Page 1

Tru Trak® Sulky

For Fixed Deck Mid-Size Mowers

Model No. 30109

Form No. 3354-303 Rev A

Register your product at www.Toro.com Original Instructions (EN)

Page 2

mec hanical infor mation and Note emphasizes g eneral

infor mation w or th y of special attention.

Introduction

R ead this infor mation carefully to lear n ho w to operate

and maintain y our product properly and to a v oid injur y

and product damag e . Y ou are responsible for operating

the product properly and safely .

Y ou ma y contact T oro directly at www .T oro .com for

product and accessor y infor mation, help finding a

dealer , or to register y our product.

W henev er y ou need ser vice , g en uine T oro par ts , or

additional infor mation, contact an A uthorized Ser vice

Dealer or T oro Customer Ser vice and ha v e the model

and serial n umbers of y our product ready . Figure 1

identifies the location of the model and serial n umbers

on the product. W rite the n umbers in the space

pro vided.

Figure 1

1. Model and serial number location

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safe Operating Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1 Installing the Axle on a Hy dro Dri v e

Mo w er . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Installing the Axle on a Gear Dri v e

Mo w er . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Installing the Sulk y Assemblies . . . . . . . . . . . . . . . . . . . . . . . 7

4 Adjusting the Handle Height . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Adjusting the Dri v e Belts on a Gear Dri v e

Mac hine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6 Installing the Lanyard on a Hy dro Dri v e

Mac hine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7 Installing the Lanyard on a Gear Dri v e

Mac hine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

8 Installing the Lanyard Adjustment

Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

9 Installing the W eight Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

10 Adjusting the P arking Brak e . . . . . . . . . . . . . . . . . . . . . . . 11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

P ositioning the Sulk y for T ranspor t . . . . . . . . . . . . . . . . . 12

Operating Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chec king the Tire Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Greasing the Sulk y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Adjusting the Sulk y T ranspor t P osition . . . . . . . . . . . . 13

Model No.

Serial No.

T his man ual identifies potential hazards and has

safety messag es identified b y the safety aler t symbol

( Figure 2 ), whic h signals a hazard that ma y cause

serious injur y or death if y ou do not follo w the

recommended precautions .

Figure 2

1. Safety alert symbol

T his man ual uses 2 other w ords to highlight

infor mation. Impor tant calls attention to special

© 2005—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Contact us at www.Toro.com.

2

Printed in the USA.

All Rights Reserved

Page 3

Safety

Improper use or maintenance b y the operator or

o wner can result in injur y . T o reduce the potential

for injur y , comply with these safety instr uctions

and alw a ys pa y attention to the safety aler t symbol,

whic h means CA UTION , W ARNING , or

D ANGER -“personal safety instr uction." F ailure

to comply with the instr uction ma y result in

personal injur y or death.

Safe Operating Practices

General Operation

• Do not modify the sulk y or use it on

non-appro v ed mac hines .

• Ensure that the sulk y is properly attac hed to

the mac hine and is in g ood w orking order

prior to use .

• Allo w only the mac hine operator on the sulk y .

• Do not allo w use of the sulk y b y untrained

operators .

• Use appropriate personal protecti v e apparatus

for eyes , ears , feet, hands , and head.

• Practice operating the mac hine without the

sulk y until familiar with the controls .

• Practice operation of the mac hine with sulk y

attac hed on larg e open, lev el ter rain with no

obstacles present before use . T he sulk y will

affect the mac hine operation, especially on

slopes , when tur ning, and when stopping .

• Use caution when riding the sulk y o v er curbs ,

roc ks , roots , or other obstr uctions .

• Slo w do wn before making tur ns and use extra

caution on rough ter rain and on slopes .

• T ra v el across slopes , a v oiding operation on

stee p slopes .

• Look behind and do wn before bac king up to

be sure of a clear path. Use extra care when

operating in rev erse .

• Dismount and latc h the sulk y in the transpor t

position when loading and unloading the

mac hine .

3

Page 4

Setup

Loose Parts

Use the chart below to verify that all parts have been shipped.

Step

Axle

1

2

3

4

5

6

7

8

New long spacer (2–3/4 inches)

Locknut, (3/8 inch)

Axle

Flat spacer

Locknut, (3/8 inch)

Bolt, (3/8 x 1-3/4 inches)

Left sulky assembly

Right sulky assembly

Lynch pin

Washer, (1-3/4 inches)

No parts required

No parts required

Lanyard

Shoulder bolt, (5/16 x 1-1/4 inches)

Washer, (1–3/8 inch O.D.)

