Page 1

FormNo.3392-458RevA

g014793

CommercialWalk-BehindMower

FloatingDeck,T-Bar,GearDrivewith36inor

48inTURBOFORCE

ModelNo.30074—SerialNo.315000001andUp

ModelNo.30078—SerialNo.315000001andUp

ModelNo.39074—SerialNo.315000001andUp

®

CuttingUnit

ModelNo.39078—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3392-458*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

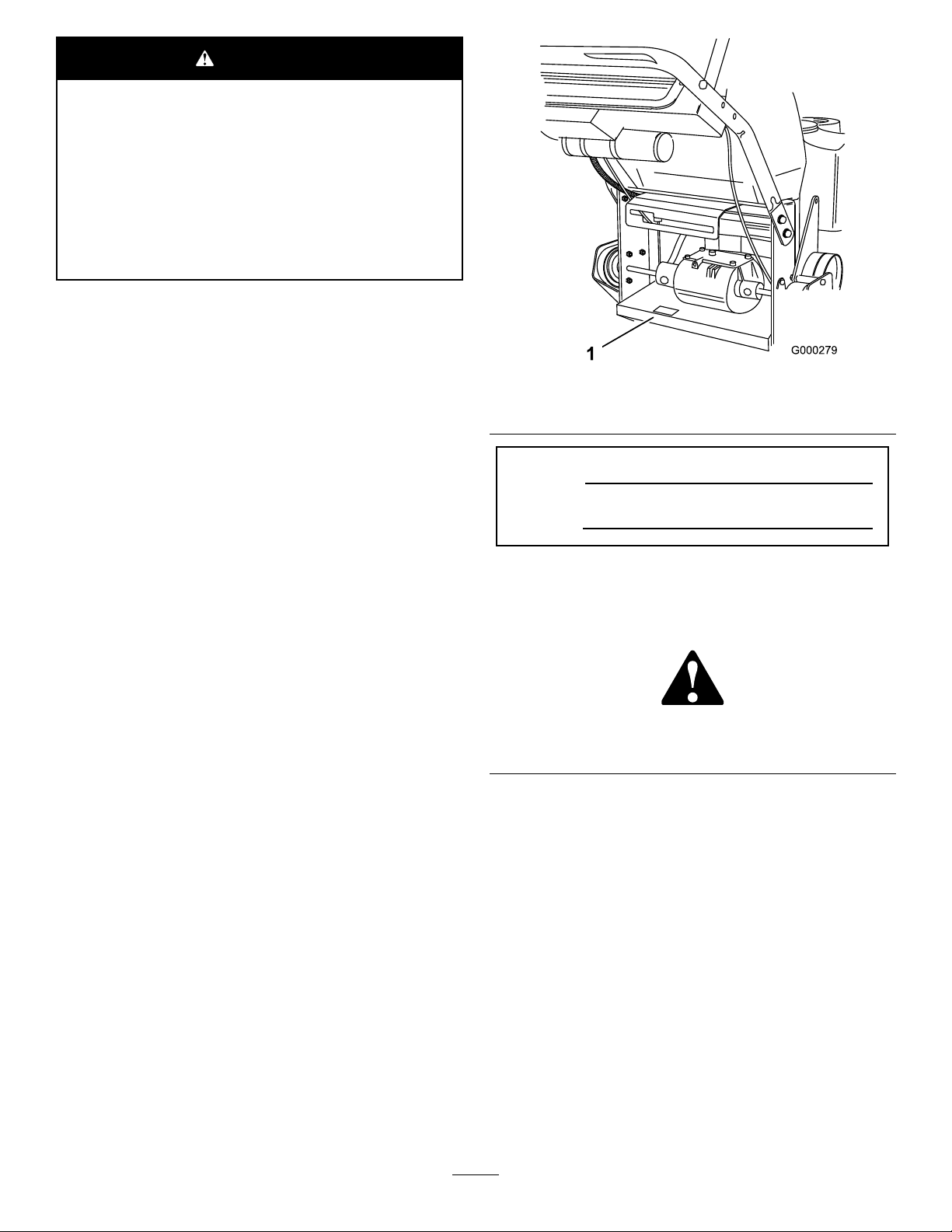

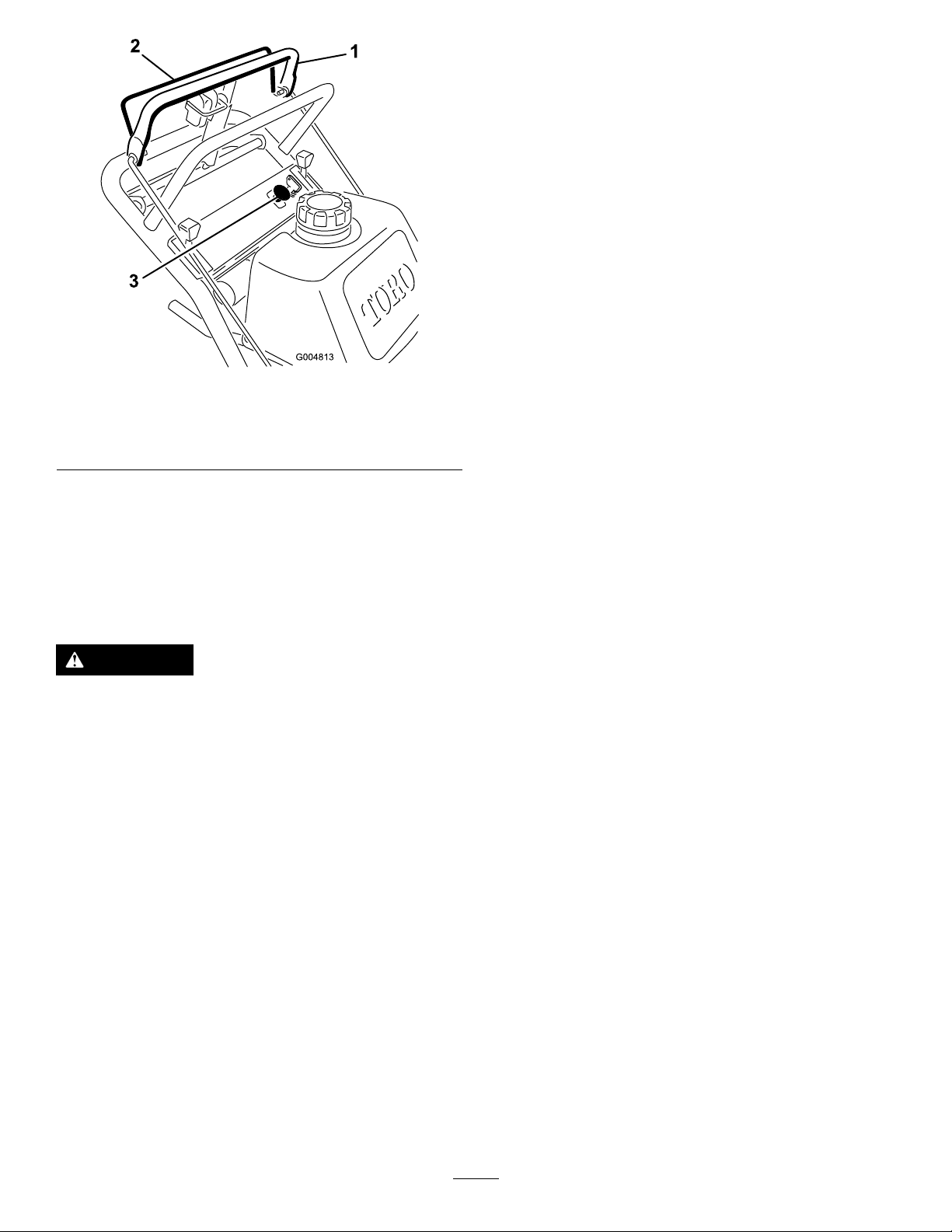

Figure1

1.Modelandserialnumberlocation

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Thisrotary-blade,lawnmowerisintendedtobe

usedbyprofessional,hiredoperatorsorresidential

homeowners.Itisdesignedprimarilyforcuttinggrass

onwell-maintainedlawnsonresidentialorcommercial

properties.Itisnotdesignedforcuttingbrushorfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................5

SlopeIndicator.......................................................6

SafetyandInstructionalDecals.................................7

ProductOverview.........................................................10

Controls...............................................................11

Specications........................................................12

Attachments/Accessories........................................12

Operation....................................................................12

AddingFuel...........................................................12

CheckingtheEngine-OilLevel.................................13

PuttingSafetyFirst.................................................13

UsingtheParkingBrake..........................................13

StartingandStoppingtheEngine..............................14

OperatingtheMowerPowerTakeOff

(PTO)...............................................................14

TheSafety-InterlockSystem....................................15

DrivingForwardorBackward..................................15

UsingtheLowerControlBar...................................16

StoppingtheMachine.............................................17

TransportingMachines............................................17

SideDischargingorMulchingtheGrass.....................18

AdjustingtheHeight-of-Cut....................................18

AdjustingtheAnti-ScalpRollers...............................18

AdjustingtheHandleHeight....................................19

AdjustingtheFlowBafe........................................20

PositioningtheFlowBafe......................................20

UsingtheMid-SizeWeight.......................................21

Maintenance.................................................................23

RecommendedMaintenanceSchedule(s)......................23

Lubrication...............................................................24

GreasingtheMachine.............................................24

LubricatingtheCasterandWheelBearings.................24

GreasingtheTransmissionCouplers.........................24

GreasingthePTO-Drive-BeltIdlerand

Mower-Deck-BeltIdler........................................24

EngineMaintenance..................................................25

ServicingtheAirCleaner.........................................25

ServicingtheEngineOil..........................................26

ServicingtheSparkPlugs.........................................28

FuelSystemMaintenance...........................................29

DrainingtheFuelTank...........................................29

ReplacingtheFuelFilter..........................................29

ElectricalSystemMaintenance....................................30

ServicingtheFuse..................................................30

DriveSystemMaintenance.........................................30

AdjustingtheControlBar........................................30

CheckingtheTirePressure......................................31

ReplacingtheCaster-Wheel-ForkBushings................31

ServicingtheCasterWheelandBearings....................32

AdjustingtheElectricClutch....................................32

CoolingSystemMaintenance......................................33

CleaningtheAir-IntakeScreen.................................33

BrakeMaintenance....................................................34

ServicingtheBrakes................................................34

BeltMaintenance......................................................35

ReplacingtheTraction-DriveBelt.............................35

ReplacingtheTransmissionBelt...............................35

ReplacingtheMowerBelt........................................35

ReplacingthePTO-DriveBelt..................................36

AdjustingthePTO-Drive-Belt-Idler-Spring

Anchor..............................................................37

MowerDeckMaintenance...........................................38

ServicingtheCuttingBlades.....................................38

CorrectingtheMowerQualityofCut........................40

FrameSetup..........................................................41

CheckingtheMowerDeckFront-to-Rear

Pitch.................................................................42

ChangingtheMowerDeckFront-to-Rear

Pitch.................................................................43

CheckingtheMowerDeckSide-to-Side

Height...............................................................43

ChangingtheMowerDeckSide-to-Side

Height...............................................................44

MatchingtheHeight-of-Cut.....................................44

ReplacingtheGrassDeector..................................44

Storage........................................................................46

CleaningandStorage..............................................46

Troubleshooting...........................................................47

Schematics...................................................................49

3

Page 4

Safety

Note:Theadditionofattachmentsmadebyother

manufacturersthatdonotmeetAmericanNationalStandards

Institutecerticationwillcausenoncomplianceofthis

machine.

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCAUTION,WARNING,

orDANGER-“personalsafetyinstruction."Failuretocomply

withtheinstructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromANSIstandard

B71.4-2012.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglishitis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

peopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glassesandhearingprotection.Longhair,looseclothing

orjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toysandwirewhichcan

bethrownbythemachine.

•Checkthatoperator'spresencecontrols,safetyswitches

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Onlystartenginefrom

theoperator'sposition.

•Besureofyourfootingwhileusingthismachine,

especiallywhenbackingup.Walk,don'trun.Never

operateonwetgrass.Reducedfootingcouldcause

slipping.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

themachine'sstability .Usecautionwhileoperatingnear

drop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neverraisedeckwiththebladesrunning.

•NeveroperatewiththePTOshield,orotherguardsnot

securelyinplace.Besureallinterlocksareattached,

adjustedproperly ,andfunctioningproperly.

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,disengagedrives,engageparking

brake(ifprovided),shutoffenginebeforeleavingthe

operator'spositionforanyreasonincludingemptyingthe

catchersoruncloggingthechute.

