Page 1

FormNo.3361-911RevA

CommercialWalk-BehindMower

FloatingDeck,T-Bar,Gearwith36in40in

48inor52inTURBOFORCE

ModelNo.30094—SerialNo.290000001andUp

ModelNo.30096—SerialNo.290000001andUp

®

CuttingUnit

ModelNo.30098—SerialNo.290000001andUp

ModelNo.30099—SerialNo.290000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.Toro.com.OriginalInstructions(EN)

Page 2

Warning

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

Theenclosed

Engine Owner’ s Man ual

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

issupplied

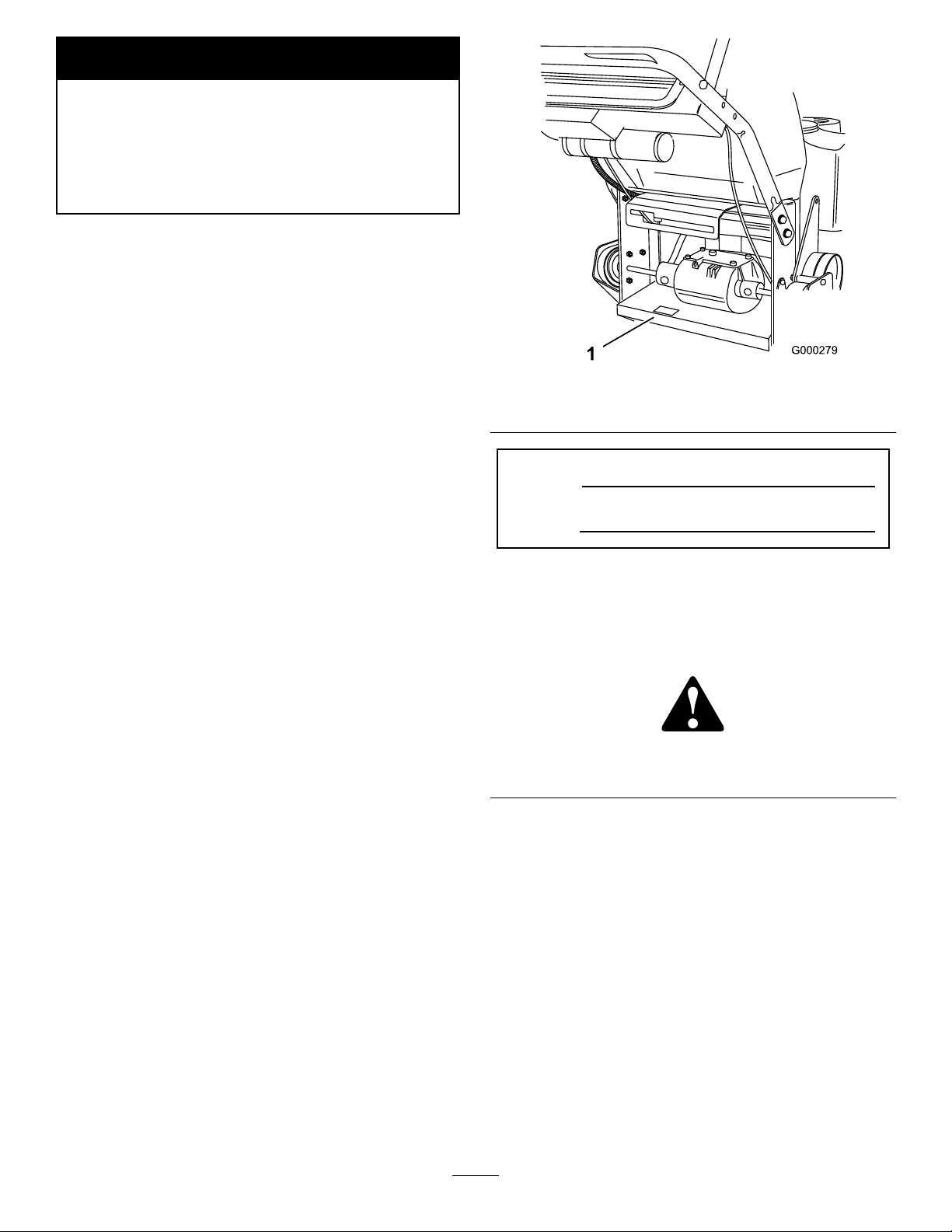

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroMowerSafety...............................................5

SlopeChart..........................................................7

SafetyandInstructionalDecals.............................8

ProductOverview......................................................10

Controls.............................................................10

©2009—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Specications.....................................................11

Attachments/Accessories...................................11

Operation...................................................................12

AddingFuel.......................................................12

CheckingtheEngineOilLevel............................13

ThinkSafetyFirst...............................................13

UsingtheParkingBrake......................................13

StartingandStoppingtheEngine........................13

OperatingtheMowerPowerTakeOff

(PTO)............................................................14

TheSafetyInterlockSystem................................15

DrivingForwardorBackward.............................15

UsingtheLowerControlBar..............................15

StoppingtheMachine.........................................16

TransportingMachines.......................................16

SideDischargingorMulchingtheGrass..............17

AdjustingtheHeight-of-Cut...............................17

AdjustingtheAnti-ScalpRollers.........................17

AdjustingtheHandleHeight..............................18

AdjustingtheFlowBafe...................................19

PositioningtheFlowBafe.................................20

UsingtheMid-SizeWeight..................................21

Maintenance...............................................................22

RecommendedMaintenanceSchedule(s)................22

Lubrication.............................................................22

HowtoGrease...................................................22

LubricatingtheCasterandWheel

Bearings.........................................................23

GreasingtheTransmissionCouplers...................23

GreasingthePTODriveBeltIdlerandMower

DeckBeltIdler...............................................23

EngineMaintenance...............................................24

ServicingtheAirCleaner....................................24

ServicingtheEngineOil.....................................25

ServicingtheSparkPlugs....................................27

FuelSystemMaintenance.......................................28

DrainingtheFuelTank.......................................28

ReplacingtheFuelFilter.....................................28

ElectricalSystemMaintenance................................29

ServicingtheFuse..............................................29

DriveSystemMaintenance.....................................30

AdjustingtheControlBar...................................30

CheckingtheTirePressure.................................30

ReplacingtheCasterWheelFork

Bushings........................................................31

ServicingtheCasterWheelandBearings.............31

AdjustingtheElectricClutch..............................32

CoolingSystemMaintenance..................................33

CleaningtheAirIntakeScreen............................33

BrakeMaintenance.................................................33

ServicingtheBrakes...........................................33

BeltMaintenance....................................................34

ReplacingtheTractionDriveBelt........................34

ReplacingtheTransmissionBelt.........................34

ReplacingtheMowerBelt...................................35

ReplacingthePTODriveBelt.............................36

AdjustingthePTODriveBeltIdlerSpring

Anchor...........................................................37

MowerDeckMaintenance......................................37

ServicingtheCuttingBlades...............................37

CorrectingtheMowerQualityofCut..................39

FrameSetUp.....................................................40

CheckingtheMowerDeckFront-to-Rear

Pitch...............................................................41

ChangingtheMowerDeckFront-to-Rear

Pitch...............................................................42

CheckingtheMowerDeckSide-to-Side

Height............................................................42

ChangingtheMowerDeckSide-to-Side

Height............................................................43

MatchingHeightofCut......................................43

ReplacingtheGrassDeector.............................44

Storage.......................................................................45

CleaningandStorage..........................................45

Troubleshooting.........................................................46

Schematics.................................................................48

3

Page 4

Safety

Note:Theadditionofattachmentsmadeby

othermanufacturersthatdonotmeetAmerican

NationalStandardsInstitutecerticationwillcause

noncomplianceofthismachine.

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol,whichmeans

CAUTION,WARNING,orDANGER-“personalsafety

instruction."Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

–Useonlyanapprovedcontainer

–Neverremovegascaporaddfuelwithengine

running.Allowenginetocoolbeforerefueling.

Donotsmoke.

–Neverrefuelordrainthemachineindoors.

•Checkthatoperator’spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

ThefollowinginstructionsarefromANSIstandard

B71.4-2004.

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readEnglishitistheowner’sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeopleorproperty.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Onlystartengine

fromtheoperator’sposition.

•Besureofyourfootingwhileusingthismachine,

especiallywhenbackingup.Walk,don’trun.Never

operateonwetgrass.Reducedfootingcouldcause

slipping.

•Slowdownanduseextracareonhillsides.Besure

totravelsidetosideonhillsides.Turfconditions

canaffectthemachine’sstability.Usecautionwhile

operatingneardrop-offs.

•Slowdownandusecautionwhenmakingturnsand

whenchangingdirectionsonslopes.

•Neverraisedeckwiththebladesrunning.

•NeveroperatewiththePTOshield,orotherguards

notsecurelyinplace.Besureallinterlocksare

attached,adjustedproperly ,andfunctioningproperly.

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glassesandhearingprotection.Longhair,loose

clothingorjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toysandwire

whichcanbethrownbythemachine.

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,disengagedrives,engage

parkingbrake,shutoffenginebeforeleavingthe

operator’spositionforanyreasonincludingemptying

thecatchersoruncloggingthechute.

•Stopequipmentandinspectbladesafterstriking

objectsorifanabnormalvibrationoccurs.Make

necessaryrepairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

4

Page 5

•Keeppetsandbystandersaway .

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesifnot

mowing.

•Beawareofthemowerdischargedirectionanddo

notpointitatanyone.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoorfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

Maintenanceandstorage

•Disengagedrives,setparkingbrake,stopengineand

removekeyordisconnectsparkplugwire.Waitfor

allmovementtostopbeforeadjusting,cleaningor

repairing.

•Cleangrassanddebrisfromcuttingunit,drives,

mufers,andenginetohelppreventres.Cleanup

oilorfuelspillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransporting.Donot

storefuelnearamesordrainindoors.

•Parkmachineonlevelground.Setparkingbrake.

Neverallowuntrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatteryorremovesparkplugwire

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositivelast.Reconnectthe

positiverstandnegativelast.

•Usecarewhencheckingblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.

Onlyreplaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

ToroMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsandothersafetyinformationyoumust

know .

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrass

or,whenequippedwithagrassbagger,forcatching

cutgrass.Anyuseforpurposesotherthanthesecould

provedangeroustouserandbystanders.

GeneralOperation

•Besuretheareaisclearofotherpeoplebefore

mowing.Stopthemachineifanyoneentersthearea.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowtocoolbefore

attemptingtomaintain,adjustorservice.

•UseonlyToroapprovedattachments.Warrantymay

bevoidedifusedwithunapprovedattachments.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

operatingunderanyobjectsanddonotcontact

them.

