FormNo.3426-517RevE

30inStand-OnAerator

ModelNo.29521—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3426-517*E

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

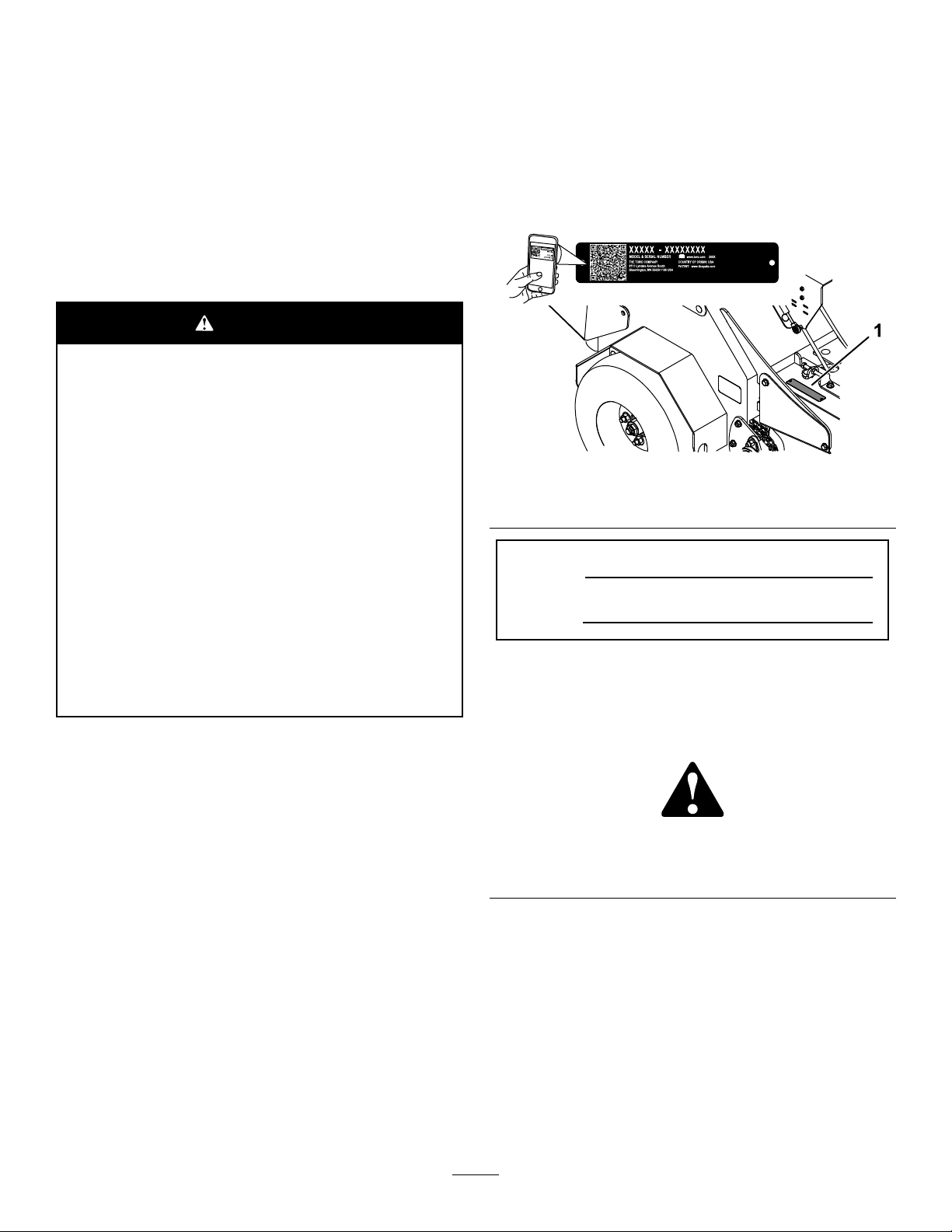

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g269064

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Introduction

Thisaeratorisintendedtobeusedbytrained

operatorsinresidentialandcommercialapplications.

Itisprimarilydesignedforaeratingareasof

well-maintainedlawnsonresidentialgrounds,parks,

sportselds,andoncommercialgrounds.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

©2020—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

2

g000502

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................4

SafetyAlertSymbol............................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

Setup........................................................................9

1CheckingTireAirPressure..............................9

2ServicingtheBattery........................................9

3ServicingtheEngineOil.................................10

4ServicingtheTransmissionFluid....................10

5ServicingtheAuxiliaryHydraulic

Fluid..............................................................10

ProductOverview....................................................11

Controls............................................................11

Specications..................................................15

Attachments/Accessories.................................15

BeforeOperation.................................................15

BeforeOperationSafety...................................15

FuelSafety.......................................................16

AddingFuel......................................................17

PerformingDailyMaintenance..........................18

DuringOperation.................................................18

DuringOperationSafety...................................18

UsingtheSmartController/ElectronicDepth

Control..........................................................20

OperatingtheMachine.....................................23

AfterOperation....................................................26

AfterOperationSafety......................................26

TransportingtheMachine.................................26

Maintenance...........................................................29

MaintenanceSafetyInformation.......................29

RecommendedMaintenanceSchedule(s)...........31

Pre-MaintenanceProcedures..............................32

PreparingfortheMachinefor

Maintenance.................................................32

AccessingtheConsoleCompartment...............32

Lubrication..........................................................33

LubricatingtheGreaseFittings.........................33

LubricatingtheChains......................................33

LubricatingtheCasters.....................................34

EngineMaintenance...........................................36

ServicingtheAirCleaner..................................36

ServicingtheEngineOil....................................37

ServicingtheSparkPlug...................................40

CheckingtheSparkArrester.............................41

FuelSystemMaintenance...................................41

ServicingtheFuelFilter....................................41

ElectricalSystemMaintenance...........................42

CheckingtheSafety-InterlockSystem..............42

ServicingtheBattery.........................................43

ServicingtheFuses..........................................46

DriveSystemMaintenance..................................46

CheckingtheAirPressureintheTires...............46

CheckingtheWheelHubNuts..........................46

CheckingtheT orqueoftheWheelLug

Nuts..............................................................47

CheckingtheT orqueoftheTransmission

OutputShaftNut...........................................47

AdjustingtheCasterPivotBearings

Pre-Load.......................................................47

BrakeMaintenance.............................................48

AdjustingtheParkingBrake..............................48

AdjustingtheBrakeSwitch...............................48

BeltMaintenance................................................49

CheckingtheConditionandT ensionofthe

Belts..............................................................49

AdjustingtheAuxiliaryPump-Drive

Belt................................................................49

ReplacingtheTransmission-DriveBelt.............49

ControlsSystemMaintenance.............................50

AdjustingtheTraction-ControlLinkage.............50

HydraulicSystemMaintenance...........................51

MaintainingtheAuxiliaryHydraulic

System..........................................................51

MaintainingtheTransmission...........................53

ChainMaintenance..............................................56

CheckingtheConditionoftheSprockets...........56

CheckingtheConditionandT ensionofthe

Chains...........................................................56

AdjustingtheJackshaftDrive-Chain

Tension.........................................................56

AdjustingtheDriveWheelChain

Tension.........................................................57

AdjustingtheTineDriveChain..........................58

TineMaintenance.................................................58

CheckingtheTines...........................................58

ChassisMaintenance...........................................59

CheckingforLooseHardware...........................59

Cleaning..............................................................60

CleaningtheEngineandtheExhaust

SystemArea.................................................60

RemovingtheEngineShroudsandCleaning

theCoolingFins............................................60

CleaningtheDebrisfromtheMachine...............60

WasteDisposal.................................................61

Storage...................................................................61

PreparingtheMachineforStorage...................61

Troubleshooting......................................................62

AlertandErrorMessages.................................62

Schematics.............................................................65

3

Safety

SafetyAlertSymbol

ThisSafetyAlertSymbol(Figure3)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents.

Thissymbolmeans:ATTENTION!BECOMEALERT!

YOURSAFETYISINVOL VED!

Figure3

SafetyAlertSymbol

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituationsand

willbefollowedbythewordDANGER,WARNING,or

CAUTION.

DANGER:Indicatesanimminentlyhazardous

situationwhich,ifnotavoided,Willresultindeathor

seriousinjury.

WARNING:Indicatesapotentiallyhazardoussituation

which,ifnotavoided,Couldresultindeathorserious

injury.

CAUTION:Indicatesapotentiallyhazardoussituation

which,ifnotavoided,Mayresultinminorormoderate

injury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

GeneralSafety

Thismachineiscapableofamputatinghandsandfeet

andofthrowingobjects.Torodesignsandteststhis

machinetoofferreasonablysafeservice;however,

failuretocomplywithsafetyinstructionsmayresultin

injuryordeath.

•Read,understand,andfollowallinstructionsand

warningsintheOperator’sManualandother

trainingmaterial,onthemachine,engine,and

attachments.Alloperatorsandmechanicsshould

betrained.Iftheoperator(s)ormechanic(s)can

notreadthismanual,itistheowner’sresponsibility

toexplainthismaterialtothem;otherlanguages

g000502

maybeavailableonourwebsite.

•Onlyallowtrained,responsible,andphysically

capableoperatorsthatarefamiliarwiththesafe

operation,operatorcontrols,andsafetysignsand

instructionstooperatethemachine.Neverlet

childrenoruntrainedpeopleoperateorservicethe

equipment.Localregulationsmayrestricttheage

oftheoperator.

•DoNotoperatethemachineneardrop-offs,

ditches,embankments,water,orotherhazards.

•DoNotputyourhandsorfeetnearmoving

componentsofthemachine.

•Neveroperatethemachinewithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicing,fueling,orunclogging

themachine.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

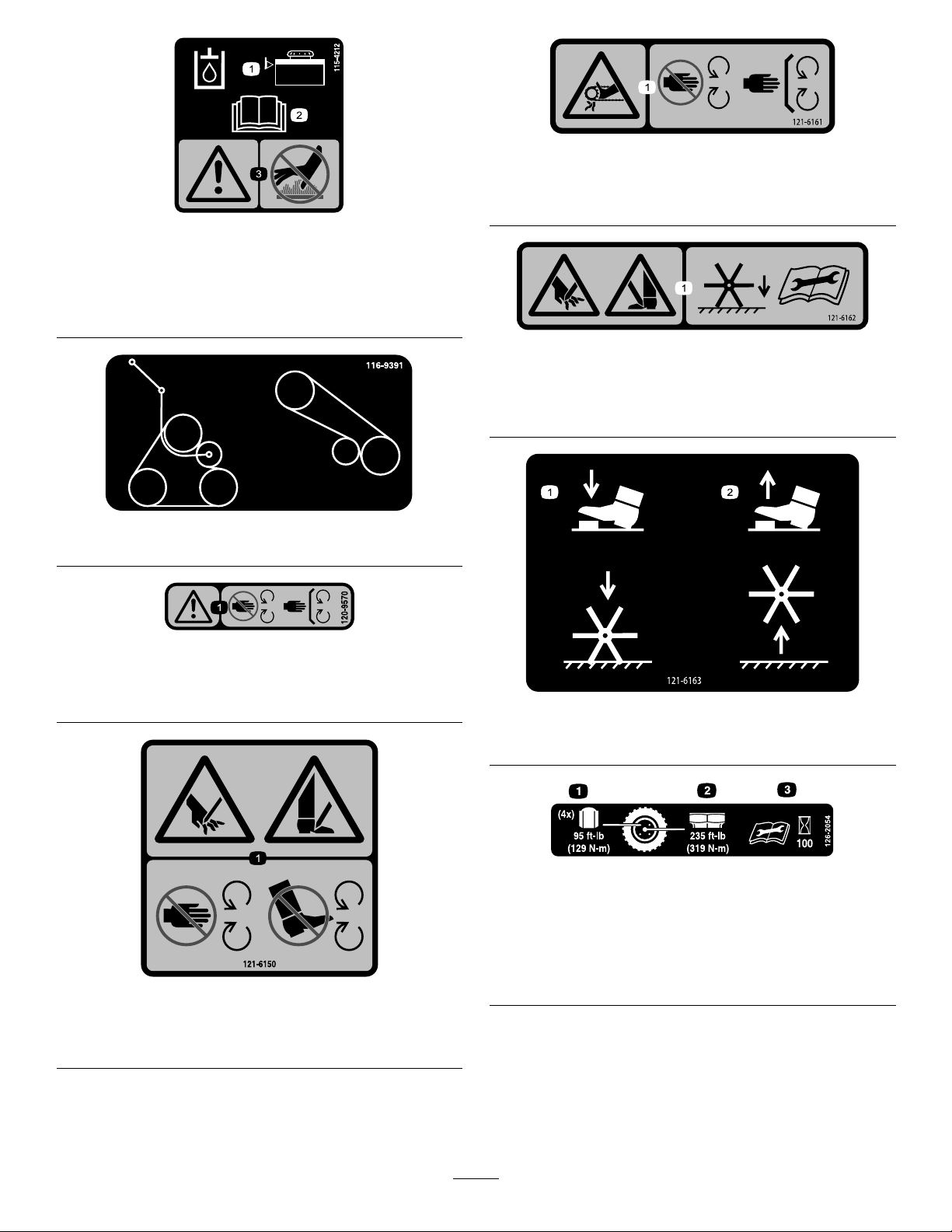

115-2047

1.Warning—donottouchthehotsurface.

decal115-2047

4

decal121-6161

121-6161

1.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsinplace.

decal115-4212

115-4212

1.Hydraulicuidlevel

3.Warning—donottouchthe

hotsurface.

2.ReadtheOperator's

Manual.

116-9391

120-9570

1.Warning—stayawayfrommovingparts;keepallguards

andshieldsinplace.

decal121-6162

121-6162

1.Cutting/dismembermenthazardofhandorfoot—lowerthe

tinestotheground;readtheOperator’sManualforthe

disassemblyprocedure.

decal116-9391

decal120-9570

decal121-6163

121-6163

121-6150

1.Cuttinghazardofhandandfoot—stayawayfrommoving

parts.

1.Presstolowerthetines.2.Releasetoraisethetines.

decal126-2054

126-2054

1.Wheellugnuttorque129N∙m(95ft-lb)(4x)

2.Wheelhubnuttorque319N∙m(235ft-lb)

3.ReadandunderstandtheOperator’sManualbefore

performinganymaintenance;checkthetorqueevery100

decal121-6150

hours.

5

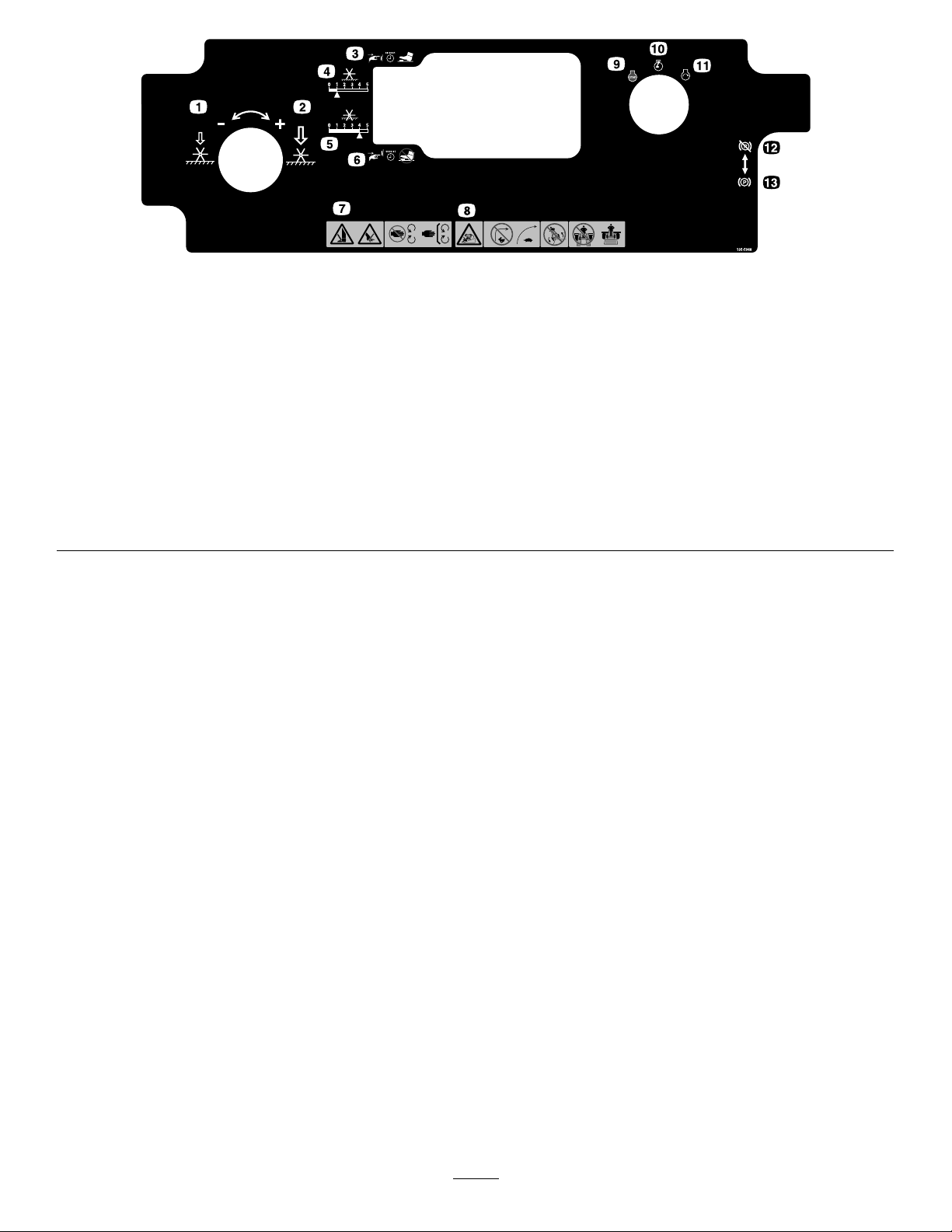

decal133-8062

133-8062

decal135-6196

135-6196

1.Electric3.Enginestartrelay

2.Accessory

1.Parkingbrake4.Depthsetting—lock

2.Tineengagementlockout

3.Tines—down

121-6164

1.Fast6.Wheelsandtinesrotatewhenmoving

2.Slow7.Continuousvariablesetting

3.Neutral

4.Reverse

5.Wheelsandtinesrotatewhenmoving

forward

backward

8.Choke—on

9.Choke—off14.Warning—stayawayfrommoving

10.Warning—readtheOperator’sManual.15.Warning—shutofftheengine,engage

decal135-1854

135-1854

switch

11.Warning—keepbystandersaway .

