Page 1

CommercialWalk-BehindMower

AllCommercialFloatingandFixedDeckWalk-behindMowers

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3365-264RevB

SetupInstructions

ProcedureDescription

1

2

3

4

5

6

7

Nopartsrequired

Nopartsrequired

Number2generalpurposelithiumbase

ormolybdenumbasegrease.(Purchase

separately.)

Number2generalpurposelithiumbase

ormolybdenumbasegrease.(Purchase

separately.)

Nopartsrequired

Nopartsrequired

Mufer

Curvedwasher

Mufershield

Bolt(M8x25mm)

Muferclamp

Mufershieldbracket

Sidelocknut

1tube

1tube

Qty.

Use

–

–

–

–

1

4

1

4

1

1

4

Unfoldthecrate.

Checkthetirepressure.

Checktheidlerarmsforgrease.

(FloatingDeckModels)

Checkthemowerbeltidlerarmfor

grease.(FixedDeckModels)

Preparethegrassdeector.

Adjusttheanti-scalprollers.(Floating

DeckModels)

Installthemufer(ifneeded).

8

9

10

11

12

13

©2010—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Nopartsrequired

Nopartsrequired

Nopartsrequired

Bulkelectrolytewith1.265specic

gravity(Purchasefromabatterysupply

outlet.)

Nopartsrequired

Nopartsrequired

Registeratwww.Toro.com.

–

–

–

80

ounces

–

–

Checktheengineoillevel.

Addfueltothemachine.

Checkthehydraulicoillevel.

ActivatethebatteryforMowerswith

ElectricStart.

ChargethebatteryforMowerswith

ElectricStart.

Checkthemachinebeforedeliveryto

thecustomer.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

Page 2

ProcedureDescription

14

Operator’sManual

EngineOwner’sManual

Enginewarrantyliterature1

RegistrationCard

Operatortrainingmaterial

Accessorybrochure1

Key1

Oildrainhose

Qty.

Use

1

1

1

1

1

Deliveringthemachinetothecustomer.

2

Page 3

1

3

UnfoldingtheCrate

NoPartsRequired

Procedure

Ifthemachineisinametalcrate,refertothePackaging

CrateInstructionsincludedwiththemachine.

