Page 1

FormNo.3391-718RevA

g020238

CommercialWalk-BehindMower

16HP ,T-Bar,HydroDrivewith91cmTURBO

FORCE

ModelNo.30071—SerialNo.315000001andUp

®

CuttingUnit

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3391-718*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

ThisproductcomplieswithallrelevantEuropeandirectives;

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

Introduction

Thisrotary-blade,lawnmowerisintendedtobeused

byresidentialhomeownersorprofessional,hired

operators.Itisdesignedprimarilyforcuttinggrasson

well-maintainedlawnsonresidentialorcommercial

properties.Itisnotdesignedforcuttingbrushorfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

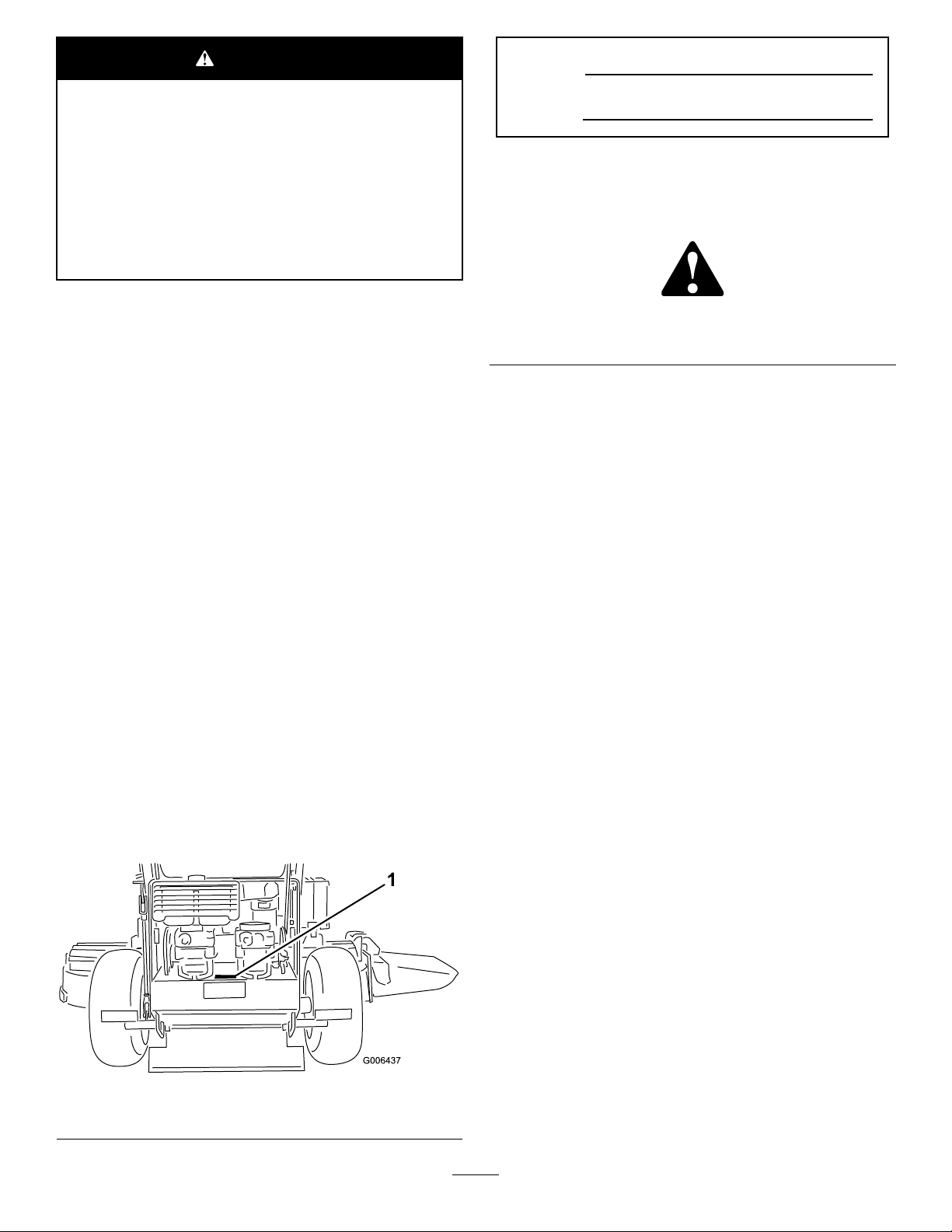

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

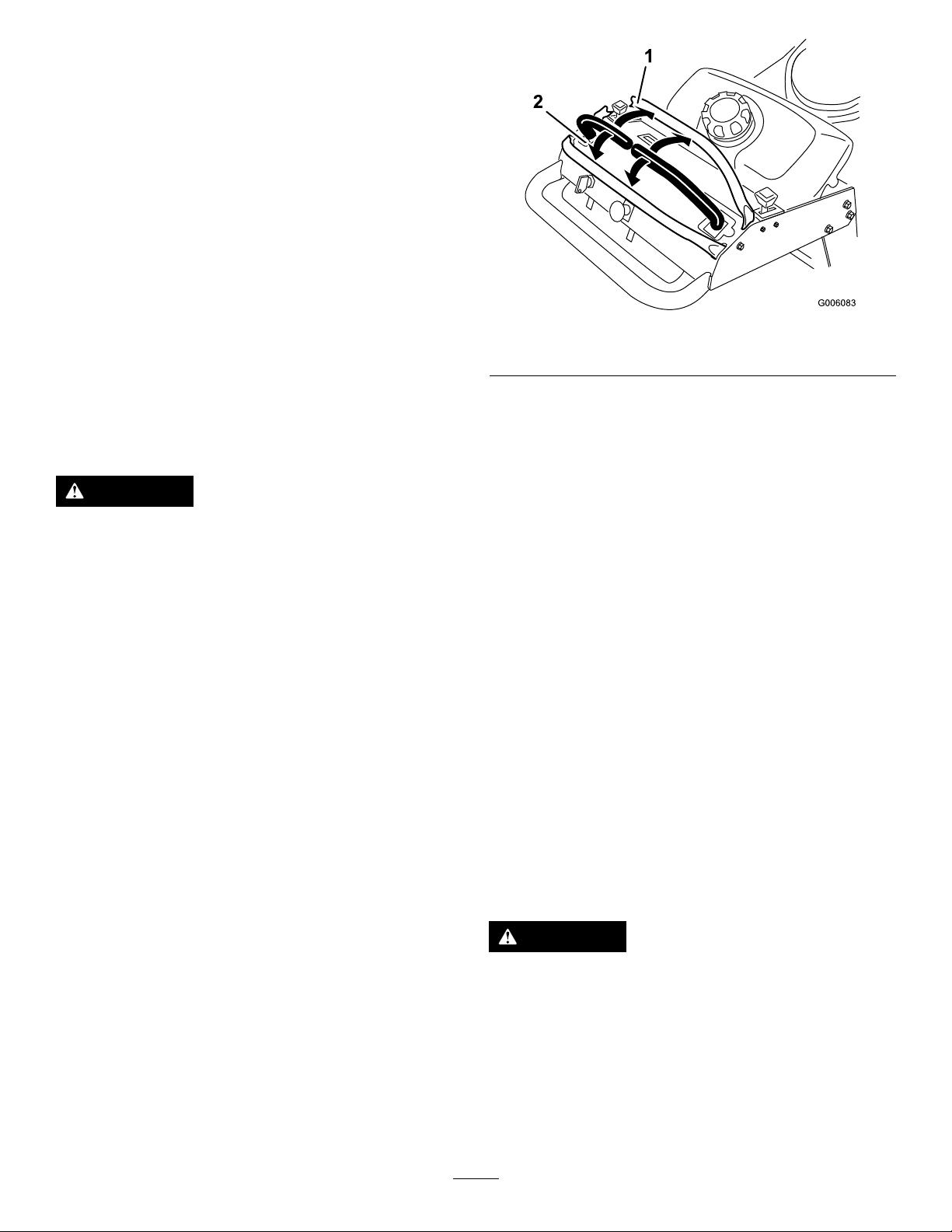

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

1.Locationofthemodelandserialnumbers

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

GeneralLawnMowerSafety.....................................4

SoundPressure.......................................................5

SoundPower..........................................................5

VibrationLevel.......................................................5

SlopeIndicator.......................................................6

SafetyandInstructionalDecals.................................7

ProductOverview.........................................................10

Controls...............................................................10

Specications........................................................11

Operation....................................................................11

AddingFuel...........................................................11

CheckingtheEngine-OilLevel.................................12

PuttingSafetyFirst.................................................12

OperatingtheParkingBrake....................................12

StartingandStoppingtheEngine..............................13

OperatingtheMowerBladeControl(PTO)................14

TheSafety-InterlockSystem....................................14

DrivingForwardorBackward..................................15

StoppingtheMachine.............................................15

PushingtheMachinebyHand..................................16

TransportingMachines............................................16

SideDischargingorMulchingtheGrass.....................16

AdjustingtheHeight-of-Cut....................................17

AdjustingtheAnti-ScalpRollers...............................17

AdjustingtheFlowBafe........................................17

PositioningtheFlowBafe......................................18

Maintenance.................................................................19

RecommendedMaintenanceSchedule(s)......................19

Lubrication...............................................................20

LubricatingtheMachine..........................................20

LubricatingtheBearings..........................................20

GreasingthePTODriveBeltIdler............................20

EngineMaintenance..................................................21

ServicingtheAirCleaner.........................................21

ServicingtheEngineOil..........................................21

ServicingtheSparkPlugs.........................................23

FuelSystemMaintenance...........................................24

DrainingtheFuelTank...........................................24

ReplacingtheFuelFilter..........................................25

ElectricalSystemMaintenance....................................25

ServicingtheFuses.................................................25

DriveSystemMaintenance.........................................26

AdjustingtheTracking...........................................26

CheckingtheTirePressure......................................26

ReplacingtheCasterWheelForkBushings.................26

ServicingtheCasterWheelandBearings....................27

AdjustingtheElectricClutch....................................28

CoolingSystemMaintenance......................................28

CleaningtheAirIntakeScreen..................................28

BrakeMaintenance....................................................29

ServicingtheBrakes................................................29

BeltMaintenance......................................................30

InspectingtheBelts................................................30

ReplacingtheMowerBelt........................................30

ReplacingthePTO-DriveBelt..................................30

AdjustingthePTO-Drive-Belt-Idler-Spring

Anchor..............................................................31

ReplacingthePump-DriveBelt................................31

ControlsSystemMaintenance.....................................32

AdjustingtheMotion-Control-Handle

Positions............................................................32

HydraulicSystemMaintenance....................................34

ServicingtheHydraulicSystem.................................34

MowerDeckMaintenance...........................................37

ServicingtheCuttingBlades.....................................37

CorrectingtheMowerQualityofCut........................38

SettinguptheFrame...............................................38

CheckingtheMowerDeckFront-to-Rear

Pitch.................................................................40

ChangingtheMowerDeckFront-to-Rear

Pitch.................................................................40

CheckingtheMowerDeckSide-to-Side

Height...............................................................41

ChangingtheMowerDeckSide-to-Side

Height...............................................................41

MatchingtheHeight-of-Cut.....................................41

ReplacingtheGrassDeector..................................42

Cleaning...................................................................42

CleaningundertheMower.......................................42

DisposingofWaste.................................................42

Storage........................................................................43

CleaningandStorage..............................................43

Troubleshooting...........................................................44

3

Page 4

Safety

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013.

Improperlyusingormaintainingthemachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeans

Danger

withtheinstructionmayresultinpersonalinjuryor

death.

—personalsafetyinstruction.Failuretocomply

GeneralLawnMowerSafety

Thiscuttingmachineiscapableofamputatinghandsandfeet

andthrowingobjects.Failuretoobservethefollowingsafety

instructionscouldresultinseriousinjuryordeath.

Training

•Readtheinstructionscarefully.Befamiliarwiththe

controlsandtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethemower.Localregulationscan

restricttheageoftheoperator.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Understandexplanationsforallpictogramsusedonthe

mowerorintheinstructions.

Gasoline

WARNING-Gasolineishighlyammable.Takethe

followingprecautions.

•Storefuelincontainersspecicallydesignedforthis

purpose.

•Refueloutdoorsonlyanddonotsmokewhilerefueling.

•Addfuelbeforestartingtheengine.Neverremovethe

capofthefueltankoradgasolinewhiletheengineis

runningorwhentheengineishot.

•Ifgasolineisspilled,donotattempttostarttheengine

butmovethemowerawayfromtheareaofspillageand

avoidcreatinganysourceofignitionuntilgasolinevapors

havedissipated.

•Replaceallfueltankandcontainercapssecurely.

Preparation

•Whilemowing,alwayswearsubstantialfootwearandlong

trousers.Donotoperatetheequipmentwhenbarefoot

orwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallstones,sticks,wires,bonesand

otherforeignobjects.

Caution, W ar ning ,

•Beforeusing,alwaysvisuallyinspecttoseethatguards,

andsafetydevices,suchasdeectorsand/orgrass

catchers,areinplaceandworkingcorrectly.

•Beforeusing,alwaysvisuallyinspecttoseethattheblades,

bladeboltsandcutterassemblyarenotwornordamaged.

Replacewornordamagedbladesandboltsinsetsto

preservebalance.

or

Starting

•Disengageallbladeanddriveclutchesandshiftinto

neutralbeforestartingtheengine.

•Donottiltmowerwhenstartingtheengineorswitching

onthemotor,unlessthemowerhastobetiltedfor

starting.Inthiscase,donottiltitmorethanabsolutely

necessaryandliftonlythepart,whichisawayfromthe

operator.

•Starttheengineorswitchonthemotorcarefully

accordingtoinstructionsandwithfeetwellawayfrom

theblade(s)andnotinfrontofthedischargechute.

Operation

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Mowonlyindaylightoringoodarticiallight.

•Avoidoperatingthelawnmowerinwetgrass,where

feasible.

•Stayalertforholesintheterrainandotherhiddenhazards.

•Neverdirectdischargeofmaterialtowardsbystanders.

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Neverpickuporcarryalawnmowerwhiletheengineis

running.

•Useextremecautionwhenreversingorpullinga

pedestriancontrolledlawnmowertowardsyou.

•Walk,neverrun.

•Slopes:

–Donotmowexcessivelysteepslopes.

–Exerciseextremecautionwhenonslopes.

–Mowacrossthefaceofslopes,neverupanddown

andexerciseextremecautionwhenchangingdirection

onslopes.

–Alwaysbesureofyourfootingonslopes.

•Uselowthrottlesettingswhenengagingthe

traction-clutch,especiallyinhighgears.Reducespeed

onslopesandinsharpturnstopreventoverturningor

lossofcontrol.

•Stopthebladeifthelawnmowerhastobetiltedfor

transportationwhencrossingsurfacesotherthangrass

andwhentransportingthelawnmowertoandfromthe

areatobemowed.

4

Page 5

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Stoptheengine

–wheneveryouleavethelawnmower.

–beforerefueling.

–beforeremovingthegrasscatcher.

–beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator'sposition.

•Stoptheengineanddisconnectthespark-plugwireor

turnoffandremovethekey .

–beforeclearingblockagesoruncloggingchute.

–beforechecking,cleaningorworkingonthelawn

mower.

–afterstrikingaforeignobject,inspectthelawnmower

fordamageandmakerepairsbeforerestartingand

operatingthelawnmower.

–iflawnmowerstartstovibrateabnormally(check

immediately).

•Usecarewhenusingsulkies,and

–useonlyapproveddrawbarhitchpoints.

•Replacefaultysilencers.

•Ifthefueltankhastobedrained,dothisout-doors.

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatinganengineatexcessivespeedcan

increasethehazardofpersonalinjury.

•Onmultibladedlawnmowers,takecareasrotatingone

blademaycauseotherstorotate.

•Becarefulduringadjustmentofthelawnmowerto

prevententrapmentofthengersbetweenmovingblades

andxedpartsofthelawnmower.

•Toensurethebestperformanceandsafety,

purchaseonlygenuineTororeplacementpartsand

accessories.Donotuse

theymaycauseasafetyhazard.

will t

partsandaccessories;

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof88

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Thesoundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

–limitloadstothoseyoucansafelycontrol.

–donotturnsharply:usecarewhenreversing.

–donotcarrypassengers.

•Watchoutfortrafcwhencrossingornearroadways.

•Beforeleavingtheoperator'sposition

–disengagethepowertake-offandlowerthe

attachments.

–changeintoneutralandsettheparkingbrake.

–stoptheengineandremovethekey.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Donotusepressurecleaningequipmentonmachine.

•Neverstoretheequipmentwithgasolineinthetankand

insideabuildingwherefumescanreachanopename

orspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof100dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Thesoundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=2.8m/s

Measuredvibrationlevelforlefthand=2.1m/s

UncertaintyValue(K)=1.4m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

2

2

2

•Toreducetherehazard,keeptheengine,silencer,

batterycompartmentandgasolinestoragearefreeof

grass,leaves,orexcessivegrease.

•Checkgrasscatchercomponentsandthedischargeguard

frequentlyandreplacewithmanufacturer'srecommended

parts,whennecessary.

•Replacewornordamagedpartsforsafety.

5

Page 6

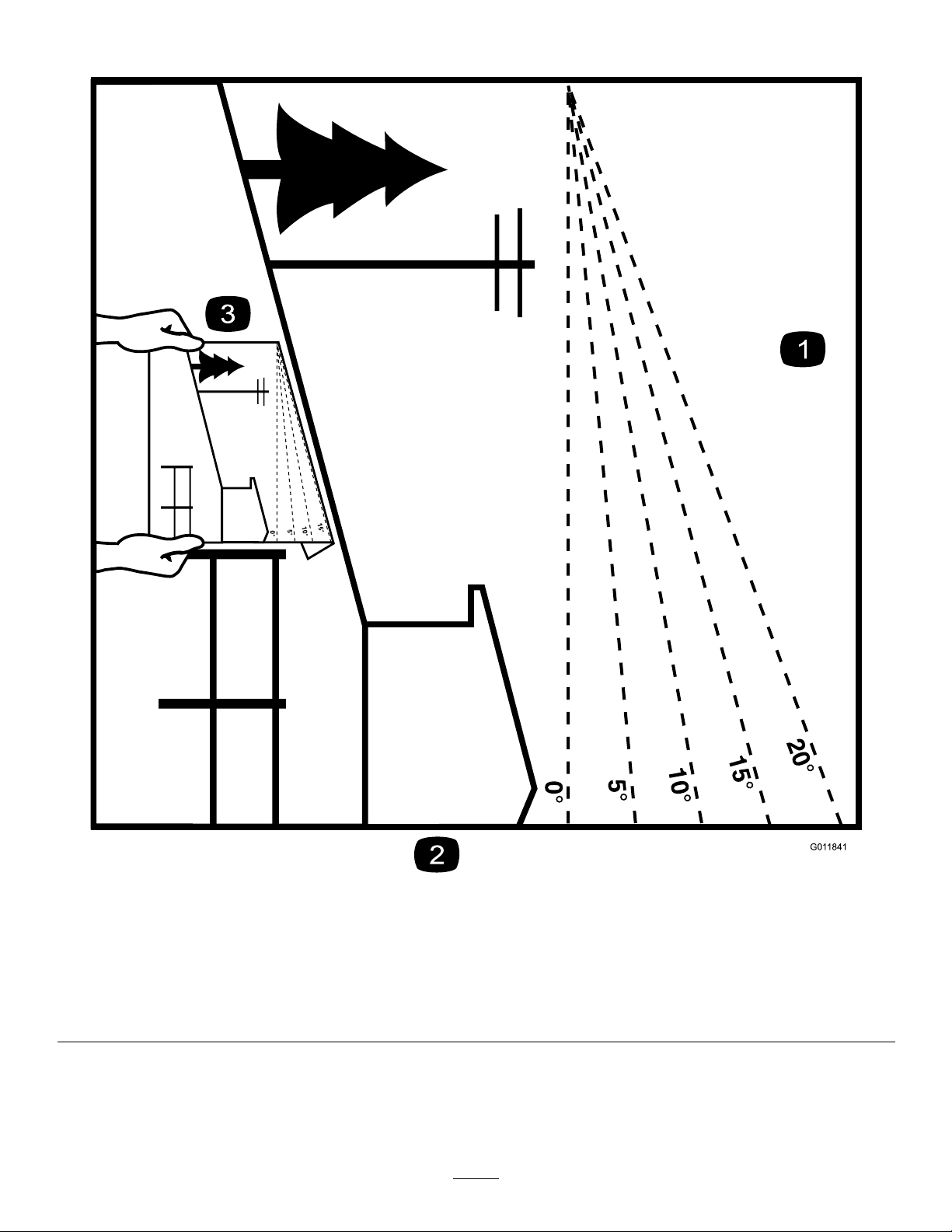

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis20degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan20degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

6

Page 7

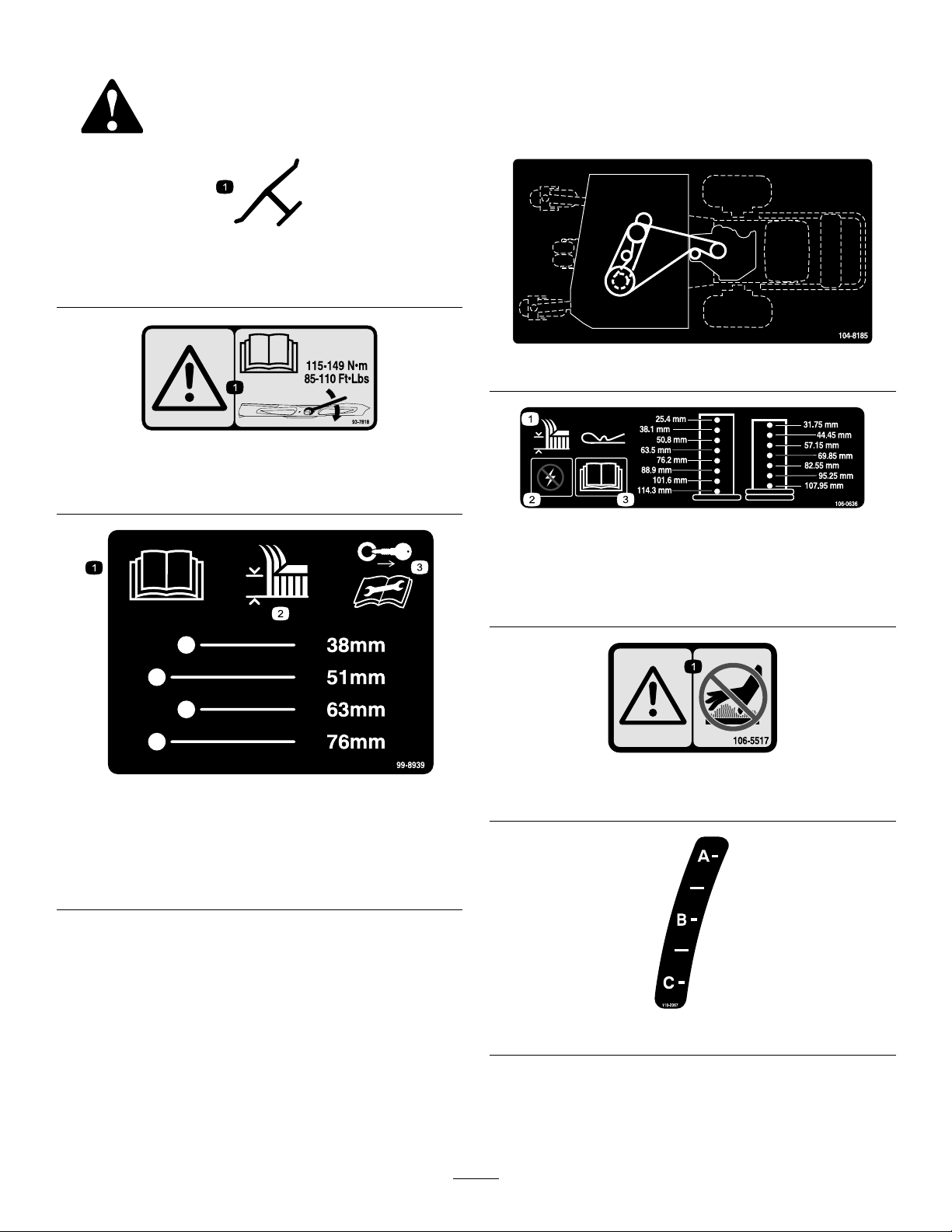

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N-m(85-110ft-lb).

