

'RUN'

Instructions

Technical Data

cylinder and

position. Open fuel tap Close starter throttle

air

holes are free from dirt to prevent over-

If

engine does not start. depress tickler

short breaks:

"STOP".

"STOP".

if

engine does

flyball

B.

Service

Bolts

Check tightness, retighten if necessary

Ignition

Chock

Spark

Check

Remove deposits or replace plug if necessary

Carburetor

Clean carburettor and fuel

Exhaust

Check

Clean if necessary eventually burn out

Piston, combustion chamber,

and cylinder transfer

Clean from carbon deposits

Mechanical

Corrosion

Use

and

and nuts and

breaker

plug

spark

plug

for

carbon deposits.

flyball

50

cm

JLO

Maintenance

Servicing

Work

other

connections

point gap and

gap

governor maintanance

Corroilte

ignition

and adjust if necessary

filter.

also

ports

for

engines

to

be

M,

order no.

timing

tank if necessary

temporarilly

002.75.001.000,

stored

and observe the instruction included.

5

free

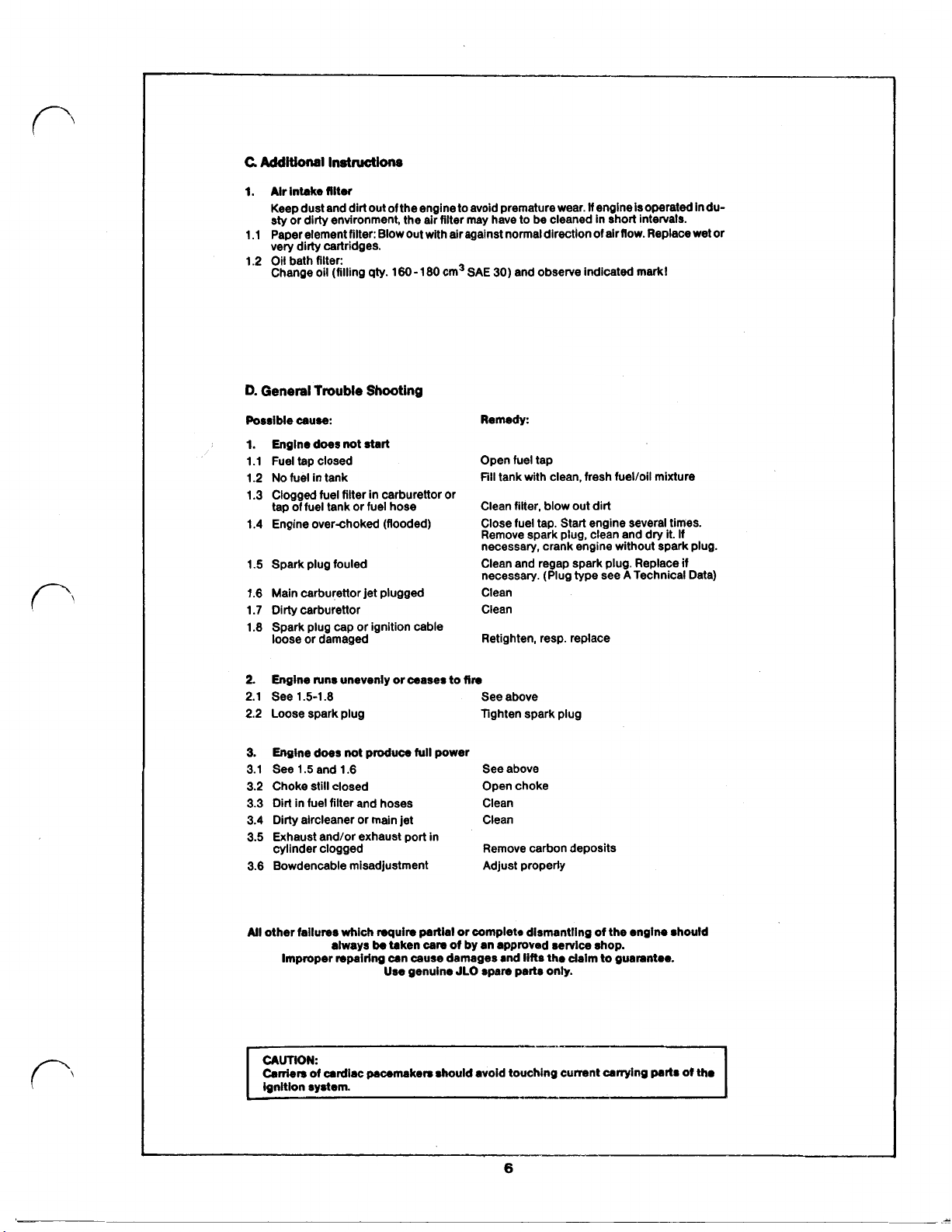

Page 8

C

Additional Instructions

1.

Alr

Intake

filter

Keep dust and dirt out of the engine to avoid premature wear.

sty or

dirty

1.1 Paper element filter: Blow out with air against normal direction

very dirty cartridges.

1.2 Oil bath filter:

Change oil (filling qty. 160- 180 cm³ SAE

D.

General Trouble Shooting

environment, the air filter may have to be cleaned in short intervals.

30)

and observe indicated mark!

If

engineisoperated lndu-

of

airflow. Replace wet or

Possible cause:

1.

Englne does not start

1.1 Fuel tap closed

1.2

No

fuel in tank

1.3 Clogged fuel filter in carburettor or

tap

of

fuel tank or fuel hose

1.4 Engine over-choked (flooded)

1.5 Spark plug fouled

1.6 Main carburettor jet plugged

1.7 Dirty carburettor

1.8 Spark plug cap

loose or damaged

2

Engine runs unevenly

2.1 See 1.5-1.8 See above

2.2 Loose spark plug Tighten spark plug

3.

Engine does

3.1 See 1.5 and 1.6 See above

3.2 Choke still closed Open choke

3.3

Dirt in fuel filter and hoses Clean

3.4 Dirty aircleaner or main jet Clean

3.5 Exhaust and/or exhaust port in

cylinder clogged Remove carbon deposits

3.6 Bowdencable misadjustment Adjust properly

or

ignition cable

not

produce

or

ceases to

full

Remedy:

Open fuel tap

Fill

tank with clean, fresh fuel/oil mixture

Clean filter, blow out dirt

Close fuel tap. Start engine several times.