Flange nut, (3/8 inch)

Locknut, (3/8 inch)

Lanyard

Shoulder bolt, (5/16 x 1-1/4 inches)

Washer, (1–3/8 inch O.D.)

Locknut, (3/8 inch)

Carriage bolt, (5/16 x 1 inch)

Spacer 2

Washer, (1 inch O.D.)

Locknut, (5/16 inch)

Description

Qty.

1

4

4

1

2

4

4

1

1

2

2

–

–

2

2

2

2

2

2

2

2

2

2

2

2

Install the axle on a hydro drive

mower.

Install the axle on a gear drive

mower.

Install the sulky assemblies.

Adjust the handle height.

Adjust the drive belts on a gear

drive machine.

Install the lanyard on a hydro drive

machine.

Install the lanyard on the gear drive

machine.

Install the lanyard adjustment bolts.

Use

9

10

Weight Kit (if needed)

No parts required

4

1 or 2

–

Install the weight kit.

Adjust the parking brake.

Page 5

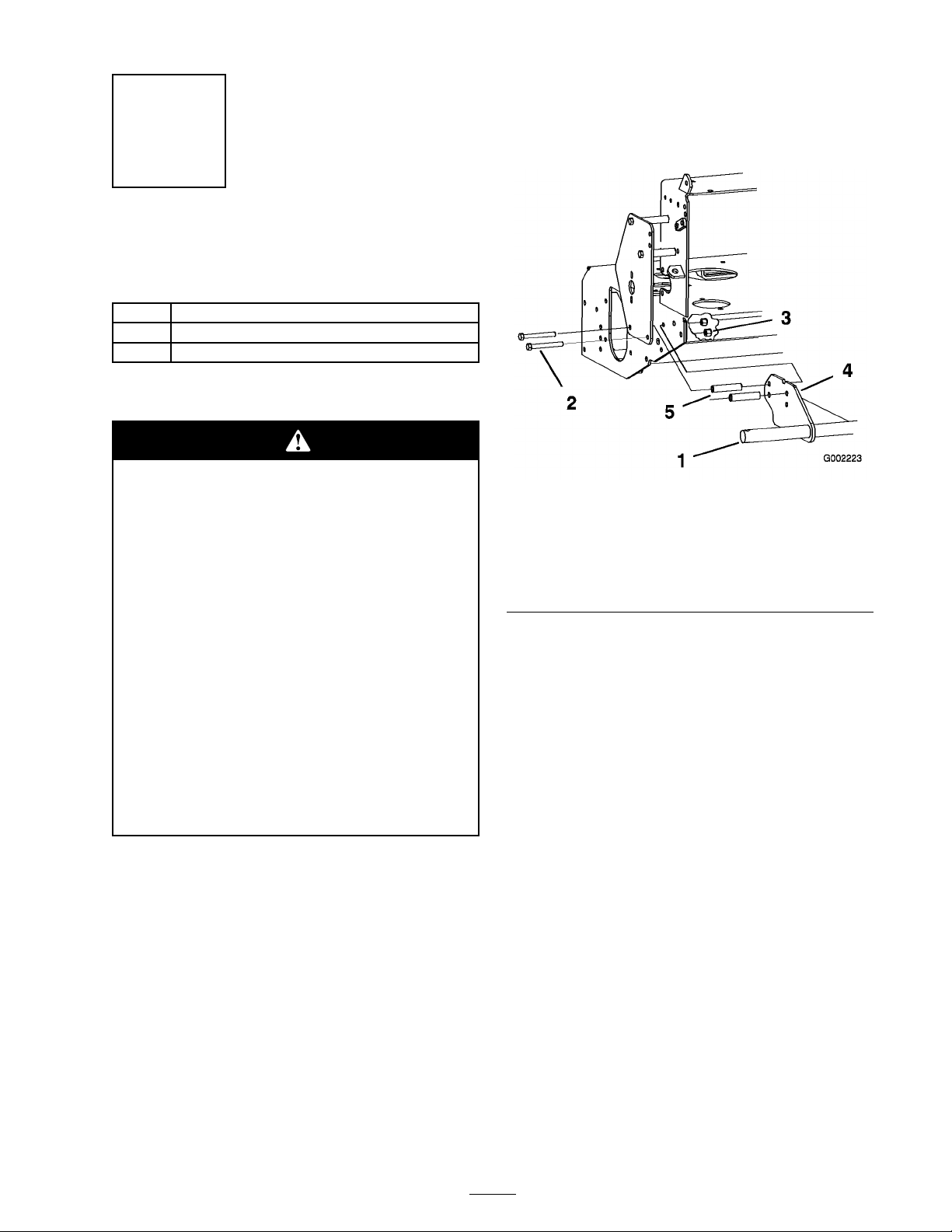

Step

1

Installing the Axle on a

Hydro Drive Mower

Parts needed for this step:

1

Axle

4

New long spacer (2–3/4 inches)

4

Locknut, (3/8 inch)

Procedure

5. Inser t the new long spacers (2–3/4 inc hes)

betw een the axle mounting brac k ets and

the frame on both sides , lining up the holes

( Figure 3 ).

Impr oper installation or application of a

sulk y can ef fect the sta bility and contr ol of

the Mid-Siz ed Mo w er s, which could cause

per sonal injur y or death.

• W eight kits mounted in the r ear position

need be r emo v ed when a sulk y is

installed.

• W eight Kits installed in the fr ont position

ar e r equir ed on Fix ed Deck Mid Siz e

mo w er s that ar e equipped with a sulk y .

• T he par king brak e must be adjusted, on

units equipped with a par king brak e,

when a sulk y is installed.

• T he sulk y is not r ecommended on Fix ed

Deck Mid Siz e mo w er s equipped with

32 inch mo w er s.

1. Diseng ag e the PTO , mo v e the motion control

lev ers to the neutral loc k ed position and set

the parking brak e .

2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

Figure 3

Left side of mower shown

1. Axle 4. Axle mounting bracket

2. Previously removed bolt,

(3/8 x 4 inches)

3. Locknut, (3/8 inch)

5. New long spacer (2–3/4

inches)

6. Install the axle to left side of the mac hine using

2 bolts previously remo v ed and 2 loc kn uts

(3/8 inc h) in the top holes in the axle ( Figure 3

and Figure 4 ).

7. Using the upper rear hole , install the axle to

right side of the mac hine using 1 previously

remo v ed bolt (3/8 x 4 inc hes), 1 new long

spacer (2–3/4 inc hes), and 1 loc kn ut (3/8 inc h)

( Figure 4 and Figure 5 ).

8. Using the upper front hole , install the axle to

right side of the mac hine using 1 bolt (3/8

x 4-1/2 inc h) previously remo v ed, 1 new

long spacer (2–3/4 inc hes), 1 shor t spacer

previously remo v ed on the outside of the

guard, and 1 loc kn ut (3/8 inc h) ( Figure 4 and

Figure 5 ).

3. R emo v e the 4 bolts , spacers , and n uts securing

the bottom of the tw o linkag e guards on both

sides of the frame (2 bolts and n uts on eac h

side and spacers on the right side) ( Figure 3 ).

Sa v e all 4 of the bolts and discard the loc kn uts .

4. Inser t the axle mounting brac k ets betw een the

linkag e guards and the frame ( Figure 3 ).

5

Page 6

Figure 4

1. For hydro machines 2. For gear drive machines

Step

2

Installing the Axle on a Gear

Drive Mower

Parts needed for this step:

1

Axle

2

Flat spacer

4

Locknut, (3/8 inch)

4

Bolt, (3/8 x 1-3/4 inches)

Procedure

Impr oper installation or application of a

sulk y can ef fect the sta bility and contr ol of

the Mid-Siz ed Mo w er s, which could cause

per sonal injur y or death.

Figure 5

1. Linkage guard 5. Axle mounting bracket

2. Axle

3. Previously removed bolt,

(3/8 x 4–1/2 inches)

4. Locknut, (3/8 inch)

6. New long spacer (2–3/4

inches)

7. Short spacer

8. Previously removed bolt

(3/8 x 4 inches)

• W eight kits mounted in the r ear position

need be r emo v ed when a sulk y is

installed.

• W eight Kits installed in the fr ont position

ar e r equir ed on Fix ed Deck Mid Siz e

mo w er s that ar e equipped with a sulk y .

• T he par king brak e must be adjusted, on

units equipped with a par king brak e,

when a sulk y is installed.

• T he sulk y is not r ecommended on Fix ed

Deck Mid Siz e mo w er s equipped with

32 inch mo w er s.

1. Diseng ag e the PTO , mo v e the motion control

lev ers to the neutral loc k ed position and set

the parking brak e .

2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

3. Inser t the axle mounting brac k ets betw een the

pulley guards and the frame ( Figure 6 ).