12.Warning—donotoperatethemachine

unlessyouaretrained.

13.Thrownobjecthazard—pickupdebris

beforeoperatingthemachine.

parts;keepallguardsinplace.

theparkingbreak,andremovethekey

beforeleavingthemachine.

5.ReadtheOperator’s

Manualbeforeperforming

maintenance.

decal121-6164

6

decal135-5948

135-5948

1.Rotatecounterclockwisetodecreasepressure.

2.Rotateclockwisetoincreasepressure.

3.Pressandholdfor1secondtoturnon—tineground

engagementfootswitchunlock

4.Electronictinedepth—decrease

5.Electronictinedepth—increase12.Parkingbrake—disengage

6.Pressandholdfor1secondtoturnoff—tineground

engagementfootswitchlock

7.Cutting/dismembermenthazardofhandorfoot,tines–stay

awayfrommovingparts;keepallguardsinplace.

8.Tippinghazard—Donotturnsharplywhiletravelingfast;slow

downandturngradually.Donotoperatethemachinenear

drop-offs.Donotusesplitramps;usefullwidthrampstoload

amachinefortransport.

9.Engine—Off

10.Engine—On

11.Engine—Start

13.Parkingbrake—engage

7

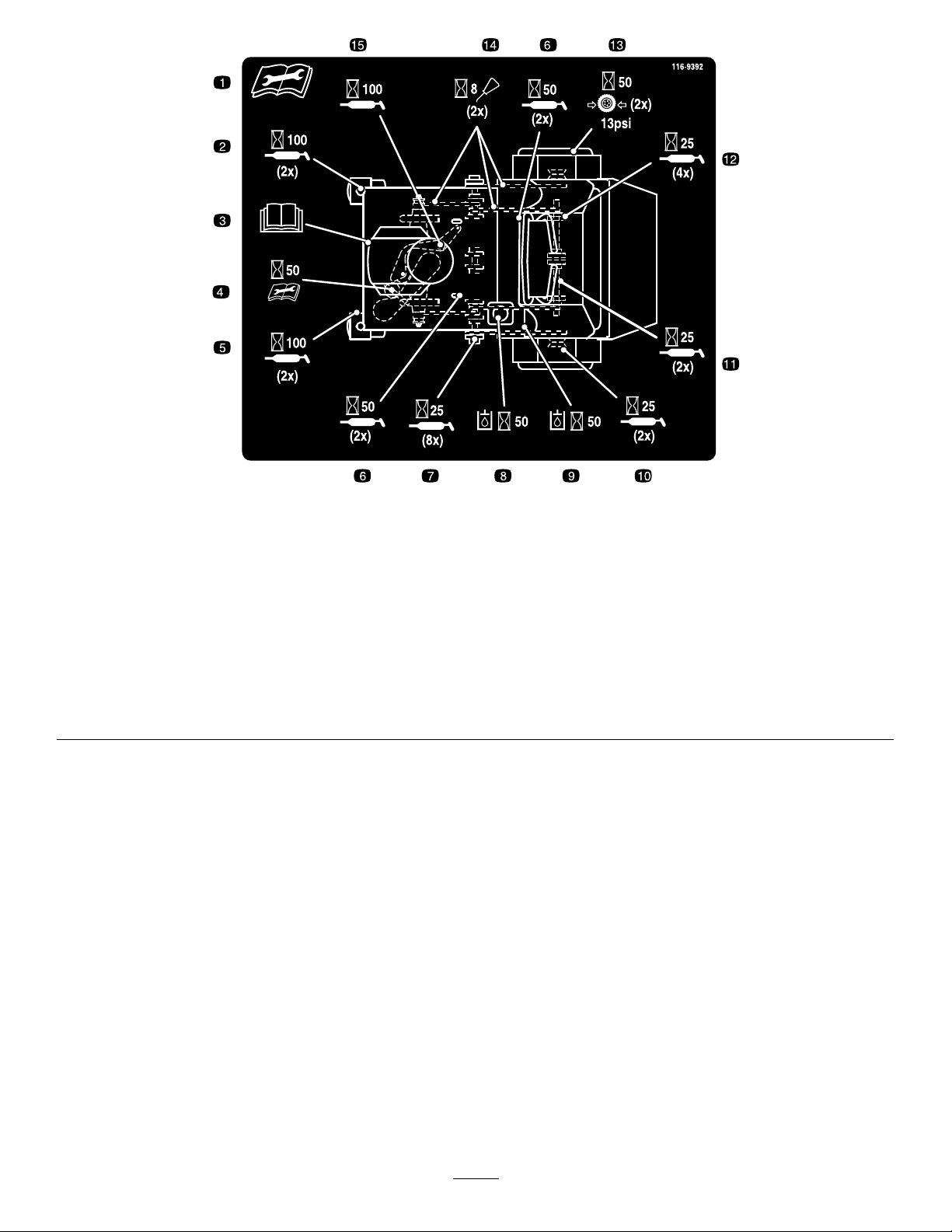

decal116-9392

116-9392

1.ReadandunderstandtheOperator’sManualbeforeservicing

9.Checktheauxiliaryhydraulictankevery50hours.

thismachine.

2.Greasethefrontcasterpivots(2x)every100hours.10.Greasethewheelbearings(2x)every25hours.

3.Refertotheengineowner’smanualforservice.11.Greasethetineassemblyidlers(2x)every25hours.

4.Checktheauxiliarypump-drivebelttensionevery50hours.12.Greasethetineshaftbearings(4x)every25hours.

5.Greasethefrontcasterwheelbearings(2x)every100hours.13.Checkthetirepressure,13psi,(2x)every50hours.

6.Greasethecontrolpivots(4x)every50hours.14.Cleanandoilthechainsandcheckthechaintension(2x)

every8hours.

7.Greasethejackshaftbearings(8x)every25hours.15.Greasethebeltidlerpivotevery100hours.

8.Checkthehydraulic-uidlevel(2x)every50hours.

8

Setup

MediaandAdditionalParts

Description

Operator'sManual

Key2

1

CheckingTireAirPressure

NoPartsRequired

Procedure

Checktheairpressureinthedrivetires,andadjust

thepressureasneeded;refertoCheckingtheAir

PressureintheTires(page46).

Note:Youdonotadjustairpressureforthe

semi-pneumaticcastertires.

2

ServicingtheBattery

NoPartsRequired

Procedure

Qty.

Use

1

Readbeforeoperatingthemachine.

Startthemachine.

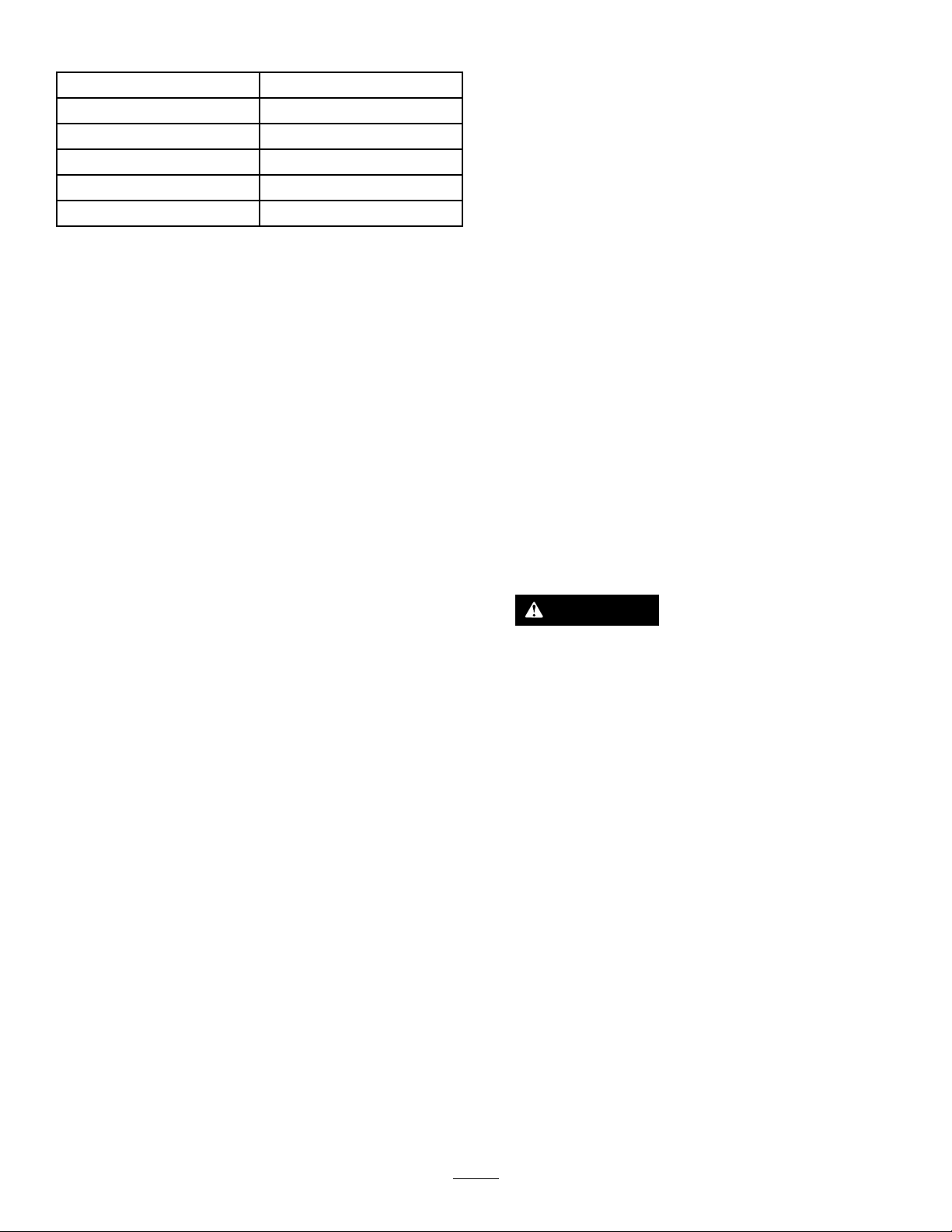

BatteryChargeTable

Voltage

Reading

12.6or

greater

12.4to12.6

12.2to12.4

12.0to12.2

11.7to12.0

11.7orless

4.Ifthepositivecableisalsodisconnected,

connectthepositive(red)cabletothepositive

batteryterminalandsliptheterminalcoverover

thepositiveterminal.

5.Removethescrew,washer,andgroundcable

fromtheengine.Connectthenegativebattery

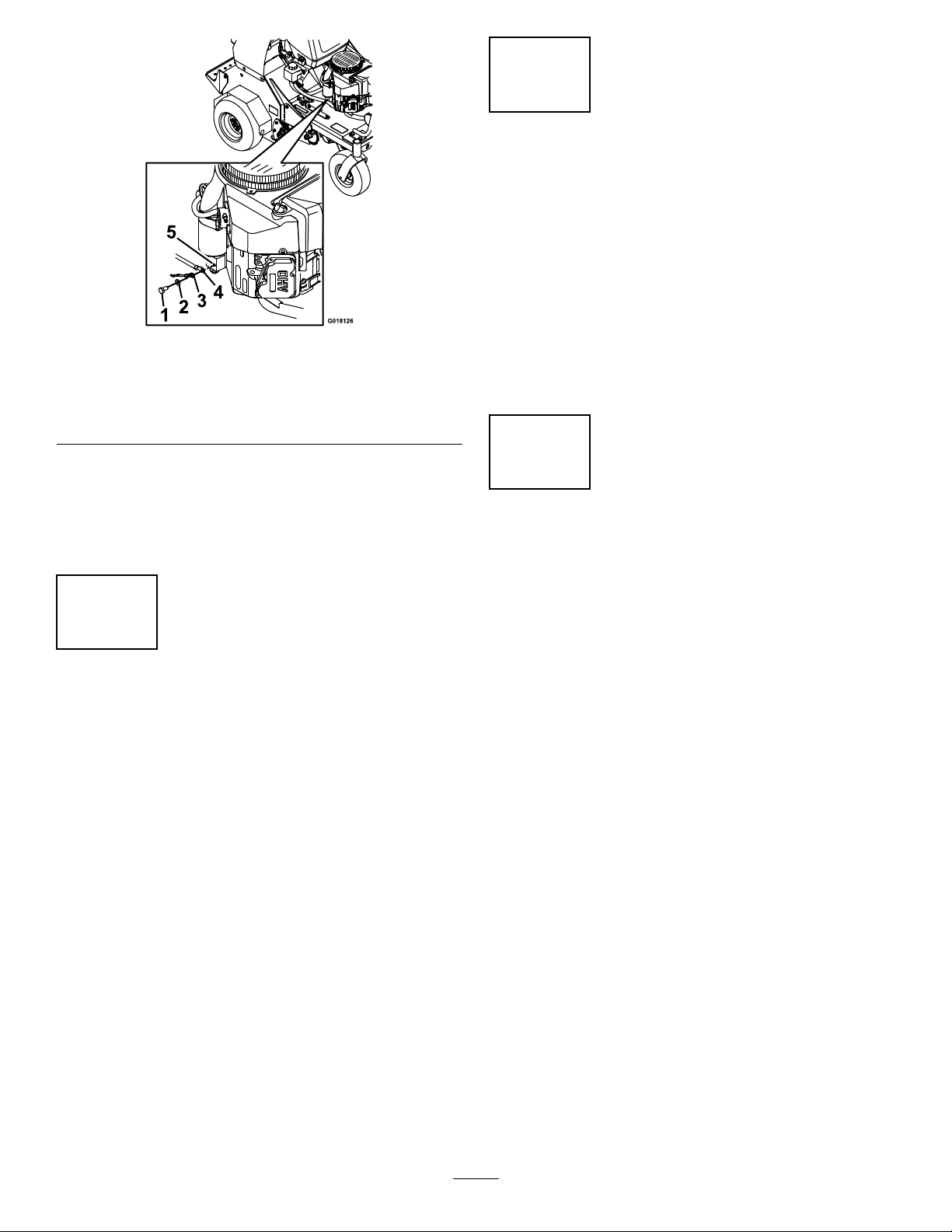

cableasshowninFigure4.

Percent

Charge

100%

75to100%

50to75%

25to50%

0to25%

0%

Maximum

Charger

Settings

16V/

7A

16V/

7A

16V/

7A

14.4V/

4A

14.4V/

4A

14.4V/

2A

Charging

Interval

Nocharging

required

30minutes

1hour

2hours

3hours

6hoursor

more

Note:Themachineisshippedwithalled,lead-acid

battery.

1.MovethekeyswitchtotheOFFpositionand

removethekey.

2.Measurethevoltageofthebatterywitha

voltmeter.

3.Usethetablethatfollowstolocatethe

chargestateorthebattery,andifneeded,the

battery-chargersettingandcharginginterval

recommendedtochargethebatteryto12.6Vor

greater;refertothebatterychargetablebelow.

Important:Makesurethatthenegative

batterycableisdisconnected,andthe

batterychargerusedforchargingthebattery

hasanoutputof16Vand7Aorlessto

avoiddamagingthebattery(seechartfor

recommendedchargersettings).

9

Figure4

1.Screw

2.Washer5.Engine

3.Groundwire

4.Negativebatterycable

4

ServicingtheTransmission

Fluid

NoPartsRequired

Procedure

Themachineisshippedwithtransmissionuid;check

g018126

thetransmission-uidleveland,ifnecessary,add

uidtotheappropriatelevel.RefertoCheckingthe

TransmissionFluidLevel(page53)forinstructions

andtheoilspecication.

Note:Iftimedoesnotpermitchargingthe

batteryorifchargingequipmentisnotavailable,

connectthenegativebatterycablesandrun

thevehiclecontinuouslyfor20to30minutesto

chargethebattery.

3

ServicingtheEngineOil

NoPartsRequired

Procedure

Theengineisshippedwithoil;checktheengine-oil

leveland,ifnecessary,addoiltotheappropriatelevel.

RefertoCheckingtheEngine-OilLevel(page37)for

instructionsandtheoilspecication.

5

ServicingtheAuxiliary

HydraulicFluid

NoPartsRequired

Procedure

Themachineisshippedwithhydraulicuid;check

thehydraulic-uidleveland,ifnecessary,adduidto

theappropriatelevel.RefertoCheckingtheAuxiliary

Hydraulic-FluidLevel(page51)forinstructionsand

theoilspecication.

