Page 1

Form No. 3358-281 Rev A

Tru Trak® Sulky

For Floating Deck Mid-Size Mowers

Model No. 30110 —Serial No. 220000001 and Up

Register your product at www.Toro.com Original Instructions (EN)

Page 2

Introduction

R ead this infor mation carefully to lear n ho w to operate

and maintain y our product properly and to a v oid injur y

and product damag e . Y ou are responsible for operating

the product properly and safely .

T his man ual uses 2 other w ords to highlight

infor mation. Impor tant calls attention to special

mec hanical infor mation and Note emphasizes g eneral

infor mation w or th y of special attention.

Contents

Y ou ma y contact T oro directly at www .T oro .com for

product and accessor y infor mation, help finding a

dealer , or to register y our product.

W henev er y ou need ser vice , g en uine T oro par ts , or

additional infor mation, contact an A uthorized Ser vice

Dealer or T oro Customer Ser vice and ha v e the model

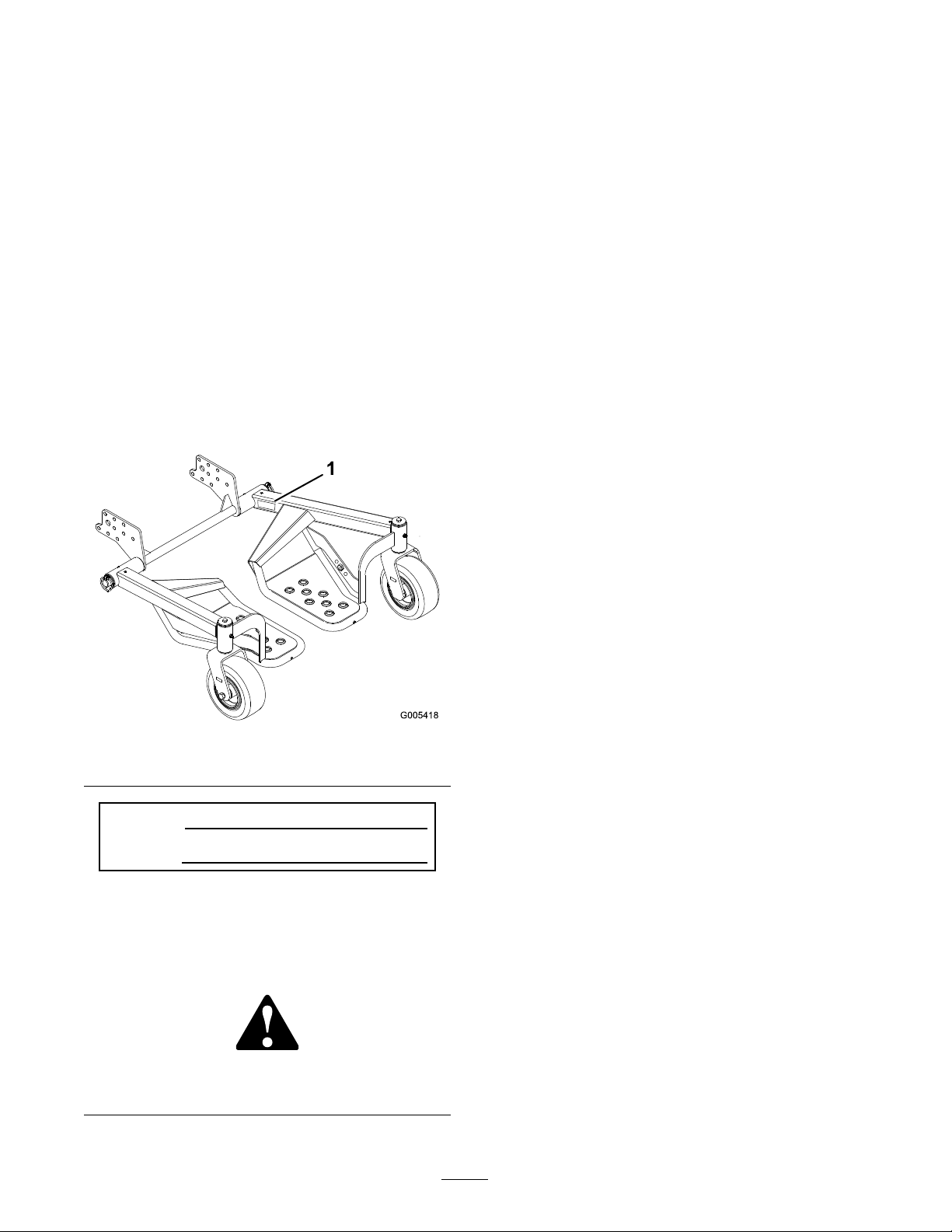

and serial n umbers of y our product ready . Figure 1

identifies the location of the model and serial n umbers

on the product. W rite the n umbers in the space

pro vided.

Figure 1

1. Model and serial number location

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safe Operating Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1 Installing the Axle on a Hy draulic

Dri v e Mo w er with Standard T -Bar

Handles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Installing the Axle on a Hy draulic Dri v e

Mo w er with T2 T -Bar Handles . . . . . . . . . . . 6

3 Installing the Axle on Gear Dri v e

Mo w ers with Pistol Grip or T -Bar

Handles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Installing the Axle on a Hy draulic

Dri v e Mo w er with Pistol Grip

Handles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 Installing the Sulk y Assemblies . . . . . . . . . . . . . . . . . . . . . . . 9

6 Adjusting the Handle Height . . . . . . . . . . . . . . . . . . . . . . . 10

7 Installing the Lanyard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8 Installing the W eight Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

9 Adjusting the P arking Brak e . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

P ositioning the Sulk y for T ranspor t . . . . . . . . . . . . . . . . . 15

R emo ving the W eight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operating Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chec king the Tire Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Greasing the Sulk y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Adjusting the Sulk y T ranspor t P osition . . . . . . . . . . . . 16

Model No.

