Page 1

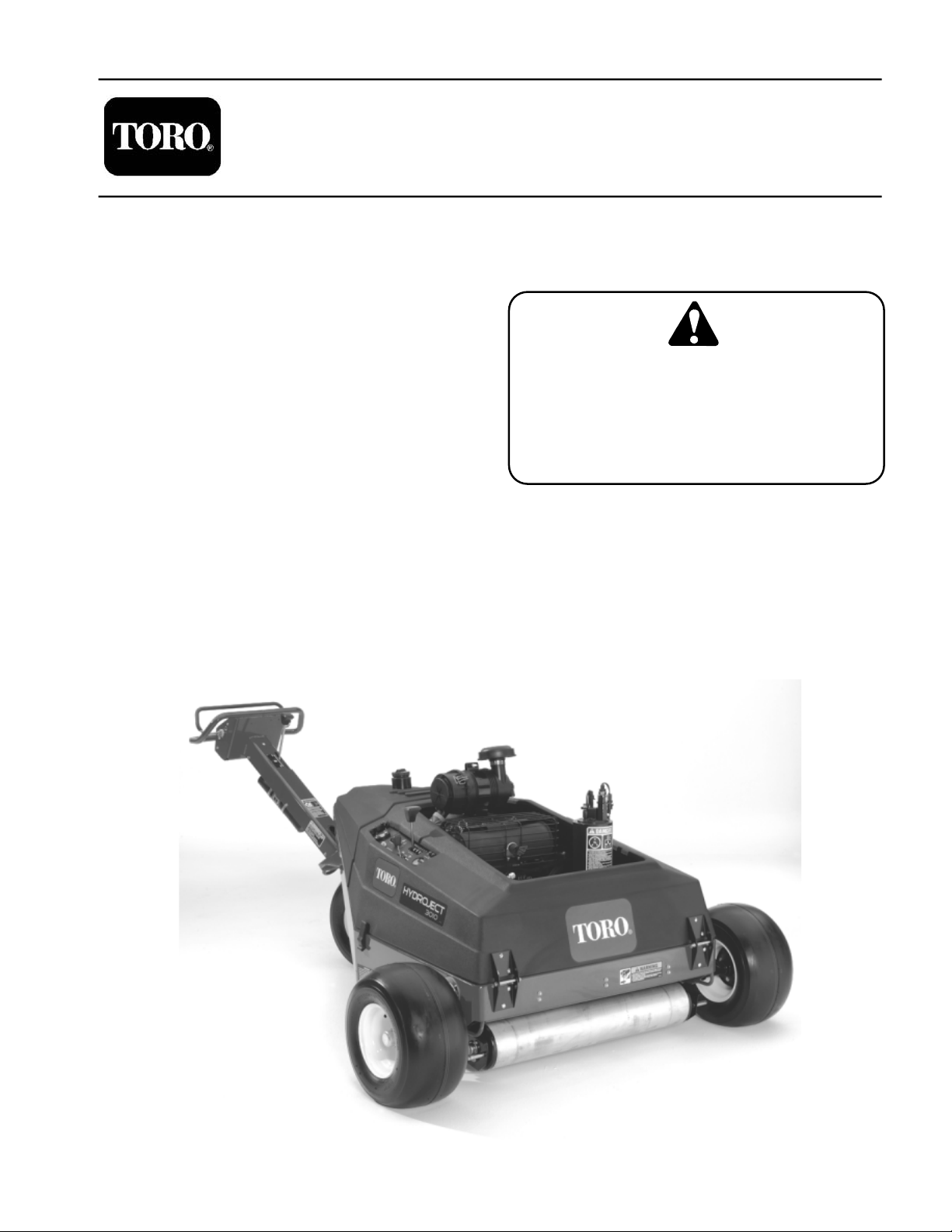

Preface

This publications provides the service technician with

information for troubleshooting, testing, and repair of the

Hydroject.

Part No. 04134SL (Rev. B)

Service Manual

Hydroject ® 3010

REFER TO THE HYDROJECT OPERATOR’S MANUAL FOR OPERATING, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS. Space is provided in

Chapter 2 of this book to insert the Operator’s Manual

and Parts Catalog for your machine. A replacement

Operator’s Manual is available by sending the complete

Model and Serial Number of the machine to:

The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420

The T oro Company reserves the right to change product

specifications or this publication without notice.

This safety symbol means DANGER,

WARNING, or CAUTION, PERSONAL SAFETY

INSTRUCTION. When you see this symbol,

carefully read the instructions that follow.

Failure to obey the instructions may result in

personal injury.

NOTE: A NOTE will give general information about the

correct operation, maintenance, service, testing or repair of the machine.

IMPORTANT: The IMPORTANT notice will give important instructions which must be followed to prevent damage to systems or components on the

machine.

© The Toro Company 2005, 2006, 2007

Page 2

Hydroject 3010

Page 3

Table Of Contents

Chapter 1 - Safety

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Chapter 2 - Product Records and Manuals

Product Records. . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Maintenance

Equivalents and Conversions . . . . . . . . . . . . . . . . 2 - 2

Torque Specifications . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Chapter 3 - Engine

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Kohler Engine Service Manual

Chapter 4 - Hydraulic System

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

General Information

Hydraulic Diagram

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 7

Troubleshooting

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 9

Adjustments

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

. . . . . . . . . . . . . . . . . . . . . . . 4 - 3

. . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

. . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

Chapter 5 - Electrical System

Wiring Schematics and Diagrams. . . . . . . . . . . . . 5 - 2

Special Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 5

Troubleshooting

Testing

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 24

Chapter 6 - Water System

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

Water System Schematic . . . . . . . . . . . . . . . . . . . 6 - 3

Special Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 9

Testing

Adjustments

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 20

Chapter 7 - Wheels, Steering and Brakes

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 2

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 3

Chapter 8 - Electrical Diagrams

Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 3

Main Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 4

Main Wiring Diagram

Control Panel Harness . . . . . . . . . . . . . . . . . . . . . 8 - 6

Control Panel Wiring Diagram . . . . . . . . . . . . . . . 8 - 7

Tiller Harness and Wiring Diagram

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 12

. . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 18

. . . . . . . . . . . . . . . . . . . . . . 8 - 5

. . . . . . . . . . . . 8 - 8

Hydroject 3010

Page 4

Hydroject 3000/4000

Page 5

Table of Contents

Chapter 1

Safety

SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . 1

Before Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

While Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Instructions

Although hazard control and accident prevention partially are dependent upon the design and configuration

of the machine, these factors are also dependent upon

the awareness, concern, and proper training of the per

sonnel involved in the operation, transport, maintenance, and storage of the machine. Improper use or

maintenance of the machine can result in injury or

death. To reduce the potential for injury or death, comply

with the following safety instructions.

Before Operating

1. Read and understand the contents of this manual

before starting and operating the machine. Become fa

miliar with all controls and know how to stop quickly. A

free replacement manual is available by sending com

plete Model and Serial Numbers to:

The Toro Company

8111 Lyndale Avenue South

Bloomington, Minnesota 55420

Use the Model and Serial Number when referring to your

machine. If you have questions about this Service

Manual, please contact:

The Toro Company

Commercial Service Department

8111 Lyndale Avenue South

Bloomington, Minnesota 55420

2. Never allow children to operate the machine. Do not

allow adults to operate machine without proper instruc

tion. Only trained operators who have read this manual

should operate this machine.

-

-

-

-

Maintenance and Service . . . . . . . . . . . . . . . . . . . . . 3

SAFETY AND INSTRUCTION DECALS

. . . . . . . . . . 4

CAUTION

TO REDUCE THE POTENTIAL FOR INJURY

OR DEATH, COMPLY WITH THE FOLLOWING

SAFETY INSTRUCTIONS.

3. Never operate the machine when under the influ-

ence of drugs or alcohol.

4. Before attempting to start engine engage parking

brake.

5. Remove all debris or other objects that might interfere with operation. Keep all bystanders away from the

work area.

6. Keep all shields and safety devices in place. If a

shield, safety device or decal is defective or damaged,

repair or replace it before operation is commenced. Also

tighten any loose nuts, bolts and screws to assure ma

chine is in safe operating condition.

7. Do not operate machine while wearing sandals, tennis shoes, sneakers or shorts. Also, do not wear loose

fitting clothing which could get caught in moving parts.

Always wear long pants and substantial shoes. Wearing

safety glasses, safety shoes, ear protection and a hel

met is advisable and required by some local ordinances

and insurance regulations.

-

-

Hydroject 3010

Page 1 – 1

Safety

Page 6

8. Fill fuel tank with gasoline before starting the en-

gine. Avoid spilling gasoline. Since gasoline is flammable, handle it carefully.

A. Use an approved gasoline container.

B. Do not fill tank while engine is hot or

running.

C. Do not smoke while handling gasoline.

While Operating

D. Fill fuel tank outdoors and up to about one

inch (25 mm) from top of the tank, not the

filler neck.

E. Wipe up any spilled gasoline.

9. Check interlock switches daily for proper operation.

If a switch fails, replace it before operating the machine.

The interlock system is for your protection, so do not by

pass it. Replace all interlock switches every two years.

-

10. DON’T TAKE AN INJURY RISK! When a person or

pet appears unexpectedly in or near the WORKING

area, STOP AERATING.

11. Keep hands and feet away from nozzle and roller

area. High velocity water jets can penetrate hands and

feet. Penetration by the high velocity water jets can

cause serious personal injury. If accidental penetration

occurs, seek medical attention immediately.

12. Never use chemicals in the water supply system.

13. Do not operate water injection system on concrete

or asphalt because water jets will permanently damage

these surfaces.

14. Start engine with parking brake engaged.

15. Do not run the engine in a confined area without ad-

equate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

16. Using the machine demands attention, and to prevent loss of control:

Maintenance

A. Use only in daylight or when there is good

artificial light.

B. Watch for holes or other hidden hazards.

C. Do not transport machine close to a sand

trap, ditch, creek or other hazard.

17. If the machine starts to vibrate abnormally, shut the

engine off. Remove wires from spark plugs to prevent

possibility of accidental starting. Check machine for

damage and defective parts. Repair any damage before

restarting the engine and operating the machine.

18. Do not touch engine or muffler while engine is running or soon after it is stopped. These areas could be hot

enough to cause a burn.

19. Before leaving the operator’s position–behind handle–engage parking brake.

20. When leaving the machine unattended, engage

parking brake , shut engine OFF and remove key from

ignition switch.

21. Disconnect wires from spark plugs to prevent accidental starting of the engine when servicing, adjusting or

storing the machine.

22. If machine must be tipped to perform maintenance

or an adjustment, close fuel shut–off valve, drain gaso

line from fuel tank, oil from crankcase and remove battery.

23. To reduce potential fire hazard, keep the engine free

of excessive grease, grass, leaves and accumulations

of dirt.

24. Be sure machine is in safe operating condition by

keeping nuts, bolts and screws tight. Check all bolts and

nuts frequently to be sure they are tightened to specifi

cation.

25. If the engine must be running to perform a maintenance adjustment, keep hands, feet, clothing and other

parts of the body away from any moving parts.

26. Make sure all hydraulic line connectors are tight, and

all hydraulic hoses and lines are in good condition be

fore applying pressure to the system.

Safety Hydroject 3010

Page 1 – 2

27. Keep body and hands away from pin hole leaks or

nozzles that eject water or hydraulic fluid under high

pressure. Use paper or cardboard, not hands, to search

for leaks. Hydraulic fluid or water escaping under pres

sure can have sufficient force to penetrate skin and do

serious damage. If either of these fluids are ejected into

the skin they must be surgically removed within a few

hours by a doctor familiar with this form of injury or gan

grene may result.

28. Before disconnecting or performing any work on the

hydraulic oil system, all pressure in system must be re

lieved by stopping engine and opening by–pass valve.

29. Make sure all water line connectors are tight, and all

hoses and lines are in good condition before applying

pressure to the system.

-

-

-

-

Page 7

30. Before disconnecting or performing any work on the

water system, all pressure in system must be relieved by

stopping engine and opening bleed valve. Opening the

the bleed valve allows any trapped water to escape from

the system and also allows the accumulator piston to

move to the bottom of the accumulator cylinder.

31. The accumulator in this machine contains high

pressure dry nitrogen. Accumulator servicing requires

special tools and precautions. Accumulators do not con

tain user serviceable components. Improper accumulator servicing can cause dismemberment or death. Do

not attempt to disassemble a accumulator, have this

work done by a Authorized Toro Distributor.

32. Do not overspeed the engine by changing governor

settings. To be sure of safety and accuracy, have an Au

thorized T0R0 Distributor check maximum engine

speed with a tachometer.

33. Engine must be shut off before checking oil or adding oil to the crankcase.

-

-

34. Allow engine to cool before storing machine in any

enclosure such as a garage or storage shed. Make sure

the fuel tank is empty if machine is to be stored in excess

of 30 days. Do not store machine near any open flame or

where gasoline fumes may be ignited by a spark. Always

store gasoline in a safety approved, red metal container.

35. When storing or transporting machine (trailering),

make sure fuel shut–off valve is closed.

36. Perform only those maintenance instructions described in this manual. If major repairs are ever needed

or assistance is desired, contact an Authorized Toro Dis

tributor. To ensure optimum performance and safety, always purchase genuine TORO replacement parts and

accessories to keep the Toro all TORO. NEVER USE

“WILL–FIT” REPLACEMENT PARTS AND ACCESSORIES MADE BY OTHER MANUFACTURERS. Look for

the TORO logo to assure genuineness. Using unap

proved replacement parts and accessories could void

the warranty of The Toro Company.

-

-

Hydroject 3010

Page 1 – 3

Safety

Page 8

Safety and Instruction Decals

Numerous safety and instruction decals are affixed to

the Hyroject 3010. If any decal becomes illegible or

damaged, install a new decal. Part numbers for replace

ment decals are listed in your Parts Catalog. Order replacement decals from your authorized Toro Distributor.