Remove spark plug, clean and dry it. If

necessary, crank engine without spark plug.

Clean and regap spark plug. Replace if

necessary. (Plug type see A Technical Data)

Clean

Clean

Retighten, resp. replace

fire

power

All

other failures which

Improper repairing can cause damages and

CAUTION

Carriers

ignition system.

of

cardiac pacemakers should avoid touching current carrying parts

always

require

be

taken

Use genuine

partial

care

or

complete dismantling

of

by an approved service shop.

JLO

spare

lifts

the

parts only.

claim

6

of

the engine should

to guarantee.

of

the

Page 9

Assembly

group1

RECO I L

DISASSEMBLY

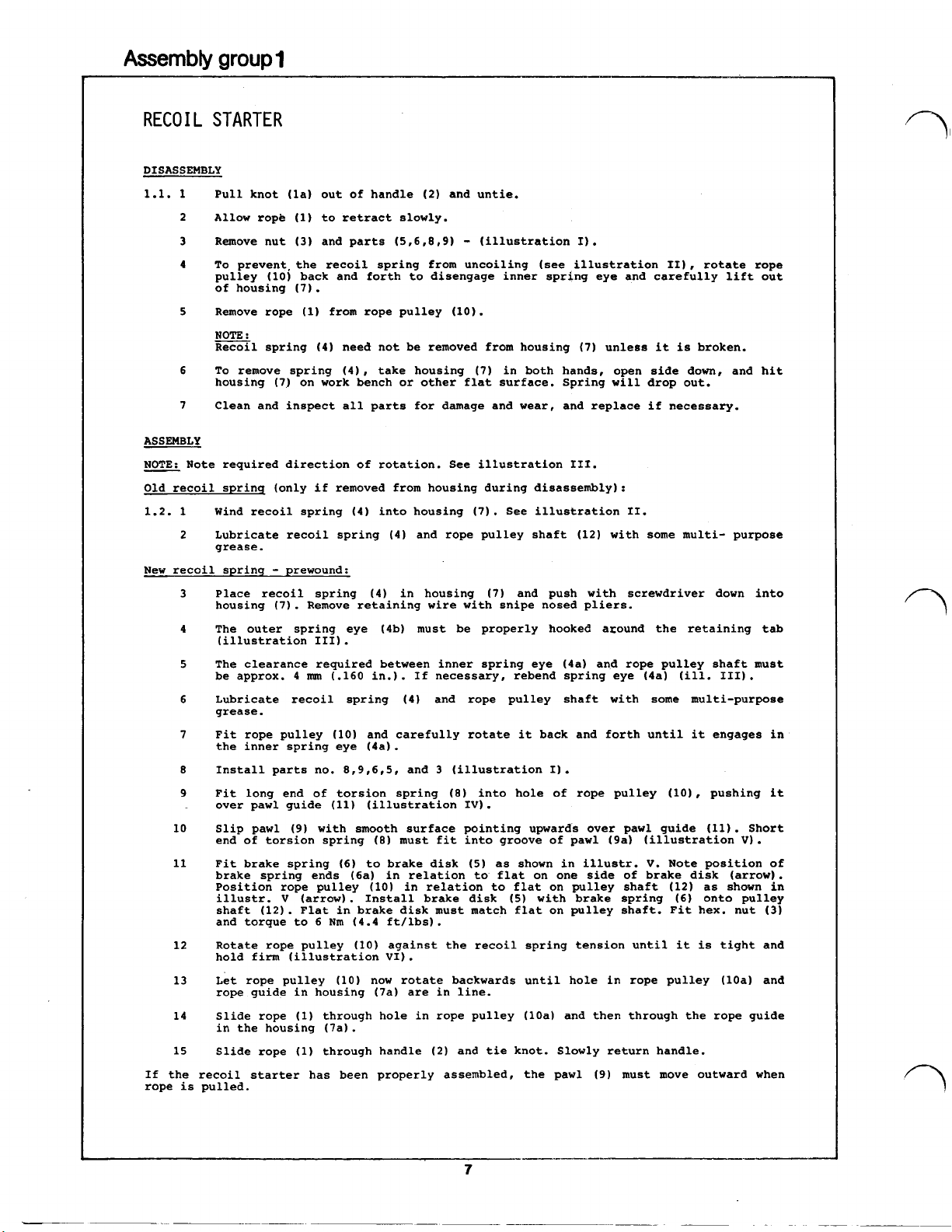

1.1. 1 Pull knot (1a) out

ASSEMBLY

NOTE: Note required direction of rotation. See illustration III.

Old recoil spring (only if removed from housing during disassembly):

1.2. 1 Wind recoil spring (4) into housing

New recoil spring - prewound:

If the recoil starter has been properly assembled, the pawl

rope is pulled.

STARTER

of

handle

2

Allow rope

3

Remove nut

4

To

prevent. the recoil spring from uncoiling (see illustration II), rotate rope

pulley (10) back and forth to disengage inner spring eye and carefully lift out

of housing

5

Remove rope (1) from rope pulley (10).

NOTE

:

Recoil

6

To

remove spring (4), take housing

housing

7

Clean and inspect all parts for damage and wear, and replace if necessary.

2

Lubricate recoil spring (4) and rope pulley shaft (12) with some multi- purpose

grease.

Place recoil spring (4) in housing

3

housing (7). Remove retaining wire with snipe nosed pliers.

4

The outer spring eye (4b) must be properly hooked around the retaining tab

(illustration III).

The clearance required between inner spring eye (4a) and rope pulley shaft must

5

be approx. 4

Lubricate recoil spring (4) and rope pulley shaft with some multi-purpose

6

grease.

7

Fit rope pulley (10) and carefully rotate it back and forth until it engages in

the inner spring eye (4a).

8

Install parts no. 8,9,6,5, and 3 (illustration I).

9

Fit long end of torsion spring

over pawl guide (11) (illustration IV).