Serial No.

T his man ual identifies potential hazards and has

safety messag es identified b y the safety aler t symbol

( Figure 2 ), whic h signals a hazard that ma y cause

serious injur y or death if y ou do not follo w the

recommended precautions .

Figure 2

1. Safety alert symbol

© 2007—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Contact us at www.Toro.com.

2

Printed in the USA.

All Rights Reserved

Page 3

Safety

Improper use or maintenance b y the operator or

o wner can result in injur y . T o reduce the potential

for injur y , comply with these safety instr uctions

and alw a ys pa y attention to the safety aler t symbol,

whic h means CA UTION , W ARNING , or

D ANGER -“personal safety instr uction." F ailure

to comply with the instr uction ma y result in

personal injur y or death.

Safe Operating Practices

General Operation

• Do not modify the sulk y or use it on

non-appro v ed mac hines .

• Ensure that the sulk y is properly attac hed to

the mac hine and is in g ood w orking order

prior to use .

• Allo w only the mac hine operator on the sulk y .

W hen tur ning, lean forw ard and to w ard the

direction of the tur n to help in k ee ping y our

balance .

• Do not allo w use of the sulk y b y untrained

operators .

• Use appropriate personal protecti v e apparatus

for eyes , ears , feet, hands , and head.

• Practice operating the mac hine without the

sulk y until y ou become familiar with the

controls .

• Before using the mac hine with the sulk y

attac hed, practice operation on a larg e open,

lev el ter rain with no obstacles . T he sulk y will

affect the mac hine operation, especially on

slopes , when tur ning, and when stopping .

• Use caution when riding the sulk y o v er curbs ,

roc ks , roots , or other obstr uctions .

• Slo w do wn before making tur ns and use extra

caution on rough ter rain and on slopes .

• T ra v el across slopes , a v oiding operation on

stee p slopes .

• Look behind and do wn before bac king up to

be sure of a clear path. Use extra care when

operating in rev erse .

• Dismount and latc h eac h sulk y assembly in

the up position when loading the mac hine for

transpor t.

• Use care when tur ning to ensure that y ou do

not swing y ourself and the sulk y into obstacles .

3

Page 4

Setup

Loose Parts

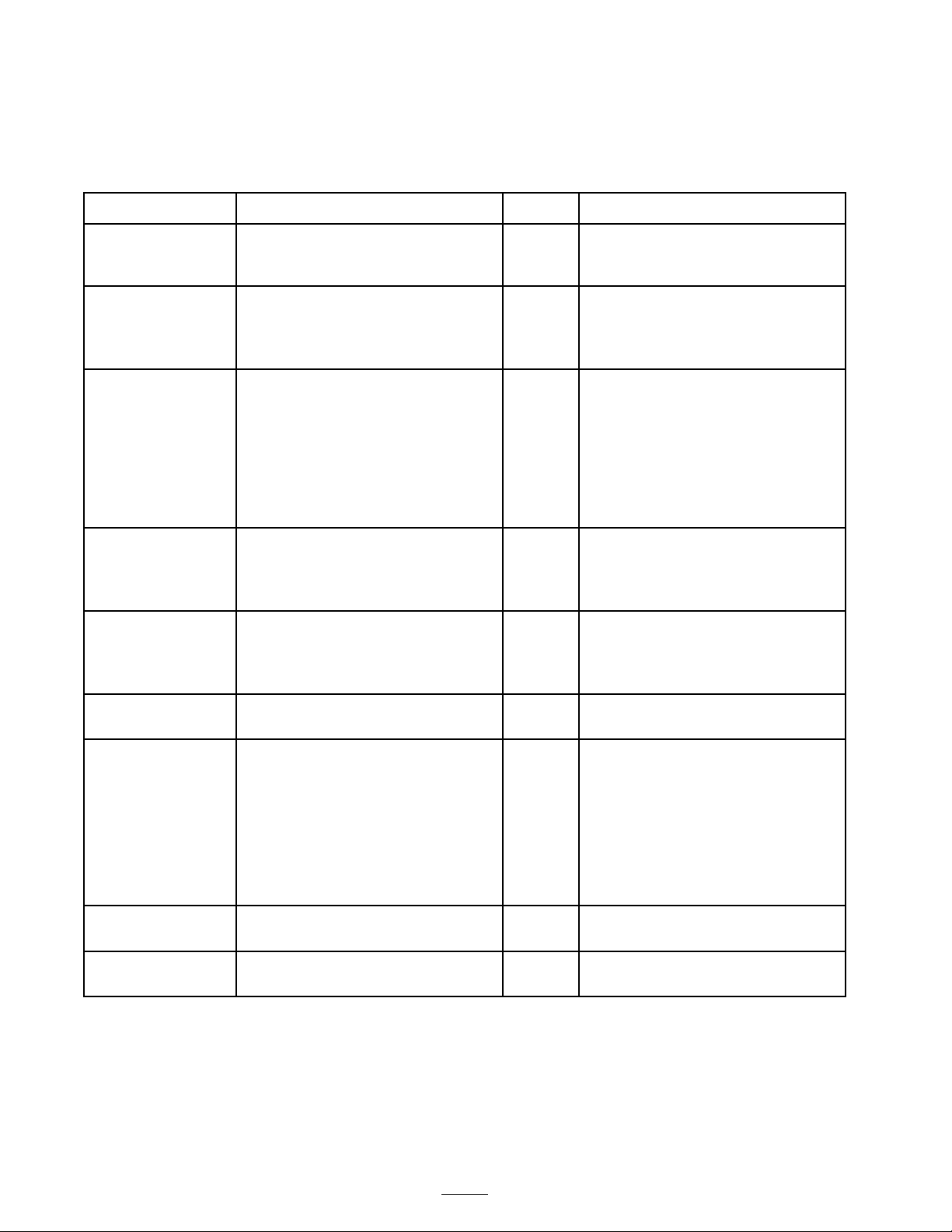

Use the chart below to verify that all parts have been shipped.