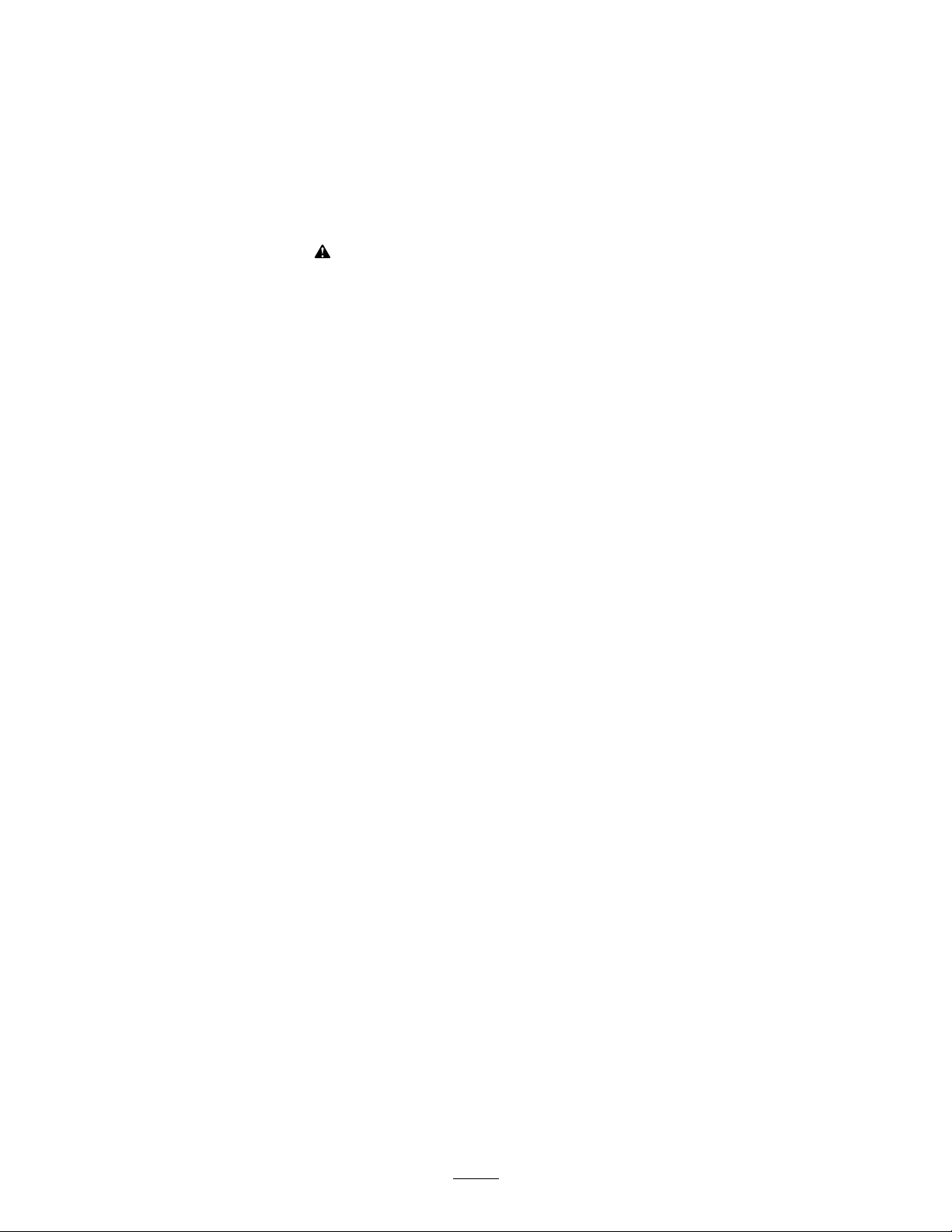

SlopeOperation

Allslopesandrampsrequireextracaution.Ifyoufeel

uneasyonaslope,donotmowit.

•Removeobstaclessuchasrocks,treelimbs,etc.from

themowingarea.

•Watchforholes,rutsorbumps.Tallgrasscanhide

obstacles.

•Usecautionneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyturnoverifawheel

goesovertheedgeofaclifforditch,orifanedge

cavesin.

•Useextracarewithgrasscatchersorother

attachments.Thesecanchangethestabilityofthe

machine.

•Keepallmovementonslopesslowandgradual.Do

notmakesuddenchangesinspeedordirection.

•Mowslopessidetoside.

•Donotmowslopesgreaterthan20degrees.

Service

•Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

•Keepnutsandboltstight,especiallytheblade

attachmentbolts.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.Checksafety

systemsforproperoperationbeforeeachuse.

5

Page 6

•Useonlygenuinereplacementpartstoensurethat

originalstandardsaremaintained.

•Checkbrakeoperationfrequently.Adjustandservice

asrequired.

6

Page 7

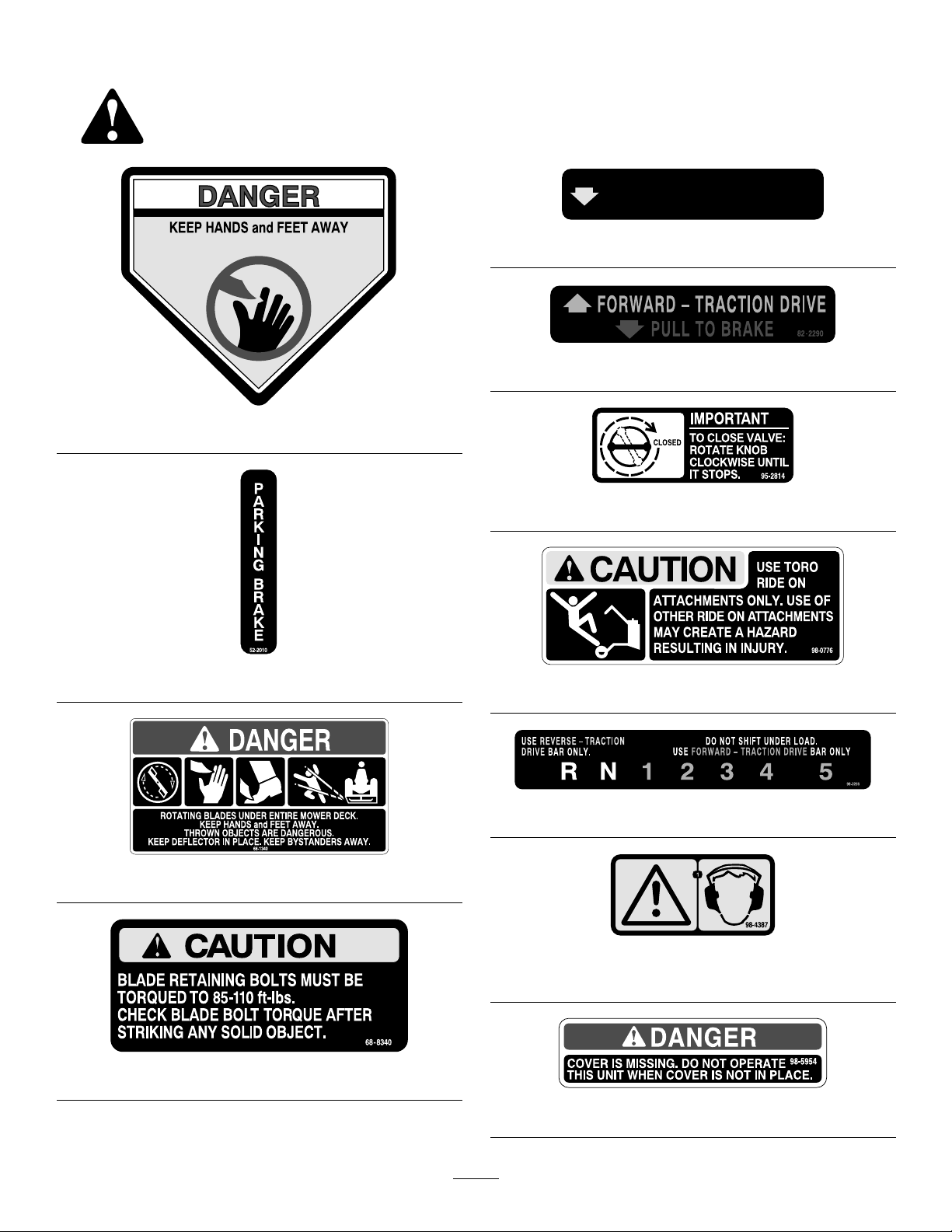

SlopeChart7SafetyandInstructionalDecals

Page 8

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

82- 2280

REV ERSE TRAC T I ON DRI V E

potentialdanger.Replaceanydecalthatisdamagedorlost.

82-2280

82-2290

43-8480

95-2814

52-2010

66-1340

1.Warning—wearhearingprotection.

68-8340

98-0776

98-3256

98-4387

98-5954

8

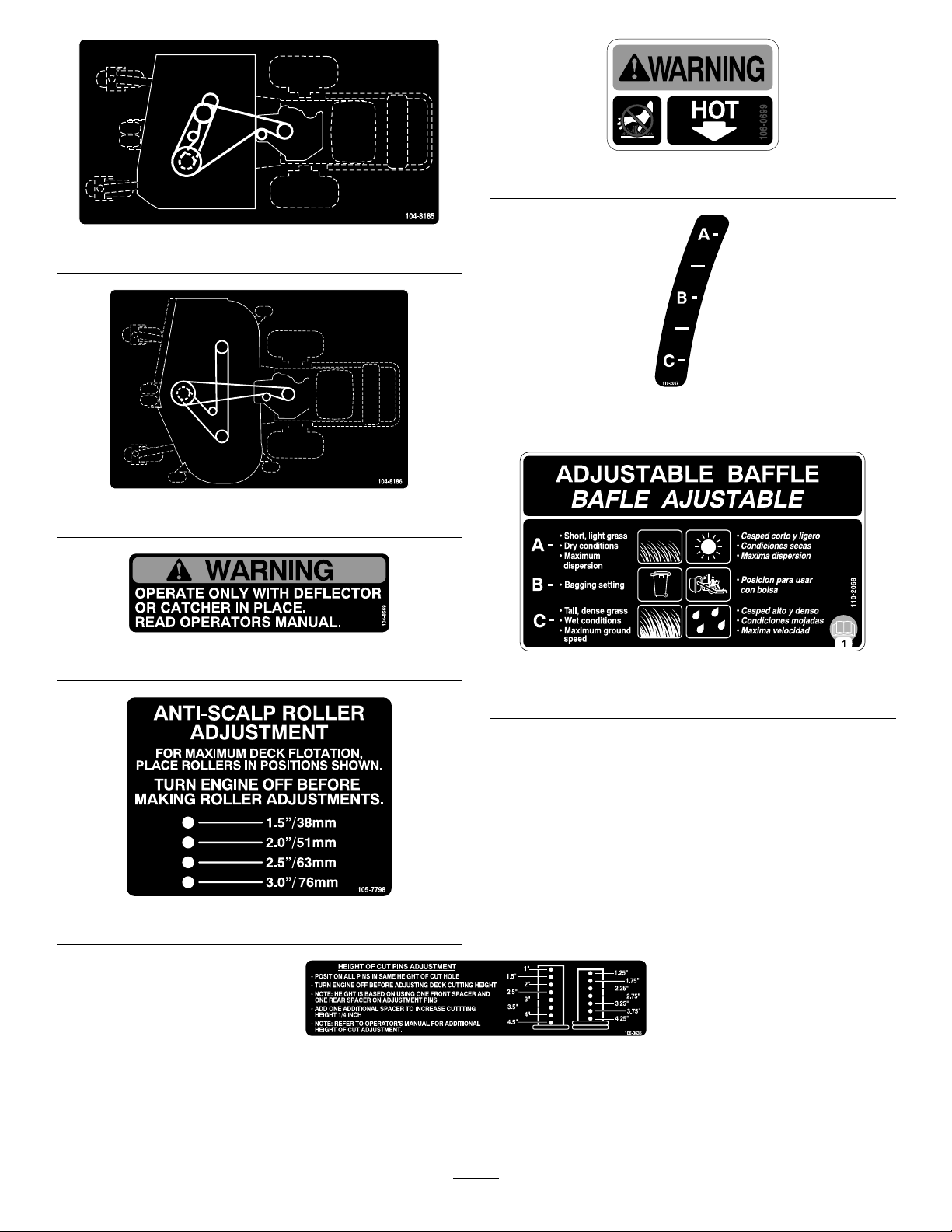

Page 9

106-0699

104-8185

110-2067

104-8186

104-8569

110-2068

1.ReadtheOperator’sManual.

