Page 1

FormNo.3417-602RevA

30inStand-OnAerator

ModelNo.29519—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3417-602*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

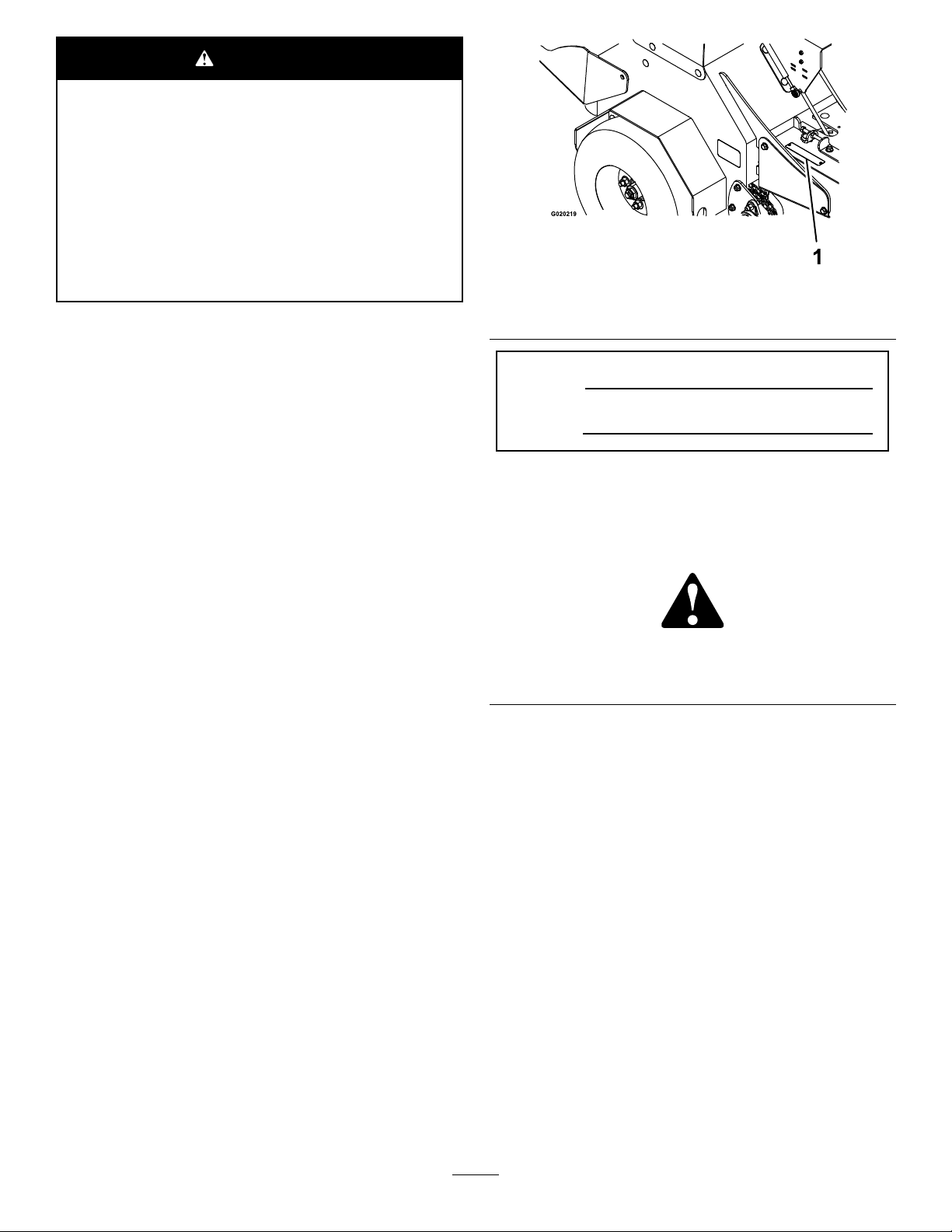

g020219

Figure1

Important:Thisengineisnotequippedwith

asparkarrestermufer.Itisaviolationof

CaliforniaPublicResourceCodeSection4442to

useoroperatetheengineonanyforest-covered,

brush-covered,orgrass-coveredland.Other

statesorfederalareasmayhavesimilarlaws.

TheenclosedEngineOwner'sManualis

suppliedforinformationregardingtheUS

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenance,andwarranty.

Replacementsmaybeorderedthroughtheengine

manufacturer.

Introduction

Thisaeratorisintendedtobeusedbytrained

operatorsinresidentialandcommercialapplications.

Itisprimarilydesignedforaeratingareasof

well-maintainedlawnsonresidentialgrounds,parks,

sportselds,andoncommercialgrounds.

Readtheinformationinthemanualcarefullytolearn

howtooperateandmaintainyourproductproperly

andtoavoidinjuryandproductdamage.Youare

responsibleforoperatingtheproductproperlyand

safely.

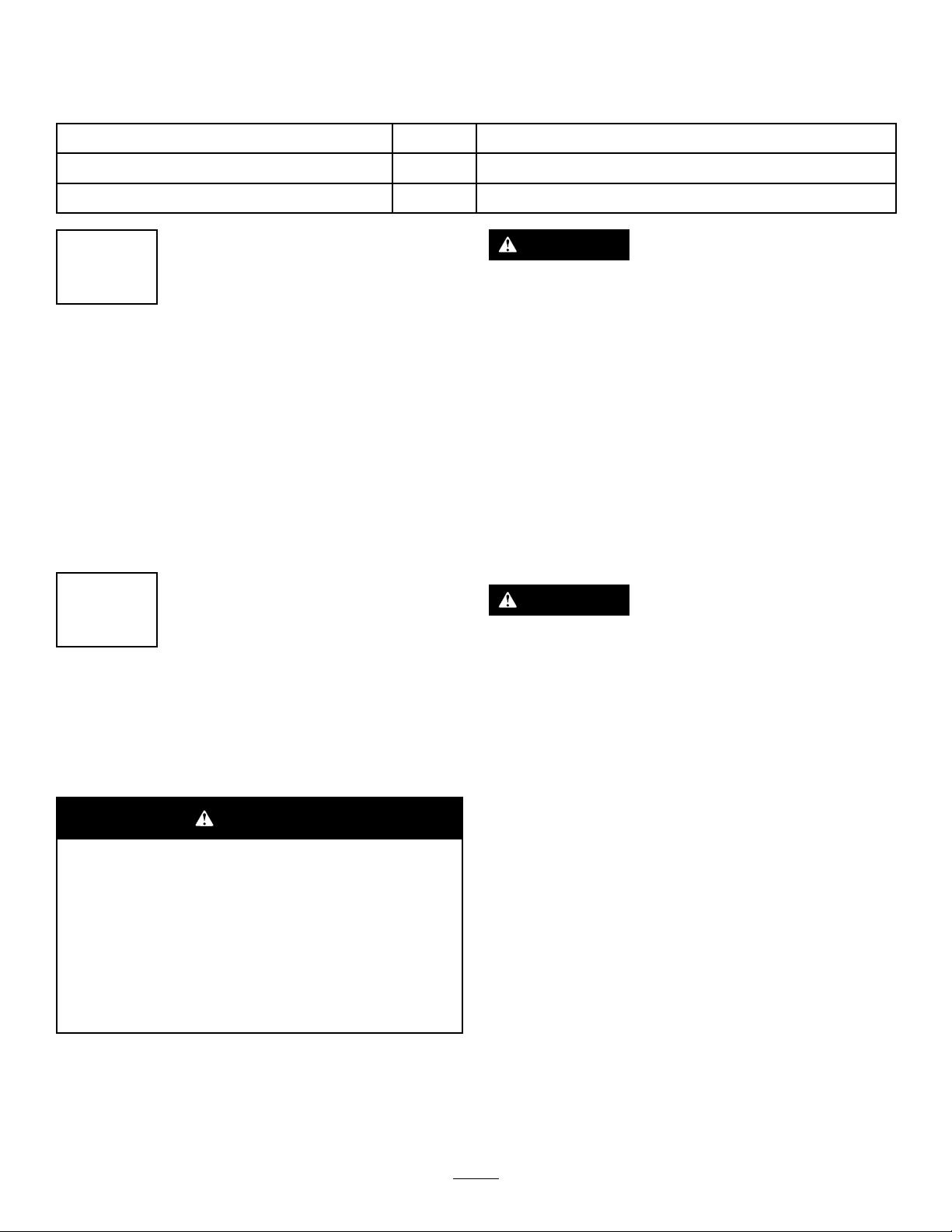

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

YoumaycontactTorodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure

1illustratesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

AeratorSafety....................................................6

SlopeIndicator...................................................7

SafetyandInstructionalDecals..........................8

Setup......................................................................12

1CheckingTirePressure..................................12

2ServicingtheBattery......................................12

3ServicingtheEngineOil.................................13

4ServicingtheTransmissionFluid....................14

5ServicingtheAuxiliaryHydraulic

Fluid..............................................................14

ProductOverview...................................................15

Controls...........................................................15

Specications..................................................18

Operation................................................................18

CheckingtheEngine-OilLevel..........................18

AddingFuel......................................................19

LubricatingtheChains......................................21

CheckingtheSafety-InterlockSystem..............22

CheckingforLooseHardware...........................22

OperatingtheMachine.....................................22

TransportingtheMachine.................................25

Maintenance...........................................................27

RecommendedMaintenanceSchedule(s)...........27

Pre-MaintenanceProcedures..............................28

PreparingfortheMachinefor

Maintenance.................................................28

AccessingtheConsoleCompartment...............28

Lubrication..........................................................29

LubricatingtheGreaseFittings.........................29

LubricatingtheCasters.....................................30

EngineMaintenance...........................................32

ServicingtheAirCleaner..................................32

ServicingtheEngineOil....................................33

ServicingtheSparkPlug...................................35

CheckingtheSparkArrester.............................36

FuelSystemMaintenance...................................36

ServicingtheFuelFilter....................................36

ElectricalSystemMaintenance...........................37

ServicingtheBattery.........................................37

ServicingtheFuses..........................................39

DriveSystemMaintenance..................................40

CheckingtheAirPressureintheTires...............40

CheckingtheWheelHubNuts..........................40

CheckingtheT orqueoftheWheelLug

Nuts..............................................................40

AdjustingtheCasterPivotBearings

Pre-Load.......................................................40

MaintainingtheChain.......................................40

CheckingtheT orqueoftheTransmission

OutputShaftNut...........................................42

BrakeMaintenance.............................................42

AdjustingtheParkingBrake..............................42

AdjustingtheBrakeSwitch...............................43

BeltMaintenance................................................43

CheckingtheConditionandTensionofthe

Belts..............................................................43

AdjustingtheAuxiliaryPump-Drive

Belt................................................................43

ReplacingtheTransmission-DriveBelt.............44

ControlsSystemMaintenance.............................45

AdjustingtheTraction-ControlLinkage.............45

HydraulicSystemMaintenance...........................46

MaintainingtheAuxiliaryHydraulic

System..........................................................46

MaintainingtheTransmission...........................47

TineMaintenance.................................................50

CheckingtheTines...........................................50

AdjustingtheTineDriveChain..........................50

Cleaning..............................................................51

CleaningtheEngineandtheExhaust

SystemArea.................................................51

RemovingtheEngineShroudsandCleaning

theCoolingFins............................................51

CleaningtheDebrisfromtheMachine...............51

WasteDisposal.................................................51

Storage...................................................................52

Troubleshooting......................................................53

Schematics.............................................................55

3

Page 4

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructions,and

payattentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—“personalsafety

instruction.”Failuretocomplywiththeinstructions

mayresultinpersonalinjuryordeath.

WARNING

Removingormodifyingoriginalequipment,

partsand/oraccessoriesmayalterthe

warranty,controllability ,andsafetyofthe

machine.Unauthorizedmodicationstothe

originalequipmentorfailuretouseoriginal

Toropartscouldleadtoseriousinjuryor

death.Unauthorizedchangestothemachine,

engine,fuelorventingsystem,mayviolate

applicablesafetyandgovernmentstandards.

Replaceallpartsincluding,butnotlimitedto,

tires,belts,andfuelsystemcomponentswith

originalT oroparts.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.4-2012.

Training

•ReadtheOperator'sManualandothertraining

material.

Note:Iftheoperator(s)ormechanic(s)cannot

readthemanuallanguage,itistheowner's

responsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.

Note:Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeople,ordamagetoproperty.

Important:Thismachinewasmanufactured

accordingtotheappropriateregulatorystandards

ineffectatthetimeofmanufacture.Modifying

thismachineinanywaymaycauseittobe

outofcompliancewiththosestandardsand

withtheinstructionsinthisOperator’sManual.

Modicationstothismachineshouldbemade

onlybyeitherthemanufactureroranAuthorized

ServiceDealer.

Thisproductiscapableofinjuringyourhandsand

feet.Followallsafetyinstructionstoavoidserious

injuryordeath.

Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeople,ordamage

toproperty.

Anyuseofthismachineotherthanaeratingturfgrass

couldprovedangeroustotheuserandbystanders.

Important:Theadditionofattachmentsmade

byothermanufacturersthatdonotmeetANSI

certicationmaycausenoncomplianceofthis

machine.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Useonlyaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothing;includingsafety

glasses,longpants,substantial,slip-resistant

footwear,gloves,andhearingprotection.Tieback

longhair.Donotwearjewelry.

•Inspecttheareawhereyouwillusetheequipment

andremoveallobjectsfromtheareabeforeusing

themachine.

•Useextracarewhenhandlingfuels.Theyare

ammableanditsvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmokenearthemachine

whentheengineisrunning.

–Donotrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

4

Page 5

Operation

Safehandlingoffuels

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Donotrunanengineinanenclosedarea.

•Operatethemachineonlyinwell-litareas,keeping

awayfromholesandhiddenhazards.

•Ensurethatalldrivesareinneutralandthatthe

parkingbrakeisengagedbeforestartingthe

engine.Starttheengineonlyfromtheoperator’s

position.

•Makesurethatyouhavegoodfootingwhileusing

thismachine,especiallywhenbackingup.

Note:Reducedfootingcouldcauseslipping.

•Slowdownanduseextracareonhillsides.Be

suretotravelsidetosideonhillsides.Turf

conditionscanaffectthestabilityofthemachine.

