Page 1

FormNo.3367-780RevA

CommercialWalk-Behind

TractionUnit

FixedDeck,PistolGrip,Hydro,Fittedwith

a48in(122cm),36in(91cm)or32in(81cm)

RearDischargeCuttingUnit

ModelNo.30033(TractionUnit)—SerialNo.311000001

andUp

ModelNo.02712(48in(122cm)CuttingUnit)—SerialNo.

311000001andUp

ModelNo.02711(36in(91cm)CuttingUnit)—SerialNo.

311000001andUp

ModelNo.02710(32in(82cm)CuttingUnit)—SerialNo.

311000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Introduction

Thisrotary-blade,lawnmowerisintendedtobeused

byresidentialhomeownersorprofessional,hired

operators.Itisdesignedprimarilyforcuttinggrasson

well-maintainedlawnsonresidentialorcommercial

properties.Itisnotdesignedforcuttingbrushorfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Thismanualshouldbeconsidered

aspartofthemachine,asitcontains,safety ,operational

andmaintenanceinformation.Themowerisaprecision

builtmachinedesignedsolelyforcuttinggrassand

similarlowlyinggroundvegetationwithinthelimitations

statedinthismanual.Youareresponsibleforoperating

theproductproperlyandsafely .

ModelNo.

SerialNo.

Figure2

1.Modelandserialnumberlocation

ModelNo.

YoumaycontactTorodirectlyforproductand

accessoryinformation,helpndingadealer,orto

registeryourproductatToroCommercialProducts

ServiceDepartmentSpellbrook,BishopsStortford,

CM234BU,England,+44(0)1279603019,Email:

uk.service@toro.com.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .

Figure1and

Figure2identifythelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

Figure3),whichsignalsahazardthatmaycauseserious

(

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure3

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

1.Modelandserialnumberlocation

©2010—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

GeneralLawnMowerSafety.................................4

SoundPressureforthe32RD,36RDand48

RD...................................................................6

SoundPowerforthe32RD ,36RDand48

RD...................................................................6

VibrationLevelforthe32RD...............................6

VibrationLevelforthe36RD...............................6

VibrationLevelforthe48RD...............................6

SlopeIndicator.....................................................7

SafetyandInstructionalDecals.............................8

Setup..........................................................................10

1CheckingtheFluidsandTyrePressure..............10

2ReadingtheManualandViewingthe

OperatorTrainingMaterial.............................10

ProductOverview......................................................11

Controls.............................................................11

Specications.....................................................12

Attachments/Acessories....................................12

Operation...................................................................13

AddingFuel.......................................................13

ThinkSafetyFirst...............................................14

OperatingtheParkingBrake...............................14

StartingandStoppingtheEngine........................14

OperatingtheNeutralLocks...............................15

OperatingtheMowerBladeControlKnob

(PTO)............................................................16

TheSafetyInterlockSystem................................16

DrivingtheMachineForwardand

Backward.......................................................17

BringingtheMachinetoNeutralPosition............18

StoppingtheMachine.........................................18

PushingtheMachinebyHand.............................18

TransportingMachines.......................................18

AdjustingtheHeight-of-Cut...............................18

AdjustingtheCasterPosition..............................19

AdjustingtheHandleHeight..............................20

HeightofCutChart............................................21

Maintenance...............................................................22

RecommendedMaintenanceSchedule(s)................22

Lubrication.............................................................22

HowtoGrease...................................................23

LubricatingtheCasterandWheel

Bearings.........................................................23

GreasingtheMowerBeltIdler............................23

GreasingthePumpControlandBell

Crank.............................................................23

EngineMaintenance...............................................24

ServicingtheAirCleaner....................................24

ServicingtheEngineOil.....................................25

ServicingtheSparkPlugs....................................26

FuelSystemMaintenance.......................................27

ServicingtheFuelTank......................................27

ServicingtheFuelFilter......................................28

DriveSystemMaintenance.....................................29

AdjustingtheSpeedControlLinkage..................29

AdjustingtheNeutralControlLinkages..............29

AdjustingtheHydroControlLinkages................30

AdjustingtheControlRod..................................32

AdjustingtheTracking.......................................33

AdjustingtheSpringAnchorLinks.....................33

CheckingtheTyrePressure.................................33

CoolingSystemMaintenance..................................34

CleaningtheAirIntakeScreen............................34

CleaningtheCoolingSystem...............................34

BrakeMaintenance.................................................34

ServicingtheBrake.............................................34

BeltMaintenance....................................................35

CheckingtheBelts..............................................35

ReplacingtheMowerBelt...................................35

AdjustingtheMowerBeltTension......................36

HydraulicSystemMaintenance...............................38

ServicingtheHydraulicSystem...........................38

MowerDeckMaintenance......................................41

ServicingtheCuttingBlades...............................41

AdjustingtheBladeBrake...................................42

Storage.......................................................................43

Troubleshooting.........................................................45

Schematics.................................................................47

3

Page 4

Safety

Improperlyusingormaintainingthismowercan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructions.

Torodesignedandtestedthismowerforreasonablysafe

service;however,failuretocomplywiththefollowing

instructionsmayresultinpersonalinjury.

Toensuremaximumsafety,bestperformance,and

togainknowledgeoftheproduct,itisessential

thatyouandanyotheroperatorofthemowerread

andunderstandthecontentsofthismanualbefore

theengineiseverstarted.Payparticularattention

tothesafetyalertsymbol(

Caution,Warning,orDanger—“personalsafety

instruction.”Readandunderstandtheinstruction

becauseithastodowithsafety.Failuretocomply

withtheinstructionmayresultinpersonalinjury.

GeneralLawnMowerSafety

ThefollowinginstructionshavebeenadaptedfromEN

836.

Figure3)whichmeans

•Ifgasolineisspilled,donotattempttostartthe

enginebutmovethemowerawayfromtheareaof

spillageandavoidcreatinganysourceofignition

untilgasolinevaporshavedissipated.

•Replaceallfueltankandcontainercapssecurely.

Preparation

•Whilemowing,alwayswearsubstantialfootwearand

longtrousers.Donotoperatetheequipmentwhen

barefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentis

tobeusedandremoveallstones,sticks,wires,bones

andotherforeignobjects.

•Beforeusing,alwaysvisuallyinspecttoseethat

guards,andsafetydevices,suchasdeectorsarein

placeandworkingcorrectly .

•Beforeusing,alwaysvisuallyinspecttoseethatthe

blades,bladeboltsandcutterassemblyarenotworn

ordamaged.Replacewornordamagedbladesand

boltsinsetstopreservebalance.

Starting

Thiscuttingmachineiscapableofamputatinghands

andfeetandthrowingobjects.Failuretoobservethe

followingsafetyinstructionscouldresultinserious

injuryordeath.

Training

•Readtheinstructionscarefully.Befamiliarwiththe

controlsandtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethemower.Localregulationscan

restricttheageoftheoperator.

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Understandexplanationsforallpictogramsusedon

themowerorintheinstructions.

Gasoline

WARNING-Gasolineishighlyammable.Takethe

followingprecautions.

•Storefuelincontainersspecicallydesignedforthis

purpose.

•Refueloutdoorsonlyanddonotsmokewhile

refueling.

•Addfuelbeforestartingtheengine.Neverremove

thecapofthefueltankoraddgasolinewhilethe

engineisrunningorwhentheengineishot.

•Disengageallbladeanddriveclutchesandplaceinto

neutralbeforestartingtheengine.

•Donottiltmowerwhenstartingtheengineor

switchingonthemotor,unlessthemowerhastobe

tiltedforstarting.Inthiscase,donottiltitmorethan

absolutelynecessaryandliftonlythepart,whichis

awayfromtheoperator.

•Starttheengineorswitchonthemotorcarefully

accordingtoinstructionsandwithfeetwellaway

fromtheblade(s).

Operation

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Nevermowwhilepeople,especiallychildren,orpets

arenearby.

•Mowonlyindaylightoringoodarticiallight.

•Avoidoperatingthelawnmowerinwetgrass,where

feasible.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Neverdirectdischargeofmaterialtowards

bystanders.

•Donotputhandsorfeetnearorunderrotating

parts.

4

Page 5

•Neverpickuporcarryalawnmowerwhilethe

engineisrunning.

•Useextremecautionwhenreversingorpullinga

pedestriancontrolledlawnmowertowardsyou.

•Walk,neverrun.

•Slopes:

–Donotmowexcessivelysteepslopes.

–Exerciseextremecautionwhenonslopes.

–Mowacrossthefaceofslopes,neverupand

downandexerciseextremecautionwhen

changingdirectiononslopes.

–Alwaysbesureofyourfootingonslopes.

•Neveroperatethelawnmowerwithdamagedguards,

orwithoutsafetydevices,forexampledeectors

and/orgrasscatchers,inplace.

•Uselowthrottlesettingswhenengagingthe

traction-clutch,especiallyinhighgears.Reduce

speedonslopesandinsharpturnstoprevent

overturningorlossofcontrol.

•Stopthebladeifthelawnmowerhastobetiltedfor

transportationwhencrossingsurfacesotherthan

grassandwhentransportingthelawnmowertoand

fromtheareatobemowed.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Stoptheengineandwhereakeyisttedremovethe

key,makesurethatallmovingpartshavecometoa

completestop:

–wheneveryouleavethelawnmower.

–beforerefueling.

–beforeremovingthegrasscatcher.

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator’s

position.

•Stoptheengineandwhereakeyisttedremovethe

key,makesurethatallmovingpartshavecometoa

completestop,anddisconnectthesparkplugwire:

–beforeclearingblockagesoruncloggingchute.

–beforechecking,cleaningorworkingonthelawn

mower.

–afterstrikingaforeignobject,inspectthelawn

mowerfordamageandmakerepairsbefore

restartingandoperatingthelawnmower.

–iflawnmowerstartstovibrateabnormally(check

immediately).

•Reducethethrottlesettingduringengineshutdown

and,iftheengineisprovidedwithashut-offvalve,

turnthefueloffattheconclusionofmowing.

•Usecarewhenusingsulkies,and

–useonlyapproveddrawbarhitchpoints.

–limitloadstothoseyoucansafelycontrol.

–donotturnsharply:usecarewhenreversing.

–donotcarrypassengers.

•Watchoutfortrafcwhencrossingornearroadways.

•Beforeleavingtheoperator’sposition

–disengagethepowertake-offandlowerthe

attachments.

–placeintoneutralandsettheparkingbrake.

–stoptheengineandremovethekey.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Donotusepressurecleaningequipmentonmachine.

•Neverstoretheequipmentwithgasolineinthetank

andinsideabuildingwherefumescanreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,silencer,

batterycompartmentandgasolinestoragearefreeof

grass,leaves,orexcessivegrease.

•Checkthedischargeguardfrequentlyandreplace

withmanufacturer’srecommendedparts,when

necessary.

•Replacewornordamagedpartsforsafety.

•Replacefaultysilencers.

•Ifthefueltankhastobedrained,dothisout-doors.

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatinganengineat

excessivespeedcanincreasethehazardofpersonal

injury.

•Onmultibladedlawnmowers,takecareasrotating

oneblademaycauseotherstorotate.

•Becarefulduringadjustmentofthelawnmowerto

prevententrapmentofthengersbetweenmoving

bladesandxedpartsofthelawnmower.

•Toensurethebestperformanceandsafety,

purchaseonlygenuineTororeplacementparts

andaccessories.Donotuse

accessories;theymaycauseasafetyhazard.

will t

partsand

5

Page 6

SoundPressureforthe32RD,

VibrationLevelforthe48RD

36RDand48RD

The32RDhasasoundpressurelevelattheoperator’s

earof91dBA,whichincludesanUncertaintyValue(K)

of1dBA.

The36RDhasasoundpressurelevelattheoperator’s

earof85dBA,whichincludesanUncertaintyValue(K)

of1dBA.

The48RDhasasoundpressurelevelattheoperator’s

earof88dBA,whichincludesanUncertaintyValue(K)

of1dBA.

Thesoundpressurelevelwasdeterminedaccordingto

theproceduresoutlinedinEN836.

SoundPowerforthe32RD,36

RDand48RD

The32RDand36RDhasaguaranteedsoundpower

levelof100dBA,whichincludesanUncertaintyValue

(K)of1dBA.