•Stopequipmentandinspectbladesafterstrikingobjects

orifanabnormalvibrationoccurs.Makenecessary

repairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Keeppetsandbystandersaway .

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesifnotmowing.

•Beawareofthemowerdischargedirectionanddonot

pointitatanyone.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

Operation

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

4

Page 5

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

MaintenanceandStorage

•Disengagedrives,setparkingbrake,stopengineand

removekeyordisconnectsparkplugwire.Waitforall

movementtostopbeforeadjusting,cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunit,drives,mufers,

andenginetohelppreventres.Cleanupoilorfuel

spillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransporting.Donotstore

fuelnearamesordrainindoors.

•Parkmachineonlevelground.Setparkingbrake.Never

allowuntrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorremovesparkplugwirebefore

makinganyrepairs.Disconnectthenegativeterminalrst

andthepositivelast.Reconnectthepositiverstand

negativelast.

•Usecarewhencheckingblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.Only

replaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsandothersafetyinformationyoumustknow.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrassor,

whenequippedwithagrassbagger,forcatchingcutgrass.

Anyuseforpurposesotherthanthesecouldprovedangerous

touserandbystanders.

GeneralOperation

•Besuretheareaisclearofotherpeoplebeforemowing.

Stopthemachineifanyoneentersthearea.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowtocoolbeforeattempting

tomaintain,adjustorservice.

•UseonlyToroapprovedattachments.Warrantymaybe

voidedifusedwithunapprovedattachments.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforeoperatingunderany

objectsanddonotcontactthem.

SlopeOperation

Allslopesandrampsrequireextracaution.Ifyoufeeluneasy

onaslope,donotmowit.

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

mowingarea.

•Watchforholes,rutsorbumps.Tallgrasscanhide

obstacles.

•Usecautionneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyturnoverifawheelgoes

overtheedgeofaclifforditch,orifanedgecavesin.

•Useextracarewithgrasscatchersorotherattachments.

Thesecanchangethestabilityofthemachine.

•Keepallmovementonslopesslowandgradual.Donot

makesuddenchangesinspeedordirection.

•Mowslopessidetoside.

•Donotmowslopesgreaterthan20degrees.

5

Page 6

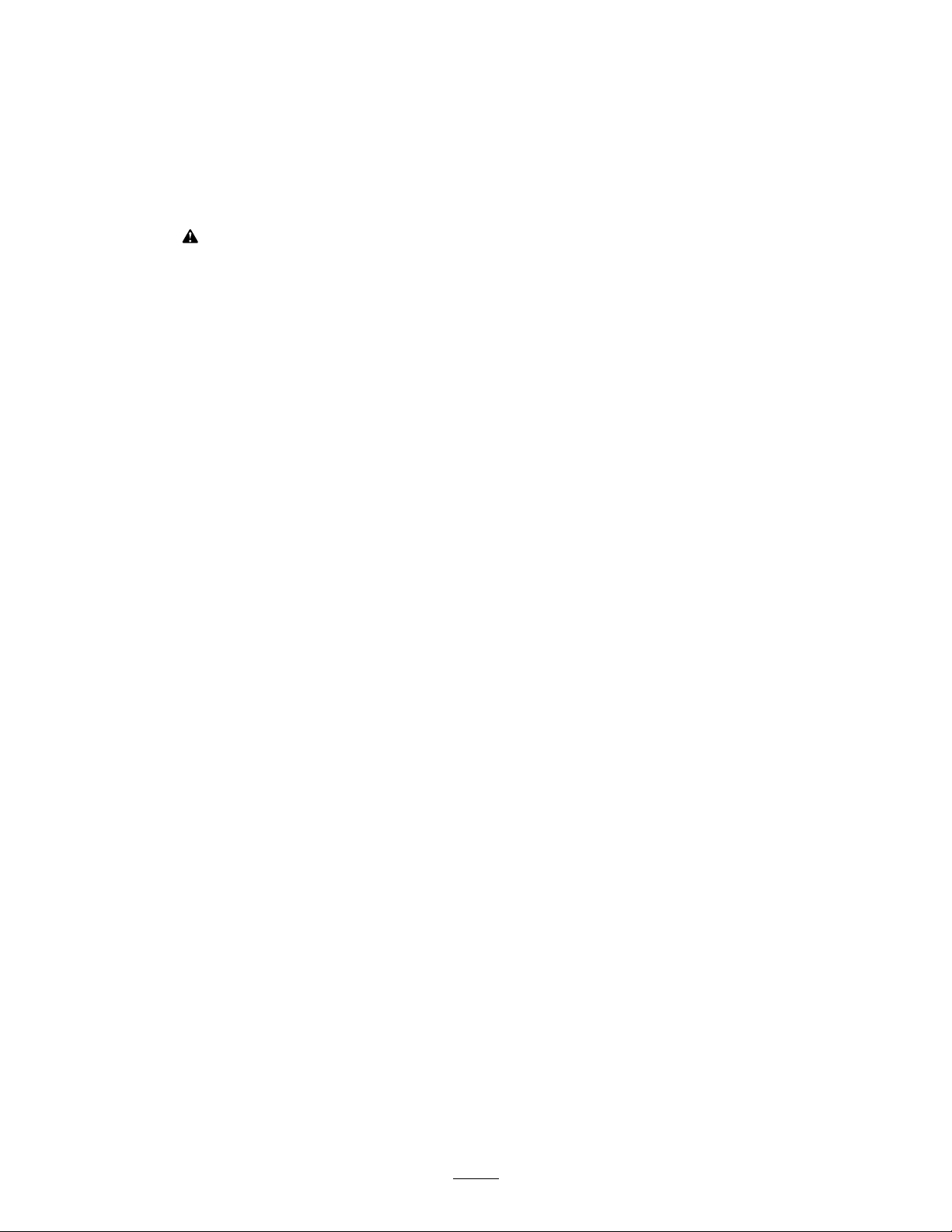

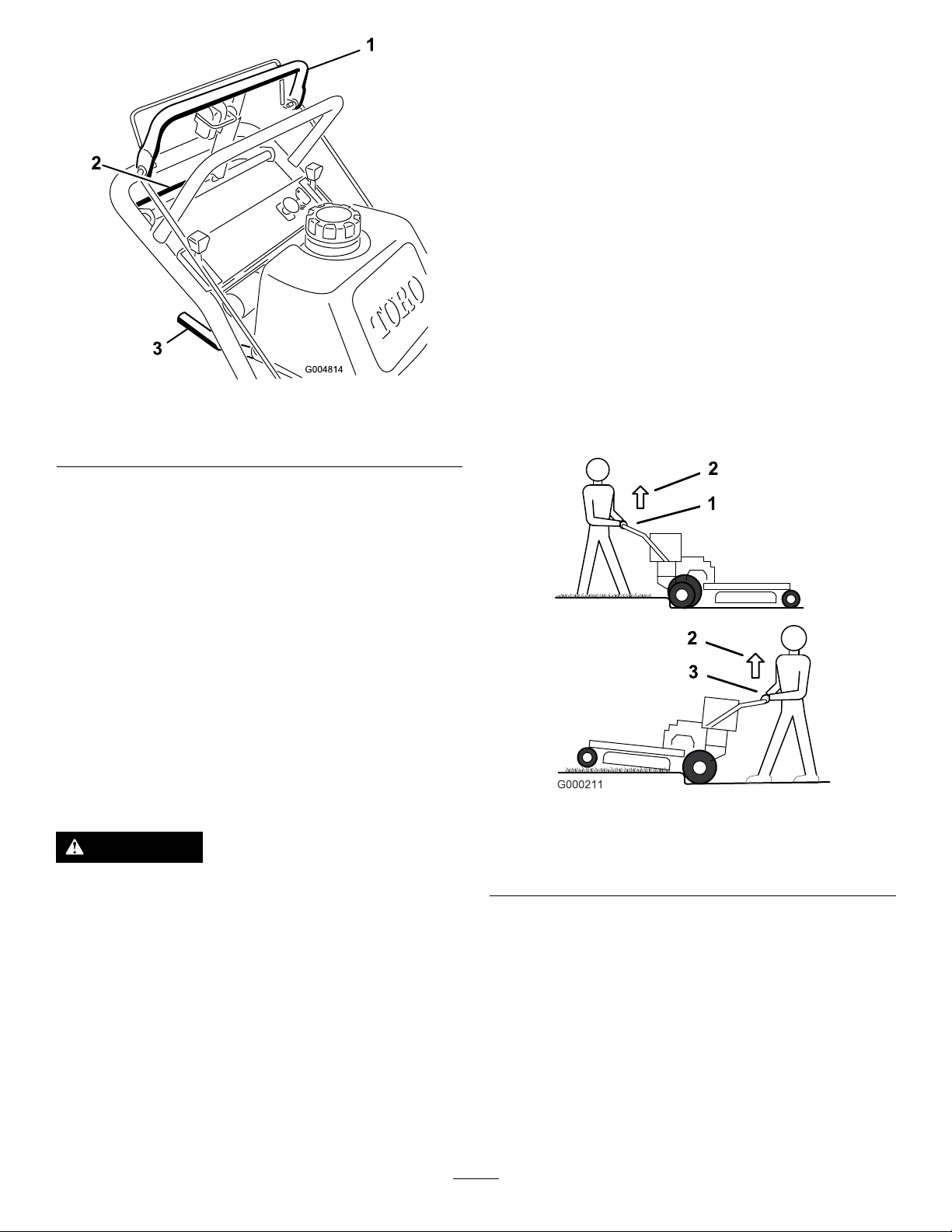

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis20degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan20degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

6

Page 7

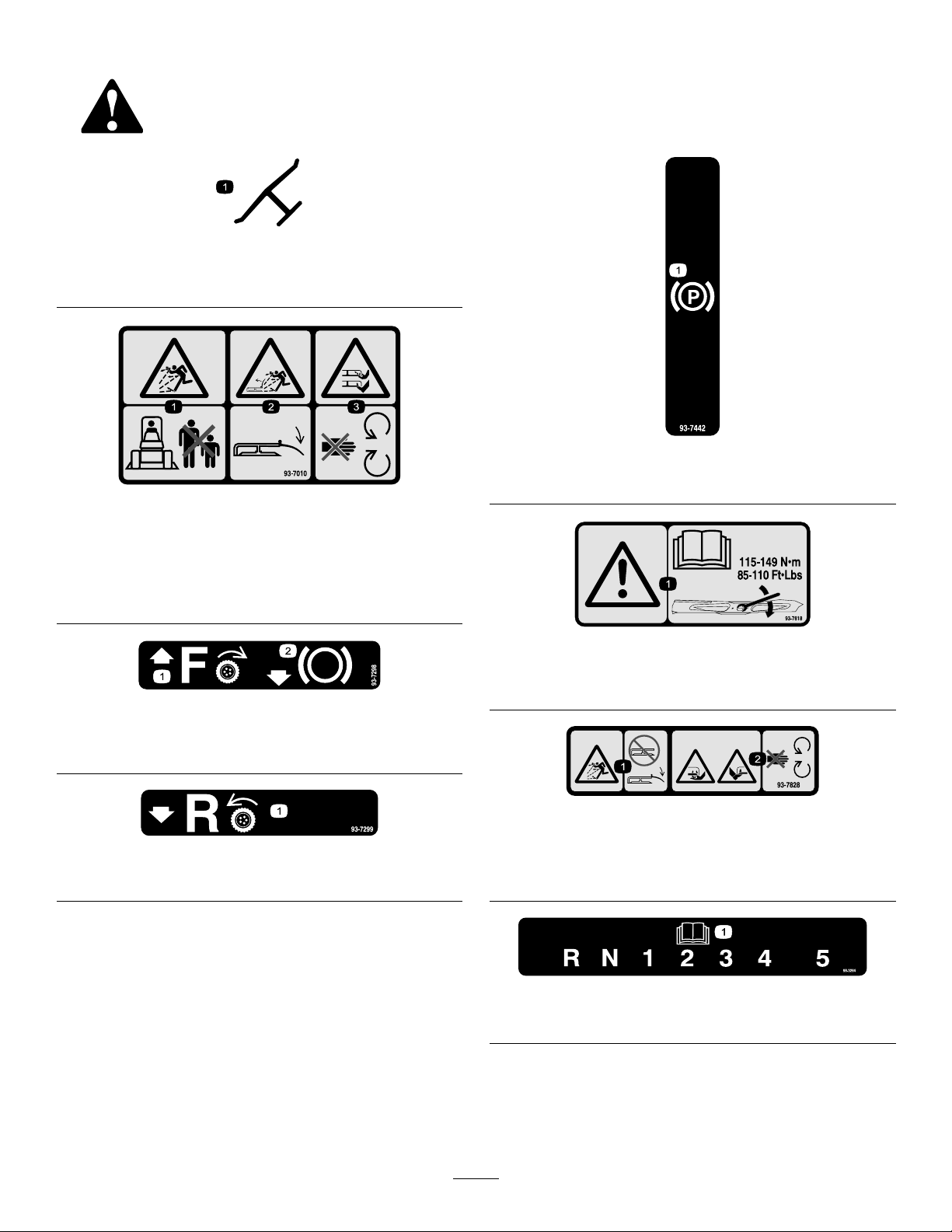

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

93-7010

93-7442

1.Parkingbrake

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—keepthedeectorinplace.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

93-7298

1.Tractiondrive—forward

2.Pulltobrake

93-7299

1.Tractiondrive—reverse

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N-m(85-110ft-lb).