105-7798

106-0635

9

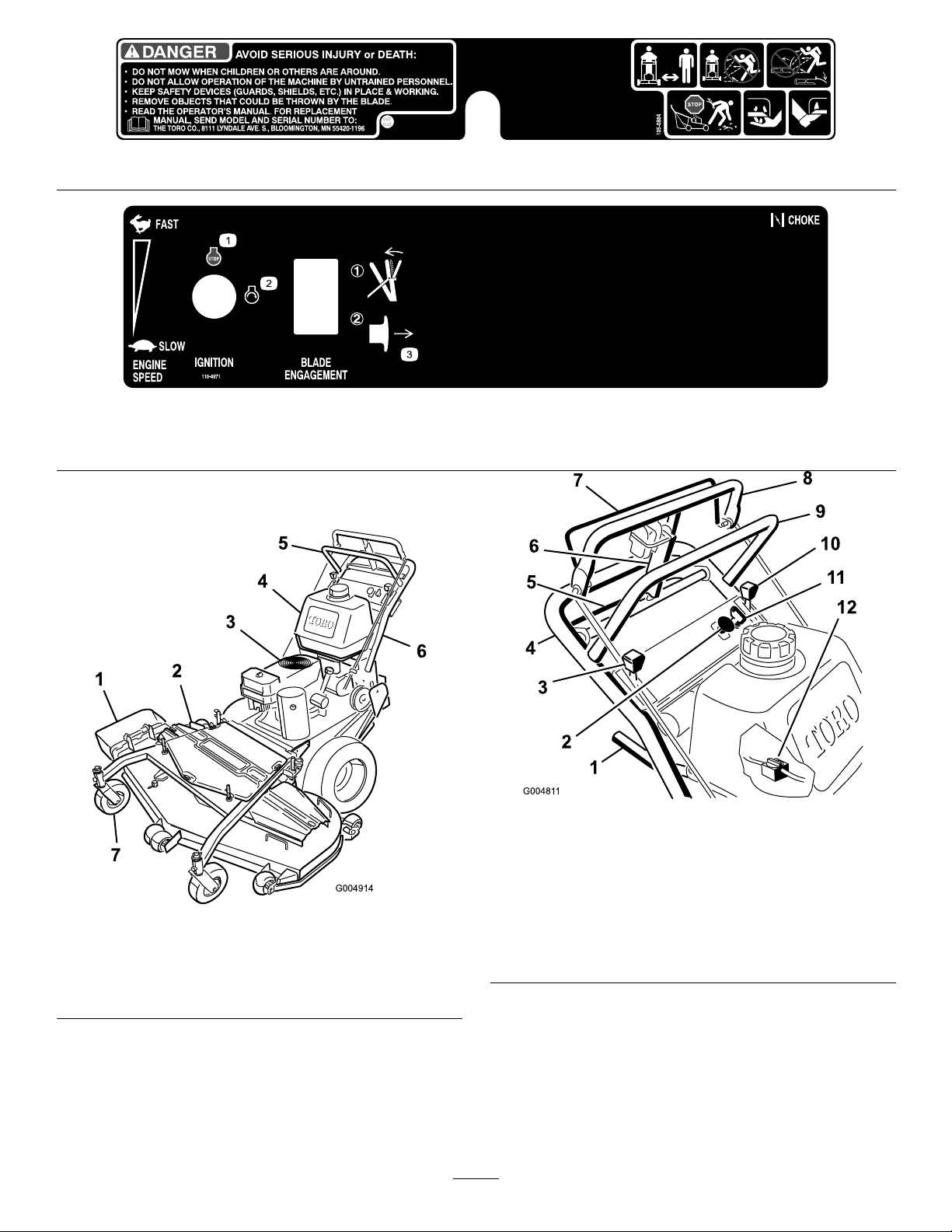

Page 10

105-0884

110-4971

1.Engine—stop

2.Engine—Start3.EngagebalethenpulloutonthePTO

toengagetheblade.

ProductOverview

Figure3

1.Sidedischargechute5.Controls

2.Mowerdeck6.Handle

3.Recoilstarter

4.Gastank

7.Casterwheel

Controls

Becomefamiliarwithallthecontrols(Figure4)before

youstarttheengineandoperatethemachine.

Figure4

1.Gearshiftlever

2.Powertakeoffswitch

(PTO)

3.Chokecontrol

4.Lowerhandle10.Throttlecontrol

5.Lowercontrolbar11.Ignitionswitch

6.Parkingbrake

lever-releasedposition

7.Bladecontrolbail

8.Uppercontrolbar

9.Upperhandle

12.Fuelshut-offvalve

ThrottleControl

Thethrottlecontrolhastwopositions:FastandSlow.

Choke

Usethechoketostartacoldengine.

10

Page 11

BladeControlBail

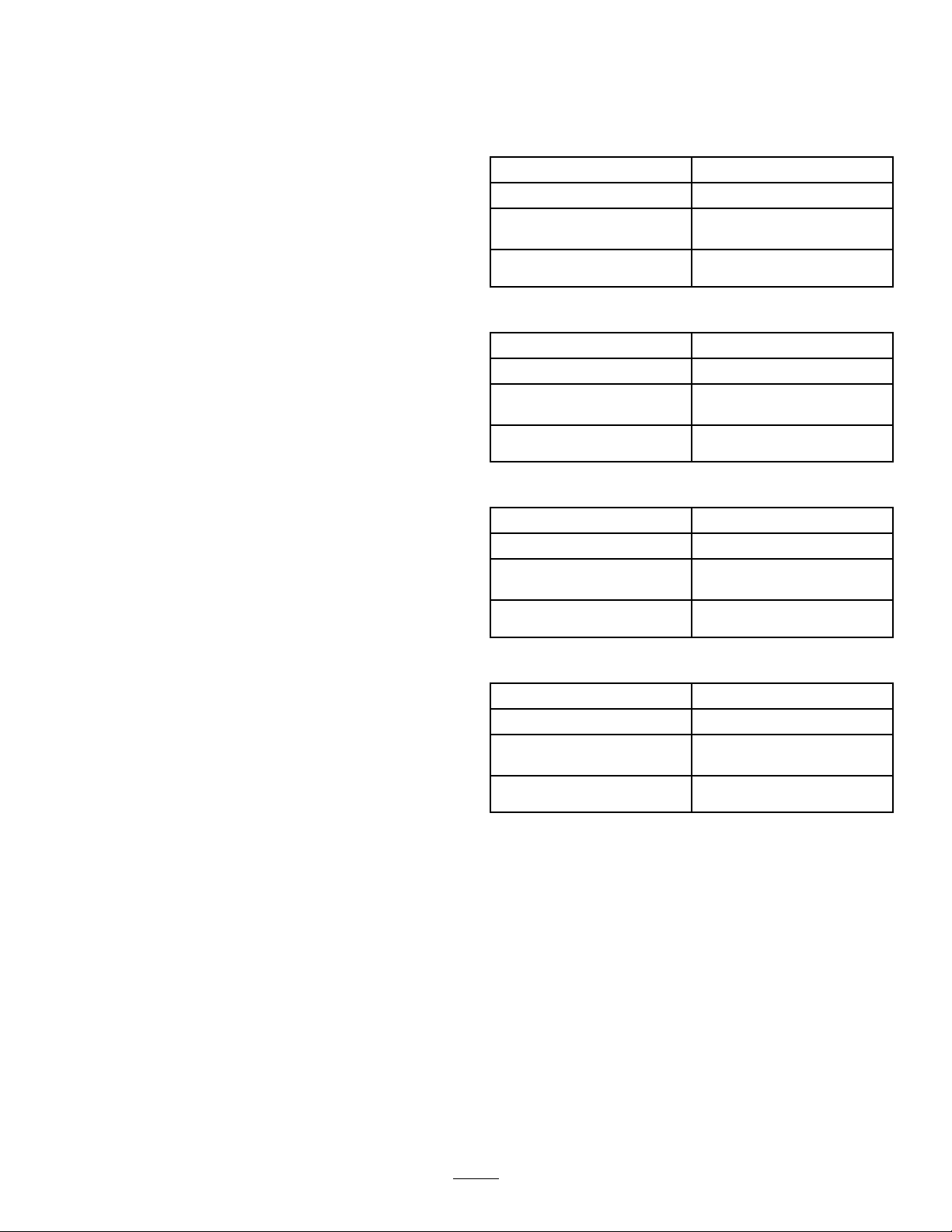

Specications

Thebailisusedinconjunctionwiththepowertakeoff

switch(PTO)toengagetheclutchtodrivethemower

blades.Releasethemowercontrolbailtodisengagethe

mowerblades.

PowerTakeOffSwitch(PTO)

Thispullswitchisusedinconjunctionwiththeblade

controlbailtoengagetheclutchtodrivethemower

blades.

GearShiftLever

Thetransmissionhasveforwardspeeds,neutraland

reverse,andhasanin-lineshiftpattern.

Important:Donotshiftwhileunitismoving,as

transmissiondamagemayoccur.

UpperControlBar

Shifttothedesiredgearandpushforwardontheupper

controlbartoengageforwardtractionoperationand

pullbacktobrakeforwardmovement.Pullbackon

rightsideofuppercontrolbartoturnrightandleftside

toturnleft.

LowerControlBar

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

36inchmowers:

Widthwithdeectordown51–1/8inches(130cm)

Length

Heightwithhandleinlowest

position

Weight

40inchmowers:

Widthwithdeectordown55–1/2inches(141cm)

Length

Heightwithhandleinlowest

position

Weight

48inchmowers:

Widthwithdeectordown63–1/2inches(161cm)

Length

Heightwithhandleinlowest

position

Weight

82–3/4inches(210cm)

41–3/16inches(105cm)

588lb(267kg)

79–1/2inches(202cm)

41–3/16inches(105cm)

596lb(270kg)

82inches(208cm)

41–3/16inches(105cm)

649lb(294kg)

Shifttransmissiontoreverseandsqueezethelower

controlbarandhandletogethertoengagerearward

tractionassistoperation.

ParkingBrakeLever

Pullbackonuppercontrolbarandswingbrakeleverup

againsttheupperhandle(Figure4).

IgnitionSwitch

Thisswitchisusedinconjunctionwithrecoilstarterand

hastwopositions:RunandOff.

RecoilStarter

Pullrecoilstarterhandletostartengine(notshownin

Figure4).

FuelShut-offValve

Closethefuelshut-offvalvewhentransportingor

storingmower.

52inchmowers:

Widthwithdeectordown67–5/8inches(171.7cm)

Length

Heightwithhandleinlowest

position

Weight

82inches(208cm)

41–3/16inches(105cm)

684lb(310kg)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

11

Page 12

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

AddingFuel

Useunleadedregulargasolinesuitableforautomotive

use(85pumpoctaneminimum).Leadedregular

gasolinemaybeusedifunleadedregularisnotavailable.

Important:Neverusemethanol,gasoline

containingmethanol,orgasoholcontainingmore

than10%ethanolbecausethefuelsystemcouldbe

damaged.Donotmixoilwithgasoline.

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupany

gasolinethatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4

to1/2inch(6to13mm)belowthebottomof

thellerneck.Thisemptyspaceinthetank

allowsgasolinetoexpand.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyofgasoline.

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethegasolinevapors.Are

orexplosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowtheloss

ofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancauseserious

injuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepgasawayfromeyesandskin.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysor

less.Forlongerstorageitisrecommendedthatthe

fueltankbedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

12

Page 13

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditioner

tothegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.Tominimizethe

chanceofvarnishdepositsinthefuelsystem,usefuel

stabilizeratalltimes.

Figure5

1.Warning—wearhearingprotection.

UsingtheParkingBrake

FillingtheFuelTank

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundeachfueltankcapandremovethecap.

3.Addunleadedregulargasolinetobothfueltanks,

untilthelevelis1/4to1/2inch(6mmto13mm)

belowthebottomofthellerneck.

Thisspaceinthetankallowsgasolinetoexpand.

Donotllthefueltankscompletelyfull.

4.Installfueltankcapssecurely.

5.Wipeupanygasolinethatmayhavespilled.

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoChecking

OilLevelin,page

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Stoponlevelground,disengagedrives,engageparking

brake,shutoffengineandremovekey.Alwayssetthe

parkingbrakewhenyoustopthemachineorleaveit

unattended.