-

Safety

Page 1 – 4

Hydroject 3010

Page 9

Product Records and Maintenance

Table of Contents

Chapter 2

PRODUCT RECORDS . . . . . . . . . . . . . . . . . . . . . . . . . 1

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

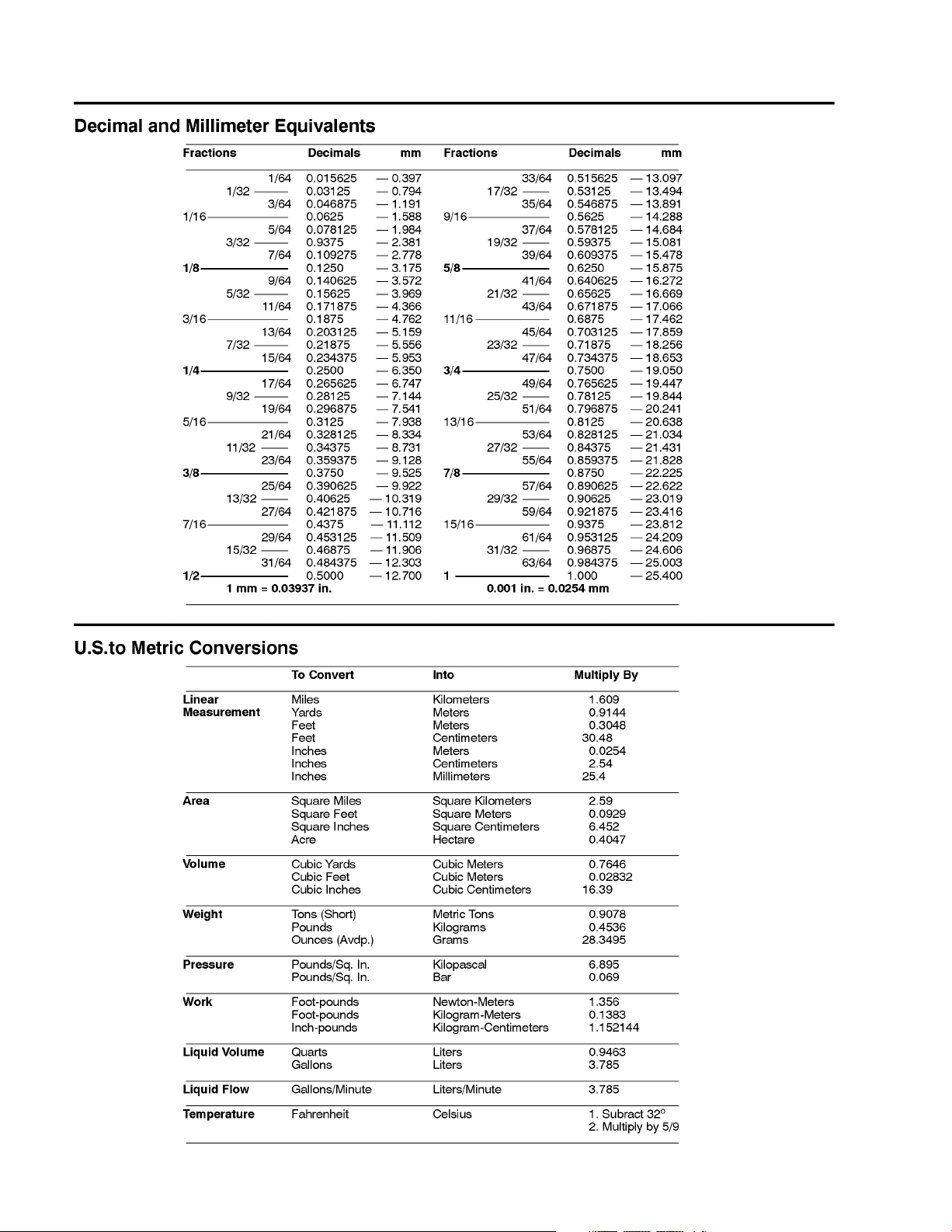

EQUIVALENTS AND CONVERSIONS . . . . . . . . . . . 2

Decimal and Millimeter Equivalents . . . . . . . . . . . . 2

U.S. to Metric Conversions . . . . . . . . . . . . . . . . . . . 2

TORQUE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . 3

Fastener Identification . . . . . . . . . . . . . . . . . . . . . . . 3

Product Records

Insert Operator’s Manual and Parts Catalog for your Hydroject 3010 at the end of this chapter. Additionally, if

any optional equipment or accessories have been

installed to your Hyroject, insert the Installation Instructions, Operator’s Manuals and Parts Catalogs for those

options at the end of this chapter.

Maintenance

Maintenance procedures and recommended service intervals for the Hydroject 3010 covered in the Operator’s

Manual. Refer to that publication when performing regular equipment maintenance. Refer to the Engine Operator’s Manual for additional engine specific maintenance

procedures.

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Inch Series) . . . . . . . . . . . . . . . 4

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Metric Fasteners) . . . . . . . . . . 5

Other Torque Specifications . . . . . . . . . . . . . . . . . . 6

Conversion Factors . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hydroject 3010

Page 2 – 1

Product Records and Maintenance

Page 10

Equivalents and Conversions

Product Records and Maintenance

Page 2 – 2

Hydroject 3010

Page 11

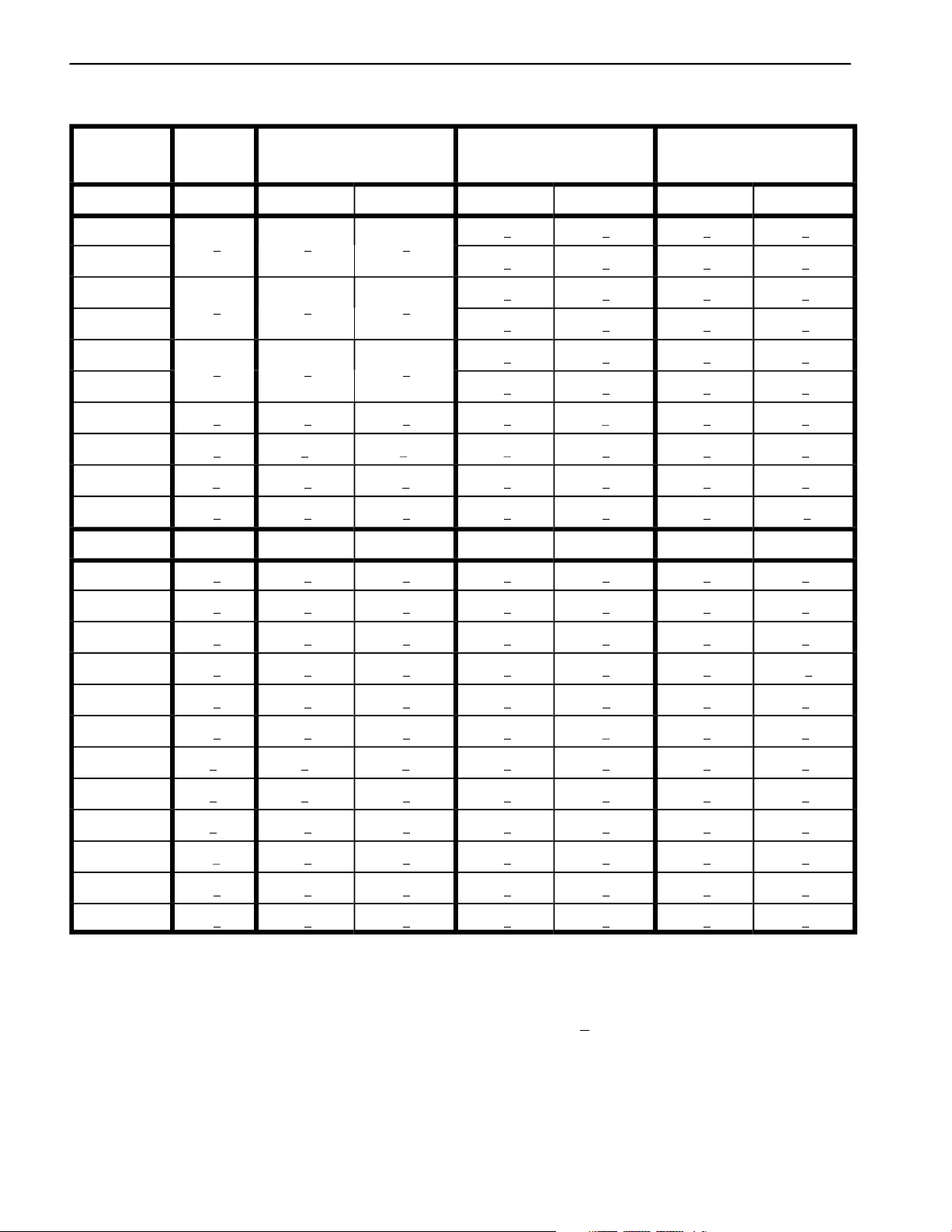

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as determined

by Toro, either the recommended torque or a torque that

is unique to the application is clearly identified and spe

cified in this Service Manual.

These Torque Specifications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a specific requirement identified in this Ser

vice Manual. The following factors shall be considered

when applying torque: cleanliness of the fastener, use

of a thread sealant (e.g. Loctite), degree of lubrication

on the fastener, presence of a prevailing torque feature,

hardness of the surface underneath the fastener’s head

or similar condition which affects the installation.

-

-

Fastener Identification

As noted in the following tables, torque values should be

reduced by 25% for lubricated fasteners to achieve

the similar stress as a dry fastener. Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specific torque value

should be determined based on the aluminum or brass

material strength, fastener size, length of thread en

gagement, etc.

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measure the torque required to tighten the fastener until

the lines match up.

-

Grade 1

Grade 5 Grade 8

Inch Series Bolts and Screws

Figure 1

Class 8.8 Class 10.9

Metric Bolts and Screws

Figure 2

Hydroject 3010

Page 2 – 3

Product Records and Maintenance

Page 12

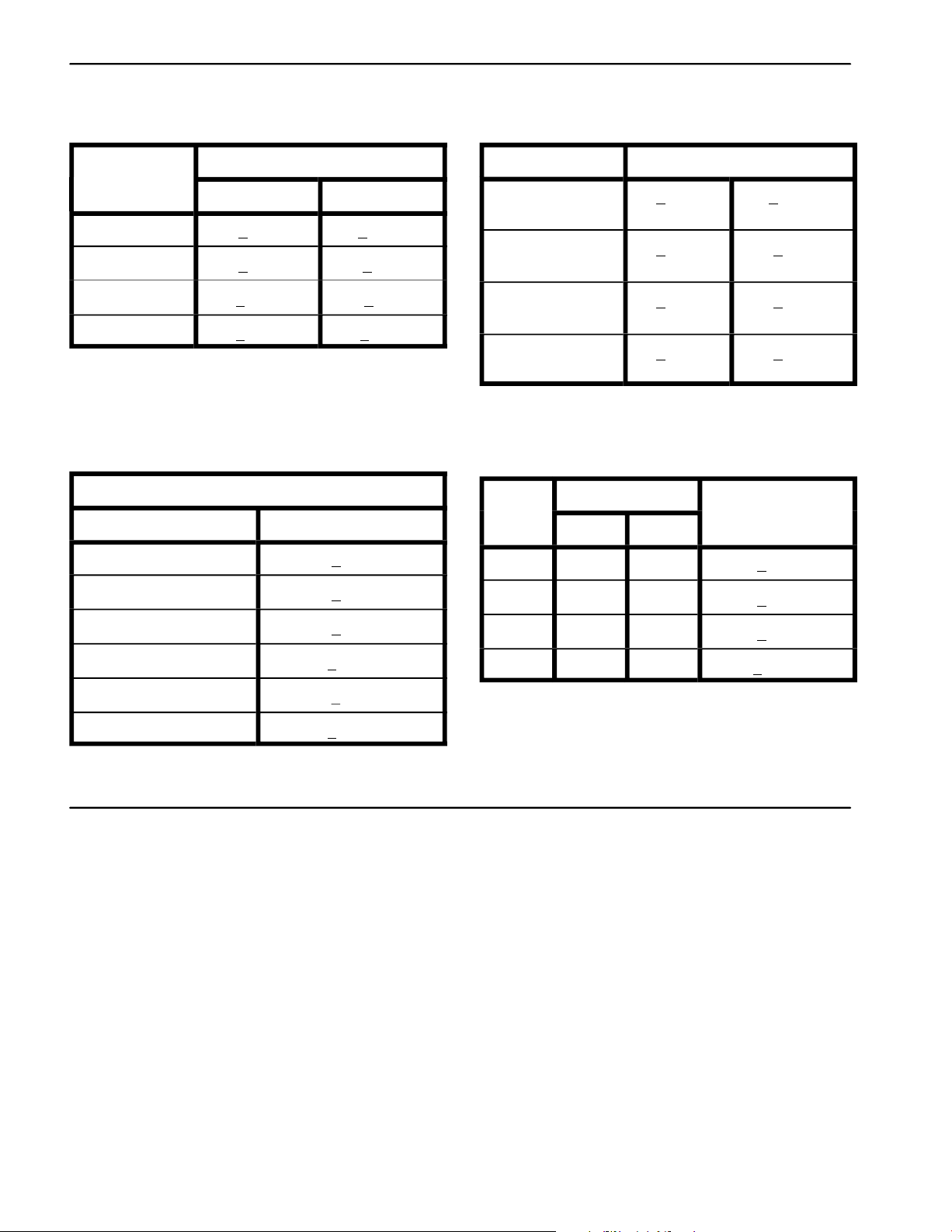

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

Grade 1, 5 &

Thread Size

# 6 – 32 UNC 15 + 2 170 + 20 23 + 2 260 + 20

# 6 – 40 UNF

# 8 – 32 UNC 29 + 3 330 + 30 41 + 4 460 + 45

# 8 – 36 UNF

# 10 – 24 UNC 42 + 4 475 + 45 60 + 6 675 + 70

# 10 – 32 UNF

1/4 – 20 UNC 48 + 7 53 + 7 599 + 79 100 + 10 100 140 + 15 1580 + 170

1/4 – 28 UNF 53 + 7 65 + 10 734 + 10 1300 + 100 160 + 15 1800 + 170

5/16 – 18 UNC 15 105 + 17 169 200 + 25 2250 + 280 300 + 30 3390 + 340

5/16 – 24 UNF 138 + 17 128 + 17 1446 + 192 225 + 25 2540 + 280 325 + 30 3670 + 340

3/8 – 16 UNC 16 + 2 16 + 2 22 + 3 30 + 3 41 + 4 43 + 4 58 + 5

8 with Thin

Height Nuts

in–lb in–lb N–cm in–lb N–cm in–lb N–cm

10 + 2 13 + 2 147 + 23

13 + 2 25 + 5 282 + 30

18 + 2 30 + 5 339 + 56

115 + 1186 +

ft–lb ft–lb N–m ft–lb N–m ft–lb N–m

SAE Grade 1 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

113 115 +

SAE Grade 5 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

17 + 2 190 + 20 25 + 2 280 + 20

31 + 3 350 + 30 43 + 4 485 + 45

48 + 4 540 + 45 68 + 6 765 + 70

1125 +

SAE Grade 8 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 5 or Stronger Nuts)

3/8 – 24 UNF 17 + 2 18 + 2 24 + 3 35 + 3 47 + 4 50 + 4 68 + 5

7/16 – 14 UNC 27 + 3 27 + 3 37 + 4 50 + 5 68 + 7 70 + 7 95 + 9

7/16 – 20 UNF 29 + 3 29 + 3 39 + 4 55 + 5 75 + 7 77 + 7 104 + 9

1/2 – 13 UNC 30 + 3 48 + 7 65 + 9 75 + 8 102 + 11 105 + 10 142 + 14

1/2 – 20 UNF 32 + 3 53 + 7 72 + 9 85 + 8 11 120 + 10 163 + 14

5/8 – 11 UNC 119 +

5/8 – 18 UNF 75 + 10 95 + 15 129 + 20 170 + 15 230 + 20 240 + 20 325 + 27

3/4 – 10 UNC 93 + 12 140 + 20 190 + 27 265 + 25 359 + 34 375 + 35 508 + 47

3/4 – 16 UNF 15 165 + 25 224 + 34 300 + 25 407 + 34 420 + 35 569 + 47

7/8 – 9 UNC 140 + 20 225 + 25 305 + 34 430 + 45 583 + 61 600 + 60 813 + 81

7/8 – 14 UNF 155 + 25 260 + 30 353 + 41 475 + 45 644 + 61 660 + 60 895 + 81

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite or thread sealant such as Loctite.