Step

Axle

1

2

3

4

5

Bolt, (3/8 x 1–3/8 inches)

Locknut, (3/8 inch)

Axle

Large spacer

Locknut, (3/8 inch)

Bolt, (3/8 x 1-3/4 inches)

Axle

Small spacer

Large spacer

Locknut, (3/8 inch)

Bolt, (3/8 x 1–3/8 inches)

Bolt, (3/8 x 4/1/2 inches) For use

with T-Bar, gear drive machine

only.

Axle

Large spacer

Locknut, (3/8 inch)

Bolt, (3/8 x 1-3/4 inches)

Left sulky assembly

Right sulky assembly

Lynch pin

Washer, (1-3/4 inches)

Description

Qty.

1

6

6

1

2

6

6

1

2

2

6

6

2

1

2

6

6

1

1

2

2

Installing the axle on a hydraulic

drive mower with standard T-Bar

handles.

Install the axle on a hydraulic drive

mower with T2 T-Bar handles.

Install the axle on gear drive

mowers with pistol grip or T-Bar

handles.

Install the axle on a hydraulic drive

mower with pistol grip handles.

Install the sulky assemblies.

Use

6

7

8

9

No parts required

Lanyard

Bolt, (5/16 x 1-1/4 inches)

Spacer 2

Small washer

Locknut, (5/16 inch)

Shoulder bolt

Washer, (1/2 inch)

Washer, (3/8 inch)

Weight Kit (if needed)

No parts required

–

2

2

2

4

2

2

2

-

–

Adjust the handle height.

Install the lanyard.

Install the weight kit.

Adjust the parking brake.

4

Page 5

Step

1

Installing the Axle on a

Hydraulic Drive Mower with

Standard T-Bar Handles

Parts needed for this step:

1

Axle

6

Bolt, (3/8 x 1–3/8 inches)

6

Locknut, (3/8 inch)

Impr oper installation or application of a

sulk y can ef fect the sta bility and contr ol of

the Mid-Siz ed Mo w er s, which could cause

per sonal injur y or death.

• W eight kits mounted in the r ear position

need to be r emo v ed when a sulk y is

installed.

• T he par king brak e must be adjusted, on

units equipped with a par king brak e,

when a sulk y is installed.

• T he sulk y is not r ecommended on Mid

Siz e mo w er s equipped with 32 inch

mo w er s.

Procedure

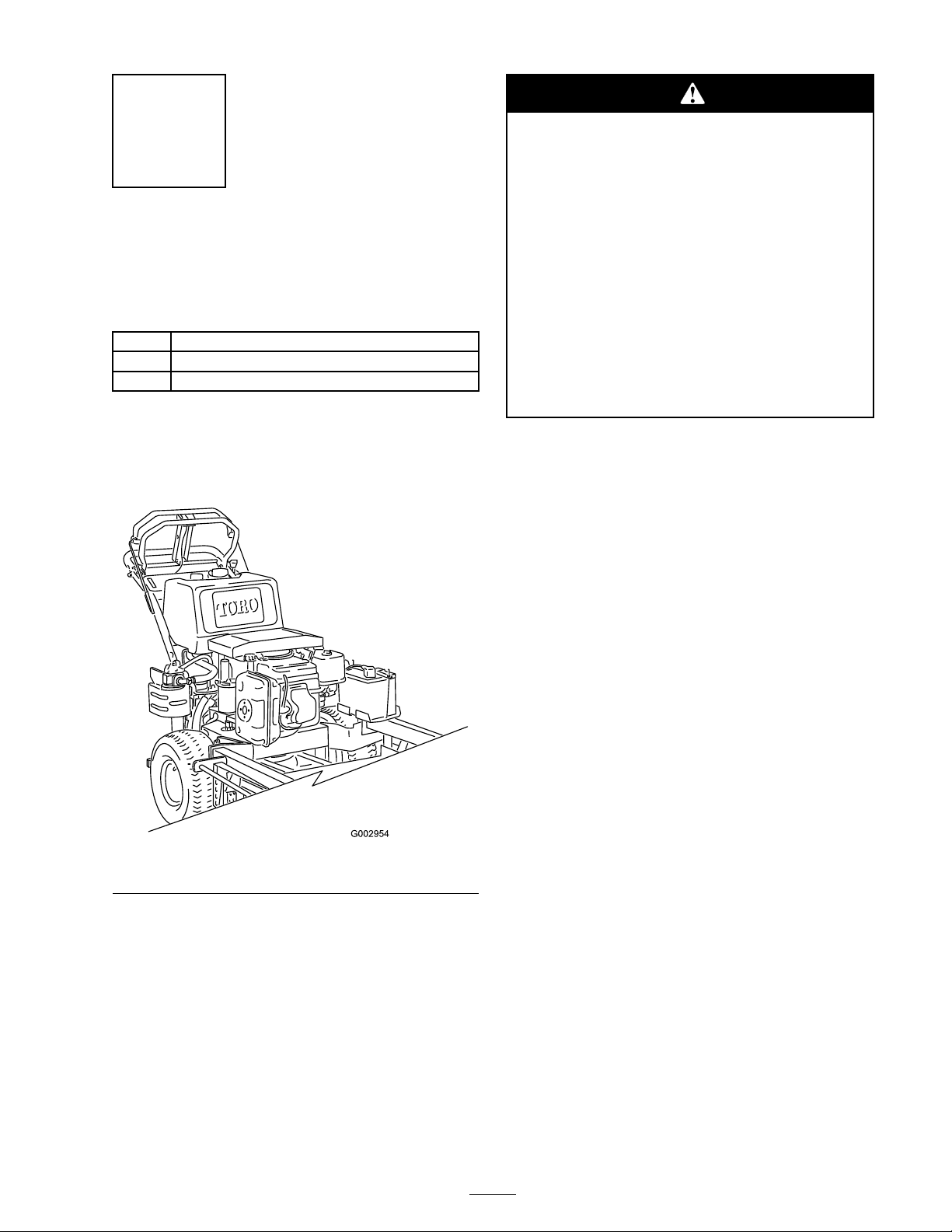

If y our mac hine has handles as sho wn in Figure 3 ,

use the follo wing instr uctions to install the axle .