Hand-Arm

Measuredvibrationlevelforrighthand=2.0m/s

Measuredvibrationlevelforlefthand=2.0m/s

UncertaintyValue(K)=1.0m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

2

2

2

The48RDhasaguaranteedsoundpowerlevelof105

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Thesoundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

VibrationLevelforthe32RD

Hand-Arm

Measuredvibrationlevelforrighthand=3.7m/s

Measuredvibrationlevelforlefthand=3.4m/s

UncertaintyValue(K)=1.0m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

2

2

VibrationLevelforthe36RD

Hand-Arm

Measuredvibrationlevelforrighthand=1.5m/s

2

2

Measuredvibrationlevelforlefthand=2.0m/s

UncertaintyValue(K)=1.0m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

2

2

6

Page 7

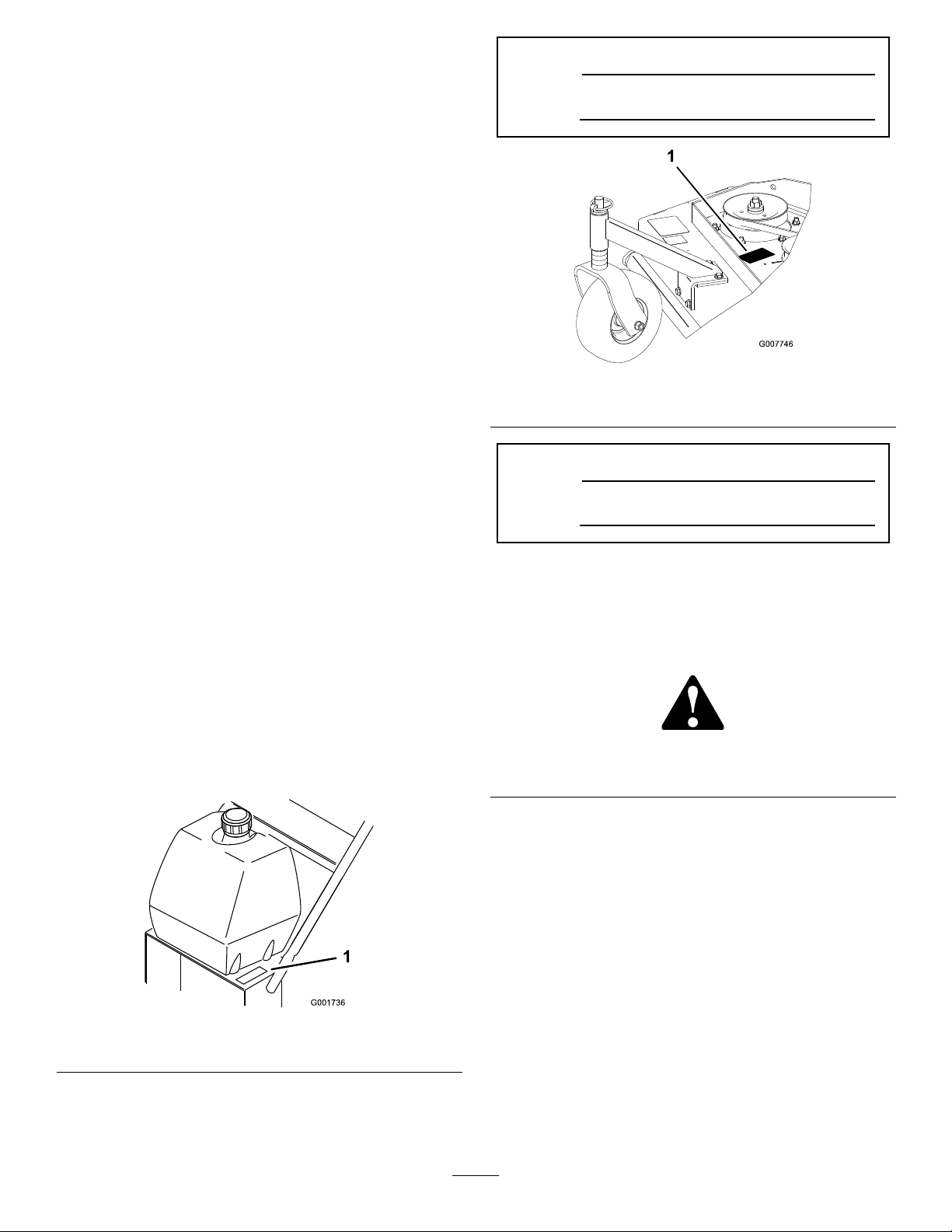

SlopeIndicator

G011841

Figure4

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis20degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan20degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

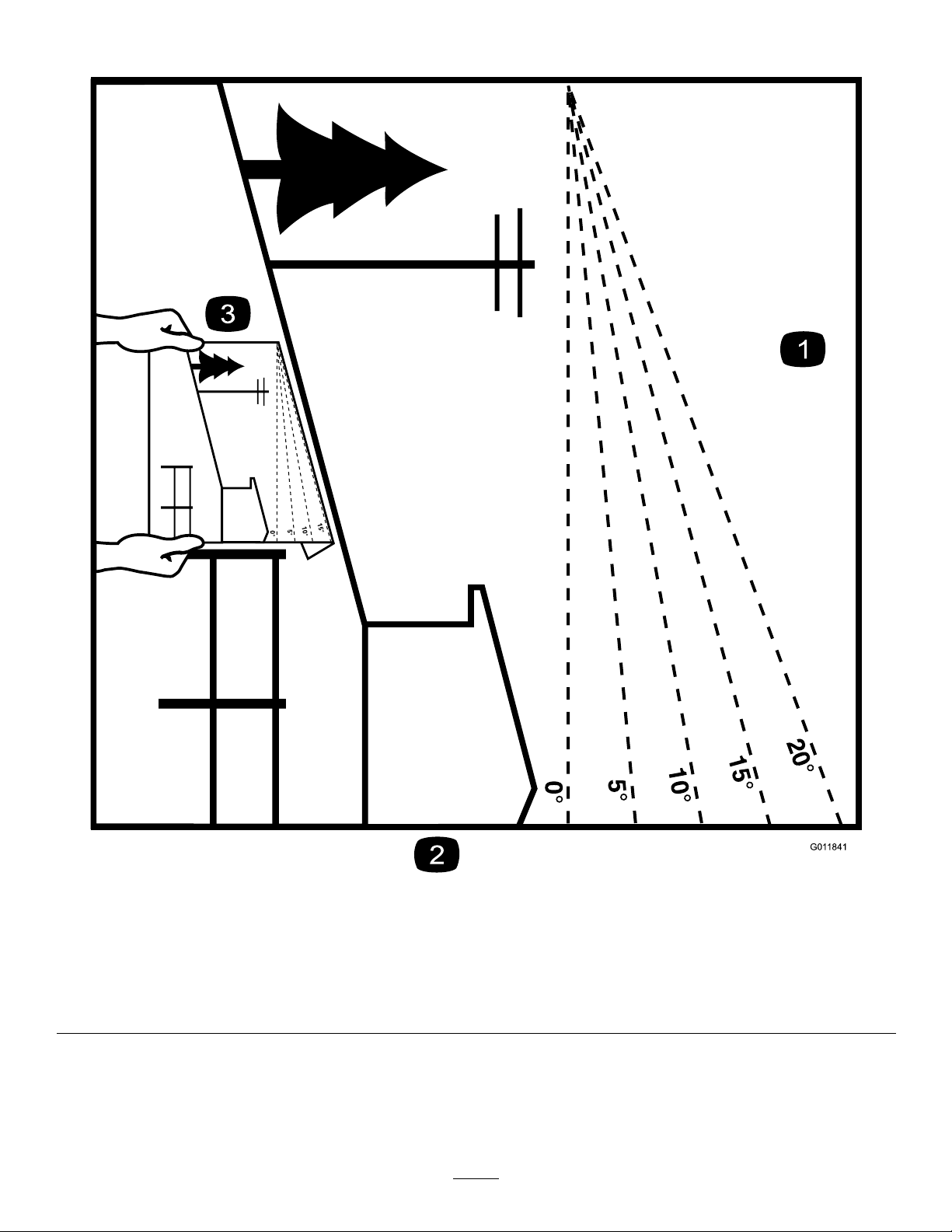

SafetyandInstructional

Decals

1.Cuttinghazardofhand

2.Cuttinghazardoffoot

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Keepsafetysignsclearandvisible,replaceanydecalthatisdamagedorlost.

40-13–010

106-2733

1.Fast

2.Continuousvariable

setting

3.Slow

1.ReadtheOperator’s

Manualforinstructionson

operatingthecuttingblade

2.Pullbacktodisengage

95-5537

105-4109

105-4110

3.Pushforwardtoengage

106-5517

1.Warning–DoNottouchthehotsurface.

Manufacturer’sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer .

8

Page 9

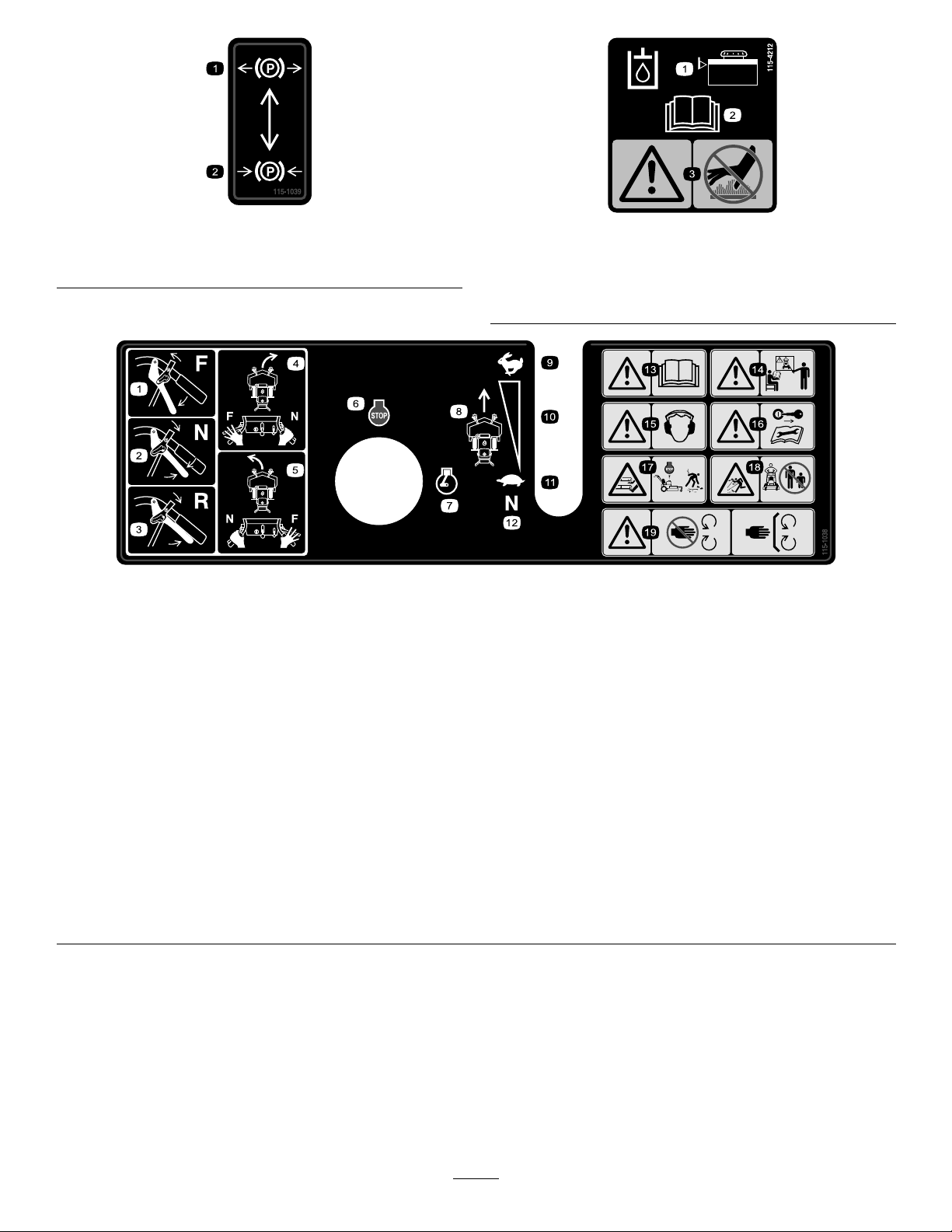

115-1039

1.Parking

brake—disengaged

2.Parkingbrake—engaged

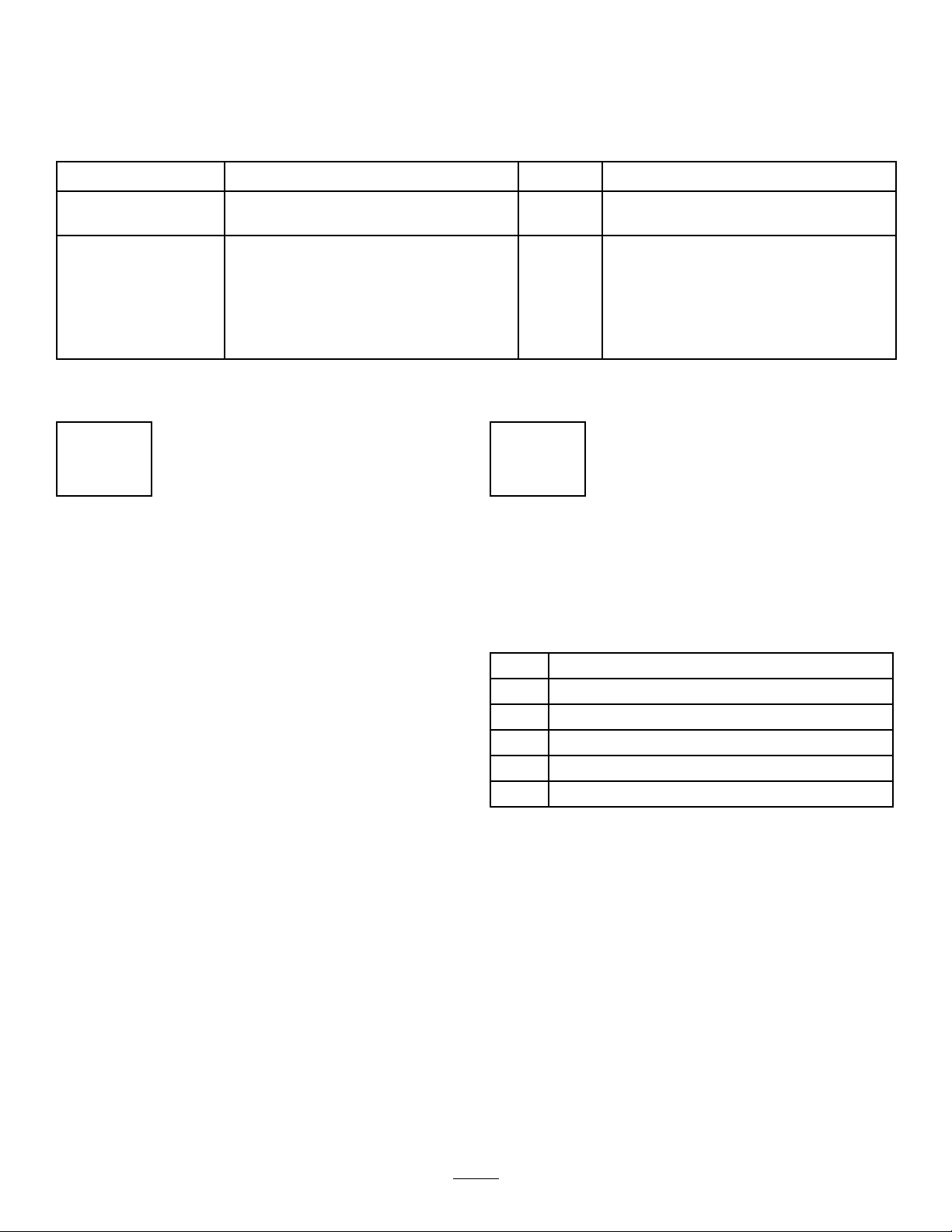

1.Hydraulicoillevel3.Warning—donottouch

2.ReadtheOperator’s

Manual.

115-4212

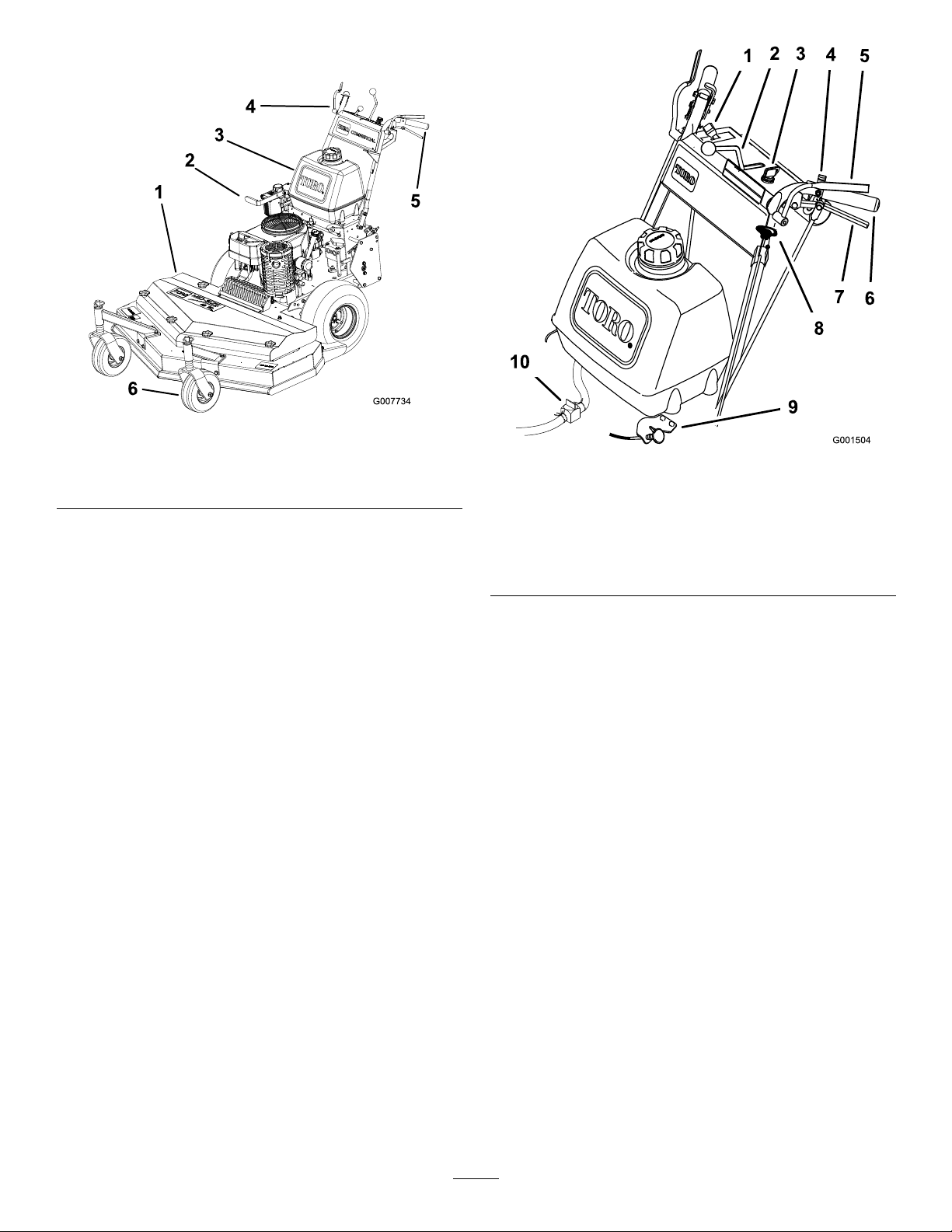

115-1038

1.Forward

2.Neutral

3.Reverse

4.Toturnrightmovethelefthandleverintotheforwardpositionwhiletherighthandleverisintheneutralposition.

5.Toturnleftmovetherighthandleverintotheforwardpositionwhilethelefthandleverisintheneutralposition.

6.Engine—stop

7.Engine—run

8.Groundspeed

9.Fast

10.Continuousvariablesetting

11.Slow

12.Neutral

13.Warning—readtheOperator’sManual.

14.Warning—donotoperatethismachineunlessyouaretrained.

15.Warning—wearhearingprotection.

16.Warning—removetheignitionkeybeforeperformingmaintenanceonthemachine.

17.Cutting/dismembermenthazardofhandorfoot,mowerblade—stoptheenginebeforeleavingtheoperatingposition.

18.Thrownobjecthazard—keepbystandersasafedistancefromthemachine.

19.Warning—stayawayfrommovingparts;keepallguardsinplace.

thehotsurface.

9

Page 10

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Nopartsrequired

Operator’sManual

EngineOperator’sManual

PartsCatalog

Operatortrainingmaterial

RegistrationCard

Oildrainhose

1

CheckingtheFluidsandTyre

Pressure

ReadingtheManualand

ViewingtheOperatorTraining

Qty.

–

1

1

1

1

1

1

2

Material

NoPartsRequired

Use

Checktheuidsandtyrepressure.

ReadtheOperator’sManualandwatch

theoperatortrainingmaterialbefore

operatingthemachine.

Procedure

•Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheEngineOilLevel.

•Checkthegreaseforthemowerandmowerdeck.

•Checkthetyrepressure;refertoCheckingthetyre

Pressure.

Note:Thecuttingbladesaresettoa2inch(51mm)

height-of-cutatinitialpurchase.TheAxlepositionis

B,with2spacesbelowthecastersand4spacesbelow

thespindle.

Partsneededforthisprocedure:

1

Operator’sManual

1

EngineOperator’sManual

1

PartsCatalog

1

Operatortrainingmaterial

1

RegistrationCard

1

Oildrainhose

Procedure

•ReadtheOperator’ sManual.

•Viewtheoperatortrainingmaterialbeforeoperating

themachine.TheDVDsuppliedisgeneraltraining

materialandthemachinemaydifferfromthat

supplied.

•Fillouttheregistrationcard.

•Usetheoildrainhosewhenchangingtheengineoil.

10

Page 11

ProductOverview

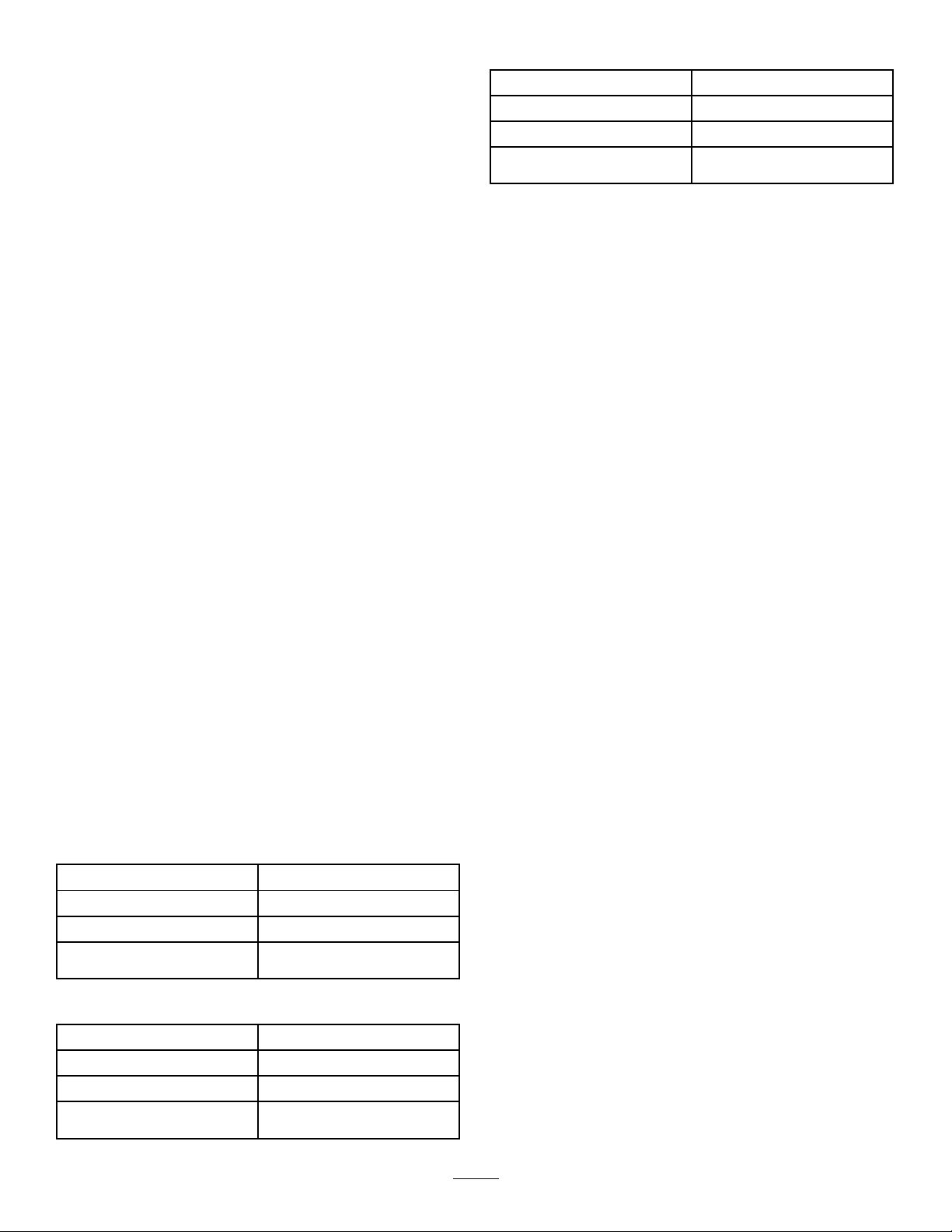

Figure5

1.Mowerdeck

2.Brake5.Handle

3.Gastank6.Casterwheel

Controls

Becomefamiliarwithallthecontrols(Figure6)before

youstarttheengineandoperatethemachine.