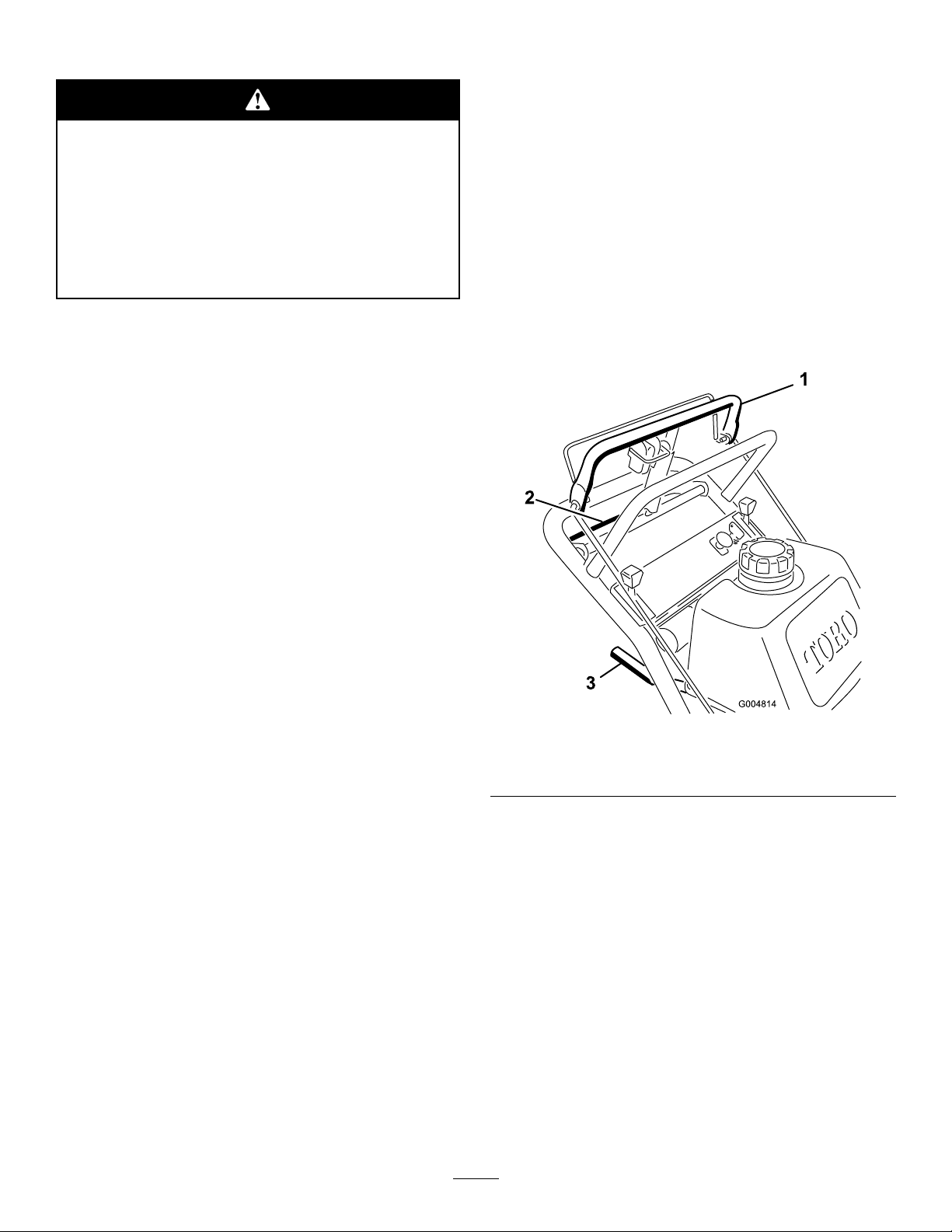

SettingtheParkingBrake

1.Pulltheuppercontrolbar(Figure6)rearwardand

holditinthisposition.

2.Lifttheparkingbrakelock(Figure6)upand

graduallyreleasetheuppercontrolbar.Thebrake

lockshouldstayintheset(locked)position.

ThinkSafetyFirst

Carefullyreadallthesafetyinstructionsanddecalsin

thesafetysection.Knowingthisinformationcould

helpyouoranybystandersavoidinjury.

Theuseofprotectiveequipmentforeyes,hearing,feet

andheadisrecommended.

Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

Figure6

1.Uppercontrolbar3.Fixedbar

2.Parkingbrakelever-set

position

ReleasingtheParkingBrake

1.Pullrearwardontheuppercontrolbar.Lowerthe

parkingbrakelocktothereleasedposition.

2.Graduallyreleasetheuppercontrolbar.

StartingandStoppingthe

Engine

StartingtheEngine

1.Makesuresparkplugwire(s)areinstalledonspark

plug(s)andfuelvalveisopen.

13

Page 14

2.Movetheshiftlevertoneutral,settheparkingbrake

andturnignitionkeytorun.

3.Movethethrottlecontroltofastandmovethe

chokelevertotheonpositionbeforestartingacold

engine.

Note:Awarmorhotengineusuallydoesnot

requireanychoking.Tostartawarmengine,move

throttlecontroltothefastposition.

OperatingtheMowerPower

TakeOff(PTO)

Thepowertakeoffswitch(PTO)inconjunctionwith

thebladecontrolbailengagesanddisengagespowerto

theelectricclutchandmowerblades.

EngagingtheMowerBlades(PTO)

4.Grasprecoilstarterhandlermlyandpullout

untilpositiveengagementresults;thenpullhandle

vigorouslytostartengineandallowropetorecoil

slowly.

Important:Donotpullrecoilropetoitslimit

orletgoofthestarterhandlewhenropeis

pulledoutbecauseropemaybreakorrecoil

assemblymaybedamaged.

StoppingtheEngine

1.Movethethrottlelevertotheslowposition

(Figure7).

2.Letengineidlefor30to60secondsbeforeturning

theignitionkeytooff.

3.Turntheignitionkeytooff(Figure7).

1.Releasetheuppercontrolbartostopthemachine

(Figure8).

2.Toengagetheblades,squeezebladecontrolbail

againsttheuppercontrolbar(Figure8).

3.Pullthepowertakeoffswitch(PTO)upand

release.Holdthebladecontrolbailagainstthe

uppercontrolbarwhileoperating.

4.Repeattheproceduretoengagethemowerbladesif

thebladecontrolbailisreleased.

Figure7

1.Throttlelever2.Ignitionkey

4.Settheparkingbrakeandremovekey.

5.Pullthewireoffsparkplug(s)topreventpossibility

ofaccidentalstartingbeforestoringmachine.

6.Closethefuelshutoffvalvebeforestoringmachine.

Important:Makesurethefuelshutoffvalveis

closedbeforetransportingorstoringmachine,

asfuelleakagemayoccur.

Figure8

1.Uppercontrolbar

2.Bladecontrolbail

3.Powertakeoffswitch

(PTO)

DisengagingtheMowerBlades(PTO)

Releasethebladecontrolbailtodisengagetheblades

(Figure8).

14

Page 15

TheSafetyInterlockSystem

Ifthesafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

throttlecontrolinthefastpositionforbestmowing

performance.

DrivingForward

1.Togoforward,movetheshiftlevertoaforward

gear(Figure9).

2.Releasetheparkingbrake;refertoReleasingthe

ParkingBrakeinOperation.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventthe

mowerbladesfromrotatingunless:

•Thecontrolbailispressedagainsttheuppercontrol

bar.

•Thepowertakeoffswitch(PTO)ispulledon.

Thesafetyinterlocksystemisdesignedtostopthe

mowerbladesifyoureleasethebladecontrolbail.

TestingtheSafetyInterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafetyinterlocksystembeforeyouusethe

machineeachtime.

3.Slowlypressontheuppercontrolbartomove

forward(Figure9).

Togostraight,applyequalpressuretobothendsof

theuppercontrolbar(Figure9).

Toturn,releasepressureontheuppercontrolbar

sideinthedirectionyouwanttoturn(Figure9).

Note:Ifthesafetysystemdoesnotoperateas

describedbelow ,haveanAuthorizedServiceDealer

repairthesafetysystemimmediately.

1.Settheparkingbrakeandstarttheengine;referto

StartingandStoppingtheEngine.

2.Squeezethebladecontrolbailagainstuppercontrol

bar.Thebladesshouldnotrotate.

3.Thencontinueholdingthebladecontrolbailand

pulluponthebladecontrolswitchandrelease.The

clutchshouldengageandthemowerbladesbegin

rotating.

4.Releasethebladecontrolbail.Thebladesshould

stoprotating.

5.Withtheenginerunning,pullupthepowertakeoff

switch(PTO)andreleasewithoutholdingtheblade

controlbail.Thebladesshouldnotrotate.

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedas

measuredinRPM(revolutionsperminute).Placethe

Figure9

1.Uppercontrolbar

2.Lowercontrolbar

3.Shiftlever

DrivingBackward

1.Togobackward,movetheshiftlevertoreversegear.

2.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake.

3.Slowlysqueezethelowercontrolbarandlower

handletogethertomoverearward(Figure9).

UsingtheLowerControlBar

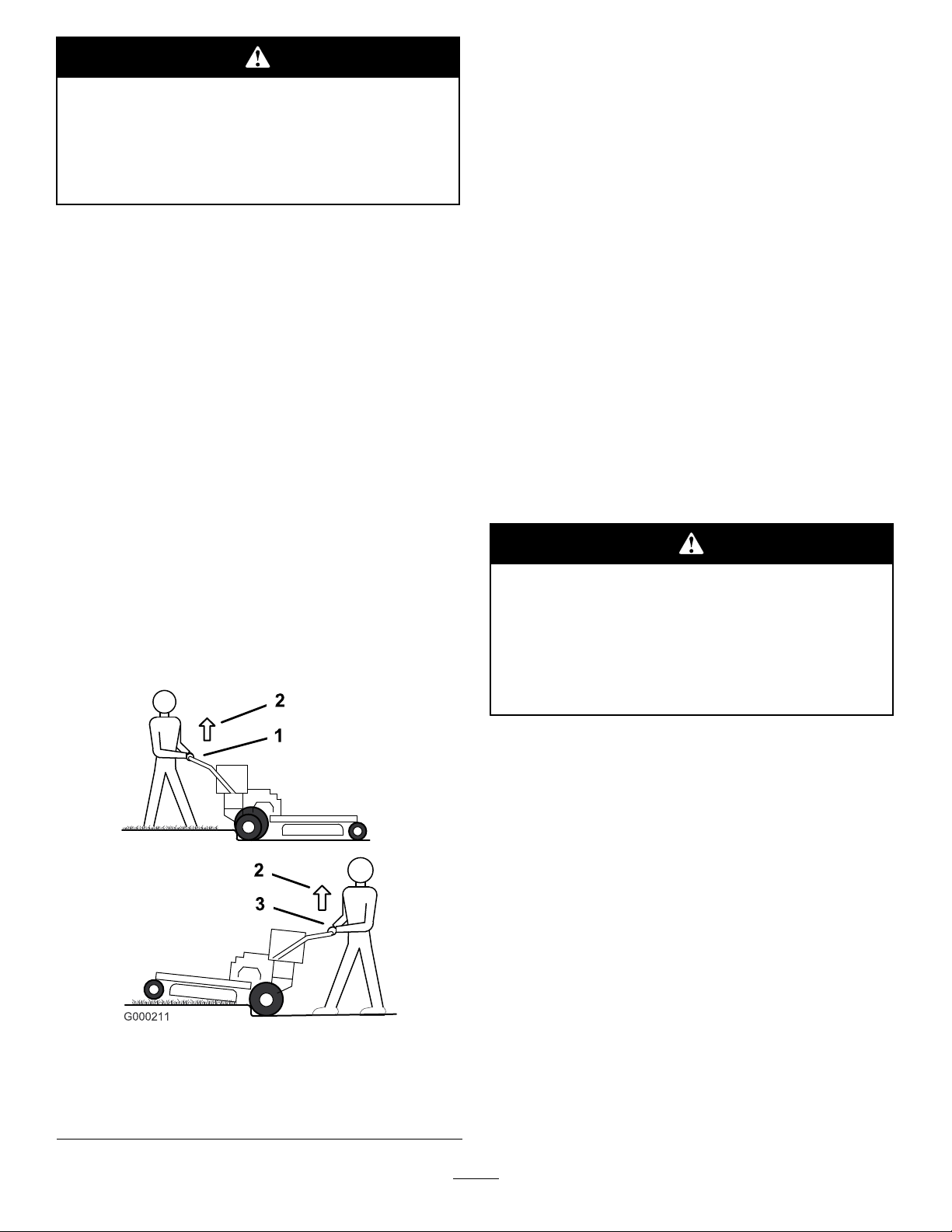

Thisprocedureisfordrivingupacurb.Thiscanbe

performedwhiledrivingforwardorbackward.

Note:Somecurbsdonotallowthereardrivetiresto

contactthecurb.Ifthishappens,drivethemachineup

thecurbatanangle.

15

Page 16

Abladecanbebentordamagedwhendriving

upacurb.Piecesofbladethatmaybethrown

couldseriouslyinjureorkillyouorbystanders.

Donotrunbladeswhiledrivingupacurb

forwardorbackward.

DrivingForwardUpaCurb

DrivingBackwardUpaCurb

1.Disengagethemowerblades.

2.Selectreversetodrivemachine.

3.Drivethemachineuntildrivewheelscontactcurb

(Figure10).

Note:Bothdrivewheelsshouldcontactthecurb

andcasterwheelsstraight.

4.Atthesametimeengagelowercontrolbarandlift

uponthelowerhandle(Figure9andFigure10).

1.Disengagethemowerblades.

2.Selectrstgeartodrivethemachine.

3.Drivemachineuntilthecastorwheelscontactthe

curb(Figure10).