Figure 3

1. Stop the engine , set the parking brak e , remo v e

the k ey , and w ait for all mo ving par ts to stop

before lea ving the operating position.

2. R emo v e the 6 bolts , spacers , and n uts securing

the bottom of the tw o pulley guards on both

sides of the frame (3 bolts and n uts on eac h

side) ( Figure 4 ). Sa v e all 6 of the bolts and

discard the loc kn uts .

3. Using the 6 bolts (3/8 x 1–3/8 inc hes) and

loc kn uts (3/8 inc h) supplied with the sulk y ,

install the axle as illustrated in Figure 4 .

5

Page 6

Step

2

Installing the Axle on a

Hydraulic Drive Mower with

T2 T-Bar Handles

Parts needed for this step:

1

Axle

Large spacer

2

6

Locknut, (3/8 inch)

6

Bolt, (3/8 x 1-3/4 inches)

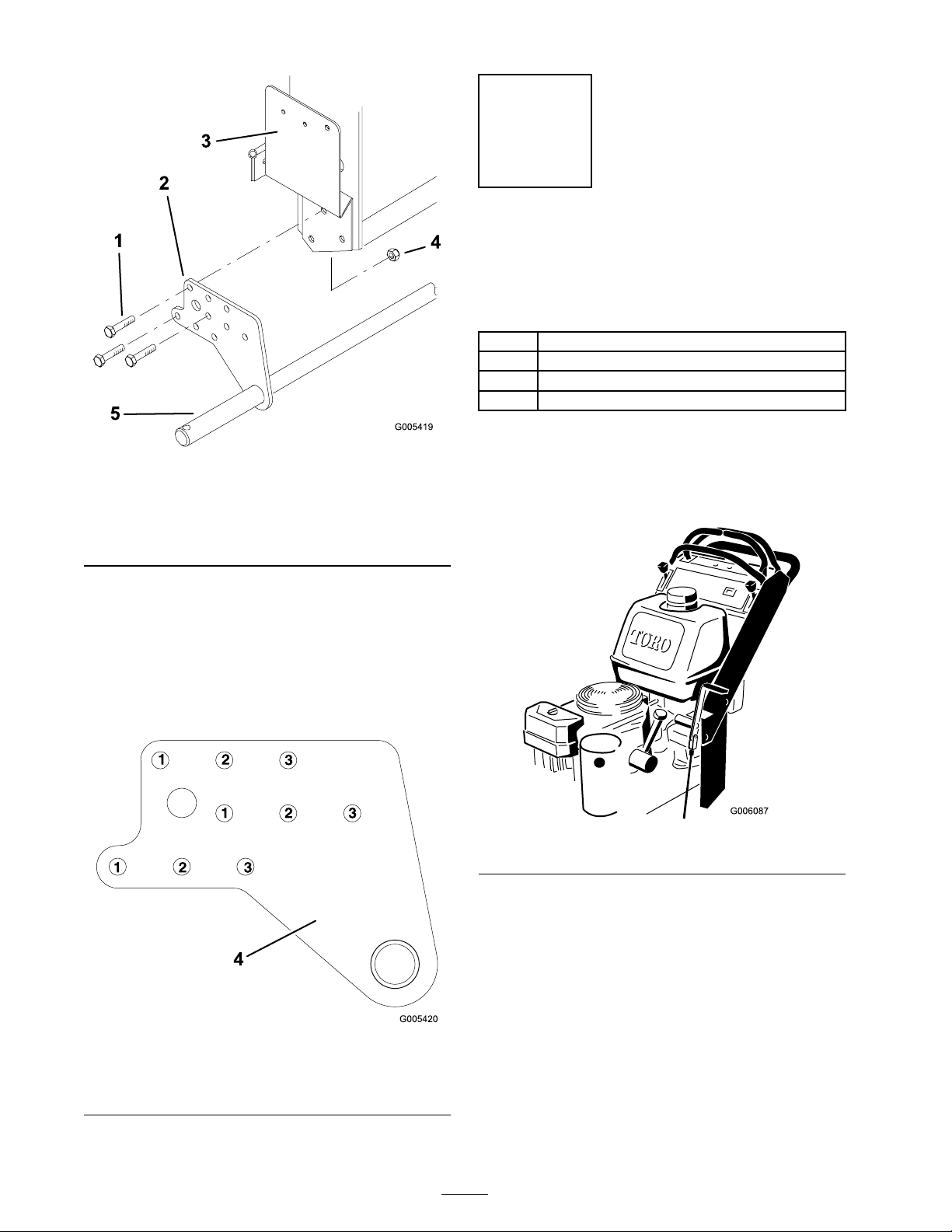

Figure 4

Left side of mower shown

1. Bolt, (3/8 x 1–3/8 inches) 4. Locknut, (3/8 inch)

2. Axle mounting bracket 5. Axle

3. Pulley guard

Note: Y ou can install the axle in one of 3

horizontal positions ( Figure 5 ). F or a T -Bar

controlled mac hine , the a v erag e person will g et

the best results using the rear holes; ho w ev er ,

if a larg e person will be using the sulk y , y ou

ma y w ant to install it using the middle or front

holes to gi v e the operator more room.

Procedure

If y our mac hine has handles as sho wn in Figure 6 ,

use the follo wing instr uctions to install the axle .