4. Inser t the flat spacers betw een the axle

mounting brac k ets and the frame , lining up the

holes ( Figure 6 ).

5. Using the bottom holes in the axle mounting

brac k et, install the 4 bolts (3/8 x 1-1/4 inc hes)

6

Page 7

and loc kn uts (3/8 inc h) supplied with the sulk y ,

secure the axle and the spacers as illustrated in

Figure 4 and Figure 6 .

Figure 7

Figure 6

1. Linkage guard

2. Axle mounting bracket 5. Flat spacer

3. Bolt, (3/8 x 1-1/4 inches)

Step

3

Installing the Sulky

Assemblies

Parts needed for this step:

1

Left sulky assembly

1

Right sulky assembly

2

Lynch pin

2

Washer, (1-3/4 inches)

Procedure

4. Locknut, (3/8 inch)

6. Axle

Left side shown

1. Axle

2. Sulky assembly 4. Lynch pin

3. Grease the sulk y; refer to Greasing the Sulk y .

3. Washer, (1–3/4 inches)

Step

4

Adjusting the Handle Height

No Parts Required

Procedure

Because the sulk y raises y ou sev eral inc hes

off of the g round, adjust the handle height to

accommodate the user on the sulk y comfor tably .

R efer to the mo w er Operator’ s Manual for more

infor mation on c hanging the handle height.

1. Slide the mounting tube on eac h sulk y assembly

o v er the ends of the axle with the foot rests

to w ards the inside ( Figure 7 ).

2. Secure the sulk y assemblies using a w asher

(1-3/4 inc h) and lync h pin on eac h side

( Figure 7 ).

7

Page 8

Step

5

Adjusting the Drive Belts on

a Gear Drive Machine

No Parts Required

Procedure

Because the sulk y increases the w eight of the

mac hine , c hec k the dri v e belts for adjustments .

R efer to the mo w er Operator’ s Manual for more

infor mation on adjusting the dri v e belts .

Step

6

Installing the Lanyard on a

Hydro Drive Machine

Parts needed for this step:

2

Lanyard

2

Shoulder bolt, (5/16 x 1-1/4 inches)

2

Washer, (1–3/8 inch O.D.)

2

Flange nut, (3/8 inch)

2

Locknut, (3/8 inch)