Usecautionwhileoperatingneardrop-offs.

•Slowdownandusecautionwhenmakingturns

andwhenchangingdirectionsonslopes.

•Donotoperatethemachinewithouttheshields

orotherguardssecurelyinplace.Besureall

interlocksareattached,adjustedproperly,and

functioningproperly.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,disengagedrives,engage

theparkingbrake(ifprovided),shutofftheengine

beforeleavingtheoperator'spositionforany

reason.

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlingfuel.Fuelisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfuelwiththe

enginerunning.

•Allowtheenginetocoolbeforefueling.

•Donotfuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlightsuchas

onawaterheateroronotherappliances.

•Donotllcontainersinsideavehicle,onatruck,

oronatrailerbedwithaplasticliner.Alwaysplace

containersonthegroundawayfromyourvehicle

beforelling.

•Removeequipmentfromthetruckortrailerand

fuelitontheground.Ifthisisnotpossible,

thenaddfuelwithsuchequipmentasaportable

containerratherthanfromafuel-dispensernozzle.

•Keepthenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntilfueling

iscomplete.Donotuseanozzlelock-opendevice.

•Iffuelisspilledonclothing,changeyourclothing

immediately.

•Donotoverllthefueltank.Replacethefuelcap

andtightenitsecurely.

•Stopequipmentandinspectthetinesafterstriking

objectsorifanabnormalvibrationoccurs.Make

thenecessaryrepairsbeforeresumingoperations.

•Keepyourhandsandfeetawayfromthetine

assembly.

•Lookbehindanddownbeforebackingupto

ensureaclearpath.

•Stopthemachineifanyoneentersthearea.Keep

petsandbystandersawayfromanoperating

machine.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Fullyraisethe

tinesifyouarenotaerating.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoorfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Donotallowuntrainedpersonneltoservicethe

machine.

•Donottouchequipmentorattachmentpartsthat

maybehotfromoperation.Allowallofthepartsof

themachinetocoolbeforeattemptingtomaintain,

adjust,orservicethemachine.

•Keepyourhandsandfeetawayfrommoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Disengagethedrives,raisethetines,engagethe

parkingbrake,shutofftheengine,andremove

thekeyordisconnectthespark-plugwire.Waitfor

allmovementtostopbeforeadjusting,cleaning,

orrepairing.

•Disconnectthebatteryorremovethespark-plug

wirebeforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositiveterminal

last.Connectthepositiverstandnegativelast.

5

Page 6

•Usecarewhencheckingthetines.Wrapthetine(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplacetines;donotstraightenorweld

them.

•Cleangrass,dirt,anddebrisfromthetines,drives,

mufers,andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Parkmachineonlevel,hardground.Neverallow

untrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Donotstorefuelnearamesordrainthefuel

indoors.

•Lettheenginecoolbeforestoringthemachine.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

Hauling

•Usecarewhenloadingorunloadingthemachine

intoatraileroratruck.

•Useafull-widthrampforloadingthemachineinto

atraileroratruck.

•Tiethemachinedownsecurelyusingstraps,

chains,cable,orropes.Bothfrontandrearstraps

shouldbedirecteddownandoutwardfromthe

machine.

AeratorSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsandothersafetyinformationyou

mustknow.

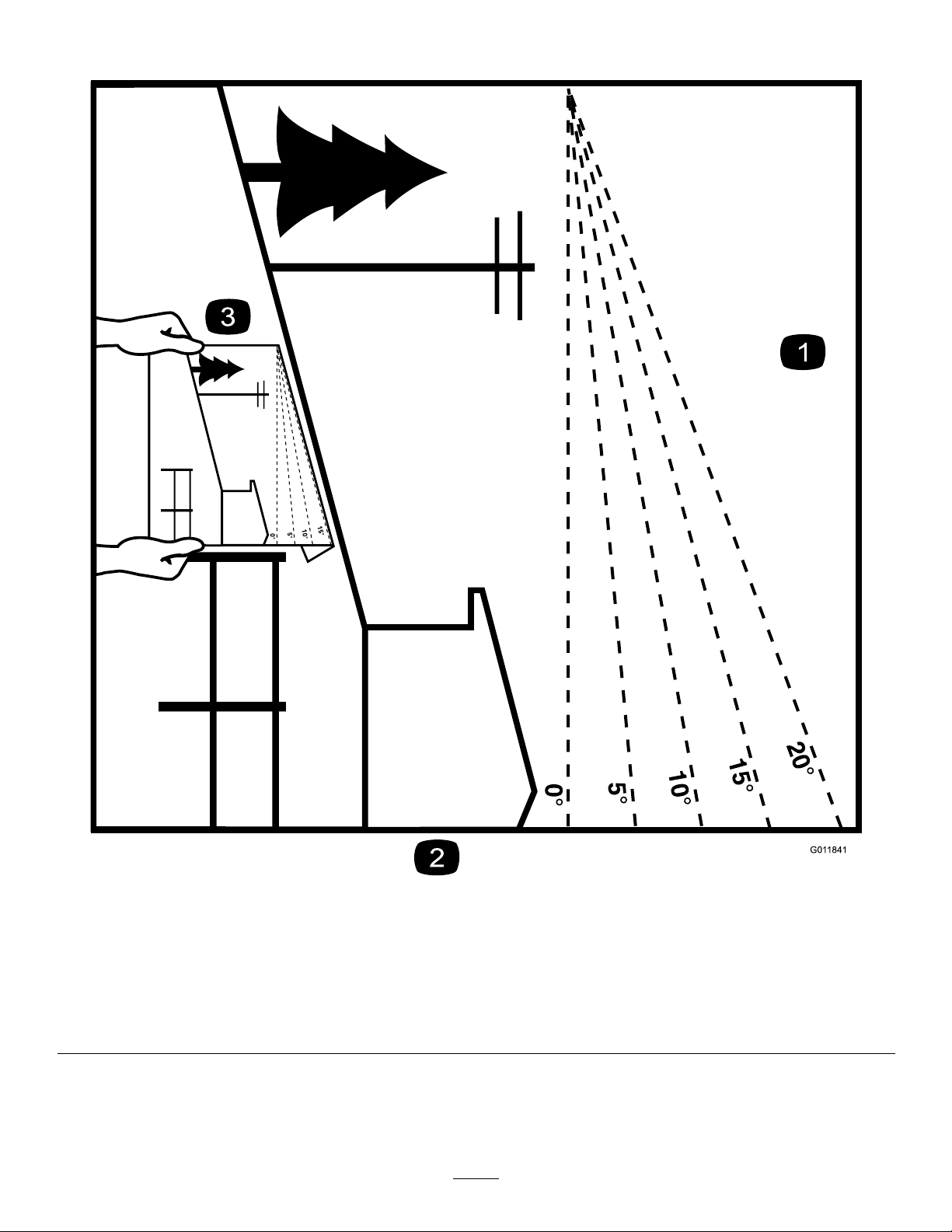

•UseFigure3tohelpyoudeterminetheappropriate

slopeangleofareatoaerate.

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromtheaeratingarea.

•Watchforholes,ruts,orbumps.

Note:T allgrasscanhideobstacles.

•Usecautionneardrop-offs,ditches,or

embankments.

Note:Themachinecouldsuddenlyturnoverifa

wheelgoesovertheedgeofaclifforditch,orif

anedgecavesin.

•Beawarethatoperatingonwetgrass,across

steepslopesordownhillmaycausethemachine

tolosetraction.Lossoftractiontothedrivewheels

mayresultinslidingandalossofbrakingand

steering.

•Donotaerateslopesgreaterthan15degrees.

•Avoidsuddenstartsandstopswhenaeratinguphill

becausethemachinemaytipbackward.

Note:Themachineismorestablegoinguphill

withthetinesraised.

•Keepallmovementonslopesslowandgradual.

•Donotmakesuddenchangesinspeedor

direction.

•Reducethetine-downpressuretopreventthe

drivetiresfromraisingoffthegroundandto

preventthefronttiresfromraisingofftheground

whileaeratinguphill.

•Followthemanufacturer’srecommendations

forwheelweightsorcounterweightstoimprove

stability.

•Useextracarewithattachments.

GeneralOperation

•Checkcarefullyforoverheadclearances(i.e.,

branches,doorways,electricalwires,etc.)before

operatingunderanyobjects,anddonotcontact

them.

•Usecautionwhenyouareridingontheplatform

anddrivingthemachineovercurbs,rocks,roots,

orotherobstructions.

•Donotjerkthecontrols;useasteadymotion.

•Donotcarrypassengers.

•Donotcarryequipmentonthemachine.

SlopeOperation

Useextremecautionwhenaeratingand/orturningon

slopesaslossoftractionand/ortip-overcouldoccur.

Youareresponsibleforsafeoperationonslopes.

Note:Useofattachmentscanchangethestability

ofthemachine.

Service

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineT ororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty.

•Neverremoveortamperwithsafetydevices.

Checktheirproperoperationregularly.Neverdo

anythingtointerferewiththeintendedfunctionofa

safetydeviceortoreducetheprotectionprovided

byasafetydevice.

•Checkthebrakeoperationfrequently.Adjustand

servicethebrakesasrequired.

6

Page 7

SlopeIndicator

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

7

g011841

Page 8

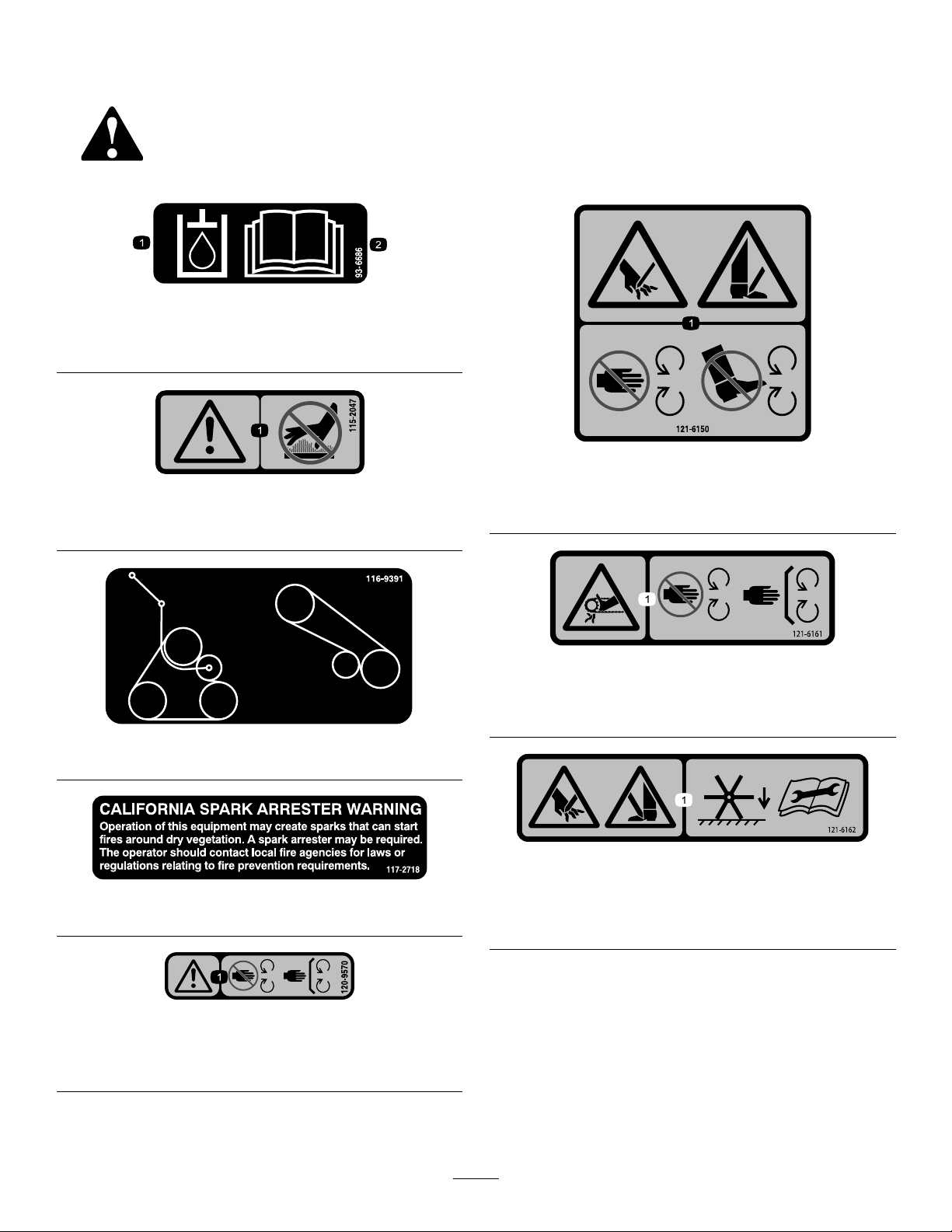

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

93-6686

decal93-6686

1.Hydraulicuid2.ReadtheOperator's

115-2047

1.Warning—donottouchthehotsurface.

116-9391

Manual.

decal121-6150

121-6150

decal115-2047

1.Cuttinghazardofhandandfoot—stayawayfrommoving

parts.

decal121-6161

121-6161

1.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsinplace.

decal116-9391

117-2718

120-9570

1.Warning—stayawayfrommovingparts;keepallguards

andshieldsinplace.

decal121-6162

121-6162

decal117-2718

decal120-9570

1.Cutting/dismembermenthazardofhandorfoot—lowerthe

tinestotheground;readtheOperator’sManualforthe

disassemblyprocedure.