93-7828

1.Thrownobjecthazard,mower—keepthedeectorinplace.

2.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

1.ReadtheOperator'sManual.

7

98-3264

Page 8

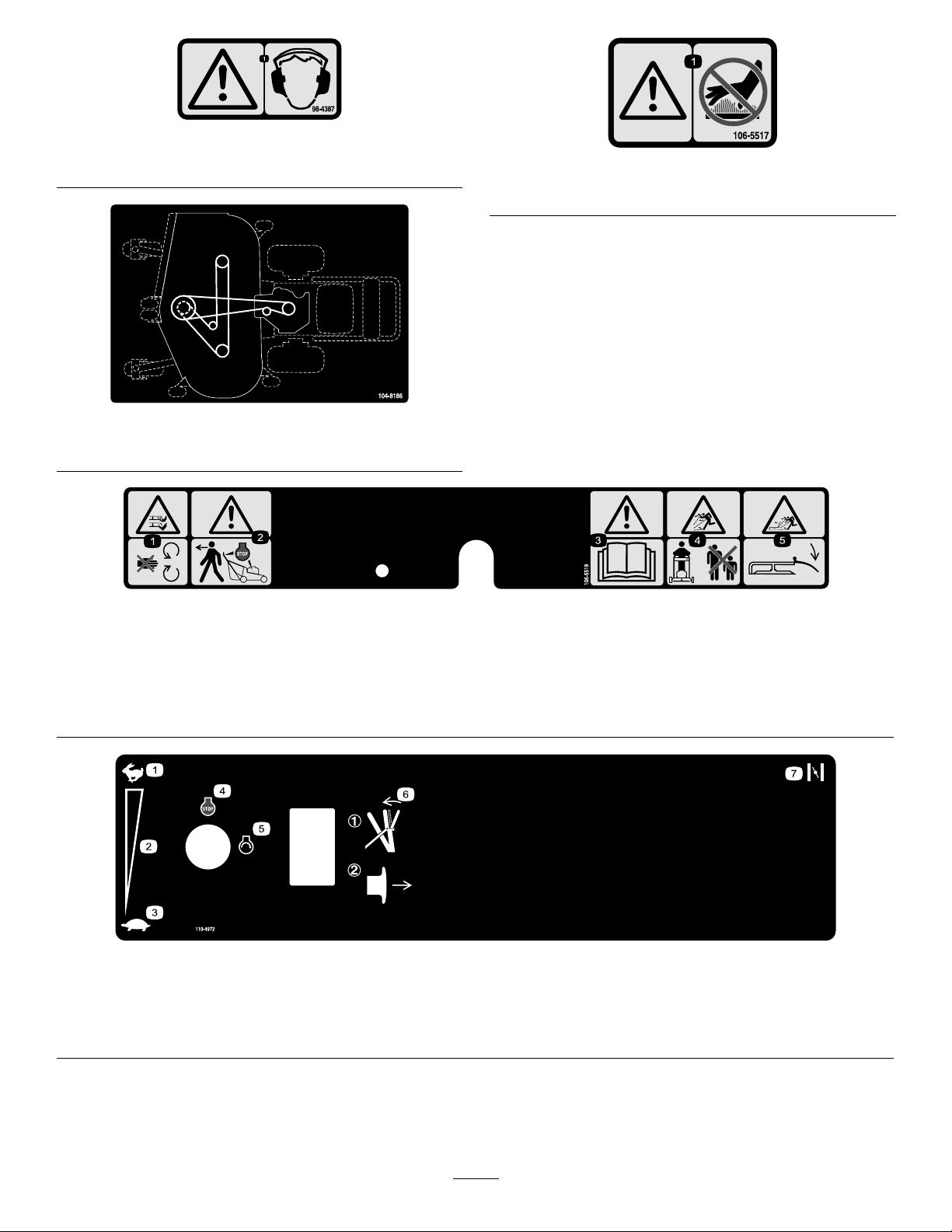

98-4387

1.Warning—wearhearingprotection.

106-5517

1.Warning—donottouchthehotsurface.

104-8186

48inchmower

106-5519

1.Severinghazardofhandorfoot,mower

blade—stayawayfrommovingparts.

2.Warning—releasethebarandensure

theenginehasstoppedbeforewalking

awayfromthemachine.

1.Fast

2.Continuousvariablesetting4.Engine—Stop

3.Warning—readtheOperator'sManual.

4.Thrownobjecthazard—keep

bystandersawayfromthemachine.

5.Thrownobjecthazard,raised

bafe—lowerthebafebeforeusing

themachine.

110-4972

3.Slow5.Engine—Start7.Choke

6.Engagebalethenpullout

onthePTOtoengagethe

blade.

8

Page 9

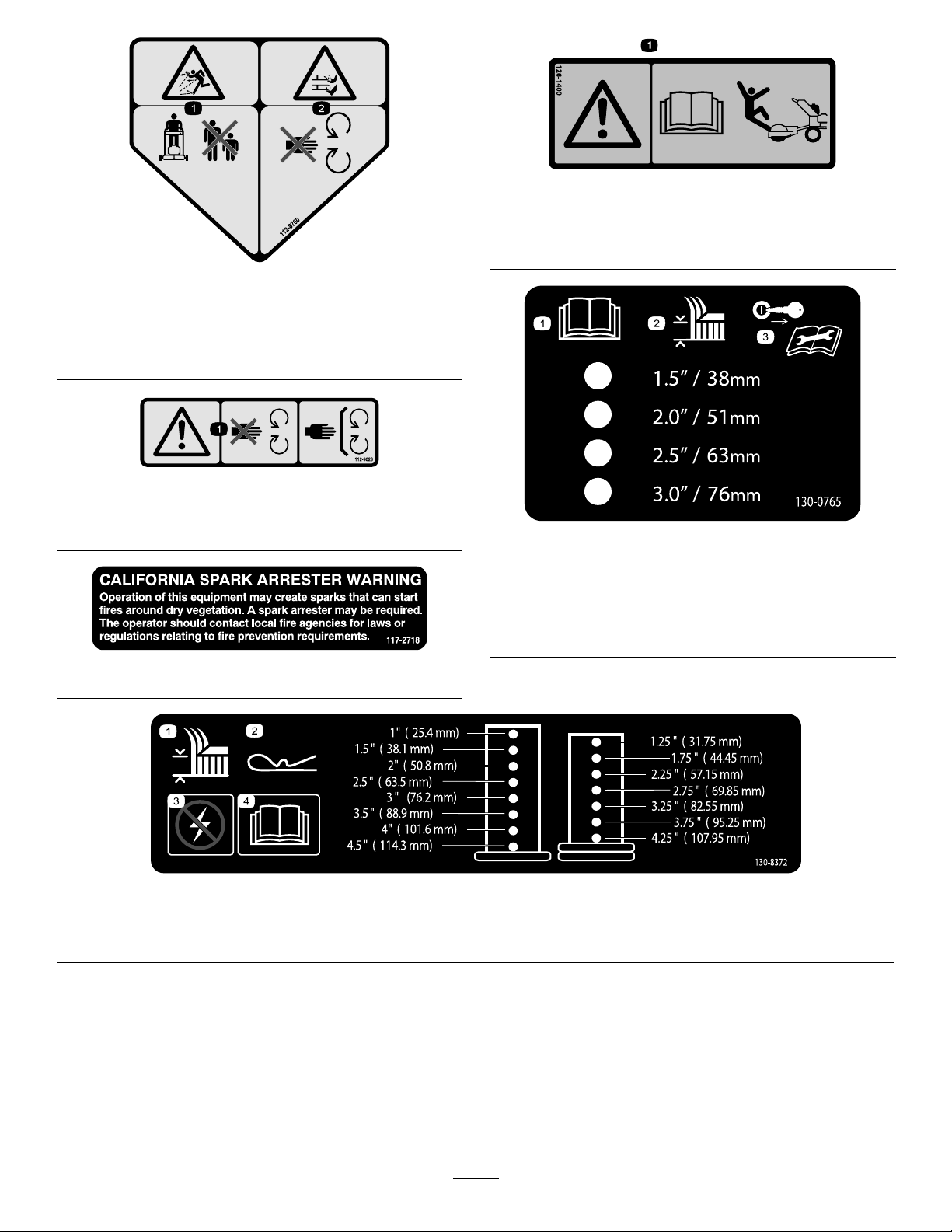

112-8760

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

112-9028

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

126-1400

1.Warning-ReadtheOperator’smanual.UseonlyTororiding

attachments.Useofotherridingattachmentsmaycreatea

hazardousconditionresultingininjury.

130-0765

1.ReadtheOperator's

Manual.

2.Height-of-cutselection

117–2718

130-8372

1.Height-of-cut3.Turnoffpowerbeforechangingheight-of-cut.

2.Hairpincotter

4.ReadtheOperator'sManual.

3.Removethekeyfrom

theignitionandreadthe

Operator'sManualbefore

permorningmaintenance.