Figure 6

Figure 5

1. Front holes (pistol grip

machines)

2. Middle holes 4. Axle mounting bracket

3. Rear holes (T-bar machines)

6

Page 7

Impr oper installation or application of a

sulk y can ef fect the sta bility and contr ol of

the Mid-Siz ed Mo w er s, which could cause

per sonal injur y or death.

• W eight kits mounted in the r ear position

need to be r emo v ed when a sulk y is

installed.

• T he par king brak e must be adjusted, on

units equipped with a par king brak e,

when a sulk y is installed.

• T he sulk y is not r ecommended on Mid

Siz e mo w er s equipped with 32 inch

mo w er s.

1. Stop the engine , set the parking brak e , remo v e

the k ey , and w ait for all mo ving par ts to stop

before lea ving the operating position.

2. P osition the axle mounting brac k ets on both

sides of the mac hine frame ( Figure 7 ).

3. Inser t the larg e spacers betw een the axle

mounting brac k ets and the frame , lining up the

holes ( Figure 7 ).

Figure 7

1. Bolt, (3/8 x 1-3/4 inches) 3. Locknut, (3/8 inch)

2. Large spacer

4. Axle mounting bracket

4. Using the 6 bolts (3/8 x 1-3/4 inc hes) and

loc kn uts (3/8 inc h) supplied with the sulk y ,

install the axle as illustrated in Figure 7 .

Note: Y ou can install the axle in one of 3

horizontal positions ( Figure 5 ). F or a T -Bar

controlled mac hine , the a v erag e person will g et

the best results using the rear holes; ho w ev er ,

if a larg e person will be using the sulk y , y ou

ma y w ant to install it using the middle or front

holes to gi v e the operator more room.

7

Page 8

Step

5. Inser t the larg e spacers betw een the axle

mounting brac k ets and the frame , lining up the

holes ( Figure 8 ).

3

Installing the Axle on Gear

Drive Mowers with Pistol

Grip or T-Bar Handles

Parts needed for this step:

1

Axle

2

Small spacer

Large spacer

2

6

Locknut, (3/8 inch)

6

Bolt, (3/8 x 1–3/8 inches)

Bolt, (3/8 x 4/1/2 inches) For use with T-Bar,

2

gear drive machine only.

Procedure

Impr oper installation or application of a

sulk y can ef fect the sta bility and contr ol of

the Mid-Siz ed Mo w er s, which could cause

per sonal injur y or death.

Note: Y ou can install the axle in one of 3

horizontal positions ( Figure 5 ). F or a T -bar

controlled mac hine , the a v erag e person will g et

the best results using the rear holes; ho w ev er ,

if a larg e person will be using the sulk y , y ou

ma y w ant to install it using the middle or front

hole to gi v e the operator more room. F or a

pistol g rip mac hine , use the front holes .

6. Using the 6 bolts (3/8 x 1–3/8 inc hes) and

loc kn uts (3/8 inc h) supplied with the sulk y ,

secure the bottom of the pulley guards , the

ax el, and the spacers as illustrated in Figure 8 .

7. Slide the small spacers betw een the top of the

pulley guards and the mounting tube on the

frame , and secure them using 2 bolts (3/8 x

4-1/2 inc h) and the n uts remo v ed in ste p 3

( Figure 8 ).

• W eight kits mounted in the r ear position

need to be r emo v ed when a sulk y is

installed.

• T he par king brak e must be adjusted, on

units equipped with a par king brak e,

when a sulk y is installed.

• T he sulk y is not r ecommended on Mid

Siz e mo w er s equipped with 32 inch

mo w er s.

1. Stop the engine , set the parking brak e , remo v e

the k ey , and w ait for all mo ving par ts to stop

before lea ving the operating position.

2. R emo v e the 4 bolts and n uts securing the

bottom of the tw o pulley guards on the sides

of the frame (2 bolts and n uts on eac h side)

( Figure 8 ).

3. R emo v e the long bolt and n ut securing the top

of eac h pulley guard ( Figure 8 ). Sa v e the bolt

for whenev er the axle is remo v ed.

4. Inser t the axle mounting brac k ets betw een the

pulley guards and the frame ( Figure 8 ).

Figure 8

1. Bolt, (3/8 x 4-1/2 inches)

2. Pulley guard 6. Axle mounting bracket

3. Small spacer

4. Locknut, (3/8 inch)

5. Large spacer

7. Bolt, (3/8 x 1–3/8 inches)

8

Page 9

Step

4

Installing the Axle on a

Hydraulic Drive Mower with

Pistol Grip Handles

Parts needed for this step:

1

Axle

Large spacer

2

6

Locknut, (3/8 inch)

6

Bolt, (3/8 x 1-3/4 inches)

Procedure

Impr oper installation or application of a

sulk y can ef fect the sta bility and contr ol of

the Mid-Siz ed Mo w er s, which could cause

per sonal injur y or death.

• W eight kits mounted in the r ear position

need to be r emo v ed when a sulk y is

installed.

• T he par king brak e must be adjusted, on

units equipped with a par king brak e,

when a sulk y is installed.