10

ProductOverview

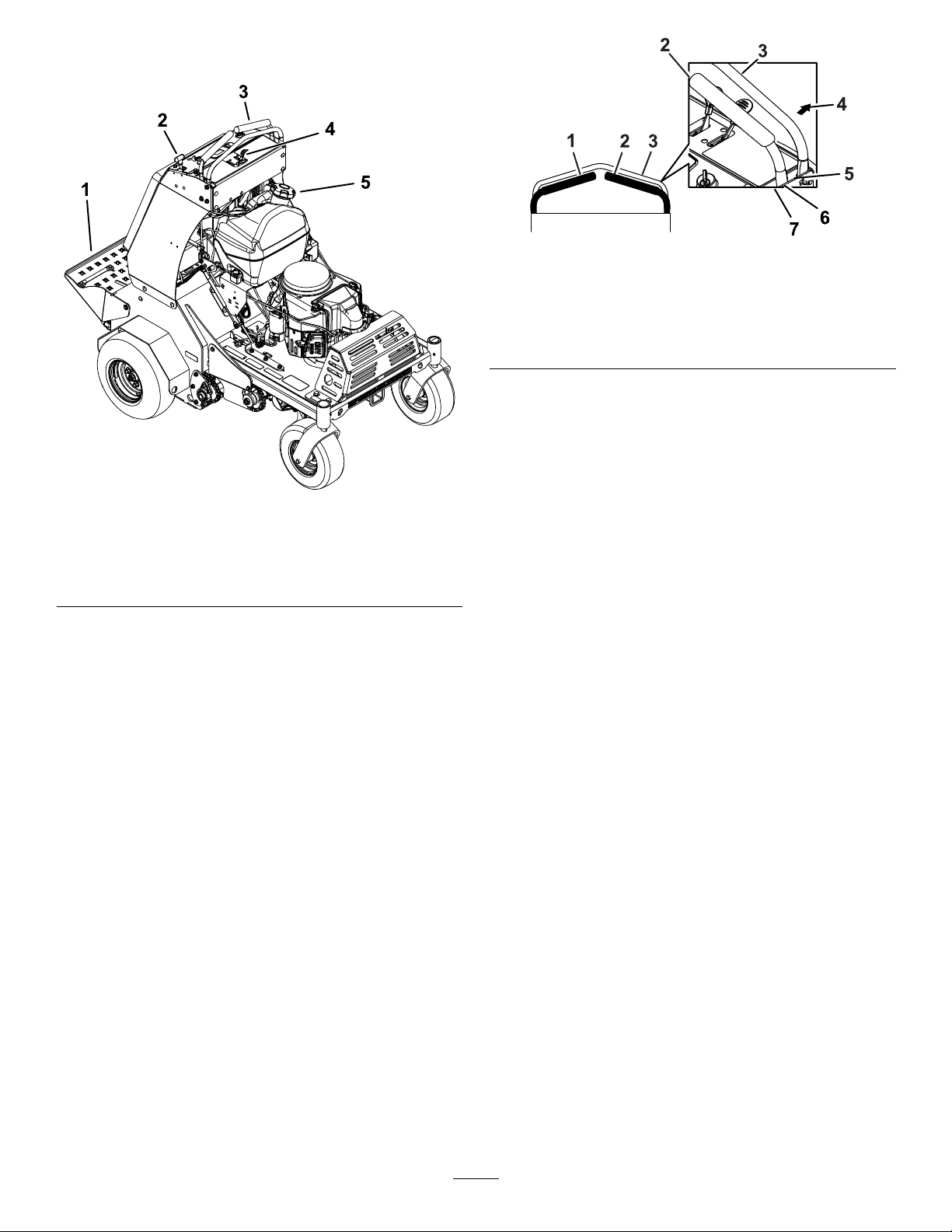

g267503

Figure6

Figure5

1.Platform

2.Parking-brakeknob5.Fuelcap

3.Motion-controllevers

4.Enginecontrols

Controls

Motion-ControlLevers

Themotion-controlleversarelocatedoneachsideof

thetopconsoleandcontroltheforwardandreverse

motionofthemachine.

Movetheleversforwardorbackwardtocontrolthe

drivewheelonthesamesideforwardorreverse

respectively.Thewheelspeedisproportionaltothe

amountyoumovethelever.

Important:Thetinesrotatewhenthe

motion-controlleversaremovedoutofthe

NEUTRALposition.

1.Leftmotion-controllever

2.Rightmotion-controllever6.Neutral

3.Frontreferencebar

4.Frontofthemachine

5.Forward

7.Reverse

ThrottleLever

Thethrottlelever(Figure7)islocatedonthecontrol

console(redlever).

g269241

Usethethrottlelevertocontrolenginespeed.Move

thethrottleleverforwardtoincreaseenginespeed;

movingthethrottleleverrearwardtodecreasethe

enginespeed.

Note:Movethethrottleleverforwardintothedetent

forfullthrottle.

ChokeLever

Thechokelever(Figure7)islocatedonthecontrol

console(blacklever).

Usethechokeleverisusedtoaidinstartingacold

engine.Movethechokeleverforwardtosetthe

choketotheONposition;movethechokelevertothe

rearwardtoreducethechoke.

Note:Pullthechokeleverbackintothedetenttoset

thechoketotheOFFposition.

Note:Donotrunawarmenginewiththechokein

theONposition.

11

1.Hour

meter/tine-engagement

display

2.Operatorweight

adjustmentcontrol

3.Multi-functionswitch

4.Leftmotion-controllever

5.Frontreferencebar

6.Throttlelever

Parking-BrakeHandle

Figure7

7.Chokelever

8.Rightmotion-controllever

9.Ignitionswitch

10.Parking-brakehandle

11.Tineground-engagement

footswitch

HourMeter/TineEngagement

Display

Locatedtotheleftoftheignitionswitchonthecontrol

console.

•Thehourmetermonitorsanddisplaystheengine

hours.

g211730

Figure8

g267524

1.LCDIndicators/Informationscreen

2.Hourdisplay

3.LEDstatuslight

Hoursaredisplayedwhenthekeyisofforwhen

themachineisrunning.Hoursarenotdisplayed

whenthemachineisaerating.

Note:TheLCDindicatorappearsinthepark

brakesettingwhenitmeetsthe“safetostart”

mode(parkingbrakeengaged).

•Thetine-engagementdisplaymonitorsand

displaystheelectronictine-depthsetting.

Hourmeterdisplay

Theparking-brakehandleislocatedonthecontrol

console,totherightofthekeyswitch(Figure7).

Note:Thebrakehandleengagesaparkingbrakein

eachofthetransmissions.

•T oengagetheparkingbrake,pullthehandleout

andslideitrearward.

•T oreleasetheparkingbrake,pushthehandle

forwardintothedetent.

Whenparkingonasteepslope,chockorblockthe

wheelsinadditiontoengagingtheparkingbrake.Tie

downthemachineandengagetheparkingbrake

whentransportingthemachine.

g211731

Figure9

Tine-engagementdisplay

1.LCDIndicators/Informationscreen

2.Tinedepthstatusbar

3.Tinedepthsettingindicator

4.LEDstatuslight

12

Thereare2waystoactivatethedisplay:

1.T apthemulti-functionswitcheitherupordown

todisplaythetine-engagementmeter.

2.Steponthetineground-engagementfootswitch.

Ahighernumberonthestatusbarincreasesthe

lengthoftheaerationplugandalowernumber

decreasesit.

Note:Ifthepluglengthisnotdesiredlength,the

machinemayneedtobeadjustedtoaccommodate

fortheweightoftheoperator;refertoAdjustingthe

OperatorWeightControlSetting(page24)formore

information.

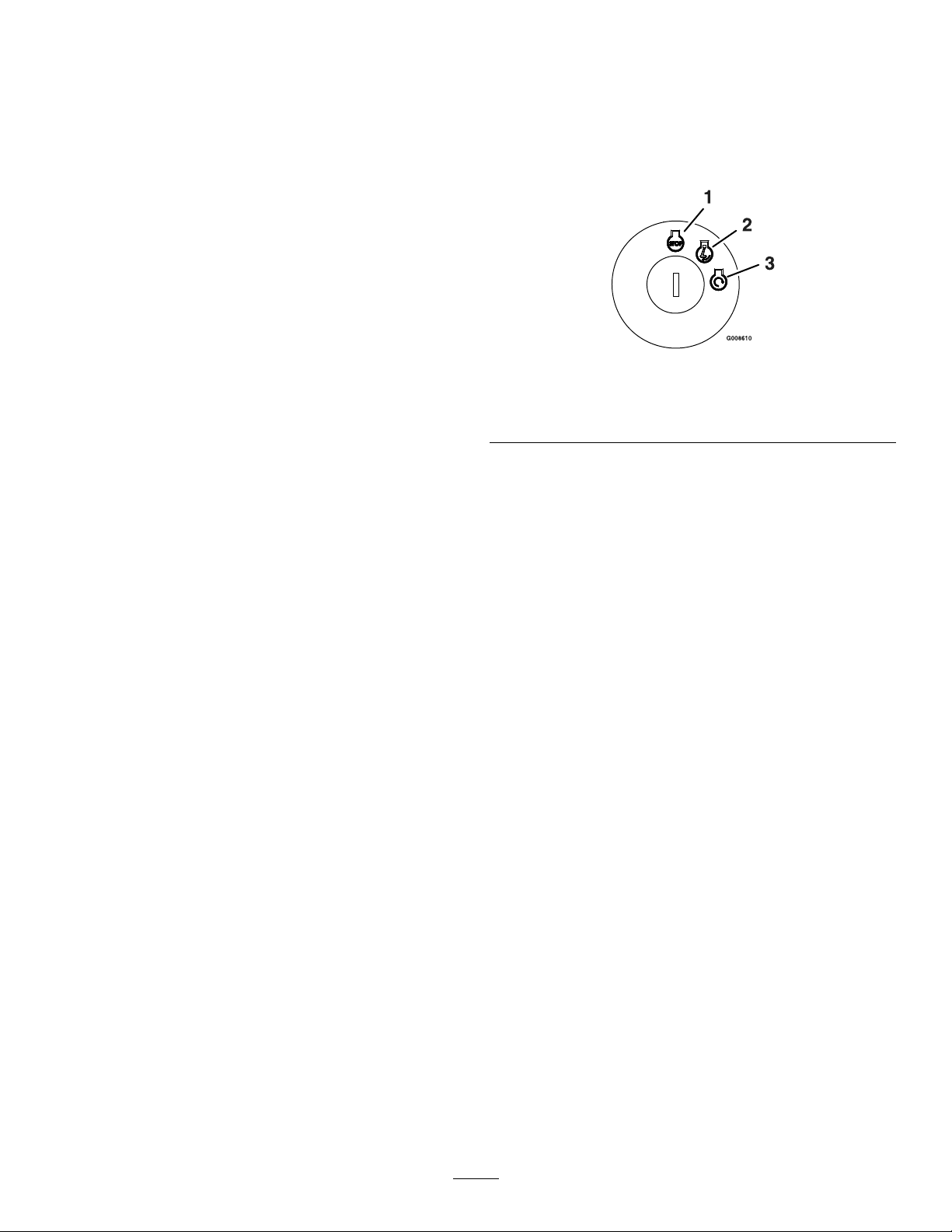

KeySwitch

Thekeyswitchislocatedontherightsideofthe

controlconsole(Figure7).

Usethekeyswitchtostartandshutofftheengine.

Theswitchhas3positions:OFF,ON,andSTART

(Figure10).

LEDStatusLights

Locatedontherightsideofthehour

meter/tine-engagementdisplay.

TheLEDismulti-coloredtoindicatethesystemstatus

andislocatedontherightsideofthepanel.

•Solidgreen—indicatesnormaloperatingactivity.

•Blinkingred—indicatesafaultisactive.

•Solidred—indicatesmaintenanceisrequired.

TinesGround-EngagementFoot

Switch

Theswitchislocatedontheoperatorplatform(Figure

7).

Tolowerthetinesintotheground,standonthetine

ground-engagementswitch.TheLEDilluminatesin

thehourmeter/tineengagementdisplaywhenthetine

engagementisactivated.T oraisethetines,remove

yourfootfromtheswitch.

Thisswitchcanbedisabledwiththemulti-function

switch.

g008610

Figure10

1.OFF3.START

2.ON

Multi-FunctionSwitch

Locatedtotheleftofthehourmeter/tine-engagement

display.

Thisswitchallowsyoutodothefollowing:

•Increase/decreasethedepthofanaerationplug.

•Lockorunlockthetine-depthsetting.

•Lockorunlockthetineground-engagementfoot

switch.

•T apandholdthebottomoftheswitchtooverride

anddisablethefootswitch.TheLEDilluminatesin

thehourmeter/tineengagementdisplay.Usethis

featurewhentransportingthemachine.

•T ounlock,tapandholdthetopofthemulti-function

switchuntiltheLEDlightdisappears.

Note:Thedisablefeatureisengagedeachtimeyou

shutofftheengine.

13

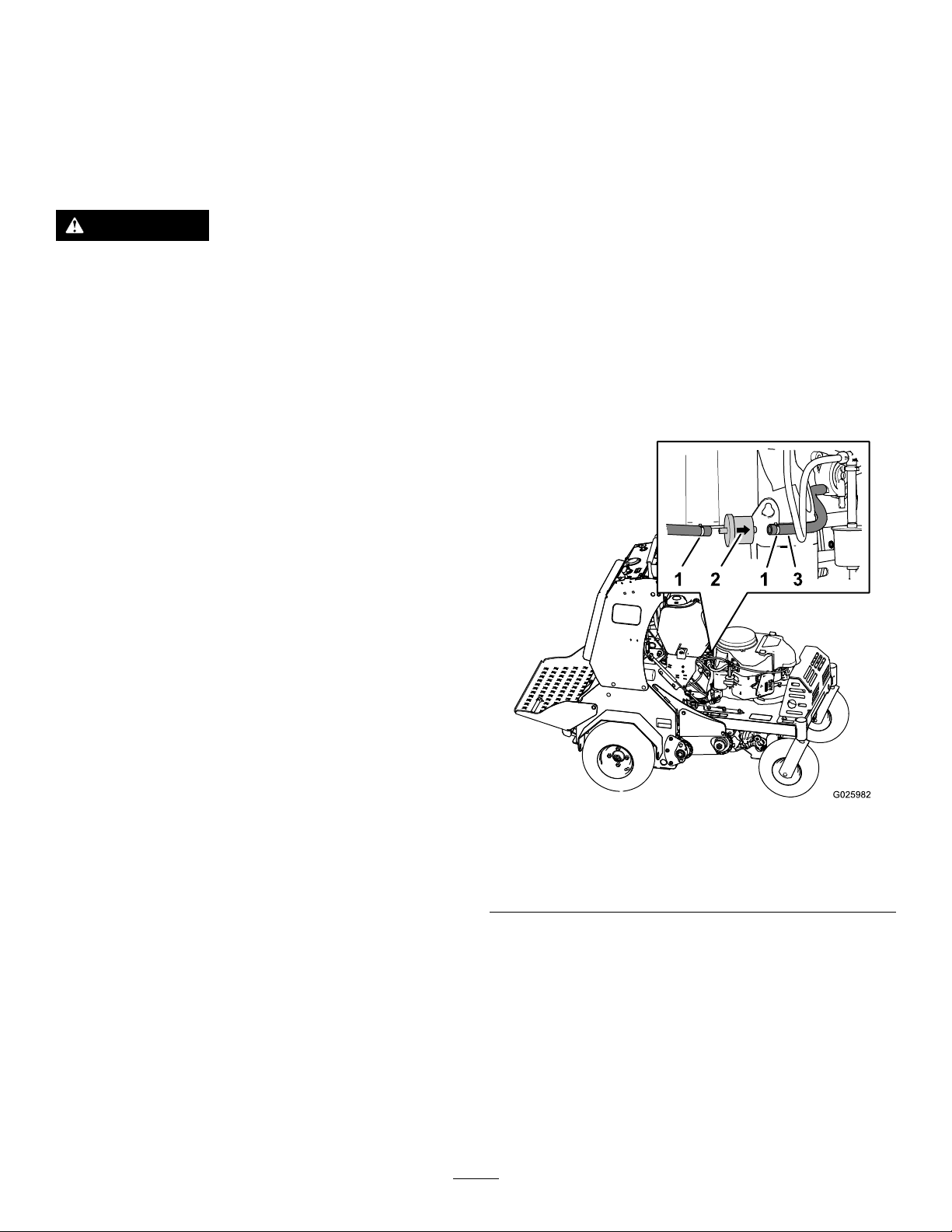

Fuel-ShutoffValve

Thefuel-shutoffvalveislocatedbehindtheengine

andunderthefueltank(Figure11).

Usethefuel-shutoffvalvetoshutoffthefuelwhen

themachinewillnotbeusedforafewdays,when

transportingthemachinetoandfromthejobsite,or

whenthemachineisparkedinsideabuilding.

•T oopenforfuel-shutoffvalve,rotatethehandle

ofthefuel-shutoffvalveuntilitisalignedwiththe

fuelline.

•T oclosethefuel-shutoffvalve,rotatethehandle

90°tothefuelline.