4.Controls

Figure6

1.Throttlecontrol6.Handle

2.Speedcontrollever

3.Ignitionswitch

4.Neutrallock

5.OperatorPresence

Controllevers(OPC)

7.DriveLever

8.Bladecontrolknob(PTO)

9.Choke

10.Fuelshut-offvalve

ThrottleControl

Thethrottlecontrolhastwopositions:FastandSlow.

OperatorPresenceControl(OPC)

Levers

WhenyousqueezetheOPCleversagainstthehandles,

theOPCsystemsensesthattheoperatorisinthe

normaloperatingposition.WhenyoureleasetheOPC

levers,theOPCsystemsensesthattheoperatorhasleft

thenormaloperatingposition,andthesystemwillstop

theengineifeitherthespeedcontrolleverisnotinthe

neutralpositionorthebladecontrol(PTO)knobis

engaged.

BladeControlKnob(PTO)

Thebladecontrolknob(PTO)isusedtoengageand

disengagethedrivebelttodrivethemowerblades

withtheOPCleverspressedagainstthehandles.Pull

theknobuptoengagethebladesandpushdownto

disengagetheblades.

11

Page 12

IgnitionSwitch

48inchmowers:

Thisswitchisusedinconjunctionwithrecoilstarterand

hastwopositions:RunandOff.

SpeedControlLever

Thismachinehasavariablespeedcontrolwithaneutral

position.Thiscontrolshowfastthemachinewilltravel.

DriveLevers

Releasedriveleverstoengageforwardtractionoperation

andsqueezetheleversuntilanincreaseinforceisfelt

togointoneutralpositionandcontinuetosqueezeto

goinreverse.Squeezerighthanddrivelevertoturnright

andlefthandlevertoturnleft.

NeutralLock

Squeezedriveleversuntilanincreaseinforceisfeltand

movelockstotherearforneutrallock.

RecoilStarter

Width

Length

Height

Weight

49–1/2inches(126cm)

76–1/2inches(194cm)

44inches(1 12cm)

547lb(248kg)

Attachments/Acessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributorforalistofall

approvedattachmentsandaccessories.

Pulltherecoilstarterhandletostartengine(Figure5).

FuelShut-offValve

Closethefuelshut-offvalvewhentransportingor

storingmower.

Choke

Usethechoketostartacoldengine.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

32inchmowers:

Width

Length

Height

Weight

35inches(89cm)

80inches(203cm)

44inches(1 12cm)

509lb(231kg)

36inchmowers:

Width

Length

Height

Weight

37inches(94cm)

80inches(203cm)

44inches(1 12cm)

511lb(232kg)

12

Page 13

Operation

AddingFuel

UseUnleadedRegularGasolinesuitablefor

automotiveuse(85pumpoctaneminimum).

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmayinsulate

thecontainerandslowthelossofanystatic

charge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystem

inplaceandinproperworkingcondition.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancauseserious

injuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillagewith

soapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysor

less.Forlongerstorageitisrecommendedthatthe

fueltankbedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountofgas

stabilizer/conditionertothegas.

13

Page 14

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshgasoline.To

minimizethechanceofvarnishdepositsinthefuel

system,usefuelstabilizeratalltimes.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileit

isunattended.

FillingtheFuelTank

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundfueltankcapandremovethecap.

Addunleadedregulargasolinetofueltank,untilthe

levelis1/4to1/2inch(6to13mm)belowthe

bottomofthellerneck.Thisspaceinthetank

allowsgasolinetoexpand.Donotllthefueltank

completelyfull.

3.Installfueltankcapsecurely.Wipeupanygasoline

thatmayhavespilled.

ThinkSafetyFirst

Carefullyreadallthesafetyinstructionsanddecalsin

thesafetysection.Knowingthisinformationcould

helpyouoranybystandersavoidinjury.

Theuseofprotectiveequipmentforeyes,hearing,feet

andheadisrecommended.

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator’searandcancausehearing

lossthroughextendedperiodsofexposure.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

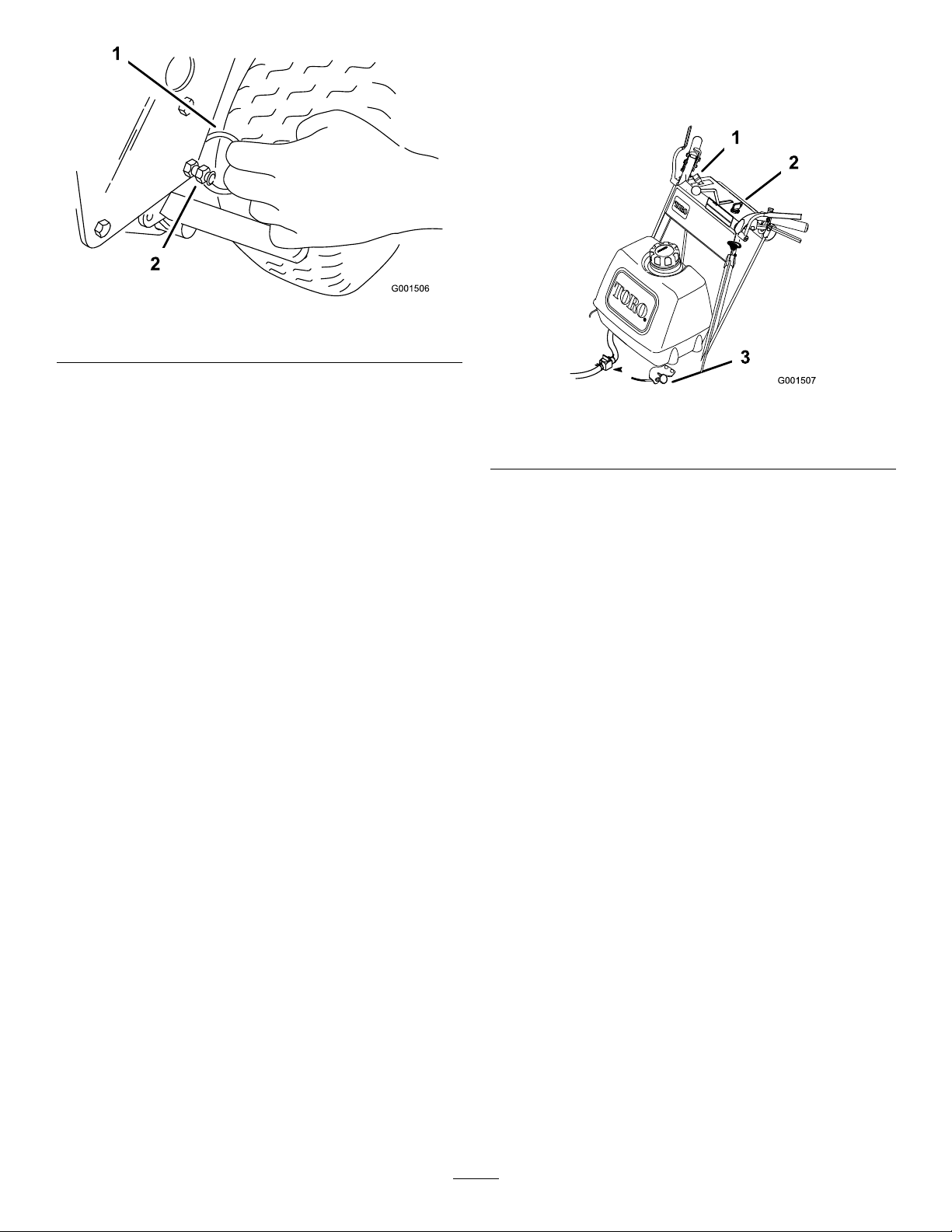

SettingtheParkingBrake

Pulltheparkingbrakeleverrearward(Figure8).

Figure8

1.Parkingbrakelever(inthereleasedposition)

ReleasingtheParkingBrake

Pushtheparkingbrakeleverforward.

Wearhearingprotectionwhenoperatingthis

machine.

Figure7

1.Warning—wearhearingprotection.

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthe

machineorleaveitunattended.Beforeeachuse,check

theparkingbrakeforproperoperation.

Iftheparkingbrakedoesnotholdsecurely,adjustit.

RefertoServicingtheParkingBrake.

StartingandStoppingthe

Engine

StartingtheEngine

1.Connectthewirestothesparkplugs.

2.Openthefuelvalve.

Note:Acoldweatherstaringkithasbeen

incorporatedtoassistenginestartingincold

weatherorwhentheunithasnotbeenrunfora

periodoftime.

Tousethecoldstartkit:

•Graspsplitring(Figure9)onrightsideof

machine,pullringandchainstraightoutfrom

sideofmachineandhookringovercontrol

shieldbolt.

14

Page 15

Figure9

1.Splitring2.Controlshieldbolt

4.Letengineidlefor30to60secondsbeforeturning

theengineoff.

5.Tostoptheengine,turntheignitionkeytooff.

•Aftertheengineisstarted,pullthechainstraight

outfromsideofmachineuntilringcanbe

removedfromshieldbolt.Slowlyreleasetension

onchain.

3.Disengagethebladecontrolknob(PTO)andmove

thespeedcontrollevertoneutral.

4.Movethedriveleverstoneutralandsettheneutral

locks.

5.Settheparkingbrake.

6.Turntheignitionkeytotherunposition(

Figure6).

7.Tostartacoldengine,movethethrottlecontrol

midwaybetweenthefastandslowpositions.

8.Tostartawarmengine,movethethrottlecontrol

tothefastposition.

9.Pullthechokeknobiftheengineiscold(

Figure6).

Note:Awarmorhotengineusuallydoesnot

requireanychoking.

10.Grasptherecoilstarterhandlermlyandpullit

outuntilpositiveengagementresults;thenpullthe

handlevigorouslytostarttheengine.Allowthe

ropetorecoilslowly.

Figure10

1.Throttlelever

2.Ignitionswitch

3.Choke

Important:Makesurefuelshutoffvalveis

closedbeforetransportingorstoringmachine,

asfuelleakagemayoccur.Beforestoring

machine,removewirefromthesparking

plug(s)topreventpossibilityofaccidental

starting.