65 + 10 88 + 12 16 150 + 15 203 + 20 210 + 20 285 + 27

115 +

NOTE: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the mini

mum proof load specified in SAE J429. The tolerance is

approximately +

115 +

10% of the nominal torque value. Thin

height nuts include jam nuts.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

-

Product Records and Maintenance

Page 2 – 4

Hydroject 3010

Page 13

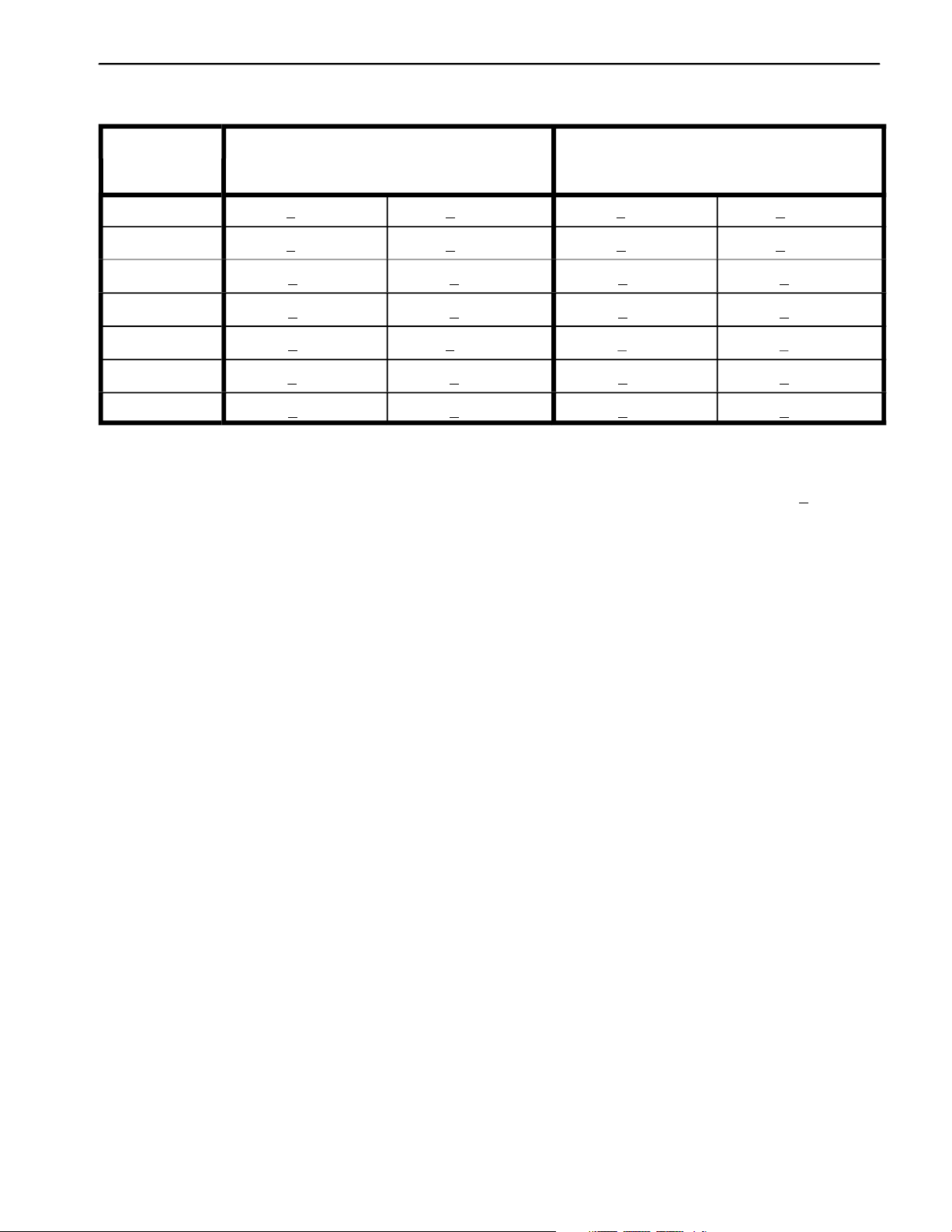

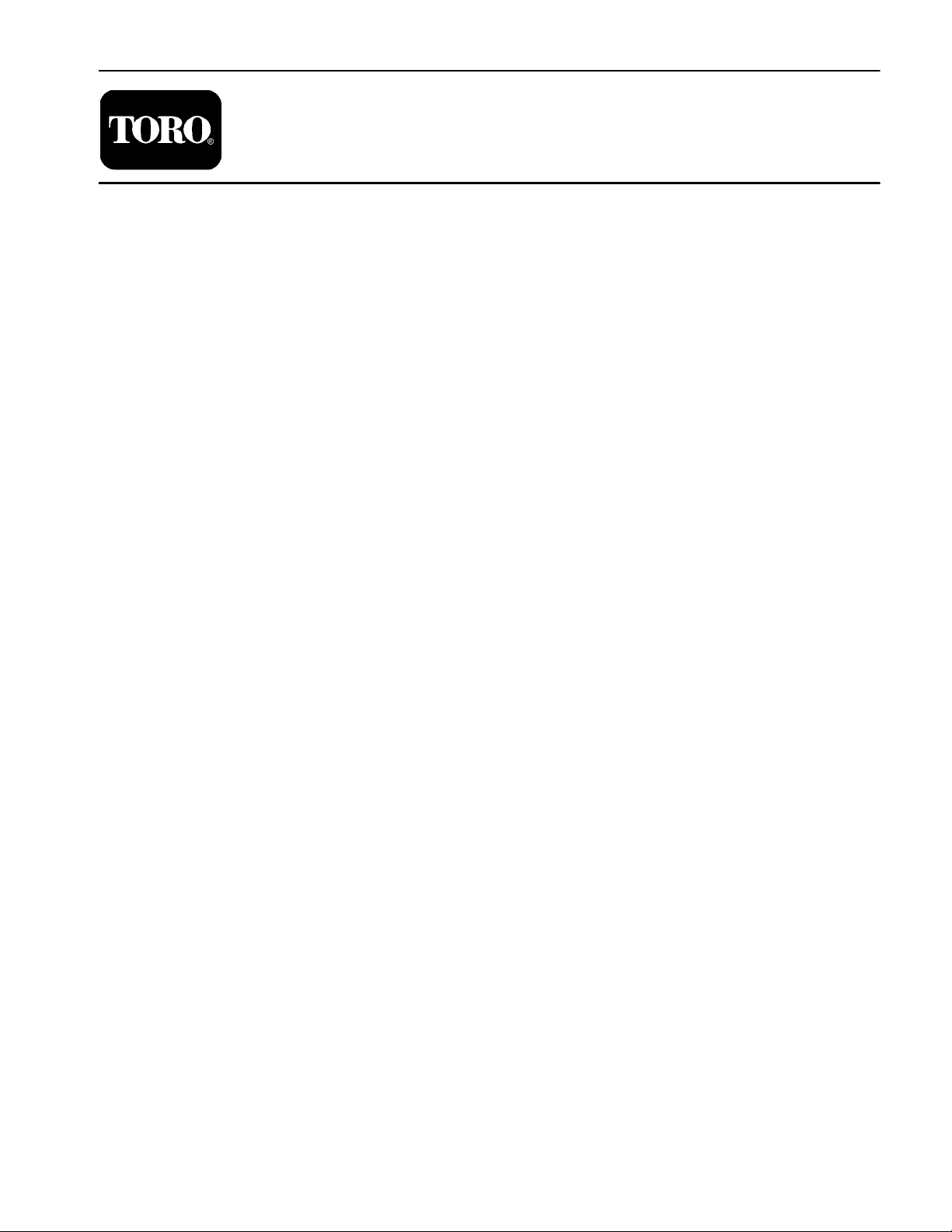

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Fasteners)

Class 8.8 Bolts, Screws and Studs with Class 10.9 Bolts, Screws and Studs with

Thread Size Regular Height Nuts

(Class 8 or Stronger Nuts)

M5 X 0.8 57 + 5 in–lb 640 + 60 N–cm 78 + 7 in–lb 885 + 80 N–cm

M6 X 1.0 96 + 9 in–lb 1018 + 100 N–cm 133 + 13 in–lb 1500 + 150 N–cm

M8 X 1.25 19 + 2 ft–lb 26 + 3 N–m 27 + 2 ft–lb 36 + 3 N–m

M10 X 1.5 38 + 4 ft–lb 52 + 5 N–m 53 + 5 ft–lb 72 + 7 N–m

Regular Height Nuts

(Class 10 or Stronger Nuts)

M12 X 1.75 66 + 7 ft–lb 90 + 10 N–m 9 ft–lb 12 N–m

M16 X 2.0 15 ft–lb 225 + 20 N–m 229 + 22 ft–lb 310 + 30 N–m

M20 X 2.5 325 + 33 ft–lb 440 + 45 N–m 450 + 37 ft–lb 610 + 50 N–m

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite or thread sealant such as Loctite.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

166 +

NOTE: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately +

nominal torque value.

92 + 125 +

10% of the

Hydroject 3010

Page 2 – 5

Product Records and Maintenance

Page 14

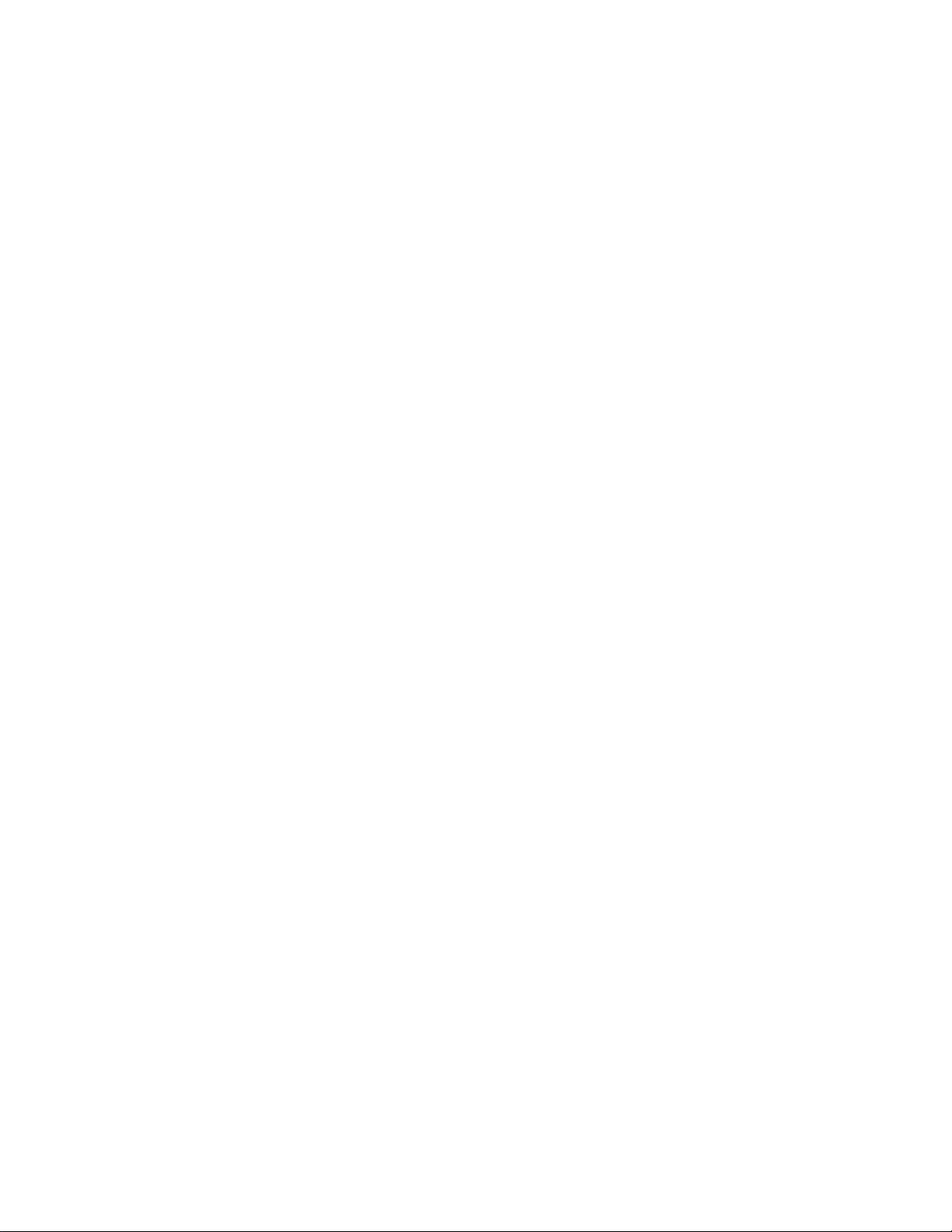

Other Torque Specifications

SAE Grade 8 Steel Set Screws Wheel Bolts and Lug Nuts

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 – 20 UNC 140 + 20 in–lb 73 + 12 in–lb

5/16 – 18 UNC 215 + 35 in–lb 145 + 20 in–lb

3/8 – 16 UNC 35 + 10 ft–lb 18 + 3 ft–lb

1/2 – 13 UNC 75 + 15 ft–lb 50 + 10 ft–lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23 or Type F

Thread Size

No. 6 – 32 UNC 20 + 5 in–lb

No. 8 – 32 UNC 30 + 5 in–lb

Baseline Torque*

Thread Size

7/16 – 20 UNF

Grade 5

1/2 – 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non–lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 + 5 in–lb

No. 8 15 18 30 + 5 in–lb

Threads per Inch

Type A Type B

Recommended Torque**

65 + 10 ft–lb 88 + 14 N–m

80 + 10 ft–lb 108 + 14 N–m

80 + 10 ft–lb 108 + 14 N–m

80 + 10 ft–lb 108 + 14 N–m

Baseline Torque*

No. 10 – 24 UNC 38 + 7 in–lb

1/4 – 20 UNC 85 + 15 in–lb

5/16 – 18 UNC 20 in–lb

3/8 – 16 UNC 200 + 100 in–lb

110 +

Conversion Factors

in–lb X 11.2985 = N–cm N–cm X 0.08851 = in–lb

ft–lb X 1.3558 = N–m N–m X 0.7376 = ft–lb

No. 10 12 16 38 + 7 in–lb

No. 12 11 14 85 + 15 in–lb

* Hole size, material strength, material thickness & finish

must be considered when determining specific torque

values. All torque values are based on non–lubricated

fasteners.