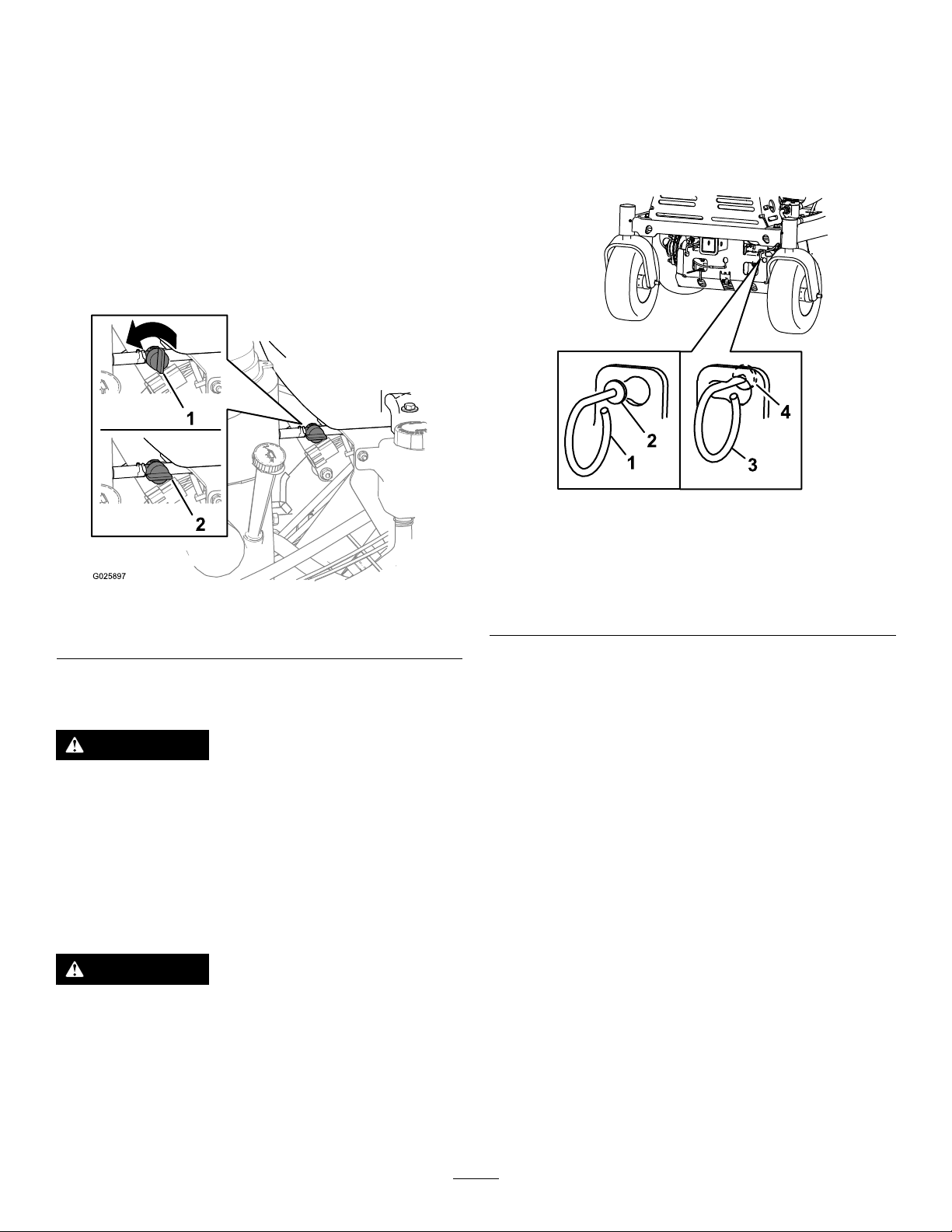

Locatedontheleftandrightsidesunderneaththe

frontofthemachine.

Duringnormaloperatingconditions,thewasheron

theleverispositionedoutsidetheslots.Ifyouneed

topushthemachinebyhand,youmustpositionthe

leverforthedrivewheelreleasevalvetothevalve

releasedposition(Figure12).

g223057

Figure12

Figure11

1.OFFposition2.ONposition

Drive-WheelReleaseValves

WARNING

Yourhandsmaybecomeentangledinthe

rotatingdrivecomponentsbelowtheengine

deck,whichcouldresultinseriousinjuryor

death.

Shutofftheengine,removethekey,andallow

allmovingpartstostopbeforeaccessingthe

drive-wheelreleasevalves.

WARNING

1.Lever—drivewheel

releasevalve(normal

g025897

operatingposition)

2.Washeroutsideoftheslot

3.Lever—drivewheel

releasevalve(pushthe

machineposition)

4.Washerinsidetheslot

(valvereleasedposition)

Toreleasethedrivewheels,movethelevertothe

largeropeningoftheslot,pushitinuntilthewasher

isinsidetheframe,thenmovetheleverbacktothe

narrowportionoftheslot.Repeatthisoneachside

ofthemachine.

Disengagetheparkingbrake.Themachineisnow

abletobepushedbyhand.

Donottowmachine.

Toresetthedrivesystembacktotheoperating

position:

Movethelevertothelargeropeningoftheslot,pull

outwarduntilthewasherisoutsidetheframe,then

movetheleverbacktothenarrowportionoftheslot.

Repeatthisoneachsideofthemachine.

Theengineandhydrauliccomponentscan

becomeveryhot.Touchingahotengine

orhydrauliccomponentscancausesevere

burns.

Allowtheengineandhydrauliccomponents

tocoolcompletelybeforeaccessingthe

drive-wheelreleasevalves.

14

Specications

Height

Length

Width

Aerationwidth

Coringrange5.1to12.7cm(2to5inches)

Weight

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.Toro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

132cm(52inches)

163cm(64inches)

121cm(48inches)

76cm(30inches)

460kg(1,015lb)

Operation

BeforeOperation

BeforeOperationSafety

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbyToro.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjects.Thesecan

bethrownorinterferewiththeoperationofthe

machineandmaycausepersonalinjurytothe

operatororbystanders.

•Markandavoidhiddenobjectssuchassprinkler

heads,undergroundwires/cables,invisiblefences,

etc.topreventdamagetothesesystemswhen

aerating.

•Wearappropriatepersonalprotectiveequipment

suchassafetyglasses,substantialslip-resistant

footwear,andhearingprotection.Tiebacklong

hairandavoidlooseclothingandloosejewelry

whichmaygettangledinmovingparts.

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperating

thismachine.

•Checkthattheoperatorpresencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly.DoNotoperateunlessthey

arefunctioningproperly.

•DoNotoperatethemachinewhenpeople,

especiallychildren,orpetsareinthearea.Stop

themachineandattachment(s)ifanyoneenters

thearea.

•DoNotoperatethemachinewithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceand

inproperworkingcondition.Frequentlycheckfor

wornordeterioratingcomponentsandreplace

themwiththemanufacturer’srecommendedparts

whennecessary.

15

FuelSafety

DANGER

Useextremecarewhenhandlingfuel.

DANGER

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburn

you,others,andcausepropertydamage.

•Fillthefueltankoutdoorsonlevelground,

inanopenarea,whentheengineiscold.

Wipeupanygasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•DoNotllthefueltankcompletelyfull.

Fillthefueltanktothebottomoftheller

neck.Theemptyspaceinthetankallows

gasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengineor

emissionsystem.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyspark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.DoNot

useanozzlelockopendevice.

•Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuel

whenengineisrunningorwhentheengine

ishot.

•Iffuelisspilled,DoNotattempttostart

theengine.Moveawayfromtheareaof

thespillandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

Tohelppreventres:

•Keepengineandengineareafreefrom

accumulationofgrass,leaves,excessivegrease

oroil,andotherdebriswhichcanaccumulatein

theseareas.

•Cleanupoilandfuelspillsandremovefuelsoaked

debris.

•Allowthemachinetocoolbeforestoringthe

machineinanyenclosure.DoNotstorenear

ameoranyenclosedareawhereopenpilotlights

orheatappliancesarepresent.

16

AddingFuel

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

andwhentheengineiscold.Wipeupany

fuelthatspills.

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleand

fueltankorconditionerbottleopening.

•Avoidcontactwithskin;washoffspills

withsoapandwater.

•Donotllthefueltankcompletelyfull.

Addfueltothefueltankuntilthelevelis6

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwhereaspark

mayignitethefuelfumes.

•Storefuelinanapprovedfuelcontainer

andkeepitoutofthereachofchildren.

•Neverbuymorethana30-daysupplyof

fuel.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleased,causingaspark,

whichcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removefuel-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

FuelSpecication

Petroleum

fuel

Ethanol

blended

fuel

Important:Forbestresults,useonlyclean,fresh

fuel(lessthan30daysold).

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

Useunleadedgasolinewithanoctaneratingof87

orhigher((R+M)/2ratingmethod).

Useanunleaded-gasolineblendwithupto10%

ethanol(gasohol)or15%MTBE(methyltertiary

butylether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeis

notapprovedforuse.Neverusegasolinethat

containsmorethan10%ethanolbyvolume,such

asE15(contains15%ethanol),E20(contains

20%ethanol),orE85(containsupto85%

ethanol).Usingunapprovedgasolinemaycause

performanceproblemsand/orenginedamage

whichmaynotbecoveredunderwarranty.

UsingStabilizer/Conditioner

Alwaysusefuelstabilizer/conditionerinthemachine

tokeepthefuelfreshlonger.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addtheamountoffuelstabilizer/conditionertofresh

fuelasdirectedbythefuel-stabilizermanufacturer.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainerratherthanfroma

fuel-dispensernozzle.

•Ifyoumustuseafuel-dispensernozzle,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

FuelingtheMachine

Fuel-tankcapacity:18.9L(5USGallons)

1.Cleanaroundthefuel-tankcap.

2.Removethecapfromthetank.

3.Fillthefueltankwithfueltowithin6to13mm

(1/4to1/2inch)fromthetopofthetank.Donot

llintothellerneck.

17

Important:Donotllthetankmorethan

6mm(1/4inch)fromthetopofthetank

becausethefuelmusthaveroomtoexpand.

4.Installthefuel-tankcapandwipeupanyspilled

fuel.

PerformingDaily

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcan

killyou.

DoNotrunengineindoorsorinasmall

connedareawheredangerouscarbon

monoxidefumescancollect.

Maintenance

Beforestartingthemachineeachday,performeach

use/dailymaintenanceproceduresthatfollow:

•LubricatingtheChains(page33)

•CheckingtheEngine-OilLevel(page37)

•CheckingtheSafety-InterlockSystem(page42)

•CheckingtheConditionoftheSprockets(page56)

•CheckingtheConditionandTensionoftheChains

(page56)

•CheckingtheTines(page58)

•CheckingforLooseHardware(page59)

•CleaningtheEngineandtheExhaustSystem

Area(page60)

•CleaningtheDebrisfromtheMachine(page60)

DuringOperation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty .

•Thismachinewasdesignedforoneoperatoronly.

Donotcarrypassengersandkeepallothersaway

frommachineduringoperation.

•DoNotoperatethemachineundertheinuence

ofalcoholordrugs.

•Operateonlyindaylightorgoodarticiallight.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,

DoNotoperatethemachine;seekshelter.

•Useextracarewhileoperatingwithaccessoriesor

attachments.Thesecanchangethestabilityof

themachineandcausealossofcontrol.Follow

directionsforcounterweightsifrequired.

•Keepawayfromholes,ruts,bumps,rocks,and

otherhiddenhazards.Usecarewhenapproaching

blindcorners,shrubs,trees,tallgrassorother

objectsthatmayhideobstaclesorobscurevision.

Uneventerraincouldoverturnthemachineor

causetheoperatortolosetheirbalanceorfooting.

DuringOperationSafety

GeneralSafety

Theoperatormustusetheirfullattentionwhen

operatingthemachine.DoNotengageinanyactivity

thatcausesdistractions;otherwise,injuryorproperty

damagemayoccur.

WARNING

Operatingengineparts,especiallythemufer,

becomeextremelyhot.Severeburnscan

occuroncontactanddebris,suchasleaves,

grass,brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,

tocoolbeforetouching.

•Removeaccumulateddebrisfrommufer

andenginearea.

•Besurealldrivesareinneutralandparkingbrake

isengagedbeforestartingengine.

•Starttheenginecarefullyaccordingtoinstructions

withfeetwellawayfromthetines.

•Neveroperatethemachinewithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Keepclearofthetinesatalltimes.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,DoNotmakeadjustmentswiththe

enginerunning.

18

WARNING

Hands,feet,hair,clothing,oraccessories

canbecomeentangledinrotatingparts.

Contactwiththerotatingpartscan

causetraumaticamputationorsevere

lacerations.

–DoNotoperatethemachinewithout

guards,shields,andsafetydevicesin

placeandworkingproperly.

–Keephands,feet,hair,jewelry,or

clothingawayfromrotatingparts.

•Beawareofthedischargepathanddirect

dischargeawayfromothers.Avoiddischarging

materialagainstawallorobstructionasthe

materialmayricochetbacktowardtheoperator.

Raisethetines,slowdown,andusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemachinetoandfromthework

area.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.DoNotoperateinreverseunless

absolutelynecessary.

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Parkthemachineonlevelground.Stopengine,

waitforallmovingpartstostop,andremovethe

sparkplugwire(s).

–Beforechecking,cleaningorworkingonthe

machine.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemachinefor

damageandmakerepairsbeforerestarting

andoperatingthemachine).

–Beforeclearingblockages.

–Wheneveryouleavethemachine.DoNot

leavearunningmachineunattended.

–Beforeandwhilebackingorchangingdirection,

lookbehind,down,andside-to-sideforsmall

children.

–Neverallowchildrentooperatethemachine.

–DoNotcarrychildren,evenwiththeblades

shutoff.Childrencouldfalloffandbeseriously

injuredorinterferewiththesafeoperationof

themachine.Childrenthathavebeengiven

ridesinthepastcouldsuddenlyappearinthe

workingareaforanotherrideandberunover

orbackedoverbythemachine.

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.Operatingthemachineon

anysloperequiresextracaution.Beforeusingthe

machineonaslope,theoperatormust:

–Reviewandunderstandtheslopeinstructions

inthemanualandonthemachine.

–Evaluatethesiteconditionsofthedayto

determineiftheslopeissafeformachine

operation.Usecommonsenseandgood

judgmentwhenperformingthisevaluation.

Changesintheterrain,suchasmoisture,can

quicklyaffecttheoperationofthemachineon

aslope.

•Operateacrossslopes,neverupanddown.Avoid

operationonexcessivelysteeporwetslopes.

•Identifyhazardsatthebaseoftheslope.Do

notoperatethemachineneardropoffs,ditches,

embankments,waterorotherhazards.The

machinecouldsuddenlyrolloverifawheelgoes

overtheedgeortheedgecollapses.Keepasafe

distance(twicethewidthofthemachine)between

themachineandanyhazard.Useawalkbehind

machineorahandheldtooltooperateinthese

areas.

•Stopengine,waitforallmovingpartstostop:

–Beforerefueling.

•Tragicaccidentscanoccuriftheoperatorisnot

alerttothepresenceofchildren.Childrenare

oftenattractedtothemachineandtheworking

activity.Neverassumethatchildrenwillremain

whereyoulastsawthem.

–Keepchildrenoutoftheworkingareaand

underthewatchfulcareofanotherresponsible

adult,nottheoperator.

–Bealertandturnthemachineoffifchildren

enterthearea.

19

UsingtheSmart

Controller/ElectronicDepth

Control

HourMeter/TineEngagement

Display

Thesmartcontroller/electronicdepthcontrolmonitors

theoverallelectricalsystemanddisplaysinformation

inthehourmeter/tineengagementdisplay.The

controllerdisplaysmachinehours,interlockstatus,

andmaintenancereminders.

Figure13

1.SafeZone—Usethemachinehere

2.DangerZone-Useawalkbehindmachineorahandheld

toolneardropoffs,ditches,embankments,waterorother

hazards.

3.Water

4.W=widthofthemachine

5.Keepasafedistance(twicethewidthofthemachine)

betweenthemachineandanyhazard.

•Avoidstarting,stoppingorturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction;turnslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steeringorstabilityisinquestion.

Beawarethatoperatingthemachineonwet

grass,acrossslopesordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.Themachinecanslideeven

ifthedrivewheelsarestopped.