9

Page 10

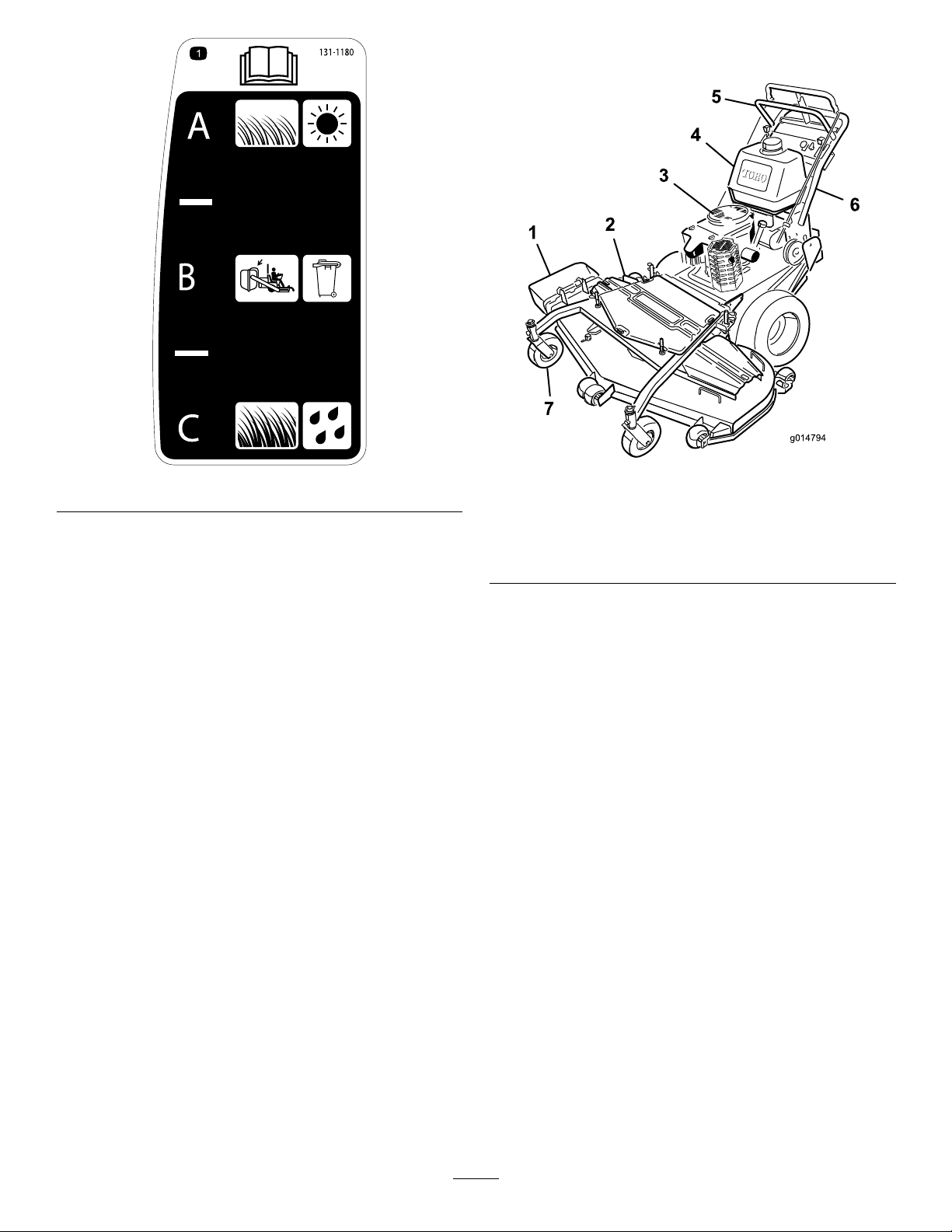

ProductOverview

g014794

131-1180

Figure4

1.Sidedischargechute5.Controls

2.Mowerdeck6.Handle

3.Recoilstarter

4.Gastank

7.Casterwheel

10

Page 11

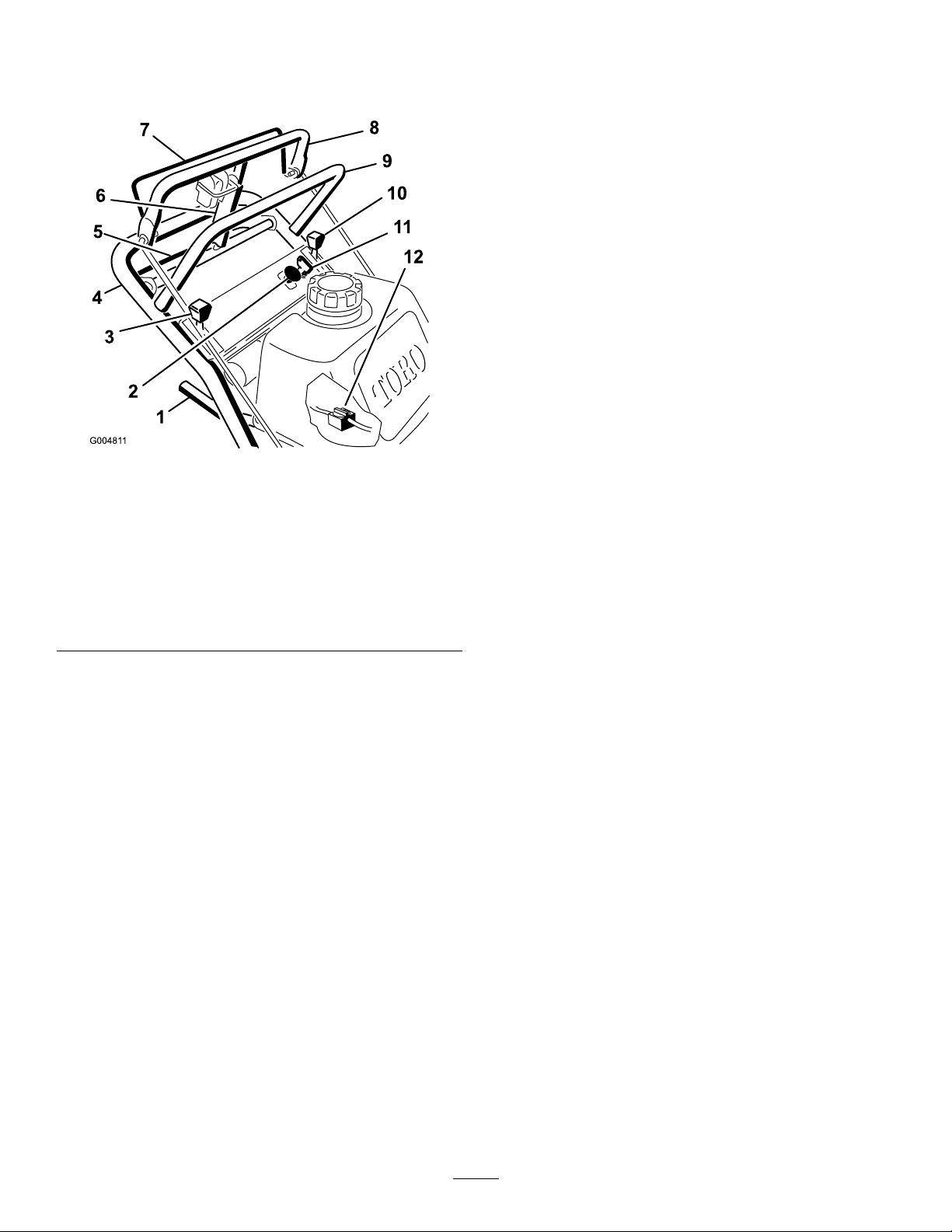

Controls

UpperControlBar

Becomefamiliarwithallthecontrols(Figure5)beforeyou

starttheengineandoperatethemachine.

Figure5

1.Gearshiftlever

2.Powertakeoffswitch

(PTO)

3.Chokecontrol

4.Lowerhandle10.Throttlecontrol

5.Lowercontrolbar11.Ignitionswitch

6.Parkingbrake

lever-releasedposition

7.Bladecontrolbail

8.Uppercontrolbar

9.Upperhandle

12.Fuelshut-offvalve

Shifttothedesiredgearandpushforwardontheupper

controlbartoengageforwardtractionoperationandpull

backtobrakeforwardmovement.Pullbackonrightsideof

uppercontrolbartoturnrightandleftsidetoturnleft.

LowerControlBar

Shifttransmissiontoreverseandsqueezethelowercontrol

barandhandletogethertoengagerearwardtractionassist

operation.

Parking-BrakeLever

Pullbackonuppercontrolbarandswingbrakeleverup

againsttheupperhandle(Figure5).

IgnitionSwitch

Thisswitchisusedinconjunctionwithrecoilstarterandhas

twopositions:RunandOff.

RecoilStarter

Pullrecoilstarterhandletostartengine(notshowninFigure

5).

Fuel-ShutoffValve

Closethefuel-shutoffvalvewhentransportingorstoring

mower.

ThrottleControl

Thethrottlecontrolhastwopositions:FastandSlow.

Choke

Usethechoketostartacoldengine.

Blade-ControlBail

Thebailisusedinconjunctionwiththepower-takeoffswitch

(PTO)toengagetheclutchtodrivethemowerblades.

Releasetheblade-controlbailtodisengagethemowerblades.

Power-TakeoffSwitch(PTO)

Thispullswitchisusedinconjunctionwiththebladecontrol

bailtoengagetheclutchtodrivethemowerblades.

Gear-ShiftLever

Thetransmissionhasveforwardspeeds,neutralandreverse,

andhasanin-lineshiftpattern.

Important:Donotshiftwhileunitismoving,as

transmissiondamagemayoccur.

11

Page 12

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

36inchMowers

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Widthwithdeectordown130cm(51–1/8inches)

Length

Heightwithhandleinlowest

position

Weight

210cm(82–3/4inches)

105cm(41–3/16inches)

267kg(588lb)

48inchMowers

Widthwithdeectordown161cm(63–1/2inches)

Length

Heightwithhandleinlowest

position

Weight

208cm(82inches)

105cm(41–3/16inches)

294kg(649lb)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

12

Page 13

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

ofvarnishdepositsinthefuelsystem,usefuelstabilizer

atalltimes.

FillingtheFuelTank

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundthefueltankcapandremovethecap.

Addunleadedregulargasolinetothefueltank,untilthe

levelis6to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisspaceinthetankallowsthe

gasolinetoexpand.Donotllthefueltankcompletely

full.

3.Installthefueltankcapsecurely.Wipeupanygasoline

thatmayhavespilled.

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,checktheoil

levelintheenginecrankcase;refertoCheckingOilLevelin

EngineMaintenance(page25)

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

PuttingSafetyFirst

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillagewith

soapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionerto

thegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.Tominimizethechance

Carefullyreadallthesafetyinstructionsanddecalsinthe

safetysection.Knowingthisinformationcouldhelpyouor

anybystandersavoidinjury.

Theuseofprotectiveequipmentforeyes,hearing,feetand

headisrecommended.

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator'searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Figure6

1.Warning—wearhearingprotection.

UsingtheParkingBrake

Stoponlevelground,disengagedrives,engageparkingbrake,

shutoffengine,andremovekey.Alwayssettheparkingbrake

whenyoustopthemachineorleaveitunattended.

13

Page 14

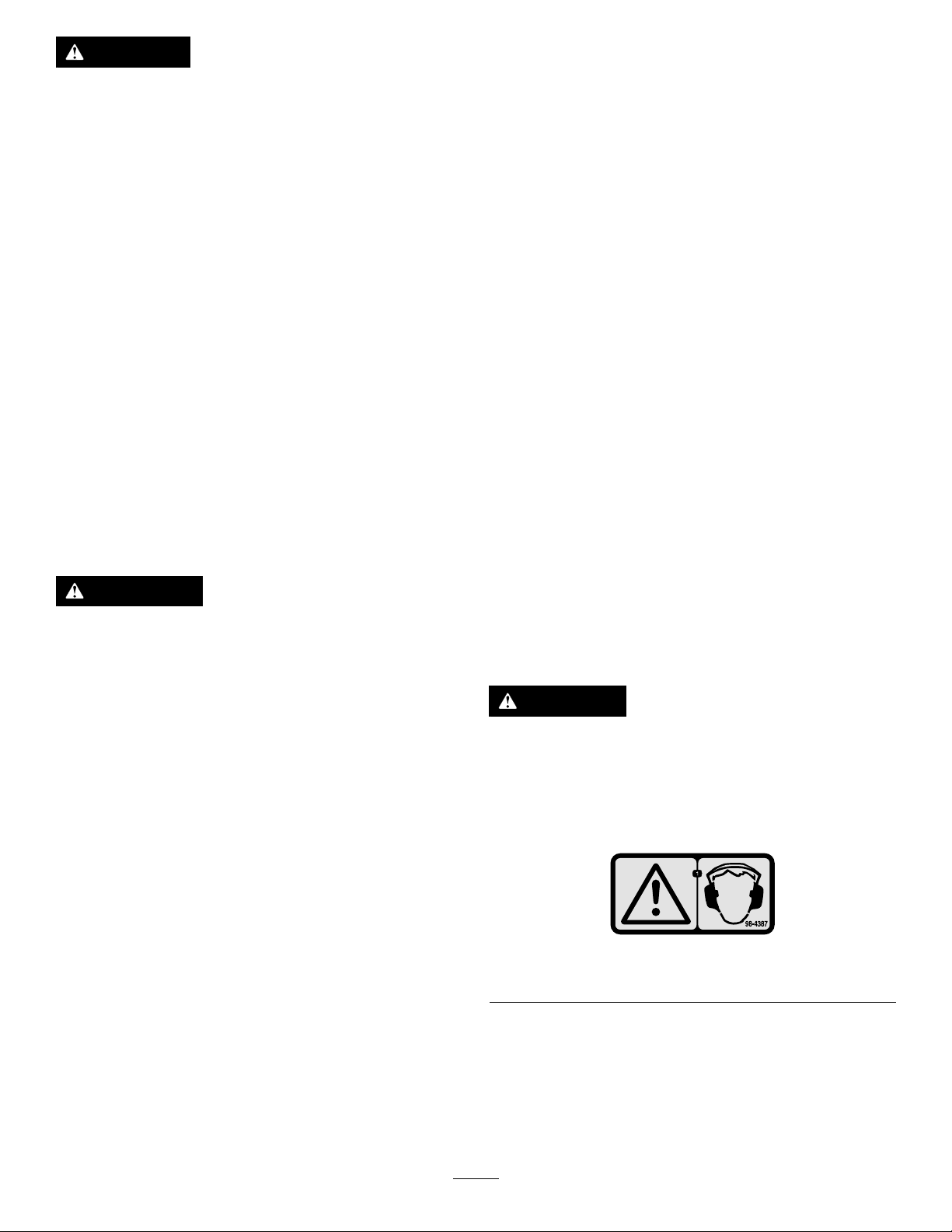

SettingtheParkingBrake

1.Pulltheuppercontrolbar(Figure7)rearwardandhold

itinthisposition.

2.Lifttheparkingbrakelock(Figure7)upandgradually

releasetheuppercontrolbar.Thebrakelockshould

stayintheset(locked)position.

Figure7

1.Uppercontrolbar3.Fixedbar

2.Parkingbrakelever-set

position

StoppingtheEngine

1.Movethethrottlelevertotheslowposition(Figure8).

2.Letengineidlefor30to60secondsbeforeturningthe

ignitionkeytooff.