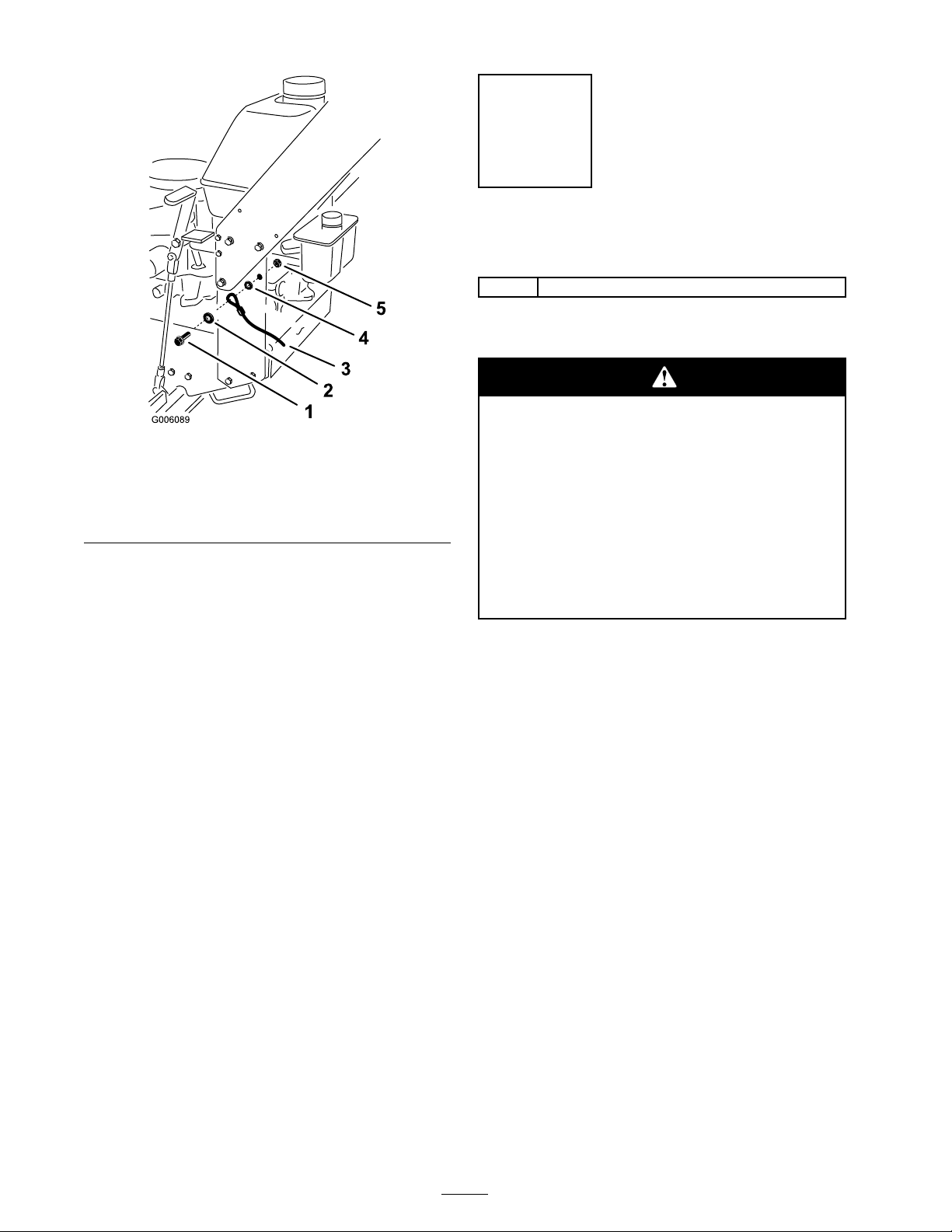

Figure 9

1. Bolt, (3/8 x 1-3/4 inches) 3. Locknut, (3/8 inch)

2. Large spacer

4. Axle mounting bracket

4. Using the 6 bolts (3/8 x 1-3/4 inc hes) and

loc kn uts (3/8 inc h) supplied with the sulk y ,

install the axle as illustrated in Figure 7 .

Note: Y ou ma y ha v e difficulty installing one

of the bolts on the right side due to interference

with the traction control lev er . If this happens ,

disconnect the control rod from the pistol g rip

( Figure 10 ) to drop the lev er out of the w a y .

W hen finished, reconnect the control rod.

• T he sulk y is not r ecommended on Mid

Siz e mo w er s equipped with 32 inch

mo w er s.

1. Stop the engine , set the parking brak e , remo v e

the k ey , and w ait for all mo ving par ts to stop

before lea ving the operating position.

2. P osition the axle mounting brac k ets on both

sides of the mac hine frame ( Figure 9 ).

3. Inser t the larg e spacers betw een the axle

mounting brac k ets and the frame , lining up the

holes ( Figure 9 ).

Note: Y ou can install the axle in one of 3

horizontal positions ( Figure 5 ). F or a pistol

g rip mac hine , use the front holes .

Figure 10

1. Pistol grip 3. Control rod

2. Clevis pin

9

4. Hairpin cotter pin

Page 10

Step

Step

5

Installing the Sulky

Assemblies

Parts needed for this step:

1

Left sulky assembly

1

Right sulky assembly

2

Lynch pin

2

Washer, (1-3/4 inches)

Procedure

1. Slide the mounting tube on eac h sulk y assembly

o v er the ends of the axle with the foot rests

to w ards the inside ( Figure 11 ).

2. Secure the sulk y assemblies using a w asher

(1-3/4 inc h) and lync h pin on eac h side

( Figure 11 ).

3. Grease the sulk y; refer to Greasing the Sulk y .

6

Adjusting the Handle Height

No Parts Required

Procedure

Note: Mac hines with a T2 handle are not

adjustable .

Because the sulk y raises y ou sev eral inc hes

off of the g round, adjust the handle height to

accommodate the user on the sulk y comfor tably .

R efer to the mo w er Operator’ s Manual for more

infor mation on c hanging the handle height.

Step

7

Figure 11

Left side shown

1. Washer, (1–3/4 inches)

2. Sulky assembly 4. Lynch pin

3. Axle

Installing the Lanyard

Parts needed for this step:

2

Lanyard

2

Bolt, (5/16 x 1-1/4 inches)

2 Spacer

2

Small washer

4

Locknut, (5/16 inch)

2

Shoulder bolt

2

Washer, (1/2 inch)

2

Washer, (3/8 inch)

Procedure

1. Install the n ut (5/16 inc h), small w asher ,

spacer , lanyard and bolt (5/16 x 1-1/4 inc hes)

into the center hole ( Figure 12 ).