•Removeormarkobstaclessuchasditches,holes,

ruts,bumps,rocksorotherhiddenhazards.T all

grasscanhideobstacles.Uneventerraincould

overturnthemachine.

g222486

ScreenIcons

Theinformationscreenusesthefollowingicons:

AeratingHoursParkingbrake

BatteryVoltageEngineOilMaintenance

HourMeter

TransmissionOil

Maintenance

•Useextracarewhileoperatingwithaccessoriesor

attachments.Thesecanchangethestabilityof

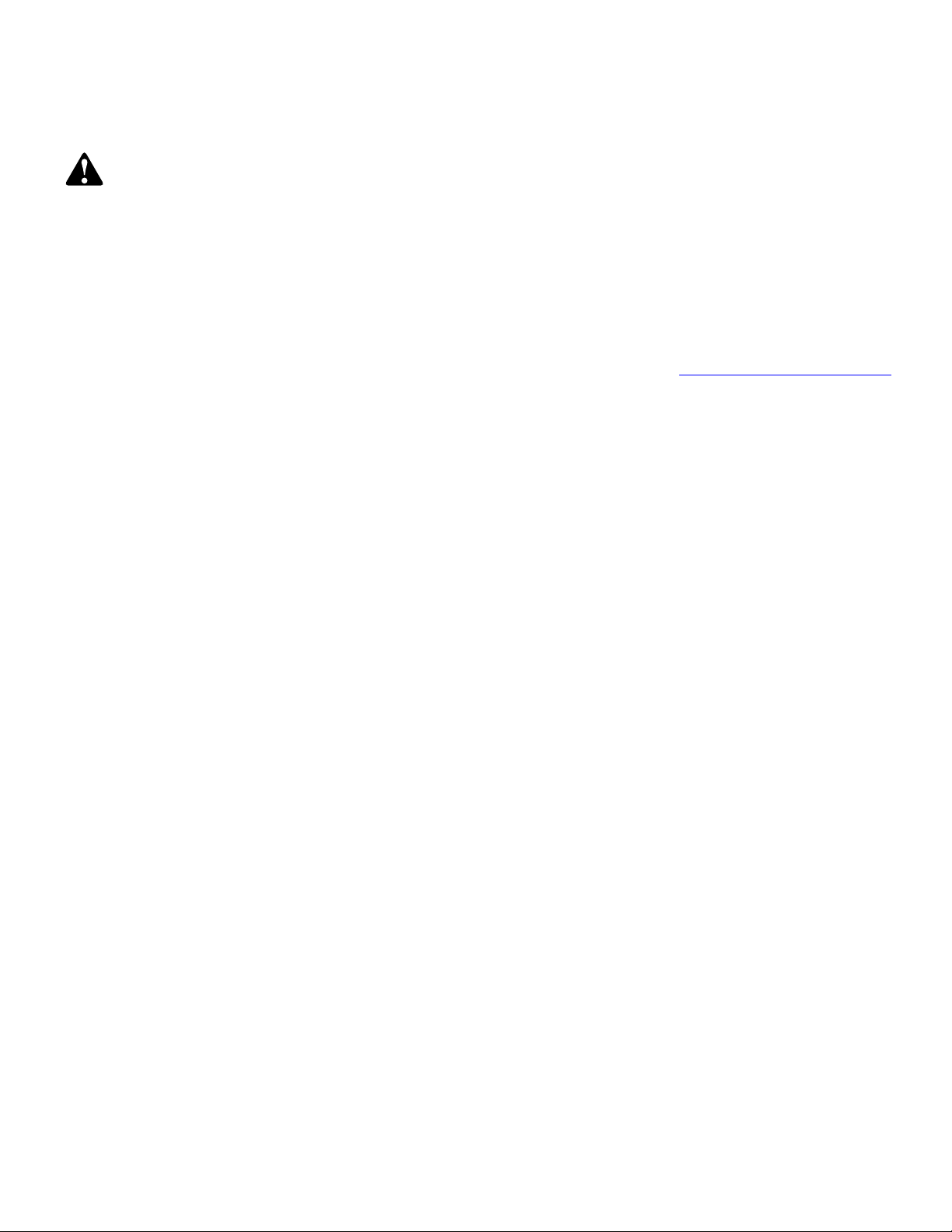

themachineandcausealossofcontrol.Follow

directionsforcounterweights.

•Ifyoulosecontrolofthemachine,stepoffand

awayfromthedirectionoftravelofthemachine.

VoltageErrorValveSolenoidError

ValveSolenoidConnection

Error

20

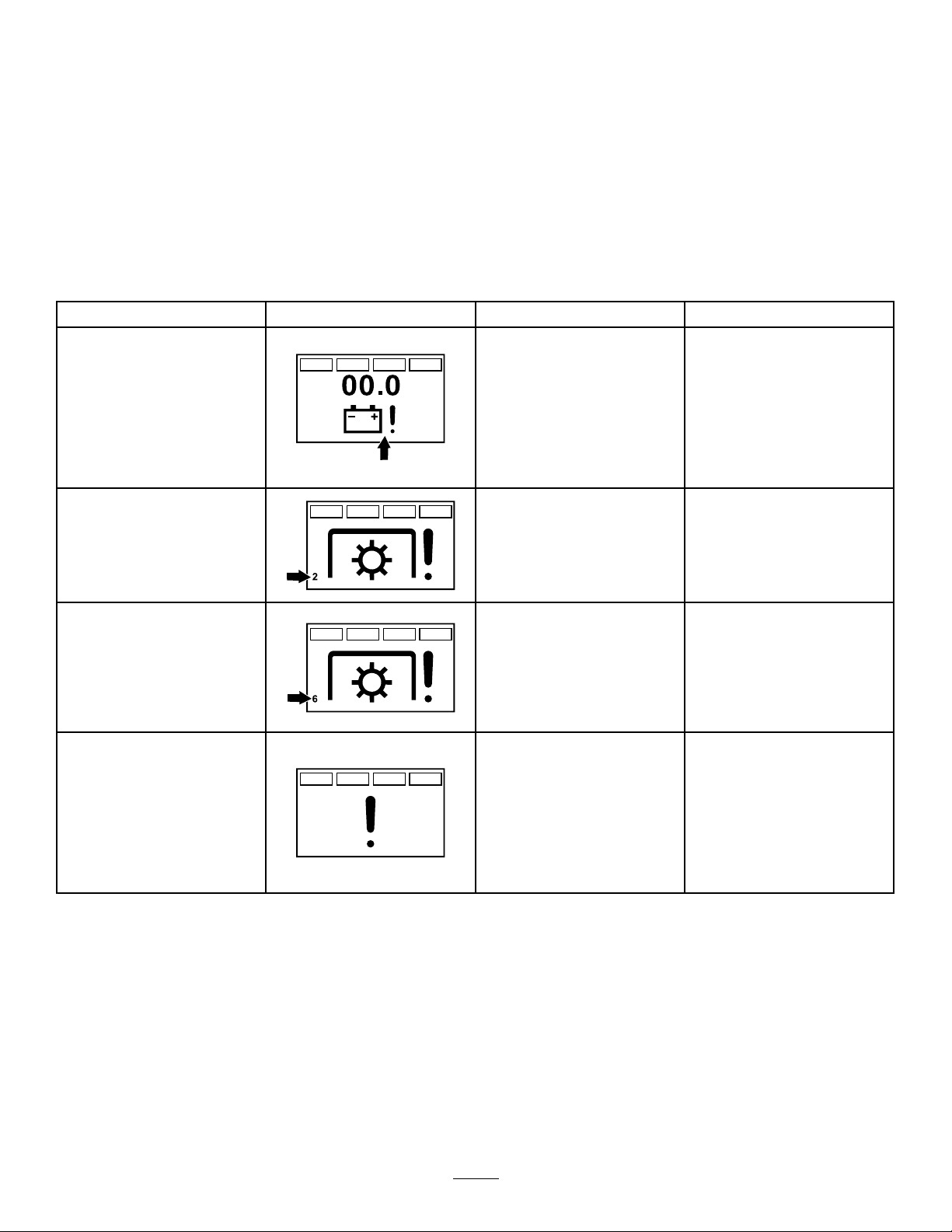

InformationScreens

Themaininformationscreensinclude:

•TheStartupScreens

•TheDefaultScreen(engine-on)

•TheTineEngagementDisplay

•MaintenanceRemindersandAlerts

•AlertsandErrorMessages

Thefourthscreendisplaysthenumberofhoursuntil

theengineoilmaintenanceisrequired.

Start-upScreens

WhenthekeyisswitchedfromOFFtoRUNposition,

thefollowingscreensdisplayfor2seconds:

Note:TheLEDstatuslightchangesfromredto

orangetogreen.

Therstscreendisplaysthermwareversion.

Figure14

Thesecondscreendisplaystheaerationhours.

g212117

Figure17

Thenalscreendisplayedisthenumberofhoursuntil

transmissionoilmaintenanceisrequired.

g212118

g212116

Figure18

TheDefaultScreen

Afterthestart-upscreensdisplay,thedefaultscreen

(Figure19)appears.

Figure15

Thethirdscreendisplaystheelectricalsystemvoltage.

Figure16

Theinformationscreendisplaysiconsandinformation

relativetomachineoperation.

g212114

g211884

Figure19

DefaultScreen

1.Informationscreen

g212115

•Thesafetyinterlockstatusindicatorilluminates

2.LEDstatuslight

whenthecontrolmeetsthe“safetostart”mode

(parkbrakeengaged).

21

•Thehourmeterdisplaysenginehourswhenthe

hourglasssymbolisashing.

•Thedisplayturnsoffafter5minutesafterthe

ignitionkeyisswitchedtotheOFFposition.

TheTineEngagementDisplay

ElectronicDepthControlScreen

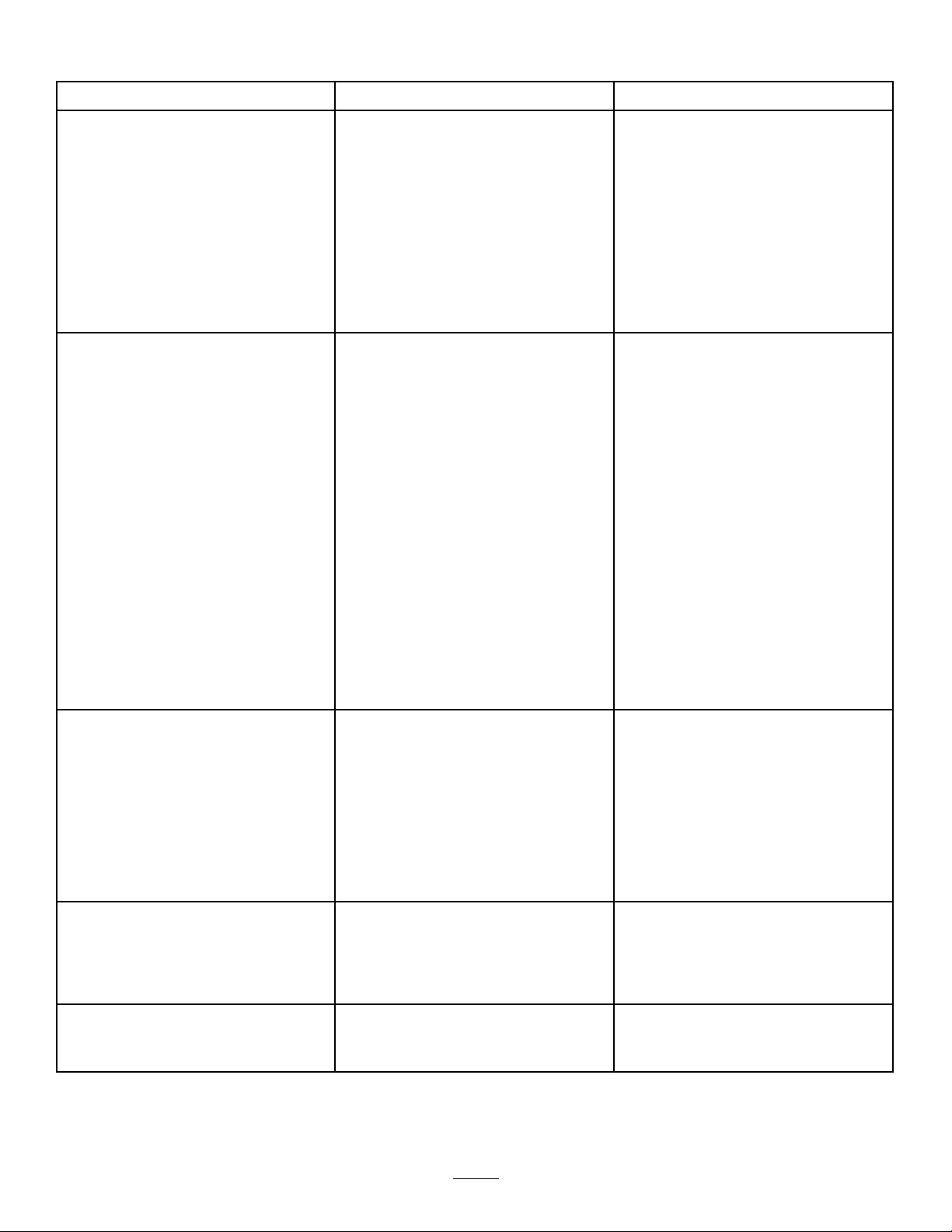

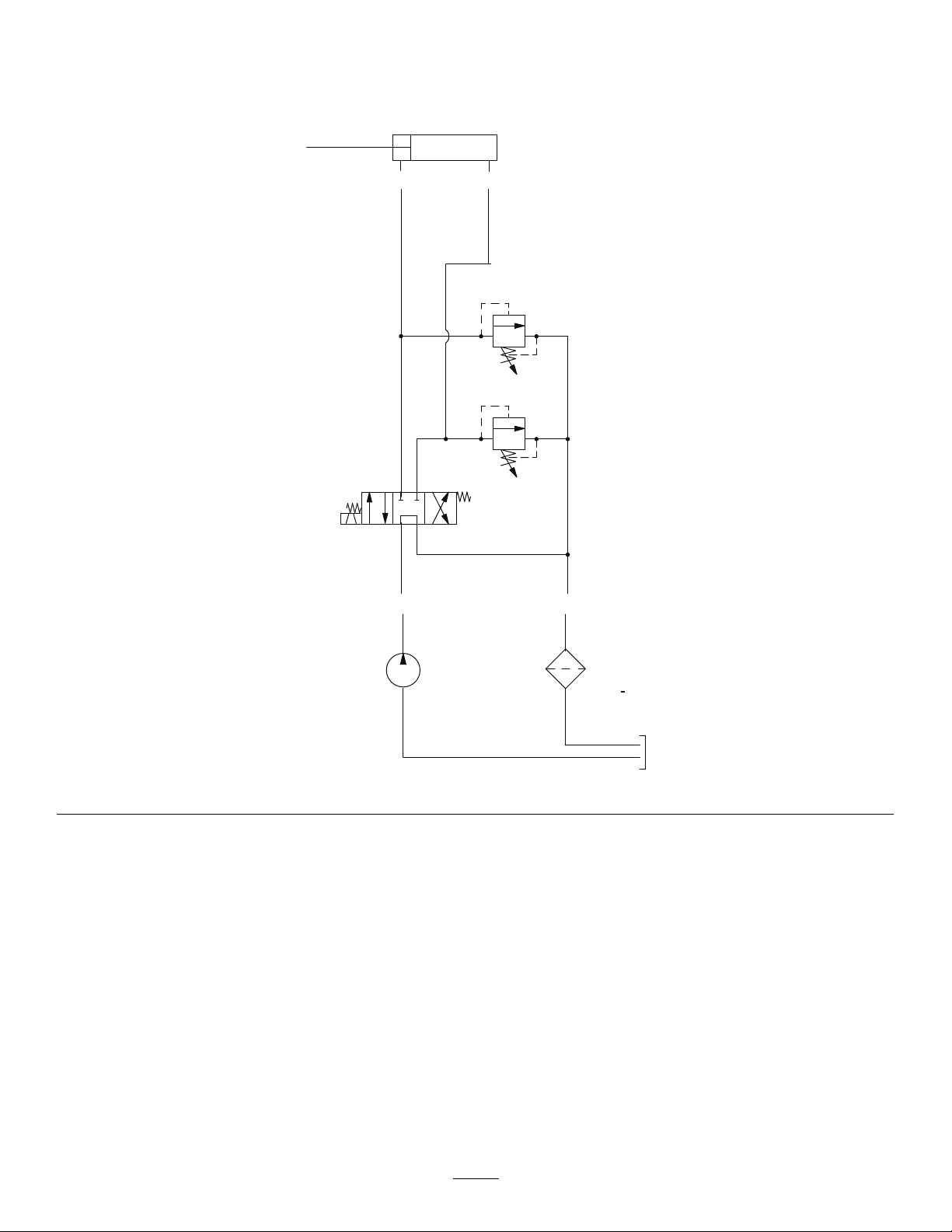

MaintenanceReminderScreens

Thehourmeterdisplaysthenumberofengine

hoursuntileithertheengineoilortransmissionoil

maintenanceisdue.Whenmaintenanceisdue,the

smartcontroller/electronicdepthcontroldisplays

ashingiconsforanengineoilmaintenancealertor

atransmissionoilmaintenancealert,andtheLED

statuslightdisplaysasteadyredlight.

Thereare2waystoactivatethetineengagement

display:

•T apthemulti-functionswitcheitherupordownto

displaythetineengagementmeter.

•Steponthetinegroundengagementfootswitch.

Figure20

1.LCDIndicators/Informationscreen

2.Tinedepthstatusbar

3.Tinedepthsettingindicator

4.LEDstatuslight

•Amaintenancealertoccurswhenthemaintenance

counterreacheszero.

•Iftheserviceisnotperformed,themaintenance

counterdisplaystimeasnegativehourstoindicate

thenumberofhourspastduefortheservice(up

to-500hours).

•Thehourmeterswitchesbetweenthedefault

screenandtheactivealertscreen.

•Ifmorethan1alertisactive,thedisplaycycles

betweenthealertsintheorderthattheyoccurred

beforecyclingbacktothedefaultscreen.

Themaintenancealertsonlydisplaywhenthedefault

screenhasbeenactivefor2seconds;however,if

thekeyismovedtotheSTARTposition,thealerts

occurimmediately.Whenthemachineisaerating,

thealertscreendoesnotdisplaybuttheLEDstatus

g211731

lightremainsasteadyred.