Product Records and Maintenance

Page 2 – 6

Hydroject 3010

Page 15

7DEOHRI&RQWHQWV

,1752'8&7,21

63(&,),&$7,216

6(59,&($1'5(3$,56

(QJLQH5HPRYDODQG,QVWDOODWLRQ

.2+/(5(1*,1(6(59,&(0$18$/

&KDSWHU

.RKOHU(QJLQH

+\GURMHFW 3DJH² .RKOHU(QJLQH

Page 16

,QWURGXFWLRQ

7KLV&KDSWHUJLYHVLQIRUPDWLRQDERXWVSHFLILFDWLRQVDQG

UHSDLURIWKH.RKOHUHQJLQHXVHGLQWKH3UR&RUH

*HQHUDOHQJLQHPDLQWHQDQFHSURFHGXUHVDUHGHVFULEHG

LQ\RXU2SHUDWRU·V0DQXDO,QIRUPDWLRQRQHQJLQHWURX

EOHVKRRWLQJ WHVWLQJ GLVDVVHPEO\ DQG UHDVVHPEO\ LV

LGHQWLILHGLQWKH.RKOHU(QJLQH6HUYLFH0DQXDOWKDWLVLQ

FOXGHGDWWKHHQGRIWKLVVHFWLRQ

0RVWUHSDLUVDQGDGMXVWPHQWVUHTXLUH WRROVZKLFKDUH

FRPPRQO\ DYDLODEOH LQ PDQ\ VHUYLFH VKRSV 6SHFLDO

WRROVDUHGHVFULEHGLQWKH.RKOHU(QJLQH6HUYLFH0DQX

DO7KHXVHRIVRPHVSHFLDOL]HGWHVWHTXLSPHQWLVH[

SODLQHG+RZHYHUWKHFRVWRIWKHWHVWHTXLSPHQWDQGWKH

VSHFLDOL]HGQDWXUHRIVRPHUHSDLUVPD\GLFWDWHWKDWWKH

ZRUNEHGRQHDWDQHQJLQHUHSDLUIDFLOLW\

6HUYLFHDQGUHSDLUSDUWVIRU.RKOHUHQJLQHVDUHVXSSOLHG

WKURXJK\RXUORFDO.RKOHUGHDOHURUGLVWULEXWRU

.RKOHU(QJLQH

3DJH²

+\GURMHFW

Page 17

6SHFLILFDWLRQV

,WHP 'HVFULSWLRQ

0DNH'HVLJQDWLRQ .RKOHU&RPPDQG3UR&DUE²VWURNH9²7ZLQ

1XPEHURI&\OLQGHUV

%RUH[6WURNH µ[µPP[PP

7RWDO'LVSODFHPHQW &XELF,QFKHVFF

&RPSUHVVLRQ5DWLR

'U\:HLJKWDSSUR[LPDWH 3RXQGV.LORJUDPV

)XHO 8QOHDGHG5HJXODU*DVROLQH0LQLPXP2FWDQH

)XHO7DQN&DSDFLW\ 86*DOORQV/LWHUV

*RYHUQRU 0HFKDQLFDO

,GOH6SHHGQRORDG ²530

+LJK,GOHQRORDG ²530

(QJLQH2LO 6HH2SHUDWRU·V0DQXDO

2LO3XPS *HDUGULYHQWURFKRLGW\SH

$LU&RROHG2+9

&UDQNFDVH2LO&DSDFLW\ 864XDUW/LWHUVZLWKILOWHU

6WDUWHU 9'&

+\GURMHFW 3DJH² .RKOHU(QJLQH

Page 18

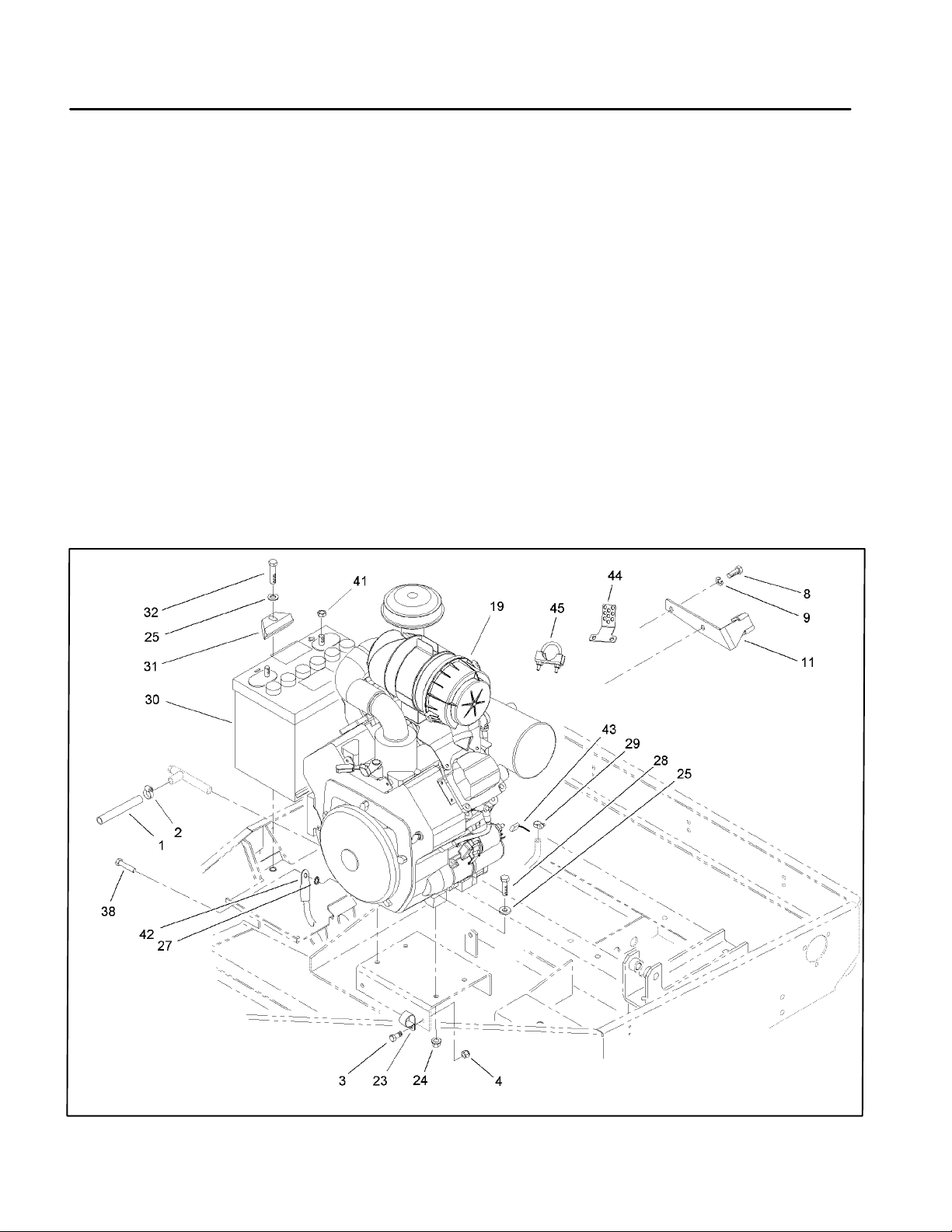

6HUYLFHDQG5HSDLUV

(QJLQH5HPRYDODQG,QVWDOODWLRQ

3DUNWKHPDFKLQHRQDOHYHOVXUIDFHHQJDJHWKHSDUN

LQJEUDNHDQGUHPRYHWKHKRRG

'LVFRQQHFW ERWK WKH SRVLWLYH DQG QHJDWLYH ²

FDEOHVIURPWKHEDWWHU\/RRVHQWKHEDWWHU\FODPS,WHP

DQGUHPRYHWKHEDWWHU\

'UDLQWKHRLOIURPWKHHQJLQHLQWRDVXLWDEOHFRQWDLQHU

'LVFRQQHFWWKHGULYHFRXSOLQJIURPWKHFOXWFKDGDSWHU

VHH'ULYH&RXSOLQJ5HPRYDODQG,QVWDOODWLRQLQ:DWHU

6\VWHP6HUYLFH

5HPRYH WKH ZDWHU SXPS GULYH EHOW DQG K\GUDXOLF

SXPSGULYHEHOW

'LVFRQQHFWWKHHQJLQHZLULQJKDUQHVVFRQQHFWRU'LV

FRQQHFWDQGSOXJWKHIXHOKRVH

5HPRYHIRXUQXWV,WHPFDSVFUHZV,WHPDQG

ZDVKHUV,WHPVHFXULQJWKHHQJLQHWRWKHIUDPH

$WWDFK DQ HQJLQH OLIWLQJ FKDLQ WR WKH HQJLQH OLIWLQJ

VWUDSV&RQQHFWWKHFKDLQWRDKRLVWRUEORFNDQGWDFNOH

DQGUHPRYHVODFNIURPWKHFKDLQDQGOLIWLQJGHYLFH2QH

SHUVRQVKRXOGRSHUDWHWKHKRLVWRUEORFNDQGWDFNOHDQG

WKHRWKHUSHUVRQVKRXOGKHOSJXLGHWKHHQJLQHRXWRIWKH

IUDPH5HPRYHWKHHQJLQHIURPWKHIUDPH

0RXQWWKHHQJLQHLQDQHQJLQHUHEXLOGLQJVWDQGRUSXW

LWRQDVWXUG\ZRUNEHQFK%HIRUHGLVDVVHPEOLQJWKHHQ

JLQHUHPRYHH[WHUQDODFFHVVRULHVVXFKDVWKHPXIIOHU

DLU FOHDQHU K\GUDXOLF SXPS FOXWFK K\GUDXOLF SXPS

SXOOH\ ZDWHU SXPS FOXWFK DQG FOXWFK NH\ VHH 'ULYH

&RXSOLQJ 5HPRYDO DQG ,QVWDOODWLRQ LQ :DWHU 6\VWHP

6HUYLFH

7RLQVWDOOWKHHQJLQHSHUIRUPVWHSV²LQUHYHUVH

RUGHU

5HSODFHWKHRLOILOWHUDQGILOOWKHHQJLQHZLWKWKHFRU

UHFWRLO

.RKOHU(QJLQH

)LJXUH

3DJH²

+\GURMHFW

Page 19

Table of Contents

Chapter 4

Hydraulic System

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 2

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . 3

Hydraulic Hose and Fitting Information . . . . . . . . 3

Pushing or Towing . . . . . . . . . . . . . . . . . . . . . . . . 5

HYDRAULIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . 6

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Hydraulic Tester. . . . . . . . . . . . . . . . . . . . . . . . . . 7

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . 8

Transmission Operates in One Direction Only . . 8

System Operates Hot, Looses Power or

Will Not Operate in Either Direction

TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Hydraulic Tests . . . . . . . . . . . . . . . . . . . . . . . . . 10

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Traction Cable Adjustment . . . . . . . . . . . . . . . . . 11

. . . . . . . . . 8

Speed Control Adjustment. . . . . . . . . . . . . . . . . 11

Transmission Neutral Adjustment . . . . . . . . . . . 12

Aeration Speed Adjustment . . . . . . . . . . . . . . . . 12

Pump Drive Belt Adjustment . . . . . . . . . . . . . . . 13

REPAIRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pump Drive Belt Replacement . . . . . . . . . . . . . 14

Hydraulic Pump Removal and Installation. . . . . 15

Pump Shaft Seal Replacement . . . . . . . . . . . . 16

Pump Charge Check Valve Service . . . . . . . . . 17

Pump Bypass Valve Service . . . . . . . . . . . . . . . 17

Charge Pump Service . . . . . . . . . . . . . . . . . . . . 18

Major Pump Repair . . . . . . . . . . . . . . . . . . . . . . 18

Wheel Motor Removal and Installation . . . . . . . 22

Wheel Motor Repair. . . . . . . . . . . . . . . . . . . . . . 23

Hydroject 3010 Page 4 - 1 Table of Contents

Page 20

Specifications

Item Description

__________________________________________________________________________________________

Pump

Rated system pressure 2100 PSI maximum, 1000 PSI continuous

Rated system flow 8.5 GPM maximum at 3500 RPM

Charge relief pressure 25 to 70 PSI psi at 3500 RPM

Oil filter

________________________________________________________________________________________________________________________________________________________

Wheel Motor Orbit rotor type

________________________________________________________________________________________________________________________________________________________

Hydraulic Oil

________________________________________________________________________________________________________________________________________________________

Reservoir (gear case) Approximately 4 - 5 quarts

Sundstrand Series 70, BDP-10L Variable Displacement Pump

25 micron screw-on type. No by-pass

See Operator’s Manual

Specifications Page 4 - 2 Hydroject 3010

Page 21

General Information

Hydraulic Hoses

Hydraulic hoses are subject to extreme conditions such

as, pressure differentials during operation and exposure

to weather, sun, chemicals, very warm storage conditions or mishandling during operation or maintenance.

These conditions can cause damage or premature deterioration. Some hoses, such as reel motor hoses, are

more susceptible to these conditions than others. Inspect the hoses frequently for signs of deterioration or

damage.

When replacing a hydraulic hose, be sure that the hose

is straight (not twisted) before tightening the fittings. This

can be done by observing the imprint on the hose. Use

two wrenches; one to hold the hose straight and one to

tighten the hose swivel nut onto the fitting.

CAUTION

Before disconnecting or performing any work

on the hydraulic system, all pressure in the

system must be relieved by stopping the engine and opening the bypass valve.

Keep body and hands away from pin hole

leaks or nozzles that eject hydraulic fluid under high pressure. Use cardboard,

not hands, to search for leaks. Hydraulic fluid

escaping under pressure can have sufficient

force to penetrate the skin and do serious

damage. If fluid is injected into the skin, it

must be surgically removed within a few

hours by a doctor familiar

injury or gangrene may result.