8

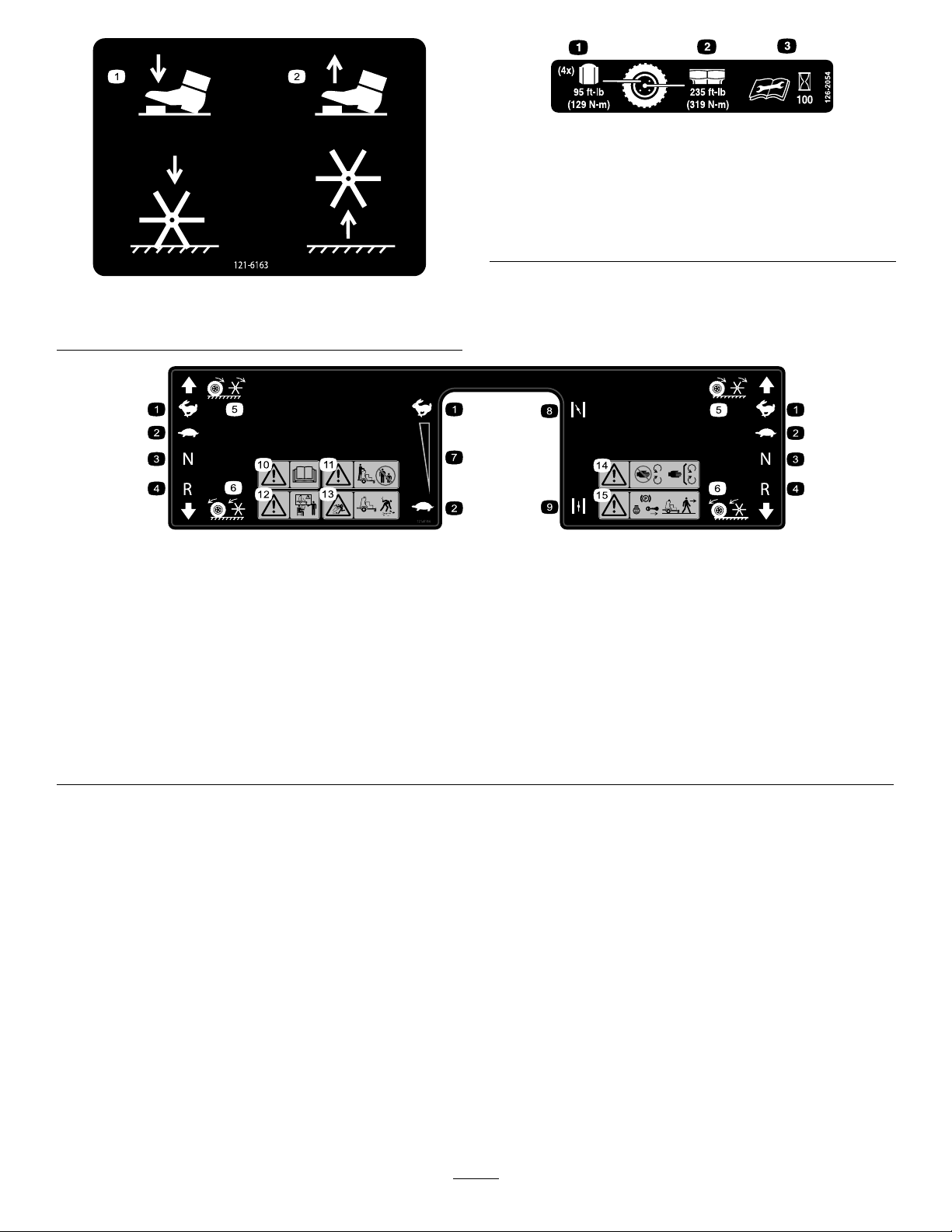

Page 9

121-6163

1.Presstolowerthetines.2.Releasetoraisethetines.

decal126-2054

126-2054

1.Wheellugnuttorque129N∙m(95ft-lb)(4x)

2.Wheelhubnuttorque319N∙m(235ft-lb)

3.ReadandunderstandtheOperator’sManualbefore

performinganymaintenance;checkthetorqueevery100

hours.

decal121-6163

decal121-6164

121-6164

1.Fast6.Wheelsandtinesrotatewhenmoving

backward

2.Slow7.Continuous-variablesetting

3.Neutral

4.Reverse

5.Wheelsandtinesrotatewhenmoving

8.Choke—on

9.Choke—off14.Warning—keepawayfrommoving

10.Warning—readtheOperator’sManual.15.Warning—shutofftheengine,engage

forward

11.Warning—keepbystandersasafe

distanceawayfromthemachine.

12.Warning—donotoperatethemachine

unlessyouaretrained.

13.Thrownobjecthazard—pickupdebris

beforeoperatingthemachine.

parts;keepallguardsinplace.

theparkingbreak,andremovethekey

beforeleavingthemachine.

9

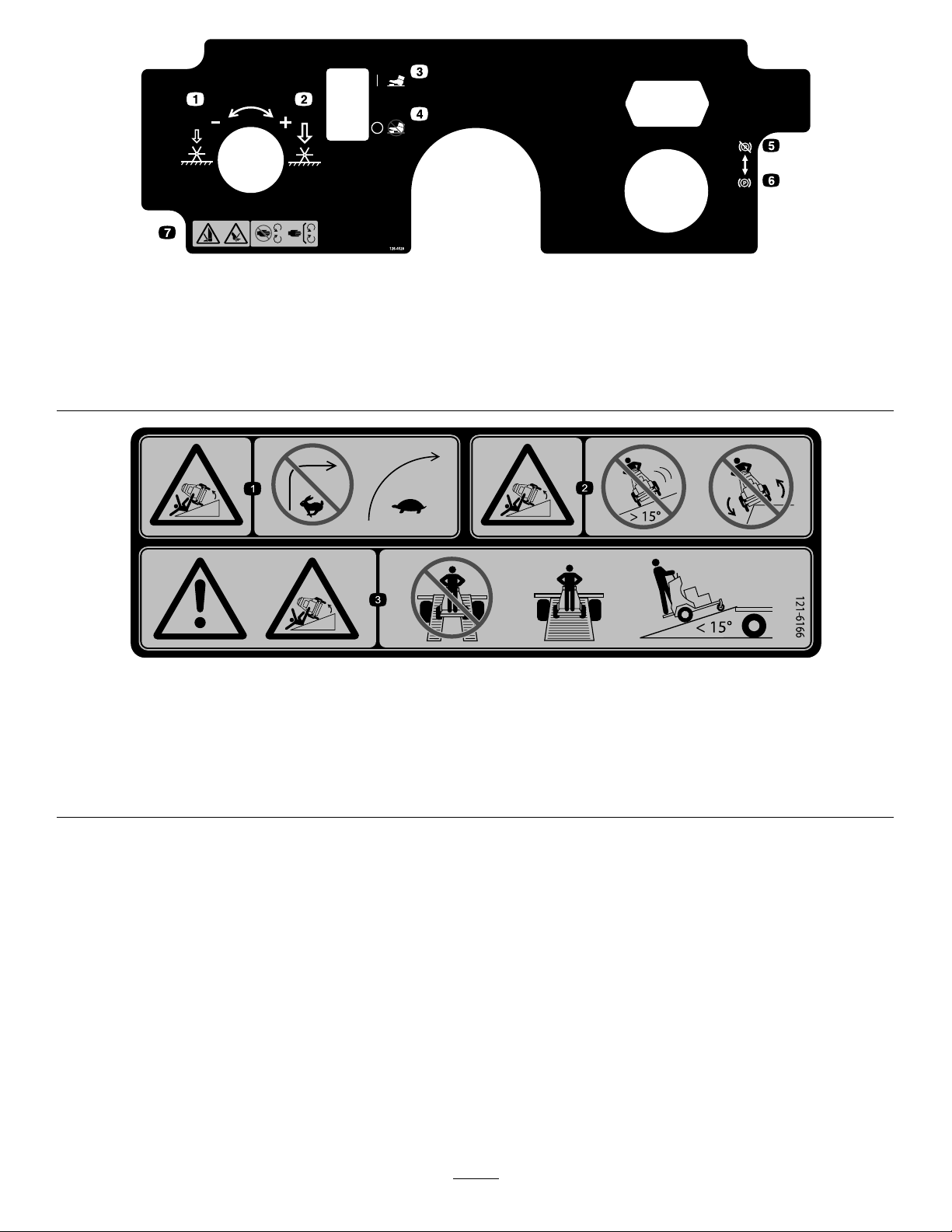

Page 10

126-4528

1.Rotatecounterclockwisetodecreasepressure5.Parkingbrake—Disengaged

2.Rotateclockwisetoincreasepressure6.Parkingbrake—Engaged

3.Tineground-engagementfootswitch—On7.Cutting/dismembermenthazardofhandorfoot,tines—stay

awayfrommovingparts;keepallguardsinplace

4.Tineground-engagementfootswitch—Off

121-6166

decal126-4528

decal121-6166

1.Tippinghazard—donotturnsharplywhiletravellingfast;slow

downandturngradually.

2.Tippinghazard—donotoperatethemachineonslopes

greaterthan15degrees;donotoperatethemachinenear

drop-offs.

3.Warning;tippinghazard—donotusesplitramps;usea

full-widthramptoloadamachinefortransport;usealoading

rampatamaximumof15degrees.

10

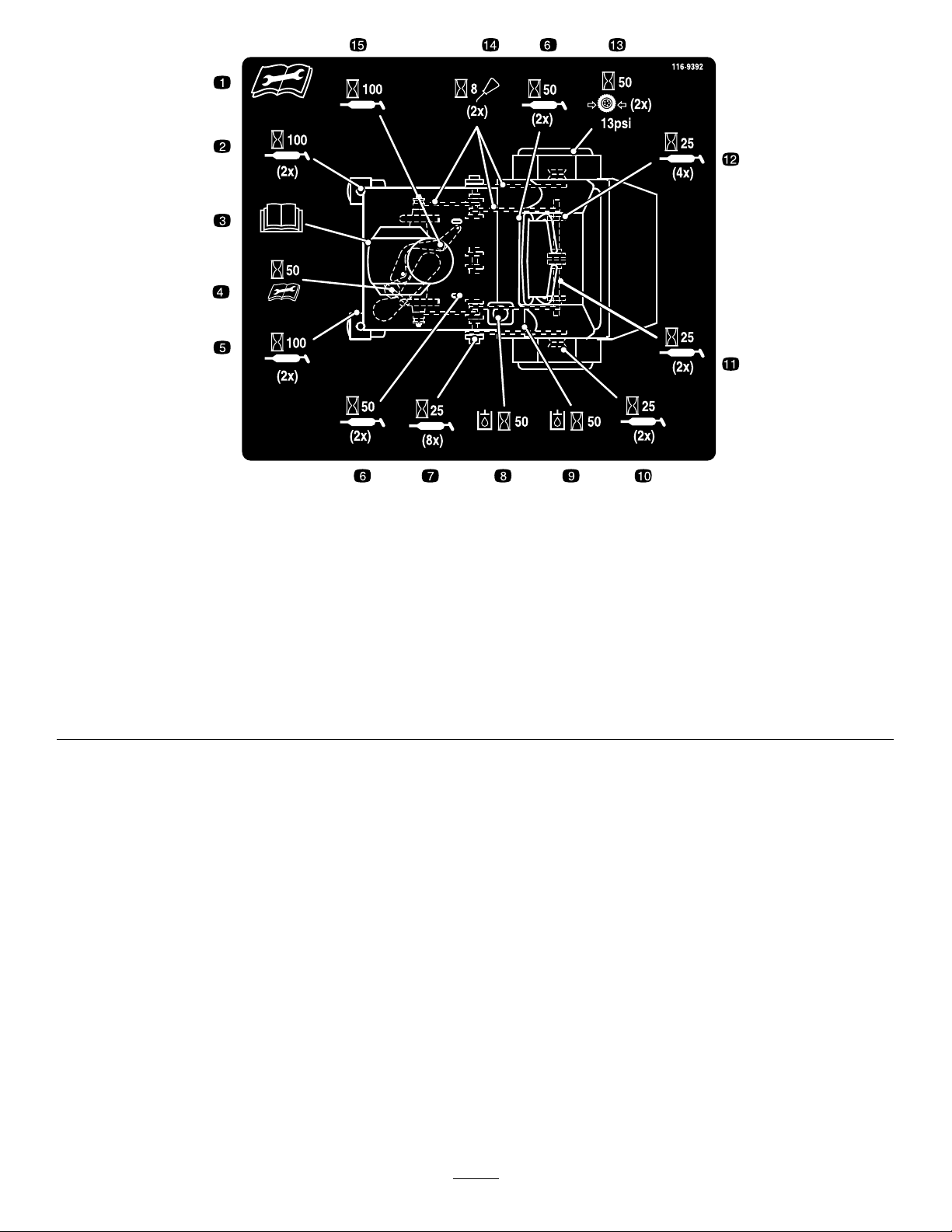

Page 11

decal116-9392

116-9392

1.ReadandunderstandtheOperator’sManualbeforeservicing

9.Checktheauxiliaryhydraulictankevery50hours.

thismachine.

2.Greasethefrontcasterpivots(2x)every100hours.10.Greasethewheelbearings(2x)every25hours.

3.Refertotheengineowner’smanualforservice.11.Greasethetineassemblyidlers(2x)every25hours.

4.Checktheauxiliarypump-drivebelttensionevery50hours.12.Greasethetineshaftbearings(4x)every25hours.

5.Greasethefrontcasterwheelbearings(2x)every100hours.13.Checkthetirepressure,13psi,(2x)every50hours.

6.Greasethecontrolpivots(4x)every50hours.14.Cleanandoilthechainsandcheckthechaintension(2x)

every8hours.

7.Greasethejackshaftbearings(8x)every25hours.15.Greasethebeltidlerpivotevery100hours.

8.Checkthehydraulic-uidlevel(2x)every50hours.

11

Page 12

Setup

MediaandAdditionalParts

Description

Operator'sManual

Key2

1

CheckingTirePressure

NoPartsRequired

Procedure

1.Checkthetirepressureinthedrivetires.

Note:Properinationfordrivetiresis83to97

kPa(12to14psi).

2.Adjustthetirepressureifnecessary .

Qty.

Use

1

Readbeforeoperatingthemachine.

Startthemachine.

DANGER

Chargingorjump-startingthebatterymay

produceexplosivegases.Batterygasescan

explode,causingseriousinjury.

•Keepsparks,ames,orcigarettesaway

fromthebattery.

•Ventilatewhenchargingorusingthe

batteryinanenclosedspace.

•Makesurethattheventingpathofthe

batteryisalwaysopenoncethebatteryis

lledwithacid.

•Alwaysshieldyoureyesandfacefromthe

battery.

2

ServicingtheBattery

NoPartsRequired

Procedure

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

DANGER

Batteryelectrolytecontainssulfuricacid,

whichispoisonousandcancausesevere

burns.Swallowingelectrolytecanbefatalor

ifittouchesskincancausesevereburns.