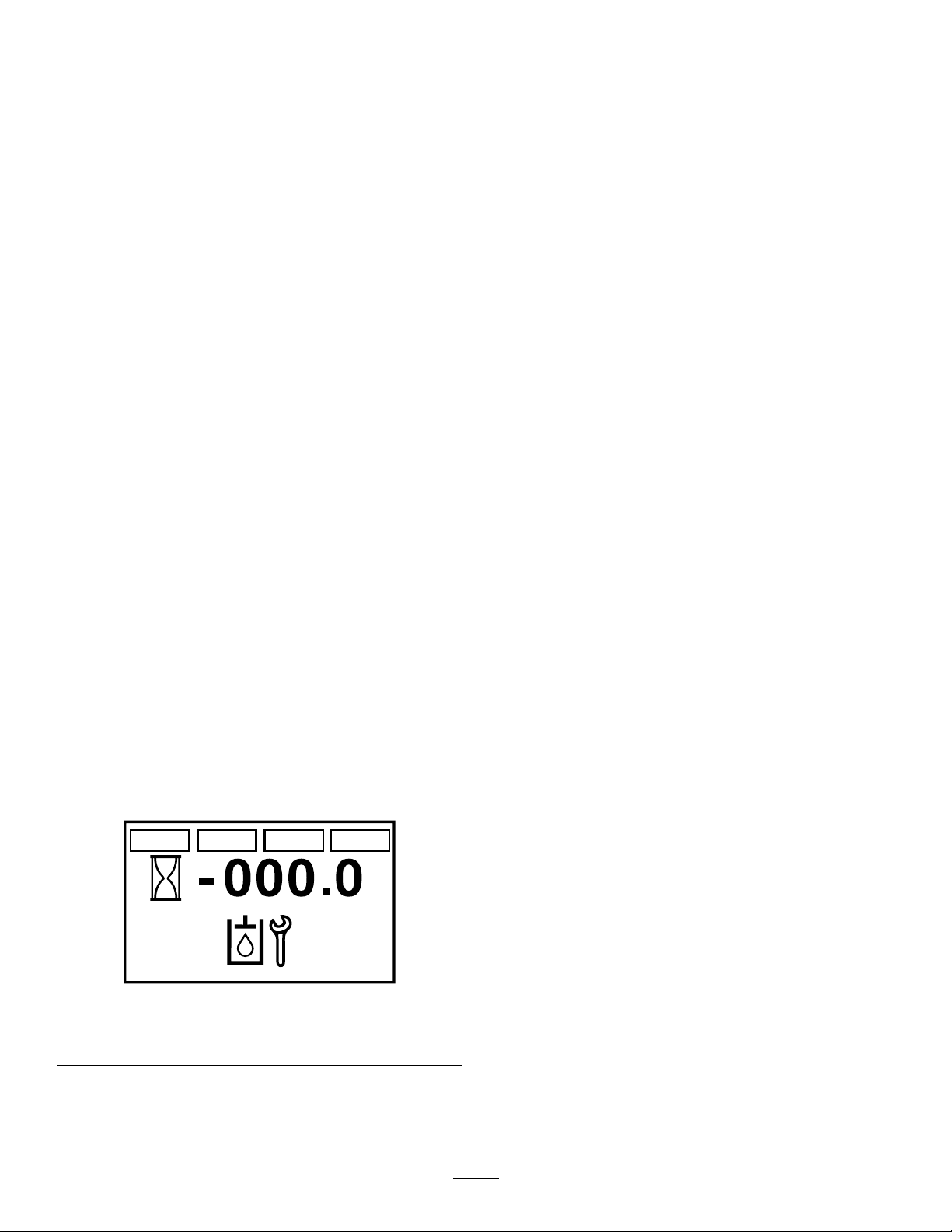

ServiceEngineReminder

Theengine-oilservicereminder(Figure21)counts

downfromtheinitialbreak-inserviceintervalof5

enginehoursandthencountsdownfrom100hours

foreachserviceintervalthereafter.

Ahighernumberonthestatusbar(Figure20)

increasesthelengthoftheaerationplugandalower

numberdecreasesit.

Note:Ifthepluglengthisnotthedesiredlength,you

mayneedtoadjustthemachinetoaccommodatefor

yourweight;refertoAdjustingtheOperatorWeight

ControlSetting(page24).

LEDStatusLight

TheLEDismulti-coloredlight(Figure19andFigure

20)usedtoindicatethesystemstatus:

•SolidGreen—indicatesnormaloperatingactivity

•BlinkingRed—indicatesanactivefault

•SolidRed—indicatesthatmaintenanceisrequired

g030960

Figure21

22

ServiceTransmissionReminder

Thetransmissionoilmaintenancereminder(Figure

22)countsdownfromtheinitialbreak-inservice

intervalof100enginehoursandthencountsdown

from250hoursforeachserviceintervalthereafter.

Figure22

OperatingtheMachine

3.Iftheengineiscold,pushthechokelever

forwardtotheONposition;refertoThrottle

Lever(page11).

Note:Iftheengineiswarm,pullthechokelever

totheOFFposition.

4.RotatethekeyswitchtotheSTARTposition;

refertoKeySwitch(page13).

Note:Releasetheswitchassoonastheengine

starts.

Important:Donotcranktheengine

continuouslyformorethan10secondsat

atime.Iftheenginedoesnotstart,allowa

g030965

60-secondcooldownperiodbetweenstarting

attempts.Failuretofollowtheseguidelines

canburnoutthestartermotor.

5.IfthechokeleverisintheONposition,gradually

movethelevertowardtheOFFpositionasthe

enginewarmsup.

UsingtheFuel-ShutoffValve

Rotatetheleverofthefuel-shutoffvalvetoalignthe

leverwiththefuelline.

Figure23

1.OFFposition2.ONposition

StartingtheEngine

1.Movethemotion-controlleverstotheneutral

positionandengagetheparkingbrake;refer

toMotion-ControlLevers(page11)and

Parking-BrakeHandle(page12).

Note:Tostarttheengine,theparkingbrake

mustbeengaged.Itisnotnecessaryforthe

operatortobeontheplatform.

2.Placethethrottlelevermidwaybetweenthe

SLOWandFASTpositions;refertoThrottleLever

(page11).

LoweringtheTines

DANGER

Therotatingtinesundertheenginedeckare

dangerous.Tinecontactcancauseserious

injuryorkillyou.

Donotputyourhandsorfeetunderthe

machinewhentheengineisrunning.

1.Disengagetheparkingbrake.

2.MovethethrottlelevertotheFASTposition.

3.Thelockoutfeatureisengagedeachtimethe

engineisswitchedoff.T ounlock,tapandhold

thetopofthemulti-functionswitchuntiltheLED

lightdisappears.

g025897

4.T aptheswitchoncetodisplaythe

tine-engagementdepthsetting.

Note:Adjustifnecessary.

5.Lowerthetinesbypressingthetine

ground-engagementfootswitch.

TheLEDindicatorshouldilluminateunderthe

tinedownpositiononthehourmeter.

6.Standontheswitchandmovethemotion-control

leversforwardtoaerate.

Note:Thefoot-rockerbar,locatedbehindthe

tineground-engagementfootswitch,canbe

adjustedforyourcomfort.Toadjust,loosenthe

foot-rockerbarhardware,slidethebarforward

orrearward,andtightenthehardware.

23

Locking/UnlockingtheTineDepth

Setting

Thesettingscanbelockedtoensurethatthetine

depthisnotinadvertentlychangedbytheoperator

orleftunlocked.

•T oactivatethedepthlock:turntheignitionkey

fromtheOFFpositiontotheONposition5times

(stopattheONposition).Usethemulti-function

switchtoadjustthetinedepthtothedesired

setting.Pressandholdthemulti-functionswitch

downfor1secondtolock.

•T odeactivatethedepthlock:turntheignitionkey

fromtheOFFpositiontotheONposition5times

(stopattheONposition).Pressandholdthe

multi-functionswitchupfor1secondtounlock.

SwitchthekeytotheOFFpositionorSTARTposition

whenyouarenished.

AdjustingtheOperatorWeight

ControlSetting

1.Withthetinesraised,drivethemachinetoa

hard,atsurface(suchasconcrete)andstop

theaerator,butleaveitrunning.

2.SetthrottletotheFASTpositionanddisengage

theparkingbrake.

3.Usethemulti-functionswitchtosetthetine

depthto3.0;refertoAdjustingtheTine-Depth

Setting(page24).

4.Pressandholdthetineground-engagementfoot

switchtolowerthetines.

•Ifthemachineraisesandthegroundtires

arenolongertouching,rotatetheoperator

weight-adjustmentcontrolcounterclockwise

tolowerthemachineuntilthetirestouchthe

ground.

•Ifthetinesarenottouchingtheground,

rotatetheoperatorweight-adjustmentcontrol

clockwiseuntilthetineslowerandtouchthe

ground(butdonotraisethemachine).

Tapthetopoftheswitchtodecreasethetinedepth

toremoveashorterplug.

Note:Y oucanmaketine-depthadjustmentswiththe

multi-functionswitchonly.Theidealplugdepthis6.4

to7.6cm(2-1/2to3inches).Adjustthecontrolsto

adapttothesoilconditions.

RaisingtheTines

Toraisethetines,removeyourfootfromthe

tine-elevationswitch(Figure7).

Important:Thetinesrotatewhenthe

motion-controlleverismovedoutoftheneutral

position.

ShuttingOfftheEngine

1.Movethemotion-controlleverstotheneutral

positionandbringthemachinetoafullstop;

refertoMotion-ControlLevers(page11).

2.Liftyourfootoffthetineground-engagement

footswitchcontroltoraisethetines;referto

RaisingtheTines(page24).

3.Placethethrottleinthemidwaybetweenthe

SLOWandFASTpositions;refertoThrottleLever

(page11).

4.Allowtheenginetorunforaminimumof15

seconds,thenturnthekeyswitchtotheOFF

positiontoshutofftheengine;refertoKey

Switch(page13).

5.Engagetheparkingbrake;refertoParking-Brake

Handle(page12).

6.Removethekeytopreventchildrenorother

unauthorizedpersonsfromstartingtheengine.

7.Closethefuel-shutoffvalvewhenthemachine

willnotbeusedforafewdays,when

transporting,orwhenthemachineisparked

insideabuilding;refertoUsingtheFuel-Shutoff

Valve(page23).

DrivingtheMachine

Important:Tomaximizelateralmachine

stability,alwayskeepthedrivetiresonthe

ground.

5.Releasethetineground-engagementfoot

switch.

AdjustingtheTine-DepthSetting

Tapthemulti-functionswitchupordowntosetthe

aerationdepth.

Tapthebottomofthemulti-functionswitchtoincrease

thetinedepthtoremovealongerplug.

CAUTION

Machinecanspinveryrapidlybypositioning

1levertoomuchaheadoftheother.Youmay

losecontrolofthemachine,whichmaycause

damagetothemachineorinjury.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

Important:T odrivethemachine(forwardor

backward),disengagethebrakeleverbeforeyou

canmovethemotion-controllevers.

24

5.T omakezero-turns,liftyourfootoffthetine

engagementfootswitchcontroltoraisethe

tines.Theheadraisesin1second.

Important:Donotmakeazero-turnwhen

thetinesaredown,otherwiseyoumaytear

theturf.

6.T ostopthemachine,movebothmotion-control

leverstotheneutralposition.

Figure24

1.Leftmotion-controllever

2.Rightmotion-controllever6.Neutral

3.Frontreferencebar

4.Frontofthemachine

5.Forward

7.Reverse

DrivingForward

1.Makesurethatthemotion-controlleversarein

theneutralposition.

2.Disengagetheparkingbrake.

3.T omoveforwardinastraightline,moveboth

leversforwardwithequalpressure.

Note:Themachinemovesfasterthefarther

themotion-controlleversaremovedfromthe

neutralposition.

g020241

DrivinginReverse

1.Movethemotion-controlleverstotheneutral

position.

2.T omoverearwardinastraightline,slowlymove

bothleversrearwardwithequalpressure.

g016673

Figure26

Figure25

4.T oturnleftorright,pullthemotion-controllever

backtowardneutralinthedesiredturndirection.

Thetinescanbeinthedownpositionwhen

makinggradualturns.

3.T oturnleftorright,releasepressureonthe

motion-controllevertowardthedesiredturn

direction.

4.T omakezero-turns,liftyourfootoffthe

tine-elevationswitchtoraisethetines.Thehead

raisesin1second.

Important:Donotmakeazero-turnwhen

thetinesareinthedownposition.

5.T ostopthemachine,positionbothmotion-control

leversintheneutraloperateposition.

AdjustingtheFront

g016672

Reference/Speed-ControlBar

Adjustthefrontreference/speedcontrolbarfor

desiredmaximumforwardspeed.

1.Stopthemachineandmovethemotion-control

leverstotheNEUTRALposition.

2.Loosenthenutsoneachsideofthecontrol

panel(Figure27).

25

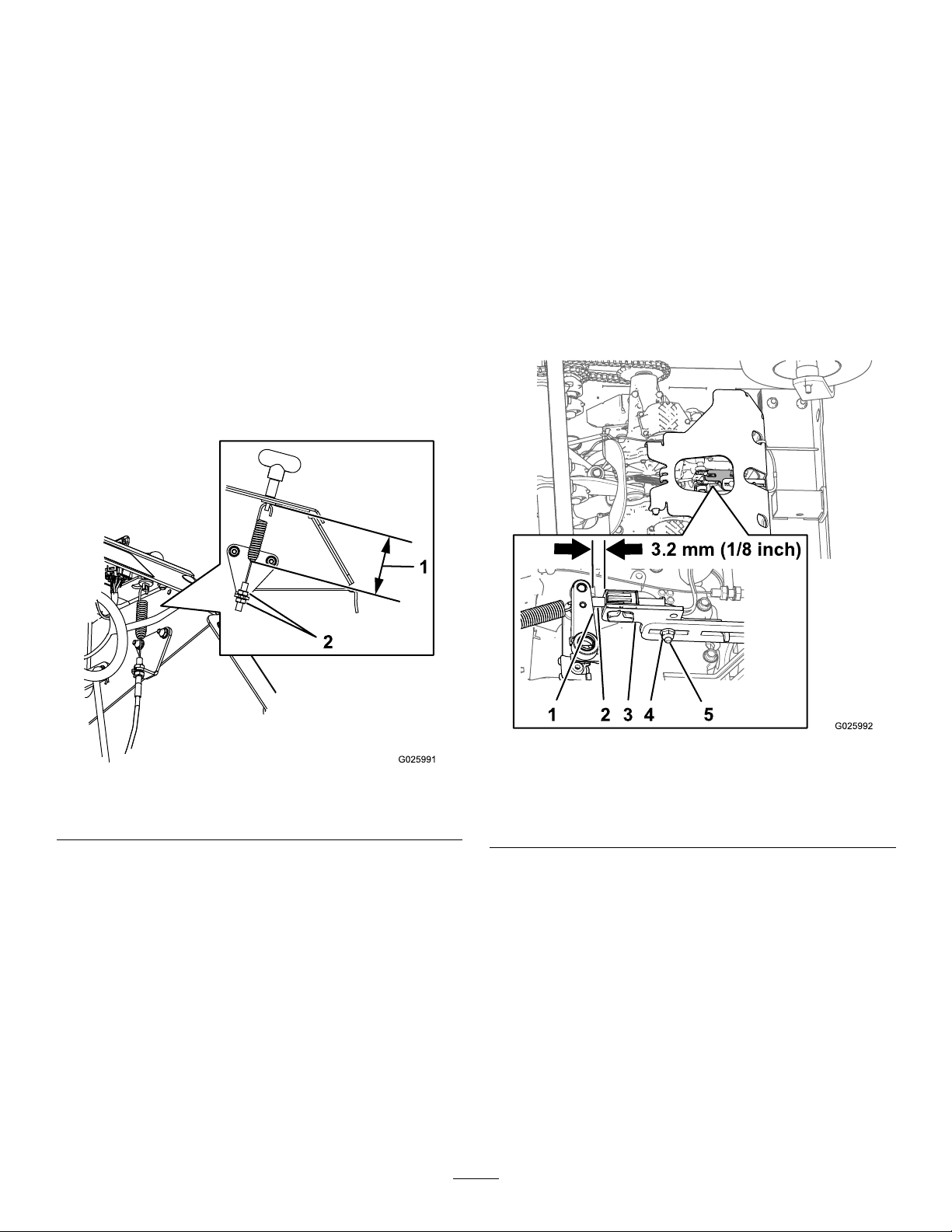

Figure27

1.Nut2.Front

reference/speed-control

bar

3.Movethebarforwardtoobtainthefastestspeed.

Movethebarrearwardtoobtaintheslowest

speed.

4.Onbothsides,tightenthenutsandbolts.

Important:Ensurethatthenutsandboltsare

tightsothatthefrontreference/speed-controlbar

doesnotmoveduringoperation.

AfterOperation

AfterOperationSafety

GeneralSafety

•Parkmachineonlevelground,disengagedrives,

setparkingbrake,stopengine,removekeyor

disconnectsparkplugwire.Waitforallmovement

tostopandallowthemachinetocoolbefore

adjusting,cleaning,repairing,orstoring.Never

allowuntrainedpersonneltoservicemachine.

•CleanthemachineasstatedintheMaintenance

g270084

section.Keepengineandengineareafreefrom

accumulationofgrass,leaves,excessivegrease

oroil,andotherdebriswhichcanaccumulate

intheseareas.Thesematerialscanbecome

combustibleandmayresultinare.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.Tighten

loosehardware.

TransportingtheMachine

Machineweight:460kg(1,015lb)

CAUTION

Thismachinedoesnothaveproperturn

signals,lights,reectivemarkings,ora

slowmovingvehicleemblem.Drivingona

streetorroadwaywithoutsuchequipment

isdangerousandcanleadtoaccidents,

causingpersonalinjury.Drivingonastreetor

roadwaywithoutsuchequipmentmayalso

beaviolationofstatelaws,andyoumaybe

subjecttotrafcticketsand/ornes.