paper or

with this

type of

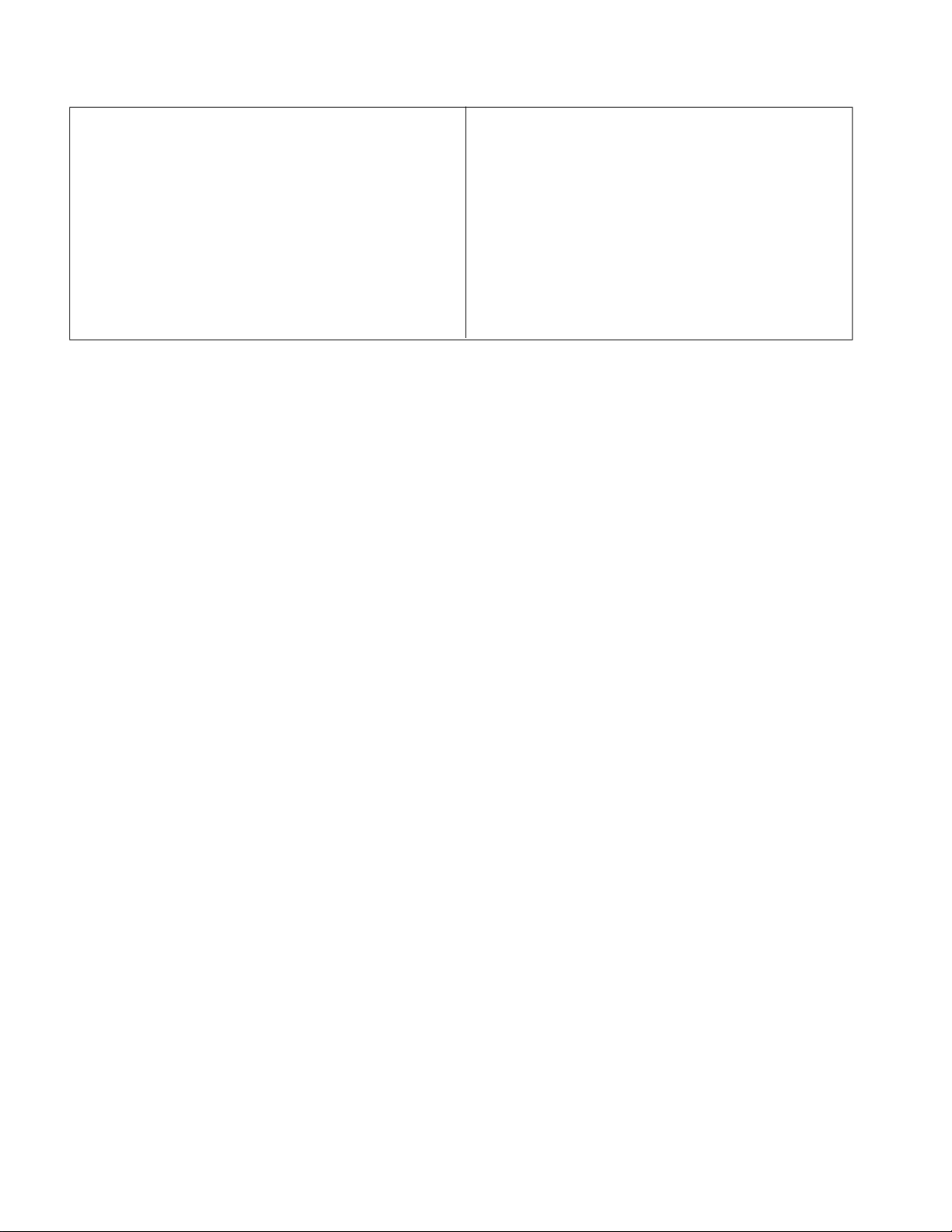

Hydraulic Fitting Installation

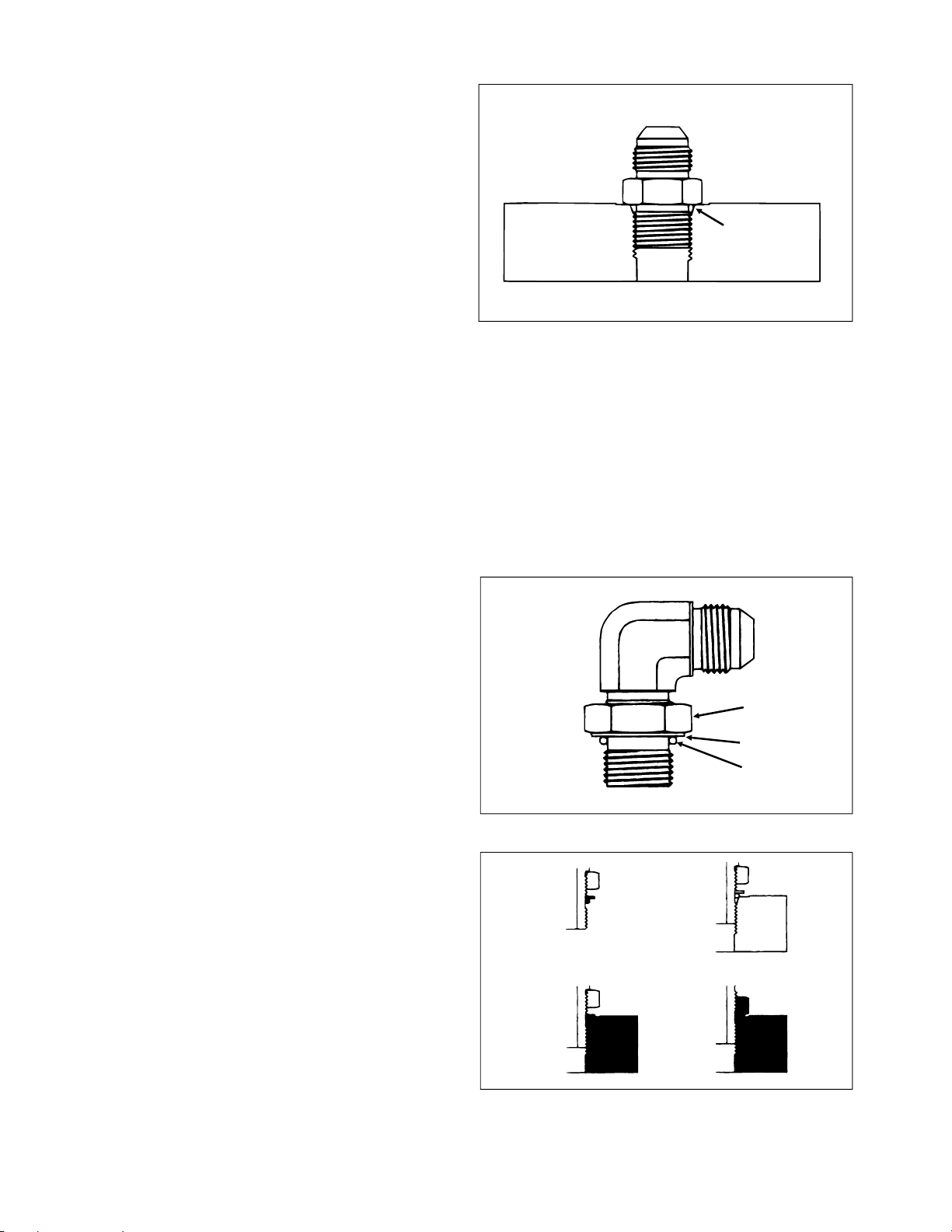

O-Ring Face Seal (Fig. 2, 3)

1. Make sure both threads and sealing surfaces are free

of burrs, nicks, scratches, or any foreign material.

2. Make sure the O-ring is installed and properly seated

in the groove. It is recommended that the O-ring be

replaced any time the connection is opened.

3. Lubricate the O-ring with a light coating of oil.

4. Put the tube and nut squarely into position on the face

seal end of the fitting and tighten the nut until finger tight.

5. Mark the nut and fitting body. Hold the body with a

wrench. Use another wrench to tighten the nut to the

correct flats from finger tight (F .F.F .T.). The markings on

the nut and fitting body will verify that the connection has

been tightened.

Size F.F.F.T.

4 (1/4 in. nominal hose or tubing) .75 r .25

6 (3/8 in.) r .25

8 (1/2 in.) .75 r .25

10 (5/8 in.) r .25

12 (3/4 in.) r .25

16 (1 in.) .75 r .25

.75

1.00

.75

Nut

Sleeve

Seal

Body

Figure 2

Mark Nut

and Body

Finger Tight After Proper Tightening

Final

Position

Extend Line

Initial

Position

Figure 3

Hydroject 3010 Page 4 - 3 General Information

Page 22

SAE Straight Thread O-Ring Port - Non-adjustable

(Fig. 4)

1. Make sure both threads and sealing surfaces are free

of burrs, nicks, scratches, or any foreign material.

2. Always replace the O-ring seal when this type of fitting

shows signs of leakage.

3. Lubricate the O-ring with a light coating of oil.

4. Install the fitting into the port and tighten it down full

length until finger tight.

5. Tighten the fitting to the correct flats from finger tight

(F.F.F.T.).

Size F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00 r .25

6 (3/8 in.) 1.50 r .25

8 (1/2 in.) 1.50 r .25

10 (5/8 in.) 1.50 r .25

12 (3/4 in.) 1.50 r .25

16 (1 in.) 1.50 r .25

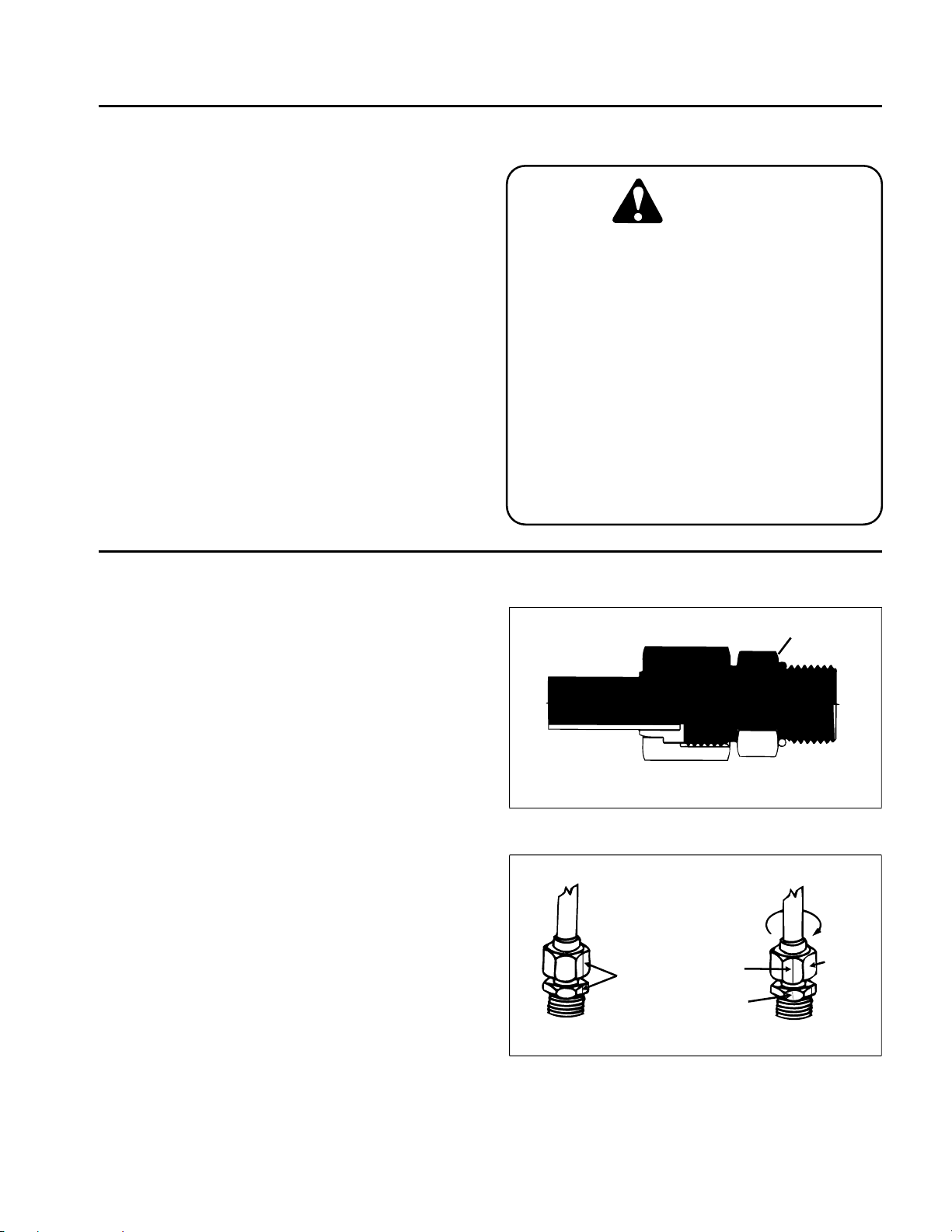

SAE Straight Thread O-Ring Port - Adjustable

(Fig. 5, 6)

1. Make sure both threads and sealing surfaces are free

of burrs, nicks, scratches, or any foreign material.

2. Always replace the O-ring seal when this type of fitting

shows signs of leakage.

3. Lubricate the O-ring with a light coating of oil.

4. Turn back the jam nut as far as possible. Make sure

the back up washer is not loose and is pushed up as far

as possible (Step 1).

O-Ring

Figure 4

Lock Nut

Back-Up Washer

O-Ring

5. Install the fitting into the port and tighten finger tight

Figure 5

until the washer contacts the face of the port (Step 2).

6. T o put the fitting in the desired position, unscrew it by

the required amount, but no more than one full turn

Step 1

Step 3

(Step 3).

7. Hold the fitting in the desired position with a wrench

and turn the jam nut with another wrench to the correct

flats from finger tight (F.F.F.T.) (Step 4)

Size F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00 r .25

6 (3/8 in.) 1.50 r .25

8 (1/2 in.) 1.50 r .25

10 (5/8 in.) 1.50 r .25

12 (3/4 in.) 1.50 r .25

16 (1 in.) 1.50 r .25

Step 2

Step 4

Figure 6

General Information Page 4 - 4 Hydroject 3010

Page 23

Pushing or Towing (Fig. 7)

The machine can be pushed or towed for very short

distances with the engine off, if necessary.

IMPORT ANT: Do not push or tow the machine faster

than 5 MPH because the hydraulic pump may be

damaged. If the machine must be moved further

than a few feet, transport it on a trailer or pull with

traction wheel raised and secured to a dolly . Whenever the machine is pushed or towed, the by-pass

valve must be open. Hook on front of handle is used

for a tie-down only, not a hitch point.

1. Stop the engine and raise the hood.

1

2. Open the by-pass valve by turning it counterclockwise

(2 turns maximum).

3. After moving the machine, close the by-pass valve by

turning it clockwise. Tighten the by-pass valve to a

torque of 7 to 10 ft-lb.

IMPORTANT: Operating the machine with the bypass valve open will cause improper operation and

overheating of the hydraulic system.