104-8185

1.ReadtheOperator's

Manual.

2.Heightofcut

99-8939

3.Removetheignitionkey

andreadtheinstructions

beforeservicingor

performingmaintenance.

106-0636

1.Height-of-cut3.ReadtheOperator's

Manualformore

information.

2.Warning—power

106-5517

1.Warning–DoNottouchthehotsurface.

110-2067

7

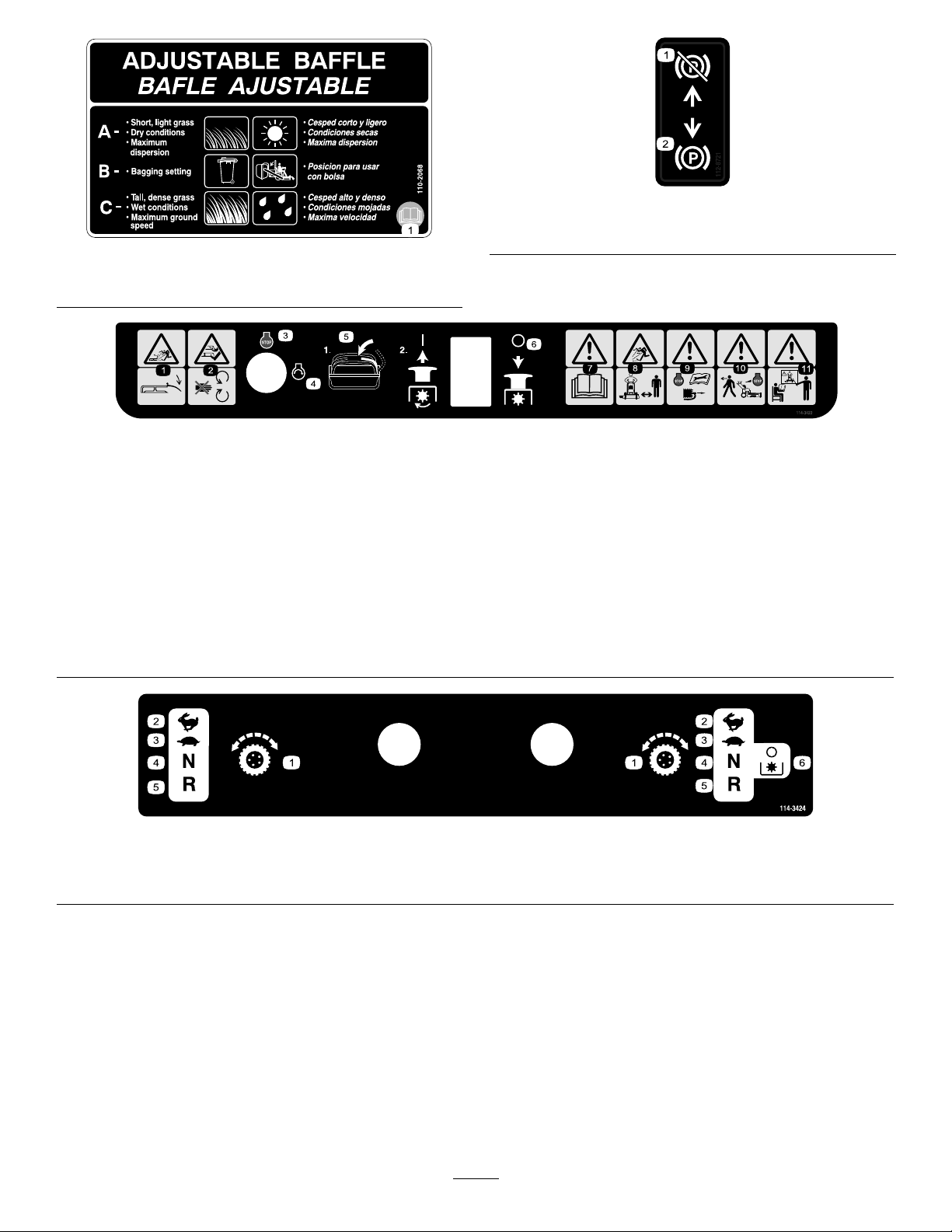

Page 8

112-8721

110-2068

1.ReadtheOperator'sManual.

1.Thrownobject

hazard—keepdeector

inplace.

2.Cutting,dismemberment

hazardofhandor

foot—stayawayfrom

movingparts.

3.Engine—stop

1.Parkingbrake—off

114-3422

4.Engine—start7.Warning—readthe

5.Movethemotioncontrol

levertotheneutralposition,

thenpulloutonPTO(Power

TakeOff)switchtoengage

theblades.

6.PushinonthePTO(Power

TakeOff)todisengagethe

blades.

Operator'sManual.

8.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

9.Warning—stoptheengine

andremovethesparkplug

wirebeforeperforming

anymaintenanceonthe

machine.

2.Parkingbrake—on

10.Warning—stoptheengine

beforeleavingthemachine.

11.Warning—donotoperate

thismachineunlessyou

aretrained.

1.Tractioncontrol

2.Fast4.Neutral

114-3424

3.Slow

5.Reverse

6.DisengagethePTO(PowerTake-off)

8

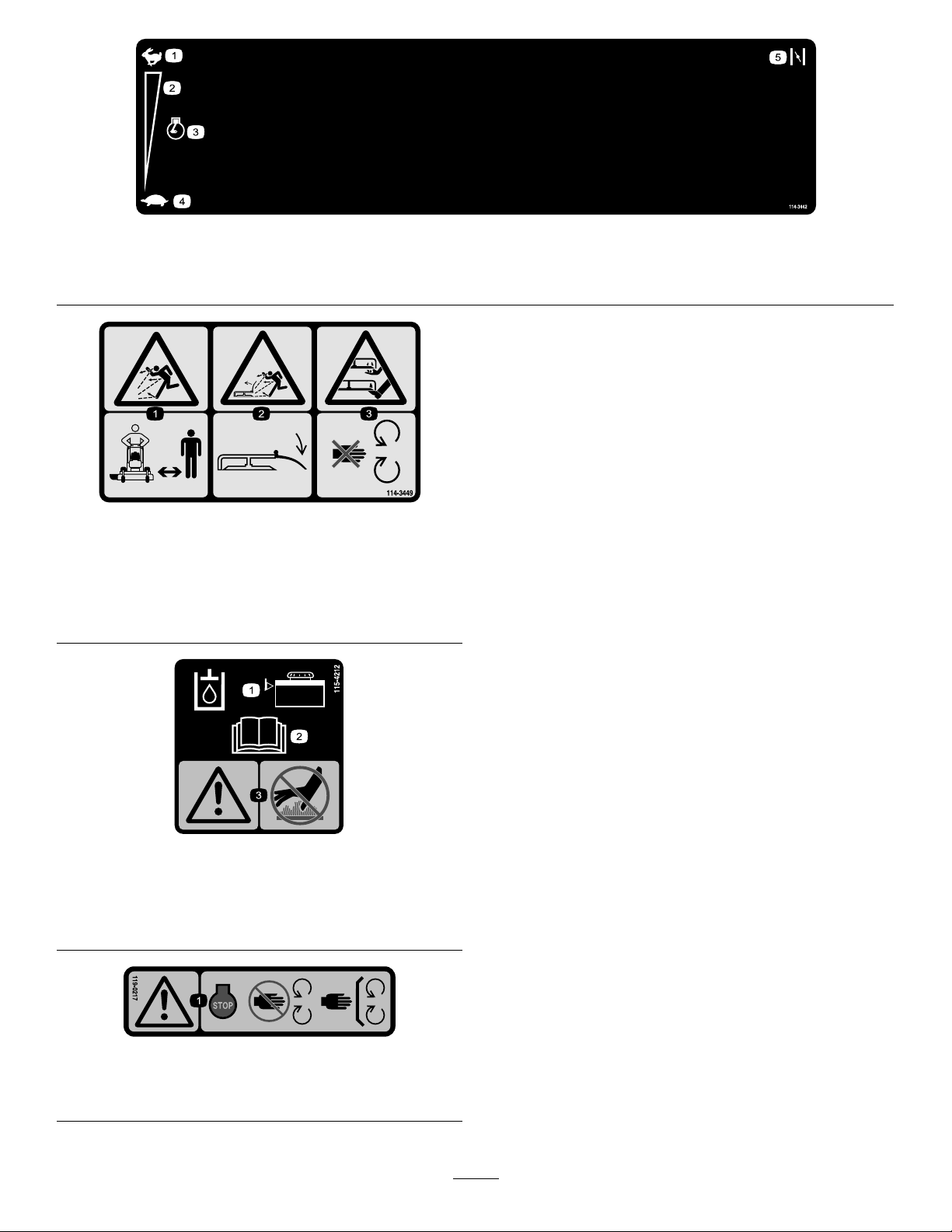

Page 9

114-3442

1.Fast3.Engine

2.Continuousvariablesetting4.Slow

114-3449

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—keepthedeectorinplace.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

5.Choke

115-4212

1.Hydraulicoillevel3.Warning—donottouchthe

hotsurface.

2.ReadtheOperator's

Manual.

119-0217

1.Warning—stoptheengine;stayawayfrommovingparts;

keepallguardsandshieldsinplace.

9

Page 10

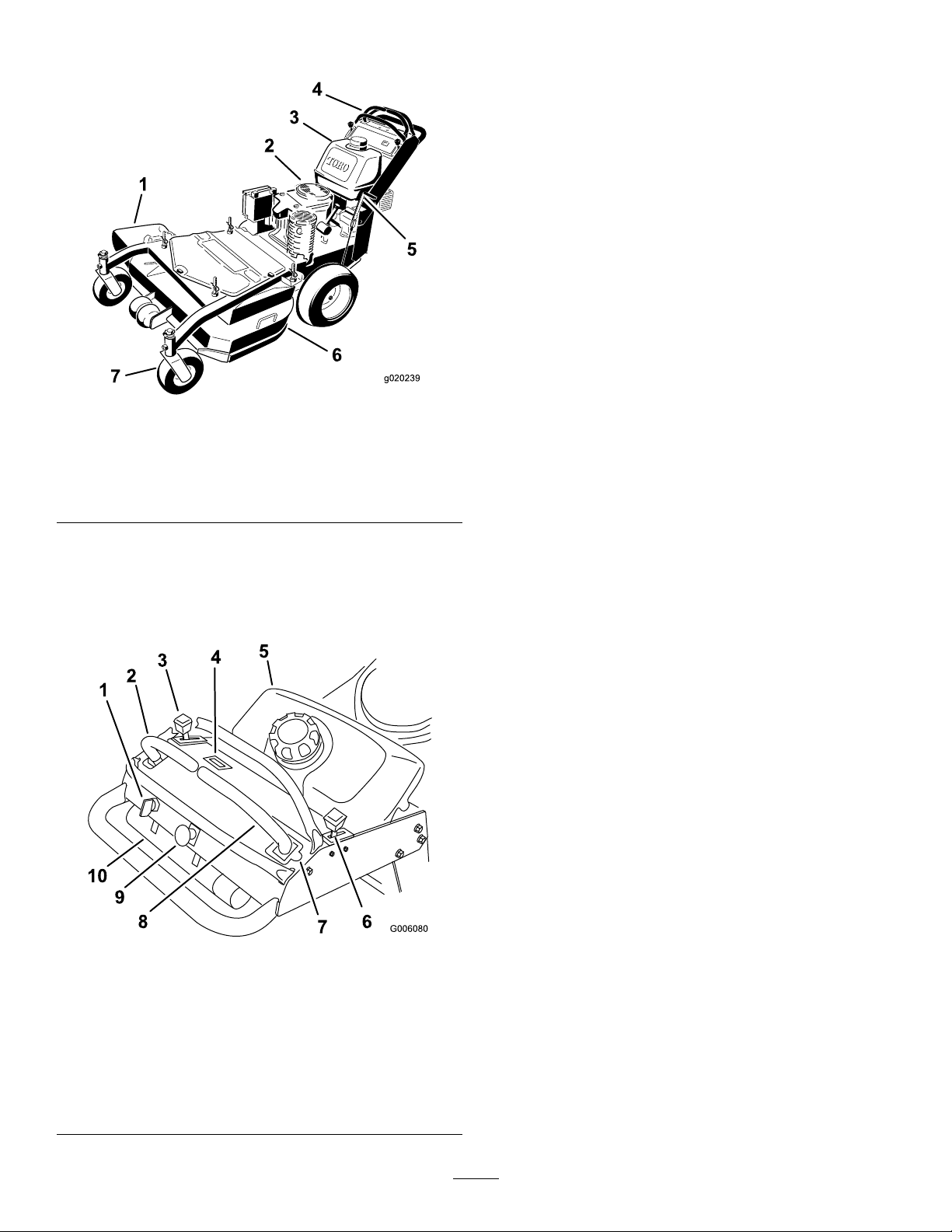

ProductOverview

g020239

Figure4

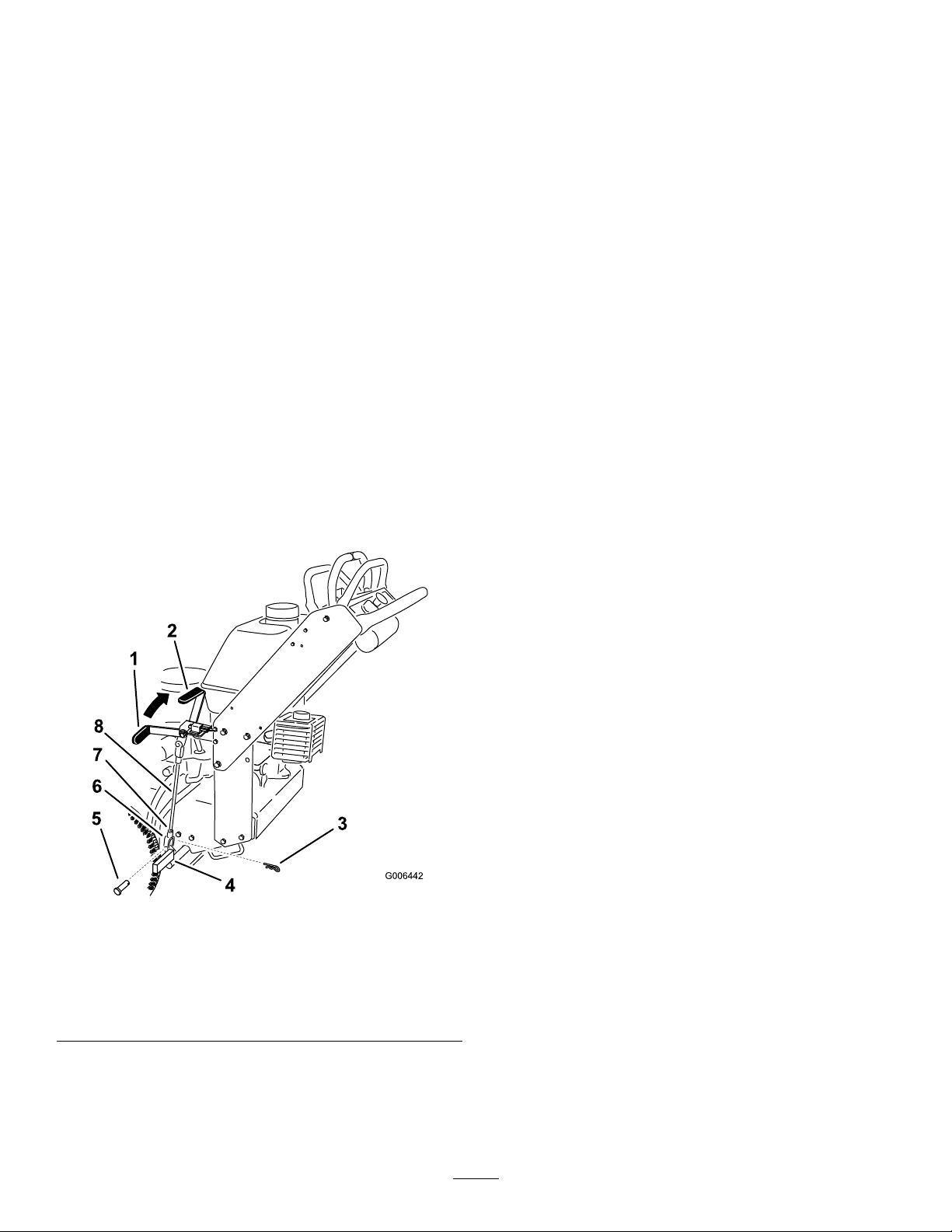

1.Side-dischargechute

2.Engine6.Mowerdeck

3.Gastank

4.Controls

5.Parkingbrake

7.Frontcasterwheel

ThrottleControl

Thethrottlecontrolhas2positions:FastandSlow.

Choke

Usethechoketostartacoldengine.

Blade-ControlSwitch(PTO)

Theblade-controlswitch(PTO)isusedtoengagetheelectric

clutchtodrivethemowerbladeswiththerightmotion-control

leverinthecenter,unlockedposition.Pulltheswitchupto

engagethebladesandrelease.Todisengagetheblades,push

theblade-controlswitch(PTO)downormoveorreleasethe

rightmotion-controlleverintotheNeutral-Lockposition.

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhas3

positions:Start,Run,andOff.

Motion-ControlLevers

Themotion-controlleversareusedtodrivethemachine

forward,reverse,andturneitherdirection.

Controls

Becomefamiliarwithallthecontrols(Figure5)beforeyou

starttheengineandoperatethemachine.

Figure5

1.Ignitionswitch

2.Leftmotion-controllever7.Neutral-Lockpositionfor

3.Throttlecontrol8.Rightmotion-controllever

4.Hourmeter9.Blade-controlswitch

5.Fueltank

6.Choke

therightmotion-control

lever

(PTO)

10.Operator-manualtube

Neutral-LockPosition

TheNeutral-Lockpositionisusedwiththesafetyinterlock

systemtoengageanddisengagethemowerbladesandto

determinetheNeutralposition.

FuelShut-offValve

Closethefuelshut-offvalve(underthefueltank)when

transportingorstoringthemower.

HourMeter

Showsthetotalhoursthemachinehasbeenoperated.This

operatesonlywhenthemowerbladesareoperating.

Thehourmeterwillash3hoursbeforeandafteraservice

interval.Theserviceintervalsaresetfortherst8hours,

every100hoursthereafter,andevery400hours.

Note:Makesuremaintenanceisdoneatallrecommended

intervalsshownintheRecommendedMaintenanceSchedule.

10

Page 11

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

Operation

AddingFuel

•Forbestresults,useonlyclean,fresh,unleadedgasoline

withanoctaneratingof87orhigher((R+M)/2rating

method).

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Widthwithdeectordown130cm(51-1/8inches)

Length

Height

Weight

199cm(78-1/2inches)

117cm(46inches)

303kg(667lb)

•Oxygenatedfuelwithupto10%ethanolor15%MTBE

byvolumeisacceptable.

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotuseethanolblendsofgasoline(suchasE15

orE85)withmorethan10%ethanolbyvolume.

Performanceproblemsand/orenginedamagemayresult

whichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

11

Page 12

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

FillingtheFuelTank

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundeachfueltankcapandremovethecap.

3.Addunleadedregulargasolinetobothfueltanks,until

thelevelis6to13mm(1/4to1/2inch)belowthe

bottomofthellerneck.

Thisspaceinthetankallowsgasolinetoexpand.Do

notllthefueltankscompletelyfull.

4.Installfueltankcapssecurely .

5.Wipeupanygasolinethatmayhavespilled.

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,checktheoil

levelintheenginecrankcase;refertoCheckingOilLevelin

EngineMaintenance(page21).