4.Liftthefrontofthemachinebypushingdownon

thelowerhandle(Figure10).

5.Drivethemachineuntildrivewheelscontactthe

curb(Figure10).

6.Lowerthefrontofthemachine(Figure10).

Note:Bothdrivewheelsshouldcontactthecurb

andcasterwheelsstraight.

7.Atthesametime,engagethelowercontrolbarand

liftuponthelowerhandletodriveoverthecurb

(Figure9andFigure10).

Note:Liftinguponthelowerhandlewillassist

drivingthemachineupacurbandnotspinthe

drivewheels.

Note:Liftinguponthelowerhandlewillassist

drivingthemachineupacurbandnotspinthe

drivewheels.

StoppingtheMachine

Tostopthemachine,pullbackontheuppercontrol

bar,releasethebladecontrolbail,andturntheignition

keytooff.Alsosettheparkingbrakeifyouleavethe

machineunattended;refertoSettingtheParkingBrake

in,page.Remembertoremovethekeyfromthe

ignitionswitch.

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

1.LowerControlBar

engagedandmower

inreverse.

2.Pulluptoassistmachine

Figure10

3.LowerControlBar

engagedandmower

goingforward.

TransportingMachines

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarybrakes,lighting,andmarkingasrequiredby

law .Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

petsorbystandersavoidinjury.

Totransportthemachine:

1.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Stoptheengine,removethekey ,setthebrake,and

closethefuelvalve.

5.Usethemetaltiedownloopsonthemachineto

securelyfastenthemachinetothetrailerortruck

withstraps,chains,cable,orropes(Figure11).

16

Page 17

Figure11

1.Tractionunittiedownloop

SideDischargingorMulching

theGrass

Thismowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

Note:Allheight-of-cutpinscanusetwospacers

maximum.

1.Selectholeinheight-of-cutpostandnumberof

spacerscorrespondingtotheheight-of-cutdesired

(Figure12).

2.Usingthelifthandle,raisesideofdeckandremove

hairpincotter(Figure12).

3.Addorremovespacersifneededandthenalignthe

holesandinsertthehairpincotter(Figure12).

Note:Spareheight-of-cutspacersmaybestored

onpostsandretainedbyahairpincotter.

Important:Allfourhairpincotterpinsmustbe

inthesameholelocationandwiththecorrect

numberofspacersforalevelcut.

Withoutthegrassdeector,dischargecover,

orcompletegrasscatcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebriswill

causeinjuryordeath.

•Neverremovethegrassdeectorfrom

themowerbecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mower.

•Nevertrytocleardischargeareaormower

bladesunlessyoureleasethebailandthe

powertakeoff(PTO)isoff.Rotatethe

ignitionkeytoOff.Alsoremovethekeyand

pullthewire(s)offthesparkplug(s).

AdjustingtheHeight-of-Cut

Theheight-of-cutcanbeadjustedfrom1to4-1/2

inches(25to114mm)in1/4inch(6mm)increments.

Adjustmentisdonebyrelocatingfourhairpincotter

pinsindifferentholelocationsandbyaddingor

removingspacers.

Figure12

1.CarrierFrame4.Spacers

2.HairpinCotter5.Frontheight-of-cutpost

3.Backheight-of-cutpost

AdjustingtheAnti-Scalp

Rollers

Theanti-scalprollersneedtobeadjustedintheproper

holelocationforeachheight-of-cutposition.There

needstobe3/8inch(10mm)minimumclearance

abovetheground.

Note:Allheight-of-cutpinsneedatleastonespacer

ordamagecanoccurtothebushingifnoneareused.

Note:Iftheanit-scalprollersareadjustedtoolow,it

cancauseexcesswearoftherollers.

17

Page 18

1.Afteradjustingtheheight-of-cut,checkthe

anti-scalprollerssothatthereisaminimumof

3/8inch(10mm)clearanceabovetheground

(Figure13,Figure14,Figure15).

2.Ifadjustmentisneeded,removethebolt,washers

andnut(Figure13,Figure14,Figure15).

3.Selectaholepositionsotheanti-scalprollersare

aminimumof3/8inch(10mm)offtheground

(Figure13,Figure14,Figure15).

4.Installtheboltandnut(Figure13,Figure14,

Figure15).

Figure14

40inch,48inch,and52inchMowerDecks

1.Mowerdeck4.Bushing

2.Bolt5.Anti-scalprollers

3.Spacer

6.Nut

Figure13

40inch,48inch,and52inchMowerDecks

1.Mowerdeck4.Anti-scalprollers

2.Bolt5.Nut

3.Spacer

Figure15

36inchMowerDeck

1.Mowerdeck4.Anti-scalprollers

2.Bolt5.Nut

3.Spacer

5.Incertainmowingconditionsandterrain,a

mismatchofcuttingheightmaybeseen.Adjusting

theoutsideanti-scalprollerstotheminimumsetting

of3/8inch(10mm)willhelppreventthemower

deckcuttingtoolowontheoutsideandminimize

themismatch.

AdjustingtheHandleHeight

Thehandlepositioncanbeadjustedtomatchthe

operator’sheightpreference.

18

Page 19

1.Removethehairpincotter,washerandclevispin

securingcontrolrodttingtotheidlerbracket

(Figure16).

Figure16

1.Controlrodandtting

2.Idlerbracket5.Hairpincotter

3.Clevispin6.Rodtting

4.Washer

5.Checkthecontrolbarforcorrectadjustment.Refer

toAdjustingtheControlBarinthemaintenance

section.

6.Checktheparkingbrakeadjustment.Referto

CheckingtheBrakesinthemaintenancesection.

AdjustingtheFlowBafe

Themowerdischargeowcanbeadjustedfordifferent

typesofmowingconditions.Positionthecamlockand

bafetogivethebestqualityofcut.

1.DisengagethePTO,movethemotioncontrol

leverstotheneutrallockedpositionandsetthe

parkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Toadjustthecamlock,swingtheleveruptoloosen

thecamlock(Figure18).

2.Loosentheupperangebolts(3/8x1inch)and

theangenutsecuringthehandletotherearframe

(Figure17).

Figure17

1.Upperhandle5.Uppermountinghole

2.Rearframe

3.Flangenut,(3/8inch)

4.Flangebolt,(3/8x1inch)

6.Lowermountingholes

7.Lowposition

8.Highposition

3.Removethelowerangebolts(3/8x1inch)and

angenutssecuringthehandletotherearframe

(Figure17).

4.Adjustthebafeandcamlockintheslottothe

desireddischargeow.

5.Swingtheleverbackovertotightenthebafeand

camlock(Figure18).

6.Ifthecamdoesnotlockthebafeintoplaceoritis

tootight,loosentheleverandthenrotatethecam

lock.Adjustthecamlockuntilthedesiredlocking

pressureisachieved.

Figure18

1.Camlock4.Slot

2.Lever5.Rotatethelevertorelease

orlockthecam

3.Rotatecamtoincreaseor

decreaselockingpressure

4.Pivotthehandletothedesiredoperatingposition

andinstallthelowerangebolts(3/8x1inch)and

theangenutsintothemountingholes.Tighten

allangebolts.

19

Page 20

PositioningtheFlowBafe

Thefollowingguresareonlyrecommendationsfor

use.Adjustmentswillvarybygrasstype,moisture

content,andheightofgrass.

Note:Iftheenginepowerdrawsdownandthemower

groundspeedisthesame,openupthebafe.

PositionA

Thisisthefullrearposition(seeFigure19).The

suggesteduseforthispositionisafollows.

•Useforshort,lightgrassmowingconditions.

•Useindryconditions.

•Forsmallergrassclippings.

•Propelsgrassclippingsfartherawayfromthe

mower.

Figure20

PositionC

Figure19

PositionB

Usethispositionwhenbagging(Figure20).

Thisisthefullopenposition.Thesuggestedusefor

thispositionisasfollows(Figure21).

•Useintall,densegrassmowingconditions.

•Useinwetconditions.

•Lowerstheenginepowerconsumption.

•Allowsincreasedgroundspeedinheavyconditions.

•ThispositionissimilartothebenetsoftheToro

SFSmower.

Figure21

20

Page 21

UsingtheMid-SizeWeight

Weightsareinstalledoncertainmowerstoimprove

balanceandimproveperformance.Theweightscanbe

movedorremovedtocreateoptimizedperformance

underdifferentmowingconditionsandforoperator

preference(Figure22orFigure23).

Thefollowingtableindicatesthepositionoftheweight

asinstalledatthefactory.

MowerDeckSizeNumberofweights

36inches

40inches1Front

48inches2Rear

52inches3Rear

install

nonenone

Positionofthe

•Anyrearweightmustberemovedwhena

Tru-Track

•WhenaTru-Track

®

Sulkyisinstalled.

®

Sulkyisinstalledfrontweights

areneeded.ContactanAuthorizedServiceDealer

forthecorrectquantityofweightsandplacement.

Thefrontendofthemachinecanrapidlyrise

upwhenthemowerisremoved.Thiscould

causeseriousinjurytoyouorbystanders.

Supporttherearofthemachinewhenremoving

themowerformthecarrierframe.

weight

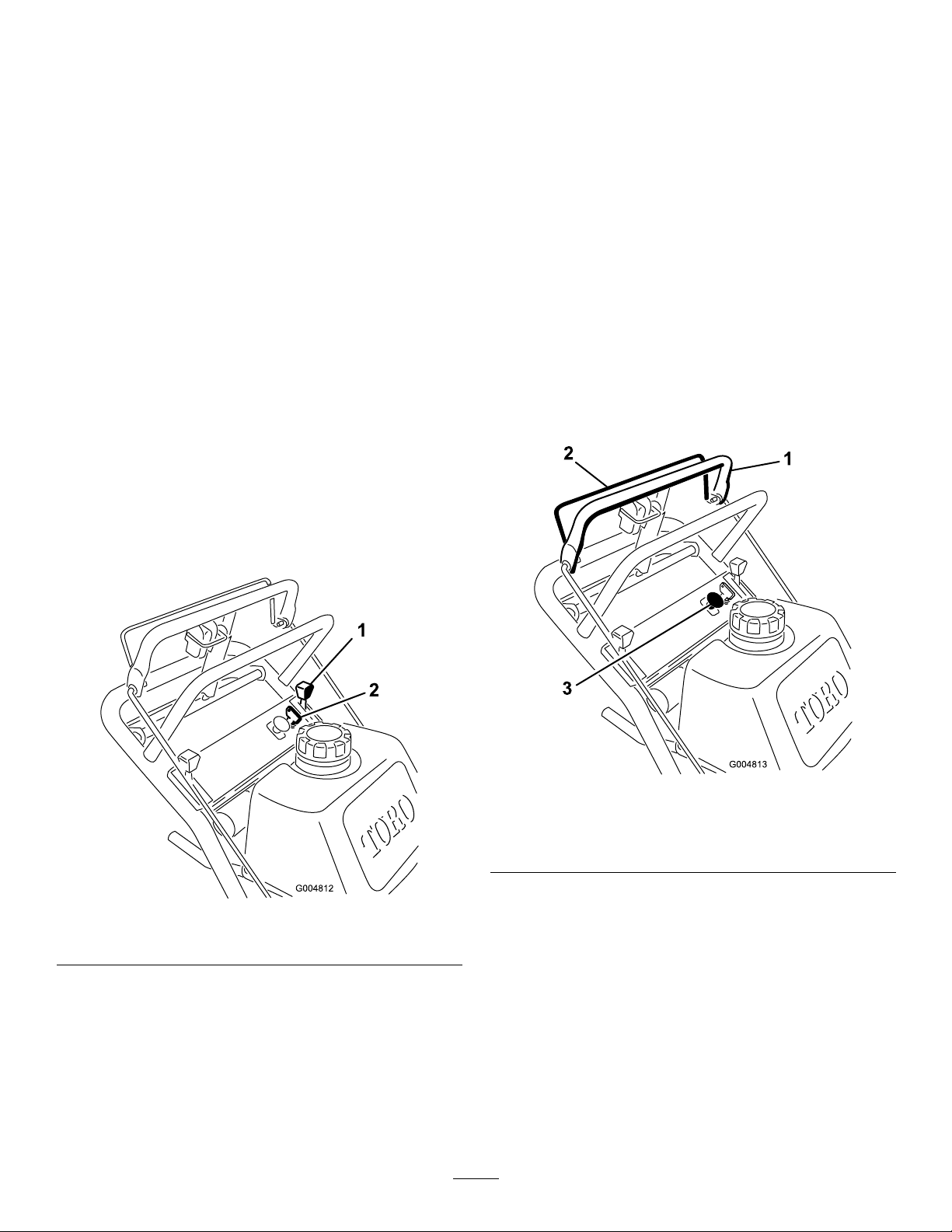

Figure22

Installingthefrontweight.