•Wearsafetyglassestoshieldyoureyes

andrubberglovestoprotectyourskinand

clothingwhenhandlingelectrolyte.

•Donotswallowelectrolyte.

•Intheeventofanaccident,ushwithwater

andcalladoctorimmediately.

Note:Themachineisshippedwithalled,lead-acid

battery.

12

Page 13

1.MovethekeyswitchtotheOFFpositionand

removethekey.

2.Measurethevoltageofthebatterywitha

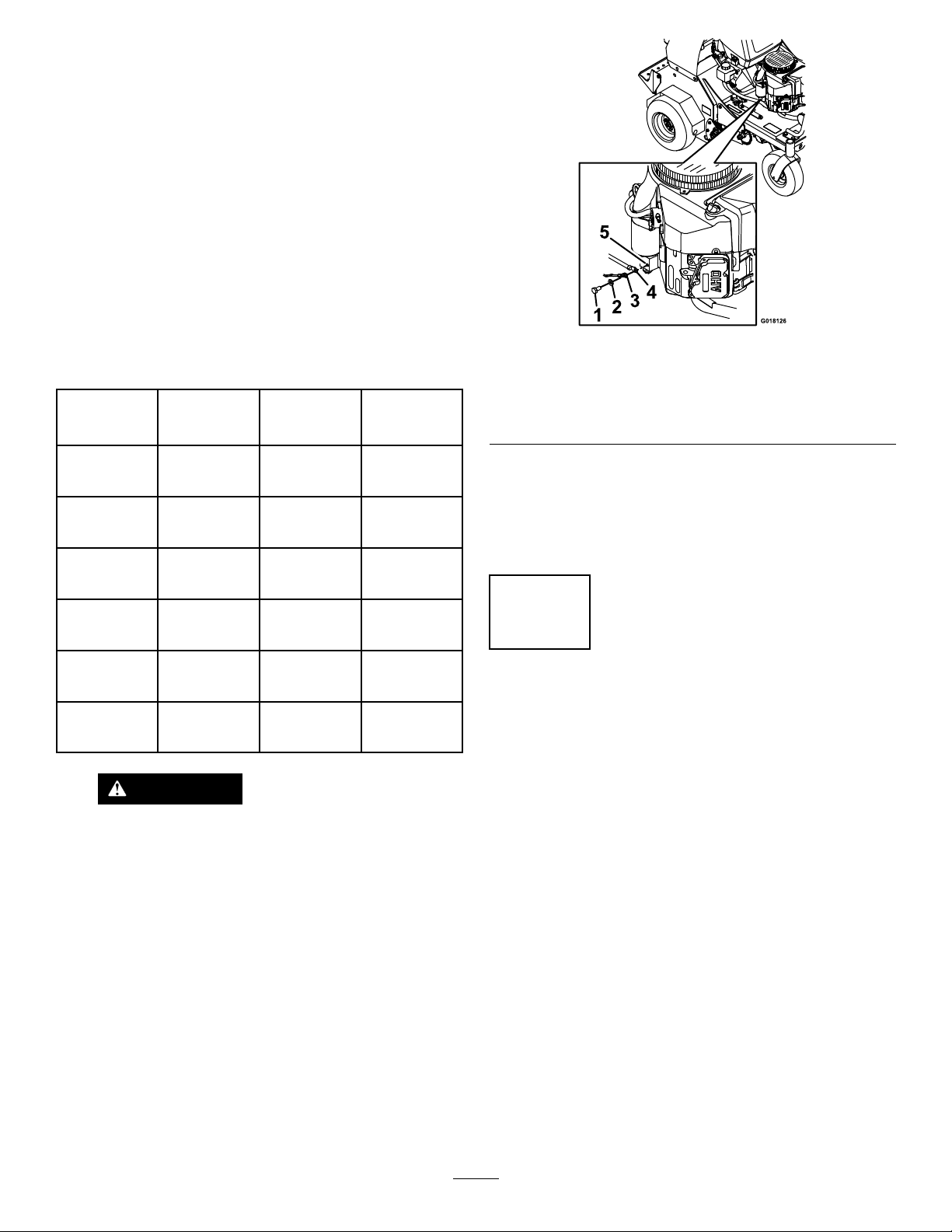

voltmeter.

3.Usethetablebelowtolocatethechargestate

orthebattery,andifneeded,thebattery-charger

settingandchargingintervalrecommendedto

chargethebatteryto12.6Vorgreater;referto

thebatterychargetablebelow.

Important:Makesurethatthenegative

batterycableisdisconnectedandthe

batterychargerusedforchargingthebattery

hasanoutputof16Vand7Aorlessto

avoiddamagingthebattery(seechartfor

recommendedchargersettings).

BatteryChargeTable

Voltage

Reading

12.6or

greater

12.4to12.6

12.2to12.4

12.0to12.2

11.7to12.0

11.7orless

Percent

Charge

100%

75to100%

50to75%

25to50%

0to25%

0%

Maximum

Charger

Settings

16V/

7A

16V/

7A

16V/

7A

14.4V/

4A

14.4V/

4A

14.4V/

2A

Charging

Interval

Nocharging

required

30minutes

1hour

2hours

3hours

6hoursor

more

Figure4

1.Screw

2.Washer5.Engine

3.Groundwire

4.Negativebatterycable

Note:Iftimedoesnotpermitchargingthe

batteryorifchargingequipmentisnotavailable,

connectthenegativebatterycablesandrun

thevehiclecontinuouslyfor20to30minutesto

chargethebattery.

3

ServicingtheEngineOil

NoPartsRequired

g018126

CAUTION

IfthekeyswitchisintheONposition,

thereispotentialforsparksand

engagementofcomponents.Sparks

couldcauseanexplosionormoving

partscouldaccidentallyengage,causing

personalinjury .

EnsurethatthekeyswitchisintheOFF

positionbeforechargingthebattery.

4.Ifthepositivecableisalsodisconnected,

connectthepositive(red)cabletothepositive

batteryterminalandsliptheterminalcoverover

thepositiveterminal.

5.Removethescrew,washer,andgroundcable

fromtheengine.Connectthenegativebattery

cableasshowninFigure4.

Procedure

Theengineisshippedwithoil;checktheengine-oil

leveland,ifnecessary,addoiltotheappropriatelevel.

RefertoCheckingtheEngine-OilLevel(page18)for

instructionsandtheoilspecication.

13

Page 14

4

5

ServicingtheTransmission Fluid

NoPartsRequired

Procedure

Transmissionuidtype:T oroHypr-oil500

Themachineisshippedwithhydraulicuidinthe

expansiontank.

1.Runthemachineforapproximately15minutes

topurgeanyextraairoutofthehydraulic

system.

2.Shutofftheengineandallowthemachineto

cool.

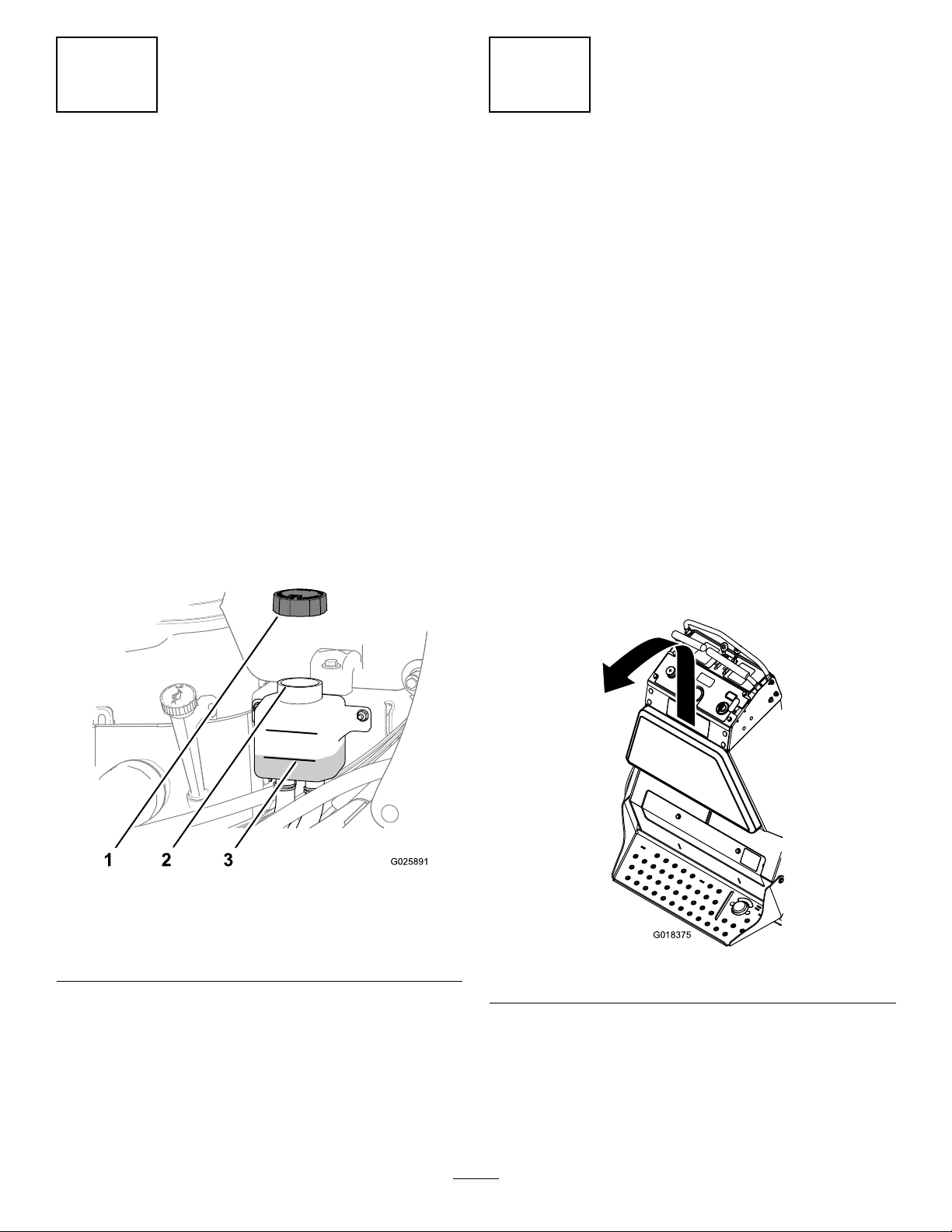

3.Checkthehydraulic-uidlevelintheexpansion

tank(Figure5).

Note:Thetransmission-uidlevelshouldcover

theFullColdlinemoldedintothesideofthe

tank.

ServicingtheAuxiliary HydraulicFluid

NoPartsRequired

Procedure

Hydraulicuidtype:AW-32hydraulicuid

Note:Themachineisshippedwithhydraulicuid

inthereservoir.

1.Runthemachineforapproximately15minutes

topurgeanyextraairoutofthehydraulic

system.

2.Completelyraiseandlowerthetines3timesto

purgetheair.

3.Shutofftheengineandallowthemachineto

cool.

4.Loosenthe4boltsinsidetheframesecuringthe

padtothemachine.

5.Liftthepadupandbacktoremoveit(Figure6).

Figure5

1.Cap3.FullColdline

2.Fillerneck(expansion

tank)

4.Ifnecessary,addthespeciedtransmissionuid

untiltheuidlevelisattheFullColdlineofthe

expansiontank(Figure5).

5.Installthecapontotheexpansiontankand

tightenthecapuntilitissnug.

Note:Donotovertightenexpansion-tank

cap.

g025891

g018375

Figure6

6.Removethecapandcheckthehydraulic-uid

levelinthereservoir(Figure7).

Note:Thehydraulic-uidlevelshouldcoverthe

wordColdthatisembossedintothebafeof

thereservoir.

14

Page 15

Figure7

1.Colduidlevel2.Hotuidlevel

ProductOverview

g025893

7.Ifnecessary ,addthespeciedhydraulicuidto

thereservoiruntiltheuidcoverstheColduid

levelonthebafe(Figure7).

Note:ThebafeinthereservoirislabeledHot

andCold.Fillthereservoirtotheappropriate

leveldependinguponthetemperatureofthe

uid.Theuidlevelvarieswiththetemperature

oftheuid.TheColdlevelshowsthelevelof

theuidwhenitisat24°C(75°F).TheHot

levelshowsthelevelofuidwhenitisat107°C

(225°F).

Forexample:Iftheuidisatambient-air

temperature,about24°C(75°F),llonlytothe

Coldlevel.Iftheuidisabout65°C(150°F),ll

tohalfwaybetweentheHotandColdlevels.

8.Replacethehydraulicreservoircapandtighten

ituntilsnug(Figure7).

Note:Donotovertightenthereservoircap.

9.Installthepadthatyouremovedinsteps4and

5toptheframe,andtightenthe4boltsto1978

to2542N∙cm(175to225in-lb).