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

PuttingSafetyFirst

Carefullyreadallthesafetyinstructionsanddecalsinthe

safetysection.Knowingthisinformationcouldhelpyouor

anybystandersavoidinjury.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepgasawayfromeyesandskin.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionertothe

gas.

Note:Afuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

Theuseofprotectiveequipmentforeyes,hearing,feet,and

headisrecommended.

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator'searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.Beforeeachuse,checktheparkingbrake

forproperoperation.

Iftheparkingbrakedoesnotholdsecurely,adjustit.Referto

ServicingtheBrakes(page29).

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

12

Page 13

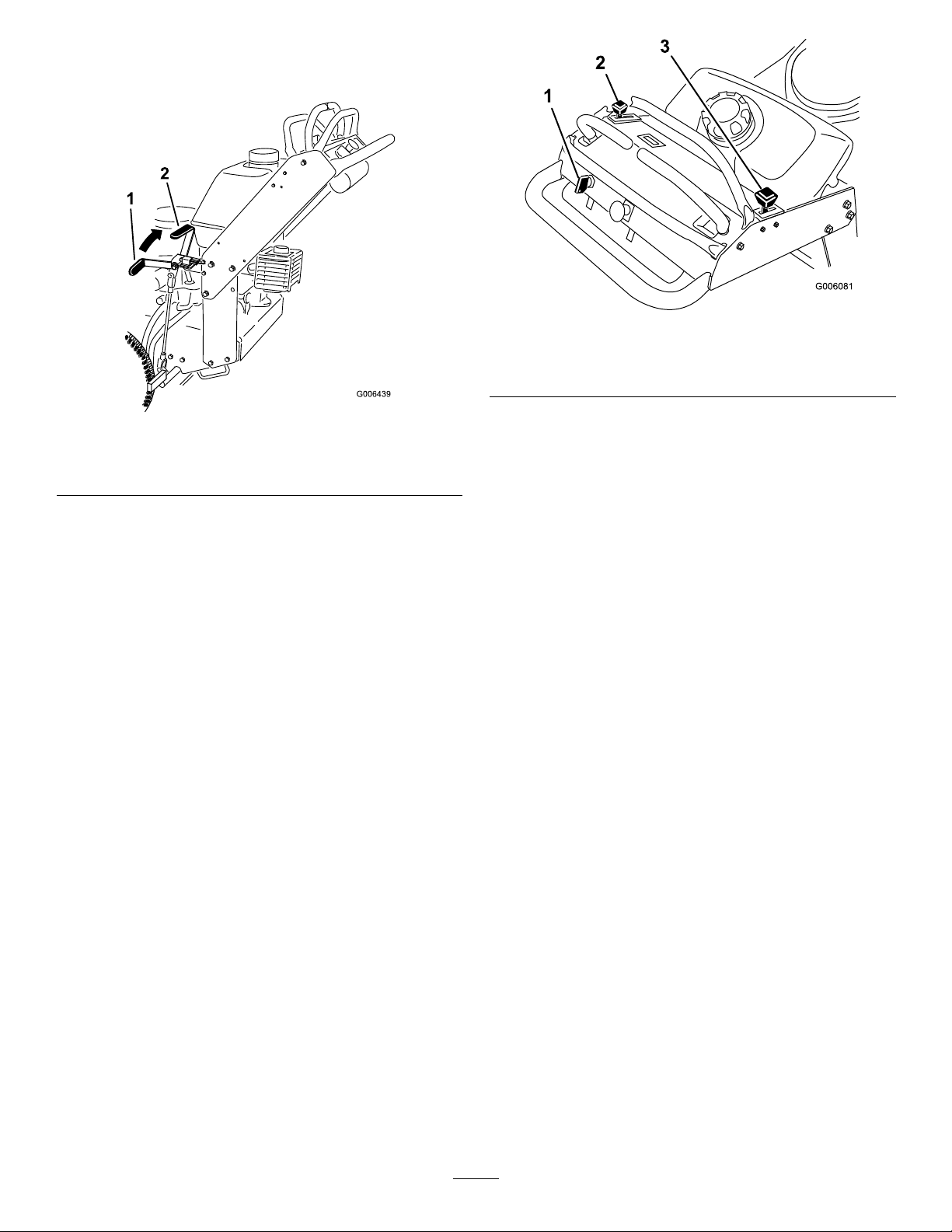

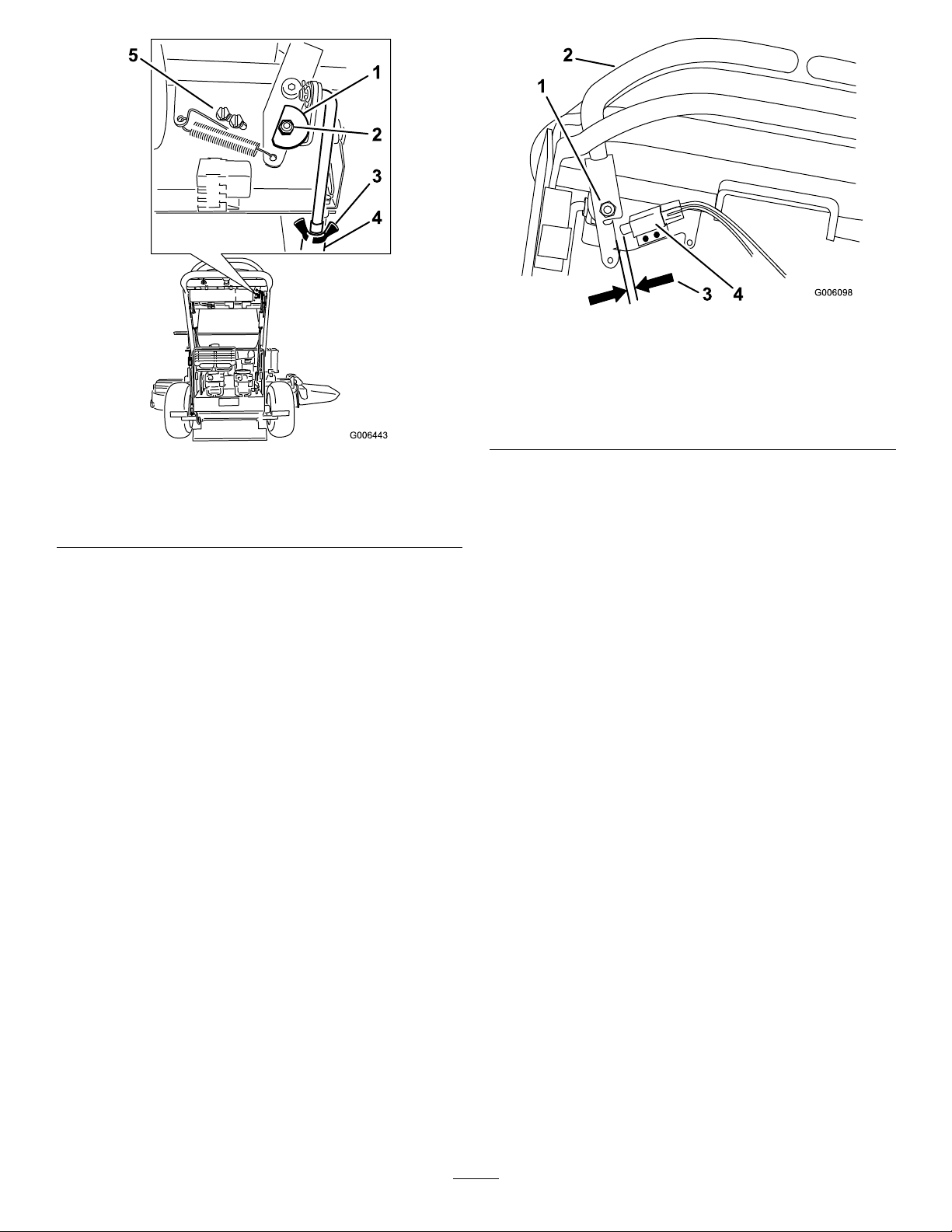

SettingtheParkingBrake

Pulltheparkingbrakeleverrearward(Figure6).

Figure7

Figure6

1.Parkingbrakelever(inthe

releasedposition)

2.Parkingbrakelever(inthe

engagedposition)

ReleasingtheParkingBrake

Pushtheparkingbrakeleverforward.

StartingandStoppingthe Engine

StartingtheEngine

1.Connectthewirestothesparkplugs.

2.Openthefuelvalve.

3.Settheparkingbrake.

4.Movethethrottlecontroltofastandmovethechoke

levertotheonpositionbeforestartingacoldengine

(Figure7).

Note:Awarmorhotenginemaynotrequirechoking.

Tostartawarmengine,movethrottlecontrolmidway

betweentheFastandSlowpositions.

1.Ignitionswitch

2.Throttlelever

5.Turntheignitionkeytothestartpositiontoenergize

thestarter.Whentheenginestarts,releasethekey.

Note:Donotengagethestarterformorethan5

secondsatatime.Iftheenginefailstostart,allow

fora15secondcool-downperiodbetweenattempts.

Failuretofollowtheseinstructionscanburnoutthe

startermotor.

6.Whenenginestarts,movethethrottlecontrolbetween

thefastandslowpositionandmovethechokeleverto

theoffposition.Allowtheenginetowarmupandthen

movethethrottlecontroltothefastposition.

3.Choke

StoppingtheEngine

1.Movethemotion-controlleverstotheNeutralposition

andmovetherightmotion-controlleverintothe

Neutral-Lockposition.

2.Movethethrottlelevertoslow(Figure7).

3.Iftheenginehasbeenworkinghardorishot,letthe

engineidlefor30to60secondsbeforeturningthe

engineoff.

4.Tostoptheengine,turntheignitionkeytooff.

Important:Makesurefuelshutoffvalveisclosed

beforetransportingorstoringthemachine,asfuel

leakagemayoccur.Beforestoringthemachine,

pullwireoffsparkplug(s)topreventpossibilityof

accidentalstarting.

13

Page 14

OperatingtheMowerBlade

TheSafety-InterlockSystem

Control(PTO)

Theblade-controlswitch(PTO)isusedinconjunctionwith

therightmotion-controllevertoengageanddisengagethe

mowerblades.

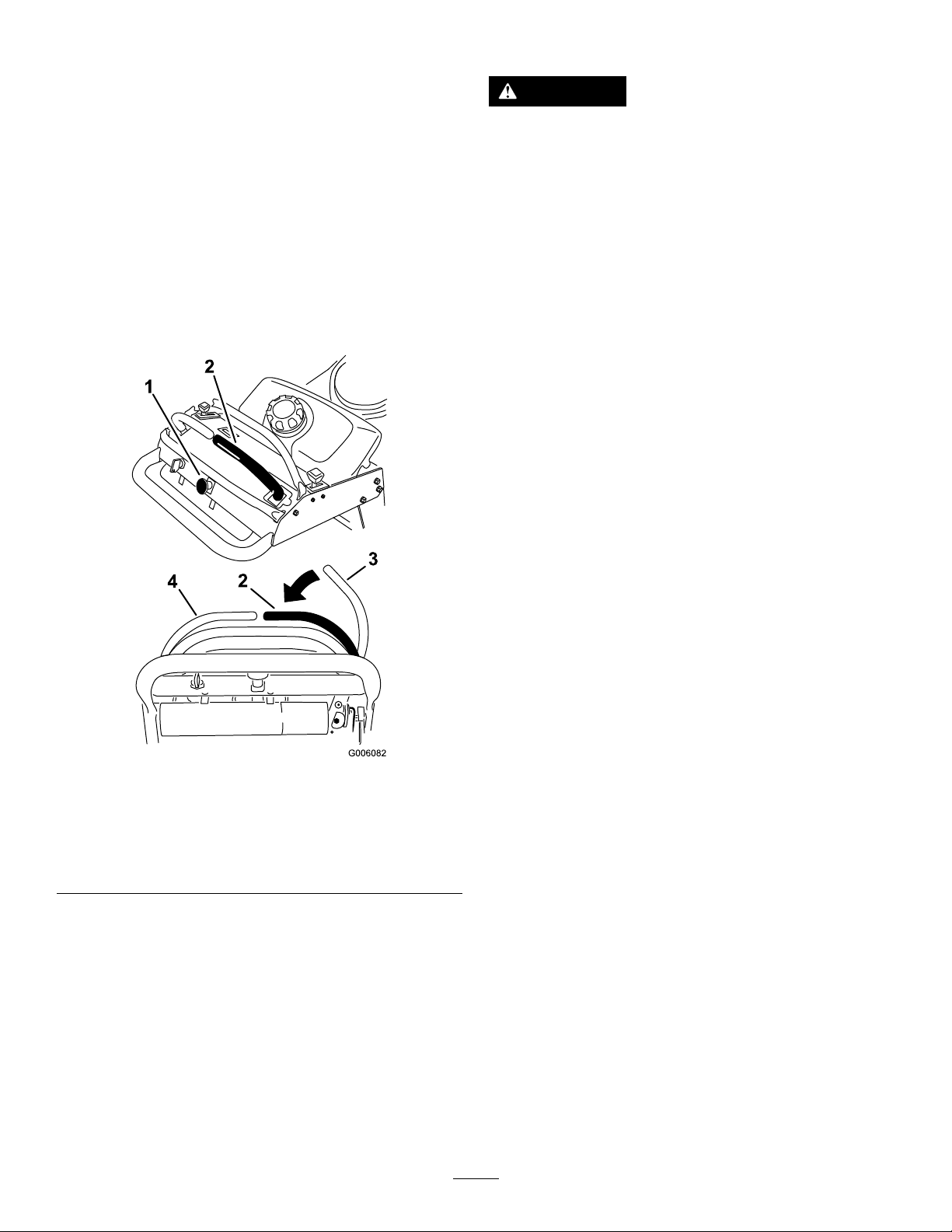

EngagingtheMowerBlades(PTO)

1.Toengagethemowerblades,movetheright

motion-controllevertothecenter,unlockedposition

(Figure8).

2.Pulltheblade-controlswitch(PTO)upandreleaseit

whileholdingdowntherightmotion-controlleverin

thecenter,unlockedposition.

CAUTION

Ifthesafety-interlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly,

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafety-Interlock

System

Thesafety-interlocksystemisdesignedtopreventthemower

bladesfromrotatingunless:

•Therightmotion-controlleverismovedtothecenter,

unlockedposition.

•Theblade-controlswitch(PTO)ispulledtotheOn

position.

Thesafety-interlocksystemisdesignedtostopthemower

bladesifyoumoveorreleasetherightmotion-control

leverintotheNeutral-Lockposition.

Figure8

1.Blade-controlswitch

(PTO)

2.Rightmotion-controllever

pusheddownintothe

center,unlockedposition

3.Rightmotion-controllever

inNeutral-Lockposition

4.Leftmotion-controllever

DisengagingtheMowerBlades(PTO)

Thefollowingare2optionsfordisengagingthemowerblades.

•Pushtheblade-controlswitch(PTO)downtotheOff

position.

•Movethemotion-controlleverstotheNeutralposition

andmovetherightmotion-controlleverintothe

Neutral-Lockposition.

TestingtheSafety-InterlockSystem

ServiceInterval:Beforeeachuseordaily

Note:Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Starttheengine;refertoStartingandStoppingthe

EngineinStartingandStoppingtheEngine(page13).

2.Settheparkingbrake.

3.Movetherightmotion-controllevertothecenter,

unlockedposition.

Note:Thebladesshouldnotrotate.

4.Movethemotion-controlleversforward.

Note:Theengineshouldkill.

5.Starttheengineandreleasetheparkingbrake.

6.Movetherightmotion-controllevertothecenter,

unlockedposition.

7.Continueholdingtherightmotion-controlleverin

thecenter,unlockedpositionandpulluponthe

blade-controlswitch(PTO)andrelease.

Note:Theclutchshouldengageandthemower

bladesbeginrotating.

8.Moveorreleasetherightmotion-controlleverintothe

Neutral-Lockposition.

Note:Thebladesshouldstoprotating.

9.Movetherightmotion-controllevertothecenter,

unlockedposition.

14

Page 15

10.Continueholdingtherightmotion-controlleverin

thecenter,unlockedpositionandpullupontheblade

controlswitch(PTO)andrelease.

Theclutchshouldengageandthemowerbladesbegin

rotating.

11.Pushtheblade-controlswitch(PTO)downtotheOff

position.

Note:Thebladesshouldstoprotating.

12.Withtheenginerunning,pulluptheblade-control

switch(PTO)andreleasewithoutholdingright

motion-controllevertothecenter,unlockedposition.

Note:Thebladesshouldnotrotate.

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

thefastpositionforbestperformance.Alwaysoperateinthe

fullthrottlepositionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormaylose

controlofmachineandcausepersonalinjuryor

damagetomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

DrivingForward

1.Releasetheparkingbrake;refertoReleasingtheParking

BrakeinStartingandStoppingtheEngine(page13).

2.Movetherightmotion-controllevertothecenter,

un-lockedposition.

3.Togoforward,slowlypushthemotion-controllevers

forward(Figure9).

Note:Theenginewillkillifthetraction-controllevers

aremovedwiththeparkingbrakeengaged.

Togostraight,applyequalpressuretoboth

motion-controllevers(Figure9).

Toturn,movethemotion-controllevertowardthe

Neutralpositioninthedirectionyouwanttoturn

(Figure9).

Thefartheryoumovethetraction-controlleversin

eitherdirection,thefasterthemachinewillmovein

thatdirection.

Tostop,pullthemotion-controlleversbacktothe

Neutralposition.

Figure9

1.Forward2.Backward

DrivingBackward

1.Movetherightmotion-controllevertothecenter,

unlockedposition.

2.Togobackward,slowlypullthemotion-controllevers

rearward(Figure9).

Togostraight,applyequalpressuretoboth

motion-controllevers(Figure9).

Toturn,releasepressureonthemotion-controllever

towardthedirectionyouwanttoturn(Figure9).

Tostop,pushthemotion-controlleverstotheNeutral

position.

StoppingtheMachine

Tostopthemachine,movethemotion-controlleverstothe

Neutralposition,movetherightmotion-controlleverintothe

Neutral-Lockposition,disengagethepowertake-off(PTO),

andturntheignitionkeytotheOffposition.

Settheparkingbrakewhenyouleavethemachine;referto

SettingtheParkingBrakeinStartingandStoppingtheEngine

(page13).

Removethekeyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

15

Page 16

PushingtheMachinebyHand

Theby-passvalvesallowthemachinetobepushedbyhand

withouttheenginerunning.

Important:Alwayspushthemachinebyhand.Never

towthemachinebecausehydraulicdamagemayoccur.

1.DisengagethePTO ,movethemotion-controlleversto

theNeutral-Lockedpositionandsettheparkingbrake.

2.Opentheby-passvalveonbothpumpsbyturning

themcounterclockwise1to2turns.Thisallows

hydraulicuidtoby-passthepumpsandthewheels

toturn(Figure10).

Note:Rotatetheby-passvalvesamaximumof2turns

sothevalvedoesnotcomeoutofthebodycausing

uidtorunout.

3.Loadthemachineontothetrailerortruck.

4.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Usethemetaltiedownloopsonthemachineto

securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropes(Figure11).

6.Fastenthefrontofthemachinetothetrailerortruck

withstraps,chains,cable,orropes.

Figure11

1.Tiedownloop

Figure10

1.Pumpby-passvalve

3.Releasetheparkingbrake.

4.Pushthemachinetothedesiredlocation.

5.Settheparkingbrake.

6.Closetheby-passvalves,butdonotovertightenthem.

Important:Donotstartoroperatethemachine

withtheby-passvalvesopen.Damagetosystem

mayoccur.

TransportingMachines

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,pets,orbystandersavoidinjury.

SideDischargingorMulching theGrass

Thismowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutthegrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthemower

becausethegrassdeectorroutesmaterialdown

towardtheturf.Ifthegrassdeectorisever

damaged,replaceitimmediately .

•Neverputyourhandsorfeetunderthemower.

•Nevertrytocleardischargeareaormower

bladesunlessyoureleasethebailandthepower

takeoff(PTO)isoff.Rotatetheignitionkeyto

Off.Alsoremovethekeyandpullthewire(s)off

thesparkplug(s).