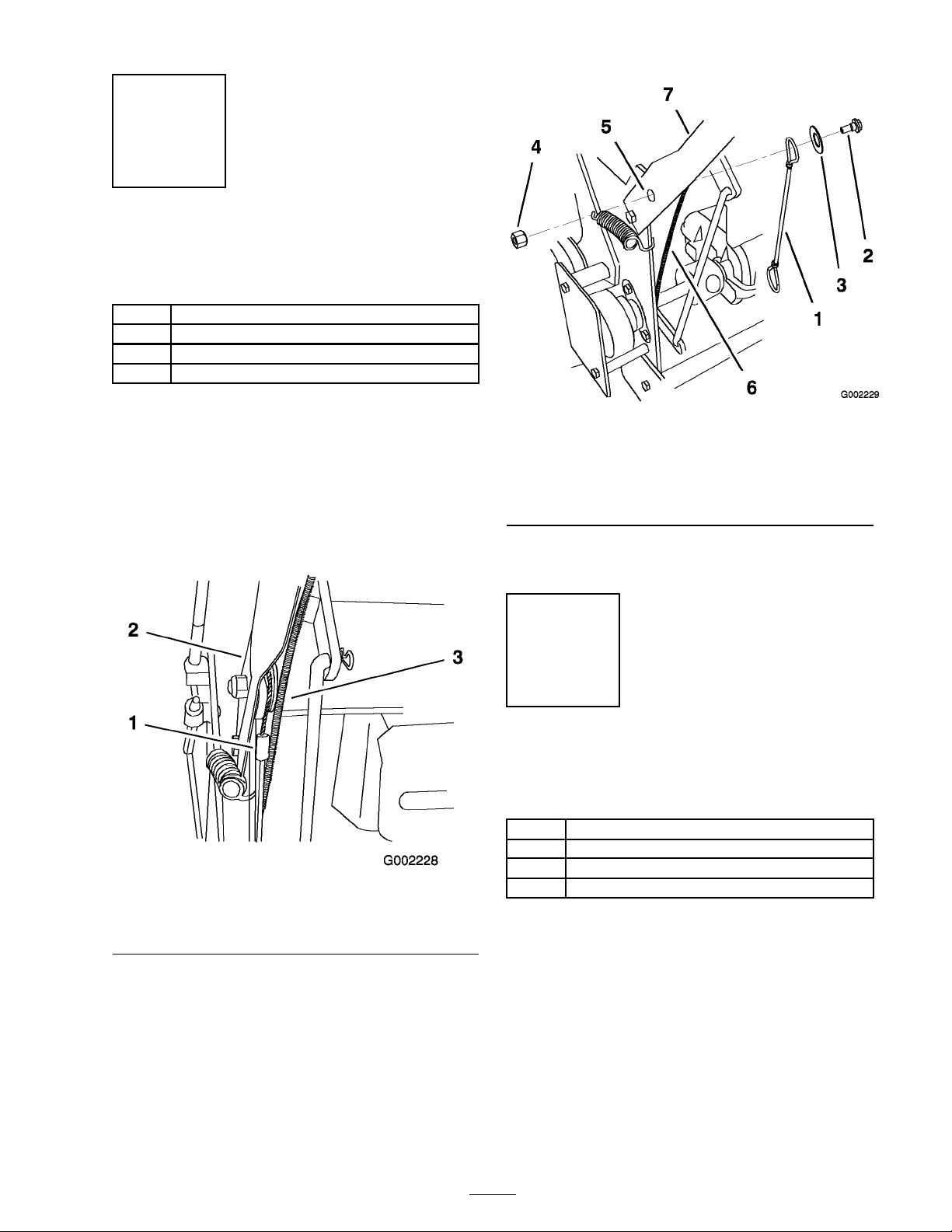

Figure 8

1. Linkage guard 3. Drill a 11/32 inch hole here

2. Upper rear hole

4. Drill the hole for the opposite side .

5. Install the lanyard to the rear hole in the

linkag e guard as sho wn in Figure 9 . Secure the

lanyard with 1 shoulder bolt, 1 flang e n ut, 1

w asher (1–3/8 inc hes O .D .) and 1 loc kn ut (3/8

inc h) ( Figure 9 ).

Procedure

1. Inspect the linkag e guard and deter mine if

there is an extra hole in the guard belo w the

upper rear hole . R efer to Figure 8 for the

cor rect location. If there is no existing hole ,

perfor m items 2 and 3 for drilling a hole .

If a hole exists , proceed to item 4 of this

procedure .

2. Measure 1 inc h (25 mm) directly under the

existing hole in the linkag e guard.

3. Mark the location and drill a 11/32 inc h hole

into the linkag e guard ( Figure 8 ).

Figure 9

1. Lanyard

2. Linkage guard 6. Hole to install lanyard

3. Shoulder Bolt 7. Flange nut

4. Washer, (1–3/8 inches

O.D.)

6. Install the other lanyard on the opposite side

using the previous instr uctions .

8

5. Locknut, (5/16 inch)

Page 9

Step

7

Installing the Lanyard on a

Gear Drive Machine

Parts needed for this step:

2

Lanyard

2

Shoulder bolt, (5/16 x 1-1/4 inches)

2

Washer, (1–3/8 inch O.D.)

2

Locknut, (3/8 inch)

Procedure

1. R emo v e the bolt and n ut in the upper hole

where the handle is connected to the frame .

Note: T he lanyard on the left side needs to

be betw een the frame and the throttle cable

( Figure 10 ).

Figure 10

1. Lanyard 3. Throttle cable

2. Handle

Figure 11

1. Lanyard 5. Upper hole

2. Shoulder Bolt 6. Throttle cable

3. Washer, (1–3/8 inches

O.D.)

4. Locknut, (5/16 inch)

3. Install the other lanyard on the opposite side

using the previous instr uctions .

7. Handle

Step

8

Installing the Lanyard

Adjustment Bolts

Parts needed for this step:

2

Carriage bolt, (5/16 x 1 inch)

2 Spacer

2

Washer, (1 inch O.D.)

2

Locknut, (5/16 inch)

Procedure

2. Install the lanyard with 1 shoulder bolt, 1

w asher (1–3/8 inc hes O .D .) and 1 loc kn ut (3/8

inc h) ( ).

1. Deter mine the handle height position. R efer

to the mo w er Operator’ s Manual for the handle

height position.

2. Locate the three adjustment holes in the sulk y

assemblies ( Figure 12 ). T he hole closest to

the sulk y wheel is used when the handle is in

the high position. T he middle hole is for the

middle handle height position and the front

hole is for the lo w handle height position.