Figure 7

1. By-pass valve

Hydroject 3010 Page 4 - 5 General Information

Page 24

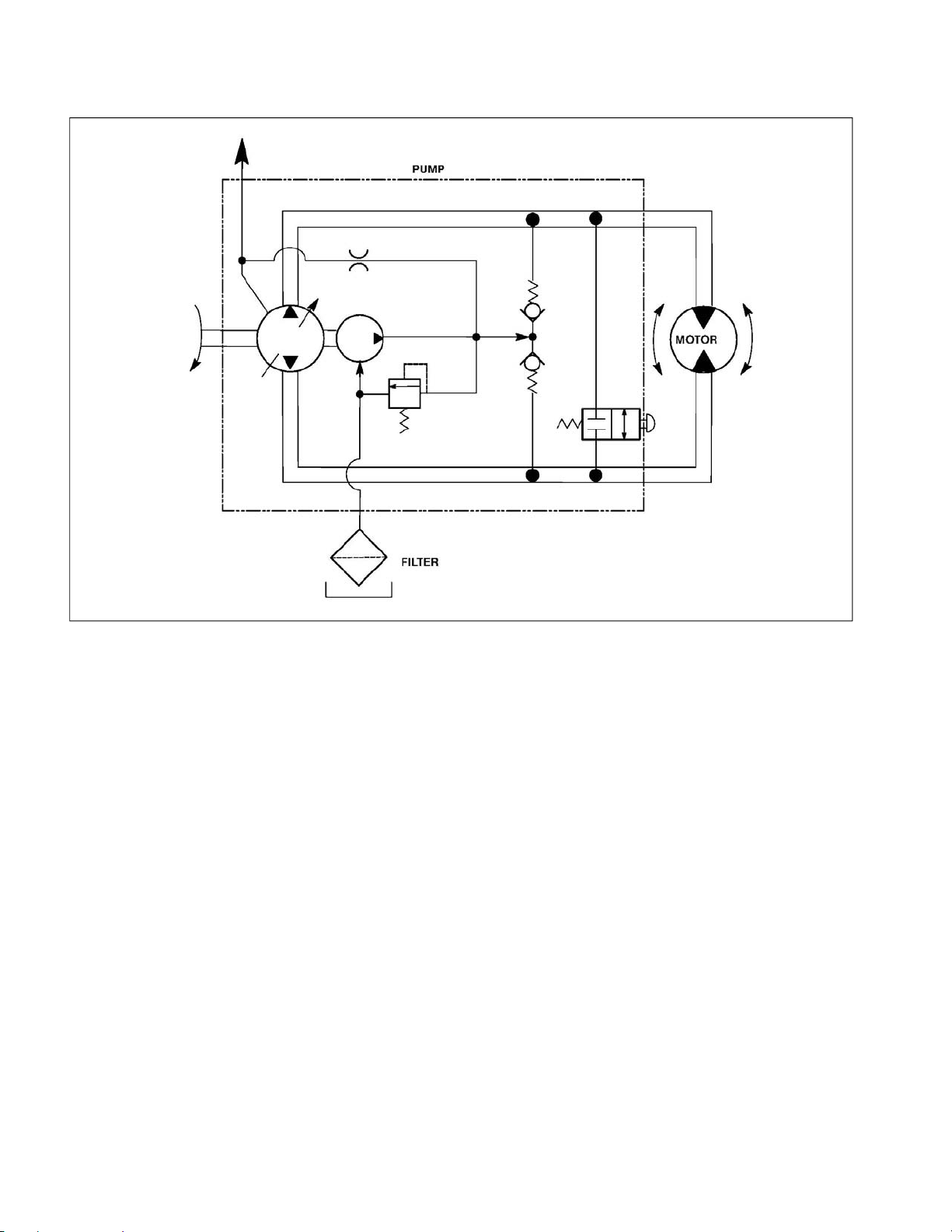

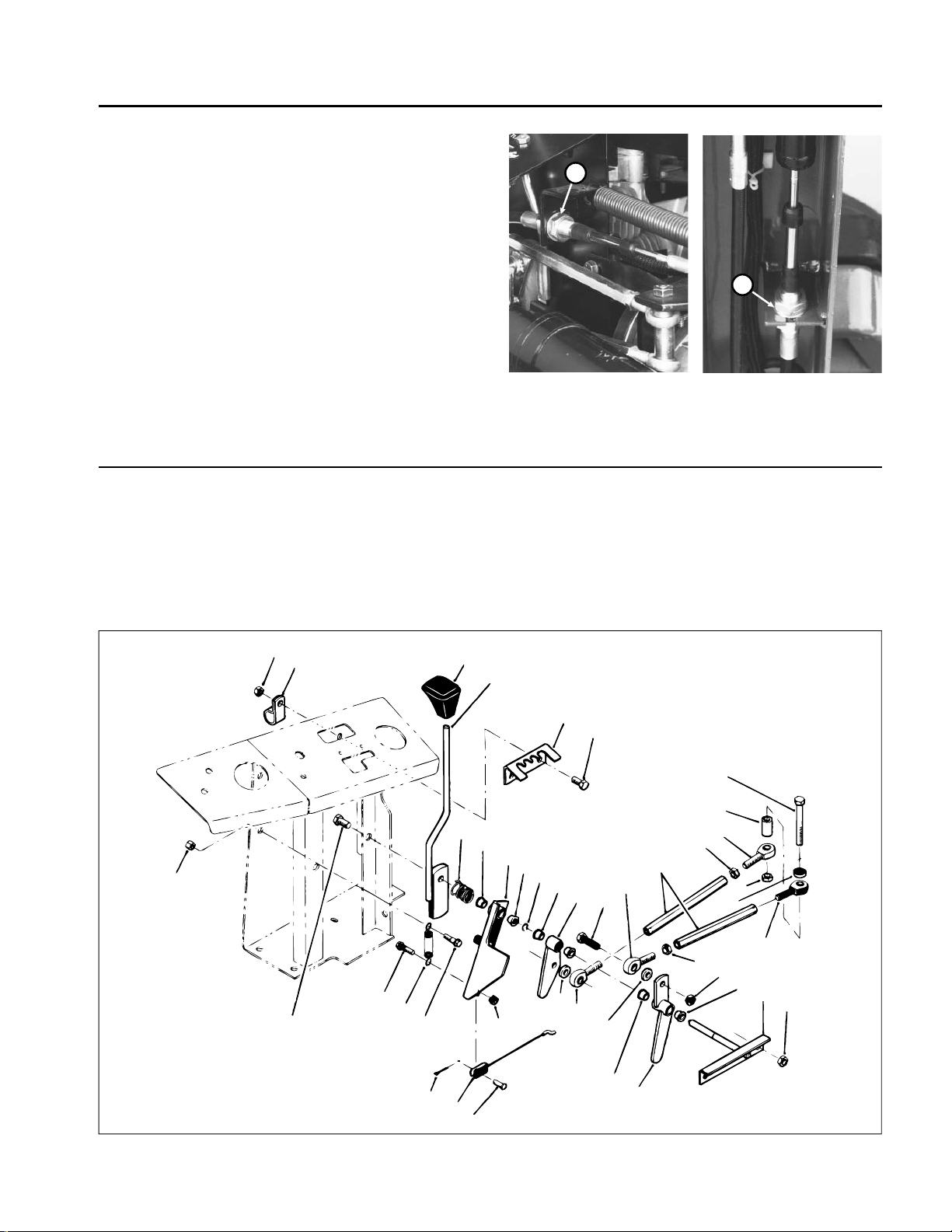

Hydraulic Diagram

Cooling

Orifice

Input

(Belt Drive)

Variable

Disp. Pump

Inlet

Filter

Charge

Pump

Reservoir

(Gear Case)

Charge Relief

Val

ve

Figure 8

Charge

Check

ves

Val

By-pass

ve

Val

Wheel

Motor

Hydraulic Diagram Page 4 - 6 Hydroject 3010

Page 25

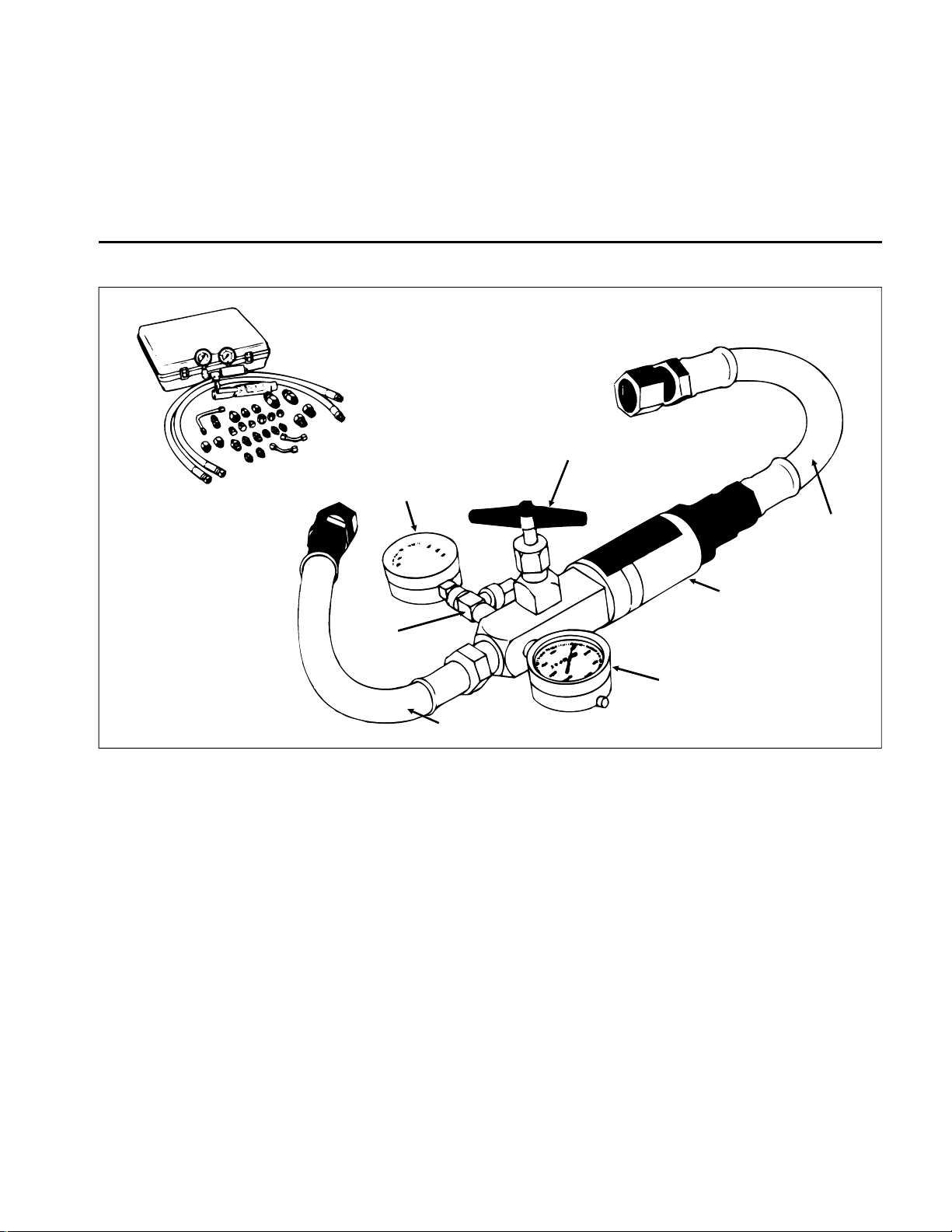

Special Tools

NOTE: Order special tools from the TORO SPECIAL

TOOLS AND APPLICATIONS GUIDE (COMMERCIAL

PRODUCTS). Some tools may be listed in the

Hydroject 3010 Parts Catalog. Some tools may also be

available from a local supplier.

Hydraulic Tester - With Pressure and Flow Capabilities (Fig. 9)

Load Valve

Low Pressure

Gauge

Outlet

Hose

Gauge

Protector Valve

Inlet Hose

Figure 9

You must have o-ring face seal (ORFS) adapter fittings

for this tester to use it on the HydroJect 3010.

1. INLET HOSE: Hose connected from the system

circuit to the inlet side of the hydraulic tester.

2. LOAD VALVE: If required, upon turning the valve to

restrict flow, a simulated working load is created in the

circuit.

3. LOW PRESSURE GAUGE: Low range gauge to

provide accurate reading at low pressure, 0 - 1000 psi.

This gauge has a protector valve which cuts out

when pressure is about to exceed the normal range

for the gauge. The cutout pressure is adjustable.

Flow Meter

High Pressure

Gauge

4. HIGH PRESSURE GAUGE: High range gauge to

accommodate pressure beyond the capacity of the low

pressure gauge, 0 - 5000.

5. FLOW METER: This meter measures actual oil flow

in the operation circuit, with a gauge rated at 15 GPM.

6. OUTLET HOSE: Hose from the outlet side of the

hydraulic tester to be connected to the hydraulic system

circuit.

Hydroject 3010 Page 4 - 7 Special Tools

Page 26

Troubleshooting

The cause of an improperly functioning hydraulic system is best diagnosed with the use of proper testing

system could lead to extensive internal component

damage.

equipment and a thorough understanding of the complete hydraulic system.

The charts that follow contain detailed information to

assist in troubleshooting. There may possibly be more

A hydraulic system with an excessive increase in heat

or noise is a potential failure. Should either of these

conditions be noticed, immediately stop the machine,

than one cause for a machine malfunction. All causes

should be checked in the order in which they are listed

on the charts.

turn off the engine, locate the cause of the trouble, and

correct it before allowing the machine to be used again.

Continued use of an improperly functioning hydraulic

Refer to the Testing section of this Chapter for precau-

tions and specific test procedures.

Tr ansmission Operates in One Direction Only

Cause Correction

__________________________________________________________________________________________

Faulty traction control linkage. Repair linkage

________________________________________________________________________________________________________________________________________________________

Transmission charge check valve defective. Inspect and clean or replace charge/check.

System Operates Hot, Looses Power or Will Not Operate in Either Direction

Cause Correction

__________________________________________________________________________________________

Faulty control linkage. Repair linkage

________________________________________________________________________________________________________________________________________________________

Parking brake engaged. Disengage parking brake.

________________________________________________________________________________________________________________________________________________________

Hydraulic oil level too low. Fill to proper level.

________________________________________________________________________________________________________________________________________________________

By-pass valve open. Close by-pass valve.

________________________________________________________________________________________________________________________________________________________

Clogged hydraulic filter. Replace filter.

________________________________________________________________________________________________________________________________________________________

Low charge pressure - Test A. Inspect charge relief valve and replace if faulty.

________________________________________________________________________________________________________________________________________________________

Low traction pump flow/pressure - Test B. Repair or replace pump.

________________________________________________________________________________________________________________________________________________________

Inspect charge pump and replace if faulty.

Low traction motor efficiency - Test C. Repair or replace traction motor.

Troubleshooting Page 4 - 8 Hydroject 3010

Page 27

Testing

The most effective method for isolating problems in the

hydraulic system is by using hydraulic test equipment

such as pressure gauges and flow meters in the circuits

during various operational checks. (See the Special

Tools section in this Chapter.)

CAUTION

Failure to use gauges with the recommended

pressure (psi) rating as listed in the test procedures could result in damage to the gauge

and possible personal injury from leaking hot

oil.

Before Performing Hydraulic Tests

All obvious areas such as oil supply, filter, binding

linkage, loose fasteners, or improper adjustments must

be checked before assuming that a hydraulic component is the source of the problem being experienced.

W ARNING

Before disconnecting or performing any work

on the hydraulic system, all pressure in the

system must be relieved by stopping the engine and opening the bypass valve.

Keep body and hands away from pin hole

leaks or nozzles that eject hydraulic fluid under high pressure. Use paper or cardboard,

not hands, to search for leaks. Hydraulic fluid

escaping under pressure can have sufficient

force to penetrate skin and do serious damage. If fluid is injected into the skin, it must be

surgically removed within a few hours by a

doctor familiar with this type of injury or gangrene may result.

1. Thoroughly clean the machine before disconnecting

or disassembling any hydraulic components. Always

keep in mind the need for cleanliness when working on

hydraulic equipment.

2. Put caps or plugs on any hydraulic lines left open or

exposed during testing or removal of components.

3. The engine must be in good operating condition. Use

a tachometer when making a hydraulic test. Engine

speed can affect the accuracy of the tester readings.

4. T o prevent damage to tester or components, the inlet

and the outlet hoses must be properly connected, and

not reversed (tester with pressure and flow capabilities).

5. T o minimize the possibility of damaging components,

completely open the load valve by turning it counterclockwise (tester with pressure and flow capabilities).

6. Install fittings finger tight, far enough to insure that

they are not cross-threaded, before tightening with a

wrench.

7. Position the tester hoses so that rotating machine

parts will not make contact with them and result in hose

or tester damage.

8. Check the oil level in the reservoir.

9. Check the control linkage for improper adjustment,

binding or broken parts.

10. All hydraulic tests should be made with the hydraulic

oil at normal operating temperature.

Hydroject 3010 Page 4 - 9 Testing

Page 28

Hydraulic Tests (Fig. 10, 11)

1. Make sure hydraulic oil is at normal operating temperature by operating the machine for approximately 10

minutes.

2. Engage parking brake and stop the engine. Make

sure parking brake is properly adjusted before performing hydraulic tests.

3. With engine off, disconnect hose from bulkhead fitting

and install tester in series between traction pump and

wheel motor. Make sure tester flow control valve is

OPEN.

IMPORTANT: Make sure that the oil flow indicator

arrow on the flow gauge is showing that oil will flow

from pump, through tester and to wheel motor.

T est A: Charge Pressure

4. Start the engine and move throttle to full engine RPM

(approx. 3500 RPM).

GAUGE READING: 25 to 70 PSI no load.

5. If there is no pressure, or pressure is low, inspect for

restriction in pump intake line and inlet filter. Inspect

charge relief valve and valve seat. Inspect for sheared

charge pump key. Disassemble charge pump and inspect for internal damage or worn parts. If charge pump

is in good condition (no scoring, scratches, or excessive

wear), piston pump and motor might be suspected of

wear and inefficiency, thus charge pump is unable to

keep up with internal leakage.