2

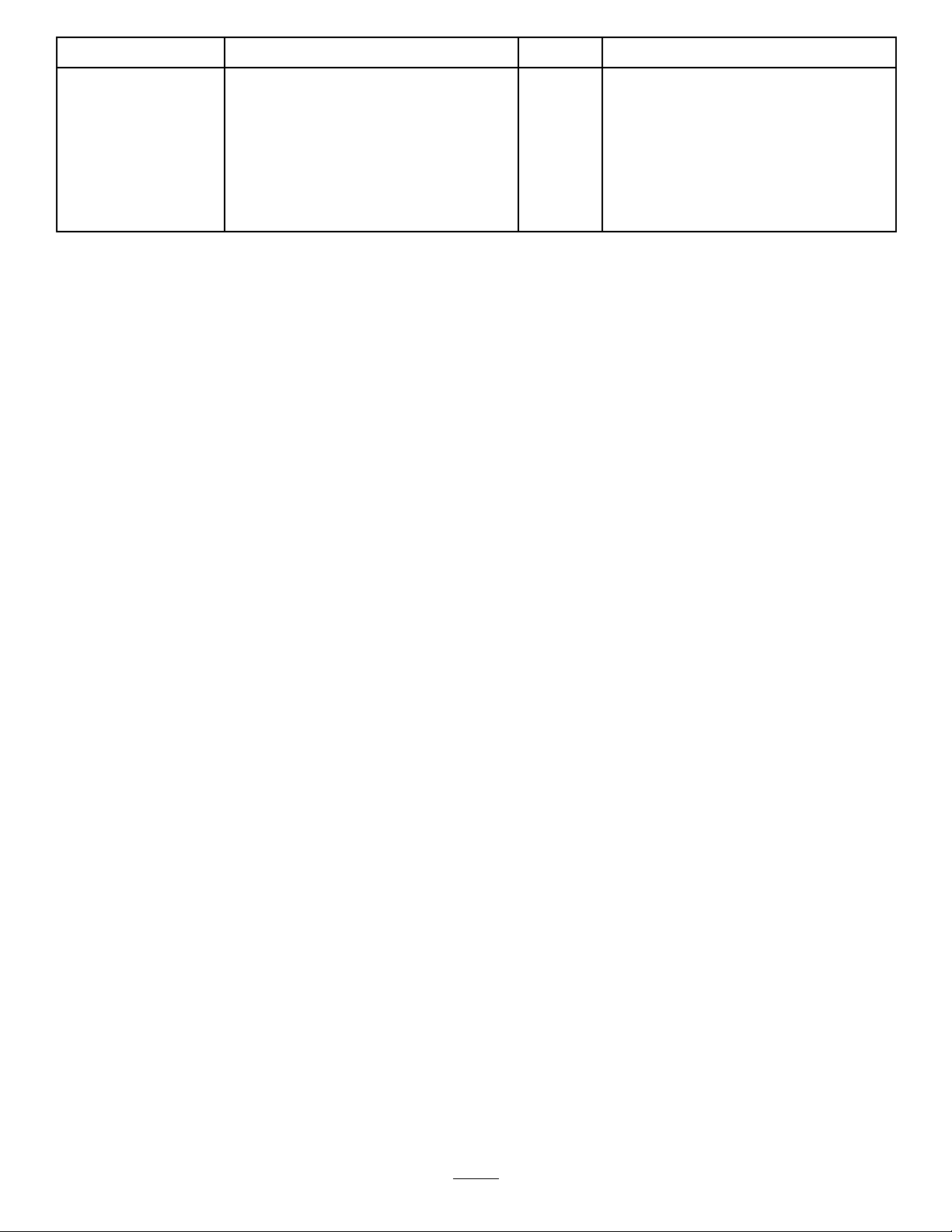

CheckingtheTirePressure

NoPartsRequired

Procedure

Pressure:12to14psi(83to97kPa)

Pressurefor60inchmowers:14to16psi(97to110kPa)