9

Page 10

3. Install the n ut (5/16 inc h), w asher (1 inc h

O .D .), spacer and bolt (5/16 x 1 inc h) into

the cor rect hole location deter mined abo v e

( Figure 12 ).

4. Install the other adjustment bolt on the

opposite side .

1. Sulky assembly

2. Side support

3. Carriage bolt,(5/16 x 1

inch)

4. Washer, (1 inch O.D.)

Figure 12

5. Spacer

6. Locknut, (5/16 inch)

7. Center hole

8. Sulky wheel

10

Page 11

Step

9

Installing the Weight Kit

Due to the added w eight of the sulk y and the

operator at the rear of the mac hine , cer tain

mac hines require additional front w eight kits

installed in order to meet safety standards .

Important: If the sulk y and axle ar e

r emo v ed fr om the machine, r emo v e an y

w eights f or use with the sulk y .

Parts needed for this step:

1 or 2

Procedure

Use the cor r ect w eight kits when the sulk y

is installed or per sonal injur y or death could

occur .

• Nev er operate the machine with out

• Do not use the r ear w eight kit when a

Weight Kit (if needed)

r ecommended fr ont w eight kits.

sulk y is installed.

Number of Weight Kits Required when a Sulky is installed.

Mower Deck Size

32 inch Do not use a sulky on

36 inch

40 inch No model available

48 inch

Important: Do not use r ear w eight kit when

the sulk y is installed.

Use the follo wing table to deter mine whic h models

require front w eights and the n umber of front

w eight kits needed when installing a sulk y . F ront

w eight kits are a v ailable through an A uthorized

Ser vice Dealer . R efer to the w eight kit for the

cor rect procedures to install the w eight.

All 2005 and Earlier

Models

32 inch mowers.

2

1 1

2006 and After Pistol Grip,

Hydro Models Only

Do not use a sulky on 32

inch mowers.

1

2

Step

10

Adjusting the Parking Brake

No Parts Required

Procedure

After installing the sulk y , adjust the mac hine’ s

parking brak e to compensate for the increased

mac hine w eight.

11

Page 12

Operation

Note: Deter mine the left and right sides of the

mac hine from the nor mal operating position.

W hen tur ning, lean forw ard and to w ard the

direction of the tur n to help in k ee ping y our

balance .

Adjusting the Wheel Drive Traction

Positioning the Sulky for

Transport

Before placing the mac hine on a trailer , lift eac h

sulk y assembly up and secure them with the

lanyards ( Figure 13 ). T his will k ee p the sulk y from

bouncing during transpor t and mak e the mac hine

more compact.

If y our mac hine is a g ear dri v e , pistol g rip mac hine ,

y ou ma y need to adjust the wheel dri v e tension;

refer to y our mac hine Operator’ s Manual .

Figure 13

1. Lanyard

Operating Tips

Learning to Drive

Dri v e slo wly and tak e time to lear n ho w the sulk y

mo v es when using it for the first time .

Turning with a Sulky

Use care when tur ning to ensure that y ou do not

swing y ourself and the sulk y into obstacles .

12

Page 13

Maintenance

Checking the Tire Pressure

Ensure that the caster wheel tires are filled with

air to 50 psi (345 kP a) ev er y 8 operating hours or

before eac h use .

Greasing the Sulky

Grease all g rease fittings ev er y 25 operating hours

and immediately after ev er y w ashing .

Grease type: General-pur pose g rease .

1. Clean the g rease fittings with a rag .

2. Connect a g rease gun to eac h fitting .

3. Pump g rease into the fittings until g rease

begins to ooze out of the bearings .

4. Wipe up any ex cess g rease .

the sulk y wheel is used when the handle is in

the high position. T he middle hole is for the

middle handle height position and the front

hole is for the lo w handle height position.

4. Install the n ut (5/16 inc h), small w asher ,

spacer , lanyard and bolt (5/16 x 1 inc h) into

the desired hole ( Figure 15 ).

Figure 14

Adjusting the Sulky

Transport Position

T he sulk y transpor t position can be raised or

lo w ered b y using the three different holes in the

sulk y side suppor t.

1. R emo v e the n ut (5/16 inc h), small w asher ,

spacer , lanyard and bolt (5/16 x 1-1/4 inc hes)

from the sulk y side suppor t ( Figure 15 ).

2. Deter mine the handle height position. R efer

to the Operator’ s Manual for the handle height

position.

3. Locate the three adjustment holes in the sulk y

assemblies ( Figure 15 ). T he hole closest to

Figure 15

13

Page 14

Page 15

Page 16

Loading...

Loading...