NOTE: At pressures above approximately 500 PSI,

mechanical override in handle will cause pump to begin

to de-stroke.

11. If you cannot get 7 GPM or 500 PSI, traction pump

may have internal damage or excessive wear.

TEST C: Traction Motor Efficiency

12. Lower drive wheel to ground and engage parking

brake. Block front and rear of all wheels. Chain machine

to an immovable object and remove slack from chain.

13. With tester flow control valve open, slowly move

traction handle (up or down) so flow is from the pump,

through the tester, then to the wheel motor. Move trac-

tion handle until maximum pressure is attained with

wheel not rotating and read flow gauge.

14. If flow reading is higher than 1.5 GPM, motor may

have internal damage or excessive wear.

1

2

TEST B: Traction Pump Flow

6. Lift the drive wheel off the ground using a jack. Block

front and rear of the other wheels. Make sure the tester

flow control valve is OPEN.

7. Start the engine and release the parking brake.

8. While watching flow and pressure gauges, move

traction handle (up or down) so flow is from the pump,

through the tester, then to the wheel motor. Move traction handle until 6 GPM is obtained.

9. If pressure is less than 200 to 300 PSI go to step 10.

If pressure is more than 200 to 300 PSI stop the engine

and inspect for binding parking brake. Inspect for restriction in lines to and from motor. If there are no restrictions,

motor should be suspected of having internal damage.

10. While watching flow and pressure gauges, move

traction handle (up or down) to full speed position so

flow is from the pump, through the tester, then to the

wheel motor. Slowly close flow control valve until you

get readings of 7 GPM and 500 PSI.

Figure 10

1. Hose 2. Bulkhead fitting

Variable Displacement Pump

Tes ter

Figure 11

Wheel

Motor

Testing Page 4 - 10 Hydroject 3010

Page 29

Adjustments

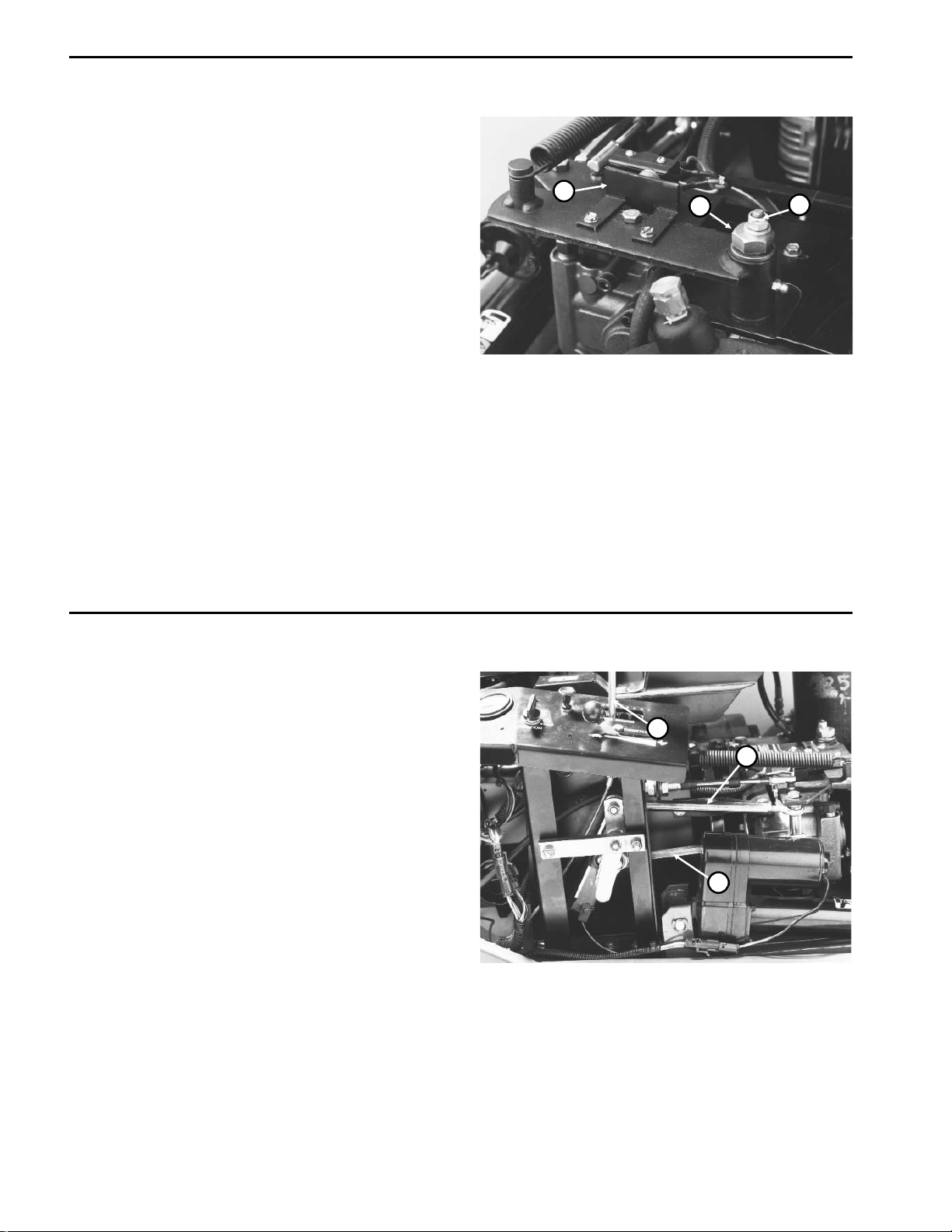

Tr action Cable Adjustment (Fig. 12)

1. Park machine on a level surface, stop the engine and

open the hood. Remove lower cover from handle.

2. Adjust pump end of push-pull cable with pump lever

in neutral starting position by adjusting jam nuts so

distance from seal to threads is 1.00 r 0.05 in.

3. Adjust jam nuts at tiller end of push-pull cable so

traction handle is centered on control handle.

Speed Control Adjustment (Fig. 13)

1. Park machine on a level surface, stop the engine and

open the hood.

2. Adjust speed control cable (Item 26) so speed stop

lever (Item 9) can move to horizontal position.

1

2

Figure 12

1. Jam nuts - pump end 2. Jam nuts - tiller end

3. Adjust speed rods (Item 14) so rod end mounting

holes in pivot arms (Items 11, 23) are located vertically

in line with pivot pin (Item 22).

24

1

2

28

30

29

27

28

26

3

7

25

4

5

6

17

16

8

9

24

8

10

8

11

12

19

20

19

14

13

8

23

15

15

13

19

21

18

20

8

22

18

Figure 13

Hydroject 3010 Page 4 - 11 Adjustments

Page 30

Tr ansmission Neutral Adjustment (Fig. 14)

If machine moves when lever is released, transmission

neutral adjustment is needed.

1. Park machine on a level surface, stop the engine and

open the hood.

2. Lift drive wheel off the ground using a jack. Block front

and rear of other wheels.

3. Start engine and release parking brake.

4. Slightly loosen locknut on top of neutral adjustment

cam and rotate cam hex until traction wheel stops

rotating. Tighten the locknut.

5. Move traction bail completely up and down. Release

handle and check for wheel rotation. If wheel continues

rotating, repeat step 4.

6. If problem continues, stop the engine, check linkage

for binding or damage, then do adjustment procedure

again.

7. Loosen two (2) screws and adjust switch tab so

switches are actuated when pump control is in neutral

and not actuated when pump control is stroked.

3

1

2

Figure 14

1. Neutral adjustment cam

2. Locknut

3. Switch tab

Aeration Speed Adjustment (Fig. 15)

1. Park machine on a level surface, stop the engine and

open the hood.

2. Put speed control lever into second slot from left

(while facing control panel).

3. Lower machine into aerate mode so transport wheels

are off the ground.

4. Lift drive wheel off ground using a jack.

5. Start the engine and release the parking brake.

6. Operate engine at full speed.

7. Move traction handle UP to full speed position.

8. Loosen jam nuts and adjust LOWER speed rod until

traction wheel rotates at 20-22 RPM. Tighten jam nuts.

9. Move traction handle DOWN to full speed position.

10. Adjust UPPER speed rod until traction wheel rotates

at 20-22 RPM. Tighten jam nuts.

1

3

2

Figure 15

1. Speed control lever

2. Lower speed rod

3. Upper speed rod

Adjustments Page 4 - 12 Hydroject 3010

Page 31

Tr action Pump Belt Adjustment (Fig. 16, 17)

1. Park machine on a level surface, stop the engine and

open the hood.

2. Check belt tension by depressing belt midway between pulleys with 3 lb. of force. Belt should deflect

1/4 in.

3. If adjustment is necessary:

A. Loosen pivot nut securing pump mount to pump

support.

B. Loosen adjusting nut securing pump and pump

mount to slotted pump support.

C. Loose three (3) capscrews securing pulley guard

bracket (Fig. 20, Item 21) to control panel and pump

support.

D. Use a pry bar in hole on pump bracket to pull pump

towards outside of machine until you get proper belt

tension, then tighten adjusting nut to secure pump

and pump mount to pump support.

E. Tighten pivot nut. Tighten three (3) capscrews

securing pulley guard bracket.

1

Figure 16

1. Traction pump belt

1

2

Figure 17

1. Adjusting nut

2. Pivot nut

Hydroject 3010 Page 4 - 13 Adjustments

Page 32

Repairs

Tr action Pump Belt Replacement (Fig. 18, 19)

1. Park machine on a level surface, engage parking

brake, open hood and disconnect engine spark plug

wires.

2. Remove pulley guard bracket (Fig. 20, Item 21).

3. Remove drive coupling (see Drive Coupling Removal

and Installation in Chapter 6 - Water System).

4. Disconnect valve clutch electrical connector.

5. Remove valve clutch stops.

6. Loosen pivot nut securing pump mount to pump

support.

1

3

4

2

Figure 18

7. Loosen adjusting nut securing pump and pump mount

to slotted pump support.

8. Push pump towards inside of machine to loosen belt

tension and remove the belt.

9. Reverse steps 2 - 8 to install new belt.

10. Adjust belt tension (see Traction Pump Belt

Adjustment).

1. Pump drive belt

2. Drive coupling

3. Valve clutch

4. Valve clutch stops

1

2

Figure 19

1. Adjusting nut

2. Pivot nut

Repairs Page 4 - 14 Hydroject 3010

Page 33

Hydraulic Pump Removal and Installation (Fig. 20)

1. Park machine on a level surface, engage parking

brake, open hood and disconnect engine spark plug

wires.

2. Disconnect wires from neutral and pump switches

(Item 31) on hydraulic pump. Label wires for proper

reinstallation.

3. Remove extension spring (Item 17).

4. Disconnect stroke control cable ball joint (Item 43)

from pump lever (Item 30). Disconnect upper and lower

speed adjustment rods from pump lever (see Fig. 14).

5. Loosen belt tension and remove belt from pump

pulley (see Pump Belt Tension Adjustment).

6. Disconnect hydraulic lines from fittings on pump. Put

caps on open lines and fittings to prevent contamination.

Put labels on hydraulic lines for proper reinstallation.

13

14

59

12

11

10

9

8

7

6

2

1

5

4

3

15

16

17

19

20

19

13

18

14

53

52

7. Remove locknut (Item 46), capscrew (Item 5) and

washers (Item 47). Remove locknut (Item 54) and capscrew (Item 57).

8. Remove pump assembly from pump support

(Item 55) and put pump on a work bench.

9. Loosen jam nuts (Item 3) and set screws (Item 2).

Remove pulley (Item 4) from pump shaft.

10. Remove pump mount (Item 6) from pump.

11. Loosen locknuts (Item 36) and remove roll pin

(Item 34). Pull pump lever (Item 30) off of pump control

shaft.

12. Remove hydraulic fittings from pump and plug ports.

13. Reverse steps 2 - 12 to install pump.

39

38

35

36

37

47

40

41

42

43

44

45

46

22

23

24

25

26

27

51

28

50

29

41

30

49

33

32

31

34

48

47

54

55

47

57

56

5

Figure 20

Hydroject 3010 Page 4 - 15 Repairs

Page 34

Pump Shaft Seal Replacement (Fig. 21)

Lip type seals are used on input shaft and displacement

control shaft. These seals can be replaced without major

disassembly of pump.

1. Remove retaining ring from housing (input shaft seal

only).

2. Carefully pull seal out of housing bore. A “hook” type

tool may be used to grasp seal and pull it out, or a slide

hammer type puller may be used to remove seal. Be

careful not to damage housing bore, shaft sealing surface, or bearing. After the seal is removed, it cannot be

used again.

IMPORTANT: When input shaft seal is removed,

pump block spring may push shaft partially out of

housing. Do not attempt to pull shaft out of housing.

Internal parts could move out of alignment or fall

into pump, requiring major disassembly of pump.

3. Inspect sealing area of shaft for rust, wear or contamination. Polish sealing area on shaft if necessary.

4. Lubricate new seal with petroleum jelly.

Top of pump when

installed in machine

4

3

1

2

Figure 21

1. Retaining ring

2. Seal (input shaft)

3. Spacer

4. Seal (displacement control shaft)

5. Wrap shaft with thin plastic or use a seal protector to

prevent damage to seal lip during installation.

6. Slide seal over shaft and press it into housing bore.

Be careful not to damage the seal.

7. Install seal retaining ring into housing (input shaft seal

only).

Repairs Page 4 - 16 Hydroject 3010

Page 35

Pump Charge Check Valve Service (Fig. 22)

1. Remove check valve plug with a 1/4 in. internal hex

wrench.

2. Remove valve spring and check ball from pump end

cap.

IMPORTANT: Do not allow check balls to fall into

closed loop passages in end cap.

3. Inspect check balls and mating seats in end cap for

damage or foreign material.

4. Lay pump on its side and reinstall check ball, spring

and plug (with O-ring) into end cap. Make sure check

ball does not fall into closed loop passage inside pump.

Tighten plug to a torque of 15 to 35 ft-lb. T urn pump over

and repeat installation procedure for other check valve.

Top of pump when

installed in machine

5

4

Figure 22

1. Check valve plug

2. O-ring

3. Check valve spring

4. Check ball

5. Pump end cap

Torque to

15 to 35 ft-lb.

3

2

1

Pump Bypass Valve Service (Fig. 23)

1. Unscrew bypass valve from end cap of pump.

2. Inspect valve and mating seat in end cap for damage

and foreign material. It is recommended that the O-ring

and back-up ring be replaced.

3. Reinstall bypass valve into end cap. Tighten to a

torque of 7 to 10 ft-lb.

7 to 10 ft-lb.

1

2

3

Top of pump whenTorque to

installed in machine

4

Figure 23

1. Bypass valve

2. Back-up ring

3. O-ring

4. Pump end cap

Hydroject 3010 Page 4 - 17 Repairs

Page 36

Charge Pump Service (Fig. 24)

1. Use a 5 mm internal hex wrench to remove the two

(2) screws holding charge pump cover to pump end cap.

NOTE: Charge pump rotation is determined by orientation of charge pump cover on pump end cap. Cast boss

on charge pump cover indicates orientation. Note orientation of cast boss before removing charge pump cover.