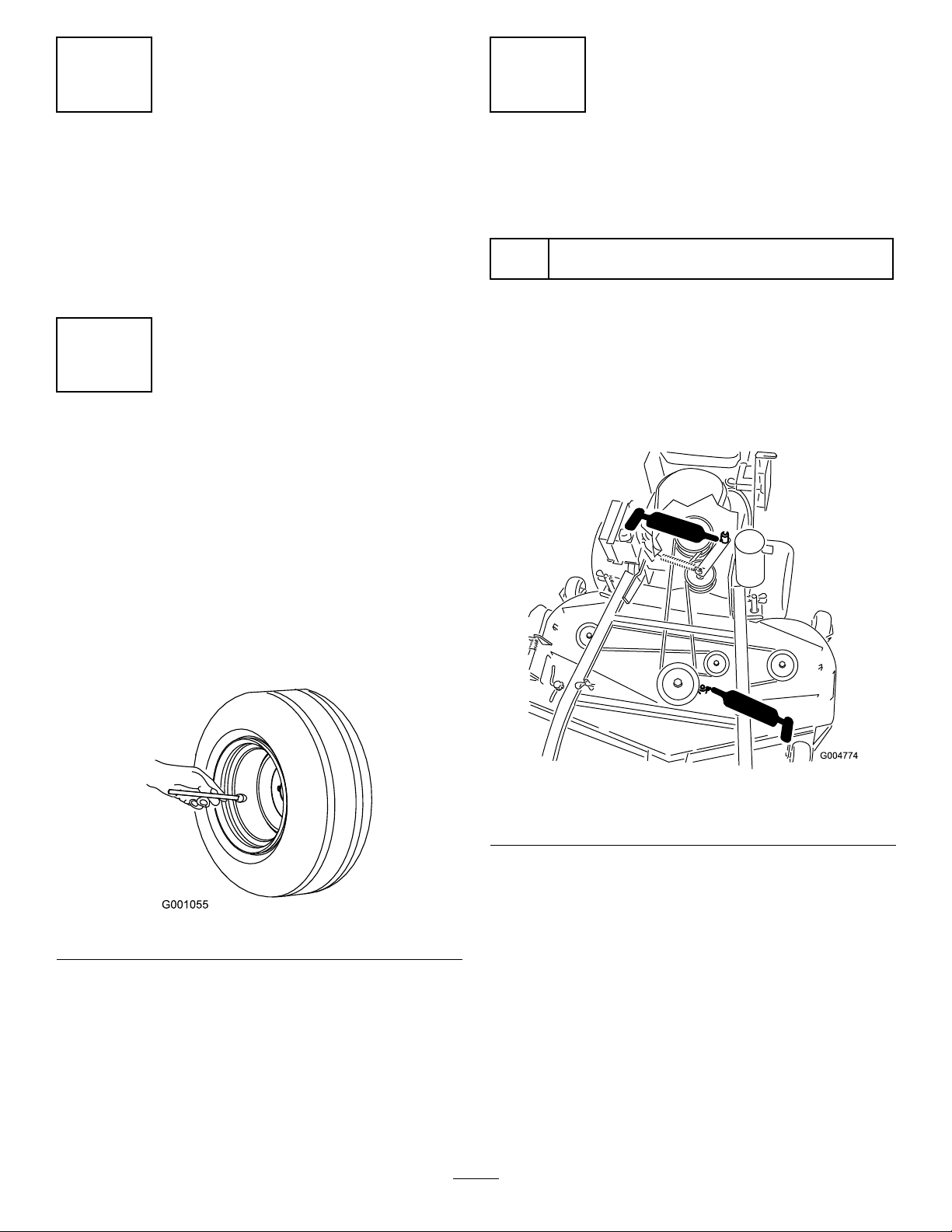

CheckingtheIdlerArmsfor

Grease(FloatingDeckModels)

Partsneededforthisprocedure:

1tube

Procedure

1.Removethecarrierframecover.

2.Checkthemowerbeltidlerarmforgrease(

3.Installthecarriercover.

Number2generalpurposelithiumbaseor

molybdenumbasegrease.(Purchaseseparately.)

orFigure3).

Figure2

Note:Thefrontcasterwheelisasemi-pneumatictire

anddoesnotneedtobechecked.

Checktheairpressureinthedrivetires.

Figure1

Figure2

40inch,48inch,and52inchMowerDeckshown

3

Page 4

Figure4

5

Figure3

36inchMowerDeckshown

4.Undertheenginedeck,checkthePTOdrivebelt

idlerarmforgrease.

4

CheckingtheMowerBeltIdler

ArmforGrease(FixedDeck

Models)

Partsneededforthisprocedure:

1tube

Procedure

1.Removethemowerdeckcover.

2.Checkthemowerbeltidlerarmforgrease(Figure4).

3.Installthemowerdeckcover.

Number2generalpurposelithiumbaseor

molybdenumbasegrease.(Purchaseseparately.)