10

Slip pawl

end of torsion spring

11

Fit brake spring

brake spring ends (6a) in relation to flat on one side

Position rope pulley (10) in relation to flat on pulley shaft (12) as shown in

illustr. V (arrow). Install brake disk

shaft (12). Flat in brake disk must match flat on pulley shaft. Fit hex. nut

and torque to 6 Nm (4.4 ft/lbs).

Rotate rope pulley (10) against the recoil spring tension until it is tight and

12

hold firm (illustration VI).

Let rope pulley

13

rope guide in housing (7a) are in line.

Slide rope (1) through hole in rope pulley (10a) and then through the rope guide

14

in the housing (7a).

Slide rope (1) through handle

15

(1)

to retract slowly.

(3)

and parts

(7).

spring (4) need not be removed from housing

(7)

on work bench or other flat surface. Spring will drop out.

mm

(.160 in.). If necessary, rebend spring eye (4a) (ill. III).

(9)

with smooth surface pointing upwards over pawl guide (11). Short

(8)

(6)

to brake disk

(10)

now rotate backwards until hole in rope pulley (10a) and

(2)

and untie.

(5,6,8,9)

must fit into groove of pawl (9a) (illustration

-

(illustration I).

(7)

unless it is broken.

(7)

in both hands, open side down, and hit

(7).

See illustration II.

(7)

and push with screwdriver down into

(8)

into hole of rope pulley (10), pushing it

(5)

as shown in illustr.

(5)

with brake spring

(2)

and tie knot. Slowly return handle.

(9)

V.

Note position

of

brake disk (arrow).

(6)

must move outward when

V).

of

onto pulley

(3)

Page 10

5

I

6

I

le

7

2

11

10

6a

Oa

Page 11

Assembly

group

2

FLYWHEEL,

Special JLO Tools

Flywheel puller (11) 444.31.843.100

DISASSEMBLY

2.1.

1

2

3

4

5

6

7

8

ASSEMBLY

2.2. 1

2

3

4

5

6

7

8

9

10

11

IGNITION

Remove screws (1) with lock washer (2) carrier (3).

Remove screws

Remove hex. nut (7). spring washer

To

pull off flywheel (10) use puller (II). Unless magnetic flywheel (25) is defective

it need not

fanwheel remove hex. nuts (24), lock washers (23). and screws (22).

NOTE

:

Holes

in magnetic flywheel are unevenly spaced,

in one position.

Remove key (12), cam (13), spring (14), washer (15) , and pin (16).

Note or mark position of armature plate in crankcase. Remove screws (17), lock

washers (18), and flat washers (19). Remove armature plate (20).

Check coils, condenser, and breaker points, and replace if necessary. (For specifica-

tions, please refer to page

If engine is

Slightly lubricate wires with silicon spray and feed them-through their corresponding

grommets.

Install armature plate (20) and fasten with screws (17), lock washers (18), and flat

washers (19).

If engine is equipped with a 12 Volt, 75/23 Watts ignition system, the green and

green/black lead of the 23 Watts coil must be connected.

(See wiring diagram on page 12).

Place thrust washer (15) and spring (14) on crankshaft. Install cam locating pin (16)

in its groove (16a).

NOTE

:

Cam

(13)

If the engine is to run counterclockwise, you must use the groove with the arrow

pointing to the clockwise rotation. (Groove "L" as shown in illustr.

II and III).

Position cam on crankshaft. Be sure pin (16) is properly seated in cam groove.

To properly set ignition timing, please refer to timing section on page 11/12.

Degrease crankshaft taper and mating taper in fanwheel (10).

Place key (12) in keyway on crankshaft. Inspect inside of magnetic flywheel to

be sure no foreign parts cling to magnets.

NOTE

:

Fanwheel (10) has 2 keyways. If the engine is to run counterclockwise, you must

use the keyway with the arrow pointing to the clockwise rotation. (Keyway

shown in illustr. II)

Place fanwheel (10) on crankshaft. Be sure key (12) is located in proper keyway.

To

prevent water from getting into the ignition area through the unused keyway,

apply sealing compound (10a) to face

washer

Nm. (65-75 ft/lbs).

Install fan cover (6) with lock washers

Install carrier (3) with lock washers (2) and screws (1).

(9),

SYSTEMS

(4)

with lock washer (5) and fan cover (6).

be

removed from fanwheel (10). To separate magnetic flywheel (25) from

so

equipped, remove external ignition coil

has 2 grooves on the inner periphery. Each groove is marked with an arrow.

.

spring washer

(8),

and flat washer (9).

so

flywheel will only fit in fanwheel

4).

(21).

of

(8),

and hex. nut (7). Torque hex. nut (7) to 90-100

fanwheel hub as shown. Install flat

(5)

and screws (4).

"L"

as

9

Page 12

25

15

cam

14

13

clockwise

erclockwise

\

rotation

Page 13

Assembly

group

3

PROCEDURE

Special

Timing gauge

Timing light (2) 000.15.330.000

TIMING DATA:

JLO

Tools

(1)

441.31.875.000

-

Engine Model

L/RM

252

-

Timing BTDC .110 - .126 inches (2.8 - 3.2

Breaker Point Gap .012 - .016 inches

Spark plug gap .020 inches (0.5

PREPARATIONS

3.1.

1 Screw timing gauge (1) into spark plug hole of cylinder head.

2

Connect one lead of timing light to engine ground, the other lead to

the disconnected wire of the ignition system.

3

Bring piston into top dead center position.

BREAKER

IGNITION TIMING

NOTE

Breaker points must be adjusted to proper gap PRIOR to timing the engine.

POINT GAP

4

Check breaker point gap with feeler gauge.

5 To adjust breaker point gap, loosen retaining screw

specified gap by moving fixed part of point set (5).

6

Tighten retaining screw (4), and re-check gap.

:

7

Note reading

position.

of

timing gauge with the piston still in top dead center

(0.3

-

mm)

0.4

mm)

mm)

(4)

and ad just to

8

9

10

11

Turn crankshaft approx.

of rotation (away from TDC), then slowly turn flywheel towards TDC

until timing light (2) changes from dim to bright

device changes loudness (timing point).

Note reading on timing gauge. The difference between the 2 readings

(step

of timing gauge, before TDC.

To

plate in required direction.