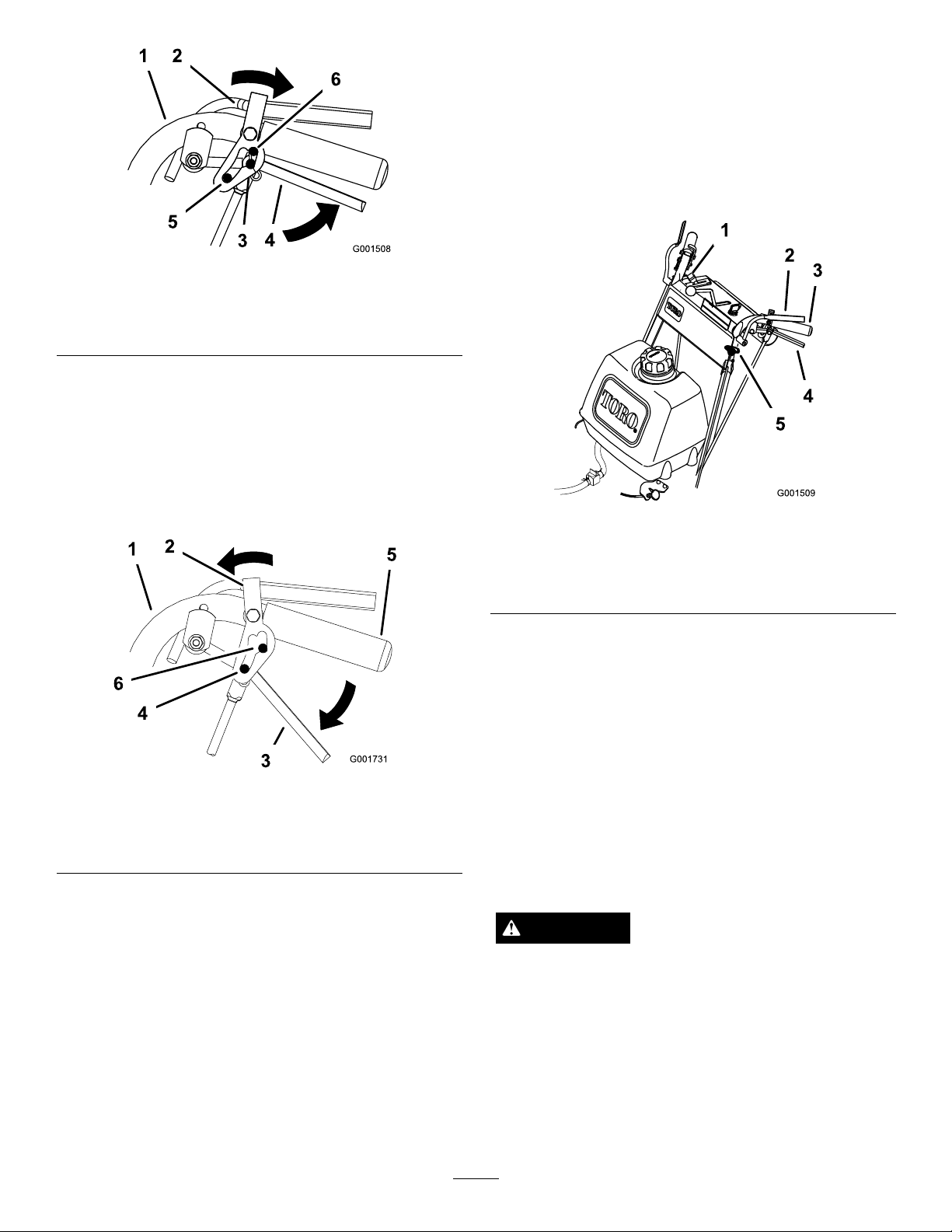

OperatingtheNeutralLocks

Alwayssettheneutrallockwhenyoustopthemachine.

Settheparkingbrakeifitisleftunattended.

SettingtheNeutralLock

1.Squeezethedriveleversbackuntilanincreasein

forceisfelt.

2.Placethumbsontheupperpartofthelocksand

movethembackuntilthepinsareintheneutral

position(

Figure11).

11.Pushthechoketooffastheenginewarmsup

(Figure10).

12.Iftheengineiscold,allowittowarmupandthen

movethethrottlecontroltothefastposition.

StoppingtheEngine

1.Movedriveleverstoneutralandsetneutrallocks.

2.Movethethrottlelevertoslow(Figure10).

3.Disengagethebladecontrolknob(PTO)andmove

thespeedcontrollevertoneutral.

15

Page 16

Figure11

1.Handle4.Drivelever

2.Neutrallock

3.Neutralposition6.Reverseposition

5.Fullspeedforward

ReleasingtheNeutralLock

1.Squeezethedriveleversbackuntilanincreasein

forceisfelt.

2.Placethumbsontheupperpartoflocksandmove

themforwarduntilthepinsareintheforwardslot

Figure12).

(

2.Pullbladecontrolknob(PTO)up.HoldtheOPC

leversagainsthandlegrip.

Note:ReleasingtheOPCleverswiththemower

bladesrunningwillkilltheengine.

3.Restarttheengineandrepeattheprocedureto

engagethemowerbladesiftheoperatorpresence

control(OPC)leversarereleased.

Figure13

1.Throttlelever4.DriveLever

2.OperatorPresence

Controllevers(OPC)

3.Handle

5.Bladecontrolknob(PTO)

Figure12

1.Handle

2.Neutrallock5.Handle

3.Drivelever6.Forwardslot

4.Pininfullspeedforward

OperatingtheMowerBlade

ControlKnob(PTO)

Thebladecontrolknob(PTO)isusedinconjunction

withtheOperatorPresenceControl(OPC)leversto

engageanddisengagethemowerblades.

EngagingtheMowerBlades(PTO)

1.Toengageblades,squeezetheOperatorPresence

Control(OPC)leversagainsthandlegrips

(Figure13).

DisengagingtheMowerBlades(PTO)

Themowerbladescanbedisengagedbyoneofthe

followingsteps.

1.Pushthebladecontrolknob(PTO)downtooff

(Figure13).

2.ReleasingtheOperatorPresenceControl(OPC)

leverswillkilltheengineandstoptheblades

Figure13)withthebladecontrolleverengaged.

(

TheSafetyInterlockSystem

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

16

Page 17

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventthe

mowerfromstartingunless:

•Thebladecontrolknob(PTO)ispushedoff.

•Thespeedcontrolleverisinneutral.

7.Withtheenginerunning,movethespeedcontrol

leverforward.ReleasetheOPClevers.Theengine

shouldkill.

8.Ifalltheaboveconditionsarenotmethavean

AuthorizedServiceDealerrepairthesafetysystem

immediately.

Thesafetyinterlocksystemisdesignedtokillthe

enginewhen:

•TheOperatorPresenceControl(OPC)leversare

releasedwiththemowerengagedand/orthespeed

controlisoutofneutral.

•Thespeedcontrolleverisshiftedoutofneutral

withoutholdingOPCleversorwiththebrake

engaged.

•Thebladecontrolknob(PTO)ispulledupwithout

holdingtheOPClevers.

TestingtheSafetyInterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafetyinterlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribed,haveanAuthorizedService

Dealerrepairthesafetysystemimmediately.

WARNING

Whiletestingthesafetyinterlocksystem,the

machinemaymoveforwardandcausepersonal

injuryorpropertydamage.

DrivingtheMachineForward

andBackward

Thethrottlecontrolregulatestheenginespeedas

measuredinRPM(revolutionsperminute).Placethe

throttlecontrolinthefastpositionforbestmowing

performance.

DrivingForward

1.Releasetheparkingbrake.

2.Togoforward,movethespeedcontrolleverto

desiredspeed.

3.Releasetheneutrallock.RefertoReleasingthe

NeutralLock.

4.Slowlyreleasethedriveleverstomoveforward

Figure14).

(

Togostraight,releasedriveleversequally

(Figure14).

Toturn,squeezethedriveleveronthesideand

directionyouwanttoturn(

Figure14).

•Performthesafetyinterlocktestinanopen

area.

•Ensurenooneisstandinginfrontofthe

machinewhileperformingthesafetyinterlock

test.

1.Settheneutrallocksandplacespeedcontrollever

inneutral.

2.Starttheengine;refertoStartingandStoppingthe

Engine.

3.WithoutholdingtheOperatorPresenceControl

(OPC)levers,pullthebladecontrolknob(PTO)up.

Theengineshouldkill.

4.Pushthebladecontrolknobdowntooff.

5.Withenginerunning,holddowntheOPClevers.

Pullthebladecontrolknob(PTO)up.Thedrive

beltshouldengageandthemowerbladesbegin

rotating.

6.ReleasetheOPClevers.Theengineshouldkill.

Figure14

1.Drivelever

2.Speedcontrollever

DrivingBackward

Slowlysqueezethedriveleverstothehandletomove

rearward(Figure14).

17

Page 18

BringingtheMachineto

NeutralPosition

Alwayssettheneutrallockandparkingbrakewhenyou

stopthemachine.

1.Squeezethedriveleverstoneutralposition.

2.Settheneutrallocks.RefertoOperatingNeutral

Locks.

3.Movespeedcontrollevertoneutralposition.

StoppingtheMachine

1.Tostopthemachine,squeezethedriveleversto

neutralpositionandengageneutrallocks.

2.Movespeedcontrolleverintoneutral.

Note:Rotatetheby-passvalvesamaximumof2

turnssothevalvedoesnotcomeoutofthebody

causinguidtorunout.

Important:Donotstartoroperatethe

machinewiththeby-passvalvesopen.Damage

tosystemmayoccur.

3.Stoptheengine;refertoStoppingtheEngine.

4.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.Settheparkingbrake.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileit

isunattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

PushingtheMachinebyHand

Theby-passvalvesallowthemachinetobepushedby

handwithouttheenginerunning.

Important:Alwayspushthemachinebyhand.

Nevertowthemachinebecausehydraulicdamage

mayoccur.

ToPushtheMachine

1.DisengagethePTO,movethemotioncontrol

leverstotheneutrallockedpositionandsetthe

parkingbrake.

2.Opentheby-passvalvesbyturningthemcounter

clockwise1to2.Thisallowshydraulicuid

toby-passthepumpsandthewheelstoturn

(Figure15).

3.Releasetheparkingbrake.

4.Pushthemachinetothedesiredlocation.

5.Settheparkingbrake.

6.Closetheby-passvalves,butdonotovertighten

them.

Figure15

1.Hydraulicpump2.By-passvalve

TransportingMachines

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarylightingandmarkingasrequiredbylaw .

Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

petsorbystandersavoidinjury.

Totransportthemachine:

•Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

•Securelyfastenthemachinetothetrailerortruck

withstraps,chains,cable,orropes.

•Secureatrailertotowingvehiclewithsafetychains.

AdjustingtheHeight-of-Cut

Thismachinehasa1to4-1/4inch(26to108mm)

rangeforheight-of-cut.Thiscanbeachievedby

adjustingbladespacers,rearaxleheightandfrontcaster

spacers.UsetheHeight-of-Cutcharttoselectthe

combinationofadjustmentsrequired

AdjustingtheBladeHeight

AdjusttheBladesbyusingthe4spacers(1/4inch)

spacersonthebladespindlebolts.Thisallowsfora

1-inch(25mm)adjustmentrangeofcuttingheight,

in1/4inch(6mm)increments,inanyaxleposition.

Usethesamenumberofbladespacersonallbladesto

achievealevelcut(2aboveand2below ,1aboveand3

below,etc.).

18

Page 19

1.DisengagethePTOandpullthethrottletothe

slowposition.

2.Turntheignitionswitchtooff.

3.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.Settheparkingbrake.

4.Holdthebladeboltandremovethenut.Slidethe

boltdownthroughthespindle,andchangethe

spacersasneeded(

Figure16).

3.Placeajackundertheengineframe.Raisetheback

endoftheengineframeupenoughtoremovethe

drivewheels.

4.Removethedrivewheels.

5.Loosen,butdonotremove,the2topaxlebolts

Figure17).

(

6.Removethe2loweraxlebolts(Figure17).

Figure16

1.Blade

2.Bladebolt5.Thinwasher

3.Curvedwasher

4.Spacer

6.Nut

5.Installthebolt,curvedwasher,blade,addextra

spacers,andsecurethemwithathinwasheranda

nut(Figure16).

6.Torquethebladeboltto75-80ft.-lb.(101-108N-m).

Figure17

1.Topaxlebolt2.Loweraxlebolt

7.Raiseorlowerthemountingbracket,sothatyou

caninstallthe2axleadjustmentboltsinthedesired

holelocation(Figure17).Ataperedpunchcanbe

usedtohelpaligntheholes.