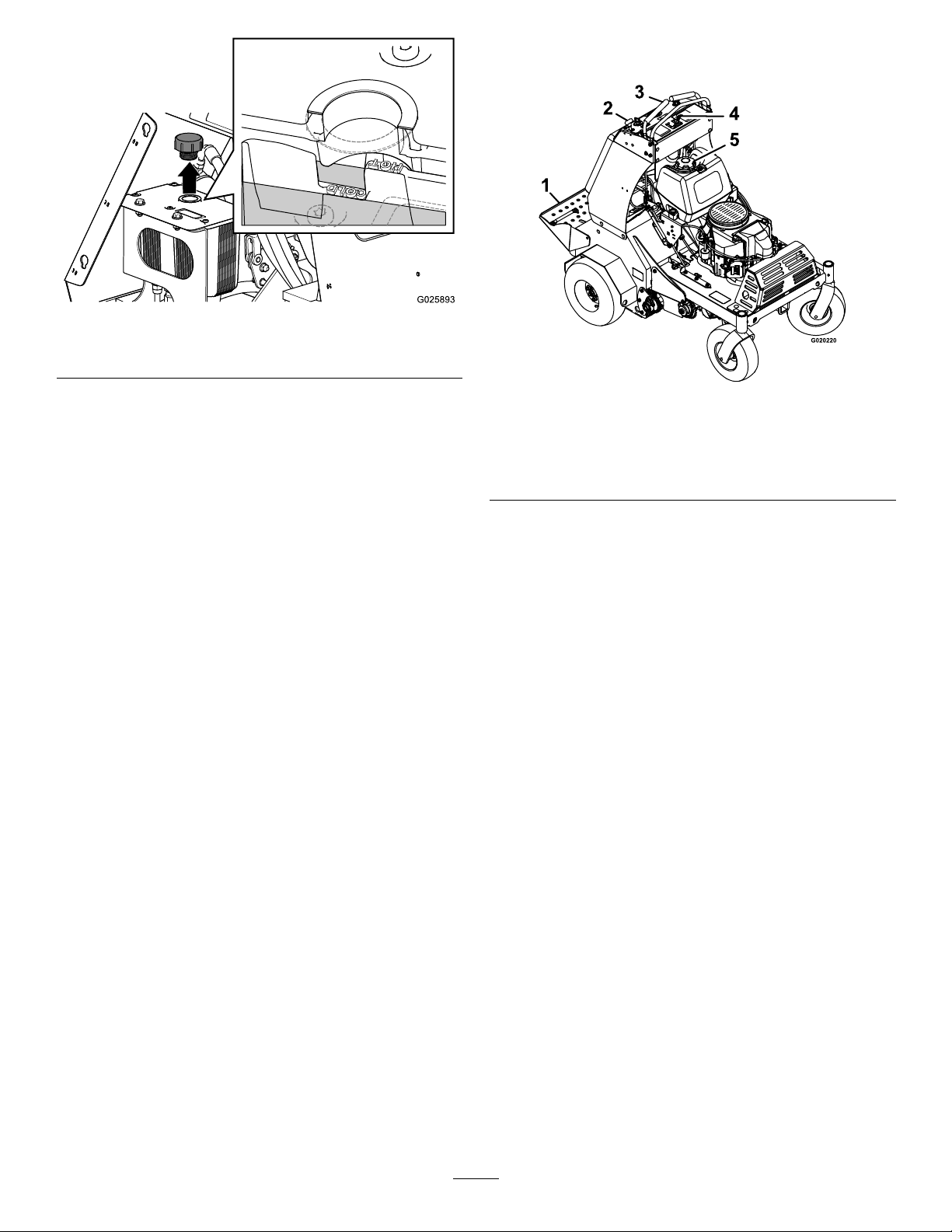

Figure8

1.Platform

2.Parking-brakeknob5.Fuelcap

3.Motion-controllevers

4.Enginecontrols

Controls

Motion-ControlLevers

Themotion-controlleversarelocatedoneachsideof

thetopconsoleandcontroltheforwardandreverse

motionofthemachine.

Movetheleversforwardorbackwardtocontrolthe

drivewheelonthesamesideforwardorreverse

respectively.Thewheelspeedisproportionaltothe

amountyoumovethelever.

Important:Thetinesrotatewhenthe

motion-controlleversaremovedoutofthe

NEUTRALposition.

g020220

15

Page 16

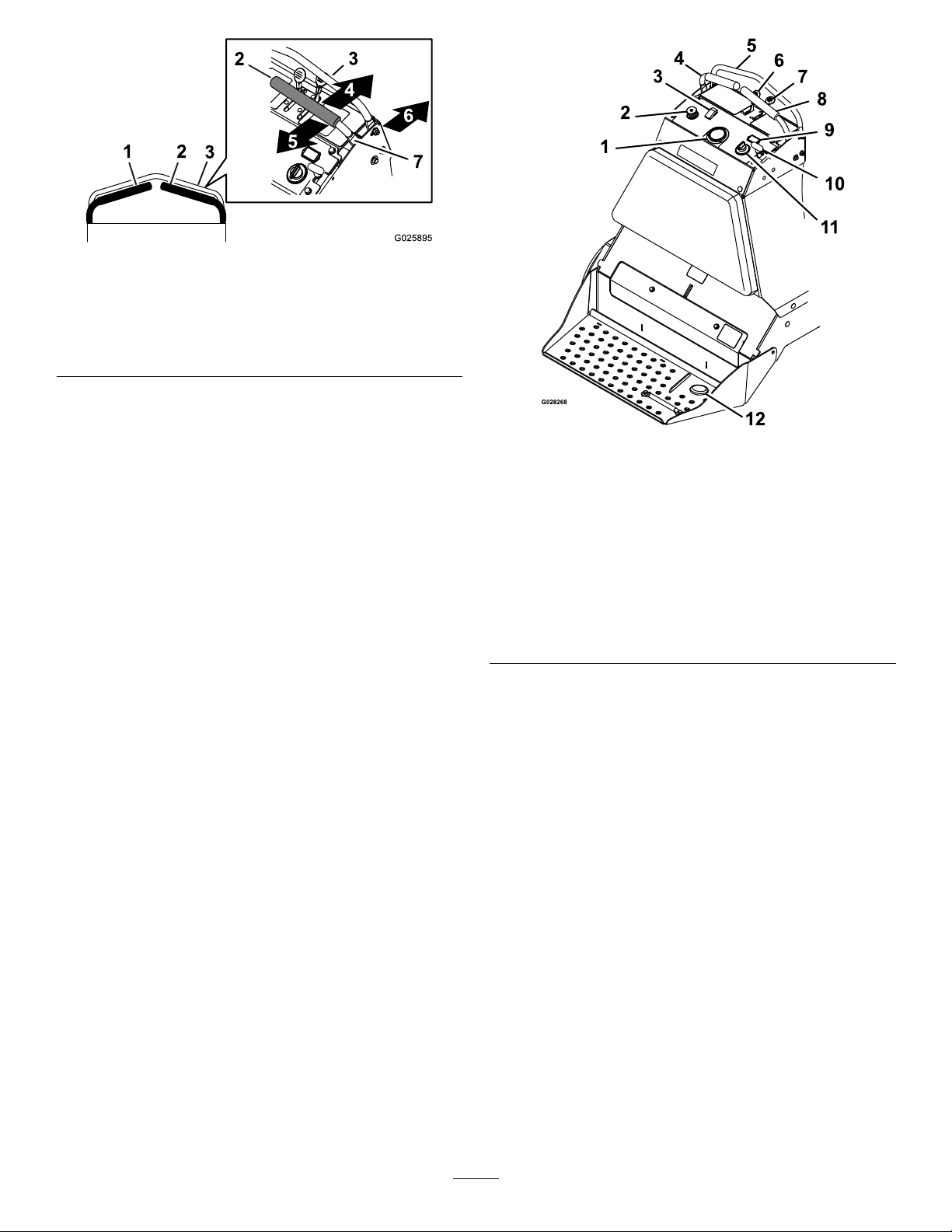

Figure9

g025895

1.Leftmotion-controllever

2.Rightmotion-controllever

3.Frontreferencebar

4.Forward

5.Reverse

6.Frontofthemachine

7.Neutral

Tine-PressureControl

Thetine-pressurecontrolislocatedontheleftsideof

thecontrolconsole(Figure10).

Usethetine-pressurecontroltoadjustthedownward

pressureonthetinesandcoredepth.Rotatethe

controlcounterclockwisetodecreasethepressure

andthelengthoftheaerationplug;rotateclockwise

toincreasepressureandincreasethelengthofthe

aerationplug.

Figure10

1.Tinedownpressuregauge

2.Tinedownpressure

control

3.On/Off-Tine

ground-engagement

footswitch

4.Leftmotion-controllever

5.Frontreferencebar

6.Throttlelever12.Tineground-engagement

7.Chokelever

8.Rightmotion-controllever

9.Hourmeter

10.Parkingbrake

11.Keyswitch

footswitch

ThrottleLever

Thethrottlelever(Figure10)islocatedonthecontrol

console(redlever).

g028268

Usethethrottlelevertocontrolenginespeed.Move

thethrottleleverforwardtoincreaseenginespeed;

movingthethrottleleverrearwardtodecreasethe

enginespeed.

Note:Movethethrottleleverforwardintothedetent

forfullthrottle.

ChokeLever

Thechokelever(Figure10)islocatedonthecontrol

console(blacklever).

Usethechokeleverisusedtoaidinstartingacold

engine.Movethechokeleverforwardtosetthe

choketotheONposition;movethechokelevertothe

rearwardtoreducethechoke.

Note:Pullthechokeleverbackintothedetenttoset

thechoketotheOFFposition.

16

Page 17

Note:Donotrunawarmenginewiththechokein

theONposition.

On/OffTineGround-Engagement

FootSwitch

Parking-BrakeHandle

Theparking-brakehandleislocatedonthecontrol

console,totherightofthekeyswitch(Figure10).

Note:Thebrakehandleengagesaparkingbrakein

eachofthetransmissions.

•T oengagetheparkingbrake,pullthehandleout

andslideitrearward.

•T oreleasetheparkingbrake,pushthehandle

forwardintothedetent.

Whenparkingonasteepslope,chockorblockthe

wheelsinadditiontoengagingtheparkingbrake.Tie

downthemachineandengagetheparkingbrake

whentransportingthemachine.

HourMeter

Thehourmeterislocatedabovethekeyswitch

(Figure10).

Thehourmeterdisplaysthetotalnumberofhours

thatyouhaverunthemachine.

Thetineground-engagementfootswitchislocated

abovethetinedownpressurecontrolonthecontrol

console.

Pushdownonthetopoftheswitchtoenablethetine

ground-engagementfootswitch.Pushdowntherear

oftheswitchtodisablethefootswitch.

Tine-PressureGauge

Thetine-pressuregaugeislocatedinthemiddleof

thecontrolconsole(Figure10).

Thetine-pressuregaugetoindicatesthedownward

pressurethemachineexertsonthetineswhen

aerating.

Tines-ElevationSwitch

Keepyourhandsandfeetawayfromthetines.

Makesurethatthetinesareaisclearofany

obstructionsbeforeloweringit.

Thetine-elevationswitchislocatedontheoperator

platform(Figure10).

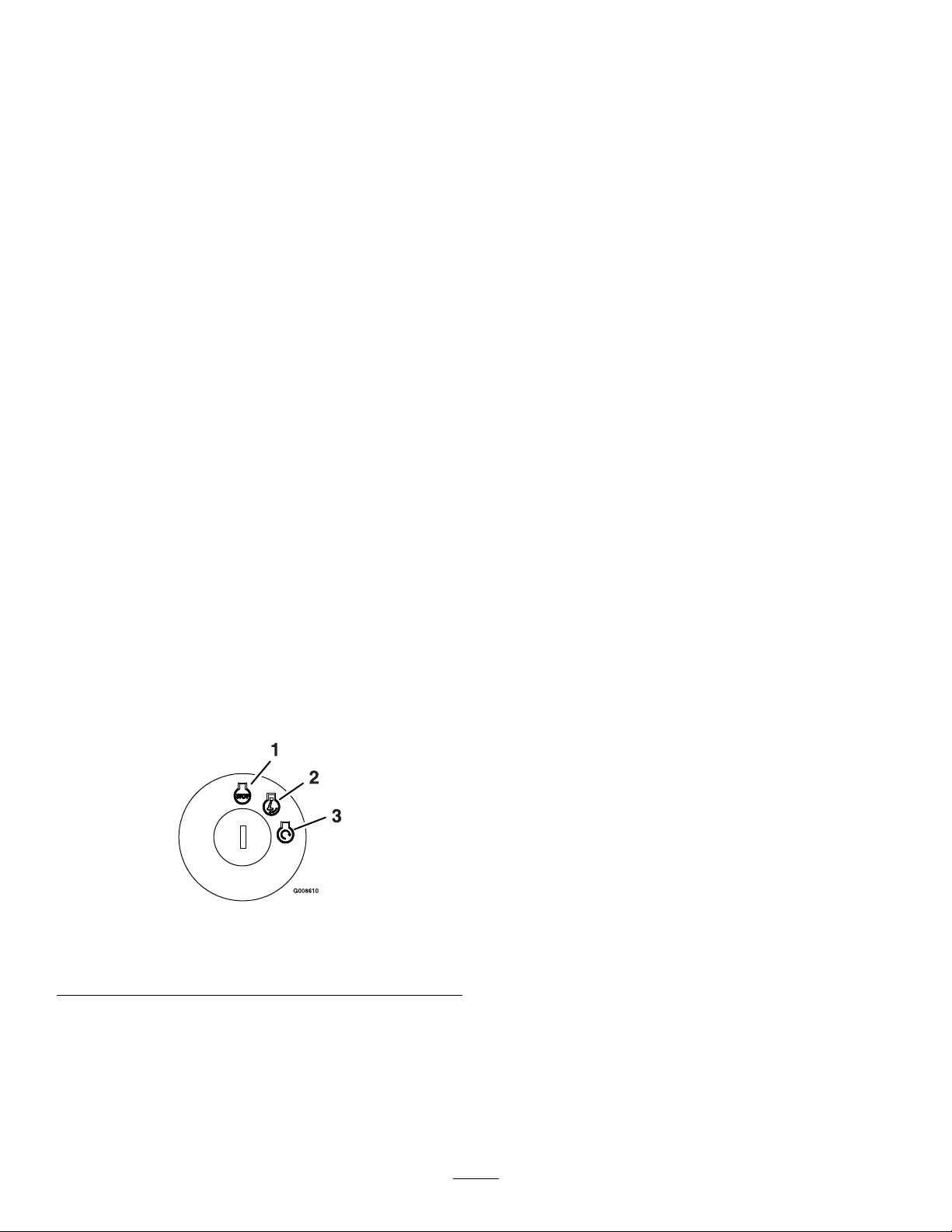

KeySwitch

Thekeyswitchislocatedontherightsideofthe

controlconsole(Figure10).

Usethekeyswitchtostartandshutofftheengine.

Theswitchhas3positions:OFF,ON,andSTART

(Figure11).

Figure11

1.OFF3.START

2.ON

Tolowerthetinesintotheground,standonthe

tine-elevationswitch.T oraisethetines,removeyour

footfromtheswitch.

Fuel-ShutoffValve

Thefuel-shutoffvalveislocatedbehindtheengine

andunderthefueltank(Figure12).

Usethefuel-shutoffvalvetoshutoffthefuelwhen

themachinewillnotbeusedforafewdays,when

transportingthemachinetoandfromthejobsite,or

whenthemachineisparkedinsideabuilding.