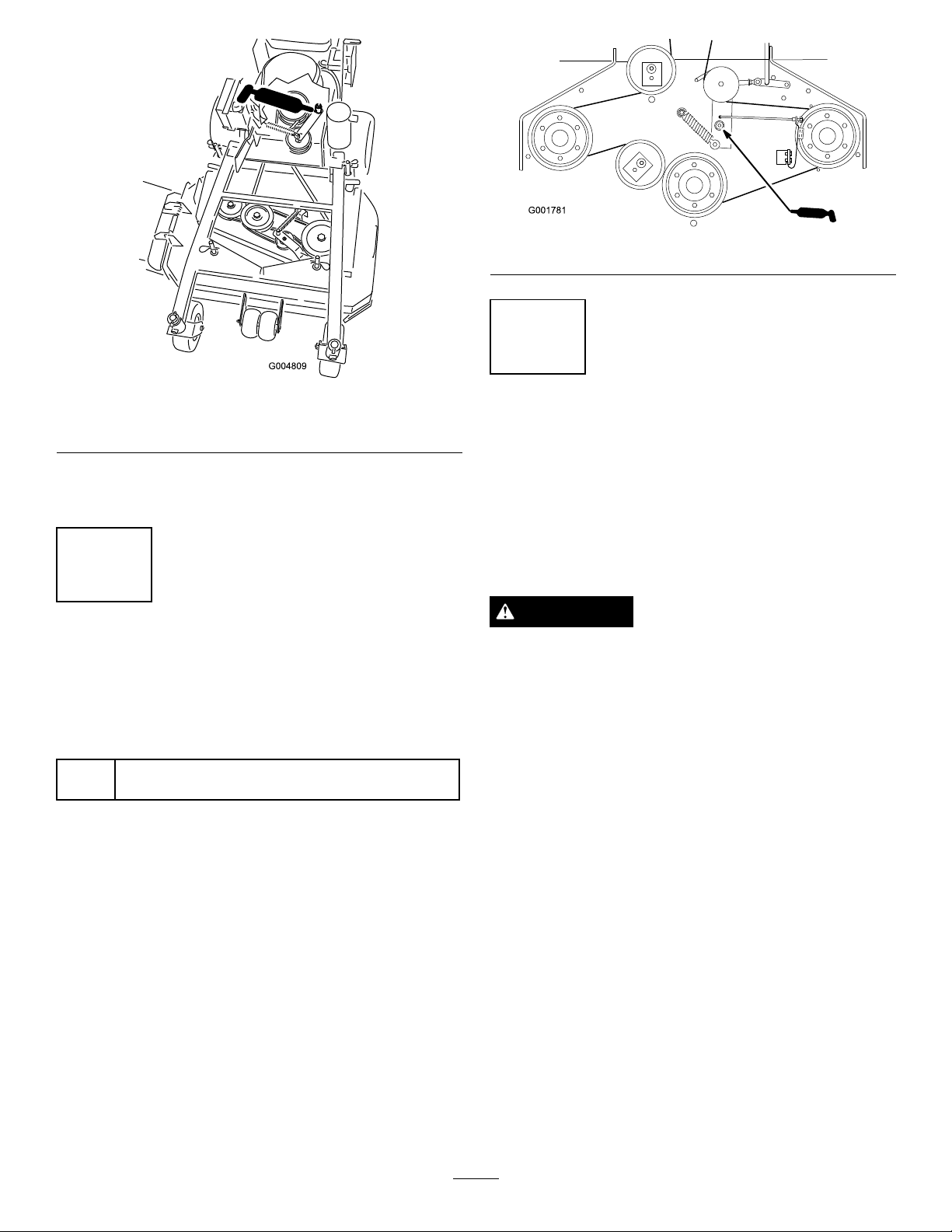

PreparingtheGrassDeector

NoPartsRequired

Procedure

Checkifyourmachinehasthegrassdeectorspring

installedcorrectly.Thegrassdeectorneedstohave

downwardtension.

WARNING

Anuncovereddischargeopeningcouldallowthe

lawnmowertothrowobjectsintheoperator’sor

bystander’sdirectionandresultinseriousinjuryor

death.Also,contactwiththebladecouldoccur.

Neveroperatethelawnmowerwiththegrass

deectorremovedunlessyouinstallacoverplate,a

mulchplate,oragrasschuteandcatcher.

1.MakesuretheLendofspringisinstalledbehind

thedeckedgebeforeinstallingtheboltasshownin

Figure5.

2.PlacetheJhookendofspringaroundgrassdeector

(Figure5).