Totransportthemachine:

1.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

16

Page 17

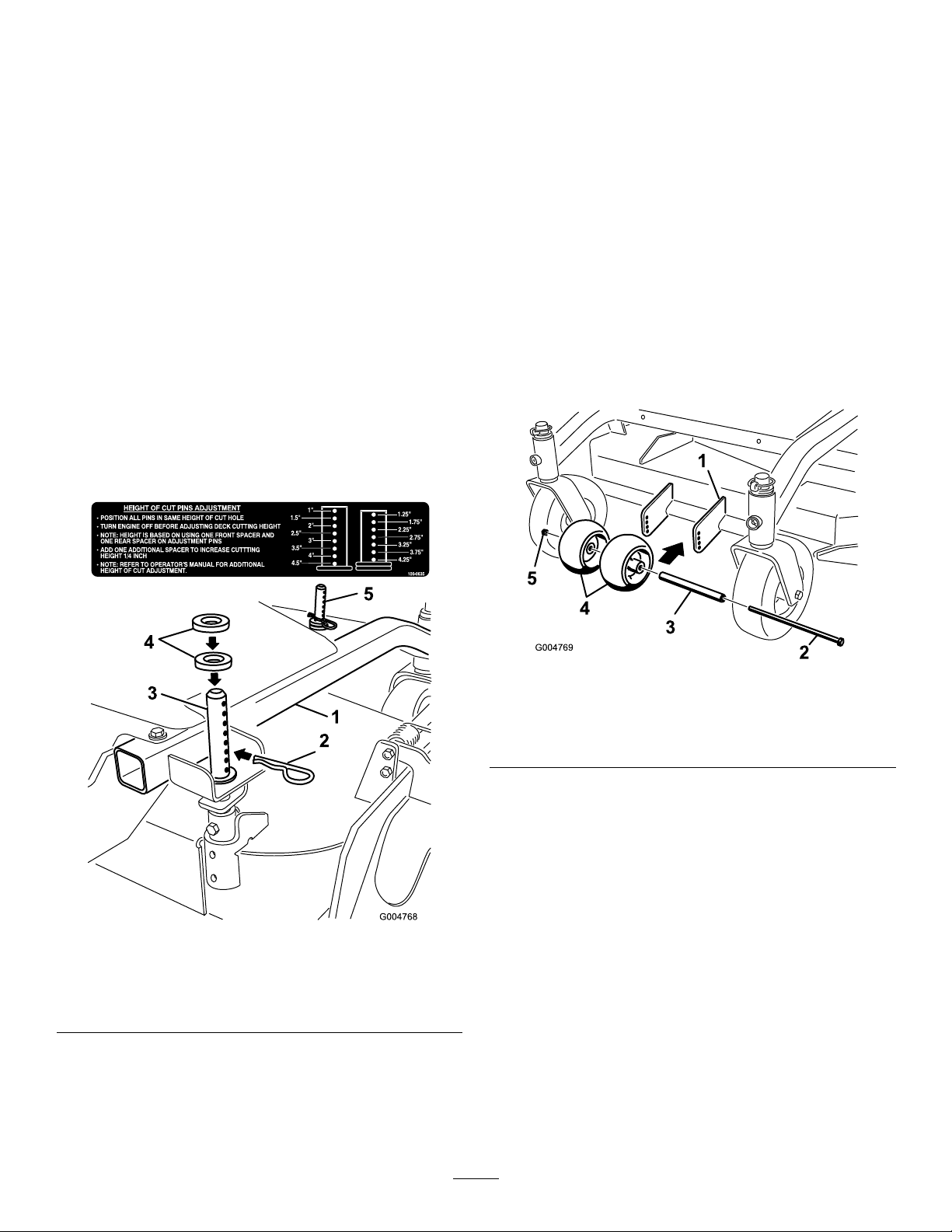

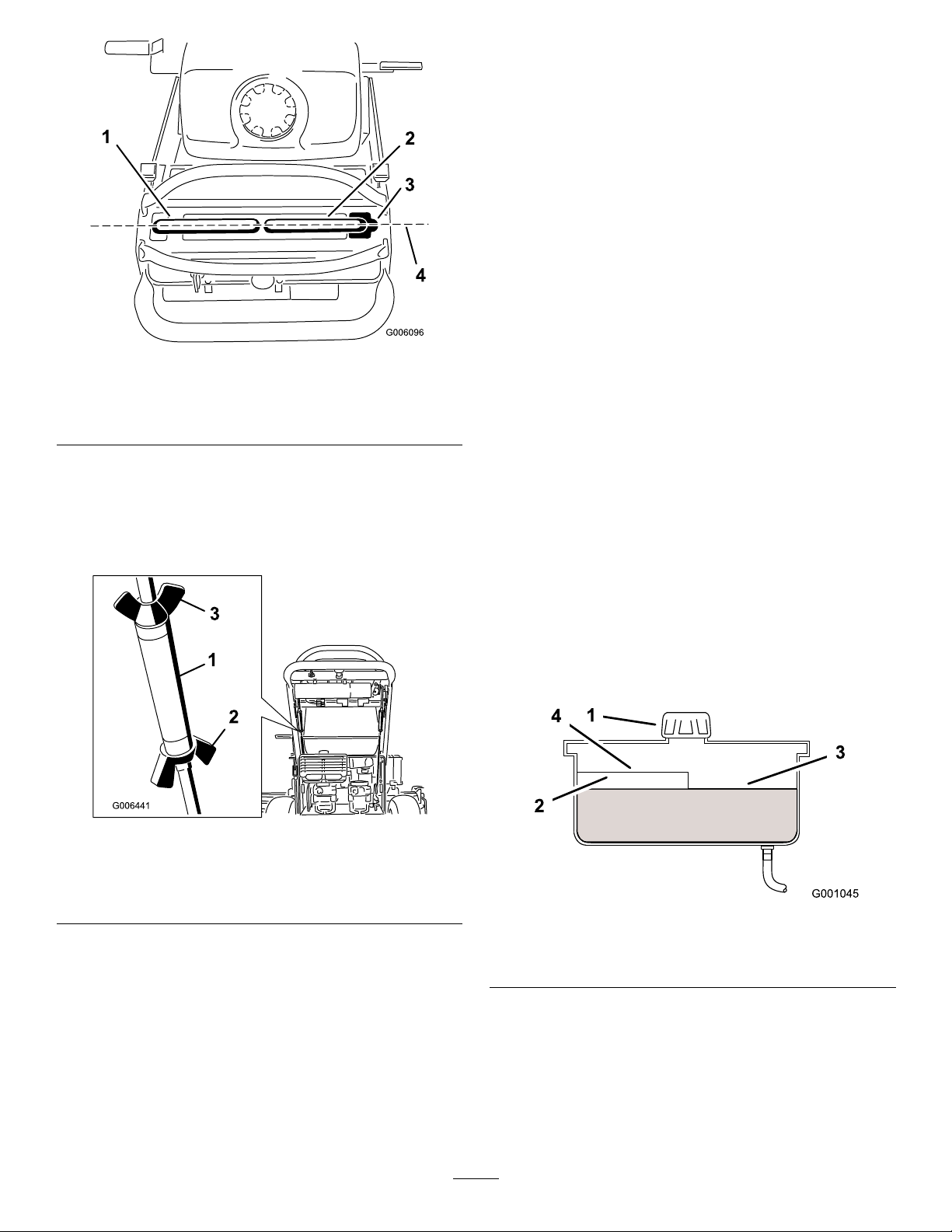

AdjustingtheHeight-of-Cut

AdjustingtheAnti-Scalp

Theheight-of-cutcanbeadjustedfrom25to114mm(1

to4-1/2inch)in6mm(1/4inch)increments.Adjustment

isdonebyrelocating4hairpincotterpinsindifferenthole

locationandbyaddingorremovingspacers.

Note:Allheight-of-cutpinsneedatleast1spacerordamage

canoccurtobushingifnoneareused.

Note:Allheight-of-cutpinscanuse2spacersmaximum.

1.Selectholeinheight-of-cutpostandnumberofspacers

correspondingtotheheight-of-cutdesired(Figure12).

2.Usingthelifthandle,raisesideofdeckandremove

hairpincotter(Figure12).

3.Addorremovespacersifneededandthenalignholes

andinserthairpincotter(Figure12).

Note:Spareheight-of-cutspacersmaybestoredon

postsandretainedbyahairpincotter.

Important:All4hairpincotterpinsmustbeinthe

sameholelocationandwiththecorrectnumberof

spacersforalevelcut.

Rollers

Theanti-scalprollersneedtobeadjustedintheproperhole

locationforeachheight-of-cutposition.Thereneedstobe10

mm(3/8inch)minimumclearanceabovetheground.

Note:Iftheanti-scalprollersareadjustedtoolowitcan

causeexcesswearoftherollers.

1.Afteradjustingheight-of-cut,checktheanti-scalp

rollerssothatthereisaminimumof10mm(3/8inch)

clearanceabovetheground(Figure13).

2.Ifadjustmentisneeded,removethebolt,washersand

nut(Figure13).

3.Selectaholepositionsotheanti-scalprollersarea

minimumof10mm(3/8inch)offtheground(Figure

13).

4.Installtheboltandnut(Figure13).

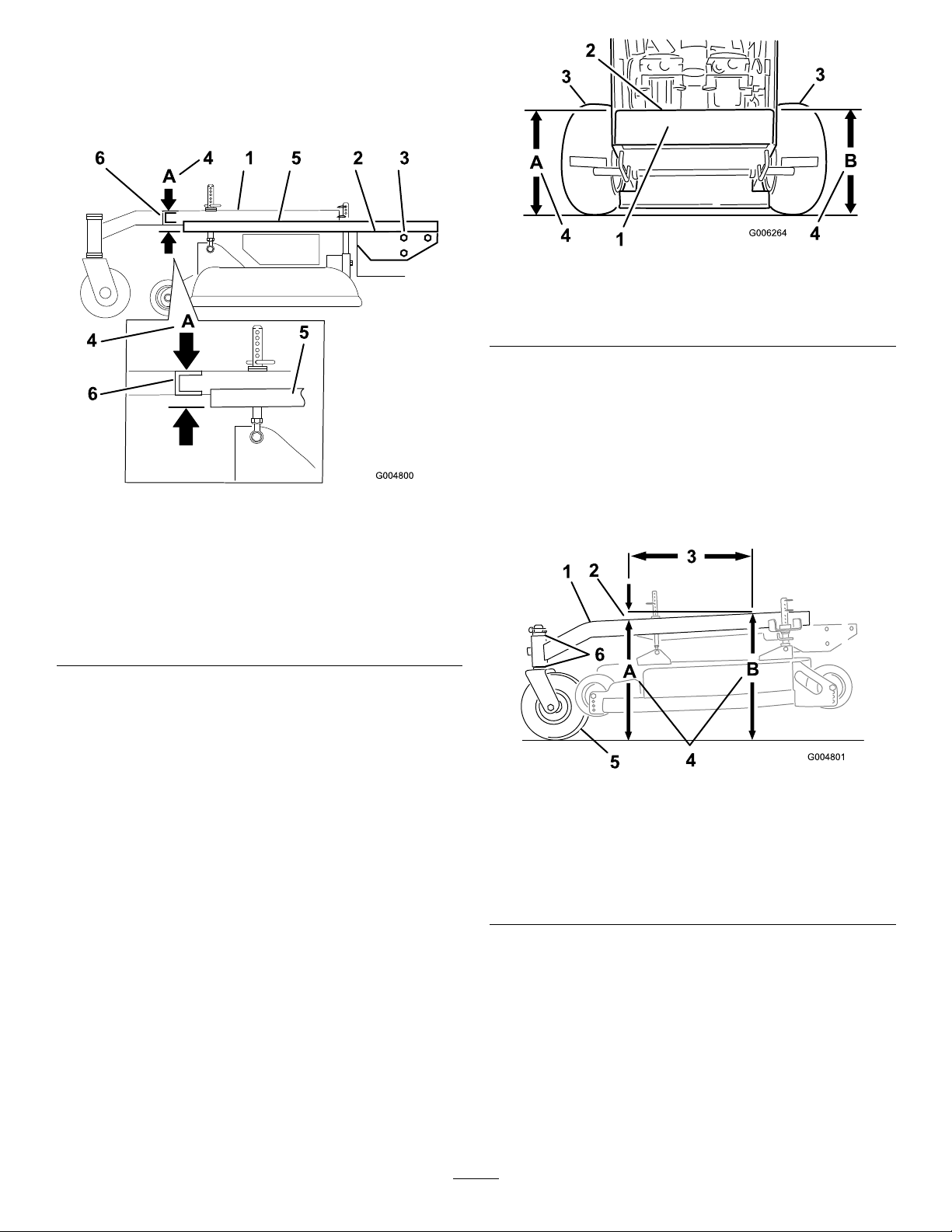

Figure12

1.Carrierframe4.Spacers

2.Hairpincotter

3.Backheight-of-cutpost

5.Frontheight-of-cutpost

Figure13

1.Mowerdeck4.Anti-scalprollers

2.Bolt5.Nut

3.Spacer

5.Incertainmowingconditionsandterrain,amismatch

ofcuttingheightmaybeseen.Adjustingtheoutside

anti-scalprollerstotheminimumsettingof10mm

(3/8inch)willhelppreventthemowerdeckcutting

toolowontheoutsideandminimizethemismatch.

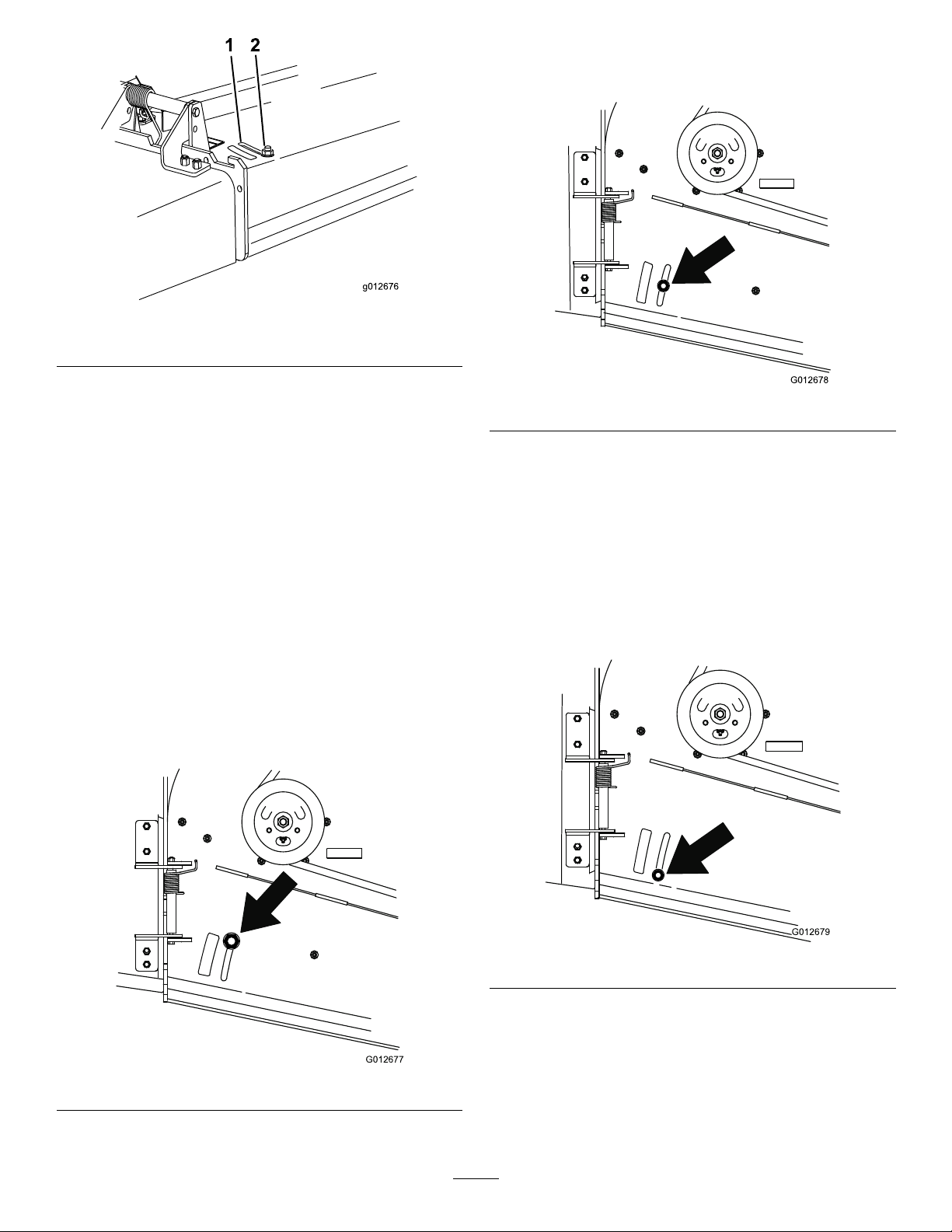

AdjustingtheFlowBafe

Themowerdischargeowcanbeadjustedfordifferenttypes

ofmowingconditions.Positionthecamlockandbafeto

givethebestqualityofcut.

1.DisengagethePTO ,movethemotion-controlleversto

theNeutral-Lockedpositionandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Toadjustthebafe,loosenthenut(Figure14).

4.Adjustthebafeandnutintheslottothedesired

dischargeowandtightenthenut.

17

Page 18

g012676

1 2

Figure14

G012677

G012678

G012679

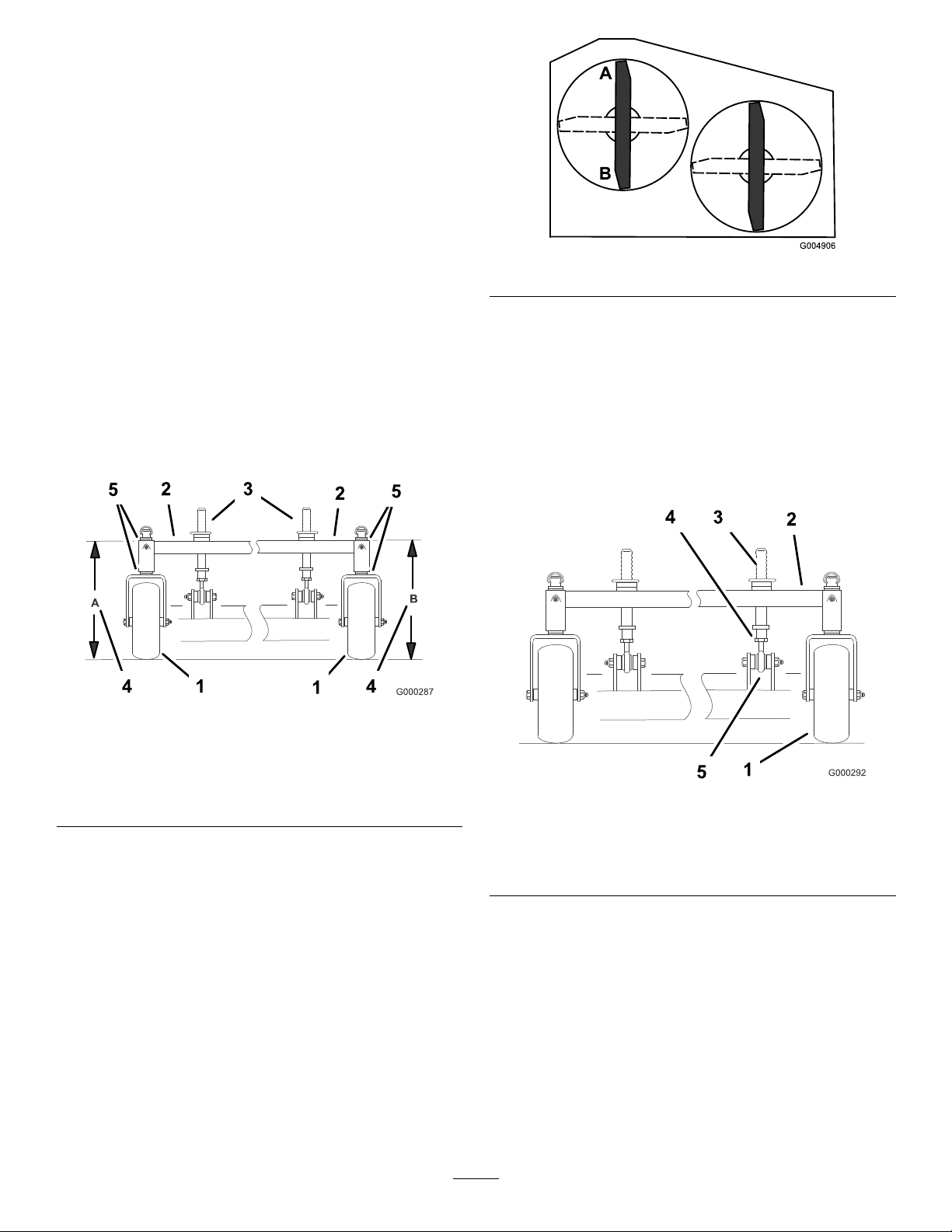

PositionB

Usethispositionwhenbagging(Figure16).

1.Slot

2.Nut

PositioningtheFlowBafe

Thefollowingguresareonlyrecommendationsforuse.

Adjustmentswillvarybygrasstype,moisturecontent,and

heightofgrass.

Note:Iftheenginepowerdrawsdownandthemower

groundspeedisthesame,openupthebafe.

PositionA

Thisisthefullrearposition(seeFigure15).Thesuggested

useforthispositionisafollows:

•Useforshort,lightgrassmowingconditions.

•Useindryconditions.

•Forsmallergrassclippings.

•Propelsgrassclippingsfartherawayfromthemower.

Figure16

PositionC

Thisisthefullopenposition.Thesuggesteduseforthis

positionisasfollows(Figure17):

•Useintall,densegrassmowingconditions.

•Useinwetconditions.

•Lowerstheenginepowerconsumption.

•Allowsincreasedgroundspeedinheavyconditions.

Figure15

Figure17

18

Page 19

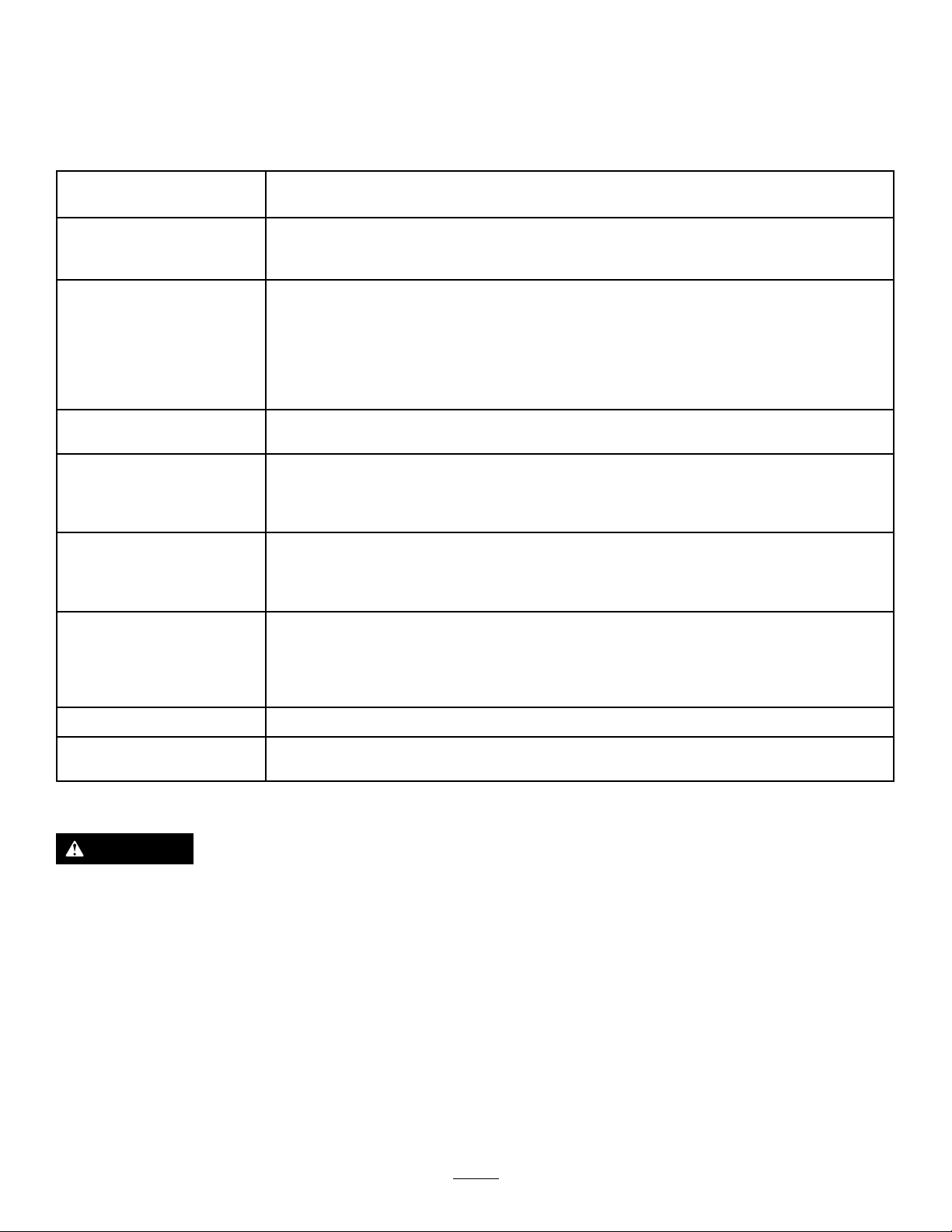

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every200hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthehydraulicuid.