3.Turntheignitionkeytooff(Figure8).

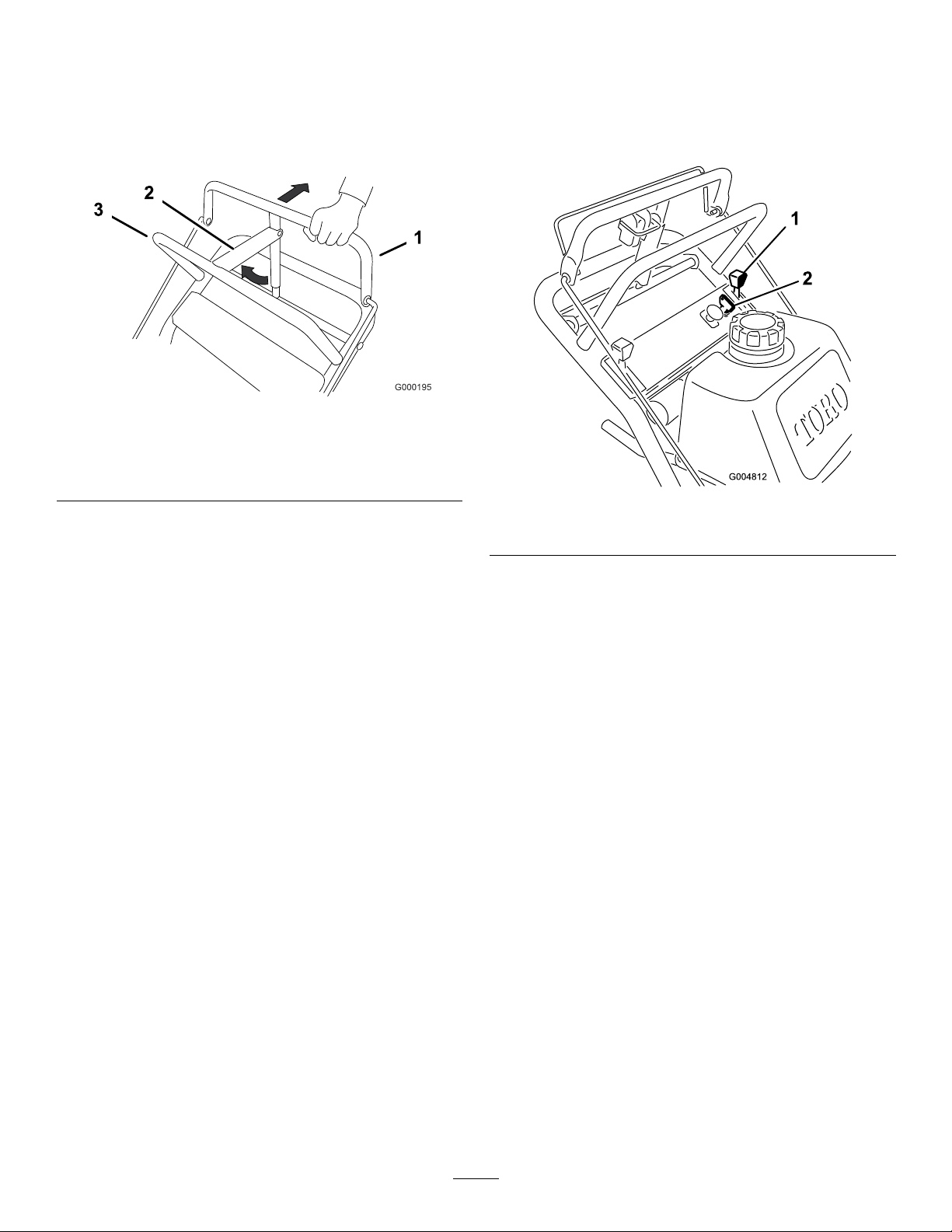

Figure8

ReleasingtheParkingBrake

1.Pullrearwardontheuppercontrolbar.

2.Lowertheparkingbrakelocktothereleasedposition.

3.Graduallyreleasetheuppercontrolbar.

StartingandStoppingthe Engine

StartingtheEngine

1.Makesurethatthesparkplugwire(s)areinstalledon

thesparkplug(s)andthefuelvalveisopen.

2.Movetheshiftlevertoneutral,settheparkingbrake,

andturnignitionkeytorun.

3.Movethethrottlecontroltothefastpositionandmove

thechokelevertotheonpositionbeforestartinga

coldengine.

Note:Awarmorhotengineusuallydoesnotrequire

anychoking.Tostartawarmengine,movethrottle

controltothefastposition.

4.Grasptherecoilstarterhandlermlyandpullout

untilpositiveengagementresults;thenpullthehandle

vigorouslytostarttheengineandallowtheropeto

recoilslowly .

Important:Donotpulltherecoilropetoits

limitorletgoofthestarterhandlewhentherope

ispulledoutbecausetheropemaybreakorthe

recoilassemblymaybecomedamaged.

1.Throttlelever2.Ignitionkey

4.Settheparkingbrakeandremovethekey.

5.Pullthewireoffofthesparkplug(s)topreventthe

possibilityofaccidentalstartingoftheenginebefore

storingthemachine.

6.Closethefuelshutoffvalvebeforestoringthemachine.

Important:Makesurethatthefuelshutoff

valveisclosedbeforetransportingorstoringthe

machine,asfuelleakagemayoccur.

OperatingtheMowerPower TakeOff(PTO)

Thepowertakeoffswitch(PTO)inconjunctionwiththe

bladecontrolbailengagesanddisengagespowertothe

electricclutchandmowerblades.

EngagingtheMowerBlades(PTO)

1.Releasetheuppercontrolbartostopthemachine

(Figure9).

2.Toengagetheblades,squeezethebladecontrolbail

againsttheuppercontrolbar(Figure9).

3.Pullthepowertakeoffswitch(PTO)upandreleaseit.

Note:Holdthebladecontrolbailagainsttheupper

controlbarwhileoperatingthemachine.

4.Repeattheproceduretoengagethemowerbladesif

thebladecontrolbailisreleased.

14

Page 15

Figure9

1.Uppercontrolbar

2.Bladecontrolbail

3.Powertakeoffswitch

(PTO)

DisengagingtheMowerBlades(PTO)

TestingtheSafety-InterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafetyinterlocksystembeforeyouusethemachine

eachtime.

Note:Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Settheparkingbrakeandstarttheengine;referto

StartingandStoppingtheEngine(page14).

2.Squeezetheblade-controlbailagainstuppercontrol

bar.

Note:Thebladesshouldnotrotate.

3.Thencontinueholdingtheblade-controlbailandpull

uponthebladecontrolswitchandrelease.Theclutch

shouldengageandthemowerbladesbeginrotating.

4.Releasetheblade-controlbail.

Note:Thebladesshouldstoprotating.

5.Withtheenginerunning,pullupthepowertakeoff

switch(PTO)andreleasewithoutholdingtheblade

controlbail.Thebladesshouldnotrotate.

Releasethebladecontrolbailtodisengagetheblades(Figure

9).

TheSafety-InterlockSystem

CAUTION

Ifthesafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafety-Interlock

System

Thesafety-interlocksystemisdesignedtopreventthemower

bladesfromrotatingunless:

•Thecontrolbailispressedagainsttheuppercontrolbar.

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

theFastpositionforbestmowingperformance.

DrivingForward

1.Togoforward,movetheshiftlevertoaforwardgear

(Figure10).

2.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake(page14).

3.Slowlypressontheuppercontrolbartomoveforward

(Figure10).

Togostraight,applyequalpressuretobothendsofthe

uppercontrolbar(Figure10).

Toturn,releasepressureontheuppercontrolbarside

inthedirectionyouwanttoturn(Figure10).

•Thepower-takeoffswitch(PTO)ispulledtotheOn

position.

Thesafety-interlocksystemisdesignedtostopthemower

bladesifyoureleasethebladecontrolbail.

15

Page 16

1.Uppercontrolbar

2.Lowercontrolbar

Figure10

3.Shiftlever

DrivingForwardupaCurb

1.Disengagethemowerblades.

2.Selecttherstgeartodrivethemachine.

3.Drivemachineuntilthecasterwheelscontactthecurb

(Figure11).

4.Liftthefrontofthemachinebypushingdownonthe

lowerhandle(Figure11).

5.Drivethemachineuntilthedrivewheelscontactthe

curb(Figure11).

6.Lowerthefrontofthemachine(Figure11).

Note:Bothdrivewheelsshouldcontactthecurband

casterwheelsstraight.

7.Atthesametimeengagethelowercontrolbarandlift

uponthelowerhandletodriveoverthecurb(Figure

10andFigure11).

Note:Liftinguponthelowerhandlewillassistdriving

themachineupacurbandnotspinthedrivewheels.

DrivingBackward

1.Togobackward,movetheshiftlevertoreversegear.

2.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake(page14).

3.Slowlysqueezethelowercontrolbarandlowerhandle

togethertomoverearward(Figure10).

UsingtheLowerControlBar

Thisprocedureisfordrivingupacurb.Thiscanbe

performedwhiledrivingforwardorbackward.

Note:Somecurbsdonotallowthereardrivetirestocontact

thecurb.Ifthishappens,drivethemachineupthecurbatan

angle.

WARNING

Abladecanbebentordamagedwhendrivingup

acurb.Piecesofbladethatmaybethrowncould

seriouslyinjureorkillyouorbystanders.

Donotrunbladeswhiledrivingupacurbforward

orbackward.

Figure11

1.Lowercontrolbarengaged

andmowerinreverse

2.Pulluptoassistmachine

3.Lowercontrolbarengaged

DrivingBackwardupaCurb

1.Disengagethemowerblades.

2.Selectreversetodrivethemachine.

andmowergoingforward

3.Drivethemachineuntildrivewheelscontactcurb

(Figure11).

Note:Bothdrivewheelsshouldcontactthecurband

casterwheelsstraight.

4.Atthesametimeengagelowercontrolbarandliftup

onthelowerhandle(Figure10andFigure12).

16

Page 17

Note:Liftinguponthelowerhandlewillassistdriving

themachineupacurbandnotspinthedrivewheels.

Figure12

StoppingtheMachine

Tostopthemachine,pullbackontheuppercontrolbar,

releasethebladecontrolbail,andturntheignitionkeyto

off.Alsosettheparkingbrakeifyouleavethemachine

unattended;refertoSettingtheParkingBrakeinSettingthe

ParkingBrake(page14).Remembertoremovethekeyfrom

theignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

1.Lowercontrolbar

(engaged)

2.Handle

TransportingMachines

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,petsorbystandersavoidinjury.

Totransportthemachine:

1.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Usethemetaltiedownloopsonthemachineto

securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropes(Figure13).

1.Tractionunittiedownloop

17

Figure13

Page 18

SideDischargingorMulching theGrass

Thismowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutthegrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthemower

becausethegrassdeectorroutesmaterialdown

towardtheturf.Ifthegrassdeectorisever

damaged,replaceitimmediately .

•Neverputyourhandsorfeetunderthemower.

•Nevertrytocleardischargeareaormower

bladesunlessyoureleasethebailandthepower

takeoff(PTO)isoff.Rotatetheignitionkeyto

Off.Alsoremovethekeyandpullthewire(s)off

thesparkplug(s).

AdjustingtheHeight-of-Cut

Theheight-of-cutcanbeadjustedfrom25to114mm(1to

4-1/2inches)in6mm(1/4inch)increments.Adjustments

aredonebyrelocatingthe4hairpincotterpinsindifferent

holelocationsandbyaddingorremovingspacers.

Note:Allheight-of-cutpinsneedatleast1spacerordamage

canoccurtothebushing.

Note:Allheight-of-cutpinscanuse2spacersmaximum.

1.Selectaholeintheheight-of-cutpostandthenumber

ofspacerscorrespondingtotheheight-of-cutdesired

(Figure14).

2.Usingthelifthandle,raisethesideofthedeckand

removethehairpincotter(Figure14).

3.Addorremovespacersifneededandthenalignthe

holesandinsertthehairpincotter(Figure14).

Note:Thespareheight-of-cutspacersmaybestored

onpostsandretainedbyahairpincotter.

Important:All4hairpincotterpinsmustbeinthe

sameholelocationandwiththecorrectnumberof

spacersforalevelcut.

Figure14

1.Carrierframe4.Spacers

2.Hairpincotter

3.Backheight-of-cutpost

5.Frontheight-of-cutpost

AdjustingtheAnti-Scalp Rollers

Theanti-scalprollersneedtobeadjustedintheproperhole

locationforeachheight-of-cutposition.Thereneedstobe10

mm(3/8inch)minimumclearanceabovetheground.