1.Bolt3.Weight

2.Washer4.Nut

Figure23

Installingtherearweight.

1.Nut3.Washer

2.Weight4.Bolt

21

Page 22

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every200hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthesafetyinterlocksystem.

•Greasethecasterwheelsandcasterpivot.

•Checktheengineoillevel.

•Cleantheairintakescreen.

•Checkthebrakesonbothalevelsurfaceandslope.

•Inspecttheblades.

•Cleanfoamaircleanerelement.

•GreasethePTObeltidler.

•Greasethemowerdeckbeltidler.

•Checkthepaperaircleanerelement.

•Checkthetirepressure

•Checkthetractiondrivebelt

•Checkthetransmissionbelt.

•Checkthemowerbelt.

•CheckthePTOdrivebelt.

•Changetheengineoil.

•Checkthesparkplugs.

•Adjusttheelectricclutch.

•Replacethepaperaircleanerelement.

•Changetheoillter.

•Replacethefuellter.

Every250hours

Every400hours

Beforestorage

•Greasethetransmissioncouplers(moreoftenindirtyordustyconditions).

•Greasethefrontwheelbearings(moreoftenindirtyordustyconditions).

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator’smanualforadditionalmaintenanceprocedures.

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnectthesparkplugwiresfromthesparkplugsbeforeyou

doanymaintenance.Setthewiresasidesothattheydonotaccidentallycontactthesparkplugs.

Lubrication

GreasewithNo.2generalpurposelithiumbaseor

molybdenumbasegrease.

HowtoGrease

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

22

Page 23

3.Cleanthegreasettingswitharag.Makesureto

scrapeanypaintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pumpgrease

intothettingsuntilgreasebeginstooozeoutof

thebearings.

5.Wipeupanyexcessgrease.

LubricatingtheCasterand

WheelBearings

ServiceInterval:Beforeeachuseordaily

Every400hours

1.Lubricatethefrontcasterwheelbearingsandfront

pivots(Figure24).

2.Raisetherearofthemachineandusejackstands

tosupportthemachine.

Figure25

3.Removetherearwheelandtireassemblies.

4.Removetherearwheelgreasecap.Lubricatetherear

wheelbearing(Figure24).

5.Installthegreasecap.

6.Installtherearwheelandtireassembly.

Note:Makesuretherearwheelgreasecapsare

removedbeforelubricatingrearwheels.

GreasingthePTODriveBelt

IdlerandMowerDeckBelt

Idler

ServiceInterval:Every50hours—GreasethePTO

beltidler.

Every50hours—Greasethemower

deckbeltidler.

Greasetheidlerpulleypivots(Figure26orFigure27).

Note:Youwillhavetoremovethecarriercoversto

accessthegreasettingforthemowerdeck.

Figure24

GreasingtheTransmission

Couplers

ServiceInterval:Every250hours

Lubricatethetransmissioncouplerslocatedintheback

ofthemachine(Figure25).

Figure26

40inch,48inch,and52inchMowerDeckshown

23

Page 24

Figure27

36inchMowerDeckshown

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval/Specication

ServiceInterval:Every25hours—Cleanfoamair

cleanerelement.

Every50hours—Checkthepaperair

cleanerelement.

Every200hours—Replacethepaper

aircleanerelement.

Note:Servicetheaircleanermorefrequently(every

fewoperatinghours)iftheoperatingconditionsare

extremelydustyorsandy.

Important:Donotoilthefoamorpaperelement.

RemovingtheFoamandPaper

Elements

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Cleanaroundtheaircleanertopreventdirt

fromgettingintotheengineandcausingdamage

(Figure28).

4.Unscrewthecoverknobandremovetheaircleaner

cover(Figure28).

5.Removethe2wingnutsandremovetheaircleaner

assembly(Figure28).

6.Carefullypullthefoamelementoffthepaper

element(Figure28).

24

Page 25

2.Placetheaircleanerassemblyontotheaircleaner

baseandsecureitwiththe2wingnuts(Figure28).

3.Placetheaircleanercoverintopositionandtighten

thecoverknob(Figure28).

ServicingtheEngineOil

ServiceInterval/Specication

ServiceInterval:Beforeeachuseordaily—Checkthe

engineoillevel.

Aftertherst8hours—Changethe

engineoil.

Every100hours—Changetheengine

oil.

Every200hours—Changetheoil

lter.

Note:Changetheoilmorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

Figure28

1.Engine4.Foamelement

2.Cover

3.Wingnut

5.Paperelement

6.Coverknob

CleaningtheFoamAirCleanerElement

1.Washthefoamelementinliquidsoapandwarm

water.Whentheelementisclean,rinseitthoroughly .

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifitis

tornorworn.

ServicingthePaperAirCleaner

Element

1.Donotcleanthepaperlter,replaceit(Figure28).

2.Inspecttheelementfortears,anoilylm,ordamage

totherubberseal.

3.Replacethepaperelementifitisdamaged.

InstallingtheFoamandPaperElements

OilType:Detergentoil(APIserviceSF,SG,SH,orSJ)

CrankcaseCapacity:58ounces(1.7liter)withthelter

removed;51ounces(1.5liter)withoutthelterremoved

Viscosity:Refertothetable(Figure29).

Figure29

CheckingtheEngineOilLevel

1.Parkthemachineonalevelsurface.

2.DisengagethePTOandsettheparkingbrake.

Important:Topreventenginedamage,always

operatetheenginewiththecompletefoamand

paperaircleanerassemblyinstalled.

1.Carefullyslidethefoamelementontothepaperair

cleanerelement(Figure28).

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Cleanaroundtheoildipstick(Figure30)sothatdirt

cannotfallintothellerholeanddamagetheengine.

25

Page 26

Figure30

1.Oildipstick

2.Fillertube

5.Unscrewtheoildipstickandwipetheendclean

(Figure30).

6.Slidetheoildipstickfullyintothellertube,butdo

notthreadontotube(Figure30).

7.Pullthedipstickoutandlookattheend.Iftheoil

levelislow ,slowlypouronlyenoughoilintotheller

tubetoraisetheleveltotheFullmark.

Important:Donotoverllthecrankcasewith

oilandruntheengine;enginedamagecan

result.

Figure31

1.Oildrainvalve2.Oildrainhose

9.Slowlypourapproximately80%ofthespeciedoil

intothellertube(Figure30).

10.Checktheoillevel;refertoCheckingtheEngineOil

Level.

ChangingtheEngineOil

1.Starttheengineandletitrunveminutes.This

warmstheoilsoitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

3.DisengagethePTOandsettheparkingbrake.

4.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

5.Slidethedrainhoseovertheoildrainvalve.

6.Placeapanbelowthedrainhose.Rotateoildrain

valvetoallowoiltodrain(Figure31).

7.Whenoilhasdrainedcompletely,closethedrain

valve.

8.Removethedrainhose(Figure31).

Note:Disposeoftheusedoilatarecyclingcenter.

11.SlowlyaddtheadditionaloiltobringittotheFull

mark.

ChangingtheOilFilter

Note:Changetheoilltermorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

2.Removetheoldlter(Figure32).

Figure32

1.Oillter

2.Adapter

3.Applyathincoatofnewoiltotherubbergasketon

thereplacementlter(Figure32).

26

Page 27

4.Installthereplacementoilltertothelteradapter,

1

turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional3/4turn(Figure32).

5.Fillthecrankcasewiththepropertypeofnewoil;

refertoServicingtheEngineOil.

6.Runtheengineforabout3minutes,stoptheengine,

andcheckforoilleaksaroundtheoillteranddrain

valve.

7.Checktheengineoillevelandaddoilifneeded.

8.Wipeupanyspilledoil.

ServicingtheSparkPlugs

ServiceInterval/Specication

ServiceInterval:Every100hours—Checkthespark

plugs.

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstallingthe

sparkplugsandagappingtool/feelergaugetocheckand

adjusttheairgap.Installanewsparkplugsifnecessary.

Type:Champion®RCJ8YorequivalentAirGap:

0.030inch(0.75mm)

4.Cleanaroundthesparkplugstopreventdirtfrom

fallingintotheengineandpotentiallycausing

damage.

5.Removethesparkplugsandthemetalwashers.

CheckingtheSparkPlugs

1.Lookatthecenterofthesparkplugs(Figure34).

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeansthattheaircleanerisdirty.

2.Ifneeded,cleanthesparkplugwithawirebrushto

removecarbondeposits.

Figure34

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

RemovingtheSparkPlugs

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Disconnectthewiresfromthesparkplugs

(Figure33).

Figure33

1.Spark-plugwire/sparkplug

Important:Alwaysreplacethesparkplugs

whenithaswornelectrodes,anoilylmonit,

orhascracksintheporcelain.

3.Checkthegapbetweenthecenterandsideelectrodes

(Figure34).Bendthesideelectrode(Figure34)if

thegapisnotcorrect.

InstallingtheSparkPlugs

1.Installthesparkplugsandthemetalwasher.Ensure

thattheairgapissetcorrectly.

2.Tightenthesparkplugsto16ft-lb(22N-m).

3.Connectthewirestothesparkplugs(Figure34).

27

Page 28

FuelSystem

Maintenance

DrainingtheFuelTank

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopen

area.Wipeupanygasolinethatspills.

Figure35

1.Fuelshut-offvalve2.Clamp

•Neversmokewhendraininggasoline,and

stayawayfromanopenameorwherea

sparkmayignitethegasolinefumes.

1.Parkthemachineonalevelsurface,toensurethe

fueltankdrainscompletely .Thendisengagethe

powertakeoff(PTO),settheparkingbrake,and

turntheignitionkeytooff.Removethekey .

2.Closethefuelshut-offvalveatthefueltank

(Figure35).

3.Squeezetheendsofthehoseclamptogether

andslideitupthefuellineawayfromfuellter

(Figure35).

4.Pullthefuellineoffthefuellter(Figure35).Open

thefuelshut-offvalveandallowthegasolinetodrain

intoagascanordrainpan.

Note:Nowisthebesttimetoinstallanewfuellter

becausethefueltankisempty.RefertoReplacing

theFuelFilter.

5.Installthefuellineontothefuellter.Slidethehose

clampclosetothevalvetosecurethefuelline.

ReplacingtheFuelFilter

ServiceInterval:Every200hours

Neverinstalladirtylterifitisremovedfromthefuel

line.

Note:Notehowthefuellterisinstalled.

Note:Wipeupanyspilledfuel.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Closefuelshut-offvalveatfueltank(Figure35).

Note:Removethefuellinefromthefuelvalvethat

isclosesttotheengine.

4.Squeezetheendsofthehoseclampstogetherand

slidethemawayfromthelter(Figure36).

1.Hoseclamp3.Filter

2.Fuelline

28

Figure36

Page 29

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclampsclose

tothelter.

7.Openfuelshut-offvalveatfueltank(Figure35).

8.Checkforfuelleaksandrepairifneeded.

ElectricalSystem

Maintenance

ServicingtheFuse

Theelectricalsystemisprotectedbyafuse.Itrequires

nomaintenance.Ifthefuseblows,checkthecomponent

orcircuitformalfunctionorashort.Toreplacethefuse,

pulloutonthefuse(Figure37)toremoveorreplaceit.

1.Fuse,7.5amp,bladetype

Figure37

29

Page 30

DriveSystem

Maintenance

AdjustingtheControlBar

1.Checkthegapbetweenuppercontrolbarand

xedbarwithwheeldrivefullyengaged.Thegap

shouldbeapproximately1to1-1/4inch(25-32mm)

(Figure38).

Note:Theuppercontrolbarandxedbarmustbe

parallelwhentheuppercontrolbarisintheengaged,

drive,neutral,orbrakepositions.