Note: T he sulk y transpor t position can be

raised or lo w ered. R efer to Adjusting the Sulk y

T ranspor t P osition.

10

Page 11

Figure 12

1. Sulky assembly 5. Small washer

2. Center hole

3. Side support 7. Lanyard

4. Locknut, (5/16 inch) 8. Bolt, (5/16 x 1-1/4 inches)

6. Spacer

Note: T he mac hines with T2 handles do not

need a hole drilled into the side of the mac hine

for installing the lanyard. Proceed to item 6 in

this ste p to install the lanyard ( Figure 15 ).

2. Raise the sulk y and position the lanyard loop

until it is in a clear location on the pulley guard,

both on the outside and inside of the guard

( Figure 13 ).

3. If a hole does not exist in or near this location,

mark the location of the lanyard loop .

Important: T he sulk y must be at least

1-1/2 inches (3.8 cm) fr om an y contact

point such as the machine handle or the

gear shift lev er (when pushed to the right

or left) on gear dri v e machines ( Figur e 13 ).

4. Drill a 11/32 inc h hole at the mark ed location.

5. R emo v e the lanyard from the sulk y assembly .

Figure 13

1. Lanyard 3. Mark location

2. Pulley guard 4. Sulky assembly

6. Install the shoulder bolt, w asher (1/2 inc h),

lanyard, w asher (3/8 inc h), and loc kn ut (5/16

inc h) to the pulley guard ( Figure 14 and

Figure 15 ).

Note: W hen the lanyard is attac hed to the

mac hine , it m ust not be able to be remo v ed

( Figure 14 and Figure 15 ).

Figure 14

1. Shoulder Bolt

2. Washer, (1/2 inch)

3. Lanyard

4. Washer, (3/8 inch)

5. Pulley guard

6. Locknut, (5/16 inch)

11

Page 12

Figure 15

T2 T-Bar Handle Shown

1. Shoulder Bolt

2. Washer, (1/2 inch) 5. Locknut, (5/16 inch)

3. Lanyard

7. Raise the sulk y assembly and attac h the lanyard.

Note: T he sulk y transpor t position can be

raised or lo w ered b y using the three different

holes in the sulk y side suppor t ( Figure 12 ).

8. R e peat these ste ps for the opposite sulk y

assembly .

4. Washer, (3/8 inch)

Step

8

Installing the Weight Kit

Parts needed for this step:

-

Weight Kit (if needed)

Procedure

Use the cor r ect w eight kits when the sulk y

is installed or per sonal injur y or death could

occur .

• Nev er operate the machine with out

r ecommended fr ont w eight kits.

• Do not use r ear w eights when a sulk y is

installed.

• R emo v e all r ear w eights when installing

a sulk y .

Use the follo wing figures to deter mine the w eight

kit needed for y our mo w er . If needed, a w eight kit

is a v ailable through an A uthorized Ser vice Dealer .

Note: If the handle bar is lo w ered the lanyard

ma y ha v e to be re-positioned to attain proper

clearance for the raised sulk y .

R efer to the W eight Kit for the cor rect procedures

to install the w eight.

Important: A w eight kit is r equir ed f or Mid

Siz ed mo w er s equipped with a 44 inch mo w er

deck (Classic mo w er decks)( Figur e 16 ).

W eight Kit, 106–0820, is used on Mid-Size mo w ers

(Classic mo w er dec ks) with a car rier frame and

adjusting rod sho wn in Figure 16 .

12

Page 13

Important: A w eight kit is not r equir ed f or

Mid Siz ed mo w er s with height-of-cut pins

sho wn in Figur e 18 .

T o enhance the perfor mance of the mac hine ,

install W eight Kit(s), 112–9971, onto Mid-Size

mo w ers (TURBO FOR CE mo w er dec ks) with the

style of height-of-cut pins sho wn in Figure 18 .

Use the follo wing table to deter mine the n umber

of w eights recommended to install a T r u T rak

Sulk y on a Mid-Size mo w er with a TURBO

FOR CE mo w er dec k ( Figure 18 ).

®

Figure 16

1. Carrier frame 2. Adjusting rod

Important: A w eight kit is not r equir ed f or

Mid Siz ed mo w er s with height-of-cut pins

sho wn in Figur e 17 and with a serial n umber

of 210000001 thr ough 220000001.

T o enhance the perfor mance of the mac hine ,

install W eight Kit, 106–5491, onto Mid-Size

mo w ers (SFS mo w er dec ks) with the style of

height-of-cut pins sho wn in Figure 17 .

Number of Weights to use with the TRU TRAK

Mid-Size mowers with TUBRO FORCE mower decks only

Gear Driven Mowers

Deck size

36 3

40

48

52 0 2

60

Number

of

Weights

4 Front 4 Front

1 Front

Not Available

Weight

Position

Front 4 Front

Hydraulic Driven

Mowers

Number

of

Weights

3

1 Front

®

Sulky for

Weight

Position

Front

Front

Figure 17

1. Front height-of-cut pin 2. Rear height-of-cut pin

Figure 18

1. Rear height-of-cut pin 2. Front height-of-cut pin

13

Page 14

Step

9

Adjusting the Parking Brake

No Parts Required

Procedure

After installing the sulk y , adjust the mac hine’ s

parking brak e to compensate for the increased

mac hine w eight.

R efer to the Mid-Size mo w er Operator’ s Manual for

the cor rect procedure to adjust the parking brak e .

14

Page 15

Operation

Operating Tips

Note: Deter mine the left and right sides of the

mac hine from the nor mal operating position.

Positioning the Sulky for

Transport

Before placing the mac hine on a trailer , lift eac h

sulk y assembly up and secure them with the

lanyards ( Figure 19 ). T his will k ee p the sulk y from

bouncing during transpor t and mak e the mac hine

more compact.