•T oopenforfuel-shutoffvalve,rotatethehandle

ofthefuel-shutoffvalveuntilitisalignedwiththe

fuelline.

g008610

•T oclosethefuel-shutoffvalve,rotatethehandle

90°tothefuelline.

17

Page 18

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

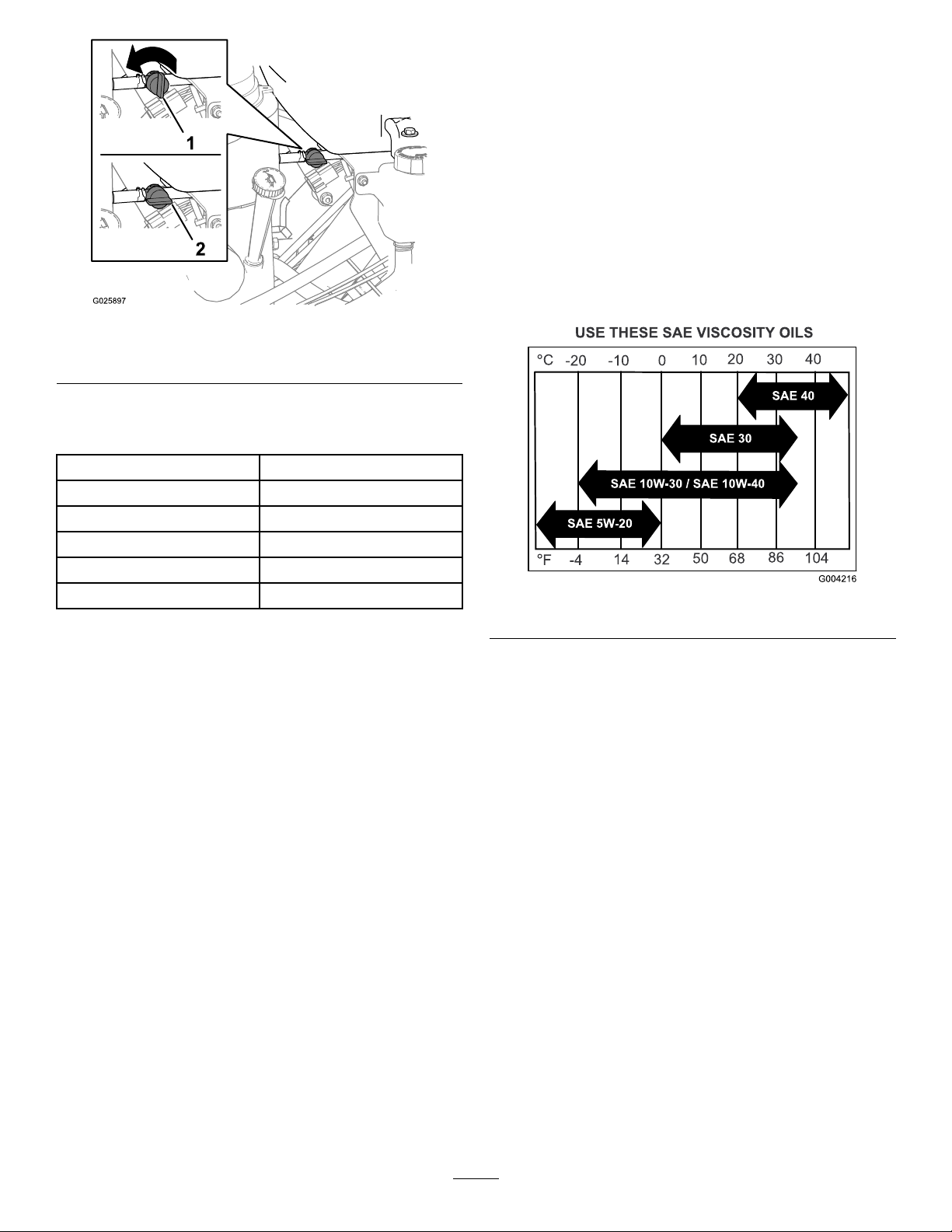

CheckingtheEngine-Oil Level

ServiceInterval:Beforeeachuseordaily

OilType:Detergentoil(APIserviceSJorhigher)

Figure12

1.OFFposition2.ONposition

Specications

Height

Length

Width

Aerationwidth

Coringrange5.1to12.7cm(2to5inches)

Weight

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributor.

Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonT oro

genuineparts.Whenitcomestoreliability,T oro

deliversreplacementpartsdesignedtotheexact

engineeringspecicationofourequipment.Forpeace

ofmind,insistonTorogenuineparts.

132cm(52inches)

163cm(64inches)

121cm(48inches)

76cm(30inches)

460kg(1,015lb)

g025897

Oilviscosity:Refertothetablebelow.

g004216

Figure13

Important:Donotoperatetheenginewiththeoil

levelbelowtheLow(orAdd)markonthedipstick,

orovertheFullmark.

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Allowtheenginetocool.

3.Checktheengine-oillevelasshowninFigure

14.

18

Page 19

AddingFuel

Fuel-tankcapacity:18.9L(5USGallons)

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

g025899

•ETHANOL:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan10%

ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

Figure14

4.Iftheoillevelislow,wipeofftheareaaround

theoilllcap,removecapandaddthespecied

oiluntiltheoillevelisattheFullmarkonthe

dipstick.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

andwhentheengineiscold.Wipeupany

fuelthatspills.

•Donotllthefueltankcompletelyfull.

Addfueltothefueltankuntilthelevelis6

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

g025898

awayfromanopenameorwhereaspark

mayignitethefuelfumes.

•Storefuelinanapprovedfuelcontainer

andkeepitoutofthereachofchildren.

•Neverbuymorethana30-daysupplyof

fuel.

Note:Donotoverlltheenginewithoil.

19

Page 20

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleased,causingaspark,

whichcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removefuel-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepfuelfreshduringstorageof90daysorless.

Forlongerstorage,drainthefueltank.

•Cleantheenginewhileitruns

•Eliminategum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuel.T ominimize

thechanceofvarnishdepositsinthefuelsystem,

usefuelstabilizeratalltimes.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainerratherthanfroma

fuel-dispensernozzle.

•Ifyoumustuseafuel-dispensernozzle,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleand

fueltankorconditionerbottleopening.

•Avoidcontactwithskin;washoffspills

withsoapandwater.

FuelingtheMachine

1.Cleanaroundthefuel-tankcap.

2.Removethecapfromthetank.

3.Fillthefueltankwithfueltowithin6to13mm

(1/4to1/2inch)fromthetopofthetank.Donot

llintothellerneck.

Important:Donotllthetankmorethan

6mm(1/4inch)fromthetopofthetank

becausethefuelmusthaveroomtoexpand.

4.Installthefuel-tankcapandwipeupanyspilled

fuel.

20

Page 21

LubricatingtheChains

CheckingtheConditionofthe

Sprockets

ServiceInterval:Beforeeachuseordaily

1.Shutofftheengine,engagetheparkingbrake,

waitforallmovingpartstostop,andremove

thekey.

2.Inspectsprocketsforwearandreplaceas

required(Figure15).

3.Ifthechainspoporsnap;refertoAdjusting

theJackshaftDrive-ChainT ension(page40),

AdjustingtheDriveWheelChainTension(page

41),orAdjustingtheTineDriveChain(page50).

LubricatingtheChains

ServiceInterval:Beforeeachuseordaily

Important:Donotlubricatechainswith

penetratingoilorsolvents.Useoilorchain

lubricant.

1.Shutofftheengine,engagetheparkingbrake,

waitforallmovingpartstostop,andremove

thekey.

2.Raisethemachineandsupportitwithjack

standswitha460kg(1,015lb)capacity.

CAUTION

Raisingthemachineforservice

ormaintenancerelyingsolelyon

mechanicalorhydraulicjackscouldbe

dangerous.Themechanicalorhydraulic

jacksmaynotbeenoughsupportormay

malfunctionallowingthemachinetofall,

whichcouldcauseinjury .

Figure15

1.Sprockets2.Chains

CheckingtheConditionofthe

Chains

ServiceInterval:Beforeeachuseordaily

1.Shutofftheengine,engagetheparkingbrake,

waitforallmovingpartstostop,andremove

thekey.

2.Checkthechaintension(Figure15)atboth

sidesofthemachine.

Note:Thechainsshouldmoveupanddown6

to12mm(1/4to1/2inch).

Donotrelysolelyonmechanical

orhydraulicjacksforsupport.Use

adequatejackstandsorequivalent

support.

3.Starttheengineandmovethethrottlelevel

aheadtothehalf-throttleposition.

WARNING

g025984

Enginemustberunninganddrivewheels

mustbeturningsoadjustmentscanbe

performed.Contactwithmovingpartsor

hotsurfacesmaycausepersonalinjury.

Keepyourngers,hands,andclothing

clearofrotatingcomponentsandhot

surfaces.

4.Disengagetheparkingbrake.

5.Withtheenginerunning,slowlymovethe

motion-controlleversforwardandlubricateall6

chains(Figure15).

6.Checktheconditionandtensionofthechains;

refertoCheckingtheConditionoftheChains

(page21).

21

Page 22

Checkingthe

Safety-InterlockSystem

ServiceInterval:Beforeeachuseordaily

CAUTION

Ifthesafety-interlockswitchesare

disconnectedordamaged,themachinecould

operateunexpectedly,causingpersonal

injury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

UnderstandingtheSafety-InterlockSystem

Thesafety-interlocksystemisdesignedtopreventthe

enginefromstartingunlessthemotion-controllevers

areintheneutralposition.

OperatingtheMachine

UsingtheFuel-ShutoffValve

Rotatetheleverofthefuel-shutoffvalvetoalignthe

leverwiththefuelline.

g025897

Figure16

CheckingtheSafety-InterlockSystem

1.Disconnectthespark-plugwires.

2.Whileonlevelground,blockthewheelsofthe

machinetopreventunintendedmovement.

3.Disengagetheparkingbrake.

4.Withthemotion-controlleversintheneutral

positionturnthekeytotheSTARTposition—the

startermustnotcrank.

Note:Ifthemachinedoesnotpassthistest,do

notoperatethemachine.ContactyourAuthorized

ServiceDealer.

Important:Itisessentialthattheoperator

safetymechanismsareconnectedandinproper

operatingconditionpriortouse.

CheckingforLoose Hardware

ServiceInterval:Beforeeachuseordaily

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingparts

tostop.

2.Visuallyinspectmachineforanyloosehardware

oranyotherpossibleproblem.

Note:Tightenallloosehardwareorrepairthe

problembeforeoperatingthemachine.

1.OFFposition2.ONposition

StartingtheEngine

1.Movethemotion-controlleverstotheneutral

positionandengagetheparkingbrake;refer

toMotion-ControlLevers(page15)and

Parking-BrakeHandle(page17).

Note:Tostarttheengine,theparkingbrake

mustbeengaged.Itisnotnecessaryforthe

operatortobeontheplatform.

2.Placethethrottlelevermidwaybetweenthe

SLOWandFASTpositions;refertoThrottleLever

(page16).

3.Iftheengineiscold,pushthechokelever

forwardtotheONposition;refertoChokeLever

(page16).

Note:Iftheengineiswarm,pullthechokelever

totheOFFposition.

4.RotatethekeyswitchtotheSTARTposition;

refertoKeySwitch(page17).

Note:Releasetheswitchassoonastheengine

starts.

Important:Donotcranktheengine

continuouslyformorethan10secondsat

atime.Iftheenginedoesnotstart,allowa

60-secondcooldownperiodbetweenstarting

attempts.Failuretofollowtheseguidelines

canburnoutthestartermotor.

22

Page 23

5.IfthechokeleverisintheONposition,gradually

movethelevertowardtheOFFpositionasthe

enginewarmsup.

LoweringtheTines

1.SetthethrottlelevermidwaybetweentheSLOW

andFASTpositions;refertoThrottleLever(page

16).

2.Steponthetine-elevationswitchtolowerthe

tines(Figure17).

g025901

Figure18

Figure17

1.Tine-elevationswitch

3.Standontheswitchandmovethemotion-control

leversforwardtoaerate(Figure17).

4.Adjustthethrottlefortheworkingconditions;

refertoThrottleLever(page16).

AdjustingtheTineDownPressure

Important:Keepthedrivetiresonthegroundat

alltimes.

1.Tine-pressurecontrol3.Decreasepressure

2.Tine-pressuregauge

(shorterplug)

4.Increasepressure(longer

plug)

•Rotatethetine-pressurecontrol

counterclockwise(Figure18)todecrease

thedownwardpressureinordertoremovea

shorterplug.

•Rotatethetine-pressurecontrolclockwise(Figure

g025900

18)toincreasedownwardpressureinorderto

removealongerplug.

Note:Idealplugdepthis7.6to10cm(3to4inches).

Rotatethetine-pressurecontroltoadapttothesoil

conditions.

RaisingtheTines

Toraisethetines,removeyourfootfromthe

tine-elevationswitch(Figure17).

Important:Thetinesrotatewhenthe

motion-controlleverismovedoutoftheneutral

position.

Adjusttheplugdepthbyrotatingthetine-pressure

controlasfollows:

Note:Firsttimeuse:setthetine-pressurecontrol

sothatthetine-pressuregauge(Figure18)indicates

24bar(350psi).

ShuttingOfftheEngine

1.Movethemotion-controlleverstotheneutral

positionandbringthemachinetoafullstop;

refertoMotion-ControlLevers(page15).

2.Liftyourfootoffthetineground-engagement

footswitchcontroltoraisethetines;referto

RaisingtheTines(page23).

3.Placethethrottleinthemidwaybetweenthe

SLOWandFASTpositions;refertoThrottleLever

(page16).

4.Allowtheenginetorunforaminimumof15

seconds,thenturnthekeyswitchtotheOFF

positiontoshutofftheengine;refertoKey

Switch(page17).

5.Engagetheparkingbrake;refertoParking-Brake

Handle(page17).

23

Page 24

6.Removethekeytopreventchildrenorother

unauthorizedpersonsfromstartingtheengine.

7.Closethefuel-shutoffvalvewhenthemachine

willnotbeusedforafewdays,when

transporting,orwhenthemachineisparked

insideabuilding;refertoUsingtheFuel-Shutoff

Valve(page22).