Figure39

1.Controlrodandtting

2.3-1/2inch(89mm)

3.Idlerbracket

4.Clevispin

5.Washer

6.Hairpincotterpin

7.Rodtting

8.HoleF

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)—Checkthetirepressure

Figure38

1.Uppercontrolbar4.Handle

2.Parkingbrakelever

3.Fixedcontrolbar

5.1to1-1/4inch(25-32mm)

gap

2.Checktheoperation.Ifadjustmentisrequired,

removehairpincotter,washerandclevispinsecuring

controlrodttingtoidlerbracket(Figure39).

3.Threadtherodttingupordownontheroduntil

theproperpositionisattainedandinstalltherod

ttingtotheidlerbracketwiththeclevispin,washer

andhairpincotter.

Checkthepressureatthevalvestem(Figure40).

Maintaintheairpressureinthereartiresat12-14psi

(83-97kPa).Uneventirepressurecancauseanuneven

cut.

Note:Thefronttiresaresemi-pneumatictiresanddo

notrequireairpressuremaintenance.

Figure40

30

Page 31

ReplacingtheCasterWheel

ForkBushings

Thecasterwheelforksaremountedinbushingspressed

intothetopandbottomofthecarrierframemounting

pivottubes.Tocheckthebushings,movethecaster

forksbackandforthandside-to-side.Ifacasterforkis

loose,thebushingsarewornandmustbereplaced.

1.Raisethecuttingunitsothecasterwheelsareoff

theoor,thensupportthefrontofthemowerwith

jackstands.

2.Removethelockingpinandspacer(s)fromthetop

ofthecasterwheelfork(Figure41).

Figure42

1.MountingTube2.Bushing

5.Greasetheinsideandoutsideofthenewbushings.

Useahammerandatplatetocarefullydrivethe

bushingsintothepivottubes.

Figure41

1.LockingPin

2.Spacers4.Casterwheel

3.Pullthecasterwheelforkoutofthemountingtube,

leavingthespacer(s)onthebottomofthefork.

Rememberthelocationofthespacersoneachfork

toensurecorrectinstallation,andtomaintainalevel

deck.

4.Insertapinpunchintothemountingtubeand

carefullydriveoutthebushings(Figure42).Clean

theinsideofthemountingtube.

3.Carrierframepivottube

6.Inspectthecasterwheelforkforwearandreplace

ifnecessary(Figure41).

7.Slidethecasterwheelforkthroughthebushingsin

themountingtube.Replacethespacer(s)ontothe

forkandsecurewiththeretainingring(Figure41).

Important:Theinsidediameterofthebushings

maycollapseslightlywheninstalled.Ifthe

casterwheelforkdoesnotslideintothenew

bushings,reambothbushingstoaninside

diameterof1.126inch(29mm).

8.Greasethettingonthecarrierframepivottubes

usingNo.2generalpurposelithiumbaseor

molybdenumbasegrease.

ServicingtheCasterWheel

andBearings

Thecasterwheelsrotateonarollerbearingsupportedby

aspannerbushing.Ifthebearingiskeptwelllubricated,

wearwillbeminimal.Failuretokeepthebearingwell

lubricatedwillcauserapidwear.Awobblycasterwheel

usuallyindicatesawornbearing.

1.Removethelocknutandwheelboltholdingthe

casterwheeltothecasterfork(Figure43).

31

Page 32

3.Repeatthisfortheremainingslots.

4.Checkeachslotagainandmakeslightadjustments

untilthefeelergaugebetweentherotorandarmature

withveryslightcontactbetweenthem.

Figure43

1.Locknut

2.Cap

3.RollerBearing6.Bushing

4.SpannerBushing

5.Wheel

2.Removeonebushing,thenpullthespannerbushing

androllerbearingoutofthewheelhub(Figure43).

3.Removetheotherbushingfromthewheelhub

andcleananygreaseanddirtfromthewheelhub

(Figure43).

4.Inspecttherollerbearing,bushings,spannerbushing

andinsideofthewheelhubforwear.Replaceany

defectiveorwornparts(Figure43).

5.Toassemble,placeonebushingintothewheelhub.

Greasetherollerbearingandspannerbushingand

slidethemintothewheelhub.Placethesecond

bushingintothewheelhub(Figure43).

6.Installthecasterwheelintothecasterforkand

securewiththewheelboltandlocknut.Tightenthe

locknutuntilthespannerbushingbottomsagainst

theinsideofthecasterforks(Figure43).

7.Greasethettingonthecasterwheel.

Figure44

1.Adjustingnut3.Feelergauge

2.Slot

AdjustingtheElectricClutch

ServiceInterval:Every100hours

Theclutchisadjustabletoensureproperengagement

andproperbraking.

1.Inserta0.015–0.021inch(0.381–0.533mm)feeler

gaugethroughoneinspectionslotinthesideofthe

assembly.Makesureitisbetweenthearmatureand

therotorfrictionsurfaces.

2.Tightenthelocknutsuntilthereisslightbindingon

thefeelergaugebutitcanbemovedeasilywithinthe

airgap(Figure44).

32

Page 33

CoolingSystem

Maintenance

BrakeMaintenance

ServicingtheBrakes

CleaningtheAirIntakeScreen

ServiceInterval:Beforeeachuseordaily

Removeanybuild-upofgrass,dirtorotherdebrisfrom

thecylinderandcylinderheadcoolingns,airintake

screenonywheelend,andcarburetor-governorlevers

andlinkage.Thiswillhelpinsureadequatecoolingand

correctenginespeedandwillreducethepossibilityof

overheatingandmechanicaldamagetotheengine.

ServiceInterval:Beforeeachuseordaily—Checkthe

brakesonbothalevelsurfaceand

slope.

Alwayssettheparkingbrakewhenyoustopthemachine

orleaveitunattended.Iftheparkingbrakedoesnot

holdsecurely ,anadjustmentisrequired.

CheckingtheBrakes

1.Parkthemachineonalevelsurface,disengagethe

PTO.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Applytheparkingbrake.Thewheelsmustlock

whenyoutrytopushthemachineforward.

4.Ifthewheelsdonotlock,adjustthebrakes.Refer

toAdjustingtheBrakes.

5.Releasethebrakeandpressuppercontrolbarvery

lightly,approximately1/2inch(13mm).Thewheels

shouldrotatefreely ,ifnot;refertoAdjustingthe

Brakes.

AdjustingtheBrakes

Thebrakeleverisontheuppercontrolbar.Ifthe

parkingbrakedoesnotholdsecurely,anadjustmentis

required.

Note:Fortheinitialadjustment,adjustthewing

nutuntilitis1-1/4inchesfromthetopoftherod

(Figure45).

1.Parkthemachineonalevelsurface,disengagethe

PTO,andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Checkthebrakebeforeyouadjustit;referto

CheckingtheBrakes.

4.Releasetheparkingbrake;refertoReleasingthe

ParkingBrakein,page.

5.Toadjustthebrakeremovethehairpincotter

andwasherfromthebrakeleverandtrunnion

(Figure45).

33

Page 34

Figure45

1.Hairpincotterandwasher5.HoleF

2.Trunnion

3.Brakelever7.Rod

4.Wingnut

6.Initialadjustment-1-1/4

inch(32mm)

BeltMaintenance

ReplacingtheTractionDrive

Belt

ServiceInterval:Every50hours/Monthly(whichever

comesrst)—Checkthetraction

drivebelt

Lookforcracks,wear,andsignsofoverheating.

1.Removethetopboltsecuringidlersupportandidler

brackettorearframe(Figure46).

6.Rotatethewingnutclockwisetoincreasethebraking

pressure.

7.Rotatethewingnutcounterclockwisetodecrease

thebrakingpressure.

8.InstallthetrunnionintoholeF(Figure45).Tighten

thewingnut.

9.Securetrunniontobrakeleverwithwasherandhair

pincotter(Figure45).

10.Checkthebrakeoperationagain;refertoChecking

theBrakes.

Important:Withtheparkingbrakereleased,

therearwheelsmustrotatefreelywhenyou

pushthemower.Ifbrakeactionandfreewheel

rotationcannotbeachievedcontactyourservice

dealerimmediately.

Figure46

1.Topbolt4.Bottombolt

2.Idlerbracket5.Tractiondrivebelt

3.Idlersupport

2.Loosenbottomtwomountingscrewsenoughto

allowbelttopassbetweendrivepulleyandidler

support(Figure46).

3.Raisethewheelofftheground,toallowthebeltto

beremoved,andremovethebelt.

4.Installanewbelt.

5.Installthetopboltsecuringtheidlersupportand

idlerbrackettotherearframe(Figure46).

6.Tightenthebottomtwomountingscrewsenoughto

allowthebelttopassbetweenthedrivepulleyand

idlersupport(Figure46).

ReplacingtheTransmission

Belt

ServiceInterval:Every50hours

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.RemovePTOdrivebelt.RefertoReplacingthe

PTODriveBeltinthe,page.

34

Page 35

4.Raisethefrontofthemachineandholdwithjack

stands.

5.Disconnectclutchwireconnectorfromwireharness.

4.Unlatchandremovethebeltcovers.

5.RemovethePTOdrivebelt.RefertoReplacingthe

PTODriveBelt.

6.Disconnectclutchretainerfromtheenginedeck

(Figure47).

Figure47

1.Transmissionbelt

2.Idlerpulley6.Pivotbolt

3.Clutchretainer

4.Tensionspring8.Enginedeck

5.Clutchwireconnector

7.Drivepulley

7.Unhooktensionspringfromsideofframe

(Figure47).

6.Disconnecttheidlerarmspringtorelievetensionon

theidlerarmandidlerpulley,thenremovetheworn

mowerbelt(Figure48orFigure49).

7.Installthenewmowerbeltaroundthetwooutside

spindlepulleys,theidlerpulley,andinthelower

grooveofthedoublespindlepulley(Figure48or

Figure49).

8.Connecttheidlerarmspring(Figure48orFigure49).

9.InstallthePTOdrivebelt.RefertoReplacingthe

PTODriveBelt.

10.Adjustthebeltguidean1/8inch(3mm)fromthe

belt(Figure48orFigure49).

11.Installthebeltcoversontothecuttingunitand

securethelatches.

12.Installthecarrierframecoverontothecuttingunit

andsecurethelatches.

8.Loosenpivotboltenoughtoremovetractionbelt

fromthedrivepulleyandclutch.

9.Installnewbeltaroundclutchanddrivepulley.

10.T orquepivotboltto35-40ft-lb(47-54N-m).Install

tensionspringbetweenidlerarmandframebracket

(Figure47).

11.Installclutchretainertotheenginedeck(Figure47).

12.Connectclutchwireconnectortowireharness.

13.InstallPTOdrivebelt.

ReplacingtheMowerBelt

ServiceInterval:Every50hours

Squealingwhenthebeltisrotating,bladesslippingwhen

cuttinggrass,frayedbeltedges,burnmarksandcracks

aresignsofaworndeckbelt.Replacethedeckbeltif

anyoftheseconditionsareevident.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

Figure48

40inch,48inch,and52inchMowerDeckshown

1.Outsidepulley

2.PTOdrivebelt

3.Idlerarmspring

4.Mowerdeckbelt

5.Beltguide

6.Centerspindlepulley

3.Unlatchandremovethecarrierframecover.

35

Page 36

Figure49

36inchMowerDeckshown

1.Mowerdeckbelt4.Idlerarmspring

2.PTOdrivebelt

3.Drivebeltpulley

5.Drivebeltpulley

9.Rollthebeltontothecenterpulleyonthemower

deck(Figure50).Usecautionwheninstallthebelt

astensionwillincreasebecauseofthespringloaded

idlerpulley.RefertoFigure51torollthenewbelt

ontotheleftpulleyfora36inchmowerdeck.

10.Installtheheatshieldtotheenginedeckandcarrier

frame.

11.Adjustthebeltguidean1/8inch(3mm)fromthe

beltfor40,48and52inchmowerdecks(Figure50).

12.Installthebeltcoversontothecuttingunitand

securethelatches.

13.Installthecarrierframecoverontothecarrierframe

andsecurethelatches.

ReplacingthePTODriveBelt

ServiceInterval:Every50hours

Squealingwhenthebeltisrotating,bladesslippingwhen

cuttinggrass,frayedbeltedges,burnmarksandcracks

aresignsofaworndrivebelt.Replacethedrivebeltif

anyoftheseconditionsareevident.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Unlatchandremovethecarrierframecover.

4.Unlatchandremovethebeltcovers.

5.Removetheheatshieldfromtheenginedeckand

carrierframe.