NOTE

Rotating the armature plate in the direction of engine rotation will

retard the timing, while rotating the armature plate in the opposite

direction of engine rotation will advance the timing. Never attempt to

advance or retard the timing by changing the breaker point gap.

Tighten armature plate retaining screws (7), and re-check timing repeating the procedure described in steps

NOTE

If timing settings cannot be obtained, breaker points

If breaker points are corroded or otherwise contaminated, engine may

tend to backfire. Clean!

If breaker points are badly pitted, they must be replaced.

Replacement armature plates (12 Volts,

lighting coil. If coil is not used, it may either be removed prior to

installing the plate

coil.

7

and

9)

is the timing in inches

change timing, loosen armature plate retaining screws (7) and rotate

:

:

90°

in opposite direction of normal direction

or

buzzer of timing

or

mm,

depending on calibration

7,

8,

and

9.

must

be replaced.

40

Watts) may be equipped with a

or

the 2 yellow leads may be cut off right at the

11

Page 14

generator

ignition

generating

8

armature plate

(11)

1

9

2

netted

switch)

I

to

kill

yellow/black.

leads when

the

coil

utilized.

I!

!

is

Page 15

Assembly

group

SPEED CONTROL

RM

252

4

FLYBALL GOVERNOR

Special

Vibration tachometer 000.15.300.100

DISASSEMBLY

4.1. 1 Remove nut

ASSEMBLY

4.2. 1 If engine stop contact (10) has been removed, re-install by

JLO

Tools

(21),

washer (18), and cover (17).

2 Disconnect throttle cable noting the hole position for re-assem-

bly. Remove clip

3

When removing lever (2) note into which of the 5 holes the

governor spring (3) is hooked. To remove lever (2)

nut (16), spring washer (15), steel washers (14), and plastic

washer (12). Note sequence. Remove screw

(7)

.

Slide governor lever

4

Engine stop contact (10) need not be removed unless it is to be

replaced.

snapping it back into the bore in governor housing. Be sure

recess in flange clears boss

2

If stud (13) is loose or has been removed, re-install in

crankcase with thread locking compound.

3 Install governor lever

(6).

4

Install lever (2) with washers (14,12), spring washer (15), and

new lock nut (16)

to section "governor adjustment procedure".

(9)

from linkage and unhook linkage (1).

,

remove lock

(6)

(8)

out

of

governor housing.

of

crankcase.

(8)

with spring washer (7) and screw

.

For precise lock nut tightness please refer

and spring washer

5 Install governor spring (3) in appropriate hole of levers 2 and

8.

6

Install governor linkage (1) and secure with new clip

7

Connect throttle cable.

8

Cover (17) with washer (18) and nut (21) should be installed

after governor has been properly adjusted. Please refer to

corresponding section in this manual.

:

NOTE

Bolts (22)

governor shaft (23). (Observe reach of screw!)

When bolts (22) are inserted correctly, lever must move freely

(ill. II).

too

long

or

inserted incorrectly might

13

(9).

jam

the

Page 16

b

Page 17

Assembly

group

4

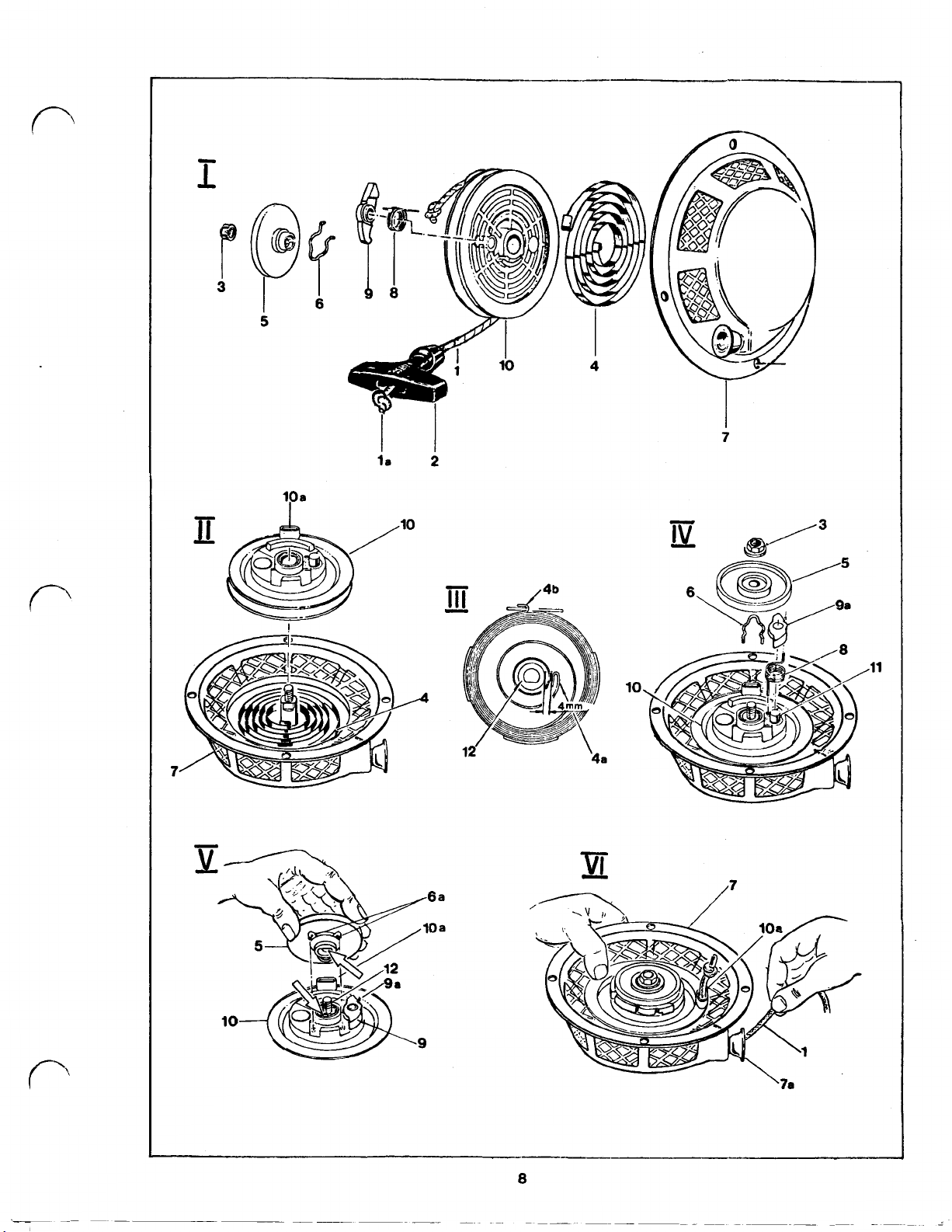

ADJUSTMENT INSTRUCTIONS-MECHANICAL

Special JLO Tools

Vibration tachometer 000.15.300.100

STOP-, IDLE-, AND NO-LOAD ADJUSTMENT with the blade fitted

NOTE

:

Check main and idle jet of carburettor for cleanliness. Set air adjusting screw

(7)

(it should be set 1/2 a turn out).

Preparations:

1. Move both speed lever (1) and throttle lever on mower handle into "Run"

(Max.) position.

2. Hook piano wire

Lightly retain the outer cable by means of screw (19) and clamp

Adjustment of No-Load Speed (throttle wide open):

3.

Hook spring (11) into lever (1) for initial adjustment. (Required no-load

rpm refer to table).

4.

Hold lever (1) in RUN (Max.) position and tighten Nylock nut

spring (11) can just move the lever (1).

5.

Start engine (take all safety rules into consideration). Check speed with

tachometer, and if necessary adjust by bending spring retainer on governor

lever

NOTE

Bending into + direction = engine runs faster

Bending into

(max.

There is no gap between damping spring and housing at no load rpm

6.

If engine tends to hunt at no-load speed, screw out damping spring (9) until

engine stops hunting.

Adjustment

7.

Move speed lever (1) into "Idle" (Min.) position.

NOTE

In this position lever and short circuit contact must still have a gap

(6)

:

-

3.00

of

Idle Speed:

:

into + or - direction. (Refer to illustration and table).

(3)

into lever (1) using the original hole position

-

direction = engine runs glower

mm

corresponds to approx. - 100 rpm)

(4).

(5)

so

that the

(2).

of

1

mm.

8.

Set the idle speed to 1200-1300 rpm by adjusting carburettor idle set screw

(8).

9. Move speed lever (1) into "Stop" position. In this position the lever (1)

must touch the short circuit contact (10). If necessary, loosen clamp screw

(12) at and adjust outer cable (3).

NOTE

:

Change carburettor jets for operation in higher areas. Following a rule

every

size. These modifications do not affect the other jets and adjustments.

3000

ft. of altitude above sea level, the main jet should be reduced

of

thumb

by

one

Page 18

(

/

I

+

higher no-load rpm

-

lower

"

"

No-load adjustment

at

by spring positioning

bore

A

approx. 2750 rpm

B

C

D

E

precise adjustment by bending tongue

max 3.0

mm

correspond with approx. 100 rpm

speed lever

2900

"

3050

3200

"

3400

"

at

wire

wire

lever

1.5

cover, outer

B(C)

6

e

mm

carburettor survey

16

ref.

to

spare parts

list

Page 19

Assembly

group

SPEED CONTROL

L

252

TOP SPEED LIMITER

4

Special

Tachometer

DISASSEMBLY

4.3.

ASSEMBLY

NOTE

Carefully inspect all air vane governor parts for excessive wear or damage.

Replace if necessary. It is particularly important that the governor spring is

not over- stretched or damaged at the spring ends.

4.4. 1 Connect air vane rod

JLO

Tools

-

Vibration Type 000.15.300.100

1

Remove carburettor from intake manifold and disconnect air vane rod

from butterfly lever

:

NOTE

The

butterfly

spindle. When removing the lever, note its original position

(see ill. IV)

2

Carefully unhook spring

3

Loosen hex. nut

4 Remove hex. nut

:

air vane

provided on cylinder (see illustr. I). Do not apply any lubricant to

air vane/spindle!

(5)

,

(2)

lever

(2)

.

(7)

and remove screw

(9)

,

star washer

fit hex. nut

(1)

(see illustr. III and IV).

is positioned by 2 flats on the butterfly

(3)

from lever (4) and airvane

(6)

.

Disconnect air vane rod

(10),

to air vane

(7)

and lock washer

and adjusting lever

(5).

Fit hex. screw

(8)

(5).

(1)

(4).

(6)

,

and install in boss

through

(1)

.

2

Tighten hex. nut

screw (spindle)

3 Connect other end of air vane rod

butterfly spindle. Install carburettor on intake manifold.

NOTE

:

With the air vane in position

tor must be in the fully open position (throttle wide open).

4 Install adjusting lever

5

Carefully hook spring (3) into both holes

as shown in illustr. II.

SPEED ADJUSTMENT

6

Start the engine, observing safety regulations.

7

Loosen hex, nut

lever, and rotate lever to obtain desired engine speed.

:

NOTE

A

=

Higher spring tension = higher speed

=

lower spring tension = lower speed

B

8

When desired speed has been obtained, tighten hex. nut

re-check engine speed with tachometer.

(7)

(6)

with only a little axial play.

(9)

,

insert small punch or drill into hole provided in

so

that air vane moves freely radially on hex.

(1)

"C",

the butterfly valve in the carburet-

(4)

with star washer

to lever

(10)

of

air vane

(2)

of carburettor

and hex. nut

(5)

and lever

(9)

securely and

(9).

(4)

Page 20

I

18

Page 21

Assembly

group

5

CARBURETTOR, CARBURETTOR DATA

DISASSEMBLY

5.1. 1

ASSEMBLY

5.2. 1

Remove air filter from carburettor (1). For filter maintenance please rever to instructions on page 5/6.

2

Close fuel shut-off valve on tank and remove fuel line from carburettor. Remove clip

(2),

governor rod (3), loosen screw (4), remove carburettor (1) from intake manifold.

3

Remove fuel line connection (36), gasket (35), idle jet (5), gasket

ment screw (18), and spring (19).

4

Remove mainjet carrier (7), gasket

5

Remove float by pulling

Remove float needle (14) with spring (15). Remove mixturizer (17).