8.Tightenall4bolts.

9.Installdrivewheelsandlowerthemower.

AdjustingtheCasterPosition

1.UsingtheHeight-of-CutChart,adjustthecaster

spacerstomatchwiththeaxleholeselected

Figure18).

(

AdjustingtheAxleHeight

Adjusttheaxlepositiontotheselectedheight-of-cut

setting.

1.DisengagethePTOandpullthethrottletothestop

position.

2.Waitforallmovingpartstostopbeforeleavingthe

operatingpositionandthensettheparkingbrake.

19

Page 20

Figure18

1.Latchpin

2.Spacer,3/16inch(5mm)

3.Spacer,1/2inch(13mm)

2.Removethelatchpin,slidethecasterfromthe

support,andchangethespacers(

Figure18).

3.Installthecasterinthesupportandinsertthelatch

pin(Figure18).

3.Removethelowerangebolts(3/8x1inch)

andangenutssecuringhandletorearframe

(Figure20).

4.Pivothandletodesiredoperatingpositionand

installlowerangebolts(3/8x1inch)andange

nutsintomountingholes.Tightenallangebolts.

AdjustingtheHandleHeight

Thehandlepositioncanbeadjustedtomatchthe

operator’sheightpreference.

1.Removethehairpincotterpinsandclevispinsfrom

thedriveleversandneutrallocks(

Figure19

1.Controlrod5.Lefthandleshown

2.Clevispin

3.Drivelever7.Hairpincotterpin

4.OperatorPresence

Controllever(OPC)

6.Neutrallock

Figure19).

Figure20

1.Controlrodtting

2.Lowermountingholes7.Lowerposition

3.Rearframe

4.Lowerangebolt(3/8x1

inch)

5.Upperangebolt(3/8x

1-1/4inches)

6.Highposition

8.Uppermountinghole

9.Handle

10.Flangenut(3/8inch)

5.Adjustthecontrolrodlengthbyrotatingthecontrol

rodintherodtting(Figure19andFigure20).

6.Installhairpincotterbetweendriveleversand

neutrallocksandintoclevispins(Figure19).

Note:Makesuretheclevispinsareinsertedinto

theneutrallocks.

7.Performthehydrauliclinkageadjustmentswhenthe

handleheightischanged;referHydraulicLinkage

Adjustments.

2.Loosentheupperangebolts(3/8x1-1/4inch)

andangenutsecuringhandletorearframe

(Figure20).

20

Page 21

HeightofCutChart

Numberofspacers

1/2inch

AxlePosition

A00

A01

A10

B01

B10

B11

B20

C

C

C

C

D21

D30

D31

D40

E31

E40

E41

(13mm)

11

20

21

30

belowcaster

3/16inch

(5mm)

Numberof1/4inch(6mm)bladespacersbelowspindle

43210

1inch(26

mm)

1–1/8inch

(29mm)

1–3/8inch

(35mm)

1–3/8inch

(35mm)

1–5/8inch

(41mm)

1–3/4inch

(45mm)

2inch(51

mm)

1–7/8inch

(48mm)

2–1/8inch

(54mm)

2–1/4inch

(57mm)

2–1/2inch

(64mm)

2–3/8inch

(60mm)

2–1/2inch

(64mm)

2–3/4inch

(70mm)

3inch(76

mm)

2–7/8inch

(73mm)

3–1/8inch

(79mm)

3–1/4inch

(83mm)

1–1/4inch

(32mm)

1–3/8inch

(35mm)

1–5/8inch

(41mm)

1–5/8inch

(41mm)

1–7/8inch

(48mm)

2inch(51

2–1/4inch

(57mm)

2–1/8inch

(54mm)

2–3/8inch

(60mm)

2–1/2inch

(64mm)

2–3/4inch

(70mm)

2–5/8inch

(67mm)

2–3/4inch

(70mm)

3inch(76

3–1/4inch

(83mm)

3–1/8inch

(79mm)

3–3/8inch

(86mm)

3–1/2inch

(89mm)

1–1/2inch

(38mm)

1–5/8inch

(41mm)

1–7/8inch

(48mm)

1–7/8inch

(48mm)

2–1/8inch

(54mm)

mm)

mm)

2–1/4inch

(57mm)

2–1/2inch

(64mm)

2–3/8inch

(60mm)

2–5/8inch

(67mm)

2–3/4inch

(70mm)

3inch(76

mm)

2–7/8inch

(73mm)

3inch(76

mm)

3–1/4inch

(83mm)

3–1/2inch

(89mm)

3–3/8inch

(86mm)

3–5/8inch

(92mm)

3–3/4inch

(95mm)

1–3/4inch

(45mm)

1–7/8inch

(48mm)

2–1/8inch

(54mm)

2–1/8inch

(54mm)

2–3/8inch

(60mm)

2–1/2inch

(64mm)

2–3/4inch

(70mm)

2–5/8inch

(67mm)

2–7/8inch

(73mm)

3inch(76

mm)

3–1/4inch

(83mm)

3–1/8inch

(79mm)

3–1/4inch

(83mm)

3–1/2inch

(89mm)

3–3/4inch

(95mm)

3–5/8inch

(92mm)

3–7/8inch

(98mm)

4inch(102

mm)

2inch(51

mm)

2–1/8inch

(54mm)

2–3/8inch

(60mm)

2–3/8inch

(60mm)

2–5/8inch

(67mm)

2–3/4inch

(70mm)

3inch(76

mm)

2–7/8inch

(73mm)

3–1/8inch

(79mm)

3–1/4inch

(83mm)

3–1/2inch

(89mm)

3–3/8inch

(86mm)

3–1/2inch

(89mm)

3–3/4inch

(95mm)

4inch(102

mm)

3–7/8inch

(98mm)

4–1/8inch

(105mm)

4–1/4inch

(108mm)

21

Page 22

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst25hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthemowerbelttension.

•Checkthehydraulicuidlevel.

•Replacethehydraulicoillter.

•Checkthemowerbelttension.

•Checkthesafetysystem.

•Greasethecasterwheelsandcasterpivot.

•Checktheengineoillevel.

•Cleantheairintakescreen.

•Inspecttheblades.

•Cleanthemowerdeck.

•Cleanfoamaircleanerelement.

•Checkthehydraulicuidlevel.

•Greasethemowerbeltidler.

•Greasethepumpdriveidlerpivot.

•Greasethepumpcontrol.

•Checkthepaperaircleanerelement.

•Checkthetyrepressure.

•Checkthebelts.

•Checkthemowerbelttension.

•Greasethebladeengagementbellcrank.

•Changetheengineoil.

•Checkthesparkplugs.

•Checkandcleanenginecoolingnsandshrouds.

•Checkhydrauliclinesandhoses.

•Replacethepaperaircleanerelement.

Every200hours

Every400hours

Beforestorage

•Replacetheengineoillter

•Replacethefuellter.

•Replacethehydraulicoillter.

•LubricatethecamlockwithNever-Seez®.

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator’smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthesparkplugwirefromthesparkplug(s)beforeyoudo

anymaintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

Lubrication

UseFigure21forlocatingthegreasepointsonthe

machine.

GreasewithNo.2generalpurposelithiumbaseor

molybdenumbasegrease.

22

Page 23

HowtoGrease

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Cleanthegreasettingswitharag.Makesureto

scrapeanypaintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pumpgrease

intothettingsuntilgreasebeginstooozeoutof

thebearings.

5.Wipeupanyexcessgrease.

LubricatingtheCasterand

WheelBearings

ServiceInterval:Beforeeachuseordaily

Lubricatethefrontwheelbearingsandfrontspindles

Figure21).

(

GreasingtheMowerBeltIdler

ServiceInterval:Every50hours

Greasethettingonthemowerbeltidlerarmpivot

Figure21).

(

Note:Removethemowerdeckcovertoaccessthe

greasettingforthemowerbeltidlerarm.

GreasingthePumpControl

andBellCrank

ServiceInterval:Every50hours—Greasethepump

driveidlerpivot.

Figure21

1.Pumpdriveidlerarm4.Mowerbeltidlerarm

2.Pumpcontrolarm

3.Bellcrank

5.Casterwheelbearing

6.Casterpivot

Every50hours—Greasethepump

control.

Every100hours—Greasetheblade

engagementbellcrank.

Every400hours—Lubricatethecam

lockwithNever-Seez

Greasethettingonthepumpdriveidlerpivotandthe

pumpcontrol.

Greasethebladeengagement(PTO)bellcrank

(Figure21).

LubricatecamlockwithNever-Seez

lubricant.

Note:Removetheguardsttedunderthemachineto

accessthegreasettingonthepumpdriveidlerpivot.

®

.

®

orequivalent

23

Page 24

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval/Specication

Note:Servicetheaircleanermorefrequently(every

fewoperatinghours)iftheoperatingconditionsare

extremelydustyorsandy.

Important:Donotoilthefoamorpaperelement.

RemovingtheFoamandPaper

Elements

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Cleanaroundtheaircleanertopreventdirt

fromgettingintotheengineandcausingdamage

Figure22).

(

4.Unscrewthecoverknobandremovetheaircleaner

cover(Figure22).

5.Removethe2wingnutsandremovetheaircleaner

assembly(Figure22).

Figure22

1.Engine4.Foamelement

2.Cover

3.Wingnut

5.Paperelement

6.Coverknob

6.Carefullypullthefoamelementoffthepaper

element(

Figure22).

CleaningtheFoamAirCleanerElement

ServiceInterval:Every25hours

1.Washthefoamelementinliquidsoapandwarm

water.Whentheelementisclean,rinseitthoroughly.

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifitis

tornorworn.

ServicingthePaperAirCleaner

Element

ServiceInterval:Every50hours

Every200hours

1.Donotcleanthepaperlter,replaceit(Figure22).

2.Inspecttheelementfortears,anoilylm,ordamage

totherubberseal.

3.Replacethepaperelementifitisdamaged.

InstallingtheFoamandPaperElements

Important:Topreventenginedamage,always

operatetheenginewiththecompletefoamand

paperaircleanerassemblyinstalled.

24

Page 25

1.Carefullyslidethefoamelementontothepaperair

cleanerelement(Figure22).

2.Placetheaircleanerassemblyontotheaircleaner

baseandsecureitwiththe2wingnuts(

Figure22).

3.Placetheaircleanercoverintopositionandtighten

thecoverknob(Figure22).

ServicingtheEngineOil

ServiceInterval/Specication

Note:Changetheoilmorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy .

OilType:Detergentoil(APIserviceSF ,SG,SH,orSJ)

CrankcaseCapacity:58ounces(1.7liter)withthelter

removed;51ounces(1.5liter)withoutthelterremoved

Viscosity:Refertothetable(Figure23).

Figure24

1.Oildipstick

2.Fillertube

5.Unscrewtheoildipstickandwipetheendclean

(Figure24).

6.Slidetheoildipstickfullyintothellertube,butdo

notthreadontotube(Figure24).

7.Pullthedipstickoutandlookattheend.Iftheoil

levelislow ,slowlypouronlyenoughoilintotheller

tubetoraisetheleveltotheFullmark.

Figure23

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface.

2.DisengagethePTOandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

Important:Donotoverllthecrankcasewith

oilandruntheengine;enginedamagecan

result.

ChangingtheOil

ServiceInterval:Aftertherst8hours

Every100hours

1.Starttheengineandletitrunveminutes.This

warmstheoilsoitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

3.DisengagethePTOandsettheparkingbrake.

4.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

5.Slidethedrainhoseovertheoildrainvalve.

6.Placeapanbelowthedrainhose.Rotateoildrain

valvetoallowoiltodrain(

Figure25).

4.Cleanaroundtheoildipstick(Figure24)sothatdirt

cannotfallintothellerholeanddamagetheengine.

7.Whenoilhasdrainedcompletely,closethedrain

valve.

8.Removethedrainhose(Figure25).

Note:Disposeoftheusedoilatarecyclingcenter.

25

Page 26

3.Applyathincoatofnewoiltotherubbergasketon

1

thereplacementlter(Figure26).

4.Installthereplacementoilltertothelteradapter,

turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional3/4turn(

Figure26).

5.Fillthecrankcasewiththepropertypeofnewoil;

refertoServicingtheEngineOil.