6.Rollthebeltoffofthecenterpulleyonthemower

deck(Figure50).RefertoFigure51torollthebelt

offleftpulleyfora36inchmowerdeck.Usecaution

whenremovingthebeltastensionwillincrease

becauseofthespringloadedidlerpulley.

7.Removethebeltfromtheenginepulleyandthe

springloadedidlerpulley(Figure50).Referto

Figure51toremovethebeltfromthe36inchmower

deckpulleys.

8.Installthenewbeltontotheenginepulleyandspring

loadedidlerpulley(Figure50).

Figure50

40inch,48inch,and52inchMowerDeckshown

1.PTOdrivebeltguide4.PTOengagementpulley

2.PTOdriveBelt5.PTOdrivebeltidlerpulley

3.Idlerspring

6.Centerspindlepulley

36

Page 37

MowerDeck

Maintenance

ServicingtheCuttingBlades

Toensureasuperiorqualityofcut,keeptheblades

sharp.Forconvenientsharpeningandreplacement,you

maywanttokeepextrabladesonhand.

Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrownintothe

operator’sorbystander’sarea,resultingin

seriouspersonalinjuryordeath.

Figure51

36inchMowerDeckshown

1.Mowerdeckbelt

2.PTODriveBelt

3.Idlerarmandspring

4.Clutchpulley

5.Idlerpulley

AdjustingthePTODriveBelt

IdlerSpringAnchor

ThepositionofthePTOidlercanbeadjustedto

increaseordecreasebelttension.

UseFigure52fortheidlerpositionoptions.

•Inspectthebladesperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagetheblades

andsettheparkingbrake.Turntheignitionkeytooff.

Removethekeyanddisconnectthesparkplugwires

fromthesparkplugs.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure53).Iftheedges

arenotsharporhavenicks,removeandsharpenthe

blades.RefertoSharpeningtheBlades.

Figure52

1.PTOdrivebeltidlerpulley4.Mosttensionforwornbelts

2.PTOdriveBelt5.Mediumtensionfornormal

3.Idlerspring

beltconditions

6.Leasttensionfornewbelts

Figure53

1.CuttingEdge3.Wear/slotformingin

curvedarea

2.Sail4.Crackinthecurvedarea

2.Inspecttheblades,especiallythecurvedarea

(Figure53).Ifyounoticeanycracks,wear,ora

slotforminginthisarea(item3inFigure53),

immediatelyinstallanewblade.

37

Page 38

CheckingforBentBlades

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Rotatethebladesuntiltheendsfaceforwardand

backward.Measurefromalevelsurfacetothe

cuttingedge,positionA,oftheblades(Figure54

).Notethisdimension.For36inchmowerdecks

useFigure55.

steps3and4mustnotexceed1/8inch(3mm).If

thisdimensionexceeds1/8inch(3mm),theblade

isbentandmustbereplaced;refertoRemovingthe

BladesandInstallingtheBlades.

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplacebentordamagedbladewith

anewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofblade.

RemovingtheBlades

Bladesmustbereplacedifasolidobjectishit,ifthe

bladeisoutofbalanceorisbent.Toensureoptimum

performanceandcontinuedsafetyconformanceof

themachine,usegenuineTororeplacementblades.

Replacementbladesmadebyothermanufacturersmay

resultinnon-conformancewithsafetystandards.

Figure54

40inch,48inch,and52inchMowerDeckshown

1.Measureherefromblade

tohardsurface

36inchMowerDeckshown

2.PositionA

Figure55

1.Holdthebladeendusingaragorthickly-padded

glove.

2.For40and48inchmowerdecks,removetheblade

bolt,curvedwasher,andbladefromthespindle

shaft(Figure56).

4.Rotatetheoppositeendsofthebladesforward.

5.Measurefromalevelsurfacetothecuttingedgeof

thebladesatthesamepositionasinstep3above.

Thedifferencebetweenthedimensionsobtainedin

38

Page 39

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothends

oftheblade(Figure58).Maintaintheoriginalangle.

Thebladeretainsitsbalanceifthesameamountof

materialisremovedfrombothcuttingedges.

Figure58

1.Sharpenatoriginalangle

Figure56

40inchand48inchMowerDecks

1.SailAreaofBlade3.Curvedwasher

2.Blade4.BladeBolt

3.For36and52inchmowerdecks,removetheblade

bolt,curvedwasher,bladestiffener,andbladefrom

thespindleshaft(Figure57).

Figure57

36inchand52inchMowerDecks

1.SailAreaofBlade4.Curvedwasher

2.Blade5.BladeBolt

3.Bladestiffener

2.Checkthebalanceofthebladebyputtingitona

bladebalancer(Figure59).

3.Ifthebladestaysinahorizontalposition,theblade

isbalancedandcanbeused.Ifthebladeisnot

balanced,lesomemetalofftheendofthesailarea

only(Figure56)

4..Repeatthisprocedureuntilthebladeisbalanced.

Figure59

1.Blade2.Balancer

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure56).

Important:Thesailpartoftheblademustbe

pointingupward,towardtheinsideofthemower

toensurepropercutting(Figure56).

2.For40inchand48inchmowerdecks,installthe

blade,curvedwasher,andbladebolt(Figure56).

3.For36inchand52inchmowerdecks,installthe

blade,stiffener,curvedwasher,andbladebolt

(Figure57).

4.Torquethebladeboltto85-110ft-lb(115-140N-m).

CorrectingtheMowerQuality

ofCut

Ifonedeckbladecutslowerthantheother,correctas

follows.

Note:Tireairpressureiscriticalintheseprocedures.

Makesurealltireshavecorrectpressure.

39

Page 40

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.Disconnectthesparkplugwire(s)from

thesparkplug(s).

3.Adjustthetirepressureinthereartiresto

specications;referto,page.

4.Checkthatthebladesandspindleshaftsarenot

bent.RefertoCheckingforBentBlades.

5.Settheheight-of-cuttothe4inch(101.6mm)

position.RefertoAdjustingtheHeight-Of-Cutin,

page.

6.PerformthestepsinthefollowingsectionsFrame

SetUp,CheckingFront-to-RearPitch,andChecking

Side-to-SideLeveling.

FrameSetUp

CheckingtheCarrierFrameandEngine

DeckAlignment

Figure60

1.CarrierFrame4.LocationA,1-5/16inch

2.Topofenginedeck5.Straightedge

3.Carrierframemounting

bolts

(33mm)±1/4inch(6mm)

6.Carrierframecross

channel

Note:MisalignmentcancauseexcesswearonthePTO

drivebelt.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Placealongstraightedgeontopoftheenginedeck

asshowninFigure60.

4.Atthecarrierframecrosschannel,measurethe

heightatlocationA(Figure60).Thismeasurement

mustbe1-5/16inch(33mm),plusorminusa1/4

inch(6mm).

5.IftheheightatlocationAisnotcorrect,adjustment

isneeded.

6.Loosenthecarrierframemountingboltsonboth

sidesofthemachine(Figure60).

7.Alignthecarrierframeandenginedecktomatch

1-5/16inch(33mm),plusorminusa1/4inch(6

mm)atlocationA(Figure60).

CheckingtheEngineDeckHeight

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Adjustthetirepressureinthereartiresto

specications;referto,page.

4.MeasureenginedeckheightatlocationA(Figure61).

8.Tightenthecarrierframemountingboltsonboth

sidesofthemachine.

Figure61

1.Backviewofmachine

2.Topofenginedeck4.Sameheightatlocations

40

3.Tires

AandB

Page 41

5.MeasureenginedeckheightatlocationB(Figure61).

6.IftheheightatlocationAandBarenotthesame,

changetirepressureslightlytomakethemthesame.

CheckingtheCarrierFrame

Front-to-RearPitch

Thecarrierframemusthaveapitchbetween1/8inch

(3mm)to3/8inch(9mm)overthelengthof24inches

(61cm)onthecarrierframe(Figure62).

1.Measureout24inches(61cm)onthecarrierframe

(Figure62).

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Adjustthetirepressureinthereartiresto

specications;referto,page.

4.MeasurecarrierframeheightatlocationA

(Figure63).

5.MeasurecarrierframeheightatlocationB

(Figure63).

6.Ifthecarrierframeheightisnotthesamemove

spacersfromtoporbottomofcasterwheel,to

makeitlevel.Thetirepressuremayalsobeadjusted

slightlytomakeitlevel.

Figure62

1.CarrierFrame

2.1/4-3/8inch(6-10mm)

pitchover24inch(61cm)

length

3.24inches(61cm)6.Casterspacers

4.HeightatlocationsAand

B

5.CasterWheel

2.MeasurecarrierframeheightatlocationA

(Figure62).

3.MeasurecarrierframeheightatlocationB

(Figure62).

4.TheheightatlocationAmustbea1/4-3/8inch(6

mm-10mm)lowerthanlocationB(Figure62).

5.Ifthecarrierframeisnotcorrect,movecaster

spacerstomakeita1/4-3/8inch(6-10mm)pitch

(Figure62).Movespacersfromtoporbottomto

makethecorrectpitch.

6.Thetirepressuremayalsobeadjustedslightlyto

makea1/4inch(6mm)pitch.

CheckingtheCarrierFrame

Side-to-SideHeight

Figure63

1.CasterWheel4.Sameheightatlocations

AandB

2.CarrierFrame5.Casterspacers

3.Frontheight-of-cutpins

CheckingtheMowerDeck

Front-to-RearPitch

1.Adjustthetirepressureinthereartiresto

specications;referto,page.

2.Positiononebladefront-to-rear.MeasureatAand

Blocationsfromalevelsurfacetothecuttingedge

ofthebladetips(Figure64orFigure65).For36

inchmowerdecksuseFigure65.

3.Themowerbladeshouldbea1/4inch(6mm)lower

infrontatAthanintherearatB.Rotatebladesand

repeatforotherblades.Ifitisnotcorrect,proceed

toChangingtheDeckFront-to-RearPitch.

Thecarrierframeneedstobeparallelside-to-sidefrom

theground.

1.DisengagethePTOandsettheparkingbrake.

41

Page 42

Figure64

40inch,48inch,and52inchMowerDeckshown

1.MeasurebladeatpointsA

andB

2.Measurefromalevel

Figure66

1.CasterWheel

2.CarrierFrame

surface

3.Frontheight-of-cutpins

4.Jamnut

5.Balljoint

2.Toraisethefrontofthedeck,loosenjamnutand

rotatethefrontpinclockwise(Figure66).

3.Tolowerthefrontofthedeck,loosenjamnutand

rotatethefrontpincounterclockwise(Figure66).

4.Positionthebladesfront-to-rear.MeasureatCand

Dlocations(Figure64)fromalevelsurfacetothe

cuttingedgeoftheblades.

5.Checktheside-to-sidelevelingofthecuttingunit.

Figure65

36inchMowerDeckshown

ChangingtheMowerDeck

Front-to-RearPitch

Changingthefront-to-rearpitchisdonebyadjustingthe

frontheight-of-cutposts.

1.Tochangethefront-to-rearpitch,thefront

height-of-cutpostscanbeadjusted(Figure66).

6.Tightenthejamnuts(Figure66).

CheckingtheMowerDeck

Side-to-SideHeight

1.Adjustthereartirepressuretospecications;refer

to,page.

2.Positionthebladesside-to-side.MeasureatCand

Dlocationsfromalevelsurfacetothecuttingedge

ofbladetips(Figure67).For36inchmowerdecks

useFigure68.

42

Page 43

Figure67

40inch,48inch,and52inchMowerDeckshown

3.Withthemachineonlevelsurface,positiononeblade

front-to-rear.MeasureatAandfromlevelsurfaceto

thecuttingedgeofthebladetips(Figure69).For36

inchmowerdecksuseFigure70.

1.Measurefromalevel

surface

36inchMowerDeckshown

2.MeasurebladeatpointsC

andD

Figure68

3.ThedifferencebetweenmeasurementsCandD

shouldbenomorethan1/4inch(6mm).

ChangingtheMowerDeck

Figure69

40inch,48inch,and52inchMowerDeckshown

1.Measurefromalevel

surface

36inchMowerDeckshown

2.MeasurebladeatpointA

Figure70

Side-to-SideHeight

Changingtheside-to-sideheightisdonebyadjustingthe

reartirepressureandcasterspacers.

1.Changethereartirepressure.Dothistothe

correspondingsidethatneedsadjustment.