Important:Thegrassdeectormustbefreeto

rotatewithdownwardtension.Liftthedeector

uptothefullopenpositionandensurethatit

rotatesfreelywithoutbindingintothefulldown

position.

4

Page 5

FixedDeckShown

Figure5

7

InstallingtheMufer

Partsneededforthisprocedure:

1

Mufer

4

Curvedwasher

1

Mufershield

4

Bolt(M8x25mm)

1

Muferclamp

1

Mufershieldbracket

4

Sidelocknut

1.GrassDeector4.Lendofspring,place

2.Spring

3.Jhookendofspring

behinddeckedgebefore

installingbolt

5.Deckedge

6

AdjustingtheAnti-Scalp

Rollers(FloatingDeckModels)

NoPartsRequired

Procedure

Adjusttheanti-scalprollers;refertoAdjustingthe

Anti-ScalpRollersintheOperator’sManual.

Procedure

1.Slidethemuferclampontothemuferinlet

andslidethemuferontotheexhaustmanifold

Figure6).

(

2.Alignthetwomountingholesonthemuferwith

thetwomountingslotsonthebracketattachedto

theengine.

3.Slidethemufershielddownoverthetopofthe

mufer.

4.Install2bolts(M8x25mm)and2curvedwashers

throughthemufershield,muferandmounting

bracket(

5.Attachthemufershieldbrackettothemufer

mountingbracketandsecuretheboltswith2side

locknuts.Torquethenutsto132in-lb(14.9N-m).

6.Install2bolts(M8x25mm)and2curvedwashers

throughthemufershieldandthemufershield

bracket.Securetheboltswith2sidelocknutsand

torquethemto132in-lb(14.9N-m)(

Figure6).

Figure6).

7.Tightenthemuferclampuntilthereisnogapleft

inthesplitstyleclamp.

5

Page 6

g013784

1 2 3

6

5

4

7

8

9

10

11

3

Figure6

1.Mufershield7.Engineexhaustmanifold

2.Curvedwasher8.Muferclamp

3.Bolt,M8x25mm

4.Mufershieldbracket10.Mufer

5.Sidelocknut11.Curvedwasher

6.Bracketattachedtothe

engine

9.Muferinlet

9

AddingFueltotheMachine

NoPartsRequired

Procedure

Addgasolinetothemachinebeforestartingit.Refer

toyourOperator’ sManual.forthecorrectfueland

procedure.

10

CheckingtheHydraulicOil

LevelforMowerswithHydro

Drive

NoPartsRequired

Procedure

Beforeyoustarttheengineandusethemachine,check

thehydraulicoillevelinthetank;refertoCheckingthe

HydraulicOilLevelintheOperator’sManual.

8

CheckingtheEngineOilLevel

NoPartsRequired

Procedure

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoChecking

theEngineOilLevelintheOperator’ sManual.

6

Page 7

11

ActivatingtheBatteryfor

MowerswithElectricStart

Partsneededforthisprocedure:

80

ounces

Bulkelectrolytewith1.265specicgravity(Purchase

fromabatterysupplyoutlet.)

Figure7

Procedure

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling .

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

Fillthebatterywherecleanwaterisalwaysavailable

forushingtheskin.

Followallinstructionsandcomplywithallsafety

messagesontheelectrolytecontainer.

3.Slowlypourelectrolyteintoeachbatterycelluntilthe

levelisuptotheupperlineonthebatterycase.

Important:Donotoverllthebatterybecause

electrolyte(sulfuricacid)cancausesevere

corrosionanddamagetothechassis.

Figure8

4.Waitvetotenminutesafterllingthebatterycells.

Addelectrolyte,ifnecessary,untiltheelectrolyte

levelisuptotheupperlineonthebatterycase.

5.Installthebatteryventcaps(Figure9).

1.Removethebatteryfromthemachine.Refertothe

Operator’sManualforinstructions.

Important:Neverllthebatterywith

electrolytewhilethebatteryisinstalledonthe

machine.Electrolytecanbespilledonother

partsandcausecorrosion.