Learning to Drive

Dri v e slo wly and tak e time to lear n ho w the sulk y

mo v es when using it for the first time .

Turning with a Sulky

Use care when tur ning to ensure that y ou do not

swing y ourself and the sulk y into obstacles .

W hen tur ning, lean forw ard and to w ard the

direction of the tur n to help k ee p y our balance .

Adjusting the Wheel Drive Traction

If y our mac hine is a g ear dri v e , pistol g rip mac hine ,

y ou ma y need to adjust the wheel dri v e tension;

refer to y our mac hine Operator’ s Manual .

Figure 19

1. Lanyard

Removing the Weight

Important: If the sulk y and axle ar e

r emo v ed fr om the machine, install the w eights

to their original position bef or e the sulk y w as

installed.

15

Page 16

Maintenance

Checking the Tire Pressure

Ensure that the caster wheel tires are filled with

air to 50 psi (345 kP a) ev er y 8 operating hours or

before eac h use .

Greasing the Sulky

Grease all g rease fittings ev er y 25 operating hours

and immediately after ev er y w ashing .

Grease type: General-pur pose g rease .

1. Clean the g rease fittings with a rag .

2. Connect a g rease gun to eac h fitting .

3. Pump g rease into the fittings until g rease

begins to ooze out of the bearings .

4. Wipe up any ex cess g rease .

the sulk y wheel is used when the handle is in

the high position. T he middle hole is for the

middle handle height position and the front

hole is for the lo w handle height position.

4. Install the n ut (5/16 inc h), small w asher ,

spacer , lanyard and bolt (5/16 x 1 inc h) into

the desired hole ( Figure 21 ).

Figure 20

Adjusting the Sulky

Transport Position

T he sulk y transpor t position can be raised or

lo w ered b y using the three different holes in the

sulk y side suppor t.

1. R emo v e the n ut (5/16 inc h), small w asher ,

spacer , lanyard and bolt (5/16 x 1-1/4 inc hes)

from the sulk y side suppor t ( Figure 21 ).

2. Deter mine the handle height position. R efer

to the Operator’ s Manual for the handle height

position.

Figure 21

1. Sulky assembly 5. Small washer

2. Center hole

3. Side support 7. Lanyard

4. Locknut, (5/16 inch) 8. Bolt, (5/16 x 1-1/4 inches)

6. Spacer

3. Locate the three adjustment holes in the sulk y

assemblies ( Figure 21 ). T he hole closest to

16

Page 17

Page 18

Page 19

Page 20

Landscape

Contractor

Equipment (LCE)

The Toro Total Coverage Guarantee

A Limited Warranty

Conditions and Products Covered

The Toro® Company and its afliate, Toro Warranty Company, pursuant to an

agreement between them, jointly promise to repair the listed Toro Products if

defective in materials or workmanship. The following time periods apply from

the date of purchase:

This warranty applies to:

•

ProLine Mid-Size Mowers and Attachments

•

Z Master Mid-Mount ZRTs and Attachments

Components

Traction Unit Frame and Carrier Frame

All Spindles

Engines* and /Hydraulic System

Deck Shells (34 ″ -72 ″ )

Z500 Series Electric Clutch

Remaining Components

* S o m e e n g i n e s u s e d o n T o r o L C E P r o d u c t s a r e w a r r a n t e d b y t h e e n g i n e m a n u f a c t u r e r .

This warranty includes the cost of parts and labor, but you must pay

transportation costs.

Warranty Period

1 year

1 year

2 year

3 years Parts

2 years Labor

2 years

2 years

2 years

1 year

Instructions for Obtaining Warranty Service

If you think that your Toro Product contains a defect in materials or

workmanship, follow this procedure:

1. Contact any Toro Authorized or Master Service Dealer to arrange service at

their dealership. To locate a dealer convenient to you, access our website at

www.Toro.com. You may also call our Toro Customer Care Department

toll free at 888–865–5676 (U.S. Customers) or 888–865–5691 (Canada

customers).

2. Bring the product and your proof of purchase (sales receipt) to the Service

Dealer.

If for any reason you are dissatised with the Service Dealer’s analysis or with

the assistance provided, contact us at:

LCB Customer Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Owner Responsibilities

You must maintain your Toro Product by following the maintenance procedures

described in the operator’s manual. Such routine maintenance, whether

performed by a dealer or by you, is at your expense.

Items and Conditions Not Covered

There is no other express warranty except for special emission system coverage

on some products. This express warranty does not cover the following:

• Cost of regular maintenance service or parts, such as lters, fuel, lubricants,

tune-up parts, blade sharpening, brake and clutch adjustments.

• Any product or part which has been altered or misused or required

replacement or repair due to normal wear, accidents, or lack of proper

maintenance.

• Repairs necessary due to improper fuel, contaminants in the fuel system, or

failure to properly prepare the fuel system prior to any period of non-use

over three months.

• Pickup and delivery charges.

General Conditions

All repairs covered by this warranty must be performed by an Authorized Toro

Service Dealer using Toro approved replacement parts.

Neither The Toro® Company nor Toro Warranty Company is liable for

indirect, incidental or consequential damages in connection with the

use of the Toro Products covered by this warranty, including any

cost or expense of providing substitute equipment or service during

reasonable periods of malfunction or non-use pending completion

of repairs under this warranty.

Some states do not allow exclusions of incidental or consequential

damages, or limitations on how long an implied warranty lasts, so

the above exclusions and limitations may not apply to you.

All implied warranties of merchantability (that the product is t

for ordinary use) and tness for use (that the product is t for

a particular purpose) are limited to the duration of the express

warranty.

This warranty gives you specic legal rights, and you may also have

other rights which vary from state to state.

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer) to obtain guarantee

policies for your country, province, or state. If for any reason you are dissatised with your Distributor’s service or have difculty obtaining guarantee information,

contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty Company.

374-0037 Rev F

Loading...

Loading...