Check butterfly shaft

6

fly shaft

(24), and foam seal

Butterfly spindle

washer (34) have been removed.

7

Choke shaft assembly (30,31,32) need normally not be removed. In case replacement is

required, note position of detent ball (37) and spring (38).

NOTE

Clean

blow-dry. Inspect all parts for damage and wear, and replace if necessary. Take into

consideration the repair kits mentioned in the preface and at the end of the spare

parts list.

If choke shaft assembly (30,31,32) has been removed, re-install, observing that

cut-out in choke plate points downward and detent ball (37) and spring (38) are in

place.

2

Insert butterfly spindle

screws (27).

NOTE

Butterfly is slightly oval and contour-ground on periphery. For proper position please

see illustr. (I)

3

Install screw (33) and lock washer (34). Fit foam seal (25), washer (24), and and

secure shaft with retainer (23) and screw

4

Install connection (36) with new gasket (35). Install mixturizer (17).

5

Check condition of float (14). and replace if necessary.

NOTE

The float needle seat (16) is pressed-in, and therefore not replaceable.

6

Connect float needle (14) to float (13) via hair pin spring

in carburettor. Fit hinge pin (12).

Float Adjustment

Turn carburettor upside down. Let float (13) close float needle (14) by its own

weight.

of float must be parallel with carburettor housing. If adjustment is required, carefully bend float hinge until parallel. (See illustr.)

7

Install mainjet (10) into mainjet carrier (7), replace gasket

float bowl (9) to carburettor.

NOTE

The float (13) should be in parallel with the surface of the housing. If not, bend the

float hinge accordingly. The float should only touch the float needle (14) slightly

when it is being placed in position. Take care that the elasticity will not be strained too much. The float needle is spring supported!

8

Install idle jet (5) with new gasket

9

Install air adjustment screw (18) with spring (19). Turn screw (18) clockwise until it

bottoms out, (do not force screw

adjustment screw half a turn open).

10

Fit carburettor to engine, tighten screw (4), connect governor linkage (3)

and secure with new clip

NOTE

Dot re-use clip

(28),

remove screw (20), lever

(28)

:

carburettor body and all components in clean fuel or other suitable solvent and

:

.

:

DO

NOT APPLY PRESSURE. Float must move freely on hinge pin (12). Bottom side

:

:

or

pushing float hinge pin (12) out of carburettor housing.

(28)

and choke shaft (31) for excessive wear. To remove butter-

(25).

Remove butterfly retaining screws (27) and butterfly (29).

may be pulled out of carburettor body after screw (33) and lock

(28)

in carburettor body, fit butterfly (29) and secure with

(2).

(2).

(6).

air adjust-

(8),

float bowl (9), and gasket (11).

(21),

screw

(22),

shaft retainer (23), washer

(22).

Mount lever

(6).

(18)

into its seat), then back up half a turn. (Air

(21)

with screw (20).

(15),

as shown and install

(8)

and (11), and fasten

to

lever,

19

Page 22

A Idle set screw

B

Idle jet

C

Air adjustment screw

D

Main jet

Float needle

spring loaded

7

8A

DRC

30S

...

Page 23

Assembly

group

6

PISTON, CYLINDER

DISASSEMBLY

1

6.1.

Loosen nuts (1) and remove spring washers (2)

and gasket (4) . Remove bolt (18) , spring washer (17) , and air

guide (16), if these parts are mounted.

2

Loosen cylinder base nuts

pull off cylinder (7). Discard gasket (8).

3

Remove circlips

(11).

4

Remove thrust washer (12) and needle bearing (13).

:

NOTE

Piston and cylinder ought to be replaced if the max. play between

piston shirt and cylinder wall exceeds

specs., page 27). All ports on the cylinder wall must be beveled,

if the cylinder is re- machined.

,

cylinder head

(5)

and remove spring washers (6), and

(9).

Push or tap out wrist pin, and remove piston

0.35

mm

(see table

(3)

,

of

ASSEMBLY

6.2.

1

2

8

9

10

NOTE

:

Clean sealing surfaces of cylinder and crankcase.

Place new cylinder base gasket (8) on crankcase.

When installing piston (11) the arrow stamped on piston crown must

point towards the exhaust port. (Piston may be installed either

ways if no arrow is shown).

of

Insert needle bearing (13) in eyelet

Install piston (11) and thrust washers (12) with wrist pin (10)

and secure by circlips (9)

Slip a wooden piston support (14) under the piston (11), and

rotate crankshaft until piston rests on support.

Slightly lubricate cylinder liner and piston.

Position piston rings around pegs in ring grooves and compress

rings with ring compressor

ring compressor (15) and piston support (14).

Torque cylinder (7) with nuts

32.4 ft/lbs (44.0 Nm).

Place a new cylinder head gasket (4).

Torque cylinder head

16.2 ft/lbs (22.0 Nm).

.

(15).

(3)

with nuts (1) and spring washers (2) to

Install cylinder

(5)

connecting rod.

(7)

and remove

and spring washers (6) to

1

1

Insert air guide (16) with slotted hole to notched pin (19) in

cylinder head (3) and fasten it with bolt (18) and spring washer

(17) on cylinder (7a)

.

Page 24

A

please

see

I

I

n

:I’

Page 25

Assembly

group

7

CRANKCASE, CRANKSHAFT-RM

Special JLO Tools

Puller 444.31.807.000 (10)

Pair of half shells

Retaining ring

DISASSEMBLY

7.1. 1

ASSEMBLY

7.2. 1

Loosen bolts (3) and remove spring washers (4).

2

Pull crankcase pto side (2) off crankshaft (5). Slide fit of ball bearing (8) and

crankcase (5) allows disassembly without heating up. Discard gasket (22).

3

Remove washer (7) and complete thrust bearing assembly (11) from the crankshaft

(5).

4

Heat crankcase half starter side (1) to approx. 100°C (212°F).

5

Lift crankcase assembly (1),

gently tap crankshaft with plastic hammer out of the crankcase. Remove shim(s) (10)

and seal (19).

6

To remove ball bearing (9) from crankshaft

7

Loosen Loctited screws (17) and remove governor fork (18).