Donotdrivethemachineonapublicstreet

orroadway.

26

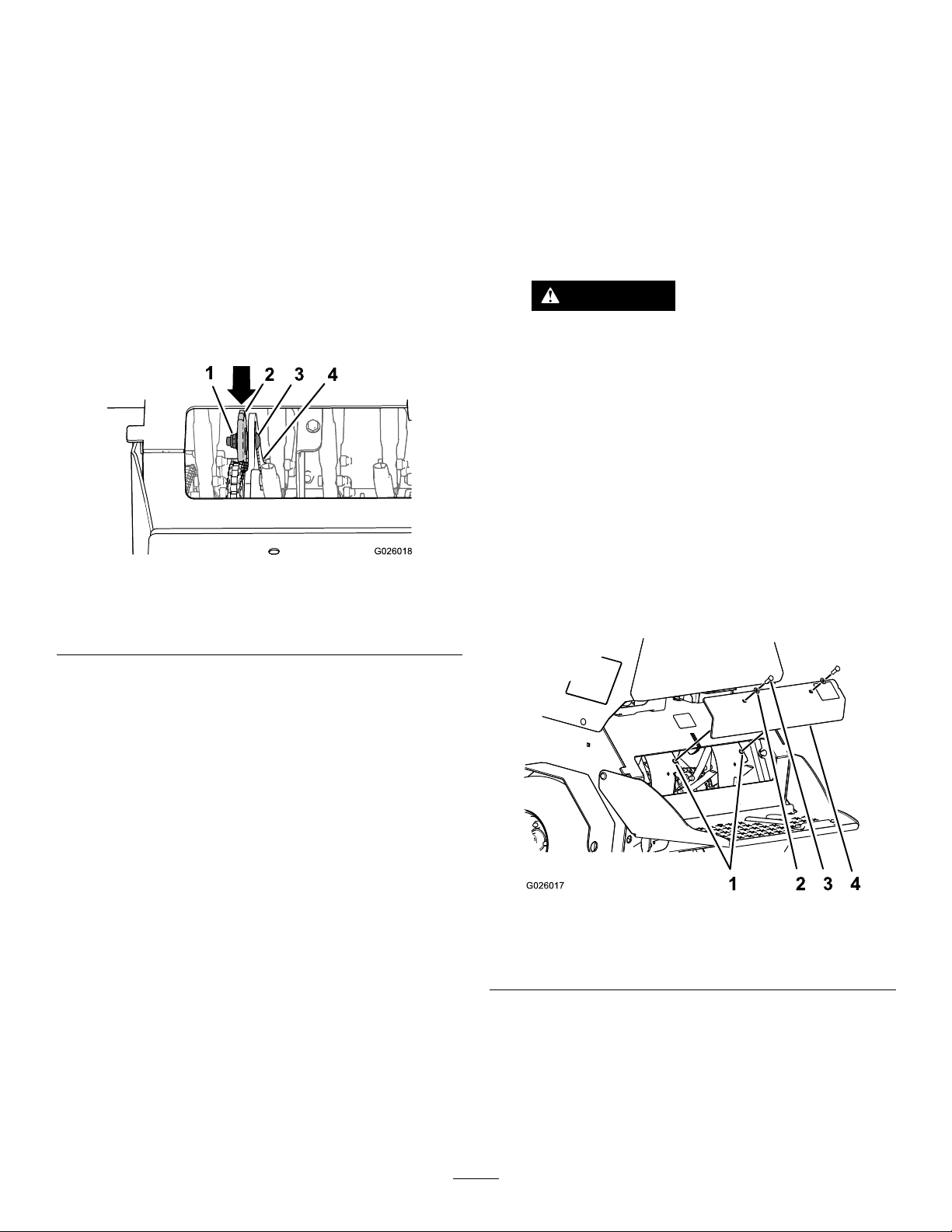

LoadingtheMachineontoa

TransportVehicle

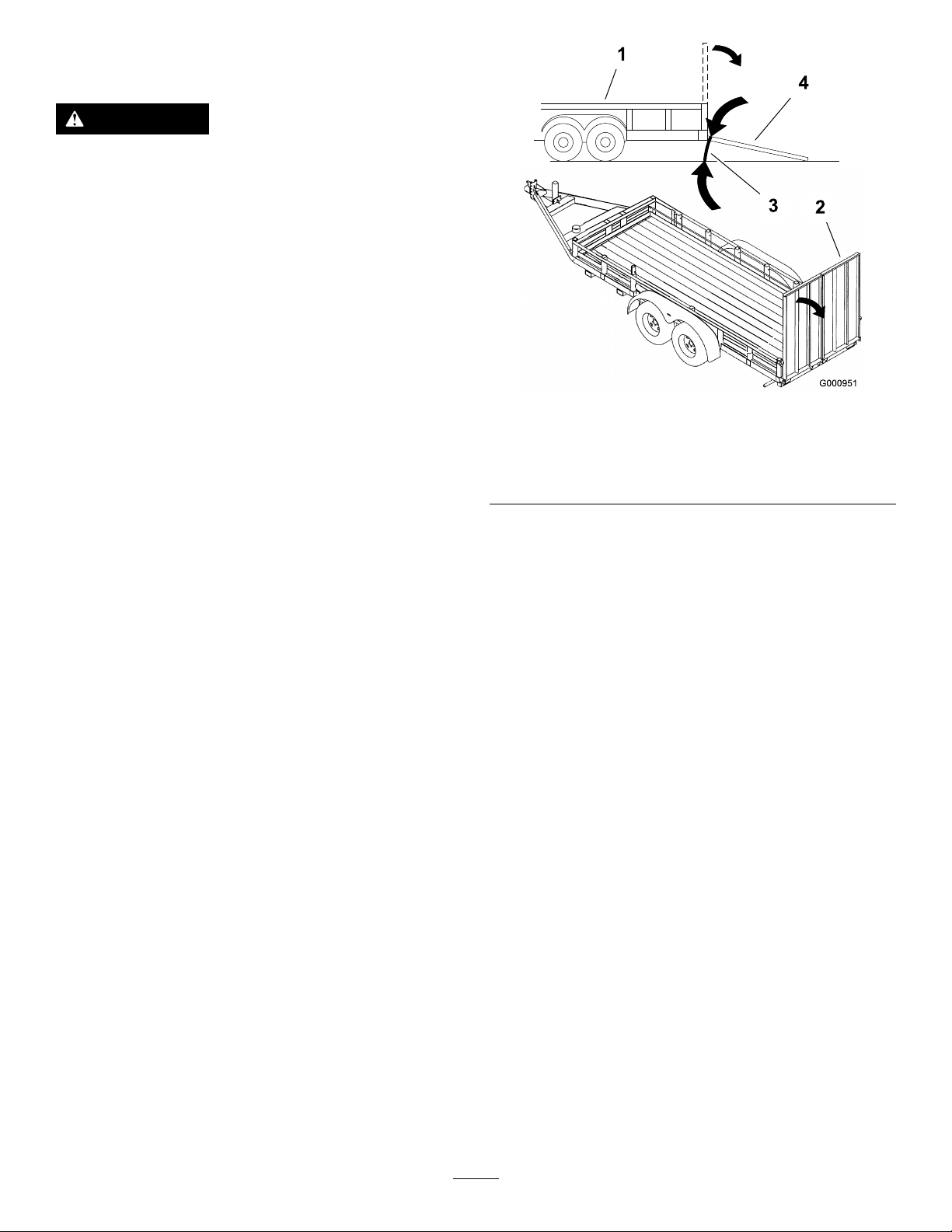

WARNING

Loadingthemachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•Useonlyasingle,full-widthramp;donot

useindividualrampsforeachsideofthe

machine.

•Ifyoumustuseindividualramps,use

enoughrampstocreateanunbrokenramp

surfacewiderthanthemachine.

•Donotexceeda15-degreeanglebetween

rampandground,orbetweenaramp,a

trailer,oratruck.

•Avoidsuddenaccelerationwhiledriving

machineuparamptoavoidtipping

backward.

•Avoidsuddendecelerationwhilebacking

machinedownaramptoavoidtipping

backward.

Figure28

1.Trailer3.Notgreaterthan

2.Full-widthramp

15degrees

4.Full-widthramp(sideview)

•Y oushoulddetermineifitisbesttohavethe

platformupordownwhenloading,dependingon

conditions.Ifitisnotpossibletouse1full-width

ramp,useenoughindividualrampstosimulatea

full-width,continuousramp.

g000951

Important:Donotattempttoturnthemachine

whileontheramp;youmaylosecontrolanddrive

offtheside.

•Useextremecautionwhenloadingunitsonto

trailersortrucks.

•Use1full-widthrampthatiswideenoughto

extendbeyondthereartiresinsteadofindividual

rampsforeachsideofthemachine(Figure28).

Theplatform,whendownandlockedintoposition,

mustextendbackbetweentherearwheels,and

servesasastopfortippingbackward.Havinga

full-widthrampprovidesasurfacefortheplatform

tocontactifthemachinestartstotipbackward.

Withtheplatformup,afull-widthrampprovidesa

surfacetowalkonbehindthemachine.

•Therampshouldbelongenoughsothatthe

anglesdonotexceed15degrees(Figure28).

Asteeperanglemaycausetinecomponentsto

getcaught,asthemachinemovesfromrampto

trailerortruck.Asteeperanglemayalsocause

themachinetotipbackward.Ifloadingonornear

aslope,positionthetrailerortrucksoitisonthe

downsideoftheslopeandtherampextendsup

theslope.Thisminimizestherampangle.The

trailerortruckshouldbeaslevelaspossible.

•Avoidsuddenaccelerationwhendrivinguparamp

andsuddendecelerationwhenbackingdowna

ramp.Bothmaneuverscancausethemachineto

tipbackward.

27

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

thenecessarybrakes,lighting,andmarkingas

requiredbylaw.Pleasecarefullyreadallthesafety

instructions.

1.Raisethetinesofthemachinebeforedriving

ontothetrailerortruck.

2.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

3.Ifapplicable,connectthetrailerbrakes.

4.Loadthemachineontothetrailerortruck.

5.Shutofftheengine,removethekey,engagethe

parkingbrake,andclosethefuelvalve.

6.Engagetheparkingbrakeandblockthetires.

7.Usethetie-downpointsonthemachineto

securelybindthemachinetothetrailerortruck

withstraps,chains,cable,orropes(Figure29).

Note:Refertoyourlocalordinancesforspecic

trailerandtie-downregulations.

1.Tie-downpoints

g025949

Figure29

28

Maintenance

MaintenanceSafety

Information

WARNING

Whilemaintenanceoradjustmentsarebeing

made,someonecouldstarttheengine.

Accidentalstartingoftheenginecould

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionswitch,

engageparkingbrake,andpullthewire(s)

offthesparkplug(s)beforeyoudoany

maintenance.Alsopushthewire(s)asideso

itdoesnotaccidentallycontactthespark

plug(s).

•Parkmachineonlevelground,raisethetines,

setparkingbrake,stopengine,removekeyor

disconnectsparkplugwire.Waitforallmovement

tostopandallowthemachinetocoolbefore

adjusting,cleaningorrepairing.Neverallow

untrainedpersonneltoservicemachine.

WARNING

Theenginecanbecomeveryhot.Touching

ahotenginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundthe

enginearea.

•Disconnectbatteryorremovesparkplugwire

beforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositivelast.

Reconnectpositiverstandnegativelast.

•Keepthemachine,guards,shieldsandall

safetydevicesinplaceandinsafeworking

condition.Frequentlycheckforwornor

deterioratingcomponentsandreplacethemwith

themanufacturer’srecommendedpartswhen

necessary.

WARNING

Removalormodicationoforiginal

equipment,partsand/oraccessories

mayalterthewarranty ,controllability,

andsafetyofthemachine.Unauthorized

modicationstotheoriginalequipmentor

failuretouseoriginalToropartscouldlead

toseriousinjuryordeath.Unauthorized

changestothemachine,engine,fuelor

ventingsystem,mayviolateapplicable

safetystandardssuchas:ANSI,OSHAand

NFPAand/orgovernmentregulationssuch

asEP AandCARB.

•Usecarewhencheckingandservicingtines.Wrap

thetine(s)orweargloves,andusecautionwhen

servicingthem.Onlyreplacedamagedtines.

Neverstraightenorweldthem.

•Usejackstandstosupportthemachineand/or

componentswhenrequired.

CAUTION

Raisingthemachineforserviceor

maintenancerelyingsolelyonmechanical

orhydraulicjackscouldbedangerous.

Themechanicalorhydraulicjacksmaynot

beenoughsupportormaymalfunction

allowingthemachinetofall,whichcould

causeinjury.

Donotrelysolelyonmechanicalor

hydraulicjacksforsupport.Useadequate

jackstandsorequivalentsupport.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

29

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.Fluid

accidentallyinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursby

adoctorfamiliarwiththisformofinjuryor

gangrenemayresult.

–Ifequipped,makesureallhydraulic

uidhosesandlinesareingood

conditionandallhydraulicconnections

andttingsaretightbeforeapplying

pressuretohydraulicsystem.

–Keepbodyandhandsawayfrom

pinholeleaksornozzlesthatejecthigh

pressurehydraulicuid.

–Usecardboardorpaper,notyourhands,

tondhydraulicleaks.

–Beforeperforminganyworkonthe

hydraulicsystem:

–Safelyrelieveallpressureinthe

grounddrivehydraulicsystemby

placingthemotioncontrolleversin

neutralandshuttingofftheengine.

–Safelyrelieveallpressureinthe

auxiliaryhydraulicsystembyshutting

offtheengine,turningtheignition

switchtothe“ON”position,and

pressingthetinegroundengagement

switch.Oncethetineshavelowered

totheground,releasethetineground

engagementswitchandturntheignition

switchtothe“OFF”position.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,DoNotmakeadjustmentswiththe

enginerunning.Ifthemaintenanceoradjustment

procedurerequiretheenginetoberunningand

componentsmoving,useextremecaution.

WARNING

Contactwithmovingpartsorhotsurfaces

maycausepersonalinjury .

Keepyourngers,hands,andclothing

clearofrotatingcomponentsandhot

surfaces.

•Checkallboltsfrequentlytomaintainproper

tightness.

30

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Aftertherst100hours

Beforeeachuseordaily

Every25hours

Every50hours

MaintenanceProcedure

•Changetheengineoil.

•Changetheengine-oillter(moreofteninextremelydustyorsandyconditions).

•Checkthetorqueofthewheelhubnuts.

•Checkthetorqueofthetransmissionoutputshaftnut.

•Changetheauxiliaryhydraulicreservoirlteranduid.

•Changethetransmissionlters.

•Fillthetransmissionwithuidwhenchangingthelter.

•Lubricatethechains.

•Checktheengine-oillevel.

•Checkthesafety-interlocksystem.

•Checktheconditionofthesprockets.

•Checktheconditionandtensionofthechains.

•Checkthetines.

•Checkforloosehardware.

•Cleantheengineandtheexhaustsystemarea(moreoftenindryordirtyconditions).

•Cleanthegrassanddebrisbuildupfromthemachine.

•Greasethejackshaftbearings.

•Greasethewheelbearings.

•Greasethetineshaftbearings.

•Greasethetineassemblyidlers.

•Greasethecontrolpivots.

•Checksparkarrester(ifequipped).

•Checkthepressureinthetires.

•Checktheconditionandtensionofthebelts.

•Checktheauxiliaryhydraulic-uidlevel.

•Checkthehydraulictransmissionuidlevel.

Every80hours

Every100hours

Every160hours

Every250hours

Every500hours

Every800hours

•Removetheengineshroudsandcleanthecoolingns.

•Changetheengineoil.

•Changetheengine-oillter(moreofteninextremelydustyorsandyconditions).

•Check,cleanandgapthesparkplug.

•Servicethefoamair-cleanerelement(moreofteninextremelydustyorsandy

conditions).

•Changetheauxiliaryhydraulicreservoirlteranduid.

•Changethetransmissionlters.

•Fillthetransmissionwithuidwhenchangingthelter.

•Replacethepaperair-cleanerelement(moreofteninextremelydustyorsandy

conditions).

•Replacethefuellter.

Monthly

Yearly

•Checkthebattery.

•Greasethefrontcasterpivots.

•Greasethebeltidlerpivot.

•Greasethecasterpivotsandhubs.

•Lubricatethecaster-wheelhubs.

•Lubricatethecaster-wheelhubs.

•Checkthetorqueofthewheelhubnuts.

•Checkthetorqueonthewheellugnuts.

•Checkthetorqueofthetransmissionoutputshaftnut.

•Preparethemachineforstorage.

31

Pre-Maintenance

AccessingtheConsole

Procedures

PreparingfortheMachine

forMaintenance

Performthefollowingbeforeservicing,cleaning,or

makinganyadjustmentstothemachine.

1.Parkthemachineonalevelsurface.

2.Shutofftheengine,engagetheparkingbrake,

waitforallmovingpartstostop.

3.Removethekeyfromthekeyswitch.