•Changethehydrauliclter.

•Checkthesafety-interlocksystem.

•Greasethefrontcasterpivotbearing.

•Checktheengineoillevel.

•Cleantheairintakescreen.

•Checkthebrakes.

•Inspecttheblades.

•Cleanthemowerdeck.

•Cleanfoamaircleanerelement.

•Checkthehydraulicuid.

•GreasethePTObeltidler .

•Checkthepaperaircleanerelement.

•Checkthetirepressure.ormonthly,whicheveroccursrst.

•Inspectthebeltsforcracksandwear.

•Changetheengineoil.

•Checkthesparkplugs.

•Adjusttheelectricclutch.

•Checkthehydrauliclines.

•Replacethepaperaircleanerelement.

•Changetheoillter.

•Replacethefuellter.oryearly,whicheveroccursrst.

•Changethehydraulicuid.

•Changethehydrauliclter.

Every400hours

Beforestorage

•Greasethefrontwheelbearings(moreoftenindirtyordustyconditions).

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthesparkplugwiresfromthesparkplugsbeforeyoudo

anymaintenance.Setthewiresasidesothattheydonotaccidentallycontactthesparkplugs.

19

Page 20

Lubrication

GreasingthePTODriveBelt

GreasewithNo.2general-purpose,lithium-basedor

molybdenum-basedgrease.

LubricatingtheMachine

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanthegreasettingswitharag.Makesuretoscrape

anypaintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pumpgrease

intothettingsuntilgreasebeginstooozeoutofthe

bearings.

5.Wipeupanyexcessgrease.

LubricatingtheBearings

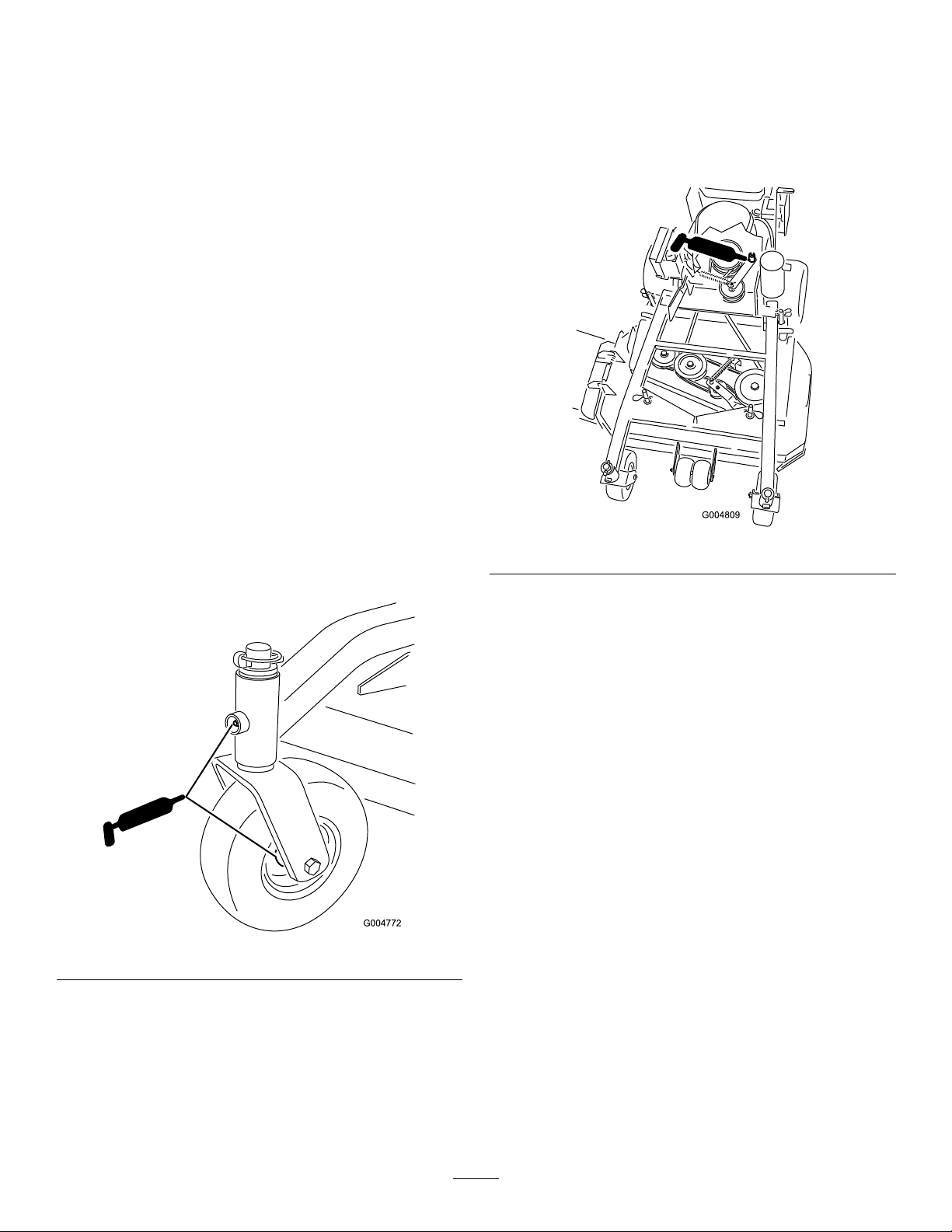

ServiceInterval:Beforeeachuseordaily—Greasethefront

casterpivotbearing.

Every400hours—Greasethefrontwheelbearings

(moreoftenindirtyordustyconditions).

Lubricatethefrontcasterwheelbearingsandfrontpivots

(Figure18).

Idler

ServiceInterval:Every50hours—GreasethePTObelt

idler.

Greasetheidlerpulleypivot(Figure19).

Figure19

Figure18

20

Page 21

EngineMaintenance

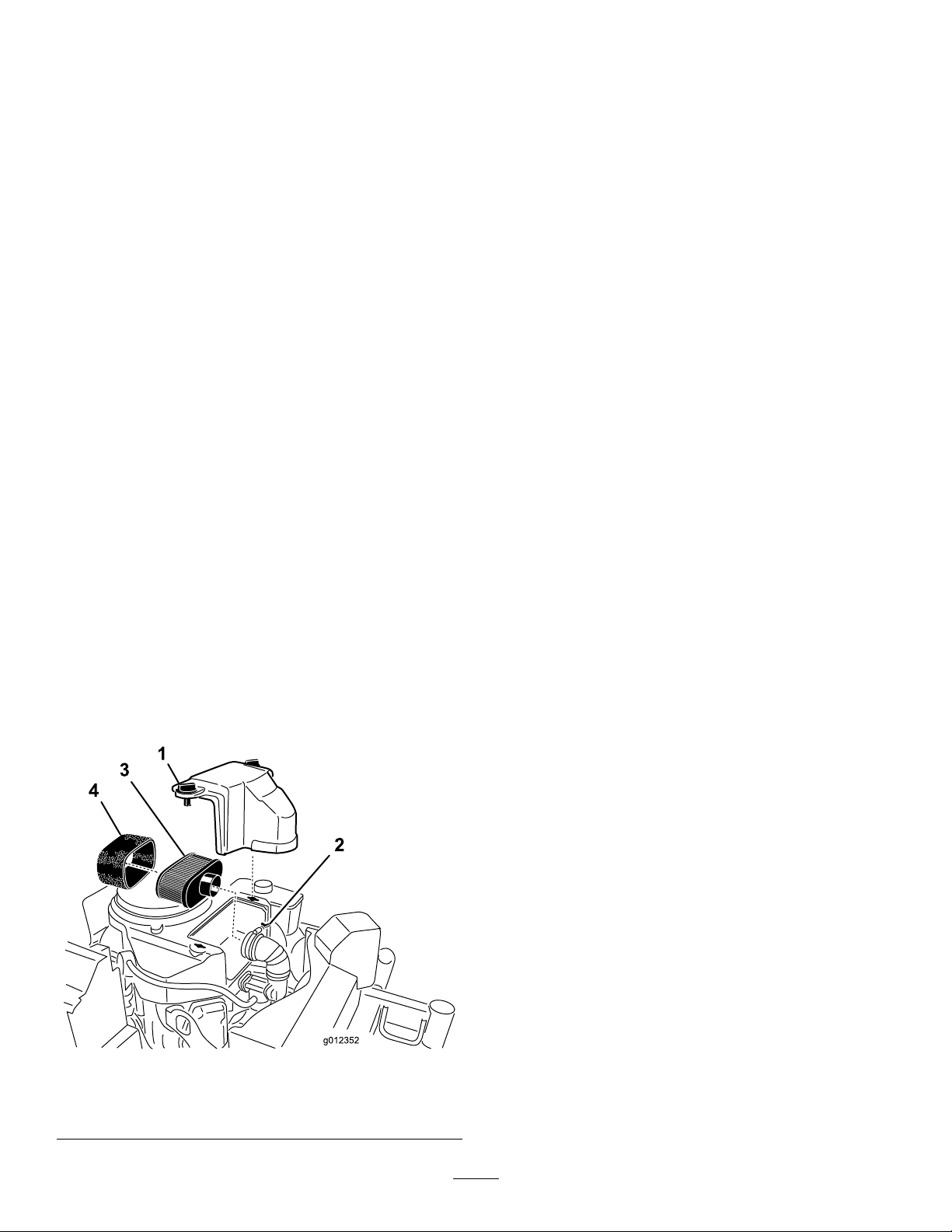

ServicingtheAirCleaner

CleaningtheFoamAir-CleanerElement

1.Washthefoamelementinliquidsoapandwarmwater.

Whentheelementisclean,rinseitthoroughly .

2.Drytheelementbysqueezingitinacleancloth.

ServiceInterval/Specication

ServiceInterval:Every25hours

Every50hours

Every200hours/Yearly(whichevercomesrst)

Inspectthefoamandpaperelementsandreplacethemifthey

aredamagedorexcessivelydirty.

Note:Servicetheaircleanermorefrequently(everyfew

operatinghours)iftheoperatingconditionsareextremely

dustyorsandy .

Important:Donotoilthefoamorpaperelement.

RemovingtheFoamandPaper

Elements

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage(Figure20).

4.Unscrewthecoverknobsandremovetheaircleaner

cover(Figure20).

Important:Replacethefoamelementifitistorn

orworn.

ServicingthePaperAir-Cleaner

Element

1.Donotcleanthepaperlter.Replaceit(Figure20).

2.Inspecttheelementfortears,anoilylm,ordamageto

therubberseal.

3.Replacethepaperelementifitisdamaged.

InstallingtheFoamandPaperElements

Important:Topreventenginedamage,alwaysoperate

theenginewiththecompletefoamandpaperaircleaner

assemblyinstalled.

1.Carefullyslidethefoamelementontothepaperair

cleanerelement(Figure20).

2.Placetheaircleanerassemblyontotheaircleanerbase

andsecureitwiththe2wingnuts(Figure20).

3.Placetheaircleanercoverintopositionandtighten

thecoverknob(Figure20).

5.Unscrewthehoseclampandremovetheaircleaner

assembly(Figure20).

6.Carefullypullthefoamelementoffthepaperelement

(Figure20).

Figure20

1.Cover

2.Hoseclamp4.Foamelement

3.Paperelement

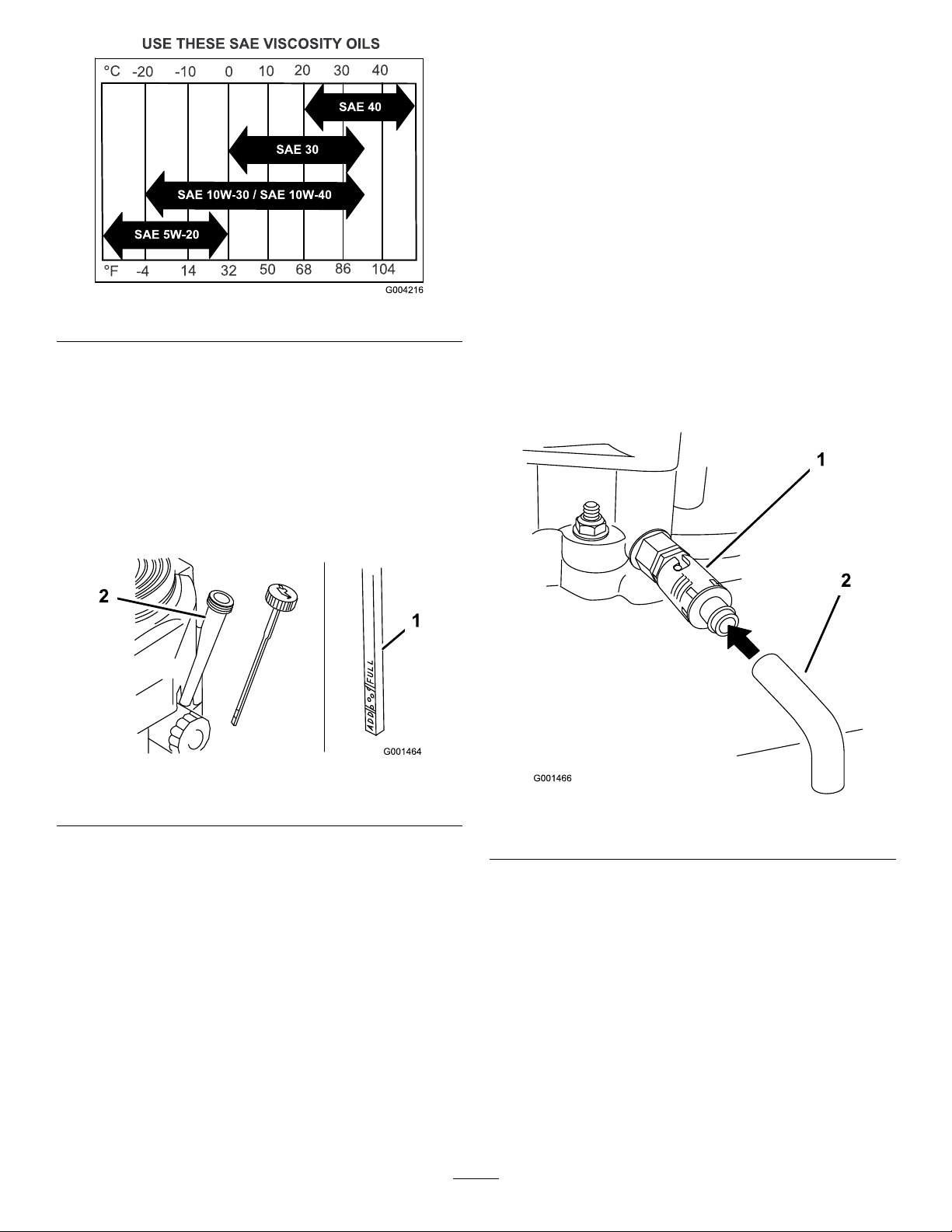

ServicingtheEngineOil

ServiceInterval:Beforeeachuseordaily

Aftertherst8hours

Every100hours

Every200hours—Changetheoillter.

Note:Changetheoilmorefrequentlywhentheoperating

conditionsareextremelydustyorsandy.

OilType:Detergentoil(APIserviceSF ,SG,SH,orSJ)

CrankcaseCapacity:1.7L(58oz)withthelterremoved;

1.5L(51oz)withoutthelterremoved

Viscosity:Refertothetable(Figure21).

21

Page 22

ChangingtheEngineOil

1.Starttheengineandletitrun5minutes.

Note:Thiswarmstheoilsoitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightlylower

thantheoppositesidetoensurethattheoildrains

completely.

3.DisengagethePTOandsettheparkingbrake.

4.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

5.Slidethedrainhoseovertheoil-drainvalve.

Figure21

CheckingtheEngine-OilLevel

1.Parkthemachineonalevelsurface.

2.DisengagethePTOandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.Cleanaroundtheoildipstick(Figure22)sothatdirt

cannotfallintothellerholeanddamagetheengine.

6.Placeapanbelowthedrainhose.Rotatetheoil-drain

valvetoallowoiltodrain(Figure23).

7.Whenoilhasdrainedcompletely,closethedrainvalve.

8.Removethedrainhose(Figure23).

Note:Disposeoftheusedoilatarecyclingcenter.

Figure22

1.Oildipstick

2.Fillertube

5.Unscrewtheoildipstickandwipetheendclean(Figure

22).

6.Slidetheoildipstickfullyintothellertube,butdonot

threadontotube(Figure22).

7.Pullthedipstickoutandlookattheend.Iftheoillevel

islow,slowlypouronlyenoughoilintothellertube

toraisetheleveltotheFullmark.

Important:Donotoverllthecrankcasewithoil

andruntheengine;enginedamagecanresult.

Figure23

1.Oil-drainvalve2.Oil-drainhose

9.Slowlypourapproximately80%ofthespeciedoil

intothellertube(Figure22).

10.Checktheoillevel;refertoCheckingtheEngine-Oil

Level(page12).

11.SlowlyaddtheadditionaloiltobringittotheFull

mark.

22

Page 23

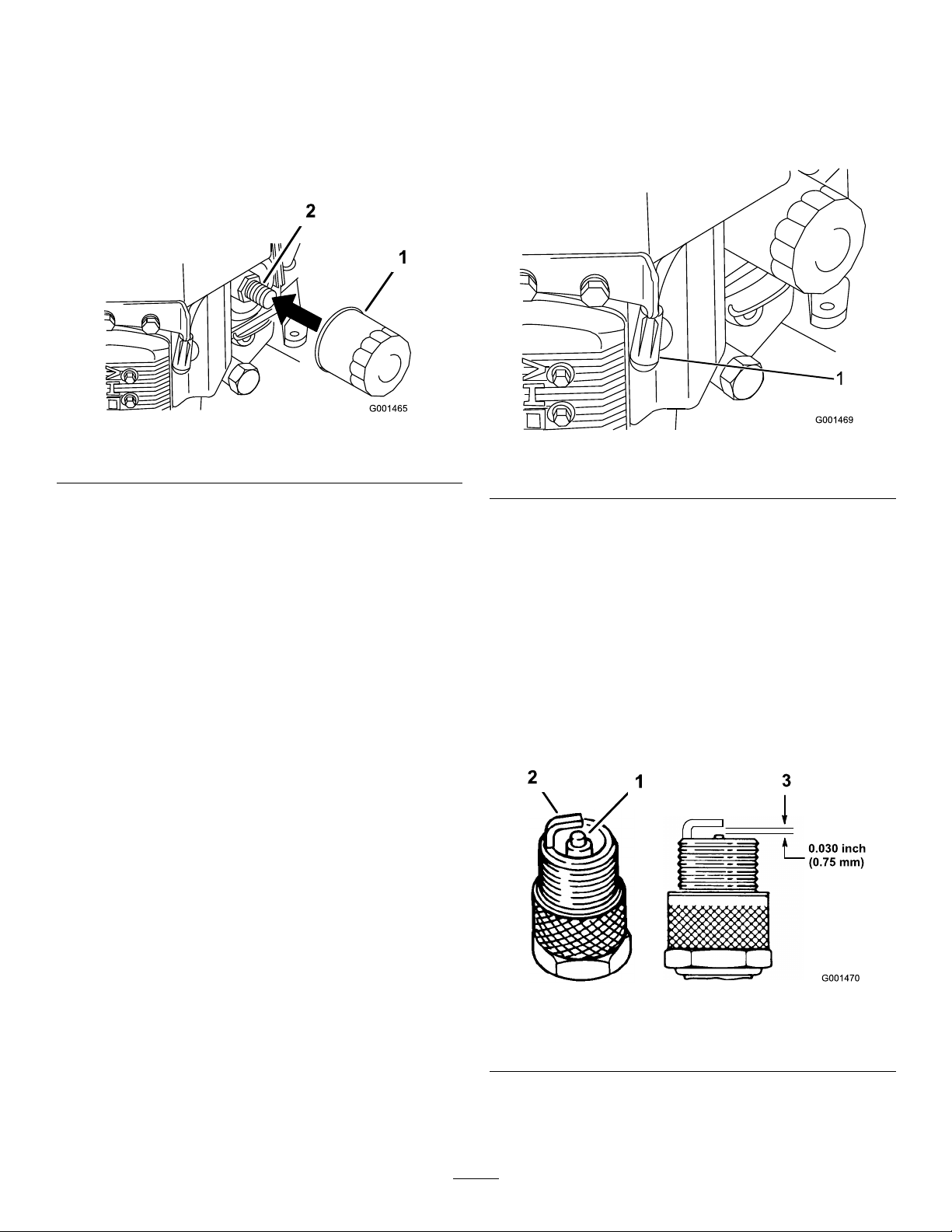

ChangingtheOilFilter

1

RemovingtheSparkPlugs

Note:Changetheoilltermorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil(page22).