Pull governor shaft (16) out of case (2). Remove washers (15) and knock out small

8

oil seal (14).

9

Heat housing pto side (2) to approx. 100°C (212°F), and tap out ball bearing (8).

10

Remove seal (19) (illustr. I).

Slightly lubricate new oil seals (19). Insert seals with oil seal installation tool

into both crankcase halves (1+2). Sealing lips facing' the inside

2

Place heat shield over oil seal (19) and heat crankcase pto side (2) to approx.

100°C (212°F). Use ball bearing driver and place ball bearing (8) into crankcase.

3

Slightly lubricate governor shaft (16). and fit thrust washers (15) into crankcase

(2) (illustr. I).

4

Use locking compound when tightening screws (17) and fit governor fork (18) on

governor shaft (16). (illustr. II).

5

Knock oil seal (14) into its position. Use slip cone

(illustr. V).

6

Warm ball bearing (9) to approx.

(starter side) by ball bearing driver. (Drive only on

7

Fit governor balls (13) into bores of pto crankweb.

Mount three piece thrust bearing (11). (see illustr. III).

8

9

Mount shim (7) with recess facing towards crankweb.

10

Insert sub-assembled crankshaft

placed slide fitted on crankshaft.

11

Lightly grease new gasket (22) with general purpose grease, and place in position

on crankcase (2).

12

Limit axial play of crankshaft (5) by using shims (10), thickness 0.2

(illustr. IV)

Measuring plane for depth gauge: upper ball bearing edge to crankcase sealing face

with gasket (22) in place (illustr. IV). Any difference between measured result and

required measure (30.1 - 30.2

(10). Thickness of shims 0.2

Place heat shield over oil seal (19), Heat crankcase starter side (1) to approx.

13

100°C (212°F), and mount it (1) on crankcase half, pto side (2).

NOTE:

14

Ensure both crankcase halves (1+2) are properly aligned and install screws (3) with

spring washers (4) fingertight.

Re-check mounting surface for cylinder. Cut off overhanging gasket part (22).

15

Tighten screws of crankcase (3).

16

After mounting cylinder (see description on page 21) tighten crankcase bolts (3).

Torque 90-100 Nm (66.4-73.7 ft/lbs).

17

Turn crankshaft (6) by hand to ensure free moving. If crankshaft will not turn

freely, tap each end of crankshaft lightly with a plastic hammer.

444.31.072.000 (10)

444.31.071.100 (10)

Remove balls (13).

.

Make sure that seals (19) will not be damaged. (Use approximate slip cone).

252

so

that pto shaft end is clear of the work bench, and

(5)

mm/

1.185-1.189 in.) has to be compensated with shims

mm

(.008 in.) (See table

(5)

use bearing puller assembly (12).

of

the crankcase.

(20),

and driver (21)

80°C

(175°F) and drive it on the crankshaft

into crankcase pto side (2) (Ball bearing is

inner

bearing race).

on

page 24).

mm

(.008 in.)

Page 26

I

19

11

5

21

18

(10)

Axial play

0.1

0.1

0.2

000.40.490.960 48

of

crankshaft Measurement

to

0.4

to

0.4

to

0.4

24

b

x

60 x 0.2

2 29.7

1

0

above

above

DIN

29.9

30.1

988

to

to

to

e

a

29.9

30.1

30.2.

Page 27

Assembly

group

7

CRANKCASE, CRANKSHAFT

Special JLO Tools

Puller

Pair of half shells

Retaining ring

DISASSEMBLY

7.3.

1

Loosen screw

2

To

separate crankcase halves

(100°C).

Lift housing that pto shaft end hangs free and carefully tap

crankshaft with plastic hammer out of crankcase.

Discard gasket

Pry or knock out oil seals

To remove ball bearings

puller assembly

ASSEMBLY

7.4.

Slightly lubricate new oil seals. Knock seals with oil seal

1

installation tool into both crankcase halves

must point into crank chamber (ill.

2

Heat ball bearings

crankshaft by a ball bearing driver (ill.

NOTE

:

Ball bearing must be driven on inner bearing race.

444.31.807.000 (10)

444.31.072.000 (10)

444.31.071.100 (10)

(3)

and remove spring washers

(7).

(6)

(10)

(8)

(ill.

(8)

II).

to approx.

(1+2),

(see ill.

from crankshaft

heat them to approx.

I).

III).

175°F

(80°C) and drive them on

IV).

(4).

(1+2)

(5)

use bearing

.

Sealing lips

212°F

Place heat shield over oil seal

3

to

212°F

firmly in place.

NOTE

Make sure that seals

cone)

Lightly grease new gasket

place in position on crankcase

Heat crankcase half

described under item

that both crankcase halves

screws

Re-check mounting surface €or cylinder. Cut off overhanging

gasket

19)

cross-tiahten crankcase screws

Turn crankshaft

crankshaft will not turn freely, tap each end of crankshaft

lightly with a plastic hammer.

(100°C) and install crankshaft

:

(6)

are not damaged (Use appropriate slip

.

(1)

to

3

and mount on crankcase half

(3)

with spring washers

(7).

After mounting the cylinder (see description on page

(5)

by hand to ensure freedom of rotation. If

(1+2)

(6)

and heat crankcase half

(5)

in crankcase. Press

(7)

with general purpose grease and

(2).

212°F

(4)

(100°C) in same manner as

(2).

are properly aligned and install

fingertight.

(3).