DrivingtheMachine

CAUTION

Machinecanspinveryrapidlybypositioning

1levertoomuchaheadoftheother.Youmay

losecontrolofthemachine,whichmaycause

damagetothemachineorinjury.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

Important:T odrivethemachine(forwardor

backward),disengagethebrakeleverbeforeyou

canmovethemotion-controllevers.

Figure19

1.Leftmotion-controllever

2.Rightmotion-controllever6.Neutral

3.Frontreferencebar

4.Frontofthemachine

5.Forward

7.Reverse

g016672

Figure20

4.T oturnleftorright,pullthemotion-controllever

backtowardneutralinthedesiredturndirection.

Thetinescanbeinthedownpositionwhen

makinggradualturns.

5.T omakezero-turns,liftyourfootoffthetine

engagementfootswitchcontroltoraisethe

tines.Theheadraisesin1second.

Important:Donotmakeazero-turnwhen

thetinesaredown,otherwiseyoumaytear

theturf.

6.T ostopthemachine,movebothmotion-control

leverstotheneutralposition.

g020241

DrivinginReverse

1.Movethemotion-controlleverstotheneutral

position.

2.T omoverearwardinastraightline,slowlymove

bothleversrearwardwithequalpressure.

DrivingForward

1.Makesurethatthemotion-controlleversarein

theneutralposition.

2.Disengagetheparkingbrake.

3.T omoveforwardinastraightline,moveboth

leversforwardwithequalpressure.

Note:Themachinemovesfasterthefarther

themotion-controlleversaremovedfromthe

neutralposition.

g016673

Figure21

24

Page 25

3.T oturnleftorright,releasepressureonthe

motion-controllevertowardthedesiredturn

direction.

LoadingtheMachineontoa

TransportVehicle

4.T omakezero-turns,liftyourfootoffthe

tine-elevationswitchtoraisethetines.Thehead

raisesin1second.

Important:Donotmakeazero-turnwhen

thetinesareinthedownposition.

5.T ostopthemachine,positionbothmotion-control

leversintheneutraloperateposition.

TransportingtheMachine

Machineweight:460kg(1,015lb)

CAUTION

Thismachinedoesnothaveproperturn

signals,lights,reectivemarkings,ora

slowmovingvehicleemblem.Drivingona

streetorroadwaywithoutsuchequipment

isdangerousandcanleadtoaccidents,

causingpersonalinjury.Drivingonastreetor

roadwaywithoutsuchequipmentmayalso

beaviolationofstatelaws,andyoumaybe

subjecttotrafcticketsand/ornes.

Donotdrivethemachineonapublicstreet

orroadway.

WARNING

Loadingthemachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•Useonlyasingle,full-widthramp;donot

useindividualrampsforeachsideofthe

machine.

•Ifyoumustuseindividualramps,use

enoughrampstocreateanunbrokenramp

surfacewiderthanthemachine.

•Donotexceeda15-degreeanglebetween

rampandground,orbetweenaramp,a

trailer,oratruck.

•Avoidsuddenaccelerationwhiledriving

machineuparamptoavoidtipping

backward.

•Avoidsuddendecelerationwhilebacking

machinedownaramptoavoidtipping

backward.

Important:Donotattempttoturnthemachine

whileontheramp;youmaylosecontrolanddrive

offtheside.

•Useextremecautionwhenloadingunitsonto

trailersortrucks.

•Use1full-widthrampthatiswideenoughto

extendbeyondthereartiresinsteadofindividual

rampsforeachsideofthemachine(Figure22).

Theplatform,whendownandlockedintoposition,

mustextendbackbetweentherearwheelsand

servesasastopfortippingbackward.Havinga

full-widthrampprovidesasurfacefortheplatform

tocontactifthemachinestartstotipbackward.

Withtheplatformup,afull-widthrampprovidesa

surfacetowalkonbehindthemachine.

•Therampshouldbelongenoughsothatthe

anglesdonotexceed15degrees(Figure22).

Asteeperanglemaycausetinecomponentsto

getcaught,asthemachinemovesfromrampto

trailerortruck.Asteeperanglemayalsocause

themachinetotipbackward.Ifloadingonornear

aslope,positionthetrailerortrucksoitisonthe

downsideoftheslopeandtherampextendsup

theslope.Thisminimizestherampangle.The

trailerortruckshouldbeaslevelaspossible.

25

Page 26

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

thenecessarybrakes,lighting,andmarkingas

requiredbylaw.Pleasecarefullyreadallthesafety

instructions.

1.Raisethetinesofthemachinebeforedriving

ontothetrailerortruck.

2.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

3.Ifapplicable,connectthetrailerbrakes.

4.Loadthemachineontothetrailerortruck.

5.Shutofftheengine,removethekey,engagethe

parkingbrake,andclosethefuelvalve.

Figure22

1.Trailer3.Notgreaterthan

2.Full-widthramp

15degrees

4.Full-widthramp(sideview)

•Y oushoulddetermineifitisbesttohavethe

platformupordownwhenloading,dependingon

conditions.Ifitisnotpossibletouse1full-width

ramp,useenoughindividualrampstosimulatea

full-width,continuousramp.

•Avoidsuddenaccelerationwhendrivinguparamp

andsuddendecelerationwhenbackingdowna

ramp.Bothmaneuverscancausethemachineto

tipbackward.

g000951

6.Engagetheparkingbrakeandblockthetires.

7.Usethetie-downpointsonthemachineto

securelybindthemachinetothetrailerortruck

withstraps,chains,cable,orropes(Figure23).

Note:Refertoyourlocalordinancesforspecic

trailerandtie-downregulations.

g025949

Figure23

1.Tie-downpoints

26

Page 27

Maintenance

WARNING

Whileyouaremaintainingoradjustingthe

machine,someonecouldstarttheengine.

Accidentallystartingtheenginecould

seriouslyinjureyouorotherbystanders.

Removethekeyfromthekeyswitch,engage

parkingbrake,andpullthewire(s)offthe

sparkplug(s)beforeyoudoanymaintenance.

Alsopushthewire(s)asidesoitdoesnot

accidentallycontactthesparkplug(s).

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst100hours

Beforeeachuseordaily

MaintenanceProcedure

•Changetheauxiliaryhydraulicreservoirlteranduid.

•Changethetransmissionlters.

•Fillthetransmissionwithuidwhenchangingthelter.

•Checktheengine-oillevel.

•Checktheconditionofthesprockets.

•Checktheconditionandtensionofthechains.

•Lubricatethechains.

•Checkthesafety-interlocksystem.

•Checkforloosehardware.

•Checkthetines.

•Cleantheengineandtheexhaustsystemarea(moreoftenindryordirtyconditions).

•Cleanthegrassanddebrisbuildupfromthemachine.

WARNING

Theenginecanbecomeveryhot.Touchinga

hotenginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundtheengine

area.

Every25hours

Every50hours

Every80hours

Every100hours

Every200hours

•Greasethejackshaftbearings.

•Greasethewheelbearings.

•Greasethetineshaftbearings.

•Greasethetineassemblyidlers.

•Cleanthefoamair-cleanerelement(moreofteninextremelydustyorsandy

conditions).

•Greasethecontrolpivots.

•Checksparkarrester(ifequipped).

•Checkthepressureinthetires.

•Checktheconditionandtensionofthebelts.

•Checktheauxiliaryhydraulic-uidlevel.

•Checkthehydraulictransmissionuidlevel.

•Removetheengineshroudsandcleanthecoolingns.

•Checkthepaperair-cleanerelement(moreofteninextremelydustyorsandy

conditions).

•Check,cleanandgapthesparkplug.

•Checkthebattery.

•Replacethepaperair-cleanerelement(moreofteninextremelydustyorsandy

conditions).

•Changetheengine-oillter(moreofteninextremelydustyorsandyconditions).

27

Page 28

MaintenanceService

Every250hours

Interval

MaintenanceProcedure

•Replacetheprimaryair-cleanerelement(moreofteninextremelydustyorsandy

conditions).

•Checkthesecondaryair-cleanerelement(moreofteninextremelydustyorsandy

conditions).

•Changetheauxiliaryhydraulicreservoirlteranduid.

•Changethetransmissionlters.

•Fillthetransmissionwithuidwhenchangingthelter.

Every500hours

Every800hours

Yearly

Yearlyorbeforestorage

•Replacethesecondaryair-cleanerelement(moreofteninextremelydustyorsandy

conditions).

•Replacethefuellter.

•Greasethefrontcasterpivots.

•Greasethebeltidlerpivot.

•Greasethecasterpivotsandhubs.

•Lubricatethecaster-wheelhubs.

•Lubricatethecaster-wheelhubs.

•Checkthetorqueofthewheelhubnuts.

•Checkthetorqueonthewheellugnuts.

•Checkthetorqueofthetransmissionoutputshaftnut.

•T ouchupareaswithchippedpaint.

Pre-Maintenance

Procedures

CAUTION

Raisingthemachineforserviceor

maintenancerelyingsolelyonmechanical

orhydraulicjackscouldbedangerous.The

mechanicalorhydraulicjacksmaynotbe

enoughsupportormaymalfunctionallowing

themachinetofall,whichcouldcauseinjury.

AccessingtheConsole Compartment

RemovingtheConsolePad

1.Loosenthe4anged-headboltsthatsecurethe

padtotheleftandrightconsolepanels(Figure

24).

Donotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstands

orequivalentsupport.

PreparingfortheMachine forMaintenance

Performthefollowingbeforeservicing,cleaning,or

makinganyadjustmentstothemachine.

1.Parkthemachineonalevelsurface.

2.Shutofftheengine,engagetheparkingbrake,

waitforallmovingpartstostop.

3.Removethekeyfromthekeyswitch.

Figure24

1.Keyholeslot(console

panel)

2.Fanged-headbolt

2.Liftuptheconsolepad(Figure24)approximately

13mm(1/2inch).

3.Pulltheconsolepadstraightbackandremove

thepadfromthemachine(Figure24).

28

g025880

3.Pad

Page 29

InstallingtheConsolePad

1.Alignthe4anged-headboltsattheforward

faceoftheconsolepadtothe4keyholeslotsin

theframeoftheconsole(Figure24).

Lubrication

LubricatingtheGrease

2.Movethepadforwarduntilthepadisushto

theconsoleframe(Figure24).

3.Movethepaddownuntiltheanged-headbolts

areseatedinthekeyholeslots(Figure24).

4.Tightentheanged-headboltsto1978to2542

N∙cm(175to225in-lb).

Fittings

Greasetype:NationalLubricatingGreaseInstitute

(NGLI)grade#2multi-purposegungrease.

Note:Refertothelubricationchartforservice

intervals.

LubricationChart

Fitting

Locations

1.FrontCaster

Pivots

2.Jackshaft

Bearings

3.Wheel

Bearings

4.TineShaft

Bearings

5.Tine

AssemblyIdlers

6.Control

Pivots

7.BeltIdler

Pivot

8.FrontCaster

Hubs

Initial

Pumps

*0

1825hours

1225hours

1425hours

1225hours

1450hours

11Y early

*0

Numberof

Places

Service

Interval

2Yearly

2Yearly

Figure25

1.Shutofftheengine,engagetheparkingbrake,

waitforallmovingpartstostop,andremove

thekey.

2.Wipecleanthegreasettingswitharag(Figure

25).

29

g020222

Page 30

3.Connectagreaseguntothetting(Figure25).

4.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings.

5.Wipeupanyexcessgrease.

LubricatingtheCaster-Hubs

Bearings

ServiceInterval:Yearly

RemovingtheCaster-WheelAssembly

LubricatingtheCasters

Greasetype:NationalLubricatingGreaseInstitute

(NGLI)gradeNo.2multi-purposegungrease.

GreasingtheCasterPivots

ServiceInterval:Yearly

1.Removecapandhexplugfromthetopofthe

casterpivot(Figure26).

1.Shutofftheengine,engagetheparkingbrake,

waitforallmovingpartstostop,andremove

thekey.

2.Liftthefrontofthemachineandsupportitwith

jackstands.

3.Removethewheelnutandbolt,andremovethe

caster-wheelassemblyfromthefork(Figure27).

g025953

Figure27

1.Wheelbolt3.Wheelnut

2.Caster-wheelassembly

Figure26

1.Hexplug

2.Greasetting4.Cap

2.Threadgreasettinginhole(Figure26).

3.Pumpgreaseintothettinguntilgreaseoozes

outaroundtopbearing(Figure26).

4.Removegreasettingandinstalltheplugthat

youremovedin1(Figure26).

5.Installthecapthatyouremovedinstep1(Figure

26).

6.Repeatsteps1through5totheothercaster.

3.Casterpivot

DisassemblingtheCaster-WheelHuband

GreasingtheBearings

ServiceInterval:Yearly

g025955

Important:Usenewbearingsealswhen

lubricatingthecaster-wheelhubs.

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoften.Spinthe

castertire.Thetireshouldnotspinfreely(more

than1or2revolutions)orhaveanysideplay.If

thewheelspinsfreely,adjusttorqueonspacer

nutuntilthereisaslightamountofdrag.Apply

thread-lockingcompound.

Greasetype:NationalLubricatingGreaseInstitute

(NGLI)gradeNo.2multi-purposegungrease.

1.Removethe2sealguardsfromthewheelhub

(Figure28).

30

Page 31

Figure28

1.Axle(spacernutstill

assembled)

2.Hub5.Bearingseal

3.Bearing

4.Spacernut

6.Sealguard

2.Remove1ofthespacernutsfromtheaxle

assemblyinthecasterwheel(Figure28).

Note:Notethatthread-lockingcompoundhas

beenappliedtolockthespacernutstotheaxle

(Figure28).

3.Removetheaxle(withtheotherspacernutstill

assembledtoit)fromthecaster-wheelassembly

(Figure28).

4.Pryoutbothbearingseals(Figure28).

Note:Discardtheoldseals.

5.Removebothbearingsandinspectthemfor

wearordamage(Figure28).

Note:Replacethebearingifitiswornor

damaged.

6.Packthe2bearingswiththespeciedgrease.

AssemblingtheCaster-WheelHub

1.Install1bearingintothehubofthewheel(Figure

28).

2.Installthebearingsealintothehubatthe

bearing(Figure28).