Note:Iftheanit-scalprollersareadjustedtoolow,itcan

causeexcesswearoftherollers.

1.Afteradjustingtheheight-of-cut,checktheanti-scalp

rollerssothatthereisaminimumof10mm(3/8

inch)clearanceabovetheground(Figure15,Figure

16,Figure17).

2.Ifanadjustmentisneeded,removethebolt,washers,

andnut(Figure15,Figure16,Figure17).

3.Selectaholepositionsothattheanti-scalprollersare

aminimumof10mm(3/8inch)offoftheground

(Figure15,Figure16,Figure17).

4.Installtheboltandnut(Figure15,Figure16,Figure

17).

18

Page 19

Figure17

36inchMowerDeck

Figure15

48inchMowerDecks

1.Mowerdeck4.Anti-scalprollers

2.Bolt5.Nut

3.Spacer

1.Mowerdeck4.Anti-scalprollers

2.Bolt5.Nut

3.Spacer

Note:Incertainmowingconditionsandterrain,a

mismatchofcuttingheightmaybeseen.Adjusting

theoutsideanti-scalprollerstotheminimumsetting

of10mm(3/8inch)willhelppreventthemower

deckcuttingtoolowontheoutsideandminimizethe

mismatch.

AdjustingtheHandleHeight

Thehandlepositioncanbeadjustedtomatchtheoperator's

heightpreference.

1.Removethehairpincotter,washer,andclevispin

securingthecontrolrodttingtotheidlerbracket

(Figure18).

Figure16

48inchMowerDecks

1.Mowerdeck4.Bushing

2.Bolt5.Anti-scalprollers

3.Spacer

6.Nut

Figure18

1.Controlrodandtting

2.Idlerbracket5.Hairpincotter

3.Clevispin6.Rodtting

19

4.Washer

Page 20

2.Loosentheupperangebolts(3/8x1inch)andthe

g012676

1 2

G012677

angenutsecuringthehandletotherearframe(Figure

19).

Figure20

Figure19

1.Upperhandle5.Uppermountinghole

2.Rearframe

3.Flangenut,(3/8inch)

4.Flangebolt,(3/8x1inch)

6.Lowermountingholes

7.Lowposition

8.Highposition

3.Removethelowerangebolts(3/8x1inch)andange

nutssecuringthehandletotherearframe(Figure19).

4.Pivotthehandletothedesiredoperatingpositionand

installthelowerangebolts(3/8x1inch)andthe

angenutsintothemountingholes.Tightenallofthe

angebolts.

5.Checkthecontrolbarforcorrectadjustment.Referto

AdjustingtheControlBarinthemaintenancesection.

6.Checktheparkingbrakeadjustment.RefertoChecking

theBrakesinthemaintenancesection.

AdjustingtheFlowBafe

1.Slot

2.Nut

PositioningtheFlowBafe

Thefollowingguresareonlyrecommendationsforuse.

Adjustmentswillvarybygrasstype,moisturecontent,and

heightofgrass.

Note:Iftheenginepowerdrawsdownandthemower

groundspeedisthesame,openupthebafe.

PositionA

Thisisthefullrearposition(seeFigure21).Thesuggested

useforthispositionisafollows:

•Useforshort,lightgrassmowingconditions.

•Useindryconditions.

•Forsmallergrassclippings.

•Propelsgrassclippingsfartherawayfromthemower.

Themowerdischargeowcanbeadjustedfordifferenttypes

ofmowingconditions.Positionthecamlockandbafeto

givethebestqualityofcut.

1.DisengagethePTO,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Toadjustthebafe,loosenthenut(Figure20).

4.Adjustthebafeandnutintheslottothedesired

dischargeowandtightenthenut.

Figure21

20

Page 21

PositionB

G012678

G012679

Usethispositionwhenbagging(Figure22).

UsingtheMid-SizeWeight

Weightsareinstalledoncertainmowerstoimprovebalance

andimproveperformance.Theweightscanbemovedor

removedtocreateoptimizedperformanceunderdifferent

mowingconditionsandforoperatorpreference(Figure24

orFigure25).

Thefollowingtableindicatesthepositionoftheweightas

installedatthefactory.

Figure22

PositionC

Thisisthefullopenposition.Thesuggesteduseforthis

positionisasfollows(Figure23):

•Useintall,densegrassmowingconditions.

•Useinwetconditions.

•Lowerstheenginepowerconsumption.

•Allowsincreasedgroundspeedinheavyconditions.

MowerDeckSizeNumberofweights

36inches

48inches2Rear

install

nonenone

Positionofthe

weight

•AnyrearweightmustberemovedwhenaTru-Track

Sulkyisinstalled.

•WhenaTru-Track

®

Sulkyisinstalledfrontweightsare

needed.ContactanAuthorizedServiceDealerforthe

correctquantityofweightsandplacement.

WARNING

Thefrontendofthemachinecanrapidlyriseup

whenthemowerisremoved.Thiscouldcause

seriousinjurytoyouorbystanders.

Supporttherearofthemachinewhenremovingthe

mowerformthecarrierframe.

®

Figure23

Figure24

Installingthefrontweight

1.Bolt3.Weight

2.Washer4.Nut

21

Page 22

Figure25

Installingtherearweight

1.Nut3.Washer

2.Weight4.Bolt

22

Page 23

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every200hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthesafetyinterlocksystem.

•Greasethecasterwheelsandcasterpivot.

•Checktheengineoillevel.

•Cleantheairintakescreen.

•Checkthebrakesonbothalevelsurfaceandslope.

•Inspecttheblades.

•Cleanthefoamaircleanerelement.

•GreasethePTO-beltidler.

•Greasethemower-deck-beltidler.

•Checkthepaperaircleanerelement.

•Checkthetirepressure

•Checkthetraction-drivebelt

•Checkthetransmissionbelt.

•Checkthemowerbelt.

•CheckthePTO-drivebelt.

•Changetheengineoil.

•Checkthesparkplugs.

•Adjusttheelectricclutch.

•Replacethepaperaircleanerelement.

•Changetheoillter.

•Replacethefuellter.

Every250hours

Every400hours

Beforestorage

•Greasethetransmissioncouplers(moreoftenindirtyordustyconditions).

•Greasethefrontwheelbearings(moreoftenindirtyordustyconditions).

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthesparkplugwiresfromthesparkplugsbeforeyoudo

anymaintenance.Setthewiresasidesothattheydonotaccidentallycontactthesparkplugs.

23

Page 24

Lubrication

GreasewithNo.2generalpurposelithiumbaseor

molybdenumbasegrease.

Note:Makesuretherearwheelgreasecapsare

removedbeforelubricatingrearwheels.

GreasingtheTransmission

GreasingtheMachine

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanthegreasettingswitharag.Makesuretoscrape

anypaintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pumpgrease

intothettingsuntilgreasebeginstooozeoutofthe

bearings.

5.Wipeupanyexcessgrease.

LubricatingtheCasterand WheelBearings

ServiceInterval:Beforeeachuseordaily

Every400hours

1.Lubricatethefrontcasterwheelbearingsandfront

pivots(Figure26).

Couplers

ServiceInterval:Every250hours

Lubricatethetransmissioncouplerslocatedinthebackof

themachine(Figure27).

Figure27

Figure26

2.Raisetherearofthemachineandusejackstandsto

supportthemachine.

3.Removetherearwheelandtireassemblies.

4.Removetherearwheelgreasecap.Lubricatetherear

wheelbearing(Figure26).

GreasingthePTO-Drive-Belt IdlerandMower-Deck-Belt Idler

ServiceInterval:Every50hours—GreasethePTO-belt

idler.

Every50hours—Greasethemower-deck-beltidler.

Greasetheidlerpulleypivots(Figure28orFigure29).

Note:Removethecarriercoverstoaccessthegreasetting

forthemowerdeck.

5.Installthegreasecap.

6.Installtherearwheelandtireassembly.

24

Page 25

g014655

Figure28

g014675

48inchMowerDeckshown

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Every25hours—Cleanthefoamair

cleanerelement.

Every50hours—Checkthepaperaircleanerelement.

Every200hours—Replacethepaperaircleaner

element.

Note:Servicetheaircleanermorefrequently(everyfew

operatinghours)iftheoperatingconditionsareextremely

dustyorsandy .

Important:Donotoilthefoamorpaperelement.

RemovingtheFoamandPaper

Elements

1.DisengagethePTOandsettheparkingbrake.

Figure29

36inchMowerDeckshown

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage(Figure30).

Figure30

1.Cover

2.Hoseclamp4.Foamelement

3.Paperelement

4.Unscrewthecoverknobsandremovetheaircleaner

cover(Figure30).

5.Unscrewthehoseclampandremovetheaircleaner

assembly(Figure30).

6.Carefullypullthefoamelementoffthepaperelement

(Figure30).

25

Page 26

CleaningtheFoamAir-CleanerElement

1.Washthefoamelementinliquidsoapandwarmwater.

Whentheelementisclean,rinseitthoroughly .

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifitistorn

orworn.

ServicingthePaperAir-Cleaner

Element

1.Donotcleanthepaperlter,replaceit(Figure30).

2.Inspecttheelementfortears,anoilylm,ordamageto

therubberseal.

3.Replacethepaperelementifitisdamaged.

InstallingtheFoamandPaperElements

Important:Topreventenginedamage,alwaysoperate

theenginewiththecompletefoamandpaperaircleaner

assemblyinstalled.

1.Carefullyslidethefoamelementontothepaperair

cleanerelement(Figure30).

2.Placetheaircleanerassemblyontotheaircleanerbase

andsecureitwiththe2wingnuts(Figure30).

3.Placetheaircleanercoverintopositionandtighten

thecoverknob(Figure30).

ServicingtheEngineOil

ServiceInterval/Specication

ServiceInterval:Beforeeachuseordaily—Checktheengine

oillevel.

Aftertherst8hours—Changetheengineoil.

Every100hours—Changetheengineoil.

Figure31

CheckingtheEngine-OilLevel

1.Parkthemachineonalevelsurface.

2.DisengagethePTOandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.Cleanaroundtheoildipstick(Figure32)sothatdirt

cannotfallintothellerholeanddamagetheengine.

Figure32

1.Oildipstick

2.Fillertube

Every200hours—Changetheoillter.

Note:Changetheoilmorefrequentlywhentheoperating

conditionsareextremelydustyorsandy.

OilType:Detergentoil(APIserviceSF,SG,SH,SJorSL)

CrankcaseCapacity:58ounces(1.7liter)withthelter

removed;51ounces(1.5liter)withoutthelterremoved

Viscosity:Refertothetable(Figure31).

5.Unscrewtheoildipstickandwipetheendclean(Figure

32).

6.Slidetheoildipstickfullyintothellertube,butdonot

threadontotube(Figure32).

7.Pullthedipstickoutandlookattheend.Iftheoillevel

islow,slowlypouronlyenoughoilintothellertube

toraisetheleveltotheFullmark.

Important:Donotoverllthecrankcasewithoil

andruntheengine;enginedamagecanresult.

26

Page 27

ChangingtheEngineOil

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

2.DisengagethePTOandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.Slidethedrainhoseovertheoildrainvalve.

5.Placeapanbelowthedrainhose.Rotateoildrainvalve

toallowoiltodrain(Figure33).

6.Whenoilhasdrainedcompletely,closethedrainvalve.

7.Removethedrainhose(Figure33).

1.Oillter

Figure34

2.Adapter

Note:Disposeoftheusedoilatarecyclingcenter.

Figure33

1.Oildrainvalve2.Oildrainhose

3.Applyathincoatofnewoiltotherubbergasketon

thereplacementlter(Figure34).

4.Installthereplacementoilltertothelteradapter,

turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional3/4turn(Figure34).

5.Fillthecrankcasewiththepropertypeofnewoil;refer

toServicingtheEngineOil.

6.Runtheengineforabout3minutes,stoptheengine,

andcheckforoilleaksaroundtheoillteranddrain

valve.

7.Checktheengineoillevelandaddoilifneeded.

8.Wipeupanyspilledoil.

8.Slowlypourapproximately80%ofthespeciedoil

intothellertube(Figure32).

9.Checktheoillevel;refertoCheckingtheEngineOil

Level.

10.SlowlyaddtheadditionaloiltobringittotheFull

mark.

ChangingtheOilFilter

Note:Changetheoilltermorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

2.Removetheoldlter(Figure34).

27

Page 28

ServicingtheSparkPlugs

1

ServiceInterval:Every100hours—Checkthesparkplugs.

Ensurethattheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkplugsanda

gappingtool/feelergaugetocheckandadjusttheairgap.