(2)

Ensure

Page 28

e

26

Page 29

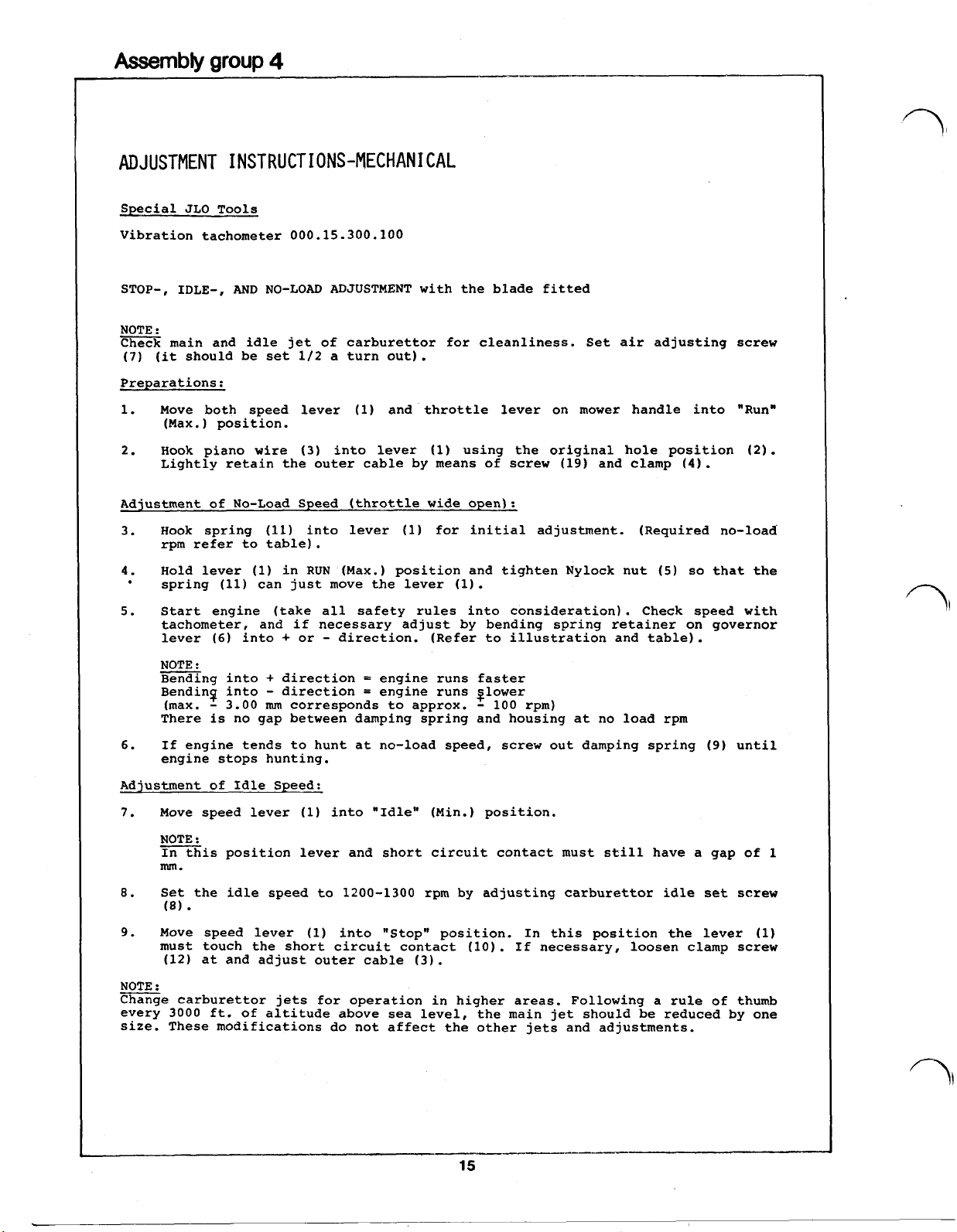

TABLE

OF

SPEC

IF

I

ON

Dim. Ref. Minimum

Bore new

1st

oversize

(+0.5

A

mm)

69,000 (2.7165)

69,500 (2.7362 69,519 (2.7370)

2nd oversize

(+1.0

mm)

70,000

ring groove

width, piston

B

top

center, bottom

C.D

ring groove dia.

1st

E

oversize

2nd oversize

F

piston ring

2,580 (0.1016)

2,565 (0.1010)

62,51 (2.461)

62,91 (2.477)

63,41 (2.496)

0,25 (0.010)

end gap

mm

(inch) Maximum

69,019 (2.7173)

(2.7560 70,019 (2.7567)

2,600

2,580

62,7

63,1

63,6 (2.504)

0,40 (0.016)

mm

(inch) Repair required

(0.1024)

(0.1016)

(2.469)

(2.484)

69,169 (2.7232)

69,669 (2.7429)

70,169 (2.7626)

2,700 (0.1063)

2,680 (0.1055)

1,25 (0.066)

G

piston ring

wall thickness

piston dia.

H

new

1st oversize

(+0.5

2nd oversize

(+1.5

J

rod bearing bore

K

wrist pin dia.

crankshaft

end play

f

measuring point

a

measuring point a

mm)

mm)

2,62 (0.103)

68,887

69,387

69,887

19,992 (0.7871)

15,986 (0.6294)

0,100 (0.004) 1,040 (0.041)

f

30

(2.7121)

(2.7318)

(2.7515)

mm

((1.18")

2,78 (0.109) 2,00 (0.079)

68,900 (2.7126)

69,400 (2.7323)

69,900 (2.7520)

20,001 (0.7874)

15,995 (0.6297)

perpendicular to the wrist pin axis up

from the bottom edge

22,5

mm

(0.886")

from cylinder top edge

68,737 (2.7062)

69,237 (2,7259)

69,737 (2.7456)

see comments

see comments

of

the piston skirt

27

Page 30

NOTE

:

Piston and cylinder ought to be replaced if the max. play between

piston skirt and cylinder wall exceeds

typ, the piston ring end play should not exceed 0.10 to

0.35

mm.

Depending on engine

0.12

mm.

COMMENTS

1.

:

Piston rings:

All three piston rings have to be replaced if piston ring end

gap exceeds the max. dimension stated in table item

end gap has to be measured in the bore of a new cylinder.

2.

Connection rod/wrist pin:

The stressed surfaces of wrist pin and connecting rod turn in a

needle bearing,

so

that the play between these surfaces cannot

easily be measured. If the wrist pin has seized or has changed

colour excessively but rod surface seems to be still undamaged,

replace the wrist pin and needle bearing.

If the bearing surface of rod eye (wrist pin rolling surface)

has seized or has excessively changed colour, the complete

crankshaft ought to be replaced.

"F".

Ring

Page 31

Telefax

1620

Pinneberg

041 01/21 40

2

Telex

0

41 01 69 12

189 113

Pinneberg

fin

PRODUCTS

COMPANY

der

Loading...

Loading...