3.Ifyouremoved(orbrokeloose)bothofthe

spacernutsfromtheaxleassembly,perform

thefollowing:

A.Cleanthethreadsoftheaxleandspacer

nut.

B.Applyathread-lockingcompoundtothe

threadsat1endoftheaxle.

C.Threadtheaxlenut,withthewrenchats

facingoutward,ontotheendoftheaxlethat

ispreparedwiththread-lockingcompound

(Figure28).

mm(1/8inch)fromtheoutersurfaceofthe

spacernuttotheendoftheaxleinsidethe

nut.

4.Inserttheassemblednutandaxleintothewheel

atthesideofthewheelwiththenewsealand

bearing(Figure28).

5.Withtheopenendofthewheelfacingup,llthe

areainsidewheelcavity(aroundtheaxle)with

thespeciedgrease.

g025954

6.Installtheotherbearingandnewsealintothe

wheel(Figure28).

7.Applyathread-lockingcompoundtothesecond

spacernutandthreaditontotheaxlewiththe

wrenchatsfacingoutward.

8.T orquethespacernutto8to9N∙m(75to80

in-lb),loosen,thentorqueit2to3N∙m(20to

25in-lb).

Note:Makesureaxledoesnotextend

beyondeithernut.

9.Installthesealguardsoverthewheelhub

(Figure28).

InstallingtheCaster-WheelAssembly

1.Aligntheholeintheaxleofthecaster-wheel

assemblybetweentheholesintheforkofthe

caster(Figure27).

2.Securethewheelassemblytotheforkwiththe

wheelnutandbolt(Figure27)thatyouremoved

instep3ofRemovingtheCaster-Wheel

Assembly(page30).

3.T orquethewheelnutto91to1 13N∙m(67to

83ft-lb).

Note:Donotthreadspacernutallofthe

wayontotheaxle.Leaveapproximately3

31

Page 32

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Every250hours—Replacethe

primaryair-cleanerelement(more

ofteninextremelydustyorsandy

conditions).

Every250hours—Checkthesecondary

air-cleanerelement(moreofteninextremely

dustyorsandyconditions).

Every500hours—Replacethesecondary

air-cleanerelement(moreofteninextremely

dustyorsandyconditions).

Inspectthefoamandpaperelements,andreplace

themiftheyaredamagedorexcessivelydirty .

Important:Donotapplyoiltothefoamorpaper

element.

RemovingtheFoamandPaper

air-cleanerassemblyfromtheinletduct(Figure

29).

5.Carefullypullthefoamelementoffthepaper

element(Figure29).

ServicingtheFoamAir-Cleaner

Element

ServiceInterval:Every25hours(moreoften

inextremelydustyorsandy

conditions).

1.Inspecttheelementfortears,anoilylm,or

damaged(Figure29).

Important:Replacethefoamelementifit

iswornordamaged.

2.Washthefoamelementinliquidsoapand

warmwater.Whentheelementisclean,rinse

itthoroughly.

3.Drytheelementbysqueezingitinacleancloth.

Elements

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage

(Figure29).

ServicingthePaperAir-Cleaner

Element

ServiceInterval:Every100hours—Checkthe

paperair-cleanerelement(more

ofteninextremelydustyorsandy

conditions).

Every200hours—Replacethepaperair-cleaner

element(moreofteninextremelydustyor

sandyconditions).

Important:Donotwashthepaperair-cleaner

element.

1.Inspecttheelementfortears,anoilylm,or

damagetotherubberseal(Figure29).

Note:Replacethepaperelementifitis

damaged.

2.Cleanthepaperelementbygentlytappingitto

removedustanddebris.

Note:Iftheelementisverydirty ,replacethe

air-cleanerelement.

Figure29

1.Cover

2.Hoseclamp4.Foamelement

3.Rotatethecoverknobs1/4turncounterclockwise

andremovetheair-cleanercover(Figure29).

4.Rotatethethumbscrewofthehoseclamp

counterclockwiseuntilyoucanseparatethe

3.Paperelement

g012352

32

Note:Donotusepressurizedairtocleanthe

paperelement.

Page 33

InstallingtheFoamandPaper

Elements

Important:Topreventenginedamage,always

operatetheenginewiththecompletefoamand

paperair-cleanerassemblyinstalled.

1.Carefullyslidethefoamelementontothepaper

air-cleanerelement(Figure29).

2.Aligntheair-cleanerassemblyontotheinletduct

andsecureitwiththehoseclamp(Figure29).

3.Aligntheair-cleanercoverontotheenginecover

andsecurethecoverbyrotatingthecoverknobs

1/4turnclockwise(Figure29).

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSJorlater)

EngineOilCapacity:1.7L(1.8USqt)withthelter

removed;1.5L(1.6USqt)withoutthelterremoved

Oilviscosity:Refertothetablebelow.

g025980

Figure31

Figure30

ChangingtheEngineOil

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoil

drainscompletely.

2.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.ChangetheengineoilasshowninFigure32.

Note:Torquedrainplugto27to33N∙m(20

to24ft-lb).

g004216

g025979

Figure32

4.Slowlypourapproximately80%ofthespecied

oilintothellertube,andslowlyaddthe

additionaloiltobringittotheFullmark(Figure

33).

33

Page 34

Figure33

5.Starttheengineanddrivetoaatarea.

6.Checktheengine-oillevel.

ChangingtheEngine-OilFilter

g025976

g026005

ServiceInterval:Every200hours(moreoften

inextremelydustyorsandy

conditions).

1.Draintheoilfromtheengine;refertoChanging

theEngineOil(page33).

2.Placearagundertheoilltertosoakupany

spilledoil.

Important:Spilledoilmaydrainunderthe

engineandontotheclutch.Oilspilledon

theclutchmaydamagetheclutch,cause

thebladestostopslowlywhentheclutchis

intheOFFposition,andcausetheclutchto

slipwhentheclutchisswitchedtotheON

position.Wipeupanyspilledoil.

3.Changetheengine-oillter(Figure34).

g026006

Figure34

Note:Ensurethattheoil-ltergaskettouches

theengine,andthenturnthelteranextra3/4

turn.

4.Fillthecrankcasewiththespeciedtypeofnew

oil;refertoFigure30.

34

Page 35

ServicingtheSparkPlug

CheckingtheSparkPlug

ServiceInterval:Every100hours

TypeforallEngines:NGKBPR4ESorequivalent

AirGap:0.75mm(0.03inch)

Makesurethattheairgapbetweenthecenterand

sideelectrodesiscorrectbeforeinstallingthespark

plug.

Useasparkplugwrenchforremovingandinstalling

thesparkplug(s)andagappingtool/feelergaugeto

checkandadjusttheairgap.Installanewspark

plug(s)ifnecessary.

RemovingtheSparkPlug

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.RemovethesparkplugasshowninFigure35.

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithasa

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeansthesparkplugisdirty .

Setthegapto0.75mm(0.03inch).

g027479

Figure36

InstallingtheSparkPlug

Figure35

Tightenthesparkplug(s)to22N∙m(16ft-lb).

g025981

g027478

g027735

Figure37

35

Page 36

CheckingtheSpark

FuelSystem

Arrester

MachineswithaSparkArrester

Only

ServiceInterval:Every50hours

WARNING

Hotexhaustsystemcomponentsmayignite

fuelvaporsevenaftertheengineisshut

off.Hotparticlesexhaustedduringengine

operationmayigniteammablematerials.

Firemayresultinpersonalinjuryorproperty

damage.

Donotrefuelorrunengineunlessspark

arresterisinstalled.

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Allowthemufertocool.

Maintenance

ServicingtheFuelFilter

ReplacingtheFuelFilter

ServiceInterval:Every800hours/Yearly(whichever

comesrst)

Note:Wipeupanyspilledfuel.

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Closethefuel-shutoffvalve;refertoUsingthe

Fuel-ShutoffValve(page22).

3.Squeezetheendsofthehoseclampstogether

andslidethemawayfromthelter(Figure38).

3.Checkthesparkarresterforbreaksinthe

screenorwelds.

Note:Replacethesparkarresterifitisworn

ordamaged.

4.Ifyouseethatthescreenisplugged,perform

thefollowing:

A.Removethesparkarrester.

B.Shakeloosetheparticlesfromthearrester

andcleanscreenwithawirebrush.

Note:Soakthearresterscreeninsolvent

ifnecessary.

C.Installsparkarresterontoexhaustoutlet.

g025982

Figure38

1.Hoseclamp3.Hose

2.Flowdirectionarrow(fuel

lter)

4.Removethelterfromthefuelhoses(Figure

38).

Note:Donotinstalladirtylterafteritis

removedfromthefuelline.

5.Installanewlterwiththeow-directionarrow

alignedasillustratedinFigure38.

Note:Ensurethatthefuelhosesarefully

seatedontothehosettingsofthefuellter.

6.Alignthehoseclampsoverthehoseandthe

fuel-lterttings(Figure38).

36

Page 37

7.Openthefuel-shutoffvalve;refertoUsingthe

Fuel-ShutoffValve(page22).

ElectricalSystem

8.Checkforfuelleaksandrepairifneeded.

9.Wipeupanyspilledfuel.

Maintenance

ServicingtheBattery

ServiceInterval:Every100hours

Alwayskeepthebatterycleanandfullycharged.Use

apapertoweltocleanthebatterycase.Ifthebattery

terminalsarecorroded,cleanthemwithasolutionof

4partswaterand1partbakingsoda.Applyalight

coatingofgreasetothebatteryterminalstoprevent

corrosion.

Voltage:12V

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

DANGER

Batteryelectrolytecontainssulfuricacid,

whichisfatalifconsumedandcausessevere

burns.

Donotdrinkelectrolyte,andavoidcontact

withskin,eyes,andclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

37

Page 38

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponents,causing

sparks.Sparkscancausethebatterygasses

toexplode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

WARNING

Incorrectbattery-cableroutingcoulddamage

themachineandcables,causingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Removetheconsolepad;refertoRemovingthe

ConsolePad(page28).

3.Onthebattery,lifttheblackterminalcoverfrom

thenegativecable(Figure39).

Figure39

1.Flangedbolt

2.Terminalcover

(black—negativebattery

terminal)

3.Terminalcover

(red—positivebattery

terminal)

4.Positive(+)battery

terminal

4.Disconnectthenegativebatterycablefromthe

negative(-)batteryterminal,andremovethe

cablefromthebattery(Figure39).

5.Slidetheredterminalcoveroffthepositive

batteryterminal(Figure39).

6.Disconnectthepositive(red)batterycable,and

removethecablefromthebattery(Figure39).

7.Removethehookofthebatterystrapfromthe

batterytray(Figure39),andremovethebattery.

5.Negative(-)battery

terminal

6.Flangednut

7.Batterytray

8.Batterystrap

g025881

InstallingtheBattery

1.Placethebatteryontothemachine(Figure39).

2.Securethebatterytothebatterytraywiththe

batterystrap.

3.Installthepositive(red)batterycabletopositive

(+)batteryterminalwithaangedboltand

angednut(Figure39).

4.Slidetheredterminalcoveroverthe

positive-batteryterminal.

5.Installthenegativebatterycableandtheground

wiretothenegative(-)batteryterminalwitha

angedboltandangednut(Figure39).

6.Slidetheblackterminalcoveroverthe

negative-batteryterminal.

38

Page 39

ChargingtheBattery

ServicingtheFuses

WARNING

Chargingthebatteryproducesgassesthat

canexplode.

Neversmokenearthebatteryandkeepsparks

andamesawayfromthebattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity)topreventbatterydamage

whenthetemperatureisbelow0°C(32°F).

1.Removethebatteryfromthechassis;referto

RemovingtheBattery(page38).

2.Checktheelectrolytelevel.

3.Ensurethatthellercapsareinstalledonthe

battery.

4.Chargethebatteryfor1hourat25to30Aor6

hoursat4to6A.

5.Whenthebatteryisfullycharged,unplugthe

chargerfromtheelectricaloutlet,anddisconnect

thechargerleadsfromthebatteryposts(Figure

40).

Theelectricalsystemisprotectedbyfuses,and

requiresnomaintenance.Ifafuseblows,checkthe

componentorcircuitforamalfunctionorshort.

1.Releasethecushionfromtherearofthe

machine.

2.Removethenegative-batterycablefromthe

batteryterminal;refertosteps4and5of

RemovingtheBattery(page38).

Note:Ensurethatthenegativebatterycable

doesnottouchthebatteryterminal.

3.Pullthefusefromthesocketofthefuseblock

(Figure41).

6.Installthebatteryontothemachineandconnect

thebatterycables;refertoInstallingtheBattery

(page38).

Note:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccur.

Figure40

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

g025983

Figure41

1.Fuseblock

4.Installafuseofthesametypeandamperesinto

thesocketofthefuseblock(Figure41).

5.Installthenegative-batterycablefromthebattery

terminal;refertosteps5and6ofInstallingthe

g000538

Battery(page38).

39

Page 40

DriveSystem

AdjustingtheCasterPivot

Maintenance

CheckingtheAirPressure intheTires

ServiceInterval:Every50hours

Note:Thesemi-pneumaticcastertiresdonotneed

tobeinated.

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Checkthepressureofthedrivetires.

3.Inatethedrivetiresto83to97kPa(12to14

psi).

CheckingtheWheelHub Nuts

ServiceInterval:Yearly

Torquethewheelhubnuts(Figure42)to285to350

N∙m(210to260ft-lb).

Note:Donotuseanti-seizecompoundonthewheel

hub.

BearingsPre-Load

Note:Ifyoudisassemblethecasterpivotbearings,

ensurethatthespring-discwashersareinstalledas

showninFigure43.

1.Removedustcapfromcasterhub(Figure43).

Figure43

1.Dustcap

2.Locknut

3.Spring-discwashers

4.Spindle

5.Casterhub

g026022

Figure42

1.Lugnut2.Hubnut

CheckingtheTorqueofthe WheelLugNuts

ServiceInterval:Yearly

Torquethewheellugnuts(Figure42)to122to129

N∙m(90to95ft-lb).

2.Tightenthelocknutclockwiseuntilthe

spring-discwashersareat(Figure43).

3.Rotatethelocknutcounterclockwise1/4turn

(Figure43).

4.Installthedustcap(Figure43).

MaintainingtheChain

AdjustingtheJackshaft

g026029

Drive-ChainTension