Compartment

RemovingtheConsolePad

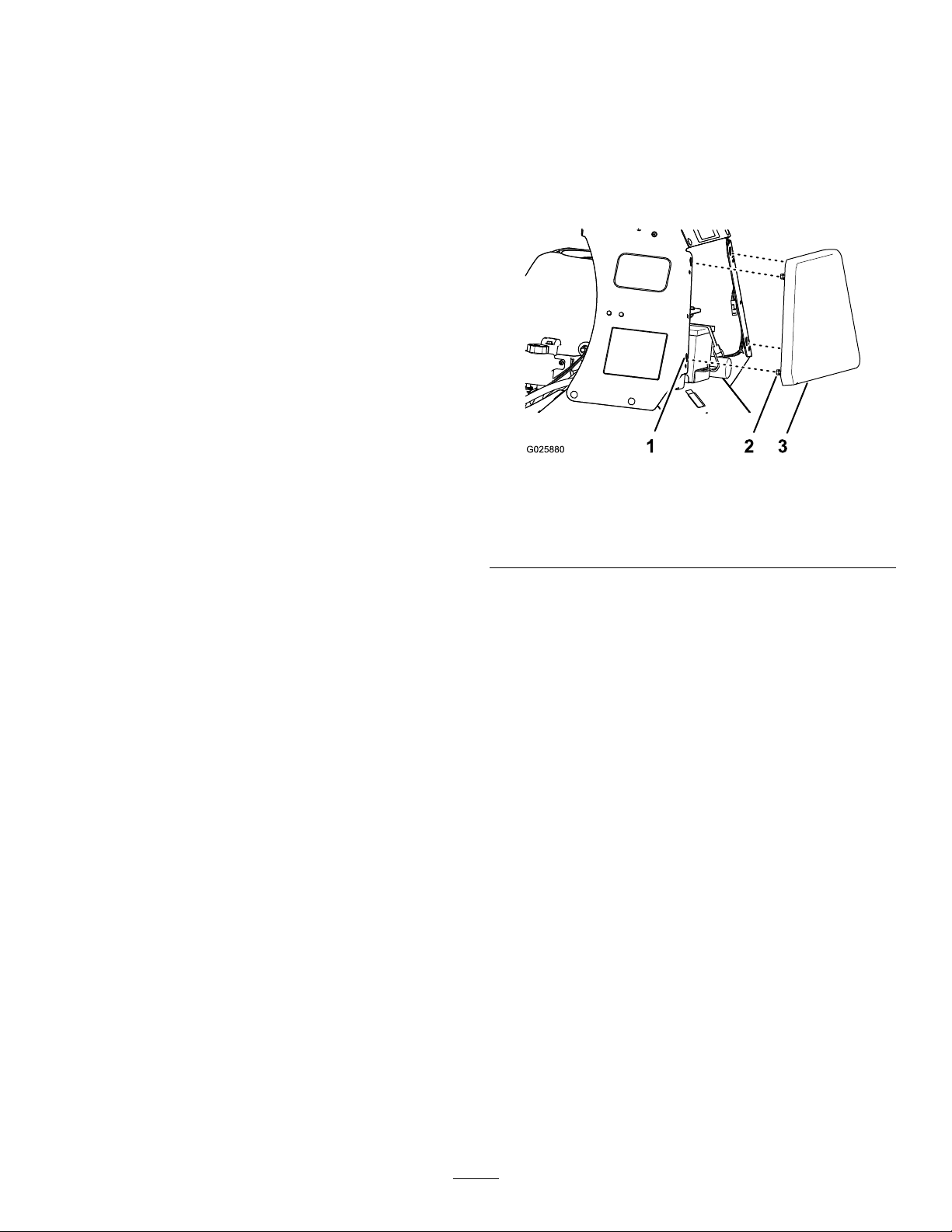

1.Loosenthe4anged-headboltsthatsecurethe

padtotheleftandrightconsolepanels(Figure

30).

Figure30

1.Keyholeslot(console

panel)

2.Fanged-headbolt

3.Pad

g025880

2.Lifttheconsolepad(Figure30)approximately

13mm(1/2inch).

3.Pulltheconsolepadstraightbackandremove

thepadfromthemachine(Figure30).

InstallingtheConsolePad

1.Alignthe4anged-headboltsattheforward

faceoftheconsolepadtothe4keyholeslotsin

theframeoftheconsole(Figure30).

2.Movethepadforwarduntilthepadisushto

theconsoleframe(Figure30).

3.Movethepaddownuntiltheanged-headbolts

areseatedinthekeyholeslots(Figure30).

4.Tightentheanged-headboltsto1978to2542

N∙cm(175to225in-lb).

32

Lubrication

LubricatingtheGrease

Fittings

Greasetype:NationalLubricatingGreaseInstitute

(NGLI)grade#2multi-purposegungrease.

Note:Refertothelubricationchartforservice

intervals.

LubricationChart

Fitting

Locations

Frontcaster

pivots

Jackshaft

bearings

Wheelbearings1225hours

Tineshaft

bearings

Tineassembly

idlers

Controlpivots

Beltidlerpivot11Yearly

Frontcaster

hubs

Initial

Pumps

*0

1825hours

1425hours

1225hours

1450hours

*0

Numberof

Places

2Yearly

2Yearly

2.Wipecleanthegreasettingswitharag(Figure

31).

3.Connectagreaseguntothetting(Figure31).

4.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings.

5.Wipeupanyexcessgrease.

LubricatingtheChains

ServiceInterval:Beforeeachuseordaily

Lubricanttype:Oilorchainlubricant.

Service

Interval

Important:Donotlubricatechainswith

penetratingoilorsolvents.

1.Shutofftheengine,engagetheparkingbrake,

waitforallmovingpartstostop,andremove

thekey.

2.Raisethemachineandsupportitwithjack

standswitha460kg(1,015lb)capacity.

CAUTION

Raisingthemachineforservice

ormaintenancerelyingsolelyon

mechanicalorhydraulicjackscouldbe

dangerous.Themechanicalorhydraulic

jacksmaynotbeenoughsupportormay

malfunctionallowingthemachinetofall,

whichcouldcauseinjury .

Figure31

1.Frontcasterpivots5.Tineassemblyidlers

2.Jackshaftbearings6.Controlpivots

3.Wheelbearings7.Beltidlerpivot

4.Tineshaftbearings

8.Frontcasterhubs

1.Shutofftheengine,engagetheparkingbrake,

waitforallmovingpartstostop,andremove

thekey.

Donotrelysolelyonmechanical

orhydraulicjacksforsupport.Use

adequatejackstandsorequivalent

support.

3.Starttheengineandmovethethrottlelevel

aheadtothehalf-throttleposition.

WARNING

Youmustruntheengineandturnthe

drivewheelssothatyoucanperform

adjustments.Contactwithmovingparts

orhotsurfacesmaycausepersonal

injury.

g020222

Keepyourngers,hands,andclothing

clearofrotatingcomponentsandhot

surfaces.

4.Disengagetheparkingbrake.

5.Withtheenginerunning,slowlymovethe

motion-controlleversforwardandlubricateall6

chains(Figure69).

6.Checktheconditionandtensionofthechains;

refertoCheckingtheConditionandTensionof

theChains(page56).

33

LubricatingtheCasters

Greasetype:NationalLubricatingGreaseInstitute

(NGLI)gradeNo.2multi-purposegungrease.

LubricatingtheCaster-Hubs

Bearings

ServiceInterval:Yearly

GreasingtheCasterPivots

ServiceInterval:Yearly

1.Removecapandhexplugfromthetopofthe

casterpivot(Figure32).

Figure32

RemovingtheCaster-WheelAssembly

1.Shutofftheengine,engagetheparkingbrake,

waitforallmovingpartstostop,andremove

thekey.

2.Liftthefrontofthemachineandsupportitwith

jackstands.

3.Removethewheelnutandbolt,andremovethe

caster-wheelassemblyfromthefork(Figure33).

g025953

Figure33

1.Wheelbolt3.Wheelnut

g025955

2.Caster-wheelassembly

1.Hexplug

2.Greasetting4.Cap

2.Threadgreasettinginhole(Figure32).

3.Pumpgreaseintothettinguntilgreaseoozes

outaroundtopbearing(Figure32).

4.Removegreasettingandinstalltheplugthat

youremovedin1(Figure32).

5.Installthecapthatyouremovedinstep1(Figure

32).

6.Repeatsteps1through5totheothercaster.

3.Casterpivot

DisassemblingtheCaster-WheelHuband

GreasingtheBearings

ServiceInterval:Yearly

Important:Usenewbearingsealswhen

lubricatingthecaster-wheelhubs.

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoften.Spinthe

castertire.Thetireshouldnotspinfreely(more

than1or2revolutions)orhaveanysideplay.If

thewheelspinsfreely,adjusttorqueonspacer

nutuntilthereisaslightamountofdrag.Apply

thread-lockingcompound.

Greasetype:NationalLubricatingGreaseInstitute

(NGLI)gradeNo.2multi-purposegungrease.

1.Removethe2sealguardsfromthewheelhub

(Figure34).

34

Figure34

1.Axle(spacernutstill

assembled)

2.Hub5.Bearingseal

3.Bearing

4.Spacernut

6.Sealguard

2.Remove1ofthespacernutsfromtheaxle

assemblyinthecasterwheel(Figure34).

Note:Notethatthread-lockingcompoundhas

beenappliedtolockthespacernutstotheaxle

(Figure34).

3.Removetheaxle(withtheotherspacernutstill

assembledtoit)fromthecaster-wheelassembly

(Figure34).

4.Pryoutbothbearingseals(Figure34).

Note:Discardtheoldseals.

5.Removebothbearingsandinspectthemfor

wearordamage(Figure34).

Note:Replacethebearingifitiswornor

damaged.

6.Packthe2bearingswiththespeciedgrease.

AssemblingtheCaster-WheelHub

1.Install1bearingintothehubofthewheel(Figure

34).

2.Installthebearingsealintothehubatthe

bearing(Figure34).

3.Ifyouremoved(orbrokeloose)bothofthe

spacernutsfromtheaxleassembly,perform

thefollowing:

A.Cleanthethreadsoftheaxleandspacer

nut.

B.Applyathread-lockingcompoundtothe

threadsat1endoftheaxle.

C.Threadtheaxlenut,withthewrenchats

facingoutward,ontotheendoftheaxlethat

ispreparedwiththread-lockingcompound

(Figure34).

mm(1/8inch)fromtheoutersurfaceofthe

spacernuttotheendoftheaxleinsidethe

nut.

4.Inserttheassemblednutandaxleintothewheel

atthesideofthewheelwiththenewsealand

bearing(Figure34).

5.Withtheopenendofthewheelfacingup,llthe

areainsidewheelcavity(aroundtheaxle)with

thespeciedgrease.

g025954

6.Installtheotherbearingandnewsealintothe

wheel(Figure34).

7.Applyathread-lockingcompoundtothesecond

spacernutandthreaditontotheaxlewiththe

wrenchatsfacingoutward.

8.T orquethespacernutto8to9N∙m(75to80

in-lb),loosen,thentorqueit2to3N∙m(20to

25in-lb).

Important:Ensurethattheaxledoesnot

extendbeyondeithernut.

9.Installthesealguardsoverthewheelhub

(Figure34).

InstallingtheCaster-WheelAssembly

1.Aligntheholeintheaxleofthecaster-wheel

assemblybetweentheholesintheforkofthe

caster(Figure33).

2.Securethewheelassemblytotheforkwiththe

wheelnutandbolt(Figure33)thatyouremoved

instep3ofRemovingtheCaster-Wheel

Assembly(page34).

3.T orquethewheelnutto91to1 13N∙m(67to

83ft-lb).

Note:Donotthreadspacernutallthe

wayontotheaxle.Leaveapproximately3

35

EngineMaintenance

2.Inspectthebothelementsfortears,anoilylm,

ordamaged(Figure35).

ServicingtheAirCleaner

Inspectthefoamandpaperelements,andreplace

themiftheyaredamagedorexcessivelydirty .

Important:Donotapplyoiltothefoamorpaper

element.

AccessingtheFoamandPaper

Elements

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage

(Figure35).

Important:Replacetheelement(s)ifitis

wornordamaged.

3.Washthefoamelementinliquidsoapand

warmwater.Whentheelementisclean,rinse

itthoroughly.

4.Drytheelementbysqueezingitinacleancloth.

5.Assemblethefoamelementontothepaper

element(Figure35).

6.Installtheair-cleanerelementsontotheinlet

ductoftheengine(Figure35).

7.Rotatethethumbscrewofthehoseclamp

clockwise(Figure35).

8.Assembletheair-cleanercoverontotheengine

androtatethecoverknobs1/4turnclockwise.

ReplacingthePaperAir-Cleaner

Element

ServiceInterval:Every500hours—Replacethe

paperair-cleanerelement(more

ofteninextremelydustyorsandy

conditions).

Figure35

1.Cover

2.Hoseclamp4.Foamelement

3.Rotatethecoverknobs1/4turncounterclockwise

andremovetheair-cleanercover(Figure35).

4.Rotatethethumbscrewofthehoseclamp

counterclockwiseuntilyoucanseparatethe

air-cleanerassemblyfromtheinletduct(Figure

35).

3.Paperelement

ServicingtheFoamAir-Cleaner

Element

Important:Donotwashthepaperair-cleaner

element.

1.Discardtheoldpaperelement.

2.Assemblethefoamelementontothenewpaper

element(Figure35).

3.Installtheair-cleanerelementsontotheinlet

g012352

ductoftheengine(Figure35).

4.Rotatethethumbscrewofthehoseclamp

clockwise(Figure35).

5.Assembletheair-cleanercoverontotheengine

androtatethecoverknobs1/4turnclockwise.

ServiceInterval:Every250hours(moreoften

inextremelydustyorsandy

conditions).

1.Carefullyremovethefoamelementfromthe

paperelement(Figure35).

36

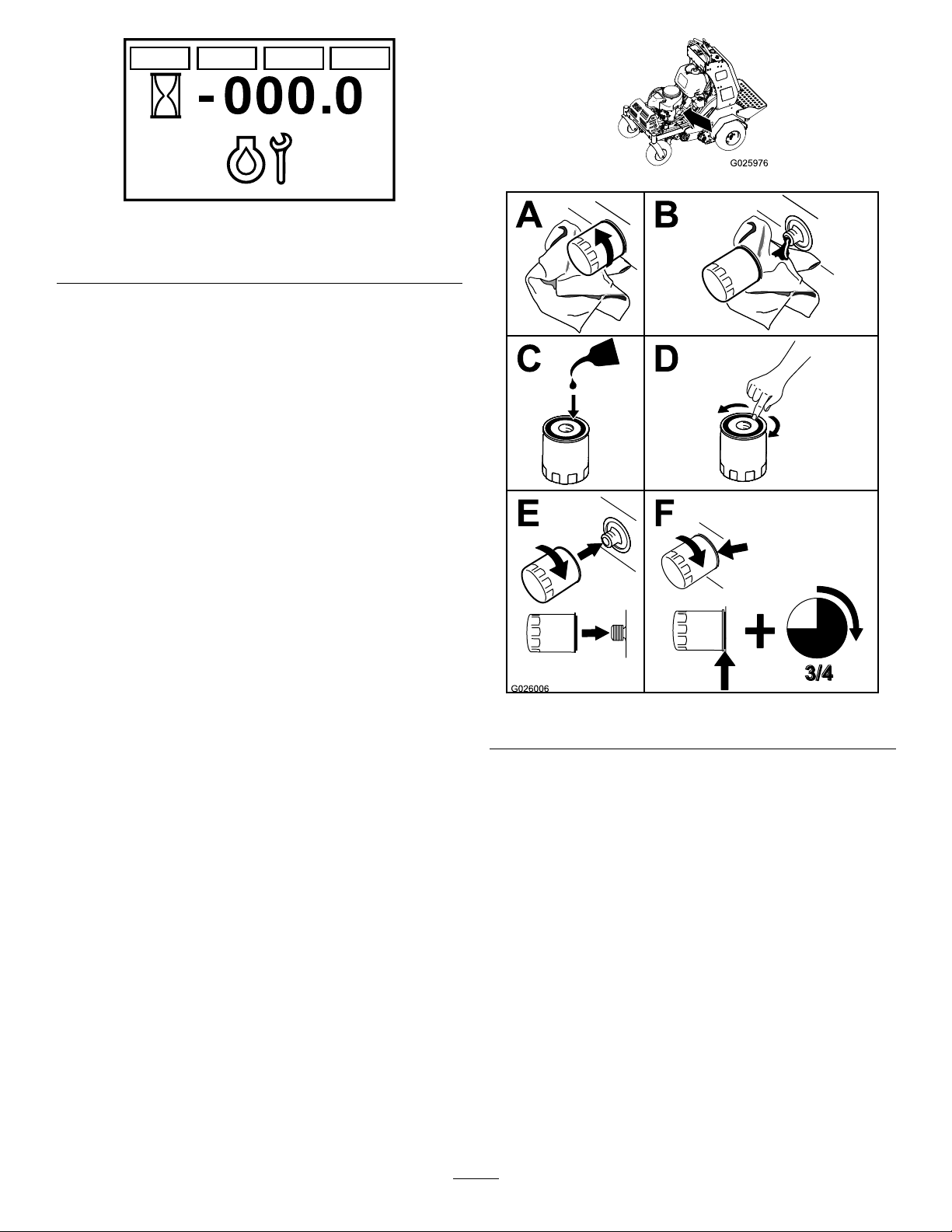

ServicingtheEngineOil

Engine-OilSpecications

OilType:Detergentoil(APIserviceSJorlater)

Engine-OilCapacity:1.7L(1.8USqt)withthelter

removed;1.5L(1.6USqt)withoutthelterremoved

Engine-OilViscosity:Refertothetablebelow.

Figure36

CheckingtheEngine-OilLevel

g025899

g004216

ServiceInterval:Beforeeachuseordaily

Important:Donotoperatetheenginewiththeoil

levelbelowtheLow(orAdd)markonthedipstick,

orovertheFullmark.