2.Removetheoldlter(Figure24).

Figure24

1.Oillter

3.Applyathincoatofnewoiltotherubbergasketon

thereplacementlter(Figure24).

4.Installthereplacementoilltertothelteradapter,

turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional3/4turn(Figure24).

5.Fillthecrankcasewiththepropertypeofnewoil;refer

toServicingtheEngineOil(page21).

6.Runtheengineforabout3minutes,stoptheengine,

andcheckforoilleaksaroundtheoillteranddrain

valve.

7.Checktheengineoillevelandaddoilifneeded.

2.Adapter

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Disconnectthewiresfromthesparkplugs(Figure25).

Figure25

1.Spark-plugwire/sparkplug

4.Cleanaroundthesparkplugstopreventdirtfrom

fallingintotheengineandpotentiallycausingdamage.

5.Removethesparkplugsandthemetalwashers.

CheckingtheSparkPlugs

1.Lookatthecenterofthesparkplugs(Figure26).If

youseelightbrownorgrayontheinsulator,theengine

isoperatingproperly.Ablackcoatingontheinsulator

usuallymeansthattheaircleanerisdirty.

2.Ifneeded,cleanthesparkplugwithawirebrushto

removecarbondeposits.

8.Wipeupanyspilledoil.

ServicingtheSparkPlugs

ServiceInterval/Specication

ServiceInterval:Every100hours

Ensurethattheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkplugsanda

gappingtool/feelergaugetocheckandadjusttheairgap.

Installanewsparkplugsifnecessary.

Type:Champion®RCJ8YorequivalentAirGap:0.75mm

(0.030inch)

Figure26

1.Center-electrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

Important:Alwaysreplacethesparkplugswhen

ithaswornelectrodes,anoilylmonit,orhas

cracksintheporcelain.

23

Page 24

3.Checkthegapbetweenthecenterandsideelectrodes

(Figure26).Bendthesideelectrode(Figure26)ifthe

gapisnotcorrect.

FuelSystem

Maintenance

InstallingtheSparkPlugs

1.Installthesparkplugsandthemetalwasher.

Note:Ensurethattheairgapissetcorrectly(Figure

26).

2.Tightenthesparkplugsto22N-m(16ft-lb).

3.Connectthewirestothesparkplugs(Figure26).

DrainingtheFuelTank

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

1.Parkthemachineonalevelsurface,toensurethatthe

fueltankdrainscompletely.

2.Disengagethepowertake-off(PTO),settheparking

brake,turntheignitionkeytotheOffposition,and

removethekey.

3.Closethefuelshut-offvalveatthefueltank(Figure27).

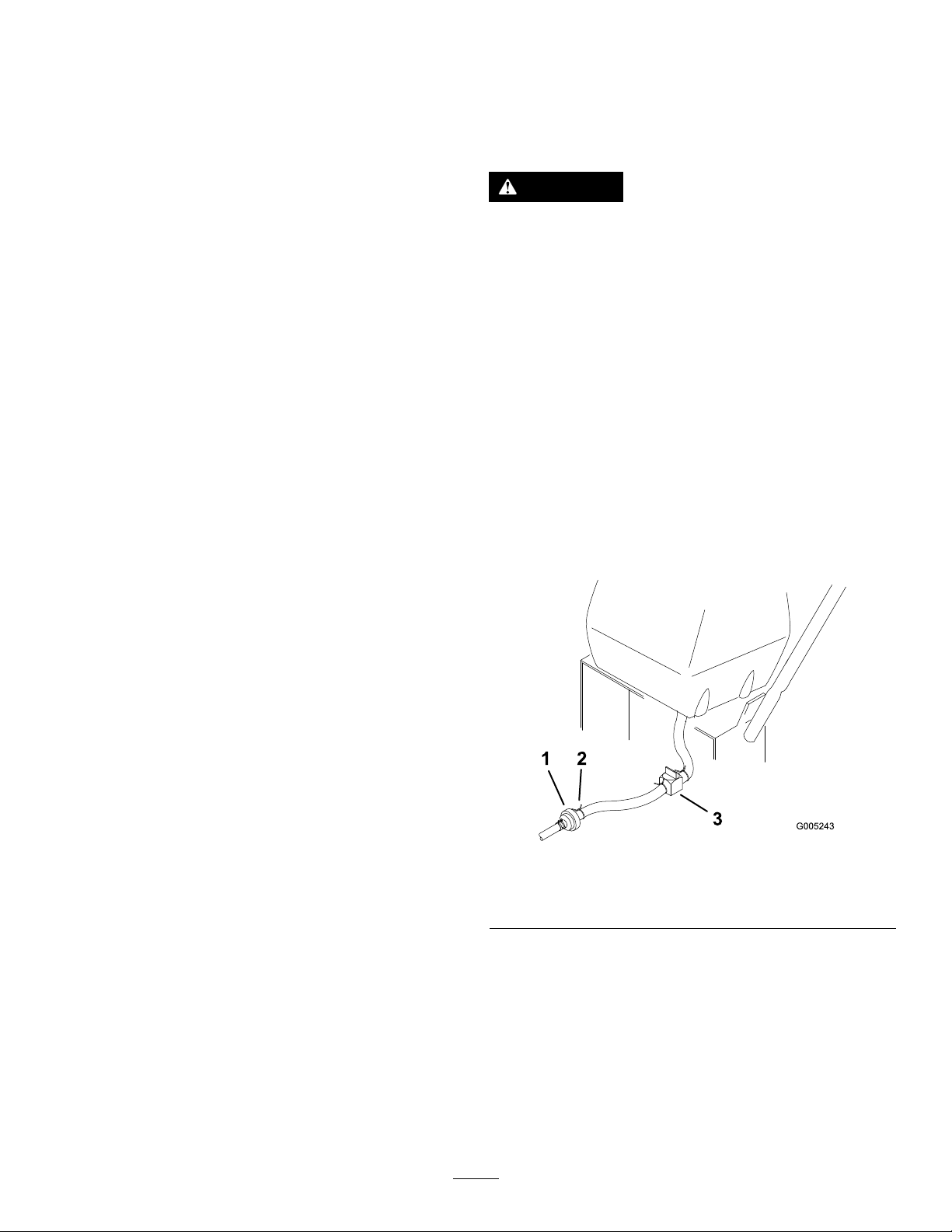

Figure27

1.Fuellter3.Fuelshut-offvalve

2.Clamp

4.Squeezetheendsofthehoseclamptogetherandslide

itupthefuellineawayfromfuellter(Figure27).

5.Pullthefuellineoffthefuellter(Figure27).

6.Openthefuelshut-offvalveandallowthegasolineto

drainintoagascanordrainpan.

Note:Nowisthebesttimetoinstallanewfuellter

becausethefueltankisempty.RefertoReplacingthe

FuelFilter(page25).

7.Installthefuellineontothefuellter.

24

Page 25

8.Slidethehoseclampclosetothevalvetosecurethe

fuelline.

ElectricalSystem

9.Wipeupanyspilledfuel.

ReplacingtheFuelFilter

ServiceInterval:Every200hoursoryearly,whichever

occursrst.

Neverinstalladirtylterifitisremovedfromthefuelline.

Note:Notehowthefuellterisinstalledinordertoinstall

thenewltercorrectly.

Note:Wipeupanyspilledfuel.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Closefuelshut-offvalveatthefueltank(Figure28).

4.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure28).

Maintenance

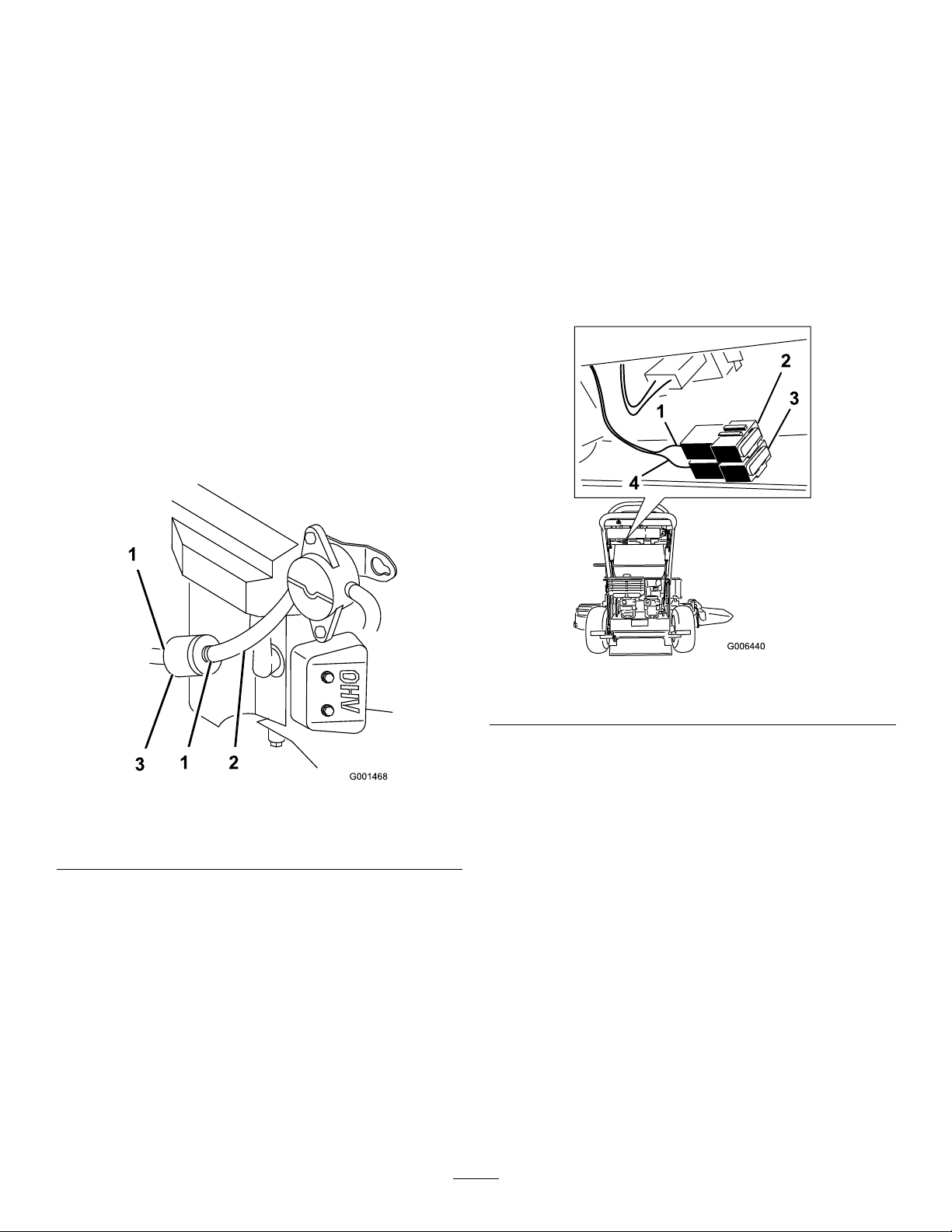

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequiresno

maintenance.Ifafuseblows,checkthecomponentorcircuit

foramalfunctionorshort.

1.Removethecoverunderthecontrolpanel.

2.Pulloutonthefusetoremoveorreplaceit(Figure29).

3.Installthecoverunderthecontrolpanel.

Figure28

1.Hoseclamp3.Filter

2.Fuelline

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclampscloseto

thelter.

7.Openfuelshut-offvalveatfueltank(Figure28).

8.Checkforfuelleaksandrepairifneeded.

9.Wipeupanyspilledfuel.

Figure29

1.Fuse,10amp,bladetype2.Fuse,20amp,bladetype

25

Page 26

DriveSystem

Maintenance

AdjustingtheTracking

Ifthemachinedoesnottrackstraight,adjustmentisrequired.

1.Checkthereartirepressure.RefertoCheckingtheTire

Pressure(page26).

2.Loosenthewingnutsontherightcontrolrodand

rotatetheturnbuckleinorouttoensuretheright

controlleveriscenteredintheNeutral-Lockposition.

3.Securetheturnbuckleinpositionwiththewingnuts

(Figure30).

Figure30

Figure31

ReplacingtheCasterWheel ForkBushings

Thecasterwheelforksaremountedinbushingspressedinto

thetopandbottomofthecarrierframemountingpivot

tubes.Tocheckthebushings,movethecasterforksbackand

forthandside-to-side.Ifacasterforkisloose,thebushings

arewornandmustbereplaced.

1.Raisethecuttingunitsothecasterwheelsareoffthe

oor,thensupportthefrontofthemowerwithjack

stands.

2.Removethelockingpinandspacer(s)fromthetopof

thecasterwheelfork(Figure32).

1.Turnbuckle

2.Bottomwingnut

4.Loosenthewingnutsontheleftcontrolrodandrotate

theturnbuckleinorouttochangethetracking.

5.Securetheturnbuckleinpositionwiththewingnuts

(Figure30).

6.Checkforpropertracking.

7.Adjusttheleftcontrolrodifachangeisneeded.

3.Topwingnut(lefthand

threaded)

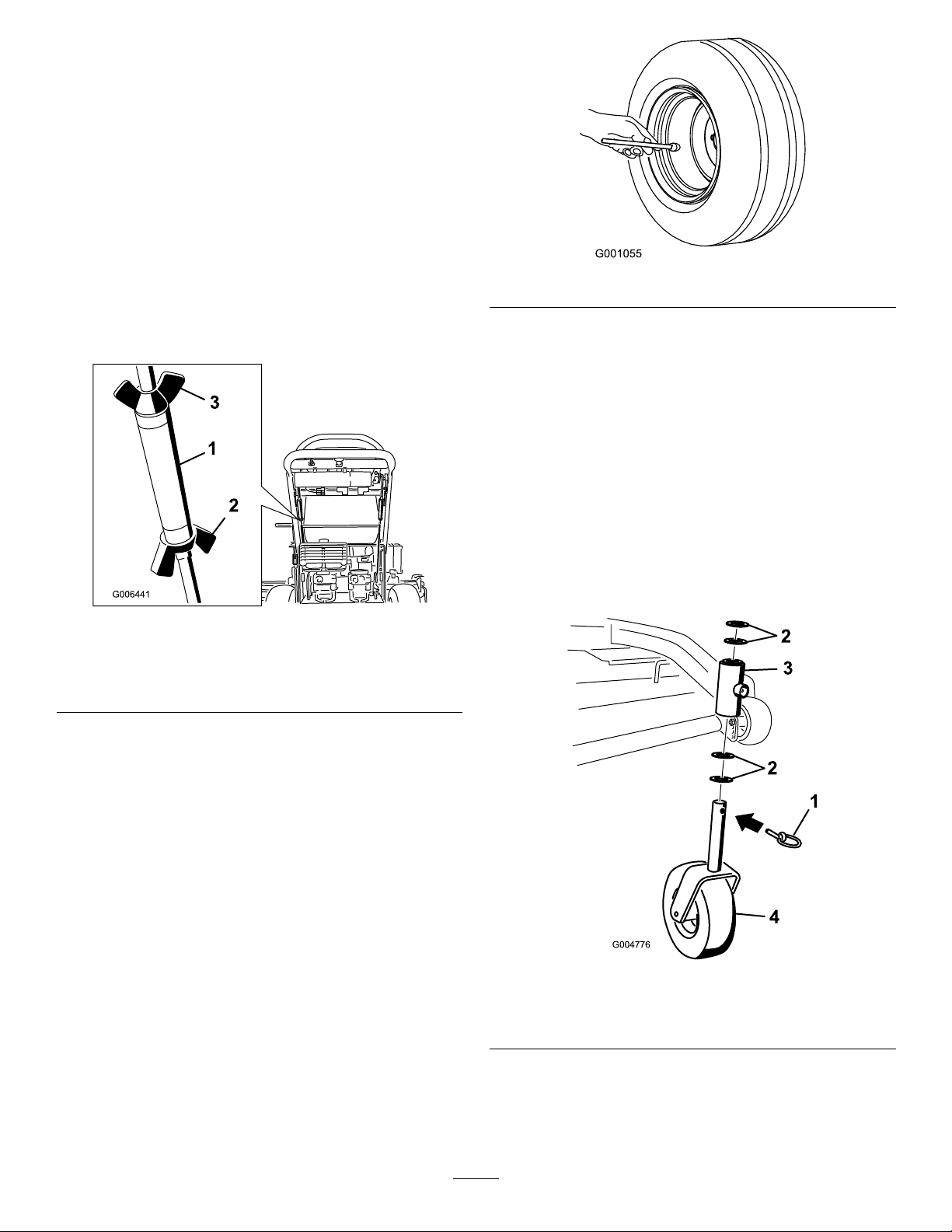

CheckingtheTirePressure

ServiceInterval:Every50hoursormonthly,whichever

occursrst.

Checkthepressureatthevalvestem(Figure31).

Maintaintheairpressureinthereartiresat83to97kPa(12

to14psi).Uneventirepressurecancauseanunevencut.

Note:Thefronttiresaresemi-pneumatictiresanddonot

requireairpressuremaintenance.

Figure32

1.Lockingpin

2.Spacers4.Caster-wheelfork

3.Pullthecasterwheelforkoutofthemountingtube,

leavingthespacer(s)onthebottomofthefork.

4.Notethelocationofthespacersoneachforktoensure

correctinstallation,andtomaintainaleveldeck.

3.Carrier-framepivottube

26

Page 27

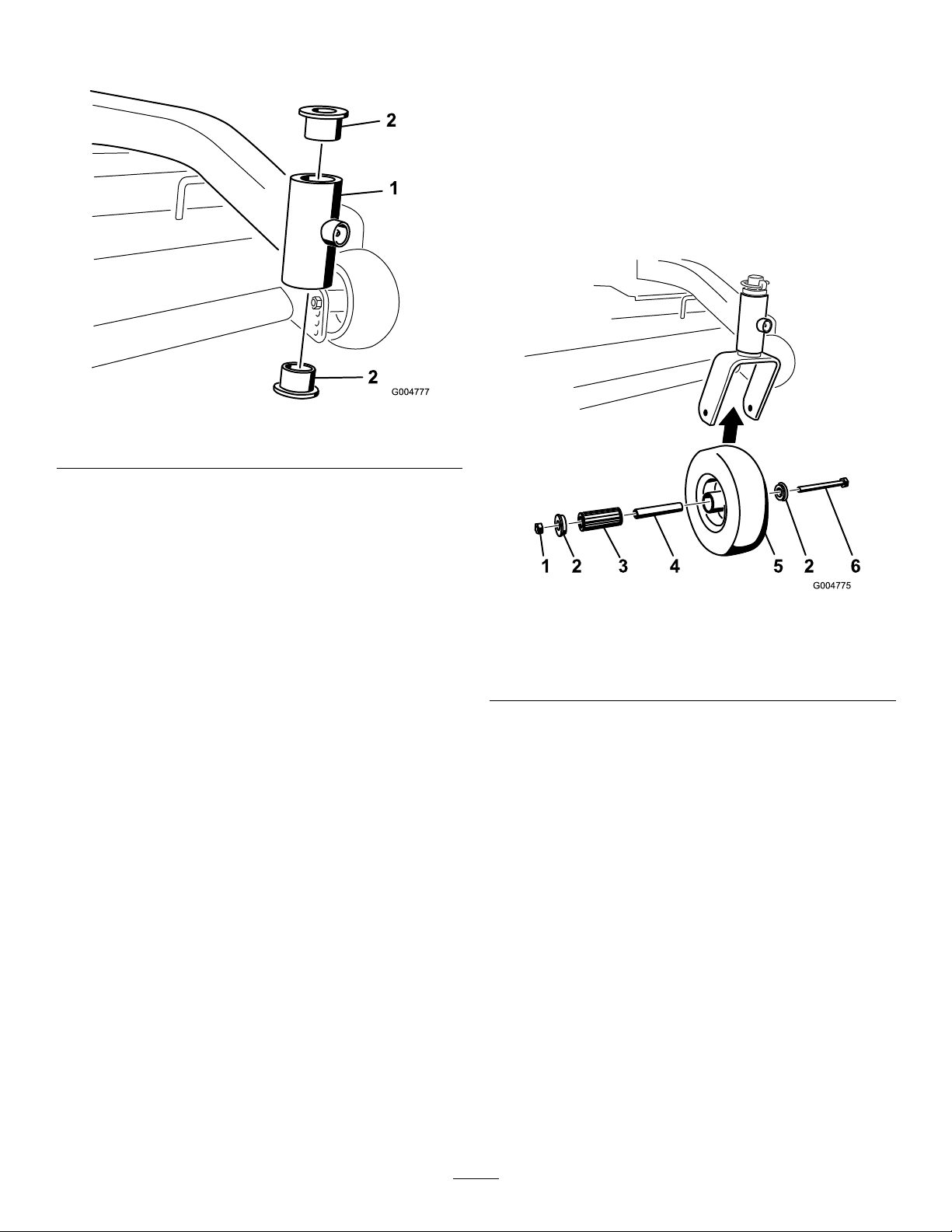

5.Insertapinpunchintothemountingtubeandcarefully

driveoutthebushings(Figure33).

Figure33

1.Mountingtube2.Bushing

6.Cleantheinsideofthemountingtube.

ServicingtheCasterWheel andBearings

Thecasterwheelsrotateonarollerbearingsupportedbya

spannerbushing.Ifthebearingiskeptwelllubricated,wear

willbeminimal.Failuretokeepthebearingwelllubricated

willcauserapidwear.Awobblycasterwheelusuallyindicates

awornbearing.

1.Removethelocknutandwheelboltholdingthecaster

wheeltothecasterfork(Figure34).

7.Greasetheinsideandoutsideofthenewbushings.