6.Runtheengineforabout3minutes,stoptheengine,

andcheckforoilleaksaroundtheoillteranddrain

valve.

7.Checktheengineoillevelandaddoilifneeded.

ServicingtheSparkPlugs

Figure25

1.Oildrainvalve2.Oildrainhose

9.Slowlypourapproximately80%ofthespeciedoil

intothellertube(Figure24).

10.Checktheoillevel;refertoCheckingtheEngineOil

Level.

11.SlowlyaddtheadditionaloiltobringittotheFull

mark.

ChangingtheOilFilter

ServiceInterval:Every200hoursoreveryotheroil

change.

Note:Changetheoilltermorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy .

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

2.Removetheoldlter(

Figure26).

ServiceInterval/Specication

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstallingthe

sparkplugsandagappingtool/feelergaugetocheckand

adjusttheairgap.Installanewsparkplugsifnecessary .

Type:Champion®RCJ8YorequivalentAirGap:

0.030inch(0.75mm)

RemovingtheSparkPlugs

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Disconnectthewiresfromthesparkplugs

Figure27).

(

1.Oillter

Figure26

Figure27

2.Adapter

1.Spark-plugwire/sparkplug

26

Page 27

4.Cleanaroundthesparkplugstopreventdirtfrom

fallingintotheengineandpotentiallycausing

damage.

5.Removethesparkplugsandthemetalwashers.

CheckingtheSparkPlugs

FuelSystem

Maintenance

ServicingtheFuelTank

ServiceInterval:Every100hours

1.Lookatthecenterofthesparkplugs(Figure28).

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly .Ablackcoatingonthe

insulatorusuallymeansthattheaircleanerisdirty.

2.Ifneeded,cleanthesparkplugwithawirebrushto

removecarbondeposits.

Figure28

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

Important:Alwaysreplacethesparkplugs

whenithasablackcoating,wornelectrodes,

anoilylm,orcracks.

3.Checkthegapbetweenthecenterandsideelectrodes

Figure28).Bendthesideelectrode(Figure28)if

(

thegapisnotcorrect.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

DrainingtheFuelTank

1.Parkthemachineonalevelsurface,toassurefuel

tankdrainscompletely.Thendisengagethepower

takeoff(PTO),settheparkingbrake,andturnthe

ignitionkeytooff.Removethekey.

2.Closethefuelshut-offvalveatthefueltank

Figure29).

(

3.Squeezetheendsofthehoseclamptogether

andslideitupthefuellineawayfromfuellter

(Figure29).

4.Pullthefuellineoffthefuellter(Figure29).Open

thefuelshut-offvalveandallowthegasolinetodrain

intoagascanordrainpan.

Note:Nowisthebesttimetoinstallanewfuellter

becausethefueltankisempty.RefertoReplacing

theFuelFilter.

InstallingtheSparkPlugs

1.Installthesparkplugsandthemetalwasher.Ensure

thattheairgapissetcorrectly .

2.Tightenthesparkplugsto16ft-lb(22N-m).

3.Connectthewirestothesparkplugs(Figure28).

5.Installthefuellineontothefuellter.Slidethehose

clampclosetothevalvetosecurethefuelline.

27

Page 28

Figure29

1.Fuelshut-offvalve2.Fuellter

ServicingtheFuelFilter

Figure30

1.Hoseclamp3.Filter

2.Fuelline

ReplacingtheFuelFilter

ServiceInterval:Every200hours/Y early(whichever

comesrst)

Neverinstalladirtylterifitisremovedfromthefuel

line.

Note:Notehowthefuellterisinstalledinorderto

installthenewltercorrectly.

Note:Wipeupanyspilledfuel.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Closefuelshut-offvalveatthefueltank(

4.Squeezetheendsofthehoseclampstogetherand

slidethemawayfromthelter(Figure30).

Figure29).

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclampsclose

tothelter.

7.Openfuelshut-offvalveatfueltank(

Figure29).

8.Checkforfuelleaksandrepairifneeded.

9.Wipeupanyspilledfuel.

28

Page 29

DriveSystem

Maintenance

Performthefollowinglinkageadjustmentswhenthe

machineneedsmaintenance.PerformstepsAdjustthe

SpeedControlLinkagethroughAdjustingtheTracking.

Ifanyadjustmentisneeded,dothemintheorderthat

theyarelisted.

AdjustingtheSpeedControl

Linkage

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Movethespeedcontrollever(locatedonthe

console)tothefullforwardposition.

4.Checktheorientationofthetabsontheendsofthe

speedcontrolcrank.Thesetabsshouldbepointing

straightdownatthe6o’clockpositionapproximately

Figure31).

(

7.Checktomakesurethesafetyswitchisdepressed

andthereisa5/16inch(8mm)spacebetweenthe

actuatingtabandtheswitch.(Figure32).

8.Ifneeded,adjustswitchlocationtocreatethe

5/16inch(8mm)space(Figure32).

5.Adjustthethreadedyokeatthebottomofthespeed

controllinkageuntilthetabsareatthe6o’clock

position(

1.Speedcontrolrod

2.Yoke5.Jamnut

3.Speedcontrolcrank

6.Pullthespeedcontrolleverbacktoneutral.

Figure31).

Figure31

4.Tabs,6o’clockposition

Figure32

1.Safetyswitch

2.5/16inch(8mm)space

3.Actuatingtab

AdjustingtheNeutralControl

Linkages

WARNING

Enginemustberunningsocontrollinkage

adjustmentscanbeperformed.Contactwith

movingpartsorhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawayfromrotatingparts,muferandother

hotsurfaces.

WARNING

Mechanicalorhydraulicjacksmayfailtosupport

machineandcauseaseriousinjury .

•Usejackstandswhensupportingmachine.

•Donotusehydraulicjacks.

29

Page 30

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Raisetherearofthemachineontojackstandsto

raisethedrivewheelsofftheground.

4.Disengagetheparkingbrake.

5.Starttheengineandmovethethrottleaheadtothe

fullthrottleposition.

6.Placetheneutrallocksinthefullforwardposition

andmovethespeedcontrollevertothemedium

speedposition.

7.HoldOPCleversdown.

Note:TheOPCleversmustbehelddown

wheneverthespeedcontrolleverisoutoftheneutral

positionortheenginewillkill.

WARNING

Electricalsystemwillnotperformpropersafety

shutoffwithOperatorPresenceControl(OPC)

levershelddowninplace.

•MakesureOperatorPresenceControl(OPC)

leversareworkingwhenadjustmentis

completed.

•NeveroperatethisunitwithOperator

PresenceControl(OPC)levershelddownin

place.

14.Afteradjustmentsaremade,tightenthenutsagainst

theyokes.

15.Repeatthisprocedurefortheoppositeside.

Figure33

1.Neutralcontrollinkage3.Adjustingbolt

2.Yoke4.Nut

AdjustingtheHydroControl

Linkages

8.Squeezeonedriveleveruntilanincreasedresistance

isfelt.Thisiswhereneutralshouldbe.

Note:Makesureyouhavenotreachedtheendof

theneutrallockslot.Ifyouhave,shortenthecontrol

leverlinkage.RefertoAdjustingtheControlRod.

9.Ifthewheelturnswhileholdingthedrivelever

inneutral,theneutralcontrollinkagesneedtobe

adjusted(

12.

10.Loosenthenutagainsttheneutralcontrollinkage

yoke(

11.Adjusttheneutralcontrollinkageuntilthe

respectivedrivewheelstopswhilethedriveleveris

pulledagainsttheneutralspring(neutralposition)

(

Figure33).

12.Turntheadjustingboltapproximately1/4turn

clockwiseifthewheelisturninginreverseorturn

theboltapproximately1/4turncounter-clockwiseif

thewheelisturningforward(Figure33).

13.Releasethedrivelevertotheforwarddriveposition

andsqueezebackintotheneutralposition.Check

toseeifthewheelstops.Ifnot,repeattheabove

adjustmentprocedure.

Figure33).Ifwheelstopsthengotostep

Figure33).

WARNING

Enginemustberunningsocontrollinkage

adjustmentscanbeperformed.Contactwith

movingpartsorhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawayfromrotatingparts,muferandother

hotsurfaces.

WARNING

Mechanicalorhydraulicjacksmayfailtosupport

machineandcauseaseriousinjury .

•Usejackstandswhensupportingmachine.

•Donotusehydraulicjacks.

AdjustingtheLeftSideLinkage

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Raisetherearofthemachineontojackstandshigh

enoughtoraisethedrivewheelsoffoftheground.

30

Page 31

4.Disengagetheparkingbrake.

5.Starttheengineandmovethethrottleaheadtothe

fullthrottleposition.

6.Placetheleftdriveleverinthefullforwardposition.

12.Afteradjustingthelefthydrocontrollinkage,move

thespeedcontrolleverforwardandthenbacktothe

neutralposition.

13.HoldtheOPCleversdown.

7.Placethespeedcontrolleverintheneutralposition.

WARNING

Electricalsystemwillnotperformpropersafety

shutoffwithOperatorPresenceControl(OPC)

leversheldinplace.

•MakesureOperatorPresenceControl(OPC)

leversareworkingwhenadjustmentis

completed.

•NeveroperatethisunitwithOperator

PresenceControl(OPC)leversheldinplace.

8.Loosenthefrontadjustingnutonlefthydrocontrol

linkageasshowninFigure35.

9.Turntheleftrearadjustingnutcounter-clockwise

untilwheelrotatesforward(

10.Turntherearadjustingnutclockwise1/4ofaturnat

atime.Thenmovethespeedcontrolleverforward

andbacktoneutral.Repeatthisuntilleftwheelstops

rotatingforward(

Figure35).

11.Turntherearnutanadditional1/2turnandtighten

thefrontadjustingnut.

Figure35).

Note:TheOPCleversmustbehelddown

wheneverthespeedcontrolleverisoutoftheneutral

positionortheenginewillkill.

14.Makesurethespeedcontrolleverisintheneutral

positionandthetyredoesnotrotate.

15.Repeattheadjustmentifneeded.

Note:Makesureatpartoflinkageisperpendicular

topinpartofswivel(

1.Hydrauliccontrollinkage

2.Swivelwithpin4.Correctpositionfor

Figure34).

Figure34

3.Incorrectpositionfor

hydrauliccontrollinkage

Hydrauliccontrollinkage,

90degrees

Figure35

1.Hydrocontrollinkage3.Rearadjustingnut

2.Frontadjustingnut

4.Controlarm

Note:Ifinconsistentneutraloccurs,checktobe

surebothspringsareproperlytightenedonthespeed

controlleverundertheconsole,especiallytherear

pivotspring.Repeataboveadjustmentsifnecessary

Figure36).

(

Figure36

1.Speedcontrollever

2.Rearpivotspring

3.spring

31

Page 32

AdjustingtheRightSideLinkage

1.Placethespeedcontrolleverintheneutralposition.

2.Placetherightdriveleverinthefullforwardposition.

3.Adjusttherightsidelinkagebyturningthequick

trackknobcounterclockwiseuntilthetyrebeginsto

rotateforward(Figure37).

4.Turntheknobclockwise1/4ofaturnatatime.

Thenmovethespeedcontrolforwardandbackto

neutral.Repeatthisuntilrightwheelstopsrotating

forward(

5.HoldtheOPCleversdown.

Note:TheOPCleversmustbehelddown

wheneverthespeedcontrolleverisoutoftheneutral

positionortheenginewillkill.

6.Thespringthatkeepstensionontheknobshould

normallynotneedadjustment.Howeverifan

adjustmentisneeded,adjustthelengthofspringto

1inch(26mm)betweenthewashers(

7.Adjustspringlengthbyturningnutatfrontofspring

Figure37).

(

Figure37).

Figure37).

Note:TheOPCleversmustbehelddown

wheneverthespeedcontrolleverisoutoftheneutral

positionortheenginewillkill.

2.Movetherespectivedriveleverupwarduntilit

reachestheneutralpositionandengageneutrallocks.

3.Ifthetyrerotatesineitherdirection,thelengthof

thecontrolrodwillneedtobeadjusted.

AdjustingtheControlRod

1.Adjusttherodlengthbyreleasingthedrivelever

andremovingthehairpincotterpinandclevispin.