2.Cleanthetopofthebatteryandremovethevent

caps(Figure9).

Figure9

1.Fillcaps3.Lowerline

2.Upperline

7

Page 8

12

ChargingtheBatteryfor

MowerswithElectricStart

NoPartsRequired

Procedure

WARNING

Chargingthebatteryproducesgassesthatcan

explodeandcauseseriousinjury.

•Keepcigarettes,sparksandamesawayfrom

thebattery.

•Makesuretheignitionswitchisoff.

•Ventilatewhenchargingorusingthebatteryin

anenclosedspace.

Important:Donotrunthemachinewiththe

batterydisconnected;electricaldamagemayoccur

totheengine.

Chargethebattery.RefertotheOperator’sManualfor

instructions.

Figure10

13

CheckingtheMachineBeforeDeliverytotheCustomer

NoPartsRequired

Procedure

Beforedeliveringthemachinetothecustomer,ensurethatyouperformorhaveperformedtheprocedureslistedin

thefollowingtableandinitialeachwhennished.RefertotheOperator’sManualforinstructionsonperforming

theseprocedures.

Initial

Checkthetirepressure.

Checkthelevelofthemower.

Checktheengineoillevel.

Forhydraulicdrivenmowers,checkthehydraulicuidlevel.

Checktheadjustmentoftheparkingbrake.

Ensurethatthemachinetrackscorrectly;refertotheOperator’sManualfortheadjustmentprocedure.

Checkthesafetyinterlocksystem;refertotheOperator’sManual.

EnsurethatthePTOworks.

Checkallfastenersyouinstalledtoensurethattheyaretight.

CheckProcedure

Whenyounishsettingupthemachine,signanddateinthespaceprovidedbelow:

Signature:

Date:

8

Page 9

14

DeliveringtheMachinetotheCustomer

Partsneededforthisprocedure:

1

Operator’sManual

1

EngineOwner’sManual

1Enginewarrantyliterature

1

RegistrationCard

1

Operatortrainingmaterial

1Accessorybrochure

1Key

1

Oildrainhose

Procedure

Atdelivery,Fillinthemodelandserialnumberandcompletetheitemslistedinthefollowingtableandinitial

eachwhennished.

ModelNo.

SerialNo.

9

Page 10

DealerInitial

CustomerInitialCheckProcedure

Showthecustomerwherethefollowingfeaturesarelocatedandhowtheyfunction:

•

Fueltankcap

•

Oilllcap/Oildipstick

•

Sparkplug(s)

•

Engineoillter

•

Engineoildrain

•

Fuellter

•

Airlter

•

Hydraulicuidreservoir(ifapplicable)

•

Hydrauliclter(ifapplicable)

•

Hydraulicbypassvalves(ifapplicable)

•

Battery(ifapplicable)

•

Ignitionswitch

•

Throttlelever

•

Chokelever

•

Powertakeoffswitch(PTO)

•

Motioncontrols

•

Parkingbrake

•

Mowerheight-of-cut

•

Mowerdeckowbafe

RefertotheOperator’sManualtopointoutsafetyprocedures,operation,and

maintenanceprocedures.

ReviewthewarrantystatementasshownintheOperator’sManual.

Describethepostsaleserviceproceduresforyourstore.

Assistthecustomerinllingoutandmailingtheregistrationcardorregisteronlineat

www.T oro.com

MakesurethatthecustomerreceivestheOperator’sManual,EngineOwner’sManual,

SetUpInstructions,andoperatortrainingmaterial.

MakesurethecustomerknowsthePartsCatalogisavailableatwww.T oro.com.

Assistthecustomerinloadingthemower.

Note:Whenyou,thedealerrepresentative,havenisheddeliveringthemachinetothecustomer,signanddatein

thespaceprovidebelowandkeepacopyofthispagefordealerrecords.

Signature:Date:

Signature:Date:

10

Page 11

Notes:

11

Page 12

Loading...

Loading...