2. Remove charge pump cover and O-ring.

3. Remove charge pump gerotor assembly.

4. Remove charge relief valve spring and ball.

5. Inspect gerotor assembly, charge pump cover and

end cap for abnormal wear, damage or foreign material.

Inspect charge relief valve seat in end cap for damage

or foreign material.

6. Before installing charge pump, apply a small amount

of petroleum jelly to inside diameter, outside diameter

and slide faces of gerotor assembly.

7. Install charge relief ball and spring.

Top of pump when

installed in machine

2

3

Torque to

84 to 120 in-lb.

1

5

4

Figure 24

1. Charge pump cover

2. O-ring

3. Gerotor assembly

4. Charge relief ball

5. Charge relief spring

8. Install charge pump gerotor assembly.

9. Install charge pump cover and O-ring. Make sure

charge relief spring enters recess in cover.

10. Install charge pump cover screws and tighten to a

torque of 84 to 120 in-lb.

Major Pump Repair (Fig. 25, 26)

The procedures on the following pages are for complete

disassembly and reassembly of the pump.

Cleanliness is a primary means of assuring satisfactory

transmission life, on either new or repair units. Cleaning

parts by using a clean solvent wash and air drying is

usually adequate. As with any precision equipment, all

parts must be kept free of foreign materials and chemicals. Protect all sealing surfaces and open cavities from

damage and foreign material.

During assembly of the pump, all surfaces which have

relative motion between two parts should be coated with

a film of clean hydraulic oil. This will assure that these

surfaces will be lubricated during start-up.

It is recommended that all gaskets, o-rings and seals be

replaced. Lightly lubricate all o-rings with clean petroleum jelly before assembly. All gasket sealing surfaces

must be cleaned before installing new gaskets.

Repairs Page 4 - 18 Hydroject 3010

Page 37

19

20

21

22

23

24

40

39

35

34

17

26

18

25

16

12

8

1

2

3

4

38

37

36

33 31 32

7

6

5

30

3

4

11

10

9

1

2

13

29

15

14

27

28

Figure 25

Disassembly of Hydraulic Pump

1. Before performing major repairs on the pump, remove

external components as described in previous procedures. These include the following:

Shaft Seals

Charge Check Valves

Bypass Valve

Charge Pump

2. Lay pump on its side. Use a 6 mm internal hex wrench

to remove the four (4) screws (Item 30) which retain end

cap to variable pump housing.

3. Internal springs will separate end cap from housing.

Remove end cap (Item 31) from housing (Item 18).

IMPORT ANT: Pump cylinder block (Item 7) will stick

to surface of end cap. Be careful to prevent damage

to end cap and cylinder block.

4. Remove gasket (Item 6) and two (2) alignment pins

(Item 15) from housing.

5. Remove cylinder block kit (Item 7) from shaft

(Item 19).

6. Remove cylinder block spring (Item 8) and washer

(Item 9) from shaft.

7. Remove swashplate assembly (Item 25) from housing.

8. Remove thrust plate (Item 11) from swashplate. The

bearing guide is pressed into the swashplate and is

usually not removed. The inner thrust washer is retained

by the bearing guide.

9. Remove slot guide block (Item 13) from displacement

control shaft (Item 12).

10. Remove swashplate cradle bearings (Item 14) from

housing.

11. Remove input shaft seal retaining ring (Item 24).

12. Carefully pull input shaft seal (Item 23) out of housing bore. A hook may be used to pry seal out, or a slide

hammer type puller may be used to remove the seal. Be

careful not to damage housing bore, shaft sealing surface, or bearing. After seal is removed it cannot be used

again.

13. Remove bearing spacer washer (Item 22).

Hydroject 3010 Page 4 - 19 Repairs

Page 38

14. Remove pump shaft (Item 19) and bearing assembly

from housing.

3. Install displacement control shaft (Item 12) into housing.

15. Remove outer bearing retaining ring (Item 21) (and

washer, if used). Press shaft out of bearing.

16. If pump block retaining spring retaining ring

(Item 10) requires replacement, remove it from pump

shaft.

17. Remove displacement control shaft from housing.

18. Pry displacement control shaft seal out of housing.

Care must be taken so as not to damage housing bore.

19. If displacement control shaft journal bearing requires replacement, press it out of housing.

Inspection and Replacement of Pump Parts

After disassembly, thoroughly clean all parts in a suitable solvent. Replace all o-rings, gaskets and seals.

Inspect all parts for damage, nicks or unusual wear

patterns. Replace all parts having unusual or excessive

wear or discoloration.

Inspect seal surfaces, bearing surfaces and shaft splines. Polish sealing areas on shafts if necessary. Replace any worn or damaged parts.

4. If block spring retaining ring (Item 10) was removed

from pump shaft, install a new retaining ring at this time.

5. Install inner bearing retaining ring (Item 20) onto

shaft. Press bearing (Item 21) onto shaft, install washer

(if used) and new outer bearing retaining ring. Be careful

not to stretch or deform retaining rings.

IMPORT ANT : Be careful not to damage shaft sealing

surface.

6. Install pump shaft and bearing assembly into housing.

7. Install bearing spacer washer (Item 22).

8. Wrap shaft with thin plastic or use a seal protector to

prevent damage to seal during installation. Lubricate

new pump shaft seal (Item 23) with petroleum jelly.

9. Slide seal over shaft and press it into housing bore.

Be careful not to damage the seal.

10. Install retaining ring (Item 24).

11. Install swashplate cradle bearings (Item 14) into

housing, making sure they are located on cast-in pins

in housing.

The pump shaft bushing (Item 5) is pressed into end cap

and is usually not removed.

The running surfaces of cylinder blocks MUST be flat

and free from scratches. If scratches or wear are found

on running surfaces of cylinder blocks or end cap, polish

or replace the parts. When polishing these surfaces, up

to 0.0004 in. may be removed. If this is not sufficient to

obtain a flat surface, free of scratches, the part should

be replaced.

Assembly of Hydraulic Pump

1. Clean and lightly oil parts before assembly. Tighten

all threaded parts to recommended torque value.

IMPORTANT: Most parts have critical, high tolerance surfaces. Use caution to prevent damage to

these surfaces during assembly. Protect exposed

surfaces, openings and ports from damage and

foreign material.

2. If displacement control shaft bearing (Item 17) has

been removed, press a new bearing into housing using

a suitable press pin. Surface of bearing should be flush

with inside surface of housing.

12. Install slot guide block (Item 13) onto displacement

control shaft.

13. Install thrust plate (Item 11) into swashplate

(Item 25). Slot on swashplate must engage guide block

(Item 13) on displacement control shaft (Item 12). Use

a tool such as a screwdriver or magnet to hold guide

block in position while installing swashplate.

14. Hold swashplate in position and use a dial indicator

or depth gauge to measure side play of displacement

control shaft. Using a suitable sleeve, press control

shaft bearing into housing until control shaft end play is

between 0.020 and 0.060 in.

15. Install thrust washer (Item 9) and cylinder block

spring (Item 8) onto pump shaft.

16. Install springs (Item 29), piston washers (Item 28)

and pistons (Item 27) into cylinder block kits. The pistons must move freely in their bores.

17. With pump swashplate in “neutral” (0 angle) position

and pump housing laying on its side, install pump cylinder block kit onto pump shaft in housing.

NOTE: The position of the bearing in the housing determines control shaft end play. Do not press bearing

deeper into housing at this time.

Repairs Page 4 - 20 Hydroject 3010

Page 39

18. Check that piston springs are centered in cylinder

block bores, If necessary, move springs into position

with a small screwdriver.

21. When end cap is properly installed, the internal

springs will hold it away from the housing approximately

3/8 in.

IMPORTANT: Do not damage running surfaces of

cylinder blocks.

19. Install two (2) alignment pins (Item 15) and install a

new gasket (Item 6) onto housing.

20. Lubricate running surfaces of end cap (Item 31) and

cylinder blocks (Item 7). Position housing opening UP

and install end cap onto housing (Item 18).

IMPORTANT: Make sure all parts are properly

aligned. Do not force end cap into position on housing. Be careful to prevent damage to end cap and

cylinder block sealing surfaces.

12

13

22. Install the four (4) capscrews which retain end cap

to housing. Tighten screws to a torque of 138 to 180

in-lb.

23. Rotate shafts to assure correct assembly. When

properly assembled, minimal torque should be required

to turn shafts.

24. Wrap end of displacement control shaft with thin

plastic or use a seal protector to prevent damage to seal

during installation. Lubricate new displacement controls

shaft seal (Item 16) with petroleum jelly. Slide seal over

shaft and press it into housing bore. Be careful not to

damage seal. Install seal flush to bottomed in bore.

24

23

22

21

20

19

16

15

14

18

17

40

39

35

34

8

1

2

3

4

38

37

36

33 31 32

7

6

5

30

3

4

11

10

9

25

26

27

28

29

1

2

Figure 26

Hydroject 3010 Page 4 - 21 Repairs

Page 40

Wheel Motor Removal and Installation (Fig. 27)

1

37

36

35

34

32

31

3

4

9

5

30

8

6

7

29

28

27

17

26

10

11

12

13

25

14

15

16

17

18

19

20

Torque to

250 to 400 ft-lb.

21

2

33

Figure 27

1. Park machine on a level surface, engage parking

brake, open hood and disconnect engine spark plug

wires. Lift drive wheel off the ground using a jack. Block

front and rear of other wheels.

2. Remove wheel nuts (Item 23) and remove wheel.

Remove large nut (Item 22) from wheel hub.

3. Mount a wheel puller to wheel mount studs and

remove wheel hub (Item 19) and brake drum (Item 18).

Remove key (Item 7) from wheel motor shaft.

IMPORTANT: To prevent damage to wheel motor,

DO NOT hit wheel hub with a hammer during removal or installation.

22

23 24

4. Disconnect hydraulic lines from fittings on wheel

motor. Put caps on open lines and fittings to prevent

contamination. Put labels on hydraulic lines for proper

reinstallation.

5. Remove four (4) capscrews (Item 1), nuts (Item 27)

and lockwashers (Item 28) to remove wheel motor

(Item 6) and brake brackets (Item 29) from steering arm

(Item 37).

6. Reverse steps 1 - 6 to install wheel motor. When

installing wheel hub onto motor shaft, tighten large nut

(Item 22) to 250 - 400 ft-lb.

Repairs Page 4 - 22 Hydroject 3010

Page 41

Wheel Motor Shaft Seal and/or Shaft Replacement (Fig. 28)

11

10

4

12

17

16

13

14

15

7

6

5

4

3

1

2

Figure 28

Disassembly of Shaft and Front Seal Assembly

1. Put motor on a clean, flat surface with shaft facing up.

Clean front end of motor to avoid contaminating internal

parts during procedure.

2. Remove key (Item 11) from shaft.

3. Remove snap ring (Item 14) using a snap ring pliers.

19

20

19

21

9

scratches, entire motor should be disassembled for

inspection.

Assembly of Shaft and Front Seal Assembly

1. Assemble thrust washers (Item 19) and thrust bearing

(Item 20) on shaft using the snap ring (Item 21). Snap

ring sharp edges MUST face away from thrust washers

with thrust bearing (Item 20) between washers.

4. Pull shaft (Item 10) out vertically.

2. Slowly lower spline end of shaft (Item 10) assembly

into motor body using caution not to rotate internal parts

IMPORTANT: When pulling shaft vertically, do not

once shaft spline starts to engage.

rotate shaft or move motor as this may alter internal

timing.

3. Put lightly oiled o-ring (Item 12) into groove in body

bore.

5. With seal retainer assembly and shaft assembly

removed, remove all parts from shaft and inspect various parts of seal assembly (Item 15, 16, 17), shaft

(Item 10) and thrust bearing assembly (Item 19, 20, 21).

Replace any worn or damaged parts. Always replace

4. Gently slide oiled seal retainer assembly (Item 15, 16,

17) over shaft, chamfered side first, and press into body

bore. When fully in place, body snap ring groove will be

visible.

seal retainer assembly (Item 15, 16, 17). The shaft

should have smooth polished surfaces in bearing and

seal areas. If the shaft is lightly scratched in these areas,

polish with fine emery paper in a circumferential direction. However, if the shaft has any pitting or deep

5. Install snap ring (Item 14) into its body groove with

snap ring’s sharp edges facing outward and retainer pin

between snap ring lugs. Be sure snap ring is completely

seated in groove.

Hydroject 3010 Page 4 - 23 Repairs

Page 42

Wheel Motor Repair (Fig. 29)

12

11

10

13

14

15

4

16

17

7

6

5

4

3

1

2

Figure 29

IMPORTANT: Before DISASSEMBLING motor, plug

open ports and clean all dirt from outside of motor .

IMPORT ANT : Before ASSEMBLING motor , lightly oil

all seals, rollers and threaded bolt ends.

19

20

19

21

9

NOTE: The check balls may fall into body tapered holes

or into body valve ports during disassembly . Be sure that

the check balls are removed.

Disassembly of Shaft Section of Motor

Disassembly of Cover Section of Motor

(See Disassembly of Shaft and Front Seal Assembly

under Main Shaft Seal and/or Shaft Replacement.)

1. Remove key (Item 11) from shaft.

Assembly of Complete Motor

2. Mount motor in a vice or other holding device with

shaft facing down.

1. Before assembly, all parts must be cleaned with a

suitable solvent and free of nicks and burrs.

3. Remove the eight capscrews (Item 1).

2. Mount body with pilot and bearing facing up in a vise

4. Remove cover & bearing assembly (Item 2) and

or other holding mechanism.

square ring seal (Item 4).

3. Insert shaft (Item 10) and install seals and thrust

5. Remove IGR assembly (Item 5) starting with outer

locating ring, rollers, outer rolls, inner rotor and valve

plate (Item 7). If any of these components are damaged,

bearings. (See Assembly of Shaft and Front Seal Assembly under Main Shaft Seal and/or Shaft Replacement.)

entire IGR assembly must be replaced.

4. Mount body with pilot and bearing facing down in a

6. Remove the two check balls (Item 6).

vise or other holding fixture.

5. Put rotary valve (Item 7) on shaft spline with “T”

shaped slots on first.

Repairs Page 4 - 24 Hydroject 3010

Page 43

6. Next put IGR inner member on shaft spline with

semi-circular roll pockets between rotary valve ports.

NOTE: Be sure not to dislodge body square ring seal

while moving locating ring.

7. Put contour member of IGR over inner and insert

seven rolls into inner pockets (large diameter rolls).

8. Lightly oil square ring seal (Item 4) and put in body

groove.

9. Put check balls (Item 6) over the two 1/8" inch

diameter holes in body. Be sure the check balls do not

fall into body tapped holes.

10. Put locating ring section (4.5 inch diameter) of IGR

(Item 5) onto body with check ball holes facing downward over balls. Align the eight bolt holes in locating ring

with eight holes in body. The holes align in only one

position.

1 1. Install the eight locating ring rollers into their pockets

and oil lightly.

12. Put other lightly oiled square ring seal (Item 4) into

groove in cover and put cover over shaft end and align

bolt holes.

13. Install the eight bolts with lightly oiled thread ends

into bolt holes and tighten diagonally to 30 ft-lb.

NOTE: The shaft may not turn freely after assembly. A

short running period may be required.

Hydroject 3010 Page 4 - 25 Repairs

Page 44

Repairs Page 4 - 26 Hydroject 3010

Page 45

Table of Contents