Rotatetherodintherodtting(

2.Lengthenthecontrolrodifthetyreisturningin

reverseandshortentherodifthetyreisturning

forward.

3.Rotatetherodseveralturnsifthetyreisrotatingfast.

Then,adjusttherodin1/2turnincrements.

4.Placetheclevispinintothedrivelever(

Figure38).

Figure38).

Figure37

1.Hydrocontrollinkage

2.Spring4.1inch(26mm)

3.Quicktrackknob

AdjustingtheControlRod

CheckingtheControlRod

1.Withrearofmachinestillonjackstandsandengine

runningatfullthrottle,movethespeedcontrollever

tothemediumspeedposition.

Figure38

1.Controlrod5.Lefthandleshown

2.Clevispin

3.Drivelever7.Hairpincotterpin

4.OperatorPresence

Controllever(OPC)

6.Neutrallock

5.Releaseandengageneutrallockcheckingthatthe

tyredoesnotrotate(Figure39).Continuethis

processuntilthetyredoesnotrotate.

6.Installthehairpincotterpinbetweenthedrive

leversandtheneutrallocksandintotheclevispins

(

Figure38).

7.Repeatthisadjustmentfortheoppositeside.

32

Page 33

Figure39

1.Handle5.Neutralposition

2.Neutrallock6.Drivelever

3.Handle

4.Neutrallockslot

7.Fullspeedforward

8.Controlrod

AdjustingtheTracking

1.Removemachinefromanyjackstands.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Foraheavierdrivesetting,relocatethespringanchor

linkstoeitherthemediumorheavydutypositions

Figure41).Thespringanchorlinksareattachedto

(

theupperrearcornerofthehydrodriveshieldson

theleftandrightsidesofthemachine.

Note:Inthemediumorheavydutypositions,the

driveleverforcesattheupperhandlewillalsobe

increased

2.Checkthereartyrepressure.RefertoCheckingthe

tyrePressure.

3.Runtheunitandobservethetrackingonalevel,

smooth,hardsurfacesuchasconcreteorasphalt.

4.Iftheunittrackstoonesideortheother,turnthe

quicktrackknob.Turntheknobrighttosteerright

andturntheknoblefttosteerleft(

Figure40

1.Quicktrackknob

Figure40).

Figure41

1.Springanchor

2.Standardsetting

3.Mediumsetting

4.Heavydutysetting

CheckingtheTyrePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthereartyresasspecied.

Checkthepressureatthevalvestem(Figure42).

RearTyrePressure:15psi(1bar)

AdjustingtheSpringAnchor

Links

Formediumorheavydutydriveconditions,suchas

operatingwithasulkyonsteepslopes,ahigherspring

forcemayberequiredonthehydropumpcontrolarms

topreventthedrivesystemfromstalling.

1.DisengagethePTOandsettheparkingbrake.

Figure42

33

Page 34

CoolingSystem

BrakeMaintenance

Maintenance

CleaningtheAirIntakeScreen

ServiceInterval:Beforeeachuseordaily

Beforeeachuseremoveanybuild-upofgrass,dirt

orotherdebrisfromthecylinderandcylinderhead

coolingns,airintakescreenonywheelend,and

carburetor-governorleversandlinkage.Thiswillhelp

insureadequatecoolingandcorrectenginespeedand

willreducethepossibilityofoverheatingandmechanical

damagetotheengine.

CleaningtheCoolingSystem

ServiceInterval:Every100hours/Y early(whichever

comesrst)

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removetheairintakescreen,recoilstarterandfan

housing(

4.Cleanthedebrisandgrassfromtheengineparts.

5.Installairintakescreen,recoilstarterandfanhousing

(Figure43).

Figure43).

ServicingtheBrake

Beforeeachuse,checktheparkingbrakeforproper

operation.

Alwayssettheparkingbrakewhenyoustopthemachine

orleaveitunattended.Iftheparkingbrakedoesnot

holdsecurely,adjustit.

CheckingtheParkingBrake

1.Movethemachineontoalevelsurface.

2.Disengagethepowertakeoff(PTO)andstopthe

engine.

3.Settheparkingbrake.

Note:Settingtheparkingbrakeshouldtakea

reasonableamountofforce.Ifitengagestoohard

ortooeasily,anadjustmentisrequired.Referto

AdjustingtheParkingBrake.

AdjustingtheParkingBrake

Theparkingbrakeleverisontherightsideofthe

machine.Iftheparkingbrakedoesnotholdsecurely,

adjustit.

1.Checktheparkingbrakebeforeyouadjustit;referto

CheckingtheParkingBrake.

2.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake.

3.Removethespringhairpinfromthelowerbrake

link(Figure44).

Figure43

1.Airintakescreen4.Bolt

2.Fanhousing5.Nut

3.Recoilstarter

Figure44

1.Brakelinkageyoke4.Lowerbrakelink

2.Lowerbrakelever

3.Springclevispin

4.Rotatethelowerbrakelinkyokeclockwiseintothe

yoketotightentheparkingbrake;rotatethebrake

34

5.1/4inch(6mm)

6.Hairpin

Page 35

linkyokecounterclockwiseoutoftheyokeoutto

loosentheparkingbrake(Figure44).

BeltMaintenance

Note:Thereshouldbeapproximately1/4inch

clearancebetweenthetyreandtheatbarwhenthe

parkingbrakeinthereleasedposition(

5.Securethelowerlinktothelowerbrakeleverwith

thehairpincotterandtheclevispin(Figure44).

6.Checkthebrakeoperationagain;refertoChecking

theParkingBrake.

Figure44).

CheckingtheBelts

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Checkthebeltsforsquealingwhenthebeltisrotating,

bladesslippingwhencuttinggrass,frayedbeltedges,

burnmarksandcracksaresignsofawornmowerbelt.

Replacethemowerbeltifanyoftheseconditionsare

evident.

ReplacingtheMowerBelt

1.Disengagethebladecontrol(PTO)leverandsetthe

parkingbrakes.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Removetheknobsandthebeltcoveronthemower.

4.Removetheidlerpulleyandthewornbelt(

5.Installthenewmowerbelt.

Figure45).

6.Installtheidlerpulley.

7.Engagethebladecontrol(PTO)leverandcheck

thebelttension.RefertoAdjustingtheMowerBelt

Tension.

Note:Thepropermowerbelttensionis10-15lbf.

(44-67N)withthebeltdeected1/2inch(13mm)

halfwaybetweenthepulleys(

Figure45).

Figure45

1.Idlerpulley

35

2.Mowerbeltwith1/2inch

(13mm)deection

Page 36

AdjustingtheMowerBelt

Tension

AdjustingtheTension

ServiceInterval:Aftertherst8hours

Aftertherst25hours

Every50hours

Important:Thebrakeneedstobeadjustedwhen

thebelttensionorthebrakelinkageisadjusted.

Important:Thebeltmustbetightenoughtonot

slipduringheavyloadswhilecuttinggrass.Over

tensioningthebeltwillreducethespindlebearing

life,thebeltlifeandtheidlerpulleylife.

Thebeltmustbetightenoughsoitdoesnotslipduring

heavyloadswhilecuttinggrassandover-tensioningwill

reducebeltandspindlebearinglife.

1.Disengagethebladecontrol(PTO)leverandsetthe

parkingbrakes.

5.Engagethebladecontrollever(PTO)andcheckthe

belttension.

6.Ifthereisnoadjustmentleftintheturnbuckleand

thebeltisstillloose,therearidlerpulleyneedstobe

positionedtothemiddleorfronthole(

Figure47).

Usetheholethatwillgivethecorrectadjustment.

7.Whentheidlerpulleyismovedthebeltguidemust

bemoved.Movethebeltguidetothefrontposition

Figure47).

(

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Loosenthelocknutontheturnbuckle(

Figure46).

4.Rotatetheturnbuckletowardtherearofthe

mowertoincreasethetensiononthebelt.Rotate

theturnbuckletowardthefrontofthemowerto

decreasethetensiononthebelt(

Figure46).

Note:Theeyeboltthreadsonbothendsofthe

turnbuckleshouldbeengagedaminimumof

5/16inch(8mm).

Figure47

1.Rearidlerpulley4.Beltguideinbackposition

2.Middlehole

3.Fronthole

5.Frontidlerpulley(48inch

mowerdeckonly)

8.Checkthebeltguideundertheengineframefor

properadjustment(Figure48).

Note:Thedistancebetweenthebeltguideand

themowerbeltshouldbe3/4inch(19mm)when

youengagethemowerbelt(Figure48).Adjustthe

mowerbeltguideasnecessary.Thedisengagedbelt

shouldnotdragorfalloffthepulleywhentheguides

areproperlyadjusted.

Figure46

1.Locknut4.Assistarm

2.Turnbuckle

3.Frontstop

5.1/2inch(13mm)deection

here

36

Page 37

Figure48

1.Beltguide

9.Checkthebladebrakeadjustment;refertoAdjusting

theBladeBrake.

AdjustingthePTOEngagement

Linkage

Figure49

1.Bellcrank4.Yoke

2.Safetyswitchlocated

underenginedeck

3.Bellcrankjustclearsthe

gussetwiththePTO

engageded

5.Nut

6.Assistarmlink

ThePTOengagementlinkageadjustmentislocated

beneaththefrontlefthandcorneroftheenginedeck.

1.Disengagethebladecontrol(PTO)leverandsetthe

parkingbrakes.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Engagethebladecontrollever(PTO).

4.Adjustthelinkagelengthtowherethelowerend

ofthebellcrankjustclearstheaxlesupportgusset

Figure49).

(

5.Makesuretheassistarmisagainsttherearassistarm

stoponthedeck(Figure50).

6.Pushthebladecontrollever(PTO)downtothe

disengagedposition.

7.Theassistarmshouldcontactthefrontassistarm

stoponthedeck.Ifitdoesnotcontact,adjustthe

bellcranksoitisclosertothegusset(

Figure50).

Figure50

1.Assistarm5.Assistarmlink

2.Frontassistarmstop6.Yoke

3.Rearassistarmstop7.Hairpincotterpin

4.Turnbuckle

8.Toadjusttheassistarmlink,removethehairpin

cotterpinfromtheassistarm(Figure50).

9.Loosenthenutagainsttheyoke(Figure49).

37

Page 38

10.Removetheassistarmlinkfromtheassistarmand

rotatethelinktoadjustthelength.

11.Installtheassistarmlinkintotheassistarmand

secureitwiththehairpincotterpin(

Figure50).

HydraulicSystem

Maintenance

12.Checkiftheassistarmhitsagainstthestops

correctly.

AdjustingthePTOSafetySwitch

1.Disengagethebladecontrol(PTO)leverandsetthe

parkingbrakes.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Disengagethebladecontrollever(PTO).Makesure

theassistarmisagainstthefrontassiststoparm.

4.Ifneeded,adjustthebladesafetyswitchbyloosening

theboltsholdingtheswitchbracket(

5.Movethemountingbracketuntilthebellcrank

depressestheplungerbya1/4inch(6mm).

6.

Note:Makesurethebellcrankdoesnottouchthe

switchbodyordamagetotheswitchcouldoccur

(Figure51).

Tightentheswitchmountingbracket.

Figure51).

ServicingtheHydraulic

System

CheckingtheHydraulicFluid

ServiceInterval:Aftertherst8hours

Every25hours

FluidType:Mobil115W -50syntheticmotoroilor

equivalentsyntheticoil.

Important:Useoilspeciedorequivalent.Other

uidscouldcausesystemdamage.

HydraulicSystemOilCapacity:77oz.(2.3l)

Note:Therearetwowaysofcheckingthehydraulicoil.

Oneiswhentheoiliswarmandoneiswhentheoilis

cold.Thebafeinsidethetankhastwolevelsdepending

iftheoiliswarmorcold.

1.Positionmachineonalevelsurface.

2.Disengagethepowertakeoff(PTO)andshutoff

theengine.

3.Waitforallmovingpartstostopbeforeleavingthe

operatingpositionandthensettheparkingbrake.

1.Bellcrank

2.Boltsandnuts

Figure51

3.Switchmountingbracket

4.Switchbody

4.Cleanareaaroundcapandllerneckofhydraulic

Figure52).

tank(

Figure52

1.Cap3.Colduidlevel-full

2.Bafe4.Hotuidlevel-full