Installanewsparkplugsifnecessary.

Type:Champion®RCJ8YorequivalentAirGap:0.75mm

(0.030inch)

RemovingtheSparkPlugs

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Disconnectthewiresfromthesparkplugs(Figure35).

Figure36

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

Important:Alwaysreplacethesparkplugswhen

ithaswornelectrodes,anoilylmonit,orhas

cracksintheporcelain.

3.Checkthegapbetweenthecenterandsideelectrodes

(Figure36).Bendthesideelectrode(Figure36)ifthe

gapisnotcorrect.

InstallingtheSparkPlugs

1.Installthesparkplugsandthemetalwasher.Ensure

thattheairgapissetcorrectly.

2.Tightenthesparkplugsto22N-m(16ft-lb).

3.Connectthewirestothesparkplugs(Figure36).

Figure35

1.Spark-plugwire/sparkplug

4.Cleanaroundthesparkplugstopreventdirtfrom

fallingintotheengineandpotentiallycausingdamage.

5.Removethesparkplugsandthemetalwashers.

CheckingtheSparkPlugs

1.Lookatthecenterofthesparkplugs(Figure36).If

youseelightbrownorgrayontheinsulator,theengine

isoperatingproperly.Ablackcoatingontheinsulator

usuallymeansthattheaircleanerisdirty.

2.Ifneeded,cleanthesparkplugwithawirebrushto

removecarbondeposits.

28

Page 29

FuelSystem

Maintenance

ReplacingtheFuelFilter

ServiceInterval:Every200hours

Neverinstalladirtylterifitisremovedfromthefuelline.

DrainingtheFuelTank

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

1.Parkthemachineonalevelsurface,toensurethefuel

tankdrainscompletely .Thendisengagethepowertake

off(PTO),settheparkingbrake,turntheignitionkey

totheOffposition,andremovethekey .

2.Closethefuelshut-offvalveatthefueltank(Figure37).

3.Squeezetheendsofthehoseclamptogetherandslide

itupthefuellineawayfromfuellter(Figure37).

Note:Notehowthefuellterisinstalled.

Note:Wipeupanyspilledfuel.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Closefuelshut-offvalveatfueltank(Figure37).

Note:Removethefuellinefromthefuelvalvethatis

closesttotheengine.

4.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure38).

4.Pullthefuellineoffthefuellter(Figure37).Open

thefuelshut-offvalveandallowthegasolinetodrain

intoagascanordrainpan.

Note:Nowisthebesttimetoinstallanewfuellter

becausethefueltankisempty.RefertoReplacingthe

FuelFilter.

5.Installthefuellineontothefuellter.Slidethehose

clampclosetothevalvetosecurethefuelline.

Figure37

Figure38

1.Hoseclamp3.Filter

2.Fuelline

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclampscloseto

thelter.

7.Openfuelshut-offvalveatfueltank(Figure37).

8.Checkforfuelleaksandrepairifneeded.

1.Fuelshut-offvalve2.Clamp

29

Page 30

ElectricalSystem

DriveSystem

Maintenance

ServicingtheFuse

Theelectricalsystemisprotectedbyafuse.Itrequiresno

maintenance.Ifthefuseblows,checkthecomponentor

circuitformalfunctionorashort.Toreplacethefuse,pull

outonthefuse(Figure39)toremoveorreplaceit.

Figure39

Maintenance

AdjustingtheControlBar

1.Checkthegapbetweenuppercontrolbarandxed

barwithwheeldrivefullyengaged.Thegapshouldbe

approximately25-32mm(1to1-1/4inch)(Figure40).

Note:Theuppercontrolbarandxedbarmustbe

parallelwhentheuppercontrolbarisintheengaged,

drive,neutral,orbrakepositions.

1.Fuse,7.5amp,bladetype

Figure40

1.Uppercontrolbar4.Handle

2.Parkingbrakelever

3.Fixedcontrolbar

2.Checktheoperation.Ifadjustmentisrequired,remove

thehairpincotter,washer,andclevispinsecuringthe

controlrodttingtoidlerbracket(Figure41).

3.Threadtherodttingupordownontheroduntilthe

properpositionisattainedandinstalltherodtting

totheidlerbracketwiththeclevispin,washer,and

hairpincotter.

5.25-32mm(1to1-1/4inch)

gap

30

Page 31

Replacingthe Caster-Wheel-ForkBushings

Thecasterwheelforksaremountedinbushingspressedinto

thetopandbottomofthecarrierframemountingpivot

tubes.Tocheckthebushings,movethecasterforksbackand

forthandside-to-side.Ifacasterforkisloose,thebushings

arewornandmustbereplaced.

1.Raisethecuttingunitsothatthecasterwheelsareoff

oftheoor,thensupportthefrontofthemowerwith

jackstands.

Figure41

1.Controlrodandtting

2.89mm(3-1/2inch)

3.Idlerbracket

4.Clevispin

5.Washer

6.Hairpincotterpin

7.Rodtting

8.HoleF

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)—Checkthetirepressure

Checkthepressureatthevalvestem(Figure42).

Maintaintheairpressureinthereartiresat12-14psi(83-97

kPa).Uneventirepressurecancauseanunevencut.

Note:Thefronttiresaresemi-pneumatictiresanddonot

requireairpressuremaintenance.

2.Removethelockingpinandspacer(s)fromthetopof

thecasterwheelfork(Figure43).

Figure43

1.Lockingpin

2.Spacers4.Casterwheel

3.Carrierframepivottube

Figure42

3.Pullthecasterwheelforkoutofthemountingtube,

leavingthespacer(s)onthebottomofthefork.

Rememberthelocationofthespacersoneachforkto

ensurecorrectinstallation,andtomaintainaleveldeck.

4.Insertapinpunchintothemountingtubeandcarefully

driveoutthebushings(Figure44).Cleantheinsideof

themountingtube.

31

Page 32

Figure44

1.MountingTube2.Bushing

5.Greasetheinsideandoutsideofthenewbushings.Use

ahammerandatplatetocarefullydrivethebushings

intothepivottubes.

6.Inspectthecasterwheelforkforwearandreplaceif

necessary(Figure43).

7.Slidethecasterwheelforkthroughthebushingsinthe

mountingtube.Replacethespacer(s)ontotheforkand

securewiththeretainingring(Figure43).

Important:Theinsidediameterofthebushings

maycollapseslightlywheninstalled.Ifthecaster

wheelforkdoesnotslideintothenewbushings,

reambothbushingstoaninsidediameterof29

mm(1.126inch).

8.Greasethettingonthecarrierframepivottubesusing

No.2generalpurposelithiumbaseormolybdenum

basegrease.

ServicingtheCasterWheel andBearings

Figure45

1.Locknut

2.Cap

3.Rollerbearing6.Bushing

2.Removeonebushing,thenpullthespannerbushing

androllerbearingoutofthewheelhub(Figure45).

3.Removetheotherbushingfromthewheelhuband

cleananygreaseanddirtfromthewheelhub(Figure

45).

4.Inspecttherollerbearing,bushings,spannerbushing,

andinsideofthewheelhubforwear.Replaceany

defectiveorwornparts(Figure45).

5.Toassemble,placeonebushingintothewheelhub.

Greasetherollerbearingandspannerbushingandslide

themintothewheelhub.Placethesecondbushing

intothewheelhub(Figure45).

6.Installthecasterwheelintothecasterforkandsecure

withthewheelboltandlocknut.Tightenthelocknut

untilthespannerbushingbottomsagainsttheinsideof

thecasterforks(Figure45).

7.Greasethettingonthecasterwheel.

4.Spannerbushing

5.Wheel

Thecasterwheelsrotateonarollerbearingsupportedbya

spannerbushing.Ifthebearingiskeptwelllubricated,wear

willbeminimal.Failuretokeepthebearingwelllubricated

willcauserapidwear.Awobblycasterwheelusuallyindicates

awornbearing.

1.Removethelocknutandwheelboltholdingthecaster

wheeltothecasterfork(Figure45).

AdjustingtheElectricClutch

ServiceInterval:Every100hours

Theclutchisadjustabletoensureproperengagementand

properbraking.

1.Inserta0.381–0.533mm(0.015–0.021inch)feeler

gaugethroughoneinspectionslotinthesideofthe

assembly.Makesureitisbetweenthearmatureand

therotorfrictionsurfaces.

2.Tightenthelocknutsuntilthereisaslightbindingon

thefeelergaugebutitcanbemovedeasilywithinthe

airgap(Figure46).

3.Repeatthisfortheremainingslots.

32

Page 33

4.Checkeachslotagainandmakeslightadjustmentsuntil

thefeelergaugebetweentherotorandarmaturewith

veryslightcontactbetweenthem.

Figure46

1.Adjustingnut3.Feelergauge

2.Slot

CoolingSystem

Maintenance

CleaningtheAir-IntakeScreen

ServiceInterval:Beforeeachuseordaily

Removeanybuild-upofgrass,dirt,orotherdebrisfromthe

cylinderandcylinderheadcoolingns,airintakescreenon

ywheelend,andcarburetor-governorleversandlinkage.

Thiswillhelpensureadequatecoolingandcorrectengine

speedandwillreducethepossibilityofoverheatingand

mechanicaldamagetotheengine.

33

Page 34

BrakeMaintenance

ServicingtheBrakes

ServiceInterval:Beforeeachuseordaily—Checkthebrakes

onbothalevelsurfaceandslope.

Alwayssettheparkingbrakewhenyoustopthemachine

orleaveitunattended.Iftheparkingbrakedoesnothold

securely,anadjustmentisrequired.

CheckingtheBrakes

1.Parkthemachineonalevelsurface,disengagethePTO.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Applytheparkingbrake.Thewheelsmustlockwhen

youtrytopushthemachineforward.

4.Ifthewheelsdonotlock,adjustthebrakes.Referto

AdjustingtheBrakes.

5.Releasethebrakeandpressuppercontrolbarvery

lightly,approximately13mm(1/2inch).Thewheels

shouldrotatefreely ,ifnot;refertoAdjustingthe

Brakes.

Figure47

1.Hairpincotterandwasher5.HoleF

2.Trunnion6.Initialadjustment-32mm

(1-1/4inch)

3.Brakelever7.Rod

4.Wingnut

AdjustingtheBrakes

Thebrakeleverisontheuppercontrolbar.Iftheparking

brakedoesnotholdsecurely,anadjustmentisrequired.

Note:Fortheinitialadjustment,adjustthewingnutuntilit

is1-1/4inchesfromthetopoftherod(Figure47).

1.Parkthemachineonalevelsurface,disengagethe

PTO,andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Checkthebrakebeforeyouadjustit;refertoChecking

theBrakes.

4.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake.

5.Toadjustthebrakeremovethehairpincotterand

washerfromthebrakeleverandtrunnion(Figure47).

6.Rotatethewingnutclockwisetoincreasethebraking

pressure.

7.Rotatethewingnutcounterclockwisetodecreasethe

brakingpressure.

8.InstallthetrunnionintoholeF(Figure47).Tighten

thewingnut.

9.Securetrunniontobrakeleverwithwasherandhair

pincotter(Figure47).

10.Checkthebrakeoperationagain;refertoChecking

theBrakes.

Important:Withtheparkingbrakereleased,the

rearwheelsmustrotatefreelywhenyoupushthe

mower.Ifbrakeactionandfreewheelrotation

cannotbeachievedcontactyourservicedealer

immediately.

34

Page 35

BeltMaintenance

5.Disconnecttheclutchwireconnectorfromthewire

harness.

ReplacingtheTraction-Drive Belt

ServiceInterval:Every50hours/Monthly(whichever

comesrst)—Checkthetraction-drive

belt

Lookforcracks,wear,andsignsofoverheating.

1.Removethetopboltsecuringidlersupportandidler

brackettorearframe(Figure48).

Figure48

1.Topbolt4.Bottombolt

2.Idlerbracket5.Traction-drivebelt

3.Idlersupport

6.Disconnecttheclutchretainerfromtheenginedeck

(Figure49).

Figure49

1.Transmissionbelt

2.Idlerpulley6.Pivotbolt

3.Clutchretainer

4.Tensionspring8.Enginedeck

7.Unhookthetensionspringfromthesideoftheframe

(Figure49).

8.Loosenthepivotboltenoughtoremovethetraction

beltfromthedrivepulleyandclutch.

5.Clutchwireconnector

7.Drivepulley

2.Loosenbottom2mountingscrewsenoughtoallow

belttopassbetweendrivepulleyandidlersupport

(Figure48).

3.Raisethewheelofftheground,toallowthebelttobe

removed,andremovethebelt.