8.Useahammerandatplatetocarefullydrivethe

bushingsintothepivottubes.

9.Inspectthecasterwheelforkforwearandreplaceif

necessary(Figure33).

10.Slidethecasterwheelforkthroughthebushingsinthe

mountingtube.

11.Replacethespacer(s)ontotheforkandsecurewiththe

retainingring(Figure33).

Important:Theinsidediameterofthebushings

maycollapseslightlywheninstalled.Ifthecaster

wheelforkdoesnotslideintothenewbushings,

reambothbushingstoaninsidediameterof1.126

inch(29mm).

12.Greasethettingonthecarrierframepivottubes

usingNo.2general-purpose,lithium-basedor

molybdenum-basedgrease.

Figure34

1.Locknut

2.Wheelbolt5.Rollerbearing

3.Bushing

2.Remove1bushing,thenpullthespannerbushingand

rollerbearingoutofthewheelhub(Figure34).

3.Removetheotherbushingfromthewheelhuband

cleananygreaseanddirtfromthewheelhub(Figure

34).

4.Inspecttherollerbearing,bushings,spannerbushing,

andinsideofthewheelhubforwear;replaceany

defectiveorwornparts(Figure34).

5.Toassemble,place1bushingintothewheelhub.

Greasetherollerbearingandspannerbushingandslide

themintothewheelhub.

6.Placethesecondbushingintothewheelhub(Figure

34).

4.Spannerbushing

7.Installthecasterwheelintothecasterforkandsecure

withthewheelboltandlocknut.

8.Tightenthelocknutuntilthespannerbushingbottoms

againsttheinsideofthecasterforks(Figure34).

9.Greasethettingonthecasterwheel.

27

Page 28

AdjustingtheElectricClutch

CoolingSystem

ServiceInterval:Every100hours

Theclutchisadjustabletoensureproperengagementand

properbraking.

1.Inserta0.381–0.533mm(0.015–0.021inch)feeler

gaugethrough1inspectionslotinthesideofthe

assembly.

Note:Makesureitisbetweenthearmatureandthe

rotorfrictionsurfaces.

2.Tightenthelocknutsuntilthereisslightbindingon

thefeelergaugebutitcanbemovedeasilywithinthe

airgap(Figure35).

3.Repeatthisfortheremainingslots.

4.Checkeachslotagainandmakeslightadjustmentsuntil

thefeelergaugebetweentherotorandarmaturewith

veryslightcontactbetweenthem.

Maintenance

CleaningtheAirIntakeScreen

ServiceInterval:Beforeeachuseordaily

Removeanybuild-upofgrass,dirt,orotherdebrisfromthe

cylinderandcylinderheadcoolingns,airintakescreenon

ywheelend,andcarburetor-governorleversandlinkage.

Thiswillhelpensureadequatecoolingandcorrectengine

speedandwillreducethepossibilityofoverheatingand

mechanicaldamagetotheengine.

Figure35

1.Adjustingnut3.Feelergauge

2.Slot

28

Page 29

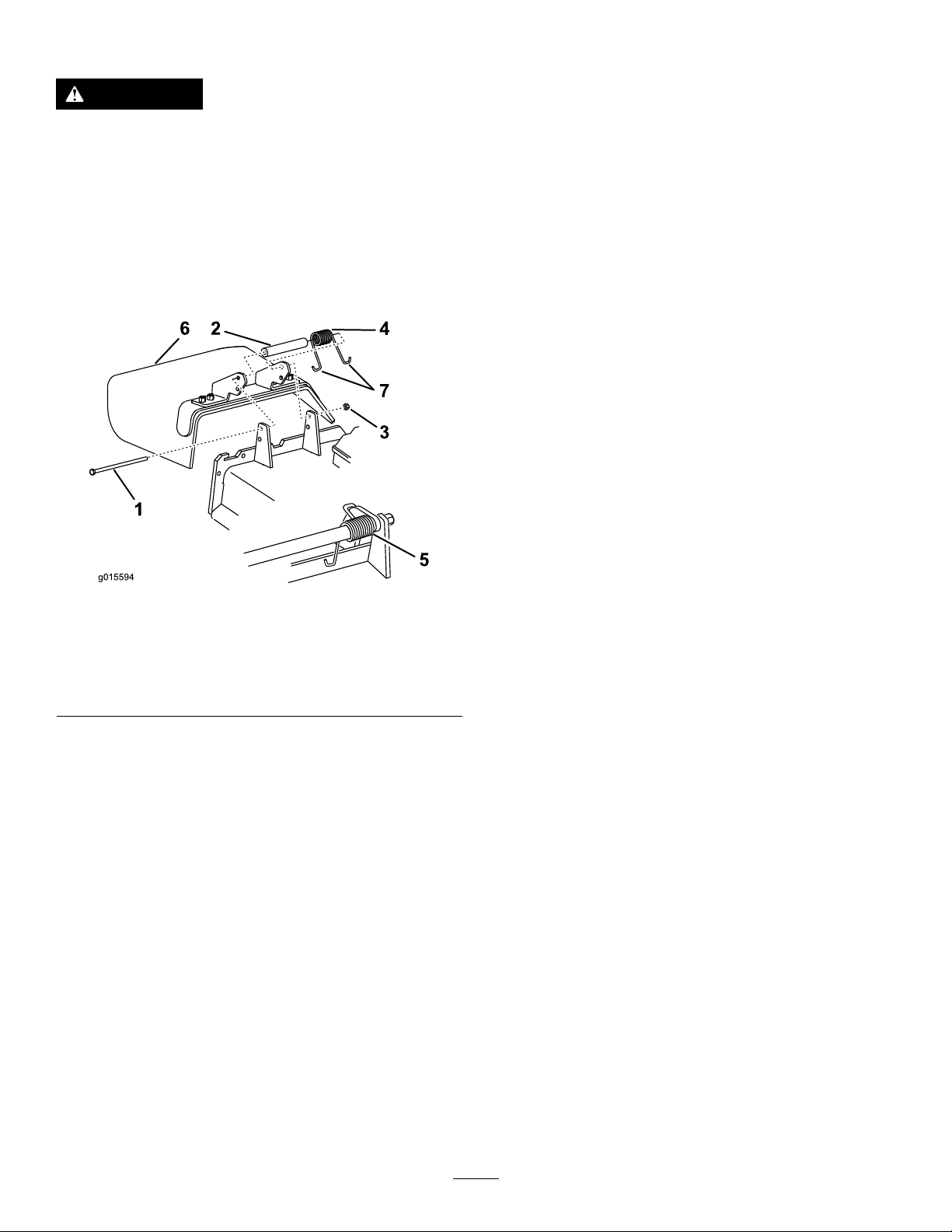

BrakeMaintenance

ServicingtheBrakes

1.Parkthemachineonalevelsurface,disengagethe

PTO,andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

Alwayssettheparkingbrakewhenyoustopthemachine

orleaveitunattended.Iftheparkingbrakedoesnothold

securely,anadjustmentisrequired.

CheckingtheBrakes

ServiceInterval:Beforeeachuseordaily

Checkthebrakesonbothalevelsurfaceandslope.

1.Parkthemachineonalevelsurface,disengagethePTO.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Applytheparkingbrake.

Note:Settingtheparkingbrakeshouldtakea

reasonableamountofforce.Iftheparkingbrakedoes

notholdsecurely,adjustit.RefertoAdjustingthe

Brakes(page29).

Note:Whenthebrakeisengaged,thebrakehandle

shouldbeinthe1o'clockposition(Figure36).

3.Checkthebrakebeforeyouadjustit;refertoChecking

theBrakes(page29).

4.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake(page13).

5.Loosenthetopandbottomjamnuts(Figure36).

6.Toadjustthebrake,removethehairpincotterand

clevispinfromthelowerbrakelever(Figure36).

7.Rotatethebrakerodintheyokes.

•Totightenthebrake,lengthentherodbetweenthe

yokes.

•Toloosenthebrake,shortentherodbetweenthe

yokes(Figure36).

Note:Thebrakerodshouldbethreadedintoboth

yokesthesamedistance.

8.Securetheyoketolowerbrakeleverwiththehairpin

cotterandclevispin(Figure36).

9.Tightenthetopandbottomjamnuts(Figure36).

10.Checkthebrakeoperationagain;refertoCheckingthe

Brakes(page29).

Figure36

1.Parkingbrakelever

(releasedposition)

2.Oneo'clockposition

3.Haripincotter7.Jamnut

4.Lowerbrakelever8.Brakerod

5.Clevispin

6.Yoke

AdjustingtheBrakes

Iftheparkingbrakedoesnotholdsecurely ,anadjustment

isrequired.

29

Page 30

BeltMaintenance

InspectingtheBelts

ServiceInterval:Every50hours

Checkthebeltsforcracks,frayededges,burnmarks,wear,

signsofoverheating,oranyotherdamage.Replaceany

damagedbelts.

ReplacingtheMowerBelt

Important:Thefastenersonthecoversofthismachine

aredesignedtoremainwiththecoverafterremoval.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Unlatchandremovethecarrierframecover.

4.Removethebeltcoverboltsandremovethebeltcover.

5.RemovethePTO-drivebelt.RefertoReplacingthe

PTO-DriveBelt(page30).

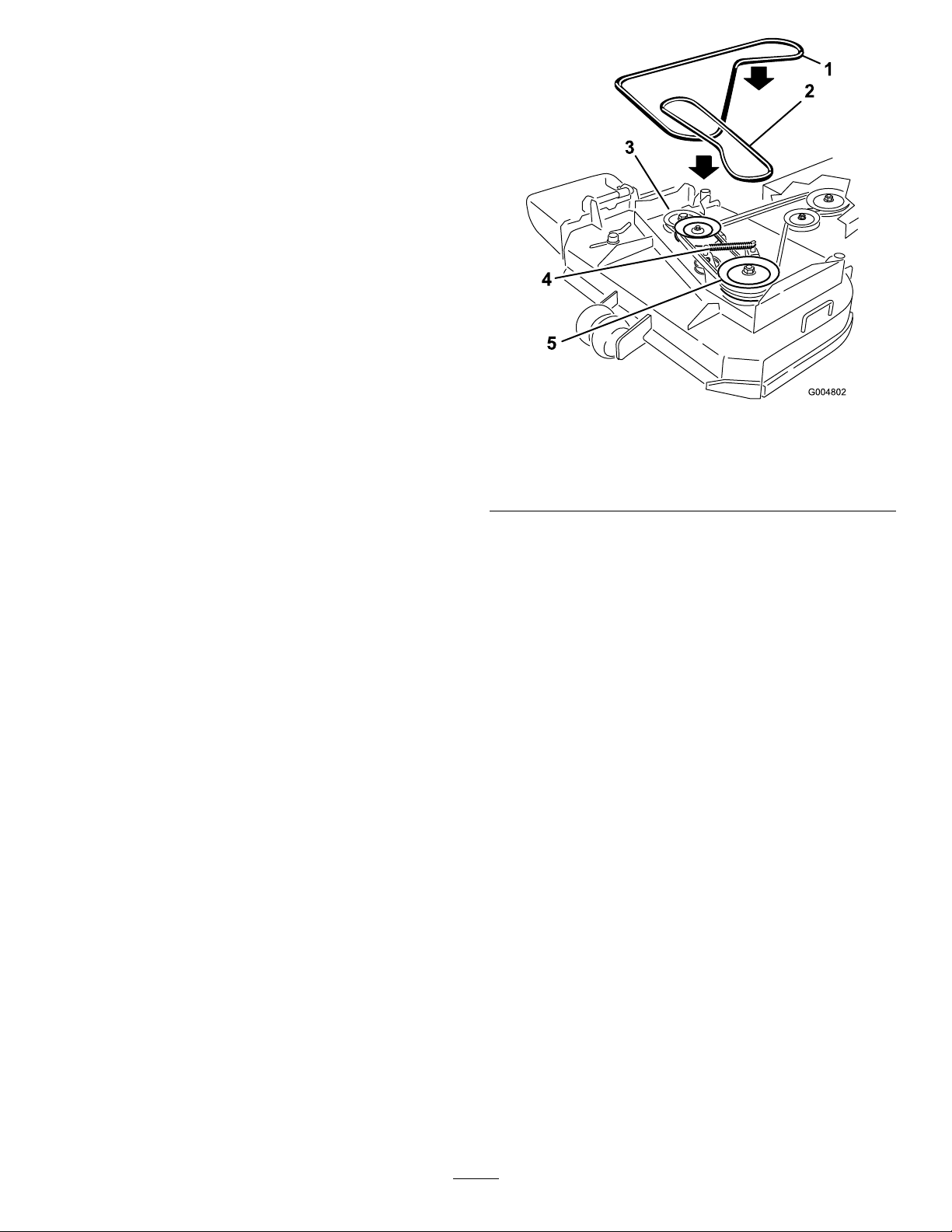

Figure37

1.Mowerdeckbelt4.Idlerarmspring

2.PTOdrivebelt

3.Drivebeltpulley

5.Drivebeltpulley

6.Disconnecttheidlerarmspringtorelievetensionon

theidlerarmandidlerpulley,thenremovetheworn

mowerbelt(Figure37).

7.Installthenewmowerbeltaroundthe2outsidespindle

pulleys,theidlerpulley,andinthelowergrooveofthe

doublespindlepulley(Figure37).

8.Connecttheidlerarmspring(Figure37).

9.InstallthePTO-drivebelt.RefertoReplacingthe

PTO-DriveBelt(page30).

10.Adjustthebeltguidean3mm(1/8inch)fromthebelt

(Figure37).

11.Installthebeltcoverontothecuttingunitandsecureit

withthebolts.

12.Installthecarrierframecoverontothecuttingunitand

securethelatches.

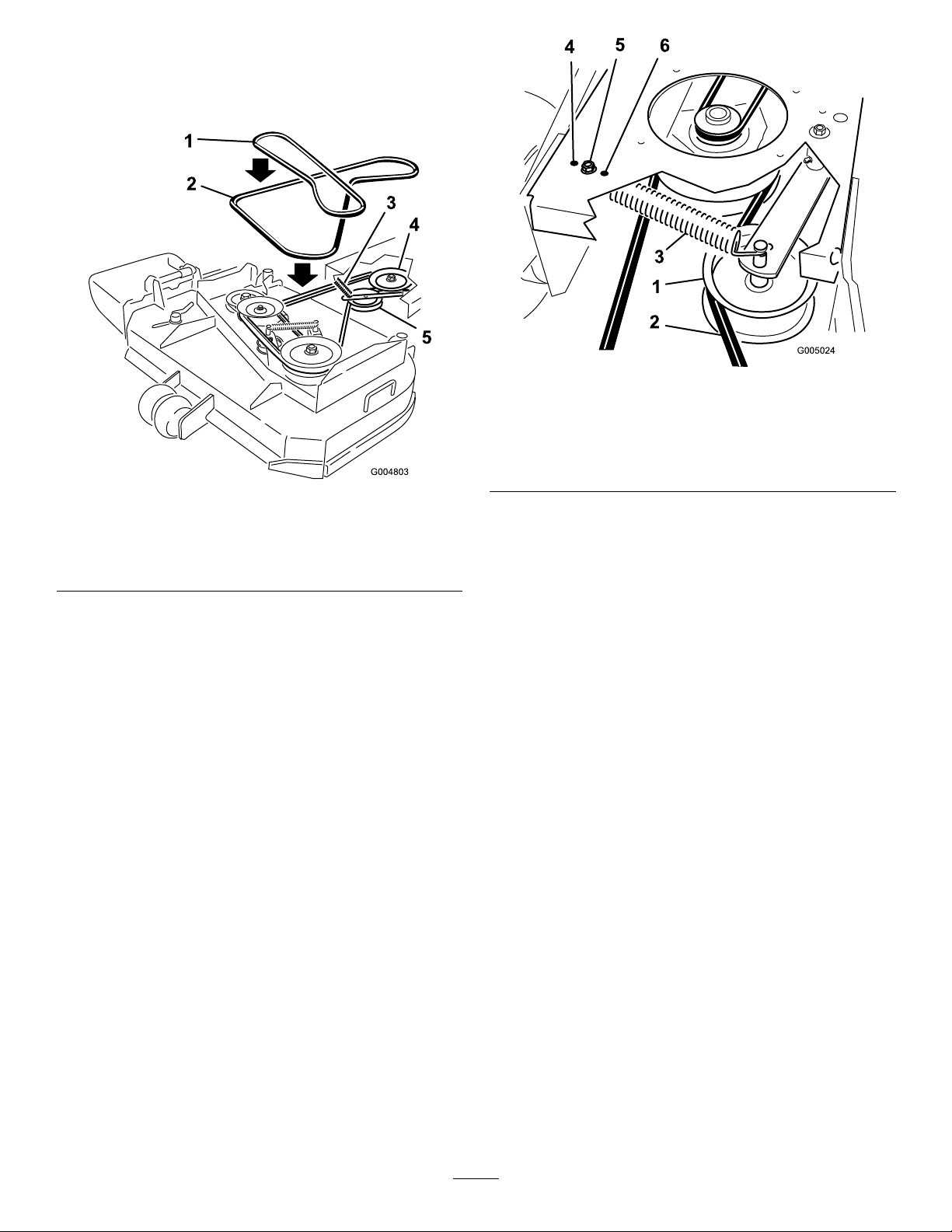

ReplacingthePTO-DriveBelt

Important:Thefastenersonthecoversofthismachine

aredesignedtoremainwiththecoverafterremoval.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Unlatchandremovethecarrierframecover.

4.Removethebeltcoverboltsandremovethebeltcover.

5.Removetheheatshieldfromtheenginedeckand

carrierframe.

6.Rollthebeltoffofthecenterpulleyonthemower

deck(Figure38).

Important:Usecautionwhenremovingthebelt

astensionwillincreasebecauseofthespring

loadedidlerpulley.

7.Removethebeltfromtheenginepulleyandthespring

loadedidlerpulley(Figure38).

8.Installthenewbeltontotheenginepulleyandspring

loadedidlerpulley(Figure38).

9.Rollthebeltontothecenterpulleyonthemowerdeck

(Figure38).

Important:Usecautionwheninstallthebeltas

tensionwillincreasebecauseofthespringloaded

idlerpulley.

10.Installtheheatshieldtotheenginedeckandcarrier

frame.

30

Page 31

11.Installthebeltcoverontothecuttingunitandsecureit

withthebolts.

12.Installthecarrierframecoverontothecarrierframe

andsecurethelatches.

Figure38

Figure39

1.PTO-drive-belt-idlerpulley4.Mosttensionforwornbelts

2.PTO-drivebelt5.Mediumtensionfornormal

3.Idlerspring

beltconditions

6.Leasttensionfornewbelts

1.Mowerdeckbelt

2.PTOdrivebelt

3.Idlerarmandspring

4.Clutchpulley

5.Idlerpulley

Adjustingthe PTO-Drive-Belt-Idler-Spring Anchor

ThepositionofthePTOidlercanbeadjustedtoincreaseor

decreasebelttension.

UseFigure39fortheidlerpositionoptions.

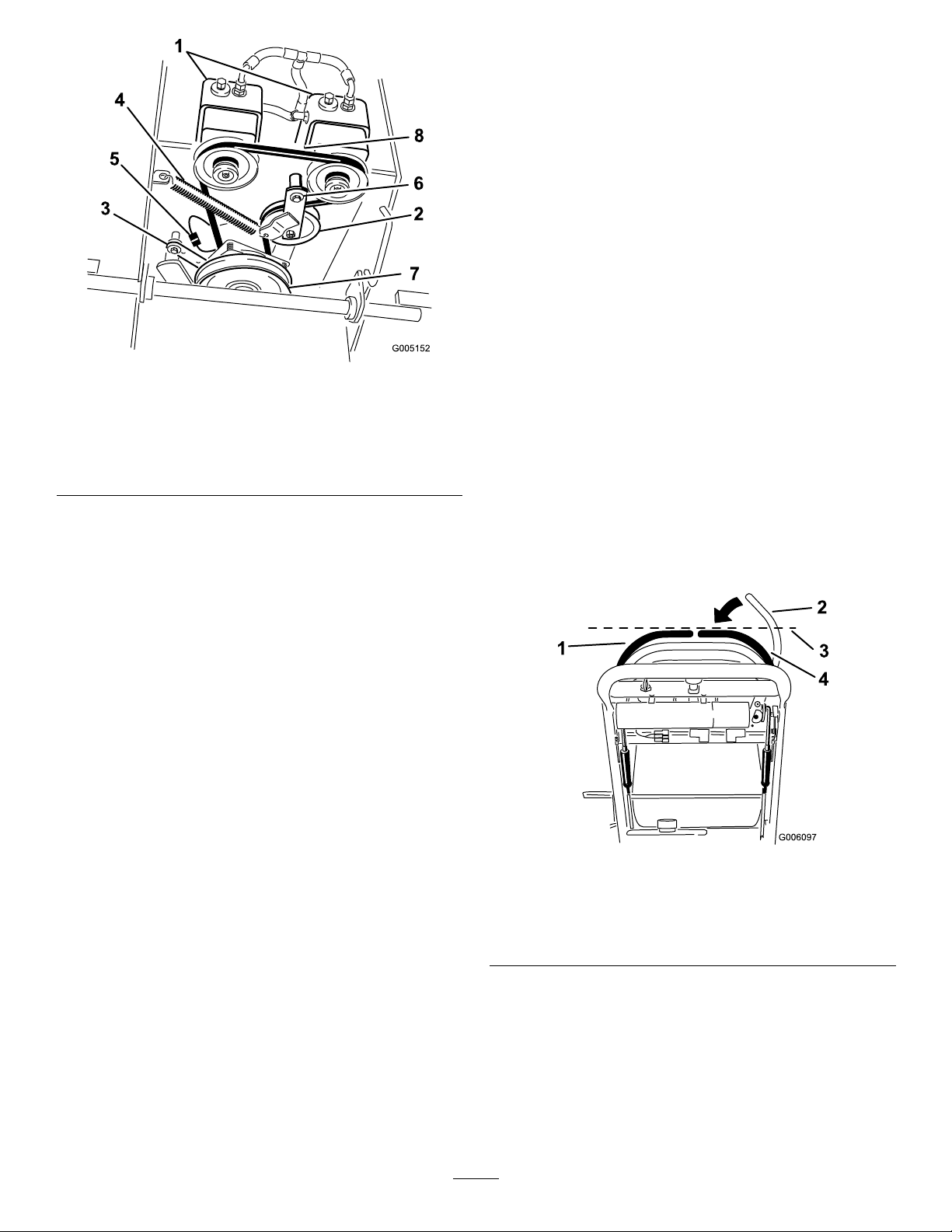

ReplacingthePump-DriveBelt

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.RemovethePTO-drivebelt.RefertoReplacingthe

PTO-DriveBelt(page30).