4.Installanewbelt.

5.Installthetopboltsecuringtheidlersupportandidler

brackettotherearframe(Figure48).

6.Tightenthebottom2mountingscrewsenoughto

allowthebelttopassbetweenthedrivepulleyandthe

idlersupport(Figure48).

ReplacingtheTransmission Belt

ServiceInterval:Every50hours

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.RemovethePTOdrivebelt.RefertoReplacingthe

PTODriveBeltintheBeltMaintenance(page35).

4.Raisethefrontofthemachineandholdwithjack

stands.

9.Installthenewbeltaroundtheclutchanddrivepulley.

10.Torquepivotboltto47-54N-m(35-40ft-lb).

11.Installthetensionspringbetweentheidlerarmand

framebracket(Figure49).

12.Installtheclutchretainertotheenginedeck(Figure49).

13.Connecttheclutchwireconnectortothewireharness.

14.InstallthePTOdrivebelt.

ReplacingtheMowerBelt

ServiceInterval:Every50hours

Squealingwhenthebeltisrotating,bladesslippingwhen

cuttinggrass,frayedbeltedges,burnmarksandcracksare

signsofaworndeckbelt.Replacethedeckbeltifanyof

theseconditionsareevident.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Unlatchandremovethecarrierframecover.

4.Unlatchandremovethebeltcovers.

5.RemovethePTOdrivebelt.RefertoReplacingthe

PTODriveBelt.

35

Page 36

6.Disconnecttheidlerarmspringtorelievetensionon

g014676

theidlerarmandidlerpulley,thenremovetheworn

mowerbelt(Figure50orFigure51).

7.Installthenewmowerbeltaroundthe2outsidespindle

pulleys,theidlerpulley,andinthelowergrooveofthe

doublespindlepulley(Figure50orFigure51).

8.Connecttheidlerarmspring(Figure50orFigure51).

9.InstallthePTOdrivebelt.RefertoReplacingthePTO

DriveBelt.

10.Adjustthebeltguidean3mm(1/8inch)fromthebelt

(Figure50orFigure51).

11.Installthebeltcoversontothecuttingunitandsecure

thelatches.

12.Installthecarrierframecoverontothecuttingunitand

securethelatches.

Figure51

36inchMowerDeckshown

1.Mower-deckbelt4.Idler-armspring

2.PTO-drivebelt

3.Drive-beltpulley

5.Drive-beltpulley

1.Outsidepulley

2.PTO-drivebelt

3.Idlerarmspring

Figure50

48inchMowerDeckshown

4.Mower-deckbelt

5.Beltguide

6.Centerspindlepulley

ReplacingthePTO-DriveBelt

ServiceInterval:Every50hours

Squealingwhenthebeltisrotating,bladesslippingwhen

cuttinggrass,frayedbeltedges,burnmarksandcracksare

signsofaworndrivebelt.Replacethedrivebeltifanyof

theseconditionsareevident.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Unlatchandremovethecarrierframecover.

4.Unlatchandremovethebeltcovers.

5.Removetheheatshieldfromtheenginedeckand

carrierframe.

6.Rollthebeltoffthecenterpulleyonthemowerdeck

(Figure52).

RefertoFigure53torollthebeltoffleftpulleyfora

36inchmowerdeck.

Note:Usecautionwhenremovingthebeltastension

willincreasebecauseofthespringloadedidlerpulley.

7.Removethebeltfromtheenginepulleyandthespring

loadedidlerpulley(Figure52).

RefertoFigure53toremovethebeltfromthe36inch

mowerdeckpulleys.

8.Installthenewbeltontotheenginepulleyandspring

loadedidlerpulley(Figure52).

36

Page 37

9.Rollthebeltontothecenterpulleyonthemowerdeck

g014677

(Figure52).

RefertoFigure53torollthenewbeltontotheleft

pulleyfora36inchmowerdeck.

Note:Usecautionwheninstallthebeltastensionwill

increasebecauseofthespringloadedidlerpulley.

10.Installtheheatshieldtotheenginedeckandcarrier

frame.

11.Adjustthebeltguidean3mm(1/8inch)fromthebelt

for48inchmowerdecks(Figure52).

12.Installthebeltcoversontothecuttingunitandsecure

thelatches.

13.Installthecarrierframecoverontothecarrierframe

andsecurethelatches.

Figure53

36inchMowerDeckshown

Figure52

48inchMowerDeckshown

1.PTO-drive-beltguide4.PTOengagementpulley

2.PTO-drive-belt5.PTO-drive-belt-idlerpulley

3.Idlerspring

6.Centerspindlepulley

1.Mower—deckbelt

2.PTO-drivebelt

3.Idlerarmandspring

4.Clutchpulley

5.Idlerpulley

Adjustingthe PTO-Drive-Belt-Idler-Spring Anchor

ThepositionofthePTOidlercanbeadjustedtoincrease

ordecreasethebelttension.

UseFigure54fortheidlerpositionoptions.

37

Page 38

Figure54

1.PTO-drive-belt-idlerpulley4.Mosttensionforwornbelts

2.PTO-drivebelt5.Mediumtensionfornormal

3.Idlerspring

beltconditions

6.Leasttensionfornewbelts

MowerDeck Maintenance

ServicingtheCuttingBlades

Toensureasuperiorqualityofcut,keepthebladessharp.

Forconvenientsharpeningandreplacement,youmaywant

tokeepextrabladesonhand.

WARNING

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladesperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagetheblades,and

settheparkingbrake..

Turntheignitionkeytooff.Removethekeyanddisconnect

thesparkplugwiresfromthesparkplugs

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure55).Iftheedges

arenotsharporhavenicks,removeandsharpenthe

blades.RefertoSharpeningtheBlades.

Figure55

1.CuttingEdge3.Wear/slotformingin

2.Sail4.Crackinthecurvedarea

curvedarea

2.Inspecttheblades,especiallythecurvedarea(Figure

55).Ifyounoticeanycracks,wear,oraslotformingin

thisarea(item3.inFigure55),installanewblade.

CheckingforBentBlades

1.DisengagethePTO,movethemotioncontrolleversto

theneutrallockedposition,andsettheparkingbrake.

38

Page 39

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Rotatethebladesuntiltheendsfaceforwardand

backward.

4.Measurefromalevelsurfacetothecuttingedge,

positionA,oftheblades(Figure56).

Note:Notethisdimension.For36inchmowerdecks

useFigure57.

WARNING

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplacebentordamagedblade

withanewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofblade.

RemovingtheBlades

Bladesmustbereplacedifasolidobjectishit,ifthebladeis

outofbalanceorisbent.Toensureoptimumperformance

andcontinuedsafetyconformanceofthemachine,use

genuineT ororeplacementblades.Replacementbladesmade

byothermanufacturersmayresultinnon-conformancewith

safetystandards.

1.Holdthebladeendusingaragorthickly-paddedglove.

2.For48inchmowerdecks,removethebladebolt,

curvedwasher,andbladefromthespindleshaft(Figure

58).

Figure56

48inchMowerDeckshown

1.Measureherefromblade

tohardsurface

36inchMowerDeckshown

2.PositionA

Figure57

5.Rotatetheoppositeendsofthebladesforward.

6.Measurefromalevelsurfacetothecuttingedgeofthe

bladesatthesamepositionasinstep4above.

Figure58

48inchMowerDecks

1.Sailareaofblade3.Curvedwasher

2.Blade4.Bladebolt

3.For36inchmowerdecks,removethebladebolt,

curvedwasher,bladestiffener,andbladefromthe

spindleshaft(Figure59).

Note:Thedifferencebetweenthedimensions

obtainedinsteps4and5mustnotexceed3mm

(1/8inch).Ifthisdimensionexceeds3mm(1/8inch),

thebladeisbentandmustbereplaced;referto

RemovingtheBladesandInstallingtheBlades.

39

Page 40

Figure59

36inchMowerDecks

1.Sailareaofblade4.Curvedwasher

2.Blade5.Bladebolt

3.Bladestiffener

Figure61

1.Blade2.Balancer

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure58).

Important:Thesailpartoftheblademustbe

pointingupward,towardtheinsideofthemower

toensurepropercutting(Figure58).

2.For48inchmowerdecks,installtheblade,curved

washer,andbladebolt(Figure58).

3.For36inchmowerdecks,installtheblade,stiffener,

curvedwasher,andbladebolt(Figure59).

4.Torquethebladeboltto115-140N-m(85-110ft-lb).

CorrectingtheMowerQuality ofCut

Ifonedeckbladecutslowerthantheother,correctasfollows.

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure60).

Note:Maintaintheoriginalangle.Thebladeretains

itsbalanceifthesameamountofmaterialisremoved

frombothcuttingedges.

Figure60

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure61).

3.Ifthebladestaysinahorizontalposition,thebladeis

balancedandcanbeused.

Note:Tireairpressureiscriticalintheseprocedures.Make

surealltireshavecorrectpressure.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Disconnectthesparkplugwire(s)fromthespark

plug(s).

4.Adjustthetirepressureinthereartirestothe

specications.

5.Checkthatthebladesandspindleshaftsarenotbent.

RefertoCheckingforBentBlades.

6.Settheheight-of-cuttothe101.6mm(4inch)position.

RefertoAdjustingtheHeight-Of-Cut.

7.Performthestepsinthefollowingsections:Frame

SetUp,CheckingFront-to-RearPitch,andChecking

Side-to-SideLeveling.

Note:Ifthebladeisnotbalanced,lesomemetaloff

theendofthesailareaonly(Figure58).

4.Repeatthisprocedureuntilthebladeisbalanced.

40

Page 41

FrameSetup

CheckingtheCarrierFrameandEngine

DeckAlignment

Note:MisalignmentcancauseexcesswearonthePTO

drivebelt.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Placealongstraightedgeontopoftheenginedeckas

showninFigure62.

4.Atthecarrierframecrosschannel,measuretheheight

atlocationA(Figure62).

Note:Thismeasurementshouldbe33mm(1-5/16

inch),plusorminus6mm(1/4inch).

5.IftheheightatlocationAisnot33mm(1-5/16inch),

anadjustmentisneeded.

6.Loosenthecarrierframemountingboltsonbothsides

ofthemachine(Figure62).

7.Alignthecarrierframeandenginedecktomatch33

mm(1-5/16inch),plusorminus6mm(1/4inch)at

locationA(Figure62).

8.Tightenthecarrierframemountingboltsonbothsides

ofthemachine.

CheckingtheEngineDeckHeight

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Adjustthetirepressureinthereartirestospecications;

refertoDriveSystemMaintenance(page30).

4.MeasuretheenginedeckheightatlocationA(Figure

63).

Figure63

1.Backviewofmachine

2.Topofenginedeck4.Sameheightatlocations

5.MeasuretheenginedeckheightatlocationB(Figure

63).

3.Tires

AandB

Figure62

1.Carrierframe4.LocationA,33mm(1-5/16

2.Topofenginedeck5.Straightedge

3.Carrierframemounting

bolts

inch),plusorminus6mm

(1/4inch)

6.Carrierframecross

channel

6.IftheheightatlocationAandBarenotthesame,

changetirepressureslightlytomakethemthesame.

CheckingtheCarrierFrame

Front-to-RearPitch

Thecarrierframemusthaveapitchbetween3mm(1/8inch)

to9mm(3/8inch)overthelengthof61cm(24inches)on

thecarrierframe(Figure64).

1.Measureout61cm(24inches)onthecarrierframe

(Figure64).

41

Page 42

Figure64

1.Carrierframe

2.6-10mm(1/4-3/8inch)

pitchover61cm(24inch)

length

3.61cm(24inches)6.Casterspacers

4.HeightatlocationsAand

5.Casterwheel

Figure65

B

1.Casterwheel4.Sameheightatlocations

AandB

2.Carrierframe5.Casterspacers

3.Frontheight-of-cutpins

2.MeasurecarrierframeheightatlocationA(Figure64).

3.MeasurecarrierframeheightatlocationB(Figure64).

4.TheheightatlocationAmustbea6mm-10mm

(1/4-3/8inch)lowerthanlocationB(Figure64).

5.Ifthecarrierframeisnotcorrect,movecasterspacers

tomakeita6mm-10mm(1/4-3/8inch))pitch

(Figure64).

Note:Movethespacersfromthetoporbottomto

makethecorrectpitch.

6.Thetirepressuremayalsobeadjustedslightlytomake

a6mm(1/4inch)pitch.

CheckingtheCarrierFrame

Side-to-SideHeight

Thecarrierframeneedstobeparallelside-to-sidefromthe

ground.

1.DisengagethePTOandsettheparkingbrake.