4.Raisethemachineandsupportitwithjackstands.

5.Disconnecttheclutchwireconnectorfromthewiring

harness.

6.Disconnecttheclutchretainerfromtheenginedeck

(Figure40).

31

Page 32

ControlsSystem

Maintenance

Adjustingthe Motion-Control-Handle Positions

AdjustingtheRightMotion-Control

Lever

Ifthemotion-controlleversdonotalignhorizontally ,adjust

therightmotion-controllever.

Figure40

1.Hydraulicpumps

2.Idlerpulley6.Pivotbolt

3.Clutchretainer

4.Tensionspring8.Pumpdrivebelt

7.Unhooktheidlerspringfromtheframe(Figure40).

8.Installthenewbeltaroundclutchandthe2drive

pulleys.

9.Installtheidlerspringbetweenidlerarmandframe

bracket(Figure40).

10.Installtheclutchretainertotheenginedeck(Figure40).

11.Connecttheclutchwireconnectortothewiring

harness.

12.InstallthePTO-drivebelt.

5.Clutchwireconnector

7.Drivepulley

Note:Adjustthehorizontalalignmentbeforethefrontto

backalignment.

1.DisengagethePTO,movetherightmotion-control

levertotheNeutralpositionandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Pushtherightmotion-controlleverdownoutof

Locked-Neutralposition(Figure41).

4.Checkifitalignshorizontallywiththeleft

motion-controllever(Figure41).

Figure41

1.Leftmotion-controllever3.Checkthehorizontal

2.Rightmotion-controllever

inNeutral-Lockedposition

Toadjusttherightmotion-controlleverhorizontally ,thecam

needstobeadjusted.

1.Removethecoverunderthecontrolpanel.

2.Loosenthenutandboltholdingthecam(Figure42).

32

alignmenthere

4.Rightmotion-controllever

Page 33

Figure43

Shownfromthefront

Figure42

1.Cam

2.Nutandbolt

3.Wingnut

4.Turnbuckle

5.Switchscrews

3.Adjustthecamuntilitalignswiththeleft

motion-controlleverandtightenthenutandboltfor

thecam.

Afterthecamisadjusted,theleverswitchneedstobe

checked.

1.Checkthegapbetweenthecontrolleverandswitchas

showninFigure43.

Note:Thegapneedstobean3mm(1/8inch).

1.Rightmotion-controllever

pivotshownundercontrols

2.Rightmotion-controllever

3.3mm(1/8inch)gap

neededbetweenswitch

andcontrollever

4.Switch

2.Ifneeded,loosenthescrewsholdingtheswitchand

adjusttheswitch(Figure43).

3.Tightenthescrewsandinstallthecoverunderthe

controlpanel.

AdjustingtheNeutralPositionforthe

Motion-ControlLevers

Important:Ensurethetrackingofthemoweriscorrect

afteradjustingthemotion-controllevers.Afteradjusting

thetracking,themotion-controlleversmaynotalignthe

exactlyfronttoback(Figure44).

Ifthemotion-controlleversdonotalignfronttoback,

ortherightcontrol-leverdoesnotmoveeasilyintothe

Neutral-Lockposition,adjustit.Adjusteachleverandcontrol

rodseparately.

Note:Adjustthehorizontalalignmentbeforethefrontto

backalignment.

1.Afterthehorizontalalignmentisnished,checkthe

fronttobackalignment(Figure44).

33

Page 34

HydraulicSystem

Maintenance

ServicingtheHydraulic System

FluidType:ToroHypr-Oil500syntheticmotoroilor

equivalentsyntheticoil.

Important:Useoilspeciedorequivalent.Otheruids

couldcausesystemdamage.

HydraulicSystemOilCapacity:2.0L(67oz)

Figure44

1.Leftmotion-controllever

2.Rightmotion-controllever4.Alignthecontrollevers

2.Loosenthewingnutsontherightcontrolrodand

rotatetheturnbuckleinorouttoensuretheright

controlleveriscenteredintheNeutral-Lockposition.

3.Securetheturnbuckleinpositionwiththewingnuts

(Figure45).

3.Neutral-Lockedposition

fronttobackhere

CheckingtheHydraulicFluid

ServiceInterval:Aftertherst8hours—Checkthe

hydraulicuid.

Every25hours—Checkthehydraulicuid.

Every200hours—Changethehydraulicuid.

Note:Thereare2waysofcheckingthehydraulicoil.One

iswhentheoiliswarmandoneiswhentheoiliscold.The

bafeinsidethetankhas2levelsdependingiftheoiliswarm

orcold.

1.Positionthemachineonalevelsurface.

2.Disengagethepowertakeoff(PTO)andshutoffthe

engine.

3.Waitforallmovingpartstostopbeforeleavingthe

operatingpositionandsettheparkingbrake.

4.Cleanareaaroundthecapandllerneckofthe

hydraulictank(Figure46).

Figure45

1.Turnbuckle

2.Bottomwingnut

4.Loosenthewingnutsontheleftcontrolrodandrotate

theturnbuckleinorouttochangethetracking.

5.Securetheturnbuckleinpositionwiththewingnuts

(Figure45).

6.Checkforpropertracking.Adjusttheleftcontrolrod

ifachangeisneeded.RefertoAdjustingtheTracking

(page26).

3.Topwingnut(lefthand

threaded)

Figure46

1.Cap3.Colduidlevel—full

2.Bafe4.Hotuidlevel—full

5.Removethecapfromllerneckandchecktheuid

levelinthereservoir.(Figure46).

6.Adduidtothereservoiruntilitreachesthecoldlevel

ofthebafe.

7.Runthemachineatlowidlefor15minutestoallow

anyairtopurgeoutofthesystemandwarmtheuid.

RefertoStartingandStoppingtheEngine(page13).

34

Page 35

8.Rechecktheuidlevelwhiletheuidiswarm.Add

uidtothereservoiruntilitreachesthehotlevelof

thebafe.

Note:Theuidlevelshouldbetothetopofthehot

levelofthebafe,whentheuidiswarm(Figure46).

9.Installthecaponthellerneck.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Ifhydraulicuidisinjectedintotheskinit

mustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththistype

ofinjury.Gangrenemayresultifthisis

notdone.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Makesureallhydraulicuidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretohydraulicsystem.

Figure47

5.Removetheoldlterandwipethelteradaptergasket

surfaceclean(Figure47).

6.Applyathincoathydraulicuidtotherubbergasket

onthereplacementlter.

7.Installthereplacementhydrauliclterontothelter

adapter.

Note:Donottighten.

8.Removetheplasticbagfromthereservoiropeningand

allowtheltertollwithhydraulicuid.

9.Whenthehydrauliclterisfull,turntheoillter

clockwiseuntiltherubbergasketcontactsthelter

adapter,thentightenthelteranadditional1/2turn

(Figure48).

ReplacingtheHydraulicFilter

ServiceInterval:Aftertherst8hours—Changethe

hydrauliclter.

Every200hours—Changethehydrauliclter.

WARNING

Hothydraulicuidcancausesevereburns.

Allowthehydraulicuidtocoolbeforeperforming

anymaintenancetothehydraulicsystem.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

Important:Donotsubstituteautomotiveoillter

orseverehydraulicsystemdamagemayresult.

3.Removethehydraulicreservoircapandtemporarily

covertheopeningwithaplasticbagandrubberband

topreventallofthehydraulicuidfromdrainingout.

4.Locatethelterunderthefueltankandplaceadrain

panunderthelter(Figure47).

Figure48

1.Hydrauliclter

2.Gasket

10.Cleanupanyspilleduid.

11.Checktheuidinthereservoir,adduidtothetank

untilitreachesthecoldbafeofthetank.

Important:Useoilspeciedorequivalent.Other

uidscouldcausesystemdamage.

12.Starttheengineandletitrunforabout2minutesto

purgetheairfromthesystem.

3.Adapter

35

Page 36

13.Stoptheengineandcheckforleaks.

Note:If1orbothwheelswillnotdrive,referto

BleedingtheHydraulicSystem(page36).

14.Rechecklevelandadduid,ifrequired.Donot

overll.

BleedingtheHydraulicSystem

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Ifhydraulicuidisinjectedintotheskinit

mustbesurgicallyremovedwithinafewhours

byadoctorfamiliarwiththistypeofinjury.

Gangrenemayresultifthisisnotdone.

Thesystemisselfbleeding,however,itmaybenecessary

tobleedthesystemiftheuidischangedorafterworkis

performedonthesystem.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Raisetherearofthemachineupontojackstandshigh

enoughtoraisethedrivewheelsofftheground.

4.Starttheengineandmovethethrottlecontroltothe

idleposition.

Ifthedrivewheeldoesnotrotate,itispossibletoassist

thepurgingofthesystembycarefullyrotatingthetire

intheforwarddirection.

5.Checkthehydraulicuidlevel.Asitdrops,adduidas

requiredtomaintaintheproperlevel.

6.Repeatthisprocedurefortheoppositewheel.

7.Thoroughlycleantheareaaroundeachofthecharge

pumphousings.

CheckingtheHydraulicLines

•Keepbodyandhandsawayfrompinholeleaks

ornozzlesthatejecthighpressurehydraulic

uid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

•Makesureallhydraulicuidhosesandlinesare

ingoodconditionandallhydraulicconnections

andttingsaretightbeforeapplyingpressureto

hydraulicsystem.

ServiceInterval:Every100hours

Checkhydrauliclinesandhosesforleaks,loosettings,kinked

lines,loosemountingsupports,wear,weatherandchemical

deterioration.Makenecessaryrepairsbeforeoperating.

Note:Keepareasaroundhydraulicsystemcleanfromgrass

anddebrisbuildup.

36

Page 37

MowerDeck Maintenance

ServicingtheCuttingBlades

Toensureasuperiorqualityofcut,keepthebladessharp.For

convenientsharpeningandreplacement,keepextrablades

onhand.

WARNING

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladesperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

PreparingtoInspectorServicethe

Blades

CheckingforBentBlades

1.DisengagethePTO ,movethemotion-controlleversto

theNeutral-Lockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Rotatethebladesuntiltheendsfaceforwardand

backward.Measurefromalevelsurfacetothecutting

edge,positionA,oftheblades(Figure50).

Figure50

Parkthemachineonalevelsurface,disengagetheblades,and

settheparkingbrake.

TurntheignitionkeytotheOffposition.

Removethekeyanddisconnectthesparkplugwiresfrom

thesparkplugs.

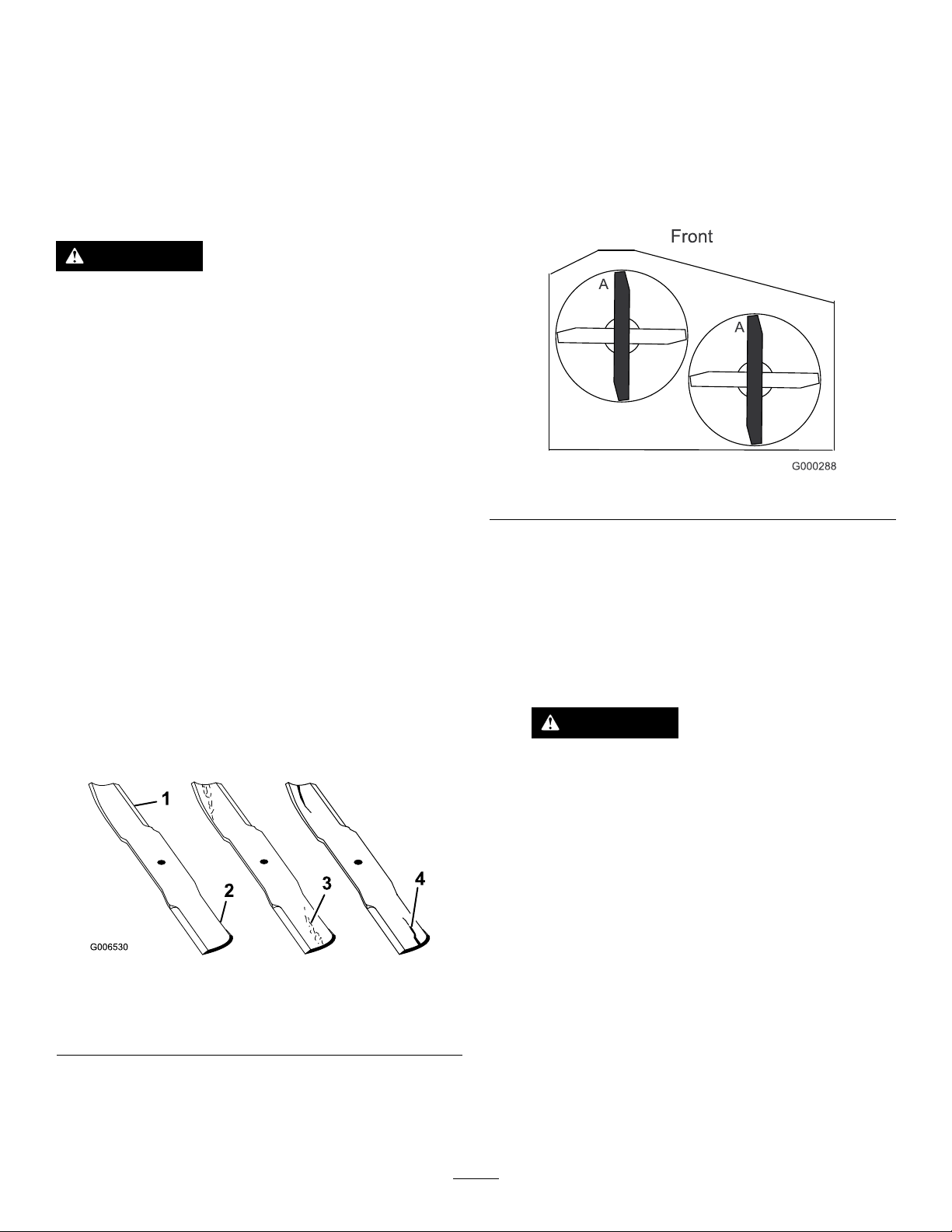

InspectingtheBlades

1.Inspectthecuttingedges(Figure49).

Note:Iftheedgesarenotsharporhavenicks,remove

andsharpentheblades.RefertoSharpeningtheBlades

(page38).

Figure49

1.CuttingEdge3.Wear/slotformingin

curvedarea

2.Sail4.Crackinthecurvedarea

2.Inspecttheblades,especiallythecurvedarea(Figure

49).Ifyounoticeanycracks,wear,oraslotforming

inthisarea(item3.inFigure49),immediatelyinstall

anewblade.

4.Rotatetheoppositeendsofthebladesforward.

5.Measurefromalevelsurfacetothecuttingedgeof

thebladesatthesamepositionasinstep3above.

Thedifferencebetweenthedimensionsobtainedin

steps3and4mustnotexceed3mm(1/8inch).Ifthis

dimensionexceeds3mm(1/8inch),thebladeisbent

andmustbereplaced;refertoRemovingtheBlades

(page37)andInstallingtheBlades(page38).

WARNING

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplacebentordamagedblade

withanewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofblade.

RemovingtheBlades

Bladesmustbereplacedifasolidobjectishit,ifthebladeis

outofbalance,orisbent.T oensureoptimumperformance

andcontinuedsafetyconformanceofthemachine,use

genuineT ororeplacementblades.Replacementbladesmade

byothermanufacturersmayresultinnon-conformancewith

safetystandards.

1.Holdthebladeendusingaragorthickly-paddedglove.

2.Removethebladebolt,curvedwasher,bladestiffener,

andbladefromthespindle(Figure51).

37

Page 38

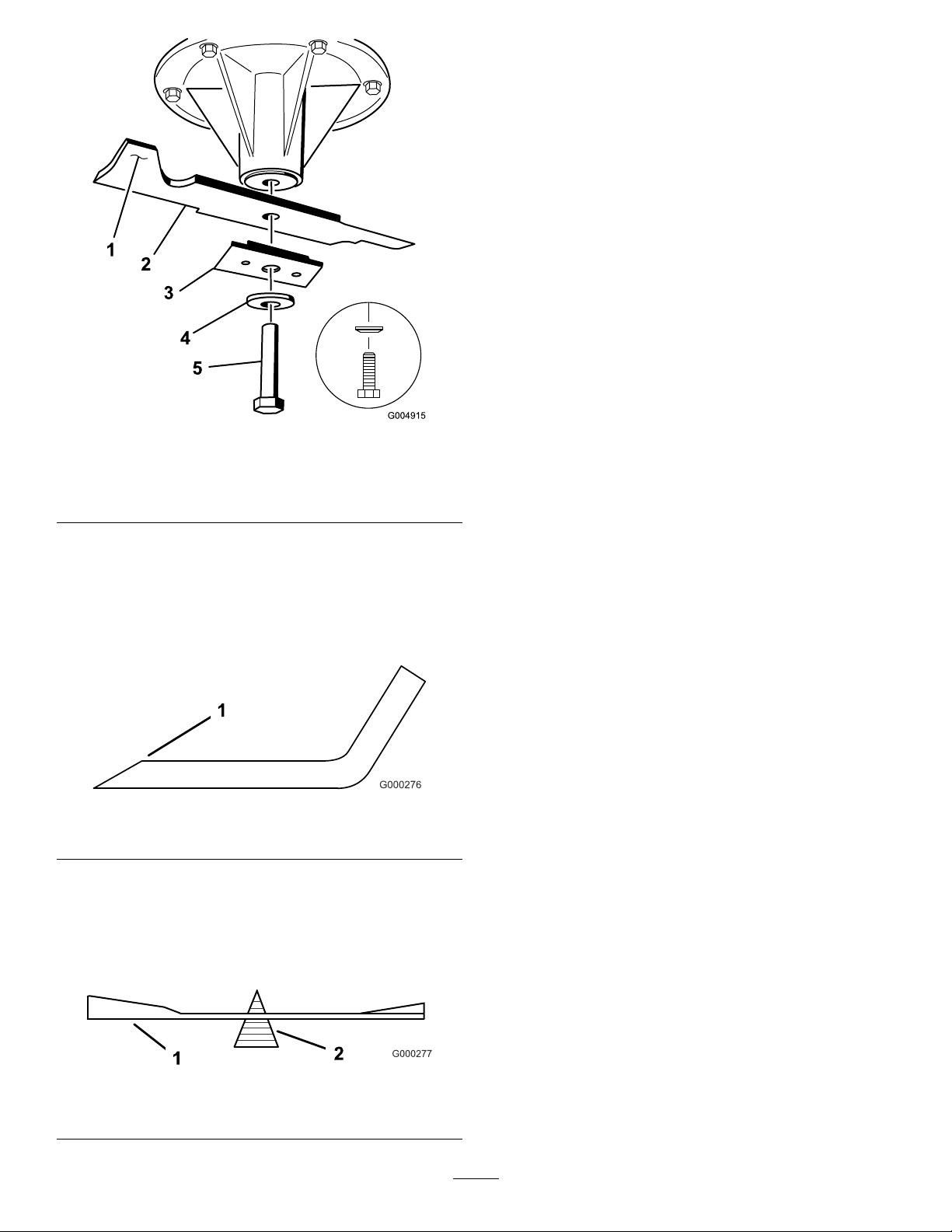

Figure51

1.Sailareaoftheblade4.Curvedwasher

2.Blade5.Bladebolt

3.Bladestiffener

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure52).Maintaintheoriginalangle.The

bladeretainsitsbalanceifthesameamountofmaterial

isremovedfrombothcuttingedges.

InstallingtheBlades

Important:Thesailpartoftheblademustbepointing

upward,towardtheinsideofthemowertoensureproper

cutting(Figure53).

1.Installtheblade,stiffener,curvedwasher,andblade

bolttothespindle(Figure53).

2.Torquethebladeboltto115-140N-m(85-110ft-lb).

CorrectingtheMowerQuality ofCut

If1deckbladecutslowerthantheother,correctasfollows.

Note:Tireairpressureiscriticalintheseprocedures.Make

surealltireshavethecorrectpressure.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Disconnectthesparkplugwire(s)fromthespark

plug(s).

4.Adjustthetirepressureinthereartirestospecications;

refertoDriveSystemMaintenance(page26).

5.Checkthatthebladesandspindleshaftsarenotbent.

RefertoCheckingforBentBlades(page37).

6.Settheheight-of-cuttothe101.6mm(4inch)position.

RefertoAdjustingtheHeight-of-Cut(page17).

7.Performthestepsinthefollowingsections:Setting

uptheFrame(page38),CheckingtheMowerDeck

Front-to-RearPitch(page40),andCheckingthe

MowerDeckSide-to-SideHeight(page41).

Figure52

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure53).Ifthebladestaysinahorizontal

position,thebladeisbalancedandcanbeused.Ifthe

bladeisnotbalanced,lesomemetalofftheendof

thesailareaonly(Figure53).Repeatthisprocedure

untilthebladeisbalanced.

Figure53

1.Blade2.Balancer

SettinguptheFrame

CheckingtheCarrierFrameandEngine

DeckAlignment

Note:MisalignmentcancauseexcesswearonthePTO

drivebelt.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Placealongstraightedgeontopoftheenginedeckas

showninFigure54.

4.Atthecarrierframecrosschannel,measuretheheight

atlocationA(Figure54).

Note:Thismeasurementmustbe33mm(1-5/16

inch),plusorminus6mm(1/4inch).